Patents

Literature

151results about How to "Improve the ratio accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

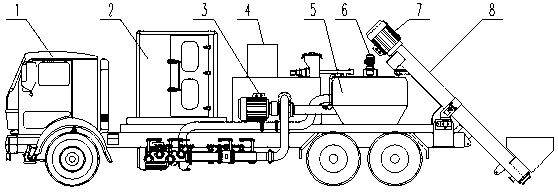

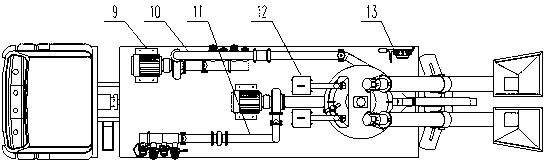

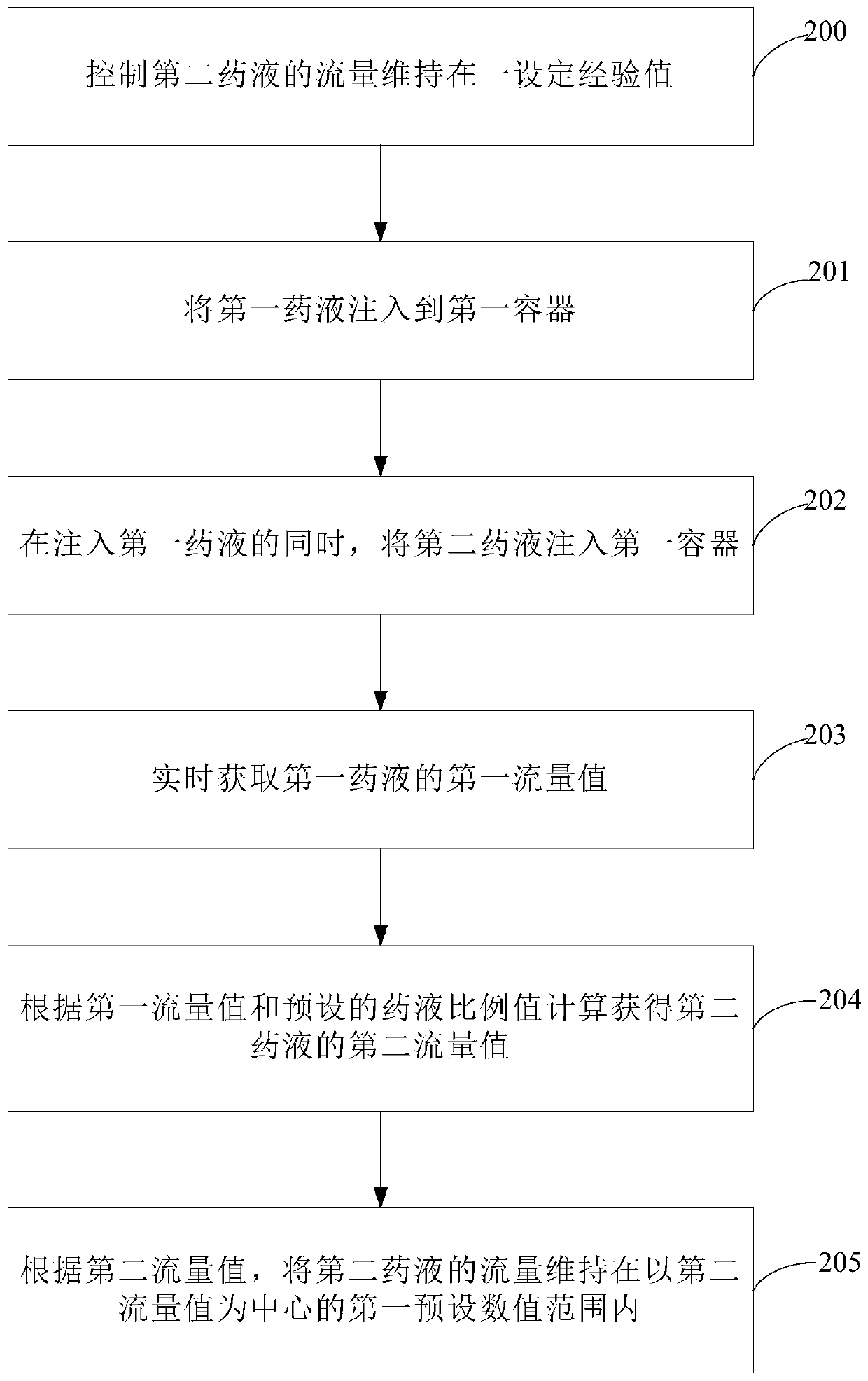

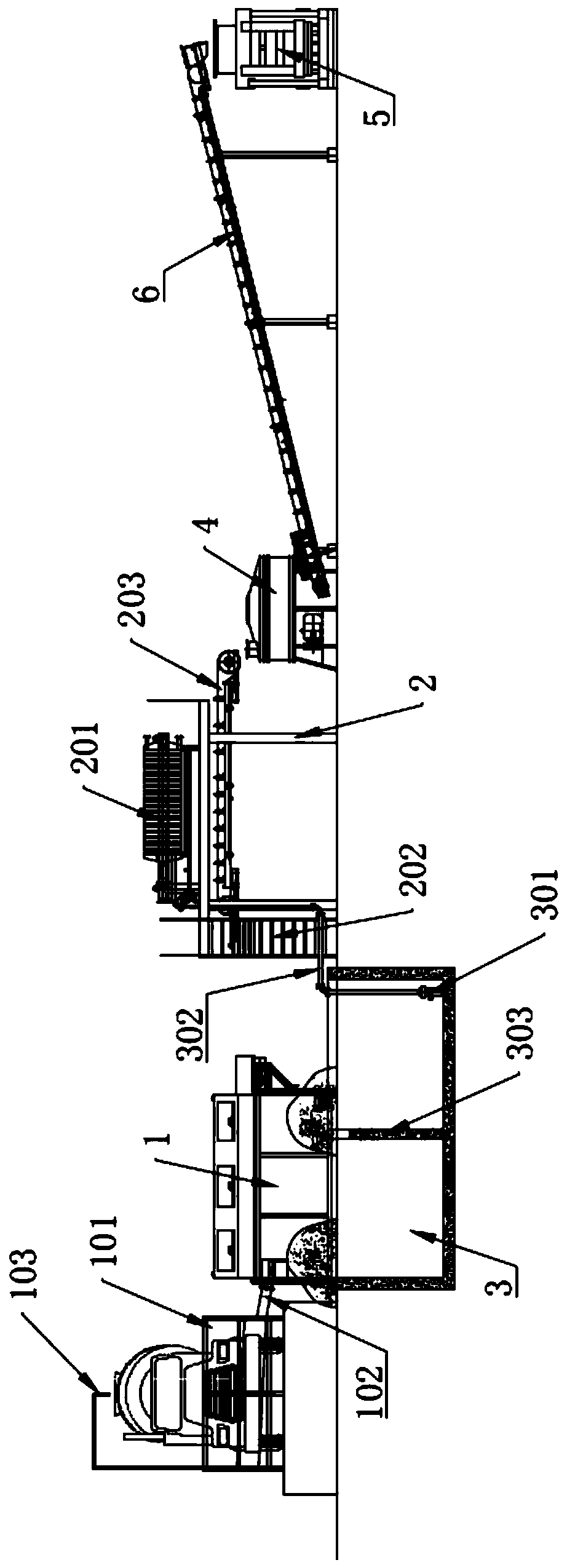

Electric drive sand mixing truck

InactiveCN103912259ASimple structureHigh localization rateFluid removalItem transportation vehiclesAutomatic controlElectric discharge

The invention belongs to the technical field of petroleum drilling and recovery and particularly relates to an electric drive sand mixing truck. The electric drive sand mixing truck comprises a truck chassis, a control room, a transformer, an electric discharge pump, an electric suction pump, a mixing tank stirring device, a sand conveying auger, a dry feeding system, a liquid feeding system, a suction manifold and a discharge manifold. The control room comprises a sand mixing truck automatic control system and a motor drive device. The electric drive sand mixing truck has the advantages that a motor is used as power source; compared with traditional sand mixing trucks using diesel engines and torque converters as main power output, the electric drive sand mixing truck is simple in structure, novel and reasonable in design, low in cost, low in noise, low in discharge, simple to control, high in sand-liquid matching precision, and convenient to popularize and use.

Owner:四机赛瓦石油钻采设备有限公司

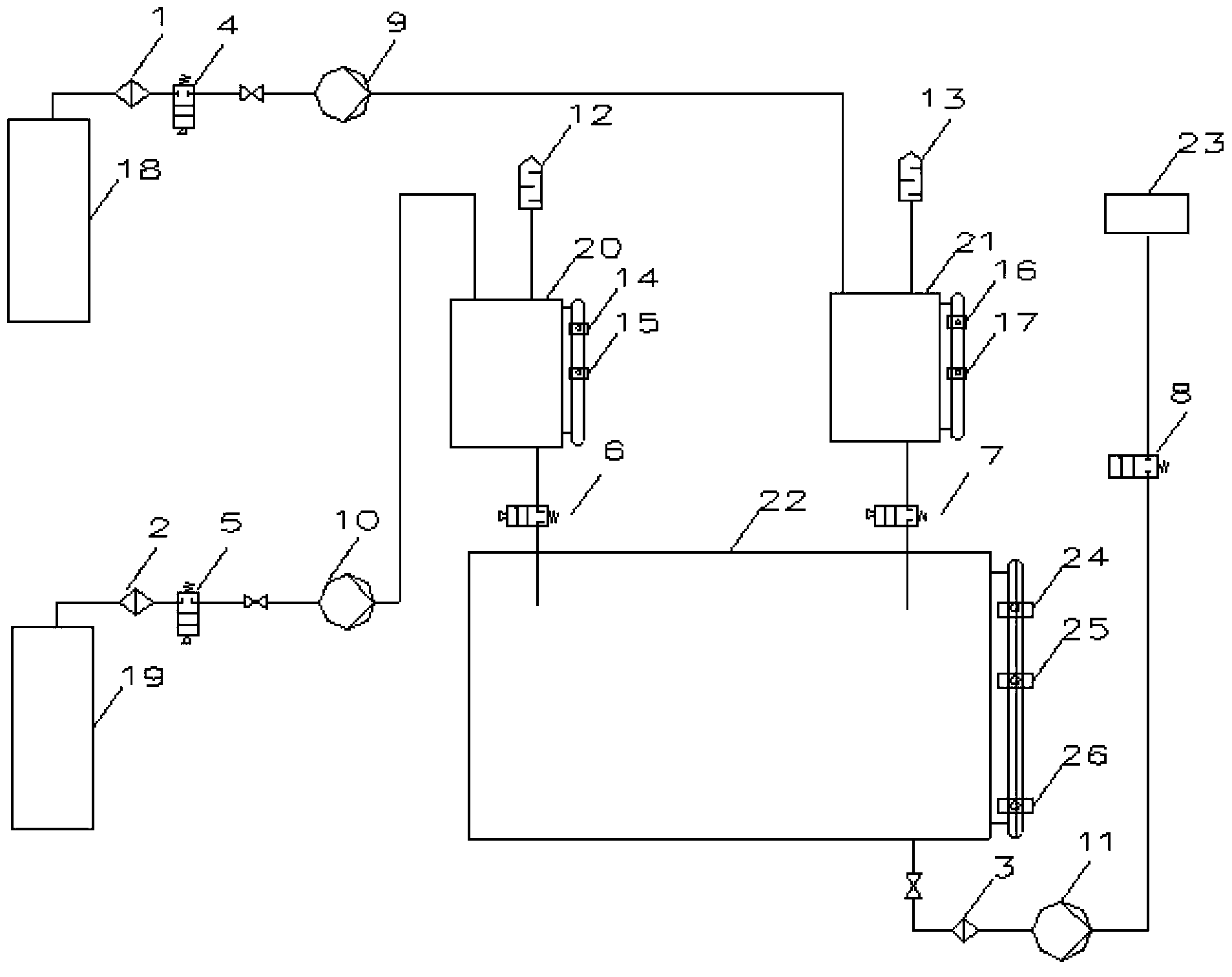

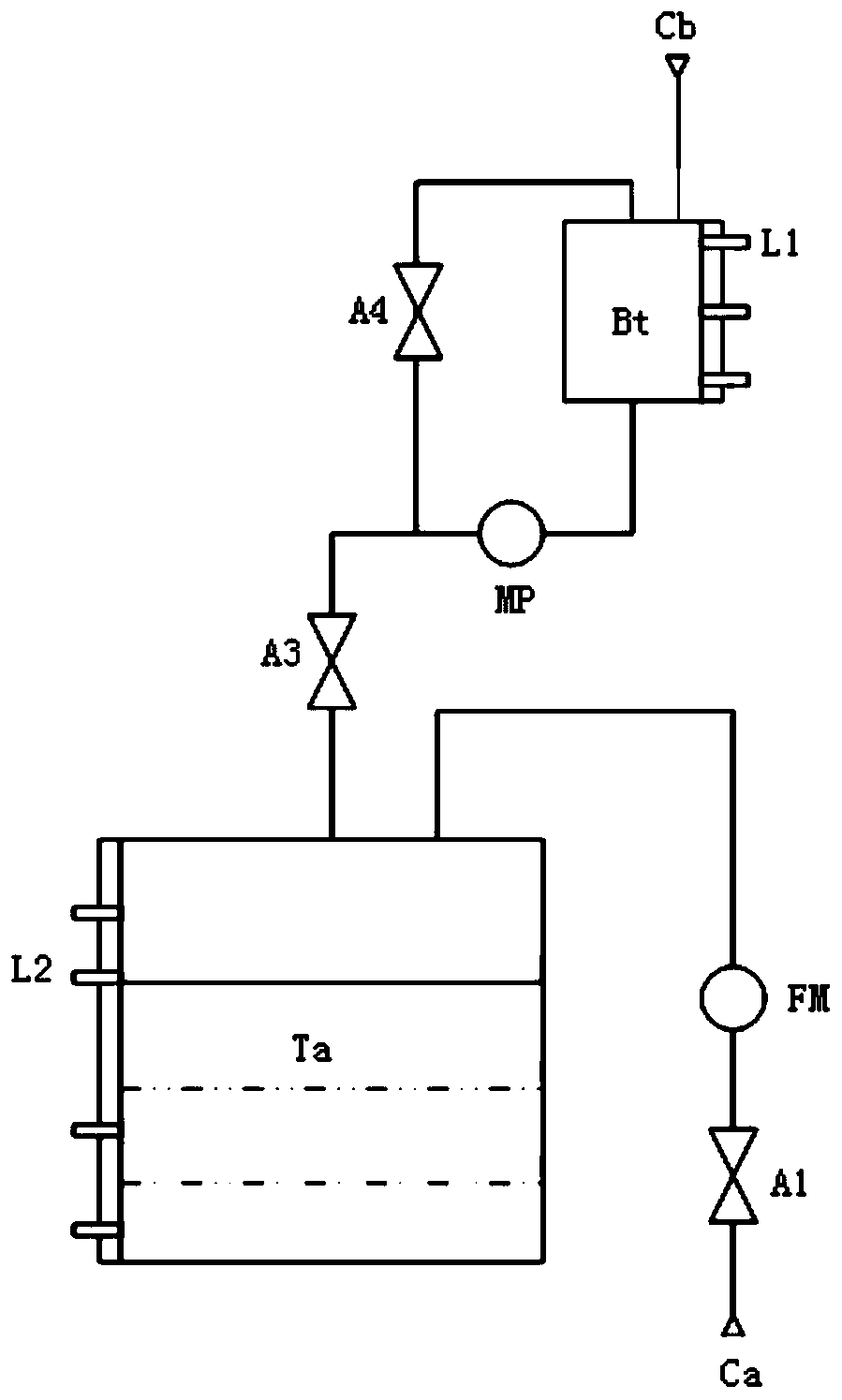

Proportion-adjustable automobile fluid matching control system and control method thereof

ActiveCN103521105AAvoid it happening againImprove the ratio accuracyMixing methodsMixer accessoriesControl systemPurified water

The invention relates to a proportion-adjustable automobile fluid matching control system and a control method thereof. The proportion-adjustable automobile fluid matching control system comprises a purified water supply tank, a purified water supplement and matching pipeline, a basic fluid supply tank, a basic fluid supplement and matching pipeline, a fluid storage tank and a cleaning fluid filling discharge pipeline, wherein the purified water supply tank is connected to the purified water supplement and matching pipeline and can supply the purified water supplement and matching pipeline with purified water; the purified water supplement and matching pipeline is connected to the fluid storage tank and can convey the purified water to the fluid storage tank; the basic fluid supply tank is connected to the basic fluid supplement and matching pipeline and can supply the basic fluid supplement and matching pipeline with basic fluid; the basic fluid supplement and matching pipeline is connected to the fluid storage bank and can convey basic fluid to the fluid storage tank; and the fluid storage tank is connected to the cleaning fluid filling discharge pipeline and can supply the cleaning fluid filling discharge pipeline with mixed fluid of the basic fluid and the purified water. The matching accuracy is high, bubbles can not be produced in a filling process, and the problems of poor matching accuracy of the basic fluid and the purified water during practical production, high manufacturing and maintenance costs of equipment and unsatisfactory product quality during in practical operation and filling processes are solved.

Owner:CHERY AUTOMOBILE CO LTD

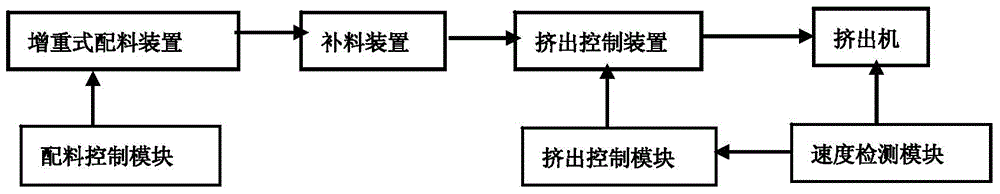

Extruder batching and flow control system and control method thereof

The invention provides an extruder batching and flow control system and a control method thereof. The control system comprises a weighing stock bin, a plurality of weighing devices, a feeding device and a mixed material bin, wherein the weighing stock bin consists of a main material bin and an auxiliary material bin; the plurality of weighing devices are respectively arranged on the main material bin and the auxiliary material bin; the feeding device is arranged below the auxiliary material bin; the mixed material bin is arranged below the main material bin and consists of a main material channel and an auxiliary material channel which are independent from each other, and the main material channel and the auxiliary material channel are commonly connected with a feed inlet of an extruder host; the extruder host consists of an extruder screw and a velocity sensor arranged on the extruder screw; outputs of a weighing sensor and the velocity sensor are respectively connected with a controller. Step-by-step operations of the batching technology management of raw materials and the quality control of products are changed into synchronous operations, so that the technology route is greatly shortened, and the environment interference link can be reduced; the original production mode that the batching management and the yield control are respectively controlled by two independent control systems is changed, the weighing, metering, mixed batching, raw material buffering and flow control are carried out simultaneously.

Owner:上海松耐智能设备有限公司

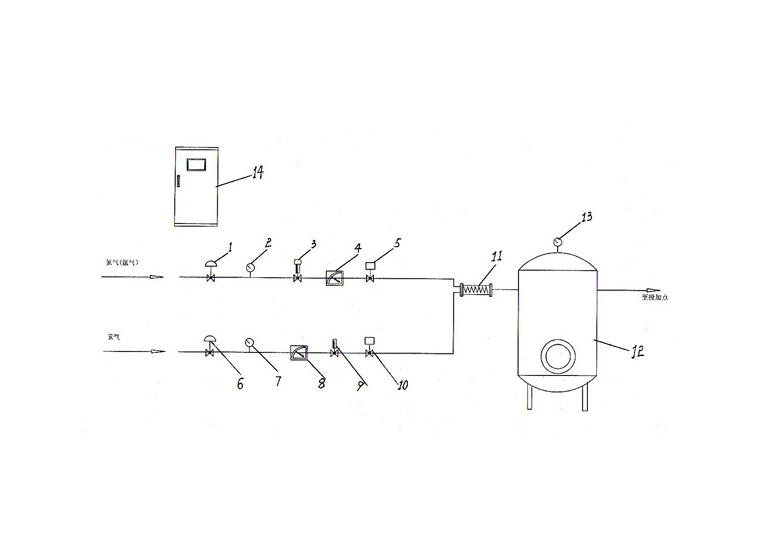

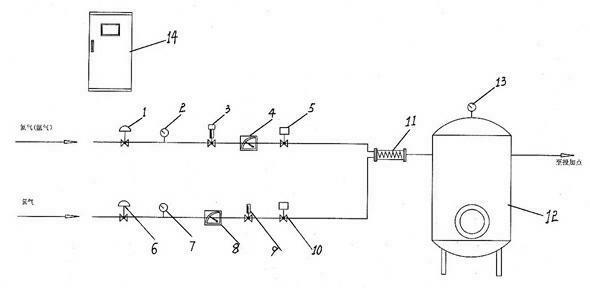

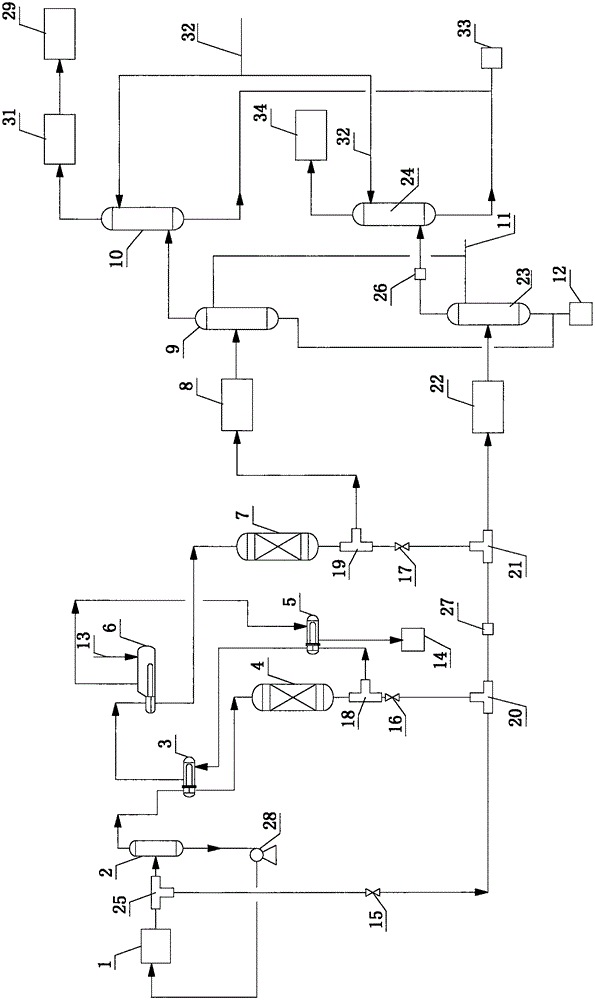

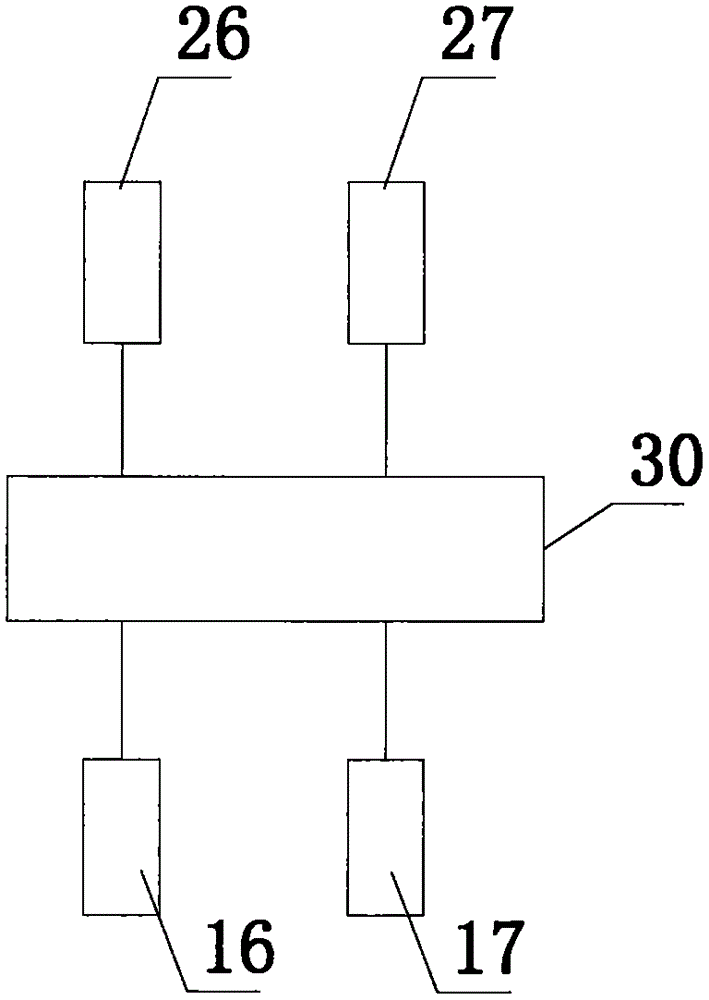

Nitrogen/chlorine (argon/chlorine) mixing and proportioning system and operation method thereof

InactiveCN102600759AImprove the ratio accuracyExtended service lifeMixer accessoriesMixing gases with gases/vapoursProgrammable logic controllerProcess engineering

The invention relates to a nitrogen / chlorine (argon / chlorine) mixing and proportioning system and an operation method thereof, aiming to overcome the defect that the manual nitrogen / chlorine (argon / chlorine) mixing and proportioning process in the prior art is completed by manual operation rather than automatic operation and is low in proportioning precision and high in operation risk. The nitrogen / chlorine (argon / chlorine) mixing and proportioning system comprises nitrogen (argon) gas running equipment, chlorine gas running equipment, a nitrogen and chlorine (argon and chlorine) mixer, a mixed gas storage tank and a PLC (programmable logic controller) control cabinet, wherein tail ends of the nitrogen (argon) gas running equipment and the chlorine gas running equipment are connected with the nitrogen and chlorine (argon and chlorine) mixer together, the nitrogen and chlorine (argon and chlorine) mixer is further connected with the mixed gas storage tank for a feeding point, a pressure sensor is arranged on the mixed gas storage tank, the PLC control cabinet is connected with all the equipment, and intelligent management and operation is realized by an internal control and management system. The nitrogen / chlorine (argon / chlorine) mixing and proportioning system and the operation method thereof have the advantages that automatic proportioning operation can be realized, operators can keep away from dangerous sources, the proportioning precision is increased, the service life of the equipment is prolonged, the service pressure of the system is stabilized, and leakage caused by long-term overhigh pressure load for the end equipment is avoided.

