Patents

Literature

36results about How to "Shorten the axial width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

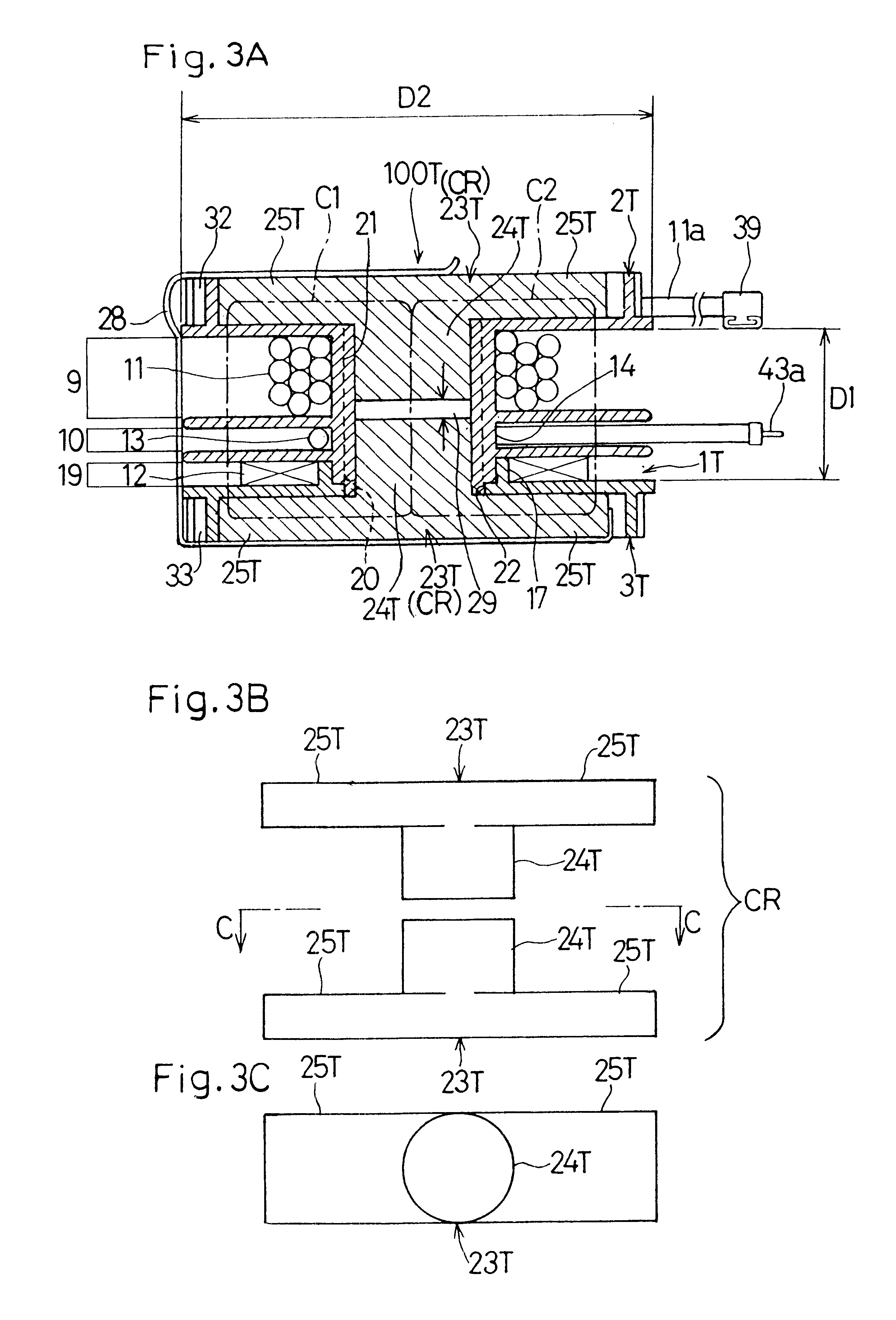

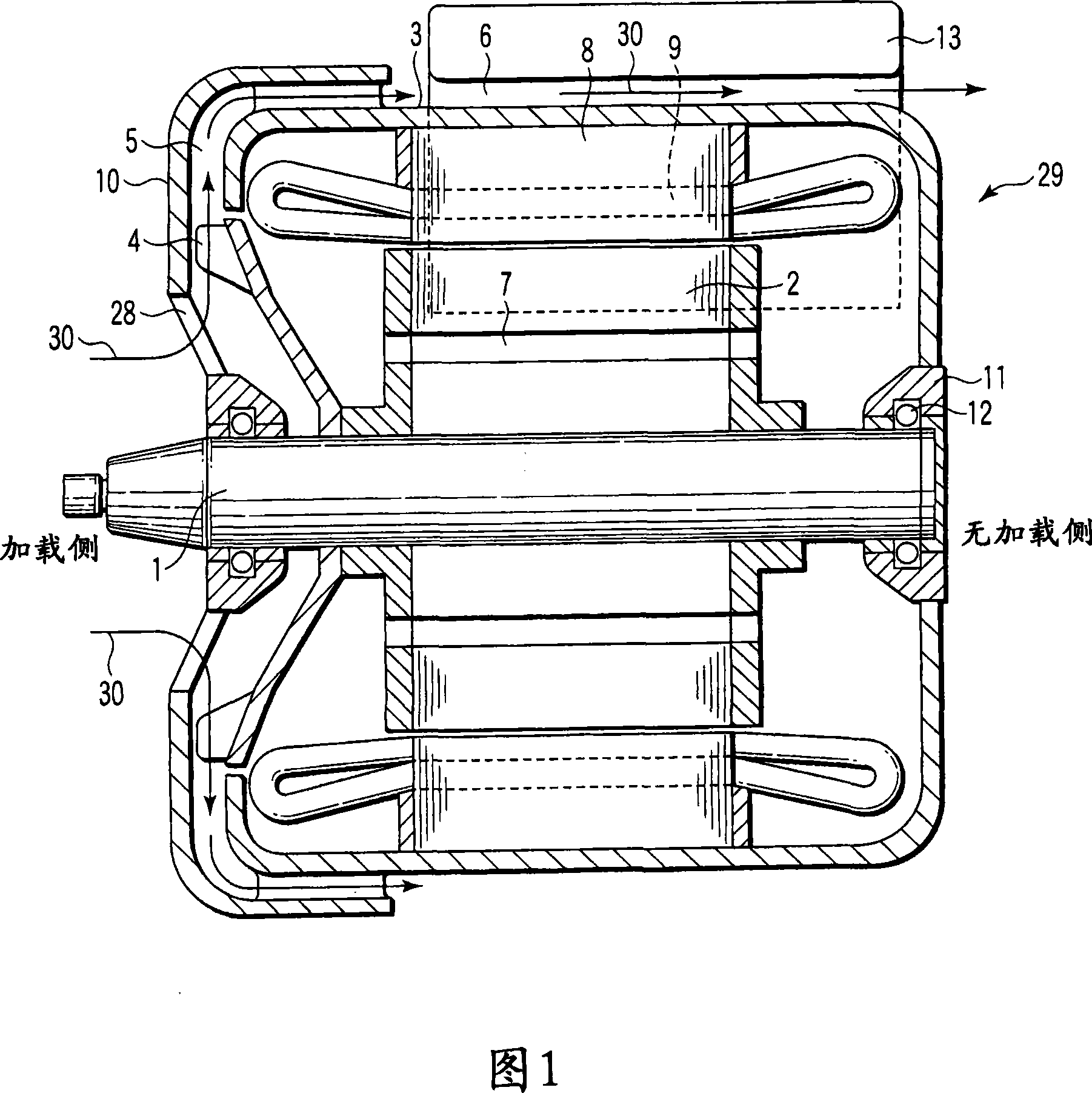

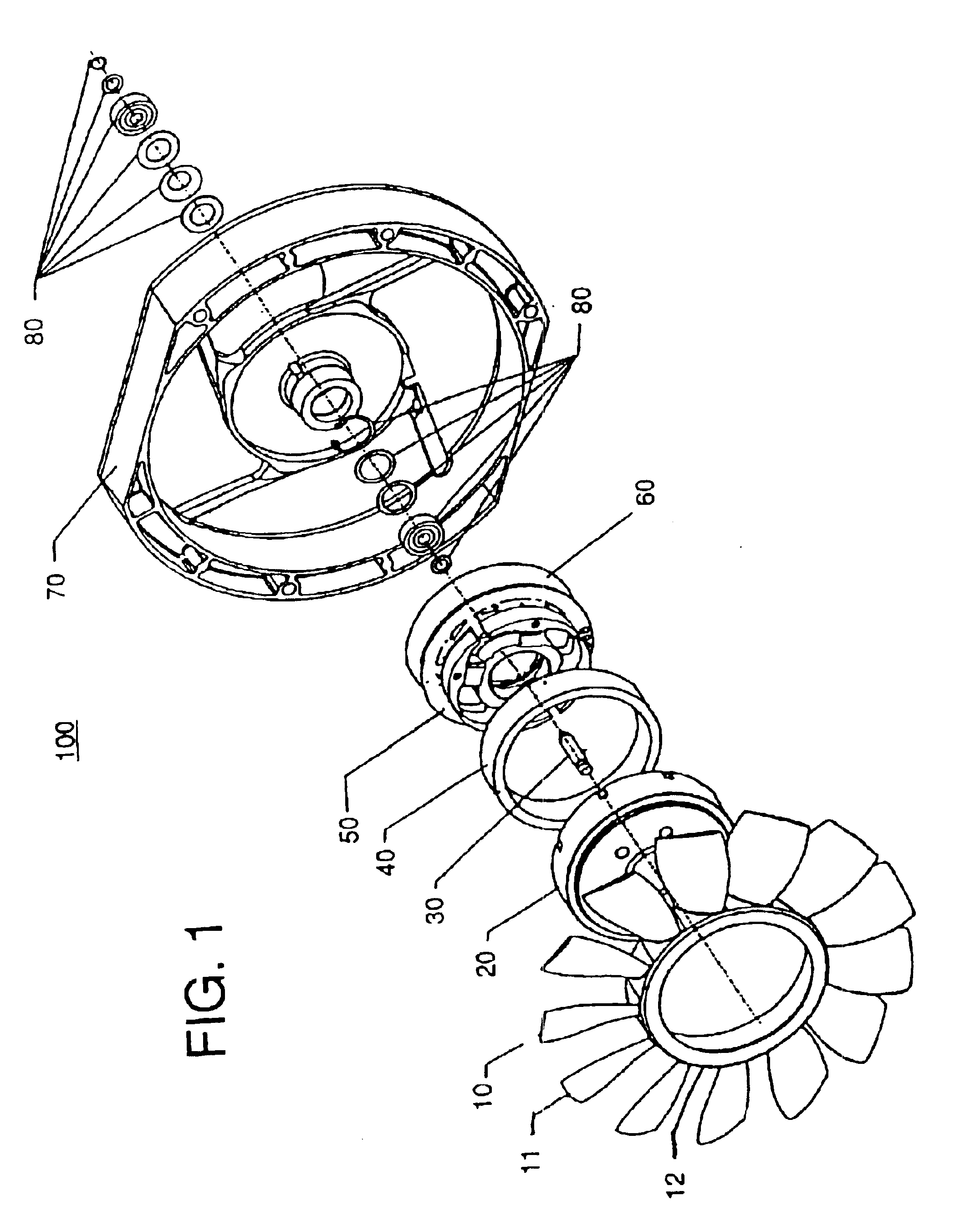

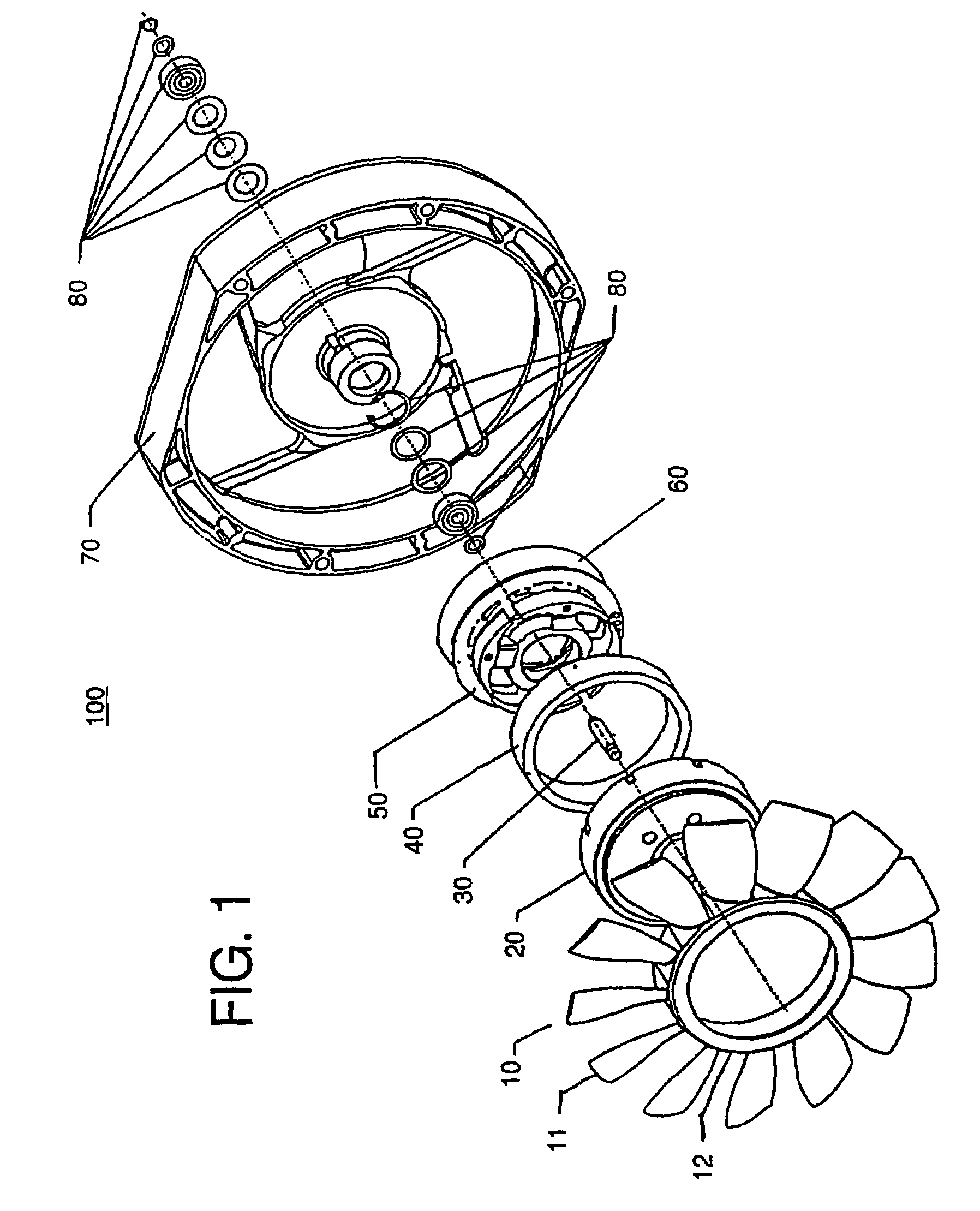

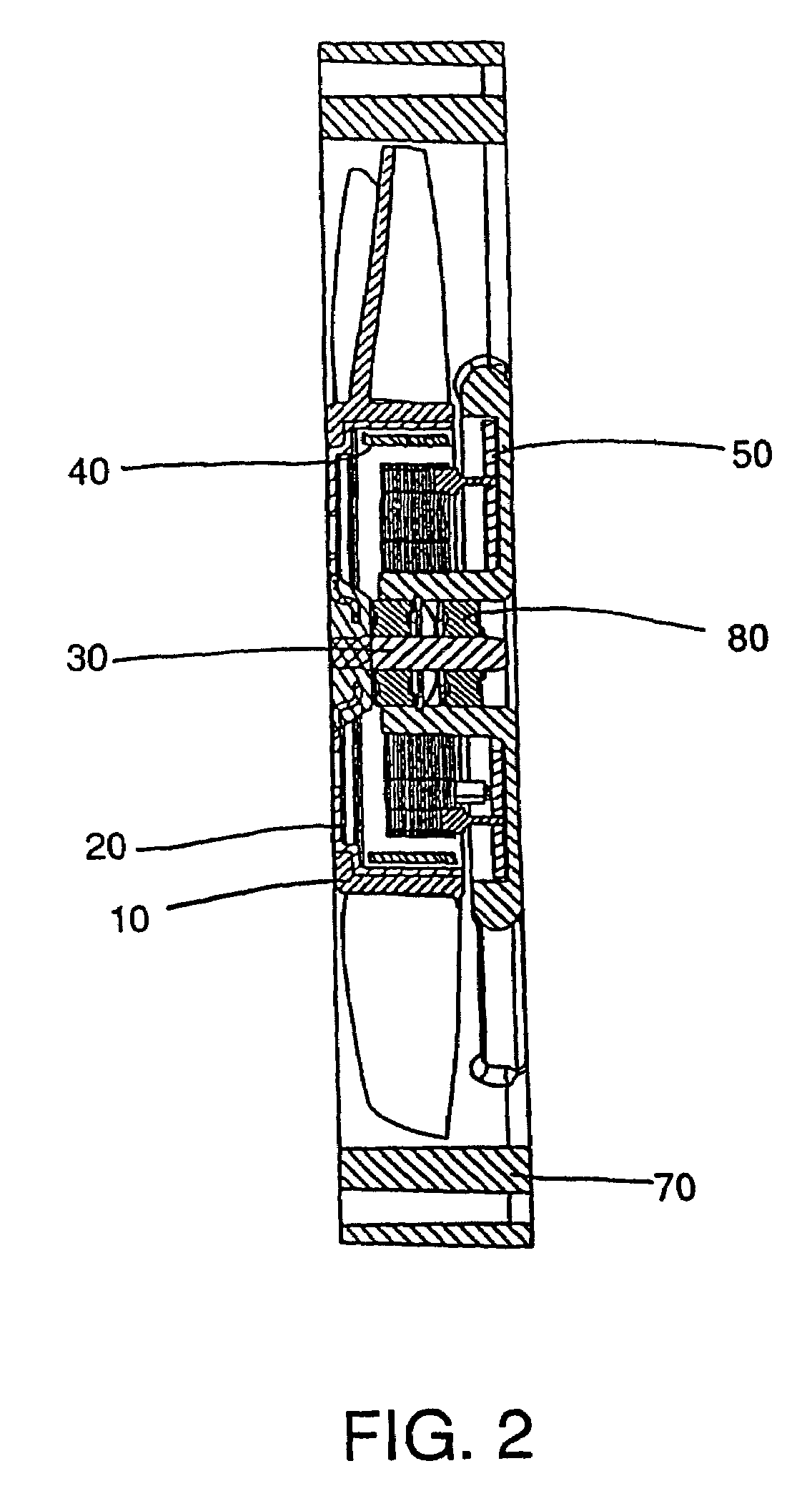

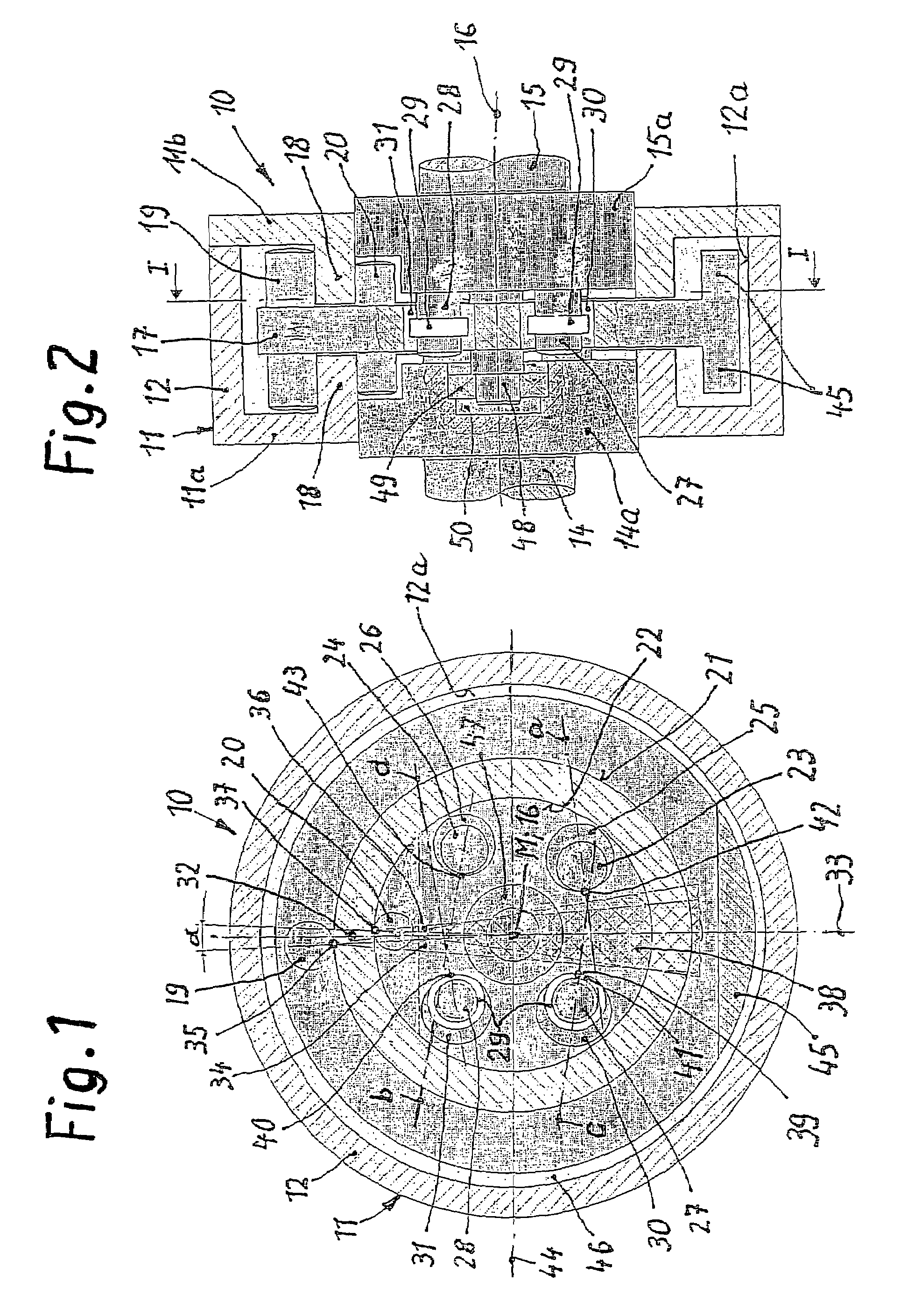

Apparatus for controller-integrated motor

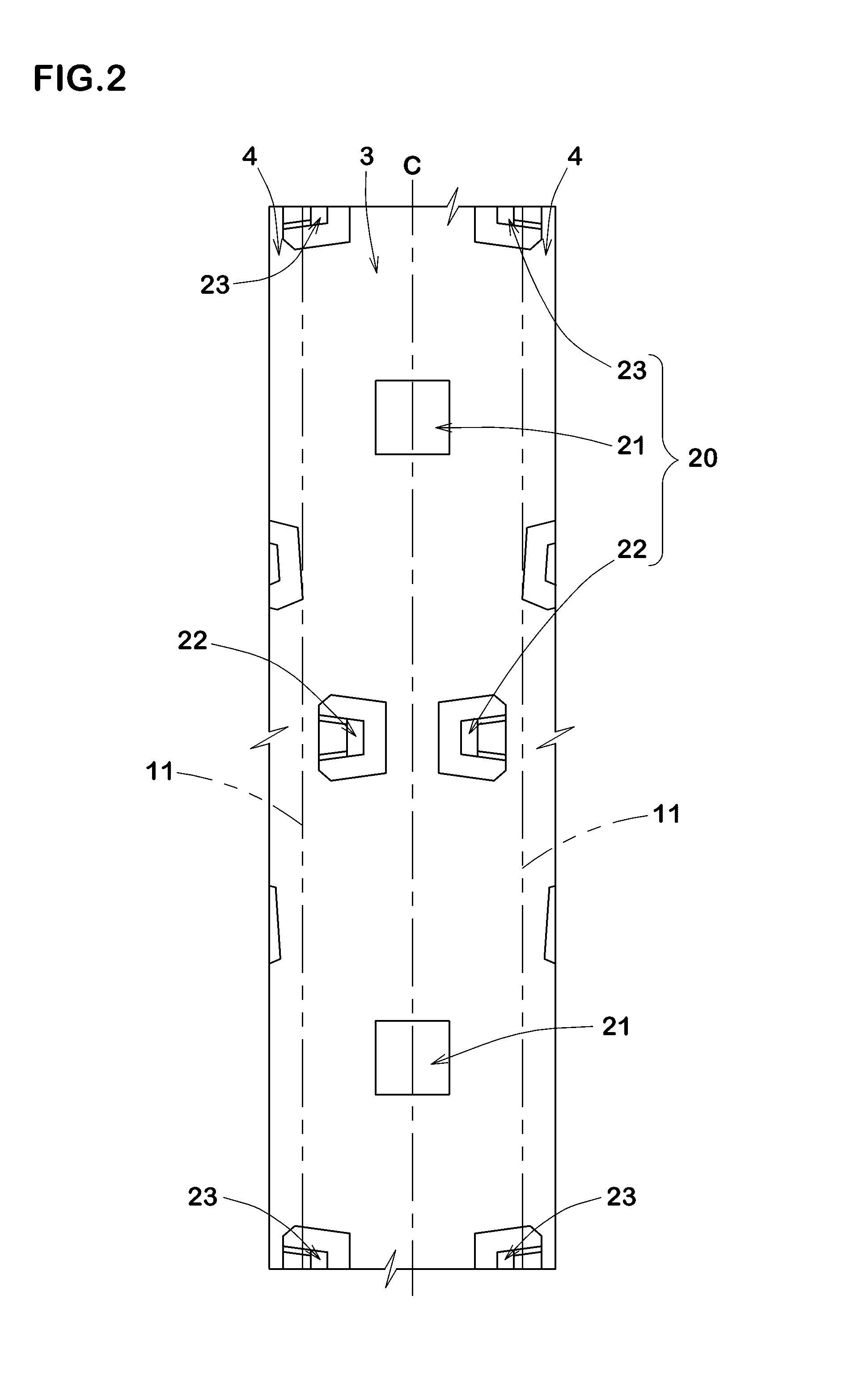

InactiveUS20070273220A1Shorten the axial widthImprove cooling efficiencyAssociation with control/drive circuitsMagnetic circuit rotating partsControl theoryElectric motor

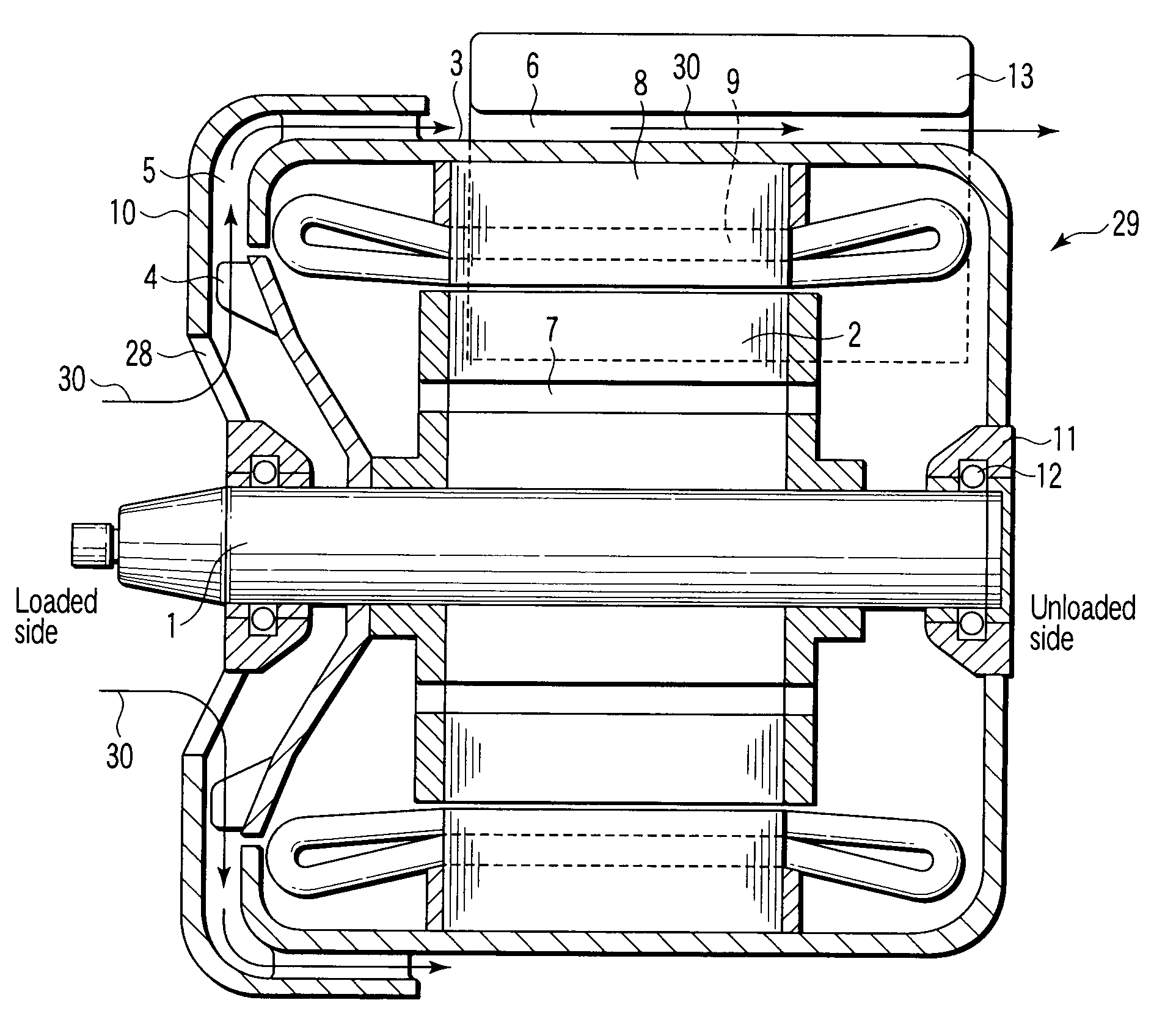

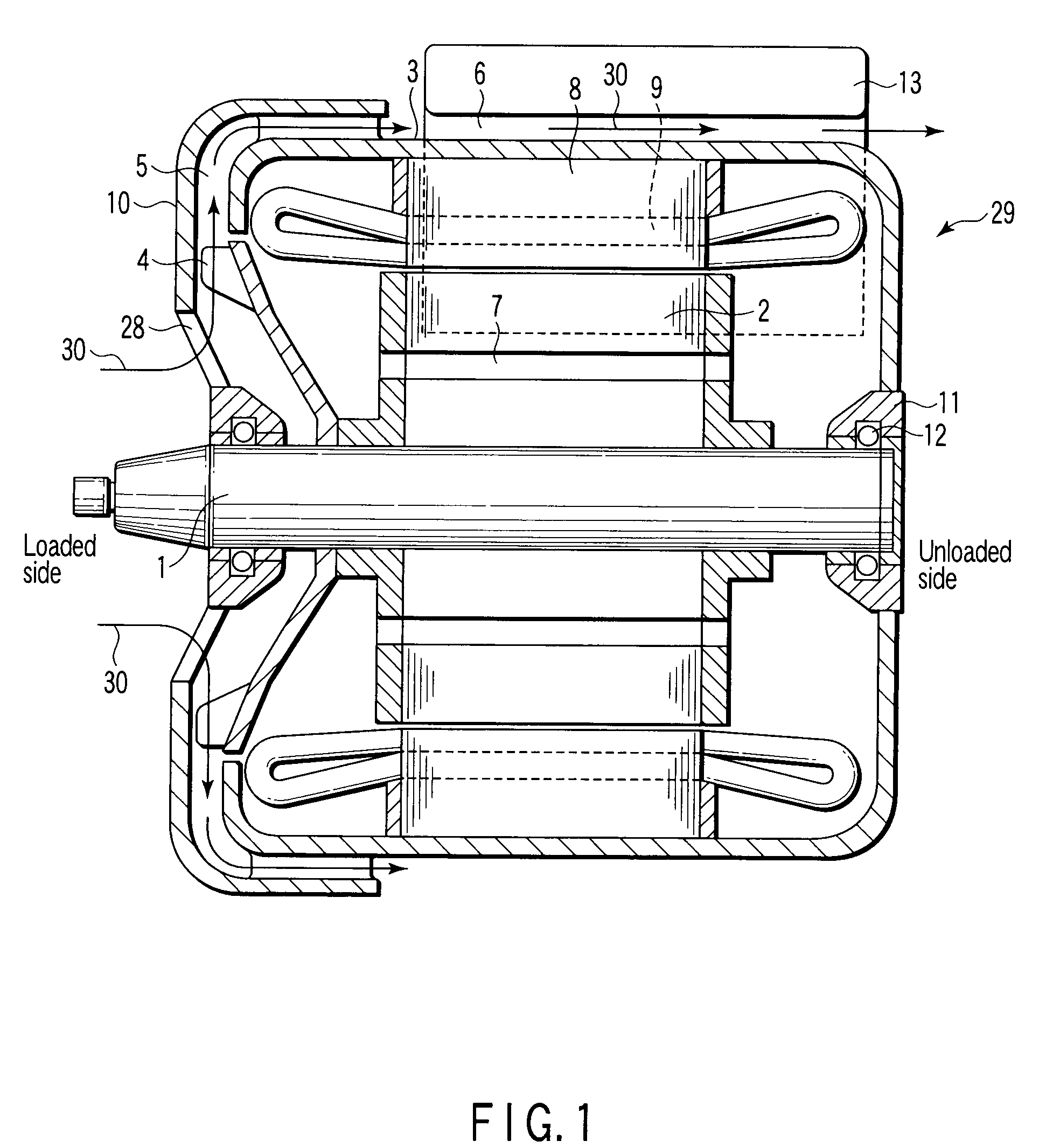

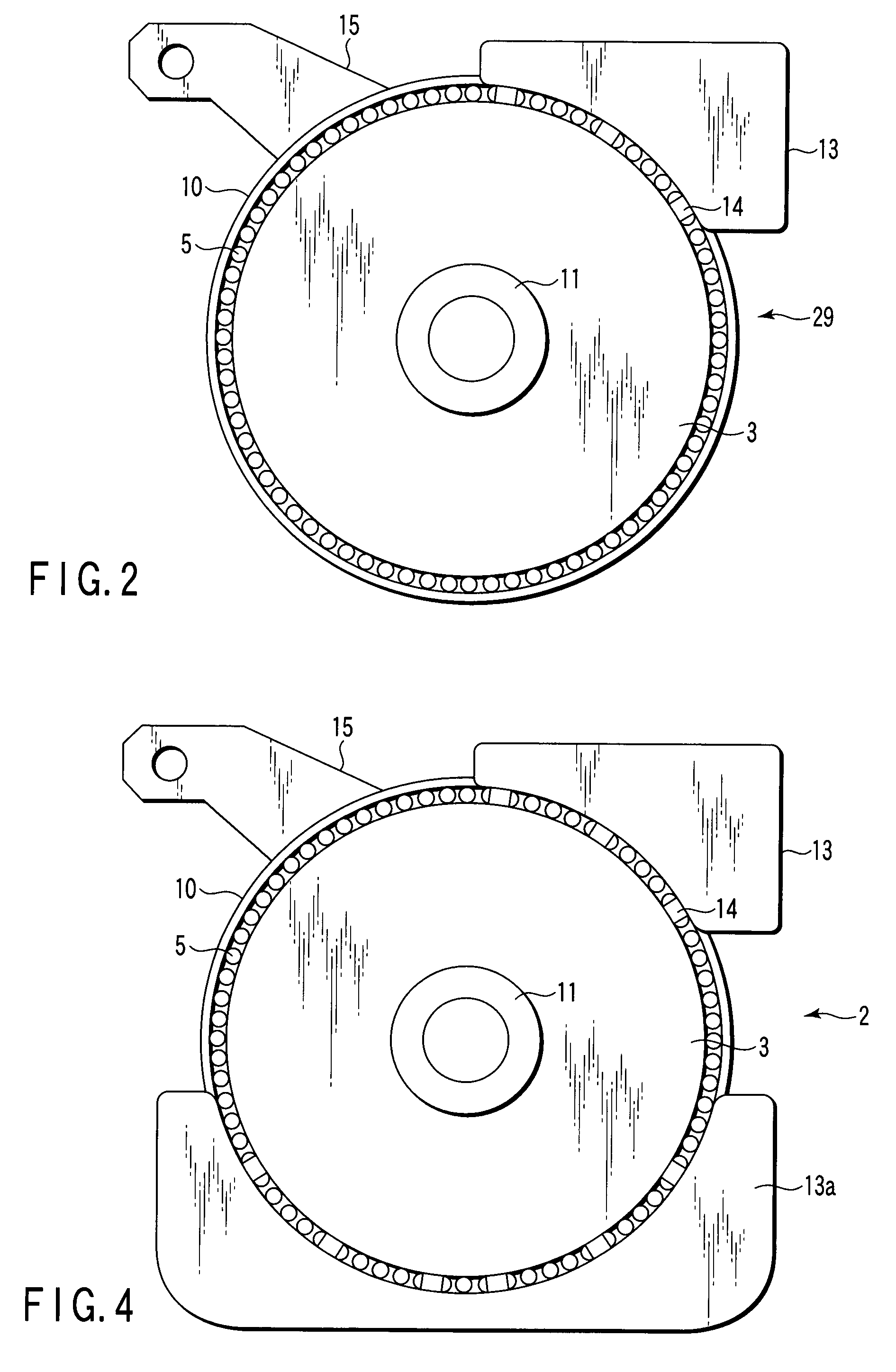

A controller-integrated motor includes a motor main body and a controller integrated with the motor main body to control the motor main body, the motor main body, including a stator core, a shaft which rotates to exert driving force on the motor main body, a frame which holds the stator core and the shaft, and an outer fan provided around the shaft so that the motor main body is recessed inward toward a rotational center of the shaft, the outer fan discharging cooling air stream to cool the motor main body, the controller being provided in proximity to an outer periphery of the frame, the motor main body being formed so that a cooling air stream from the outer fan flows in an axial direction of the shaft along an outer peripheral surface of the frame.

