Wireless charging test bench for electric vehicle

A test bench, wireless charging technology, applied in vehicle testing, machine/structural component testing, electrical measurement, etc., can solve problems such as low work efficiency, low test efficiency, and low test coverage of wireless charging systems, and achieve The effect of increasing the test distance and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

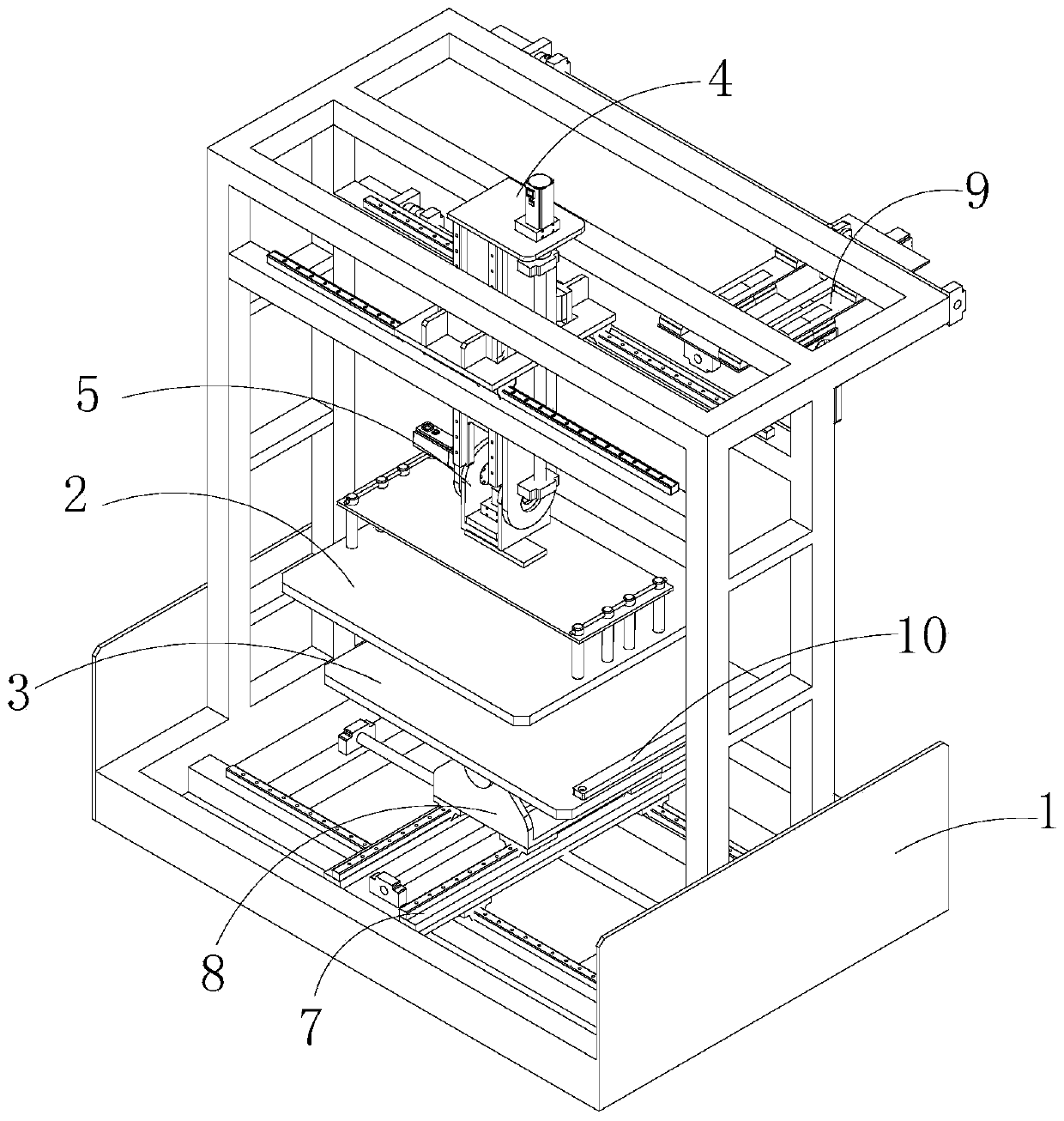

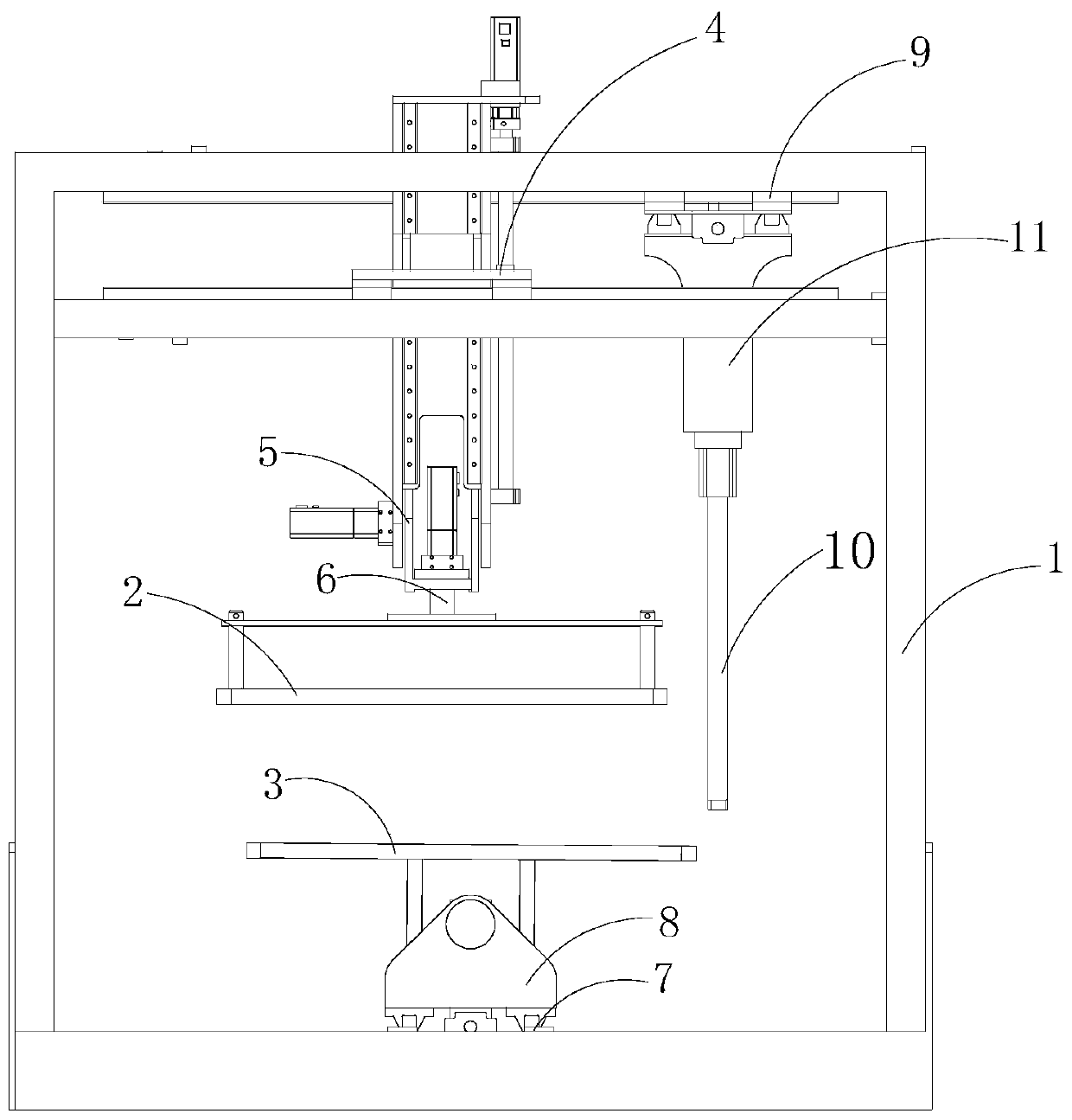

