Fluid transportation machine

A fluid conveying and mechanical technology, used in mechanical equipment, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve problems such as impeller damage and cavitation, and achieve small, compact and high output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

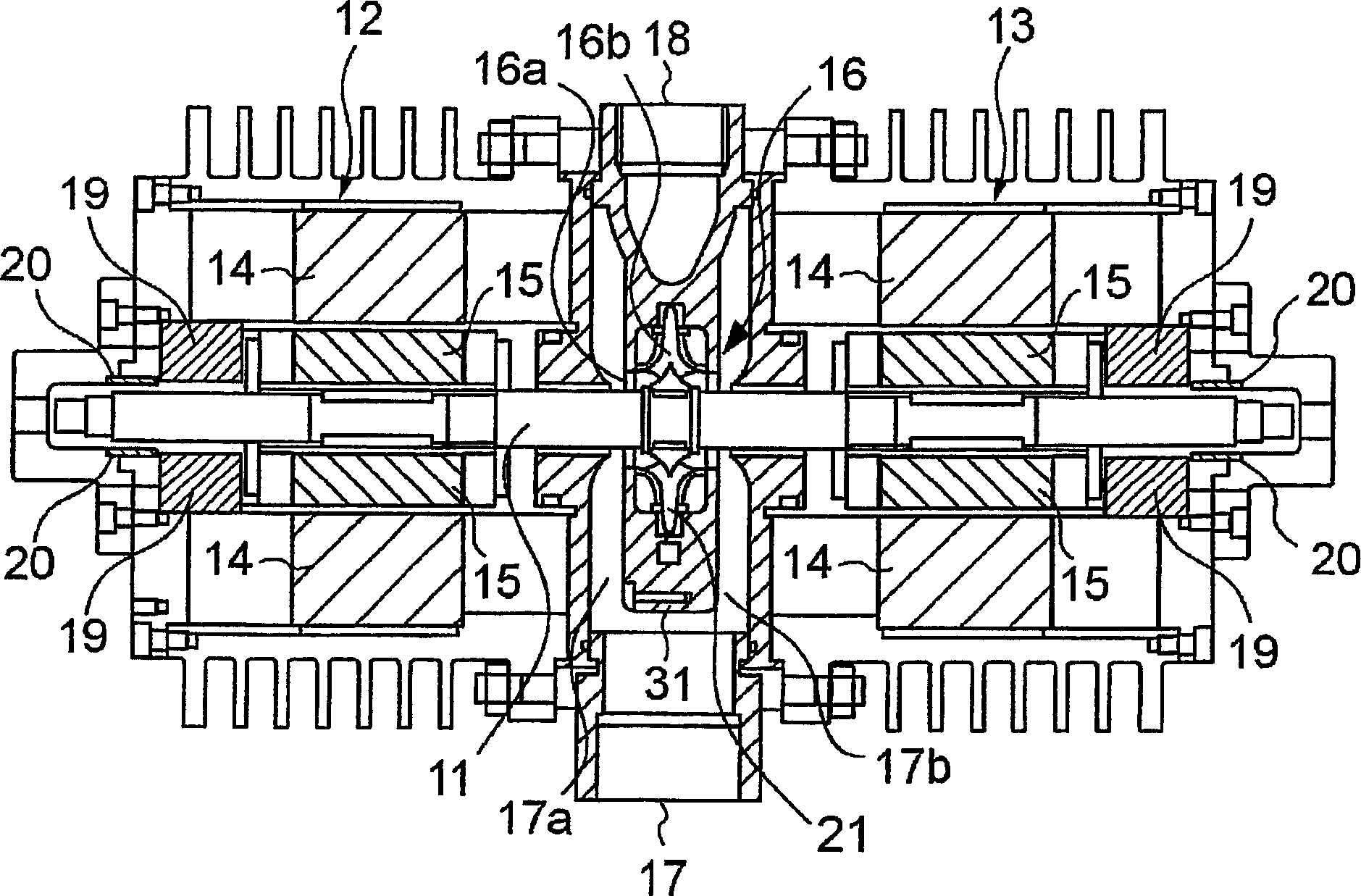

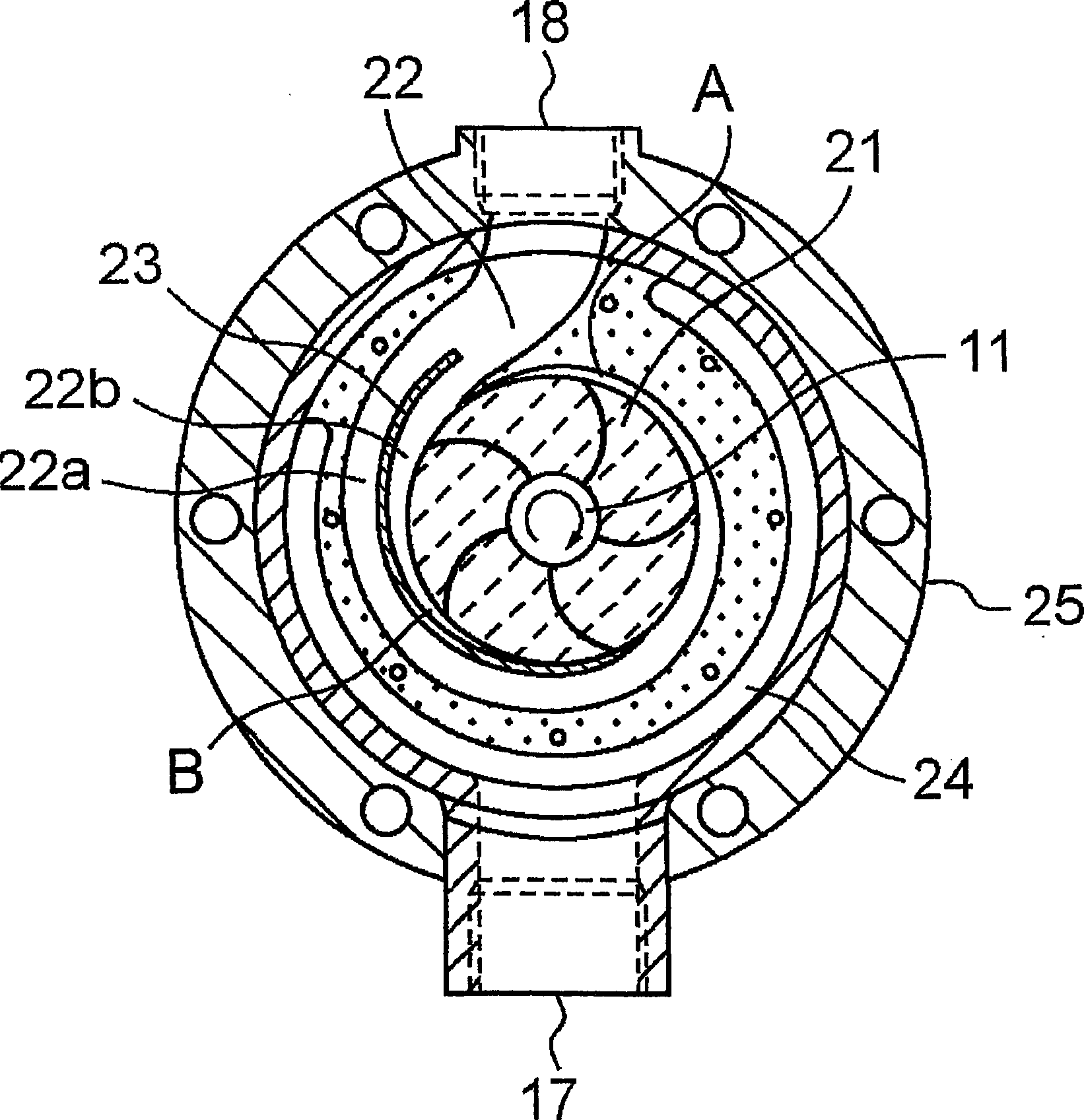

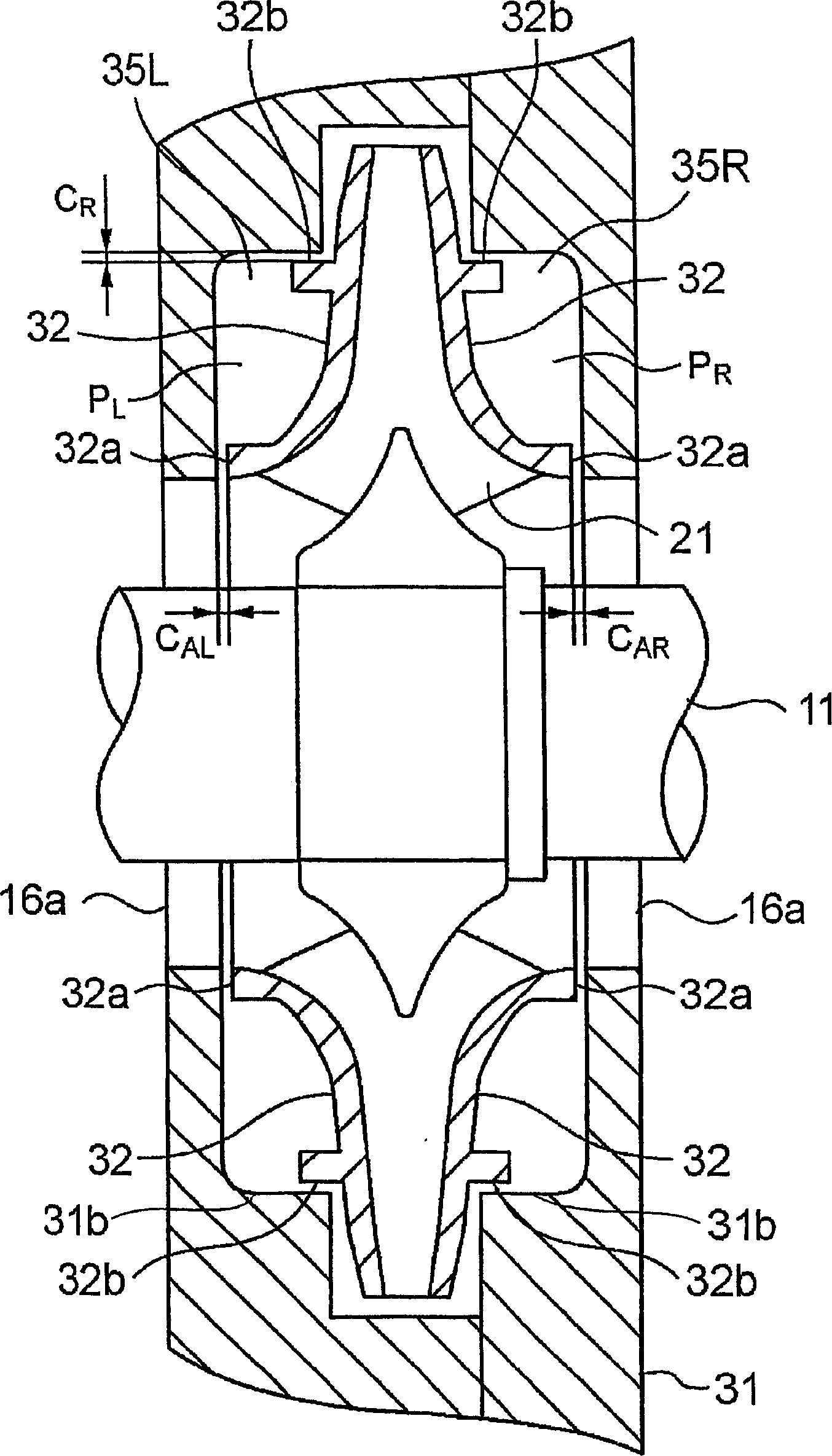

[0018] Refer below Figure 1 to Figure 4 A fluid transport machine according to an embodiment of the present invention will be described. In addition, in Figure 1 to Figure 4 In , components or elements having the same function are given the same reference numerals and repeated descriptions thereof are omitted.

[0019] figure 1 A double-suction pump (fluid transport machine) according to one embodiment of the present invention is shown. The fluid transfer machine includes a double-suction pump 16 at the center. The rotary shaft 11 of the pump 16 is rotationally driven by the magnetic levitation motors 12, 13 arranged on both sides of the pump 16, and is non-contact supported by the magnetic levitation motors 12, 13 which are radial magnetic bearings. Displacement sensors 19 are arranged on both sides of the magnetic levitation motors 12 and 13, and the magnetic levitation motors are controlled by a controller (not shown) according to the measured displacement of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com