Patents

Literature

184 results about "Pump design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

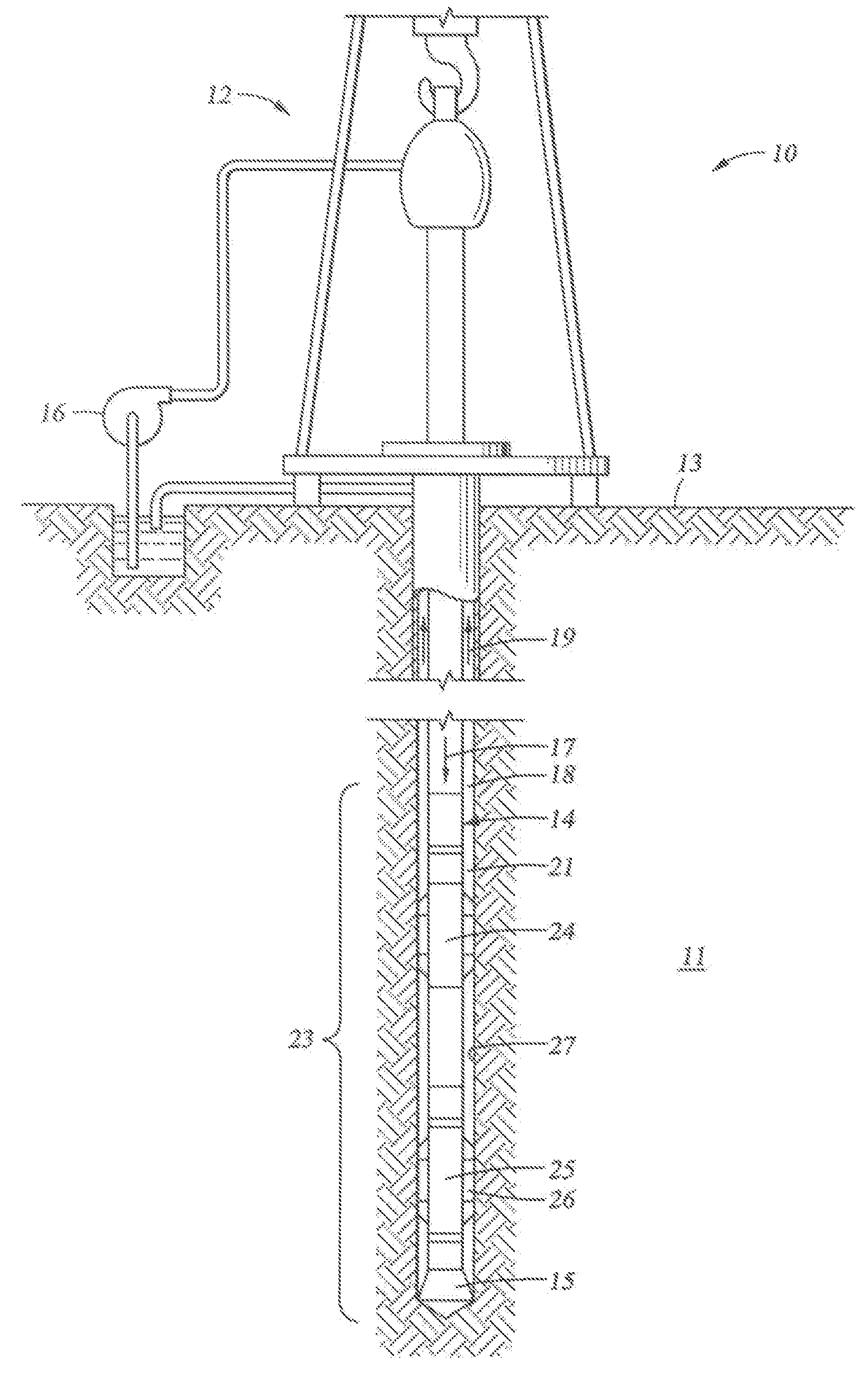

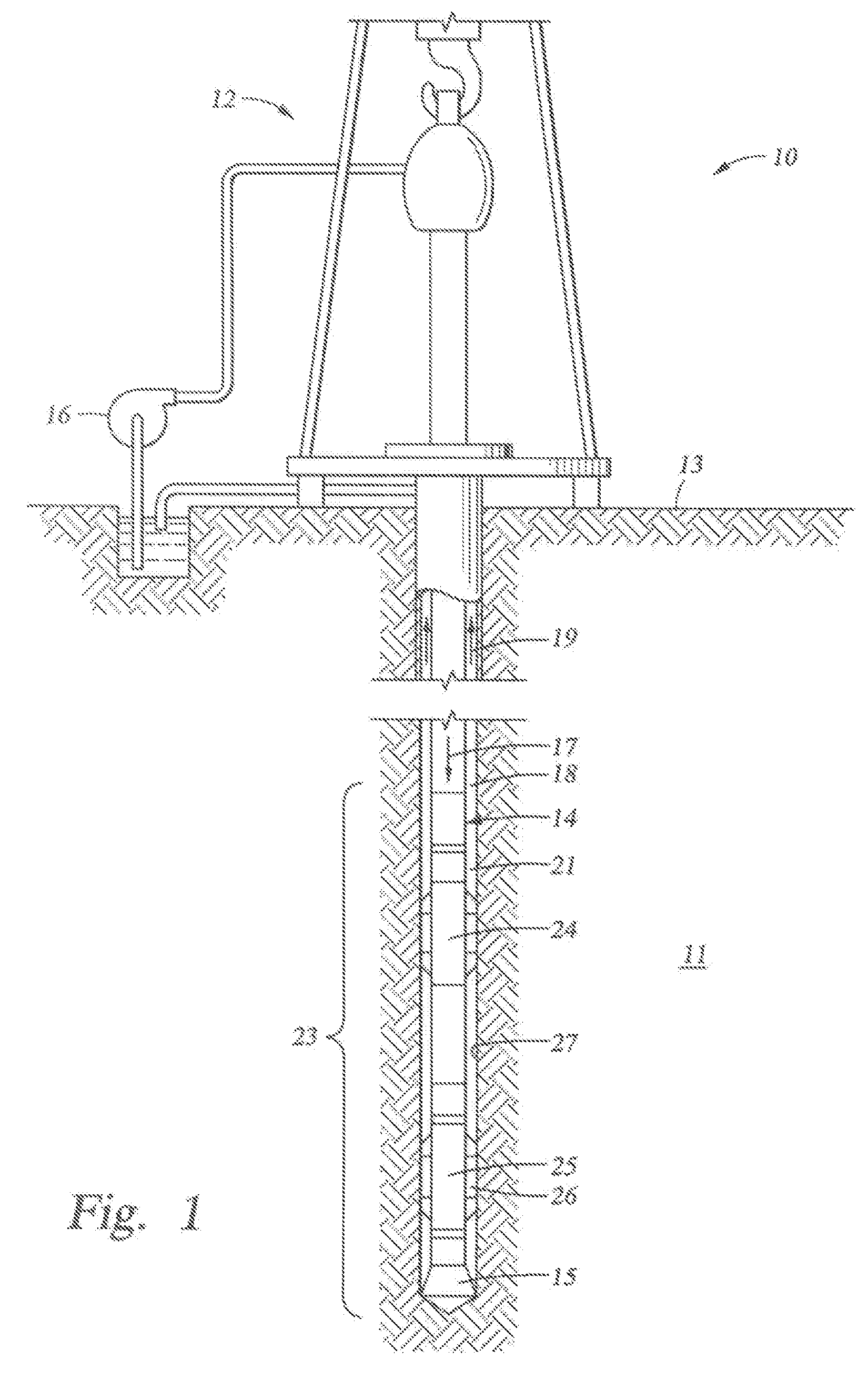

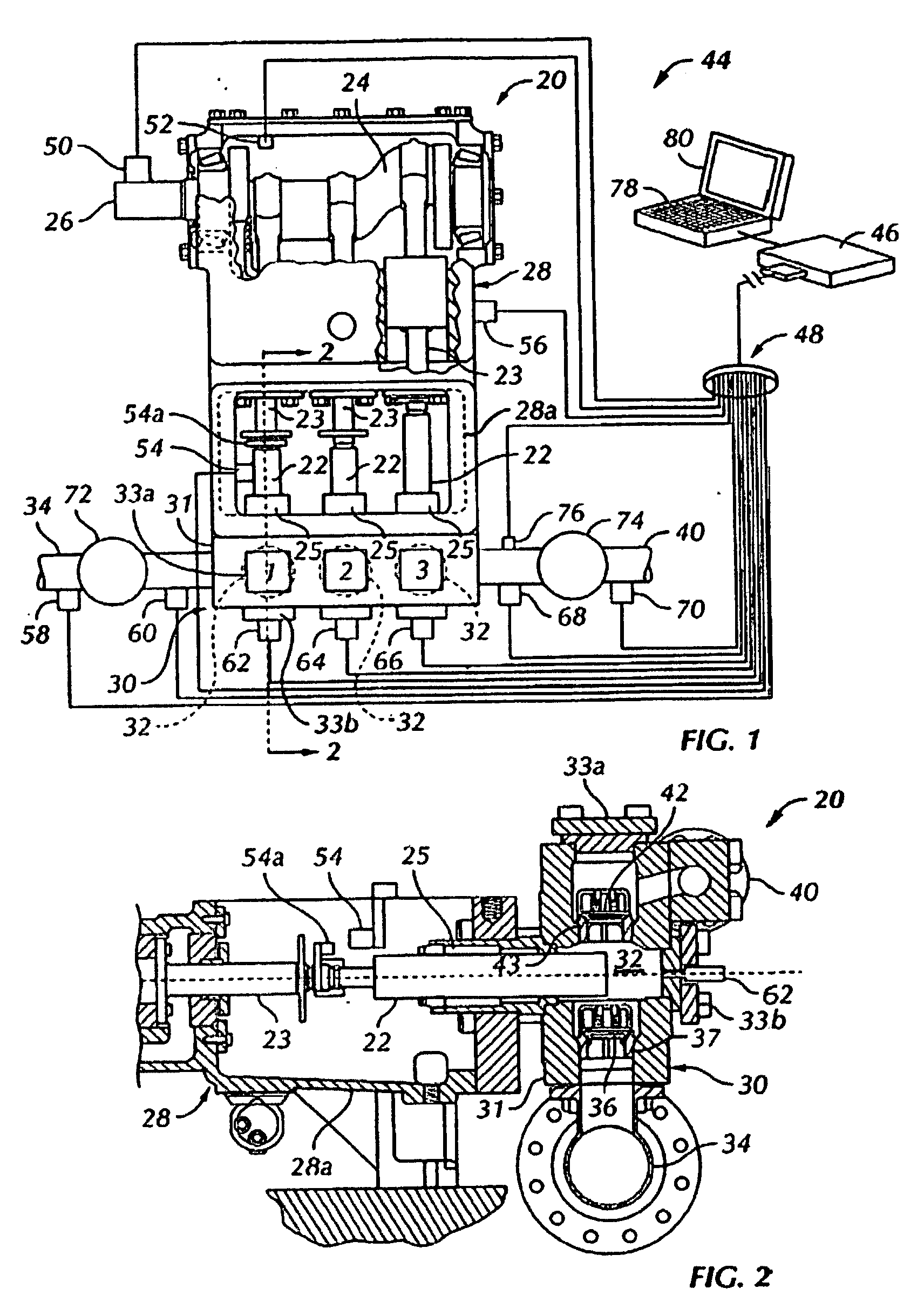

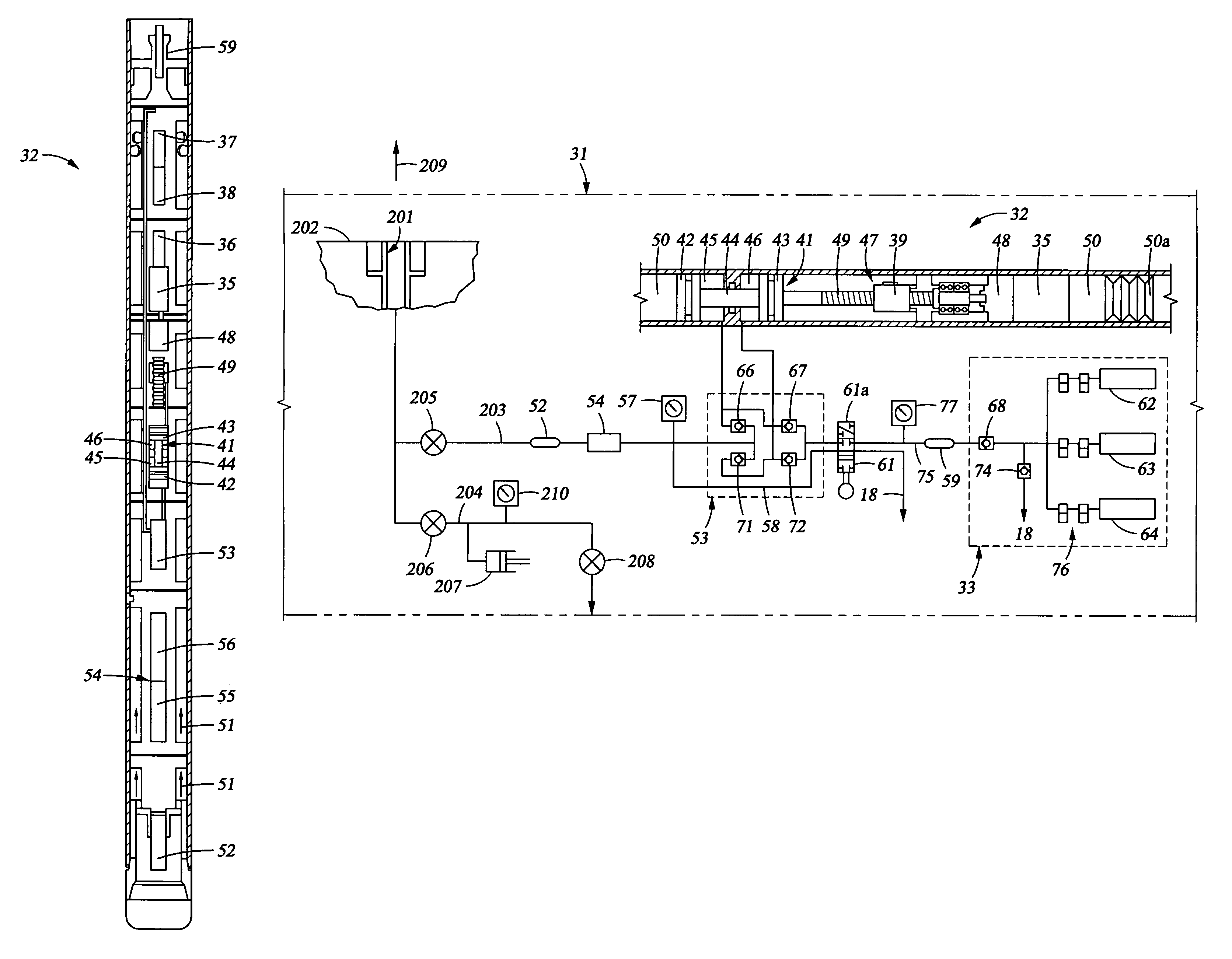

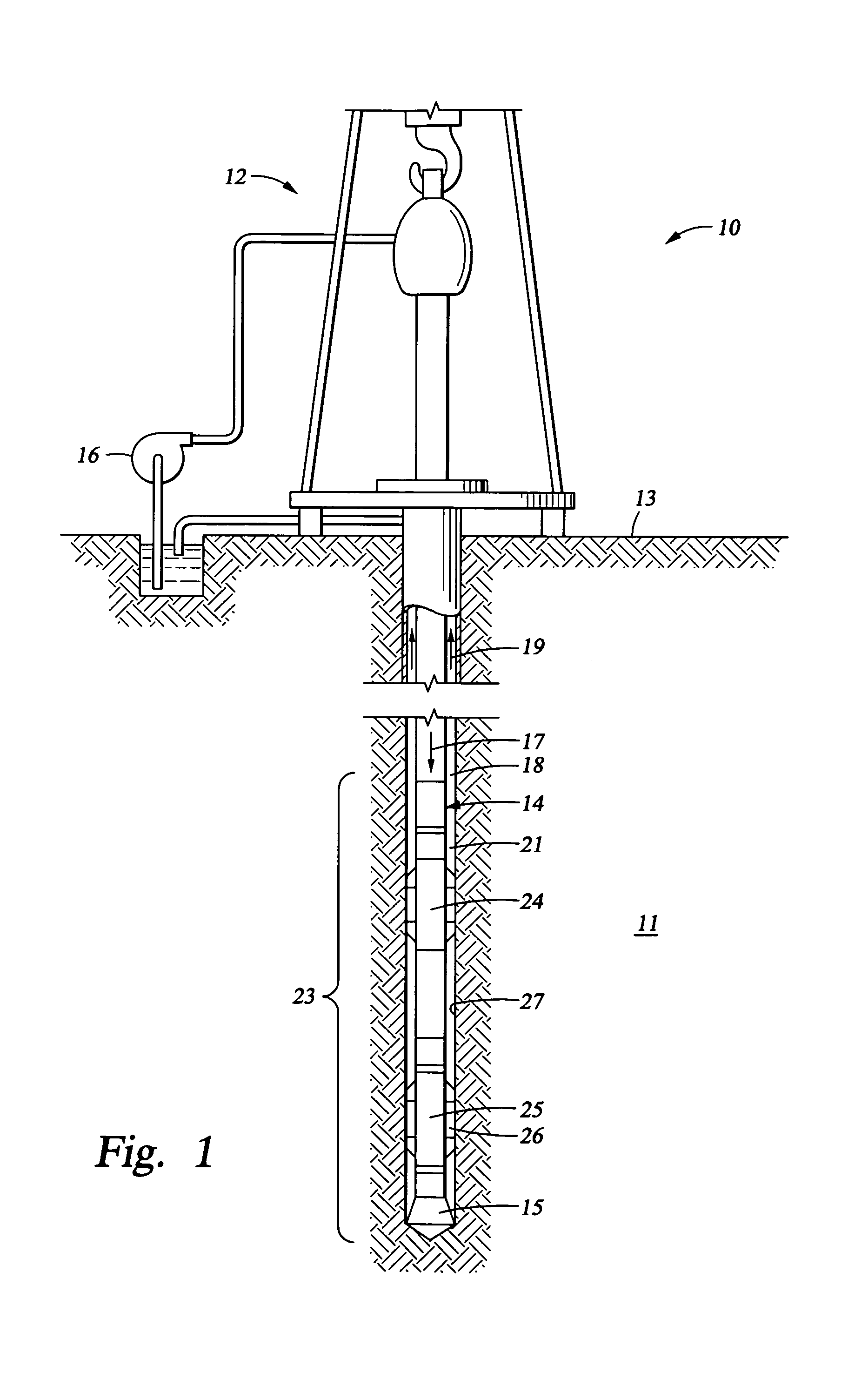

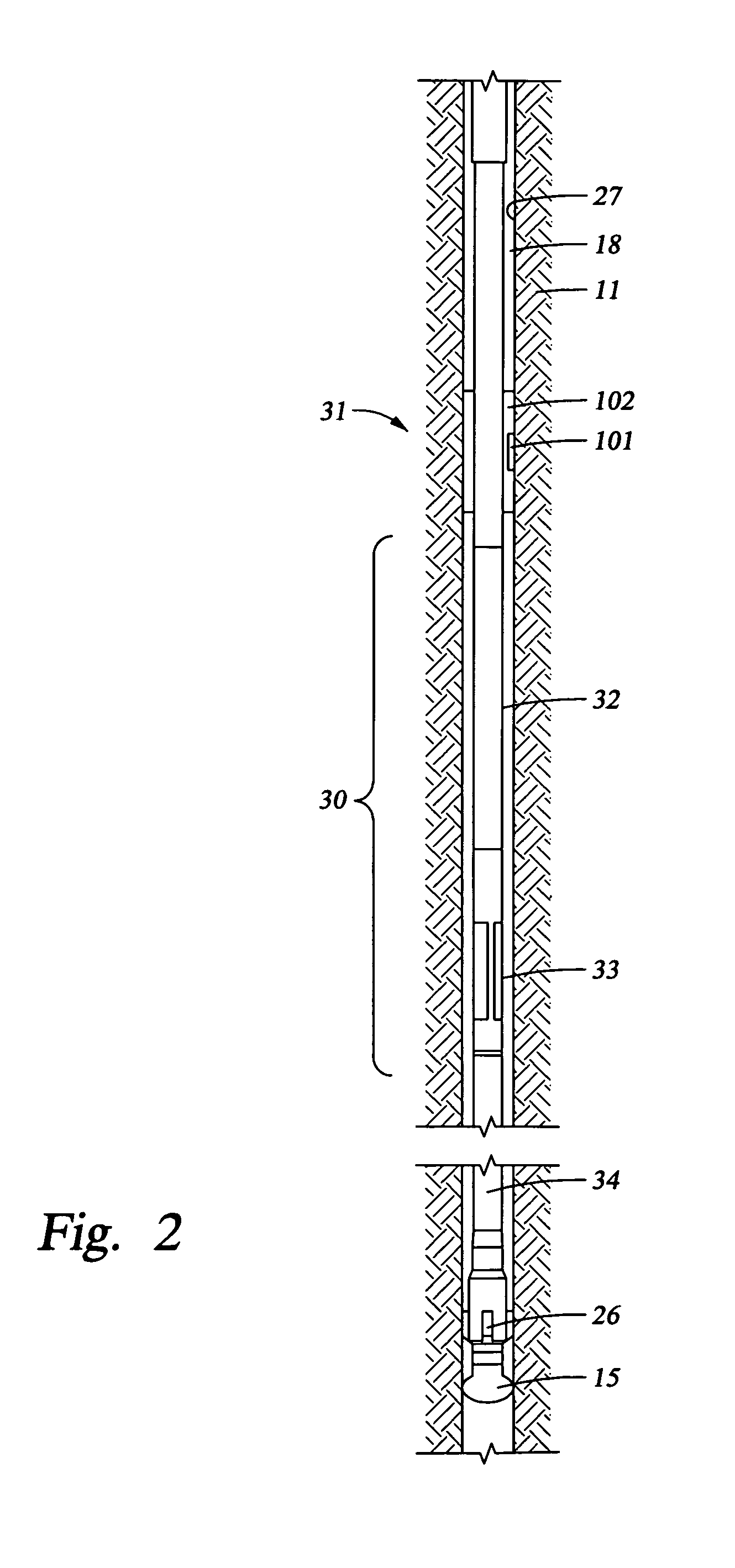

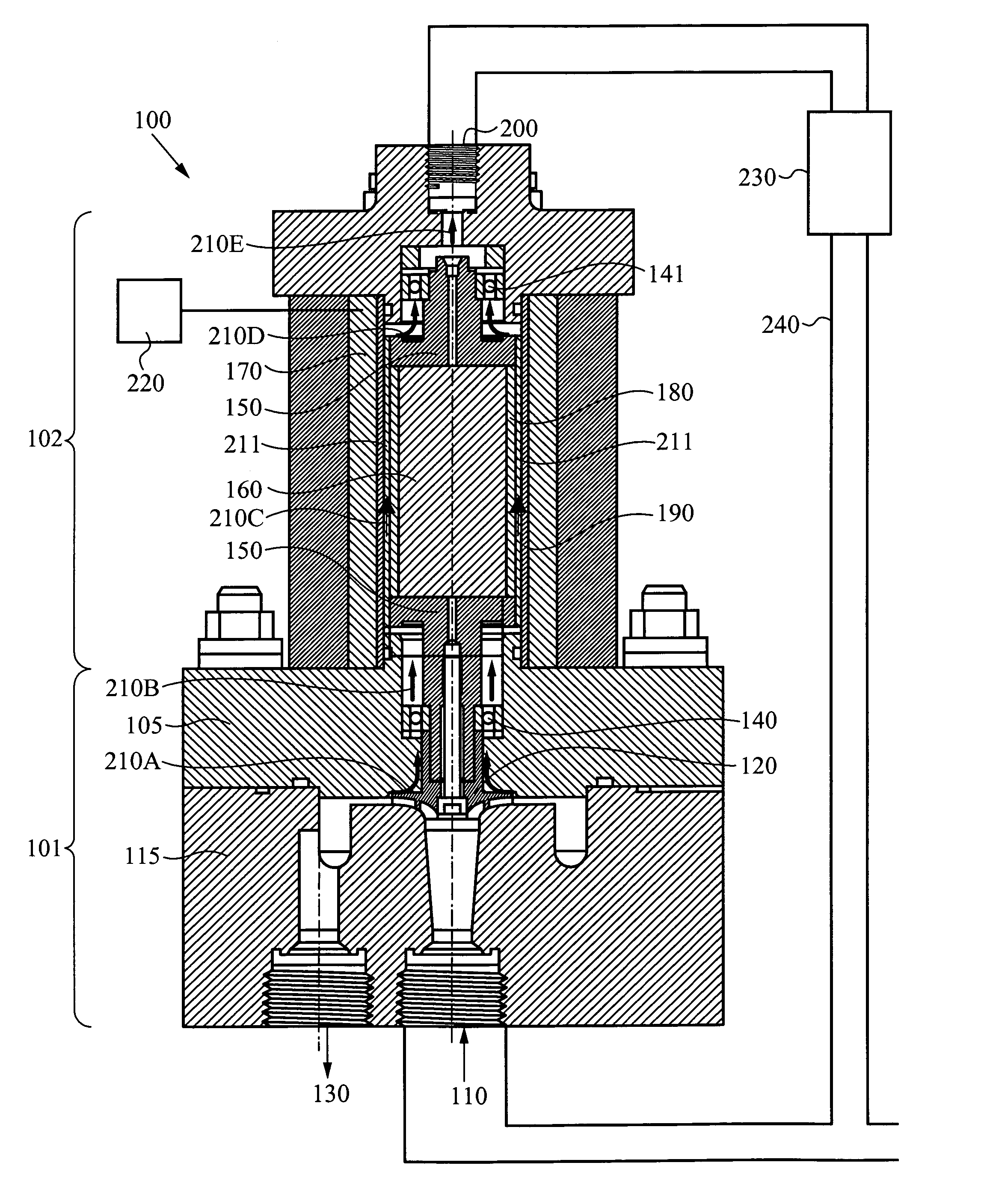

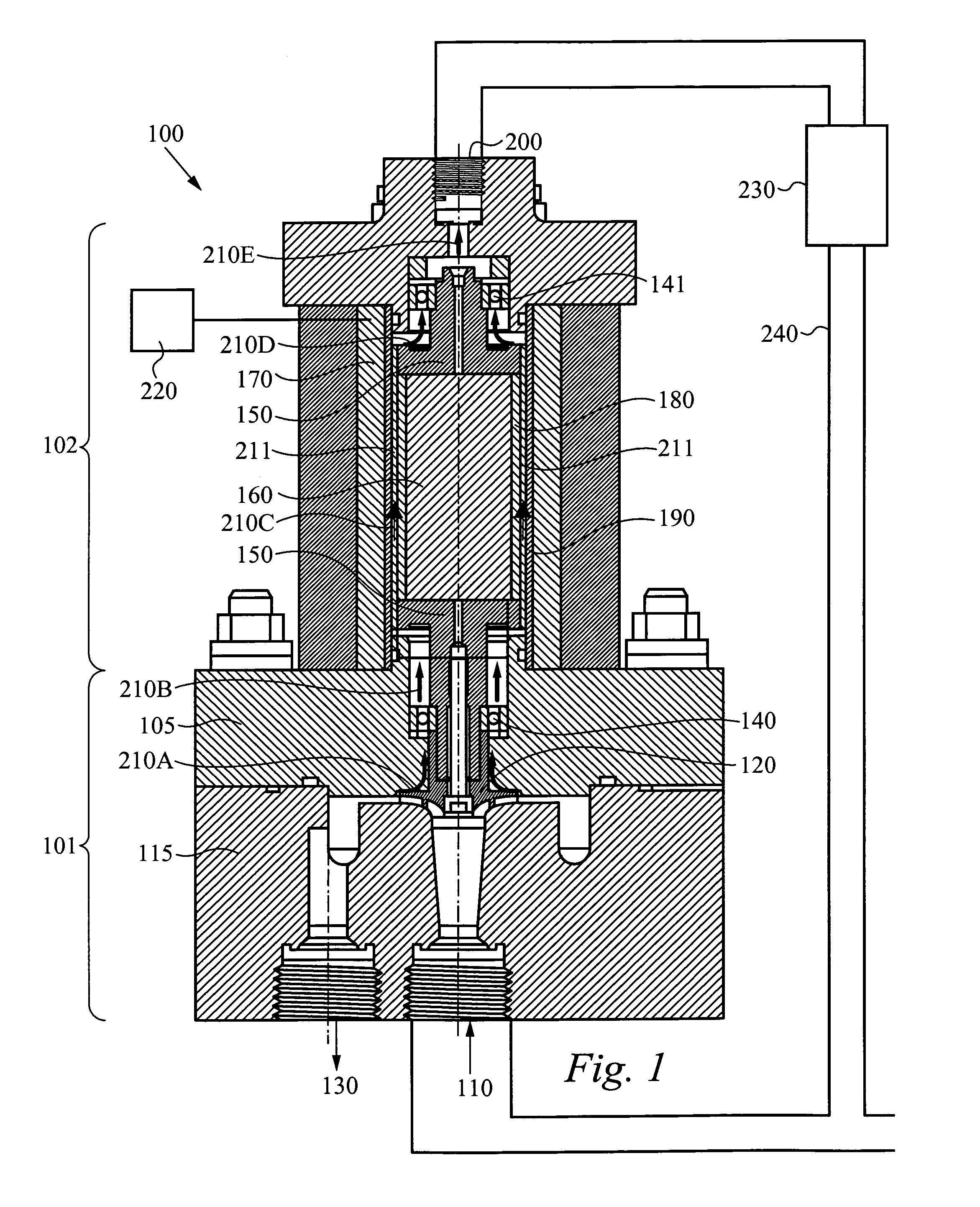

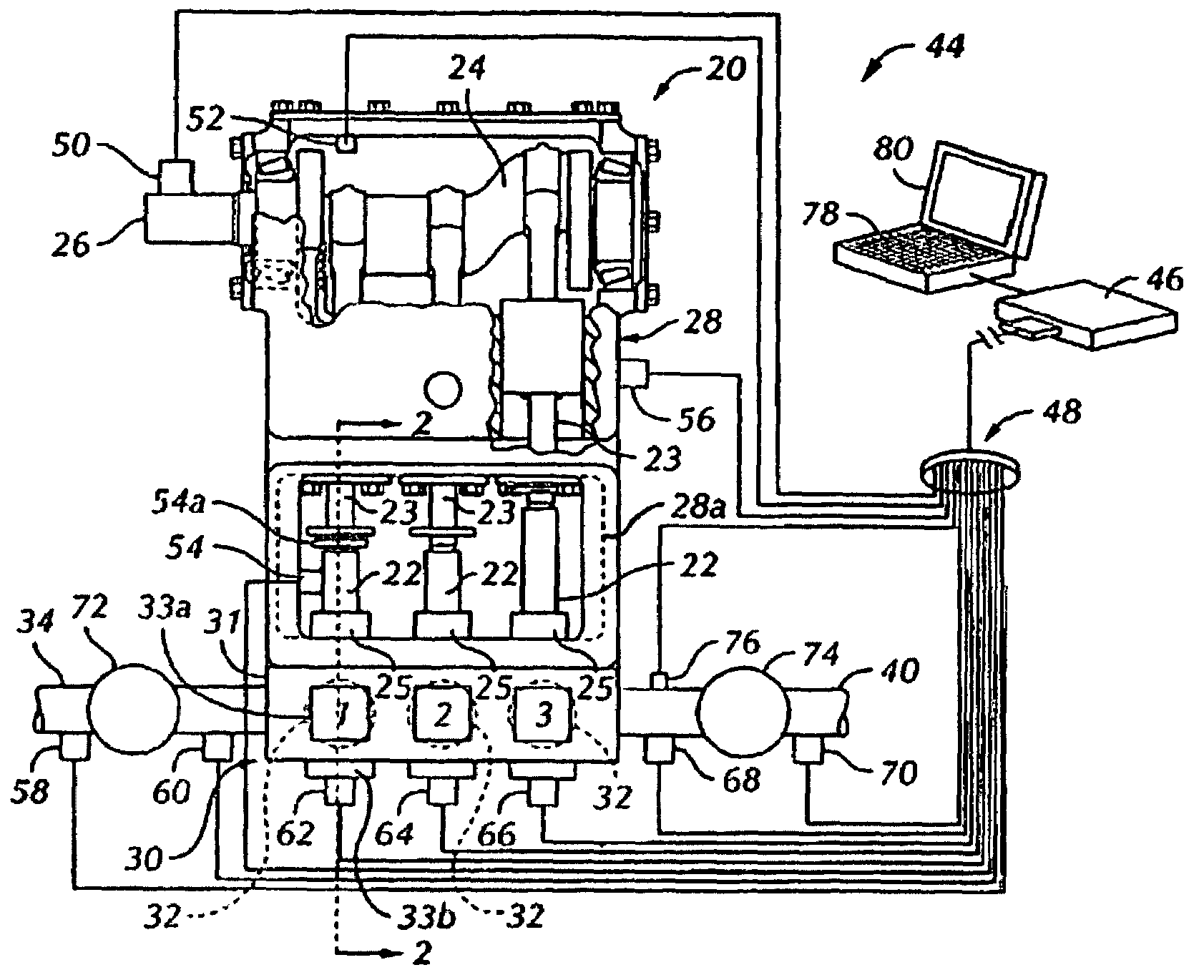

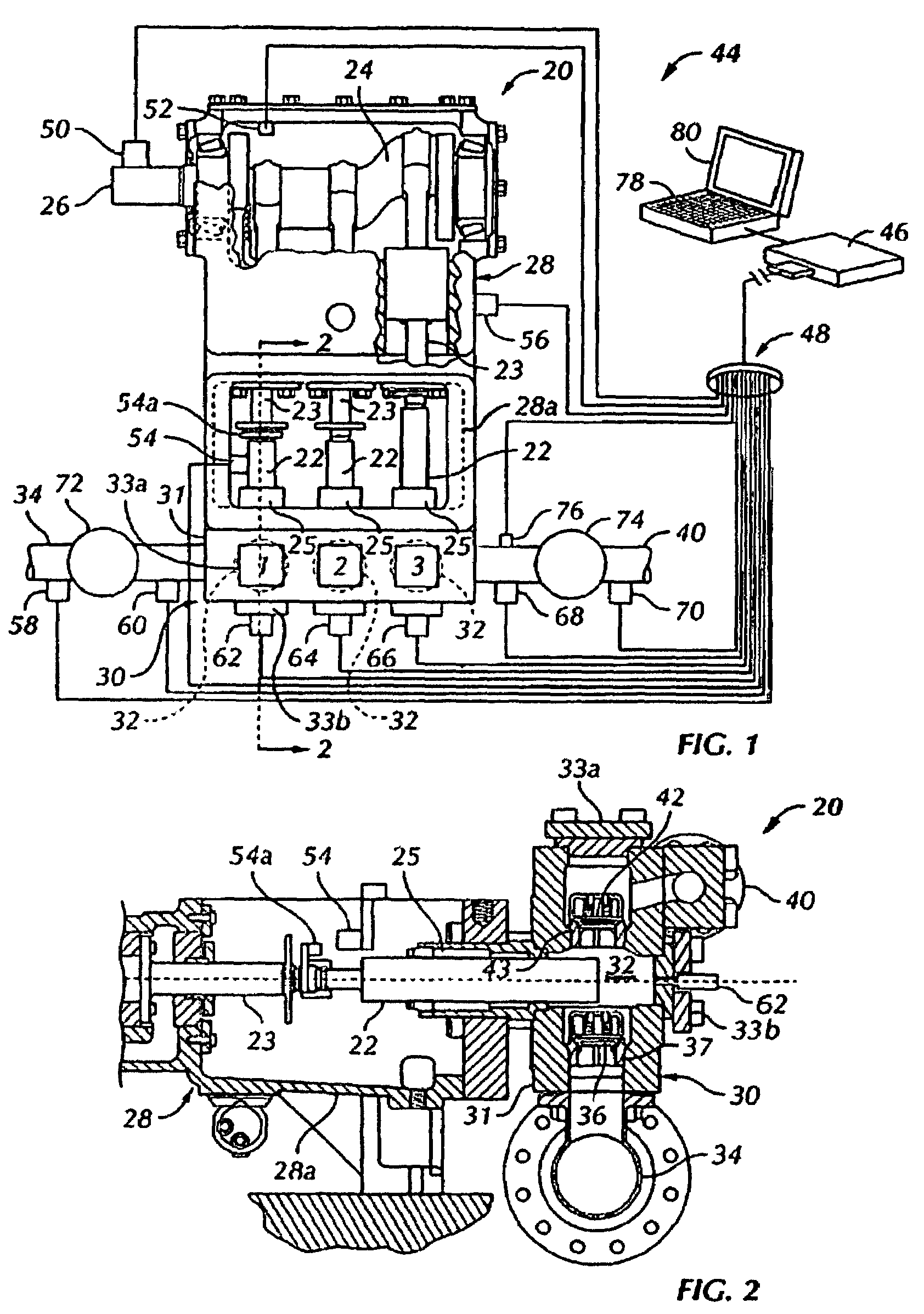

Pump Control for Formation Testing

A downhole formation fluid pumping and a sampling apparatus are disclosed that may form part of a formation evaluation while drilling tool or part of a tool pipe string. The operation of the pump is optimized based upon parameters generated from formation pressure test data as well as tool system data thereby ensuring optimum performance of the pump at higher speeds and with greater dependability. New pump designs for fluid sampling apparatuses for use in MWD systems are also disclosed.

