A three-phase electric asynchronous motor

An asynchronous motor, three-phase power technology, applied in asynchronous induction motors, electric components, electrical components, etc., can solve the problems of large occupied space, small working space, and the motor is not easy to fix, saving space and reducing shaft size. The effect of increasing the width and shortening the axis length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

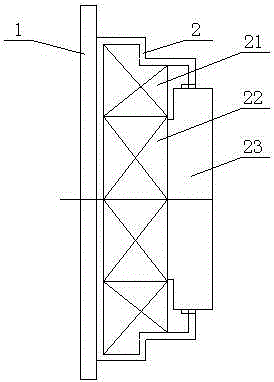

[0011] Such as figure 1 As shown, the three-phase electric asynchronous motor according to the embodiment of the present invention includes a motor installation base plate 1 and a motor housing 2, and the motor installation base plate 1 is installed on the axial non-power output end of the motor housing 2. The motor mounting base plate 1 is circular, and the diameter of the motor mounting base plate 1 is larger than the diameter of the motor housing 2. The motor housing 2 is stepped, and the corresponding stator 21 inside the motor housing 2 is also stepped. Shape, the rotor 22 is located inside the stator 21, the inside of the rotor 22 does not contain a rotating shaft, and the end of the rotor is provided with a disc-shaped output end 23.

[0012] A clutch type component can be installed on the disc-shaped output end 23 .

[0013] The diameter of the rotor 22 is more than twice the width of the rotor 22 .

[0014] The three-phase electric asynchronous motor solves the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com