Patents

Literature

82results about How to "Low stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

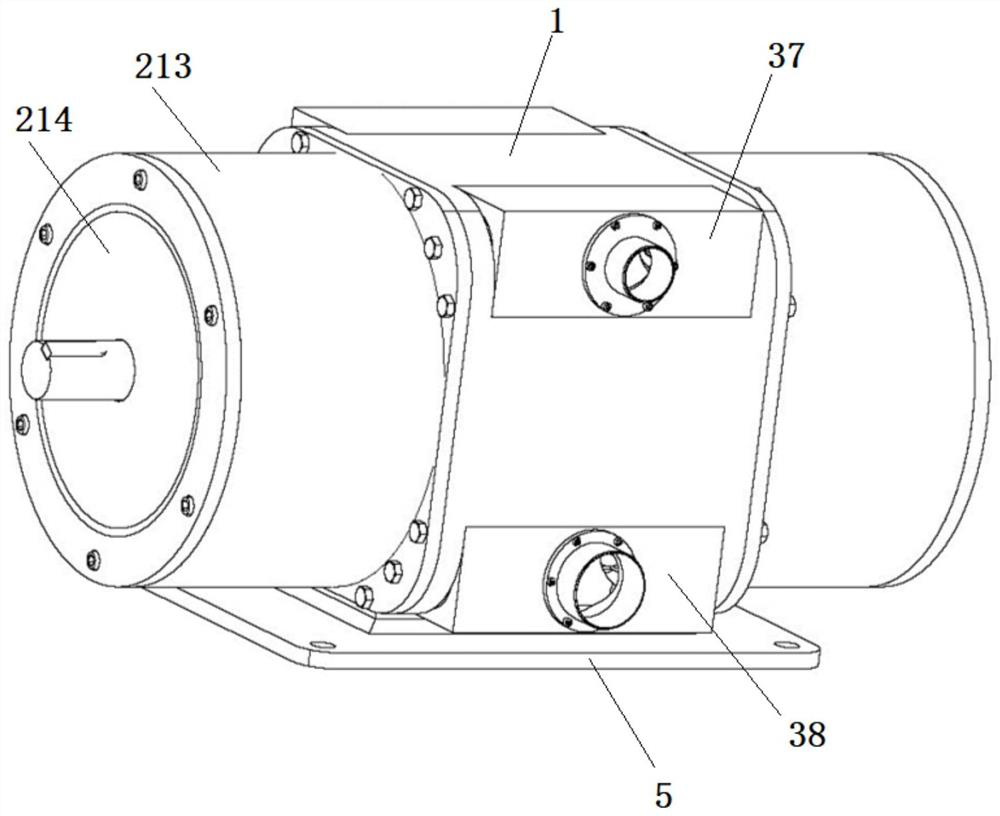

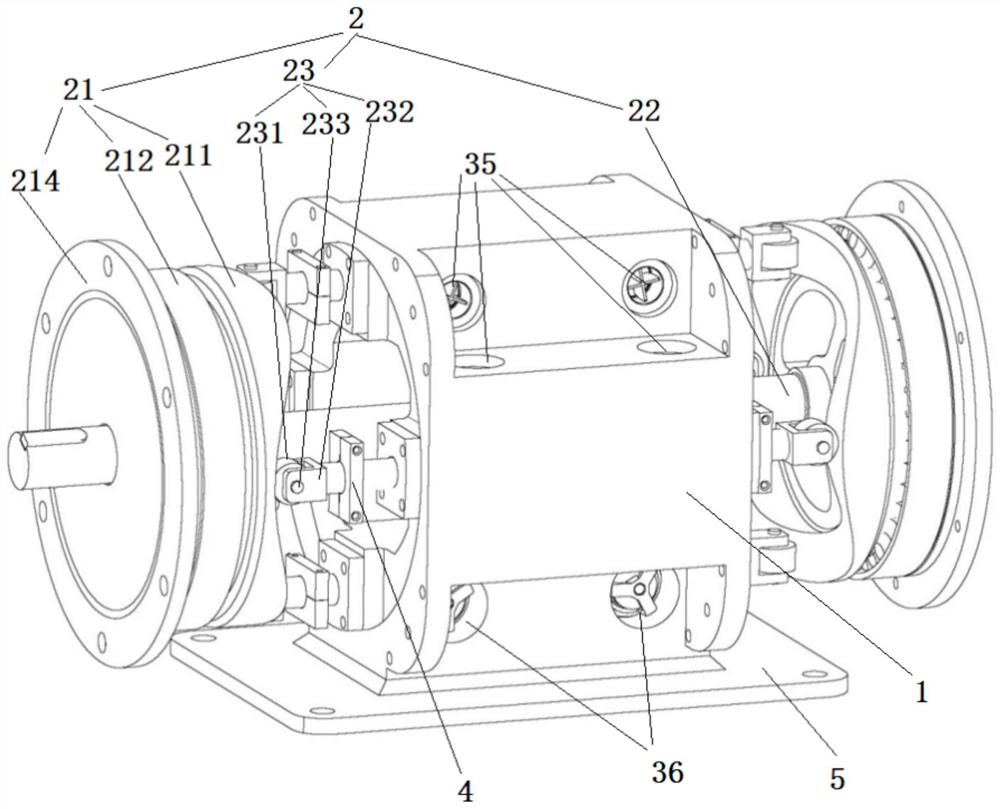

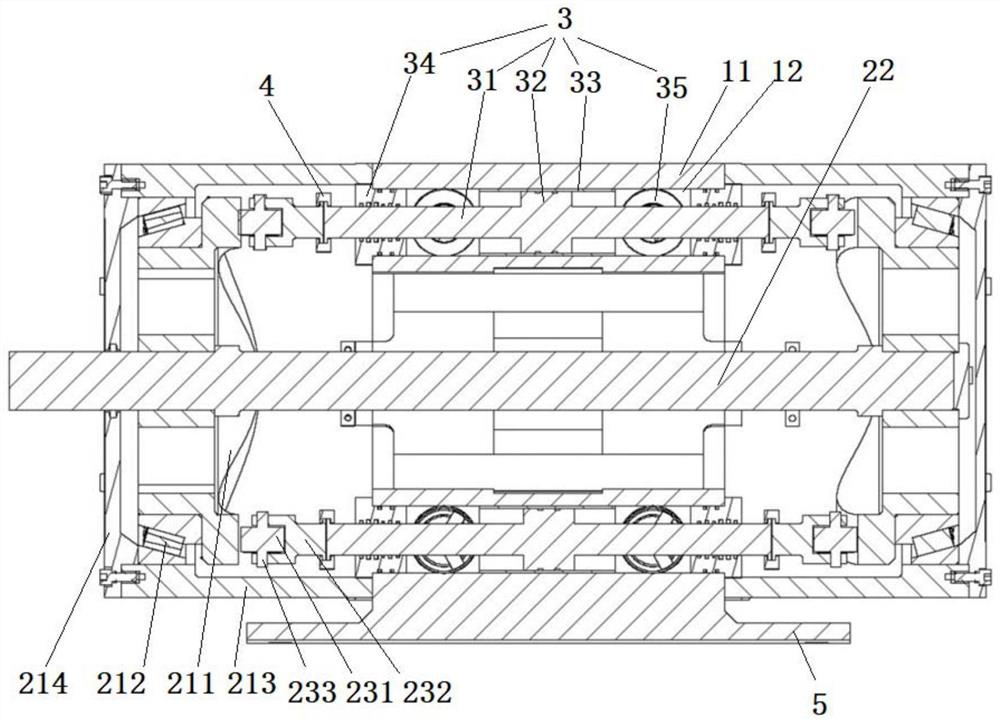

Hydraulic bidirectional pumping device

ActiveCN104612928AExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

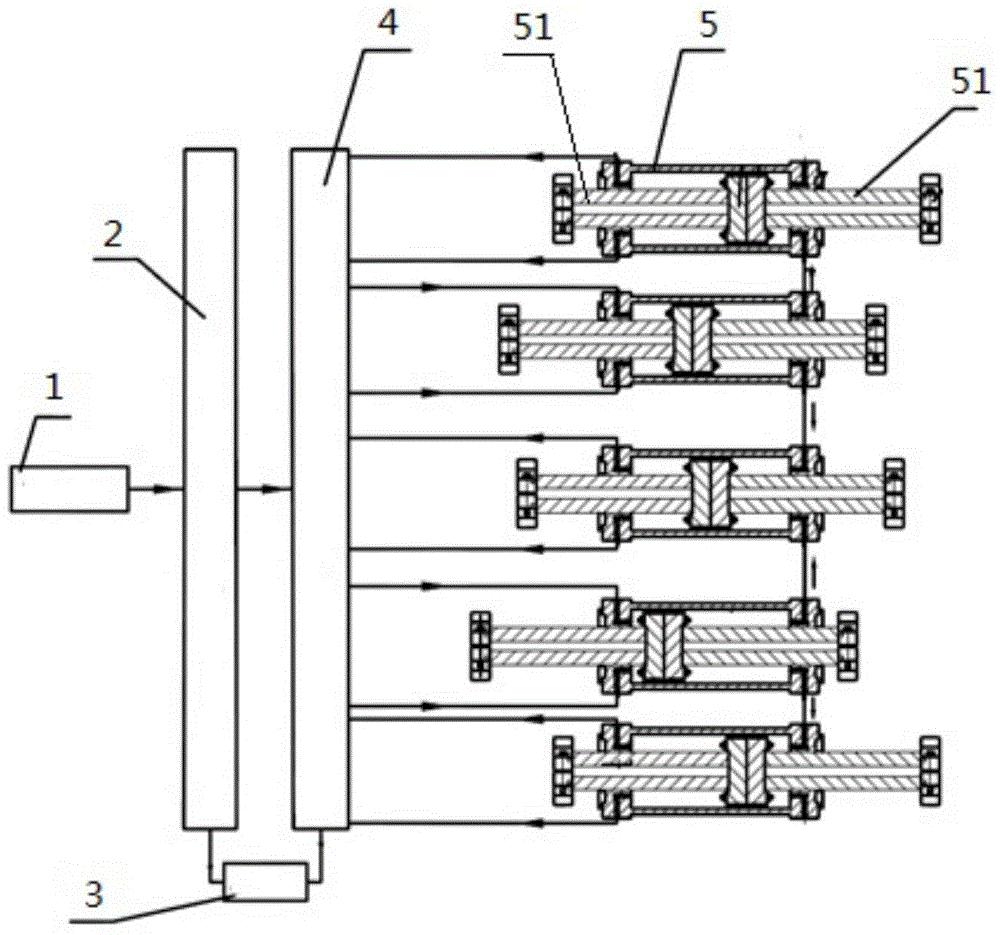

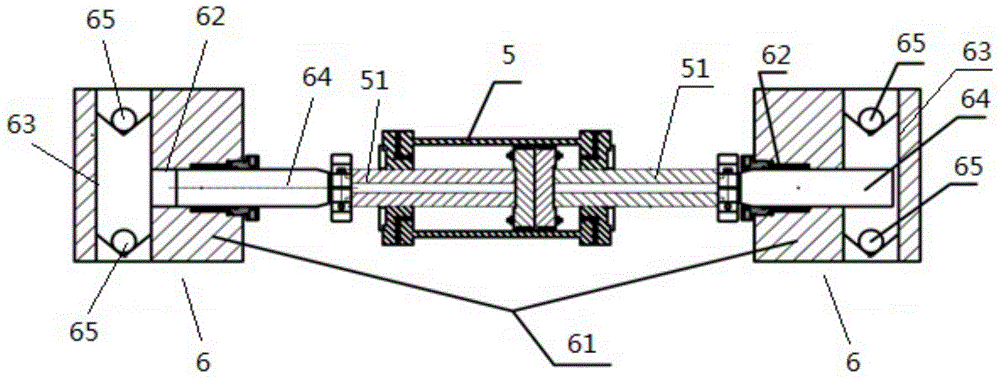

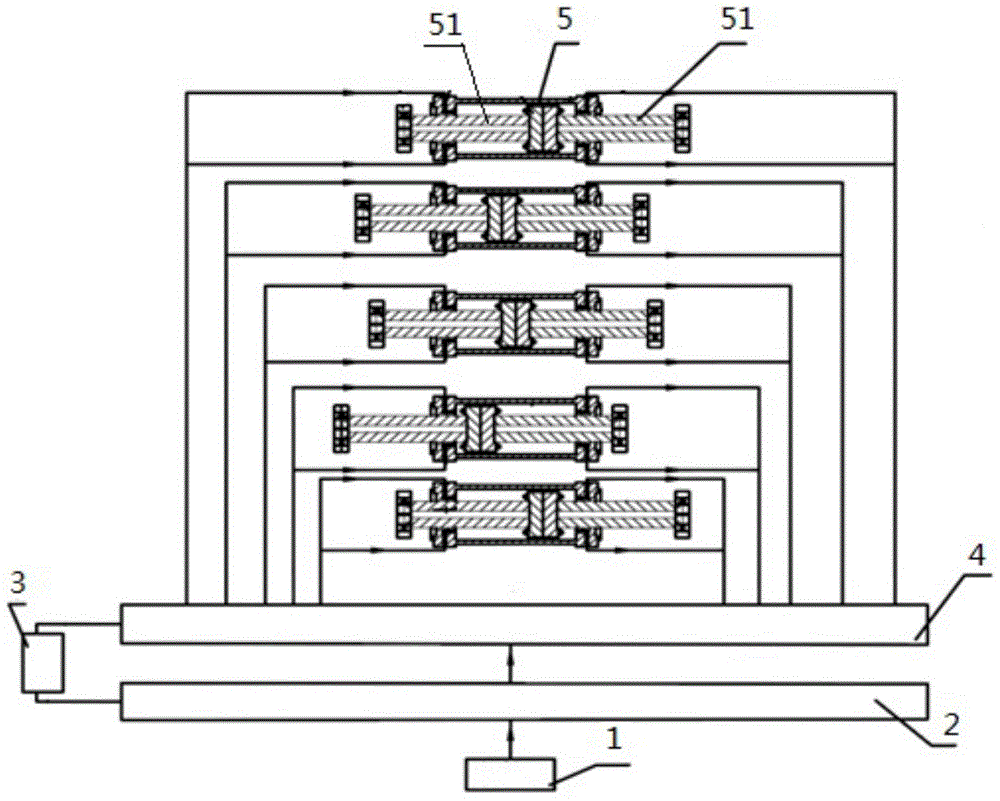

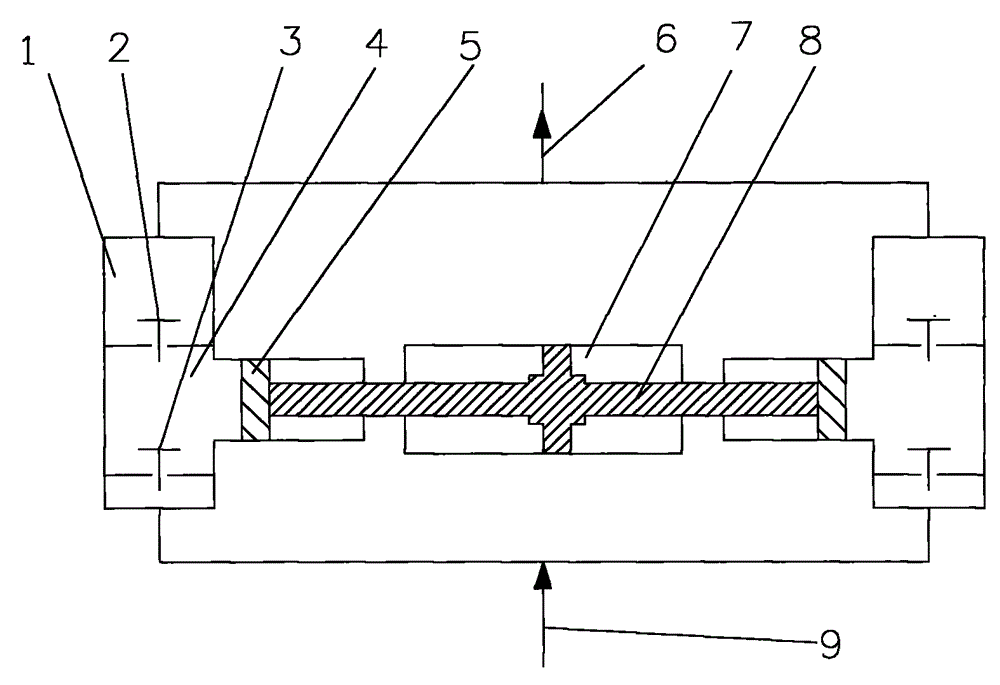

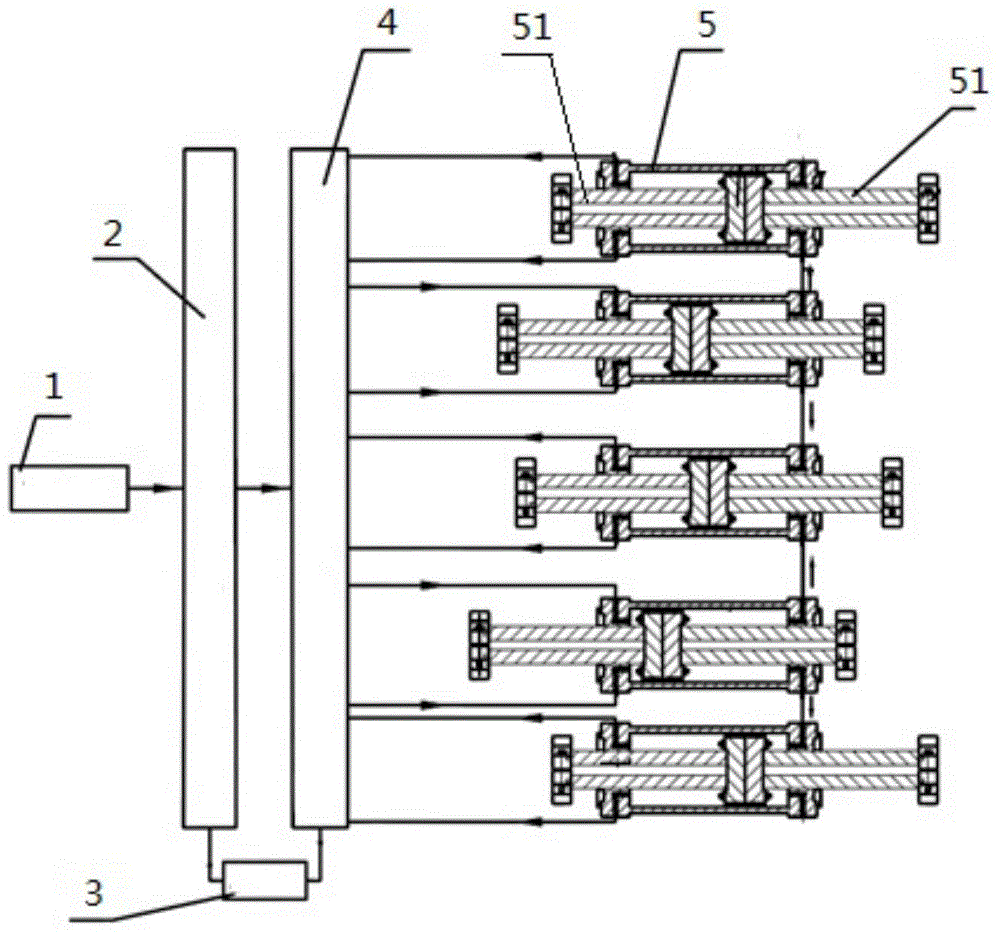

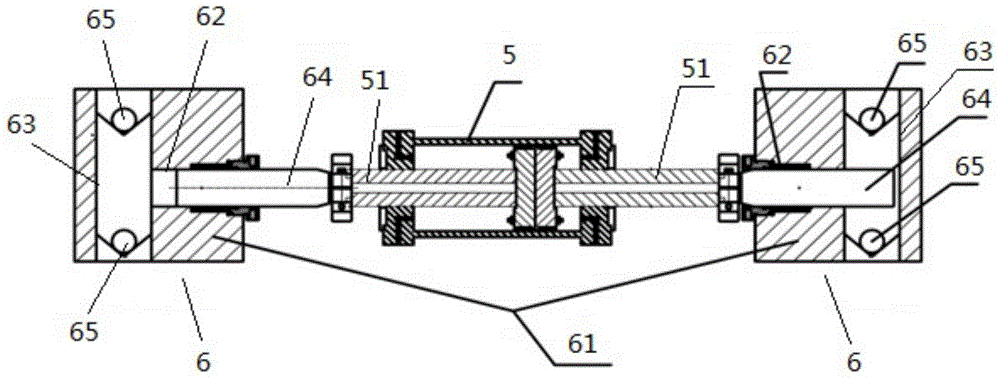

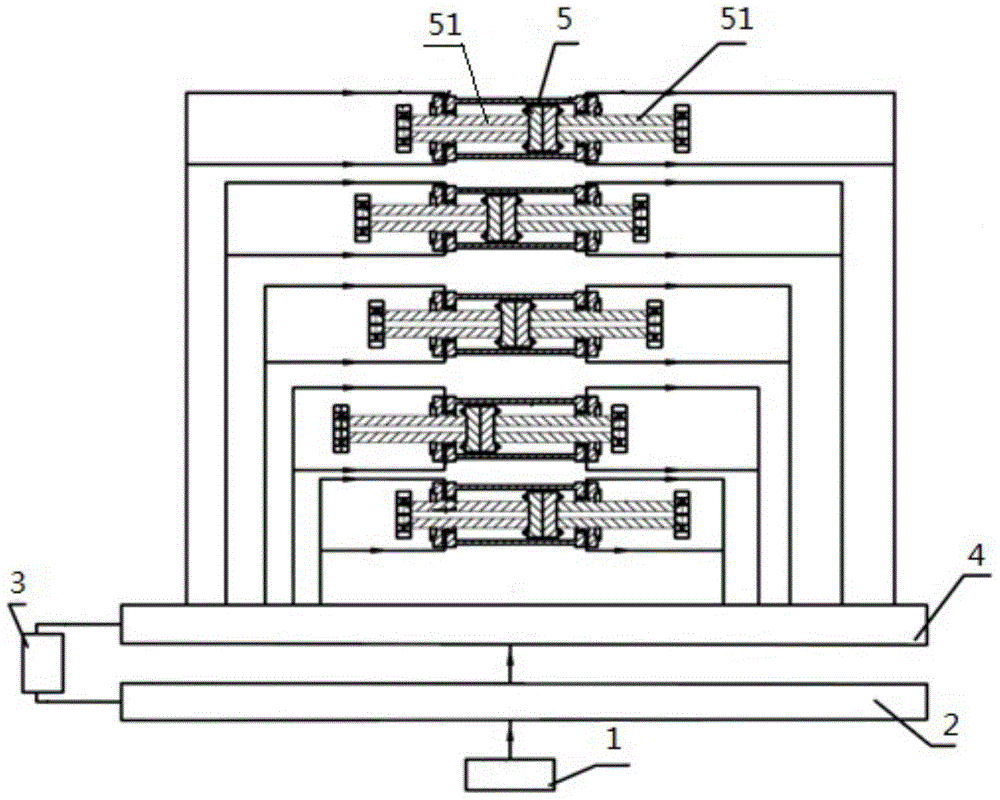

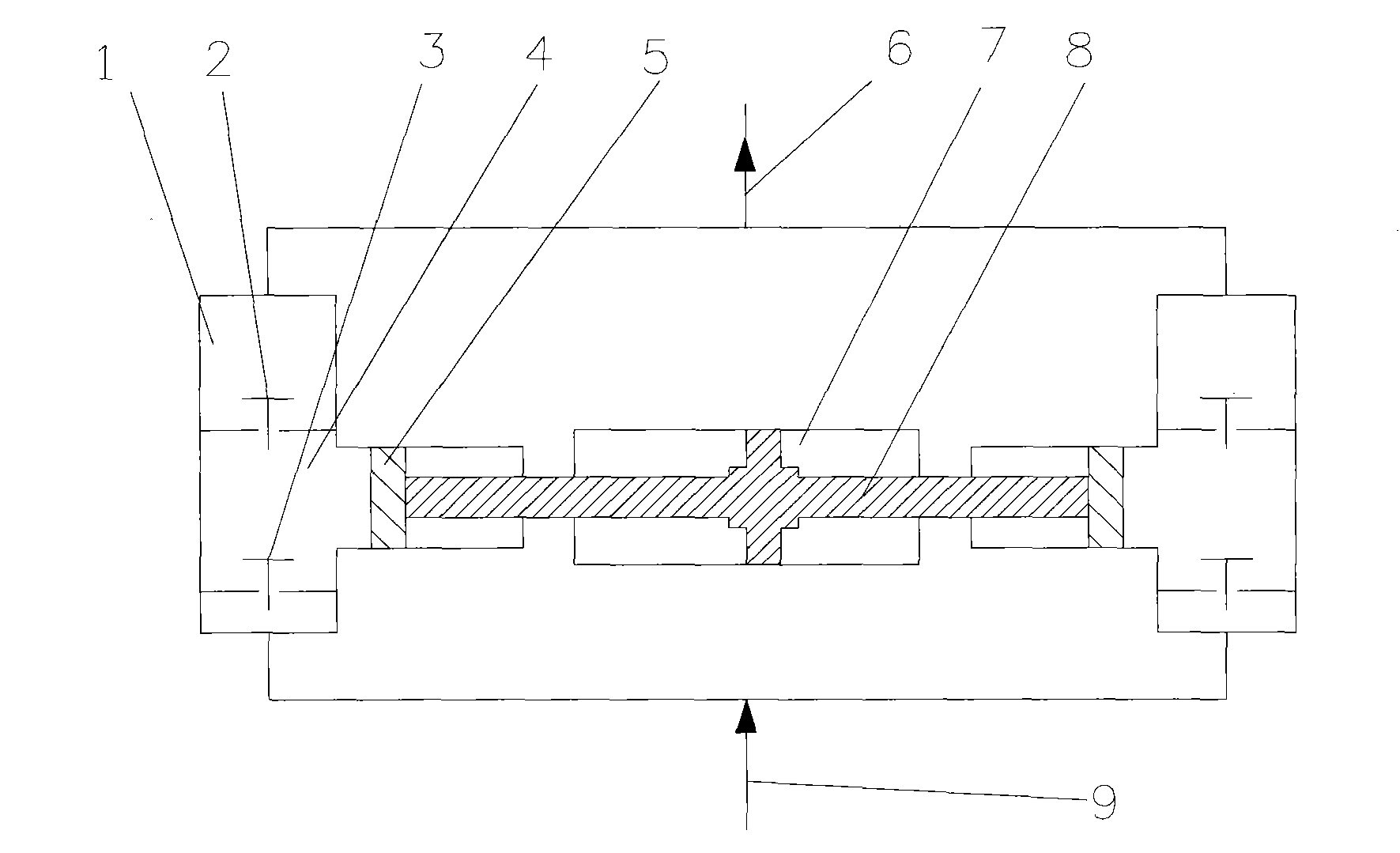

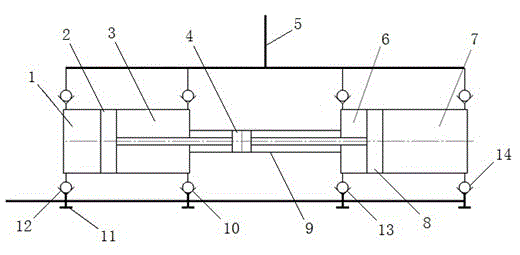

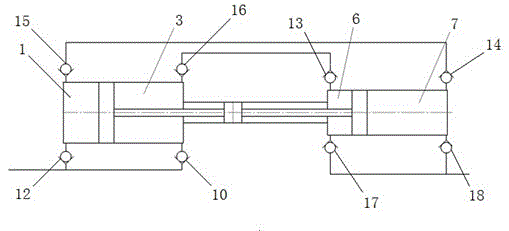

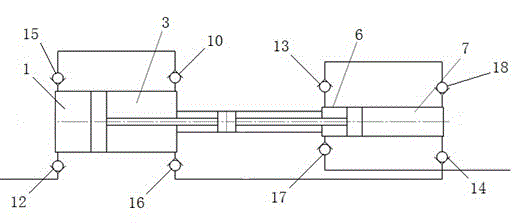

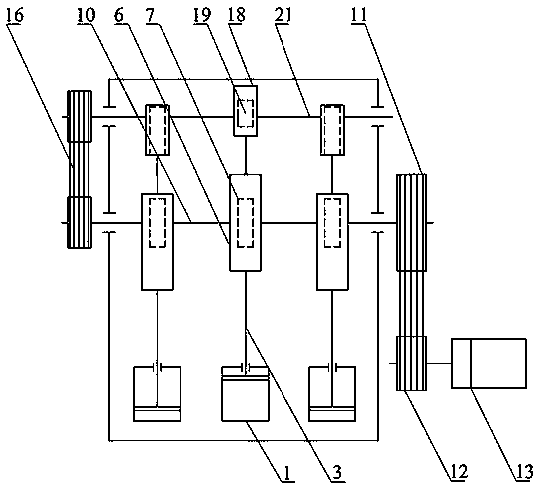

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

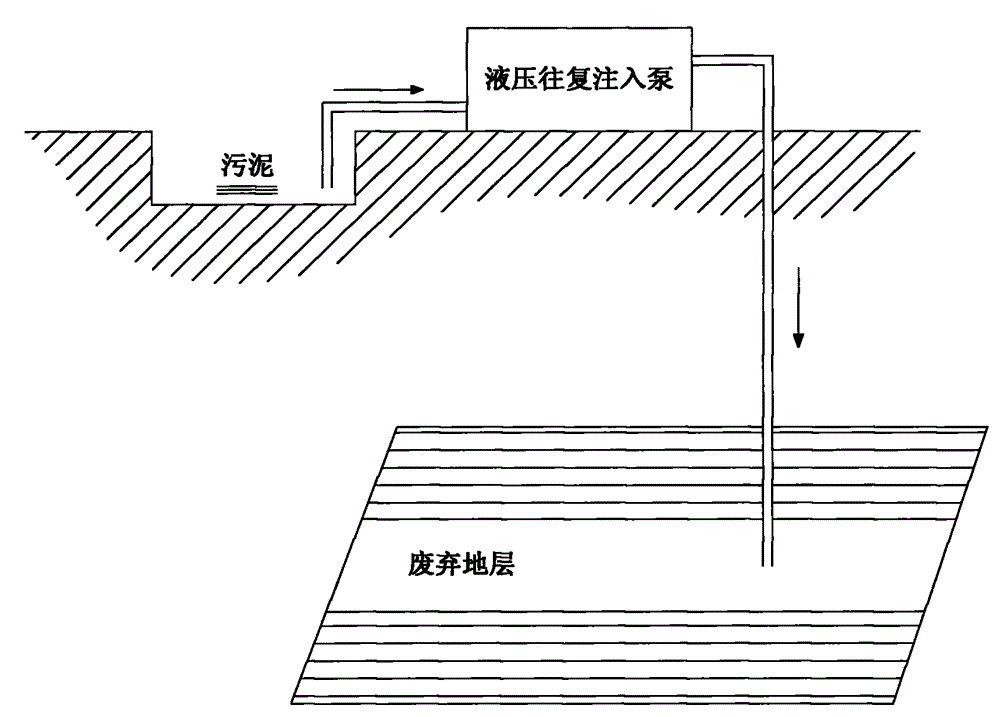

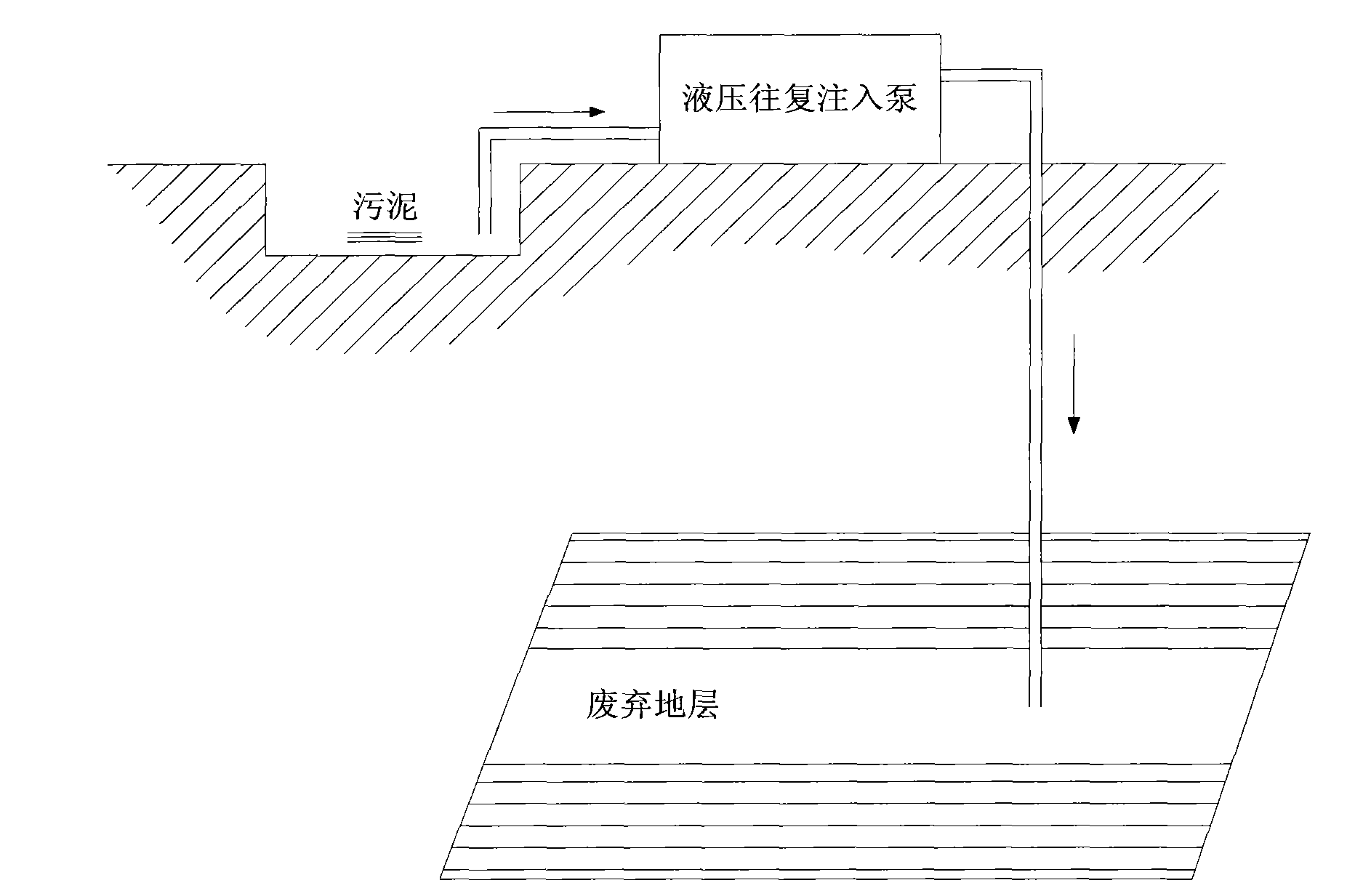

Harmless treatment method for reinjection of oil mining sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

