Intelligent super-long stroke pumping unit

A technology of ultra-long stroke and pumping unit, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as high maintenance and operation costs, oil production restrictions, and damage to flexible polished rods, so as to reduce operation and maintenance Cost, remote digital control management, effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

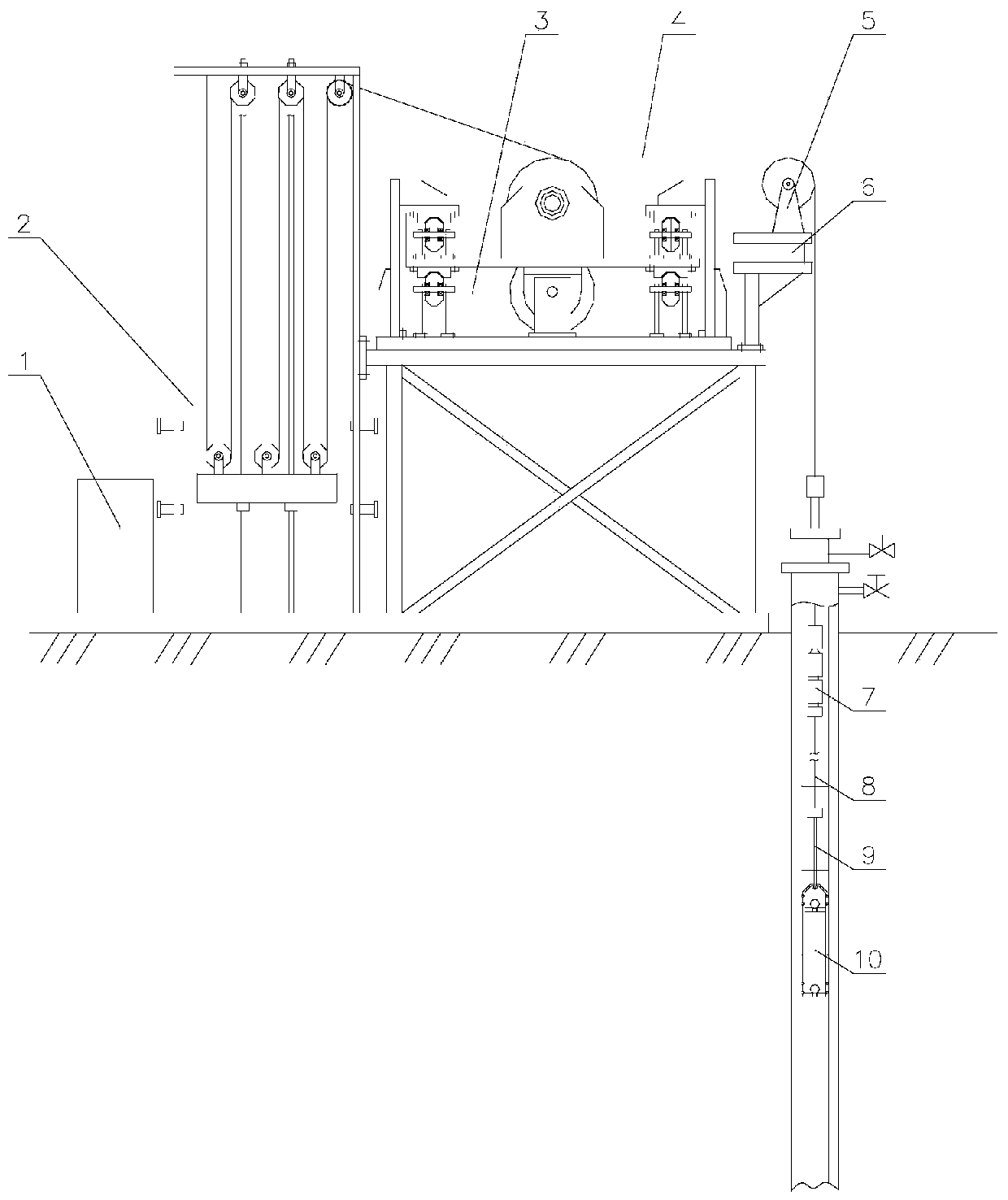

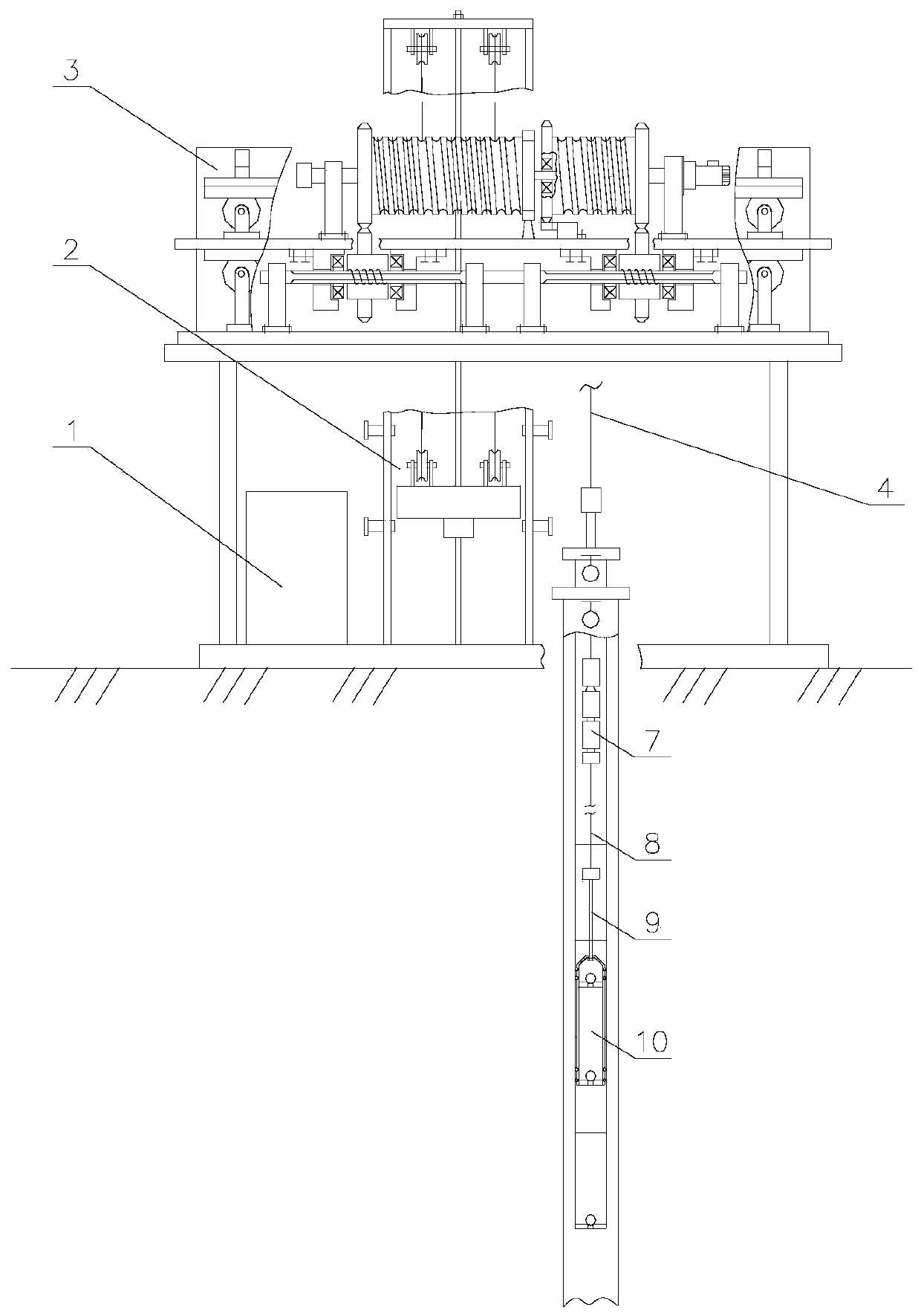

[0029] like Figure 1 to Figure 4 As shown, an intelligent ultra-long stroke pumping unit includes a driving system 3, a flexible polished rod 4 wound on the driving system, a counterweight system connected with the driving system 3, and the output end of the flexible polished rod is wound on a support wheel And connect the rotary shorting 7, the sucker rod 8, the weighting rod 9, and the ultra-long stroke pump 10 in sequence.

[0030] The counterweight system 2 includes a counterweight bracket 11, an anti-falling rod 12, a self-locking device 13, a counterweight block 14, a movable pulley 15, a fixed pulley 16, a wire rope 17, and a support pin 18. The lower end of the counterweight bracket 11 is fixed on the base Up, the support pins 18 are movably installed at the corresponding positions on both sides of the counterweight bracket 11, the lower end of the anti-drop rod 12 is fixed on the base, the anti-drop rod 12 passes through the self-locking device 13 and the hole of the...

