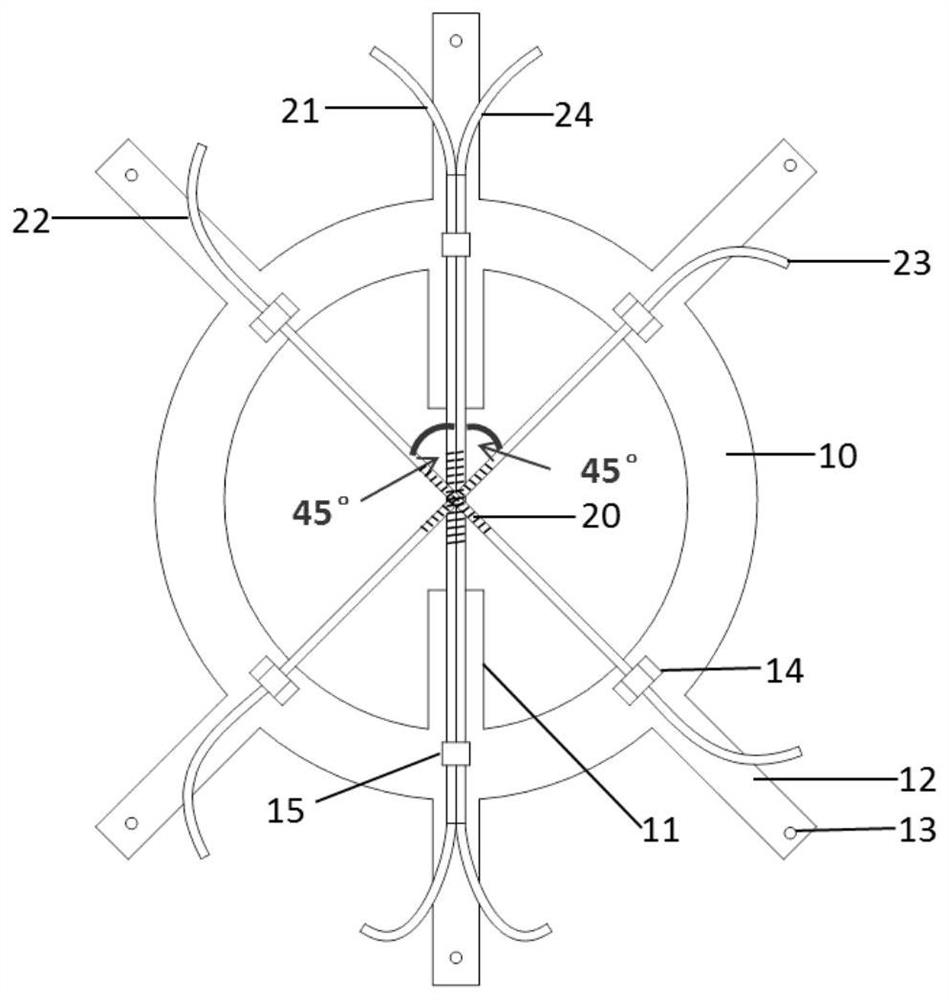

Patents

Literature

36results about How to "Avoid chirping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

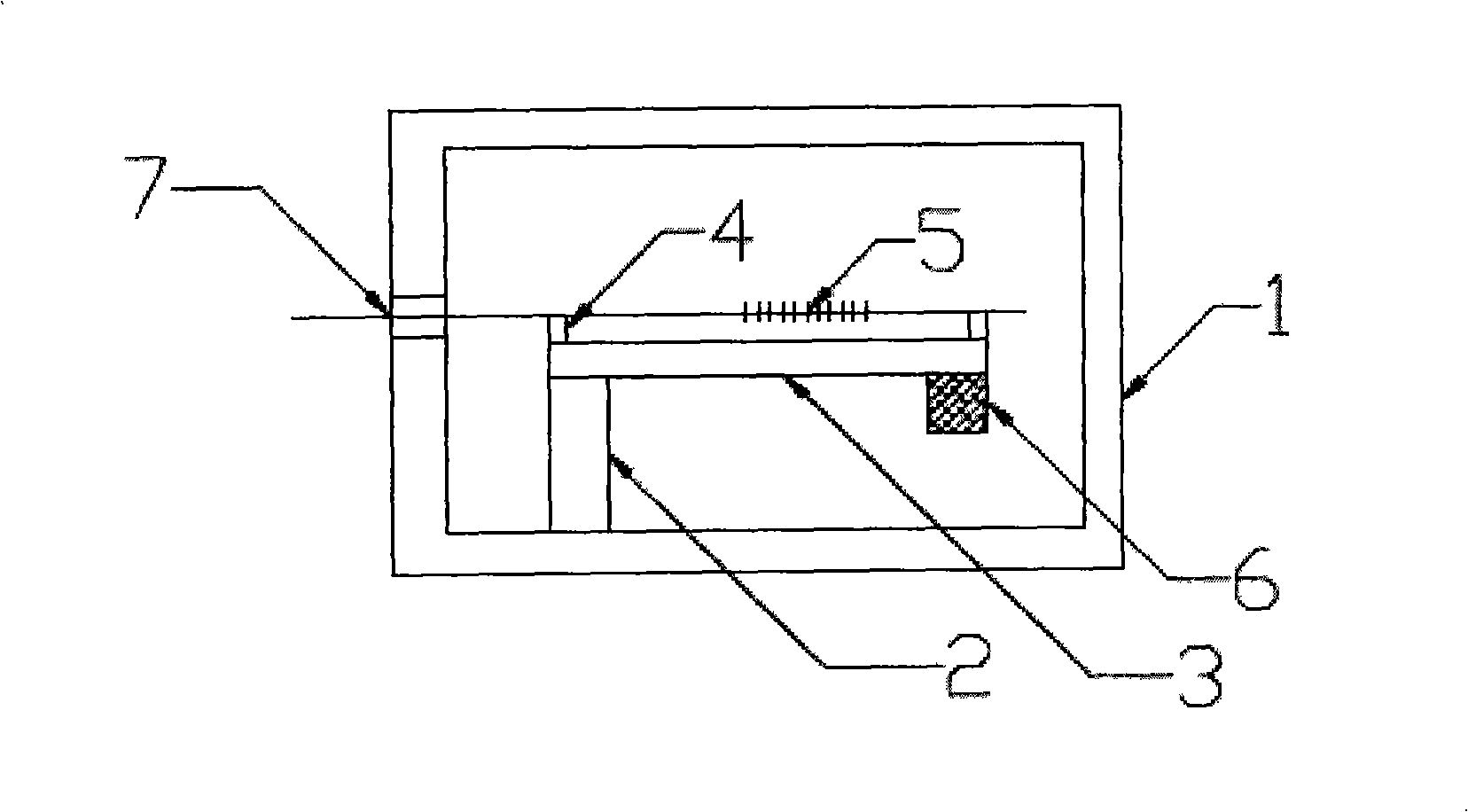

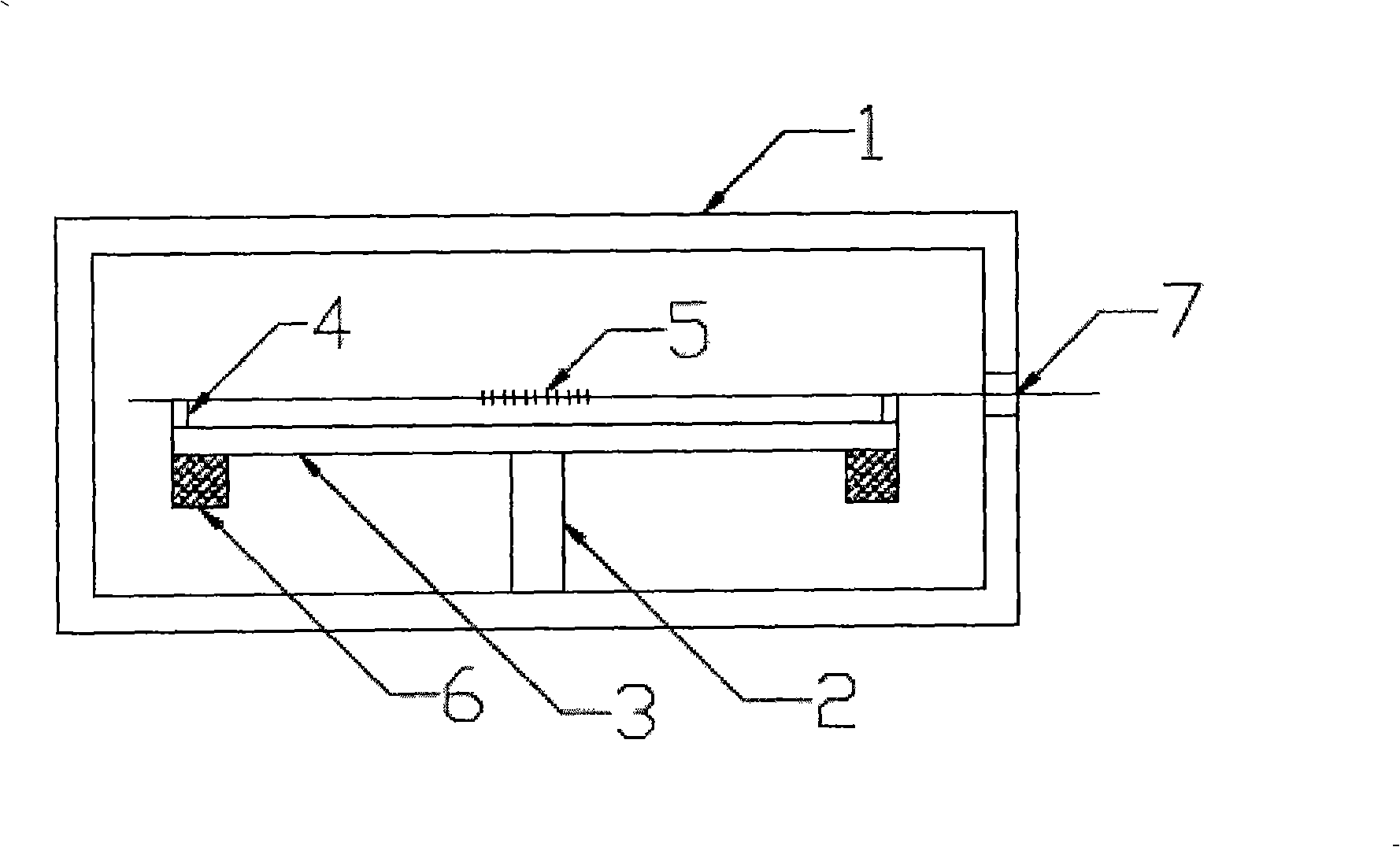

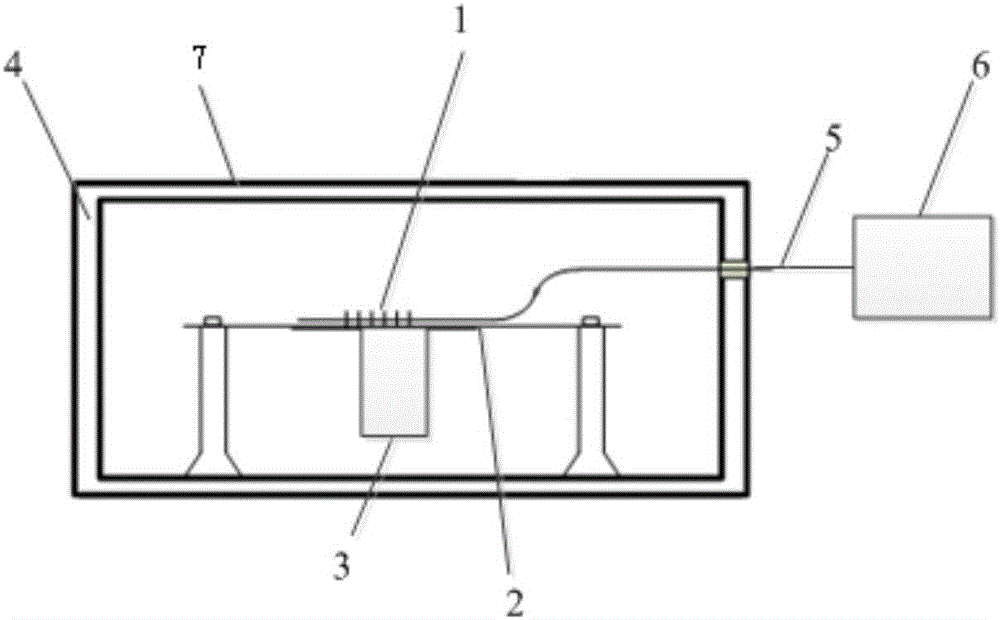

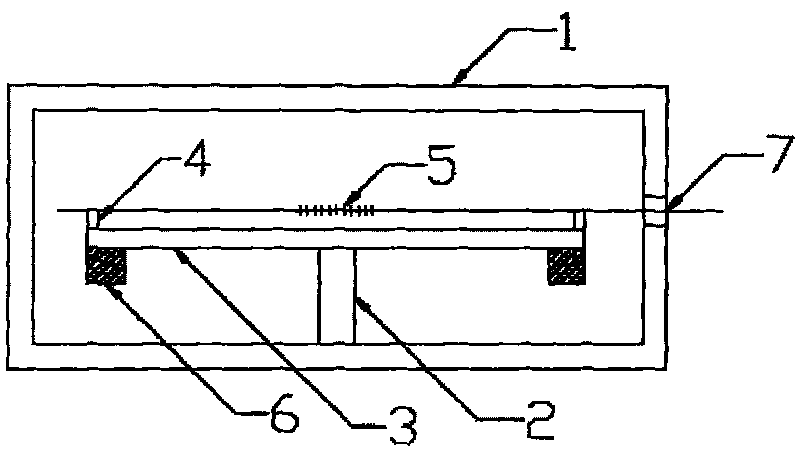

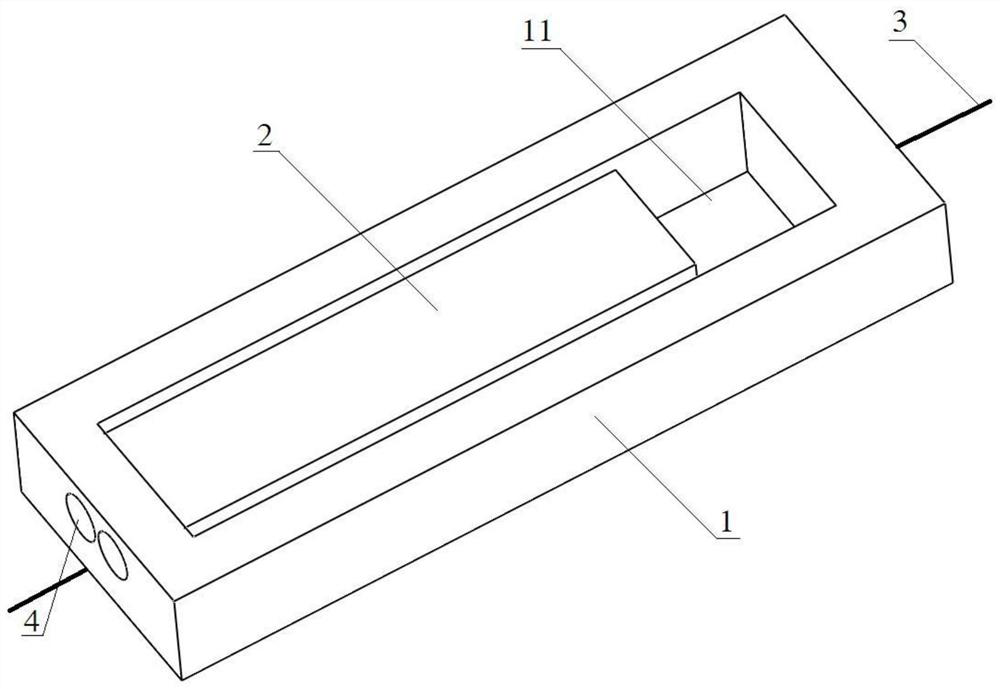

Cantilever beam type optical fibre grating accelerometer

InactiveCN101285845AAvoid chirpingSimple processTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamAccelerometer

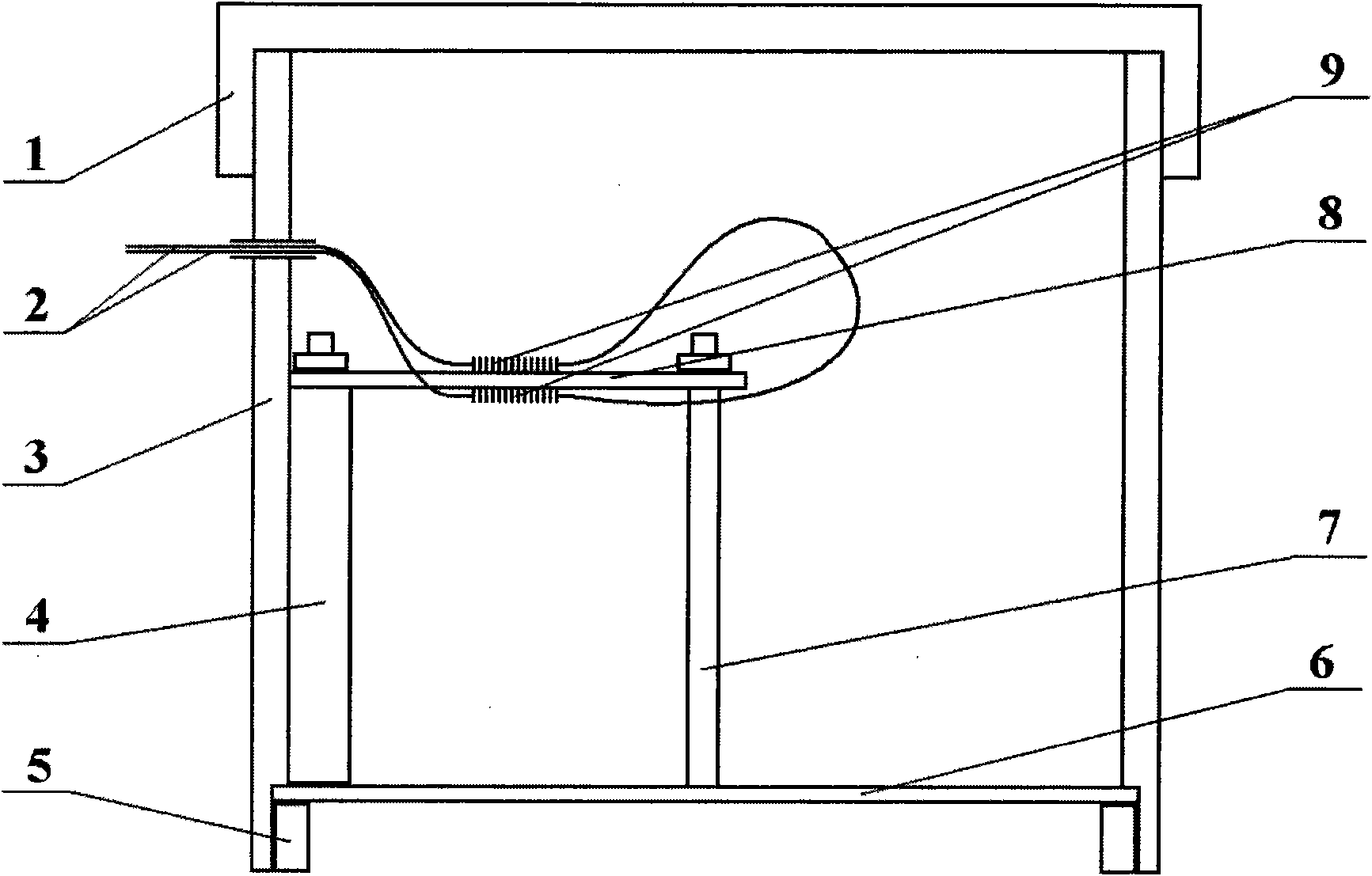

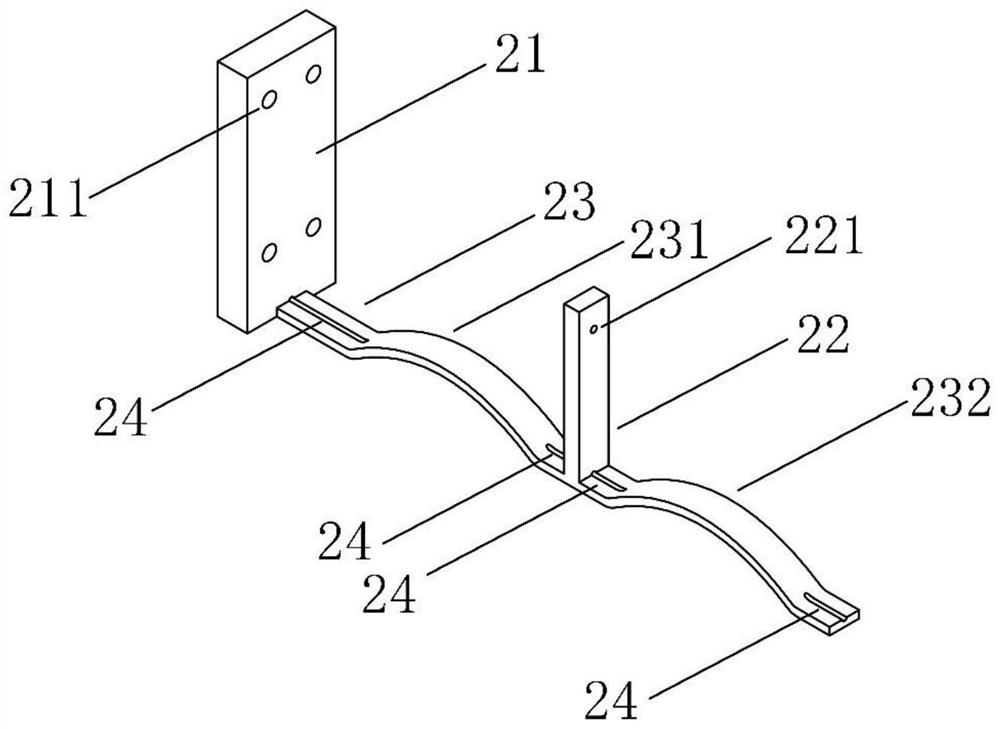

The invention relates to the optical fiber sensor technical field, disclosing a cantilever beam-type optical fiber grating accelerometer. The accelerometer comprises an outer casing used as a support structure of the accelerometer, a support column used to fix a cantilever beam, a cantilever beam, a first lug boss and a second lug boss arranged at both ends of the upside of the cantilever beam, an optical fiber grating used to measure acceleration and a mass block arranged at one end or both end of the underside of the cantilever beam, wherein one end of the support column is fixed with the cantilever beam, while the other end is fixed with the downside surface of the accelerometer; both lug bosses are used to horizontally fix the optical fiber grating and ensures a certain space between the optical fiber grating and the cantilever beam; both ends of the optical fiber grating are respectively fixed on the first lug boss and the second lug boss on the cantilever beam with one end parallel to the surface of the cantilever beam passing through the hole on the sidewall of the accelerometer to extend outside the accelerometer; and the mass block is used to adjust the sensitivity and the natural vibration frequency of the accelerometer. The cantilever beam-type optical fiber grating accelerometer increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