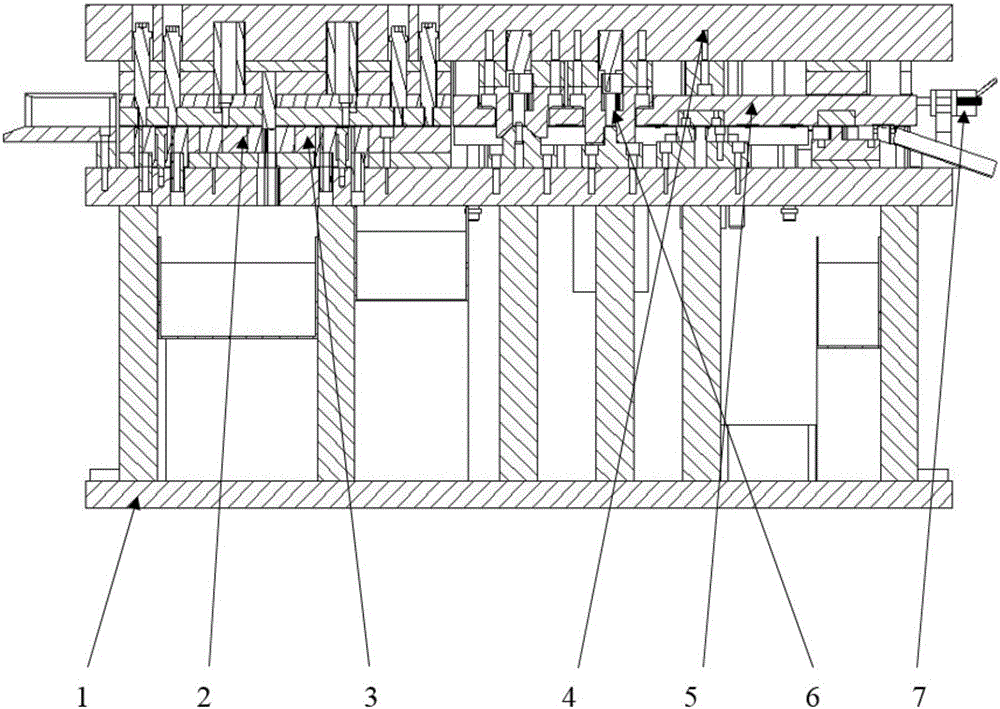

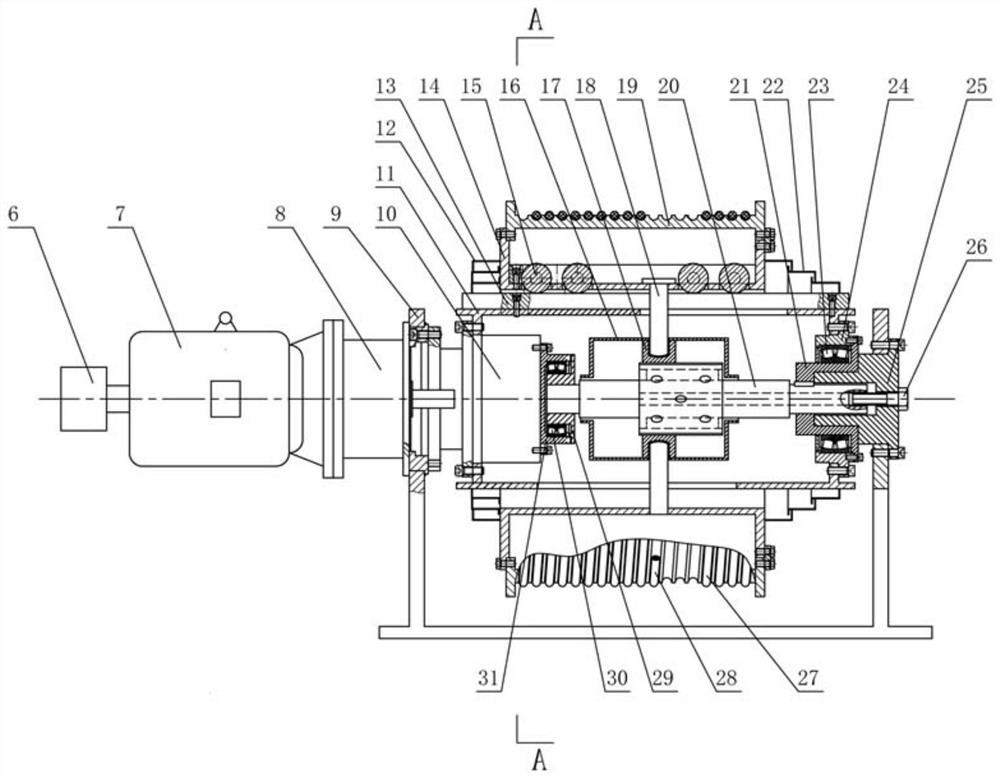

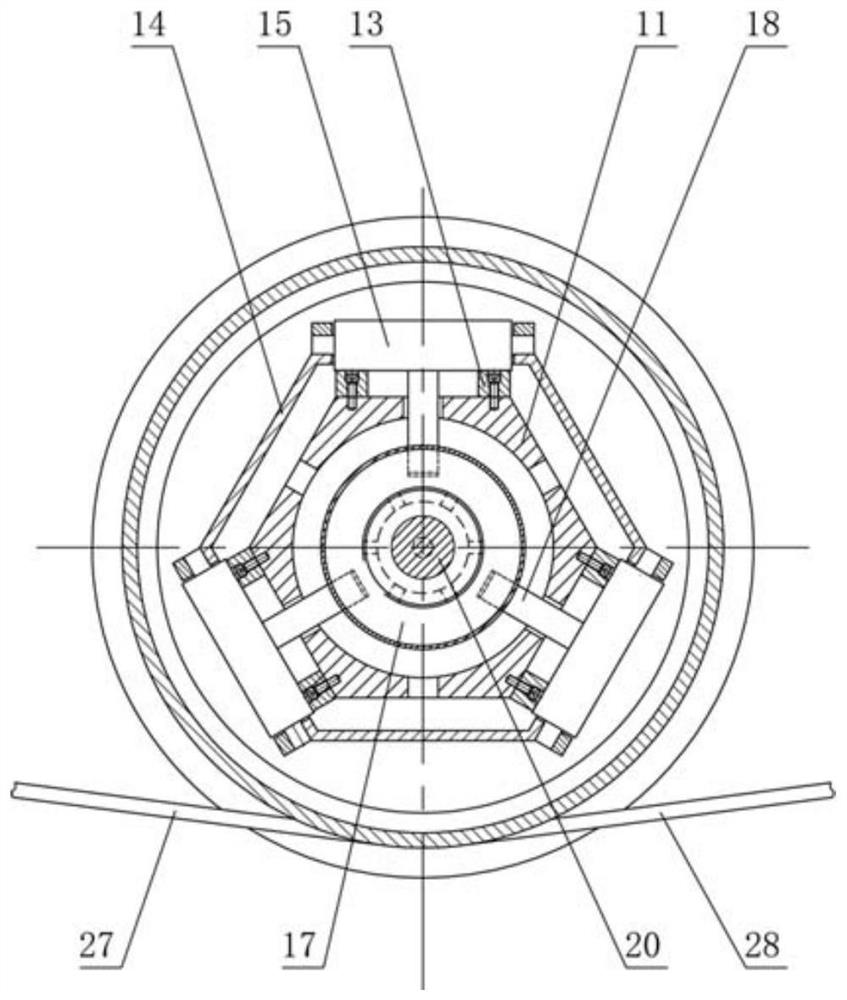

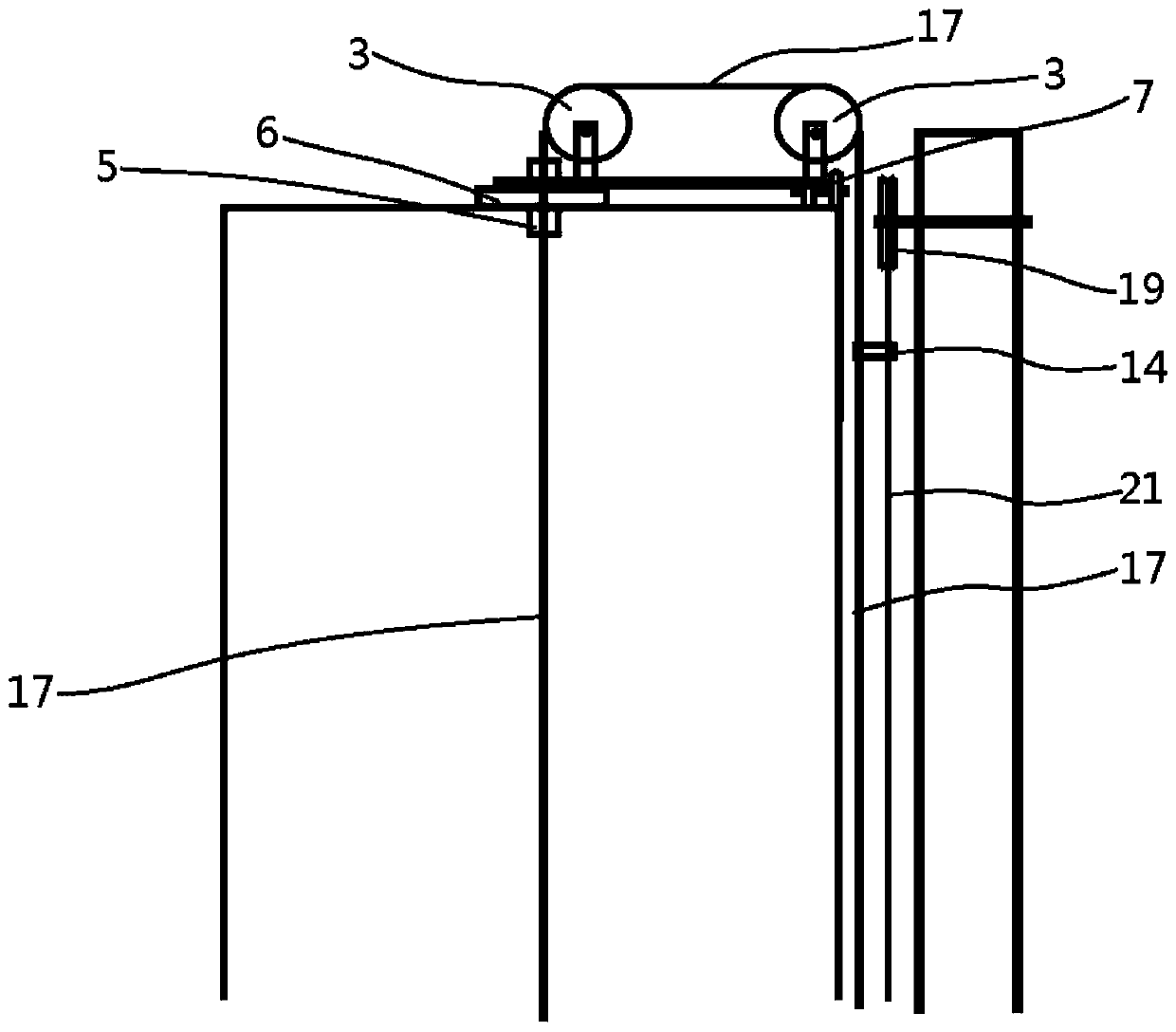

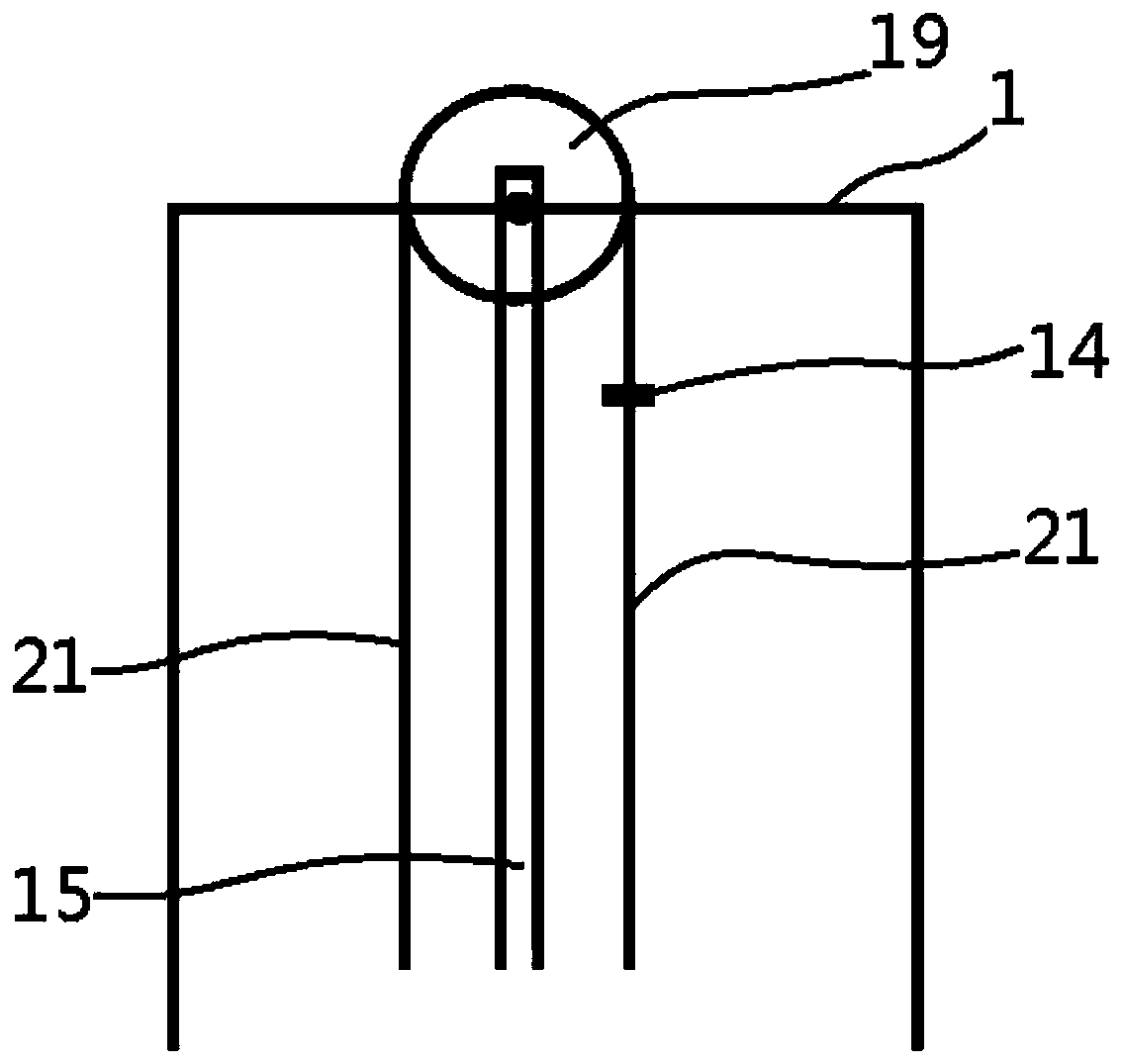

Hydraulic double acting pumping unit

ActiveCN104612928BExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

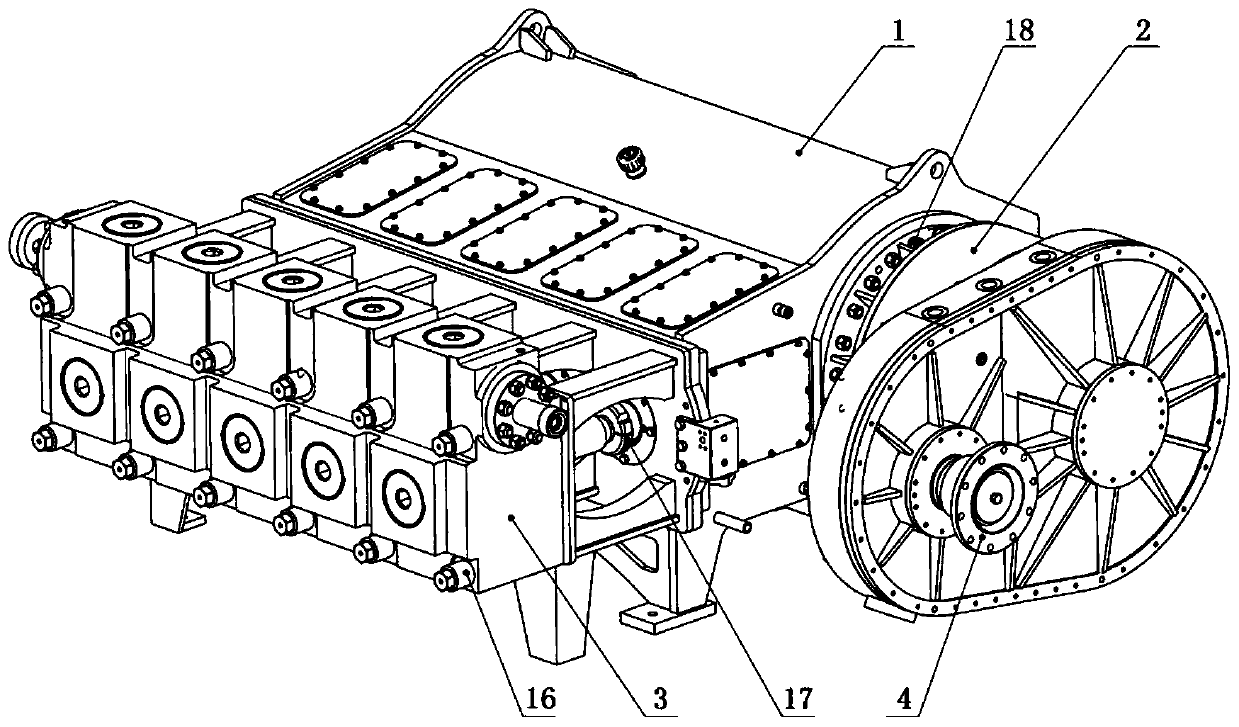

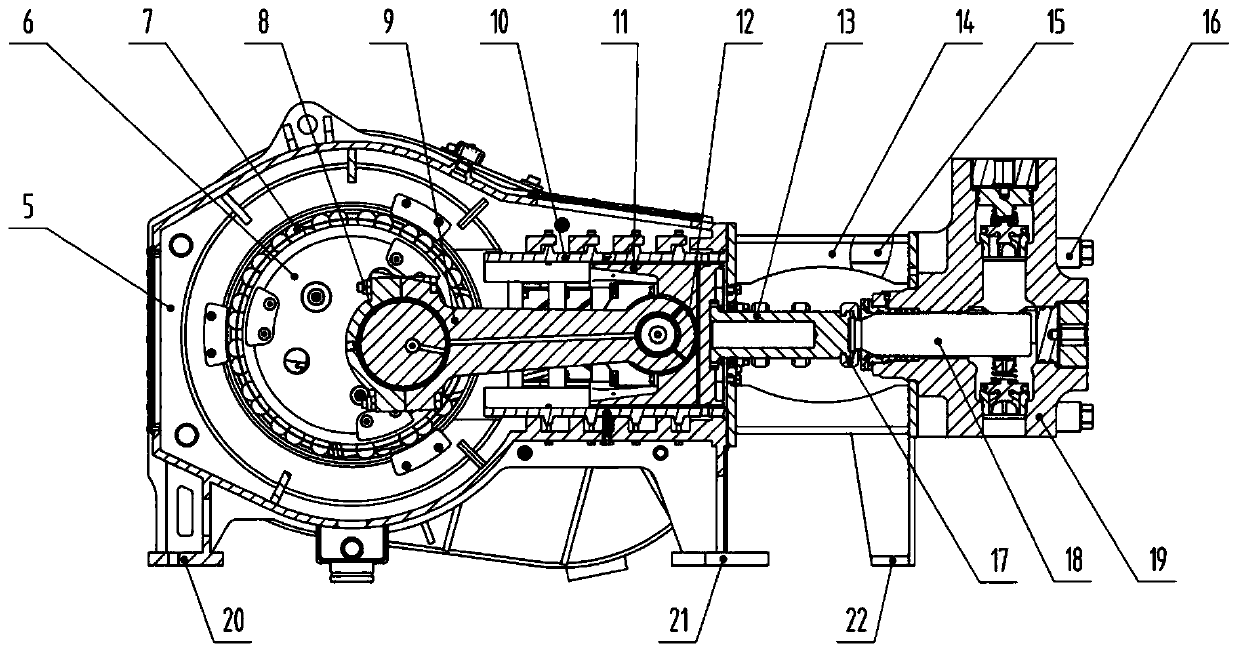

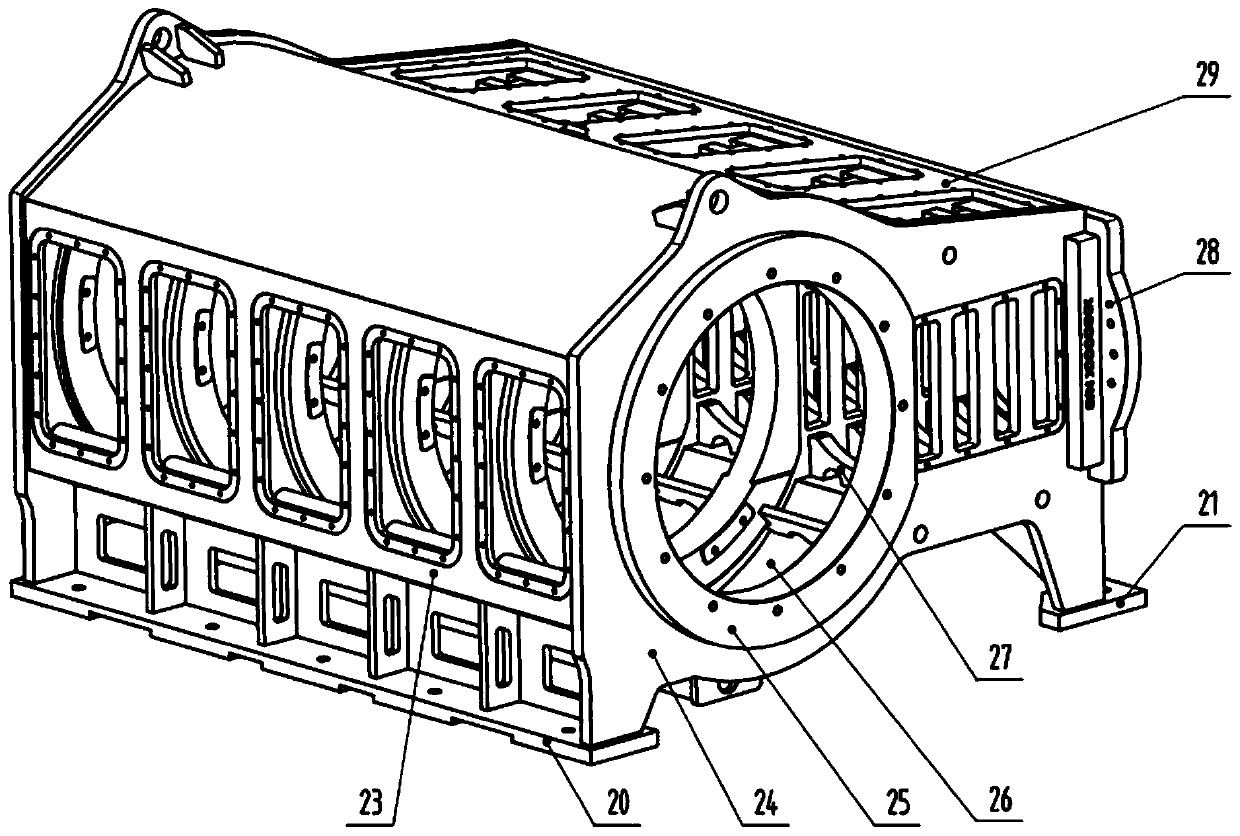

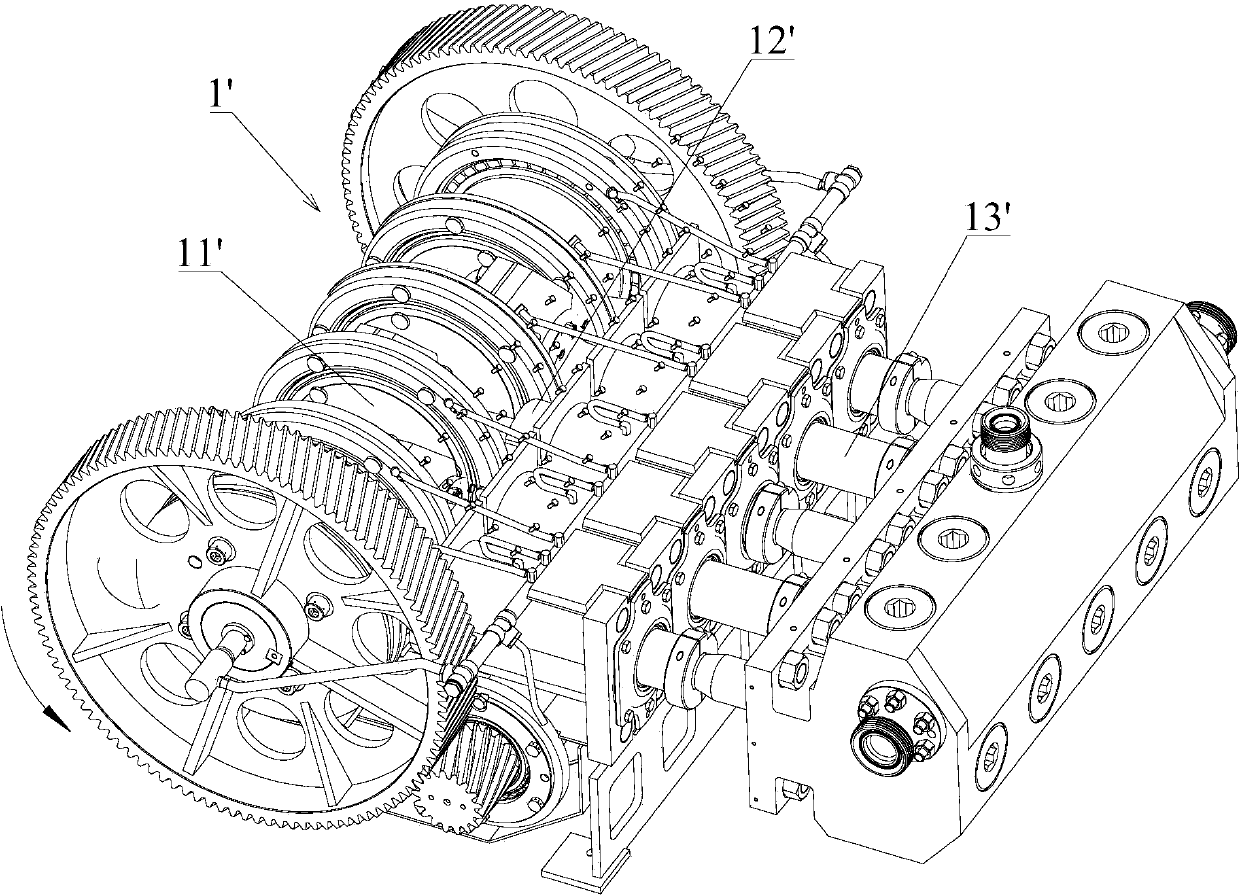

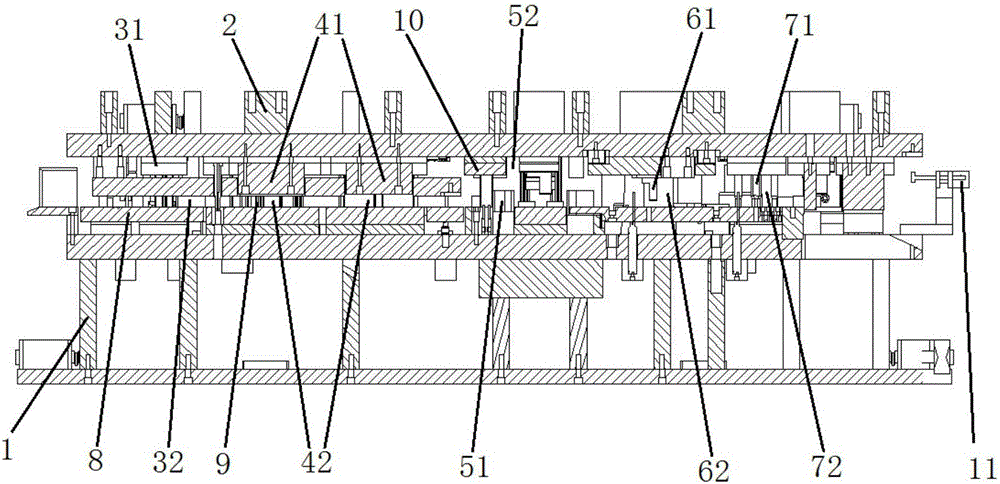

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Harmless reinjection treatment method for petroleum exploitation sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

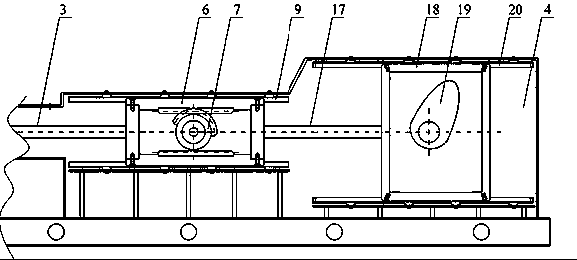

Sector and rack type reciprocating pump

InactiveCN107387355AImprove volumetric efficiencyImprove transmission efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderReciprocating motion

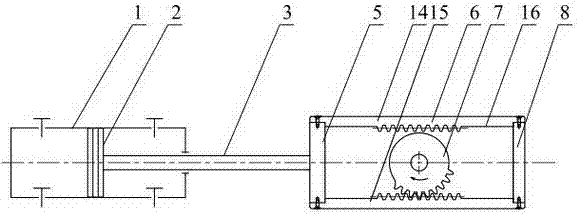

The invention relates to a sector and rack type reciprocating pump which mainly comprises a framework, an input shaft, a sector, a rack assembly, guide rails, a piston, a hydraulic cylinder and the like. The input shaft is mounted on the framework via bearings, the sector is mounted on the input shaft and meshes with the rack assembly, and the rack assembly is arranged between the upper and lower guide rails. Gear teeth of the rack are controlled in circumferential angles of 160-165 degrees, and a first tooth of the sector and tooth root circles are in smooth circular arc transition; the rack assembly comprises an upper rack, a lower rack and rack connecting pieces, smooth gaps with certain distances are reserved at the tail ends of two sides of the upper rack and the tail ends of two sides of the lower rack, and a piston rod is fixedly connected with an end of the rack assembly; the hydraulic cylinder at a hydraulic end of the sector and rack type reciprocating pump is a double-acting single-side arrangement or single-acting double-cylinder symmetric arrangement structural form. The sector