Owner:KK TOSHIBA

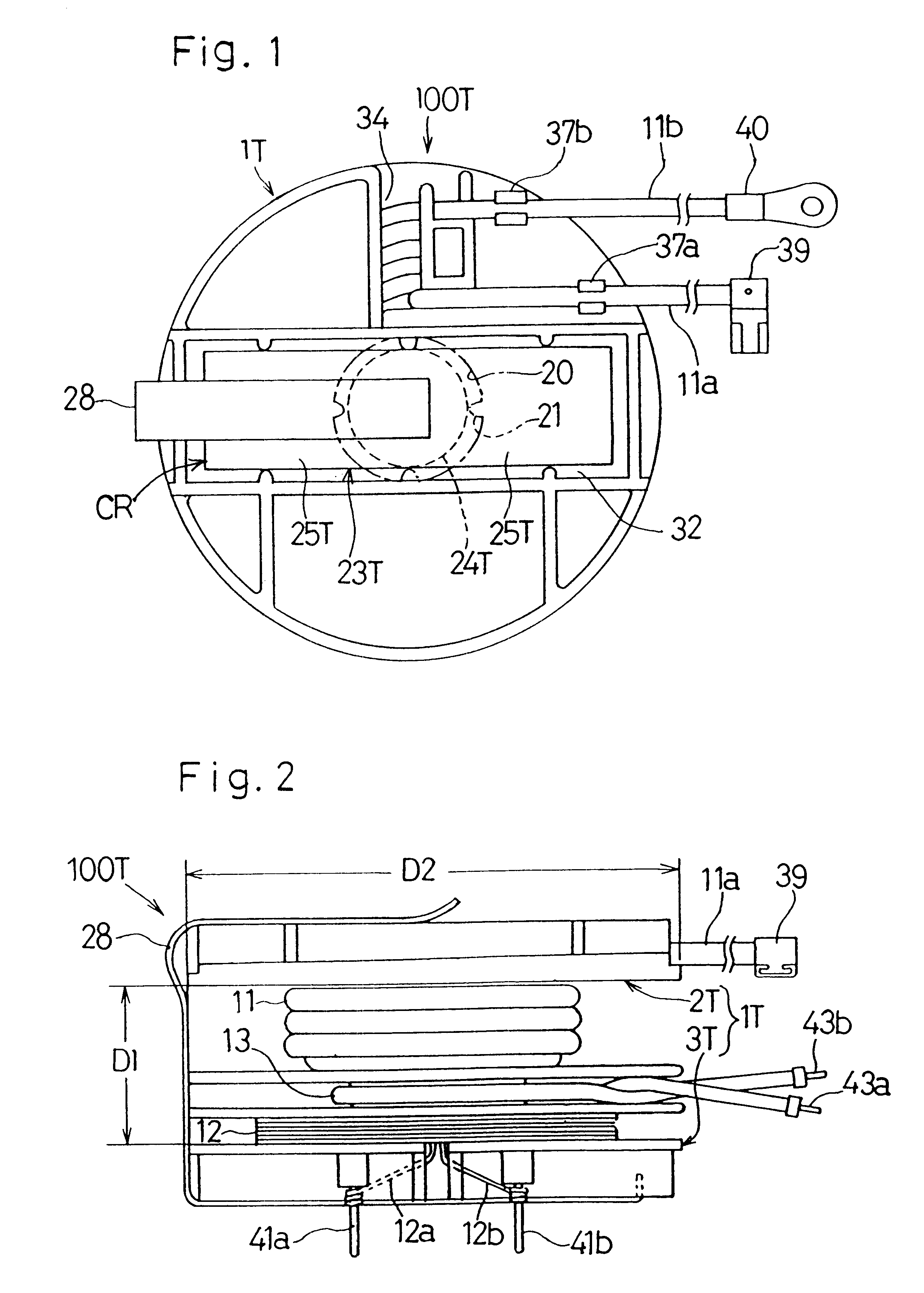

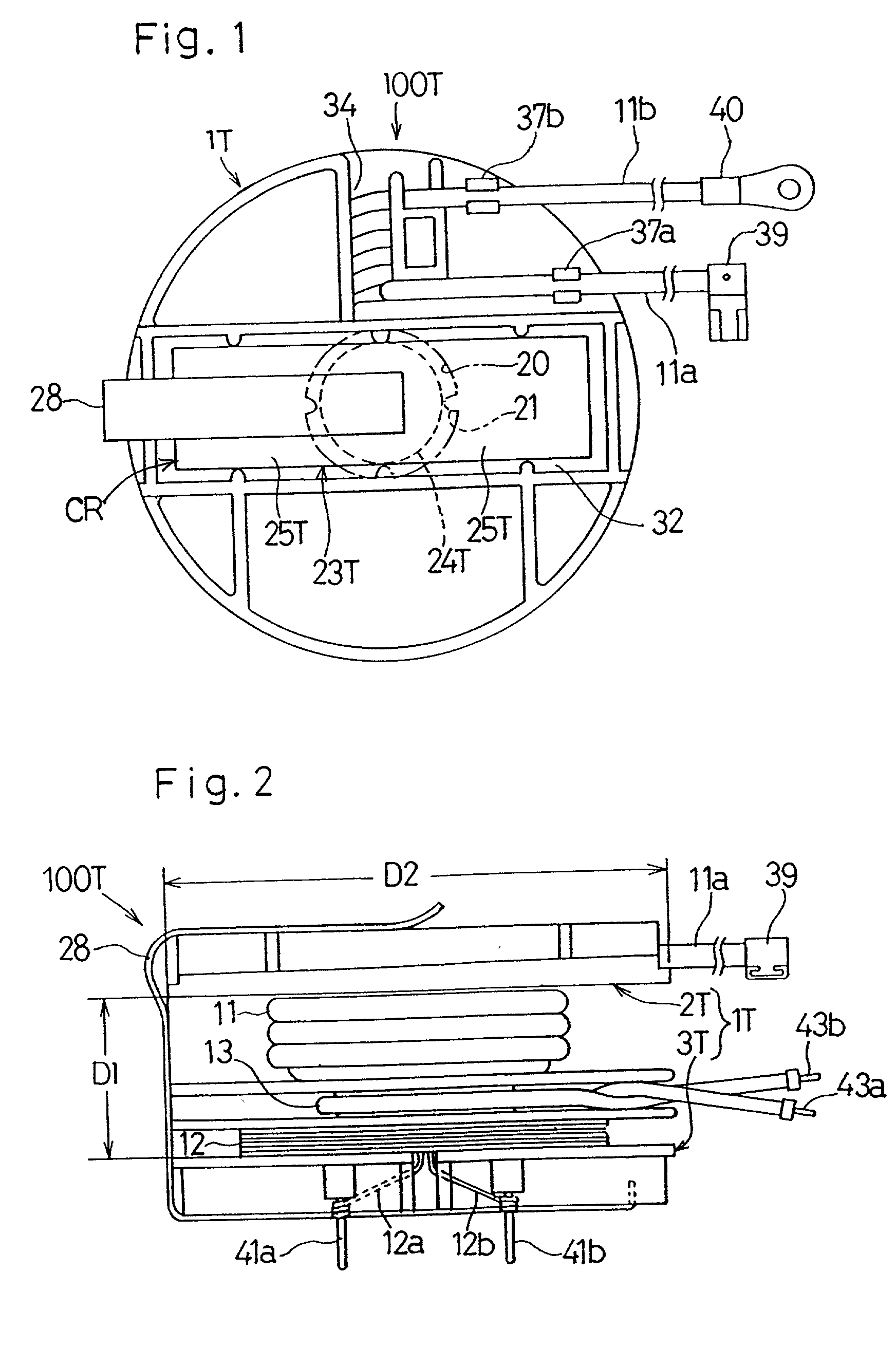

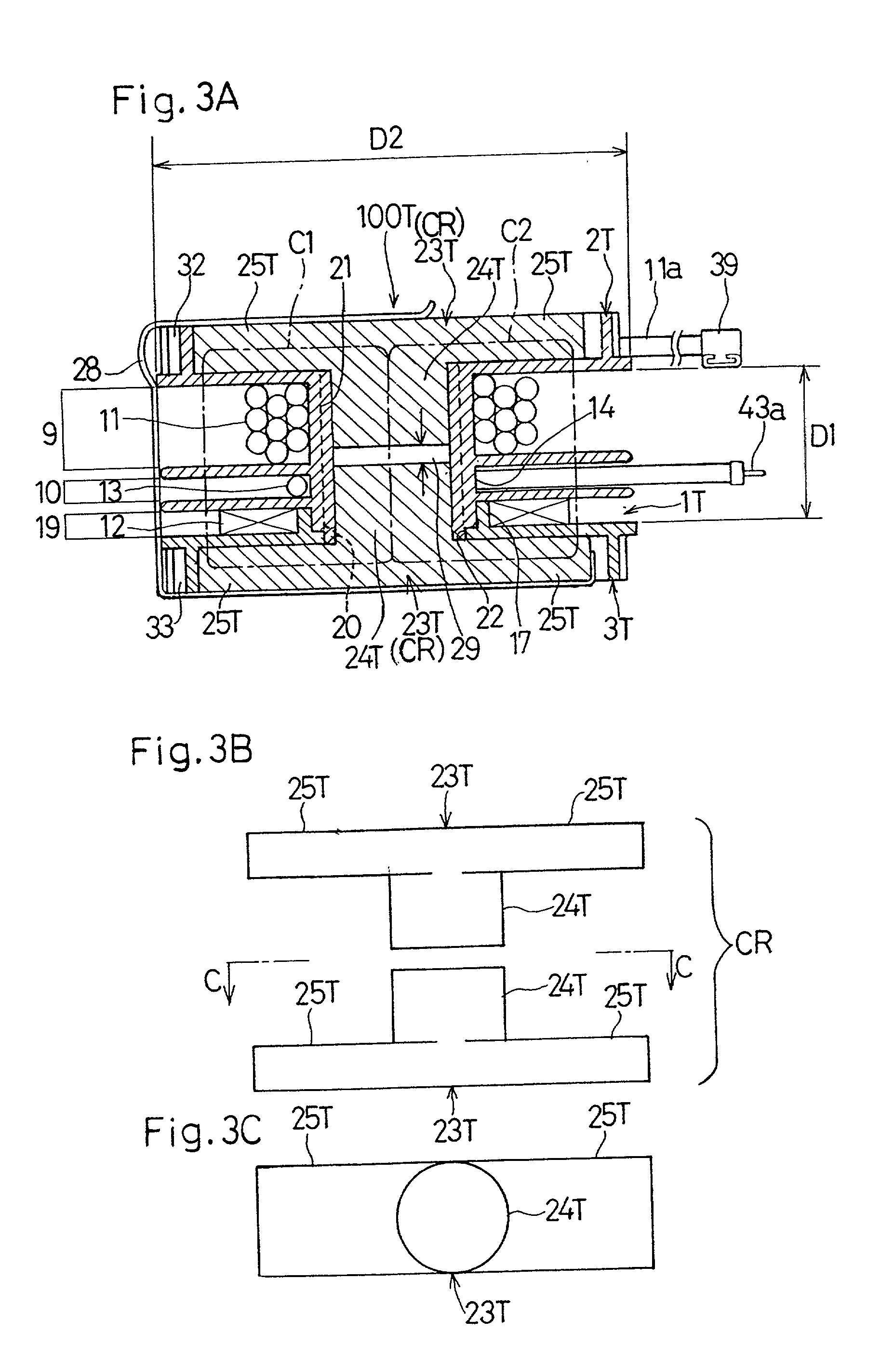

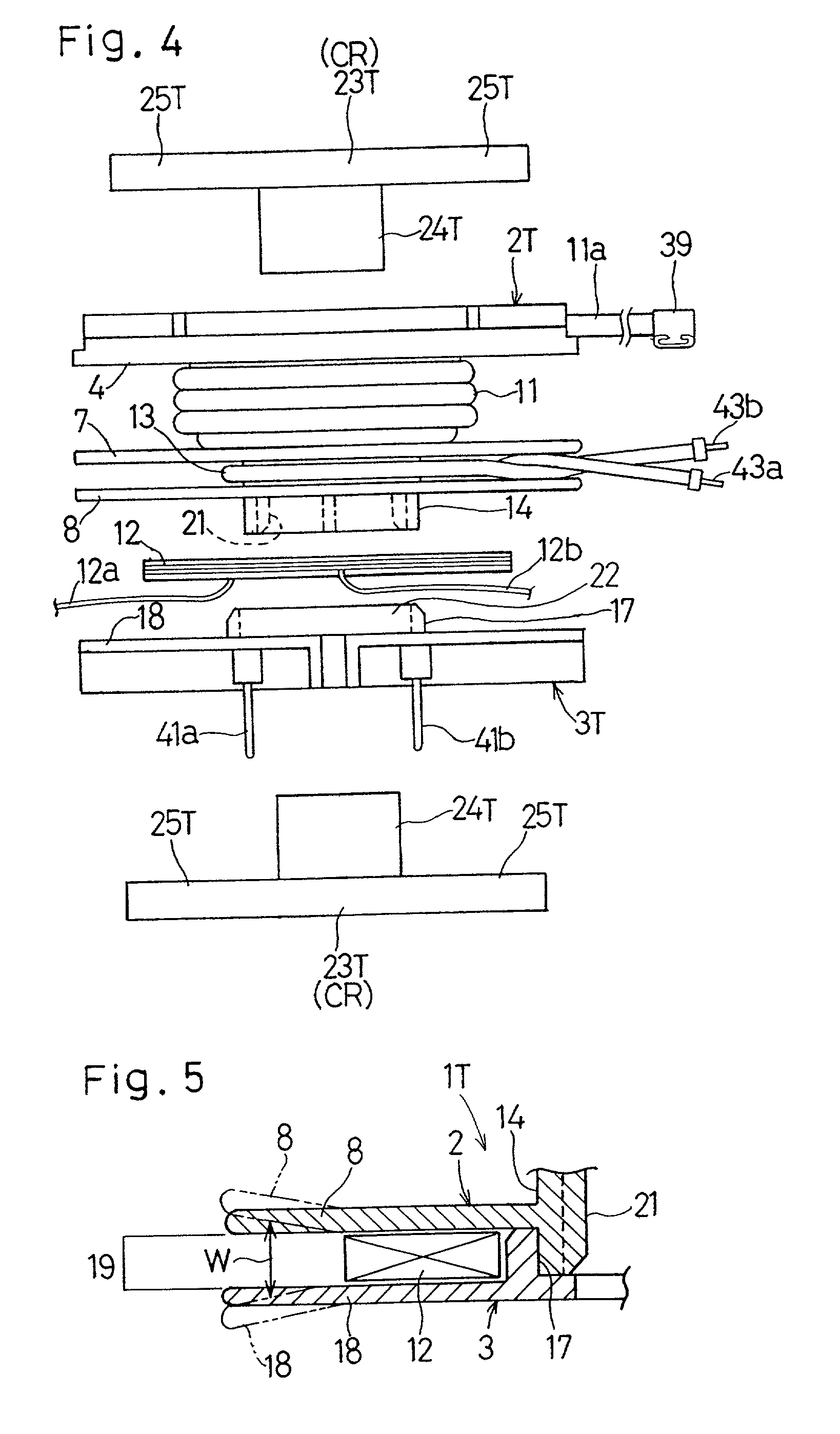

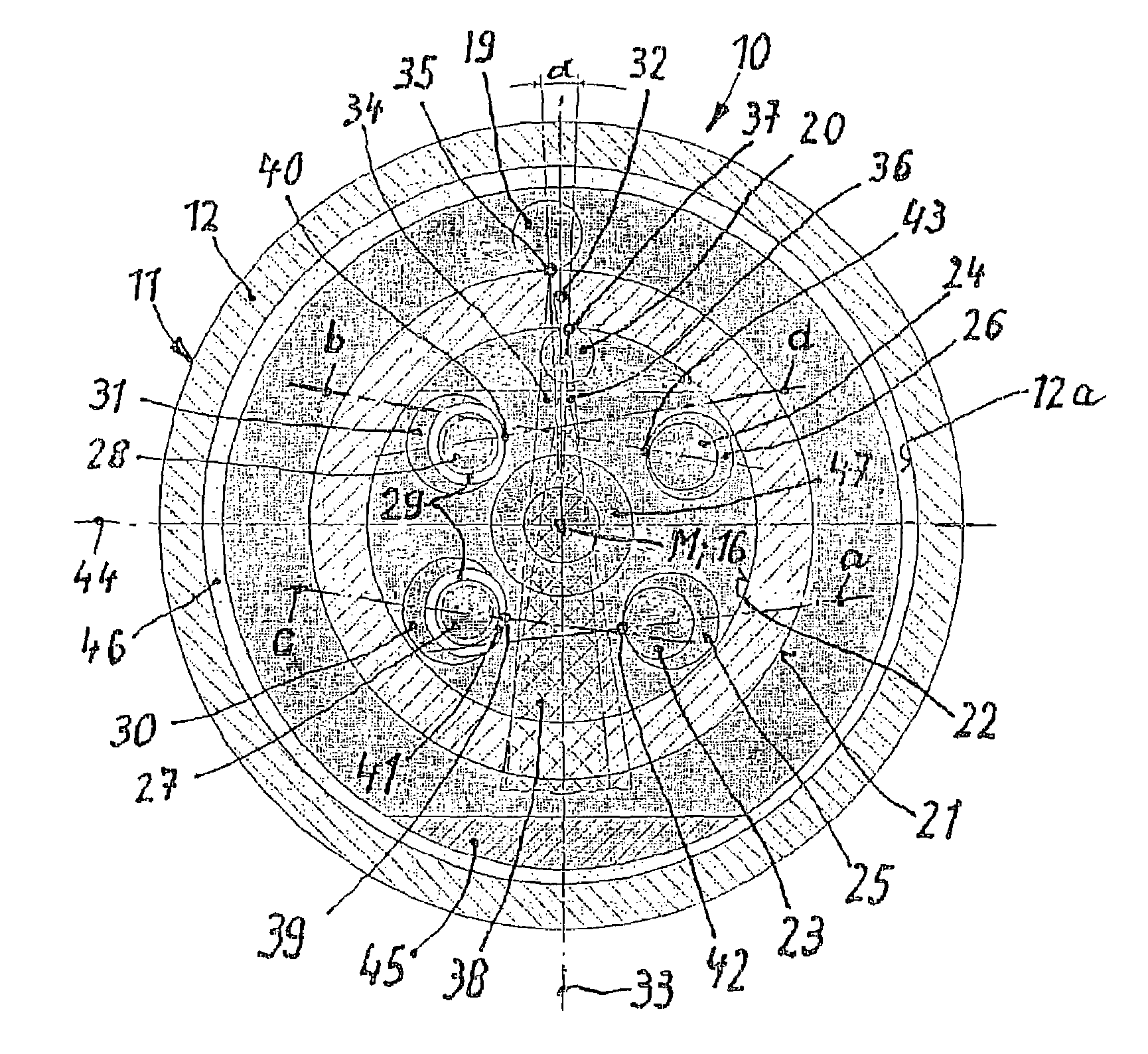

Electromagnetic induction device

InactiveUS6587023B2Reduce horizontal sizeShorten the axial widthCoil arrangementsTransformers/inductances casingsBobbinEngineering

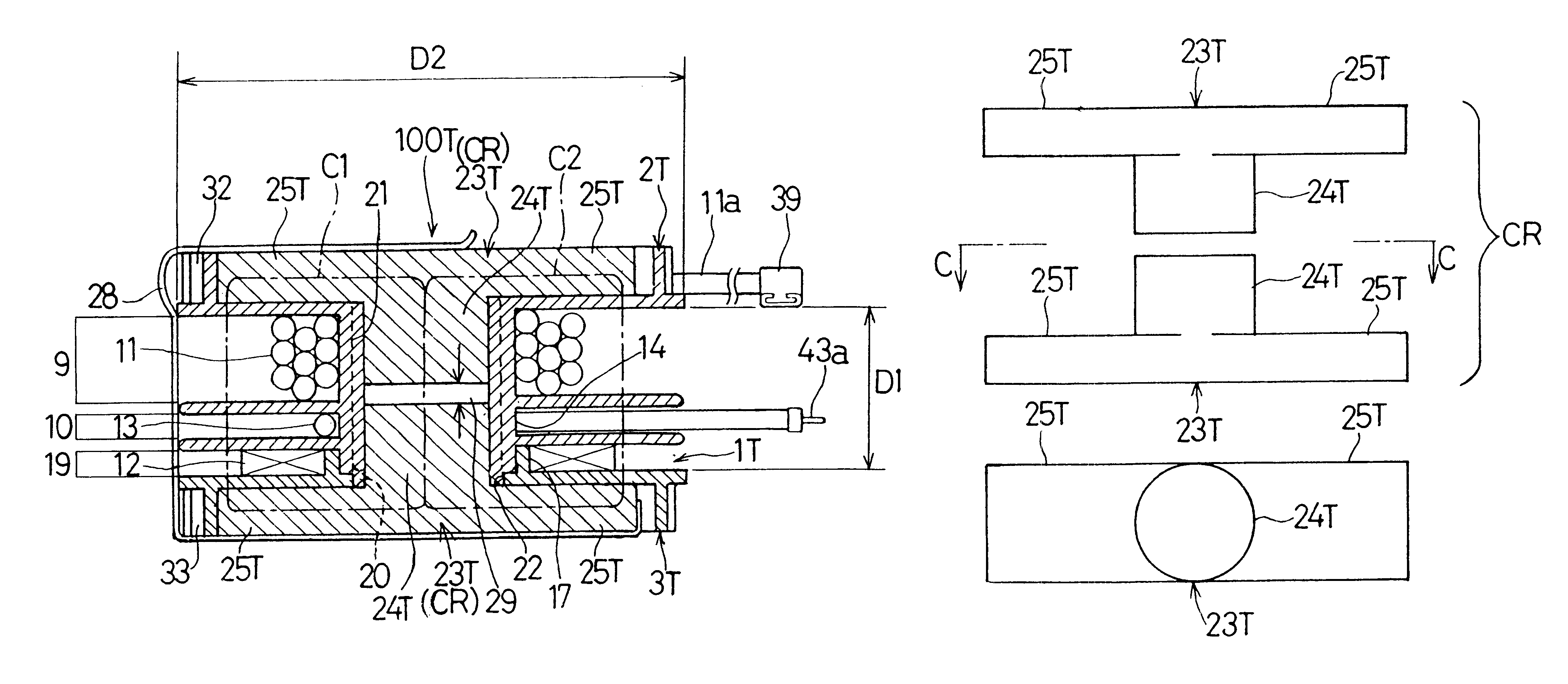

An electromagnetic induction device having a flat configuration that requires a relatively small space for installation on a circuit substrate includes a flat bobbin (1T) having a length (D1) smaller than a radial size (D2) thereof has primary and secondary windings (11, 12) wound thereon. This bobbin (1T) has coaxially aligned throughholes (20, 22) defined therein into which core legs (24T and 24T) of generally T-shaped first and second core pieces (23T, 23T) are inserted from opposite directions, respectively. Respective core arms (25T, 25T) of the first and second core pieces (23T, 23T) extend parallel to each other.

Owner:TABUCHI ELECTRIC CO LTD +1

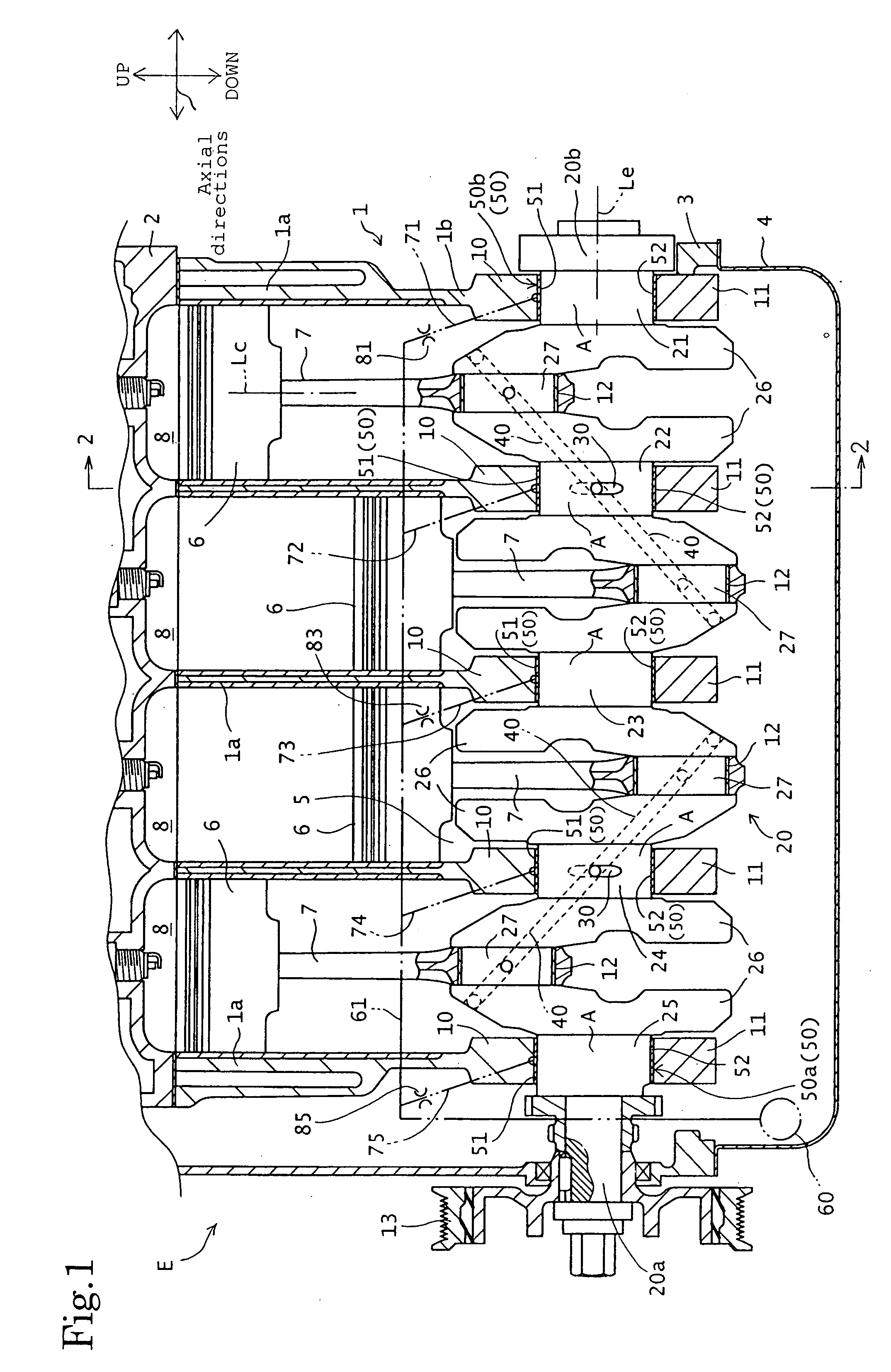

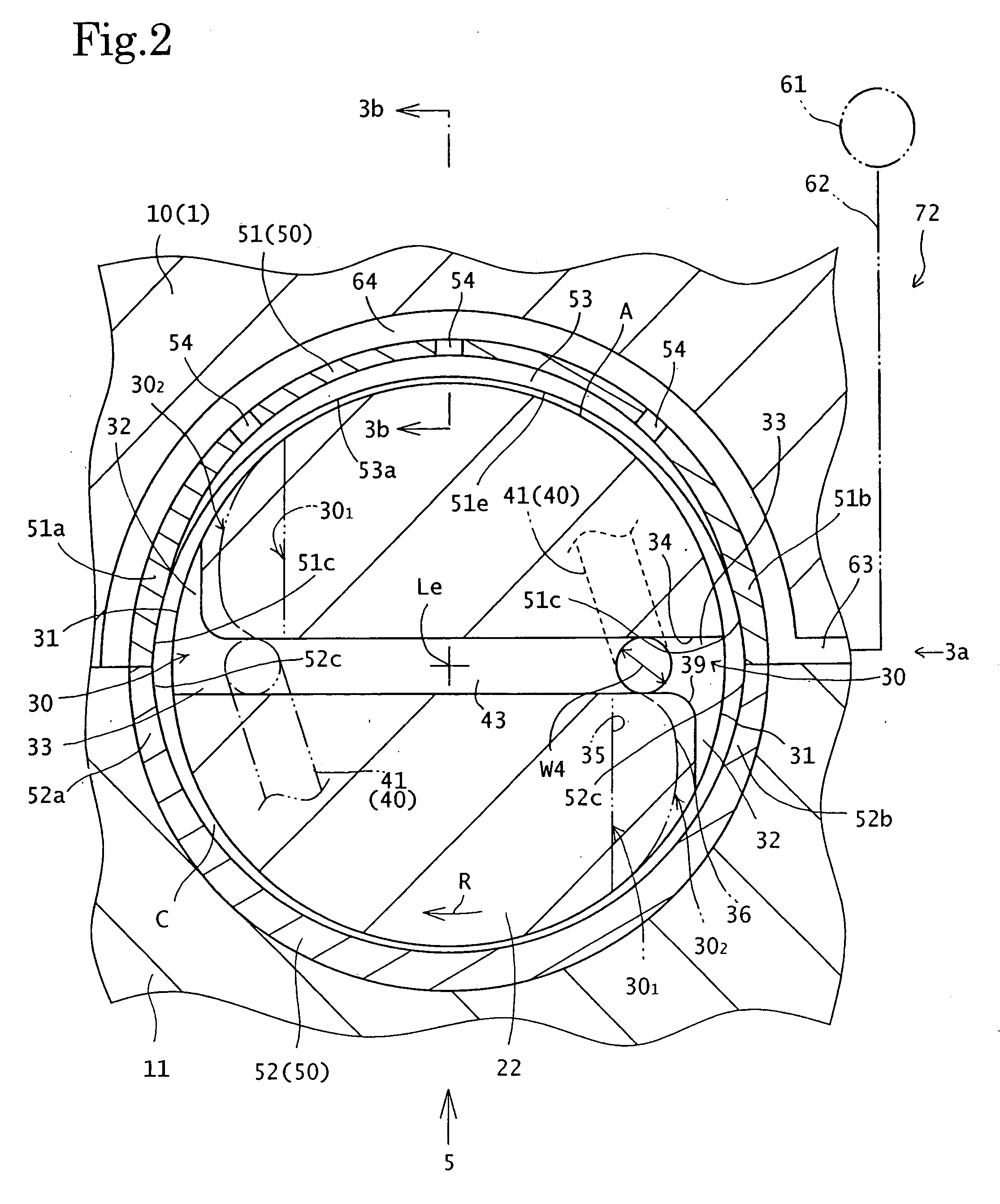

Apparatus for controller-integrated motor

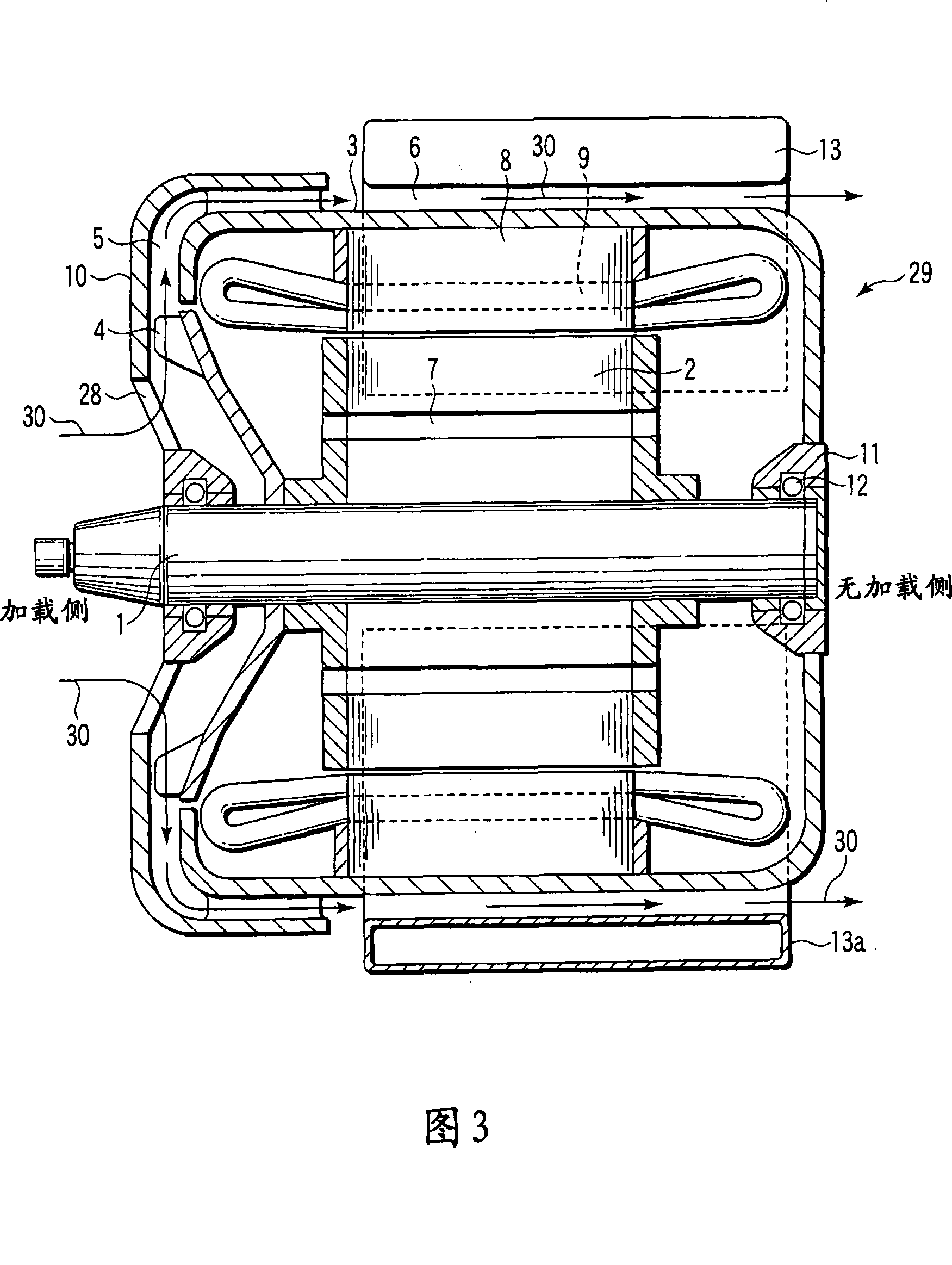

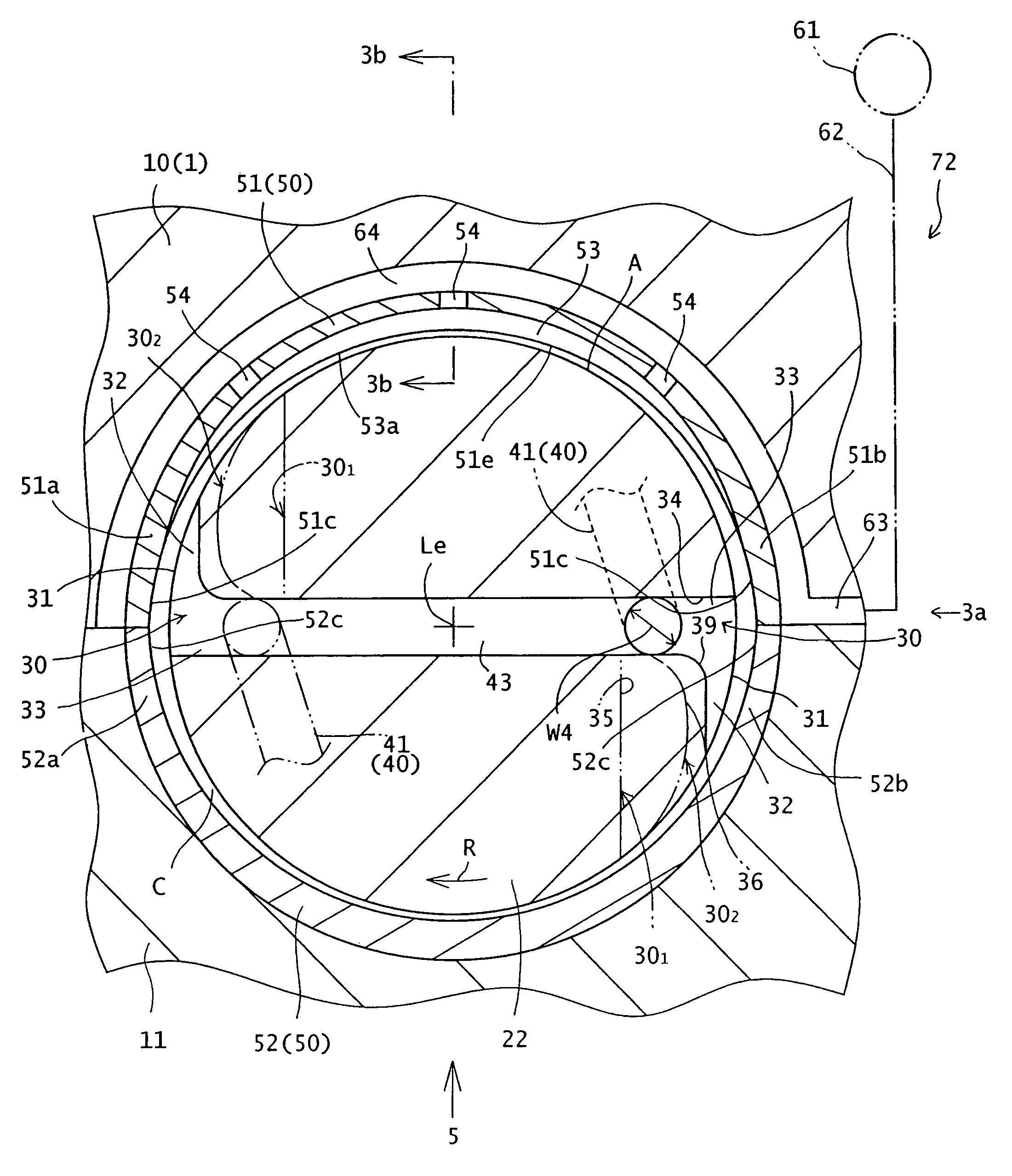

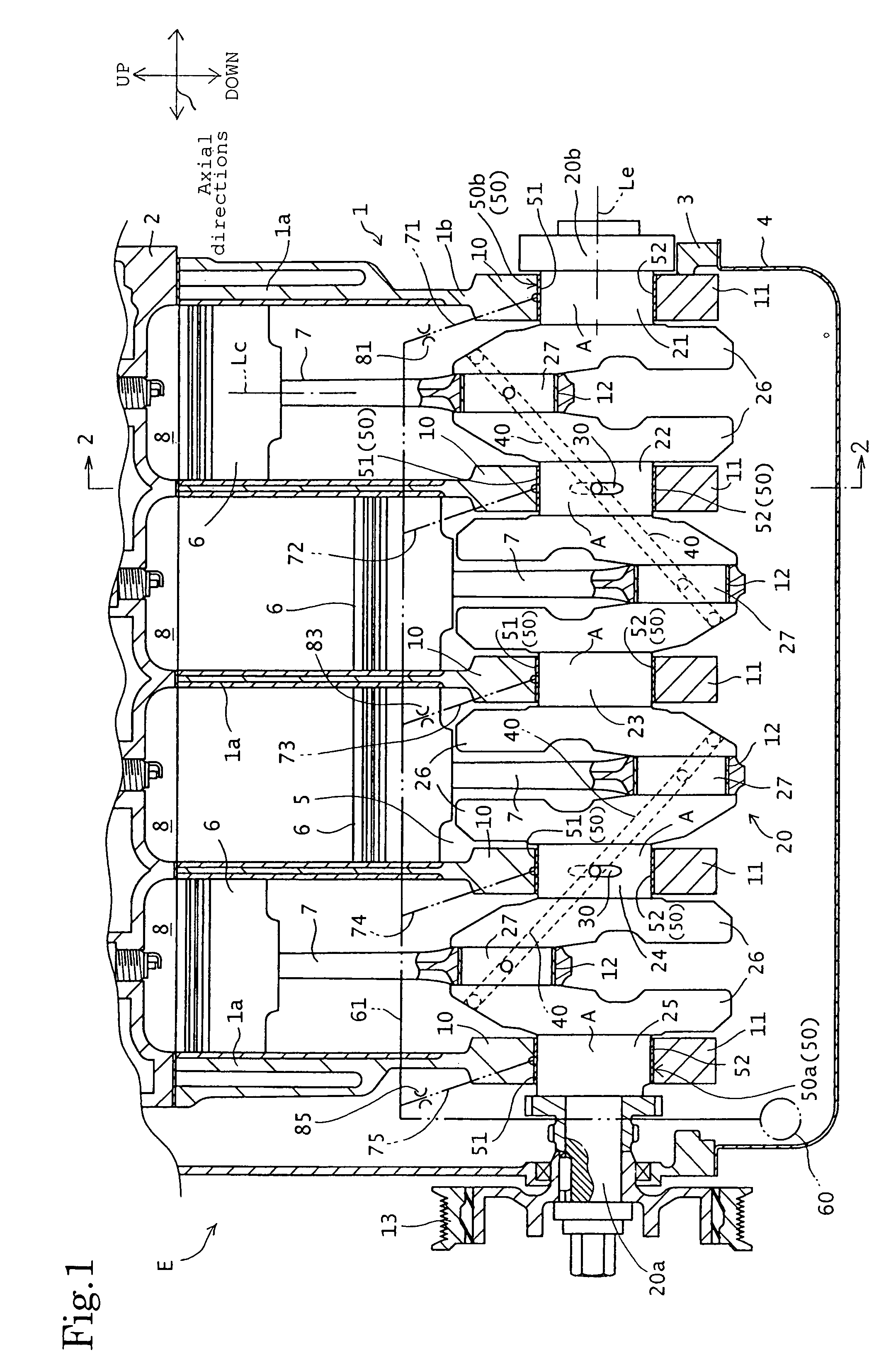

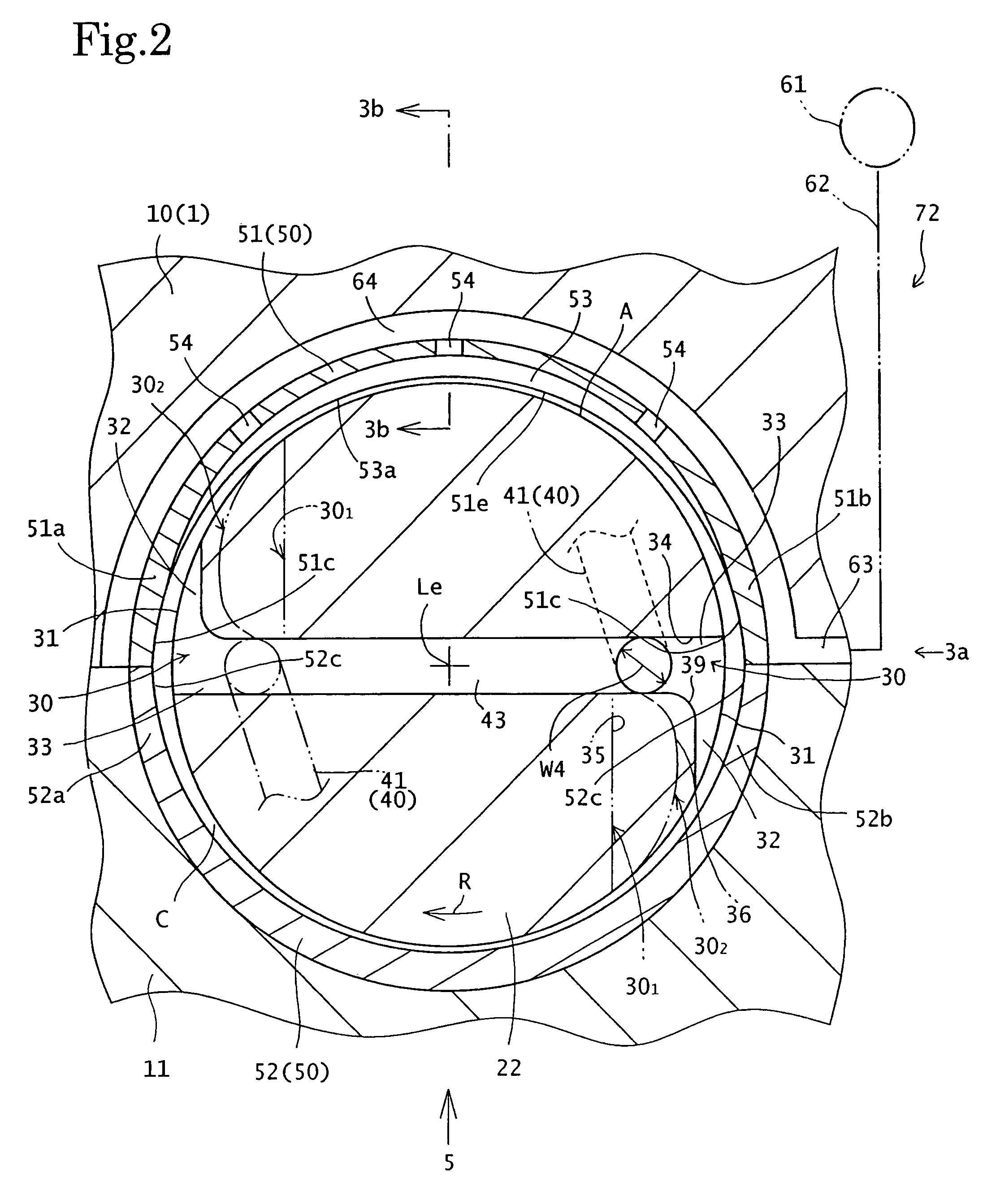

InactiveCN101090216AShorten the axial widthImprove cooling efficiencyAssociation with control/drive circuitsCooling/ventillation arrangementControl theoryAirflow

A controller-integrated motor includes a motor main body and a controller integrated with the motor main body to control the motor main body, the motor main body, including a stator core, a shaft which rotates to exert driving force on the motor main body, a frame which holds the stator core and the shaft, and an outer fan provided around the shaft so that the motor main body is recessed inward toward a rotational center of the shaft, the outer fan discharging cooling air stream to cool the motor main body, the controller being provided in proximity to an outer periphery of the frame, the motor main body being formed so that a cooling air stream from the outer fan flows in an axial direction of the shaft along an outer peripheral surface of the frame.