Owner:刘树伟

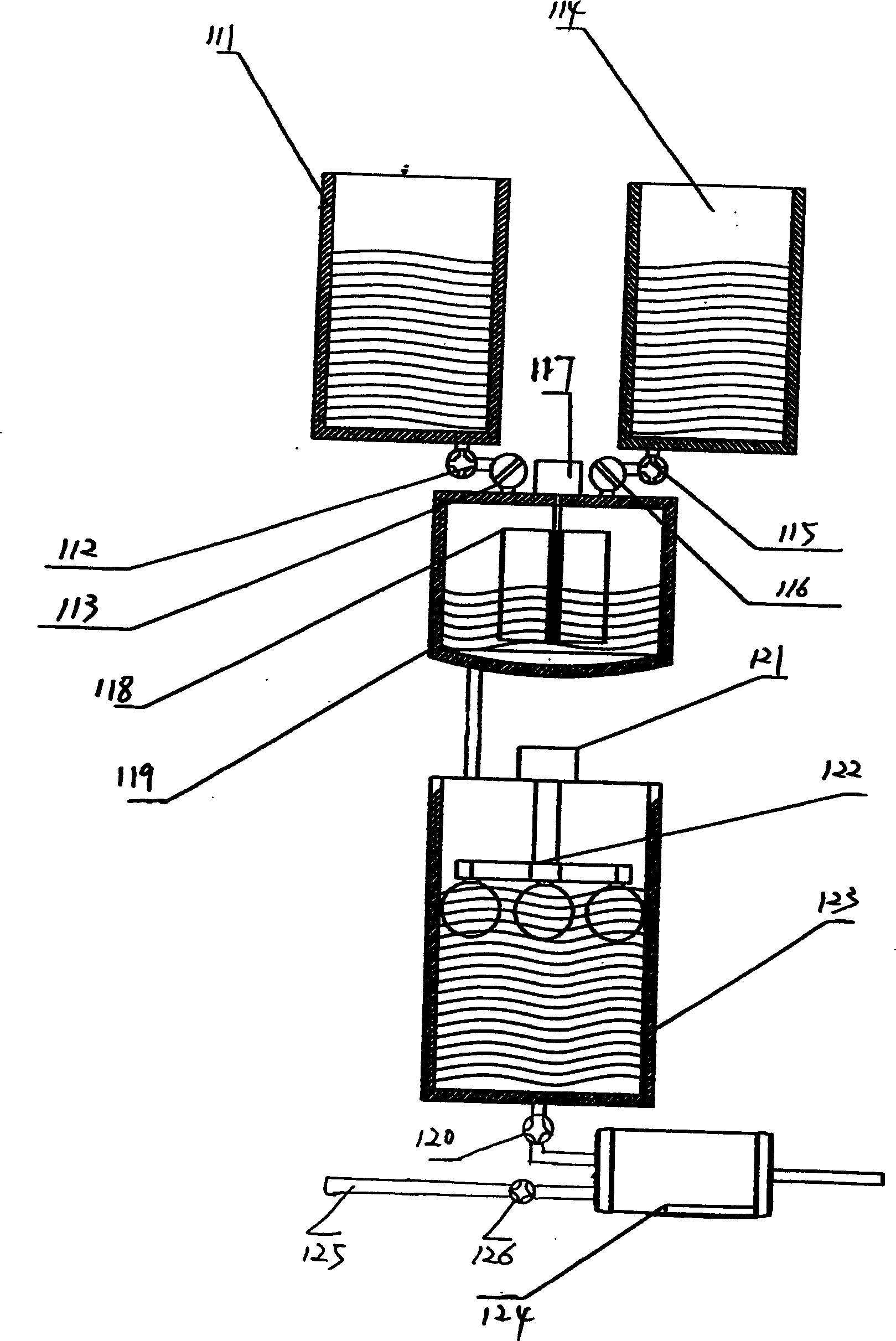

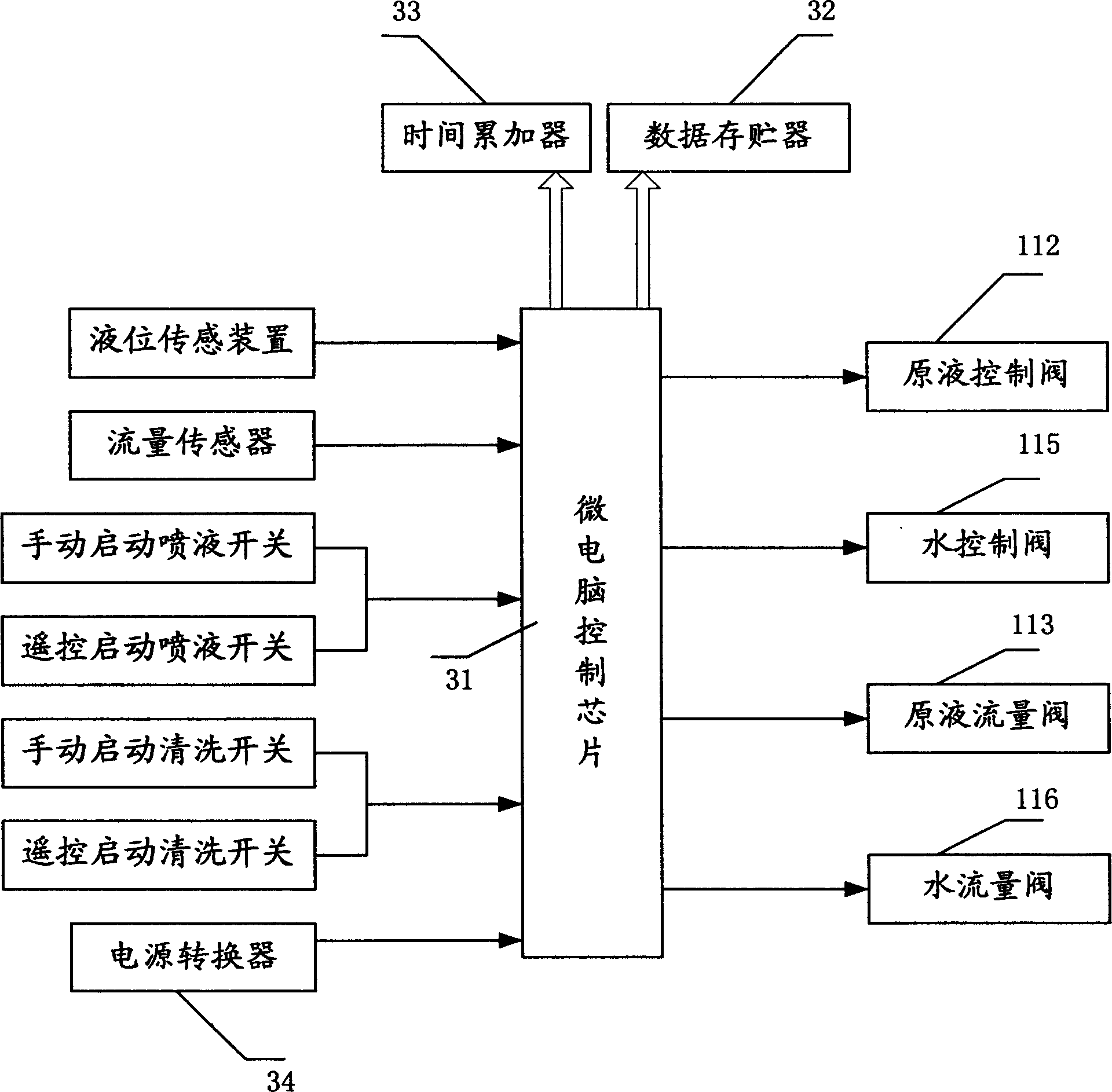

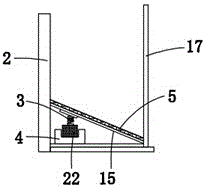

Wiping free car washer

InactiveCN1593991AUse uninterruptedReduce usageCleaning apparatus for vehicle exteriorsElectric machineEngineering

This invention discloses a kind of a non-manual car-wiping machine, which consists of mechanical part and circuit-control part. The mechanical part includes source case and water case that are connected through a pipe and a mixing device. The pipe between the source case and the mixing device is connected with the source controlling valve and source flow valve while the pipe between the water case and the mixing device is connected with a water-controlling valve and a flow valve. In the middle of the source valve and the flow valve is fixed a flow sensor. The mixing device is connected with a liquid-storing case through a pipe. There is a sense device for the liquid level. The circuit-control part includes microcomputer control chip, through which the ON / OFF switch of the source controlling valve and the water-controlling valve is controlled after the signal from the sense device for the liquid level can be received, and thus the liquid level in the liquid-controlling case is under control. Between the liquid-storing case and the spray gun there is a mixing liquid-squirting electric machine with a high pressure. This invention, the non-manual car-wiping machine, owns a simple structure which can efficiently distribute the mixing liquid and passes it into the liquid-storing case in time, besides this it can enhance the matching accuracy of source liquid and water.

Owner:刘祥军

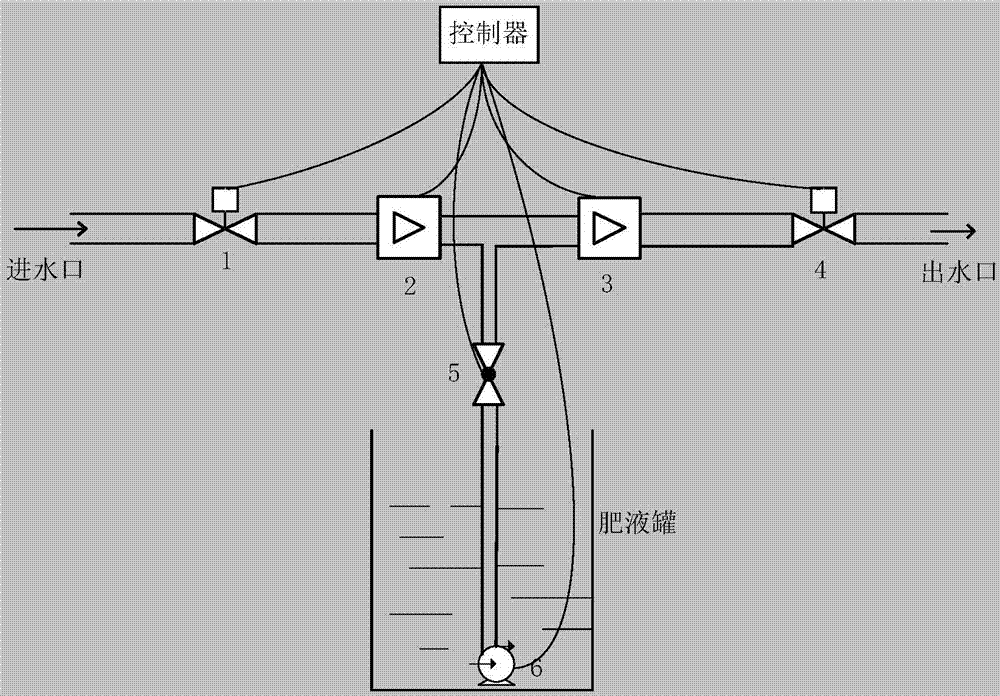

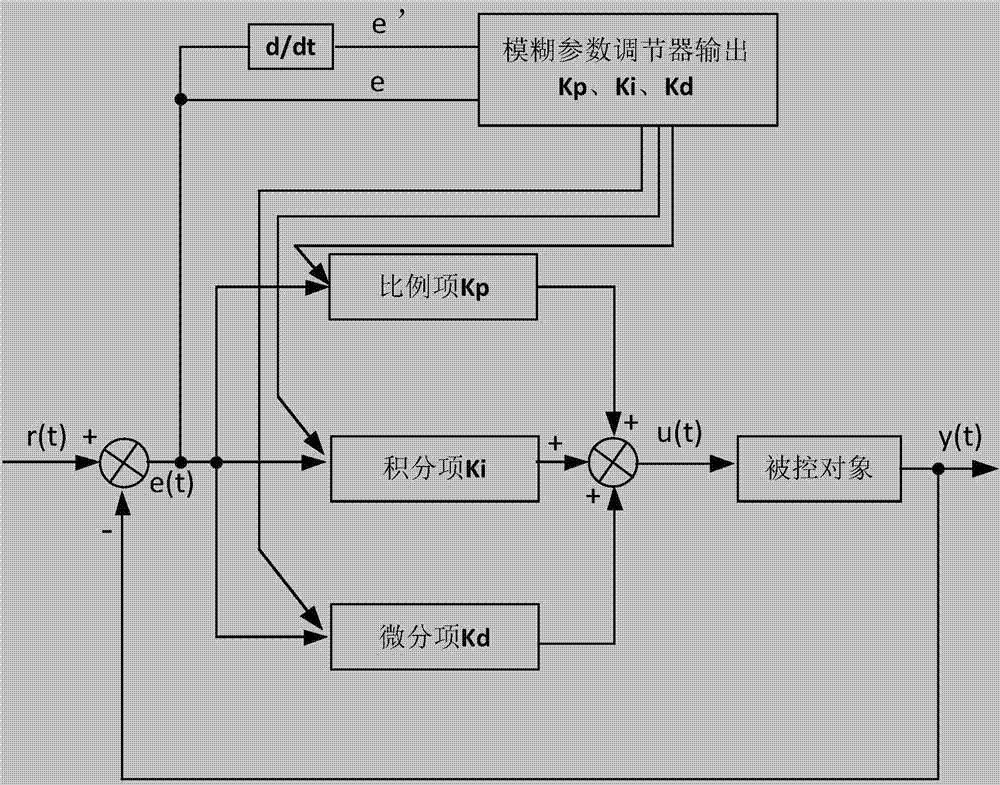

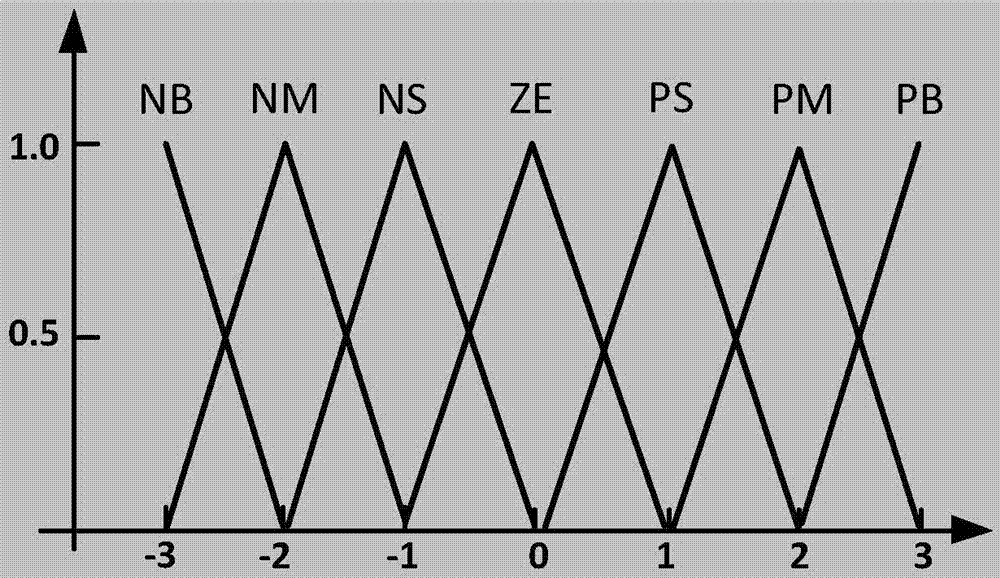

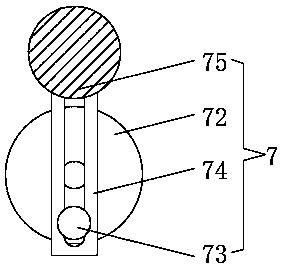

Fuzzy PID-based water and fertilizer precise ratio control system

ActiveCN107272754AImprove the accuracy of the ratioImplement variable fertilizationControlling ratio of multiple fluid flowsEmbedded technologyLine sensor

The invention relates to a fuzzy PID-based water and fertilizer precise ratio control system. The system includes a water supply pipeline, a fertilizer supply pipeline and a water and fertilizer mixing pipeline; the water supply pipeline and the water and fertilizer mixing pipeline are both provided with an electric valve and a flow meter; the fertilizer supply pipeline is provided with a water flow switch and a variable frequency pump; the outlet of the water supply pipeline and the outlet of the fertilizer supply pipe are both connected with the inlet of the water and fertilizer mixing pipeline; and the electric valves, the flow meters, the water flow switch and the variable frequency pump are all connected with a controller. When water and fertilizer integrated irrigation concentration-fixed fertilization is performed, the corresponding electric valves and water flow switch are opened; the variable frequency pump is adopted to absorb a fertilizer solution, and real-time concentration is obtained on the basis of the flow meters; and a fuzzy PID control method is adopted in a control process so as to constantly correct current fertilizer absorption quantity to make the difference of the current fertilizer absorption quantity and set fertilization concentration to be minimum. According to the system, the fuzzy PID control method is adopted, technologies such as a wireless sensor network technology, an embedded technology, an intelligent control technology and an electrical and electronic technology are combined, and therefore, regular and quantity-fixed irrigation of water, the fixed-concentration applying of the fertilizer solution and quantity-fixed fertilization are integrated.

Owner:NORTHWEST A & F UNIV

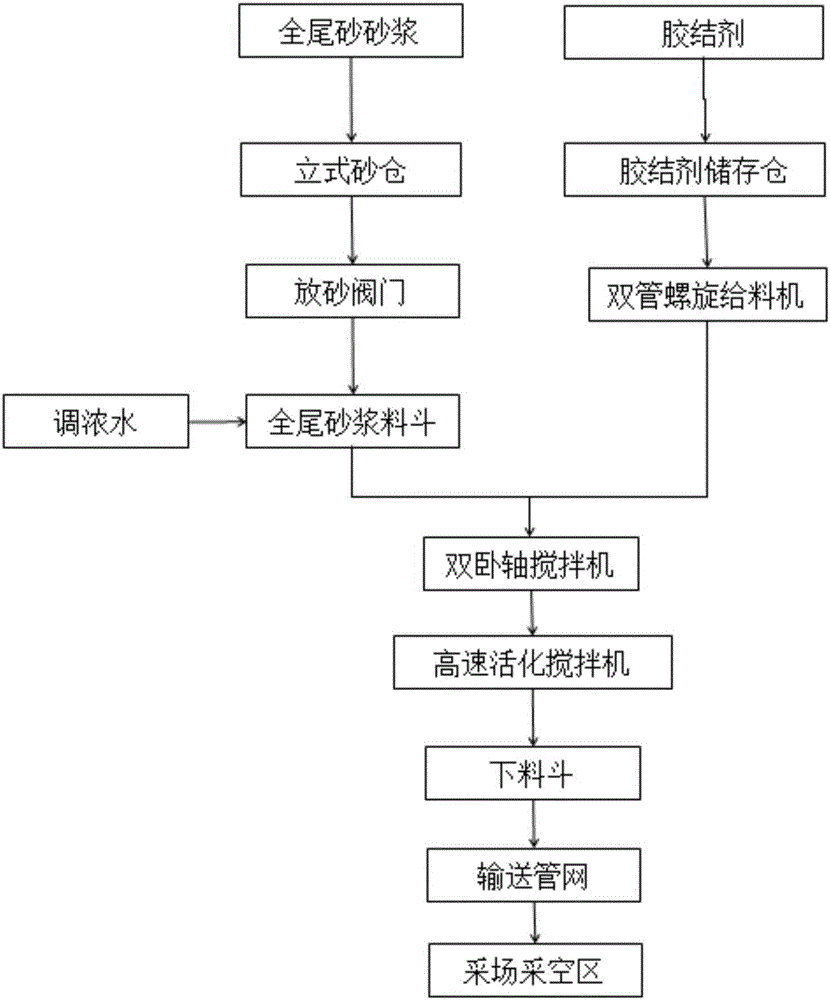

Mass flow high density structure flow entire-tailing cemented filling technology

InactiveCN106065782AEnhance mining safetyReasonable strength structureMaterial fill-upSocial benefitsHigh density

The invention discloses a mass flow high density structure flow entire-tailing cemented filling technology comprising the following steps: allowing entire-tailing mortar, a cementing agent and proper amount of concentration adjusted water to enter a feed hopper through each material supply line, wherein said materials are then conveyed to a stirrer, and all ingredients of the filling material are fully evenly stirred so as to prepare the filling slurry with proper concentration and excellent fluidity, i.e., the structure flow status can be formed; allowing the filling slurry to finally enter a filling slurry discharge hopper, wherein the filling slurry can be conveyed to fill underground stope goaf through filling drill holes and an underground filling pipe network through self-flow, thus realizing large structure stope non-interrupted high density self-flow filling, wherein the sand-lime ratio can be adjusted according to filling body intensity requirements. The mass flow high density structure flow entire-tailing cemented filling technology can satisfy large structure stope, high preparation capability, high preparation precision, and high density structure flow entire-tailing colloid filling requirements, can reduce filling cost, so the goaf filling tailings final concentration can be above 70-73%; the filing body intensity structure is reasonable, thus enhancing stope back production safety, and providing large economic benefits and social benefits.