alternately meshes with the upper rack and the lower rack when mechanisms work, and accordingly the piston can be pushed to carry out reciprocating movement. The sector and rack type reciprocating pump has the advantages of simple and compact structure, small occupied spaces, high system efficiency and low pump pressure and pump displacement fluctuation.

Owner:SOUTHWEST PETROLEUM UNIV

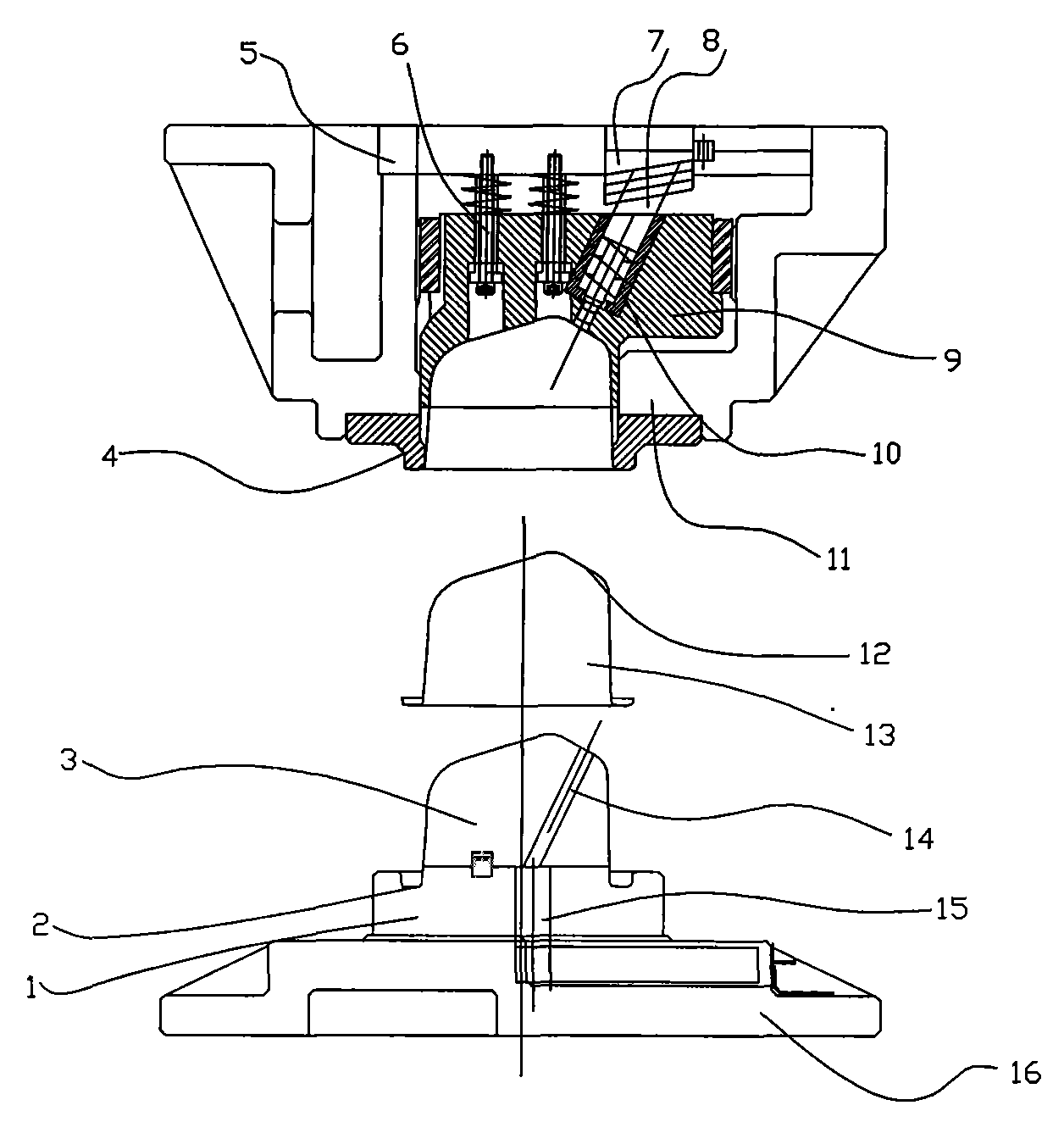

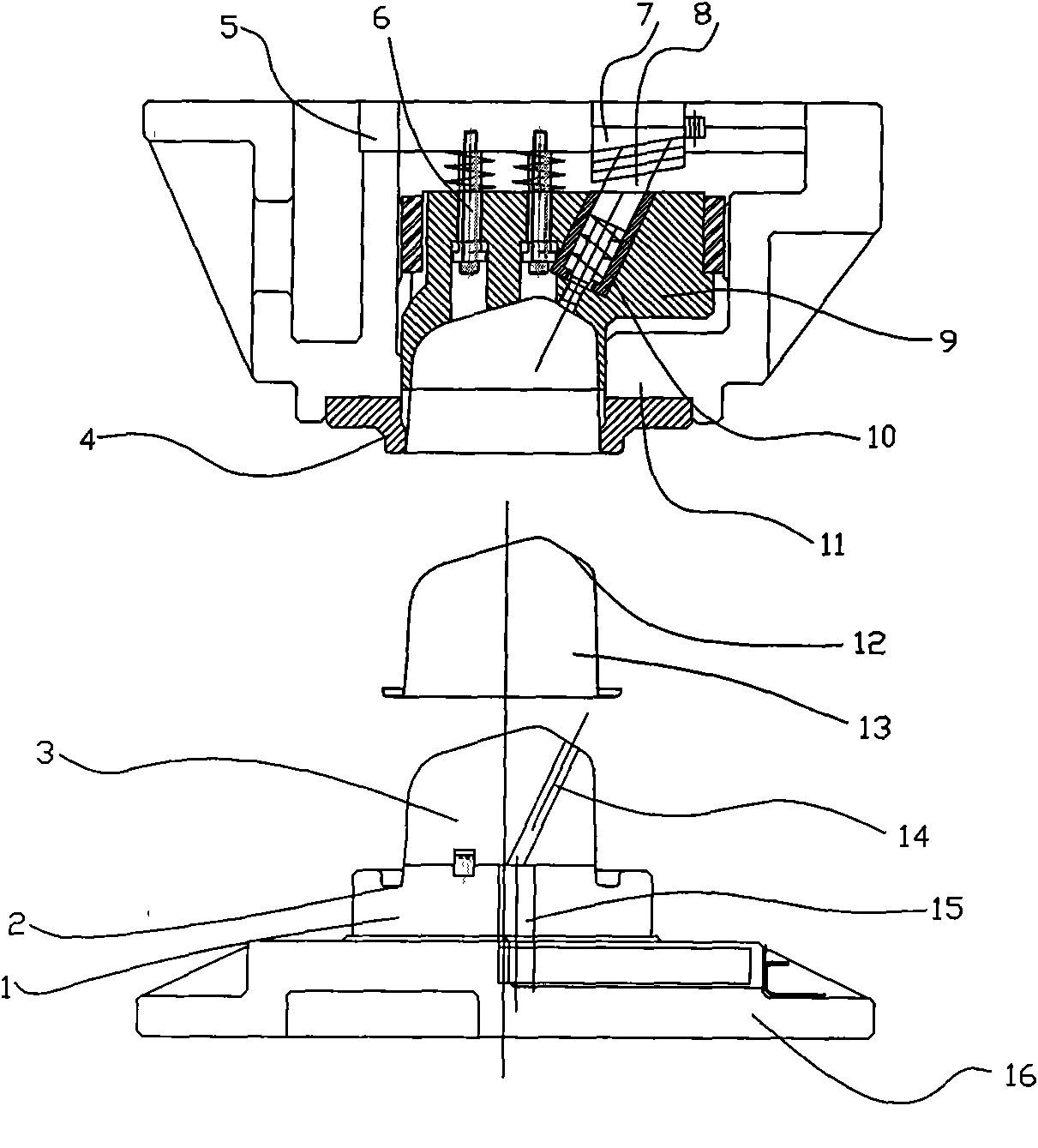

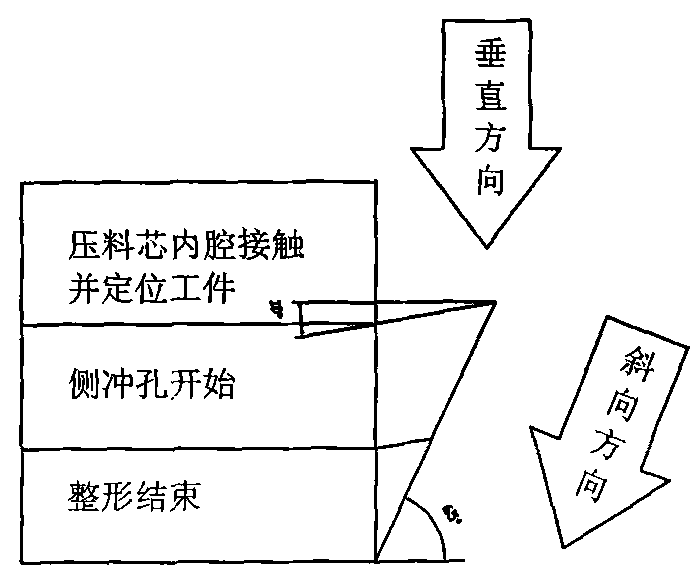

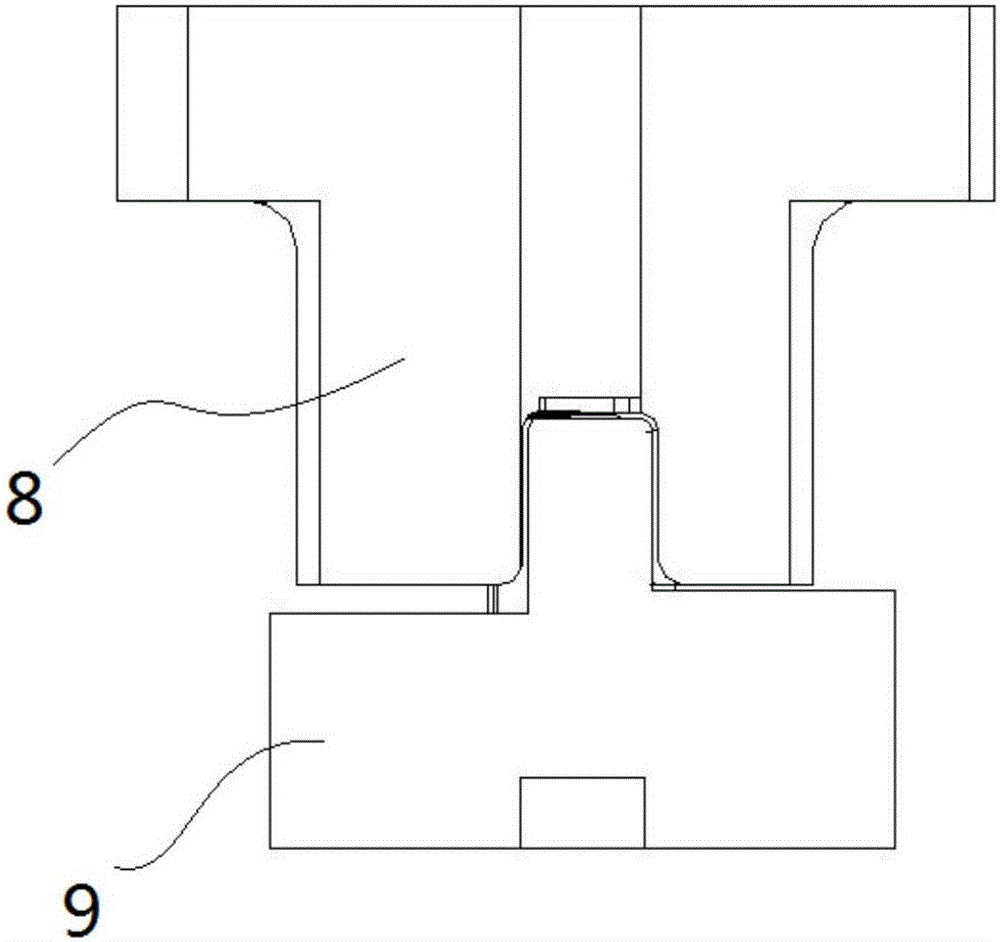

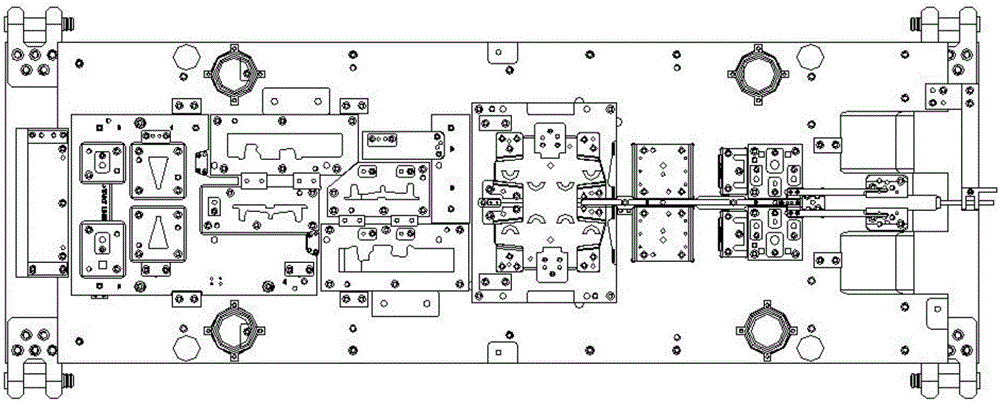

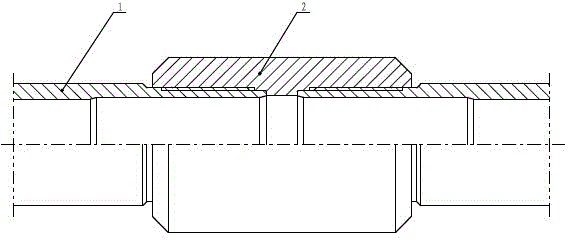

Trimming mould for automobile oil sump

The invention discloses a trimming mould for an automobile oil sump, and relates to a combined mould for shaping a plate. The mould comprises upper and lower die components capable of shaping an edge slot of the oil sump; the upper and lower die components are correspondingly provided with upper and lower trimming dies; the mould also comprises an inclined hole punching device which comprises a pressing core, a punch head, a punch head driving wedge and a bump; the bump is arranged on the lower die component and matched with the inner profile of the oil sump; the bump is provided with a lower die hole corresponding to the punch head; a waste material discharge passage which is communicated with the lower die hole is arranged in the bump; the pressing core is movably connected in the upper die component through an elastic guide mechanism; a cavity which is matched with the outer profile of the oil sump is arranged in the pressing core; the punch head is slantwise movably connected in the pressing core through an elastic resetting mechanism; the punch head driving wedge is fixedly connected with the upper die component; and the top surface of the punch head is movably connected with the punch head driving wedge through a dovetail groove or T-shaped groove. The mould has reliable action, saves the space and realizes integration of the punching mould on the trimming side of the oil sump.

