Integral soft sensing element with pressure and non-contact gap measuring functions

A non-contact, sensing element technology, applied in the field of sensors, can solve problems such as difficult installation, inability to complete non-contact gap measurement, inability to complete pressure measurement, etc., and achieve the effect of thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

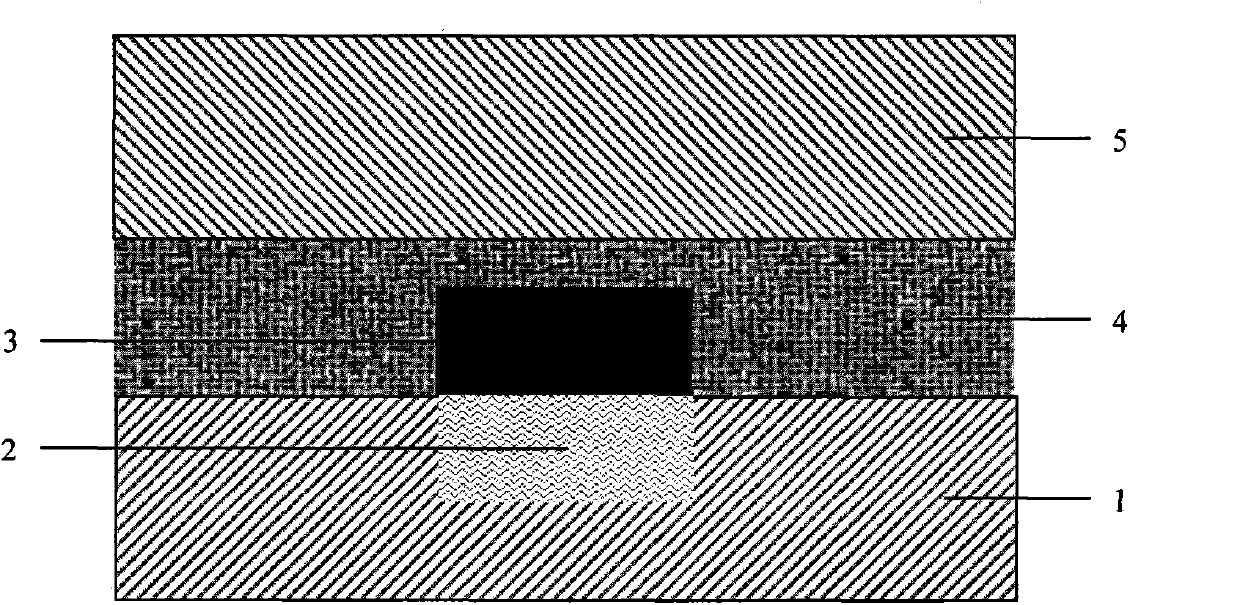

Image

Examples

Embodiment 1

[0018] Copper foil coils are laminated on the underlying polyimide film to form a planar eddy current coil film. The thickness of the polyimide film is 12.5 microns, the thickness of the copper foil coil is 10 microns, the number of turns is 50, and the line width is 0.15 mm, the line distance is 0.15 mm; the carbon black powder with an average particle size of 50 nanometers and room temperature vulcanized silicone rubber are mixed in a mass ratio of 0.08:1, and then added to n-hexane; for carbon black / silicone rubber / The mixed solution of n-hexane is stirred by high-power machinery, and at the same time supplemented by ultrasonic vibration, the carbon black is dispersed in the mixed solution at a temperature of 40-50°C. Under the action of ethyl orthosilicate and dibutyltin dilaurate, carbon black is formed. Black / silicone rubber mixture; the carbon black / silicone rubber mixture is evenly coated on the copper foil coil on the planar eddy current coil film, extruded into a fil...

Embodiment 2

[0020] Copper foil coils are laminated on the underlying polyimide film to form a planar eddy current coil film. The thickness of the polyimide film is 12.5 microns, the thickness of the copper foil coil is 10 microns, the number of turns is 30, and the line width is 0.3 mm, the line distance is 0.15 mm; carbon nanotube powder and room temperature vulcanized silicone rubber with an aspect ratio of 330 are mixed in a mass ratio of 0.03:1, and then added to n-hexane; for carbon nanotube / silicone rubber / n-hexane mixed solution for high-power mechanical stirring, supplemented by ultrasonic vibration, so that carbon nanotubes are dispersed in the mixed solution, the temperature is 40-50 ° C, under the action of ethyl orthosilicate and dibutyltin dilaurate, Form a carbon nanotube / silicone rubber mixture; coat the carbon nanotube / silicone rubber mixture evenly on the copper foil coil on the planar eddy current coil film, extrude it into a film with a rigid smooth flat plate, and wait...

Embodiment 3

[0022] Copper foil coils are laminated on the underlying polyimide film to form a planar eddy current coil film. The thickness of the polyimide film is 12.5 microns, the thickness of the copper foil coil is 10 microns, the number of turns is 60, and the line width is 0.3 mm, the line distance is 0.3 mm; the carbon black powder with an average particle size of 20 nanometers and the room temperature vulcanized silicone rubber are mixed in a mass ratio of 0.04:1, and then added to n-hexane; for carbon black / silicone rubber / The mixed solution of n-hexane is stirred by high-power machinery, and at the same time supplemented by ultrasonic vibration, the carbon black is dispersed in the mixed solution at a temperature of 40-50°C. Under the action of ethyl orthosilicate and dibutyltin dilaurate, carbon black is formed. Black / silicone rubber mixture; the carbon black / silicone rubber mixture is evenly coated on the copper foil coil on the planar eddy current coil film, extruded into a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com