Hydraulic double acting pumping unit

A two-way action, pumping device technology, applied in pumps, piston pumps, liquid variable capacity machinery, etc., can solve the problem of increasing design difficulty, design cost and manufacturing accuracy, inconvenient disassembly and maintenance, and affecting the working efficiency of the whole pump and other problems, to achieve the effect of improving maintainability, increasing the number of cylinders and hydraulic range, and improving power utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

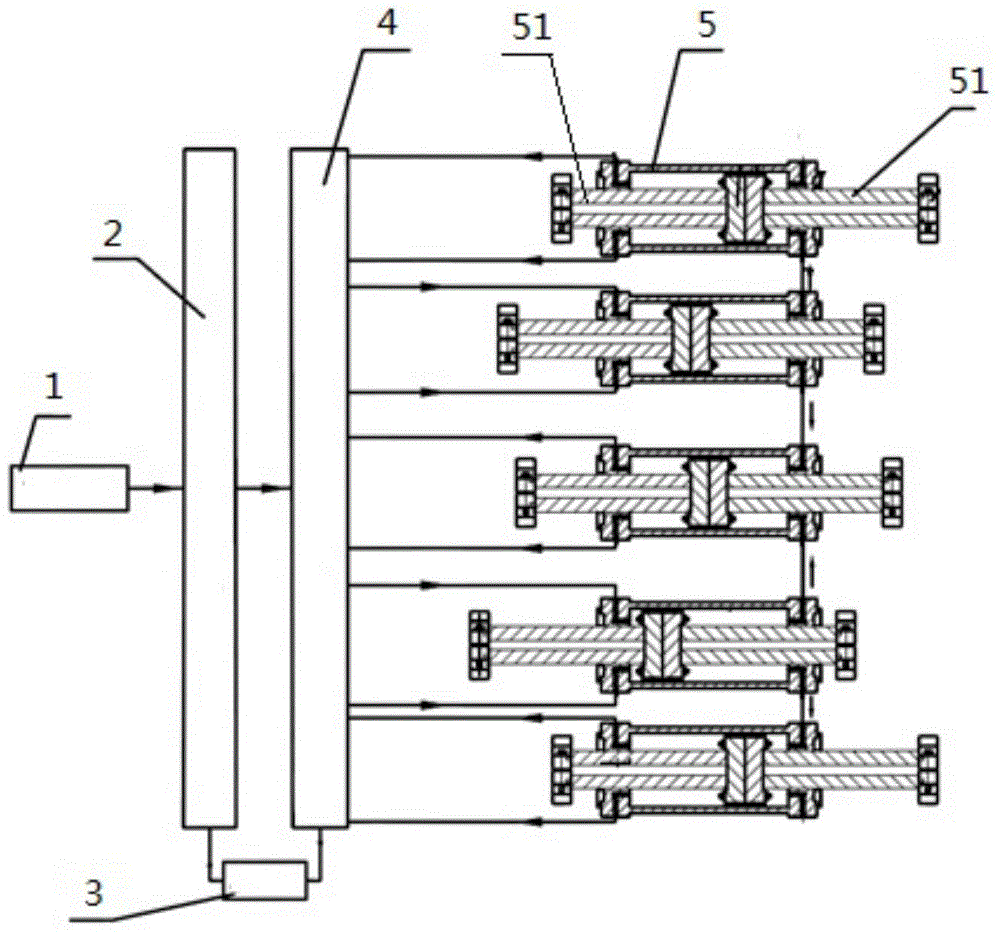

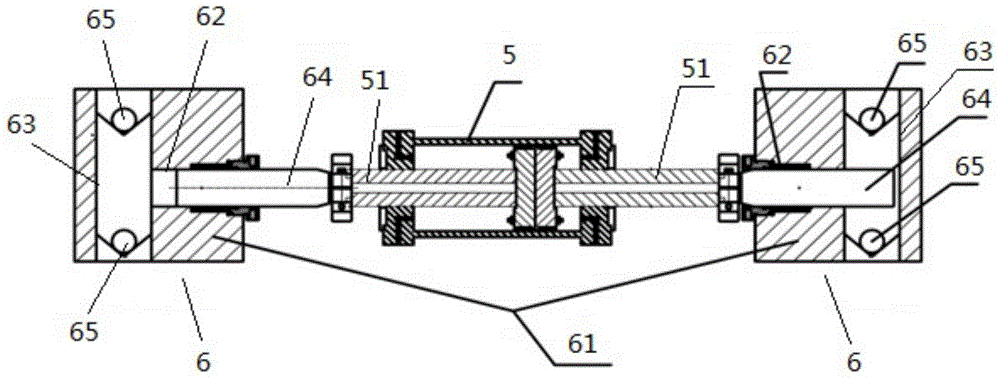

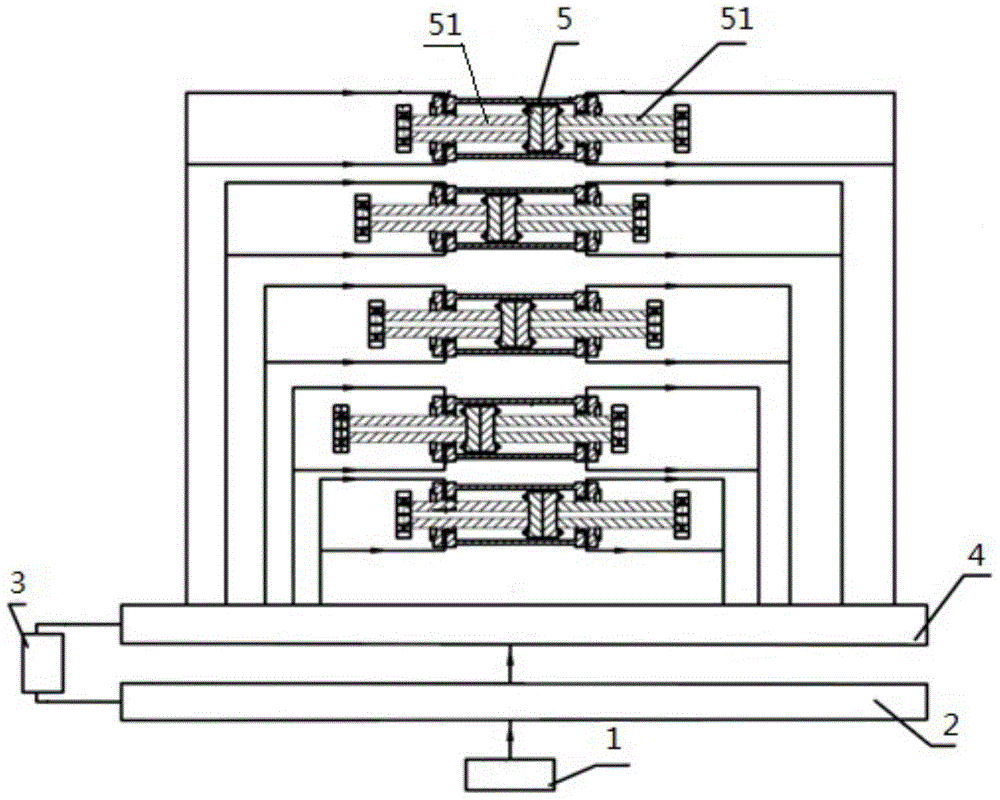

[0024] The hydraulic two-way action pumping device of the present invention, such as Figure 1 to 4 As shown, it includes a prime mover 1, a hydraulic oil pump 2, a hydraulic oil tank 3, a control valve 4, a double-acting hydraulic cylinder 5 and a plunger pump 6.

[0025] The prime mover 1 is a power device such as an engine and an electric motor, and the prime mover 1 drives a hydraulic oil pump 2. The oil outlet pipe set in the hydraulic oil tank 3 is connected to the hydraulic oil pump 2, the hydraulic oil pump 2 is connected to the control valve 4 through a pipeline, and the oil return pipe set in the hydraulic oil tank 3 is connected to the control valve 4.

[0026] Both ends of the double-acting hydraulic cylinder 5 are provided with piston rods 51, and the piston rods 51 are connected with a plunger pump 6, and the double-acting hydraulic cylinder 5 is connected to the control valve 4 through a pipeline.

[0027] There are a plurality of double-acting hydraulic cylinders 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com