Owner:JIANGSU KAMING MOLD

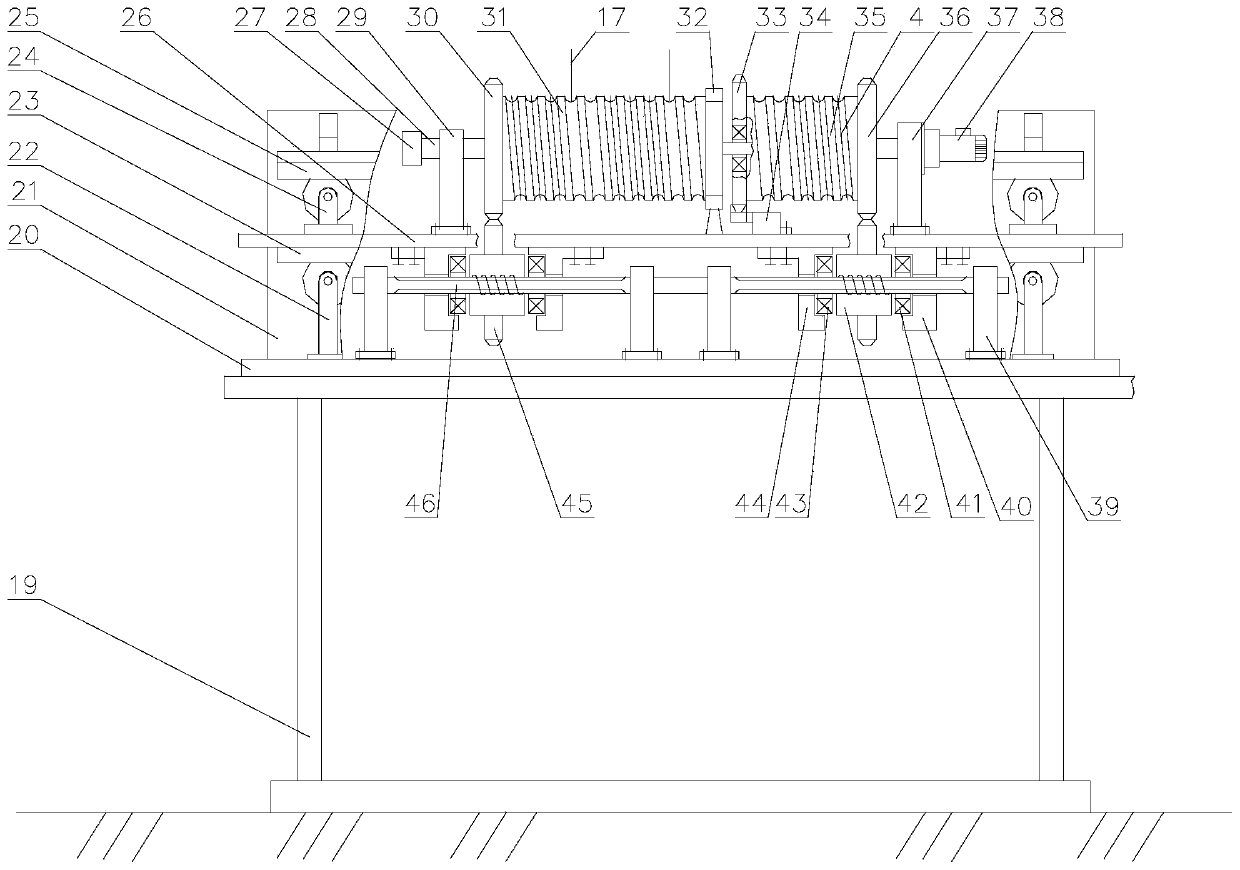

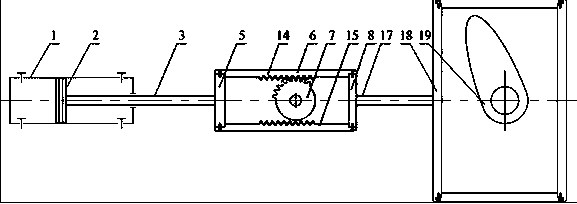

Fracturing pump system and fracturing truck

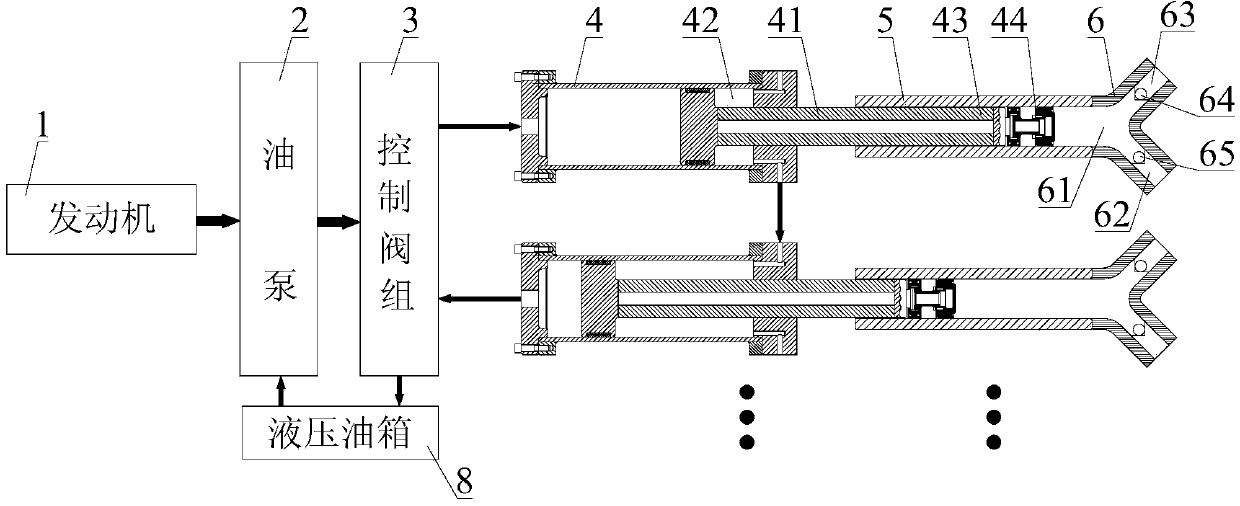

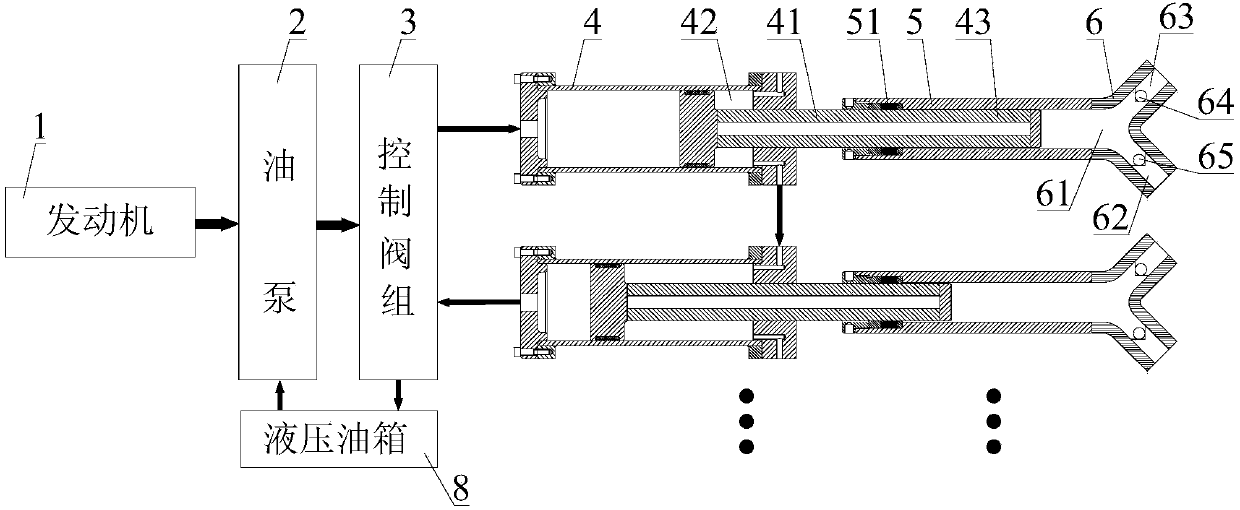

ActiveCN103742381AFlexible arrangementSimple structureFluid removalPiston pumpsEngineeringControl valves

The invention discloses a fracturing pump system and a fracturing truck. In the fracturing pump system, a first conveying mechanism and a second conveying mechanism comprise oil cylinders, supercharging cylinders and distribution valves. Each distribution valve comprises a first channel, a second channel and a third channel, wherein the first ends of the first channel, the second channel and the third channel are connected, a suction valve is arranged in the second channel, and a discharge valve is arranged in the third channel. Plug bodies are arranged at the extending end of piston rods of the oil cylinders and movably arranged in the supercharging cylinders, and outlets of the supercharging cylinders are connected with the second end of the first channel. An engine is used for driving an oil pump. A control valve group is used for controlling oil inlet and return states of the oil cylinders. By using the fracturing pump system, a stroke can be effectively increased, stoke times can be decreased, the service life of easily damaged parts can be prolonged, an output pressure and flow coverage range can be effectively widened, the structural complexity can be effectively reduced, the cost can be saved, and the lubrication and cooling requirements can be effectively reduced.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

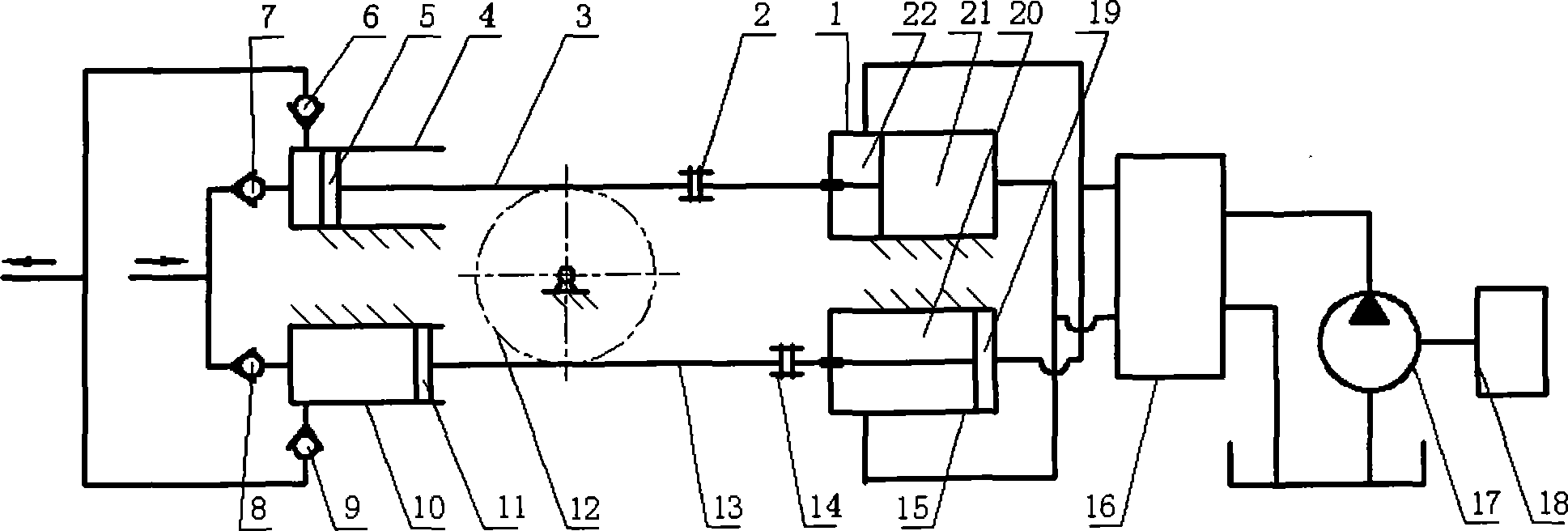

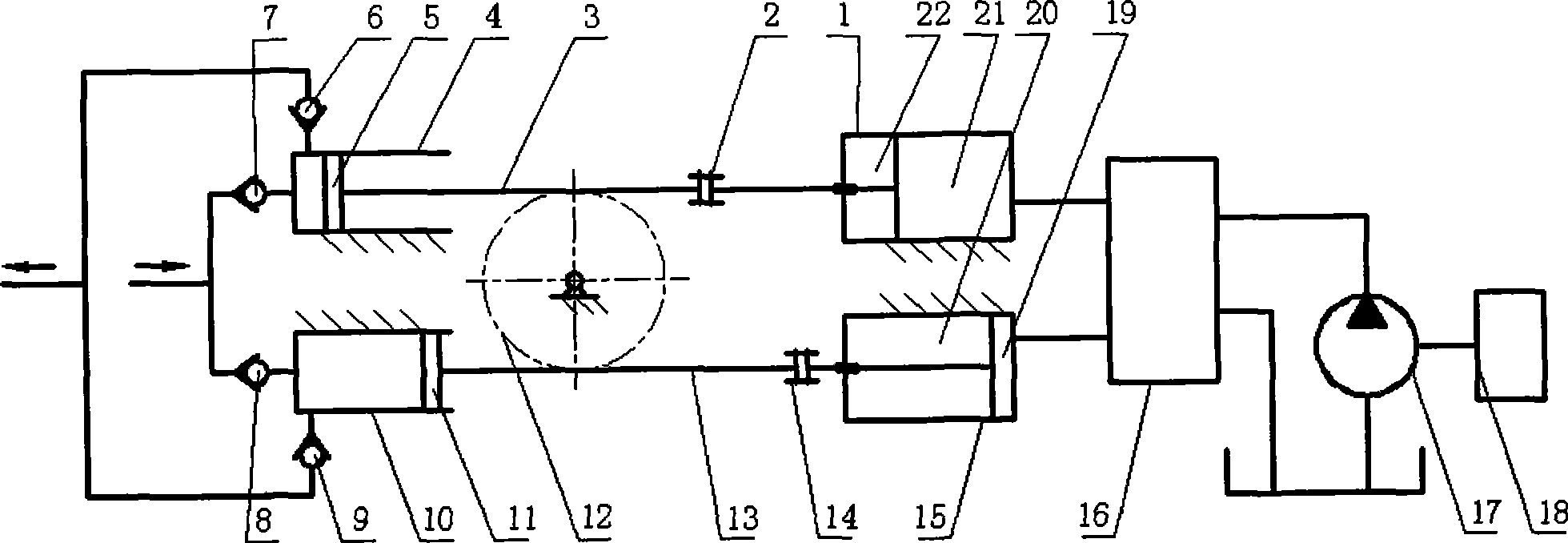

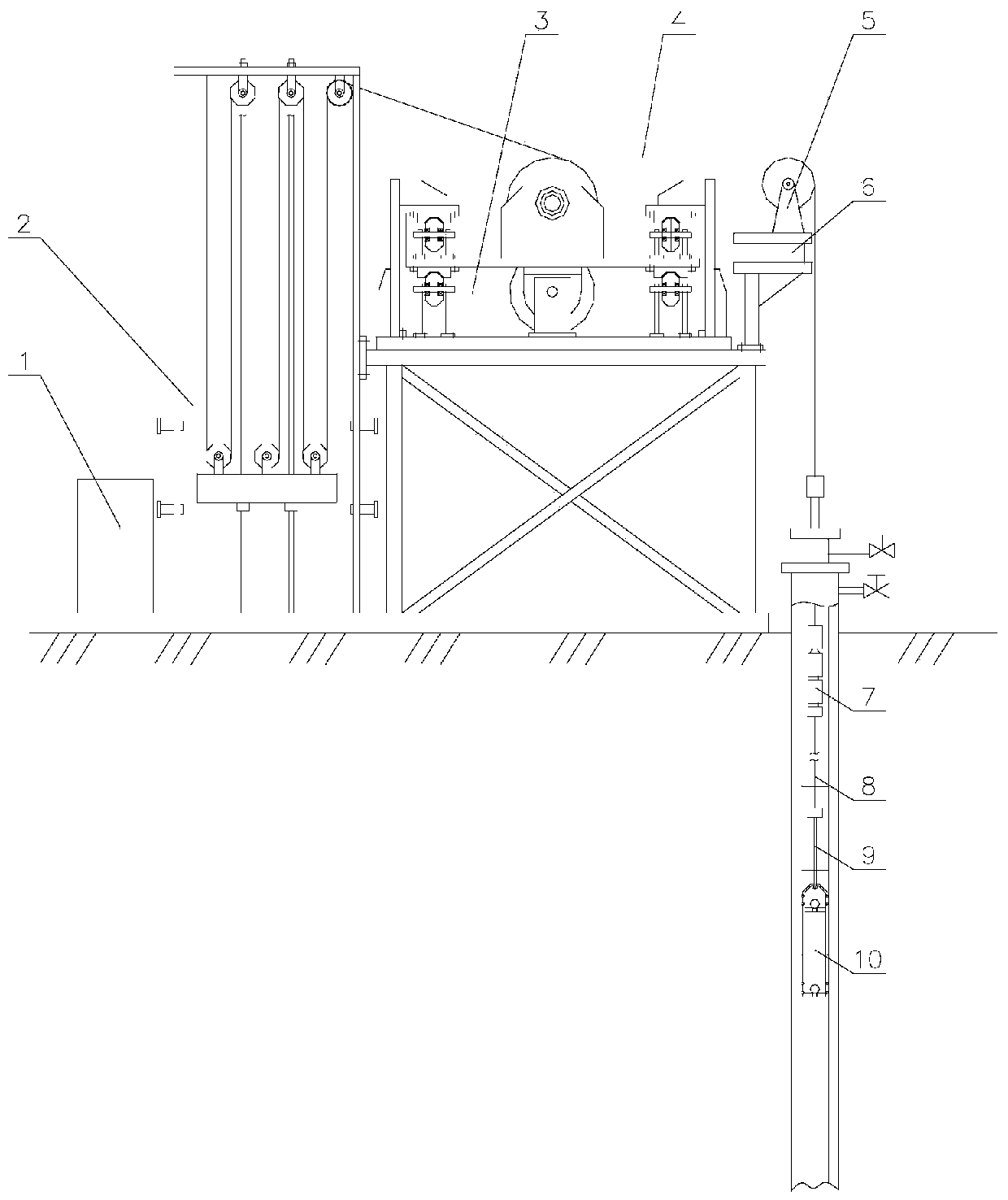

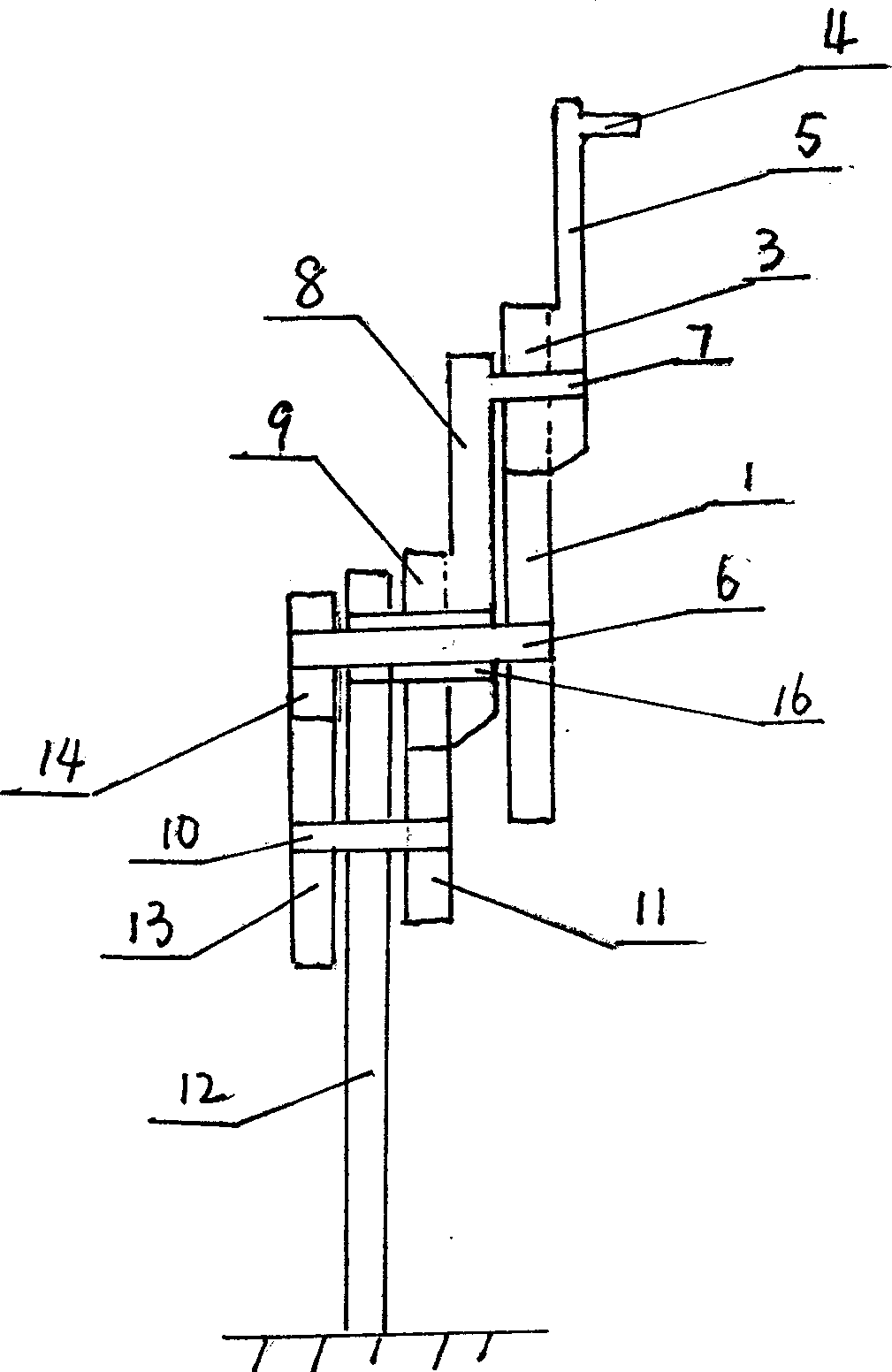

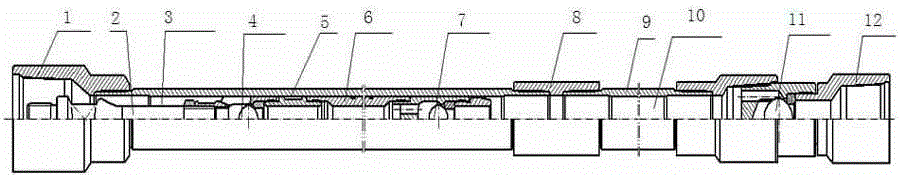

Rack-and-pinion coupled hydraulic multi-cylinder reciprocating pump

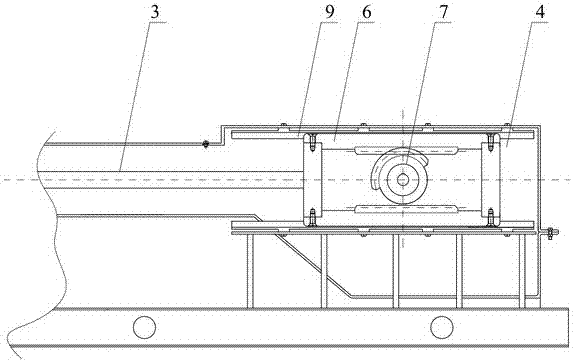

InactiveCN101476553AReduce degradationReduce shearPiston pumpsPositive-displacement liquid enginesPhase differenceGear wheel

The invention relates to a gear wheel and rack coupled hydraulic multi-cylinder reciprocating pump, which consists of a hydraulic oil cylinder, a coupling, a cylinder sleeve of a working hydraulic cylinder, a piston, a piston rod, a gear wheel, a suction valve, a discharge valve, a hydraulic directional control valve, a hydraulic oil pump, an electric motor, and the like which are assembled and connected. The piston rod is provided with a rack; the hydraulic oil cylinder and the piston rod are arranged parallelly; the gear wheel is engaged with racks on the two piston rods simultaneously; and the two piston rods are arranged according to the movement phase difference of 180 degrees. Two hydraulic oil cylinders and two working hydraulic cylinders form a basic unit, and for the two hydraulic oil cylinders in the basic unit, oil can be provided to both non-rod chambers and rod chambers, and can be only provided to the non-rod chambers of the oil cylinders. The invention can be combined into a multi-cylinder reciprocating pump with two cylinders, four cylinders, six cylinders, and more even cylinders. The hydraulic multi-cylinder reciprocating pump has the advantages of high systematic efficiency, long stroke, low stroke frequency, large displacement, high pump pressure, long service life of wearing parts, small fluctuation of the displacement and the pump pressure, good suction performance, and simple and convenient maintenance.

