Patents

Literature

151 results about "Substrate type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The types of substrate are soil, rock, gravel, clay etc, and will determine the type of foundation that will be used under a building. In retrospect, the age of the home may well determine what type has been used when it was built.

Apparatus for depositing

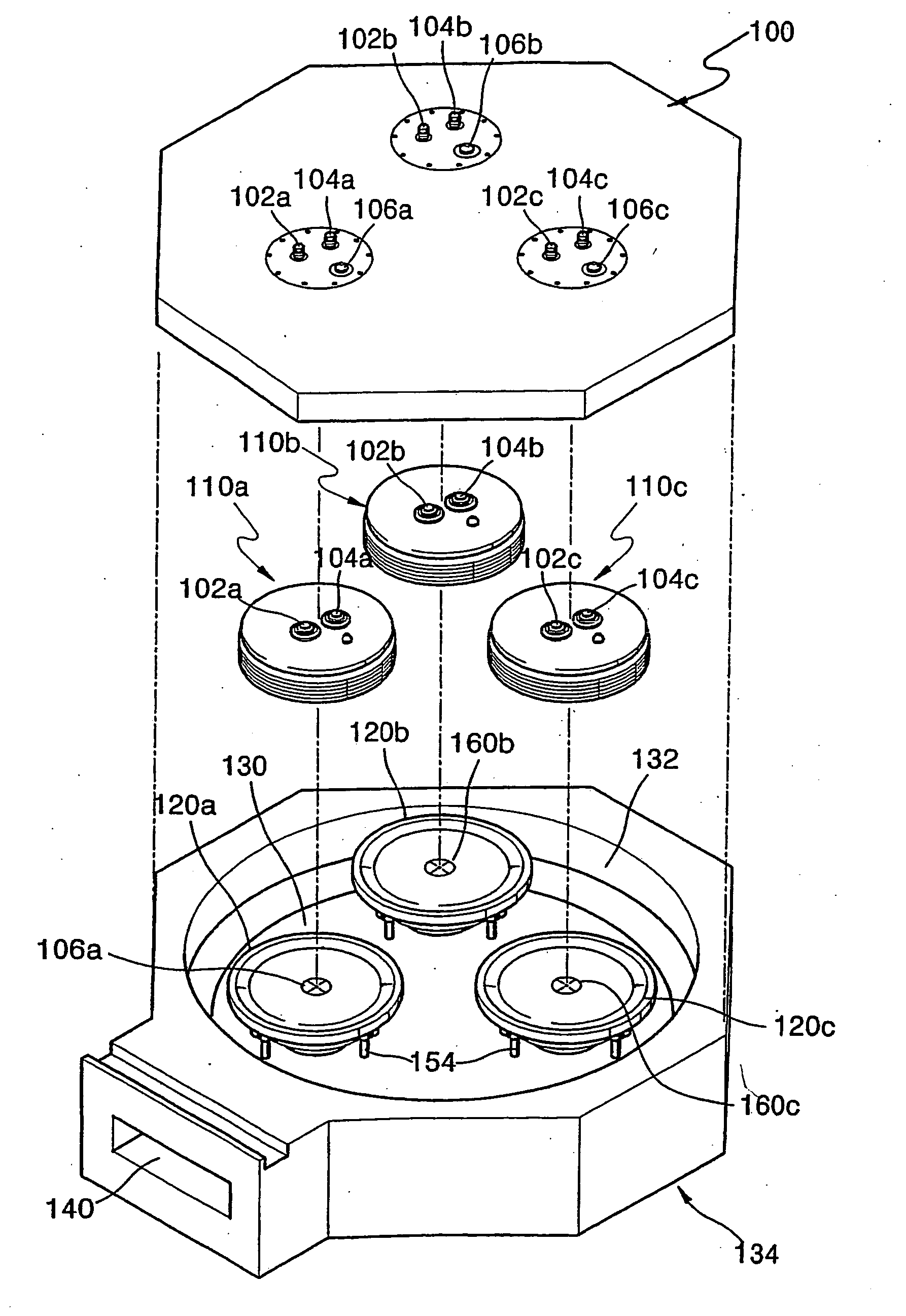

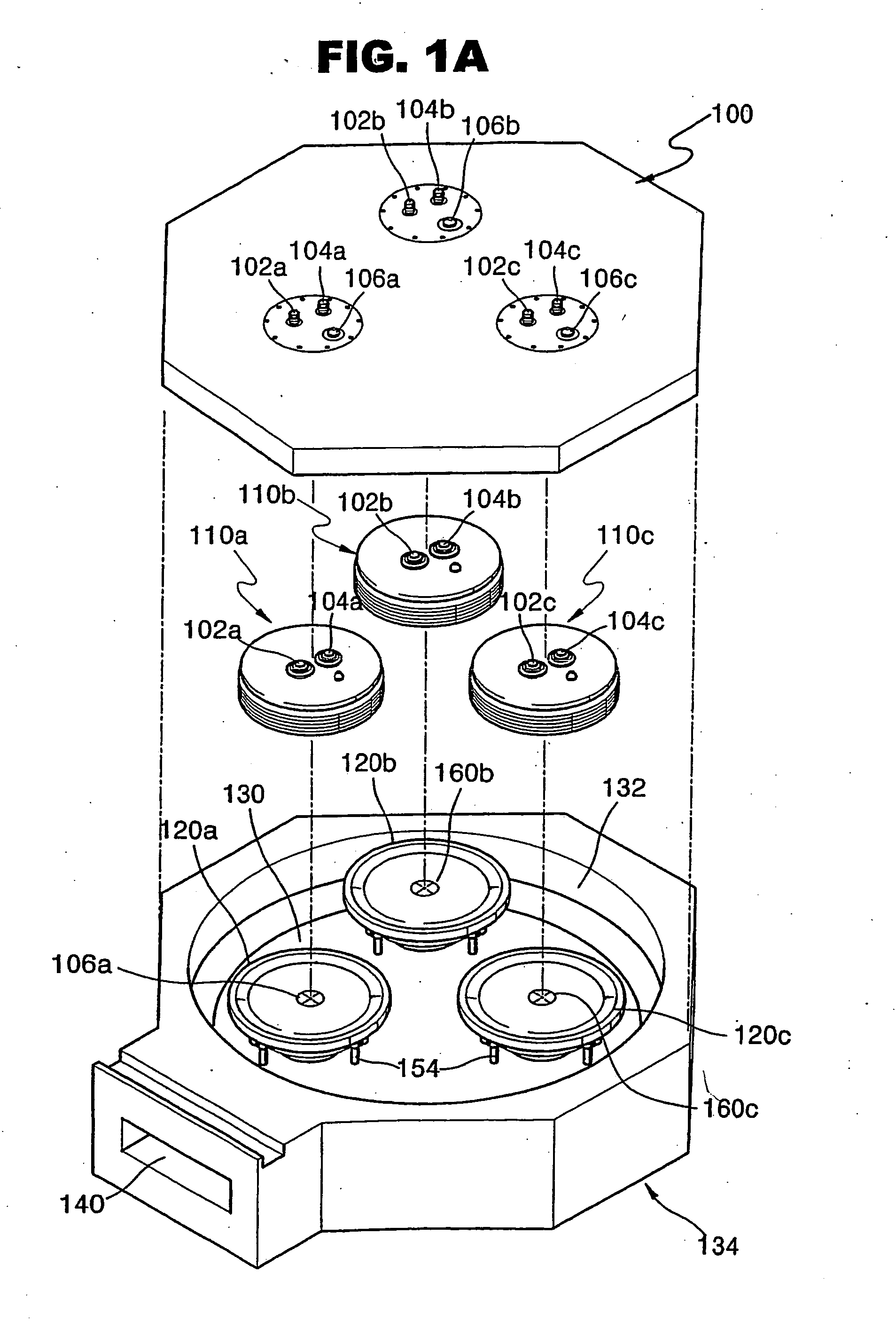

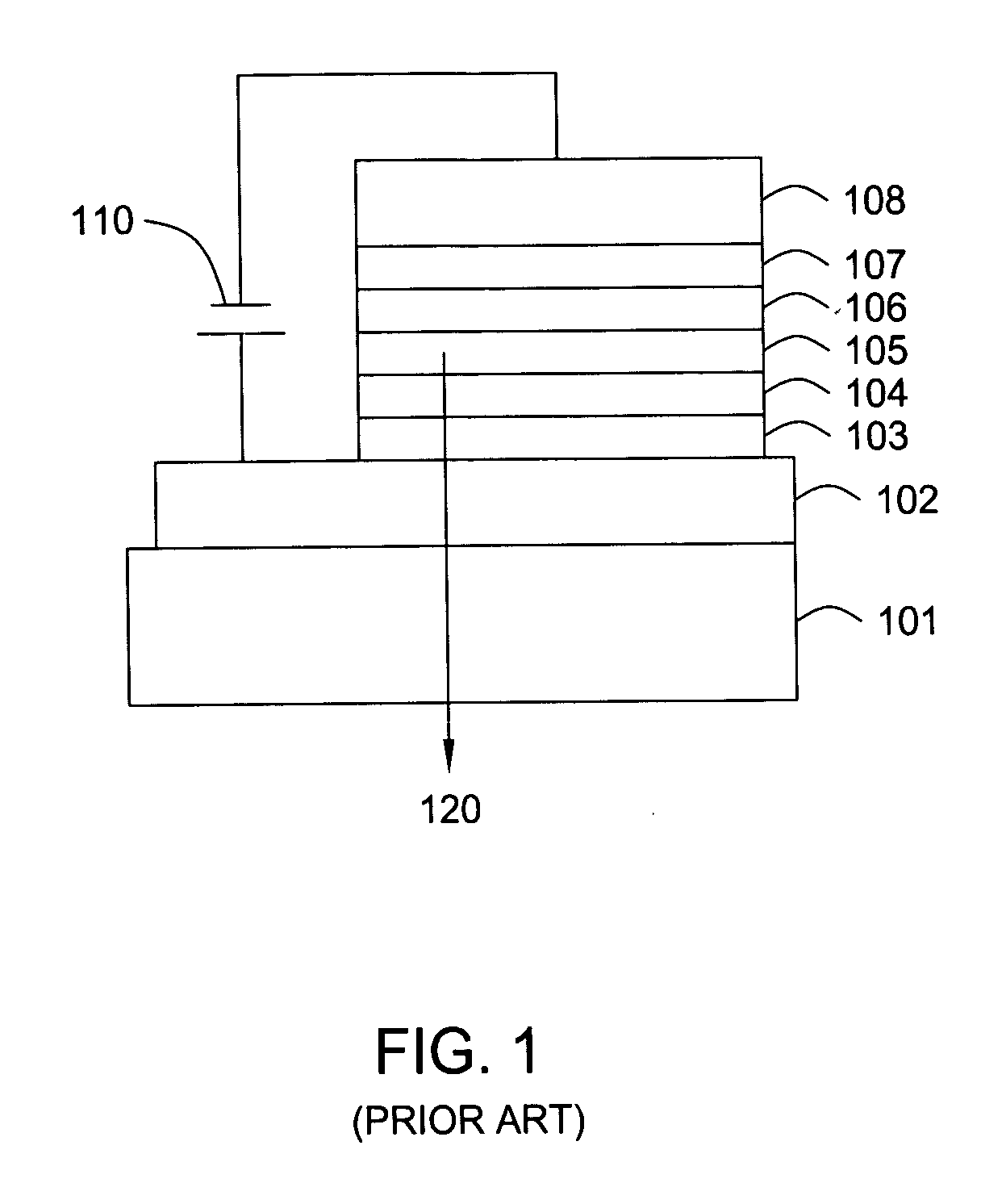

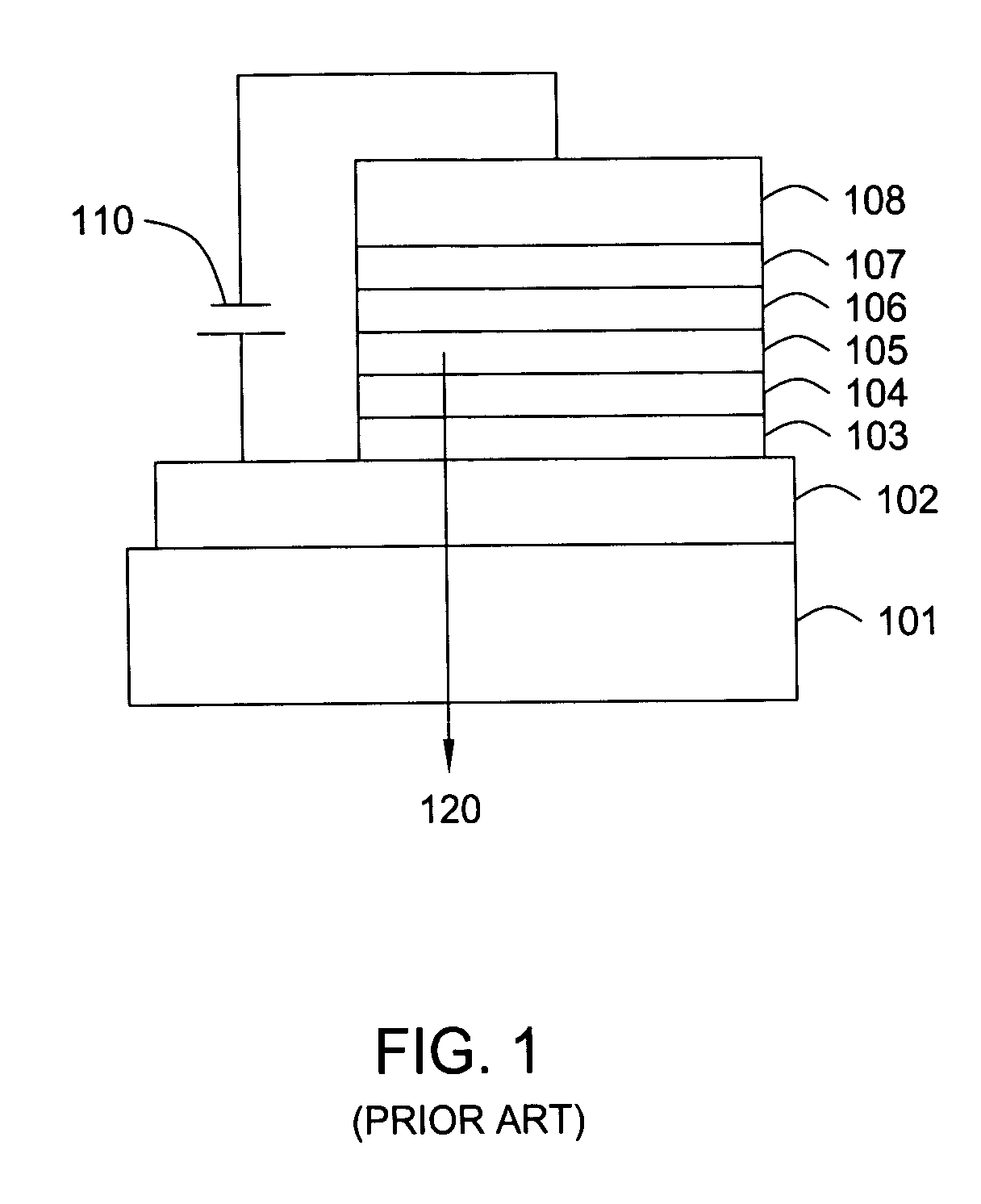

InactiveUS20050034664A1Easy to unloadEasy loading and unloadingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSubstrate typeNuclear engineering

