Wave Energy Converter

a wave energy converter and wave energy technology, applied in the direction of positive displacement liquid engine, pump, machine/engine, etc., can solve the problems of increasing capital cost, reducing reliability, and few of such devices are actually under sustained commercial development, so as to prevent fluctuations in such movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

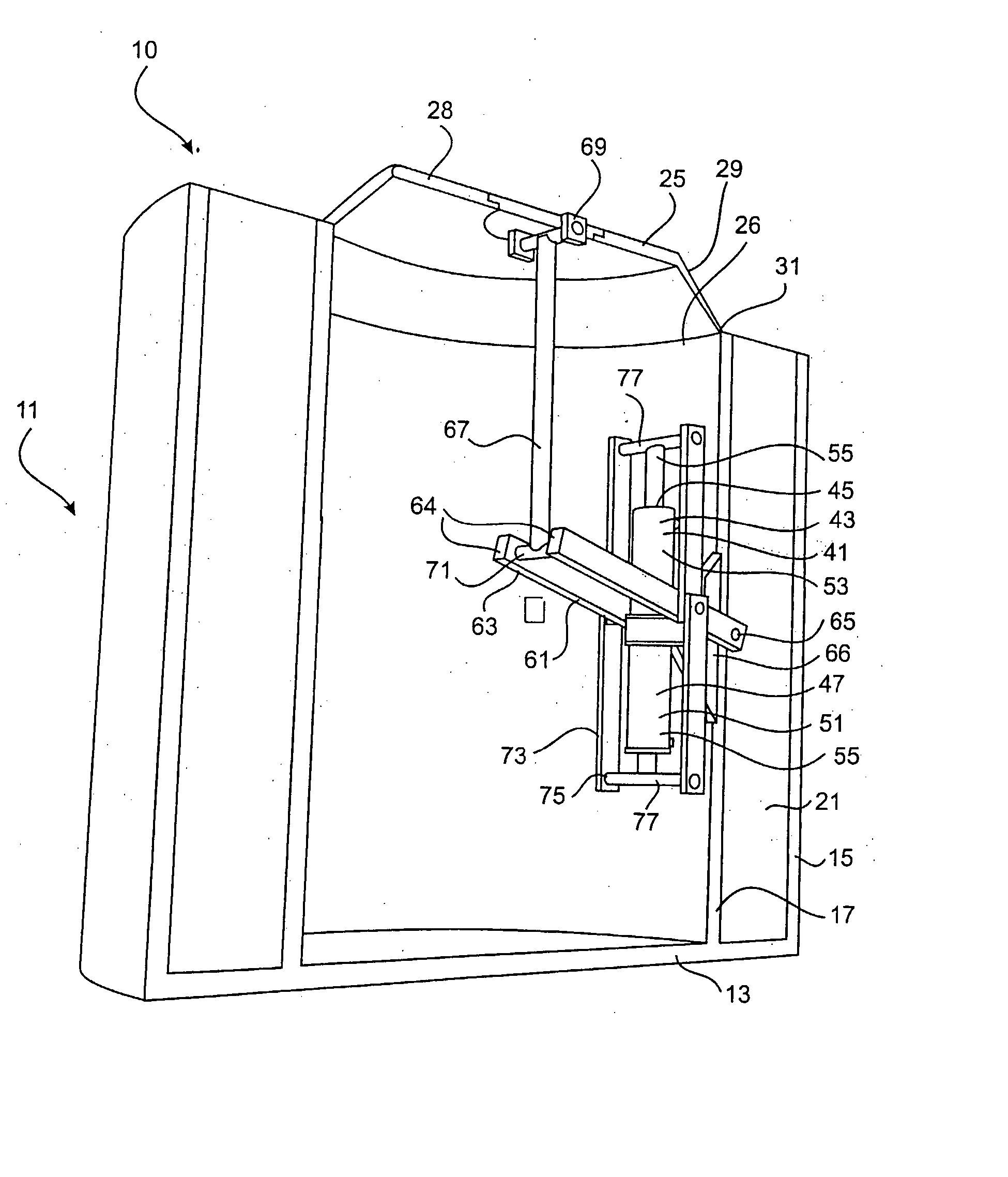

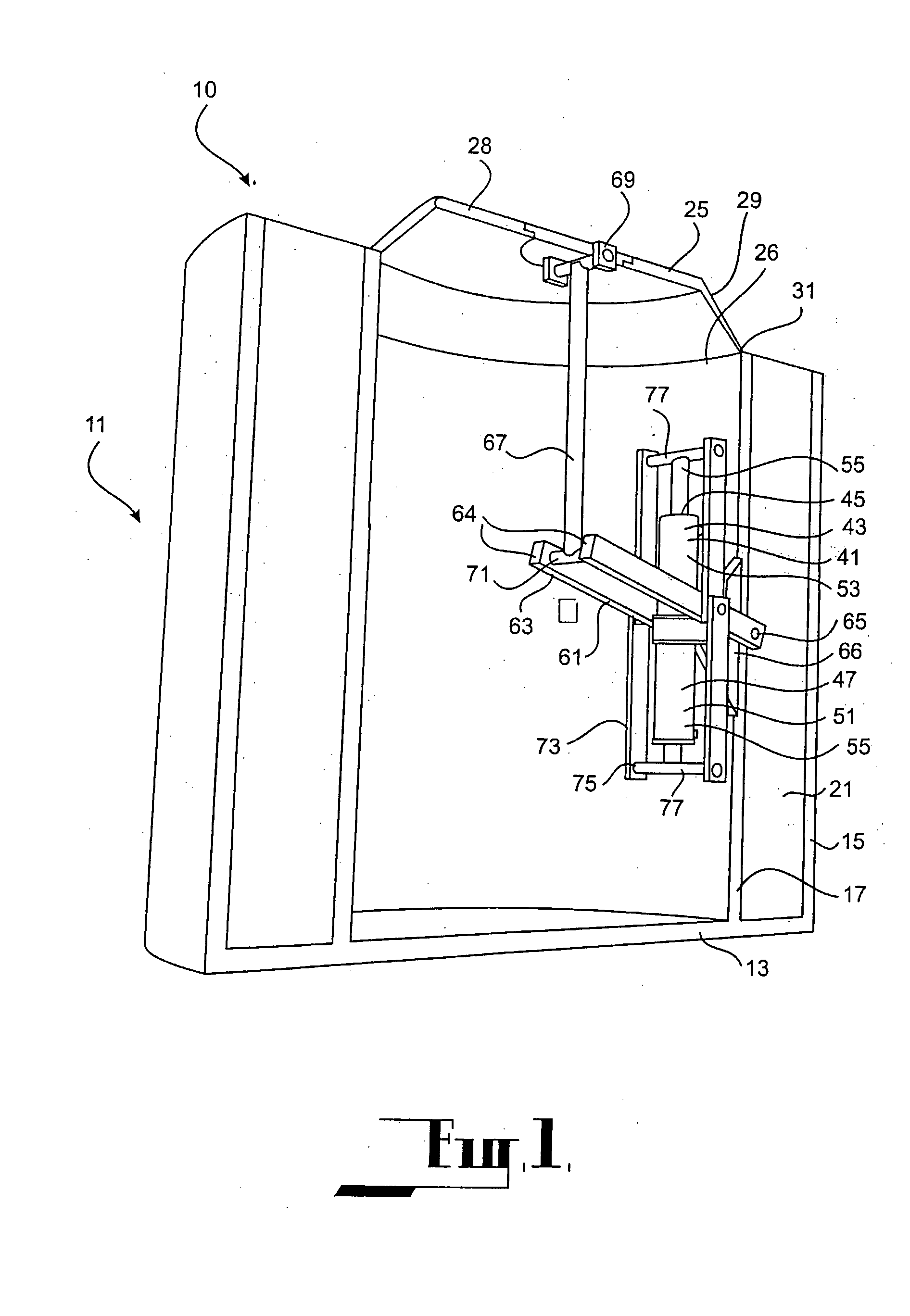

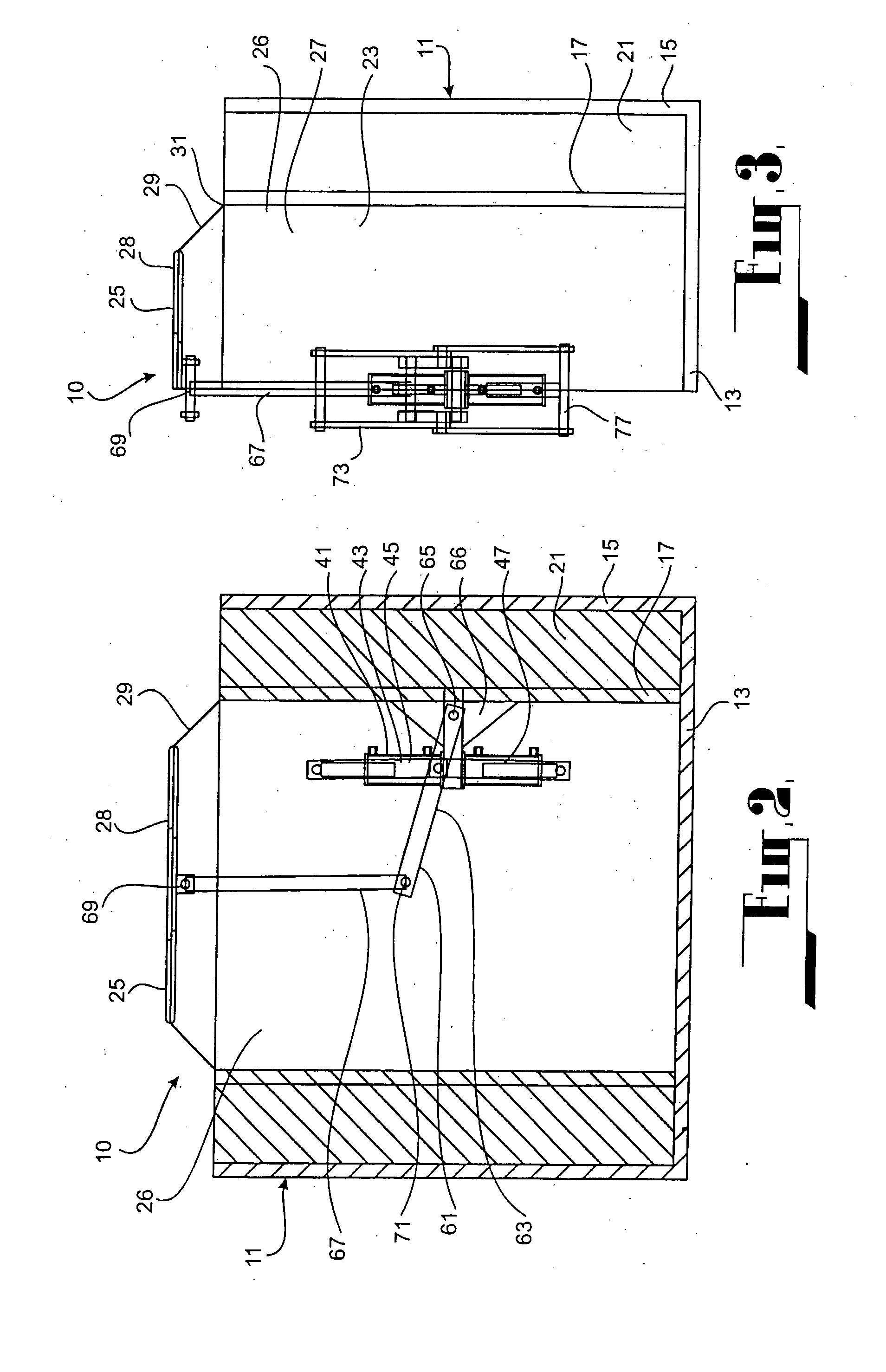

[0076] Referring to FIGS. 1, 2 and 3, there is shown apparatus 10 according to a The apparatus 10 comprises a body structure 11 comprising a base 13 which rests on the seabed, and two walls 15, 17 upstanding from the base. Typically, the base 13 and the two upstanding walls 15, 17 are of integral construction and formed of concrete. Wall 15 is of generally cylindrical construction and provides an outer peripheral wall for the body structure. Wall 17 is also of generally cylindrical construction and is spaced inwardly of wall 15 to provide an inner wall within the body structure.