Owner:SOUTHWEST PETROLEUM UNIV

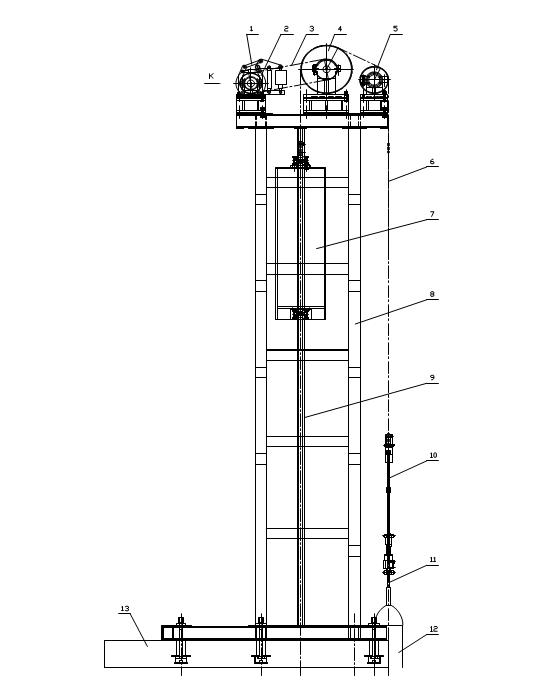

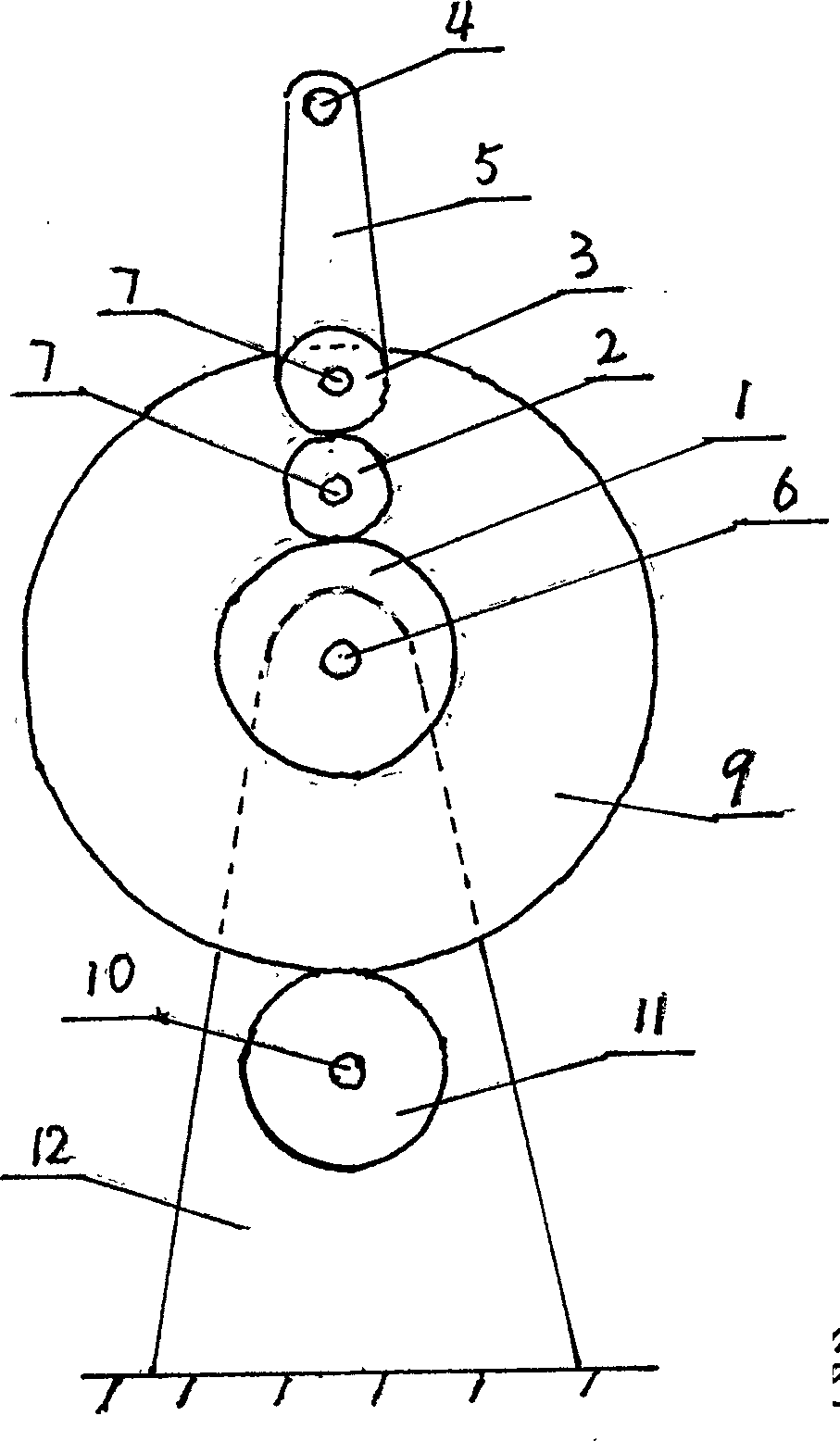

Double-roller tower type oil-pumping unit device

The invention discloses a double-roller tower type oil-pumping unit device. A roller type speed reducer drives a driven roller to rotate through an opening belt, one end of the opening belt is connected with a weight box, the other end of the opening belt is connected with a suspension assembly, the other end of the suspension assembly is connected with one end of a belt clip, the other end of the belt clip is connected with one end of an oil pumping rod, the other end of the oil pumping rod is movably connected with an oil pumping unit, and a brake is connected with a coupler assembly; an output shaft of an electric motor is connected with a belt wheel shaft through the coupler assembly, a driving synchronous belt wheel is installed on the belt wheel shaft, a driven synchronous belt wheel is installed on an input shaft of the roller type speed reducer, and synchronous belts sequentially are wounded the driving synchronous belt wheel and the driven synchronous belt wheel and then are rotationally driven to connect; and guide wheels are installed on both sides of the weight box, a guide rail is fixed on a rack, and the rack is fixed on a concrete foundation by bolts. The double-roller tower type oil-pumping unit device has the characteristics of simple structure, good stability, non-skid performance of the belts, long stroke, low stroke frequency and long fatigue service life, is convenient to use, is easy to regulate strokes and stroke frequencies and is widely used for the oil extraction industry.

Owner:周生祥

Intelligent super-long stroke pumping unit

The invention relates to an intelligent super-long stroke pumping unit which comprises an electric control cabinet, a driving system, a flexible polish rod winding the driving system and a counterweight system connected to the driving system. The output end of the flexible polish rod winds a supporting wheel and is successively connected to a rotary pup joint, a sucker rod, a weighted lever and asuper-long stroke pump. A regional central control room is connected to the electric control cabinet through a remote data wireless bridge, and the electric control cabinet is connected to the drivingsystem through a cable. The intelligent super-long stroke pumping unit is used for improving the stroke of the pumping unit, eliminating the included angle between the flexible polish rod and a hoisting sheave and prolongs the service life of the polish rod, so that a balance weight of the super-long stroke pumping unit is realized. The super-long stroke pumping unit is further energy-saving. Thepump efficiency, yield, annular liquid level position of an oil jacket can be reflected instantaneously by the electric control cabinet. The oil sucking speed or intermittent oil pumping is adjustedautomatically according to liquid supply data to achieve efficient operation, so that purposes of long stroke, low time of strokes, large displacement, intelligent control, optimized oil extraction, extension of periods of replacing a tube rod and examining the pump and remote digitalized control management are achieved.

Owner:沃森埃里克

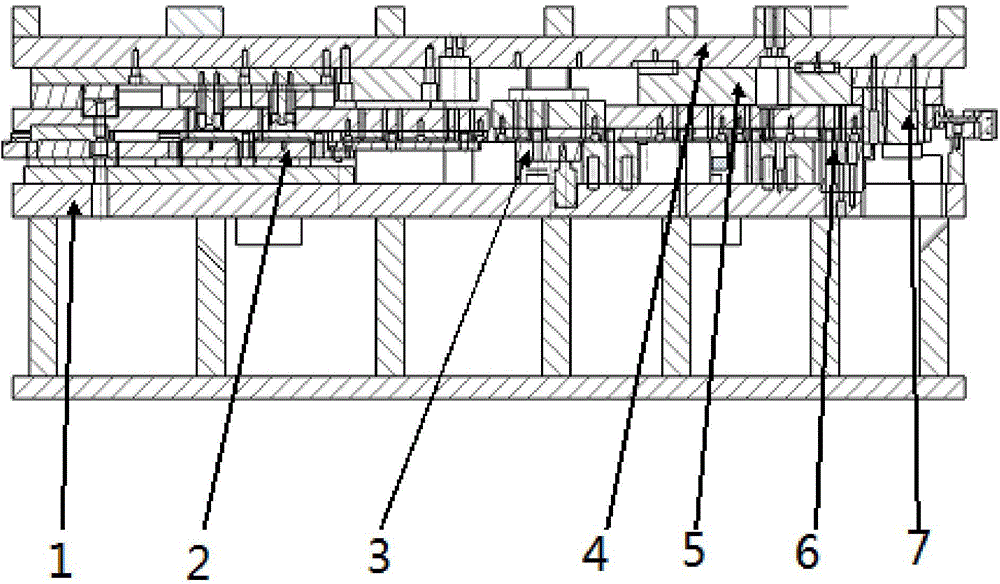

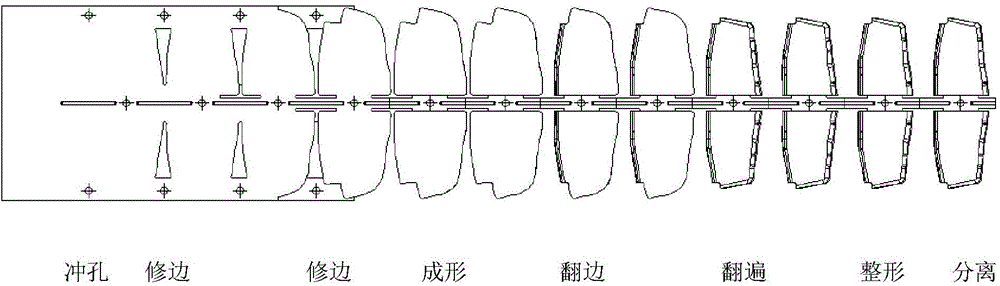

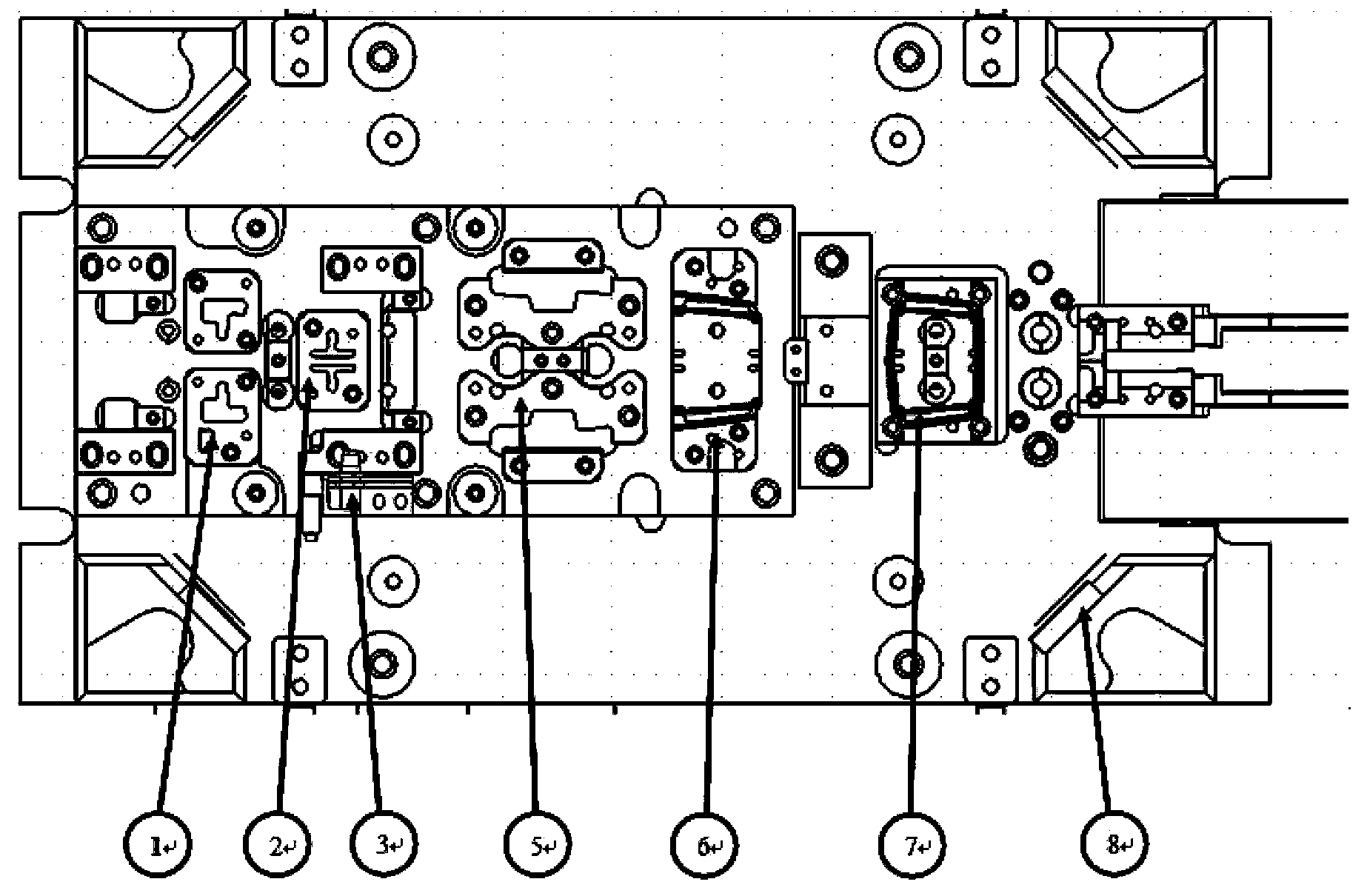

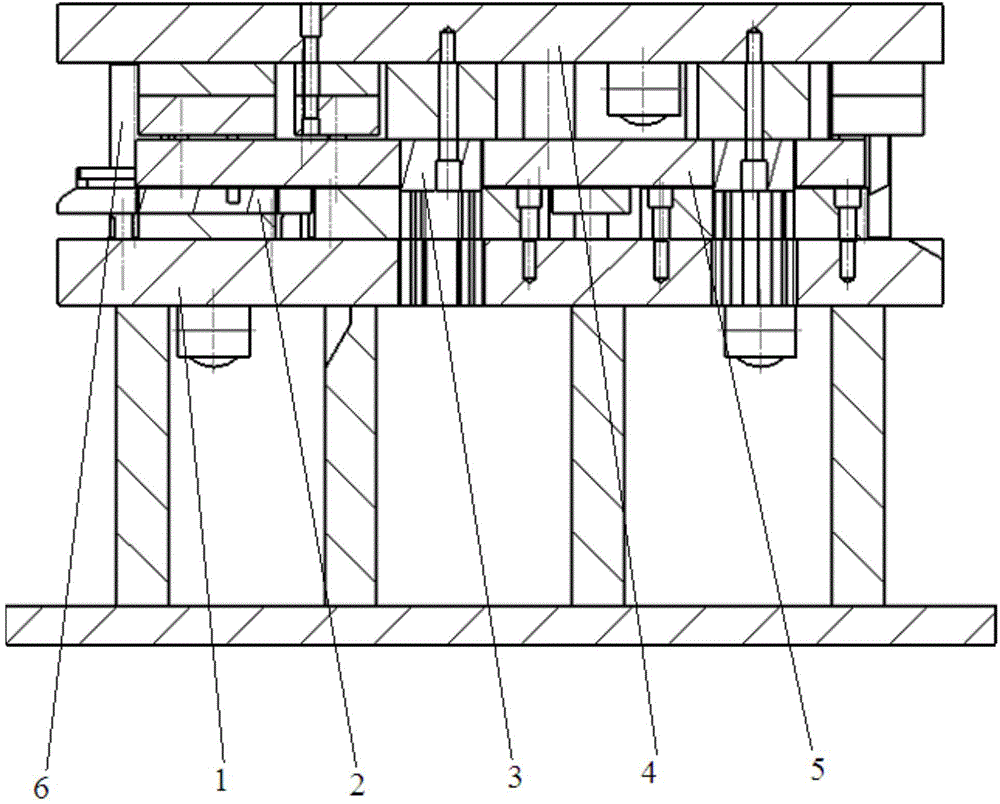

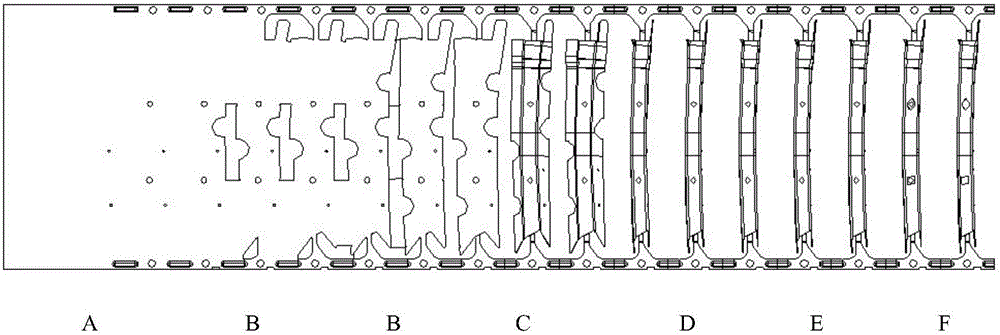

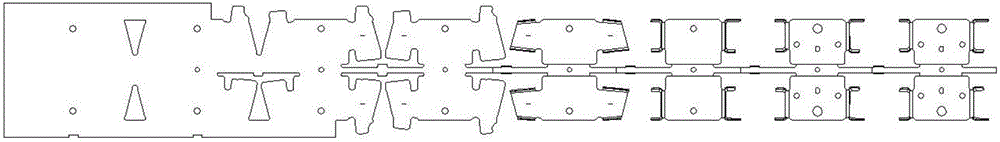

Continuous production die for rear portion blanking plate parts of automobile carling

InactiveCN104525741AExtended service lifeAvoid damageShaping toolsVehicle componentsEngineeringMechanical engineering

The invention relates to a continuous production die for rear portion blanking plate parts of an automobile carling. The continuous production die for the rear portion blanking plate parts of the automobile carling comprises a lower die portion and an upper die portion, the lower die portion comprises a lower die seat (1), a stamping female die cutter (2), a lower die trimming cutter block (3), a lower flanging male die (8), a shaping block, and a discharge opening,wherein the stamping female die cutter(2),the lower die trimming cutter block(3),the lower flanging male die(8),the shaping block and the discharge opening are arranged on the lower die seat(1) in sequence.The upper die portion comprises an upper die seat (4), a stamping male die cutter, an upper die trimming cutter block, a flanging cutter (9), a pressure plate (5) and a shaping punch (6), wherein the stamping male die cutter,the upper die trimming cutter block,the flanging cutter (9) ,the pressure plate (5) and the shaping punch (6) are arranged at the lower surface of the upper die seat (4) in sequence; the pressure plate (5) is arranged at the lower middle portion of the upper die trimming cutter block and is connected with the upper die trimming cutter block. Compared with the prior art, the continuous production die for the rear portion blanking plate parts of the automobile carling has the advantages of being high in quality, convenient to maintain low in cost and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

