Patents

Literature

217results about How to "Achieve pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

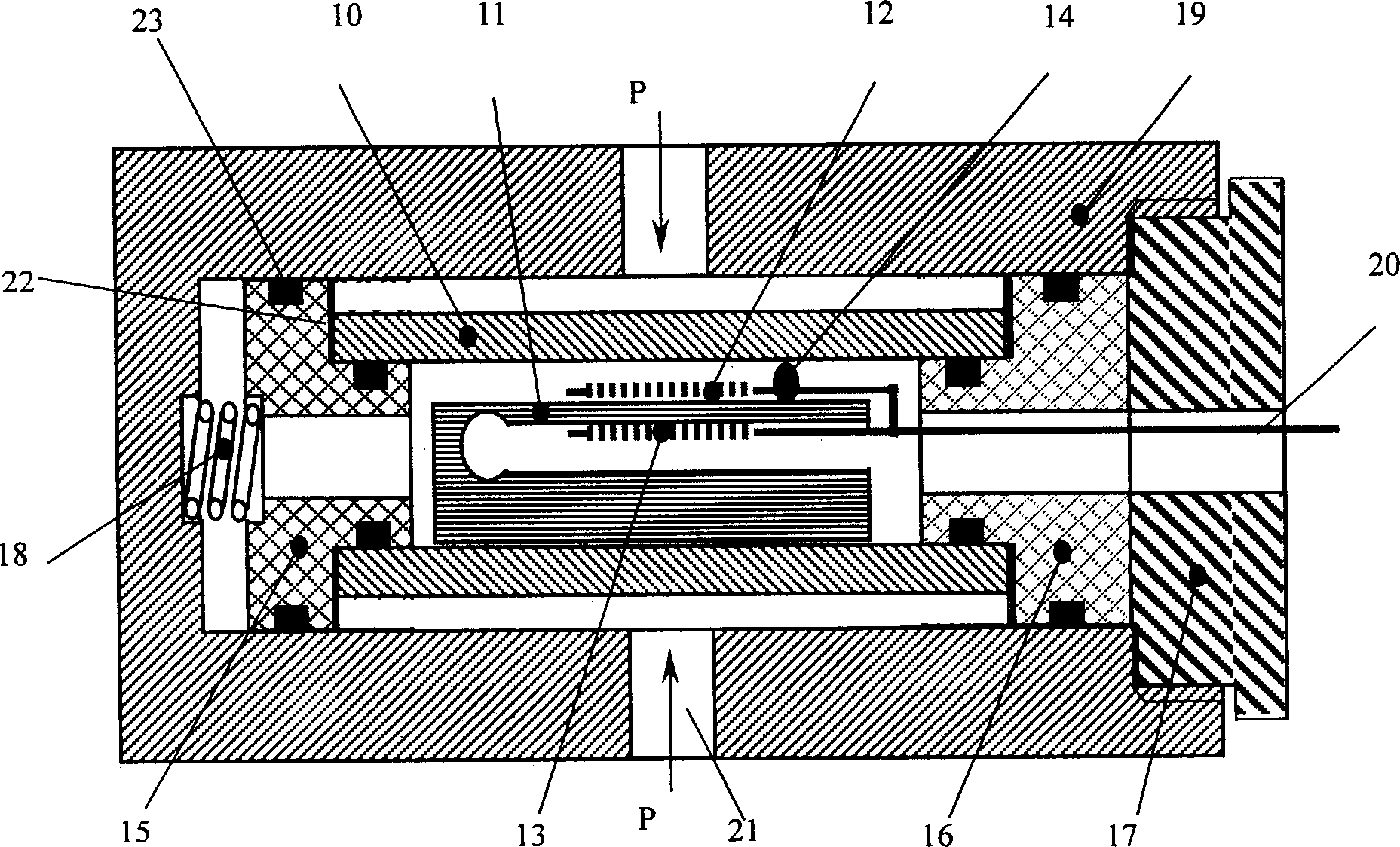

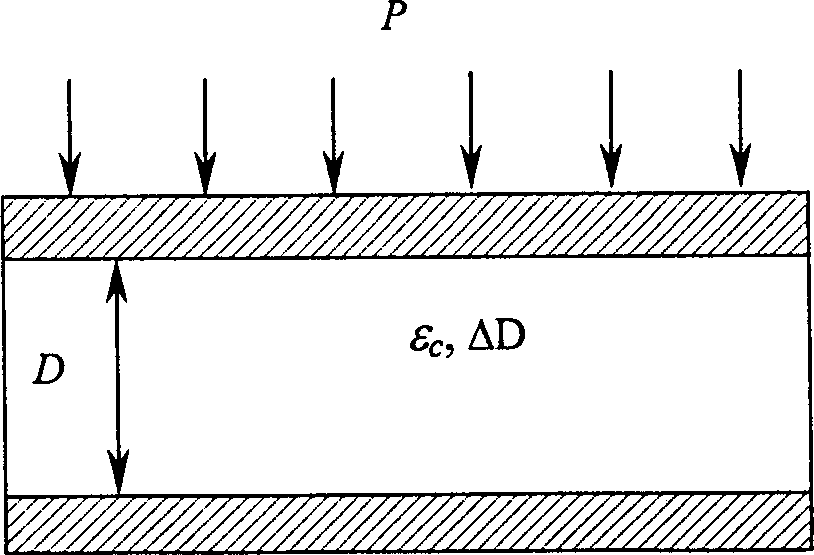

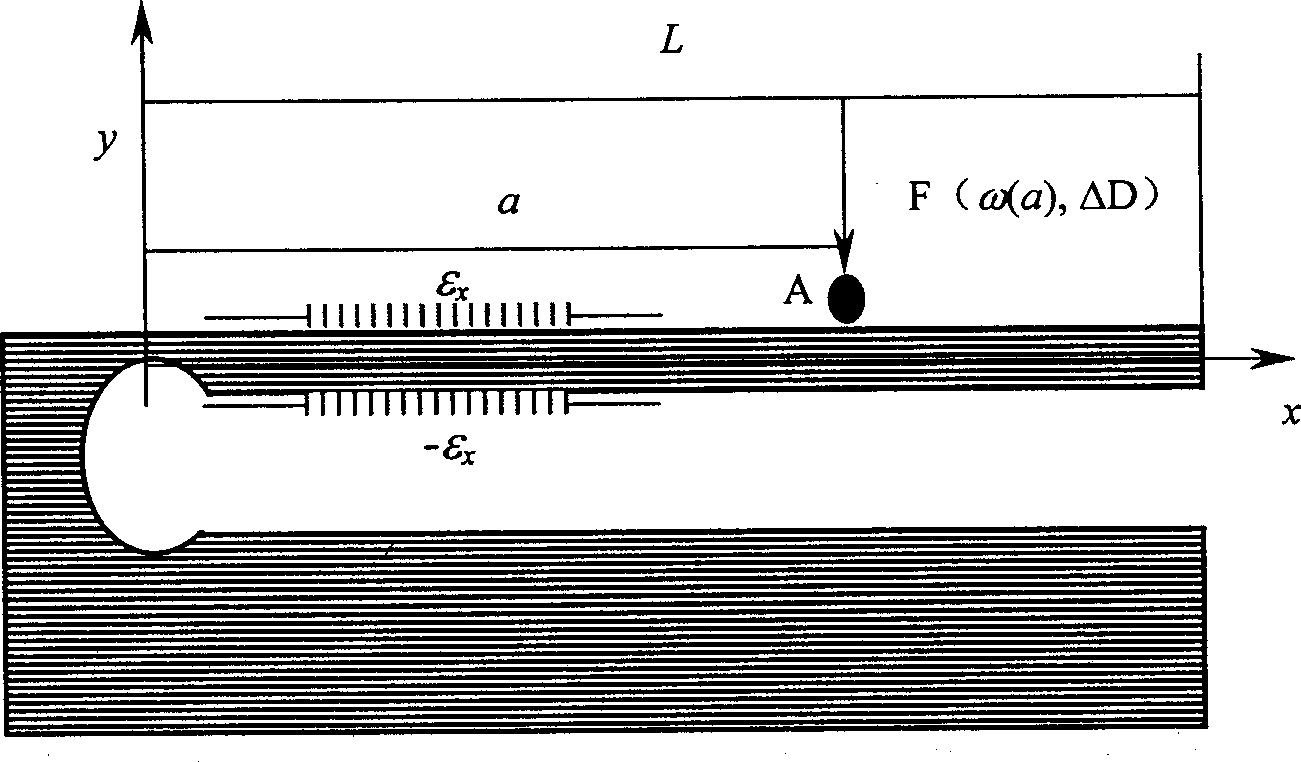

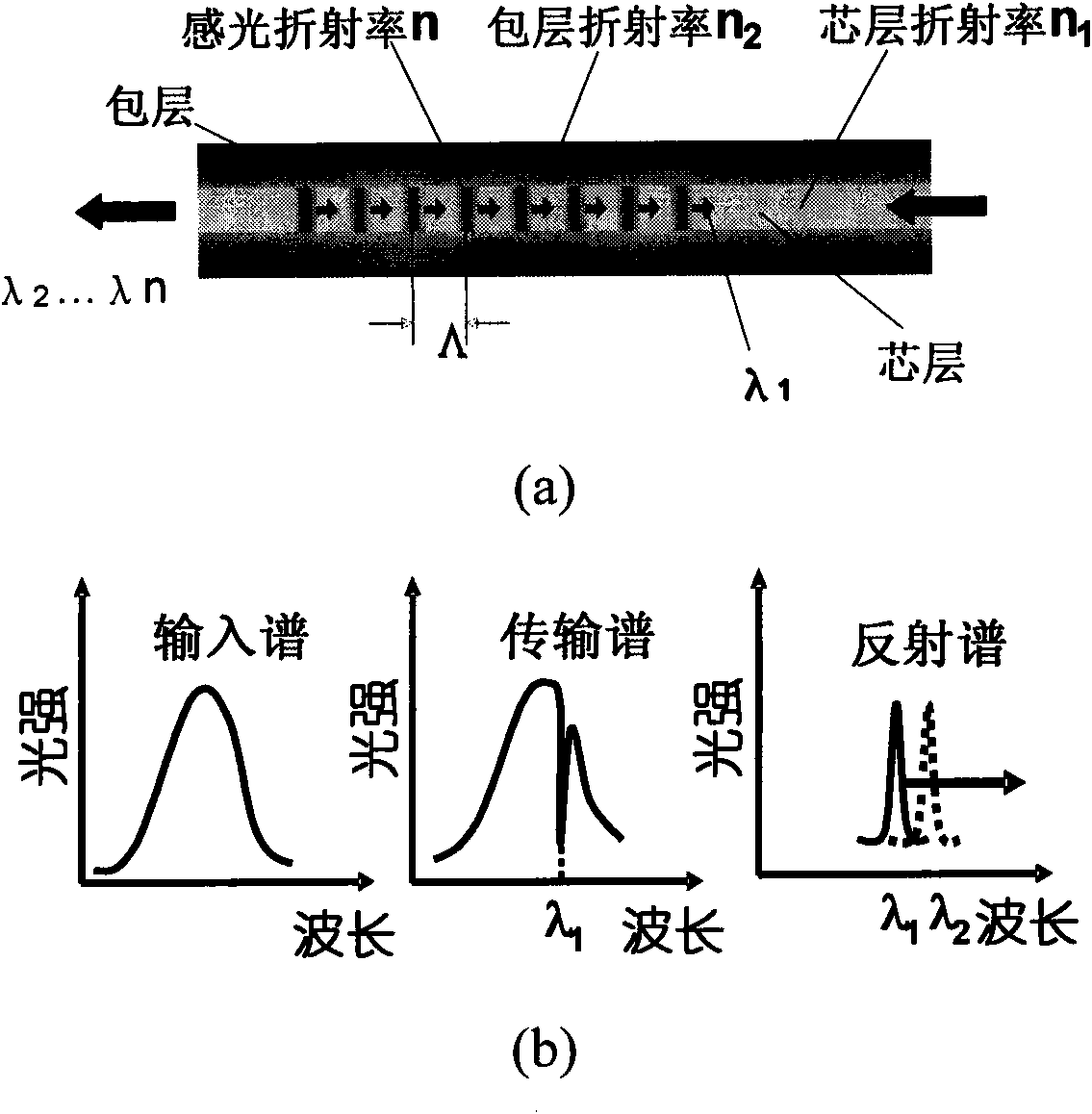

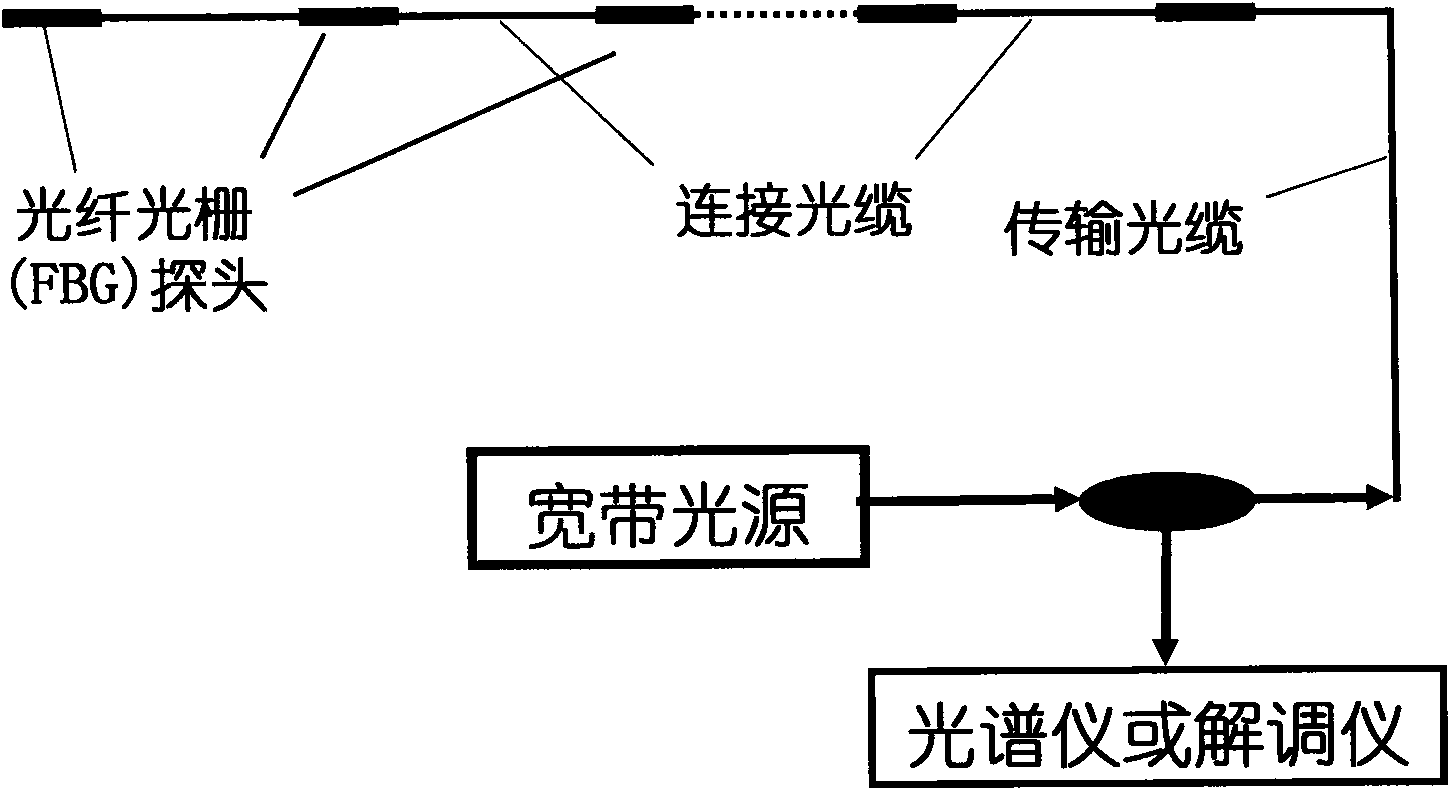

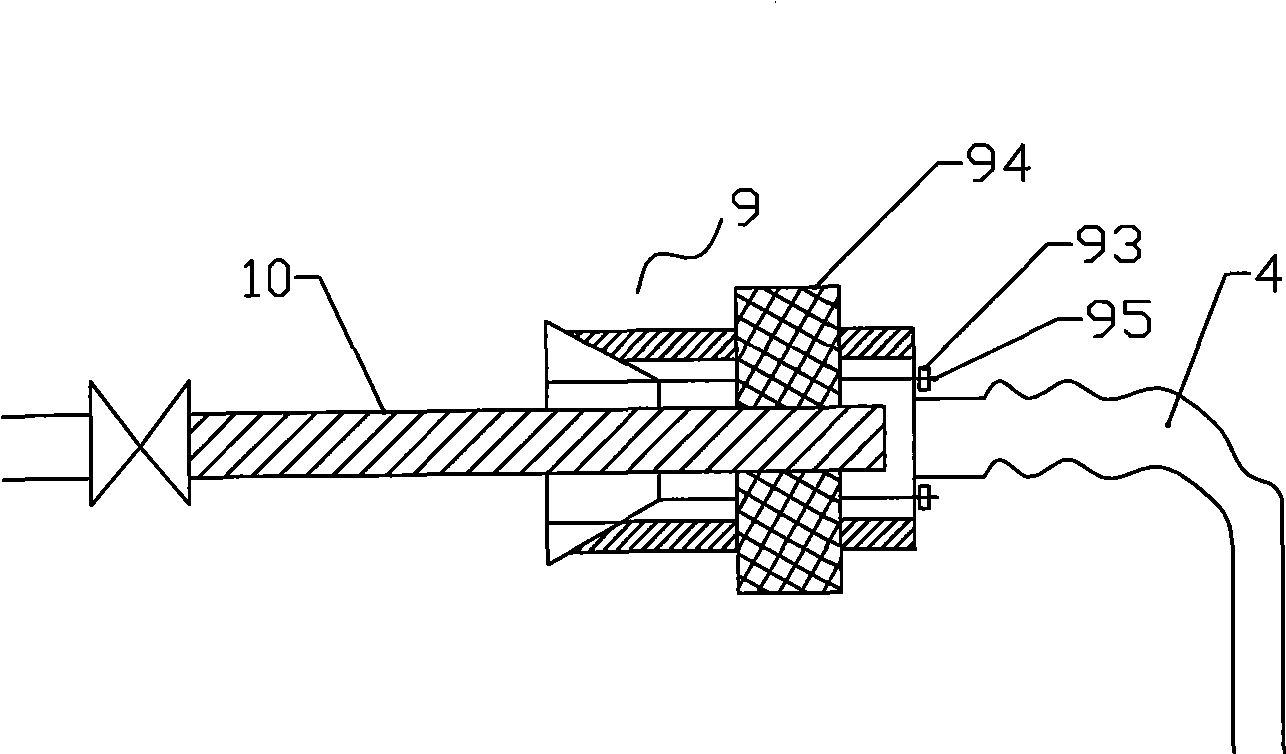

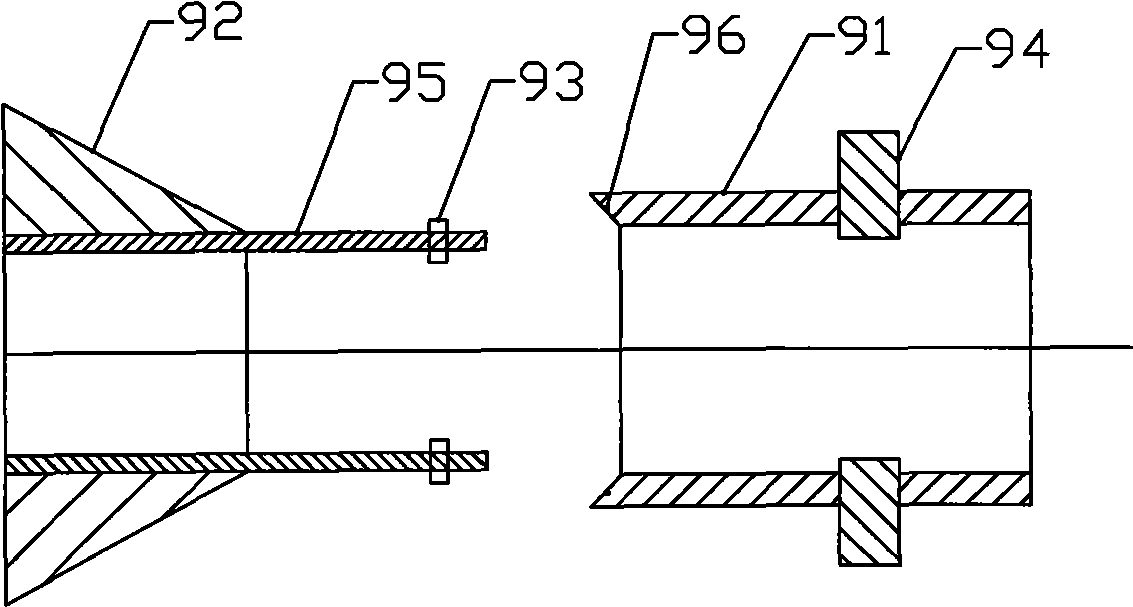

Optical-fiber grating sensor detecting pressure temperature simultaneously

InactiveCN1384341AAchieve pressureAchieve temperatureConverting sensor output opticallyPhysicsCantilevered beam

The optical fiber grating sensor detecting pressure and temperature simultaneously consists of mainly free elastic cylindrical pressure transducer, cantilever beam mechanism, fiber grating, sealed part, end element and pre-tensed spring; protective casing and transmission fiber. The technological scheme is that two fiber gratings are fixed to the upper and the lower surface of the cantilever beamin the corresponding positions and connected to transmission fiber via one fiber coupler; that the triangular cantilever beam mechanism converts the radial information of the cylinder under the outer pressure into deflection of the cantilever beam and thus the variation of the Bragg reflection wavelength with temperature and pressure, and that differential measurement technology is used to solvethe cross sensitivity of fiber grating.

Owner:TSINGHUA UNIV

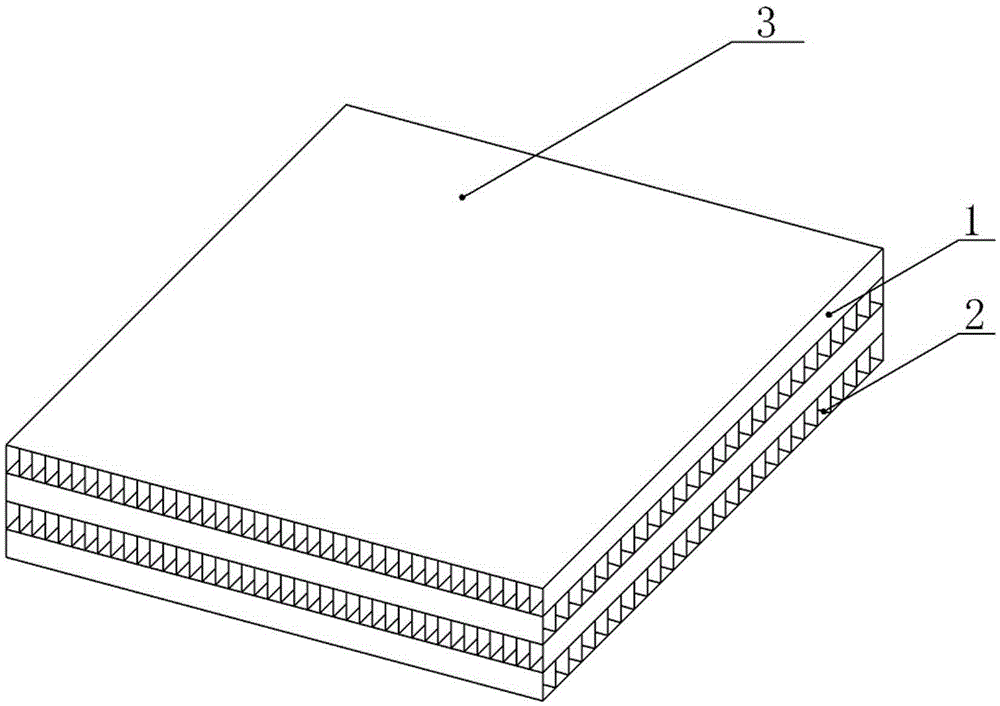

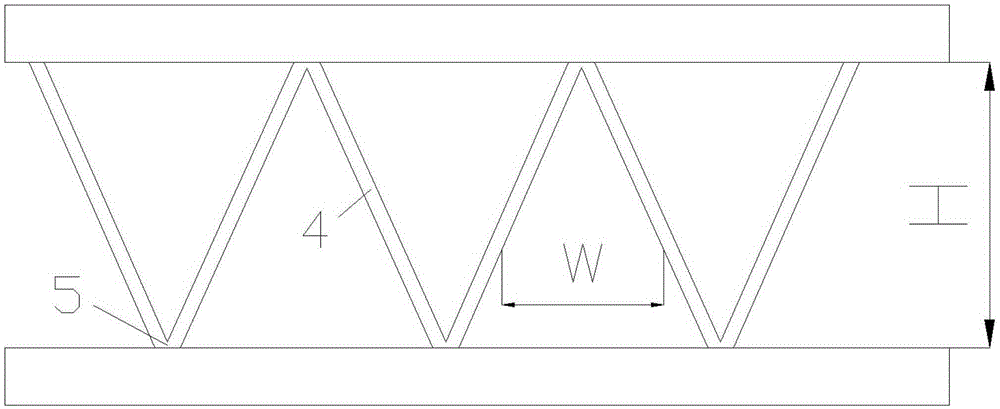

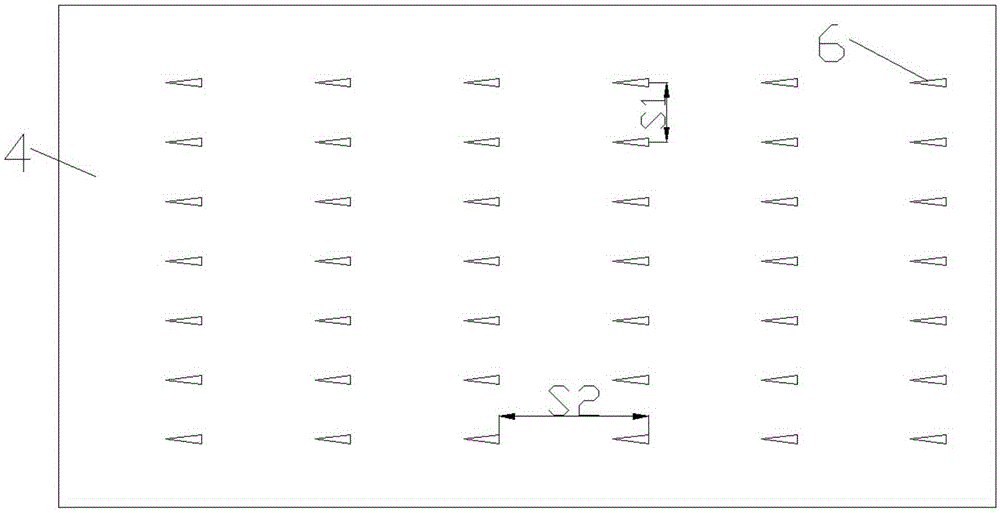

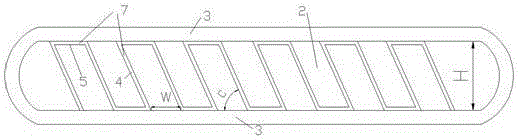

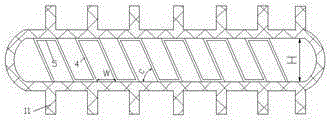

Triangular convex-stab-shaped plate-fin heat exchanger used for condensation of non-azeotropic multi-component mixture

ActiveCN105258535AOvercoming the problem of low heat transfer efficiencyImprove heat transfer efficiencyLaminated elementsStationary plate conduit assembliesBoiling pointParallel plate

The invention provides a triangular convex-stab-shaped plate-fine heat exchanger used for condensation of a non-azeotropic multi-component mixture. The plate-fin heat exchanger comprises parallel plates; fins are arranged between the plates; the fins comprise inclined parts inclining towards the plates; convex stabs are machined on the inclined parts in a stamping mode, so that fluid on the two sides of the inclined part circulates through holes formed in the inclined parts in a stamping mode, and the convex stabs extend outwards in the flowing direction of the mixture from the inclined parts. The novel triangular convex-stab-shaped plate-fine heat exchanger is suitable for being used in condensation of the non-azeotropic multi-component mixture, so that condensation of the non-azeotropic multi-component mixed medium is achieved, the heat exchange efficiency is improved, and the fluid flowing resistance is reduced.