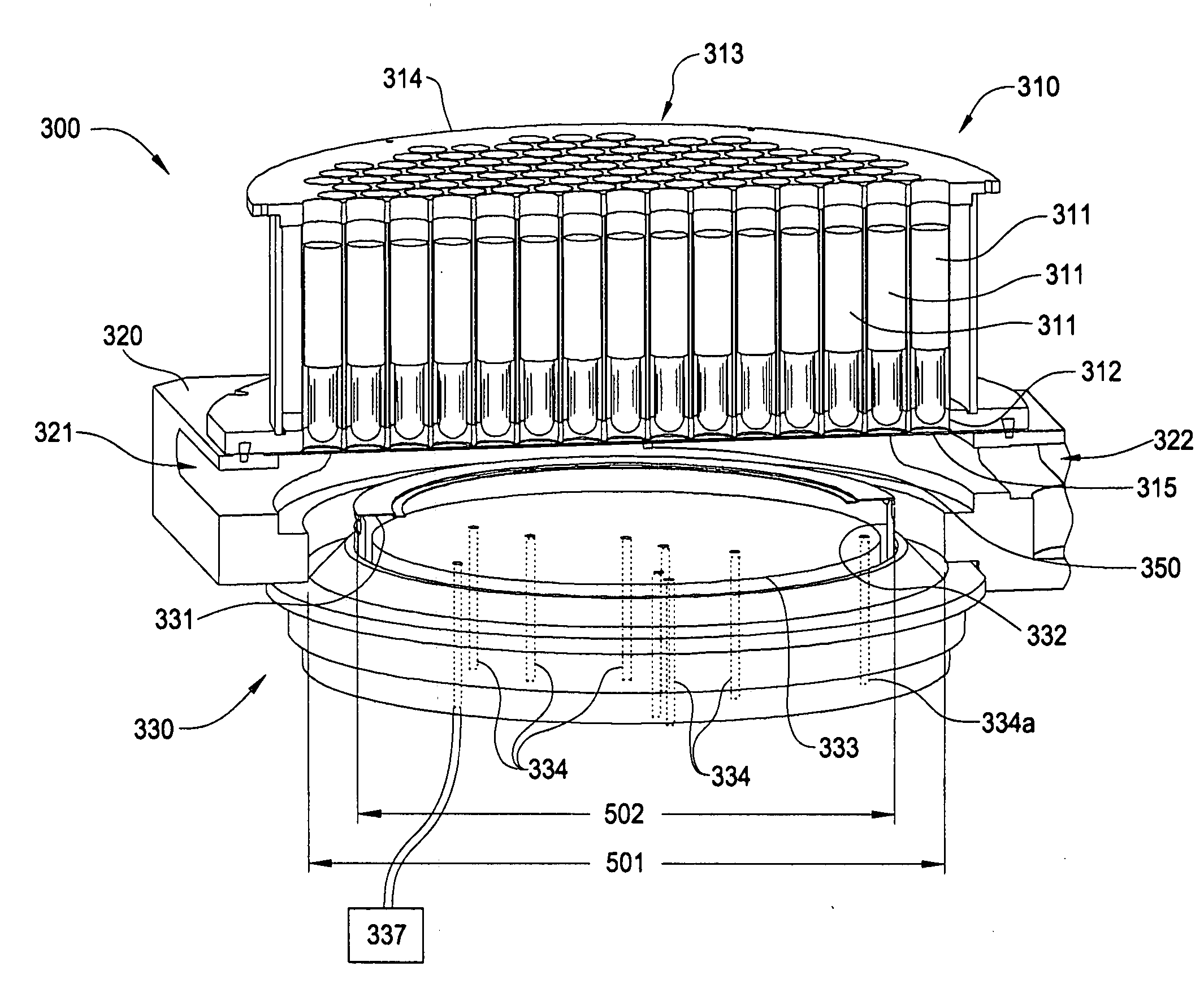

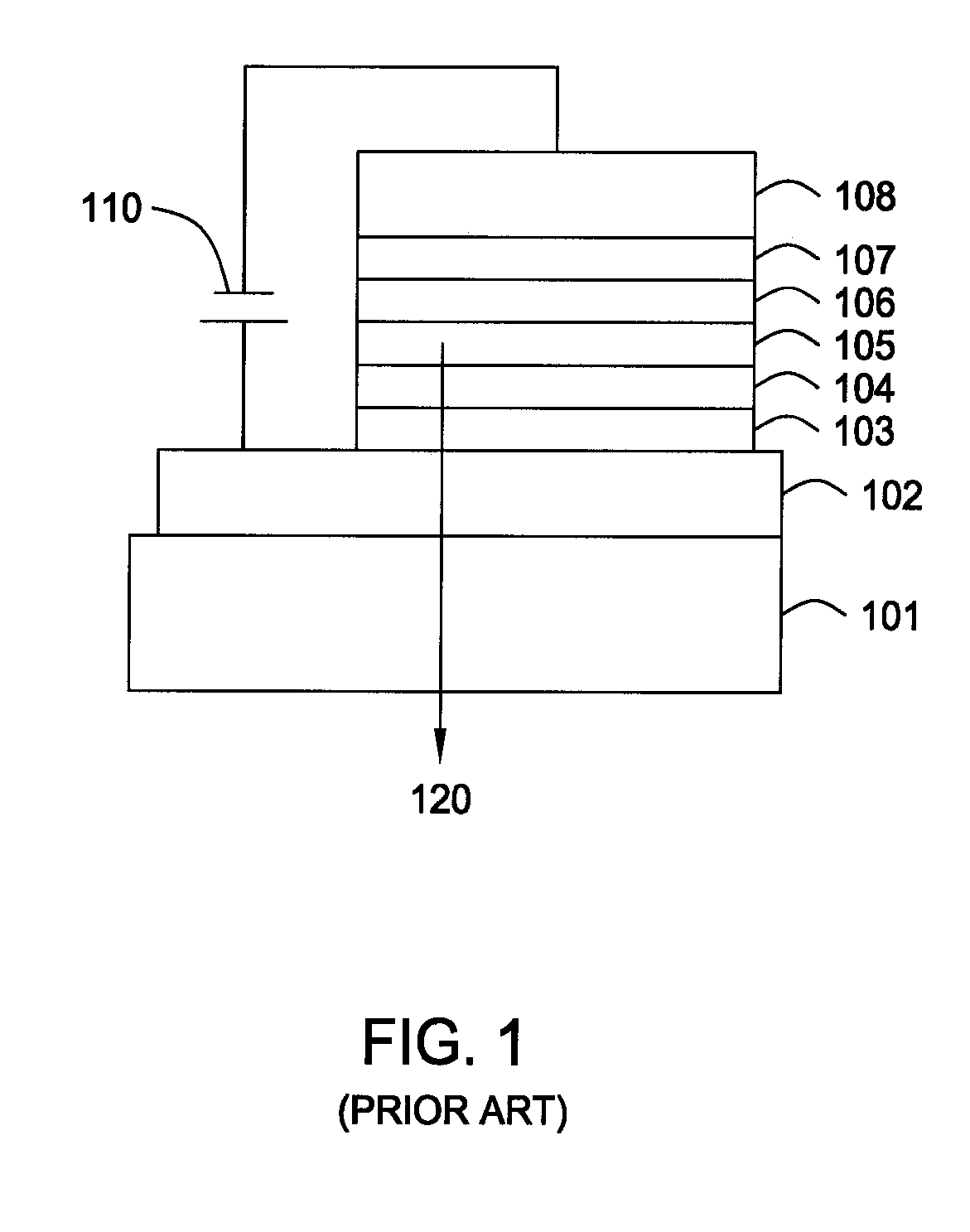

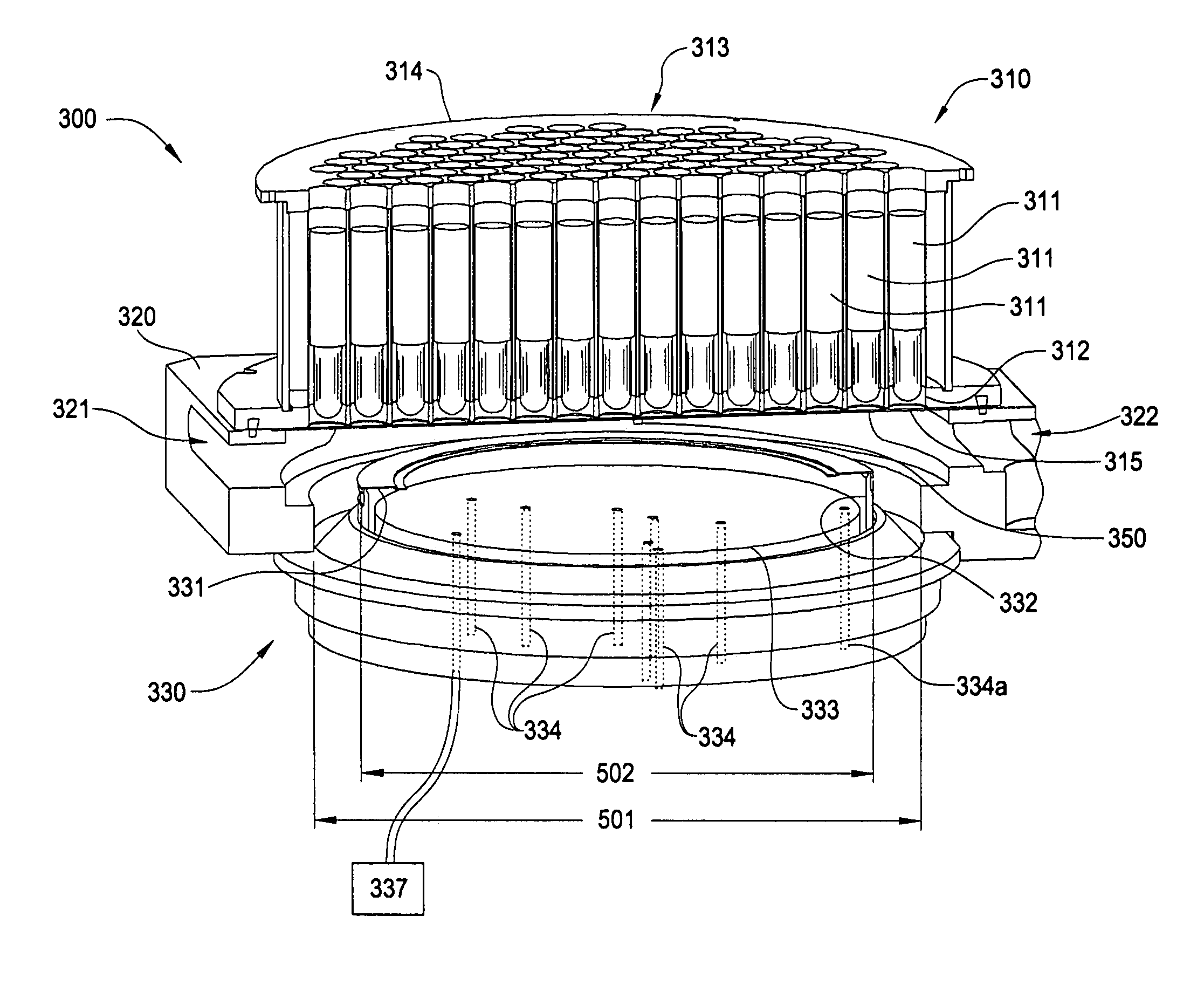

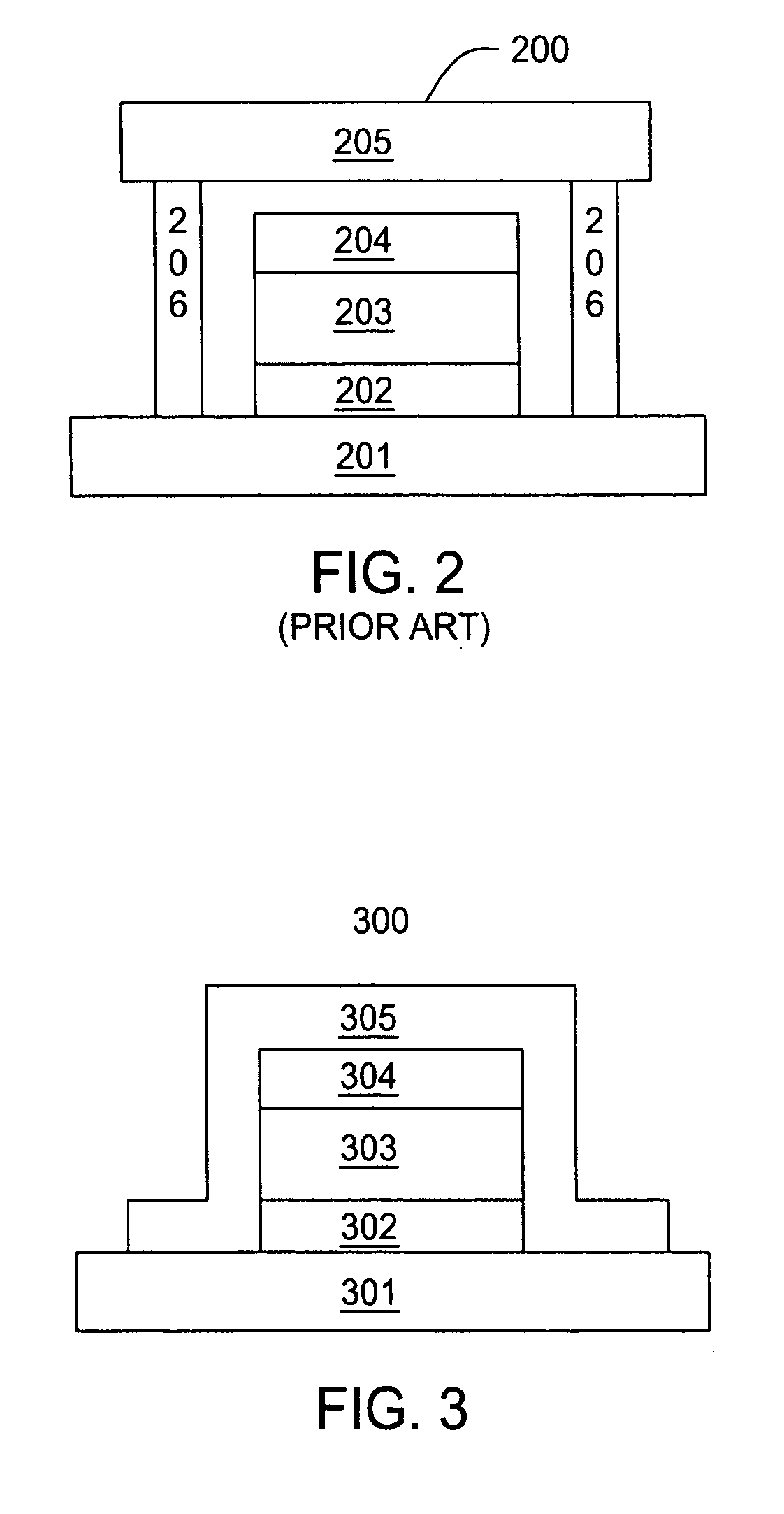

An apparatus constructed with a plural of independent reactors for depositing thin films is provided. The apparatus includes a chamber consisting of a base plate, a chamber wall and a chamber cover. A plural of identical and independent reactors are mounted inside the chamber, and each reactor has two parts; a reactor lower body and a reactor upper body, where the reactor upper body is fixed to the chamber cover and the reactor lower body is fixed to the base plate and moves up and down, thereby the up position of the reactor lower body makes a contact with the reactor upper body and thus providing a vacuum-tight processing space. Since a plural of identical and independent reactors are used, the processing steps and conditions developed for a single substrate type of reactor can be used for multiple reactors with minor adjustments, by utilizing a relatively symmetrical process gas supply inlet tube and process gas inlet tube and process gas exhaust tube arrangements. Such an arrangement also leads to high throughput, low cost and compact designs with tight footprints.

Owner:ASM GENITECH KOREA

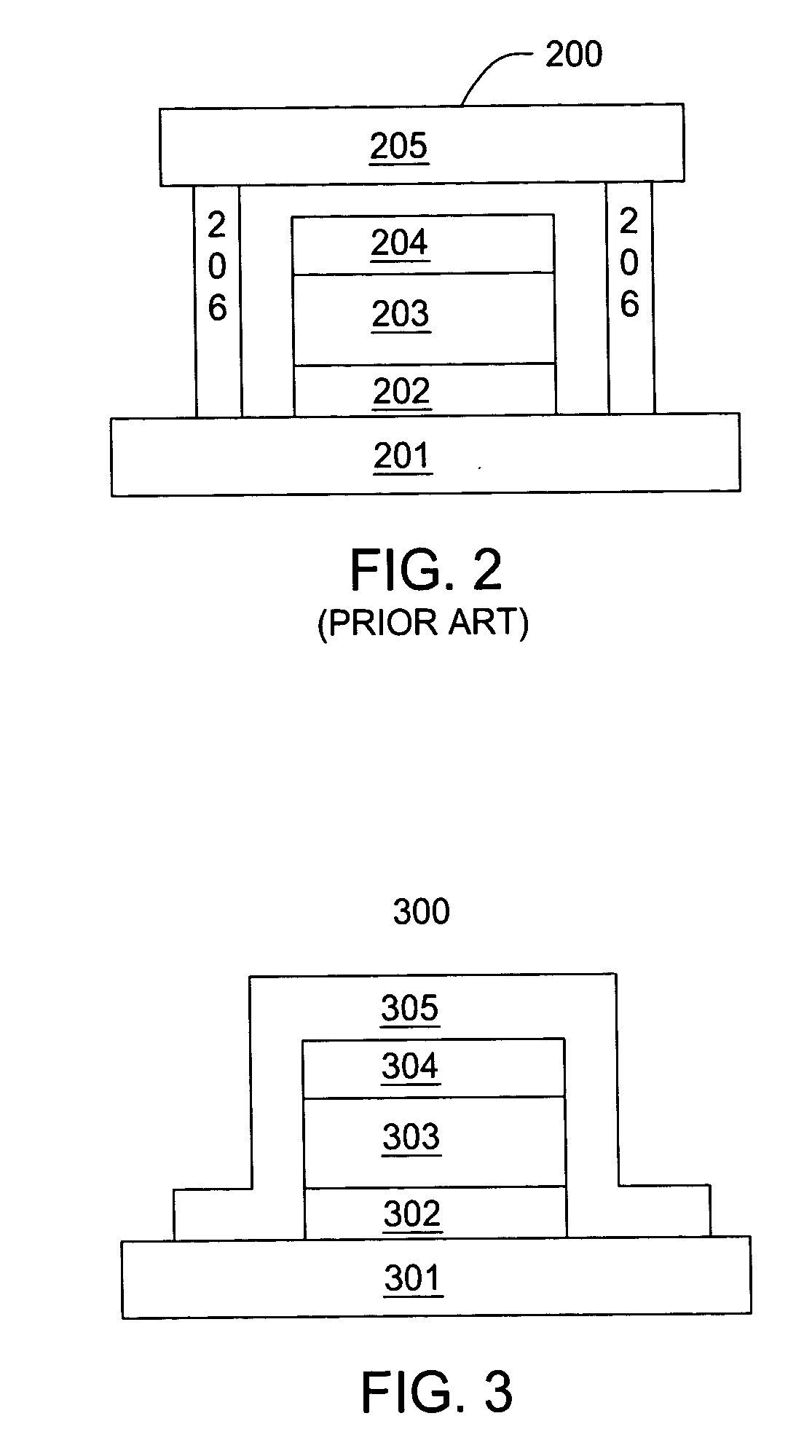

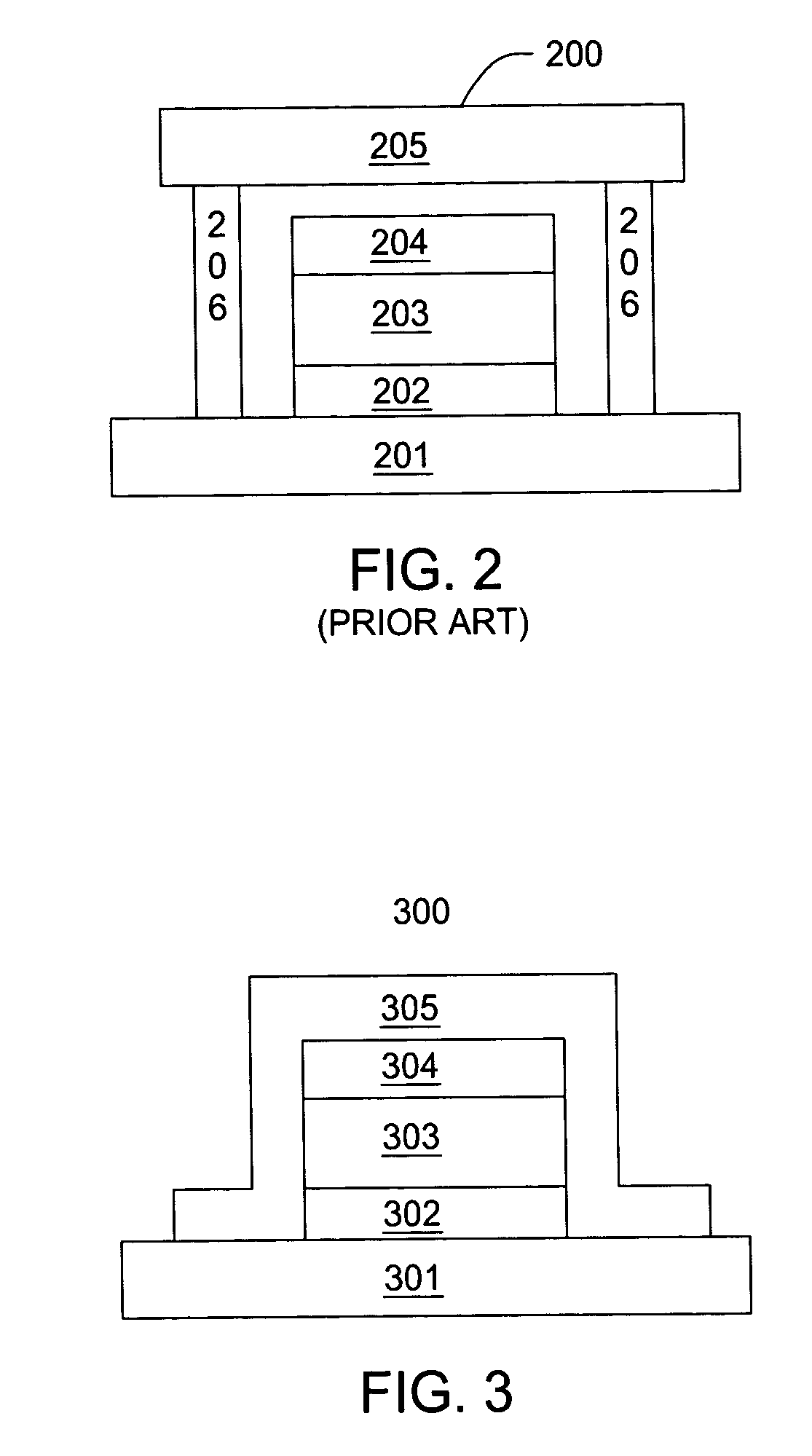

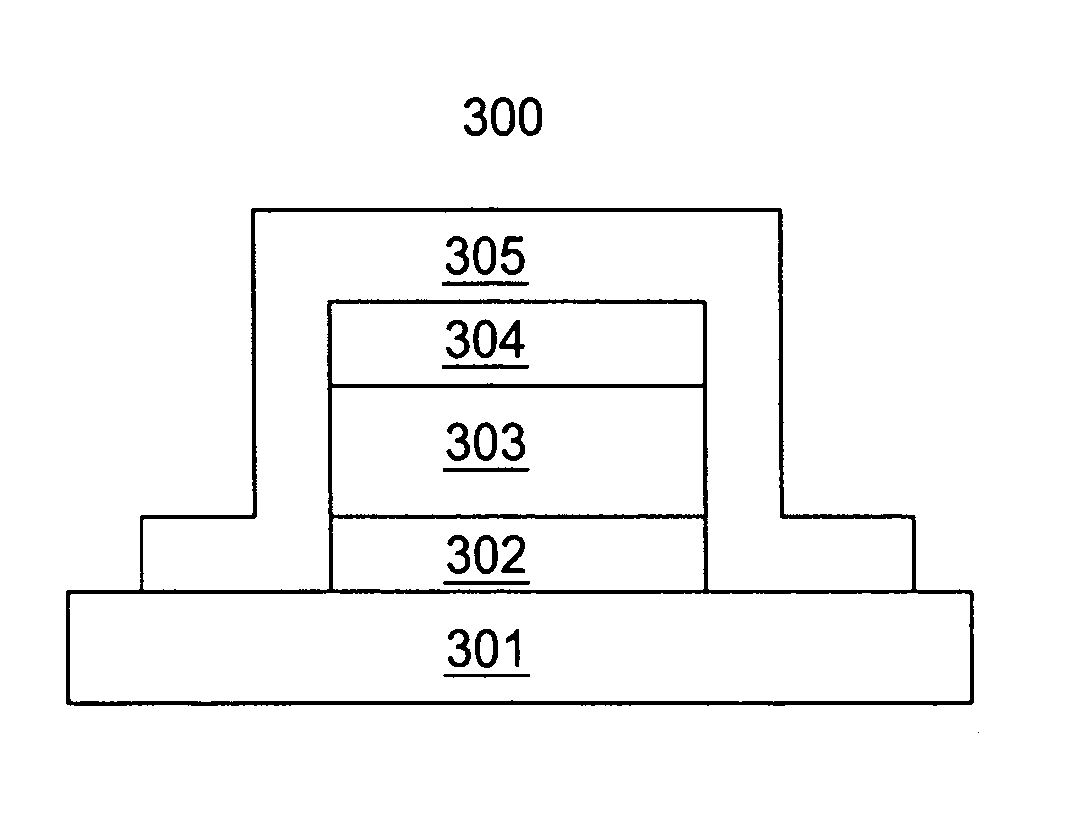

Water-barrier performance of an encapsulating film

ActiveUS20050287688A1Improve waterproof performanceGood film uniformitySemiconductor/solid-state device manufacturingSolid state diffusion coatingLow temperature depositionSubstrate type

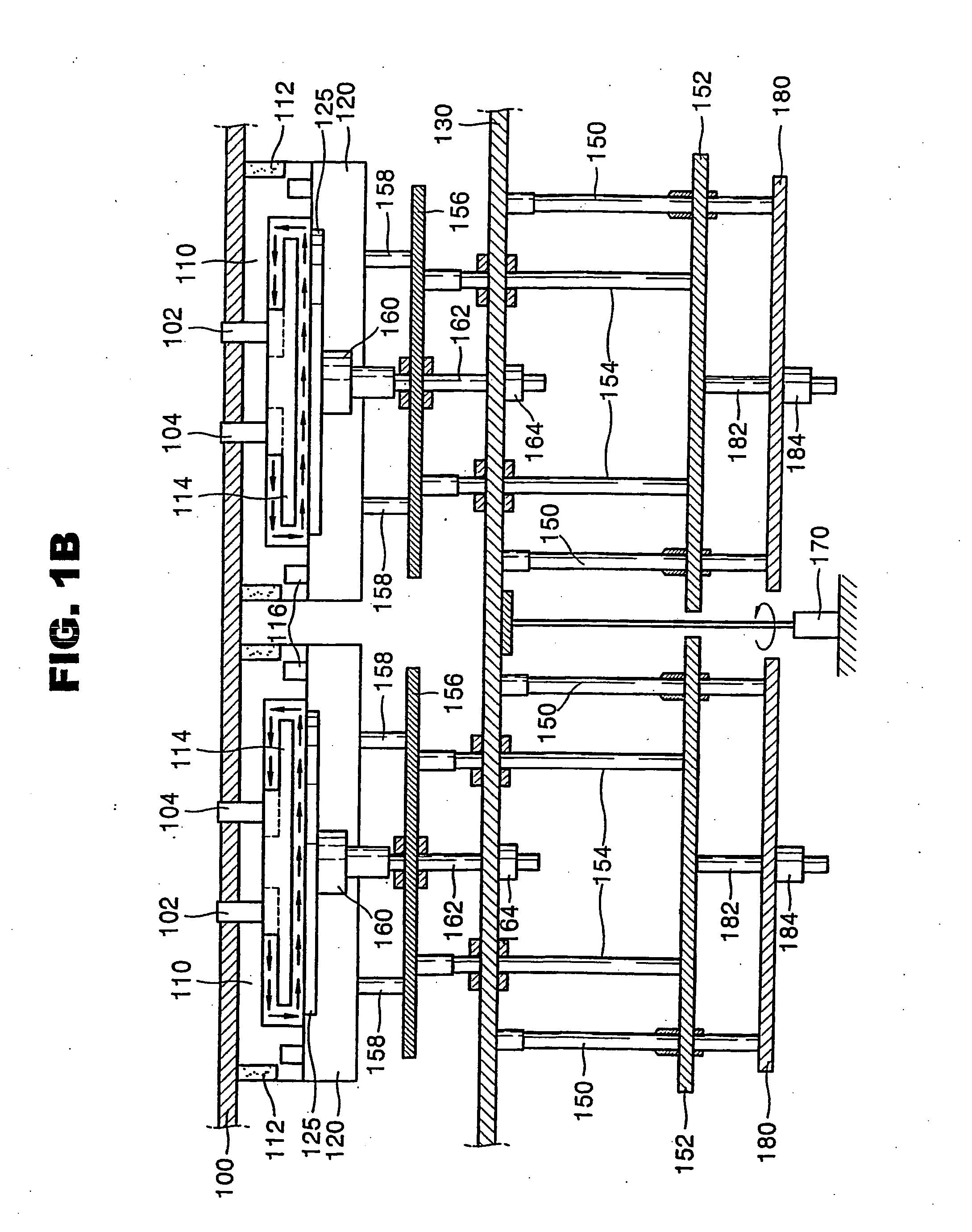

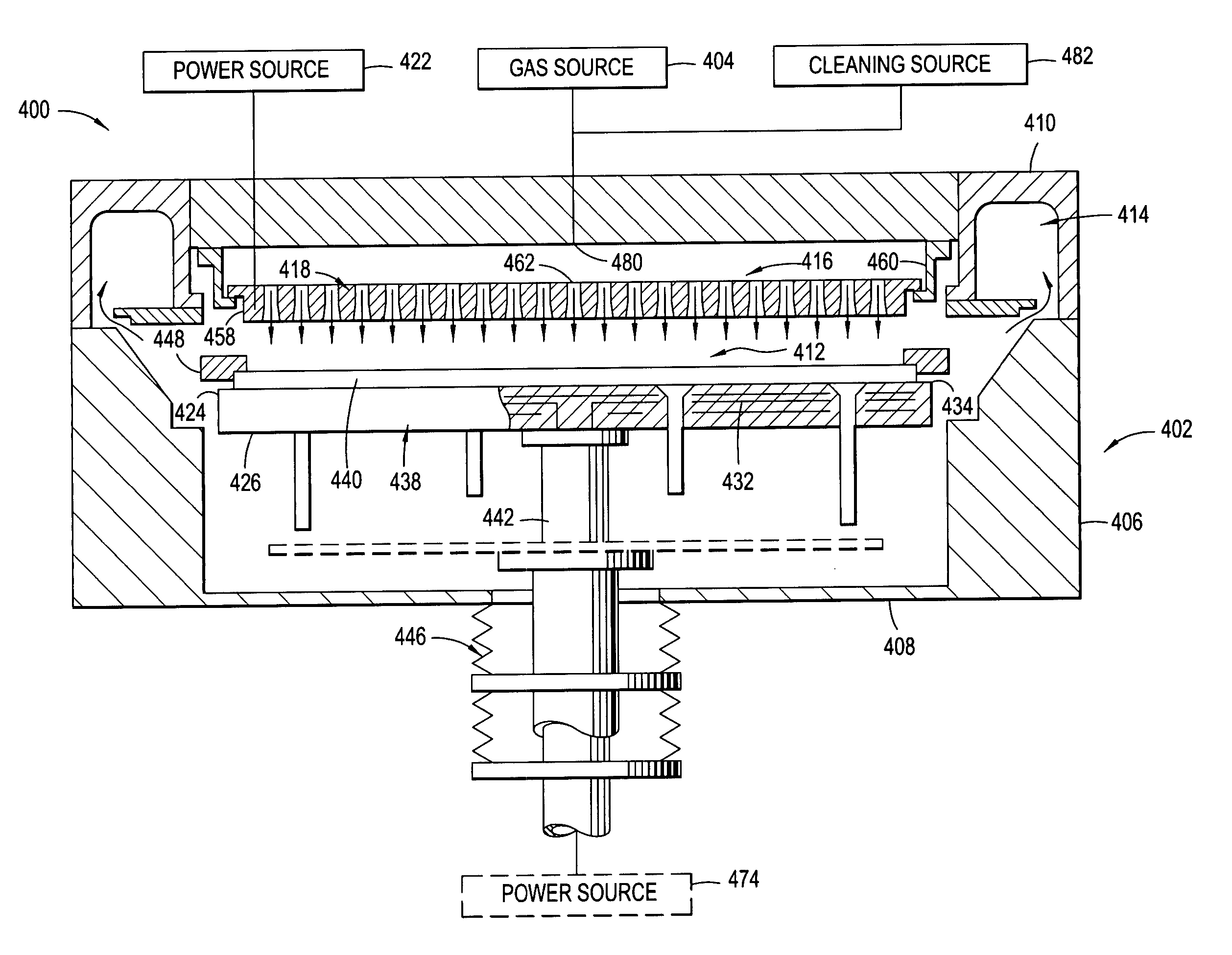

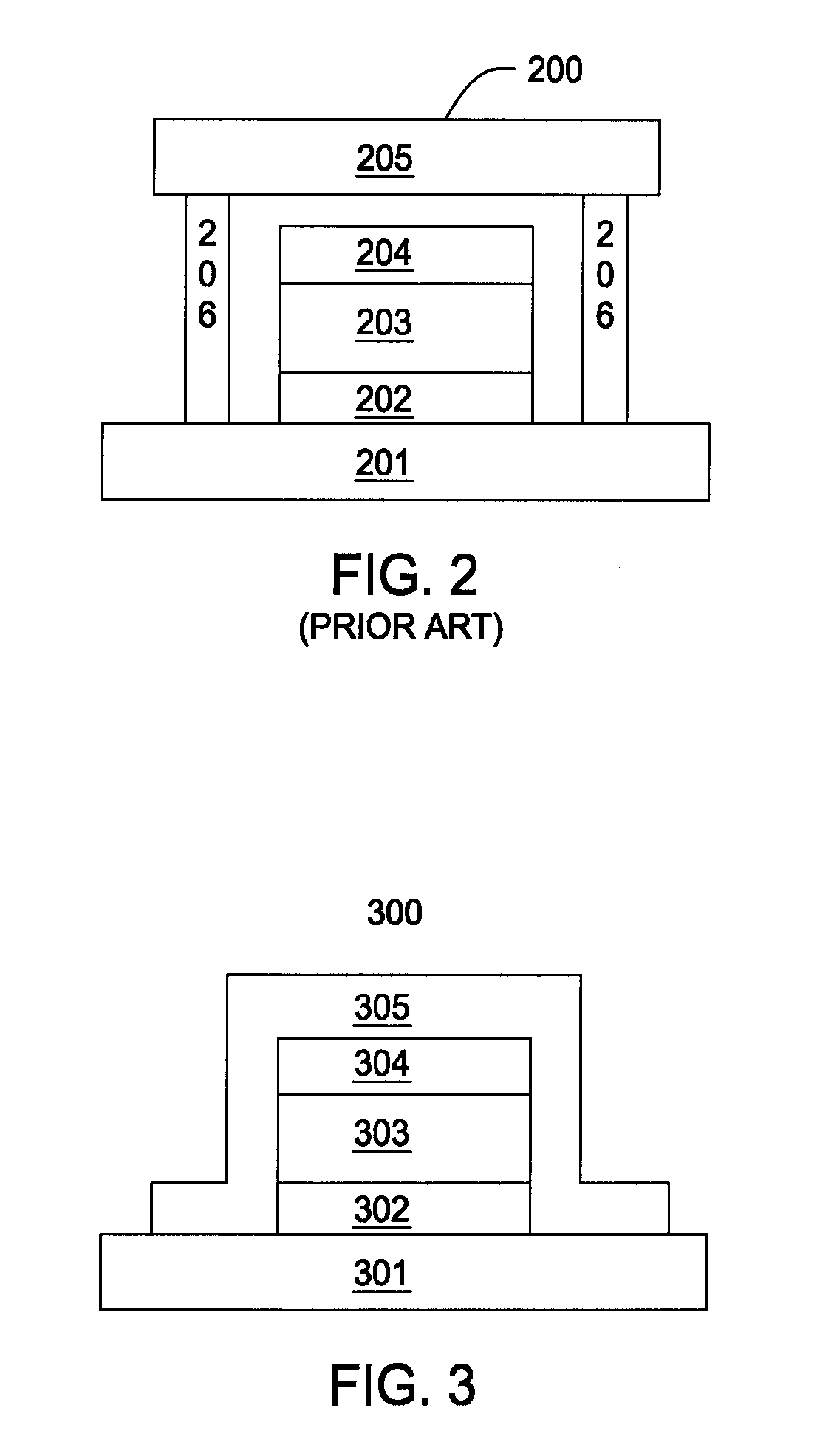

A method and apparatus for depositing a material layer onto a substrate is described. The method includes delivering a mixture of precursors for the material layer into a process chamber and depositing the material layer on the substrate at low temperature. The material layer can be used as an encapsulating layer for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. In one aspect, the encapsulating layer includes one or more material layers (multilayer) having one or more barrier layer materials and one or more low-dielectric constant materials. The encapsulating layer thus deposited provides reduced surface roughness, improved water-barrier performance, reduce thermal stress, good step coverage, and can be applied to many substrate types and many substrate sizes. Accordingly, the encapsulating layer thus deposited provides good device lifetime for various display devices, such as OLED devices. In another aspect, a method of depositing an amorphous carbon material on a substrate at low temperature is provided. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