Owner:KK TOSHIBA

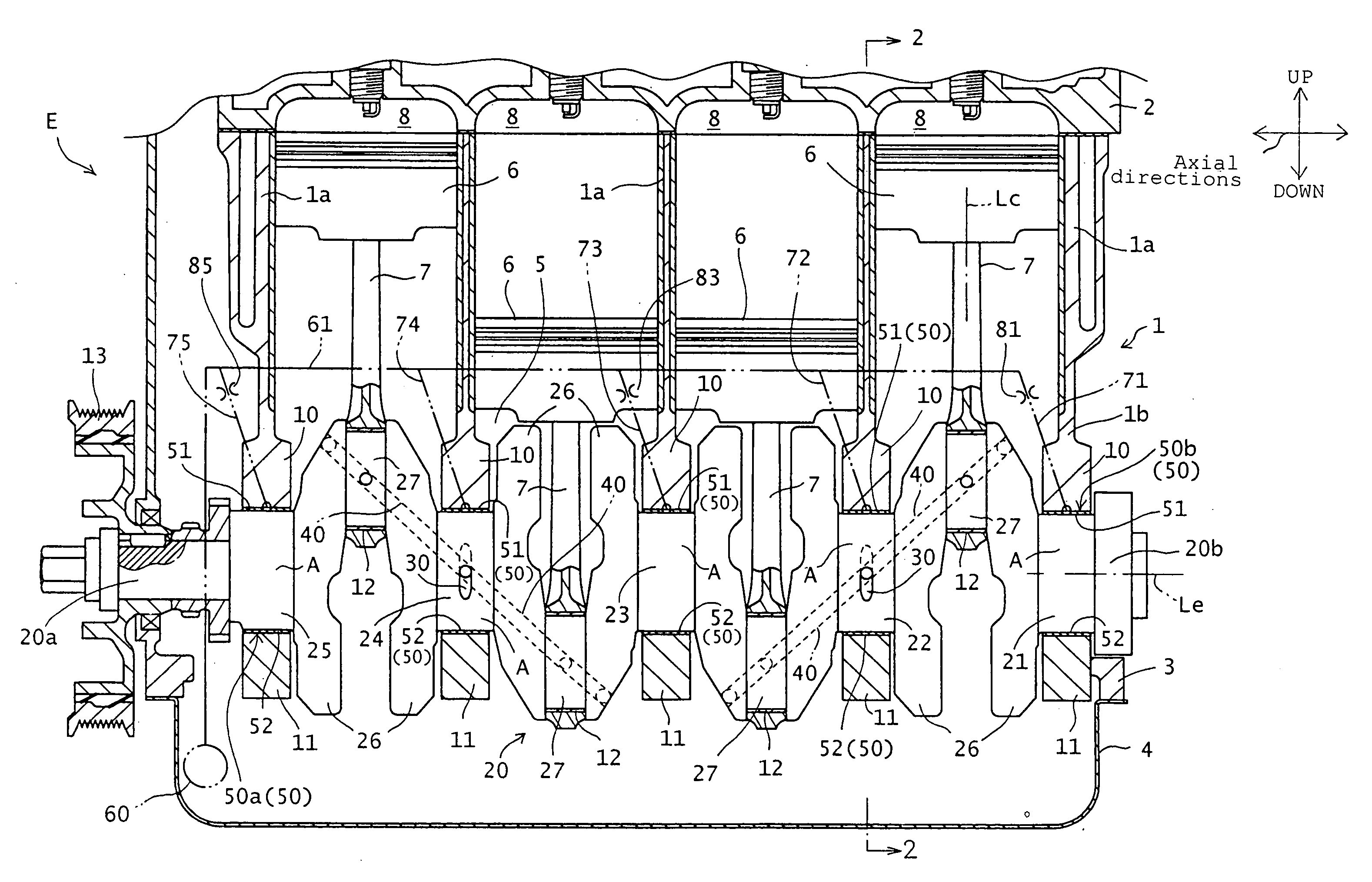

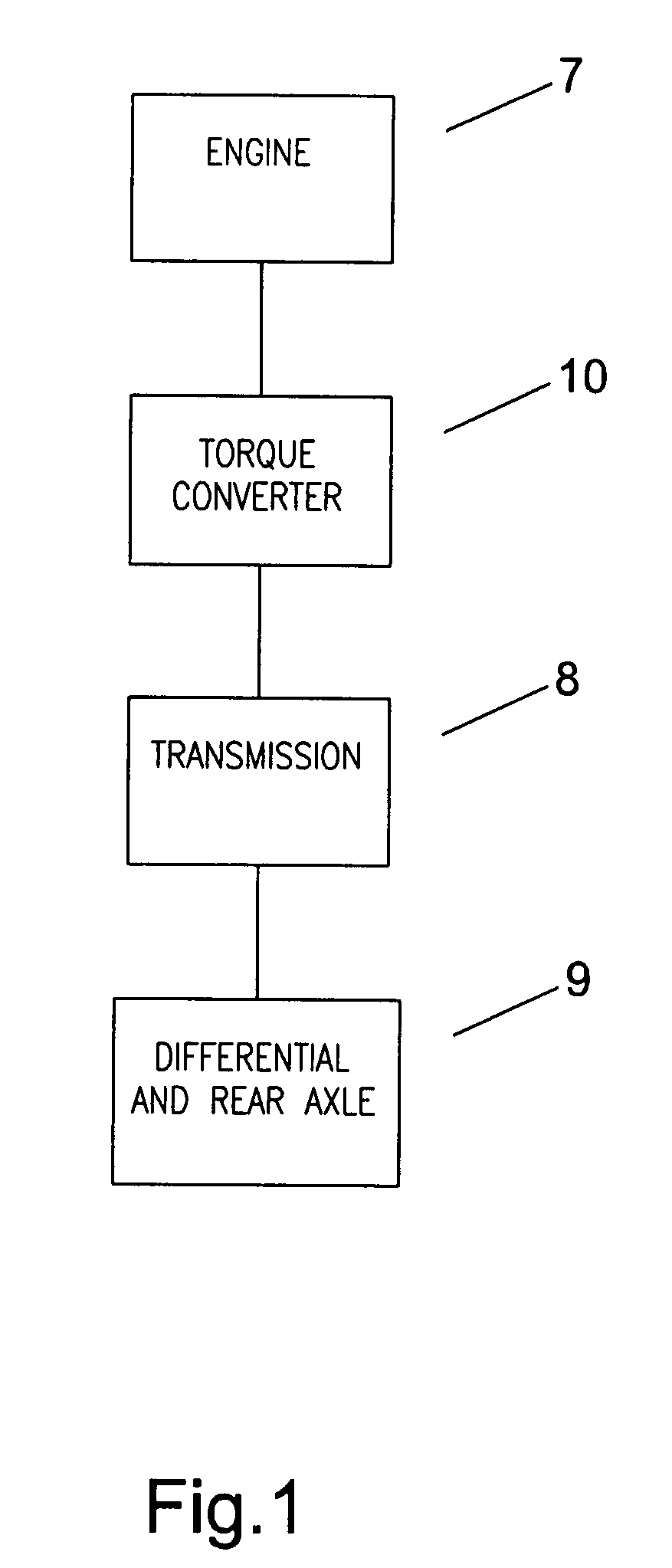

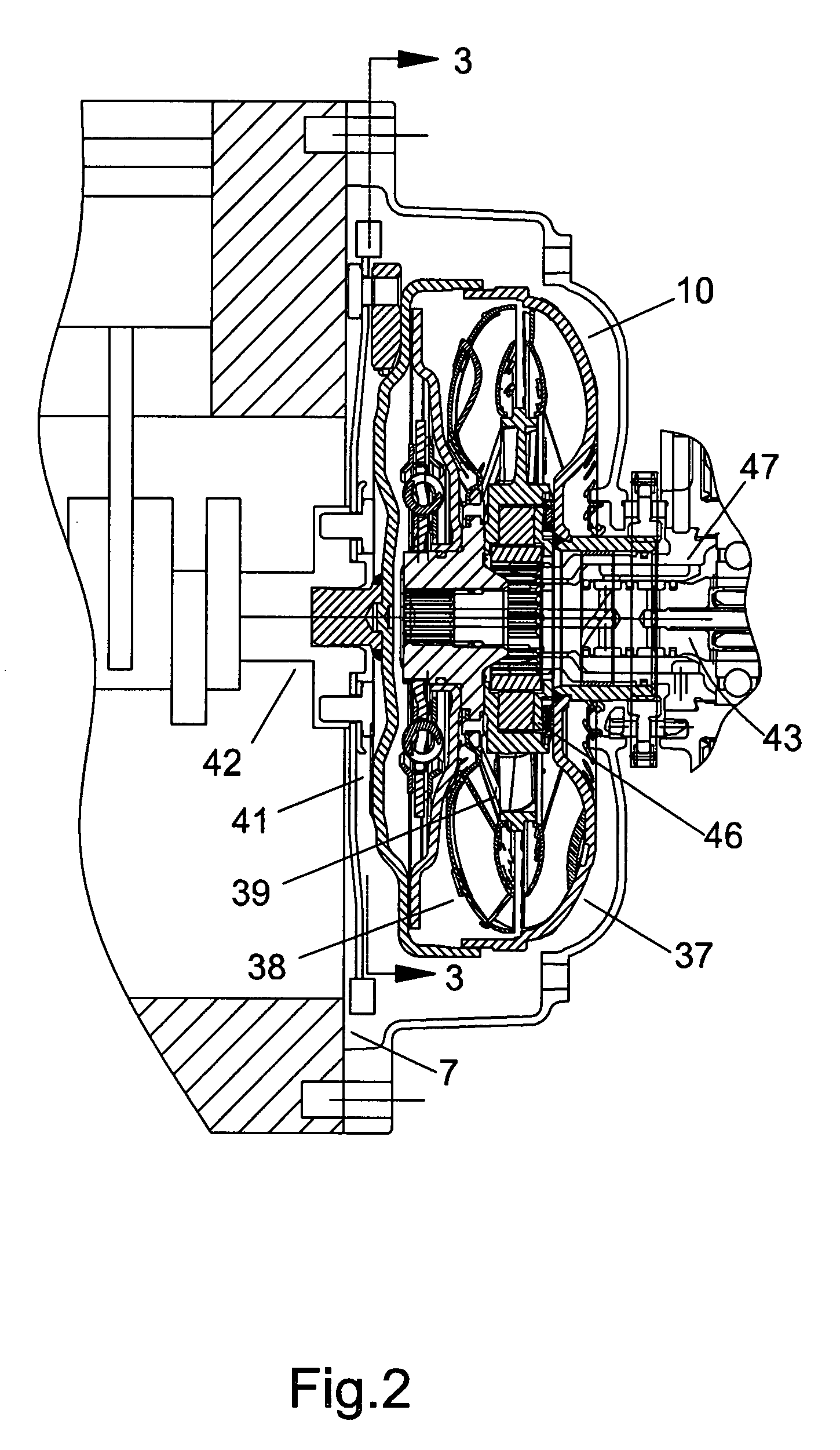

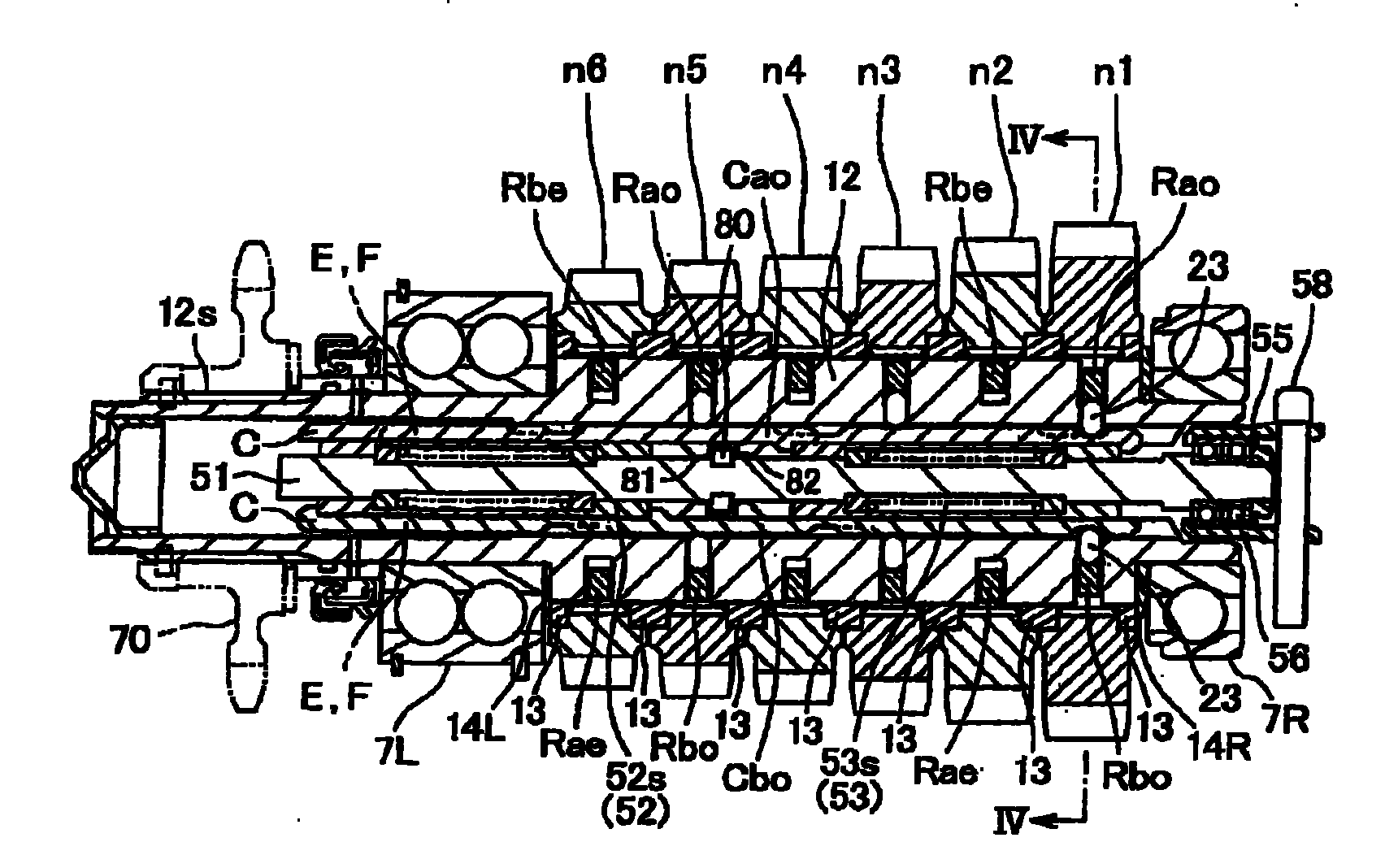

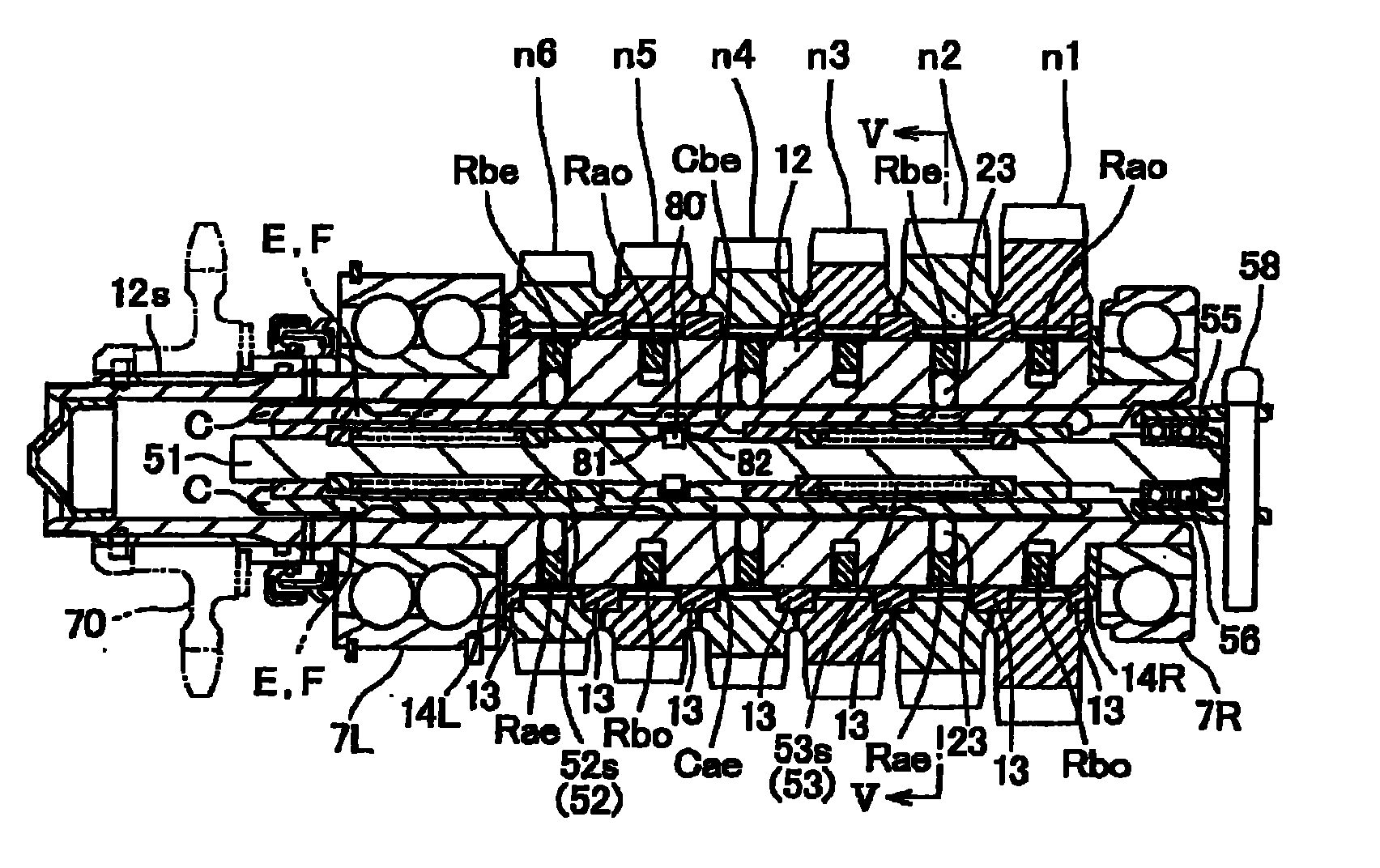

Crankshaft lubrication system

Owner:HONDA MOTOR CO LTD

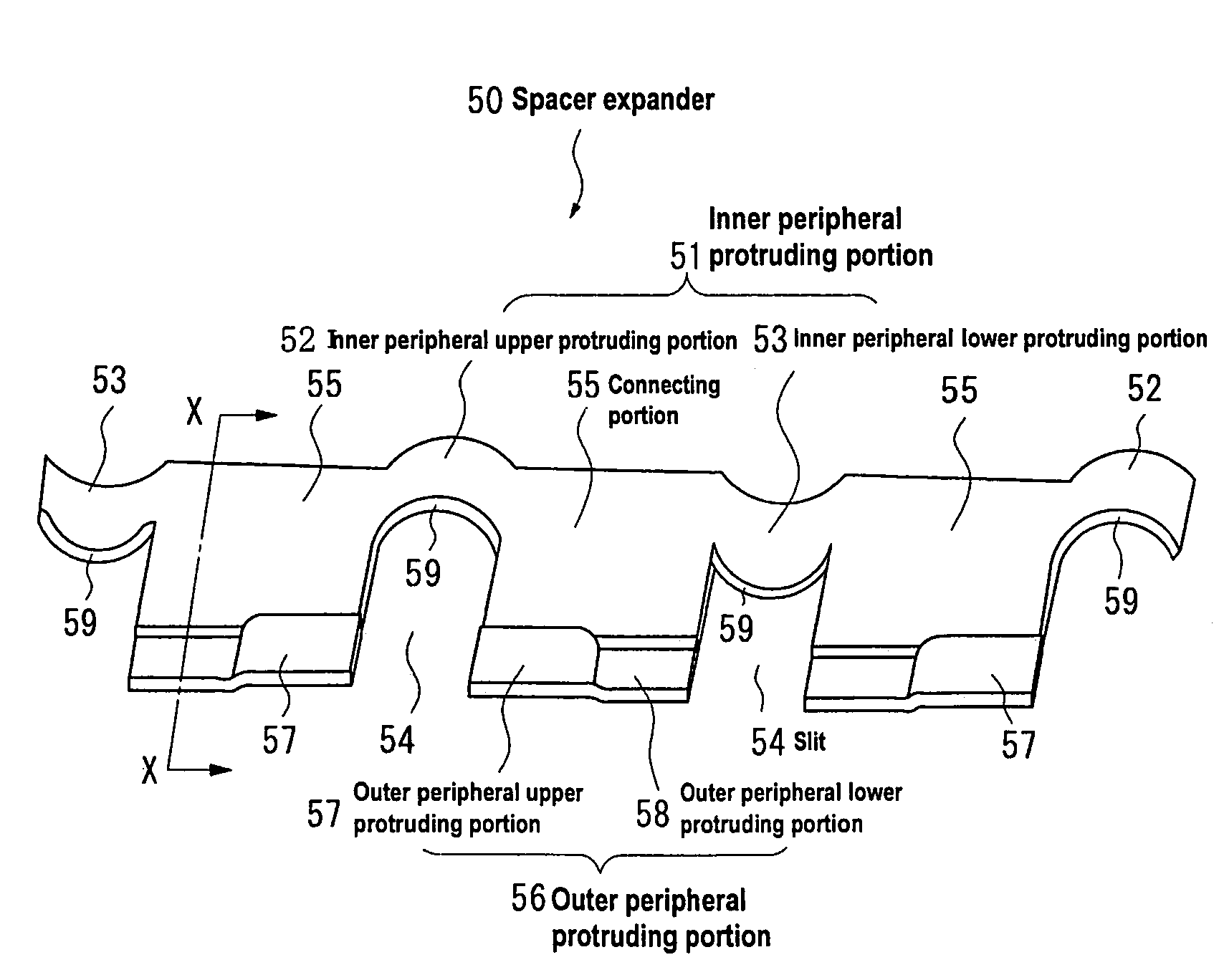

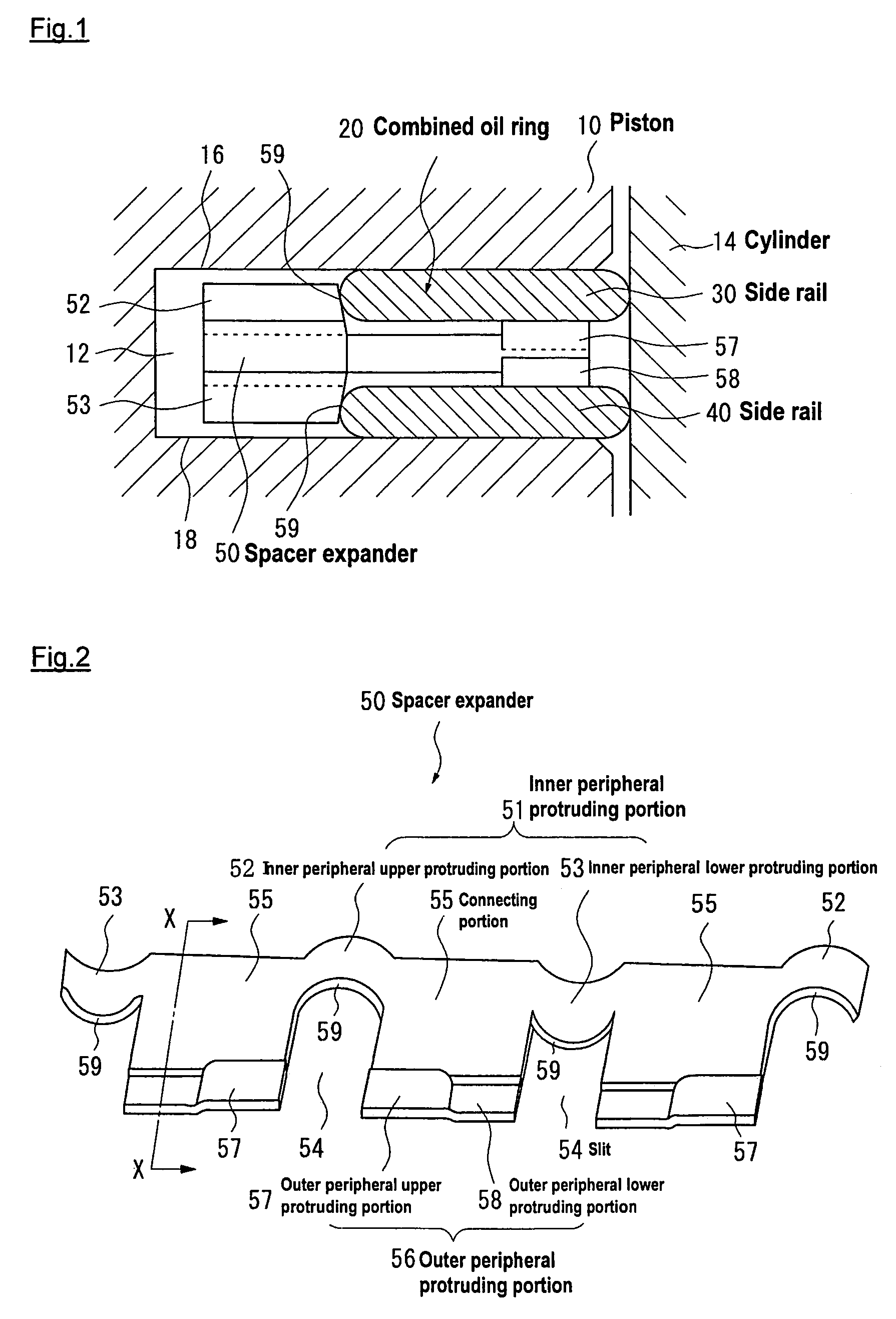

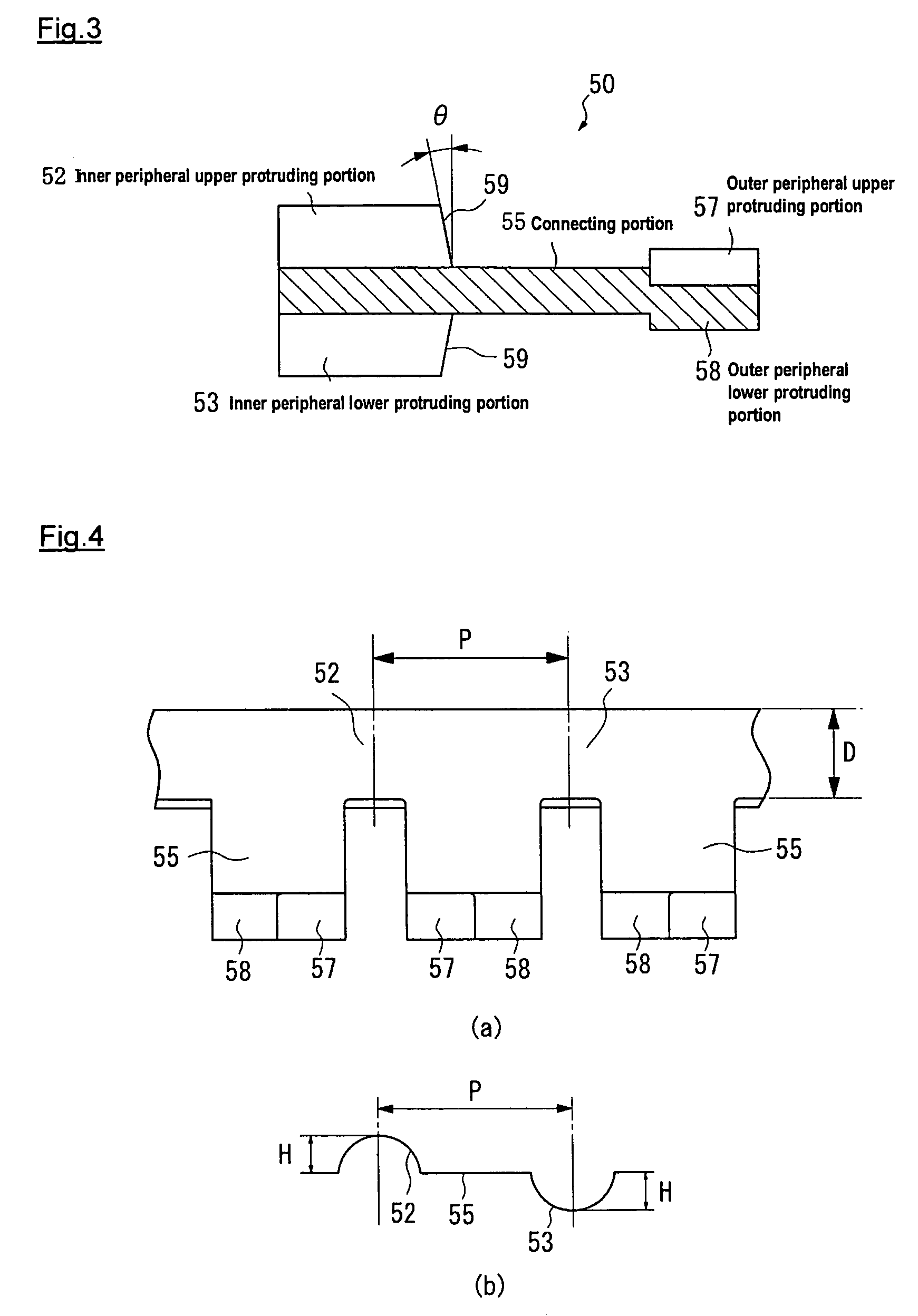

Spacer expander

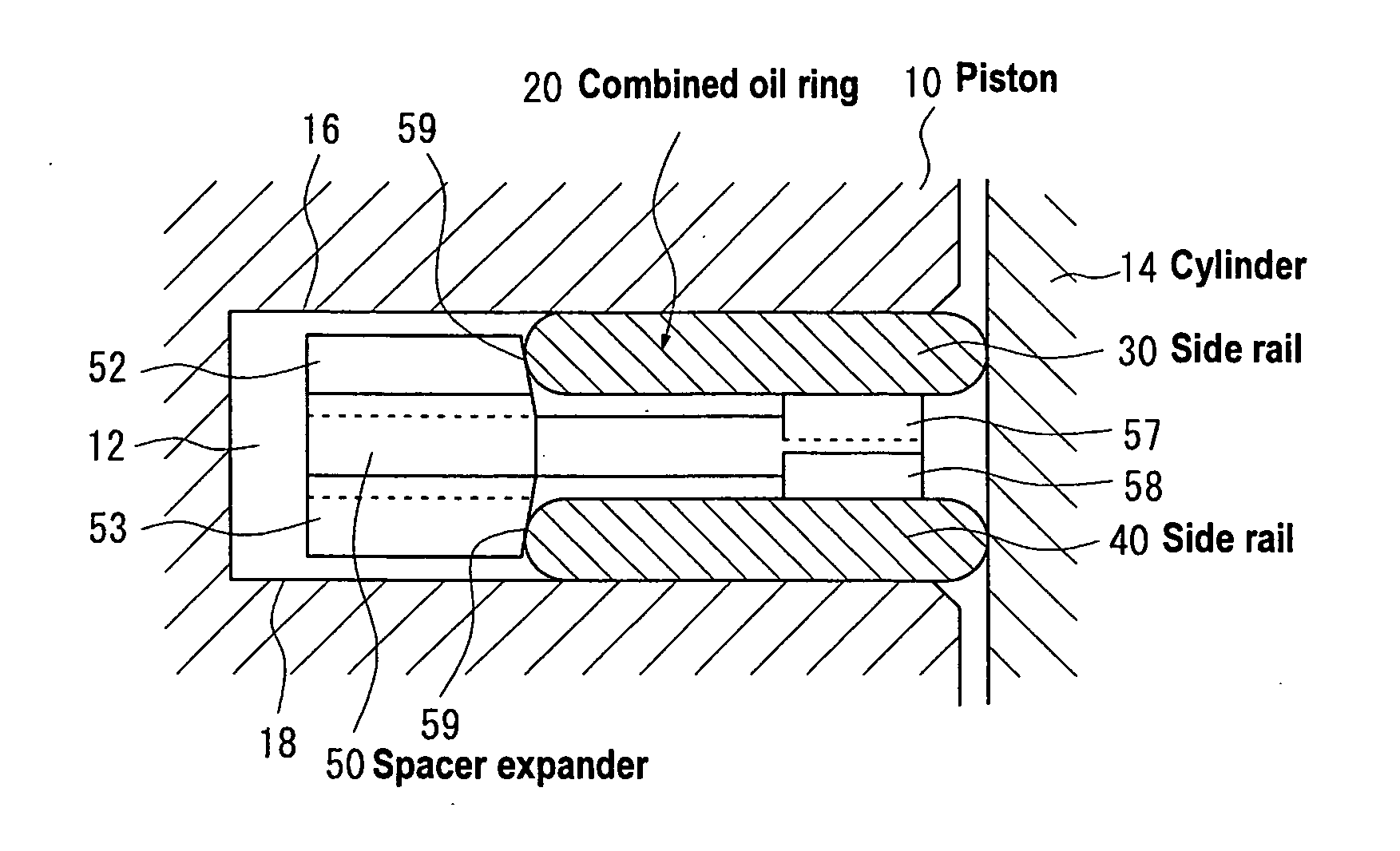

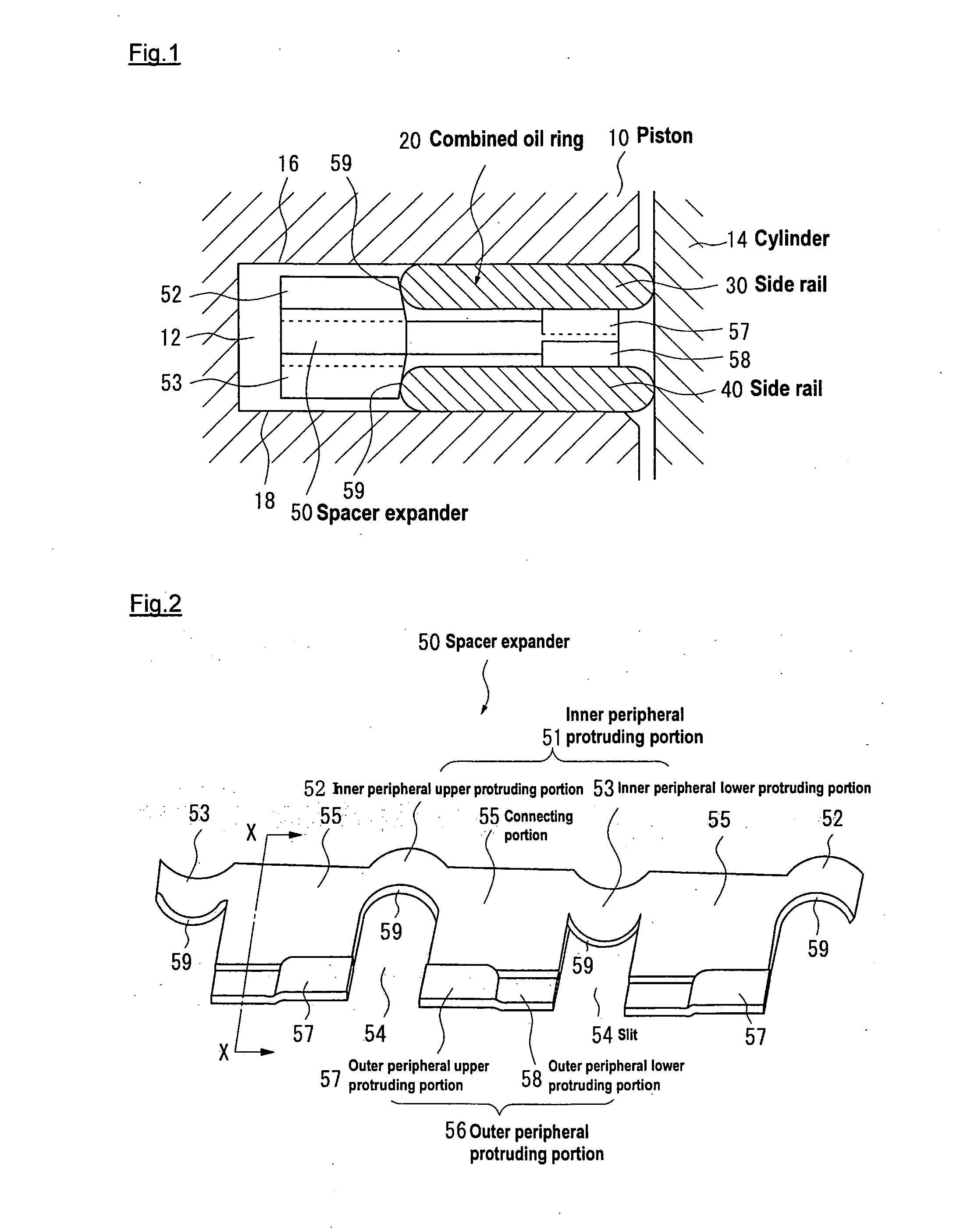

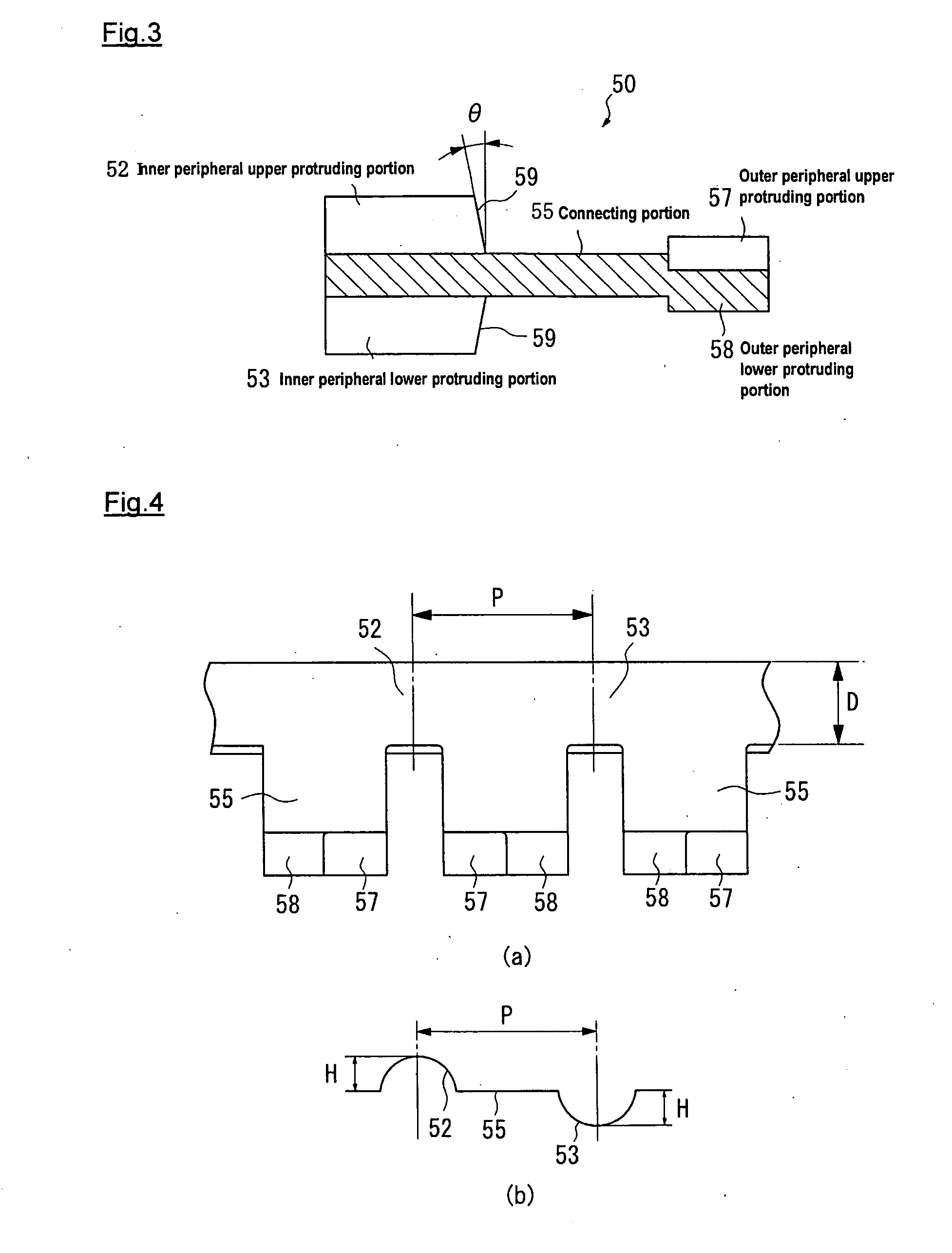

InactiveUS20060169135A1Improve fuel efficiencyImprove fitPiston ringsBraking action transmissionElectrical and Electronics engineering

In a combined oil ring having a spacer expander to be installed between a pair of upper and lower side rails, a plurality of axially protruding inner peripheral protruding portions are formed on the inner peripheral side of the spacer expander along its peripheral direction. The inner peripheral protruding portions press the inner peripheral surface of the side rails. On the outer peripheral side of the spacer expander, a plurality of slits are formed, and a plurality of connecting portions are located in the peripheral direction isolated by the slits. On the plurality of connecting portions, axially protruding outer peripheral protruding portions are formed.

Owner:RIKEN CO LTD

Crankshaft lubrication system

InactiveUS20080190699A1Reduce leakageJournal is reducedCrankshaftsConnecting rodsInternal combustion engineCrankpin

A crankshaft of an internal combustion engine has journals provided with shaft oil passages for carrying the oil to crankpins, and guide grooves having parts in which the shaft oil passages open, respectively, and opening in the cylindrical surfaces of the journals, respectively. The guide grooves has downstream end parts into which the shaft oil passages open, respectively, and extend in a circumferential direction in which the crankshaft rotates from the downstream end parts, respectively. First half bearing members of bearings are provided in their bearing surfaces with oil grooves through which the oil is supplied to the guide grooves, respectively. Each of the oil grooves are diametrically opposite to each of the guide grooves. The oil grooves have an axial width (W5) smaller than the axial width (W3) of the guide grooves. Thus oil leakage from gaps between each of the bearings and each of the journals of the crankshaft is reduced and hence an oil pump having a small capacity can be used.

Owner:HONDA MOTOR CO LTD

Electromagnetic induction device

InactiveUS20010024152A1Reduce horizontal sizeShorten the axial widthCoil arrangementsTransformers/inductances casingsBobbinEngineering

An electromagnetic induction device having a flat configuration that requires a relatively small space for installation on a circuit substrate includes a flat bobbin (1T) having a length (D1) smaller than a radial size (D2) thereof has primary and secondary windings (11, 12) wound thereon. This bobbin (1T) has coaxially aligned throughholes (20, 22) defined therein into which core legs (24T and 24T) of generally T-shaped first and second core pieces (23T, 23T) are inserted from opposite directions, respectively. Respective core arms (25T, 25T) of the first and second core pieces (23T, 23T) extend parallel to each other.

Owner:TABUCHI ELECTRIC CO LTD +1

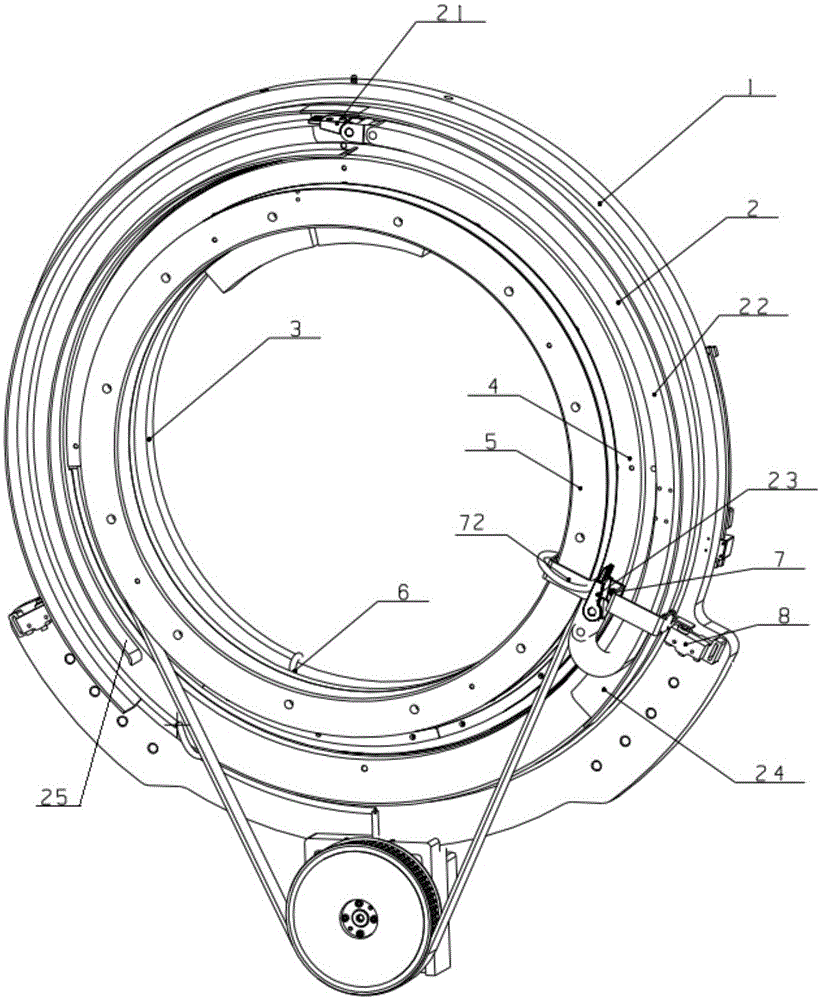

