Two-interface cementing strength testing device of cementing sheath containing hydrates and ice stratum

A cementing and hydrate-containing technology, applied in construction and other directions, can solve problems such as temporary sealing and support of difficult-hydrate well walls, and achieve the effects of accurate and reliable measurement results, convenient use and operation, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

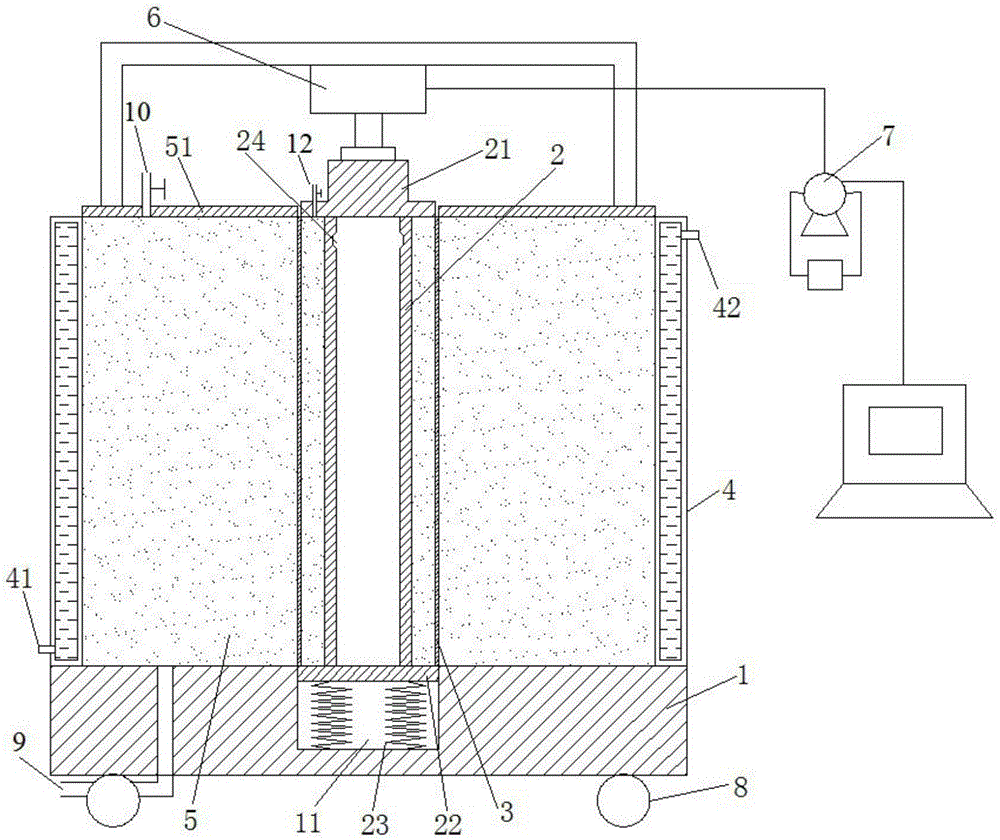

[0031] Example: such as figure 1 As shown, the cement sheath interface bonding strength test device for hydrate-containing and ice formation cementing in this embodiment includes a kettle shell base 1 and a simulated casing 2, and the above-mentioned simulated casing 2 is vertically arranged in the middle of the above-mentioned kettle shell base 1 A polyvinyl alcohol film tube 3 is arranged on the periphery of the above-mentioned simulated casing 2, an annular cavity is formed between the above-mentioned simulated casing 2 and the polyvinyl alcohol film tube 3, and a control panel is arranged around the outer edge of the top of the kettle shell base 1. Temperature circulating bath sealing cover 4, simulated formation 5 is filled between the above-mentioned temperature-controlled circulating bath sealing cover 4 and polyvinyl alcohol film tube 3, the top of the above-mentioned simulated formation 5 is covered with a formation kettle cover 51, and the top of the above-mentioned s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com