Owner:SCHLUMBERGER TECH CORP

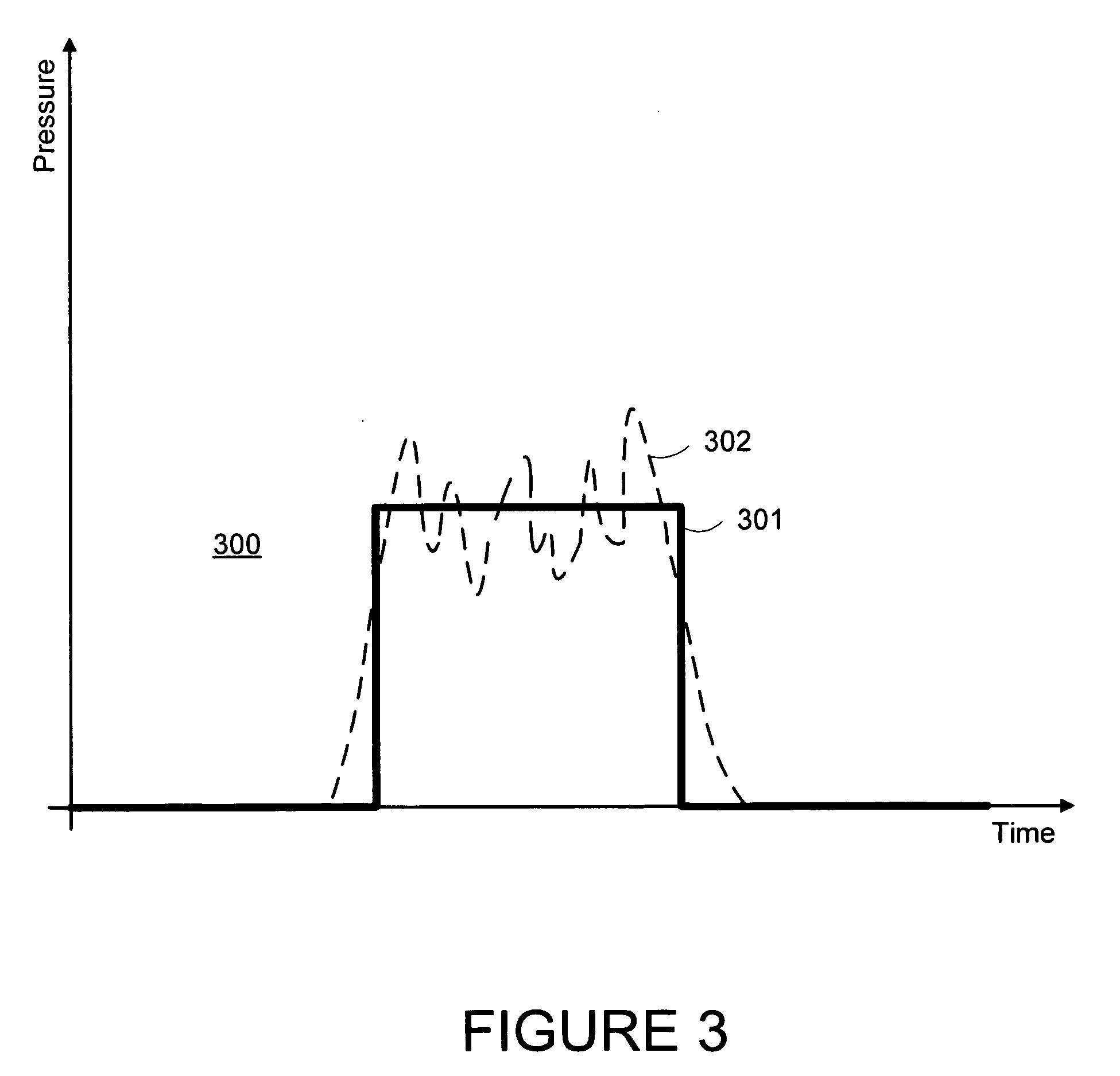

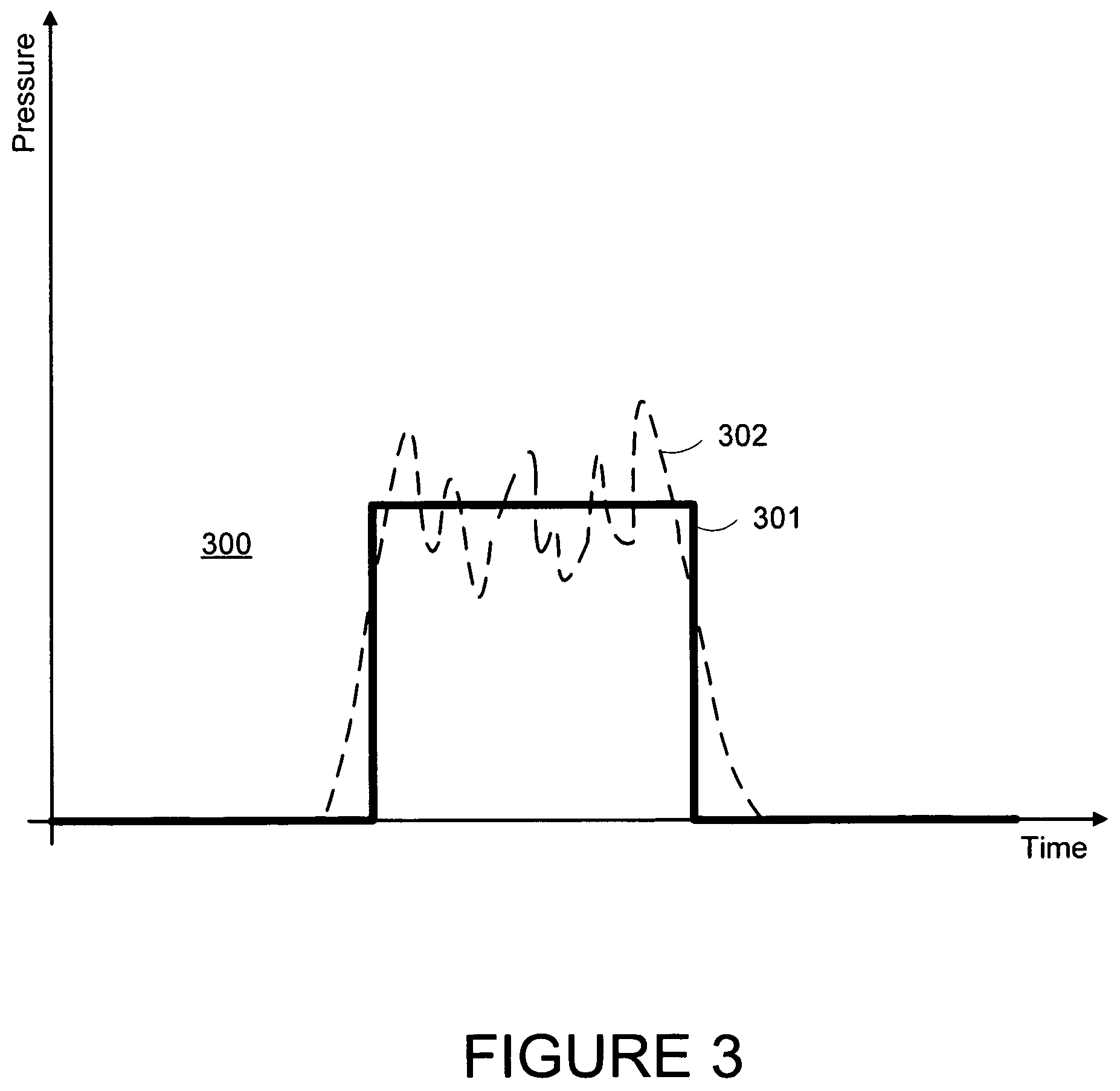

Reciprocating pump performance prediction

ActiveUS20060228225A1Failure to determineTesting/calibration apparatusAcceleration measurementOperating lifeTotal energy

Performance parameters for a reciprocating pump including pulsation energy, temperature energy, solids, Miller number and chemical energy and the like are monitored and employed to at least periodically compute a total energy number over the operating life of the pump. The current computed value is compared to a predictive failure value empirically determined for the respective pump design, to determine when failure is likely to be imminent. Scheduling of maintenance with other pumping operations and objective rating of competing designs is possible based on the total energy number.

Owner:PERFORMANCE PULSATION CONTROL

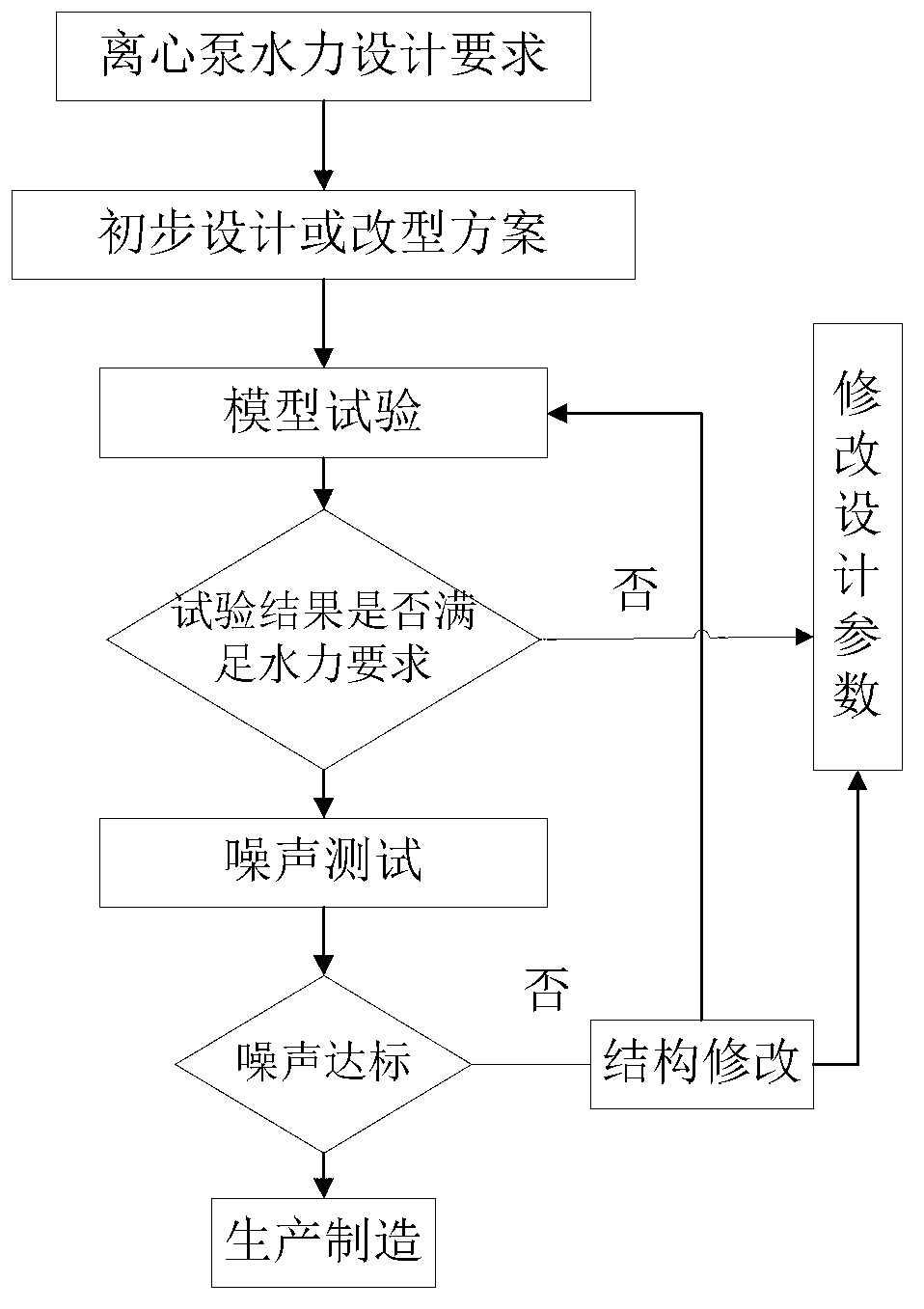

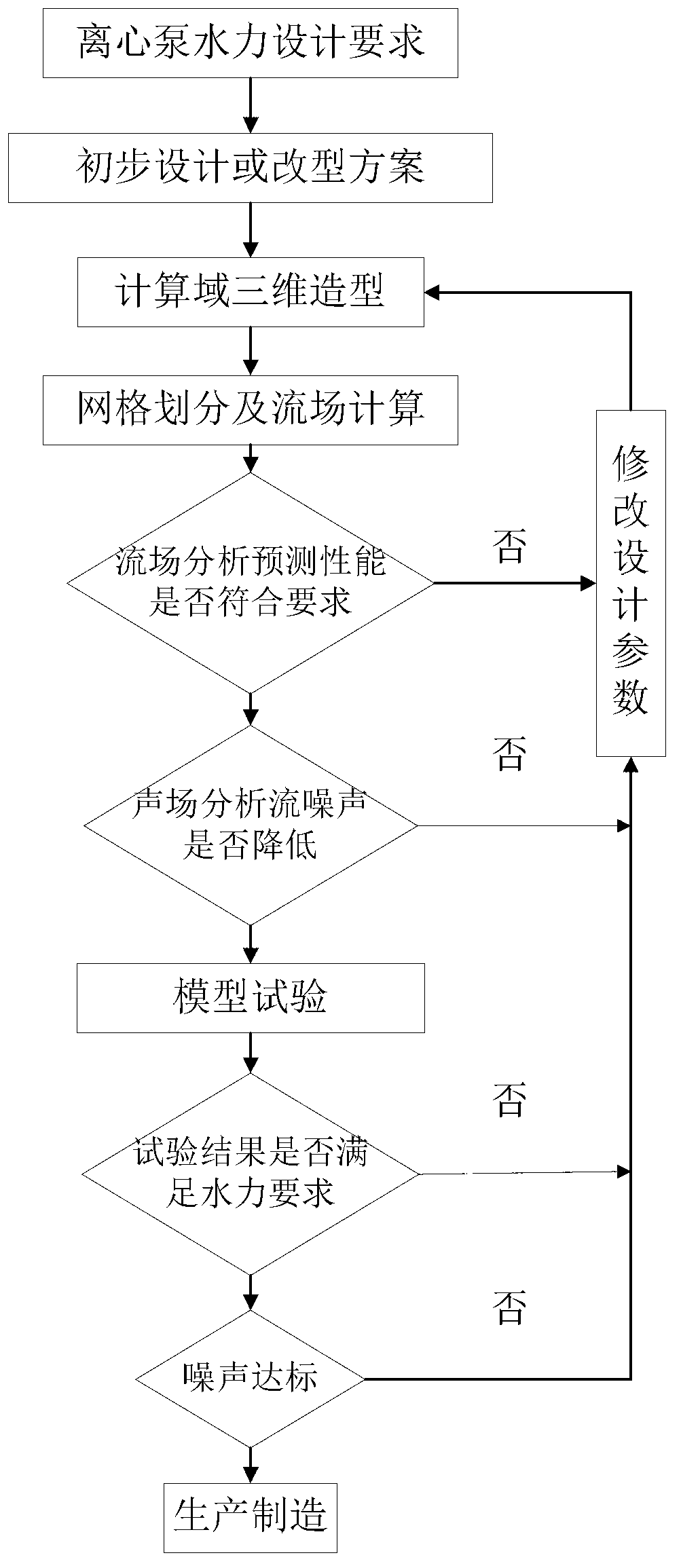

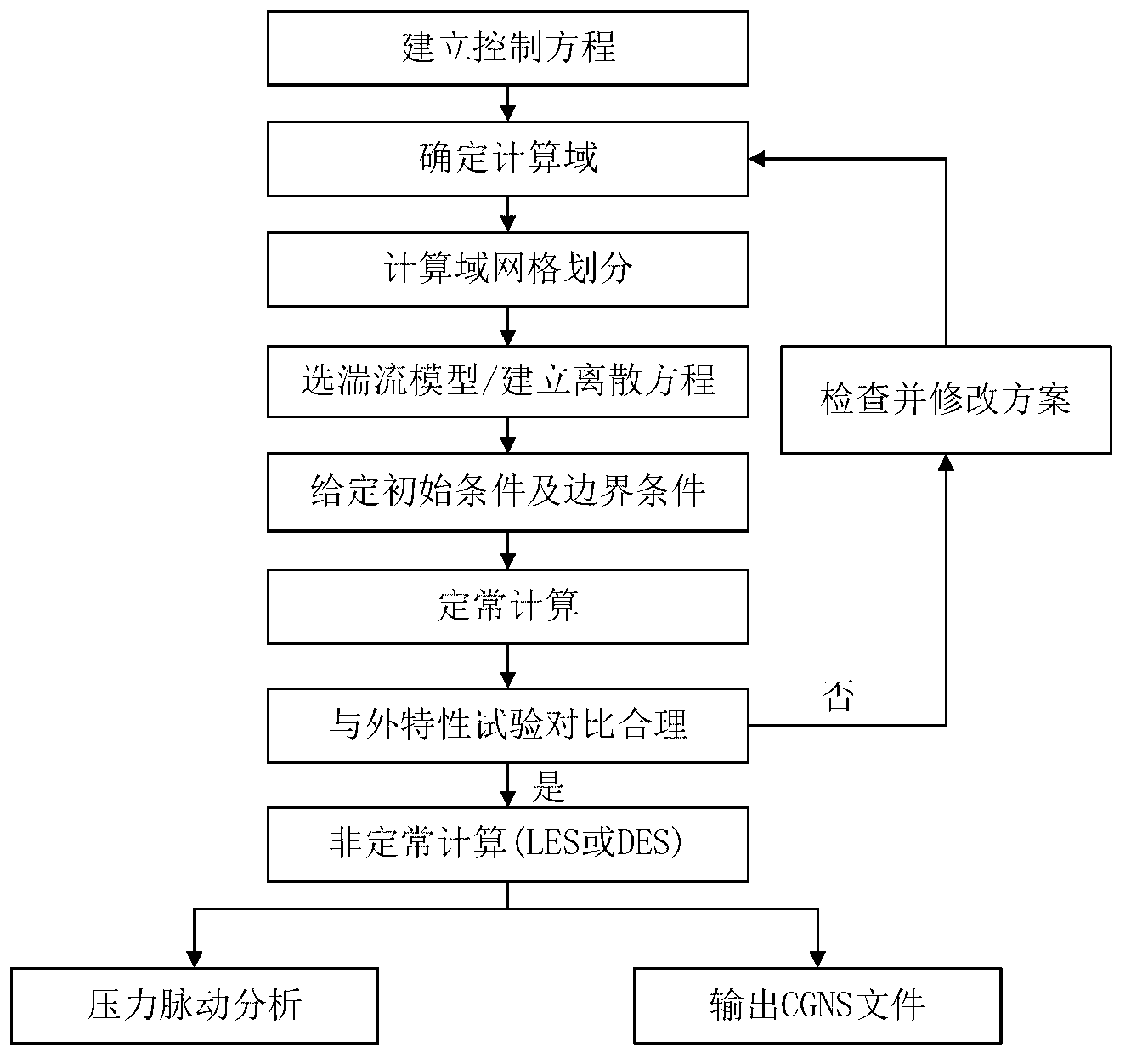

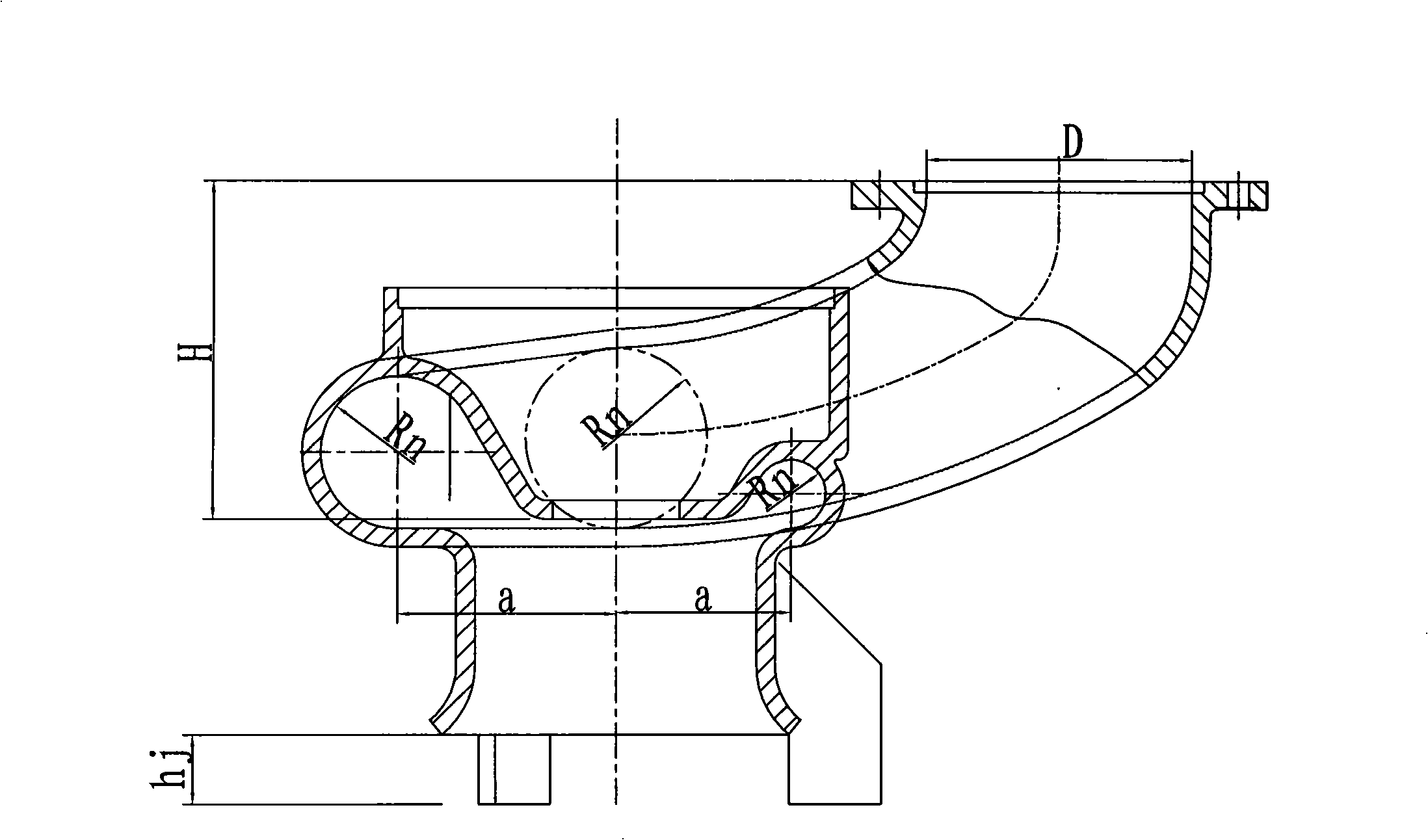

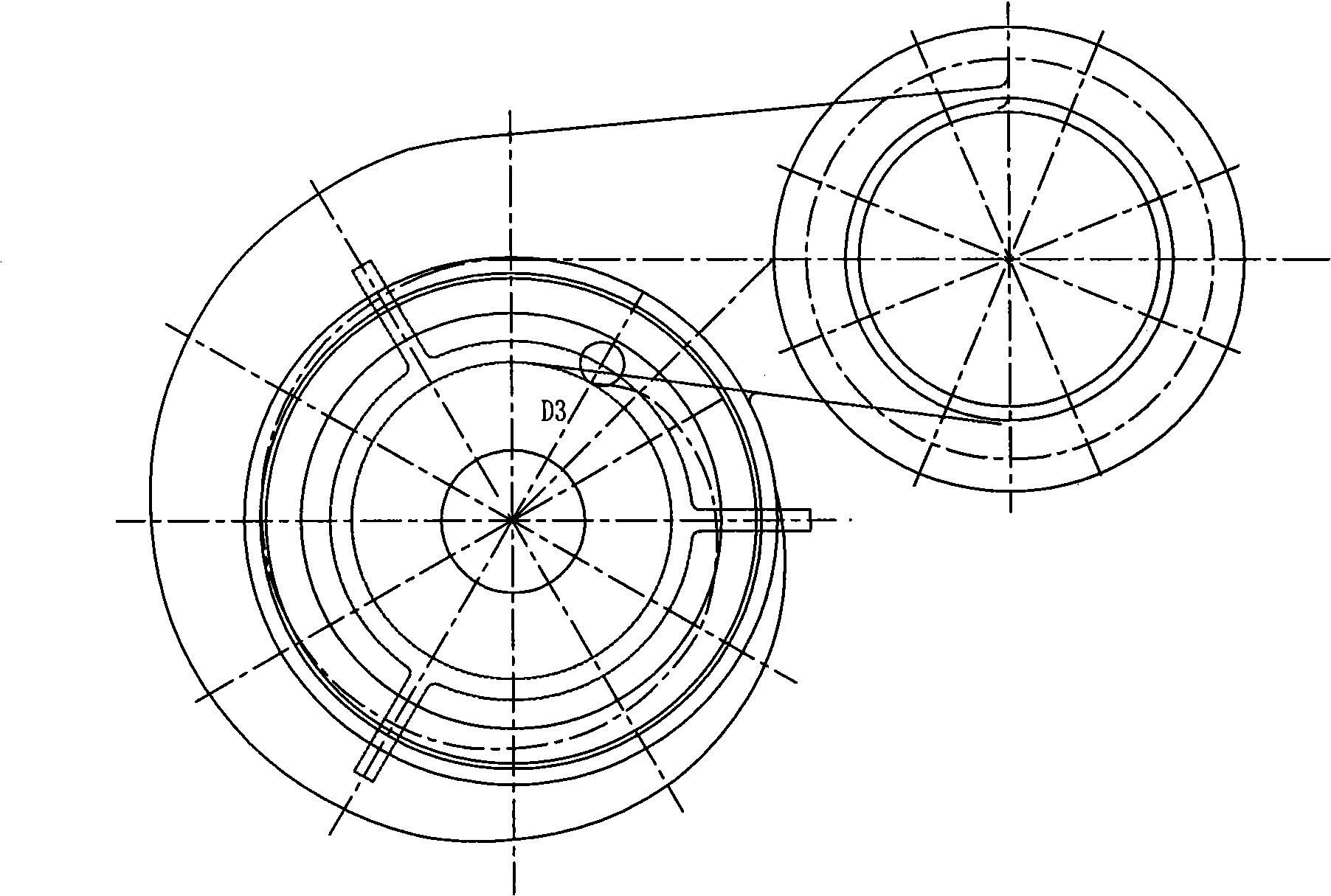

Low-noise hydraulic design method of centrifugal pump with low specific speed

ActiveCN103306985AImprove design qualityImprove machine performancePump componentsSpecial data processing applicationsLow noiseComputational acoustics

The invention discloses a low-noise design method of a centrifugal pump with low specific speed, and relates to an active control method of flow noise of turbomachinery. The design method comprises the steps that firstly, main structural dimensions of a centrifugal pump impeller and a helical pumping chamber (volute) are obtained by the traditional low-specific-speed pump design method; secondly, an internal flow field of the pump is computed by a computational fluid mechanics method; the performance of the pump is predicted whether to meet a design requirement; an optimum design improvement is performed by analyzing a stationary flow field; thirdly, flow induction noise of the pump with low specific speed is predicted by a computational acoustics method; if a flow noise index is qualified, the design is accomplished; if the flow noise index is disqualified, subsequent steps are performed; fourthly, the diameter of the impeller basically meeting a performance requirement in the design is adjusted to allow a gap between the impeller and a volute tongue to be increased continuously to 20%; splitter blades are added in the middles of blades to increase the lift, control the flow situation, and ensure the efficiency; and finally, the pump subjected to the impeller improvement design is subjected to noise prediction; if the flow noise index is qualified, the design is accomplished; and if the flow noise index is disqualified, the beginning step is repeated. The design method shortens the research and development period, saves the development cost, effectively improves the design quality of the centrifugal pump, can simultaneously meet low-noise requirements of the lift and the efficiency, and realizes optimization of the performance of the complete centrifugal pump with low specific speed.