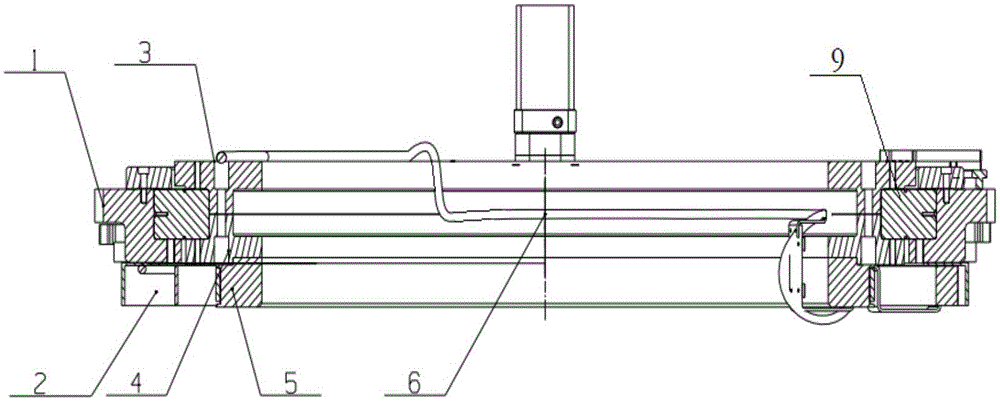

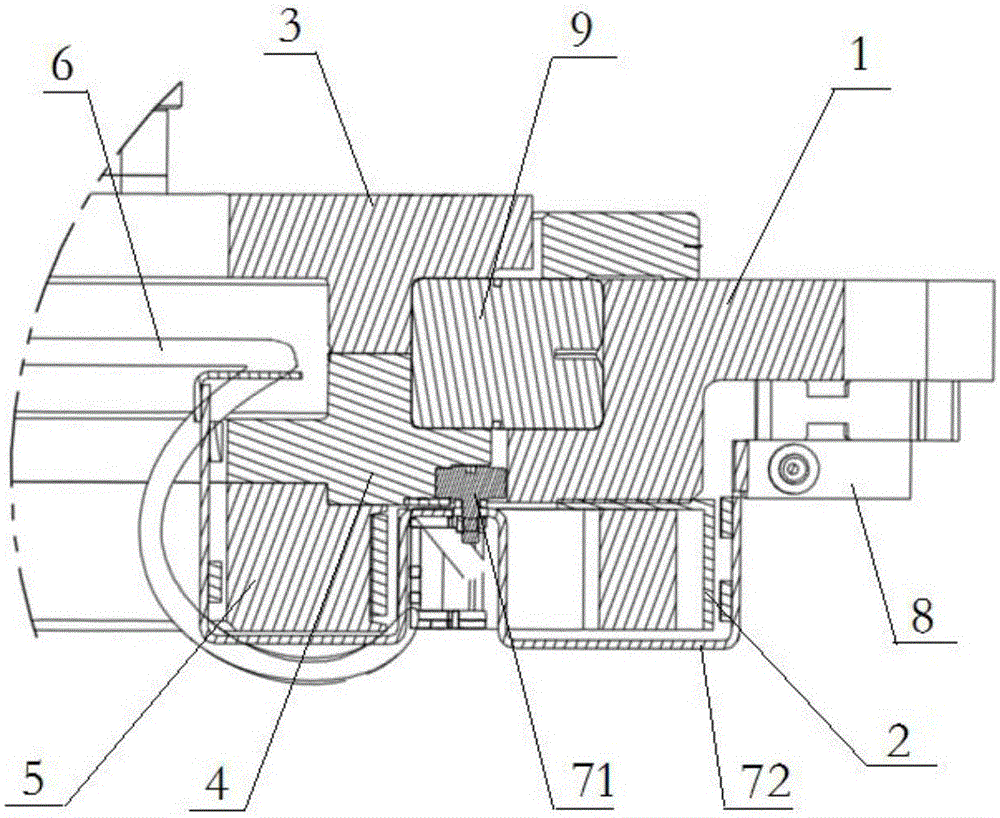

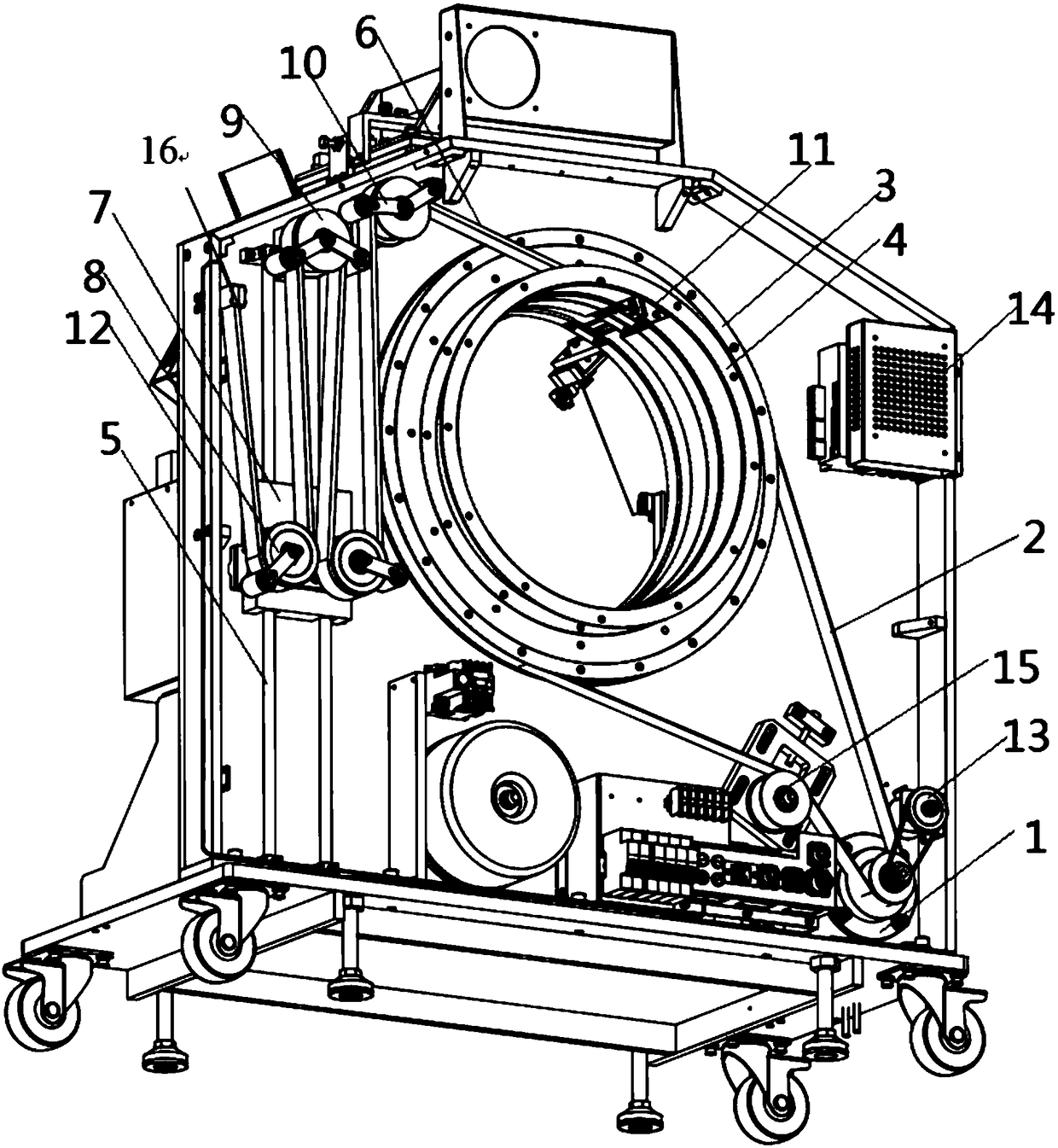

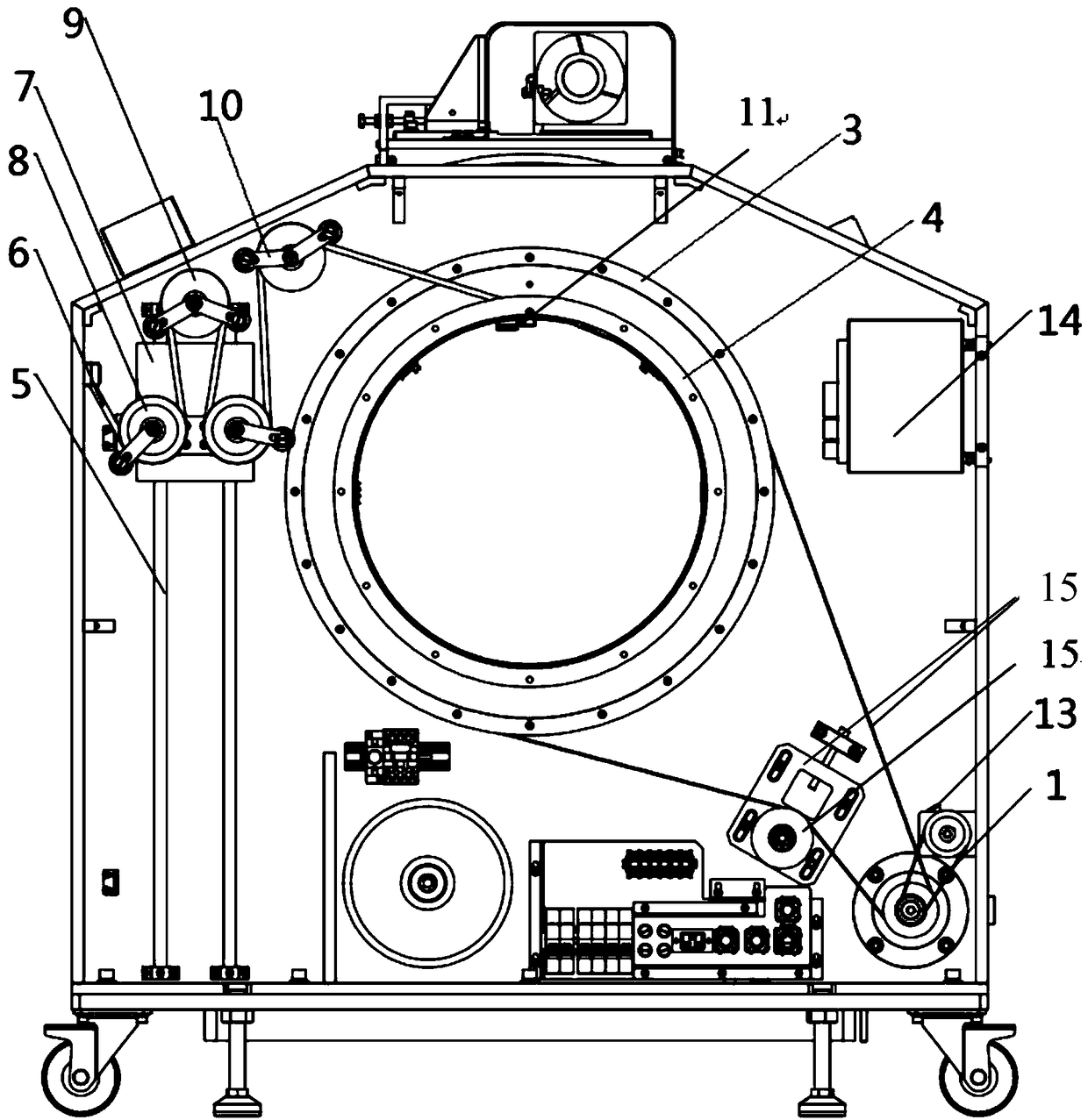

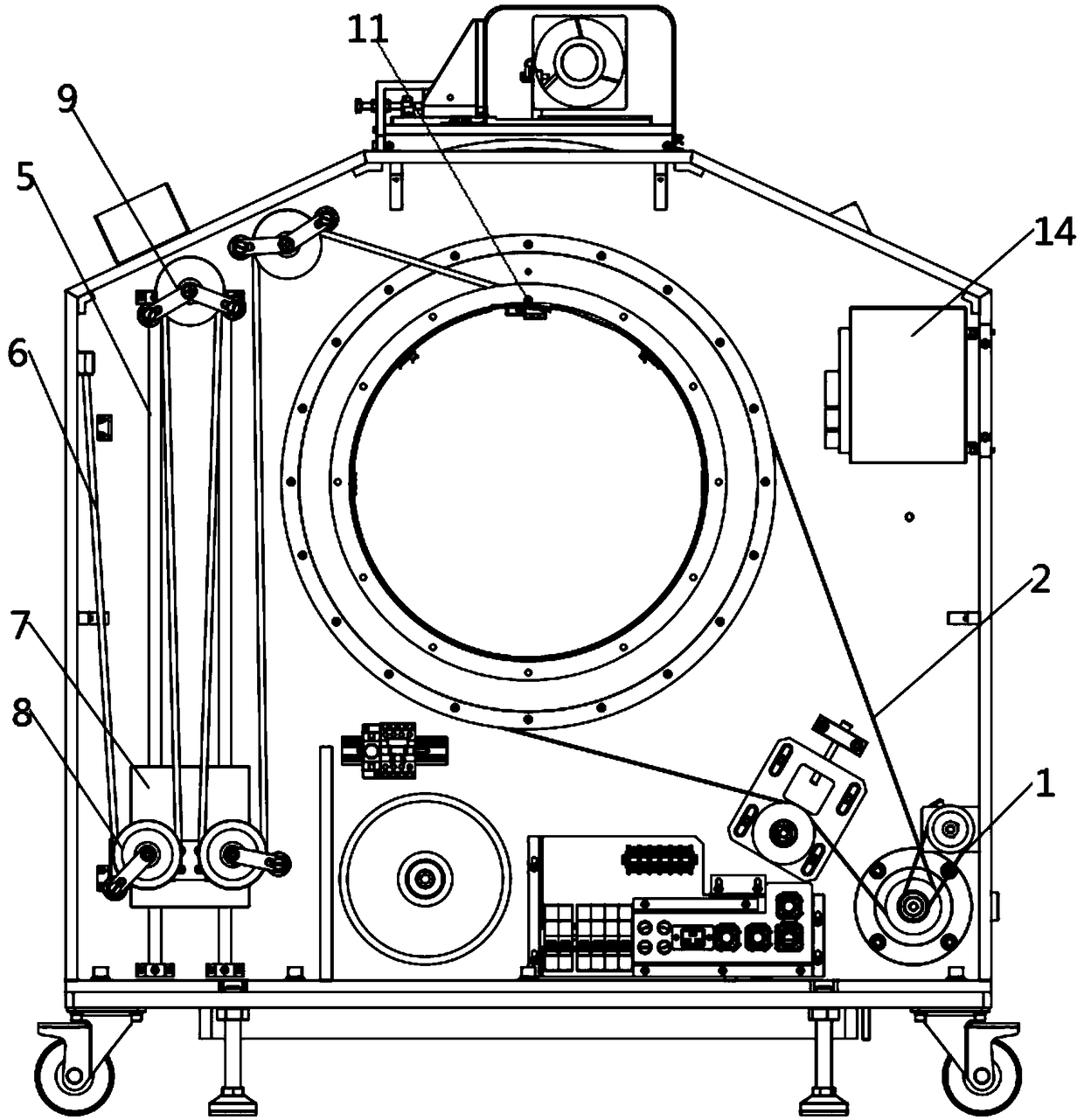

Wiring device for rotating scanning of cone beam CT machine

ActiveCN105125233AShorten the axial widthSimple structureComputerised tomographsTomographyControl theoryFlange

The invention discloses a wiring device for rotating scanning of a cone beam CT machine. The wiring device comprises a rack, a rotating part, a drag chain and a follower, wherein the rack is vertically arranged on the base of the CT machine; a pivotal bearing is arranged in the rack; the rotating part comprises a rotating disk, a flange and a synchronous pulley; the rotating disk and the flange are connected in a manner that the inner ring of the pivotal bearing is clamped by bolts; the synchronous pulley and the outer side wall of the flange are connected by bolts, and is connected with a belt pulley; the fixed end of the drag chain is arranged at the right upper end of the rack; the movable end of the drag chain is movably arranged on the side wall of the rack; the follower comprises a servo roller and a servo bent board connected with the servo roller; the servo roller is movably arranged in the space between the flange and the rack; the servo bent board is arranged on the surface of the rotating part in a bridge manner, and is tightly and fixedly connected with the movable end of the drag chain. The wiring device is compact in structure, safe and reliable in working, and cables are smoothly pulled.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Spacer expander

InactiveUS7243596B2Reduce widthShorten the axial widthPiston ringsBraking action transmissionEngineeringElectrical and Electronics engineering

In a combined oil ring having a spacer expander to be installed between a pair of upper and lower side rails, a plurality of axially protruding inner peripheral protruding portions are formed on the inner peripheral side of the spacer expander along its peripheral direction. The inner peripheral protruding portions press the inner peripheral surface of the side rails. On the outer peripheral side of the spacer expander, a plurality of slits are formed, and a plurality of connecting portions are located in the peripheral direction isolated by the slits. On the plurality of connecting portions, axially protruding outer peripheral protruding portions are formed.

Owner:RIKEN CO LTD

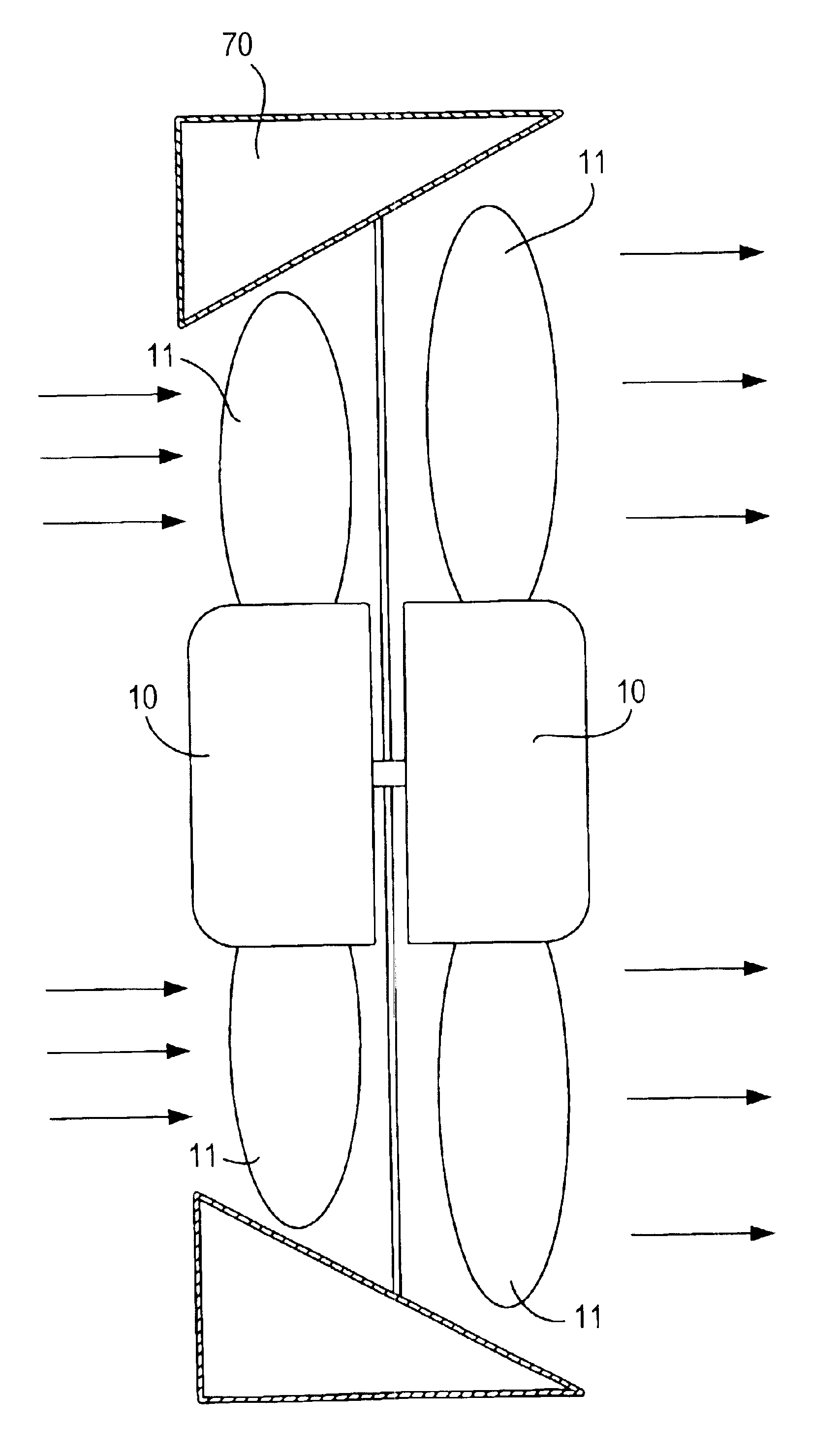

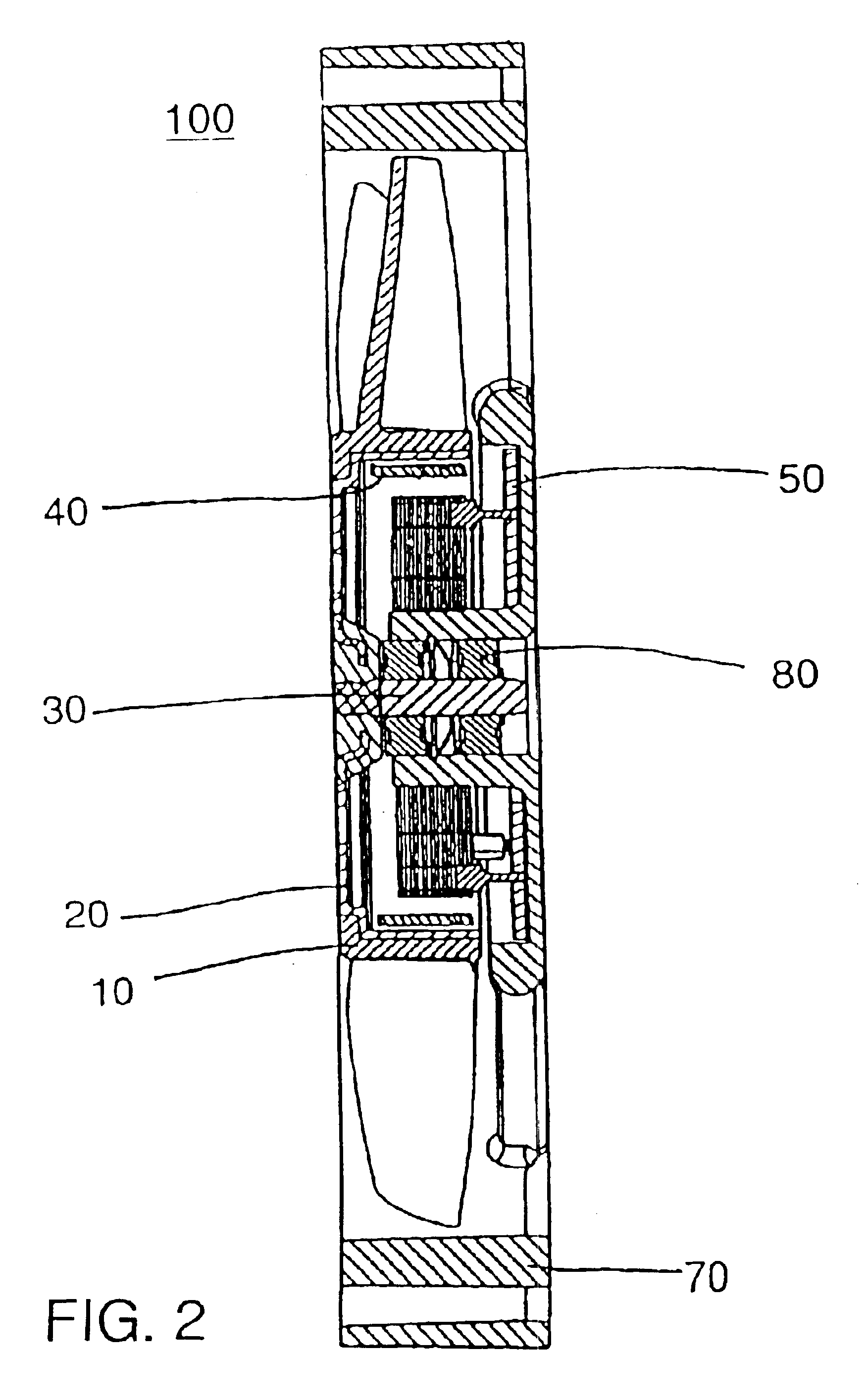

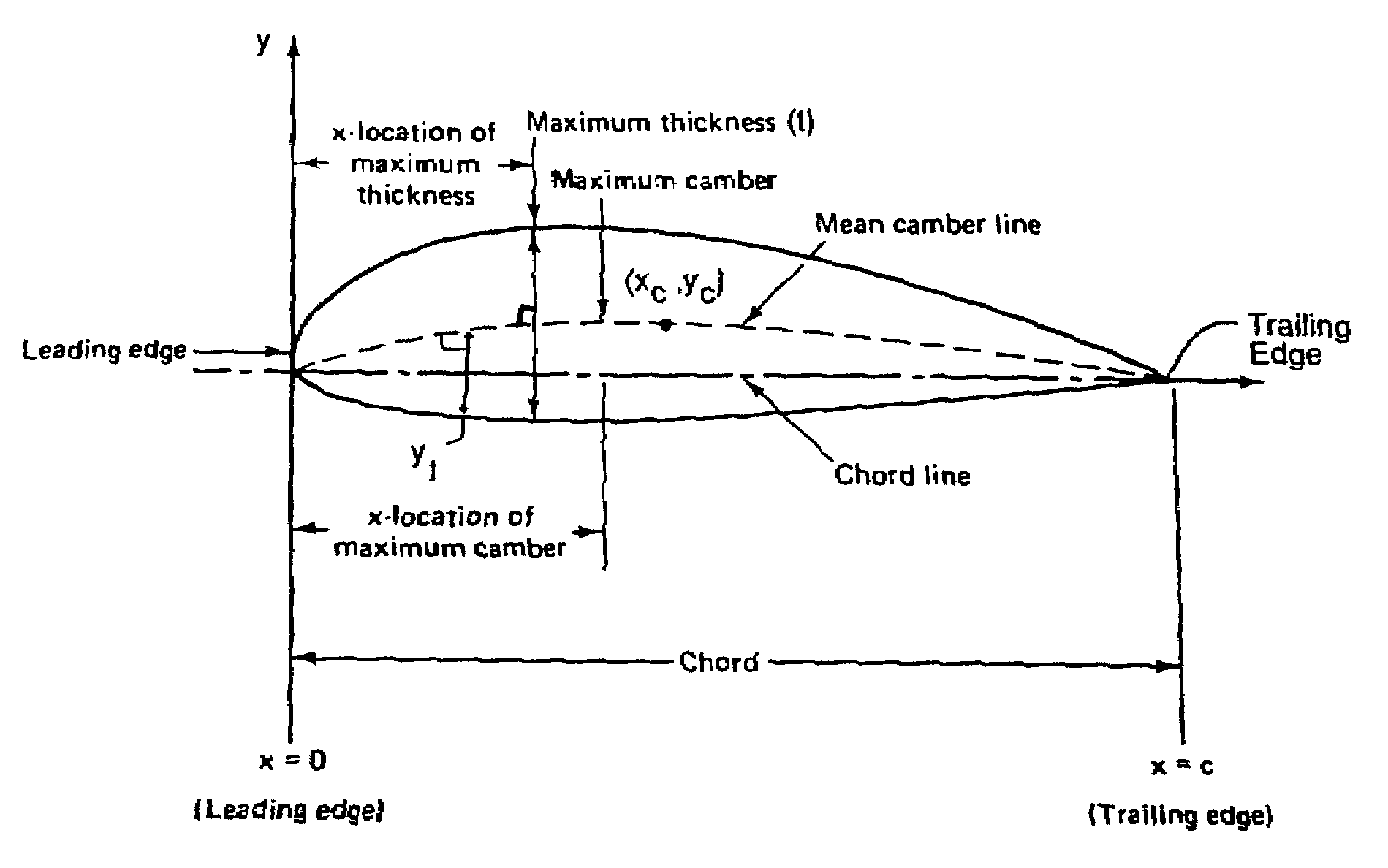

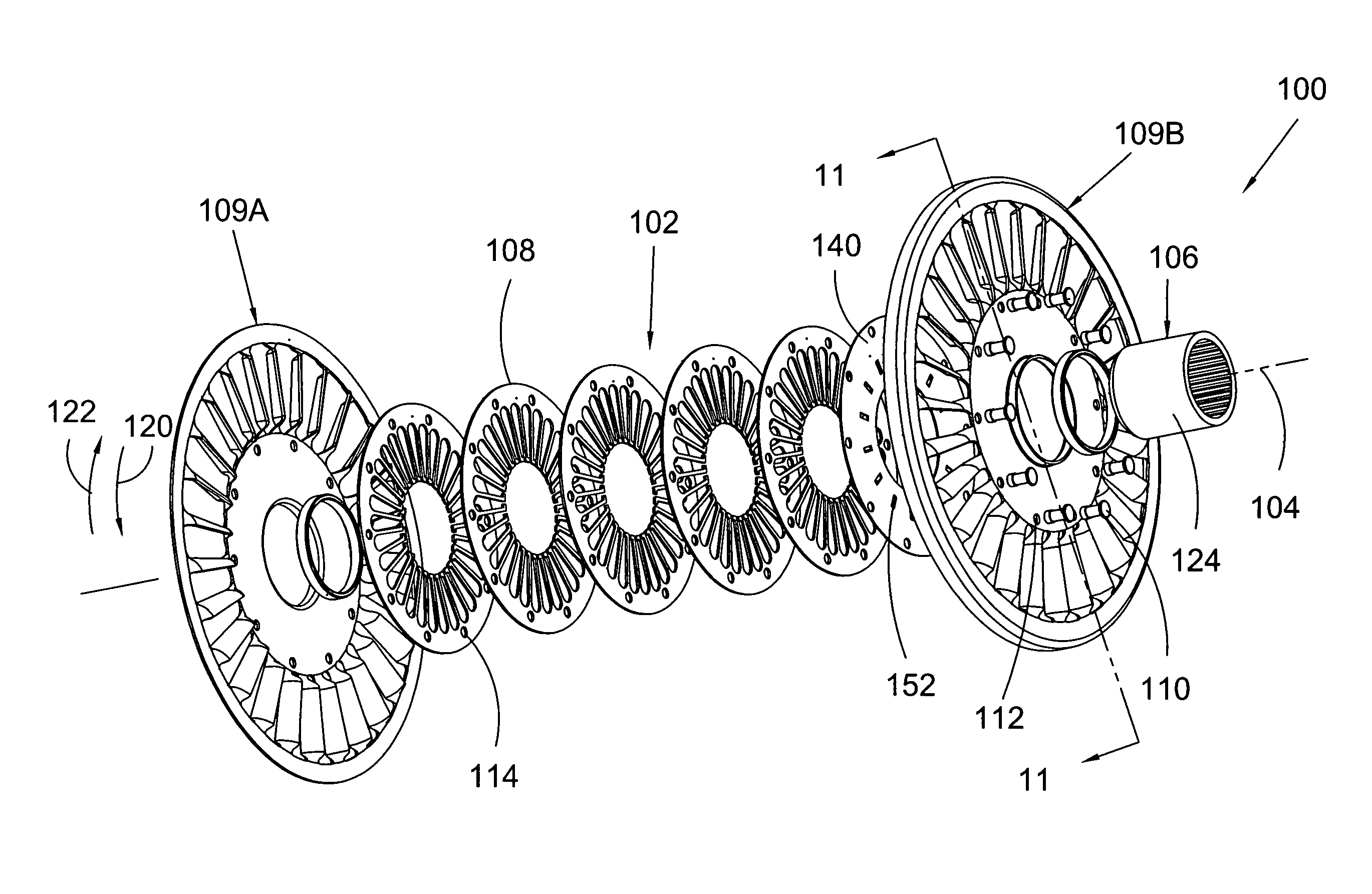

Impeller blade for axial flow fan having counter-rotating impellers

InactiveUS6856941B2Increase airflowImprove performanceFlexible member pumpsTesting/calibration of speed/acceleration/shock measurement devicesImpellerEngineering

Method for determining the camber line and thickness distribution for blades used in a cooling fan with counter-rotating impellers. The camber lines and thickness distributions for the blades of each of the impellers are determined through use of Bezier curves and chosen to reduce boundary layer separation of airflow across the blades. The Bezier control points are altered to produce a set of distributions of the camber lines and thickness distributions, and the most favorable set is found with increased cooling efficiency.