Owner:ANHUI KAIFA MINING IND

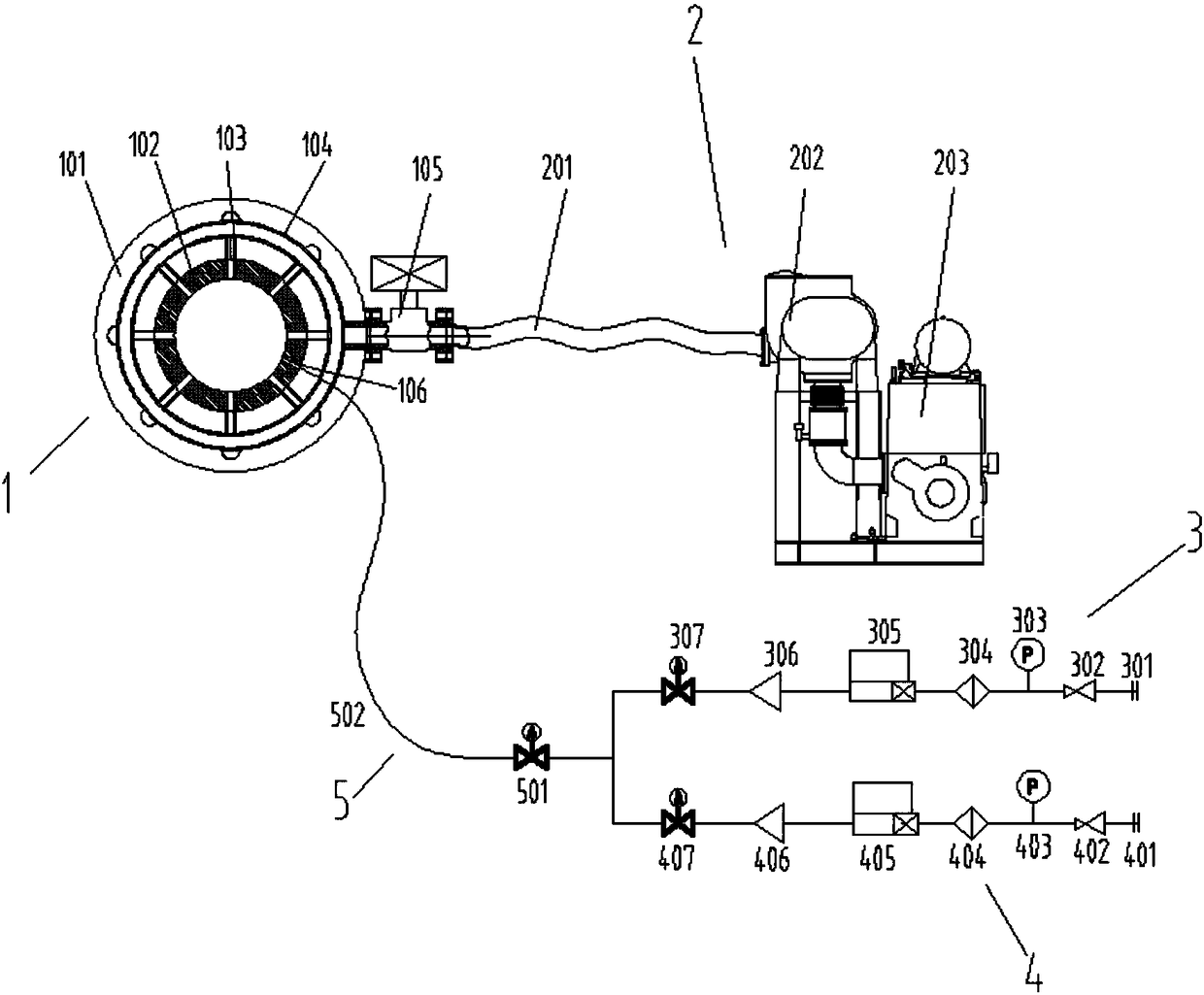

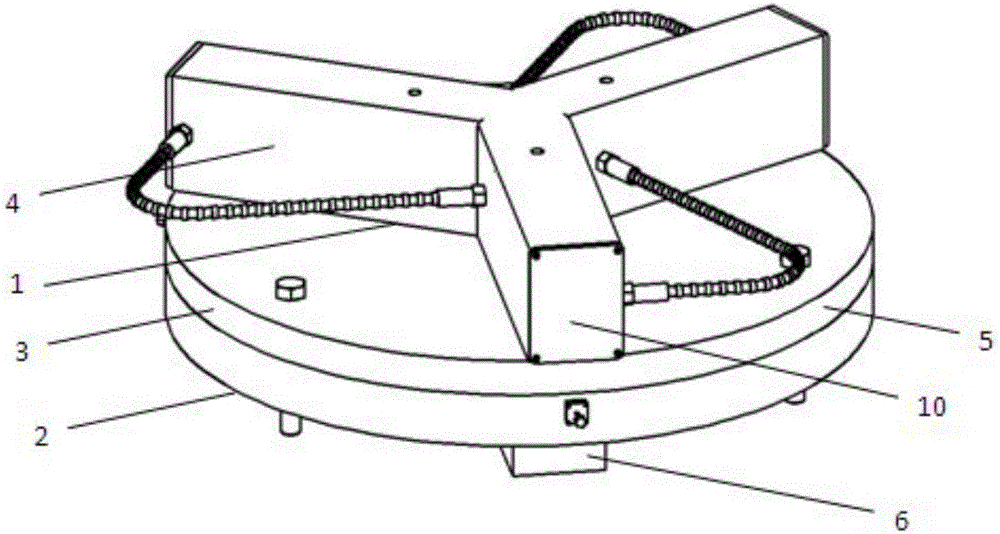

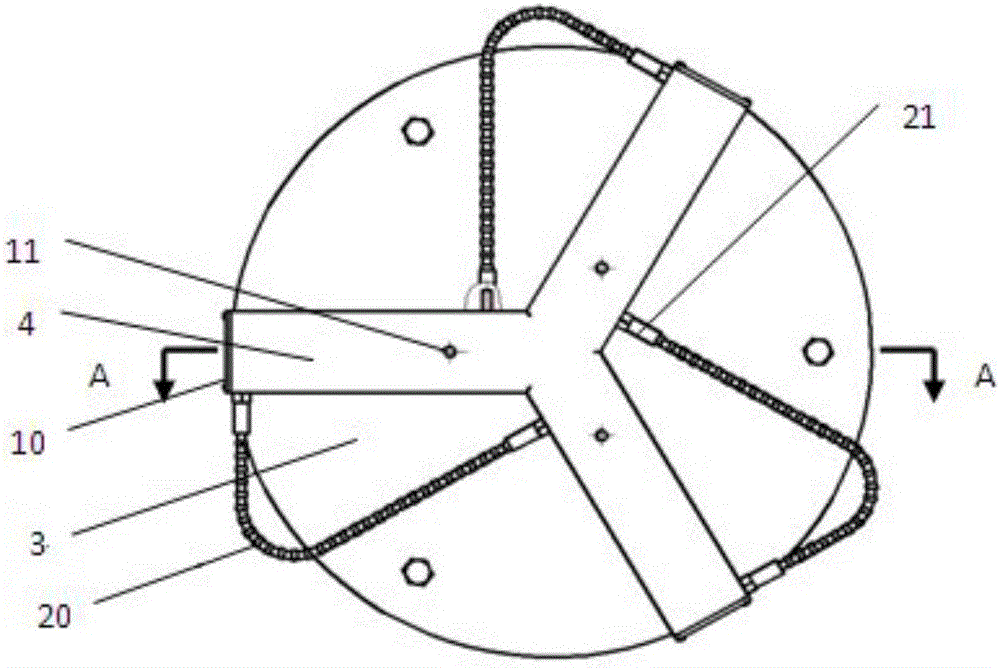

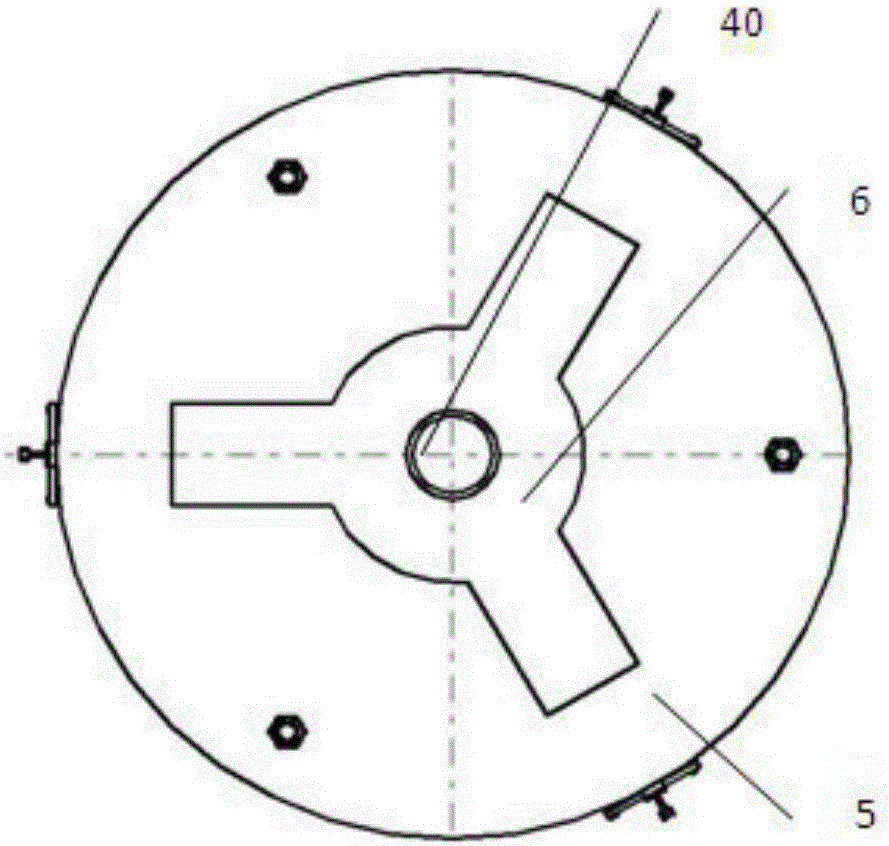

Switching device and inflating device for free piston shock tunnel compression pipe

ActiveCN108278487ASolve the problem of difficult high vacuum suctionMeet the needs of various operating statesFlanged jointsAerodynamic testingShock waveVacuum extraction

The invention relates to a switching device and an inflating device for a free piston shock tunnel compression pipe and belongs to the technical field of hypersonic speed shock tunnel engineering. According to the switching device and the inflating device, the switching device is additionally arranged in a wind tunnel structure; the problem that high-vacuum extraction of the free piston shock tunnel compression pipe is difficult to conduct is solved, and thus the gas purity is improved; and the charging ratio of helium gas to argon gas is controlled through a flow controller, the charging ratio precision is improved, and thus the requirement for multiple operation states of the free piston shock tunnel is met.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

