Patents

Literature

183results about How to "Improve Exposure Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Projection exposure apparatus and method

InactiveUS7061575B2Improve Exposure AccuracyReduce pollutionMaterial analysis by optical meansPhotomechanical exposure apparatusPhotosensitizerEngineering

Pattern transfer can be performed with improved exposure accuracy, by reducing the contamination caused by the attachment of a photosensitive agent or the like on an optical member of a projection optical member or the like. The pattern transfer onto a substrate W is performed after cleaning the objective member OB disposed at a given position by a cleaning device 8 at the time when pattern transfer is not performed, or while making flow a gas in a space between the substrate W and the optical member OB by a contamination protection device 98. Alternatively, the optical member OB disposed at a given position is inspected for contamination by a contamination inspection device 84 at the time when pattern transfer is not performed, and the pattern transfer or the cleaning or replacement of the optical member is performed based on the result.

Owner:NIKON CORP

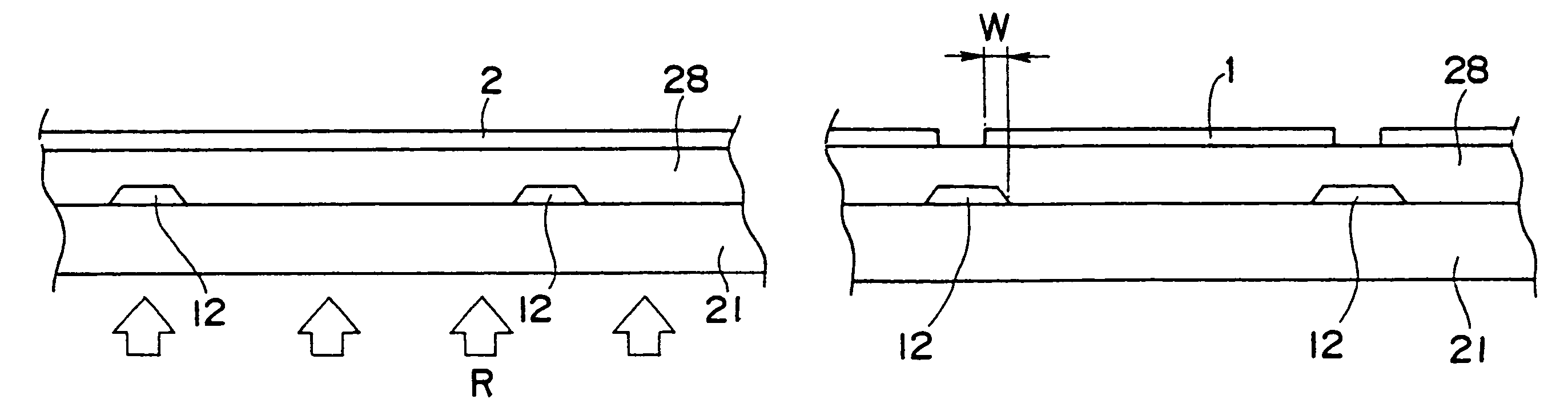

Method of making active matrix substrate with pixel electrodes of photosensitive conductive material

InactiveUS7075614B2Reduce processImprove Exposure AccuracySolid-state devicesMaterial analysis by optical meansActive matrixConductive materials

There is provided an active matrix substrate which enables to shorten a fabrication process of a pixel electrode, improve exposure precision by self alignment, and prevent leakage failures between pixel electrodes. On top of the interlayer insulating film, there are formed pixel electrodes, which are connected to the TFTs through contact holes piercing through the interlayer insulating film. The pixel electrodes are formed by applying on the interlayer insulating film a photosensitive transparent resin such as negative acrylic polymerized resin containing ITO, ATO or ZnO as transparent conductive particles, performing exposure from the back side of the substrate, and conducting development.

Owner:SHARP KK

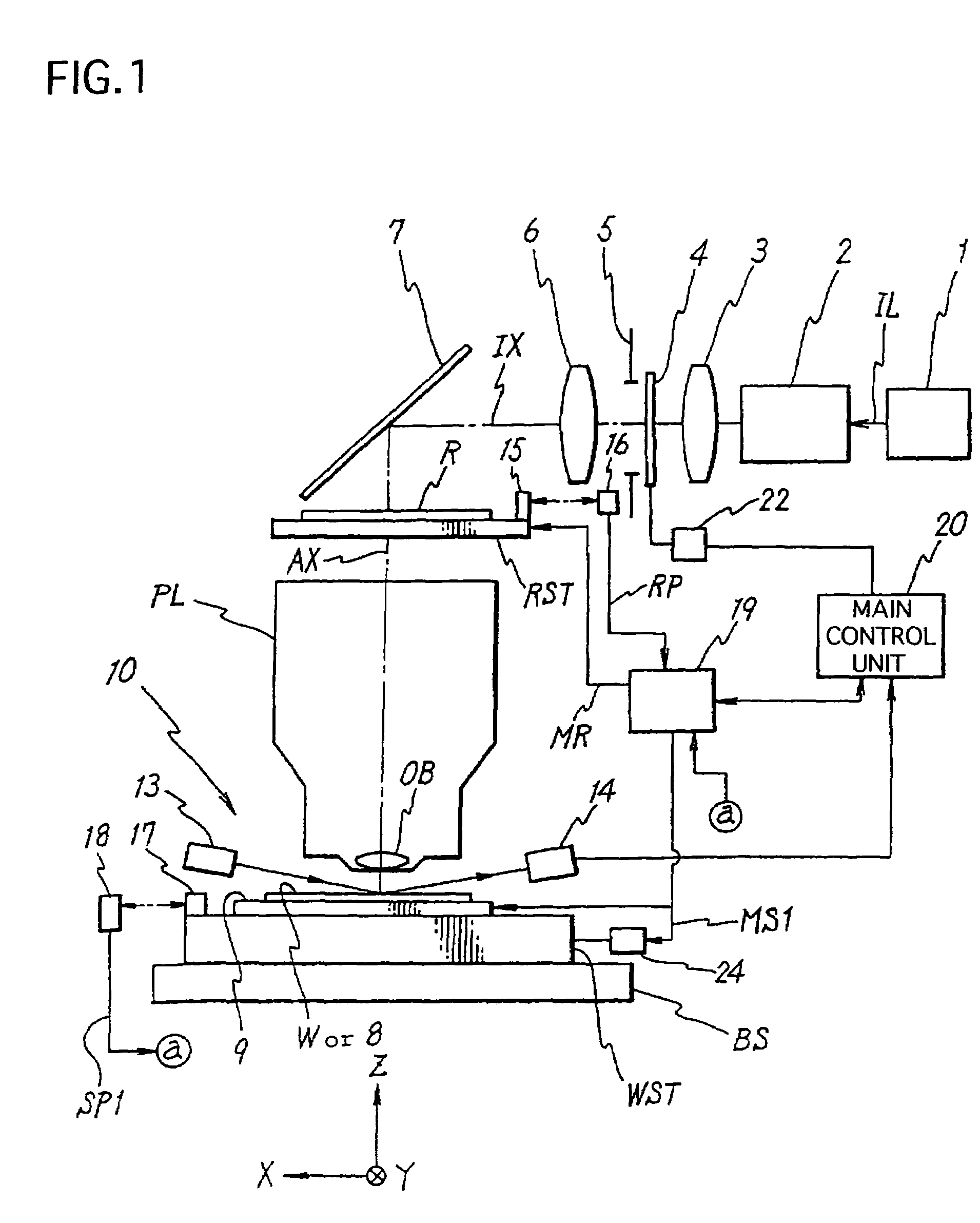

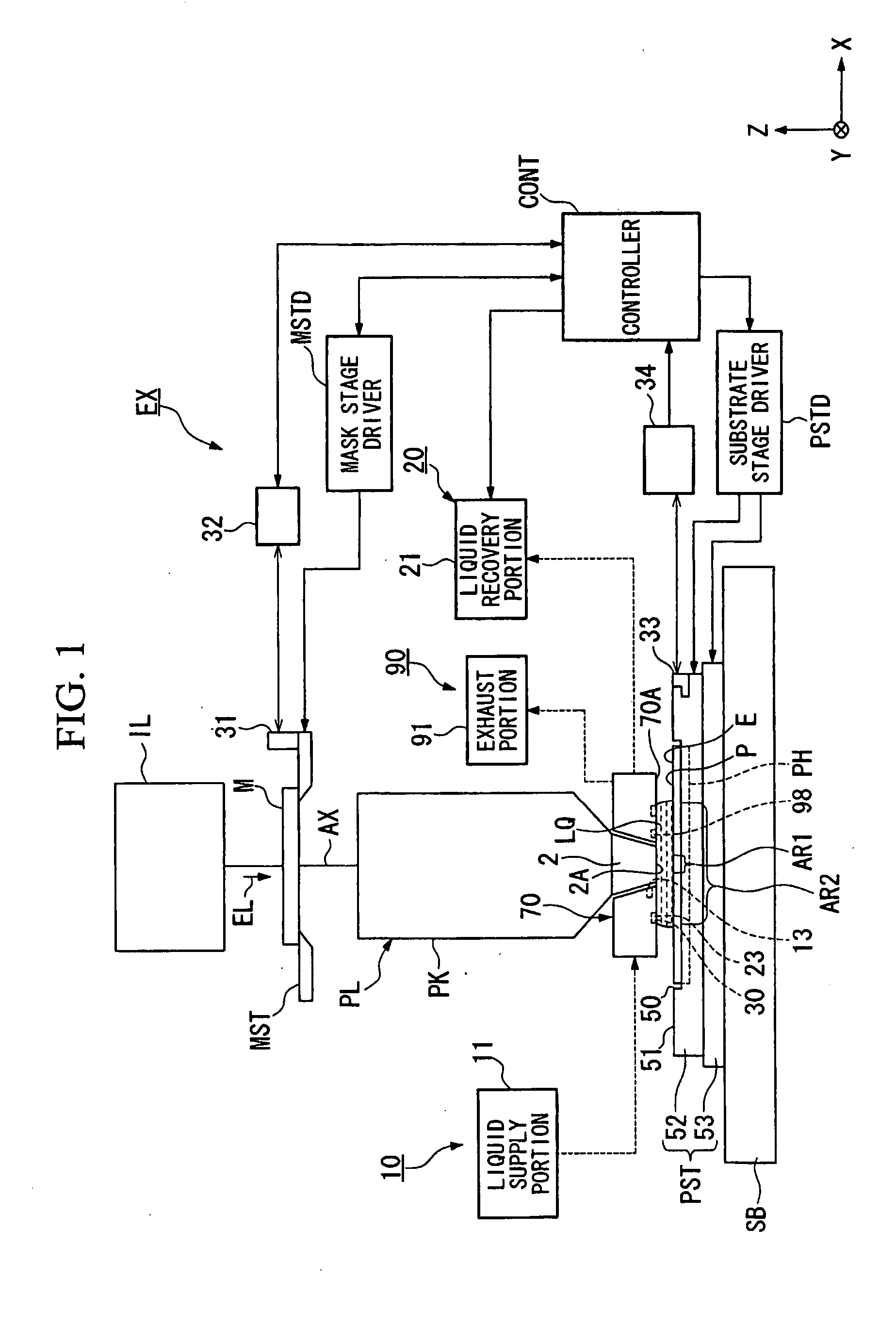

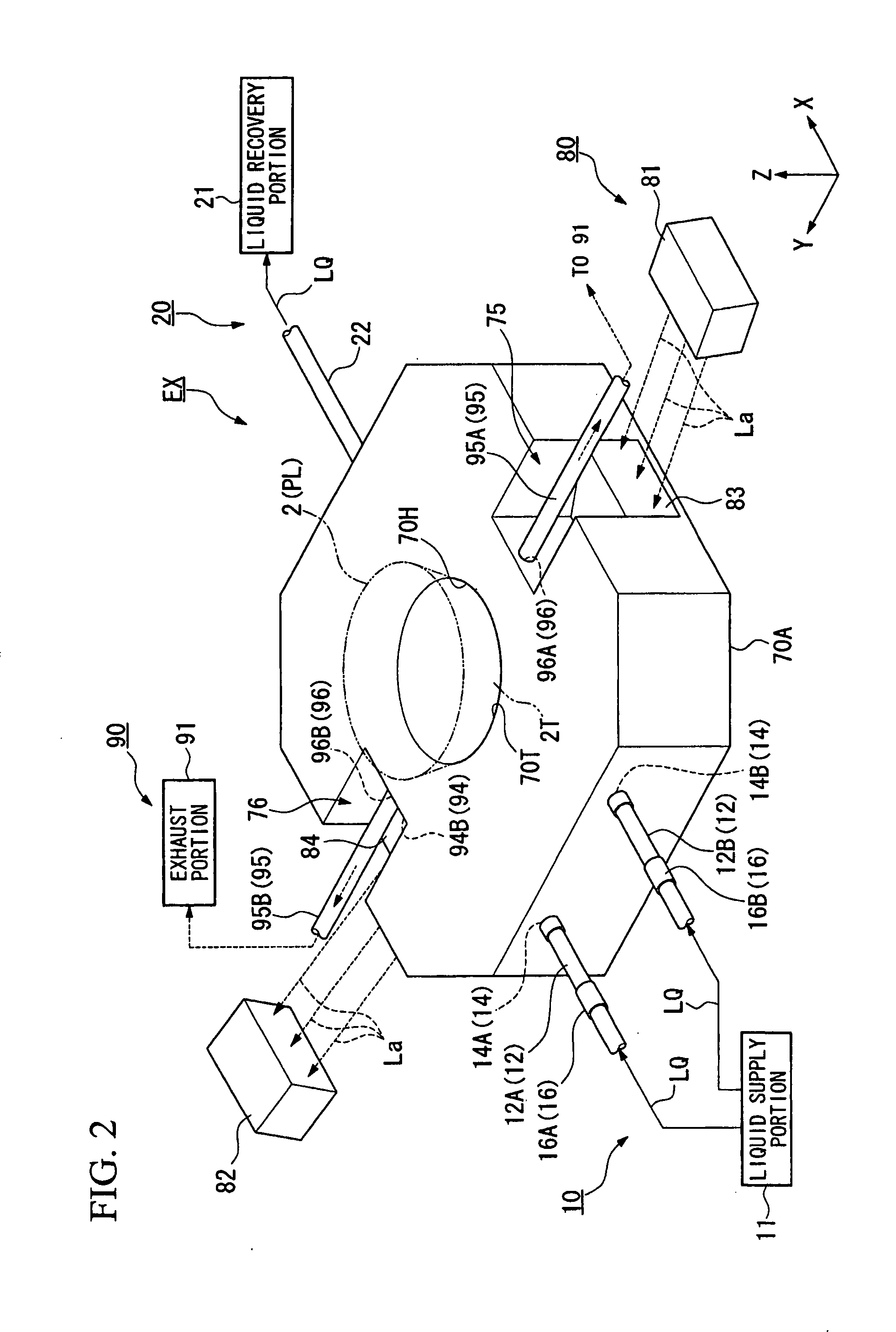

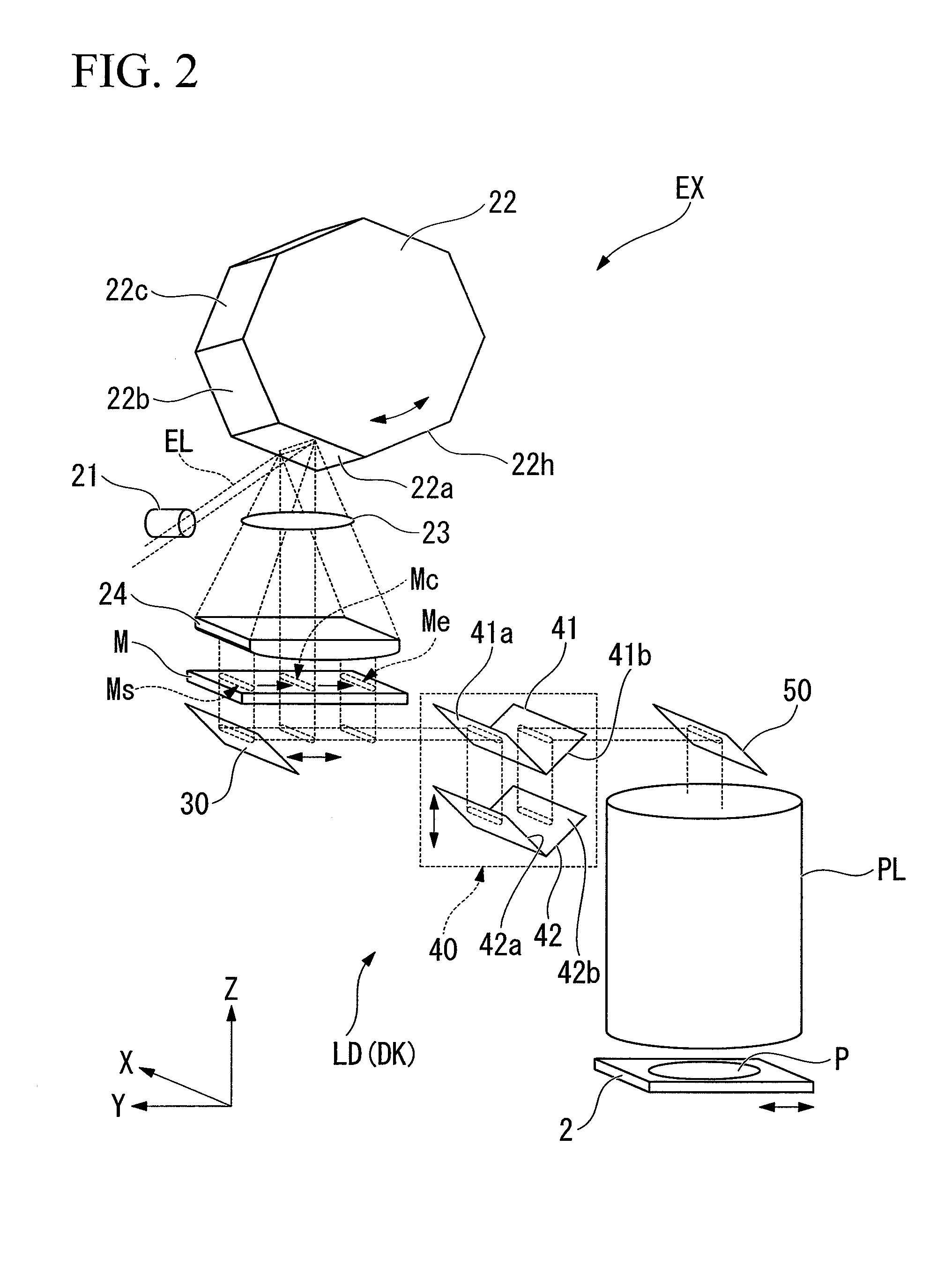

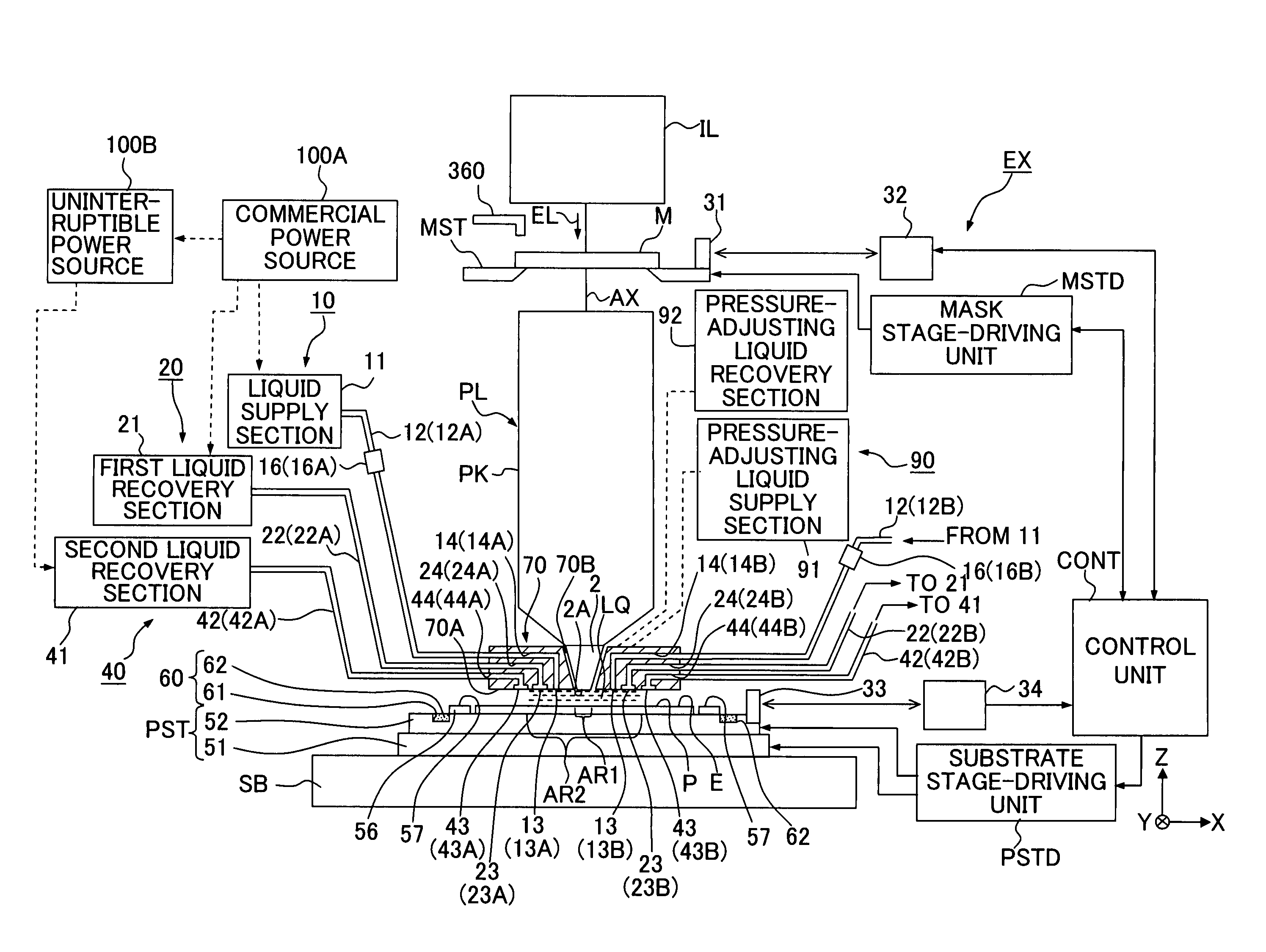

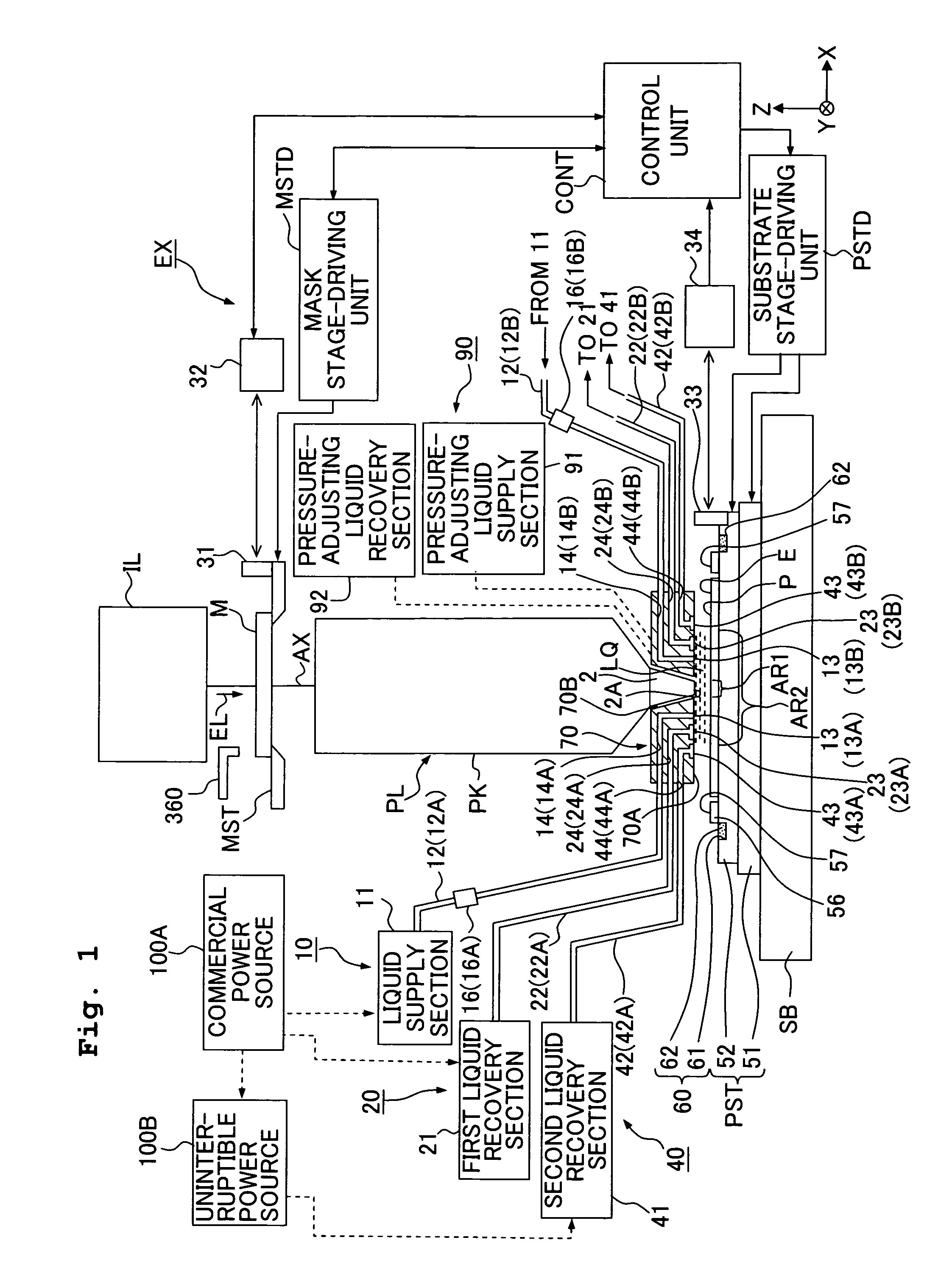

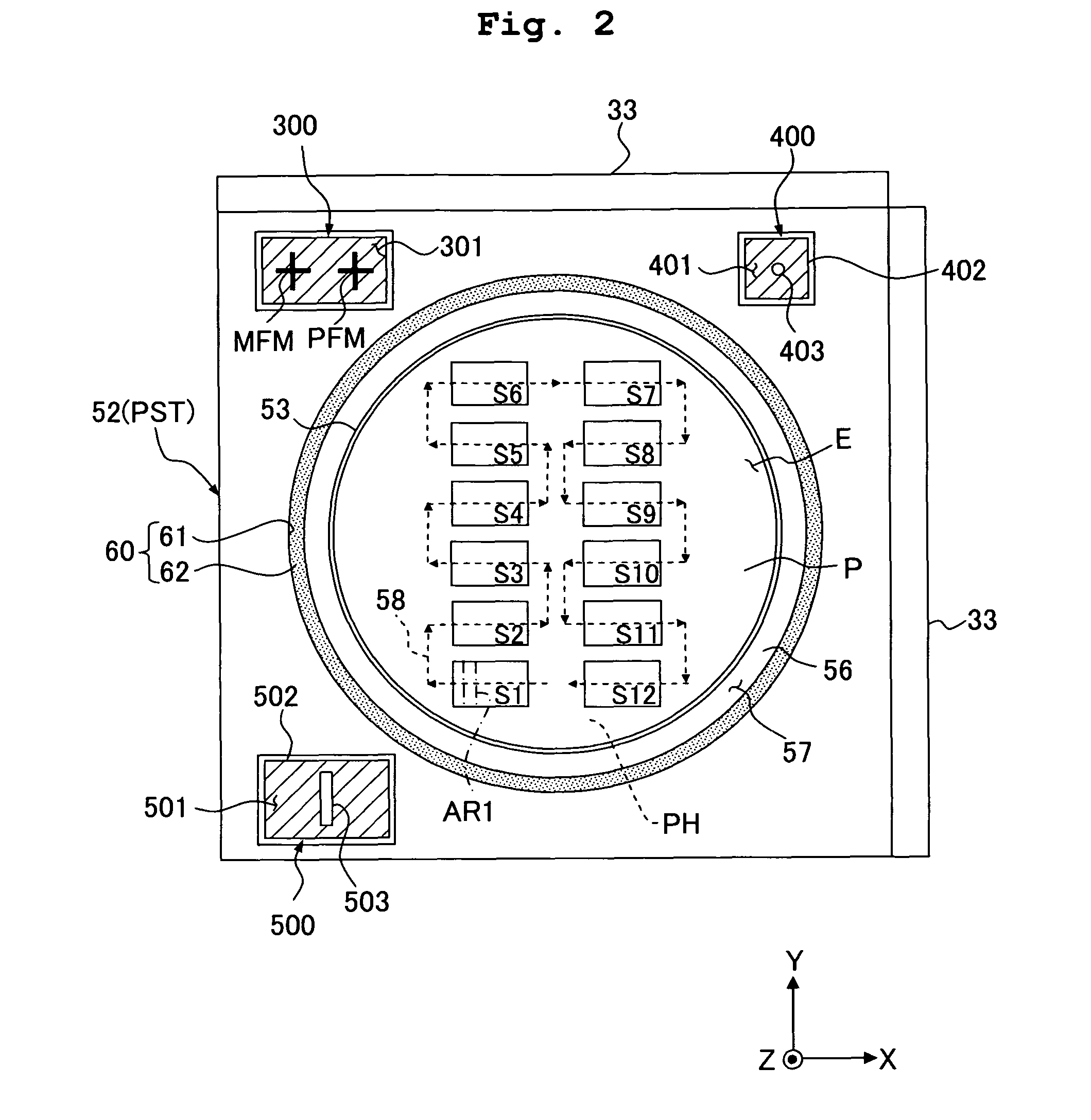

Exposure Apparatus and Device Producing Method

InactiveUS20080018866A1High measurement accuracyImprove Exposure AccuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineering

An exposure apparatus is provided that performs well a liquid supply operation for forming a liquid immersion region and a liquid recovery operation to form a liquid immersion region in a desired state, thereby allowing high exposure accuracy and high measurement accuracy. The exposure apparatus (EX) exposes a substrate (P) by irradiating exposure light (EL) onto the substrate (P) via a liquid (LQ), and includes a liquid supply mechanism (10) that has a supply port (13) capable of supplying the liquid (LQ) substantially in parallel with a surface of the substrate (P).