Owner:JIANGSU UNIV

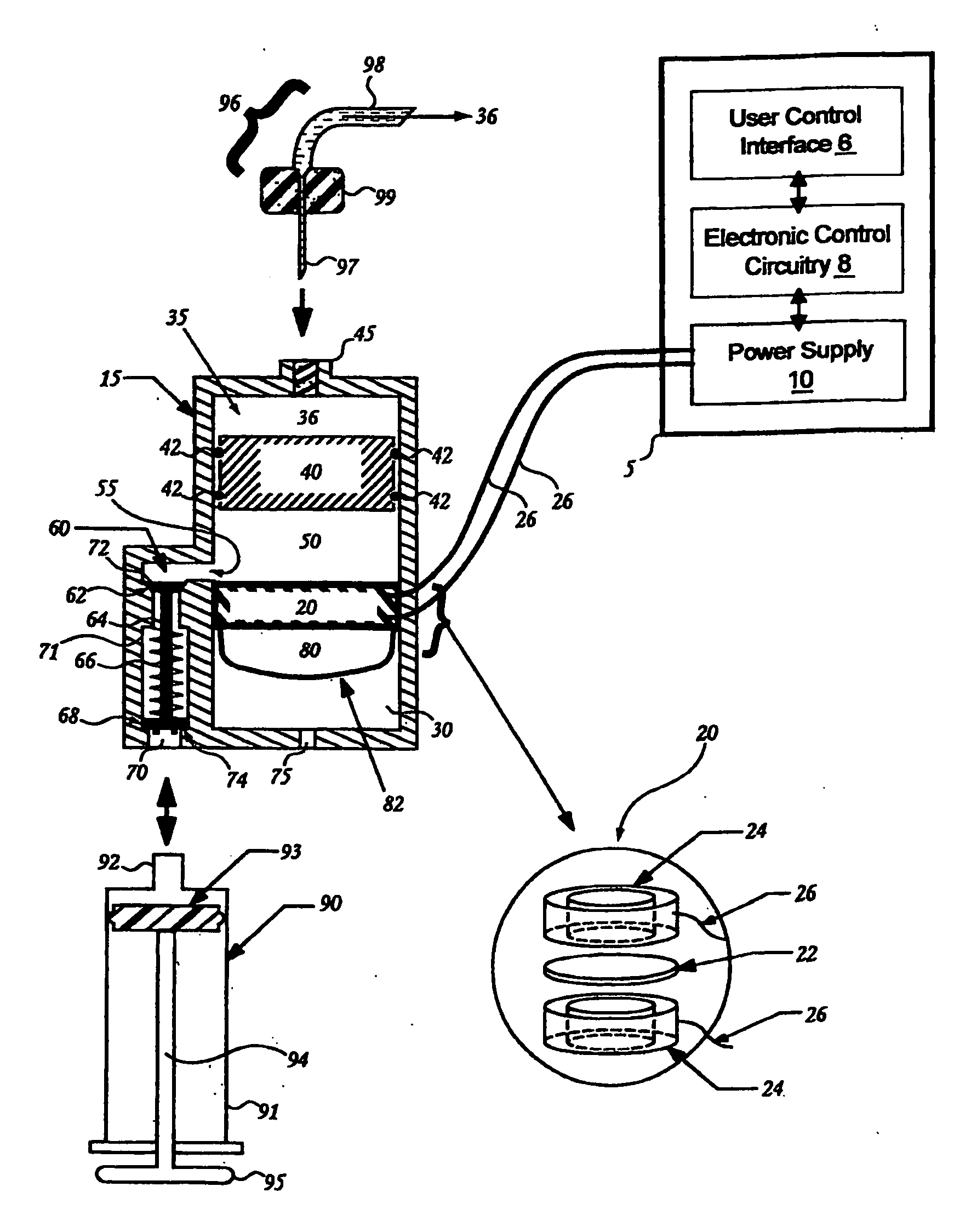

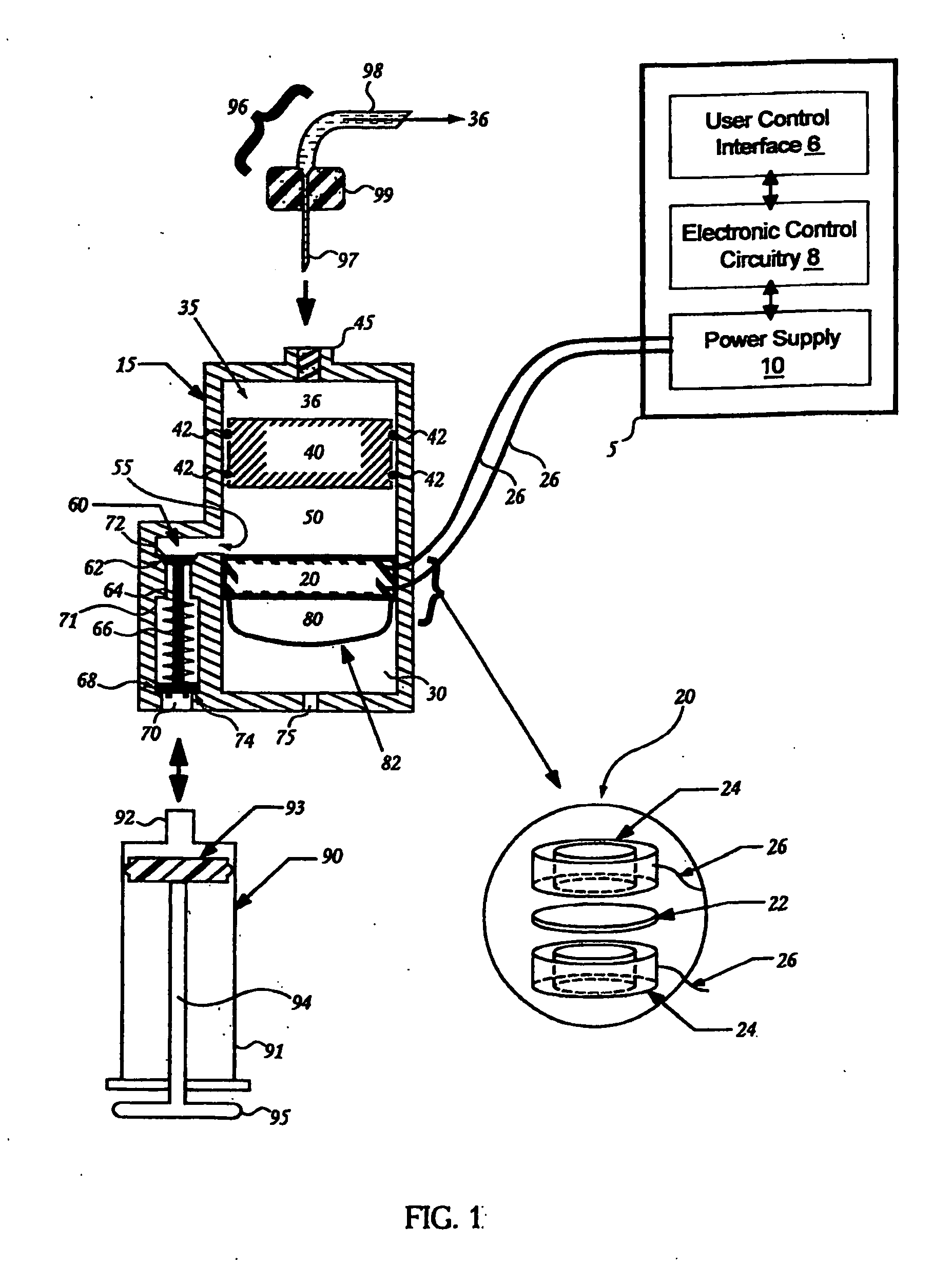

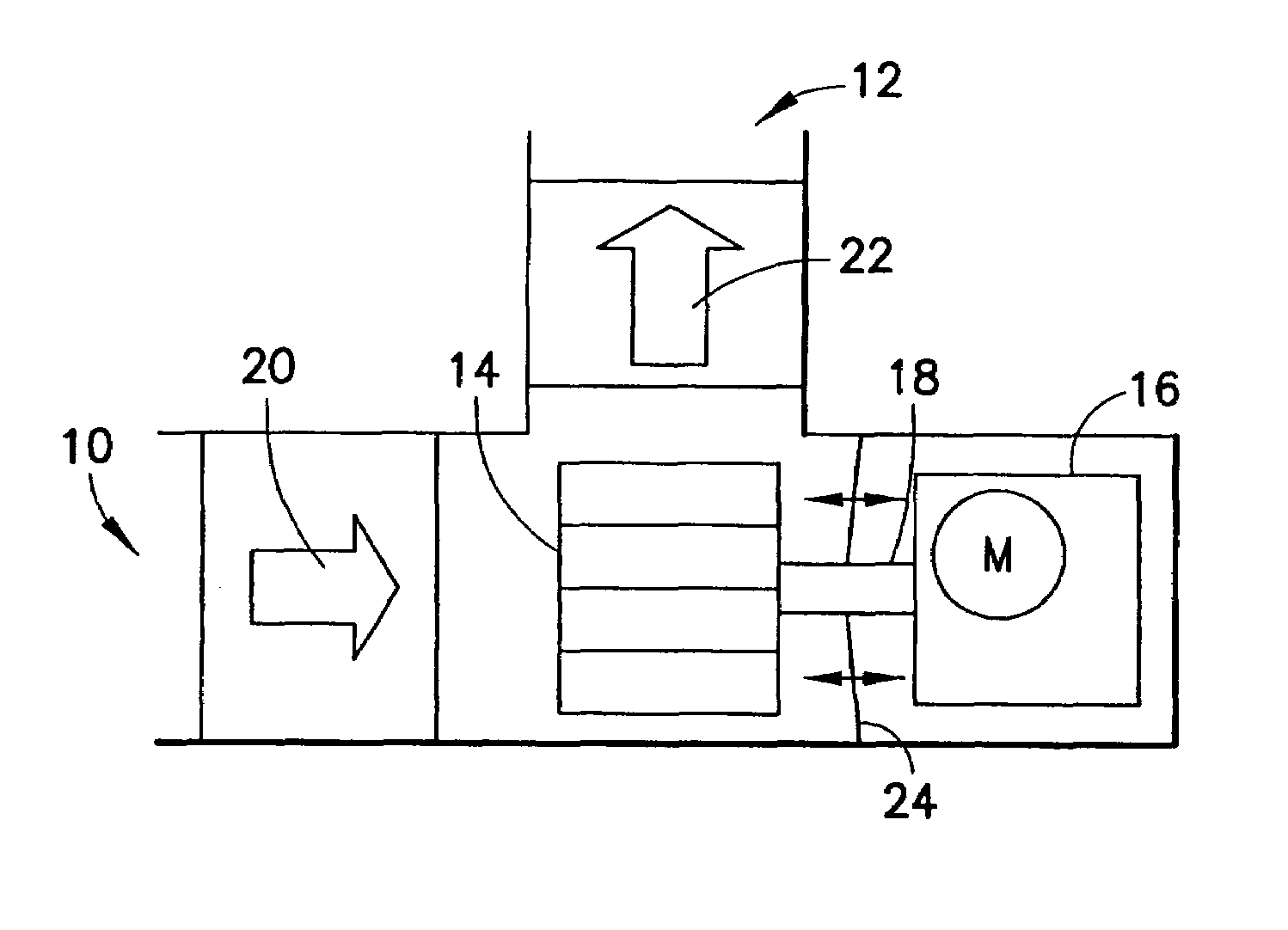

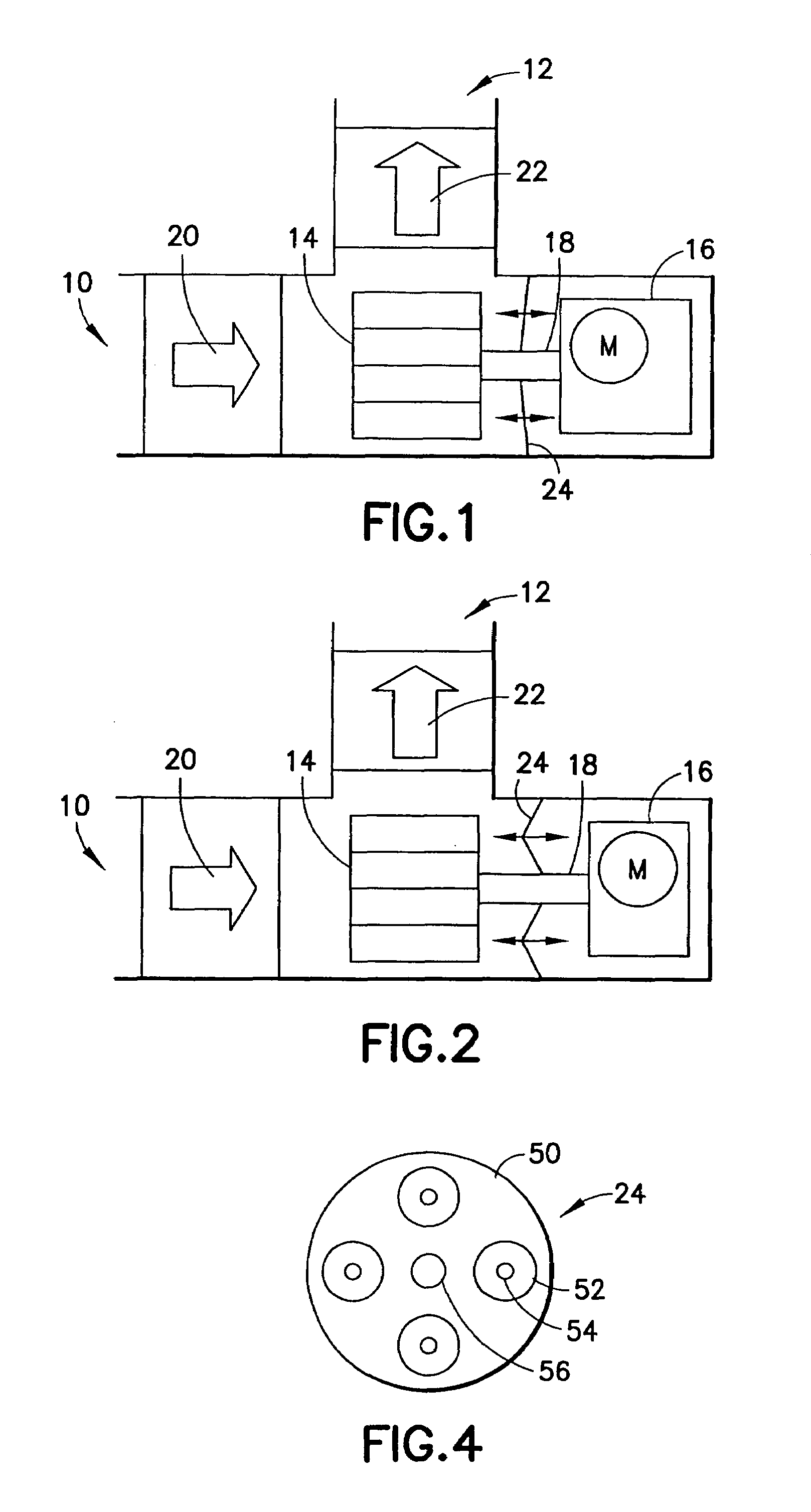

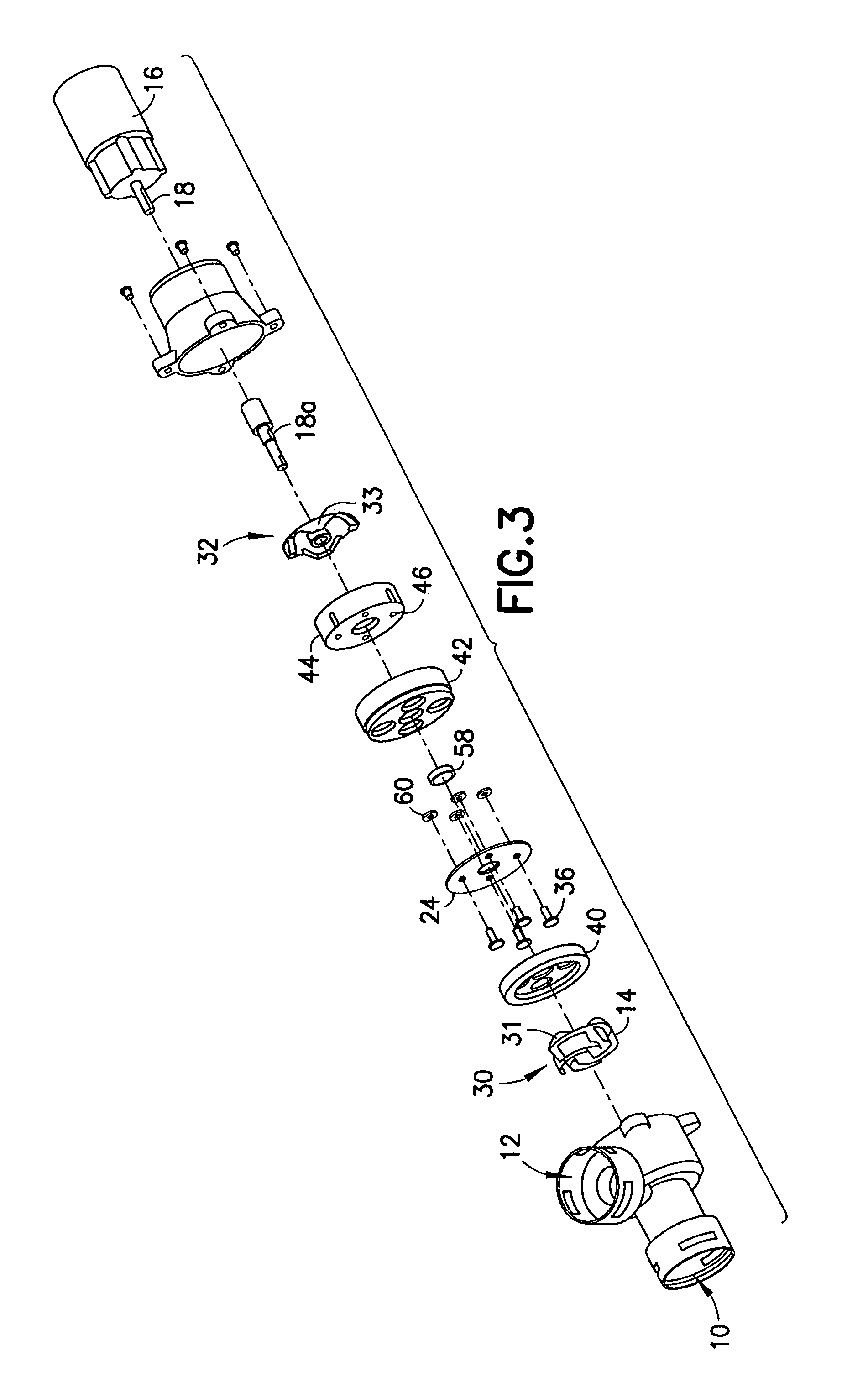

Pump control for formation testing

A downhole formation fluid pumping and a sampling apparatus are disclosed that may form part of a formation evaluation while drilling tool or part of a tool pipe string. The operation of the pump is optimized based upon parameters generated from formation pressure test data as well as tool system data thereby ensuring optimum performance of the pump at higher speeds and with greater dependability. New pump designs for fluid sampling apparatuses for use in MWD systems are also disclosed.

Owner:SCHLUMBERGER TECH CORP

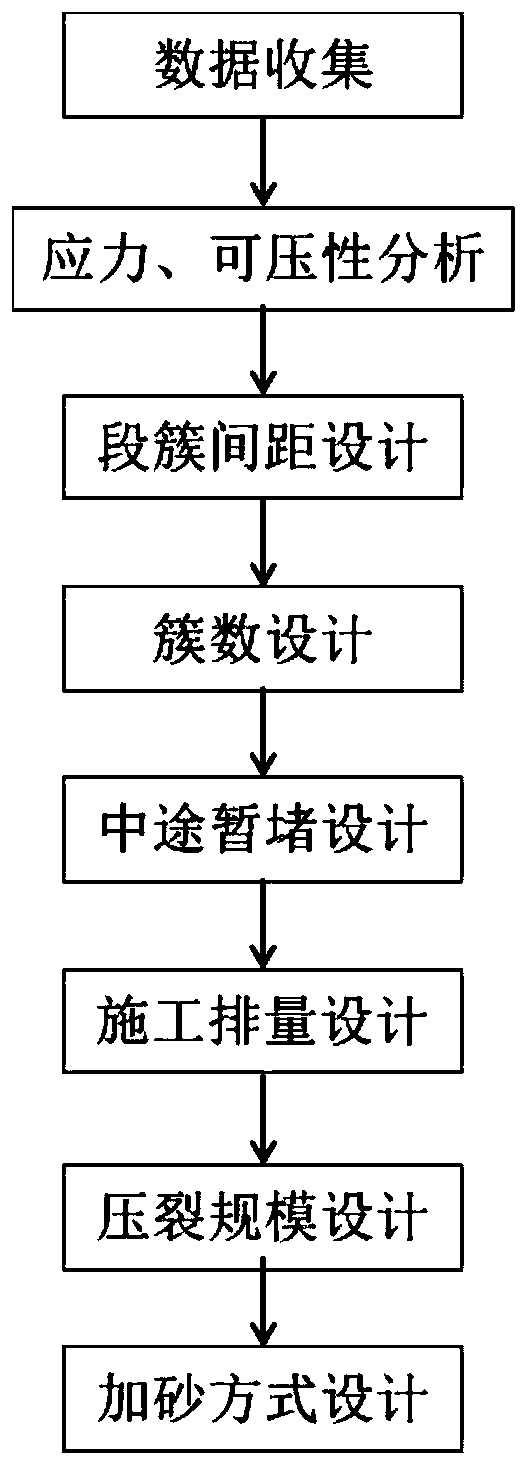

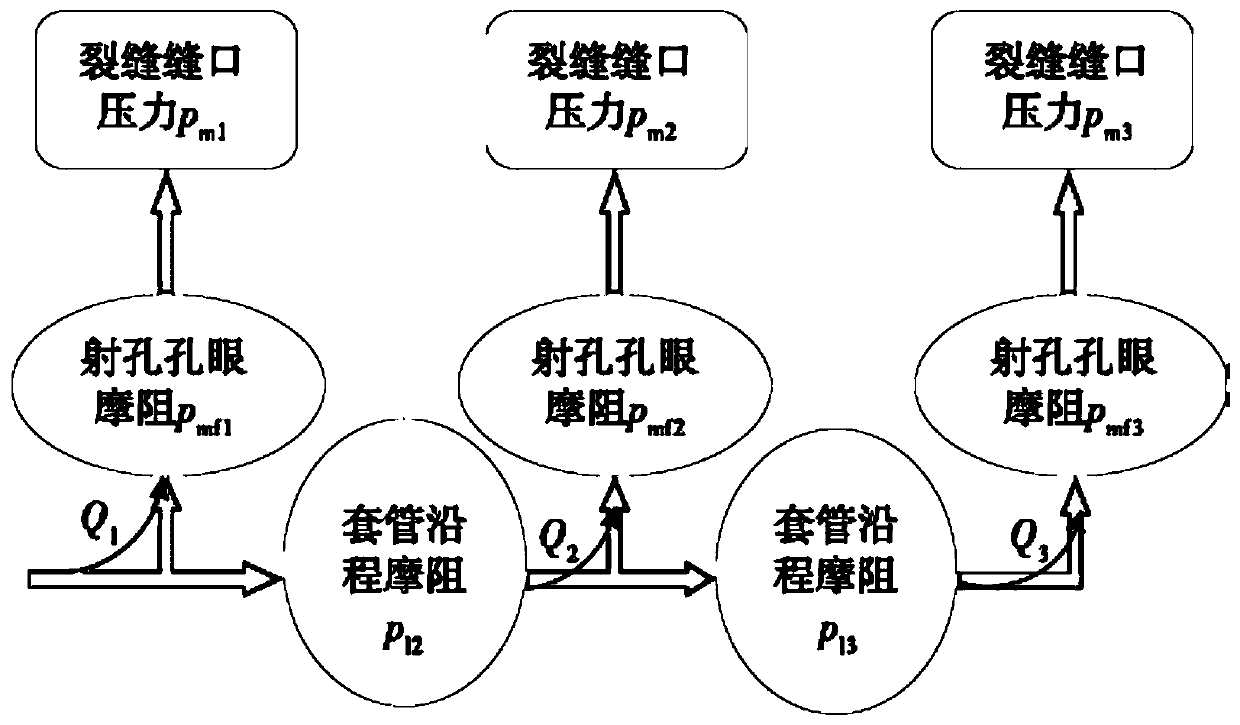

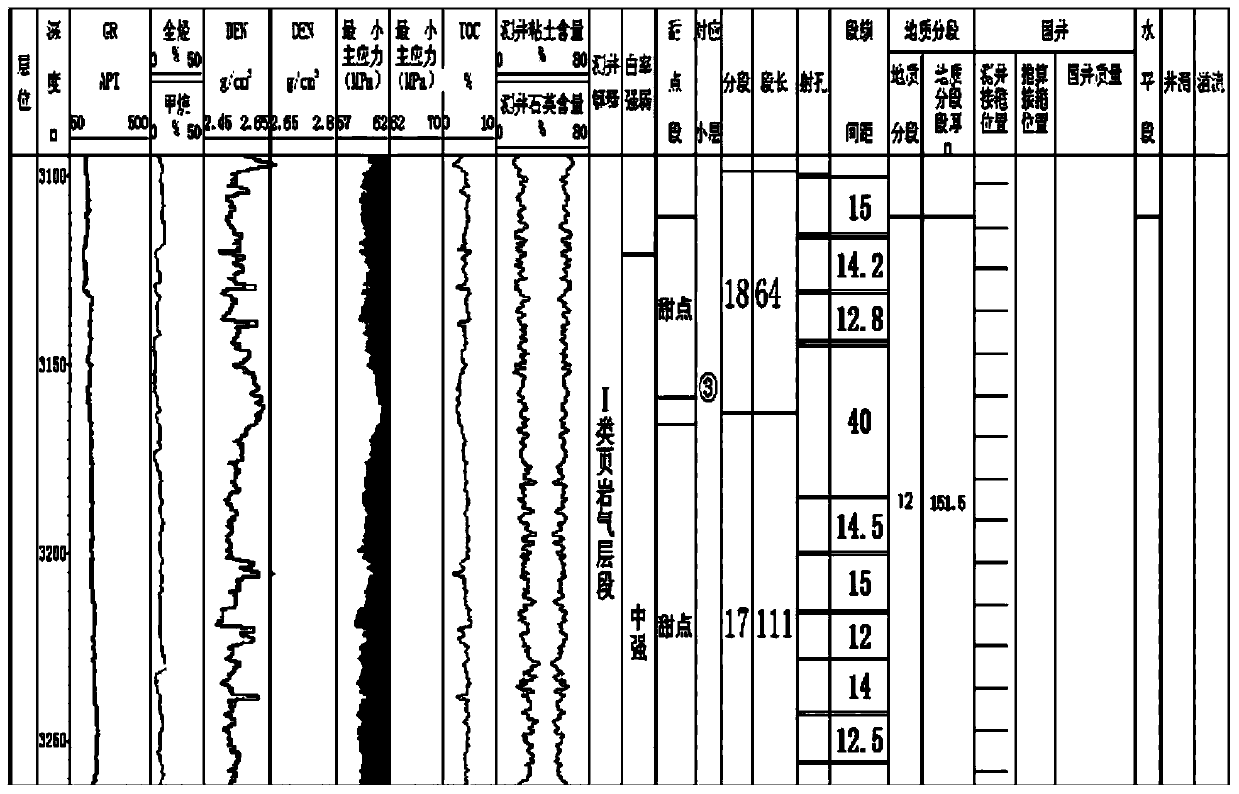

New fracturing process suitable for encrypted development of shale gas well

ActiveCN109977612AIncrease the complexity of the transformationImprove the efficiency of transformationData processing applicationsFluid removalMulti clusterTransformation efficiency

The invention relates to the technical field of horizontal well fracturing, and discloses a new fracturing process suitable for the encrypted development of a shale gas well, which comprises the following steps of (1) collecting the data; (2) analyzing the stress and compressibility; (3) designing the interval of the segment clusters; (4) designing the number of clusters; (5) carrying out the temporary plugging design in the midway; (6) designing the construction displacement; (7) designing a fracturing scale; and (8) designing a sand adding mode. According to the essence of the method, the small-section multi-cluster segmented design of reducing the section cluster spacing is carried out on the target horizontal well by analyzing the single well ground stress characteristics and the compressibility of the shale gas well of encrypted development; meanwhile, the pumping design of the variable-density perforation, midway ball throwing temporary plugging and continuous sand adding is combined, and finally, the effect of improving the single well transformation complexity and the reservoir transformation efficiency is achieved, the volume transformation of the whole horizontal well isachieved, the crack complexity is improved, the transformation strength is improved to a larger extent through improvement of a sand adding mode and a pumping program, and meanwhile the single well construction cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

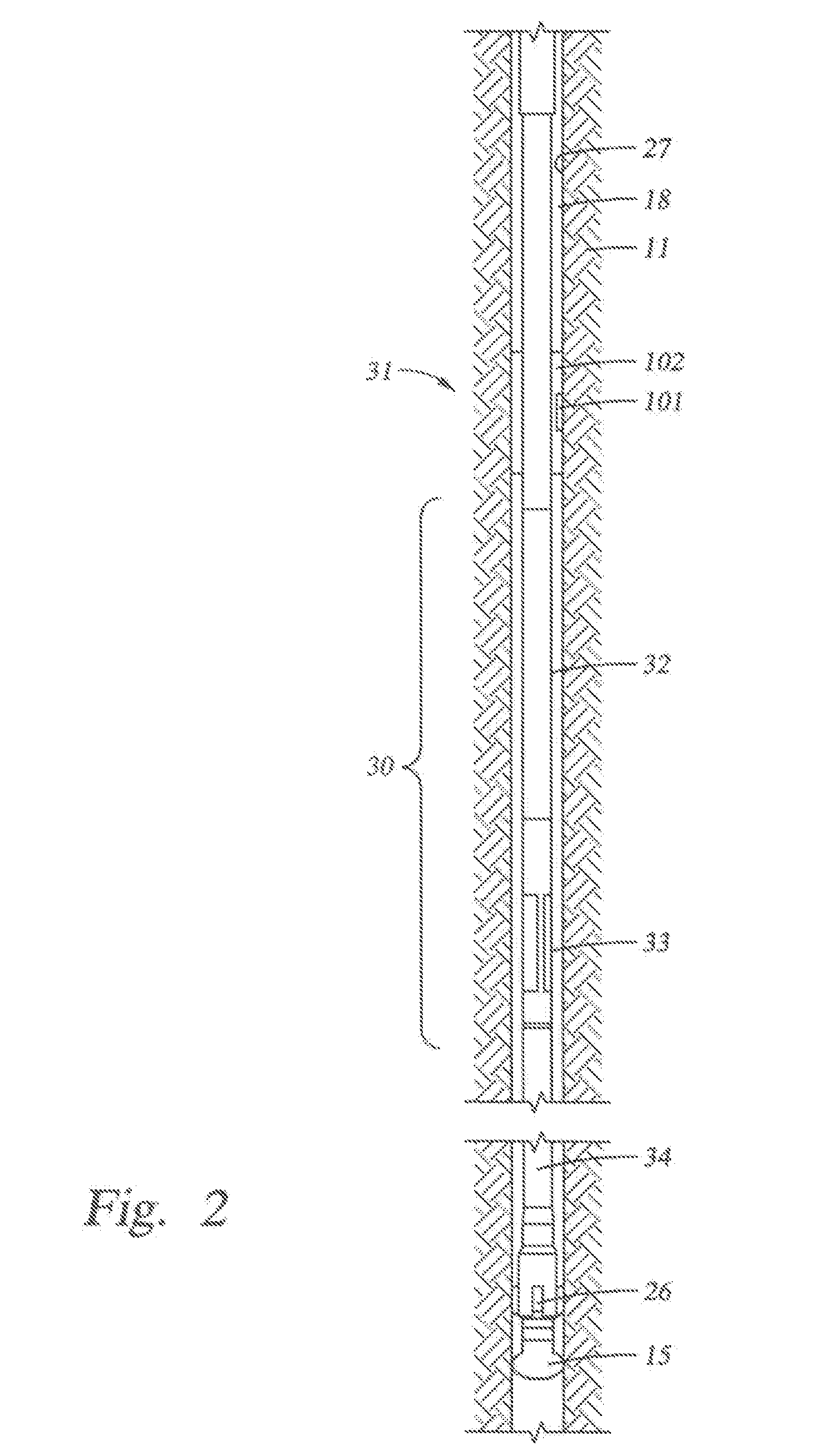

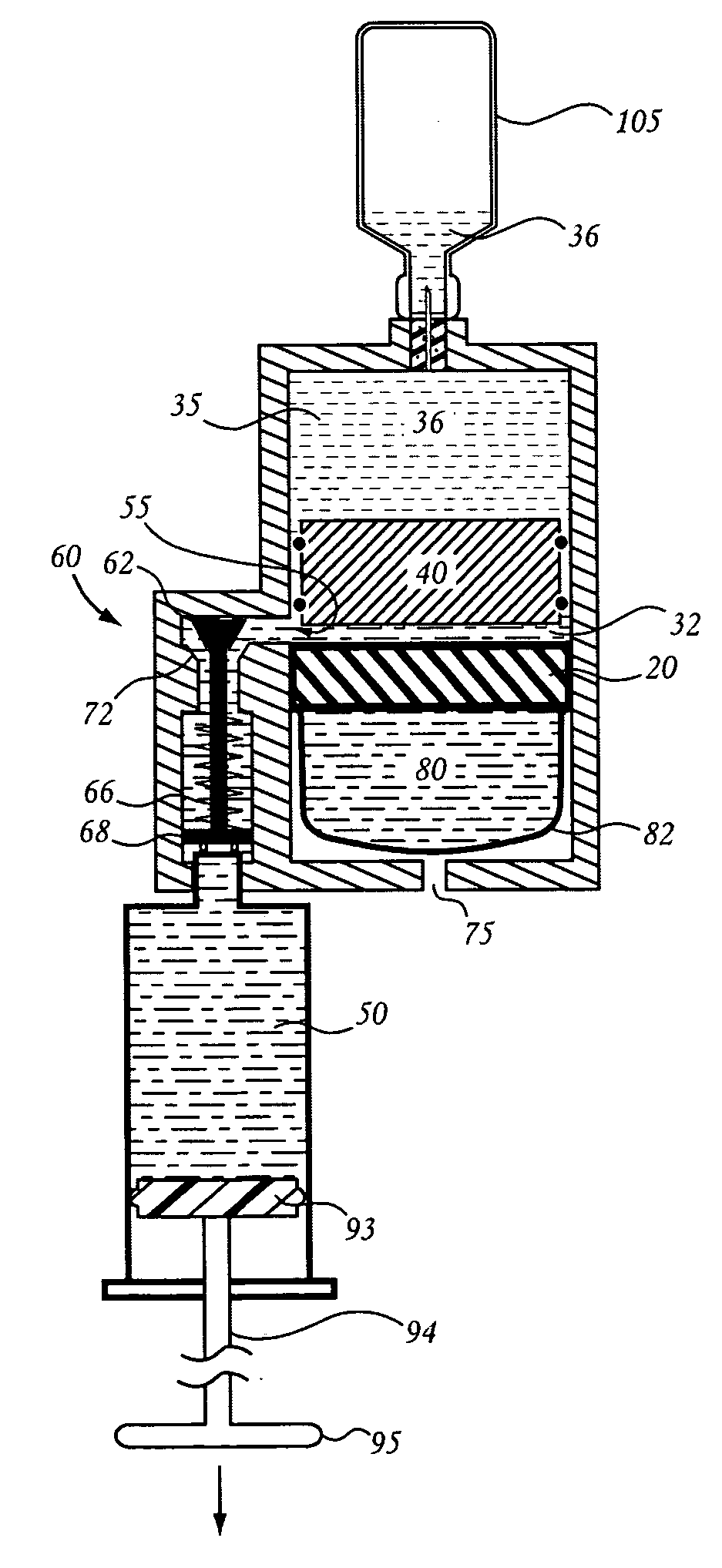

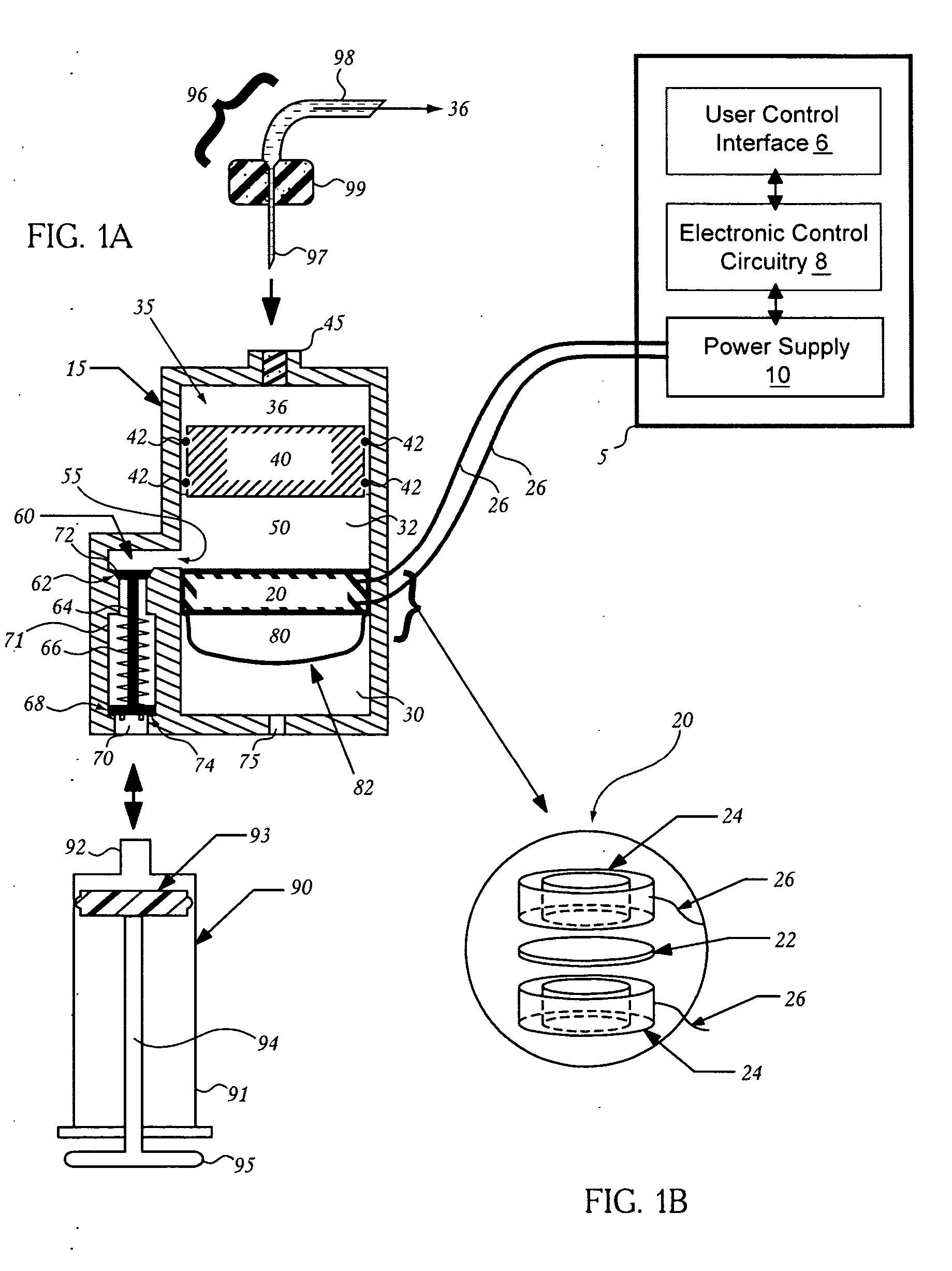

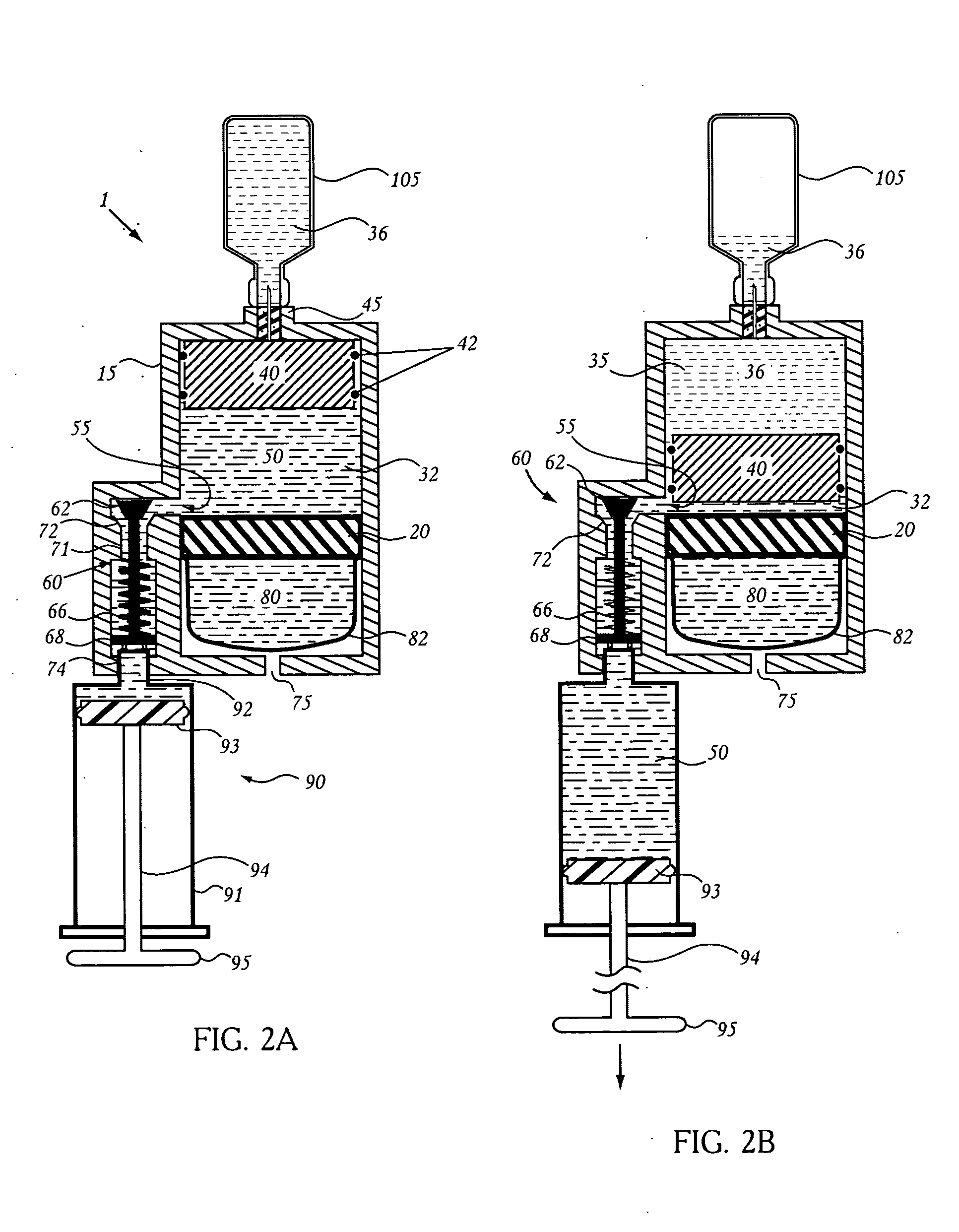

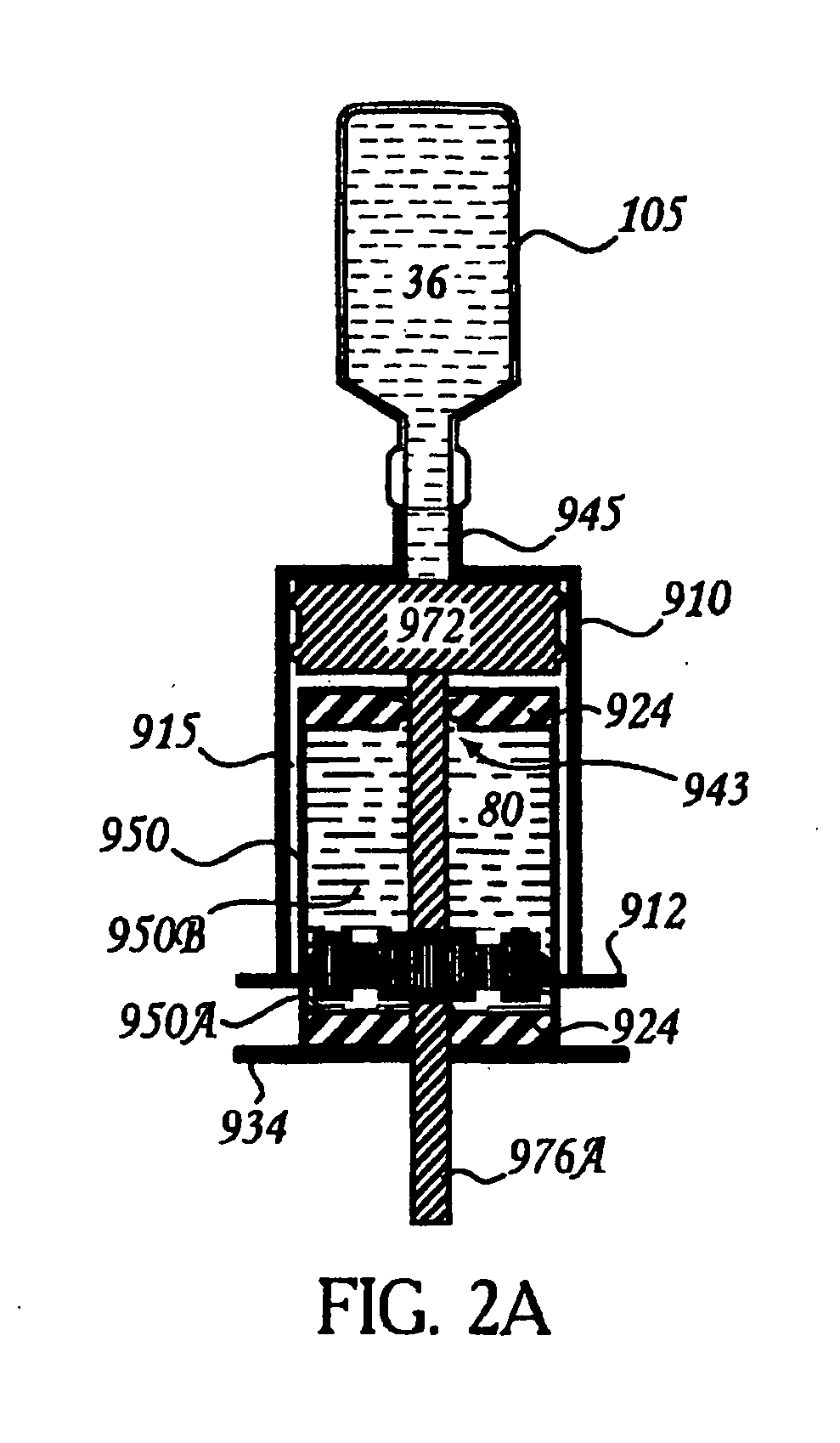

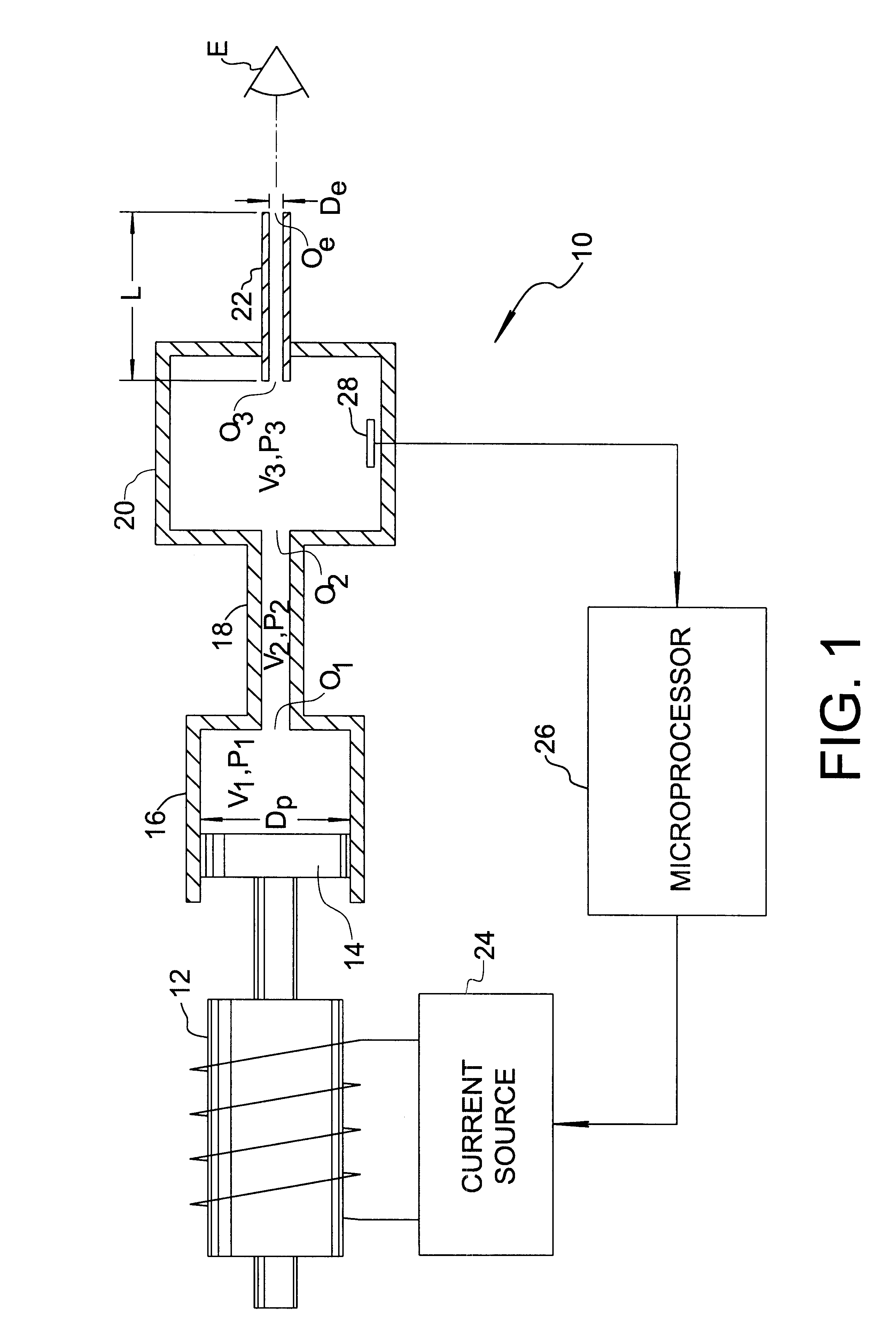

Electrokinetic pump designs and drug delivery systems

InactiveUS20070148014A1Lower the volumeIncrease volumeMedical devicesPressure infusionBiomedical engineeringDelivery system

The present invention provides a fluid delivery system having a first chamber, a second chamber and a third chamber; a flow-through pump element separating the first chamber from the second chamber; a moveable pump element separating the second chamber from the third chamber; a first outlet in communication with the third chamber; and second outlet in communication with the second chamber. Additionally, the present invention provides methods of operating a fluid delivery system having a first chamber, a second chamber and a delivery chamber by reducing the volume of the second chamber while increasing the volume of the delivery chamber without operation of a flow-through pump element that separates the second chamber from the first chamber.