Owner:SHANDONG UNIV

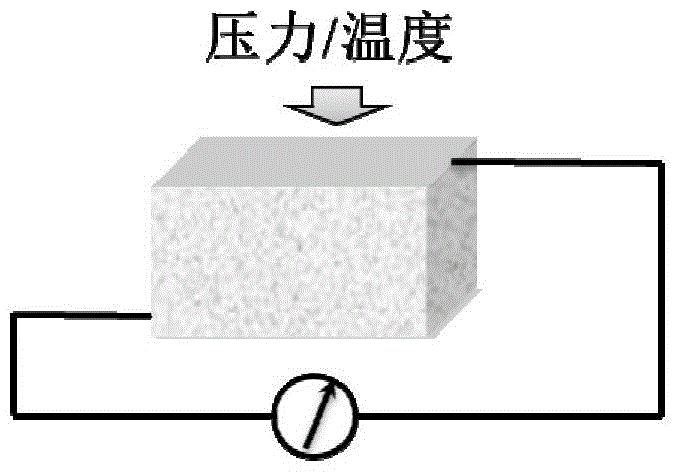

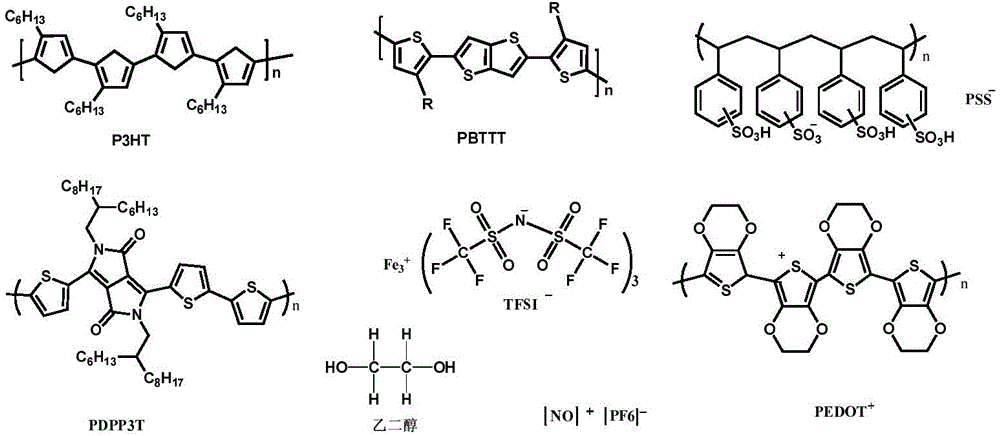

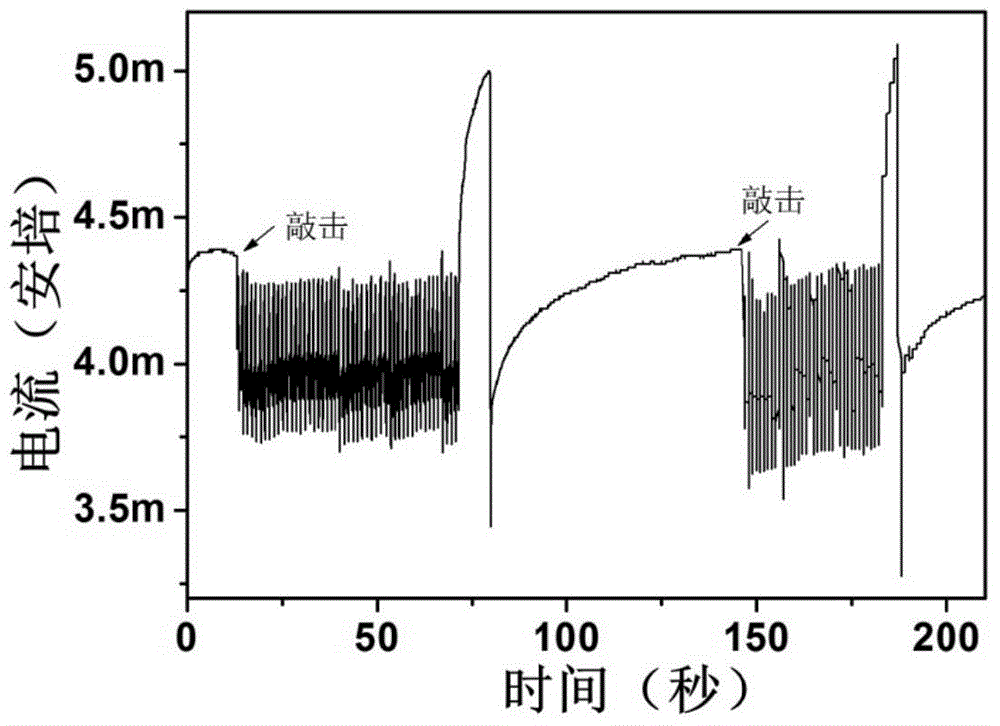

Flexible multifunctional sensor, preparation method and application thereof

ActiveCN105374926AUniversalAchieve pressureThermoelectric device manufacture/treatmentConverting sensor output electrically/magneticallyElastic networkThermoelectric materials

The invention discloses a flexible multifunctional sensor, a preparation method and an application thereof. The flexible multifunctional sensor comprises electrode layers and a flexible composite material layer, wherein two electrode layers exist and are respectively arranged at two sides of the flexible composite material layer and cover the flexible composite material layer. According to the flexible multifunctional sensor, the physical property of a thermoelectric material is used for realizing thermoelectric power generation and realizing temperature sensing. Furthermore the composite material with an elastic net structure can realize resistive pressure sensing. Based on a voltage signal and a current signal, real-time monitoring for pressure and temperature can be realized simultaneously. When a thermoelectric material composite system bears the function of a temperature field and a pressure field, a voltage signal and a current signal can be simultaneously generated. If the generated voltage is large enough, the flexible multifunctional sensor can be used as a self-powered multifunctional sensor. Through patterning an integrated matrix, selection between voltage storage and multifunctional sensing can be realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

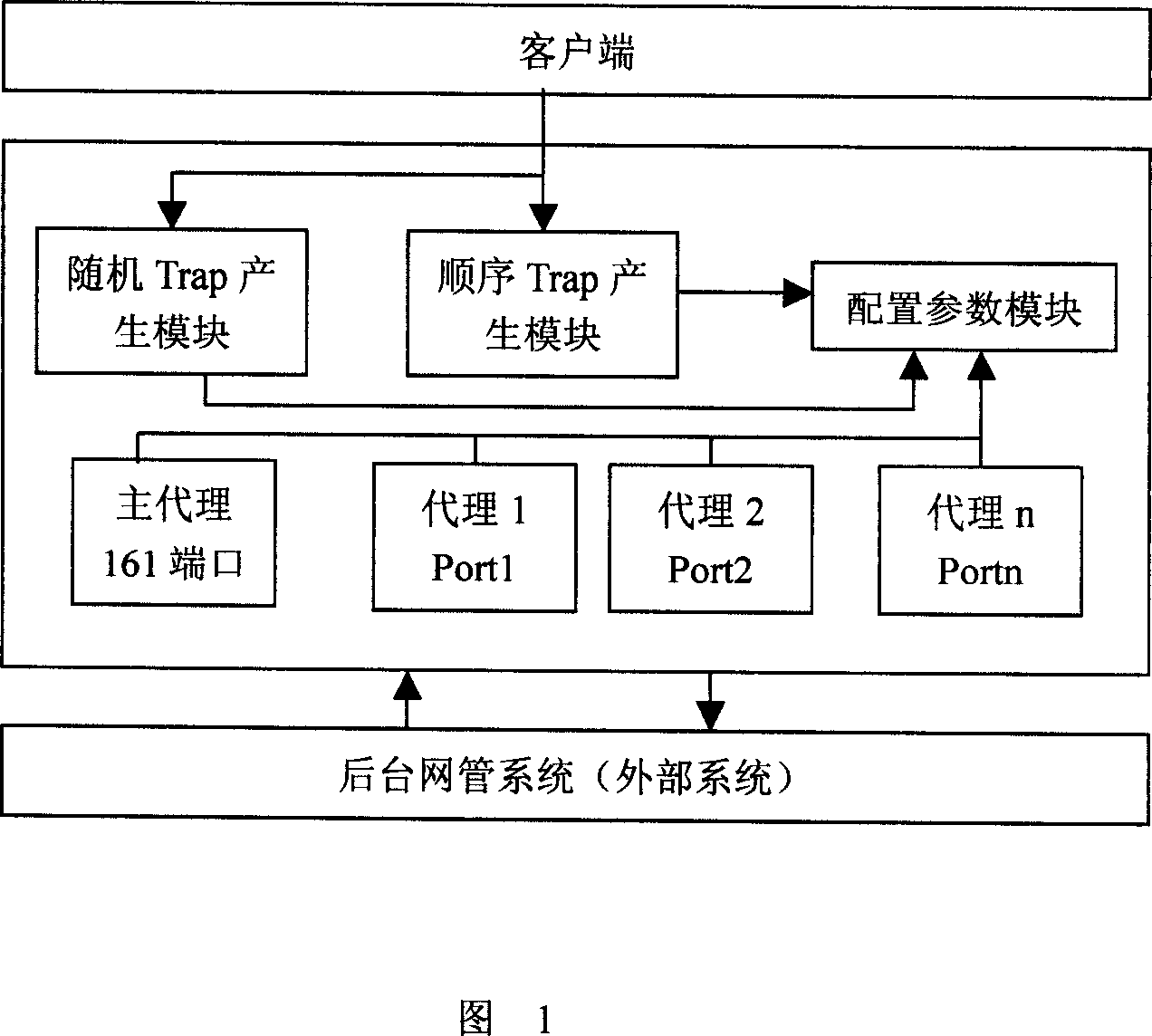

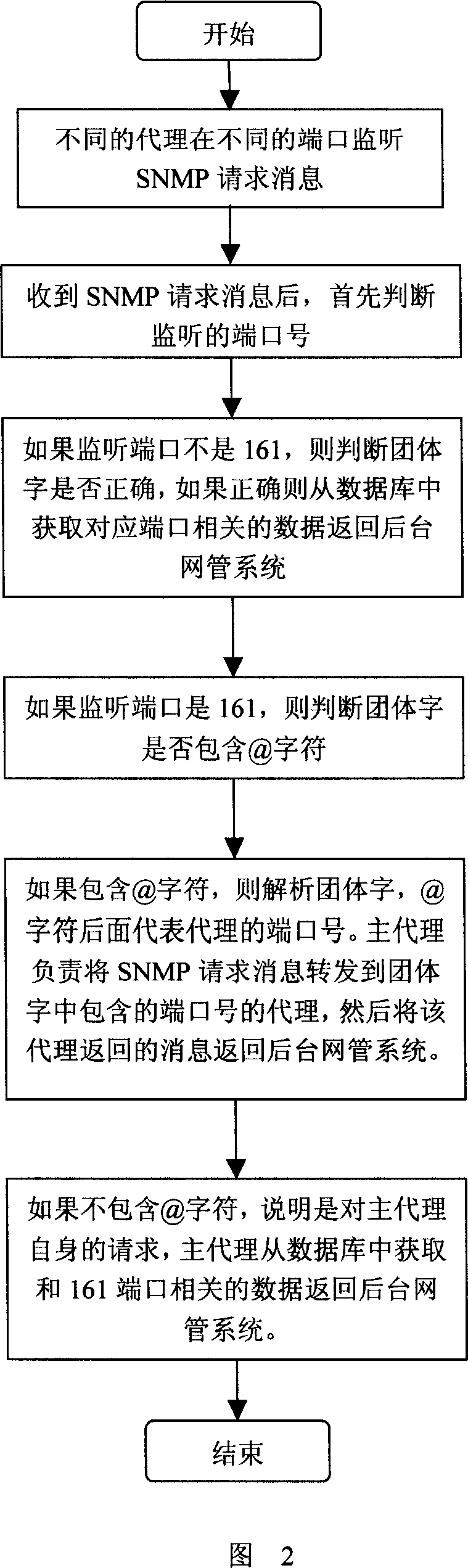

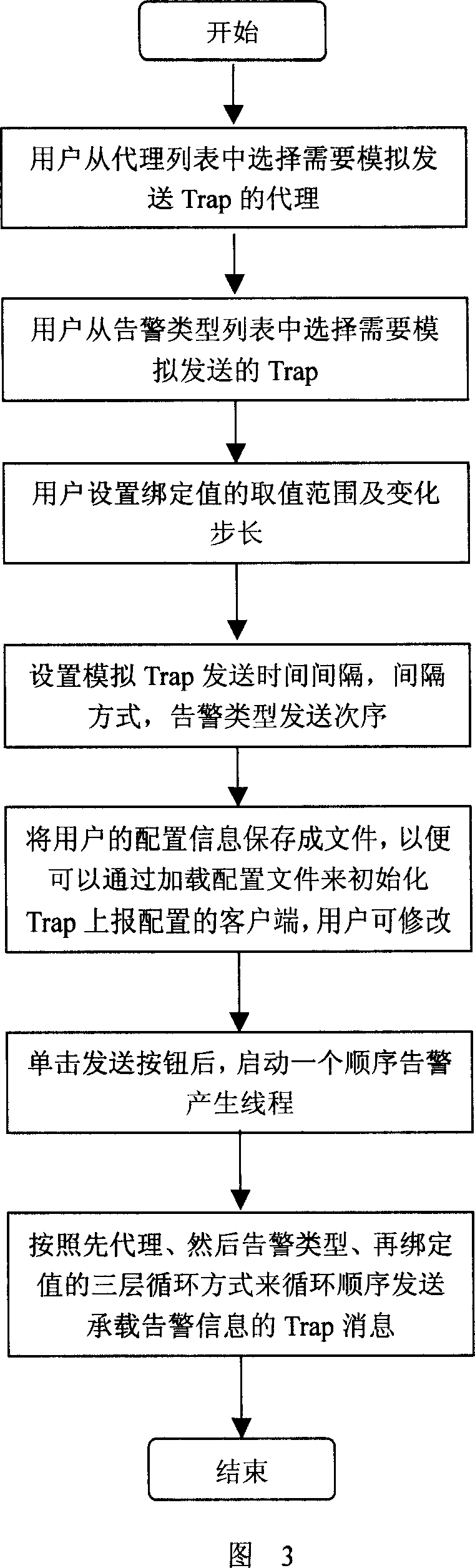

Method of simulating SNMP network element and performing network management system test with the network element

InactiveCN1992635AAchieve pressureImplement performance testingData switching networksSystem testingNetwork management

A simulation SNMP network element includes the configuration parameter module, the agent module, the sequence traps generation module and the random traps generation module; using the network element to process network management system test method: when the simulation network element startup, according to the configuration file, initializing; setting simulation agents number, the listening port number when each agent startup, and parameters and rules to simulated send alarm; at the different port number, activating multiple SNMP monitor threads; when SNMP monitoring thread receives SNMP request information, it returns the command execution result to the background network manager; using sequence order to submit Trap message to the background network manager, to debug the background network management alarm function; using random sending mode to submit the Trap message to the background network manager, to simulate the real warning handling process of the foreground network element. The invention can use simulation large-scale network elements in the laboratory to achieve the pressure and performance testing of the background network manager, and also reduce the time waiting for co-debug of the background network management.

Owner:ZTE CORP

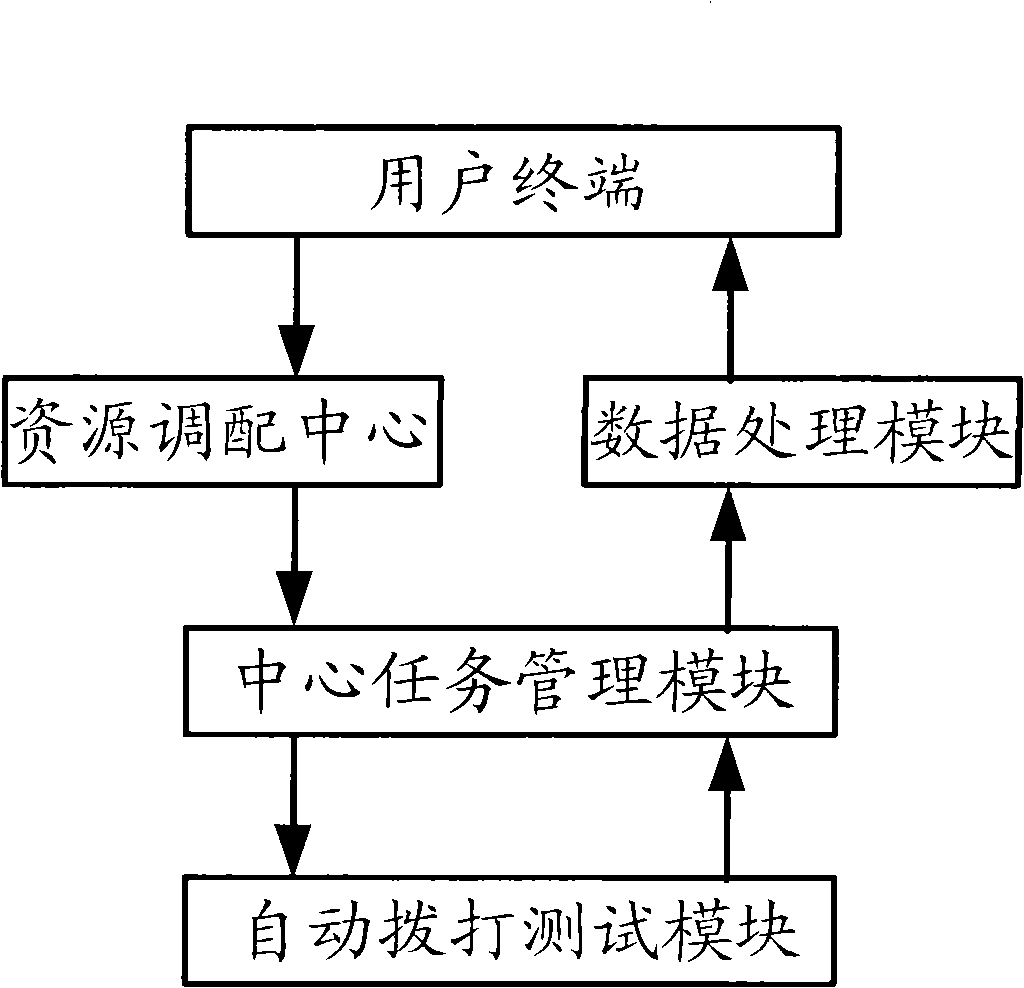

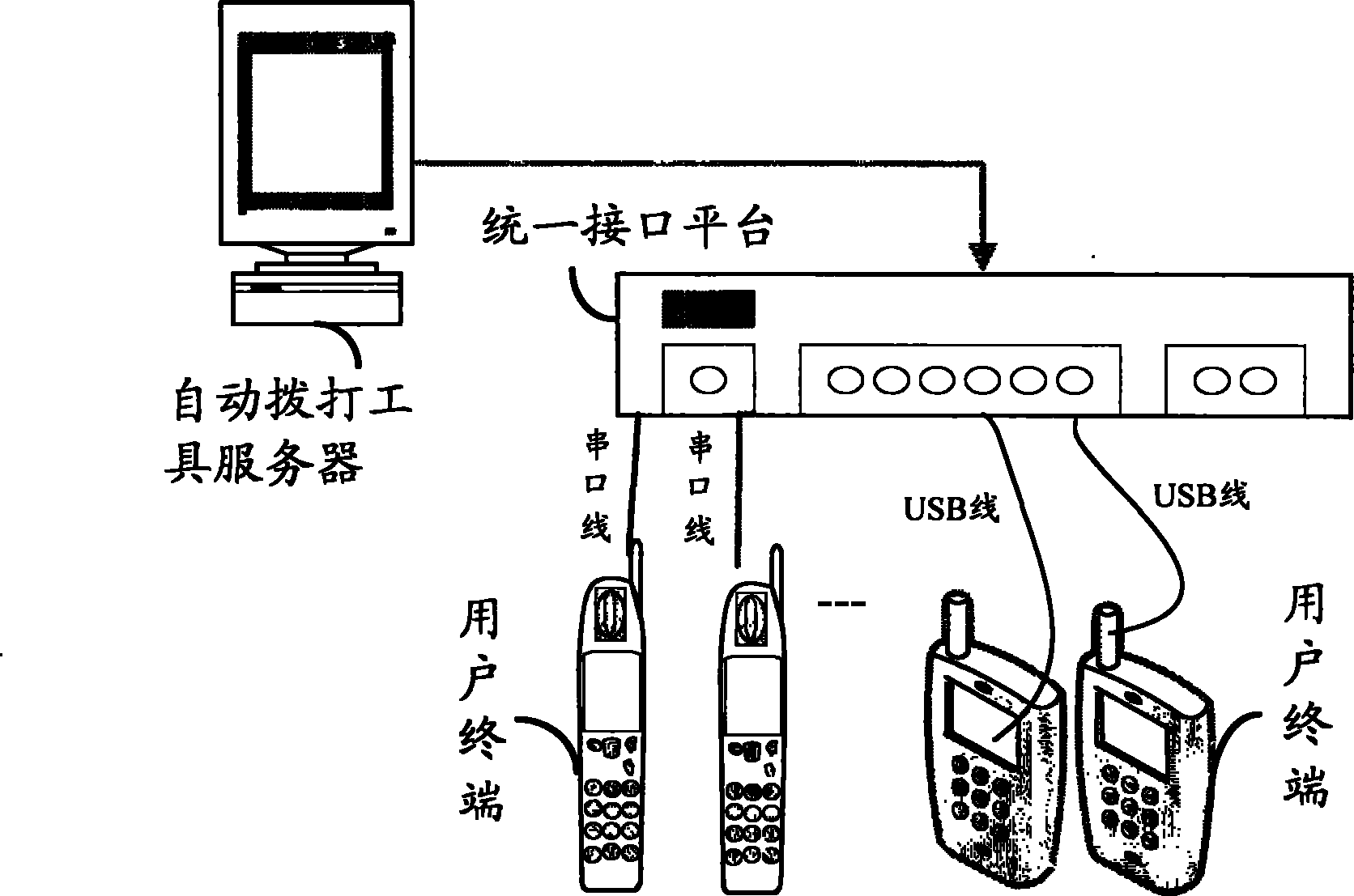

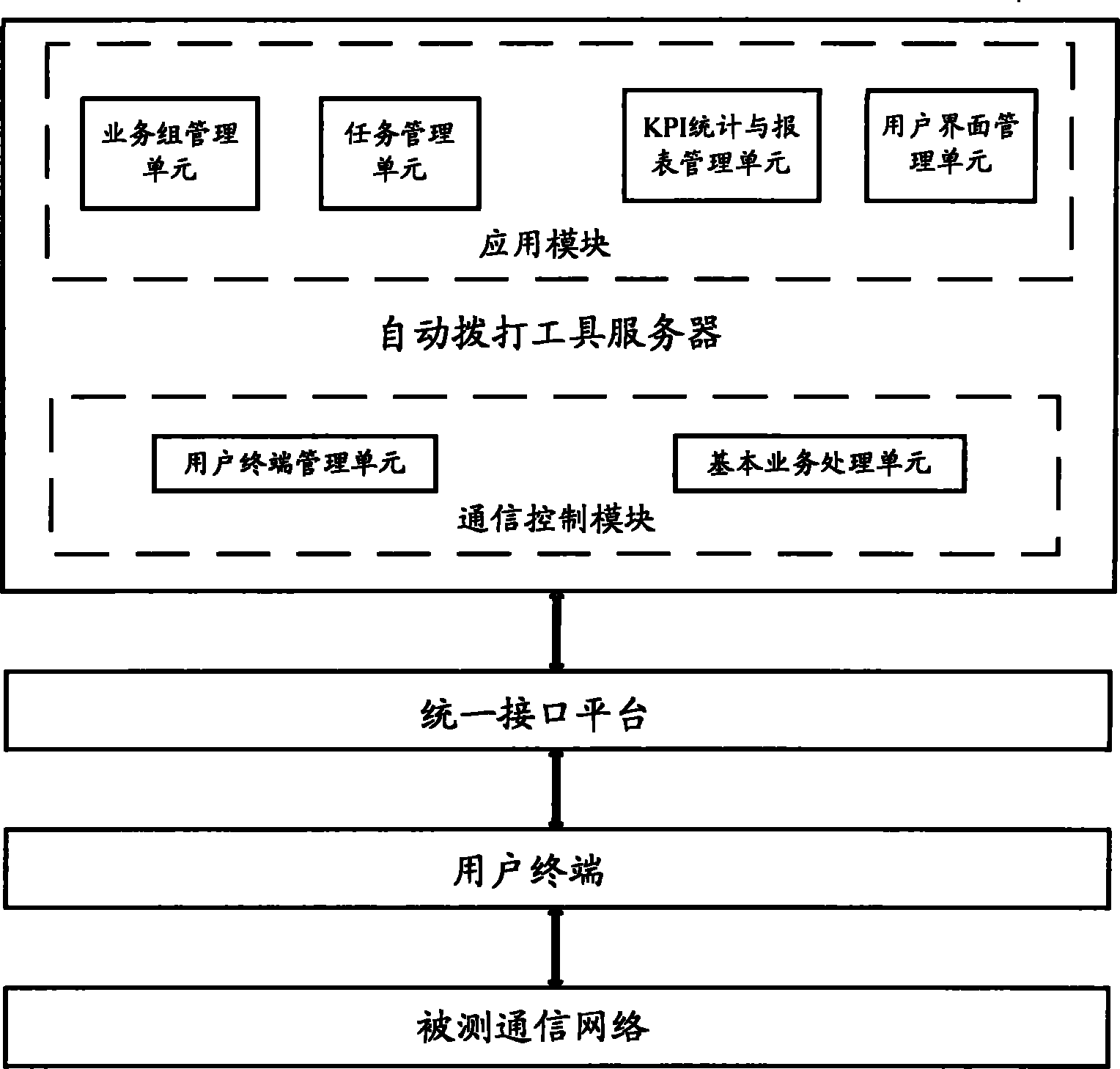

Apparatus for testing network performance parameter, system thereof, and method thereof

InactiveCN102487345AAchieve pressureImplement performance testingData switching networksTest efficiencyData information

The invention discloses an apparatus for testing network performance parameter, a system thereof, and a method thereof. The method comprises the following steps: acquiring information of all user terminals with different interface forms, wherein, the user terminals are connected with a unified interface platform; supporting a flexible telephone traffic model set function, and forming an AT instruction packaged with a test service parameter; outputting the AT instruction to the user terminals which are connected with the unified interface platform, and controlling the user terminals to carry out a test according to a set telephone traffic model; according to the received AT instruction, carrying out a network performance parameter test by the terminals, and feeding back test data information; receiving the test data information returned by the user terminals by an automatic calling server, carrying out processing to obtain a network performance test parameter, and automatically generating a KPI statistics form and a test report. By applying the apparatus, the system and the method of the invention, high capacity pressure and performance tests of a communication network can be realized, and reliability of test data and test efficiency are raised.

