Steel wire rope cleaning/detection/maintenance apparatus

A wire rope and equipment technology, applied in the field of wire rope cleaning, testing and maintenance equipment, can solve problems such as low work efficiency, accidents, and load reduction, and achieve the effects of improving work efficiency, protecting the working environment, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with embodiments:

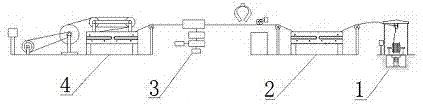

[0031] Such as figure 1 As shown, the wire rope cleaning, testing and maintenance equipment includes a torsion release device 1 for releasing the torsion of the wire rope, a cleaning device 2 for cleaning the wire rope, a detection device 3 for nondestructive testing of the wire rope, and a detection device 3 for immersing the wire rope. Oil immersion device 4 for oil maintenance; the steel wire rope passes through the torsion release device 1, the cleaning device 2, the detection device 3, and the oil immersion device 4 for torque release, cleaning, inspection and oil immersion operations, realizing all mechanized operations, for the detection of large steel ropes Maintenance can complete the work quickly and reliably in one stop.

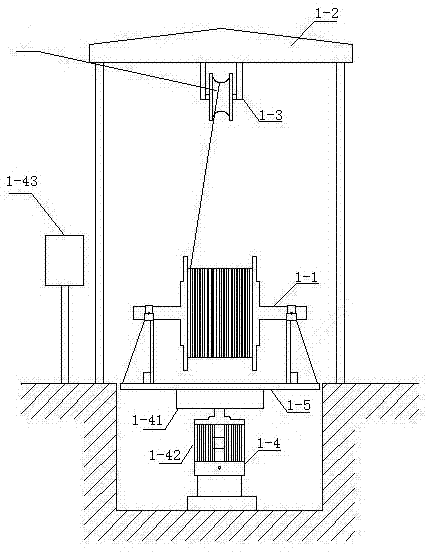

[0032] Such as figure 2 As shown, the torsion release device 1 includes a wire rope winding spool 1-1 arranged on a chassis 1-5 and a gantry 1-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com