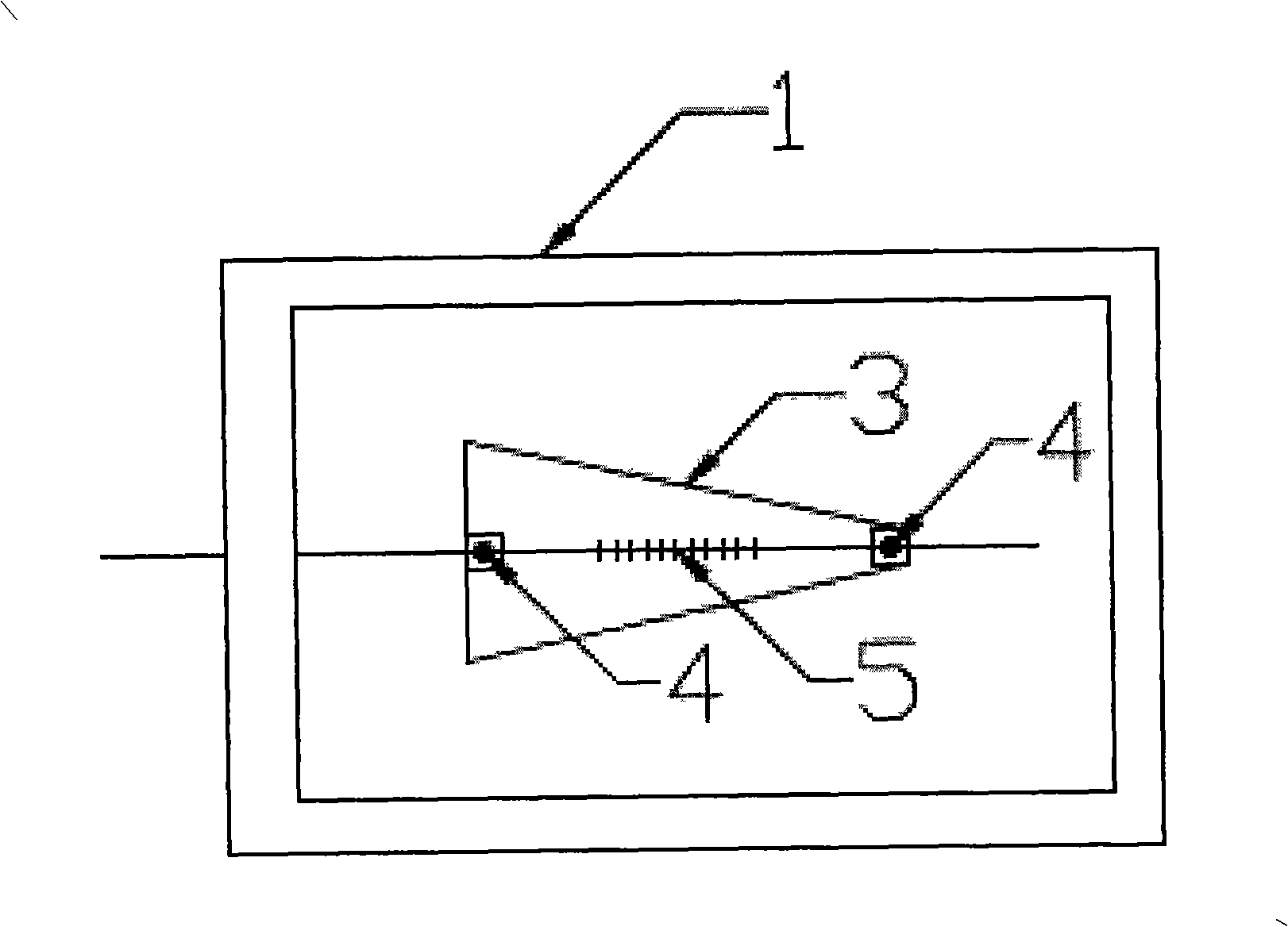

Temperature insensitive optical fibre grating acceleration sensor

InactiveCN101285847AAvoid chirpingSimple processTelevision system detailsSubsonic/sonic/ultrasonic wave measurementGratingClassical mechanics

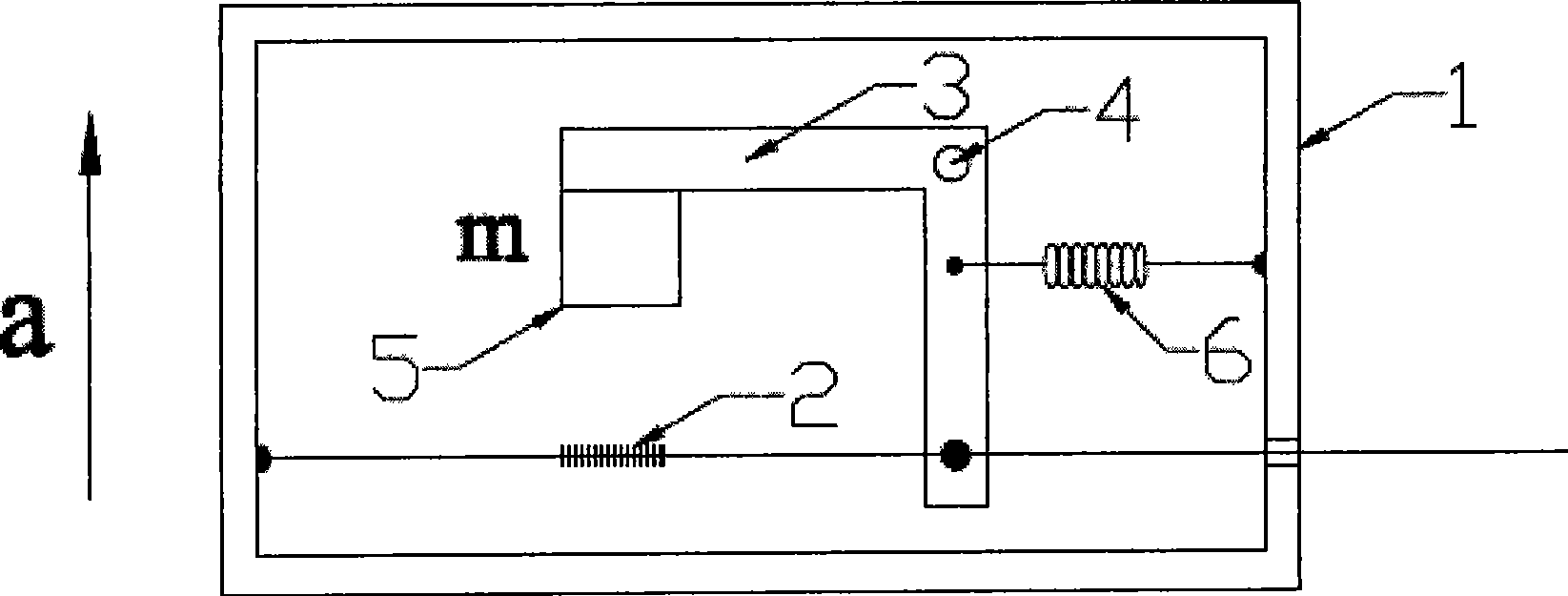

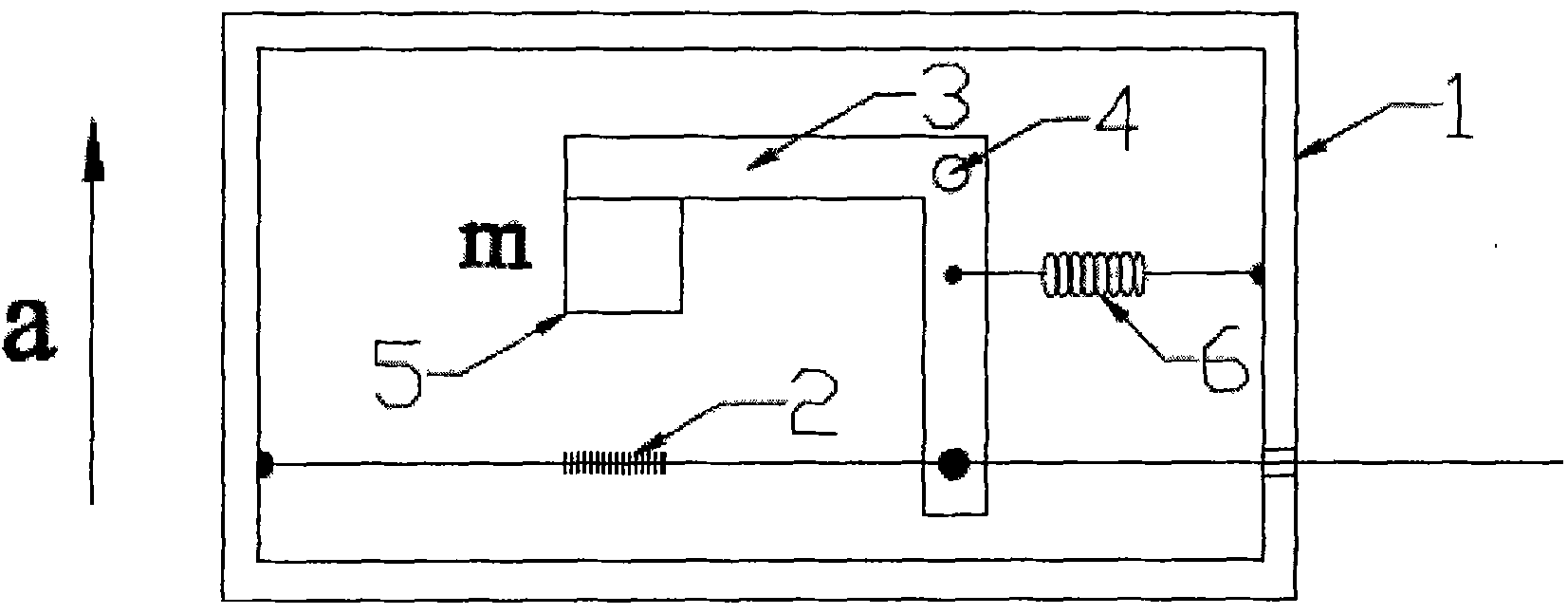

The invention discloses a temperature-insensitive optical fiber grating acceleration sensor, which comprises an outer casing used as a support structure of the acceleration sensor, an optical fiber grating used to measure acceleration, a shaft fixed on the front sidewall and the back sidewall of the acceleration sensor, an L-type lever arranged on the shaft and a mass block fixed on the horizontal end part of the lever, wherein one end of the optical fiber grating is fixed on the inner wall of one end of the acceleration sensor, while the other end parallelly passes through the small hole on the other end of the acceleration sensor and extends outside the acceleration sensor; the L-type lever is used to send vibration signal to the optical fiber grating connected with the lever, and the folding point of the cross part of the vertical part and the horizontal part of the L-type lever is in movable connection with the shaft; and the mass block is used to adjust the sensitivity and the natural vibration frequency of the sensor. The optical fiber grating acceleration sensor increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

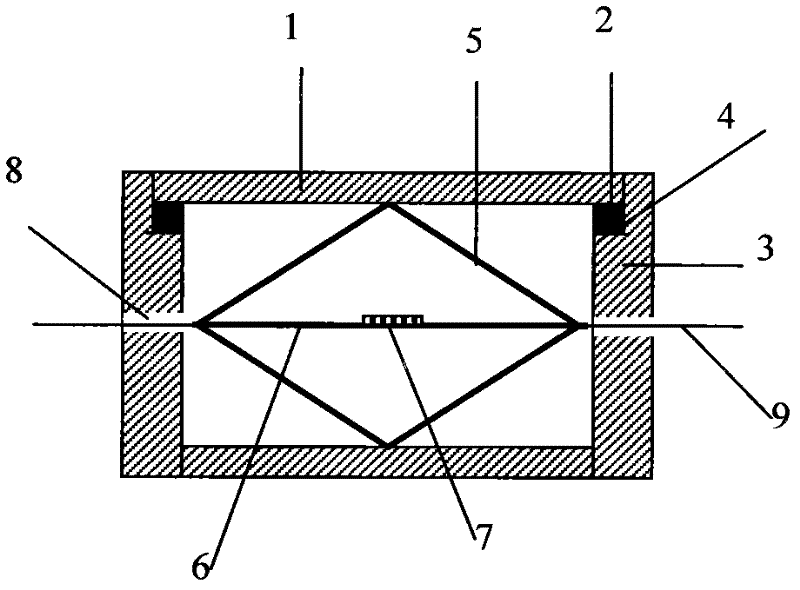

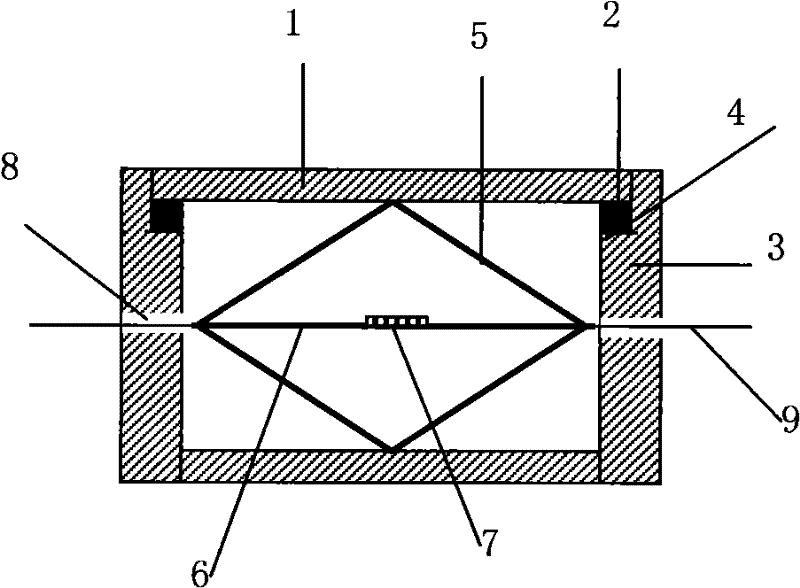

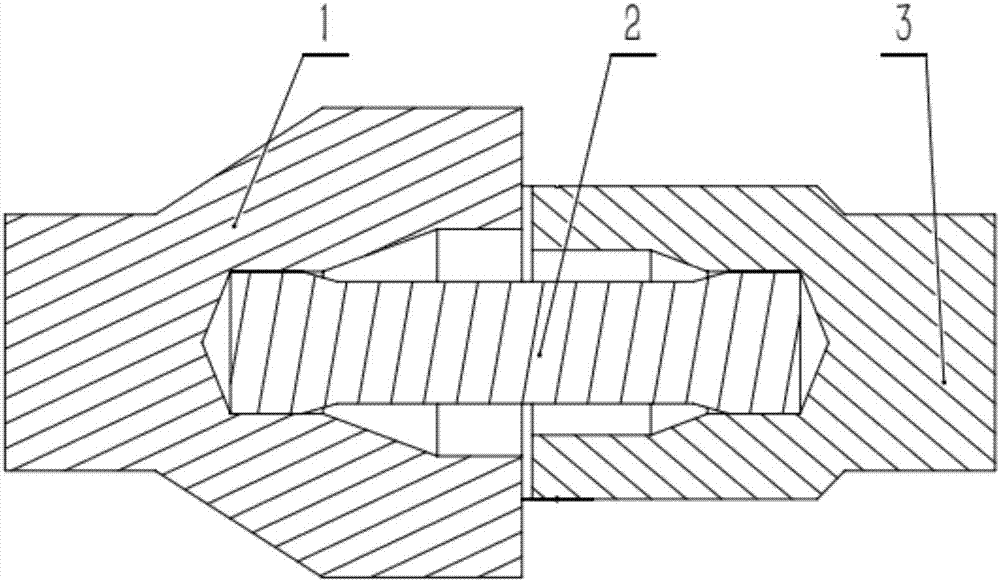

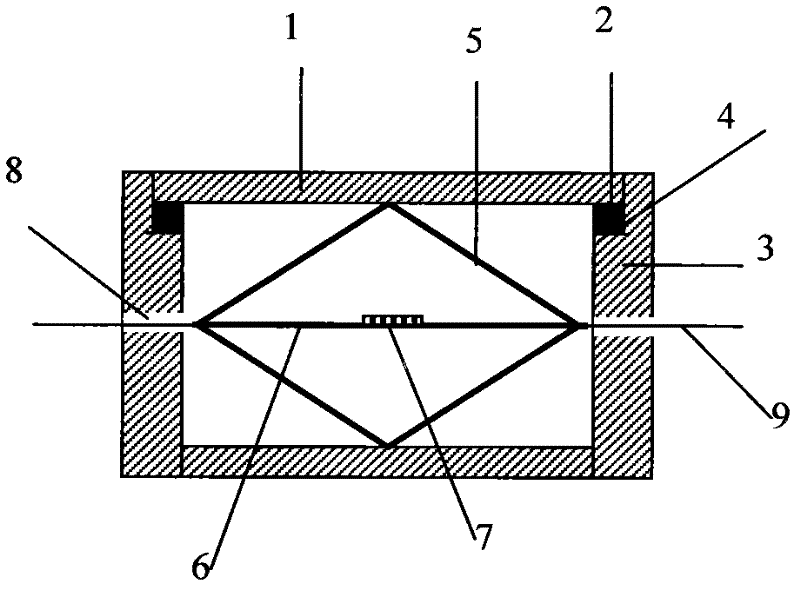

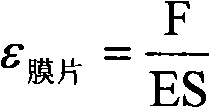

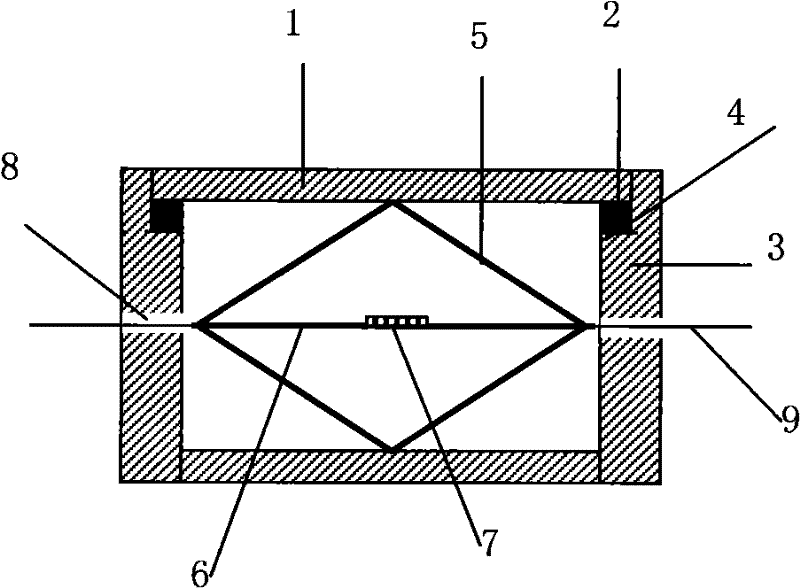

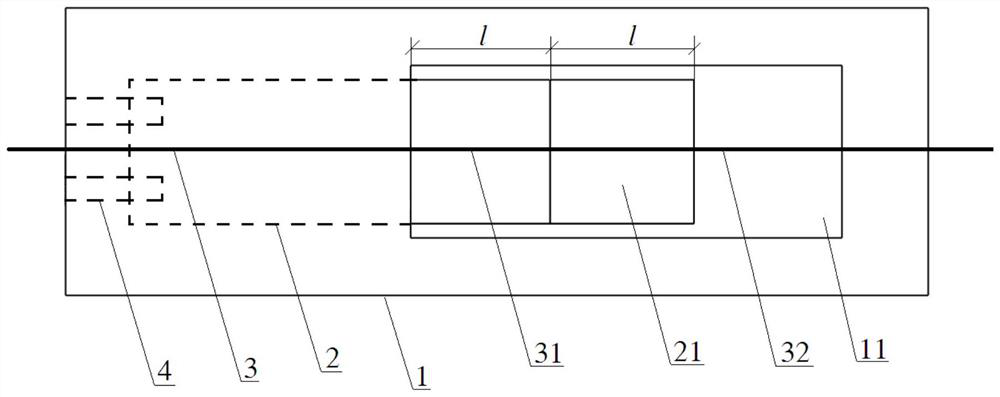

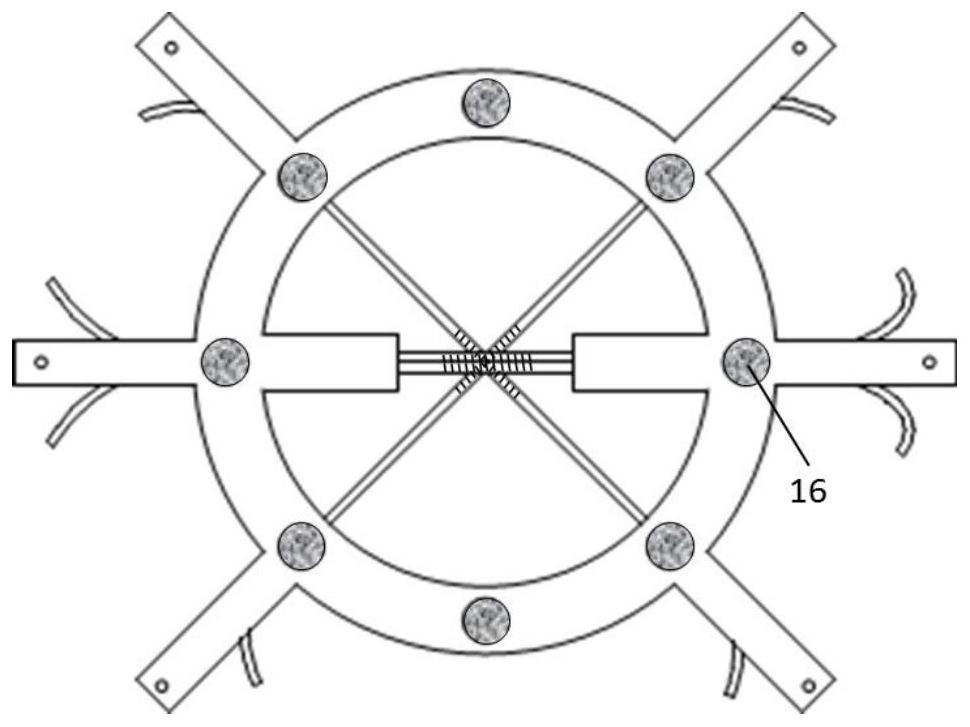

Fiber grating earth pressure sensor

ActiveCN102162757AAvoid chirpingConcentrated forceForce measurement by measuring optical property variationFiberPressure transmission

The invention discloses a fiber grating earth pressure sensor which comprises a sensor shell, a pressure transmission component and a fiber grating. The earth pressure sensor is characterized in that the pressure transmission component is of a rhombus structure, and the is positioned between a bearing-type top cover and a bottom plate, and is in contact with the bearing-type top cover and the bottom plate; clearances are arranged among the pressure transmission component and the left side and the right side of the sensor shell; a grating is pasted on a metal elastic membrane; the metal elastic membrane is arranged on a transverse diagonal line between a left angle and a right angle of the pressure transmission component; and two sides of the metal elastic membrane are fixed on the left angle and the right angle of the pressure transmission component. The earth pressure sensor provided by the invention has the characteristics of large measuring span, high accuracy and simple structure, is good for miniaturization of the integral structure.

