Patents

Literature

605results about How to "Short stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

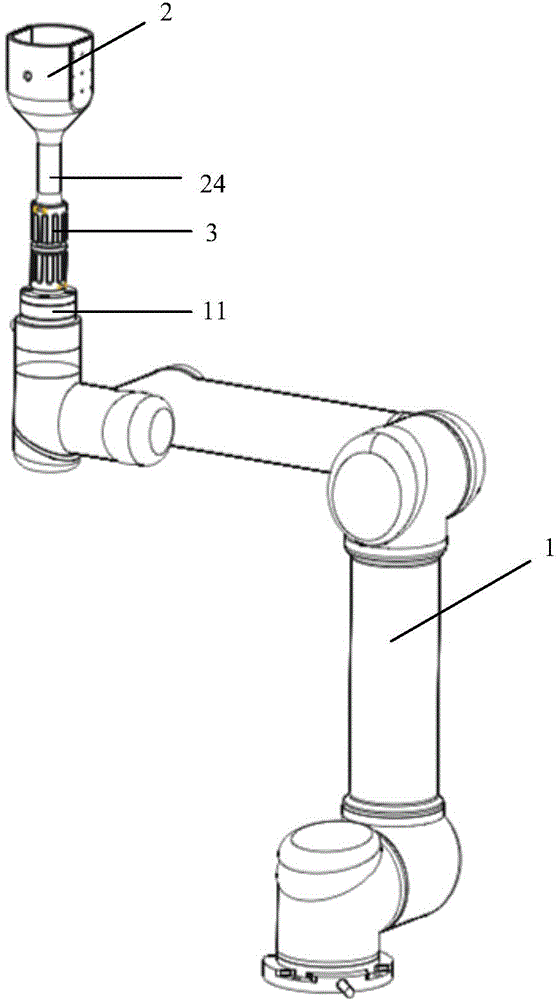

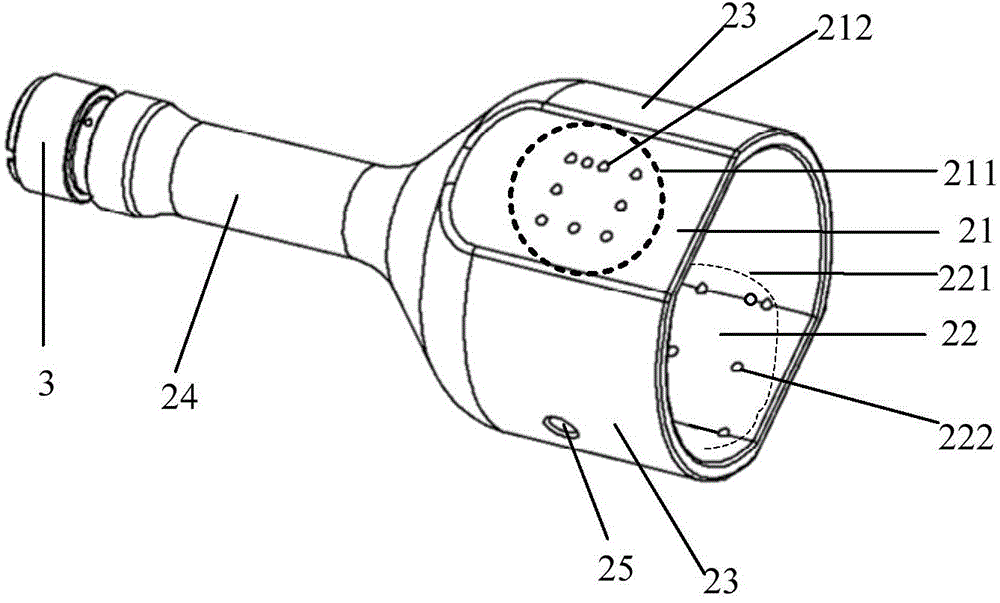

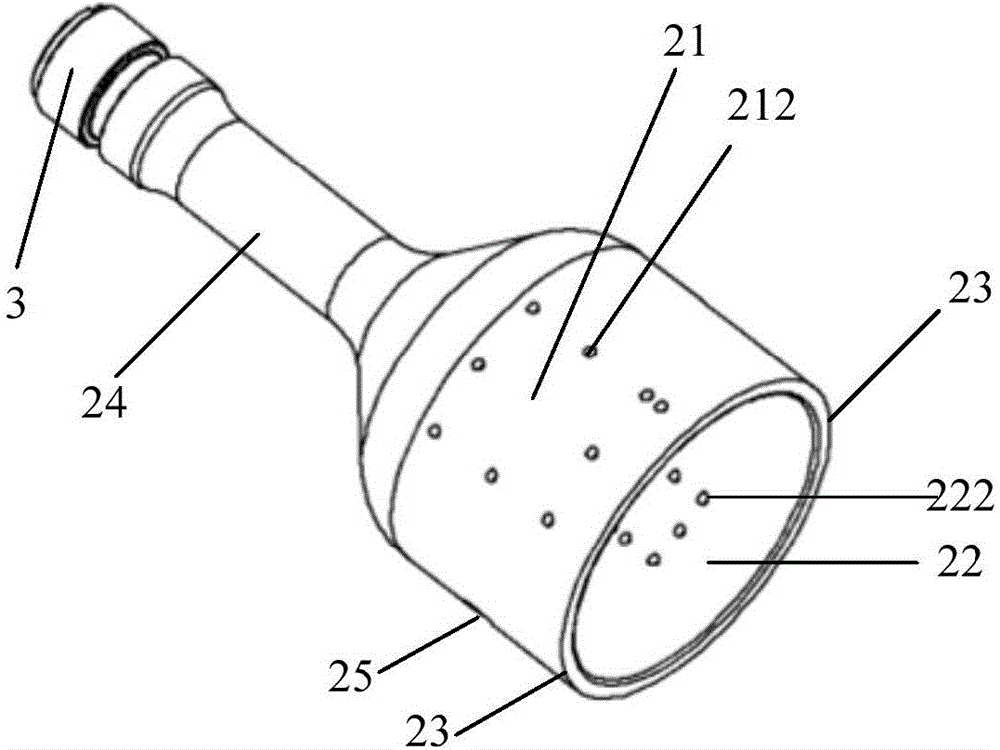

Operation positioning device and method and robot operation system

The invention relates to an operation positioning device and method and a robot operation system. The operation positioning device comprises a positioning ruler, an upper computer and a series-connection mechanical arm with at least six degrees of freedom. The upper computer is connected with the series-connection mechanical arm, the positioning ruler comprises two opposite surfaces allowing X-rays to transmit, the two opposite surfaces are fixedly connected through a connecting surface allowing X-rays to transmit, the two opposite surfaces are respectively provided with a group of marks, each group of marks comprise at least four mark points which are not located on the same straight line, and the mark points are X-ray-proof components. Any opposite surface or the connecting surface is fixedly connected with a ruler handle, and the ruler handle is connected with the tail end of the series-connection mechanical arm through a port. The upper computer adjusts the position of the positioning ruler by controlling movement of the series-connection mechanical arm, space positioning calculation is conducted according to the mark points in collected images, and a planning path is obtained. The device can achieve perspective positioning at any angle, and can eliminate system errors caused when an operation path is calculated, increase working space and improve the operation positioning accuracy.

Owner:BEIJING TINAVI MEDICAL TECH

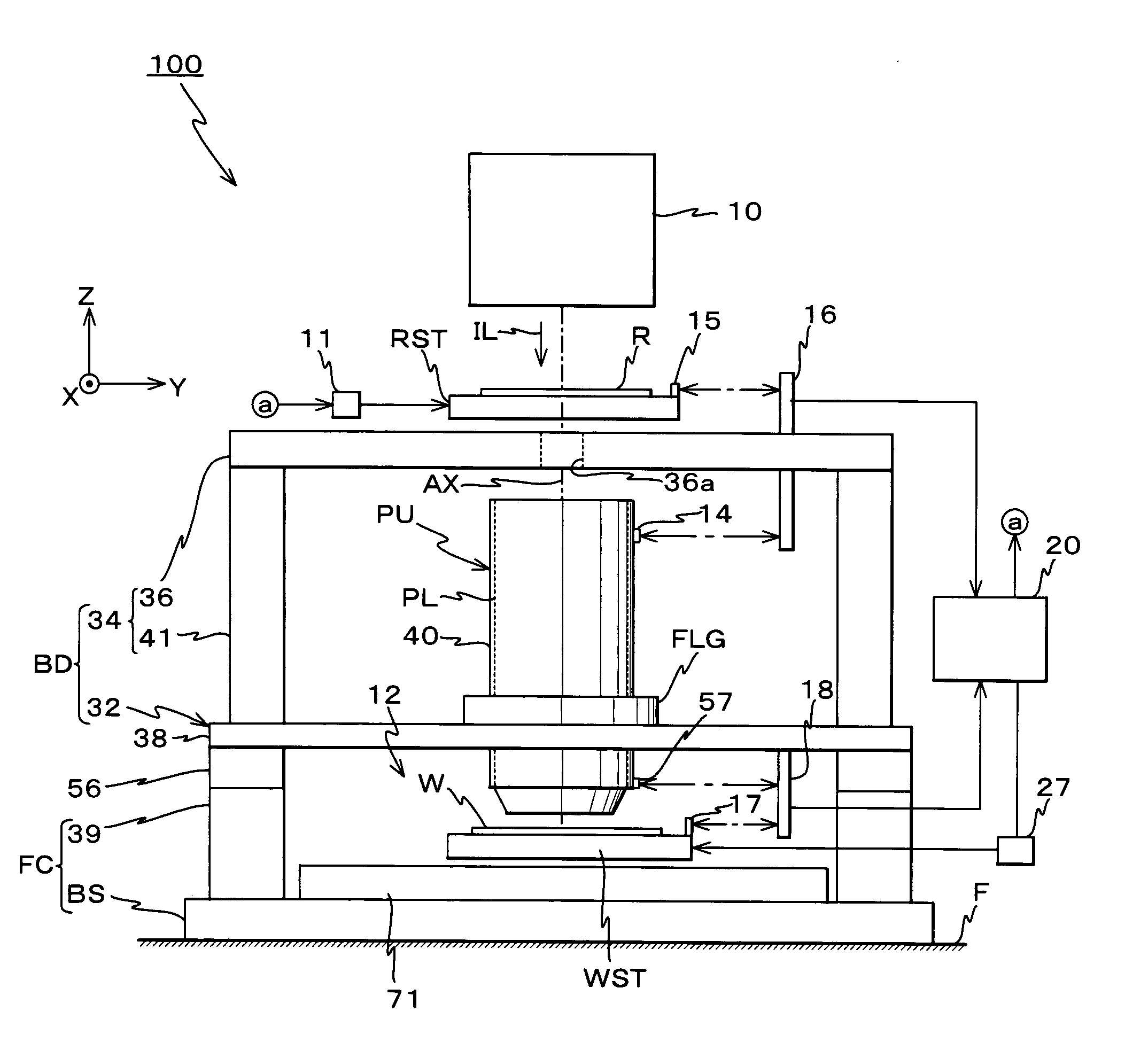

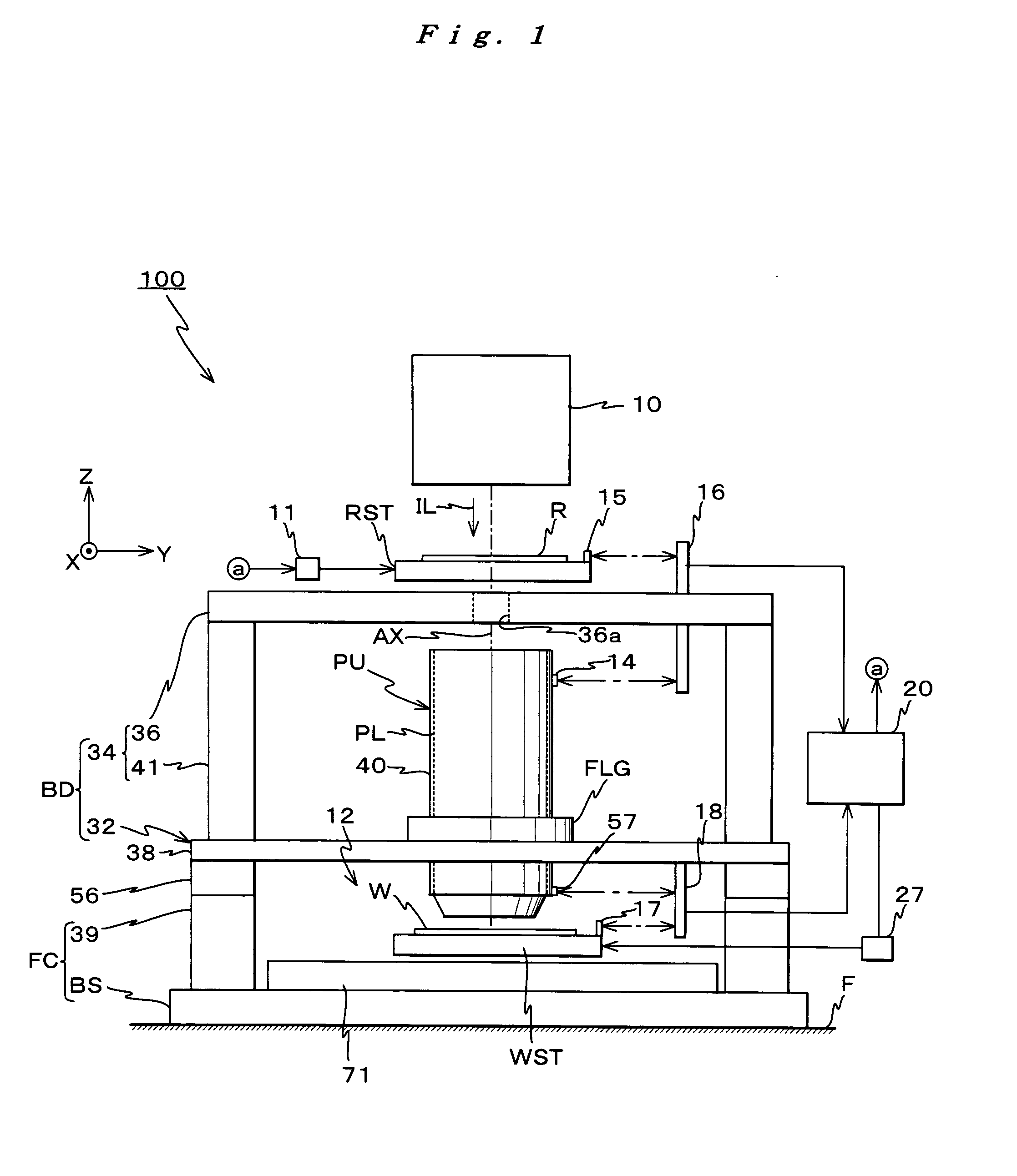

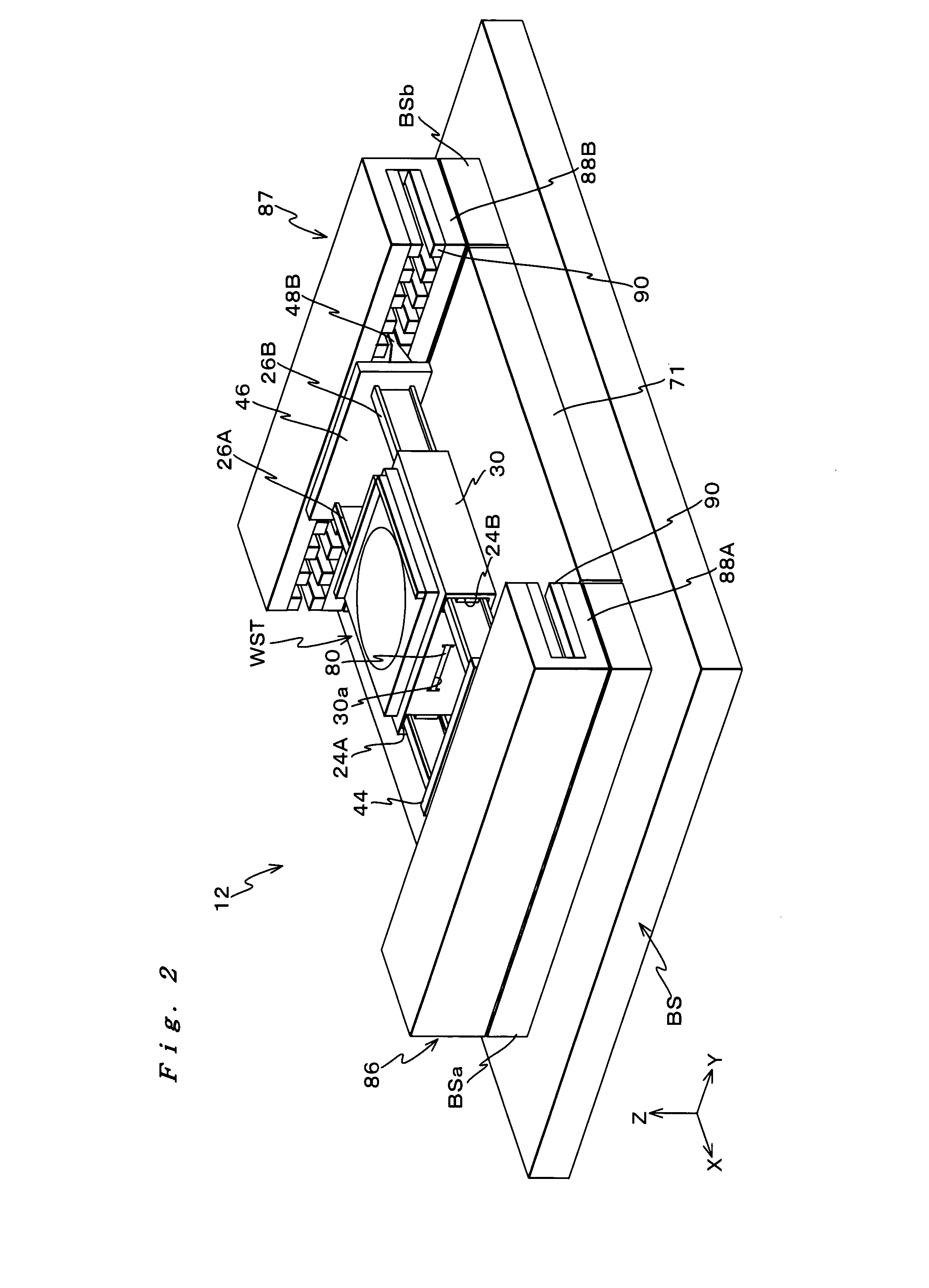

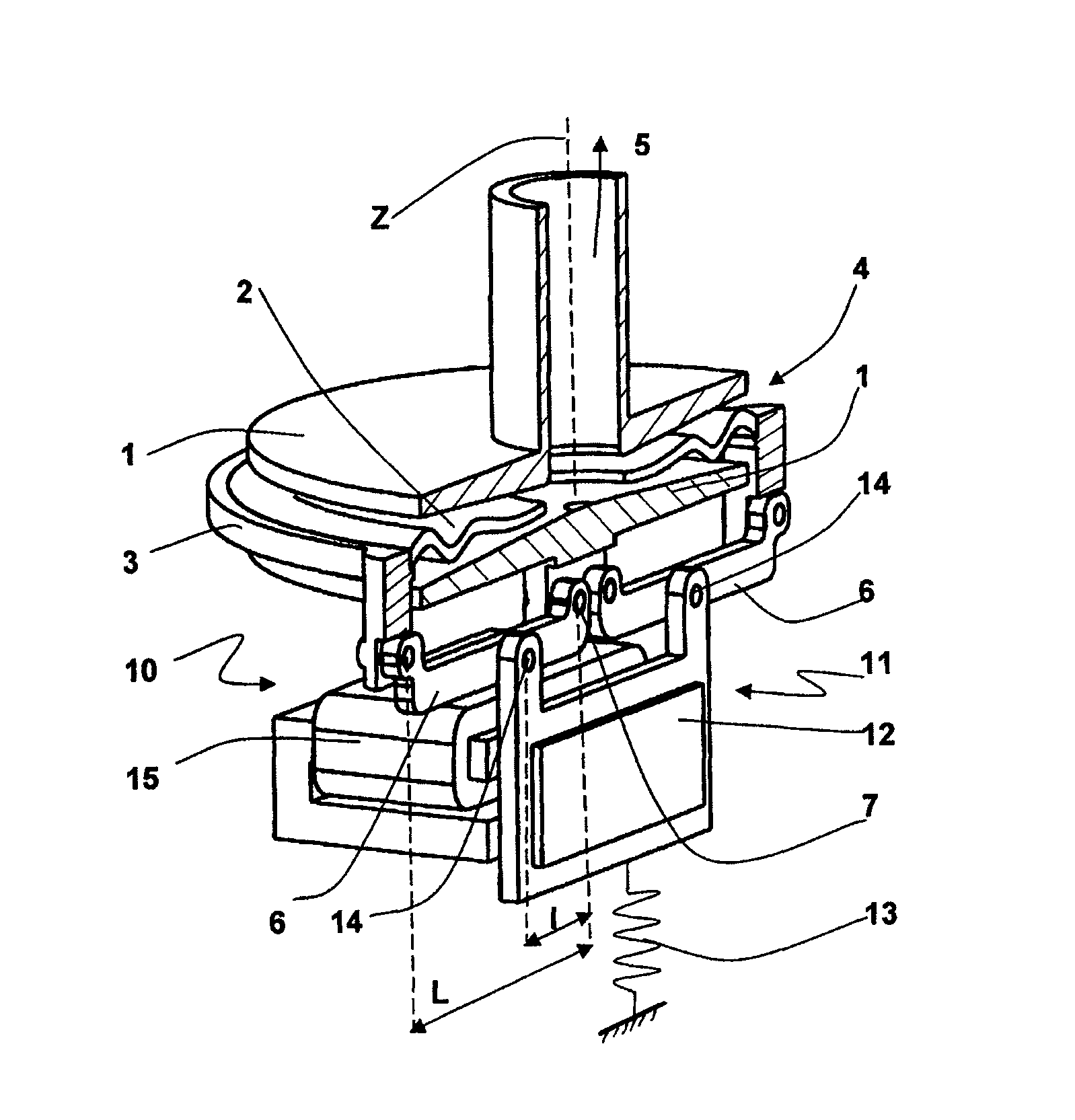

Drive Method of Moving Body, Stage Unit, and Exposure Apparatus

ActiveUS20080143994A1Short moving distanceReduce movementElement comparisonSemiconductor/solid-state device manufacturingEngineeringLinear motor

An exposure apparatus that comprises a stage (28) that moves in the X-axis direction, an X-axis linear motor (80) that drives the stage, a counter mass (30) that moves in a direction opposite to the stage due to the action of the reaction force of the drive force of the stage in the X-axis direction by the motor (80), X-axis trim motors (26A, 26B) that drives the counter mass in the X-axis direction, and a control unit that controls the trim motors and gives the counter mass an initial velocity in the +X direction when the stage is moved via the motor (80), for example, in the +X direction. Accordingly, the strokes required for the movement of the counter mass can be shortened without increasing the size of the counter mass.

