Disc cam type double-acting mud pump

A mud pump, double-acting technology, which is applied to the components of the pumping device for elastic fluid, pumps, piston pumps, etc. The effect of wearing parts life, reducing maintenance times and maintenance time, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

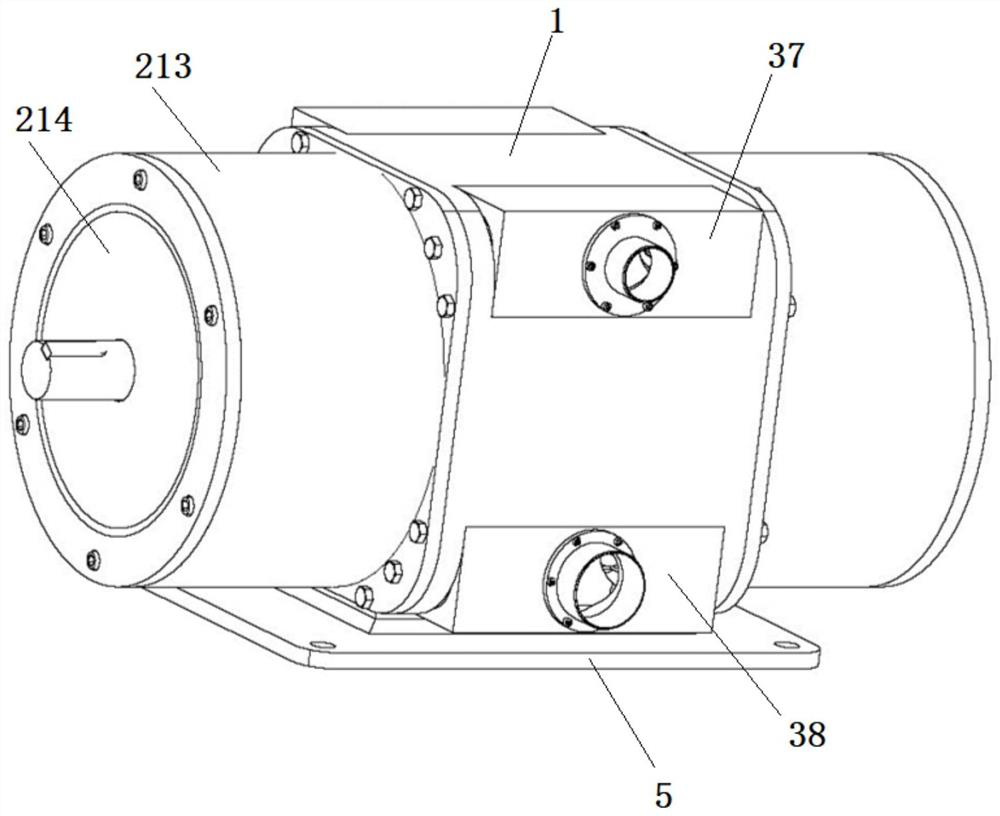

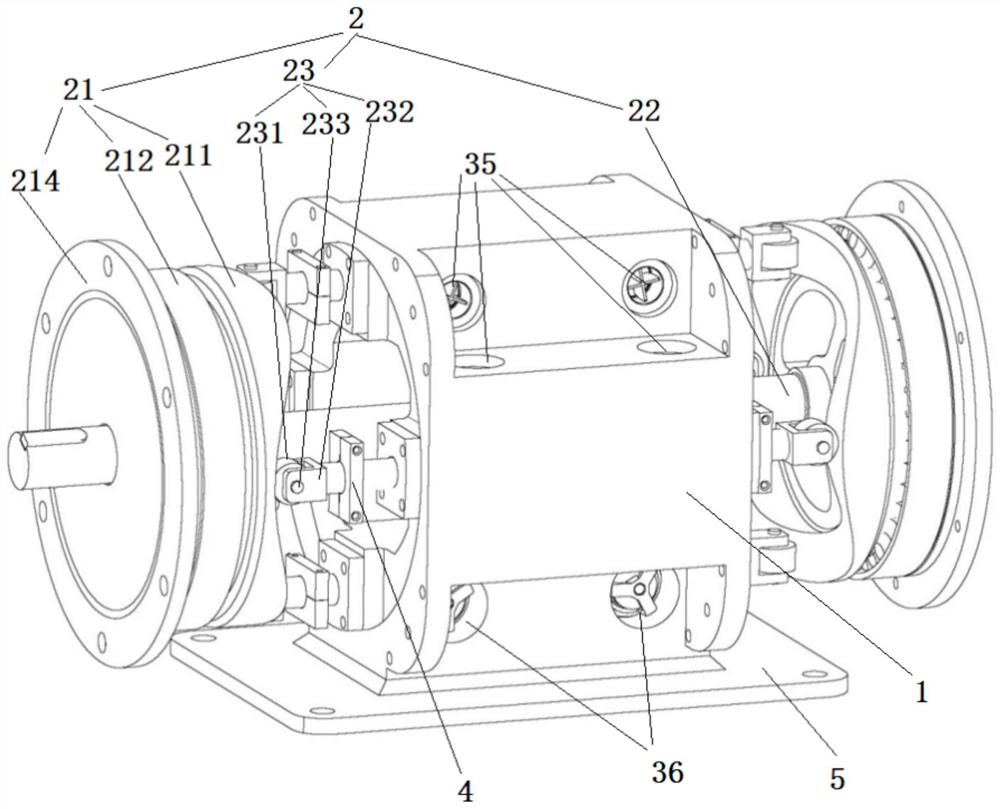

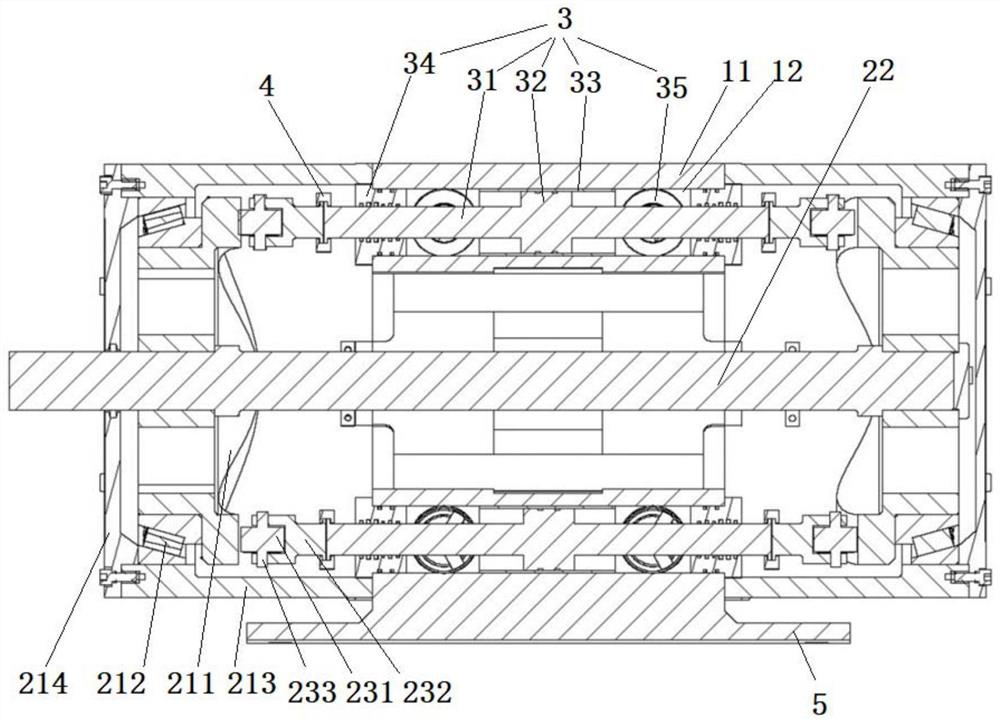

[0047] Such as Figure 1 to Figure 3As shown, this embodiment provides a disc cam type double-acting mud pump, which includes a mud pump casing 1 , a power end assembly 2 and a fluid end assembly 3 .

[0048] The power end assembly 2 includes disc cam mechanisms 21 arranged on both sides of the mud pump casing, a power connection shaft 22 connecting the two disc cam mechanisms, and a plurality of driving mechanisms 23 with roller links.

[0049] The disc cam mechanism 21 comprises: a disc cam 211, a bearing 212, a side case 213 and a side case cover 214 arranged at the end of the side case 213, which are arranged coaxially from the inside to the outside; one side of the disc cam 211 is Alternating crests and troughs, the curved surfaces of the two disc cams 211 on the side of the mud pump casing 1 are opposite and misplaced so that the crests of one disc cam 211 correspond to the troughs of the other disc cam 211 to ensure that the two disc cams 211 The axial distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com