Diagonal flow pump impeller hydraulic design method

An oblique flow pump and impeller technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, which can solve the problems of difficulty in achieving the expected effect, large discrepancy between theoretical design and actual model, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

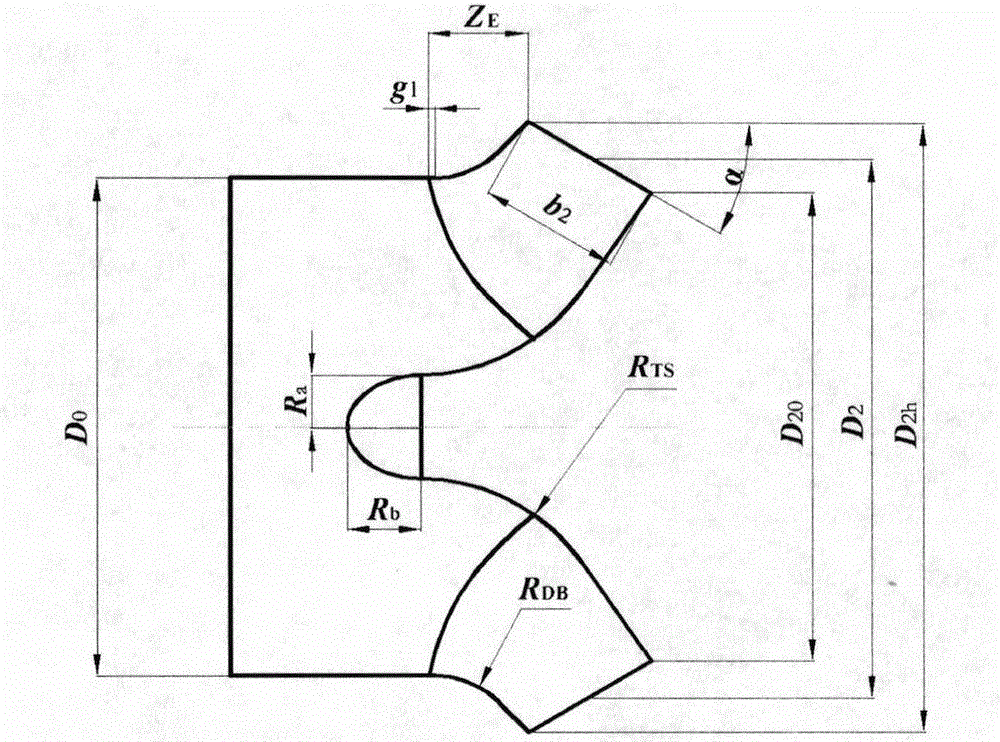

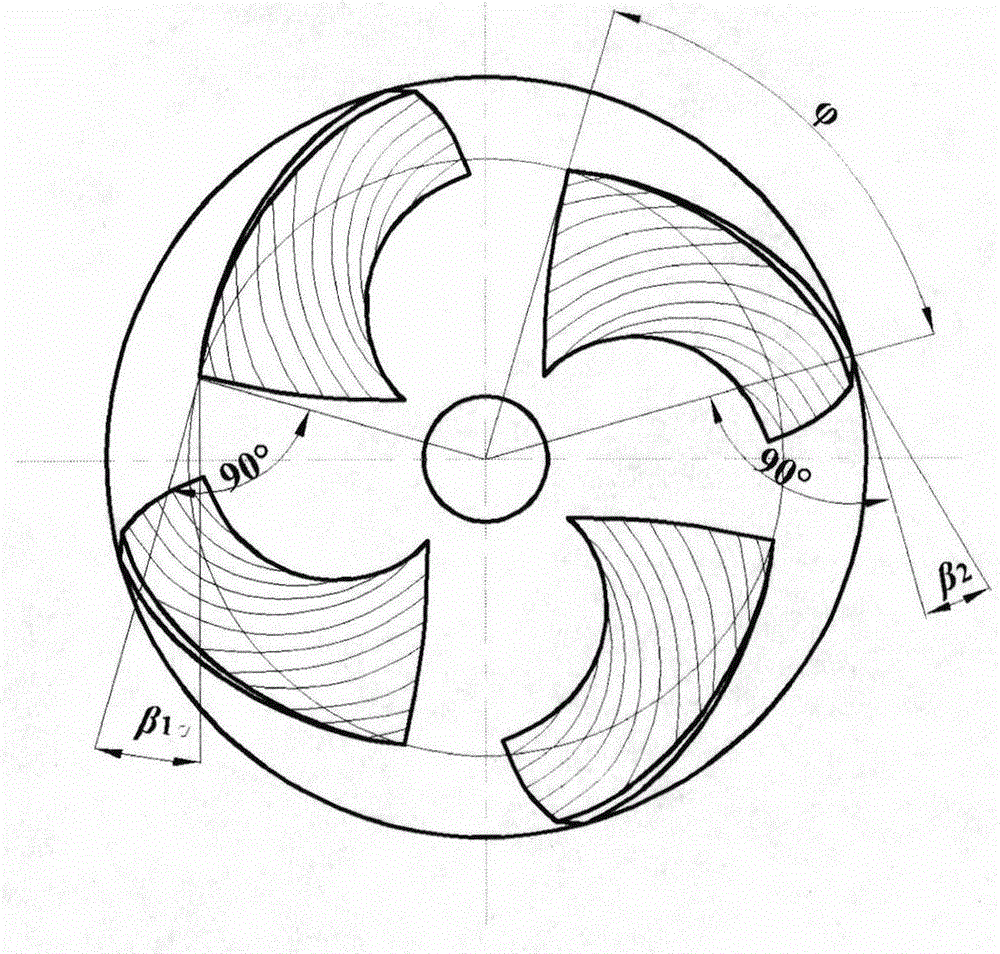

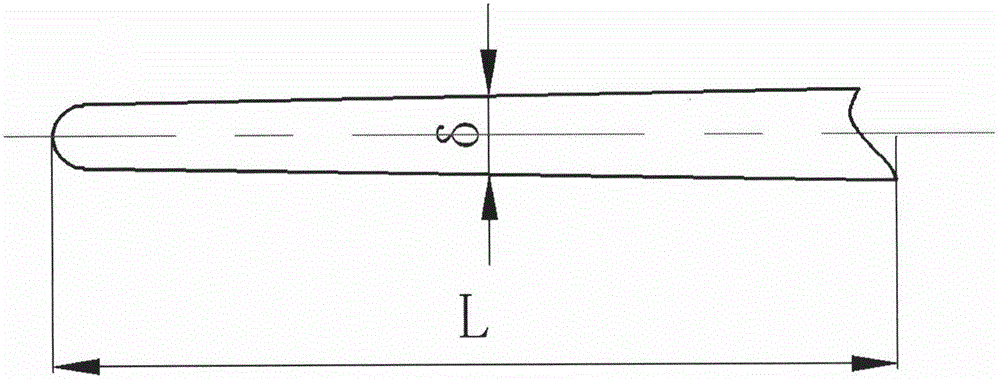

[0189] The present invention determines the impeller outlet diameter D through the following formulas 2 , impeller inlet equivalent diameter D 0 , Blade outlet width b 2 , impeller outlet diameter coefficient M D2 , impeller inlet equivalent diameter coefficient M D0 , blade outlet width coefficient M b2 , the angle between the outlet of the impeller of the oblique flow pump and the horizontal line α, the fillet radius of the inlet of the front cover of the impeller R DB , Radius R of impeller round nut a , the height of the impeller round nut R h , The inlet fillet radius R of the impeller back cover TS , the distance between the impeller front cover blade inlet and the front cover outlet Z E , The distance from the beginning end of the curve of the front cover plate to the inlet margin g 1 , blade inlet axial speed v m1 , blade outlet axial speed v m2 , blade exit peripheral speed u 2 , hydraulic efficiency η h , slip coefficient ρ, blade inlet placement angle β ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com