Owner:NIKON CORP

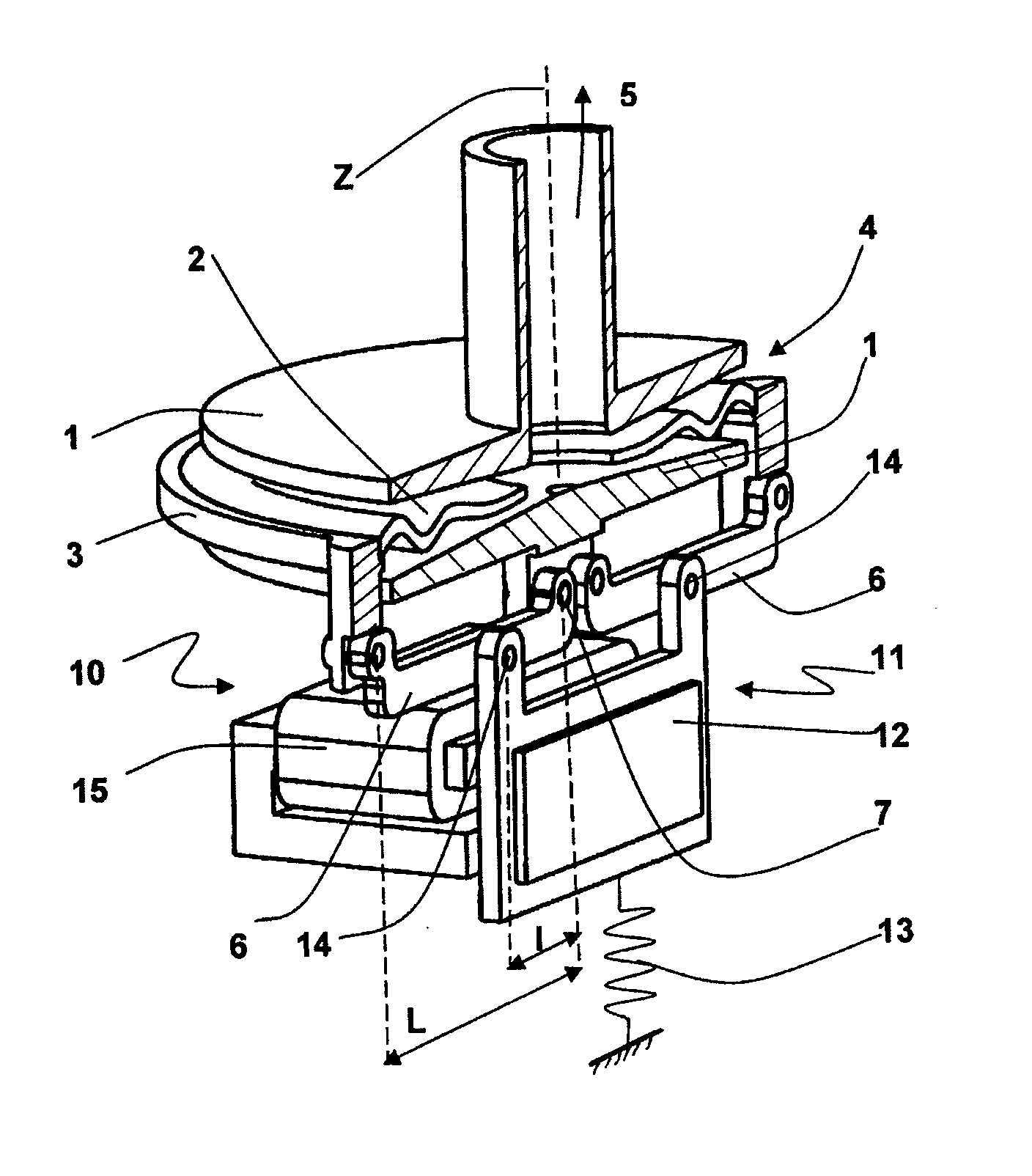

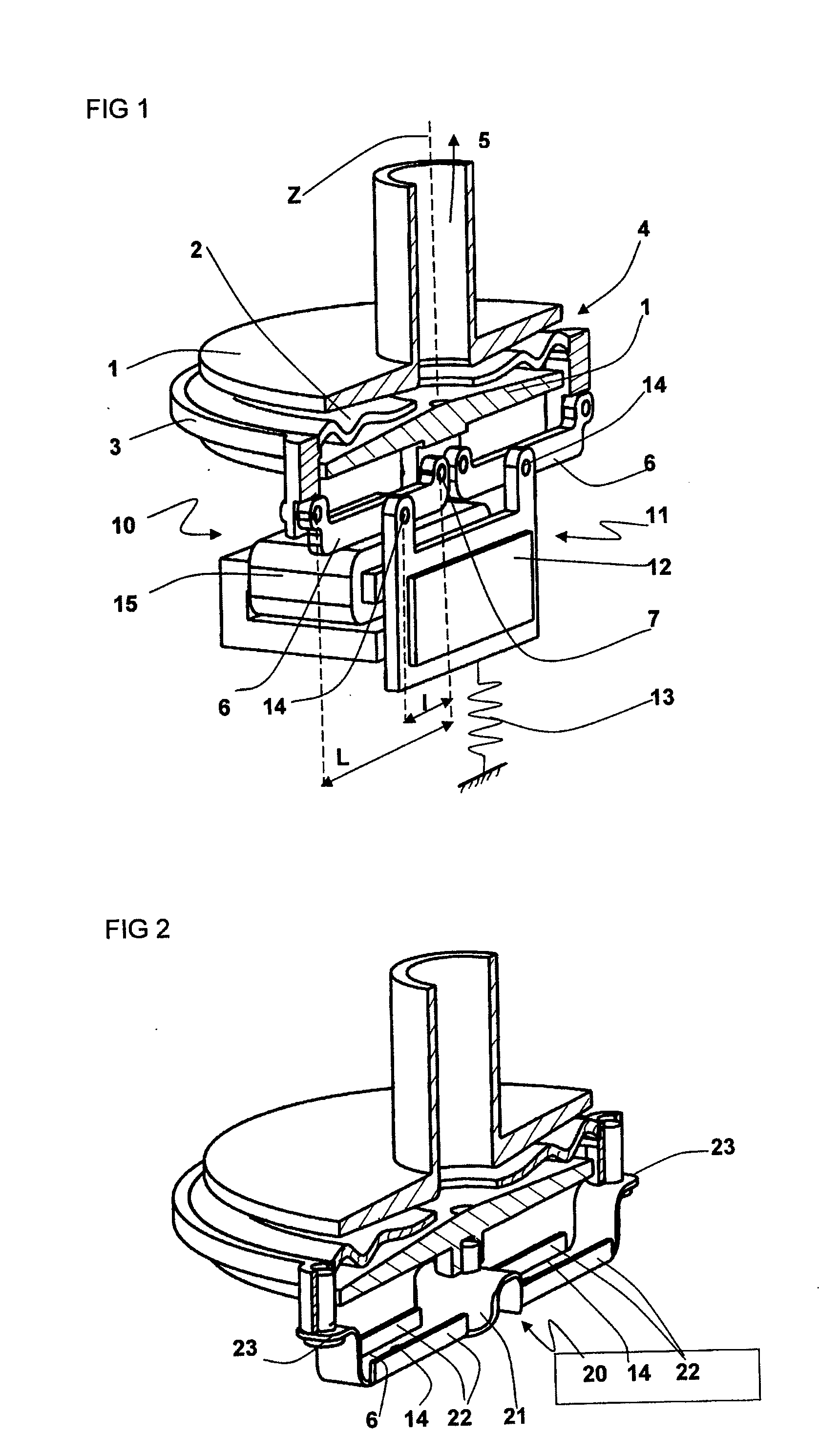

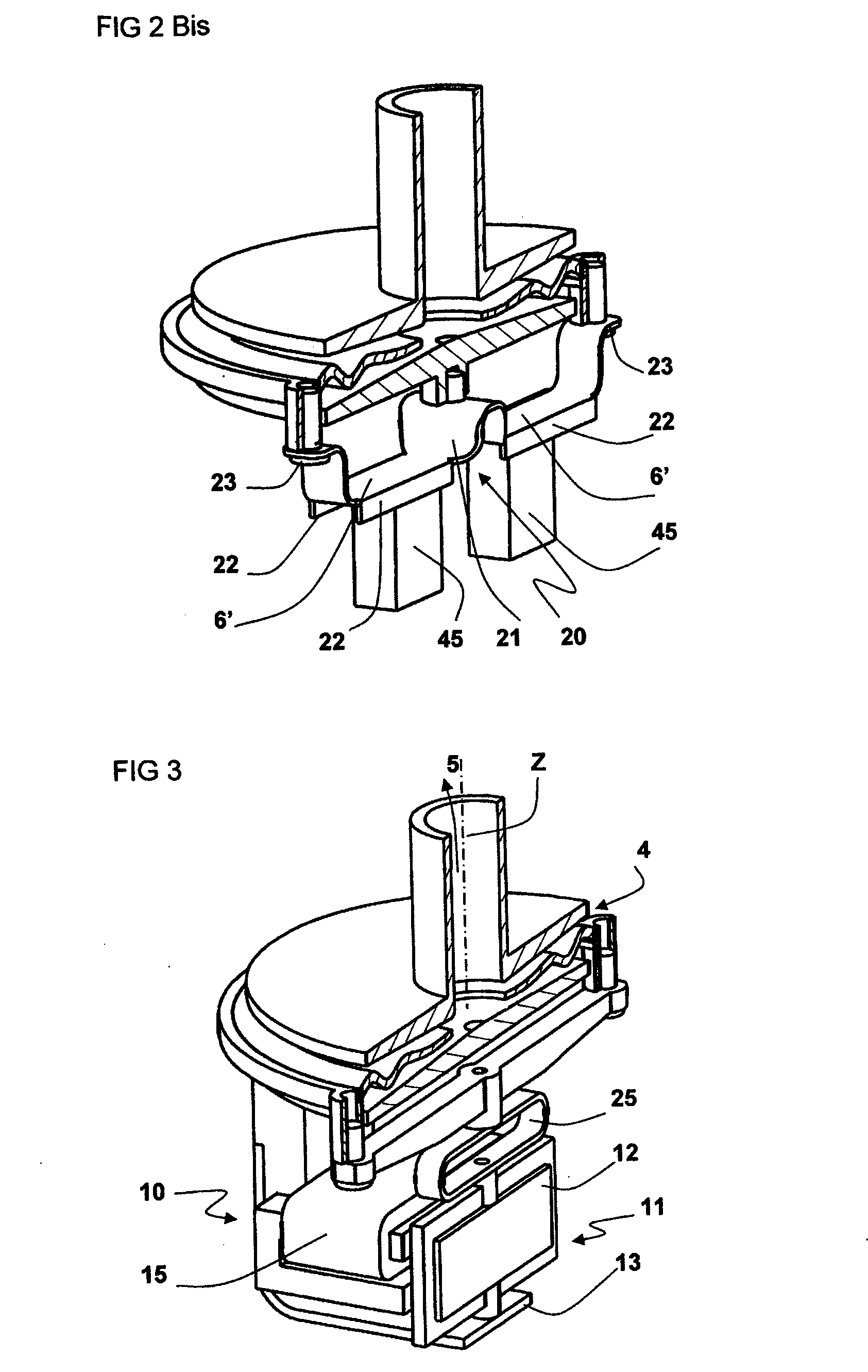

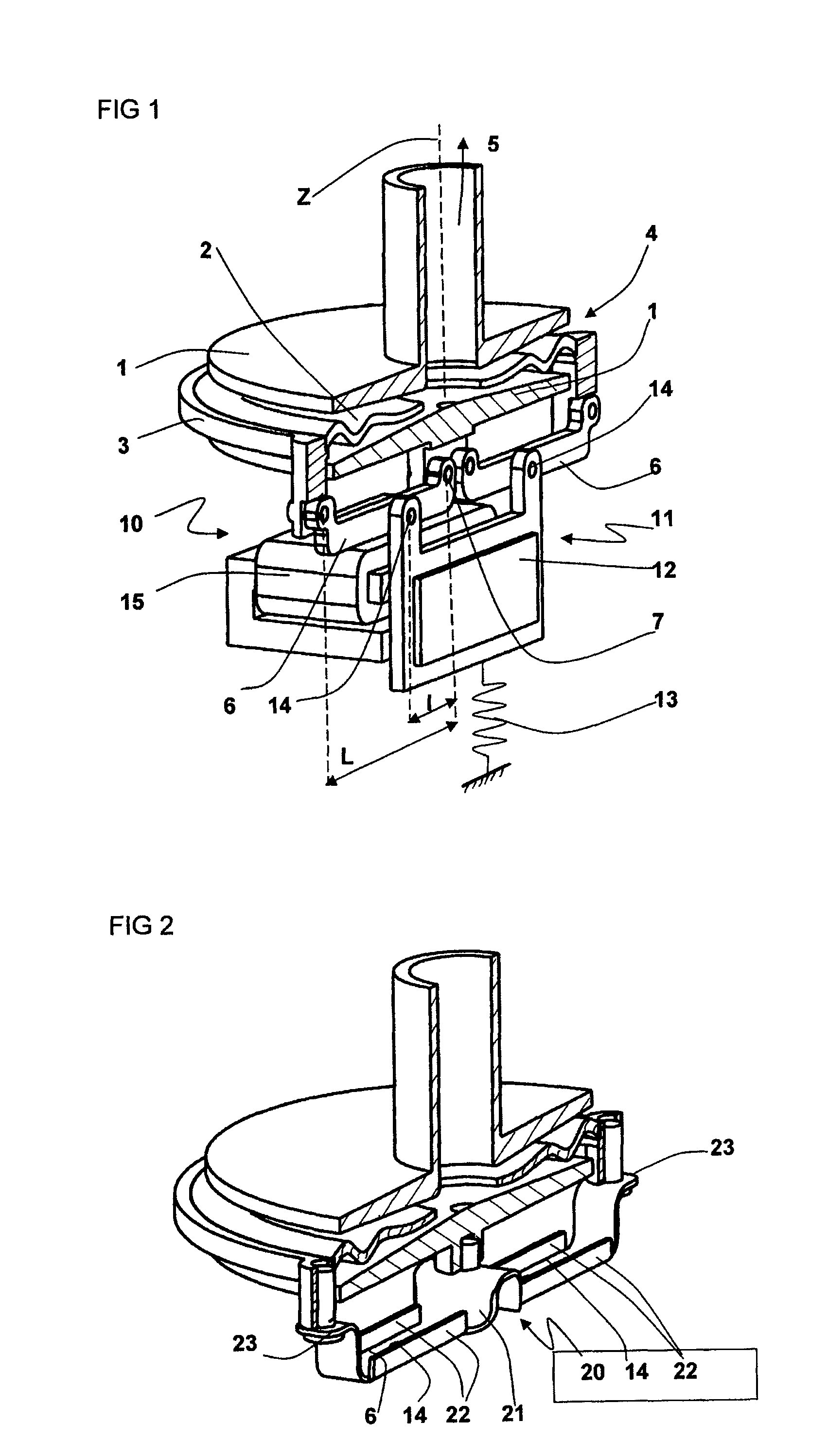

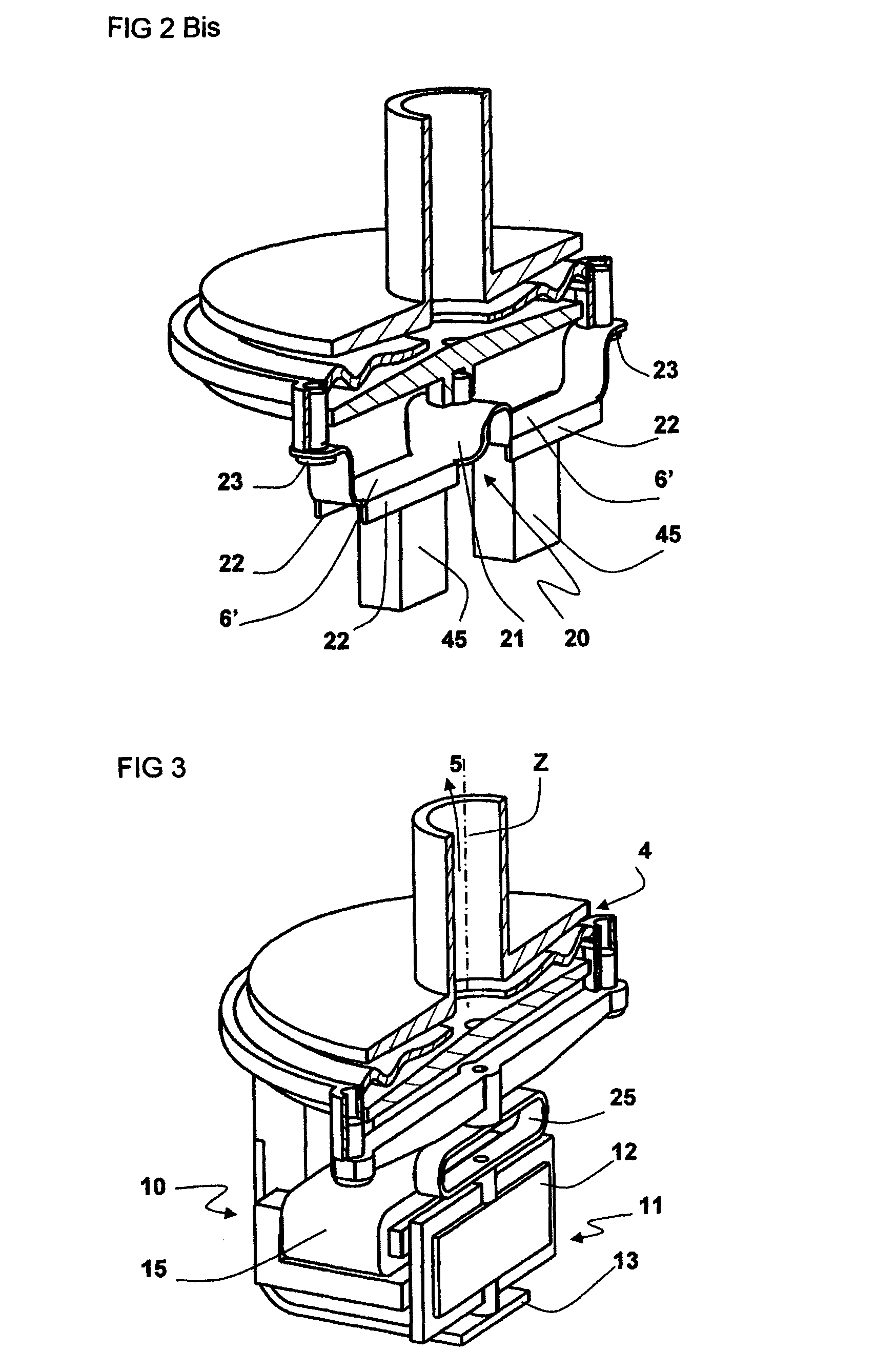

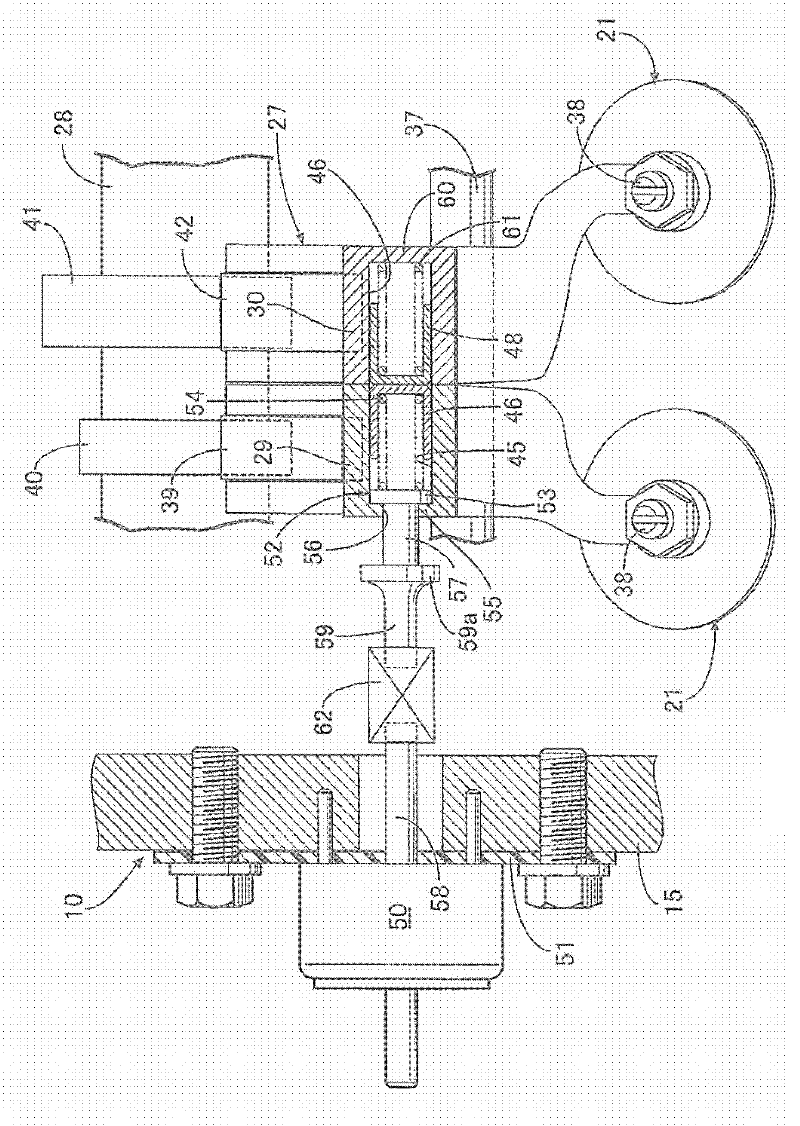

Diaphragm pump with a crinkle diaphragm of improved efficiency

ActiveUS20110176946A1Short strokeReduce vibrationFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpEngineering

A pump having an undulating diaphragm mounted for undulating between two end plates under drive from at least one electromagnetic actuator in order to transfer a fluid between an inlet of the pump and an outlet of the pump. The pump includes adapter means connecting the diaphragm support to a movable portion of the actuator in order to shorten the stroke of the movable mass of the actuator such that its stroke is shorter than the stroke of the diaphragm support.

Owner:AMS R&D

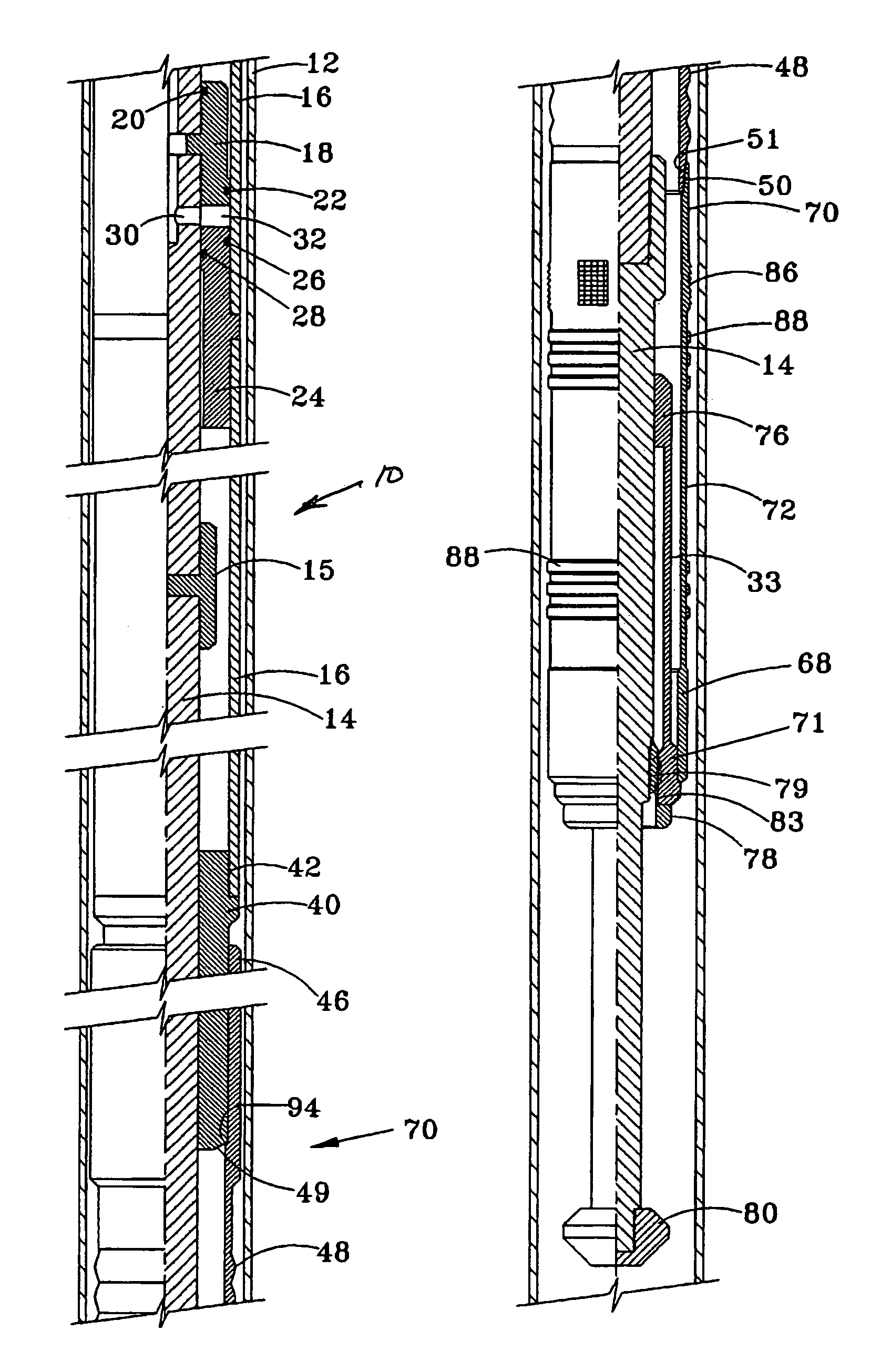

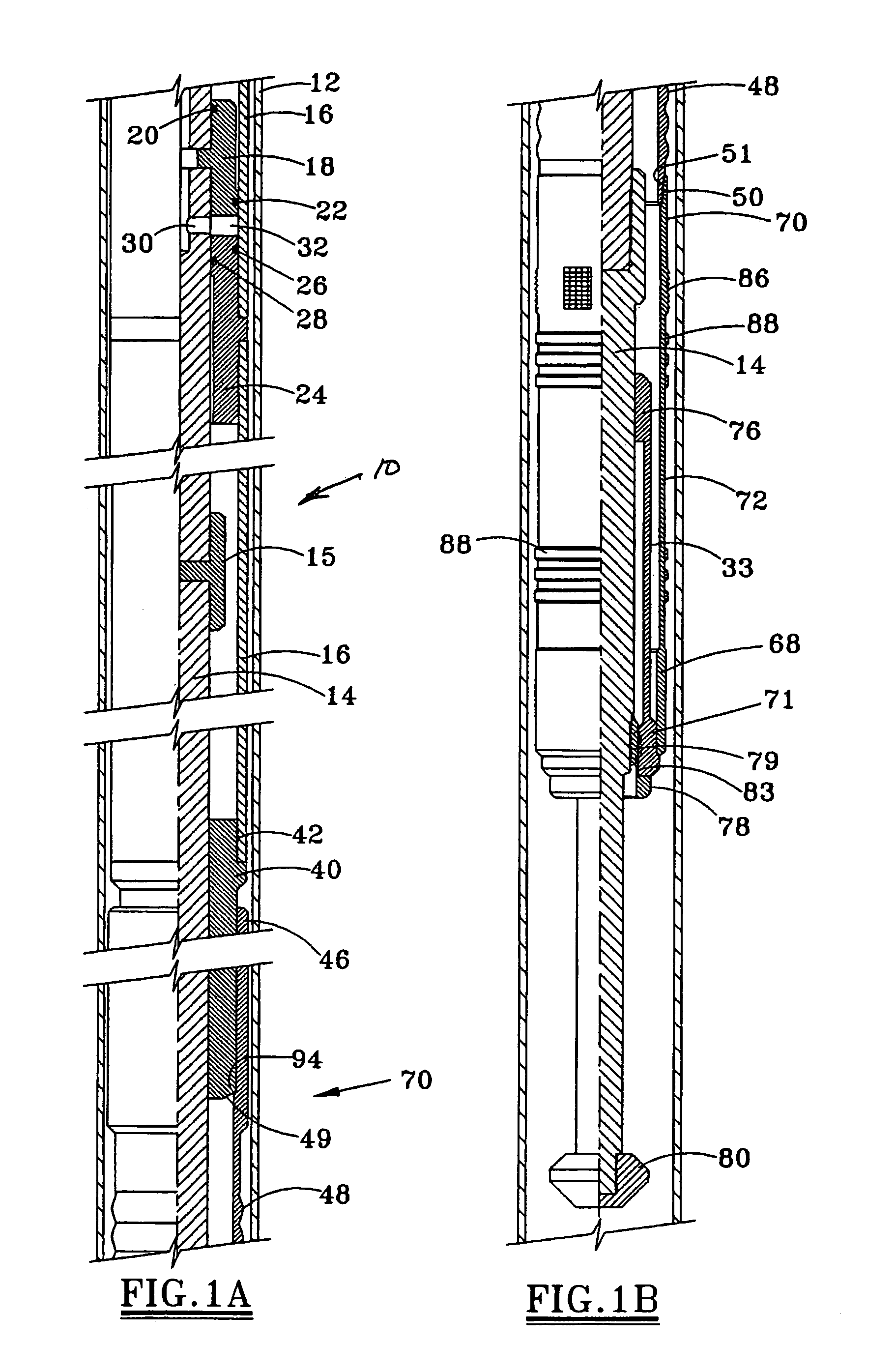

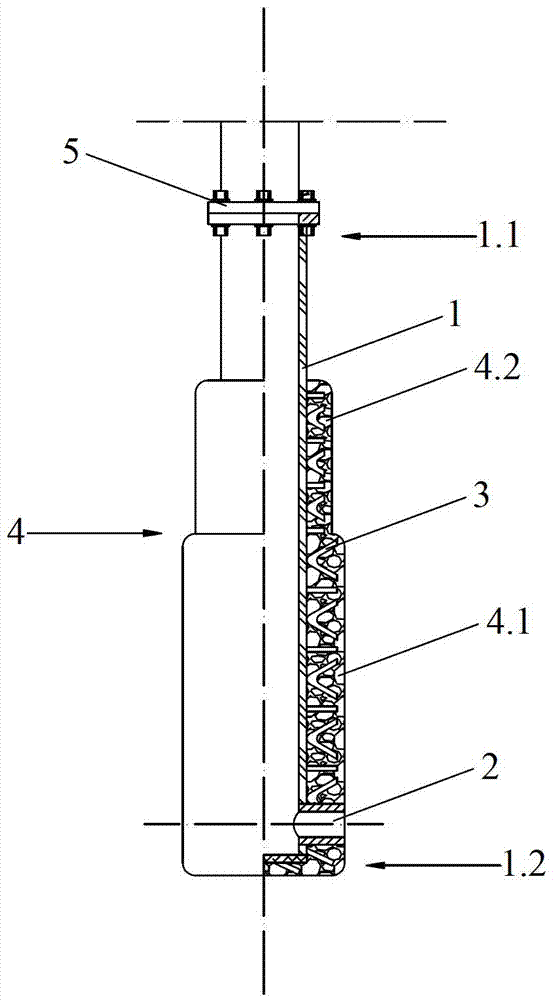

Tubular expansion fluid production assembly and method

InactiveUS7124829B2Reliable settingsConstructed moreFluid removalSealing/packingCasing stringEngineering

An expansion-set fluid production assembly transfers well fluids from a casing string 12 to a production tubing string 112. A tubular anchor 72 and tubular expander 70 may be positioned downhole on a running tool at a desired depth along the casing string 12. An actuator assembly 10 may forcibly move the tubular expander 70 into the tubular anchor 72, expanding the tubular anchor 72 to seal and secure the tubular anchor 72 against the casing string 12. The running tool actuator assembly 10 may be removed, leaving the expanded tubular anchor 72 and tubular expander 70 downhole. A seal nipple 122 may be sealed with the tubular expander 70 and to the production tubing string 112. Fluids may then be recovered from the wellbore through the casing string 12, through the fluid production assembly, and into the production tubing string 112.

