Patents

Literature

653results about "Connecting rod bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

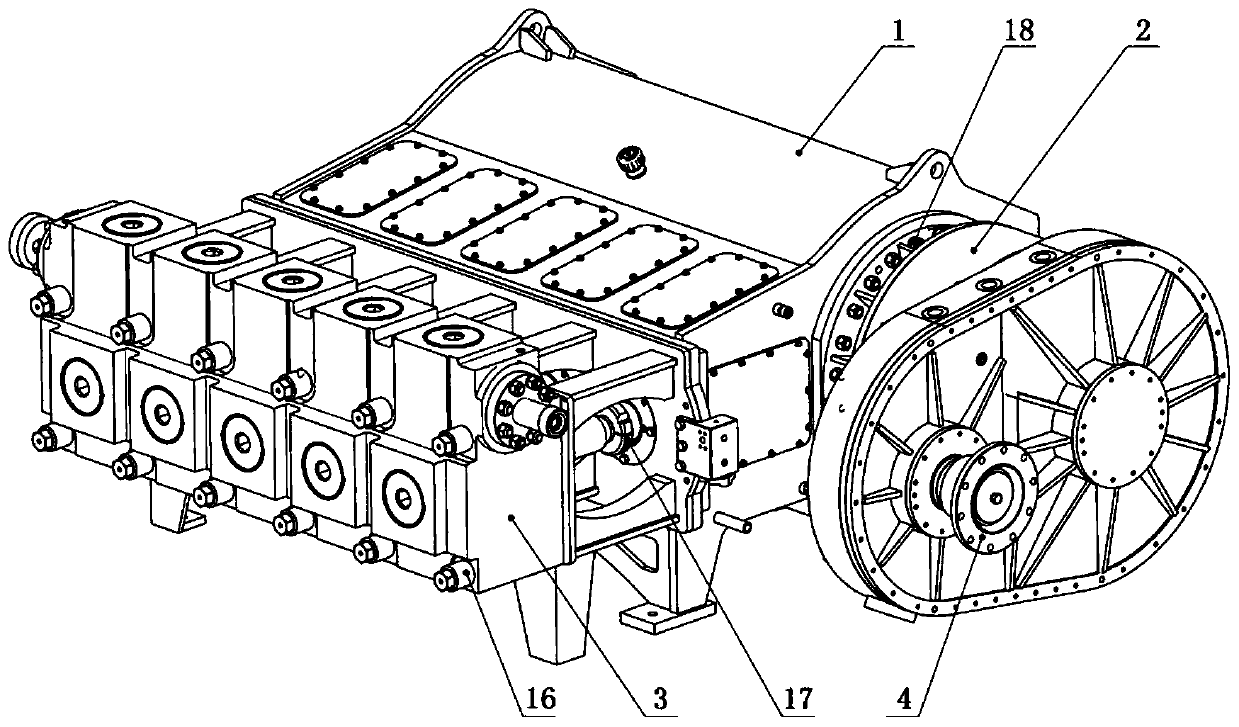

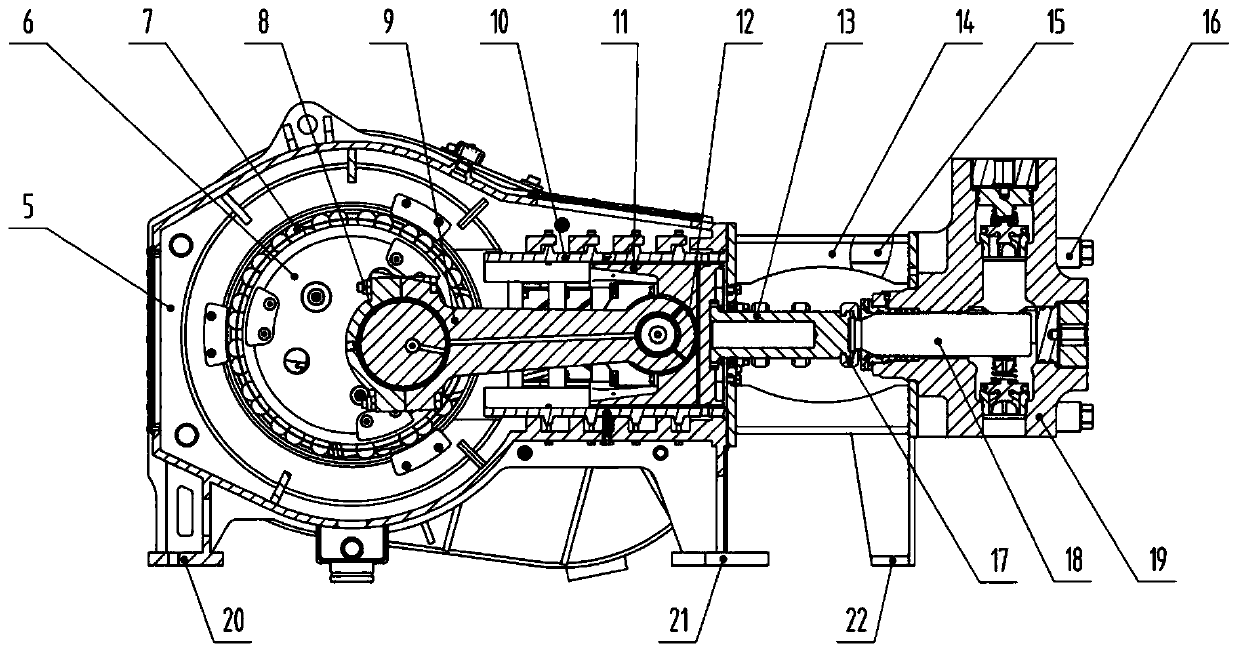

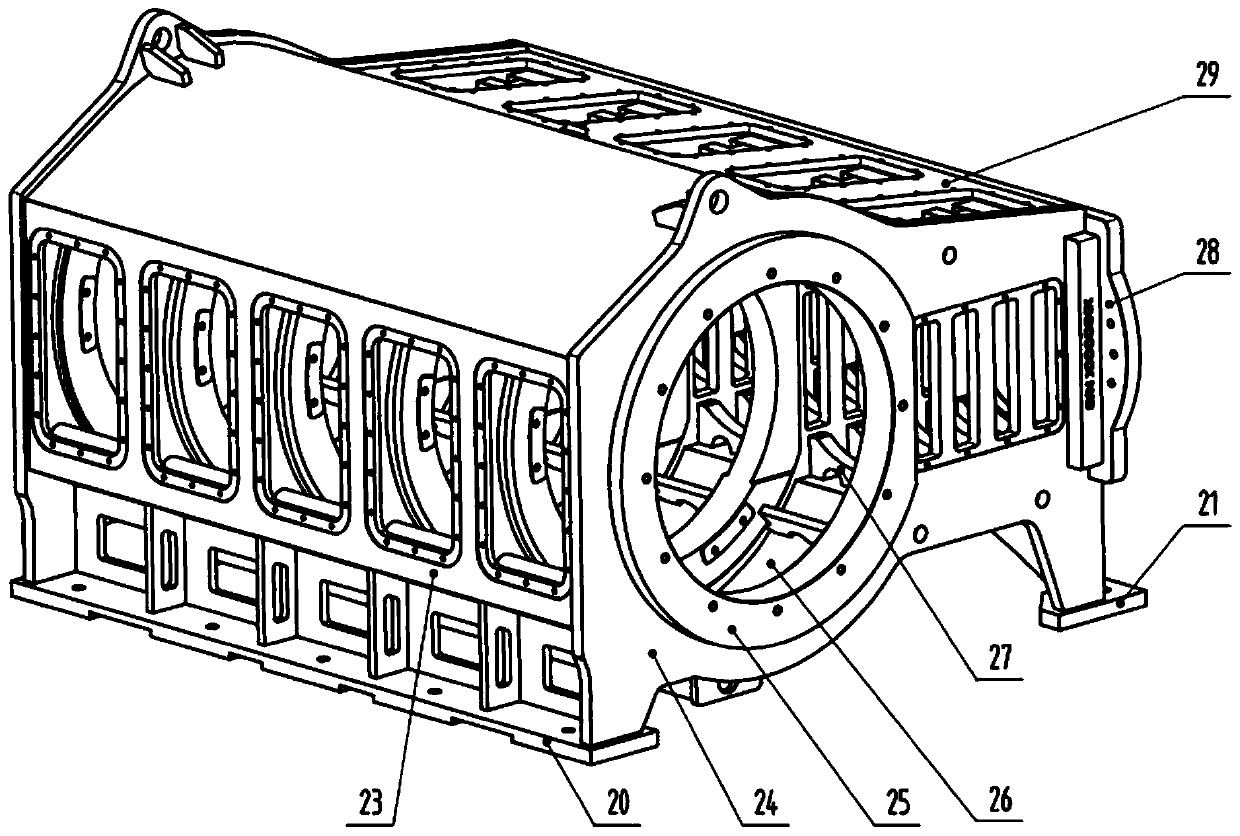

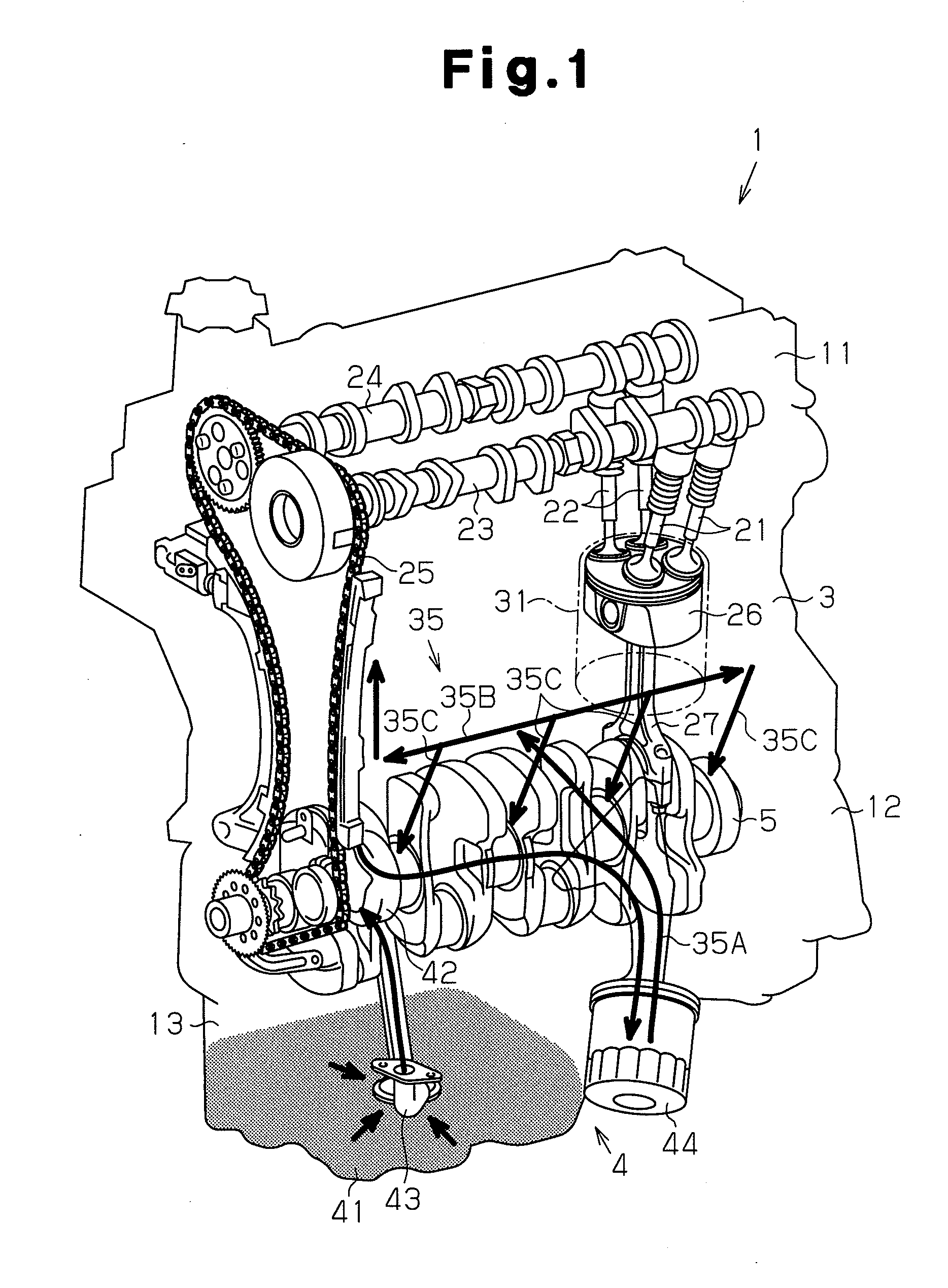

Five-cylinder plunger pump with integral power end structure

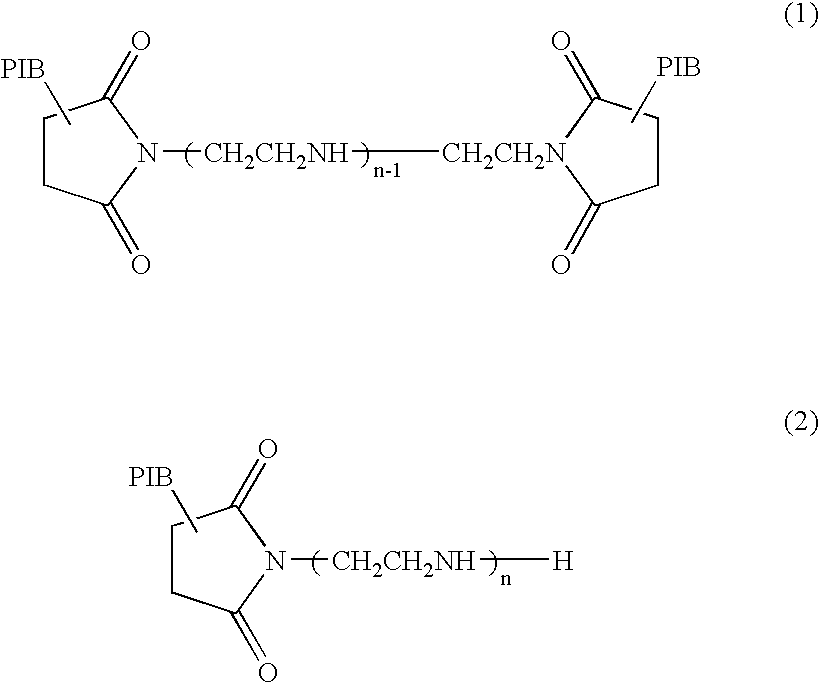

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

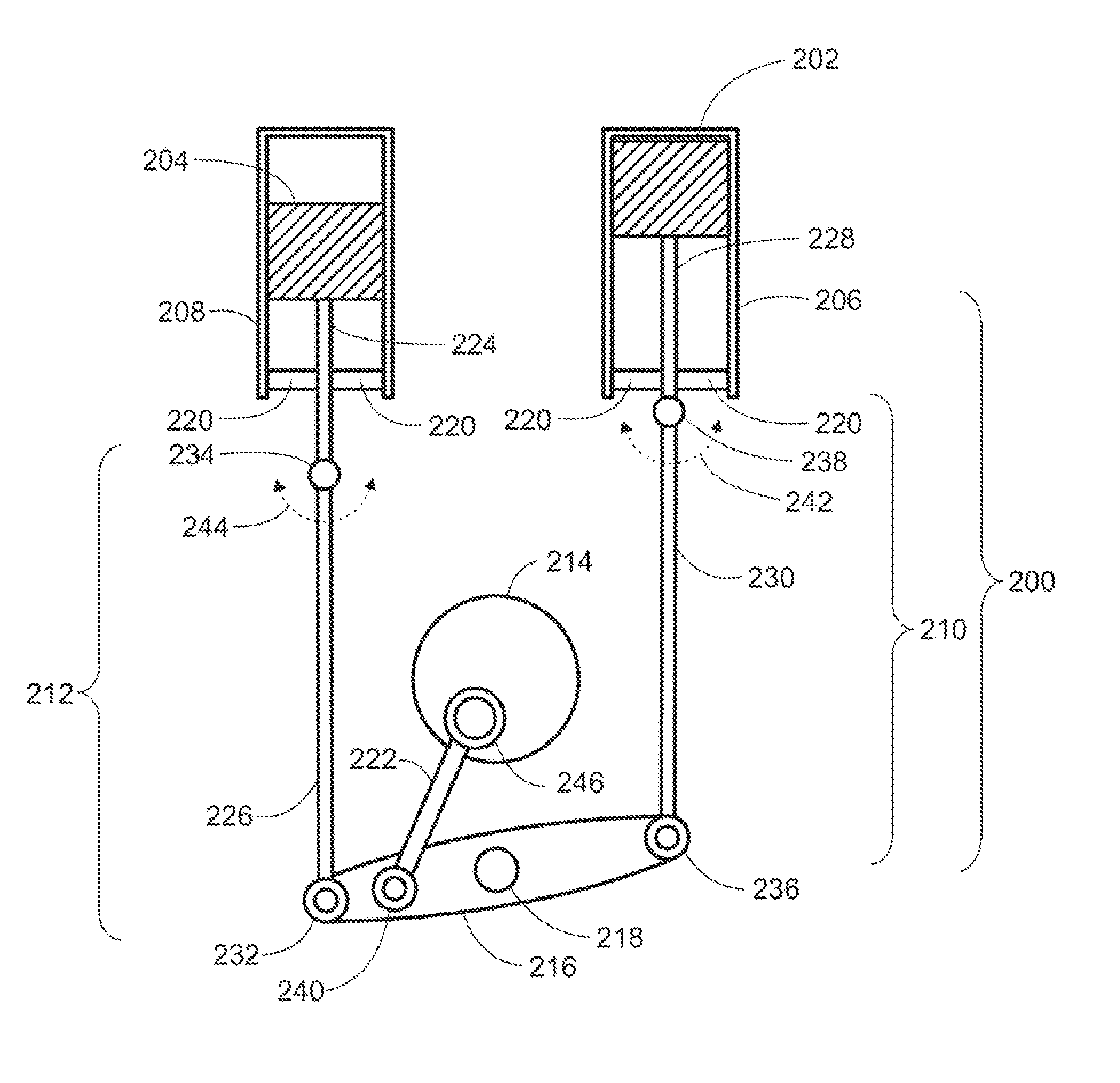

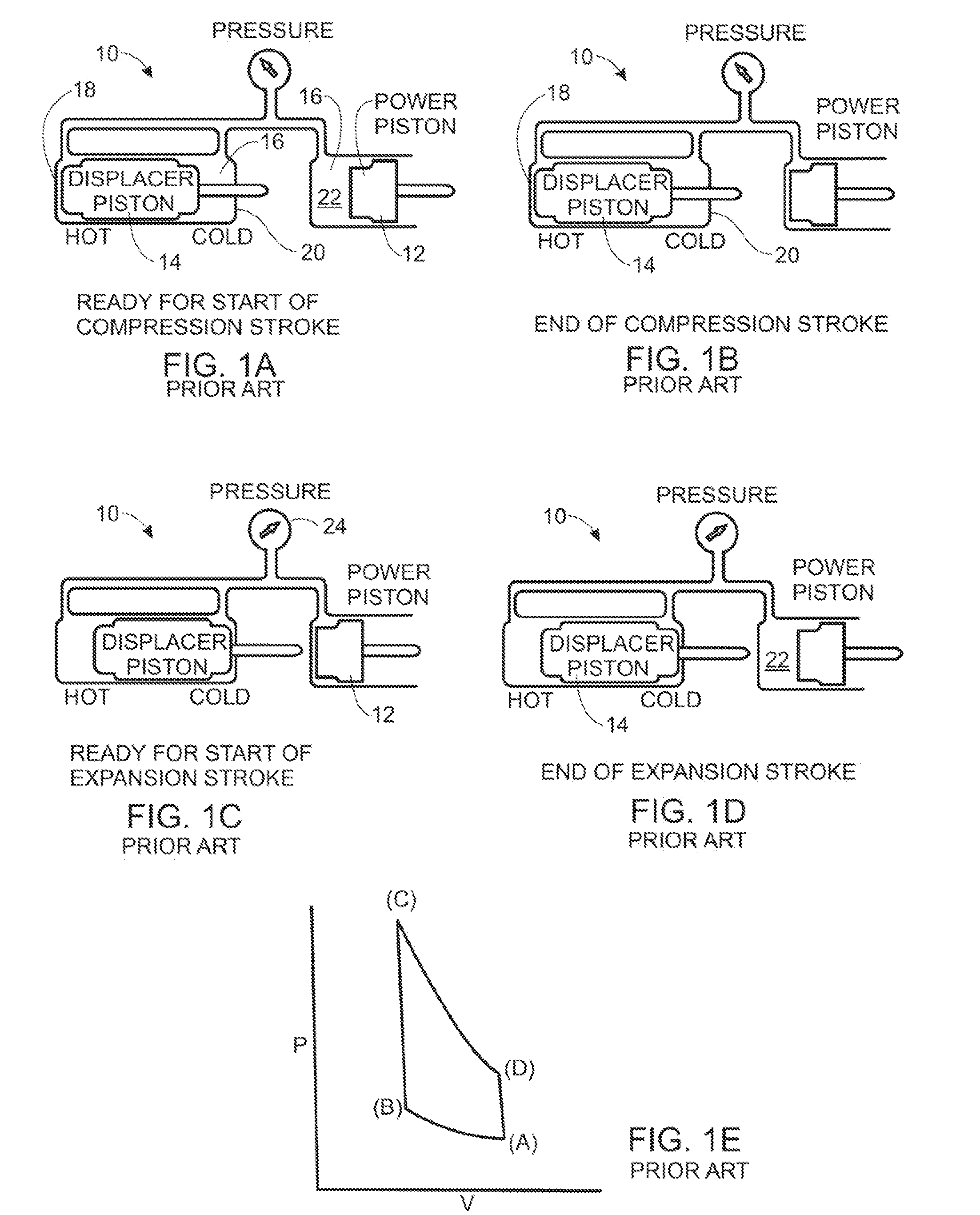

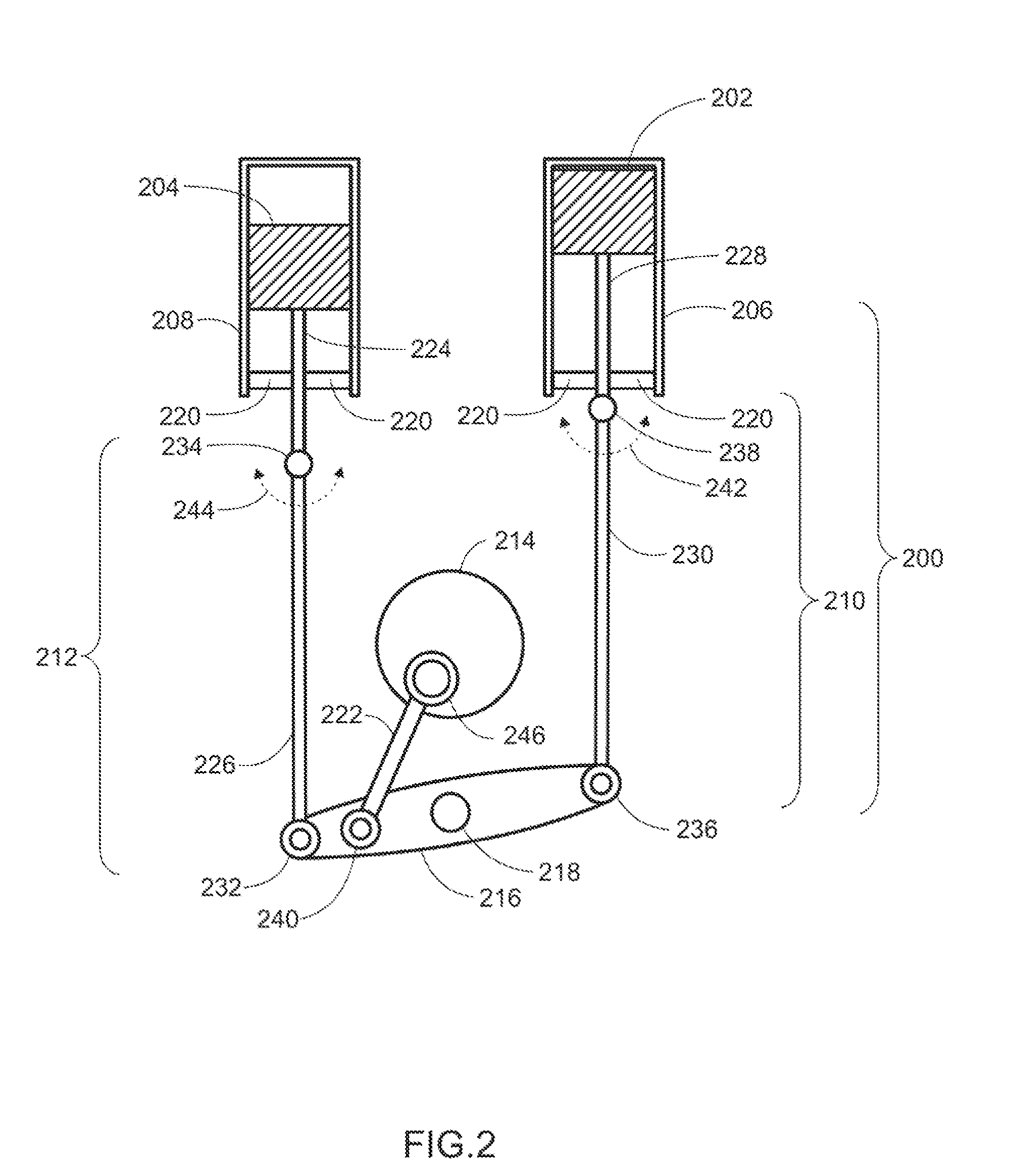

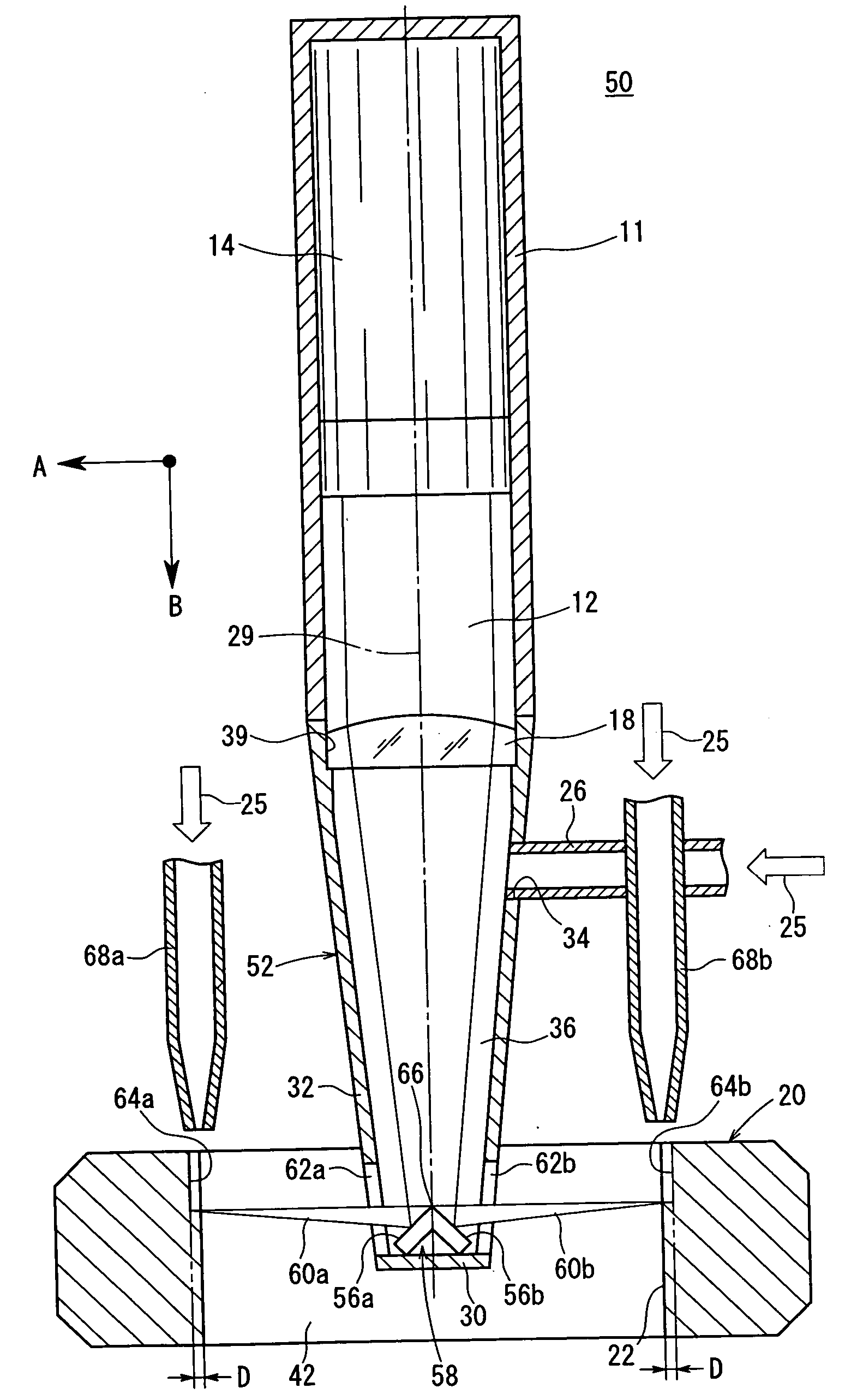

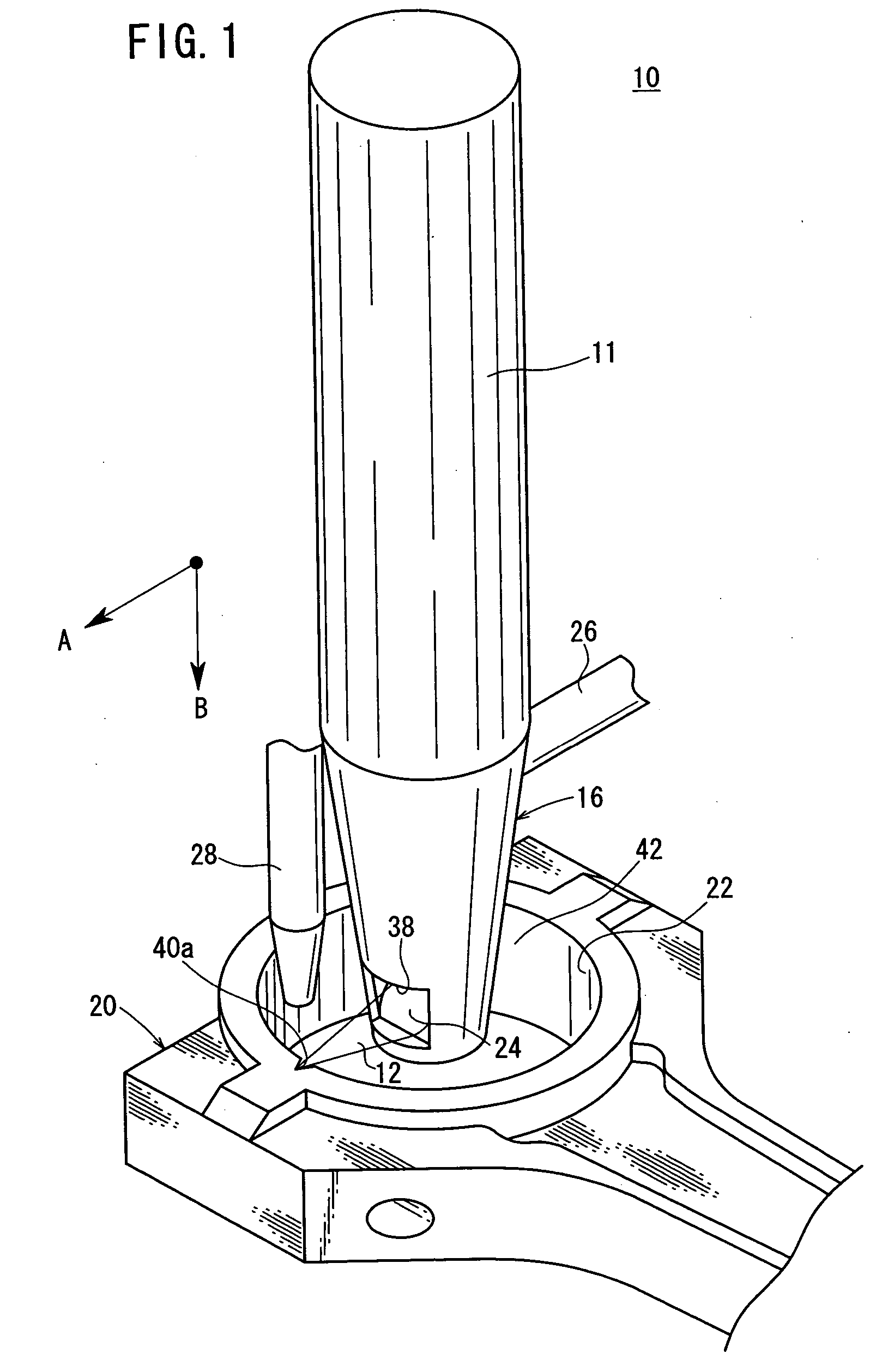

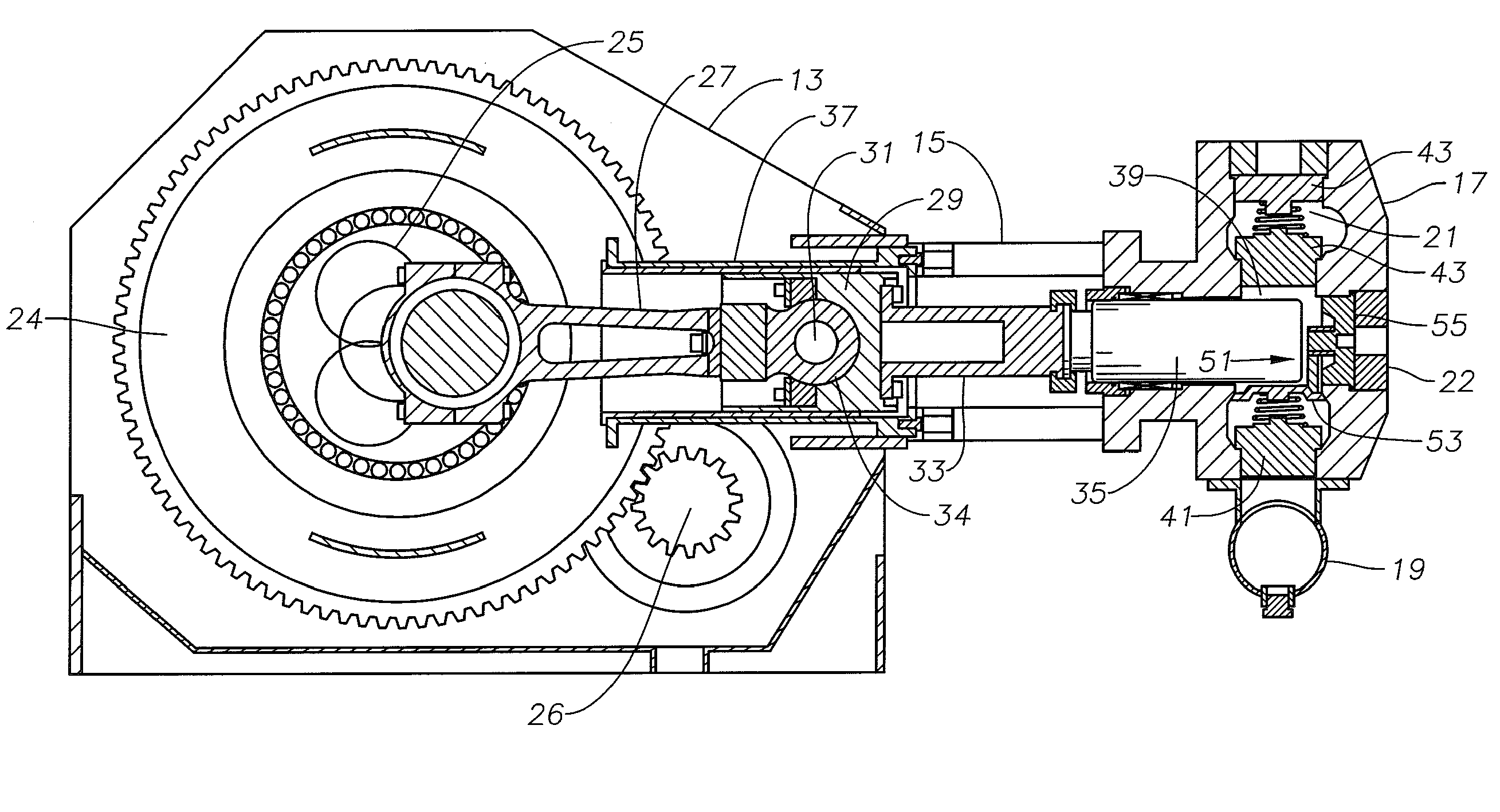

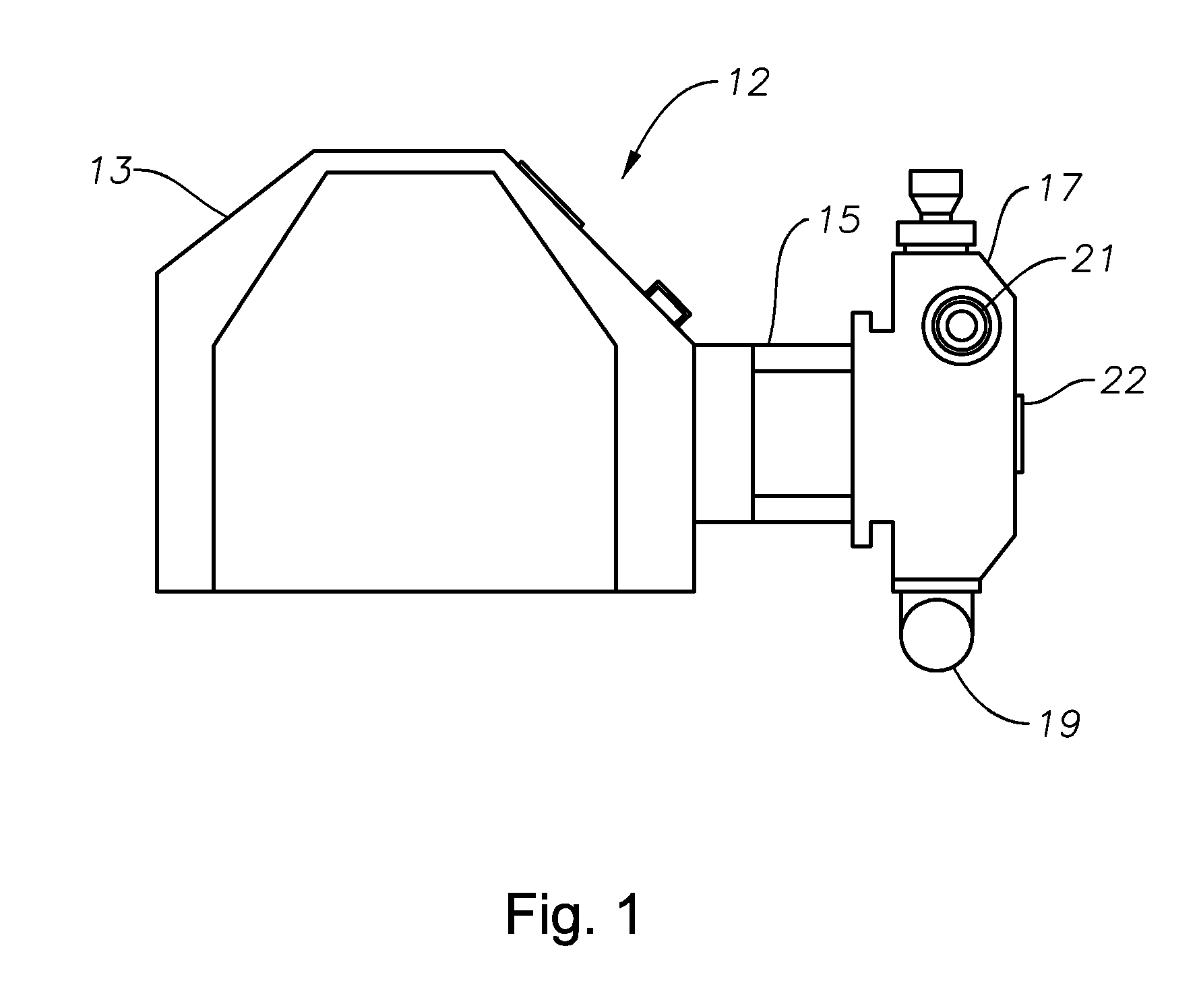

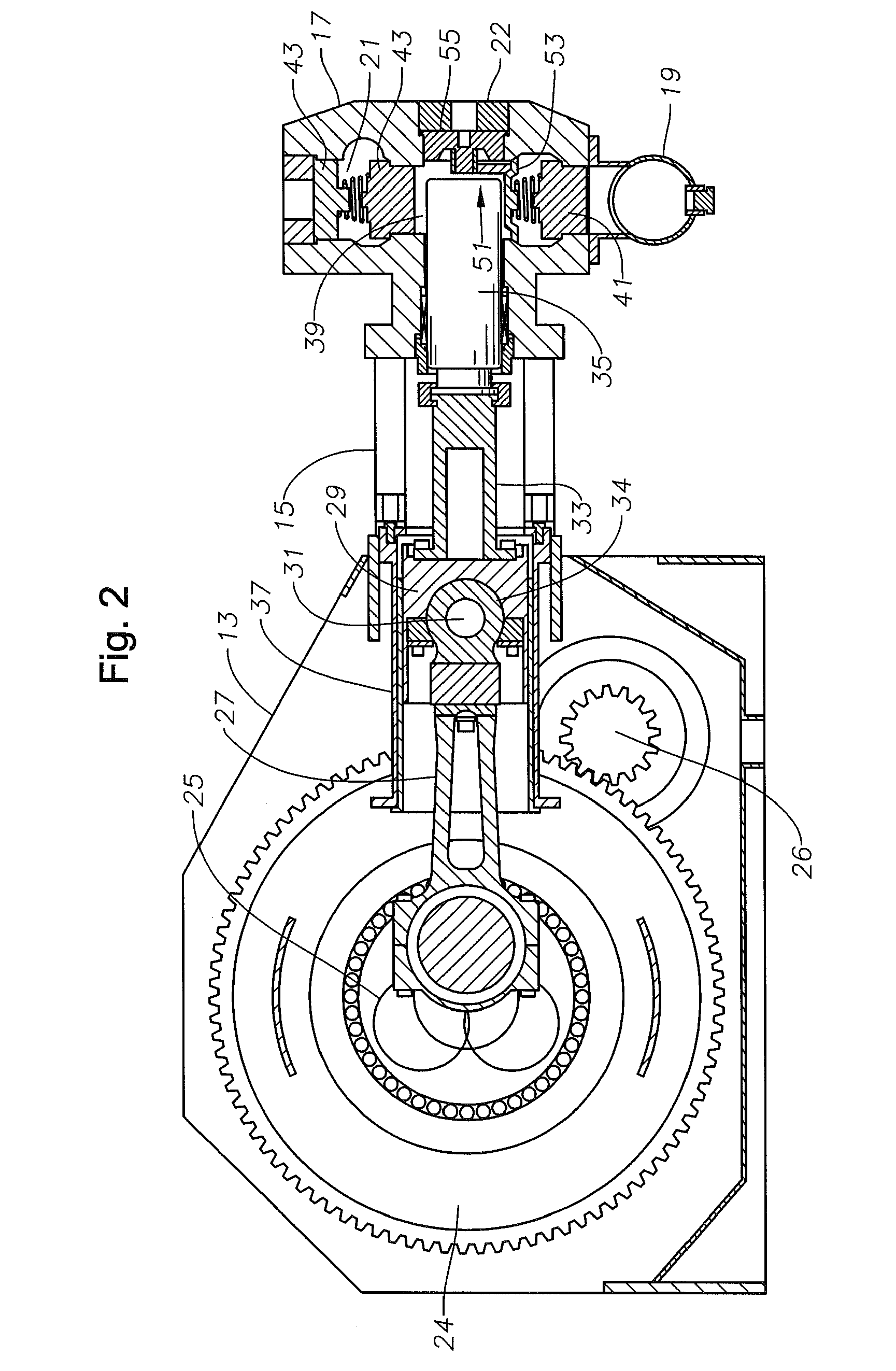

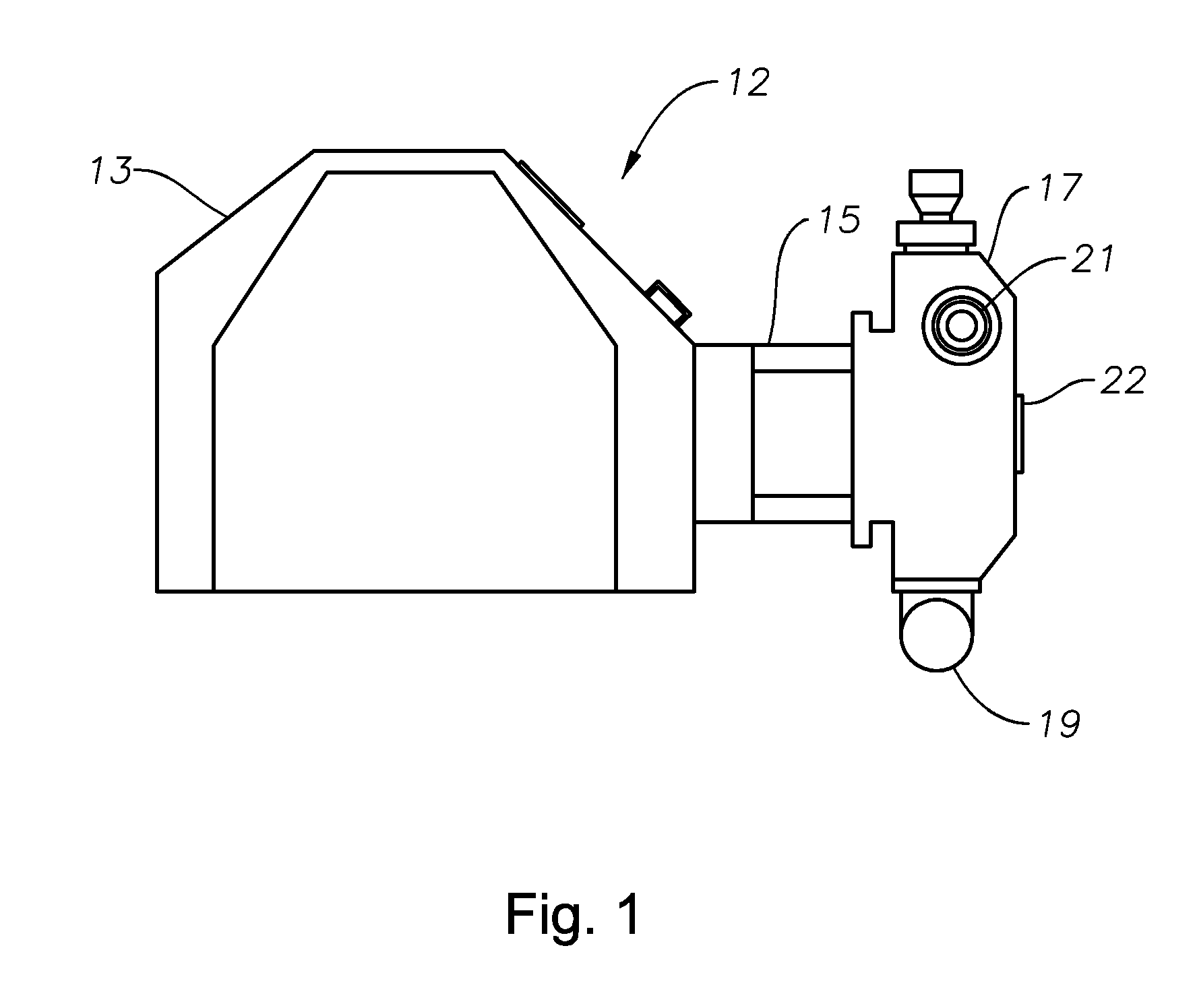

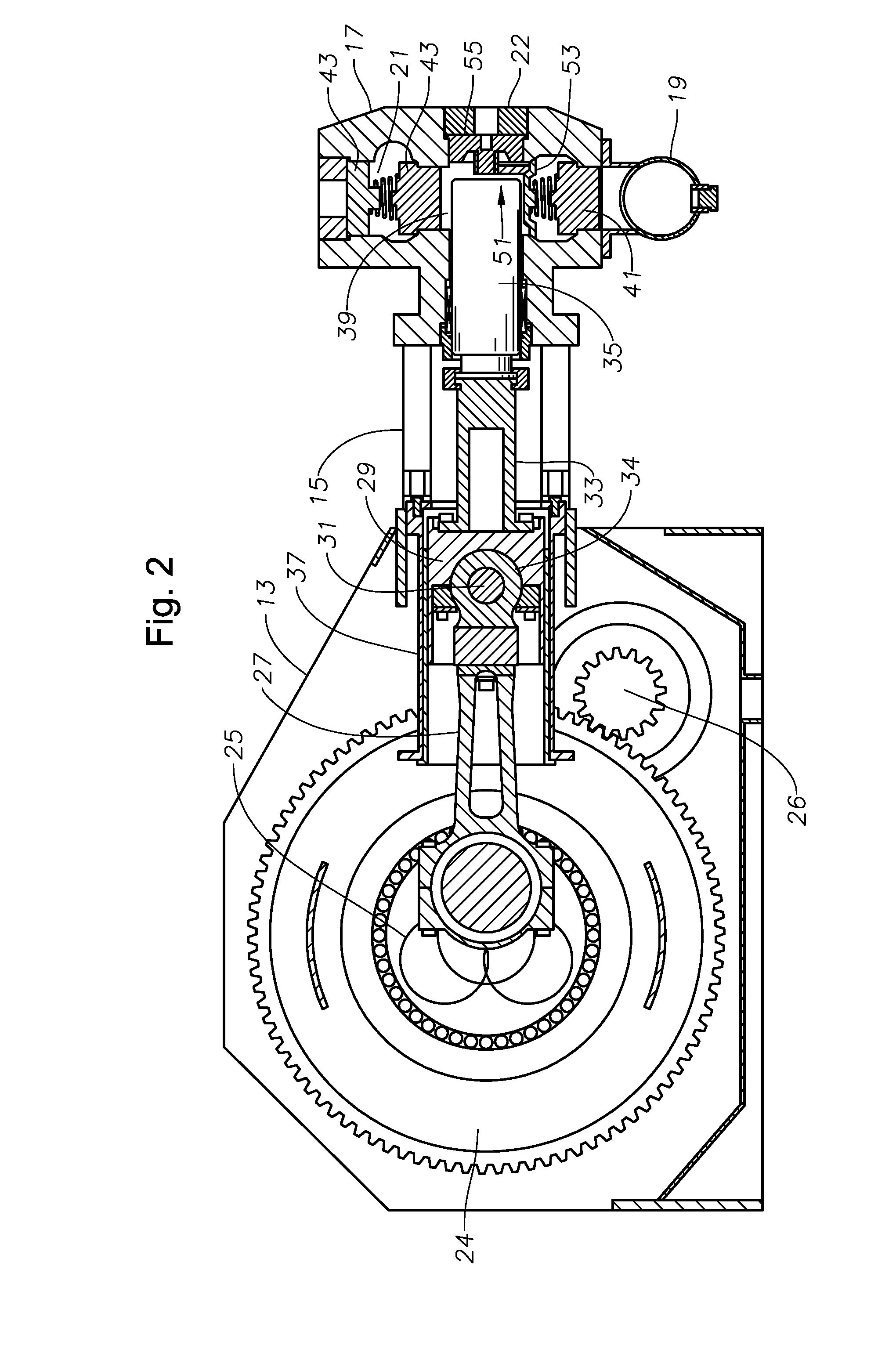

Stirling Cycle Machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The proximal end is connected to the piston and the distal end is connected to the rocking beam by an end pivot. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. A crankshaft coupled to the rocking beam by way of a connecting rod is also included. The rotary motion of the rocking beam is transferred to the crankshaft. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. A seal is included for sealing the workspace from the crankcase.

Owner:NEW POWER CONCEPTS

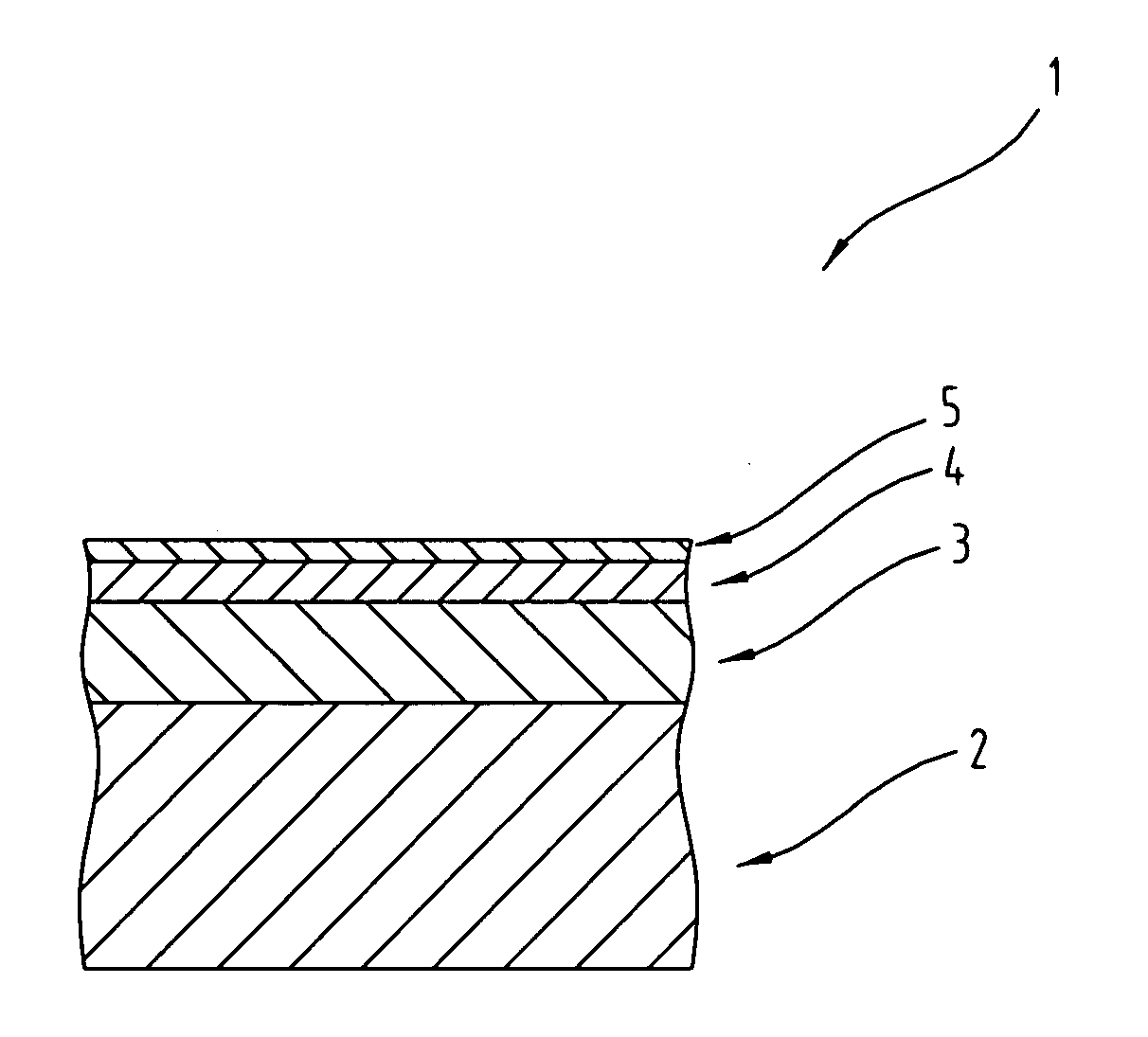

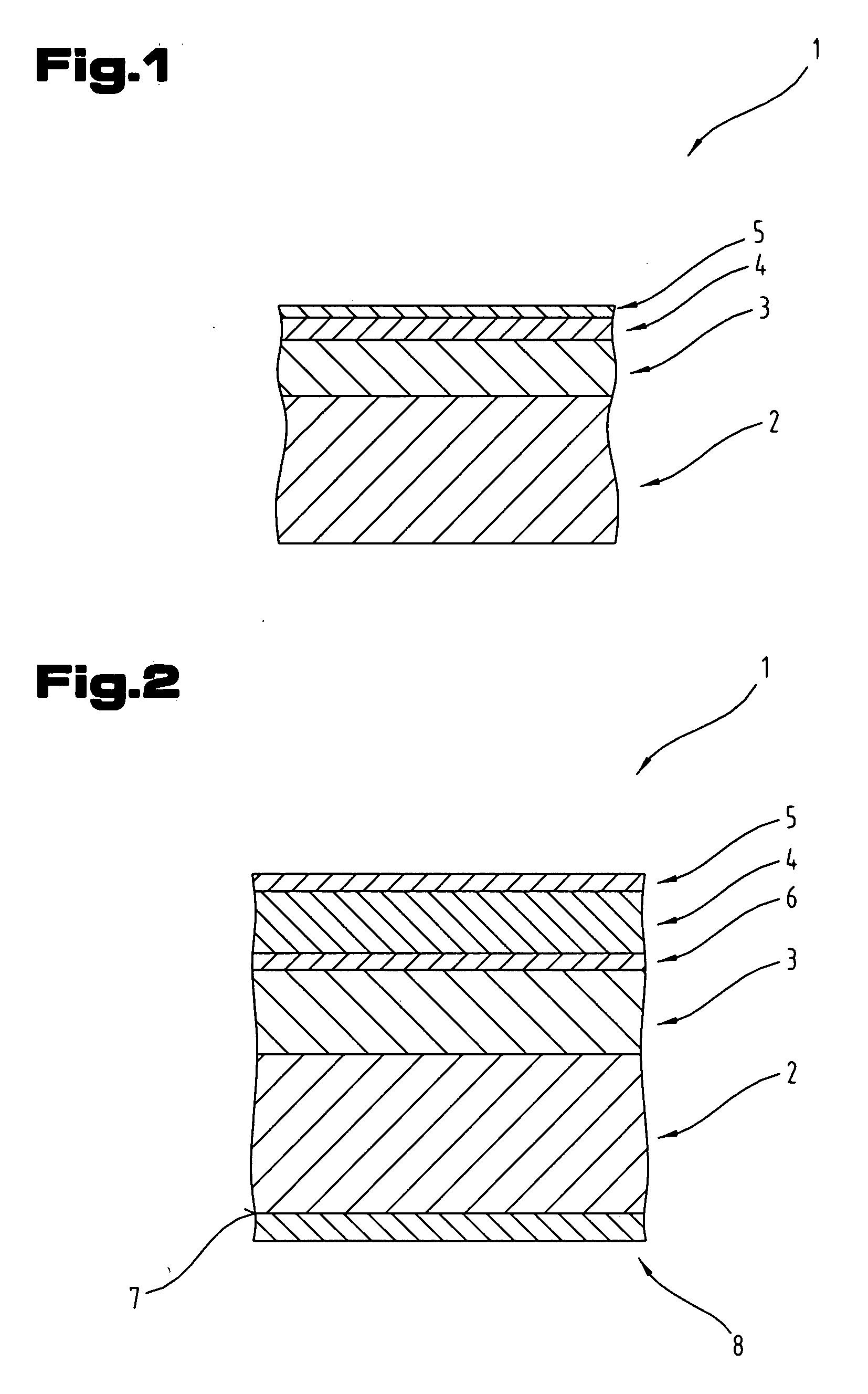

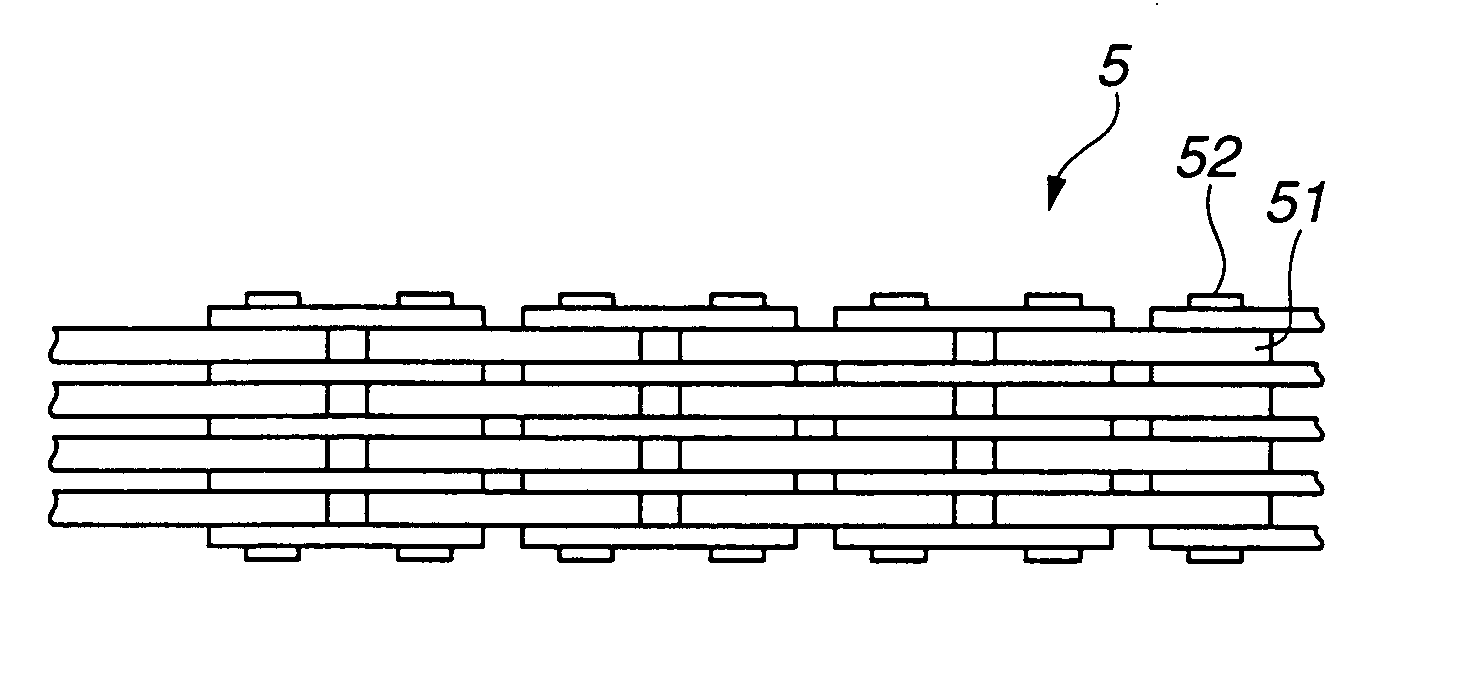

Multi-layered bearing