Owner:青岛飞博科技有限公司

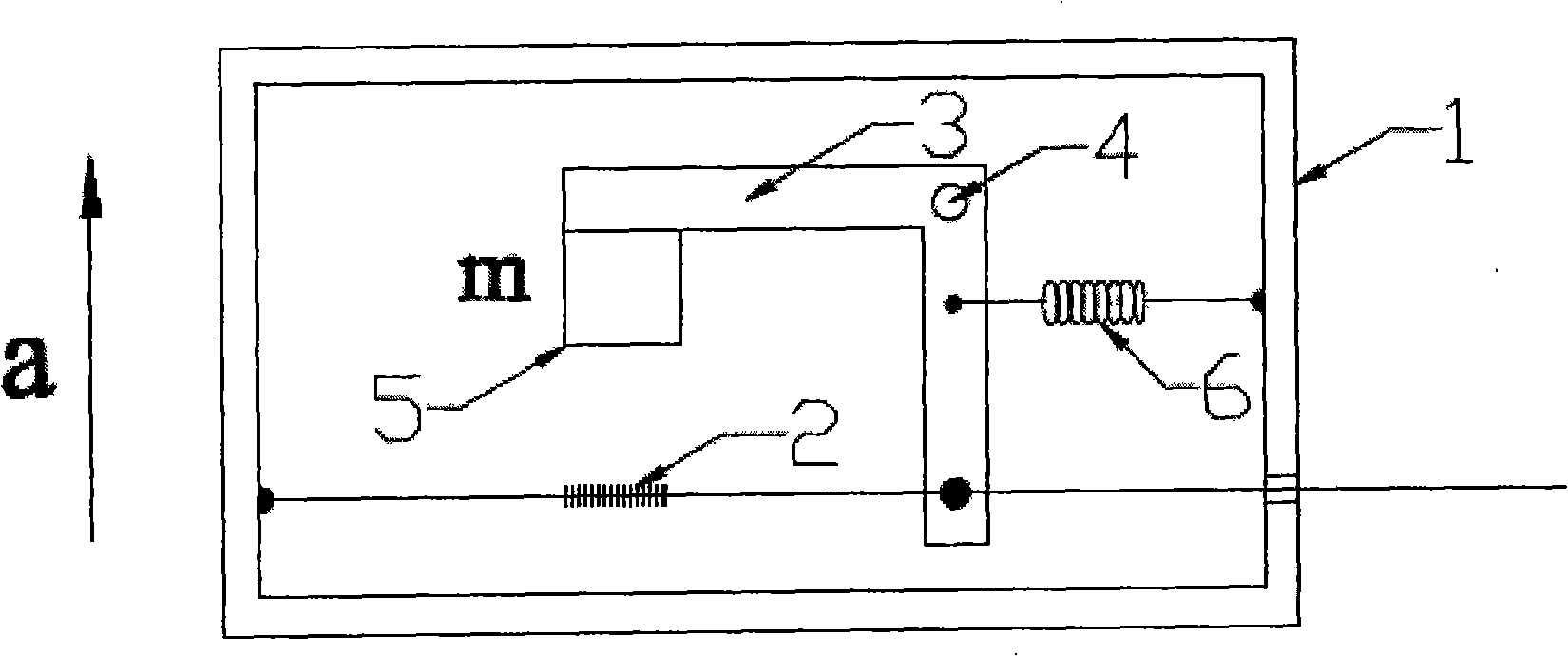

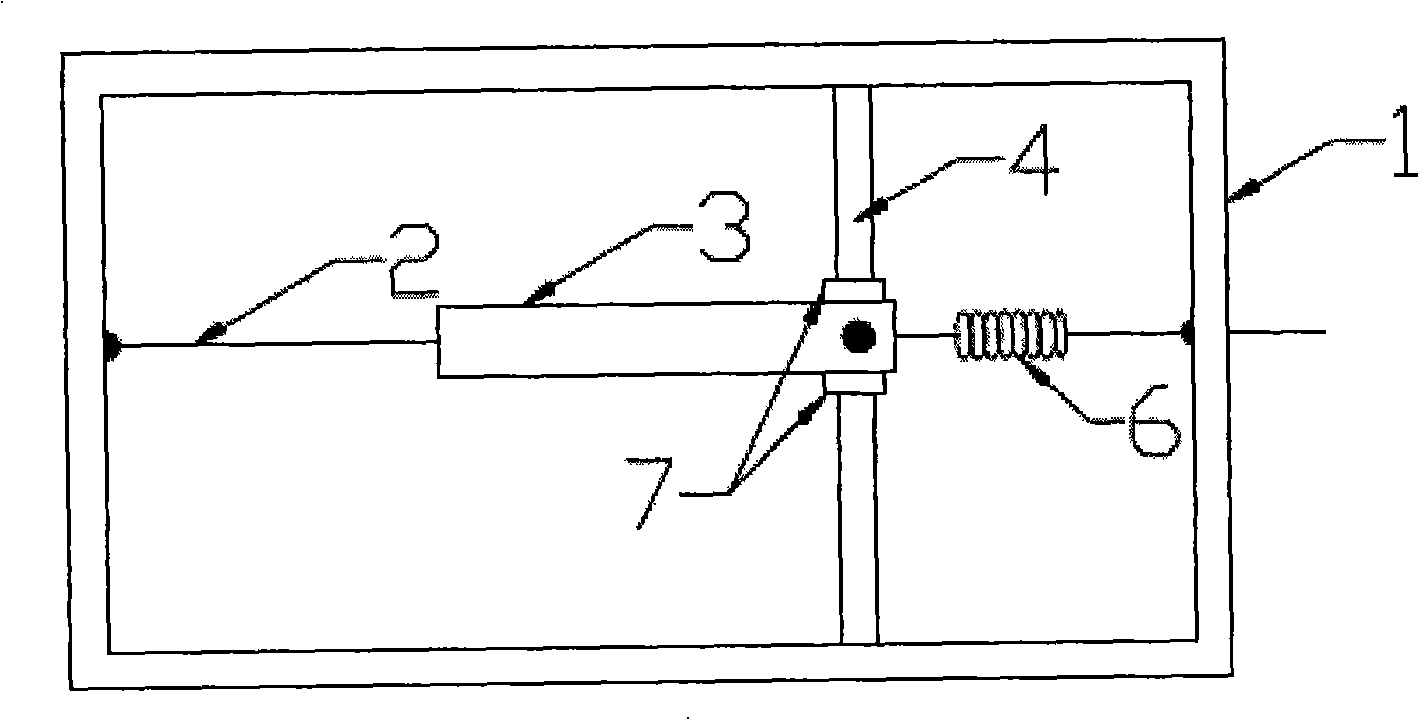

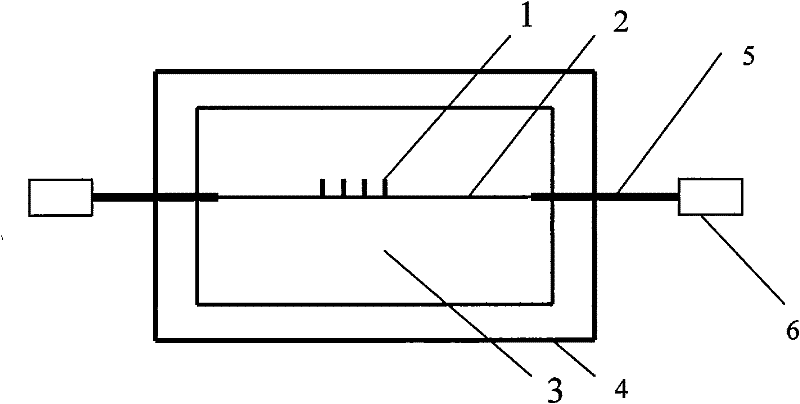

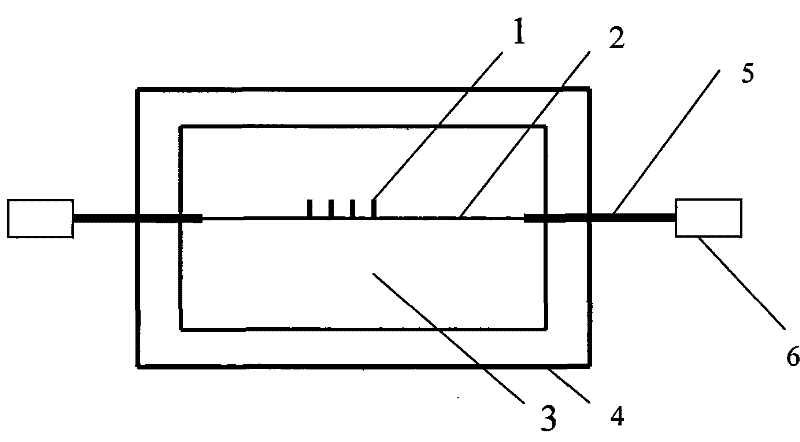

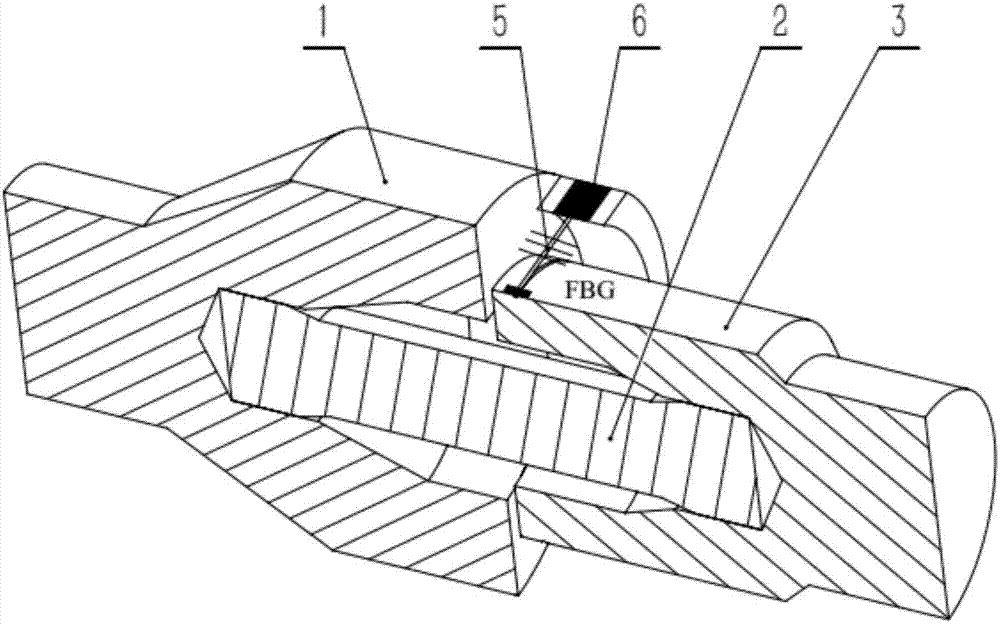

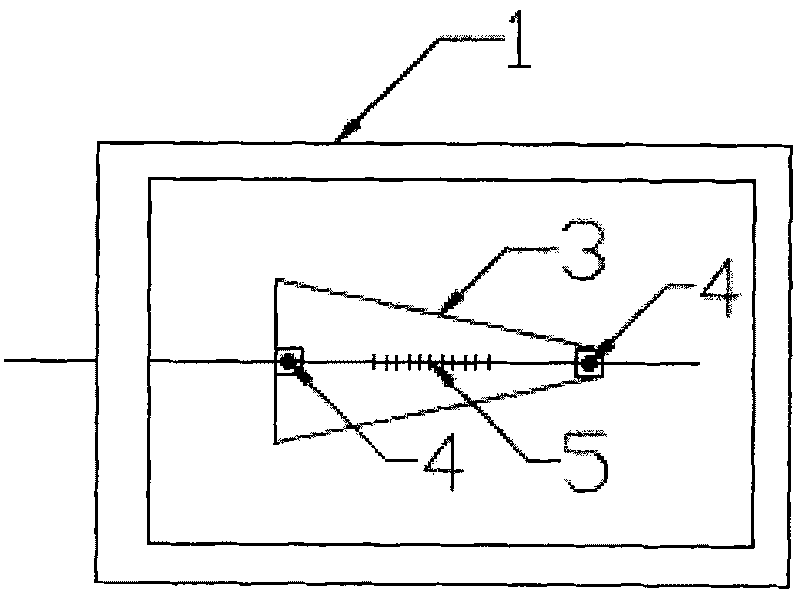

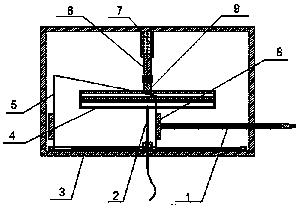

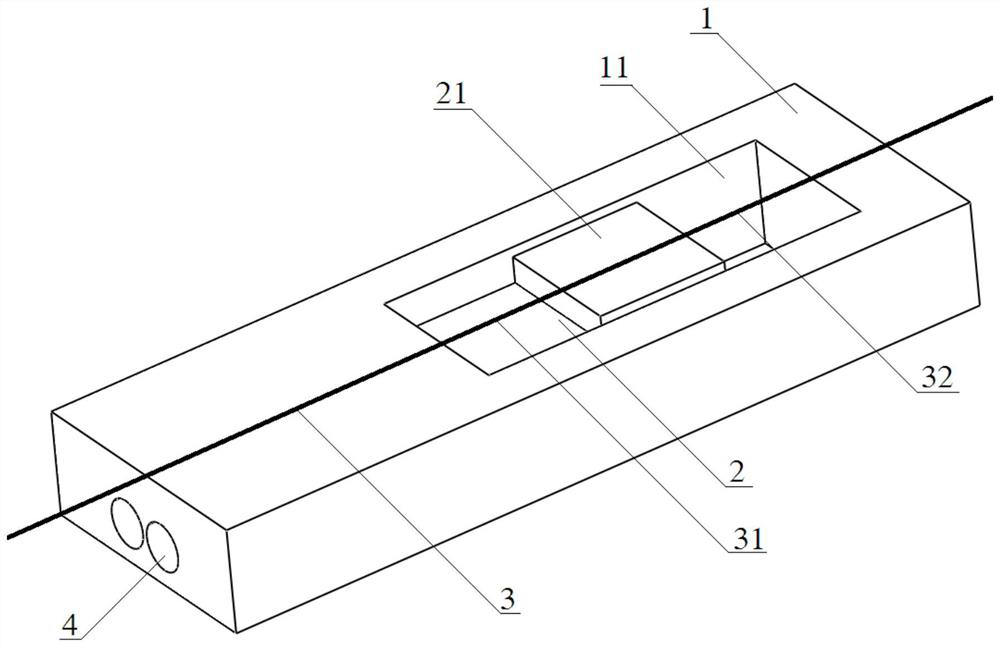

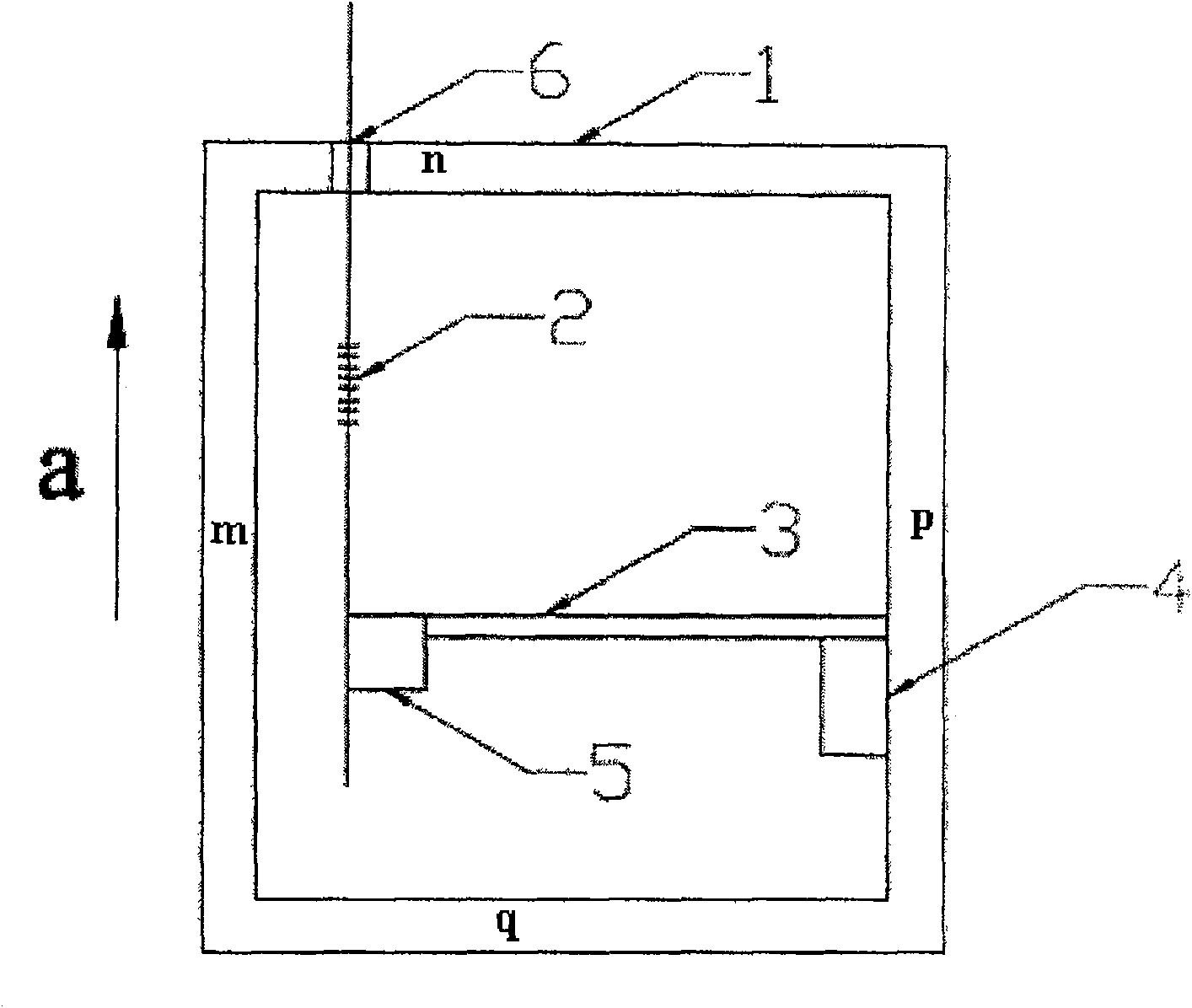

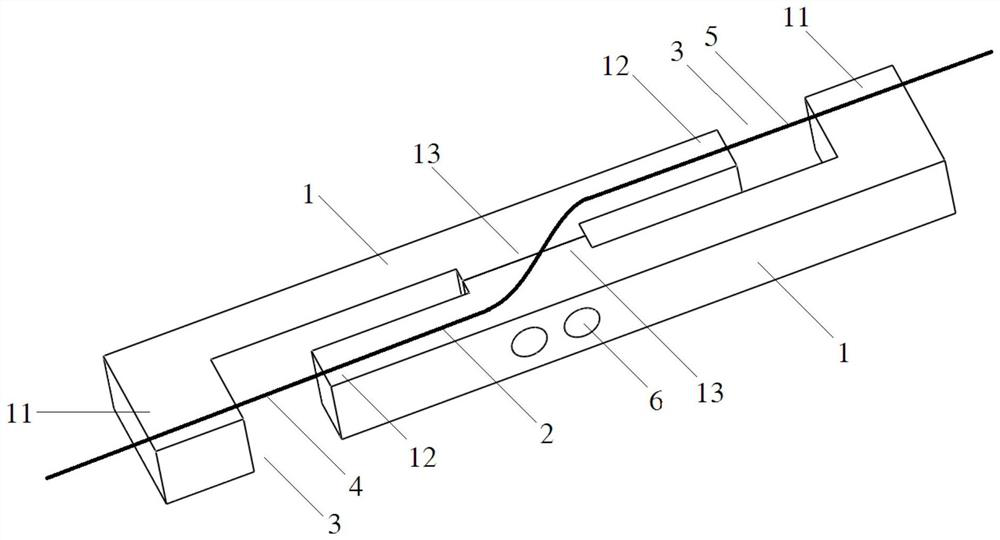

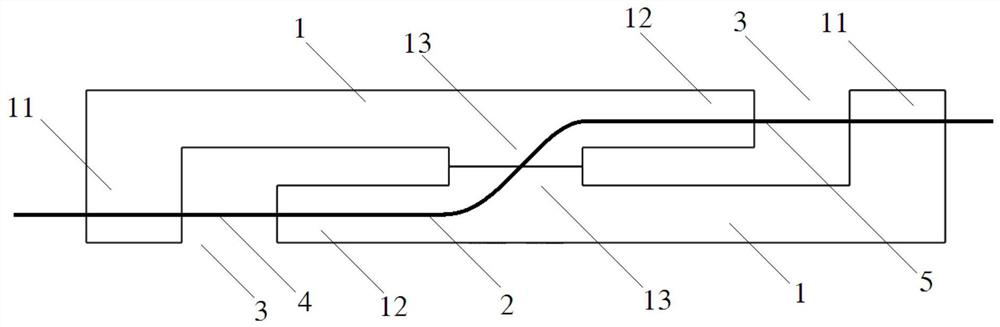

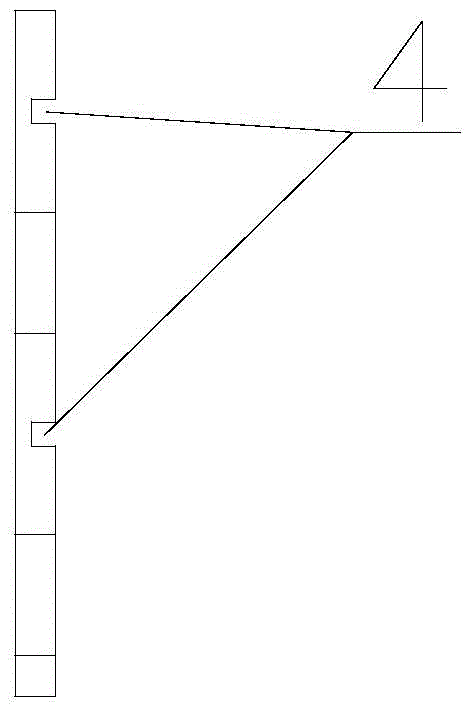

Optical fibre grating accelerometer based on cantilever beam deflection

InactiveCN101285846AHigh sensitivityLarge strainTelevision system detailsImpedence networksCantilevered beamAccelerometer

