Balancing mass system of photoetching machine

A technology of balancing mass and balancing mass, which is applied in the direction of microlithography exposure equipment, photolithography exposure device, etc., can solve problems such as inability to perform lubrication, blockage of orifice, and influence on control accuracy, so as to improve motion and Exposure accuracy, the effect of increasing damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

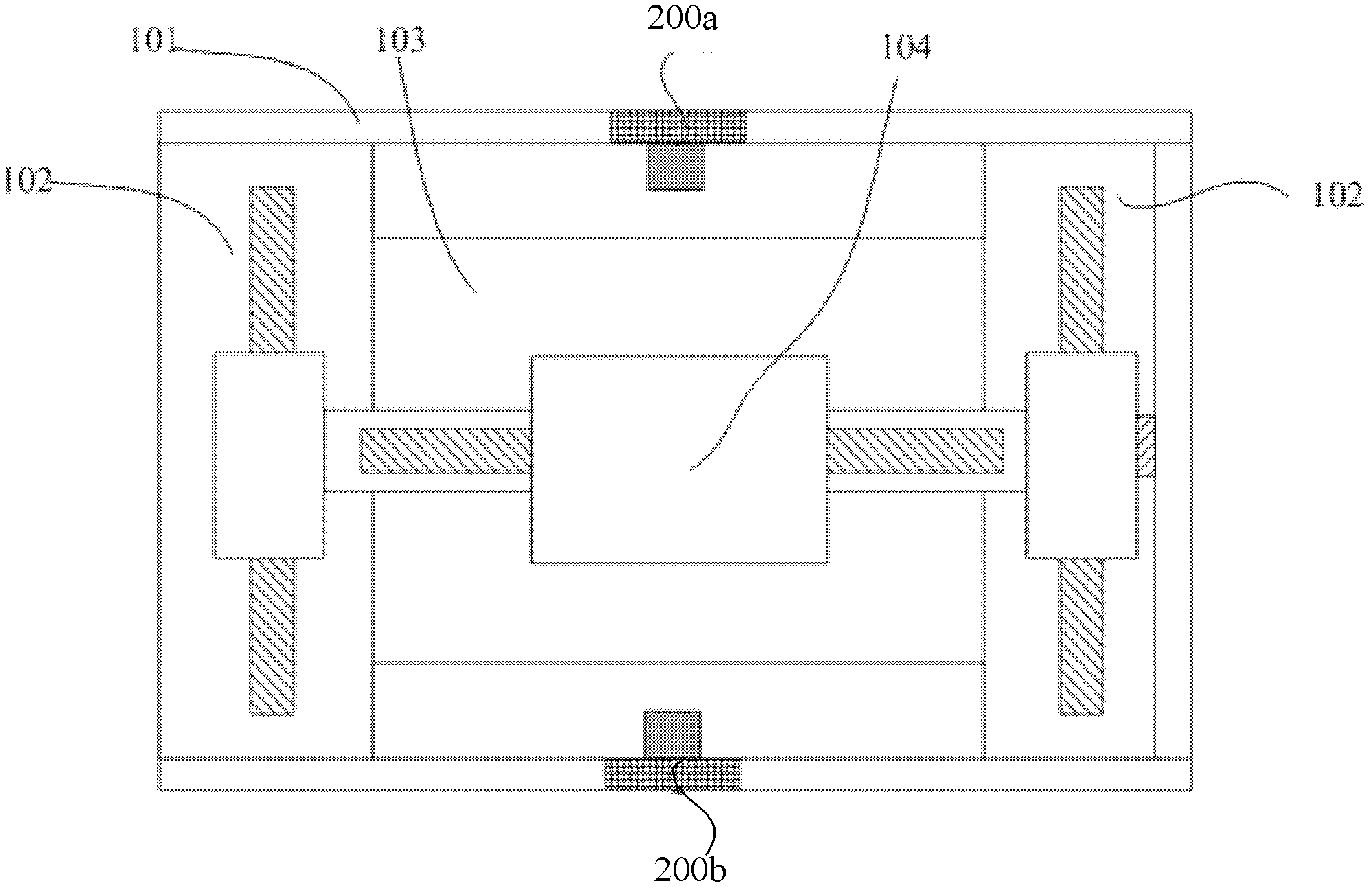

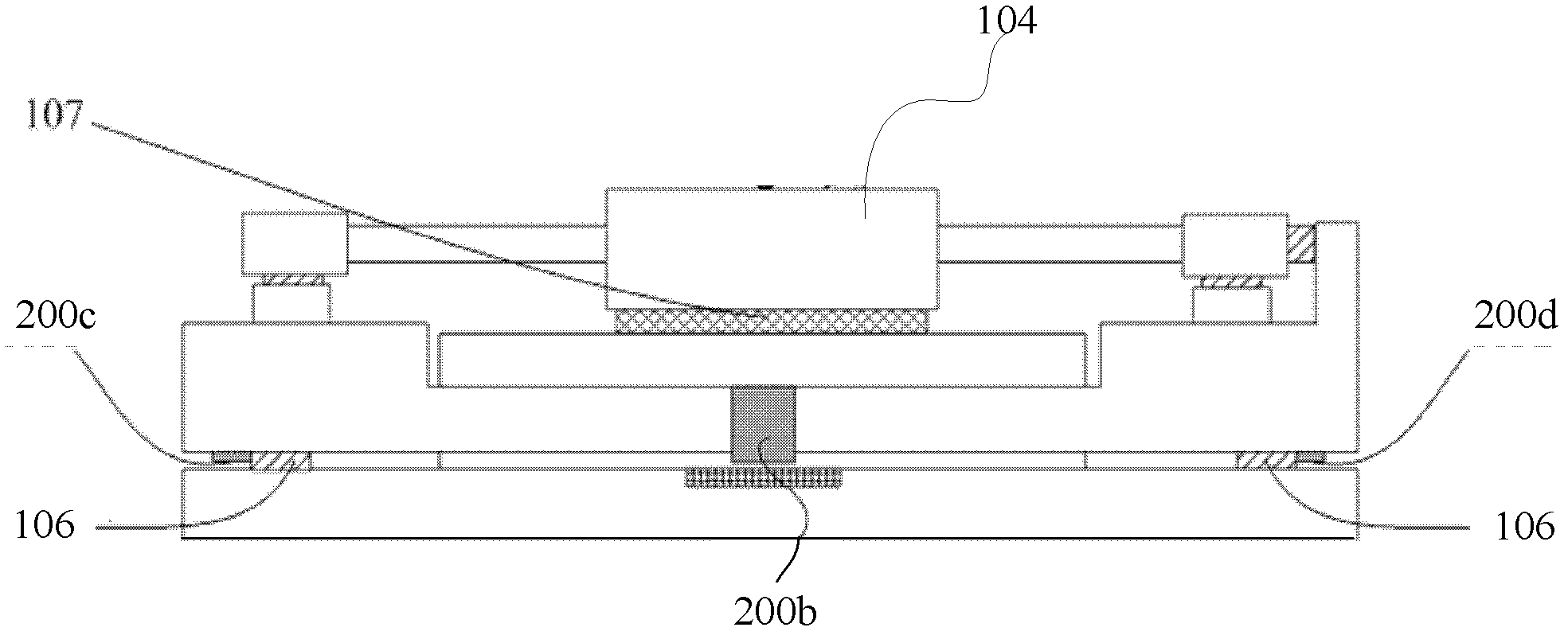

[0042] Please refer to Figure 1 to Figure 4 ,among them, figure 1 Is a top view of the balance mass system of a lithography machine provided by the first embodiment of the present invention, figure 2 This is a front view of the balance mass system of a lithography machine provided by the first embodiment of the present invention, image 3 It is a schematic diagram of the installation position of the reaction moment buffer mechanism provided by the first embodiment of the present invention, Figure 4 It is a schematic diagram of the structure of the reaction moment buffer mechanism provided by the first embodiment of the present invention, such as Figure 1 to Figure 4 As shown, the lithography machine quality balance system provided by the first embodiment of the present invention includes:

[0043] Basic frame 101;

[0044] The marble platform 103 is fixed on the base frame 101;

[0045] The micro-movement platform 104 is supported on the marble platform 103 by the first vertical a...