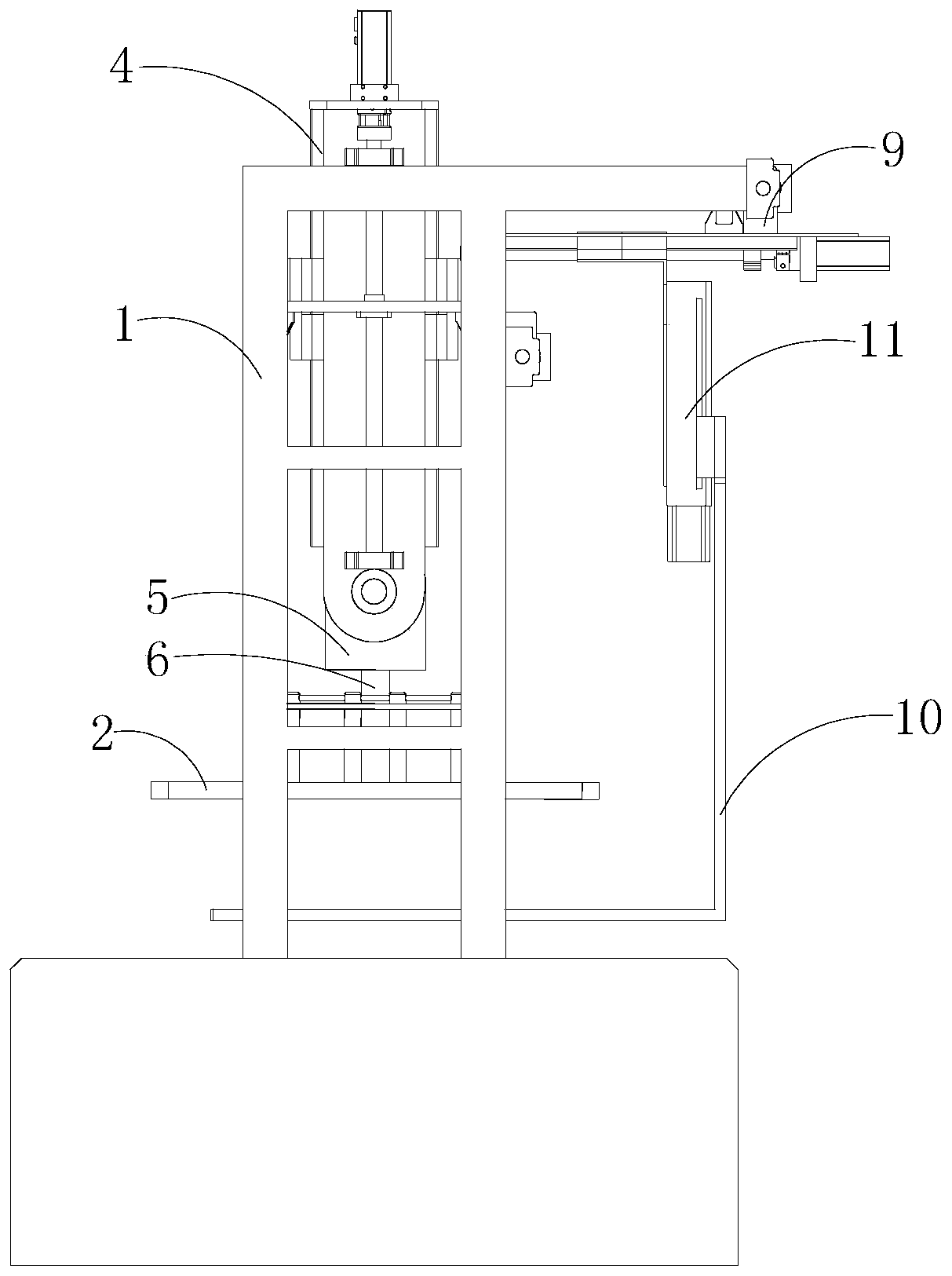

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] An electric vehicle wireless charging test bench, the test bench includes a frame 1, an upper plate 2 and a lower plate 3 installed on the frame 1, the lower plate 3 is used to place a transmitting coil, and the upper plate 2 is located on the lower plate 3 The upper part is used to place the receiving coil. Both the lower plate 3 and the upper plate 2 are made of non-metallic insulating materials, and both the upper plate 2 and the lower plate 3 can be installed on the frame 1 by sliding along the X-axis direction; Among the flat plate 2 and the lower plate 3, at least one of them can slide along the Y-axis direction, at least one of them can be lifted along the Z-axis direction, and at least one of them can rotate around its own vertical centerline, and it is installed on the frame 1 , in both the upper plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com