Intelligent ultra-long stroke winch oil pumping unit

A technology of ultra-long stroke and pumping unit, which is applied in hoisting devices, mechanical equipment, clockwork mechanisms, etc., which can solve problems such as high maintenance and operation costs, frequent pump inspections, and damage to flexible polished rods, and reduce operation and maintenance. The effect of cost, prolonging the pump inspection period and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

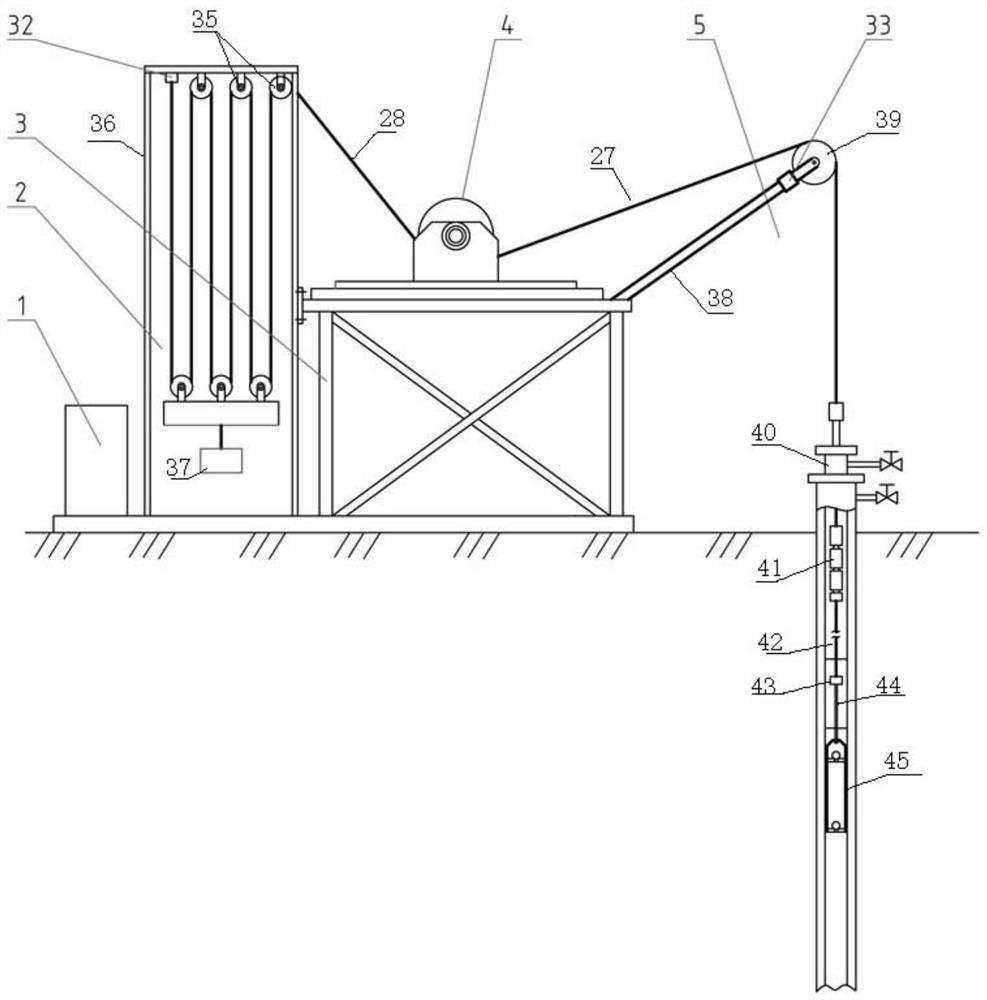

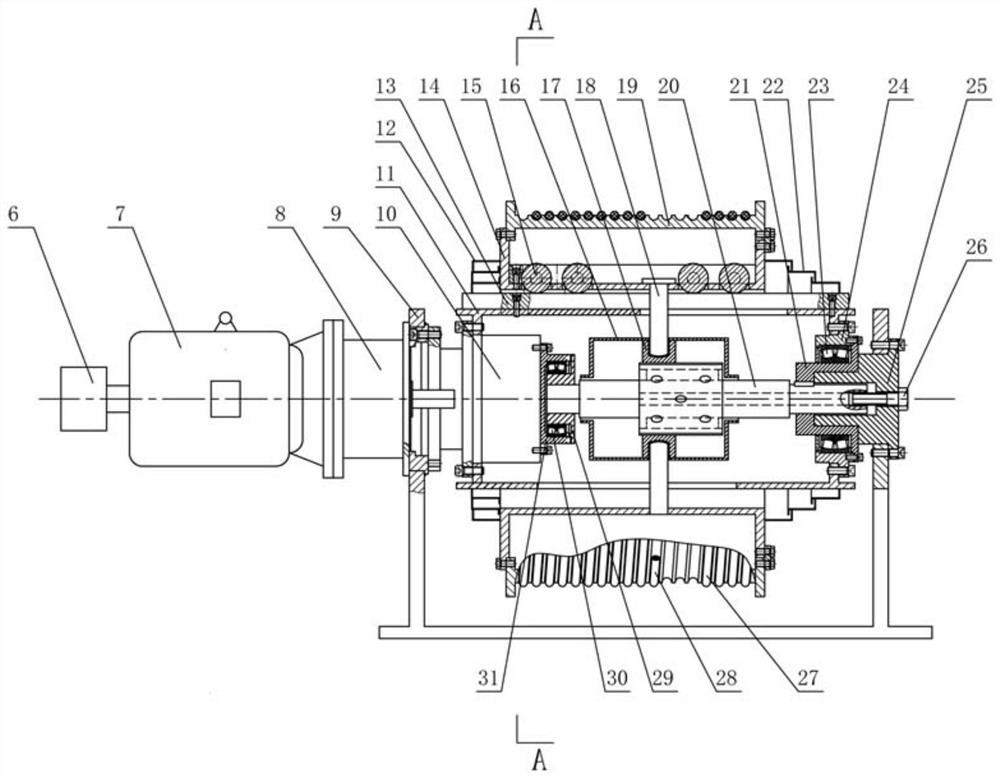

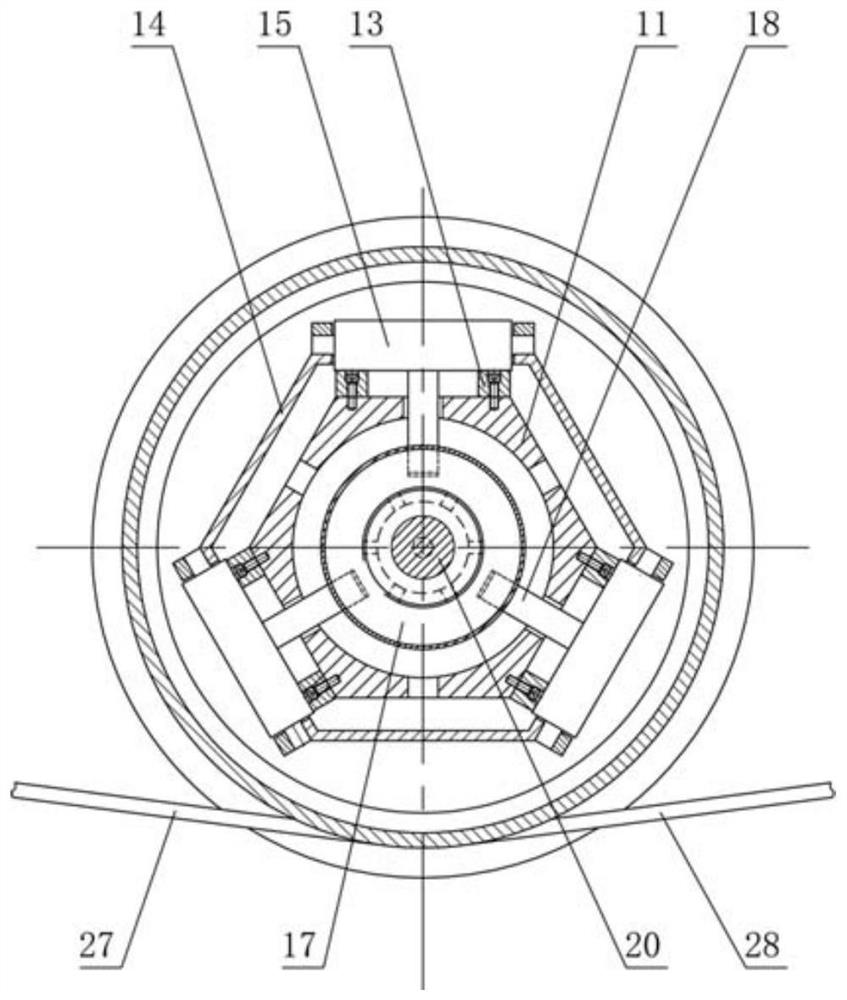

[0023] Such as Figure 1 to Figure 3 As shown, an intelligent ultra-long-stroke winch pumping unit is composed of an electric control cabinet 1, a counterweight system 2, a base 3, a winch system 4, and a suction system 5. System 2, hoisting system 4 and suction system 5 are connected, counterweight system 2 is connected with hoisting system 4 through steel wire rope 28, hoisting system 4 is connected with suction system 5 through flexible polished rod 27, and described hoisting system 4 includes Displacement sensor 6, motor 7, electromagnetic brake 8, hoisting support 9, reducer 10, outer cylinder 11 and drum 19, hoisting support 9 is fixed on the base 3, displacement sensor 6 is connected with the tail shaft of motor 7 through a key, The electromagnetic brake 8 is installed on the winch support 9, one end of the electromagnetic brake 8 is fixedly connected with the motor 7, and the other end is connected with the shaft key of the reducer 10, the reducer 10 is installed on th...

Embodiment 2

[0036] In this embodiment, the same parts as in Embodiment 1 are given the same reference numerals, and the same text descriptions are omitted.

[0037] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the winch system 4 is provided with a load sensor 34, and the load sensor 34 is used to measure the load of the winch system so as to calculate the tensile load of the flexible polished rod and then calculate it by intelligent software. other required parameters.

[0038] In summary, this equipment is used to increase the stroke of the pumping unit, eliminate the angle between the flexible polished rod and the sky wheel, prolong the service life of the flexible polished rod, realize the counterweight of the ultra-long stroke pumping unit, and further save energy. Responding to pump efficiency, output, and the position of the oil jacket annular space, the pumping speed or intermittent pumping is automatically adjusted according to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com