Water-barrier performance of an encapsulating film

ActiveUS7183197B2Improve waterproof performanceGood film uniformityTransistorSemiconductor/solid-state device manufacturingLow temperature depositionSubstrate type

A method and apparatus for depositing a material layer onto a substrate is described. The method includes delivering a mixture of precursors for the material layer into a process chamber and depositing the material layer on the substrate at low temperature. The material layer can be used as an encapsulating layer for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. In one aspect, the encapsulating layer includes one or more material layers (multilayer) having one or more barrier layer materials and one or more low-dielectric constant materials. The encapsulating layer thus deposited provides reduced surface roughness, improved water-barrier performance, reduce thermal stress, good step coverage, and can be applied to many substrate types and many substrate sizes. Accordingly, the encapsulating layer thus deposited provides good device lifetime for various display devices, such as OLED devices. In another aspect, a method of depositing an amorphous carbon material on a substrate at low temperature is provided. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

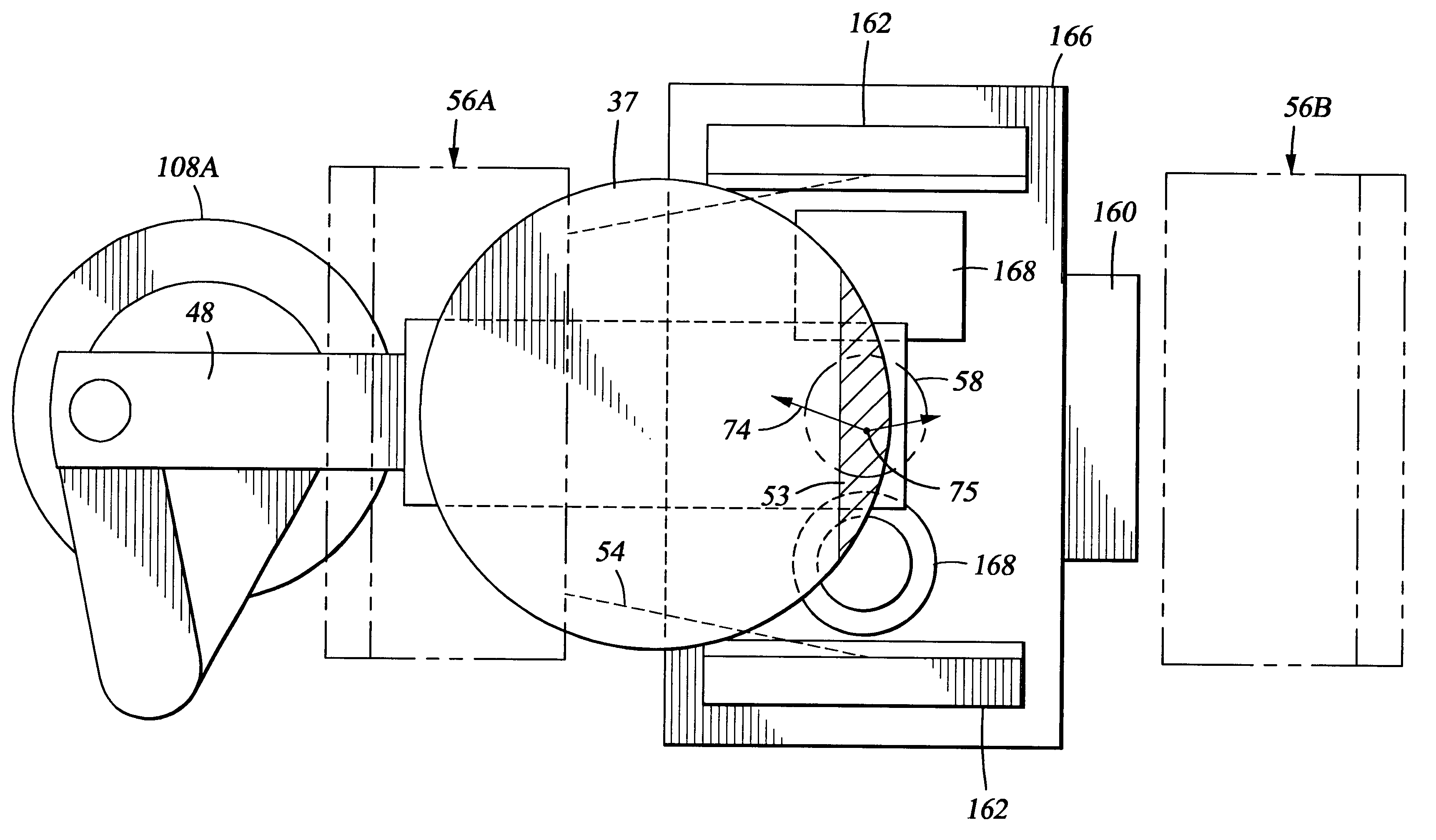

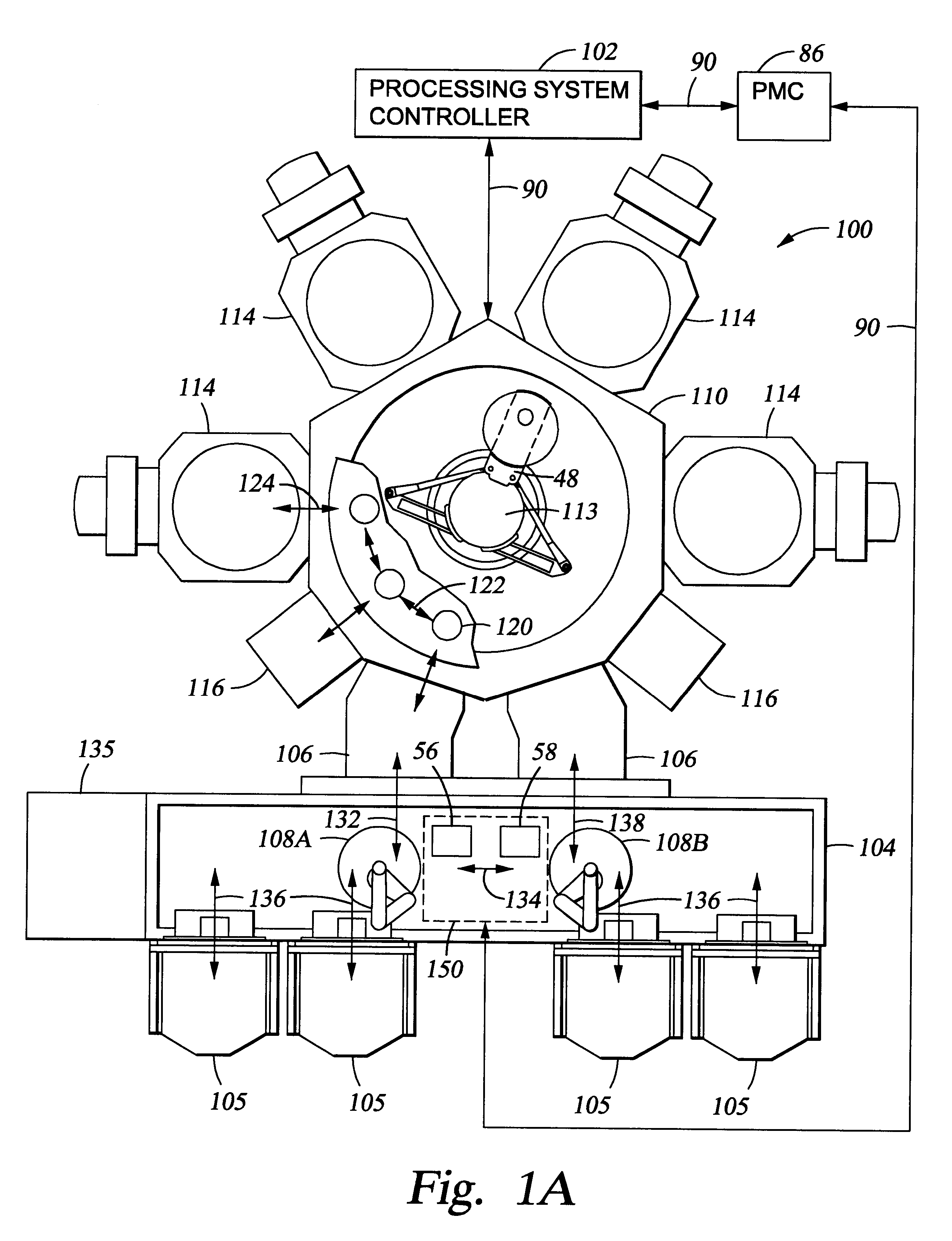

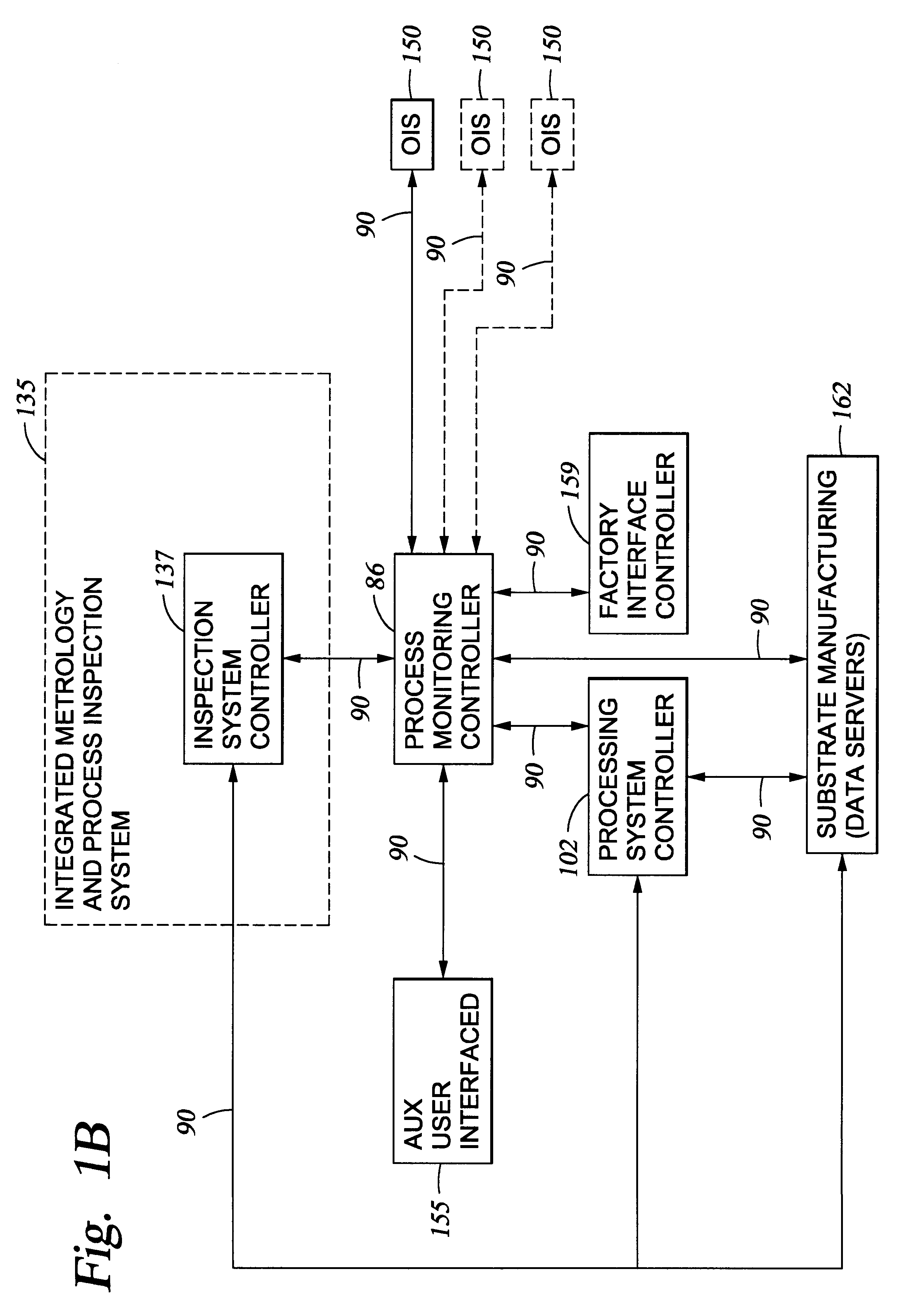

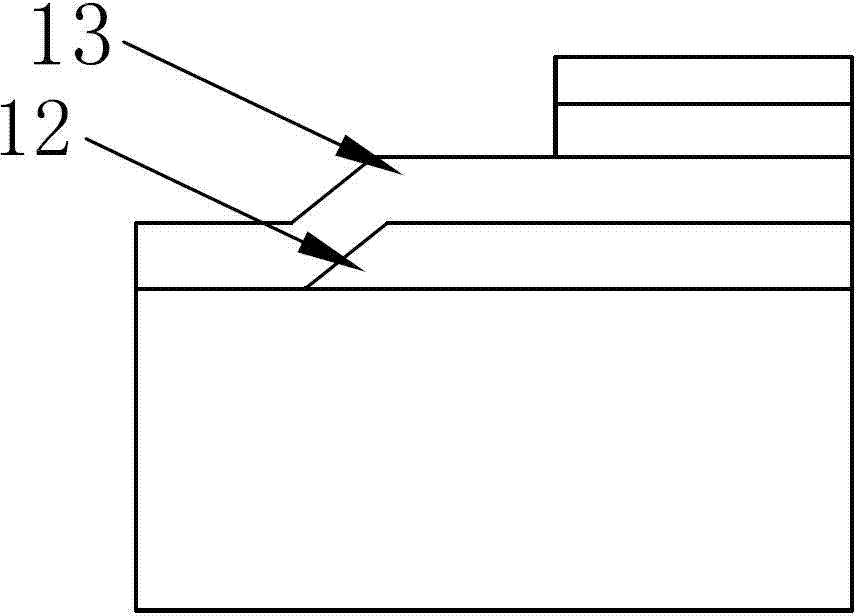

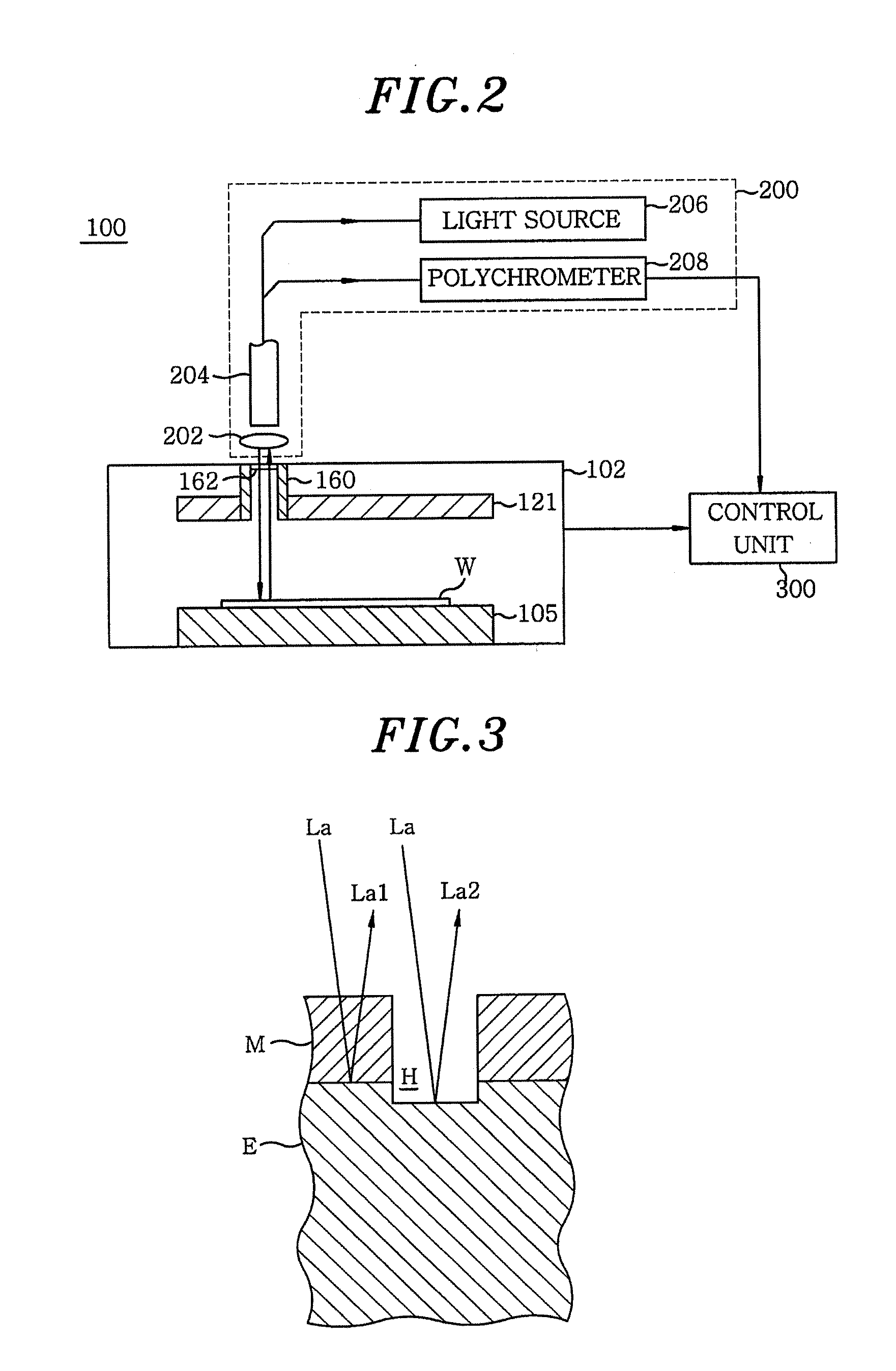

Method and apparatus for substrate surface inspection using spectral profiling techniques

InactiveUS6693708B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSubstrate typeCombined use

The present invention generally provides an apparatus and a method for inspecting a substrate in a processing system. In one aspect, a light source is used in conjunction with an optical receiving device, such as a spectrometer, to illuminate and inspect a substrate for various optical signatures. In one embodiment, spectral data collected from a given substrate is used to generate a spectral signature. The spectral signature represents the intensity distribution of the color sonstituents of a substrate surface. This color signature may then be compared to a reference color signature to determine characteristics such as the substrate type, thickness, conformity, substrate surface uniformity, and residual materials in processing.