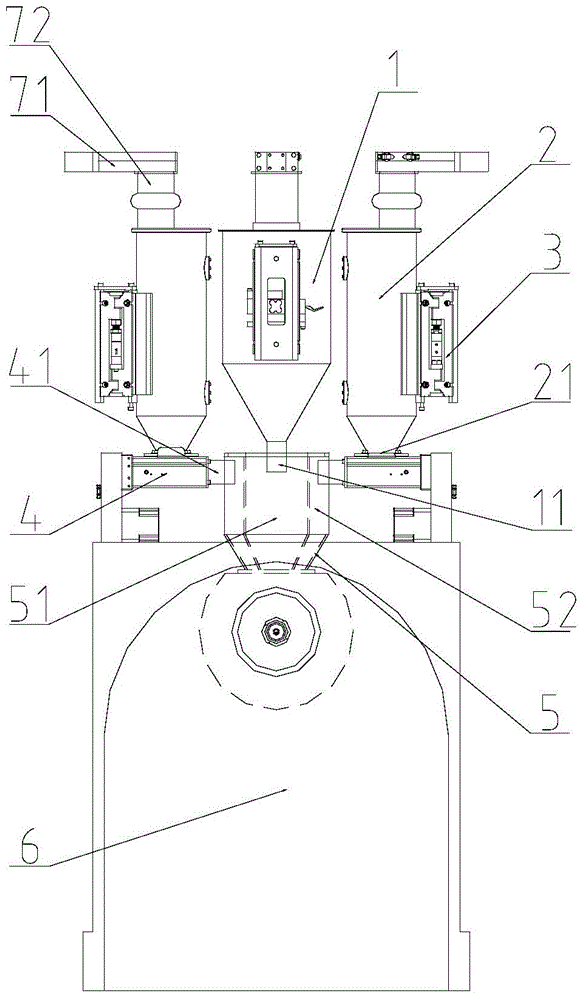

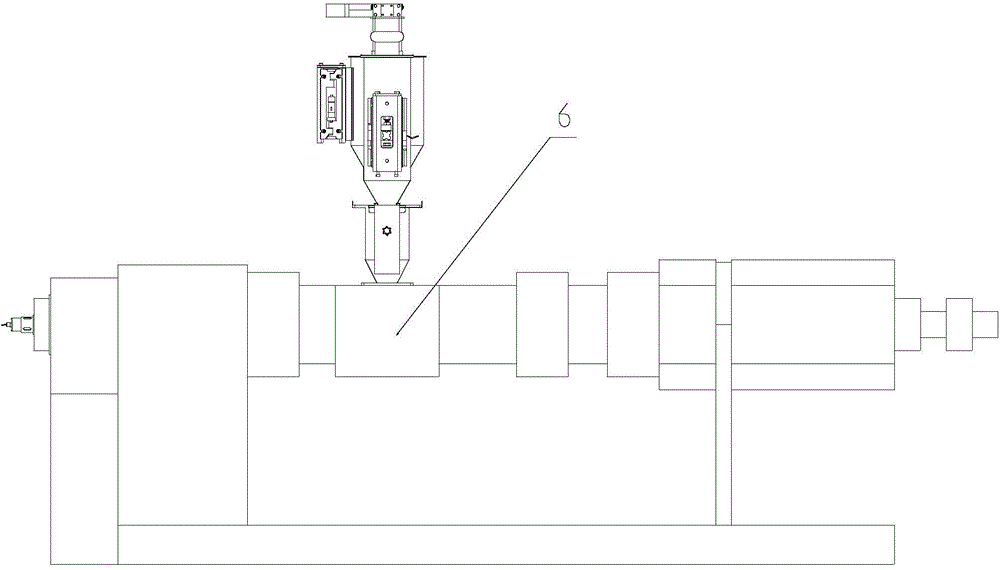

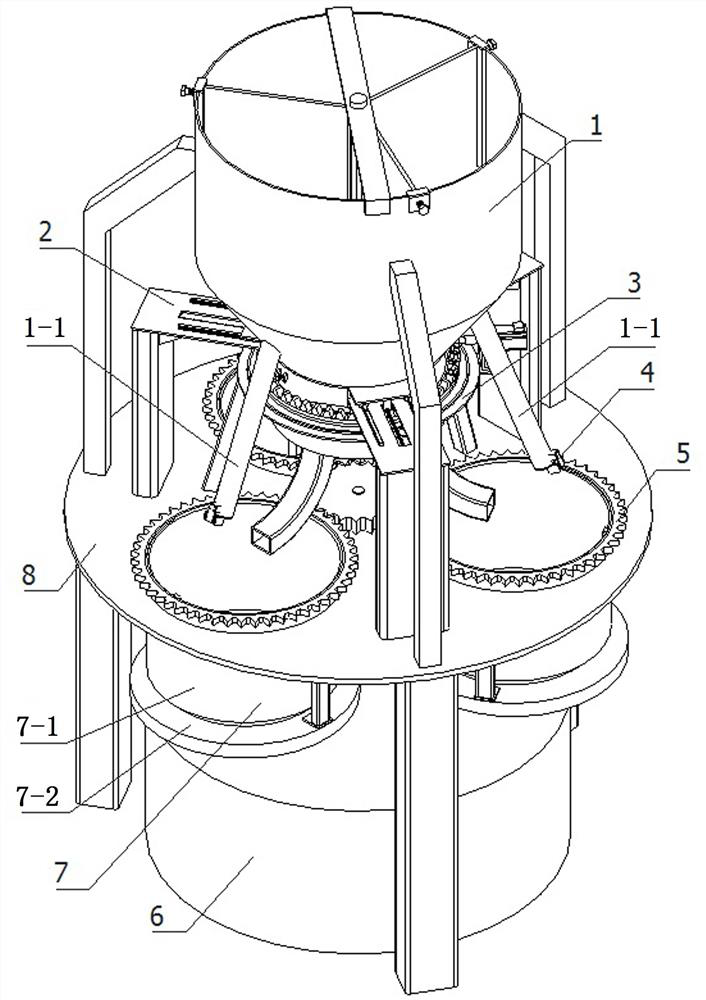

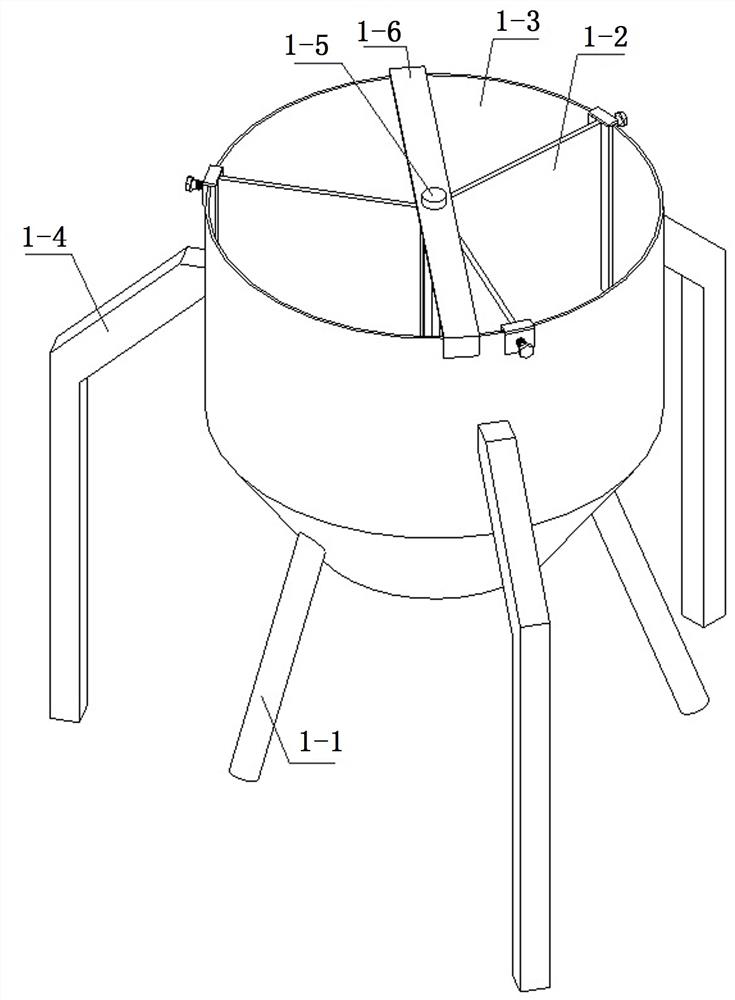

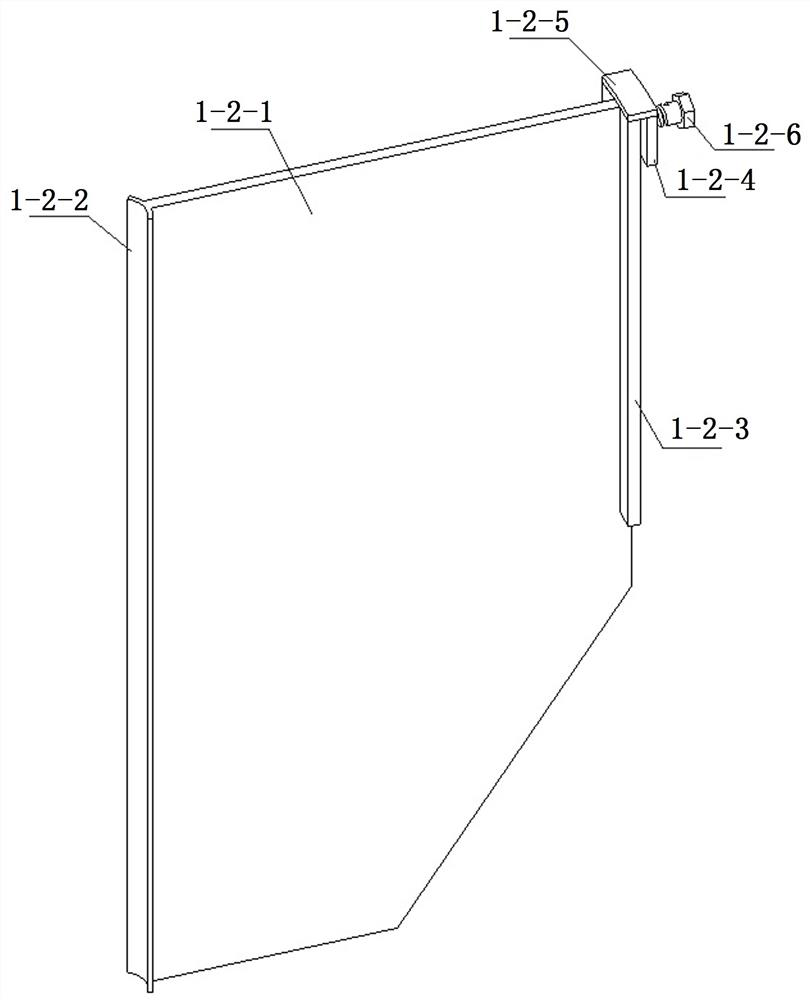

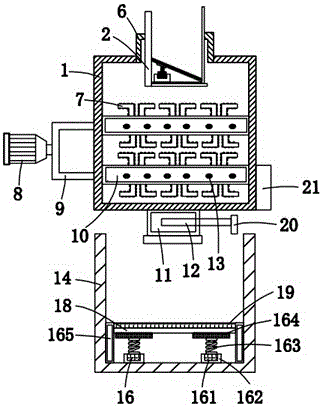

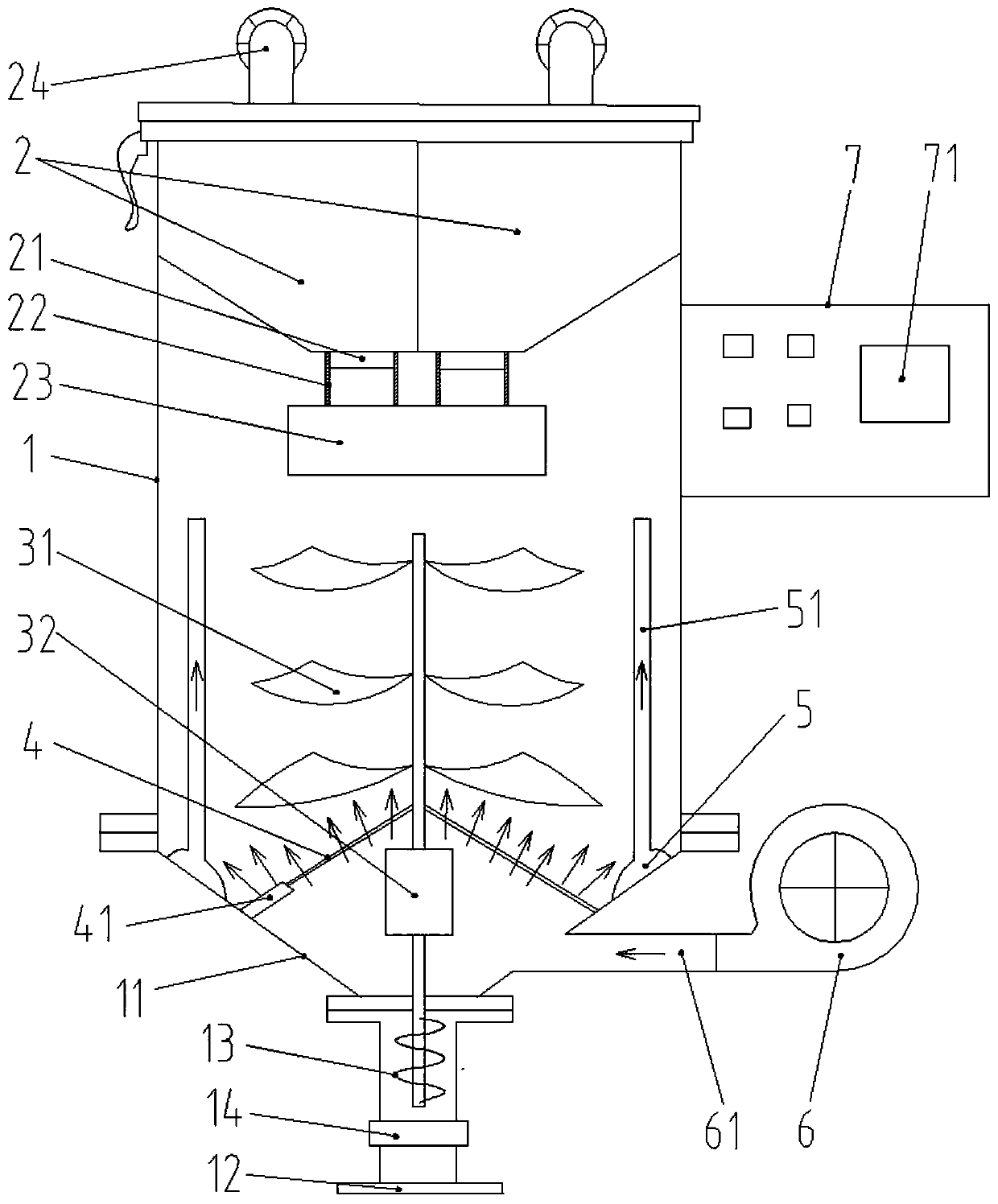

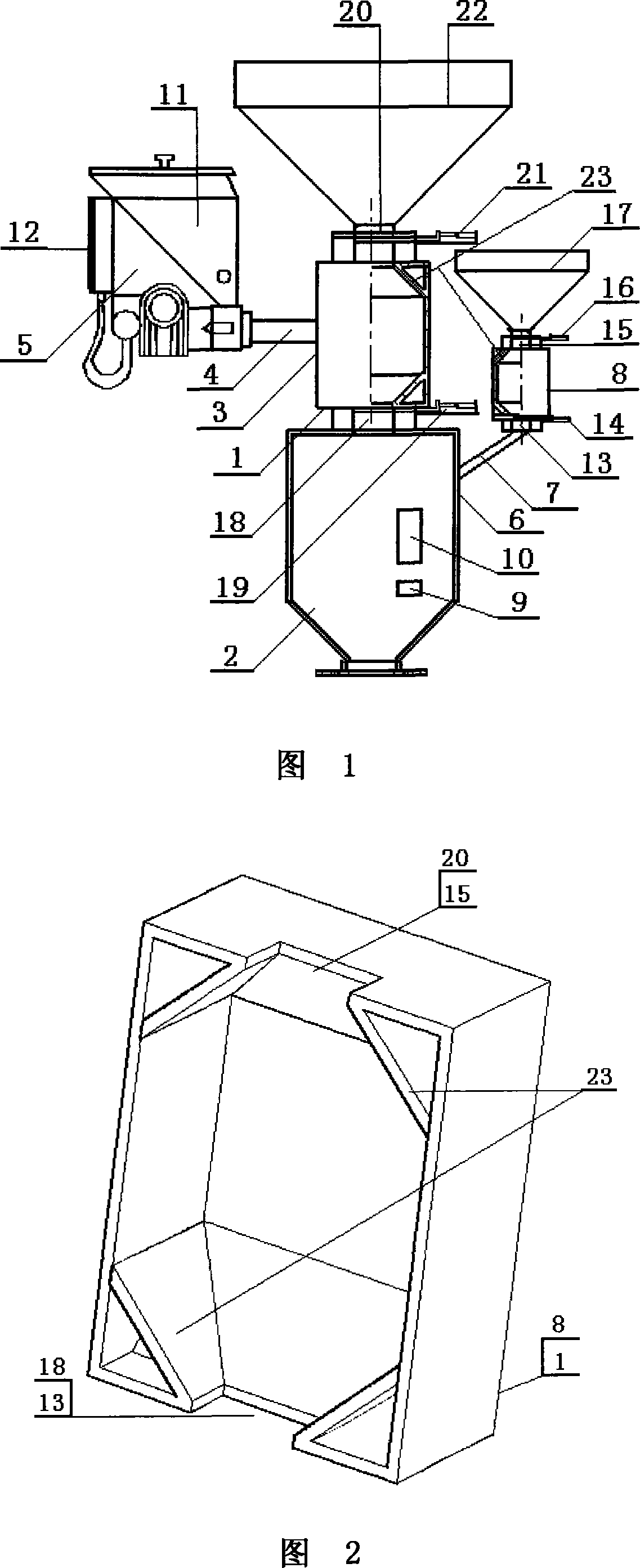

Mine powder accurate proportioning and mixing device and use method

InactiveCN112316841ASave unloading timeImprove the ratio accuracyTransportation and packagingMixer accessoriesProcess engineeringMaterial distribution

The invention relates to the field of accurate proportioning of mine powder, in particular to an mine powder accurate proportioning and mixing device and a use method. The mine powder accurate proportioning and mixing device comprises a proportioning mechanism, a gate mechanism, a material distributing barrel, a micro-proportioning gate mechanism, a scraping mechanism, a mixing barrel and three weighing barrels. According to the mine powder accurate proportioning and mixing device and the use method, The effect of adjusting the outflow volume of raw materials of different proportions is achieved through the material distribution gate plate, the effect of dividing one cylinder is further achieved, one gate mechanism can conveniently control outflow of the three raw materials to be closed atthe same time, the device can be suitable for various raw materials, and it is guaranteed that the raw materials of various proportions can flow out according to the needed raw material proportion atthe same time; a large amount of discharging time of the equipment is saved, a large amount of raw materials remaining in the three conical barrels are cleaned in time through the effect of the scraping mechanism, the proportioning precision of the raw materials is improved, the three conical barrels are synchronously cleaned, and the situation that the next proportioning speed is affected due tothe fact that the conical barrels are not synchronously cleaned up is avoided.

Owner:BACKFILL ENG LAB SHANDONG GOLD MINING TECH CO LTD

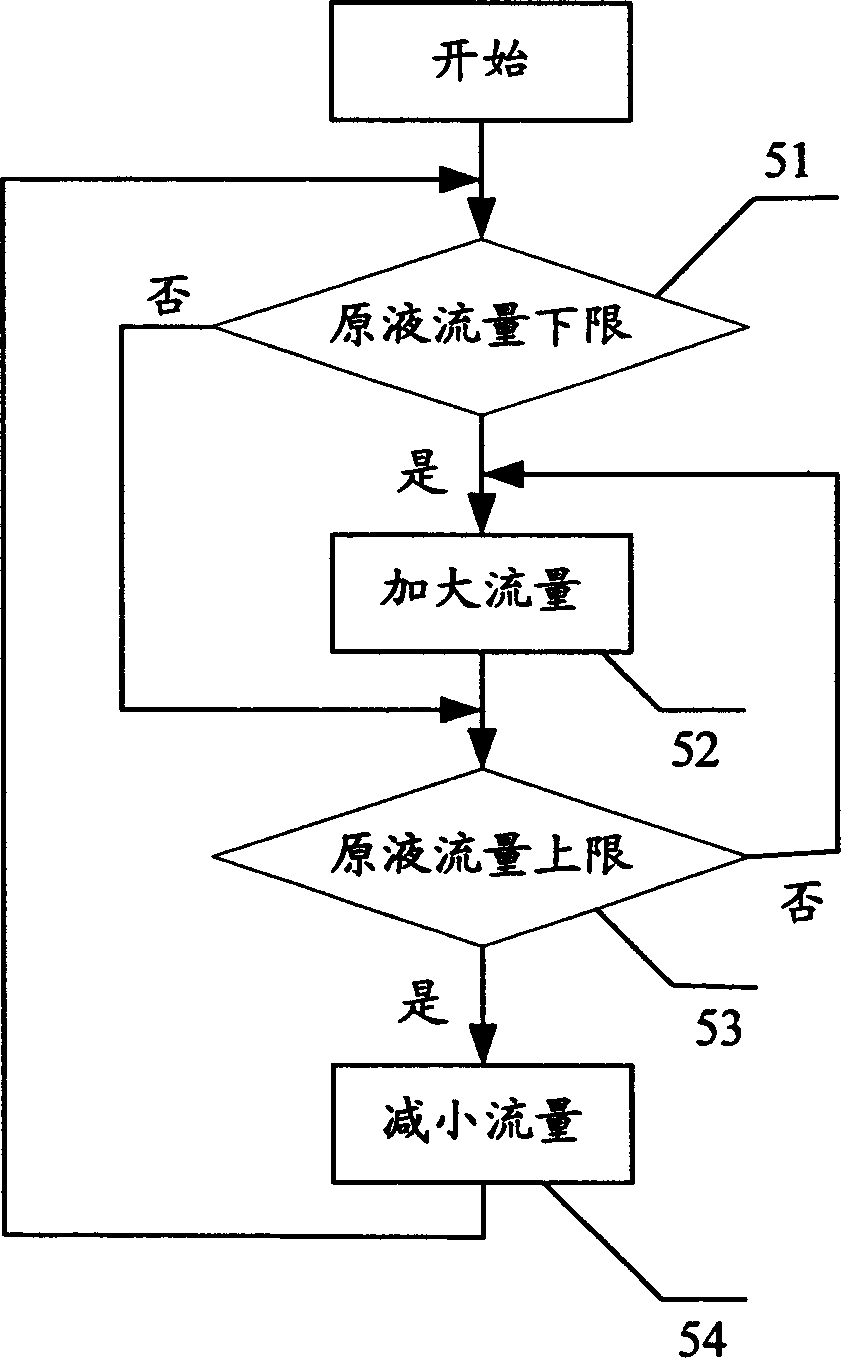

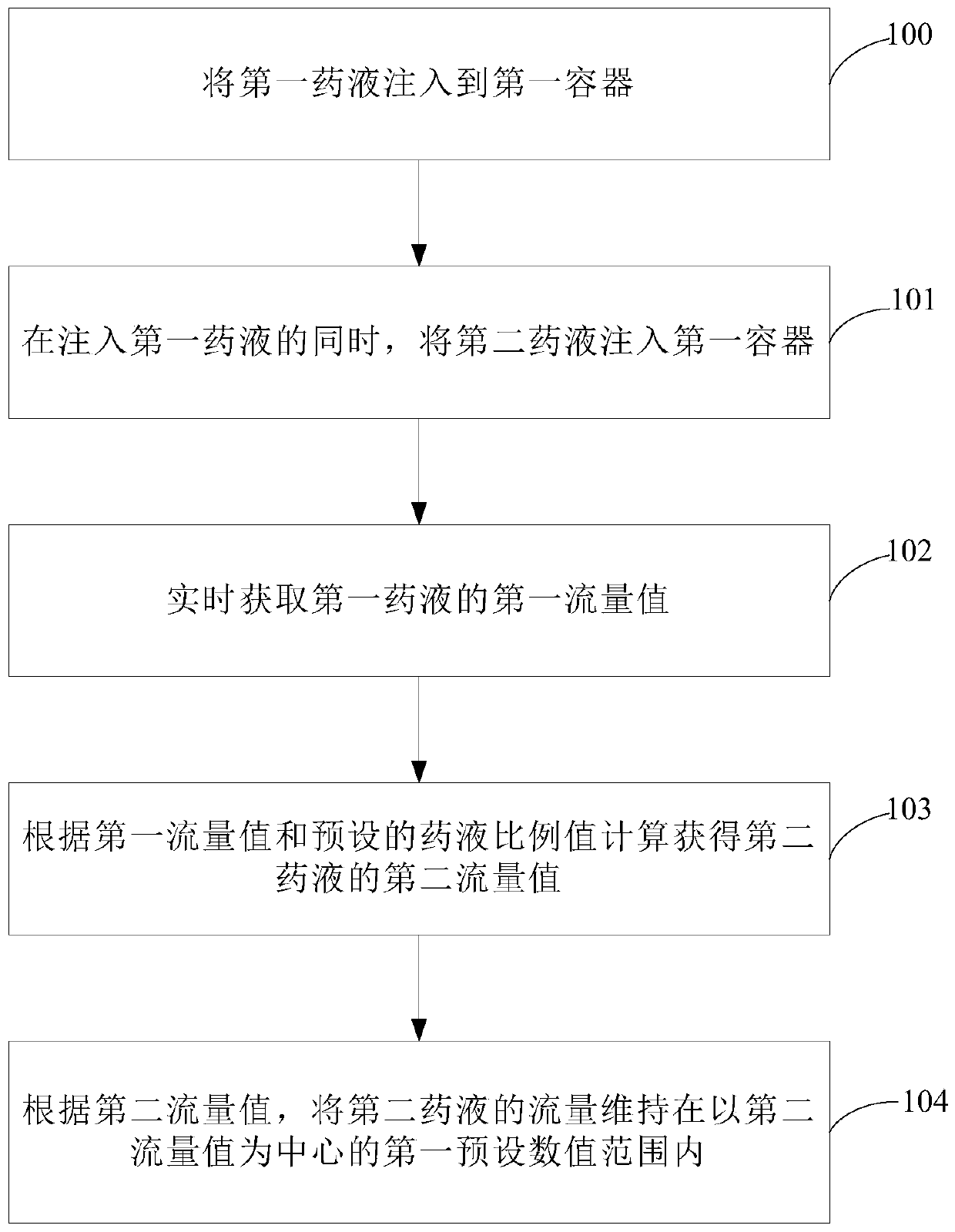

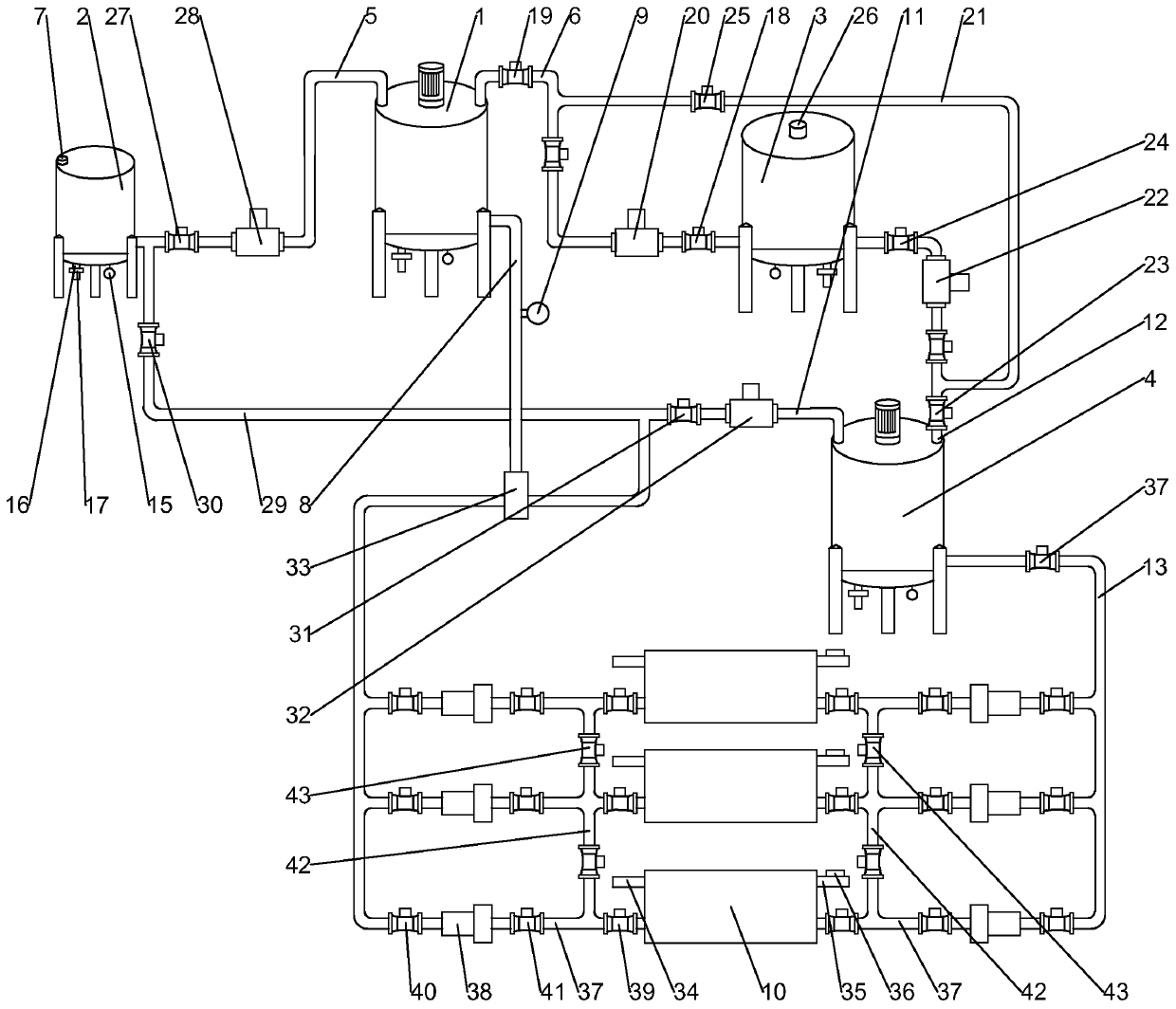

Liquid medicine proportioning method and liquid medicine proportioning device

ActiveCN111214972AImprovements cannot be monitoredShorten the mixing time of liquid medicineTransportation and packagingMixing methodsPhysicsChemistry

The invention provides a liquid medicine proportioning method and a liquid medicine proportioning device. The liquid medicine proportioning method comprises the following steps: injecting a first liquid medicine into a first container; injecting a second liquid medicine into the first container while injecting the first liquid medicine; acquiring a first flow value of the first liquid medicine inreal time; calculating to obtain a second flow value of the second liquid medicine according to the first flow value and a preset liquid medicine proportion value; and according to the second flow value, maintaining the flow of the second liquid medicine within a first preset numerical value range with the second flow value as the center. According to the invention, the liquid medicine proportioning precision and reliability are improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Nutrient solution blending device for nutritional department

InactiveCN110624452AImprove the ratio accuracyImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingNutrient solutionEngineering

The invention relates to the technical field of nutrient solution preparation, particularly to a nutrient solution blending device for nutritional department. The device comprises a base plate, a first support plate and a second support plate are welded to two sides at the top of the base plate respectively, the first support plate is located on the right side of the second support plate, a mixingbarrel is supported on the right side of the second support plate through a bearing, a partition plate is welded to the inner wall of the mixing barrel, and a stirring mechanism is fixedly installedat the top of the partition plate. According to the invention, through the setting of the base plate, the first support plate, the second support plate, the mixing barrel, the partition plate, a stirring mechanism, a uniform shaking mechanism, a feeding mechanism, a mounting plate, a proportioning mechanism and a PLC control panel, the nutrient solution blending device for nutritional department has the advantages of high proportioning precision, good mixing effect and high efficiency, at the same time solves the problems of poor precision, poor mixing uniformity and low efficiency, difficultly controllable mixing time and strength, and influence on the use effect of the nutrient solution in the existing blending mode.

Owner:冯靖雄

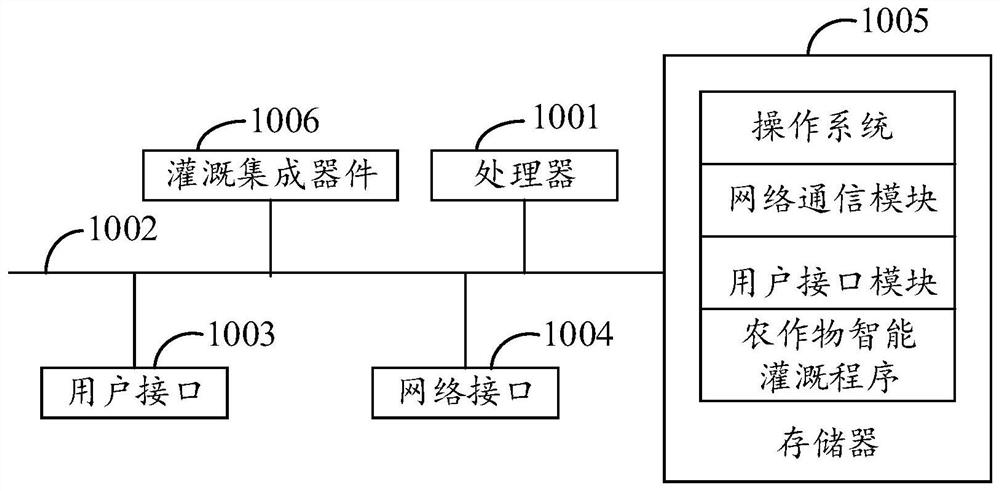

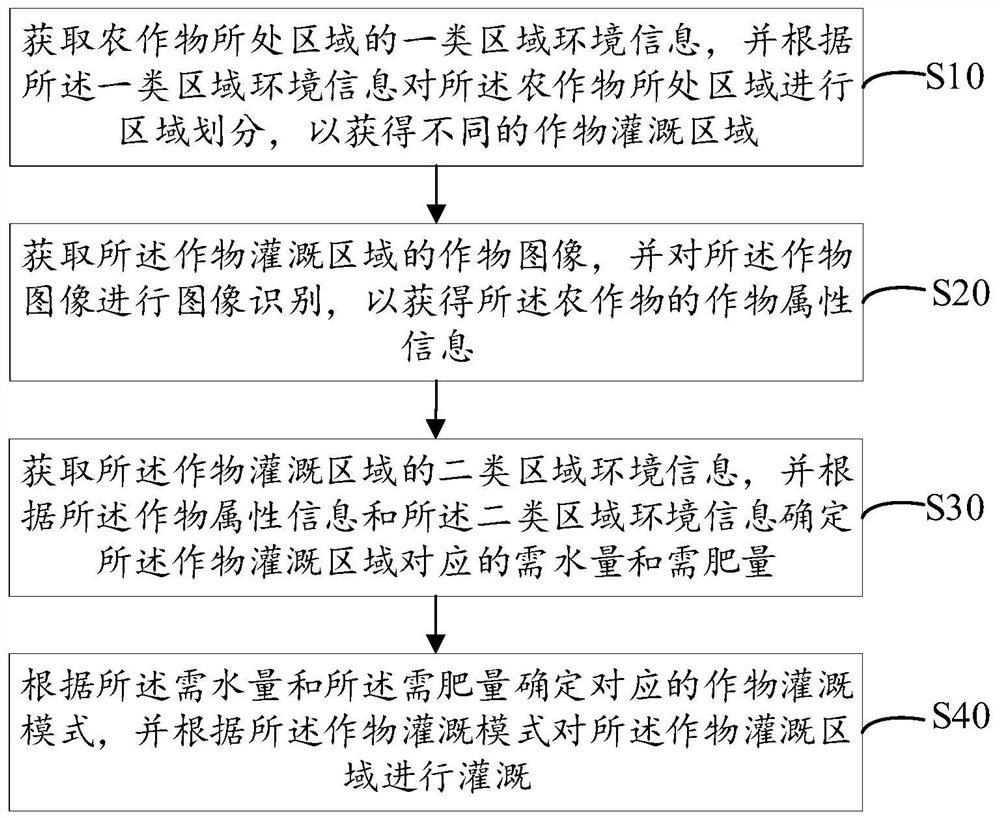

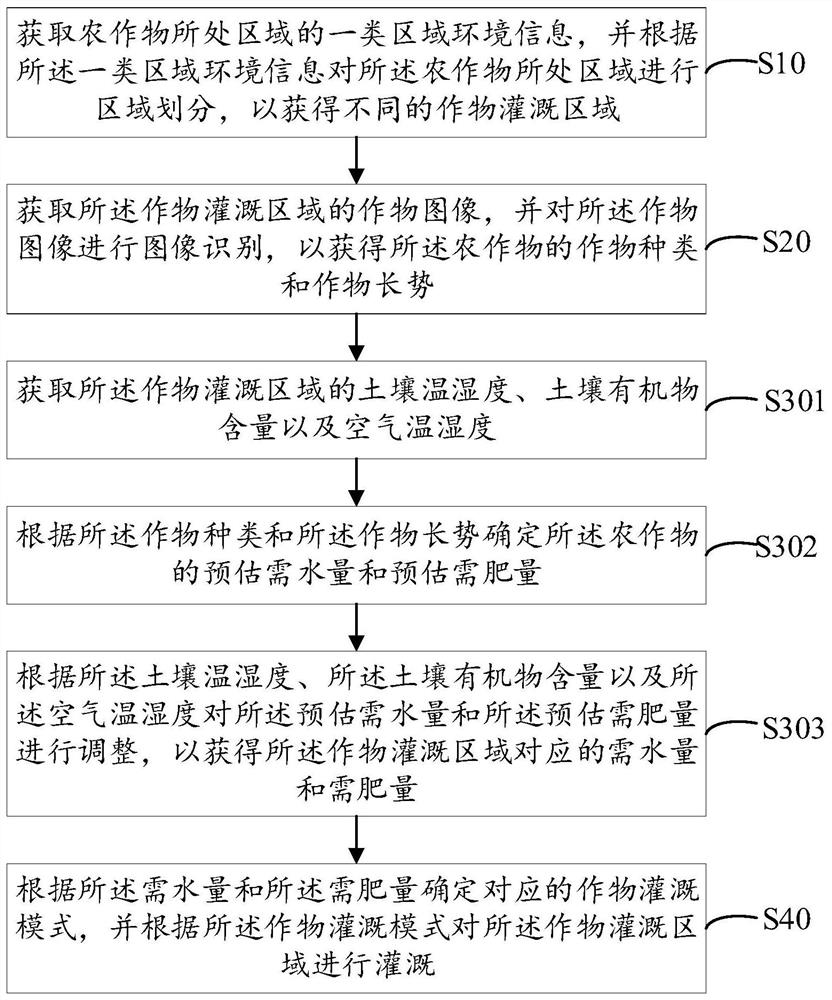

Intelligent crop irrigation method, device and equipment and storage medium

PendingCN113229123AImprove irrigation precisionImprove the ratio accuracyWatering devicesLiquid fertiliser regulation systemsAgricultural engineeringCrop mapping

The invention relates to the technical field of intelligent agriculture, and discloses an intelligent crop irrigation method, device and equipment and a storage medium. The intelligent crop irrigation method comprises the following steps that first-class region environment information of a region where crops are located is obtained, region division is carried out on the region where the crops are located according to the first-class region environment information, and different crop irrigation regions are obtained; crop images of the crop irrigation regions are obtained, and image recognition is carried out on the crop images to obtain crop attribute information of crops; second-class region environment information of the crop irrigation regions is obtained, and the water demand and fertilizer demand corresponding to the crop irrigation regions are obtained according to the crop attribute information and the second-class region environment information; and a corresponding crop irrigation mode according to the water demand and the fertilizer demand is determined, and the crop irrigation regions are irrigated according to the crop irrigation mode, so that the intelligent degree and irrigation precision are improved during crop water and fertilizer irrigation, and unnecessary water and fertilizer resource waste is reduced.