The invention describes a multi-layered bearing with a supporting metal layer, optionally a bearing metal layer disposed on top of it, an anti-friction layer on top of the latter as well as a wearing layer on top of it. The wearing layer is made from bismuth or a bismuth alloy and the anti-friction layer is made from a copper-bismuth or silver-bismuth alloy or silver.

Owner:MIBA SINTER AUSTRIA +1

Plain bearing

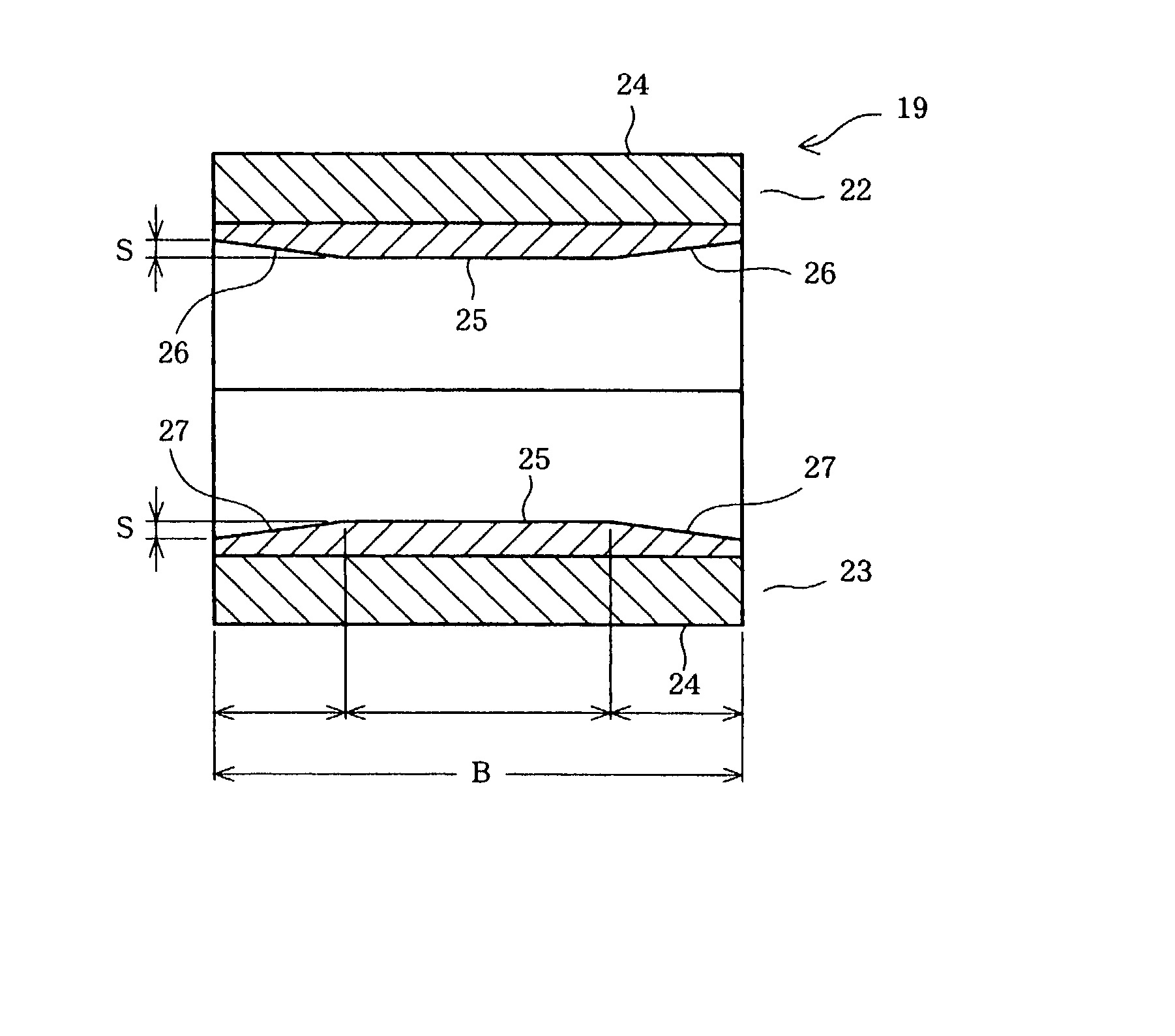

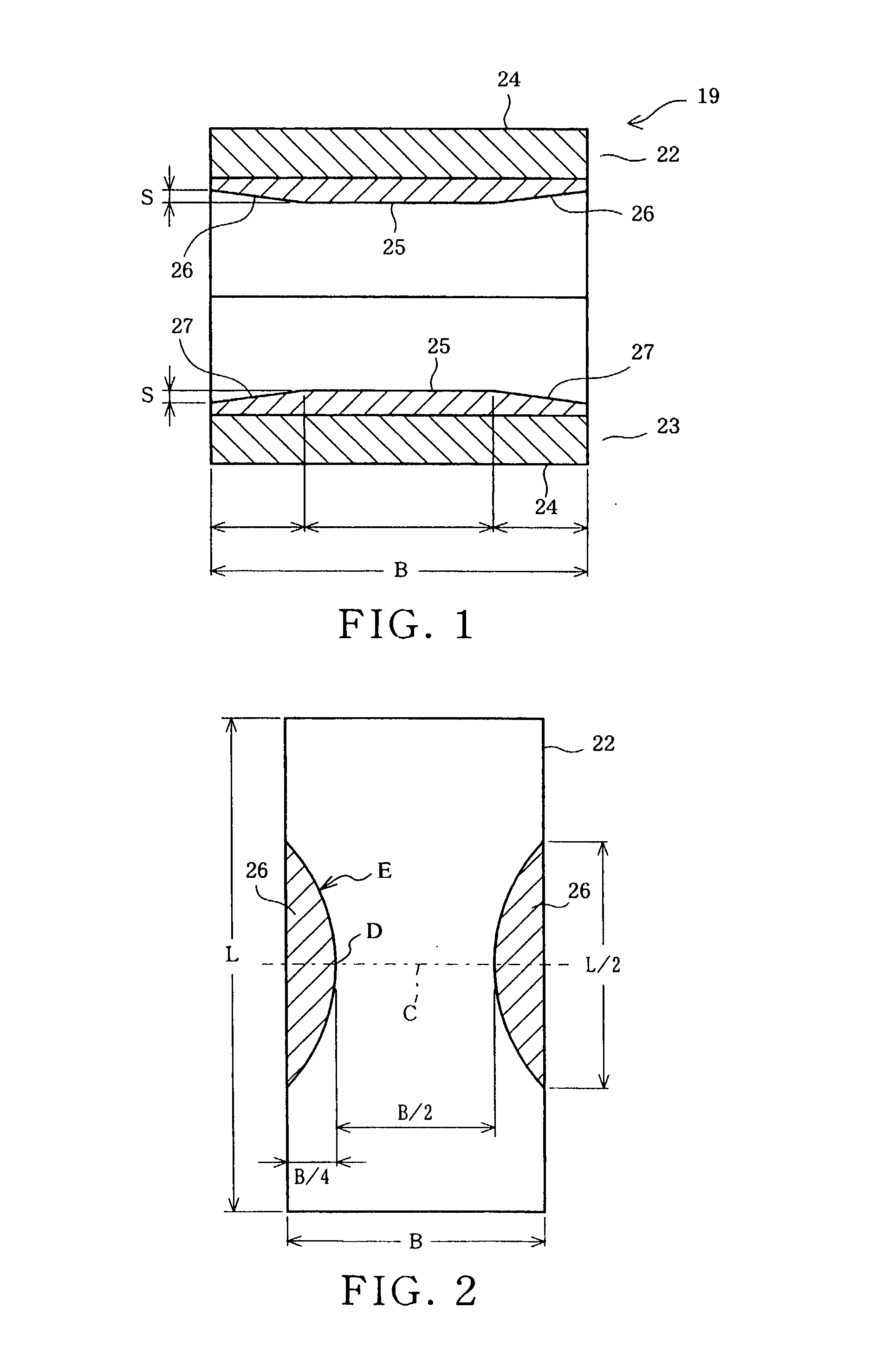

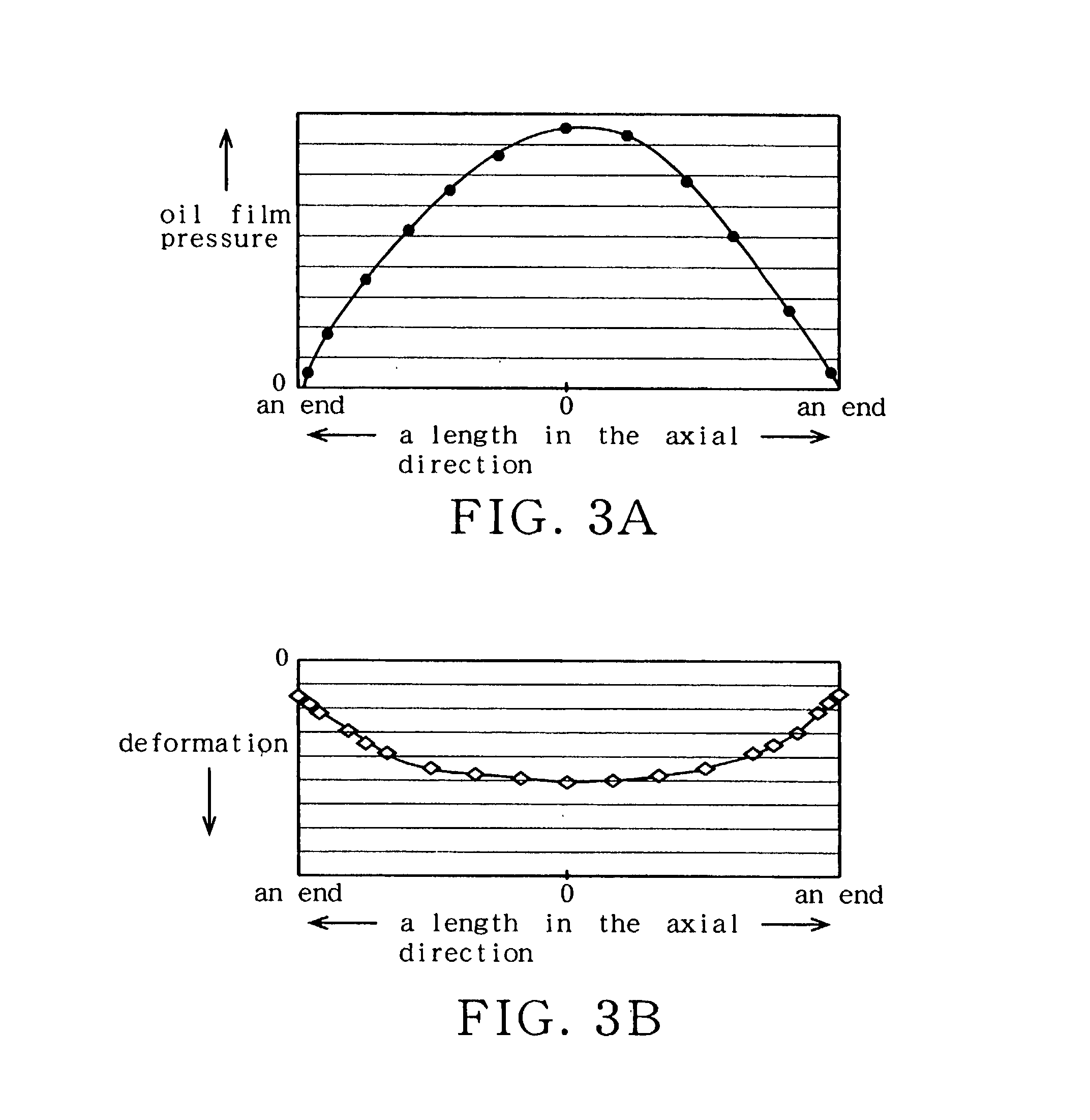

InactiveUS20020126924A1Area minimizationSuppressing decrease in load capacityConnecting rod bearingsRolling contact bearingsEngineeringAlloy

There is disclosed a plain bearing comprising: a back metal; and a bearing alloy layer bonded onto the back metal which bearing alloy layer is provided at a surface side thereof with a cylindrical bearing face extended in the direction of the axis of the plain bearing, the bearing alloy face being provided at each of axial terminal portions thereof with an inclination face inclined radially outwardly from a location defined between both of axially terminal ends of said bearing face toward said axially terminal ends thereof, the inclination face having an axial length varying along the circumference of the inclination face.

Owner:DAIDO METAL CO LTD

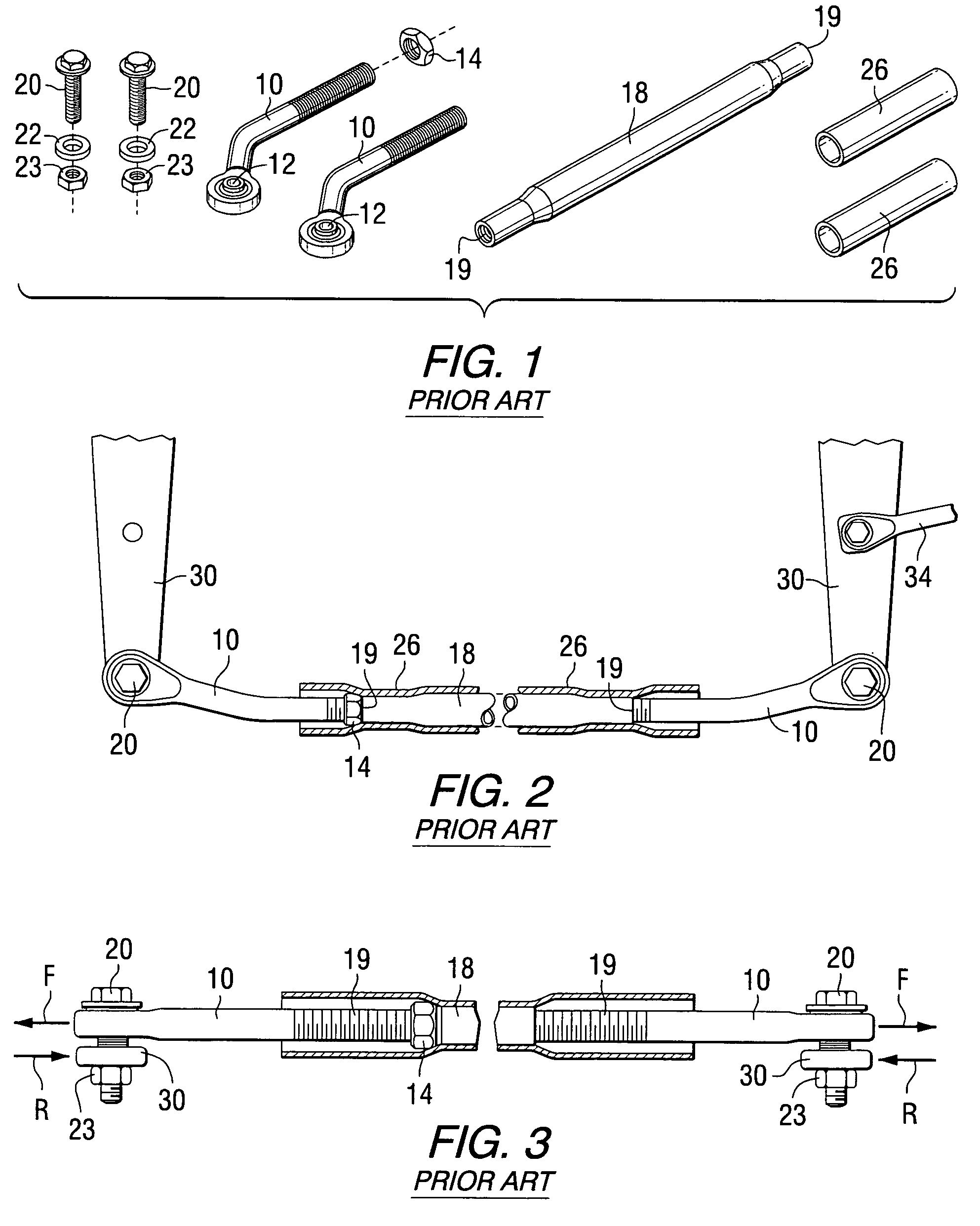

Composite strut and method of making same

InactiveUS20050056117A1Highly effective in reacting both tensionEfficiently transfer both shearConnecting rod bearingsFuselage framesBiomedical engineeringCompression load