Owner:NIKON CORP

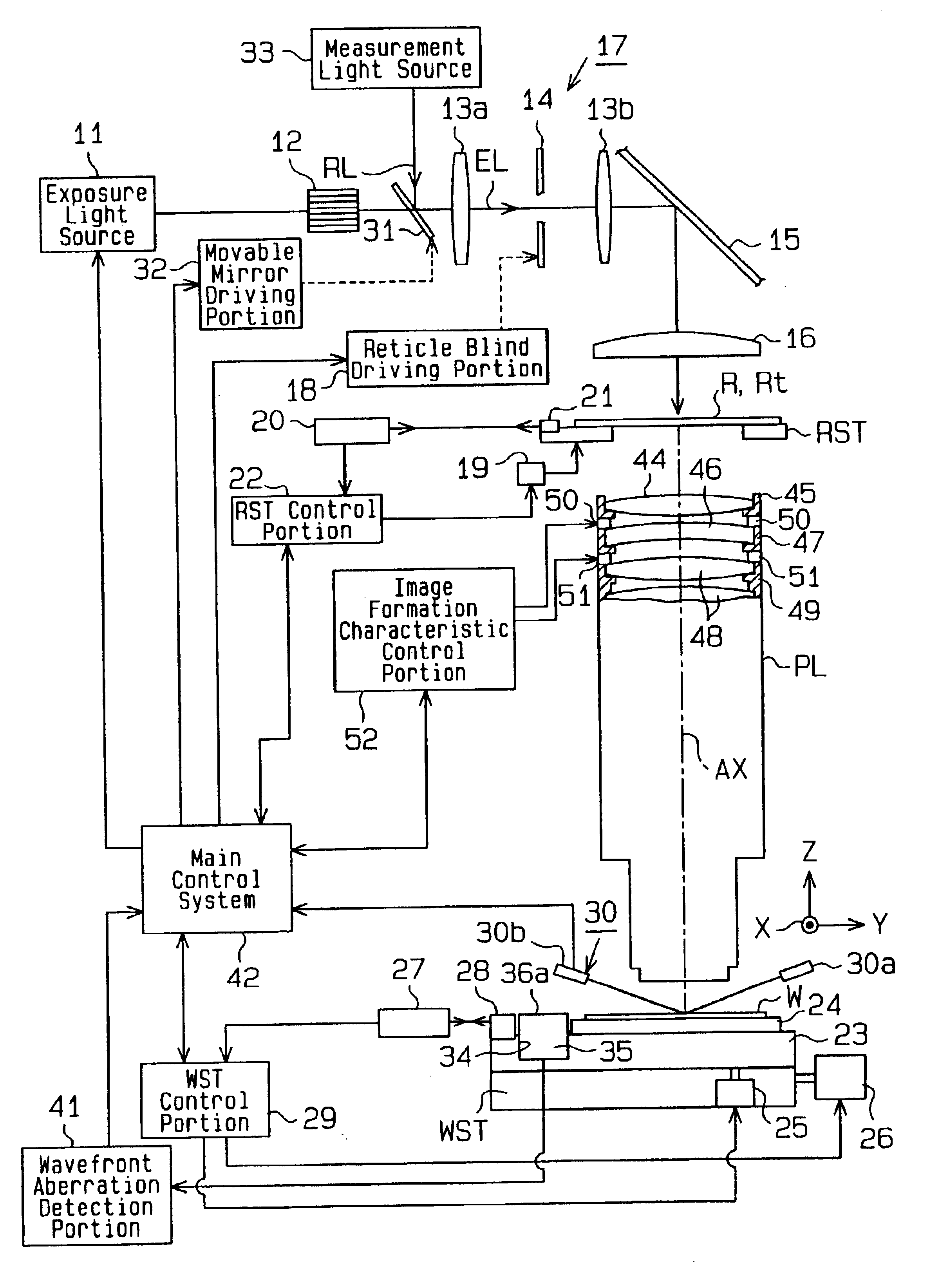

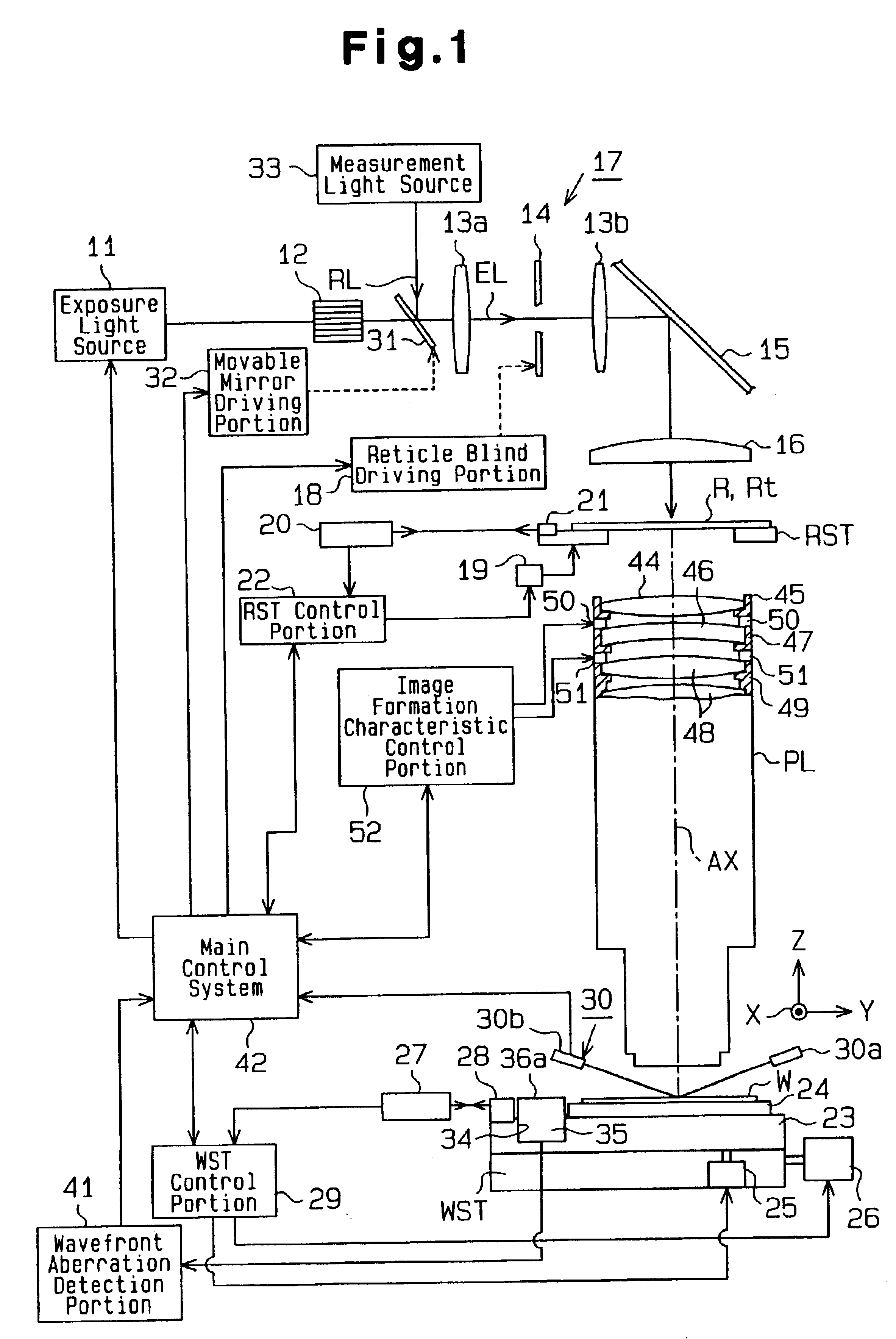

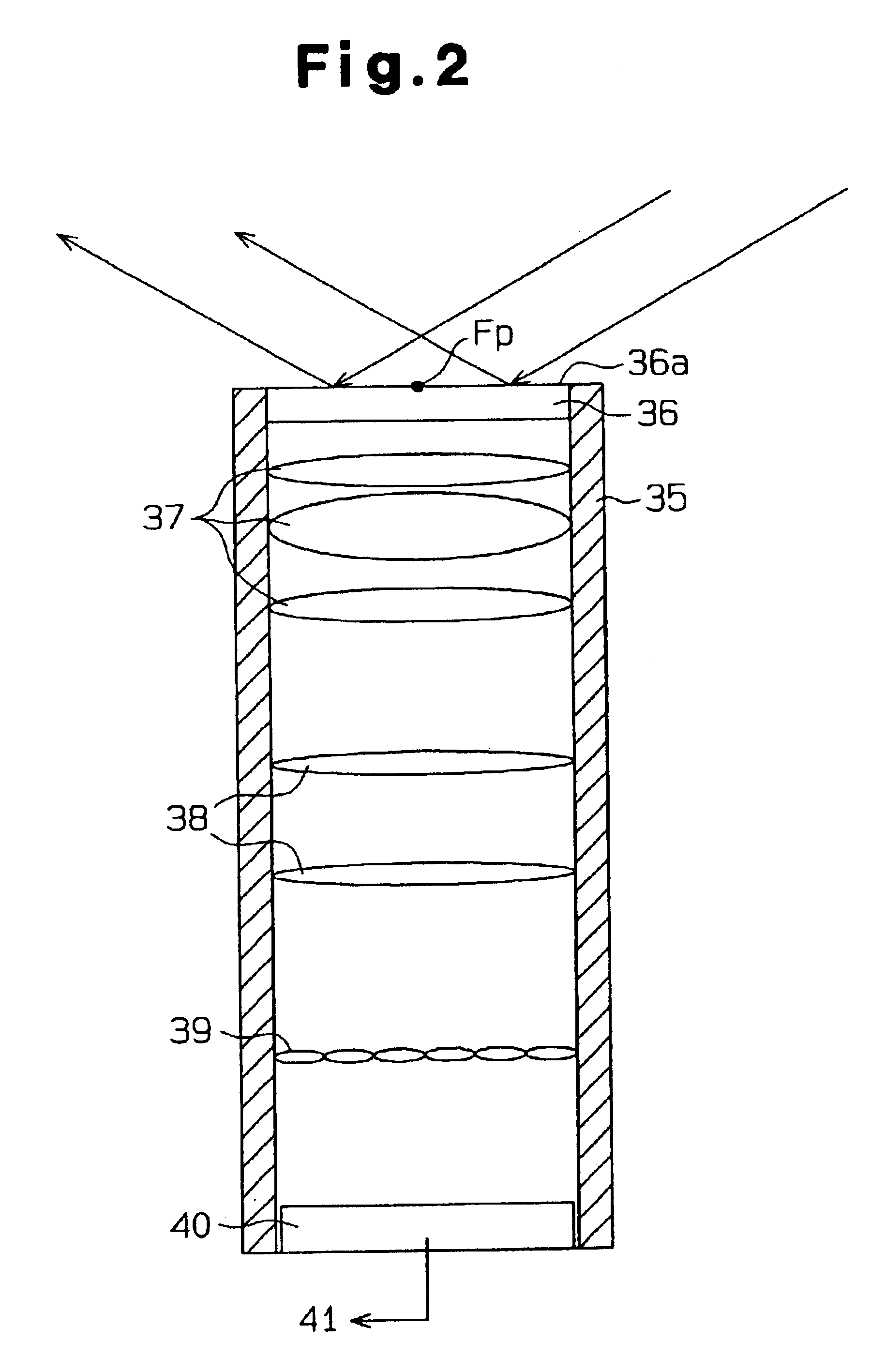

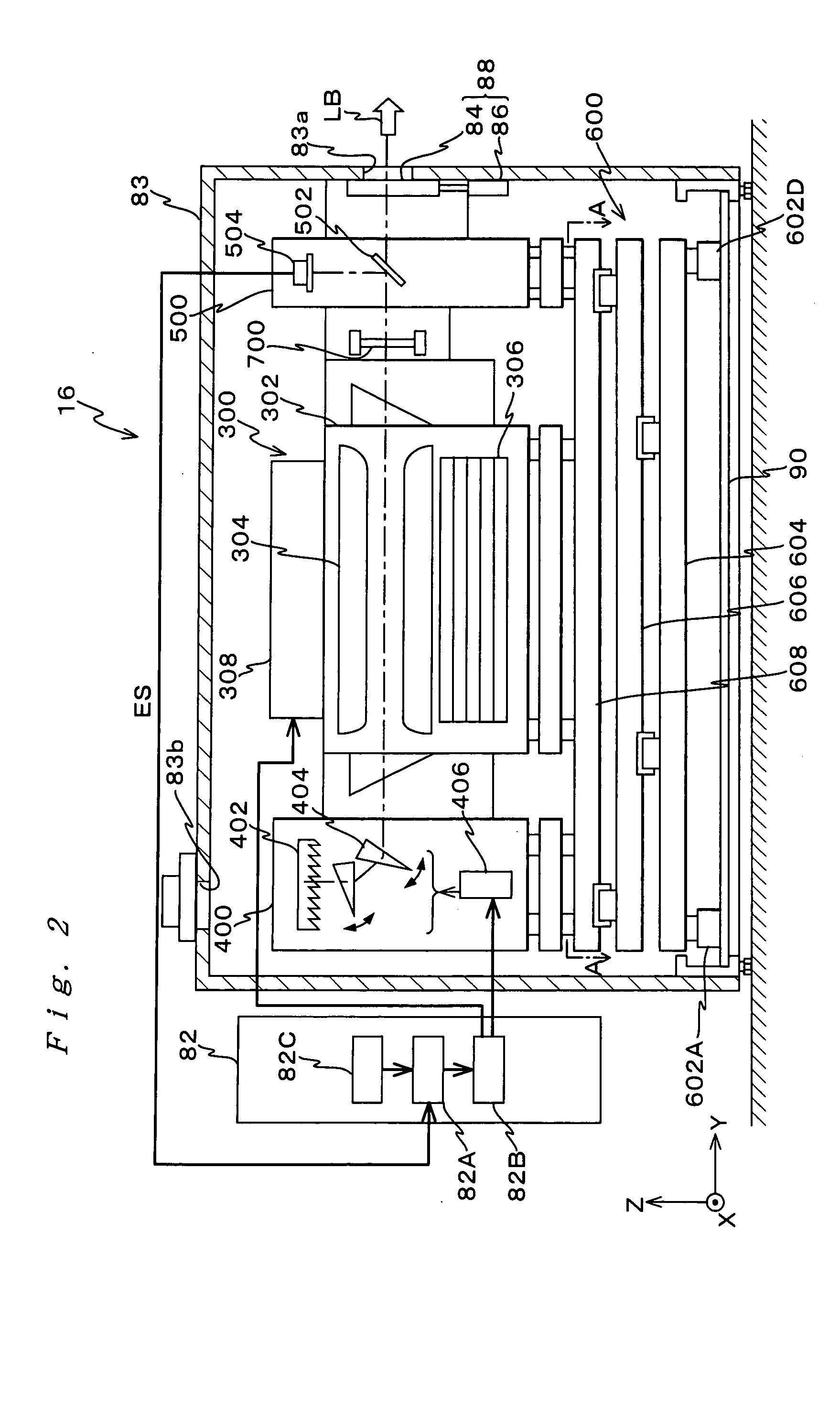

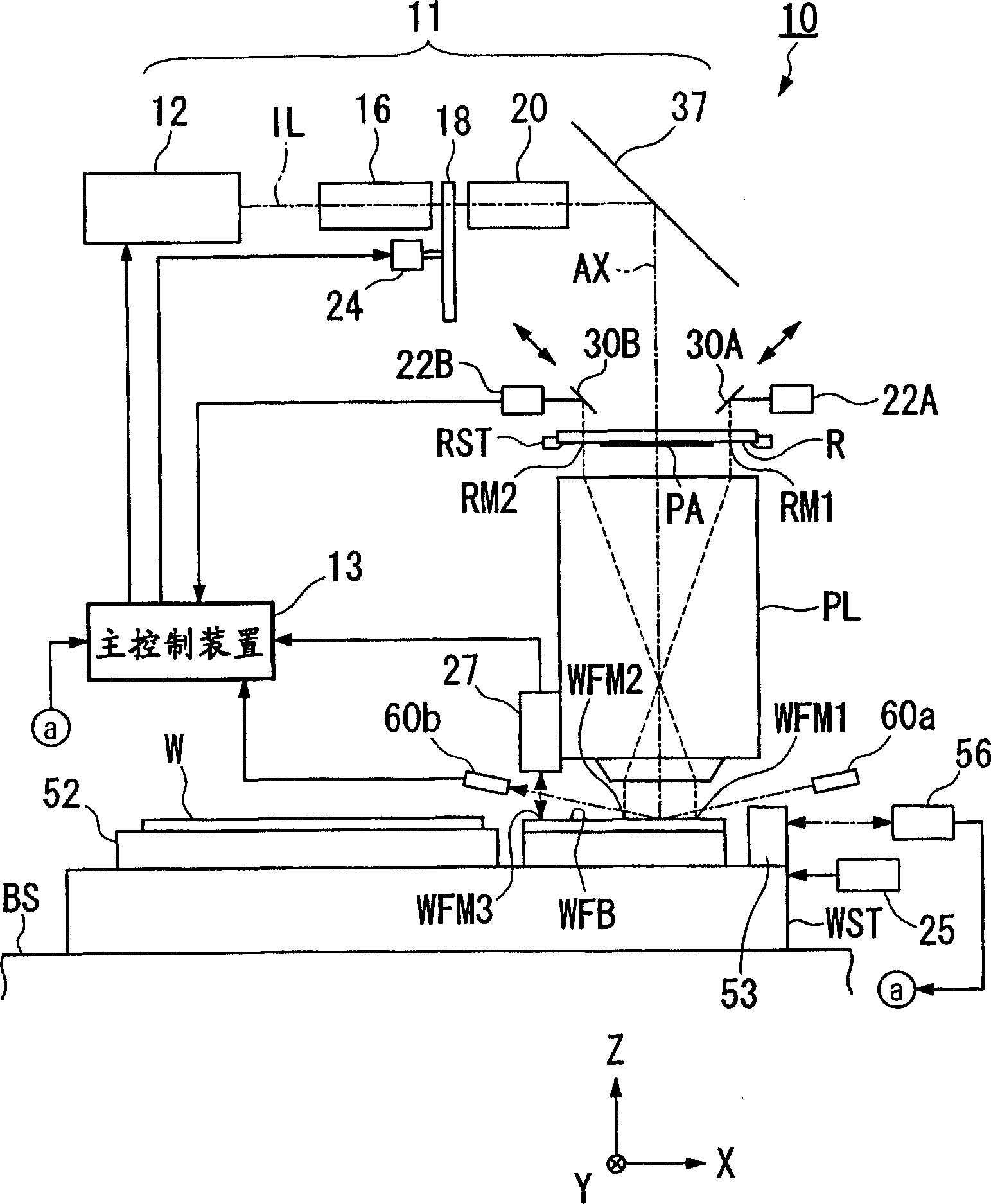

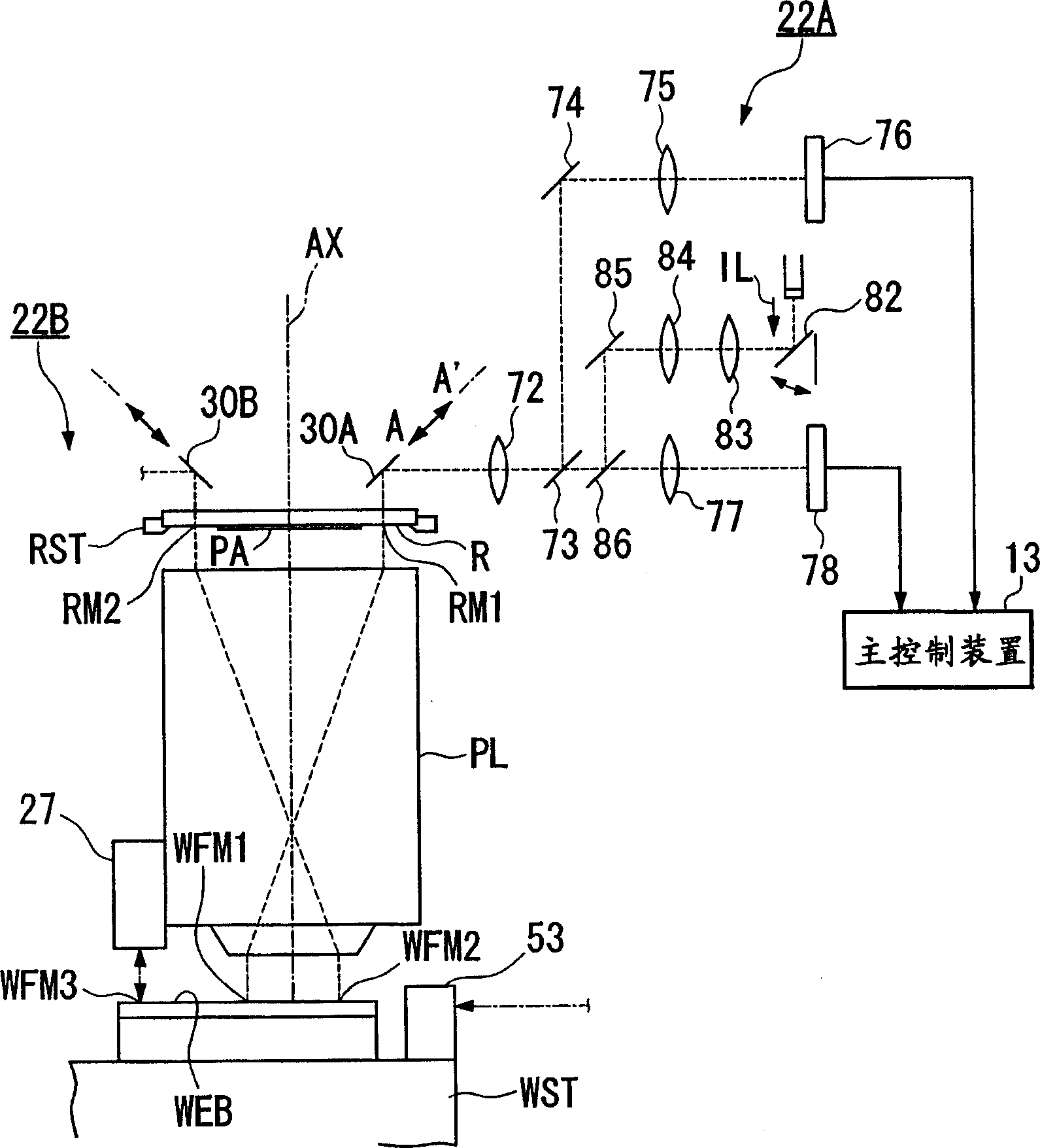

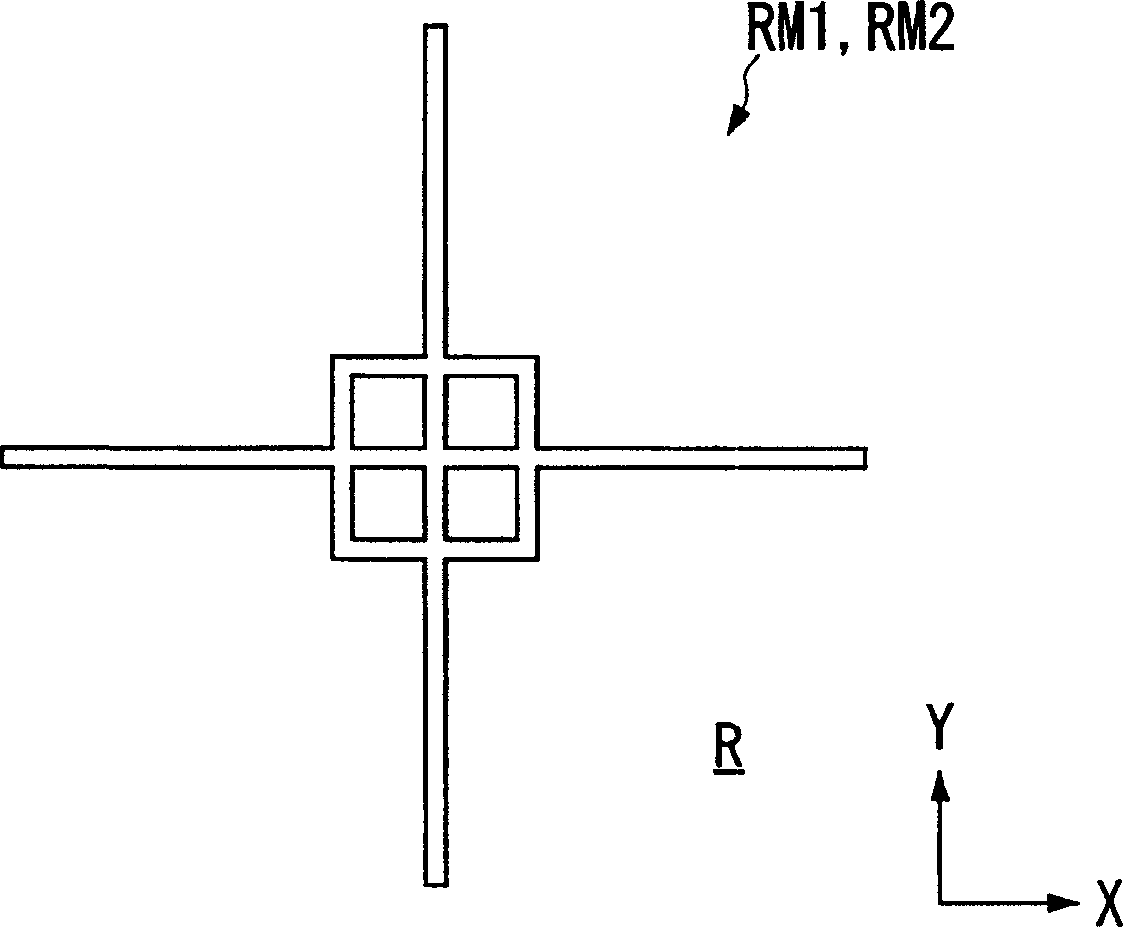

Wavefront aberration measuring instrument, wavefront aberration measuring method, exposure apparatus, and method for manufacturing micro device

InactiveUS6975387B2Accurate measurementHighly accurately manufacturedPhotometryUsing optical meansMeasuring instrumentImage formation

Before measuring a wavefront aberration of a projection optical system, an image formation position of an image of a pattern of a test reticle which is formed on a predetermined surface is detected by an AF sensor. Based on a result of this detection, the position of an incident surface of a wavefront aberration measurement unit is adjusted, and a position of an image of the pattern with respect to the incident surface is adjusted. After this adjustment, the image of the pattern formed through the projection optical system is detected by the wavefront aberration measurement unit, and a wavefront aberration detection section is used to obtain wavefront aberration information of the projection optical system based on a result of this detection.