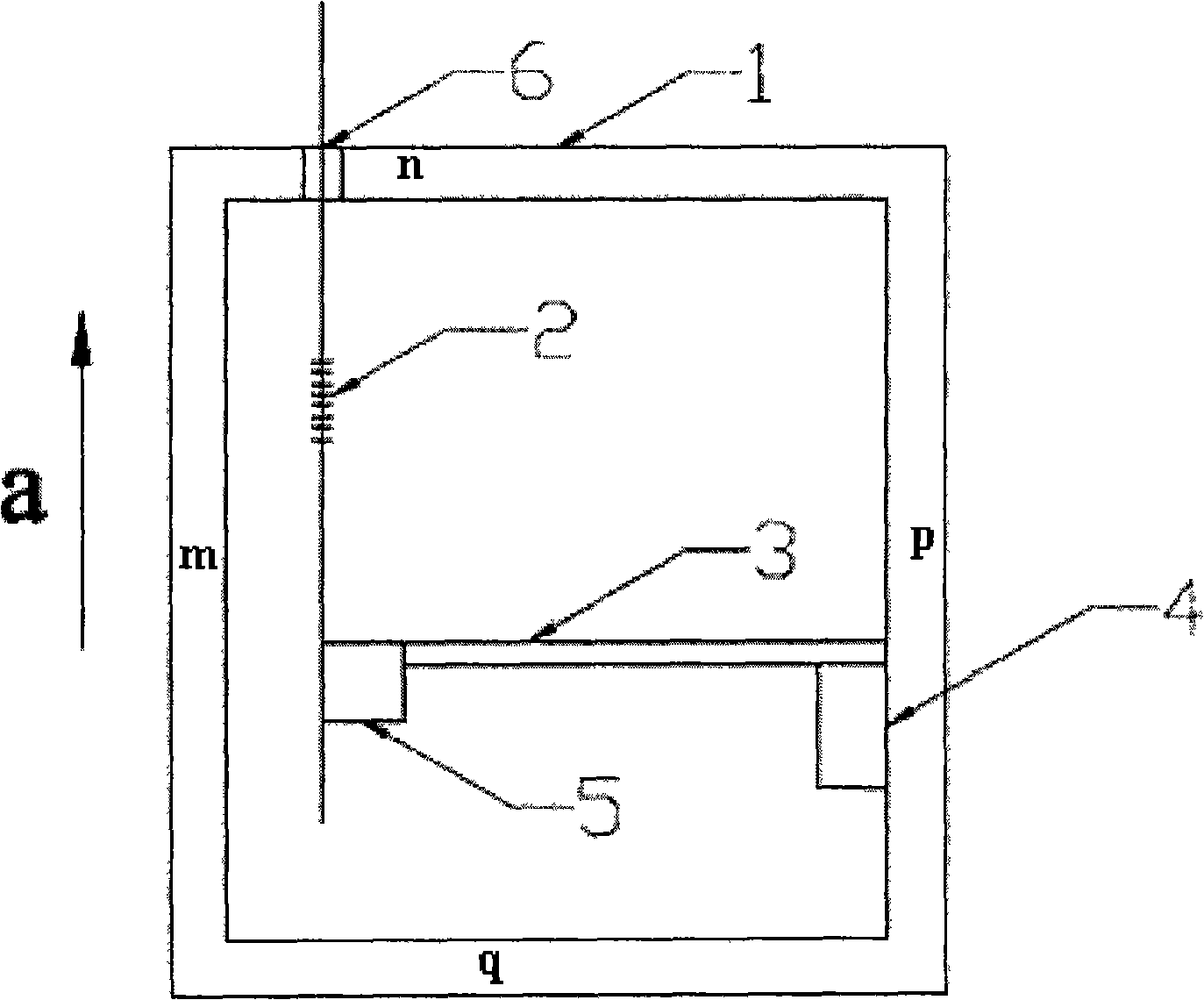

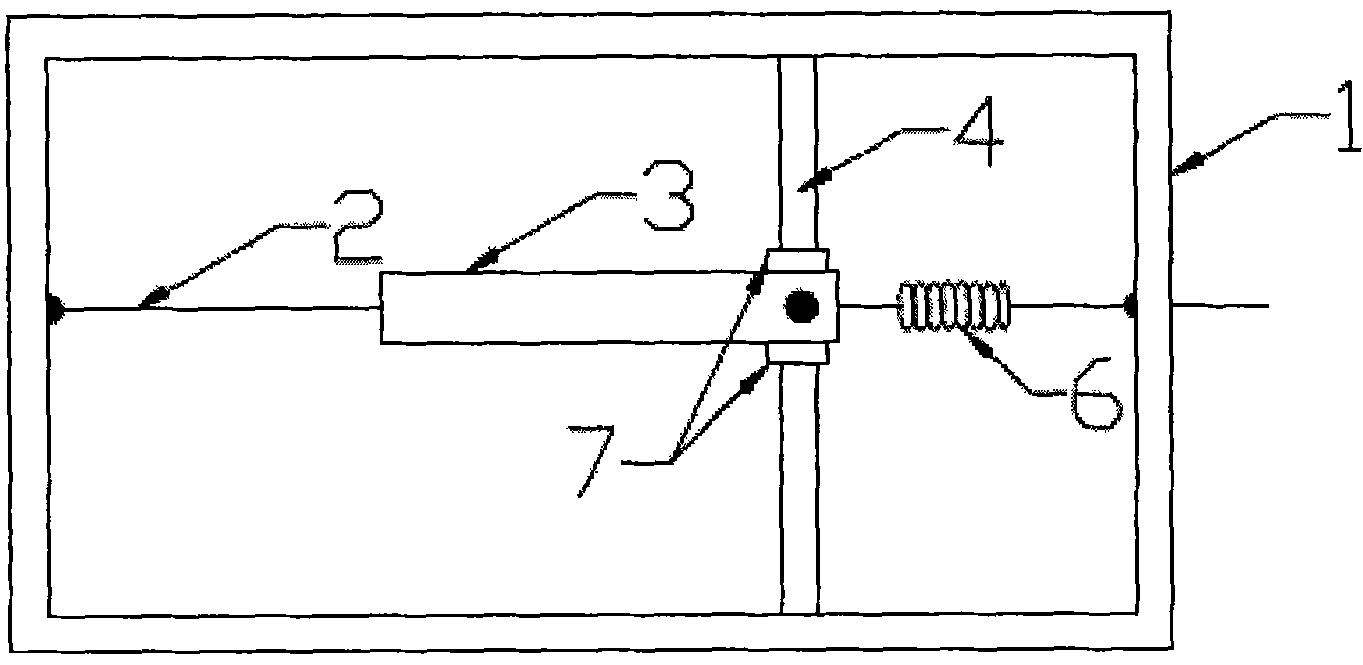

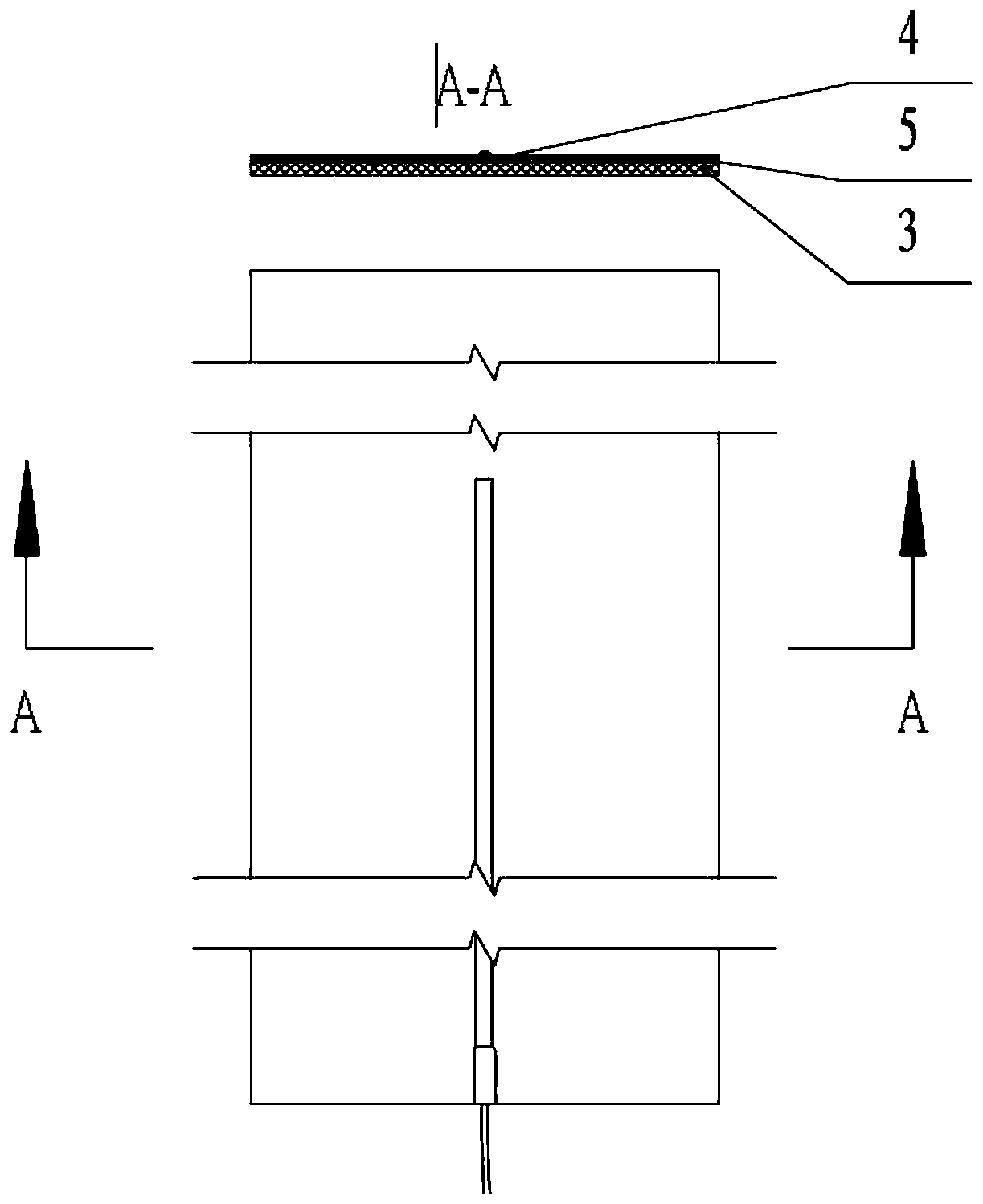

The invention relates to the optical fiber sensor technical field, disclosing an optical fiber grating accelerometer based on cantilever beam deflection. The accelerometer comprises an outer casing 1 used as a support structure of the accelerometer, an optical fiber grating 2 used to measure acceleration, a cantilever beam 3 with one end horizontally fixed on the third sidewall p of the accelerometer and a mass block 5 fixed at the other end of the cantilever beam 3, wherein the outer casing 1 has a first sidewall m, a second sidewall n, a third sidewall p and a fourth sidewall q; one end of the optical fiber grating 2 is fixed with the mass block 5, while the other end is parallel to the first sidewall m and passes through the hole 6 on the second sidewall n of the accelerometer to extend outside the accelerometer; the cantilever beam 3 is used to send vibration signal to the optical fiber grating 2; and the mass block 5 is used to adjust the sensitivity and the natural vibration frequency of the accelerometer. The optical fiber grating accelerometer increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

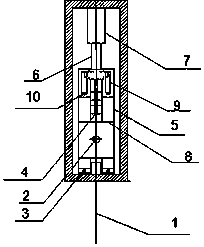

Convoluted diaphragm-type optical fiber Bragg raster liquid level sensor

InactiveCN101650209AAvoid chirpingAccurate pressure valueFluid pressure measurement by optical meansLevel indicators by pressure measurementGratingEngineering

The invention relates to a convoluted diaphragm-type optical fiber Bragg raster liquid level sensor which consists of optical fiber Bragg rasters (9), a convoluted diaphragm (6), a transfer lever (7),a constant-strength cantilever girder (8), a leading-in and leading-out optical fiber (2), a fixed seat (4), a seal ring (5) and a protective barrel (8), wherein the convoluted diaphragm (6) is connected with the constant-strength cantilever girder (8) through the transfer lever (7), and the optical fiber Bragg rasters (9) are adhered on the constant-strength cantilever girder (8); in addition, the fixed seat (4) is used for fixing the constant-strength cantilever girder (8); the convoluted diaphragm (6) is fixed between the protective barrel (8) and the seal ring (5), and the leading-in andleading-out optical fiber (2) is respectively connected to both ends of two optical fiber Bragg rasters (9) connected in series. According to the sensitivity differences of the two sensing rasters topressure and temperature, well-known differential operation in the field is adopted to measure and compensate temperature fluctuation interference pressure, thereby realizing the accurate measurementon pressure generated by static liquid level.

Owner:KUNMING UNIV OF SCI & TECH

Temperature insensitive optical fibre grating acceleration sensor

InactiveCN101285847BAvoid chirpingSimple processTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesGratingClassical mechanics

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Sensitization structure for optical fiber grating sensor

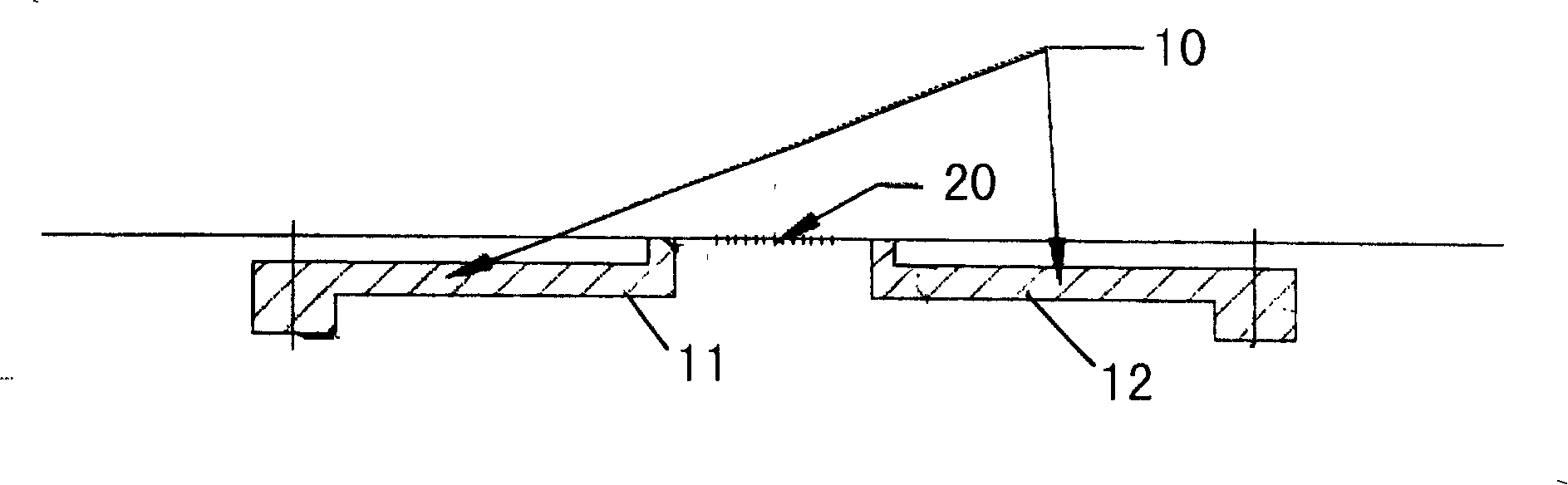

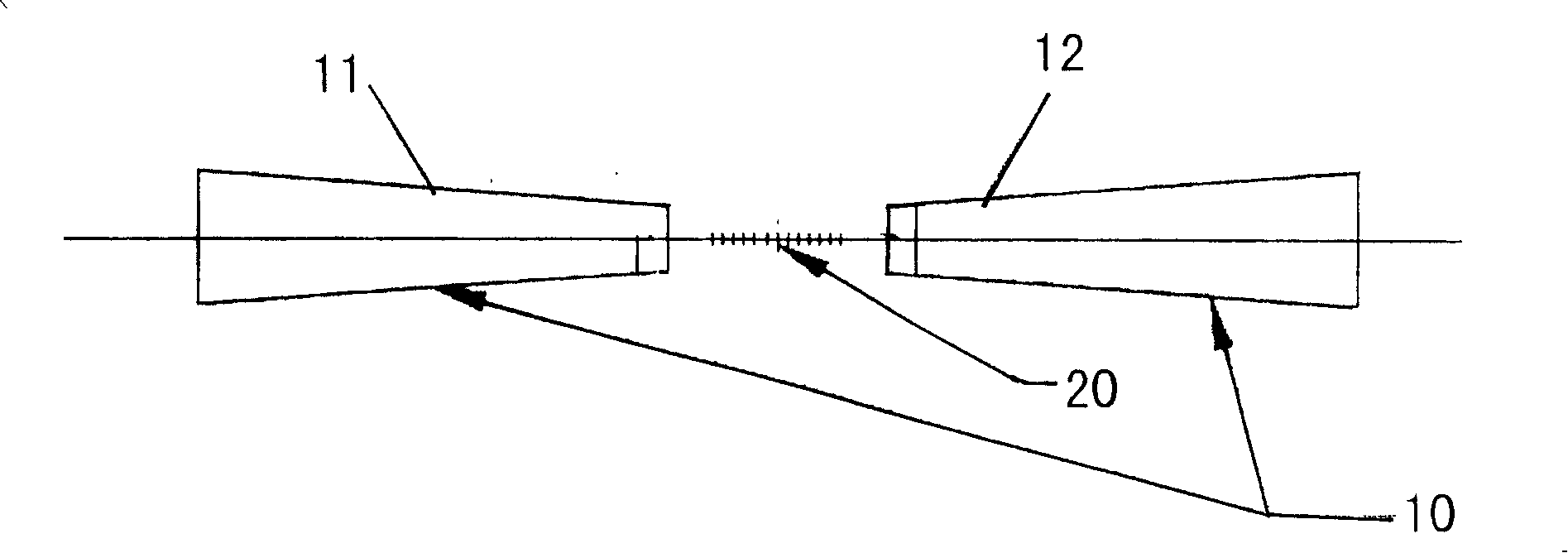

InactiveCN101206129AAvoid chirpingSimple processConverting sensor output opticallySpecial purpose recording/indication apparatusFiberGrating

The invention relates to a sensitivity enhancing structure of a fiber Bragg grating sensor, which is characterized in that: the invention comprises a support frame which comprises a left support arm and a right support arm which are arranged in Z-shaped structure with inverse directions one another; a fiber Bragg grating two ends of which are fixed on end parts of the left and right support arms of the support frame. The two ends of the fiber Bragg grating are fixed at lower ends of the left and right support arms of the support frame by adopting a bonding method.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

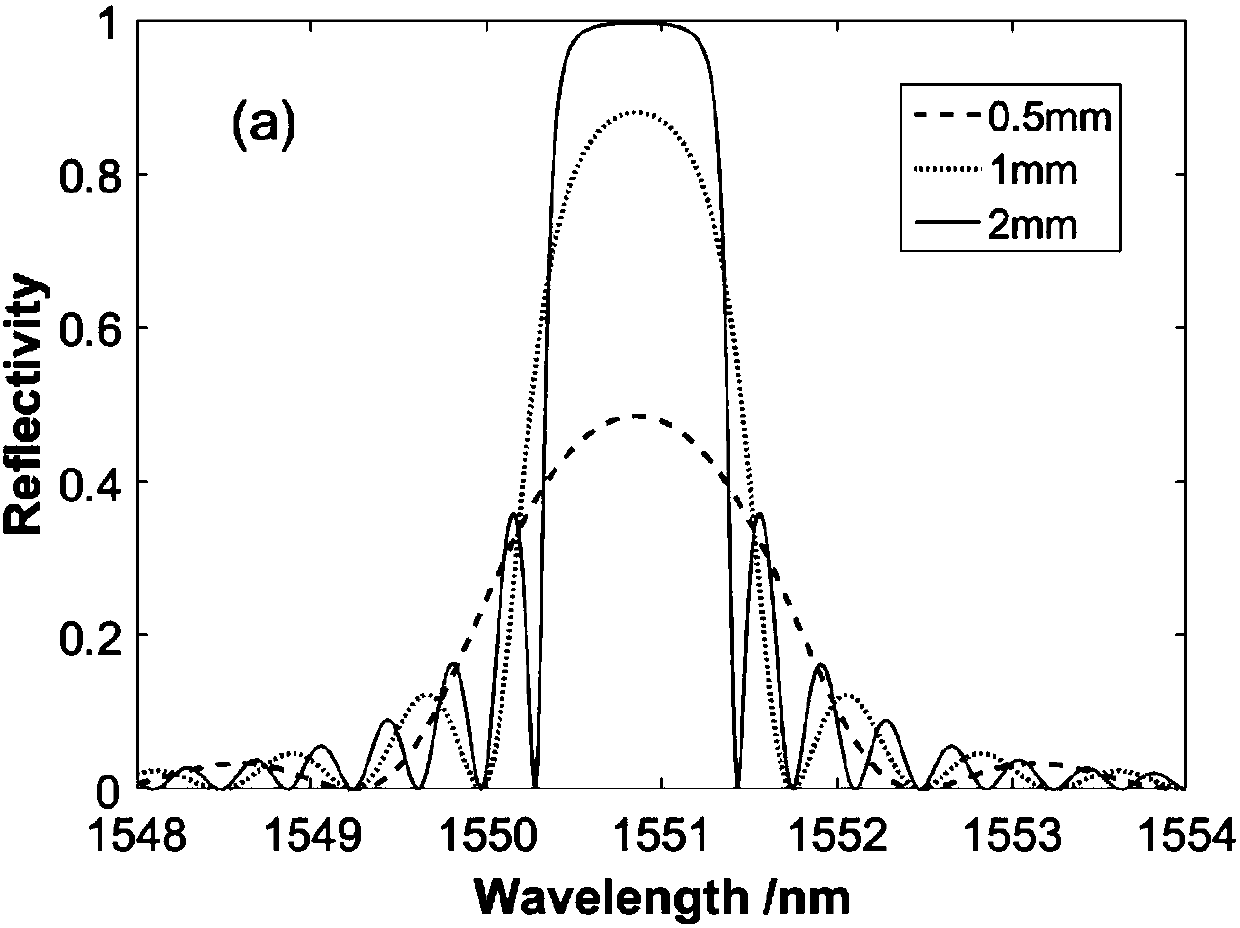

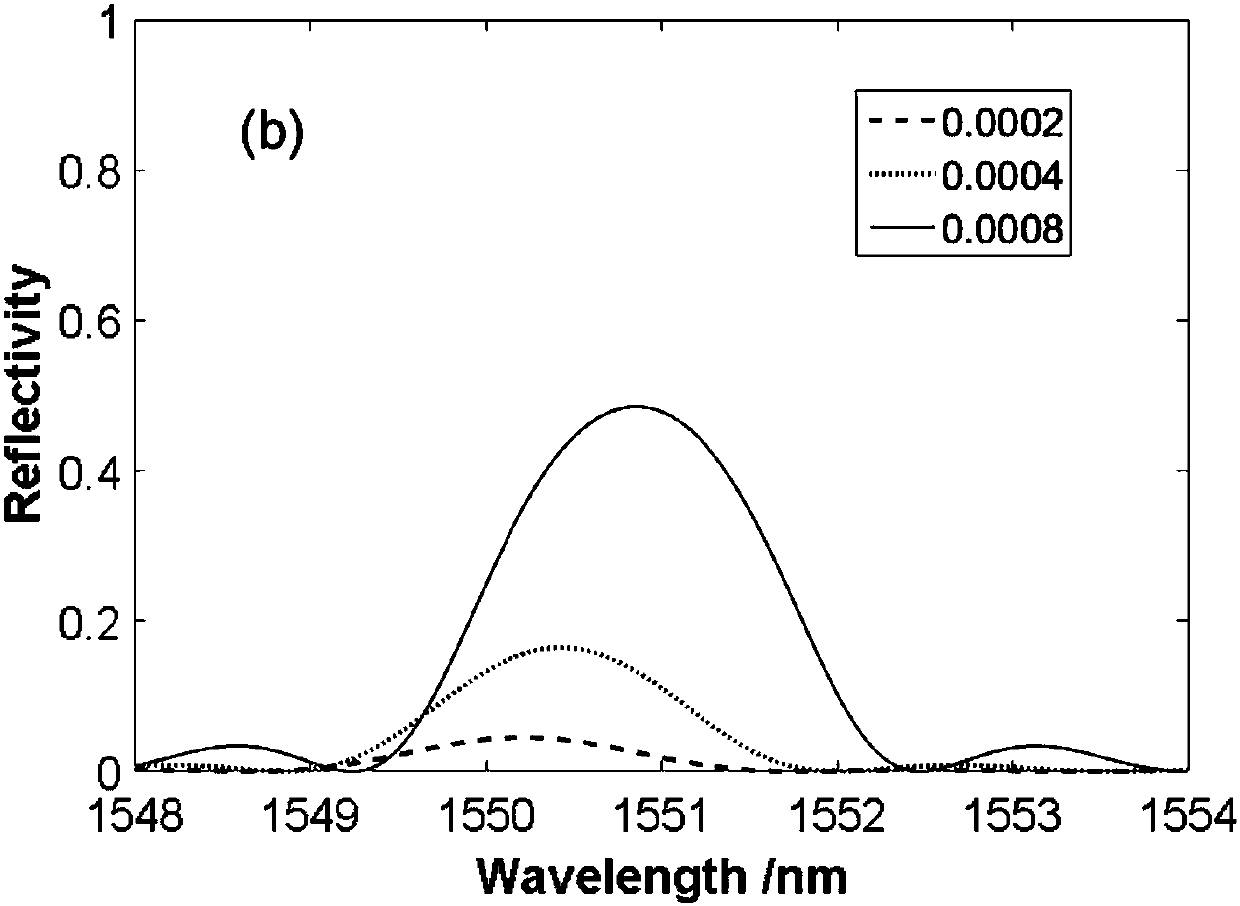

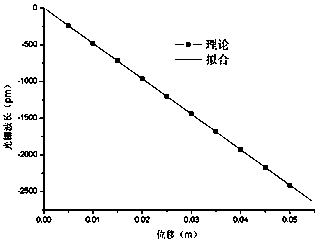

Tunable dispersion compensator designing and making method

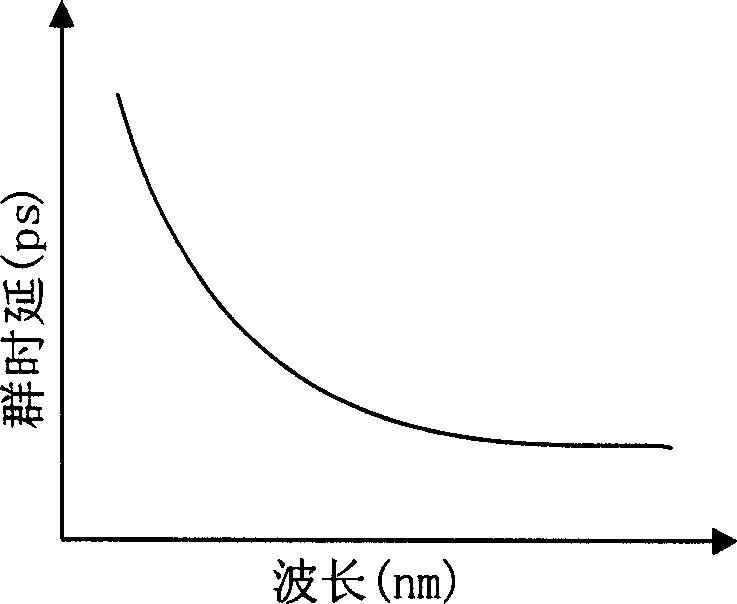

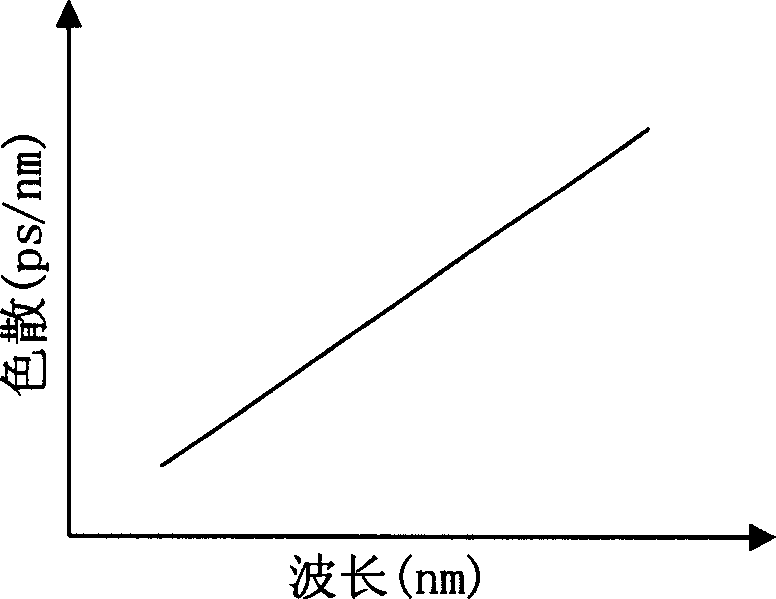

InactiveCN1641390AEasy to makeStable manufacturingCoupling light guidesDistortion/dispersion eliminationMicrocomputerGrating

The design and production of tunable dispersive compensator belongs to the fiber communications technological field. The hard core of this invention is a hit-the-toe sampling fiber raster with a twice time lag curve. The fiber raster adopts a linear chatter phasic templet production, and uses the chatter sampling period (CSP) to compensate the chatter grating period (CGP) from the templet to make the change bound of the raster sampling period narrow and then to make the producing process more simply and more steady. Otherwise in the design and producing process of the fiber raster, compensate the average refractive index change from the toe-hit by introducing the CSP. Therefore the production and toe-hit can be complete at a time in which just once exposal is needed. Finally fix the fiber raster on the exact mechanical tuning device, to extend the fiber raster under the control of microcomputer and then control the dispersive compensatory quantity.