Owner:TELEFLEX LIFE SCI PTE LTD

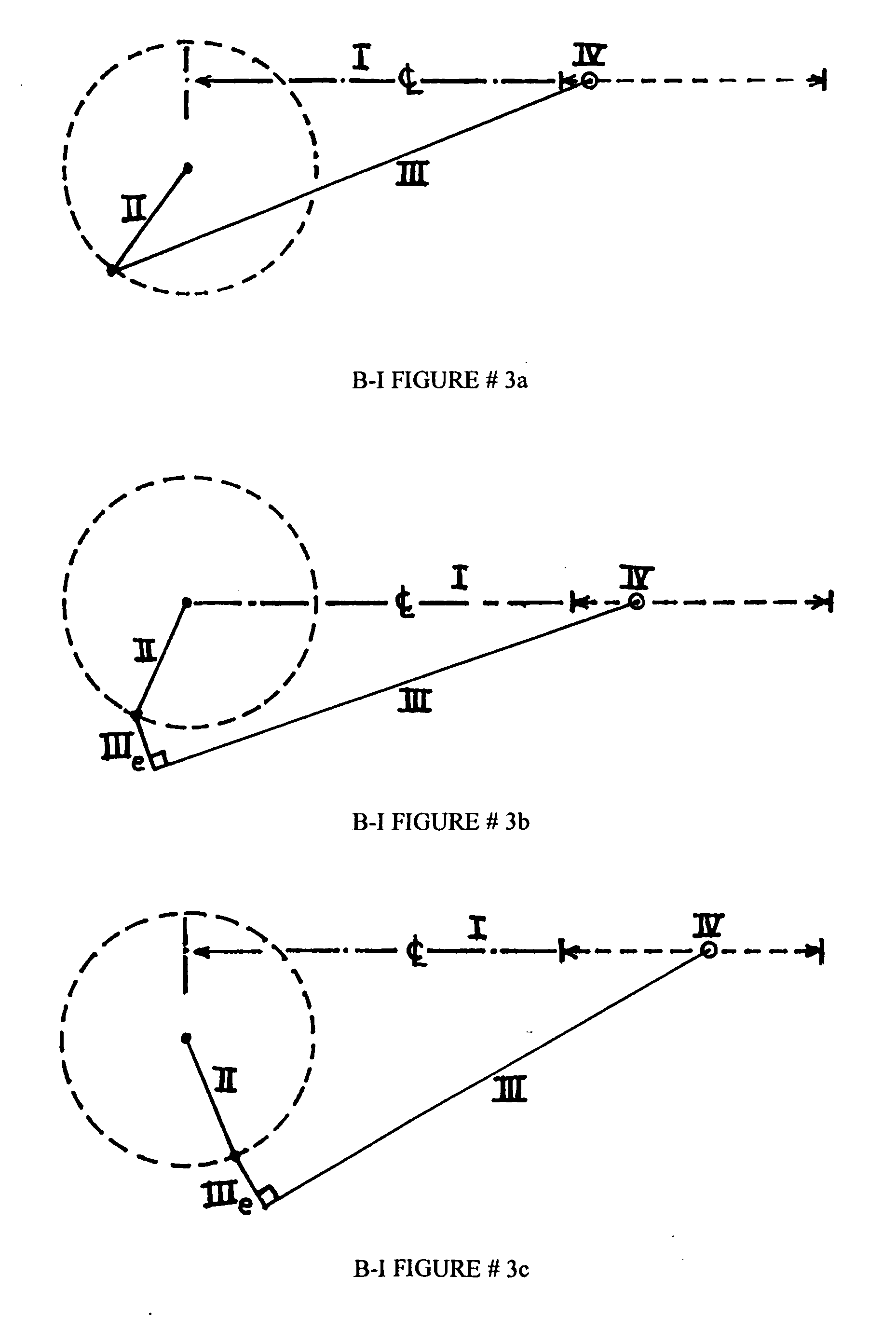

Pump design for circulating supercritical carbon dioxide

In accordance with an embodiment of the present invention, a pump assembly for circulating a supercritical fluid is disclosed. The pump assembly comprises an impeller for pumping fluid between a pump inlet and a pump outlet; a rotating pump shaft coupled to the impeller, wherein the pump shaft is supported by corrosion resistant bearings; a rotor of a DC motor potted in epoxy and encased in a non-magnetic material sleeve; and a stator sealed from the fluid via a polymer sleeve. The pump can be of centrifugal type. The bearings can be made of silicon nitride balls combined with bearing races made of Cronidur® and can operate without oil or grease lubrication. The polymer sleeve can be a PEEK™ sleeve which forms a casing for the stator. The non-magnetic material sleeve encasing the rotor of the DC motor is preferably made of stainless steel. A portion of the fluid passing through the pump assembly can be diverted over the bearings and / or the rotor and stator.

Owner:TOKYO ELECTRON LTD

Electrokinetic pump designs and drug delivery systems

One embodiment of the present invention provides a piston assembly having a piston housing filled with an electrolyte; a housing within the piston housing that divides the piston housing into a first portion and a second portion, the housing having apertures, a shaft connecting the housing to a piston head outside of the piston housing; and a porous material inside of the housing in contact with the electrolyte. Additionally, there are provided a method for filling the delivery chamber with a delivery fluid by withdrawing the piston head from within the delivery chamber. Yet another embodiment provides a method for filling a fluid delivery assembly by withdrawing a shaft from within the fluid delivery assembly to simultaneously displace a moving pump element within the delivery chamber and bypass fluid around a housing in the pump chamber.

Owner:TELEFLEX LIFE SCI PTE LTD

Sanitary design gear pump

InactiveUS20020159906A1Disadvantage numerousLimitation numerousOscillating piston enginesSealing arrangement for pumpsGear pumpDrive shaft

A sanitary design gear pump in which two gear shaft bearing blocks constitute hand removable structural end bodies of the pump. The gear shaft bearing journals extend completely through the blocks for easy cleaning and are sealed by O-rings retained by simple clamp plates. Gear cavity bore extends only the length of the largest gears, among interchangeable gear sizes. Bearing block to gear cavity seals are located at the ends of the gear bore to eliminate entrapment zones, minimal intrusion of the bearing blocks into the gear cavity allowing a large pump operating temperature range. Shaft seals of many different types can be contained in a simple hand removable cartridge. Complete pump disassembly is by one manually operated tee-handled clamp fastener. The drive and driven gear shafts are of different diameters to aid and assure correct assembly. The assembled pump slides into a pump mount with integral tie rods sealing the pump and securing it to the mount. The mount foot is reverse of the body, allowing the pump ports orientation to be selected at 90° intervals by a pin and groove engagement of the pump body and mount. The pump mount allows repeated pump removal without loss of pump-drive alignment. The drive gear shaft is splined to allow free pump removal from its mount and drive to pump disassembly without need to remove a shaft coupling. Pump displacement can be altered, requiring only interchange of gears and the drive end bearing block. The pump design meets the requirements of the 3-A Sanitary Standard 02-09 as promulgated by the 3-A Sanitary Standards Symbol Administrative Council.

Owner:ODEN MACHINERY +1

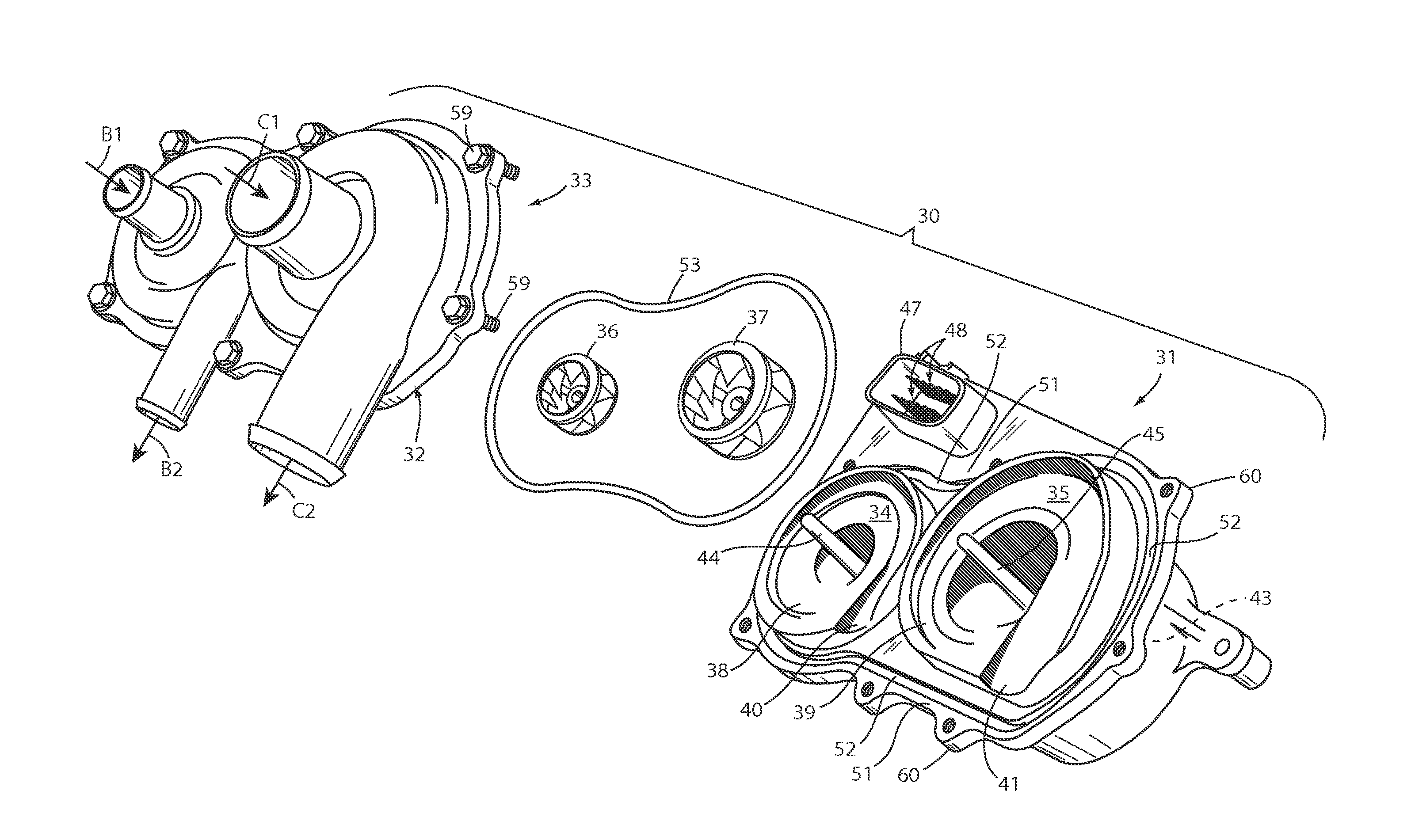

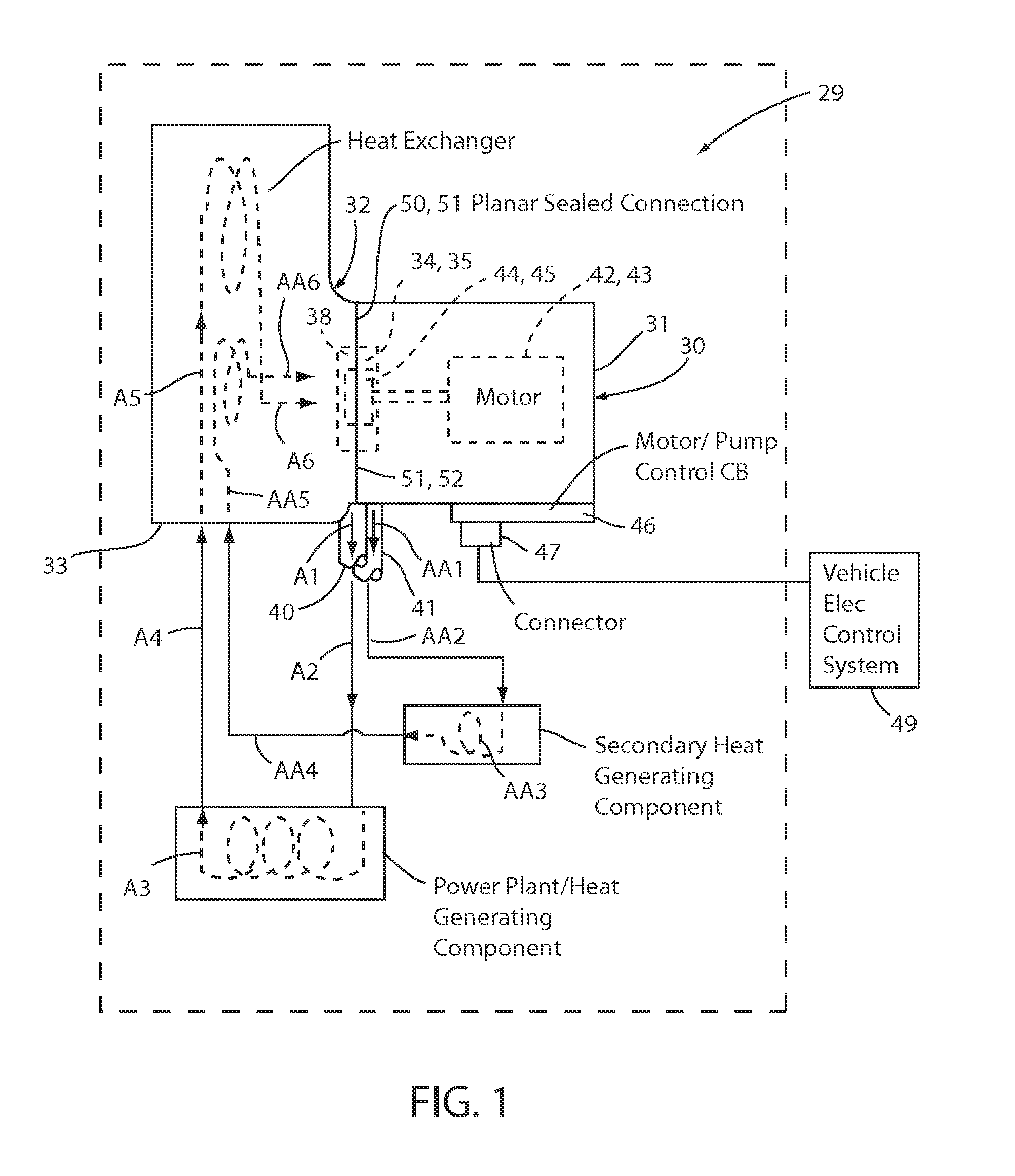

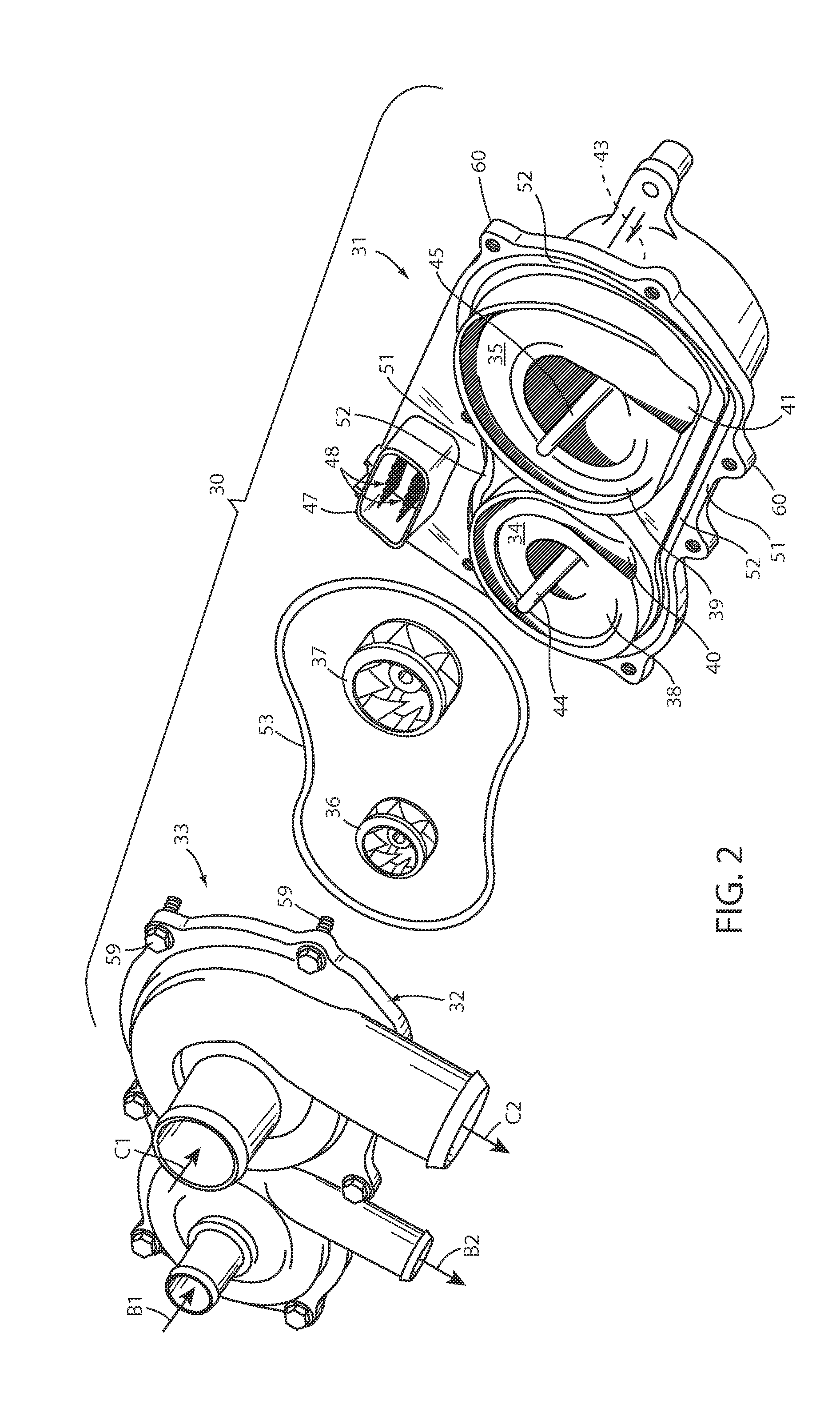

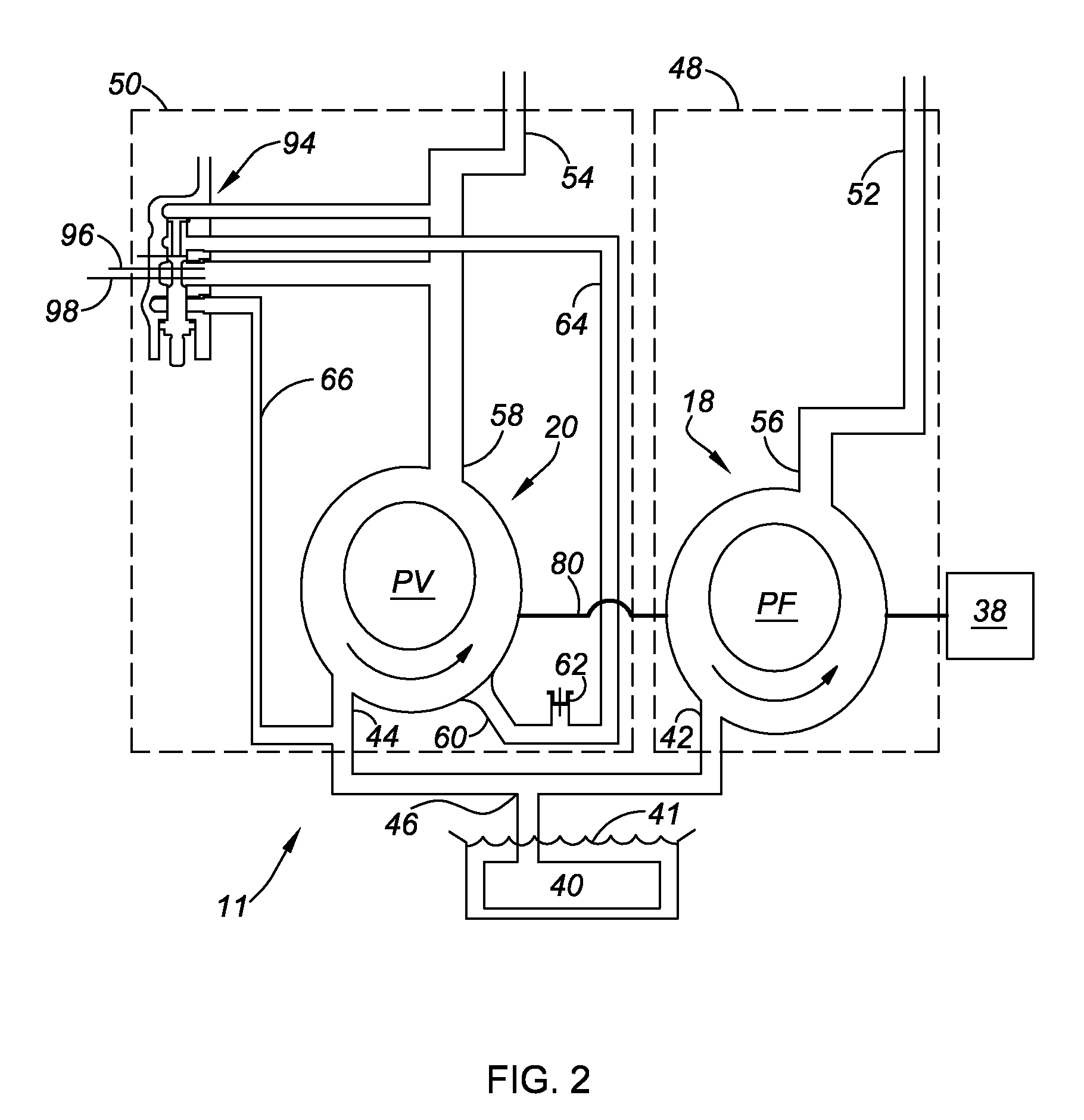

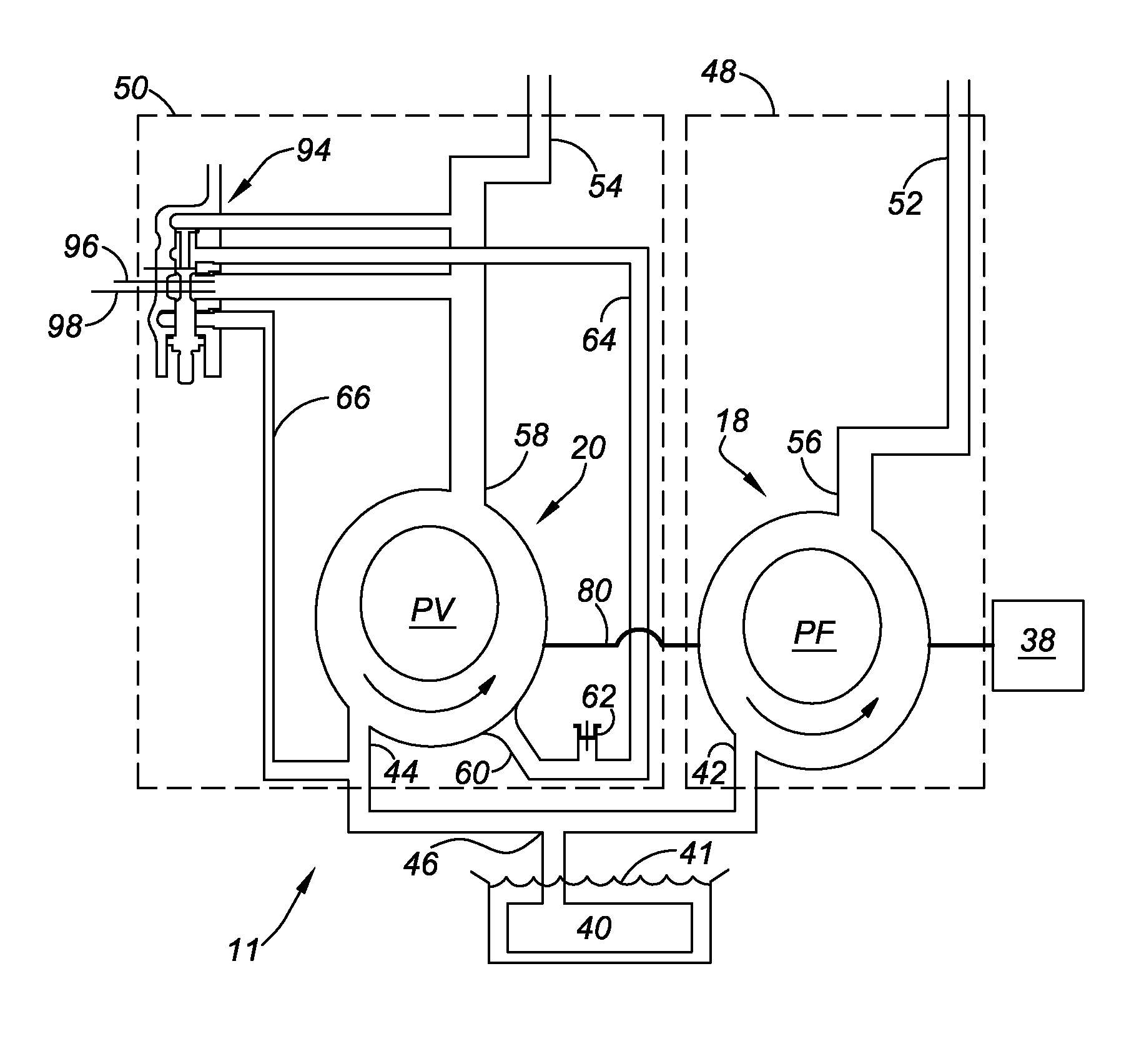

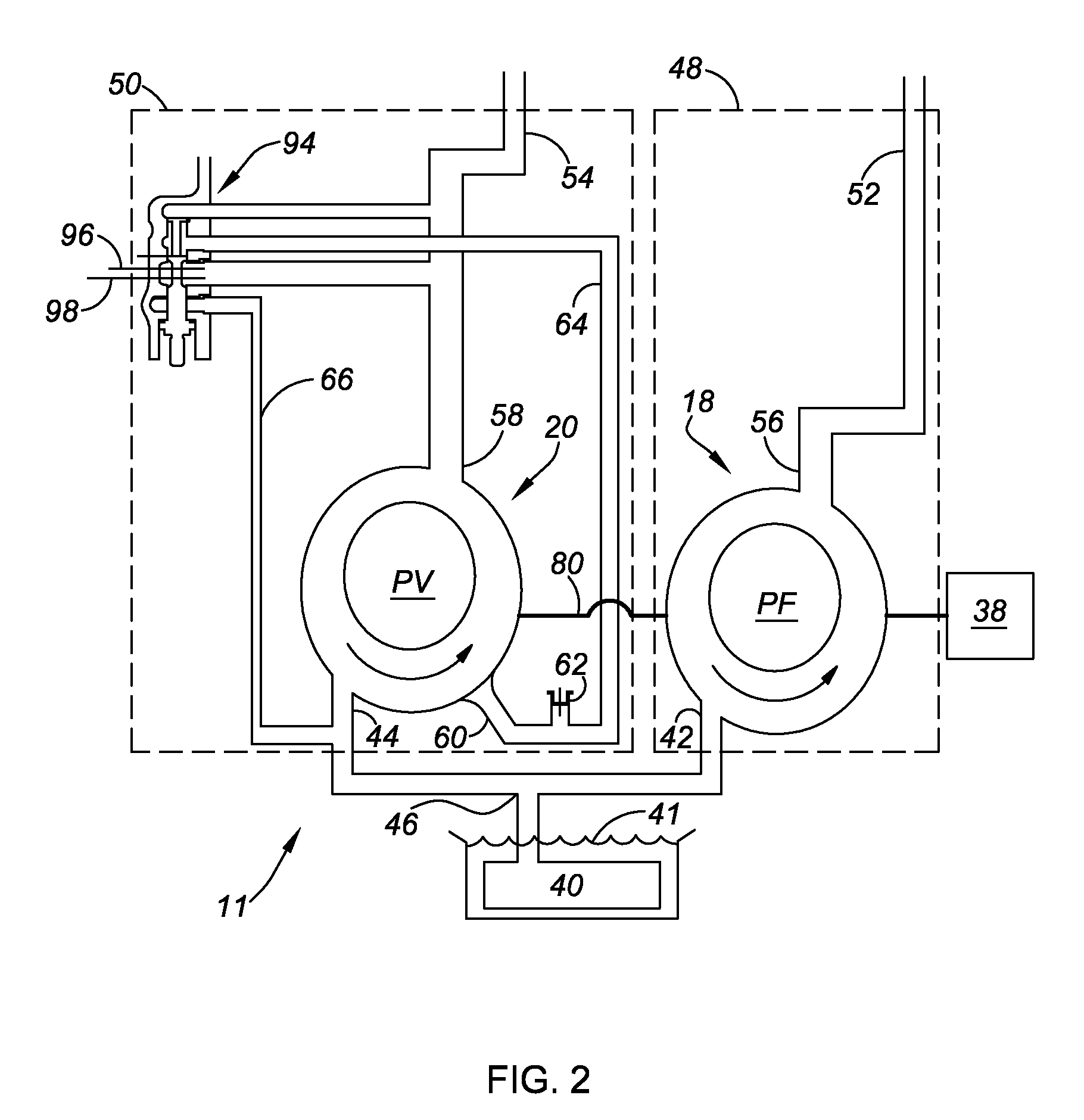

Two pump design with coplanar interface surface

A multi-pump apparatus includes a first component in a fluid heat transfer system, such as a heat exchanger, the first component including a body portion forming a first interface surface. A pumping component includes a second interface surface. The first and second interface surfaces are planar and combine to define two pump cavities and a planar interface groove supporting a seal ring that extends around the two pump cavities to prevent leakage of fluid from the pump cavities. The pumping component includes a pump impeller in each of the pump cavities and independently-controlled separate motors driving the two pump impellers using an on-board circuit board. One of the first and second components also defines a fluid inlet to and a fluid outlet from each of the pump cavities. Related methods are also defined.

