Long-stroke no-killing well working device of oil-water well

An operation device and long-stroke technology, applied in wellbore/well components, drilling equipment, cleaning appliances, etc., can solve the problems of difficult operation, long disassembly and assembly time, affecting the operation progress, etc., which is conducive to popularization and application and improves operation efficiency. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

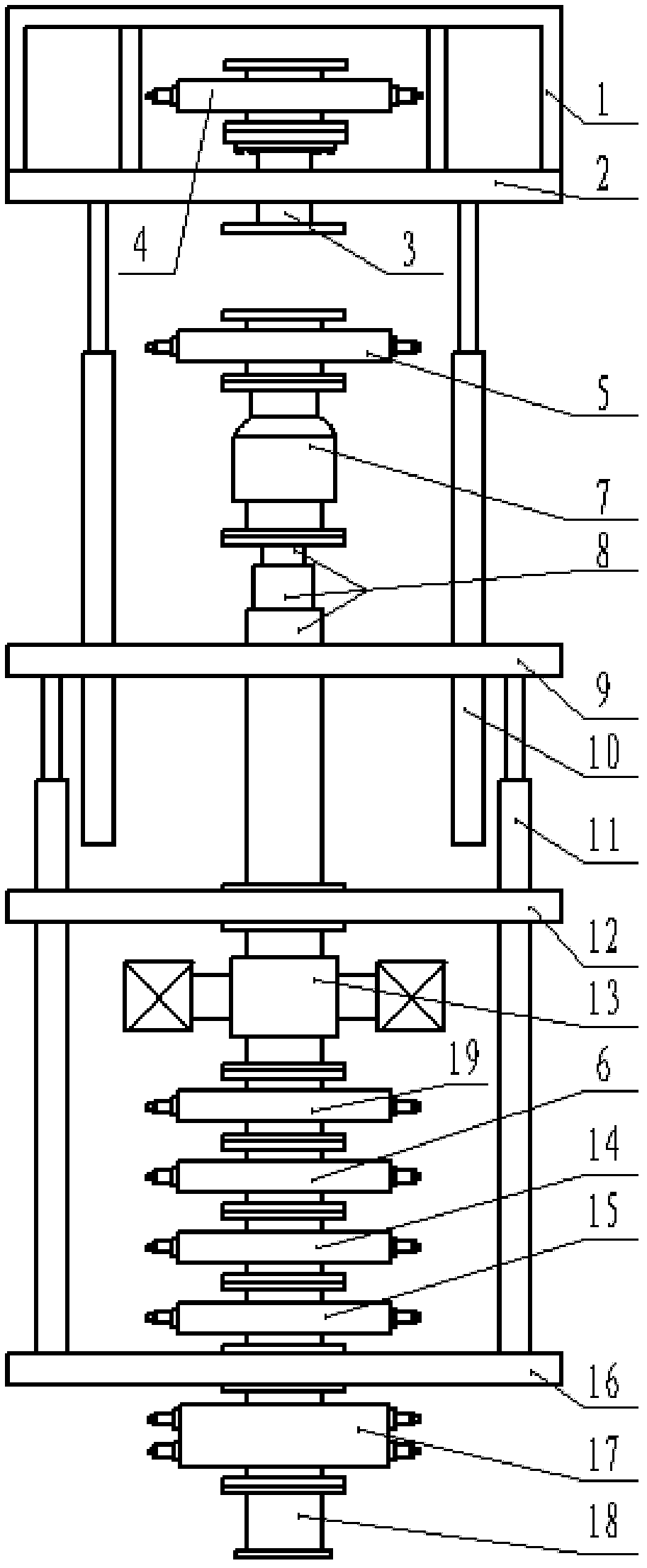

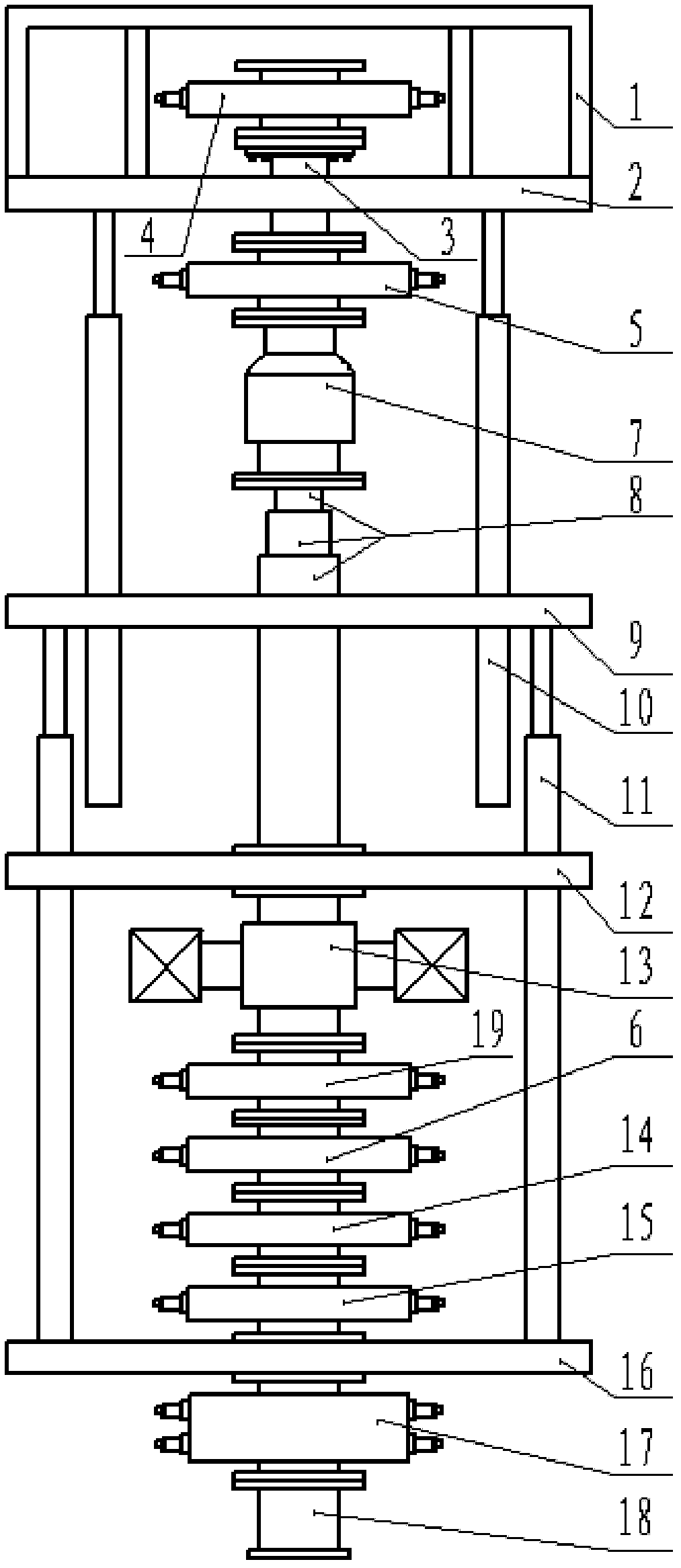

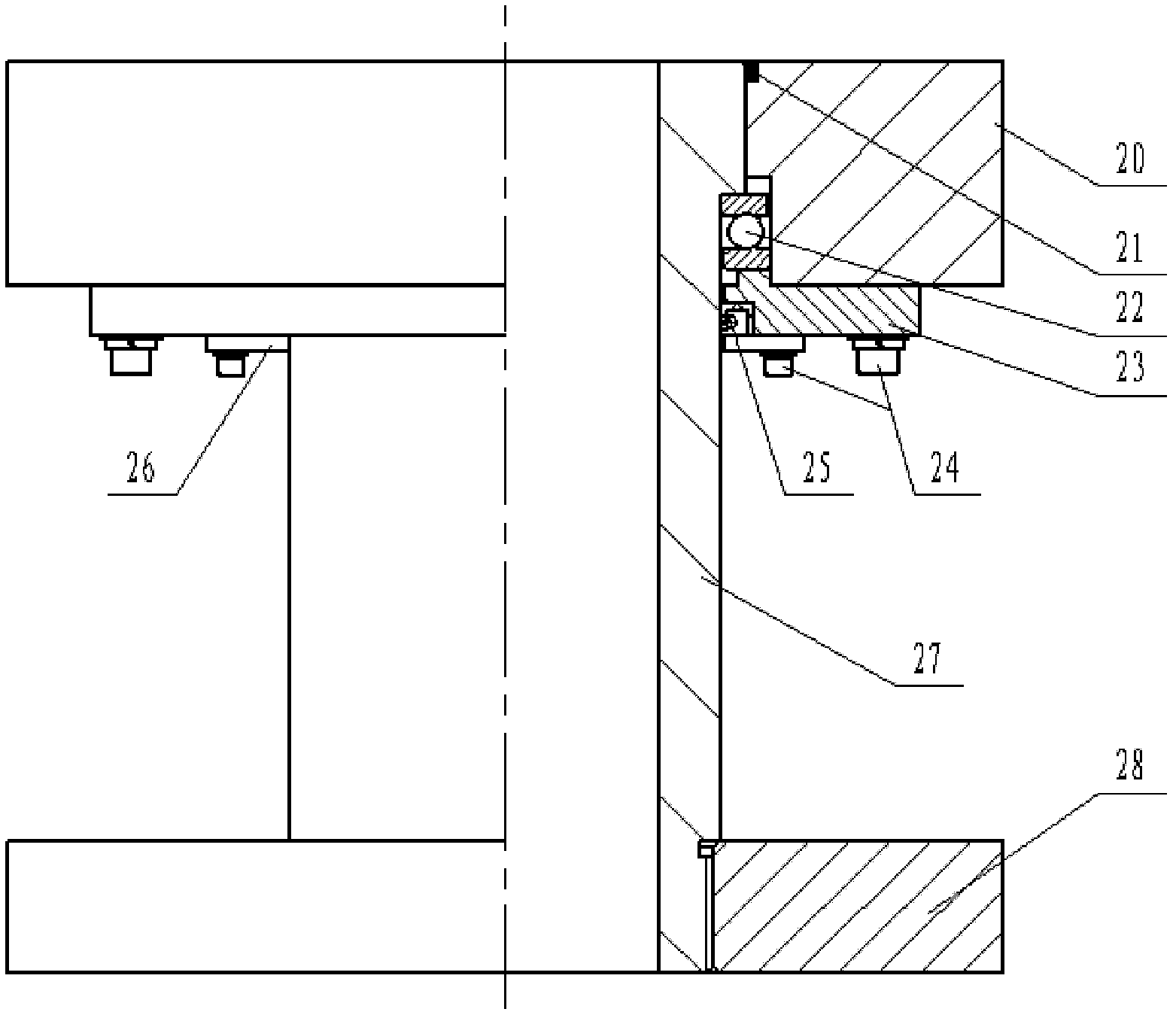

[0022] The present invention includes a guardrail 1, a working platform 2, a rotating flange 3, a moving slip 4, an upper half-enclosed blowout preventer 5, a lower half-enclosed blowout preventer 6, an annular blowout preventer 7, a telescopic cylinder 8, an intermediate platform 9, Multi-stage