Linear Drive Assembly with Rotary Union for Well Head Applications and Method Implemented Thereby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

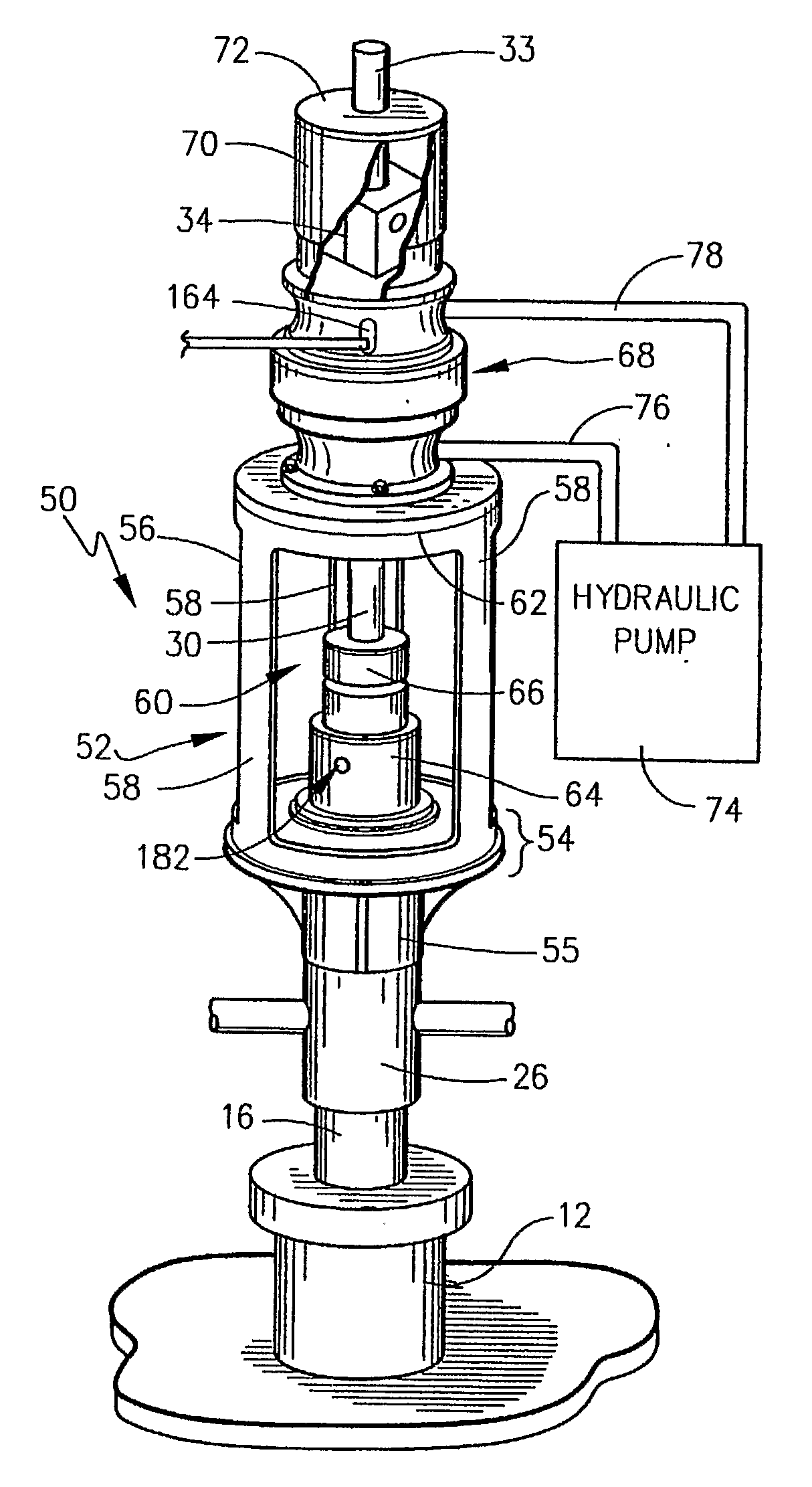

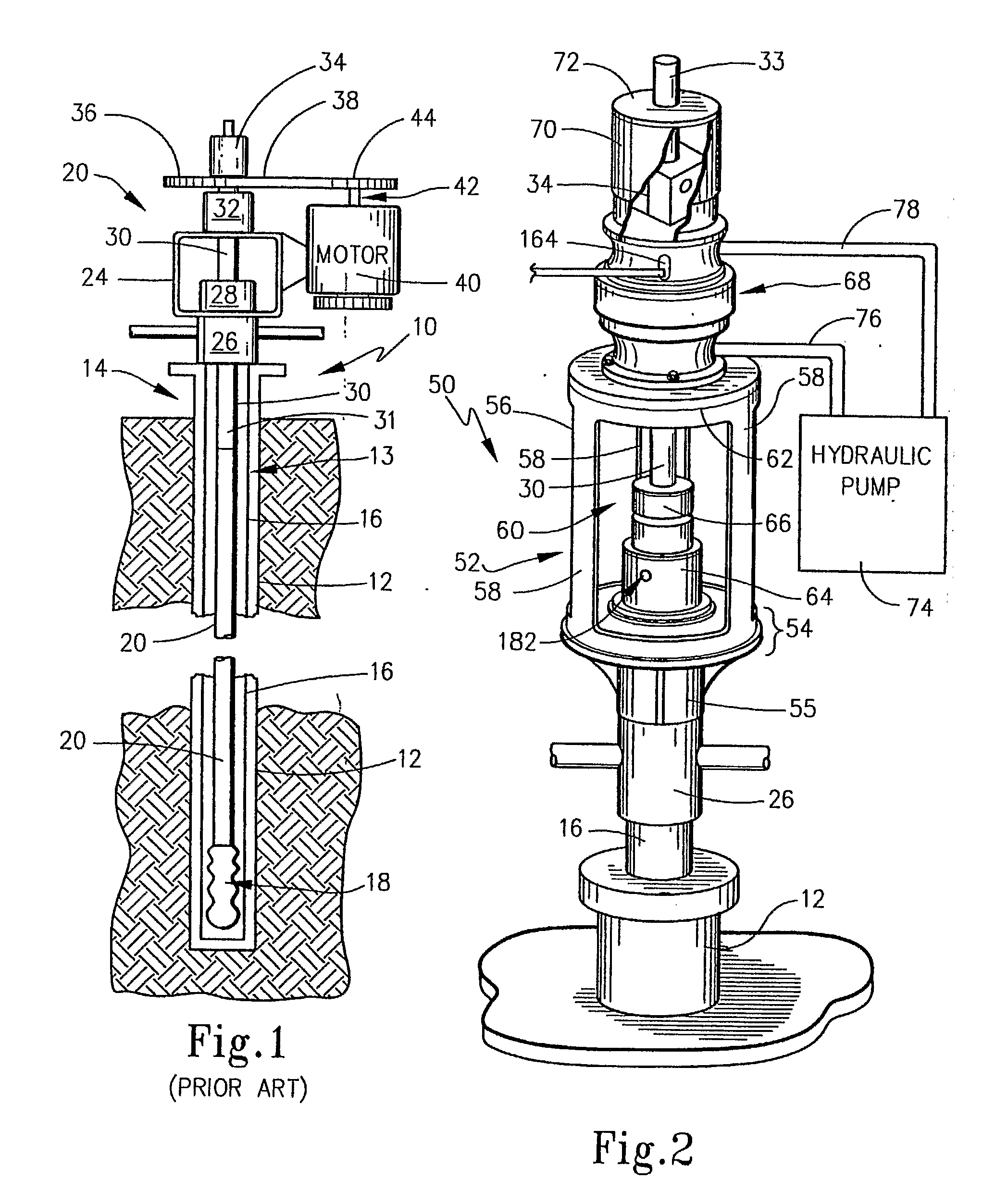

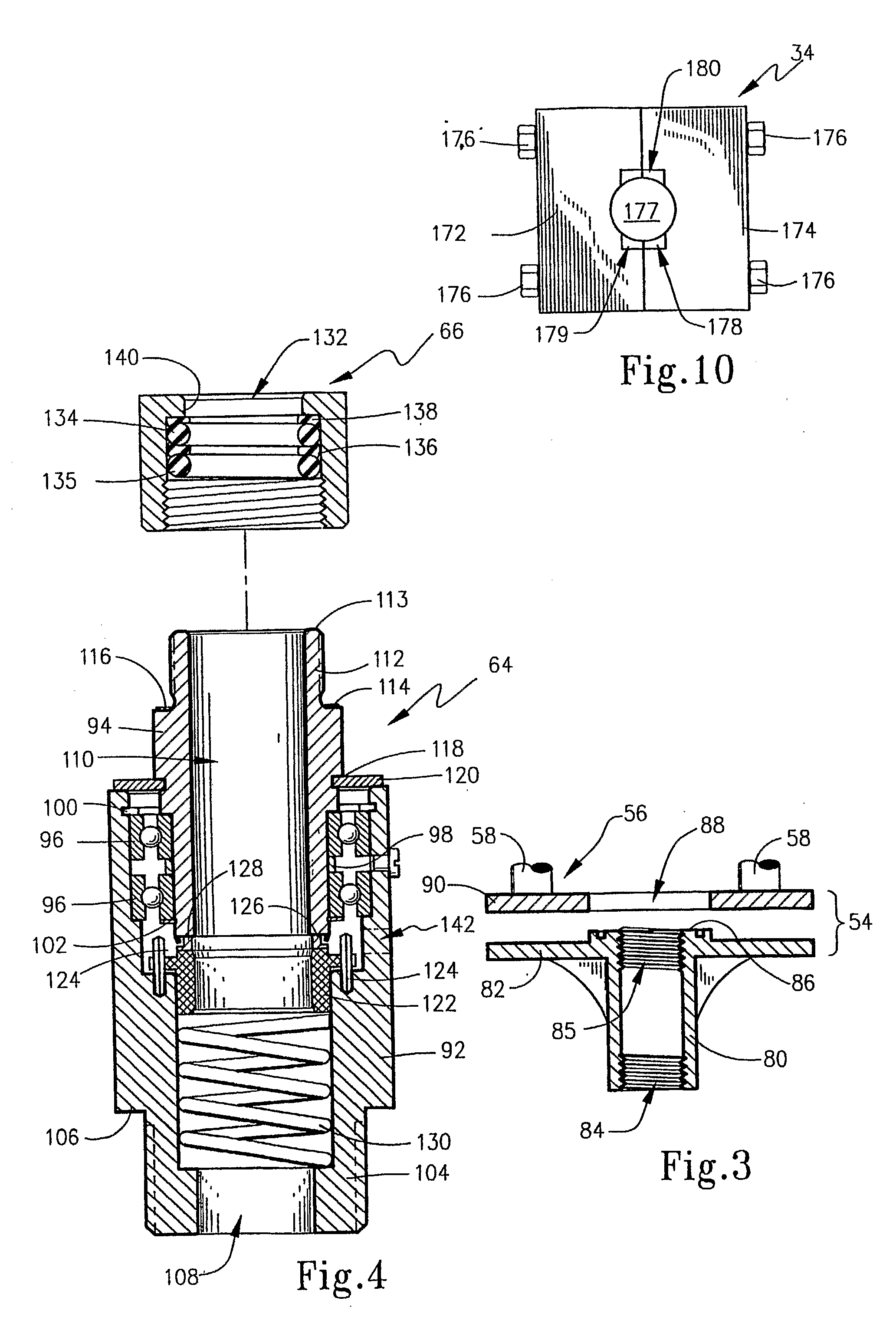

[0034]The present invention broadly concerns drive assemblies and methods for driving a progressive cavity pump that is located down hole in a well. Here, such wells are known to be provided having a casing interior and a sucker rod located in a delivery tube within the casing interior whereby rotation of the sucker rod acts to rotate the progressive cavity pump. In the exemplary embodiments, the drive assembly is a linear drive having an output shaft that is coaxial with a polish rod that is connected to the sucker rod. Another aspect of the exemplary embodiments of the present invention includes a rotary union that substantially seals the production flow through the delivery tube and that includes a friction cap that seals against the polish rod with the rotary union providing a rotary seal whereby the polish rod may be rotated in a substantially sealed rotation in the rotary union.

[0035]In order to introduce the aspects of the present invention, reference may be first made to FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com