Multi-piece connecting rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

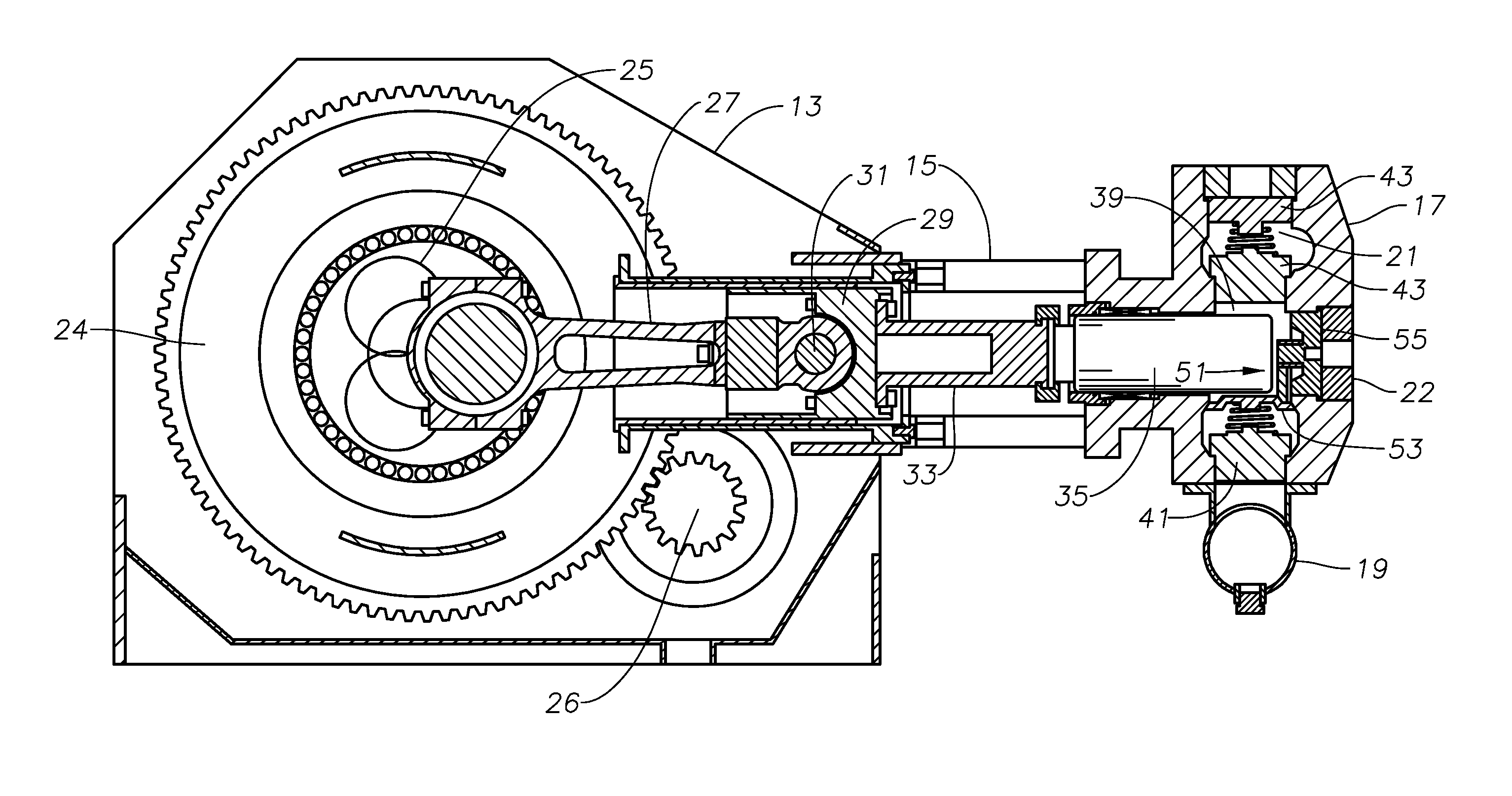

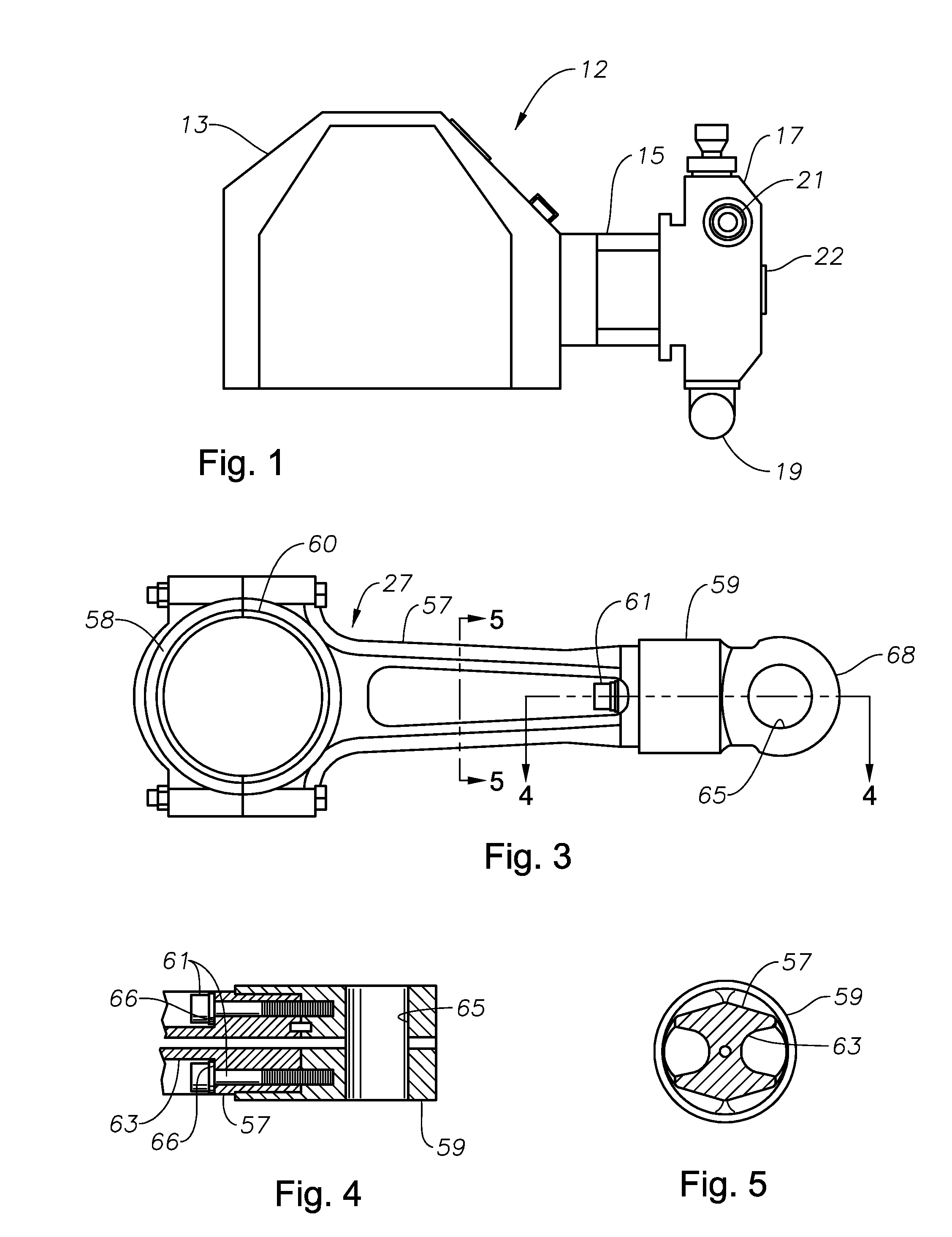

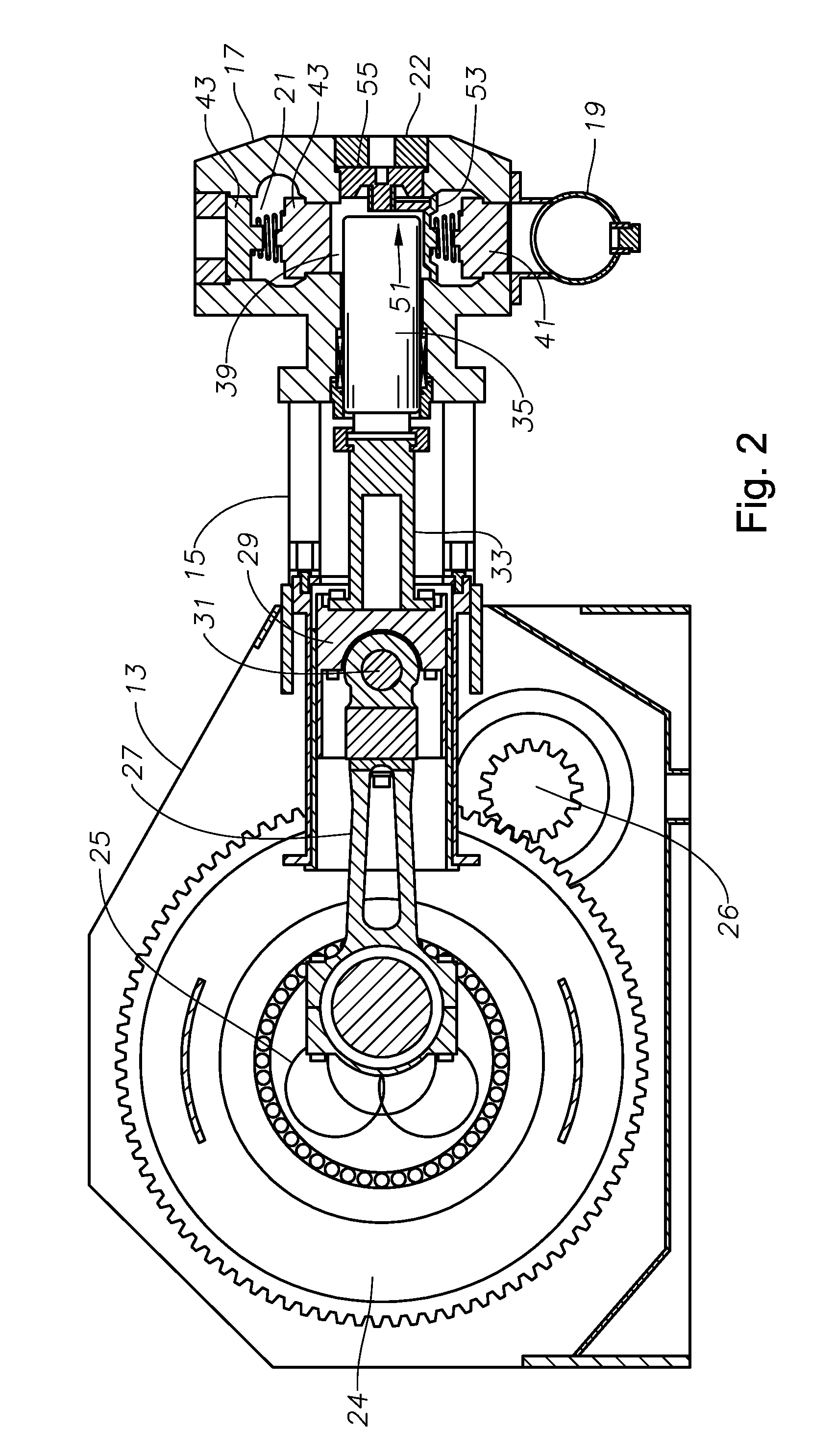

[0015]Referring to FIGS. 1 and 2, reciprocating pump assembly or pump 12 includes a crankshaft housing 13 that comprises a majority of the outer surface of reciprocating pump 12. Stay rods 15 attach to a side of crankshaft housing 13 and extend to a set of cylinders 17. Each cylinder 17 communicates with a fluid inlet 19 and a fluid outlet 21. As shown in FIGS. 1 and 2, a suction cover plate 22 connects to an end of each cylinder 17 opposite the crankshaft housing 13. Pump 12 is can be free-standing on the ground, can be mounted to a trailer that can be towed between operational sites, or mounted to a skid such as for offshore operations.

[0016]Referring to FIG. 2, a portion of reciprocating pump 12 housed within crankshaft housing 13 is shown. Crankshaft housing 13 houses a crankshaft 25, which is typically mechanically connected to a motor (not shown). The motor rotates crankshaft 25 in order to drive reciprocating pump 12 (FIG. 1). In one embodiment, crankshaft 25 is cammed so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com