Owner:APPLIED MATERIALS INC

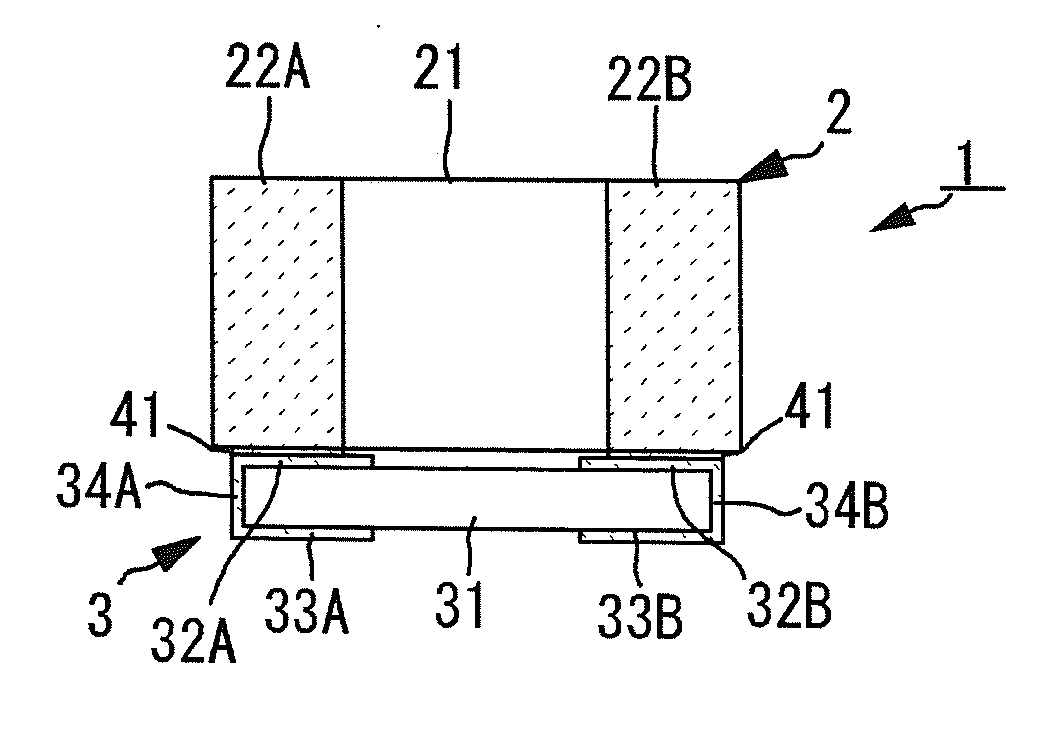

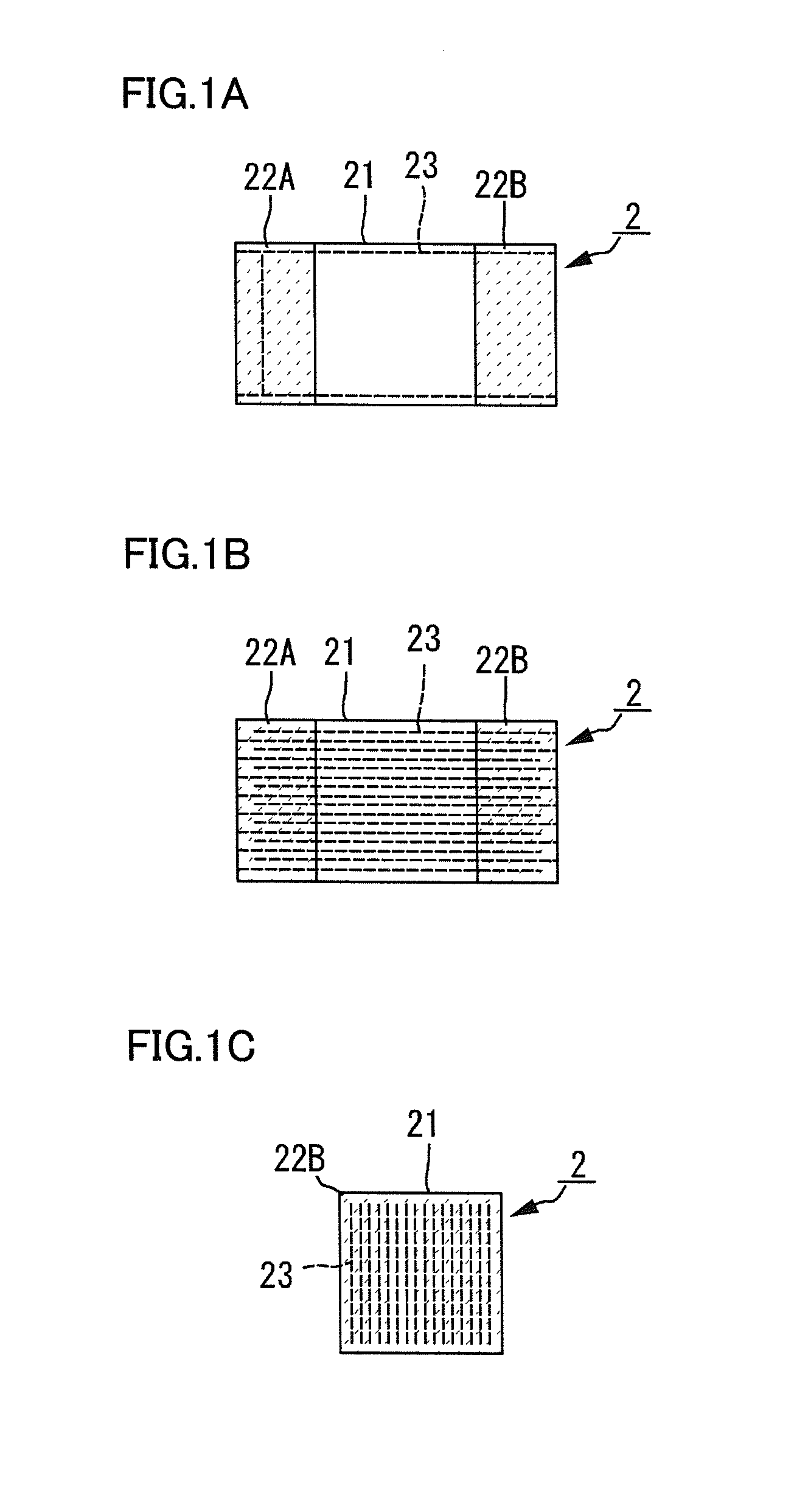

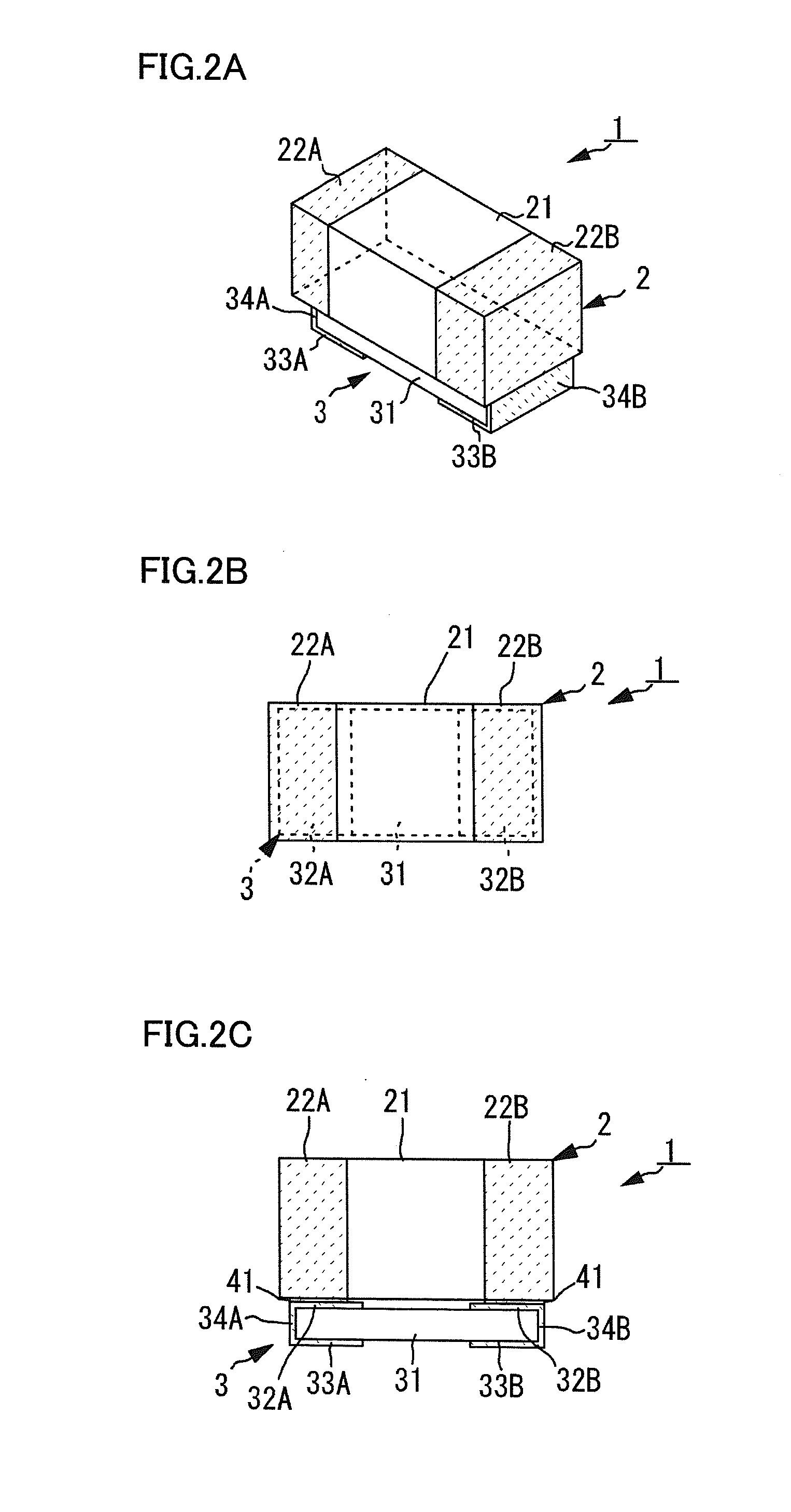

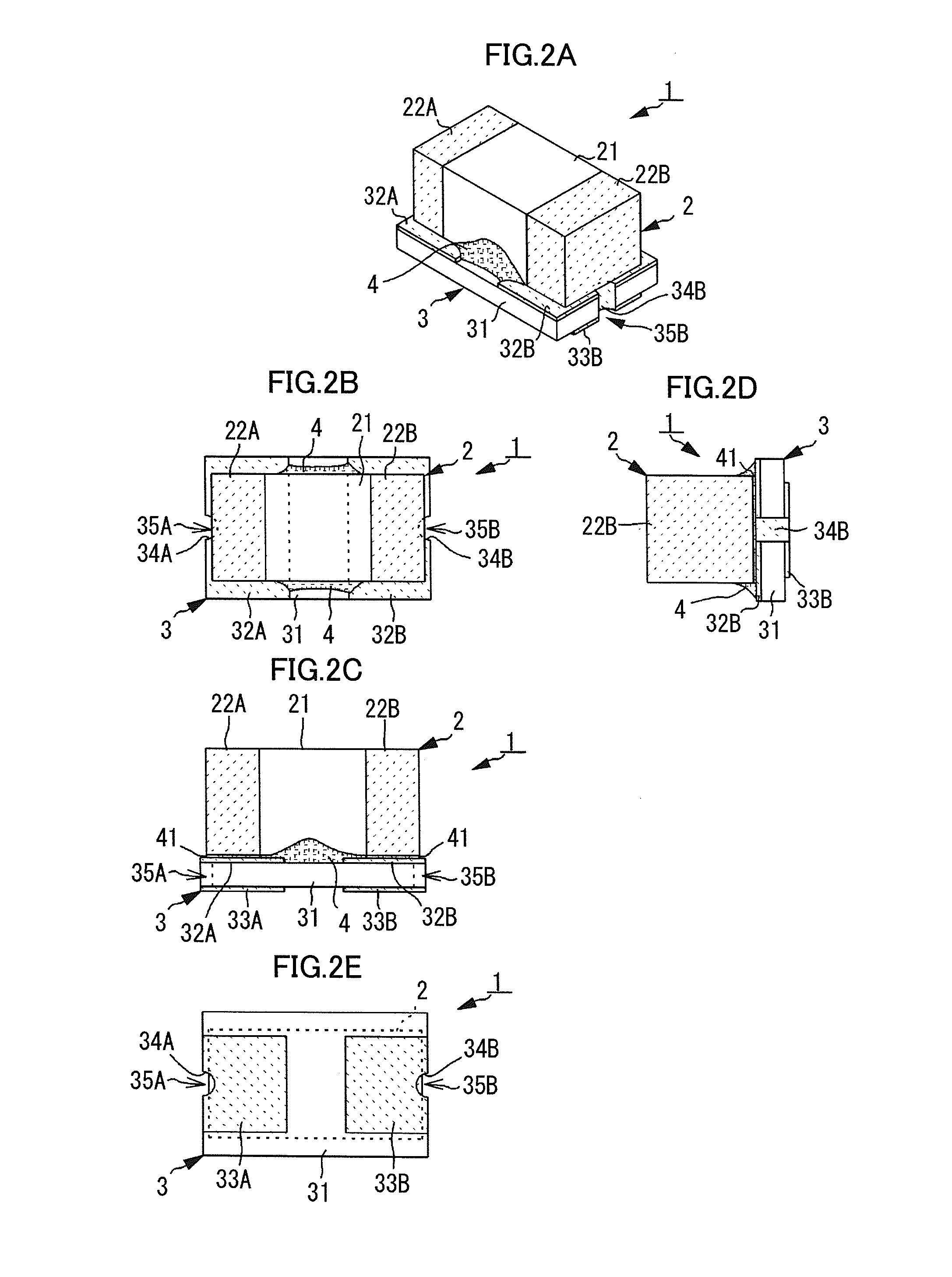

Electronic component and electronic component package

ActiveUS20140284089A1Avoid it happening againLower installation heightFinal product manufactureCross-talk/noise/interference reductionSubstrate typeEngineering

An electronic component includes a laminated capacitor and a substrate-type terminal including a substrate main body, first and second component connection electrodes, first and second external connection electrodes, and first and second connection electrodes. The substrate main body is made of a material and has a thickness that significantly reduces or prevents vibration being transmitted to a circuit substrate on which it is mounted.

Owner:MURATA MFG CO LTD

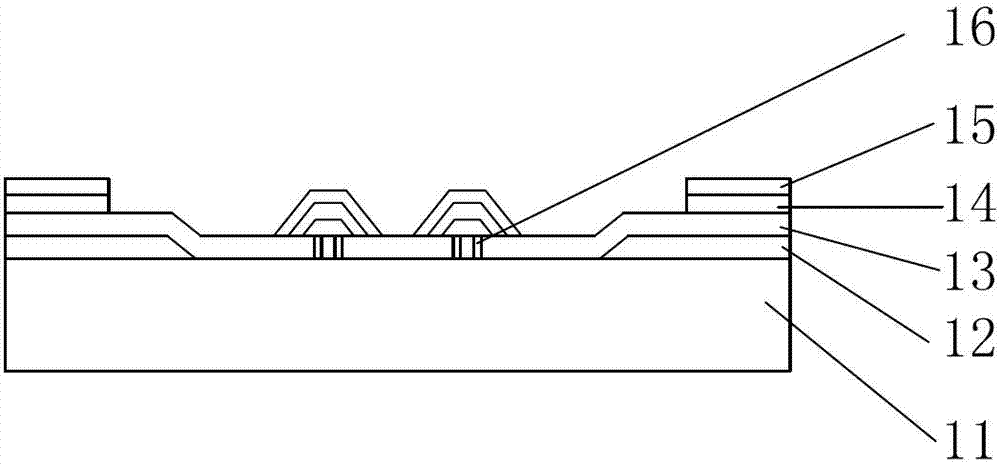

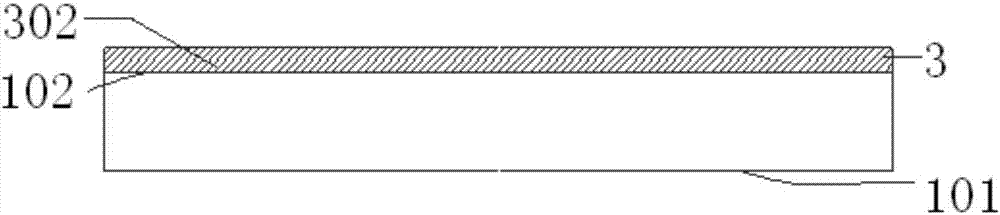

Single substrate type capacitive touch screen and manufacture method thereof

InactiveCN103034387AAvoid easy disconnectionSolve the problem that it must be made into a gentle slopeInput/output processes for data processingSubstrate typeConductive materials

The invention belongs to the field of touch technology and particularly relates to a single substrate type capacitive touch screen and a manufacture method of the single substrate type capacitive touch screen. The single substrate type capacitive touch screen comprises a transparent substrate, a transparent conductive electrode, insulation ink, a conductive metal electrode, a conductive material and an insulation material, wherein the transparent conductive electrode is arranged on one side of the transparent substrate, the insulation ink is arranged above the two ends of the transparent conductive electrode, the conductive metal electrode is arranged above the insulation ink, the insulation material is arranged above the conductive metal electrode, an open hole is formed in the insulation ink layer, the conductive material is filled in the open hole, the conductive metal electrode and the transparent conductive electrode are connected through the conductive material specially used in the invention, so that the problem that a transparent conductive electrode at the junction of the insulation ink and a touch effective area of an existing single substrate capacitive touch screen is effectively solved, and the problem that the insulation ink at the junction does not need to be made into a gradual slope shape is also solved.

Owner:深圳市中显微电子有限公司

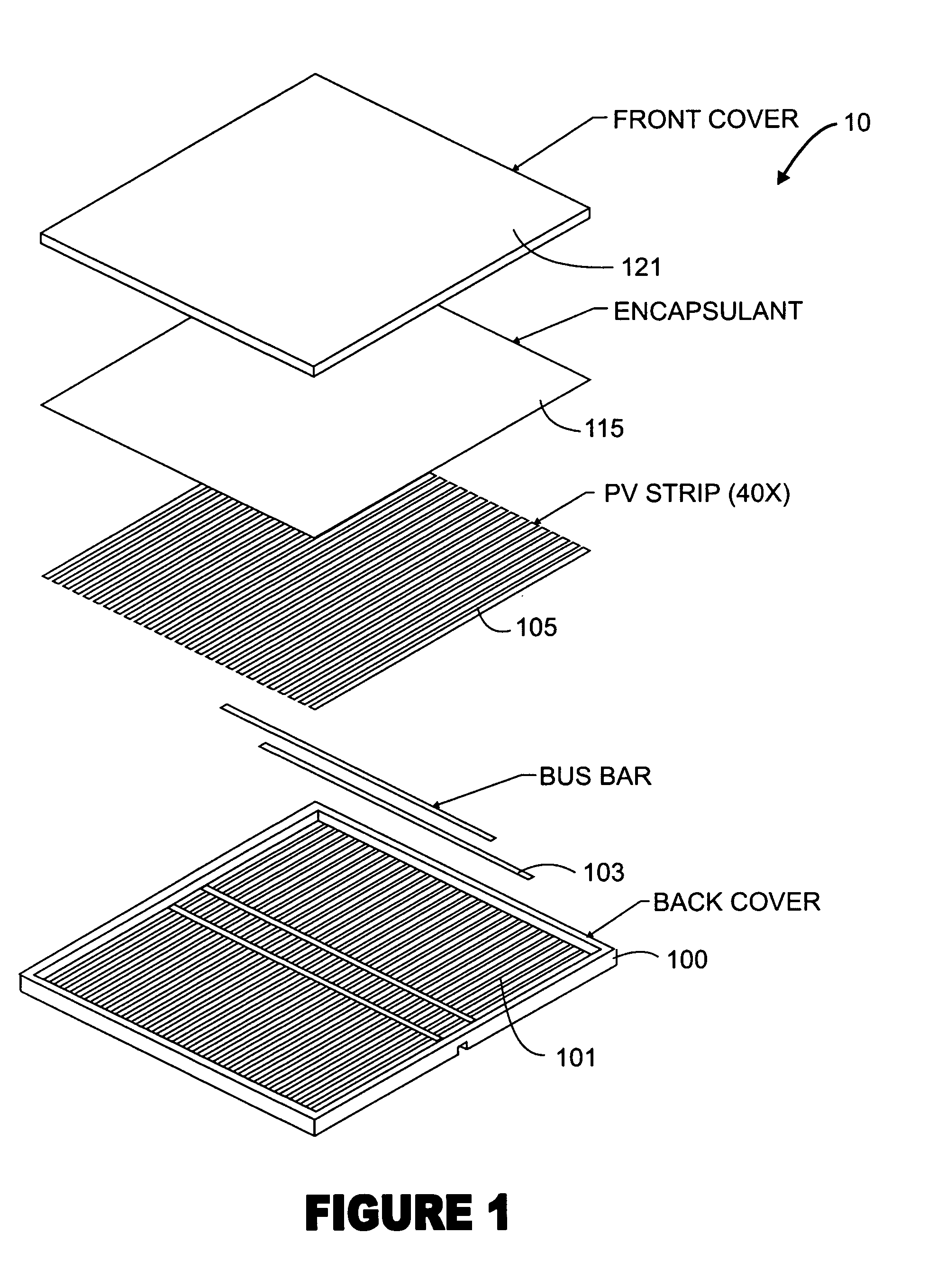

Fabrication process for photovoltaic cell

A photovoltaic strip is physically separated from a semiconductor wafer utilizing physical sawing or other techniques. In accordance with one embodiment, a type of semiconductor wafer is first determined by interrogating the wafer to identify one or more of its optical, thermal, or electrical characteristics. This information regarding substrate type is then communicated to a separation apparatus, which then accomplishes precise physical separation of the substrate into discrete strips. Electrical performance of the strips may be tested prior to their incorporation into an assembled solar cell, where they are coupled to a concentrating element utilizing an elastomer encapsulant.