Owner:MINEBEA CO LTD

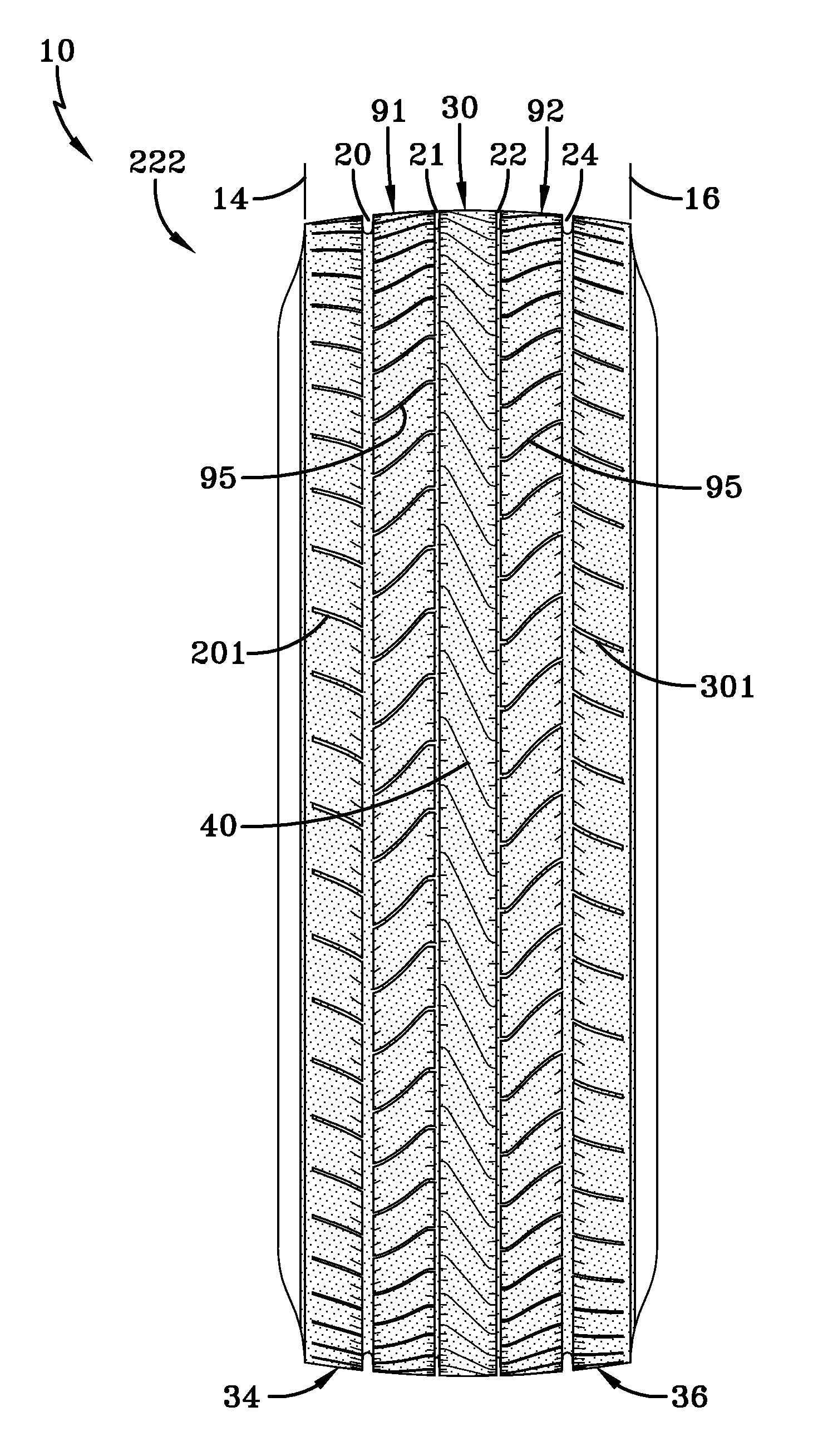

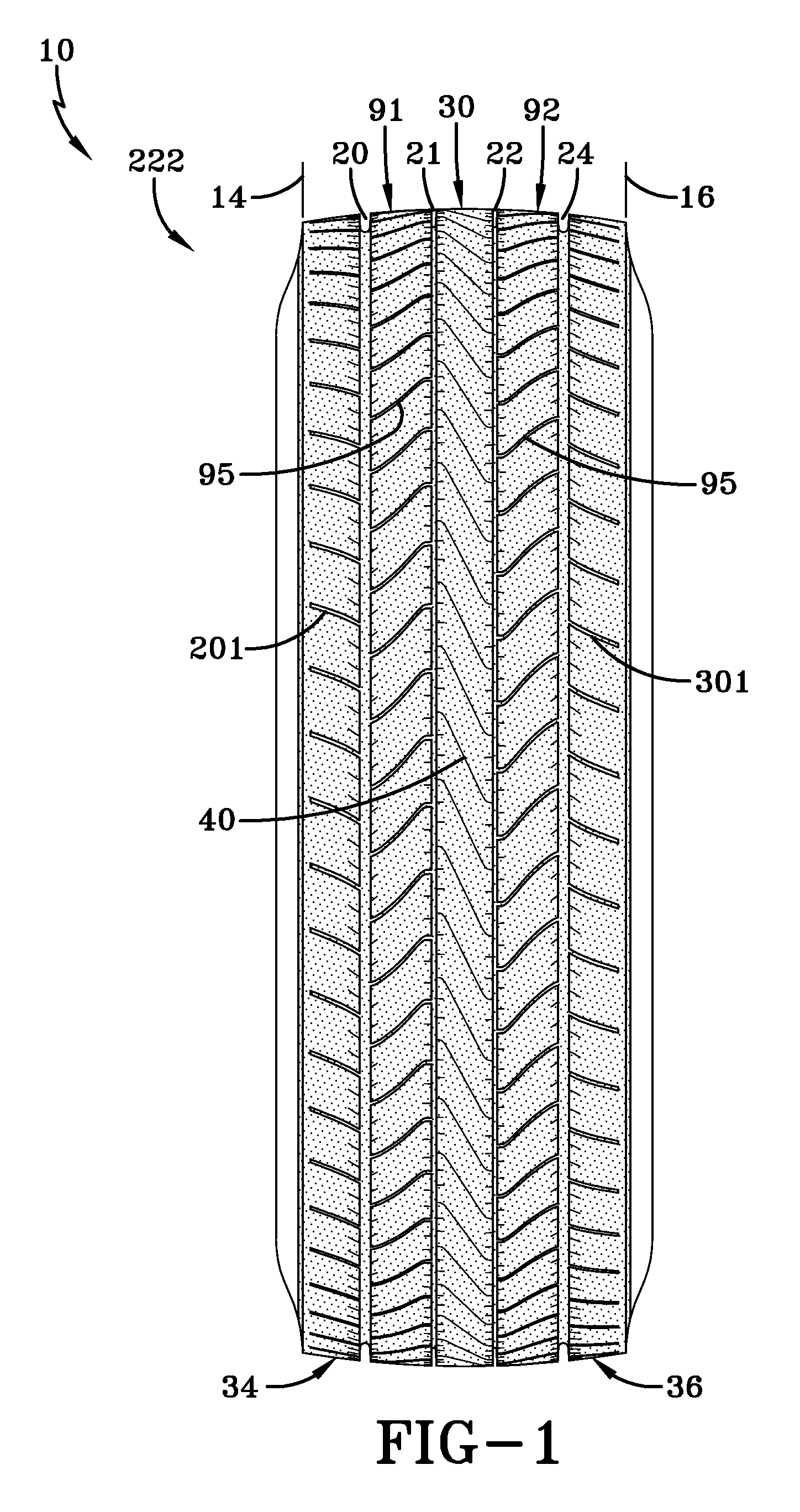

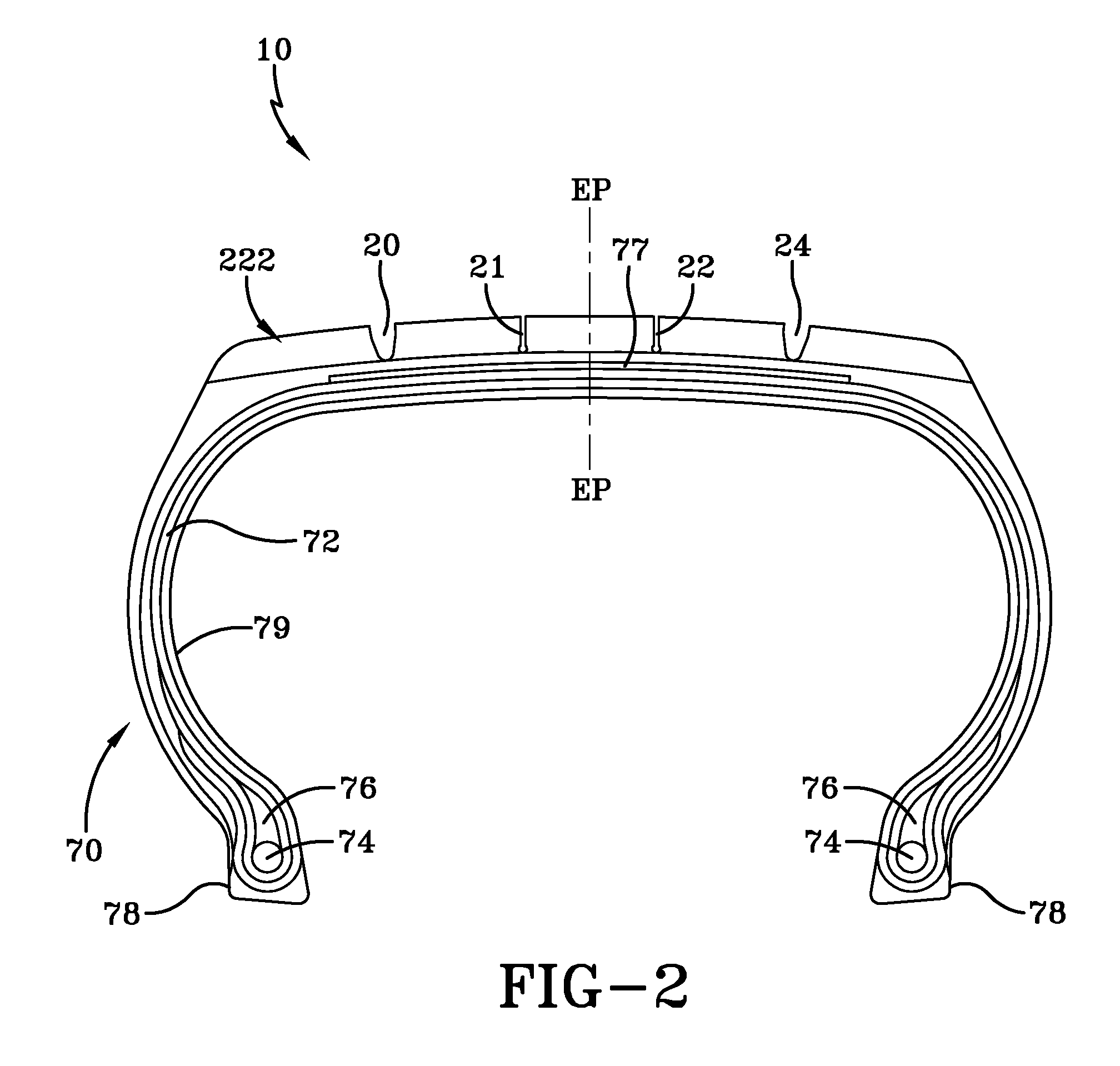

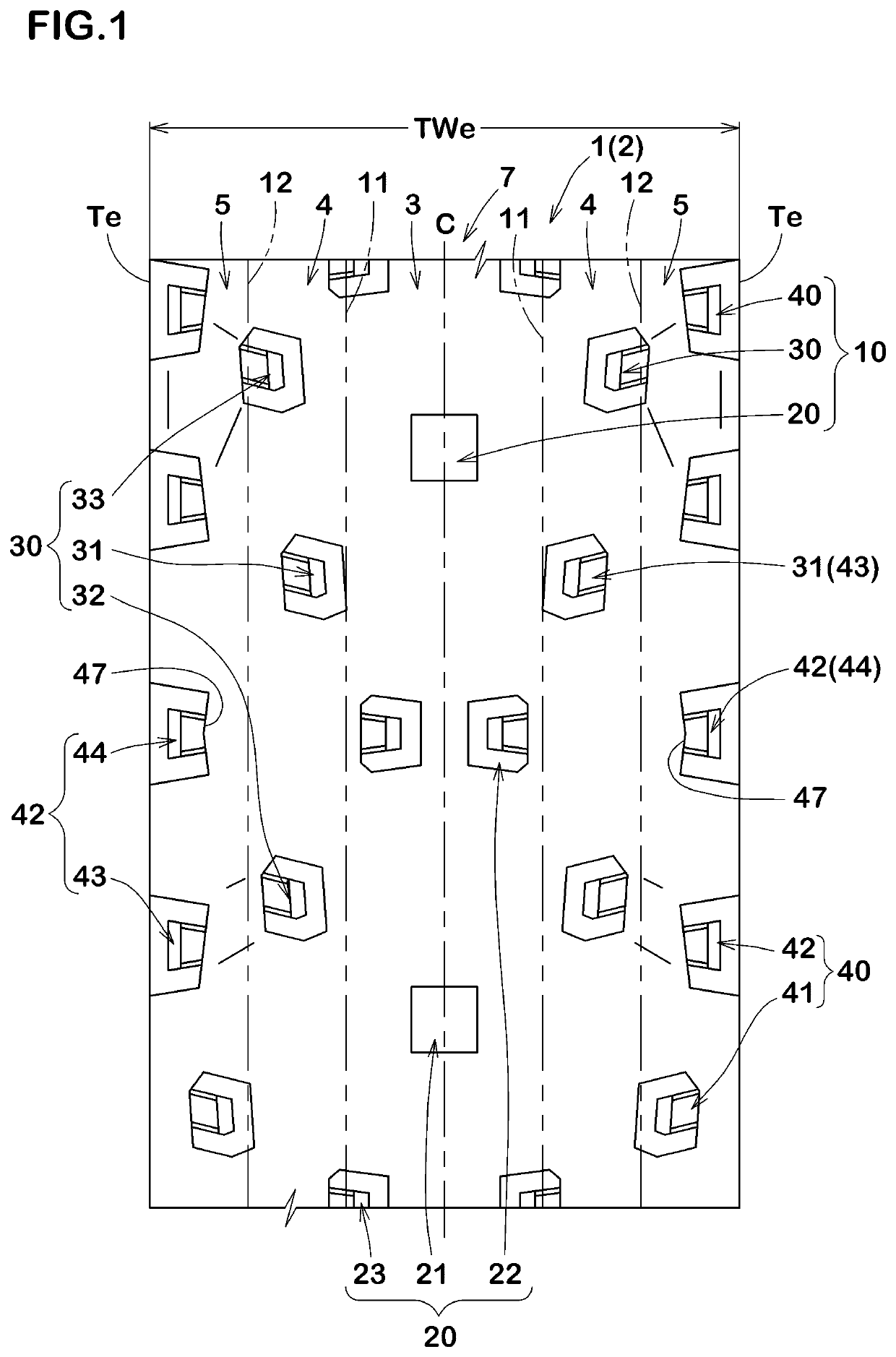

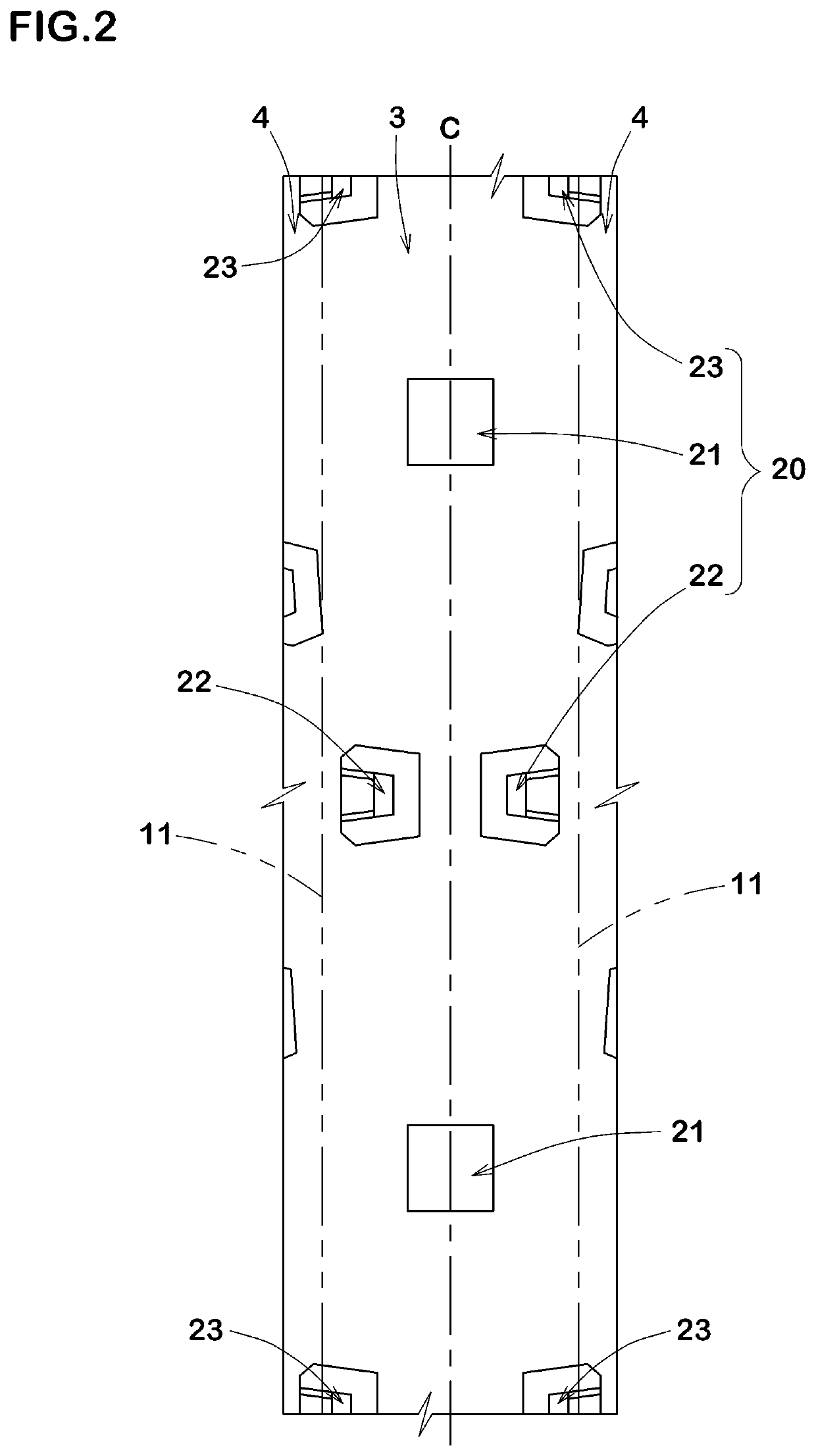

Tread for a pneumatic tire

A tread for a pneumatic tire includes a first circumferentially continuous groove, a second circumferentially continuous groove, a third circumferentially continuous groove, a fourth circumferentially continuous groove, a central rib interposed between the second and third axially inner circumferentially continuous grooves, a central rib, a first middle rib, a second middle rib, a first shoulder rib, and a second shoulder rib. The central rib extends continuously around a circumference of the tread. The first middle rib is interposed between the first and second grooves. The first middle rib extends continuously around the circumference of the tread. The second middle rib is interposed between the third and fourth grooves. The second middle rib extends continuously around the circumference of the tread. The first circumferentially extending shoulder rib is disposed laterally outside of the first circumferentially continuous groove. The second circumferentially extending shoulder rib is disposed laterally outside of the fourth circumferentially continuous groove. The central rib has a plurality of circumferentially spaced sipes originating at the second circumferentially continuous groove and extending axially and circumferentially across the central rib to the third circumferentially continuous groove. The first middle rib has a plurality of circumferentially spaced sipes originating at the second inner circumferentially continuous groove and extending axially and circumferentially across the first middle rib to the third circumferentially continuous groove. The second middle rib has a plurality of circumferentially spaced sipes originating at the third inner circumferentially continuous groove and extending axially and circumferentially across the second middle rib to the fourth circumferentially continuous groove.

Owner:GEOR FRANCOIS PIERRE CHARLES GERARD +3

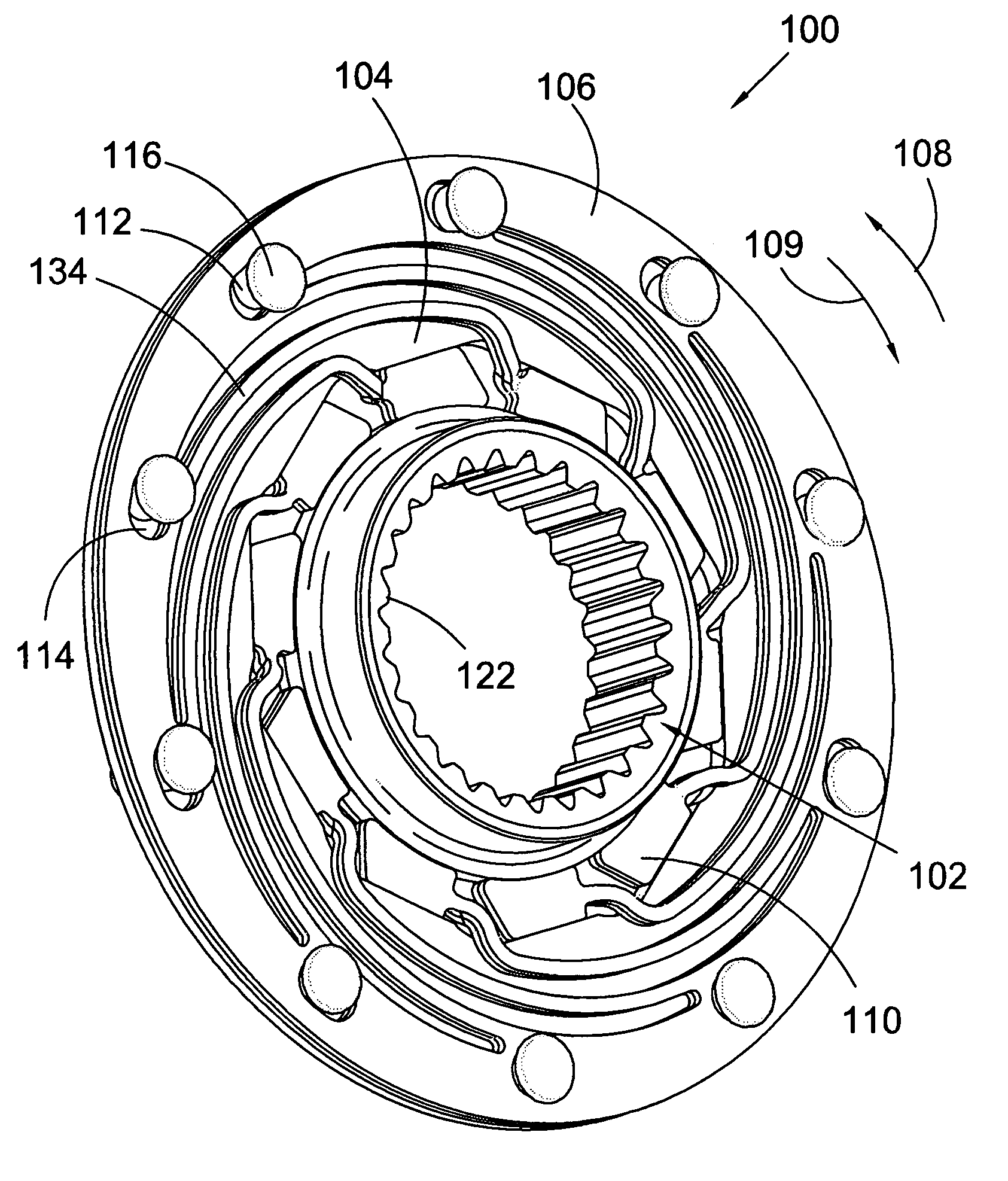

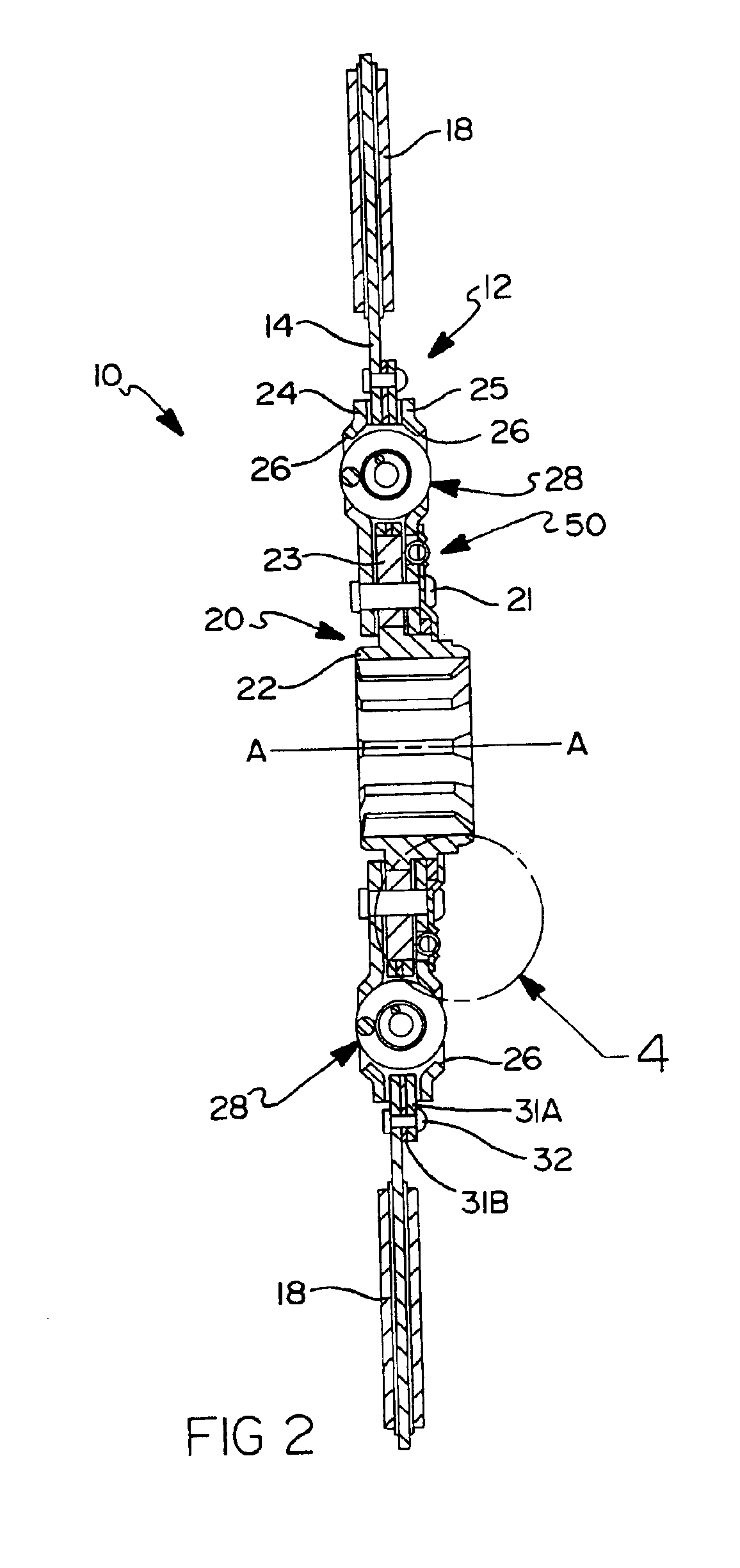

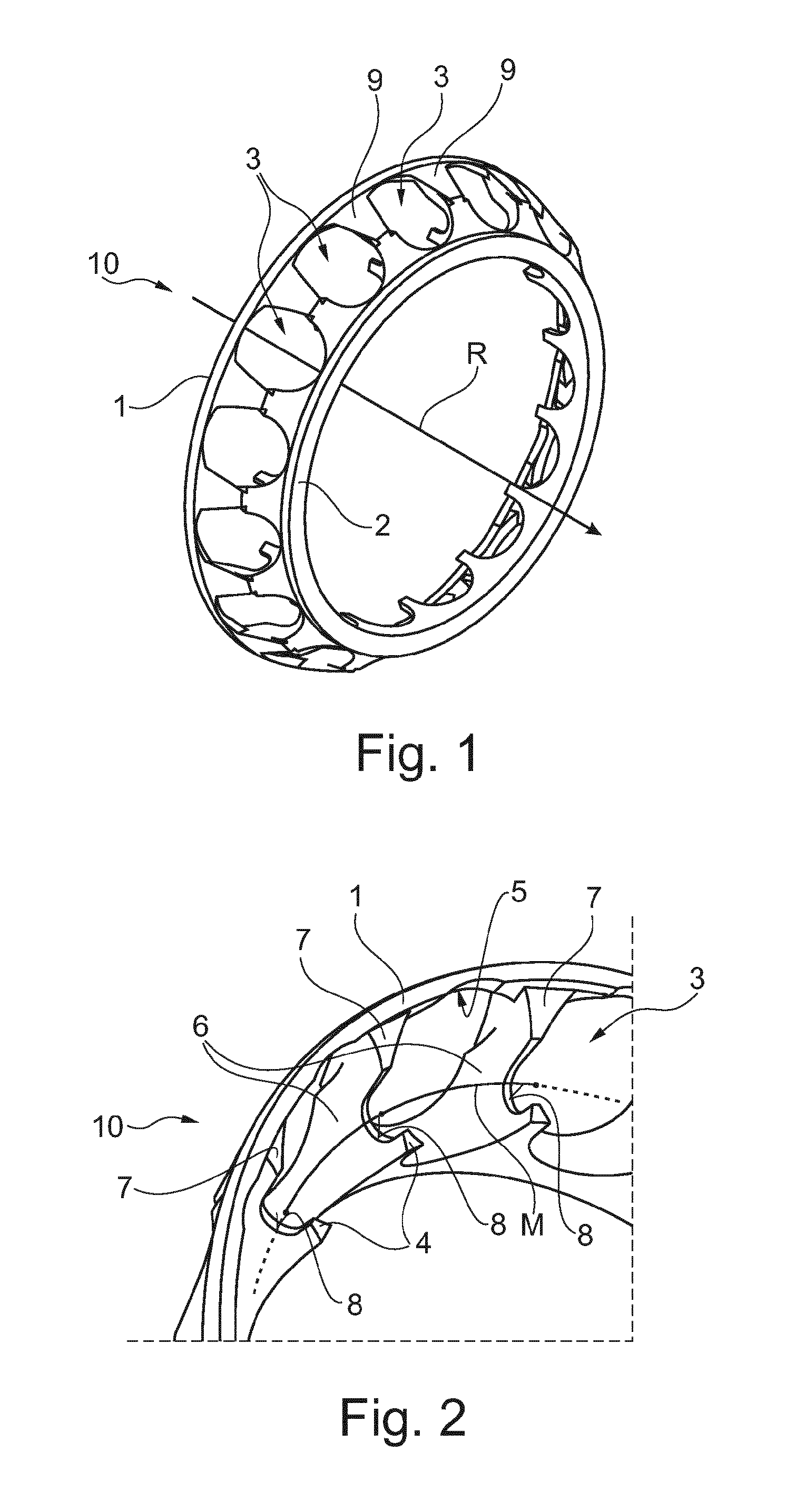

Wedge one-way clutch

InactiveUS8020681B2Reduce contact forceShorten the axial widthFriction clutchesInterengaging clutchesEngineeringClutch

Owner:SCHAEFFLER TECH AG & CO KG

Wedge one-way clutch

ActiveUS20080053784A1Shorten the axial widthReduce contact forceMechanical actuated clutchesBrake typesTorque transmissionEngineering

The present invention broadly comprises a one-way clutch, including inner and outer races and a clutch element. The outer race is arranged for rotational connection to a torque transmitting element and rotates independently of the inner race for relative rotation in a first direction. The clutch element is connected to the outer race and includes at least one engagement element radially disposed between the races. The element is biased radially inward and arranged to rotationally lock the races in response to rotation in a second direction. The present invention also broadly comprises a one-way clutch with inner and outer races, at least one engagement element, and at least one elastically deformable element. One of the races is arranged for connection to a torque transmitting element. The engagement element is radially disposed between the races and is radially asymmetrical. The deformable element biases the engagement element in a rotational direction.