Owner:CHINA POTEVIO INFORMATION IND

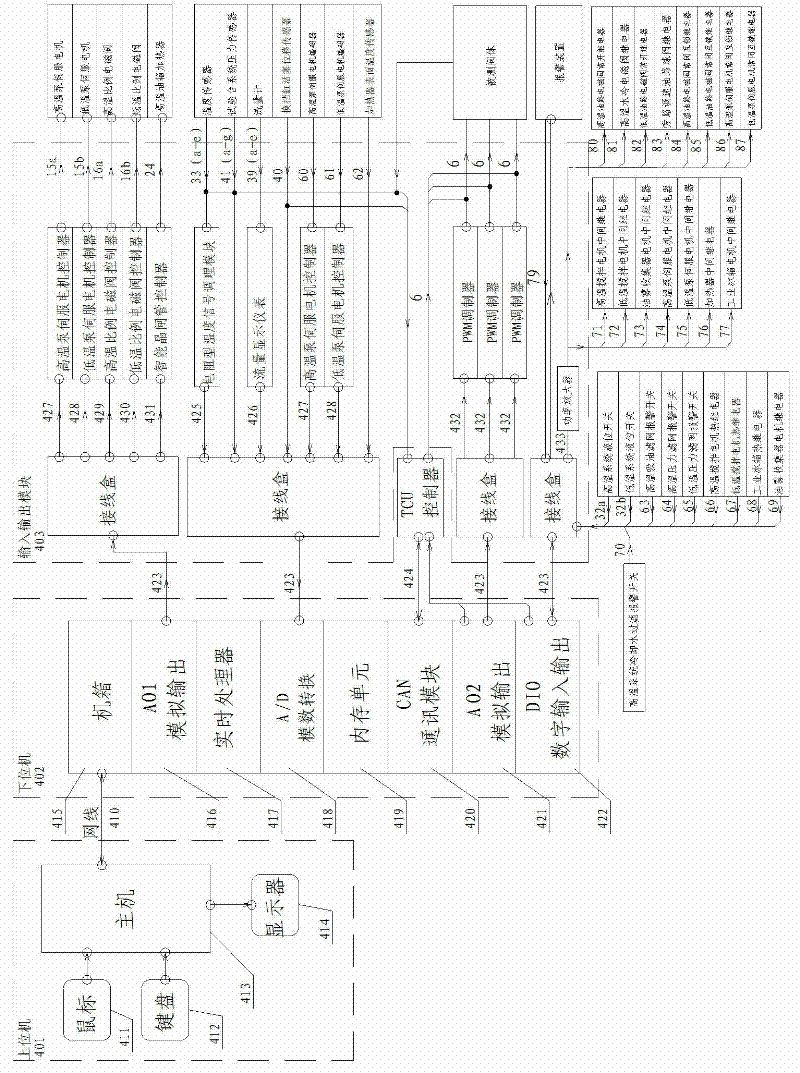

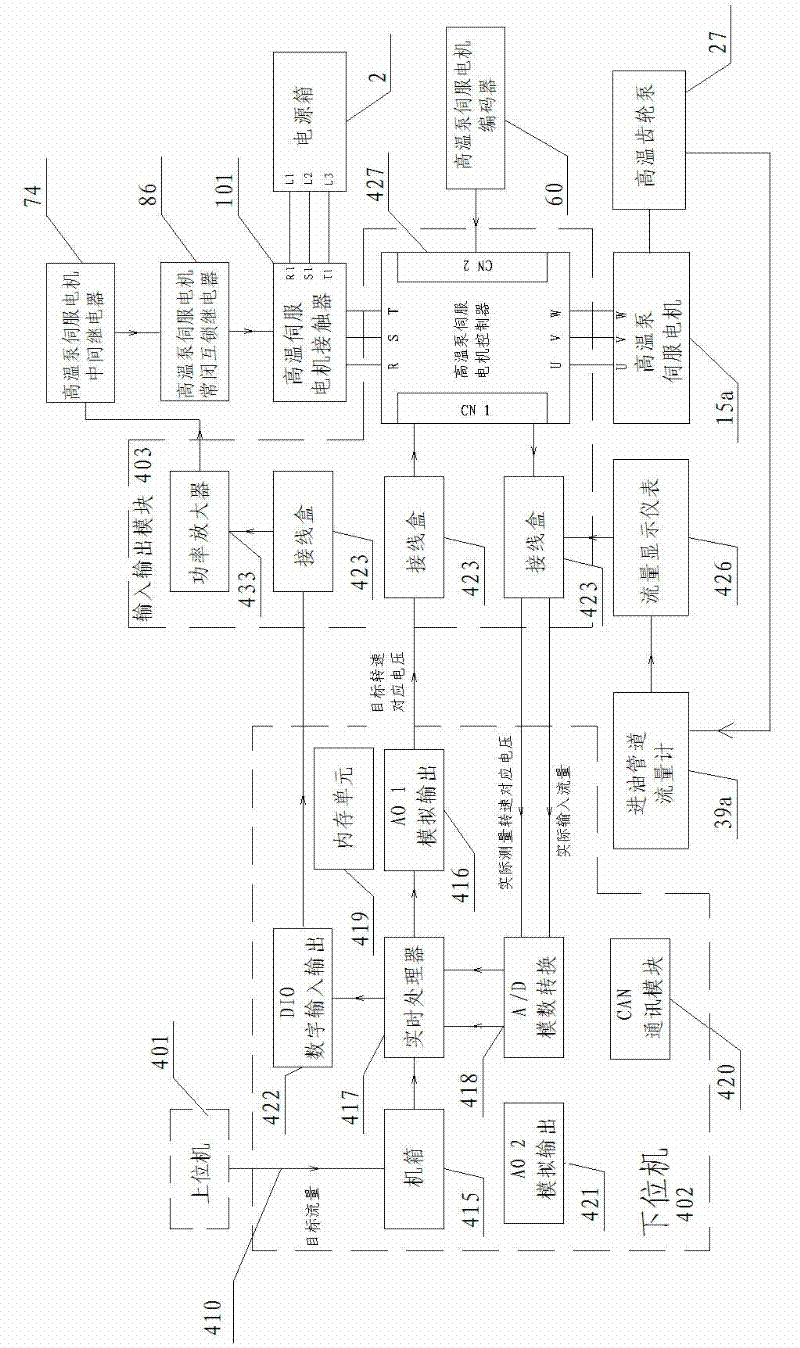

Electro-hydraulic control system of high/ low temperature test stand of automobile automation transmission valve body

ActiveCN102354168ARealize simulationAchieve pressureMachine gearing/transmission testingTotal factory controlHydraulic circuitData acquisition

The invention discloses an electro-hydraulic control system of a high / low temperature test stand of an automobile automation transmission valve body. The system comprises: an electric control system and a high / low-temperature hydraulic system. The electric control system comprises: an upper computer, a lower computer, an input / output module and a transmission control unit (TCU) controller. The input / output module and the TCU controller are connected with the lower computer as a dual redundant control mode. The valve body to be detected is directly controlled by a dual redundant control system. The high / low-temperature hydraulic system comprises an independently controlled high-temperature hydraulic circuit and a low-temperature hydraulic circuit, a high / low-temperature shared circuit which is connected with the high-temperature hydraulic circuit and the low-temperature hydraulic circuit and a detected hydraulic system which is connected with the high / low-temperature shared circuit. The detected valve body is arranged in the detected hydraulic system. In the invention, hierarchical control formed by the upper computer, a lower real-time controller and real-time interface control are adopted; through a CAN communication and signal interface module and a dual redundant valve plate control scheme which is connected with the TCU, a requirement of high speed data acquisition and test in the valve body test under the condition of the high / low temperature and operation parameter simulation can be satisfied.

Owner:CHONGQING TSINGSHAN IND

Current for acceptor current enter and reflux

InactiveCN101062660AAchieve insulationSimple mechanical structurePower current collectorsElectricityEngineering

The invention relates to the electric receiving device of the electric vehicle. The current receiver for current in and return comprises the electric boots and the spring device, with two parallel parallelogram four linking bar structure and a separation structure, each four link structure made by the top and down lining bars hinged to the corresponding side plate and isolation plate, the separation structure composed of the air cylinder, air cylinder linking pole hinged to the cylinder piston end, lower linking brake bar with two rocker arms with the lower linking brake bar hinged to the lower linking bar pin shaft fixed to two side walls, one of the rocker arm hinged to the air cylinder linking bar, the other being the stop leaning against the low linking bar, each isolation plate bottom installed with an electric receiving boot, each four link bar structure having its top link bar connected to the said spring device. It solves the technical issues of current receiver contact or separation with the electric supply track smoothly, and the grounding issue of it.

Owner:SHANGHAI MAGNETIC SUSPENSION COMM ENG TECH RES CENTE +1

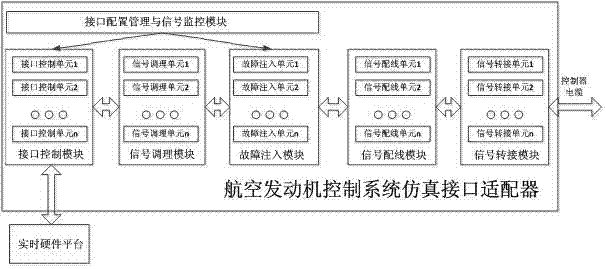

Simulated interface adapter of aircraft engine control system

InactiveCN104765281AIncrease flexibilityIncrease opennessSimulator controlSignal conditioningMaintainability

The invention discloses a simulated interface adapter of an aircraft engine control system. The simulated interface adapter comprises an interface configuration management and signal monitoring module, a signal switching module, a signal wiring module, a fault injection module, a signal conditioning module and an interface control module. The interface configuration management and signal monitoring module is connected with the signal switching module, the signal wiring module, the fault injection module, the signal conditioning module and the interface control module. The signal switching module, the signal wiring module, the fault injection module, the signal conditioning module and the interface control module are sequentially connected. The signal switching module is connected with a controller of the aircraft engine control system. The interface control module is connected with an external real-time hardware platform. The open and modularized overall simulated structure is adopted for separating all the modules from one another, the real-time simulated platform of various interfaces is supported, and expansibility and maintainability are remarkably improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

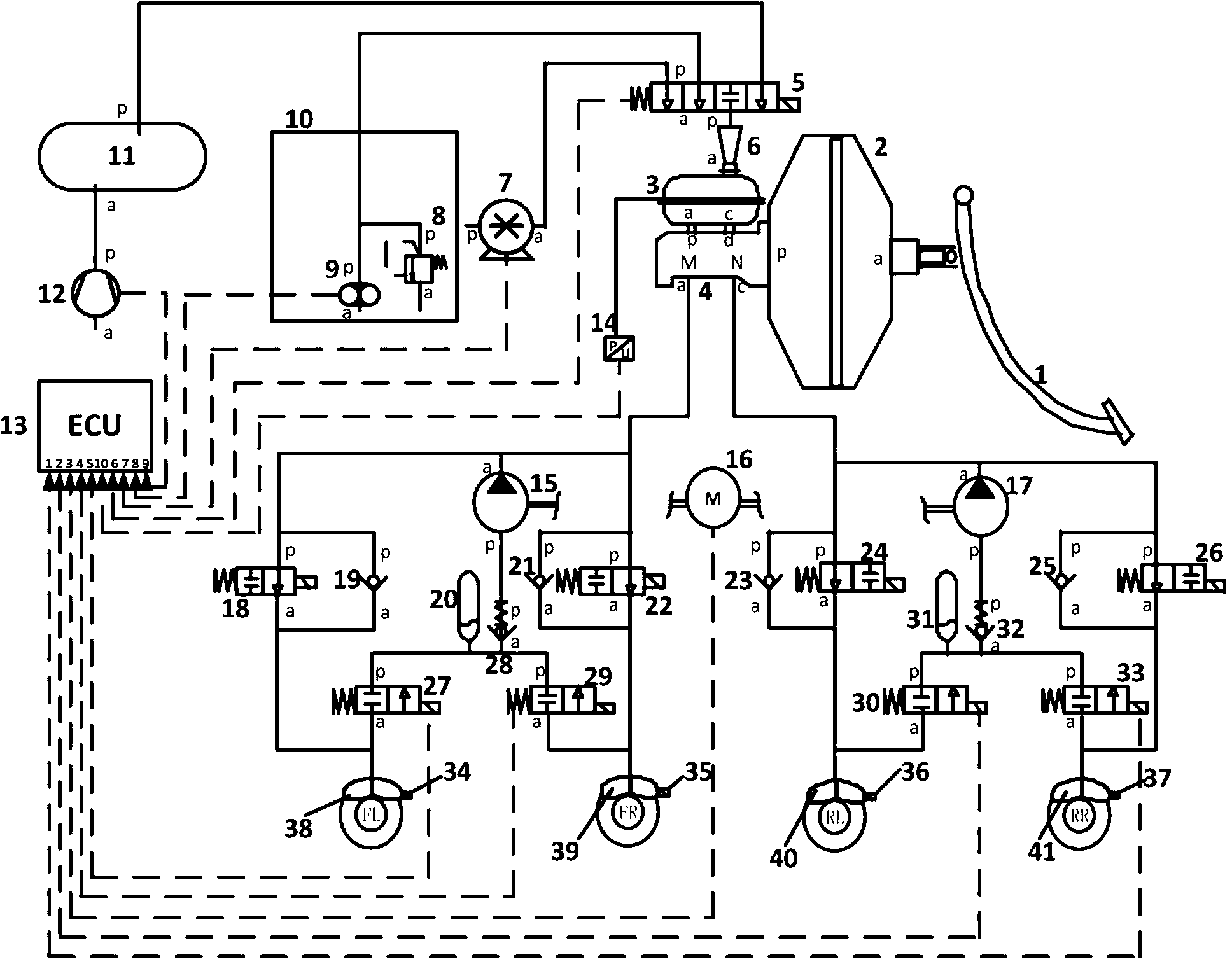

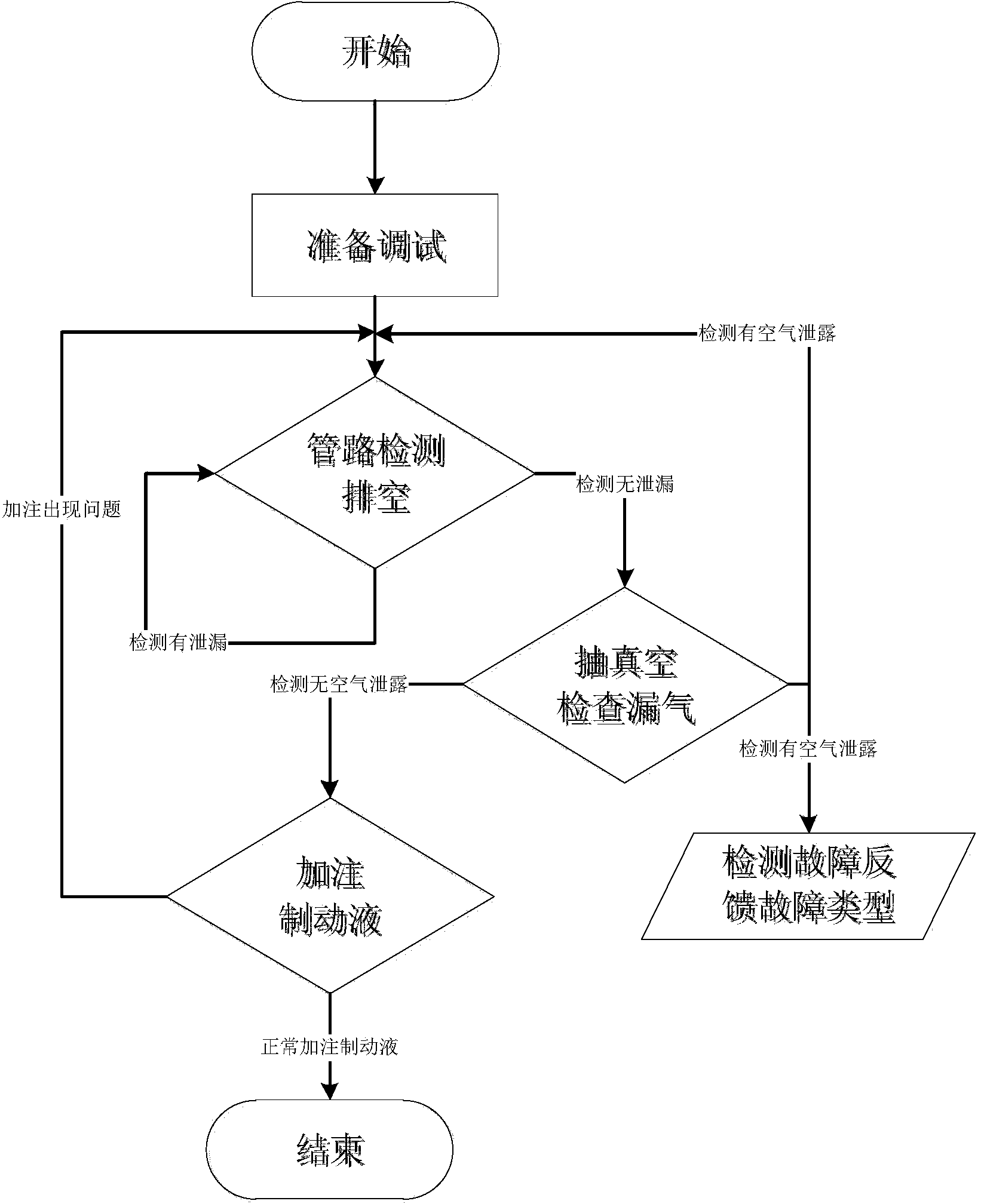

Exhaust gear applied to automotive hydraulic braking system and control method

InactiveCN104228809AEasy to controlEnables venting pressure monitoringBraking action transmissionPiping arrangementsAir compressorActuator

The invention discloses an exhaust gear applied to an automotive hydraulic braking system and a control method, and aims to overcome the problems that the structure is complex, the cost is high, and pipeline detection and the exhaust of a secondary loop in a hydraulic braking system of a vehicle with an ABS (anti-lock braking system) and an ESP (electronic stability program) during the exhaust process of the braking system cannot be completed in the prior art. The exhaust gear applied to the automotive hydraulic braking system comprises a braking control mechanism, a hydraulic regulating unit, exhaust filling equipment, a braking actuator and an exhaust control unit ECU, wherein the exhaust filling equipment comprises a four-position two-way electromagnetic valve, a filling gun, a vacuum pump, a pressure-limiting valve, an oil pump, an air pressure tank and an air compressor; the p port of the filling gun is in tube connection with the a port of the four-position two-way electromagnetic valve; the p port of the four-position two-way electromagnetic valve is in tube connection with the a port of the vacuum pump, the p port of the oil pump and the p port of the air pressure tank; the p port of the pressure-limiting valve is in tube connection with the p port of the oil pump; the a port of the air pressure tank is in tube connection with the p port of the air compressor. The invention also provides the control method adopting the exhaust gear applied to the automotive hydraulic braking system.

Owner:JILIN UNIV

Narrow-band distributed feedback laser wavelength scanning fiber bragg grating sensing device

InactiveCN101852626AChange the output wavelengthAchieve temperatureForce measurement by measuring optical property variationThermometers using physical/chemical changesDistributed feedback laserFiber

The invention discloses a narrow-band distributed feedback laser wavelength scanning fiber bragg grating sensing device, which senses and detects external physical quantities in the following way that: the device comprises a current-driven distributed feedback laser controlled by a temperature control circuit; light emitted from the laser enters a sensing fiber bragg grating through an optical isolation unit; the light passing through the fiber bragg grating enters an opto-electric receiving unit and then enters a control analysis unit in a form of electrical signal; the output wavelength of the distributed feedback laser can be regulated by changing a control temperature; and a grating reflection centre wavelength and a corresponding external physical quantity are reckoned according to an extremum output by the opto-electric receiving unit when the output wavelength of the laser is matched with the fiber bragg grating reflection centre wavelength by temperature scanning. Compared with a conventional structure where sensing is realized by performing wavelength demodulation at the output end of the fiber bragg grating with a broadband light source, the narrow-band distributed feedback laser wavelength scanning fiber bragg grating sensing device has the characteristics of great production cost reduction, and miniature and low-cost engineering.

