Scroll of turbine

A technology for turbines and vortex tubes, used in mechanical equipment, engine components, machines/engines, etc., to solve problems such as variable geometry increasing manufacturing complexity, and the need for alternative layouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

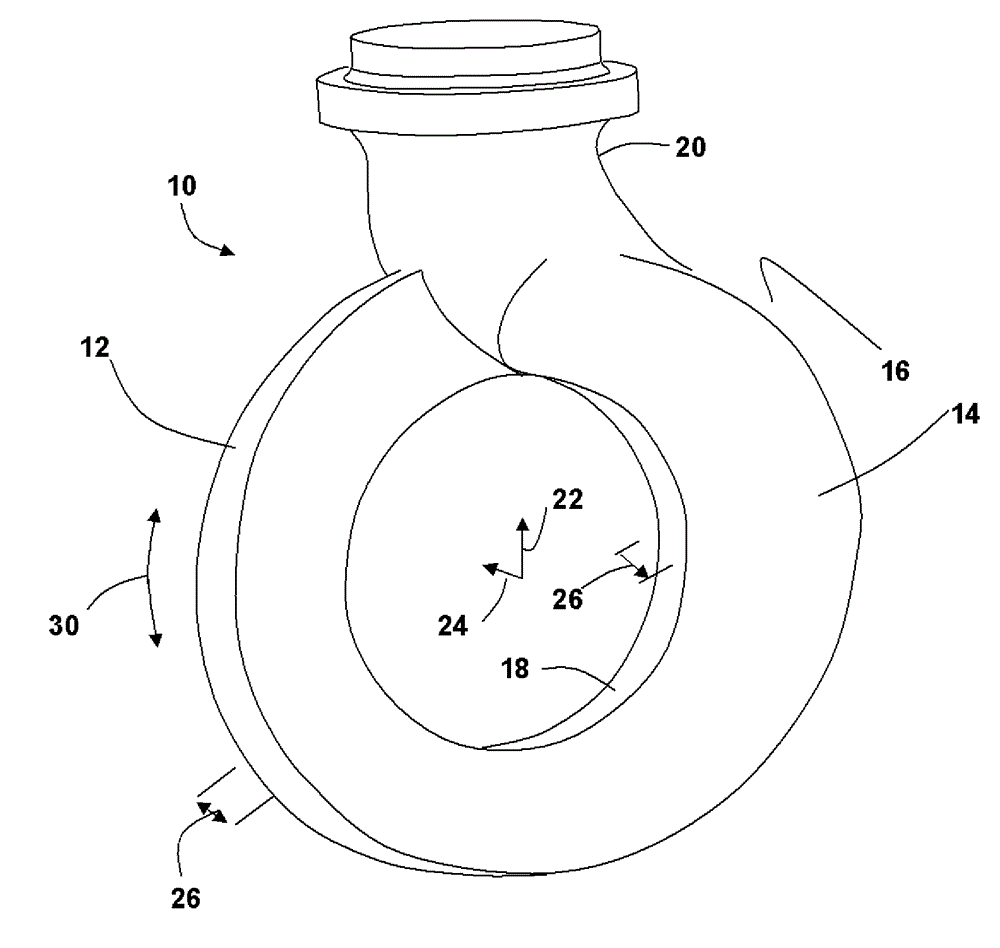

[0022] Exemplary embodiments of the present disclosure are now described with reference to the drawings, wherein like reference numerals are used to refer to like elements throughout. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the present disclosure. However, the present disclosure may be practiced without these specific details and is not limited to the exemplary embodiments disclosed herein.

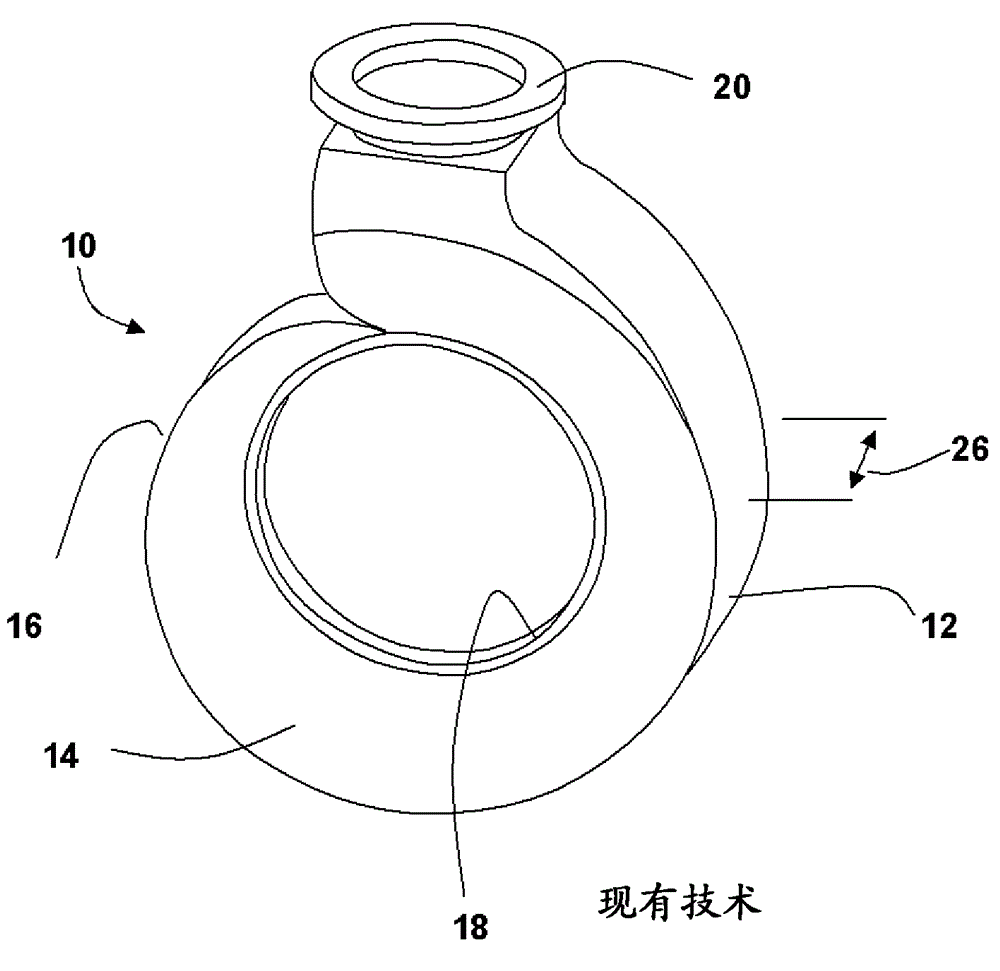

[0023] exist figure 2 The exemplary embodiment shown in is a scroll 10 for a turbomachine comprising an outer wall 12 defining a circular outer radial limit of the scroll 10 and having a constant circumferential diameter.

[0024] exist figure 2 In yet another exemplary embodiment shown in , two end walls 14 , 16 displaced in axial direction 24 extend radially inwards from outer wall 12 in radial direction 22 . The distance between the end walls 14 , 16 in the axial direction 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com