Owner:KAISER COMPOSITEK

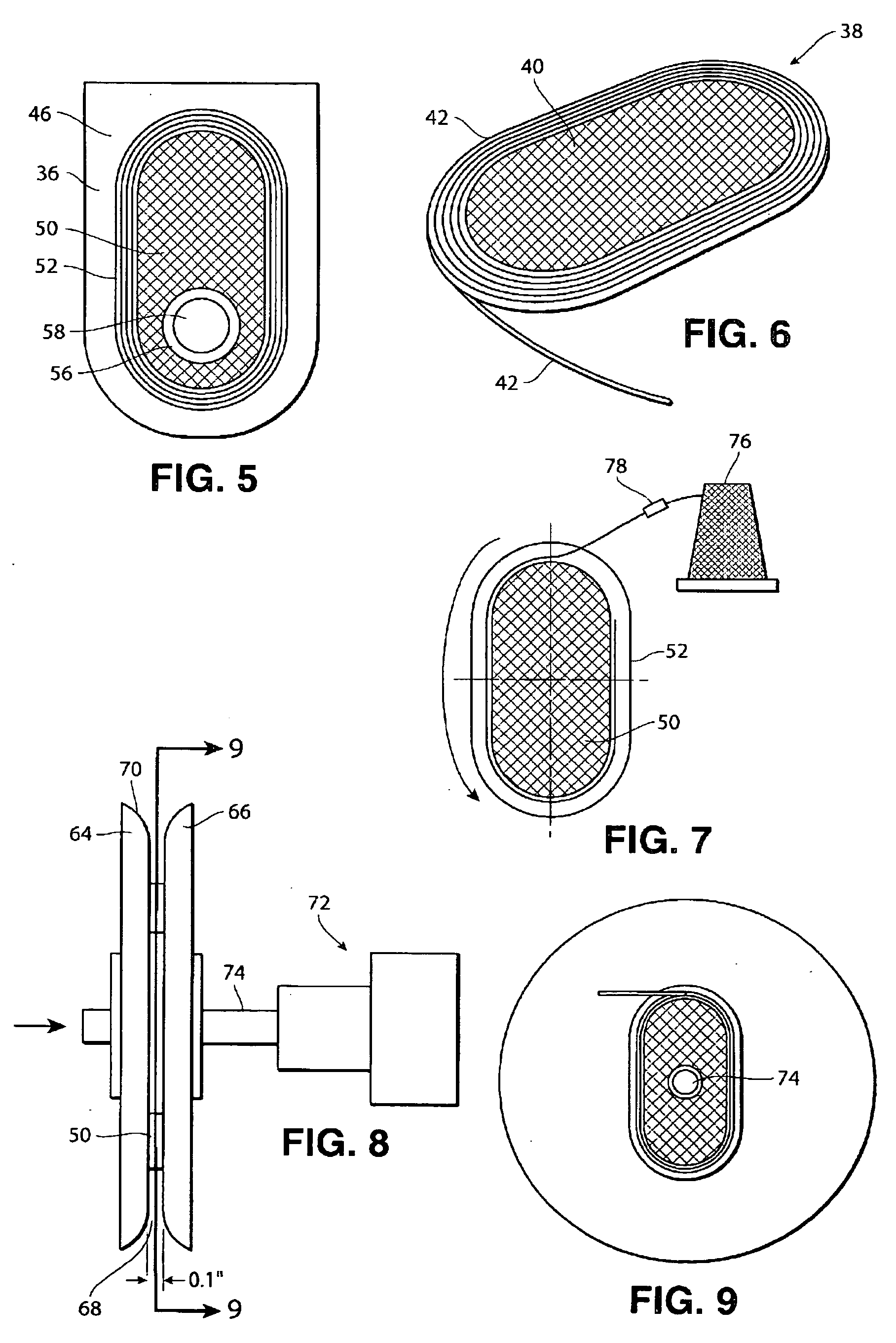

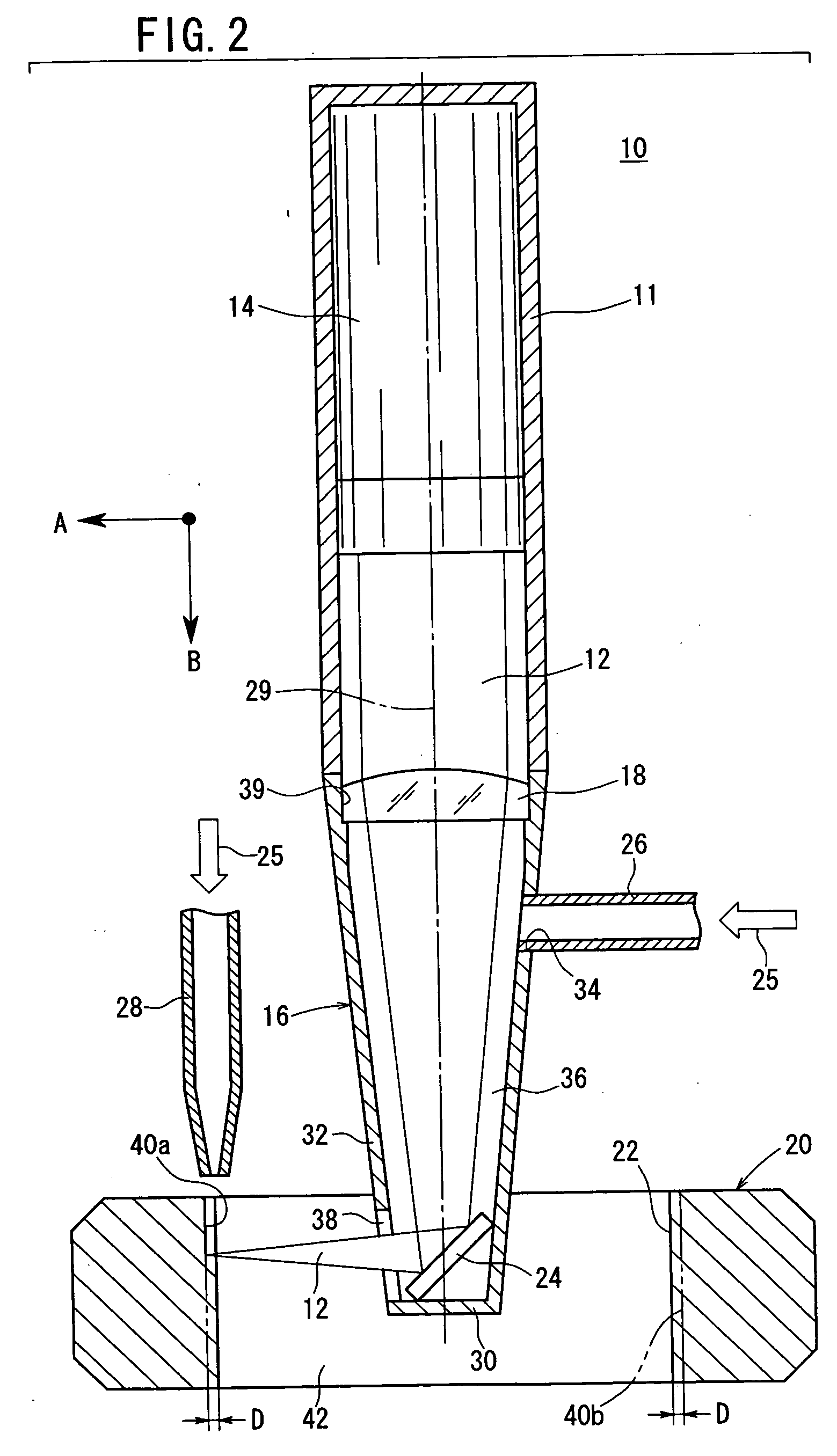

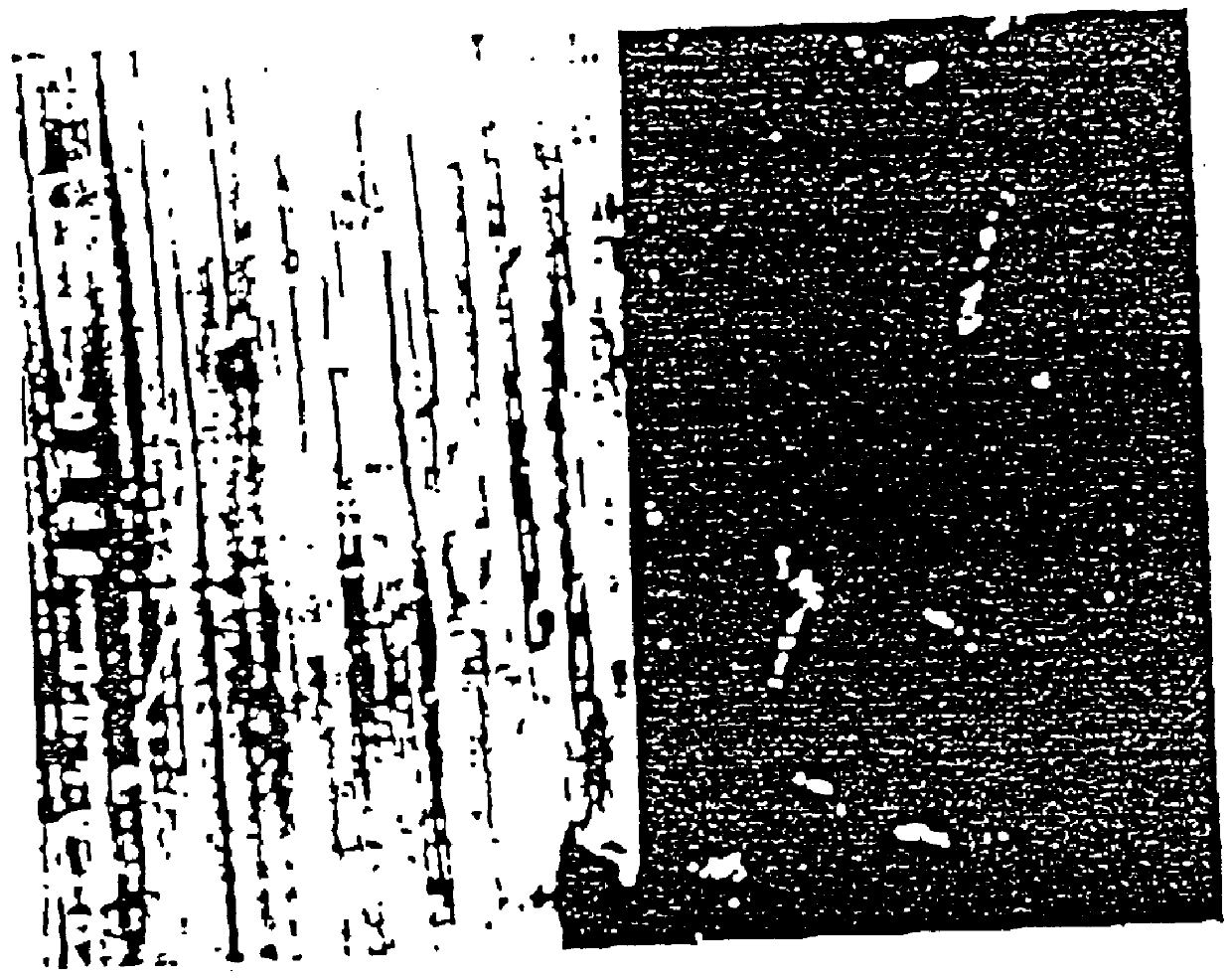

Method of and apparatus for machining groove with laser beam

A casing houses therein a laser oscillator for emitting a laser beam, and a tubular head is disposed coaxially with the laser oscillator and coupled to the casing. The laser beam emitted from the laser oscillator is converged by a condenser lens mounted on the head, and then reflected in a direction substantially perpendicular to the axis of the head by a reflecting mirror that is disposed in the head. The reflected laser beam is applied substantially perpendicular to the inner circumferential surface of a workpiece, forming grooves therein with the heat of the laser beam.

Owner:HONDA MOTOR CO LTD

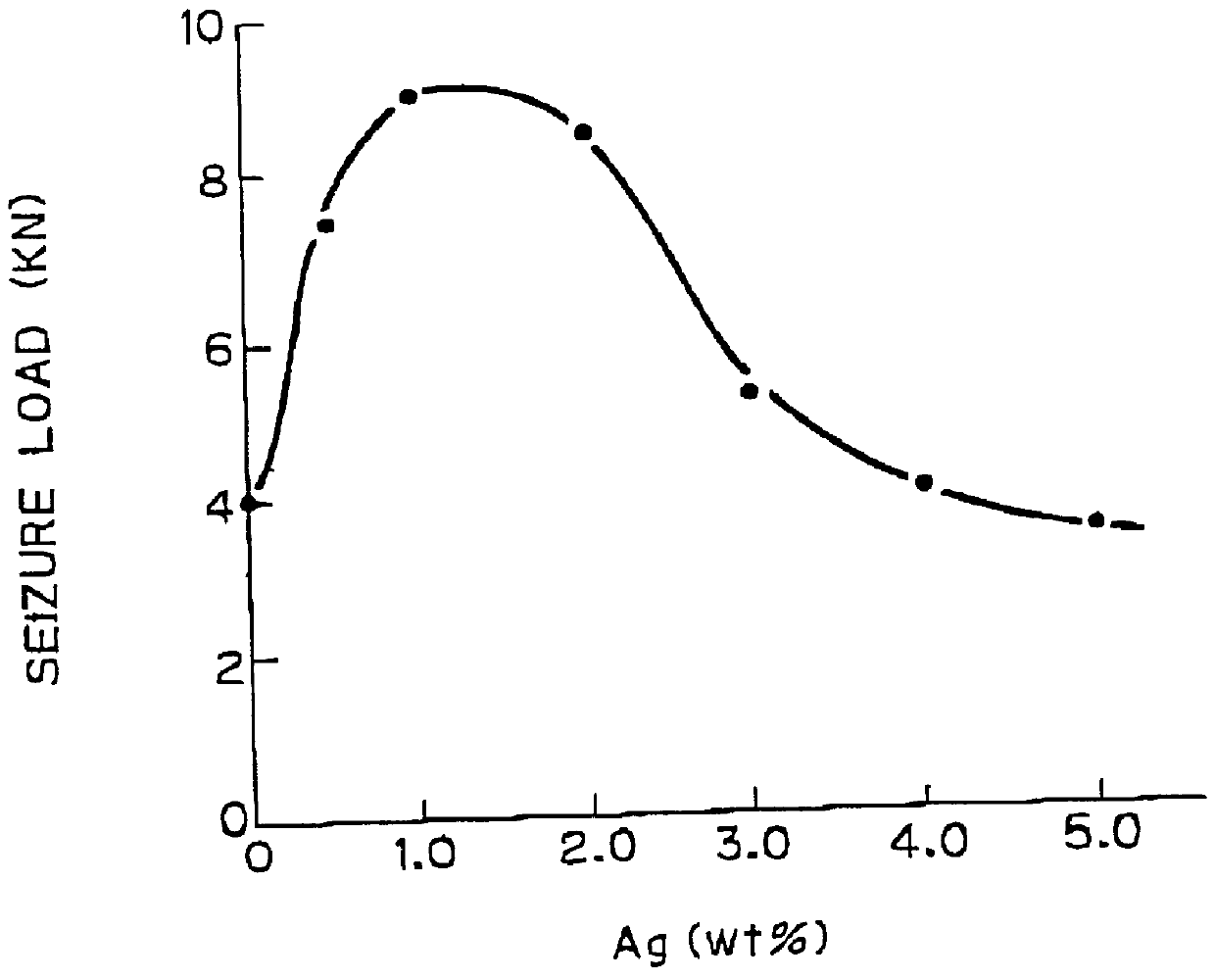

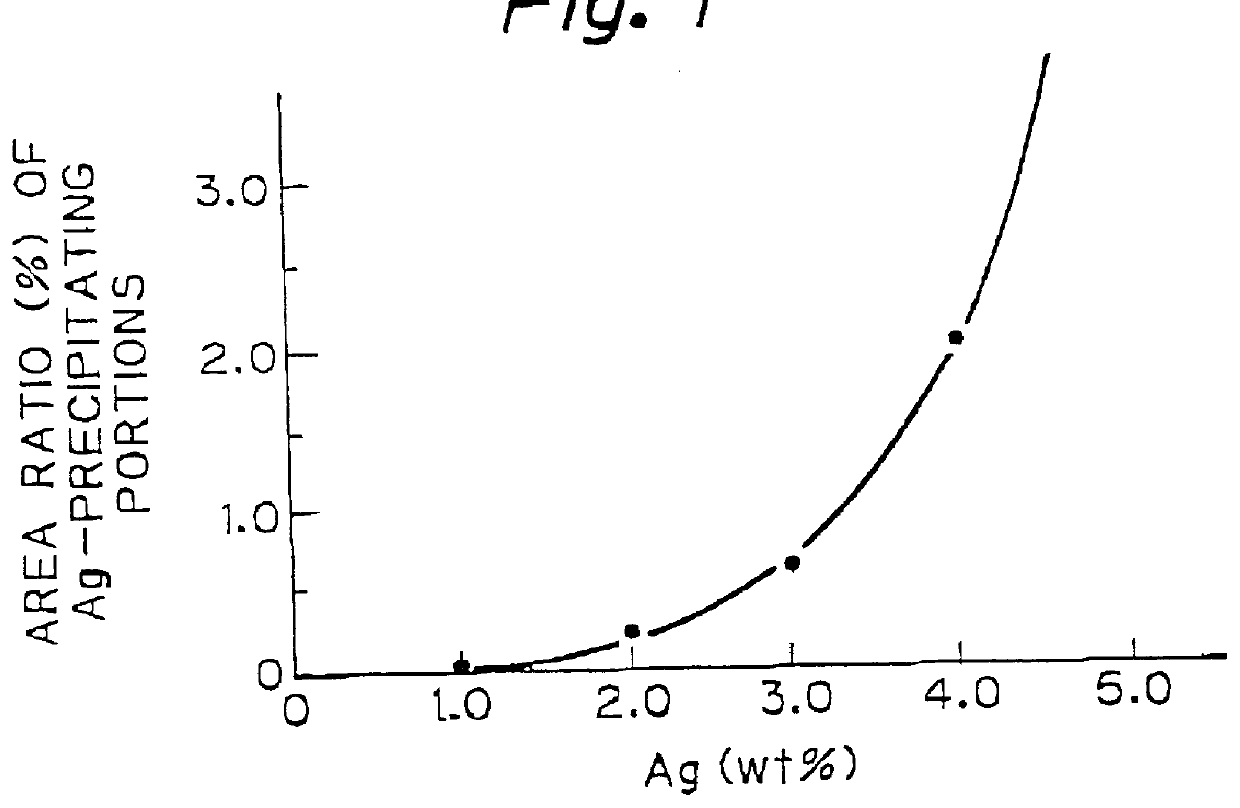

Copper-based bearing material and sliding bearing for internal combustion engines

InactiveUS6025081AEasy to slideFree cutting propertyConnecting rod bearingsCasingsCombustionInternal combustion engine

PCT No. PCT / JP96 / 03118 Sec. 371 Date Jan. 8, 1998 Sec. 102(e) Date Jan. 8, 1998 PCT Filed Oct. 25, 1996 PCT Pub. No. WO97 / 15695 PCT Pub. Date May 1, 1997The copper-based sliding material has improved seizure resistance, even if it is free of Pb, and enables thinning of the overlay. The copper alloy provided consists of from 0.1 to 2% of Ag, from 1 to 10% of Sn, and the balance consisting of Cu and unavoidable impurities and, further said Ag and Sn do not essentially form the secondary phases but are in complete or essentially solid-solution state in the Cu matrix.

Owner:TAIHO INDUSTRIES CO LTD

Slide bearing

ActiveUS20100046869A1Reduces amount of lubricantAvoid damageCrankshaftsConnecting rod bearingsEngineeringMechanical engineering

A crank bearing is disclosed that includes a semicircular upper bearing and a semicircular lower bearing, which can be split from each other. The upper bearing includes a first oil passage for introducing engine oil from the outside to a gap between the crank bearing and a crank journal, and a second oil passage for permitting the engine oil to flow in the circumferential direction of the crank bearing. The first oil passage includes an inner circumference opening, which is open to the inner circumference of the main bearing. The upper bearing includes a non-undercut portion in which no oil passage is formed on the trailing side of the inner circumference opening in the rotational direction of the crank journal. A chamfer oil passage for discharging the engine oil in the second oil passage to the outside from the axial direction of the crank bearing is provided in at least one of the lower bearing and a region on the proceeding side of the circumference opening in the rotational direction of the crank journal.

Owner:TOYOTA JIDOSHA KK

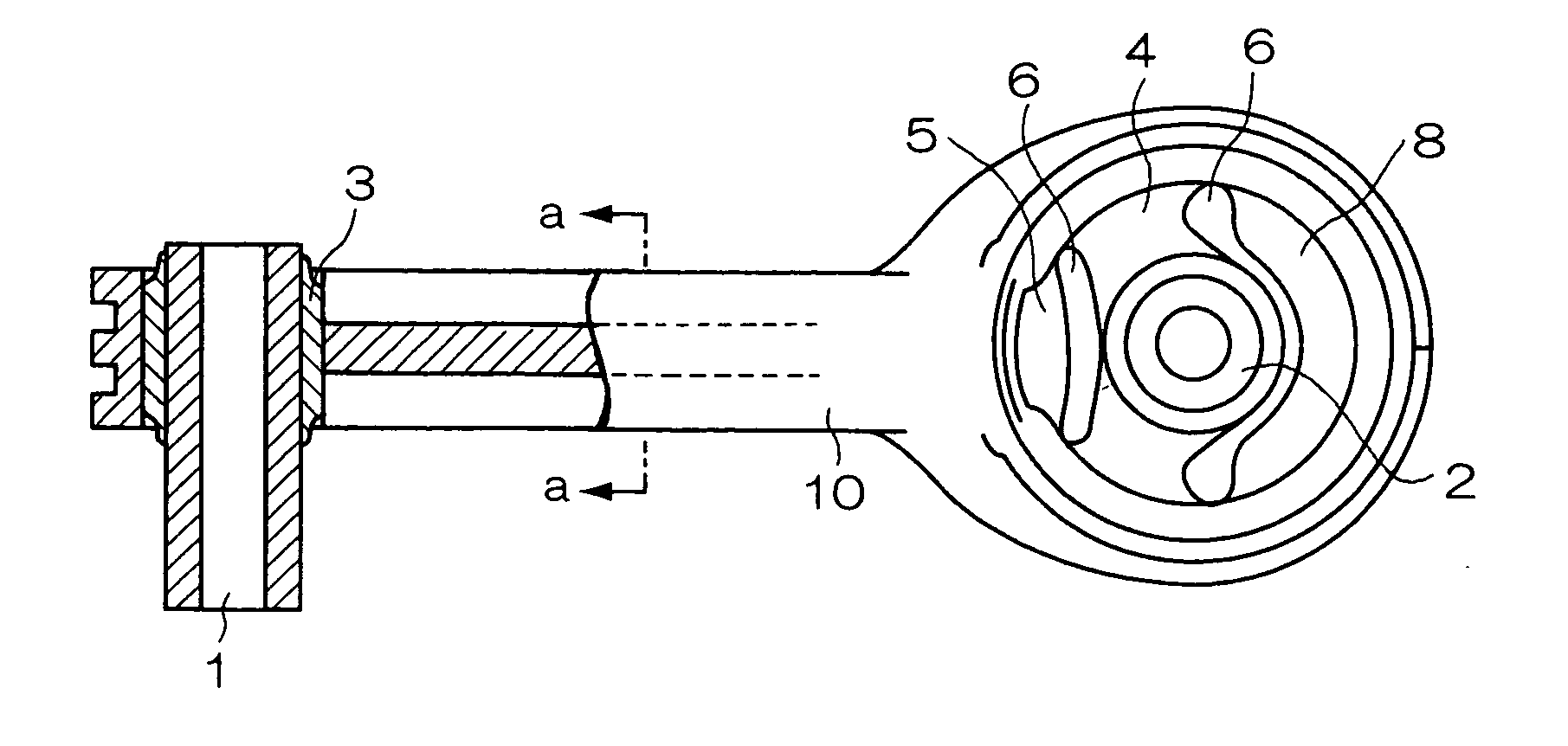

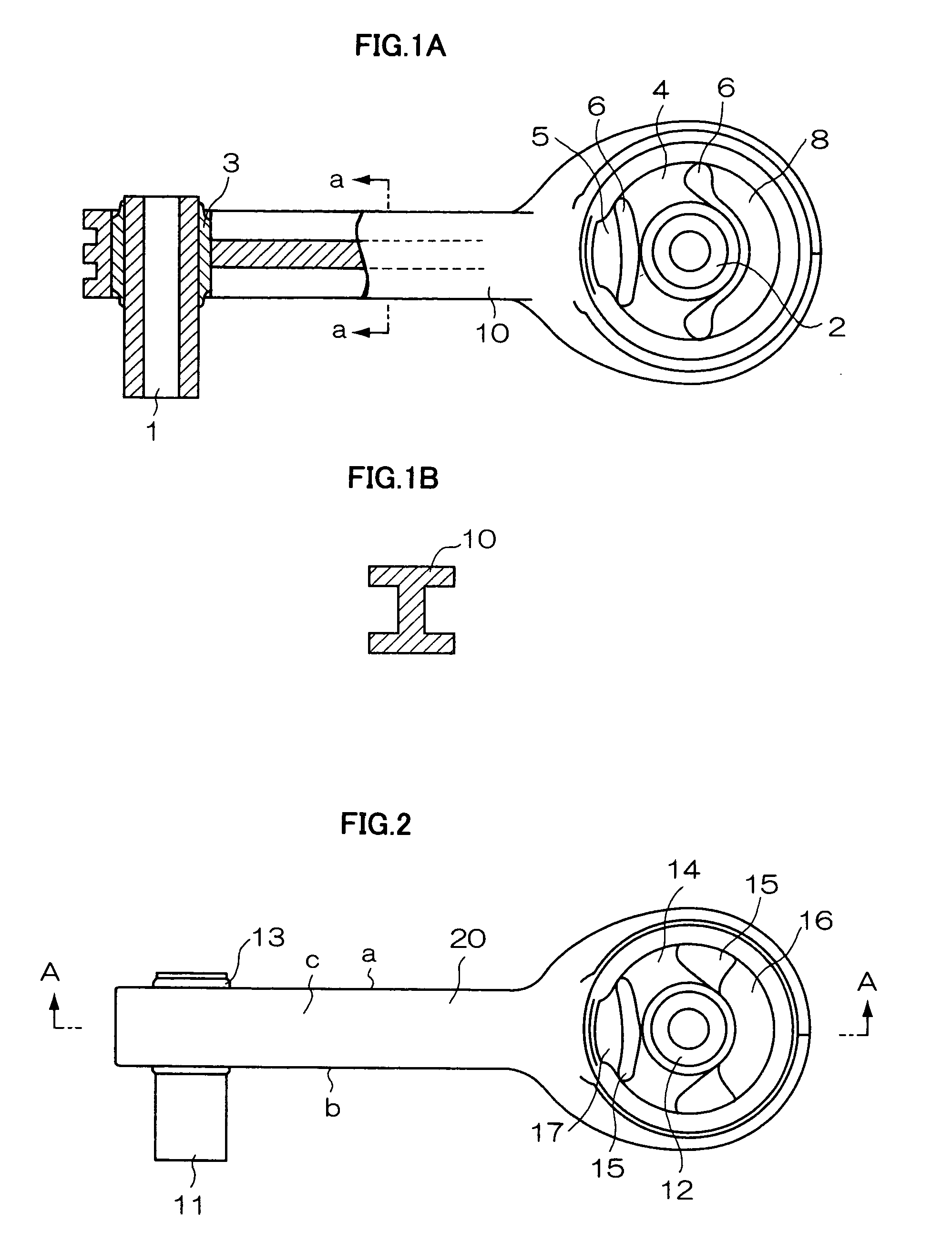

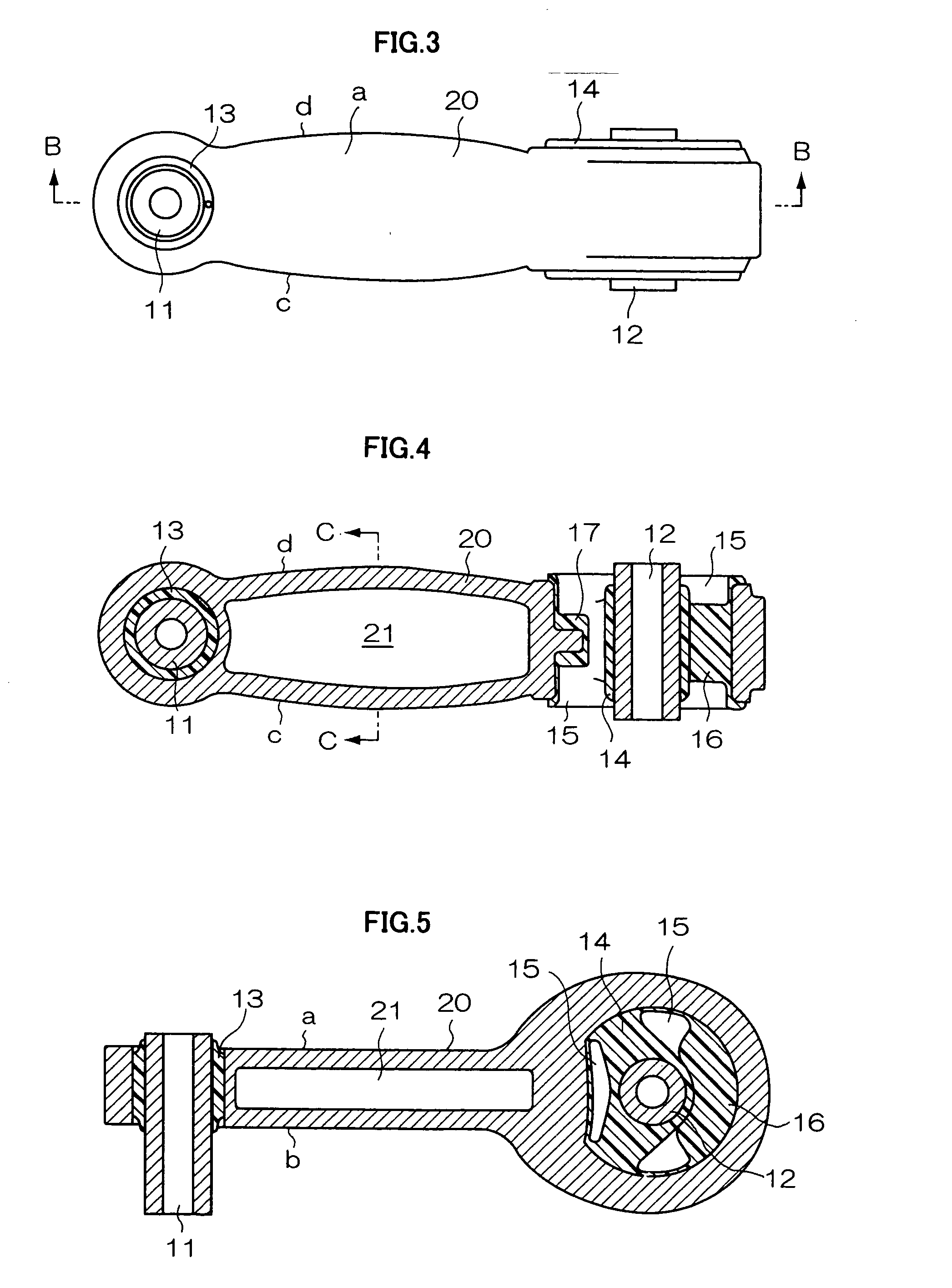

Connecting rod without wrist pin

InactiveUS8376723B2Reduce weightEliminate needConnecting rod bearingsPositive displacement pump componentsEngineeringCrankshaft

Owner:WEIR SPM

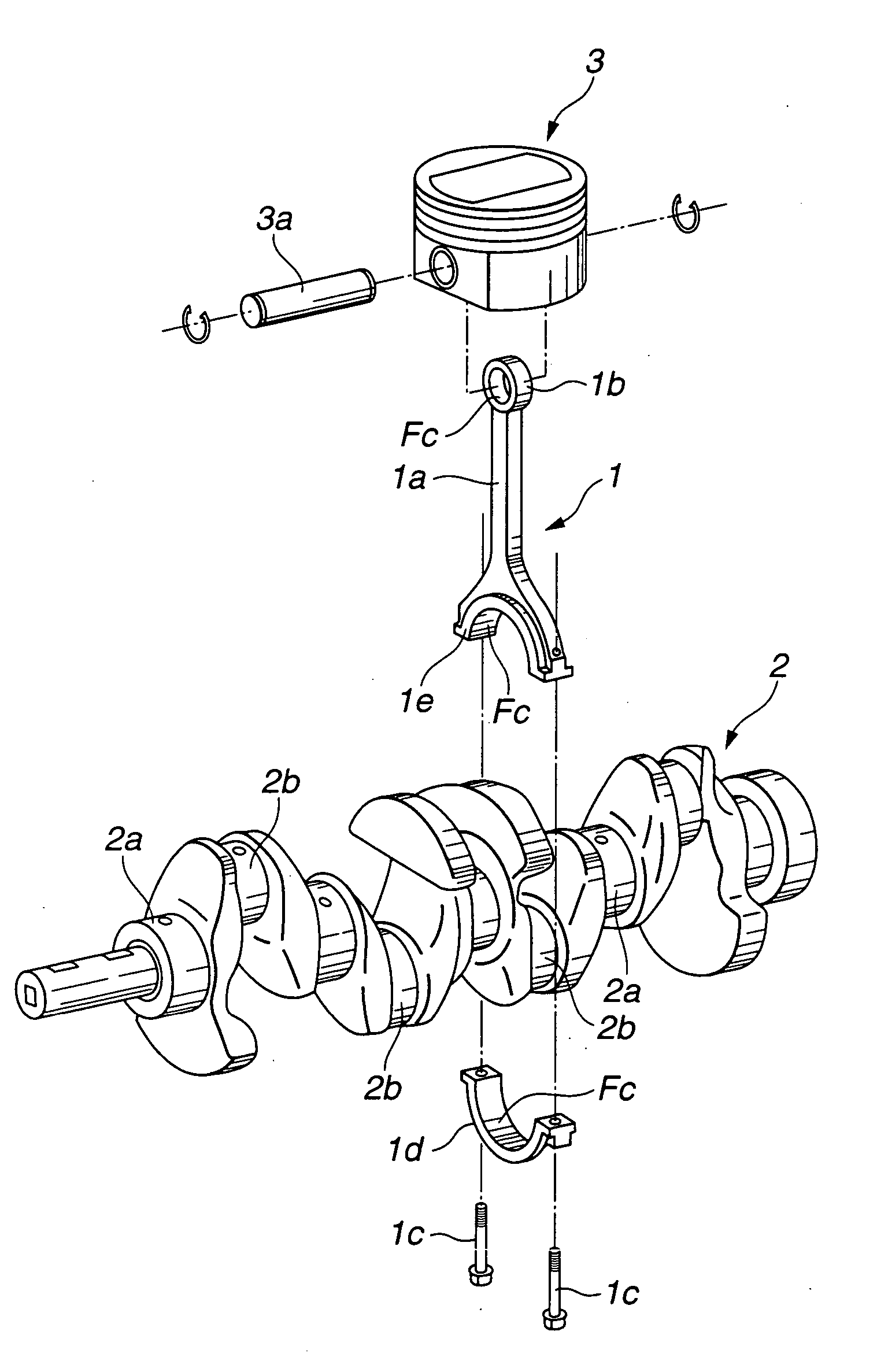

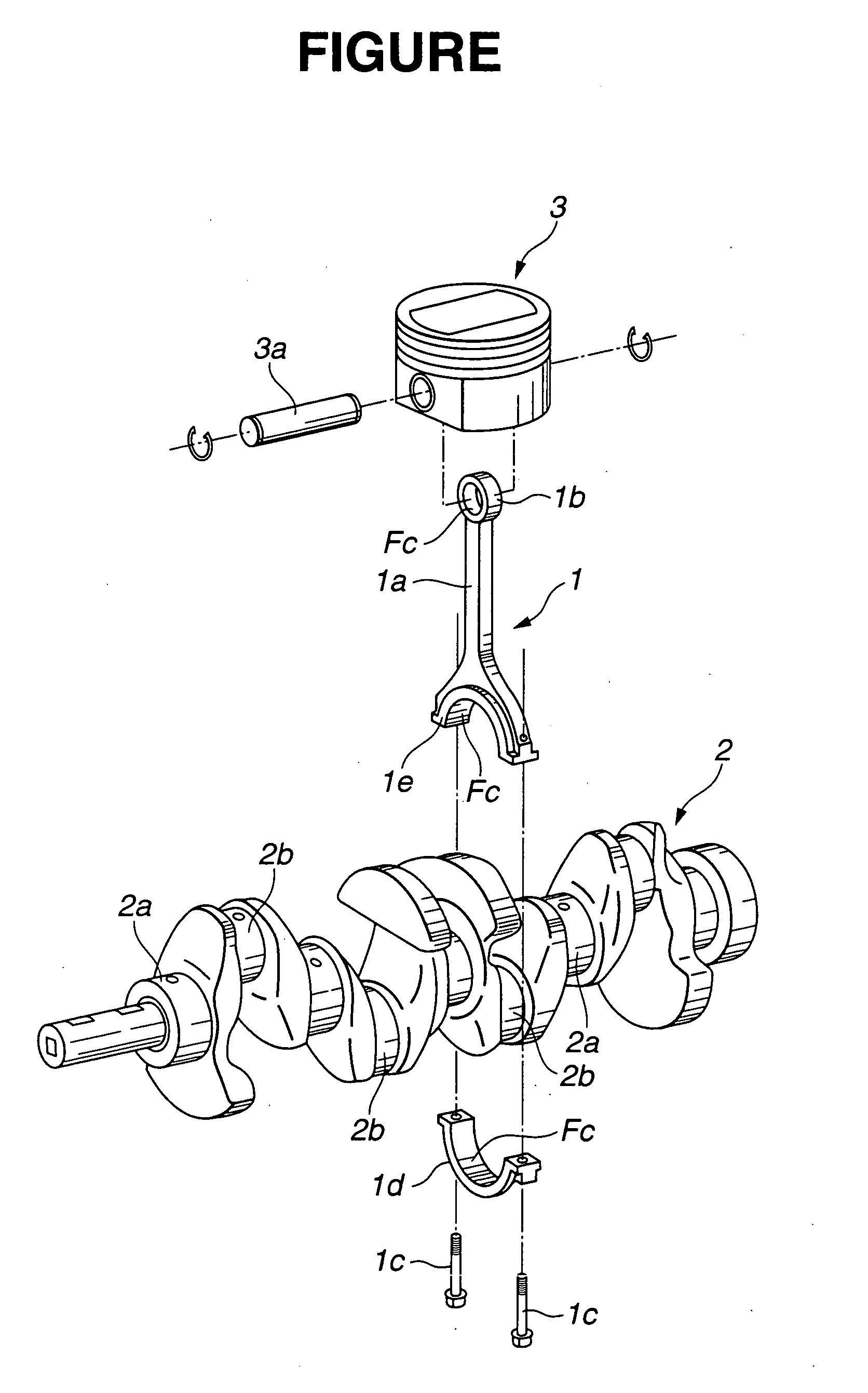

Structure for connecting piston to crankshaft

InactiveUS20050061291A1Reduce sliding frictionImprove engine performanceCrankshaftsConnecting rodsCarbon coatingHydrogen content

There is provided a structure for connecting a piston to a crankshaft in an internal combustion engine, including a piston pin fitted into the piston, a crankpin integral with the crankshaft and a connecting rod having a piston pin bearing portion slidably engaged with an outer cylindrical portion of the piston pin and a crankpin bearing portion slidably engaged with an outer cylindrical portion of the crankpin. At least one of the piston pin bearing portion of the connecting rod and the outer cylindrical portion of the piston pin and at least one of the crankpin bearing portion of the connecting rod and the outer cylindrical portion of the crankpin have hard carbon coatings formed thereon with a hydrogen content of 20 atomic % or less.

