Current internal-model decoupling controller of open-winding permanent-magnet synchronous motor

A permanent magnet synchronous motor, internal model decoupling technology, applied in the direction of motor generator control, electromechanical brake control, AC motor control, etc., can solve the drive power level low common mode voltage, dynamic performance with many adjustable parameters, robust Overshoot and other problems, to improve robustness, good control effect, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below is the concrete implementation of the present invention, is used for further description:

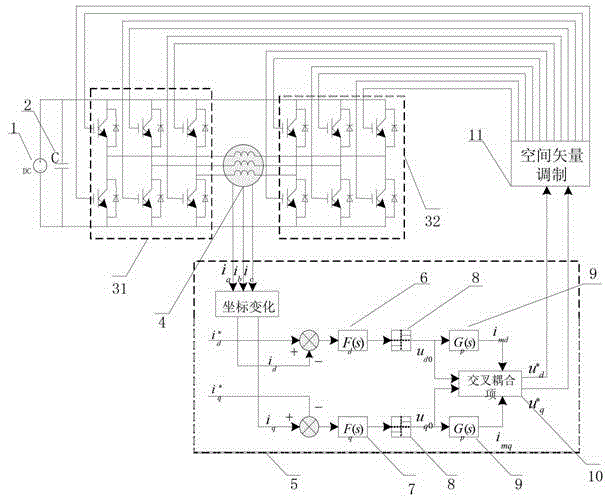

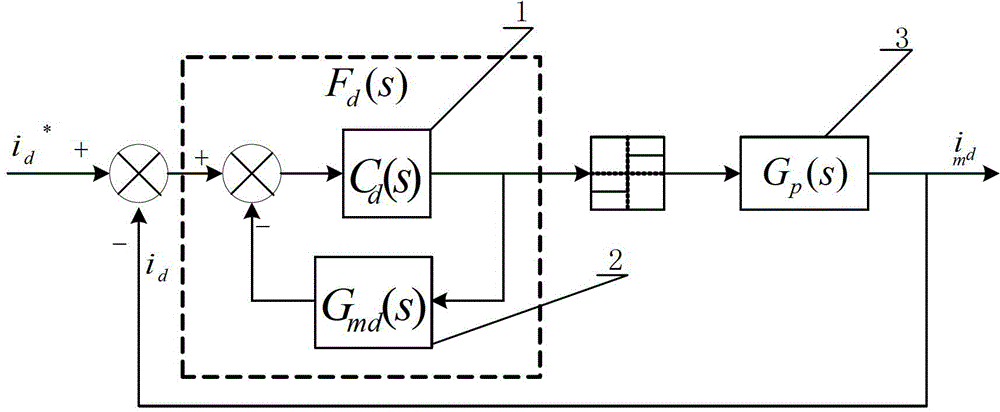

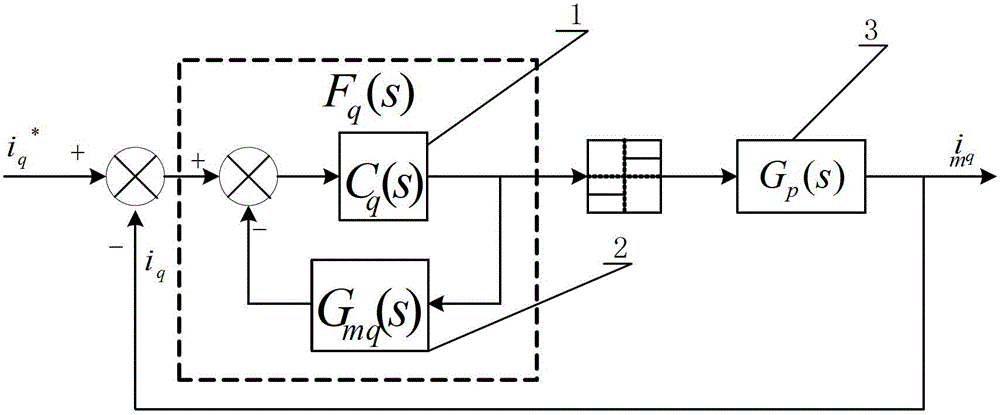

[0026] The invention is a new open-winding permanent magnet synchronous motor current internal model decoupling controller, the schematic diagram of the device figure 1 It includes a DC power supply 1 , a capacitor 2 , a first inverter 31 , a second inverter 32 , an open-winding permanent magnet synchronous motor 4 , and a current internal model decoupling controller 5 . The open-winding permanent magnet synchronous motor 4 is a three-phase permanent magnet synchronous motor whose stator winding adopts an open-circuit structure, and six terminal leads are drawn out to connect to the first inverter and the second inverter respectively. The sampling current of the stator winding is obtained by coordinate transformation i d i q , the modulation voltage u is obtained by the current internal mode decoupling controller 5 * d , u * q , and then use the voltage space vector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com