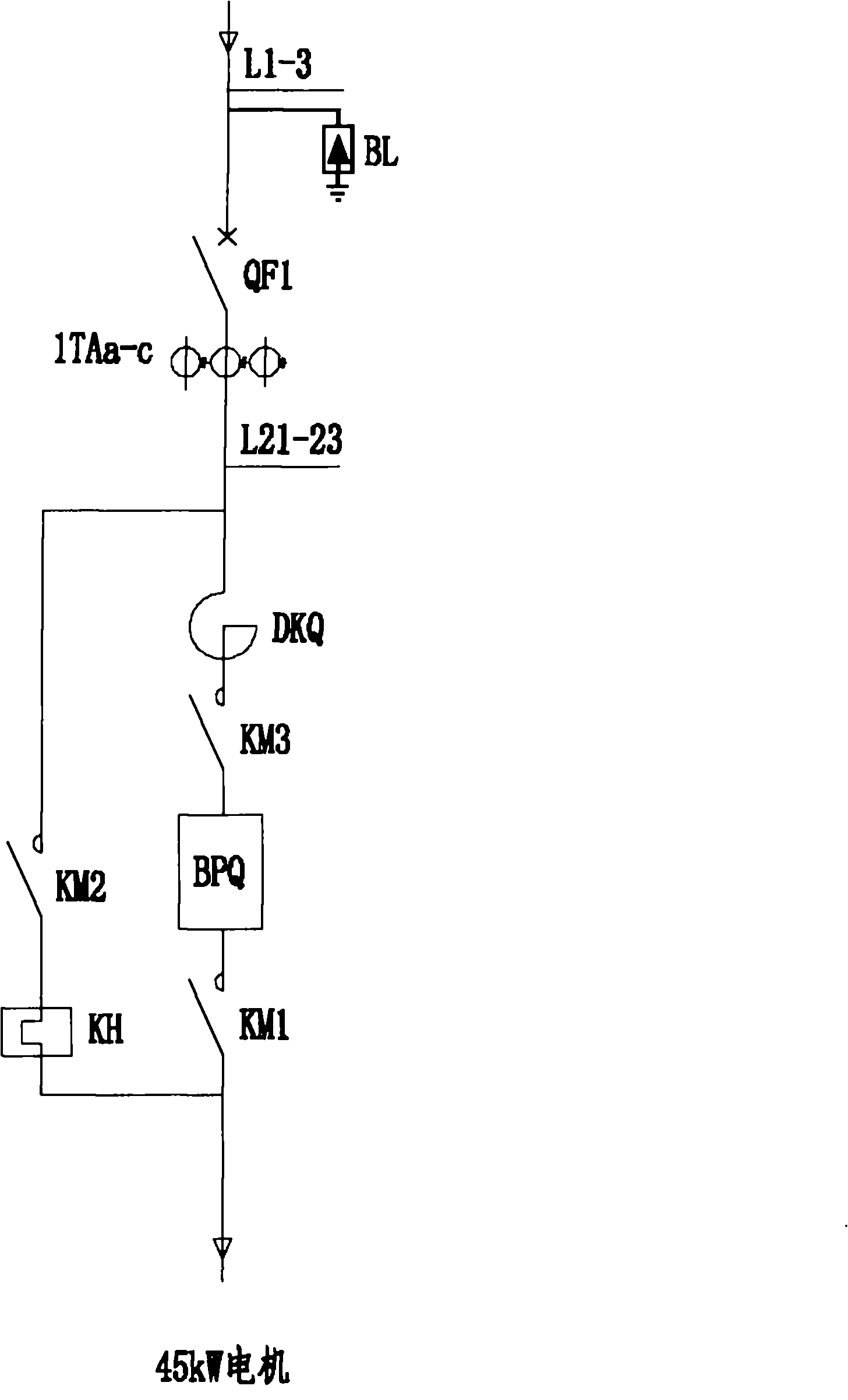

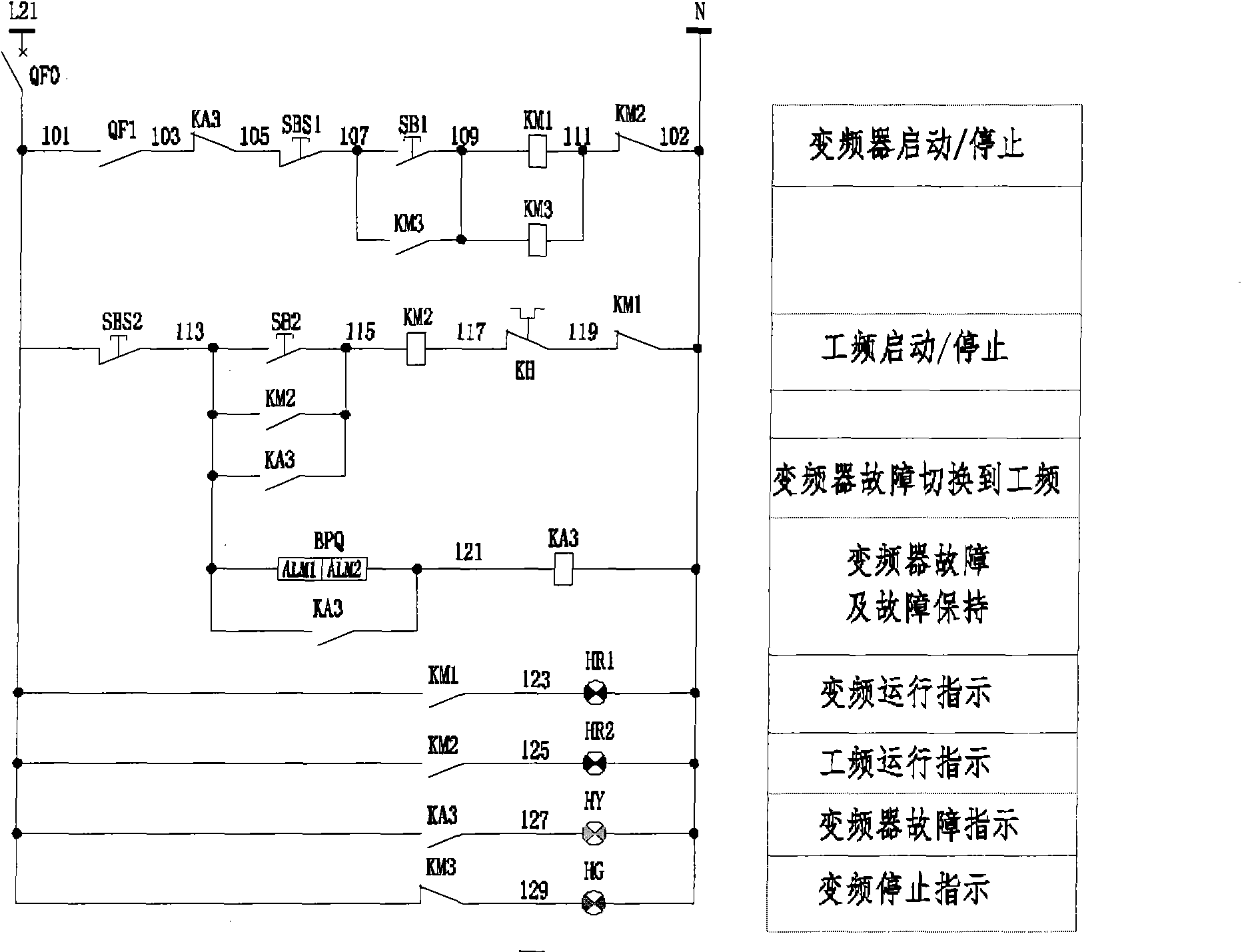

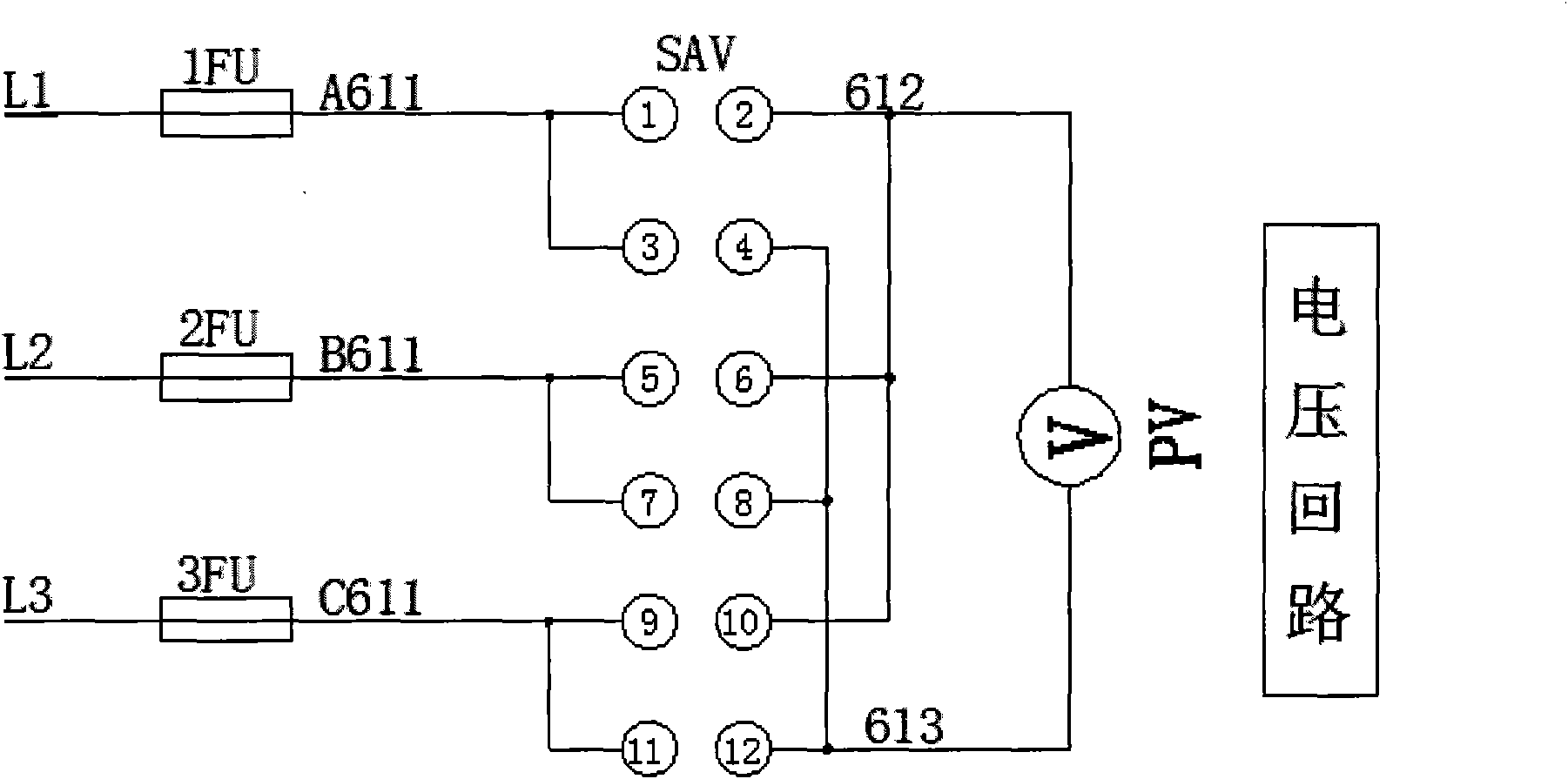

Frequency converting and energy saving device of oil pumping machine

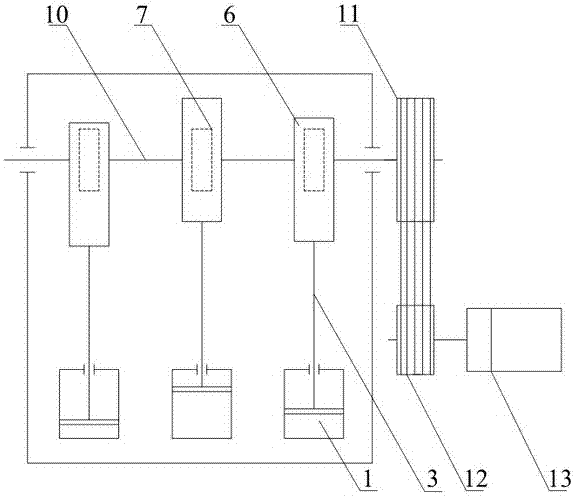

InactiveCN101777762AIncrease productionImprove pump efficiencyReactive power adjustment/elimination/compensationReactive power compensationFrequency changerPower factor

The invention relates to a frequency converting and energy saving device of an oil pumping machine in the technical field of electronic control. The device comprises a breaker, a frequency converter, a current transformer, an input reactor, a first contactor, a second contactor, a third contactor and a thermal relay, wherein an external power supply is connected with the breaker, after the external power supply is controlled by the breaker, the external power supply is divided into two paths of circuits through the current transformer, and one path of the circuit is a frequency conversion loop, while the other path of the circuit is a power frequency loop; the frequency conversion loop firstly passes through the input reactor and then enters the frequency converter through the third contactor, and after the frequency conversion loop is subjected to frequency conversion through the frequency converter, the frequency conversion loop enters the first contactor; the power frequency loop comprises the second contactor and the thermal relay which are connected in series; and the whole power frequency loop and the frequency conversion loop are connected in parallel. The frequency converter is added in a control cabinet of the oil pumping machine so as to improve the output and the pump efficiency of an oil well, compensate the power factor, avoid impacts to power grid equipment when a motor is started and realize arbitrary jig frequency regulation and segmental rotating speed control.

Owner:上海德力西集团有限公司

Hydraulic reciprocating compression air pump with quantified and variable pressurization functions

InactiveCN104595151ASimple structureFew partsMulti-stage pumpsPositive-displacement liquid enginesThree levelExhaust valve

A hydraulic reciprocating air pump with the quantified and variable pressurization functions comprises a middle power reciprocating cylinder, a left compression cylinder and a right compression cylinder. The left compression cylinder and the right compression cylinder are connected to the two ends of the power reciprocating cylinder. A piston of the left compression cylinder divides the left compression cylinder into a first working cavity and a second working cavity. A piston of the right compression cylinder divides the right compression cylinder into a third working cavity and a fourth working cavity. The cylinder diameter of the left compression cylinder is equal to the cylinder diameter of the right compression cylinder in the variable pressurization function. Air inlet valves of the first, second, third and fourth working cavities are each provided with a manual ejector rod. Exhaust valves of the four working cavities are connected in parallel and connected with an air outlet. Suction valves are connected in parallel and connected with an air inlet. The cylinder diameter of the left compression cylinder is not equal to the cylinder diameter of the right compression cylinder in the quantified pressurization function, the exhaust valves of the four working cavities and the suction valves are connected in series in different modes to obtain two pressurization effects, and parallel connection two-level pressurization and series connection three-level pressurization are achieved. According to the hydraulic reciprocating air pump, the cylinder diameters of the left and right compression cylinders are changed, and the series and parallel connection loops of the suction valves and the air inlet valves are changed, so that high pressure or super-high pressure of the gas compression pump is easy to achieve.

Owner:天津市海雅实业有限公司

Planetary transmission mechanism

InactiveCN1439822AImprove efficiencyReduce the number of acceleration changesGearingSatelliteCantilever

A novel movement mechanism with planetary gear chain for the conversions between rotation and linear reciprocation and from rotation to elliptical movement is composed of sun gear fixed to axle, planetary gear which as a diameter the equal to the radius of sun gear and can revolve around sun gear while rotate, satellite axle revolving around planetary gear, crank gear, cantilever, supporter and accessories. When the resistance arm of cantilever is equal to that of crank, the satellite axle does linear reciprocation with its stroke 4 times greater than that of resistance arm. If they are no equal to each other, the satellite axle does elliptical movement with its stroke 2-6 times greater than that of resistance arm.

Owner:尹万春

Gear sector and rack type reciprocating pump limited by cam

PendingCN107795449AImprove volumetric efficiencyImprove transmission efficiencyPiston pumpsPositive-displacement liquid enginesReciprocating motionEllipse

The invention relates to a gear sector and rack type reciprocating pump limited by a cam. The gear sector and rack type reciprocating pump mainly comprises a rack, an input shaft, a gear sector, a rack assembly, the cam, a limiting frame, a guide rail, a piston and a hydraulic cylinder, wherein the input shaft is mounted on the rack through a bearing, the gear sector is mounted on the input shaft,and the gear sector is meshed with the rack assembly; one end of the rack assembly is connected with a piston rod, the other end of the rack assembly is connected with the limiting frame, and the camis arranged in the limiting frame; the gear teeth of the gear sector consist of a cylindrical gear and a variable-transmission-ratio elliptical gear, and the inscribed angle of the part with the gearteeth is smaller than 180 degrees; and a contour line matched with the limiting frame is arranged near the farthest dwell angle of the cam. When the mechanism works, the piston is pushed to make reciprocating movement through the alternating engagement of the gear sector and upper and lower racks, and the smooth and stable reversing of the mechanism is ensured through the cooperation of the cam and the limiting framework. The reciprocating pump is simple in structure, accurate and stable in reversing, high in system efficiency and small in pump pressure and pump displacement fluctuation.

Owner:SOUTHWEST PETROLEUM UNIV

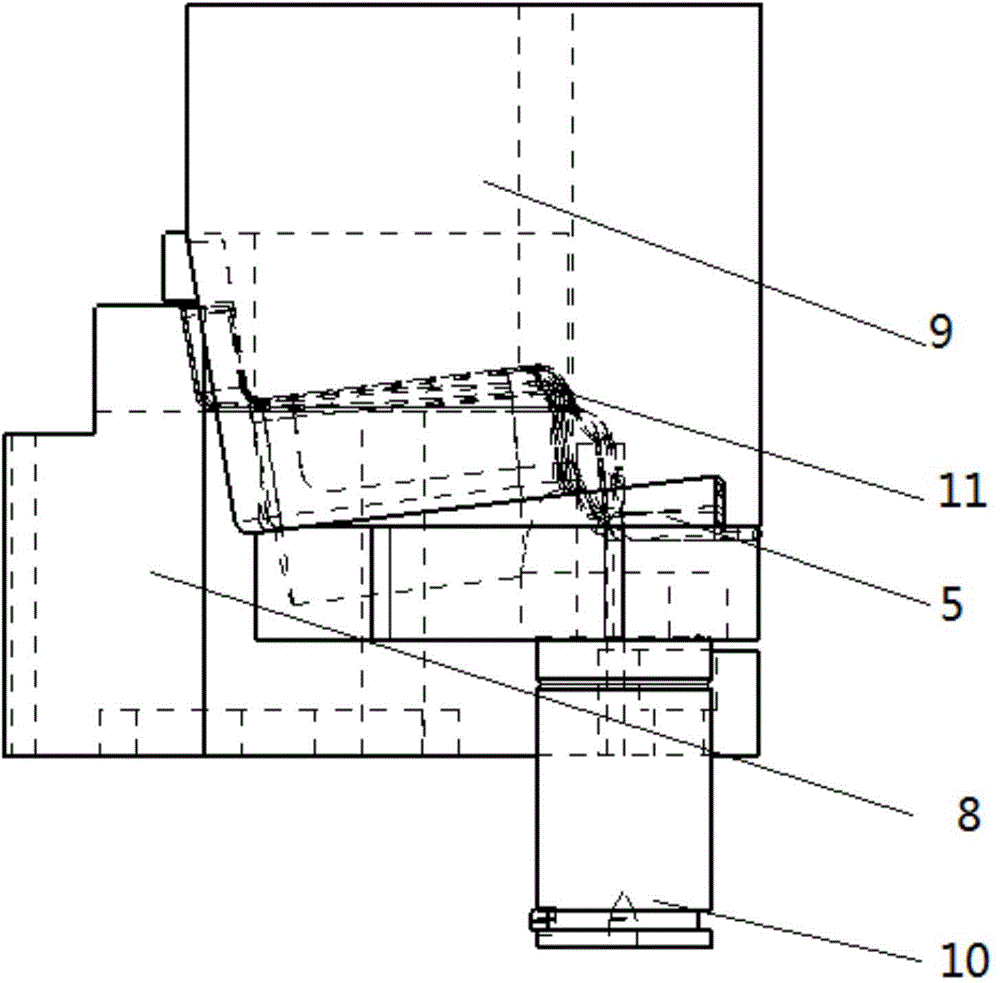

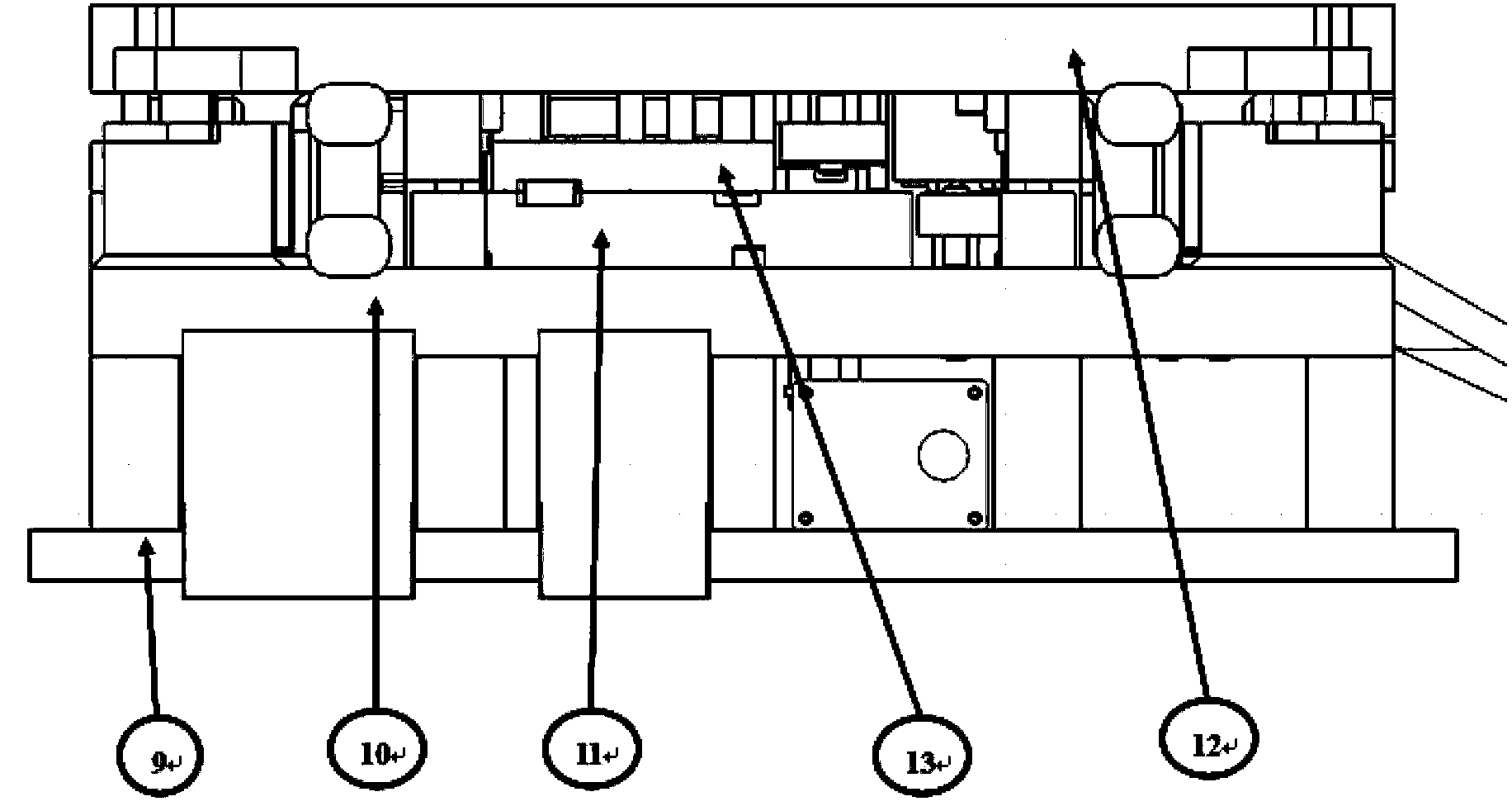

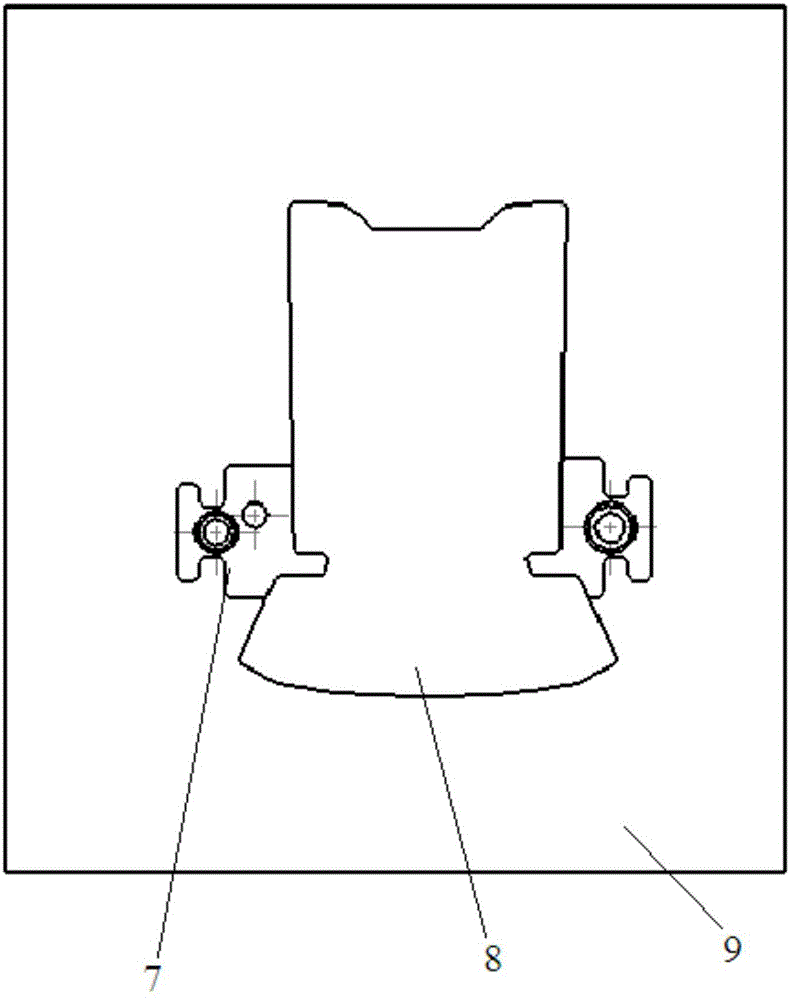

Gas spring reinforcing plate grading mold

The invention relates to a gas spring reinforcing plate grading mold which consists of a lower mold part and an upper mold part, wherein the lower mold part comprises a mold foot (9), a lower mold base (10), a lower mold punching female mold (1), a lower mold trimming cutter block (2), a feeding sensor (3), a lower mold forming cutter, a lower mold guide plate (8) and a jacking plate (11), wherein the mold foot (9) and a mold foot pad plate are arranged at the lowermost part of the mold; the lower mold base (10) is arranged on the upper plane of the mold foot (9); the lower mold punching female mold (1), lower mold trimming cutter block (2), the feeding sensor (3), the lower mold forming cutter and the jacking plate (11) are fixed on the upper surface of the lower mold base (10); the upper mold part comprises an upper mold pressing plate (13), an upper mold punching head (14), an upper mold punching trimming cutter (15), an upper mold forming cutter block (16) and an upper mold base (12). Compared with the prior art, the gas spring reinforcing plate grading mold has the advantages of simple structure, convenience in use, convenience in repairing, stable production and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

