Electro-hydraulic control system of high/ low temperature test stand of automobile automation transmission valve body

An electro-hydraulic control system, high and low temperature test technology, applied in the direction of electrical program control, fluid pressure actuation system components, comprehensive factory control, etc., can solve the lack of valve body performance test, lack of real-time high-speed data acquisition and control of test and test systems , lack of valve body performance test and other problems, to achieve the effect of improving test adaptability, compact structure and good real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The implementation process of the present invention will be further described below in conjunction with the accompanying drawings.

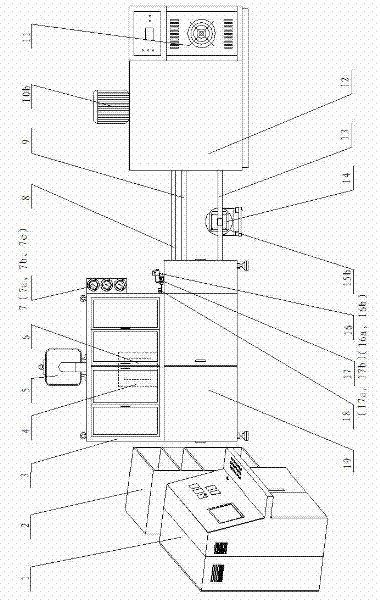

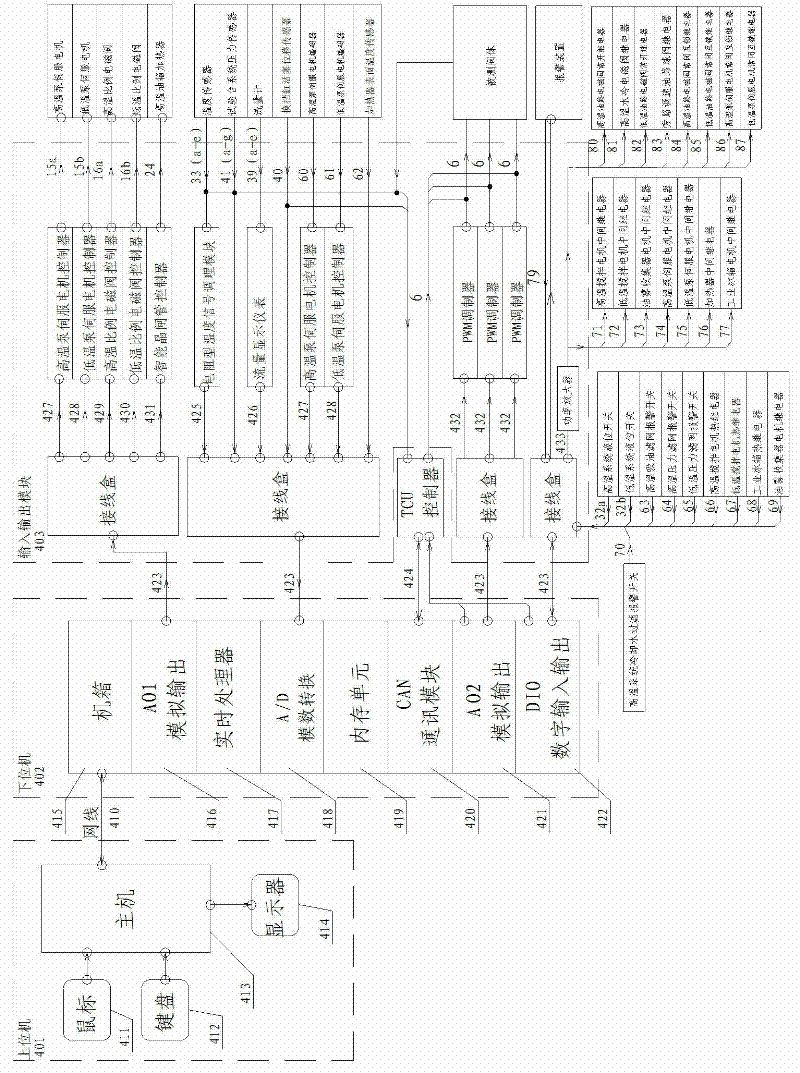

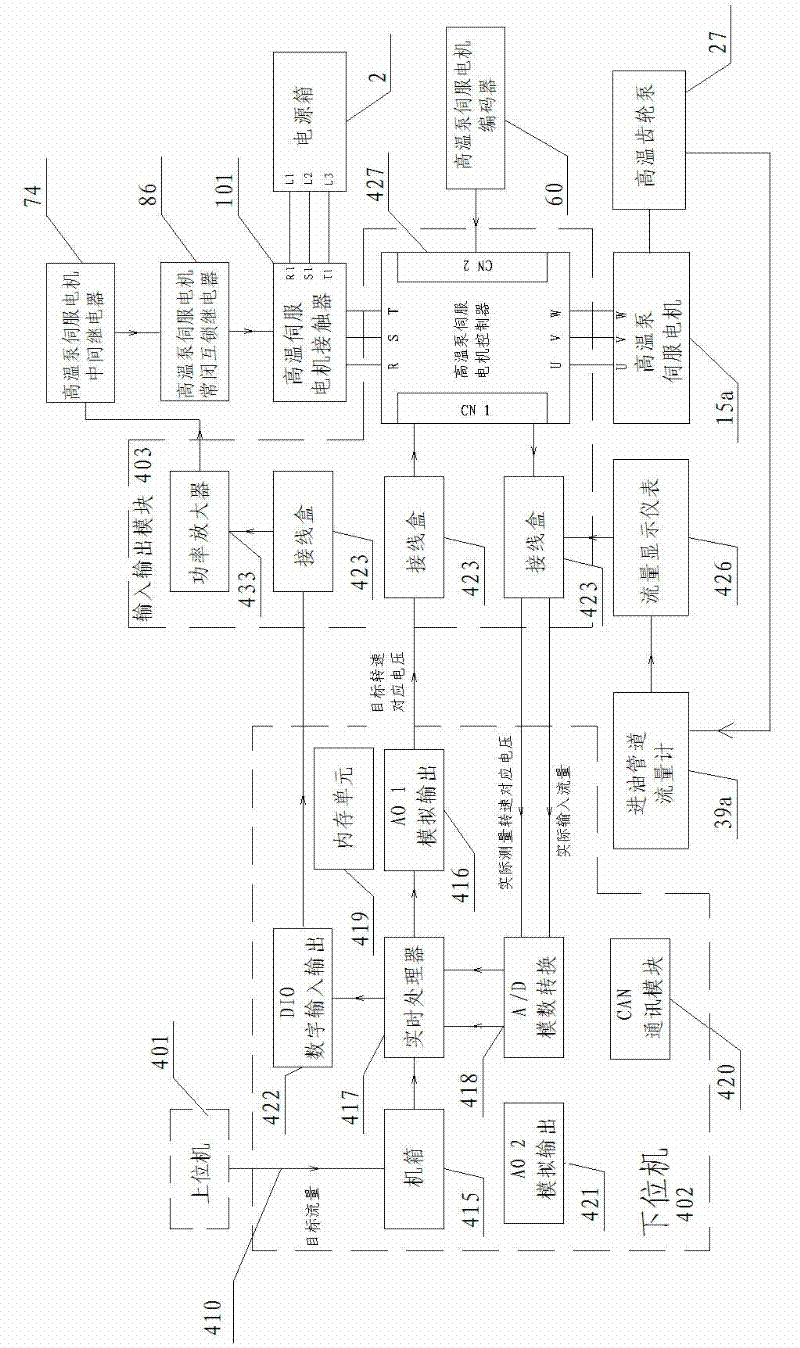

[0052] see figure 1 and Figure 7 A high and low temperature test bench for an automatic transmission valve body is shown, including a control cabinet 1, a power supply box 2, a test chamber 3 located above a high temperature hydraulic pump station 19, high and low temperature proportional solenoid valves 16a, 16b, and a high and low temperature hydraulic safety valve 17a , 17b and the speed regulating valve 18 of the main oil circuit, the measured valve body 6 and valve plate 4 in the test chamber 3, the oil mist collector 5 and the pressure gauge 7 (including High-temperature pipeline pressure gauge 7a, low-temperature pipeline pressure gauge 7b, oil inlet pipeline pressure gauge 7c); also includes low-temperature oil tank 12 and industrial refrigerator 11, low-temperature oil tank agitator 10b located on the low-temperature system oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com