hydraulic cylinder 10, lifting hydraulic cylinder 11, support platform 12, wellhead cross 13, shear blowout preventer 14, fixed slips 15, lower platform 16, double ram blowout preventer 17, reducing flange 18 , Fully sealed blowout preventer 19, upper flange 20, dustproof ring 21, bearing 22, large retaining ring 23, screw 24, sealing ring 25, small retaining ring 26, sleeve 27, lower flange 28, operating rod 30 , cleaning tool 31, guardrail 1 is installed around the upper end face of working platform 2; Rotating flange 3 is made up of upper flange 20, sleeve 27, bearing 22, large retaining ring 23, small retaining ring 26, lower flange 28, upper The flange 20 is connected with the lar...

Embodiment approach 2

[0028] The lower flange 28 of the rotating flange 3 is fixedly connected with the upper end of the upper half-sealed blowout preventer 5, so that the telescopic cylinder 8 can extend or contract as the movable slip 4 moves up and down. When lifting and lowering the oil pipe, the variable diameter flange 18 at the lower end of the device is connected to the wellhead, the annular blowout preventer 7 is not working and the annular blowout preventer 7 is in the normally open state. When the tubing is pulled up, the well pressure is sealed by the fully sealed BOP 19, and the lower half-sealed BOP 6, the fixed slip 15, the shear BOP 14, and the double ram BOP 17 are all in the open state. The slips 4 and the upper half-sealed BOP 5 clamp and seal the oil pipe and send the oil pipe to the full-sealed BOP 19 through the lifting hydraulic cylinder 11 and the multi-stage hydraulic cylinder 10, and the full-sealed BOP 19 is opened, Since the movable slip 4 is fixedly connected to the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com