[0077] The spacing between the outer and inner walls 15, 17 defines a ballast chamber 21 for receiving ballast material. Typically, the ballast material comprises saturated sand taken from the seabed. In this embodiment, the upper end of the ballast chamber 21 is open to receive the ballast material. A closure (not shown) may be provided for closing the ballast chamber 21 if desired.

[0078] The inner cylindr...

second embodiment

[0099] In the apparatus 90 the lever mechanism 61 is guided as it undergoes reciprocating movement in response to movement of the diaphragm 25 under the influence of wave action. The guided movement is provided by way of a guide mechanism 91 comprising a guide structure 93 moveable along a guide 95. In this embodiment, the guide 95 is provided by the inner surface 97 of the cylindrical inner wall 17.

[0100] The guide structure 93 comprises a guide frame 101 attached to the underside of the rigid portion 28 of the diaphragm 25. The guide frame 101 supports guide rollers 103 in rolling engagement with the wall surface 97. The guide frame 101 includes a plurality of circumferentially spaced longitudinal elements 105, each of which carries two of the guide rollers 103 spaced along the longitudinal element.

[0101] Cooperation between the guide structure 93 and the wall surface 97 guides movement of the diaphragm 25 in response to the wave action, ensuring that the diaphragm does not defl...

third embodiment

[0102] Referring now to FIGS. 6 to 9, there is shown apparatus 110 according to a The apparatus 110 comprises a body structure 111 of generally rectangular construction, having a base 113 which rests on the seabed, two opposed side walls 115, two opposed end walls 117, and a top wall 119.

[0103] Two cylindrical inner walls 121, 122 are provided within the body structure 111 between the base 113 and the top wall 119.

[0104] Each cylindrical inner wall 121, 122 is closed at the bottom by the base 113 and opens onto the top wall 119 to define an opening 127 which is closed by a respective diaphragm 129. With this arrangement, the base 113, the inner walls 121, 122 and the diaphragms 129 cooperate to form two cells 130 each defining a working chamber 123.

[0105] Each diaphragm 129 comprises a rigid central portion 131 and a flexible outer portion 133 surrounding the central portion. The outer periphery of each diaphragm 129 is sealingly connected to the upper periphery of its respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com