Owner:TSINGHUA UNIV

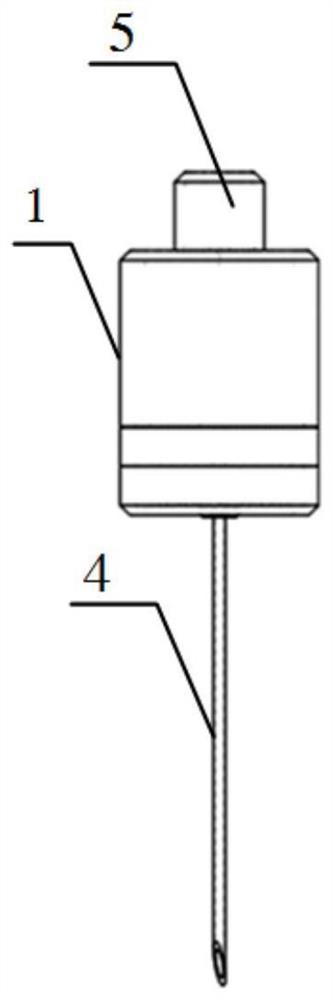

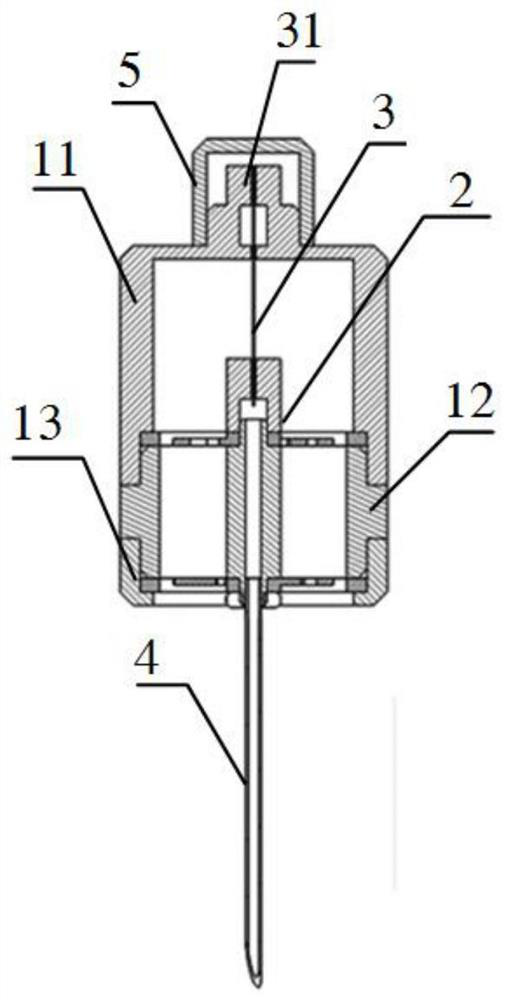

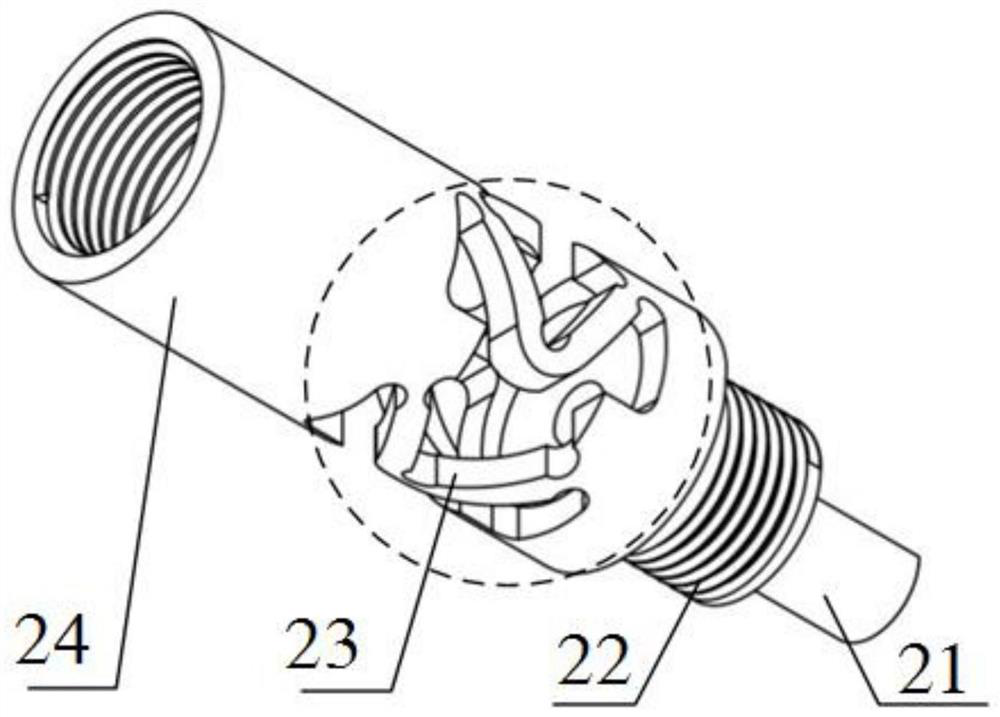

High-precision fiber grating force sensor for measuring puncture force of minimally invasive surgery

PendingCN114152370AAvoid chirpingImprove the ability to resist lateral interferenceDiagnosticsSurgeryFiberGrating

The invention relates to a high-precision fiber bragg grating force sensor for measuring puncture force in minimally invasive surgery, which comprises two plane springs, a fiber bragg grating, a sensor shell, a spring connecting piece, a puncture needle and a signal processing unit, deformation in the direction of the neutral axis of the sensor can be generated, and a puncture needle signal is converted into a grating strain signal; the optical fiber Bragg grating is hung between the sensor shell and the two plane springs under the action of pretightening force, axial strain can be generated under the action of puncture force, a strain signal is converted into an optical wavelength signal, and the sensor shell is used for fixing the optical fiber and the two plane springs; and the spring connecting piece is used for connecting and fixing the two plane springs. The sensor has the advantages of being high in resolution ratio, good in linearity, high in sensitivity and the like, can detect tiny puncture force changes, and is of great significance in assisting doctors in puncture operations and guaranteeing safety of patients.

Owner:TIANJIN UNIV

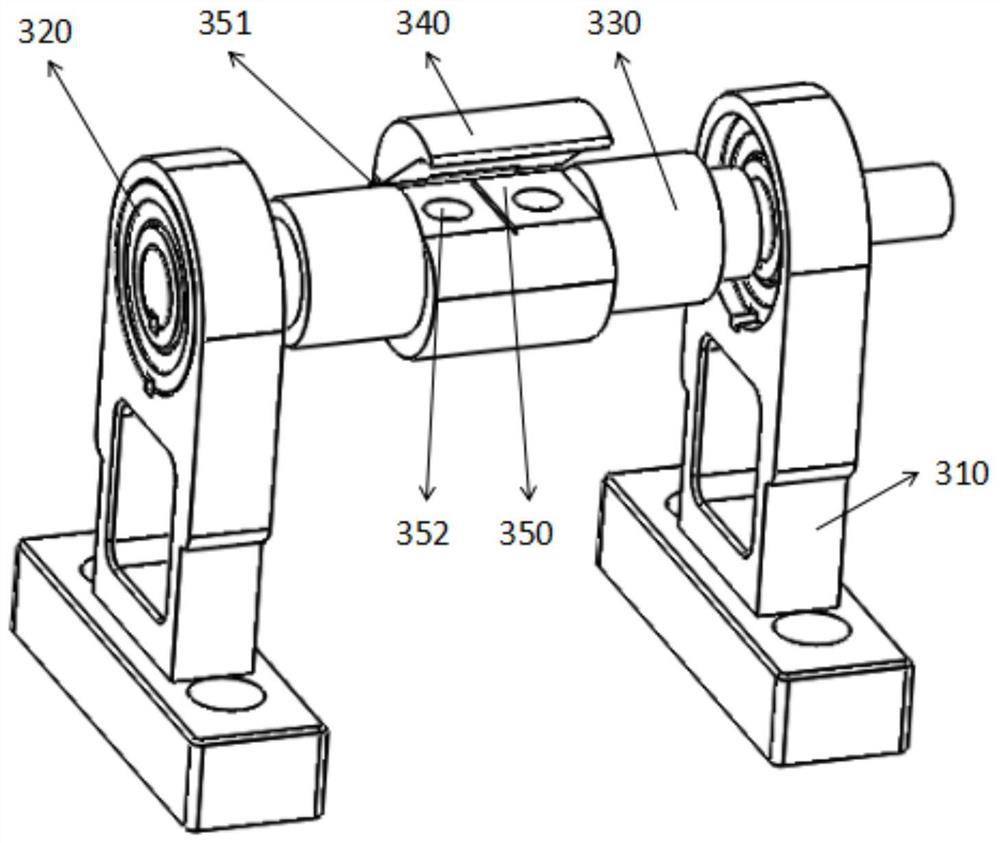

Fiber grating vibration sensor

ActiveCN104880243AAvoid chirpingImprove reliabilitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberGrating

A fiber grating vibration sensor comprises a support housing (12) and a connection rod mechanism disposed in the support housing (12). The connection rod mechanism comprises a first arm (150) in a horizontal direction and a second arm (160) in a vertical direction. A first end of the first arm (150) is a free end. A second end of the first arm (150) is connected to a second end of the second arm (160), so that the first arm (150) and the second arm (160) form an L shape. The connection rod mechanism is also provided with a first fixed rotary shaft (156). The first fixed rotary shaft (156) is perpendicular to the length direction of a strain fiber grating (120) and is fixed to the support housing (12), so that the first arm (150) can rotate relative to the first fixed rotary shaft (156), and the first arm (150) drives the second arm (160) to rotate. A first end of the strain fiber grating (120) is packaged on the second arm (160) of the connection rod mechanism, and a second end of the strain fiber grating (120) is packaged on the support housing (12). An overload protection apparatus (112) is fixed on the inner side of the support housing (12), and is used for defining a movement range of the first arm (150). The sensor can avoid a shear force in a traverse direction of the fiber grating and improve the reliability and the stability of the sensor.

Owner:NUCTECH CO LTD

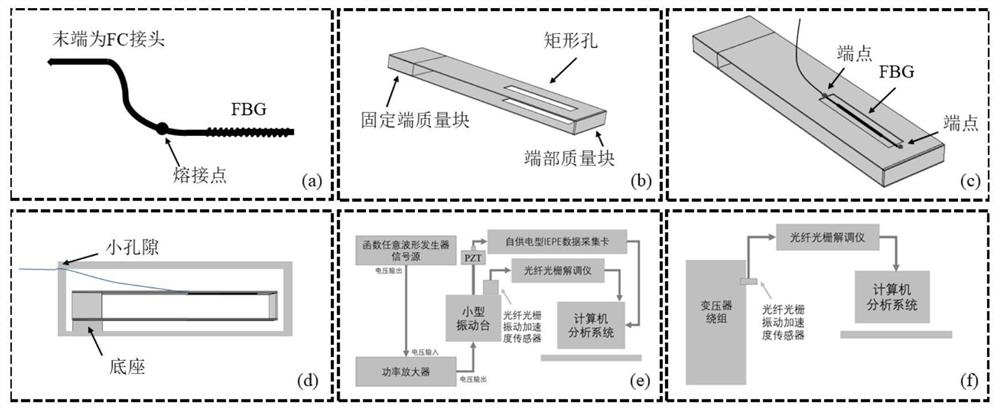

Fiber grating sensor for microearthquakes and manufacturing method of such fiber grating sensor

InactiveCN106768295AAvoid chirpingAvoid the shortcoming of short lifeSubsonic/sonic/ultrasonic wave measurementGratingElectromagnetic interference

The invention discloses a fiber grating sensor for microearthquakes and a manufacturing method of such fiber grating sensor. The fiber grating sensor mainly comprises a fiber grating, a vibrating beam, a mass block, a shell, a transmission fiber and a signal demodulator, wherein two ends of the vibrating beam are fixed in the shell, the mass block is fixed in the middle below an axial center line of a vibrating shaft, a set distance is reserved between the mass block and the bottom of the shell, a groove is engraved in the center line of the upper surface of the vibrating beam, the fiber grating is a metal-coated fiber grating, the two ends of the fiber grating are welded in the groove of the vibrating beam, and the transmission fiber is led out of one end of the shell and is used for transmitting a microearthquake signal to the signal demodulator. The fiber grating sensor for the microearthquakes has the advantages of simple structure, convenience in installation, anti-electromagnetic interference and low cost.

Owner:SHANDONG UNIV

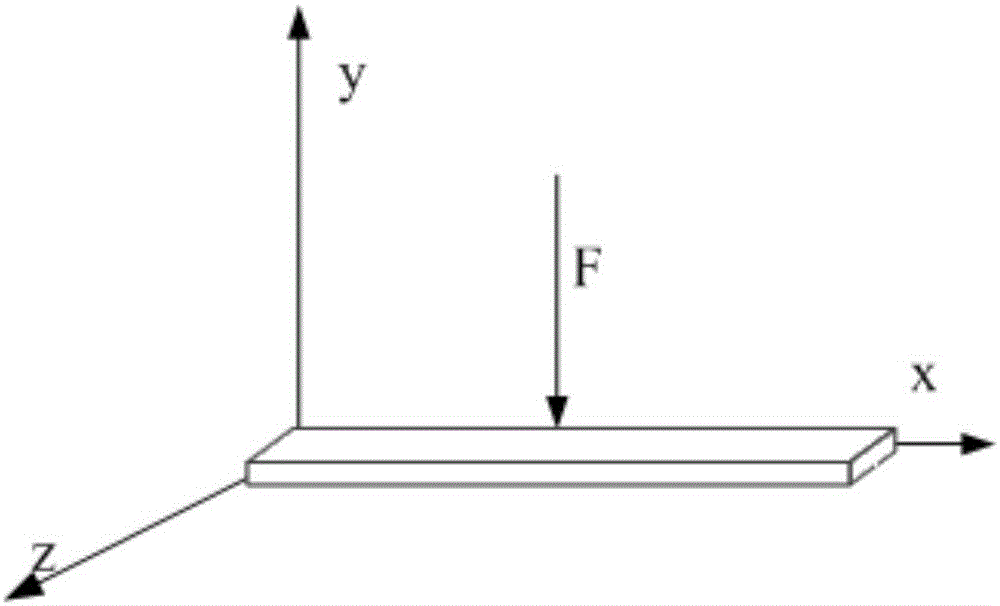

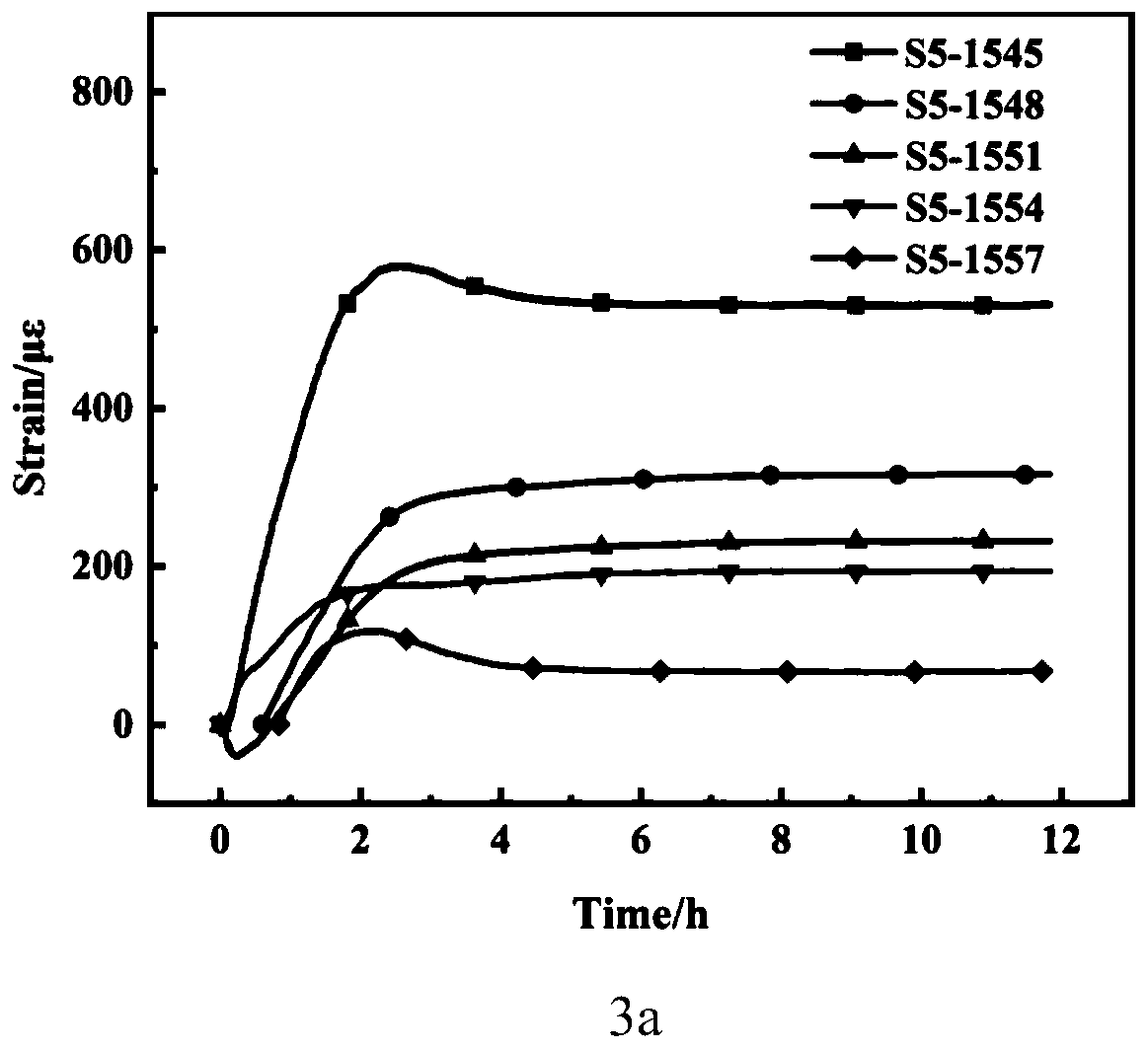

Method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain

The invention provides a method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain. In order to solve the technical problems that as fiber grating sensors are bonded to the surface of a structure through polyimide resin or epoxy resin commonly used in the prior engineering, optic fiber in service is easily destroyed; the optic fiber can get encapsulation protection but cause the concentration of surrounding stress / strain thereof if the optic fiber is directly embedded in a composite-material structure; and thermal residual stress produced in a material-curing process can cause chirp phenomena of fiber grating reflection spectrum to affect the measurement accuracy of grating strain, and the like, the invention provides the method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain. In the method, the fiber grating sensors are embedded in composite-material layers to replace resistance strain gauges commonly used in the field of monitoring structural health; by applying prestress to embedded fiber gratings, the influence of the curing residual stress of composite material on the fiber grating reflection spectrum is reduced so as to avoid the chirp phenomena; and the stability and repeatability of the sensors are improved. In addition, the composite material plays agood role in encapsulating and protecting bare fiber gratings, and meets engineering construction requirement on sensor sensitivity.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