Owner:NISSAN MOTOR CO LTD

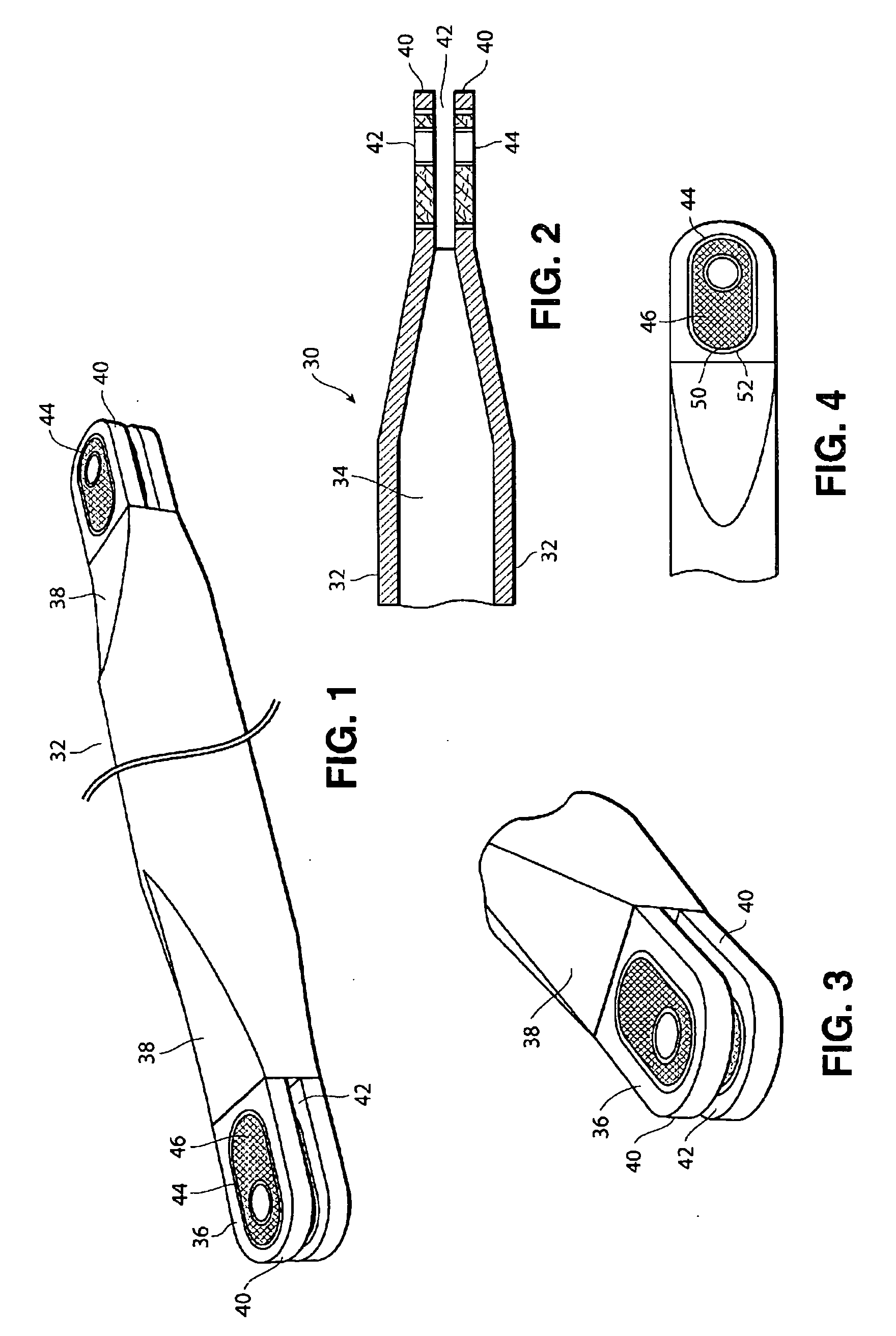

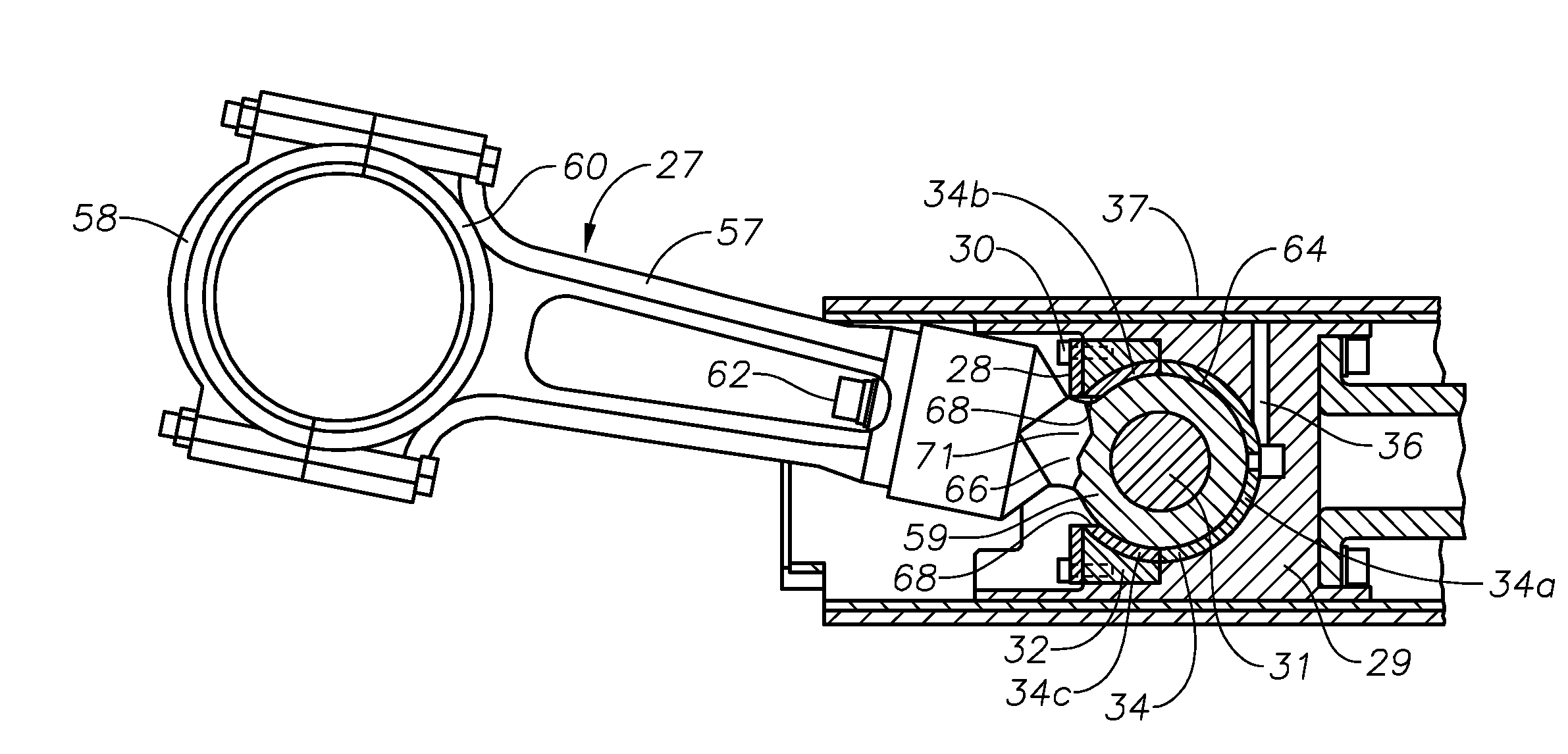

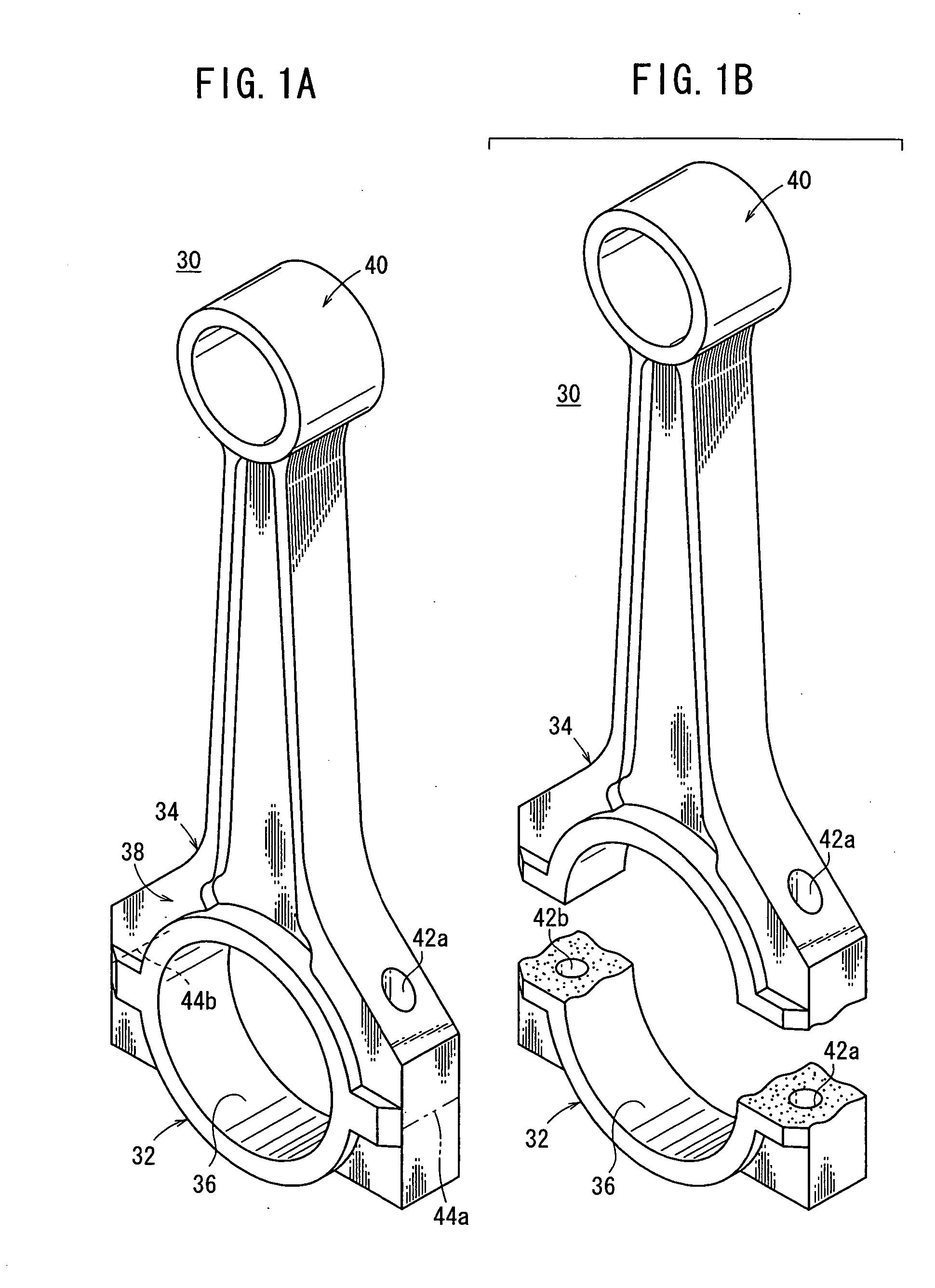

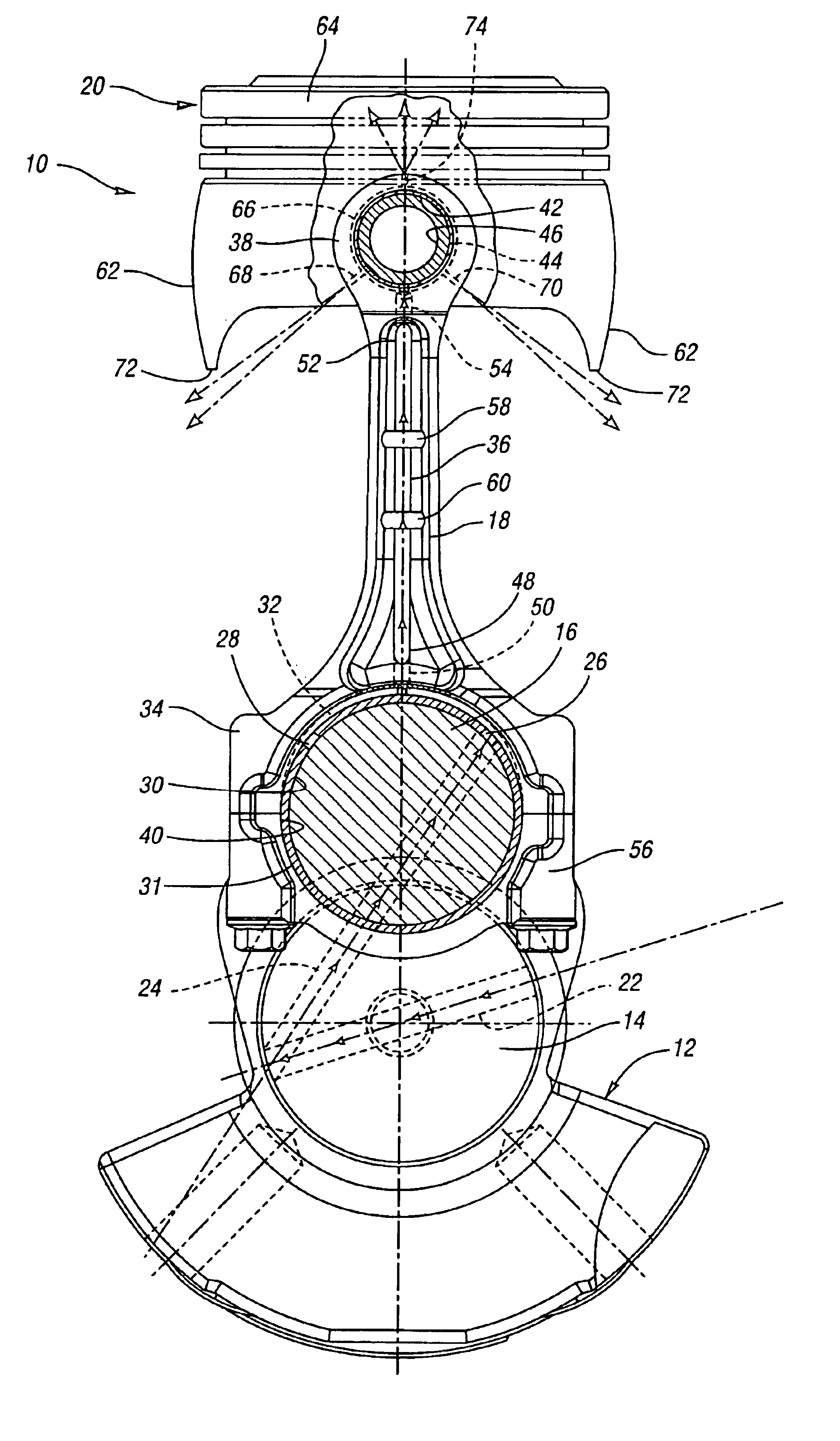

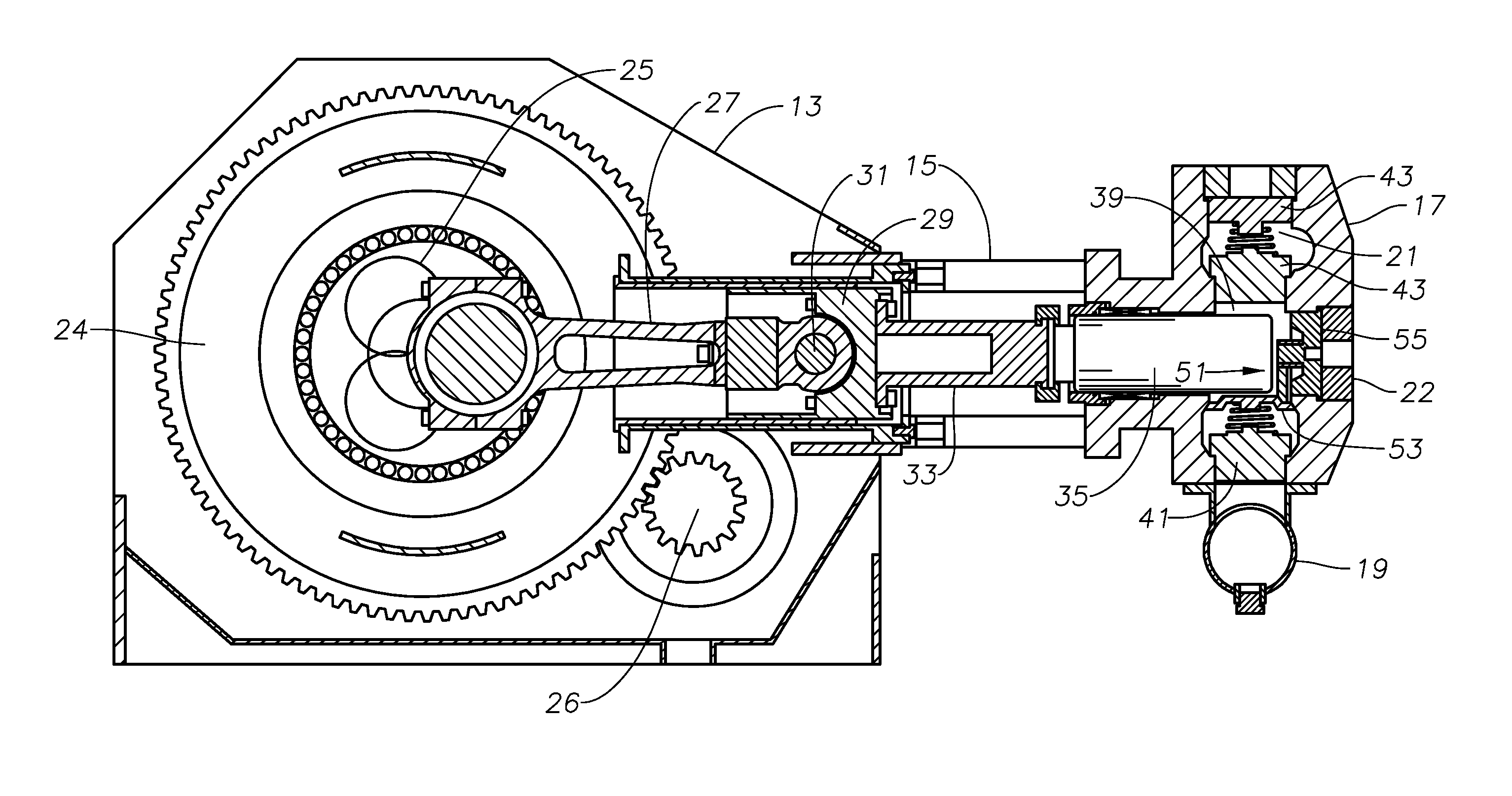

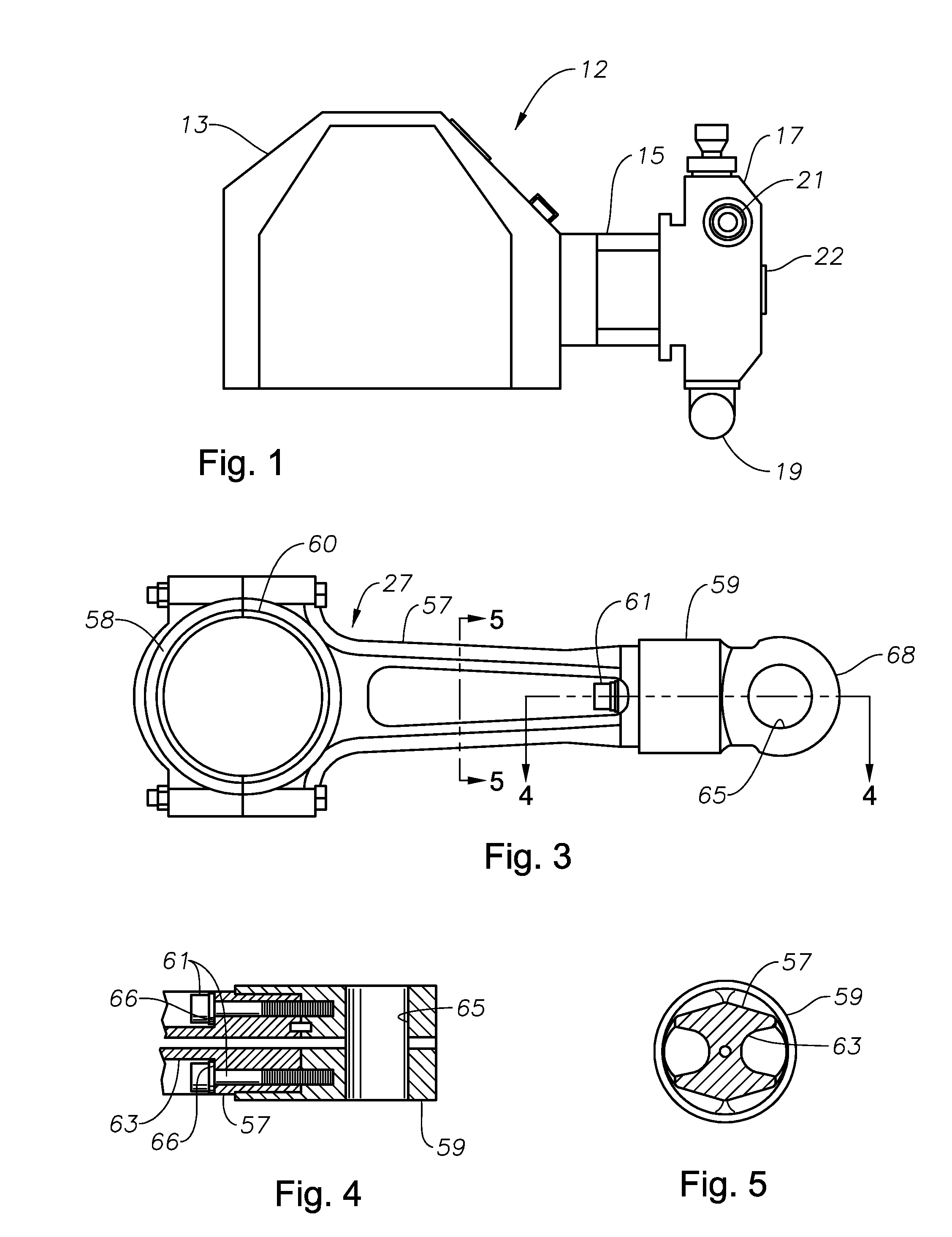

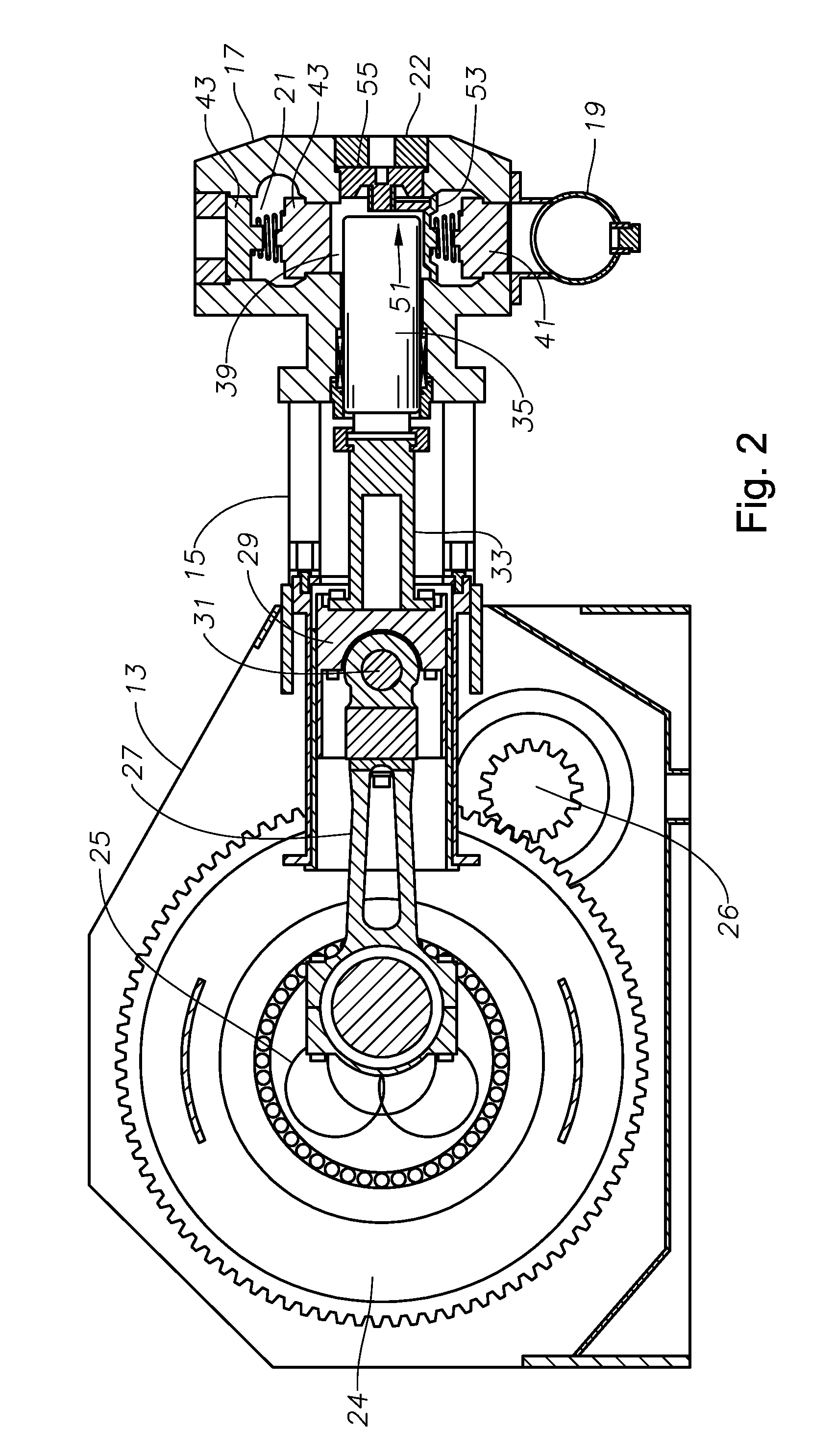

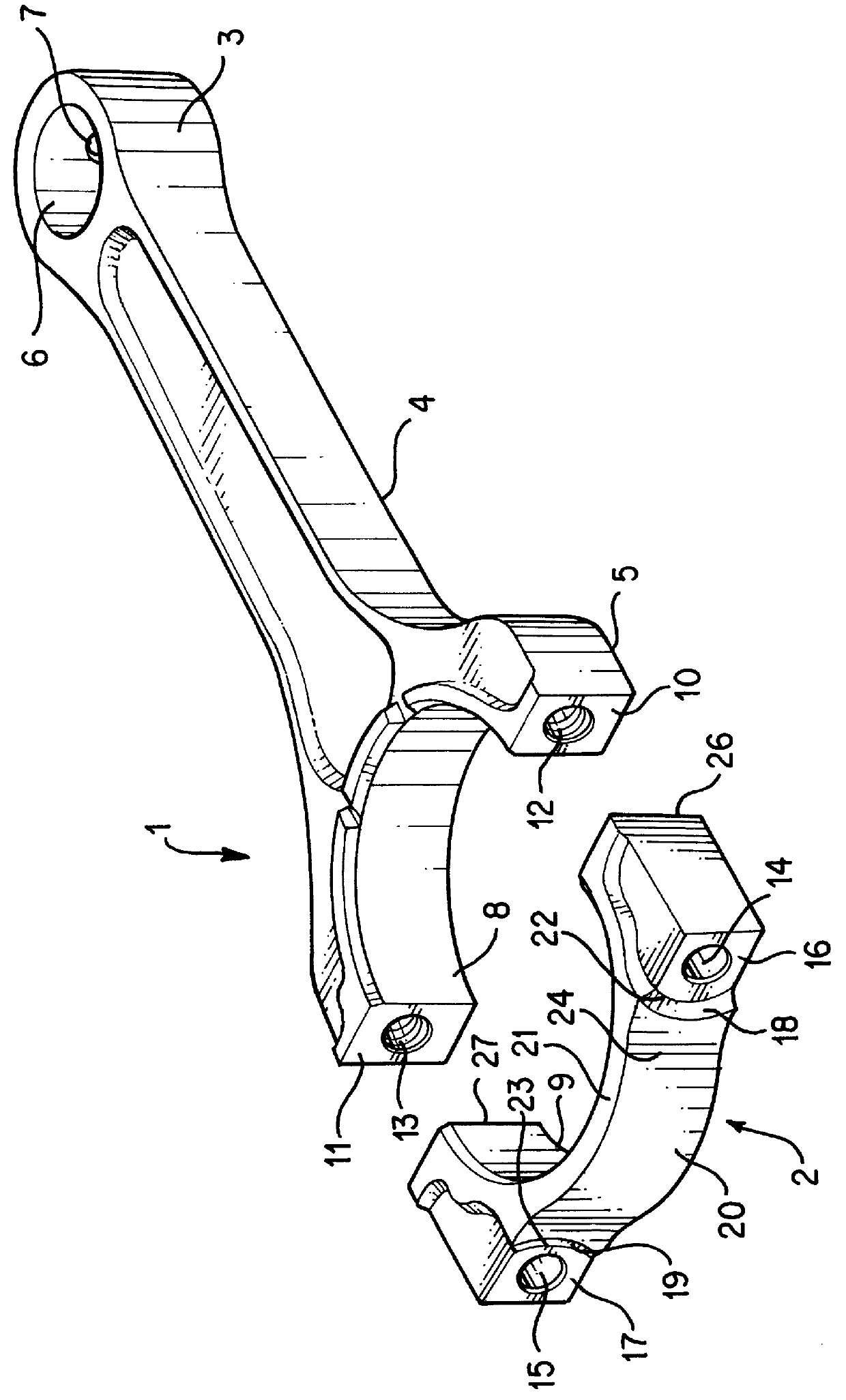

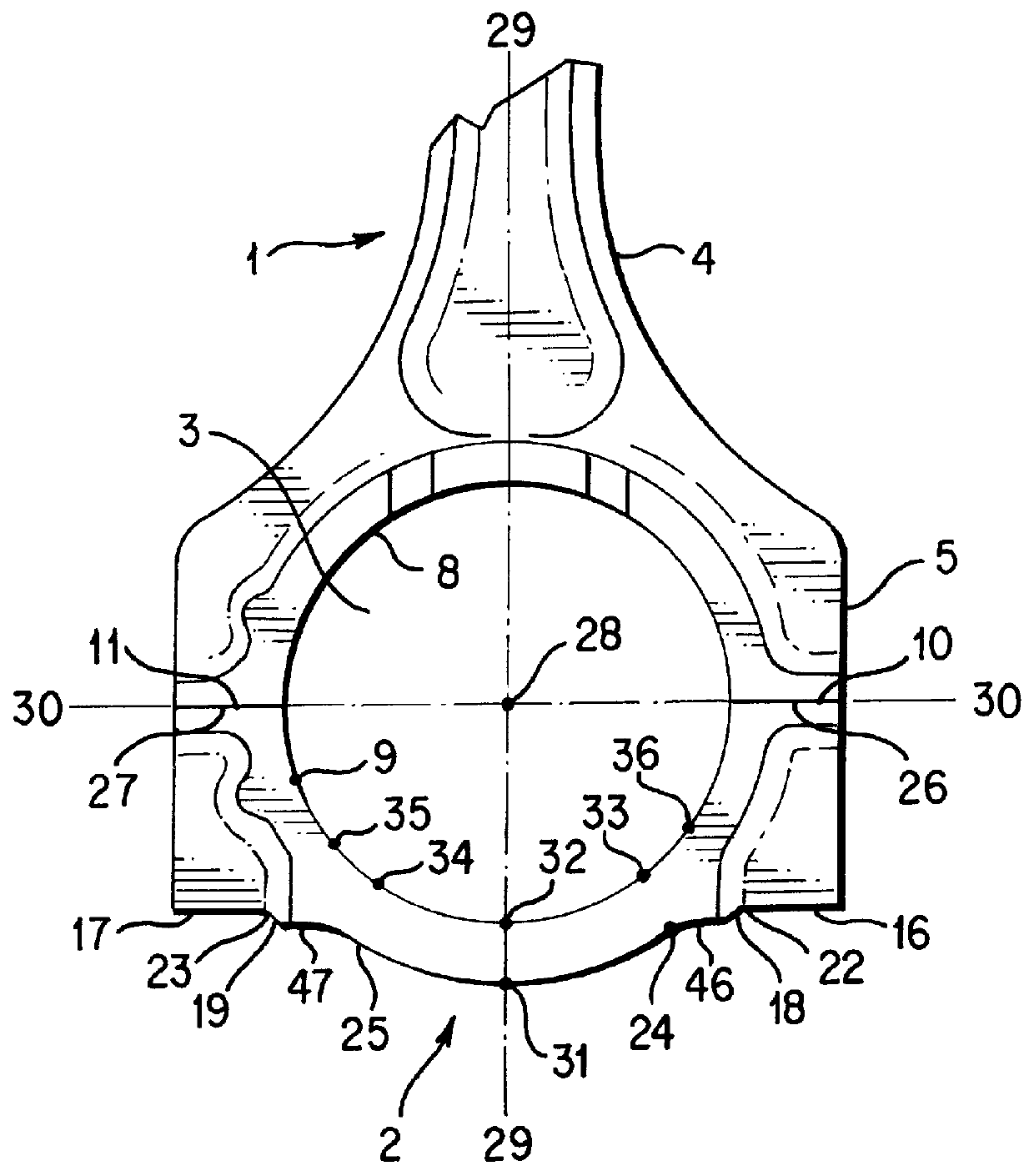

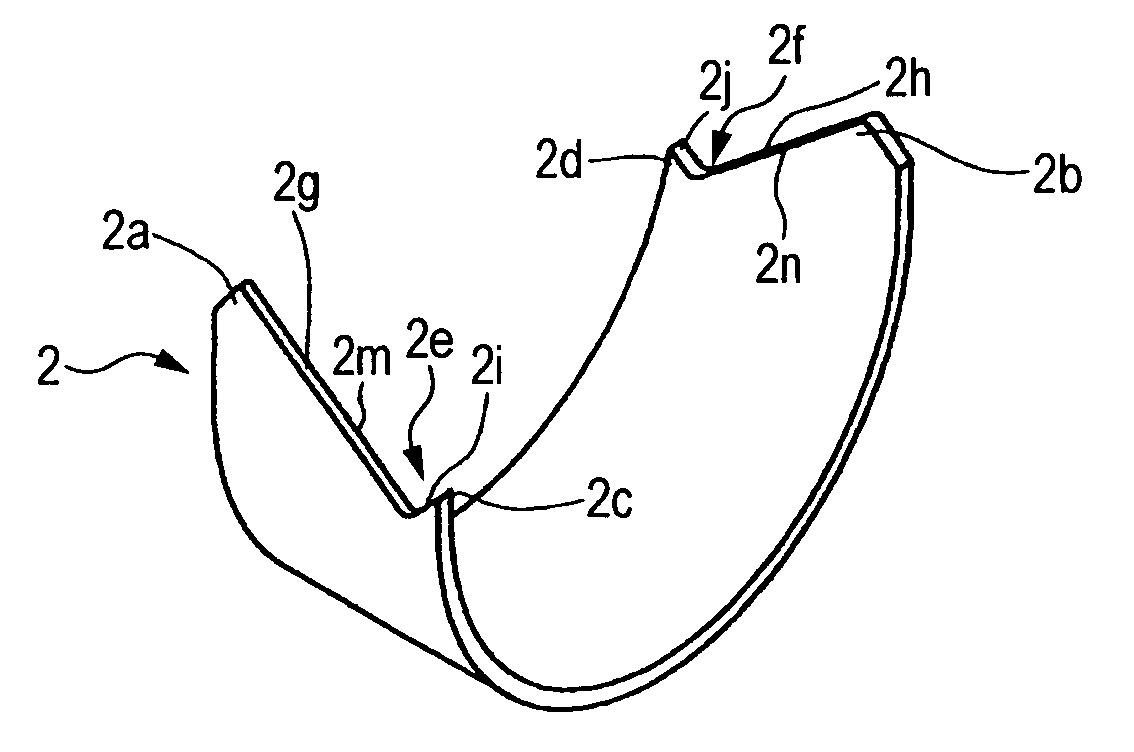

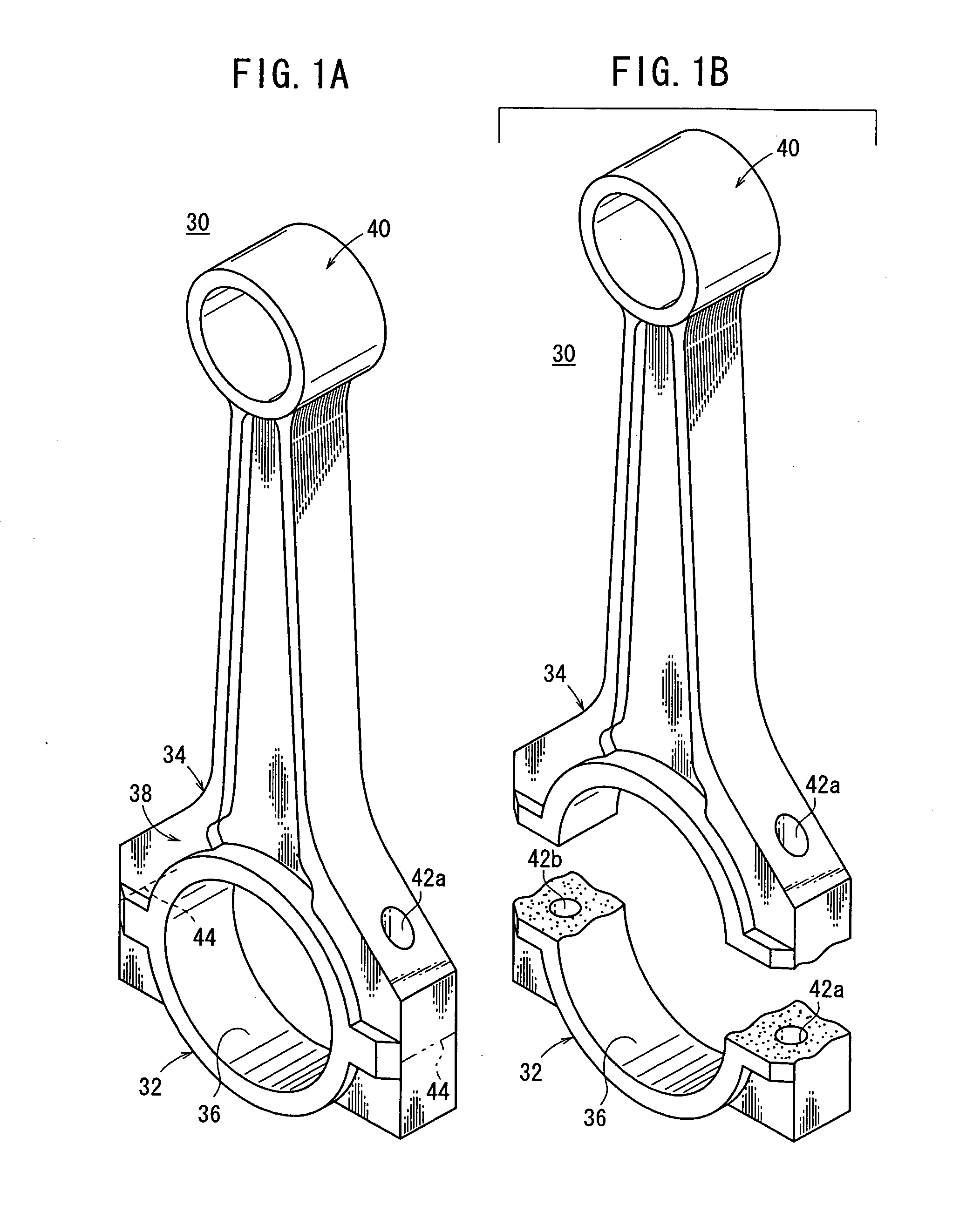

Connecting rod without wrist pin

InactiveUS20100172778A1Reduce weightEliminate needConnecting rod bearingsPositive displacement pump componentsLinear motionEngineering

A reciprocating pump assembly has a pump within a housing. The pump has a crankshaft that rotates and a crosshead that is connected to a plunger via a pony rod. The plunger pumps fluid through cylinders in the pump. A connecting rod connects at one end to the crankshaft and at another end to the crosshead to translate the crankshaft's rotational movement into linear movement of the crosshead and thereby the plunger. The end connected to the crosshead is secured to the crosshead by a bushing located within the crosshead that allows the connecting rod end to pivot during operation. The bushing extends more than 180 degrees, retaining the connecting rod with the crosshead without the need for a wrist pin. The end secured by the bushing can be retained within the bushing by a lock plate, and retainers without the need for a wrist pin.