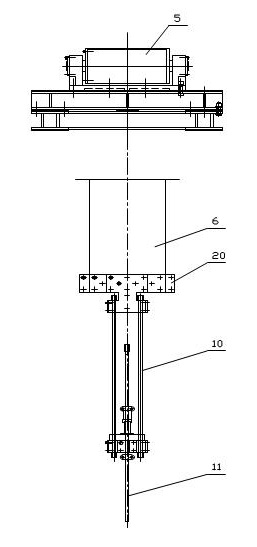

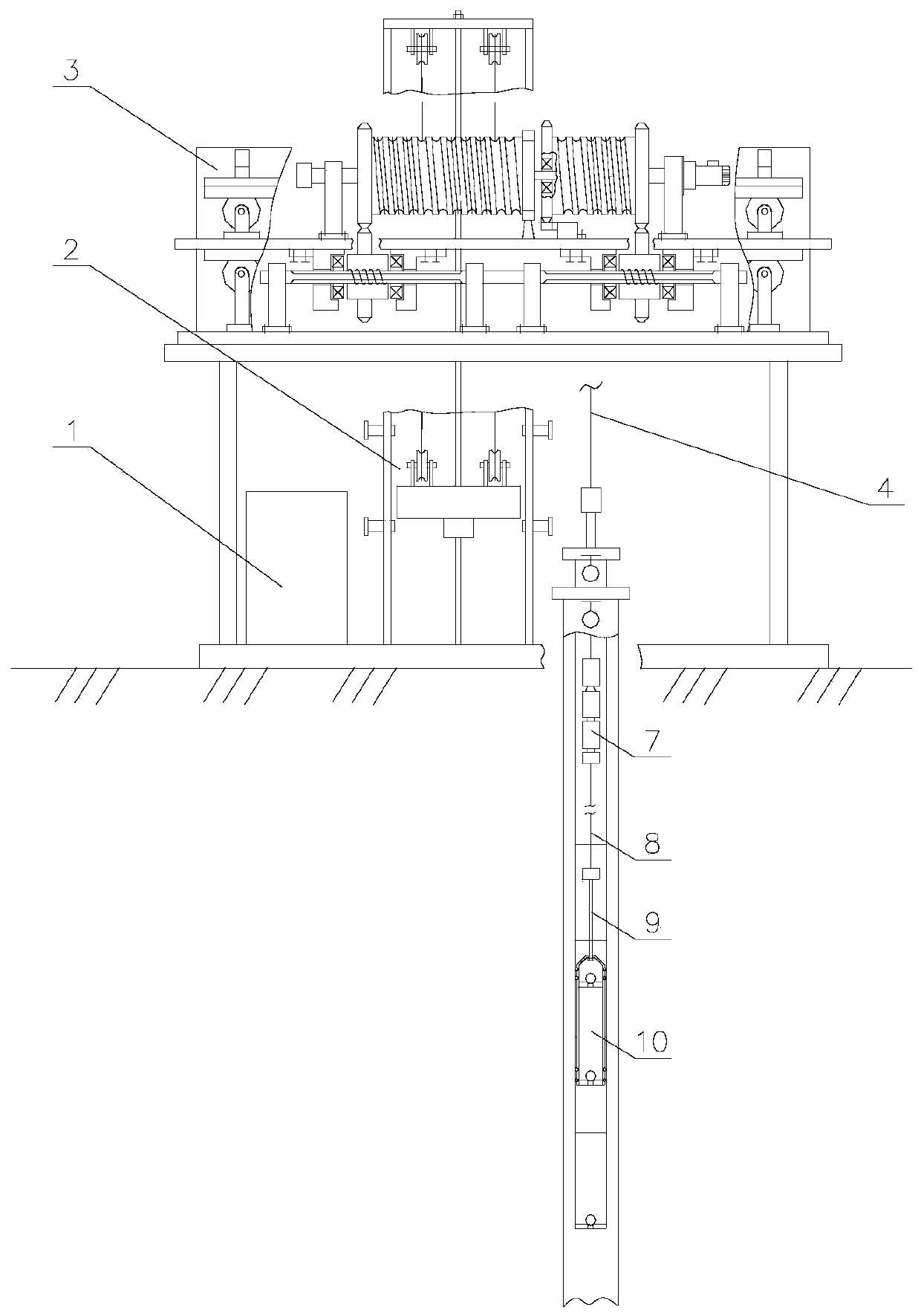

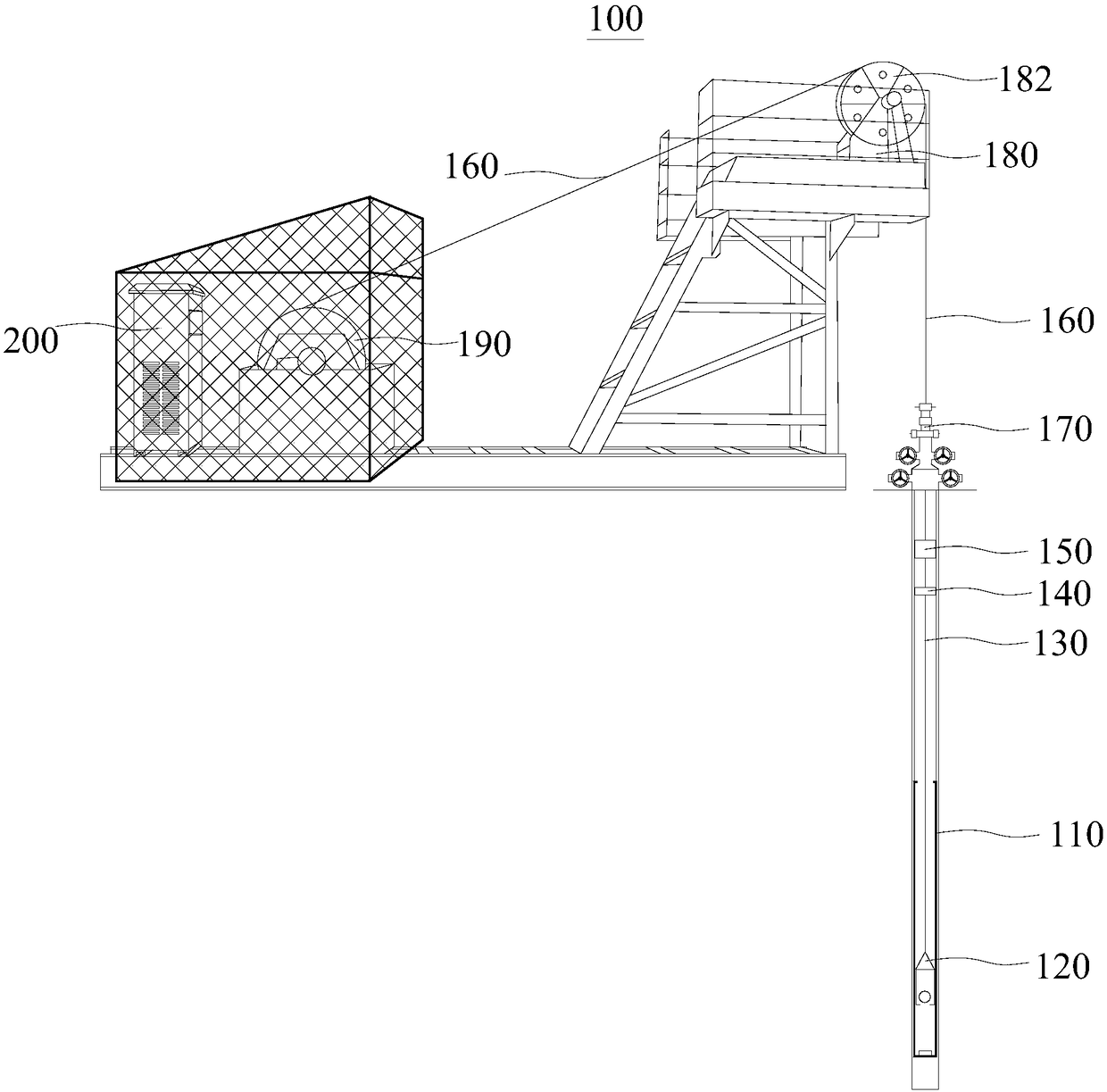

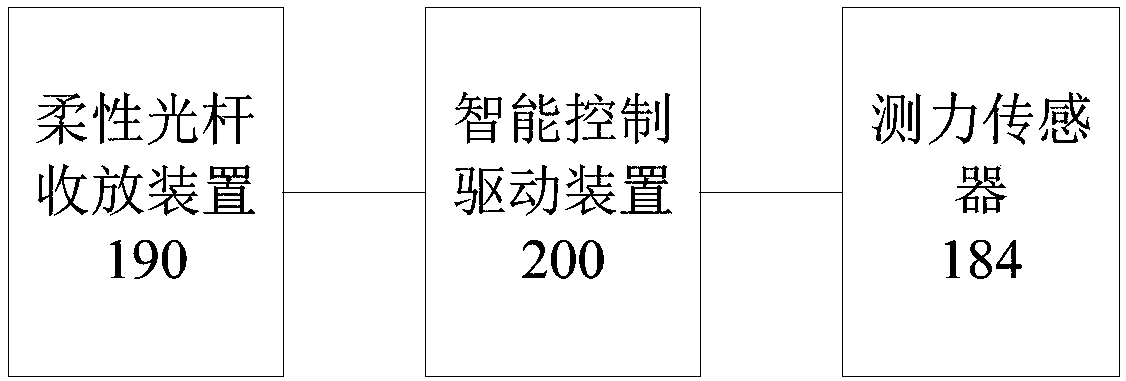

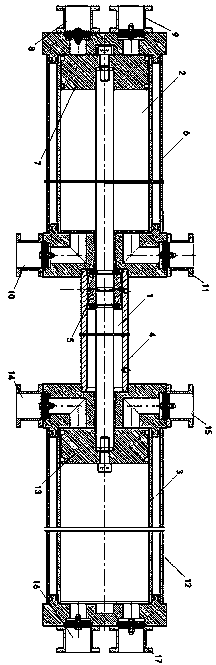

Oil production device and system

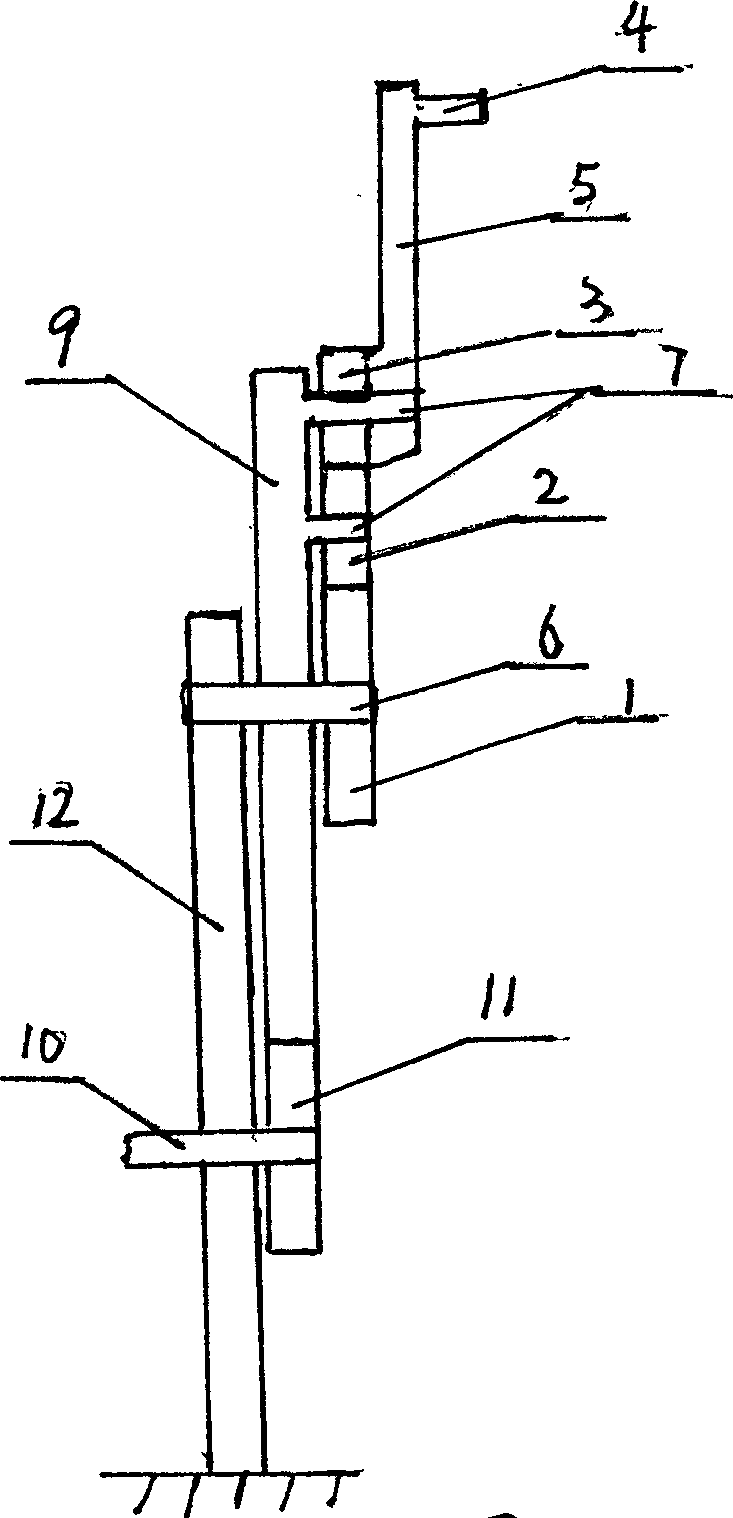

PendingCN108397162ALow strokeReduce stroke lossDrilling rodsFluid removalReciprocating motionOil production

The embodiment of the invention provides an oil production device and system. The oil production device comprises an oil production pump, an oil pumping plunger, a flexible polish rod, a packing box,a steering bracket and a flexible polish rod winding and unwinding device. The oil production pump is mounted in a downhole oil pipe; the oil pumping plunger is arranged inside the oil production pumpand used for delivering downhole crude oil; a steering pulley is arranged on the steering bracket; one end of the flexible polish rod is connected with the oil pumping plunger, and the other end of the flexible polish rod is connected with the flexible polish rod winding and unwinding device through the packing box and the steering pulley; and the flexible polish rod and the oil pumping plunger are driven to move in the oil production pump in a reciprocating mode under driving of the flexible polish rod winding and unwinding device. Thus, the oil production device has all the advantages of aplunger-pump-type oil pumping unit; and the stroke of the oil pumping plunger is determined by the length of the oil production pump, the length of the flexible polish rod and the travel of the winding and unwinding device, so that the stroke of the oil pumping plunger far exceeds the long stroke of a traditional walking-beam-type oil pumping unit quite easily, and thus the characteristics of lesstimes of stroke, less stroke loss and high pump efficiency are further achieved.

Owner:青岛新胜石油机械有限公司

Hydraulic gas vacuum pump

InactiveCN103470473ASimple structureAdd partsPiston pumpsPositive-displacement liquid enginesHydraulic cylinderExhaust valve

The invention discloses a hydraulic gas vacuum pump. The vacuum pump comprises an oil cylinder part, a left compression cylinder part and a right compression cylinder part, wherein the oil cylinder part for driving hydraulic oil is arranged in the middle of the hydraulic gas vacuum pump, and the left compression cylinder part and the right compression cylinder part are connected at the two ends of the oil cylinder part; the oil cylinder part comprises an oil cylinder barrel and an oil cylinder piston in the oil cylinder barrel; each compression cylinder part comprises a compression cylinder barrel and a compression cylinder piston, and the two ends of each compression cylinder barrel are provided with an air suction valve and a vent valve. The compression cylinder pistons and the oil cylinder piston are connected on the same piston rod. The hydraulic oil cylinder part adopts a hydraulic control way and performs commutation control by a hydraulic control reciprocating machine, so that the reciprocating motion of the hydraulic oil cylinder can be realized. According to the hydraulic gas vacuum pump, the pistons are directly driven to move through hydraulic oil driving so as to realize the low-jig-frequency and long-stroke motion of the pistons, so that the service life is long, the trouble is little and the maintenance cost is low. The gas vacuum pump is simple in structure, few in parts, small in size and light in weight. Compared with a traditional mechanical drive triplex pump, the number of the parts of the hydraulic gas vacuum pump is reduced by 65%, and the size and weight is reduced by more than 60%.

Owner:天津市海雅实业有限公司

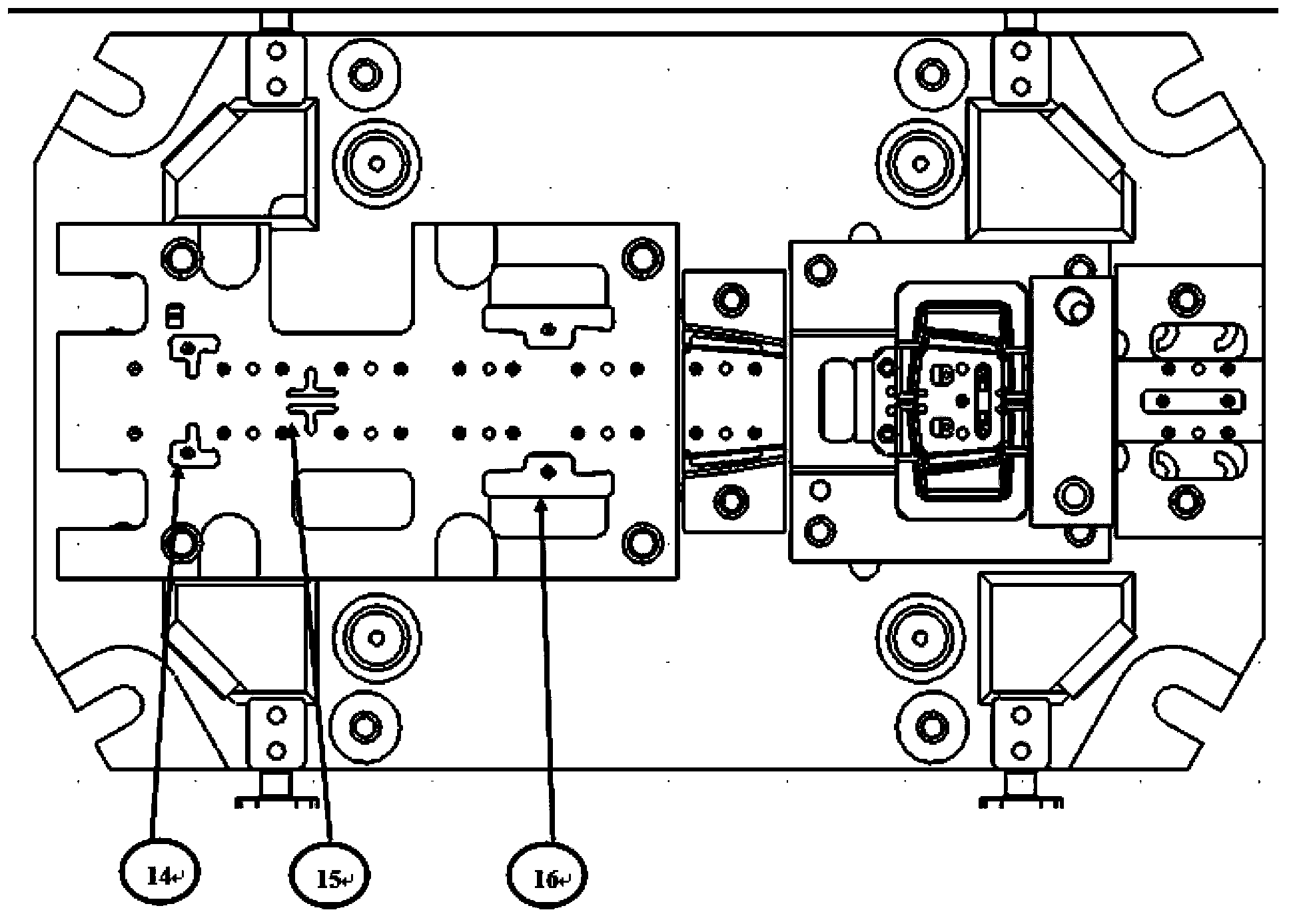

Automobile door outer plate reinforcing plate part die

The invention relates to an automobile door outer plate reinforcing plate part die which comprises an upper die component and a lower die component. The upper die component comprises an upper die holder, as well as an upper die core, an upper die insert block and an upper die eccentric swage, which are arranged on the upper die holder; the upper die core is positioned below the upper die holder; the lower die component comprises a lower die holder, as well as a lower die core and an ejector, which are arranged on the lower die holder; the lower die core is positioned above the lower die holder; the upper die component further comprises a plurality of upper push rods; the upper push rods penetrate through the upper die holder and are propped against the top of the upper die core; a shaving hole punching female die, flanging sizing female die, a trimming female die and a side hole punching female die are arranged on the upper die core; and a shaving hole punching male die, flanging sizing male die, a trimming male die and a side hole punching male die are arranged on lower die core. Compared with the prior art, the automobile door outer plate reinforcing plate part die has the advantages that three dies are integrated into one die, production processes are reduced, and the upper ejector structure is adopted to facilitate maintain.

Owner:SHANGHAI ZHONGDA AUTO PARTS

Trimming and flanging die of automobile water tank assembly parts

InactiveCN104492940AReduce manufacturing costIncrease productivityShaping toolsVehicle componentsEngineeringFlanging

The invention relates to a trimming and flanging die of automobile water tank assembly parts. The die comprises an upper die assembly, a lower die assembly and upper and lower die guide plates, wherein the upper die assembly comprises an upper die base, an upper die flanging cutter block and an upper die pressure plate which are sequentially arranged on the upper die base, the lower die assembly comprises a lower die base, a trimming cutter block, a lower die pressure plate and a lower die flanging cutter block which are sequentially arranged on the lower die base, the upper die flanging cutter block is arranged on the right side of the lower die pressure plate, the lower die flanging cutter block is arranged on the right side of the upper die pressure plate, the upper and lower die guide plates comprise an upper die guide plate and a lower die guide plate, the upper die guide plate is arranged on the upper die base and corresponded to the lower die guide plate on the lower die base. The production cost is low, the production efficiency is high, and the die is convenient to maintain.

Owner:SHANGHAI ZHONGDA AUTO PARTS

Continuous production die for automobile activated carbon canister support parts

The invention relates to a continuous production die for automobile activated carbon canister support parts. The continuous production die comprises an upper die part, a lower die part and guide pillars, wherein the lower die part comprises a lower die base, a stamping concave die knife and a lower die trimming knife block, and the stamping concave die knife and the lower die trimming knife block are fixed to the upper surface of the lower die base; the upper die part comprises an upper die base, a pressure plate, a punch and an upper die trimming knife block, the pressure plate, the punch and the upper die trimming knife block are fixed to the lower surface of the upper die base, the pressure plate is arranged on the upper die trimming knife block and connected with the upper die trimming knife block, and the punch is arranged on the pressure plate; the upper die base is connected with the lower die base through the guide pillars. Compared with the prior art, the continuous production die has the advantages of being long in service life, convenient to maintain, high in stamping efficiency, low in stamping cost and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

Automobile part continuous production die provided with pre-flanging mechanism

InactiveCN105964785AExtended service lifeAvoid damageShaping toolsVehicle componentsPunchingEngineering

The invention relates to an automobile part continuous production die provided with a pre-flanging mechanism. The automobile part continuous production die provided with the pre-flanging mechanism comprises an upper die part, a lower die part and guide posts. The upper die part comprises an upper die seat, a press plate, a puncher pin, an upper die trimming knife, an upper die pre-flanging mechanism body, an upper die complete flanging mechanism body and a material ejection groove, wherein the press plate, the puncher pin, the upper die trimming knife, the upper die pre-flanging mechanism body and the upper die complete flanging mechanism body are fixed to the lower surface of the upper die seat; and the material ejection groove is formed in the lower surface of the upper die seat. The lower die part comprises a lower die seat, a punching female die body, a lower die trimming knife, a lower die pre-flanging mechanism body, a lower die complete flanging mechanism body and a material ejection rod, wherein the punching female die body, the lower die trimming knife, the lower die pre-flanging mechanism body, the lower die complete flanging mechanism body and the material ejection rod are fixed to the upper surface of the lower die seat. In the working process, the puncher pin and the punching female die body are matched for conducting punching action; the lower die trimming knife and the upper die trimming knife are matched for conducting trimming action; the upper die pre-flanging mechanism body and the lower die pre-flanging mechanism body are matched for conducting pre-flanging action; and the upper die complete flanging mechanism body and the lower die complete flanging mechanism body are matched for conducting complete flanging action. Compared with the prior art, the automobile part continuous production die provided with the pre-flanging mechanism has the advantages of being long in service life, convenient to maintain, high in punching efficiency and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