Owner:NIKON CORP

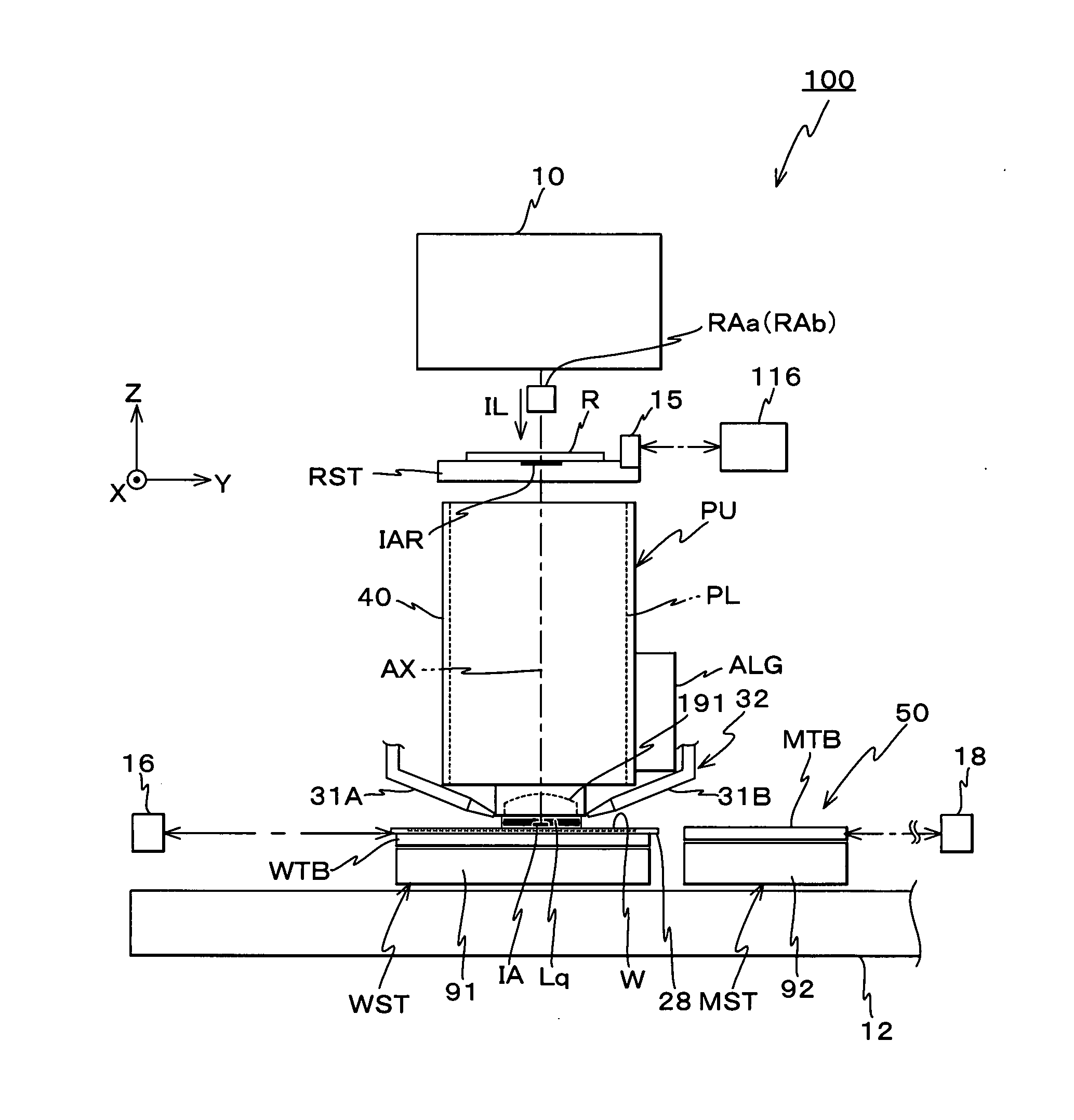

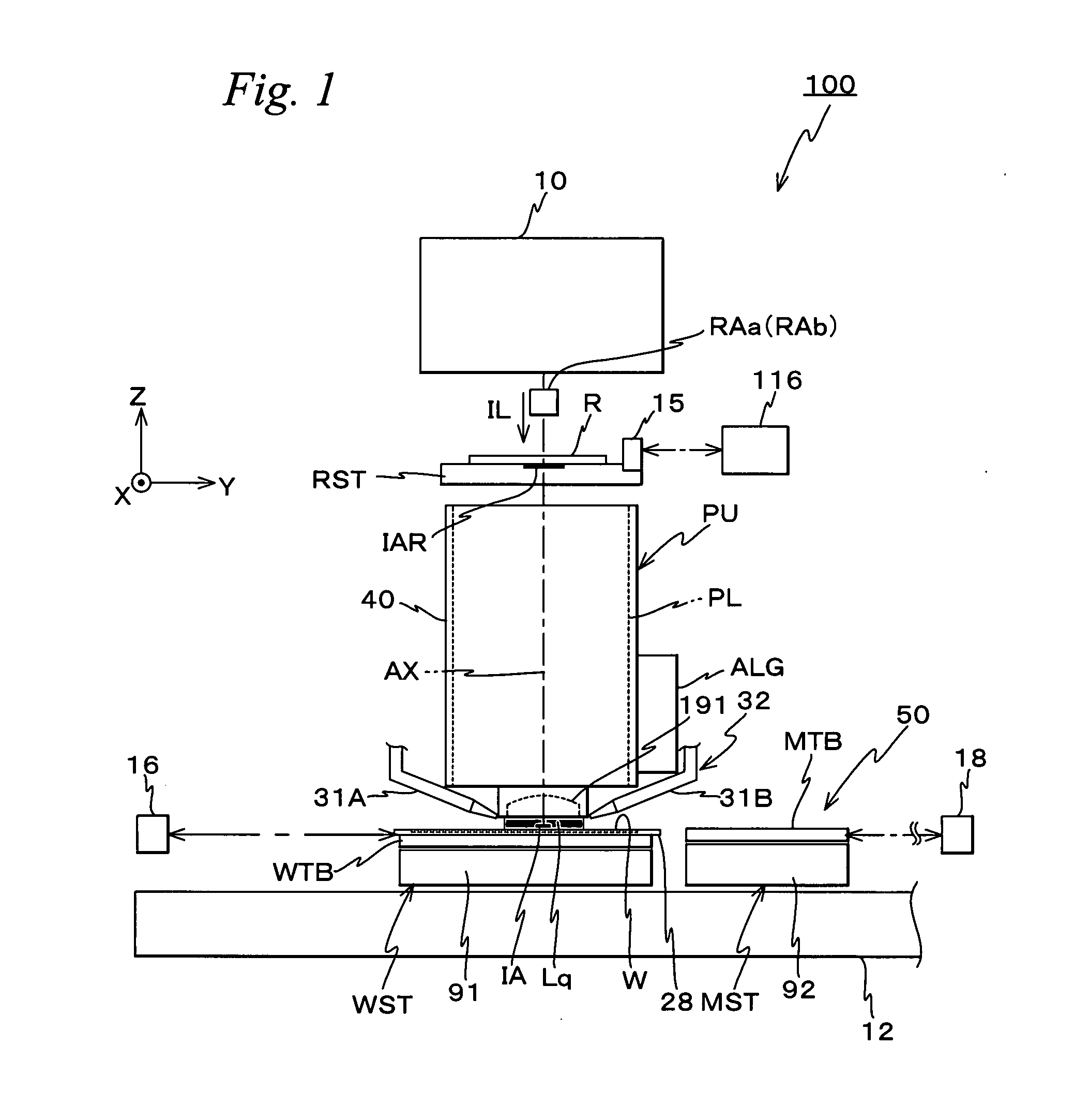

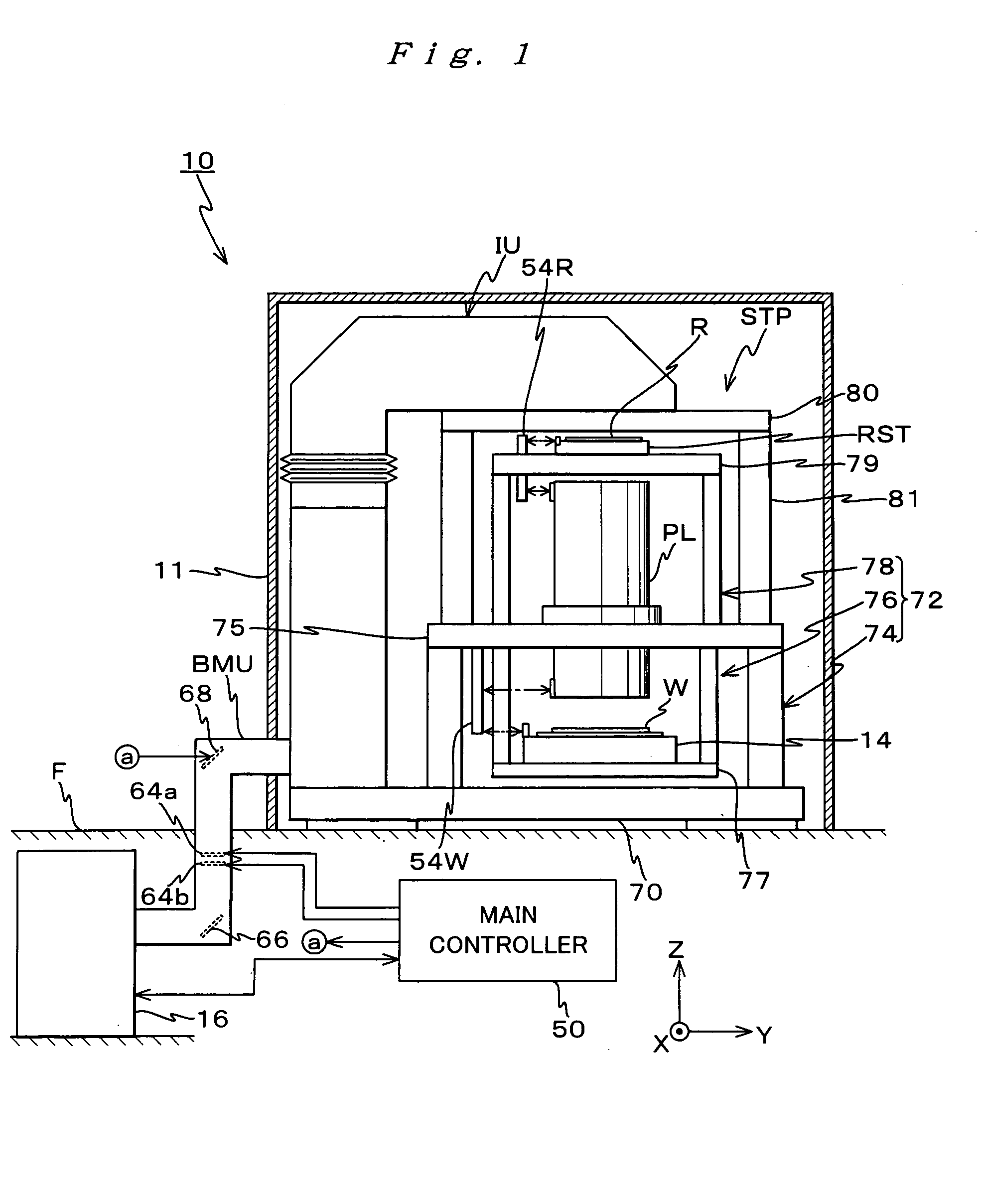

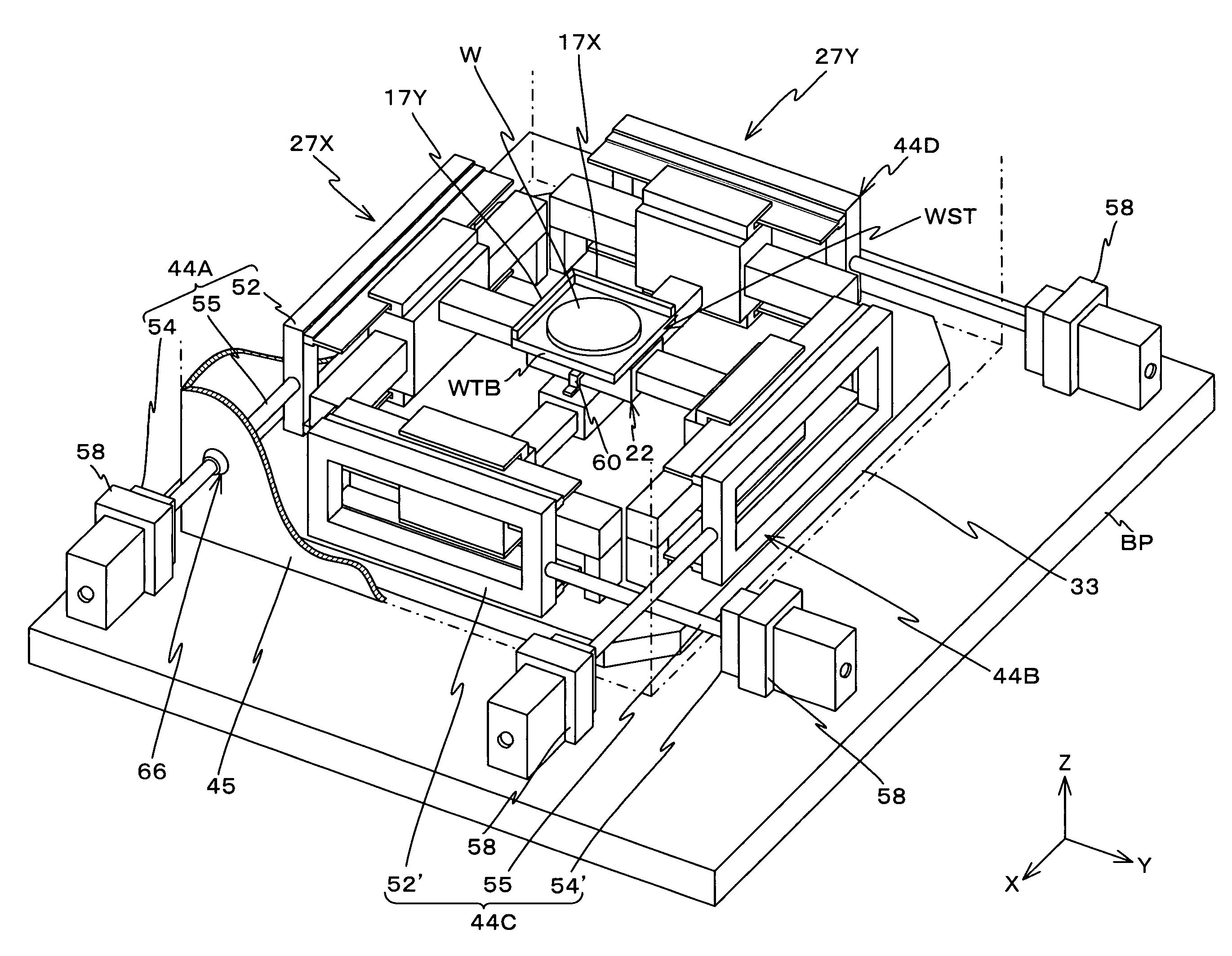

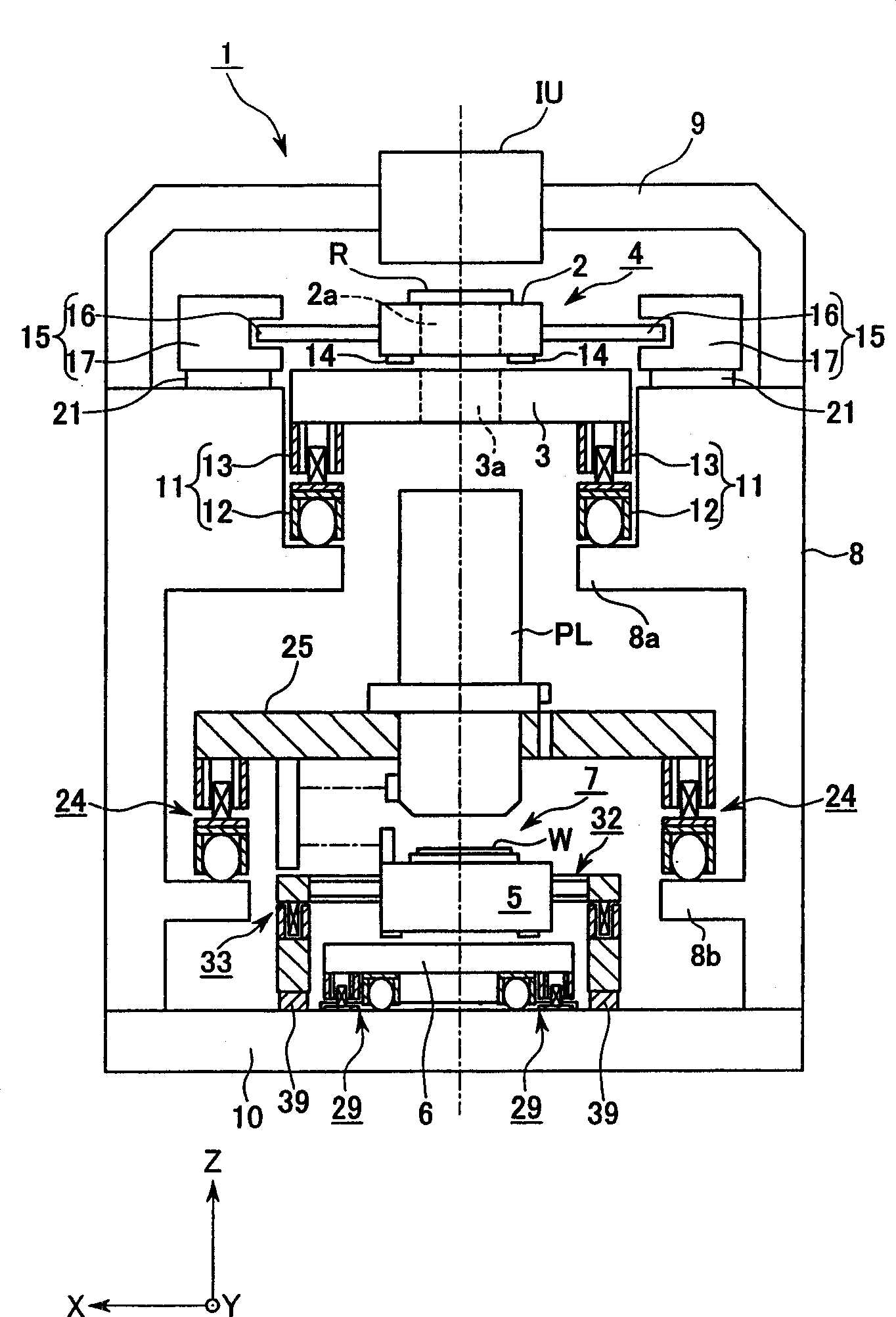

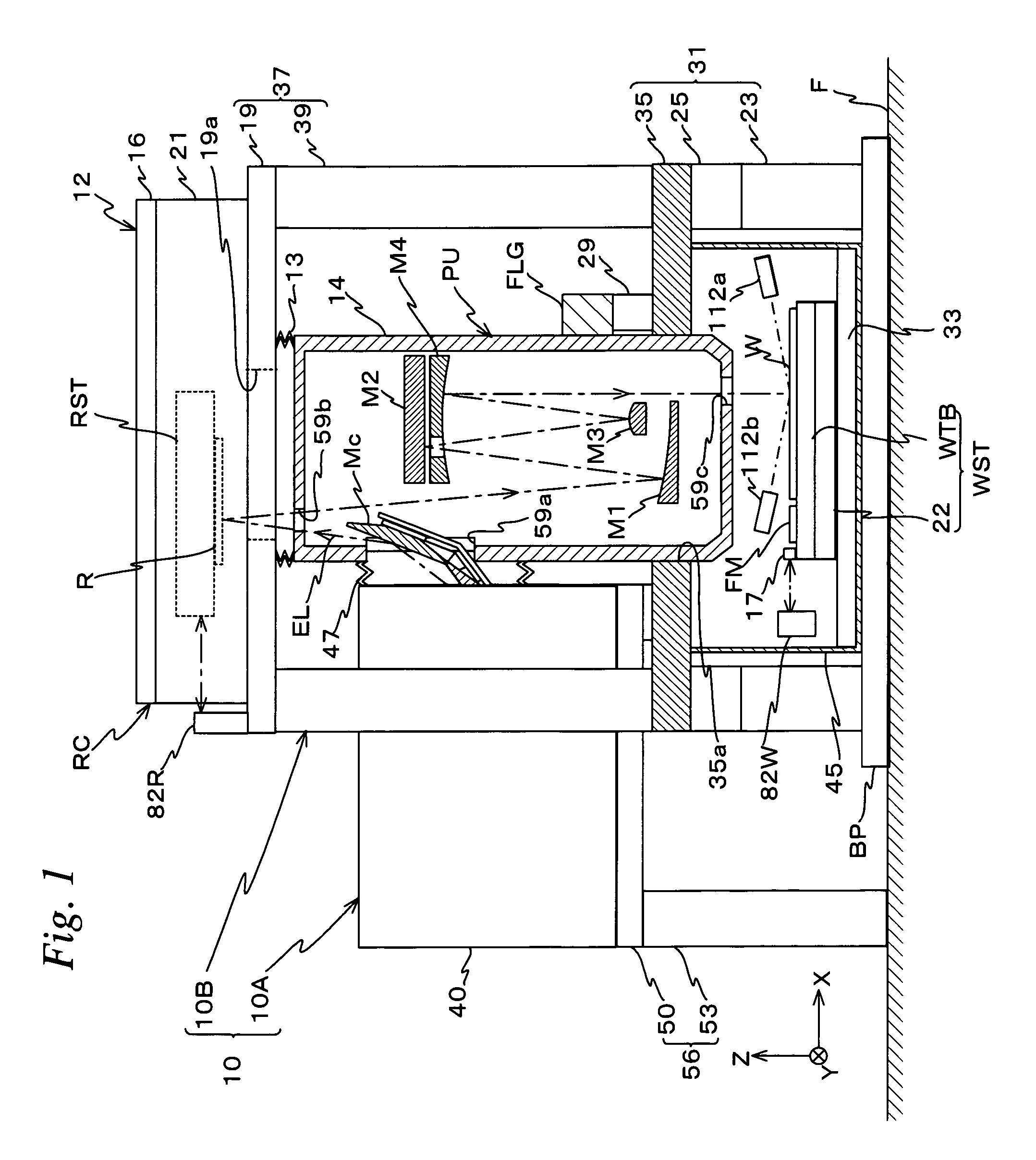

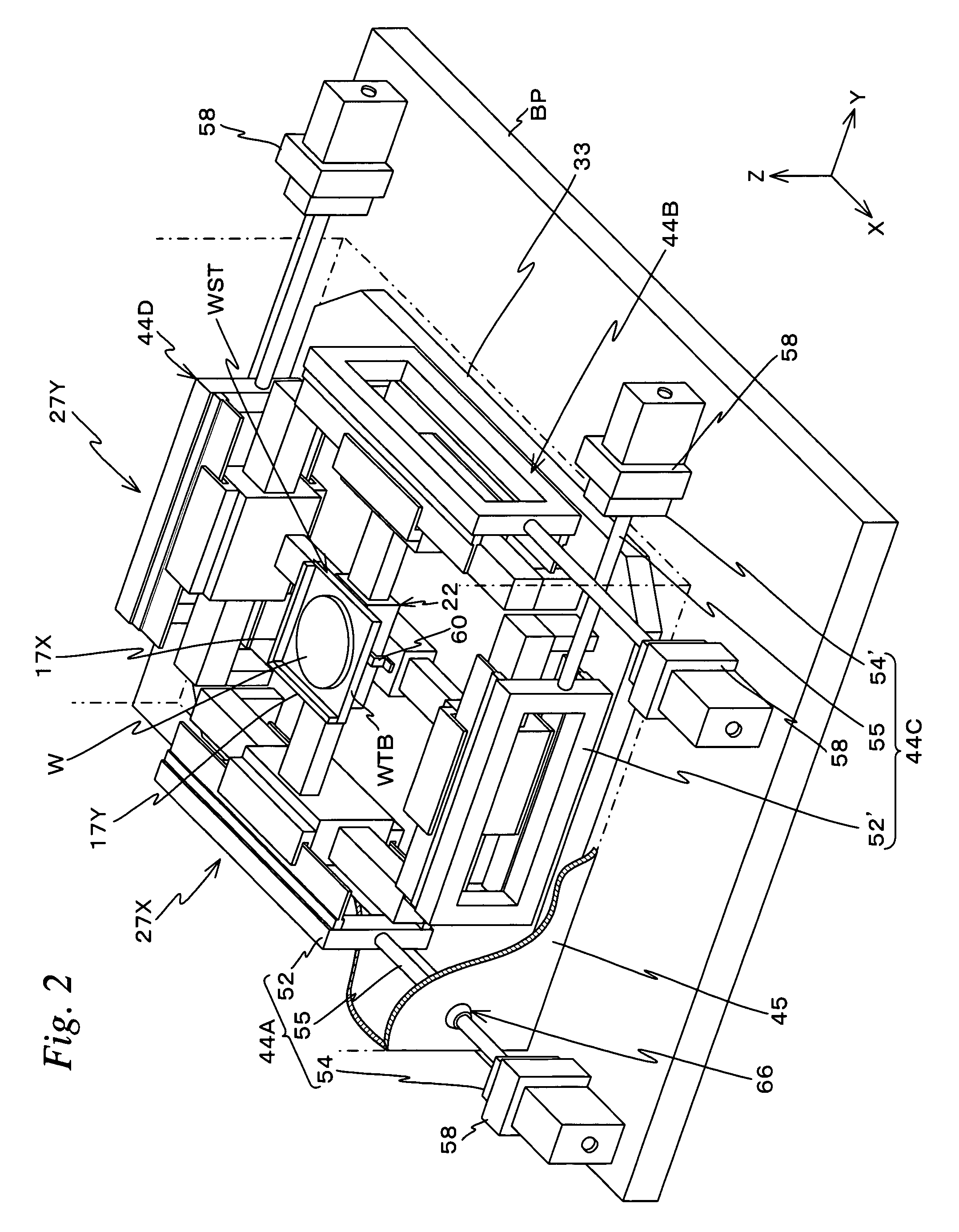

Movable Body System, Exposure Apparatus, And Device Manufacturing Method

InactiveUS20080123067A1Improve productivityImprove controllabilityPhotomechanical apparatusSemiconductor/solid-state device manufacturingBody systemElectrical and Electronics engineering

Stopper mechanisms keep a wafer table and a measurement table from moving closer than a predetermined distance, and the blocking by the stopper mechanisms can also be released by a drive mechanism. Therefore, for example, in the case X-axis stators are driven independently, even if at least one of the two tables go out of control, the stopper mechanisms can keep the tables from coming into contact with each other, and for example, in the case the tables are to be in a state closer than the predetermined distance, by a release mechanism that releases the blocking of the stopper mechanisms, the tables can approach each other without the stopper mechanisms interfering.

Owner:NIKON CORP

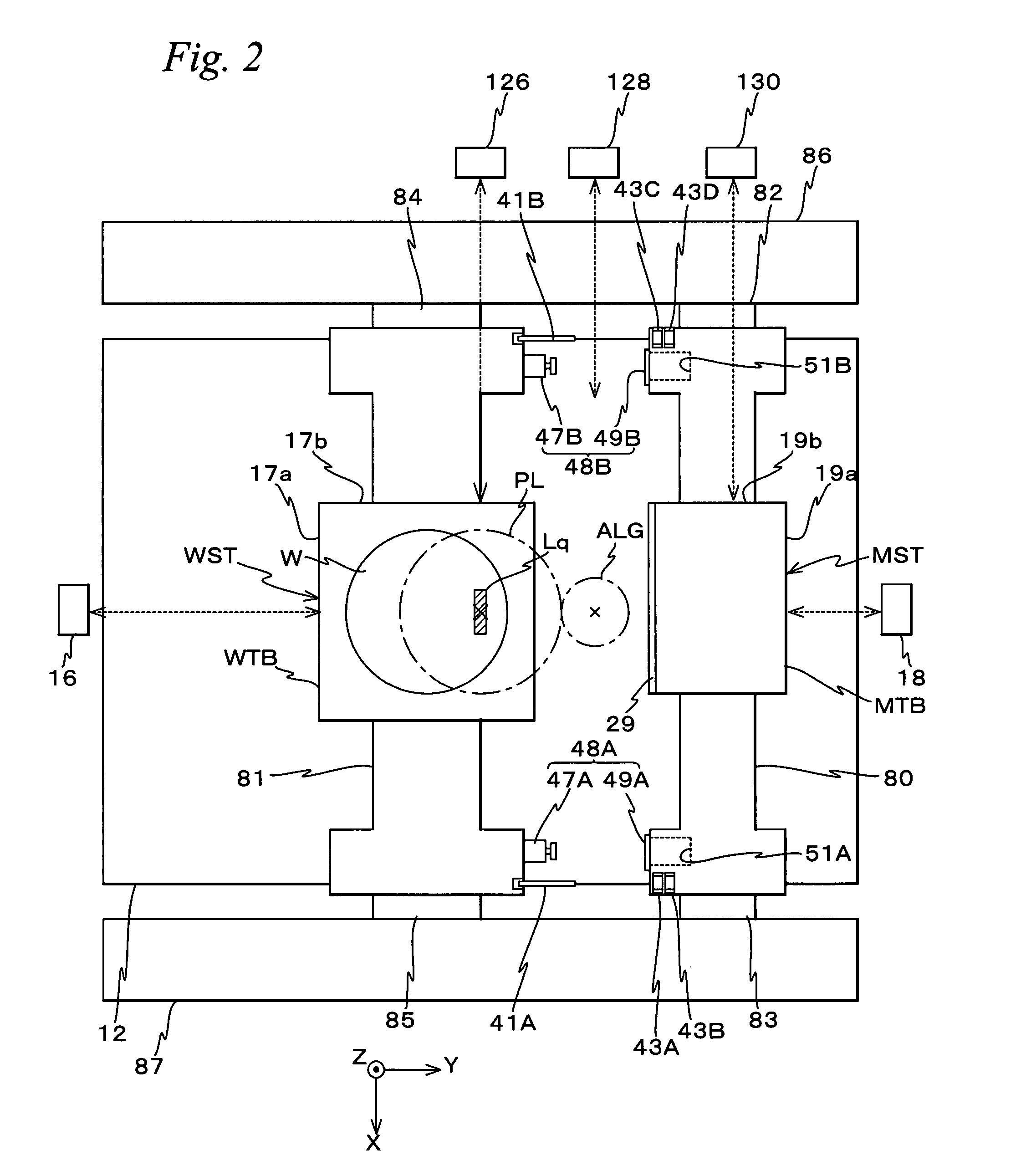

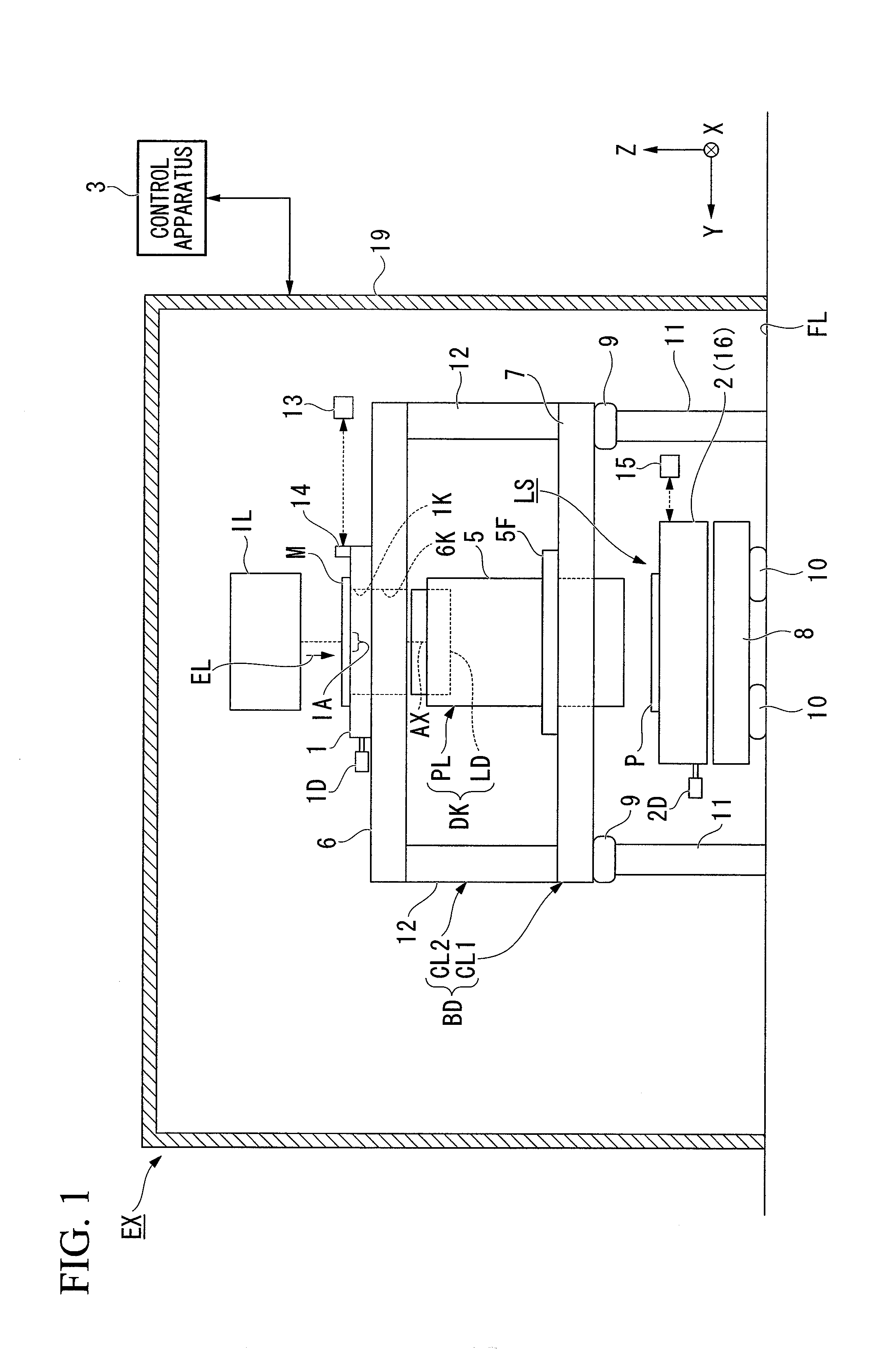

Exposure method and exposure apparatus, light source unit and adjustment method of light source unit, and device manufacturing method

InactiveUS20050094122A1Small workloadImprove Exposure AccuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPulse numberPulse energy

When scanning exposure is performed by illuminating an illumination area on a mask with a pulse light from a pulse light source, synchronously moving the mask and a photosensitive object, and transferring a pattern of the mask onto the photosensitive object, a main controller performs dose control on a high sensitivity range where scanning velocity of the mask and the photosensitive object is set at a maximum so as to maintain an exposure pulse number at a minimum exposure pulse number. A pulse light source, which pulse energy is variable within a predetermined range, maintains the exposure pulse number at the minimum exposure pulse number within the variable range. The pulse light source comprises a housing in which an outgoing opening that emits a light is formed, a plurality of units housed in the housing, and a drive unit that moves the plurality of units, partially or in total inside the housing.

Owner:NIKON CORP

Exposure apparatus and exposure method

InactiveUS20090073407A1Improve exposure accuracyIncrease in costPhotomechanical apparatusPhotographic printingPhysicsLight beam

An exposure apparatus illuminates a pattern on a first object with an illuminating beam to expose an area to be exposed on a second object with a pattern image. The exposure apparatus includes a scanning apparatus that scans the first object in a prescribed scanning direction with the illuminating beam, and an optical guiding device that guides the illuminating beam which has scanned the first object onto the area to be exposed on the second object.

Owner:NIKON CORP

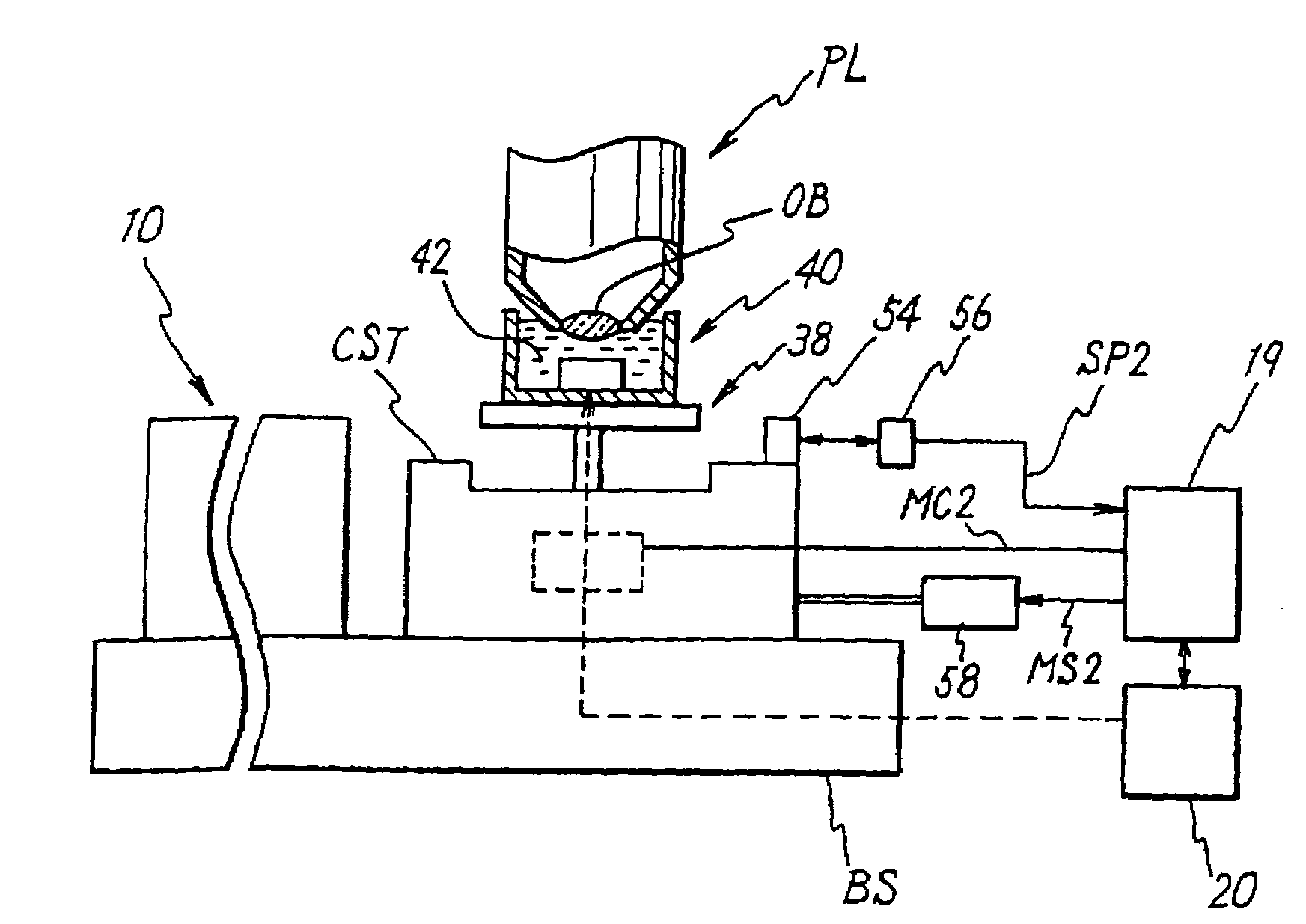

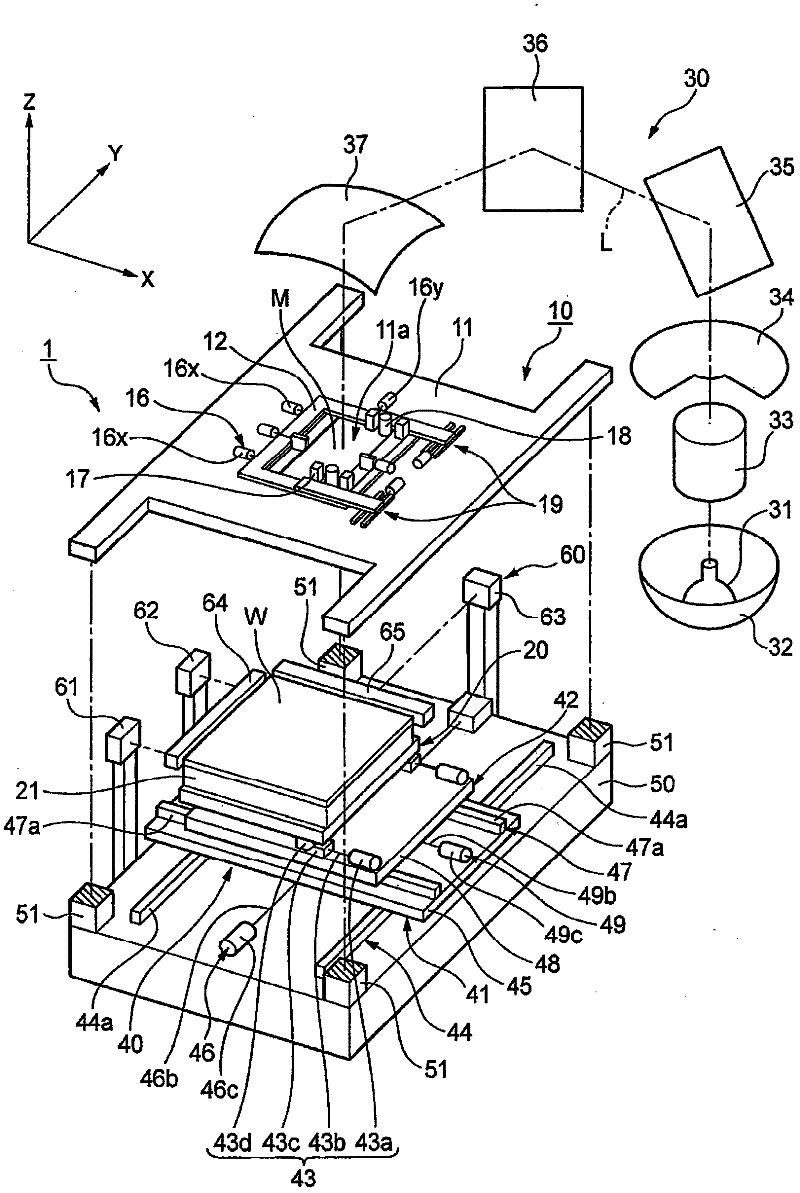

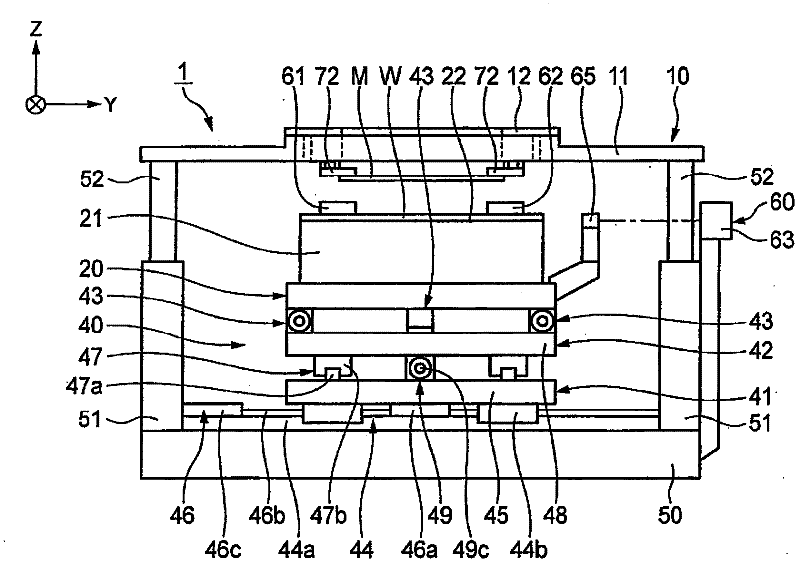

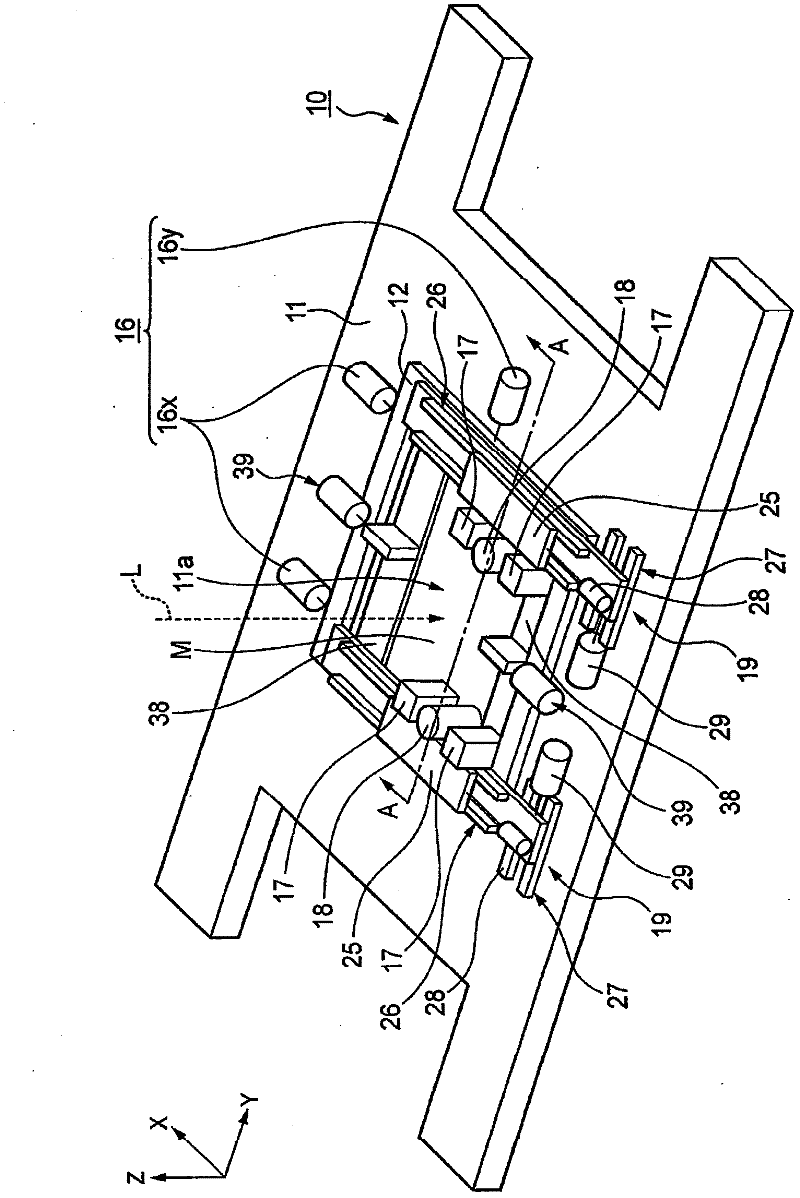

Stage unit and exposure apparatus

ActiveUS20070103660A1Degree of freedomIncrease freedomPhotomechanical apparatusAircraft stabilisation by gravity apparatusEngineeringMechanical engineering

When a stage on which a wafer is mounted is driven in an X-axis direction by a liner motor, a reaction force of the drive force is generated at a stator and acts on a counterweight via the stator, and thereby the counterweight moves in a direction opposite to the stage in accordance with movement of the stage in the X-axis direction. Accordingly, the reaction force generated by the drive of the stage can substantially be canceled by the movement of the counterweight. Further, since the counterweight has a first section that is connected to the stator, and a second section that is separated from the first section in the X-axis direction and connected to the first section via a connection section, a partition wall of a chamber can be placed using the connected portion as a boundary, and the second section of the counterweight can be located outside the partition wall. Thus, a stage housing space can be set to smaller.

Owner:NIKON CORP

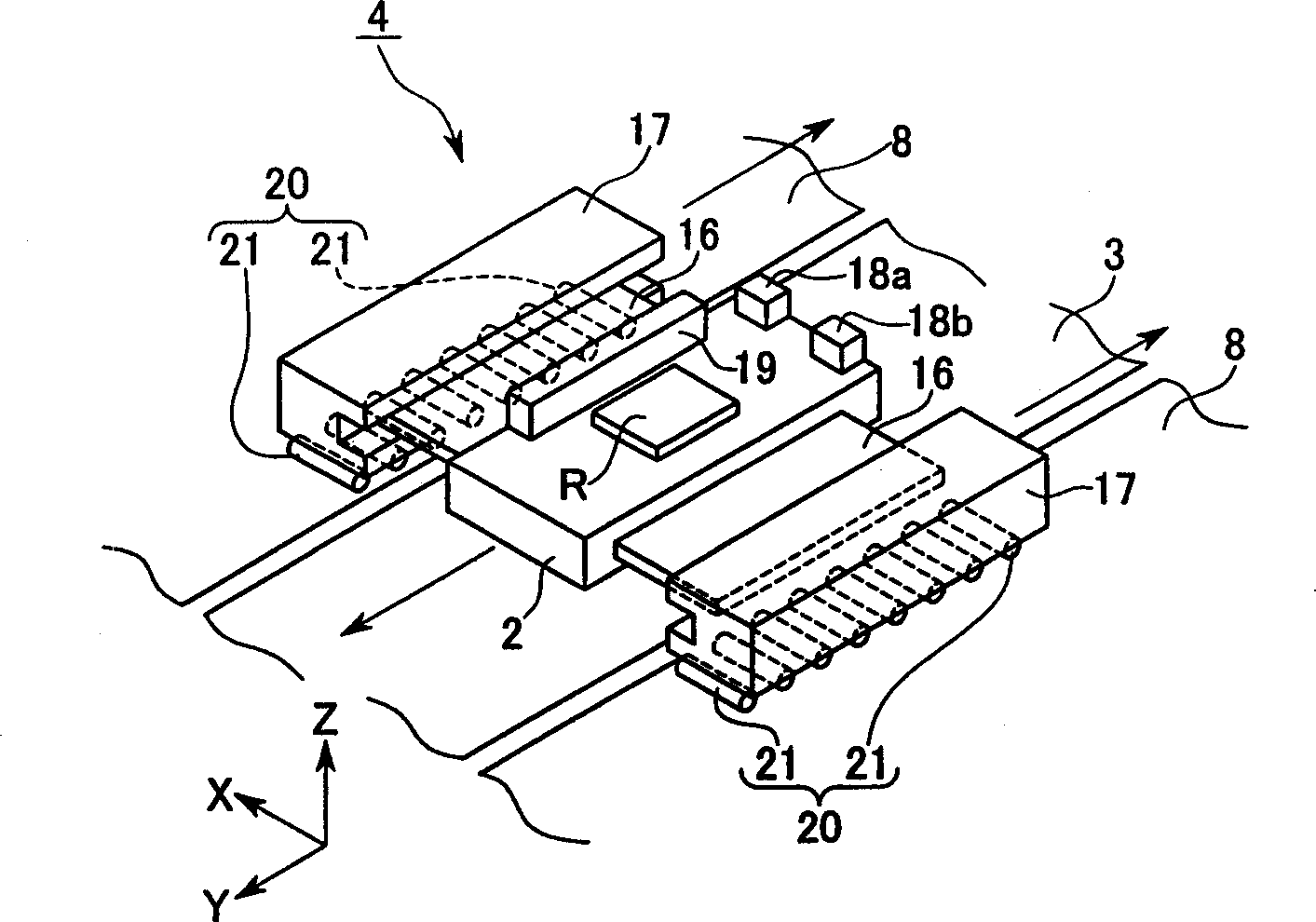

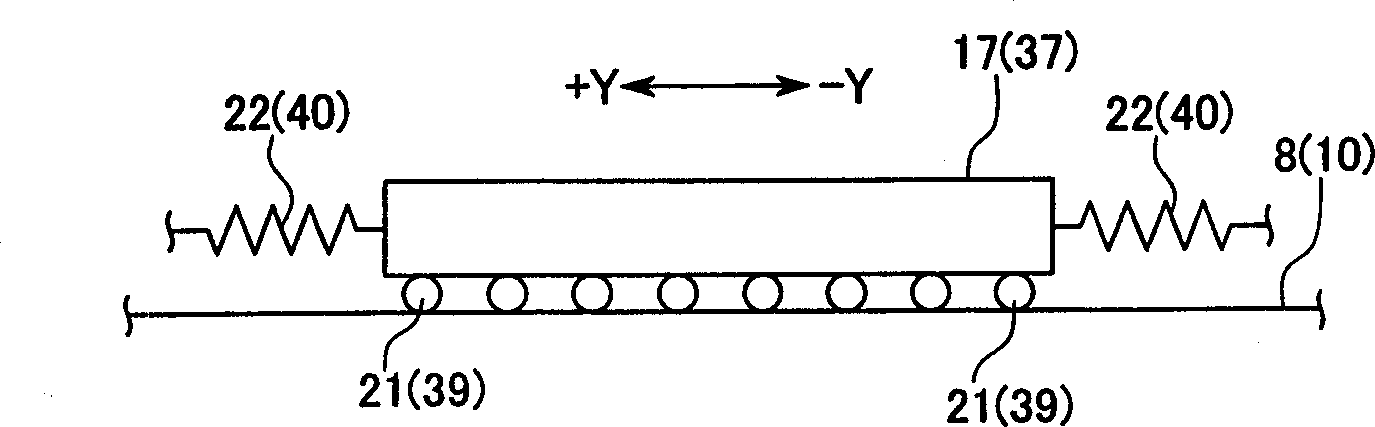

Substrate, stage device, method of driving stage, exposure system and exposure method

InactiveCN1373900AMaintain positional controlAvoid problems such as swayingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusProduction rateResidual vibration

The object stage device (4) includes: a support part (8), which is vibrateably and independently arranged relative to the fixed plate (3); and a reaction force stage (17), which is The resulting reaction force is free to move on the support (8) in said one direction. Thereby, since problems such as shaking due to the reaction force can be avoided, the adjustment time can be shortened, productivity can be improved, and transmission of residual vibration of the support portion to the fixed plate can be suppressed.

