Ternary gas matching and mixing device

A mixing device and ternary gas technology, applied in gas and gas/steam mixing, mixing machines, mixing methods, etc., can solve problems such as harsh environmental conditions, inability to adapt to humid air, and harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

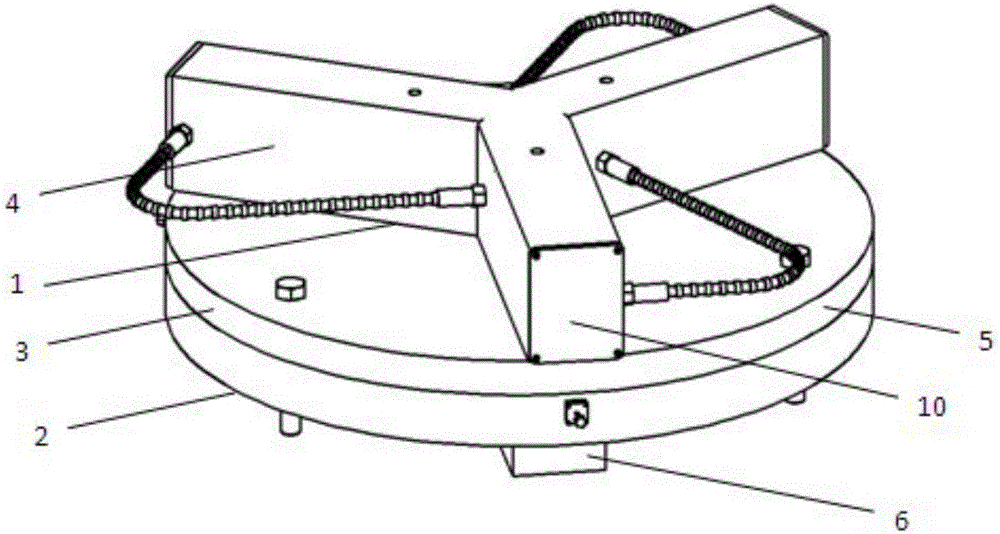

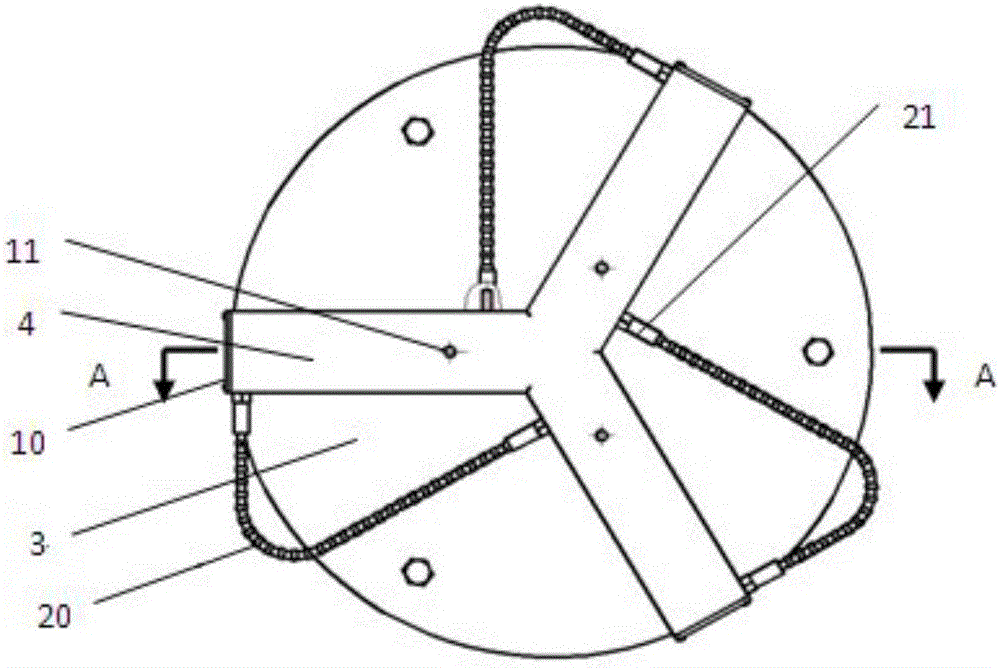

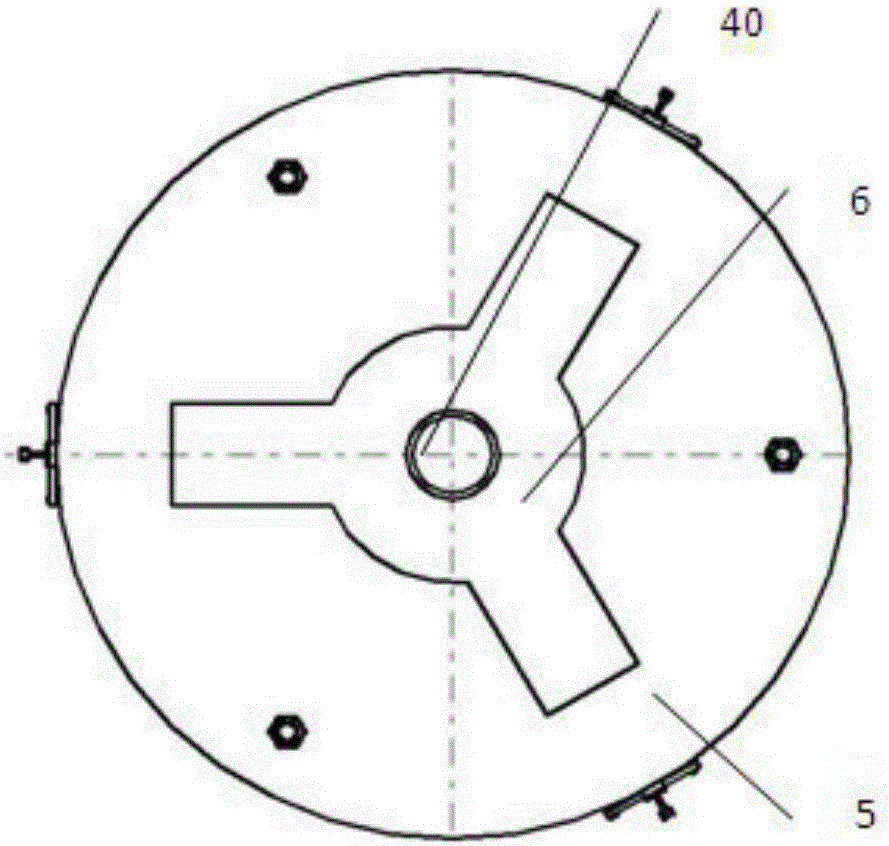

[0036] A ternary gas proportioning and mixing device, including a shell, a pressure compensating device, a fluid ratio regulating device, a temperature compensating device and a fluid mixing device; as figure 1 As shown, the housing includes an upper end cover 1 and a lower end cover 2; as figure 2 As shown, the upper part of the upper end cover 1 is divided into three pressure regulating chambers 4 arranged in a star shape, and the lower part is the upper end cover column seat 3; the upper end cover column seat 3 is in the shape of a circular platform; the pressure regulating chamber The cross-section of the body 4 is square; the three pressure regulating chambers 4 are evenly distributed on the upper end cover column seat 3 at an angle of 120°. Such as image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com