Super-long-stroke oil extraction pump

A technology with ultra-long stroke, which is applied in the field of ultra-long-stroke oil production pumps, can solve the problems of not much improved pump efficiency ratio, difficulty in guaranteeing processing quality, difficult maintenance, etc., achieve long stroke, obvious energy-saving effect, and reduce maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

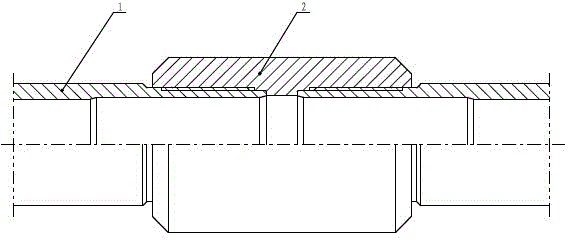

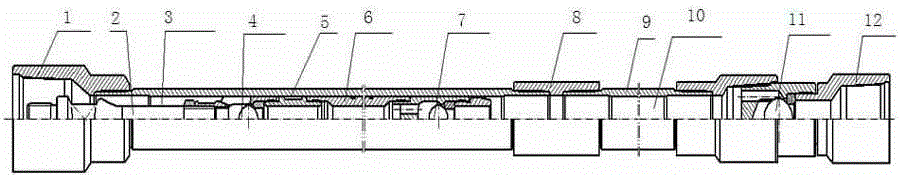

[0008] The total length of the pump barrel of the present invention is usually greater than or equal to about 50 meters, and it is composed of more than 5 pump barrels. The pump barrels are connected by threads to ensure that the concentricity error of the inner diameter of each two pump barrels is not greater than 0.02mm after the connection. The concentricity with the pump barrel is not more than 0.01mm. Plunger raw material: use No. 45 steel cold-drawn seamless steel pipe. Under the premise of ensuring that the material strength meets the relevant national material standards and national standards for oil well pumps, the deviation of wall thickness is required to be no more than 0.10mm; the roundness of the outer diameter is no more than 0.05mm; Straightness does not exceed 0.10mm / M. This provides the necessary technical guarantee for the quality assurance of the centerless grinding and straightening process in our follow-up processing.

[0009] The valve ball and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com