Owner:NIKON CORP

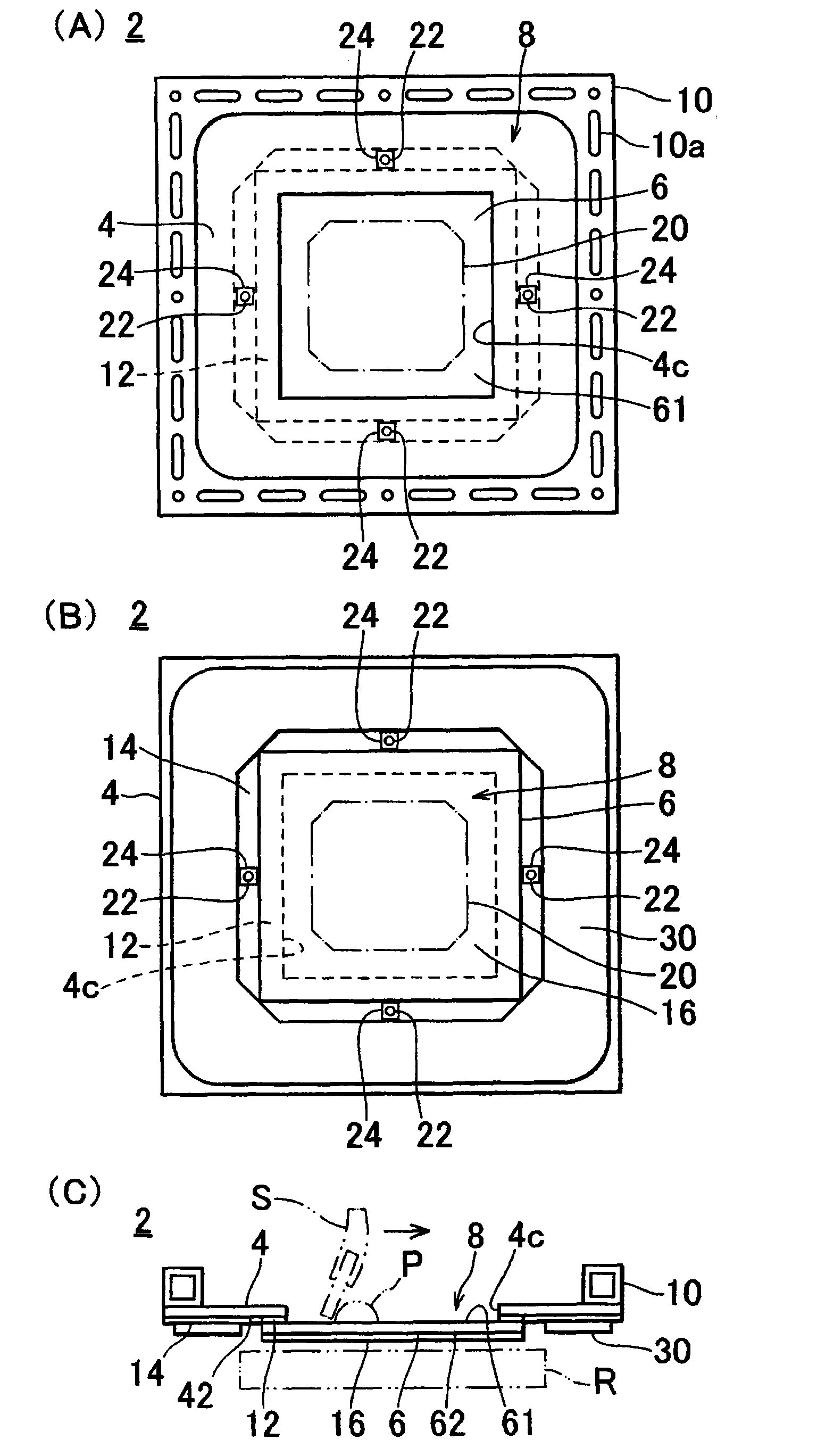

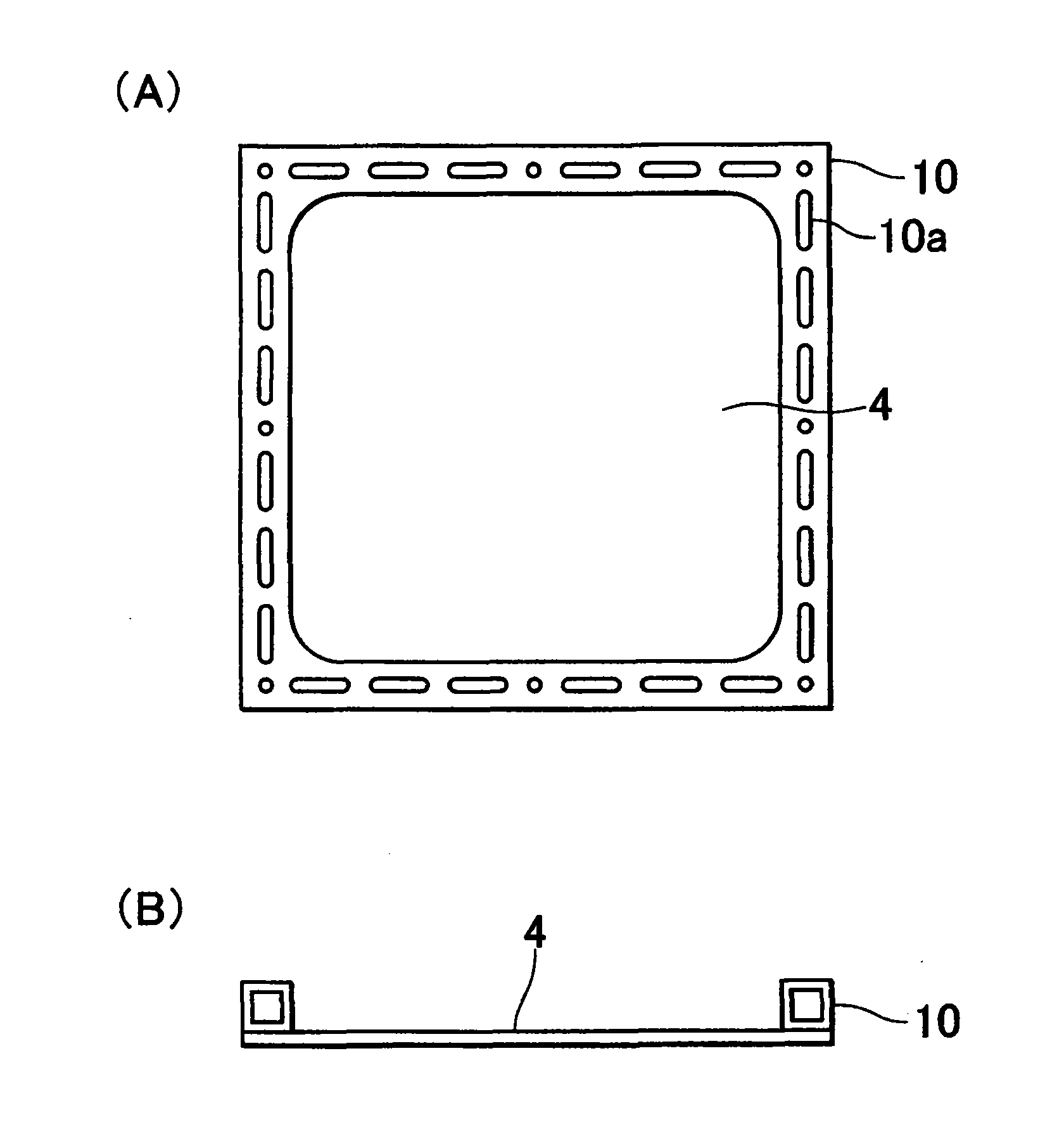

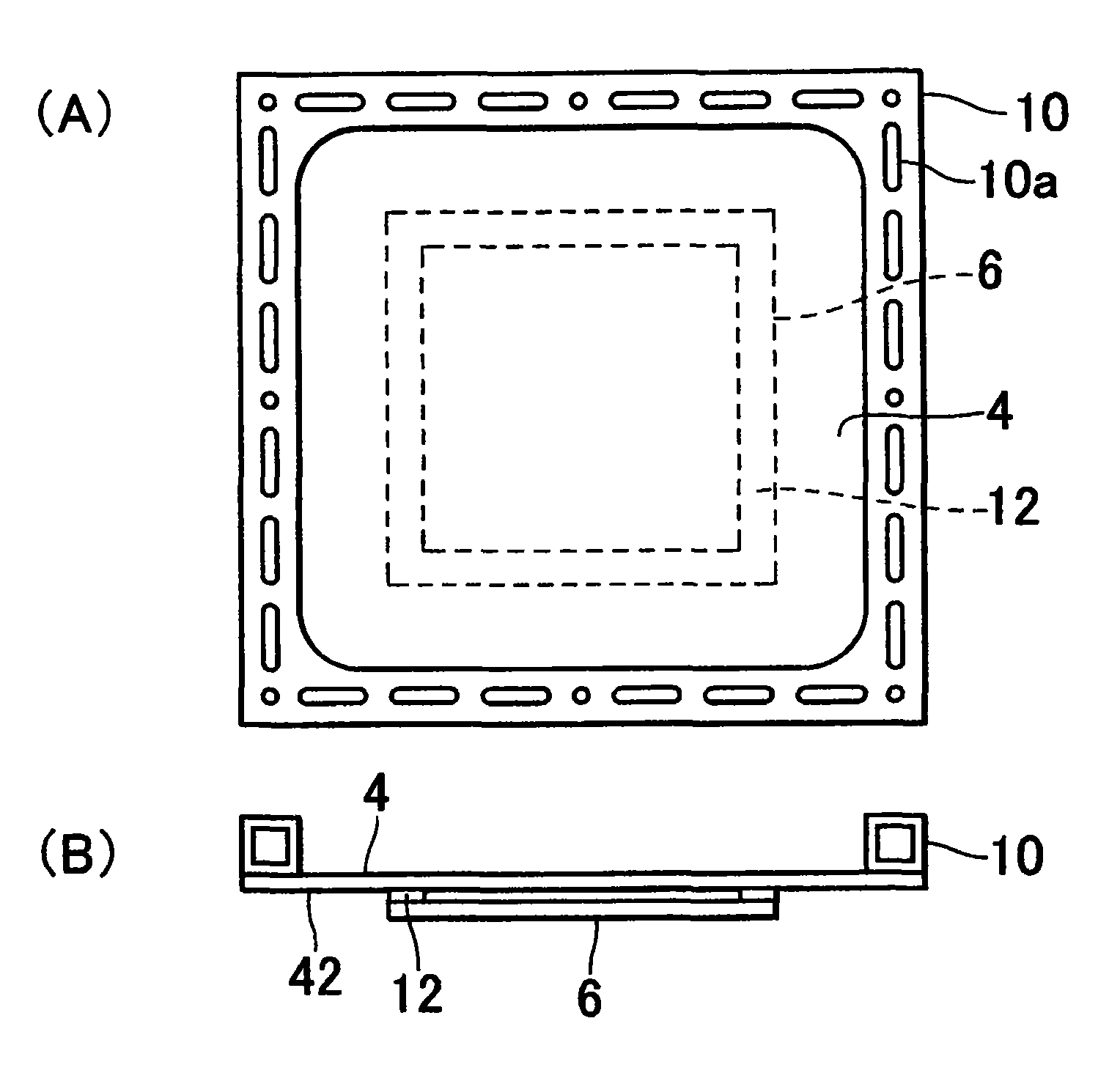

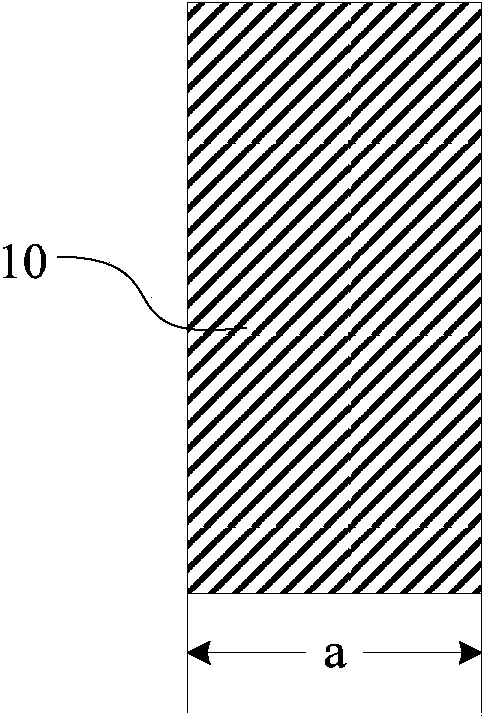

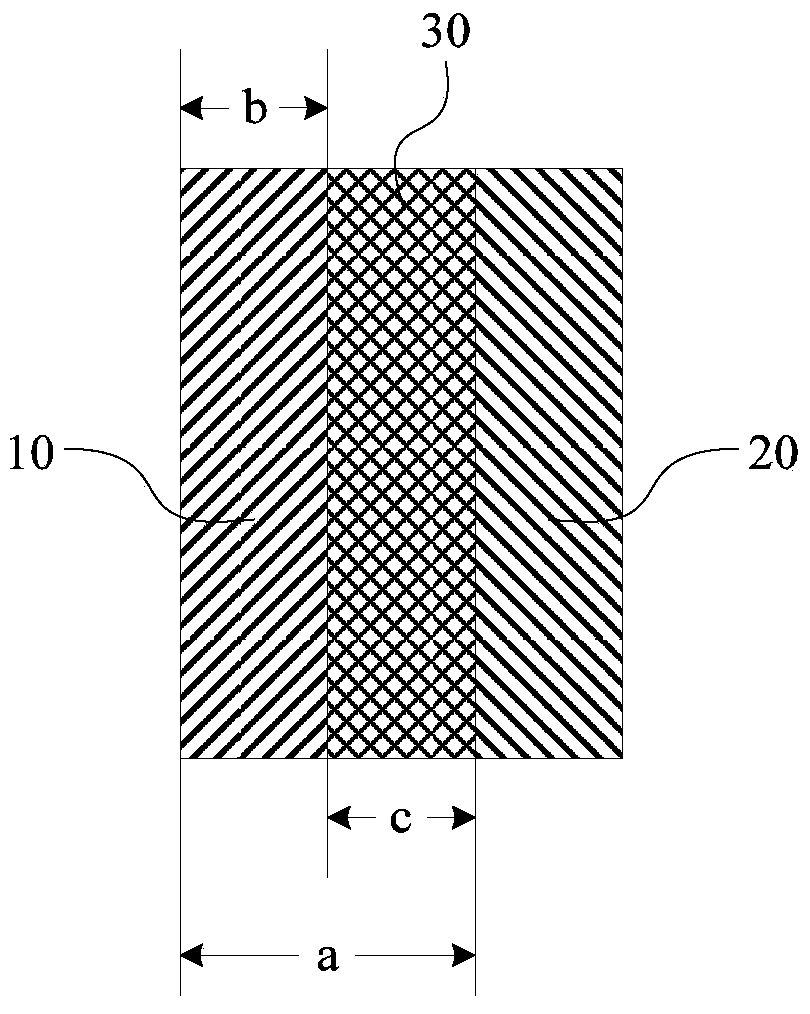

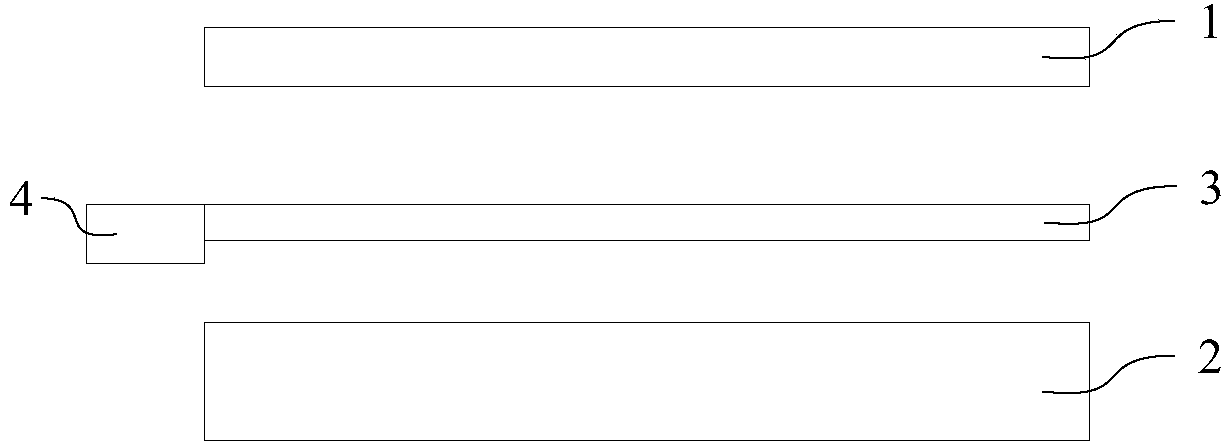

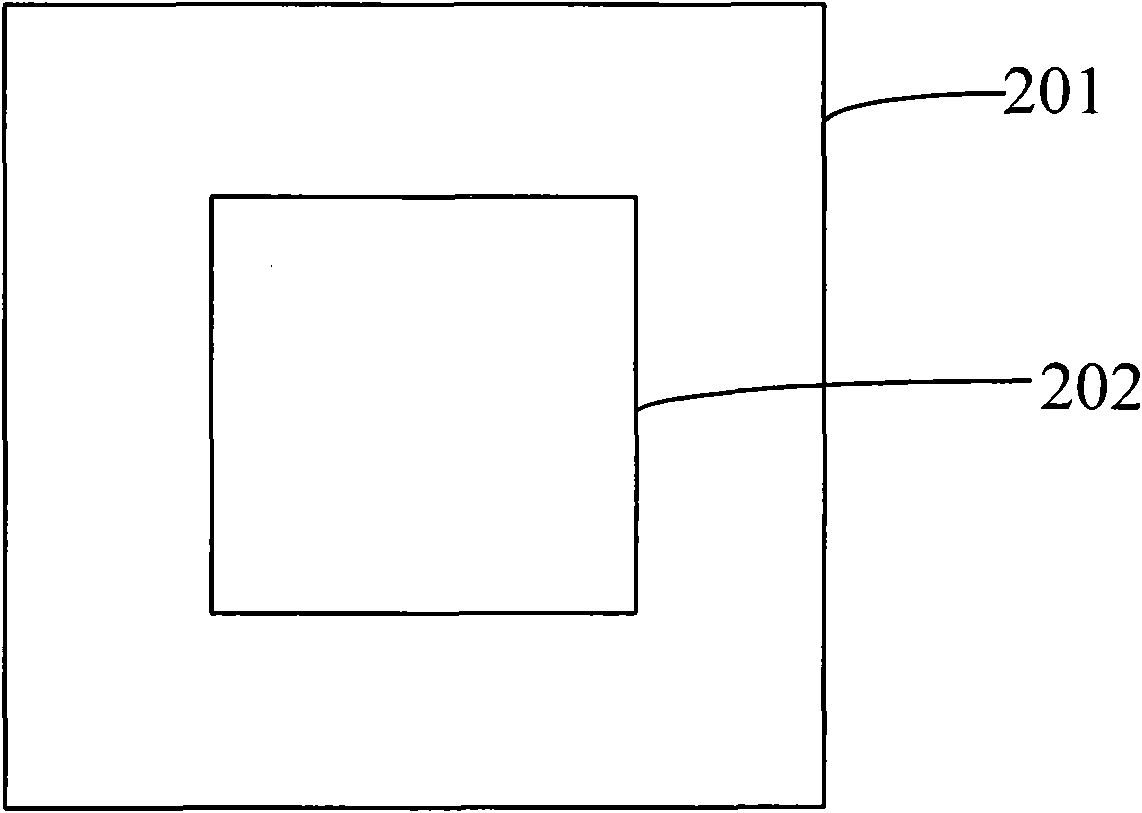

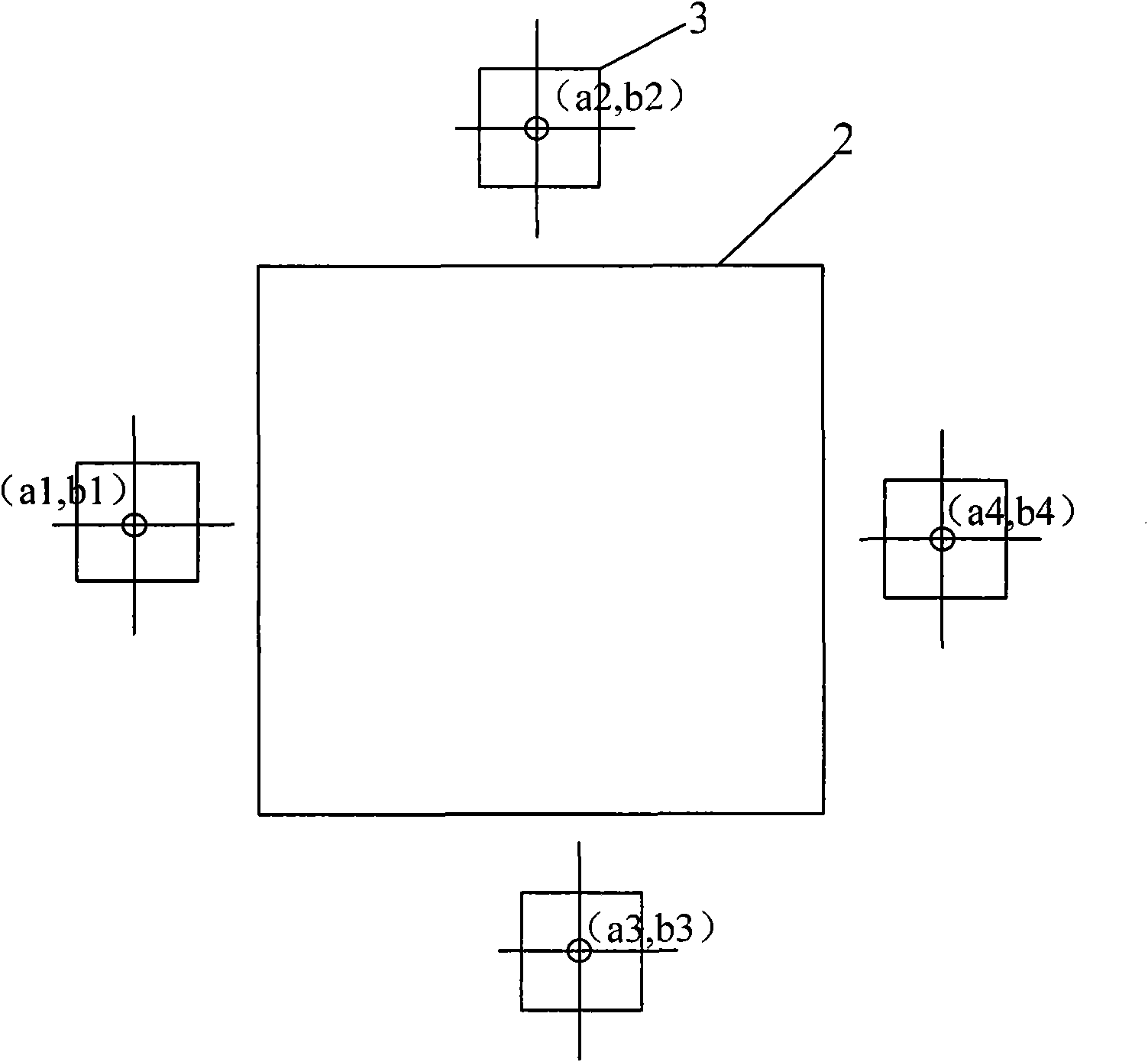

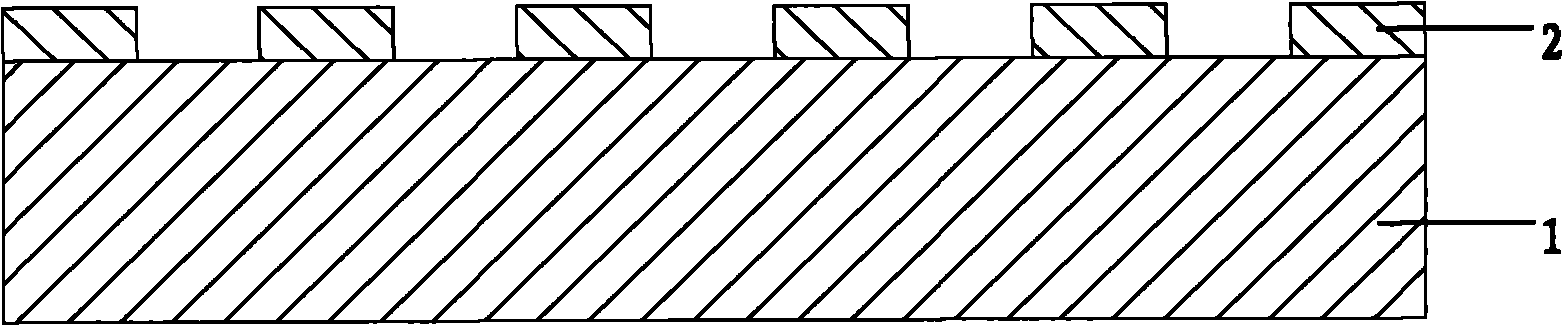

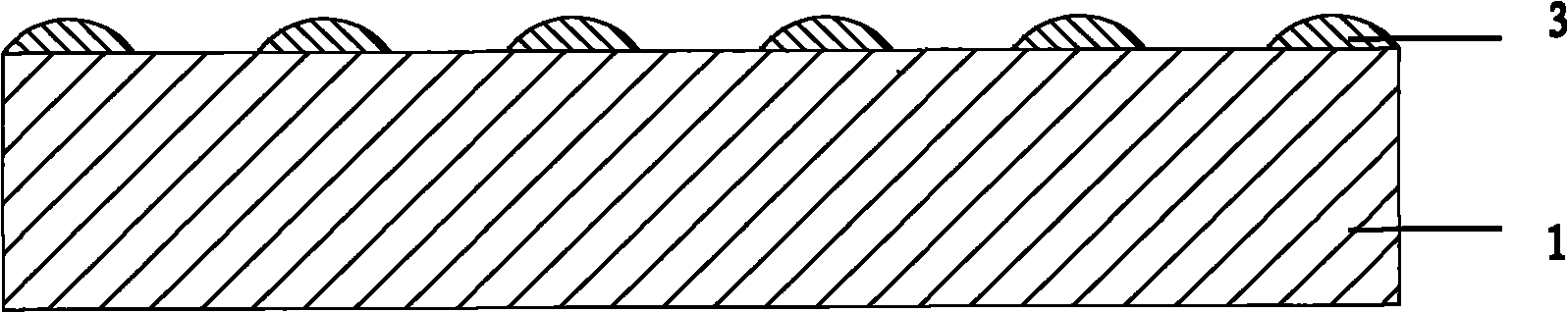

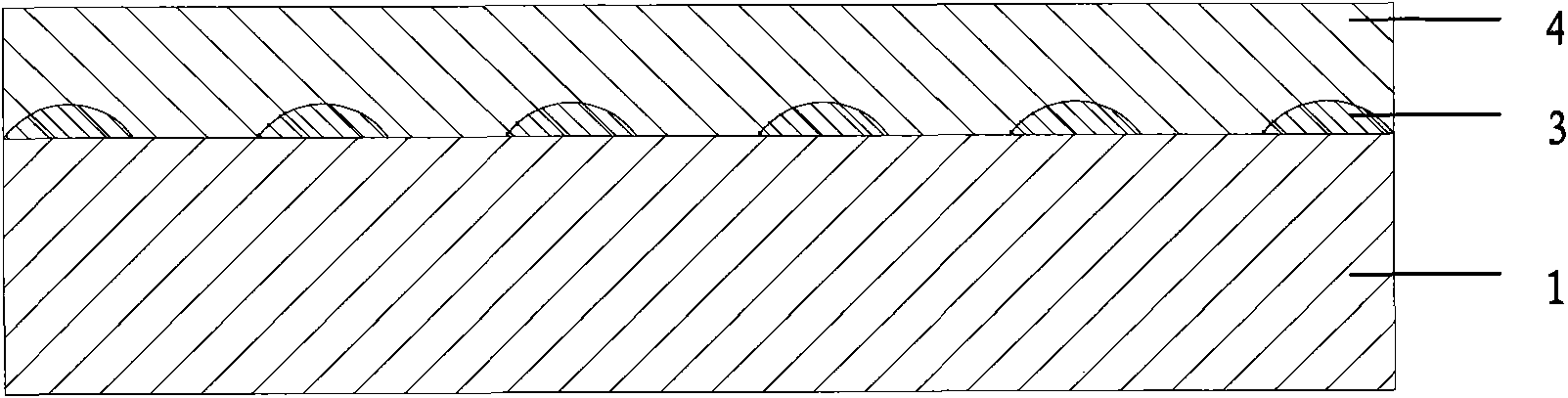

Screen printing plate and manufacturing method thereof

ActiveCN102211446ANo deterioration in exposure accuracy occursExcellent productivityScreen printersForme preparationYarnRelative displacement

The invention provides a screen printing plate and a manufacturing method thereof. The screen printing plate (2) comprises an outer yarn (4) of an opening part (4c) made of resin net; an inner yarn (6) matched with the outer yarn (4) of the opening part (4c) and made of metal net; an emulsion layer (16) for printed patterns made of phototonus resin and formed with printed patterns (20) on the inner yarn (6); an emulsion layer (14) for alignment marks made of phototonus resin and formed with alignment marks (22) on the outer yarn (4). The printed patterns (20) and the alignment marks (22) being separated by a photo mask (F) are formed by exposing and developing the emulsion layer (16) for printed patterns and the emulsion layer (14) for alignment marks. Therefore, the relative displacement between the printed patterns of the inner yarn and the alignment marks of the outer yarn is avoided and the manufacturing cost is low.

Owner:MURATA MFG CO LTD

Exposure apparatus

InactiveUS20070035713A1Improve Exposure AccuracyReduce displacementPhotomechanical apparatusPhotographic printingRelative displacementEngineering

An exposure apparatus includes a first structure which supports a projection unit which projects an exposure beam onto a substrate, a first anti-vibration supporting leg which includes a first actuator and supports the first structure, a second structure which supports a substrate stage which aligns the substrate, a second anti-vibration supporting leg which includes a second actuator and supports the second structure, and a control unit which controls at least one of the first actuator and the second actuator to reduce the relative displacement between the first structure and the second structure.

Owner:CANON KK

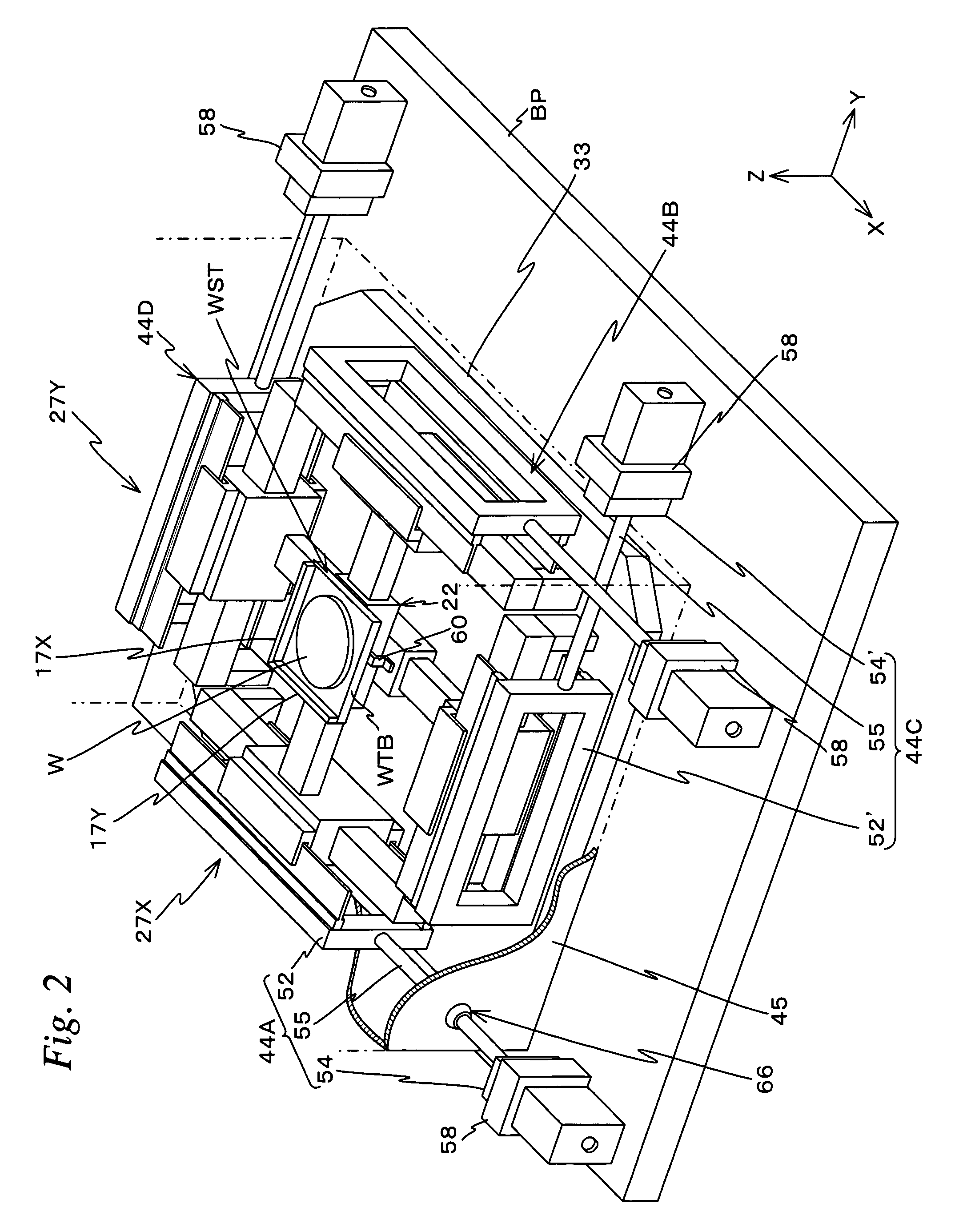

Stage unit and exposure apparatus

ActiveUS7557529B2Increase freedomImprove Exposure AccuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

When a stage on which a wafer is mounted is driven in an X-axis direction by a liner motor, a reaction force of the drive force is generated at a stator and acts on a counterweight via the stator, and thereby the counterweight moves in a direction opposite to the stage in accordance with movement of the stage in the X-axis direction. Accordingly, the reaction force generated by the drive of the stage can substantially be canceled by the movement of the counterweight. Further, since the counterweight has a first section that is connected to the stator, and a second section that is separated from the first section in the X-axis direction and connected to the first section via a connection section, a partition wall of a chamber can be placed using the connected portion as a boundary, and the second section of the counterweight can be located outside the partition wall. Thus, a stage housing space can be set to smaller.