Owner:SCHAEFFLER TECH AG & CO KG

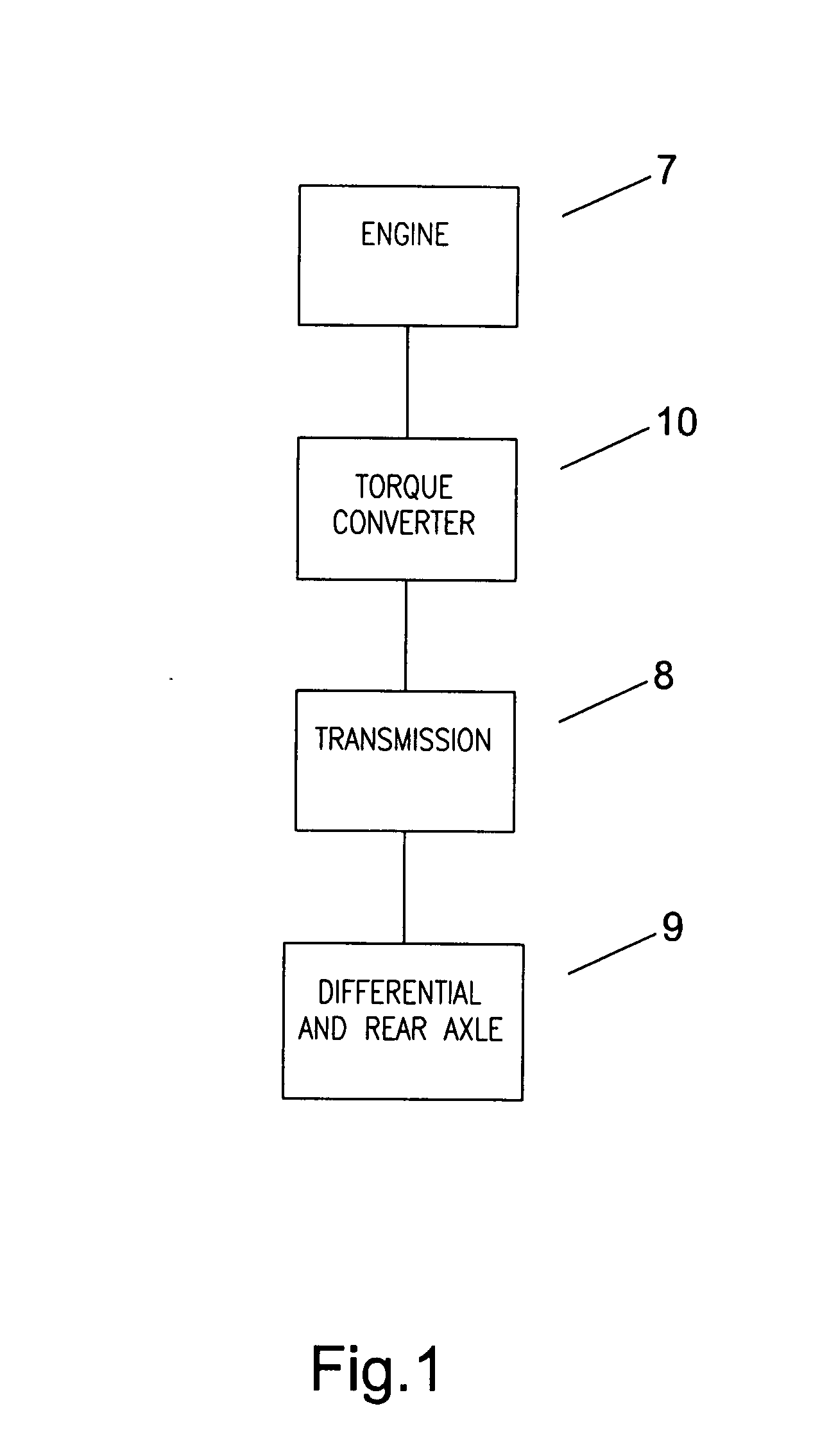

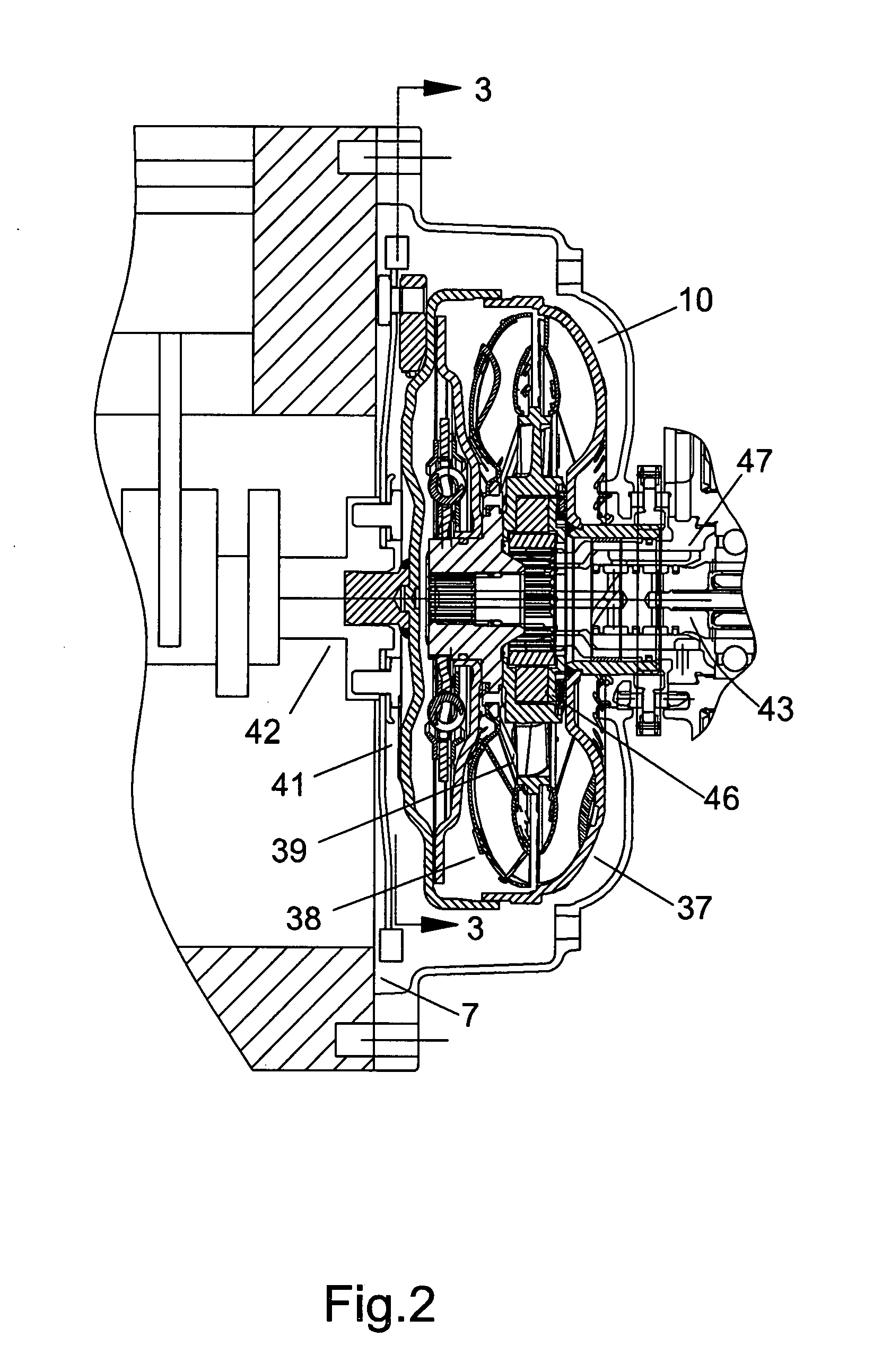

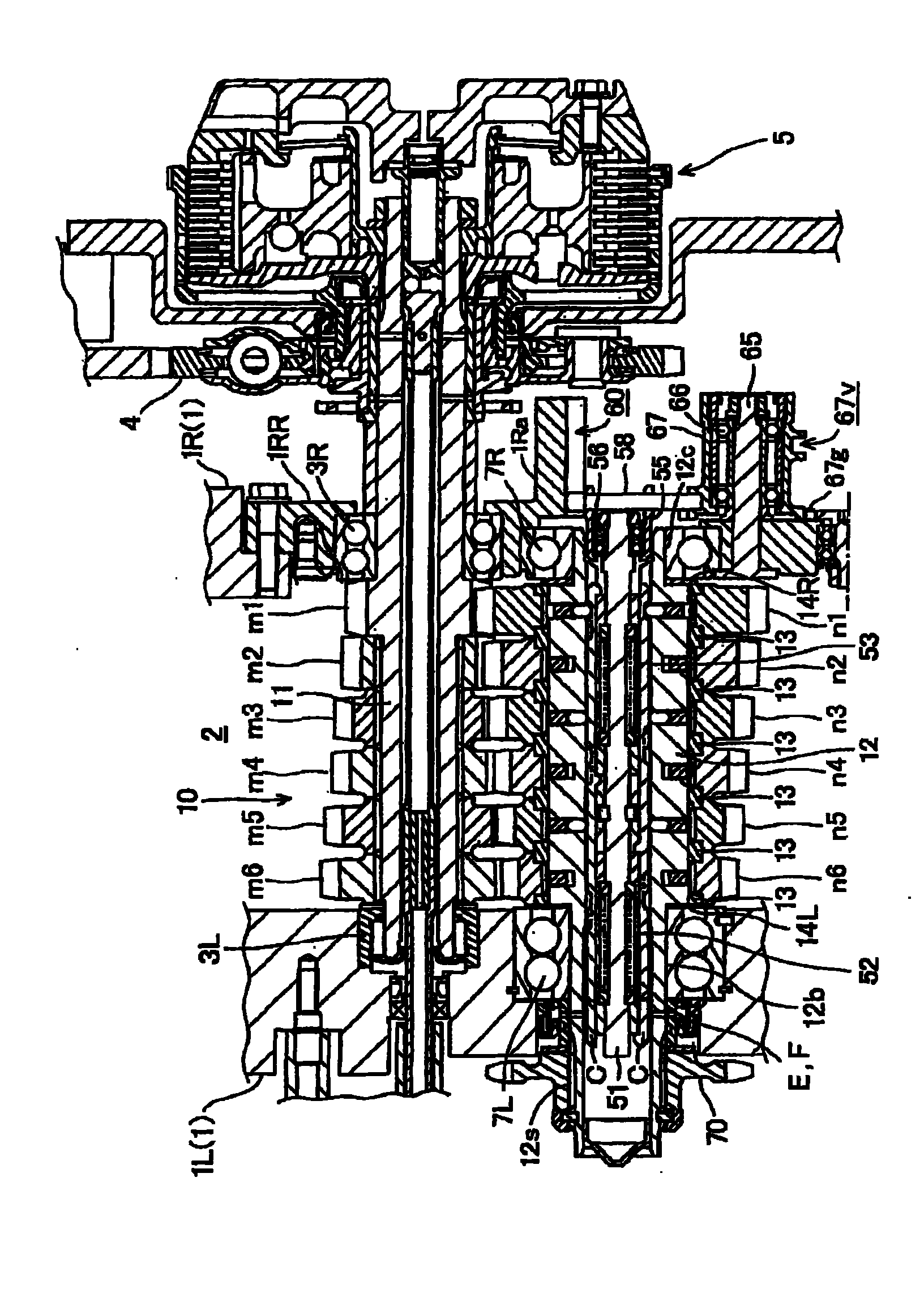

Multistage transmission

A multistage transmission includes a lost motion mechanism for regulating the operation for a downward shift in acceleration and for an upward shift in deceleration. Regulating rods are integrally moved with a control rod. A cutout into which a pin can be fitted together with a cam groove of the slidingly touched cam rod is formed corresponding to each cam groove in the regulating rods. The cutout of the regulating rods corresponding to the cam groove of the cam rod for normal rotation is formed longer than the corresponding cam groove on the reverse side to a moving direction of the control rod in an upward shift in a state in which shifted speed is established. The cutout of the regulating rods corresponding to the cam groove of the cam rod for reverse rotation is formed longer than thecorresponding cam groove on the reverse side to a moving direction.

Owner:HONDA MOTOR CO LTD

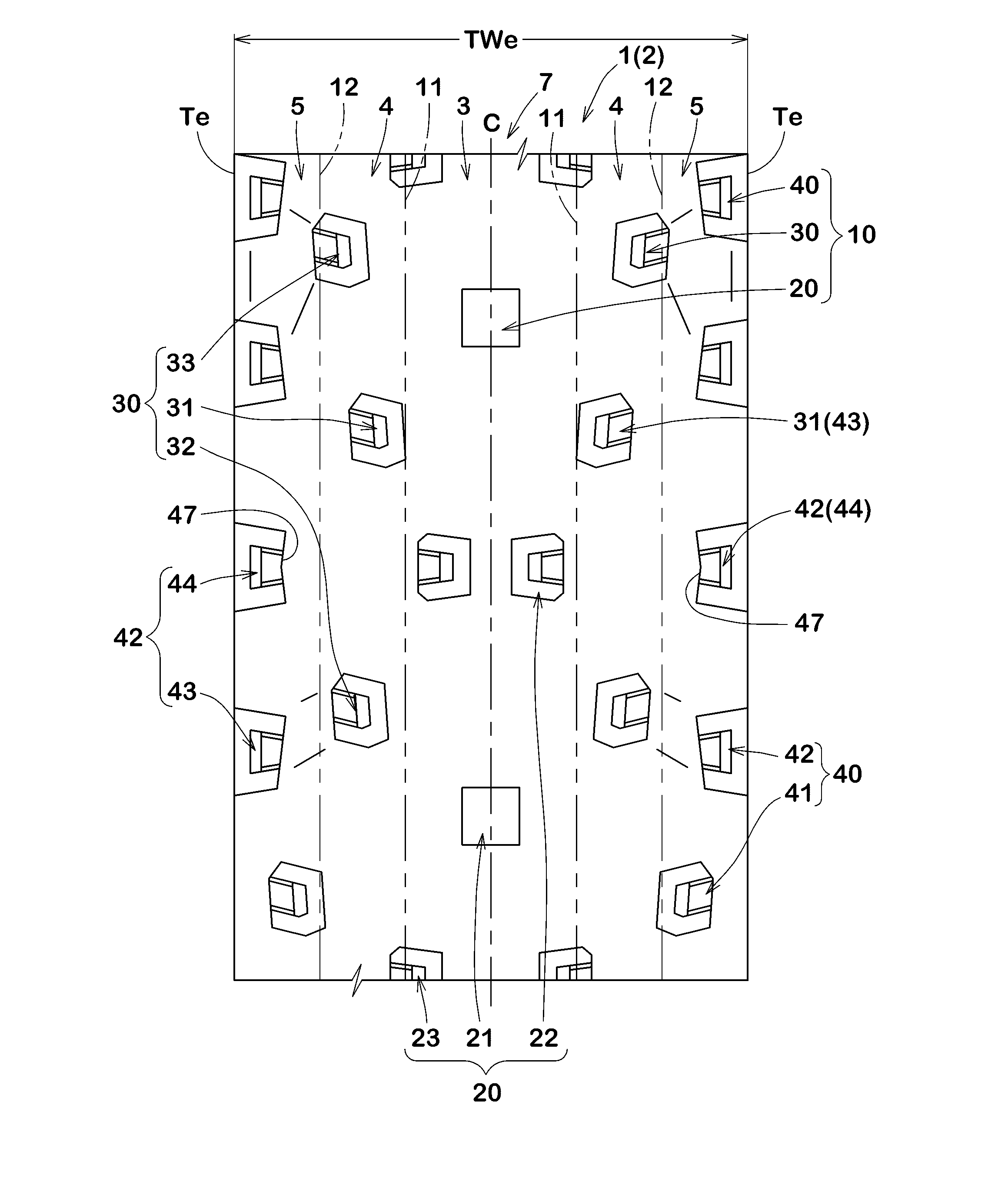

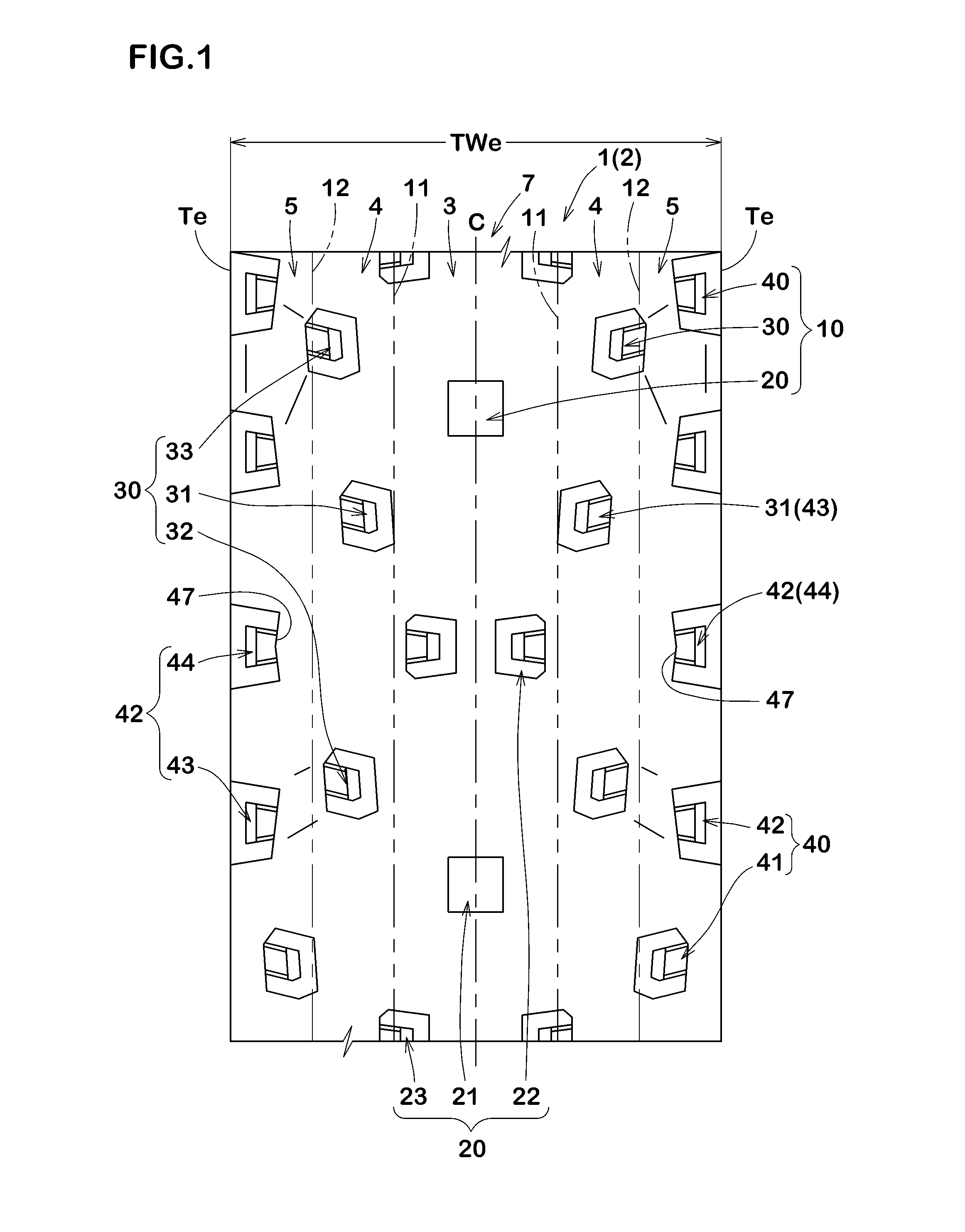

Motorcycle tire for running on rough terrain

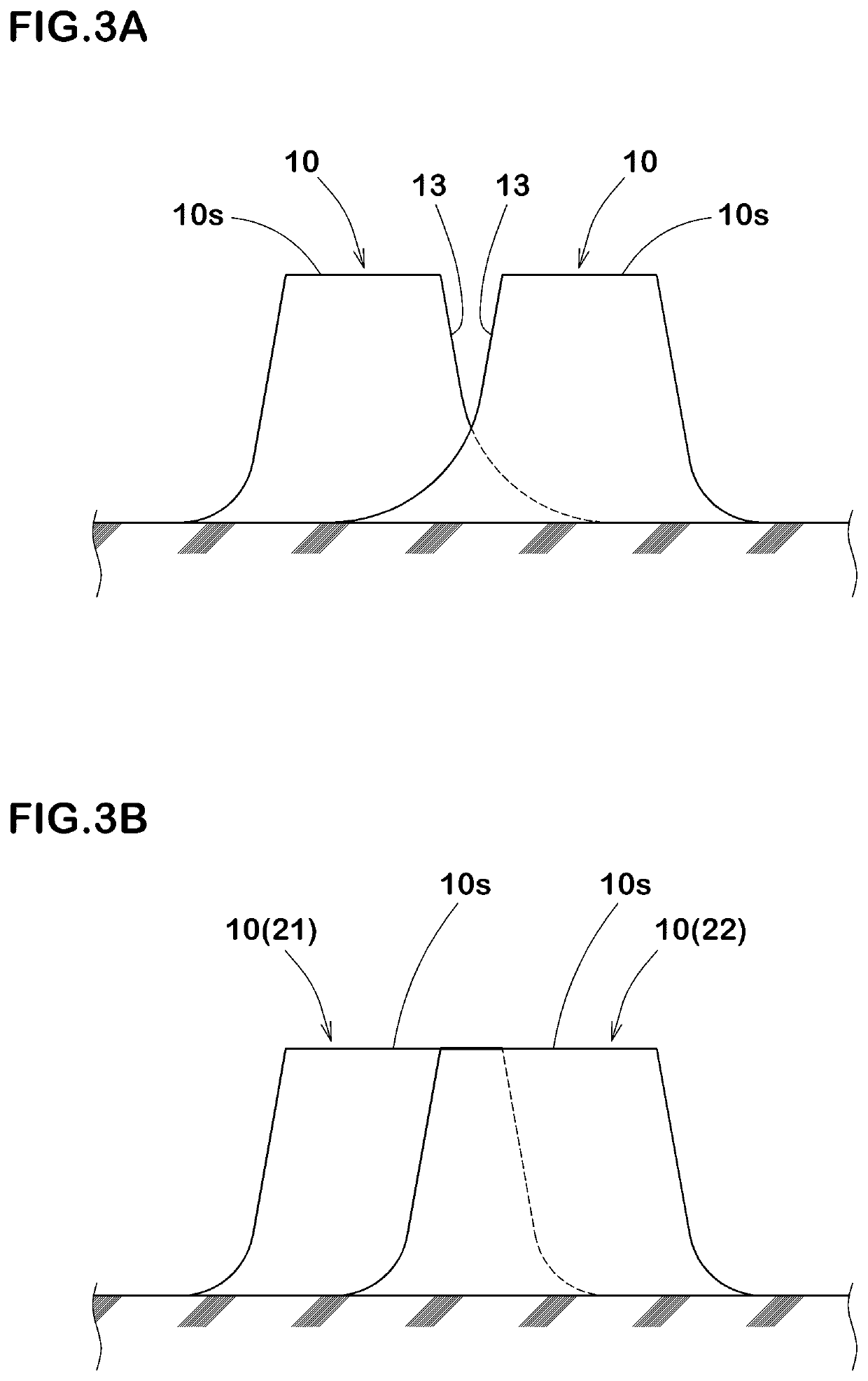

ActiveUS20160214439A1Improved tread block arrangementImprove transient characteristicsOff-road vehicle tyresMotorcycle tyresTerrainGround contact

A motorcycle tire for running on rough terrain, the tire includes a tread portion including a central region, a pair of shoulder regions and a middle region. The tread portion is provided with at least one central block with a ground contact face whose centroid is located within the central region, at least one shoulder block with a ground contact face whose centroid is located within the shoulder region on each side of a tire equator, and at least one middle block with a ground contact face whose centroid is located within the middle region on each side of the tire equator. When the respective blocks are projected onto a tire meridian cross section along a circumferential direction of the tire, every pair of axially adjacent two blocks are arranged so as to overlap one another at least partially on the tire meridian cross section.

Owner:SUMITOMO RUBBER IND LTD

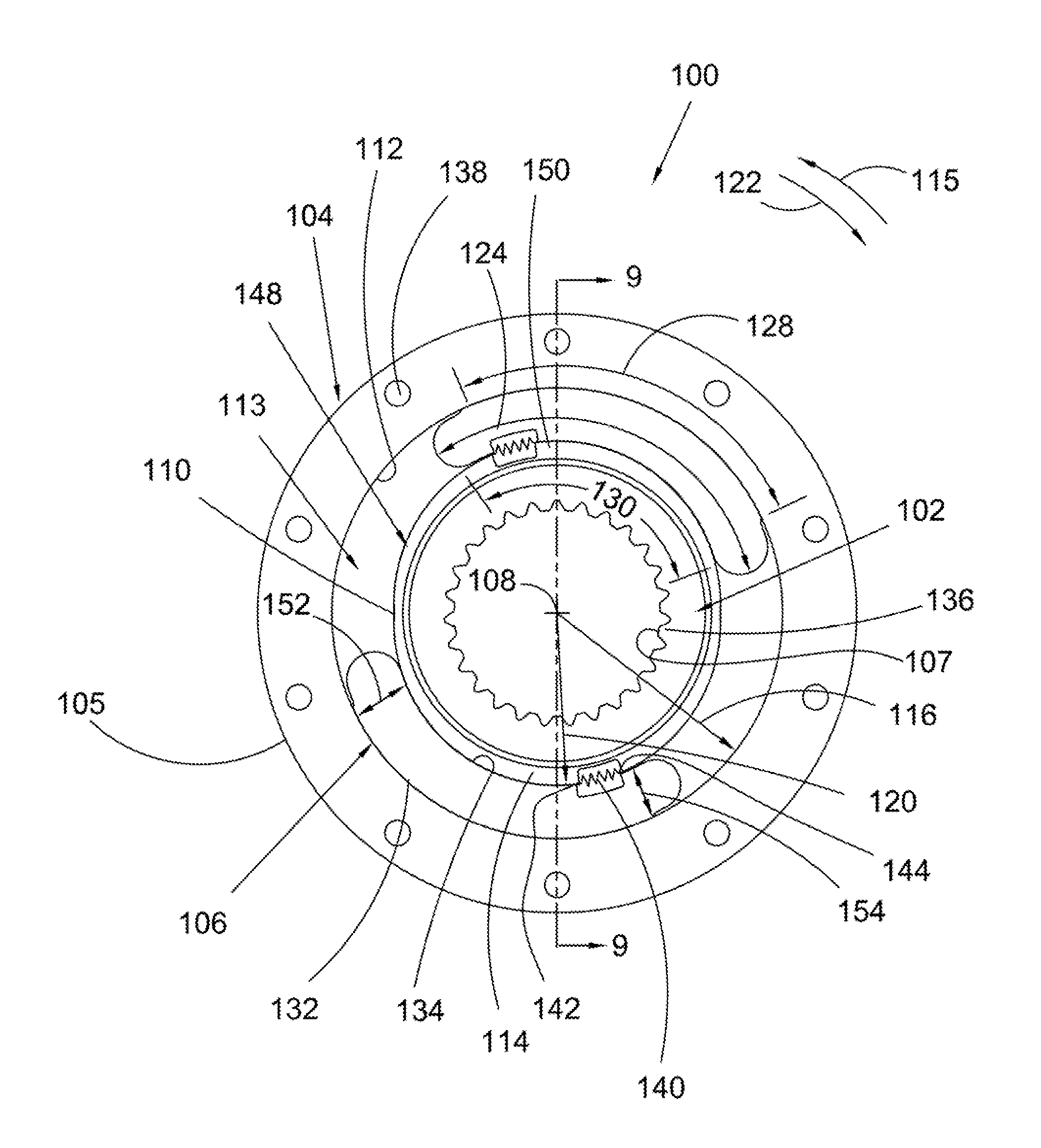

Single component one-way clutch

InactiveUS20080149447A1Shorten the axial widthAvoid compressionMechanical actuated clutchesRotary clutchesSingle componentClutch

A one-way clutch including a race disposed about an axis for the clutch and a wedge plate with a plurality of finger elements extending toward the race and in contact with the race. One of the plate or race is arranged for rotational connection to a torque transmitting element in an automotive device and is arranged to rotate independently of the other of the plate or race for rotation, with respect to the other of the plate or race, in a first rotational direction. The plurality of fingers are arranged to grip the race, to rotationally lock the plate and race, for relative rotation of the plate or race in a second rotational direction, opposite the first rotational direction.