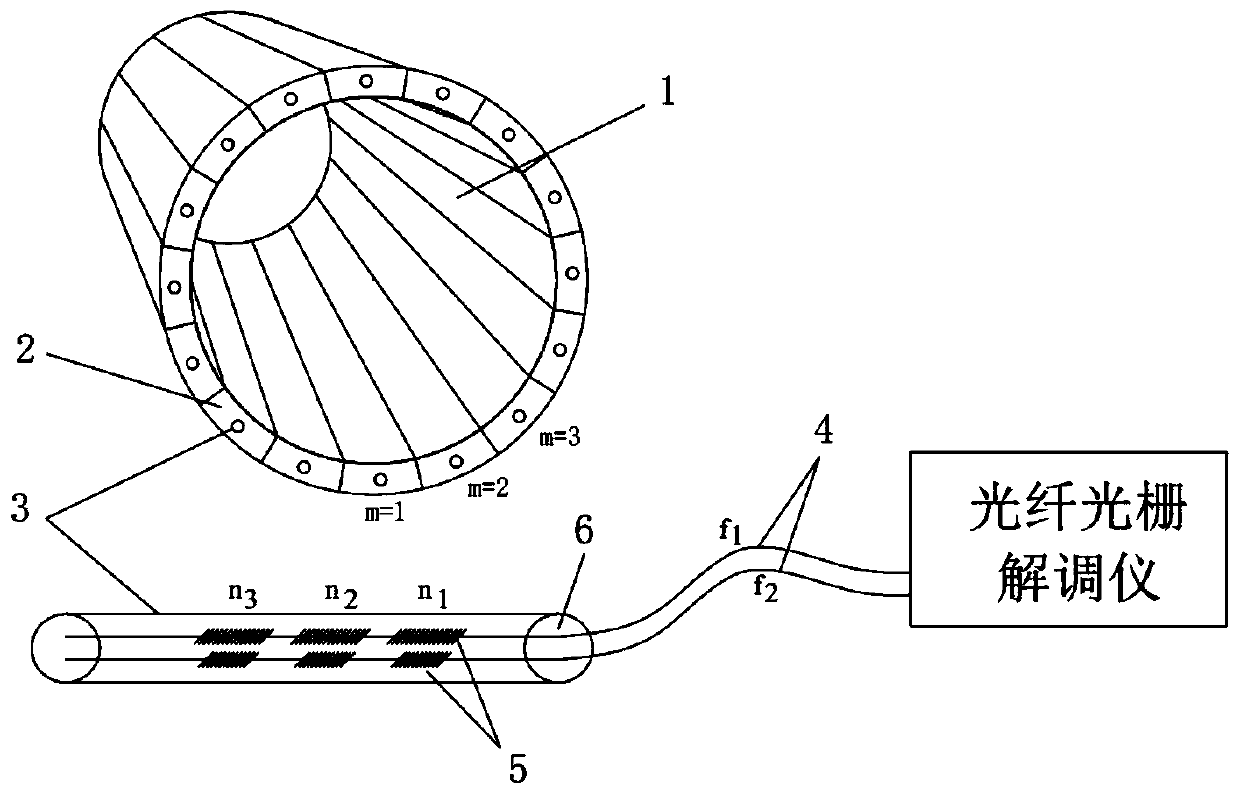

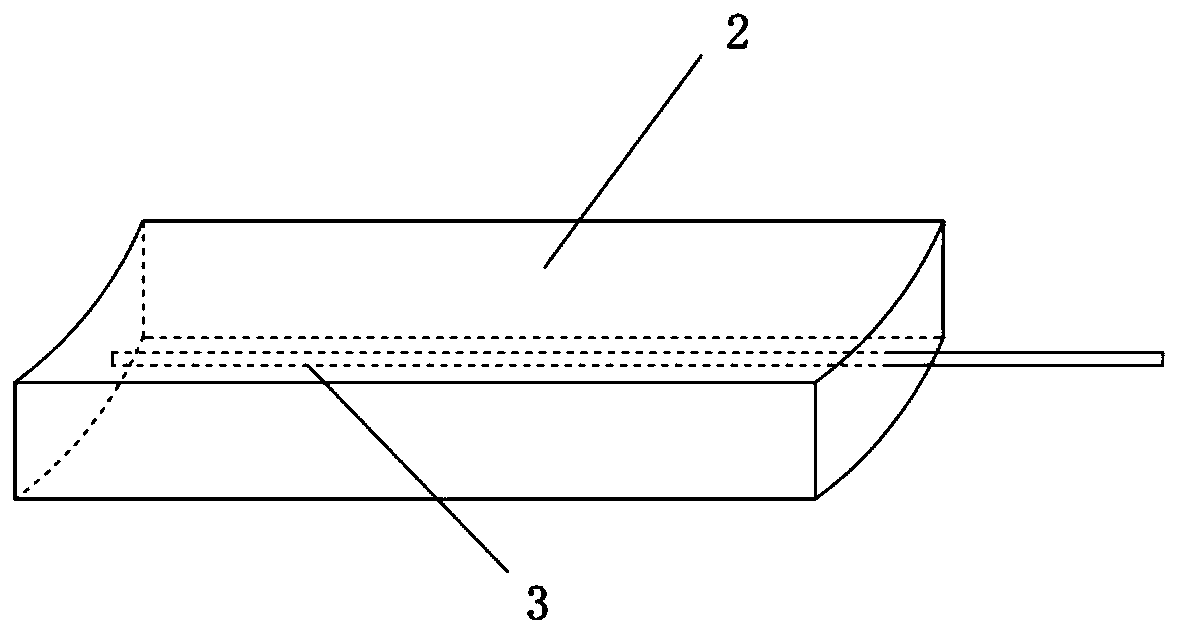

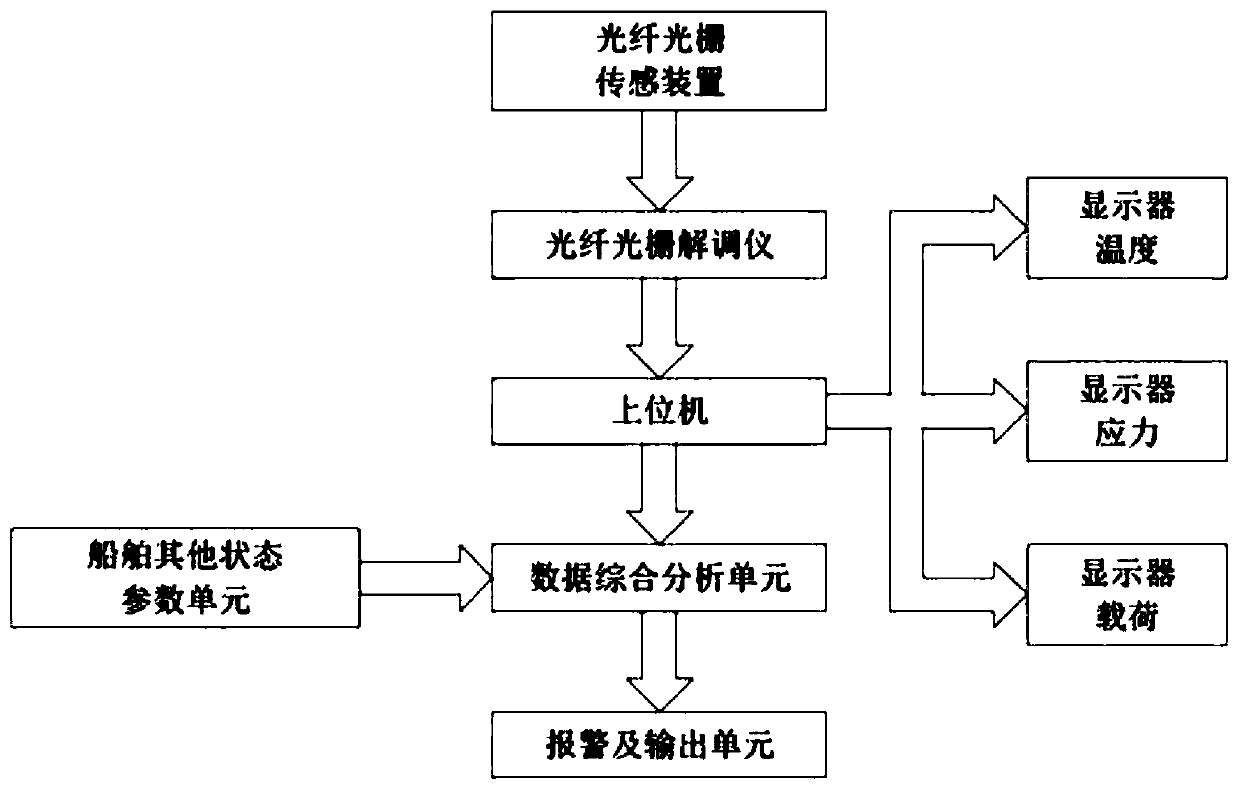

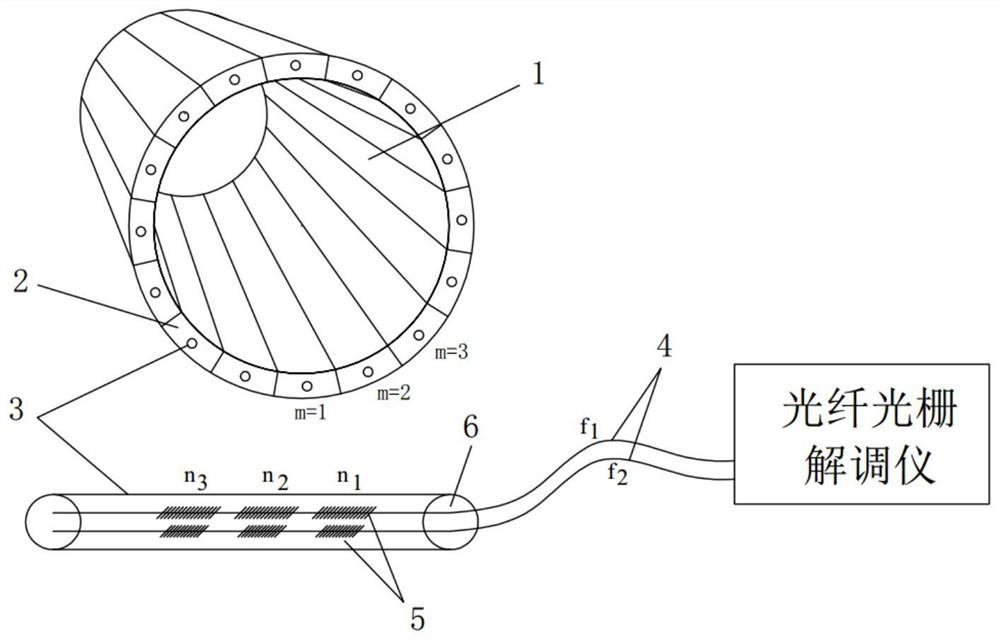

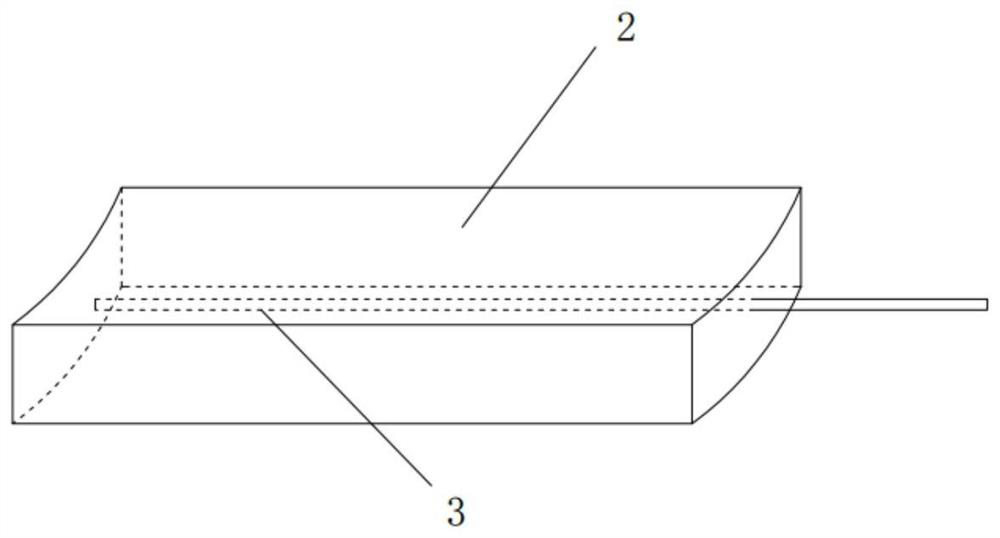

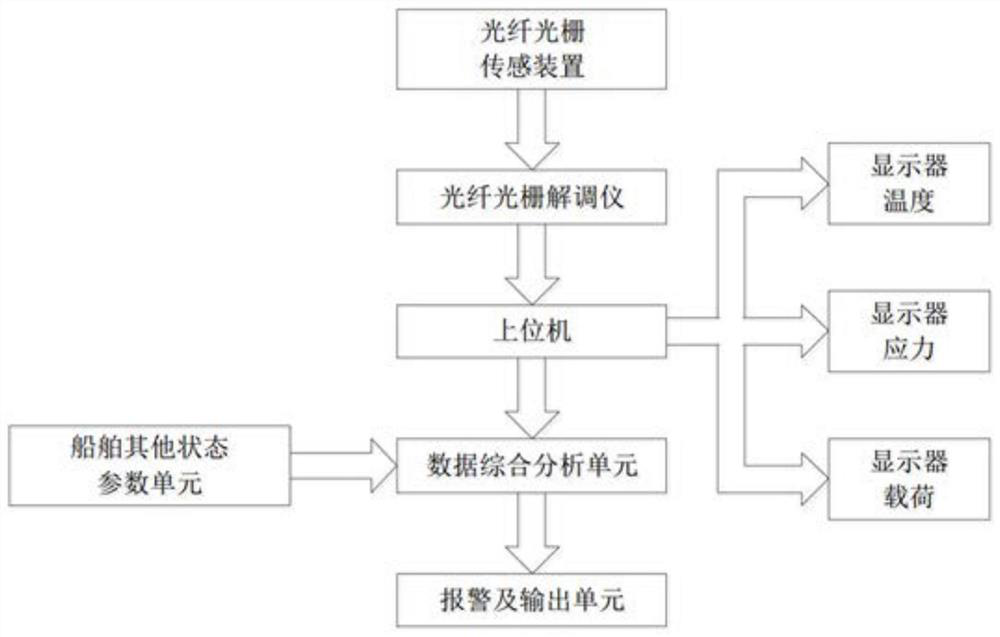

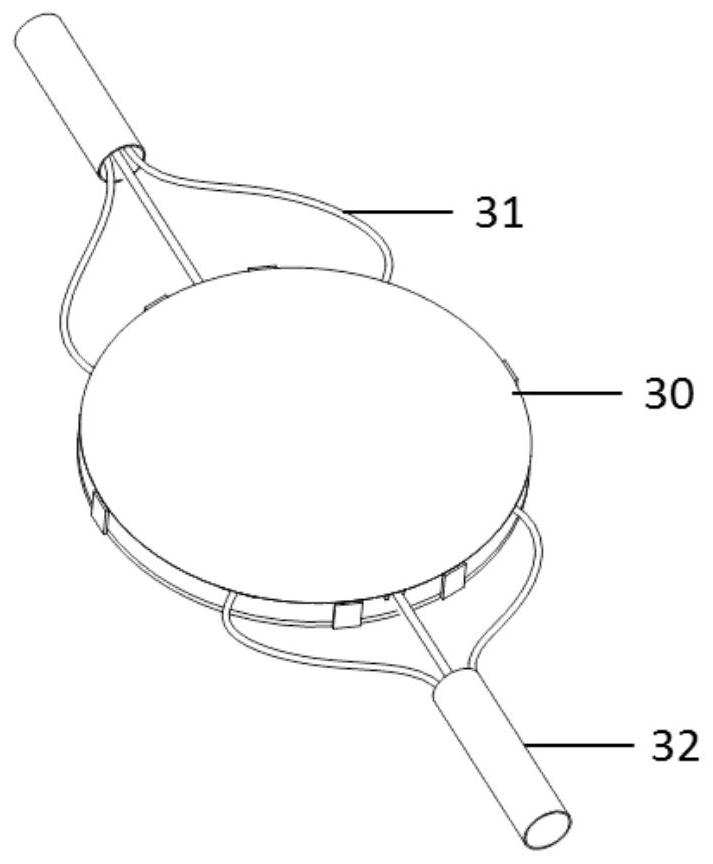

Fiber grating sensing device for detecting stress state of water lubricated bearing and monitoring system thereof

The present invention discloses a fiber grating sensing device for detecting stress state of a water lubricated bearing and a monitoring system thereof, and solves the problems such as low success rate of fiber grating sensor implantation, short service life and high cost. The fiber grating sensing device of the invention comprises a rubber bearing composed of a plurality of rubber bearing strips;and at least one rubber bearing strip is embedded with a fiber grating sensing unit. The fiber grating sensing unit comprises a capillary axially embedded in the rubber bearing strip, optical fiber encapsulated in the capillary and filler filled between the capillary and the optical fiber. A plurality of gratings are provided on the optical fiber. The monitoring system of the invention comprisesa fiber grating sensing device, a fiber grating demodulator, a host computer, a data comprehensive analysis unit and an alarm and output unit. The invention has the advantages of easy manufacture, lowcost, good reliability, long service life, high accuracy and ability to synchronously and continuously monitoring load, temperature and stress of the bearing.

Owner:NAVAL UNIV OF ENG PLA

Torque sensor device based on fiber gratings

InactiveCN107576429AEasy to measureWith anti-electromagnetic interferenceWork measurementTorque measurementFiberGrating

The invention relates to a torque sensor device based on fiber gratings. The device comprises the fiber gratings, an input shaft having the same axis as the fiber grating, a torsion rod and an outputshaft, wherein two ends of the torsion rod are connected with the input shaft and the output shaft through a spline, one end of the input shaft is provided with partially-annular projections symmetricto the axis, an outer circumferential surface of one end of the output shaft is provided with a groove, fiber is tensioned in a straight line mode and is tangent to the output shaft, two ends of thefiber are fixed with the partially-annular projections, the middle of the fiber is fixed on the groove, two suspended gratings are uniformly distributed among three fiber fixing points, and a tail fiber fits the surface of the input shaft, is led out along the surface of the input shaft and is then connected with a rotary connector. The device is advantaged in that a relative torsion angle is converted into stretching or compression deflection of the fiber, torque can be acquired through measuring wavelength drift amount of the fiber grating, measurement is simple and easy, anti-electromagnetic interference and temperature compensation functions are realized, sensitivity is high, and signal stability is further realized.

Owner:WUHAN UNIV OF TECH

Cantilever beam type optical fibre grating accelerometer

InactiveCN101285845BAvoid chirpingSimple processVibration measurement in solidsTelevision system detailsCantilevered beamGrating

The invention relates to the optical fiber sensor technical field, disclosing a cantilever beam-type optical fiber grating accelerometer. The accelerometer comprises an outer casing used as a supportstructure of the accelerometer, a support column used to fix a cantilever beam, a cantilever beam, a first lug boss and a second lug boss arranged at both ends of the upside of the cantilever beam, anoptical fiber grating used to measure acceleration and a mass block arranged at one end or both end of the underside of the cantilever beam, wherein one end of the support column is fixed with the cantilever beam, while the other end is fixed with the downside surface of the accelerometer; both lug bosses are used to horizontally fix the optical fiber grating and ensures a certain space between the optical fiber grating and the cantilever beam; both ends of the optical fiber grating are respectively fixed on the first lug boss and the second lug boss on the cantilever beam with one end parallel to the surface of the cantilever beam passing through the hole on the sidewall of the accelerometer to extend outside the accelerometer; and the mass block is used to adjust the sensitivity and thenatural vibration frequency of the accelerometer. The cantilever beam-type optical fiber grating accelerometer increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

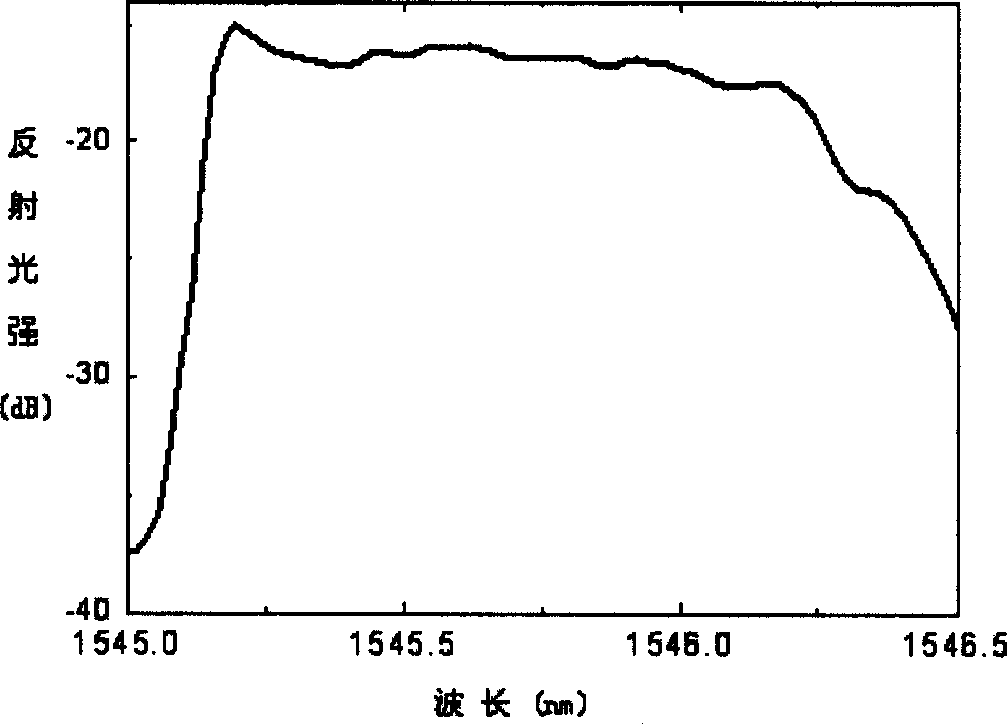

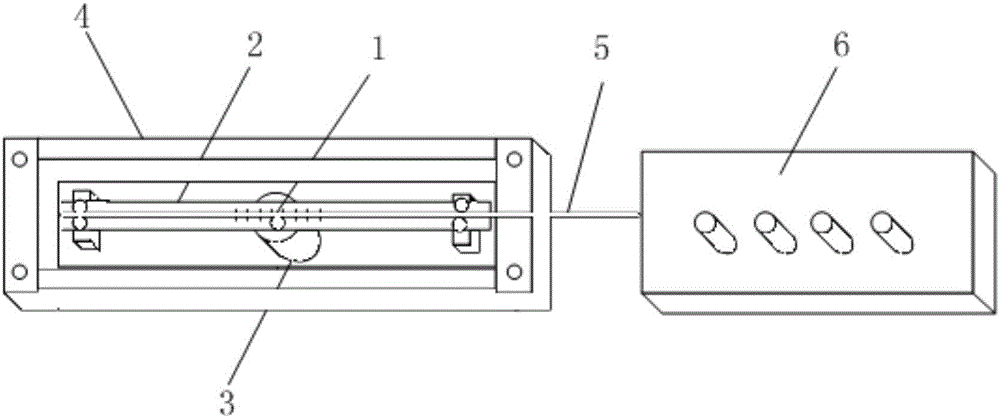

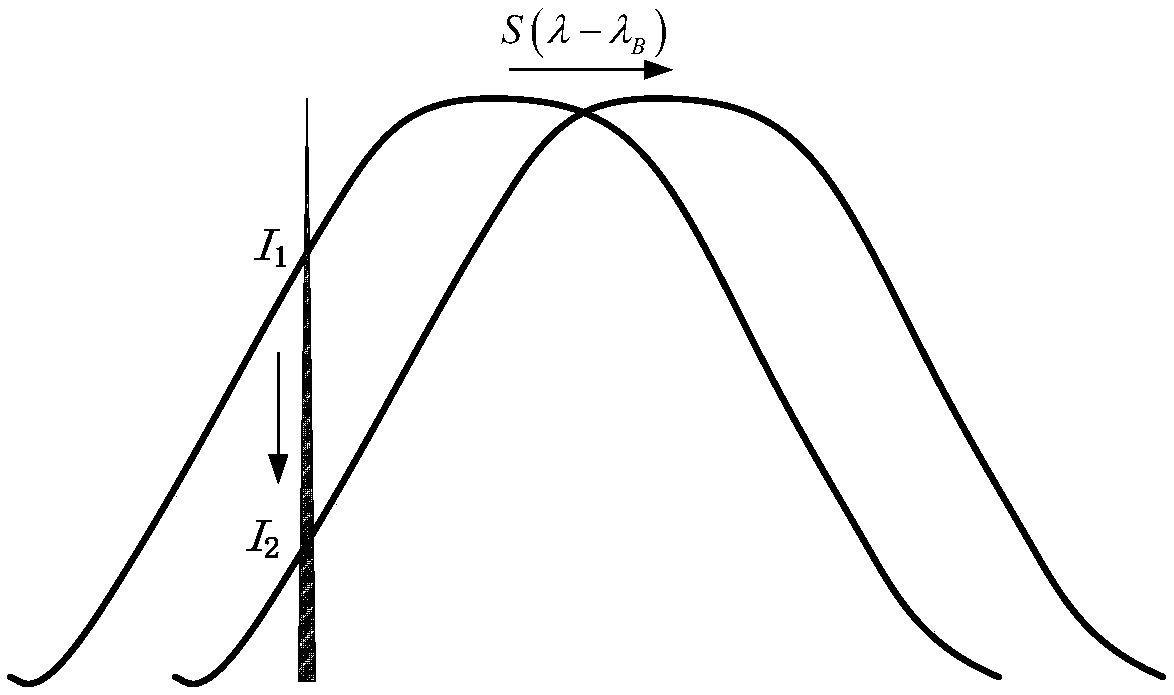

Strain sensing system based on ultra short FBG (fiber bragg grating) spectrum linear region

The invention discloses a strain sensing system based on an ultra short FBG (fiber bragg grating) spectrum linear region, which comprises a frequency stabilized laser, a circulator, an ultra short FBGand a photodiode, wherein one end of the circulator is connected with one end of the frequency stabilized laser, and the other end of the circulator is connected with the ultra short FBG; the photodiode is used for receiving the reflected light power after a laser beam reflected back by the ultra short FBG passes through the circulator; the frequency stabilized laser is an 8164A tunable laser light source, the maximum output power is 8dBm, the laser line width is less than 5pm, and the wavelength stability is less than 1pm. According to the strain sensing system based on the ultra short FBG spectrum linear region, light power reflected by an edge linear region of the ultra short FBG of the laser beam outputted by the frequency stabilized laser is used for demodulation, the structure is simple, the power consumption is low, the ultra short FBG is adopted as a sensing element, the problem of chirp generation during a packaging process due to a long gate area can be avoided, and high spatial resolution measurement can be realized.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Fiber Bragg Grating Displacement Sensor

ActiveCN104792267BWill not be disturbedOvercome the defect of large driftUsing optical meansFiberGrating

Owner:江西云沛科技发展有限公司

Optical Fiber Bragg Grating Sensing Device and Its Monitoring System Used to Detect the Forced State of Water-lubricated Bearings

The invention discloses an optical fiber grating sensor device and a monitoring system for detecting the force state of a water-lubricated bearing, which solves the problems of low implantation success rate, short service life and high cost of the optical fiber grating sensor. The fiber Bragg grating sensing device of the present invention includes a rubber bush composed of a plurality of rubber bush strips, at least one rubber bush strip is embedded with an optical fiber grating sensing unit along the inner edge, and the fiber grating sensing unit includes an axially embedded The capillary in the rubber bush strip, the optical fiber packaged in the capillary, and the filler filled between the capillary and the optical fiber; multiple gratings are arranged on the optical fiber. The monitoring system of the invention comprises a fiber grating sensing device, a fiber grating demodulator, a host computer, a data comprehensive analysis unit and an alarm and output unit. The invention is easy to manufacture, low in cost, good in reliability, long in service life, high in accuracy, and can monitor the load, temperature and stress of the bearing bush synchronously and continuously.