Owner:GHSP

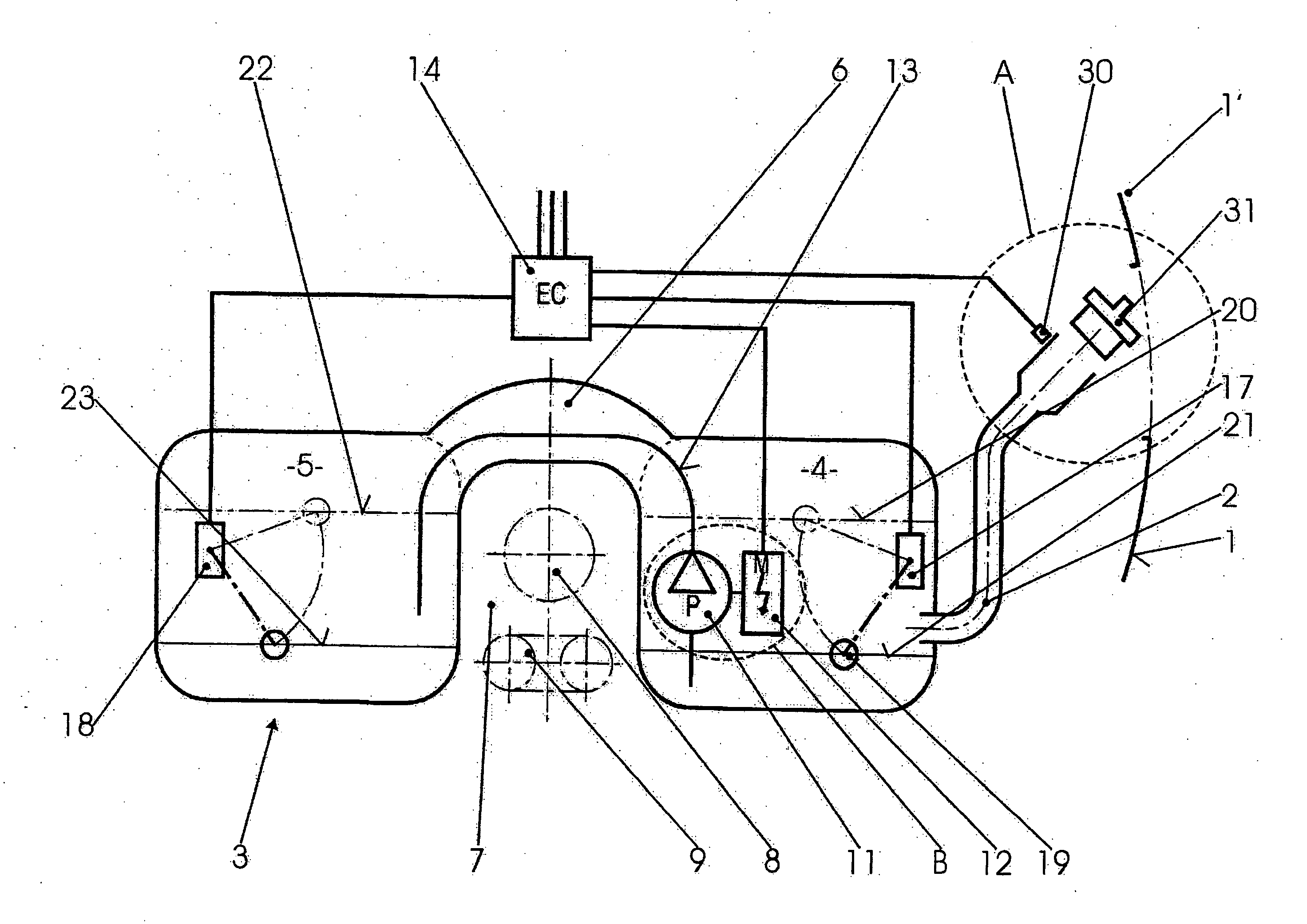

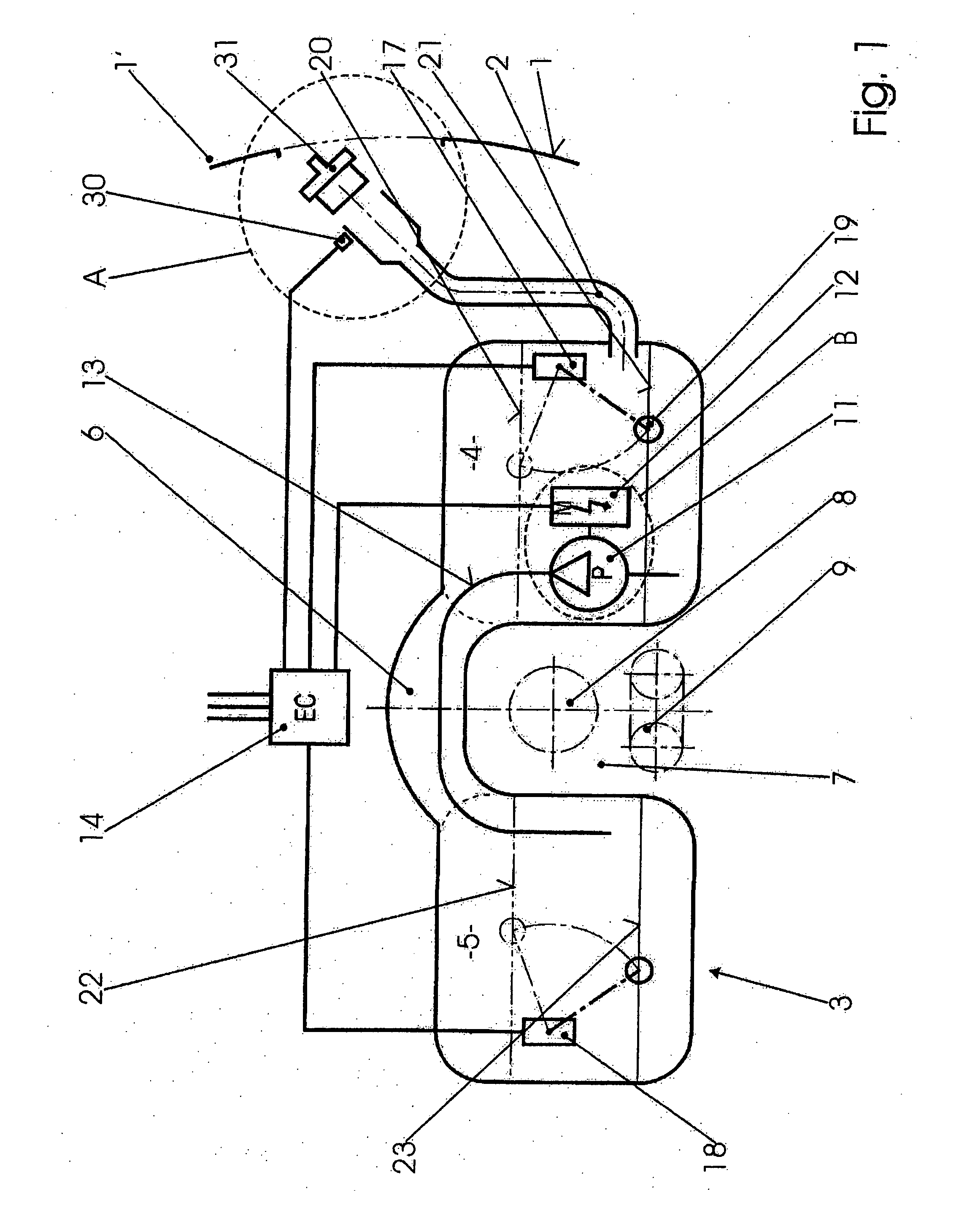

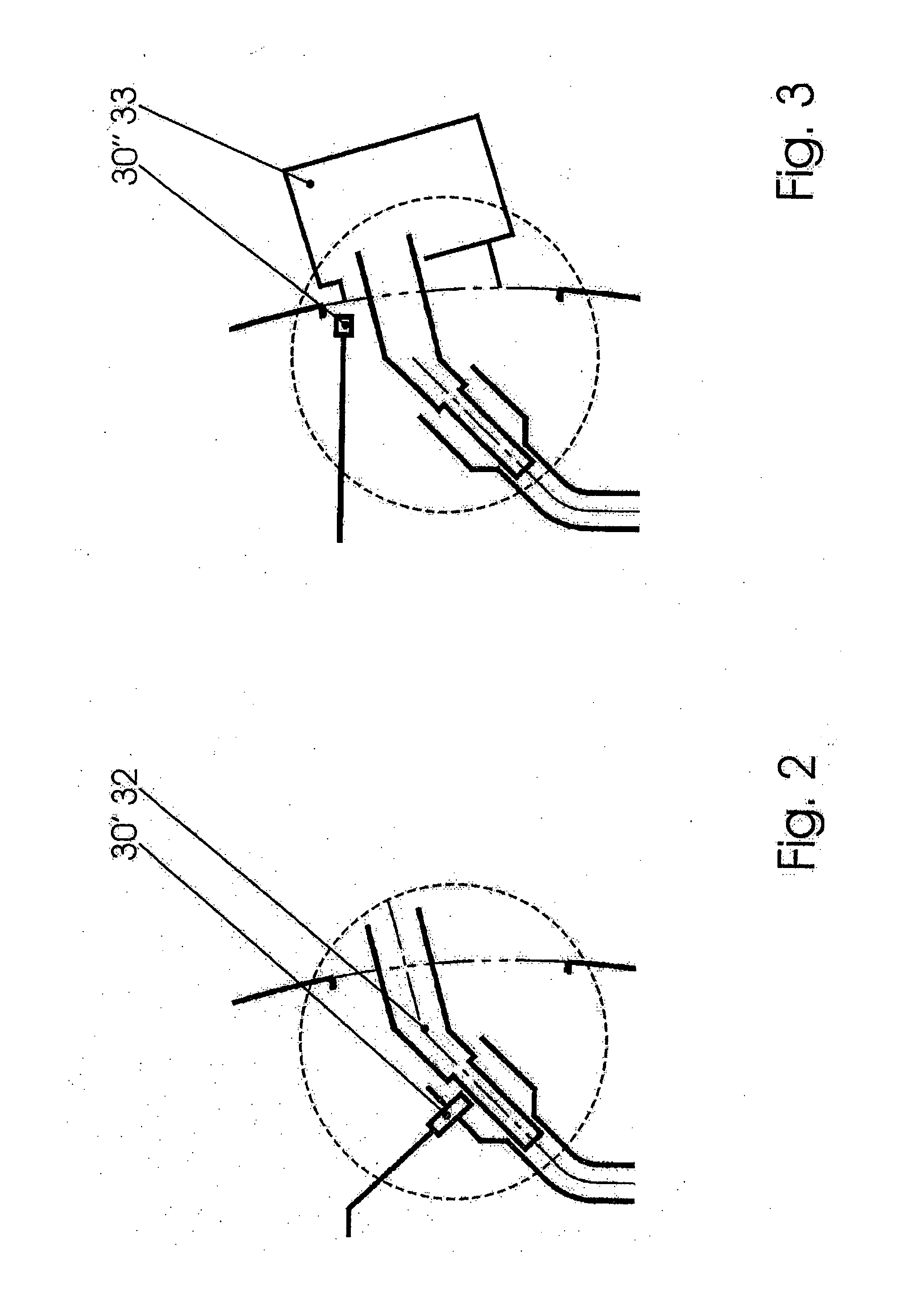

Multichamber tank for motor vehicles

A multichamber tank for motor vehicles comprises two chambers (4, 5) connected via a constricted region (6) located high up in the chambers, a first chamber (4) having a filler neck (2), and a line (13) bridging the constriction forming the connection to a second chamber (5). In order that both chambers are filled at approximately the same speed during filling-up through the filler neck (2), a pump (11) designed for level equalization during filling-up and driven by an electric motor (12) is provided in the line (13), and a level sensor (17, 18) is provided in each of the two chambers (4, 5), the output signals of which sensors are available to a control unit (14) which controls the electric motor (12) of the pump (11).

Owner:TESMA MOTOREN UND GETRIEBETECHN

Reciprocating pump performance prediction

ActiveUS7542875B2Testing/calibration apparatusStructural/machines measurementPredictive valueOperating life

Performance parameters for a reciprocating pump including pulsation energy, temperature energy, solids, Miller number and chemical energy and the like are monitored and employed to at least periodically compute a total energy number over the operating life of the pump. The current computed value is compared to a predictive failure value empirically determined for the respective pump design, to determine when failure is likely to be imminent. Scheduling of maintenance with other pumping operations and objective rating of competing designs is possible based on the total energy number.

Owner:PERFORMANCE PULSATION CONTROL

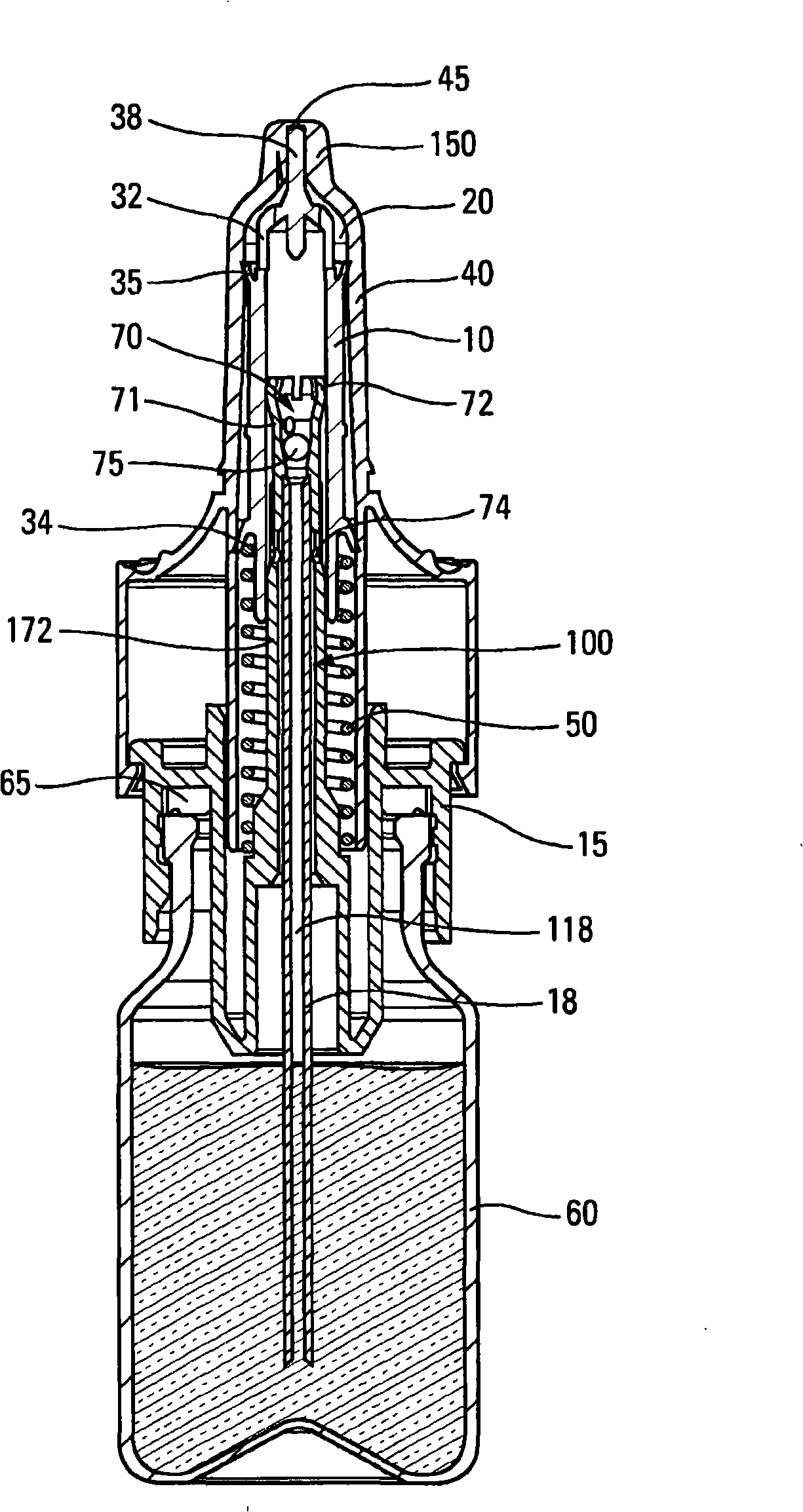

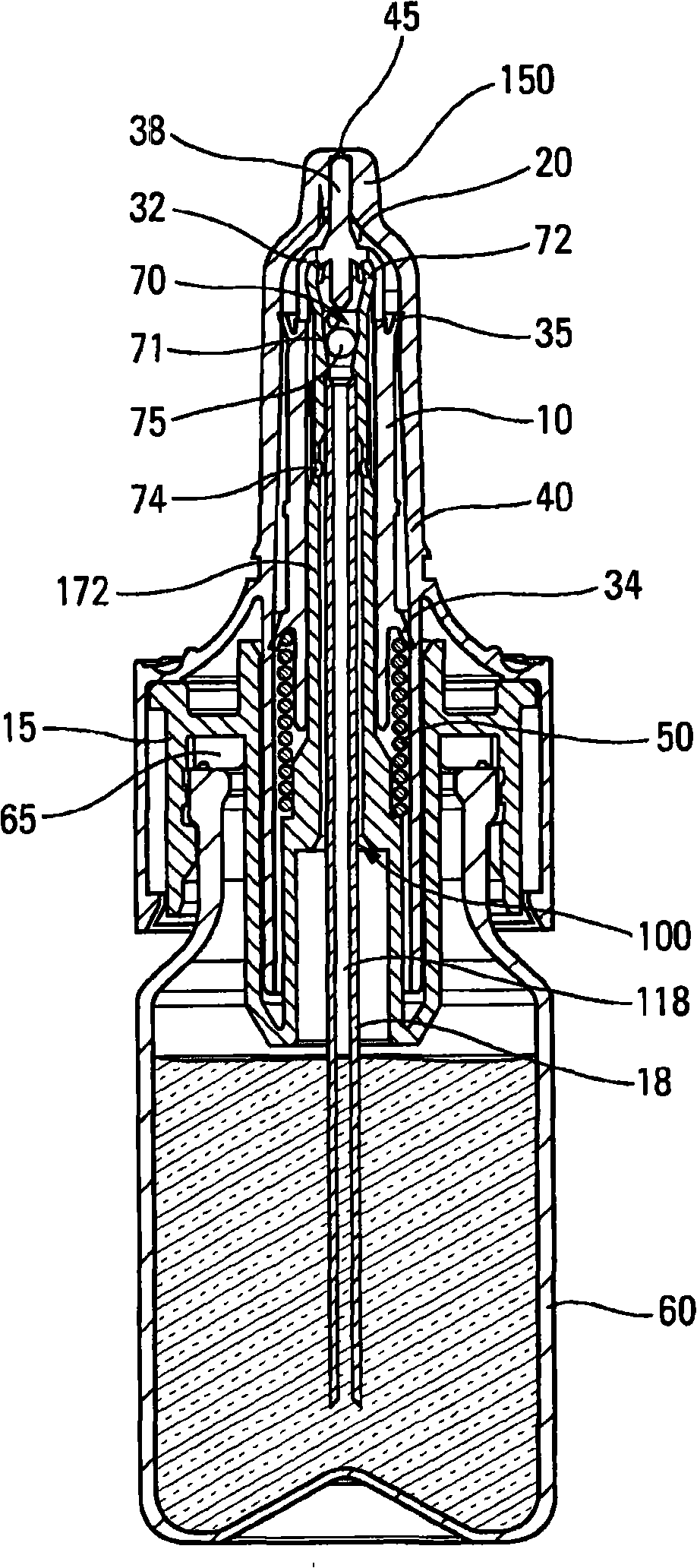

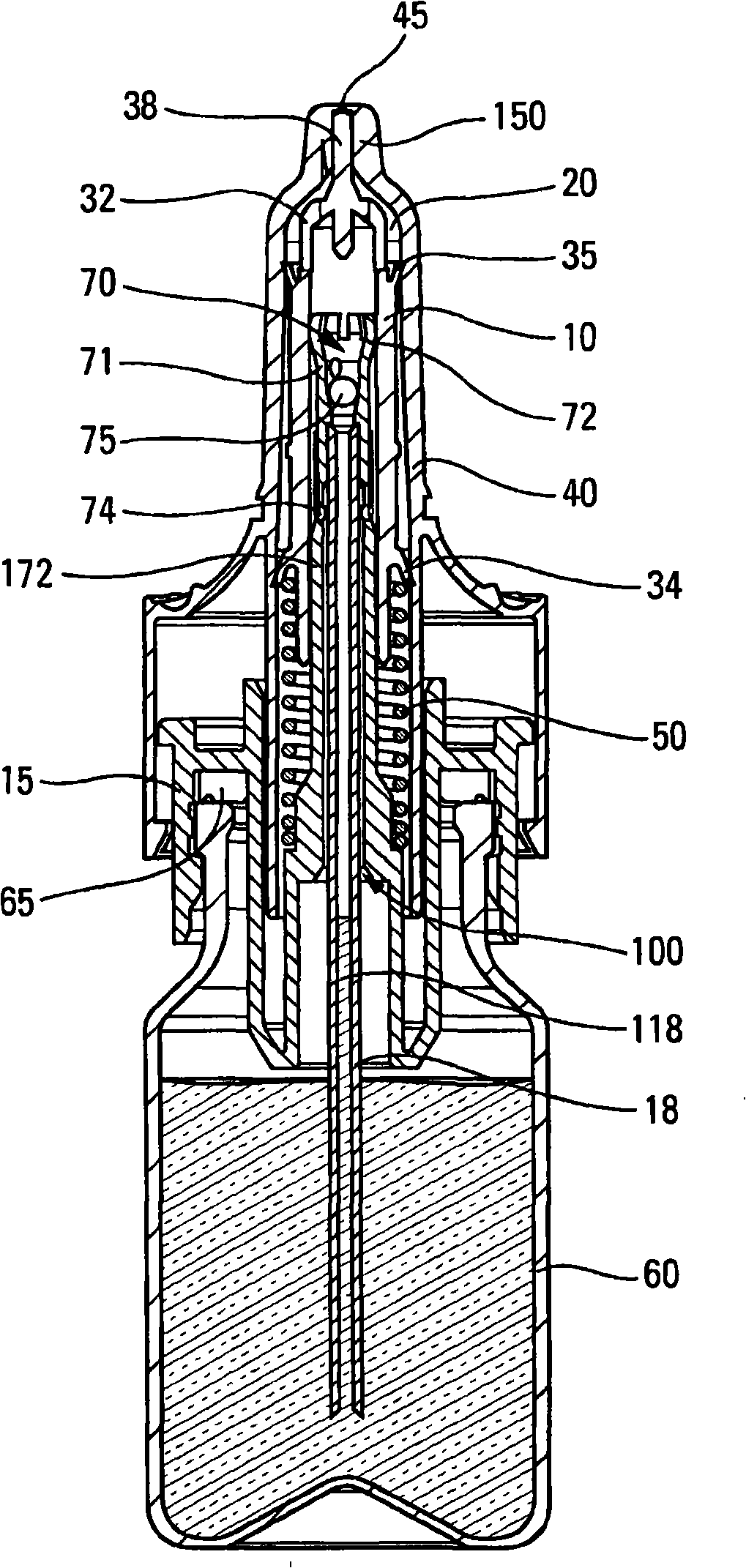

Fluid product dispensing pump

ActiveCN101316660ASafe and reliable startGuaranteed mist sprayingSingle-unit apparatusPiston pumpsPump chamberEngineering

The invention concerns a fluid product dispensing pump designed to be associated with a fluid product reservoir (60), said pump comprising a pump body (10), a pump chamber (20), and at least one first piston (72) sliding in said pump chamber (20) to dispense the fluid product through a dispensing orifice (45), said pump including an air priming channel (100) connecting said pump chamber (20) to said reservoir (60) when the pump is primed.

Owner:APTAR FRANCE SAS

Pump design for circulating supercritical carbon dioxide

In accordance with an embodiment of the present invention, a pump assembly for circulating a supercritical fluid is disclosed. The pump assembly comprises an impeller for pumping fluid between a pump inlet and a pump outlet; a rotating pump shaft coupled to the impeller, wherein the pump shaft is supported by corrosion resistant bearings; a rotor of a DC motor potted in epoxy and encased in a non-magnetic material sleeve; and a stator sealed from the fluid via a polymer sleeve. The pump can be of centrifugal type. The bearings can be made of silicon nitride balls combined with bearing races made of Cronidur® and can operate without oil or grease lubrication. The polymer sleeve can be a PEEK™ sleeve which forms a casing for the stator. The non-magnetic material sleeve encasing the rotor of the DC motor is preferably made of stainless steel. A portion of the fluid passing through the pump assembly can be diverted over the bearings and / or the rotor and stator.

Owner:TOKYO ELECTRON LTD

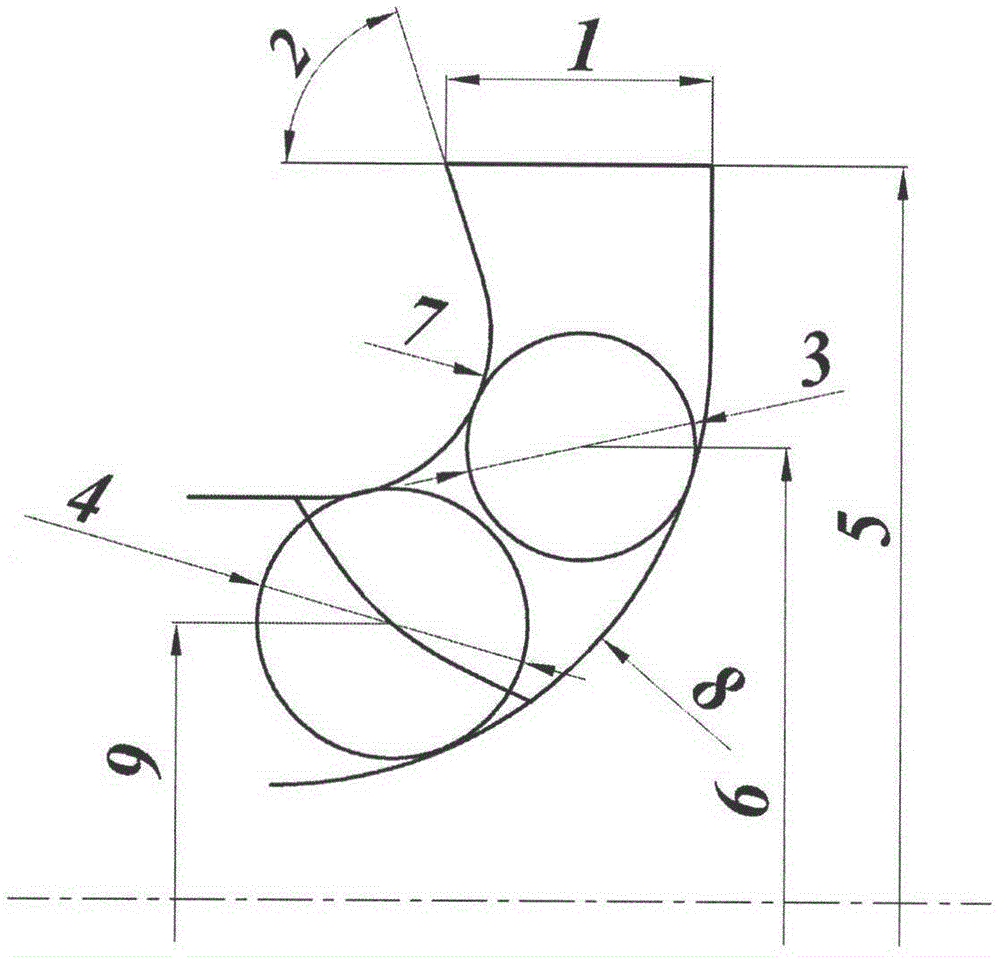

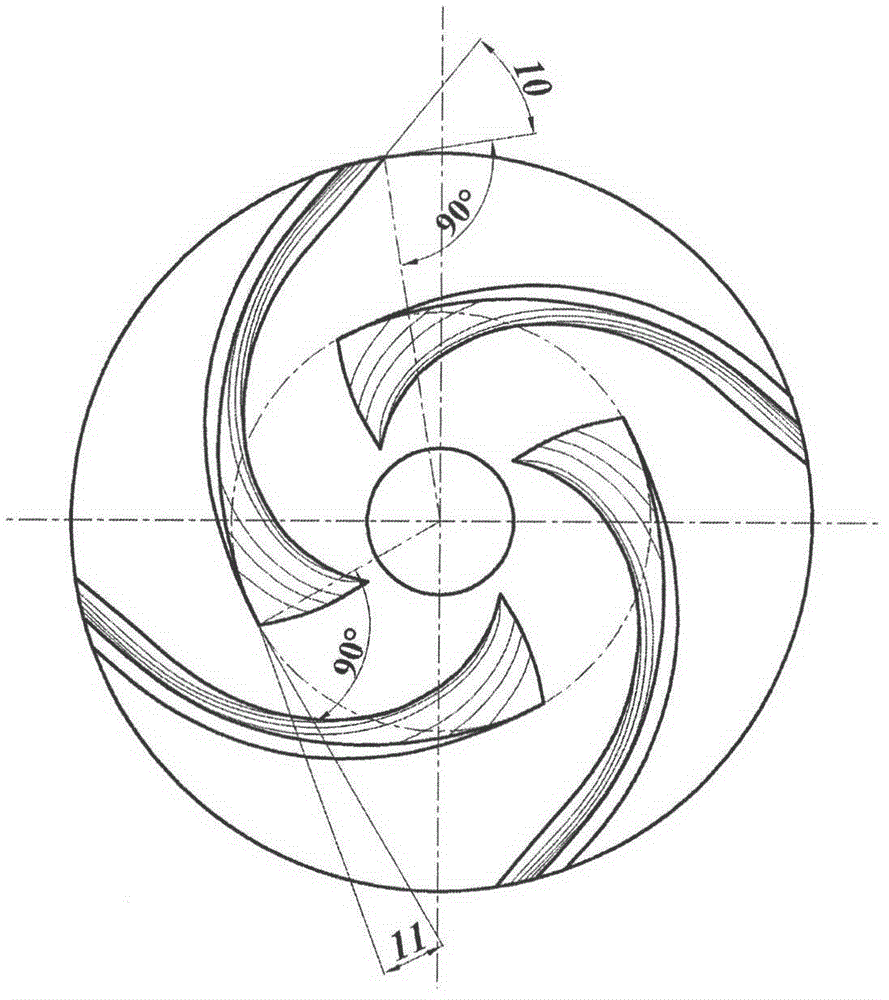

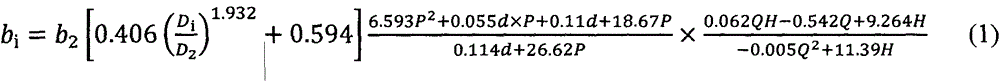

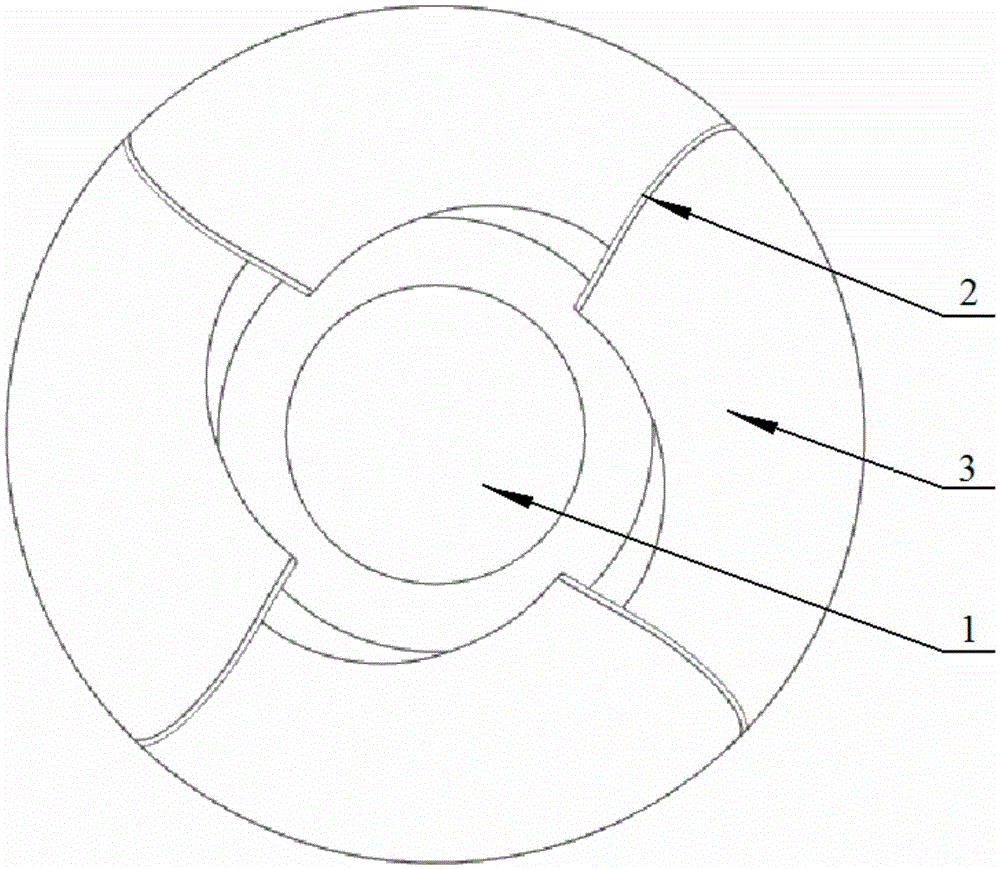

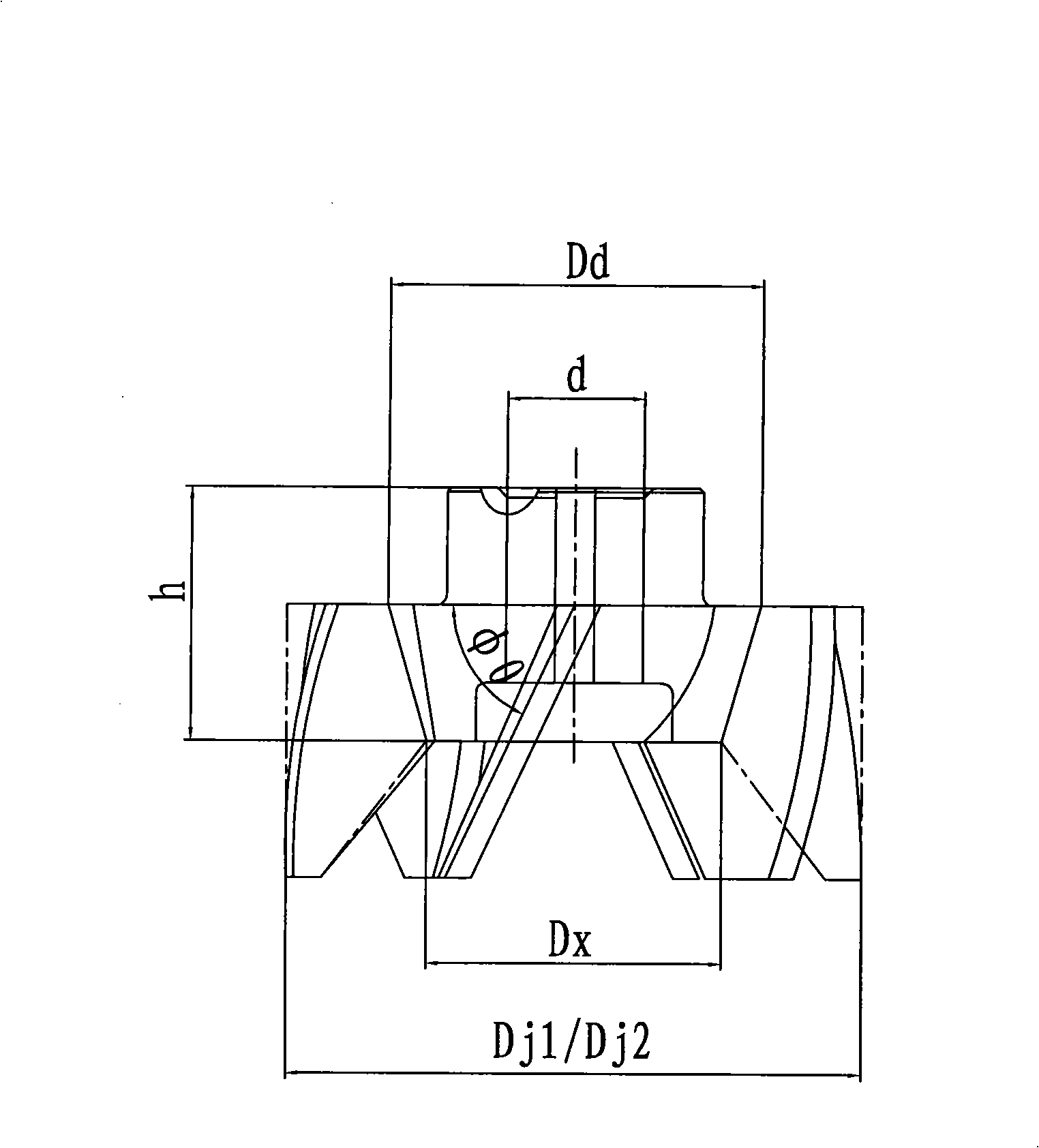

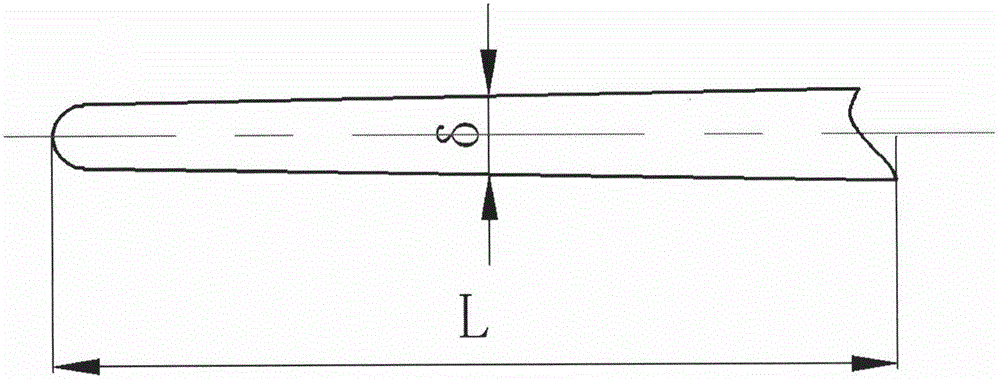

Impeller water power design method of solid-liquid two-phase flow pump

The invention relates to an impeller water power design method of a solid-liquid two-phase flow pump, in particular to an impeller water power design method of a centrifugal solid-liquid two-phase flow pump high in specific speed. The impeller water power design method includes determines important design parameters such as the impeller outlet diameter D2, the blade outlet width b2, the blade outlet arrangement angle beta 2, the blade outlet arrangement angle allowance delta beta 2, the blade inlet arrangement angle beta 1, the number z of blades, the blade inlet excretion coefficient Psi 1, the blade outlet excretion coefficient Psi 2, the real blade thickness delta, the all-over blade width bi, the axial inclined angle theta of the blade outlet tangent line, the arc radius Ra of an impeller front cover plate, and the arc radius Rb of an impeller rear cover plate. Through production practice and test, design efficiency and standard of the solid-liquid two-phase flow pump are greatly improved, and design cost and risk are reduced. The solid-liquid two-phase flow pump designed and produced by the impeller water power design method has the advantages of excellent using performance and high economic benefits.