Owner:SOUTHWEST JIAOTONG UNIV

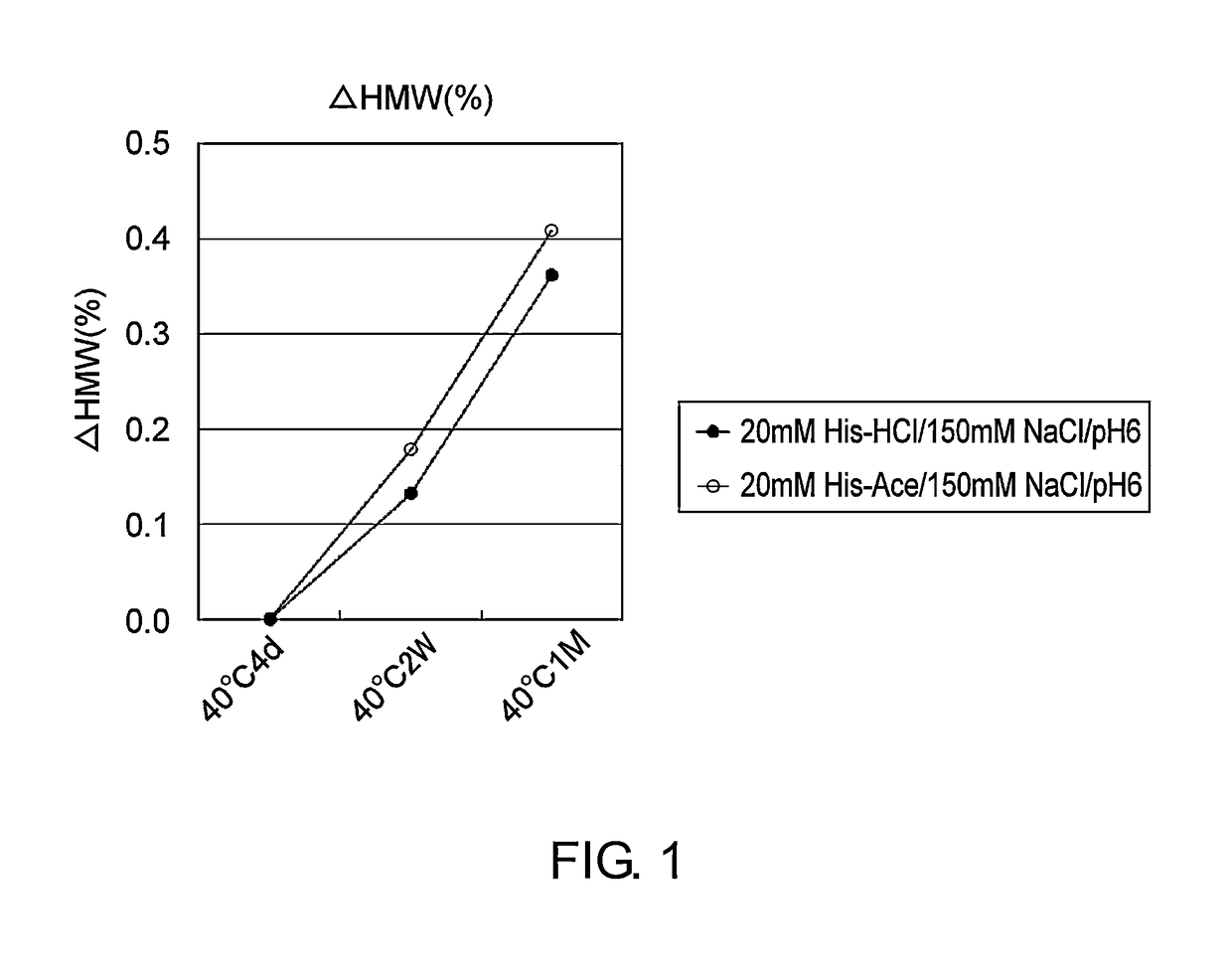

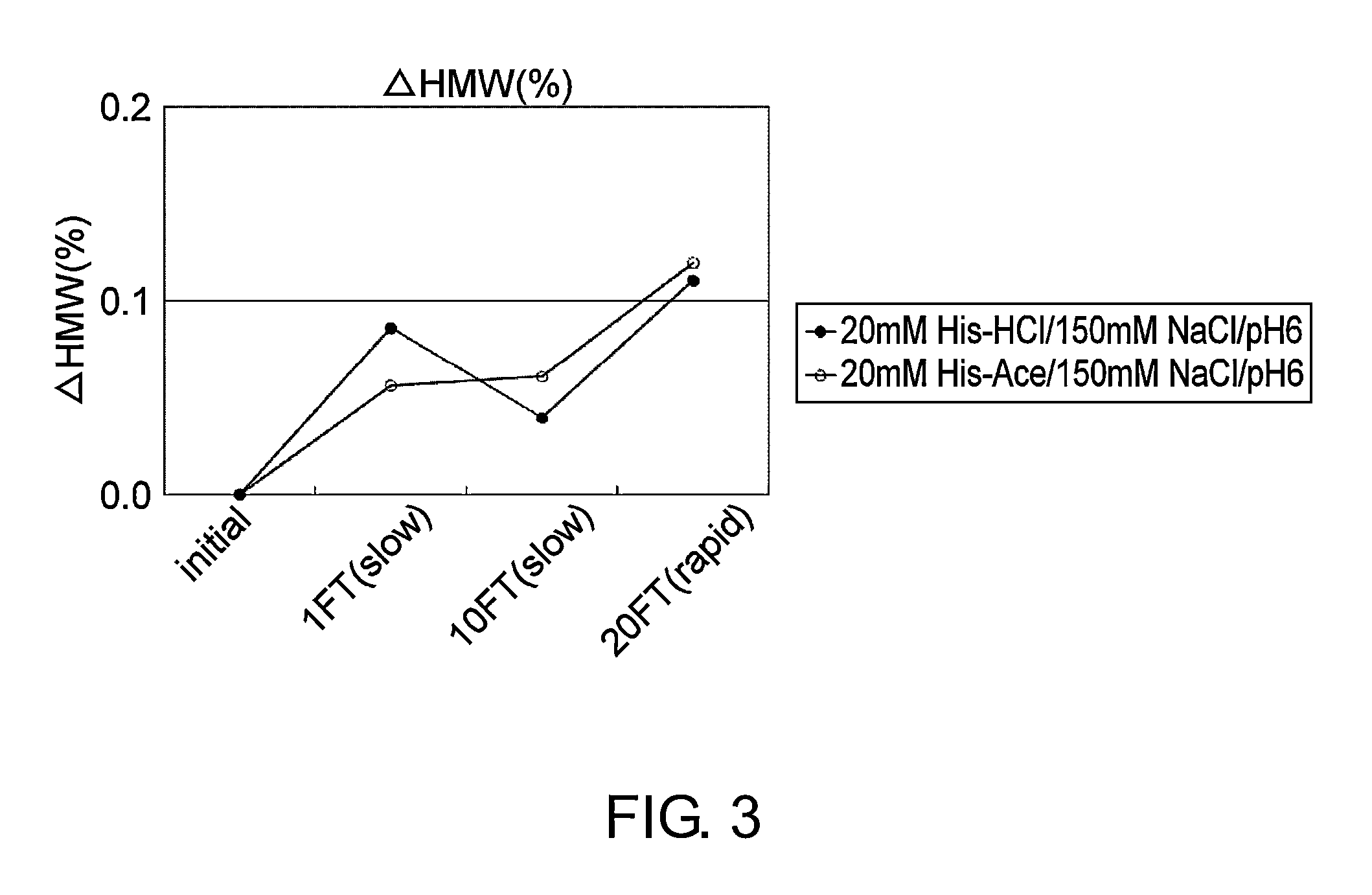

Stabilized antibody-containing liquid formulations

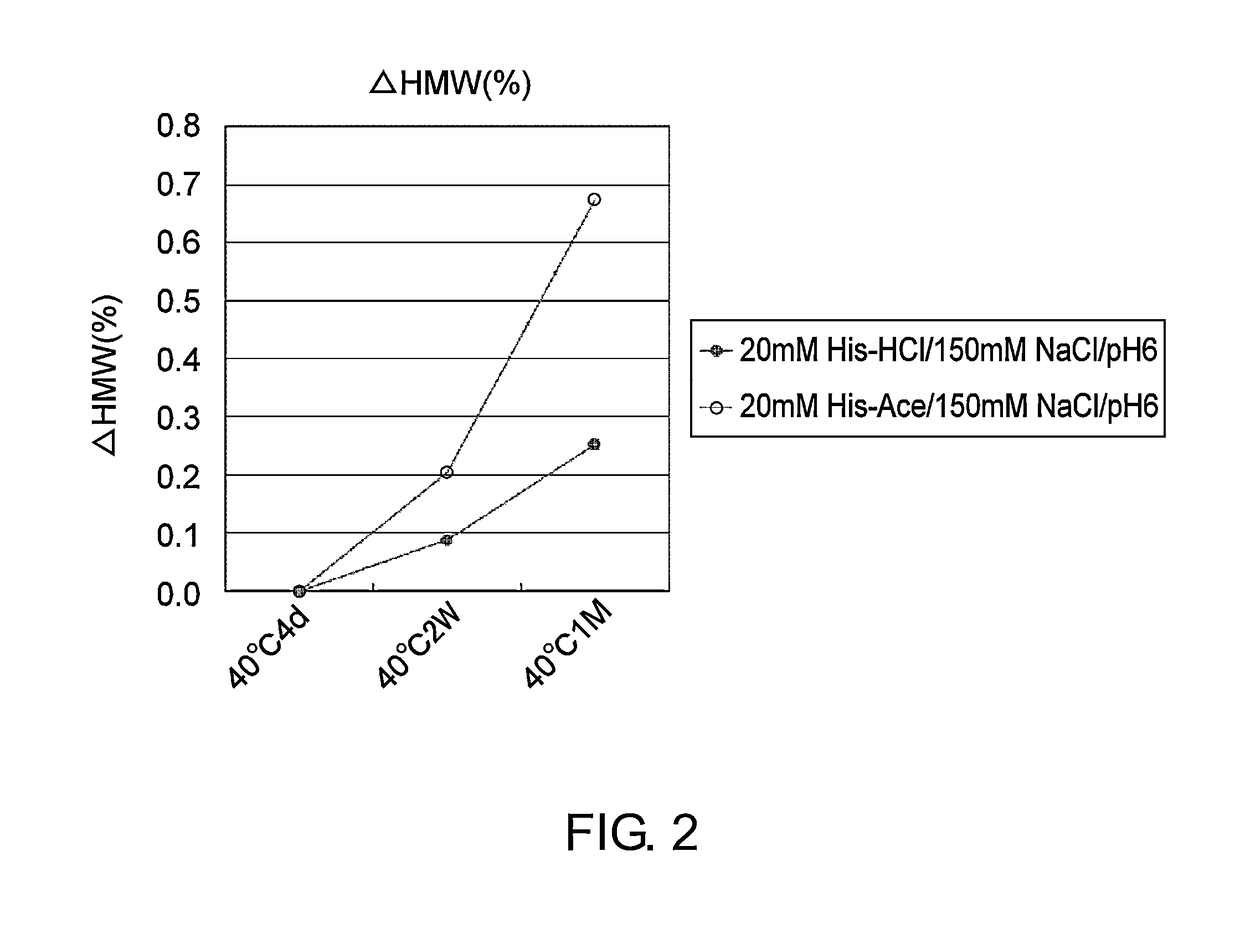

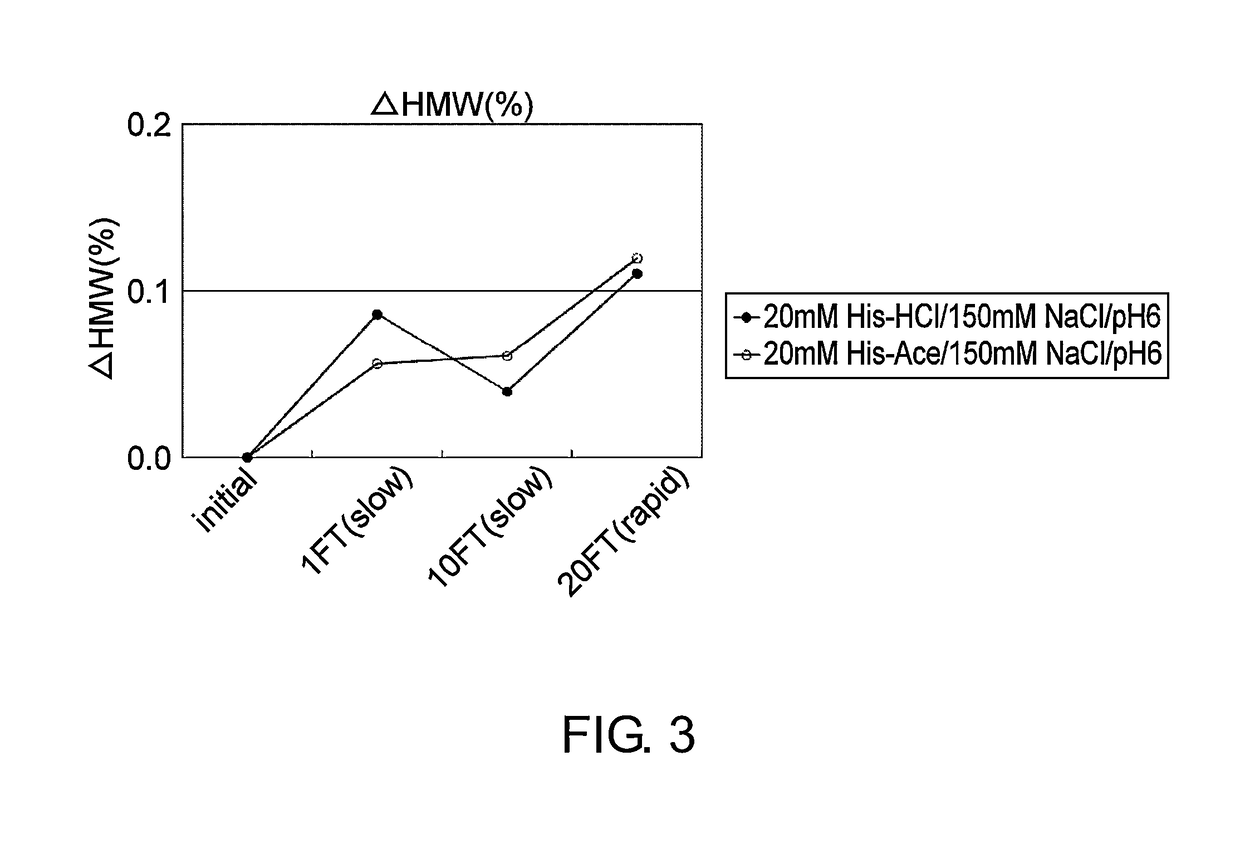

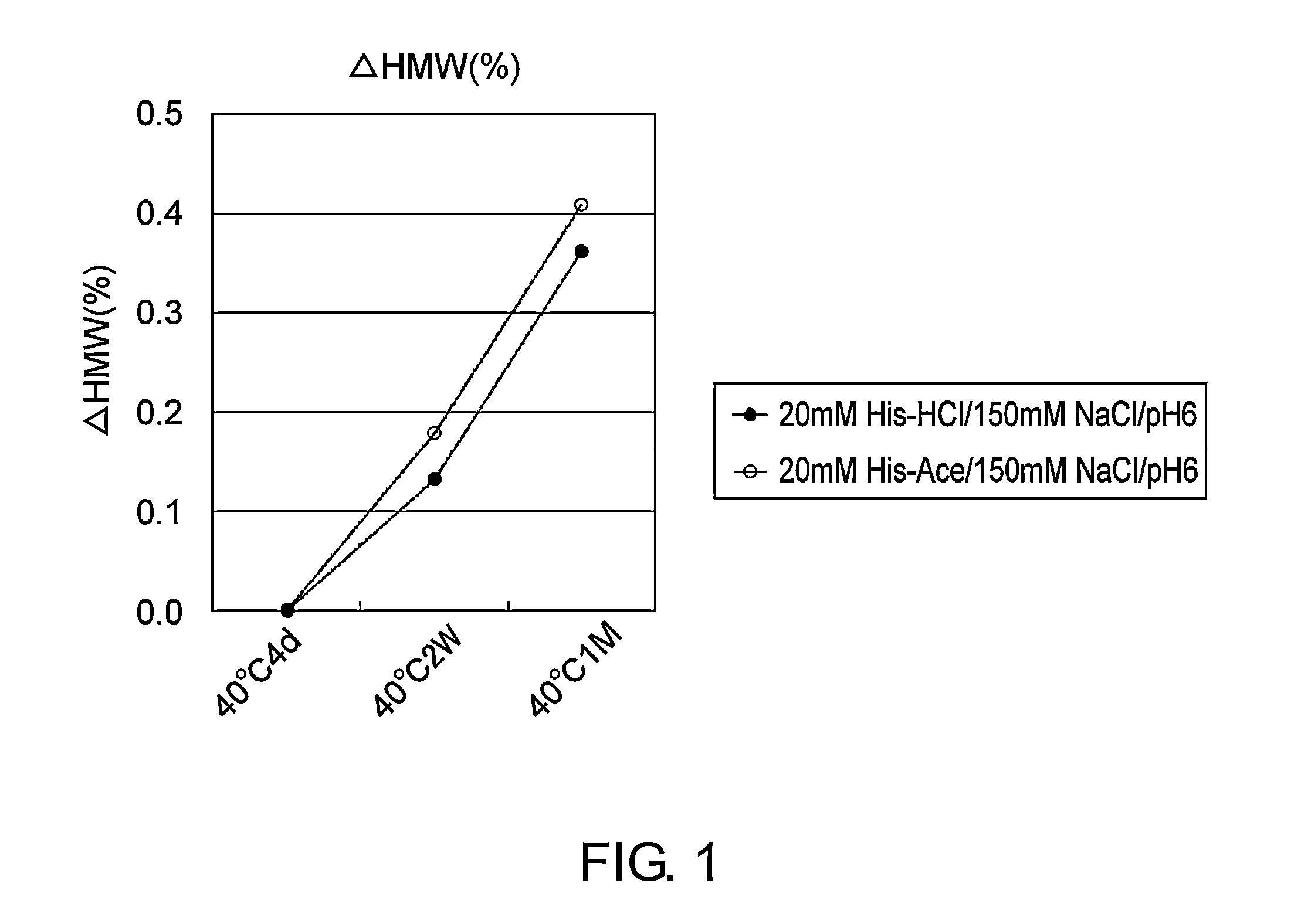

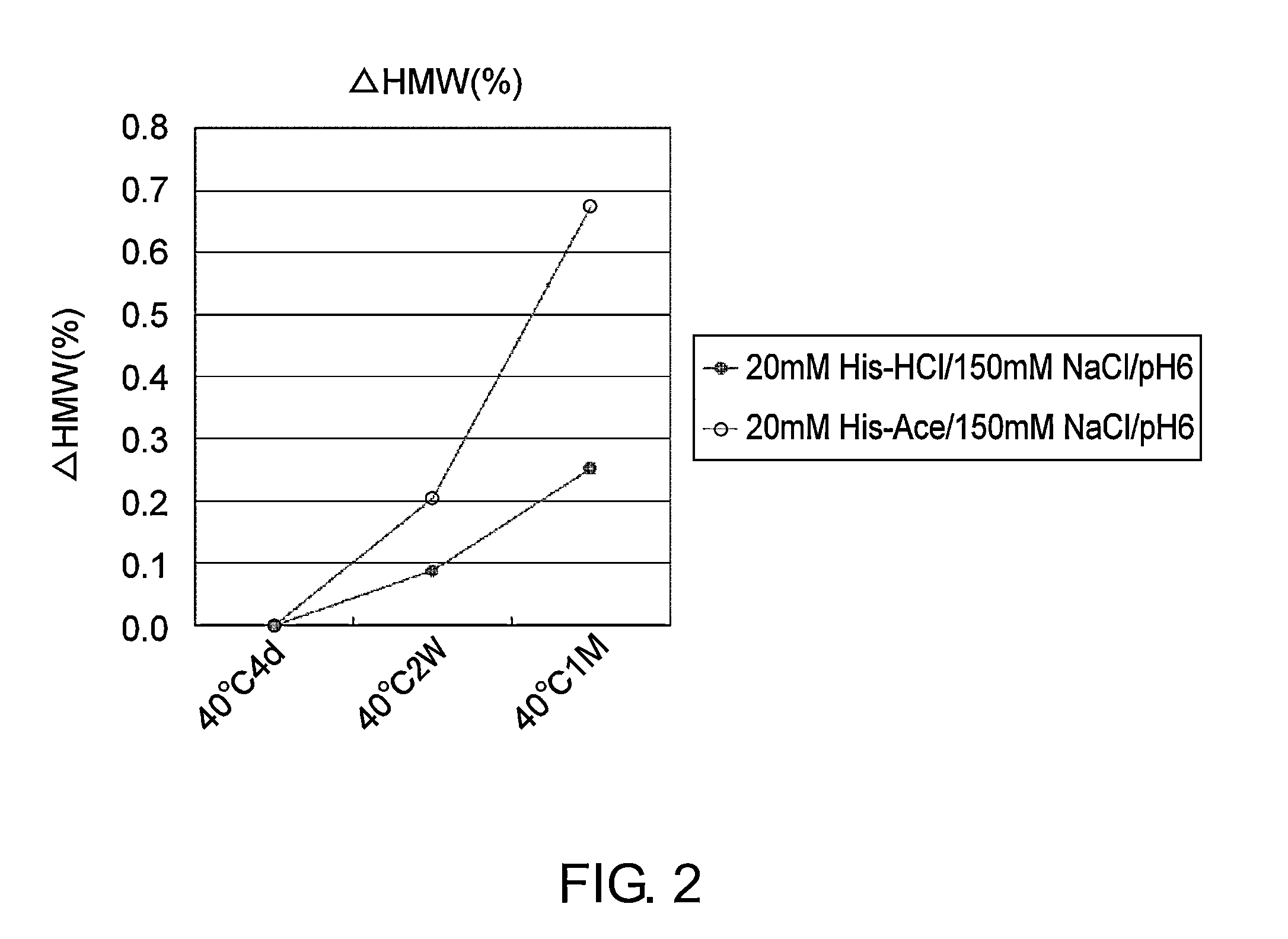

ActiveUS10022319B2Improve stabilityStable storageAntibody ingredientsImmunoglobulinsArginine glutamateSignificant Stabilization

An objective of the present invention is to provide stable antibody-containing formulations which are suitable for subcutaneous administration and in which aggregation formation is suppressed during long-term storage.The present inventors discovered that a significant stabilization effect was achieved by using an acidic amino acid, aspartic acid or glutamic acid as a counter ion species in histidine buffer or tris(hydroxymethyl)aminomethane, specifically by using histidine-aspartate buffer or histidine-glutamate buffer, or tris(hydroxymethyl)aminomethane-aspartate or tris(hydroxymethyl)aminomethane-glutamate as a buffer. The present inventors also discovered that a significant stabilization effect was achieved by using an acidic amino acid, aspartic acid or glutamic acid, as a counter ion species to a basic amino acid such as arginine, specifically by using arginine-aspartate or arginine-glutamate.

Owner:CHUGAI PHARMA CO LTD

Stabilized Antibody-Containing Liquid Formulations

ActiveUS20130022625A1Improve stabilityStable storageImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsSignificant StabilizationHistidine

An objective of the present invention is to provide stable antibody-containing formulations which are suitable for subcutaneous administration and in which aggregation formation is suppressed during long-term storage.The present inventors discovered that a significant stabilization effect was achieved by using an acidic amino acid, aspartic acid or glutamic acid as a counter ion species in histidine buffer or tris(hydroxymethyl)aminomethane, specifically by using histidine-aspartate buffer or histidine-glutamate buffer, or tris(hydroxymethyl)aminomethane-aspartate or tris(hydroxymethyl)aminomethane-glutamate as a buffer. The present inventors also discovered that a significant stabilization effect was achieved by using an acidic amino acid, aspartic acid or glutamic acid, as a counter ion species to a basic amino acid such as arginine, specifically by using arginine-aspartate or arginine-glutamate.

Owner:CHUGAI PHARMA CO LTD

Liquid pressure forming method of composite material

The invention belongs to a resin based composite material liquid forming technique, and relates to a composite material liquid pressure forming method. The periphery of a predetermined mold body is filled with resin, and the predetermined mold body is continuously pressurized and cured successively by resin via a first pressure source and a second pressure source. According to the invention, the predetermined mold body is pressurized and cured continuously by resin; a molded composite material product not only has high fiber volume content equivalent to a composite material molded by a prepreg / autoclave technique, but also has the high precision equal to the composite material molded by an RTM technique; the applicable range of the composite material molded by a liquid forming technique is expanded; the molding efficiency is improved obviously; the manufacturing cost is reduced.

Owner:AVIC COMPOSITES

Method for recovering relief gas in process for examining and repairing gas pipe network

The invention discloses a recovery device for leaked gas in the maintaining operation process of gas pipe network, comprising a pressure device provided with a gas inlet and a gas outlet, a gas inlet pipeline, a gas outlet pipeline, a maintaining side pipeline, an operation side pipeline, an inert gas bomb and an air inlet; wherein the maintaining side pipeline and gas inlet pipeline are connected by a control valve (81); the operation side pipeline and gas outlet pipeline are connected by a control valve (82); the other sides of the maintaining side pipeline and operation side pipeline are respectively connected with a hose tube; the maintaining side pipeline and gas outlet pipeline are connected by a control valve (83); the operation side pipeline and gas inlet pipeline are connected by a control valve (84); the inert gas bomb is connected with the maintaining side pipeline by a control valve; and the air inlet is connected with the gas inlet pipeline by a control valve. The recovery device recycles and uses the gas wasted in traditional operation manner, polluting atmospheric environment and having potential safety hazard, substantially implements zero emission and avoids safety accident.

Owner:HUASHEN GAS BURNING IND TIANJIN

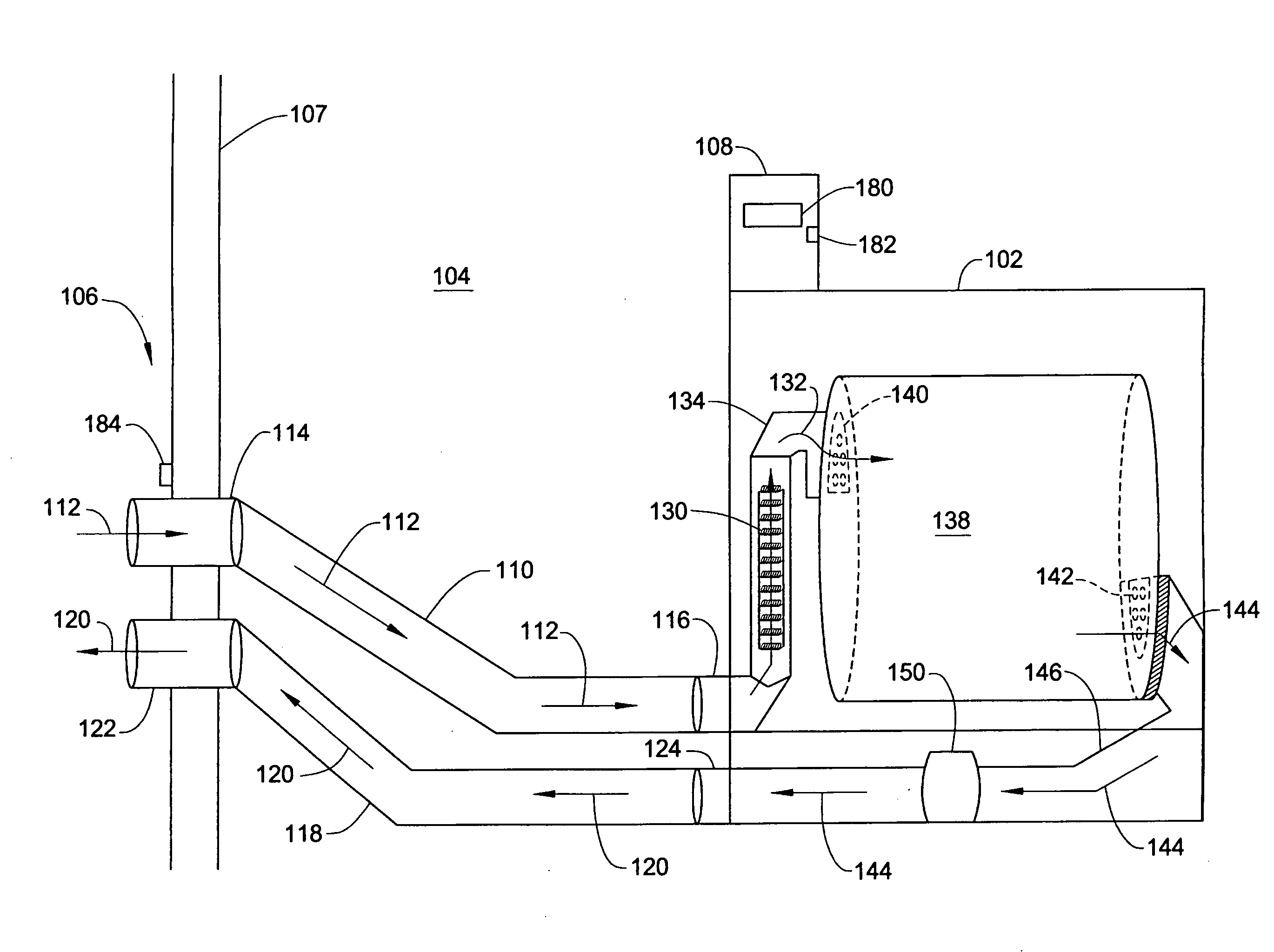

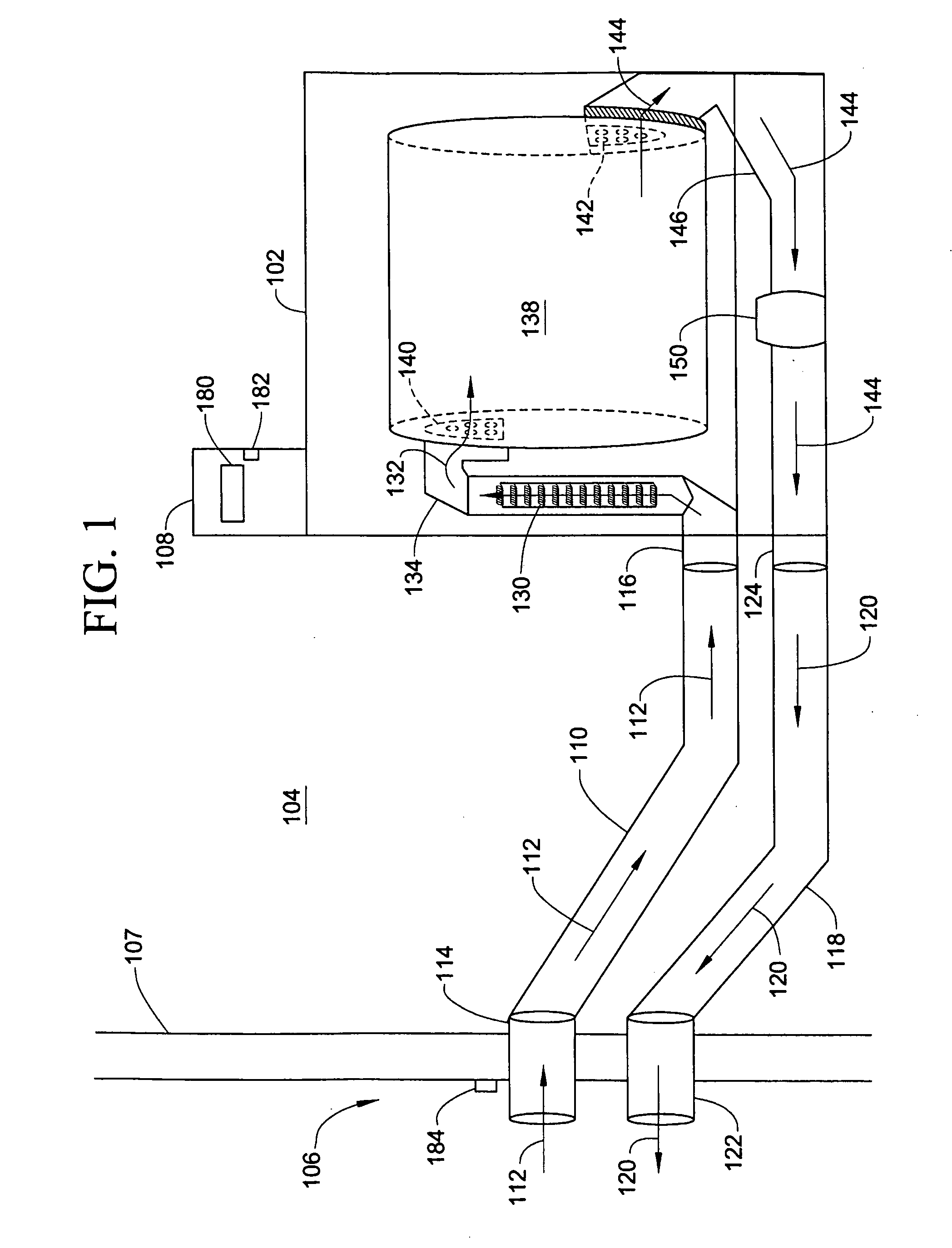

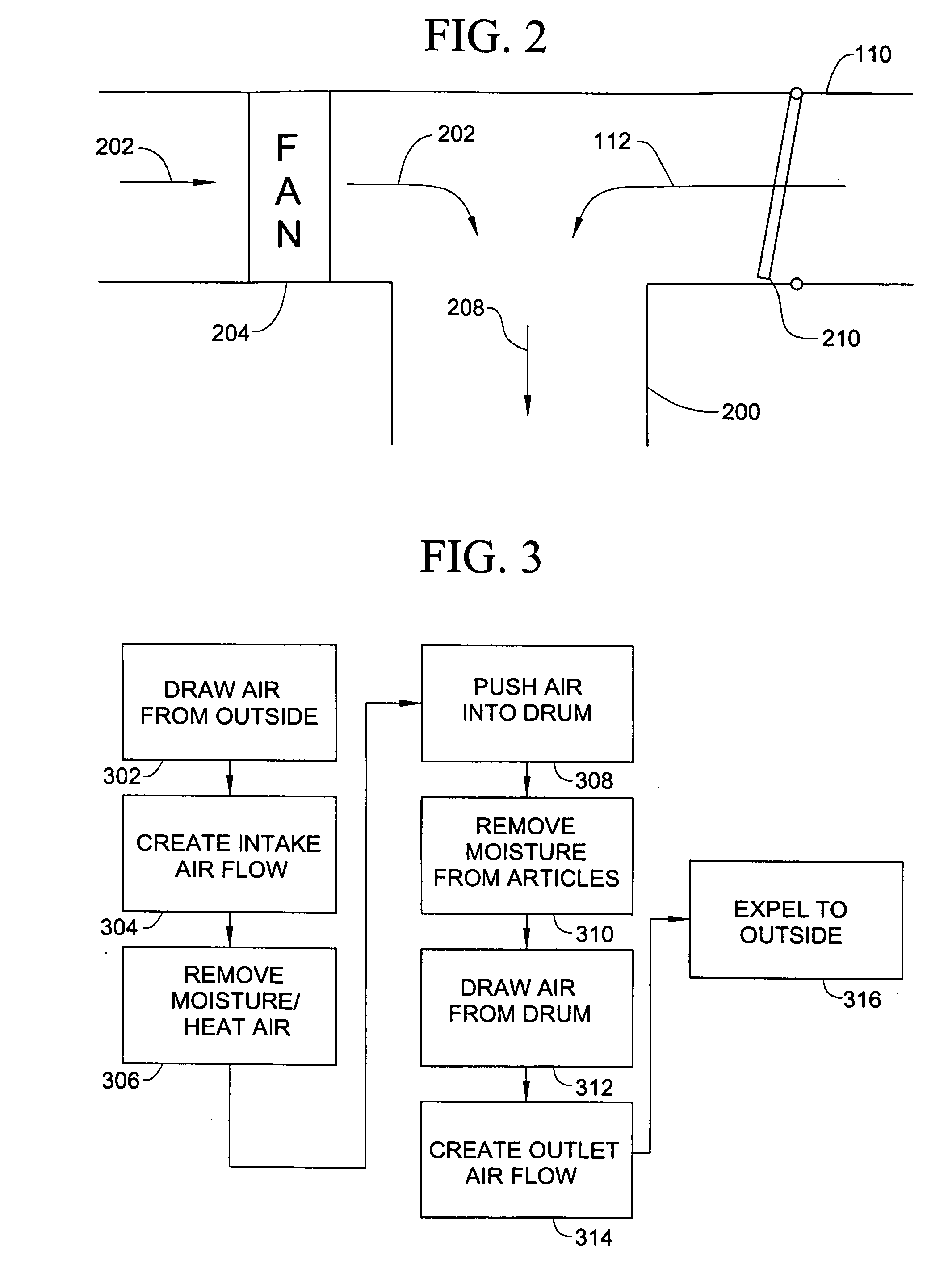

Dryer and adapter having ducting system

InactiveUS20090205220A1Improve drying efficiencyReduce energy consumptionDrying solid materials with heatDrying gas arrangementsEngineeringEnergy expenditure

An adapter to a dryer, or a new configuration to a dryer, allows articles, such as clothes, towels, sheets and the like to dry with reduced energy consumption. The adapted configuration draws air from outside the room or structure housing the dryer. The outside air is then used to dry the articles. The outside air can be heated within the dryer using the existing heater prior to entering the drum holding the articles. After the heated air removes moisture from the articles, the moist, hot air is expelled outside the room or structure through an outlet air duct. Thus, air within the room or structure is not used for the drying process and conditions such as temperature and pressure are not changed when the dryer is on.

Owner:PROTEGE ENTERPRISES

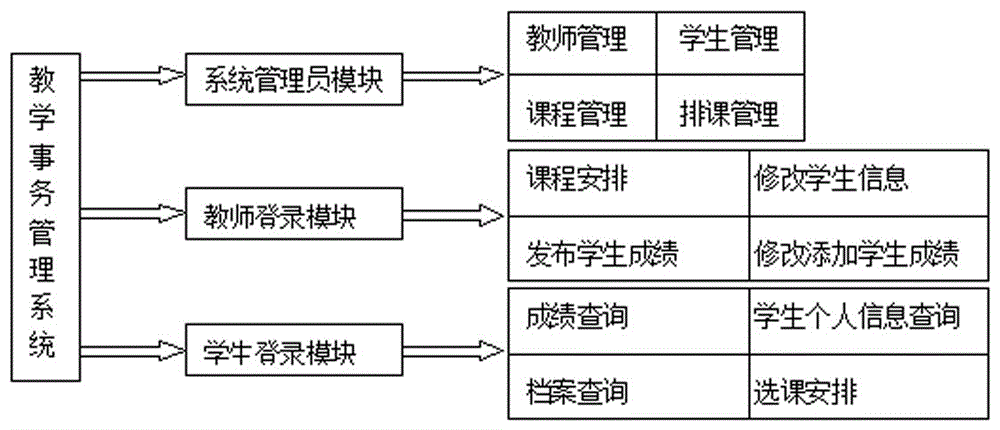

College teaching affair management system

InactiveCN106530155AAchieve pressureRelieve stressData processing applicationsThe InternetManagement efficiency

The invention discloses a college teaching affair management system and the system is used for managing the interaction between teachers and students at various types of colleges. The system comprises a system administrator module used for maintaining the normal operation and the security settings of the system; a teacher login module used for enabling a teacher to manage students in a class managed by the teacher; and a student login module used for managing and viewing the personal information of students. When teachers and students are managed based on the system, each student needs to log in a course selection system to select courses. Therefore, the pressure on teachers and students at colleges is alleviated. Compared with the traditional manual operation mode with the problems of data loss, statistical errors, high labor intensity and slow speed, data can be transmitted over the internet, so that the data sharing is realized after the interconnection of the system. As a result, the repeated operation is avoided, and teaching management behaviors are standardized. In this way, the management efficiency and the management level are improved.