Embodiment 2

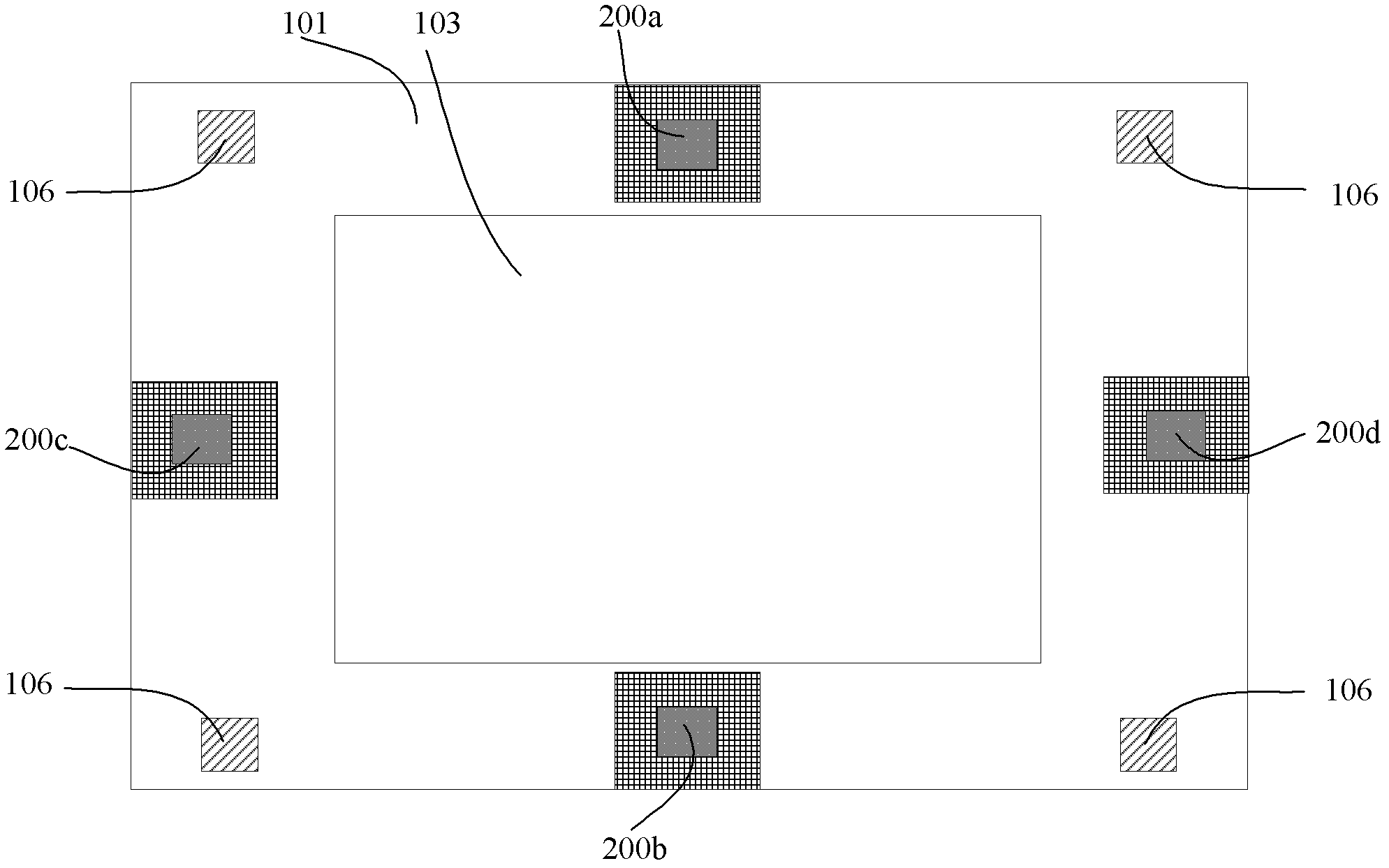

[0061] Please refer to Figure 5 to Figure 6 ,among them, Figure 5 Is a schematic diagram of the installation position of the reaction moment buffer mechanism provided by the second embodiment of the present invention, Image 6 This is a schematic diagram of the structure of the reaction moment buffer mechanism provided by the second embodiment of the present invention, such as Figure 5 to Figure 6 Shown and combined with reference figure 1 and figure 2 , The second embodiment of the present invention provides a lithography machine balance quality system including:

[0062] Basic frame 101;

[0063] The marble platform 103 is fixed on the base frame 101;

[0064] The micro-movement platform 104 is supported on the marble platform 103 by the first vertical air floating cushion 107, and moves relative to the marble platform 103 along the X direction and the Y direction;

[0065] The balance mass 102 is connected to the base frame 101 through a second vertical air cushion 106, the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com