Embedded fiber bragg grating sensor and preparation method thereof

A fiber grating and sensor technology, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problem of difficulty in online monitoring of blade molds, and achieve the effects of improving test accuracy and stability and reducing air bubble content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

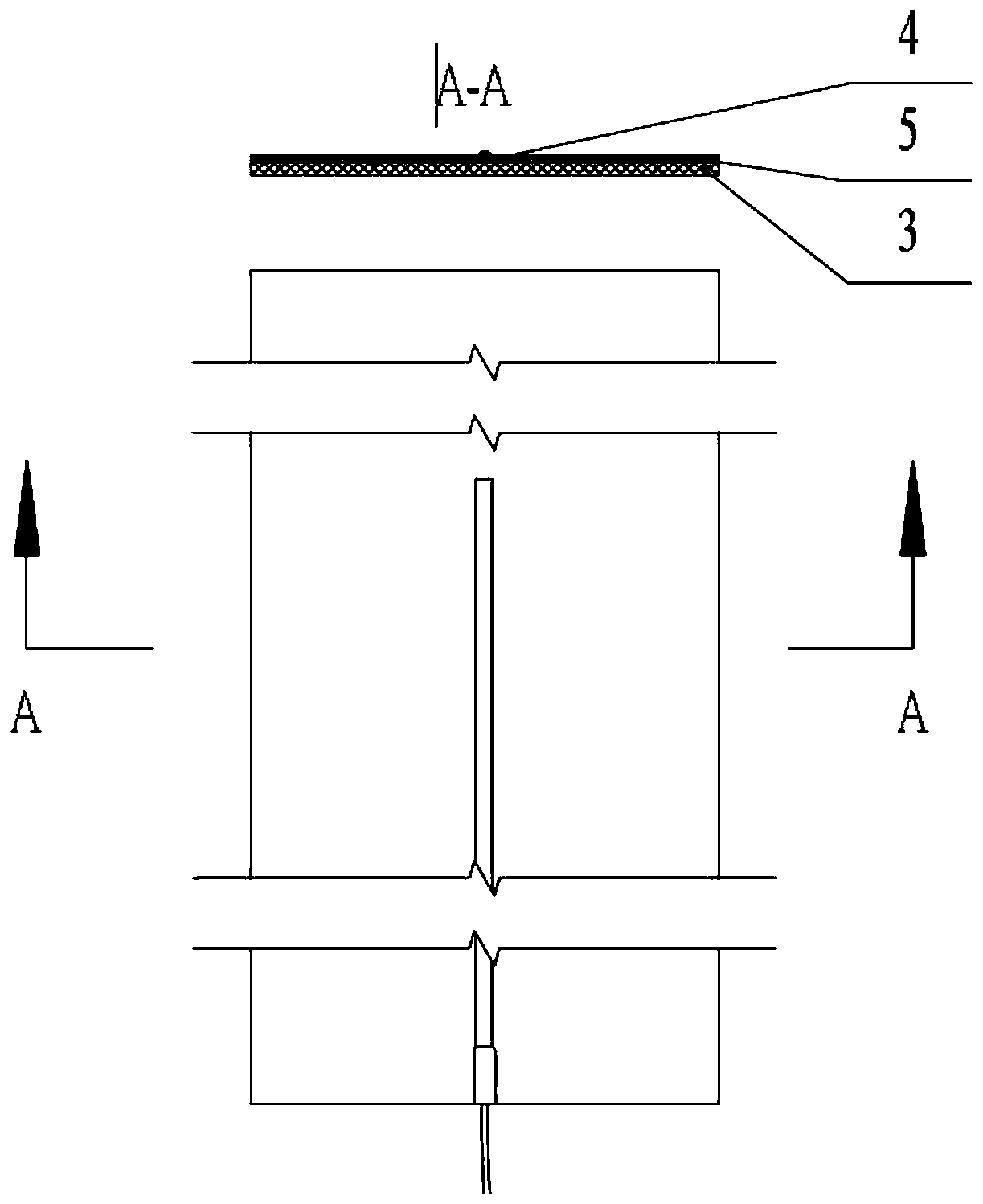

[0073] A glass fiber / epoxy resin composite substrate type fiber grating sensor, its structure is as follows figure 1 As shown in a and 1b, it includes: glass fiber / epoxy resin composite material substrate 2; polymer non-woven fabrics 3, 5; fiber grating string 4 loaded on the upper surface of glass fiber / epoxy resin composite material substrate 2; covered on The upper dry glass fiber cloth 6; and the fiber unidirectional bundle 17 wrapped around the grid area.