Owner:BEIHAI YISHENGYUAN AGRI TRADE CO LTD

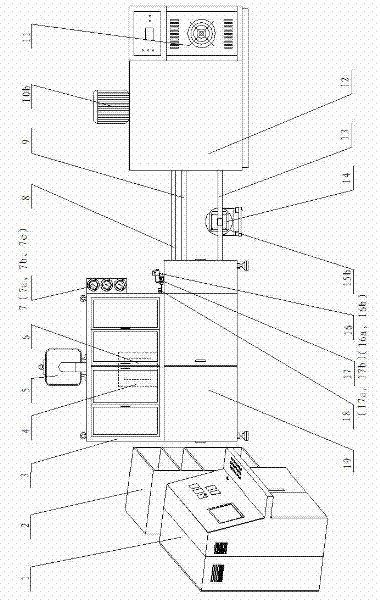

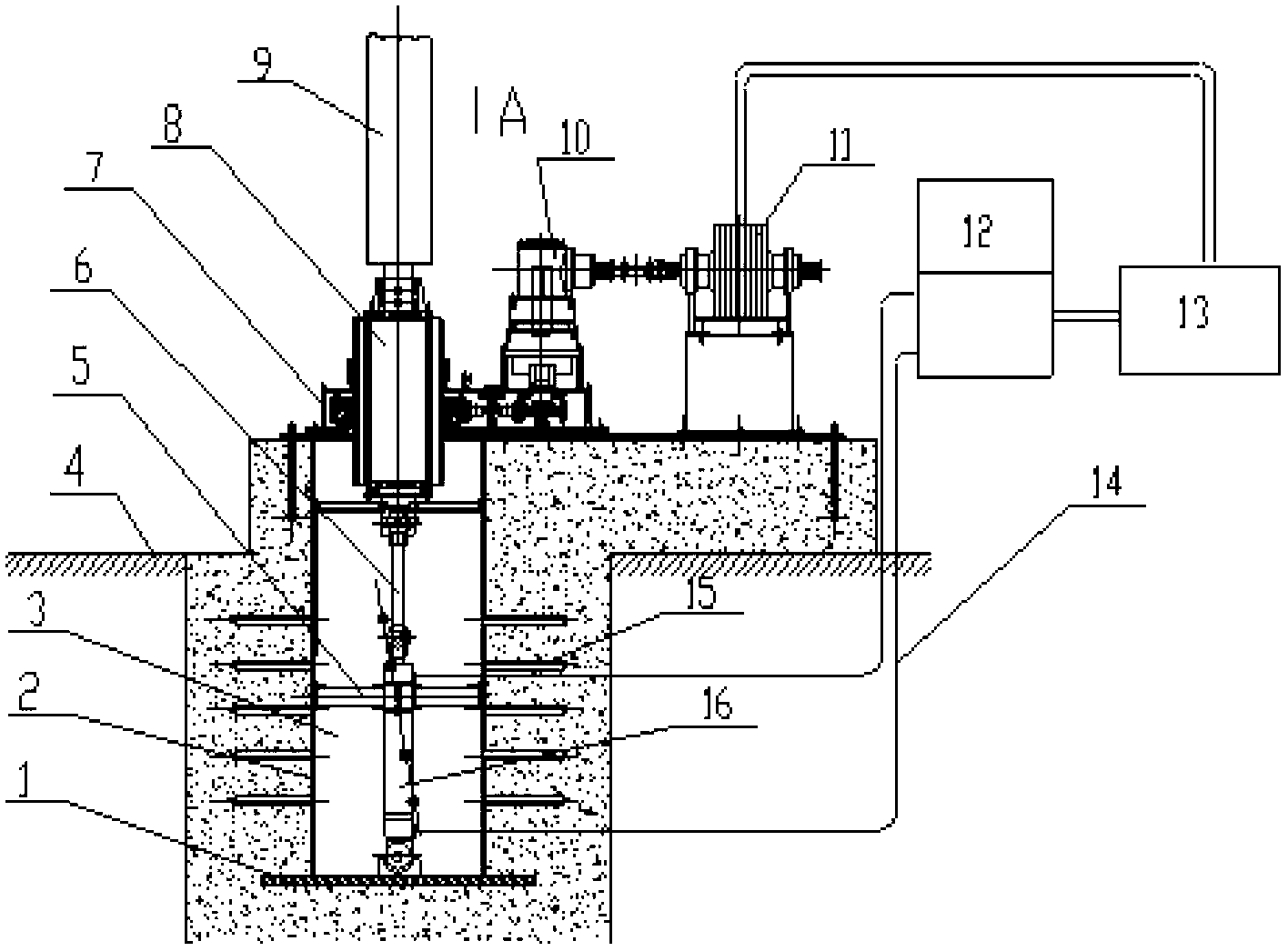

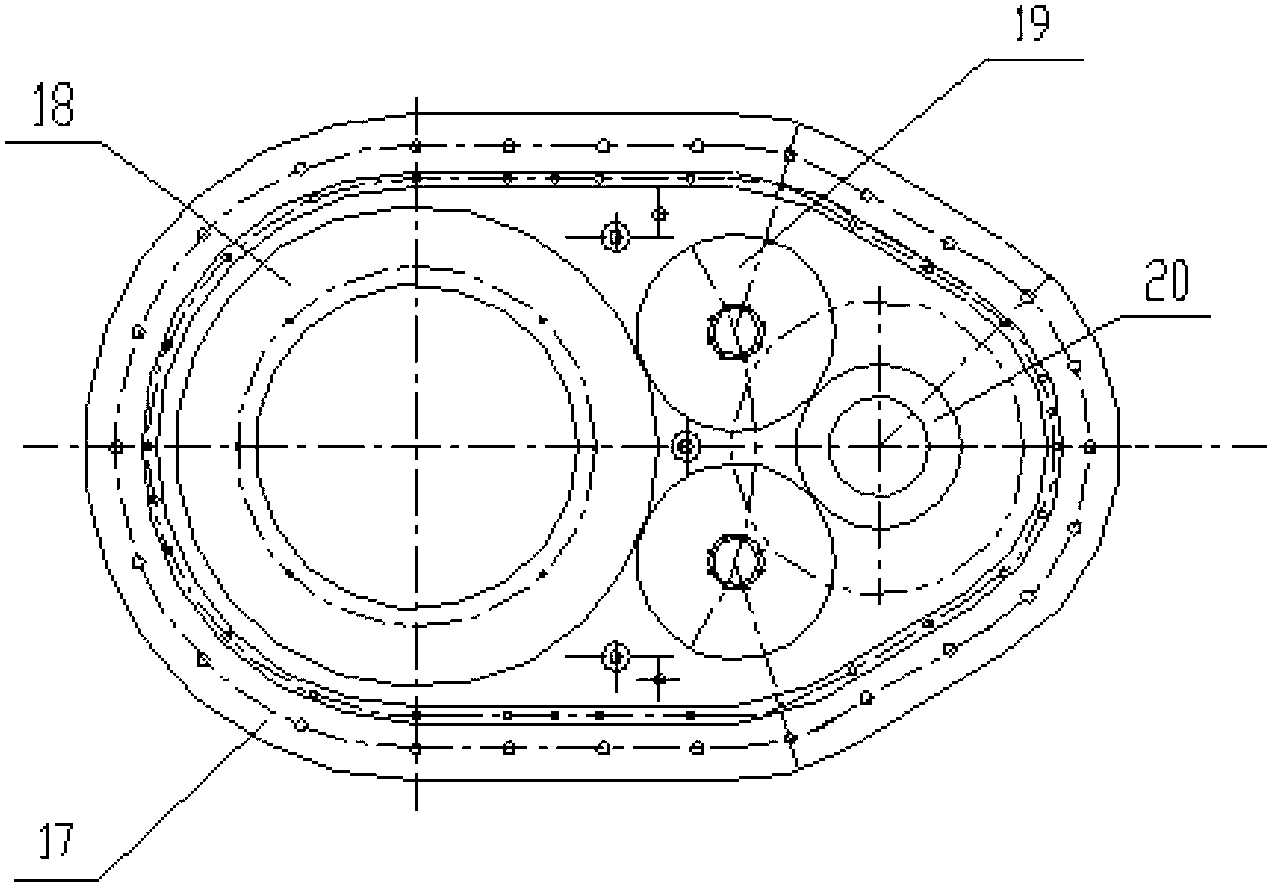

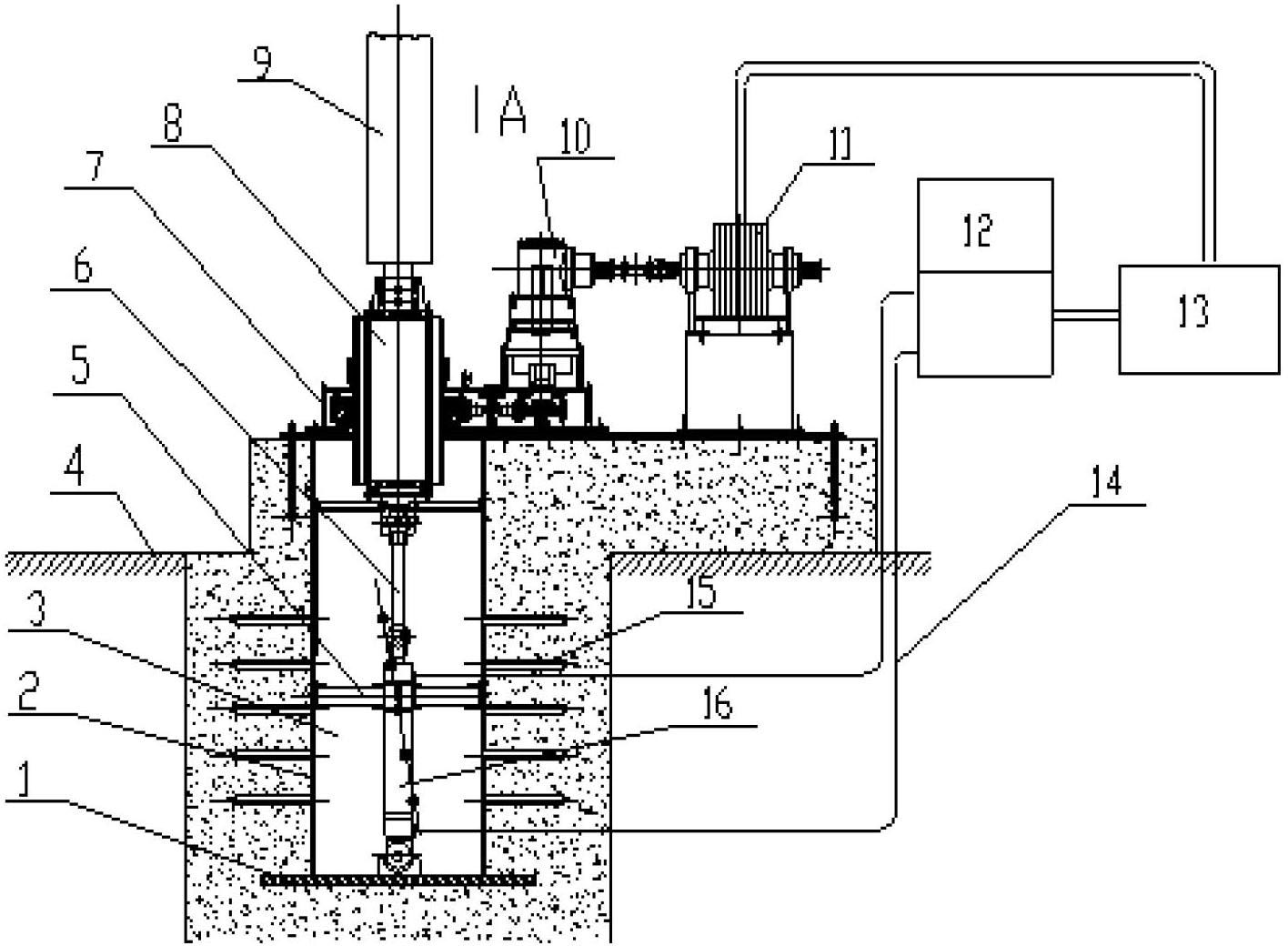

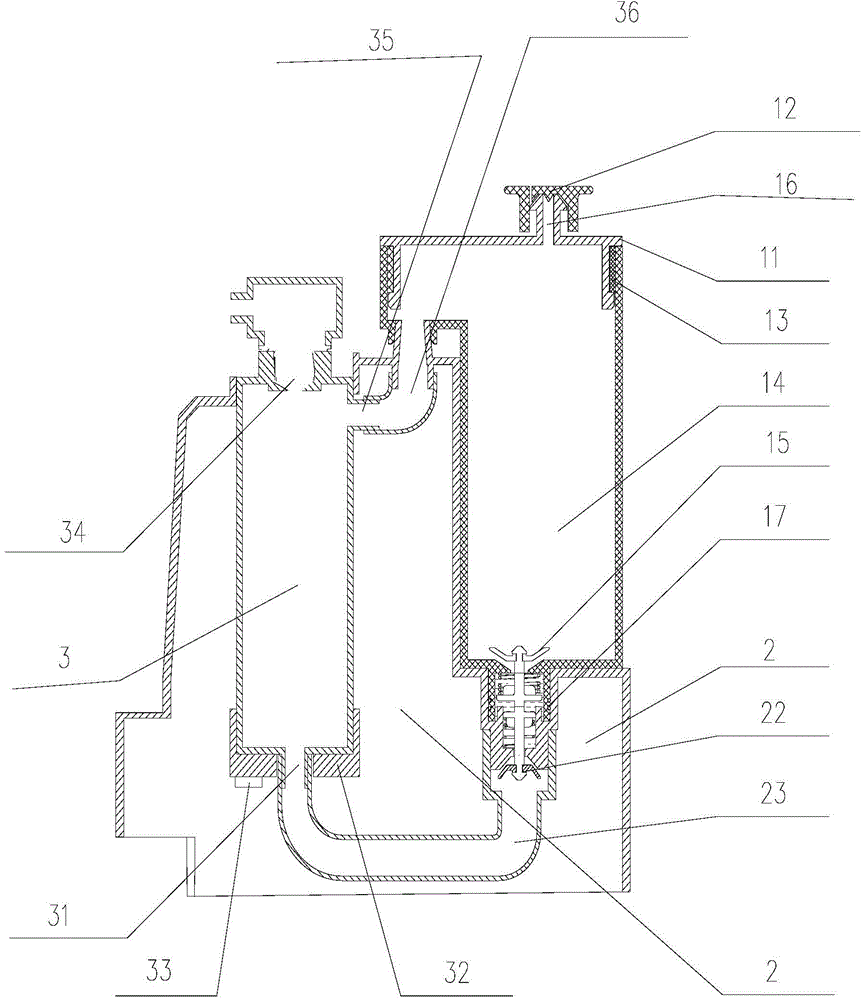

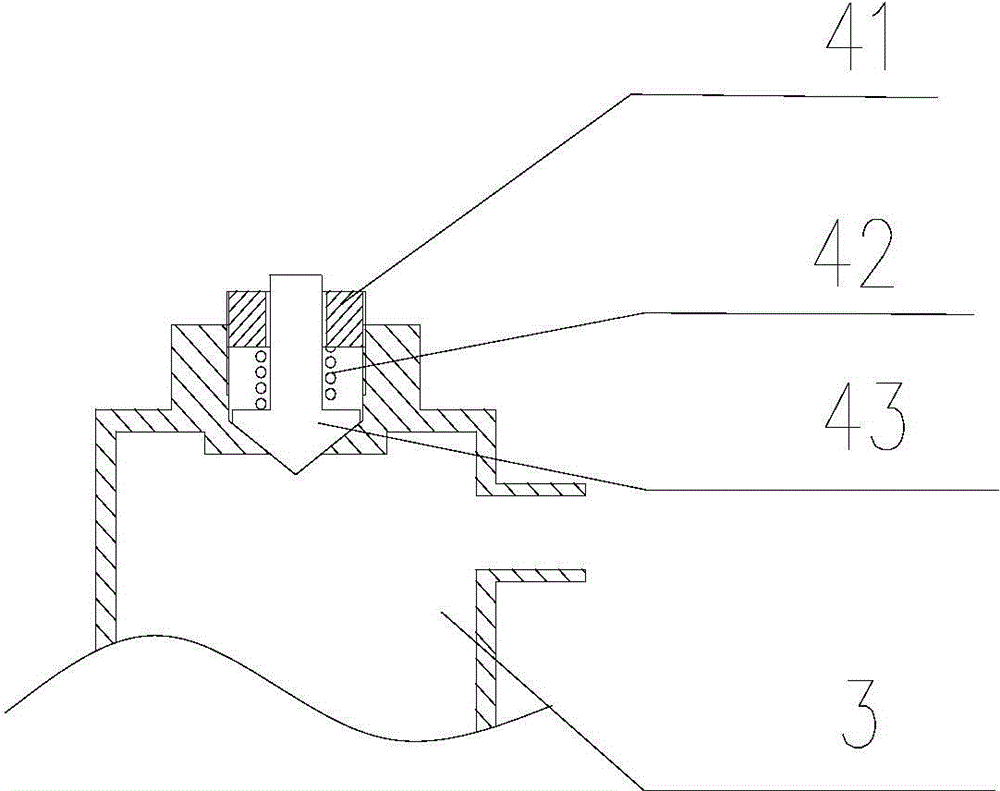

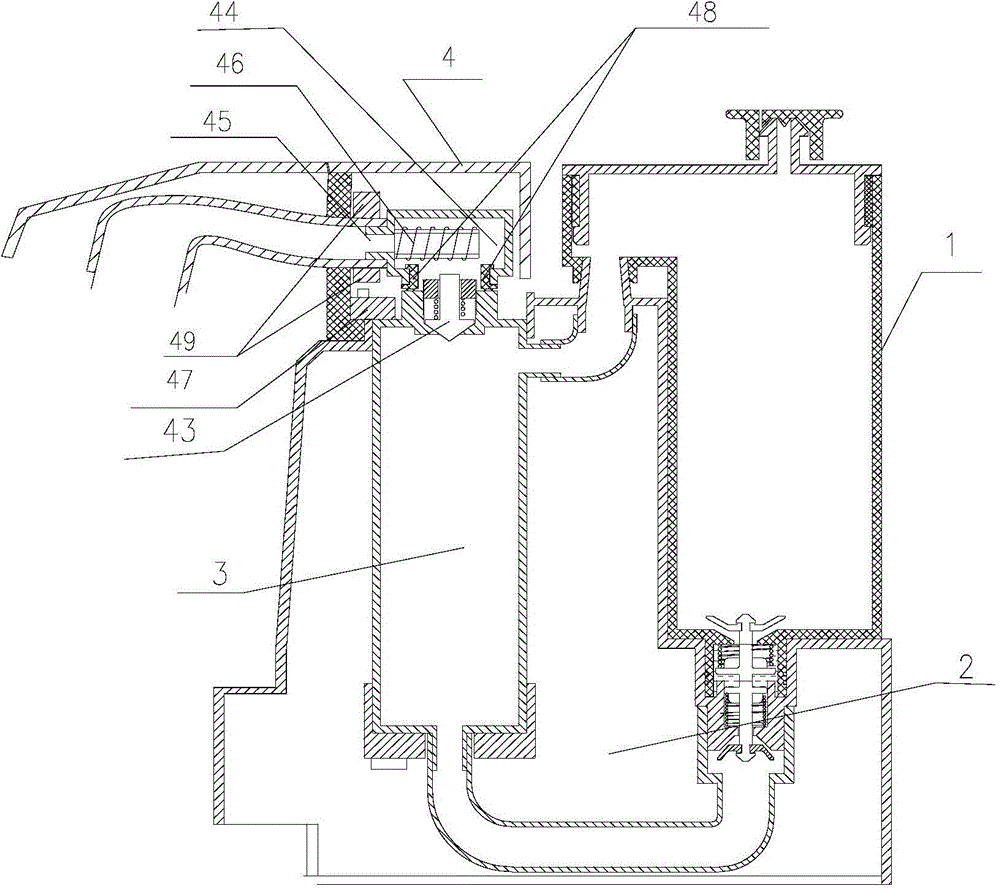

Whole-machine data analysis and testing device for rotary drilling rig

ActiveCN102706673ARealize man-machine dialogueSimple structureStructural/machines measurementComputer control systemPower sensor

The invention discloses a whole-machine data analysis and testing device for a rotary drilling rig. The whole-machine data analysis and testing device comprises a driving shaft (8), a power box (7), a dynamometer (11), a pile casing (2), a floor (1), an anchor rod (15) and a hydraulic damping system, wherein the pile casing and the anchor rod are pre-buried in a foundation, the power box is mounted at the top of the pile casing, an output transmission shaft of the power box is coaxially connected with the dynamometer, and torque, rotational speed and power sensor signal circuits of the dynamometer, as well as pressure and lifting force sensor signal circuits of the hydraulic damping system are connected into a computer control system. According to the whole-machine data analysis and testing device disclosed by the invention, on the one hand, the structure is simple, reliable and practical; on the other hand, the whole-machine data analysis and testing device can ensure the accuracy in measurement of technical parameters so as to manufacture high-quality products; and furthermore, the whole-machine data analysis and testing device can give out different data values according to different geological conditions, test according to a prescribed program and save ground resources.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

Automatic water supplementing steam generating device

ActiveCN104482521AReduce manufacturing costReduce energy consumptionSteam generation heating methodsWater feed controlPotential riskEngineering

The invention discloses an automatic water supplementing steam generating device comprising a water tank assembly, a steam generator, a steam pot, a heating body and an anti-burning device. The water tank assembly is flexibly arranged above a water tank seat, the steam generator is fixedly arranged above the water tank seat, the heating body is arranged under the steam pot, the lower end of the water tank is provided with a water outlet valve, the water outlet valve is communicated with the lower end of the steam pot through a connecting pipe, and the connecting pipe is arranged in the water tank; the end of the connecting pipe connected with the water outlet valve is provided with a water inlet valve, the water inlet valve is mutually matched with the water outlet valve, the upper end of the steam pot is communicated with the inner upper end of the water tank of the water tank assembly through an air pressure balance pipe. By the application of the automatic water supplementing steam generating device, automatic water supplementing is achieved, water pumps are omitted, and cost is effectively decreased; by the arrangement of an automatic decompression device and an anti-dry burning temperature sensor, the performance of safety use is high, the pressure of steam outputting is adjustable and potential risk is eliminated effectively by the arranged anti-burning device.