Embodiment 2

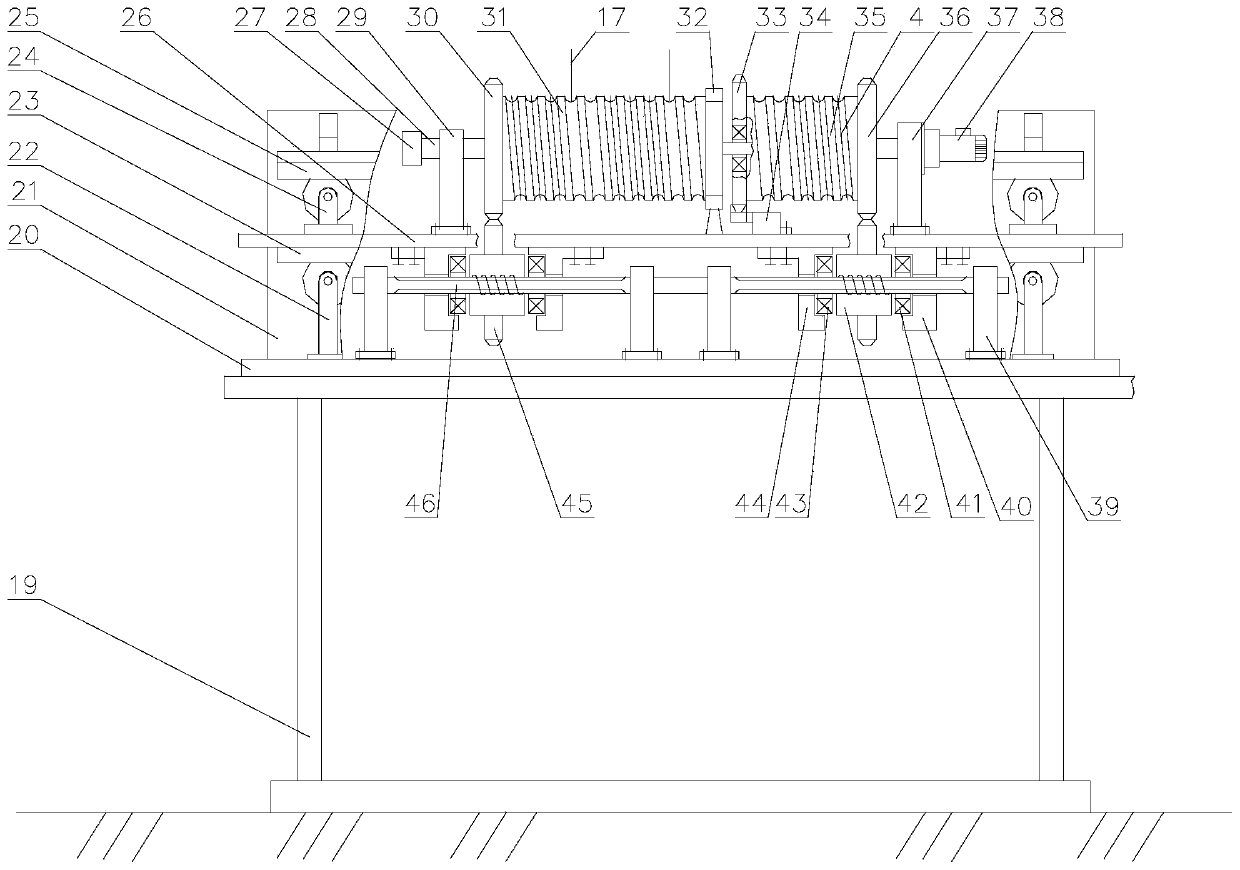

[0043] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the counterweight drum 31 and the hoisting drum 35 are integrated, the middle part is the hoisting drum 35, and the parts on both sides are the counterweight drum 31, and the counterweight drum 31 and the hoisting drum The outer surface of the cylinder 35 is all processed with the same helical direction and is semicircular threaded grooves, the surface of the threaded grooves is melted with wear-resistant, elastic and temperature-resistant non-metallic material, and the pitch of the threaded grooves is consistent with the diameter of the flexible polished rod 4. The two wire ropes in the counterweight system are respectively fixed on the counterweight drum 31 on both sides of the hoisting drum 35, and the rolling bracket 32 is between the hoisting drum 35 and the counterweight drum 31, so that the hoisting pull and the counterweight pulling force can be achieved. balanced.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com