Owner:SCHAEFFLER TECH AG & CO KG

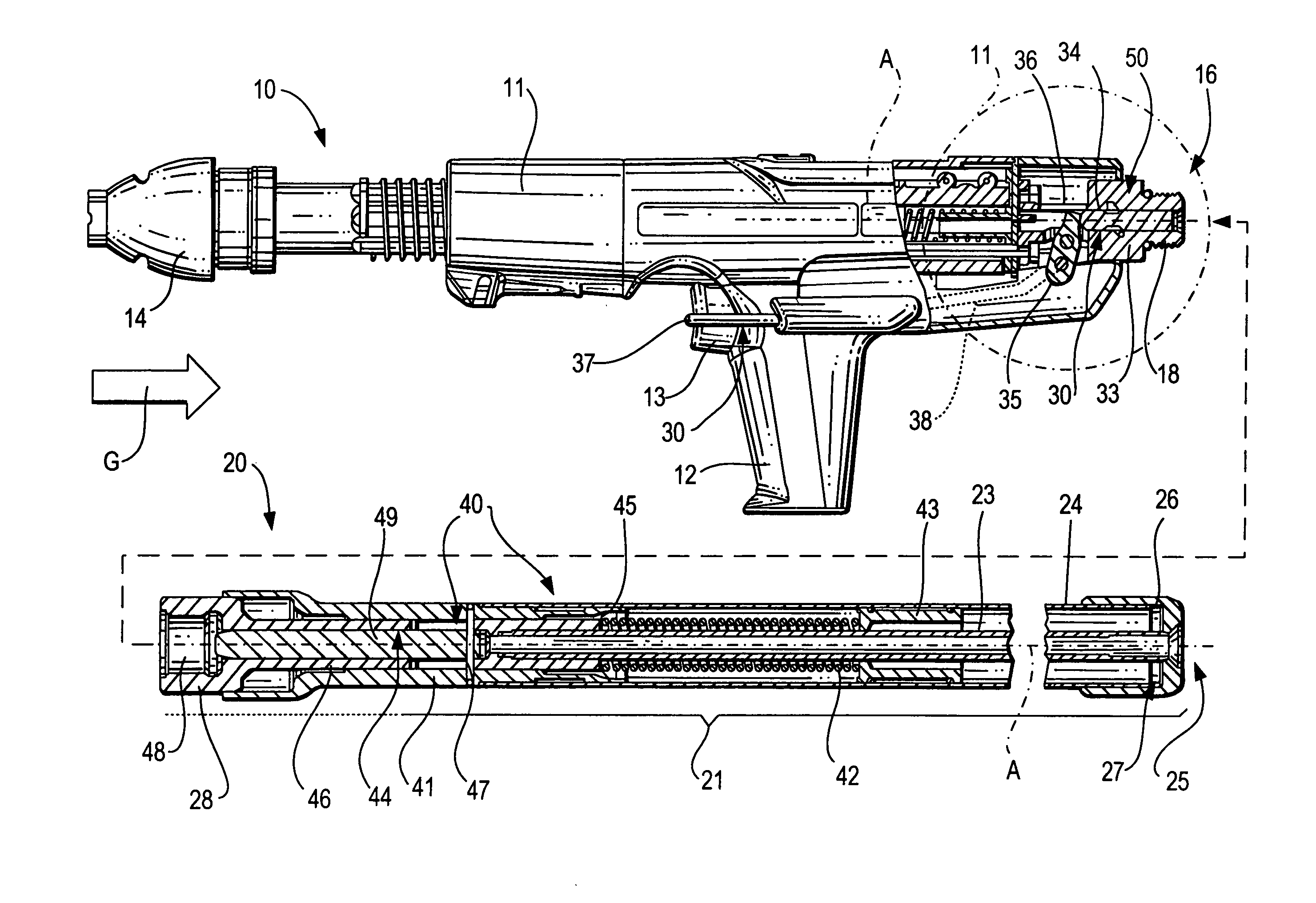

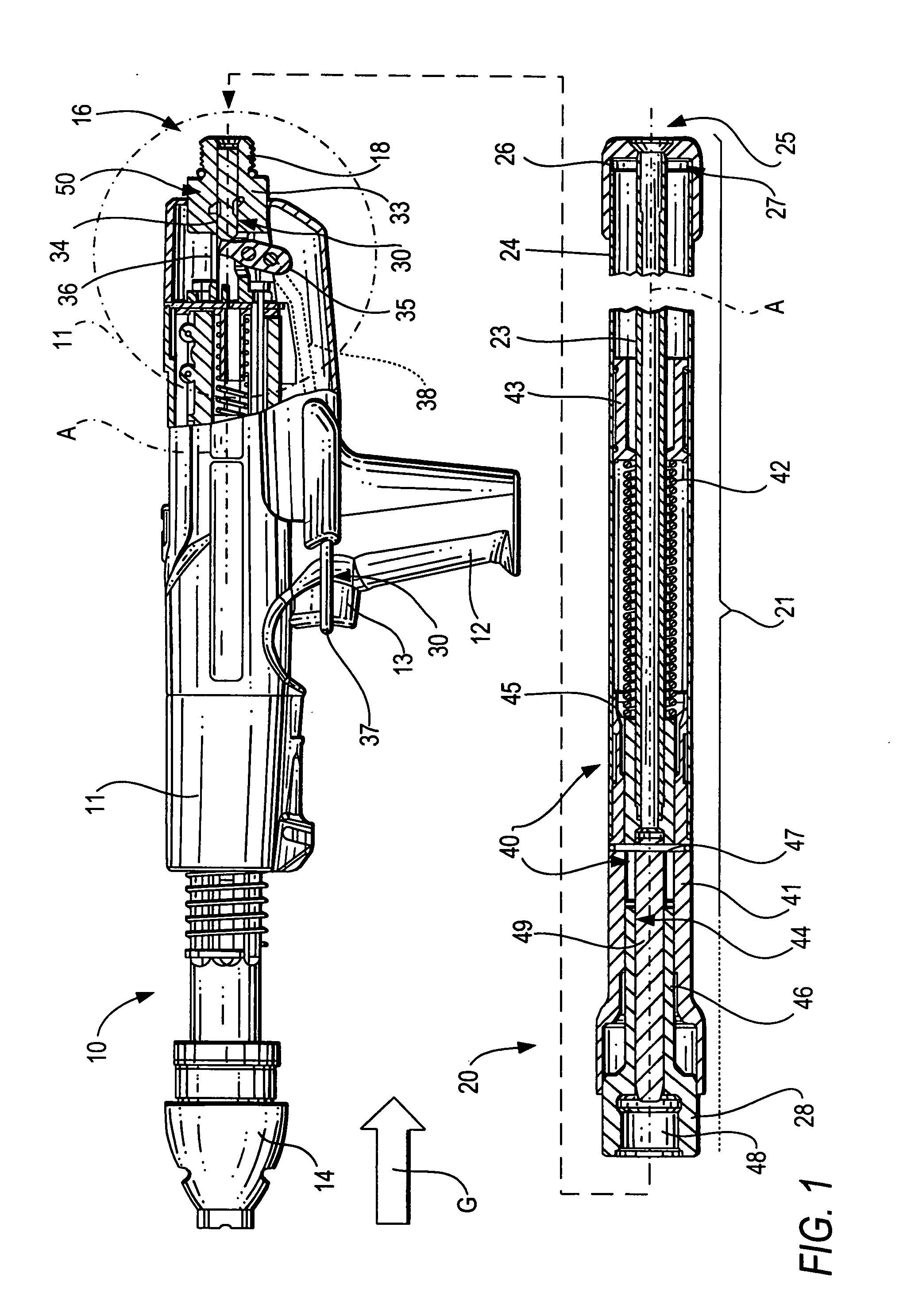

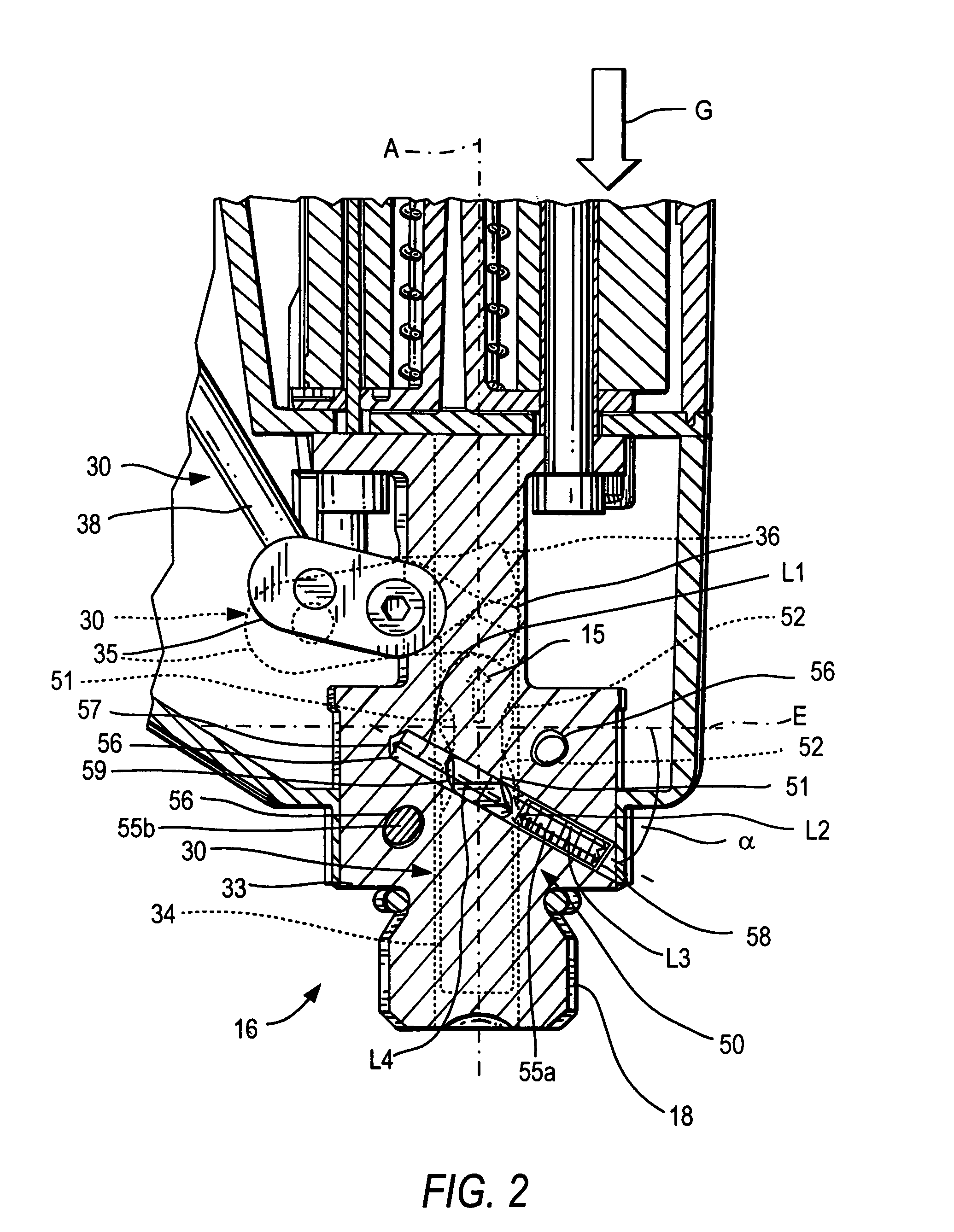

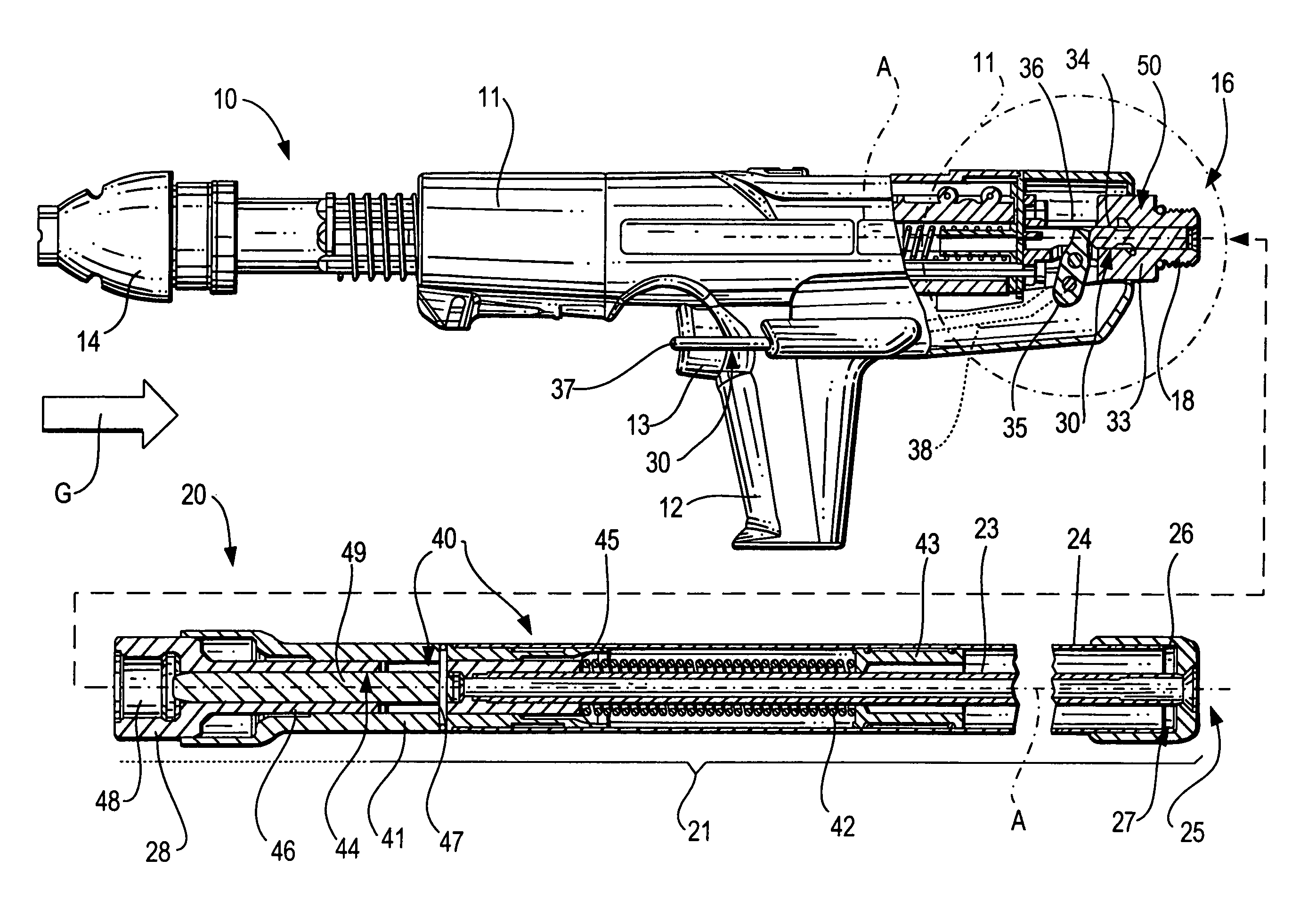

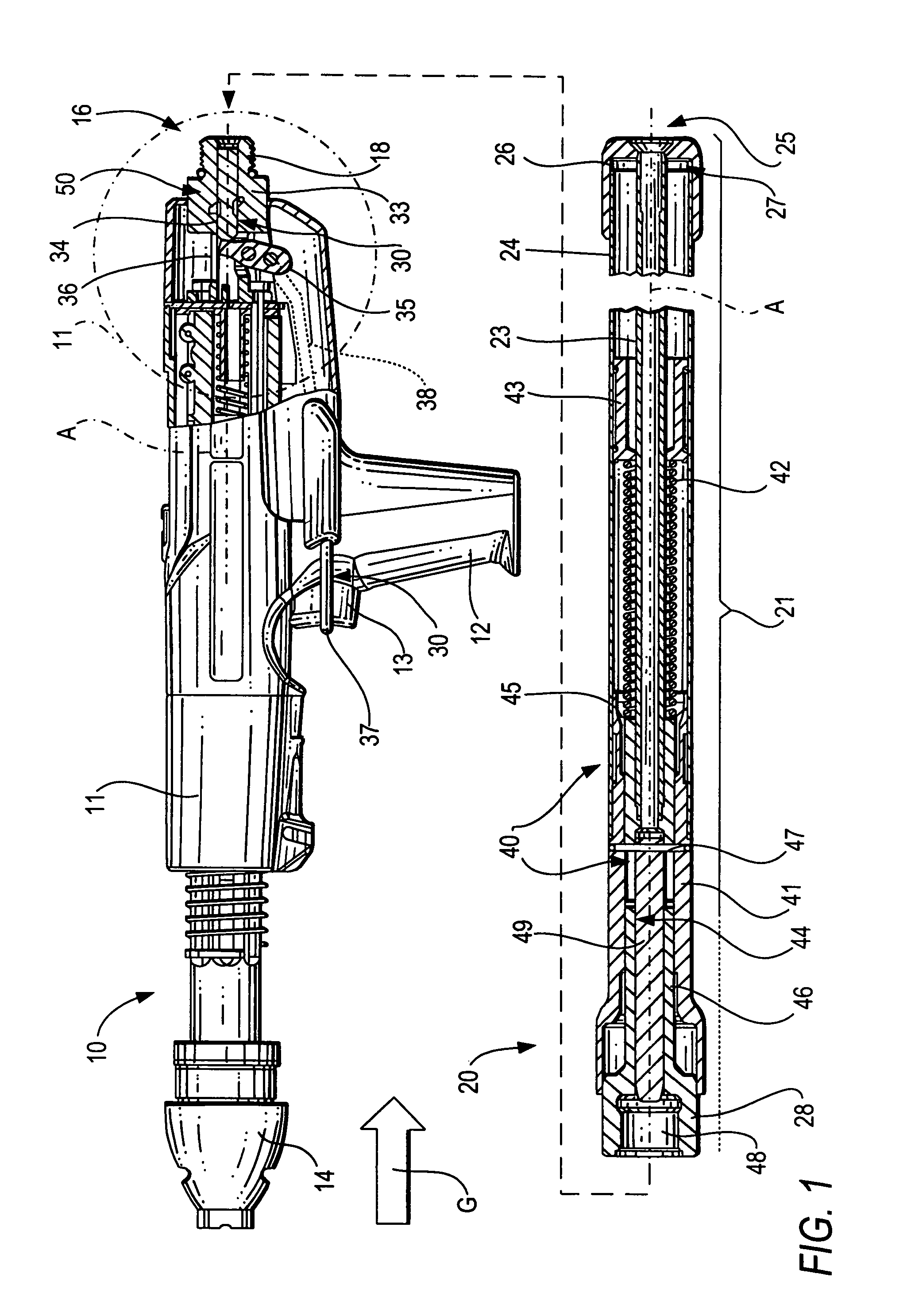

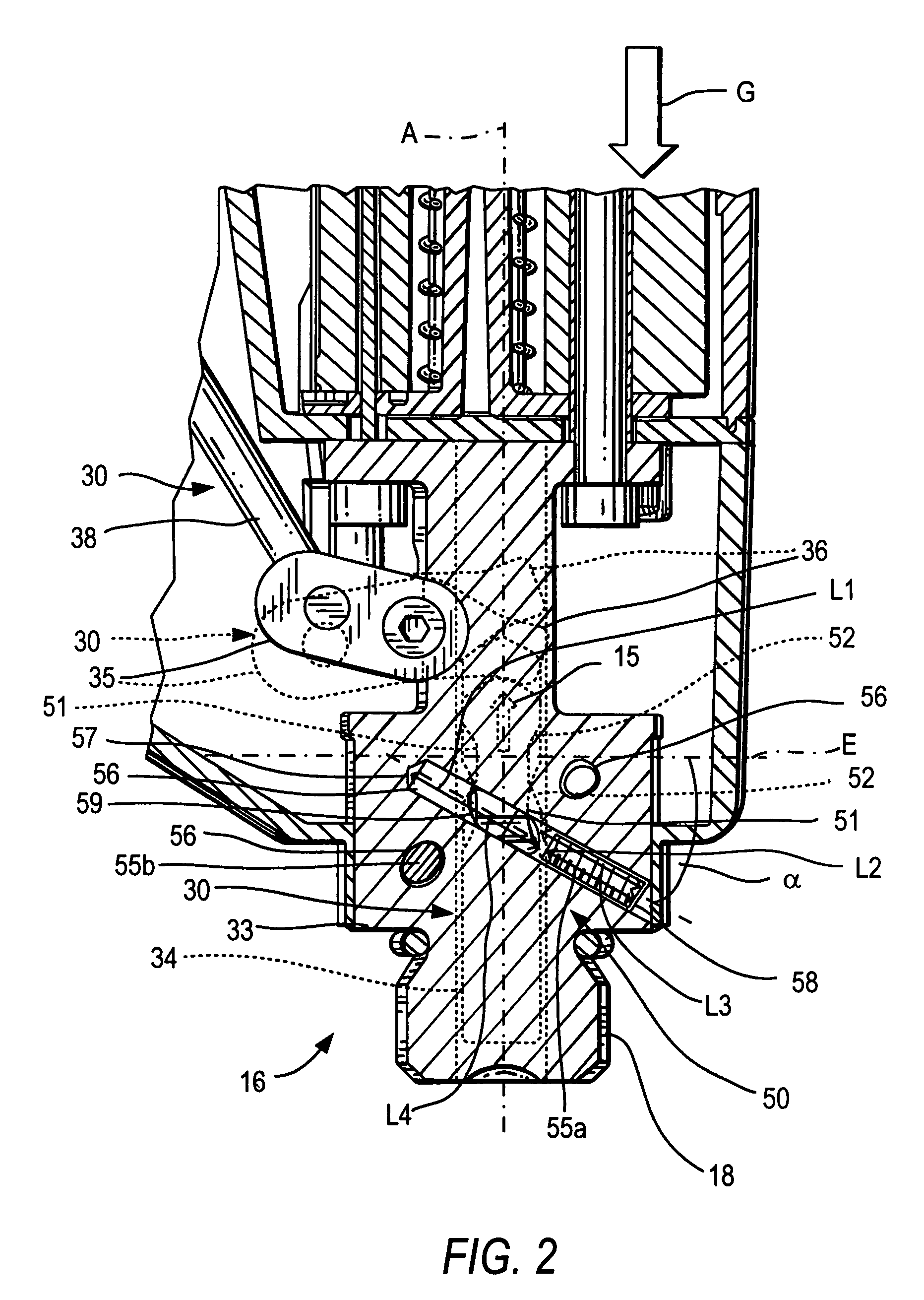

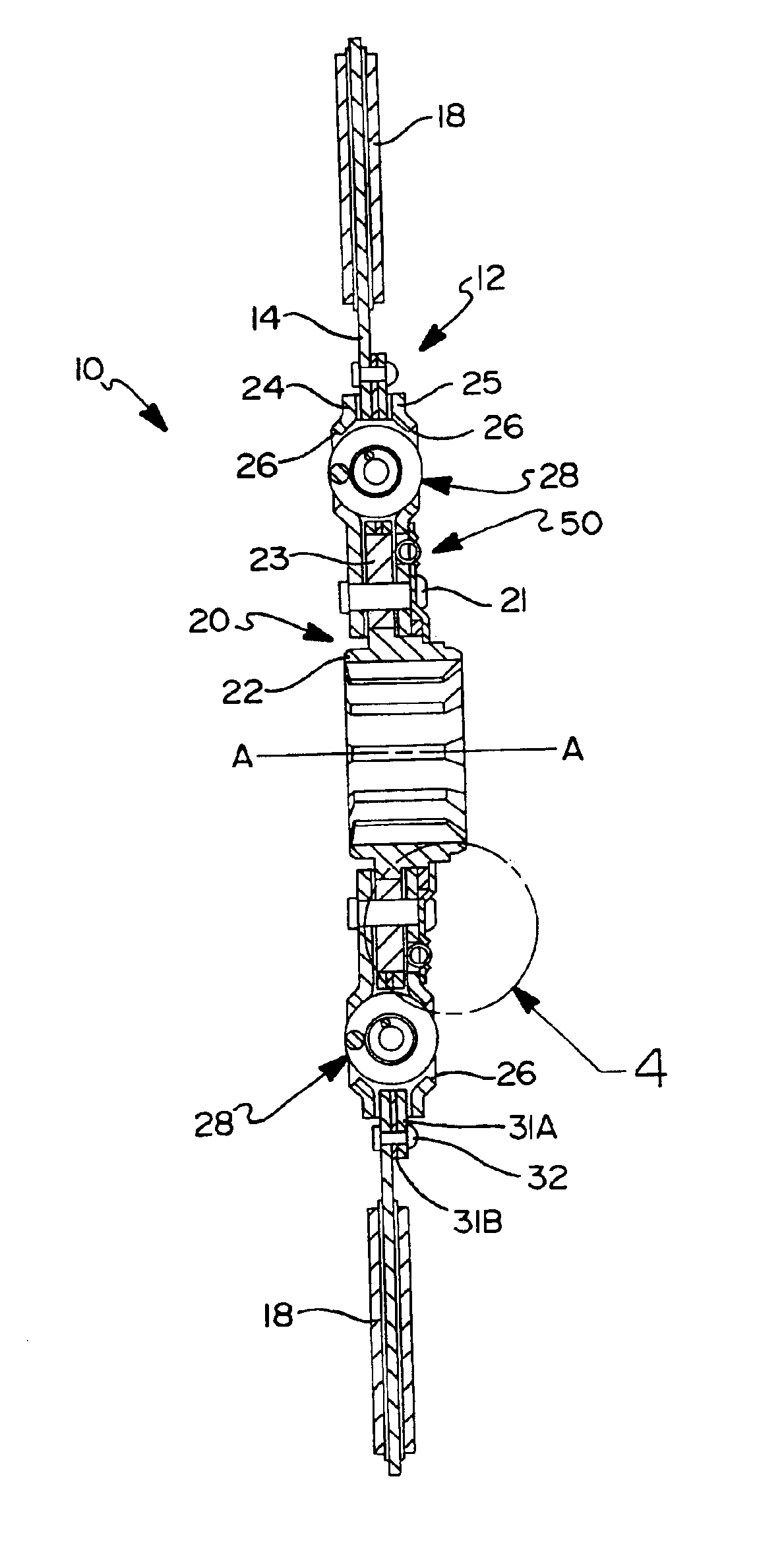

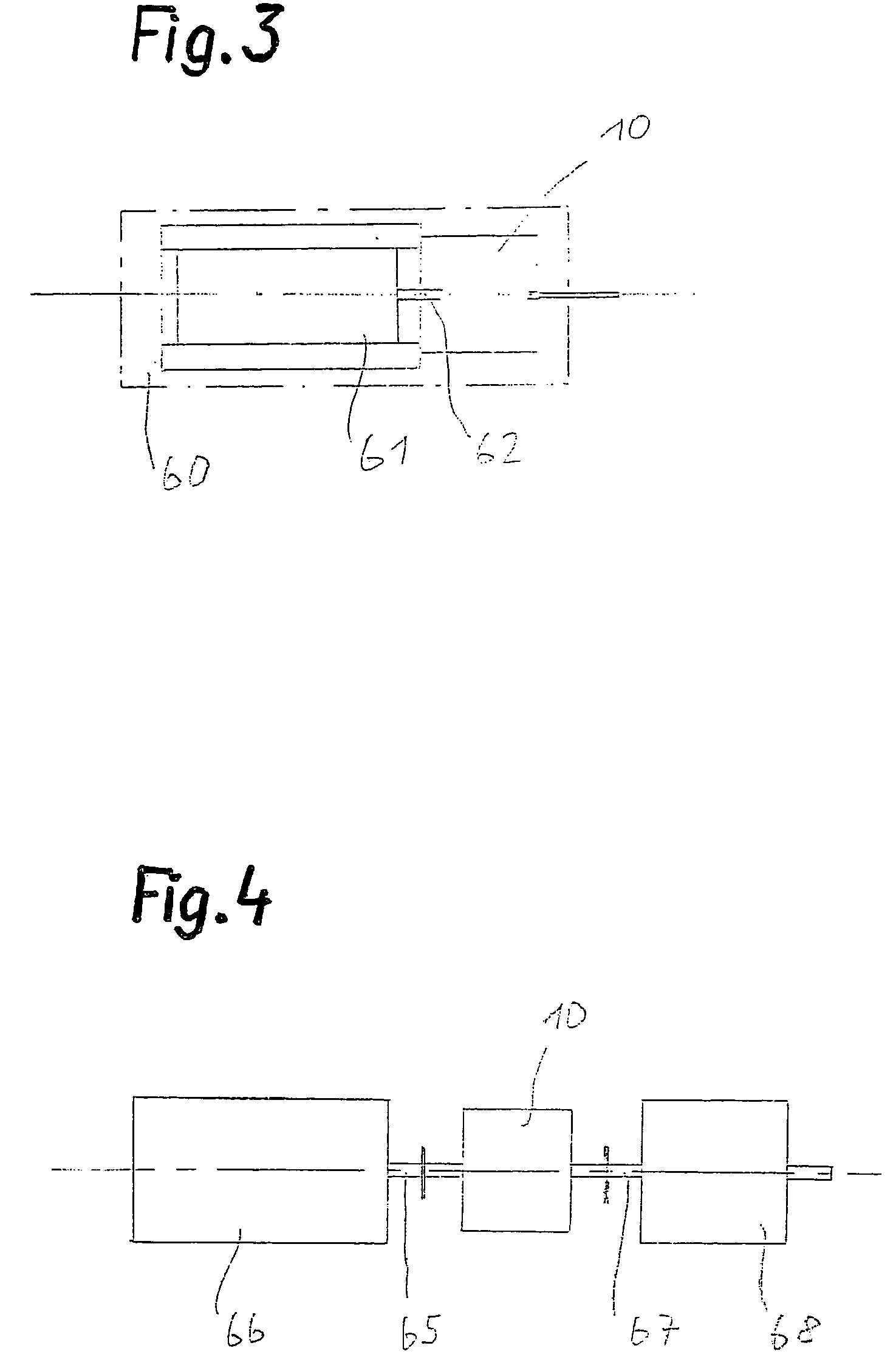

Hand-held setting tool with connection means for a positioning device

ActiveUS20080302849A1Premature releaseAvoid premature releaseStapling toolsNailing toolsHand heldAxial projection

A hand-held setting tool (10) includes a connection element (16) for connecting the setting tool (10) with a positioning device (20) having an actuation element (24), a switching link (30) for connecting the actuation element (24) to the actuation switch (13) of the setting tool (10) and having a first switching element (34) axially displaceable relative in a structural component (33), and a safety device (50) for preventing actuation of the actuation switch (13) at an orientation of the setting tool (10) other than a predetermined orientation and including at least three blocking members (55a, 55b, 55c) displaceable in at least three separate channels (56) respectively, and receivable in a recess (51) formed in the first, switching element (34) and opening toward the structural component, with the channels (56) being inclined with respect to a plane (E) extending perpendicular to a longitudinal axis (A), of the positioning device, and with at least three channels (56) intersecting, in some regions, an axial projection of the switching element (34) in form of a secant and opening toward the first, switching element (34) in respective overlapping regions (59).

Owner:HILTI AG

Impeller blade

Impeller blades and a method for designing impeller blades wherein the blades comprise a plurality of specially designed airfoil sections, each section having along substantially the entire length thereof, a cross-sectional shape characterized by a maximum thickness located substantially constantly between about 16% chord to about 23% chord and a maximum camber located substantially constantly between about 40% chord to about 51% chord. The blades are designed so that the axial width of the blades is decreased while maintaining performance parameters and design constraints.

Owner:MINEBEA CO LTD

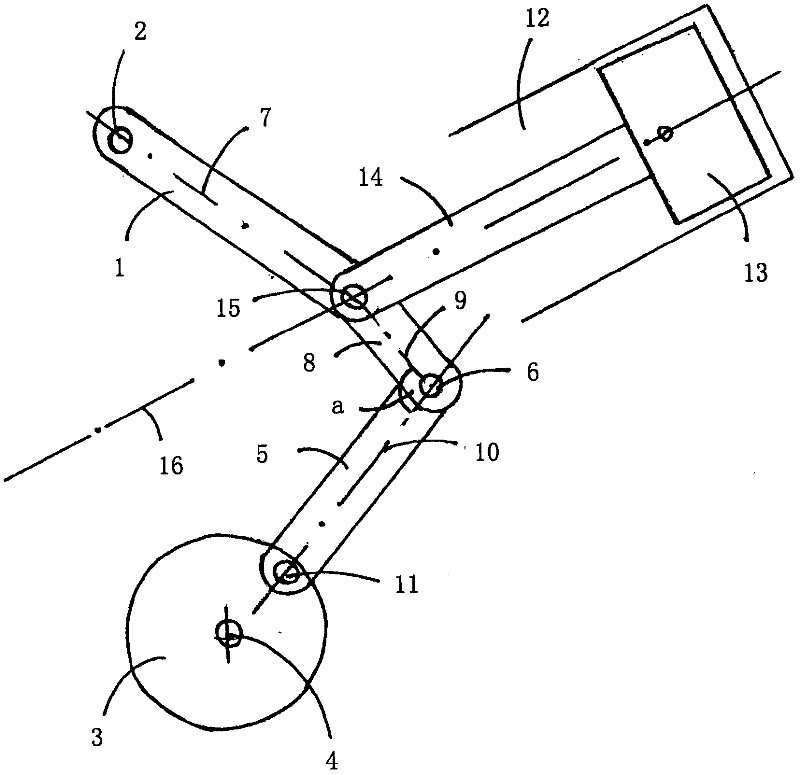

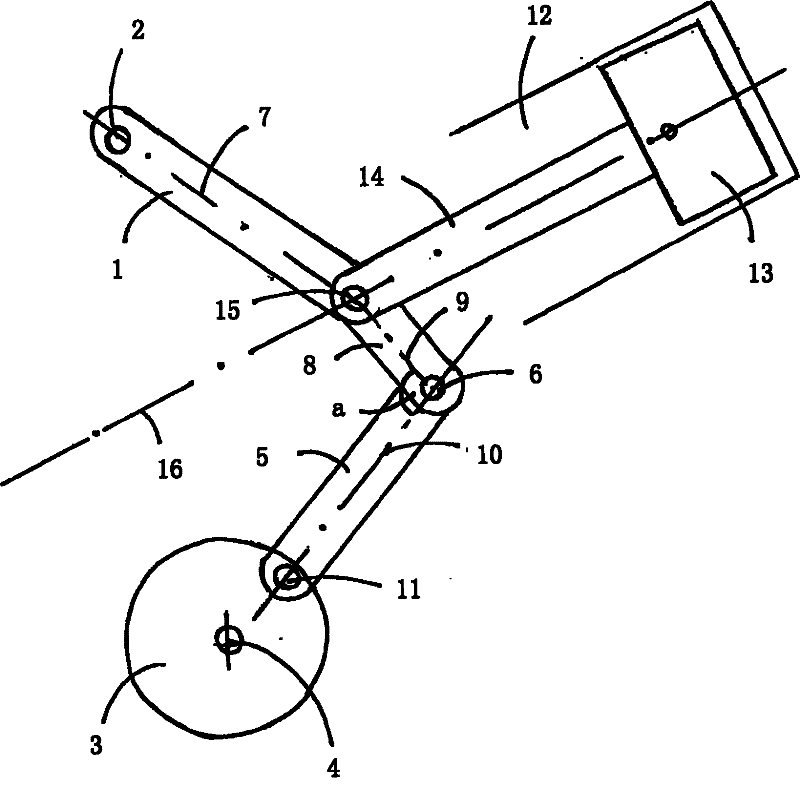

Crank drive

InactiveCN102472164AReduce the height of the structureCompact structureCombustion enginesControl theoryPiston

The invention relates to a crank drive, having a frame, which may be formed in particular by a housing, having a rocker (1) positionally fixedly mounted on the frame, having a crank (3) which is positionally fixedly mounted on the frame and which forms the drive output, and having a coupler (5) which connects the rocker (1) and the crank (3), wherein the coupler (5) is articulatedly connected in each case to the crank (3) and to an end, which is situated opposite the positionally fixed mounting (2), of the rocker (1), wherein to drive the crank (3), a first cylinder (12) is provided which has a movably mounted piston (13), wherein the piston (13) and the rocker (1) are articulatedly connected to one another via a push rod (14) such that the axial movement of the piston (13) sets the rocker (1) in an oscillating swinging motion, and wherein the rocker (1) comprises a section (8); which is remote from the positionally fixed mounting of the rocker (1) and which is inclined by a fixed angle towards the coupler (5).

Owner:K 赫曼斯

Hand-held setting tool with connection means for a positioning device

ActiveUS7914005B2Adequate switchingLittle expenditure of forceStapling toolsNailing toolsHand heldEngineering

