Trimming mould for automobile oil sump

A technology of oil pan, automobile, applied in the field of sheet forming molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

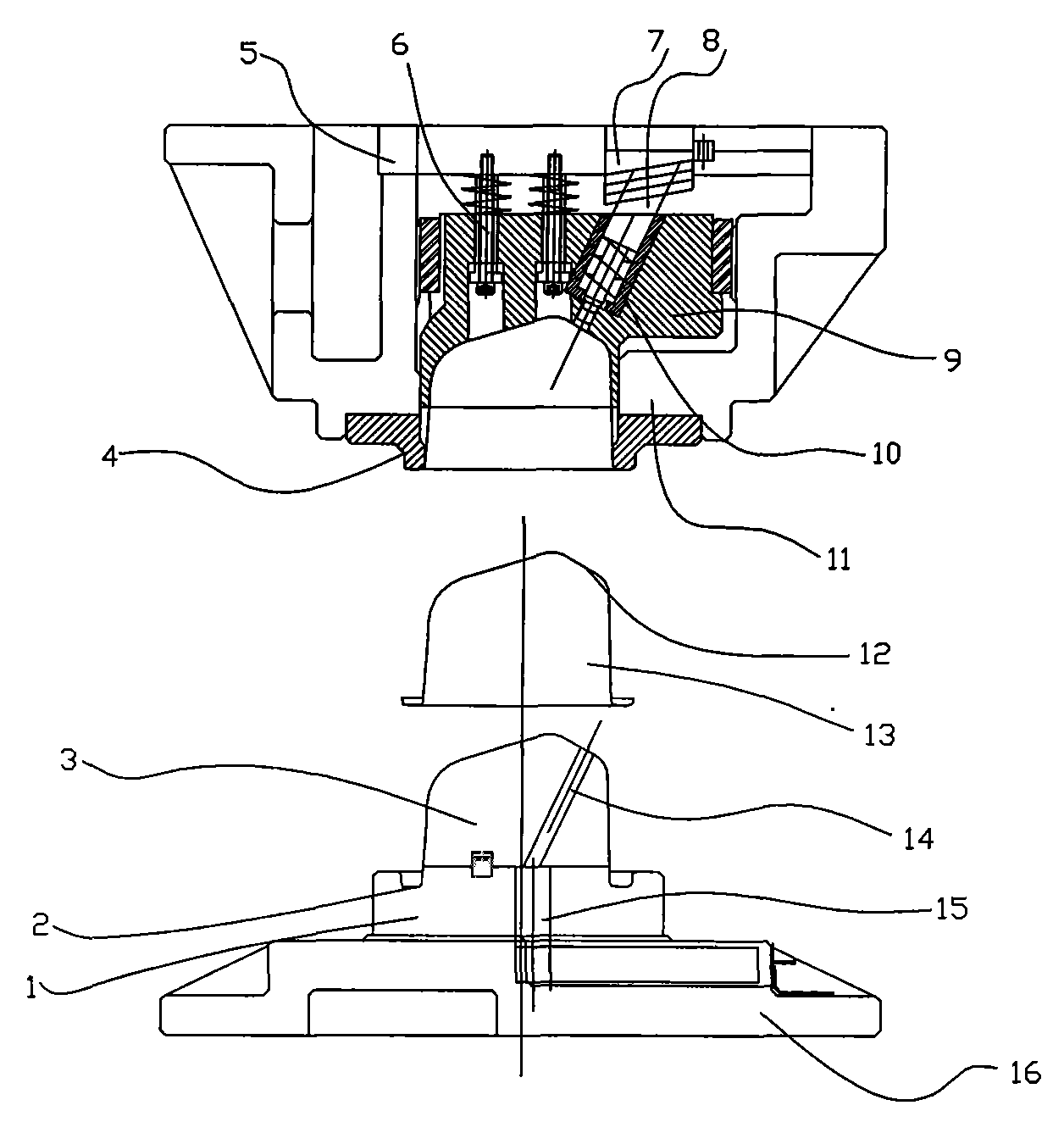

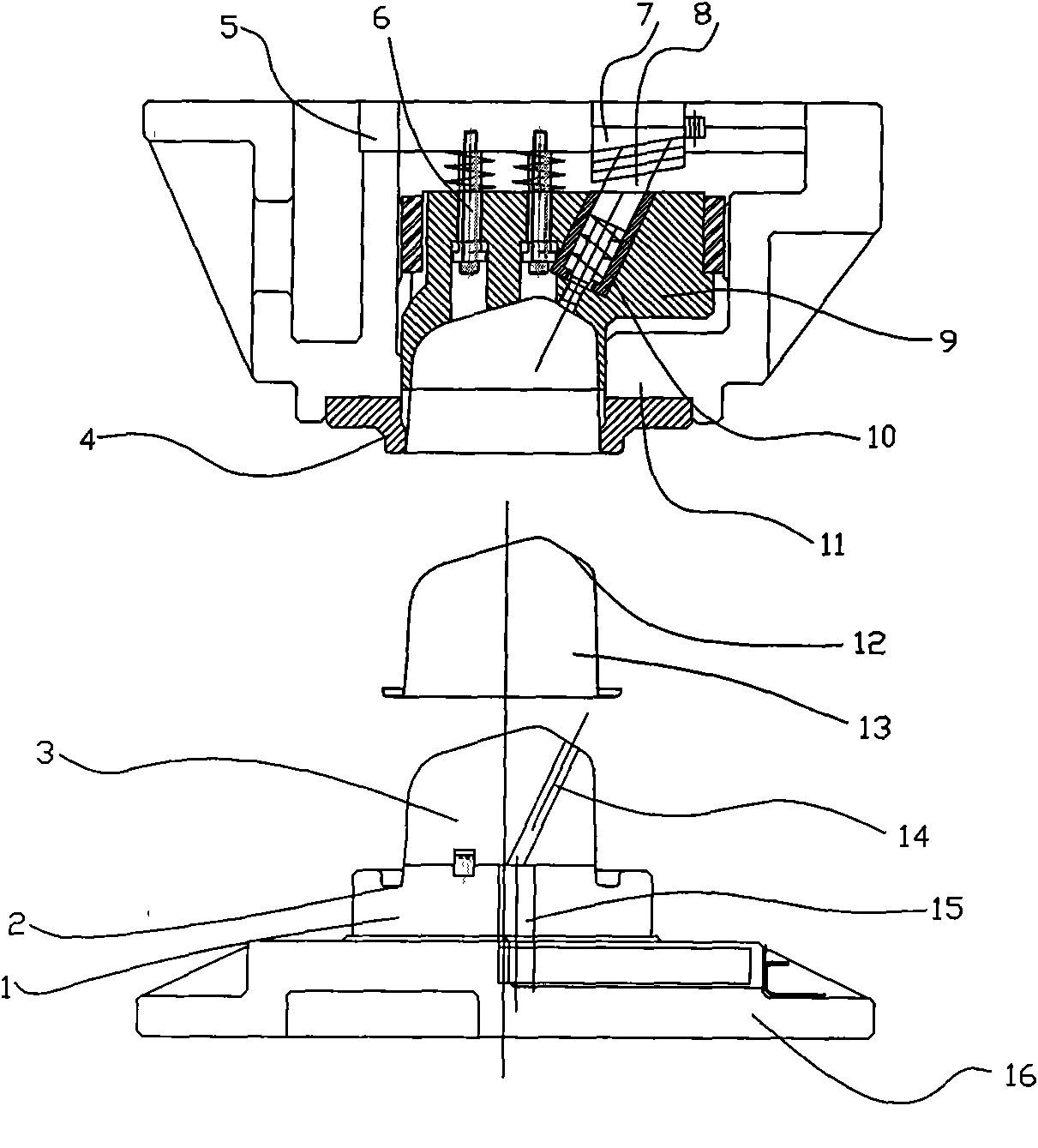

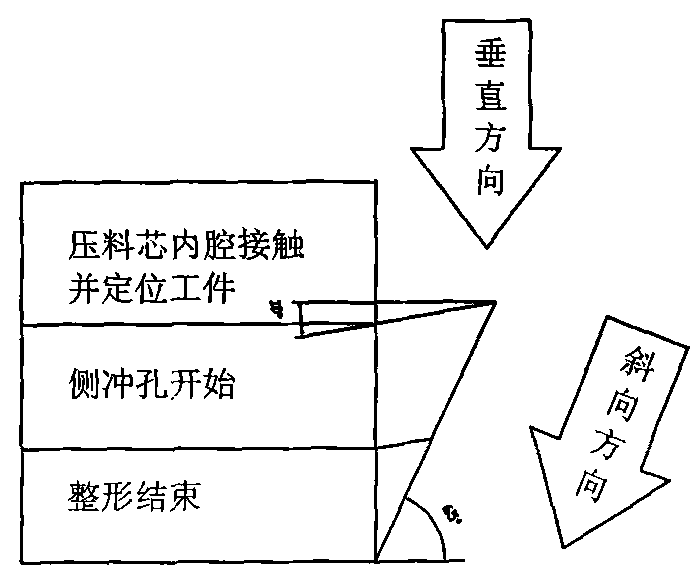

[0021] As shown in Figures 1-8, the present invention includes an upper mold assembly 11 and a lower mold assembly 16 that can shape the side groove of the oil pan 13, and the upper mold assembly 11 and the lower mold assembly 16 are equipped with upper Die shaping insert 4 and lower mold shaping insert 1, it also includes punching inclined hole device; punching inclined hole device includes: pressing material core 9, punch 8, punch drive wedge 7; And be arranged on lower die assembly 16 The bump 3 on the top is adapted to the inner contour shape of the oil pan 13, the corresponding punch 8 on the bump 3 is provided with a lower die hole 14, and the bump 3 is provided with a waste discharge channel 15 communicating with the lower die hole 14 ; The pressing core 9 is movably connected in the upper die assembly 11 through the elastic guide mechanism 6, and the pressing core 9 is provided with an inner cavity adapted to the outline of the oil pan 13; the punch 8 is inclined to It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com