Oil sucker with eccentric wheel and without beam

An eccentric wheel, no-beam technology, used in machines/engines, mechanical equipment, liquid variable-capacity machines, etc., can solve problems such as stroke limitation, impact on the service life of the whole machine, poor lubrication conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

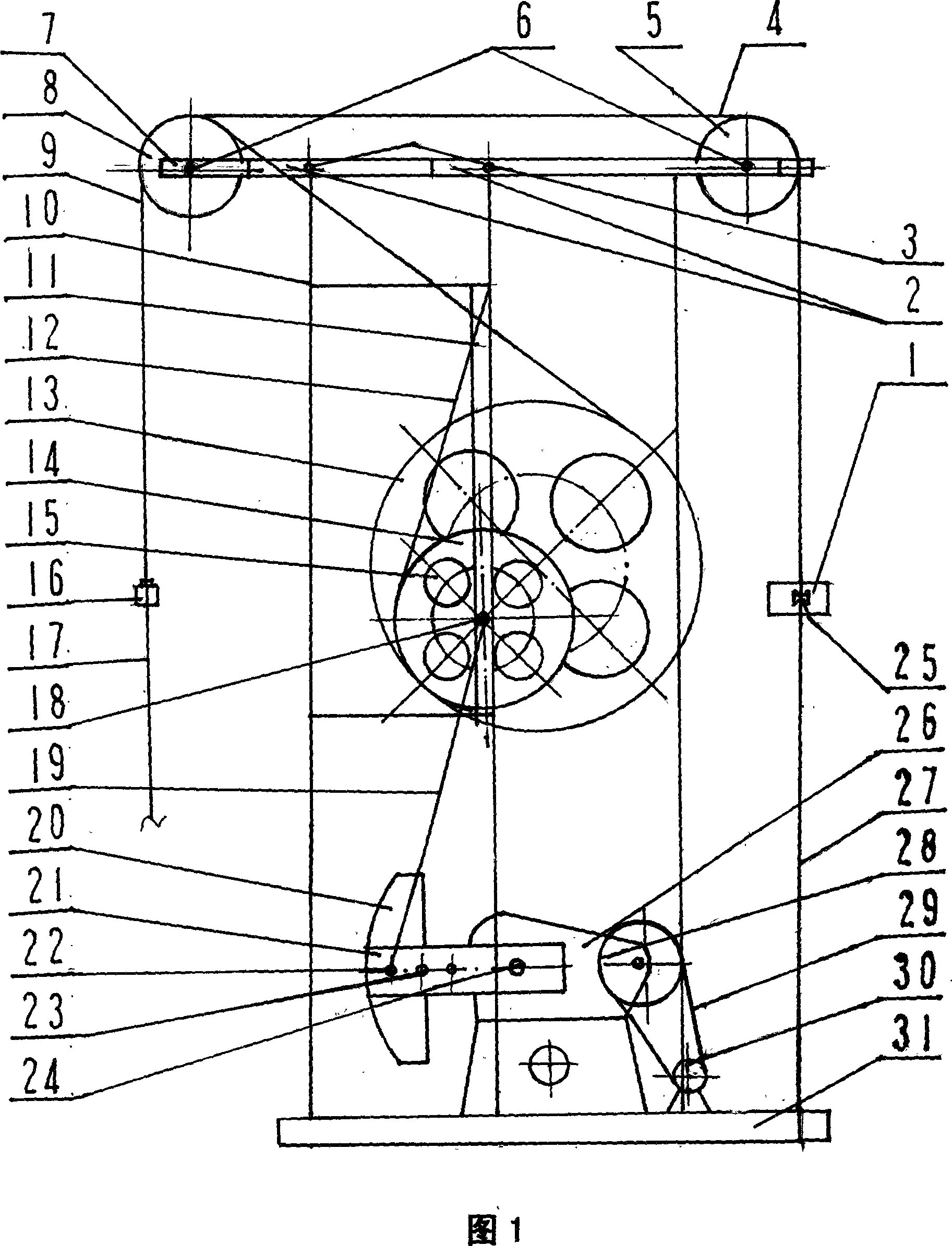

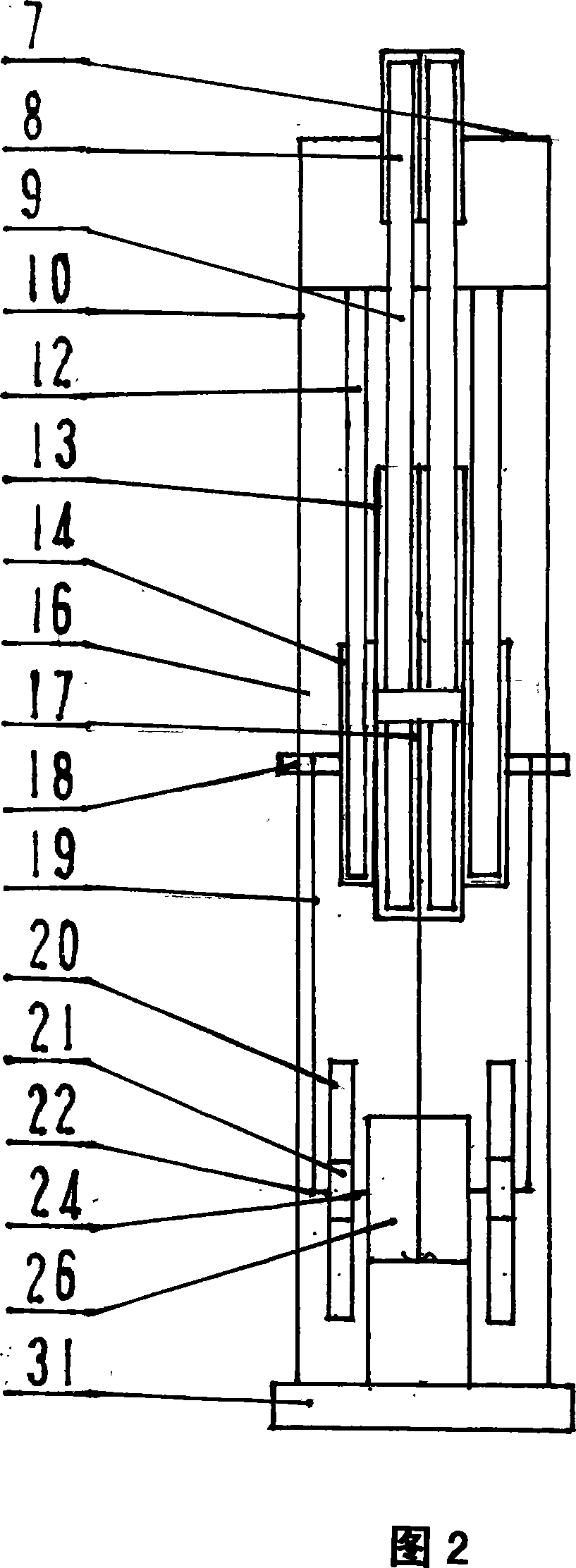

[0010] Implementation of the present invention will be further elaborated below in conjunction with accompanying drawing:

[0011] The present invention comprises: balance box 1, guide wheel 25, guide rope 27, balance belt 4, balance wheel 5, crossbeam 7, fixed bolt 3, wheel axle 6, suspension weight wheel 8, suspension weight belt 9, suspension belt device 16, power Belt 12, eccentric wheel 13, power wheel 14, central shaft 18, connecting rod 19, balance weight 20, crank 21, crank pin 22, output shaft 24, reducer 26, large pulley 28, V-belt 29, motor 30, bracket 10. The base 31; the bracket 10 is a cuboid quilting frame structure, the suspension wheel 8 and the balance wheel 5 are respectively located at the left and right ends of the beam 7 on the top of the bracket 10, the middle and left end of the beam 7 are provided with guide grooves 2, the beam 7 and the bracket 10 Connected by the fixed bolt 3, the beam 7 can move left and right along the fixed bolt 3 through the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com