Owner:HUBEI ENG UNIV

Device and method for making shifted gas for synthesis of ammonia synthesis poly-generation methanol

ActiveCN105565269AHigh proportioning efficiency and precisionRich adjustment meansHydrogenHydrogen/synthetic gas productionOnline analysisProcess engineering

The invention belongs to a device and method for making shifted gas for synthesis of ammonia synthesis poly-generation methanol. The device comprises a mechanical part and a control part. The mechanical part comprises a gasification washing tower, an outlet of the gasification washing tower is connected with an inlet of a second heat and condensate recycling unit through a pipe, the pipe between the outlet of the gasification washing tower and the second heat and condensate recycling unit is sequentially provided with a fifth tee joint, a first self-regulating valve, a first tee joint and a second tee joint, an outlet of the second heat and condensate recycling unit is connected with an inlet in the middle of a second ammonia-washing tower, and a gas phase outlet in the top of the second ammonia-washing tower is connected with an inlet in the lower portion of a shifted gas washing tower for synthesis of methanol through a pipe; the control part comprises a first online analysis and calculation display instrument, a second online analysis and calculation display instrument, a second self-regulating valve and a third self-regulating valve. The device and method have the advantages that matching efficiency and accuracy are high, a great number of regulating means are adopted, a great amount of high-quality steam is generated, and meanwhile the content of COS in the methanol removing and washing shifted gas is lowered.

Owner:HENAN XINLIANXIN FERTILIZER +2

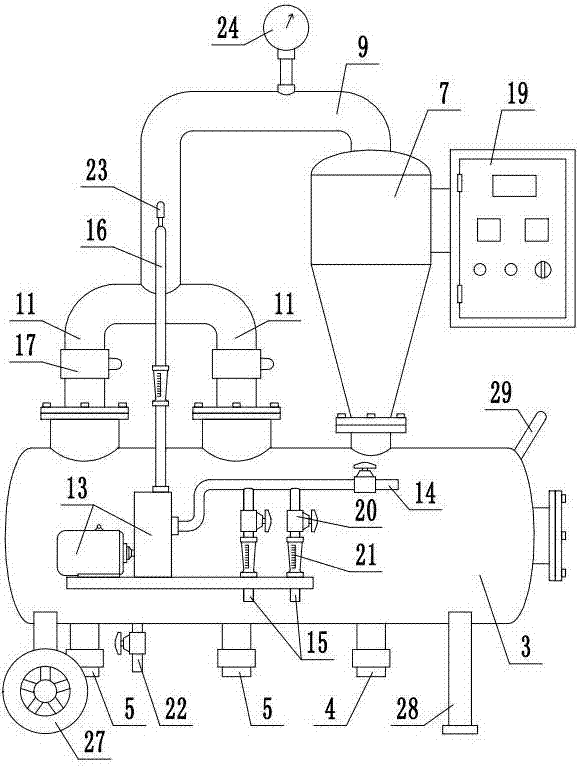

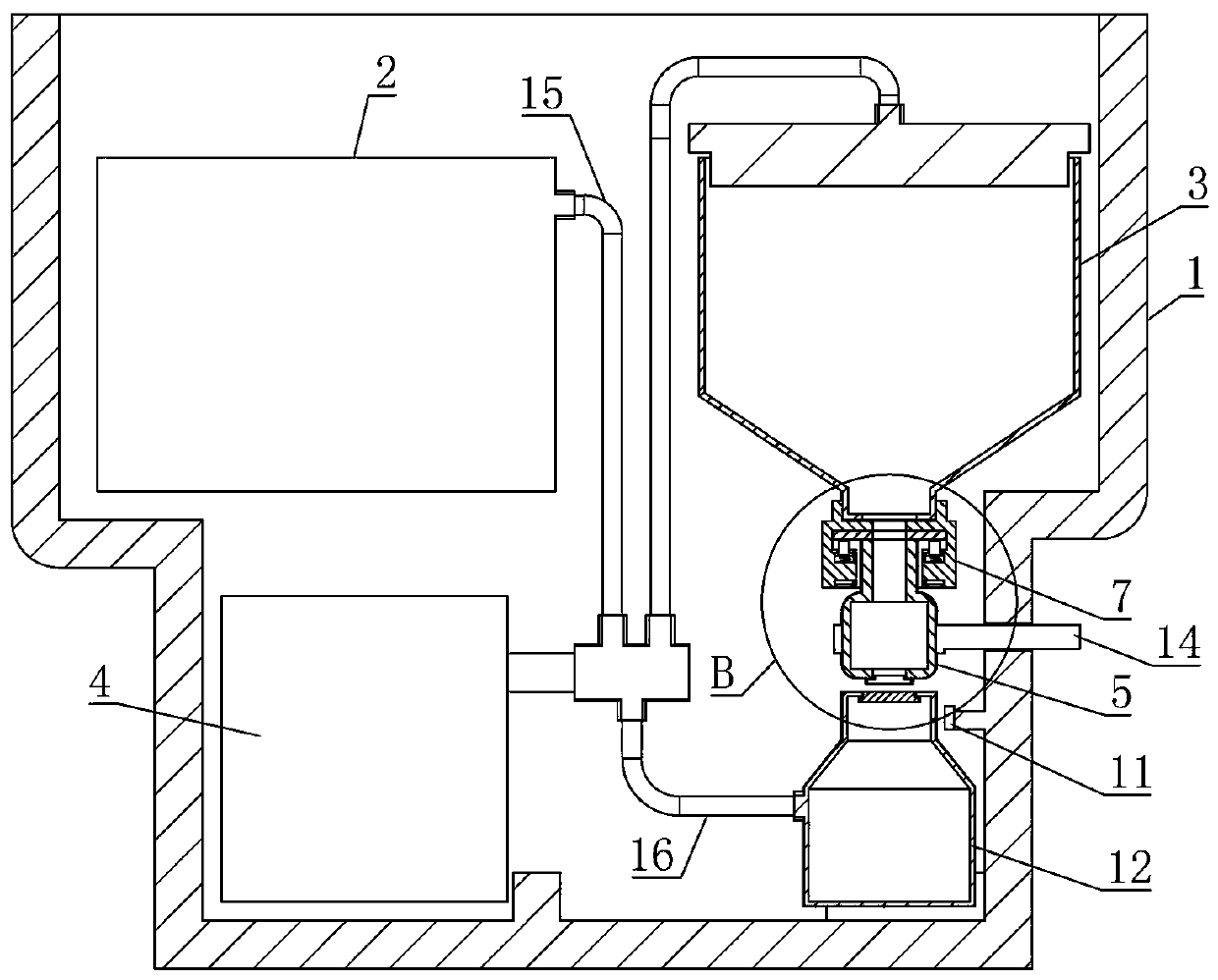

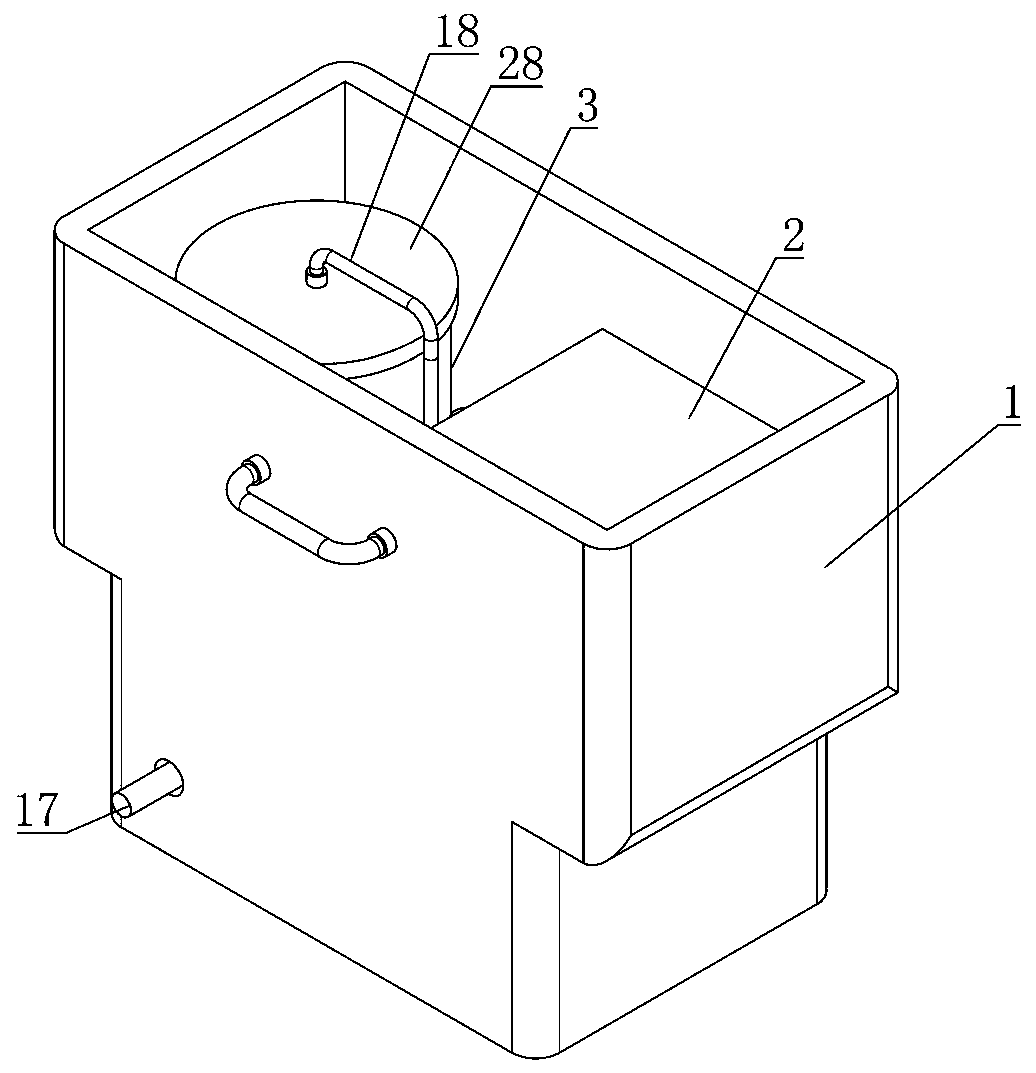

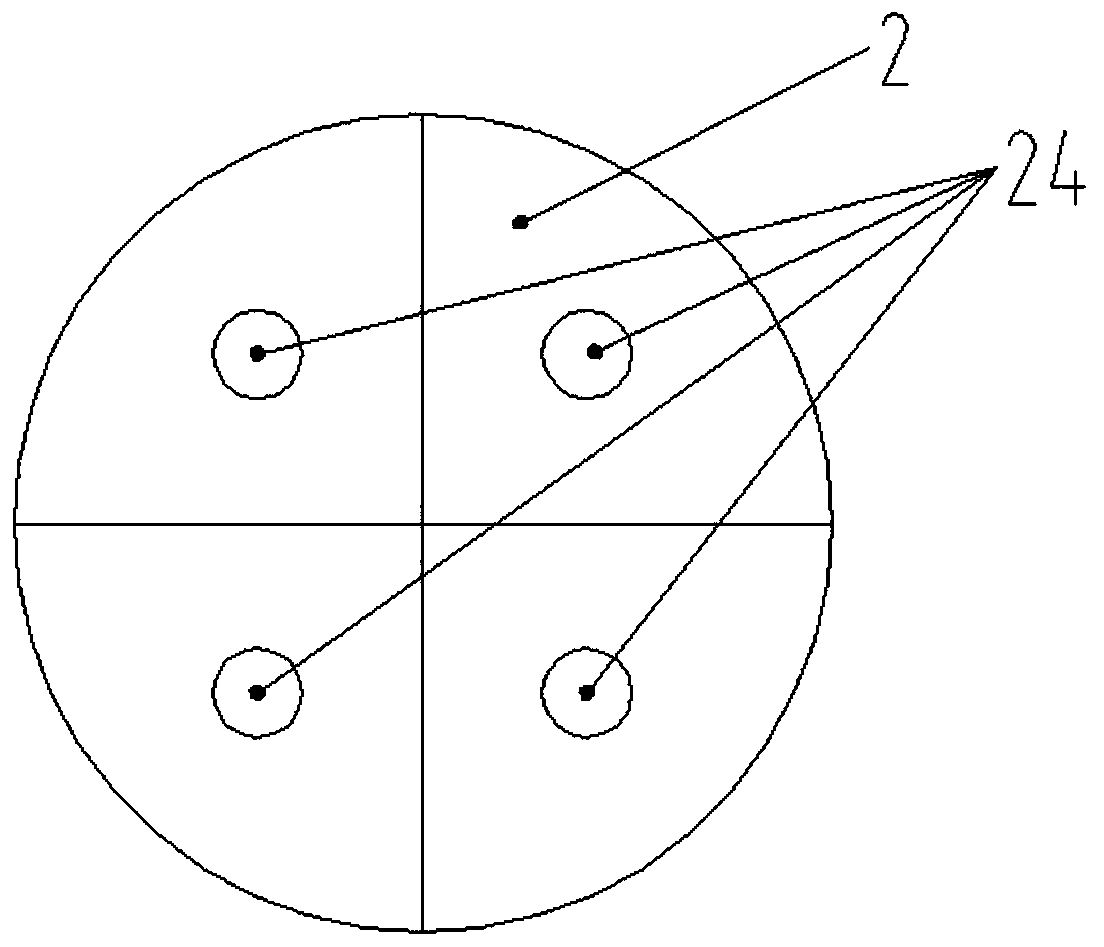

Water purification and fertilization all-in-one machine

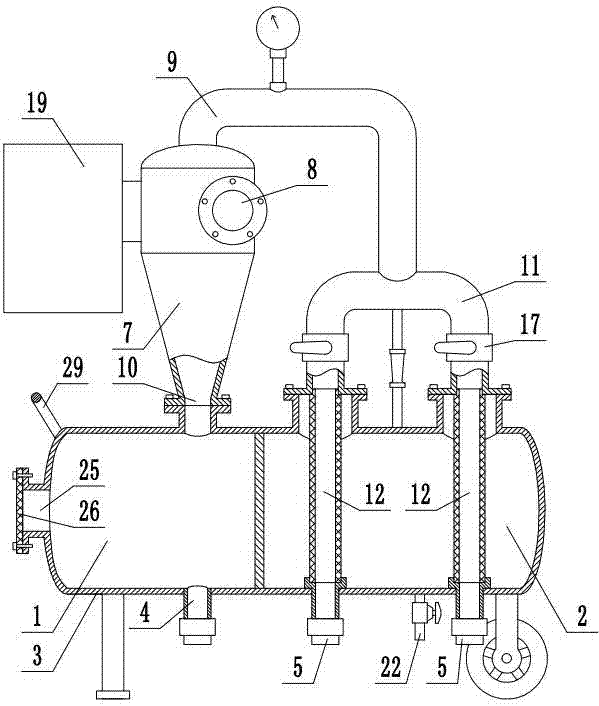

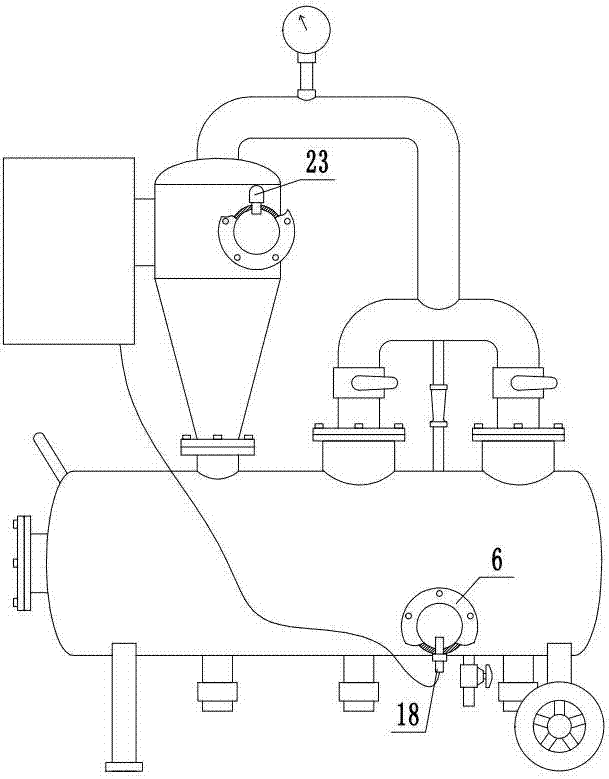

PendingCN107258197AFully filteredWell mixedTreatment involving filtrationPressurised distribution of liquid fertiliserEngineeringSewage

The invention discloses a water purification and fertilization all-in-one machine. The water purification and fertilization all-in-one machine comprises a tank body provided with a sand deposition cavity and a liquid storage cavity, wherein main sewage pipes and a fertilization pipe which communicate with the liquid storage cavity, and a secondary sewage pipe which communicates with the sand deposition cavity are arranged at the bottom of the tank body; the tank body is connected with a cyclone sand remover; the cyclone sand remover is provided with a sand remover water inlet pipe, a sand remover water outlet pipe and a sand falling opening which communicates with the sand deposition cavity; the tail end of the sand remover water outlet pipe is further connected with water distribution pipes which communicate with the liquid storage cavity; the liquid storage cavity is internally provided with filter cartridges; one end of each filter cartridge communicates with a pipe cavity of the corresponding water distribution pipe and the other end of each filter cartridge communicates with a pipe cavity of the corresponding main sewage pipe; the tank body is further connected with a fertilizer suction pump; the fertilizer suction pump is connected with a water suction pipe and fertilizer suction pipes; and a fertilizer supply pipe is further connected between the fertilizer suction pump and the sand remover water outlet pipe. The all-in-one machine disclosed by the invention is convenient to transport and can be used for sufficiently filtering well water and a water-fertilizer solution; and the water-fertilizer solution which has a relatively good mixing degree and high water-fertilizer proportioning precision can be obtained.