Owner:WEIR SPM

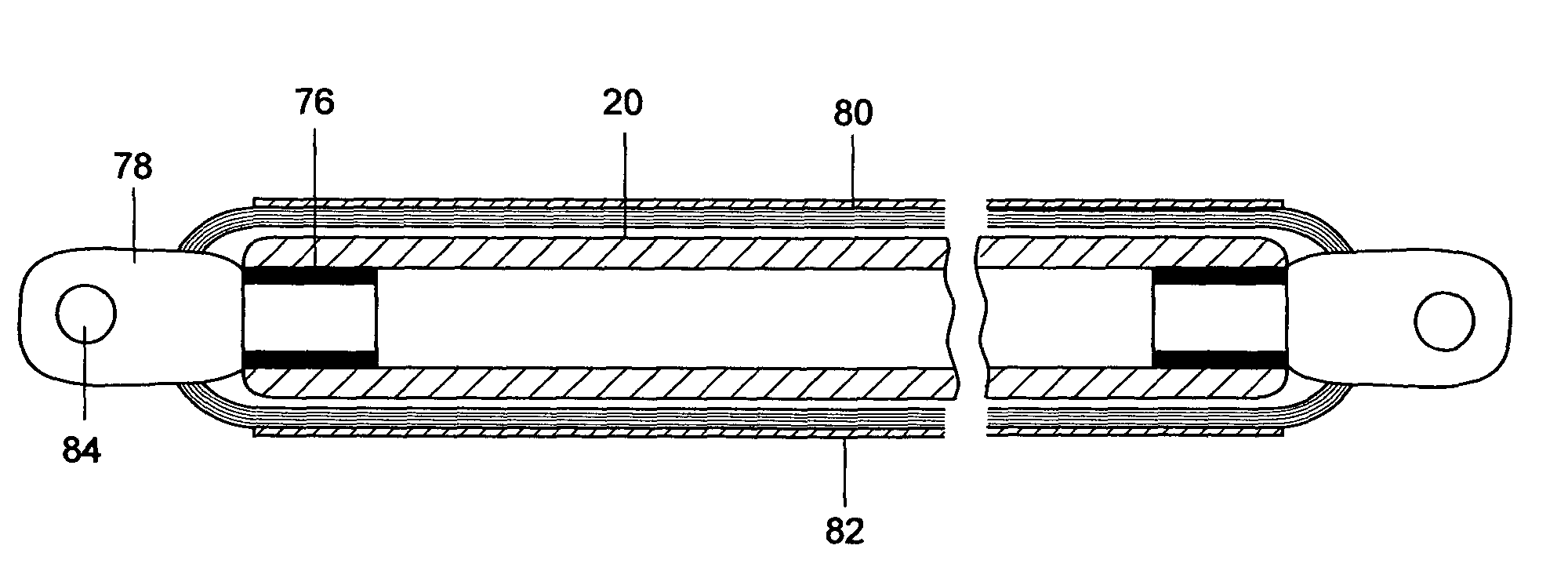

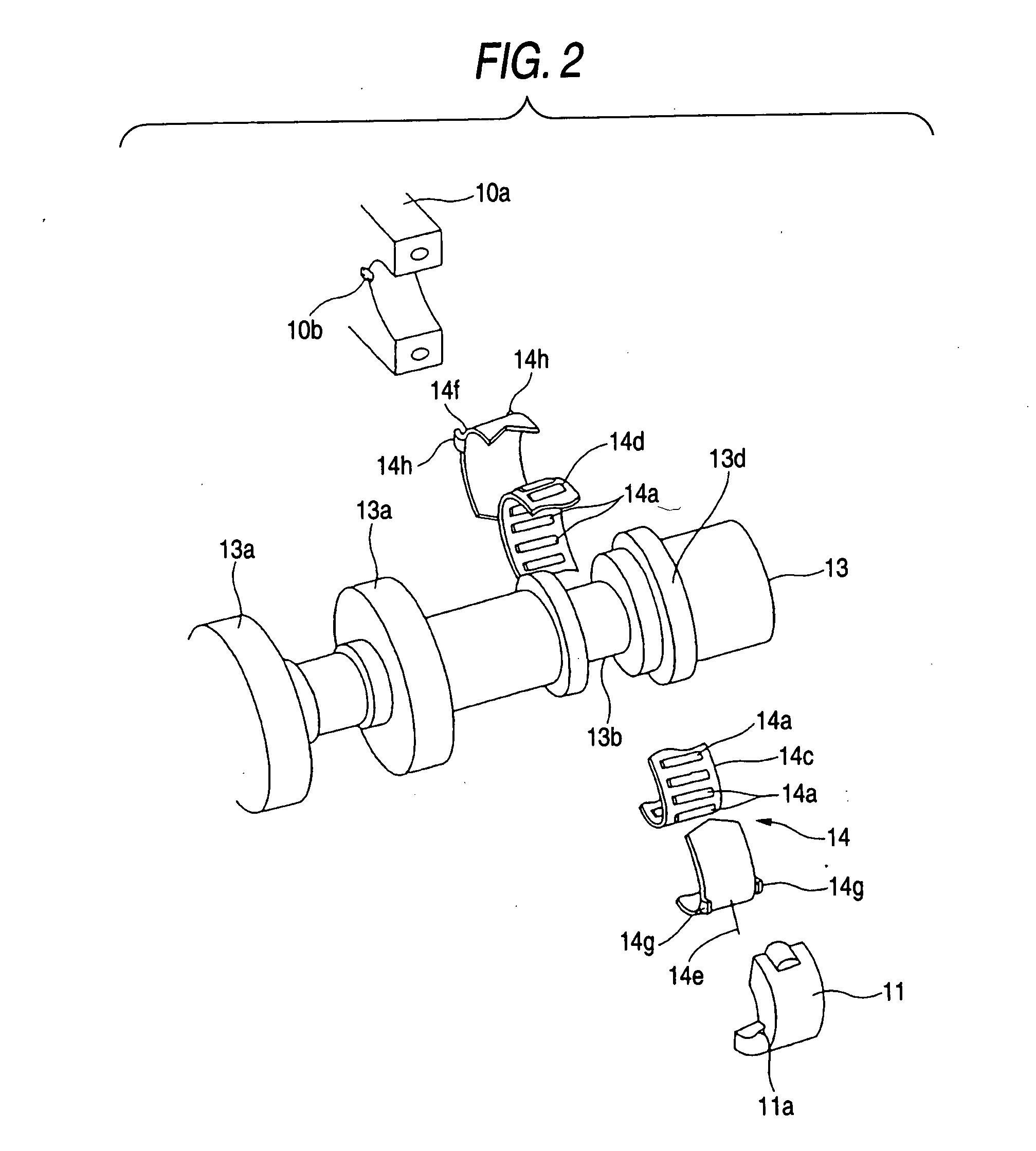

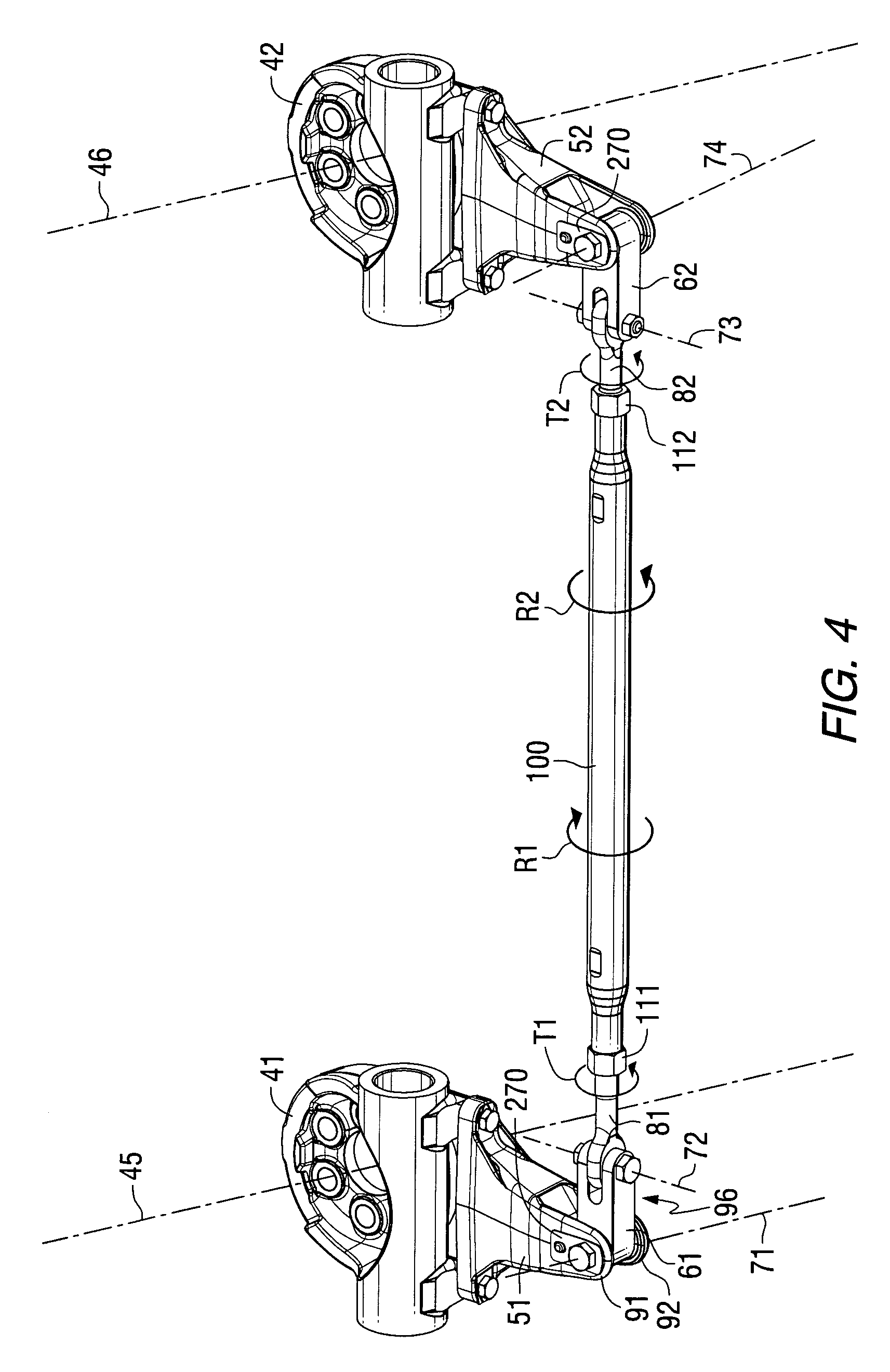

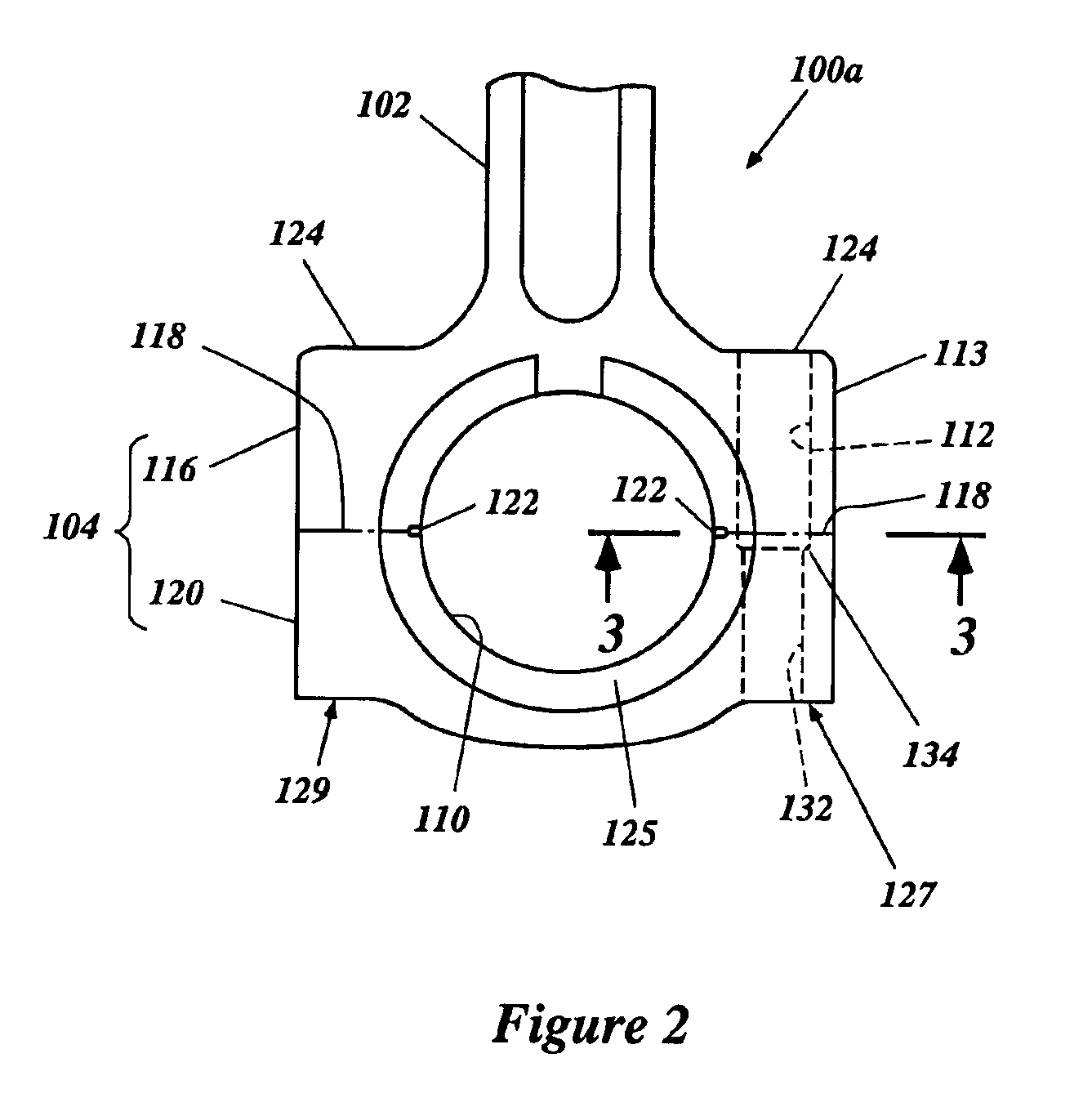

Torque Rod Structure

InactiveUS20070272051A1Increase stiffnessConnecting rod bearingsConnecting rodsEngineeringCompressive strength

Owner:HONDA MOTOR CO LTD

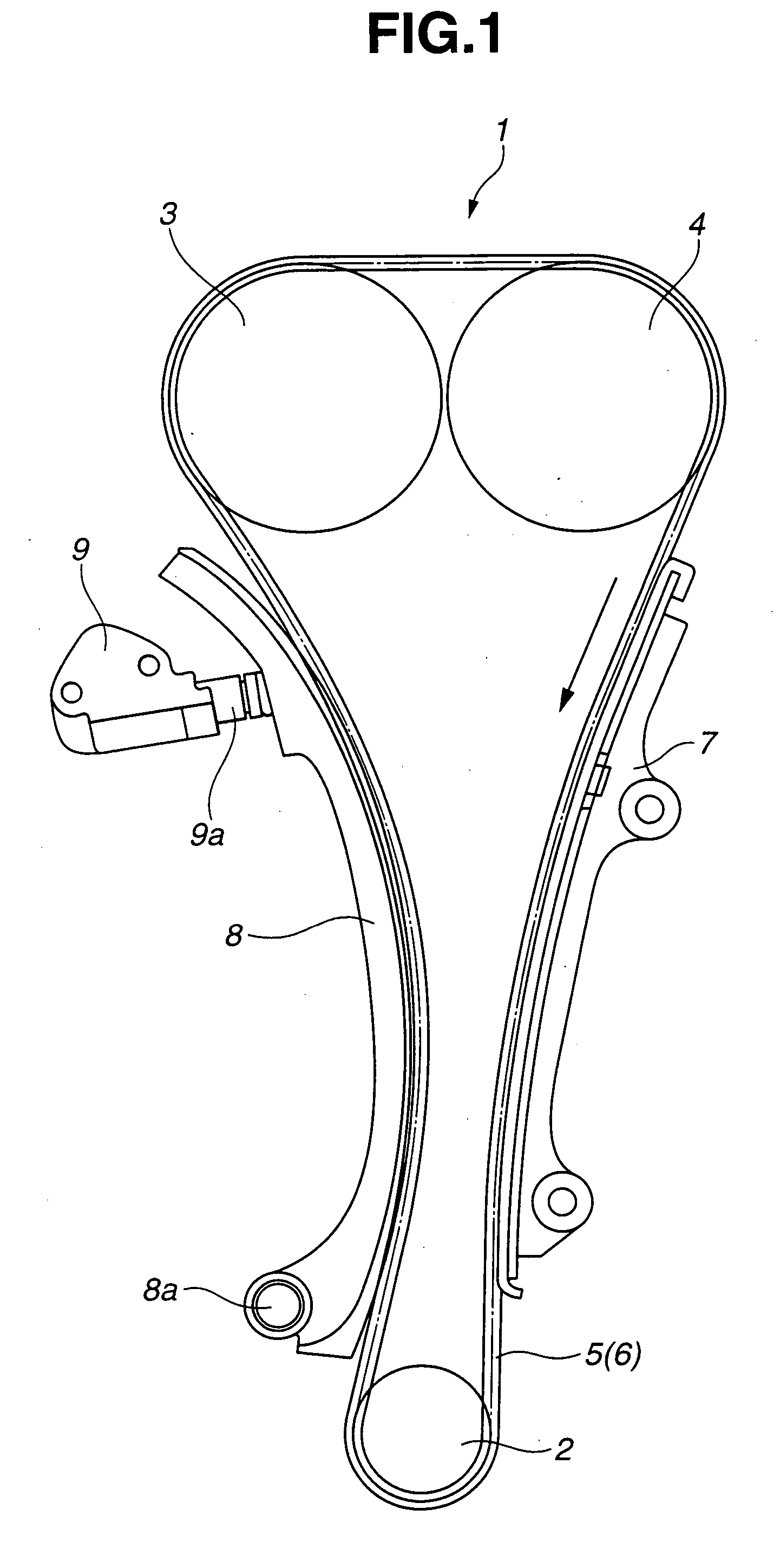

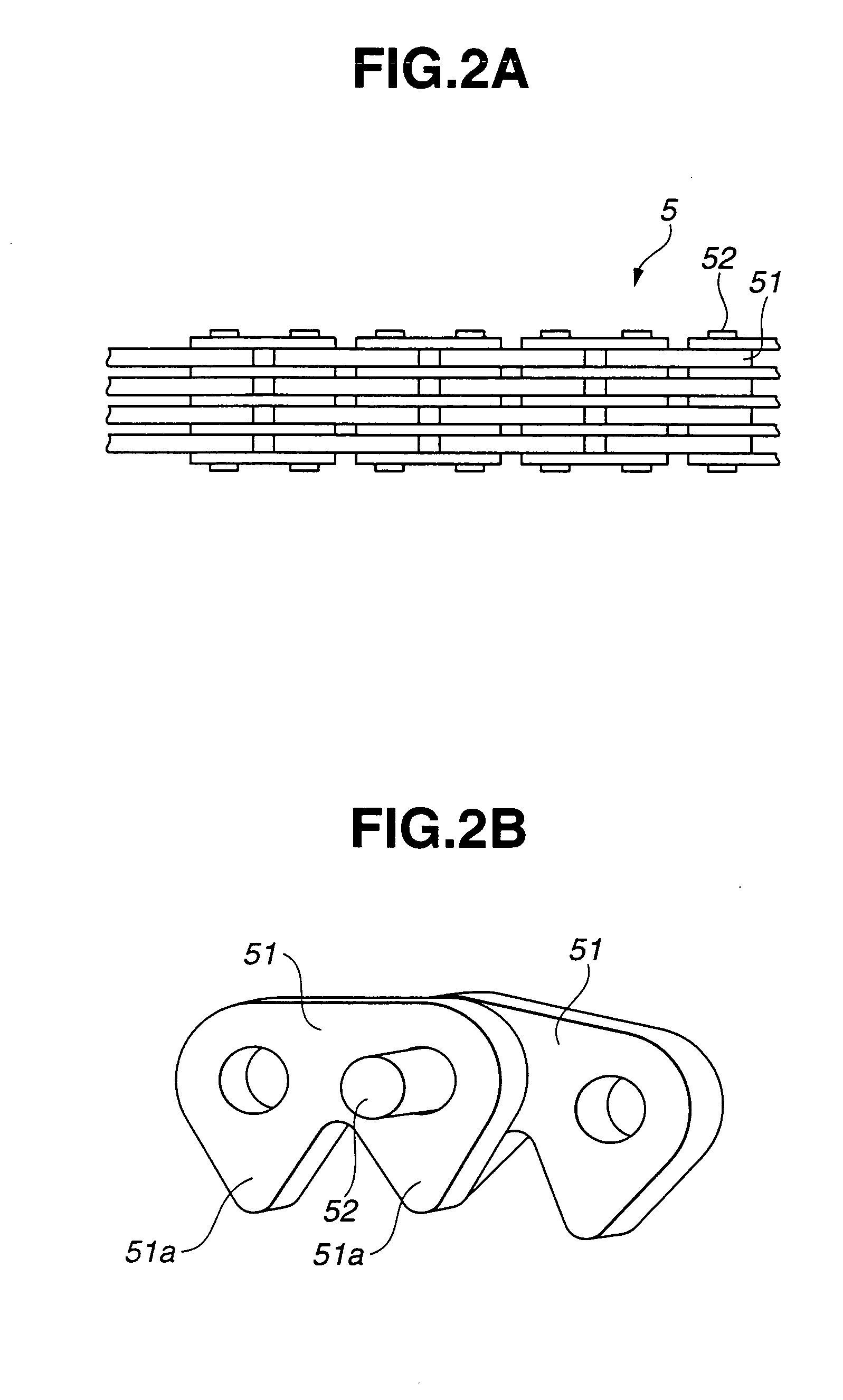

Chain drive system

InactiveUS20050037879A1Avoid excessive frictional resistanceAvoid excessive wearConnecting rod bearingsV-beltsCarbon coatingHydrogen content

A chain drive system includes a drive sprocket, a driven sprocket and a chain looped over the drive sprocket and the driven sprocket. The chain and the sprocket having respective sliding surfaces slidable relative to each other in the presence of lubricating oil, and any adjacent chain components of the chain having respective sliding surfaces slidable relative to each other in the presence of lubricating oil. At least one of the sliding surfaces between the chain and the sprocket and at least one of the sliding surfaces between any adjacent chain components have hard carbon coatings formed on base portions thereof. Each of the hard carbon coatings has a hydrogen content of 10 atomic % or less.

Owner:NISSAN MOTOR CO LTD

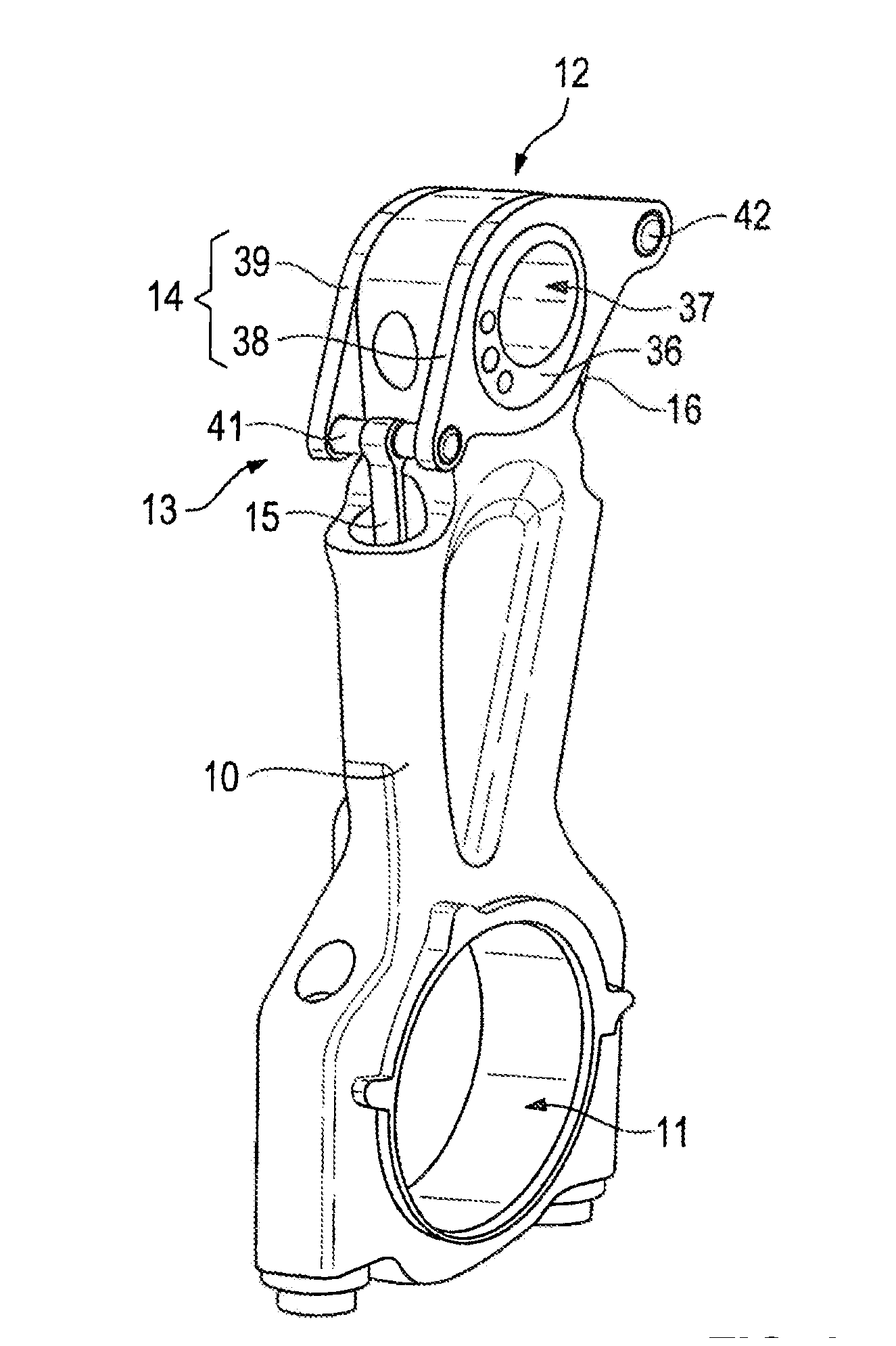

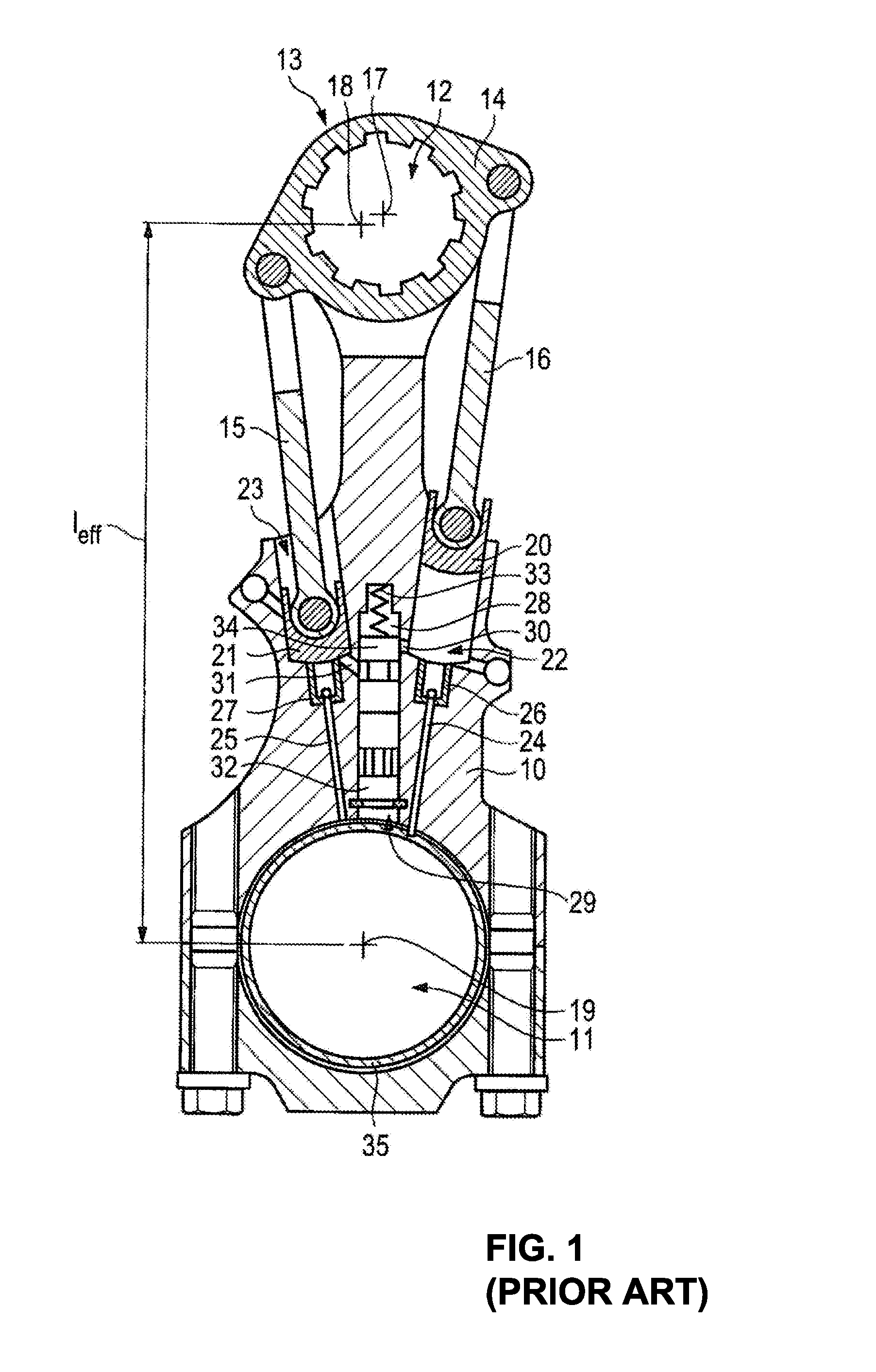

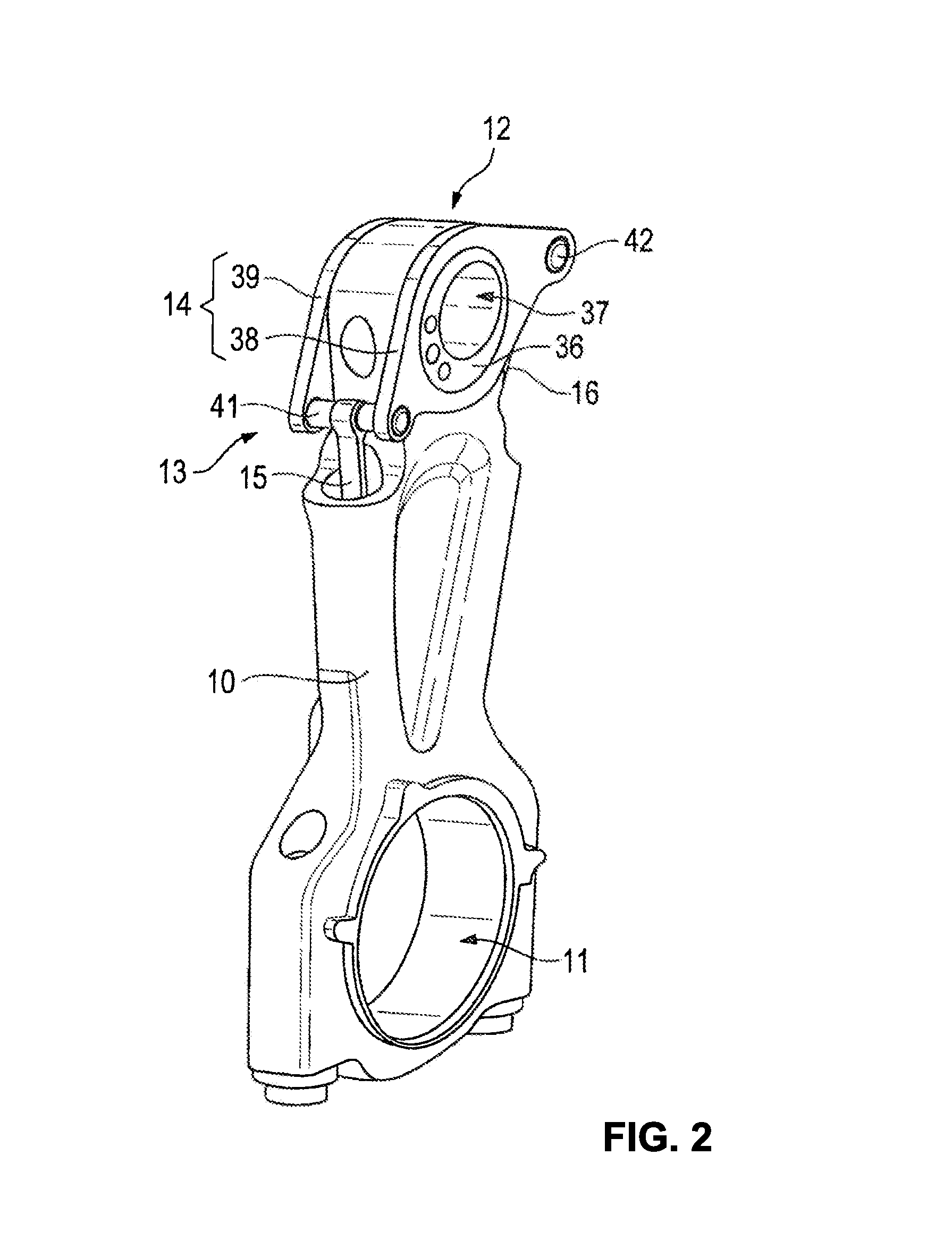

Internal combustion engine and connecting rod

ActiveUS20150059683A1Reduce productionReduce assembly complexityRotary bearingsConnecting rod bearingsExternal combustion engineEngineering

An internal combustion engine with adjustable compression ratio with a connecting rod bearing eye for connecting to a piston of the at least one cylinder and an eccentrical element adjustment device for adjusting an effective connecting rod length, and wherein the eccentrical element adjustment device includes an eccentrical element cooperating with an eccentrical element lever and eccentrical element rods engaging the eccentrical element lever, wherein the eccentrical element rods are loaded with a hydraulic pressure that is provided in hydraulic cavities interacting with the eccentrical element rods, wherein the eccentrical element lever includes at least one eccentrical element lever segment, wherein the at least one eccentrical element lever segment is positioned in axial direction of the eccentrical element in front and / or behind the connecting rod bearing eye, and wherein the at least one eccentrical element lever segment is fixated at the eccentrical element.

Owner:HILITE GERMANY +1

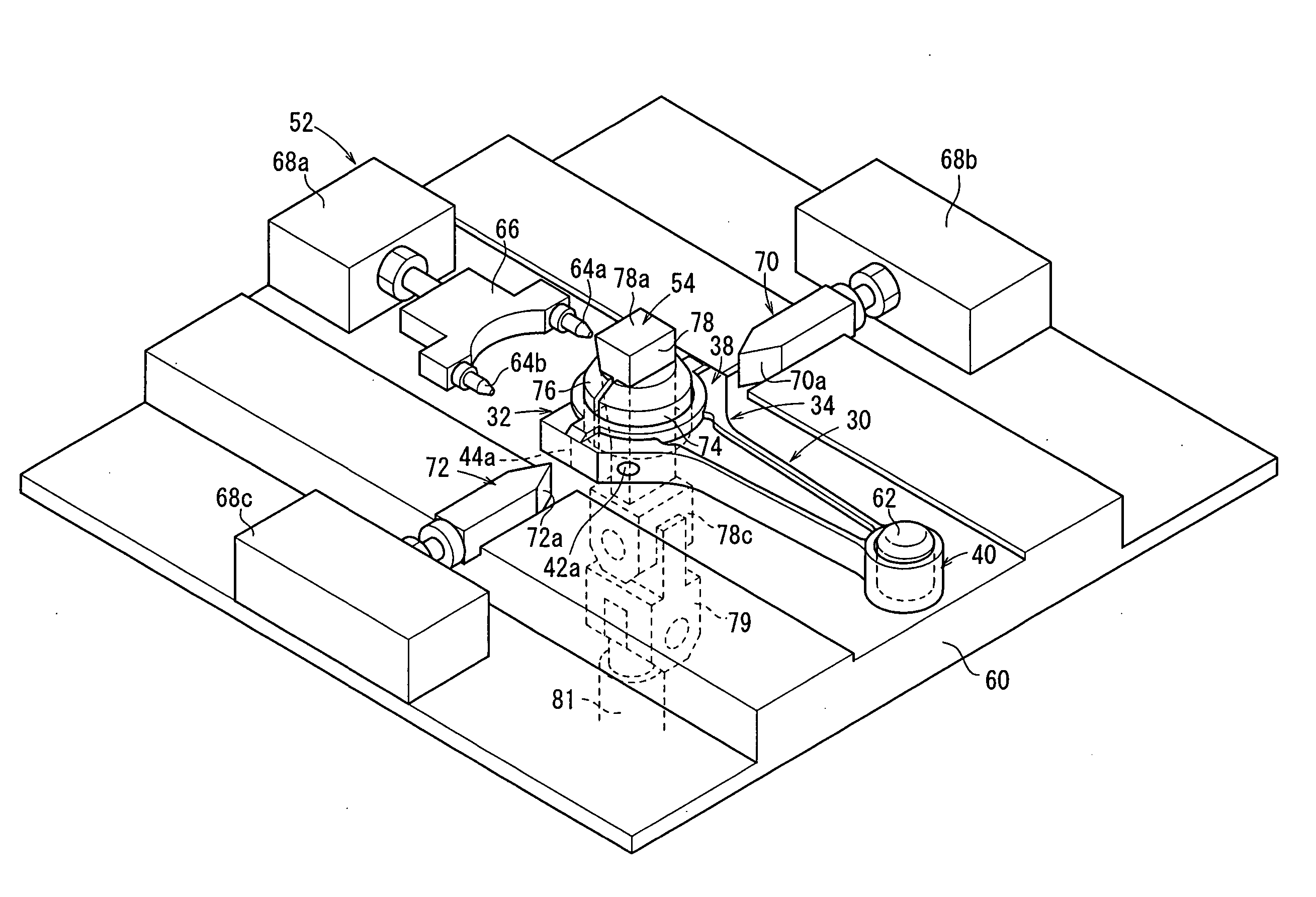

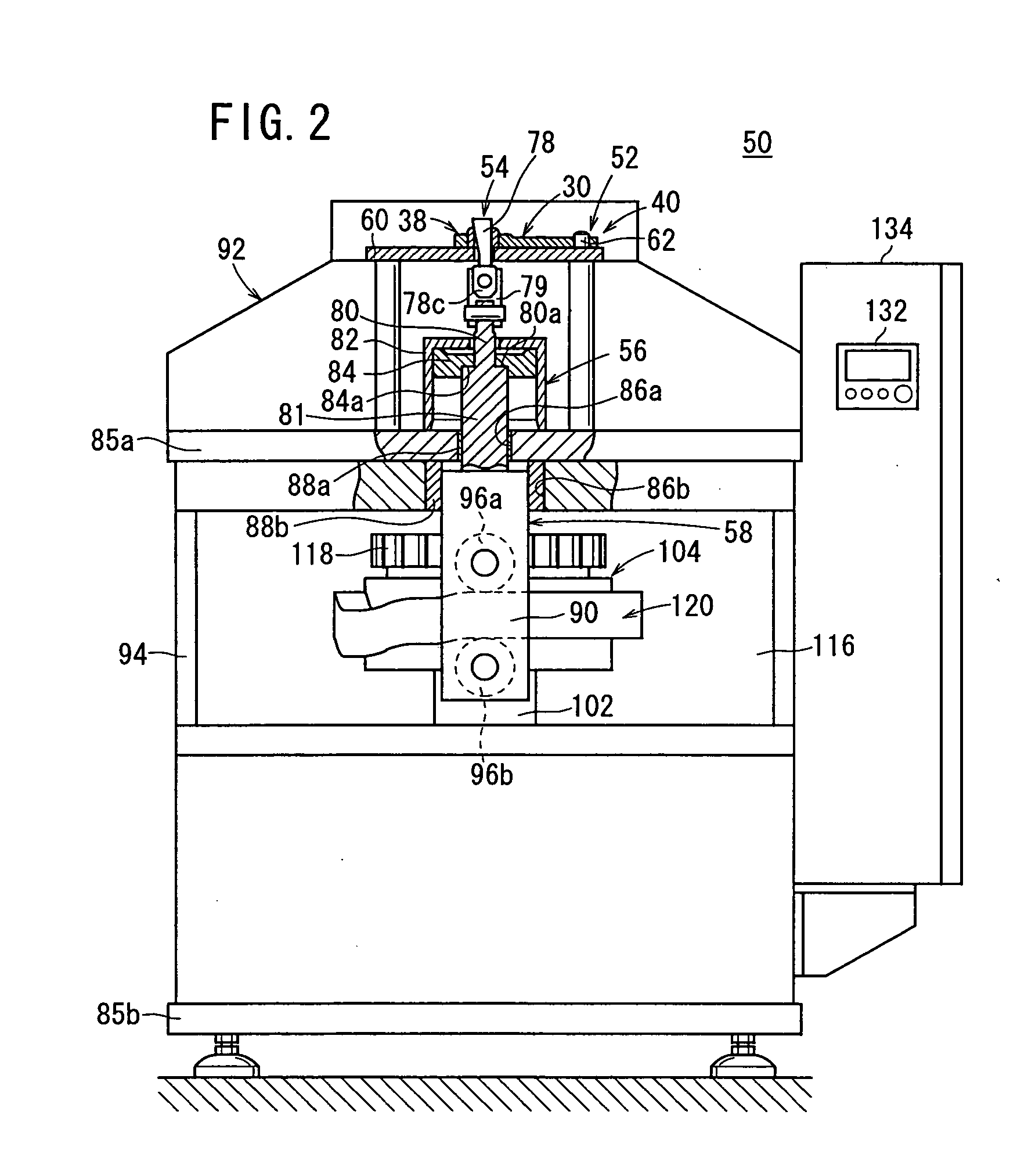

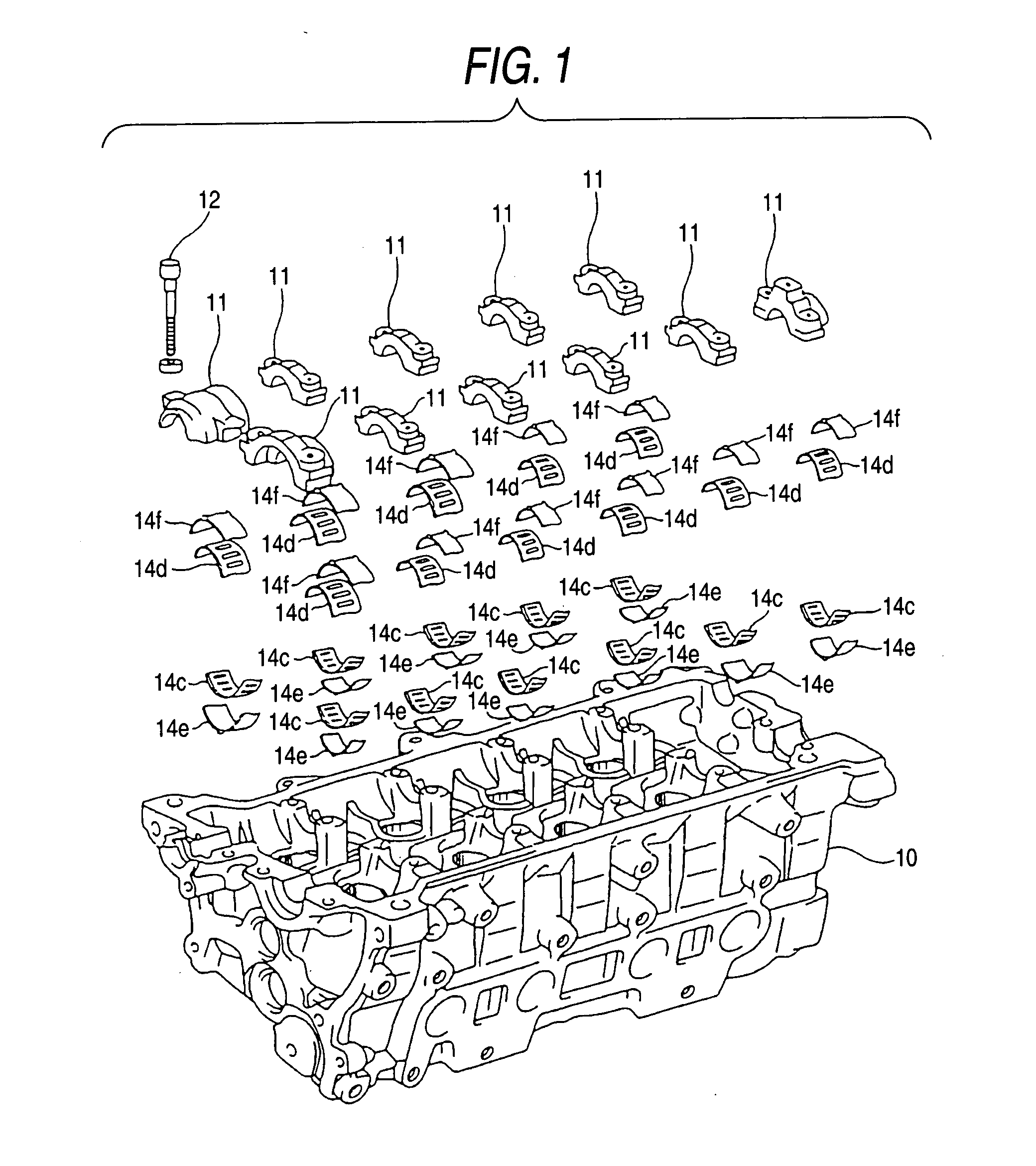

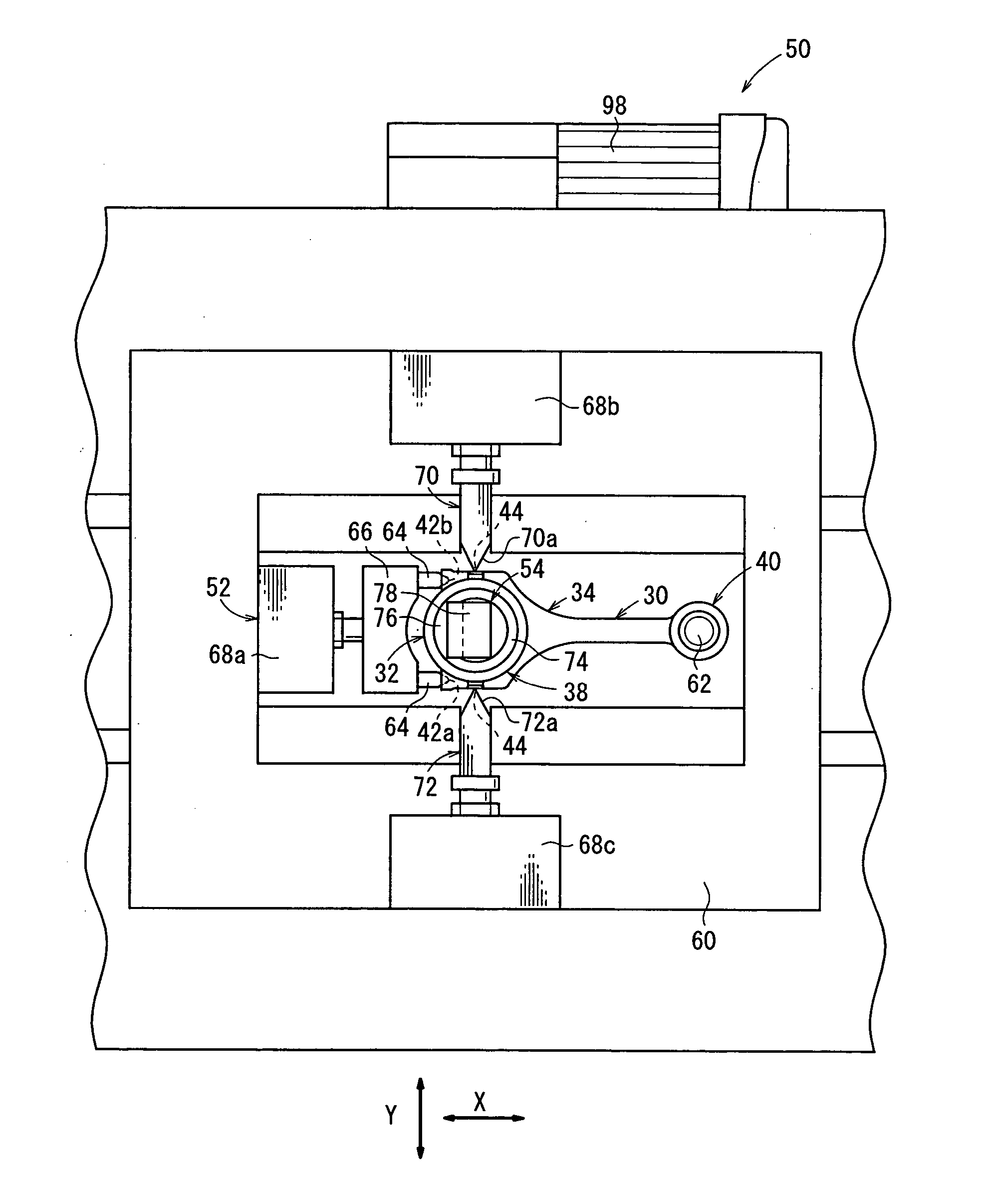

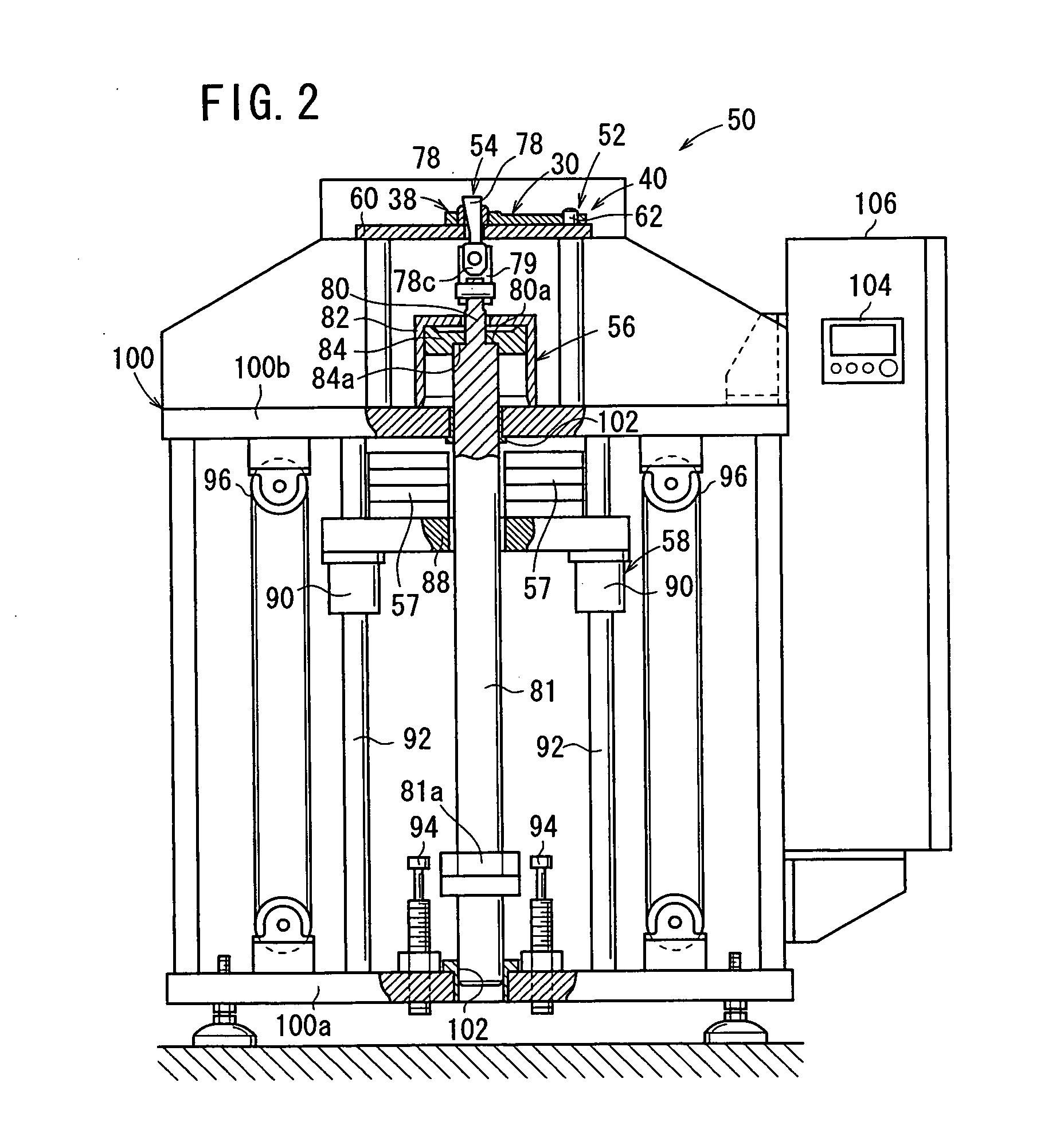

Method of and apparatus for cracking connecting rod

InactiveUS20050044706A1Accurately controlling magnitudeEasy to controlConnecting rod bearingsConnecting rodsMechanical engineering

A cracking apparatus has a pair of spreaders to be placed in a joint hole defined in a larger end of a connecting rod, a wedge that is pressed in between the spreaders, a preloading mechanism for imparting a preload to the wedge, and a loading mechanism for imparting an impact load to the wedge in the direction in which the wedge is pressed, by energizing a rotational drive source and transmitting rotational drive power from the rotational drive source through a shaft connected to the wedge, after the preload has been applied to the wedge by the preloading mechanism.