Owner:JIANGSU UNIV

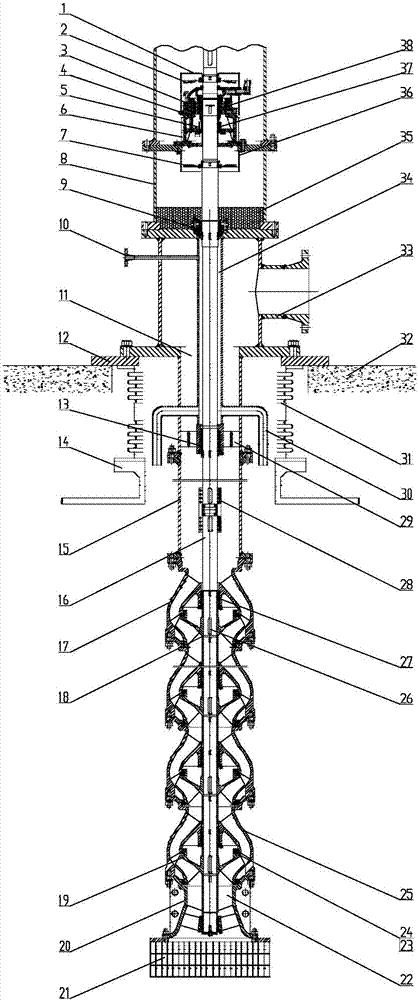

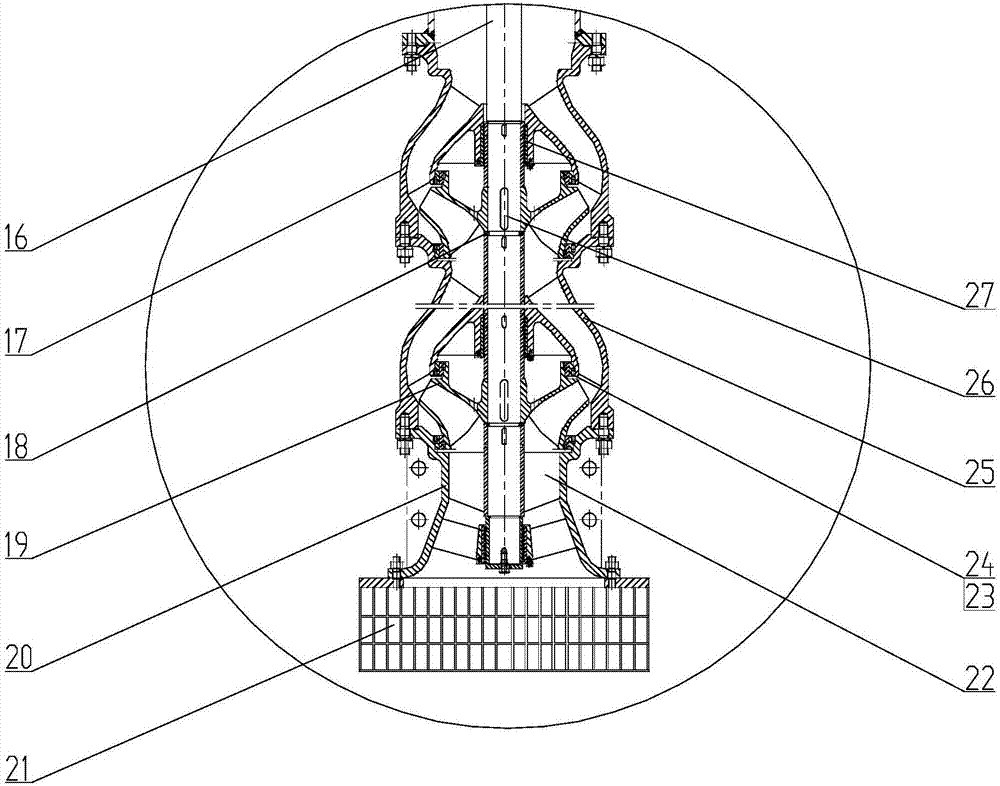

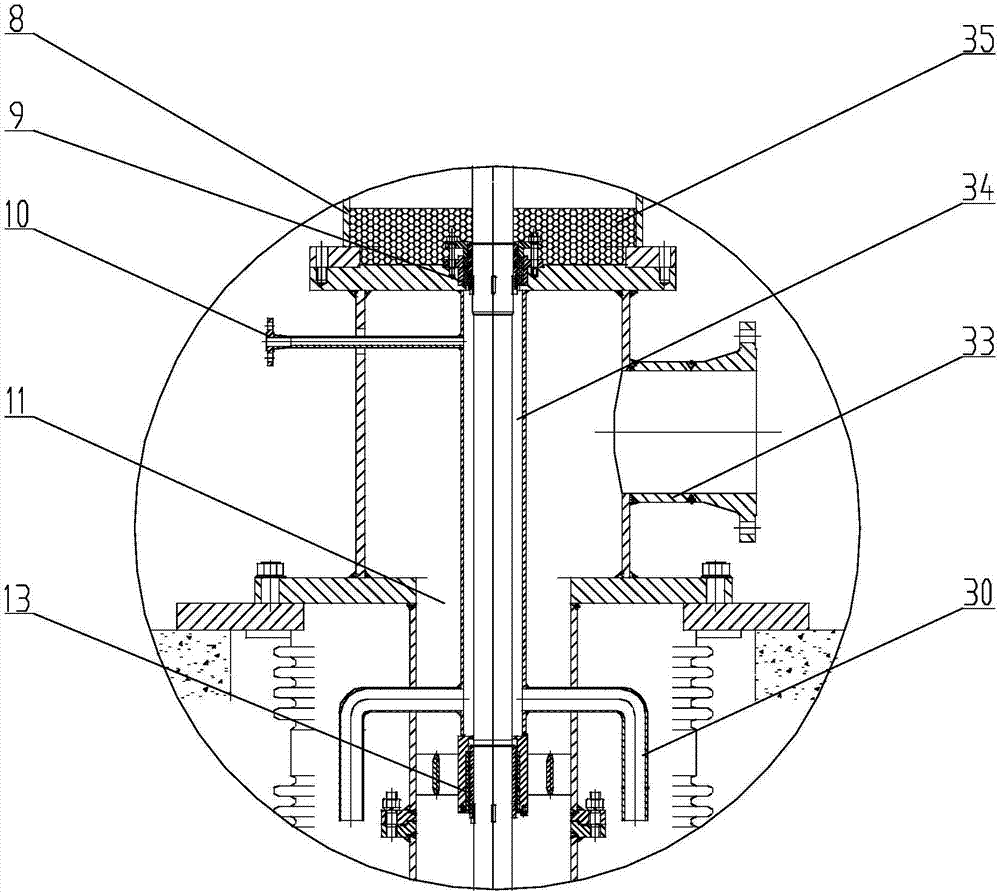

Solar thermal power high-temperature long shaft molten salt pump

PendingCN107355389AFlow state is stableMaximize power generationSpecific fluid pumpsPump componentsThermal dilatationMolten salt

The invention discloses a solar thermal power high-temperature long shaft molten salt pump. The solar thermal power high-temperature long shaft molten salt pump comprises a pump shaft, a hydraulic part, a supporting vibration reduction structure, a fluid seal structure and a bearing cooling device are sequentially arranged on the pump shaft from bottom to top, a suction segment is arranged at the front end of the hydraulic part, a blade grid type filter is arranged on the front end of the suction segment, a tail stage flow guide shell is arranged at the tail end of the hydraulic part, the tail end of the tail stage flow guide shell and the front end of a supporting pipe of the supporting vibration reduction structure are fixedly connected, and the tail end of the supporting pipe of the supporting vibration reduction structure is fixedly connected with the bottom of the outlet segment of the fluid seal structure through a flange plate. The solar thermal power high-temperature long shaft molten salt pump is designed to be in the center flow-out manner, thermal expansion uniformity under the high-temperature state can be ensured, through solution schemes of reliable fluid seal design, reasonable cooling structures, flange type expansion joint vibration reduction configuration and the like, safe, reliable and efficient running of the solar thermal power high-temperature long shaft molten salt pump is ensured, and meanwhile, various property indexes are met.

Owner:DALIAN DEEP BLUE PUMP CO LTD

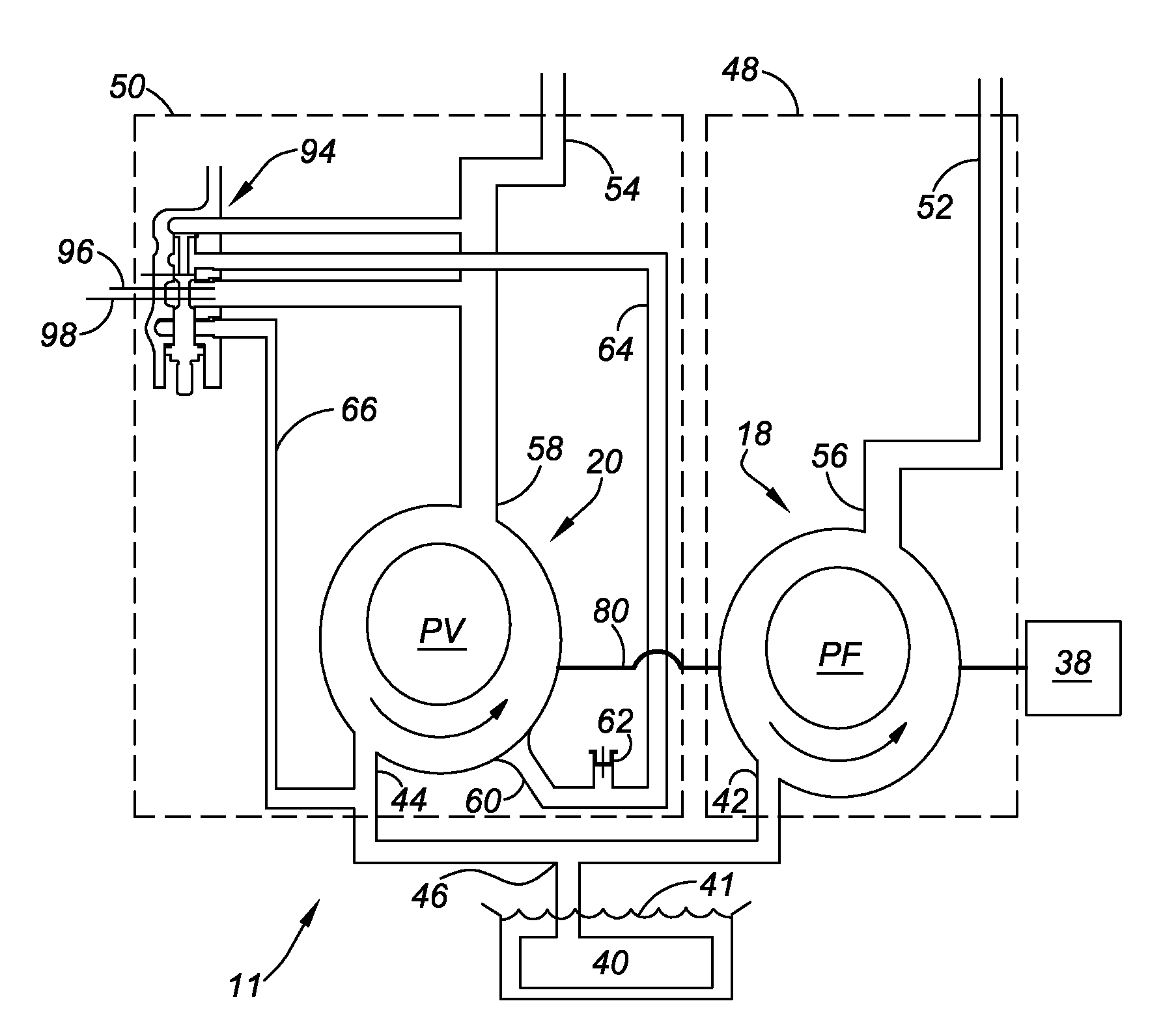

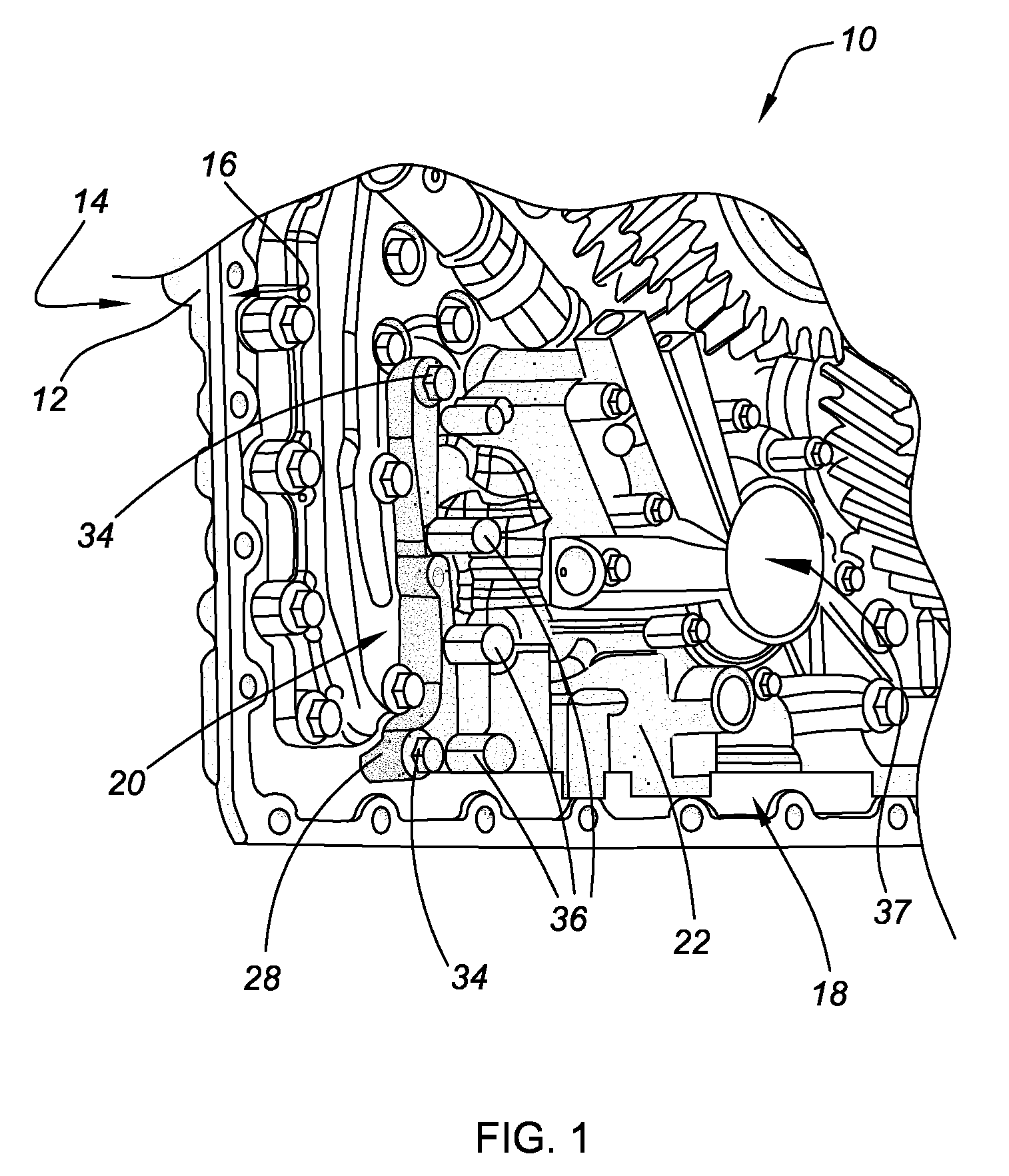

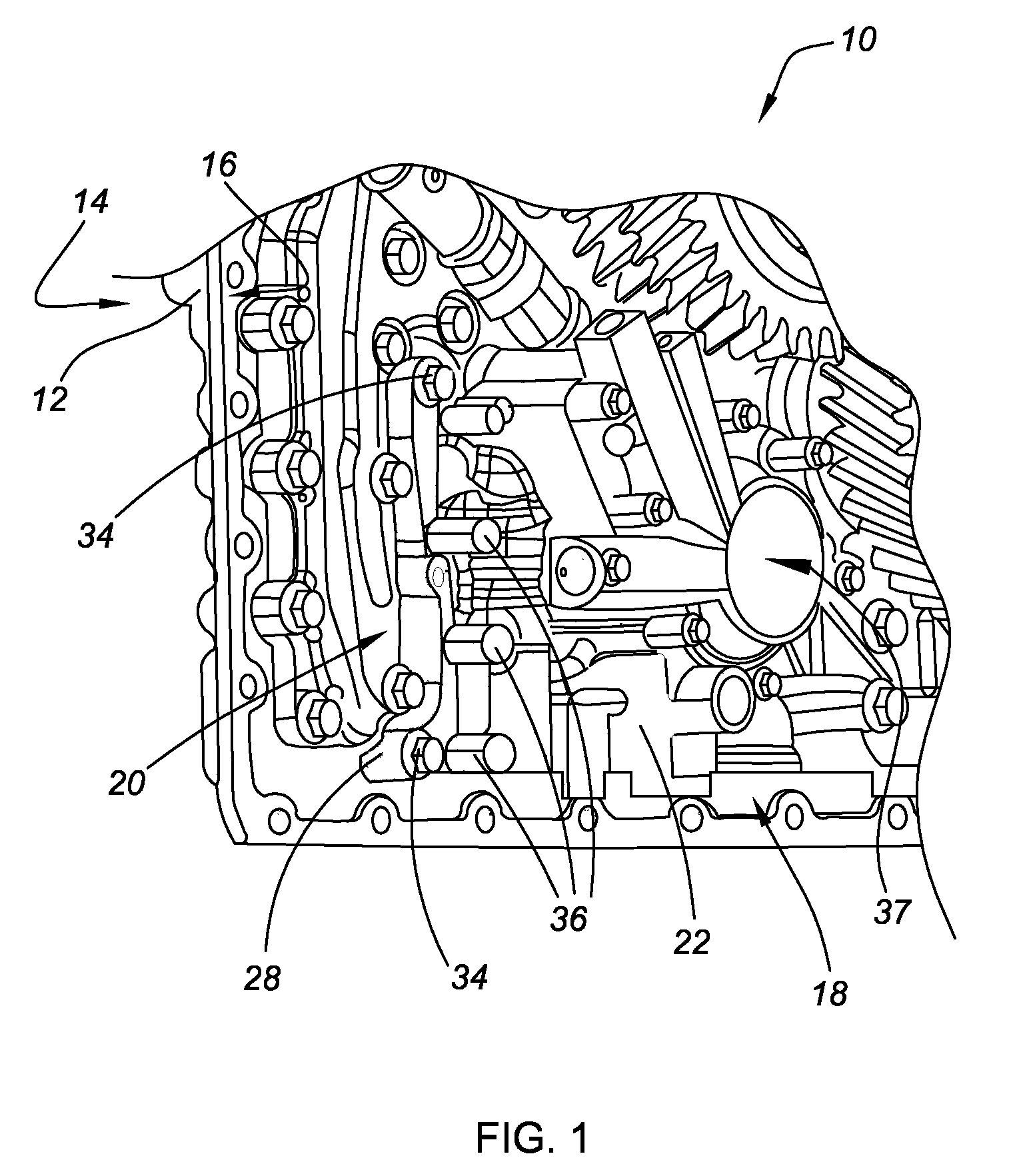

Split-Pressure Dual Pump Hydraulic Fluid Supply System for a Multi-Speed Transmission and Method

ActiveUS20080247882A1Reduce trafficMaximizes performance and efficiency and dependabilityEngine of arcuate-engagement typeOscillating piston enginesEngineeringHigh pressure

A split-pressure, dual-pump system for supplying hydraulic fluid to a multi-speed transmission is provided. The system includes a low-pressure work circuit operatively connected to a fixed displacement pump, and a high-pressure work circuit operatively connected to a variable displacement pump. The system also includes a regulator valve fluidly coupled to the variable displacement pump via a decrease circuit and an overage circuit for regulating the flow of fluid to the high-pressure work circuit. The invention consists of separating the high-pressure needs of the system into a separate work circuit from the low-pressure needs of the system, and optimizing pump design separately for each work circuit to maximize transmission efficiency and reduce parasitic losses. A method of supplying hydraulic fluid to a multi-speed transmission at variable flow and pressure is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

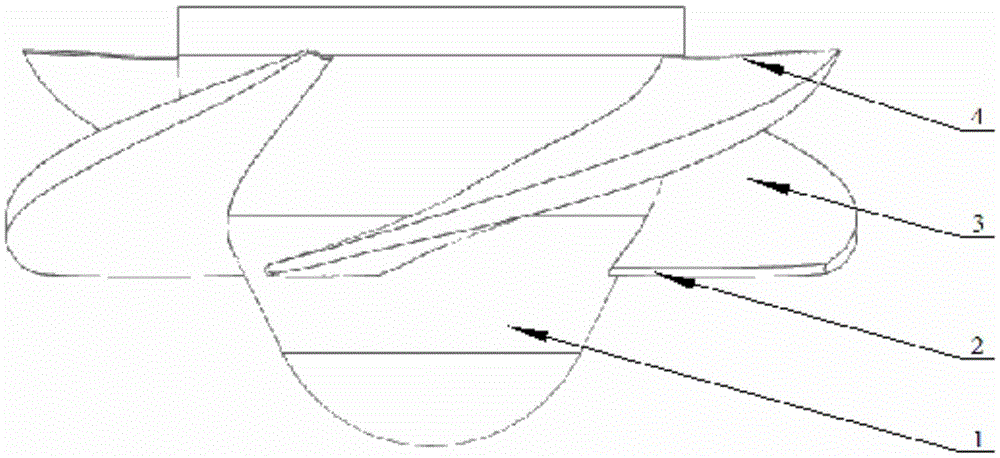

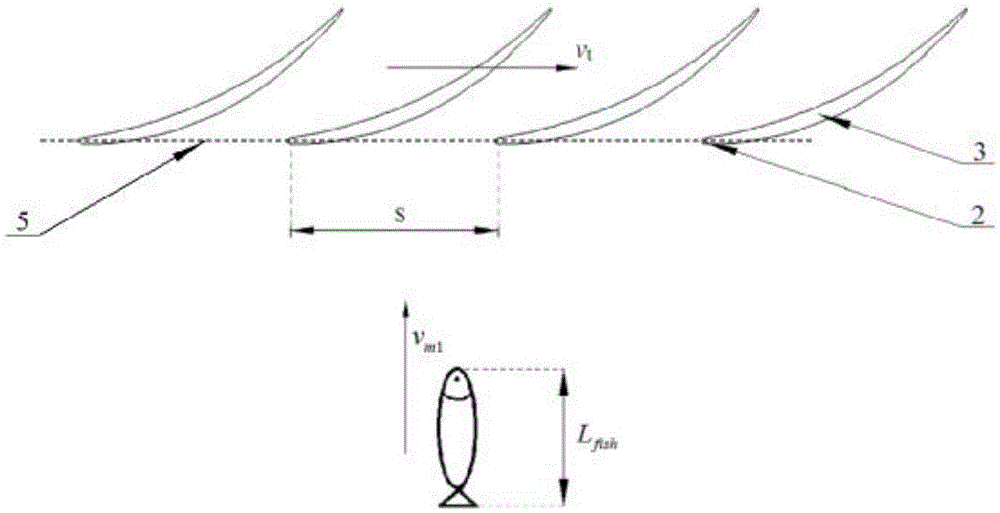

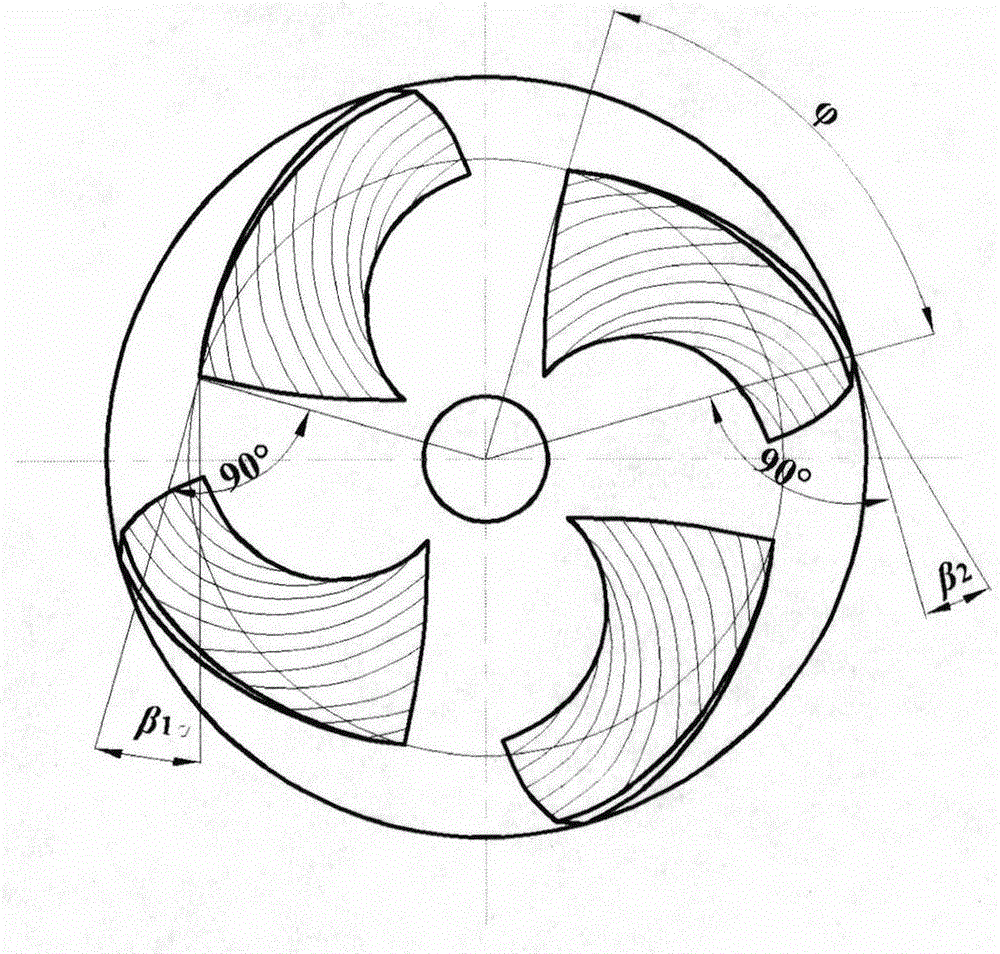

Designing method of fish-friendly axial flow pump based on fish survival rate prediction

InactiveCN105626573AImprove survival rateReduce the probability of impactPump componentsPumpsAxial-flow pumpMathematical model

The invention provides a designing method of a fish-friendly axial flow pump based on fish survival rate prediction. A relation between a pump design parameter and the fish passing survival rate is predicted by adopting a mathematical model, and thus a fish-friendly design of an axial flow pump is guided. The mathematical model is mainly composed of the blade leading edge impact probability and the impact death rate; the impact probability is a ratio of the time that fishes pass through the cross section of passage of the blade leading edge and the time needed by an impeller rotating around a blade pitch; the impact death rate is relevant to the impact velocity, the fish length and the thickness of the blade leading edge; and the impact velocity adoptsa velocity component of a vertical leading edge. The fish-friendly axial flow pump design comprises the following steps: lowering the blade leading edge impact probability by adopting two blade impellers, lowering the impact death rate by adopting the blade leading edge with linear sweepforward protraction, and ensuring good hydraulic performance by virtue of airfoil parameter design. According to the designing method, a fish survival rate prediction model is high in goodness of fit to an experiment value, and the fish-friendly axial flow pump designed by guidance can greatly lower the fish death rate.

Owner:JIANGSU UNIV

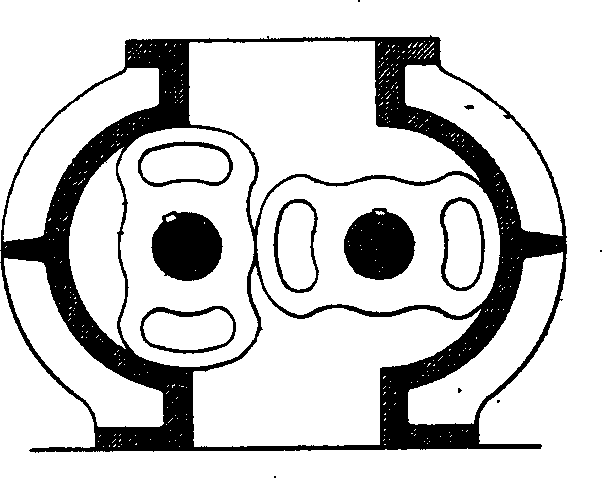

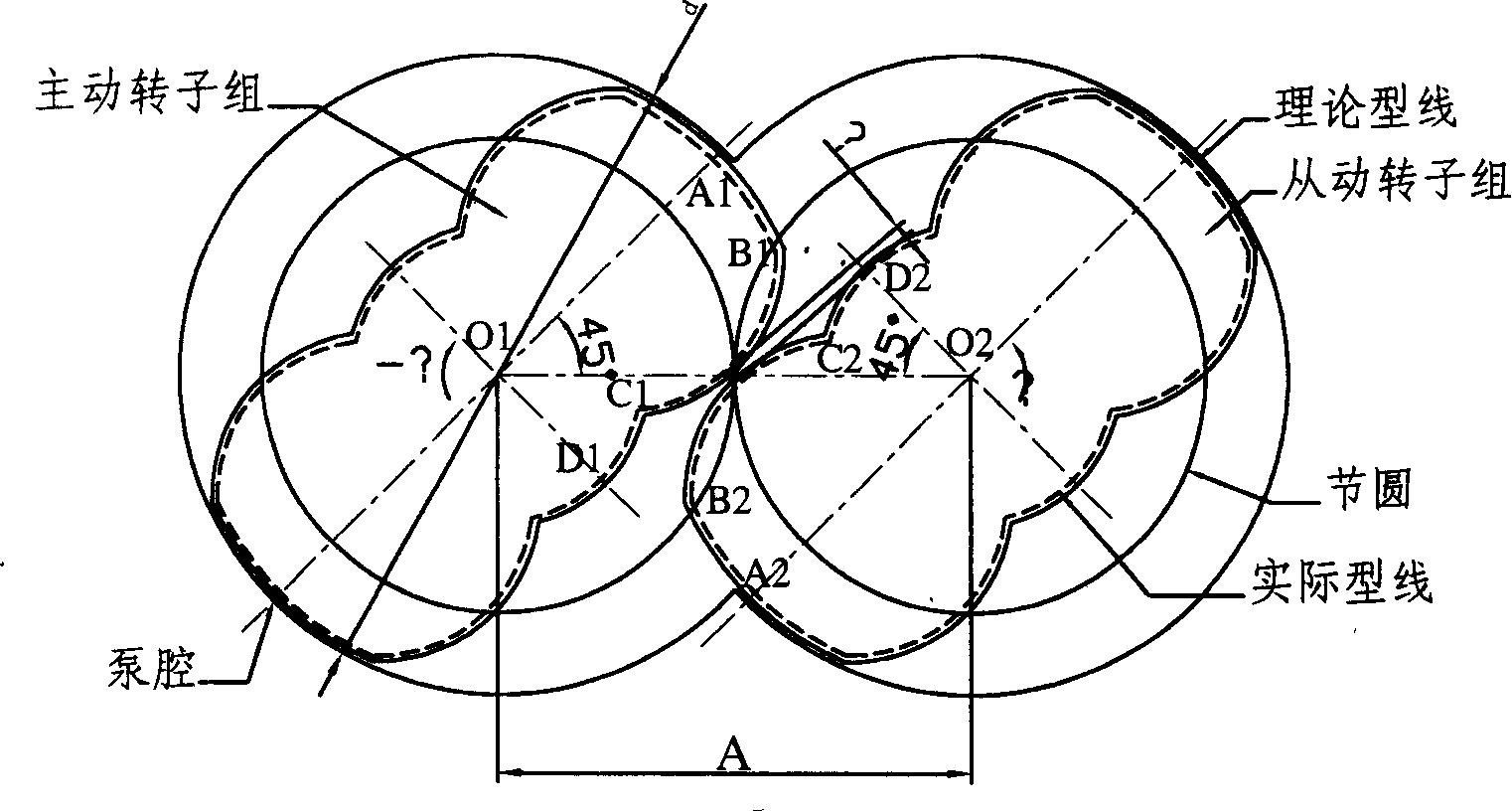

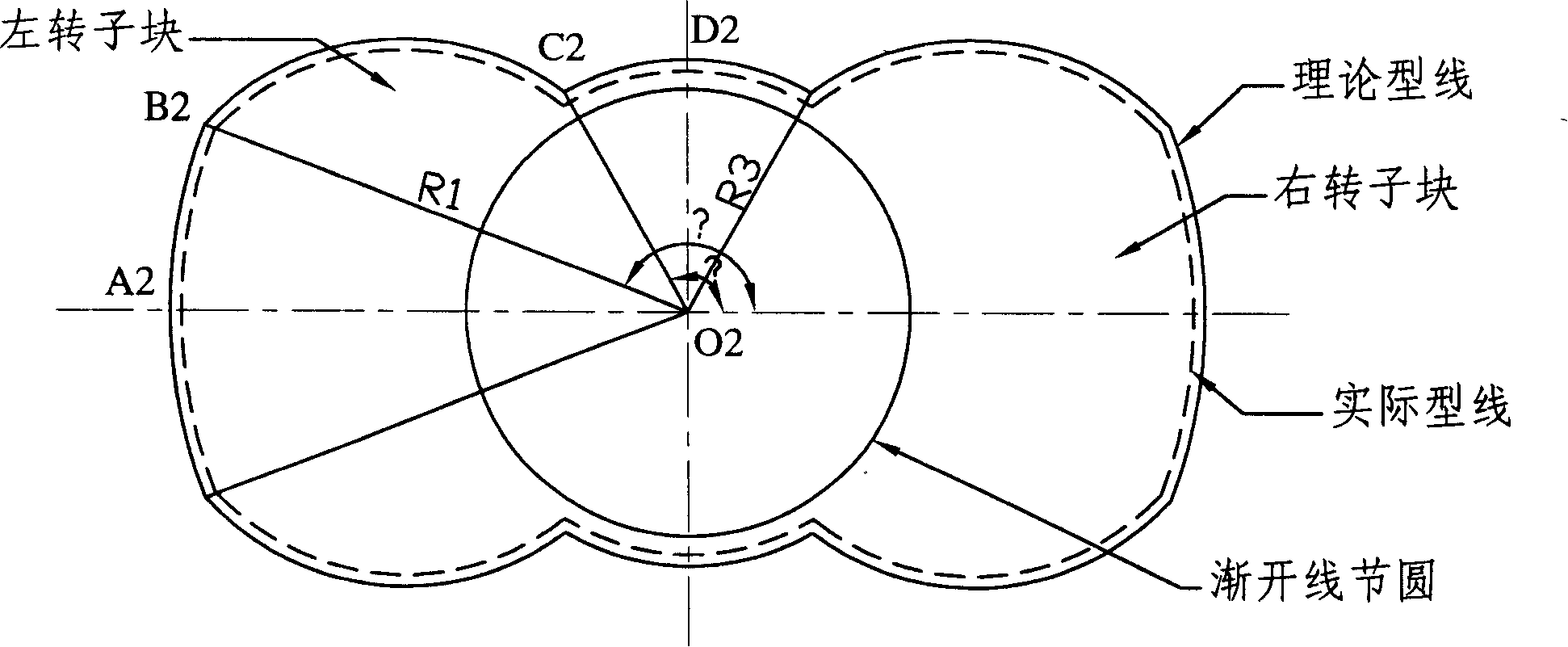

Roots dry type vacuum pump rotor capable of directly discharging to air and processing technique thereof

ActiveCN101210556AReduce processing costsExtended service lifeRotary piston pumpsRotary piston liquid enginesInvoluteEngineering

The invention relates to a design of a Roots pump, in particular to a rotor of a Roots dry vacuum pump which discharges directly into atmosphere and processing technology thereof. The processing technology substitutes a waist arc for an involute to design a rotor block, the rotor block is separately processed and then assembled with a spigot shaft. The processing steps are as follows: (1) processing the rotor block: a ductile cast iron bar is selected as roughcast; processing method: firstly processing the outer surface and the two end surfaces of the bar, incising the bar according to the thickness of the rotor block, then processing other two surfaces (outer circular surface and inner circular surface) of the rotor block, finally incising the bar into the rotor block with needed thickness according to application requirements; (2) joining two rotor blocks and a pin roll into a whole via a pin hole. The invention has the advantages of simple processing technology, low cost, high versatility of parts, suitability for IC equipments, etc.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