Owner:伊立浦集团股份有限公司

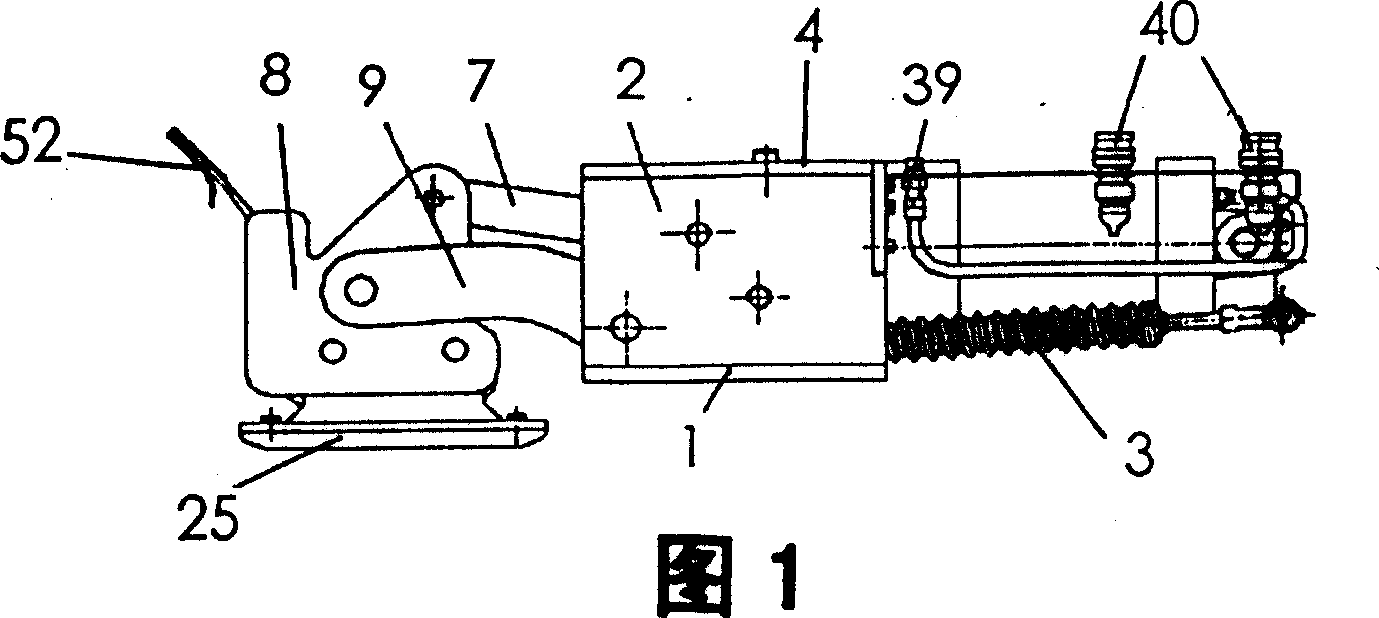

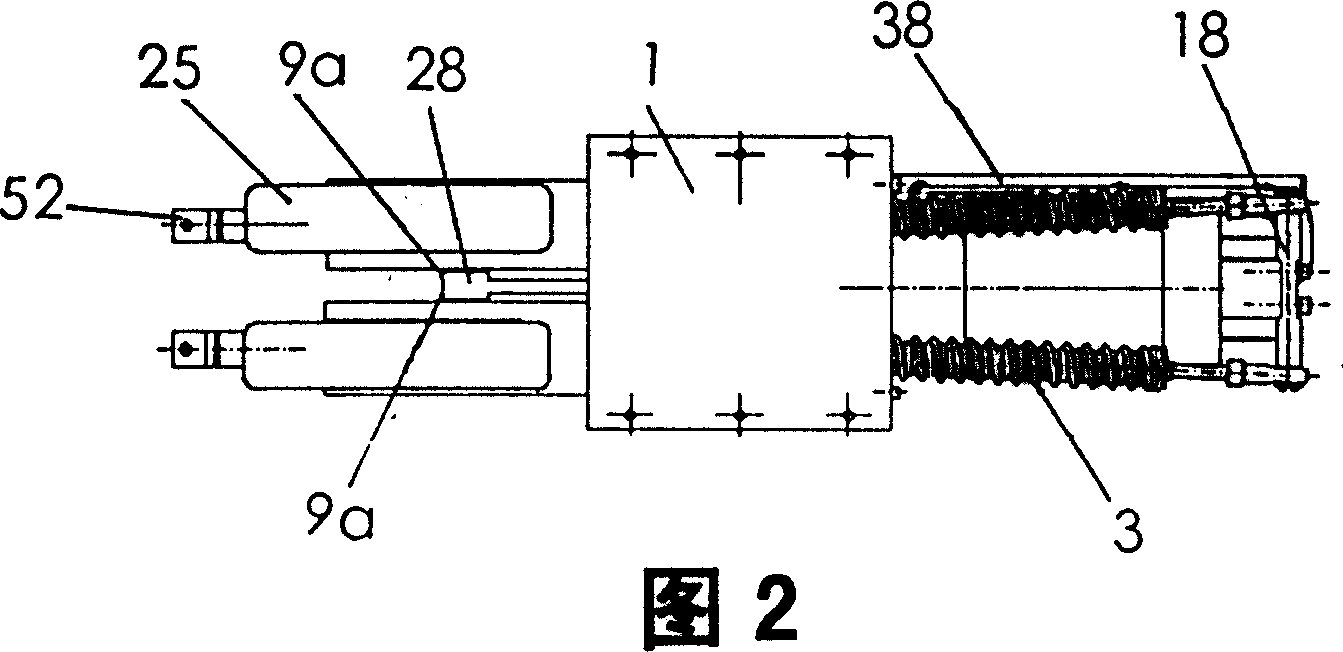

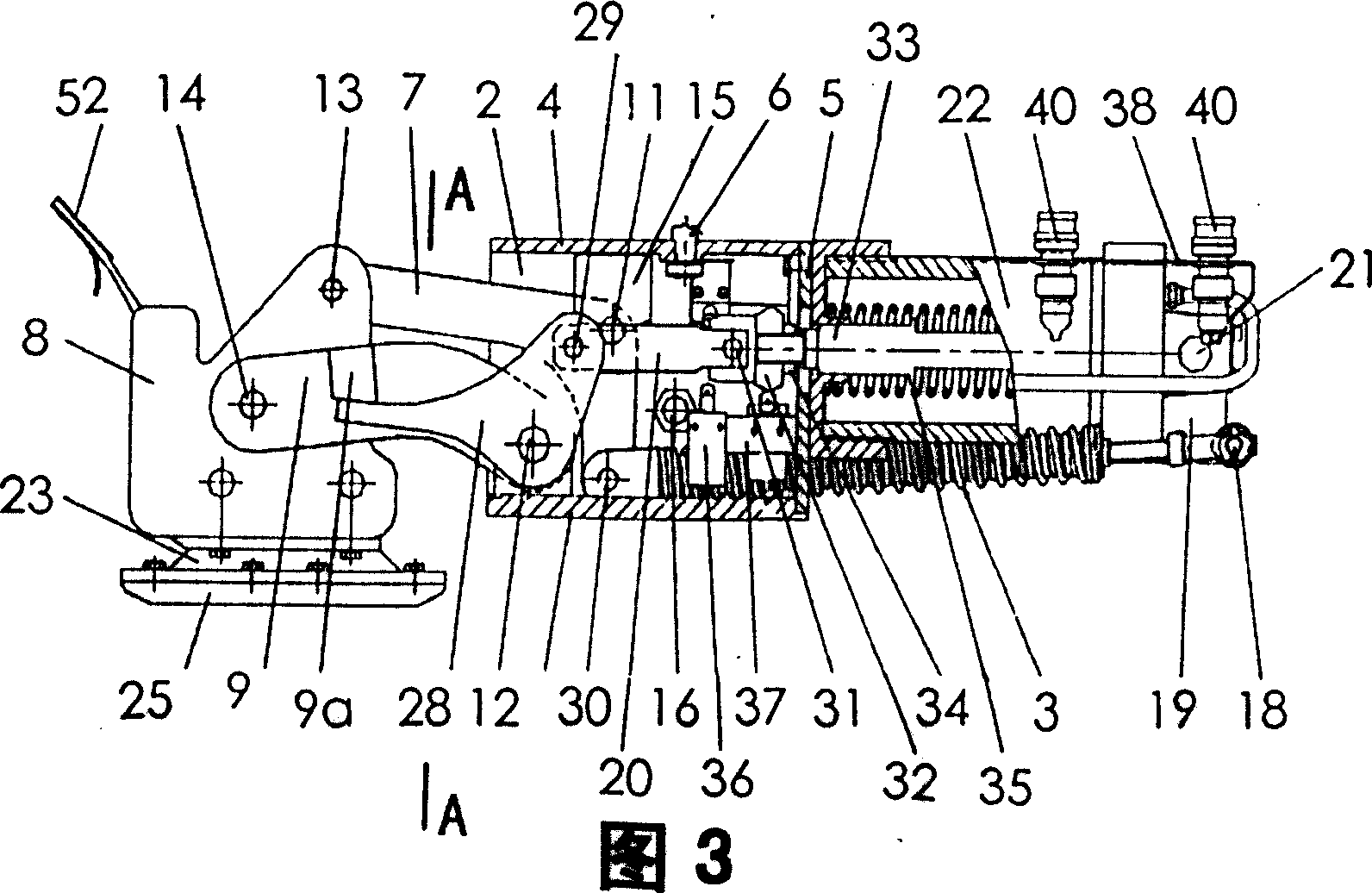

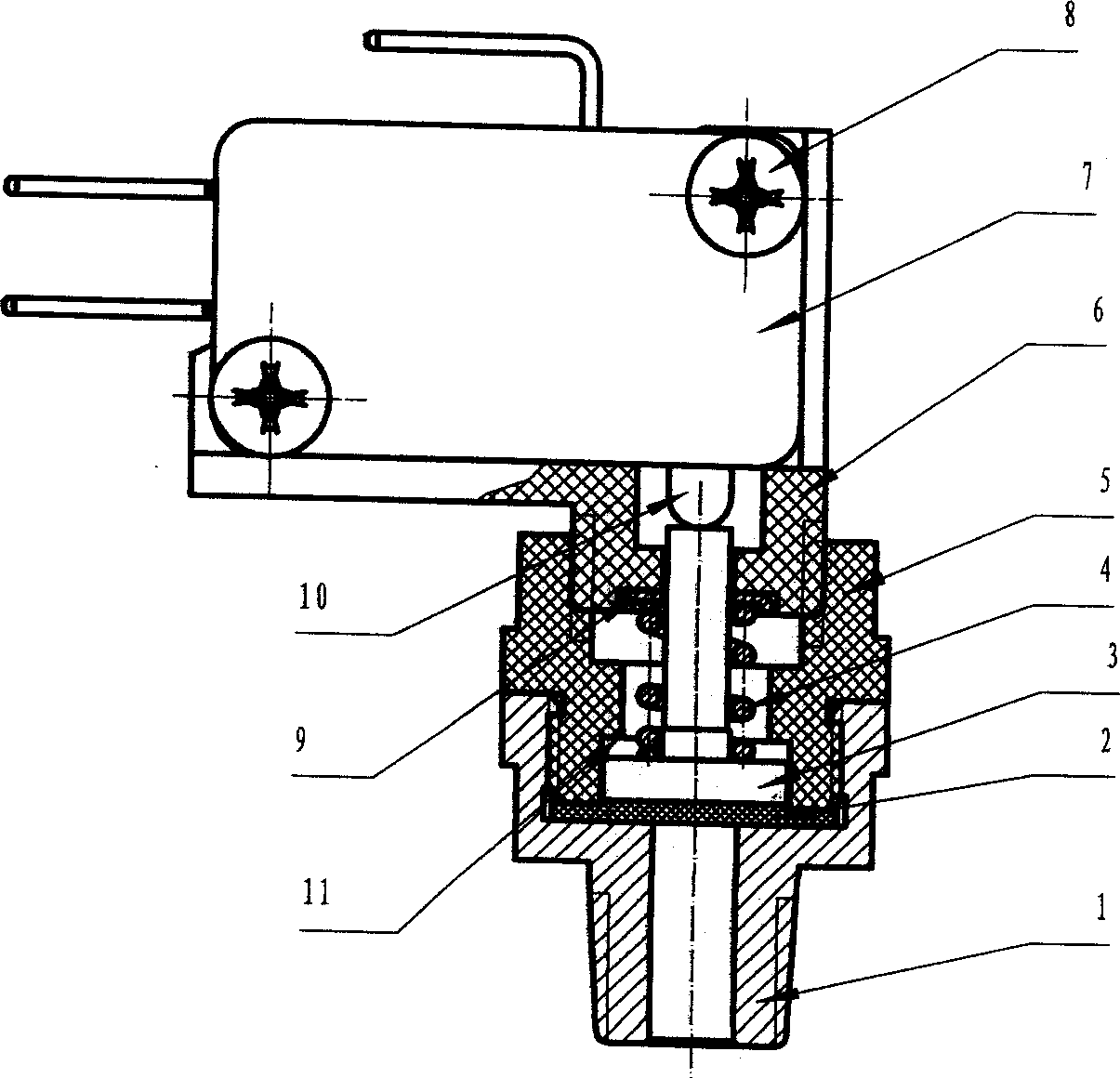

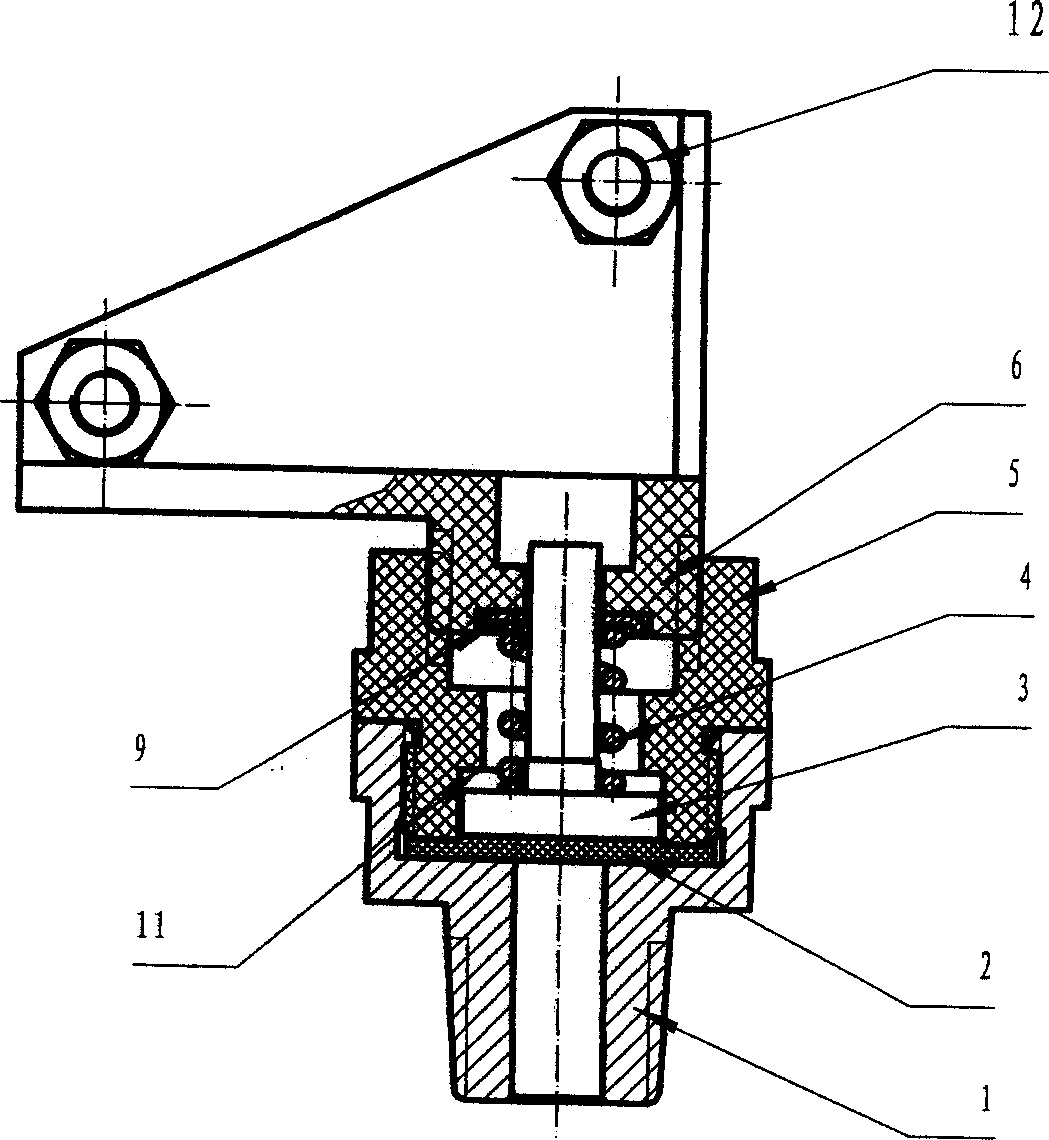

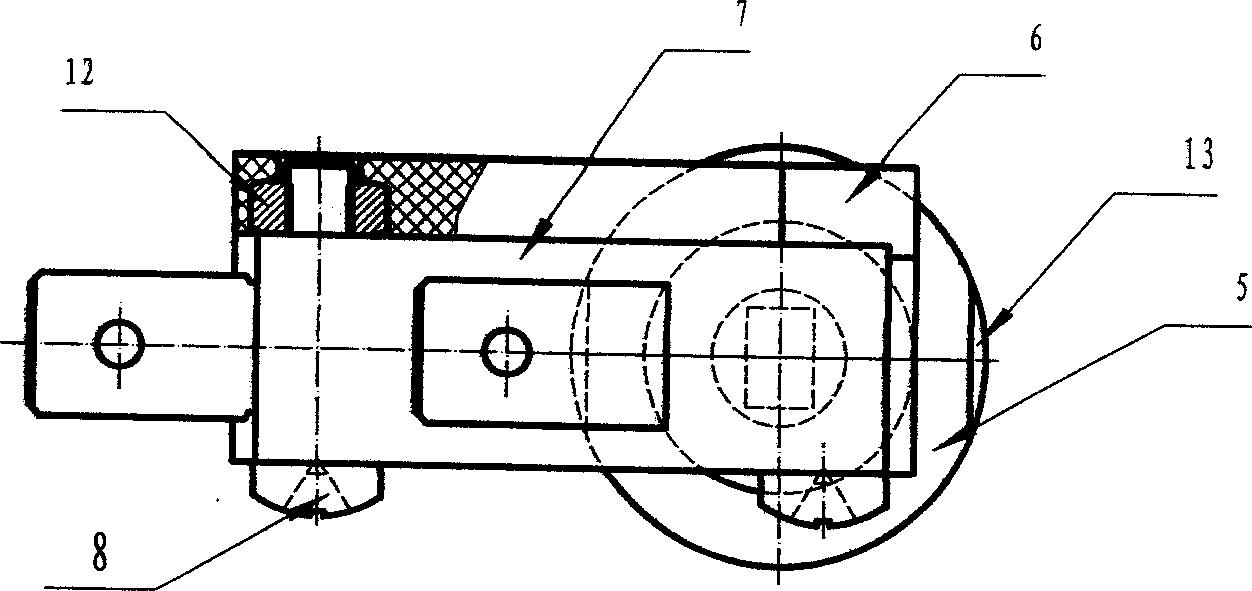

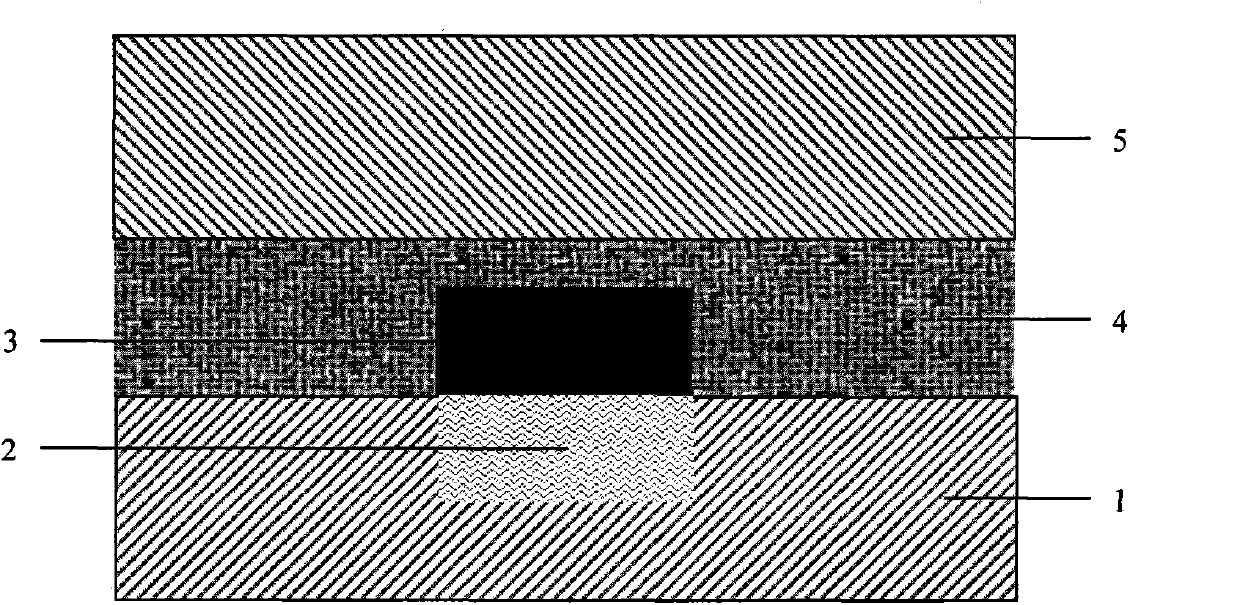

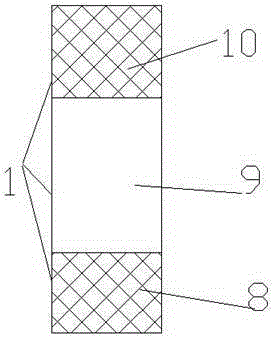

Pressure switch

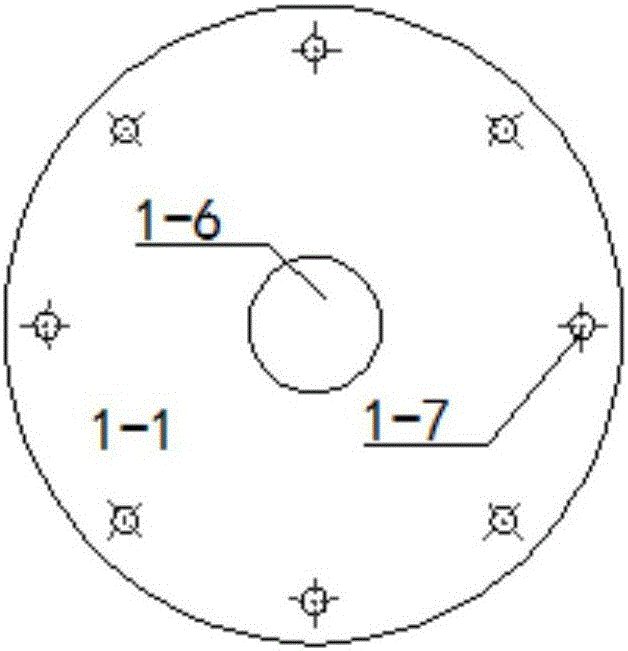

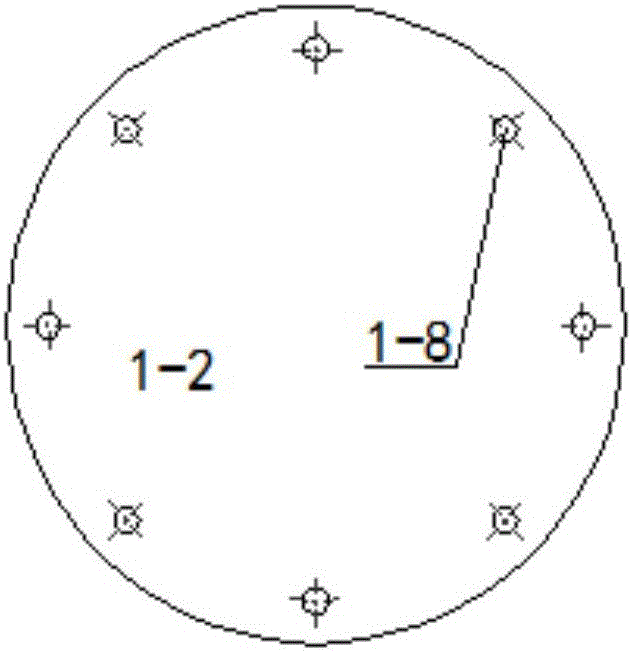

The invention relates to a pressure switch used in over-pressure protection of family micro boiler steam generator, wherein it is formed by connector 1, sealing membrane 2, top rod 3, spring 4, frame 5, switch base 6, and micro switch 7; as picture 1, the connector 1 connects the pressure switch and the steam generator, as well as the mounting base of sealing membrane 2; the frame 5 mounts the membrane 2 and the top rod 3 inside the connector 1; the frame 5 mounts the switch base 6 after mounting the spring 4 and the pad 9, to form pressure sensor; the pressure volume is converted into the displacement of top rod 3, to push the trigger 10 of micro switch 7 mounted on the switch base 6; via adjusting the screw dept of switch base 6 in the frame 5, setting the operation point of pressure switch; then adhering the switch base 6 and the frame 5 with sealing rubber. Said invention uses rubber sealing membrane to replace the metal membrane, to realize lower cost and micro volume.

Owner:宁波市塞纳电热电器有限公司

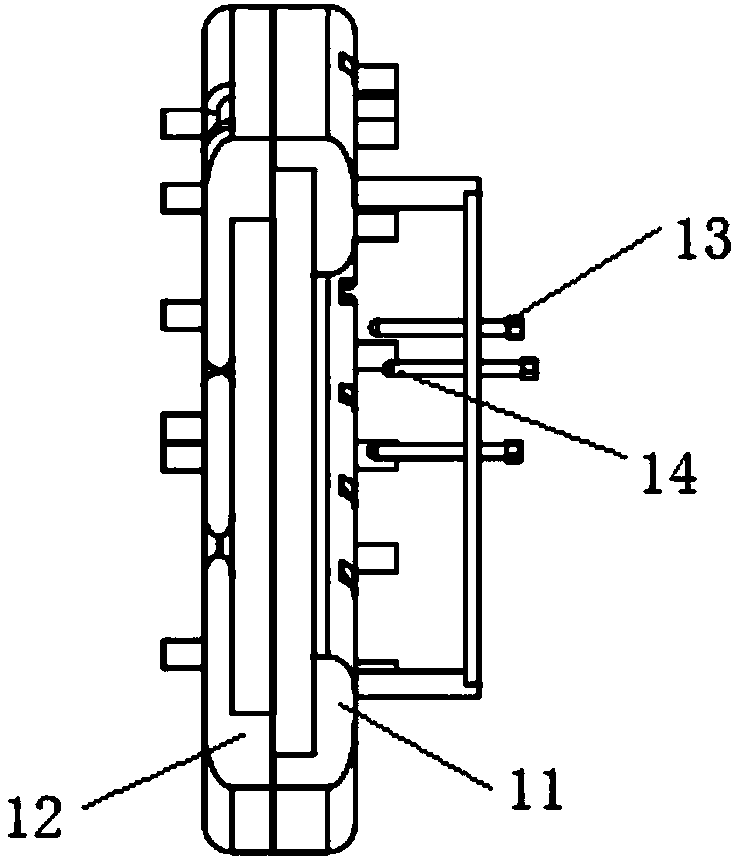

Integral soft sensing element with pressure and non-contact gap measuring functions

InactiveCN103743504AAchieve pressureEnables non-contact gap measurementForce measurementUsing electrical meansSoft sensingCopper foil

The invention relates to an integral soft sensing element with pressure and non-contact gap measuring functions, and belongs to the technical field of sensors. The integral soft sensing element comprises an insulation encapsulation film, a pressure-sensitive film and a plane type eddy current coil film, wherein the insulation encapsulation film is made of polyimide, the pressure-sensitive film layer is made of conducting polymer composite materials, the plane type eddy current coil film consists of a polyimide film and a copper foil coil compounded on the polyimide film, the conducting polymer composite materials are directly vulcanized on the naked copper foil coil to form an integral structure, and the pressure and non-contact gap measurement is realized through obtaining the impedance of the integral structure. The integral sensing element developed by the invention has the advantages that the softness is good, the thickness is small, the process is simple, the cost is low, the pressure measurement and the non-contact gap measurement can be realized only through one set of sensing system, the integral soft sensing element is applicable to the interlayer pressure and gap measurement of narrow and small curved surfaces of industrial equipment, and the key technology can also be applied to the development of multifunction electronic skin.

Owner:NORTHEASTERN UNIV

Heat pipe provided with fins at external part

InactiveCN105202955AEven heat dissipationExtend your lifeIndirect heat exchangersTubular elementsEngineeringHeat pipe

The invention provides a heat pipe. The heat pipe comprises a flat pipe, wherein the flat pipe comprises pipe walls which are parallel to each other; a fluid channel is formed between the adjacent pipe walls; external fins are arranged at the outer parts of the pipe walls; and the heights of the fins are gradually reduced from the middle of the transverse section to the two sides of the flat pipe. According to the heat pipe provided by the invention, the heat dissipation of the whole heat pipe is uniform, a local temperature of the heat pipe is prevented from overheating, the heat dissipation effect is improved and the service life of the heat pipe is prolonged.

Owner:盐城市轩源加热设备科技有限公司

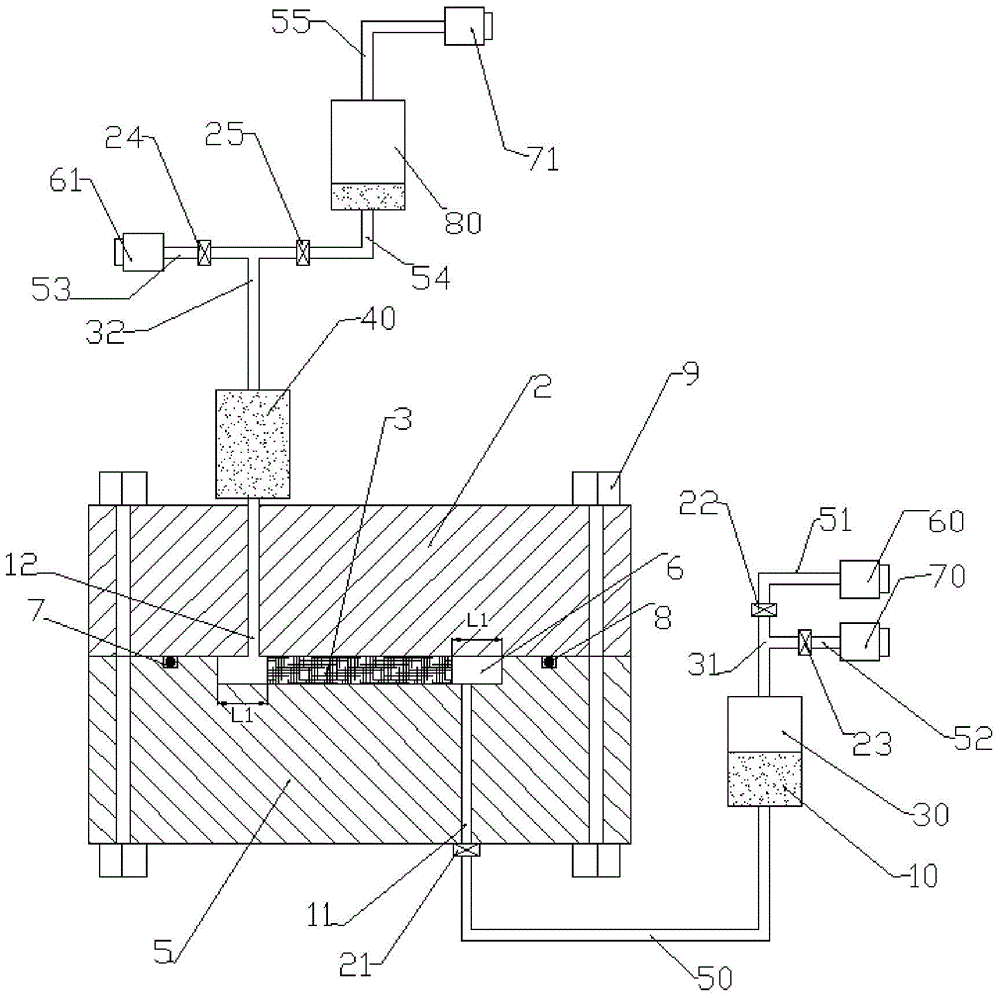

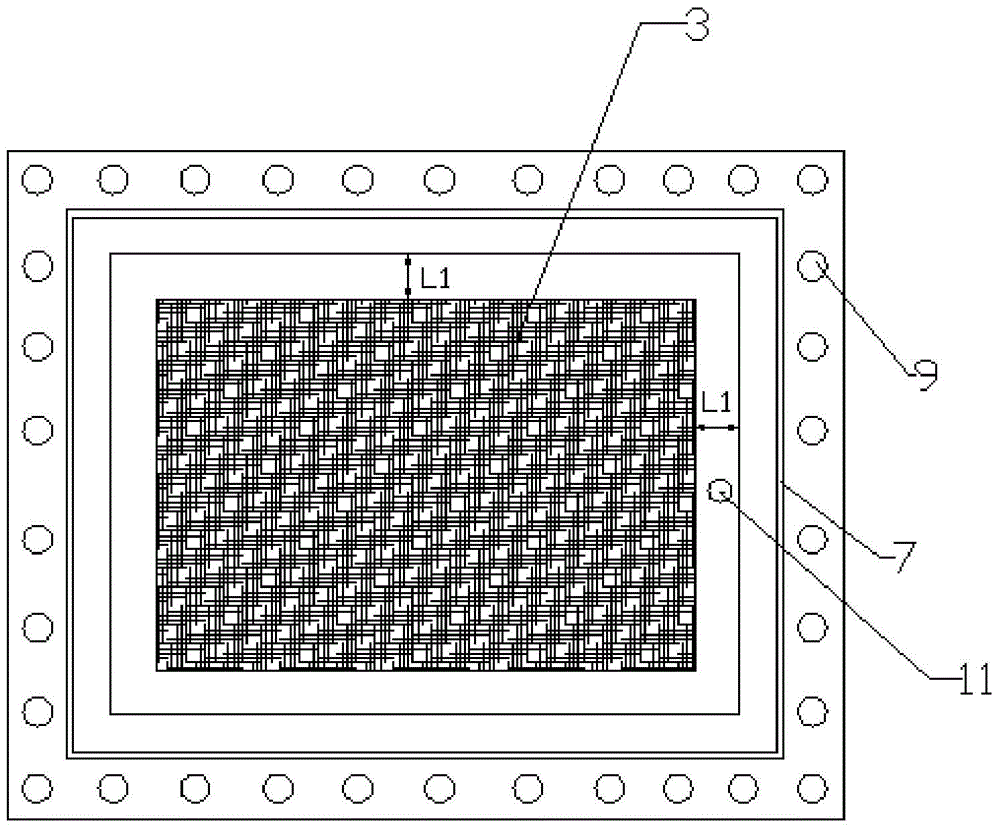

Grouting pump for high-pressure constant-flow test

ActiveCN105727781AStir wellAchieve pressureFlow mixersTransportation and packagingMonitoring systemSlurry

The invention discloses a grouting pump for a high-pressure constant-flow test.The grouting pump comprises a high-pressure slurry storage tank, a propelling, pressurizing and flow stabilizing system, a built-in stirring system, a slurry input / output system, a monitoring system and a base.The propelling, pressurizing and flow stabilizing system extends into the high-pressure slurry storage tank.The built-in stirring system is located in the high-pressure slurry storage tank so that uniform stirring of output slurry can be achieved.One end of the built-in stirring system makes contact with the propelling, pressurizing and flow stabilizing system in the high-pressure slurry storage tank.The slurry input / output system is communicated with the high-pressure slurry storage tank.The monitoring system is arranged on the slurry input / output system.The high-pressure slurry storage tank and the propelling, pressurizing and flow stabilizing system are arranged on the base.The propelling, pressurizing and flow stabilizing system uses a stepping motor as the power source, the consistency of slurry output flow can be met, the grouting speed is adjusted by adjusting the rotating speed of the stepping motor, and dual-liquid grouting tests of different ratios can be guaranteed when multiple instruments are used at the same time.The requirements for high grouting pressure and constant grouting speed in grouting tests are met.