Owner:TIW

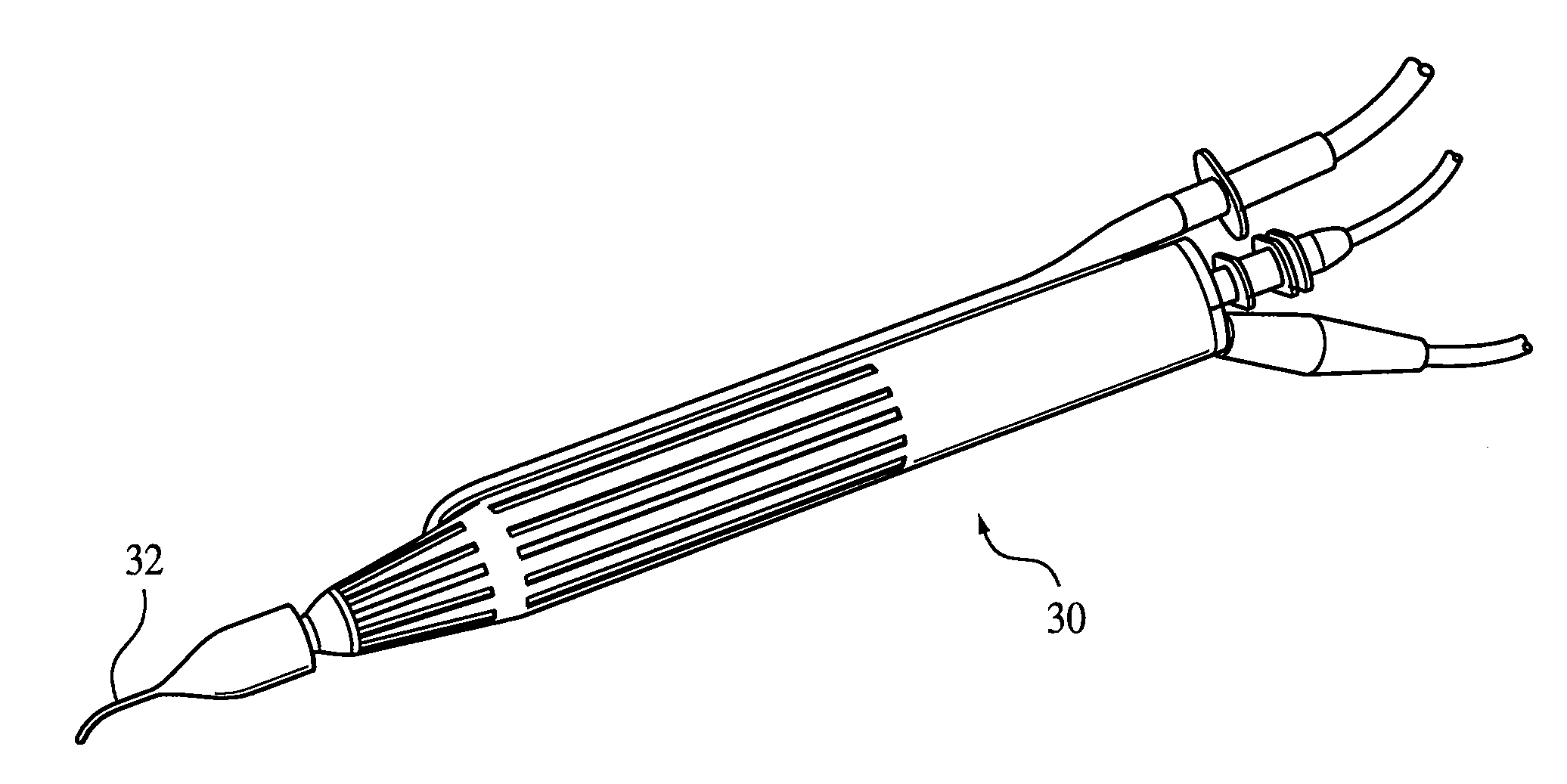

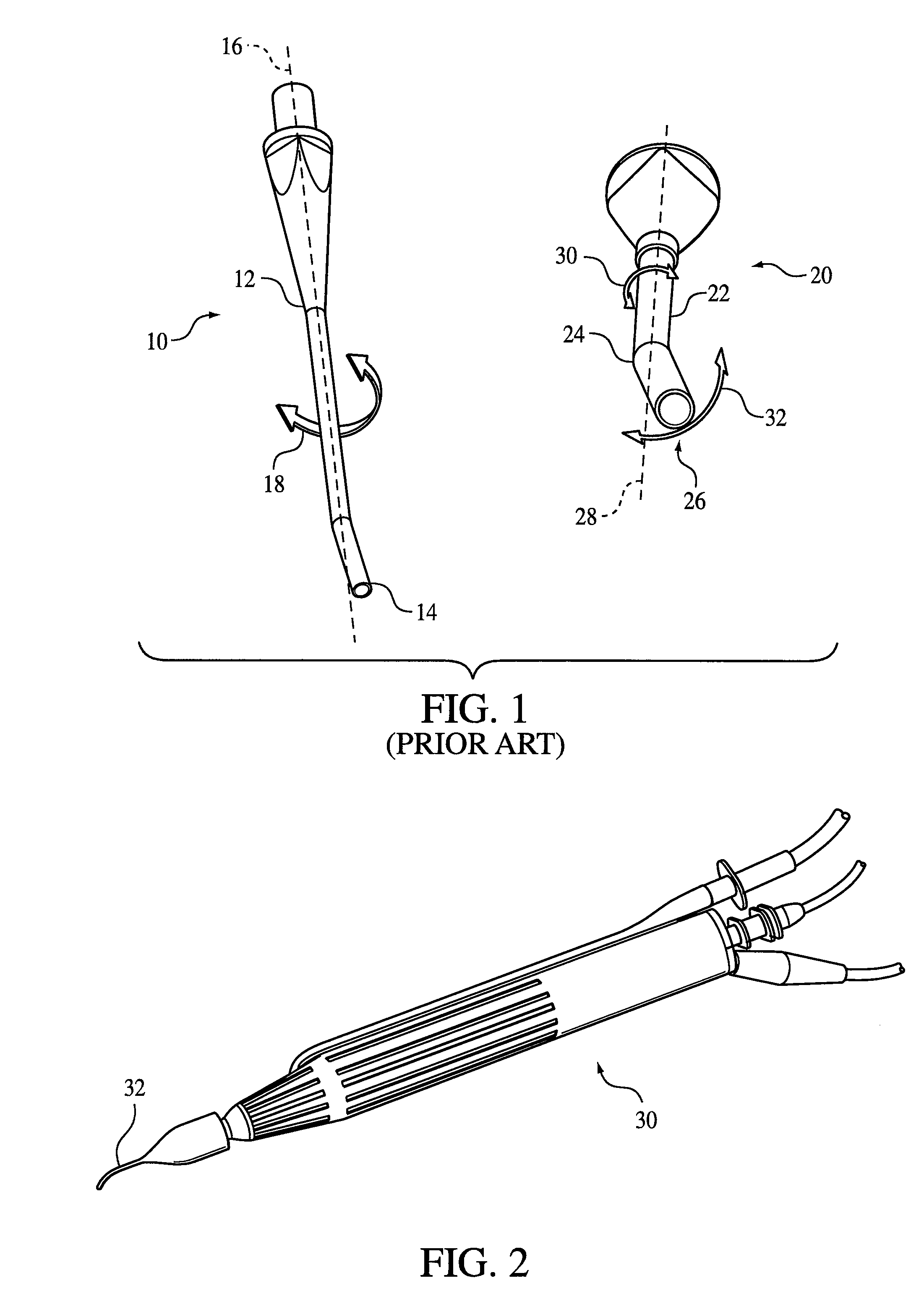

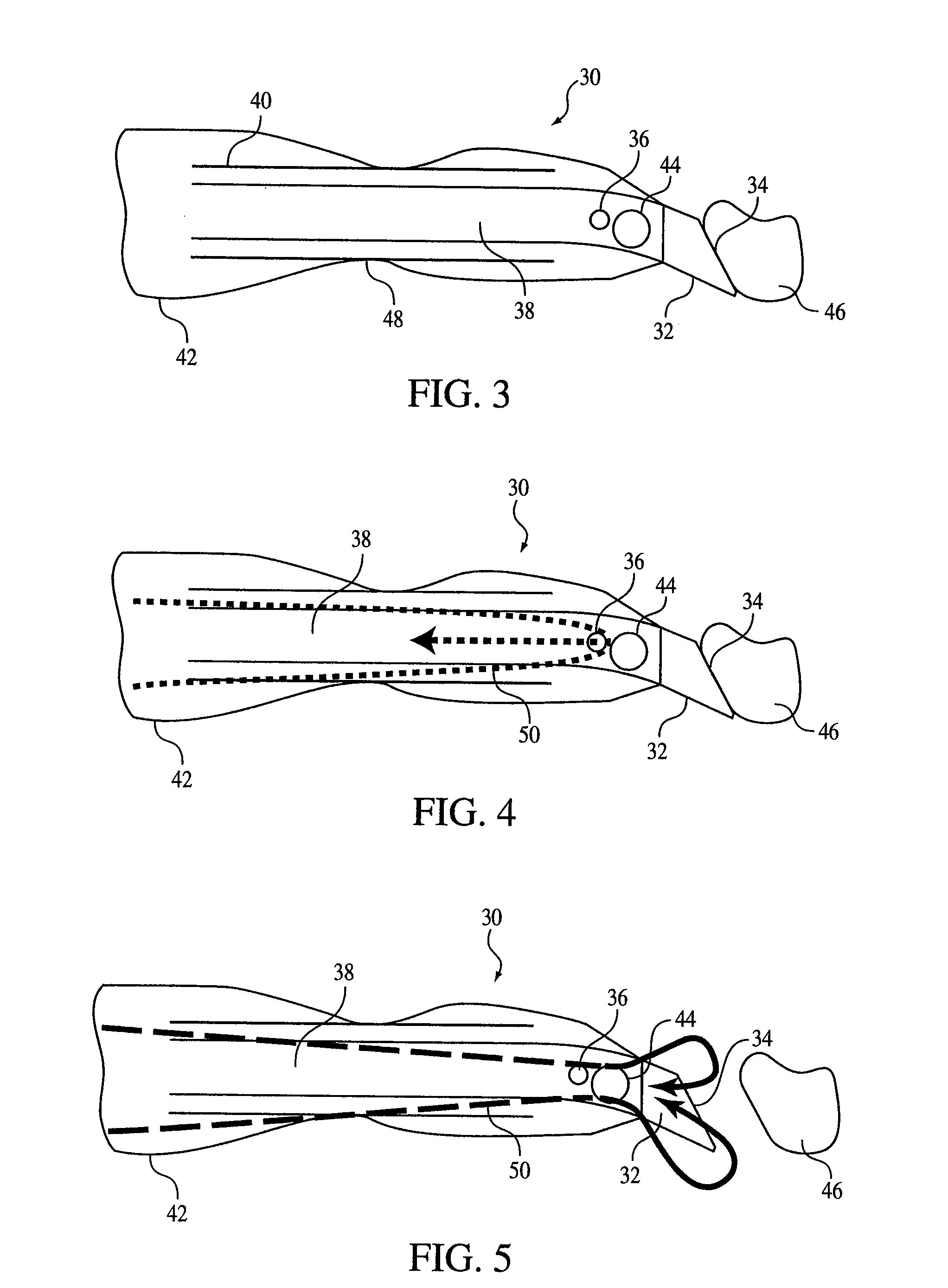

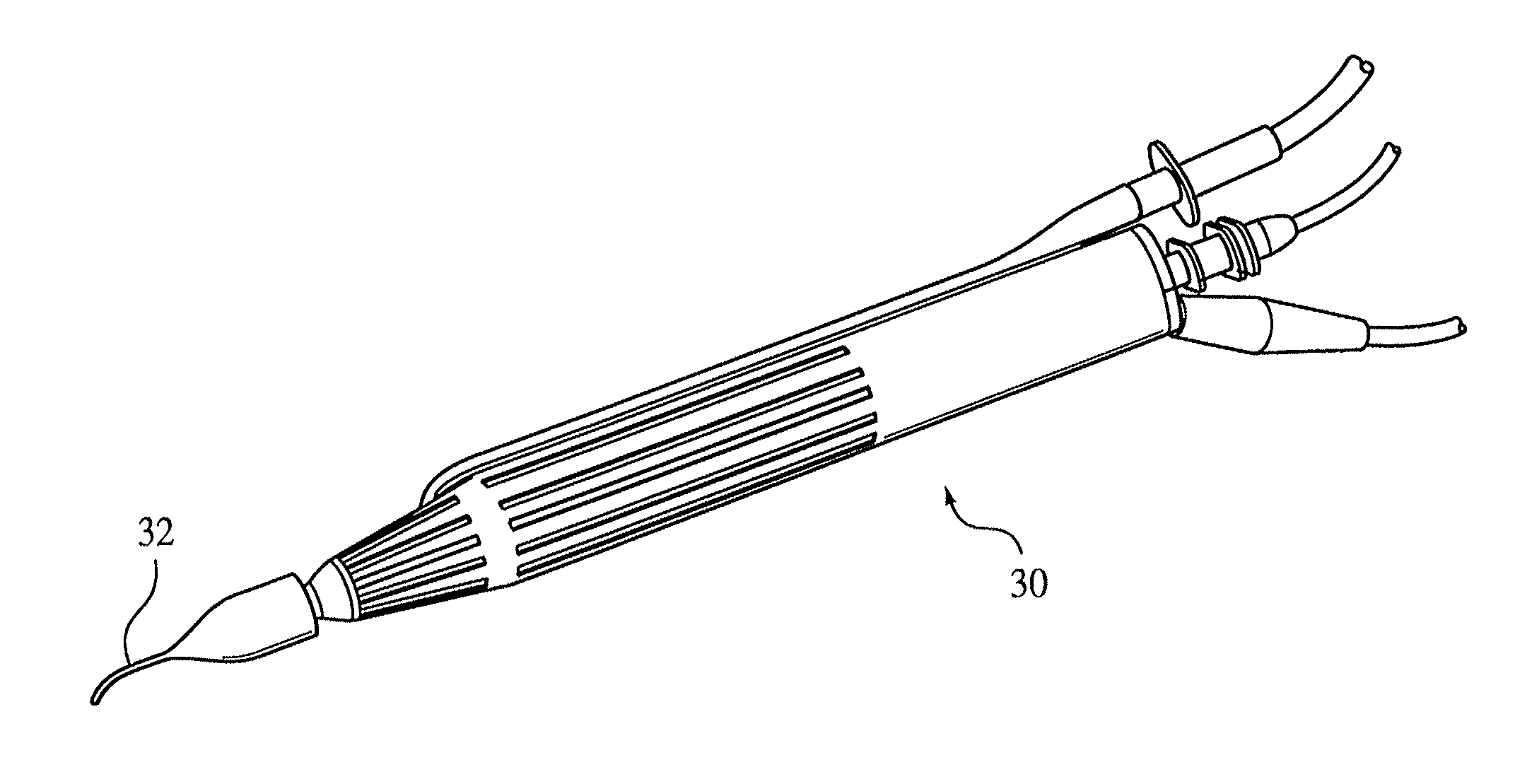

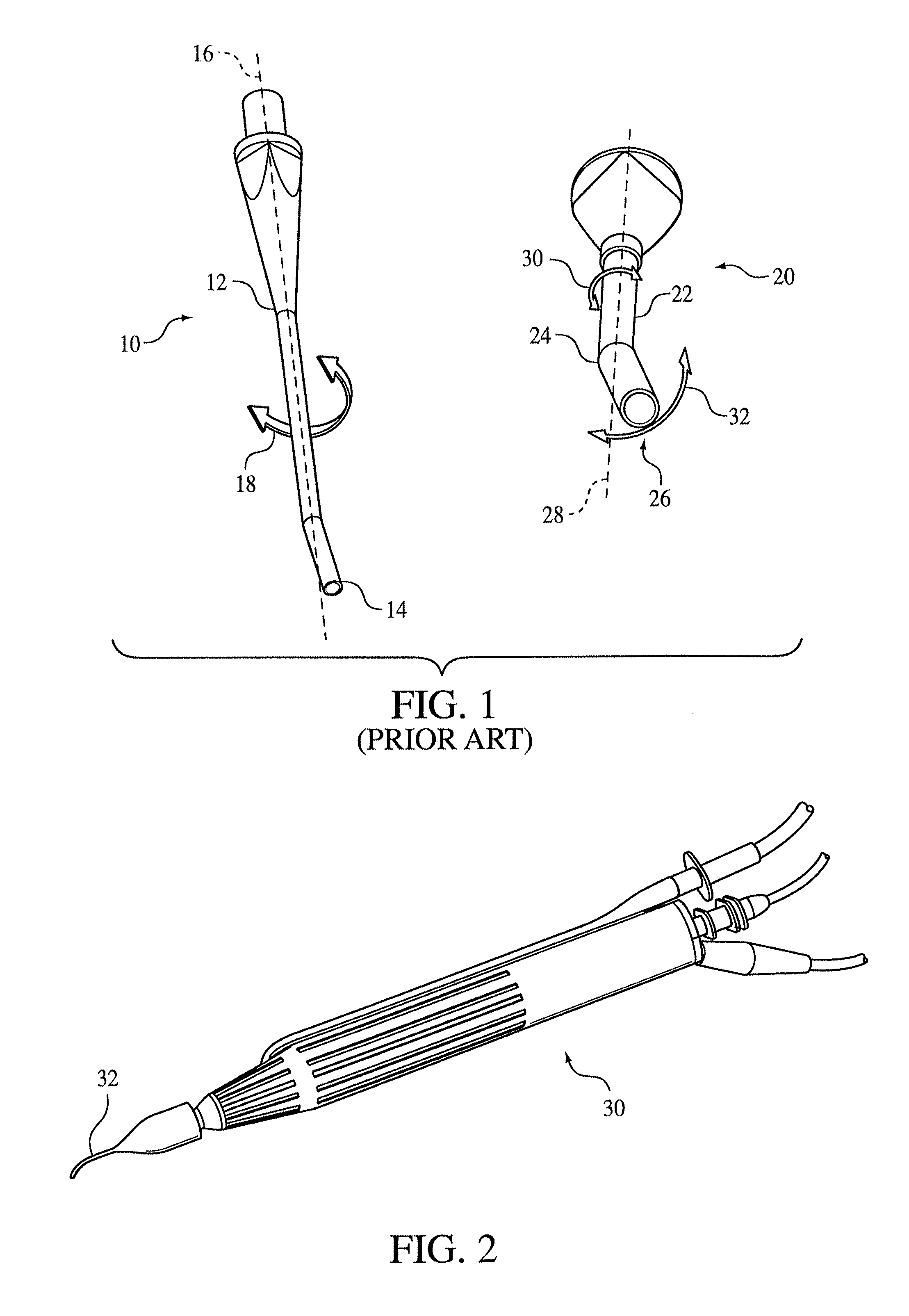

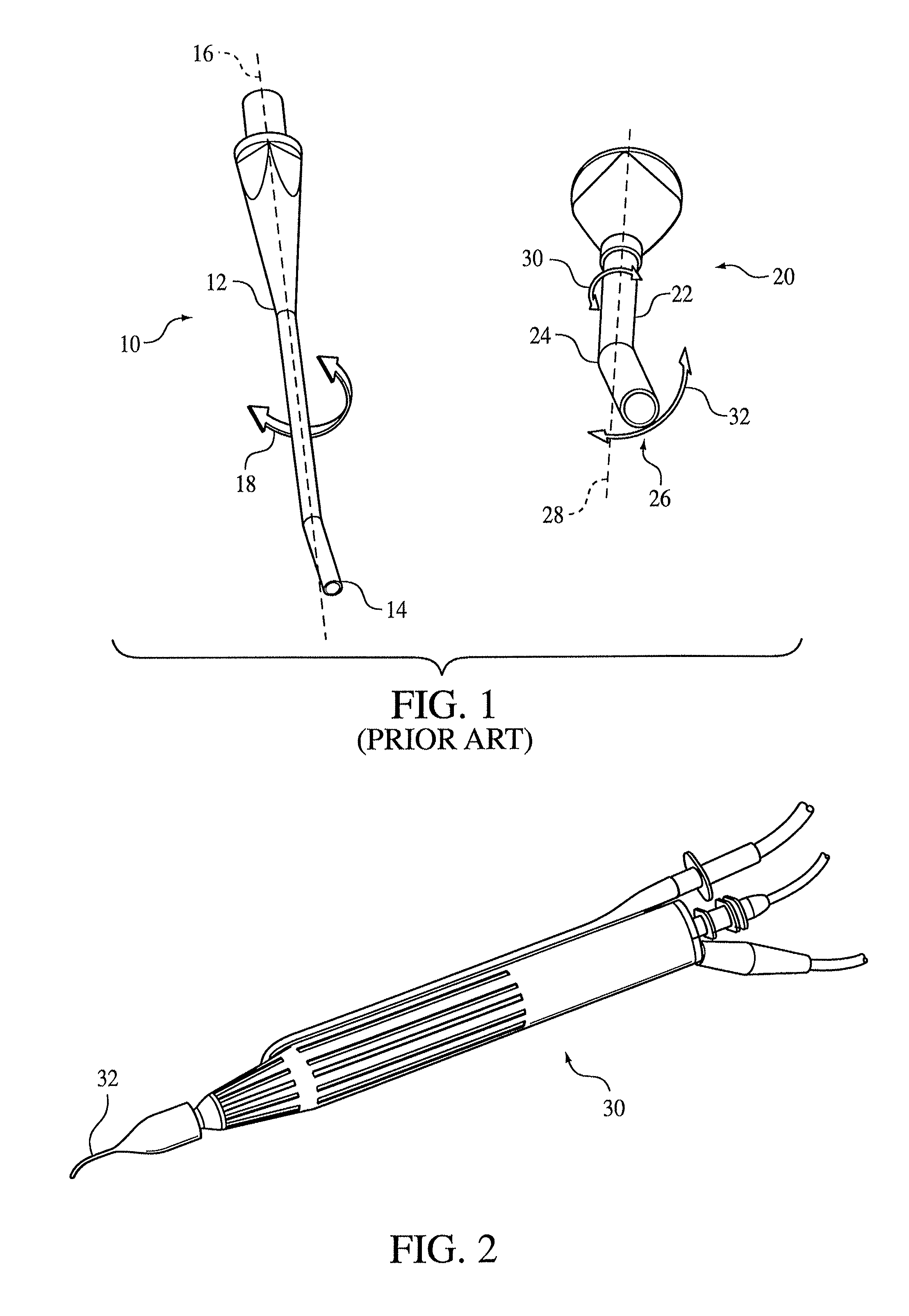

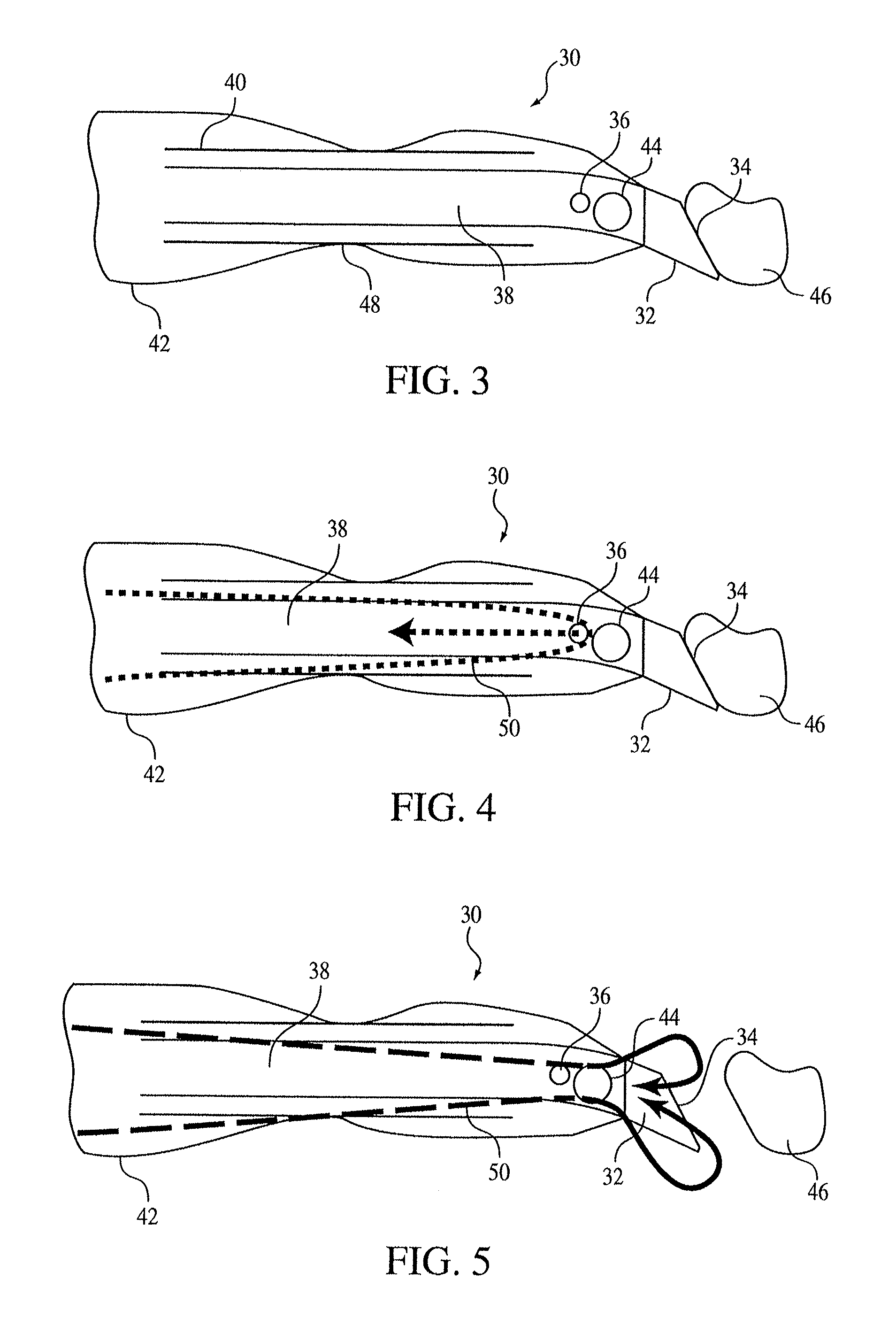

Torsional Ultrasound at Resonant Frequencies That Eliminate Chatter

InactiveUS20080139994A1Less movementShort strokeUltrasound therapyEye surgerySonificationSyringe needle

A torsional ultrasound surgical instrument that lessens or eliminates chatter from lens material by imparting a twisting, rotary motion to a tip of a phacoemulsification needle at a resonant frequency in excess of 32 kHz. Heat generation is reduced either through the use of a polyimide tubing situated between the needle and the infusion sleeve, through the use of thermal watch to prevent overheating at the incision, and / or through the use of a bypass hole in the needle that diverts flow under suction into the needle via the bypass hole instead of exiting through an irrigation opening in the infusion sleeve when a tip port is occluded by lens material.

Owner:ALCON INC

Diaphragm pump with a crinkle diaphragm of improved efficiency

ActiveUS8714944B2Short strokeRaise the ratioFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpControl theory

Owner:AMS R&D

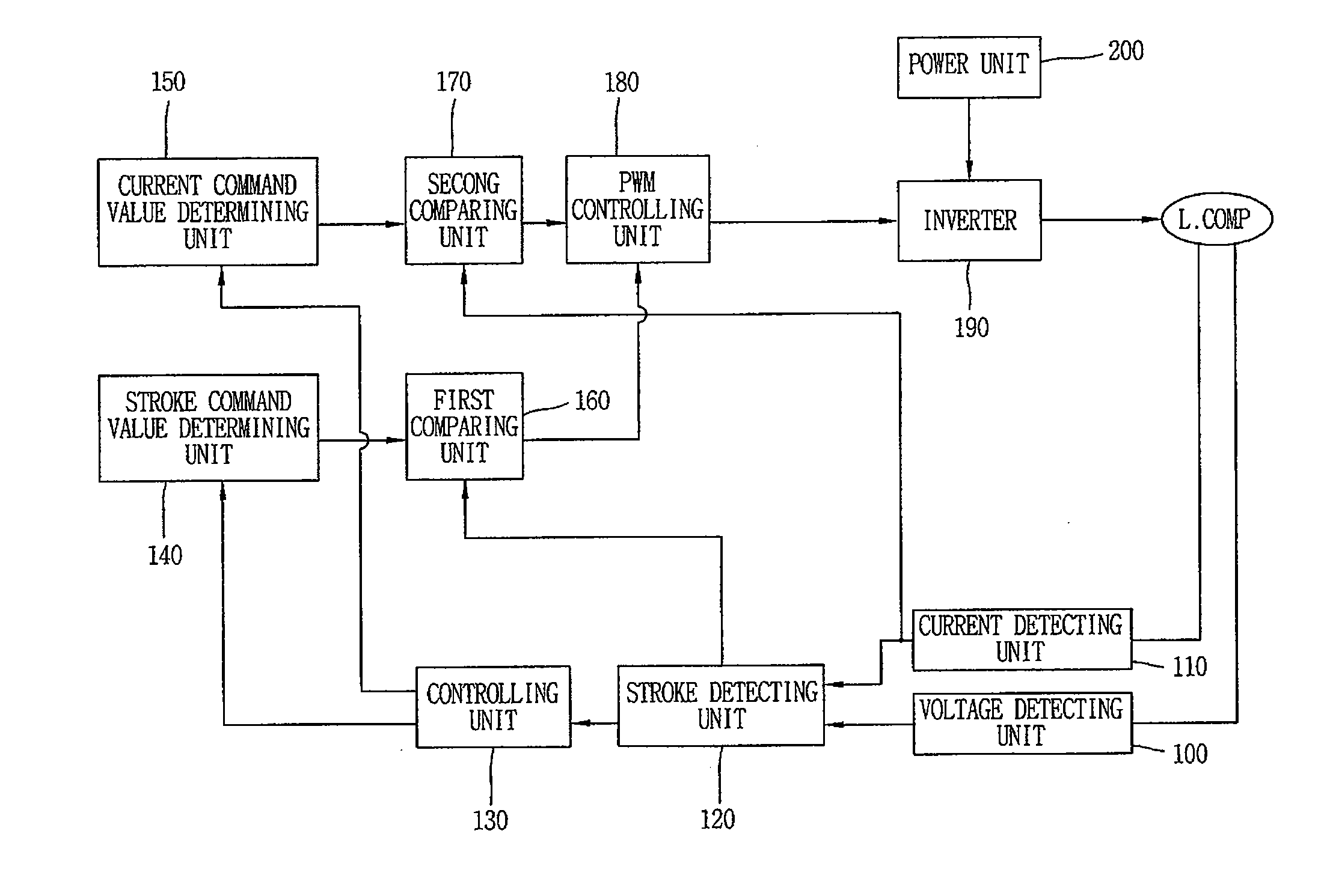

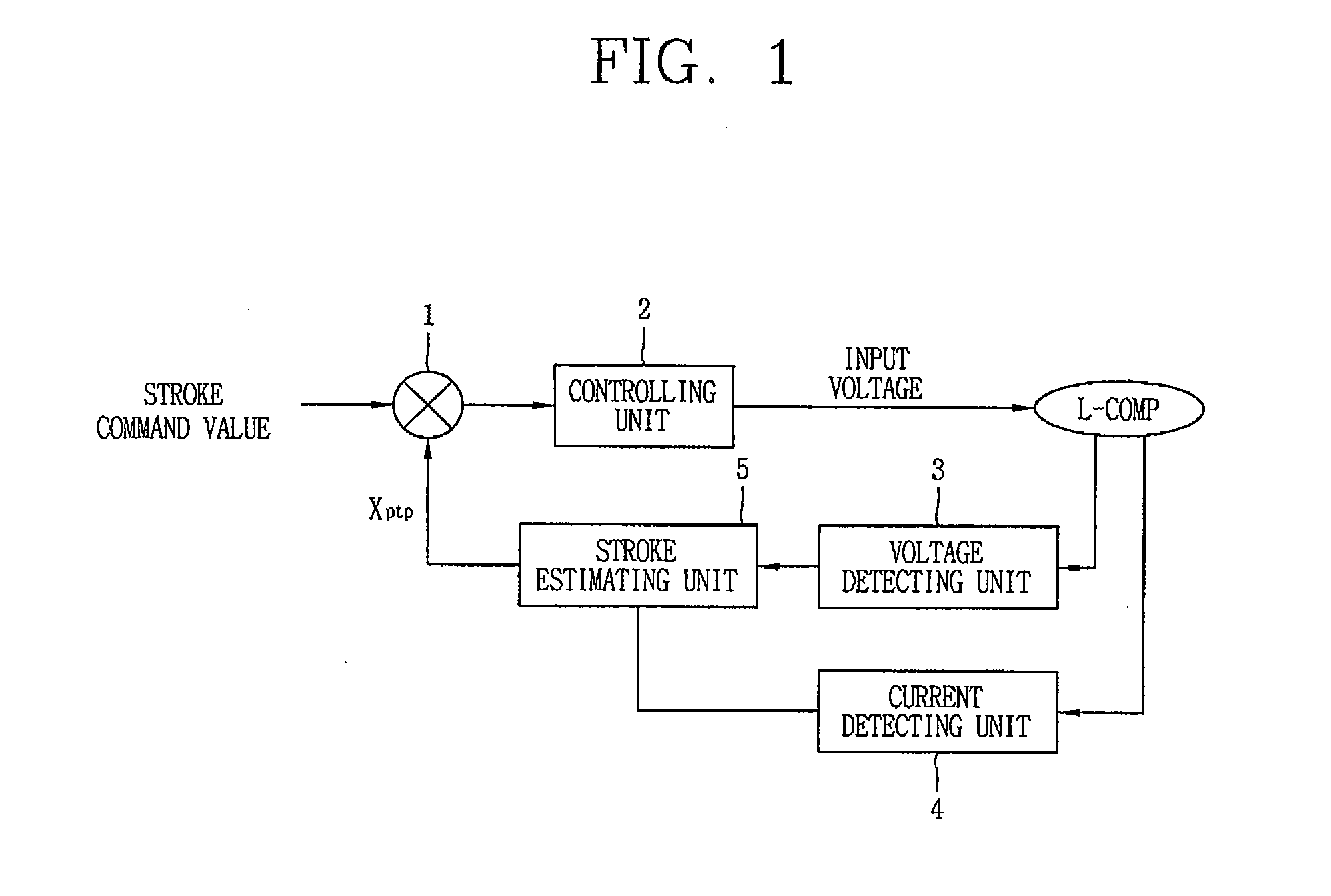

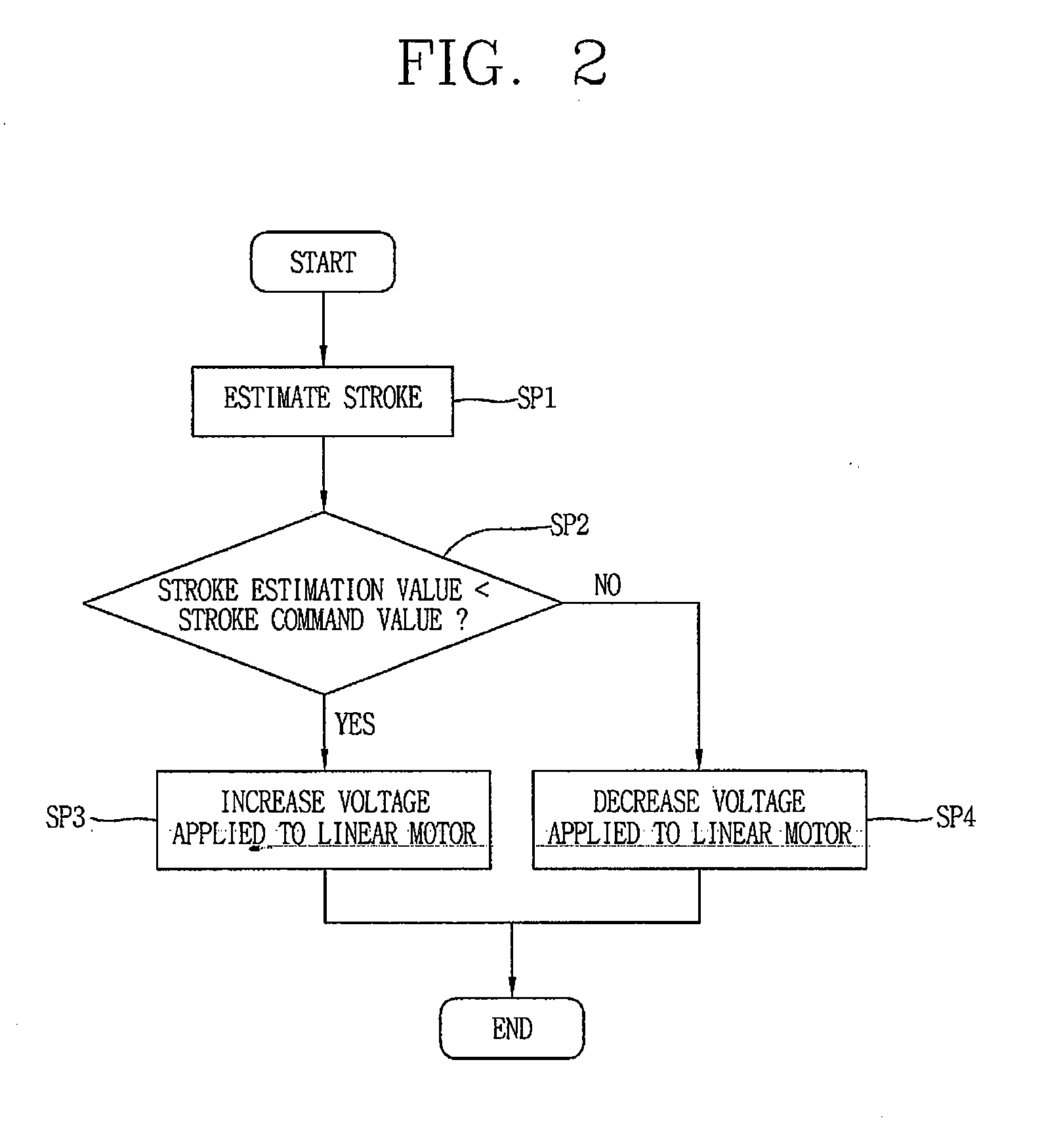

Driving controlling apparatus for linear compressor and method thereof

ActiveUS20070241697A1Short strokeIncrease currentMotor/generator/converter stoppersDC motor speed/torque controlPhase differenceLinear compressor

A driving controlling apparatus for a linear compressor, comprises a controlling unit for detecting a TDC by a phase difference inflection point between a stoke and a current with increasing the stroke by controlling the current applied to a linear motor, and for varying the current applied to the linear motor based on the detected TDC.

Owner:LG ELECTRONICS INC

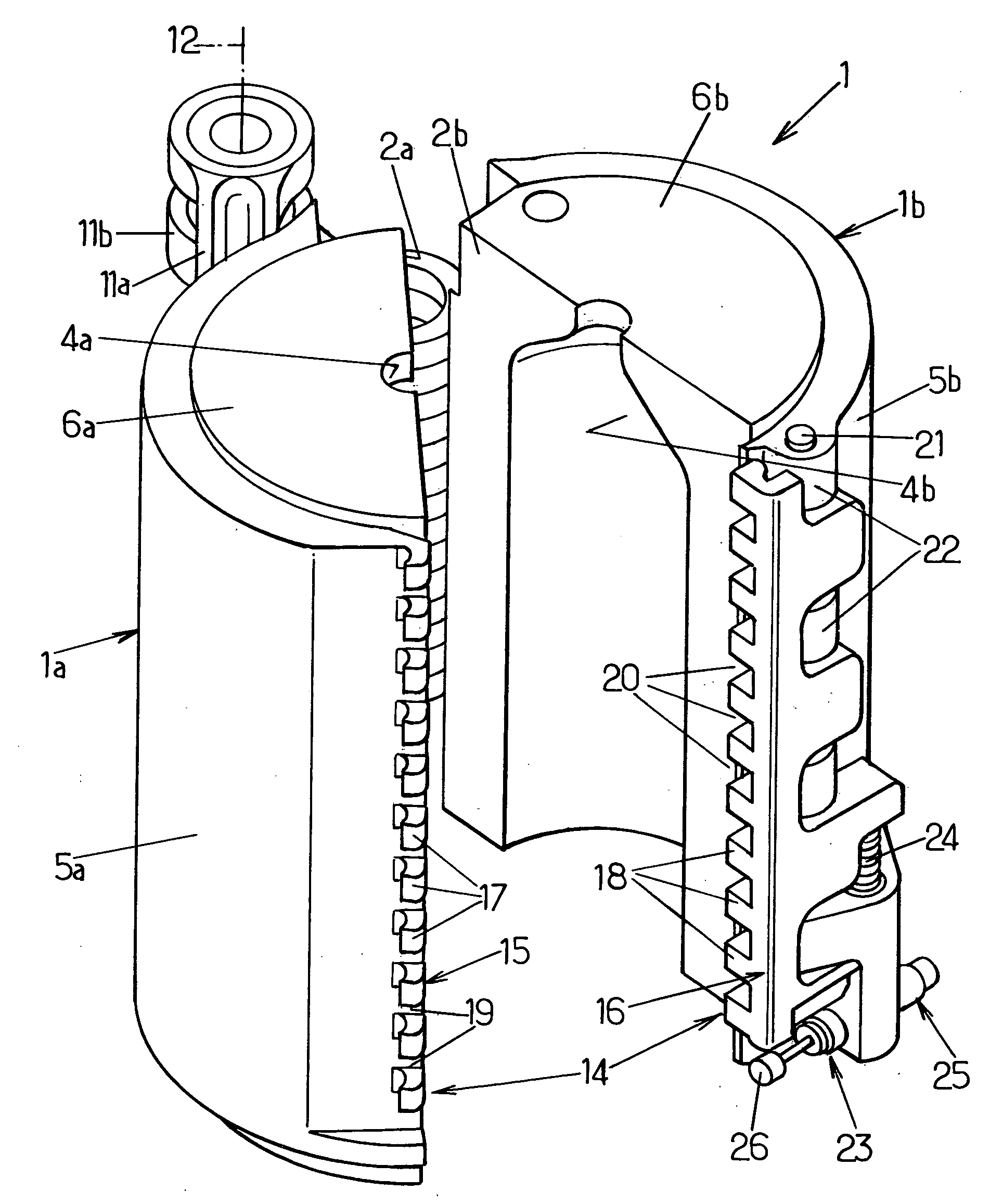

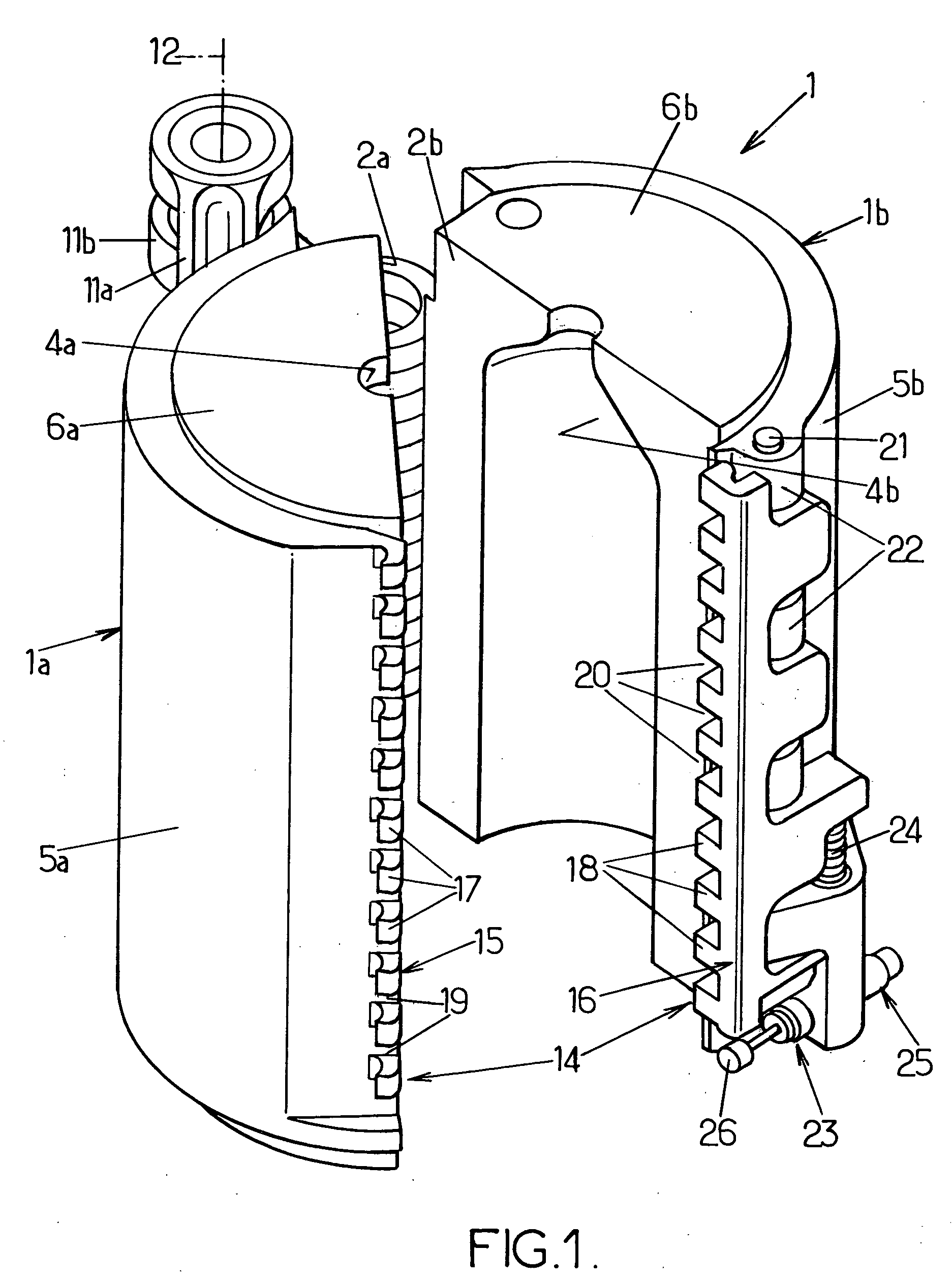

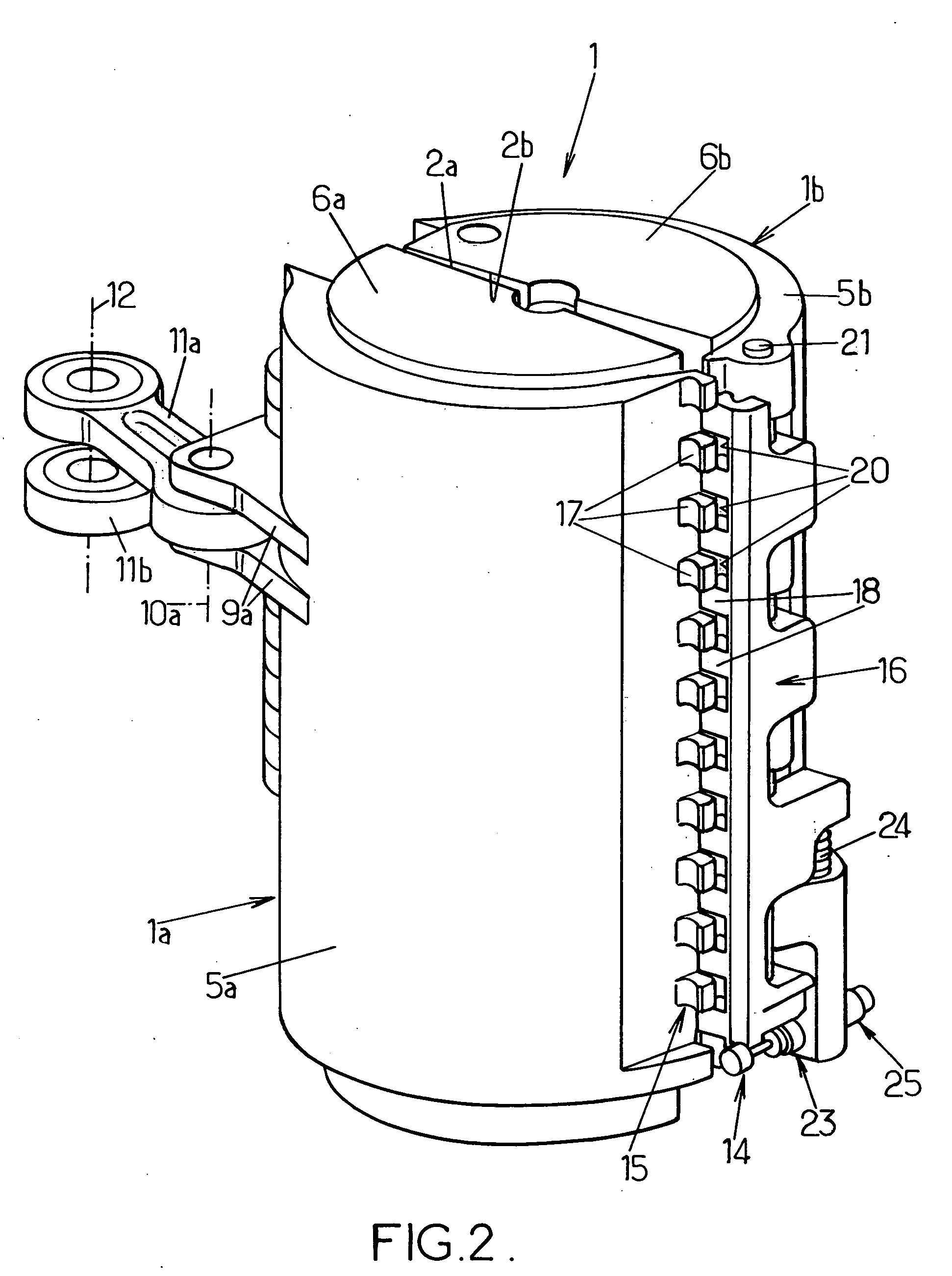

Moulding device for the production of containers in thermoplastic material

A moulding device for the production of containers in thermoplastic material, by blowing or blow-drawing, including a mould with two mould halves mutually mobile and provided with a locking device with two lock elements extending over the total height of the respective mould halves and provided with a number of projecting fingers in catches spaced at intervals, one lock element being fixed on one mould half and the other lock element sliding on the other mould half under the action of an actuator device.