Owner:NIKON CORP

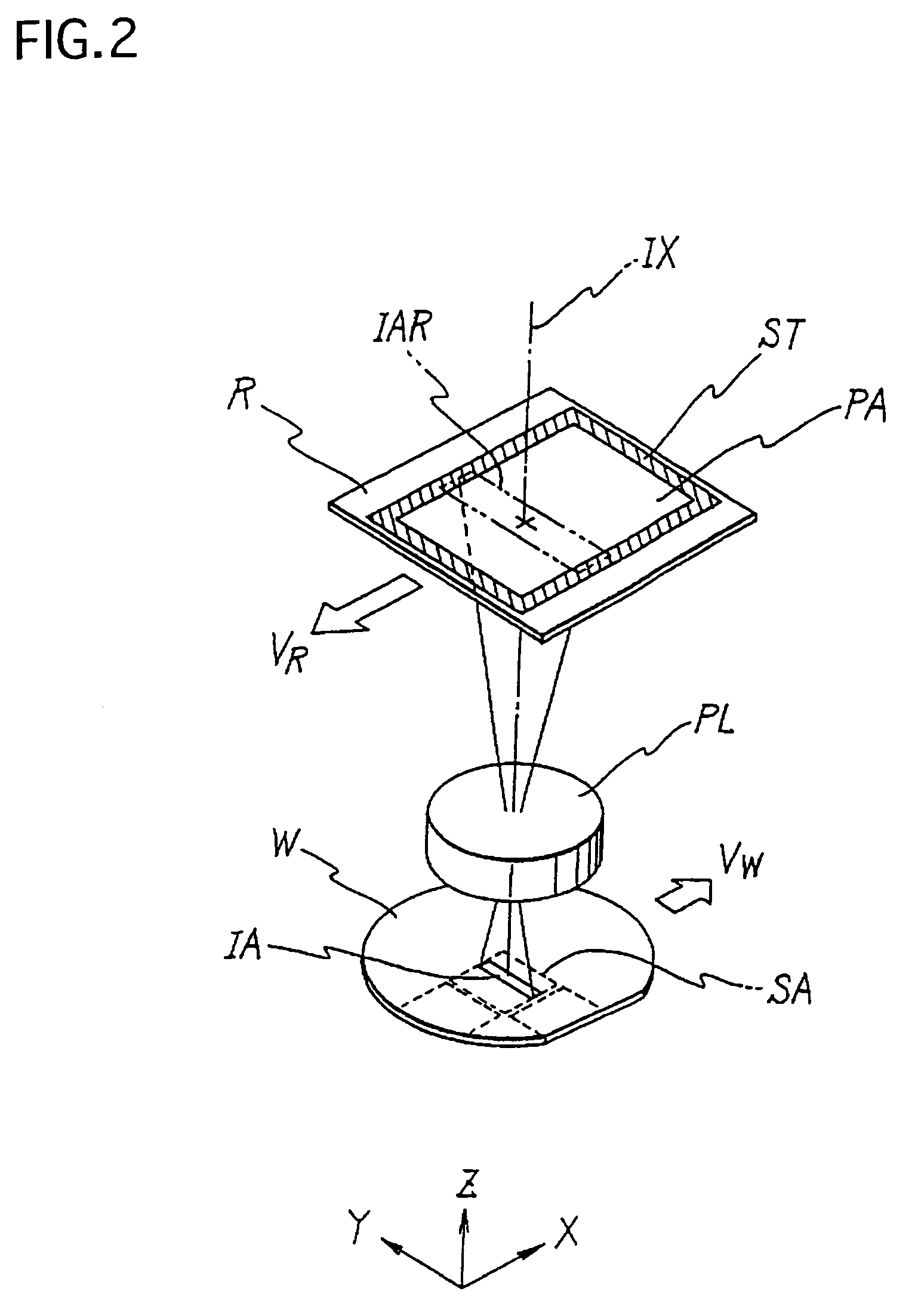

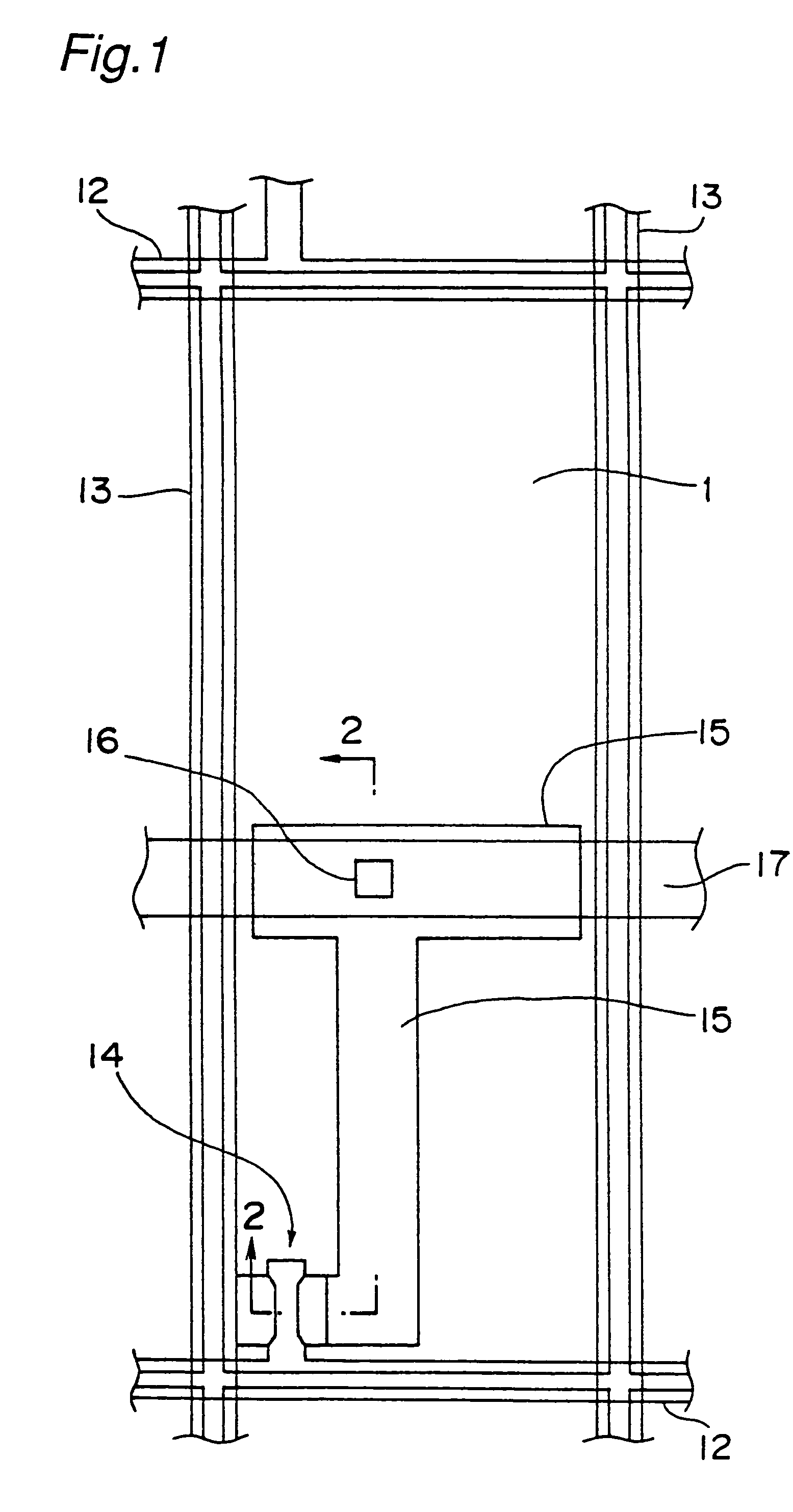

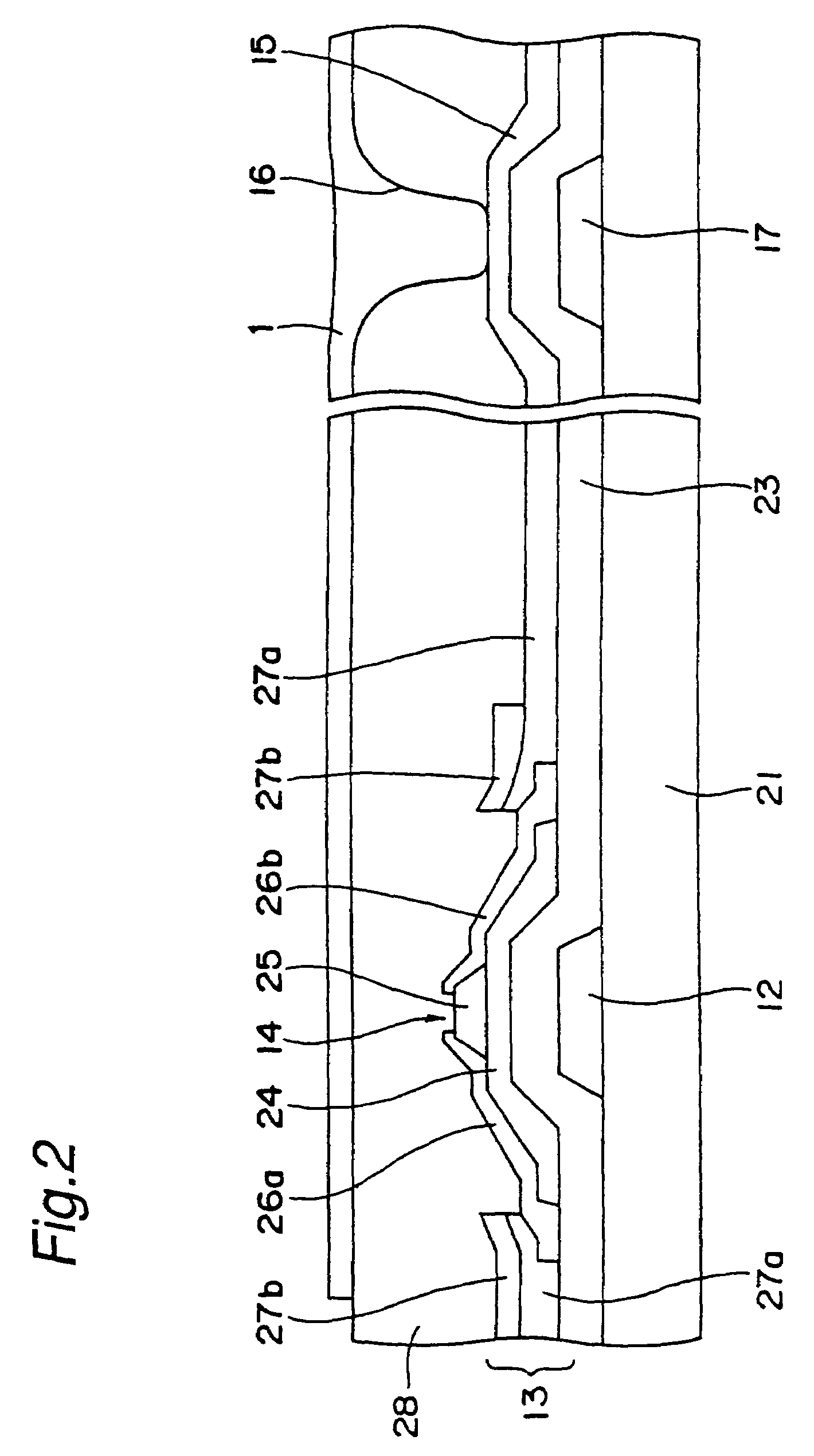

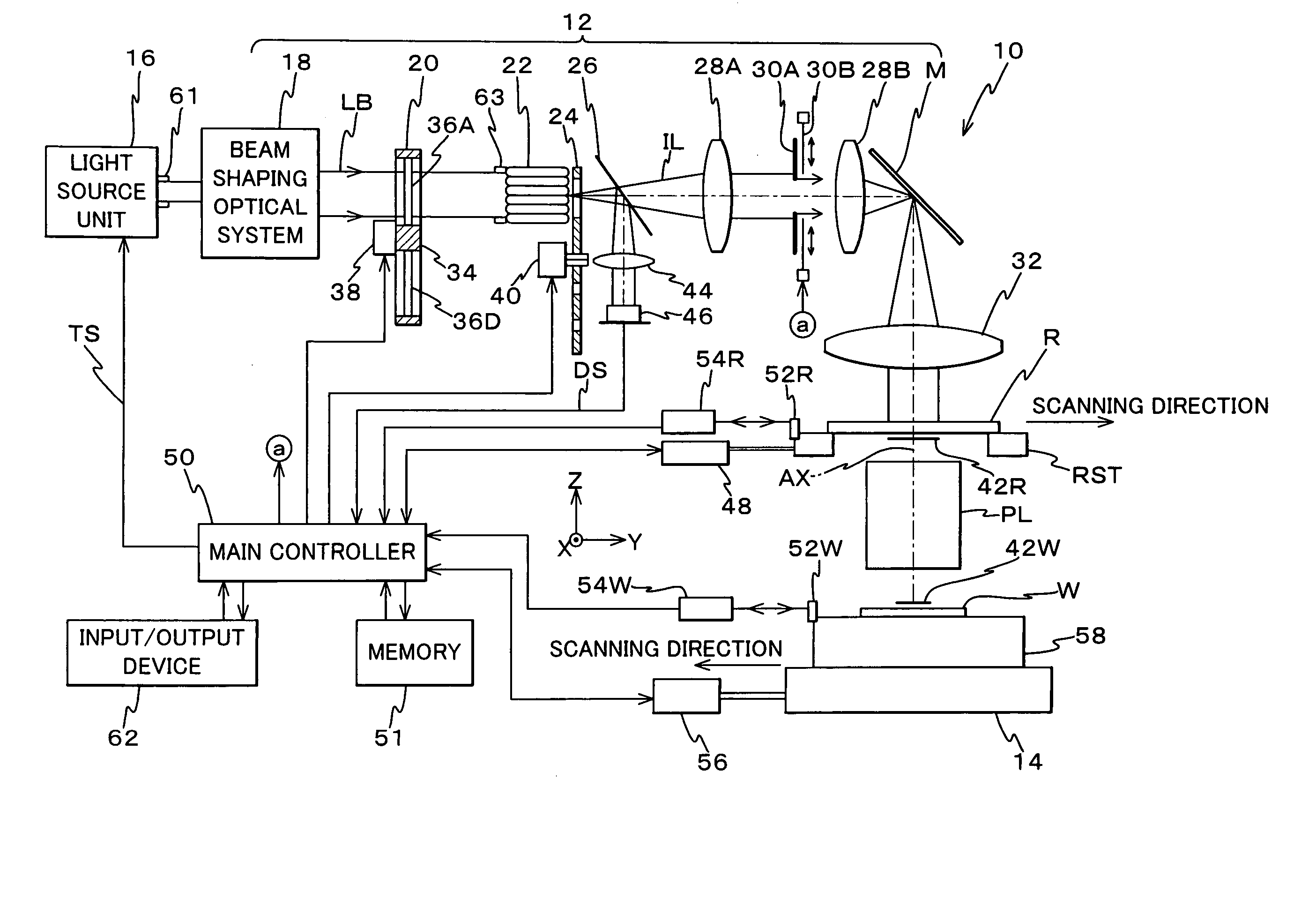

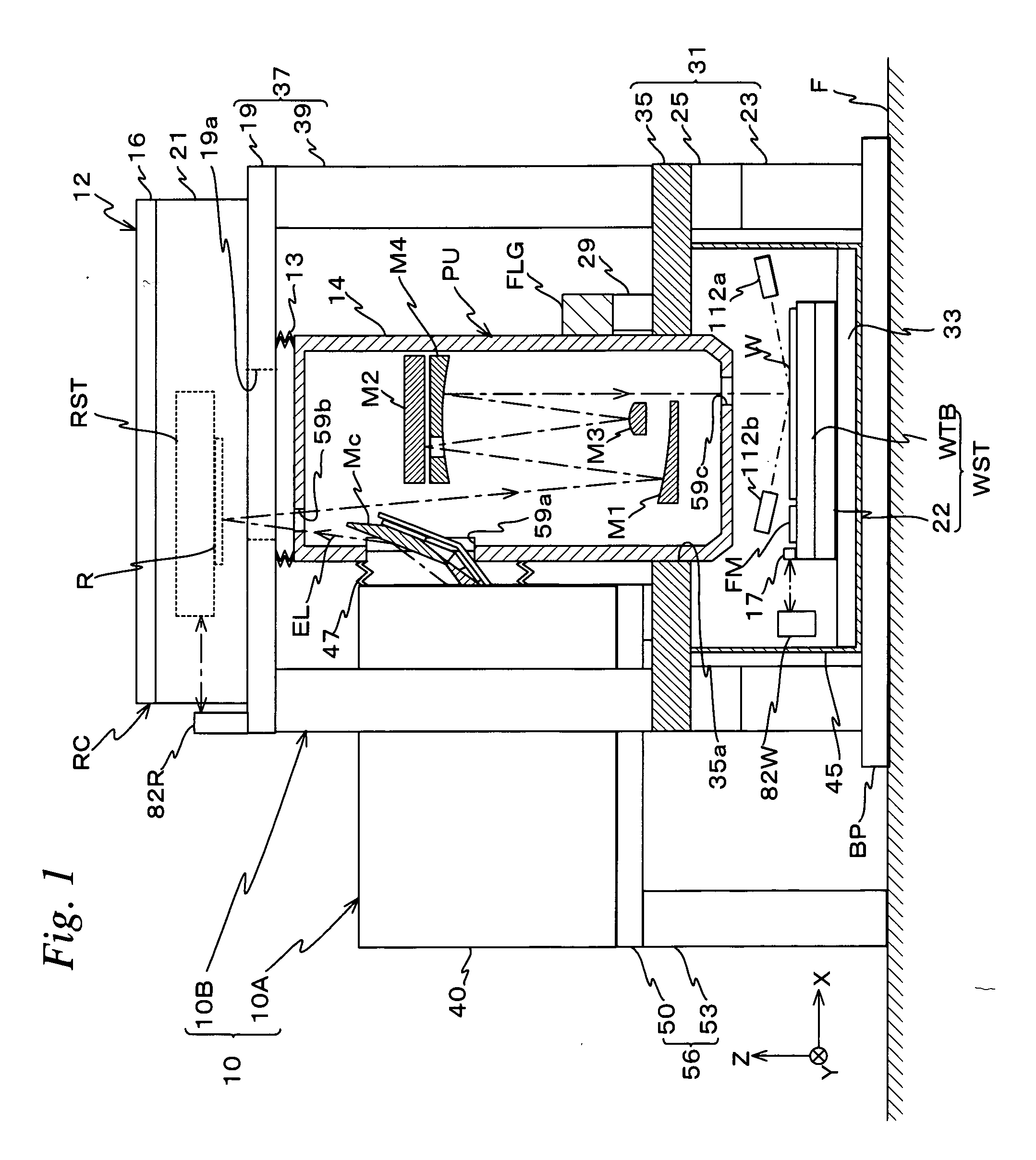

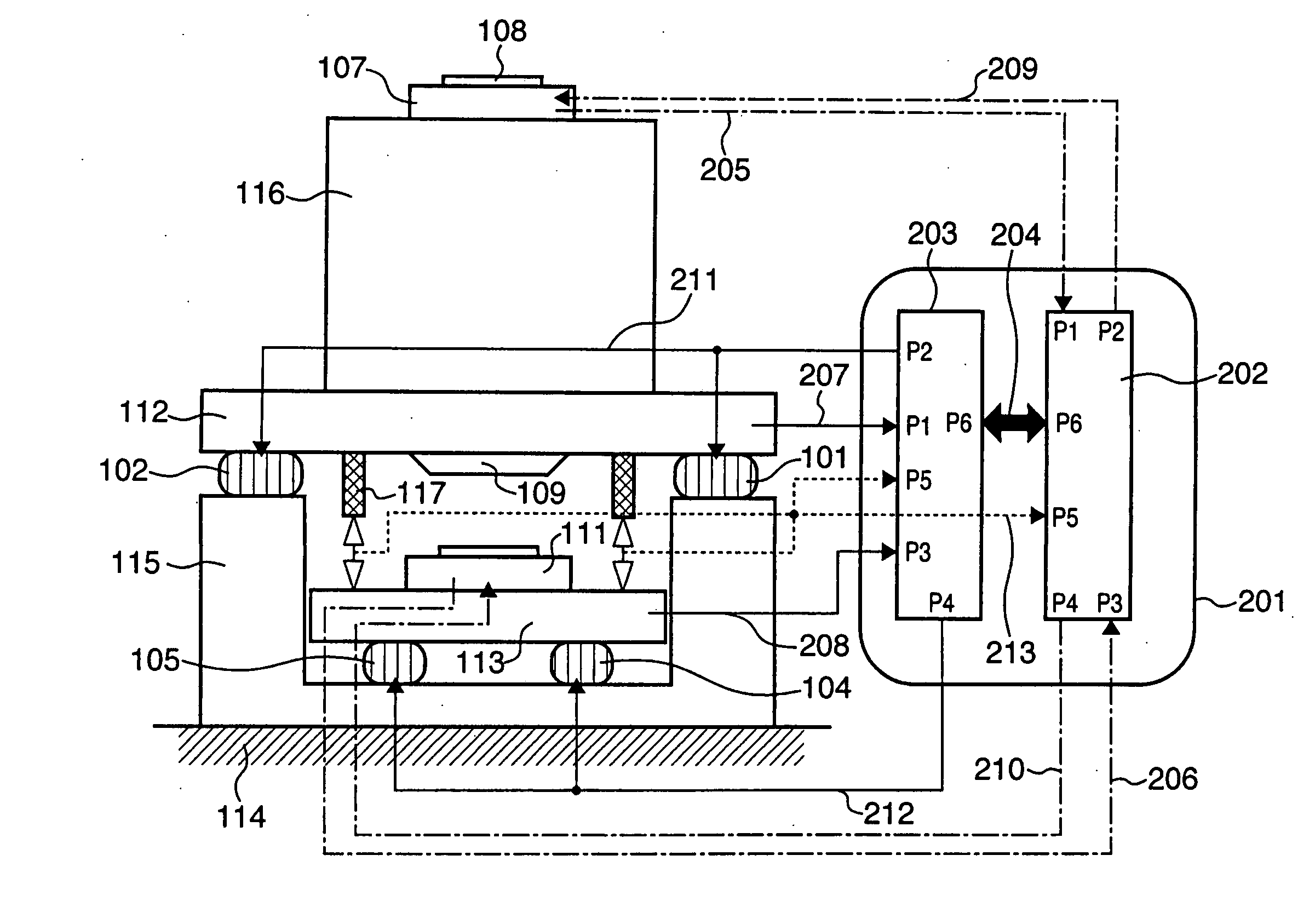

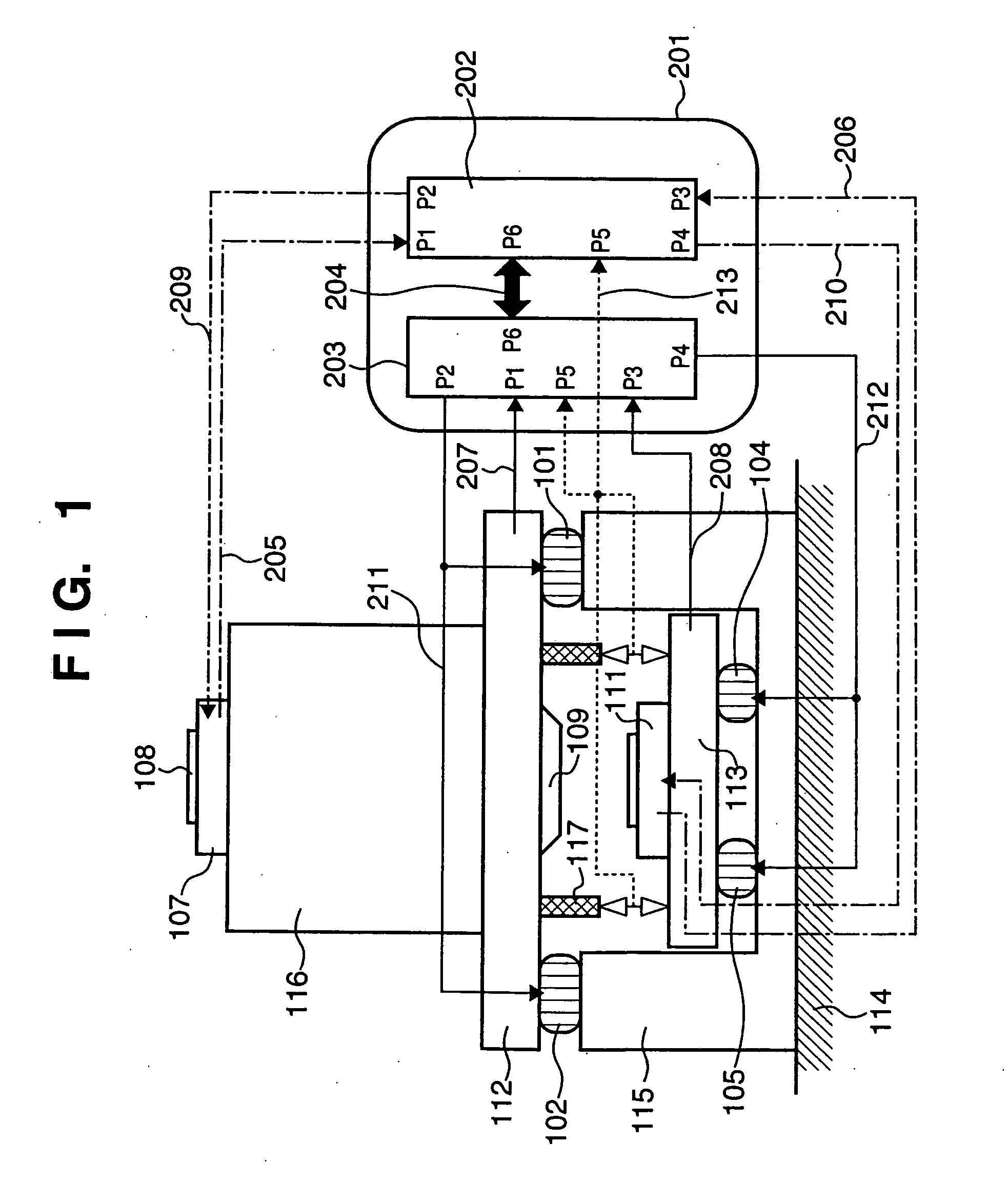

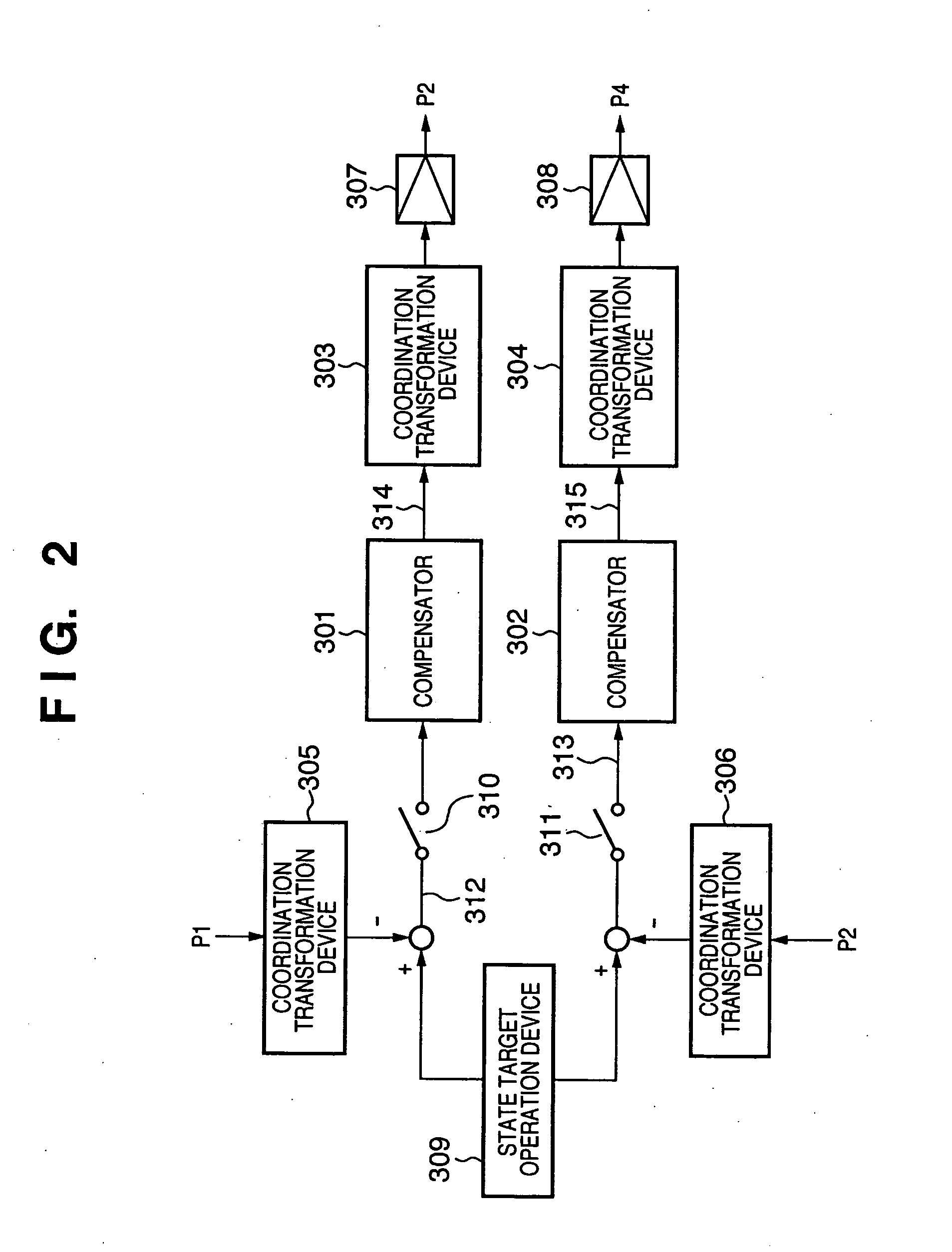

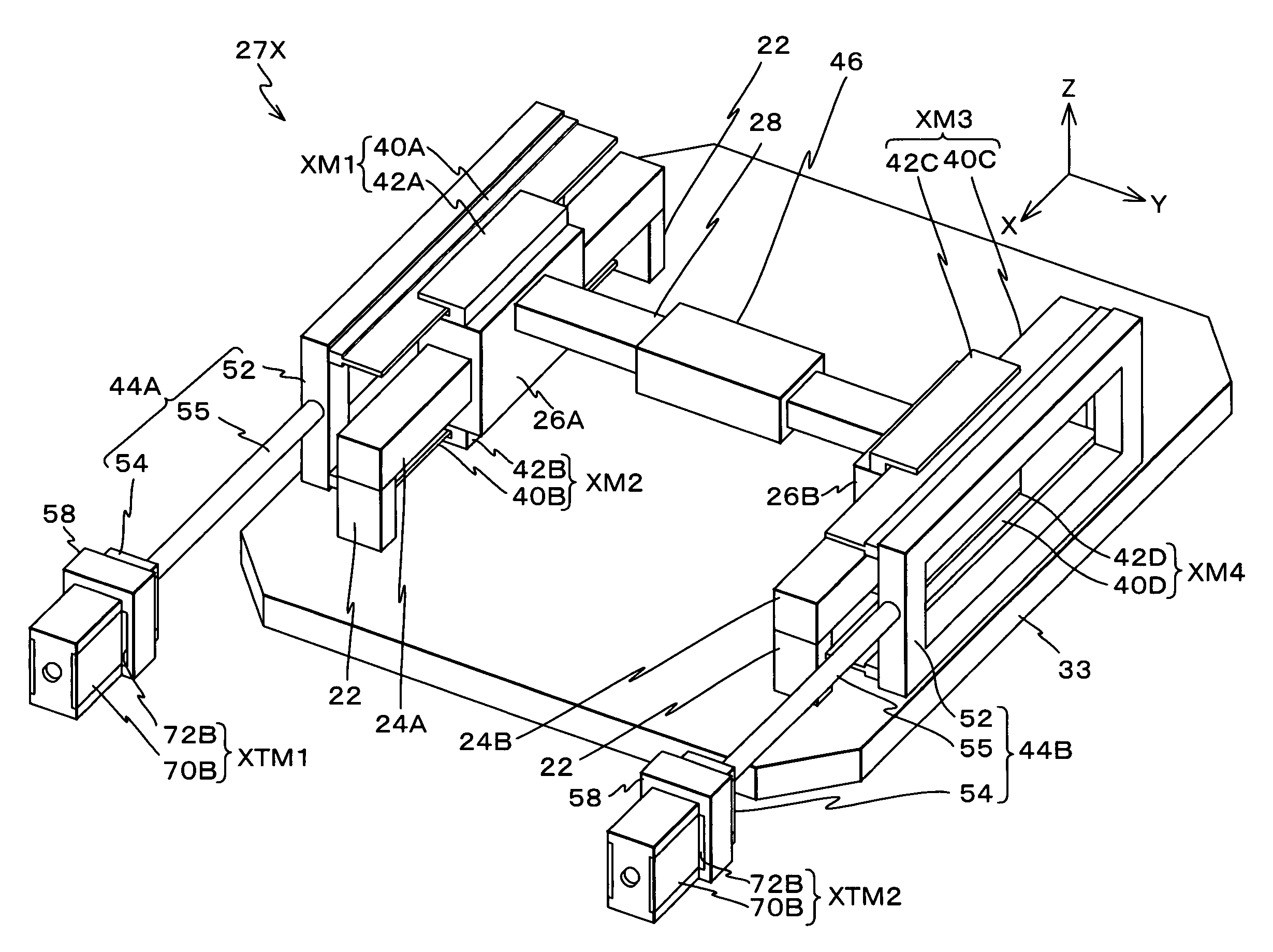

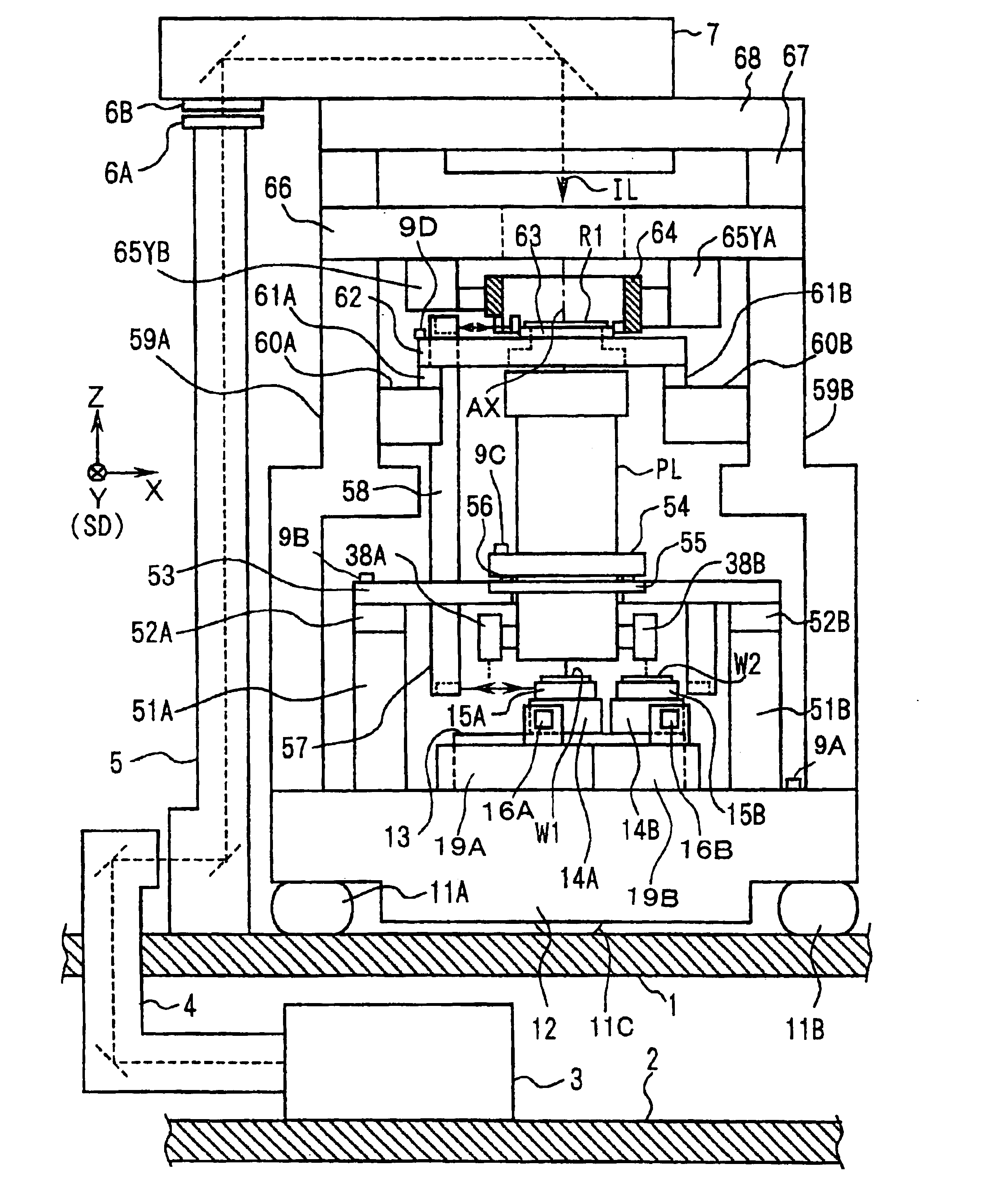

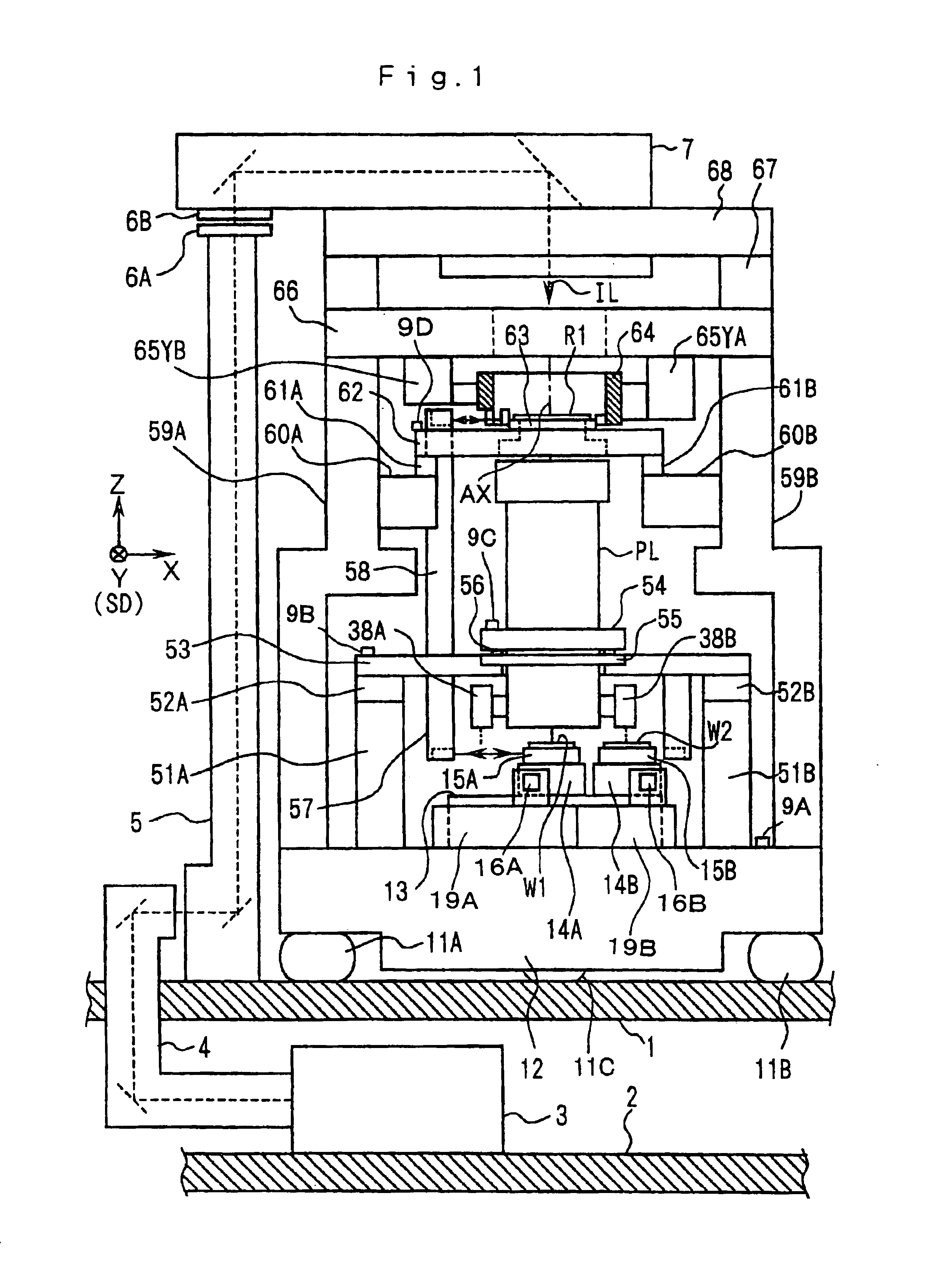

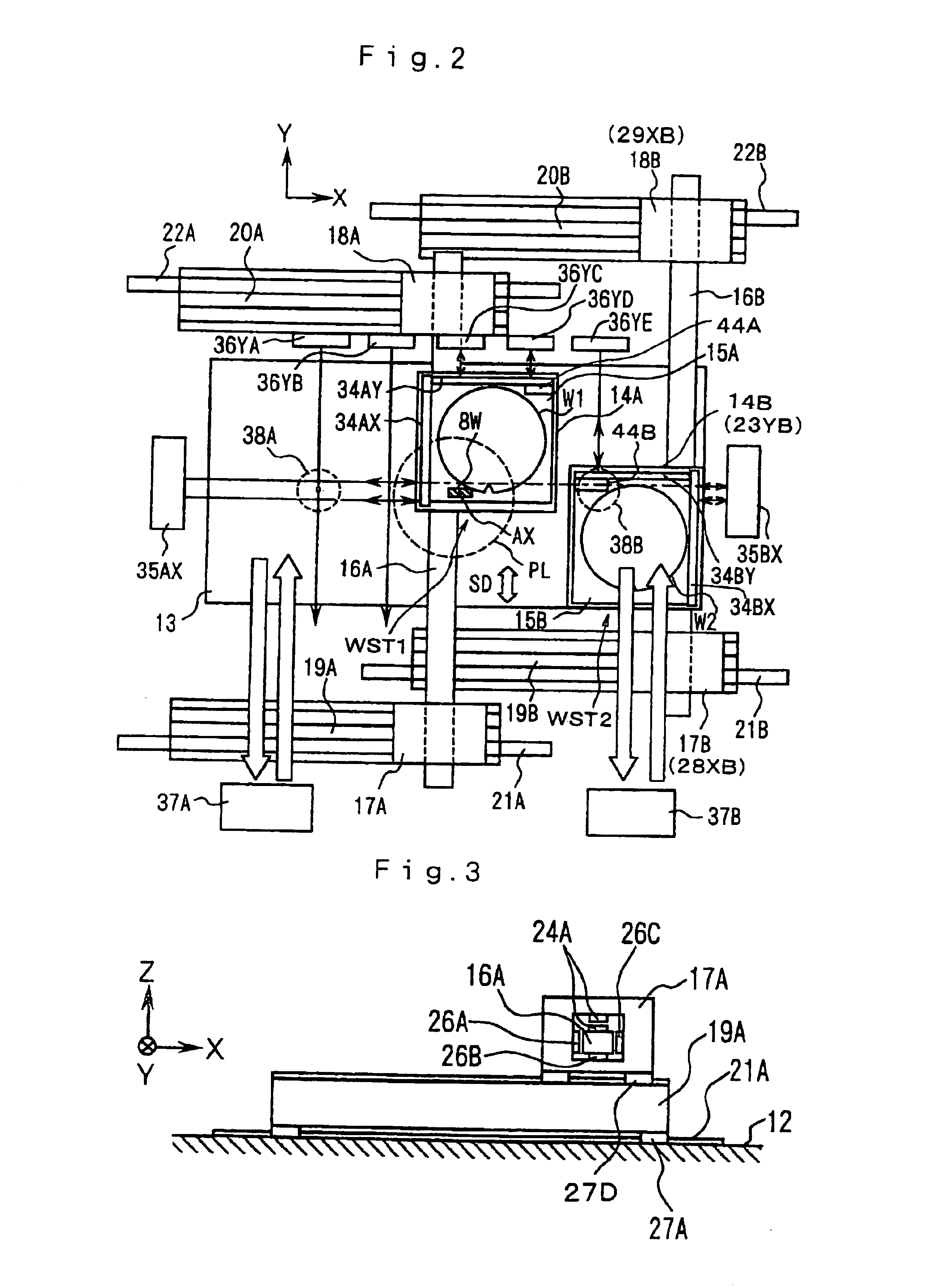

Exposure method and apparatus

InactiveUS6836093B1Improve Exposure AccuracyFunctionalPortable framesStands/trestlesClassical mechanics

There are provided an exposure method and an exposure apparatus in which the influence of vibration is not mutually transmitted so much when two movable stages are used. X axis sliders (19A, 20A) are arranged movably in the X direction on both sides in the Y direction of a wafer base (13). A first Y axis slider (16A) is arranged movably in the Y direction for the X axis sliders (19A, 20A). A first wafer stage (WST1) is arranged movably in the Y direction (scanning direction) along the Y axis slider (16A). X axis sliders (19B, 20B) are arranged in parallel to the X axis sliders (19A, 20A). A second Y axis slider (16B) is arranged for the X axis sliders (19B, 20B). A second wafer stage (WST2) is arranged movably along the Y axis slider (16B). When exposure is performed on the side of the first wafer stage (WST1), wafer exchange or wafer alignment is performed on the side of the second wafer stage (WST2).