Owner:山东圣大节水科技有限公司

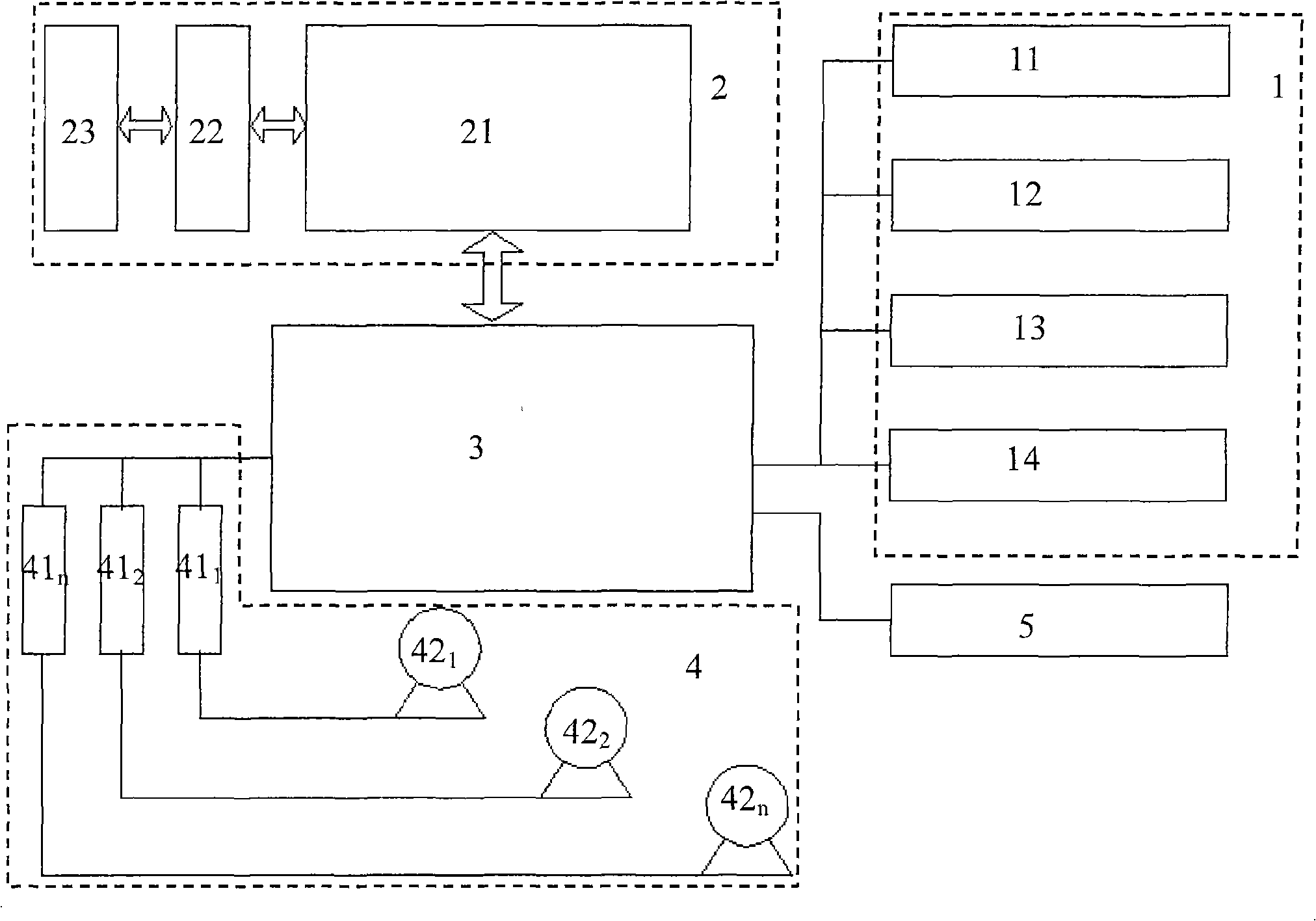

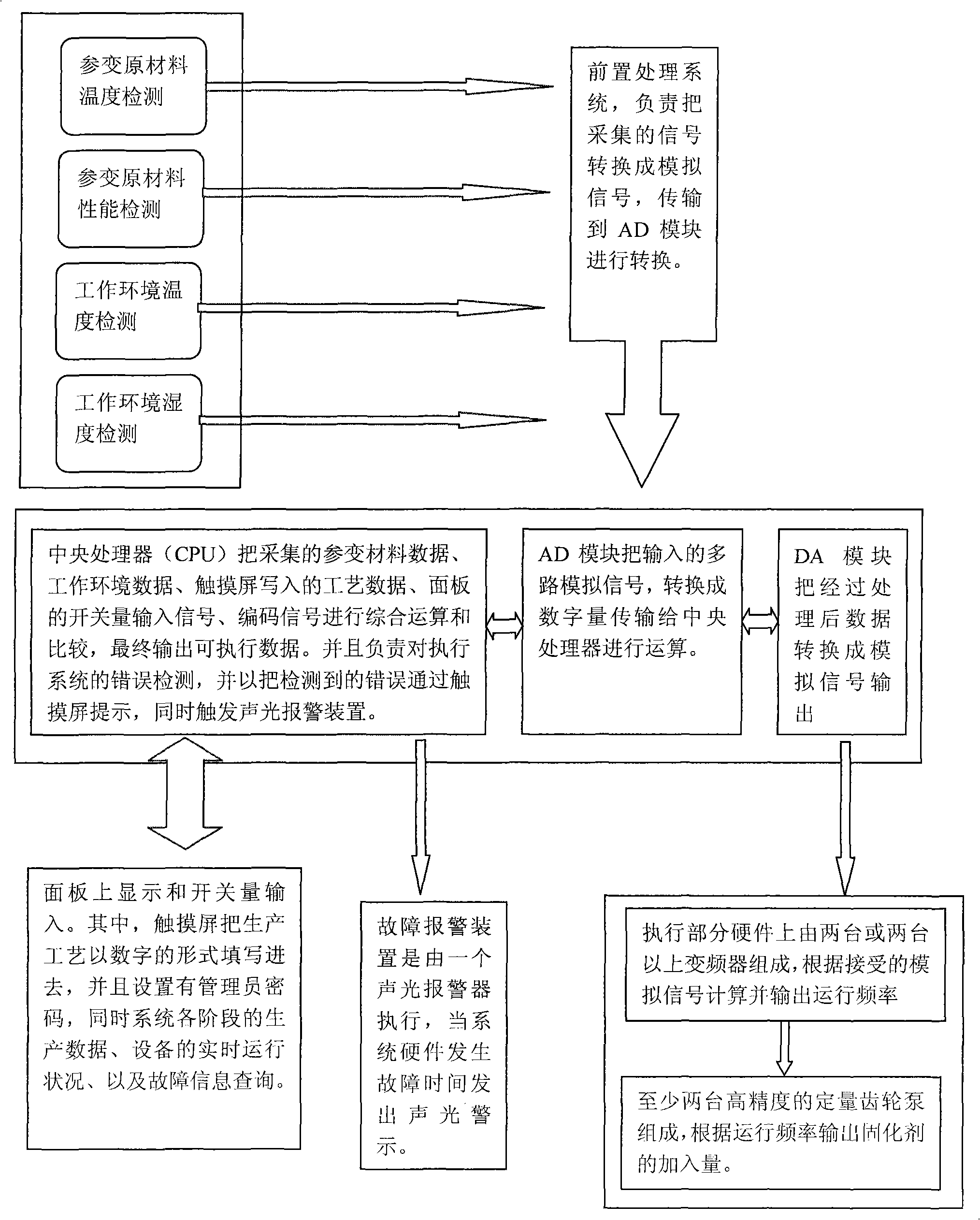

Intelligent liquid raw material proportioning control system

InactiveCN101493703ASimple and fast operationEasy to operateControlling ratio of multiple fluid flowsControlling mixing ratio of fluids with different temperaturesLiquid stateControl system

The invention discloses an intelligent liquid material proportion control system, comprising a parameter collecting module used for detecting the material and environment parameters, a preset processing system for carrying out the pre-processing to the data collected by the parameter collecting module, an executing mechanism, a central processing system used for processing signals of the preset processing system and outputting execution signals to the executing mechanism, and a display setting panel used for displaying and setting the parameters of the central processing system. The control system solves the problems of proportion precision and safety and can realize the online synchronous running with parametric material operation equipment without the independent operation so as to realize the authentic man-machine interaction.

Owner:SUZHOU XINGYE MATERIALS TECH

Technique for ternary laser gas mixture weighing preparation

InactiveCN103071407AImprove the ratio accuracyEase of mass productionMixing gases with gases/vapoursGas cylinderGas mixing

The invention discloses a technique for ternary laser gas mixture weighing preparation. The specific scheme is as follows: (1), preparing a gas cylinder of the following high-purity virgin gases: CO2, He, N2 and V=a(L); (2), calculating the quantities of gases required to be injected according to the component proportions of all the gases; (3), weighing the mass of the empty gas cylinder: m1=b(g); (4), injecting CO2 into the gas cylinder and enabling the weight of the gas cylinder m2=m1+m CO2 to stop; (5), injecting He into the gas cylinder and enabling the weight of the gas cylinder m3=m2+m He to stop; (6), injecting N2 into the gas cylinder and enabling the weight of the gas cylinder m4=m3+m N2 to stop; (7), calculating the weighing result through the difference method and obtaining the definite value; and (8), examining after mixing the prepared gas cylinder by a gas mixing device. As the definite-value weighing gas-mixing method is utilized, the proportioning precision of laser gas is high, and batch production is facilitated; as the prepared laser gas is uniformly mixed, the product prepared by the technique is insusceptible to working conditions and environments, can be used stably, and saves the equipment investment in comparison with the field mixing technique.

Owner:HEFEI JUWANG GASES & ENG

Mixing device for raw materials of plastic product

The invention discloses a mixing device for raw materials of a plastic product. The mixing device comprises a mixing box; a reinforcing rod is fixedly mounted at the top of the mixing box; a feeding pipeline is arranged at an inner side of the reinforcing rod; a first spring is arranged at the top of a first vibrator; an inclined plate is arranged at the top of the first spring; a weight sensor is arranged at the top of the inclined plate; a rotary shaft is arranged in an inner cavity of the mixing box. According to the mixing device for the raw materials of the plastic product, materials to be mixed can be conveyed into the feeding pipeline and the weight of the materials can be sensed through the weight sensor; after the weight reaches proper weight, the materials can be conveyed into the mixing box through pulling a pull plate; the inclined plate is continuously vibrated through the first vibrator and the materials can be rapidly conveyed into the mixing box; a double-through pipe is driven by a motor to rotate, so that the double-through pipe drives the rotary shaft to rotate and starts to stir the materials; when the materials are uniformly stirred, a mixing ratio can be strictly controlled.

Owner:安庆市东源印刷包装有限公司

Medicine atomization device for ear-nose-throat nursing

ActiveCN110354346AAvoid wastingAffect the treatment effectPharmaceutical containersMedical devicesMedicineGear wheel

The invention relates to a medicine atomization device for ear-nose-throat nursing. A baffle is arranged at the upper end of a metering bottle, a guide base is fixed to the lower end of a medicine storage tank, and the baffle is slidingly connected with the guide base; a medicine outlet is formed in the bottom of the medicine storage tank, wherein the guide base runs through the medicine outlet, an inlet is formed in the top of the metering bottle, wherein the baffle runs through the inlet, and the metering bottle is slidingly connected with the guide base, so that the medicine outlet can be communicated with the inlet, and the baffle can seal the medicine outlet; the lower end of the metering bottle is rotatably connected with a metering door for sealing the outlet through a rotation shaft, and the rotation shaft is provided with a gear; a rack which is parallel to the sliding direction of the baffle and can be meshed with the gear is arranged in a shell, a sealing door for sealing anopening in a medicine mixing bottle is rotatably connected to the medicine mixing bottle, and the medicine mixing bottle is sealed when the sealing door is not subjected to downward application force. Medicine liquid can be used immediately after preparation, waste of the prepared medicine liquid is avoided, and the situation is avoided that the time delay caused by medicine liquid preparation influences the treatment effect for a patient; through gradual addition for the metering bottle, quantitative addition and proportioning are achieved, and the proportioning precision of the medicine liquid is improved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Mixing and drying integrated particle material treatment device

The invention relates to the technical field of injection molding machining, and discloses a mixing and drying integrated particle material treatment device. A mixing barrel and a plurality of storagebarrels are included, and an air inlet of the mixing barrel communicates with a hot air mechanism. A plurality of mixing packing augers stirring materials are arranged in the mixing barrel. A discharging port of each storage barrel communicates with a feeding port of the mixing barrel. The discharging port of each storage barrel is provided with a discharging amount control unit. Each dischargingamount control unit comprises an adjusting valve located at the discharging port of the corresponding storage barrel and used for adjusting the material discharging speed. According to the scheme, according to the mixing proportion of various materials, the adjusting valves are used for adjusting the material discharging speed of the corresponding storage barrel discharging ports, and the discharging speed proportion of different materials is the same with the mixing proportion; within the same time, the proportion that the materials enter the mixing barrel is the same with the mixing barrel,the burdening precision is high, manual matching is not needed, and the labor intensity of people is lowered; and the treatment device can conduct mixing and drying at the same time, and the production efficiency is improved.

Owner:HUBEI UNIV FOR NATITIES +1

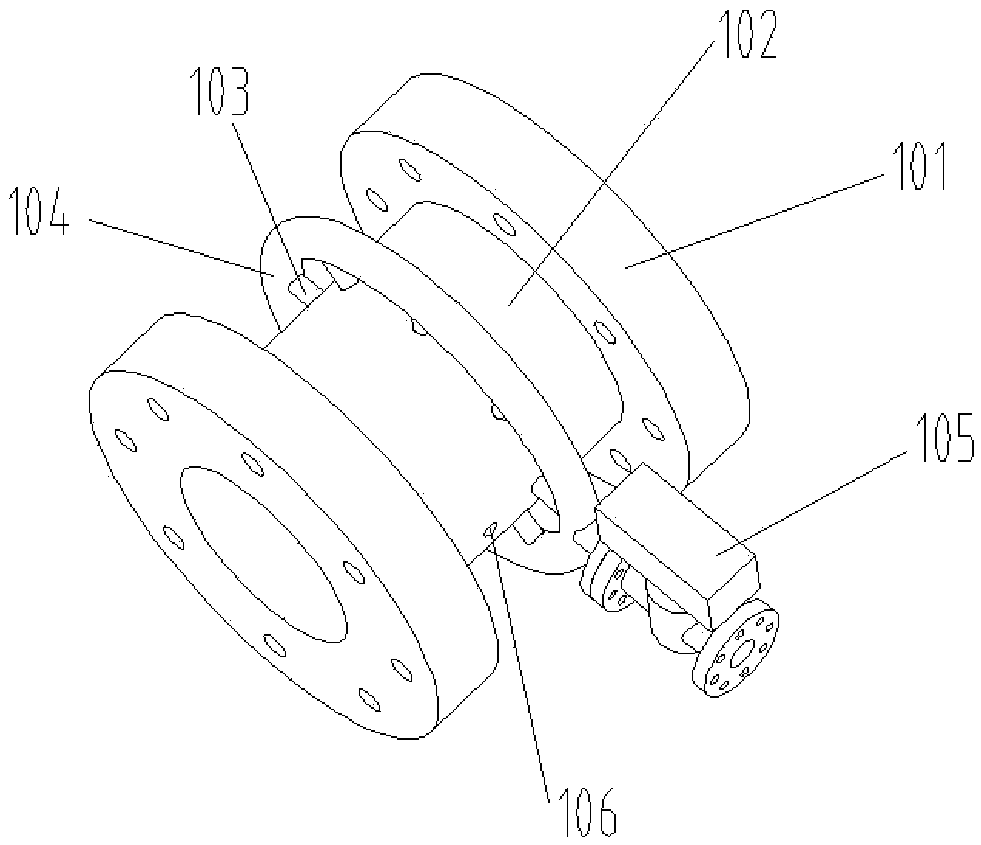

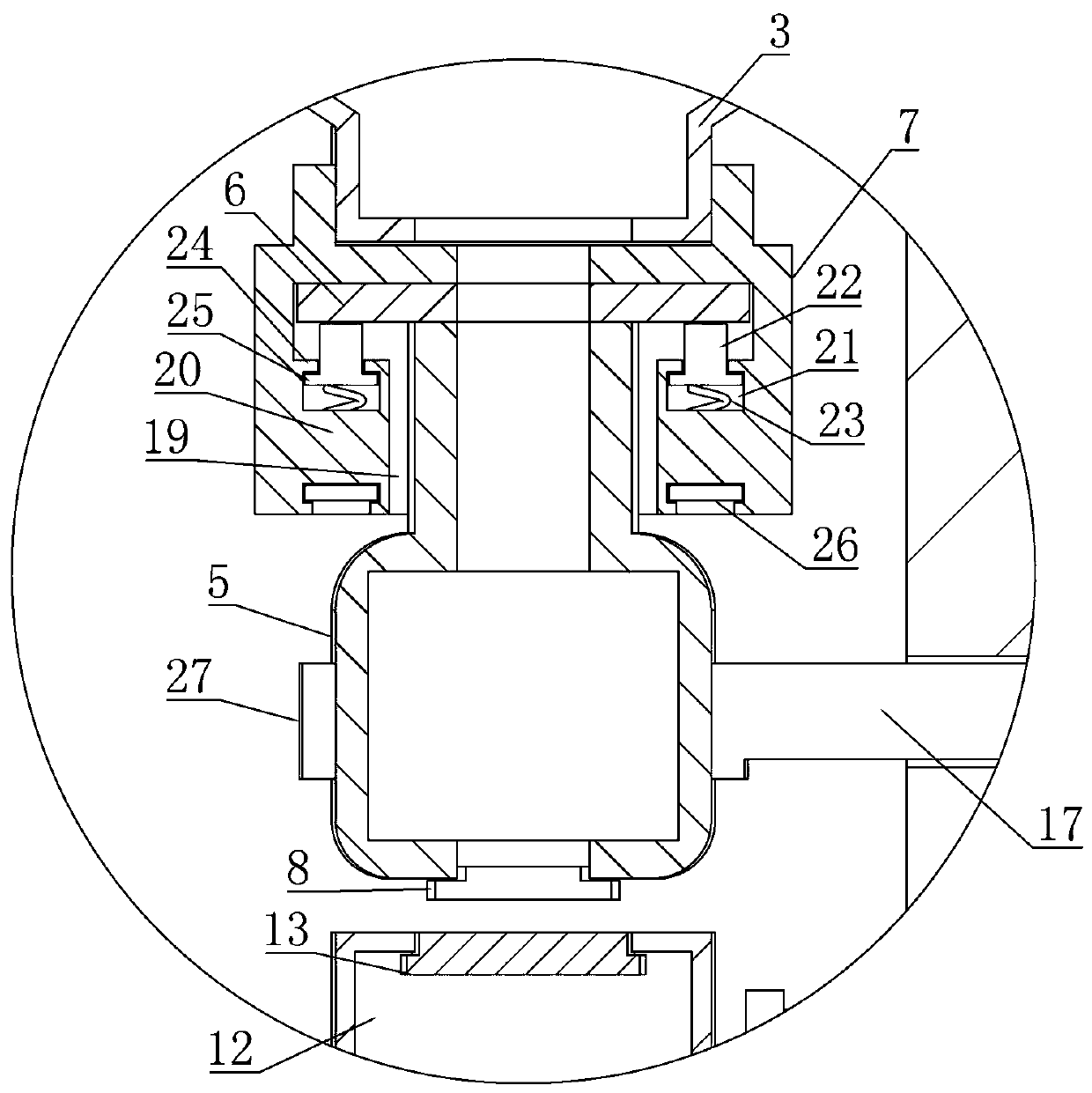

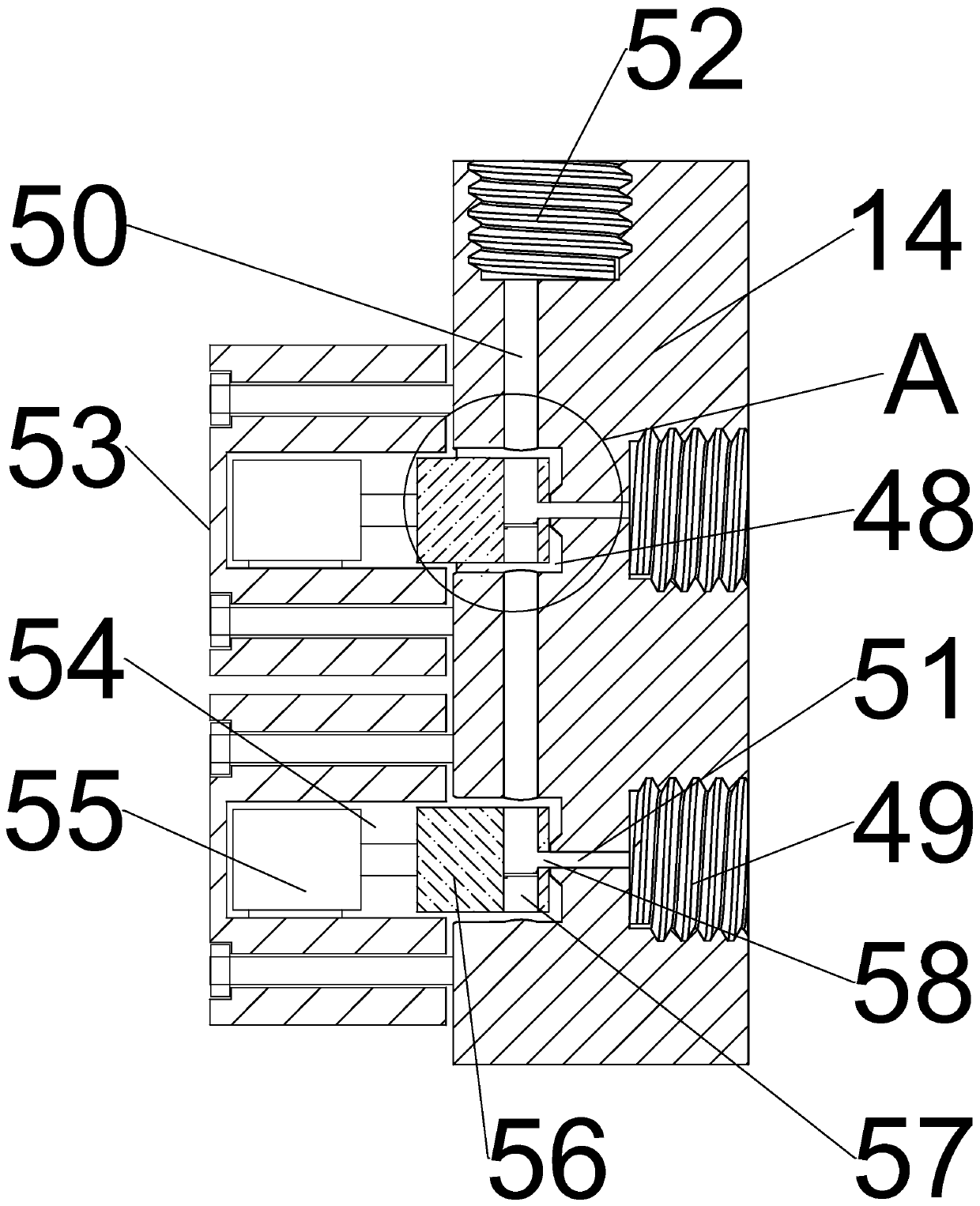

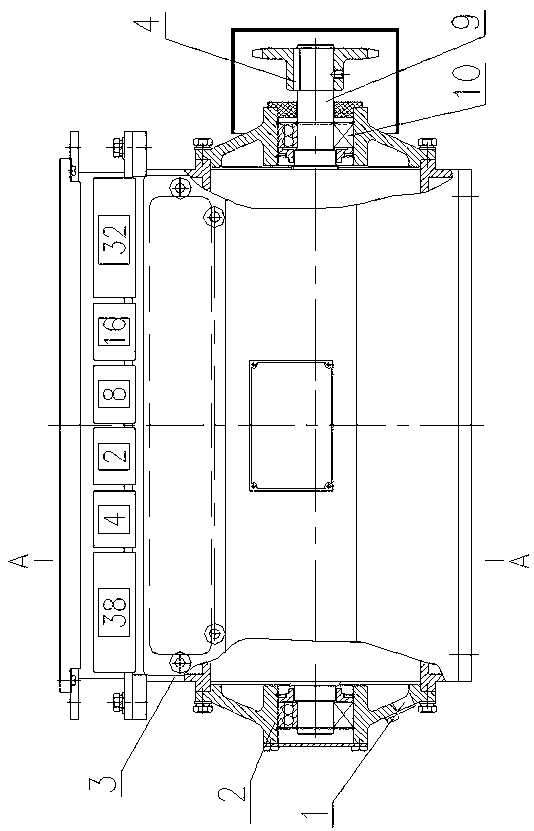

Ternary gas matching and mixing device

ActiveCN105817153ACompact structureReduce in quantityFlow mixersTransportation and packagingCoil springEngineering

The invention provides a ternary gas matching and mixing device which comprises a shell, a pressure compensation device, a fluid proportion adjusting device, a temperature compensation device and a fluid mixing device .The shell comprises an upper end cover and a lower end cover .The pressure compensation device comprises a tubular valve element, a spring A, a spring B and an upper side end cover .Top pressure regulating holes and bottom pressure regulating holes in three pressure regulating cavities are sequentially connected in series through gas channels .A flow regulating cavity is formed below an upper end cover cavity gas outlet hole, and the front portion of the bottom face of the flow regulating cavity is communicated with a gas outlet hole .The fluid proportion adjusting device comprises an adjusting lead screw, a shaft sleeve, a bearing, a bearing cover, a temperature compensation cavity, a temperature compensation cavity cover, a square guide groove and an inserting plate .The temperature compensation device comprises a coil spring fixing pin, a compensation cover, a compensation cover connector, a coil spring locating pin and a bimetallic coil spring .The fluid mixing device comprises a fluid channel, a mixing cavity and a mixed as output hole .The device can achieve pressure and temperature compensation, and can be suitable for the working conditions with large electromagnetic influence and severe environmental conditions.