Owner:SIDEL PARTICIPATIONS SAS

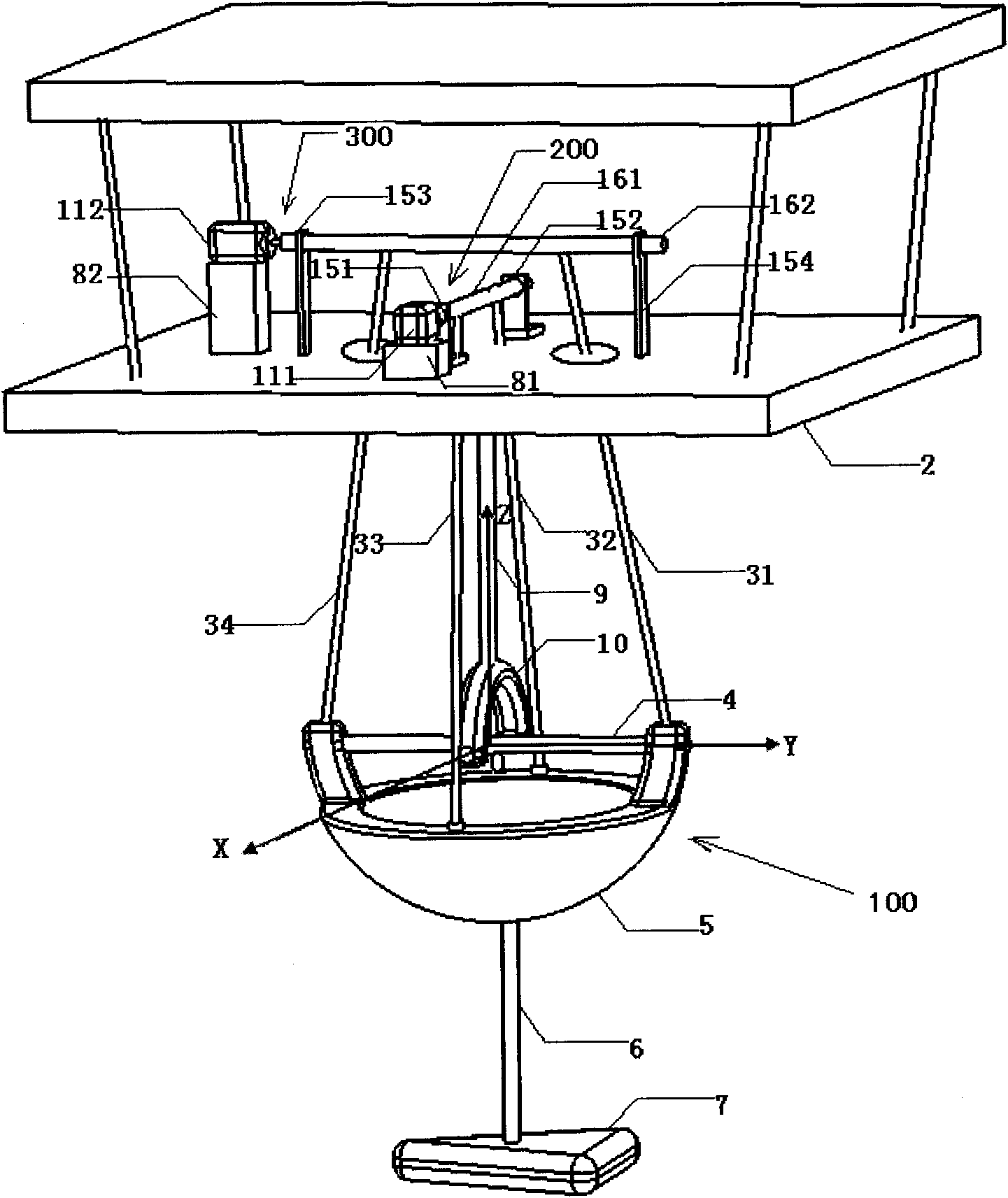

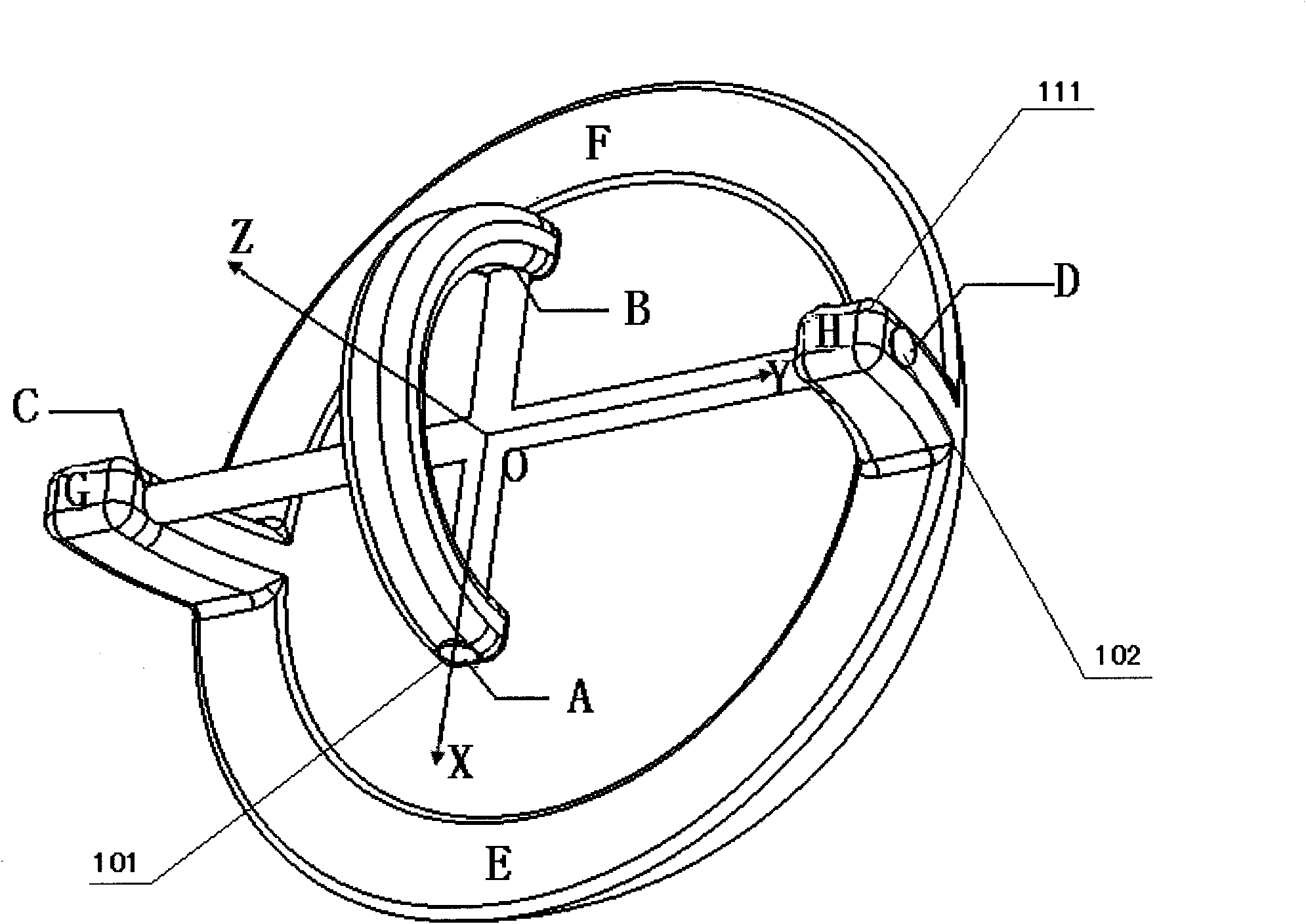

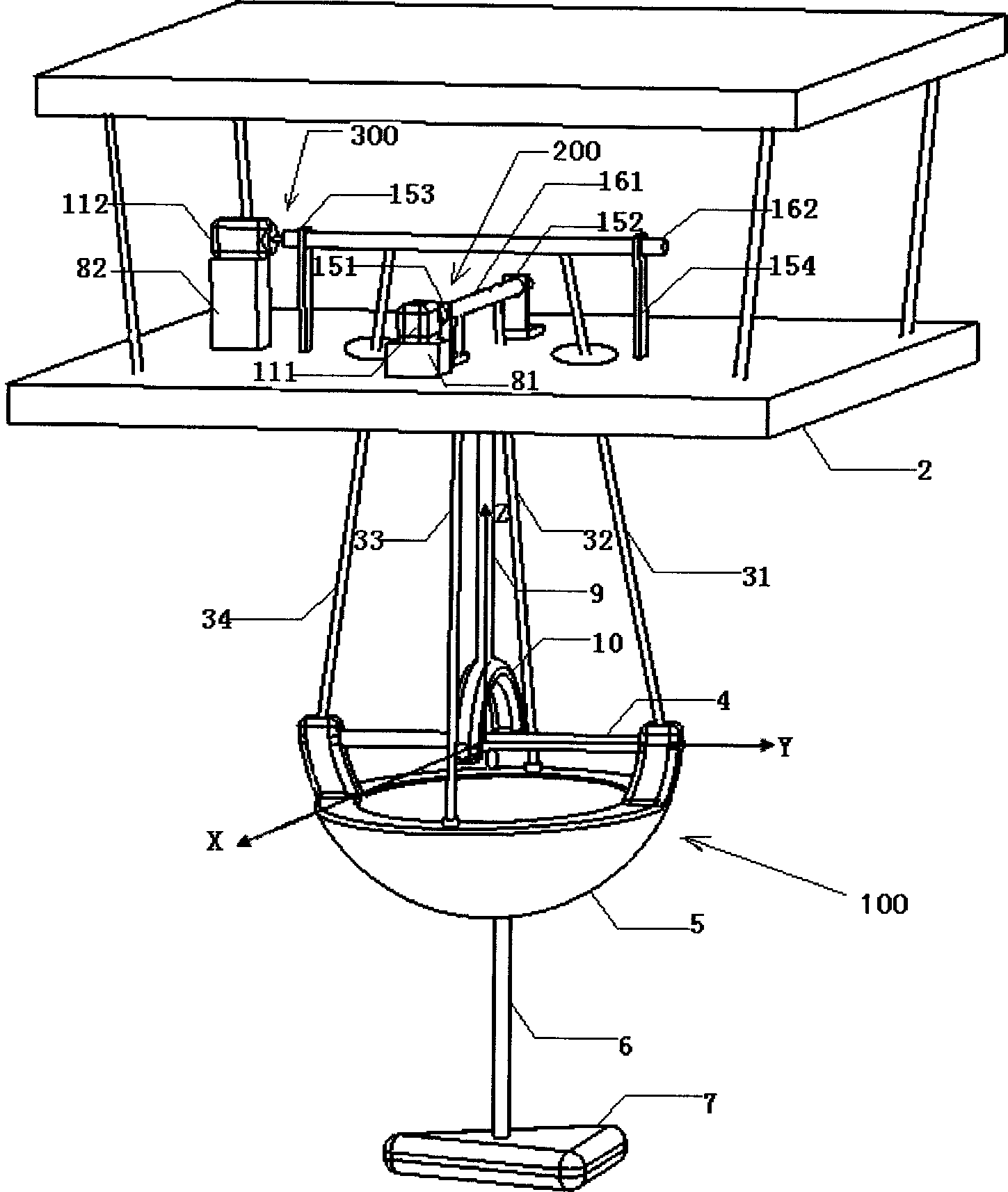

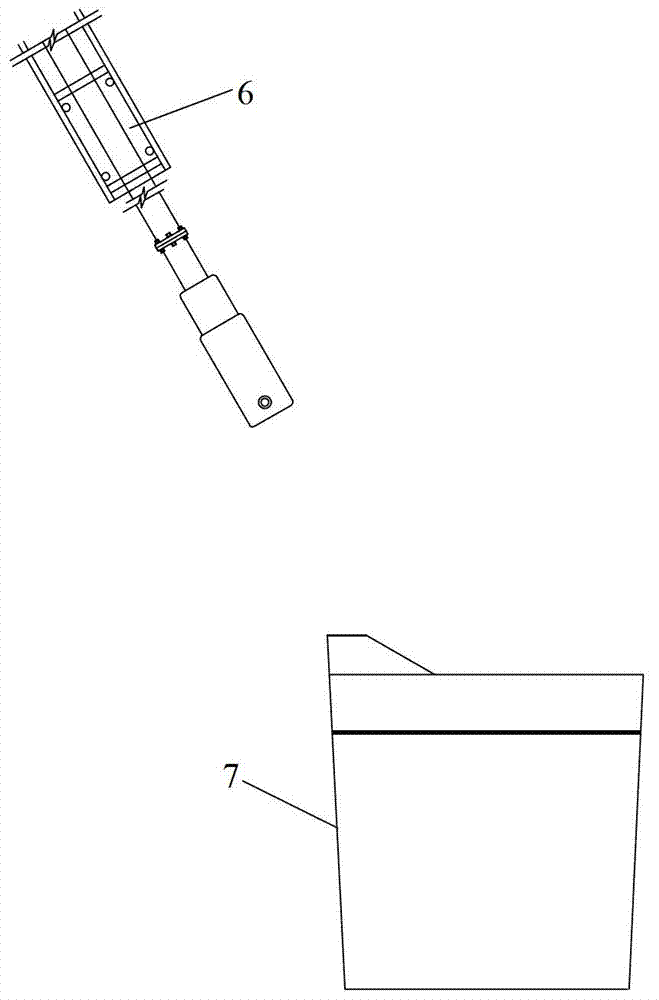

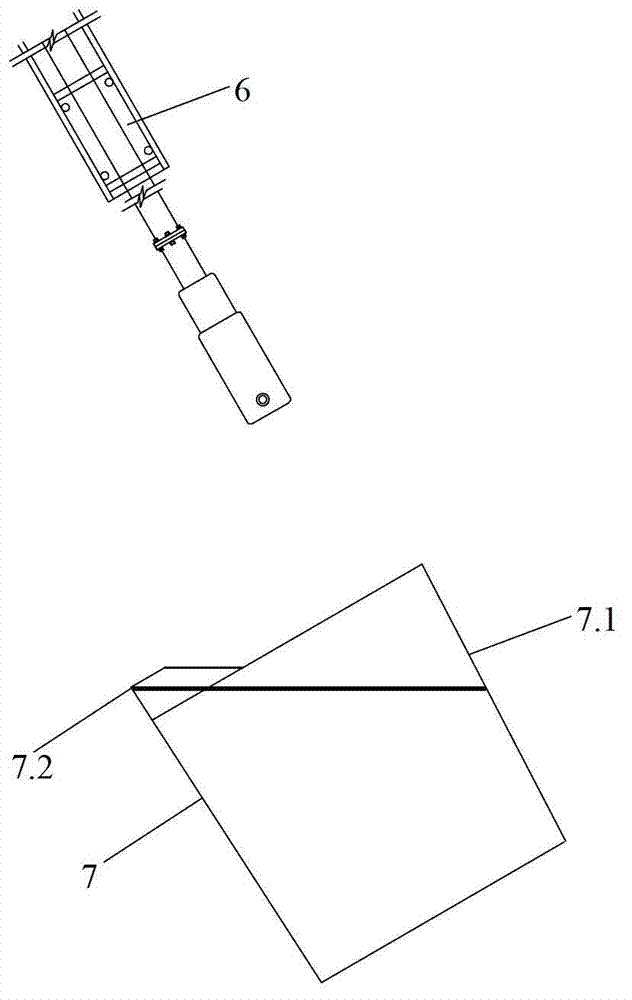

Wind tunnel model supporting device

InactiveCN101793592ARaise pitchImprove roll attitude realization abilityAerodynamic testingEngineeringDrive motor

The invention discloses a wind tunnel model supporting device which comprises a movable platform, a clamping device, a first driving unit and a second driving unit, wherein the movable platform has three translational freedom degrees and at least one rotation freedom degree. The clamping device is connected with the movable platform and is used for fixing and supporting the model. The first driving unit and the second driving unit are arranged on the movable platform and used for driving the clamping device, and therefore, the clamping device obtains the freedom degrees of rotation in horizontal and transversal directions. The first driving unit comprises a first driving motor and a first rope traction mechanism. The second driving unit comprises a second driving motor and a second rope traction mechanism. The wind tunnel model supporting device with simple and reliable structure can realize six freedom degrees of the model in the wind tunnel test, effectively expand the model pitch and the roll amplitude capable of being realized by model supporting, and decrease the acceleration, the motion speed and the motion travel of the driving units through the first driving unit and second driving unit which are connected in parallel.

Owner:TSINGHUA UNIV

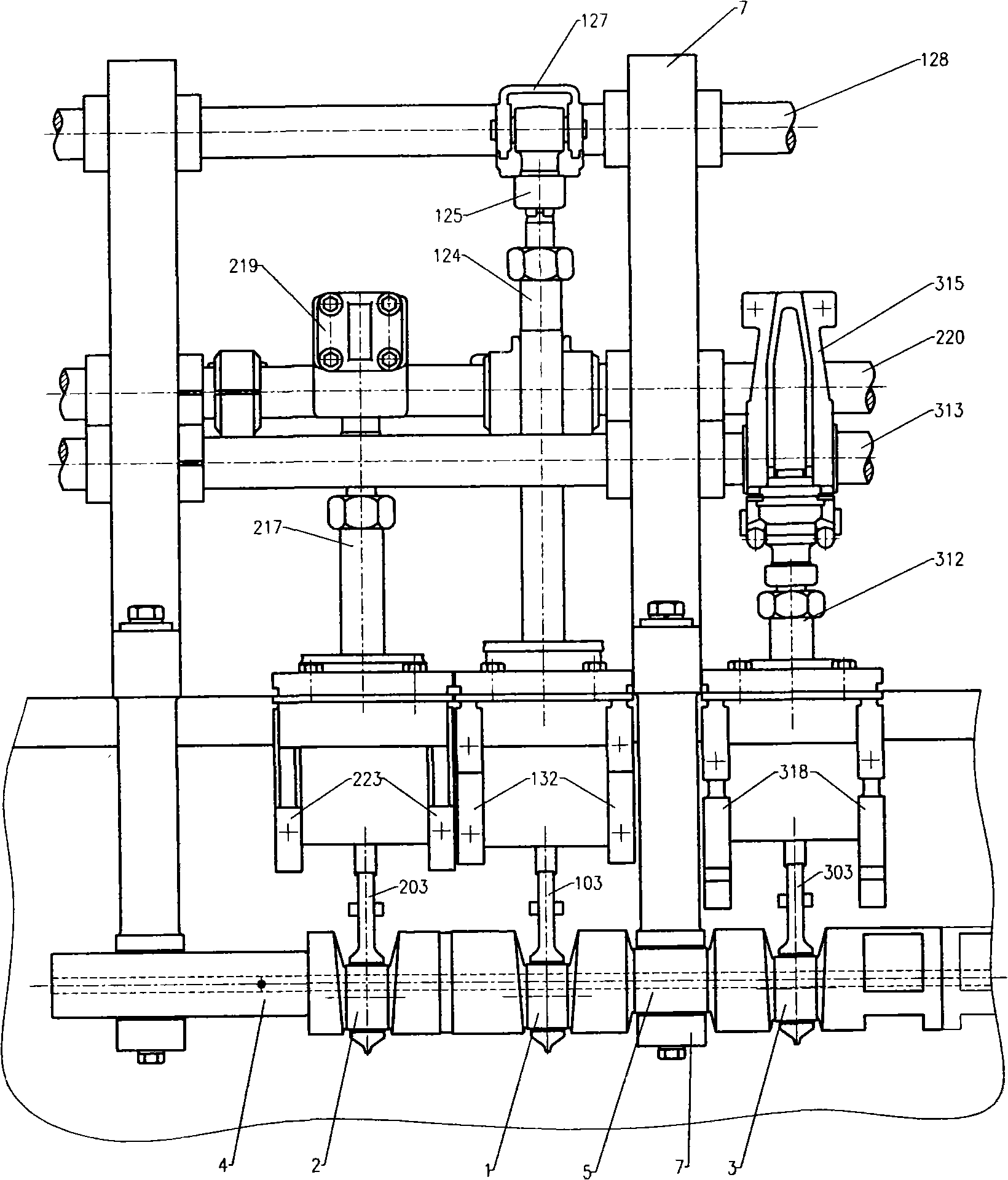

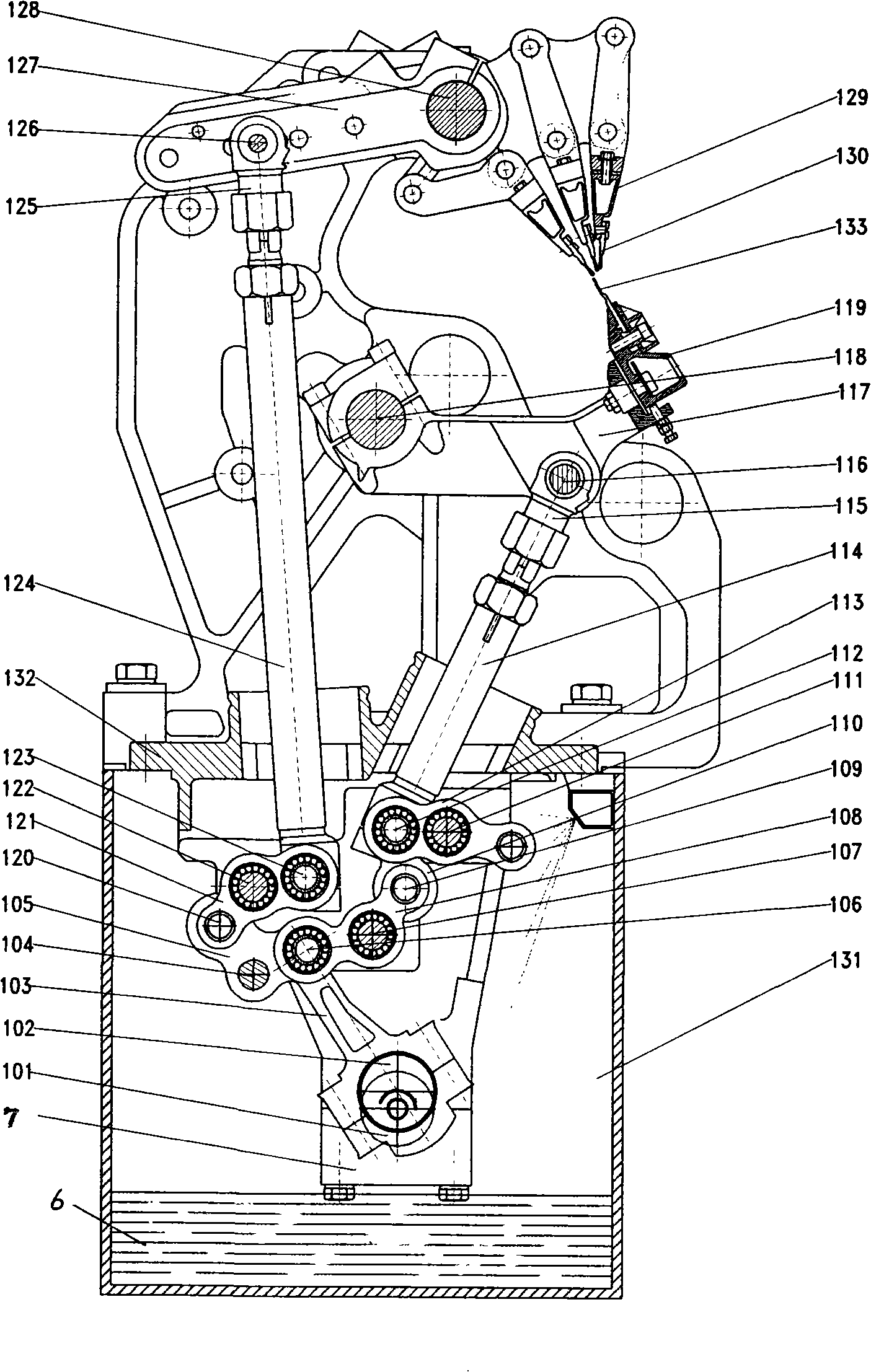

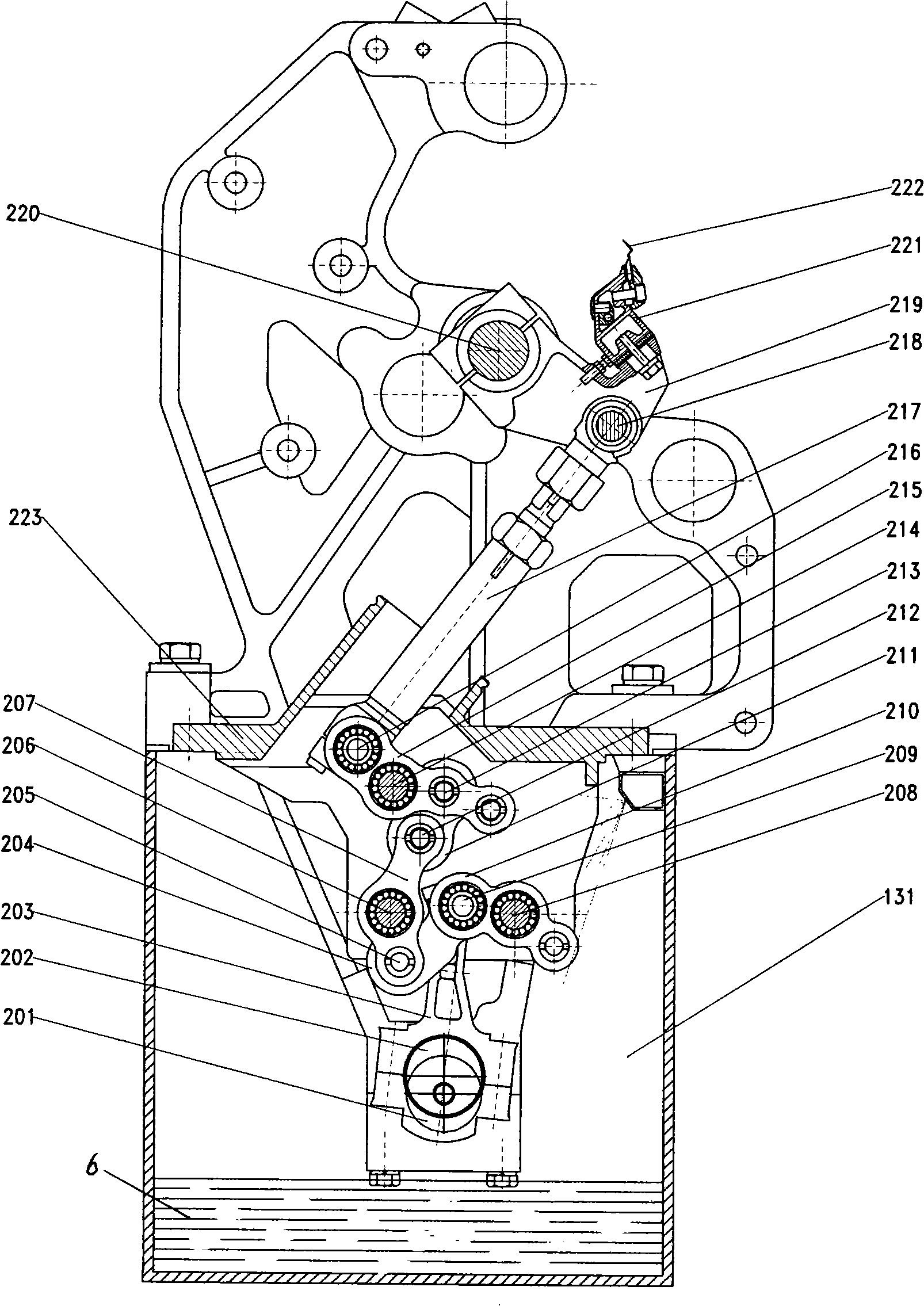

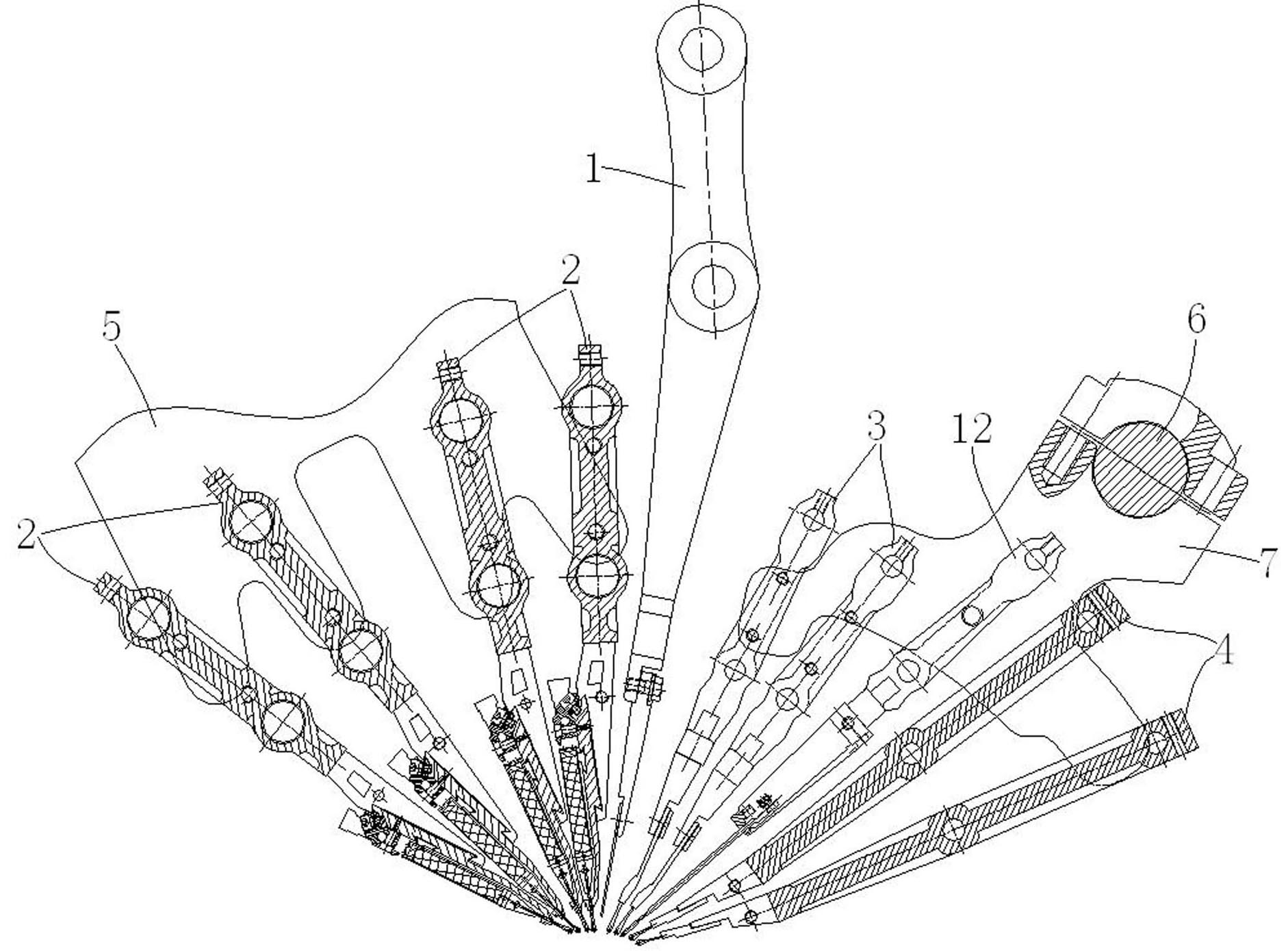

Short tranverse crankshaft connecting rod device of warp knitting machine

The invention discloses a short-stroke crankshaft connecting rod device for a tricot machine. The invention comprises eccentric shafts, a first shaft journal (4), a second shaft journal (5), a central wall plate (7), a grooved needle bed connected with a first eccentric shaft (1), a yarn guide needle bed crankshaft connecting rod mechanism, a stylet bed crankshaft connecting rod mechanism connected with a second eccentric shaft (2), and a sinker bed crankshaft connecting rod mechanism connected with a third eccentric shaft (3). The first shaft journal (4) and the second shaft journal (5) are respectively and fixedly connected with the end parts of the second eccentric shaft (2) and the third eccentric shaft (3). The second eccentric shaft (2), the first eccentric shaft (1) and the third eccentric shaft (3) are connected with each other in turn and are rotated around the first and second shaft journals (4, 5). The short-stroke crankshaft connecting rod device effectively shortens the motion stroke of weaving elements; the grooved needle travel is between 8 and 12 millimeters; the moving time of yarn guide needles is between 1.5 and 1.8 microseconds; the engine speed is improved to be 2500 to 3000 turns per minute; the noise is less than or equal to 85 decibels; the vibration is small; the energy consumption is low; the device is suitable for high-speed rotation; the power is small; and the productivity is obviously improved.

Owner:NEWTRY COMPOSITE

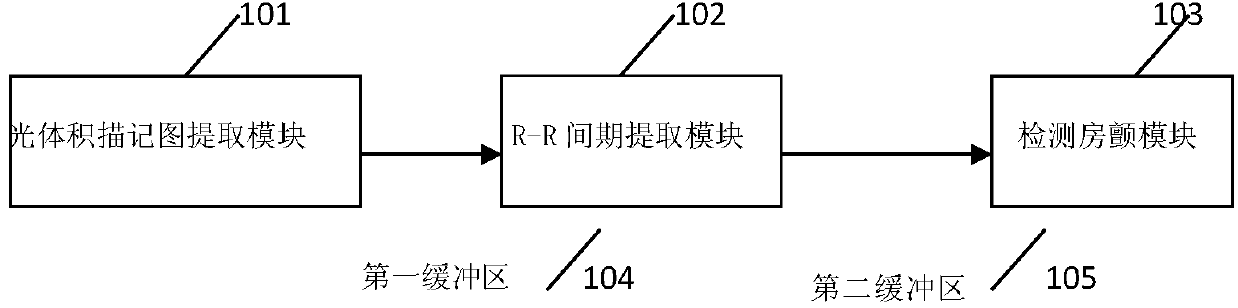

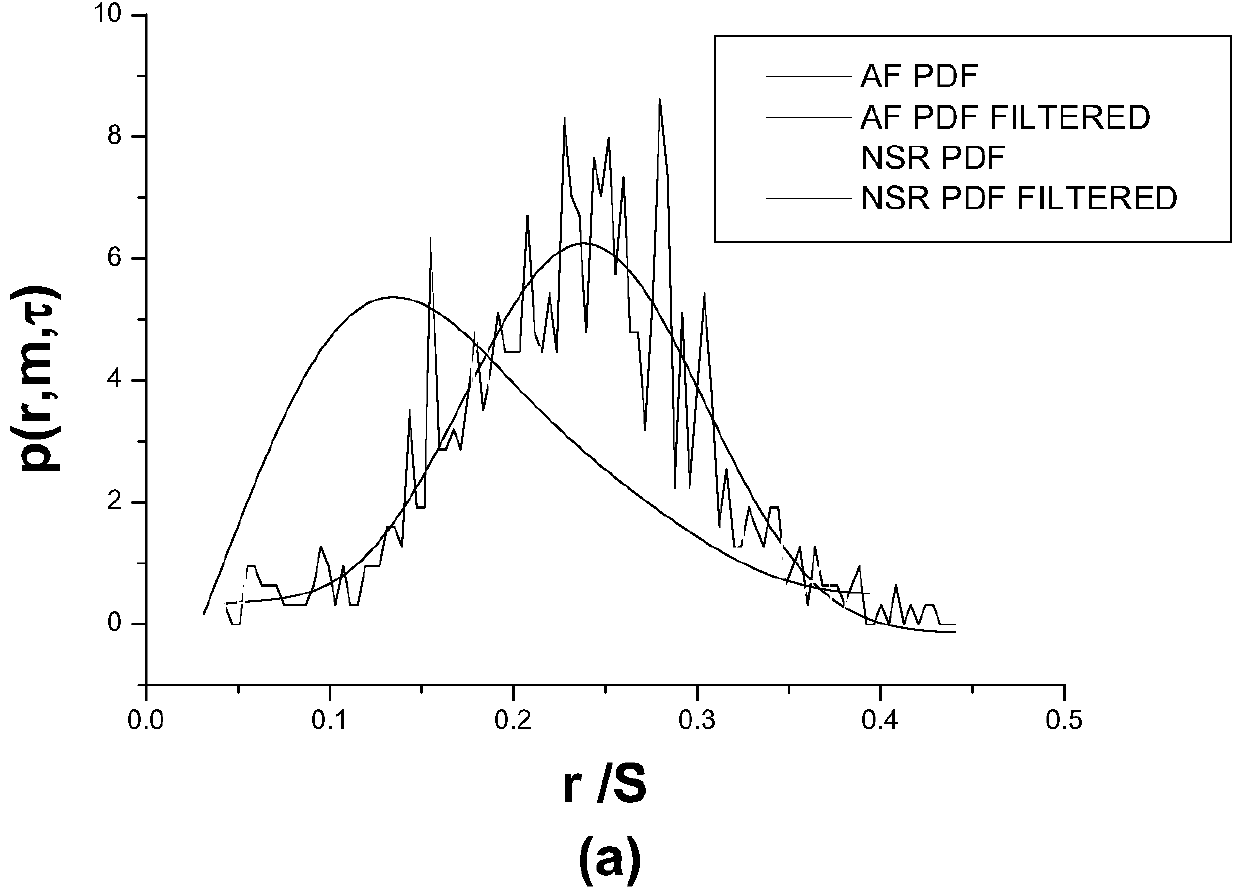

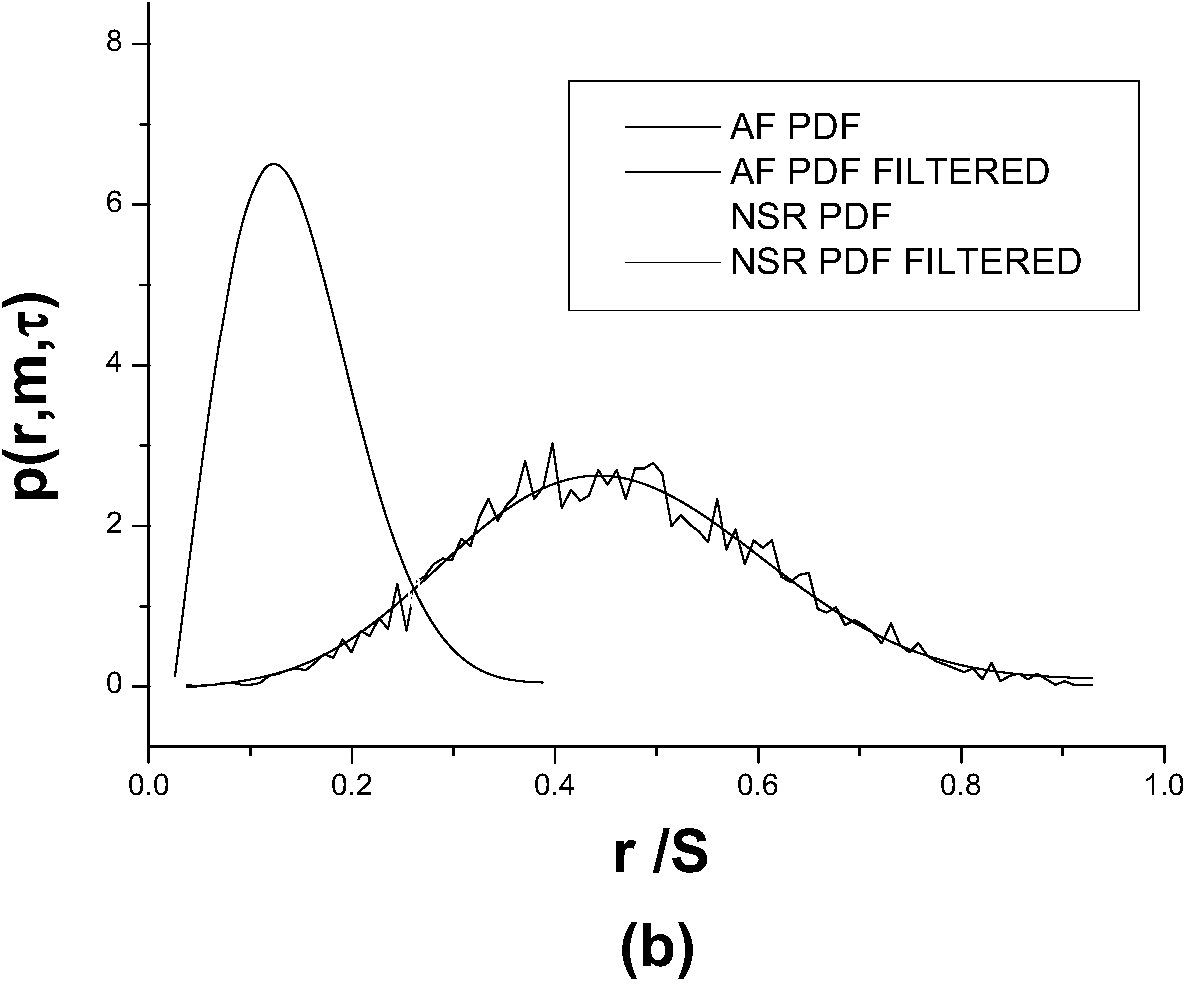

Atrial fibrillation automatic detection system based on smartphone

InactiveCN103340622ATimely diagnosis and treatmentShort strokeDiagnostic recording/measuringSensorsPulsed waveTimely diagnosis

The invention provides an atrial fibrillation automatic detection system based on a smartphone. The atrial fibrillation automatic detection system based on the smartphone does not need additional hardware and only needs the smartphone provided with an atrial fibrillation automatic detection application program. When detection is conducted, people gently put the fingertips on a camera and an LED flash lamp of the smartphone, pulse waves is extracted from images taken by the smartphone, the electrocardio R-R interphase is obtained, and therefore atrial fibrillation can be automatically detected by means of the R-R interphase and the generality density function algorithm. The atrial fibrillation automatic detection system based on the smartphone is cheap, simple, easy to use, capable of being used anytime and anywhere, easy to popularize, and capable of detecting more patients who suffer atrial fibrillation, enabling the patients to receive timely diagnosis and treatment, reducing the possibility of stroke and the medical cost and having significant social and economic value.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

