Piezoelectric actuator, acoustic element, and electronic device

A piezoelectric actuator, piezoelectric element technology, applied to piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive transducers, piezoelectric effect/electrostrictive or magnetostrictive Motors and other directions can solve the problems of poor performance of acoustic components, large average amplitude, and inability to provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

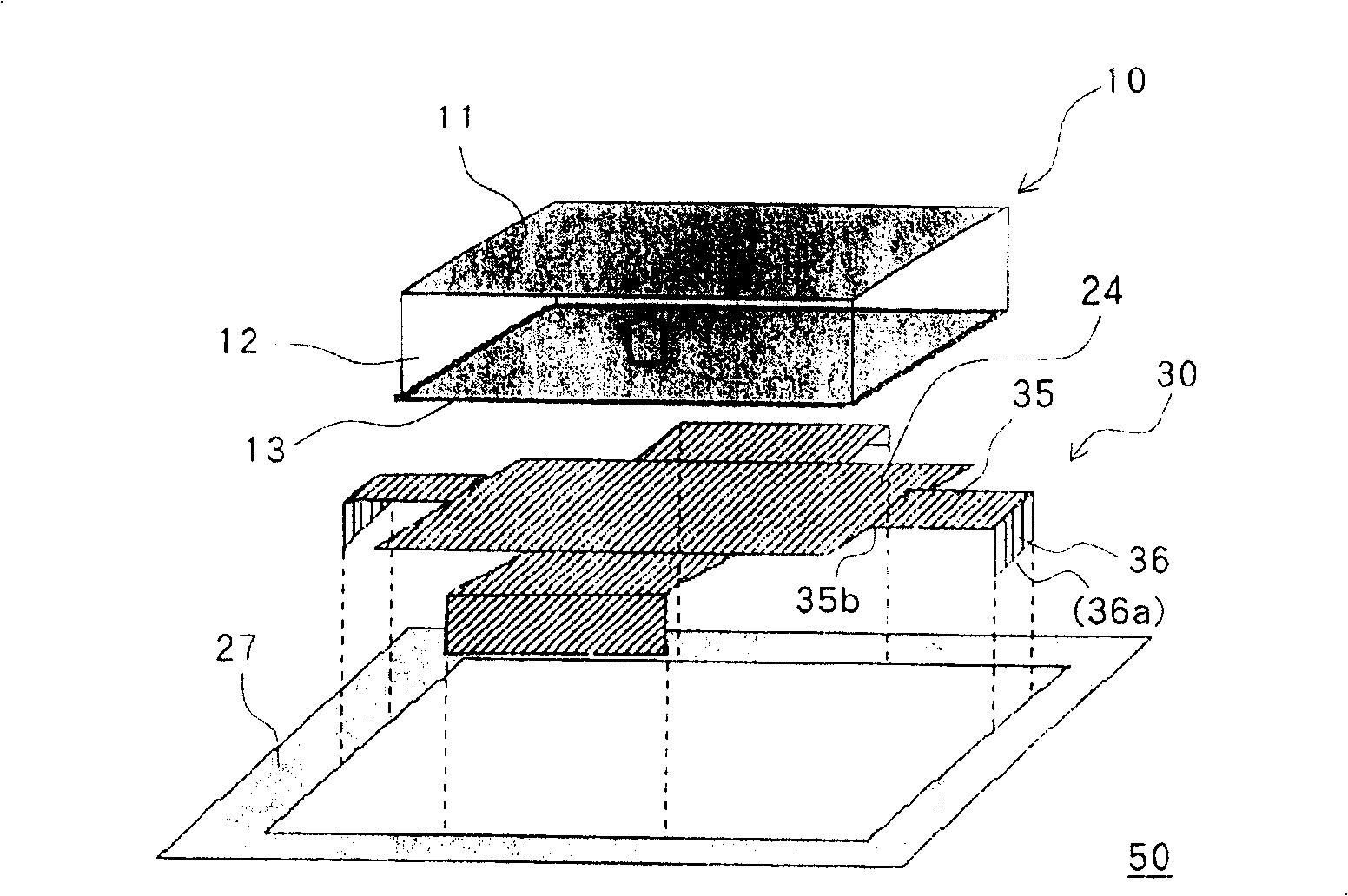

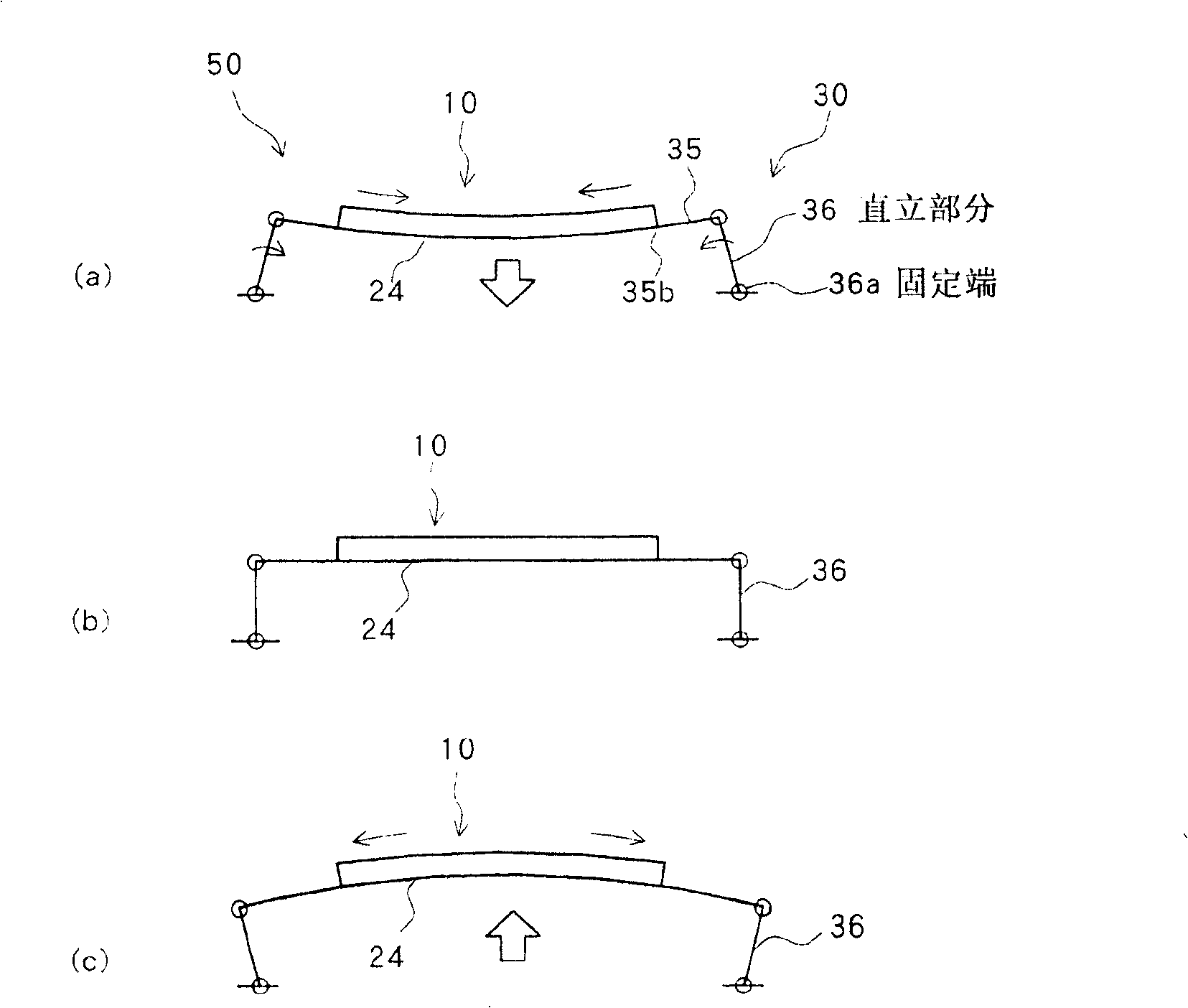

[0148] Manufactured according to Invention Example 1 as Figure 15A The piezoelectric actuator having the piezoelectric element 10 placed on the lower surface of the bottom plate 24 is shown in and 15B.

[0149] The specific structure is as follows:

[0150] Piezoelectric element: Upper and lower electrode layers (piezoelectric material layer, see figure 1 ), each of which has a thickness of 8 μm.

[0151] Elastomer: The elastomer with a thickness of 0.05 is made of phosphor bronze. By "elastomeric body" is meant an integrated structure comprising a base plate, extensions and uprights.

[0152] Beam: upright portion height = 1.0 mm, extension portion length = 2.0 mm, beam width: 4.0 mm, and beam bending angle = 90°.

[0153] Support member: Shape = circular with a diameter of 17mm, thickness = 1.55mm, gap L 1 = 1.0 m, and material = SUS304.