Owner:HONDA MOTOR CO LTD

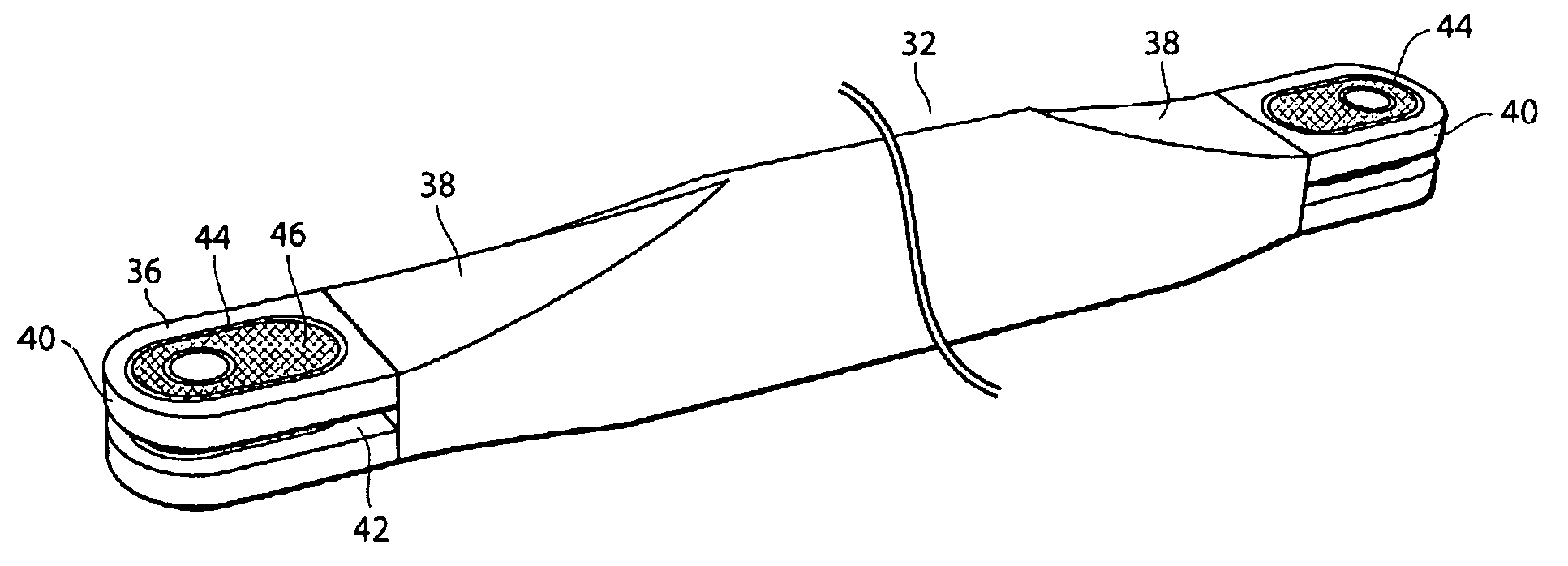

Reinforced tension and compression reacting strut and method of making same

InactiveUS20050044984A1Efficient responseLow costControlling membersConnecting rod bearingsAdhesiveFiber-reinforced composite

A reinforced composite strut capable of reacting both compression and tension loads. The strut is preferably comprised of a fiber reinforced composite elongate body with fittings, such as metal fittings, secured to the ends thereof. The fittings may be secured by means of an adhesive and are reinforced by means of a filament band wound about the fittings and the elongate body. The strap wound upon the body allows for reacting tension loads and the body reacts to compression loads. A method of making the strut is also disclosed.

Owner:KAISER COMPOSITEK

Connecting rod with lubricant tube

InactiveUS6907848B2Easy to adaptLess oil pump demandConnecting rod bearingsConnecting rodsEngineeringLubricant

Owner:GM GLOBAL TECH OPERATIONS LLC

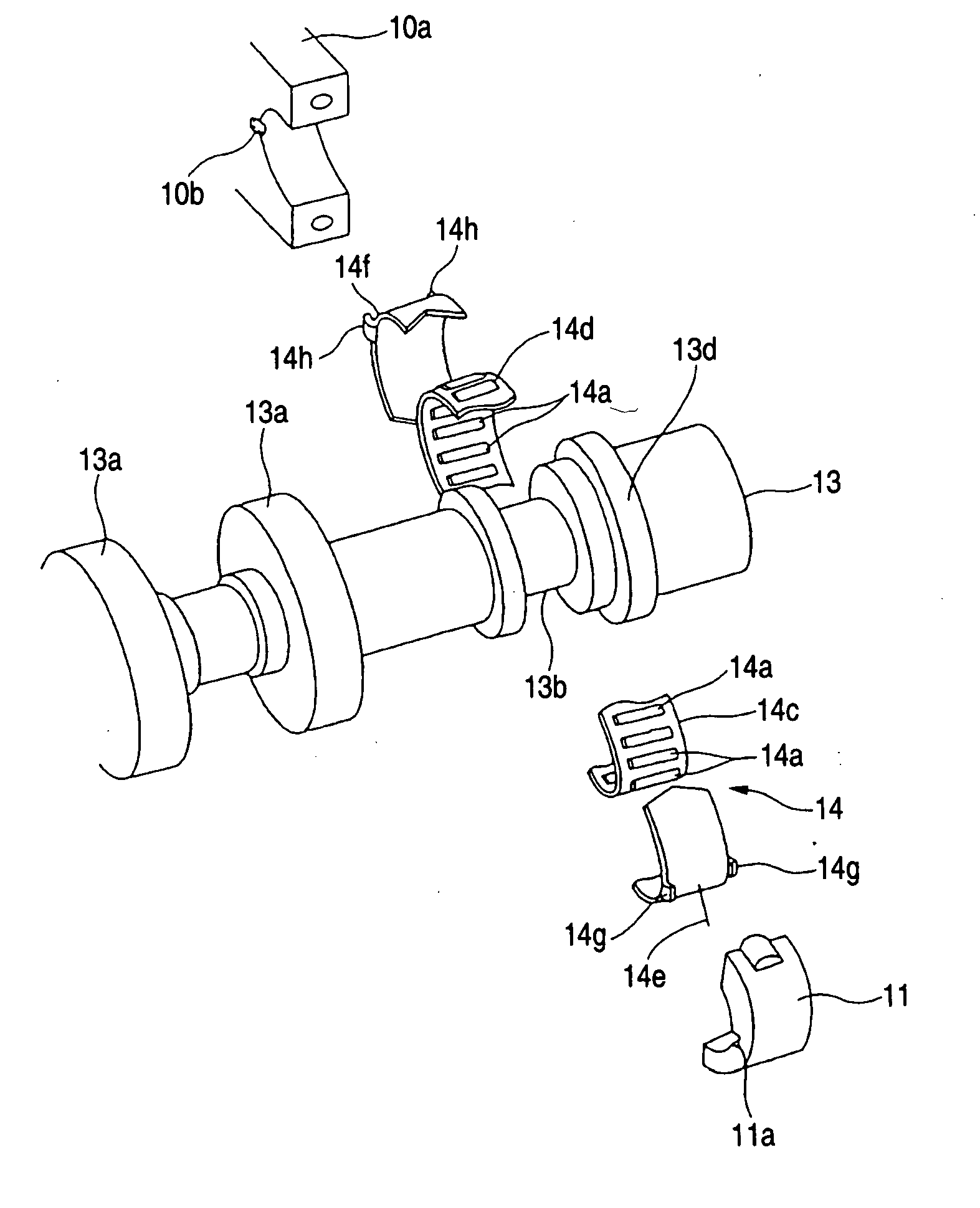

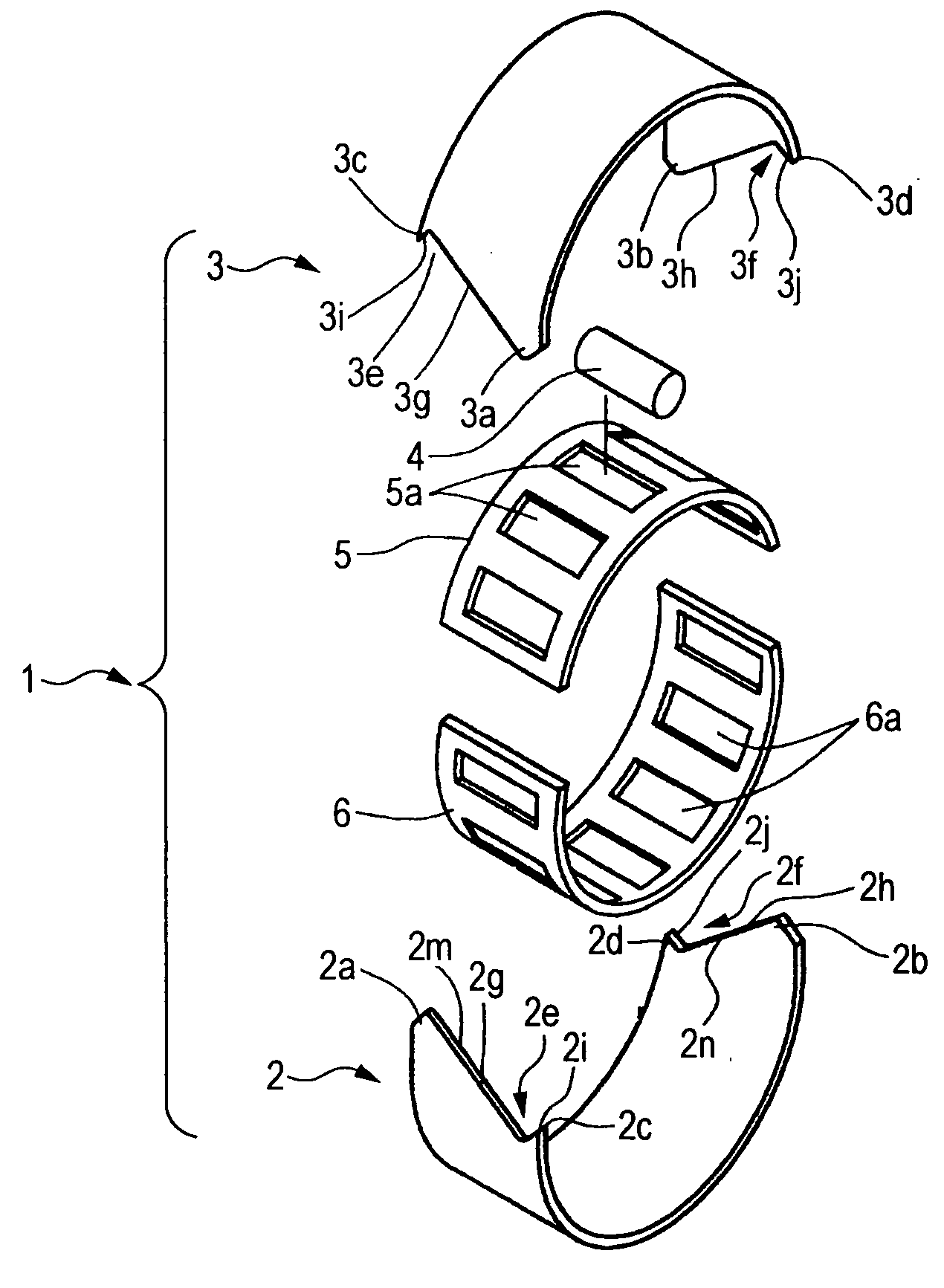

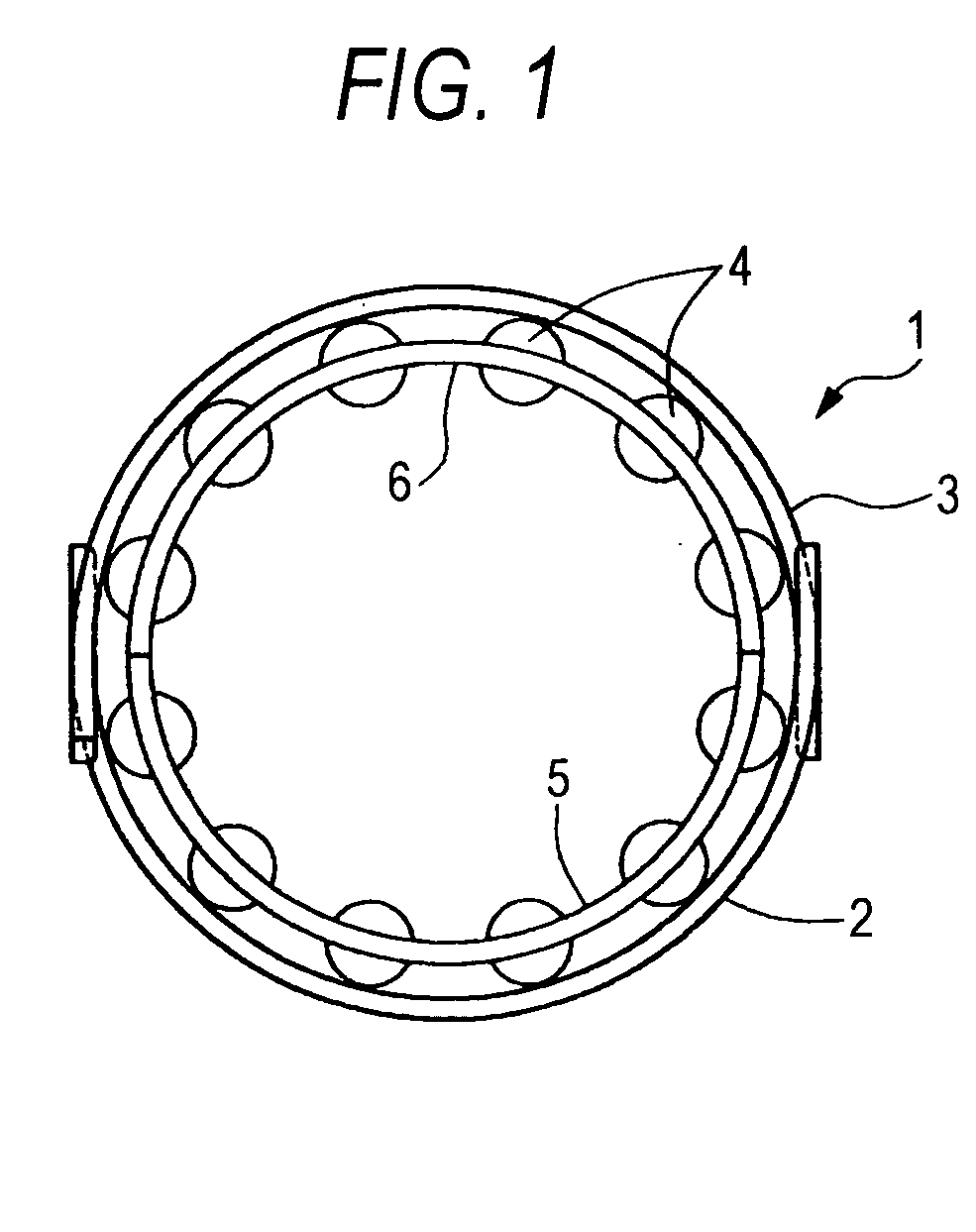

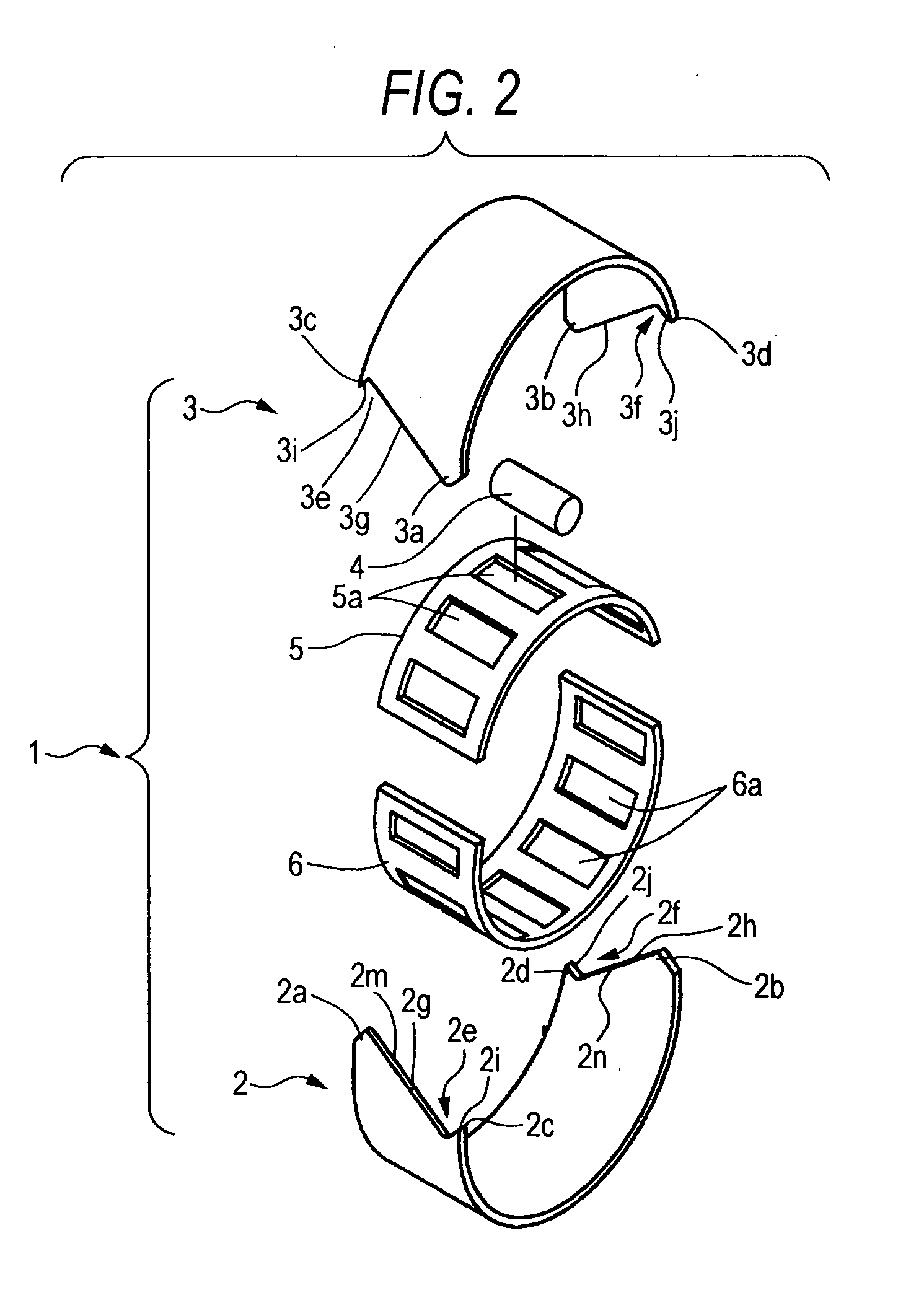

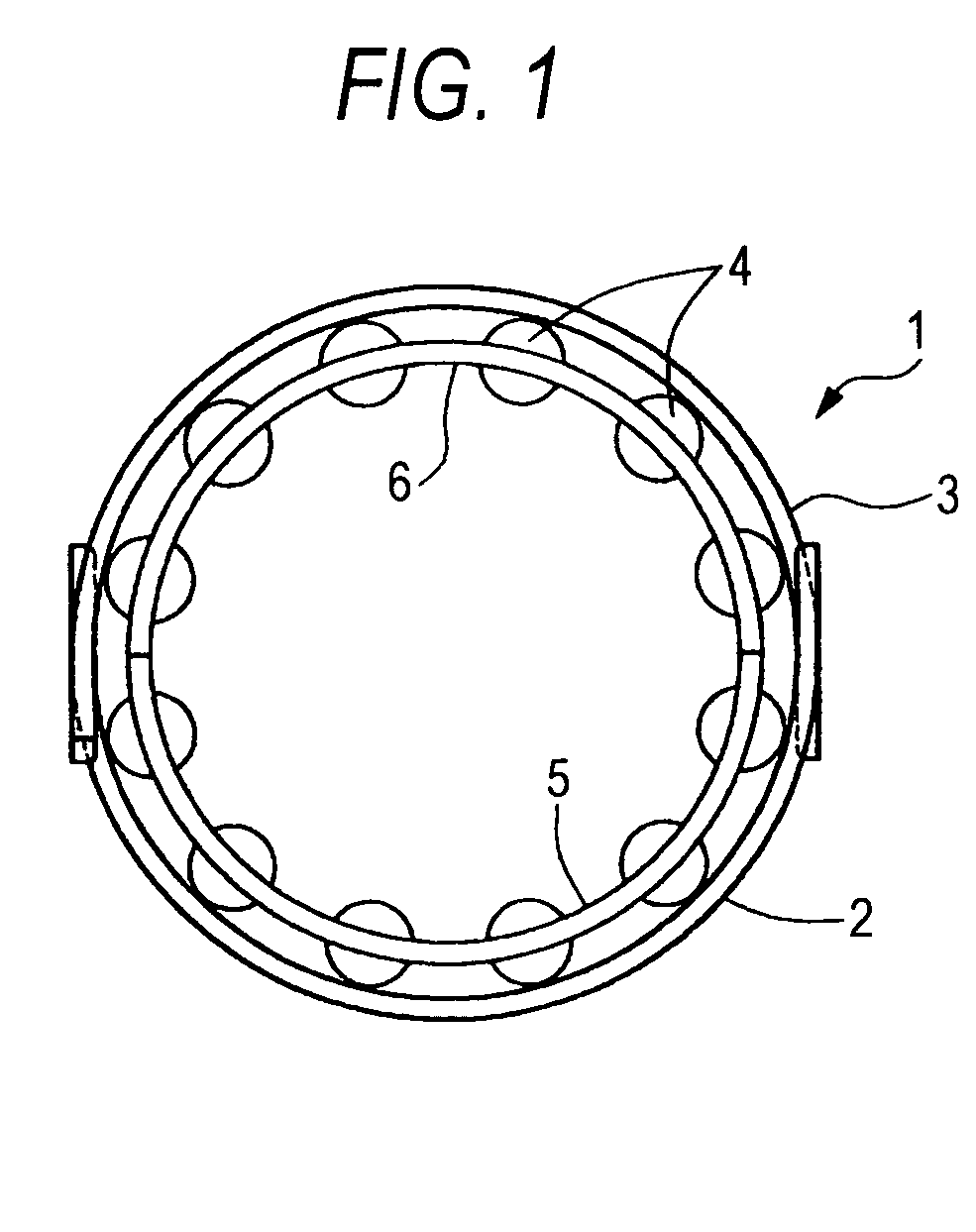

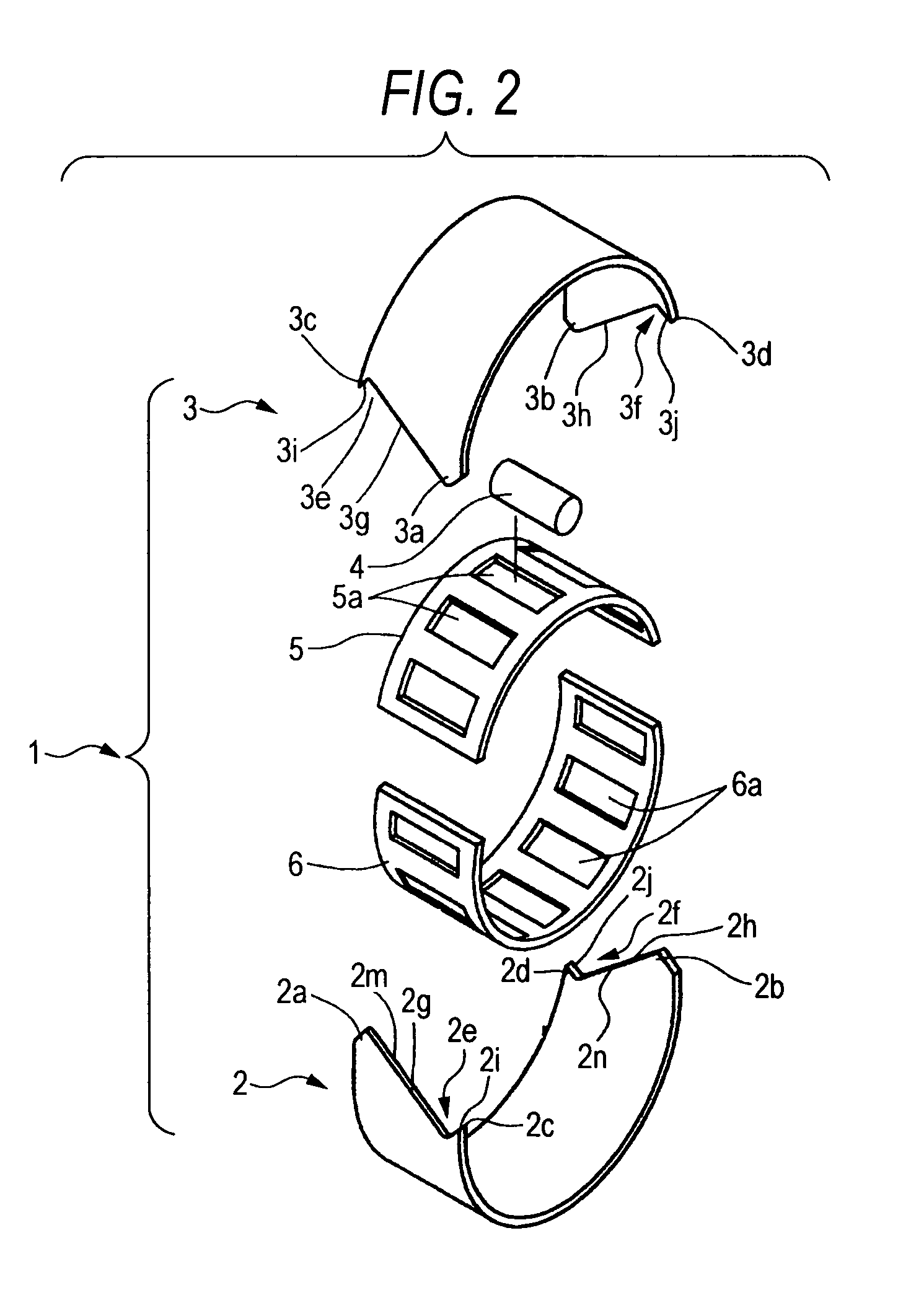

Roller bearing

A roller bearing for rotatably supporting a rotating shaft of an internal combustion engine between a main body and a cap of the internal combustion engine. The roller bearing including: a plurality of rollers; a retainer which is cirumferentially splittable and supports the plurality of rollers; and an outer race which is cirumferentially splittable and forms a raceway surface for the plurality of rollers. The retainer is split into a plurality of retaining members. The outer race is split into a plurality of race plates. At least one of the race plates is provided with one of a projection and a cavity to be engaged with one of the main body and the cap to restrict a relative movement between the one of the race plates and the one of the cylinder head and the cap.