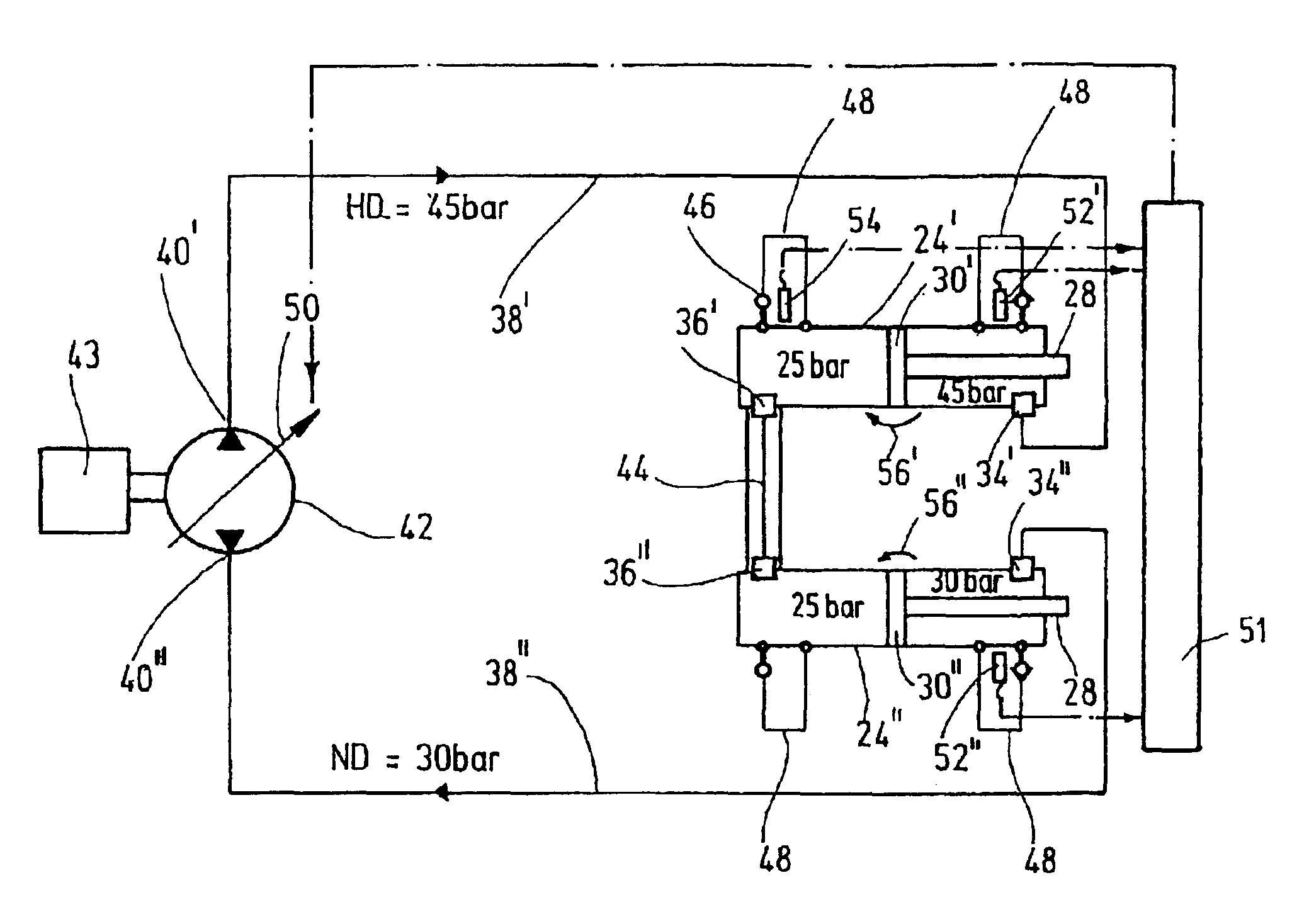

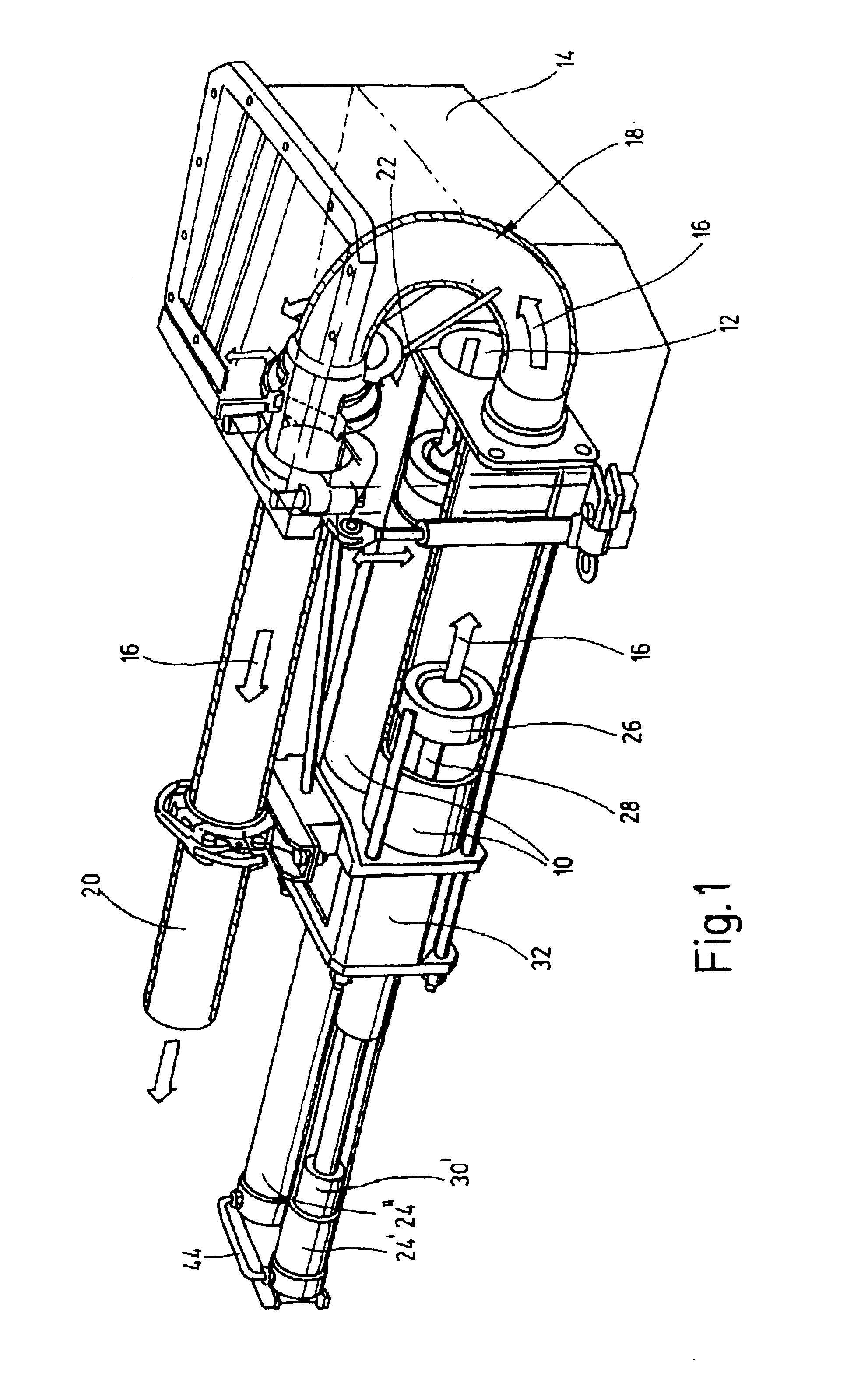

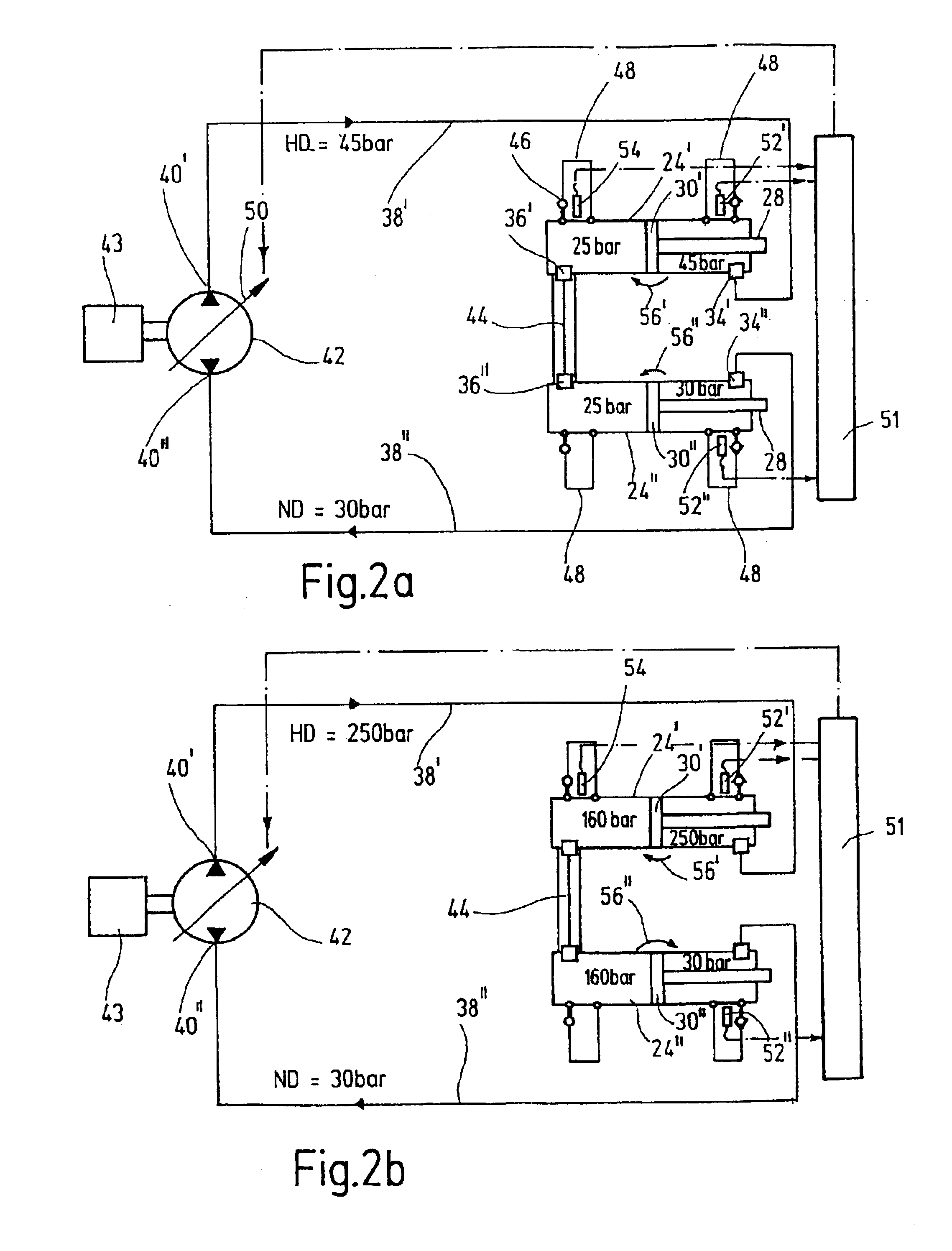

Thick matter pump

In a thick matter pump, especially for delivering concrete, comprising two delivery cylinders, it is known to provide two position sensors in one of the two cylinders for control of the pistons. However, leakage of hydraulic fluid can lead to an imbalance of the two cylinders. In the invention two position sensors (52′, 52″) are provided, which are arranged at a defined distance from one of the ends of the drive cylinders and which respond to a drive piston (30′, 30″) that is passing by. To prevent the formation of concrete clots inside the delivery cylinders (10) and to prevent the occurrence of a slamming when the drive pistons (30′, 30″) reach their end of travel, the invention provides that both position sensors (52′, 52″) are arranged at a distance from the piston rod-side ends of both drive cylinders (24′, 24″) and, in addition, a correcting sensor (54) is arranged at a defined distance from the piston head-side end of one of the drive cylinders (24′). This correcting sensor can be temporarily activated for initiating a reversing process overruling the rod-side position sensor (52″) of the other drive cylinder (24″).

Owner:PUTZMEISTER ENG

Jiggling phase searching method for three-phase AC servo motor

ActiveCN101604955AShort strokeCause disturbanceElectronic commutation motor controlVector control systemsMagnetic polesLinear motor

The invention relates to a jiggling phase searching method, wherein a phase searching current is applied to the winding of the three-phase AC servo motor, and an electric angle alpha of the rotor magnetic pole relative to the stator is determined through measuring jiggling of the motor, which includes steps: 1. defining and initializing the phase searching parameters; 2. applying a gradually increased phase searching current corresponding to the assumed value of the electric angle alpha[0] so as to generate jiggling of the rotor, then turning to the step 5 if the phase searching current reaches a maximum value I[max] and the movement of the rotor still does not exceed a permitted deviation angle delta; 3. determining an angle modification value theta; 4. modifying the assumed value of the electric angle alpha[0] based on jiggling direction of the servo motor and the angle modification value theta, then returning to the step 2; 5. using the assumed value of the electric angle alpha' as the actual value of the electric angle alpha; and optionally 6. determining and correcting the phase sequence of the three-phase winding wiring of the motor, wherein the angle modification value can be determined by subsequently using a bisection method and a bias weighted stepping method. Comparing with methods in prior art, the method has features of small stroke, fast phase searching speed, high phase searching precision, and wide range of compatibility because it is applicable not only to the rotation motors, but also to the linear motors.

Owner:河北海纳电测仪器股份有限公司

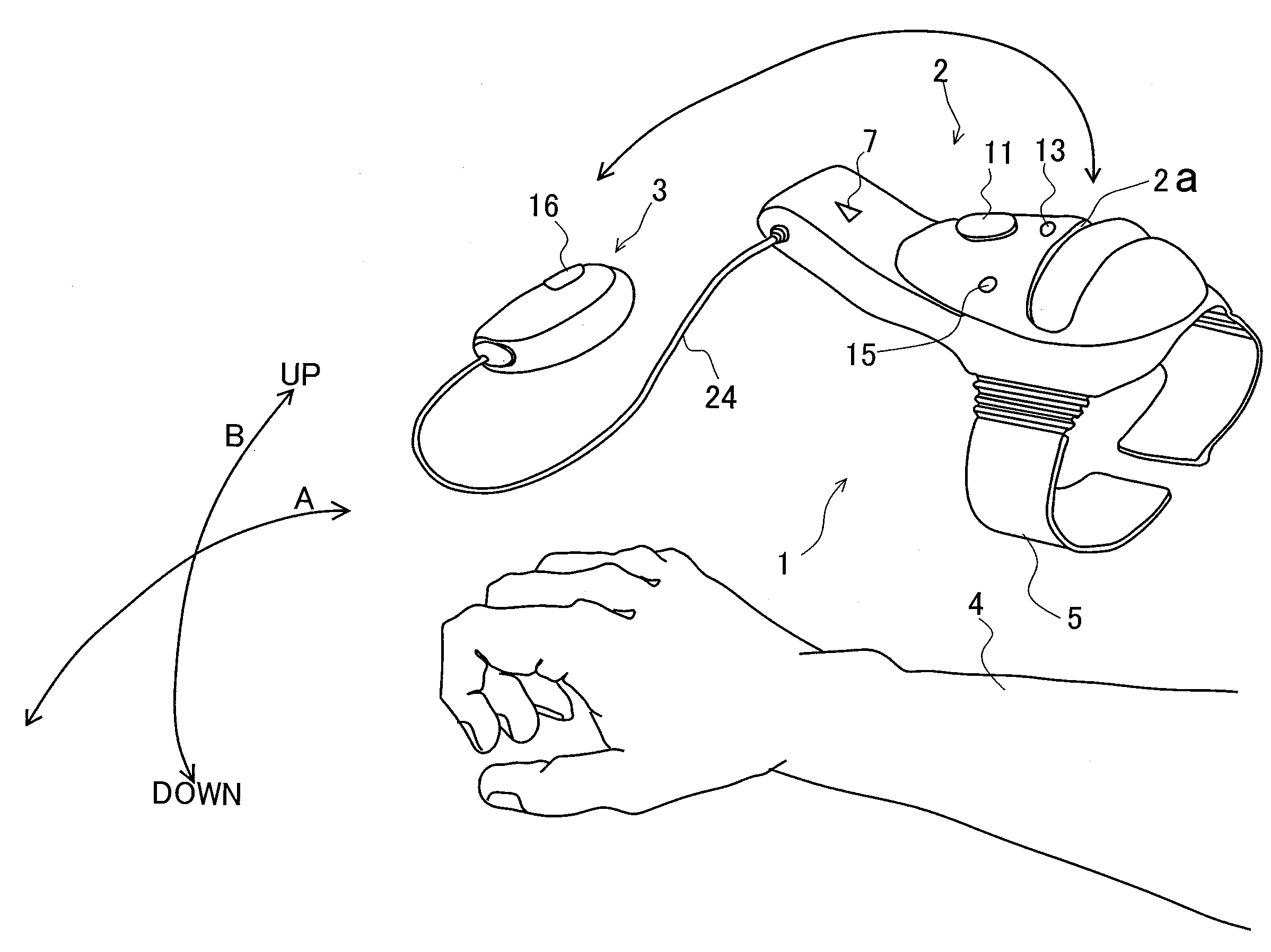

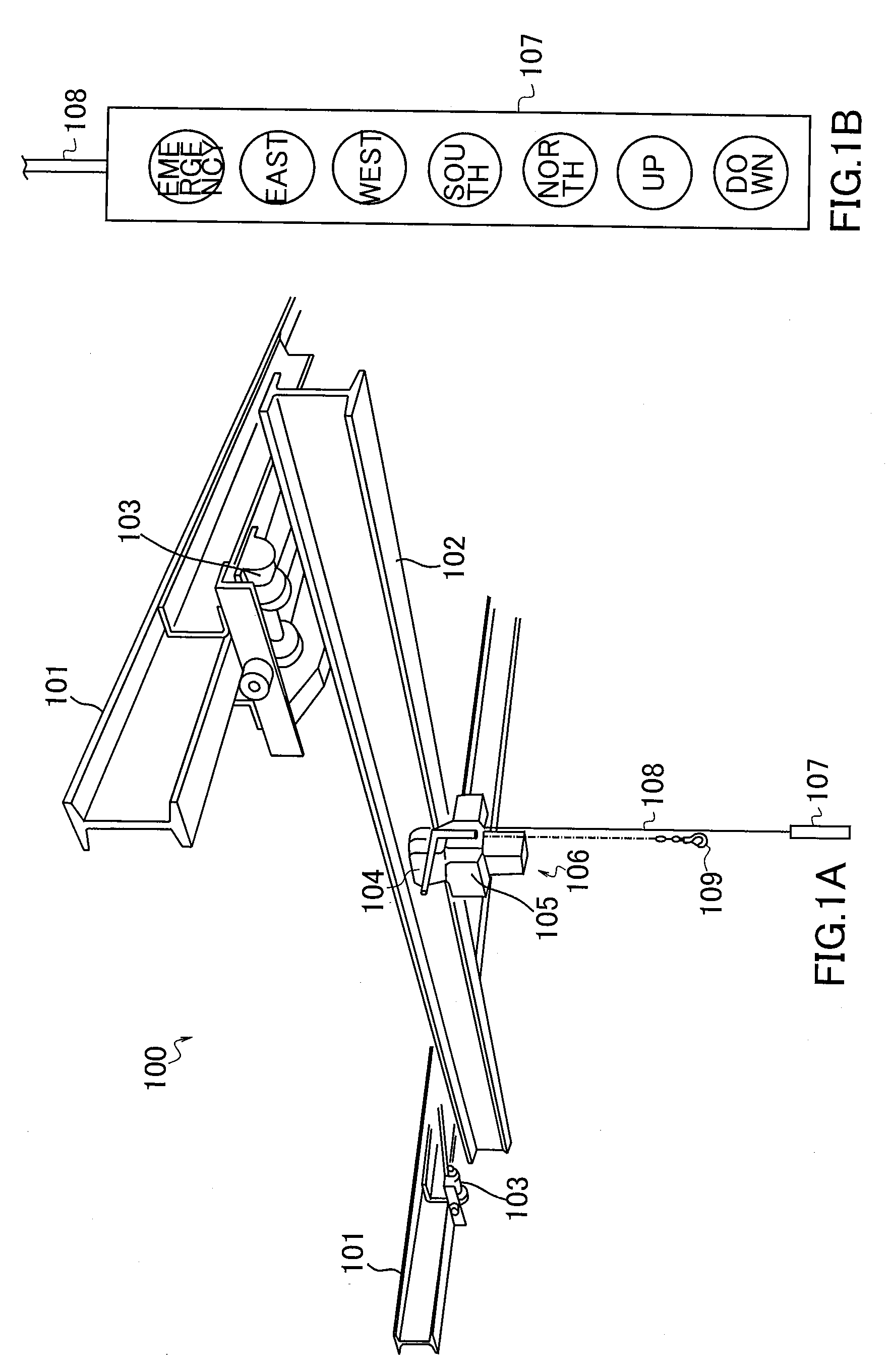

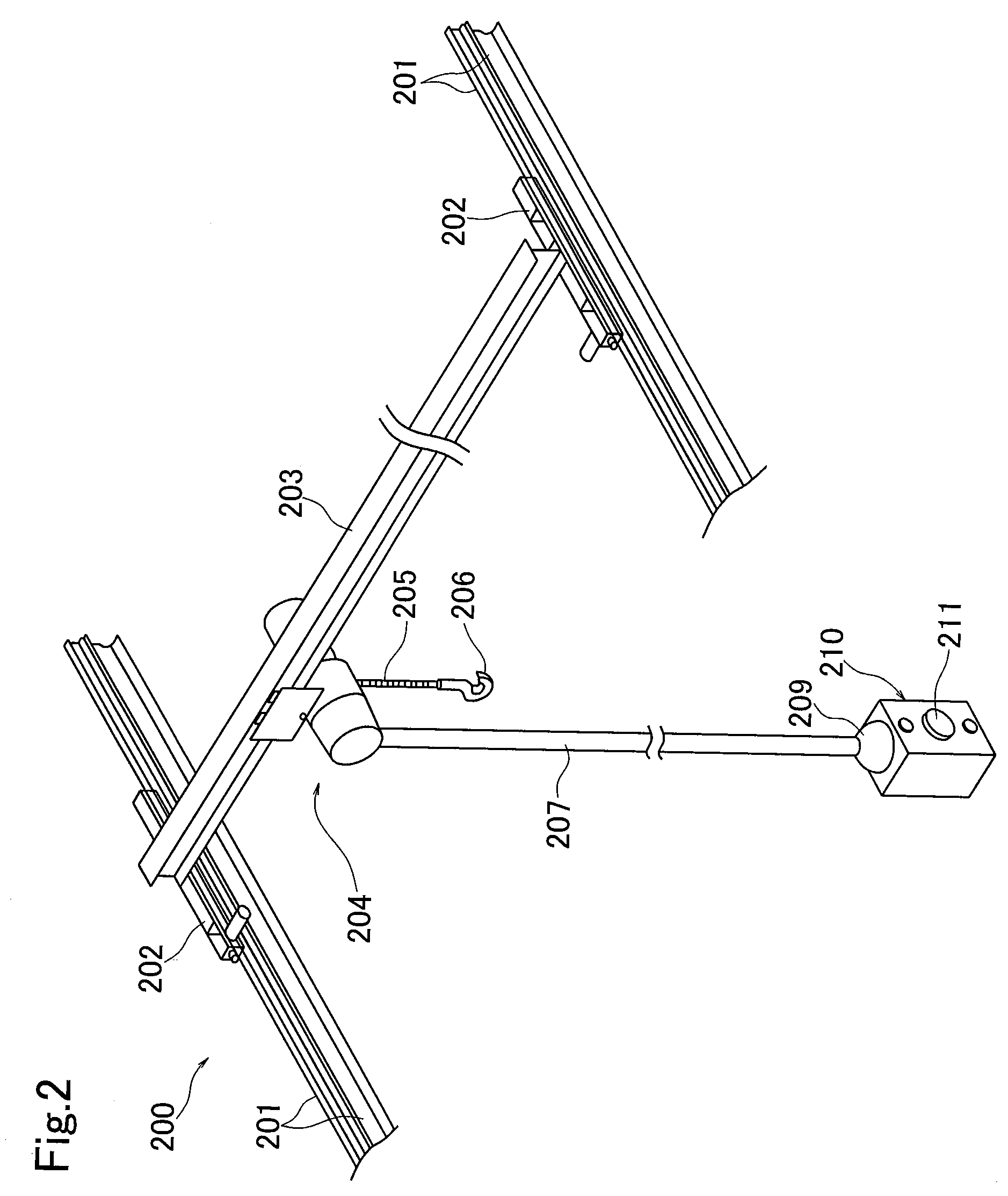

Traveling crane operation control apparatus and method

ActiveUS20110066335A1Good effectSmall sizeAnalogue computers for trafficComputations using stochastic pulse trainsVertical planeEngineering

To provide a traveling crane operation control apparatus and method enabling an operator to operate a traveling crane quickly and accurately by one hand and by a motion of his or her body with a controller worn thereon, without the need to gaze at his or her hand, and also allowing variable-speed control and fine speed control of each drive unit.An operation control apparatus for a traveling crane has an operation control circuit section 1 including a base unit 2 wearable on an arm 4 of an operator and a control unit 3 operable by a hand. The base unit 2 has base unit tilt detecting means detecting a tilt direction and tilt angle of the base unit 2 in a vertical plane, base unit direction detecting means detecting a direction in which the base unit 2 points in a horizontal plane, and command signal generating means generating a travel command signal and a travel speed command signal for a travel motor, a traverse command signal and a traverse speed command signal for a traverse motor, and an elevation command signal and an elevation speed command signal for an elevation motor. The traveling crane can be controlled to perform travel, traverse, lifting and lowering operations simply by pointing the base unit 2 in a direction in which travel and traverse motions are desired to occur and in a vertical direction in which a lifting or lowering motion is desired to occur, and actuating the control unit 3.

Owner:KITO CORP

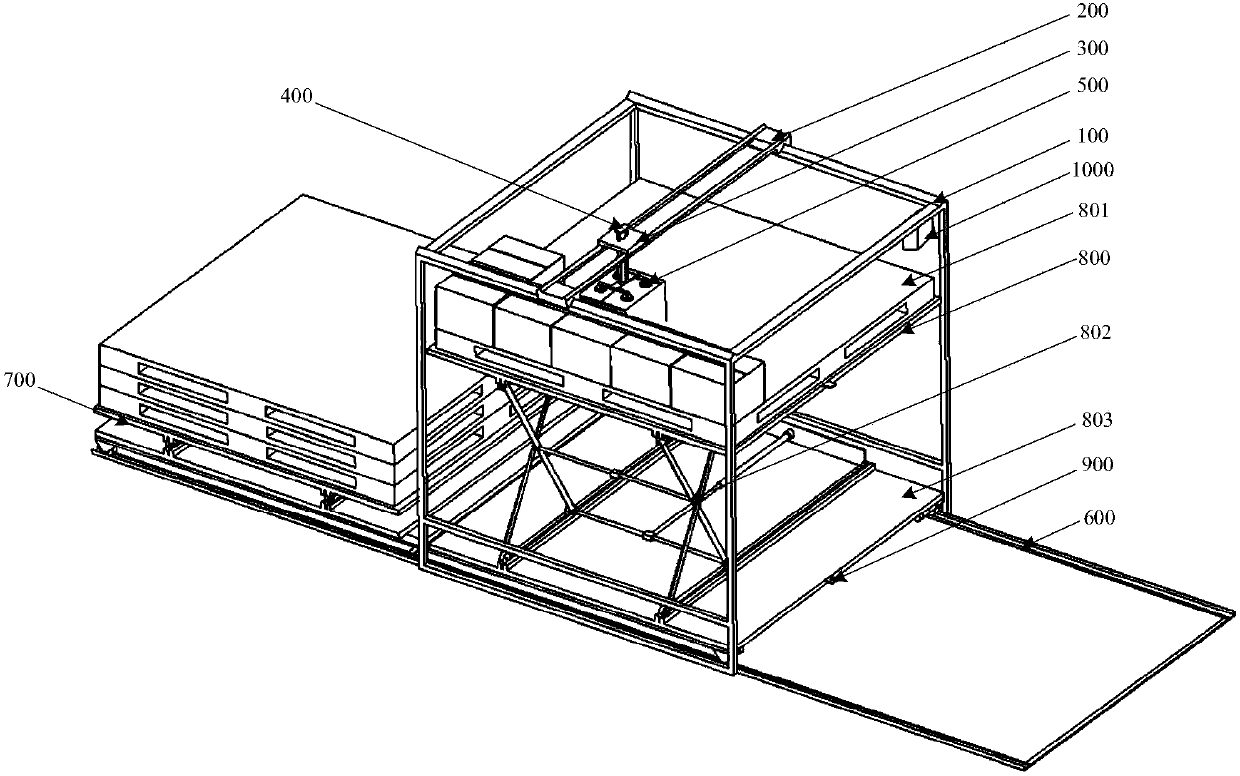

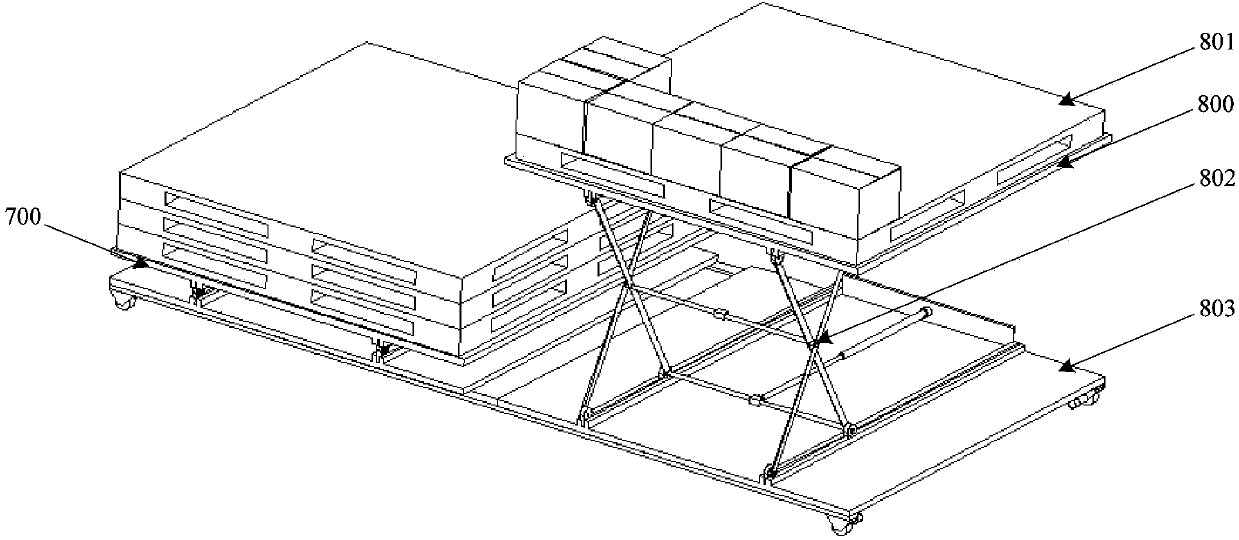

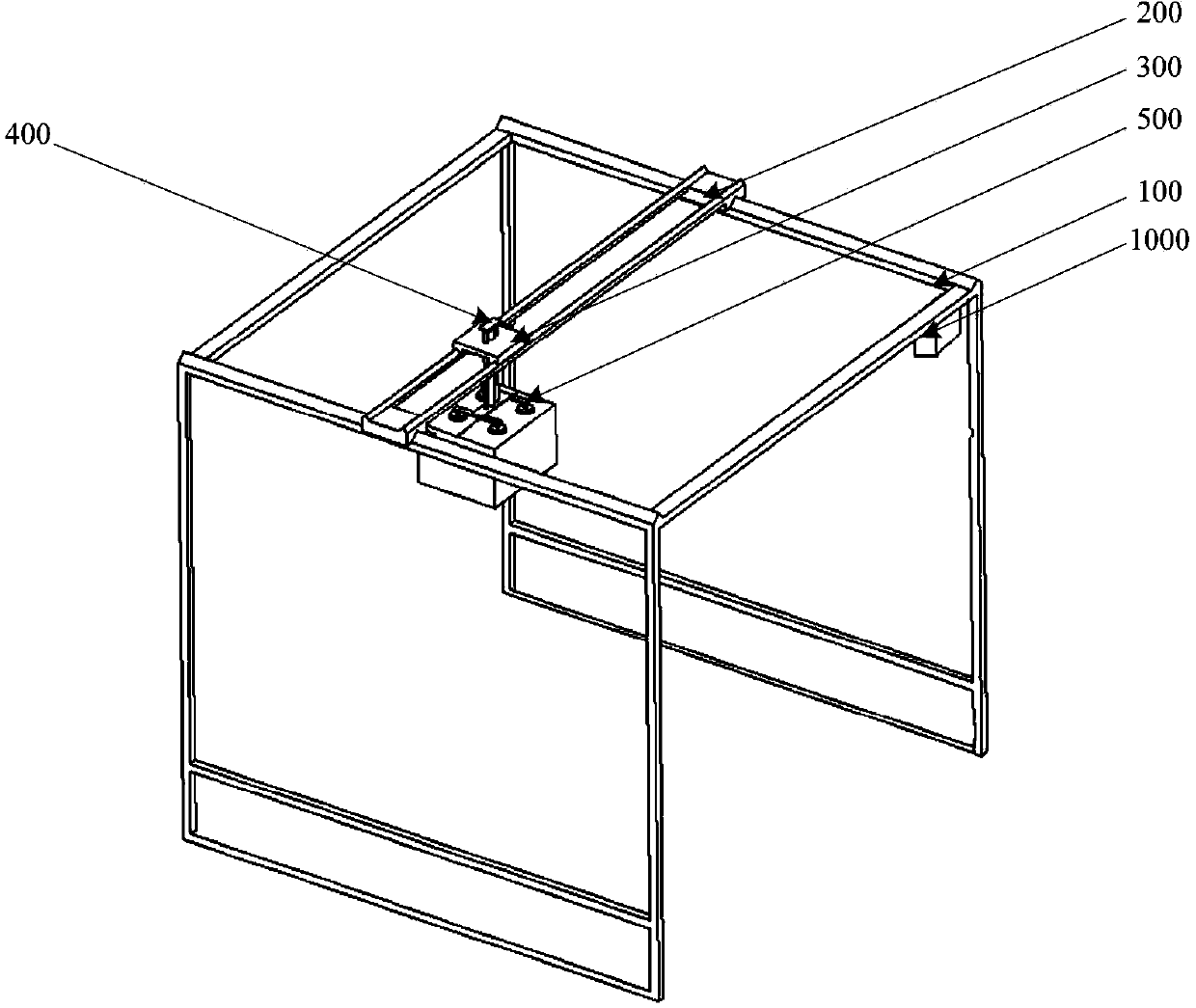

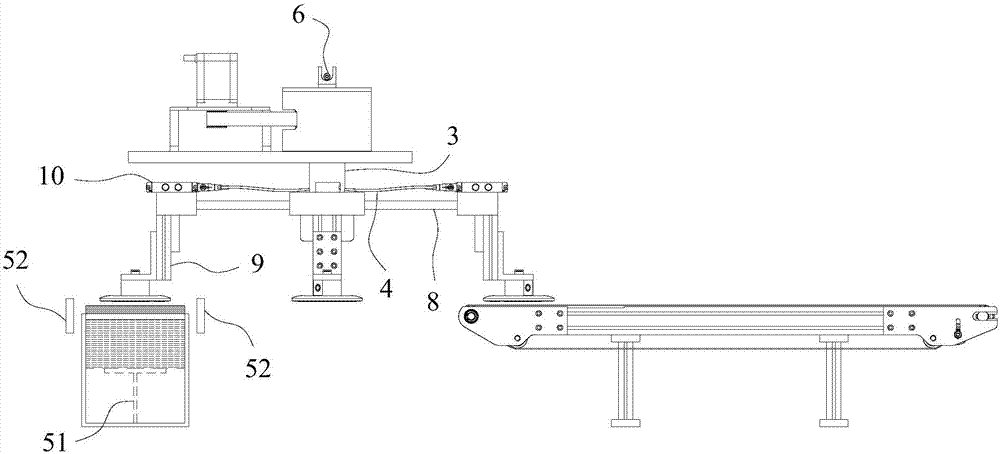

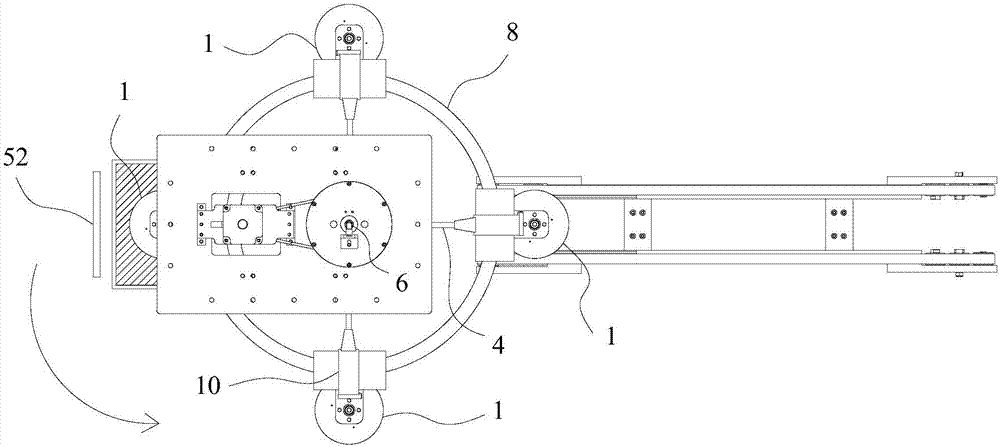

Automatic stacking system

ActiveCN103466333AShort strokePrevent unbalanced situationsStacking articlesDe-stacking articlesElectricityEngineering

The invention relates to an automatic stacking system which comprises a frame, a first horizontal moving mechanism, a second horizontal moving mechanism, a vertical moving mechanism, a mechanical arm, a main guide rail, at least two pallet platform components, a first transmission mechanism, a first communication module, a distance sensor and a control box. Each pallet platform component comprises a pallet platform, a lifting mechanism for controlling the pallet platform to move up and down and a translation mechanism, the pallet platform is fixedly connected with the translation mechanism through the lifting mechanism, the translation mechanism is bridged on the main guide rail, and the lifting mechanism and the translation mechanism are connected with the first transmission mechanism. The first communication module is electrically connected with the control box. By the automatic stacking system, motion displacement for stacking goods of the mechanical arm can be reduced, goods stacking efficiency can be increased, burden of a mechanical arm motor is relieved, service life of the mechanical arm motor and related parts is prolonged, and cost is lowered.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