[0154] The piezoelectric plate is made of zirconate lead titanate ceramics, and the electrode layer is made of silver / palladium a...

example 2

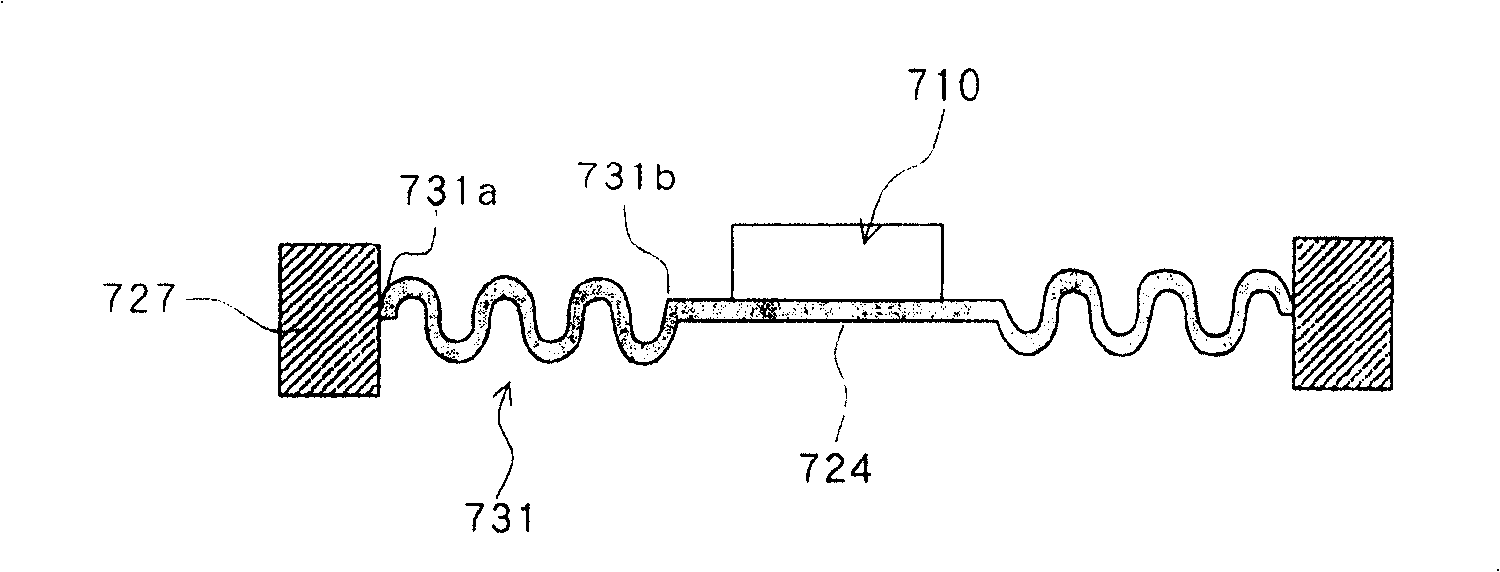

[0174] Manufactured according to Invention Example 2 as Figure 17A and 17B The piezoelectric actuator shown. This piezoelectric actuator differs from the piezoelectric actuator according to Inventive Example 1 in that the structure of the beam 30 is different. Beams have such Figure 8 The curved portion 37 is shown. Other structural details are the same as the piezoelectric actuator according to Inventive Example 1.

[0175] The specific structure is as follows:

[0176] Piezoelectric element: Same as Inventive Example 1.

[0177] Elastomer: Same as Inventive Example 1.

[0178] Beam: upright portion height = 1.0 mm, extension portion length (including curved portion) = 2.0 mm, beam width: 4.0 mm, and curvature radius of curved portion = R2.0.

[0179] Support member: the same as Invention Example 1.

[0180] 【result】

[0181] Resonant frequency = 472Hz

[0182] Maximum vibration velocity amplitude = 345mm / s

[0183] Vibration velocity ratio = 0.91

[0184] Vibra...

example 3

[0187] Manufactured according to Invention Example 3 as Figure 18 The piezoelectric actuator shown. This piezoelectric actuator differs from the piezoelectric actuator according to Inventive Example 1 in that piezoelectric elements are provided on both surfaces of the base plate, having a bimorph structure. Other structural details are the same as the piezoelectric actuator according to Inventive Example 1.

[0188] The specific structure is as follows:

[0189] Piezoelectric element: shape = square with a side length of 10 mm, thickness = 0.4 mm. The upper and lower electrode layers of each piezoelectric element were the same as Inventive Example 1 and had a thickness of 8 μm.

[0190] Elastomer: Same as Inventive Example 1.

[0191] Beam: same as Invention Example 1.

[0192] Support member: Shape = circular with a diameter of 17mm, thickness = 1.95mm, gap L 1 = 1.0 m.

[0193] 【result】

[0194] Resonant frequency = 662Hz

[0195] Maximum vibration velocity amplitude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com