Owner:NSK LTD

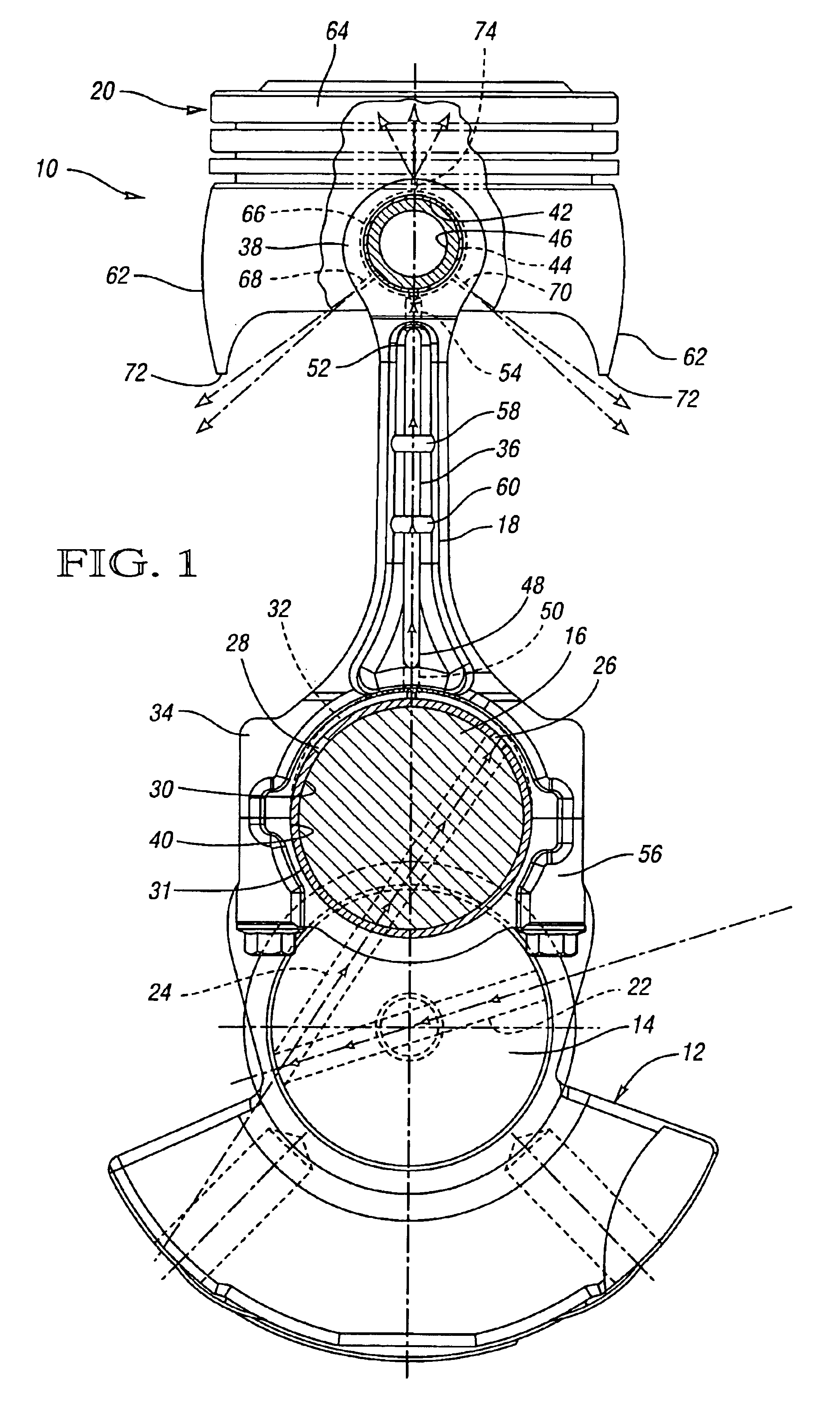

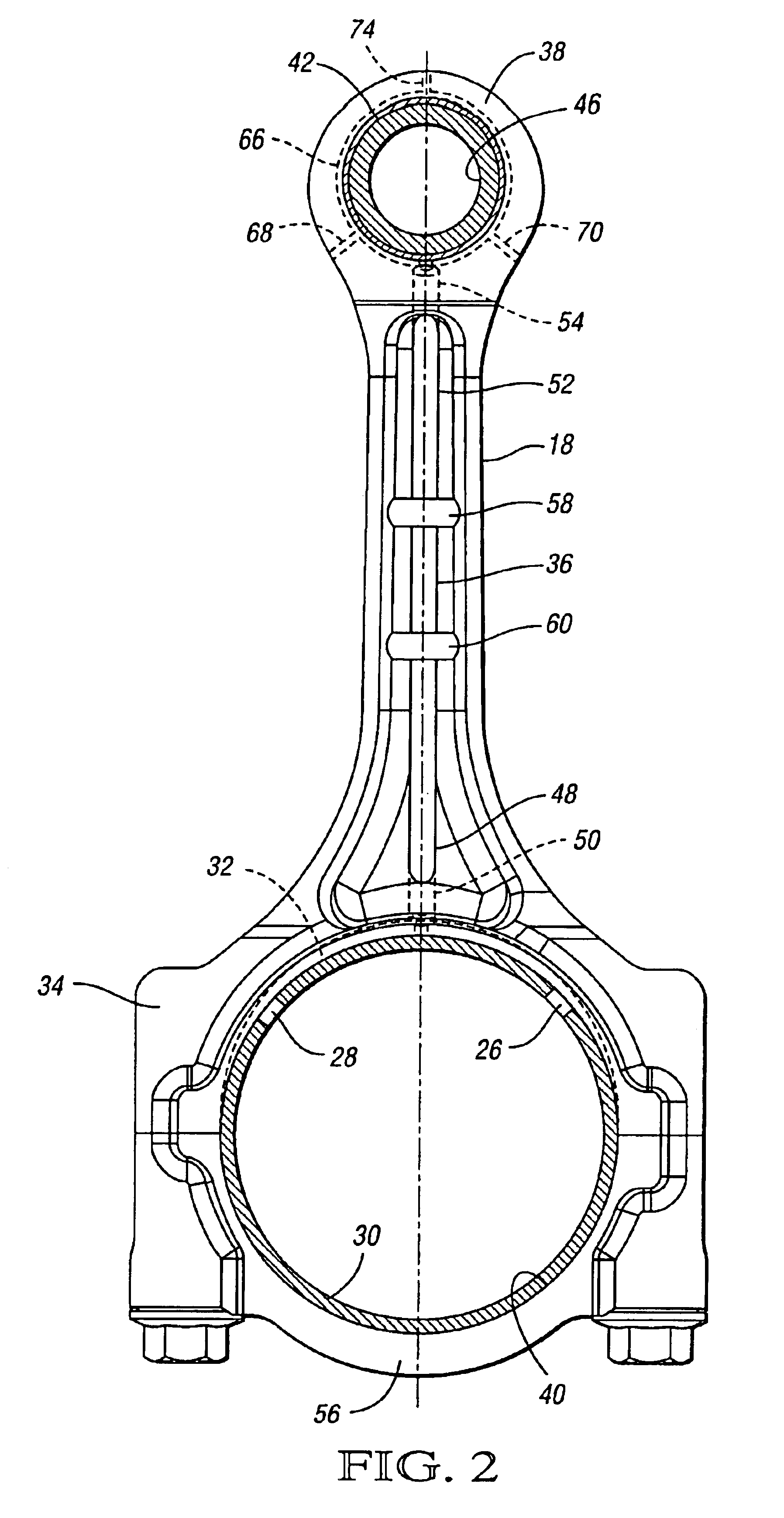

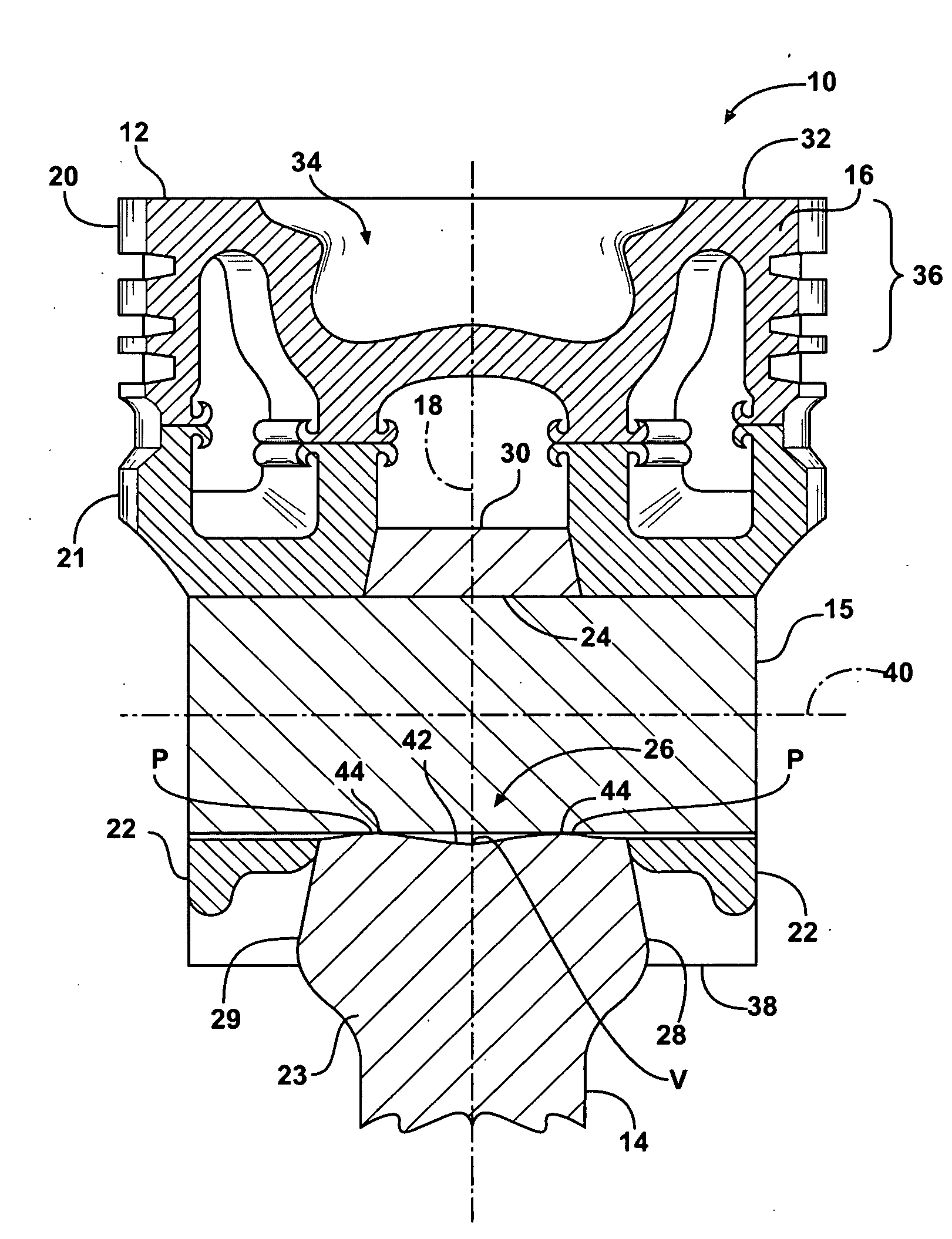

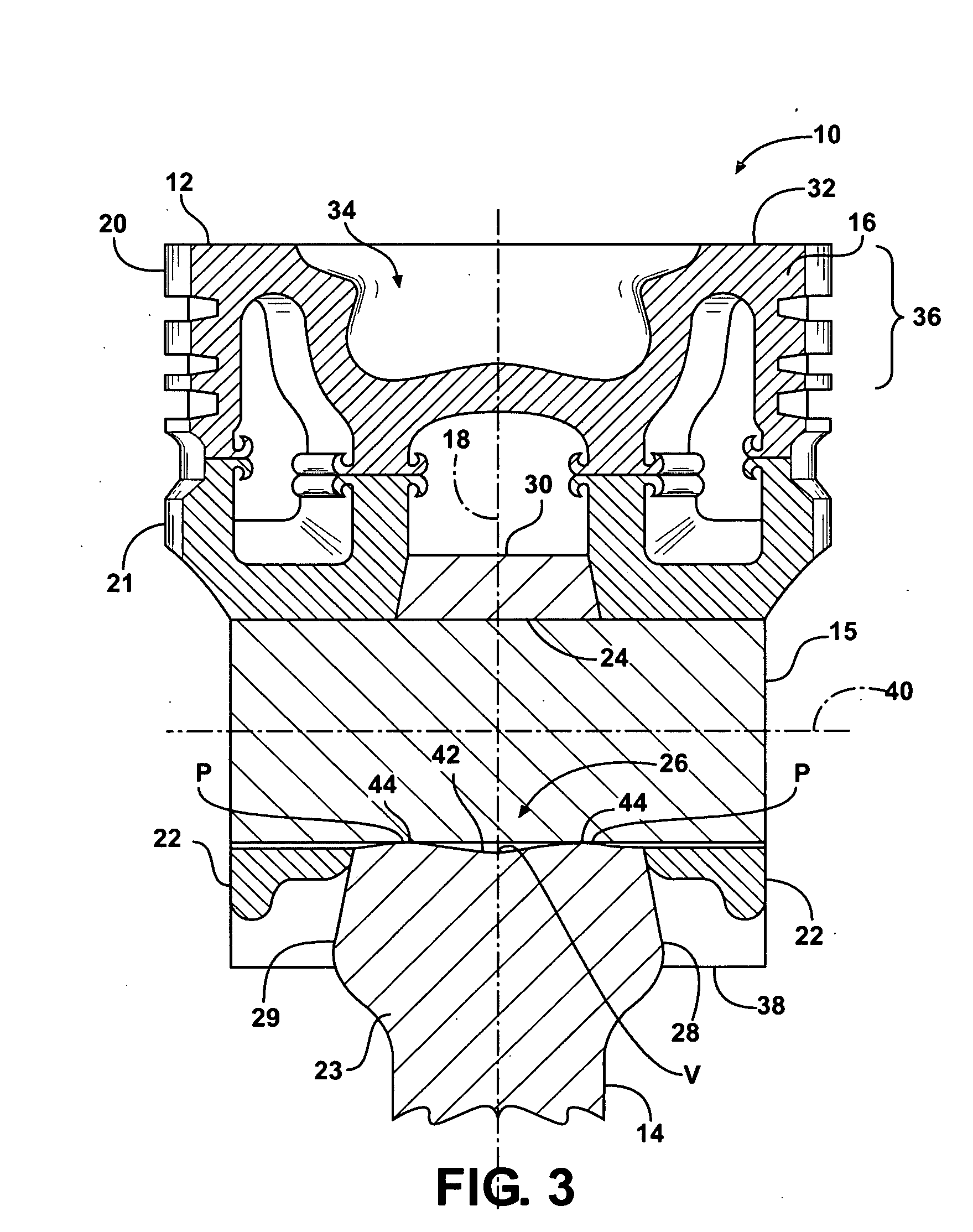

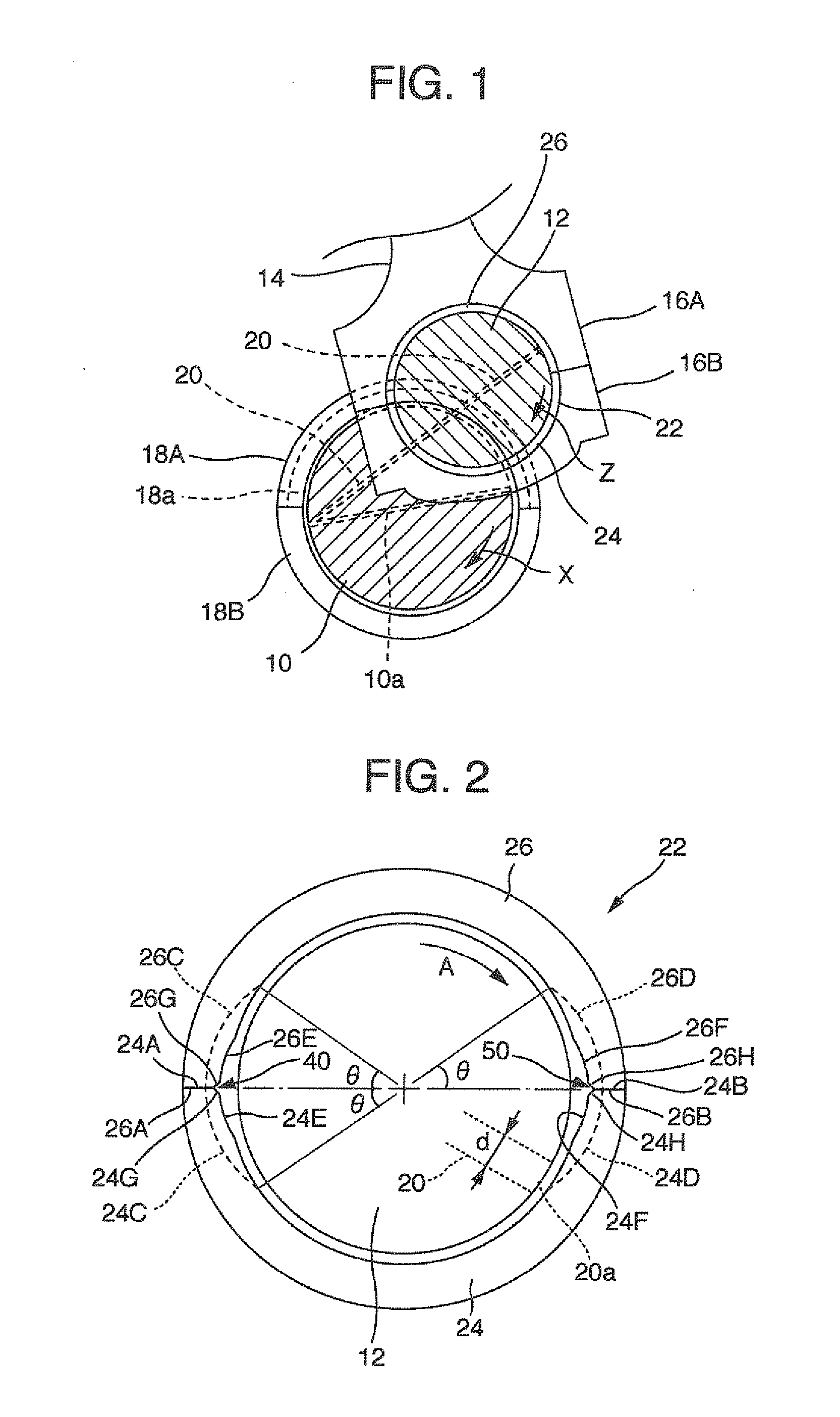

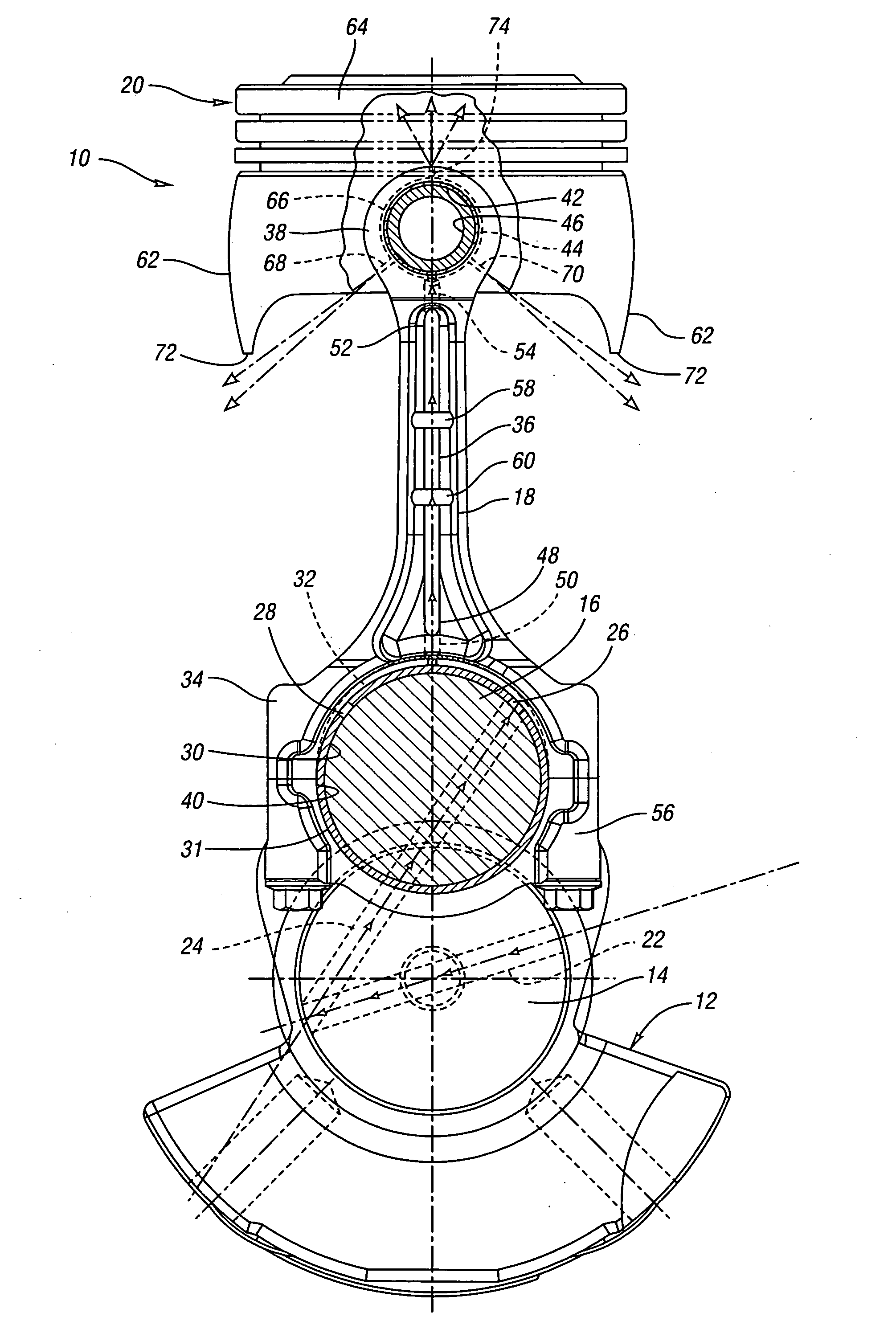

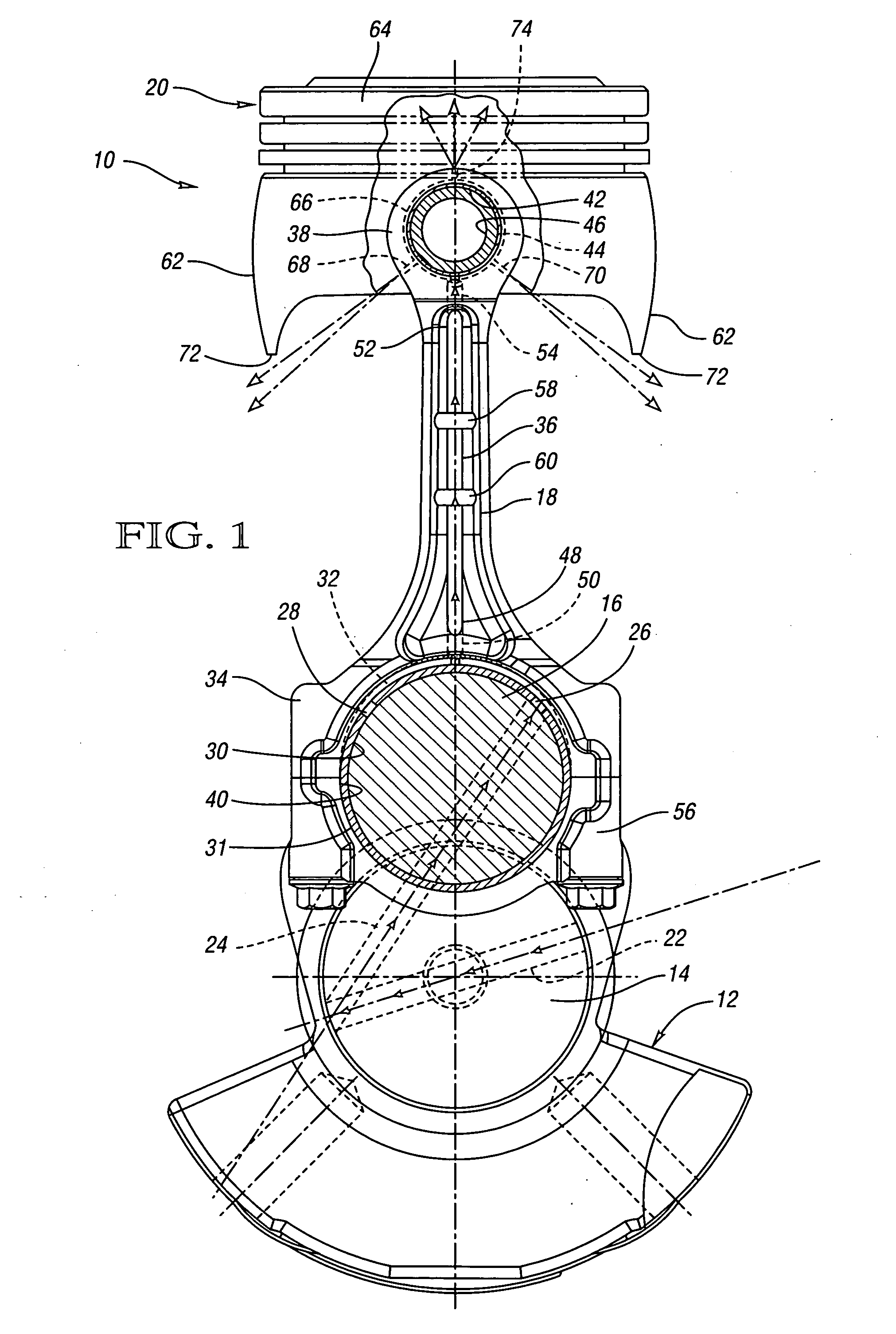

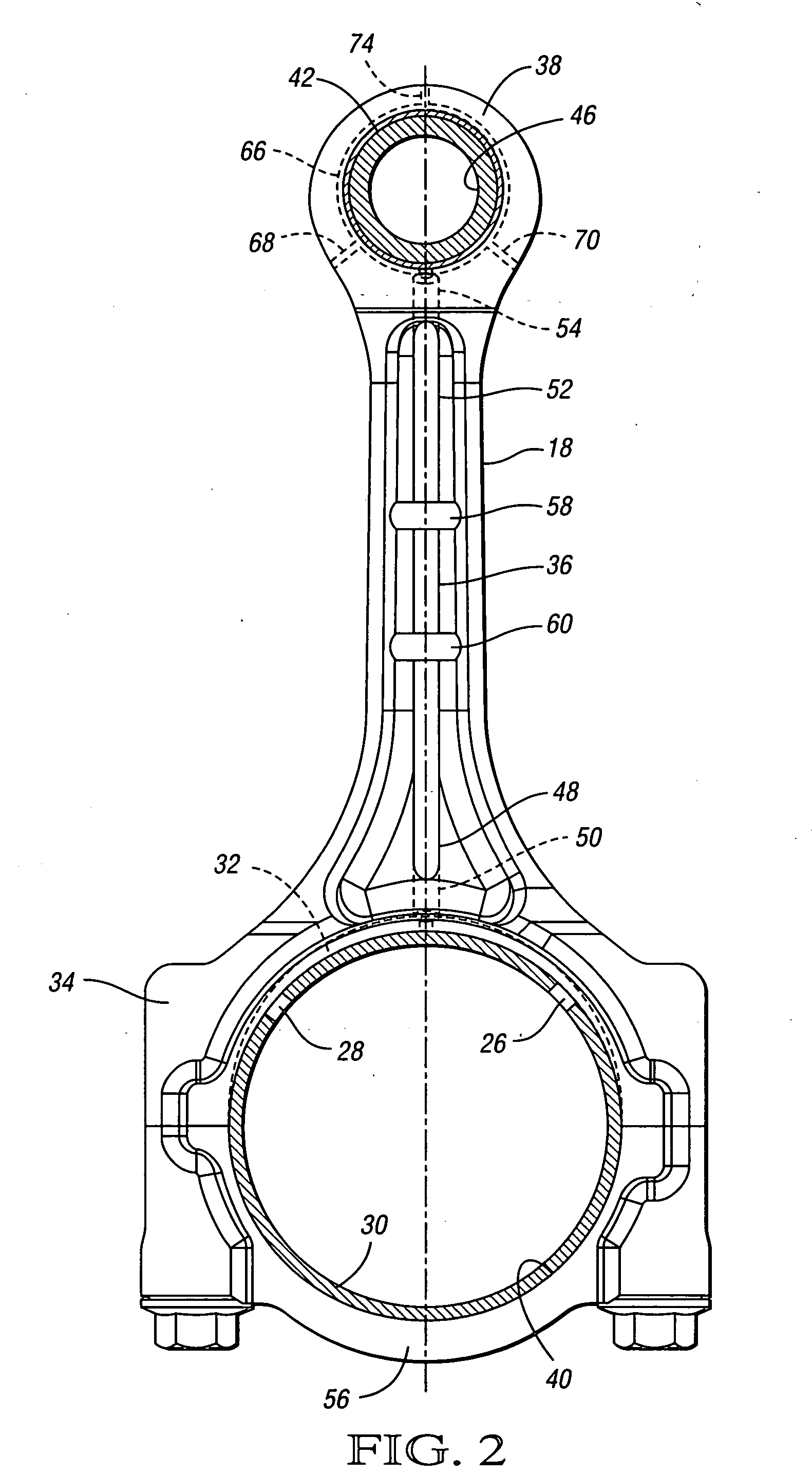

Piston assembly and connecting rod having a profiled wrist pin bore therefor

A piston assembly and connecting rod therefor is provided. The connecting rod has an elongate body extending to an end for operable attachment to a piston. The end has a wrist pin bore extending between opposite sides of the body. The wrist pin bore has a wavy profile extending between the sides. The wavy profile has at least one concave surface with a valley extending along a circumferential direction of the wrist pin bore and convex surfaces having peaks extending along a circumferential direction of the wrist pin bore on laterally opposite sides of the valley. The peaks and valleys cooperate to form a smooth load gradient and uniform lubrication flow across the interface region between the wrist pin bore and the wrist pin extending therethrough.

Owner:FEDERAL MOGUL CORP

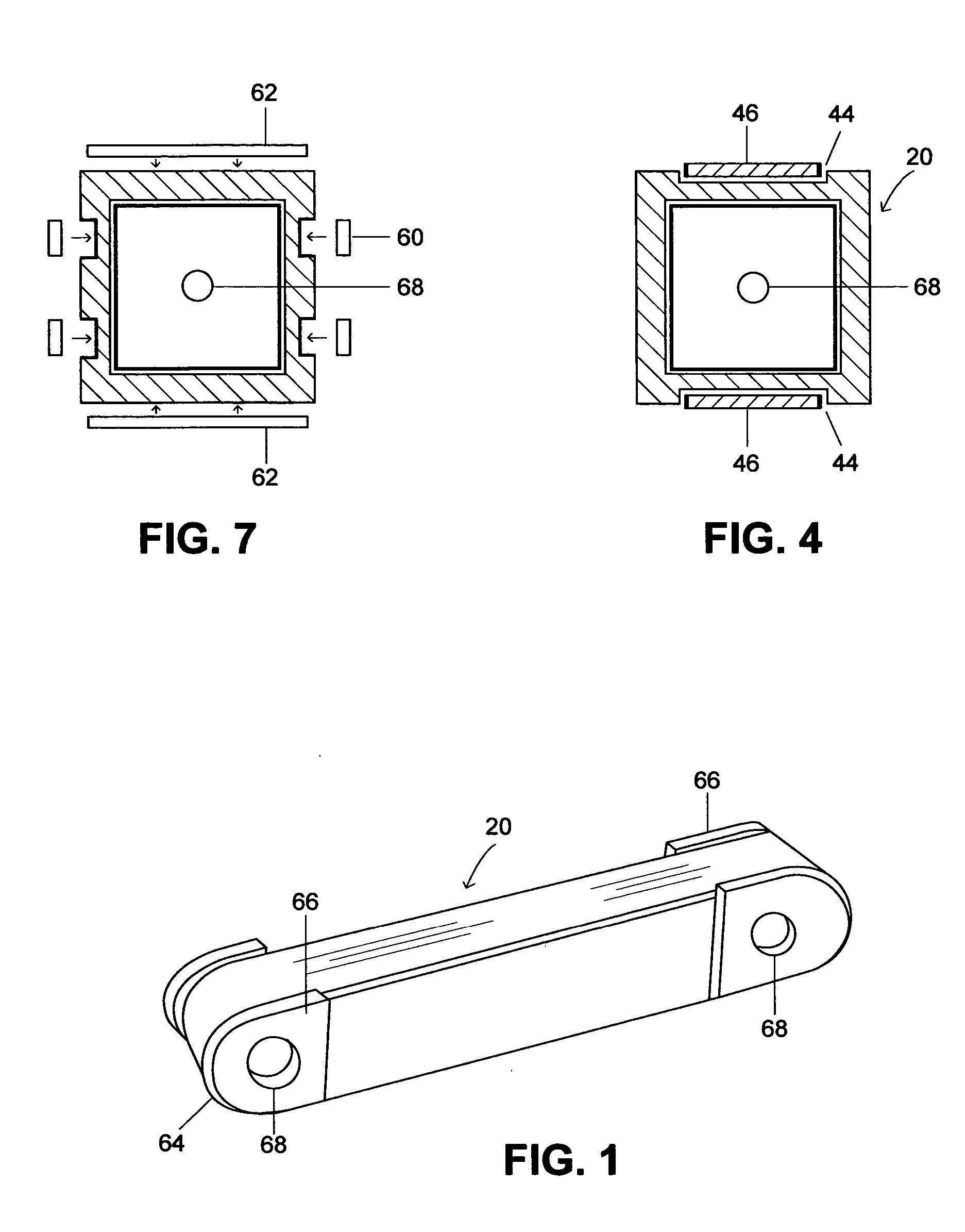

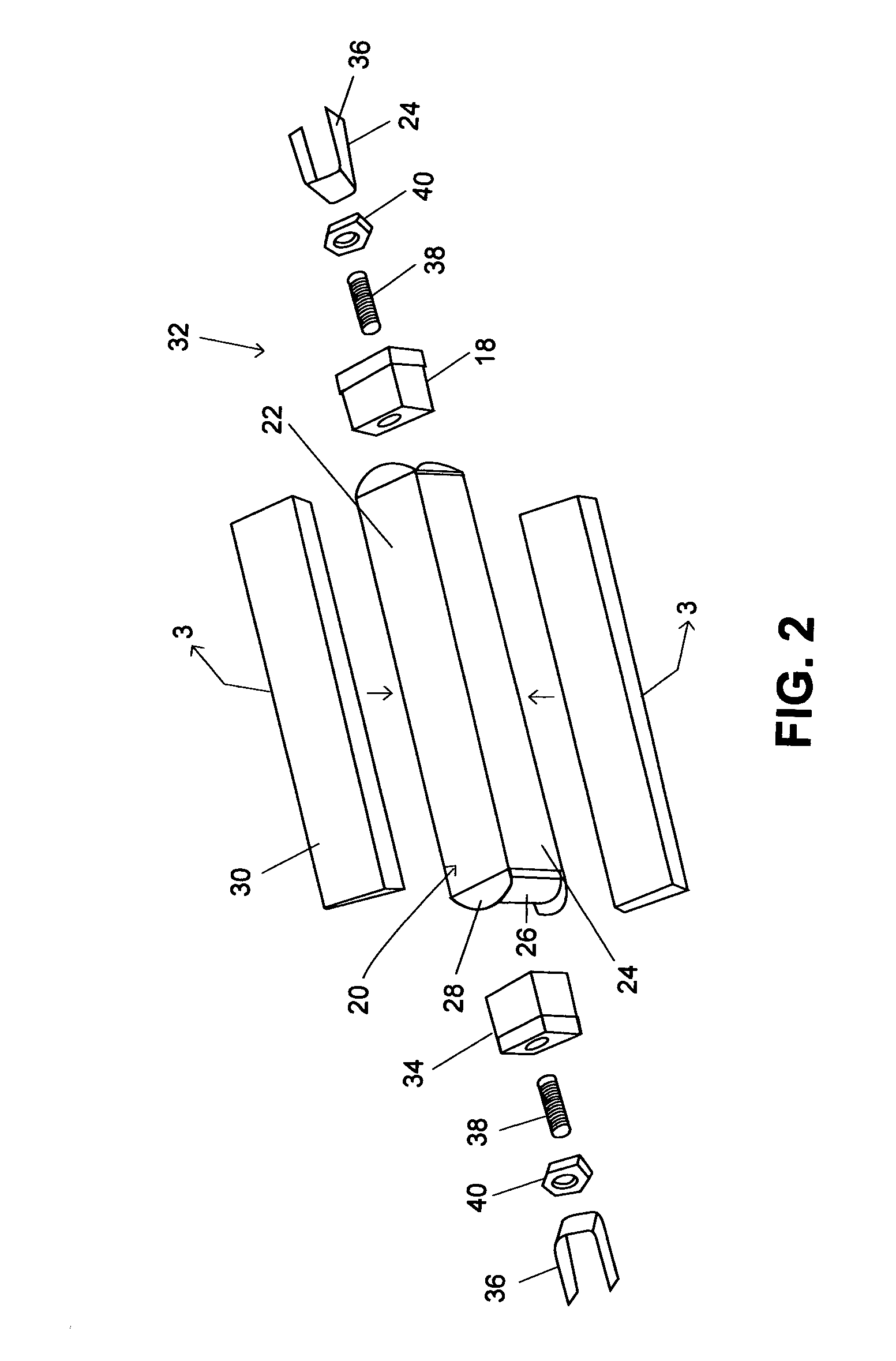

Multi-piece connecting rod

InactiveUS20100260631A1Reduce weightEasy to transportConnecting rod bearingsConnecting rodsLinear motionEngineering

A reciprocating pump assembly having a pump within a housing. The pump having a crankshaft that rotates and a crosshead that is connected to a plunger via a pony rod. The plunger pumps fluid through cylinders in the pump. A connecting rod connects at one end to the crankshaft and at another end to the crosshead to translate the crankshaft's rotational movement into linear movement of the crosshead and thereby the plunger. The connecting rod is fabricated from multiple pieces, with the body of the connecting rod fabricated out of light weight aluminum and the end connected to the crosshead fabricated out of steel. The steel end of the connecting rod can withstand the stress at the crosshead. The lighter weight of the connecting rod lightens the weight of the pump and its transportation is easier and less costly.

Owner:WEIR SPM

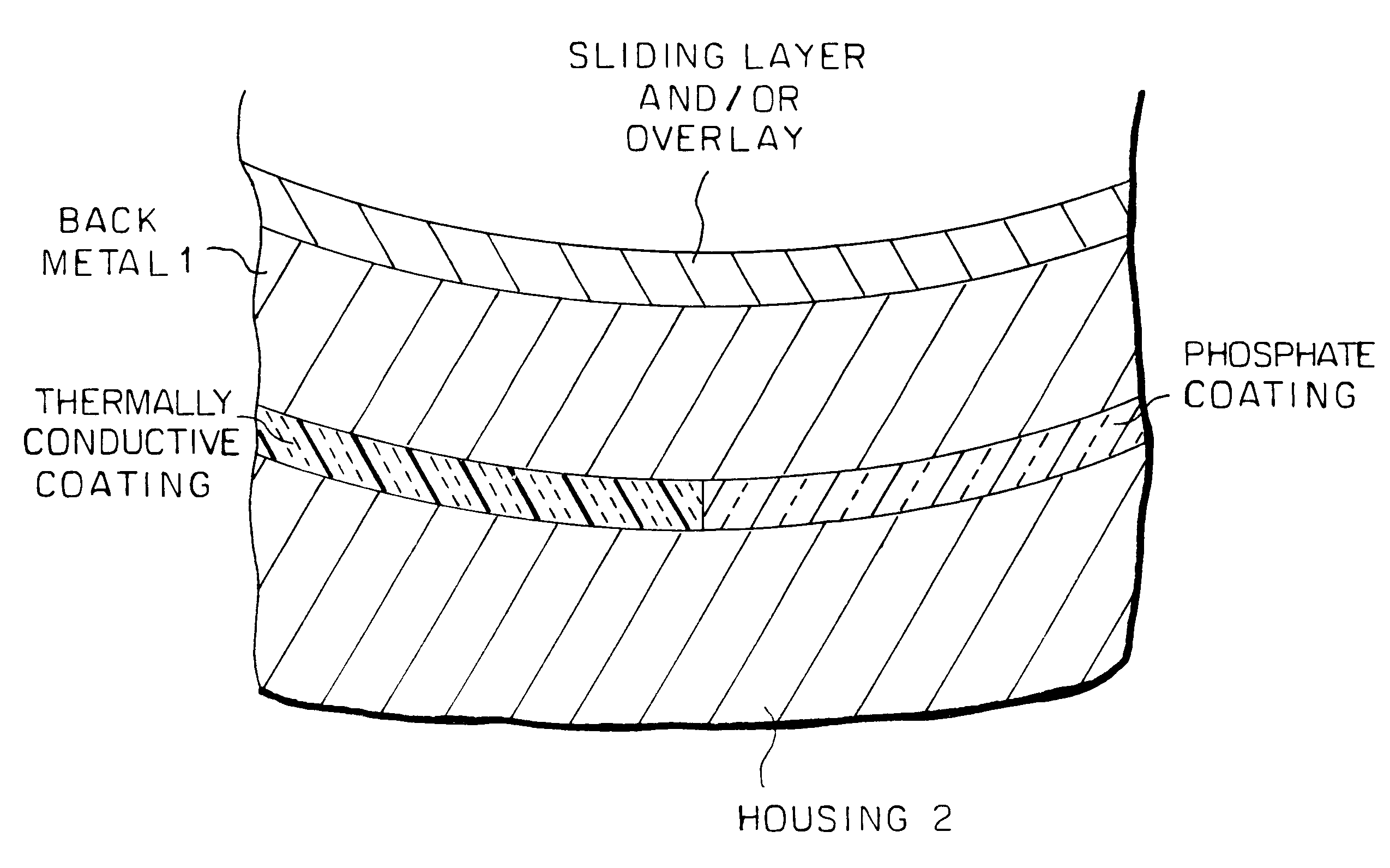

Sliding bearing and sliding bearing structure

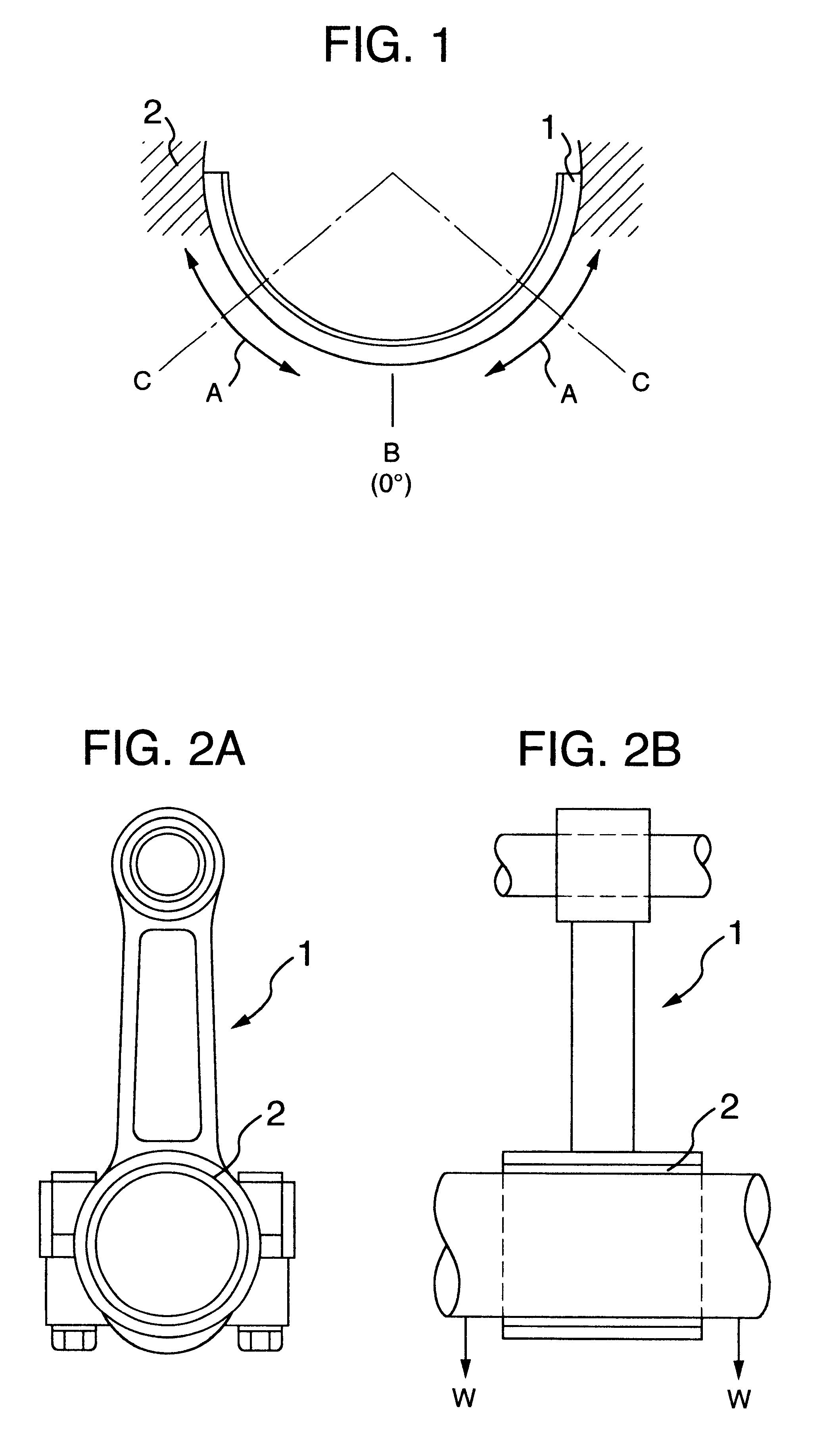

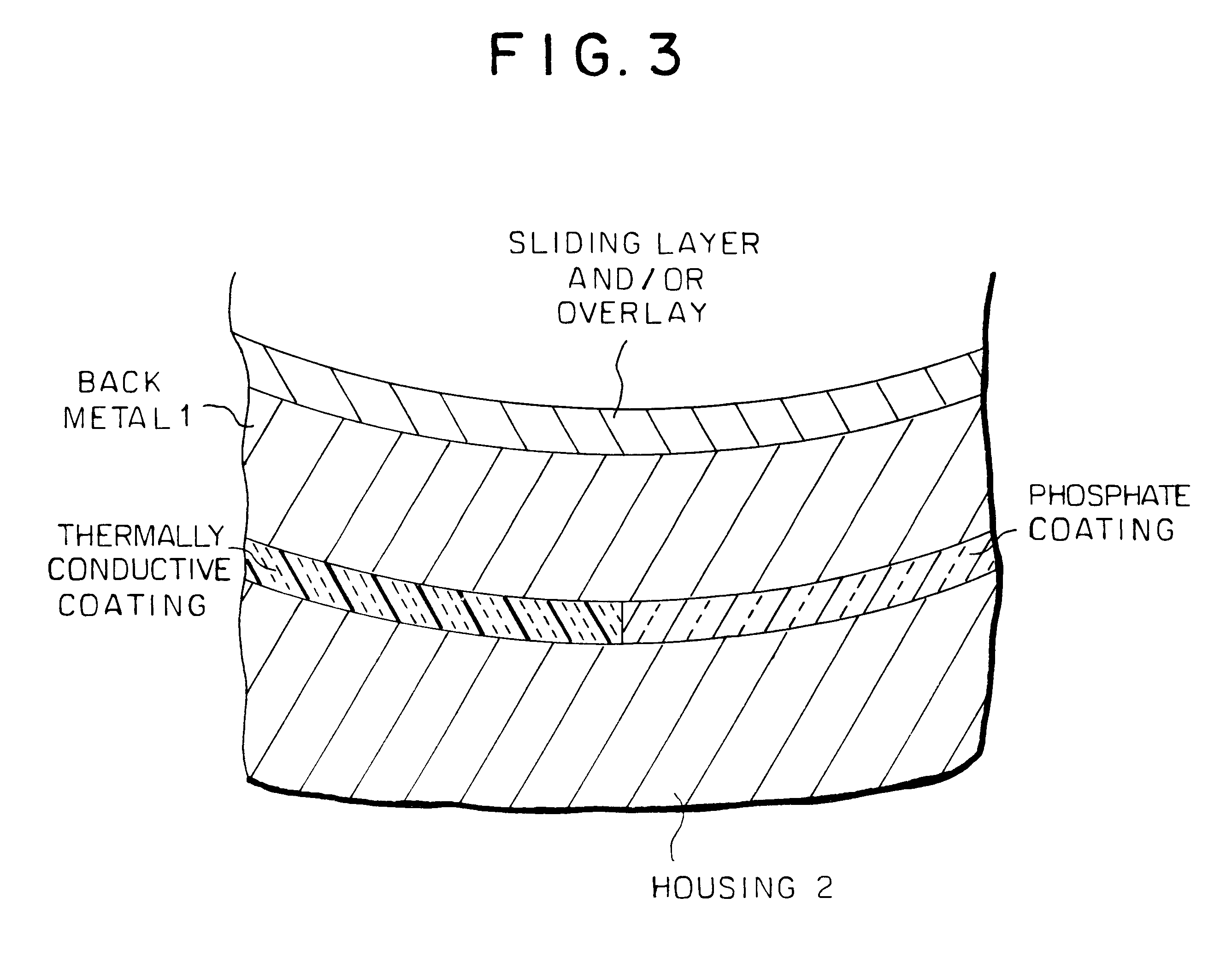

InactiveUS6357918B1Improve the immunityGood anti-occlusion performanceConnecting rod bearingsCrankshaft bearingsElectrical conductorFretting wear

There is disclosed a sliding bearing provided with a sliding bearing layer and a back metal layer bonded to the outer face of the sliding bearing layer, the back face of which back metal layer being coated with a phosphate coating at a portion where fretting wear is apt to occur while coated with a coating of a thermally good conductor at another portion where no phosphate coating is provided, whereby seizure resistance as well as fretting resistance is improved because the dispersing of heat can be improved by the coating of the thermally good conductor.

Owner:DAIDO METAL CO LTD

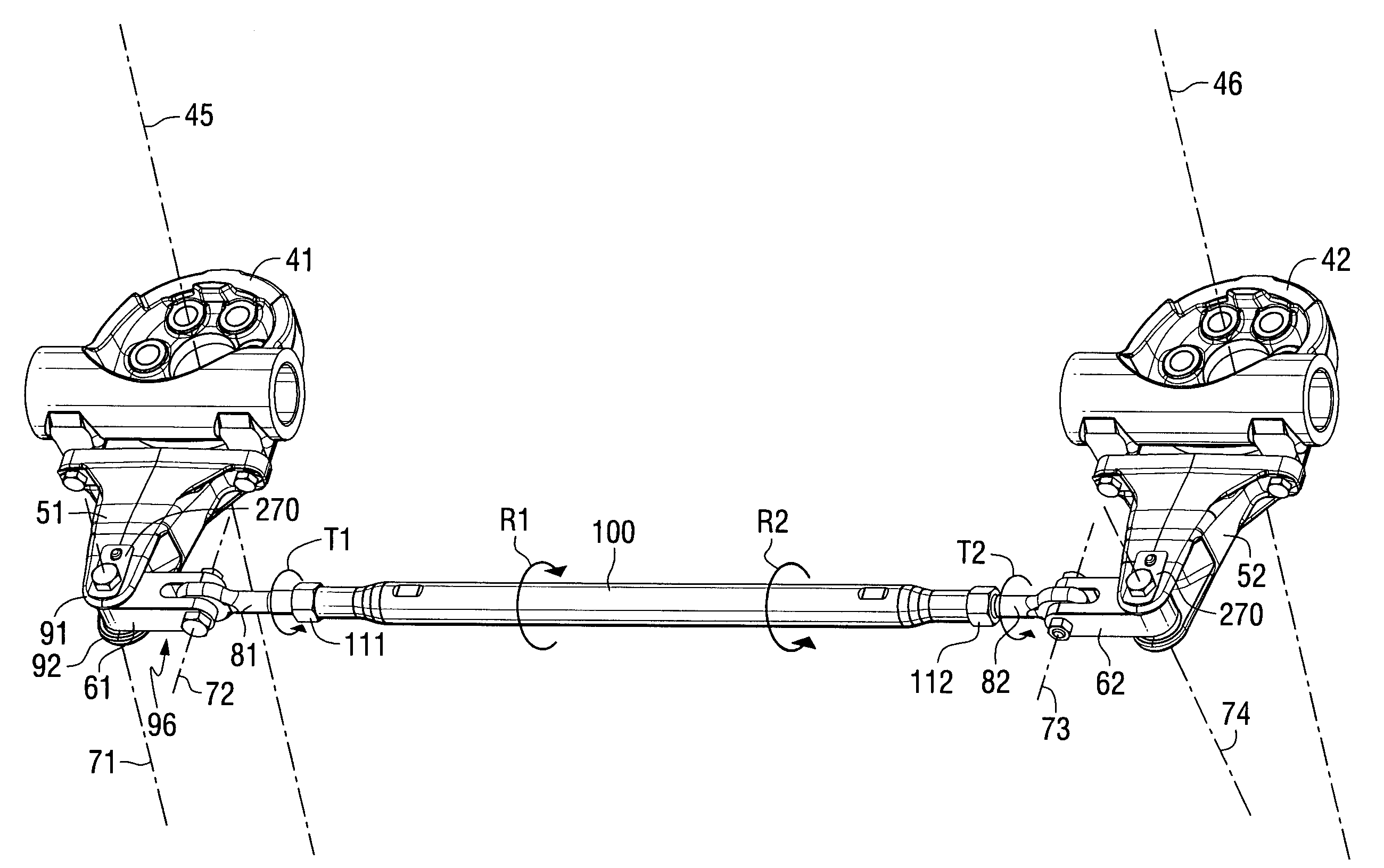

Tandem connection system for two or more marine propulsion devices

A connection system for connecting two or more marine propulsion devices together provides a coupler that can be rotated in place, without detachment from other components, to adjust the distances between the tie bar arms. In addition, the use of various clevis ends and pairs of attachment plates on the components significantly reduces the possibility of creating moments when forces and their reactions occur between the various components.