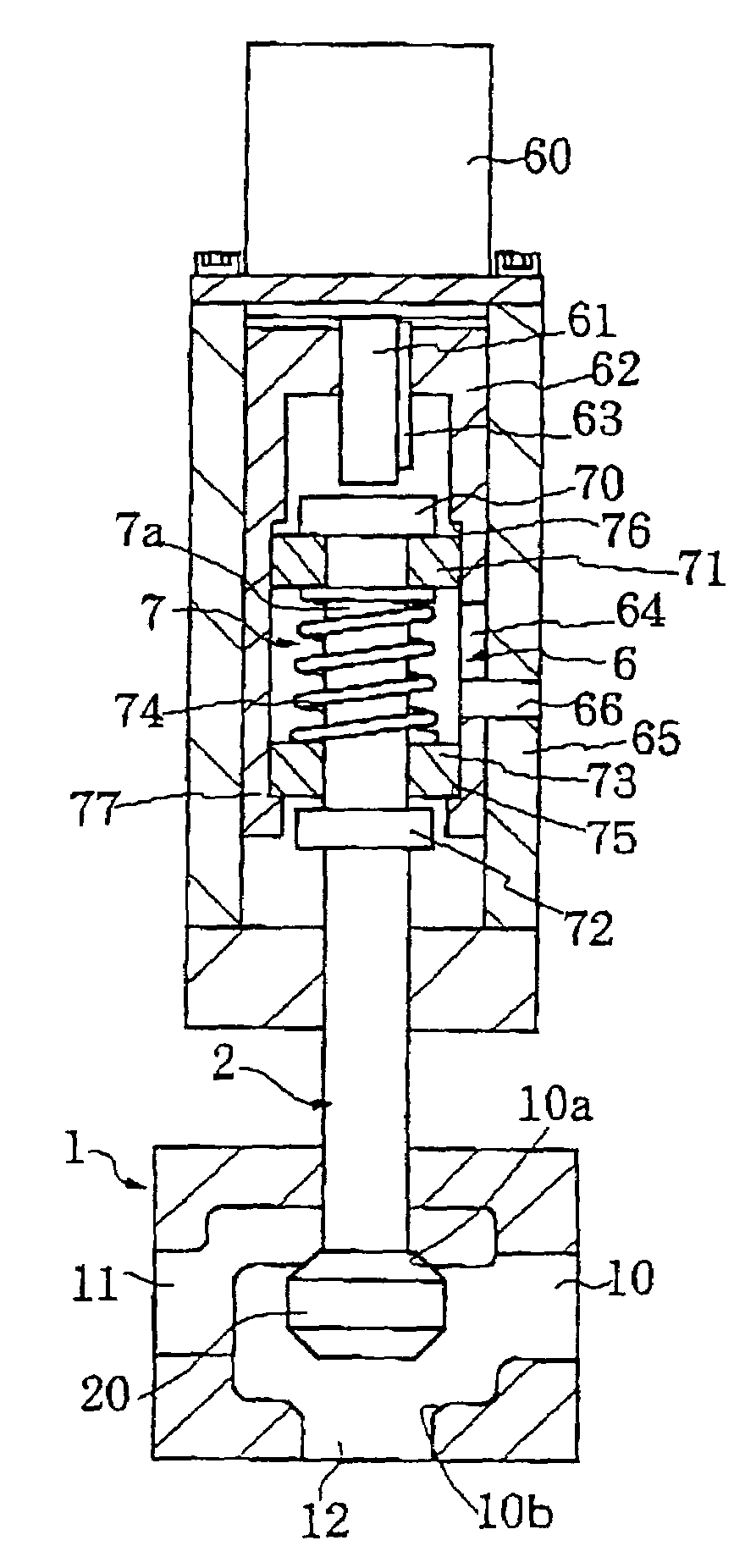

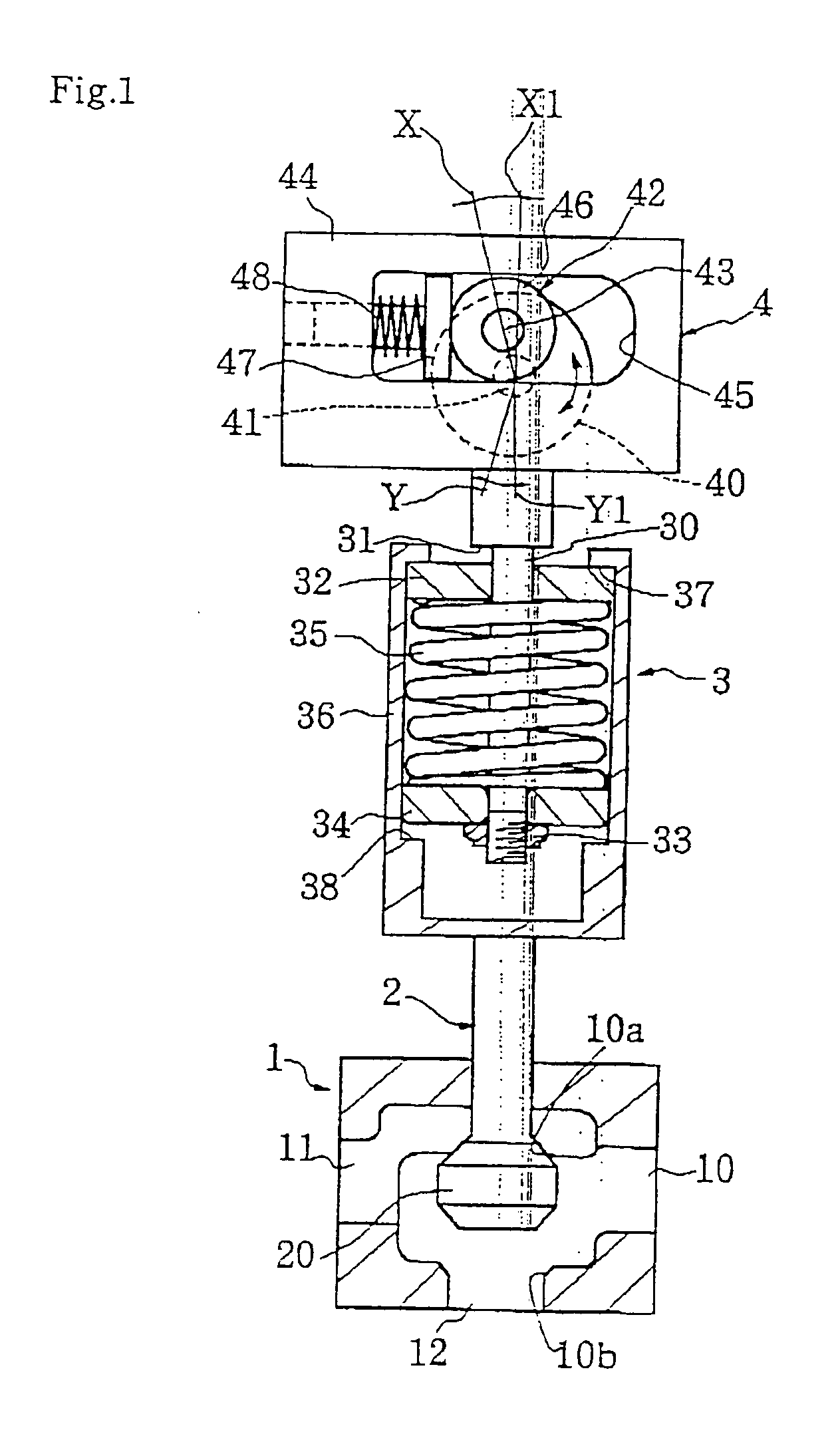

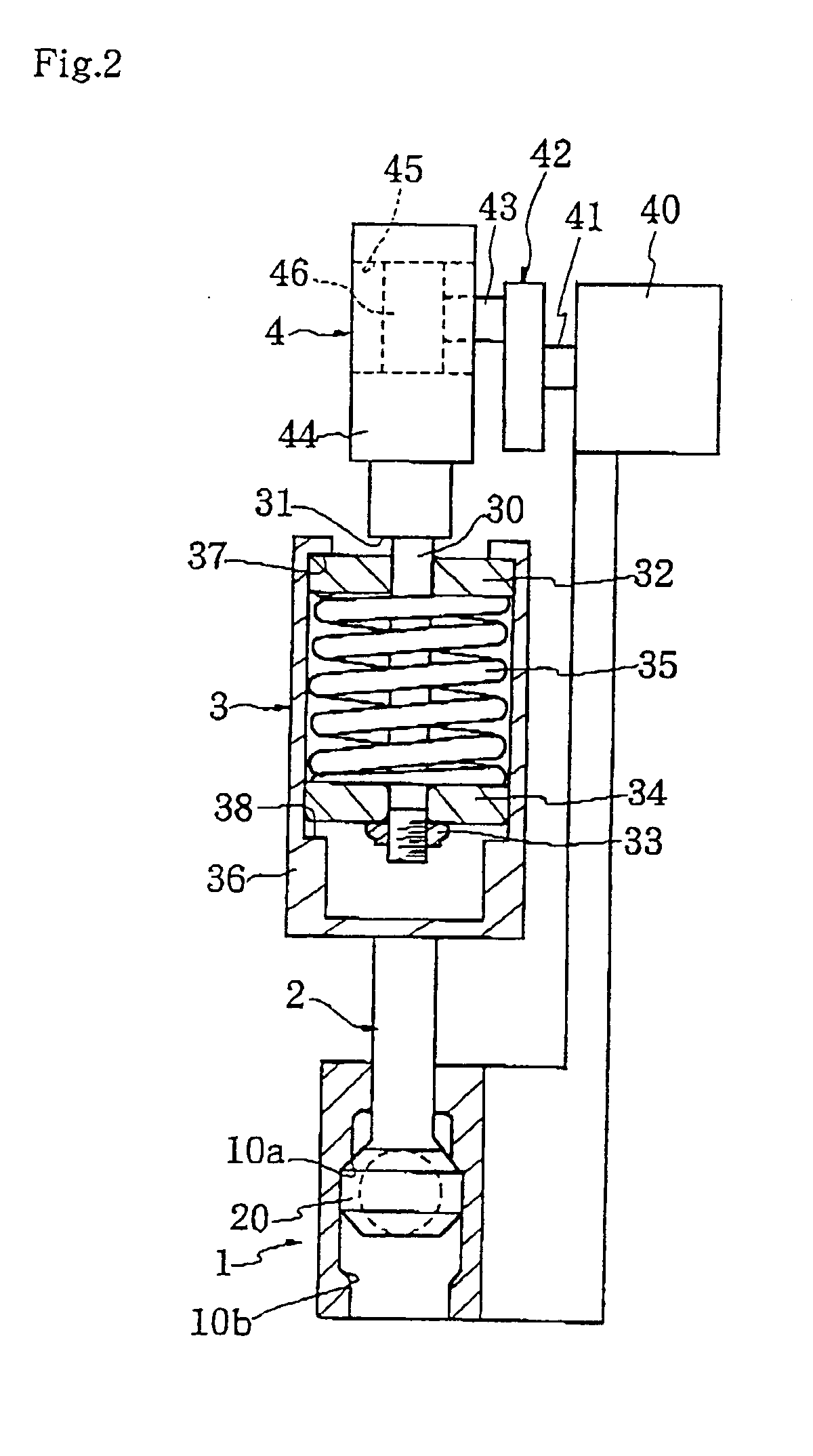

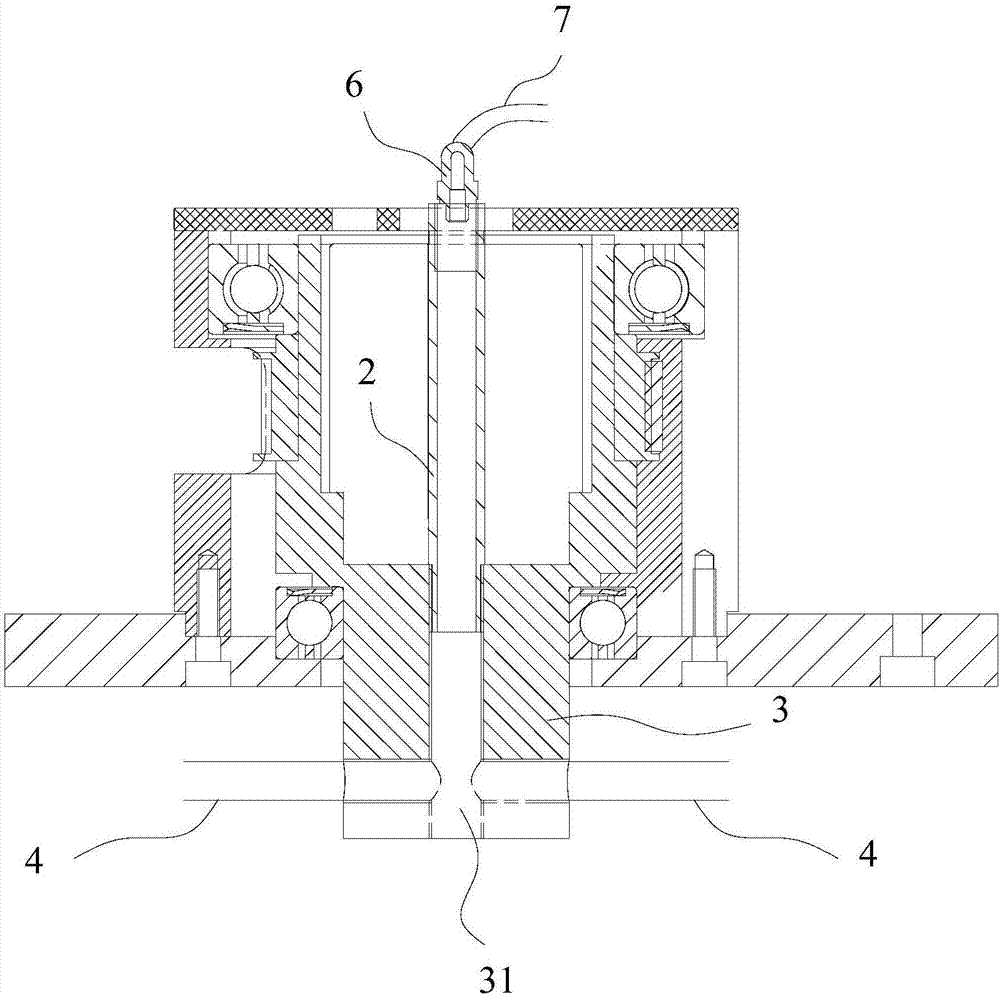

Direct-acting electric operated valve

InactiveUS6971628B2Limit reverse rotationShort strokeOperating means/releasing devices for valvesGearingTop dead centerReciprocating motion

A direct-acting electric operated valve has a stem which reciprocates by an electric motor without using air pressure.In this direct-acting electric operated valve, as the stem 2 vertically reciprocates, a first passage 11 and a second passage 12 are switched over. A cam mechanism 4 is formed for converting rotary reciprocating motion of an eccentric cam 42 which rotary reciprocates by an electric motor 40 into vertical reciprocating motion. The eccentric cam is retained at an upper retaining position X which is slightly exceeding a top dead center X1 and at a lower retaining position Y which is slightly exceeding a bottom dead center Y1. In a state in which an integral coil spring 35 which is previously held between an upper spring seat 32 and a lower spring seat 34 in its compressed state is mounted to a spring shaft 30 which extends from a cam mechanism, the coil spring 35 is accommodated in a spring case 36 connected to the stem.

Owner:ICHIMARU GIKEN

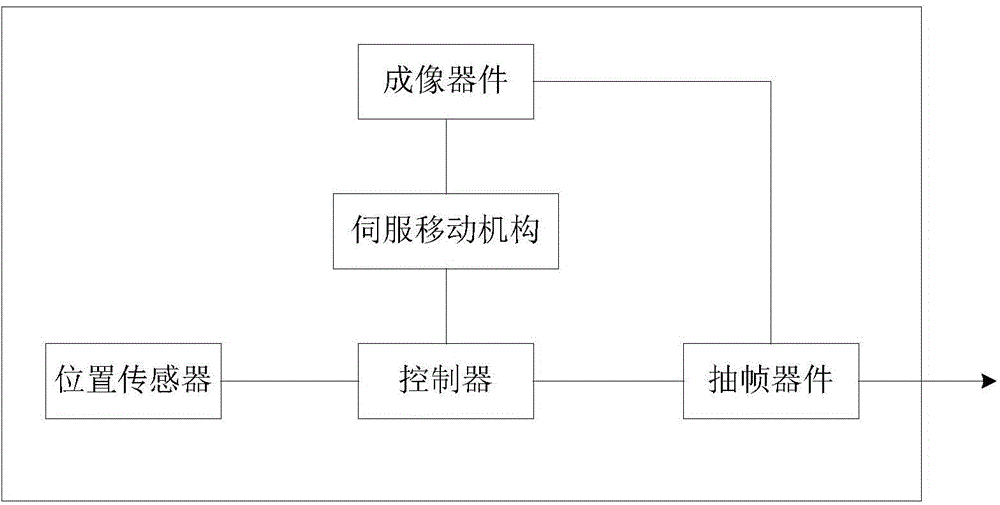

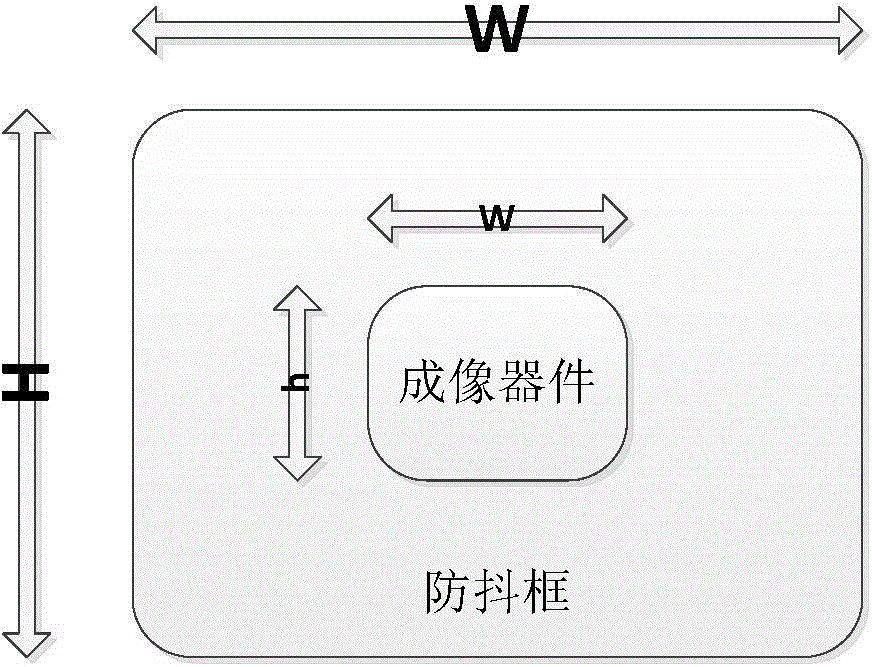

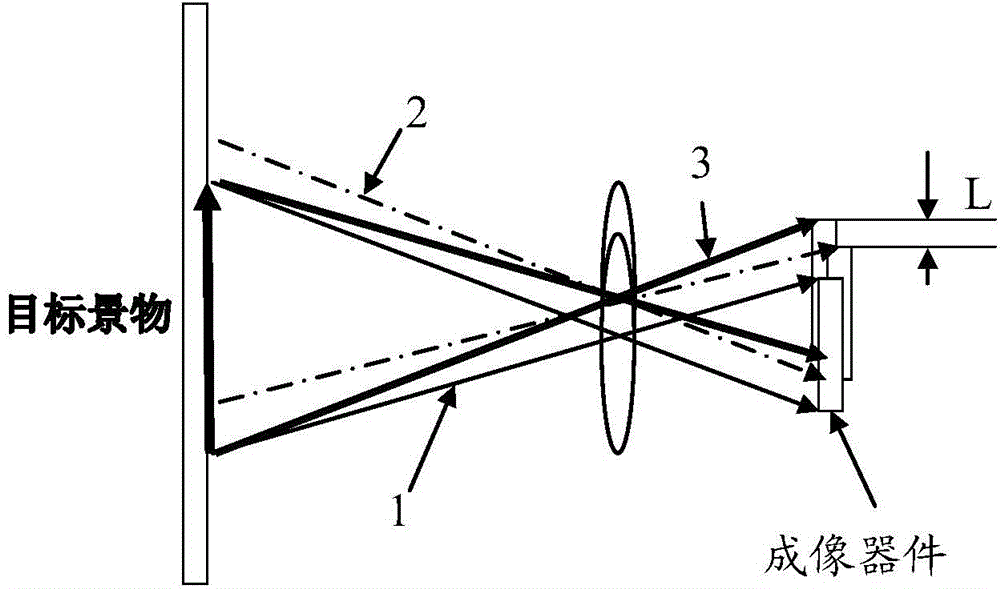

Anti-shake device and method of video camera

ActiveCN104601897AShort working hoursShort strokeTelevision system detailsColor television detailsClassical mechanicsAngular acceleration

The invention discloses an anti-shake device and method of a video camera. The anti-shake device comprises a position sensor, a controller, a servo mechanism, an imaging device and a frame extraction device, the position sensor measures linear acceleration and angular acceleration caused by shaking of the video camera and transmits the linear acceleration and the angular acceleration to the controller, the linear acceleration and the angular acceleration caused by shaking can be converted into mobile distance and angle by the controller, the mobile distance and angle are then compared with the maximum distance and the maximum angle of moving of the imaging device, image frames with the moving distance and angle caused by shaking and exceeding the maximum distance and the maximum angle of moving of the imaging device is abandoned in advance, and on the premise of no influence on subjective feeling of videos, the image frames exceeding the set frame number are abandoned actively according to preset strategies, the servo mechanism is controlled to stop actions within the framing period of abandoning the image frames in advance and the frame extraction device is controlled to abandon the image frames to be abandoned. By the anti-shake device and method, operation time and distance of the servo mechanism are reduced, and servo accuracy requirements are lowered.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

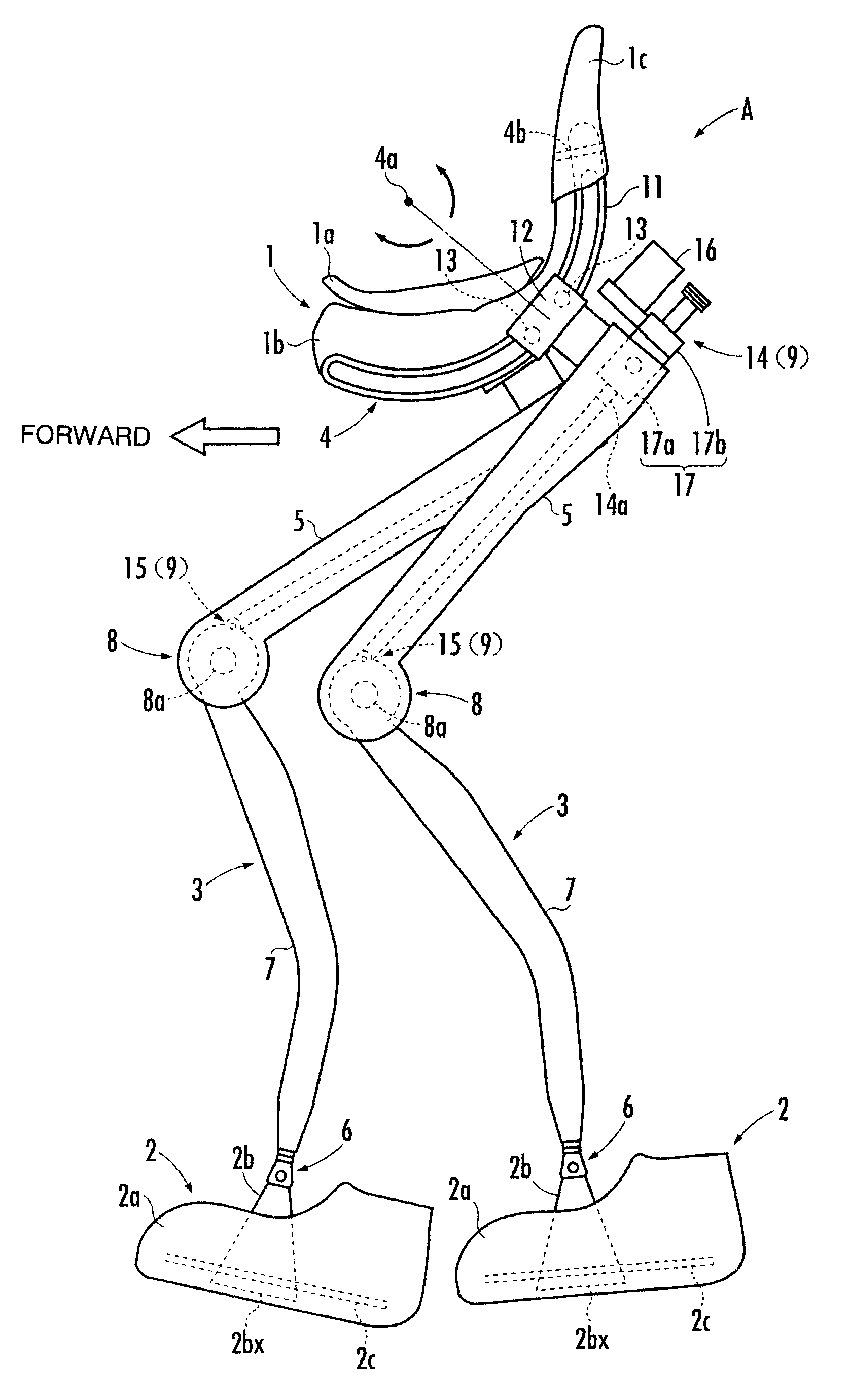

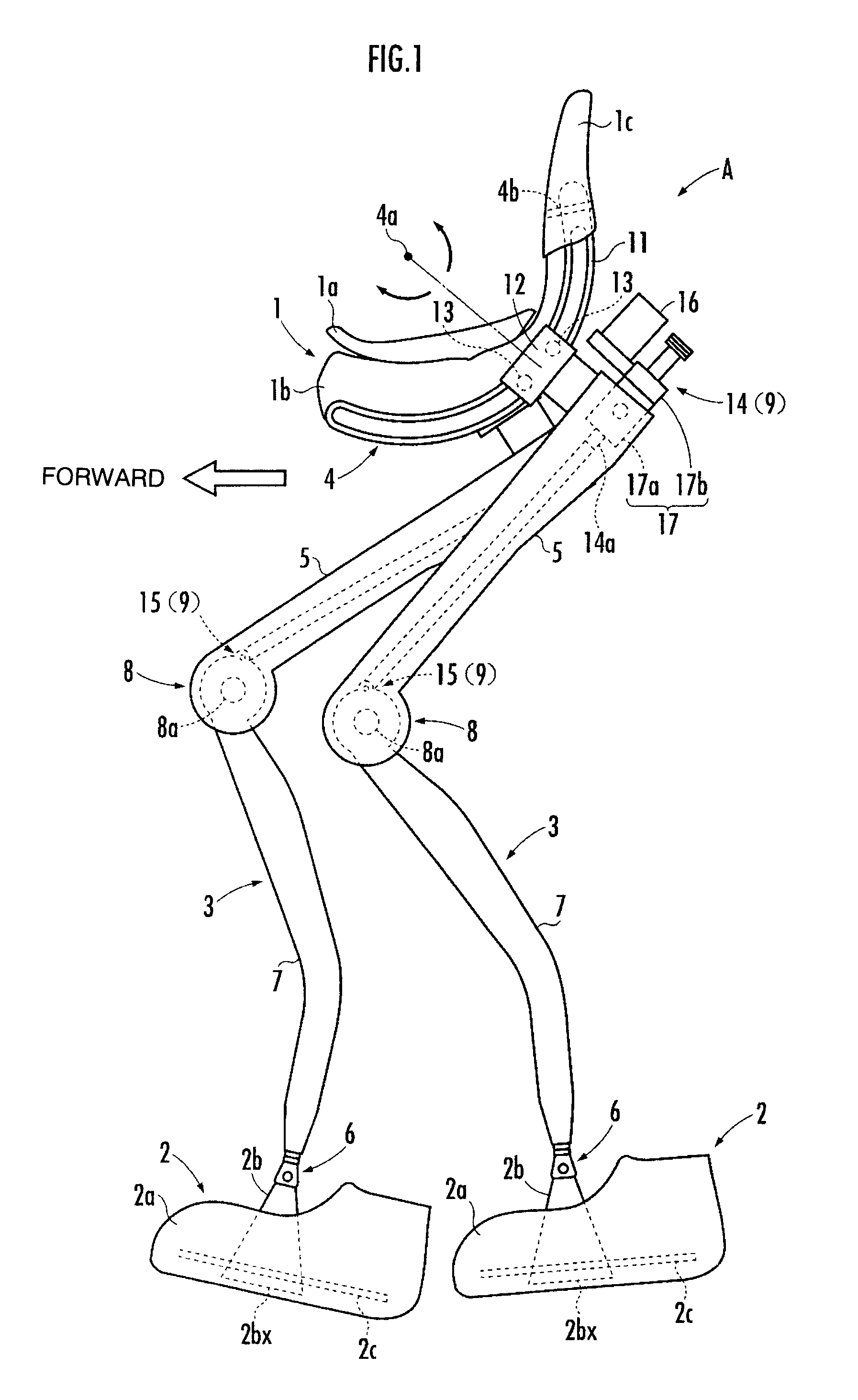

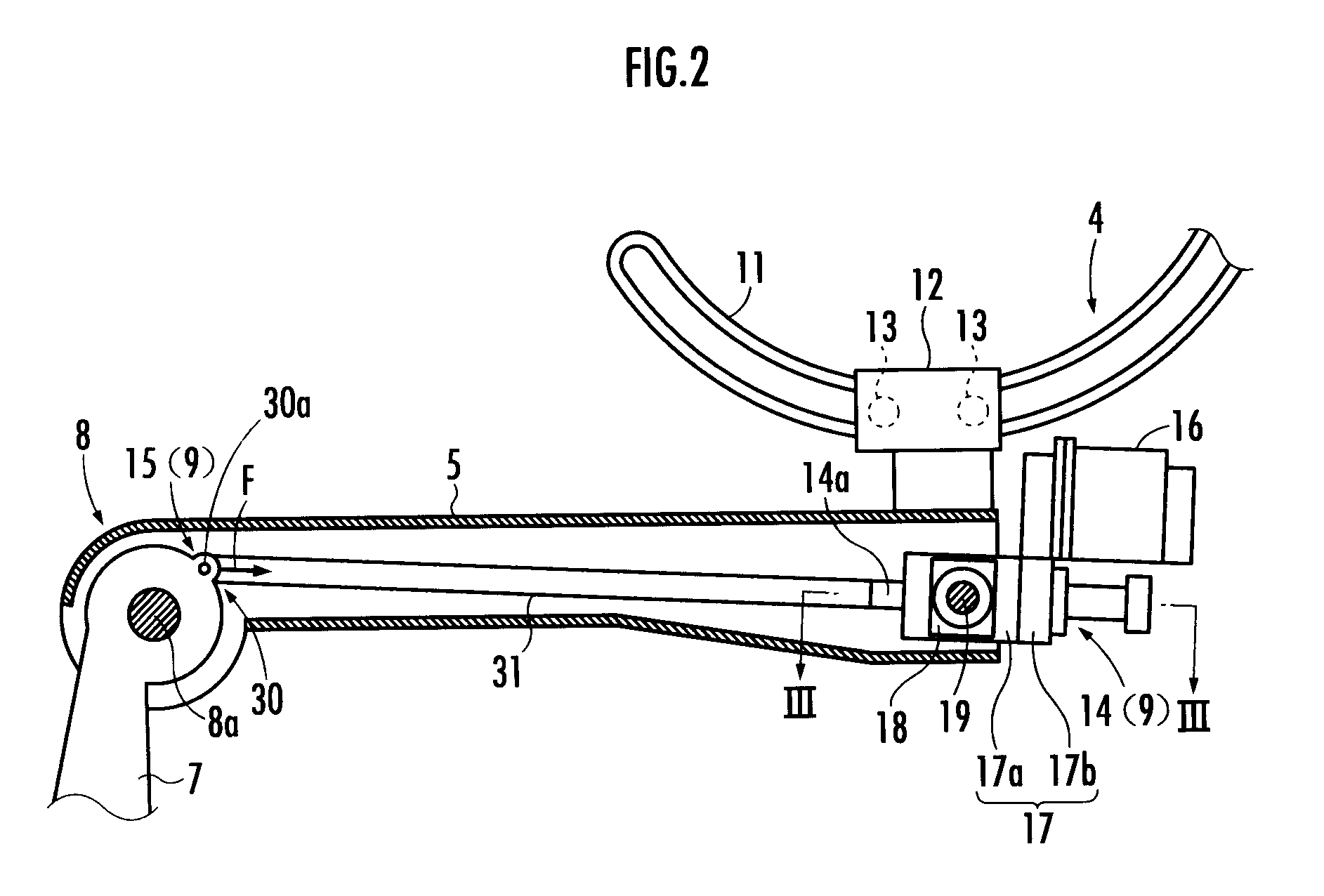

Walking assistance device

ActiveUS20100113988A1Small diameterIncreased durabilityChiropractic devicesWalking aidsLinear motionEngineering

A walking assistance device has a drive mechanism, which is provided with a linear-motion actuator including an electric motor installed in the upper link member, nut members which are rotationally driven by the electric motor, and a linear-motion output shaft which linearly moves in the direction of the axial centers of the nut members, and a crank arm which is secured to the lower link member coaxially with a joint axis of a third joint and swingably attached to one end of the linear-motion output shaft. The drive mechanism is constructed such that a translational force output from the linear-motion output shaft of the linear-motion actuator is converted into a rotational driving force of the third joint through the crank arm.

Owner:HONDA MOTOR CO LTD

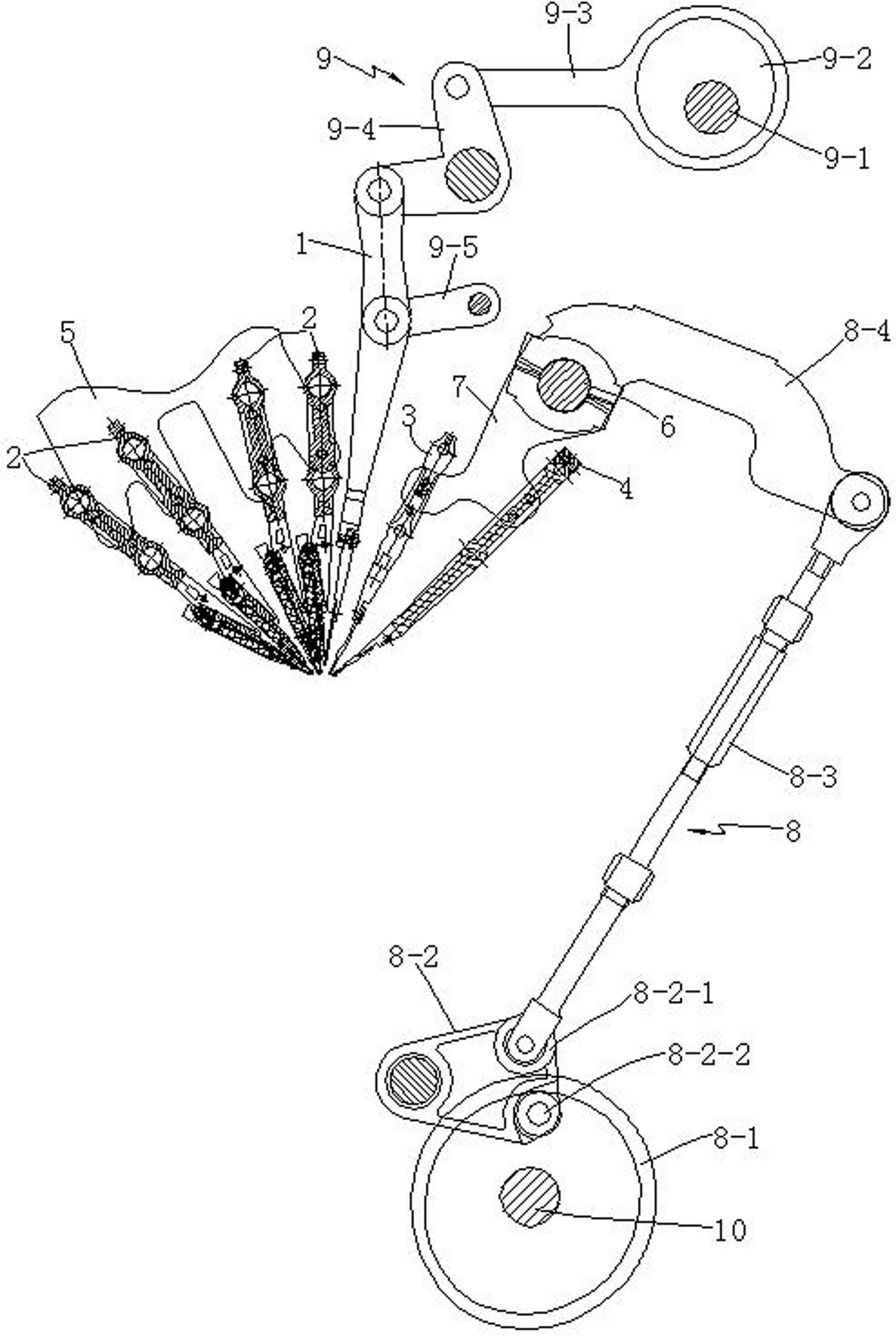

Guide bar device for yarn pressing warp knitting machine

The invention discloses a guide bar device for a yarn pressing warp knitting machine. The guide bar device comprises a yarn pressing plate, a yarn pressing guide bar, at least one ground guide bar and a polyurethane guide bar; the yarn pressing guide bar is arranged on a first guide bar seat fixedly connected with a rack of the warp knitting machine; the guide bar device also comprises a swing shaft and a second guide bar seat fixedly connected with the swing shaft; the first and second guide bar seats are arranged on the front and rear sides of the yarn pressing plate respectively; the ground guide bar and the polyurethane guide bar are arranged on the second guide bar seat; the swing shaft is driven by a swing transmission mechanism to swing; the yarn pressing plate is driven by a planar connecting rod mechanism to move; and the yarn pressing guide bar is one or two separate full-gauge yarn pressing jacquard guide bars. The swing transmission mechanism preferably consists of a cam, a swing rod, a connecting rod and a swing arm; and the planar connecting rod mechanism preferably consists of a rotating shaft, an eccentric wheel, an eccentric sleeve, a V-shaped swing rod and a connecting rod. The guide bar device enables a knitting needle and the yarn pressing plate to work cooperatively, can knit richer patterns compared with the conventional yarn pressing warp knitting machine, is suitable for high speed, and has high production efficiency.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

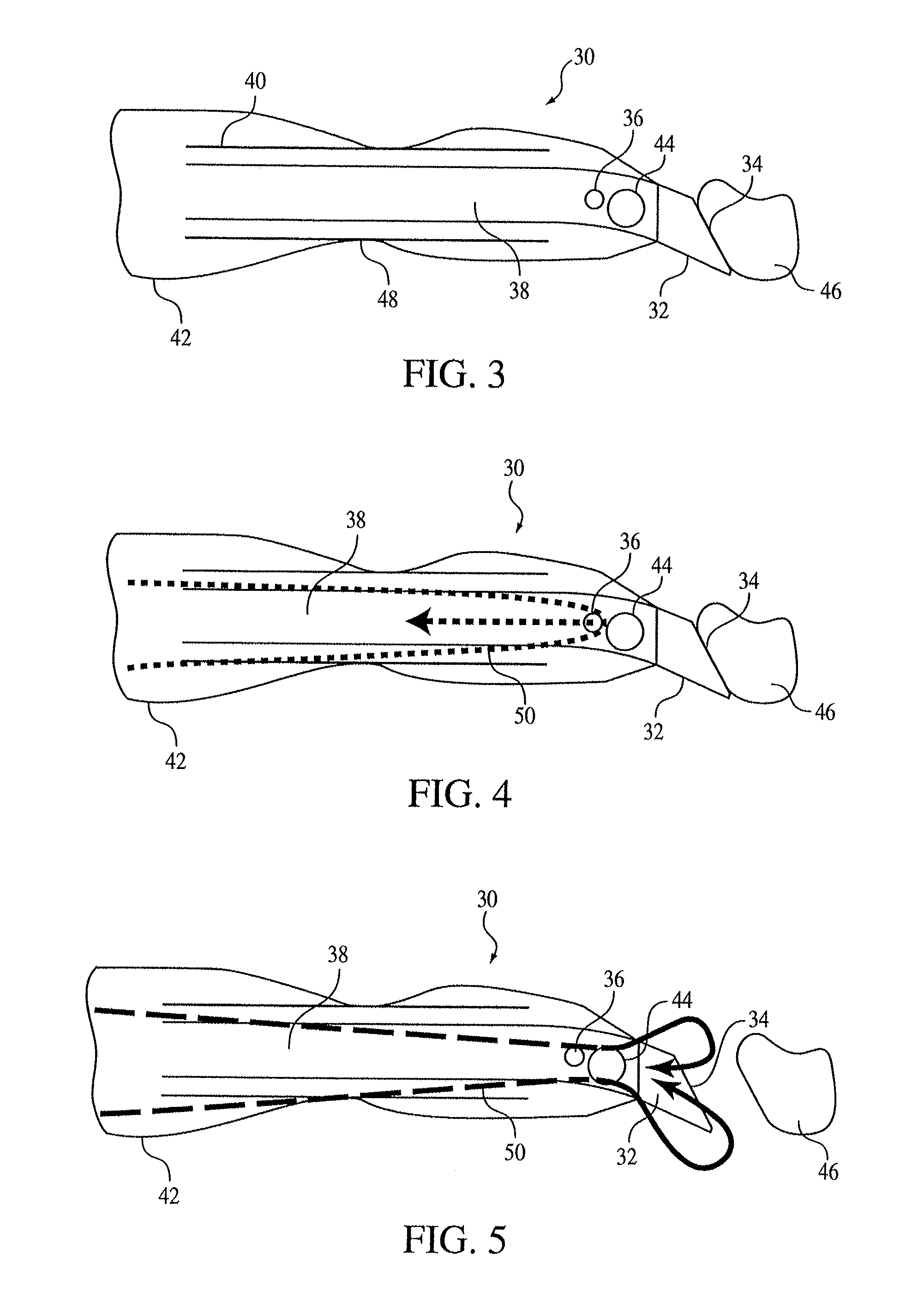

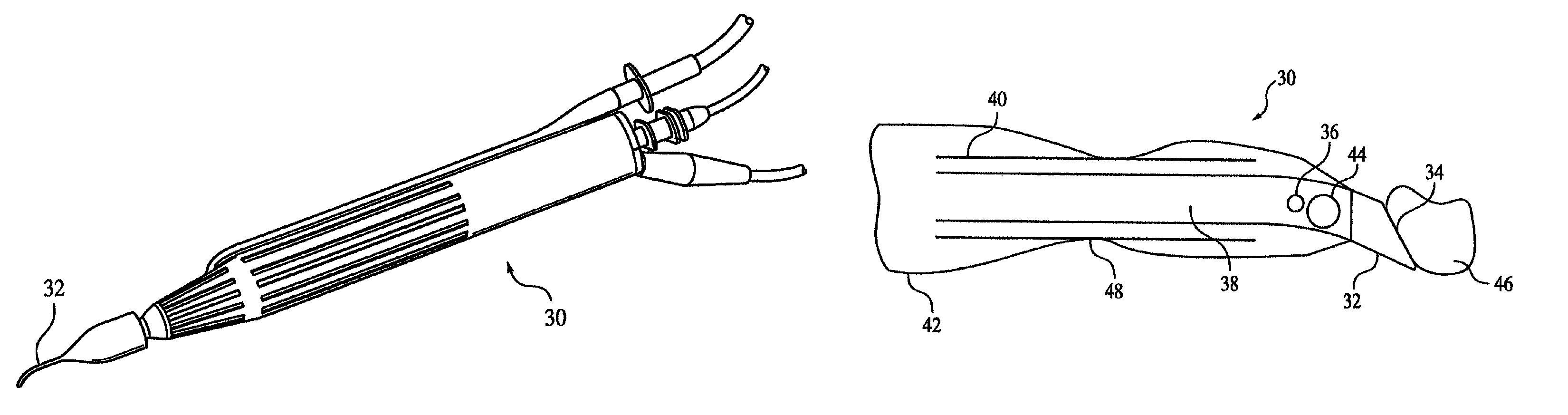

Torsional Ultrasound Hand Piece That Eliminates Chatter

ActiveUS20100324581A1Low heat generationReduce the temperatureEye surgerySurgeryFluid shiftingHand held

A torsional ultrasound surgical hand piece lessens or eliminates chatter from lens material by imparting a twisting, rotary motion to a tip of a phacoemulsification needle at a resonant frequency in excess of 32 kHz. The hand piece has a horn that is designed to operate at an elevated frequency while maintaining size constraints for hand-held ophthalmic instruments. Optionally, heat generation is reduced either through the use of a polyimide tubing situated between the needle and the infusion sleeve, through the use of thermal watch to prevent overheating at the incision, and / or through the use of a bypass hole in the needle that diverts flow under suction into the needle via the bypass hole instead of exiting through an irrigation opening in the infusion sleeve when a tip port is occluded by lens material.

