Low delivery head great specific gravity fluid delivery pump

A liquid transfer pump, low head technology, used in special fluid pumps, liquid fuel engines, pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

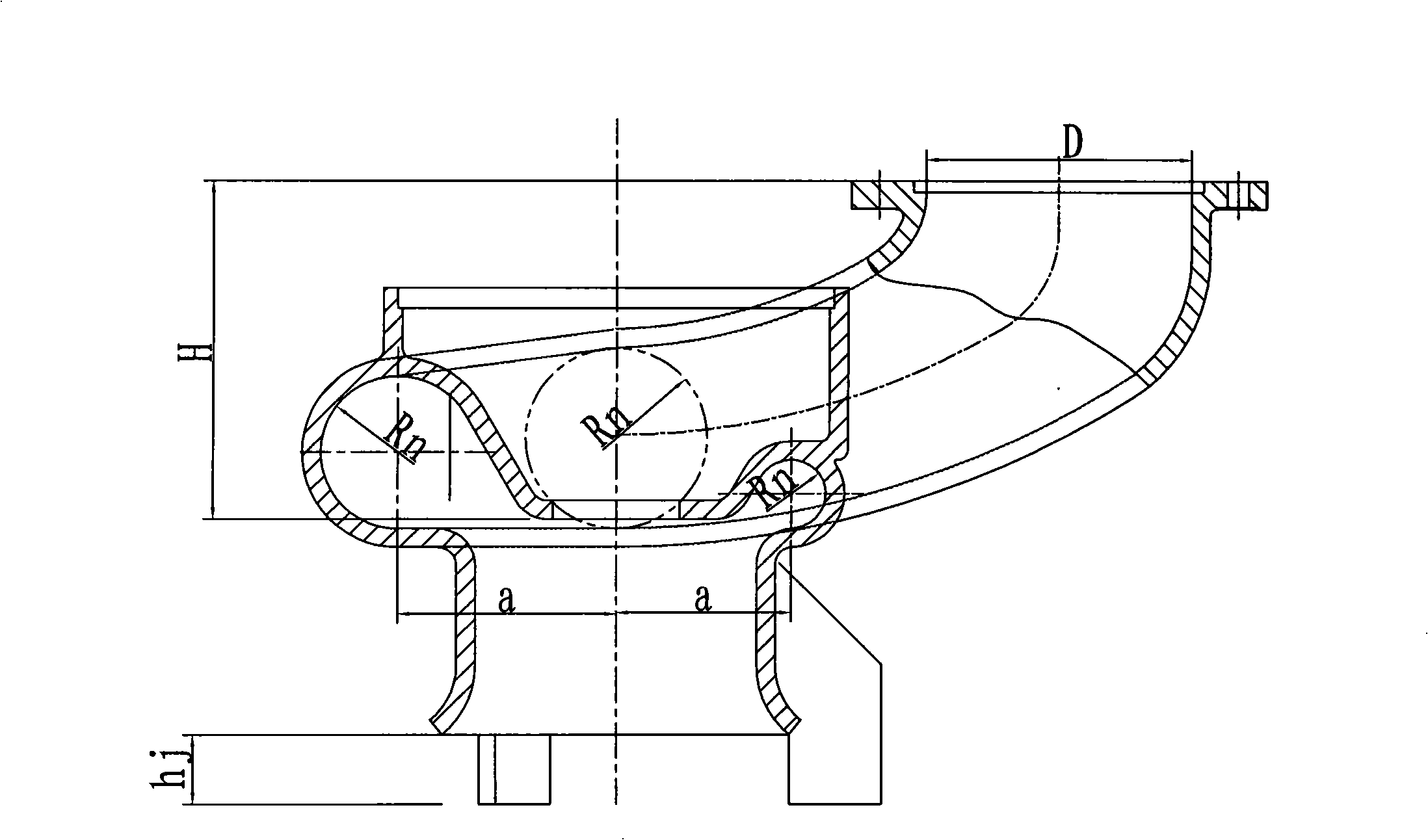

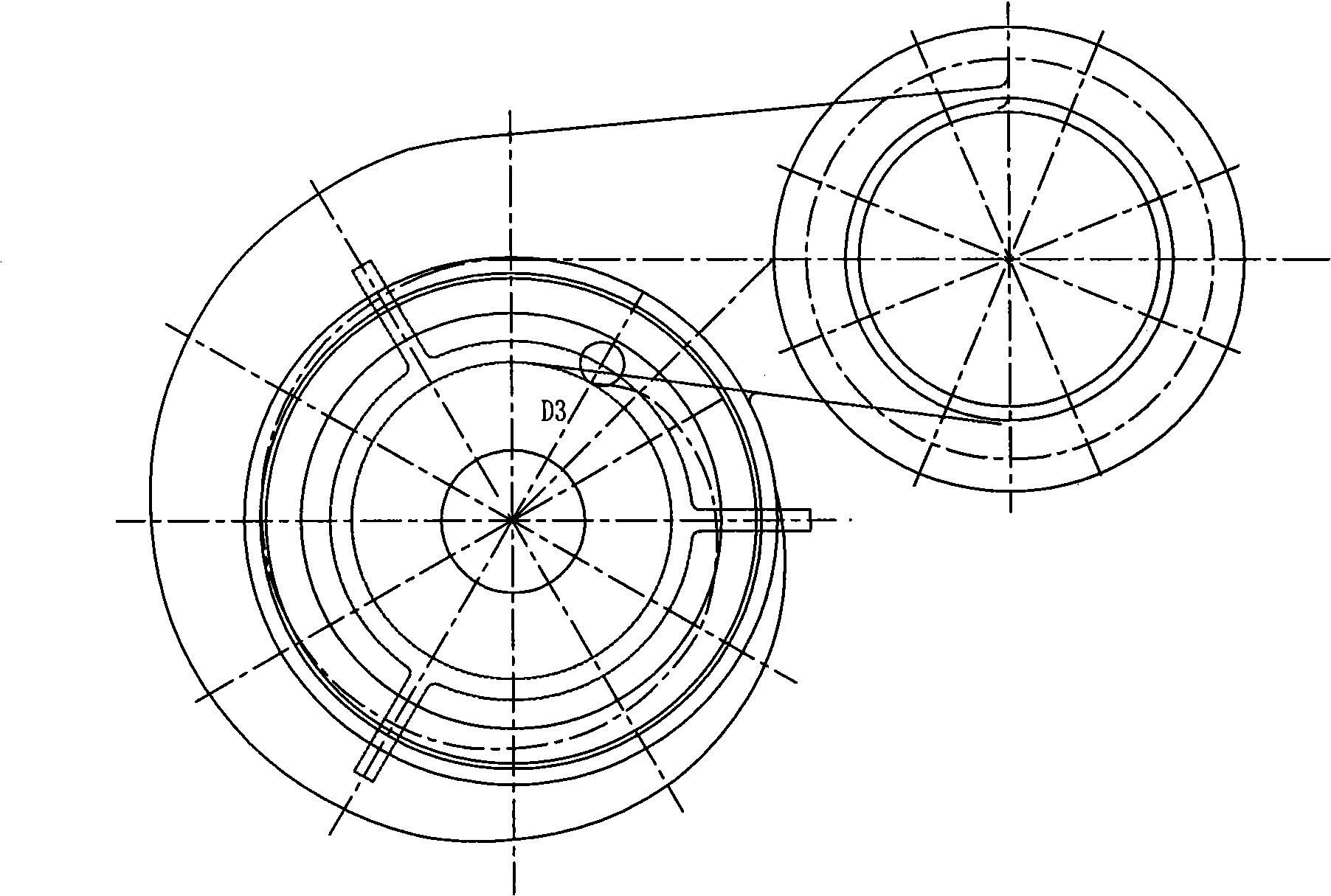

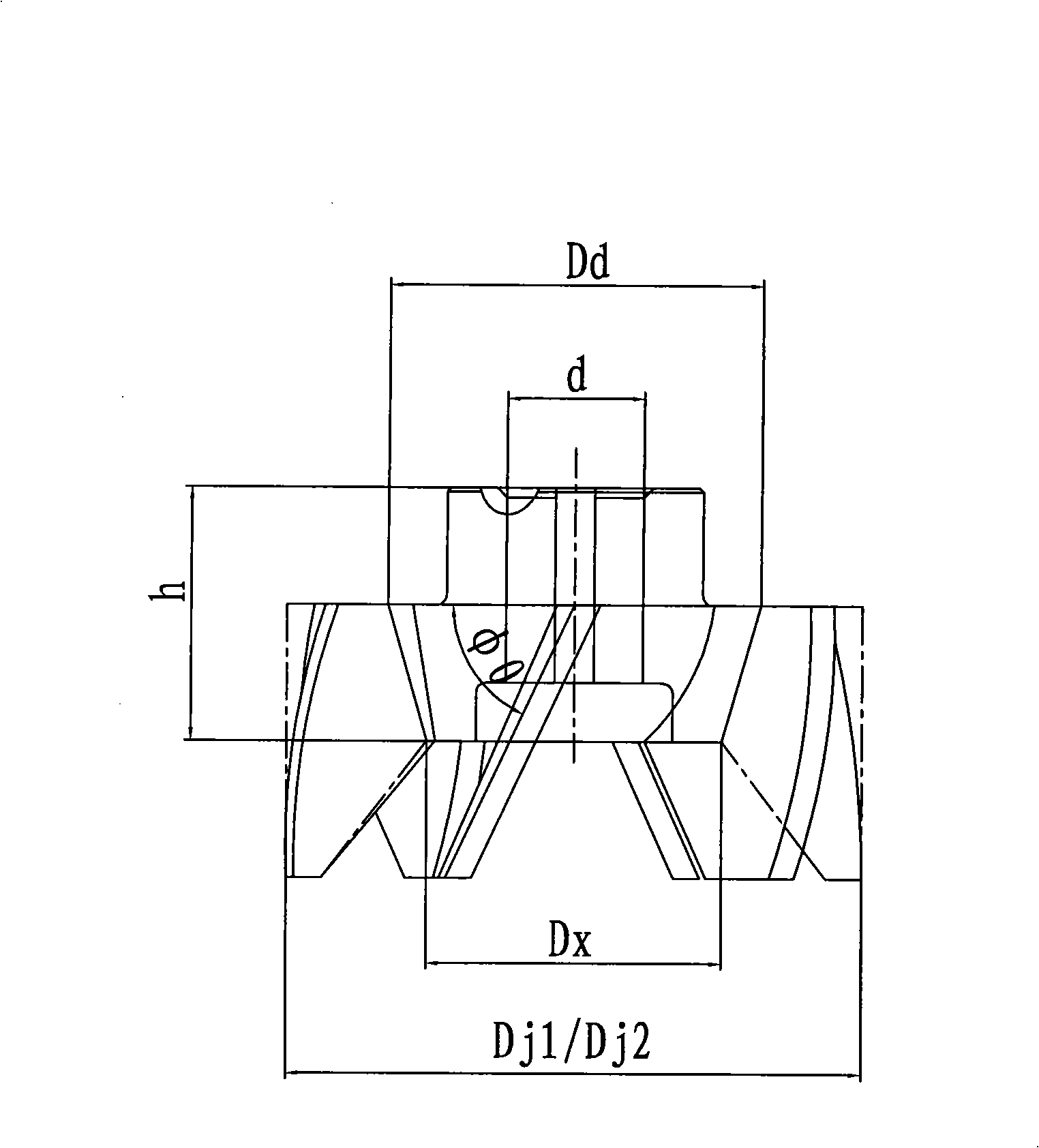

[0144] The process configuration design requires double-pipe transportation, the transportation capacity is 5100t / h, the head is 2,2m, (the specific gravity of lead liquid is 10.5t / m 3 ).

[0145] (1) Overall scheme design (determination of main parameters)

[0146] 1. Calculate the motor power N according to the pump capacity:

[0147] No=Q*γ*H / (102*η)(KW)

[0148] In the formula: Q——Single-pipe flow rate,

[0149] γ=10500(kg / m 3 )

[0150] Q=5100 / (2*10.5*3600)=0.0675(m 3 / s)

[0151] H=2.2m

[0152] η=0.2 (comprehensive efficiency)

[0153] No=0.0675*10500*2.2 / (102*0.2)=76.43(KW)

[0154] N 电 (=K*N=1.2*76.43=91.76(KW)

[0155] N 电 (In order to select the parameter basis of the motor, select the standard value series of the motor after rounding. According to experience, the theoretical calculation of the lead pump processing capacity is often greater than the actual requirement. In order to improve the power utilization of the motor and achieve the purpose of ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com