Owner:NIKON CORP

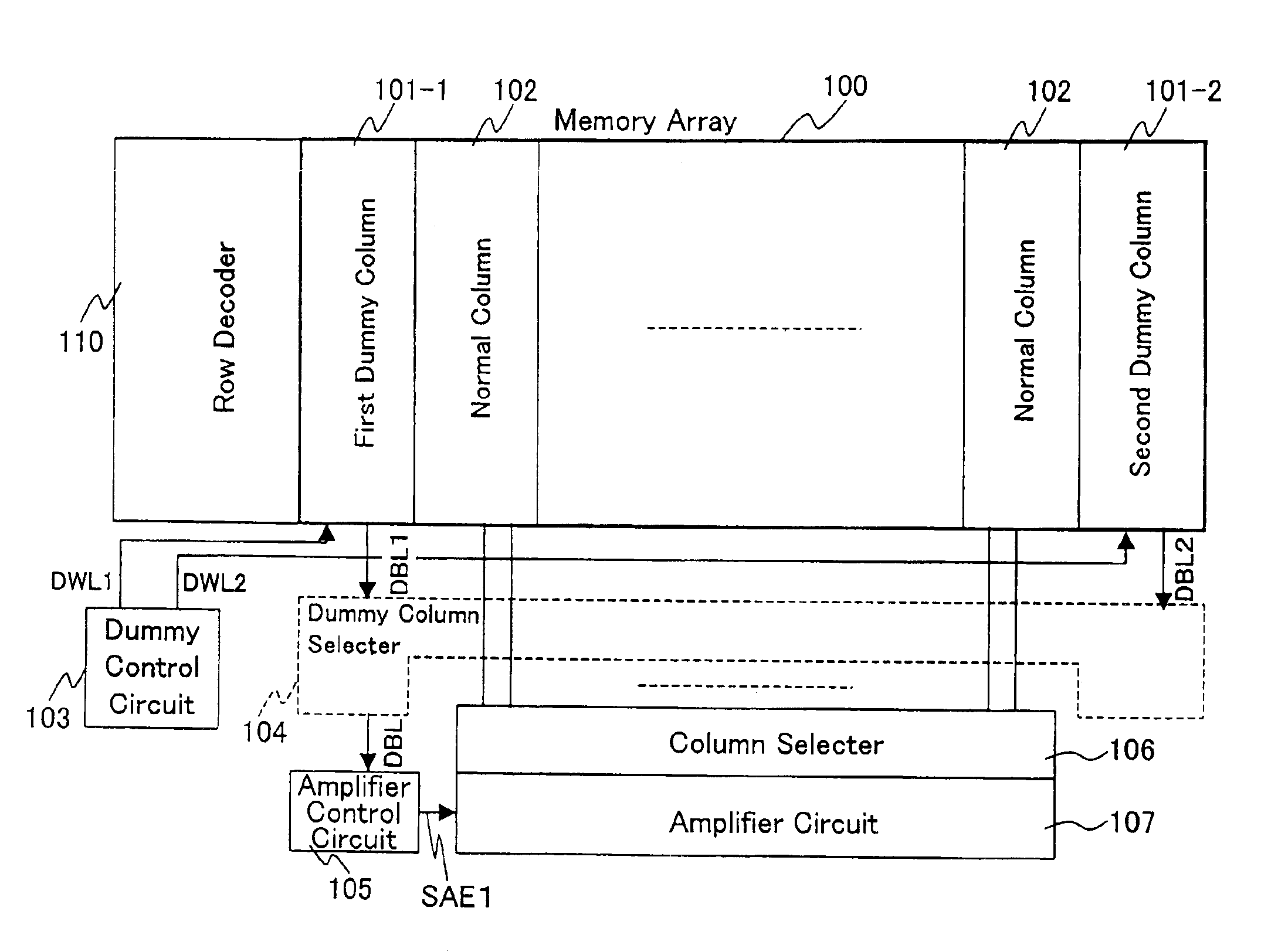

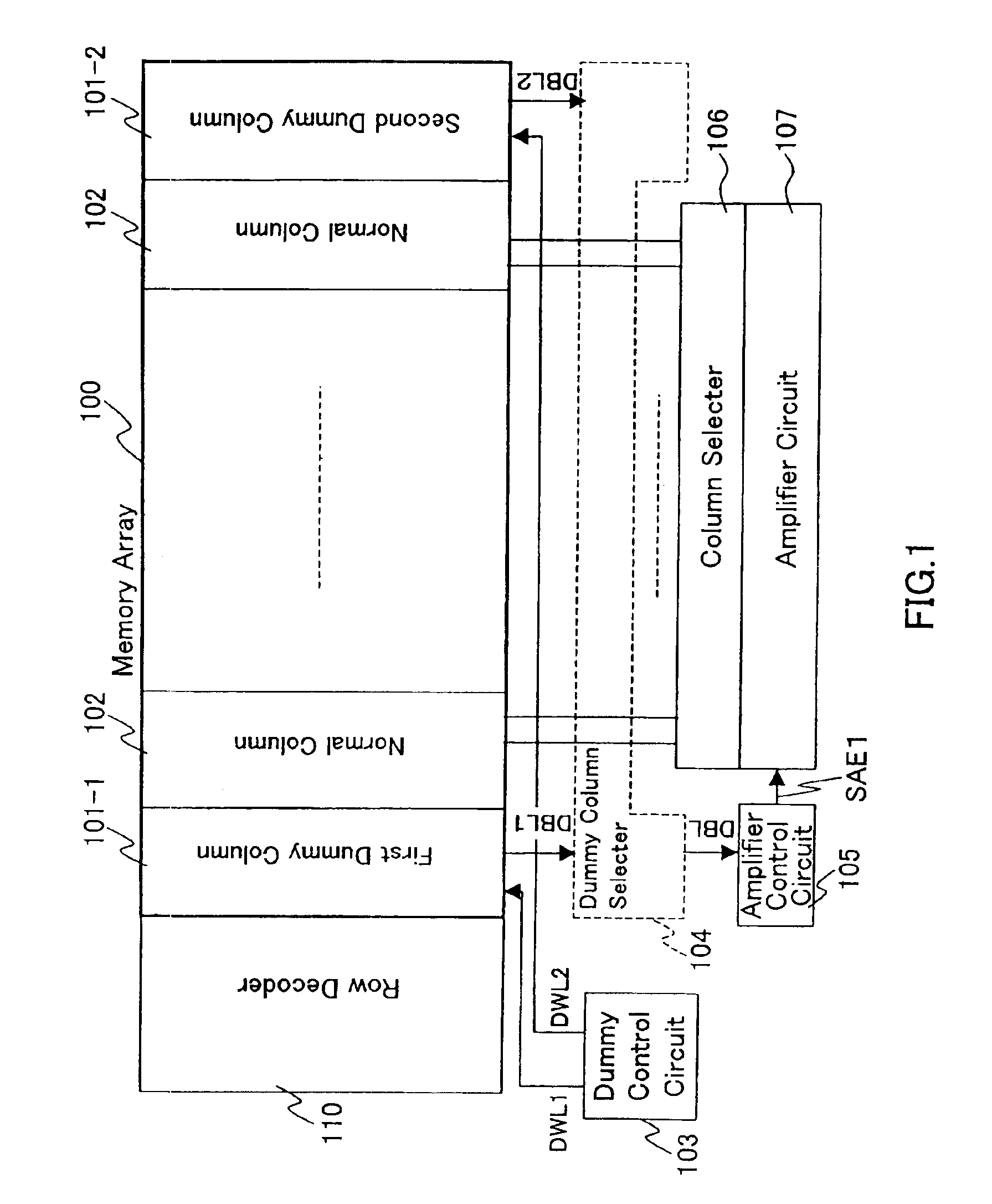

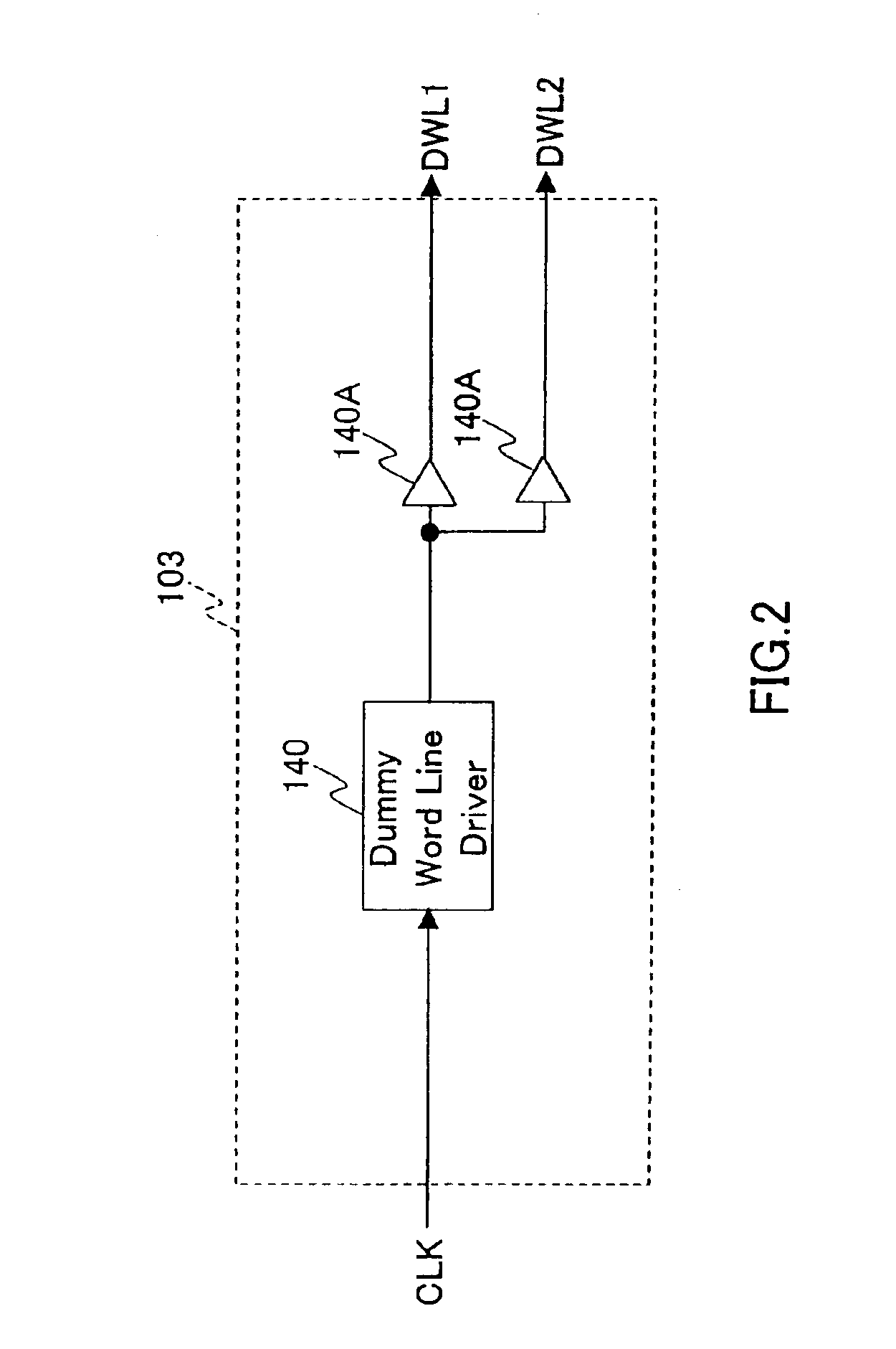

Semiconductor memory device

InactiveUS6950362B2Improve production yieldImprove Exposure AccuracySolid-state devicesSemiconductor/solid-state device manufacturingBit lineAudio power amplifier

A semiconductor memory device capable of enhancing a production yield is provided. A dummy control circuit activates a first dummy column including a plurality of dummy cells placed at a position close to a row decoder in a row direction and a second dummy column including a plurality of dummy cells placed at a position farthest from the row decoder in a row direction with a plurality of memory cells interposed between the first dummy column and the second dummy column, through first and second dummy word lines. A dummy column selector selects either one of a signal on a first dummy bit line connected to the first dummy column and a signal on a second dummy bit line connected to the second dummy column, and outputs the selected signal to an amplifier control circuit. The amplifier control circuit generates an amplifier startup signal with respect to an amplifier circuit based on a signal from the dummy column selector.

Owner:PANASONIC CORP

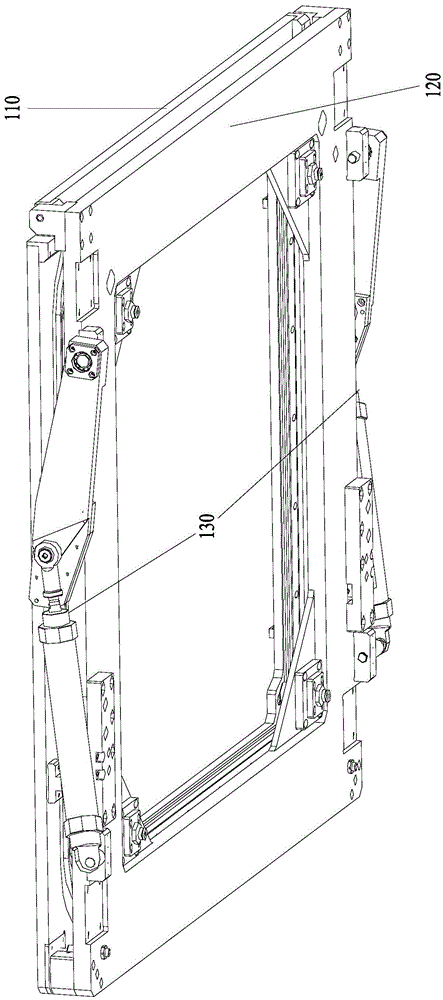

Exposure apparatus

ActiveCN102449553AImprove Exposure AccuracyImprove adsorption capacitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineering

A mask stage (10) is provided with: a mask stage base (11); four mask holders (71, 72) with the ability to adhere to and hold each edge of a mask (M); linear guides (73) disposed between a pair of mask holders (72) that adhere to and hold the side of the mask stage base (11) and the short sides of the mask (M); a drive mechanism (74) that forces the mask holders (72) to move on the short side; and a tilt angle adjustment mechanism (80) that is disposed between the side of the mask stage base (11) and the sides of the mask holders (72), and has the ability to adjust the tilt angle of the mask (M). This configuration enables a plurality of masks of different sizes to be accommodated in a state in which flatness is kept constant.

Owner:V TECH CO LTD

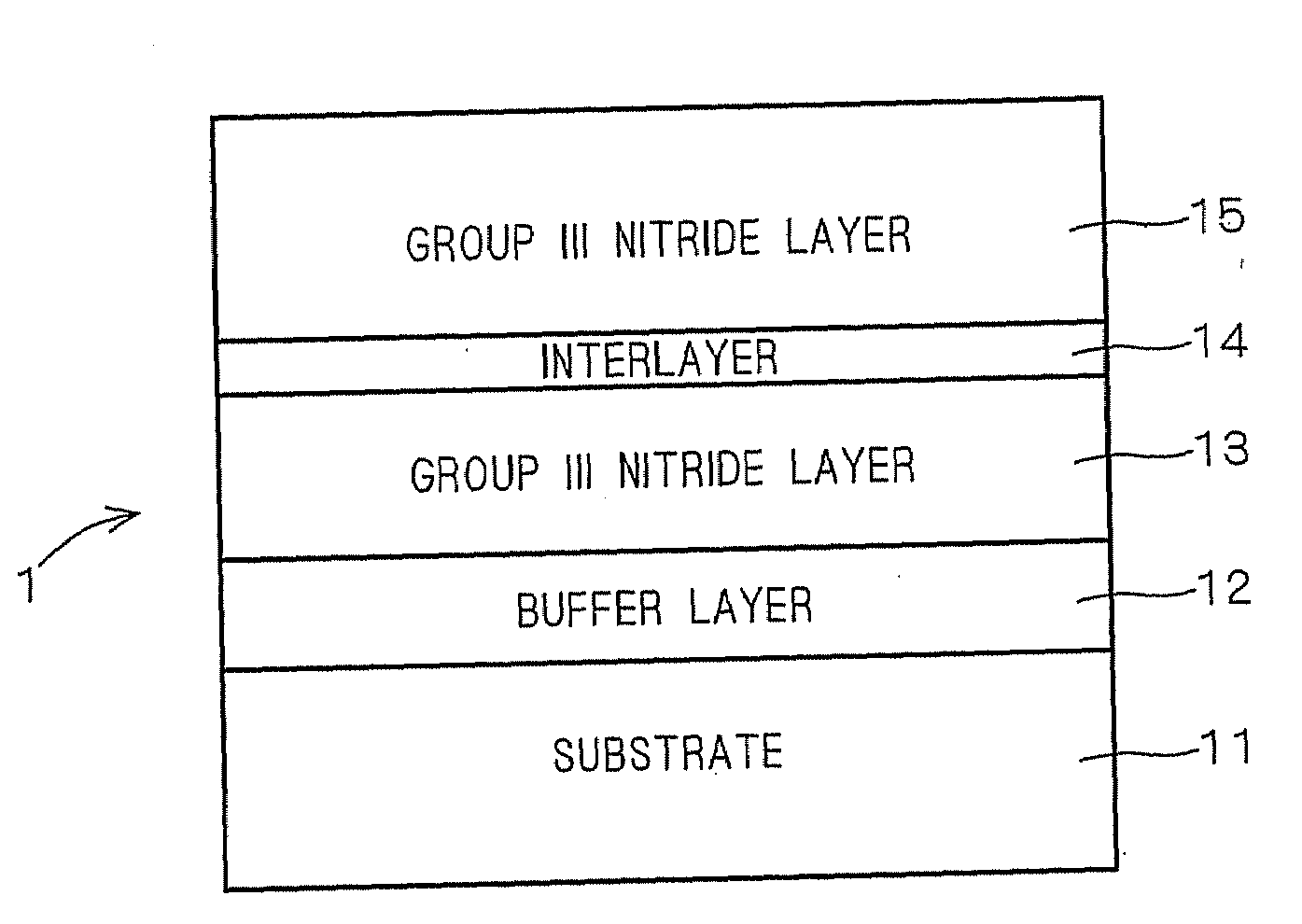

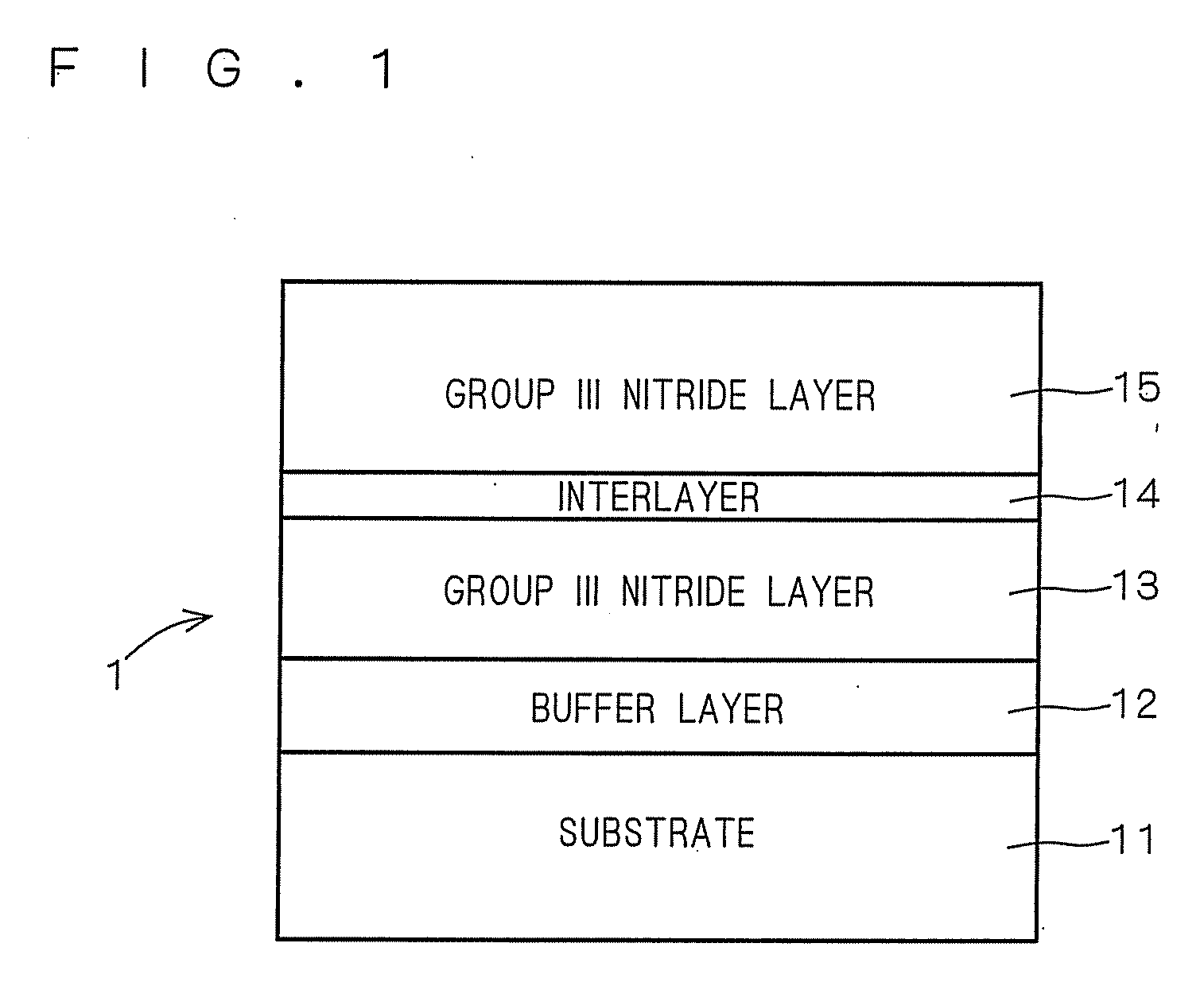

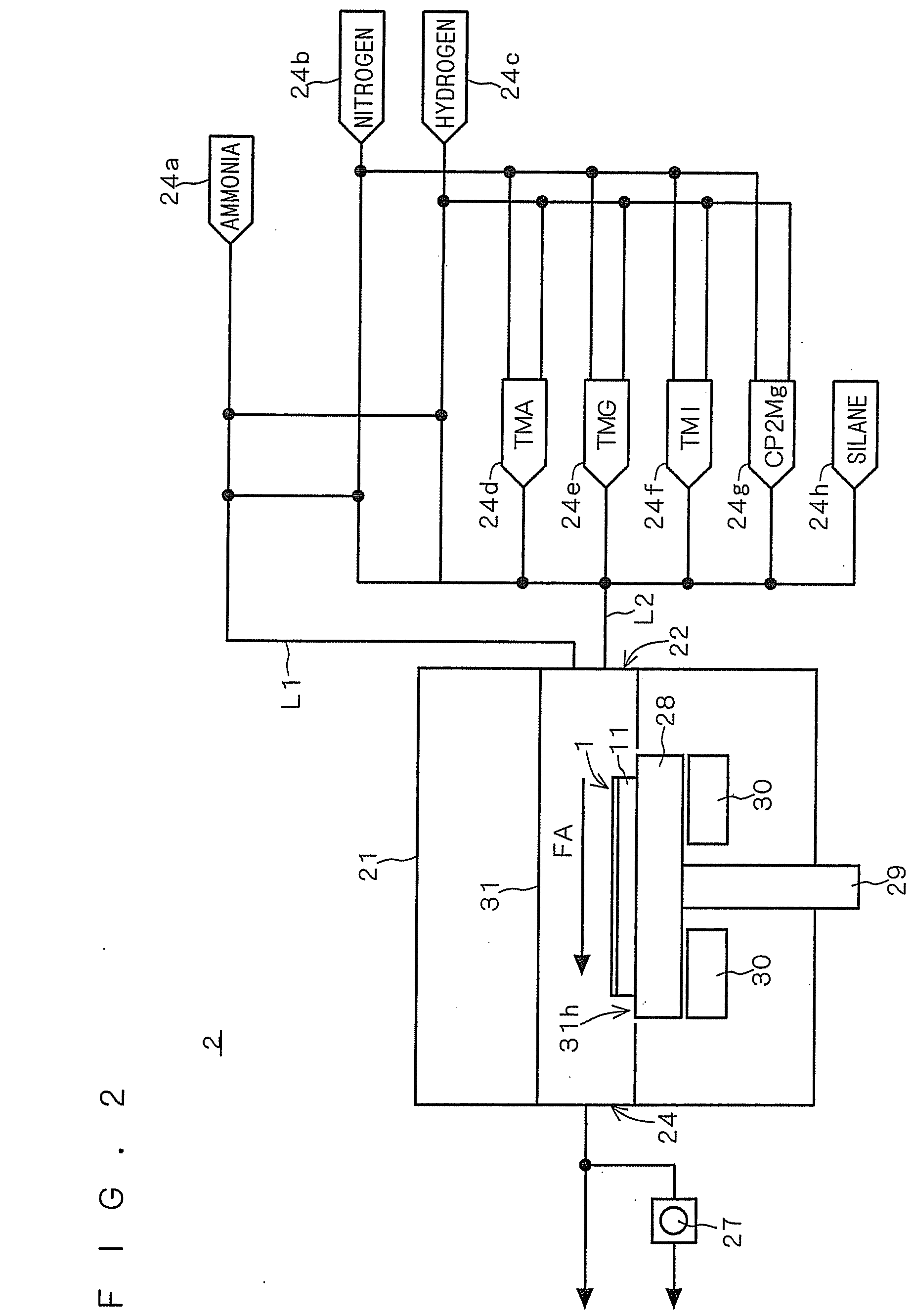

Epitaxial wafers, method for manufacturing of epitaxial wafers, method of suppressing bowing of these epitaxial wafers and semiconductor multilayer structures using these epitaxial wafers

ActiveUS20080308909A1Suppressing bowingAvoid crackingPolycrystalline material growthLayered productsWaferingNitride

A technique for suppressing the bowing of an epitaxial wafer is provided. The epitaxial wafer is prepared by successively epitaxially growing a target group III-nitride layer, an interlayer and another group III-nitride layer on a substrate with a buffer layer. The interlayer is mainly composed of a mixed crystal of GaN and InN expressed in a general formula (GaxIny)N (0≦x≦1, 0≦y≦1, x+y=1) (or a crystal of GaN), and does not contain Al. The interlayer is epitaxially formed at a lower growth temperature than those of the group III-nitride layers, more specifically at a temperature in a range of at least 350° C. to not more than 1000° C.

Owner:NGK INSULATORS LTD

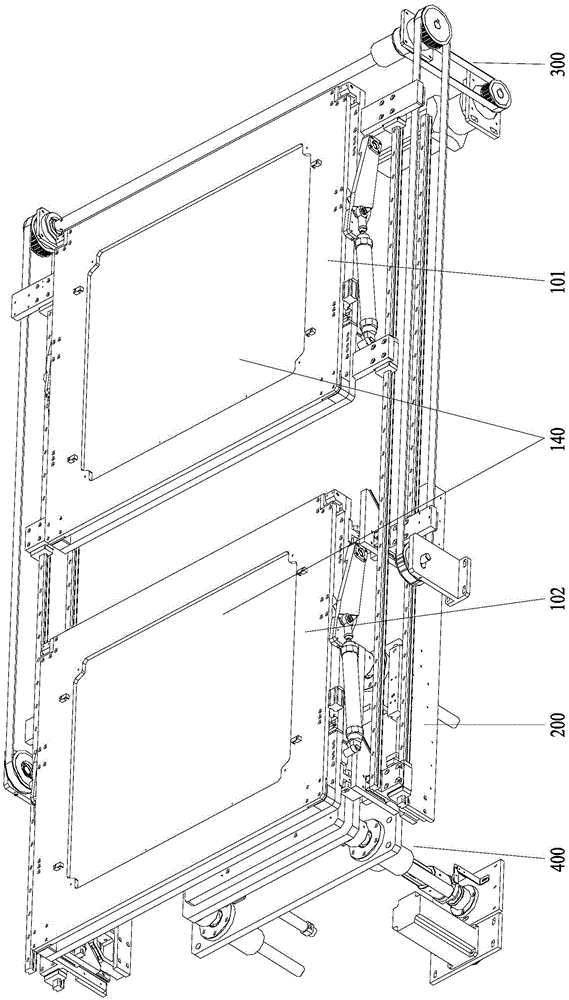

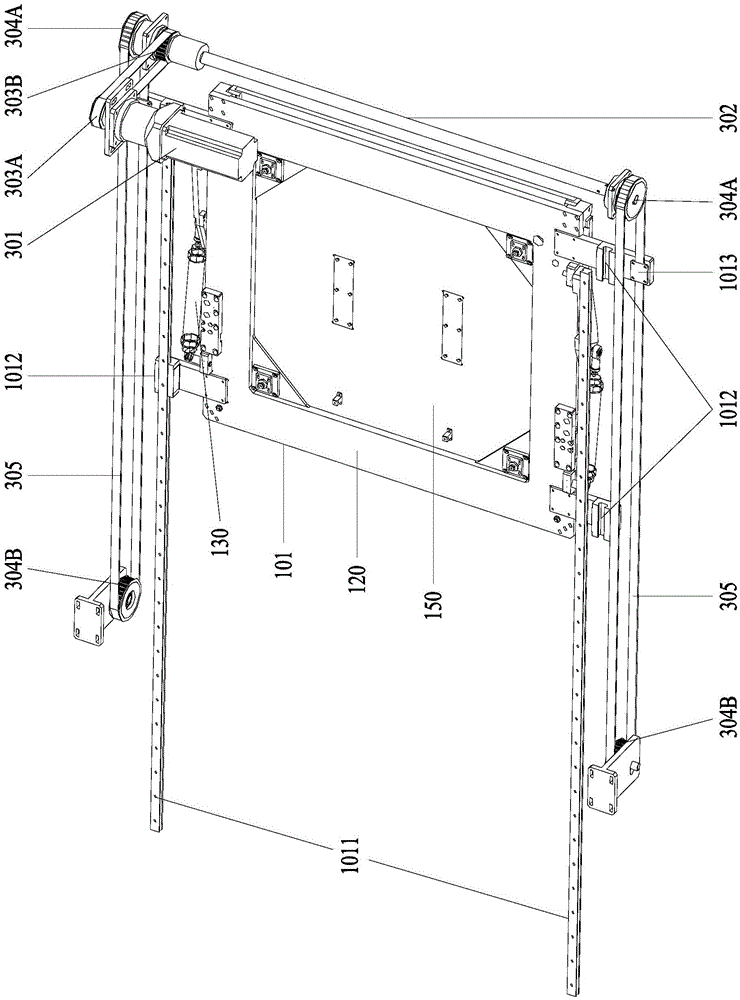

Automatic exposure machine mechanism

ActiveCN105607428ASimple structureImprove stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineering

The invention discloses an automatic exposure machine mechanism, which comprises a frame, a lower frame lifting mechanism, a frame change mechanism and a lifting alignment device, wherein the frame is used for clamping a negative film and a substrate in the up-down direction; the frame is divided into a lower frame and an upper frame, which are arranged at the left side and the right side; the lower frame lifting mechanism is arranged at the bottom end of the lower frame and is used for controlling lifting of the lower frame to the same height as the upper frame; the frame change mechanism is used for exchanging the positions of the upper frame and the lower frame in the left-right direction; and the lifting alignment device is arranged below the lower frame and is used for adjusting the position, relative to the upper negative film, of the lower substrate. The automatic exposure machine mechanism is simple in structure, good in stability and high in exposure accuracy. The lower frame is provided with the lower frame lifting mechanism, so that the condition that an industrial camera does not generate an error due to a focusing problem of the lower stage frame when collecting an image is ensured; the lifting alignment device can adjust the position, relative to the negative film, of the lower substrate, so that accurate alignment is achieved; the upper frame and the lower frame are subjected to left and right position exchange through the frame change mechanism; the automatic exposure machine mechanism is simple to run and convenient to operate; an exposure machine can stably run; and the work efficiency is also improved.

Owner:深圳市研宝工业科技有限公司

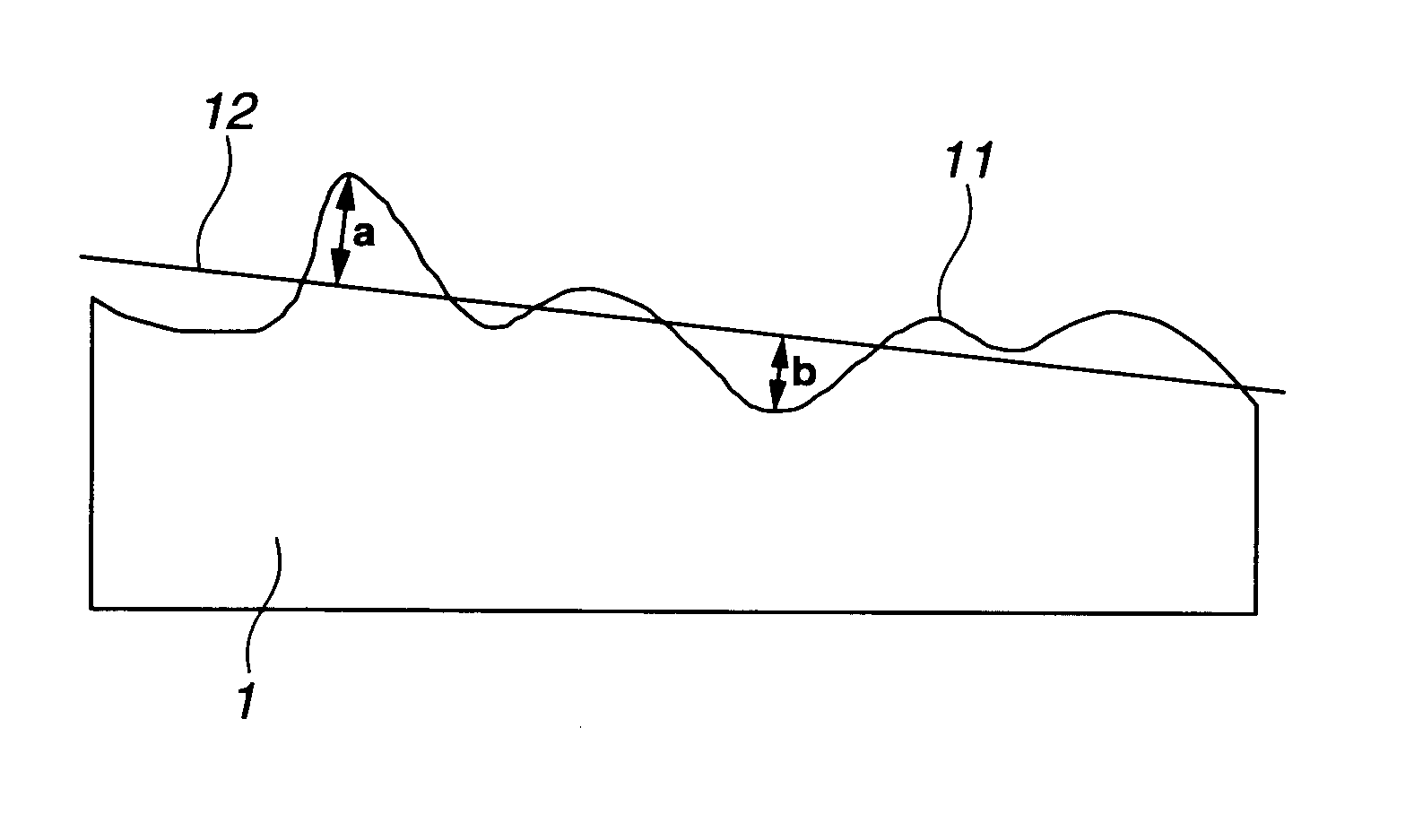

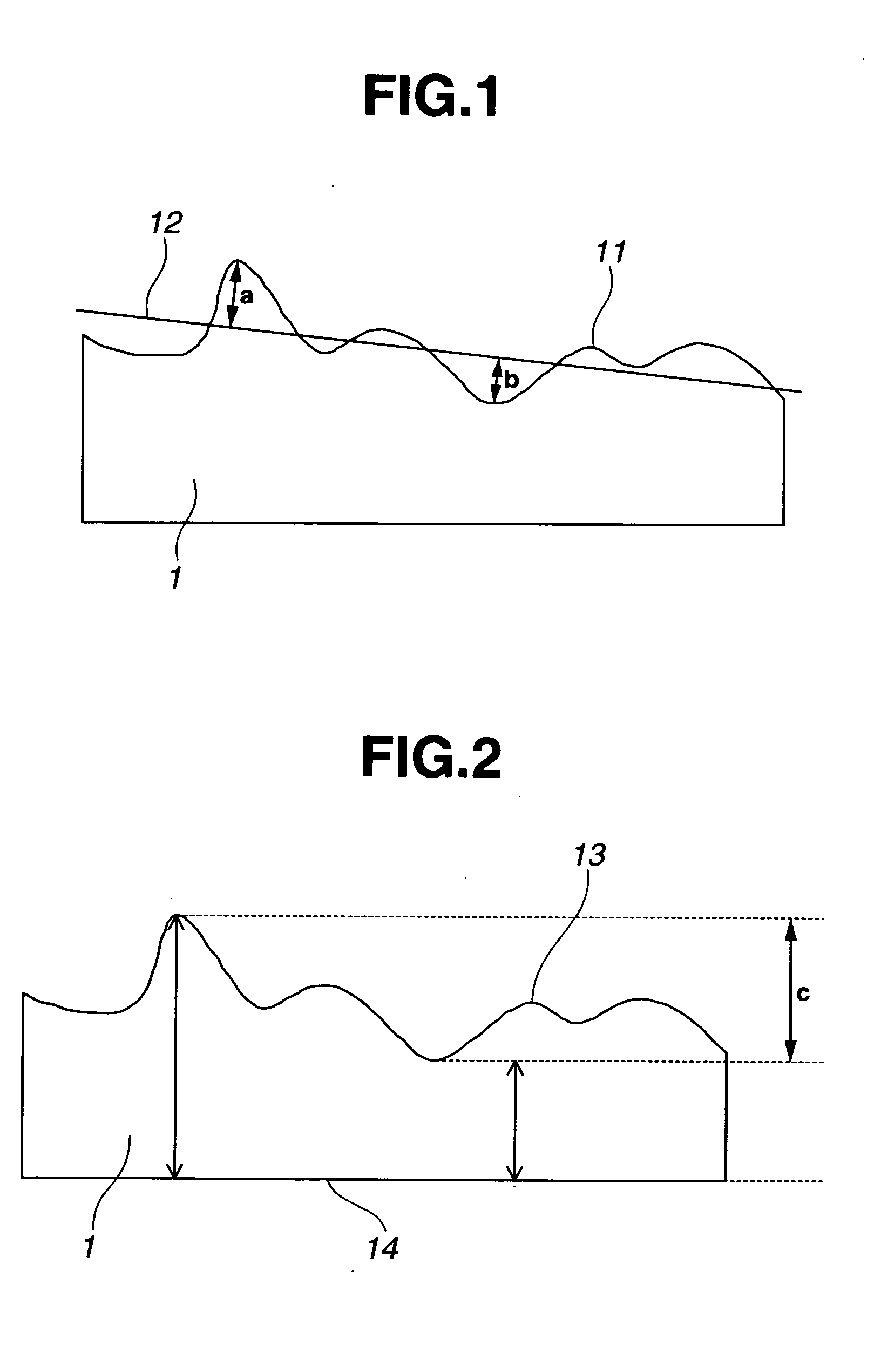

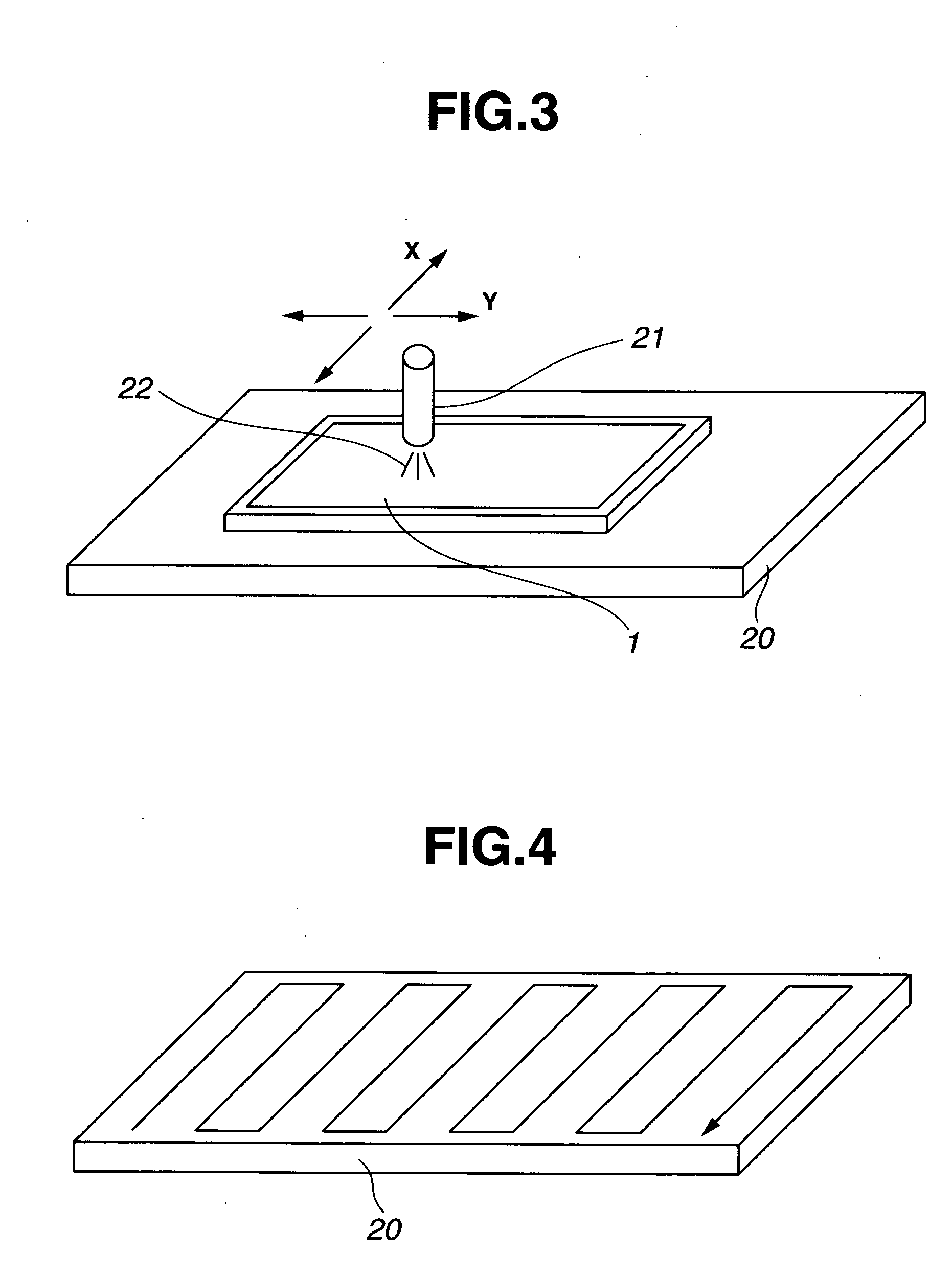

Large-Size Glass Substrate For Photomask and Making Method, Computer-Readable Recording Medium, and Mother Glass Exposure Method

ActiveUS20080261119A1Reduce the burden onImprove production yieldSemiconductor/solid-state device testing/measurementPhotosensitive materialsEngineeringLarge size

A large-size glass substrate, from which a photomask substrate is formed, is prepared by processing a large-size glass substrate stock by (1) a flattening removal quantity based on height data of the substrate stock in the vertical attitude plus a deformation-corrective removal quantity. The deformation-corrective removal quantity is calculated from (2) a deflection of the substrate stock by its own weight in the horizontal attitude, (3) a deformation of the photomask substrate caused by chucking in an exposure apparatus, and (4) an accuracy distortion of a platen for supporting a mother glass.