Owner:SOLARIA CORP

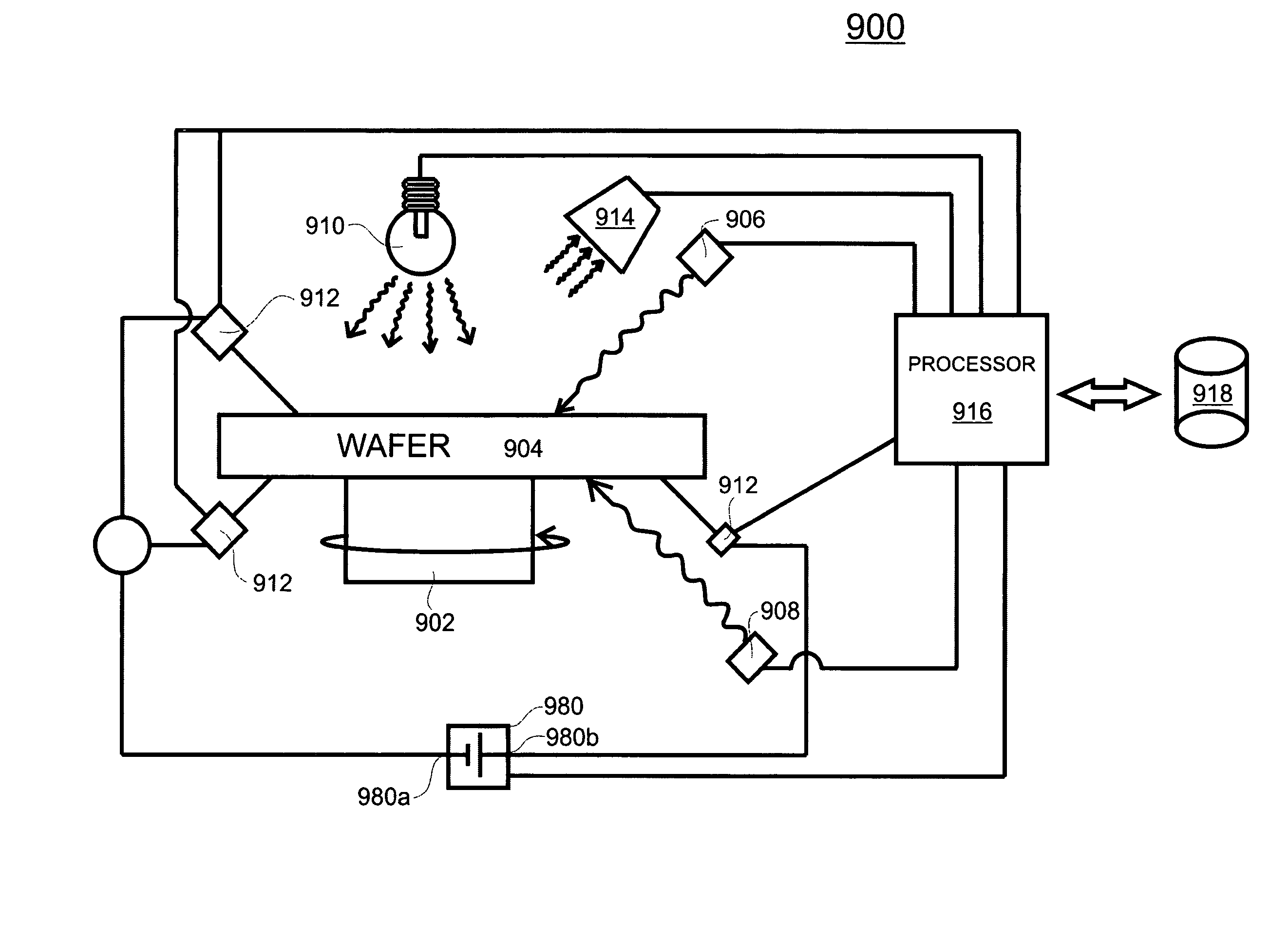

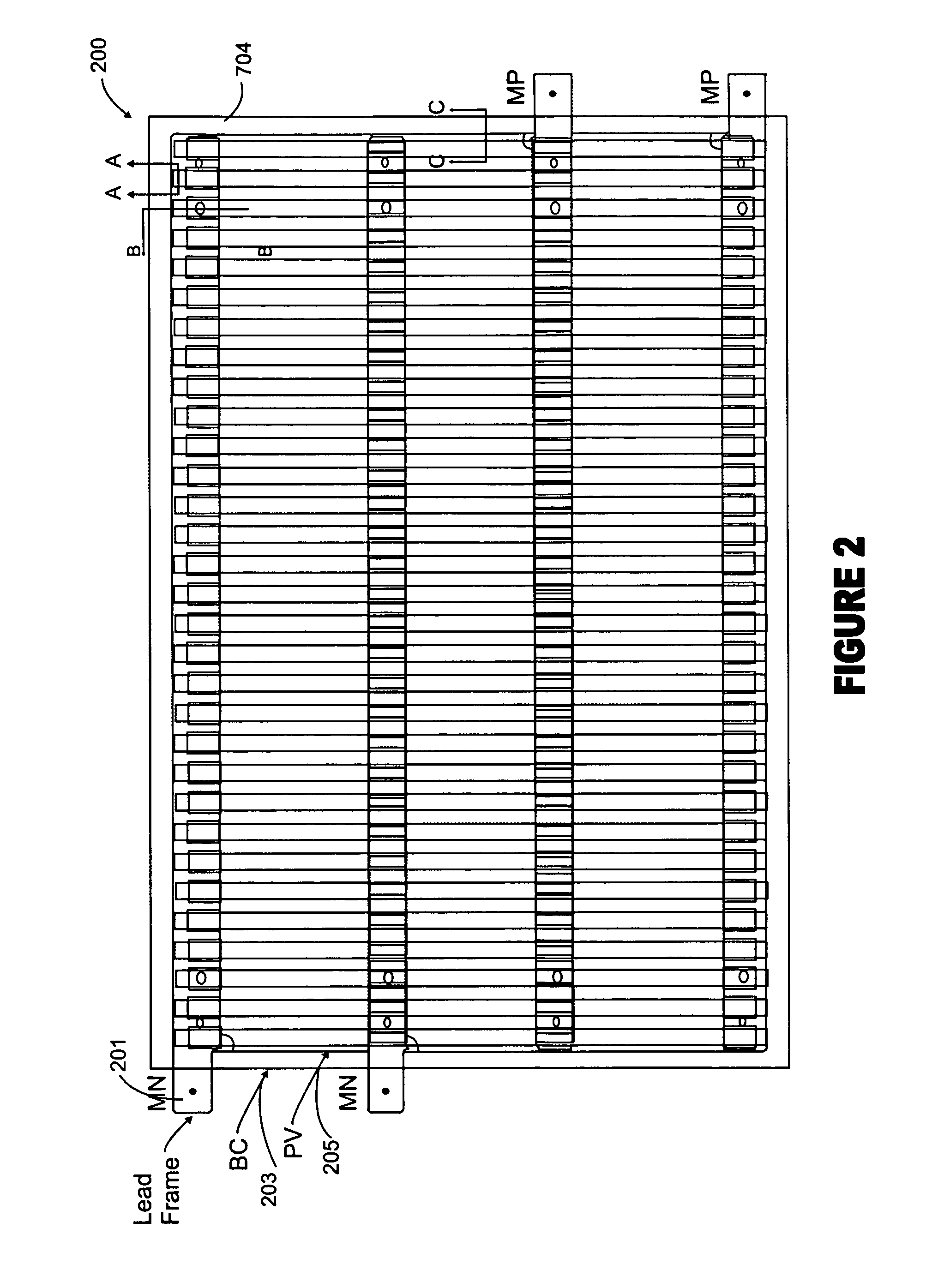

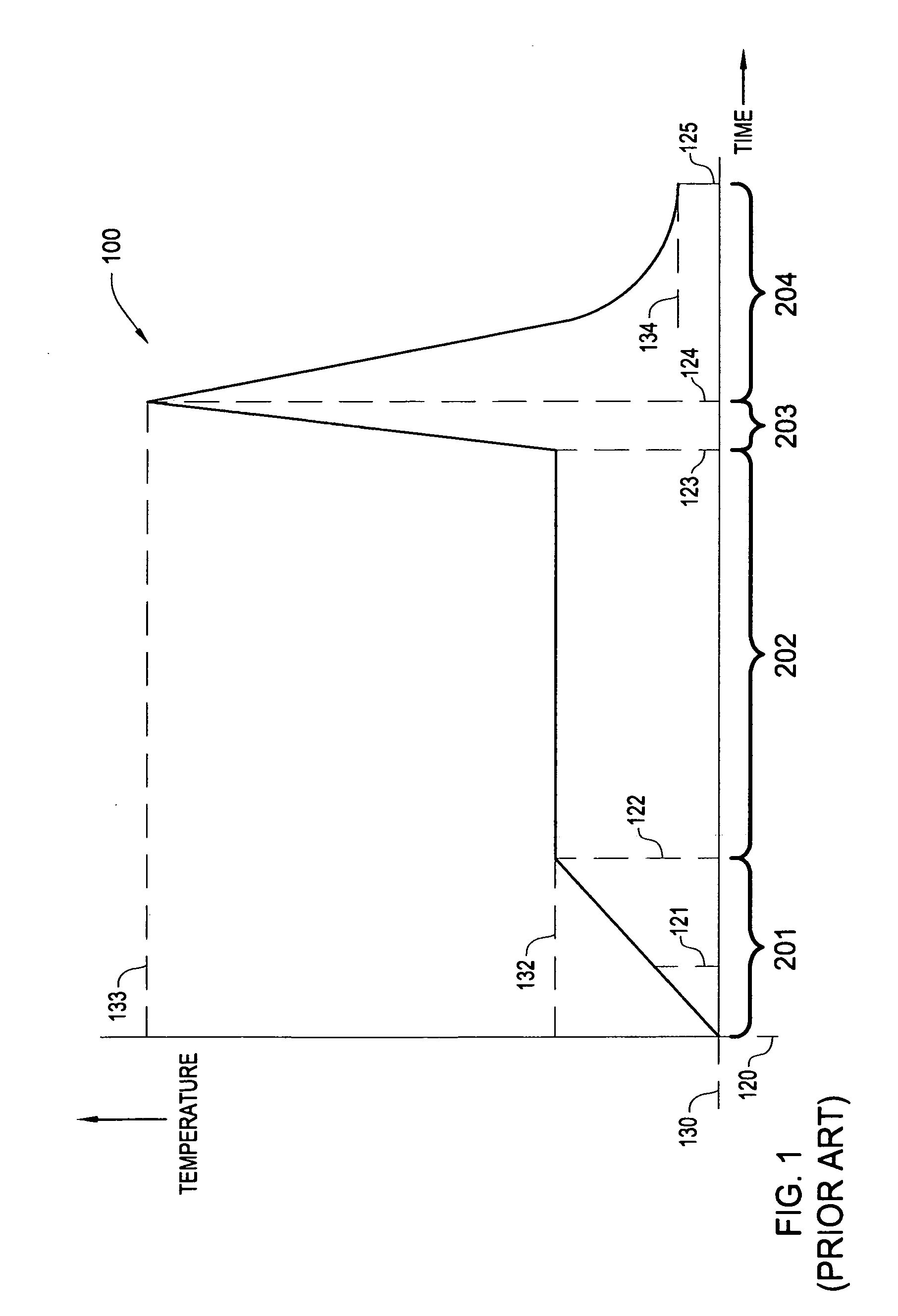

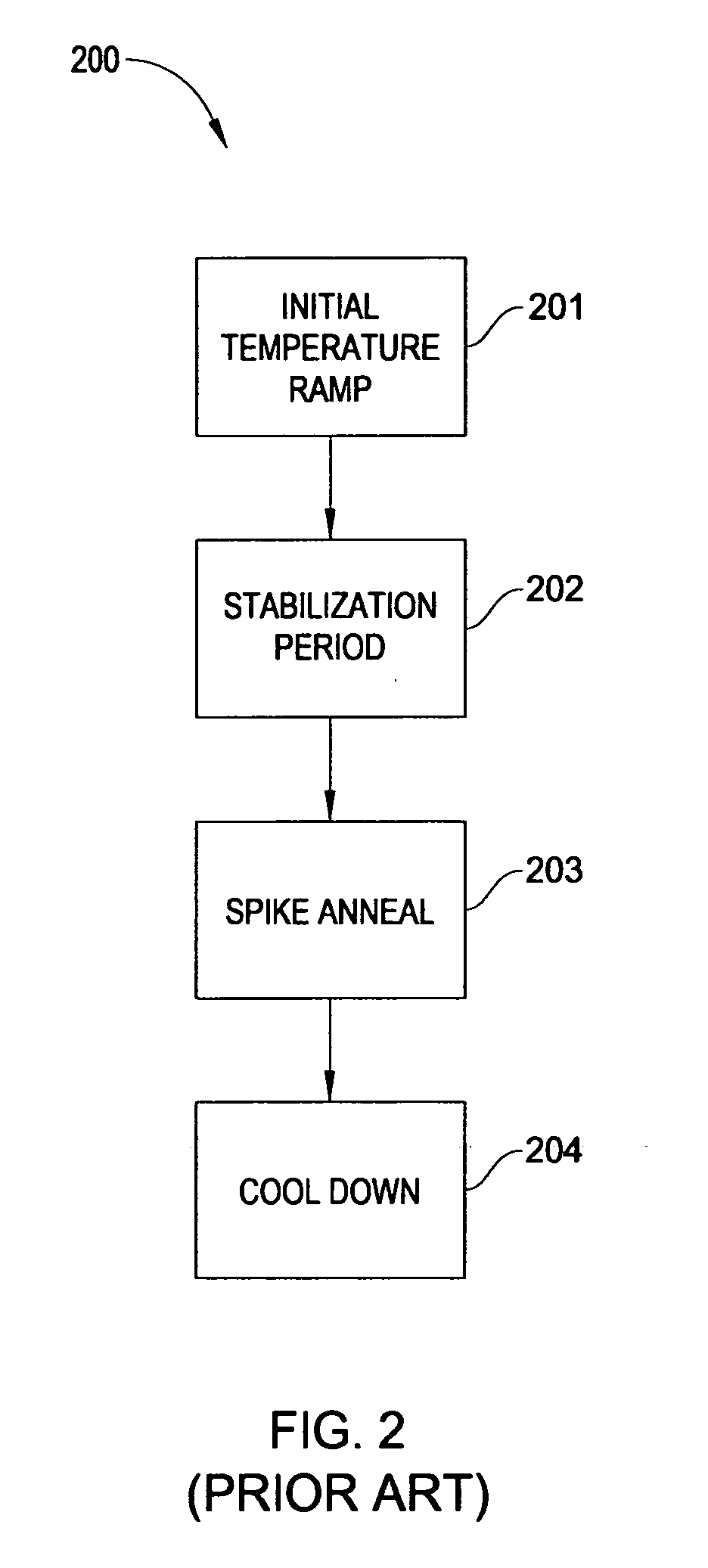

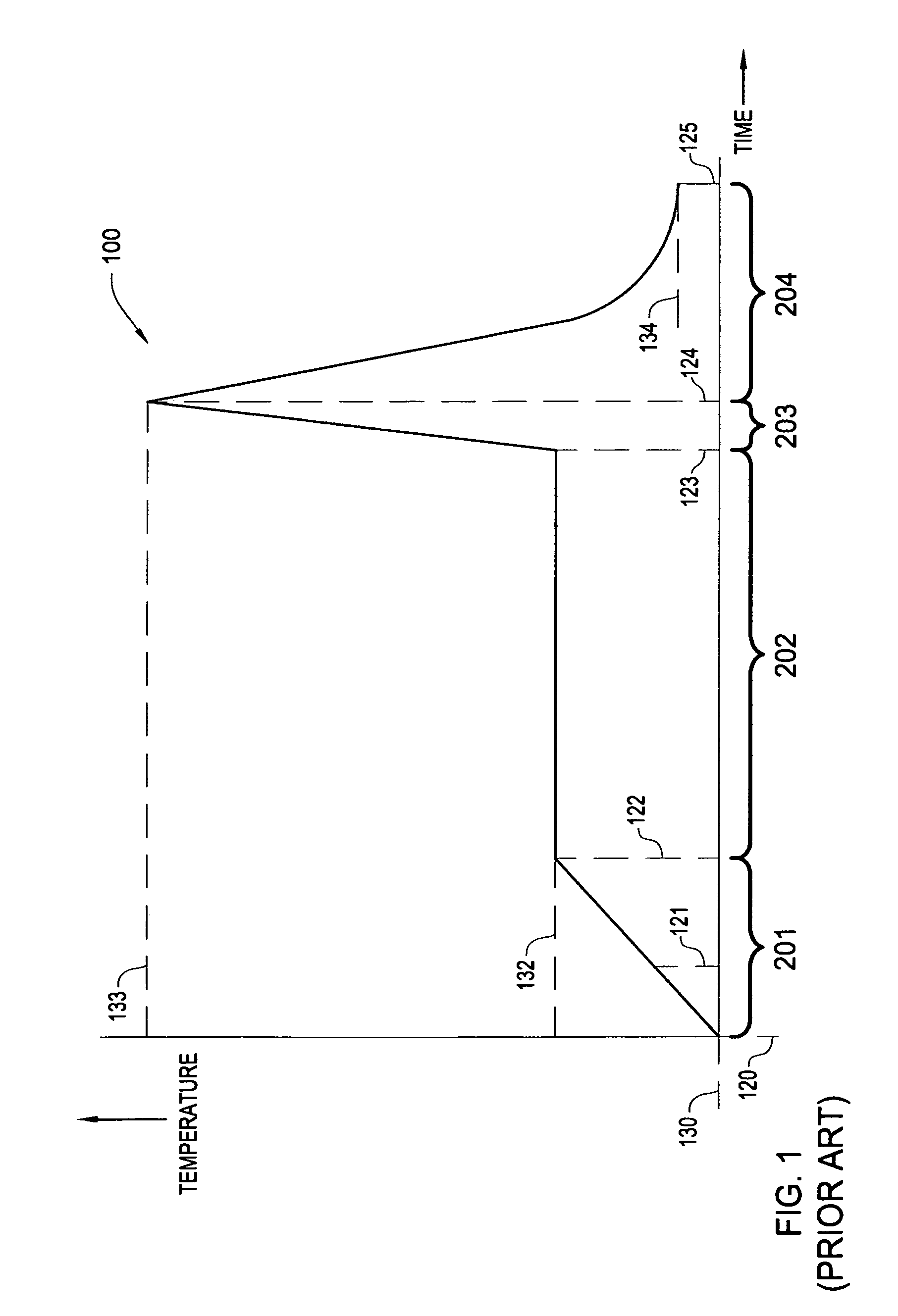

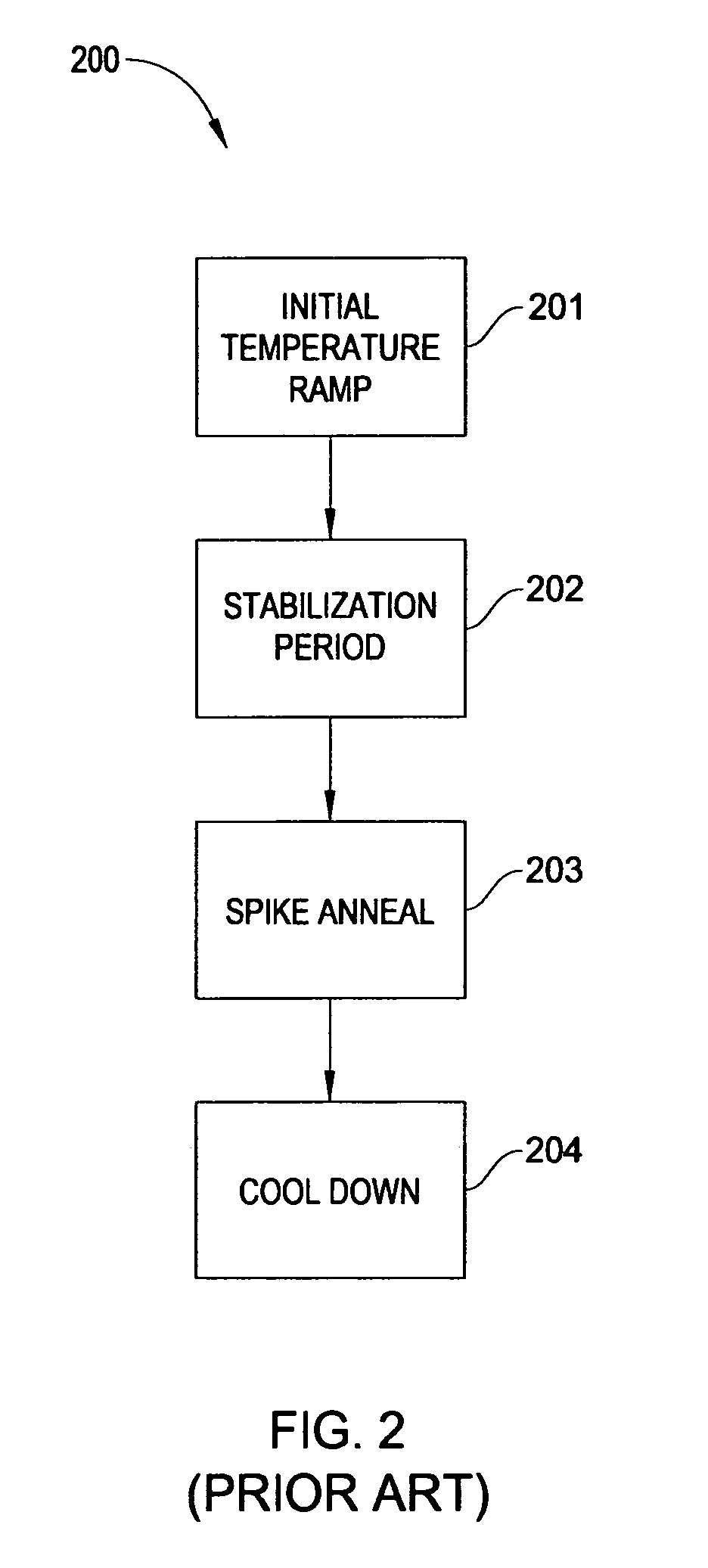

Adaptive control method for rapid thermal processing of a substrate

ActiveUS20070238202A1Rapid heat treatmentRadiation pyrometrySemiconductor/solid-state device testing/measurementSubstrate typeOptical property

The present invention generally relates to methods for the rapid thermal processing (RTP) of a substrate. Embodiments of the invention include controlling a thermal process using either a real-time adaptive control algorithm or by using a control algorithm that is selected from a suite of fixed control algorithms designed for a variety of substrate types. Selection of the control algorithm is based on optical properties of the substrate measured during the thermal process. In one embodiment, a combination of control algorithms are used, wherein the majority of lamp groupings are controlled with a fixed control algorithm and a substantially smaller number of lamp zones are controlled by an adaptive control algorithm.