Owner:SHANDONG UNIV OF SCI & TECH

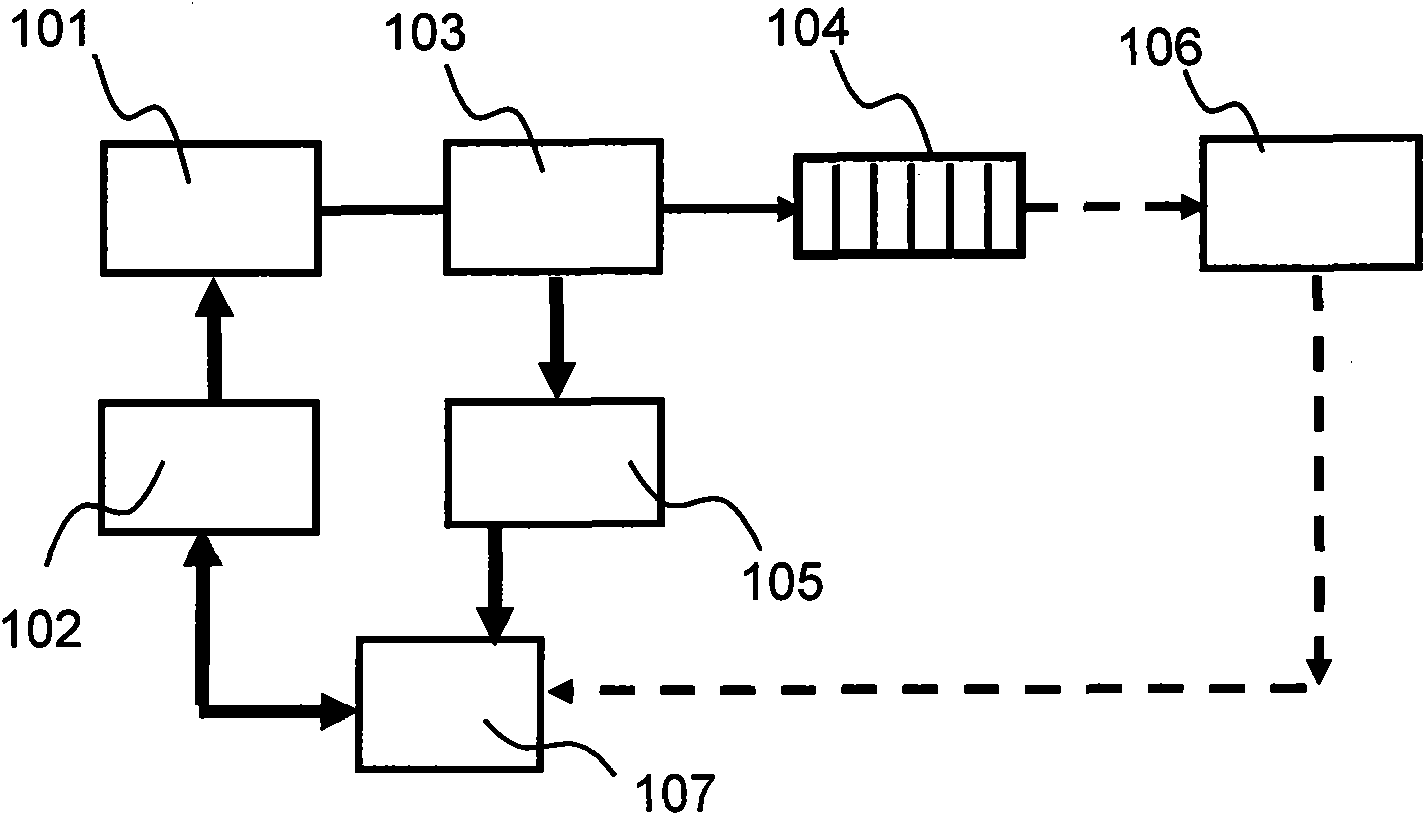

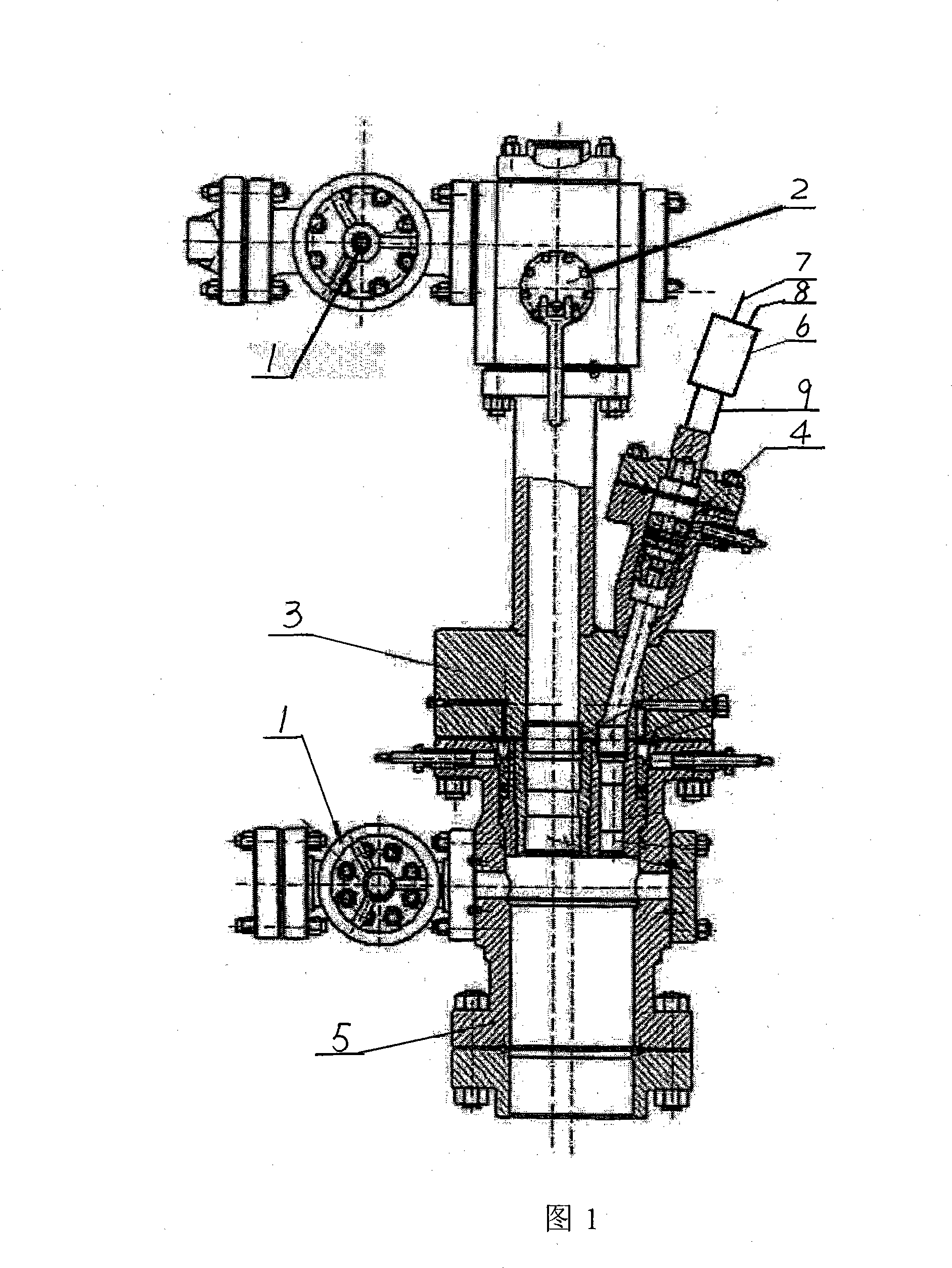

Ultra-thick oil down-hole temperature, pressure double parameter (multi-point) dynamic measurement system

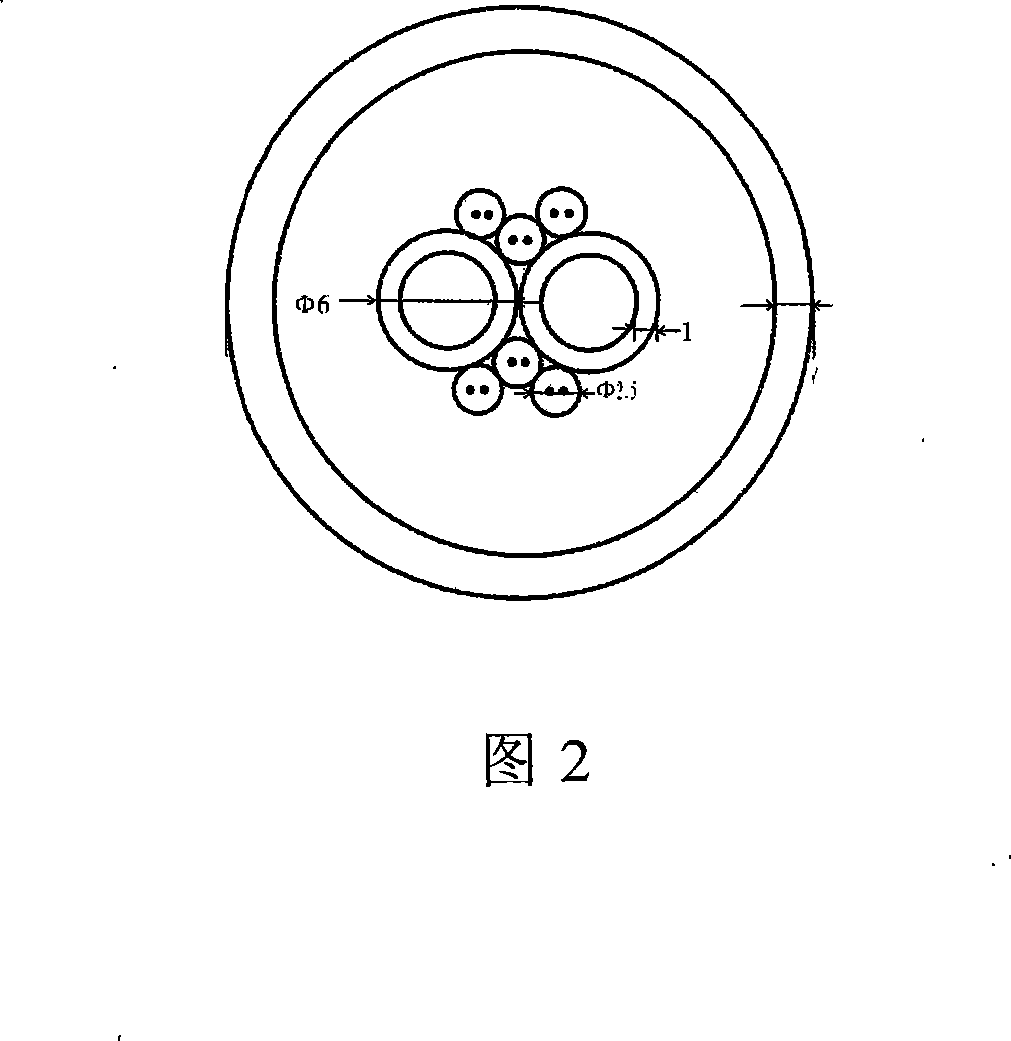

An measuring system for measuring ultra-thick oil underground temperature and pressure two-parameter (multi-point) dynamic, applied in the art of temperature and pressure measuring technology, consists of a flat valve, a well shutting device, an upper flange, a continuous oil-pipe seal, a cross joint, a connector, an armoured thermocouple, a capillary, a continuous oil pipe and a continuous oil-pipe suspending device. The present invention is characterized in that the upper part of the cross joint is provided with the upper flange and the left part of the cross joint is provided with the flat valve; the upper part of the upper flange is provided with the well shutting device; the right shoulder of the upper part of the upper flange is provided with the continuous oil-pipe suspending device and the continuous oil-pipe seal; the left part of the well shutting device is provided with the flat valve; the continuous oil-pipe suspending device is provided with the continuous oil pipe and the connector; the connector is provided with the armoured thermocouple and the capillary. The system with novel and scientific design can achieve the collecting, displaying, storing and transferring of system pressure and temperature.

Owner:沈阳东大传感技术有限公司

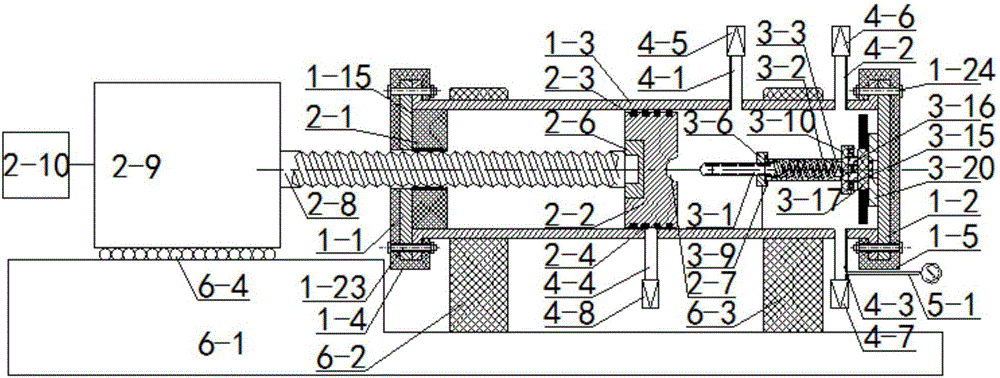

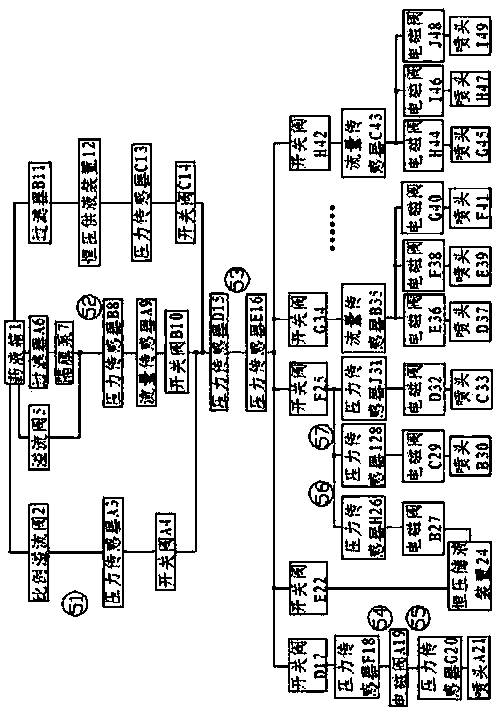

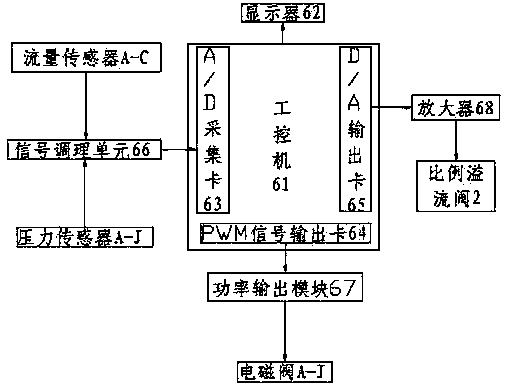

Characteristic test bench of pulse-width modulation (PWM) intermittent spray variable spraying system

ActiveCN103630418ARealize internal flow field testingAchieve pressureStructural/machines measurementDiaphragm pumpCollection system

The invention discloses a characteristic test bench of a pulse-width modulation (PWM) intermittent spray variable spraying system. The characteristic test bench comprises a measurement and control system and a pipeline system, wherein the measurement and control system comprises an industrial personal computer, a signal conditioning unit, a power output module and an amplifier; the pipeline system comprises a diaphragm pump liquid supply device, an electric overflow device, a plurality of variable spraying units, a constant pressure liquid supply branch, a constant pressure outlet branch, an electromagnetic valve dynamic characteristic test unit and a multi-source pressure surge coupling characteristic test unit; a plurality of transparent pipeline sections and pressure sensors are arranged on a connection pipeline among a diaphragm pump outlet, a proportional overflow valve outlet, an electromagnetic valve inlet and outlet hole, a main pipeline and an electromagnetic valve, so as to carry out internal flow field characteristic test of the pipeline and pressure monitoring by using a high-speed image collection system or a flow field test system. The characteristic test bench of the PWM intermittent spray variable spraying system can be applied to testing of diaphragm pump pressure pulsation characteristics of the PWM intermittent spray variable spraying system, proportional overflow valve dynamic characteristics, electromagnetic valve dynamic characteristics and propagation characteristics of a multi-source pressure surge in the pipeline.

Owner:JIANGSU UNIV

Rodenticide

ActiveCN106879580AImprove palatabilityImprove efficiencyBiocideAnimal repellantsWater contentSolvent

The invention discloses a rodenticide and belongs to the technical field of insect damage removal. The invention provides the rodenticide which is low in cost, high in palatability, easy to store and significant in rat killing effect. The rodenticide comprises 10-80 parts by weight of base material, 0.002-0.5 part by weight rat killing active ingredient and 2-40 parts by weight auxiliary material. The base material is prepared by solid-liquid separation, breaking, sorting, slurrying, dryness and grinding of kitchen waste into powder; a protein content in the base material powder is greater than or equal to 20%; a starch content is greater than or equal to 45%; an oil content is less than 7%; and a water content is less than 10%. The rat killing active ingredient is a safe second generation rat killing active ingredient. The auxiliary material comprises an excipient, an adhesive, a water absorber, a surfactant, a preservative, a colorant, a corrigent and a solvent. The rodenticide is high in palatability, suitable for long-time rat destruction, good in rat killing effect and low in cost; and a novel approach is provided for comprehensive utilization of the kitchen waste.

Owner:付学锋 +1

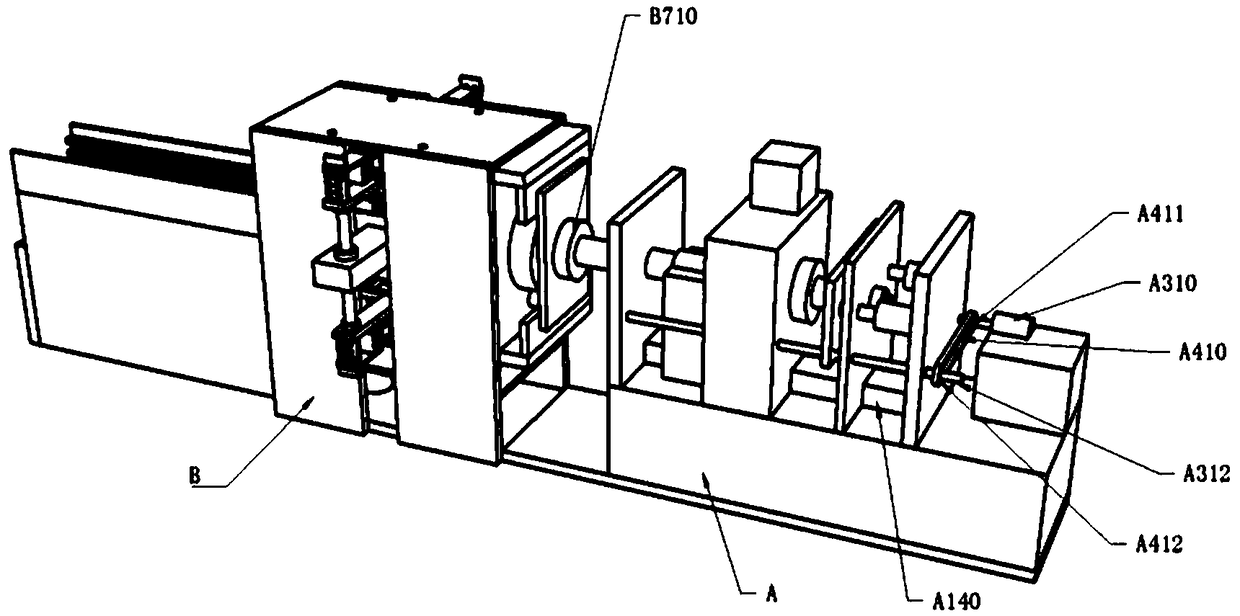

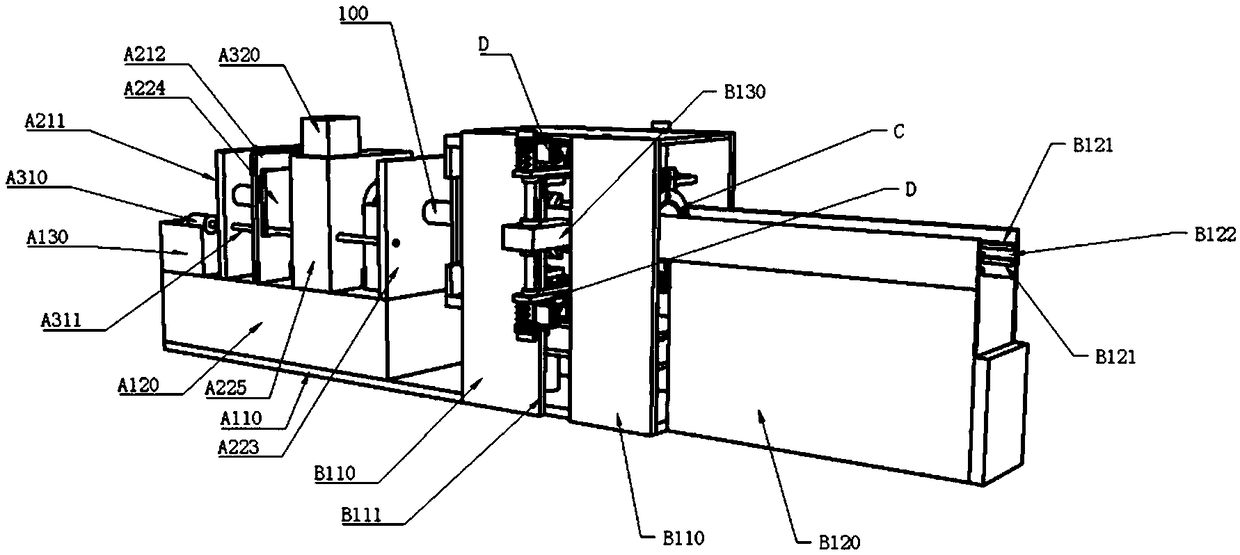

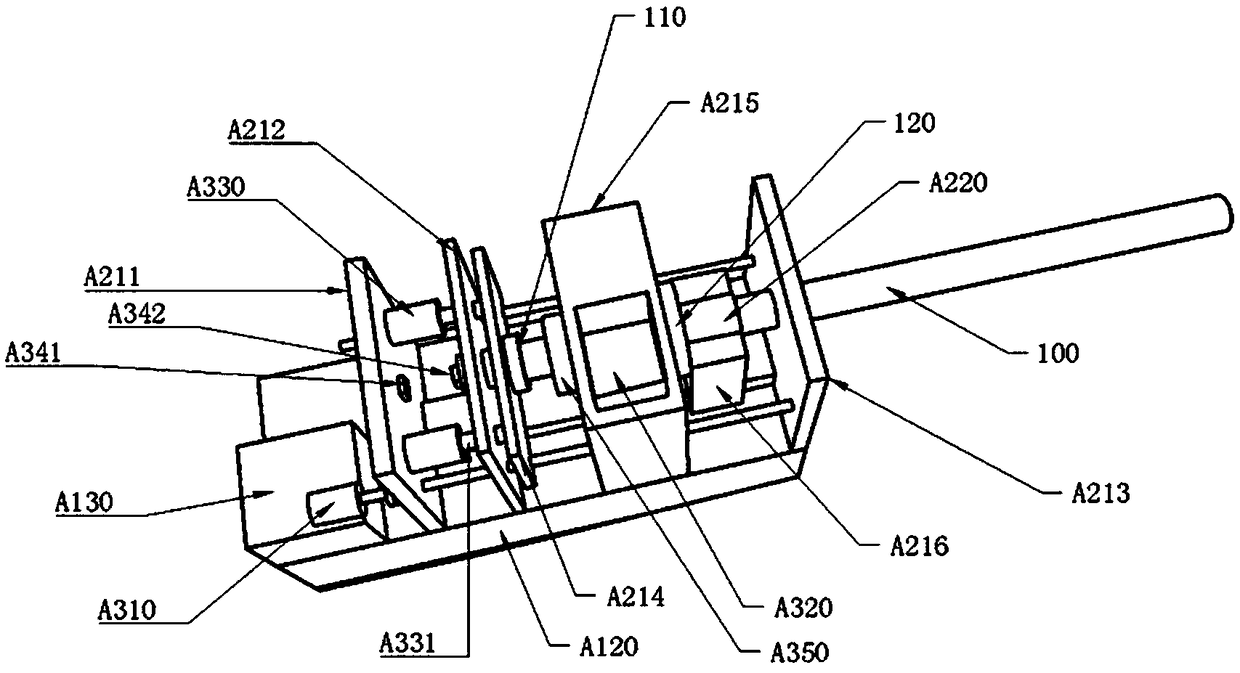

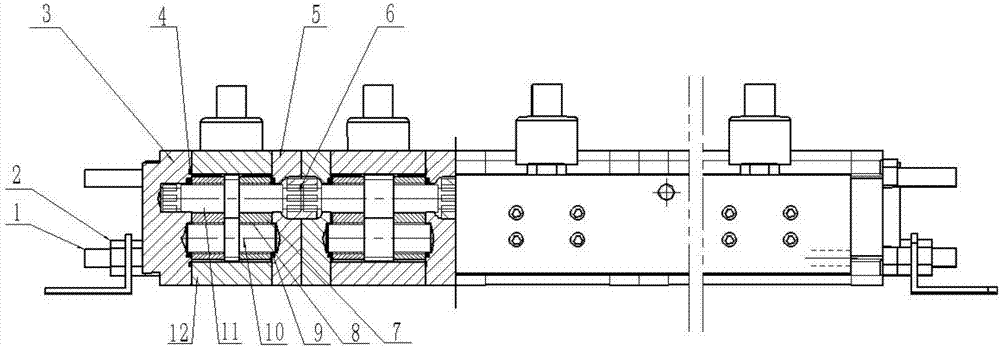

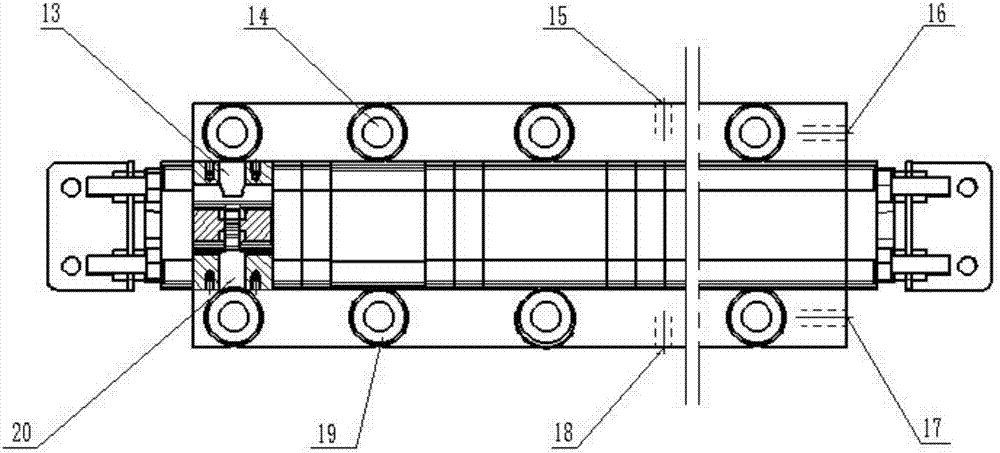

Supercharger mechanism and anchor rod comprehensive mechanical performance test platform thereof

ActiveCN109470552AGet the real situationTrue restorationMachine part testingEducational modelsEngineeringTest platform

The invention discloses a supercharging mechanism and an anchor rod comprehensive mechanical performance test platform thereof. The supercharging mechanism comprises a fulcrum assembly, wherein the fulcrum assembly is mounted at the end, far away from a first pressure connecting rod and a second pressure connecting rod, of a pressure applying plate; the fulcrum assembly comprises a fulcrum supportplate which is fixed on the pressure applying plate; a step-down sliding slot is formed in the fulcrum support plate; the step-down sliding slot is glidingly assembled with a limit sliding rod; one end of the limit sliding rod is fixedly connected with a telescopic support plate; the limit sliding rod passes through one end of a stop plate to be fixedly connected with one end of a first fulcrum spring; the other end of the first fulcrum spring is fixedly connected with the pressure applying plate; the telescopic support plate is assembled and fixed with each of the first fulcrum support plateand the second fulcrum support plate; a fulcrum switching electromagnet is mounted between the first fulcrum support plate and the second fulcrum support plate; and the fulcrum switching electromagnet is assembled with one end of a fulcrum switching telescopic shaft; and the other end of the fulcrum switching telescopic shaft passes through the second fulcrum support plate to be assembled and fixed with a fulcrum block.