Owner:SHIN ETSU CHEM IND CO LTD

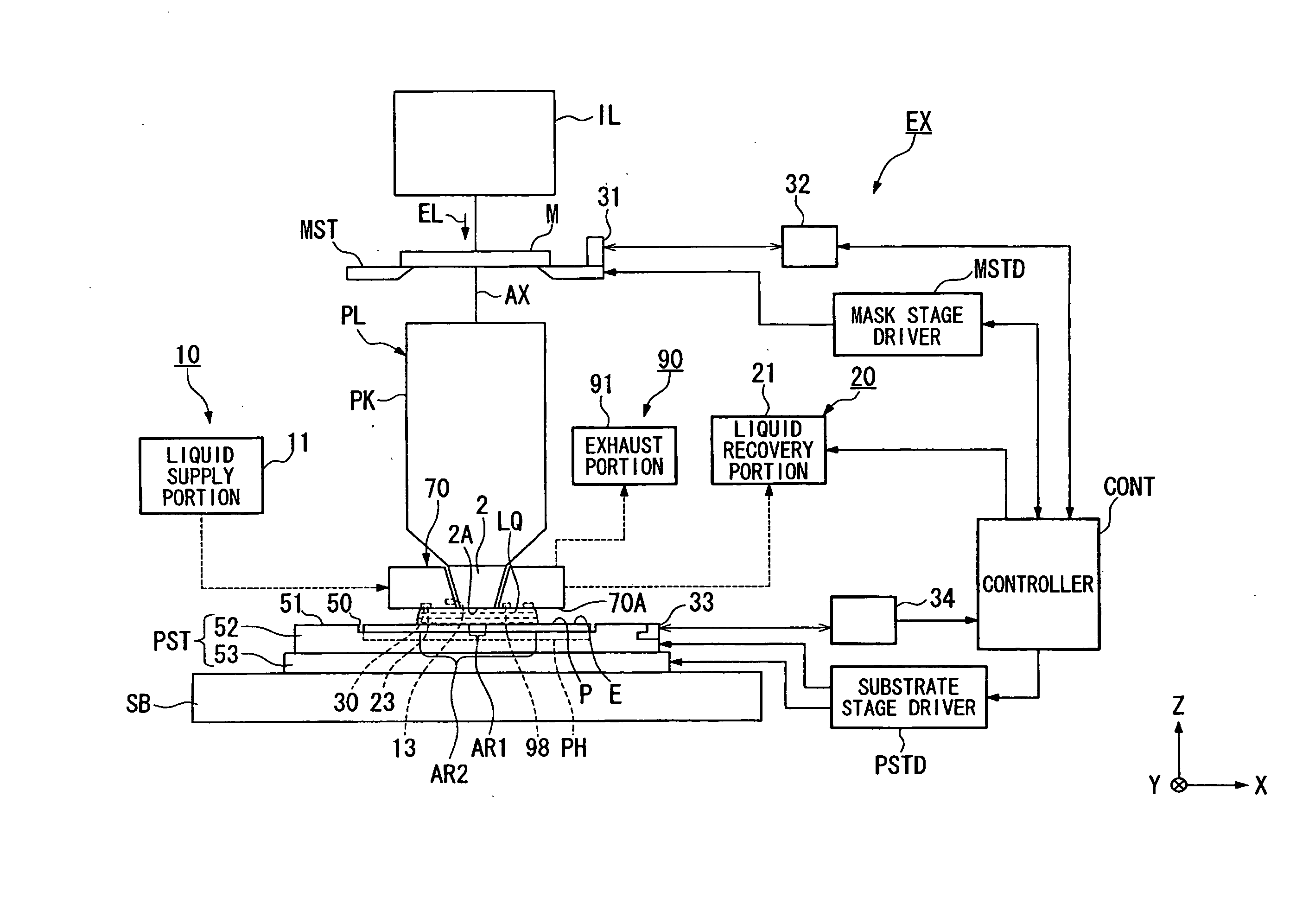

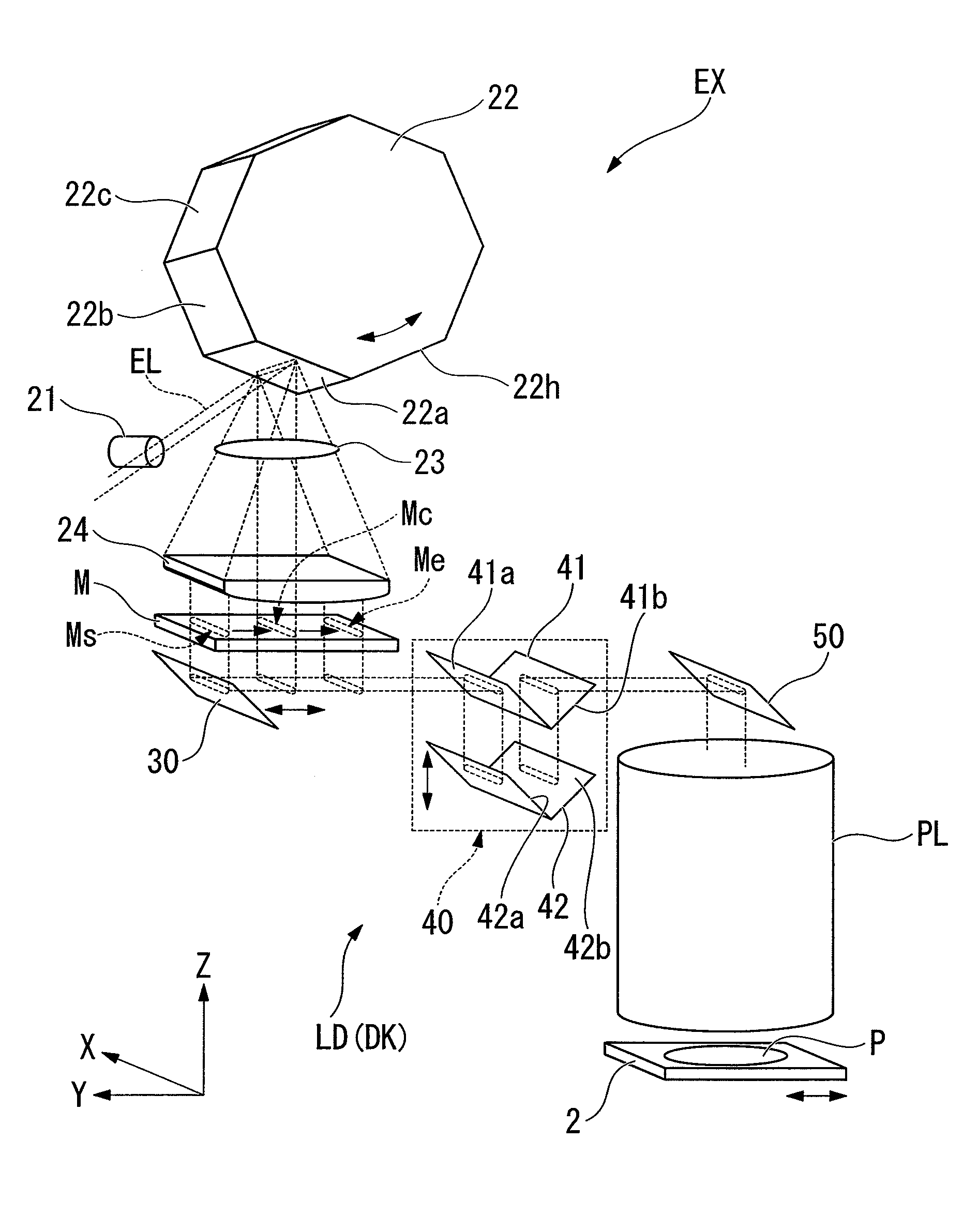

Exposure apparatus, exposure method, and device producing method

ActiveUS8064044B2Improve Exposure AccuracyHigh measurement accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineering

An exposure apparatus (EX) exposes a substrate (P) by irradiating exposure light (EL) on the substrate (P) via a projection optical system (PL) and a liquid (LQ) supplied from a liquid supply mechanism (10). The exposure apparatus (EX) has a pressure adjustment mechanism (90) for adjusting pressure of the liquid (LQ) supplied from the liquid supply mechanism (10). A liquid immersion area is satisfactorily formed to obtain high exposure accuracy and measurement accuracy.

Owner:NIKON CORP

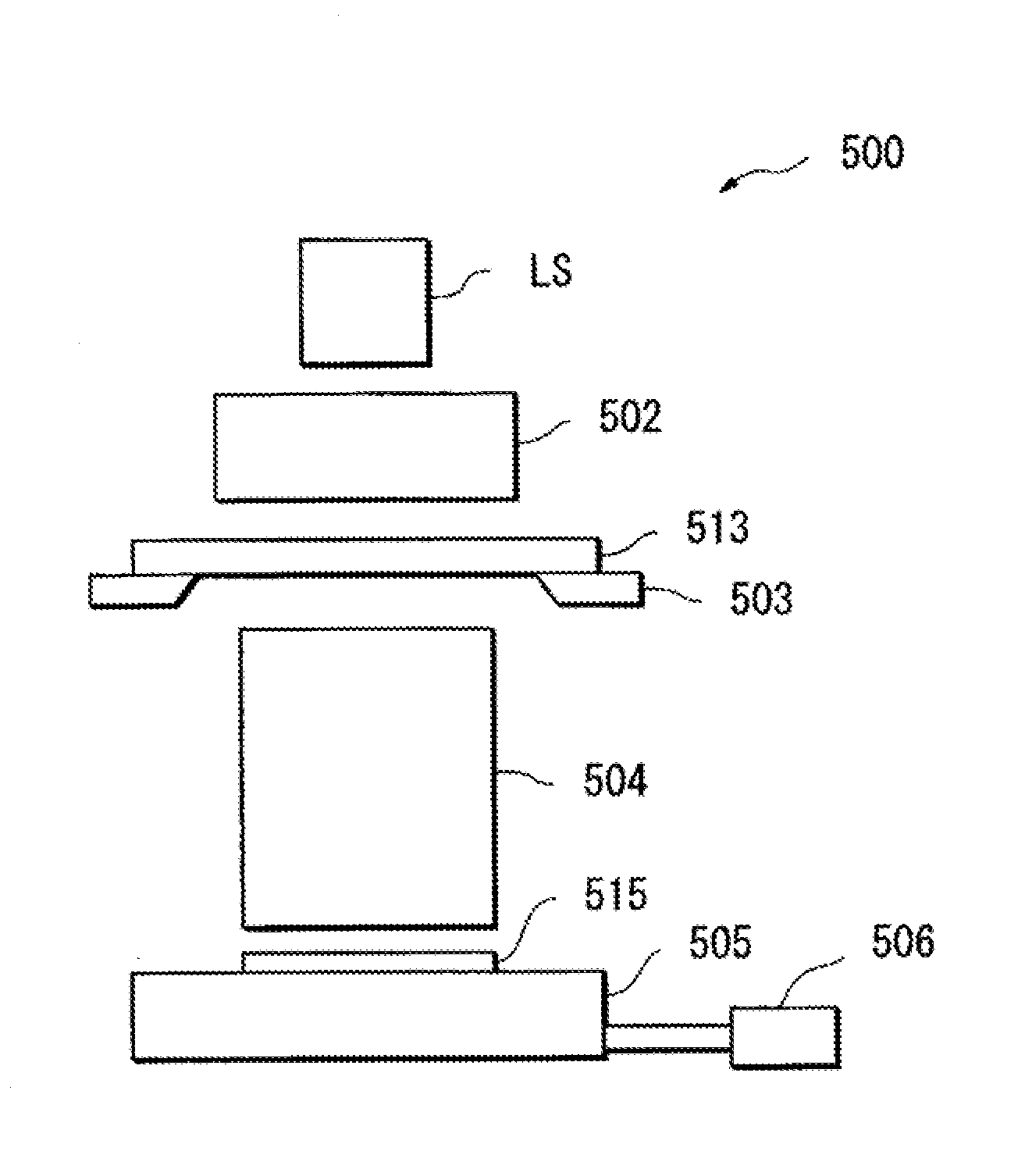

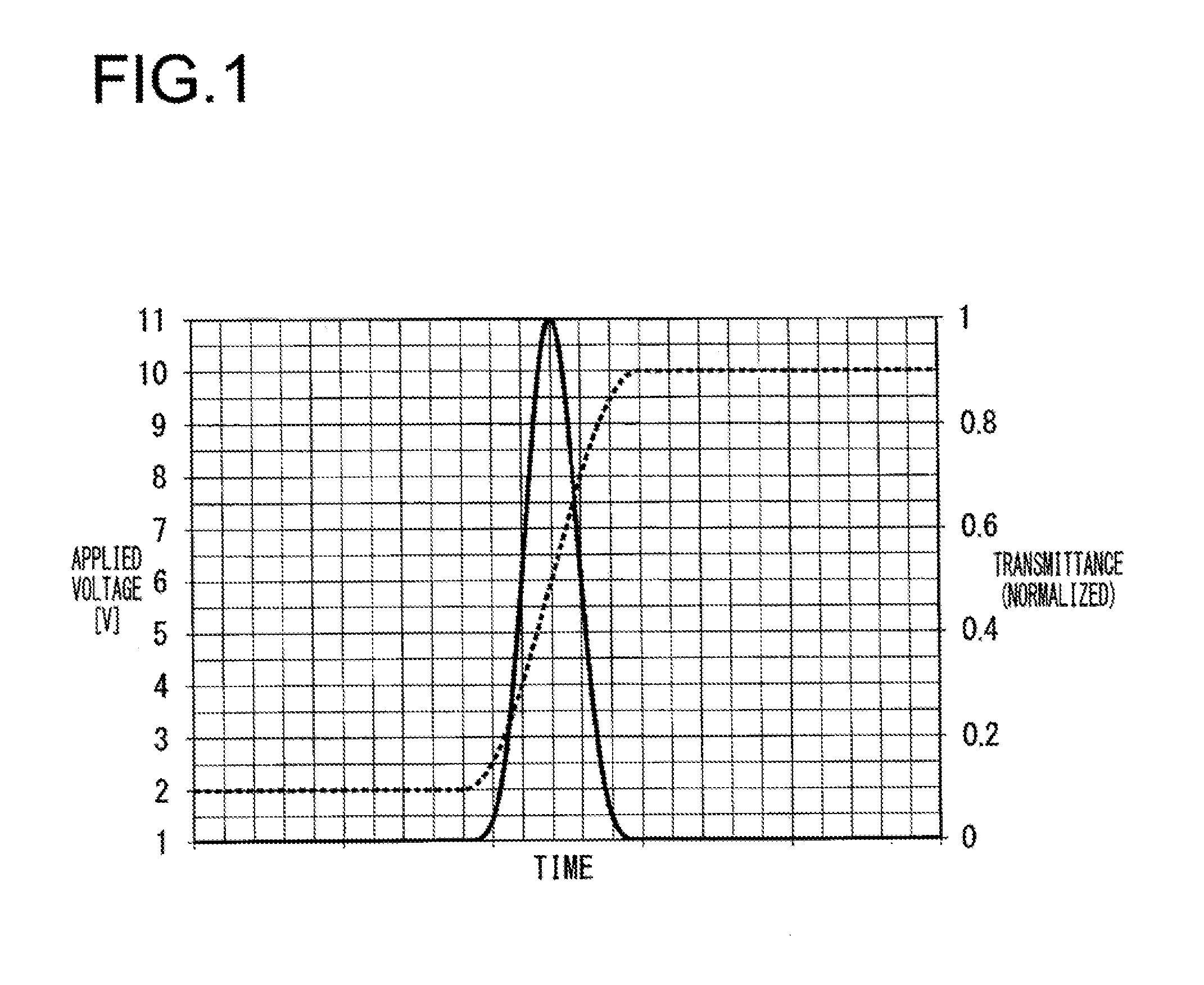

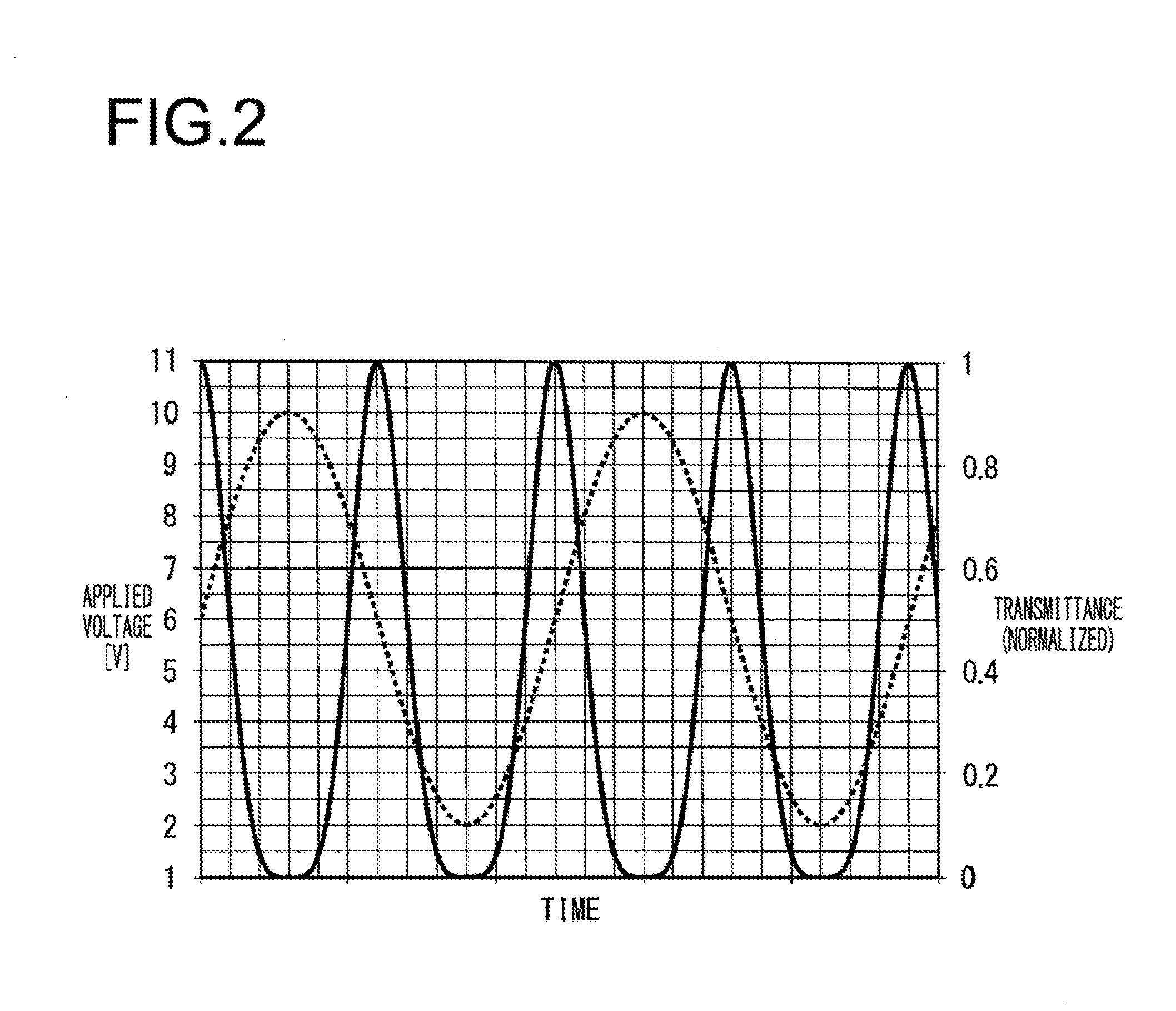

Pulsed light generating method, pulse laser apparatus, exposure apparatus having pulse laser apparatus, and inspection apparatus having pulse laser apparatus

ActiveUS20160359290A1Large sizeCost be expensiveLaser detailsPhotomechanical exposure apparatusLaser lightTransmittance

A pulsed light generating method for generating a pulsed light by cutting out a laser light outputted from a laser light source with an intensity modulation type electro optic modulator, wherein: the electro optic modulator is driven by use of a drive signal that changes a voltage applied to the electro optic modulator between a voltage lower than a reference voltage and a voltage higher than the reference voltage, the reference voltage being a voltage applied to the electro optic modulator at which a transmittance of the laser light transmitting through the electro optic modulator is local maximum.

Owner:NIKON CORP

Position measurement method, exposure method, exposure device, and manufacturing method of device

InactiveCN1656354AHigh precisionImprove Exposure AccuracySemiconductor/solid-state device manufacturingUsing optical meansPosition dependentLight beam

With this position measurement method, a mark which has been formed upon an object is illuminated with an illumination beam, a beam which is generated from this mark is picked up via an observation system, and the resultant image signal is signal processed so as to measure positional information which is related to the mark. This signal processing is performed based upon information related to the noise which is included in the component dependent upon the amount of light which is included in the image signal, and upon said image signal. As a result, it is possible to measure the positional information for the mark with good accuracy, even if noise is included in the image signal.A position measurement method includes a step of illuminating a mark formed on an object by an illumination beam, a step of imaging a beam generated from the mark via an observation system, and a step of processing the imaging signal so as to measure the position information associated with the mark position. The signal processing is performed according to information on a noise containing a light-quantity-dependent component contained in the imaging signal and the imaging signal. As a result, it is possible to accurately measure the mark position information even when the imaging signal contains a noise.

Owner:NIKON CORP

Exposure device and method

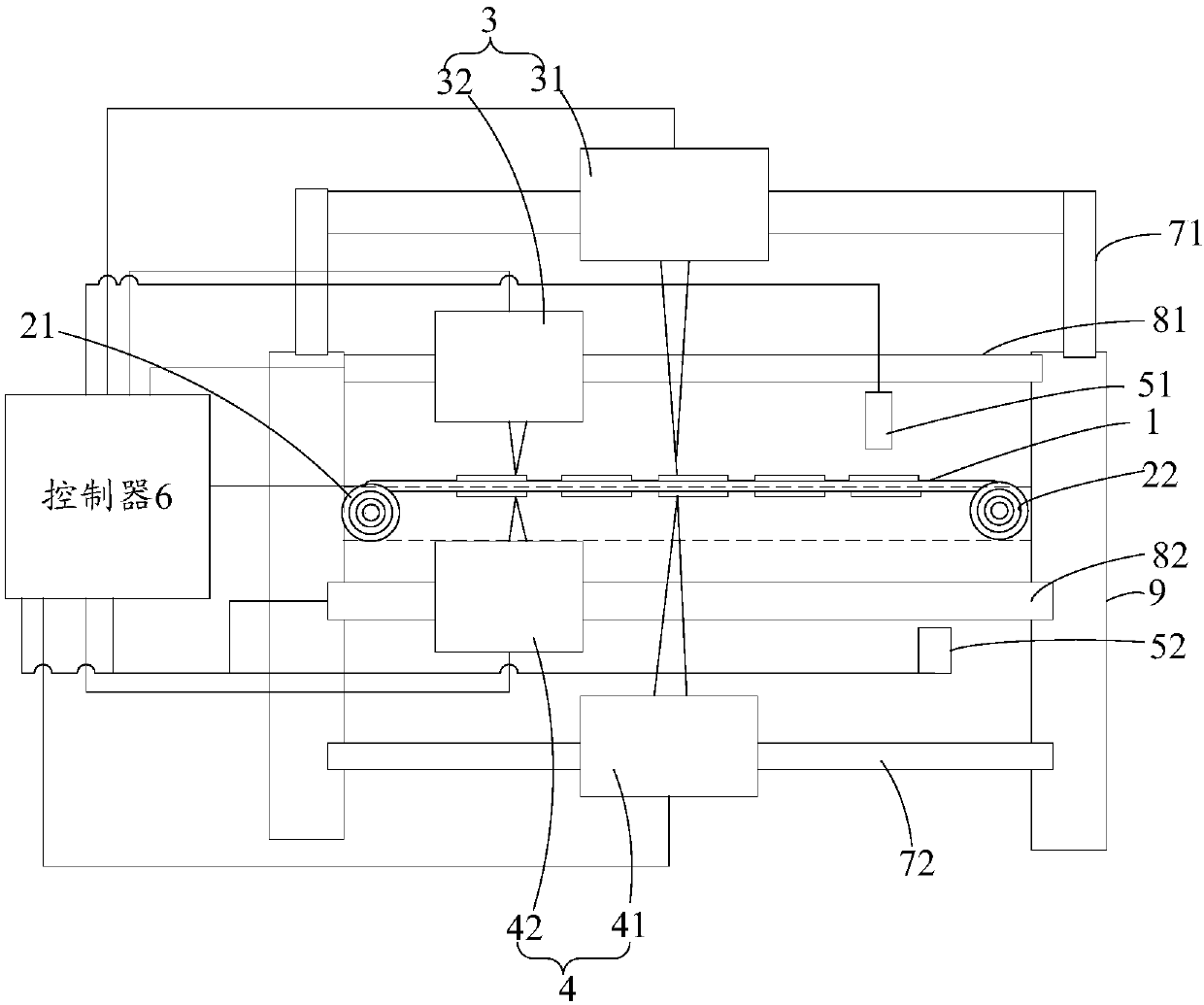

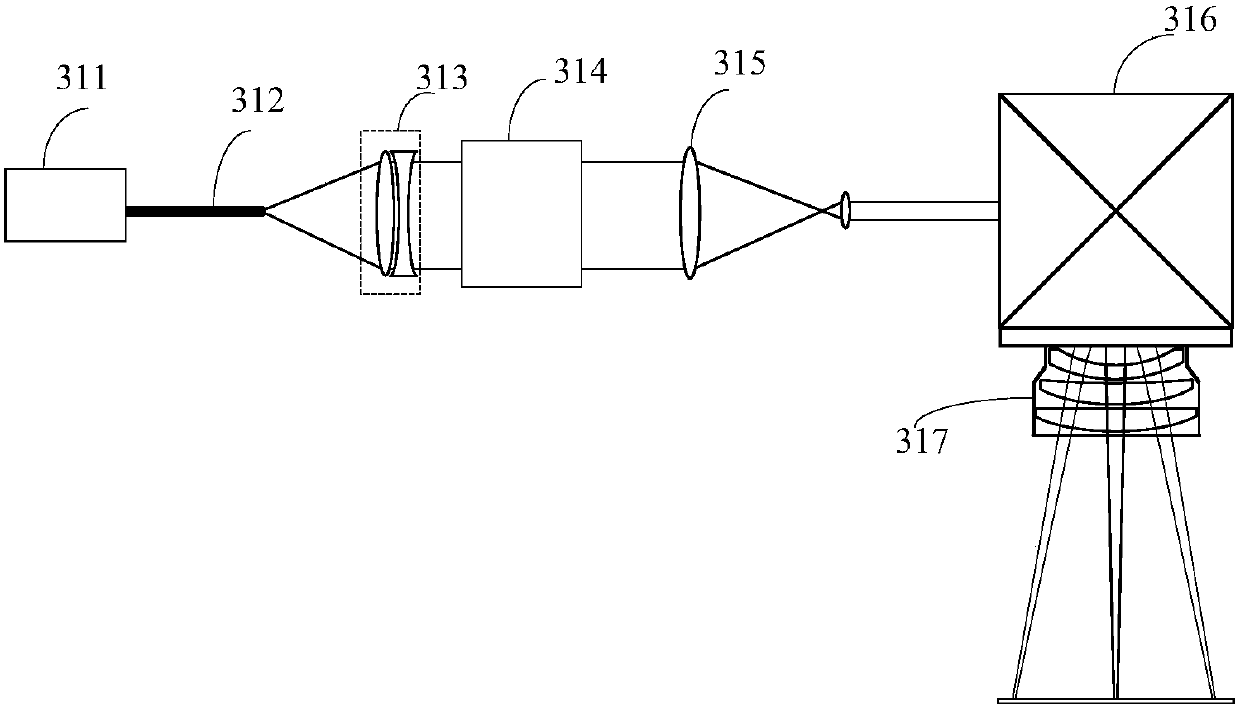

ActiveCN107664924AImprove exposure efficiencyImprove Exposure AccuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusControl systemEngineering

The invention discloses an exposure device and an exposure method. The device comprises a flexible substrate and a reel-to-reel transmission system, wherein the reel-to-reel transmission system is used for transmitting and fixing the flexible substrate; the exposure device also comprises a frontal-surface exposure system and a back-surface exposure system which are symmetrical about the axial direction of the flexible substrate, measurement systems which are corresponding to the frontal surface and the back surface of the flexible substrate respectively, and a master control system which is connected with the reel-to-reel transmission system, the frontal-surface exposure system, the back-surface exposure system and the measurement systems respectively. Through arranging the frontal-surfaceexposure system and the back-surface exposure system, the frontal surface and the back surface in the flexible substrate are exposed respectively; not only is the exposure efficiency improved; but also two different exposure systems are arranged respectively in the frontal-surface exposure system and the back-surface exposure system at the same time to realize the coarse exposure and the correction exposure on different exposed graphs on the flexible substrate; the exposure device can adapt to different deformation amounts and the exposure precision is greatly improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

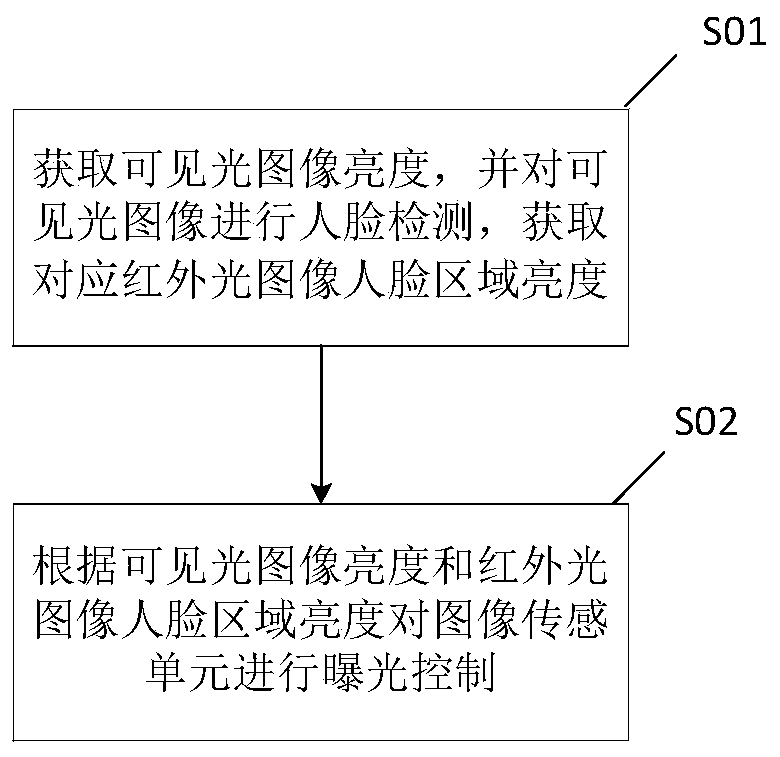

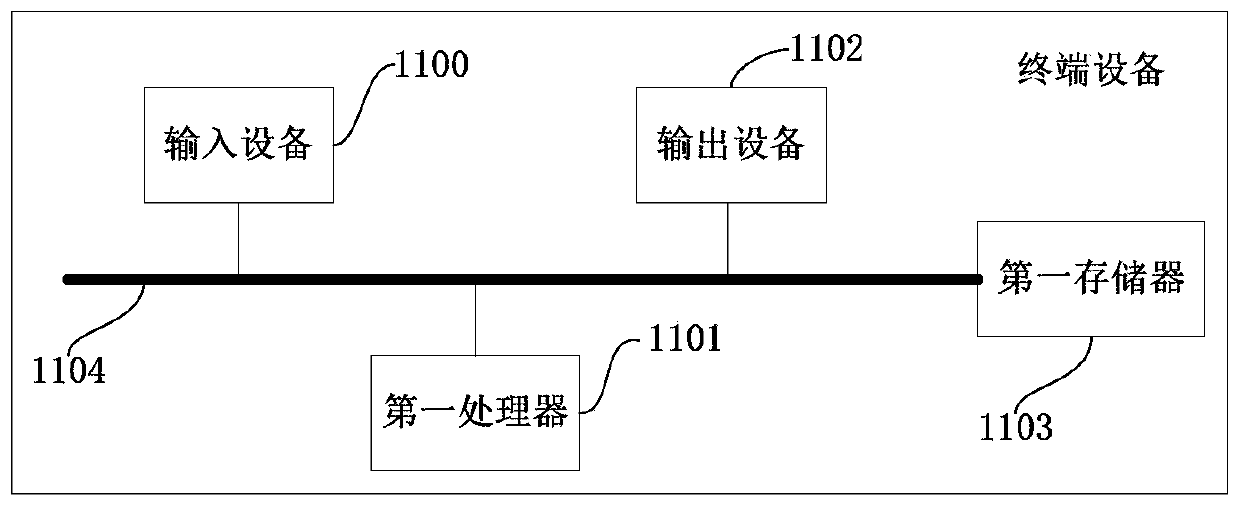

Camera shooting brightness control method, system and device and medium

ActiveCN110784660AImprove Exposure AccuracyTelevision system detailsColor television detailsFace detectionExposure control

The invention provides a camera shooting brightness control method, system and device and a medium, and the method comprises the steps: obtaining the brightness of a visible light image, carrying outthe face detection of the visible light image, and obtaining the face region brightness of a corresponding infrared light image; performing exposure control on an image sensing unit according to the visible light image brightness and the infrared light image face area brightness. According to the invention, the exposure precision can be effectively improved through brightness feedback of infraredand visible light images.