Owner:APPLIED MATERIALS INC

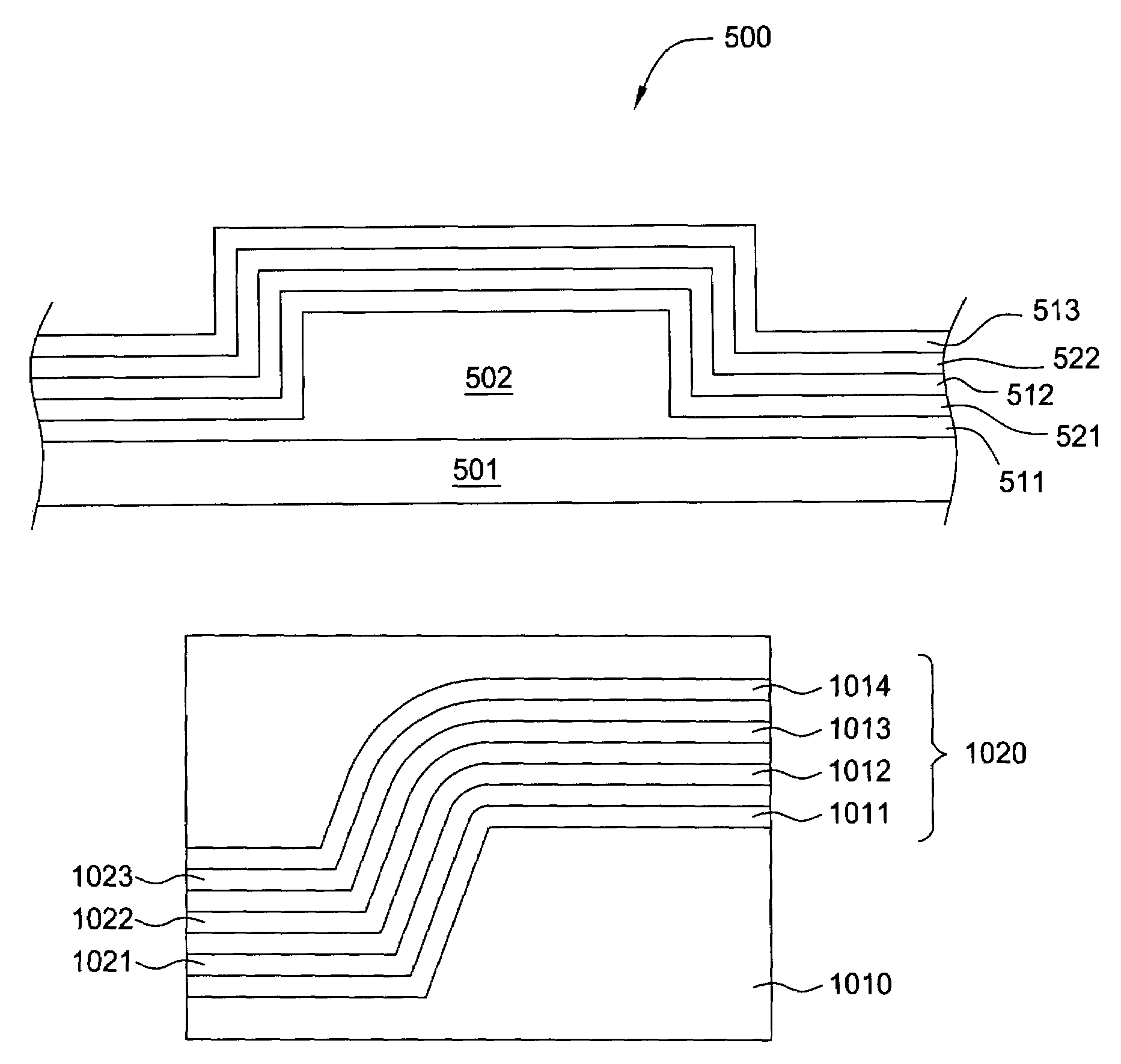

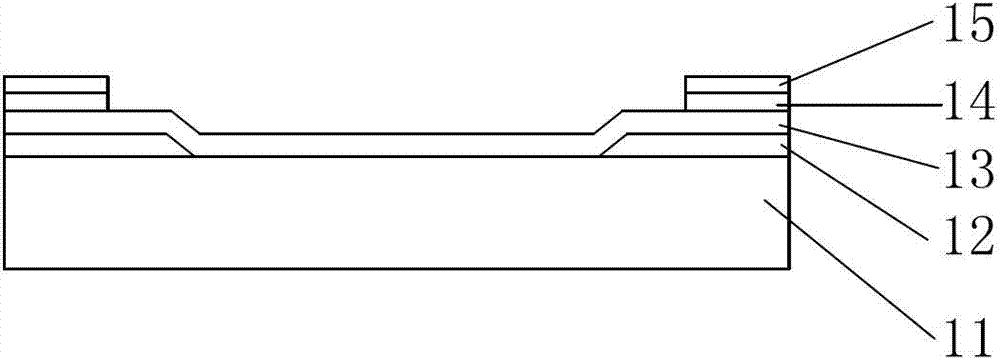

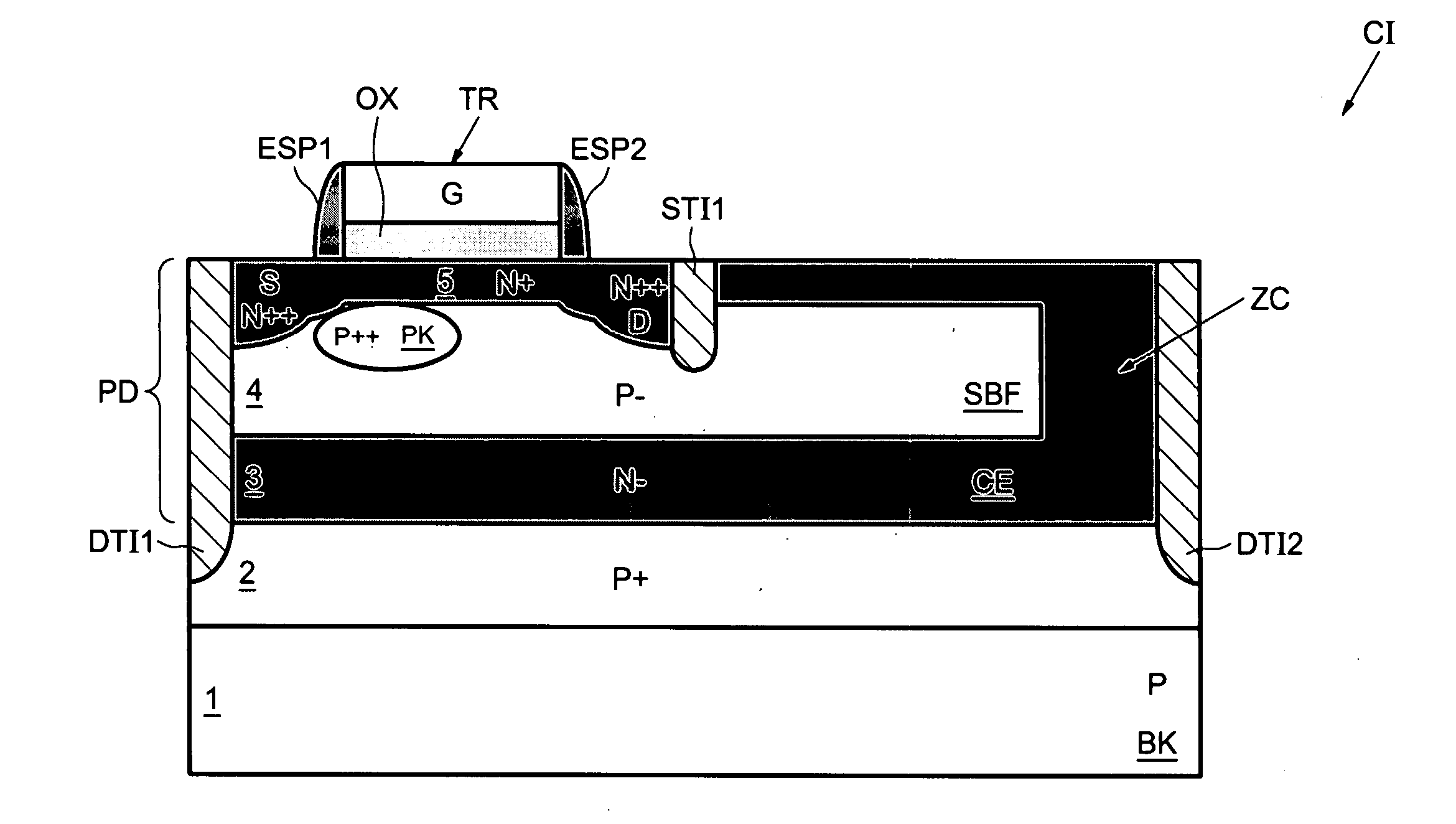

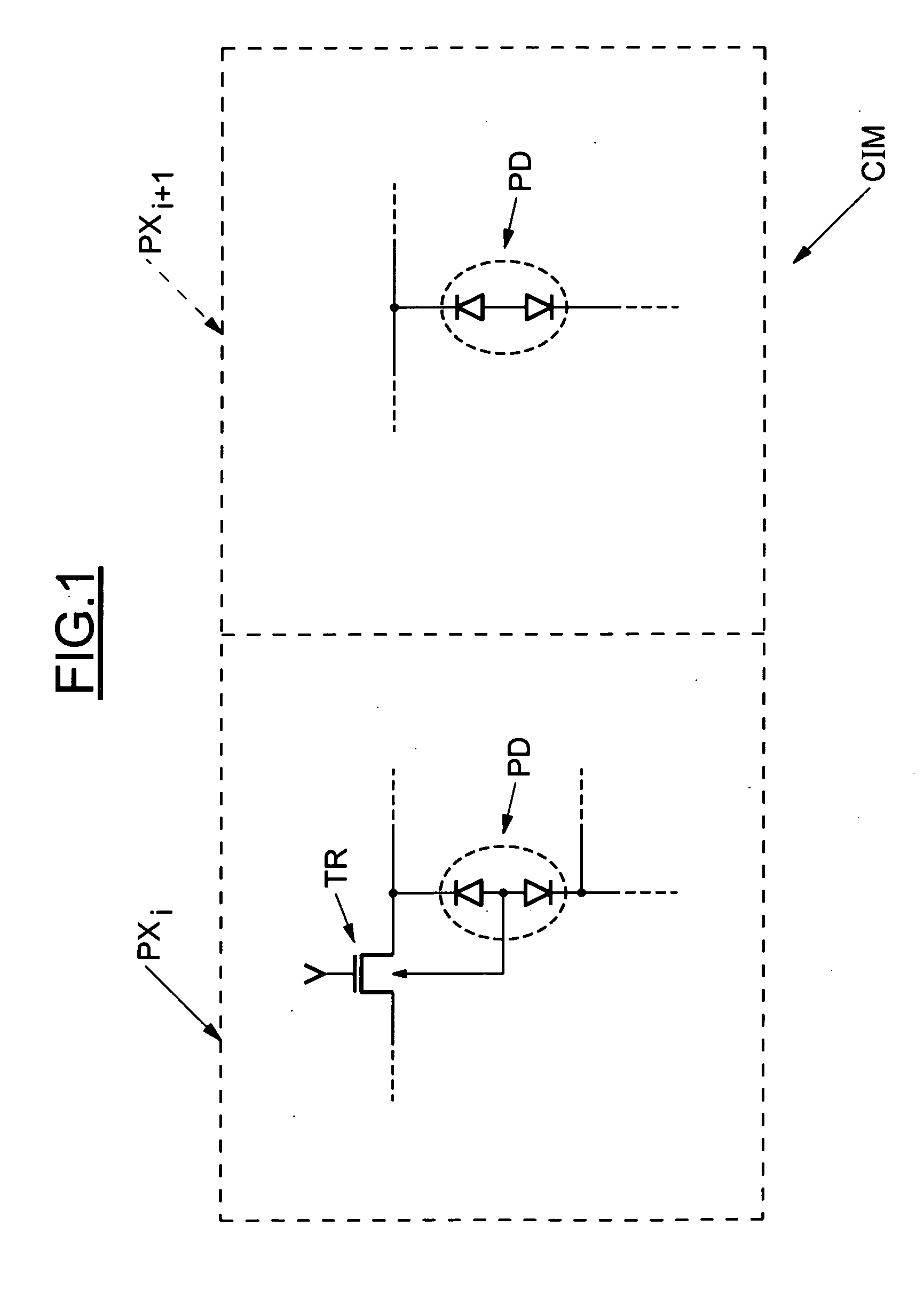

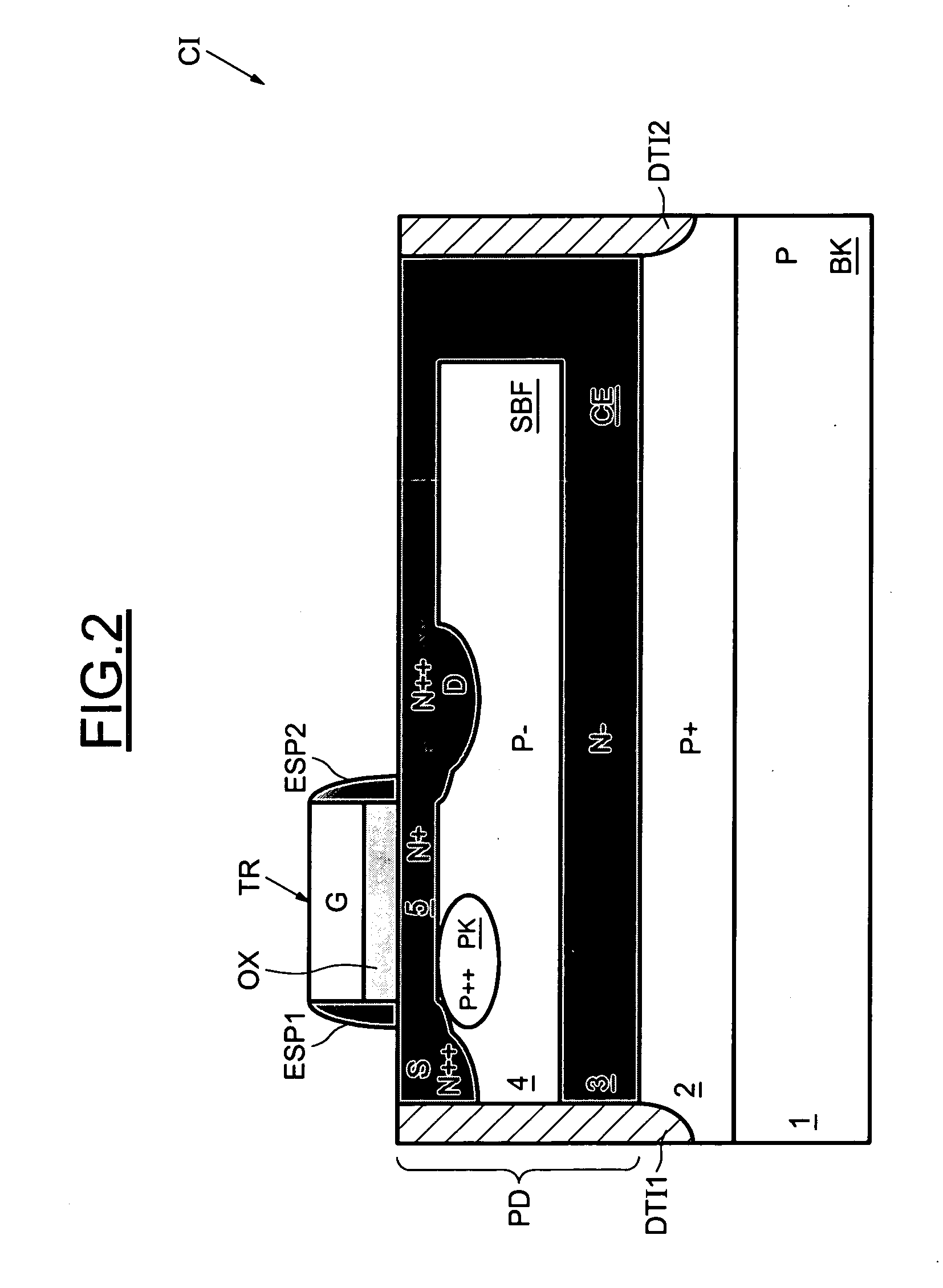

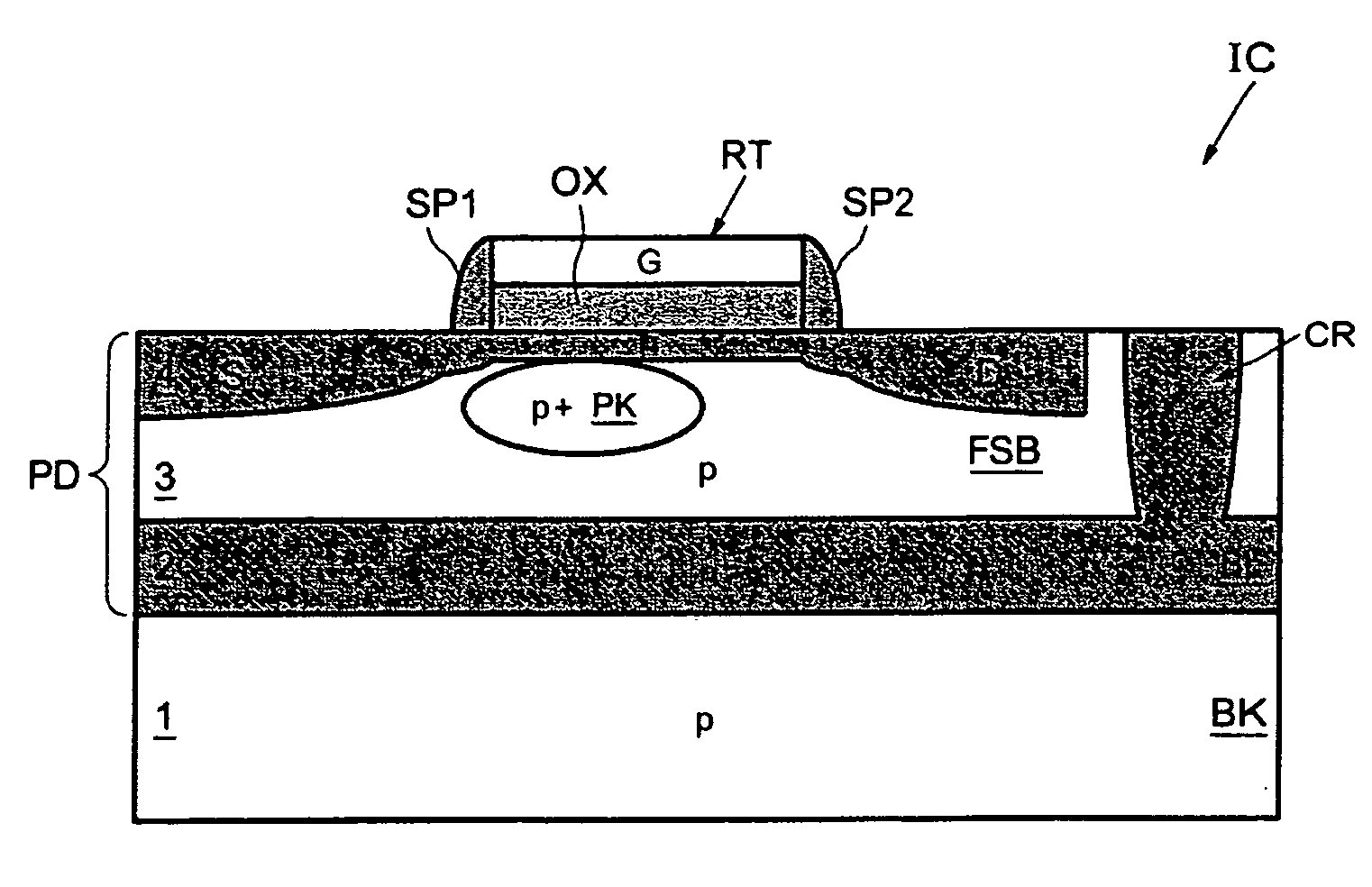

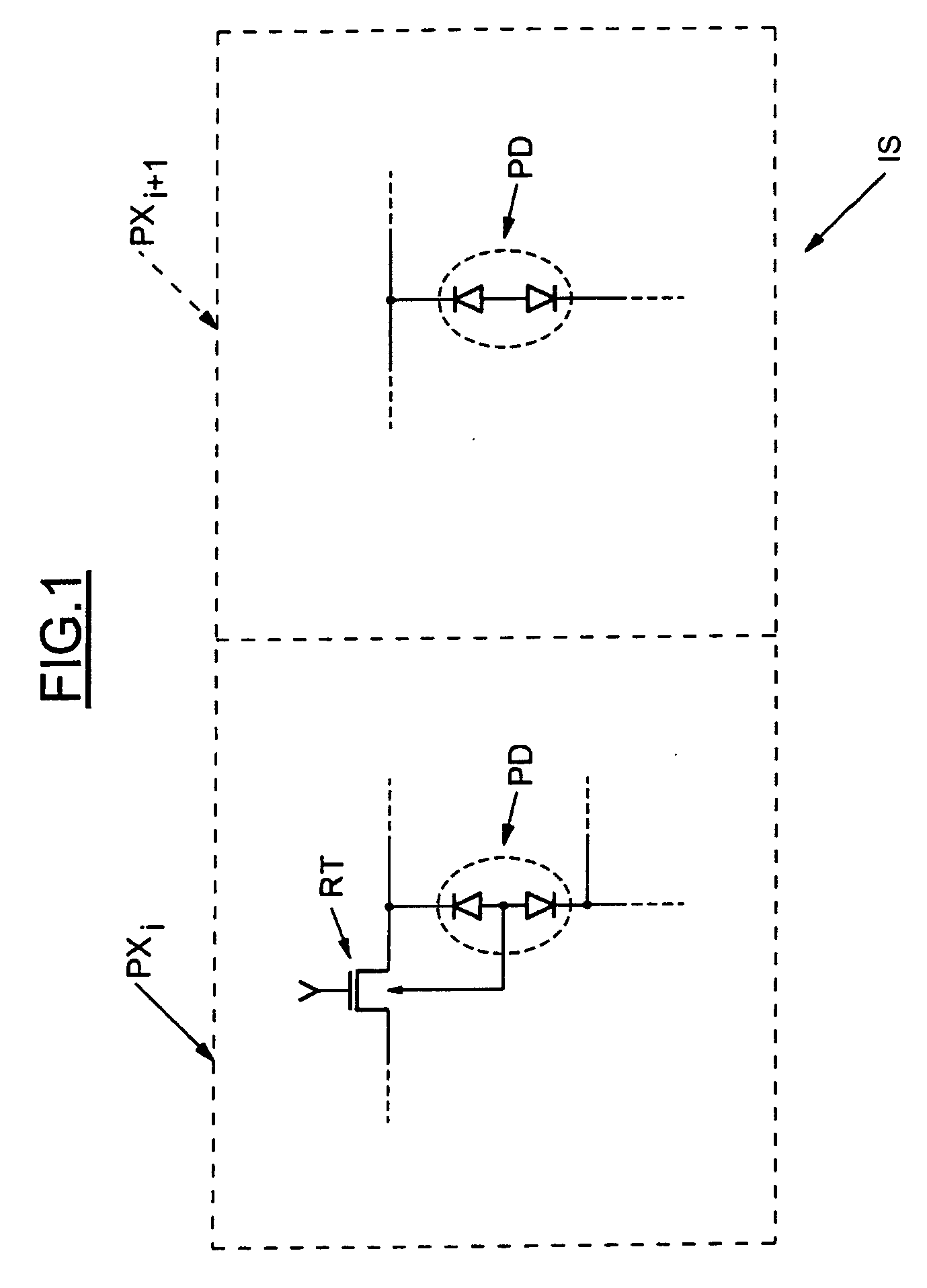

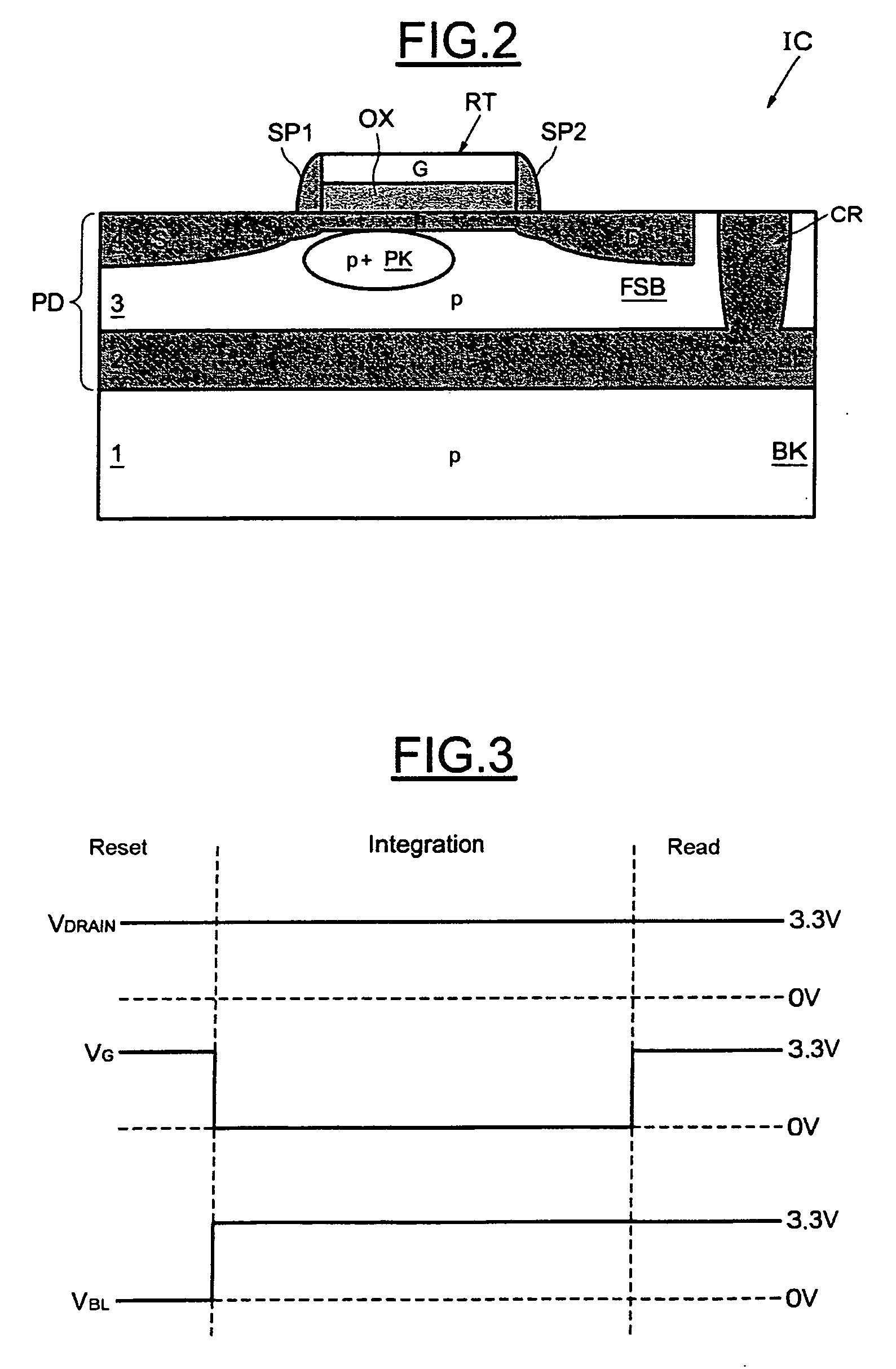

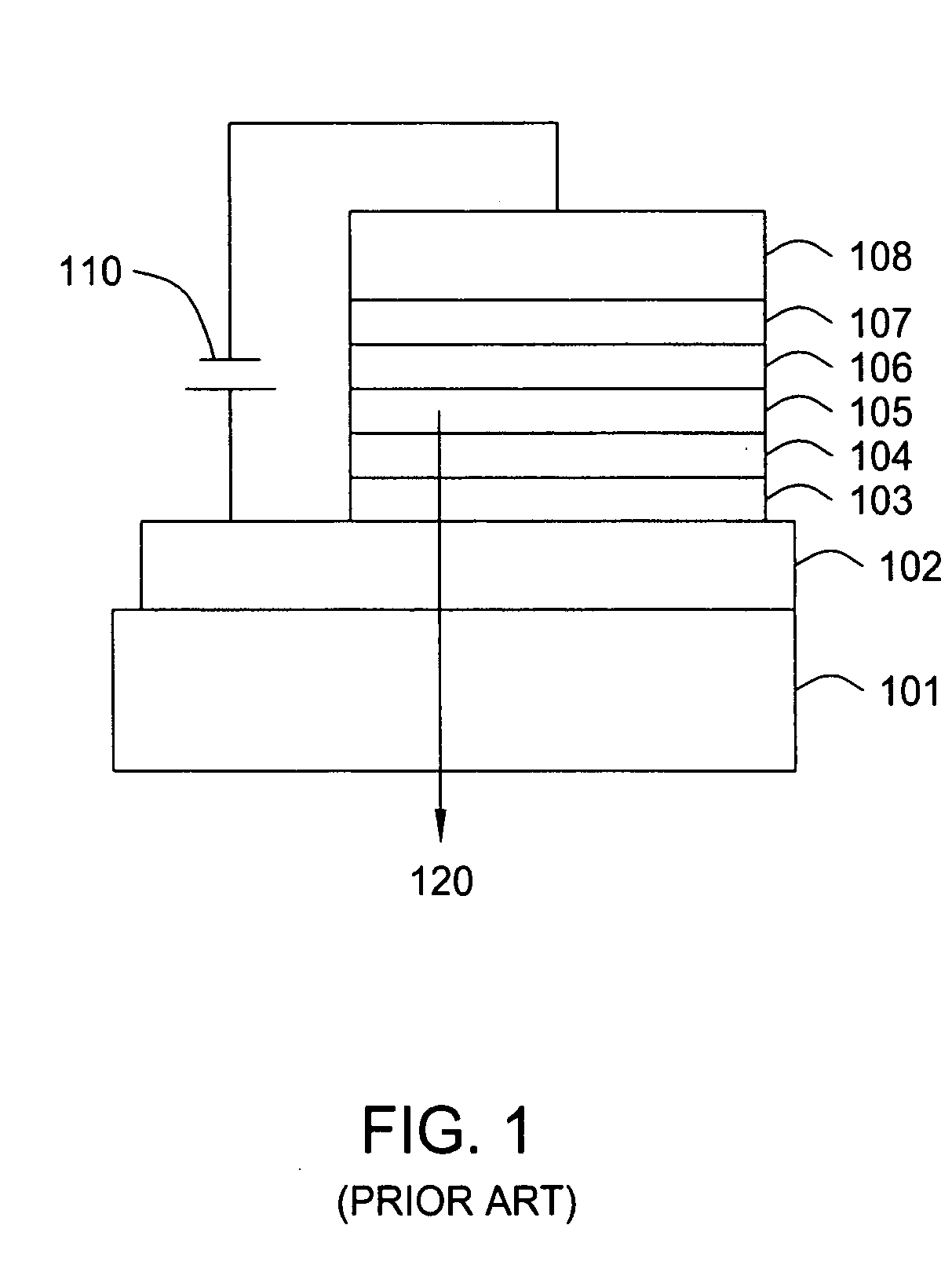

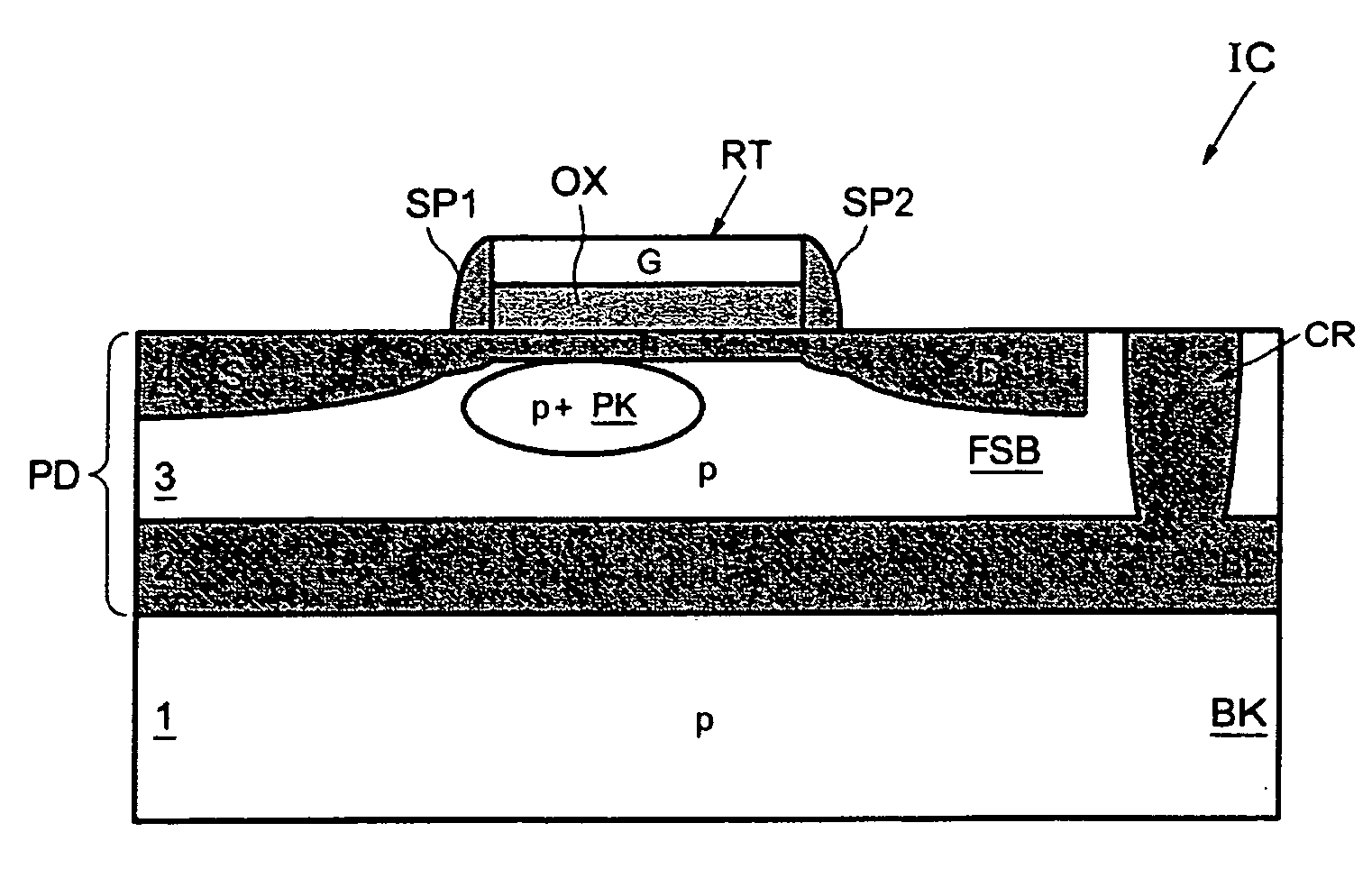

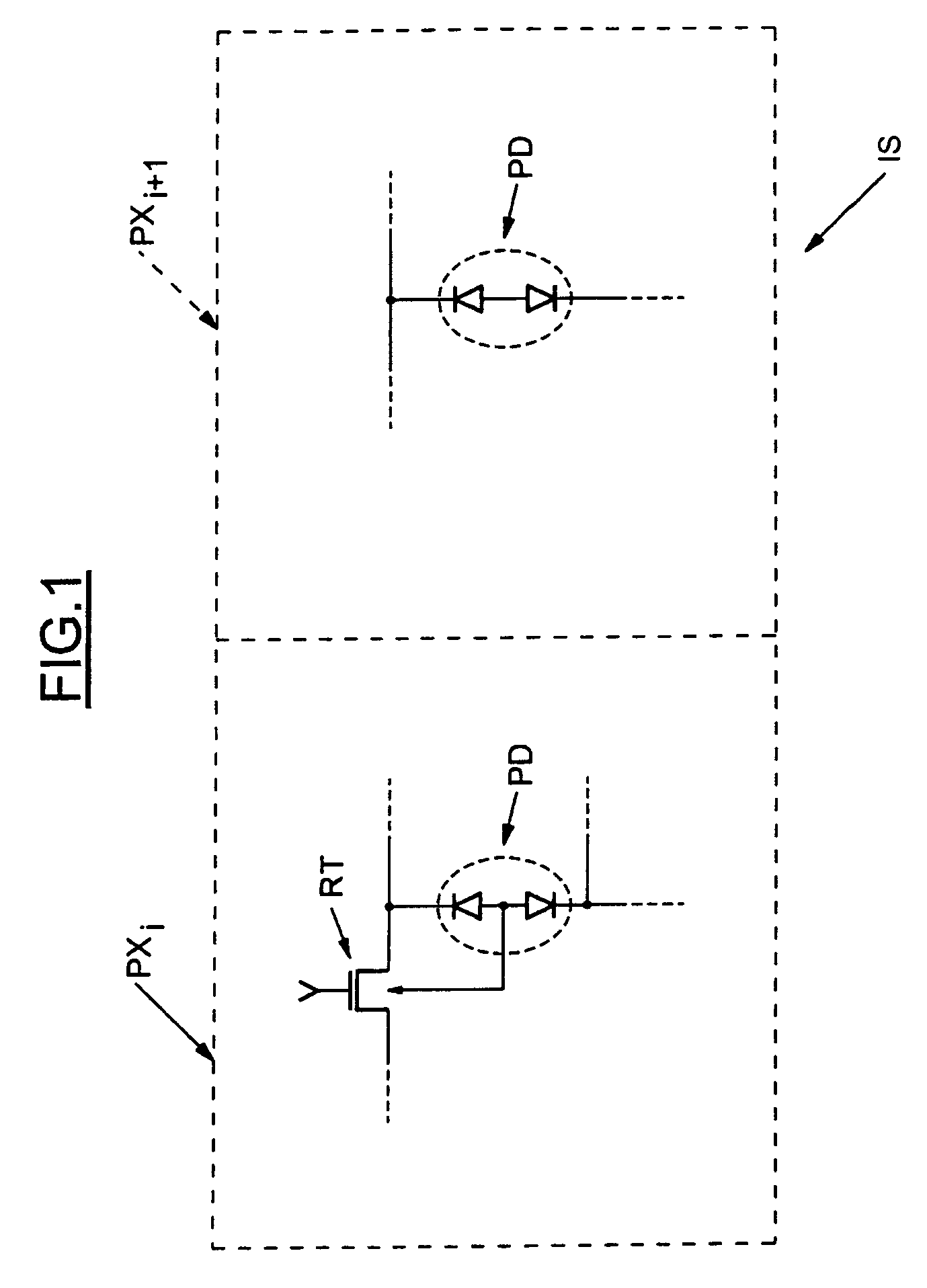

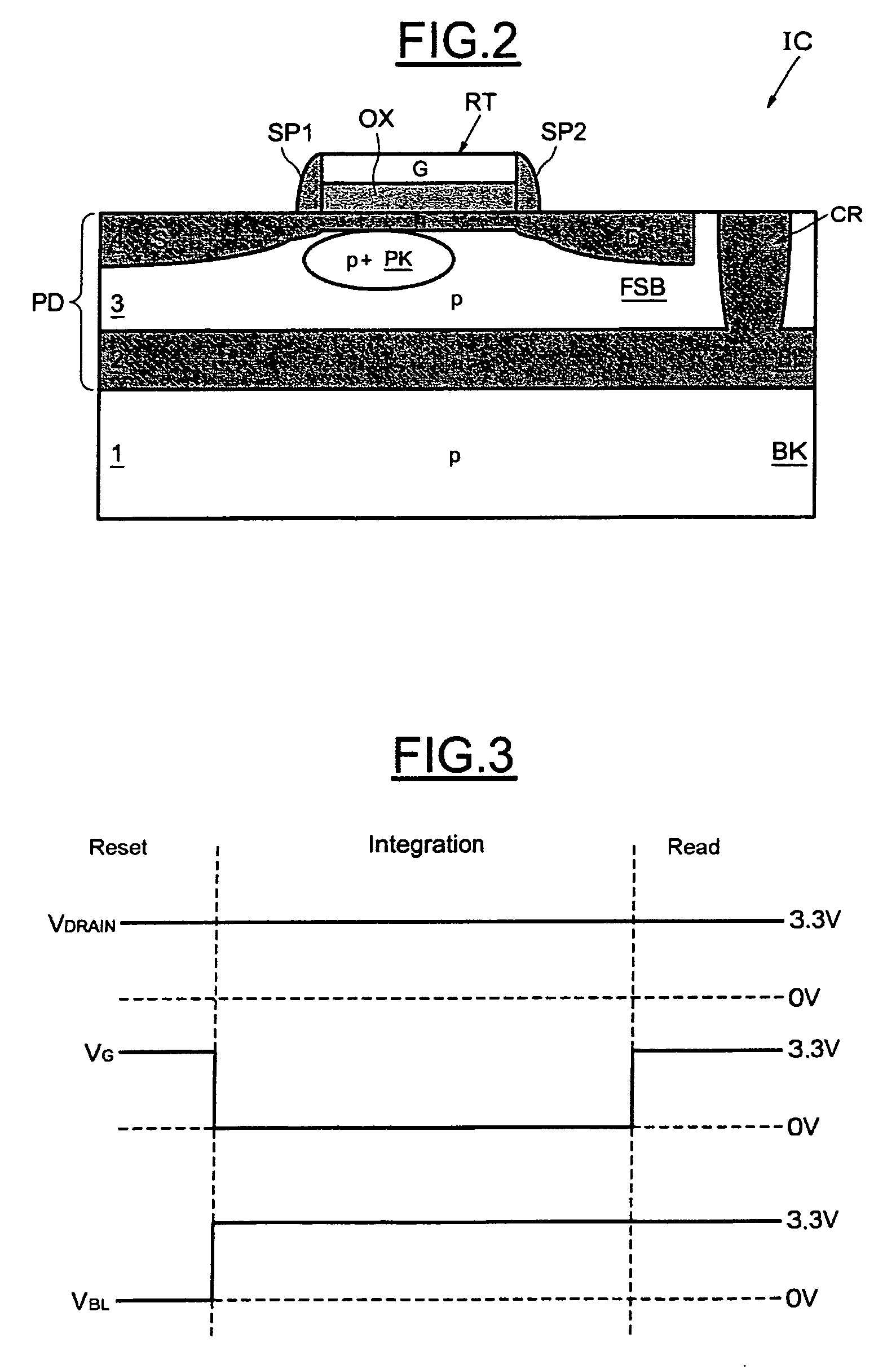

Integrated photodiode of the floating substrate type

ActiveUS20060258042A1Minimal footprintReduce areaSolid-state devicesSemiconductor/solid-state device manufacturingSubstrate typePhotodiode

An integrated circuit includes at least one photodiode of the floating substrate type which is associated with a read transistor. The photodiode is formed from a buried layer lying beneath the floating substrate and an upper layer lying on the floating substrate. The upper layer incorporates the source and drain regions of the read transistor. The source and drain regions are produced on either side of the gate of the read transistor. An isolating trench is located alongside the source region and extends from the upper surface of the upper layer down to below the buried layer, so as to isolate the source region from said buried layer.