Owner:HILTI AG

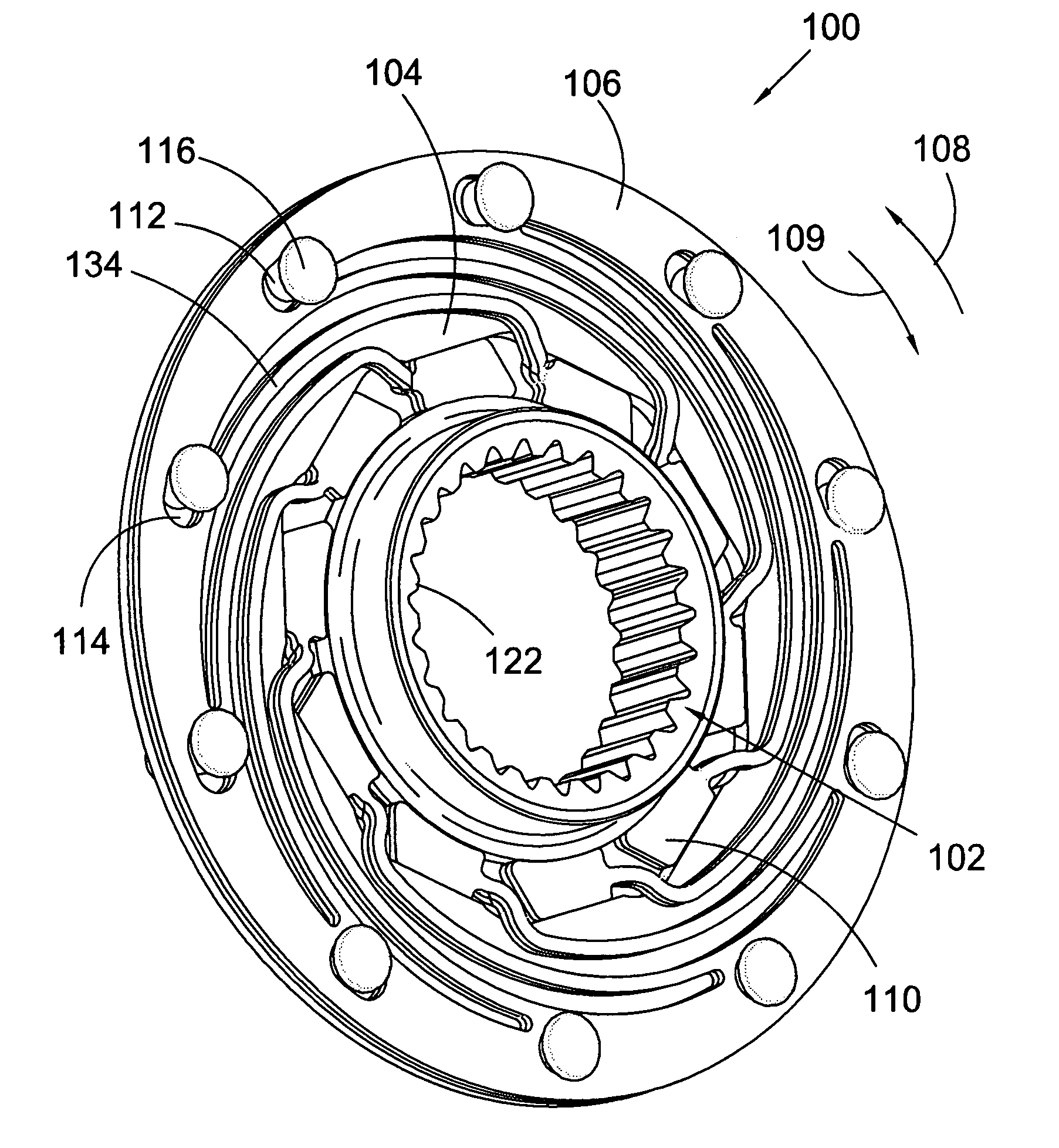

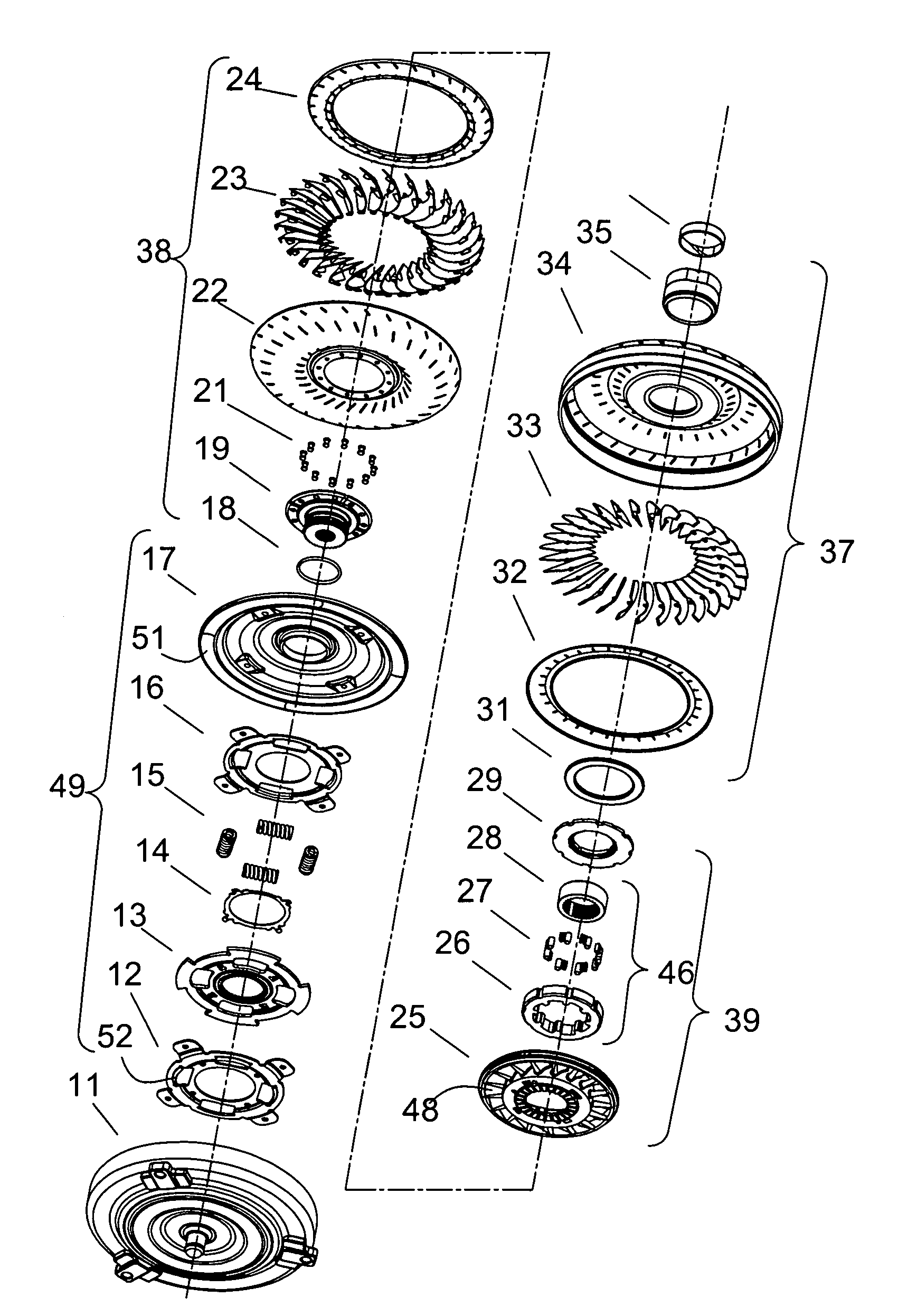

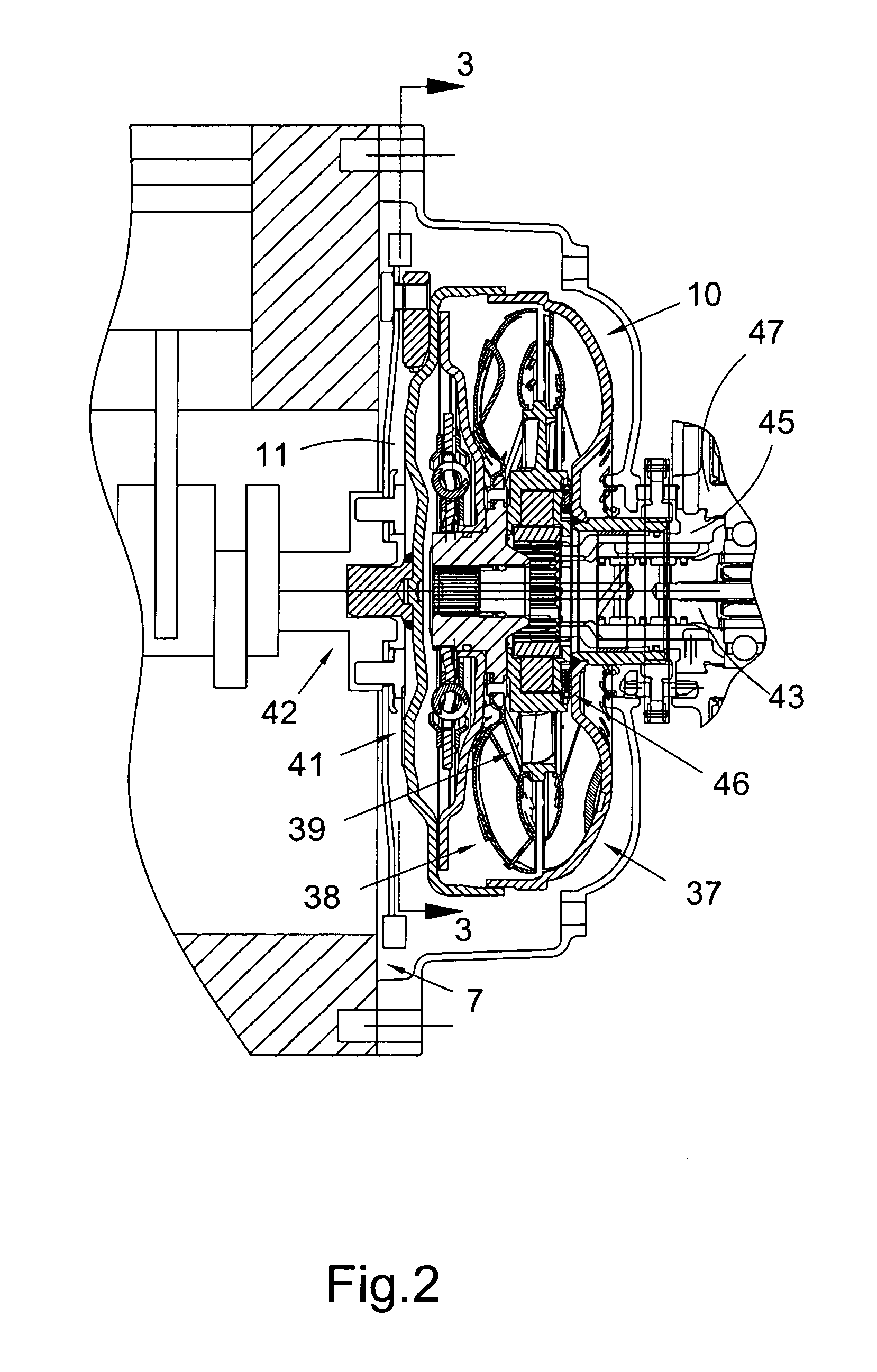

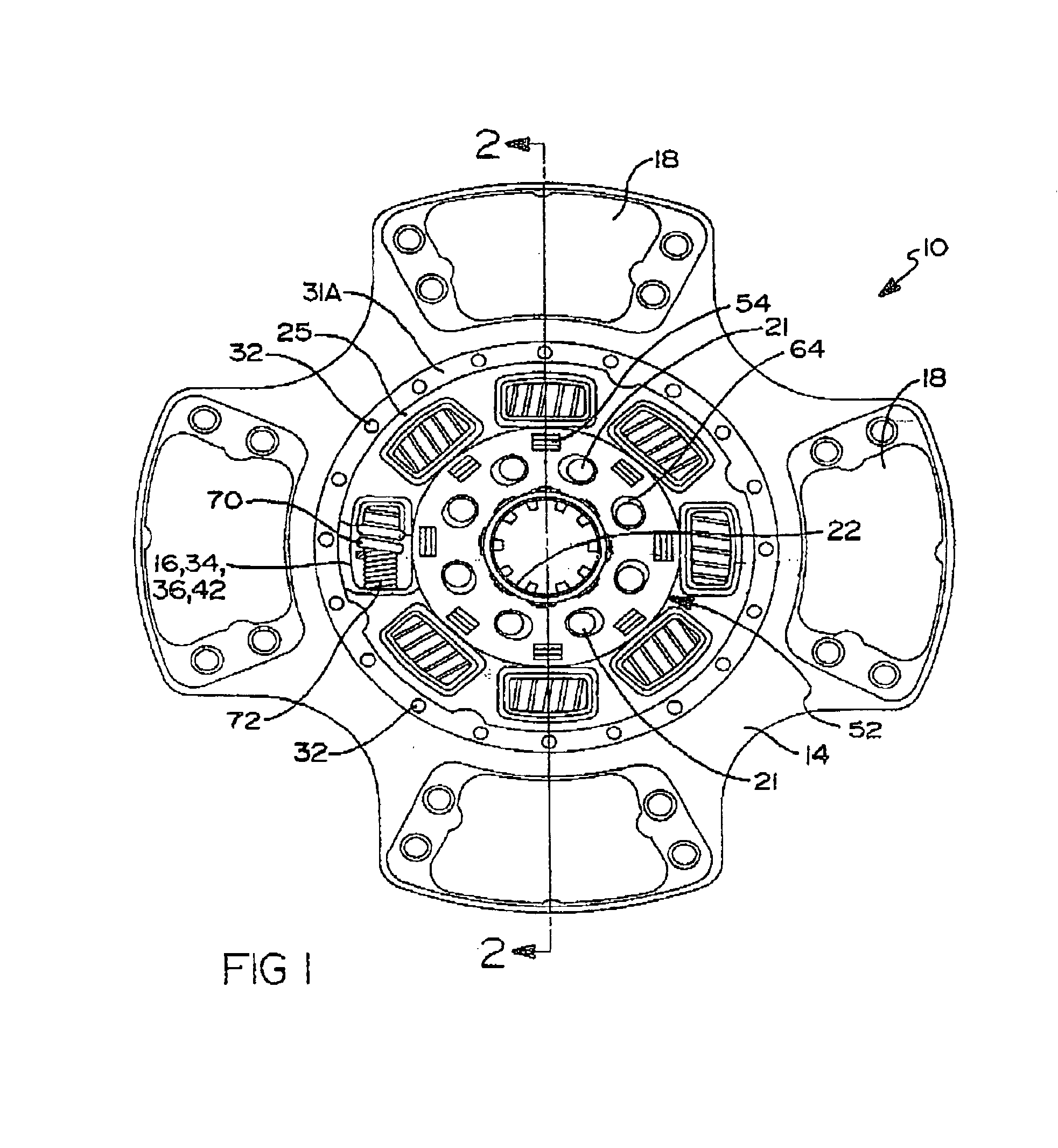

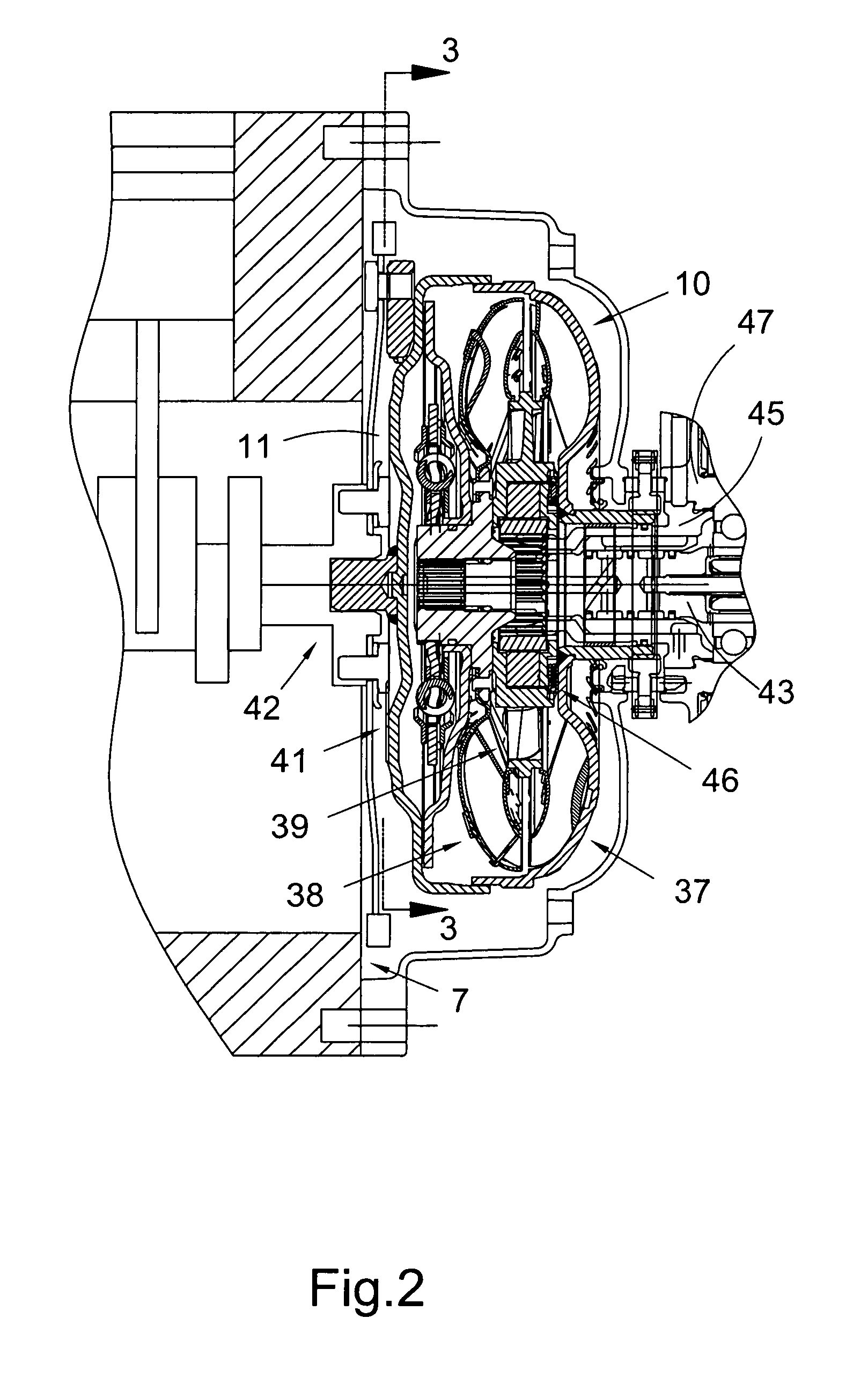

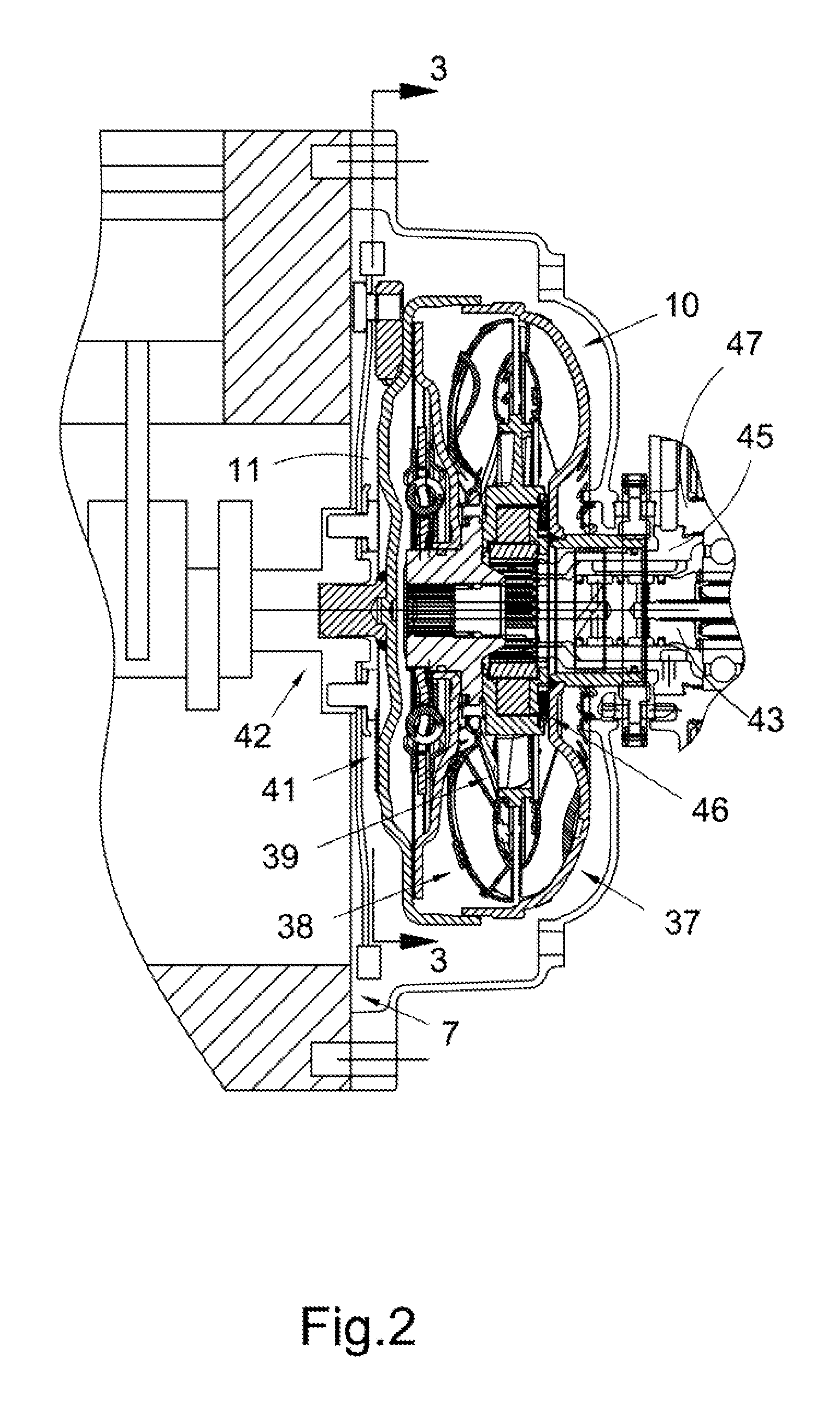

Clutch driven disk with predamper

InactiveUS6923305B2Shorten the axial widthYielding couplingFriction clutchesEngineeringDriven element

A driven disk is disclosed that includes an inner hub and an outer hub secured to at least one cover plate. The driven disk includes a predamper having a driving element and a driven element. The driving element includes the cover plate and the driven element includes a predamper driven plate fixed to the inner hub. The cover plate includes a number of apertures and the predamper driven plate includes a number of sockets at least partially aligned with the apertures in the cover plate. An energy storage member is disposed within the apertures in the cover plate and the sockets in the predamper driven plate for absorbing torque as a function of relative rotation between the inner hub and the outer hub.

Owner:EATON INTELLIGENT POWER LTD

Single component one-way clutch

InactiveUS8033371B2Shorten the axial widthAvoid compressionRotary clutchesFriction clutchesEngineeringSingle component

A one-way clutch including a race disposed about an axis for the clutch and a wedge plate with a plurality of finger elements extending toward the race and in contact with the race. One of the plate or race is arranged for rotational connection to a torque transmitting element in an automotive device and is arranged to rotate independently of the other of the plate or race for rotation, with respect to the other of the plate or race, in a first rotational direction. The plurality of fingers are arranged to grip the race, to rotationally lock the plate and race, for relative rotation of the plate or race in a second rotational direction, opposite the first rotational direction.

Owner:SCHAEFFLER TECH AG & CO KG

Wedge one-way clutch

InactiveUS7987958B2Shorten the axial widthMechanical actuated clutchesRotary clutchesEngineeringClutch

A one-way clutch including first and second races with radially opposed circumferential surfaces and at least one wedge separate from the races and disposed radially between the races. The first race is arranged for rotational connection to a torque transmitting element in an automotive device and is arranged to rotate independently of the second race for relative rotation in a first direction. A circumference for one of the circumferential surfaces has a uniform radius. A circumference for the other of the circumferential surfaces includes at least one radial protrusion. The wedge elements are arranged to engage the protrusions and the opposing circumferential surface to rotationally lock the first and second races for relative rotation of the first race in a second rotational direction, opposite the first rotational direction. During lockup, a circumferential extent of the wedge elements in contact with the second race is greater than an axial extent.

Owner:SCHAEFFLER TECH AG & CO KG

Load torque blocking device

InactiveUS6994199B2Avoid it happening againClamp firmlySelf acting brakesEngineering safety devicesRotational axisDrive shaft

The invention concerns a load torque lock for automatically locking load-side torques in the case of a decrease or cessation of a drive-side torque having a housing (11) fixed to a frame, a locking ring (17) permanently connected to it and a locking body (17) cooperating with it and revolving on the drive side, with locking devices which, on the one hand, clamp on the locking ring (17) with the occurrence of a load torque by swiveling the locking body (17) by means of locking elements (27, 28) of the output shaft (15) and, on the other hand, release from the locking ring (17) by swiveling the locking body (17) back by means of driving elements (23, 24) of the drive shaft (14). To avoid undesired friction or defective jamming of the locking devices on the locking ring (18) by the centrifugal forces of the locking body (17) it is embodied in such a way that its mass center of gravity (M) lies in the area of the rotational axis of the drive shaft and the output shaft that are aligned with one another.

Owner:ROBERT BOSCH GMBH

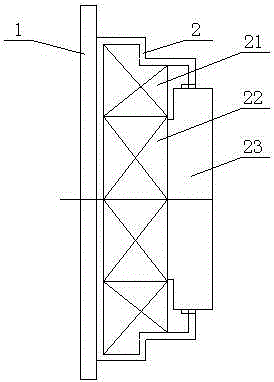

A three-phase electric asynchronous motor

ActiveCN102969855BShorten shaft lengthShorten the axial widthAsynchronous induction motorsSupports/enclosures/casingsThree phase asynchronous motorEngineering

The invention discloses a three-phase electric asynchronous motor. The three-phase electric asynchronous motor comprises a motor installation base plate and a motor casing, wherein the motor installation base plate is installed at an axial non-power output end of the motor casing, the motor installation base plate is round, the diameter of the motor installation base plate is larger than that of the motor casing, the motor casing is in a step shape, a corresponding stator inside the motor casing is also in the step shape, a rotor is located inside the stator, no rotating shaft exists in the rotor, and a disc-shaped output end is arranged on the end portion of the rotor. A clutch type component can be installed at the disc-shaped output end. The diameter of the rotor is more than twice the width of the rotor. According to the three-phase electric asynchronous motor, the problem of large sizes of three-phase asynchronous motors can be solved, the axial length of the motor can be greatly shortened, the axial width of the motor can be shortened, and the occupied space of the motor can be saved.

Owner:WUXI NEW GREAT POWER ELECTRICAL MACHINE

Motorcycle tire for running on rough terrain

ActiveUS10562354B2Shorten the axial widthOff-road vehicle tyresMotorcycle tyresGround contactMotorcycle tyre

A motorcycle tire for running on rough terrain, the tire includes a tread portion including a central region, a pair of shoulder regions and a middle region. The tread portion is provided with at least one central block with a ground contact face whose centroid is located within the central region, at least one shoulder block with a ground contact face whose centroid is located within the shoulder region on each side of a tire equator, and at least one middle block with a ground contact face whose centroid is located within the middle region on each side of the tire equator. When the respective blocks are projected onto a tire meridian cross section along a circumferential direction of the tire, every pair of axially adjacent two blocks are arranged so as to overlap one another at least partially on the tire meridian cross section.

Owner:SUMITOMO RUBBER IND LTD

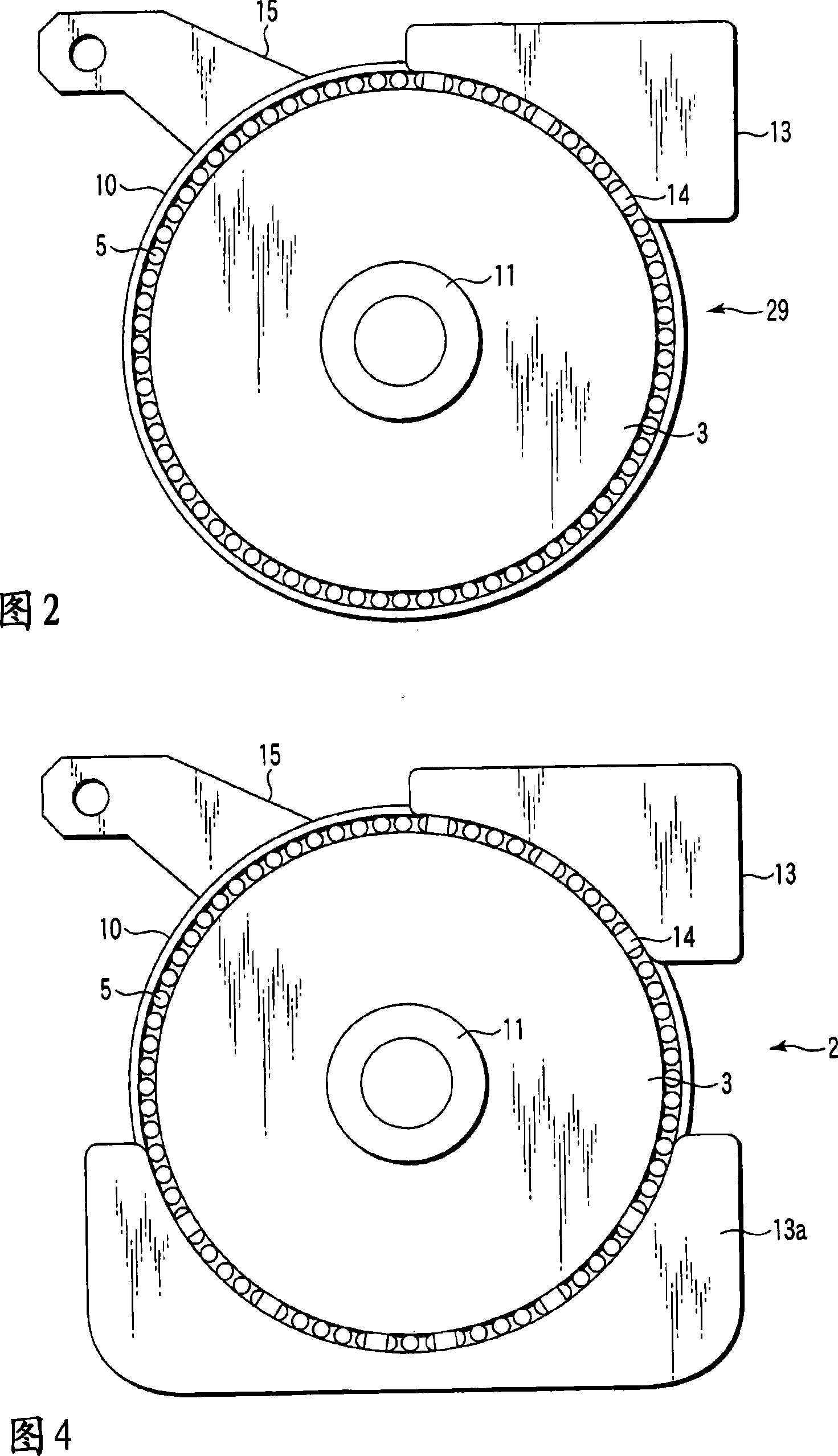

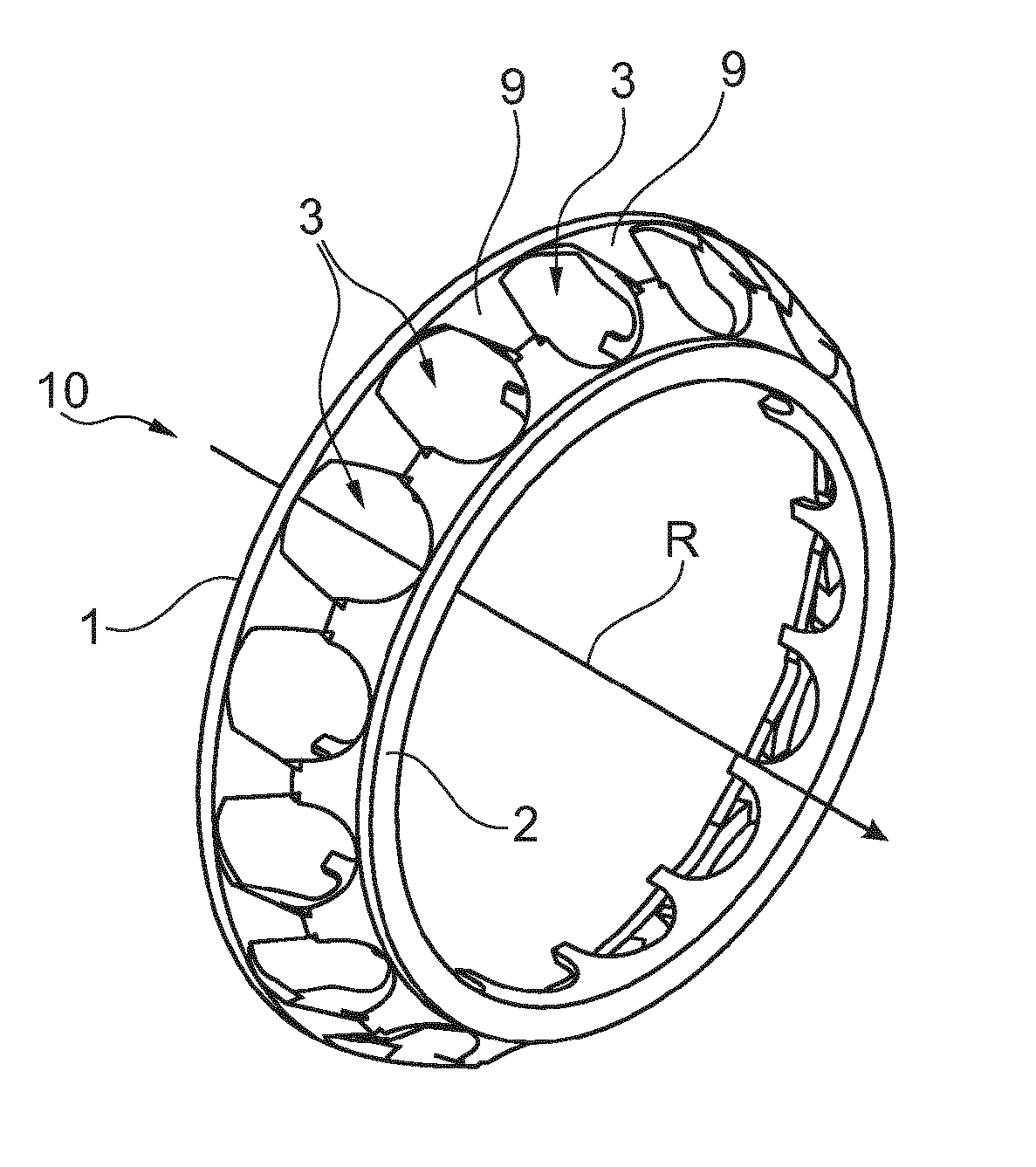

Cage for inclined ball bearing

InactiveUS20160040714A1Small axial widthHigh load rateBall bearingsCastorsMechanical engineeringRolling-element bearing

A rolling bearing cage 10 with two rings 1,2 connected by webs 9, wherein webs 9 provided with bifurcations 8 are used to solve the problem of reducing weight while simultaneously ensuring increased load rating, wherein said webs 9 permit adjacent rolling bodies to be arranged very close to one another. Furthermore, a plurality of identical cages 10 are prevented from tangling in each other when said cages are heaped in large quantities. Overall, the cage 10 allows a more compact design for inclined ball bearings and also reduces their moment of friction.

Owner:SCHAEFFLER TECH AG & CO KG

Wire arrangement device of moving cone beam CT

The invention relates to a wire arrangement device for moving cone beam CT. A synchronous belt wheel is arranged on a rack, a rotating cylinder is arranged on the synchronous belt wheel, a motor drives the synchronous belt wheel to rotate through a first synchronous belt, a guide rail is fixed to the rack, a balancing weight is arranged on the guide rail, a wire arrangement movable pulley is arranged on the balancing weight, a wire arrangement fixed pulley is located above the guide rail, a wire arrangement groove is formed in the rotating cylinder, a cable is fixed to the wire arrangement groove and then is arranged in an arranged wire in a penetrating manner, the arranged wire sequentially passes through the wire arrangement fixed pulley and the wire arrangement movable pulley and is fixed into a wire arrangement fixed buckle, when the CT machine works, the synchronous belt wheel drives the X light source and the rotating cylinder on the two sides of the rack to rotate by 360 degrees, the rotating cylinder drives the arranged wire, the arranged wire drives the balancing weight to move up and down on the guide rail through the wire arrangement fixed pulley and the wire arrangementmovable pulley, and therefore during spiral CT axial moving continuous rotating scanning, smooth traction and work of the wire arrangement cable and the synchronous wheel are safe and reliable, the wiring device is compact in structure, and the equipment size is effectively saved.

Owner:天津金曦医疗设备有限公司

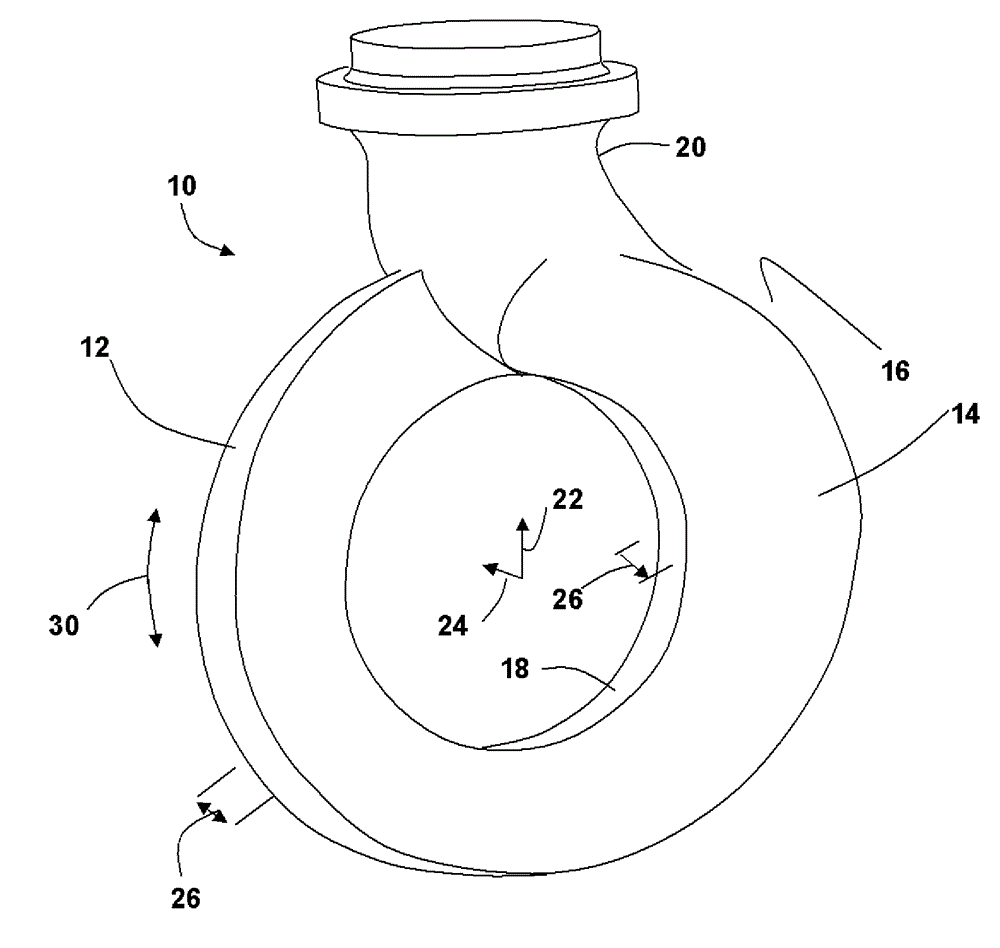

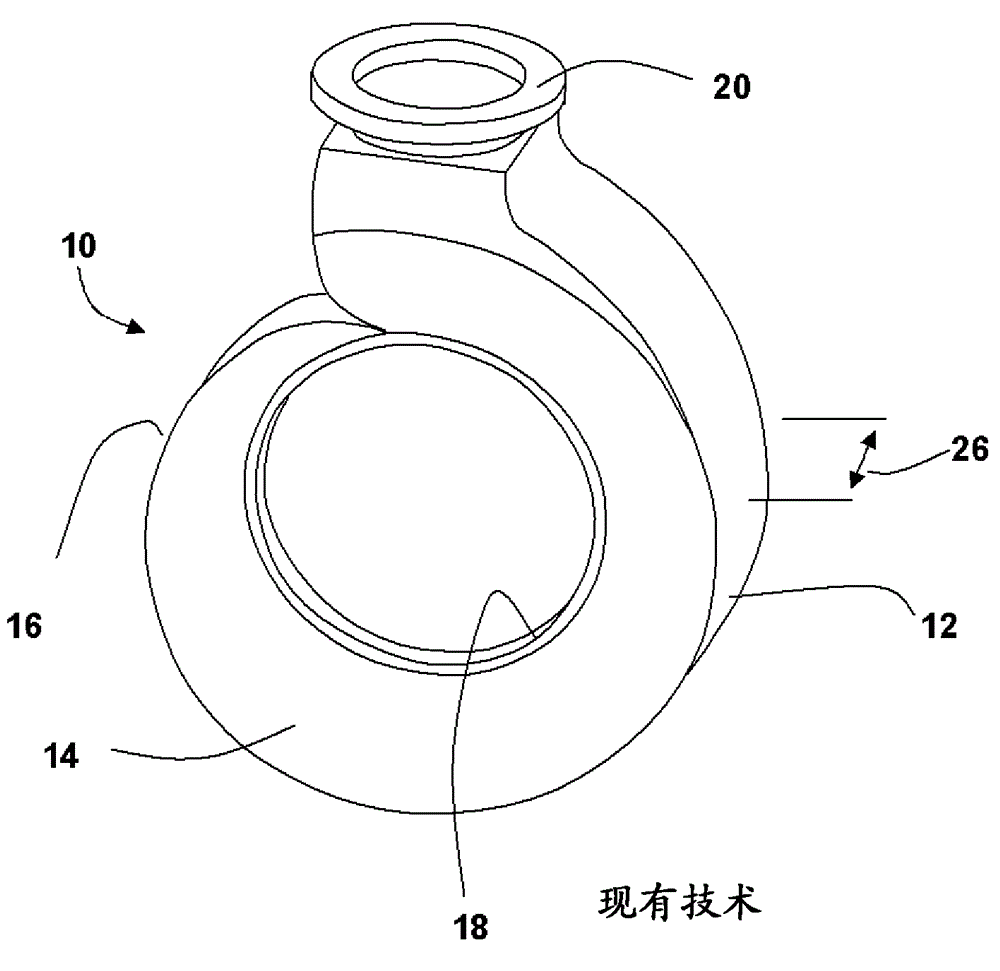

Scroll of turbine

InactiveCN106032758AShorten the axial widthAxial width constantStatorsMachines/enginesEngineeringTurbine

The invention relates to a scroll (10) used for a turbine, and the scroll comprises an outer wall (12). The outer wall (12) defines round external radial limitation of the scroll (10). The scroll (10) is characterized in that the outer wall (12) has constant circumferential diameter. The scroll also comprises end walls (14,16) which can be separated axially, and the end walls (14,16) extend inward from the radial direction of the outer wall (12), to limit an air chamber between the end walls, and a periphery internal opening (20) on the radial internal boundary of the scroll (10). Any one of the first end wall (14) and the second end wall (16) or both of the first end wall (14) and the second end wall (16) can curl, so that on a circumferential direction (28), the first end wall (14) and the second end wall (16) extend from a first point of the outer wall (12) and get back to the first point of the outer wall (12), and the axial width (26) of the outer wall (12) is reduced.

Owner:GENERAL ELECTRIC TECH GMBH

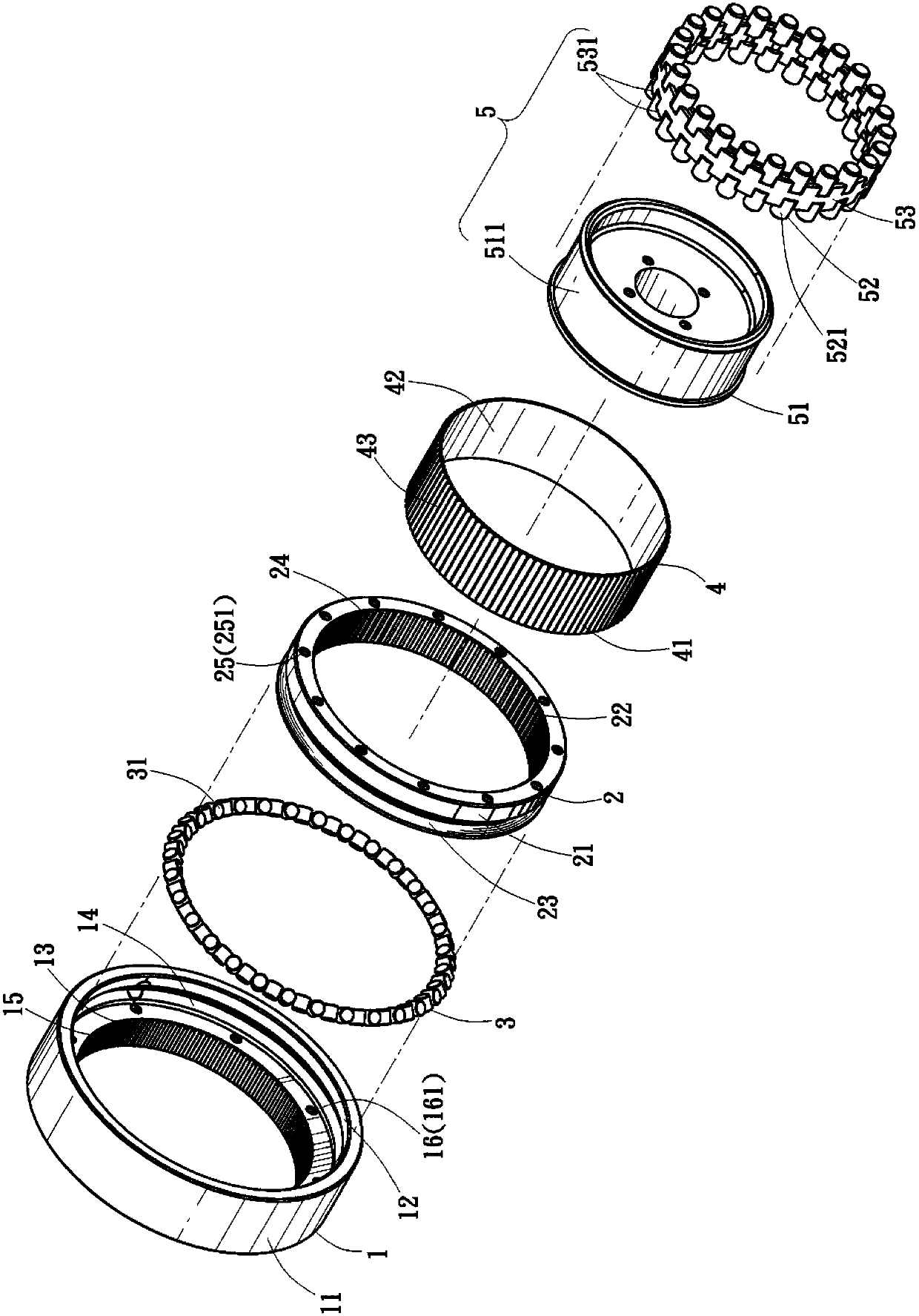

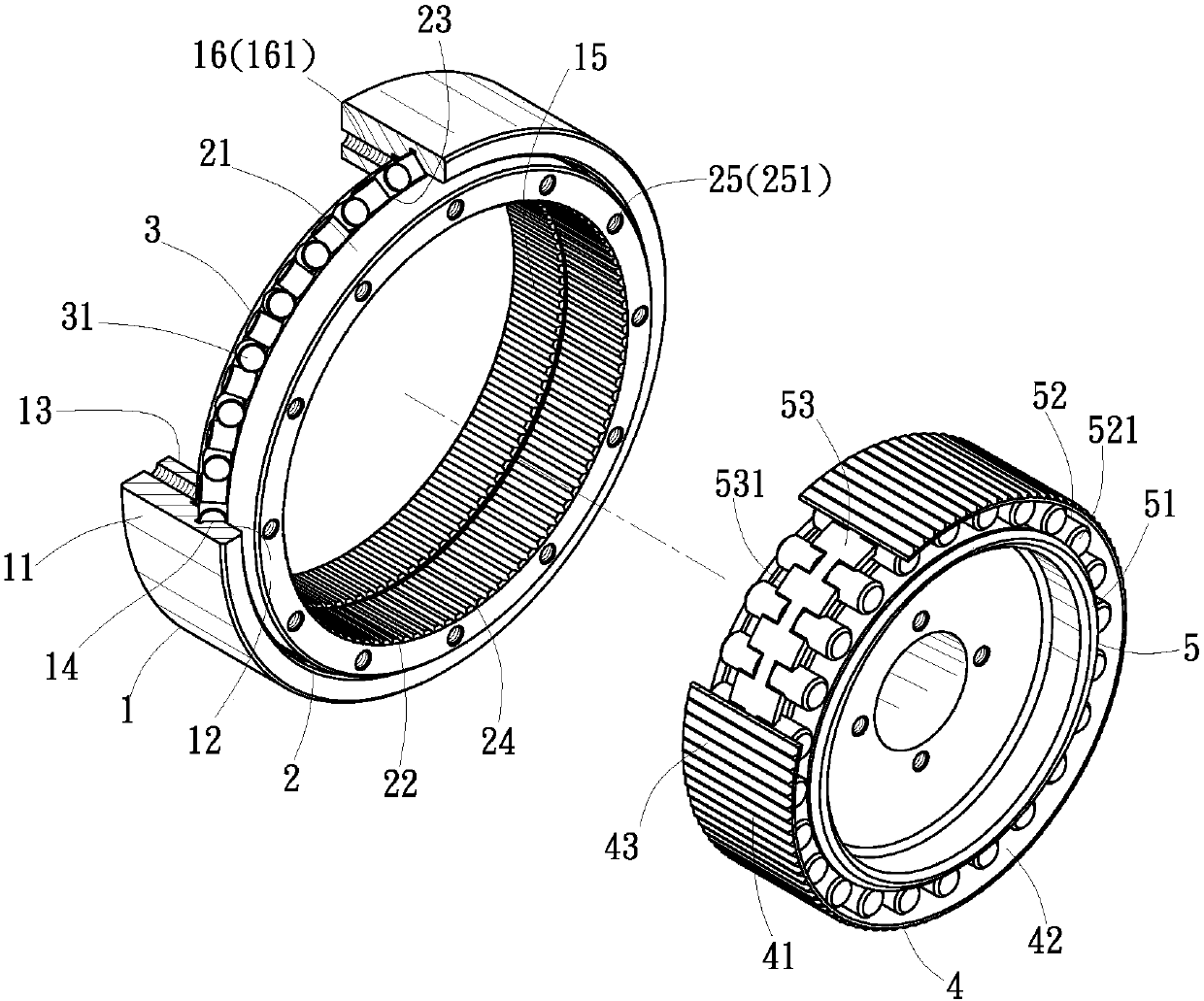

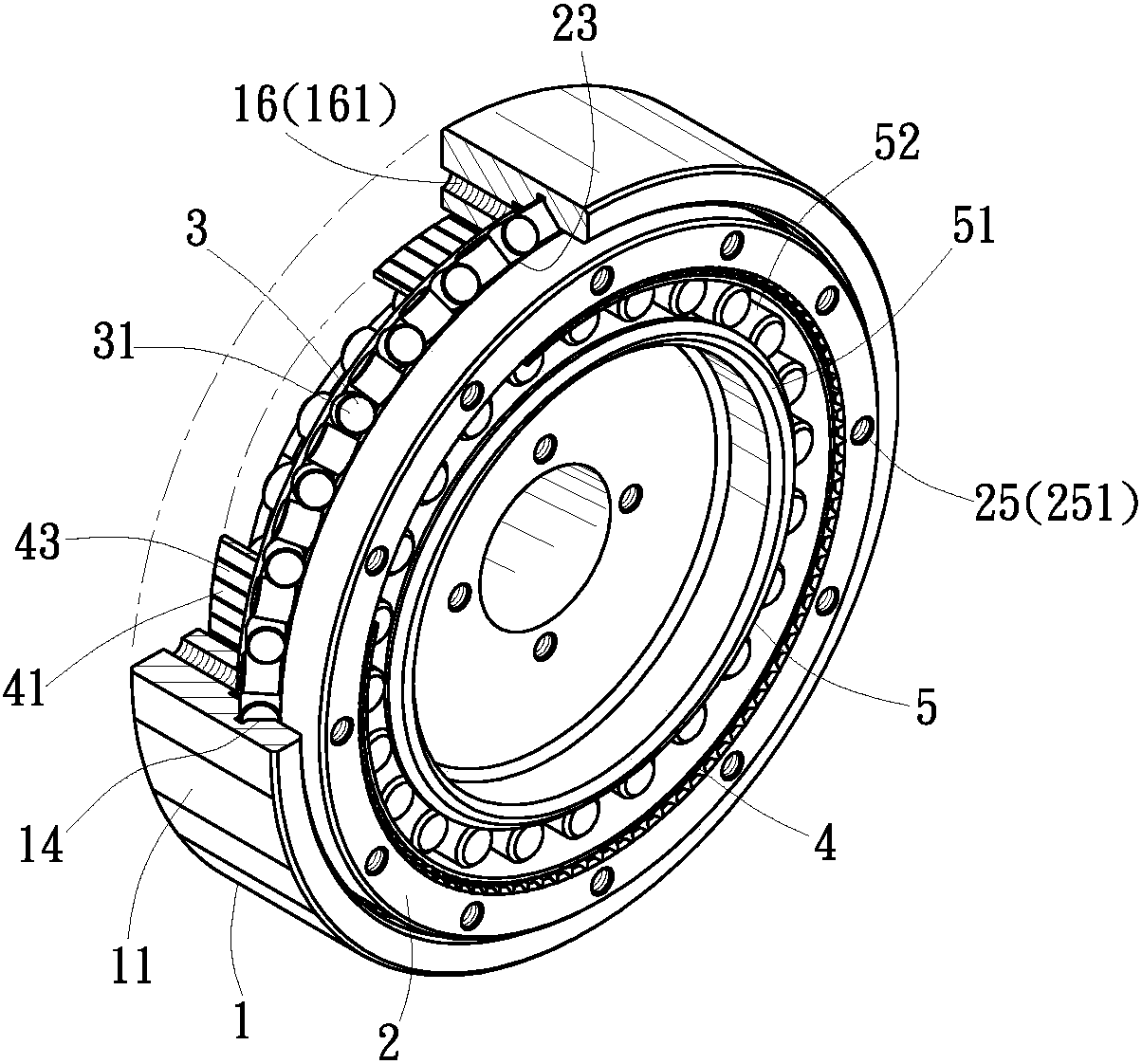

Reduction transmission bearing

ActiveCN104343894BShorten the axial widthPrevent axial disengagementRolling contact bearingsToothed gearingsEngineeringTooth number

Owner:国际精工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com