Owner:ALCON INC

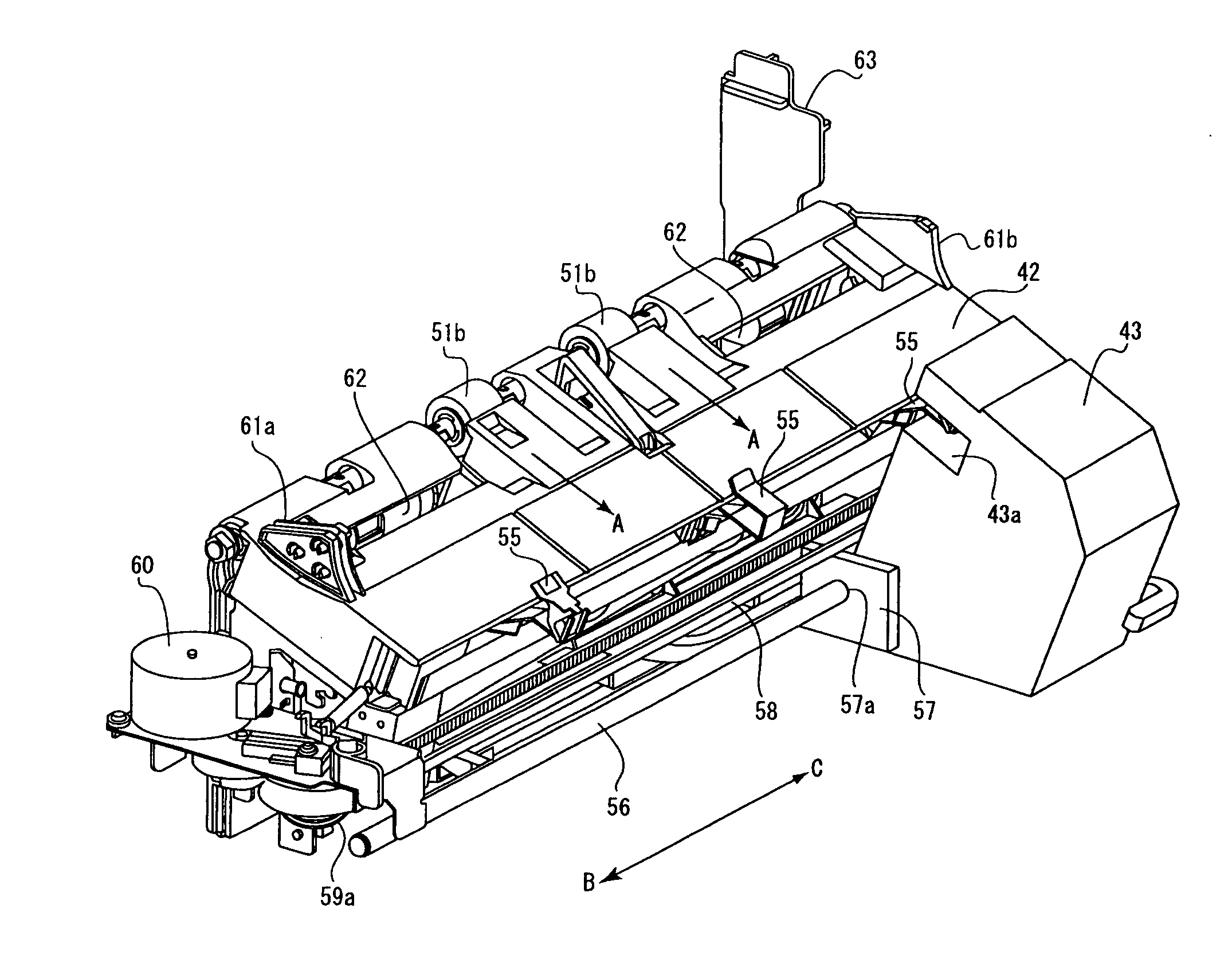

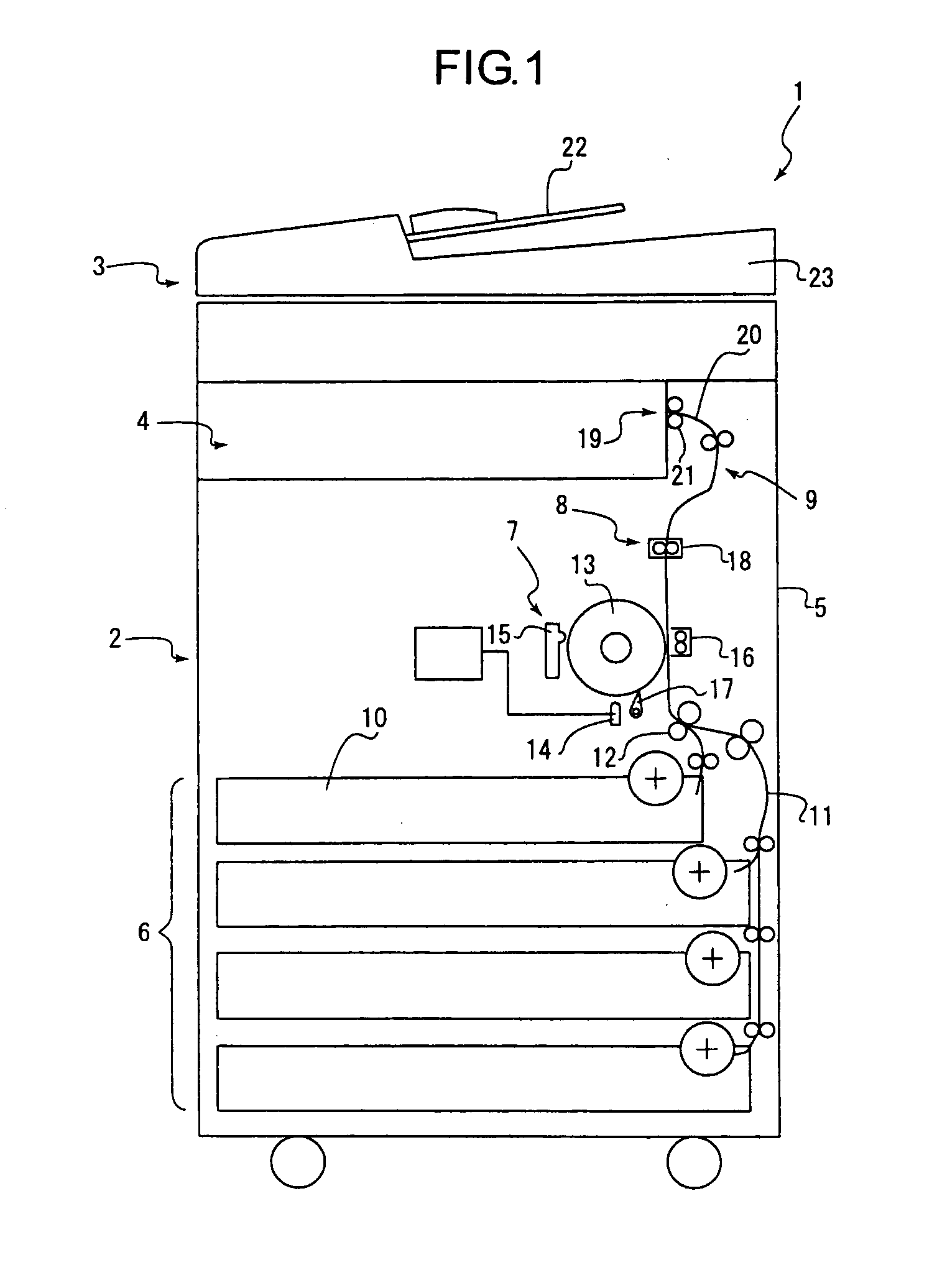

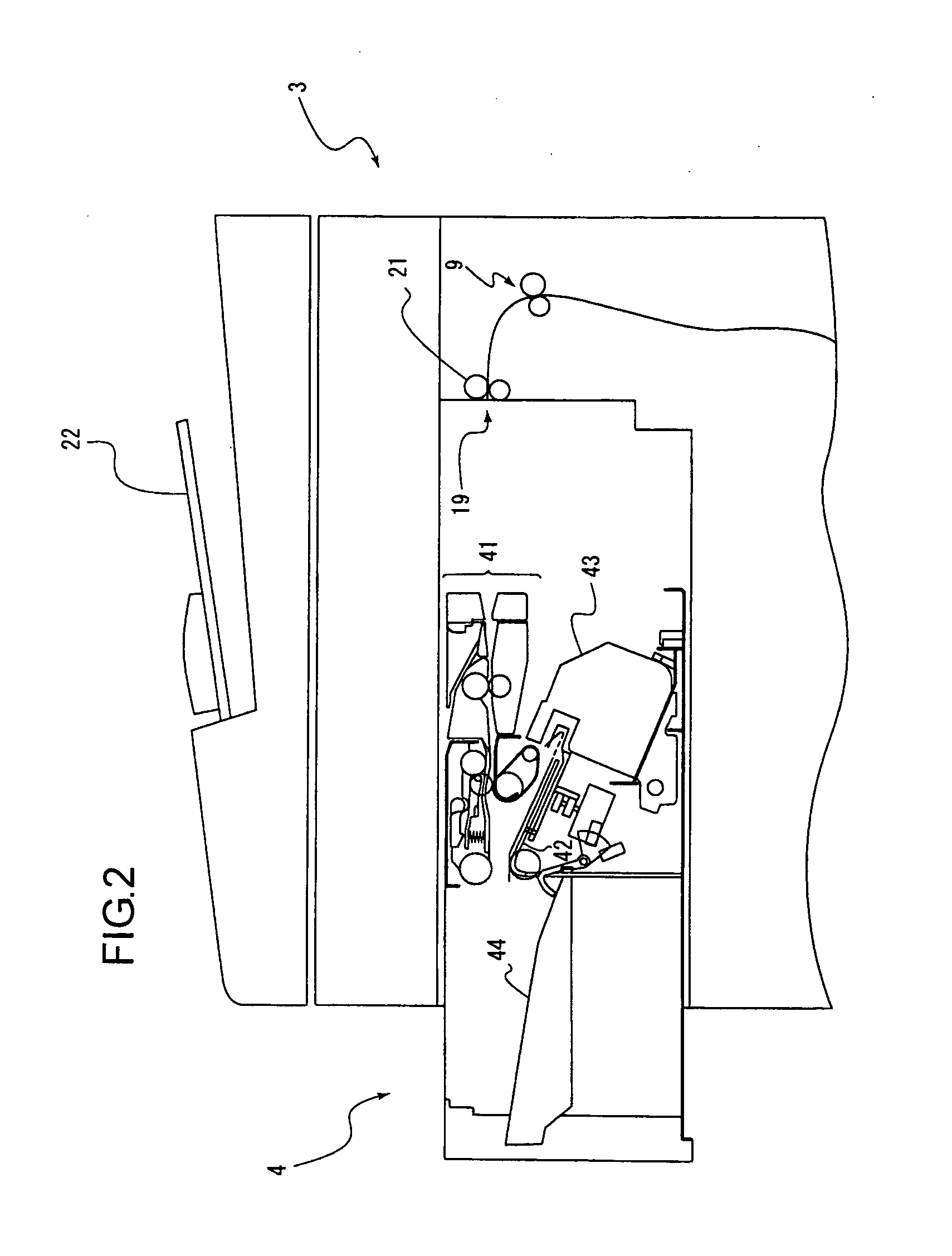

Sheet post-processing apparatus and image formation apparatus provided with the same

ActiveUS20060202403A1Reduced amount of travelShort strokeSheet bindingArticle deliveryImage formationSheet material

An apparatus is provided with a processing tray 42 to mount sheets ejected from an image formation section, aligning means (aligning plates 61, etc.) for aligning end portions of a sheet ejected on the processing tray 42, a post-processing apparatus 43 that performs binding processing on the sheets aligned by the aligning means, and moving means (unit moving motor 60, etc.) for moving the post-processing apparatus 43 to a plurality of post-processing positions set to perform the binding processing at different binding processing target position on the sheets, and moves the sheets to a post-processing undergoing position corresponding to the post-processing position substantially in parallel with a travel direction of the post-processing apparatus 43. It is thereby possible to perform the binding processing on the ejected sheets appropriately while implementing the apparatus compact in size.

Owner:SHARP KK +1

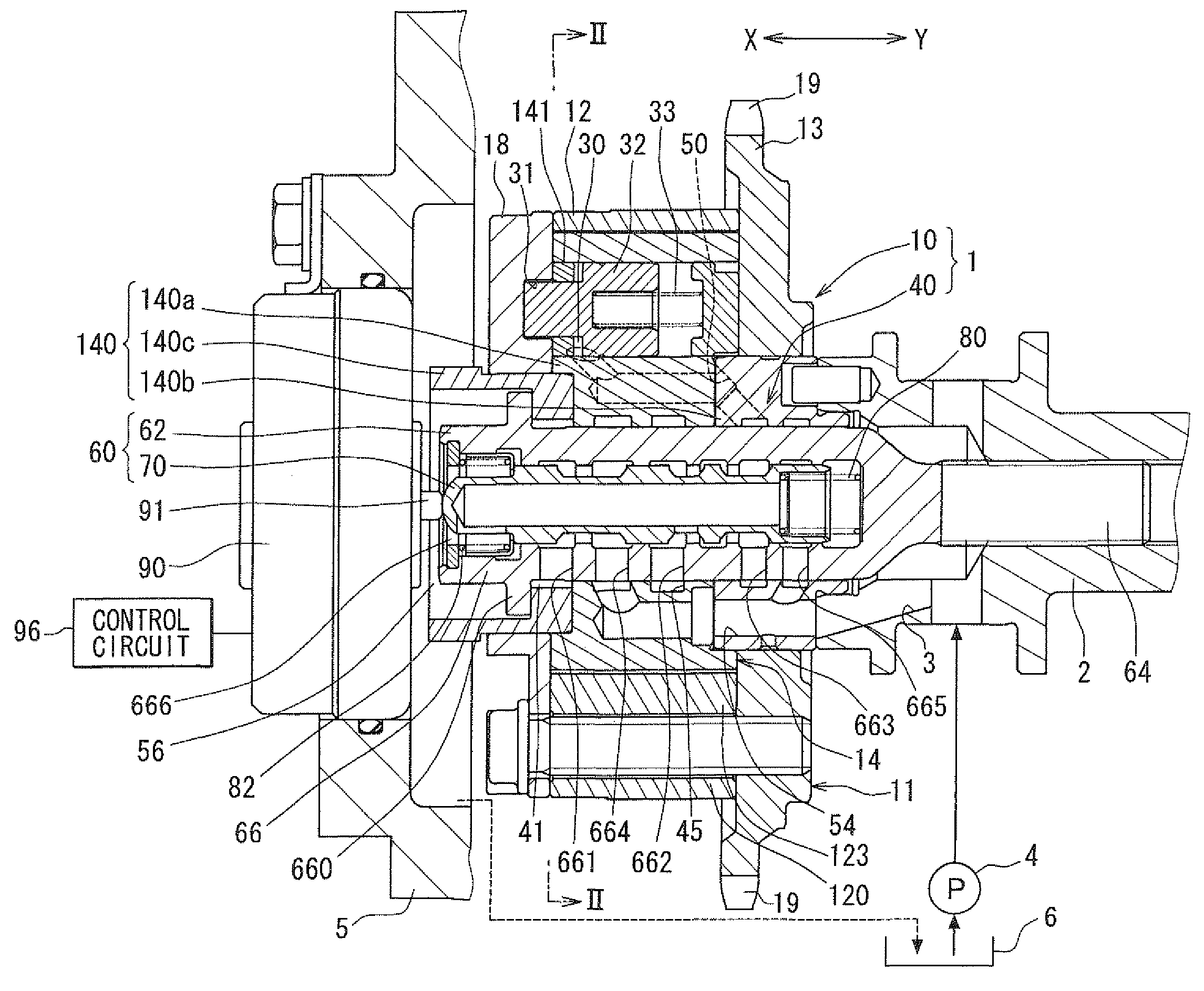

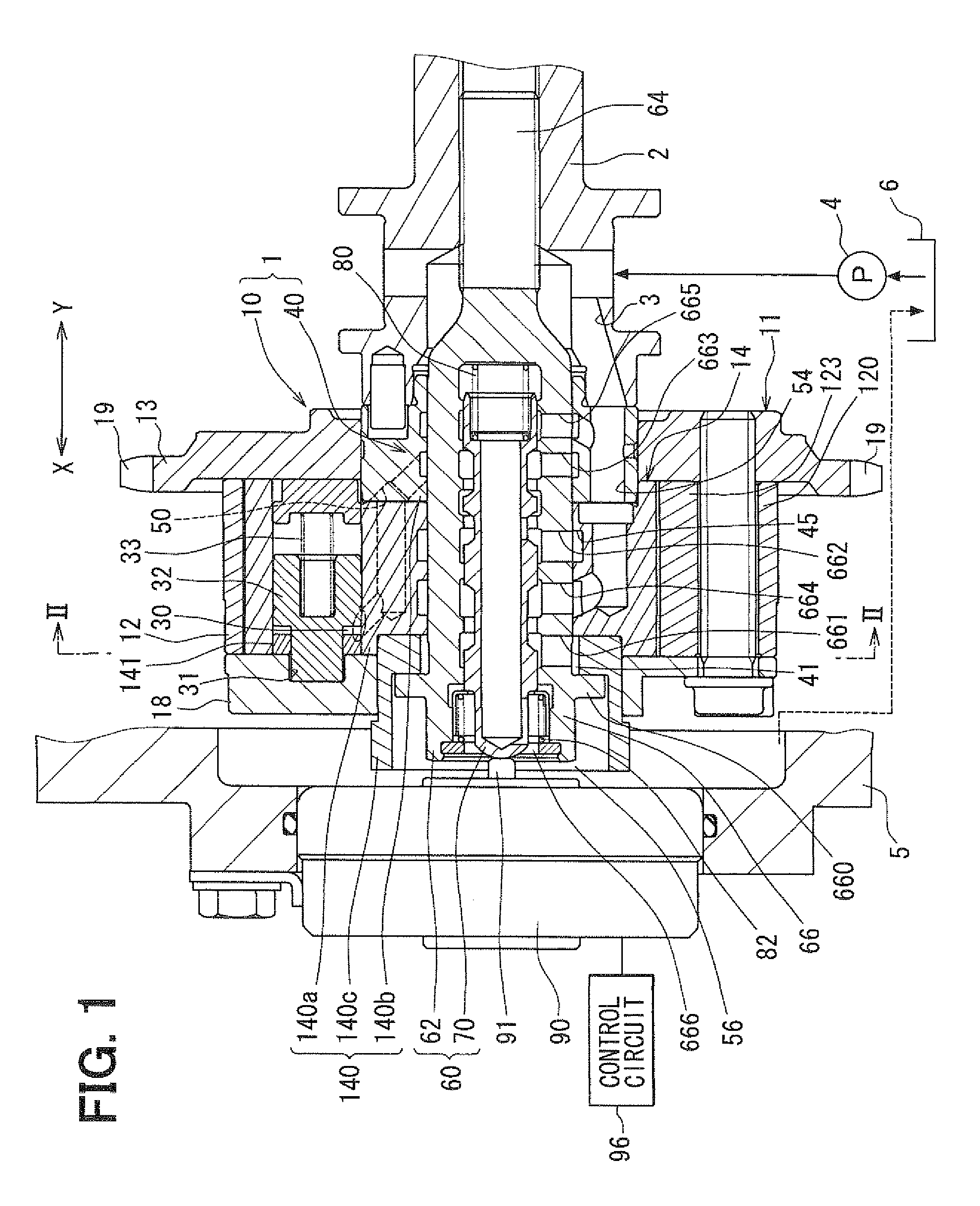

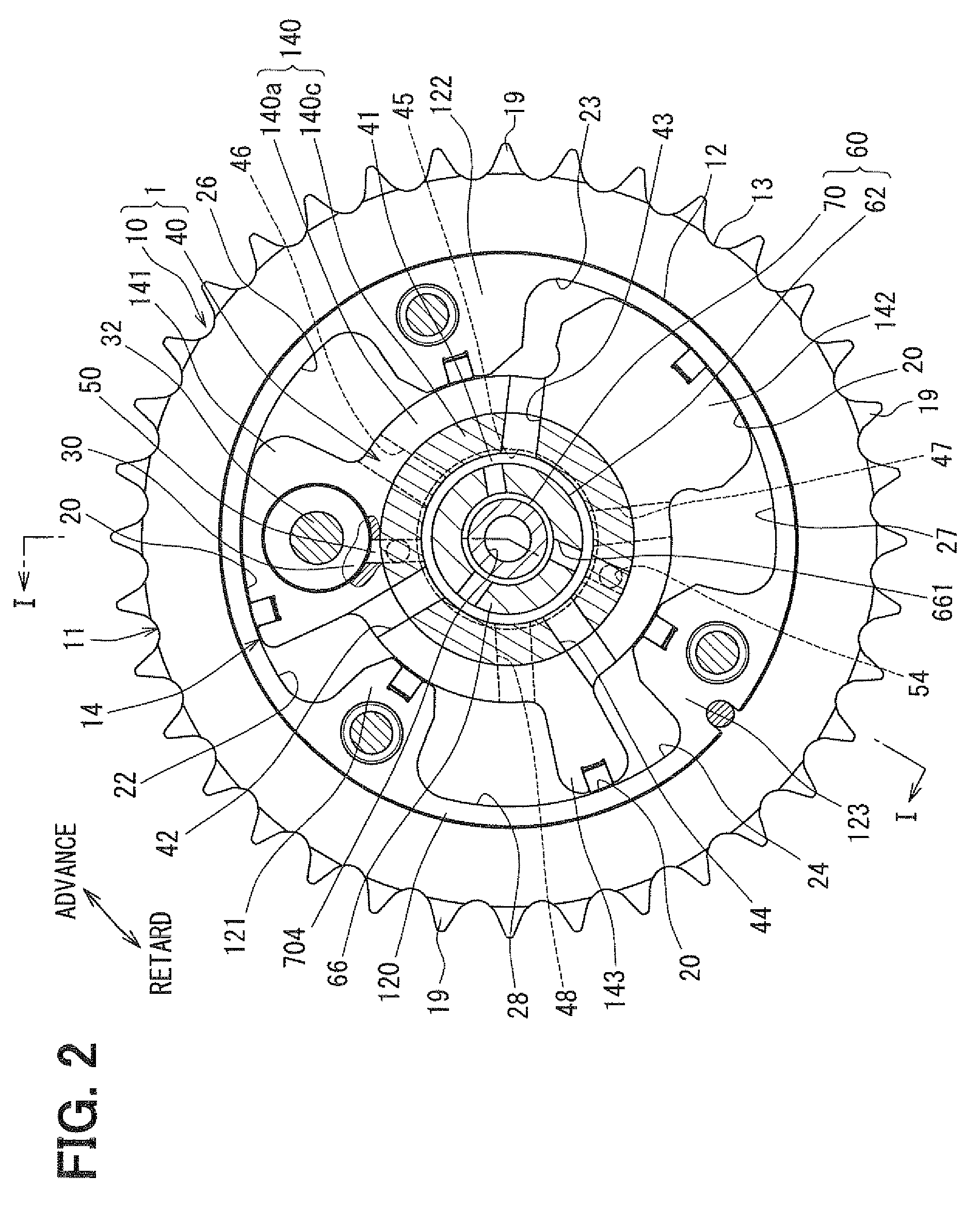

Valve timing controller

ActiveUS20100175651A1Small sizeStroke of the valve member can be shortenedValve arrangementsYielding couplingEngineeringMechanical engineering

When a spool is positioned in a lock range including a stroke end in a first direction, an advance port and a lock port are respectively connected to a supply port and a discharge port. When the spool is positioned in an advance range deviating from the lock range in a second direction, the advance port and the lock port are fluidly connected to the supply port. While a driving source generates a driving force to move the spool in the second direction, a biasing member biases the spool in the first direction. When the spool is positioned at a limit position of the advance range, a biasing force biasing the spool in the first direction is stepwise varied by a specified variation width.

Owner:DENSO CORP

Torsional ultrasound hand piece that eliminates chatter

A torsional ultrasound surgical hand piece lessens or eliminates chatter from lens material by imparting a twisting, rotary motion to a tip of a phacoemulsification needle at a resonant frequency in excess of 32 kHz. The hand piece has a horn that is designed to operate at an elevated frequency while maintaining size constraints for hand-held ophthalmic instruments. Optionally, heat generation is reduced either through the use of a polyimide tubing situated between the needle and the infusion sleeve, through the use of thermal watch to prevent overheating at the incision, and / or through the use of a bypass hole in the needle that diverts flow under suction into the needle via the bypass hole instead of exiting through an irrigation opening in the infusion sleeve when a tip port is occluded by lens material.

Owner:ALCON INC

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

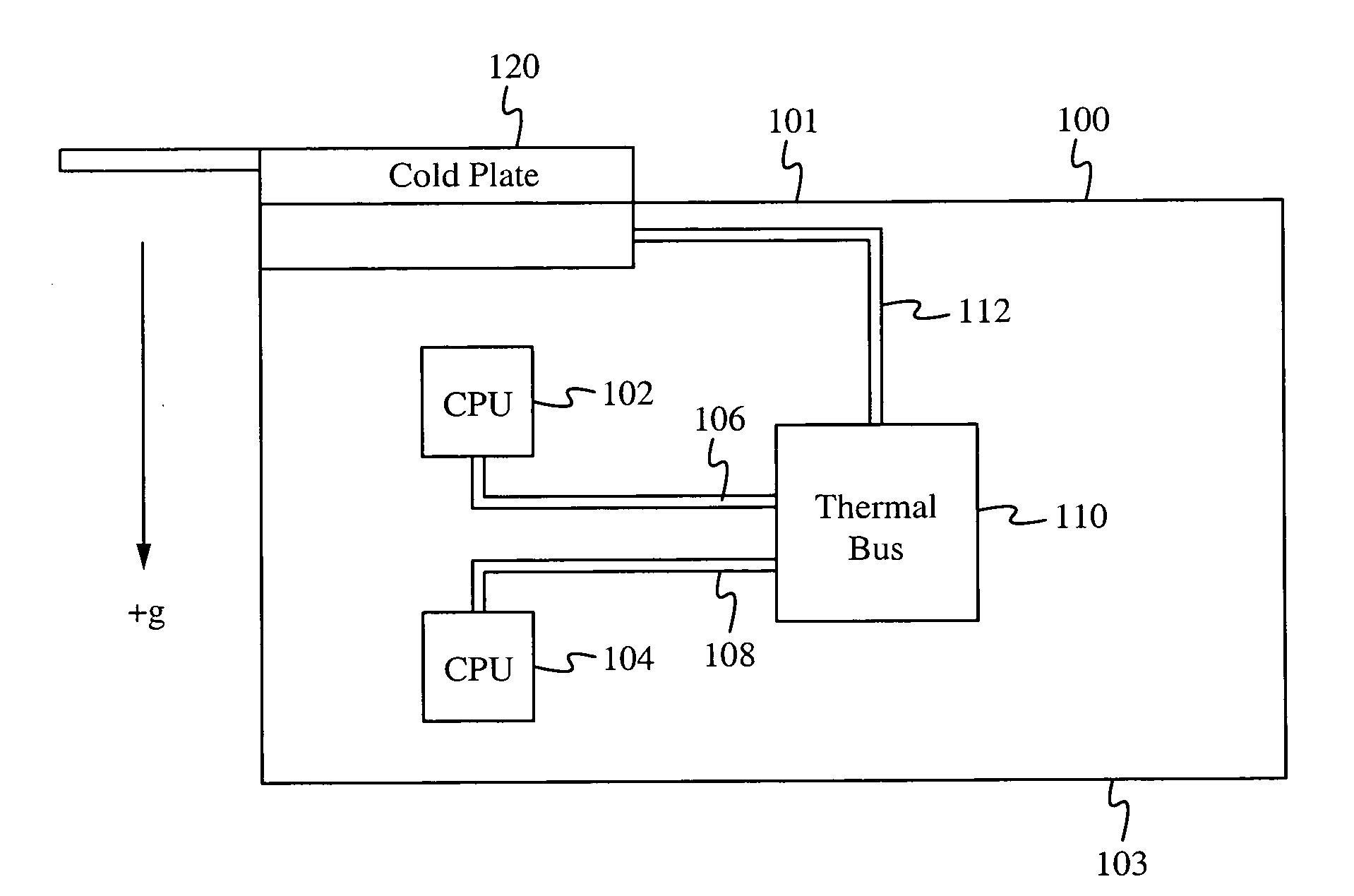

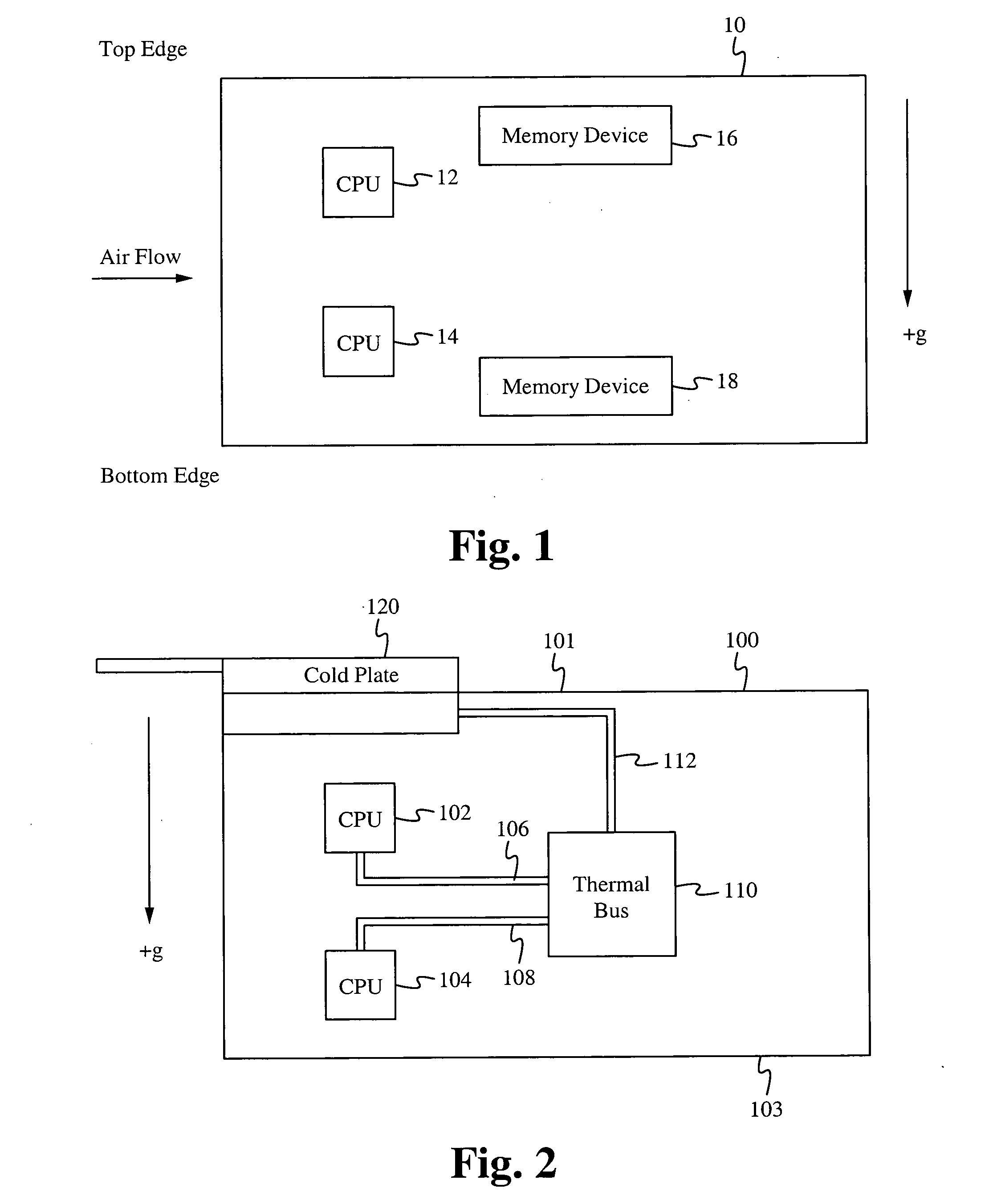

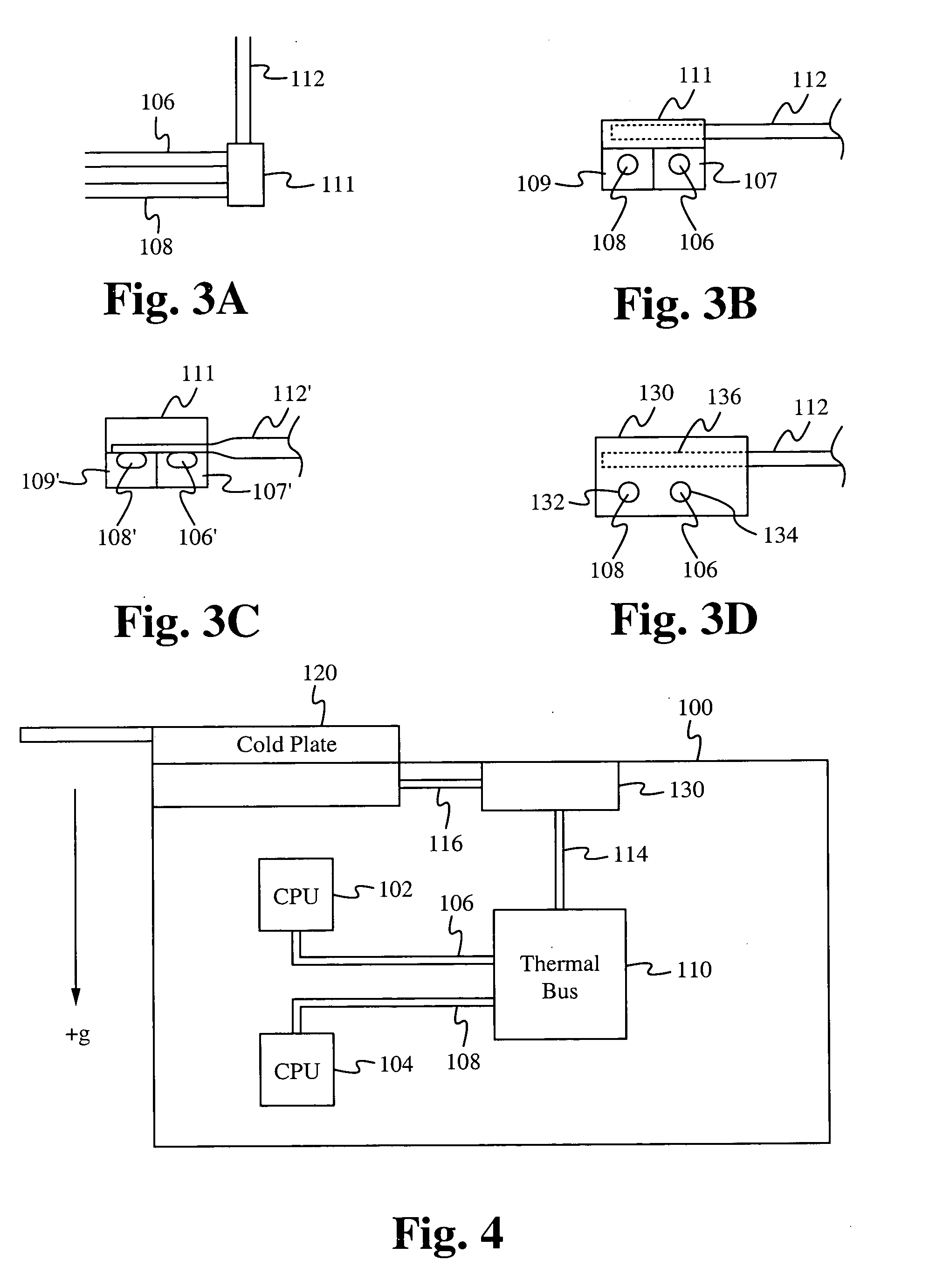

Thermal bus or junction for the removal of heat from electronic components

InactiveUS20090225515A1Shorten the lengthShort strokeWing accessoriesIndirect heat exchangersWorking fluidEngineering

A thermal bus enables the use of multiple separate heat pipe assemblies instead of using a single heat pipe assembly spanning the distance from heat source to cold plate. The use of a thermal bus can decrease the orientation effects as well as decrease the travel length of any single heat pipe assembly. In addition, the use of multiple heat pipe assemblies enables each individual heat pipe assembly to be optimized to meet localized heat transfer characteristics between each heat source, the thermal bus, and the cold plate. Such optimization can include the use of differently sized heat pipes, wick structures within the heat pipe, and working fluid used within the heat pipe. The thermal bus provides an intermediate thermal transfer from one heat pipe assembly serially coupled to another heat pipe assembly, thereby enabling multiple serially coupled heat pipe assemblies to transfer heat from a given heat source to the cold plate at the edge of the electronics board.