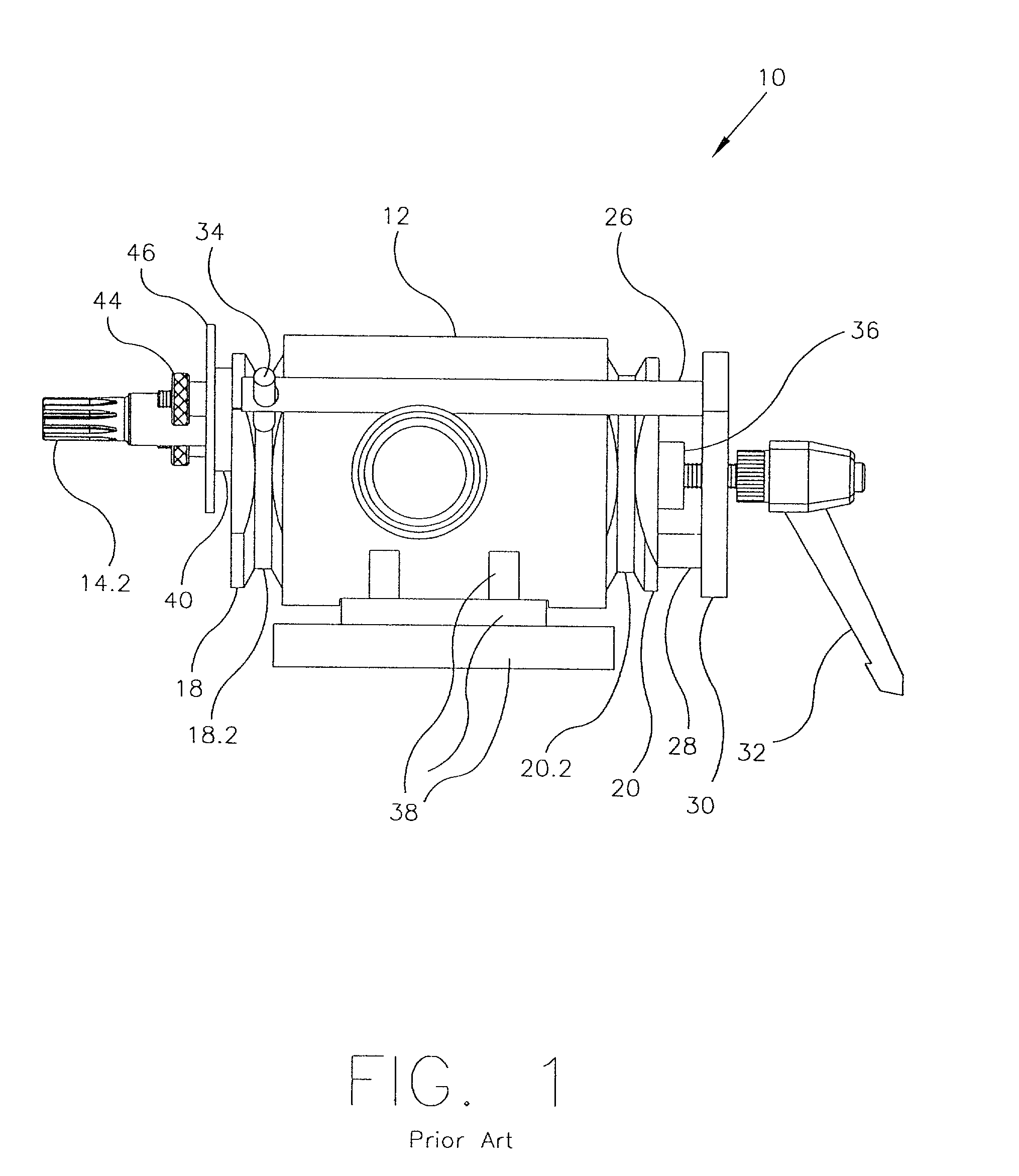

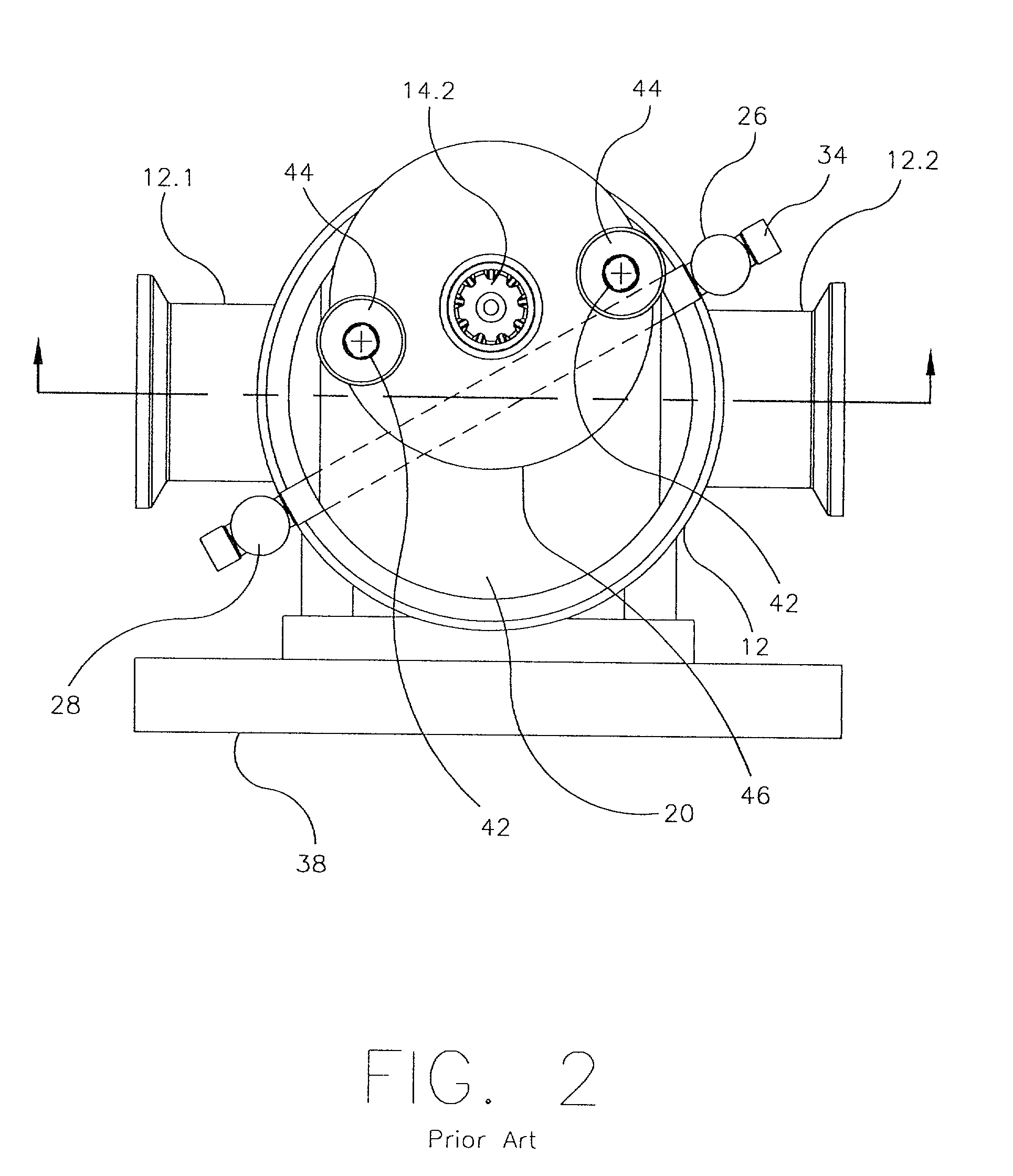

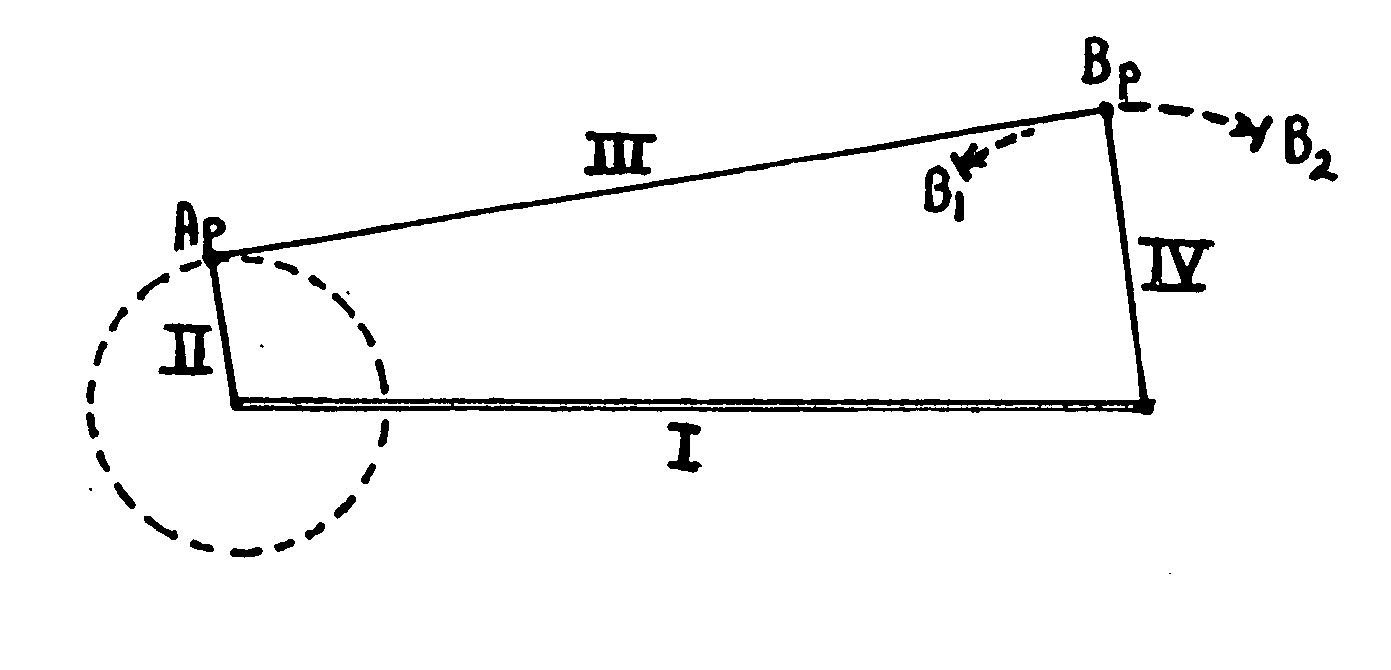

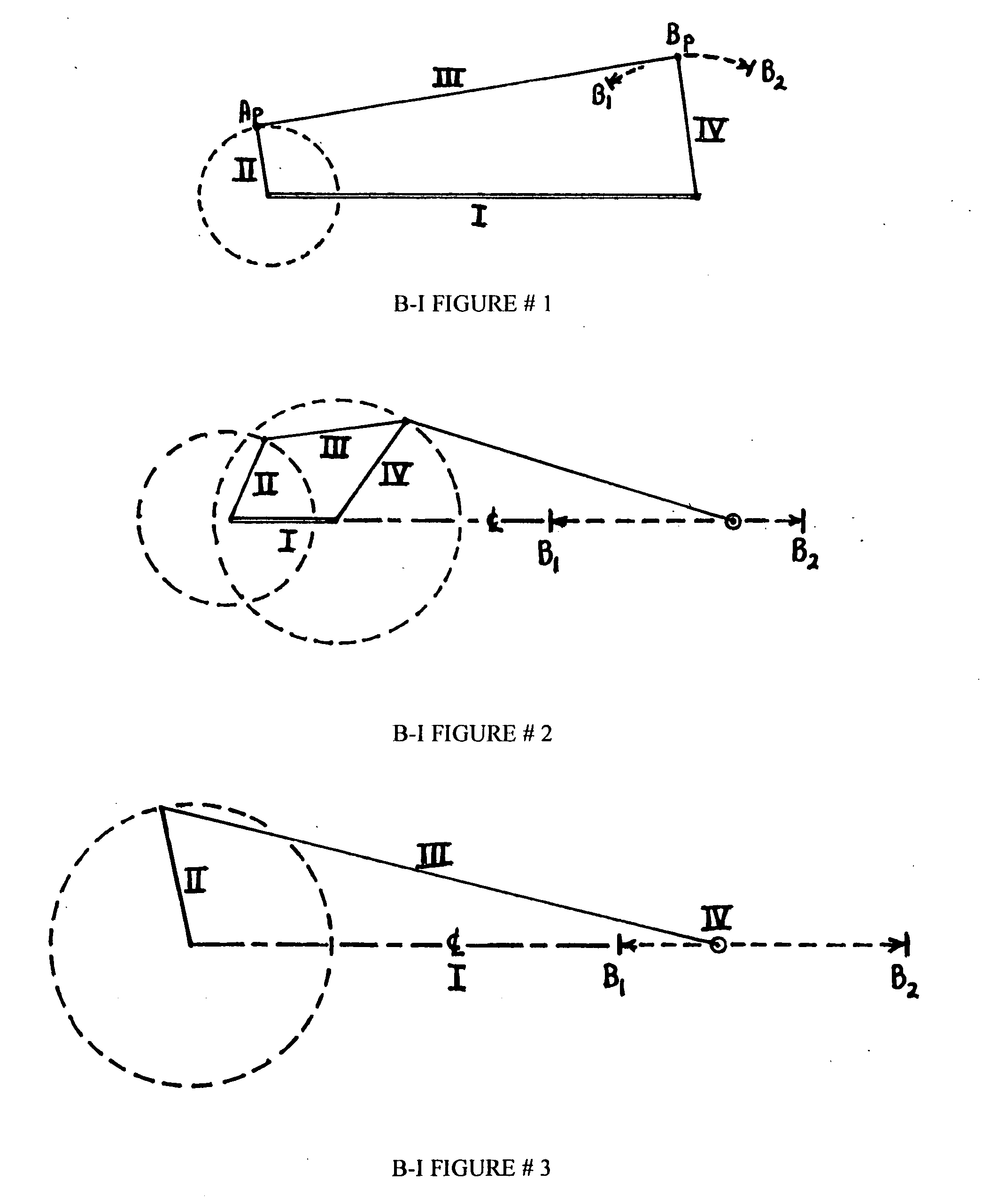

Styled the system, asymmetric, engine/pump design

InactiveUS20070256650A1Increase and decrease effective/functional working lengthIncrease discreet energy efficiency/fuel economyCasingsConnecting rodsWork cycleEffective length

What is new in the art (or rather, technique) in the structuring of the linkage mechanism as it is most commonly used in the design of reciprocating piston heat / pressure engines and pumping / compressing machines are the two alterations and the combination thereof that I have invented. They are, #1, establishing a (very large) fixed and permanent offsetting, or asymmetry, between the geometric center axi of the cylinder and crankshaft for the purpose of altering the fundamentals of the working cycle, #2, the addition of a sub-link to the connecting rod such that it then also functions as an extension (alternately increasing and decreasing the working, or effective length) of the crankshaft arm during the rotation of the crankshaft, and #3, the combining of these two improvements as one unit, or in one machine.

Owner:ETHELMER PFLUGHOEFT STEPHEN ANTONIUS

Dual chamber mixing pump

A dual chamber mixing pump design is disclosed which allows two different sources of fluid to be combined into one mixed product fluid. The pump is divided into two chambers, the proximal chamber and the distal chamber. The chambers are defined in part by a piston having proximal and distal ends and recessed sections. The pump utilizes one common driving mechanism to axially rotate and laterally reciprocate the piston to provide continuous pumping of fluids with reduced pulsations. Each fluid enters through its own pump inlet and outlet. For mixing applications, the outlets are joined together. The flow volume per stroke of each chamber is determined by the lateral stroke of the entire piston assembly and also by the annular areas of the proximal and distal ends of the piston. The flow volume per stroke may be altered by varying the piston and shaft diameters for each chamber. This allows mixing of two fluids in any ratio or proportion desired. Alternating pulses of the two chambers provide a stream which has small segments of alternating fluid from each inlet. Such segmented streams can become more thoroughly mixed through normal flow characteristics of the downstream flow path, providing more effective mixing.

Owner:FLUID MANAGEMENT LLC

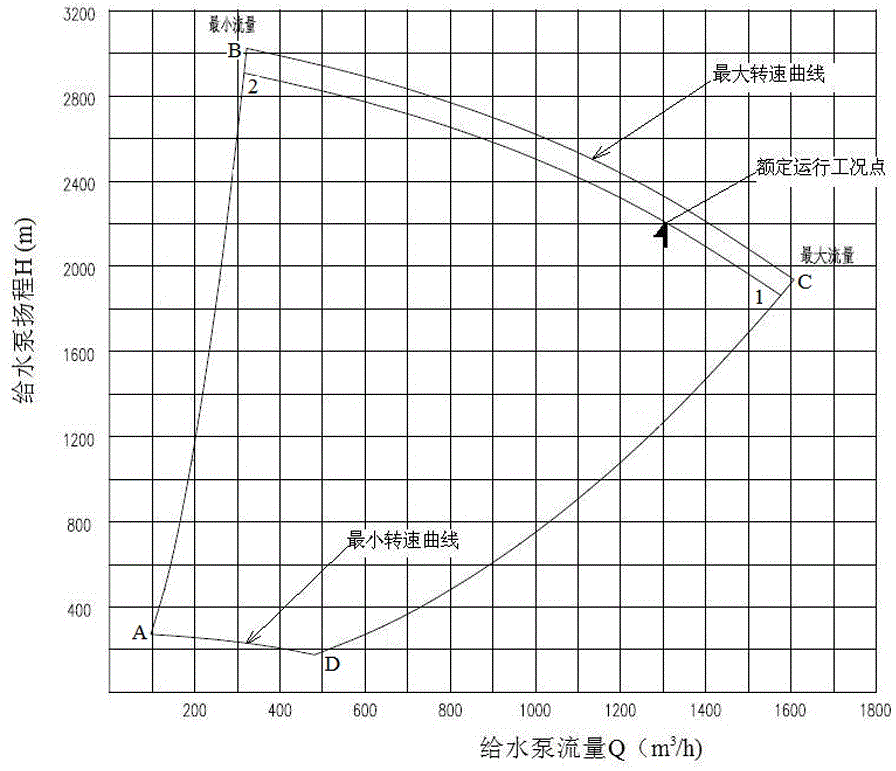

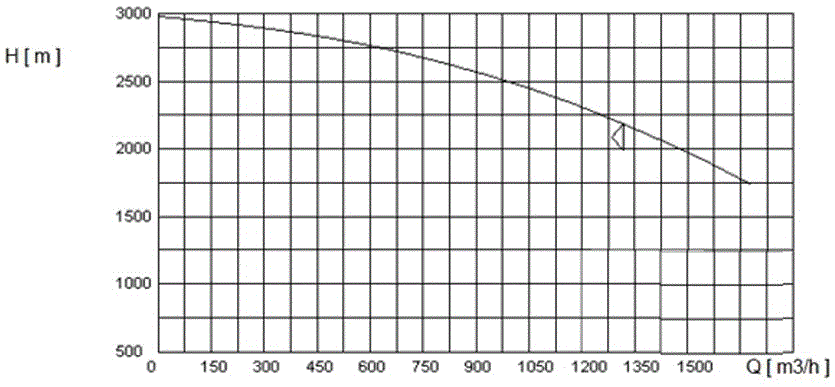

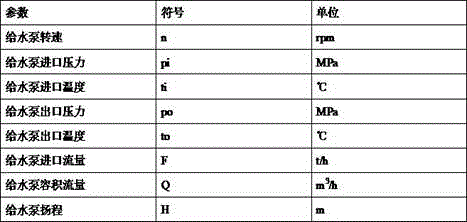

Online monitoring method for operation state of large-sized variable-speed water-feeding pump

ActiveCN106050637AMeet the needs of condition-based maintenanceEasy accessPump testingPump controlDaily operationEngineering

The invention relates to an online monitoring method for the operation state of a large-sized variable-speed water-feeding pump. The method comprises the steps of recording the operation parameter of the water-feeding pump in a monitored state, according to a designed flow-head curve of the water-feeding pump, determining the numerical function of the boundaries of the normal operation area of the water-feeding pump, collecting the operation data of the water-feeding pump in a normal new running state, fitting out the flow-head performance curve of the water-feeding pump at a certain specific rotation speed after amendment, judging whether the water-feeding pump operates in the normal operation area or not according to the operation parameter of the water-feeding pump in the monitored state, if not, giving out an abnormal operation state alarm prompt, carrying out amendment till the certain specific rotation speed of the water-feeding pump is matched with the normal state curve according to the operation parameter of the water-feeding pump in the monitored state, and giving out an alarm prompt for the abnormal operation state of the water-feeding pump if the deviation between the rotation speed and the normal state curve exceeds a certain degree. By means of the method, the daily operation state of the water-feeding pump can be monitored, and judging criteria for the situation that the operation state of the water-feeding pump deviates from the normal operation area are provided

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +2

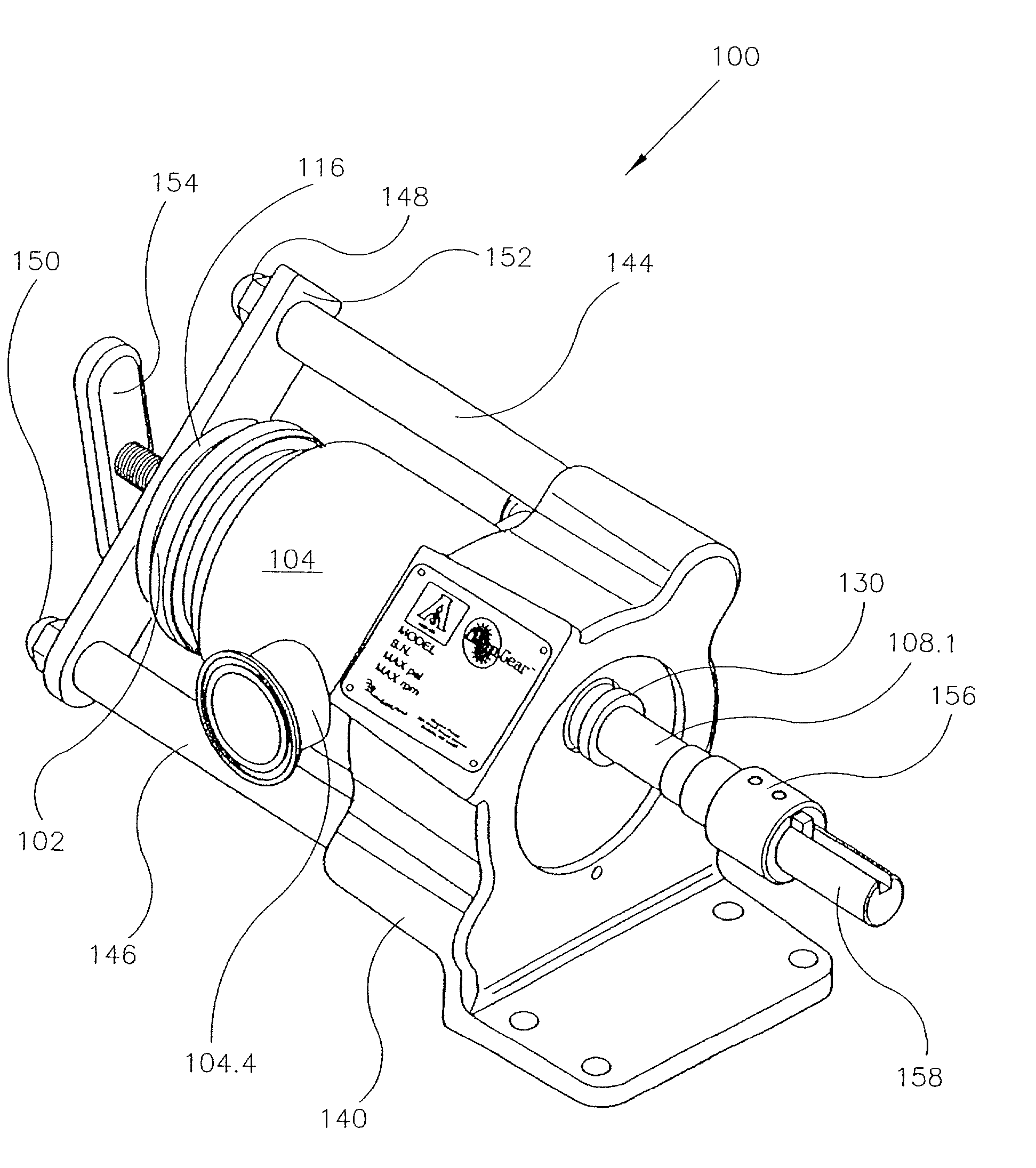

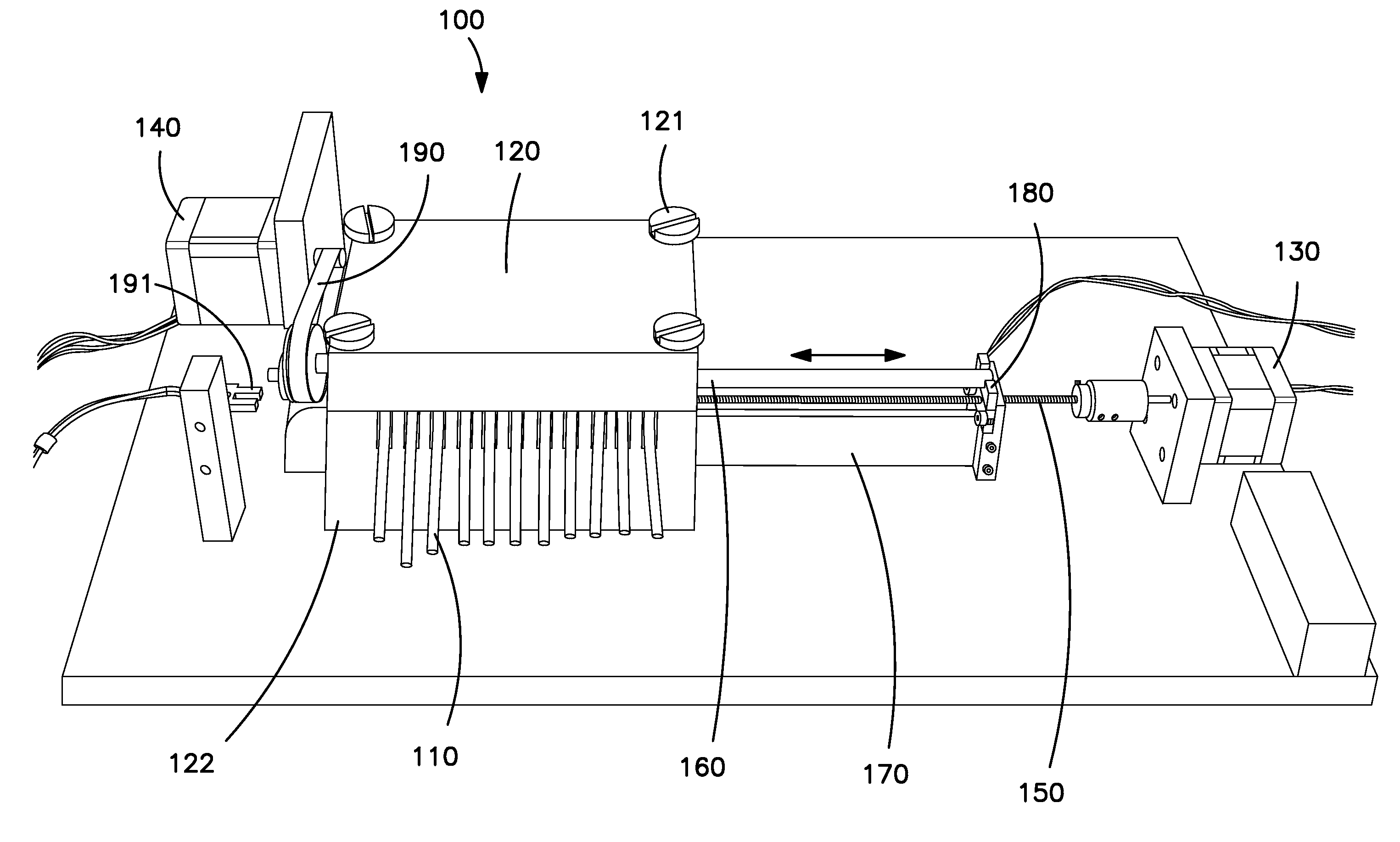

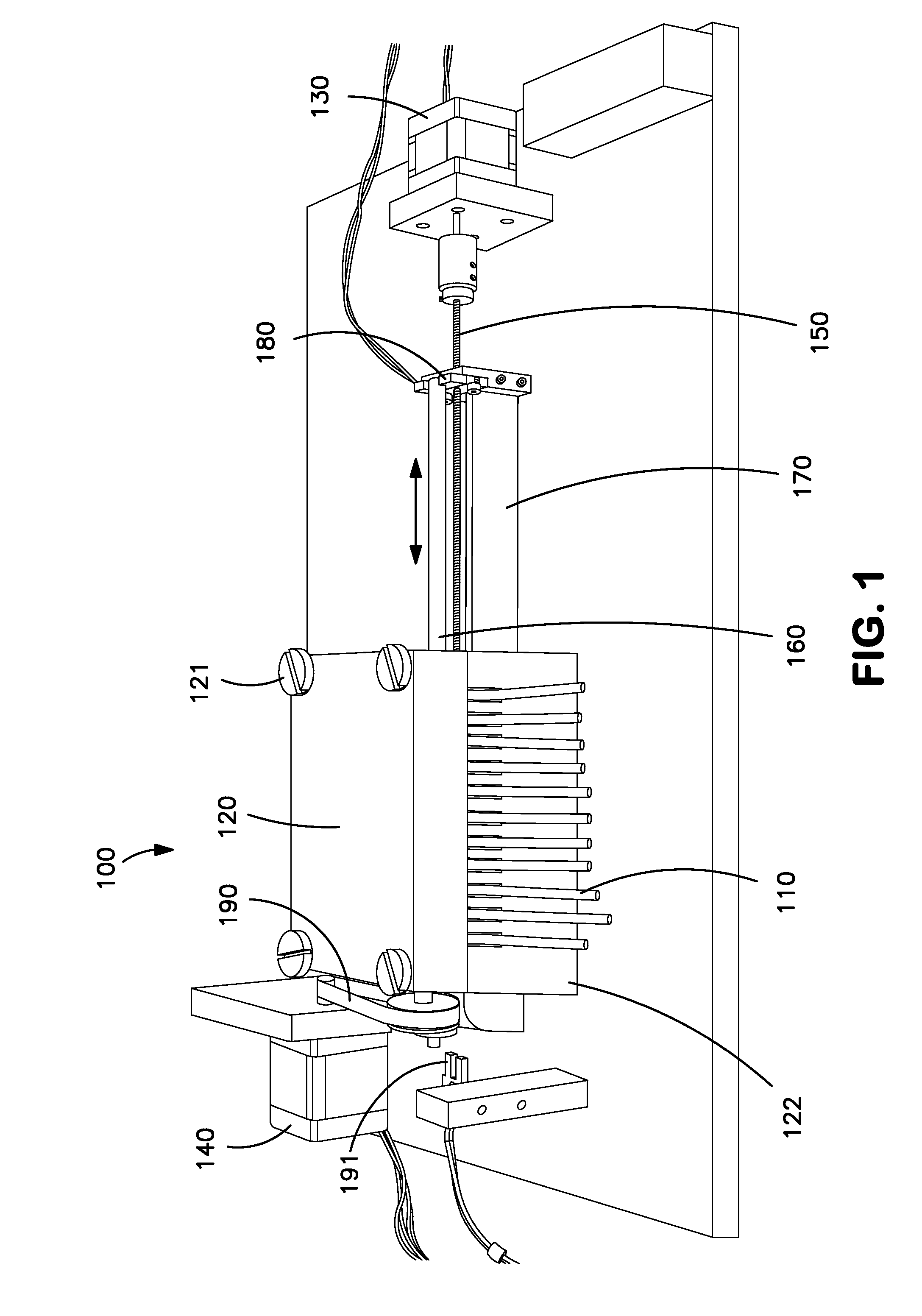

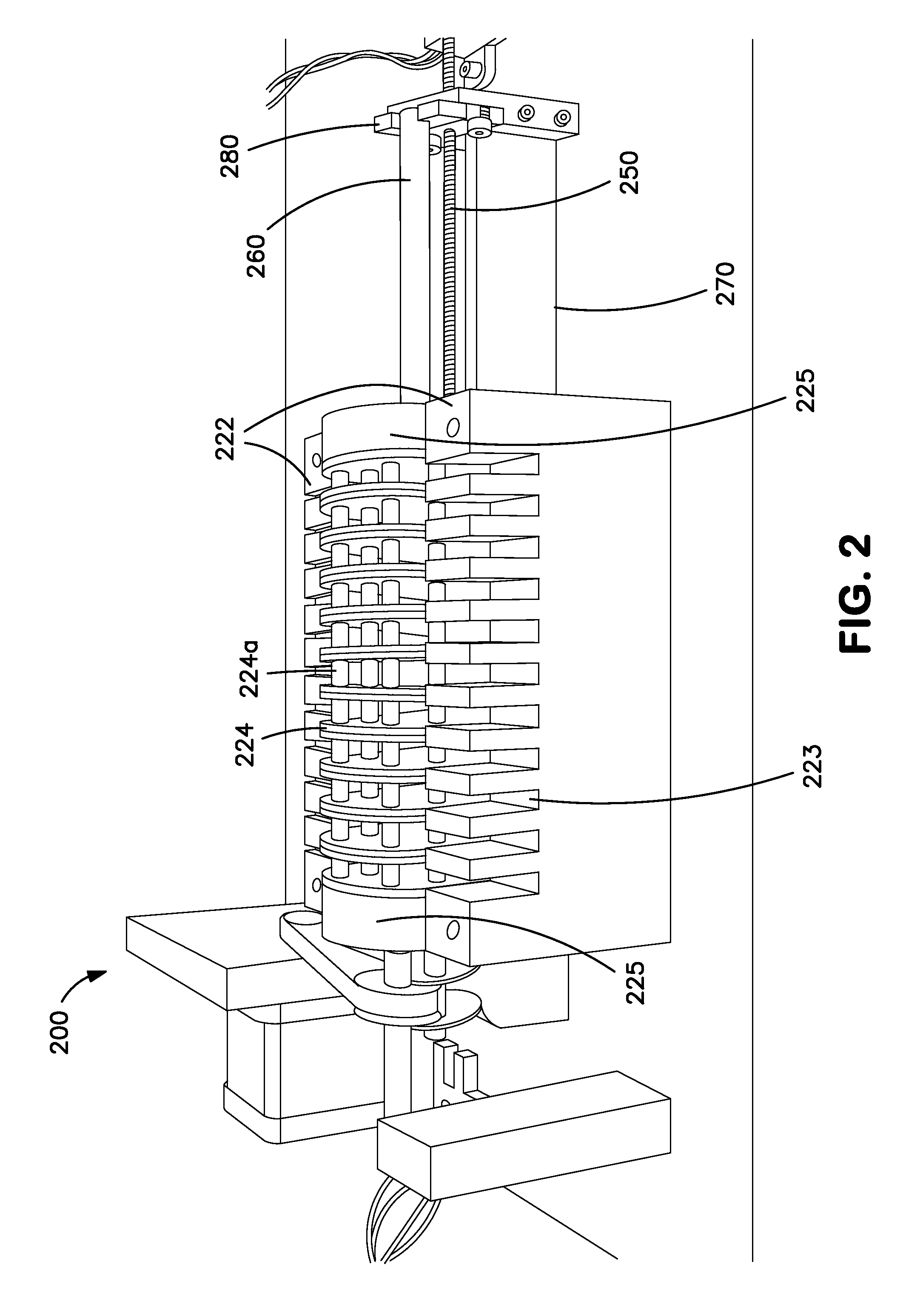

Addressable Multi-Channel Peristaltic Pump

InactiveUS20090035165A1Load minimizationPrevent rotationFlexible member pumpsPump controlPeristaltic pumpDrive shaft

The present invention provides an addressable multi-channel peristaltic pump. According to the invention, this pump design allows for selection and operation of one or more pump heads on a drive shaft, while locking other non-selected pump heads in a stationary position. It is possible to operate the multi-channel pump using a limited number of motors, preferably two motors: a selector motor and a dispense motor. Thus, the pump provides for pumping or dispensing of one or more fluids without the need for multiple pumps. Likewise, compared with typical single motor multi-channel systems, where all pump heads on the drive shaft must rotate at the same time, the present invention provides for selective dispensing of one or more fluids. The pumps of the present invention are suitable for any multiple fluid transfer application, including in automated multi-channel reagent dispensing systems, such as nucleic acid purification systems.