Owner:STMICROELECTRONICS SRL

Water-barrier performance of an encapsulating film

ActiveUS7504332B2Improve waterproof performanceGood film uniformitySolid-state devicesSemiconductor/solid-state device manufacturingSubstrate typeLow temperature deposition

A method and apparatus for depositing a material layer onto a substrate is described. The method includes delivering a mixture of precursors for the material layer into a process chamber and depositing the material layer on the substrate at low temperature. The material layer can be used as an encapsulating layer for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. In one aspect, the encapsulating layer includes one or more material layers (multilayer) having one or more barrier layer materials and one or more low-dielectric constant materials. The encapsulating layer thus deposited provides reduced surface roughness, improved water-barrier performance, reduce thermal stress, good step coverage, and can be applied to many substrate types and many substrate sizes. Accordingly, the encapsulating layer thus deposited provides good device lifetime for various display devices, such as OLED devices. In another aspect, a method of depositing an amorphous carbon material on a substrate at low temperature is provided. The amorphous carbon material can be used to reduce thermal stress and prevent the deposited thin film from peeling off the substrate.

Owner:APPLIED MATERIALS INC

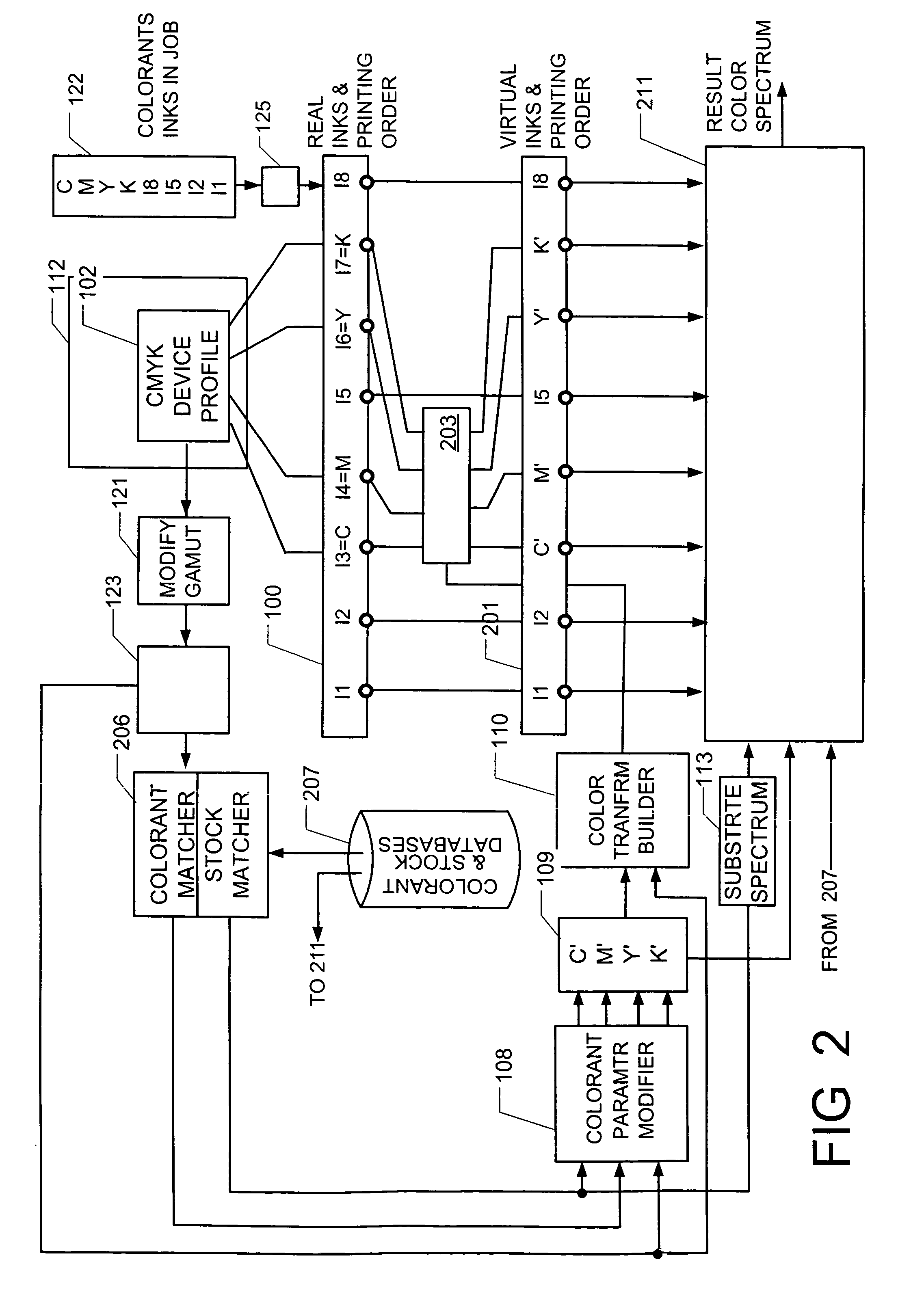

Method and device for determining the color appearance of color overprints

InactiveUS7199903B2Digitally marking record carriersDigital computer detailsSubstrate typePattern recognition

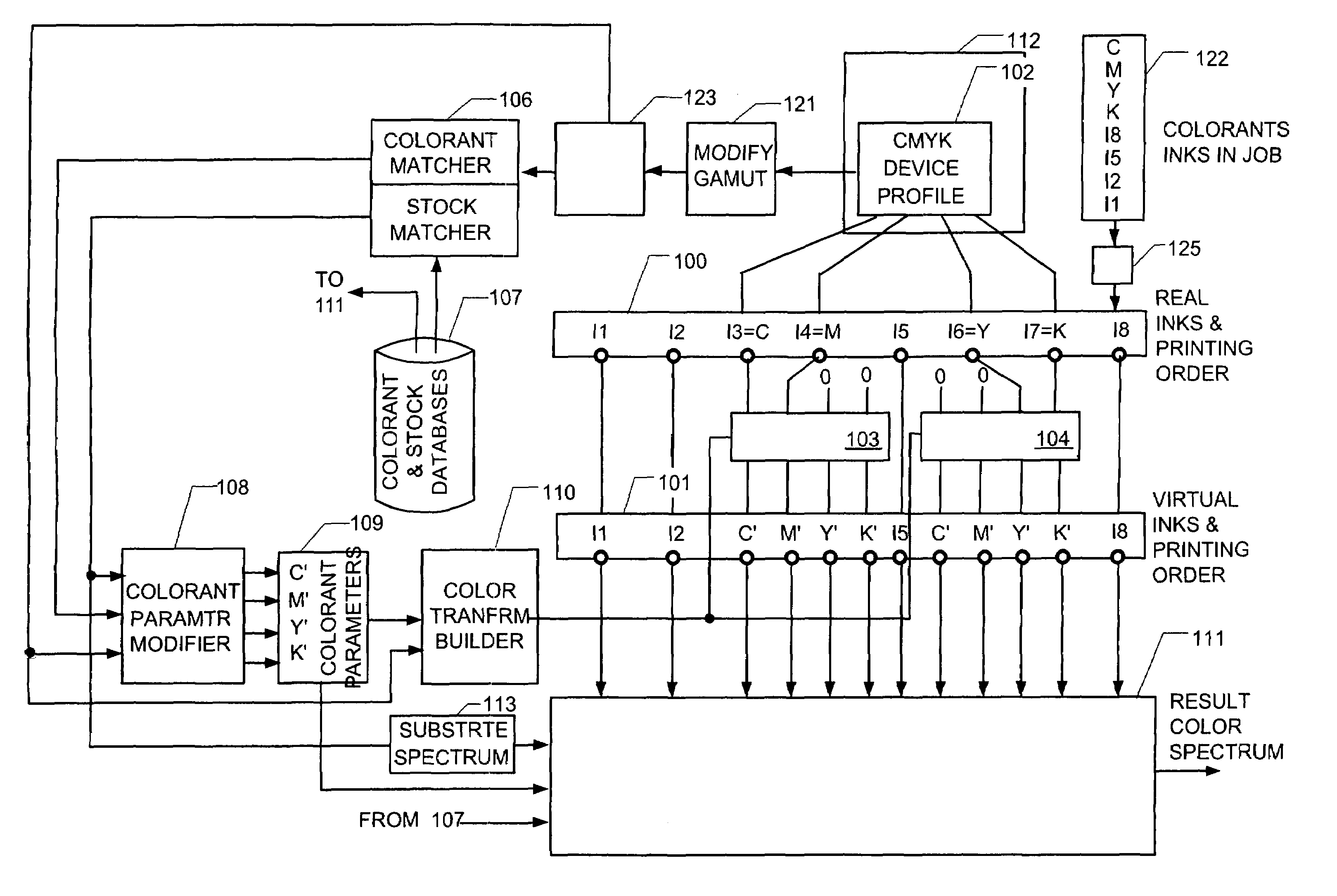

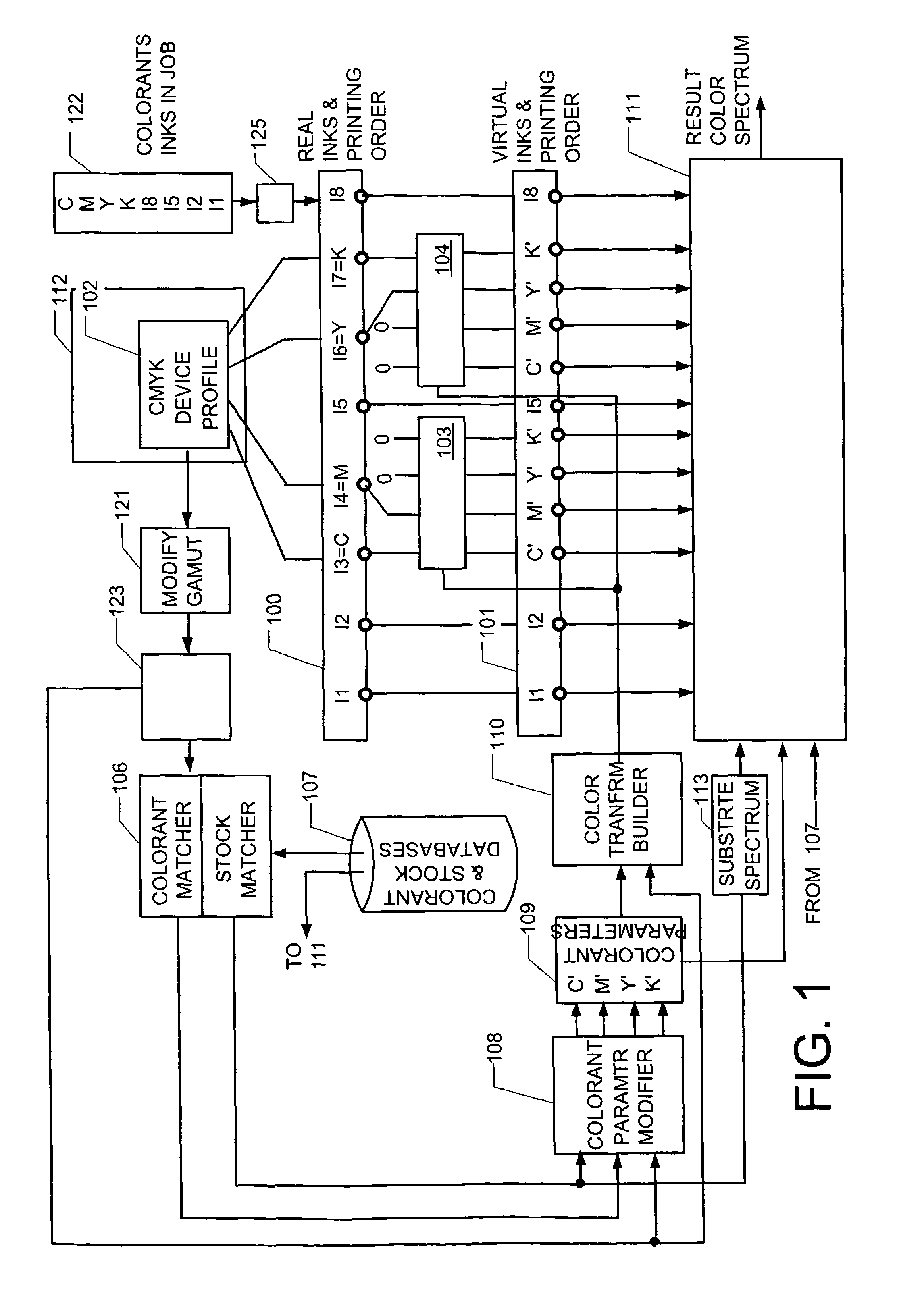

A method and apparatus to predict the color of an overprint of a set of colorants at a set of respective coverage percentages on a substrate of a substrate type using a printing technique. The colorants include some for which a device profile is provided. The method includes determining the colorant parameters of the device profile colorants; determining the spectrum of the substrate, providing spectral colorant parameters for the non-device profile colorants, and determining the color of the overprint. One version including modifying the data of the device profile such that the colorant parameters determined in the step of determining colorant parameters determines the colorant parameters of modified colorants that match the color of the device profile colorants and that cover at least the gamut of the device profile colorants. In one version, the step of determining the determining the color of the overprint includes determining the coverage percentages of the modified colorants corresponding to the colorants of each subset, and using the coverage percentages of the modified colorants to determine the color of the overprint.

Owner:AGFA NV

Integrated circuit comprising a photodiode of the floating substrate type and corresponding fabrication process

InactiveUS20060255371A1Readily biasedMinimum voltageSolid-state devicesSemiconductor/solid-state device manufacturingSubstrate typeEngineering

An integrated circuit includes at least one photodiode associated with a read transistor. The photodiode is formed from a stack of three semiconductor layers comprising a buried layer, an floating substrate layer and an upper layer. The drain region and / or the source region of the transistor are incorporated within the upper layer. The buried layer is electrically isolated from the upper layer so as to allow the buried layer to be biased independently of the upper layer.