Owner:四川云从天府人工智能科技有限公司

Exposure method and exposure machine

ActiveCN104166315AReach saturation exposureExposure accuracy is lowPhotomechanical exposure apparatusMicrolithography exposure apparatusLiquid-crystal displayPhotoresist

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Balancing mass system of photoetching machine

ActiveCN102809902AEliminate torqueIncrease dampingPhotomechanical exposure apparatusMicrolithography exposure apparatusGravity centerEngineering

The invention discloses a balancing mass system of a photoetching machine. The system comprises a foundation frame, a marble platform, a micro-motion platform, a balancing mass and a countertorque buffering mechanism; the marble platform is fixed on the foundation frame; the micro-motion platform is supported on the marble platform through a vertical air floating cushion, and moves relative to the marble platform along an X direction and a Y direction; the balancing mass is connected with the foundation frame through another vertical air floating cushion, the vertical air floating cushion is fixed on the foundation frame, and the movement condition of the balancing mass is opposite to that of the micro-motion platform; the countertorque buffering mechanism is connected with the foundation frame and the balancing mass, and is used for eliminating torque generated due to the fact that the gravity center of the balancing mass shifts when the balancing mass moves, and vibration which is transmitted to the foundation frame by the balancing mass is attenuated. Accordingly, properties of the system of the photoetching machine can be improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

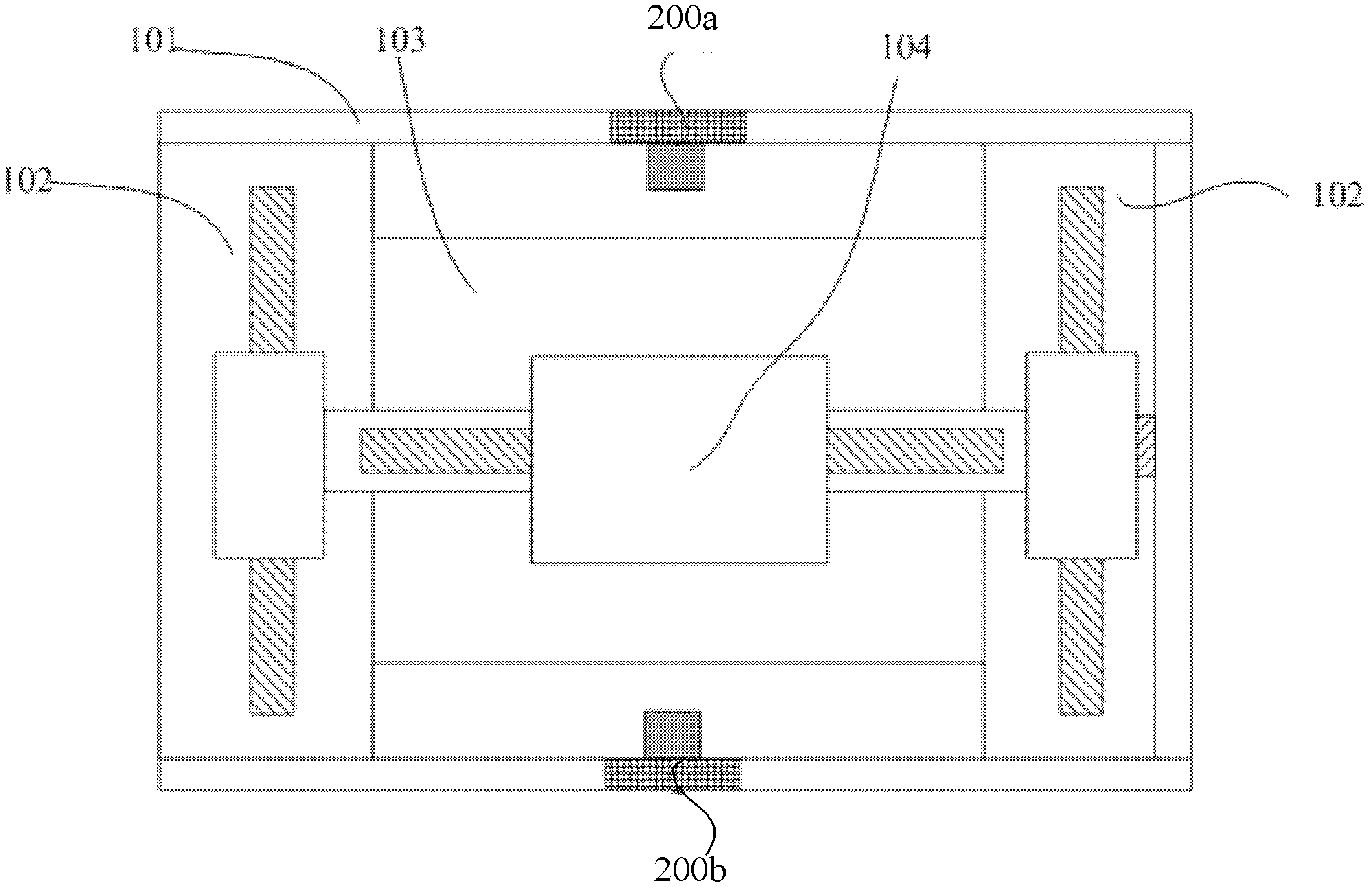

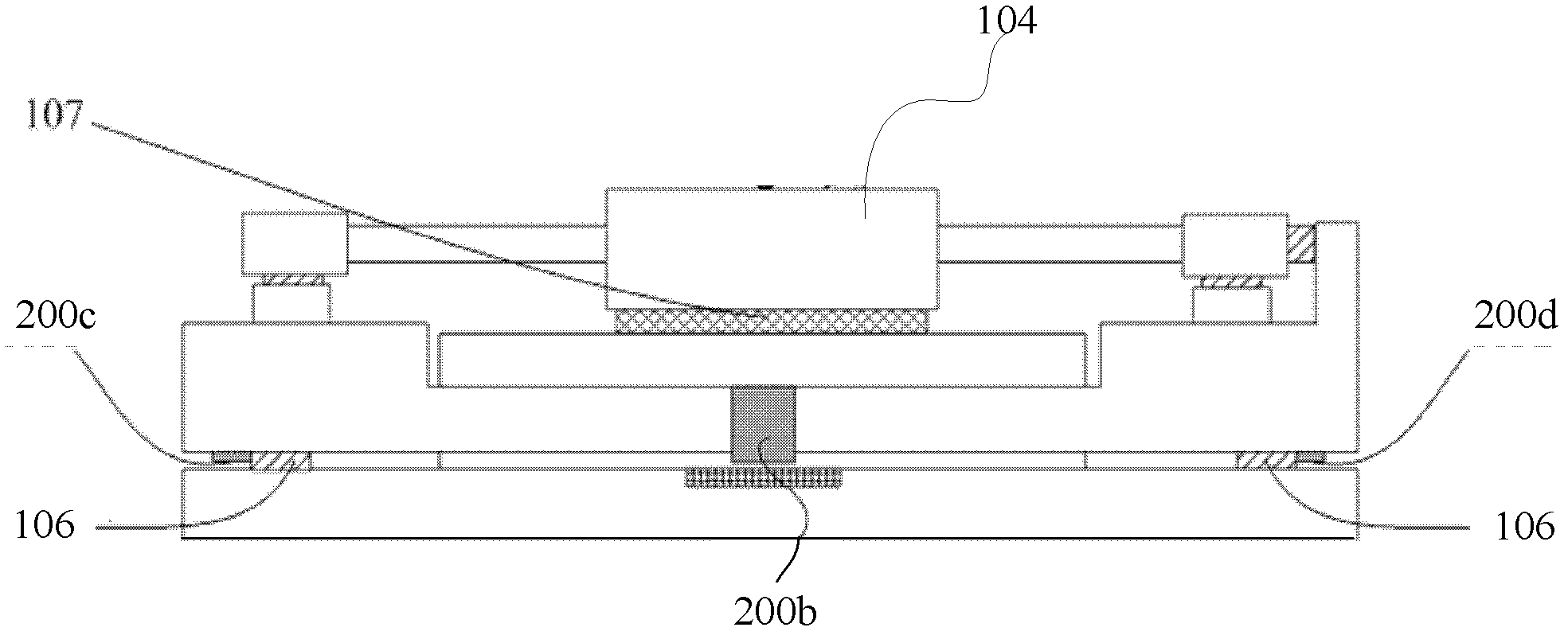

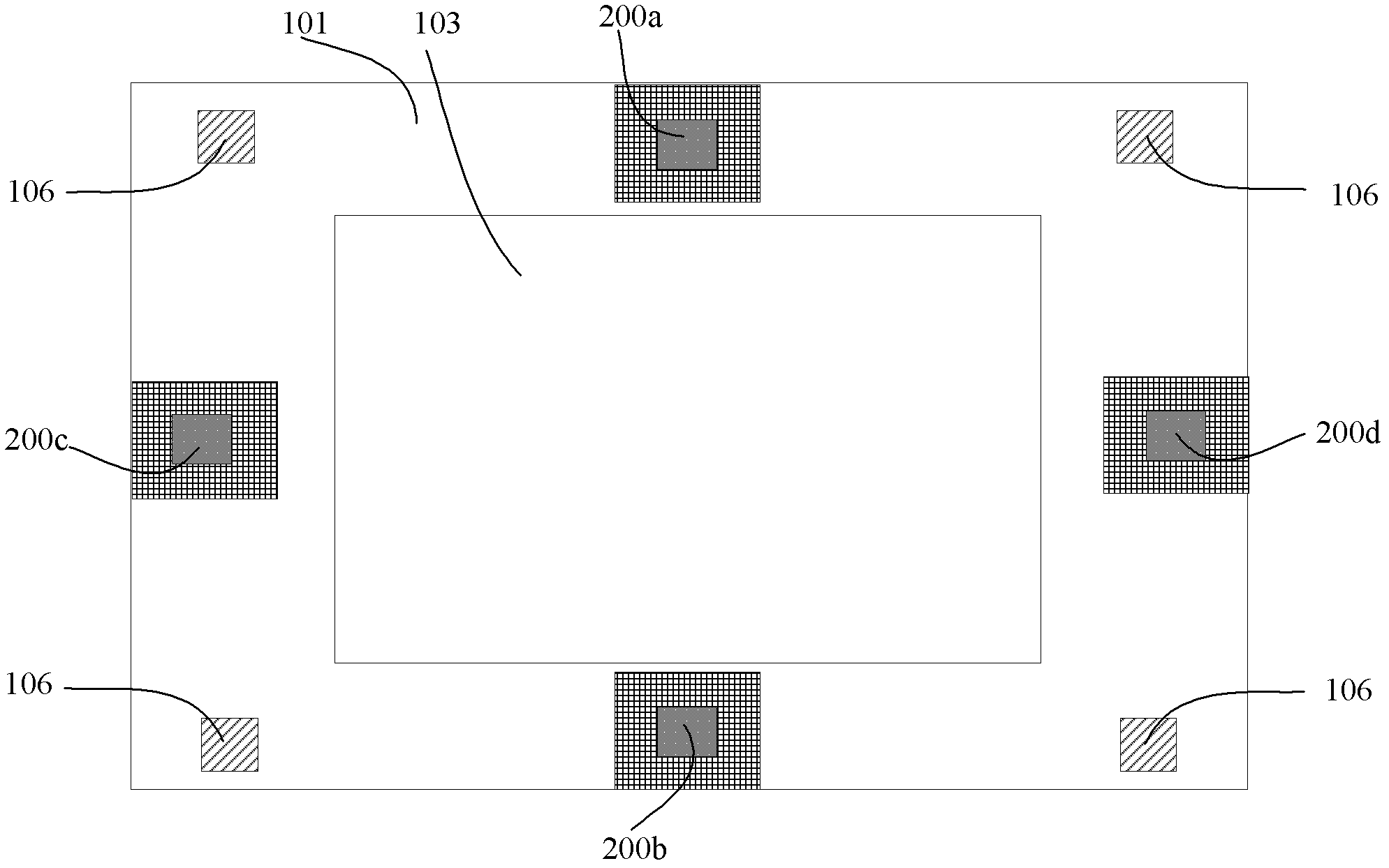

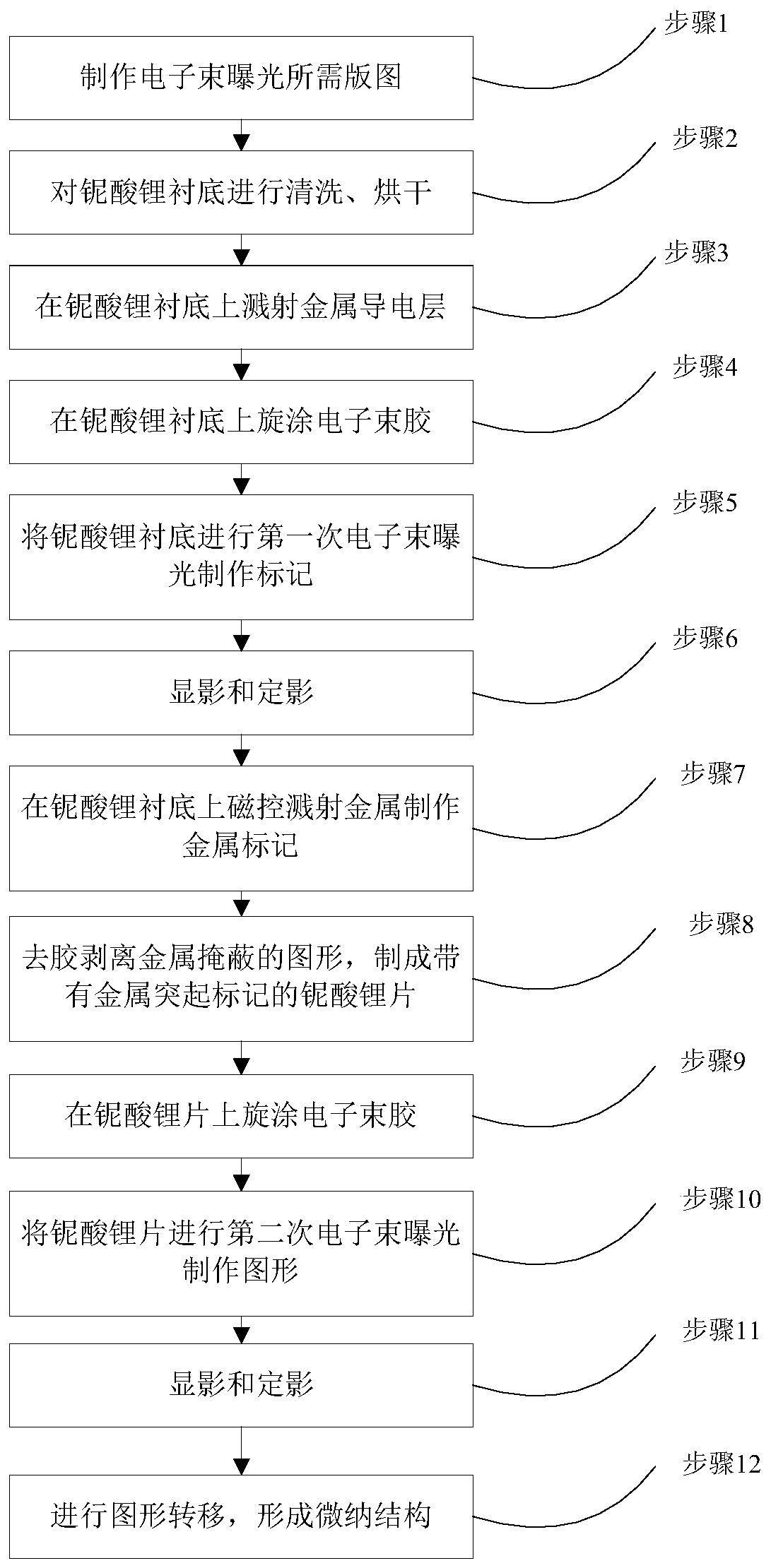

Method for manufacturing optical micro-nano pattern on surface of lithium niobate film

ActiveCN110850688AImprove Exposure AccuracyReliable technical solutions for exposing HSQPhotomechanical exposure apparatusMicrolithography exposure apparatusSputteringNano structuring

The invention relates to a method for manufacturing an optical micro-nano pattern on the surface of a lithium niobate film, which belongs to the technical field of micro-nano processing. The method comprises the following steps: manufacturing a layout required by electron beam exposure; cleaning and drying a lithium niobate substrate; sputtering a metal conductive layer on the lithium niobate substrate; spin-coating the lithium niobate substrate with electron beam glue; carrying out first electron beam exposure on the lithium niobate substrate to manufacture a mark; carrying out developing andfixing; carrying out magnetron sputtering of metal on the lithium niobate substrate to manufacture a metal mark; removing the photoresist and stripping a metal-masked pattern to prepare a lithium niobate sheet with a metal bulge mark; spin-coating the lithium niobate sheet with electron beam glue; carrying out second electron beam exposure on the lithium niobate sheet to manufacture a pattern; carrying out developing and fixing; and carrying out pattern transfer to form a micro-nano structure. By means of the method, a pattern with a steep side wall can be manufactured on a non-conductive lithium niobate material, a micro-nano pattern with the size smaller than 900nm can be manufactured, the manufactured optical waveguide is large in refractive index contrast ratio, the size of an opticaldevice can be reduced, and the performance of the optical device can be improved.

Owner:TSINGHUA UNIV +1

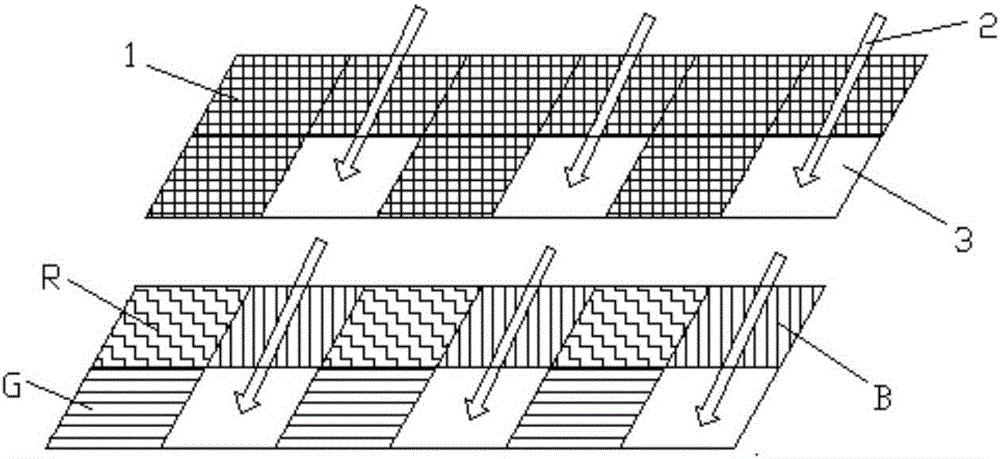

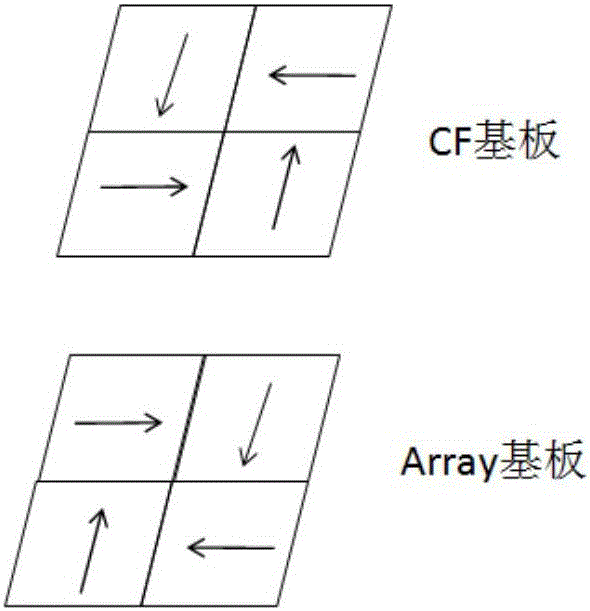

Liquid crystal display and method for manufacturing same

InactiveCN106773216AIncrease the areaImprove Exposure AccuracyNon-linear opticsLiquid-crystal displayQuantum dot

The invention discloses a liquid crystal display which comprises a plurality of square pixel structures. Each square pixel structure comprises a red sub-pixel, a green sub-pixel and a blue sub-pixel and is divided into four square sub-regions with the equal sizes, and the area of each blue sub-pixel is two times the area of each red sub-pixel or each green sub-pixel. The liquid crystal display has the advantages that the areas of blue pixels can be enlarged by the square pixel structures, and accordingly the blue light efficiency can be improved; the square pixel structures and blue light excitation quantum dots are combined with one another, and accordingly the liquid crystal display is high in exposure accuracy, color saturation, contrast, response speed and resolution, wide in visual angle and free of color cast without increase of extra cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

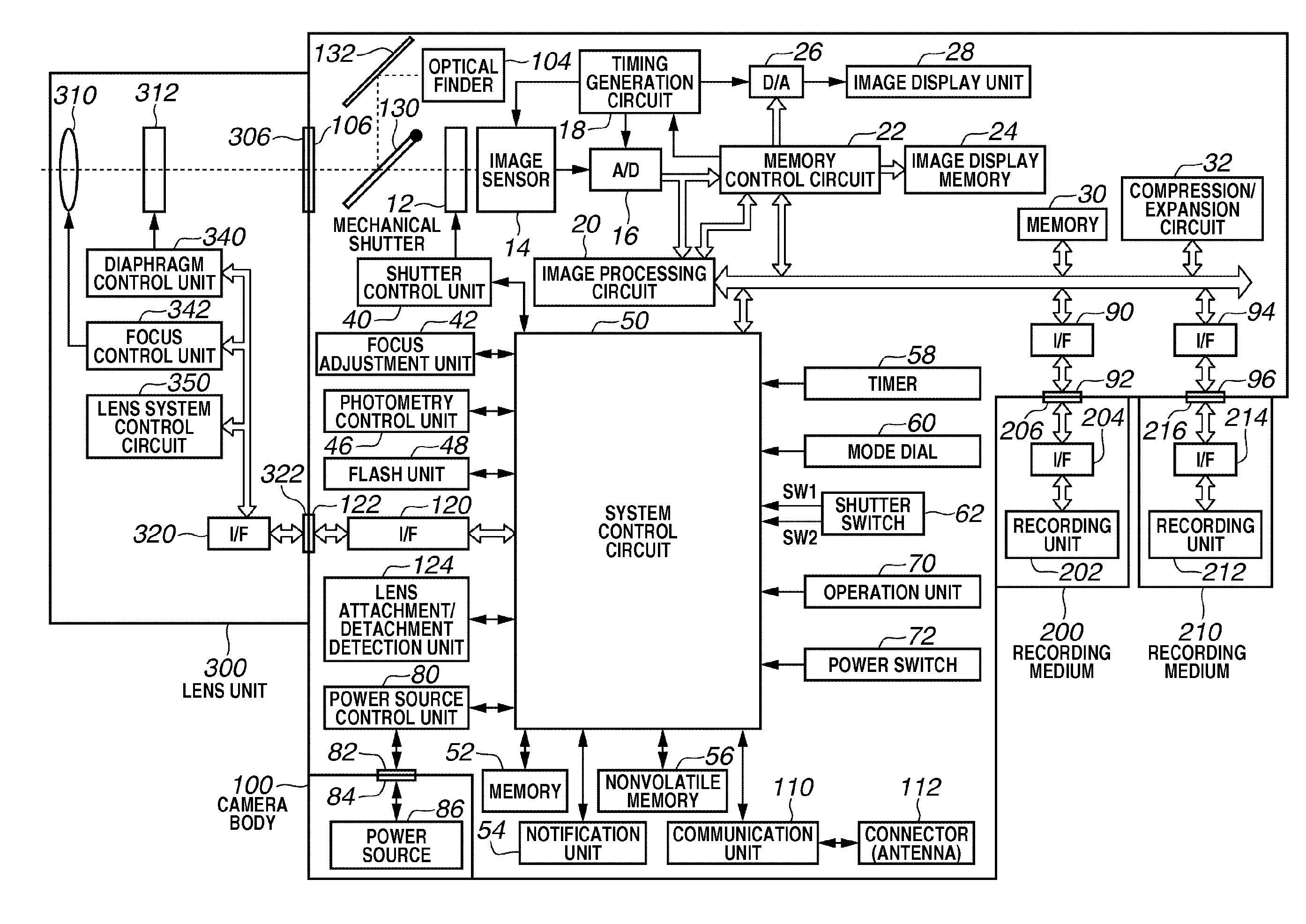

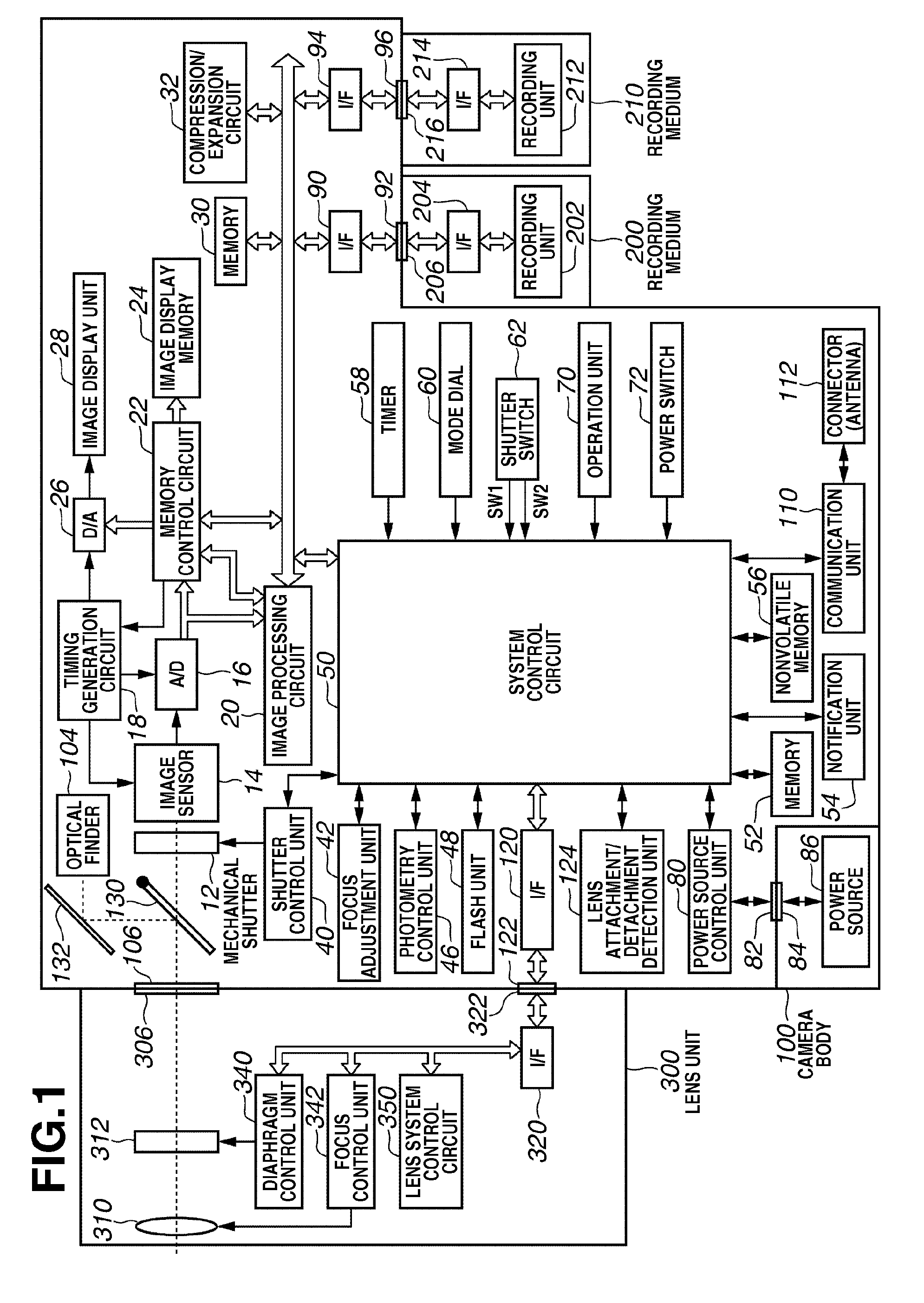

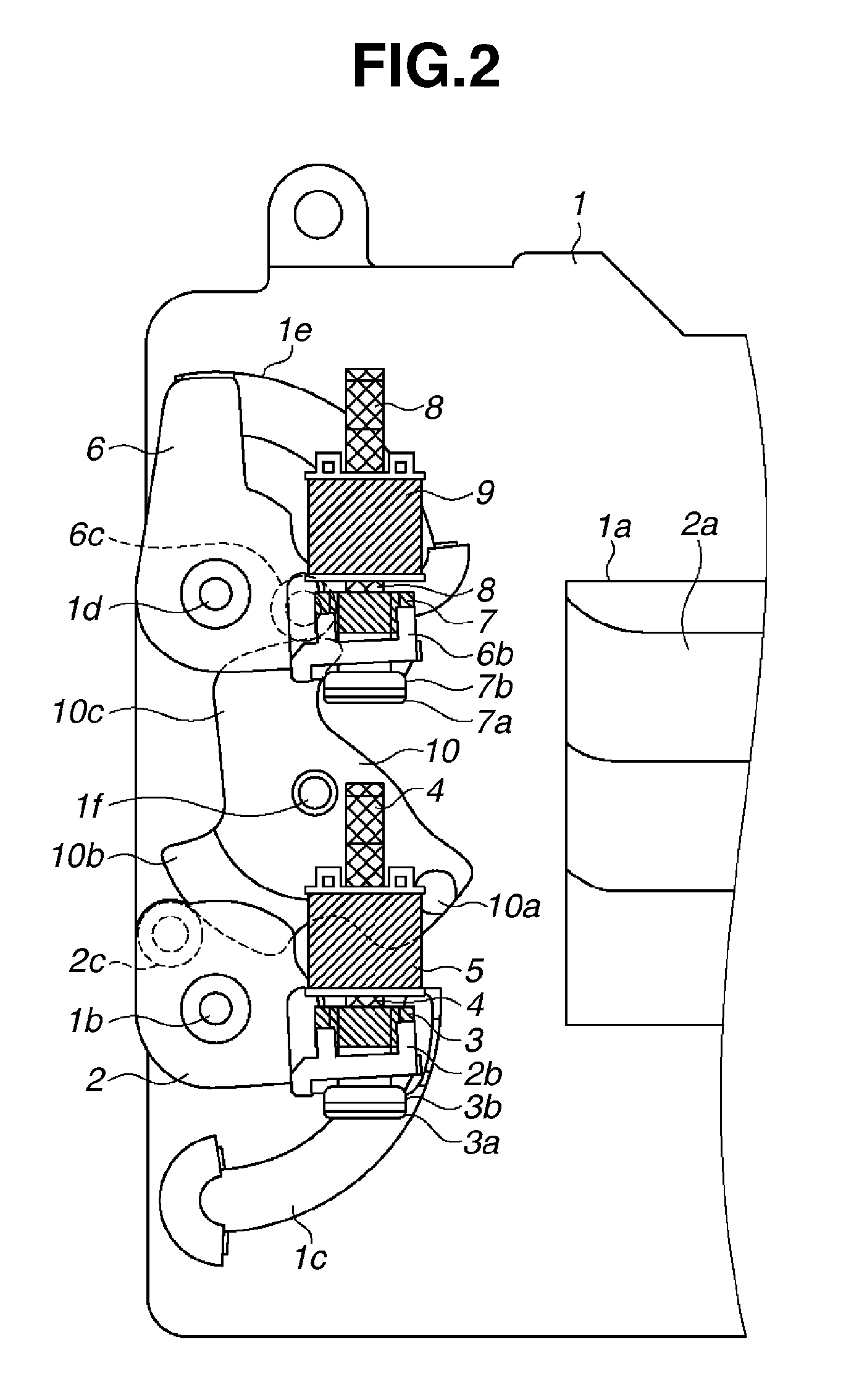

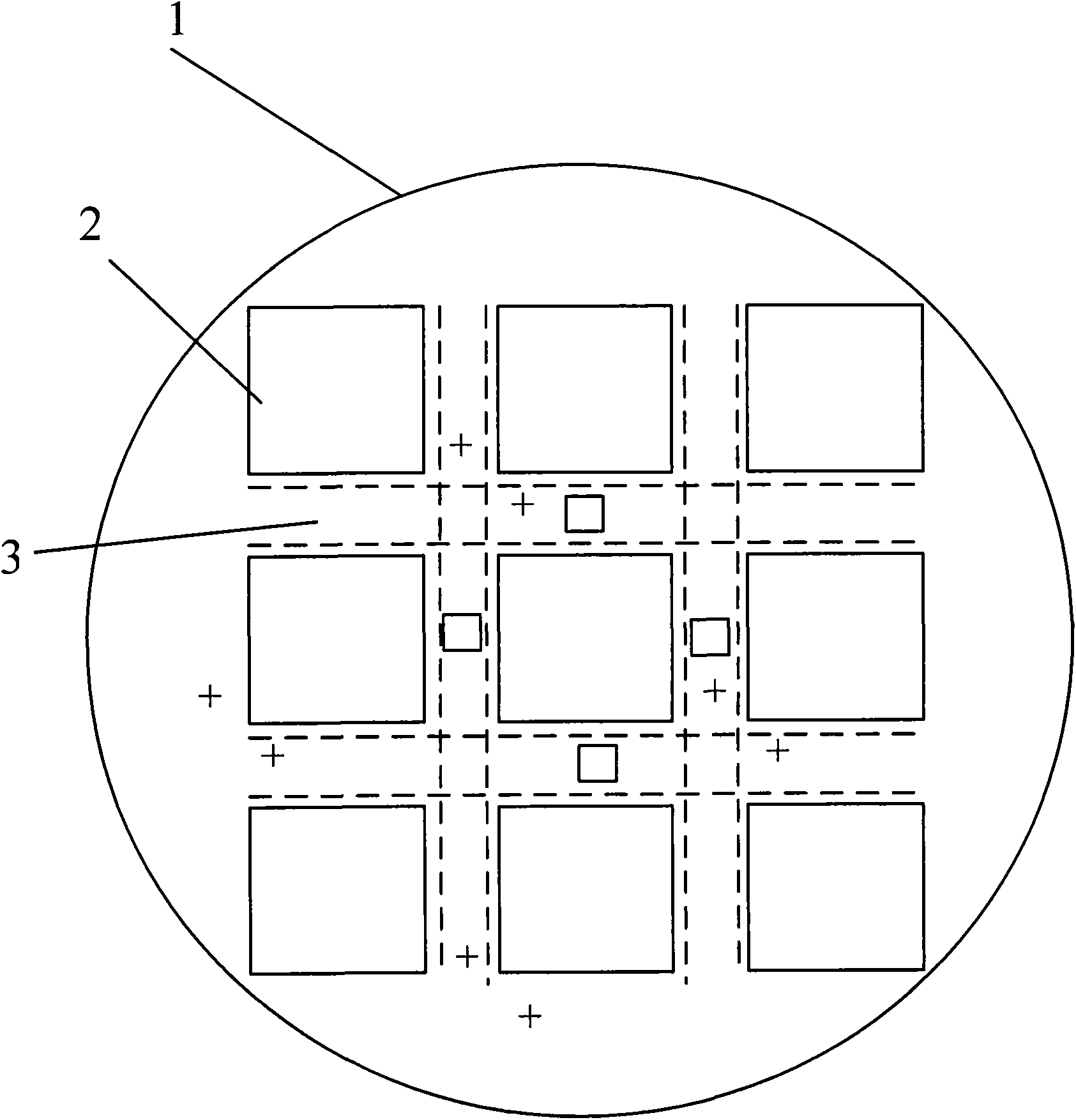

Imaging apparatus and method for controlling the same

InactiveUS20080260374A1Improve Exposure AccuracyImprove accuracyTelevision system detailsColor television detailsImage sensorEngineering

An imaging apparatus includes an image sensor configured to capture an image of an object, a mechanical shutter including a second curtain and a second-curtain holding mechanism configured to electromagnetically hold the second curtain at an initial position prior to a travel, a first temperature sensor disposed within a predetermined range from the second-curtain holding mechanism, a second temperature sensor disposed outside the predetermined range from the second-curtain holding mechanism, a determination unit configured to determine an exposure time for the image sensor according to a brightness of the object, an adjustment unit configured to adjust the exposure time if a temperature difference between temperatures detected by the first and second temperature sensors is greater than a predetermined threshold, and an exposure control unit configured to perform exposure control for the image sensor based on the exposure time adjusted by the adjustment unit if the temperature difference is greater than the predetermined threshold.

Owner:CANON KK

Method for forming semiconductor device layer by exposure

InactiveCN101788769AImprove Exposure AccuracyIncrease productivityPhotomechanical exposure apparatusMicrolithography exposure apparatusSemiconductorSemiconductor device

The invention discloses a method for forming a semiconductor device layer by exposure, which is characterized by comprising that: A, when a lighthouse is aligned with a front layer, the lighthouse measures an alignment mark of the front layer to acquire characteristic information of a front layer wafer, and the lighthouse measures an overlapped precision measuring identifier of the front layer to acquire characteristic information of an exposure unit in the front layer; B, the characteristic information of the front layer wafer and the characteristic information of the exposure unit in the front layer are fed back to the lighthouse; and C, the lighthouse performs exposure to form the layer according to the fed back characteristic information of the wafer and characteristic information of the exposure unit. Due to the adoption of the method, the production efficiency of the wafer can be greatly improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Self-aligned process for preparing convex graphical substrate

The invention discloses a method for preparing a convex graphical substrate used for the epitaxial growth of nitrides, namely, a self-aligned process for preparing the convex graphical substrate. The method comprises the following steps of: carbonizing a plurality of convex graphical microstructures which are made of thin photoresist and arranged on a sapphire substrate by high-temperature processing; coating a thick photoresist layer on the carbonized microstructures, and carrying out self-aligned exposure on the thick photoresist layer by using the carbonized convex graphical microstructures as a masking film; and fusing the carbonized convex graphical microstructures and the developed photoresist graphs to convex round balls by using high temperature hardening, and finally transferring the graphical structure to the substrate by using the dry etching technology so as to obtain the convex graphical substrate. By adopting the self-aligned process of the invention, the problem that the convex graph made of thick photoresist is easy to drop can be solved, a high-precision exposure requirement can be met by using a common exposure machine, and the uniformity of the graph can be greatly improved, so that the process for preparing the convex graphical substrate can realize industrialization.

Owner:EPILIGHT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com