Owner:ANHUI UNIV OF SCI & TECH

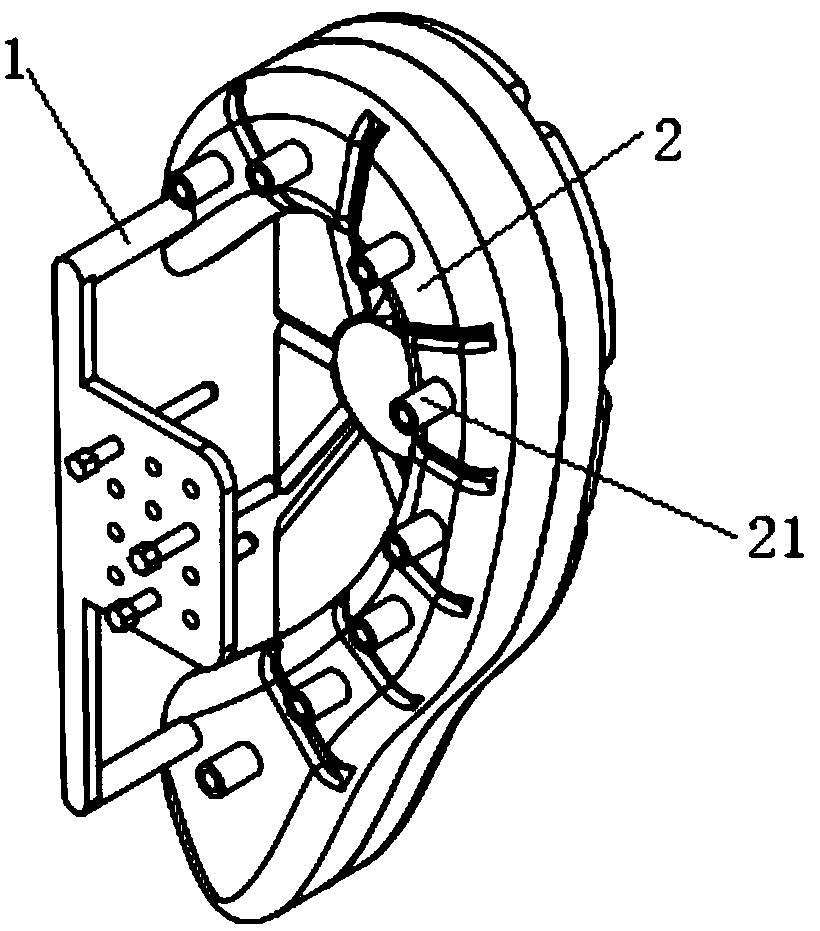

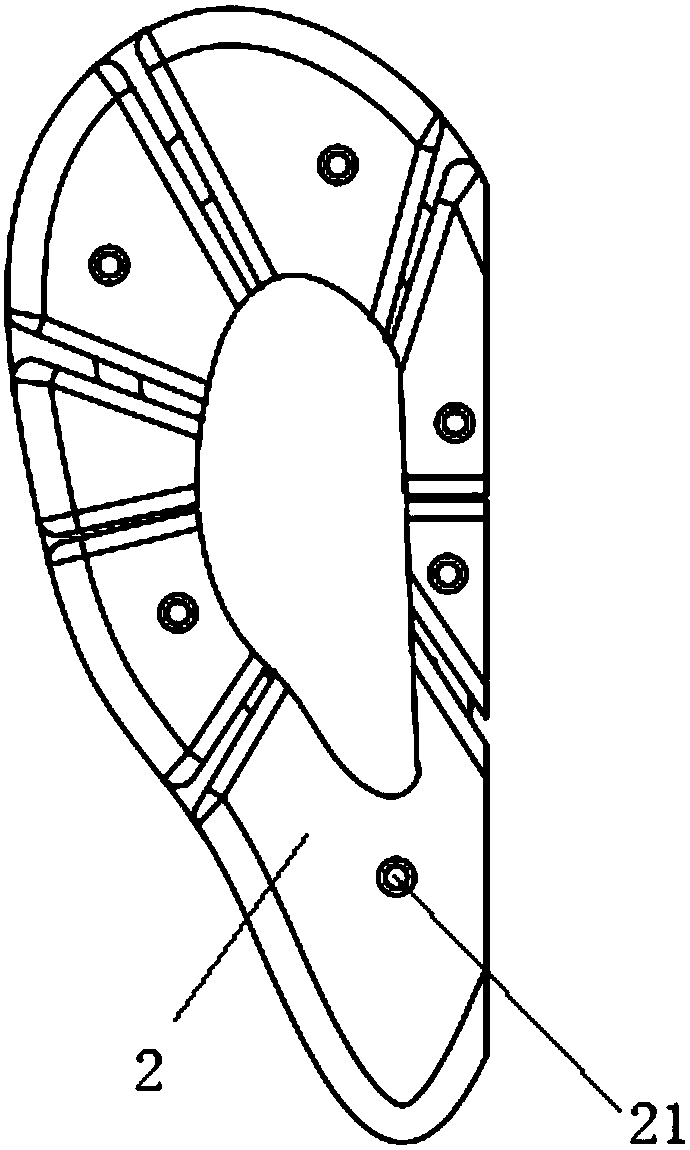

Pressure device for treating keloids of outer auricles

The invention discloses a pressure device for treating keloids of outer auricles, and belongs to the technical field of medical instruments. The pressure device comprises an ear fixing device, an airbag and a pressurization air pump. The airbag is mounted on the ear fixing device, and is used for pressurizing the keloids on the outer auricles. The pressurization air pump is connected with the airbag, and is used for inflating the airbag. The ear fixing device is used for fixing the airbag to the positions of the outer auricles. The airbag is fixed to the positions of the outer auricles by theear fixing device, and is pressurized by the pressurization air pump, and pressure is provided to the keloids of the outer auricles. The pressure device has great importance in postoperative rehabilitation of the keloids of the outer auricles.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

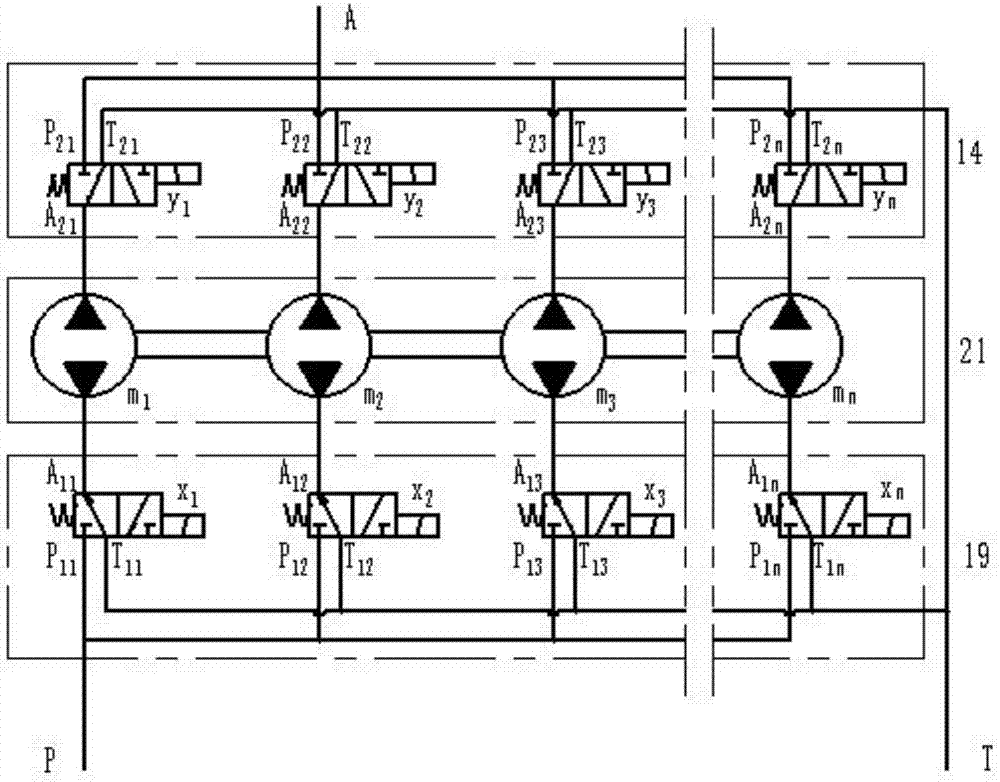

Digital type hydraulic transformer

ActiveCN106958546AAchieve pressureRealize traffic conversionFluid-pressure convertersEnergy lossHydraulic transformer

The invention discloses a digital type hydraulic transformer. A main body of the transformer comprises a flow shunting / collecting system comprising n gear pump / motor units and two control valve groups; each control valve group comprises n two-position three-way electromagnetic switch valves; the n gear pump / motor units are fixed side by side through manifold screws and fastening nuts, the displacements of the n gear pump / motor units are sequentially configured as per the law of indexes of 2, and n is an integer larger than 2; the state of the n two-position three-way electromagnetic switch valves of the inlet control valve group corresponds to an n-bit binary number Ni; the state of the n two-position three-way electromagnetic switch valves of the outlet control valve group corresponds to an n-bit binary number No; and pressure and flow conversion between an external load oil port and an external oil source port is realized through binary digital control on the working state of the inlet control valve group and the working state of the outlet control valve group. The transformer is compact in structure, the transformer ratio is convenient and labor-saving to adjust and is large in range, external leakage is avoided, and the energy loss is low.

Owner:YANSHAN UNIV

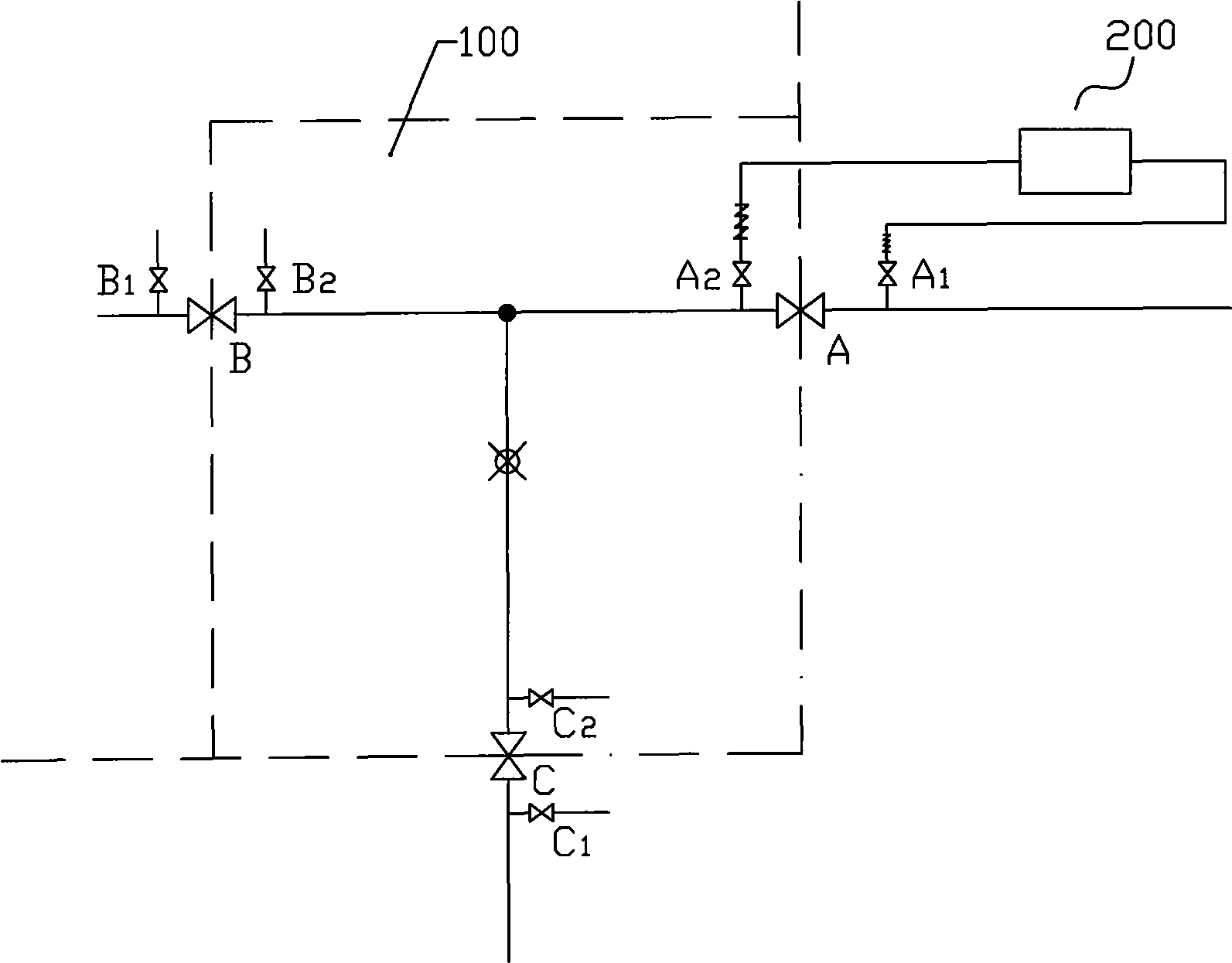

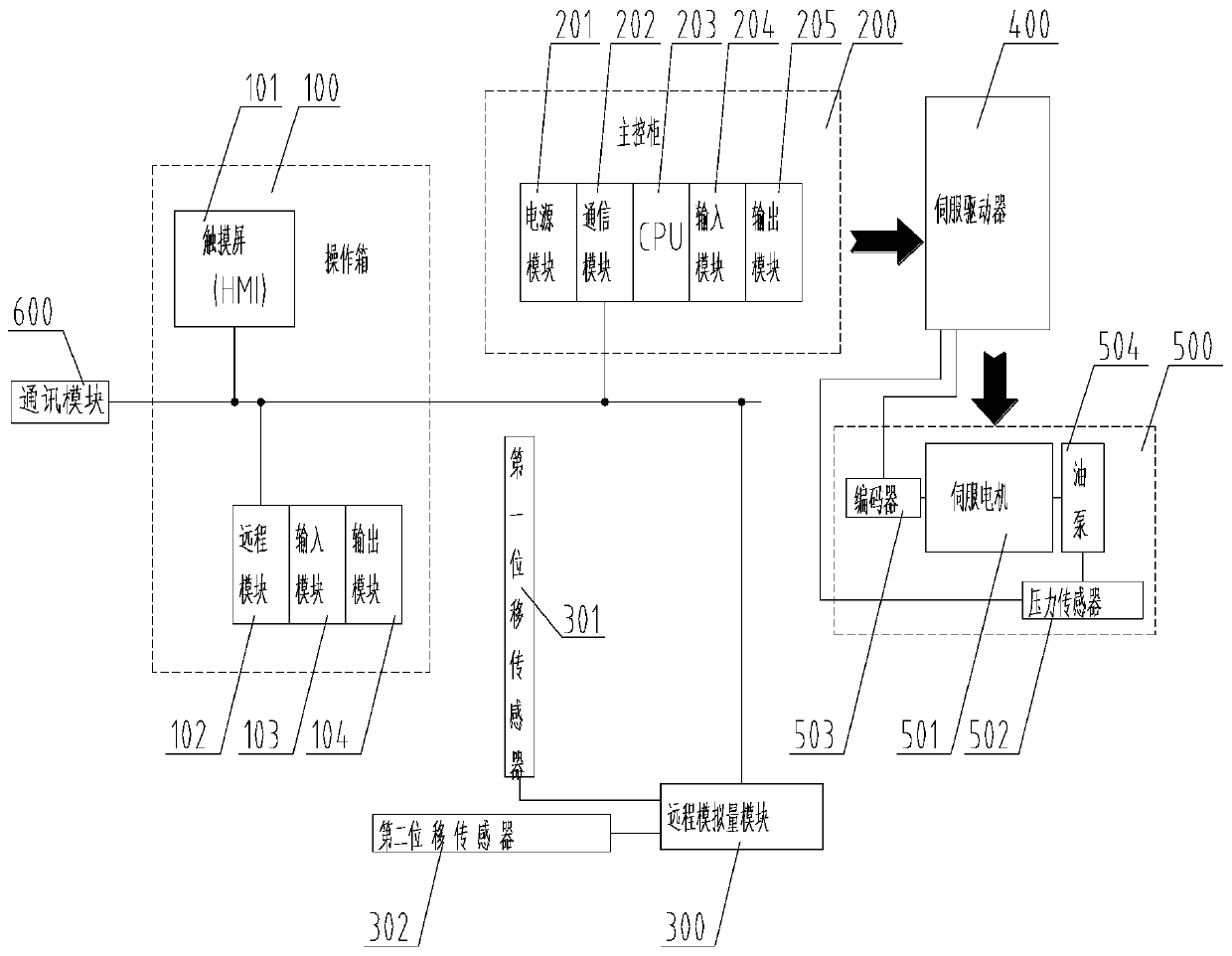

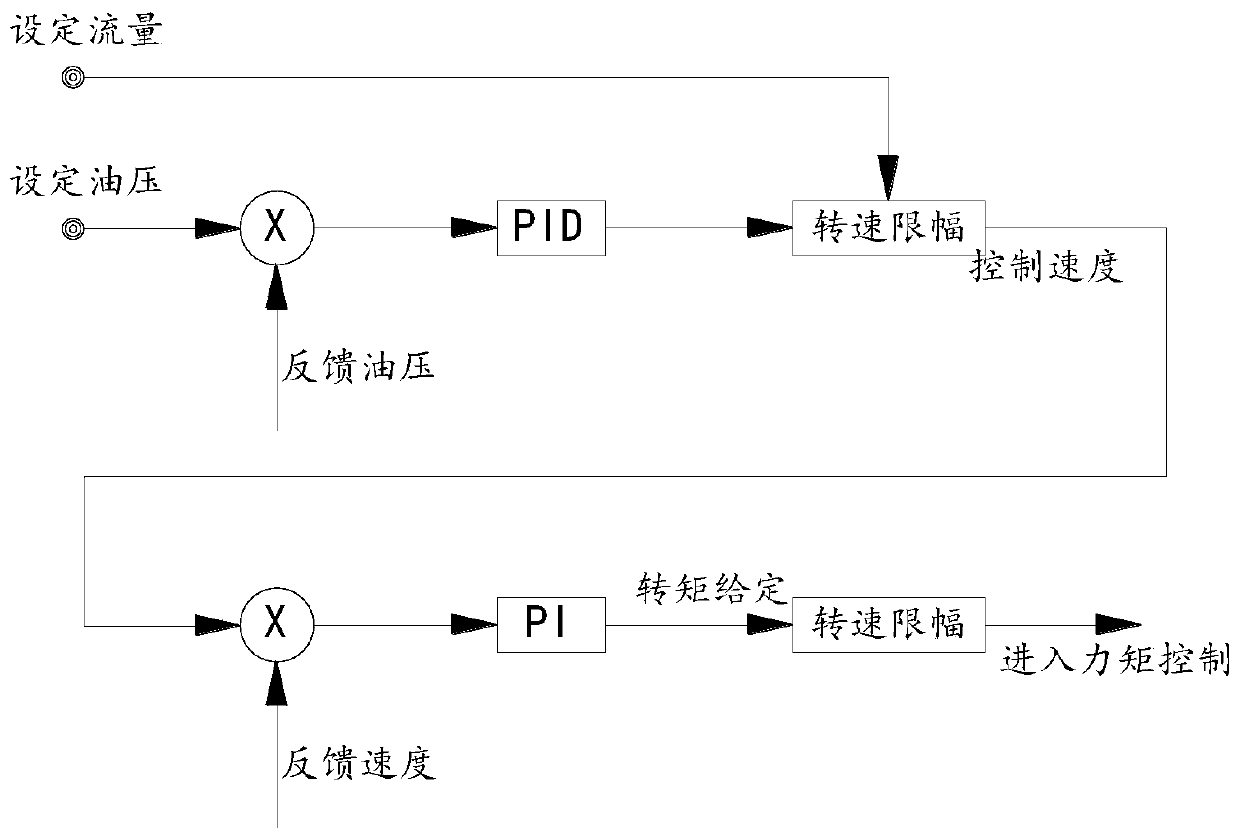

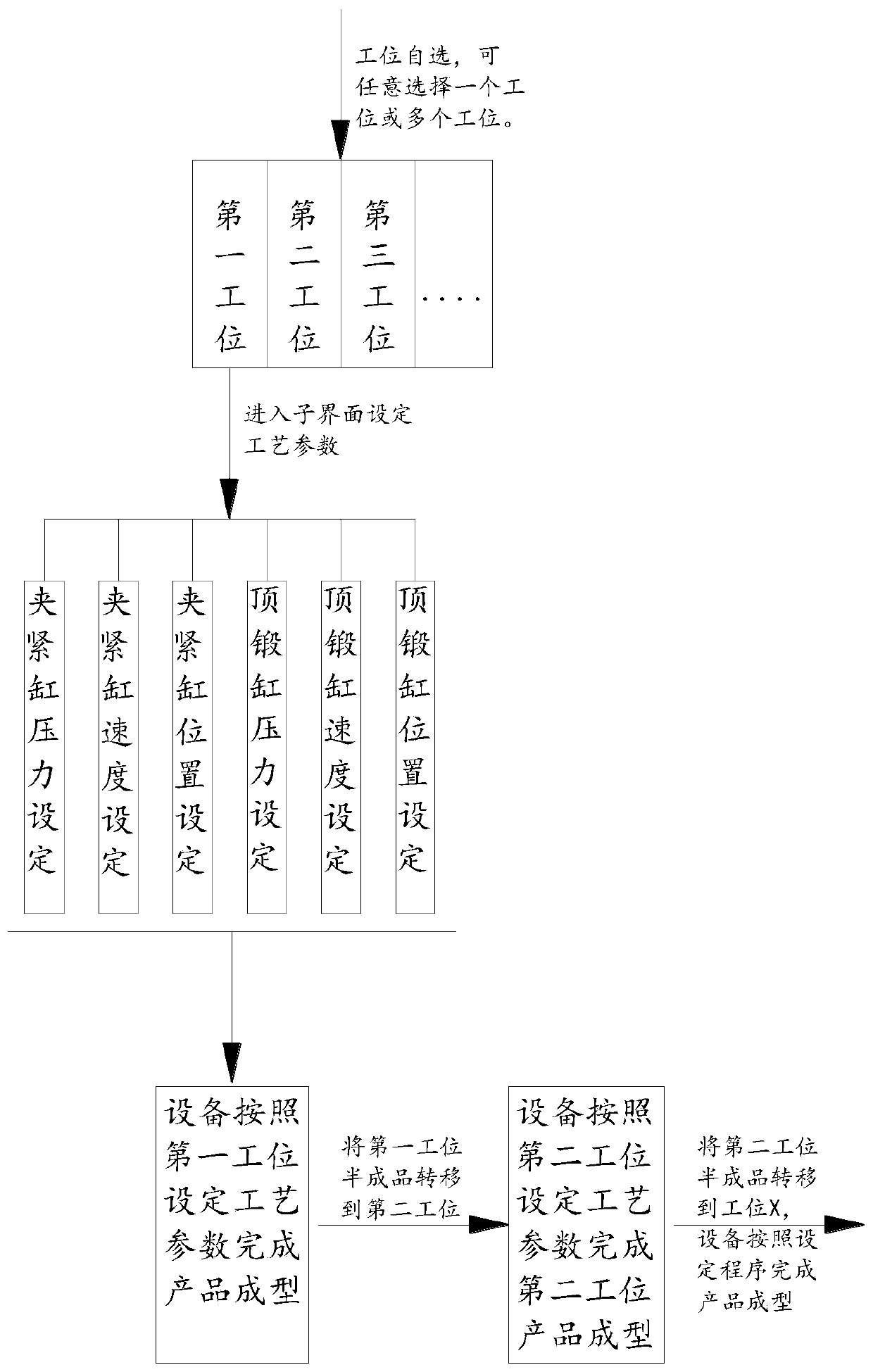

Molding position optional hydraulic horizontal forging machine control system and method

ActiveCN109732024AEasy to controlConvenient multi-station multi-directional die forgingTool carrier control devicesForging/hammering/pressing machinesMachine controlControl system

The invention discloses a molding position optional hydraulic horizontal forging machine control system. The control system comprises an operation box (100), a master control cabinet (200), a remote simulation module (300), a servo driver (400), a hydraulic module (500) and a communication module (600). The master control cabinet (200) is connected with the servo driver (400). The servo driver (400) is connected with the hydraulic module (500). The master control cabinet (200) controls the servo driver (400) to drive the hydraulic module (500) to do rectilinear motion and implement signal feedback according to an input signal so as to realize accurate control over a hydraulic horizontal forging machine. The invention further discloses a corresponding control method. The control system provided by the invention drives the hydraulic module to do rectilinear motion and signal feedback through the servo driver to achieve accurate control over the hydraulic horizontal forging machine. The control system greatly facilitates multi-position and multi-direction die forging on complex parts, is convenient to operate and high in process flexibility and improves the production efficiency.

Owner:WUHAN NEWWISH TECH

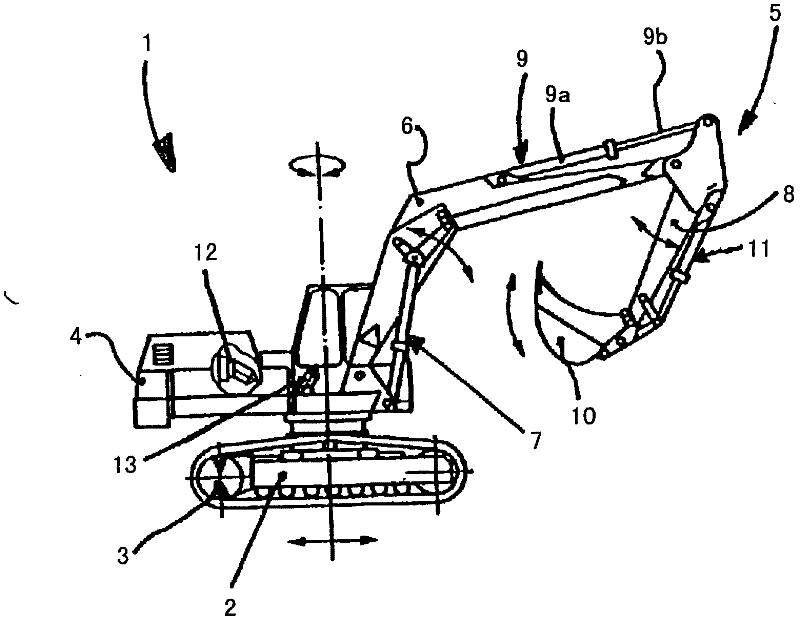

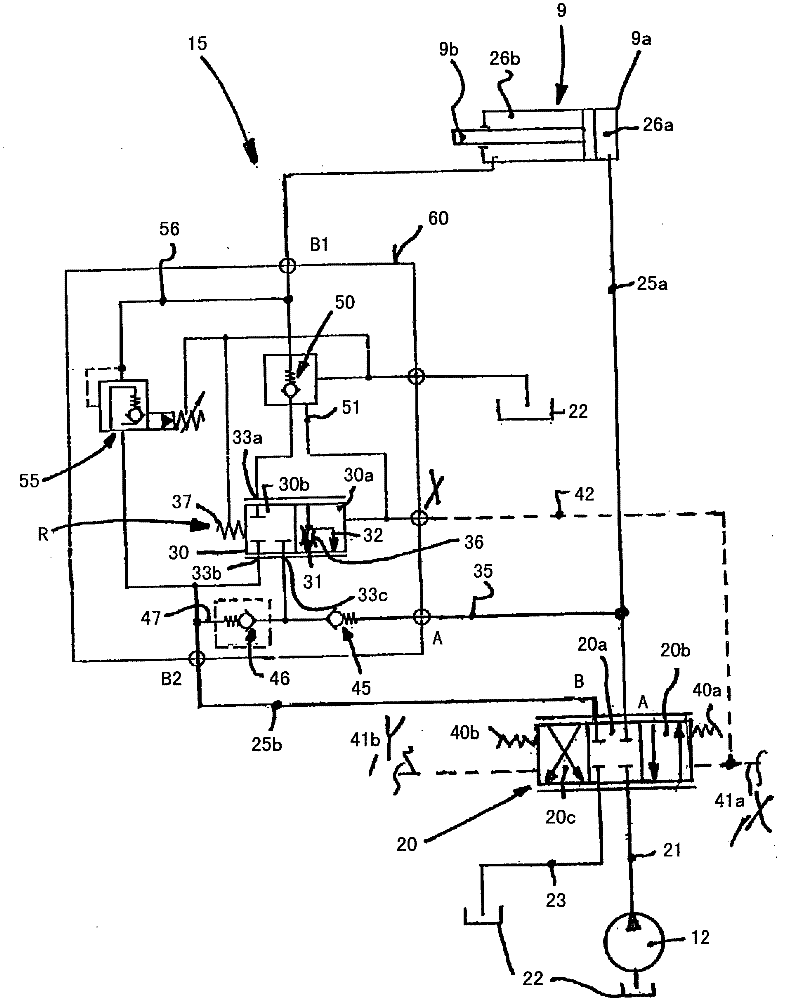

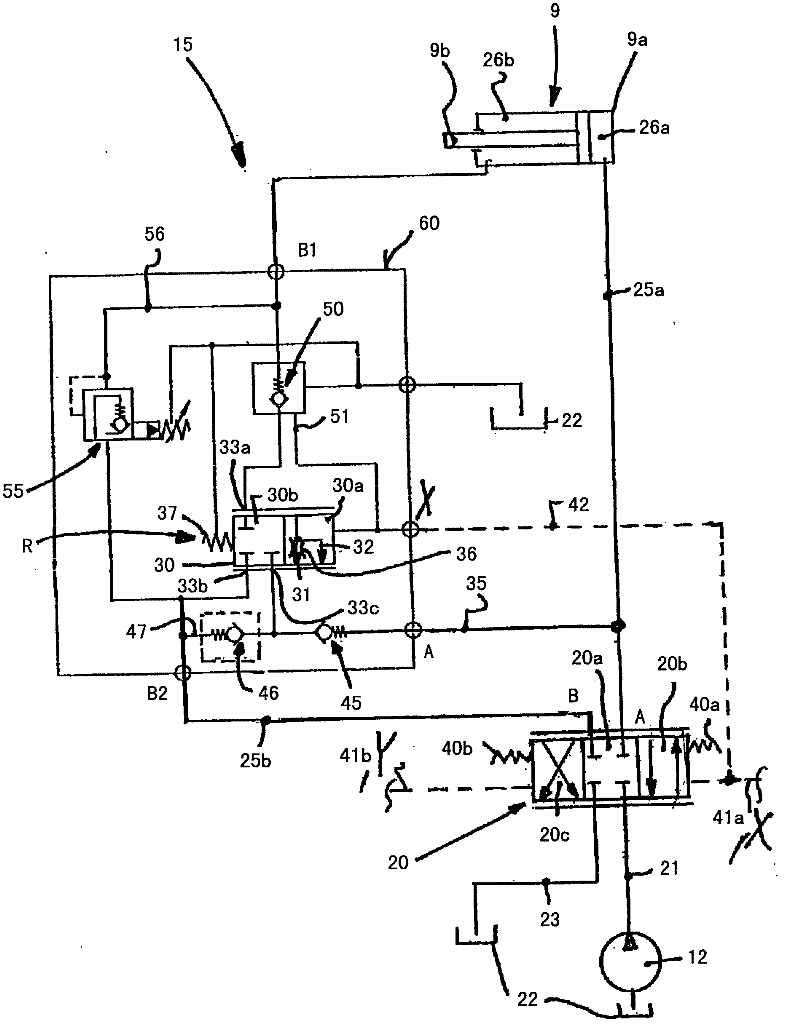

Control valve device of double-acting arm cylinder for operating mobile working machine

InactiveCN102588362AAchieve protectionAchieve pressureServomotor componentsServomotorsEngineeringControl valves

A control valve device (15) of a double-acting arm cylinder (9) for operating a mobile working machine possesses a control valve (20) and a regenerating unit (R). The control valve controls the connection between a first pressure medium line (25a) comprising the inflow side of the arm cylinder (9) and a pump (12), and the connection between a second pressure medium line (25b) comprising the backflow side of the arm cylinder (9) and a container (22). With the regenerating unit, the back side of the arm cylinder (9) and the inflow side of the arm cylinder can be connected. The regenerating unit (R) possesses a regenerating valve (30), the regenerating valve (30) runs from the backflow side of the arm cylinder (9) toward the second pressure medium line (25b) of the control valve (20). The regenerating valve (30) possesses a regenerating position (30a), the regenerating valve (30) at the regenerating position enables at least part of the second pressure medium line (25b) to be stopped and enables the backflow side of the arm cylinder (9) to be connected with the inflow side of the arm cylinder (9).

Owner:LINDE HYDRAULICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com