Owner:COOLIGY INC

Salt-free soy

The invention which belongs to the technical field of flavorings especially relates to a salt-free soy. A technical scheme of the salt-free soy comprises the following steps: 1, mixing raw materials of soybean (bean cakes and soybean meal oil cakes), wheat bran (or crushed wheat) or rice husk, moistening, and steaming them in a boiler; 2, air-cooling the raw materials, mixing the raw materials with a koji forming material, adding water, uniformly stirring them, fermenting the raw materials in a pool, and spraying oil to leach after the fermentation; and 3, heating a raw soy, adding a flavoring as needed, directly clarifying the heated raw soy if the taste needs no adjustments, sterilization-disinfecting, and packaging to form finished products after the quality detection qualification. The salt-free soy has the following beneficial effects: the oxidation resistance of the salt-free soy is 150 times higher than the oxidation resistance of vitamin C; and generations of arteriosclerosis, myocardial infarction, apoplexy, hypertension, heat diseases and cataract are reduced after the salt-free soy is taken for a long term. The salt-free soy is suitable for people needing light diets and a proper amount of salt.

Owner:高巍

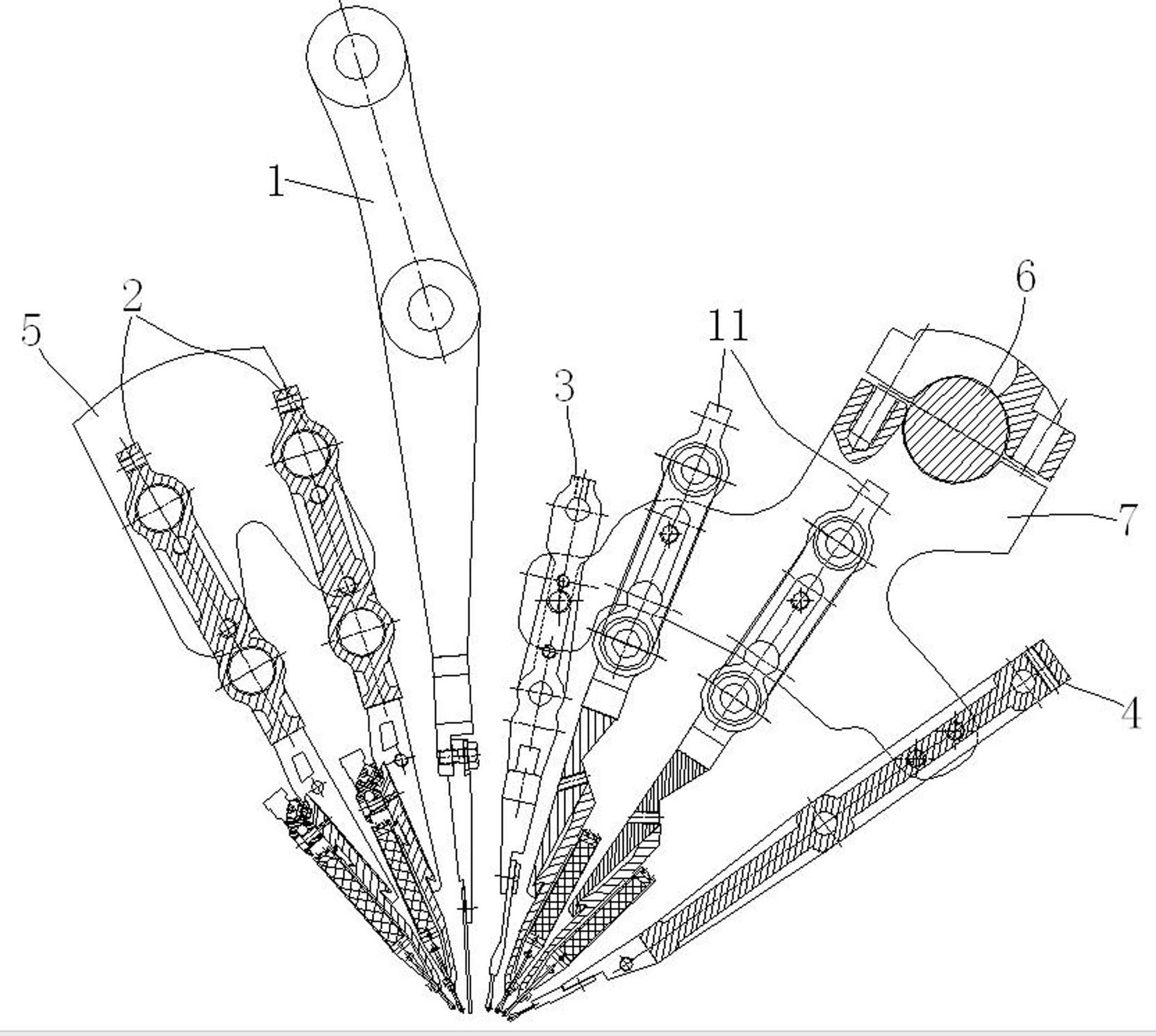

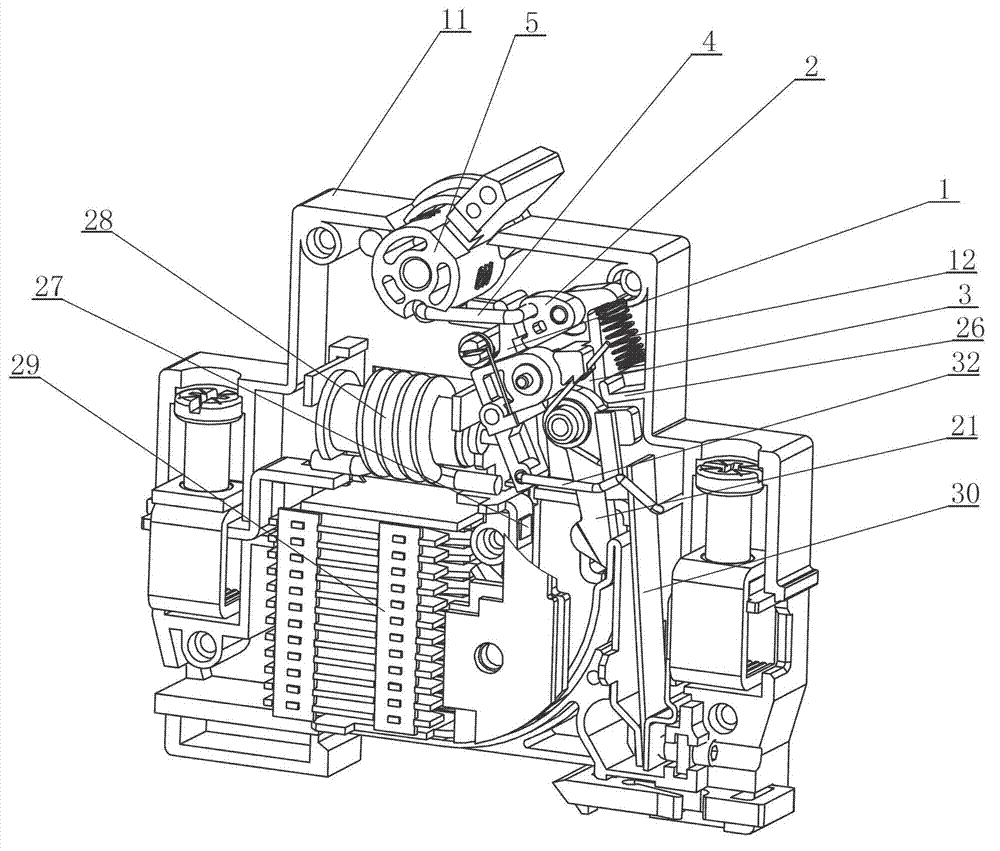

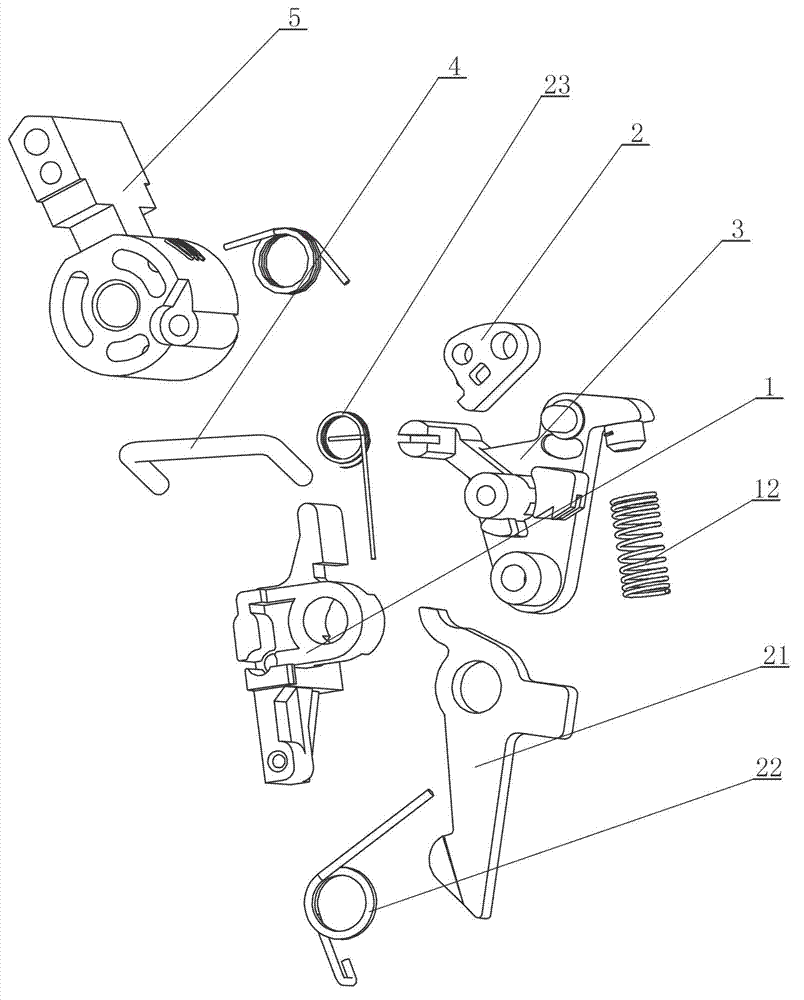

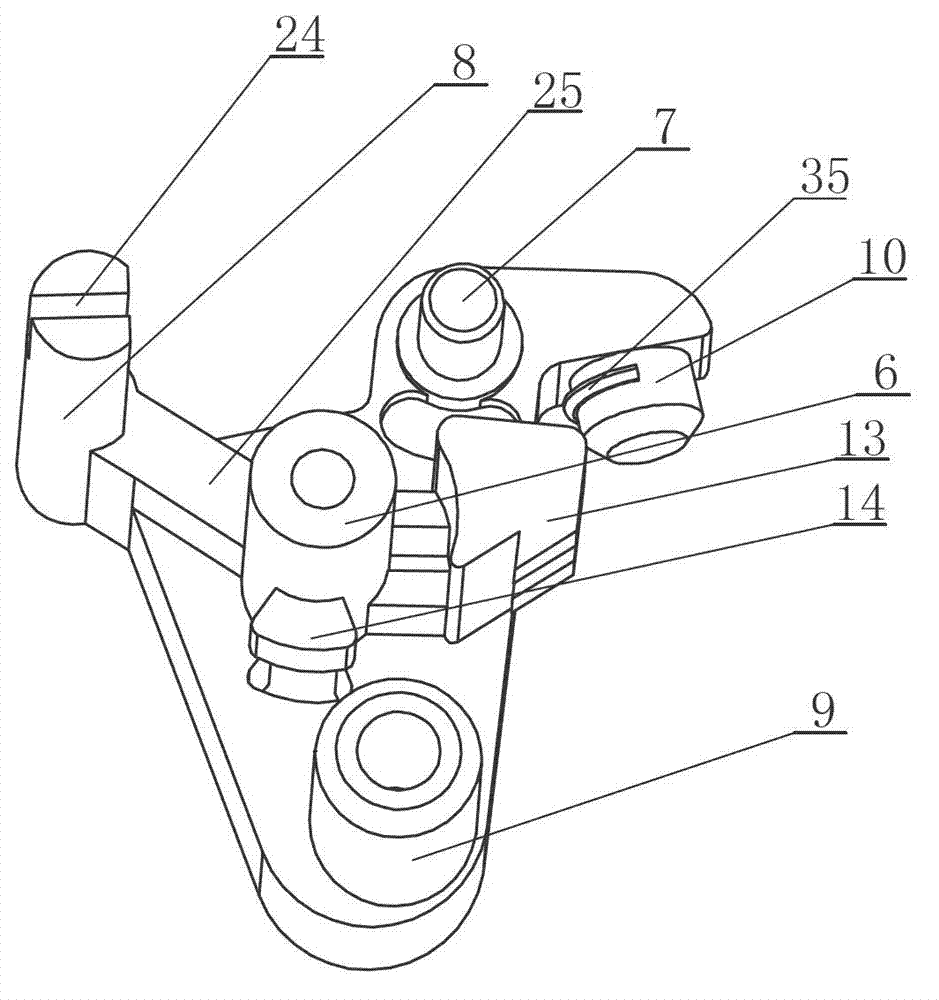

Operating mechanism and miniature circuit breaker

ActiveCN102881530AChange connection methodIncrease stiffnessProtective switch operating/release mechanismsFailure rateEngineering

The invention discloses an operating mechanism and a miniature circuit breaker. The problems that false tripping of the conventional miniature circuit breaker easily happens, or the conventional miniature circuit breaker is insensitive to trip, the assembling difficulty is high and the failure rate is high are mainly solved. The operating mechanism is characterized in that a bracket (3) has an integral structure; a central shaft sleeve (6) provided with a central hole and a trip hinged shaft (7), a latch resetting torsion spring mounting shaft (8) and a moving contact mounting shaft (9) which are distributed in a triangle shape are arranged on the bracket (3); a trip (2) is a body piece; a moving contact torsion spring (22) is wound outside the moving contact mounting shaft (9); a mounting seat (18) on the trip (2) is sleeved outside the central shaft sleeve (6) and can rotate relative to the central shaft sleeve (6); and a latch resetting torsion spring (23) is wound on the latch resetting torsion spring mounting shaft (8). By the operating mechanism, the structure of the bracket is changed, and the operating mechanism is compact in structure and convenient to mount; and moreover, the miniature circuit breaker is convenient to assemble and is sensitively and reliably tripped.

Owner:ZHEJIANG TENGEN ELECTRIC

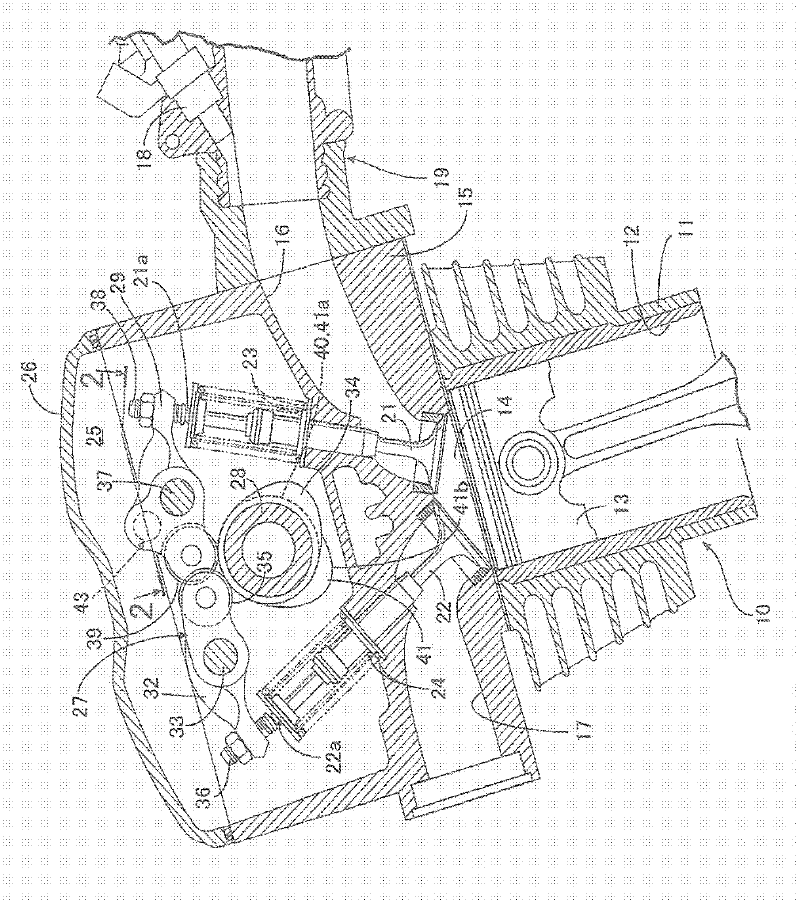

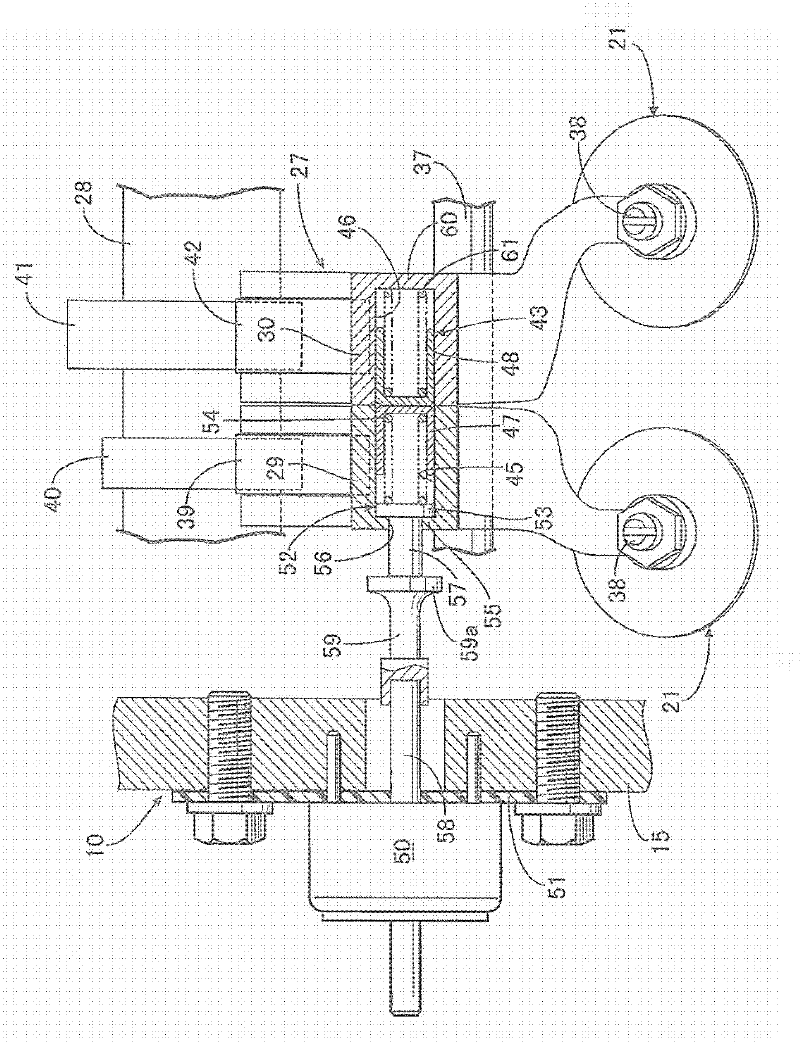

Changeable valve device of internal combustion engine

InactiveCN102296999AShort strokeLow costValve arrangementsMachines/enginesEngineeringInternal combustion engine

The invention provides a changeable valve device of an internal combustion engine. A plurality of rocker arms are respectively provided with a guide hole. The guide holes can have connecting pins embedded in a sliding way. The connecting pins can axially move between a connecting position connecting the adjacent rocker arms and a connection releasing position releasing the connection and abut on one another. Pressing force can be exerted on the connecting pins through an idle running mechanism from an actuator. Meanwhile, miniaturization of the actuator can be achieved. At least a part of the idle running mechanism (52) equipped between the actuator (50) axially exerting pressing force on the multiple connecting pins (47, 48) and the multiple connecting pins (47, 48) is coaxially accommodated in one guide hole (45). The guide hole (45) is equipped on at least one end of a rocker arm (29) of the multiple rocker arms (29, 30).

Owner:HONDA MOTOR CO LTD

Feeding mechanism for solar silicon wafers

InactiveCN107104069ASimple structureShort strokeSemiconductor/solid-state device manufacturingConveyor partsControl systemReciprocating motion

The invention relates to a feeding mechanism for solar silicon wafers. The feeding mechanism comprises a capturing component which comprises at least one sucker, wherein all suckers are located in the same plane; an annular track, wherein all suckers are in slide connection with the annular track; a drive system which drives the capturing component; and a control system which controls the drive system. Through adoption of the mechanism, the capturing component is driven to rotate to different stations through the rotating component; the control system controls the capturing component to capture and place the silicon wafers; the capturing component is always kept in the same plane and always rotates along the same direction; the capturing component is prevented from carrying out descending, ascending and circular reciprocating motions; the mechanical motion distance is reduced; the working time is reduced; when a plurality of suckers are configured, the silicon wafers can be captured and placed at the same time; when the operation time of different suckers is different, each sucker is operated independently, thereby facilitating control; the working efficiency is improved; and mechanical losses are reduced.

Owner:CHENGDU FUYU TECH

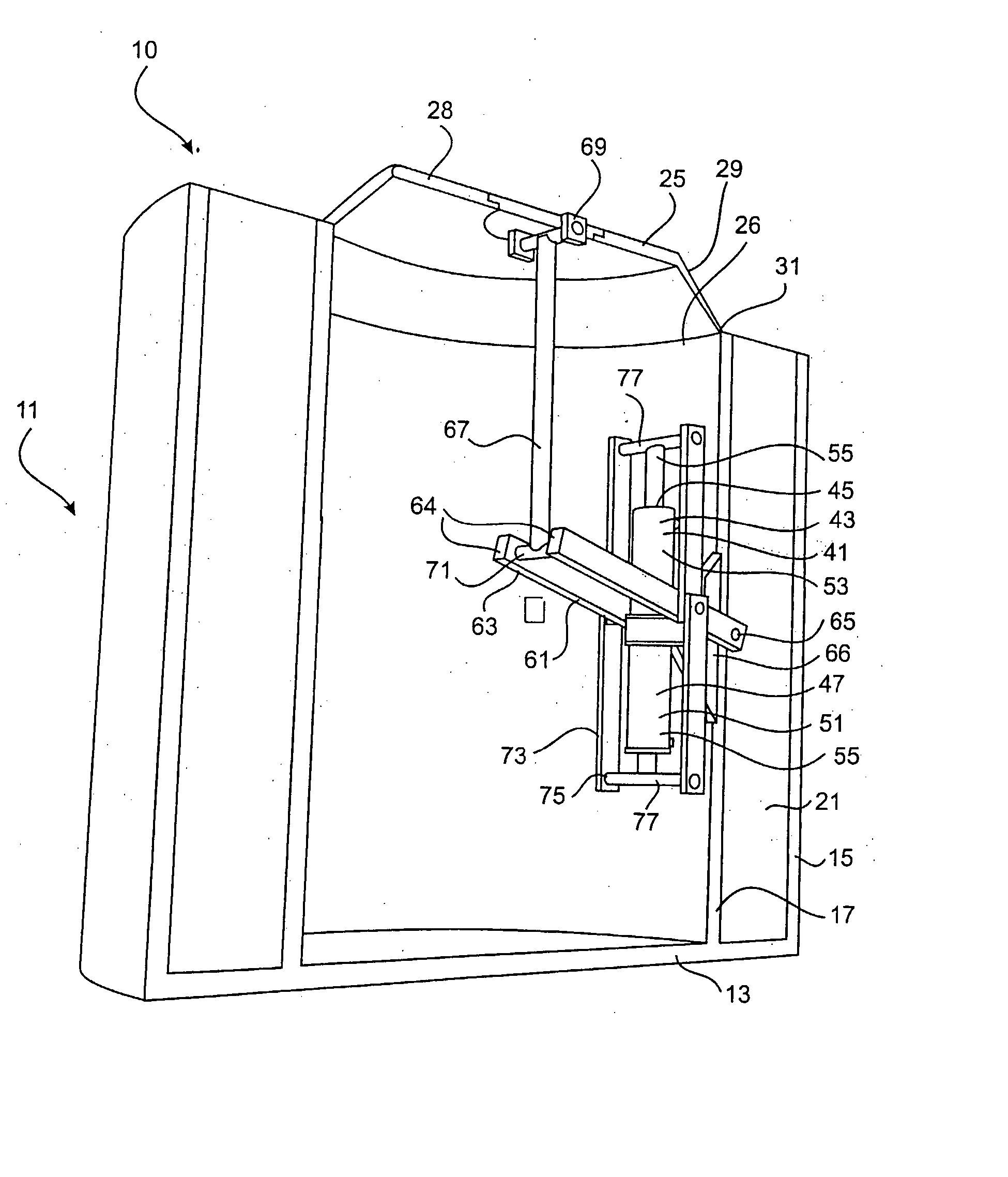

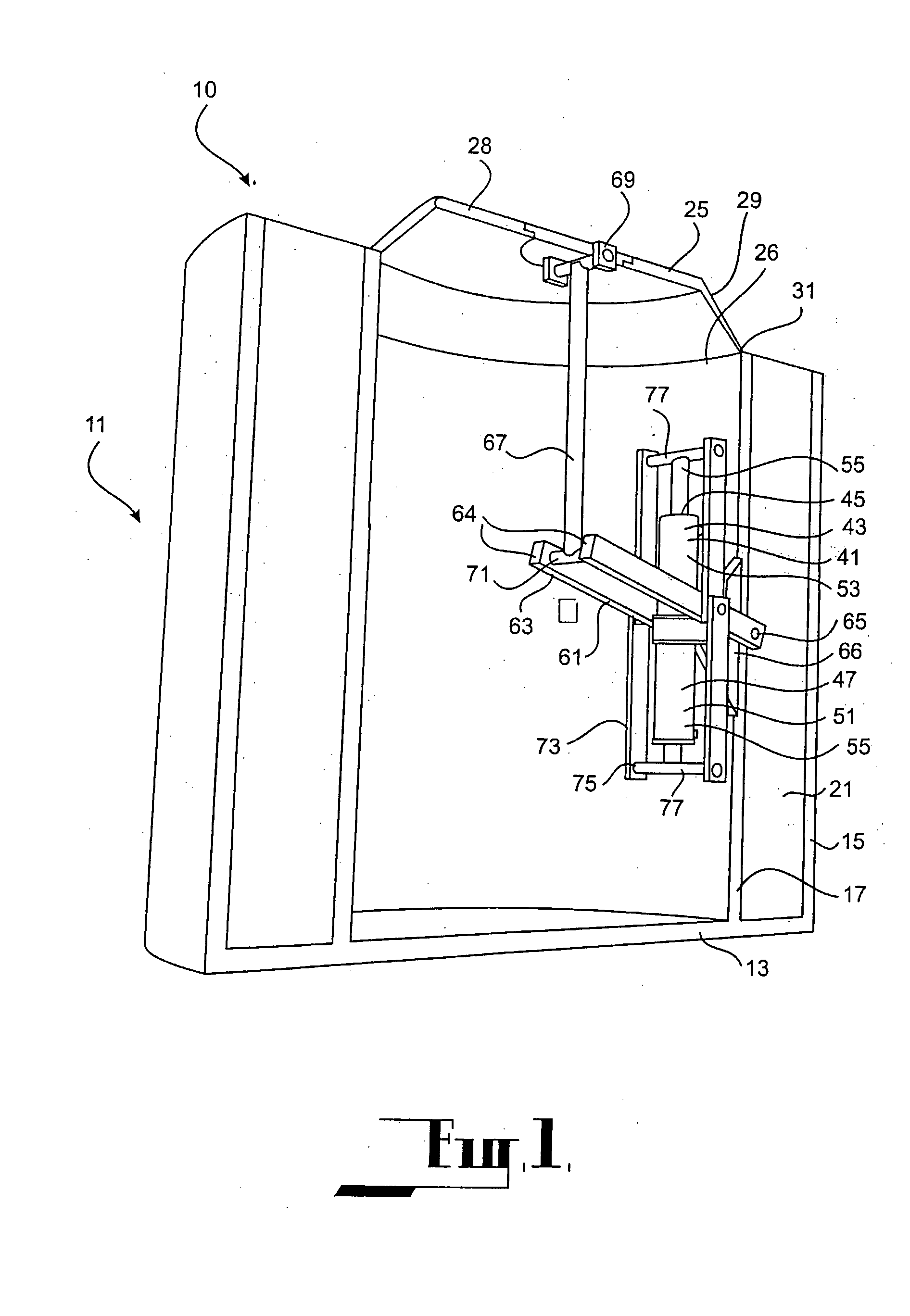

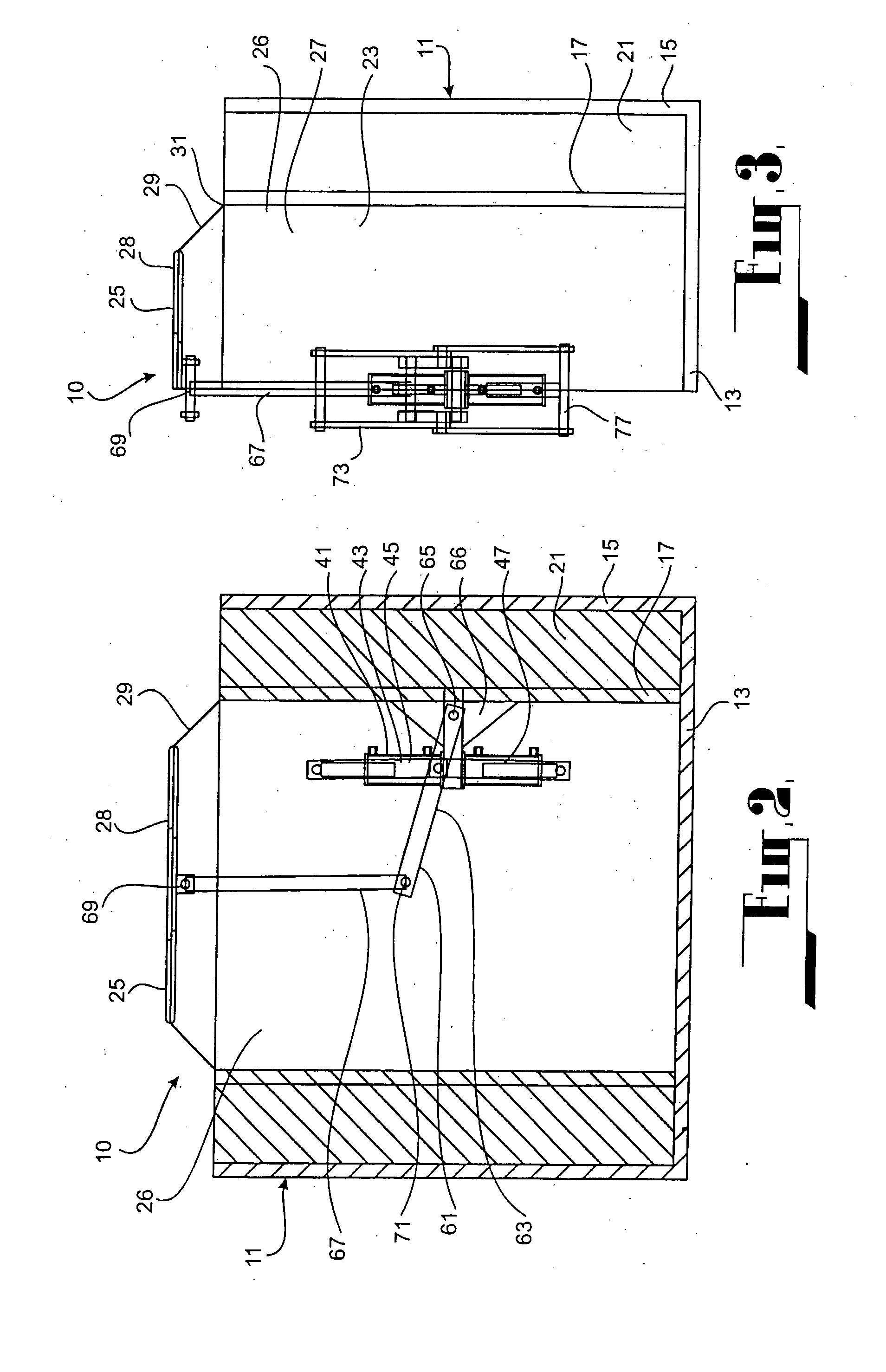

Wave Energy Converter

InactiveUS20070253841A1Suppress fluctuationsShort strokeGeneral water supply conservationPiston pumpsEngineeringHigh pressure

Apparatus (10) rests on the seabed at a location below sea level for capturing wave energy. The apparatus (10) comprises a body structure (11) having a diaphragm (25) adapted to deflect in response to wave action. A working chamber (27) is disposed immediately below the diaphragm (25) and contains a compressible fluid such as air. A pump system (43) is accommodated within the working chamber (27). The pump system (43) comprises two reciprocating pumps (45, 47) operating in opposition. The pumps (45, 47) are operably connected to the diaphragm (25) through a lever mechanism (61). Because of the geometry of the lever mechanism (61), the stroke length of each pump (45, 47) is less than the amplitude of displacement of the diaphragm (25) as it moves in response to wave action. Thus, the lever mechanism (61) increases the force acting on each pump (45, 47) by a given ratio and reduces the stroke of each pump by the same ratio. The reduction in stroke length provides for compact construction so that the pumps (45, 47) can be readily accommodated within the working chamber (27). The pumps (45, 47) draw seawater from the environment about the apparatus (10) and discharge the seawater at a high-pressure. The high-pressure seawater generated by the pumps can be piped to shore for use in any appropriate purpose.

Owner:SEAPOWER PACIFIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com