Owner:BRUNSWICK CORPORATION

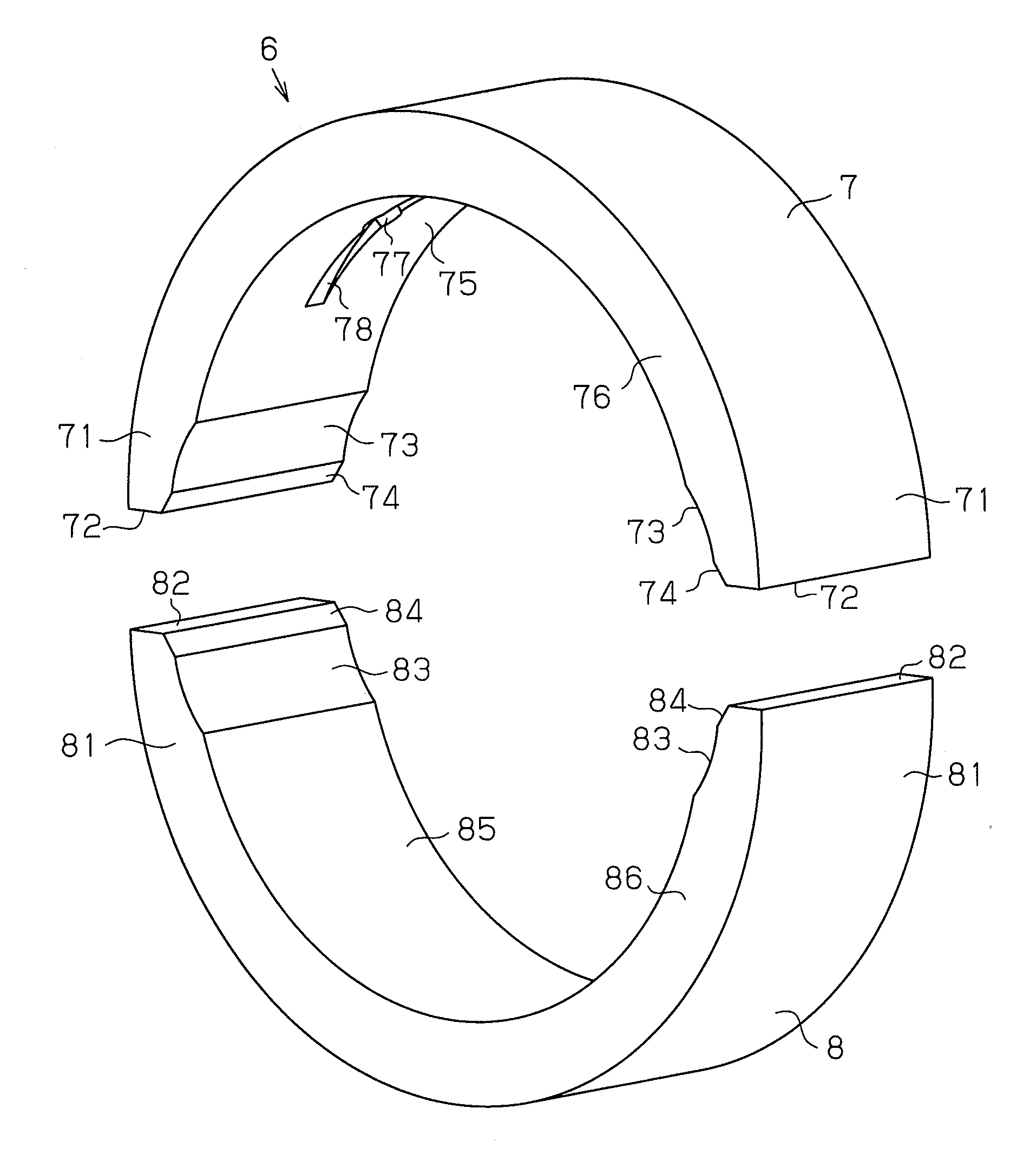

Split outer race, split rolling bearing using same, and manufacturing method for split outer race

ActiveUS20050265644A1Improve accuracyImprove manufacturing yieldConnecting rod bearingsShaftsRolling-element bearingBand shape

Owner:JTEKT CORP

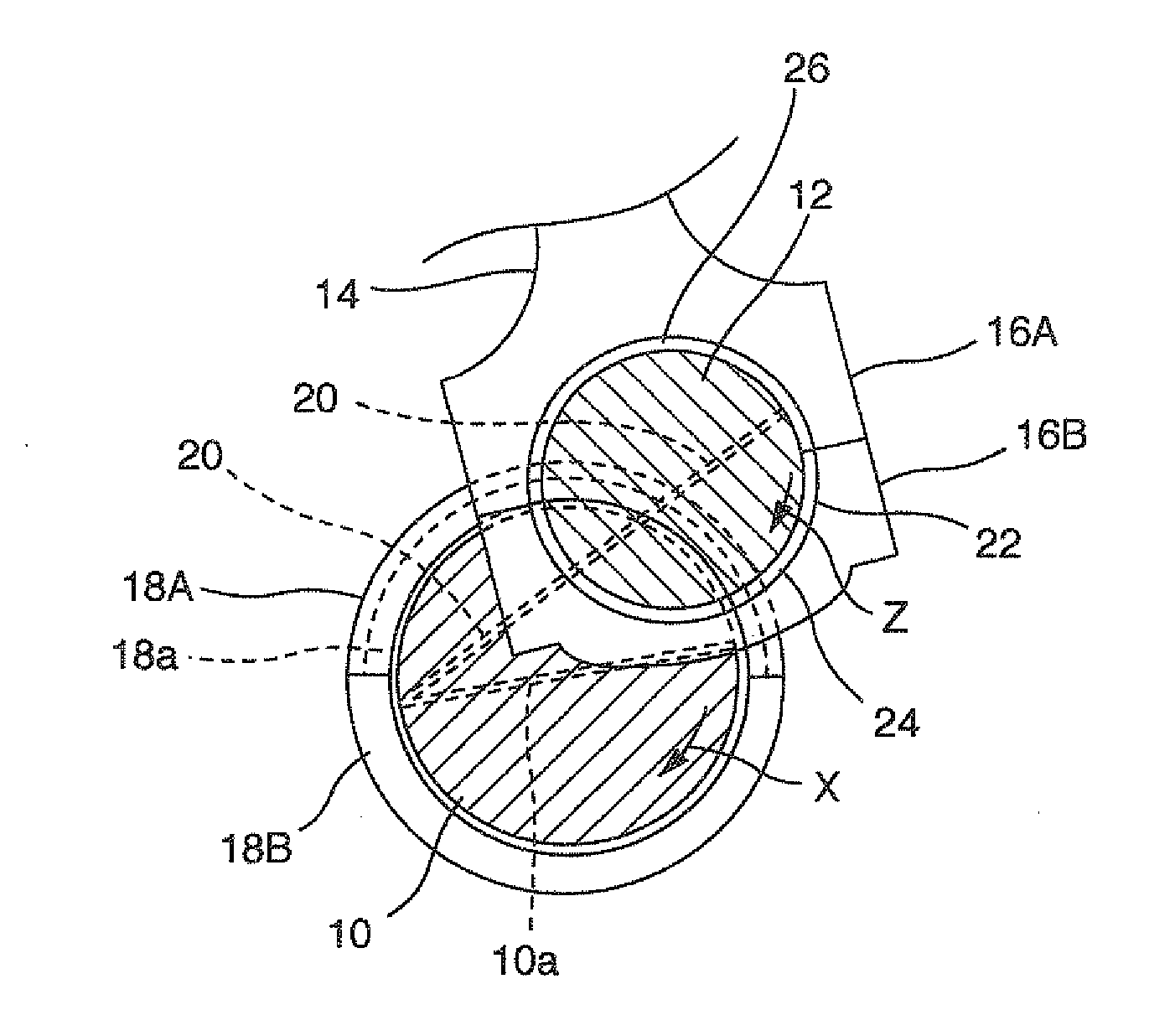

Sliding bearing for internal combustion engine and sliding bearing device

InactiveUS20100119181A1Increase stiffnessInhibition effectConnecting rod bearingsCrankshaft bearingsHigh stiffnessEngineering

Disclosed is a sliding bearing consisting of a pair of semi-cylindrical bearings for supporting a crankshaft or a crank pin in an internal combustion engine. The sliding bearing is incorporated in a split-type bearing housing. One of the semi-cylindrical bearings being incorporated in at least one of the pair of housing halves, which one housing half has a relatively higher stiffness, is provided with a number of circumferential grooves on an inner surface of the semi-cylindrical bearing so as to extend circumferentially along the inner surface of the semi-cylindrical bearing. The circumferential grooves existing at least one circumferential end region of the inner surface of the semi-cylindrical bearing have a depth of not less than 10 μm, the circumferential end region including a circumferential bearing end face orientating a direction opposite to the rotation direction of the shaft or pin.

Owner:DAIDO METAL CO LTD

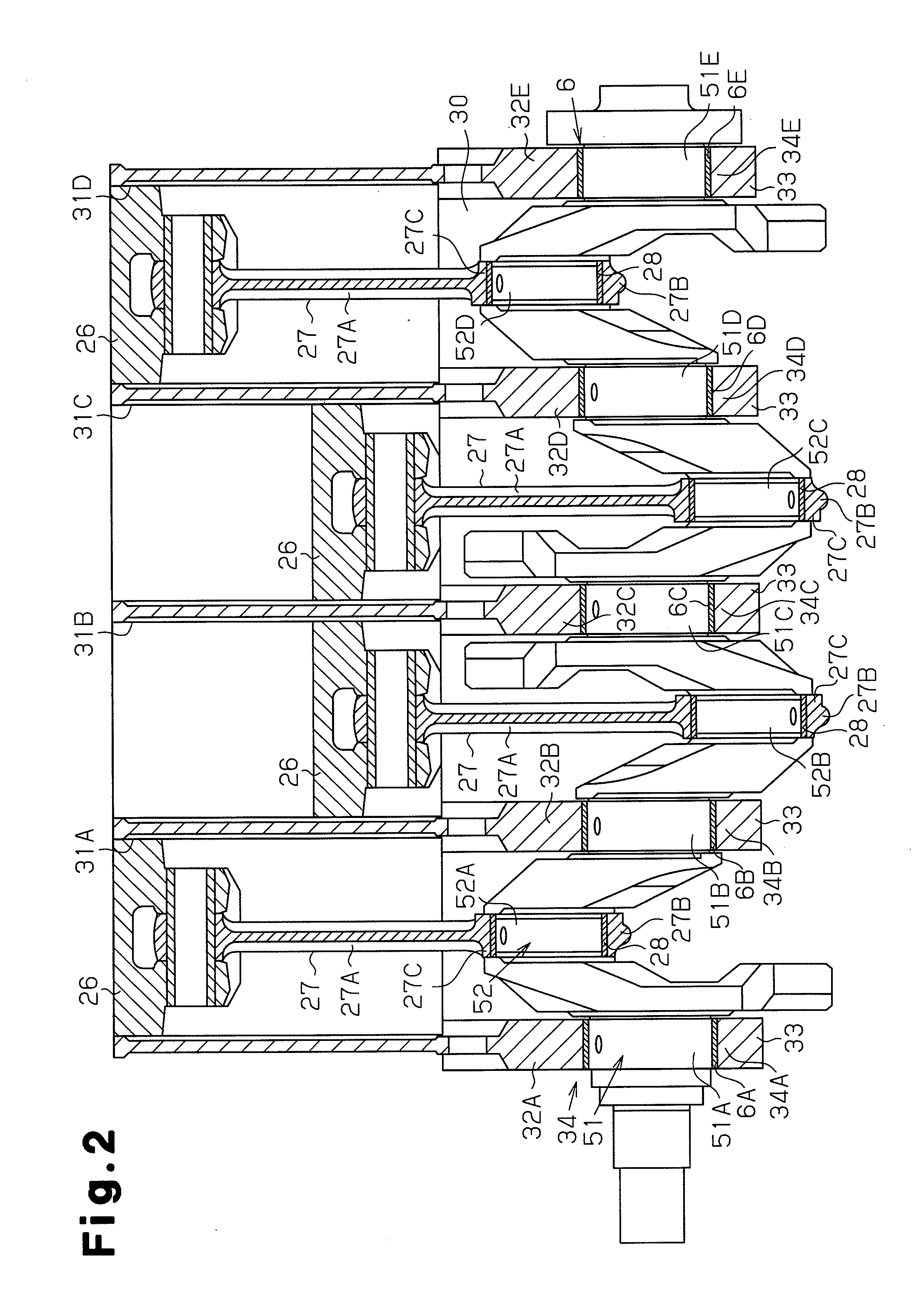

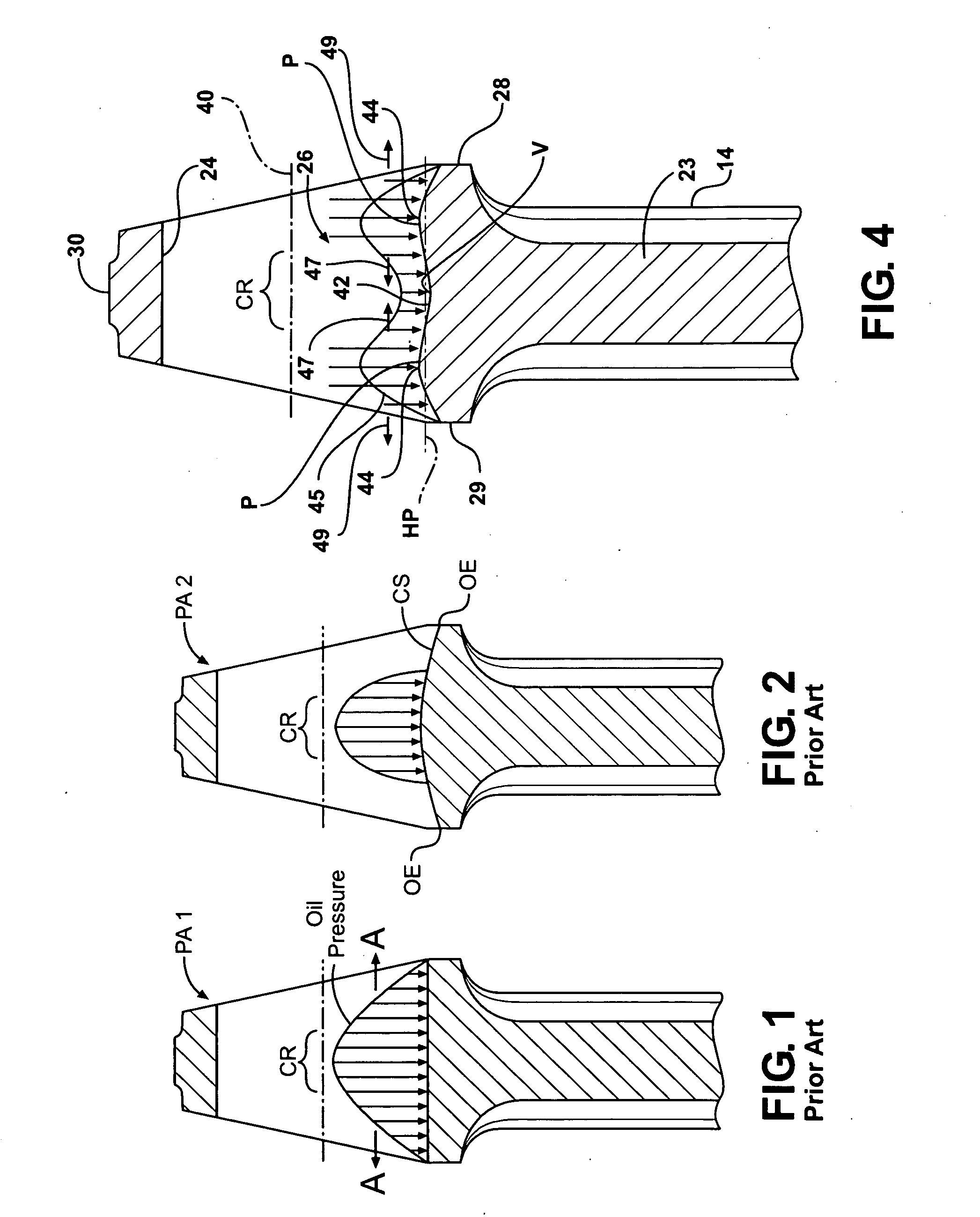

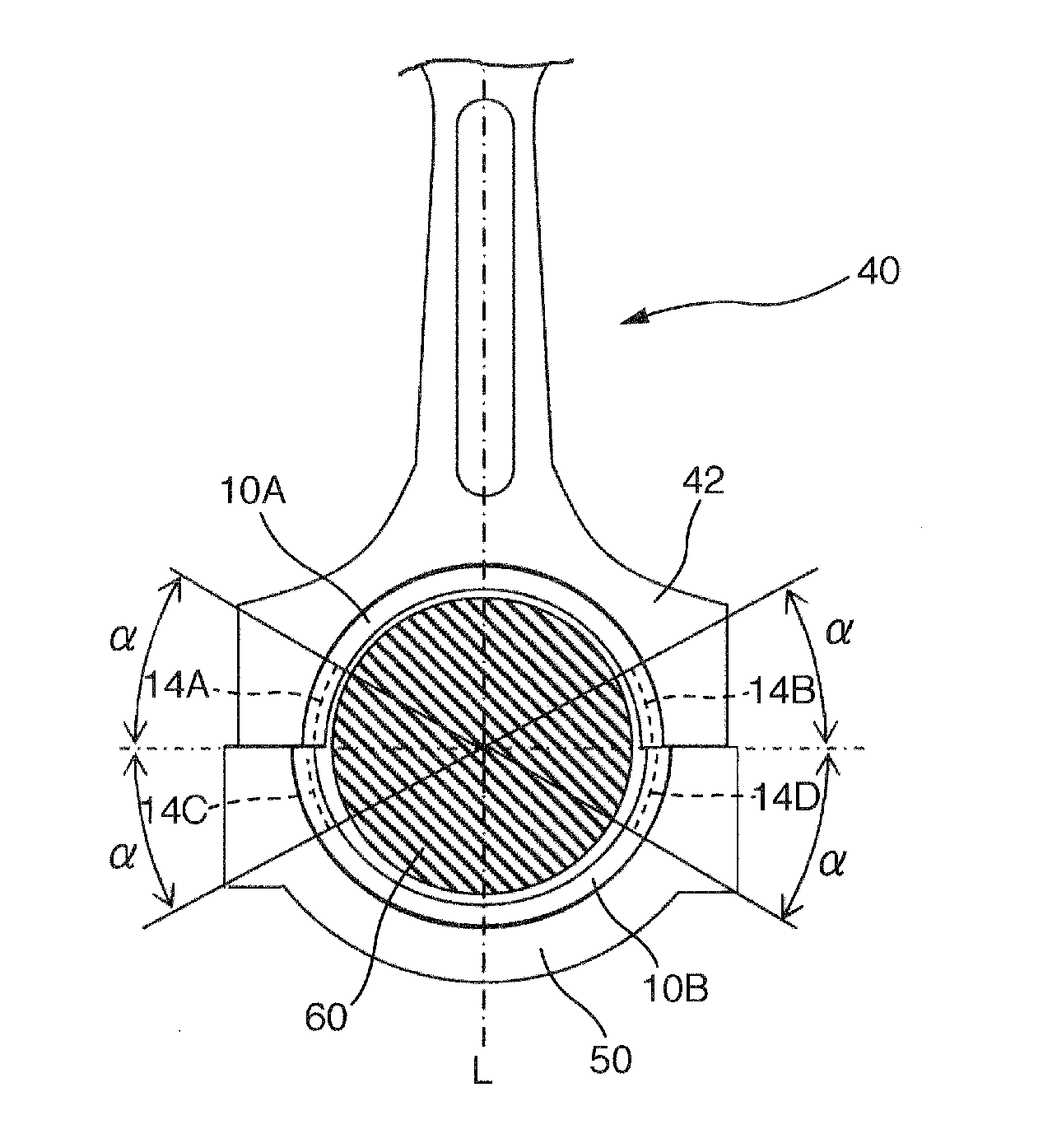

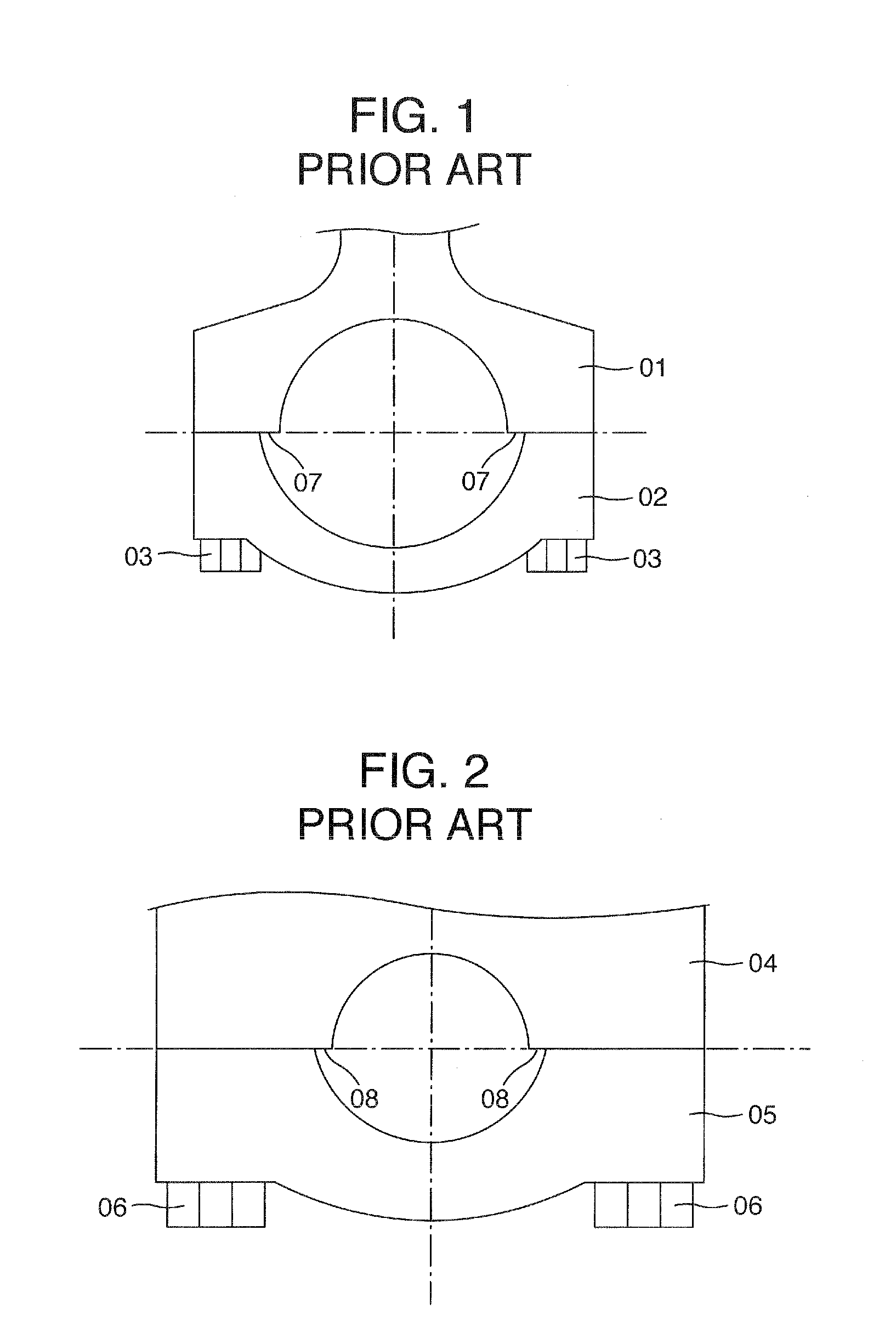

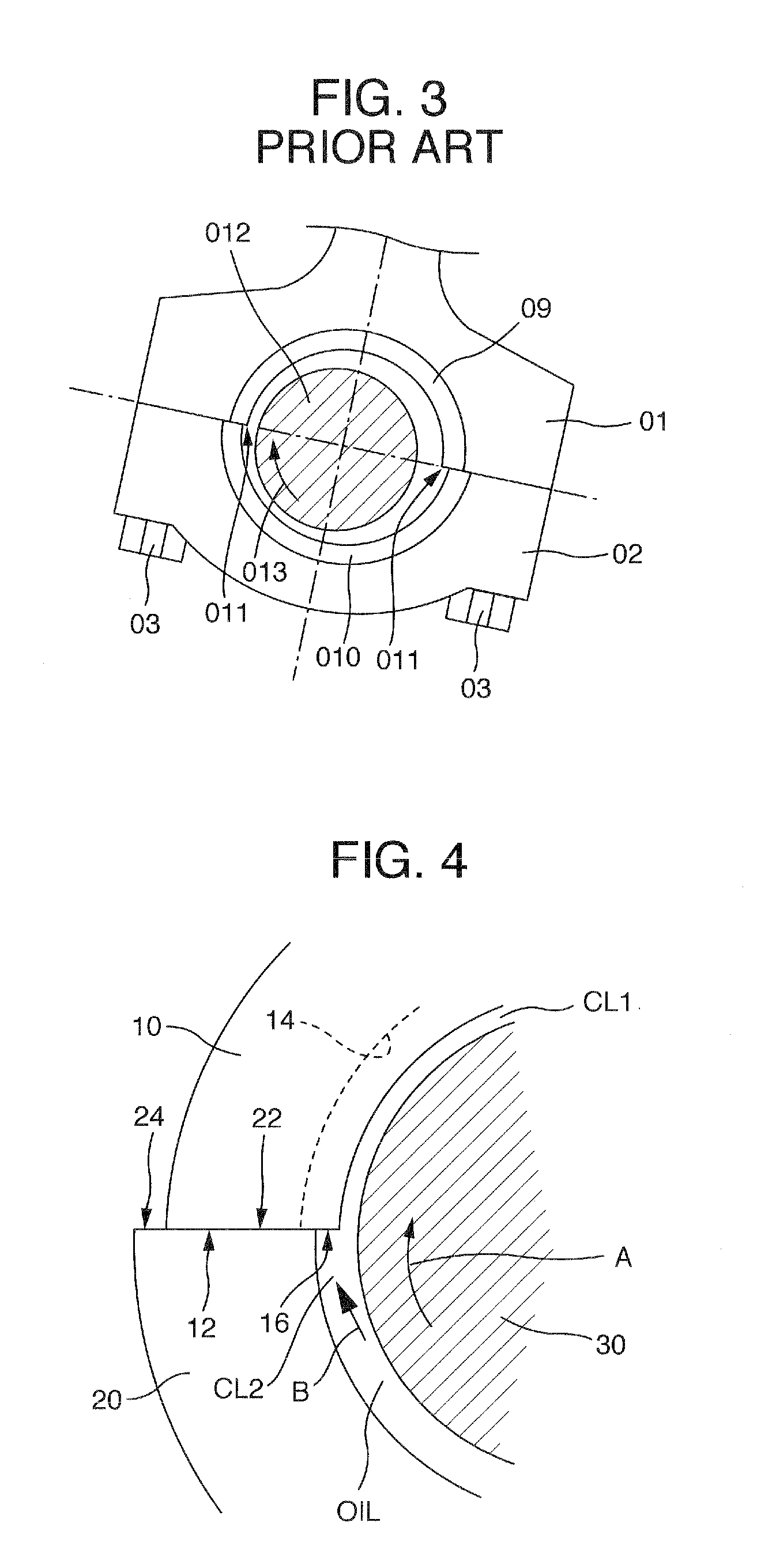

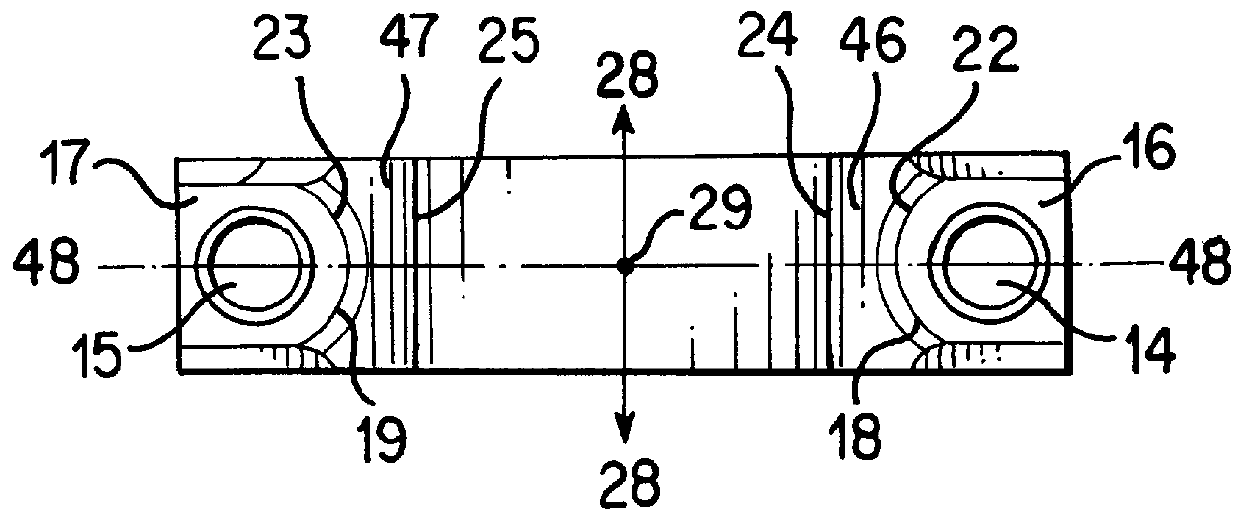

Connecting rod bearing for internal combustion engines and connecting rod bearing device

ActiveUS20100316313A1Improve discharge performanceConnecting rod bearingsBearing componentsCombustionExternal combustion engine

Disclosed is a connecting rod bearing for crankshafts having a pair of semi-cylindrical bearings. Circumferential grooves (CG) on the bearing inner surface extend from each circumferential end toward the circumferential center within a maximum circumferential angle of 45 degrees and divide reduced wall thickness region into two sections. Axial grooves communicating with the CG are provided along abutted ends of the bearings. Circumferential length of the CG is larger than that of the reduced region. Depth of the CG becomes gradually smaller from the end toward the center. Width of the CG is not smaller than one-quarter of a diameter of lubricant-oil outlet of internal lubricant-oil passage in a crankpin and less than the diameter. Cross-sectional area of the CG is larger than that of the axial grooves at a connection portion thereof.

Owner:DAIDO METAL CO LTD

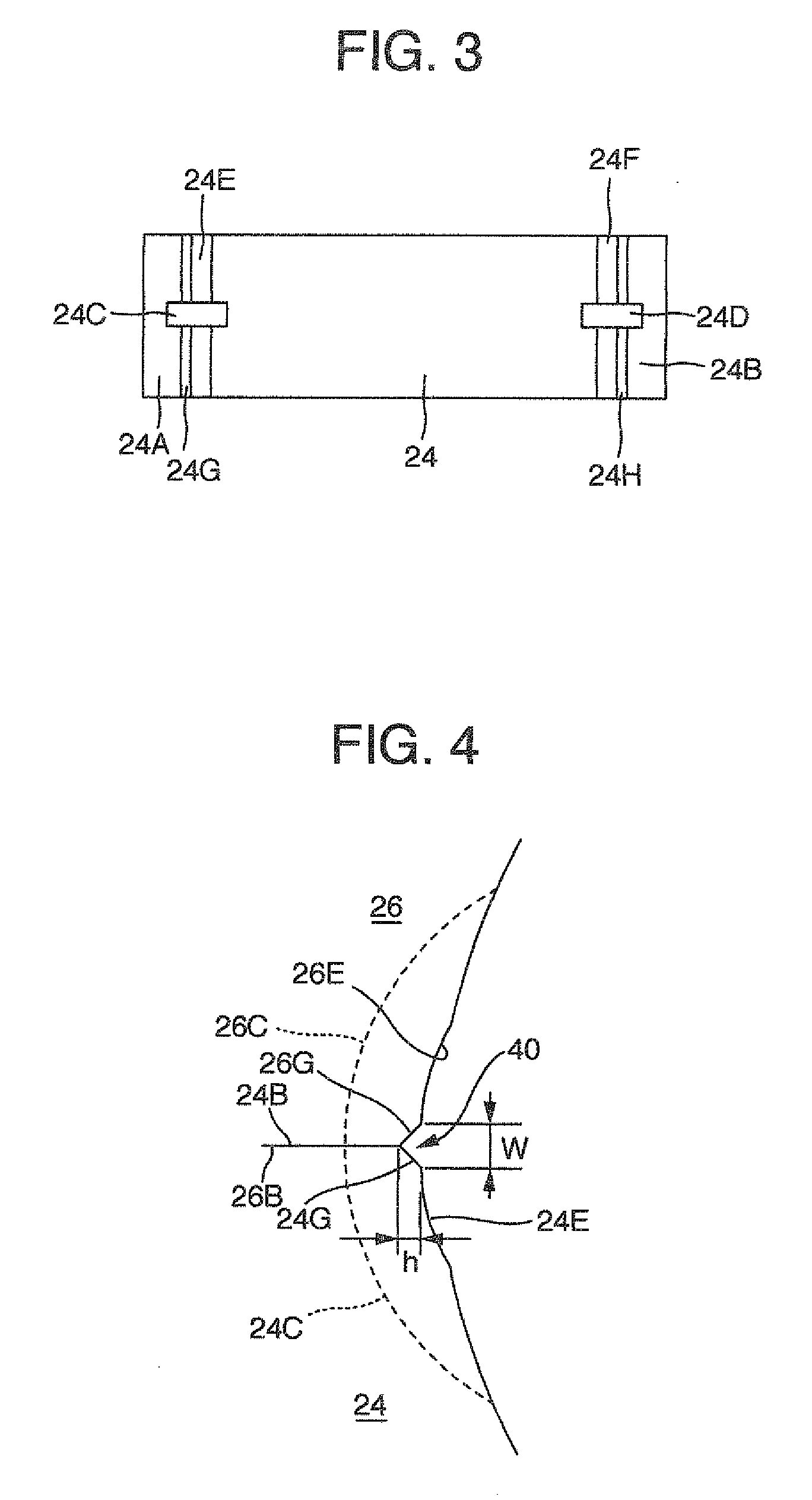

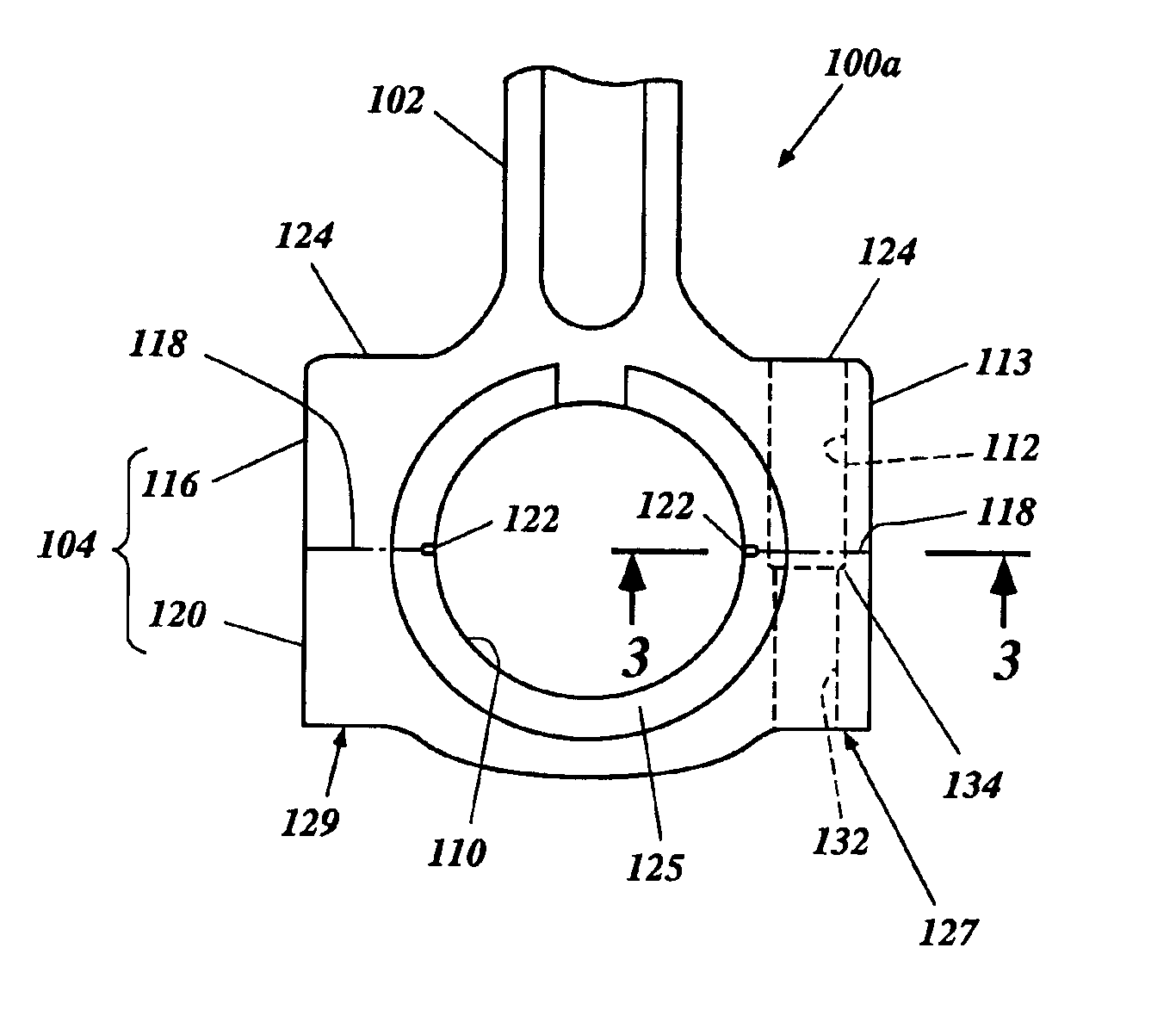

Fracture split method for connecting rod

A connecting rod is formed using a method that includes providing a connecting rod blank. The connecting rod blank has a rod section disposed between a big end and a small end. The big end has a first hole generally sized to receive a crankpin of a crankshaft and at least one second hole generally sized to receive a bolt, wherein the axes of the first and second holes are generally normal to each other. The big end of the connecting rod has a dividing plane that extends through both the first and second holes. The connecting rod blank is processed by hardening at least the big end to a sufficient depth such that a first region of the big end lying between the first and second holes at the dividing plane is hardened, while leaving a substantial second region of the big end at the dividing plane generally unhardened. The connecting rod blank is further processed by splitting the big end along the dividing plane to produce a rod part fracture surface and a cap part fracture surface.

Owner:YAMAHA MOTOR CO LTD

Connecting rod with lubricant tube

InactiveUS20050076858A1Easy to adaptLess oil pump demandConnecting rod bearingsConnecting rodsEngineeringLubricant

Owner:GM GLOBAL TECH OPERATIONS LLC

Automobile connecting rod

A light-weight bearing cap for attaching a connecting rod to a journal of a crankshaft pin has two longitudinally extending shoulders separated by an arcuate span conforming to the shape of the journal The shoulders are adapted to receive fasteners which connect mating surfaces of the connecting rod to those of the bearing cap. Mass is conserved by ensuring that the inner and outer arcuate surfaces are shaped as arcs of non-concentric circles such that the maximum thickness of the span occurs at the bisecting points of the respective arcs and the minimum thickness of the span occurs in the region between the shoulders and the maximum thickness. The thickness where the machined surface on the shoulder is located is greater than in the region between the shoulder and the region of maximum thickness.

Owner:HONDA MOTOR CO LTD

Split outer race, split rolling bearing using same, and manufacturing method for split outer race

ActiveUS7270484B2Suppress and prevent and noiseSuppress and prevent vibrationConnecting rod bearingsShaftsRolling-element bearingEngineering

Owner:JTEKT CORP

Method of and apparatus for cracking connecting rod

InactiveUS20050011925A1Simplified and inexpensive overall apparatus structureIncrease productivityConnecting rod bearingsConnecting rodsEngineeringFlange

A preload is applied to a wedge pressed in between a pair of spreaders by a preloading mechanism to press the spreaders against an inner surface of a joint hole defined in a larger end of a connecting rod. While the spreaders are pressed against the inner surface of the joint hole, a movable table with weights placed thereon is caused to drop into impingement against a flange coupled to an end of a shaft. The shaft is pulled downwardly to apply an impact load to the wedge, which is coupled to the shaft, in the direction in which the wedge is pressed in, thereby fracturing the larger end into a cap and a rod.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com