Owner:JIANGSU UNIV

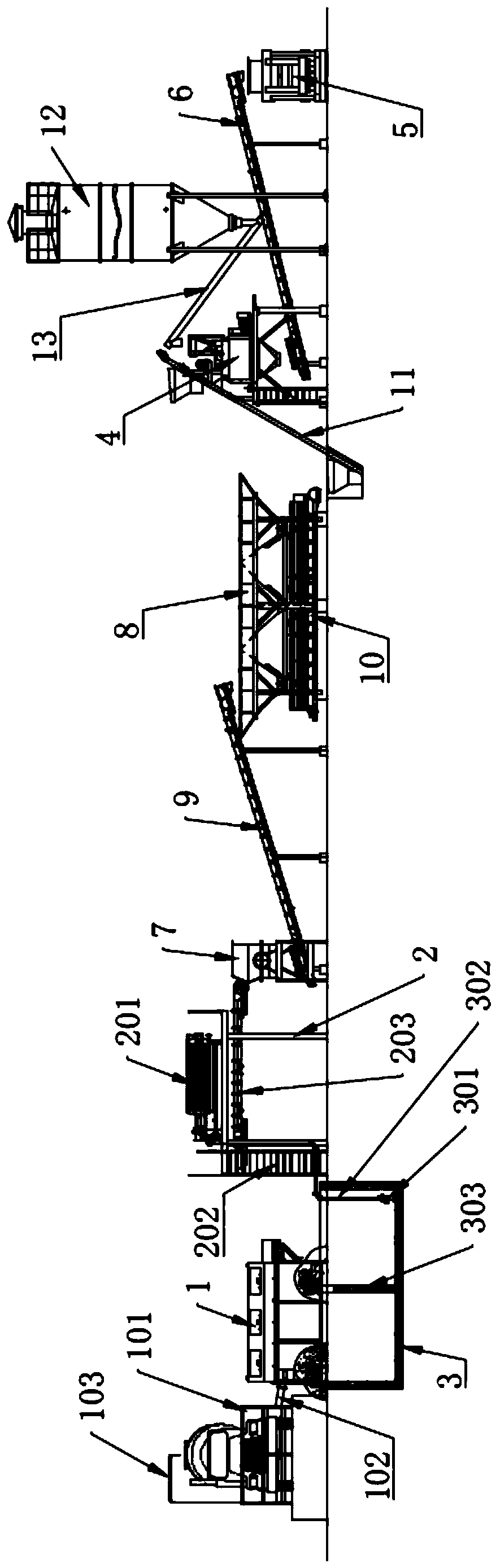

Brick making production line for recycling concrete cleaning waste

InactiveCN110757644AEfficient reuseEfficient use ofSludge treatmentCeramic shaping plantsBrickProcess engineering

The invention discloses a brick making production line for recycling concrete cleaning waste. The brick making production line comprises a gravel separator. A support frame is arranged downstream relative to the gravel separator. A filter press is arranged on the support frame. A first belt conveyor is arranged on the support frame located below the filter press. A sedimentation tank is arranged between the gravel separator and the support frame and communicates with the filter press. A stirring element is connected to the downstream of the first belt conveyor. A brick making machine is arranged downstream relative to the stirring element. A second belt conveyor is connected between the stirring element and the brick making machine. The concrete cleaning waste is effectively reused. The problems that random discharging is not allowed, and concrete cannot be introduced for use in the concrete production industry are solved. Moreover, benefits are greatly increased. Meanwhile, the brickmaking production line is simple in structure, low in investment cost, high in practicability and suitable for being popularized and used in the concrete production industry.

Owner:SHANDONG BOCHUANG HEAVY IND CO LTD

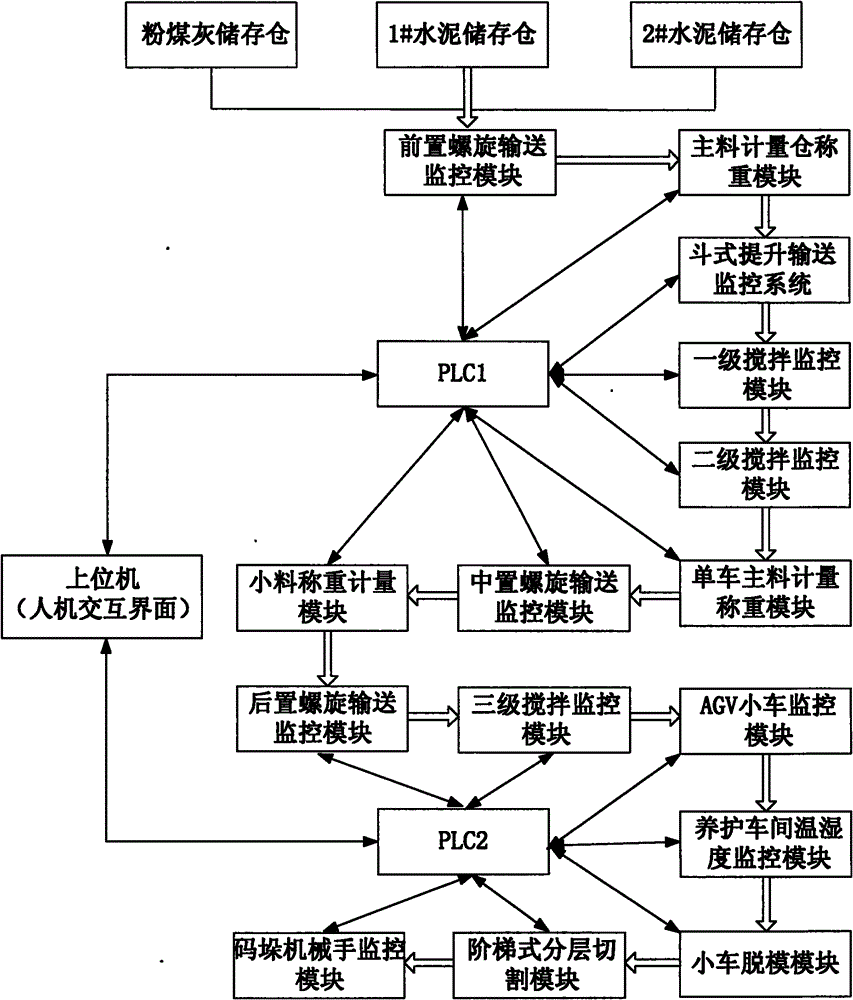

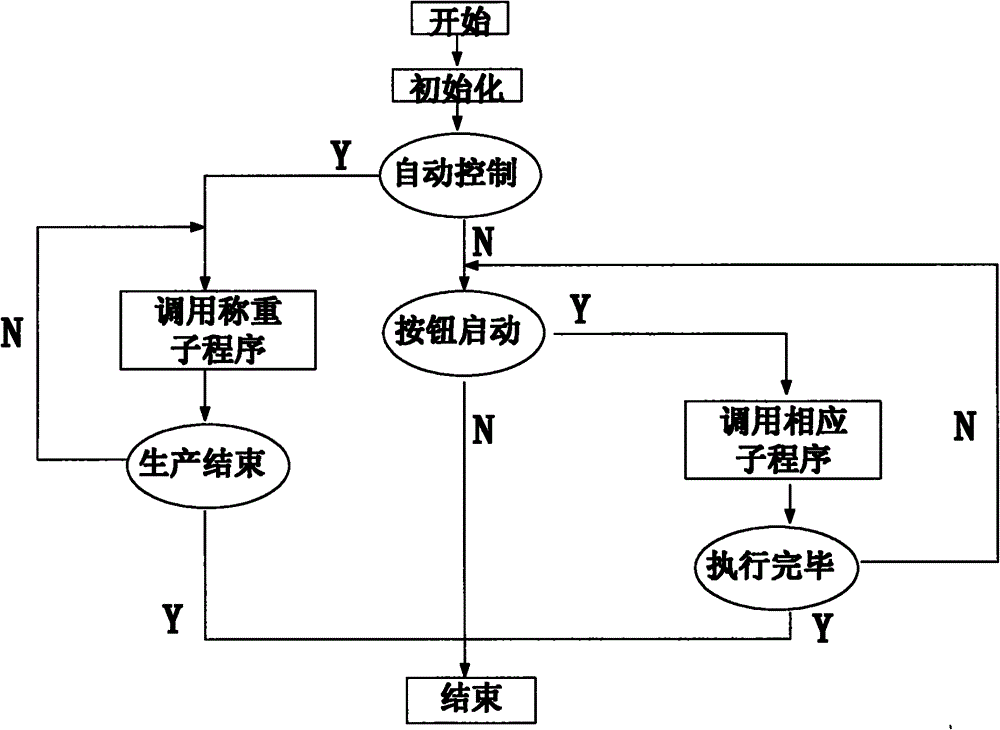

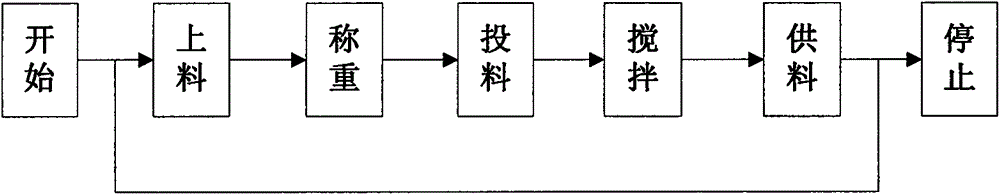

Intelligent monitoring system of foamed cement component production line

InactiveCN104441250AOriginalityImprove the ratio accuracyCement mixing apparatusControl apparatusIntelligent lightingInteraction systems

The invention relates to an intelligent monitoring system of a foamed cement component production line, and in particular relates to an automatic monitoring system of a foamed cement component production line based on a PLC (Programmed Logic Controller) and a man-computer interaction system. The system comprises a host computer, the PLC, the man-computer interaction system, a weighing measuring module, a conveying monitoring module, a stirring monitoring module, an AGV (Automatic Guided Vehicle) mold trolley monitoring module, a maintenance cabin temperature and humidity monitoring module, a trolley demolding monitoring module, a step type layering cutting monitoring module and a stacking manipulator monitoring module, wherein the host computer is used for controlling the conveying monitoring module, the stirring monitoring module, the step type layering cutting monitoring module and the AGV mold trolley monitoring module through the PLC, is used for acquiring information of the weighing measuring monitoring module and the maintenance cabin temperature and humidity monitoring module, and is used for uploading the information to the host computer; and the man-computer interaction system is capable of displaying the operation situation, the fault state and the acquired information of the production line at real time, and giving an alarm in time. The system can be used for carrying out full-automatic production monitoring, has the characteristics of high proportioning precision, accurate control, high reliability, good maintenance property and the like, is unique and innovative, and can improve the production efficiency remarkably.

Owner:TIANJIN BOLE TECH

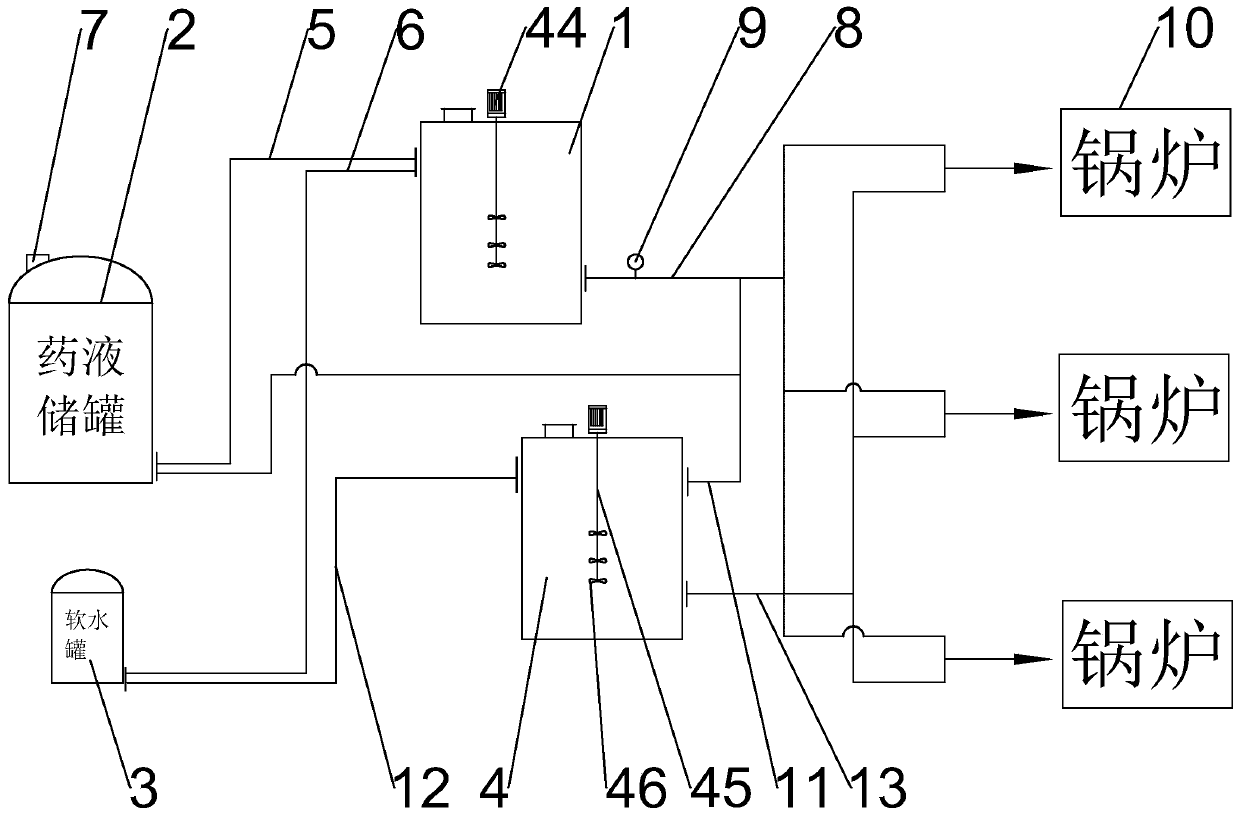

Intelligent vaporizing, cooling and dosing system and method for heating furnaces

ActiveCN110465236AImprove dissolution rateSpeed up the mixingMixing methodsTransportation and packagingChemical solutionSoft water

The invention discloses an intelligent vaporizing, cooling and dosing system and method for heating furnaces. The intelligent vaporizing, cooling and dosing system comprises a dissolving and dilutingtank, a chemical solution storage tank, a soft water tank, a proportioning tank and a plurality of heating furnaces. The top of the dissolving and diluting tank is provided with a liquid inlet pipe 1and a water inlet pipe 1. The dissolving and diluting tank communicates with the chemical solution storage tank through the liquid inlet pipe 1. The dissolving and diluting tank communicates with thesoft water tank through the water inlet pipe 1. The bottom of the dissolving and diluting tank is provided with a liquid outlet pipe 1. A liquid concentration sensor is arranged on the liquid outlet pipe 1. The dissolving and diluting tank separately communicates with the proportioning tank and the plurality of heating furnaces through the liquid outlet pipe 1. The top of the proportioning tank isprovided with a liquid inlet pipe 2 and a water inlet pipe 2. The proportioning tank separately communicates with the liquid outlet pipe 1 and the bottom of the chemical solution storage tank throughthe liquid inlet pipe 2. The proportioning tank communicates with the soft water tank through the water inlet pipe 2. The bottom of the proportioning tank is provided with a liquid outlet pipe 2. Theproportioning tank separately communicates with the plurality of heating furnaces through the water outlet pipe 2. The intelligent vaporizing, cooling and dosing system of the invention has the beneficial effects of higher proportioning accuracy of a chemical solution.

Owner:宁波精亦自动化工程技术有限公司

Fastener manufacturing method monitored by computer during whole process

The invention relates to a fastener manufacturing method monitored by a computer during the whole process. The manufacturing steps comprise: preparing a material and sampling, and increasing an auxiliary material; smelting the raw materials; carrying out slagging and electric furnace bottom blowing; refining outside the furnace; casting, and carrying out a heat treatment; carrying out an annealing treatment; carrying out a hot stamping treatment; removing degrease and water, and drying; carrying out a surface treatment; and carrying out thermal insulation drying. According to the present invention, the computer is used to monitor the whole manufacturing process of the whole fastener, such that the fastener with characteristics of extremely high matching precision, production from the alloy steel, and extremely high performance can be obtained, the unnecessary testing procedures are removed, and the part of the programs are improved so as to simplify the production process and improve the production efficiency.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

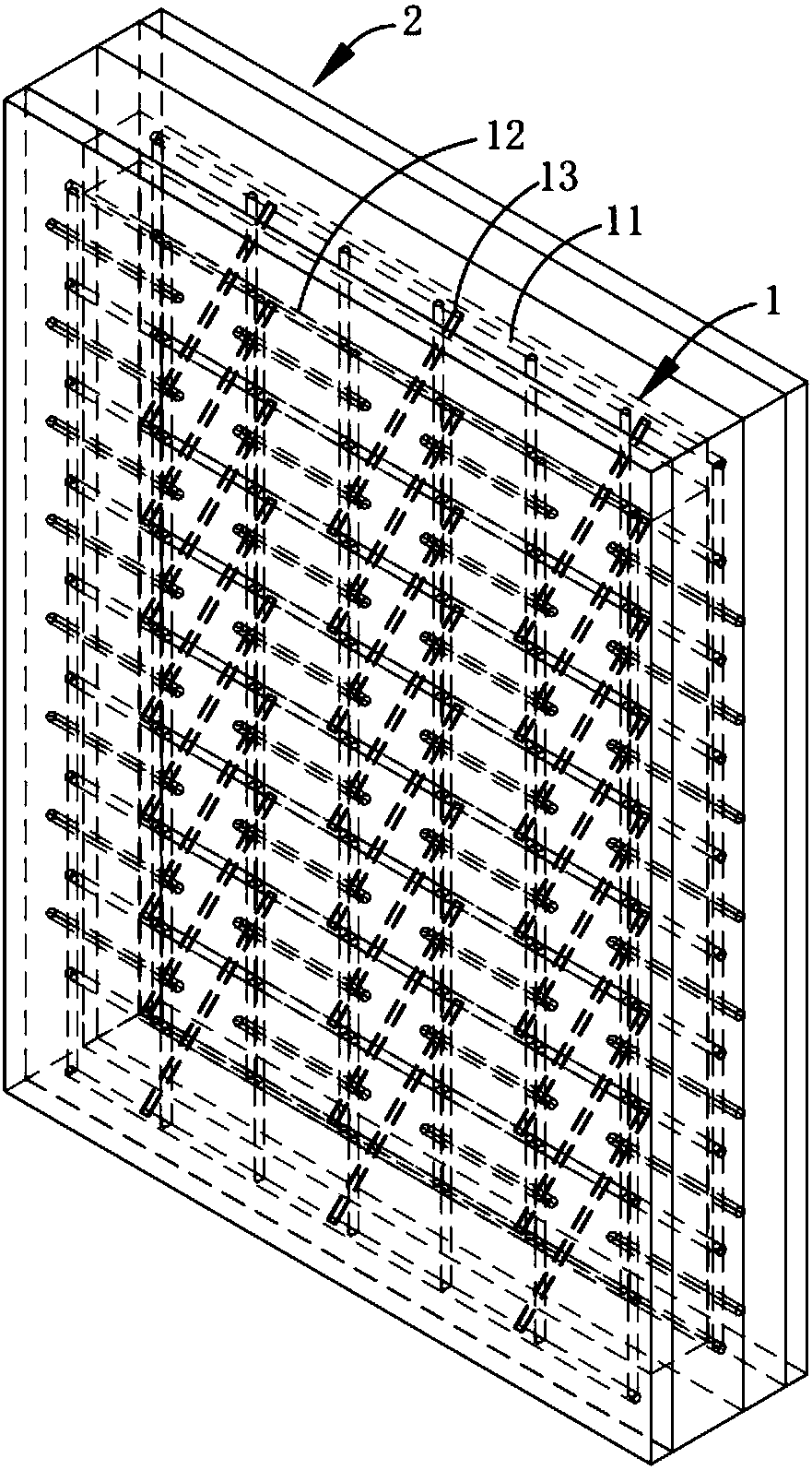

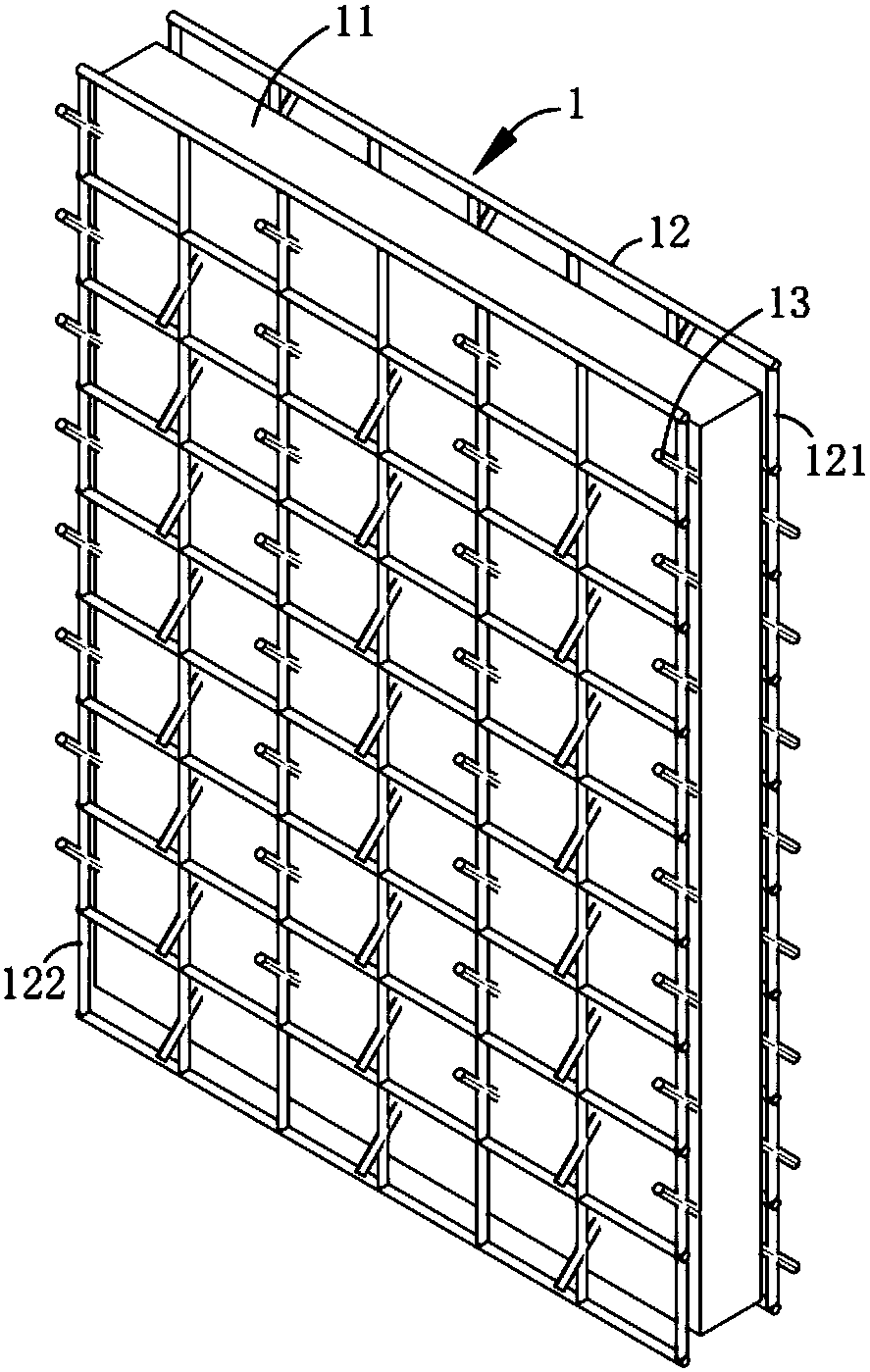

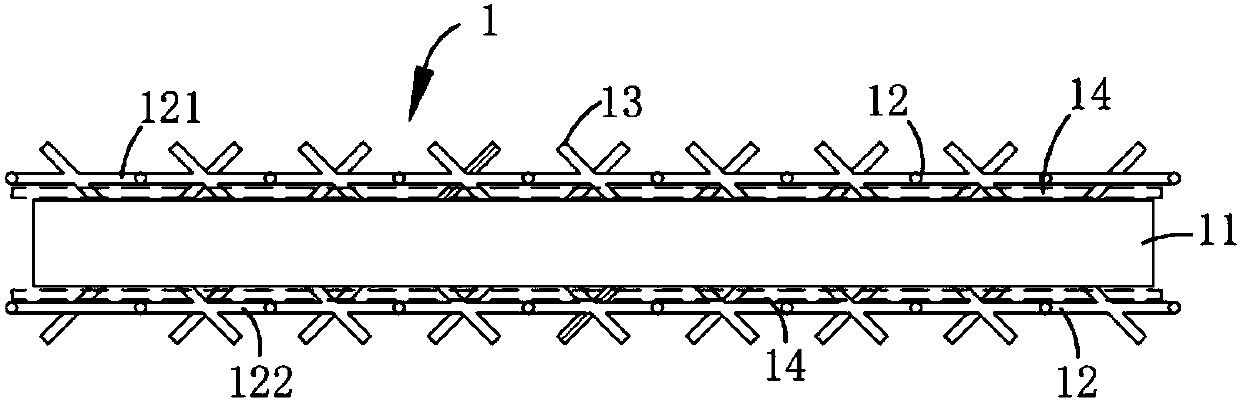

Light and composite multifunctional wall body and production technology thereof

InactiveCN107816167AStable supportImprove stress resistanceBuilding componentsHigh intensityEngineering

The invention relates to a light and composite multifunctional wall body and a production technology thereof. The light and composite multifunctional wall body comprises a core and a wall board structure, wherein the core comprises a light board, a bearing structure and a plurality of supporting parts, wherein the bearing structure and the plurality of supporting parts are arranged on the outer side of the light board; an integration area is formed between the bearing structure and the surface of the light board; the supporting parts are in multi-row linear distribution on the light board; theend part of each supporting part respectively penetrates through the integration area and is connected with the bearing structure; the wall board structure coats the outer part of the core and is inintegral pouring forming through light concrete; integral pouring is carried out through the wall board structure and the core which contains a plurality of supporting units to form the light composite wall body with high intensity, high wind pressure resistance and light weight, and the technical problems of high wall body quality, poor wind pressure resistance and low supporting performance in the prior art can be solved.