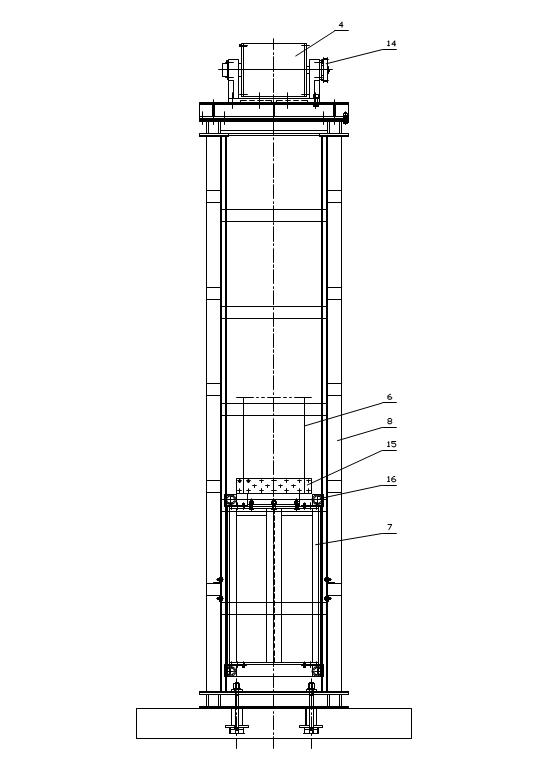

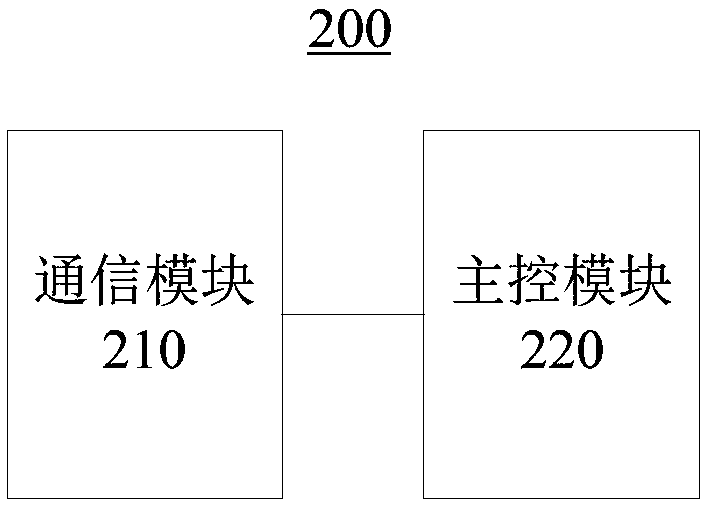

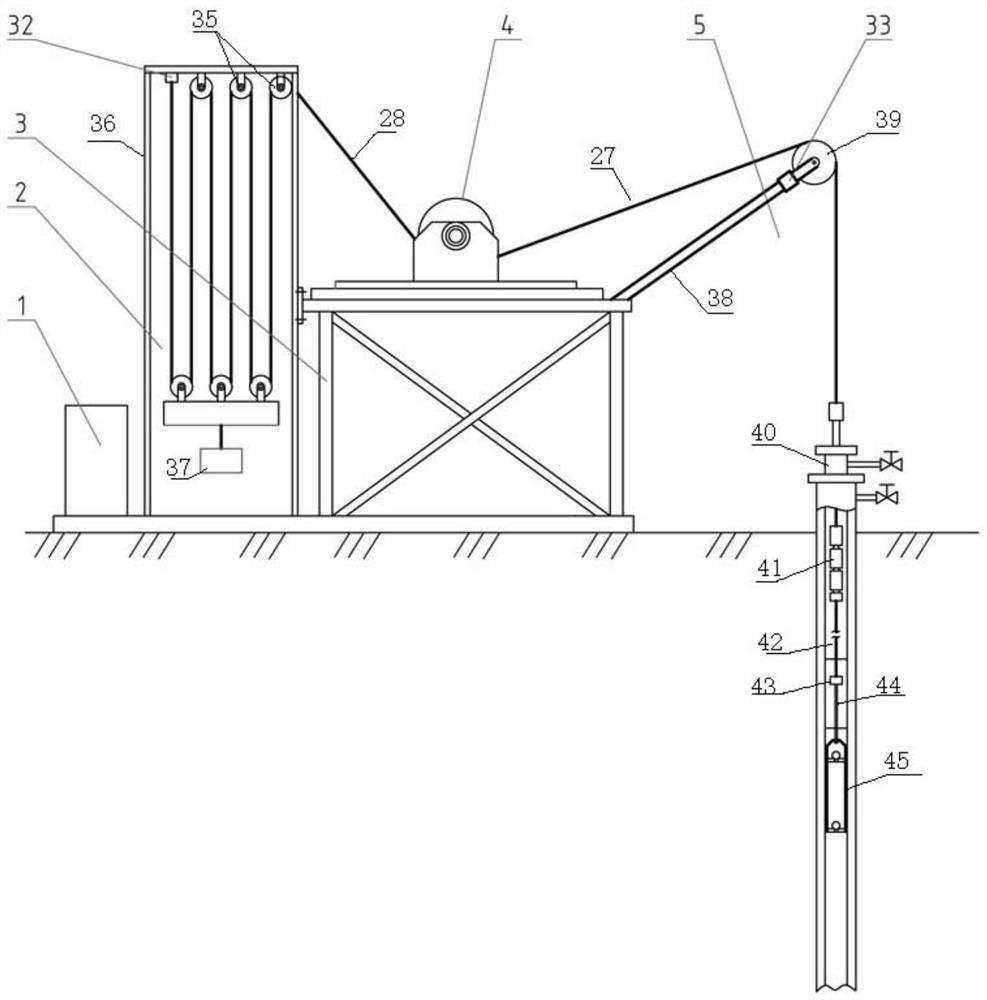

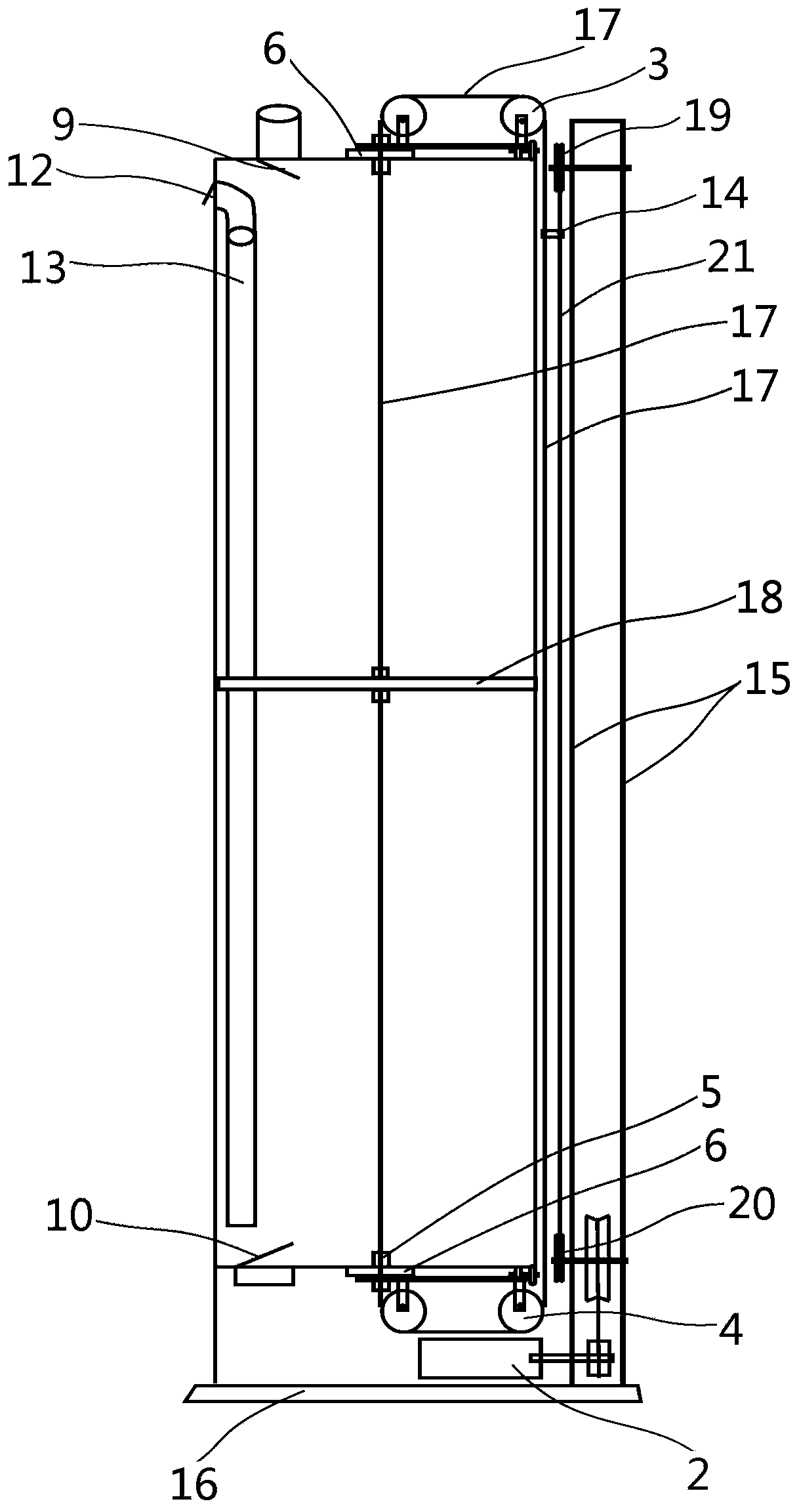

Intelligent ultra-long stroke winch oil pumping unit

ActiveCN111911114AIncrease the total strokeEliminate angleFlexible member pumpsFluid removalReduction driveElectric machine

The invention relates to an intelligent ultra-long stroke winch oil pumping unit which is composed of an electric control cabinet, a balance weight system, a base, a winch system and a pumping system.The electric control cabinet is connected with the balance weight system, the winch system and the pumping system through cables, the balance weight system is connected with the winch system througha steel wire rope, and the winch system is connected with the pumping system through a flexible polish rod. The winch system comprises a displacement sensor, a motor, an electromagnetic brake, a winchsupport, a speed reducer, an outer-square cylinder and a roller. Steel wire rope tension of the balance weight system and flexible polish rod tension of the pumping system are located at the two endsof the axis of the roller and are opposite in direction. The intelligent ultra-long stroke winch oil pumping unit is used for improving the stroke of the oil pumping unit, eliminating an included angle generated between the flexible polish rod and a head sheave, prolonging the service life of the flexible polish rod, realizing the balance weight of the ultra-long stroke oil pumping unit, and further saving energy, by adding an intelligent chip, the pump efficiency, the yield and the annulus liquid level position of an oil jacket can be instantly reflected, and the oil pumping speed is automatically adjusted or oil is intermittently pumped according to liquid supply data. Efficient operation is achieved.

Owner:沃森埃里克

Mold for vehicle support part

InactiveCN105945142AGuaranteed accuracyGuaranteed stabilityShaping toolsVehicle componentsPunchingEngineering

The invention relates to a mold for a vehicle support part. The mold comprises a lower mold base and an upper mold base; a drawing unit, a trimming and punching unit, a flanging and shaping unit and a punching and separation unit are arranged between the upper mold base and the lower mold base in a strip moving direction in sequence; and the flanging and shaping unit includes a first flanging and shaping mechanism and a second flanging and shaping mechanism arranged in the strip moving direction in sequence. Compared with the prior art, four procedures of drawing, trimming and punching, flanging and shaping and punching and separation are combined, and can be synchronously performed in each punching, so that three pairs of molds are saved, three punching times are reduced, machine tools and staff are saved, the production cost and the maintenance cost are reduced, and the production efficiency is improved; and the structural machinability is excellent, so that the part production precision and stability are guaranteed, and the effects of safety and reliability are achieved.

Owner:SHANGHAI ZHONGDA AUTO PARTS

Super-long-stroke oil extraction pump

ActiveCN104632592ALow maintenanceLess one-time investmentPositive displacement pump componentsFlexible member pumpsBusiness efficiencyCoupling

The invention discloses a super-long-stroke oil extraction pump which comprises pump cylinders, a plunger, a valve seat and tubing couplings. A plunger oil outlet valve and a pump cylinder oil inlet valve are arranged at the two ends of a piston in the pump cylinders respectively, the overall length of the pump cylinders of the super-long-stroke oil well pump is larger than 50 m, the super-long-stroke oil well pump is formed by connecting five or more pump cylinders, the length of each pump cylinder I or each pump cylinder II is larger than or equal to 10 m, the pump cylinders are in threaded connection through pump cylinder couplings, it is guaranteed that the inner diameter concentricity error generated after every two pump cylinders are connected is not larger than 0.02 mm, the concentricity error of the thread axis and the pump cylinders is not larger than 0.02 mm, a spraying welding plunder is adopted as the plunger, the length of the sealing face of the plunder is larger than or equal to 1.5 m, and the matching clearance between the plunder and the pump cylinders is the first-level clearance of 0.03 to 0.07. The one-time investment of the super-long-stroke oil extraction pump is small, the extraction quantity is improved, the pump efficiency ratio is high, the energy saving effect is obvious, and use is convenient. The super-long-stroke oil extraction pump is suitable for being used in oil fields of various conditions.

Owner:青岛新胜石油机械有限公司

Piston type two-stroke fan

PendingCN109944770ALong strokeLow strokePositive displacement pump componentsPiston pumpsAir volumeThrust bearing

The invention discloses a piston type two-stroke fan, and relates to the technical field of air blowers. According to the specific technical scheme, the two-stroke fan is composed of a two-stroke fanair cylinder, a speed adjustment motor, upper dual pulleys, lower dual pulleys, hollow bolts, thrust bearings, an upper rolling wheel, a lower rolling wheel, an upper one-way air inlet valve, a lowerone-way air inlet valve, an upper one-way air outlet valve, a lower one-way air outlet valve, a lower one-way air outlet pipe, an annular rope, a piston type air plate, an upper chain wheel, a lower chain wheel, a chain, a rotating shaft telescopic buckle and a support. The piston type two-stroke fan has the advantages that the two-stroke fan is long in stroke, low in stroke frequency, large in cylinder diameter, large in blast capacity, high in air pressure and low in noise and is suitable for multiple scenes achieving spaced air blowing.

Owner:吴平安

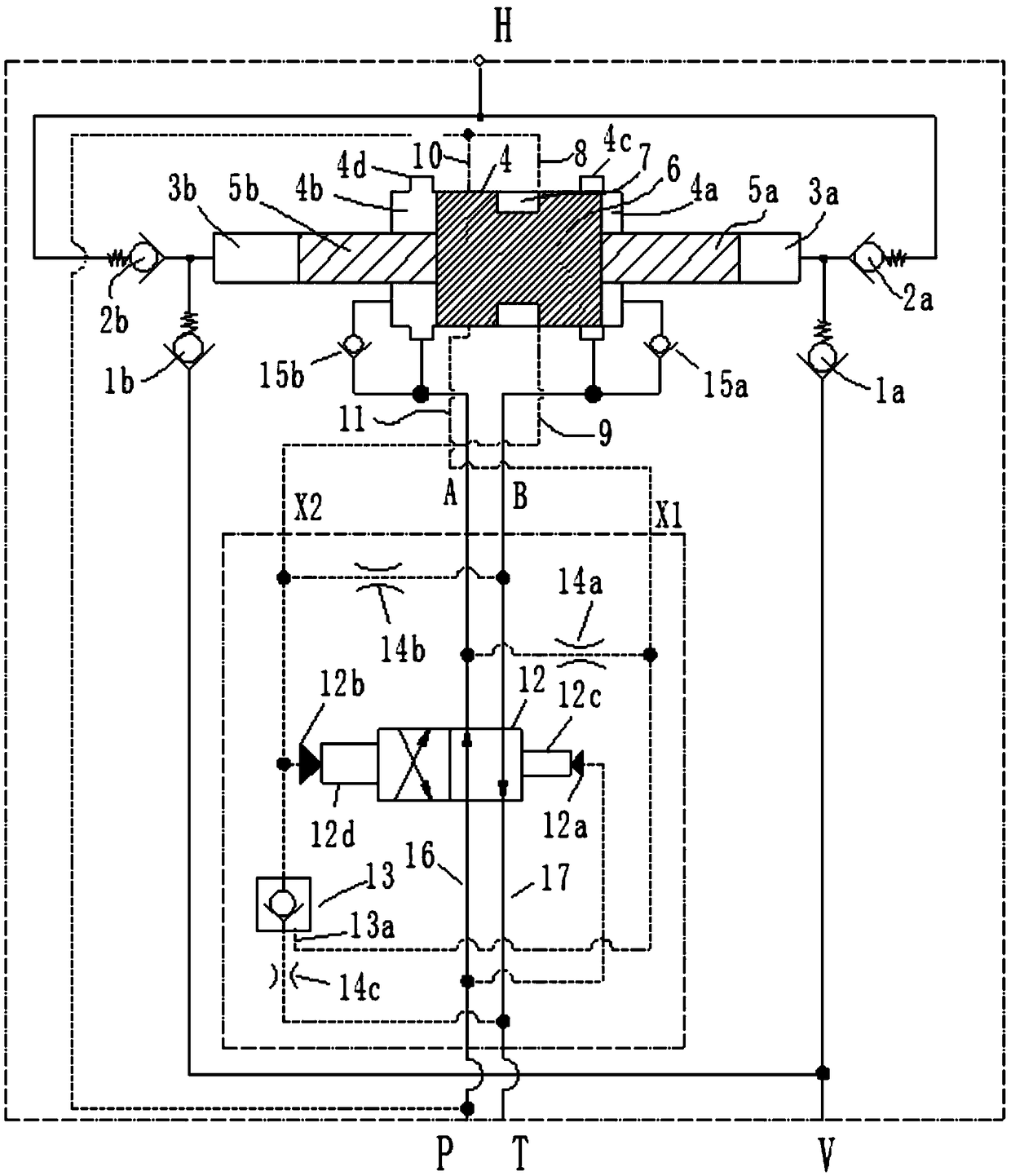

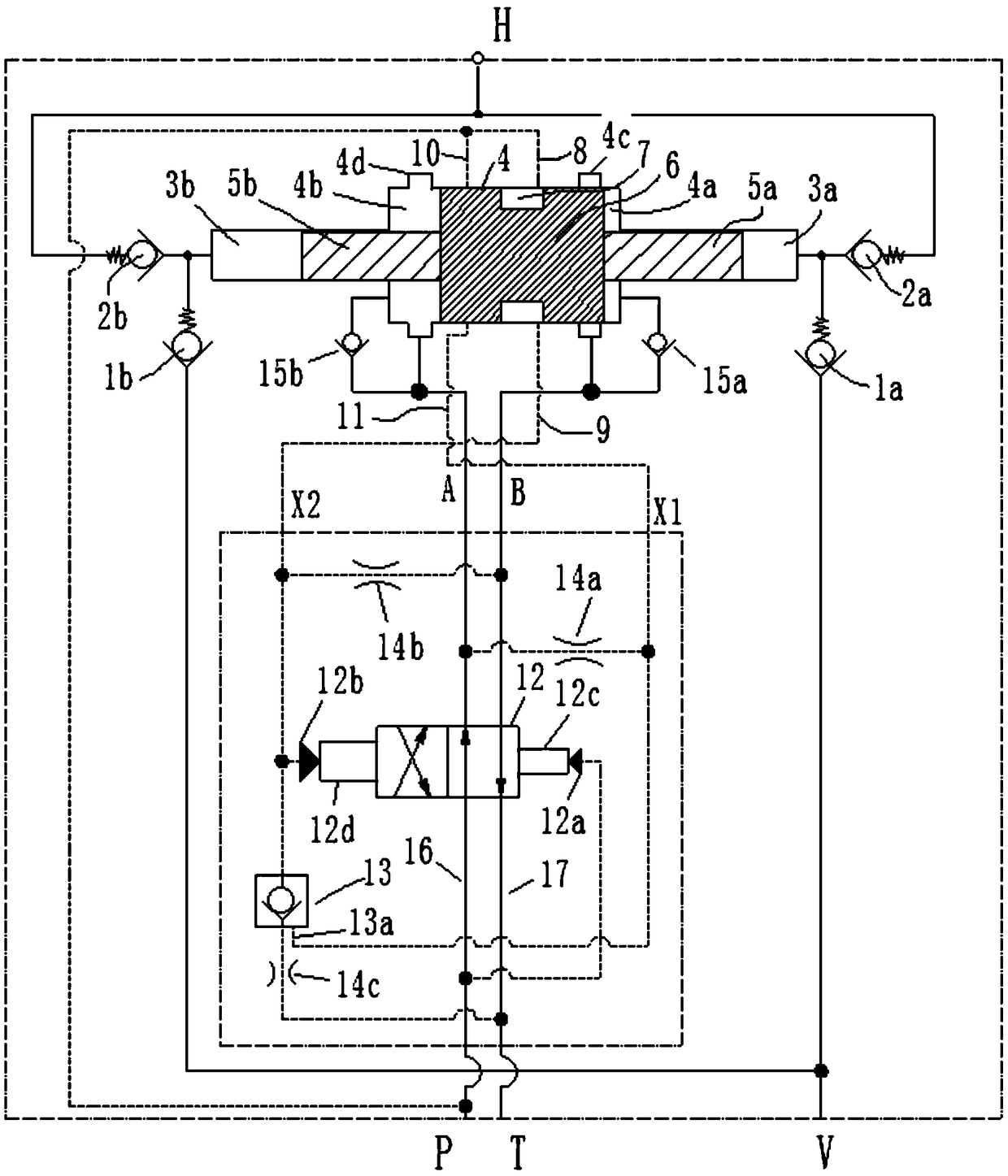

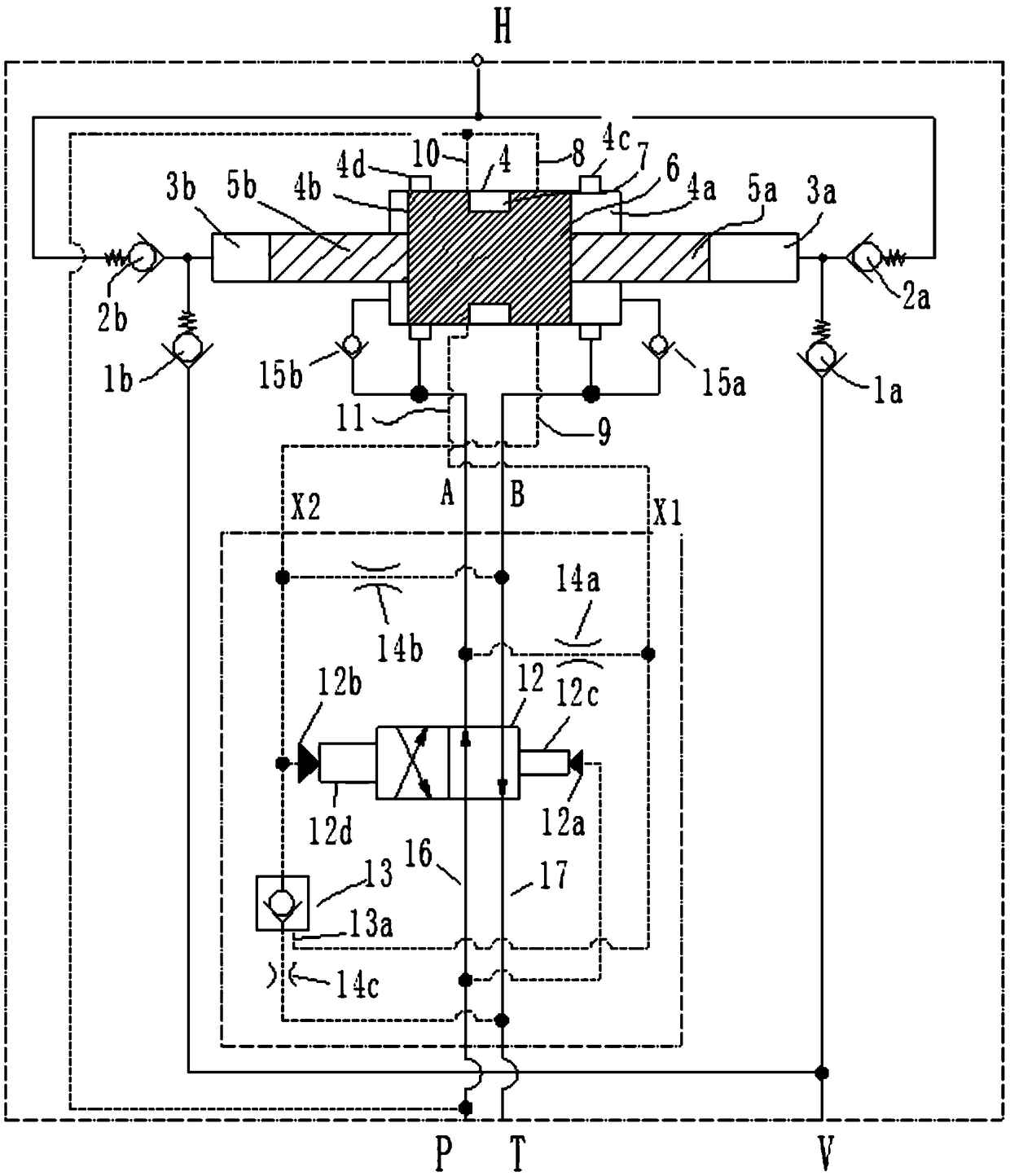

Hydraulic mud pump

The invention discloses a hydraulic mud pump which is provided with an oil inlet P, an oil return opening T, a pulp inlet V and a high-pressure pulp outlet H, and comprises a pressure cylinder and a hydraulic operated directional valve assembly. The pressure cylinder comprises a low pressure cylinder, a low pressure piston, a left high pressure plunger, a right high pressure plunger, a left high pressure cylinder and a right high pressure cylinder; a first oil inlet passageway, a second oil inlet passageway, a first control passageway and a second control passageway are arranged on the low pressure cylinder; an annular communicating groove is formed in the low pressure piston; when the low pressure piston leftwards moves to a position completely covering a first through-flow groove, the first oil inlet passageway and the first control passageway communicate through the communicating groove, the hydraulic operated directional valve assembly is controlled to reverse, and the low-pressurepiston is braked through a sealed left piston cavity; and when the low pressure piston rightwards moves to a position completely covering a second through-flow groove, the second oil inlet passagewayand the second control passageway communicate through the communicating groove, the hydraulic operated directional valve assembly is controlled to reverse, and the low-pressure piston is braked through a sealed right piston cavity. The hydraulic mud pump not only is simple in structure, but also has no need to be electrically controlled, and has low noise.

Owner:高建国

Disc cam type double-acting mud pump

ActiveCN111894825AAchieve outputExtend your lifePositive displacement pump componentsPiston pumpsCircular discReciprocating motion

The invention discloses a disc cam type double-acting mud pump which comprises a mud pump box body, a power end assembly and a hydraulic end assembly. The power end assembly comprises a disc cam mechanism, a power connecting shaft for connecting the two disc cam mechanisms and a plurality of connecting rod driving mechanisms with rollers. The hydraulic end assembly comprises a piston rod, a piston, a piston cylinder liner and end face sealing covers arranged at the two ends of the piston cylinder; the side walls of cavities on the two sides of the piston are each provided with a suction high-pressure valve and a discharge high-pressure valve; the two ends of the piston rod are connected with roller frames, and the rollers fluctuate on the curved surface when disc cams rotate, so that the piston rod can axially reciprocate between the two disc cams; when the piston moves in one direction in the piston cylinder, a valve element of the discharge high-pressure valve in the cavity, toward the moving direction, of the piston cavity is opened to output media, and a valve element of the suction high-pressure valve in the other cavity is opened to suck in media. Single-cylinder double action can be realized, and the effects of low stroke frequency, short stroke and large displacement can be realized.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

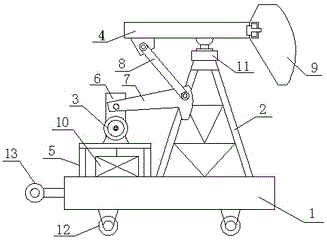

Improved oil field pumping unit

The invention discloses an improved oil field pumping unit. The improved oil field pumping unit comprises a base, a support frame, a driving device and a crossbeam, wherein the support frame is arranged on the base; the crossbeam is arranged on the support frame; a frame is arranged on the base; the driving device is arranged on the frame; the output end of the driving device is connected with a gearbox; the output end of the gearbox is connected with a crank rod; a connecting rod is hinged to the front end of the crank rod; one end of the connecting rod is hinged to the crossbeam; the front end of the crossbeam is provided with a horse head; the base is provided with a back-up power supply; the back-up power supply is connected with the driving device. The improved oil field pumping unit is simple in structure, convenient to use and mount, simple in operation, low in cost, high in work efficiency, low in energy consumption, conveniently moved, wide in application range and long in service life, and has safe and reliable effects.

Owner:CHENGDU JUZHI IND DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com