Piston type two-stroke fan

A piston type, two-stroke technology, used in piston pumps, liquid variable capacity machinery, mechanical equipment, etc., can solve problems such as poor adjustment accuracy, difficult to meet modern industrial production and services, and serious negative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

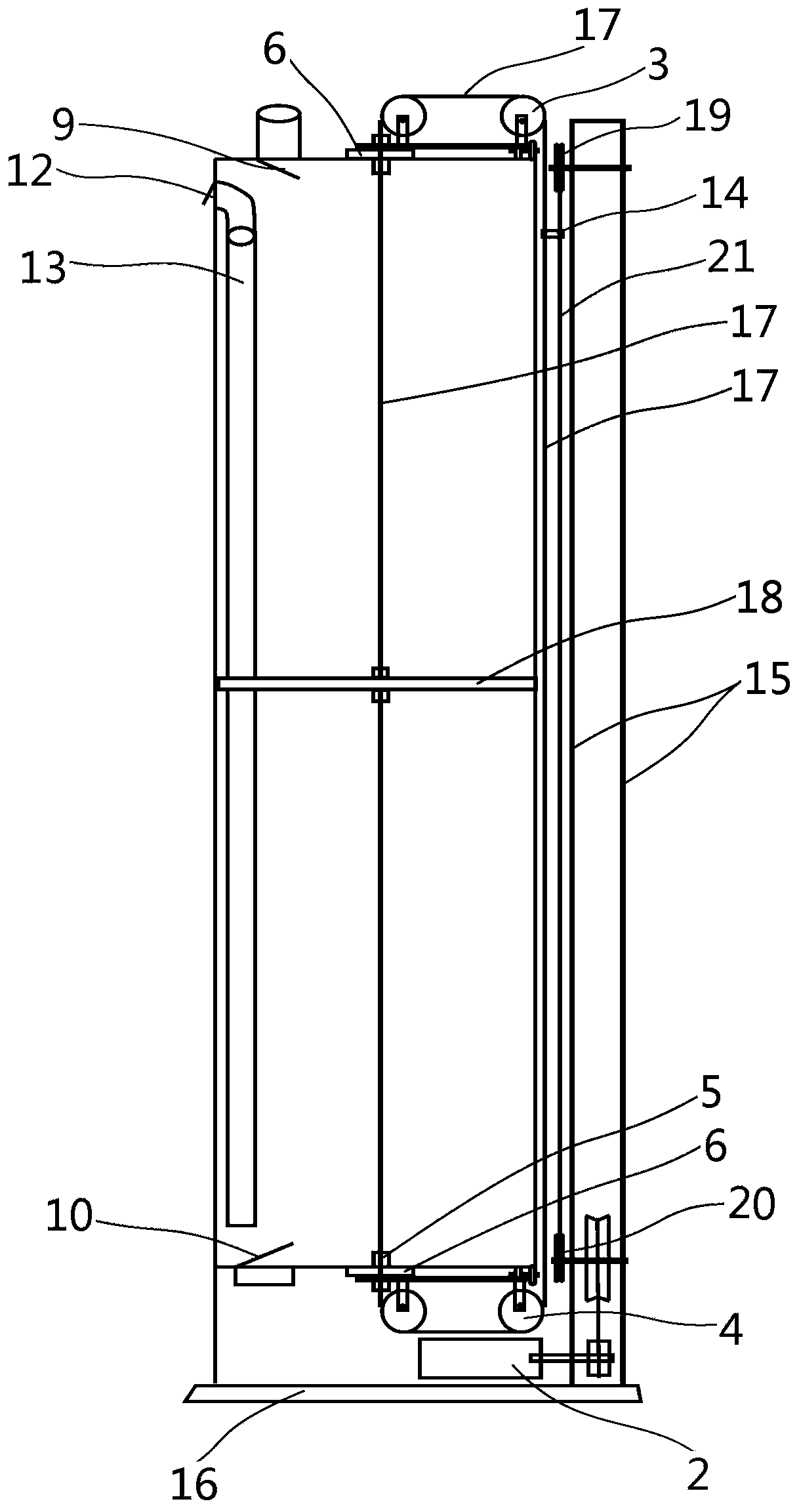

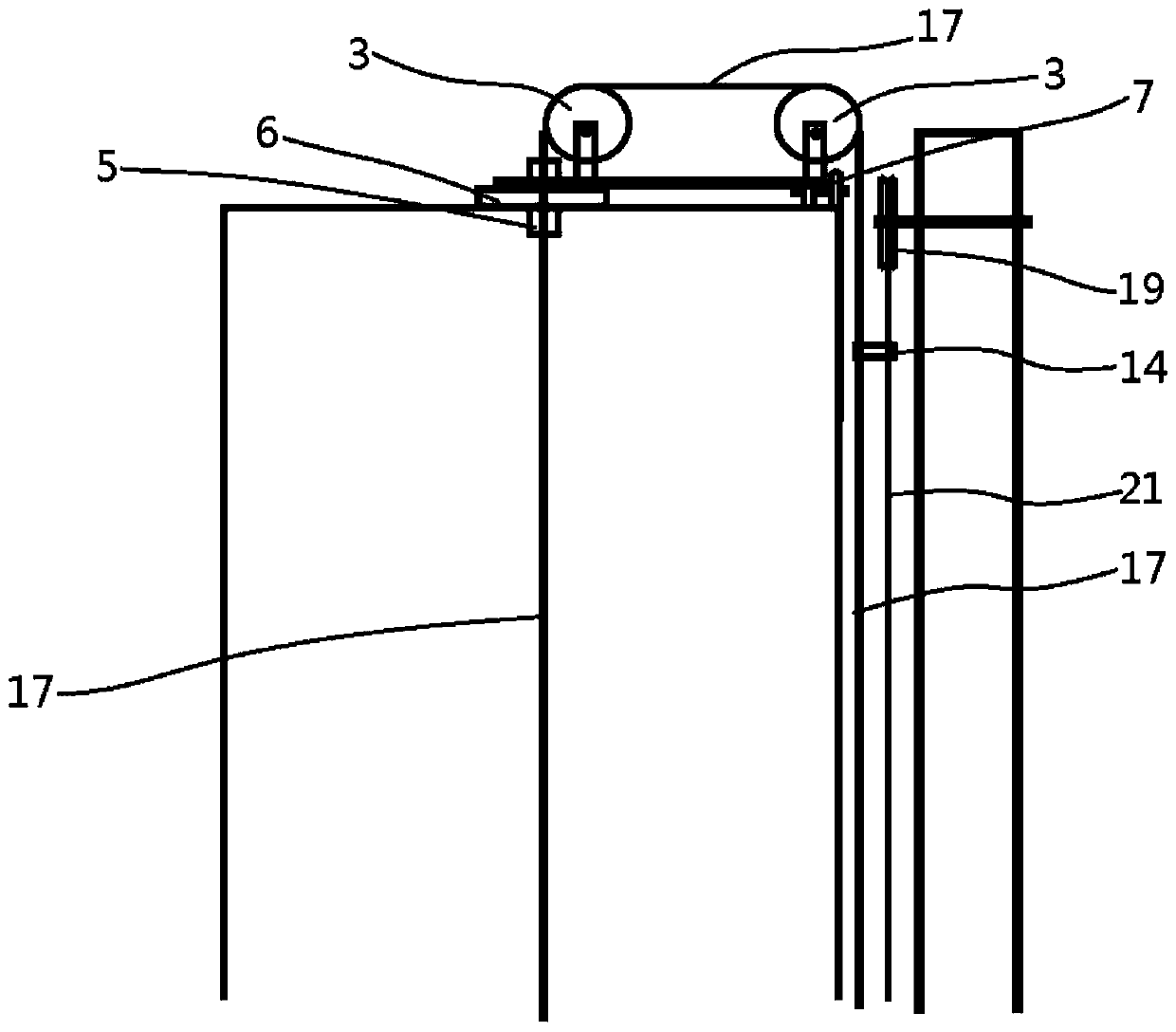

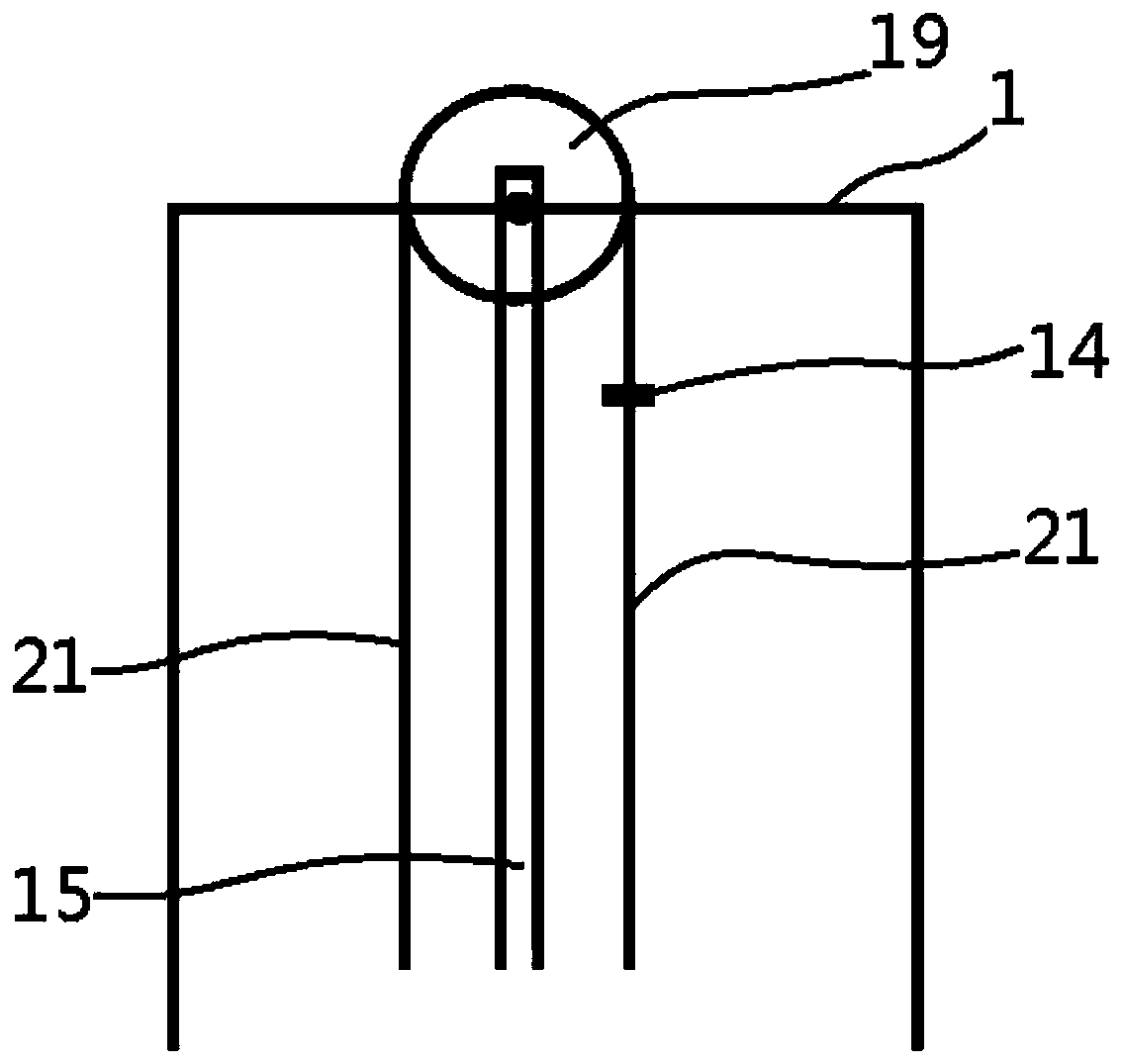

[0025] As shown in the figure; a piston-type two-stroke fan according to the present invention is characterized in that the two-stroke fan consists of a two-stroke fan cylinder 1, a speed regulating motor 2, an upper double pulley 3, a lower double pulley 4, a hollow bolt 5, Thrust bearing 6, upper roller 7, lower roller 8, upper one-way air inlet valve 9, lower one-way air inlet valve 10, upper one-way air outlet valve 11, lower one-way air outlet valve 12, lower one-way air outlet pipe 13. An annular rope 17, a piston wind plate 18, an upper sprocket 19, a lower sprocket 20, a chain 21, a rotating shaft telescopic buckle 14, and a bracket 15; wherein the speed regulating motor 2 is arranged on the base 16; wherein the hollow There are two bolts 5, which are located at the center point of the top plate and the bottom plate of the double-stroke fan 1; one of the hollow bolts 5 passes through the center hole of the thrust bearing 6 to fix the upper double pulley 3, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com