Owner:ZHEJIANG FAEN INTEGRATED HOUSING CO LTD

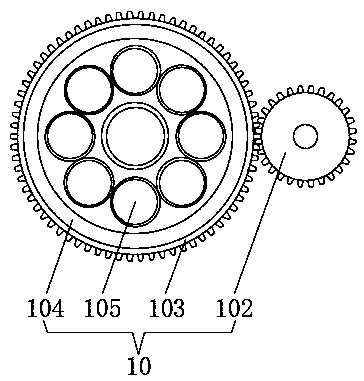

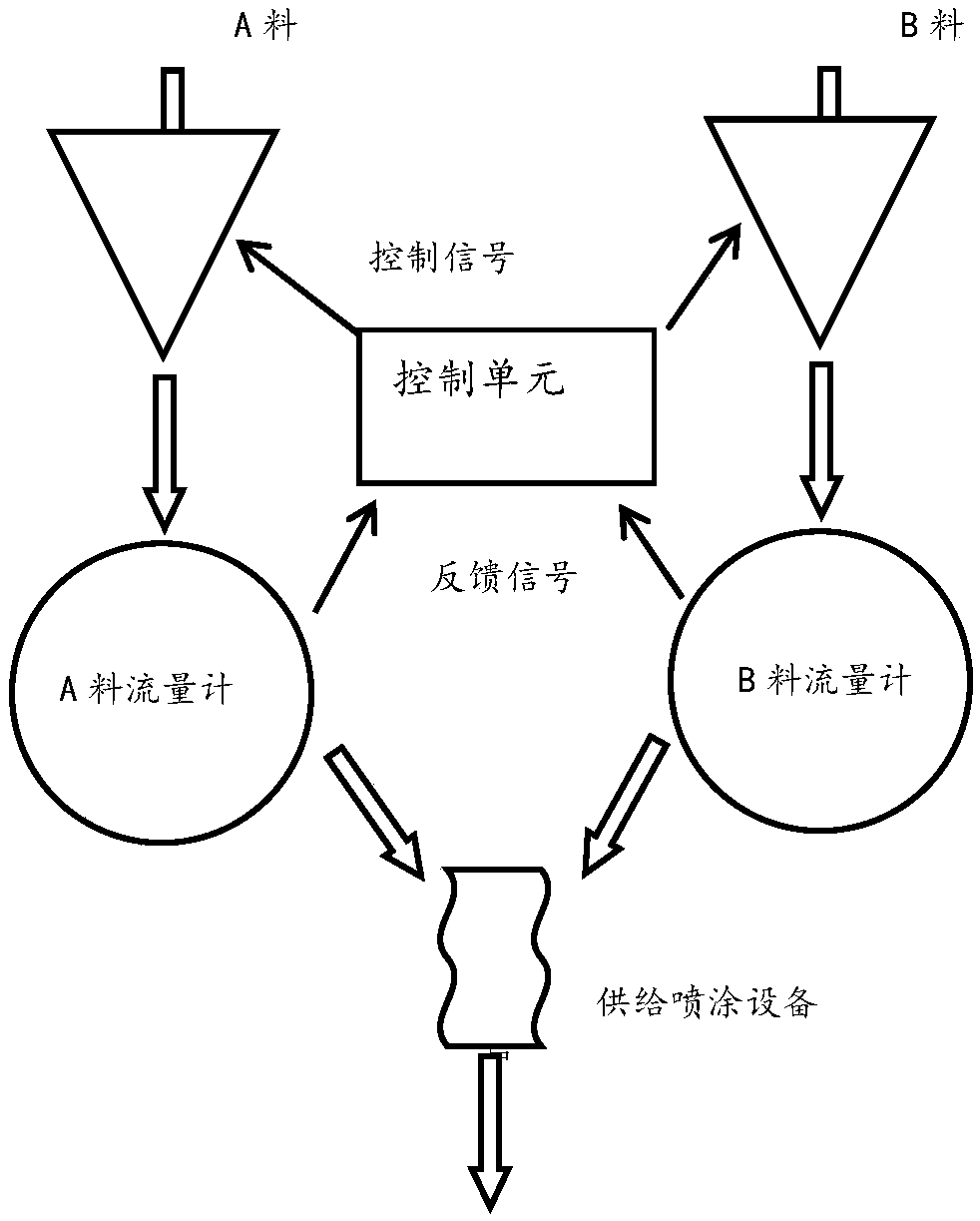

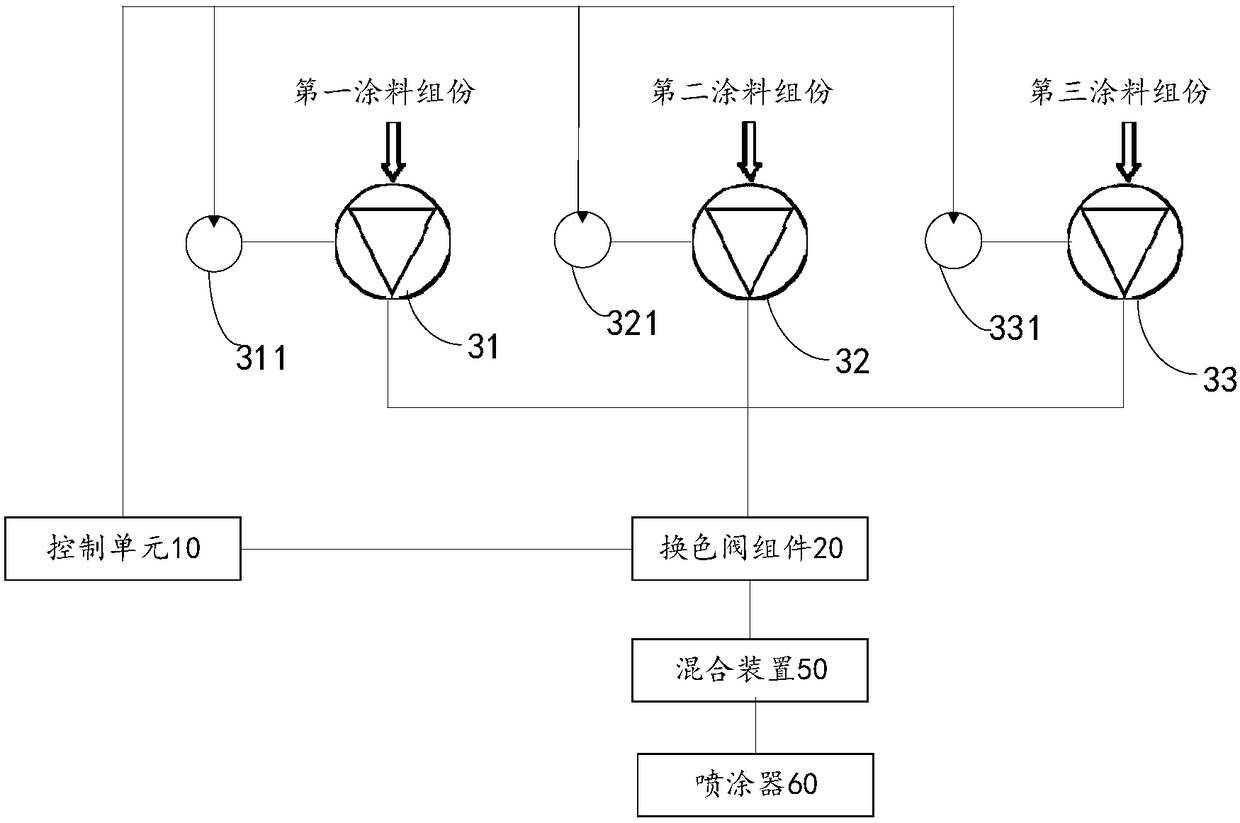

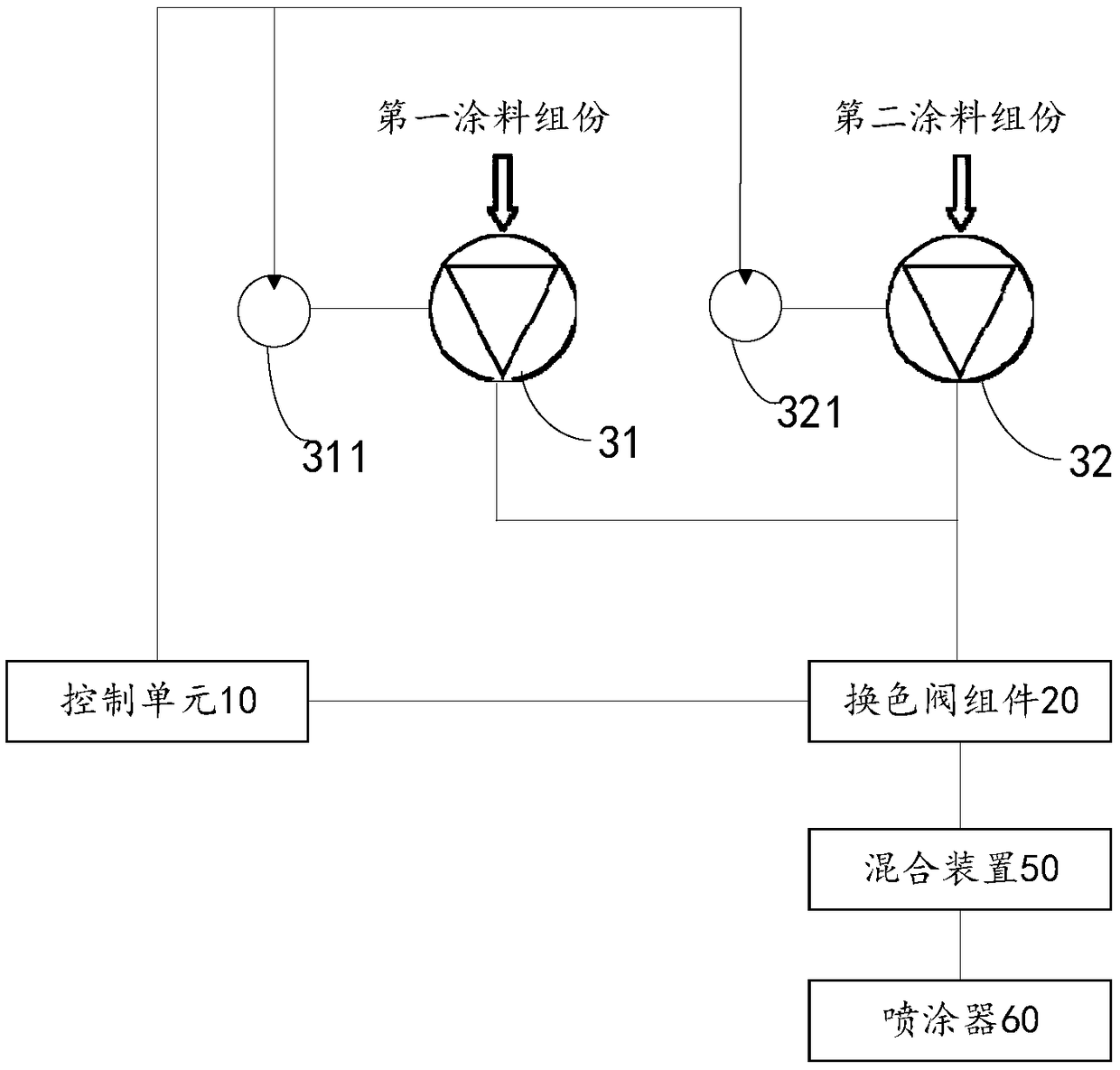

Multi-component proportional paint supply system and painting robot

InactiveCN108889491AImprove the ratio accuracyLow costSpraying apparatusManipulatorProportional controlPaint robot

The invention discloses a multi-component proportional paint supply system and a painting robot. The multi-component proportional paint supply system comprises a control unit and also comprises at least two gear pumps corresponding to different coating components and a mixing device; every gear pump is communicated with the mixing device and is connected with a driving device for flow control; allthe driving devices are connected with the control unit; the control unit controls the different driving devices according to paint component ratios to drive the corresponding gear pumps so that painting components determined according to the ratios are injected into the mixing device; the mixing device mixes well the different paint components injected. The gear pumps of the multi-component proportional paint supply system are used to actively pump the paint components so that the ratio precision is high and stable, and are also sued for controlling painting flow so that system cost is reduced.

Owner:深圳市柳溪机器人有限公司

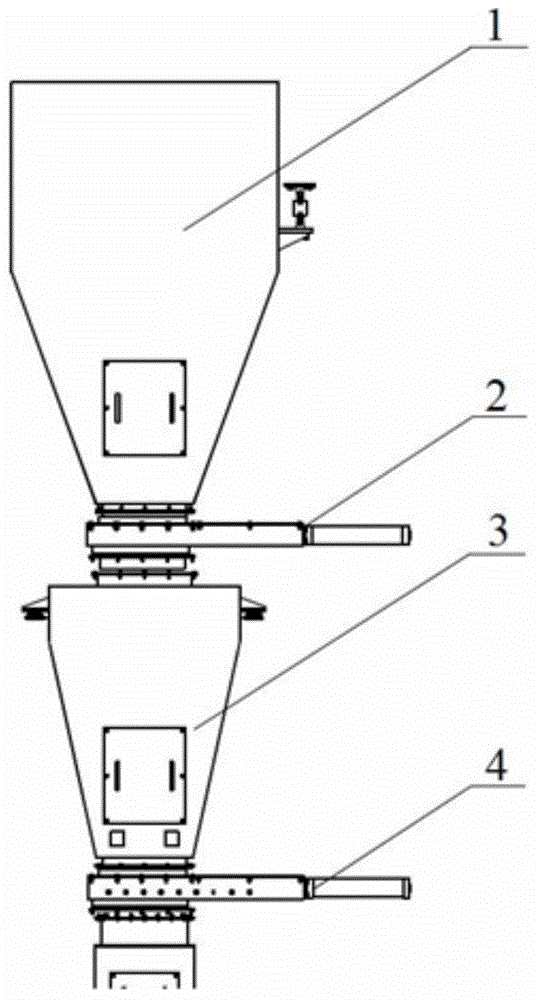

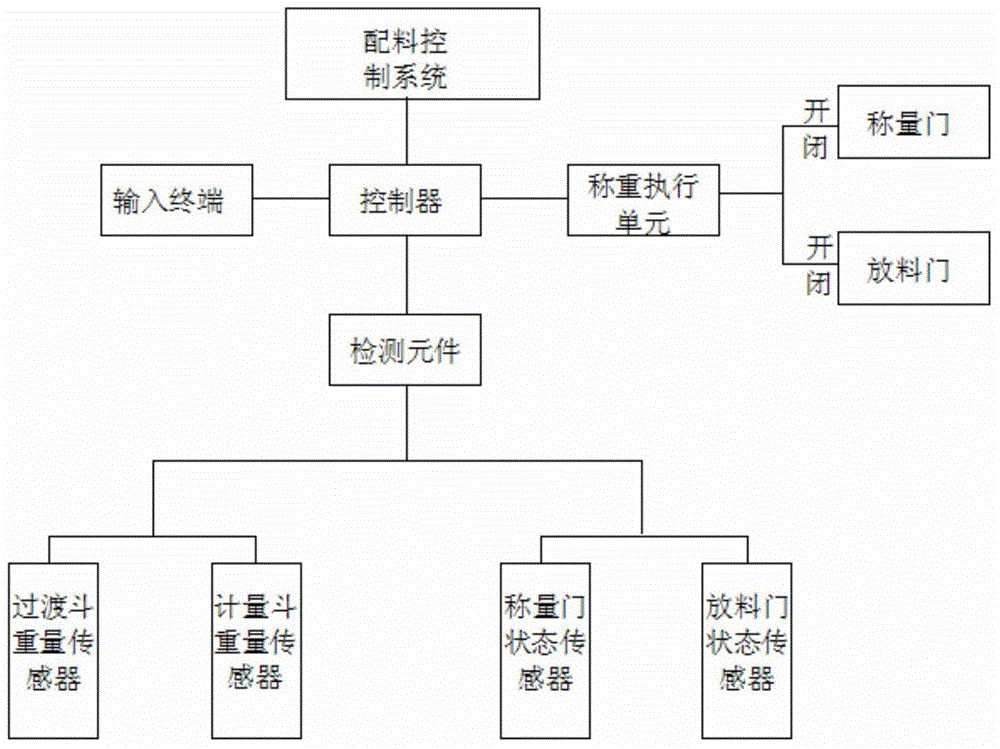

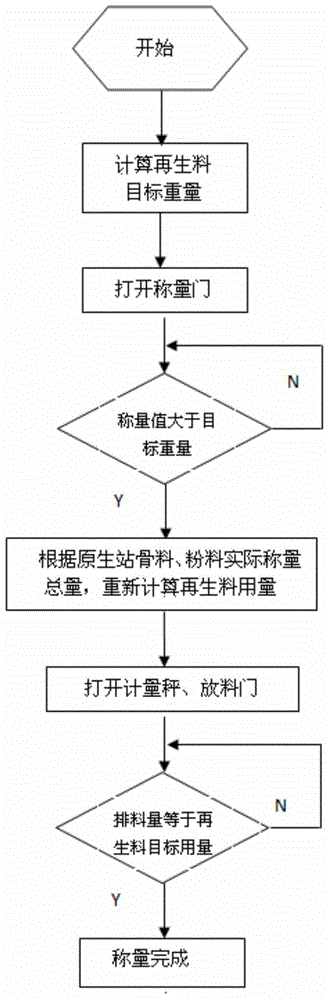

Use method of precise blending device for asphalt pavement reclaimed material

InactiveCN104790277AHigh control precisionImprove the ratio accuracyRoads maintainenceRoad engineeringEngineering

The invention discloses a use method of a precise blending device for an asphalt pavement reclaimed material and belongs to the field of road engineering machinery. The method comprises the following steps: calculating a target amount of the reclaimed material according to a use proportion of a reclaimed asphalt mixture, opening a weighing door below a transition hopper, closing the weighing door after required the material enters a weighing hopper, calculating precise weight of the reclaimed material actually required according to the weight of actually weighed aggregate and powder in a raw station after weighing the aggregate and the powder in the raw station, discharging the required weight of the reclaimed material from a discharge door by a reduced metering manner in the weighing hopper and accomplishing the whole weighing process, wherein the weight of the material metered for the first time is greater than the target weight. According to the method, the weighing hopper in the precise blending device carries out secondary weighing of the reclaimed material to ensure a more accurate weighing result, the proportion precision of the reclaimed material, the aggregate and the powder is improved, and the property stability of the reclaimed asphalt mixture is ensured truly.

Owner:XUZHOU XUGONG ROAD CONSTR MACHINERY

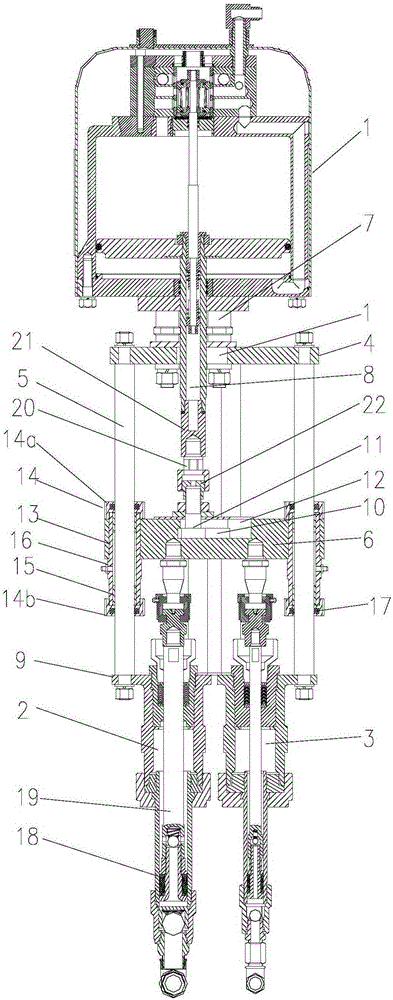

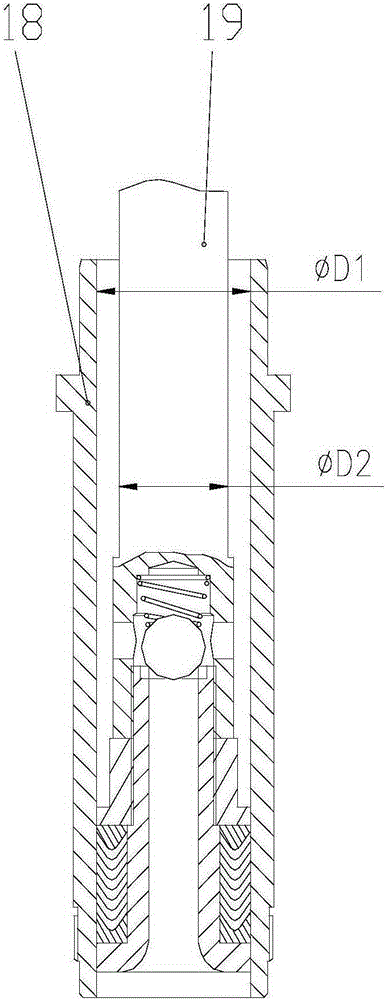

Specific-proportion bi-component fluid output device

ActiveCN105251634AHigh mixing ratio accuracyReduce manufacturing costSpraying apparatusHigh pressurePiston

The invention discloses a specific-proportion bi-component fluid output device. The specific-proportion bi-component fluid output device comprises a power device, a driving proportion adjusting mechanism and high pressure cylinder components. At least three sorts of the high pressure cylinder components are arranged. The driving proportion adjusting mechanism is provided with two power output ends, and each power output end is provided with the corresponding high pressure cylinder component. The driving proportion adjusting mechanism is used for conducting equilibrium partitioning on an input power of the power device and outputting the power, and the differences of areas among the multiple sorts of the high pressure cylinder components are arranged in multiple sorts of proportions. Six sorts of different proportions of 1 to 1, 1.5 to 1, 2 to 1, 2.5 to 1, 3 to 1 and 4 to 1 of bi-component fluid definite-proportion conveying can be achieved by setting the proportions of different values of cross sectional areas between cylinder body inner cavities and pistons among the various high pressure cylinders, so that the higher and higher technical requirement by users is met, and the matching precision of the spraying is improved. In addition, the structure is simple; the cost is low; the convenience and practicability are achieved; the popularization is easy.

Owner:CHONGQING CHANGJIANG COATING EQUIP

Volumetric wheat blender

The invention discloses a volumetric wheat blender and relates to grain processing machinery. The volumetric wheat blender comprises a shell, wherein a material separation body is connected to a part above the shell; six proportioning insertion plates are inserted between the front side of the material separation body and the front side of the shell; a main shaft penetrates through the shell; two ends of the main shaft are connected with bearing end covers through bearings respectively; each bearing end cover is connected with the shell; one end of the main shaft is connected with a chain wheel; a rotor is connected to the main shaft in the shell, and comprises six groups of steel plate assemblies which are connected to the main shaft along the axial direction of the main shaft respectively; each group of steel plate assembly is arranged below the corresponding proportioning insertion plate. The rotor rotates and is partitioned into six chambers of different sizes along the axial direction; wheat enters the shell from the material separation body; by pulling out different numbers of insertion plates, 2 to 100 percent of materials can be obtained; the materials are quickly discharged out of a discharging port in the lower end of the shell from an external channel of a quantitative part of the rotor. The volumetric wheat blender is simple in structure, low in cost and high in proportioning accuracy.

Owner:扬州市仙龙粮食机械有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com