Owner:NAVAL UNIV OF ENG PLA

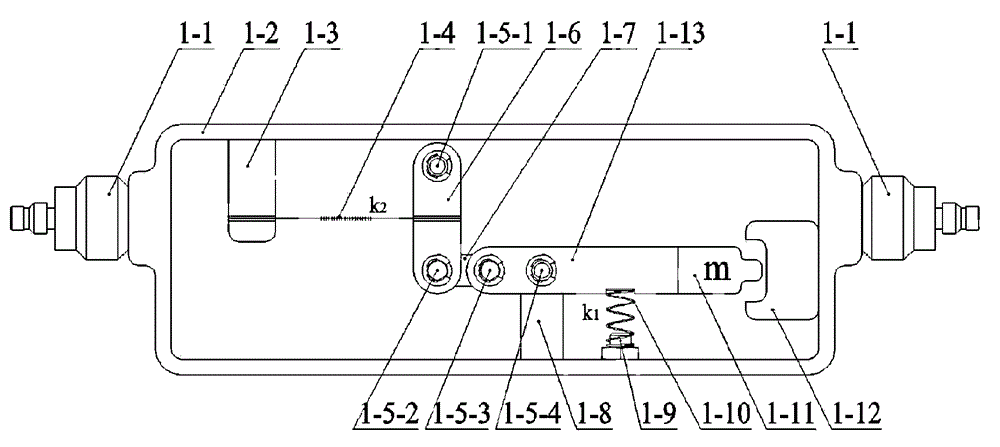

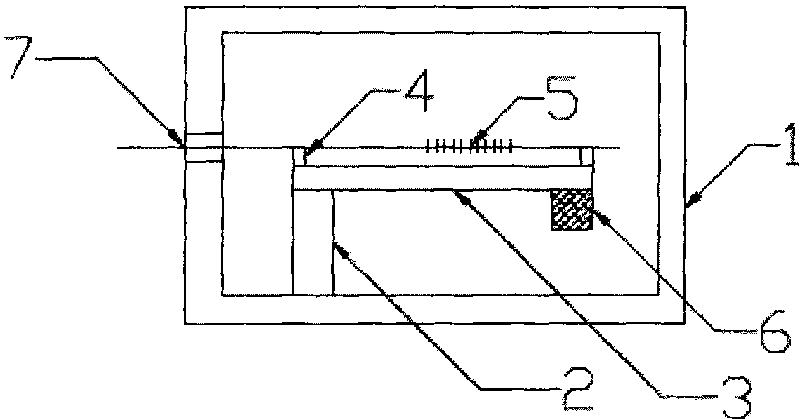

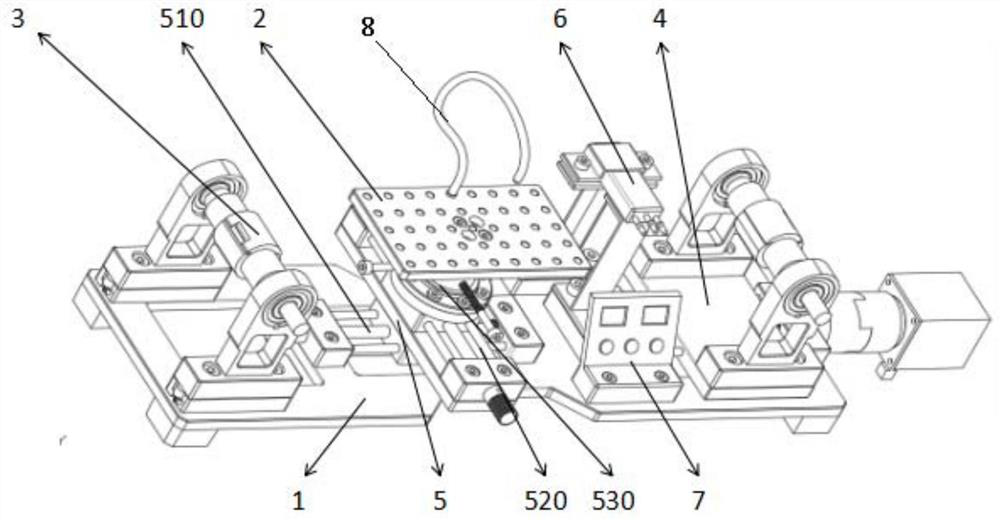

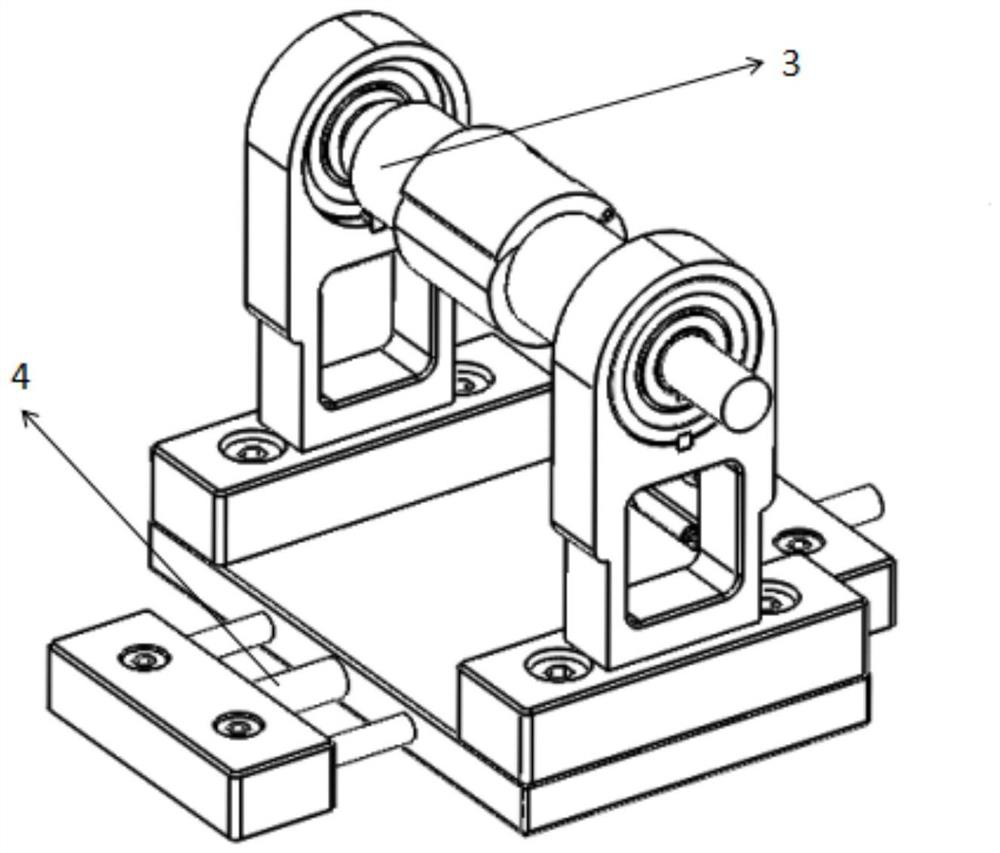

A fiber grating sensor packaging device and method

ActiveCN109099946BAvoid chirpingPrevent Waveform DistortionConverting sensor output opticallyFiberEngineering

The invention relates to an optical fiber grating sensor packaging device, which comprises a base, a worktable, a heating device, a glue coating device, two optical fiber clamping mechanisms and a prestressing adjusting device. The prestressing adjusting device is arranged on the base; one of the two optical fiber clamping mechanisms is arranged on the output end of the prestressing adjusting device and the other one is arranged on the base; the optical fiber clamping mechanism arranged on the output end of the prestressing adjusting device adjusts the distance from the optical fiber clampingmechanism to the other fiber clamping mechanism by the action of the prestressing adjusting device; the worktable is arranged on the base which is located between the two optical fiber clamping mechanisms; and the heating device is arranged between the base and the worktable. According to the optical fiber grating sensor packaging device and the method, which has the advantages of easy operation,stable and reliable work, and fine adjustment, constant prestressing can be applied to the optical fiber grating sensor, and the same pre-stress can be applied to avoid optical fiber grating defects and waveform distortion, therefore stable and good consistency of wavelength temperature characteristics is guaranteed.

Owner:绍兴市上虞区武汉理工大学高等研究院

One-dimensional palpation force sensor based on fiber Bragg grating

PendingCN113804338AImprove securityAccurate judgmentForce measurement by measuring optical property variationSurgical manipulatorsHuman bodyEngineering

The invention relates to a one-dimensional palpation force sensor based on a fiber bragg grating. The sensor comprises a contact part, a force-sensitive flexible part, a fiber bragg grating and a support part, and is characterized in that the contact part, the force-sensitive flexible part and the support part are connected in sequence; the force-sensitive flexible part is formed by carrying out a configuration comprehensive design on a sarrus mechanism by adopting a rigid body replacement method, and is used for converting a contact force signal into a strain signal; the fiber bragg grating is suspended in the center of the force-sensitive flexible part under the action of a pre-tightening force, is used as a sensing element and is used for converting the strain signal into an optical signal; the contact part is provided with a hemispherical tip for concentrating a contact force at one point; and the supporting part is used for supporting and fixing the whole sensor. The force sensor has the advantages of being high in sensitivity, large in measurement range, high in linearity, high in biocompatibility, resistant to electromagnetic interference and the like, and interaction force information between a minimally invasive surgery robot and human tissue can be provided in minimally invasive surgery tissue palpation.

Owner:TIANJIN UNIV

Fiber grating earth pressure sensor

ActiveCN102162757BAvoid chirpingConcentrated forceForce measurement by measuring optical property variationFiberGrating

Owner:青岛飞博科技有限公司

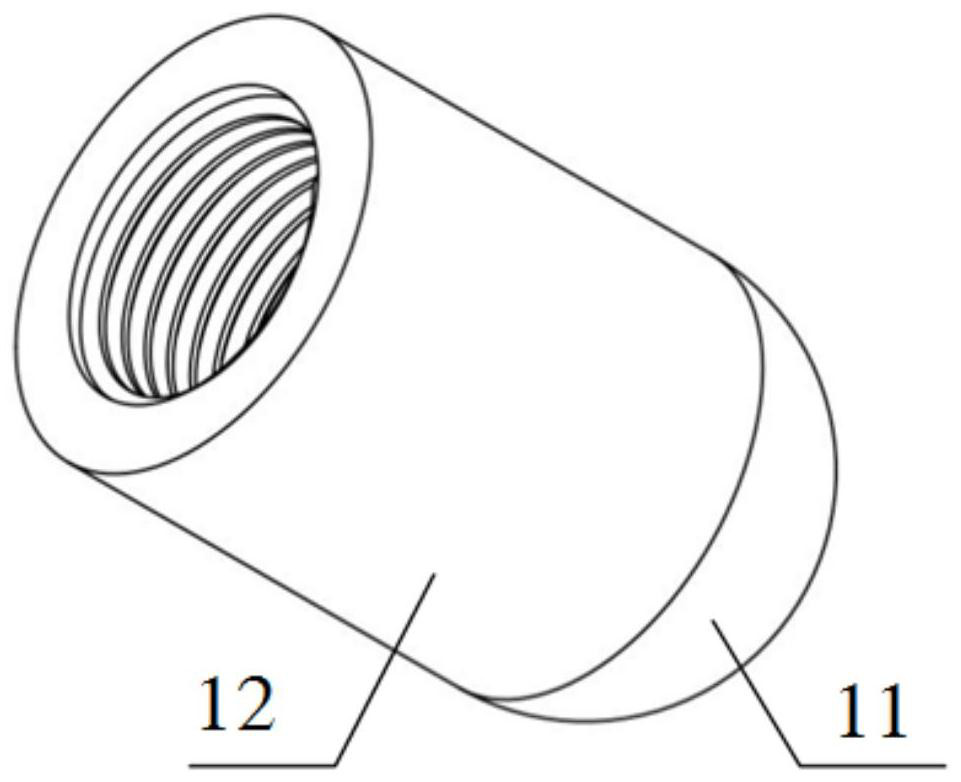

Cold and hot extension type fiber bragg grating temperature sensor

PendingCN114088240AImprove stabilityImprove reliabilityThermometer detailsThermometers using physical/chemical changesFiberThermal dilatation

The invention discloses a cold and hot extension type fiber bragg grating temperature sensor which is composed of a first installation part, a second installation part and an optical fiber, the thermal expansion coefficients of the first installation part and the second installation part are different, the first installation part is provided with a notch, one end of the second installation part is fixedly connected with the first installation part, and the other end of the second installation part is provided with a boss, the boss divides the notch into two grating installation spaces, the optical fibers are provided with a first fiber grating and a second fiber grating, the first fiber grating is installed in one grating installation space, the optical fibers at the two ends of the first fiber grating are fixed to the first installation part and the boss respectively, and the second fiber grating is installed in the other grating installation space, optical fibers at the two ends of the second fiber grating are fixed to the boss and the first installation part respectively. No matter in cold or hot, one of the fiber gratings is always in a suspended stretching state, so that chirp and initial large pre-stress are effectively avoided, the sensitivity is still kept at a high level, and the temperature measurement range is also doubled.