[0074] Specifically:

[0075] The glass fiber / epoxy resin composite substrate 2 is located at the bottom of the entire fiber grating sensor, its upper surface is used to load the fiber grating string 4, and its lower surface is pasted on the structure to be tested. The glass fiber / epoxy resin composite material substrate 2 mainly plays the role of positioning, loading the fiber grating string 4 and transferring the strain of the measured structural member to the grating area, which requires that the substrate should h...

Embodiment 2

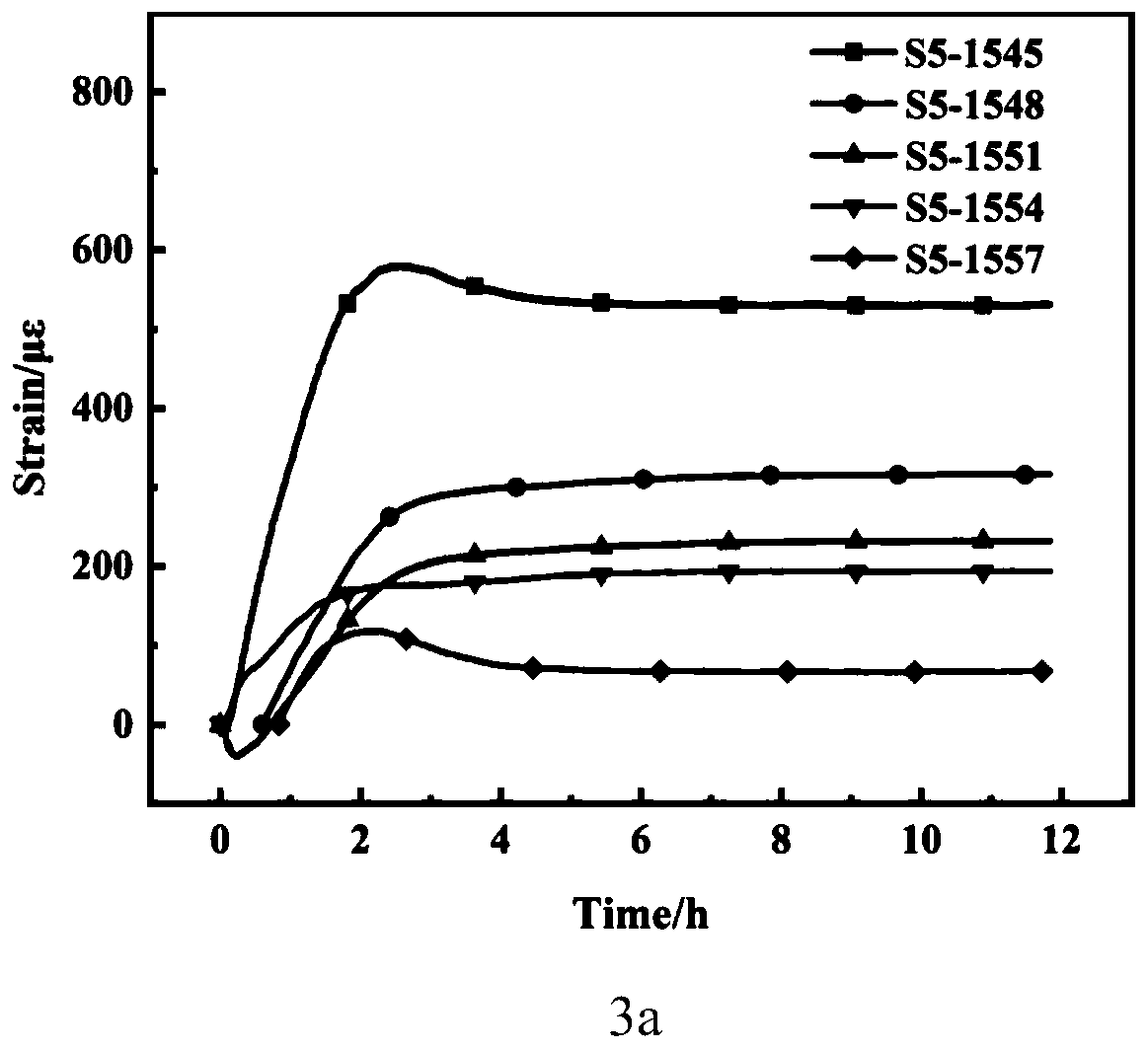

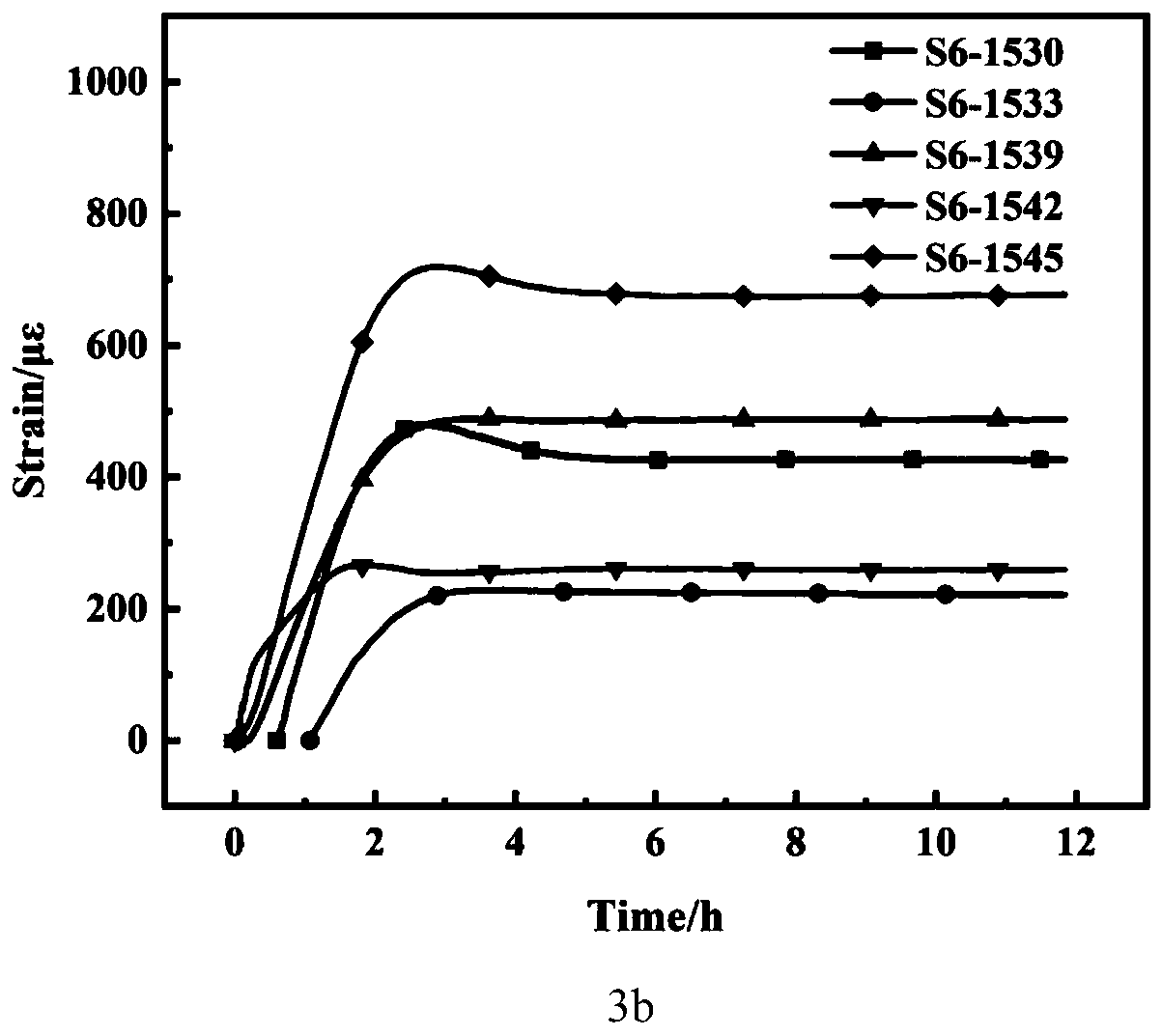

[0094] The difference from Example 1 is that the polymer non-woven fabric is made of PEEK (polyether ether ketone) non-woven fabric. Using the glass fiber / epoxy resin composite substrate type FBG sensor manufactured in this example, the center wavelength change of the FBG reflected light in the curing stage during the manufacturing process of the wind power blade mold was actually measured. The FBG sensor can detect the mold The strain conditions at different positions improve the survival rate of the sensor, avoid the chirp phenomenon, and have high test stability and test accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com