Owner:AGILENT TECH INC

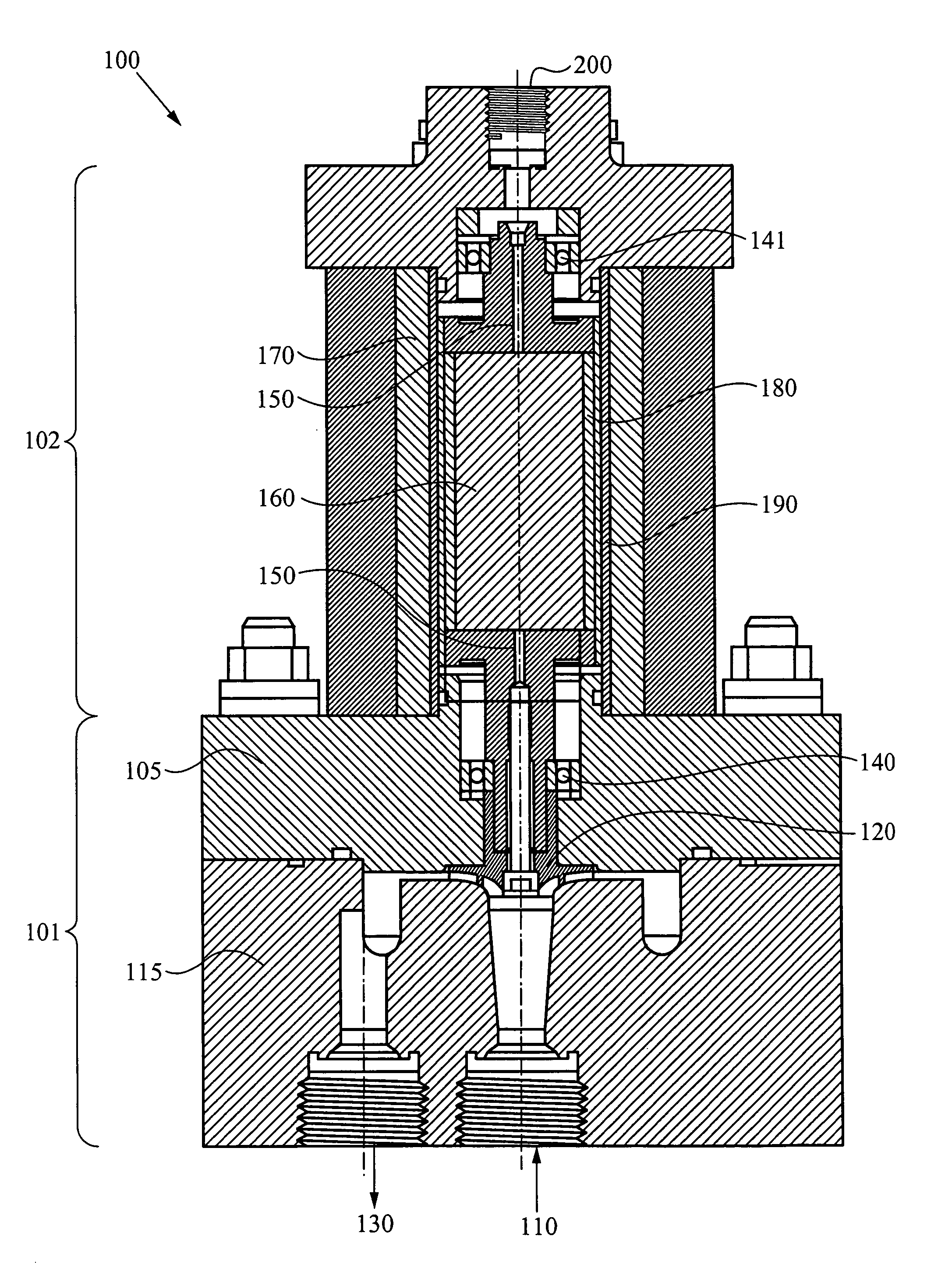

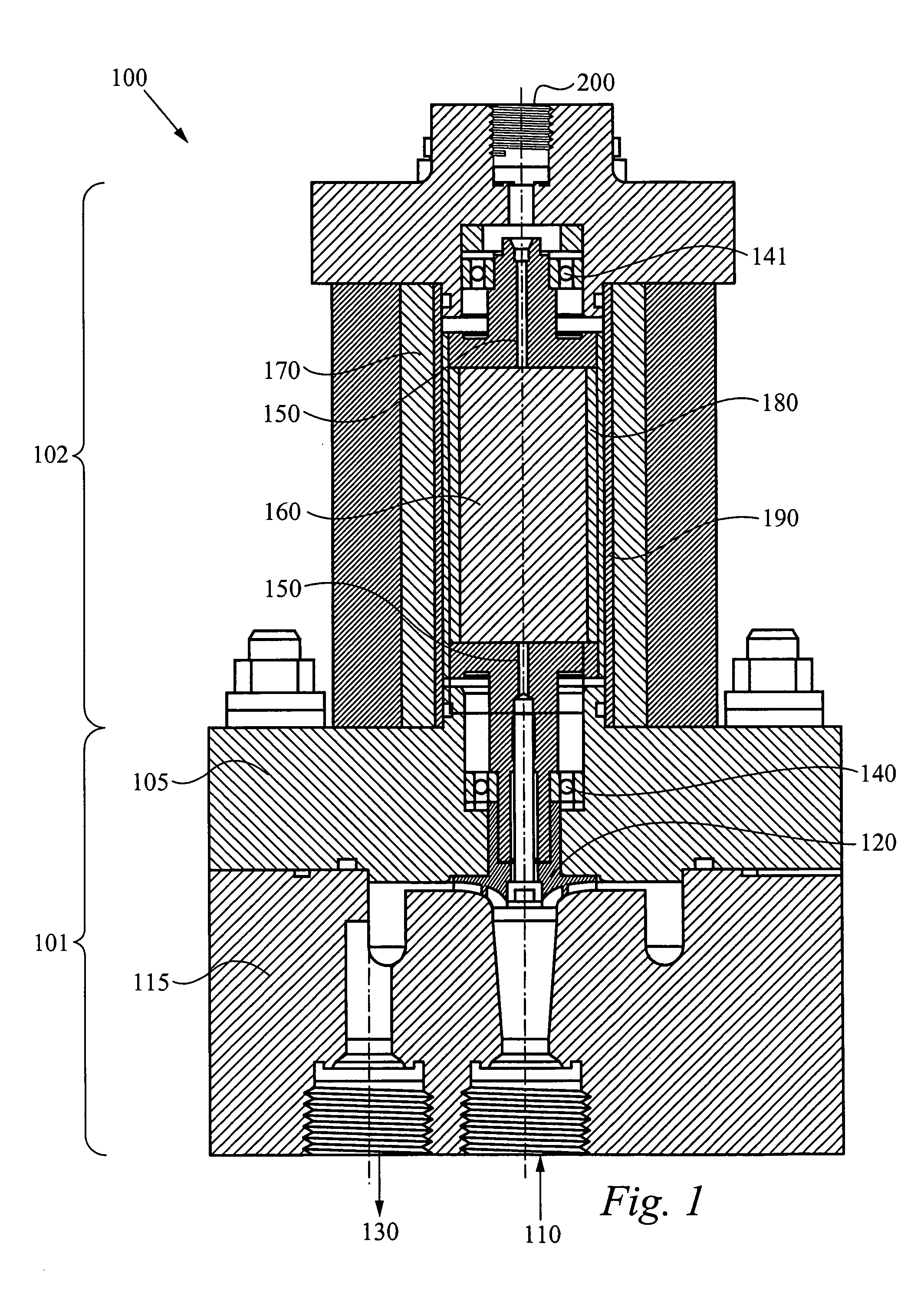

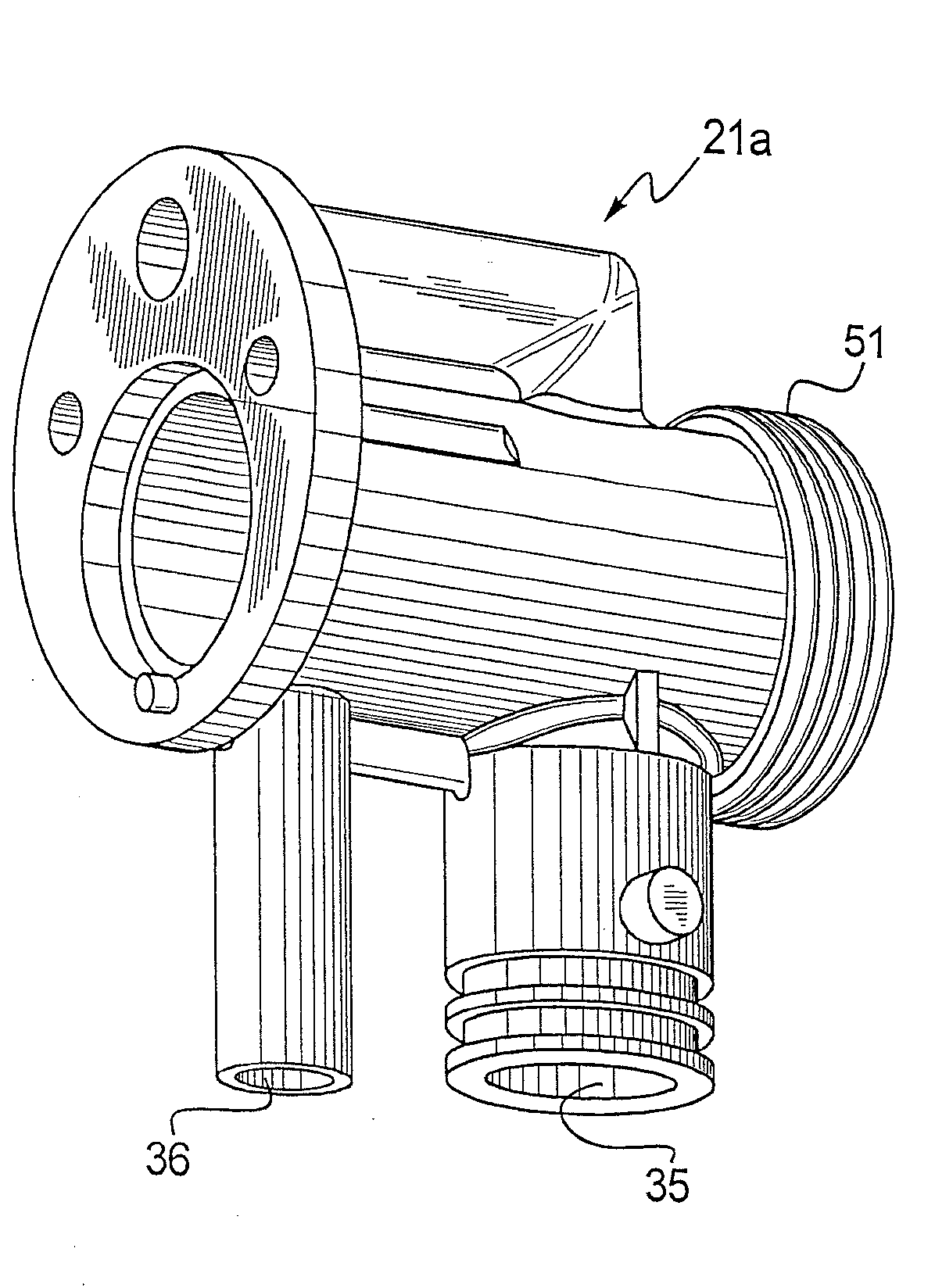

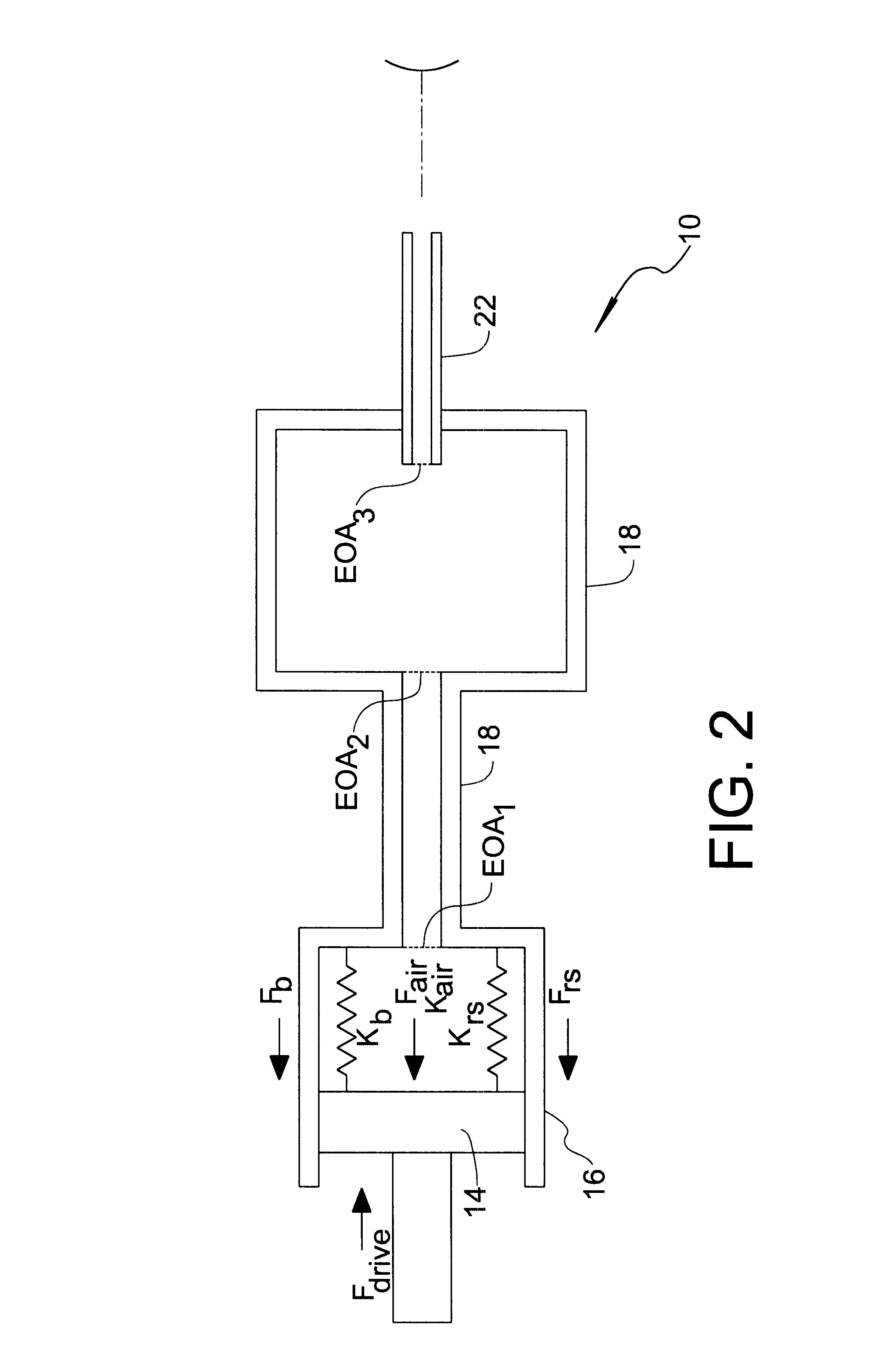

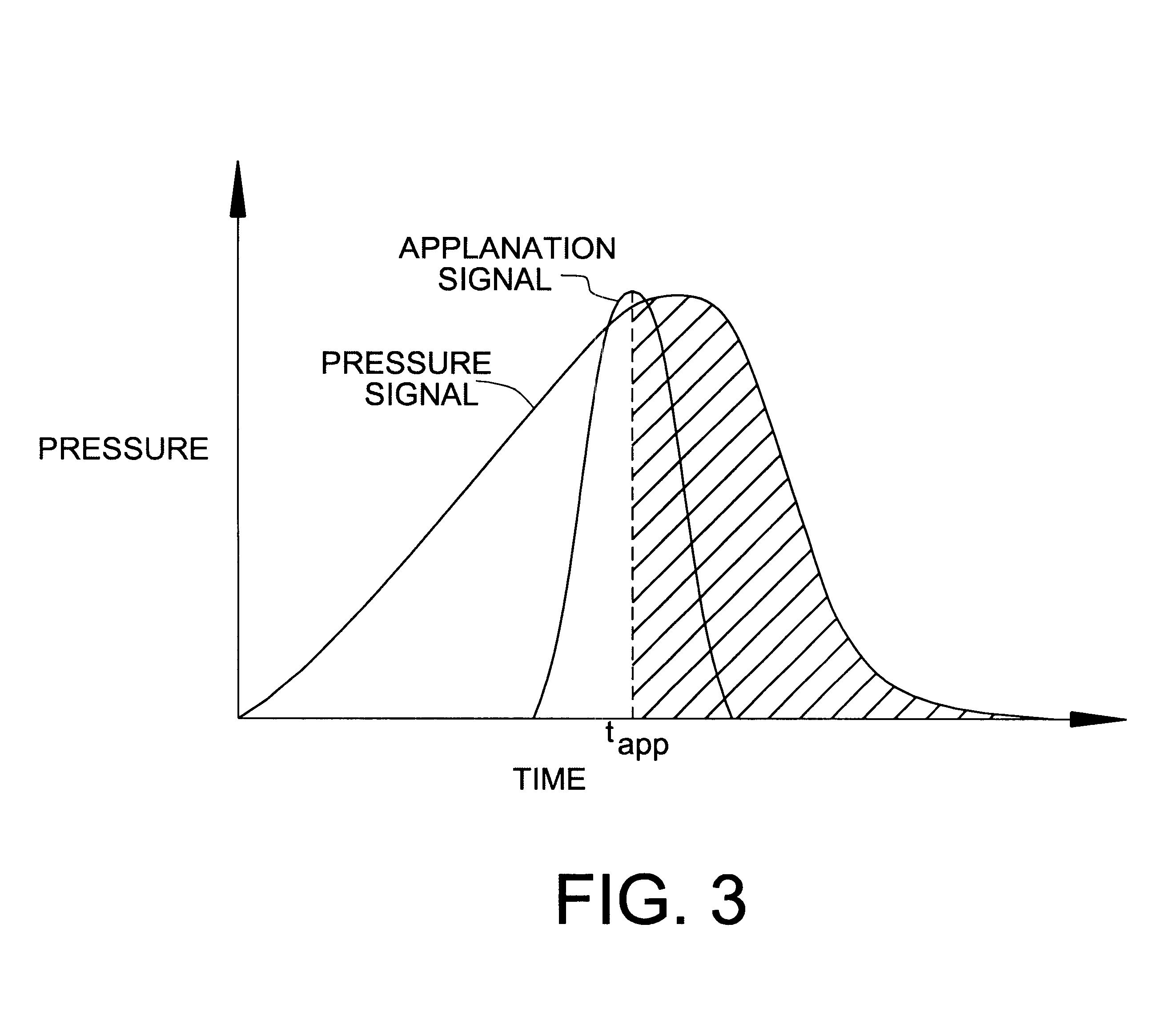

Method for optimizing piston diameter in a non-contact tonometer, and non-contact tonometer having fluid pump designed by said method

A fluid pump system of a non-contact tonometer is numerically simulated through its compression stroke by a simulation software program. System dynamic behavior is modeled for a variety of piston diameters, whereby an optimal piston diameter or range of piston diameters is selected in view of stoke length limitations and target applanation pressure requirements.

Owner:REICHERT

Split-pressure dual pump hydraulic fluid supply system for a multi-speed transmission and method

ActiveUS8128377B2Maximizes performance and efficiency and dependabilityMaximize transfer efficiencyGear lubrication/coolingRotary piston pumpsEngineeringHydraulic fluid

A split-pressure, dual-pump system for supplying hydraulic fluid to a multi-speed transmission is provided. The system includes a low-pressure work circuit operatively connected to a fixed displacement pump, and a high-pressure work circuit operatively connected to a variable displacement pump. The system also includes a regulator valve fluidly coupled to the variable displacement pump via a decrease circuit and an overage circuit for regulating the flow of fluid to the high-pressure work circuit. The invention consists of separating the high-pressure needs of the system into a separate work circuit from the low-pressure needs of the system, and optimizing pump design separately for each work circuit to maximize transmission efficiency and reduce parasitic losses. A method of supplying hydraulic fluid to a multi-speed transmission at variable flow and pressure is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

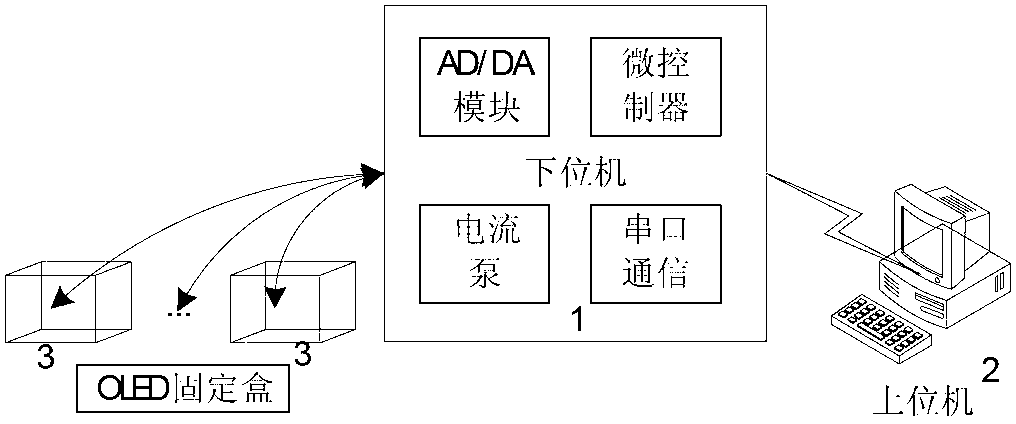

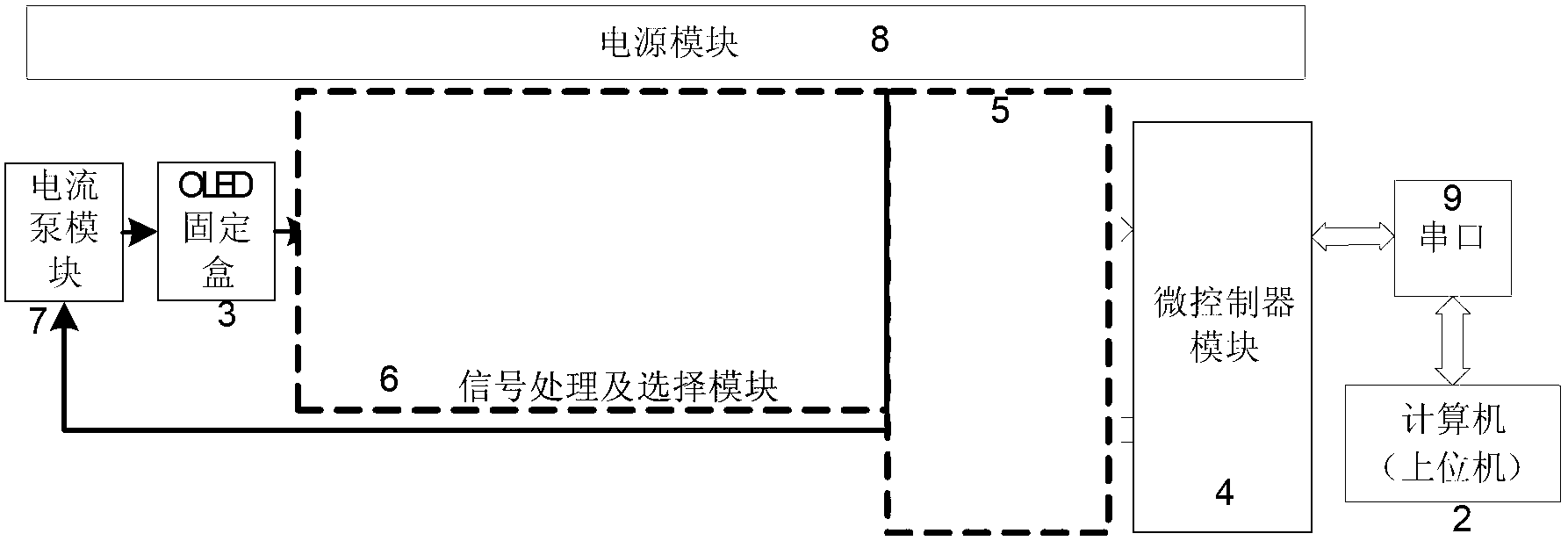

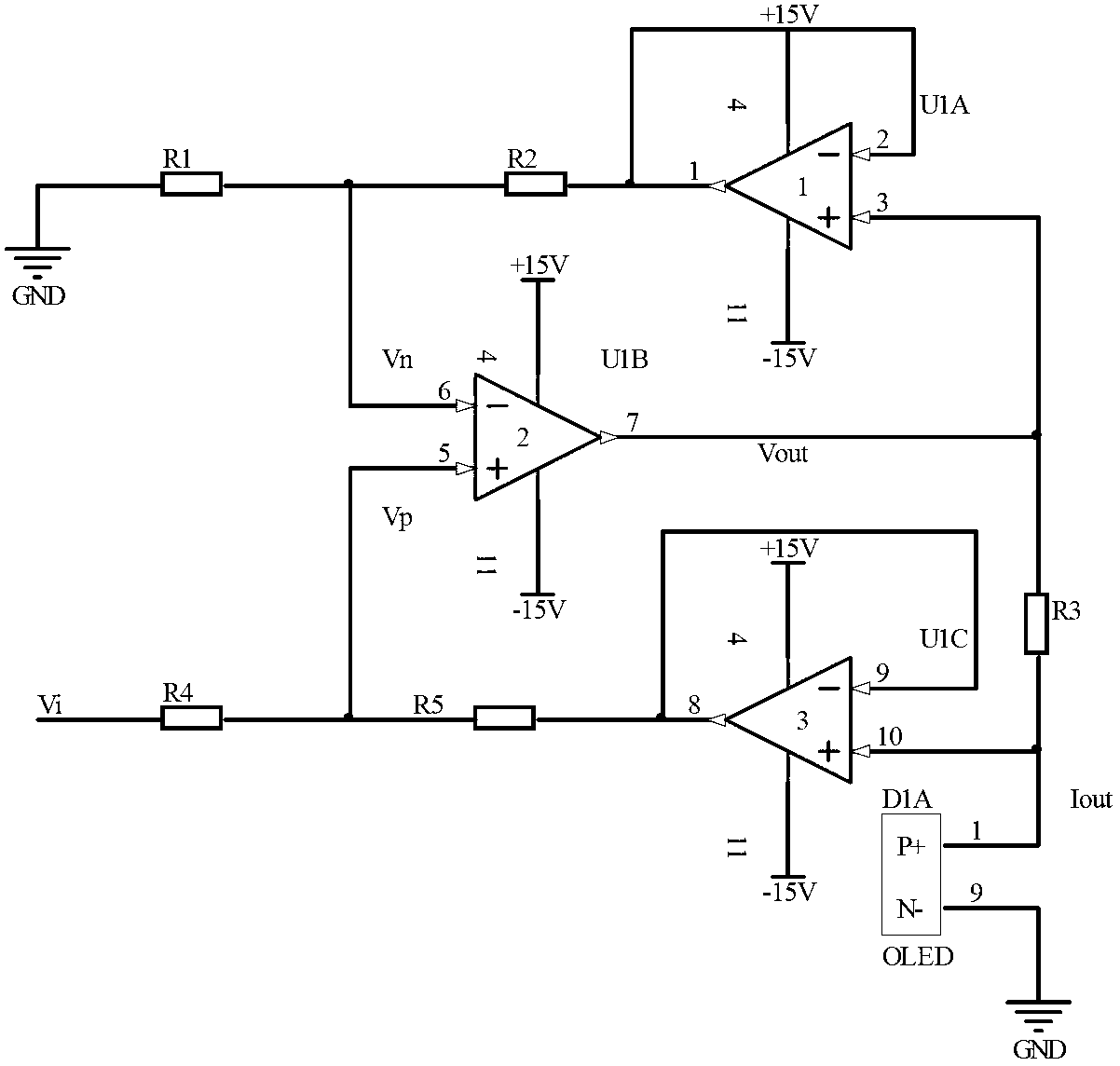

Multichannel OLED (Organic Light Emitting Diode) life testing system based on Howland current pump

InactiveCN103197224AWork independentlyImprove stabilityIndividual semiconductor device testingComputer designLight-emitting diode

The invention discloses a multichannel OLED (Organic Light Emitting Diode) life testing system based on a Howland current pump, comprising a lower computer, an upper computer and a plurality of OLED sample fixing boxes, wherein the lower computer comprises a micro controller module, an AD / DA (analog-to-digital / digital-to-analog) module, a current pump module, a signal processing and selecting module and a serial port; the current pump module, the OLED sample fixing boxes, the signal processing and selecting module, the AD / DA module, the micro controller module, the serial port and the upper computer are connected sequentially; and the AD / DA module is connected with the current pump module. The multichannel OLED life testing system disclosed by the invention adopts an improved Howland power pump design and provides the accurate and stable constant current output; combined with the upper computer design based on Labview, the multichannel OLED life testing system is simple, convenient and fast and supports the simultaneous testing operation of a plurality of samples, the half-life period of each point on the sample under certain constant current can be obtained from returned data, and the half-life period under any current can be calculated, so that the testing efficiency is greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

Self-priming centrifugal pump

Owner:XYLEM IP HLDG

Low delivery head great specific gravity fluid delivery pump

InactiveCN101285473AAchieve high outputSpecific fluid pumpsPump componentsFrequency conversionLiquid metal

The invention relates to a pump, in particular to a pump for conveying fluent metal. The invention reaches a design aim through changing the related size of the pump. A low pump lift and large specific gravity liquid delivery pump designed according to the technical proposal provided by the invention has the minimal production capacity which can achieve the conveying capacity of 500 ton per hour in a minimal rotational speed in a frequency-conversion and speed-regulation range, thereby realizing a large output quantity of large specific gravity liquid and meeting the needs of improving process and production capacity.

Owner:CINF ENG CO LTD

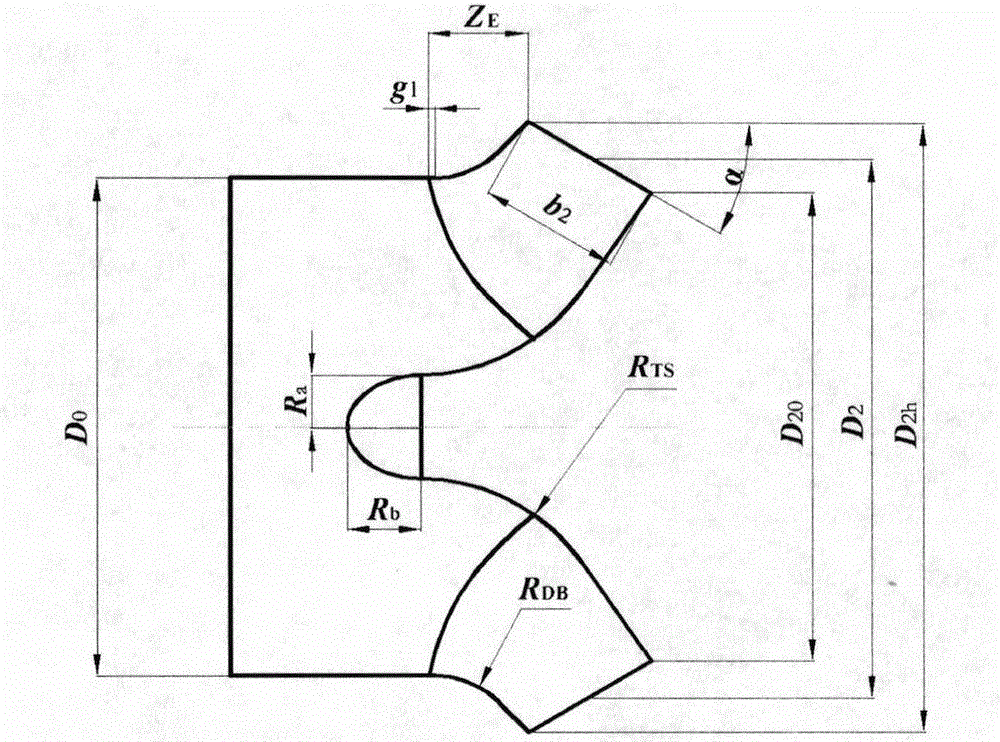

Diagonal flow pump impeller hydraulic design method

The invention relates to a diagonal flow pump impeller hydraulic design method. A design formula about main geometric parameters of the impeller is given, and includes an included angle Alpha between the outlet of the diagonal flow pump impeller and the horizontal line, the actual thickness Delta of each point of each vane, vane wrap angle Phi, the inlet fillet radius RTS of the rear cover plate of the impeller, the number z of impeller vanes, the diameter D2 of the impeller outlet, the width b2 of the vane outlet, the equivalent diameter D0 of the impeller inlet, a distance ZE between the vane inlet of the front cover plate and the outlet of the front cover plate of the impeller, a distance g1 from the inlet edge to the initial end of the curve of the front cover plate, the inlet fillet radius RDB of the front cover plate of the impeller, round nut radius Ra of the impeller, round nut height Rb of the impeller, the placing angle of the vane Beta, the placing angles Beta1 of inlet of the vane, the placing angles Beta2 of inlet of the vane, the slipping coefficient Rho and the hydraulic efficiency Etah. According to the impeller of the diagonal flow pump designed by the invention, the hydraulic efficiency of the impeller and the stability performance of the diagonal flow pump are improved, and computer programming is facilitated, and thereby the original similar design method and the velocity coefficient method of the diagonal flow pump can be replaced to a great extent.

Owner:JIANGSU UNIV

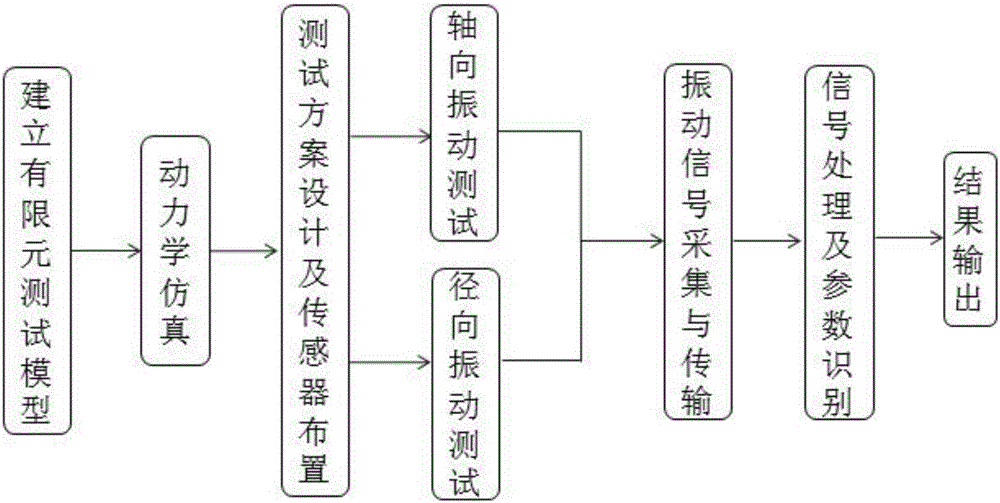

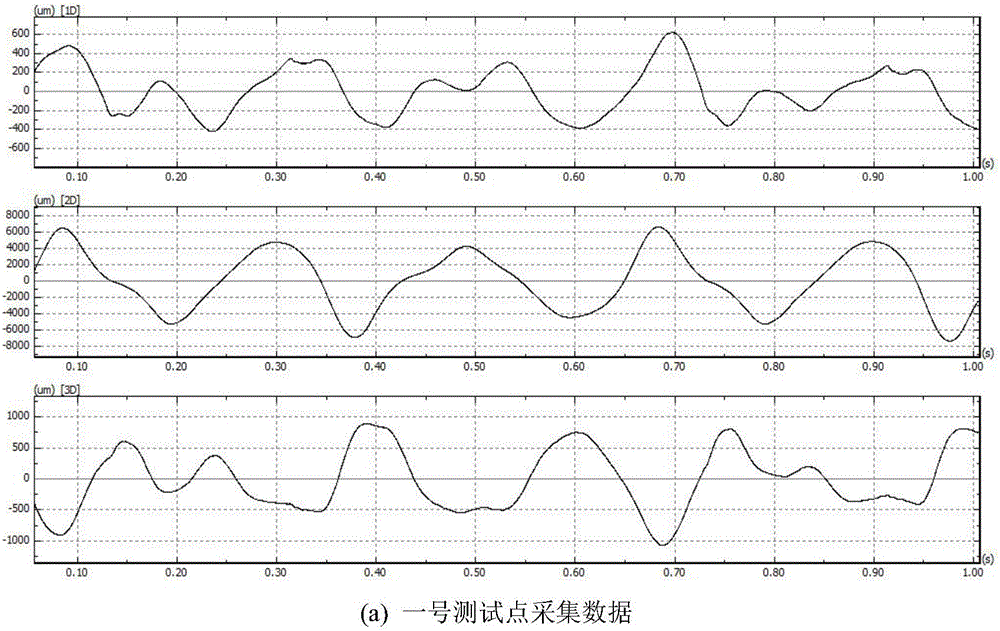

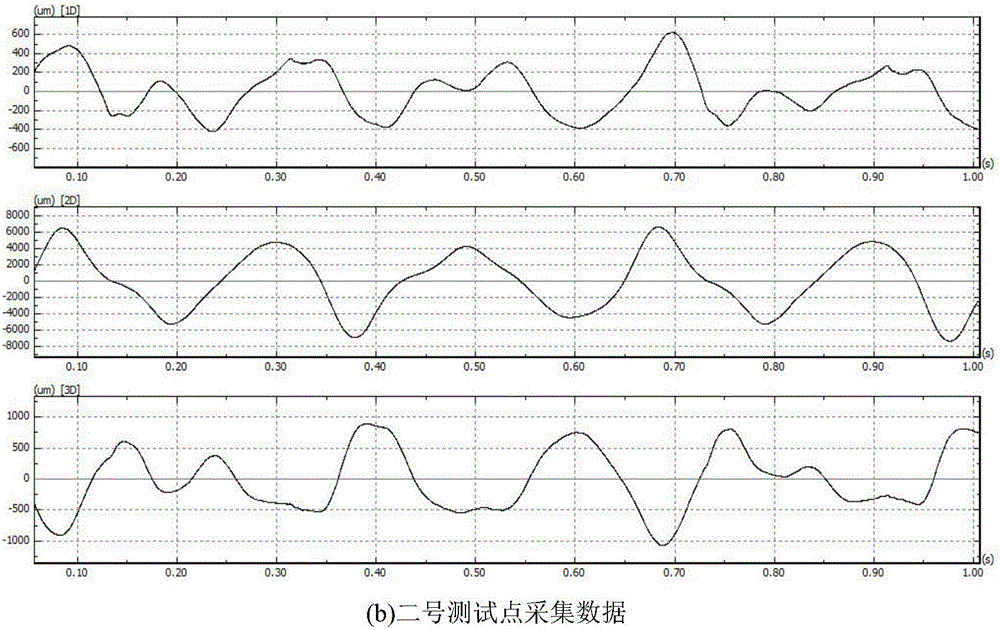

Method for testing resonant frequency of direct-drive plunger pump for ship

InactiveCN106762592AOvercome Difficulty MotivatingSolve problems that are susceptible to external environmental factorsPump testingPositive-displacement liquid enginesResonanceData acquisition

The invention provides a method for testing resonant frequency of a direct-drive plunger pump for a ship. The method for testing the resonant frequency of the direct-drive plunger pump for the ship aims at overcoming the defects of an existing method for testing the resonance frequency of the pump for the ship, and the requirements of scientific research and engineering design can be met through simple and convenient operation, convenient data output and wider applicability. The method for testing the resonance frequency of the direct-drive plunger pump for the ship includes the steps that firstly, a reasonable monitoring point arrangement scheme is determined, an external excitation mode is adopted for exciting a system, and vibration responses of key nodes of the system are tested by adopting an acceleration sensor; and then, vibration data of the direct-drive plunger pump are collected through a data acquisition system, data processing is carried out by utilizing a back-end server, and the resonant frequency of various orders of the direct-drive pump system is determined. In order to meet the requirements for design, safety, detection and the like of a large ship pump, developing and establishing the method for testing the resonant frequency which is simple and convenient in operation have important significance.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com