Owner:XI'AN PETROLEUM UNIVERSITY +1

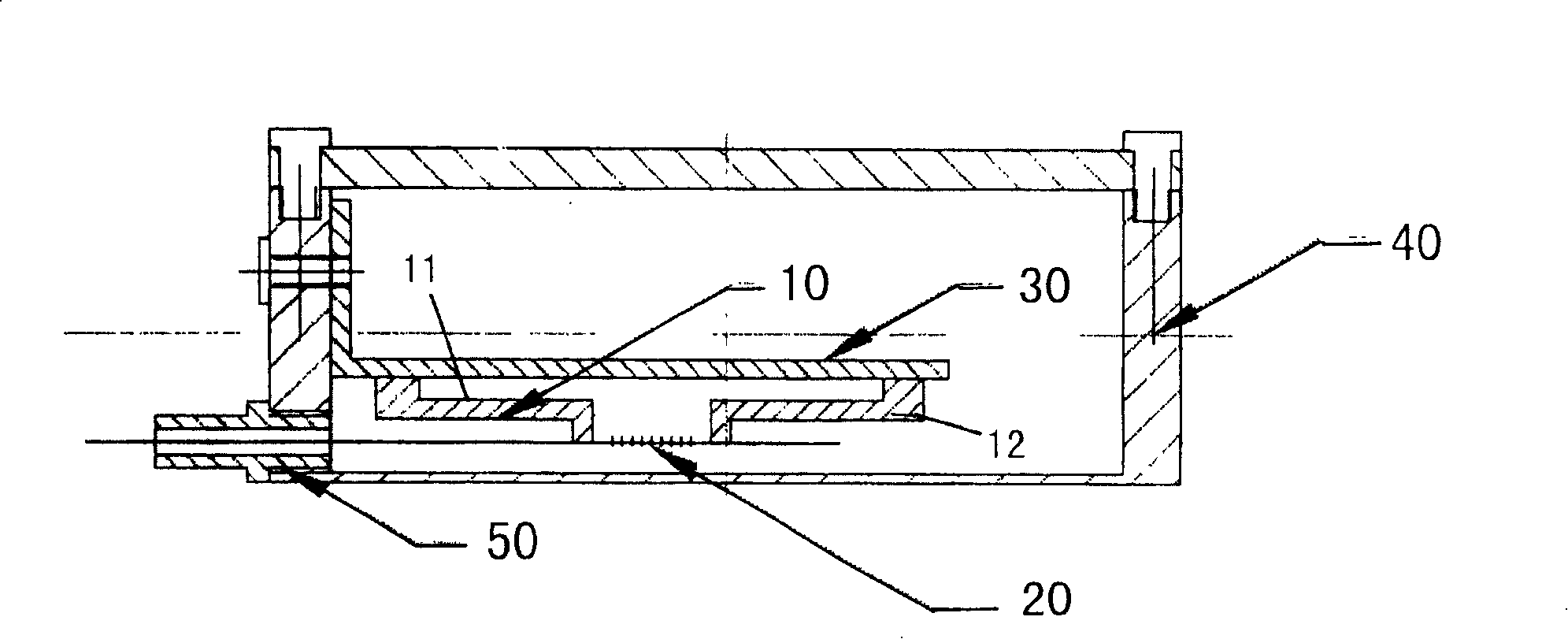

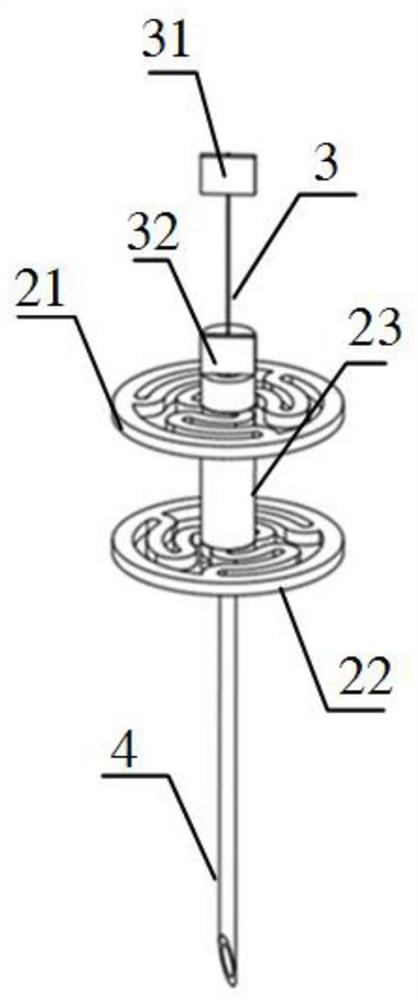

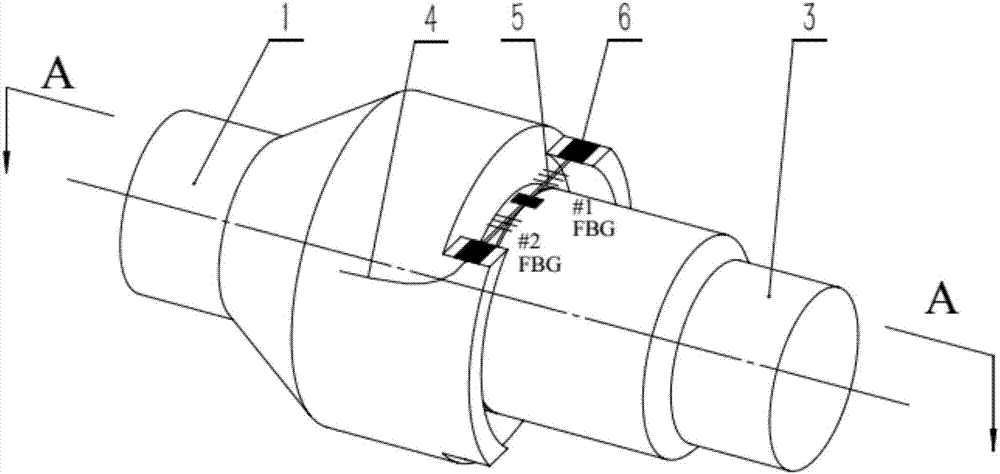

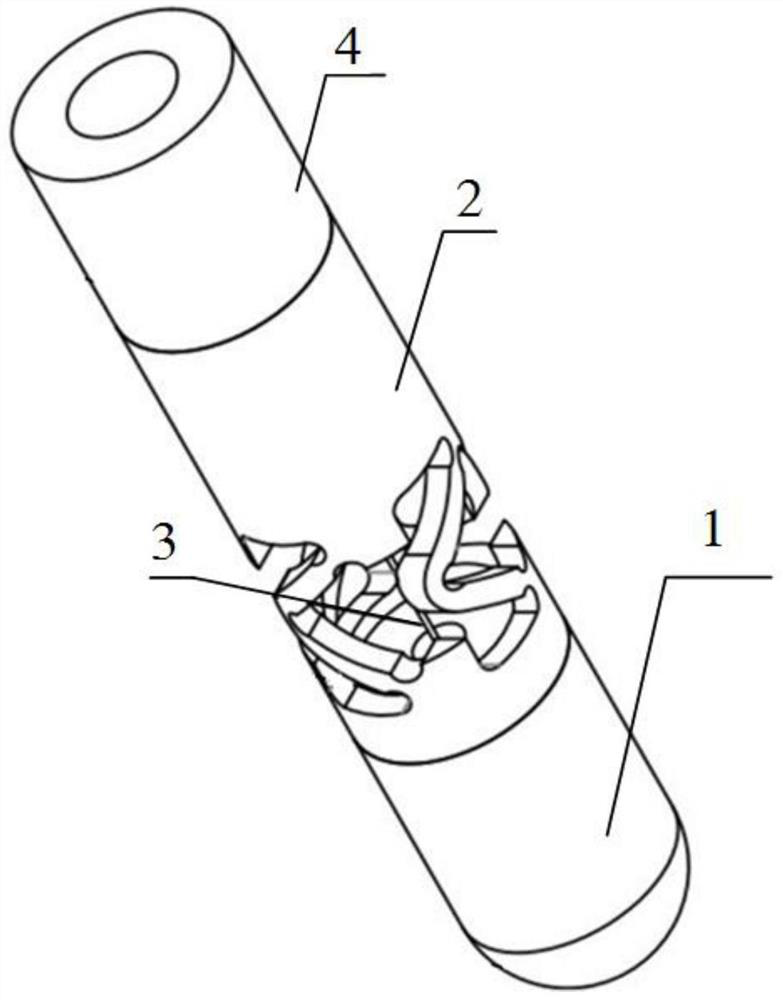

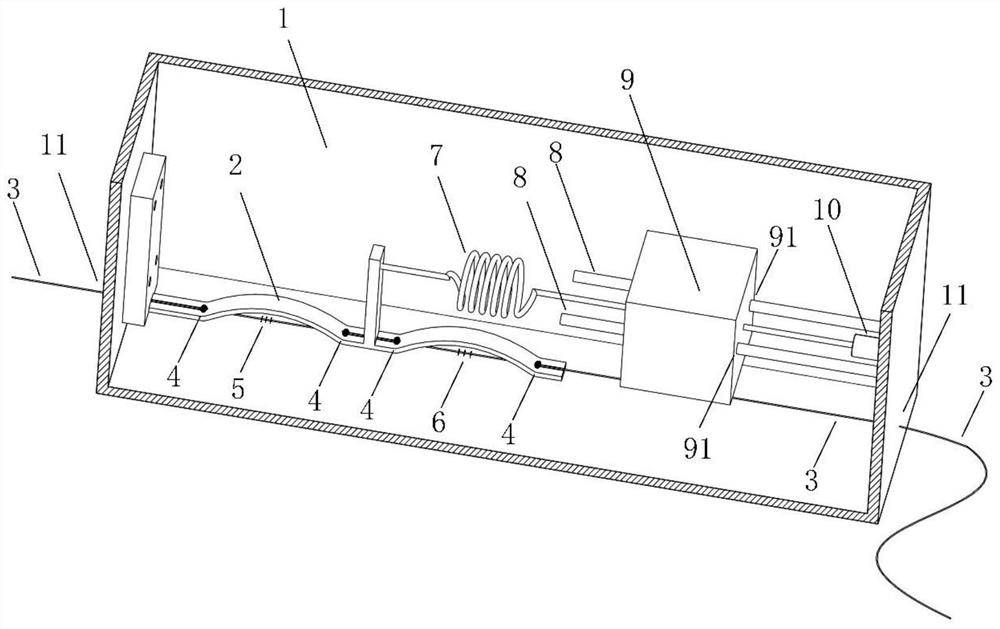

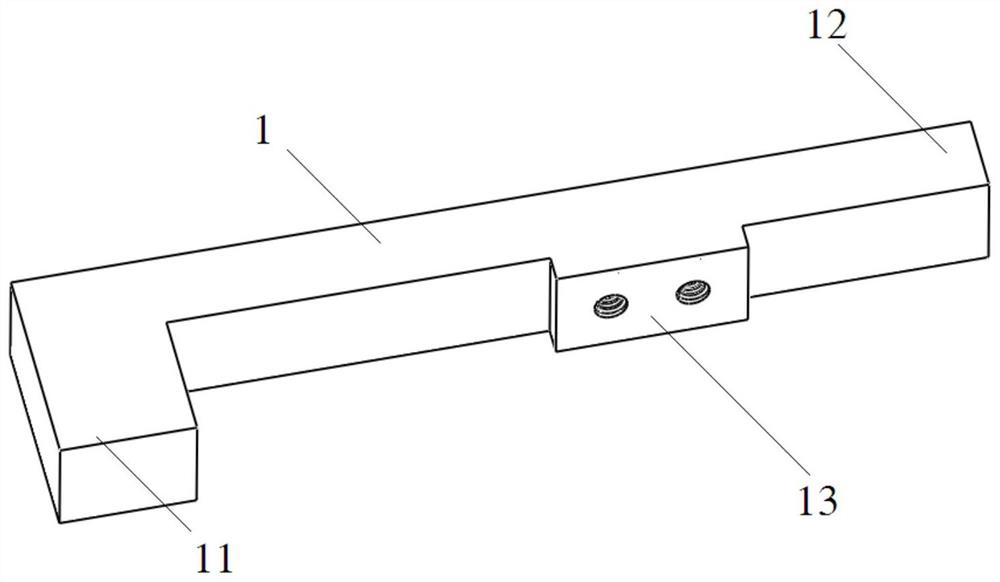

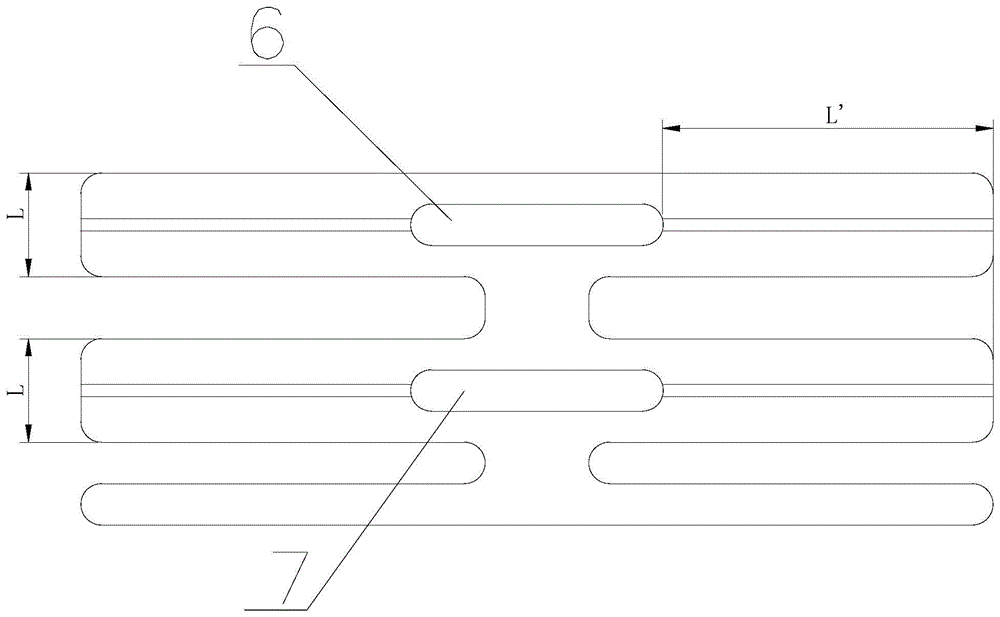

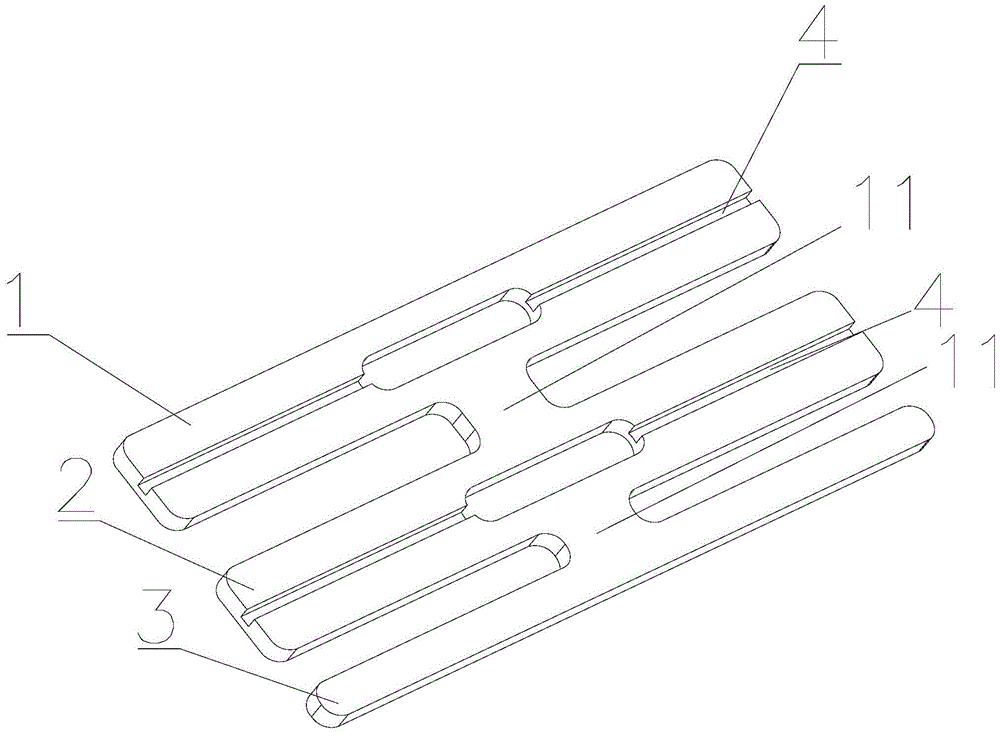

A high-sensitivity temperature-compensated fiber grating acceleration sensor

ActiveCN109991443BHigh sensitivityIncrease rangeAcceleration measurement using interia forcesFiberAccelerometer

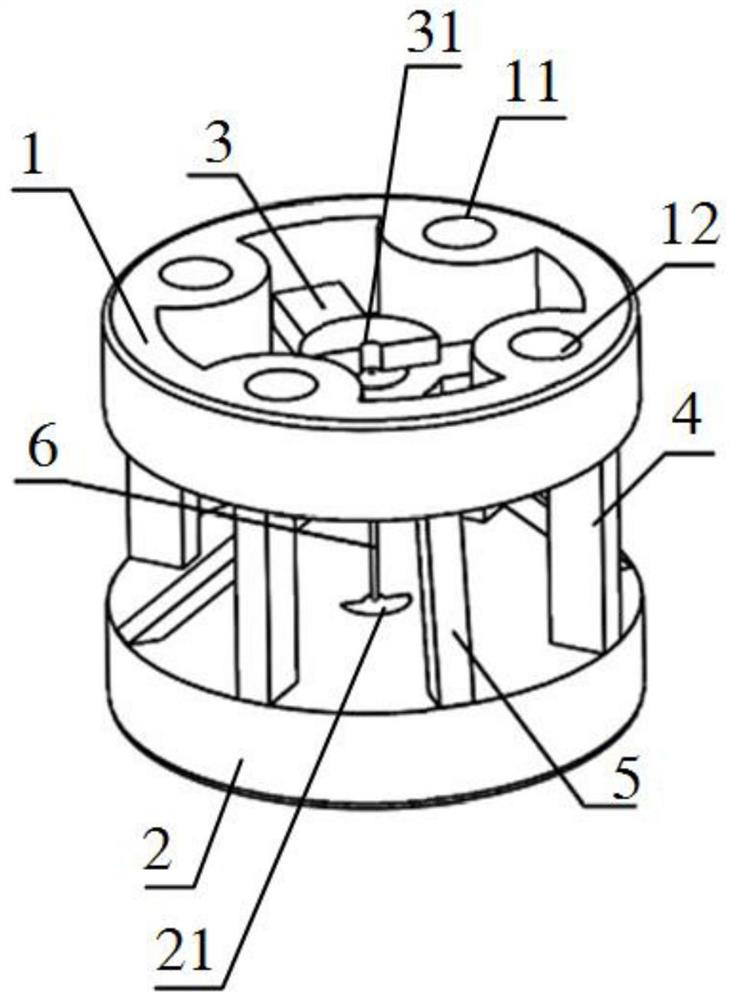

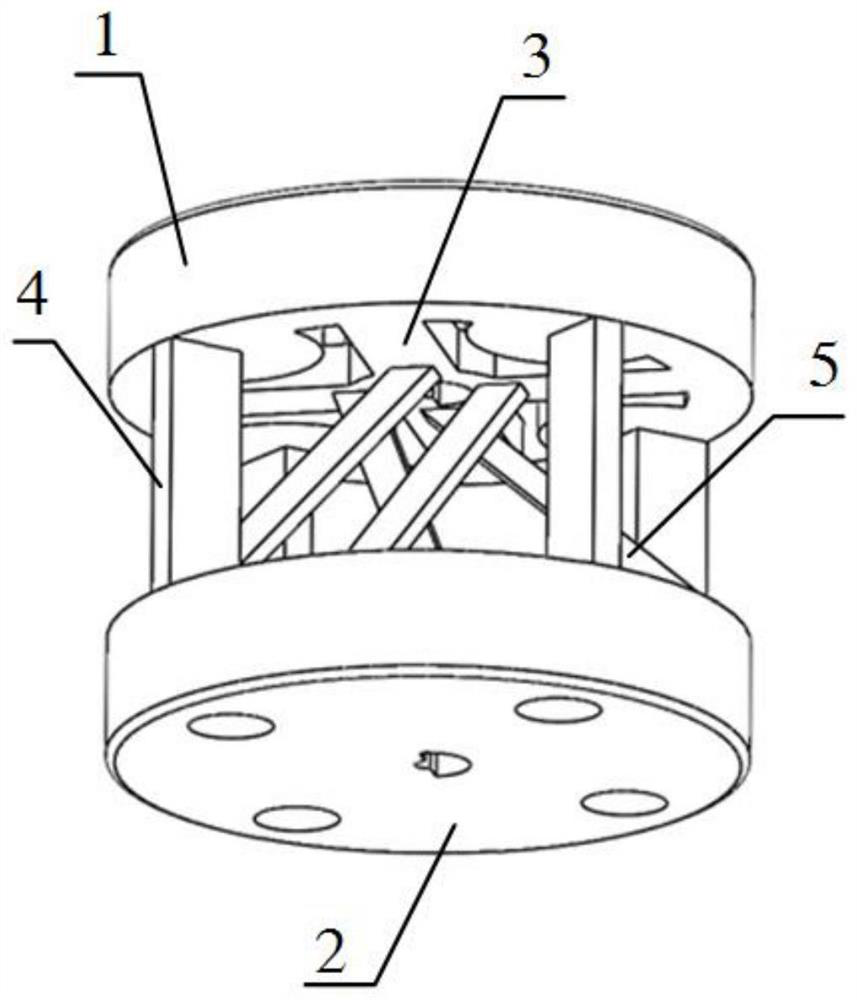

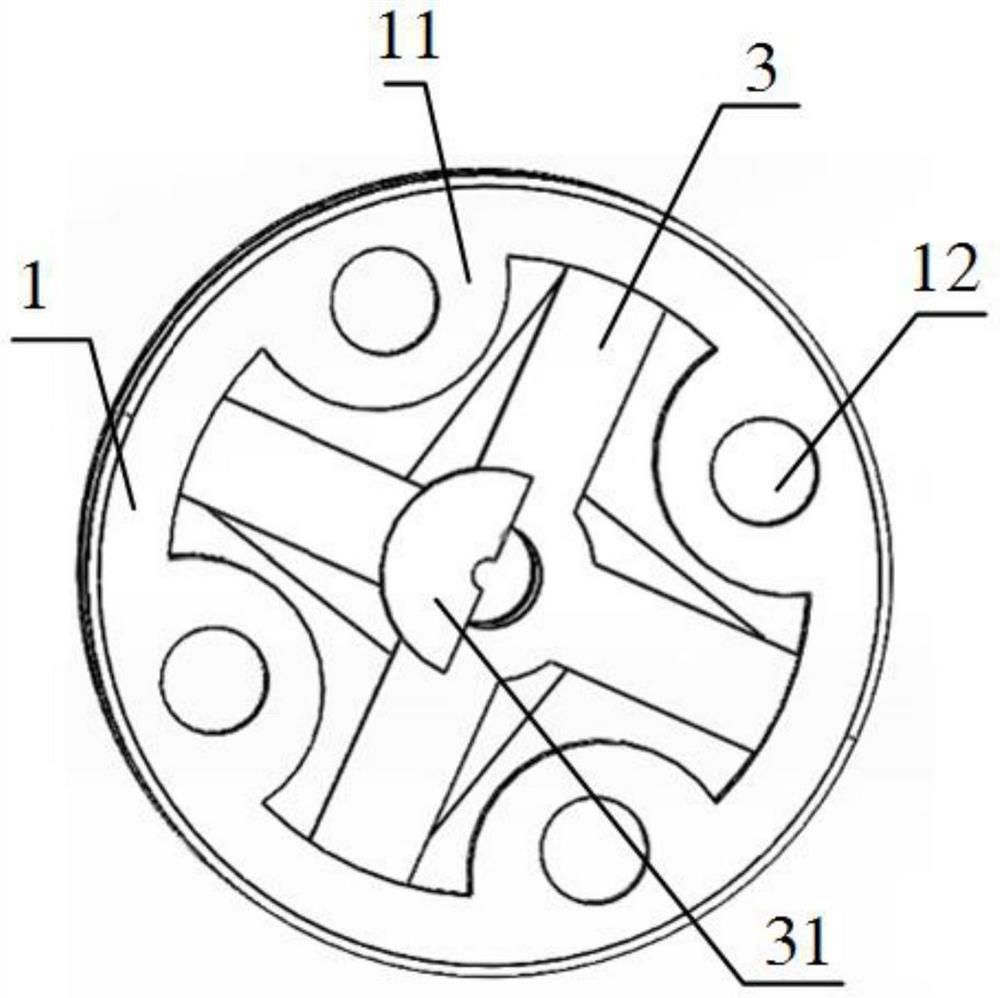

The invention provides a high-sensitivity temperature compensation type fiber Bragg grating acceleration sensor, which comprises a cubic shell (1), a double-arched elastic structure beam (2) fixed ona shell panel, and double fiber Bragg gratings, i.e., a 1# fiber Bragg grating (5) and a 2# fiber Bragg grating (6) fixed on the double-arched elastic structure beam, wherein the middle of the double-arched elastic structure beam (2) is provided with a vertical beam (22); one side of the shell (1) is fixedly provided with rigid sliding rods (8) and a damper (10); a mass block (9) is positioned onthe rigid sliding rods (8) and is connected with the damper (10); and one end of a prestressed spring (7) is fixed on the vertical beam (22), and the other end of the prestressed spring (7) is fixed on one side of the mass block (9). By use of the sensor, the double-arched elastic structure beam is used for fixing double fiber Bragg gratings below the arched beam, so that the sensitivity of the fiber Bragg grating acceleration sensor is greatly improved, tail fibers on two ends of the sensor are both free ends so as to be connected with other fiber Bragg grating sensors in series, and a sensing array or network can be formed to realize distributed sensing.

Owner:SOUTHEAST UNIV

High-precision miniature torque sensor based on fiber bragg grating

ActiveCN114152374AHigh sensitivityImprove linearityWork measurementTorque measurementFiberAxial displacement

The invention relates to a high-precision miniature torque sensor based on a fiber bragg grating, which comprises a torsion sensitive flexure structure, a fiber bragg grating and a signal processing unit, and is characterized in that the torsion sensitive flexure structure has a function of converting torsion motion into linear motion and can transmit axial displacement to an optical fiber; the fiber bragg grating is suspended on the central axis of the torsion sensitive flexure structure under the action of pretightening force, and when the torsion sensitive flexure structure rotates and generates axial displacement, the arrangement direction of the fiber is overlapped with the running direction of the linear displacement of the structure; the optical fiber can generate optical fiber strain signals which are more uniform, more sensitive and higher in linearity; the signal processing unit comprises a fiber bragg grating demodulator and a computer system and is used for converting optical signals into digital signals. The sensor disclosed by the invention has the characteristics of high sensitivity, large measurement range, high linearity, high measurement accuracy and the like.

Owner:TIANJIN UNIV

Embedded fiber bragg grating sensor and preparation method thereof

InactiveCN111284039ACorrosion resistanceGood environmental compatibilityConverting sensor output opticallyFiber bragg grating sensorNonwoven fabric

The invention provides an embedded fiber bragg grating sensor. The embedded fiber bragg grating sensor structurally comprises a composite material substrate, dry-state fiber cloth, macromolecular non-woven fabric, a fiber one-way bundle, vacuum-poured liquid resin and a fiber bragg grating, wherein the composite material substrate is located at the bottom of the whole embedded fiber bragg gratingsensor and serves as a carrier of the fiber bragg grating sensor; the dry-state fiber cloth serves as a covering layer and is located at the top of the whole embedded fiber bragg grating sensor; the fiber bragg grating and the macromolecular non-woven fabric which are wrapped in the fiber one-way bundle are arranged between the dry-state fiber cloth and the composite material substrate, and the macromolecular non-woven fabric is located on the upper side and the lower side of the fiber bragg grating; the vacuum-poured liquid resin is distributed in an area between the composite material substrate and the dry-state fiber cloth, and after the liquid resin is cured, the liquid resin, the upper-layer dry-state fiber cloth and the bottom composite material substrate form a strong interface relation. According to the embedded fiber bragg grating sensor and the preparation method thereof, the survival rate and the long-term use stability of the embedded fiber bragg grating sensor are improved, and the problem that a blade mold is difficult to monitor on line is solved.

Owner:SHANDONG UNIV +1

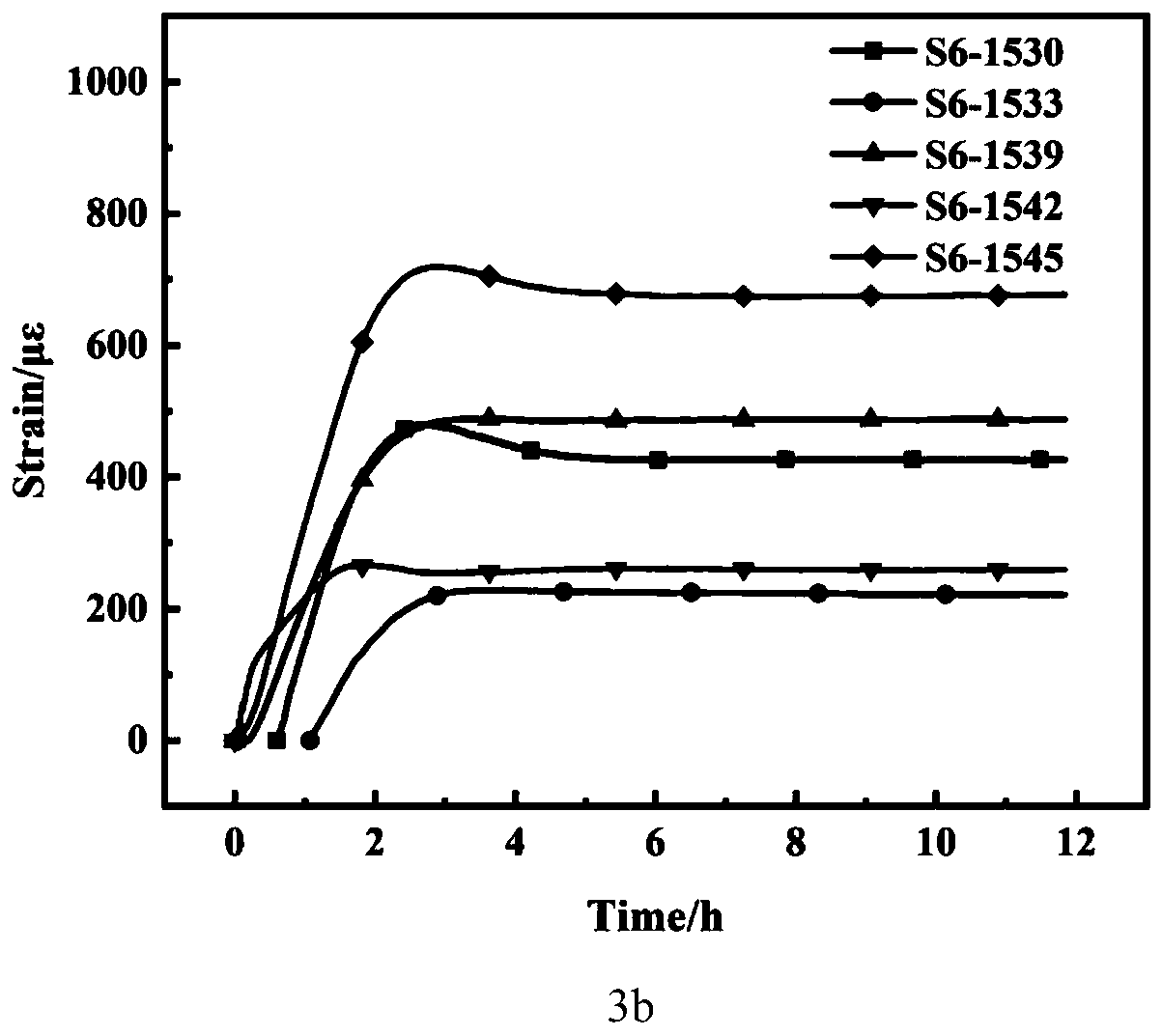

A fiber grating high temperature strain gauge and its calibration method

The invention discloses a fiber grating high-temperature strain gauge, which comprises a sensor substrate, an optical fiber installation arm and an optical fiber arranged on the sensor substrate, the sensor substrate is circular, and the optical fiber installation arm is arranged along the The inner circumference of the sensor substrate extends inwardly, and the optical fiber is arranged along the diameter direction of the sensor substrate; the optical fiber includes a temperature optical fiber for only sensing temperature; the sensor substrate is provided with different heights The boss is used to fix the optical fiber, and the boss is used to avoid cross contact between different optical fibers. The fiber grating high-temperature strain gauge of the present invention eliminates the influence of temperature on strain measurement; the boss design on the sensor substrate can effectively avoid the chirp phenomenon caused by the cross contact of FBG optical fibers; the strain gauge has simple structure and multi-directional strain synchronization With the advantages of measurement, temperature compensation, and high measurement accuracy, it can be used for simultaneous measurement of multi-directional strain on the surface of structures.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Optical fibre grating accelerometer based on cantilever beam deflection

InactiveCN100585407CHigh sensitivityLarge strainTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamAccelerometer

The invention relates to the optical fiber sensor technical field, disclosing an optical fiber grating accelerometer based on cantilever beam deflection. The accelerometer comprises an outer casing 1 used as a support structure of the accelerometer, an optical fiber grating 2 used to measure acceleration, a cantilever beam 3 with one end horizontally fixed on the third sidewall p of the accelerometer and a mass block 5 fixed at the other end of the cantilever beam 3, wherein the outer casing 1 has a first sidewall m, a second sidewall n, a third sidewall p and a fourth sidewall q; one end of the optical fiber grating 2 is fixed with the mass block 5, while the other end is parallel to the first sidewall m and passes through the hole 6 on the second sidewall n of the accelerometer to extend outside the accelerometer; the cantilever beam 3 is used to send vibration signal to the optical fiber grating 2; and the mass block 5 is used to adjust the sensitivity and the natural vibration frequency of the accelerometer. The optical fiber grating accelerometer increases sensitivity and improves packaging technology.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Fiber bragg grating transformer winding vibration acceleration sensor and processing method thereof

PendingCN113670429AAvoid chirpingHigh sensitivitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberCantilevered beam

The invention discloses a fiber bragg grating transformer winding vibration acceleration sensor and a processing method thereof, the sensor comprises a fiber bragg grating, a double-cantilever beam and a shell, and the double-cantilever beam is provided with double rectangular holes; two end points of the fiber bragg grating are fixed on the double rectangular holes of the double- cantilever beam, the fiber bragg grating is in a tightened state and located at the center line position of the rectangular holes, the fiber bragg grating is packaged in the shell along with the double-cantilever beam, and fibers of the fiber bragg grating are led out of the shell. The design of the double-cantilever beam increases directional interference resistance, and the two-point packaging design increases the sensitivity of the sensor and solves the problem of grating chirp.

Owner:CHONGQING UNIV +1

Double-F-shaped fiber grating temperature sensor

PendingCN114046897AHigh sensitivityLarge measuring rangeThermometers using physical/chemical changesThermal dilatationFiber gratings

The invention discloses a double-F-shaped fiber grating temperature sensor, which comprises two F-shaped structural members and an optical fiber, wherein the thermal expansion coefficients of the two F-shaped structural members are different, the two F-shaped structural members are arranged in a central symmetry manner, the middle parts of the two F-shaped structural members are fixedly connected, and a gap is formed between the head end cross beam of each F-shaped structural member and the tail end of the other F-shaped structural member. The optical fiber is provided with a first optical fiber grating and a second optical fiber grating, wherein the first optical fiber grating and the second optical fiber grating are located at the two gaps respectively, and the optical fibers on the two sides of the optical fiber gratings are fixedly connected with the head end cross beam of one F-shaped structural part and the tail end of the other F-shaped structural part respectively. The two F-shaped structural members have a large thermal expansion coefficient difference, and the relative displacement change, caused by the temperature, of the two F-shaped structural members is converted into the strain change of the fiber bragg grating, so that the sensitivity of the temperature sensor is improved. When the temperature rises and drops, the central wavelength change of one fiber grating is used for detection, and the measurement range is doubled.

Owner:CCCC FIRST HIGHWAY CONSULTANTS +1

A king-shaped optical fiber grating sensor patch

The invention discloses a king-shaped optical fiber grating sensor patch. The patch has a symmetrical king-shaped structure as a whole. There are two connecting parts, the strain temperature horizontal side is connected to the single temperature horizontal side through the connecting part, and the single temperature horizontal side is connected to the pasting side through another connecting part. The fiber grating in the second hole of the patch can directly measure the temperature of the structure, and the result of the fiber grating in the first hole can be subtracted from the result of the fiber grating in the second hole to get the strain of the structure, which can prevent the fiber The grating produces a chirp phenomenon, and the size of each part of the patch can be designed according to the measurement requirements of different occasions combined with the average strain transfer rate formula, so that the size of the patch is small and suitable for pasting.

Owner:GUANGZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com