Intelligent stranded wire for overhead line system of electrified railway and preparation method of intelligent stranded wire

A technology for electrifying railways, catenary, used in the direction of power cables, circuits, electrical components, etc. for overhead applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

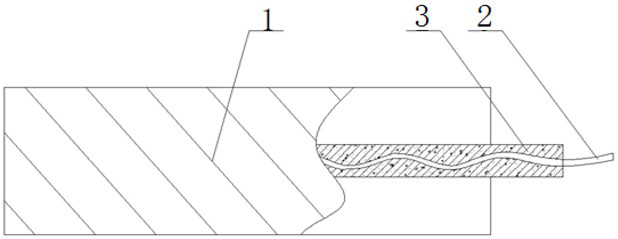

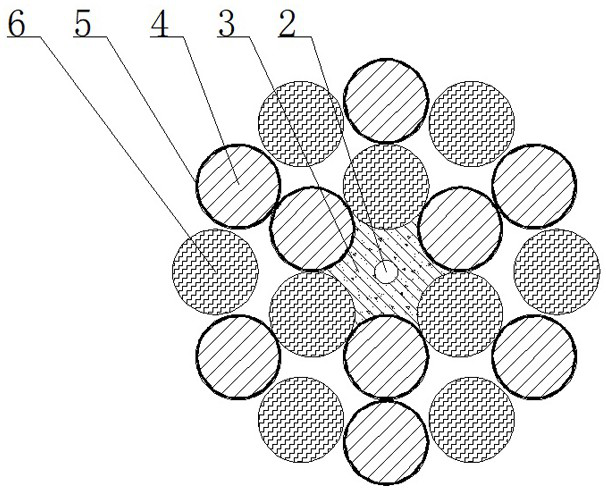

[0034] See figure 1 with figure 2 , figure 1 A schematic structural diagram of a smart strand for an electrorating railway contact network is drawn. As shown, a smart strand for an electrified railway contact network comprising a smart stranded body 1, the intelligent stranded body 1 is a monofilament with a multi-single wire. A single-core multilayer stranded wire, the peripheral monofilament including a copper alloy monofilament 4 and a carbon fiber composite monofilament 6, the central monofilament including the rubber material 3 and the optical fiber 2, the center of the rubber material 3 is set one Optical fiber 2, the optical fiber 2 is present in the core of the rubber material 3.

[0035] The surface of the copper alloy monofilament 4 has a preservative coating 5.

[0036] The optical fiber 2 is covered with the rubber material 3 by a heat squeeze.

[0037] The diameter of the peripheral monofilament is greater than the diameter of the peripheral monofilament.

[0038] The...

Embodiment 2

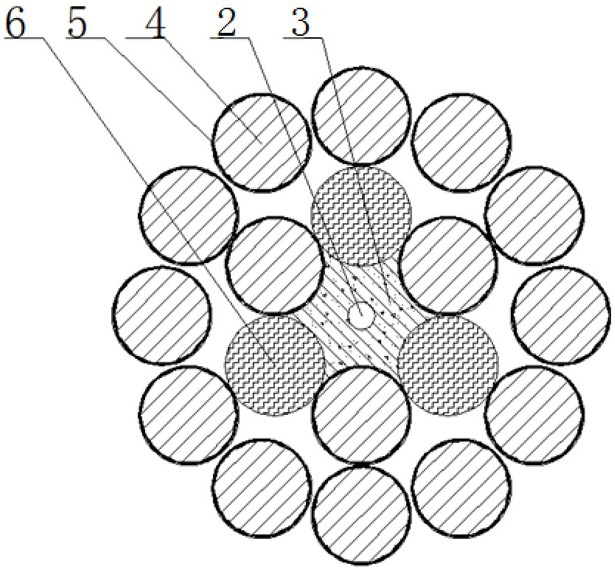

[0047] See figure 1 with image 3 , figure 1 A schematic structural diagram of a smart strand for an electrorating railway contact network is drawn. As shown, in fact, the peripheral monofilament includes two laps surrounding the center monofilament, wherein the inner ring of the inner ring close to the center monofilament is made of a copper alloy monofilament 4 and a carbon fiber composite material. Single wire 6 is uniformly spaced apart, and the outer ring of the outer ring away from the central monofilament is a copper alloy monofilament 4.

[0048] SeeFigure 4 The structures of the intelligent strand 1 include, but are not limited to Figure 4 The species shown, that is, 1 * 7, 1 * 19, 1 * 37, 1 * 7 * (1 + 6), 1 * 7 * (3 + 9), according to the actual use, copper with anti-corrosion coating 5 The alloy monofilament 4 and the carbon fiber composite monofilament 6 are distributed in any position of the strand.

[0049] The present invention is applied to an online intelligent mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com