Owner:STMICROELECTRONICS SRL

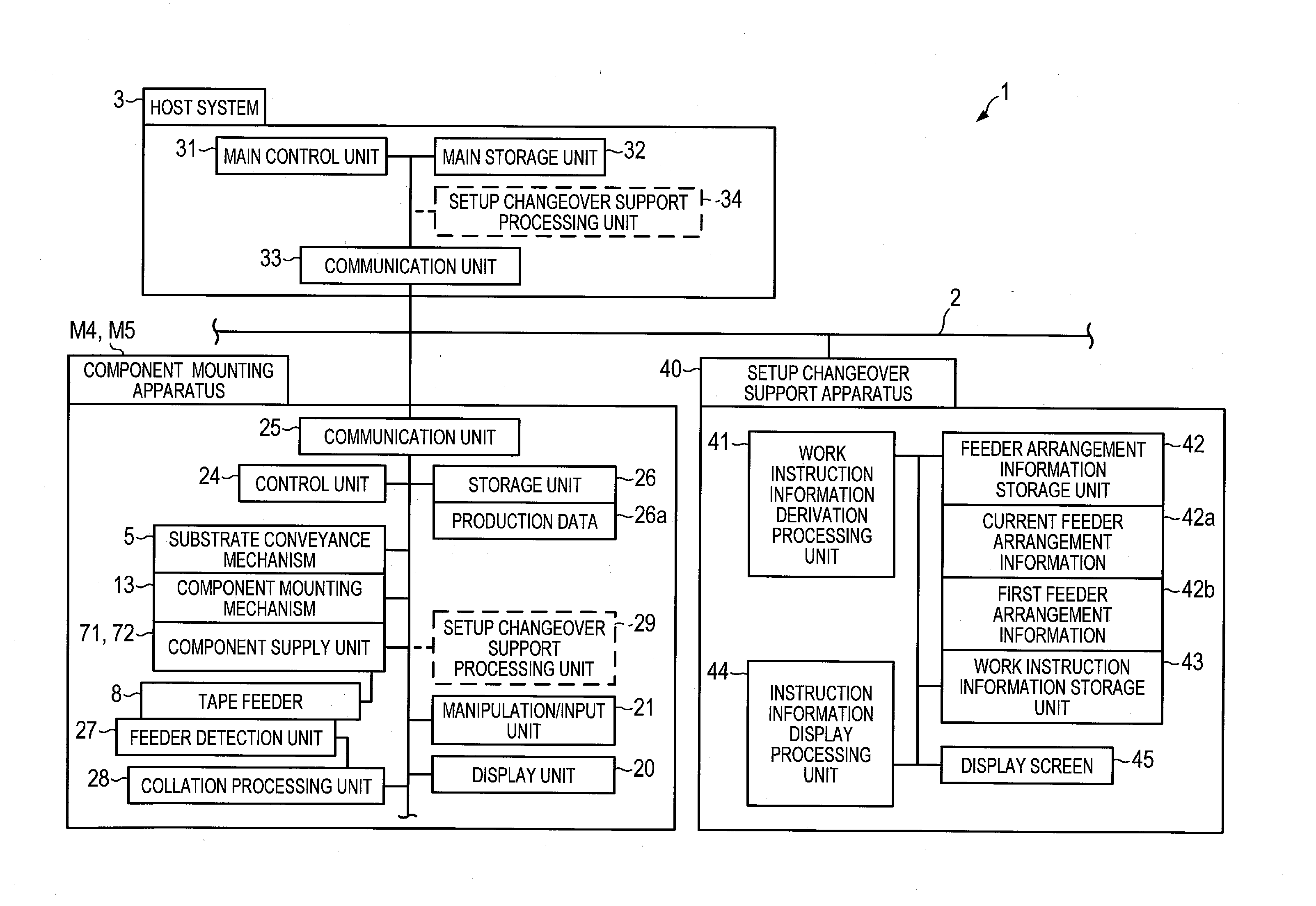

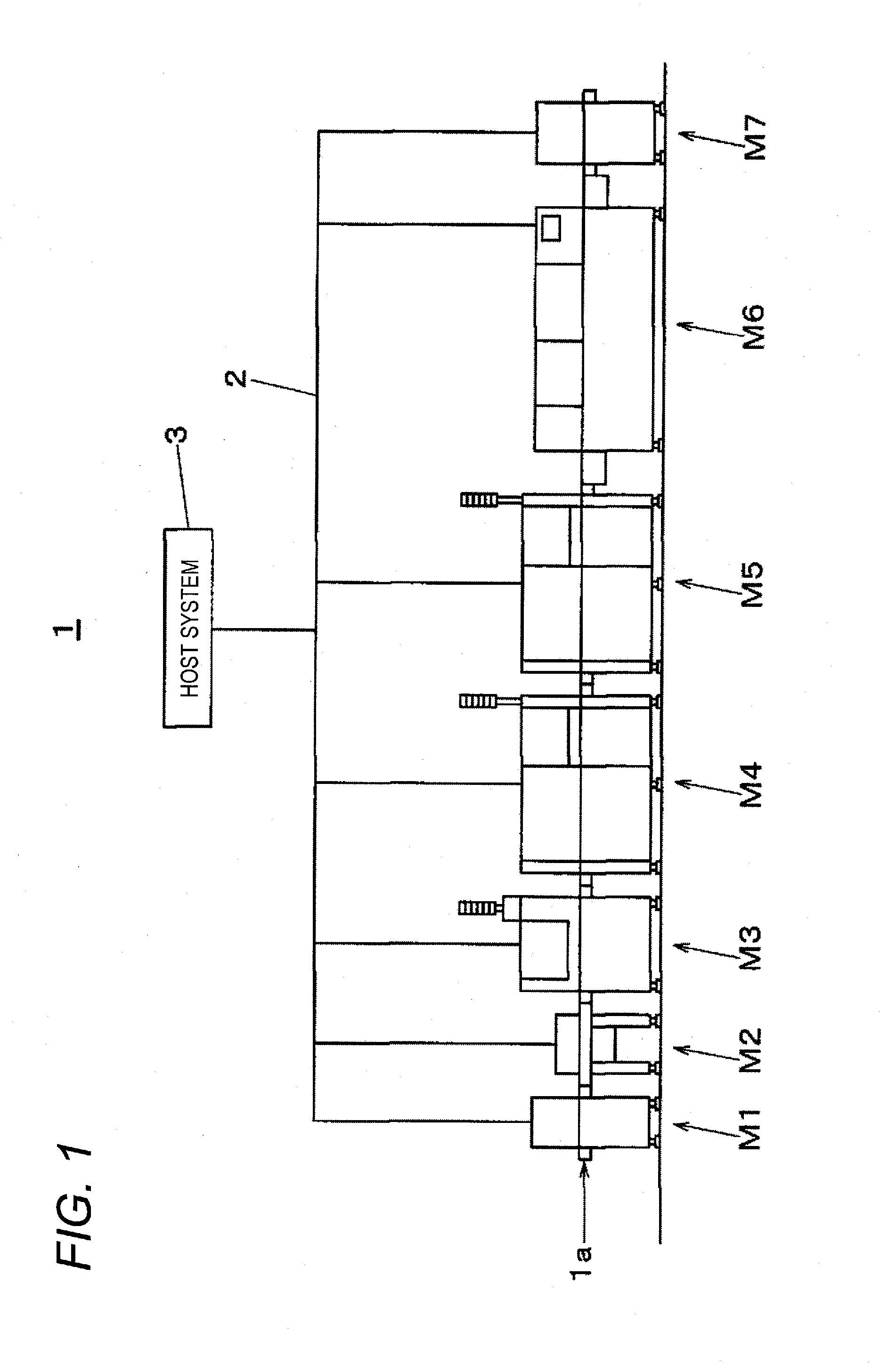

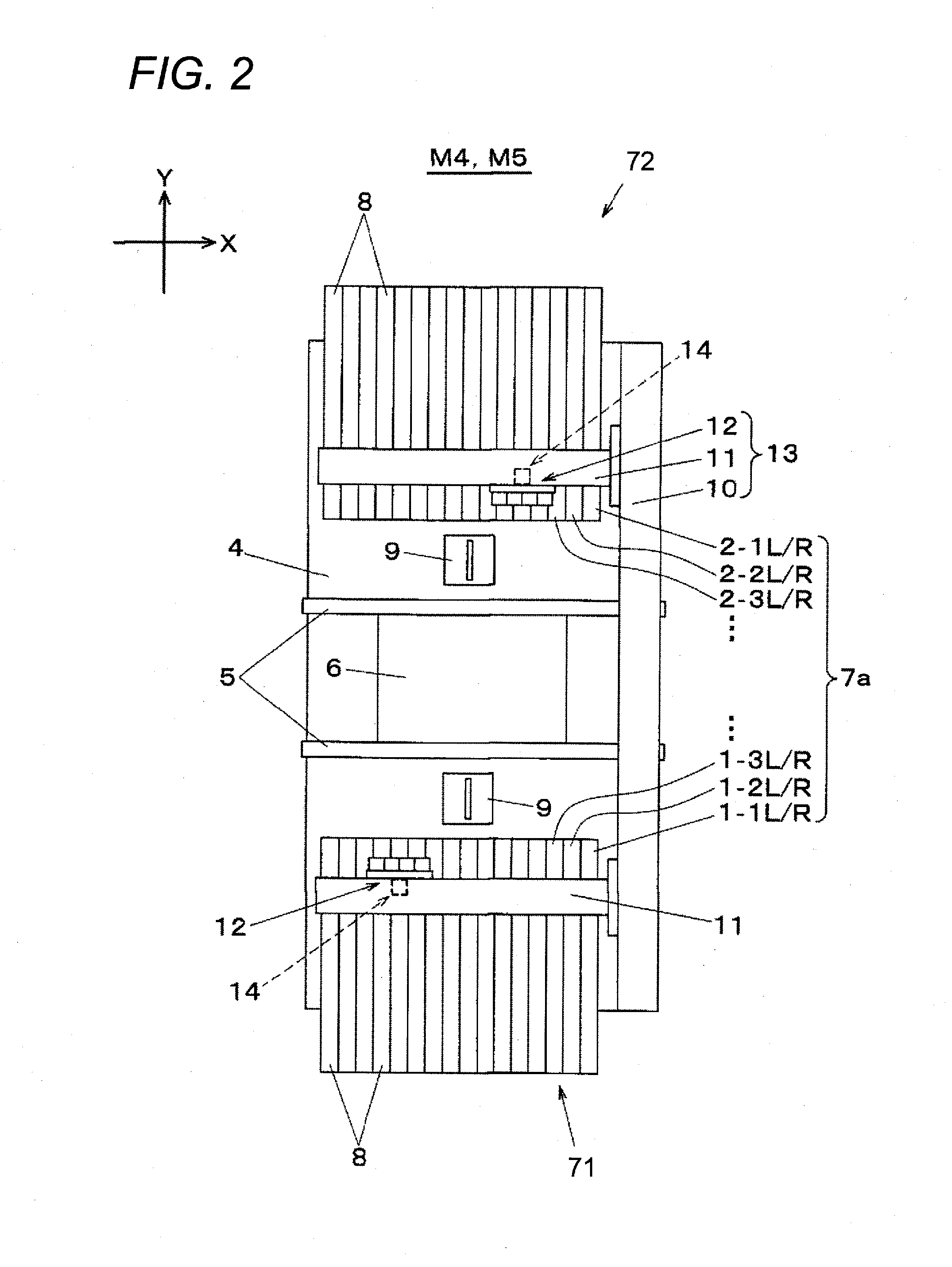

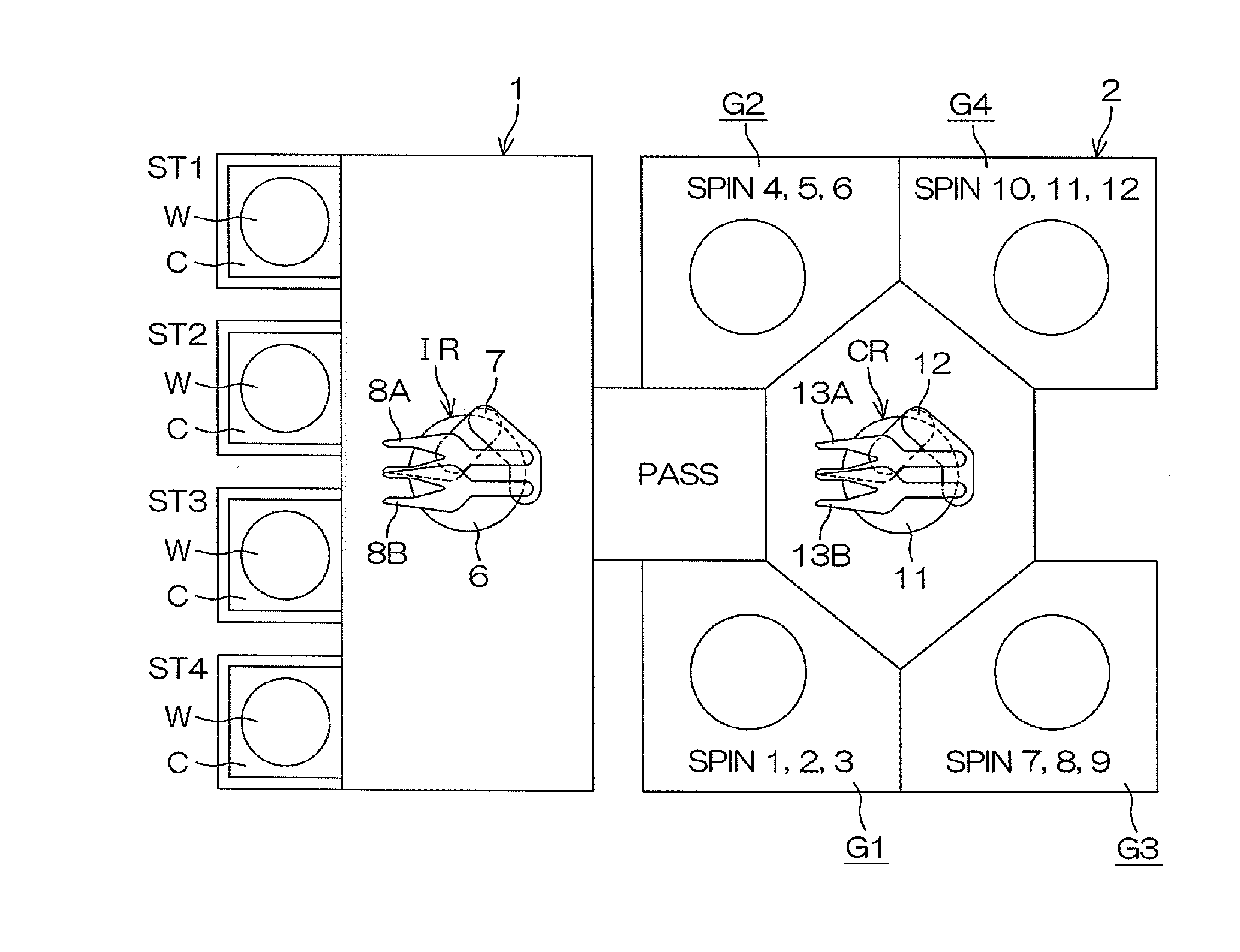

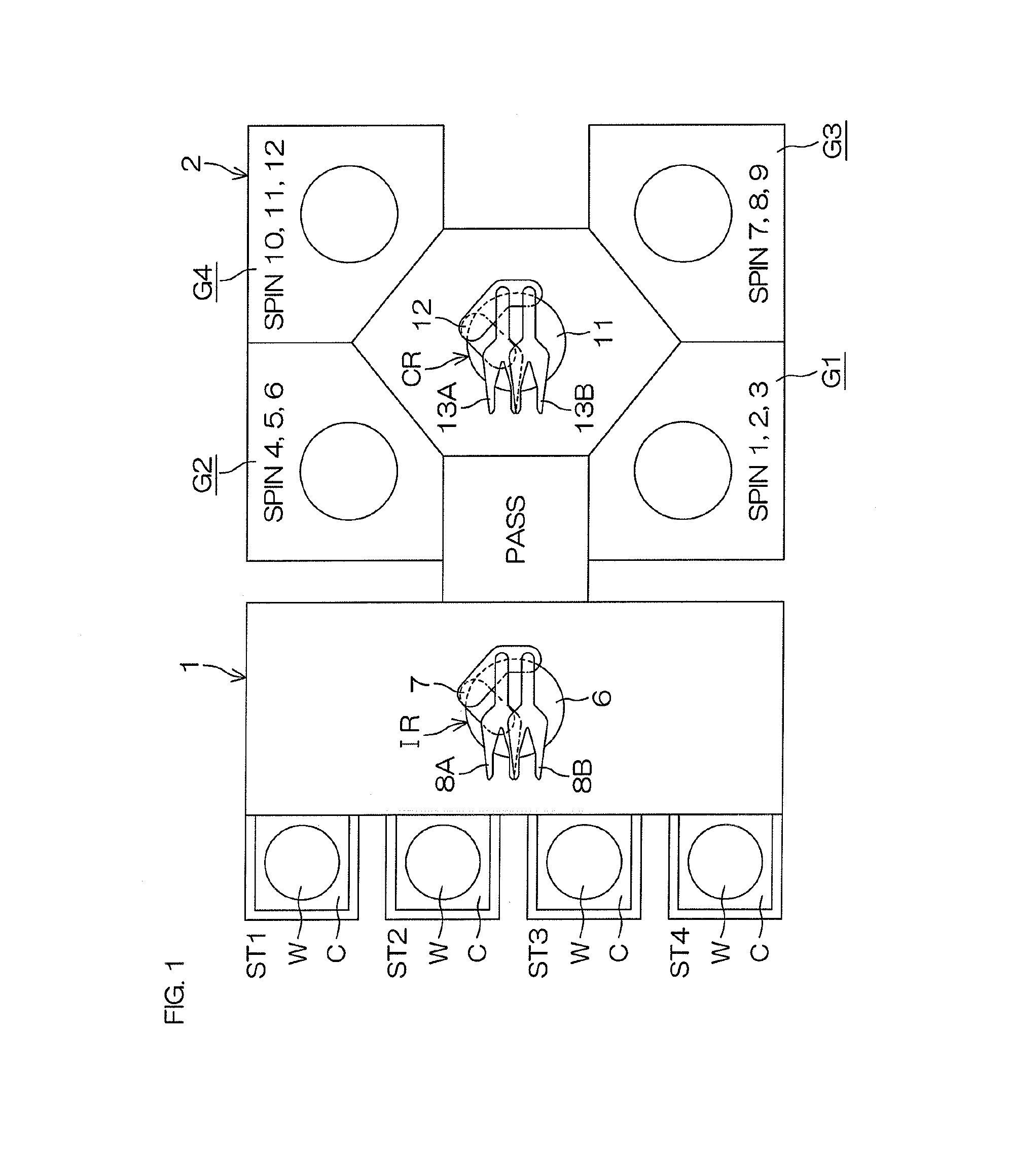

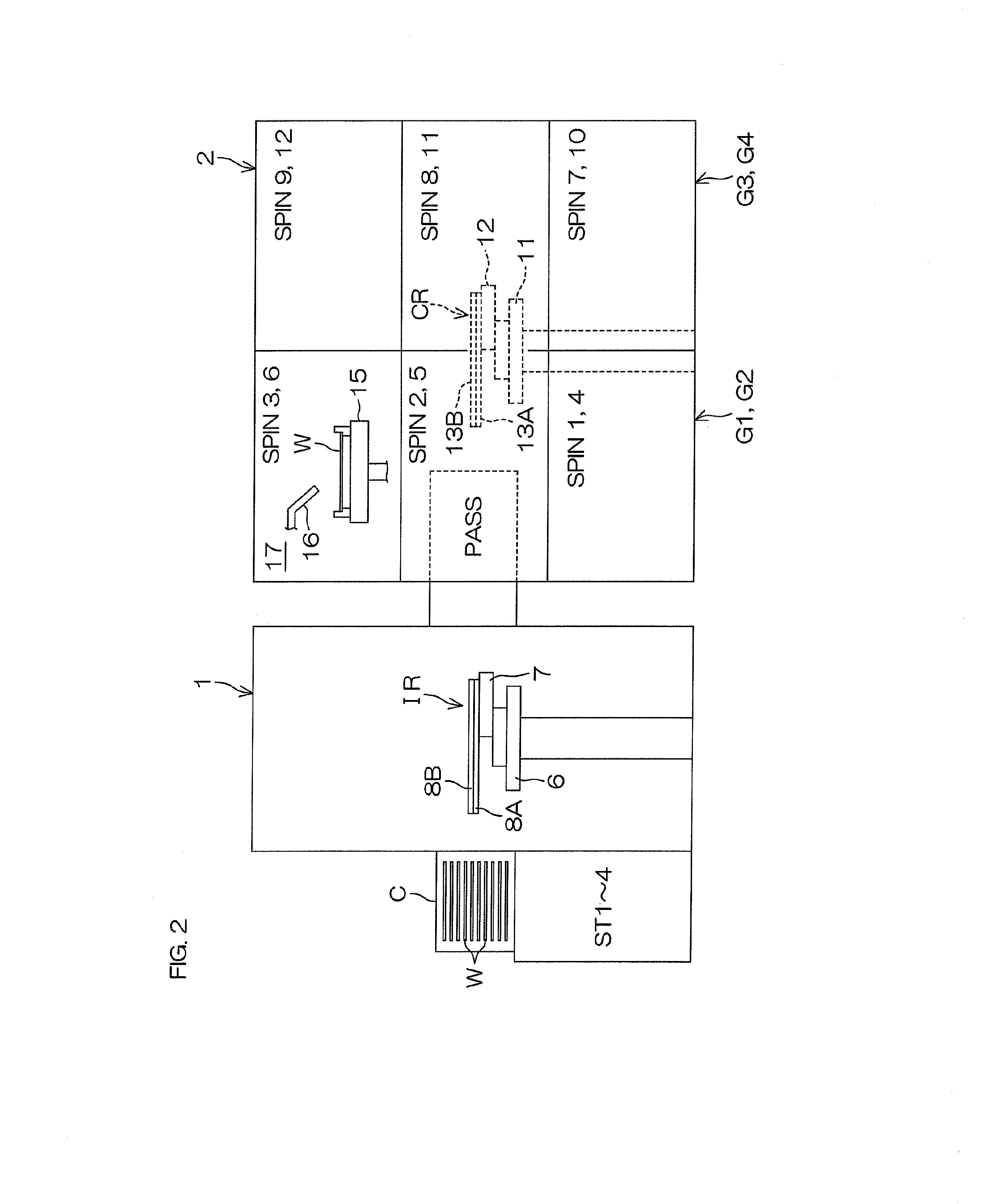

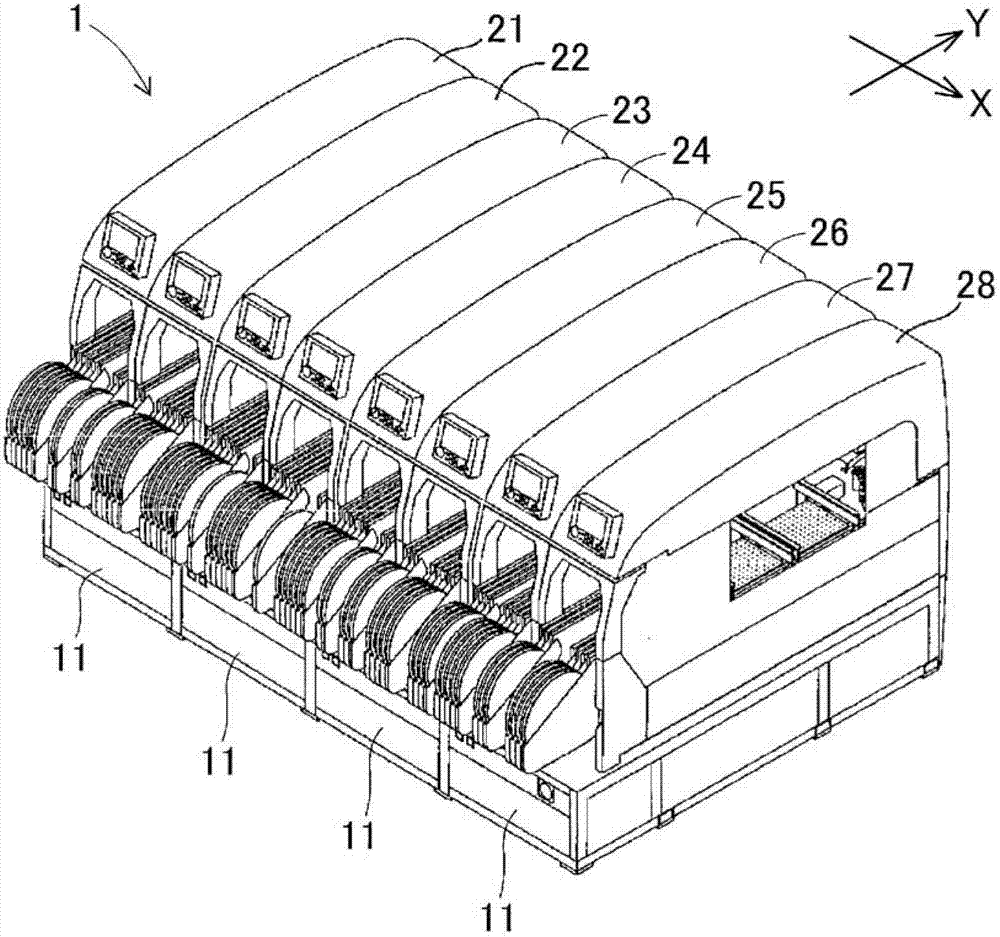

Method for providing instruction on setup changeover work in component mounting system, and component mounting system

ActiveUS20150039115A1Executed efficiently and easilyEfficiently and easily executing setup changeoverTotal factory controlSpecial data processing applicationsSubstrate typeIndustrial engineering

A component mounting system derives work instruction information defining setup changeover work necessary to change an arrangement state of parts feeders from a current arrangement state to a first arrangement state for producing a first substrate type based on current feeder arrangement information corresponding to the current arrangement state and first feeder arrangement information corresponding to the first arrangement state. The work instruction information includes a plurality of pieces of unit work information. Each of the pieces of the unit work information includes kind information indicating a kind of execution operation and feeder state information indicating states before and after execution of work on the parts feeder targeted in the setup changeover work. The pieces of unit work information are displayed on the display screen so as to be arranged in work sequence to be executed.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

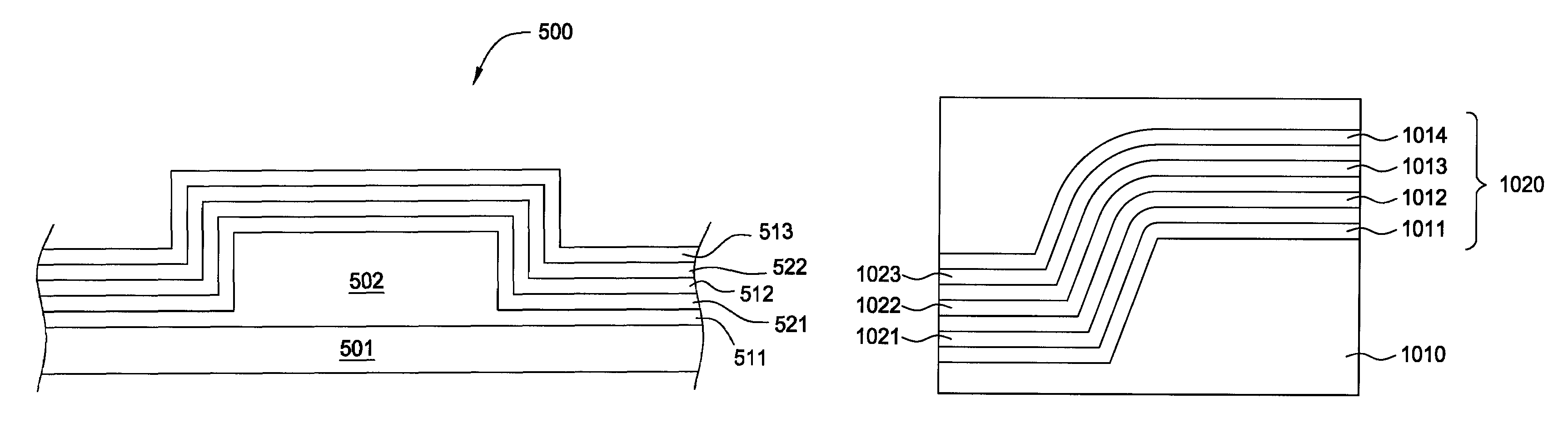

Chip embedded silicon substrate type fan-out type packaging structure and manufacturing method therefor

ActiveCN106876356AReduce warpageImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSubstrate typeEngineering

The invention discloses a chip embedded silicon substrate type fan-out type packaging structure and a manufacturing method therefor. The packaging structure comprises a silicon substrate, wherein the silicon substrate has a first surface and a second surface; at least one groove A which extends to the second surface is formed in the first surface of the silicon substrate; at least one chip with an upward bonding pad surface is arranged in the groove A; the bonding pad surface of the chip is higher than the first surface of the silicon substrate for a certain distance; a thick adhesive layer which exposes the groove A and the chip is paved on the first surface; the sum of the thickness of the thick adhesive layer and the depth of the groove A is close to or equal to the thickness of the chip; and the electric power of the bonding pad of the chip is fan out to the upward side of the thick adhesive layer through a metal wiring layer. The thick adhesive layer is introduced to the surface of the silicon substrate, and the thick adhesive layer and the silicon substrate are jointly used as a chip fan-out carrier, so that requirement on the groove etching depth and the groove bottom etching uniformity in embedding the chip in the silicon substrate can be lowered, and the purposes of shortening etching process time on the silicon substrate, lowering etching and packaging costs and reducing warping degree are achieved.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

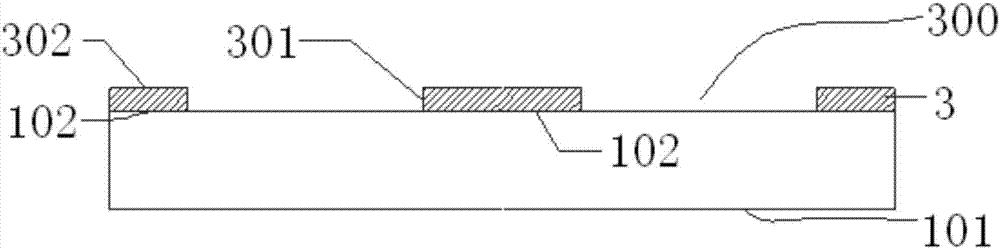

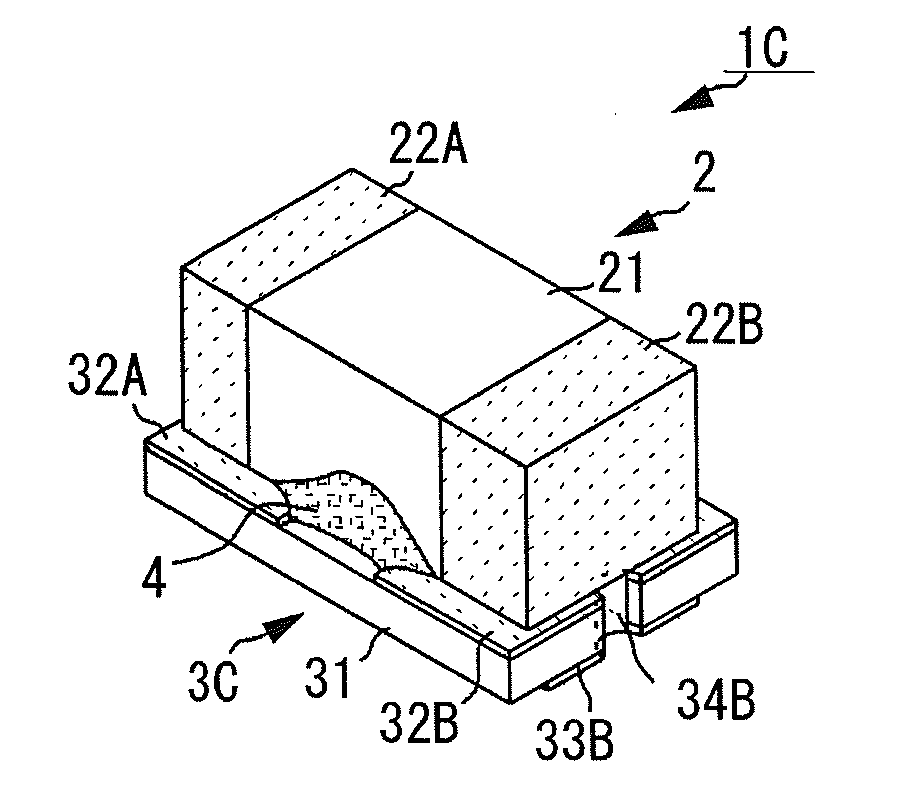

Electronic component

ActiveUS20140268486A1Reduce and prevent occurrenceReduce the amplitudeFixed capacitor housing/encapsulationStacked capacitorsSubstrate typeElectronic component

An electronic component includes a laminated capacitor and a substrate-type terminal on which the laminated capacitor is mounted, with an viscoelastic resin located in a space between the laminated capacitor and the substrate-type terminal. The substrate-type terminal includes a substrate body, component connecting electrodes to mount the laminated capacitor are located on a component mounting surface of the substrate body, and external connecting electrodes to be connected to a circuit board are located on a substrate mounting surface of the substrate body.

Owner:MURATA MFG CO LTD

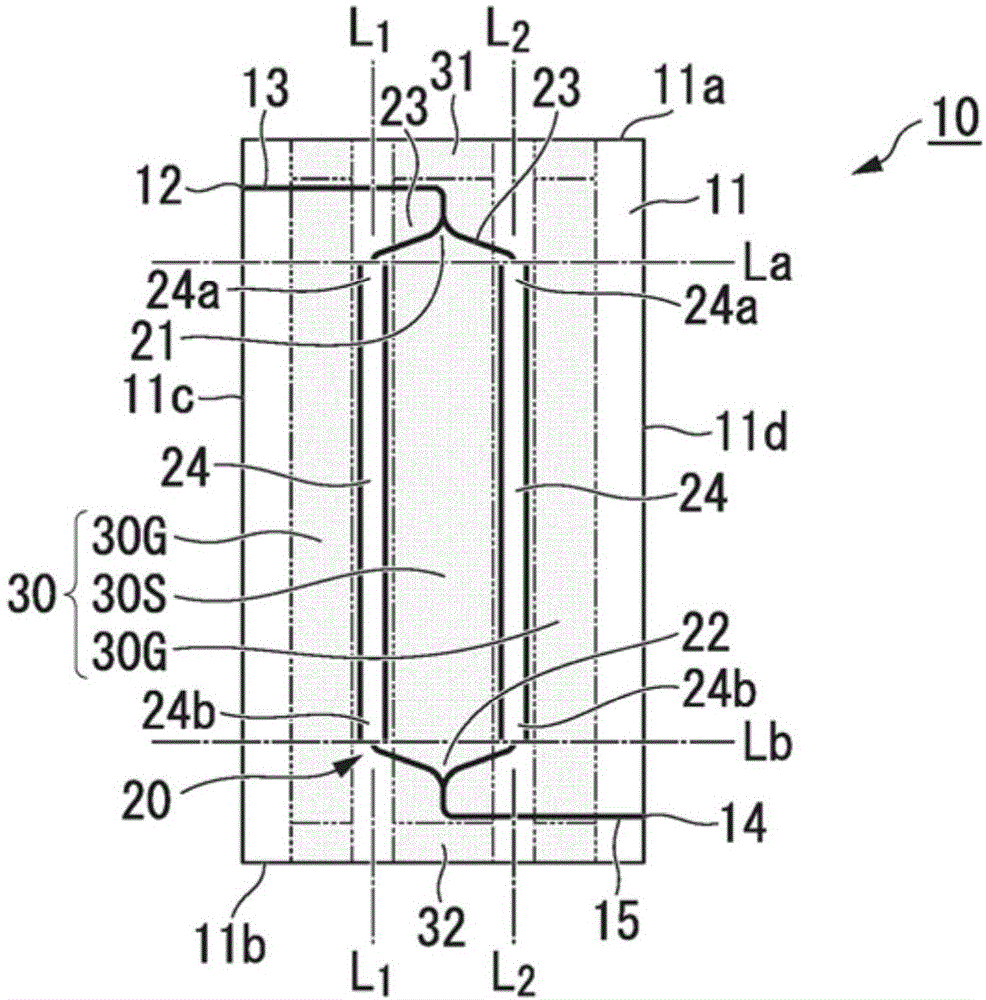

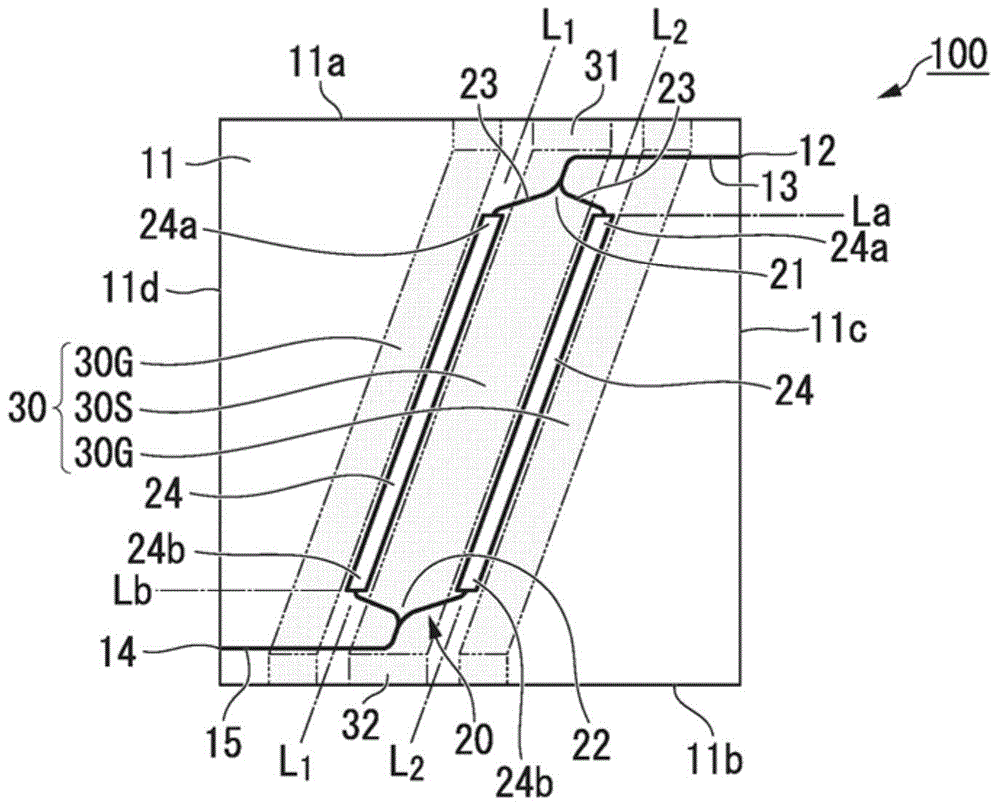

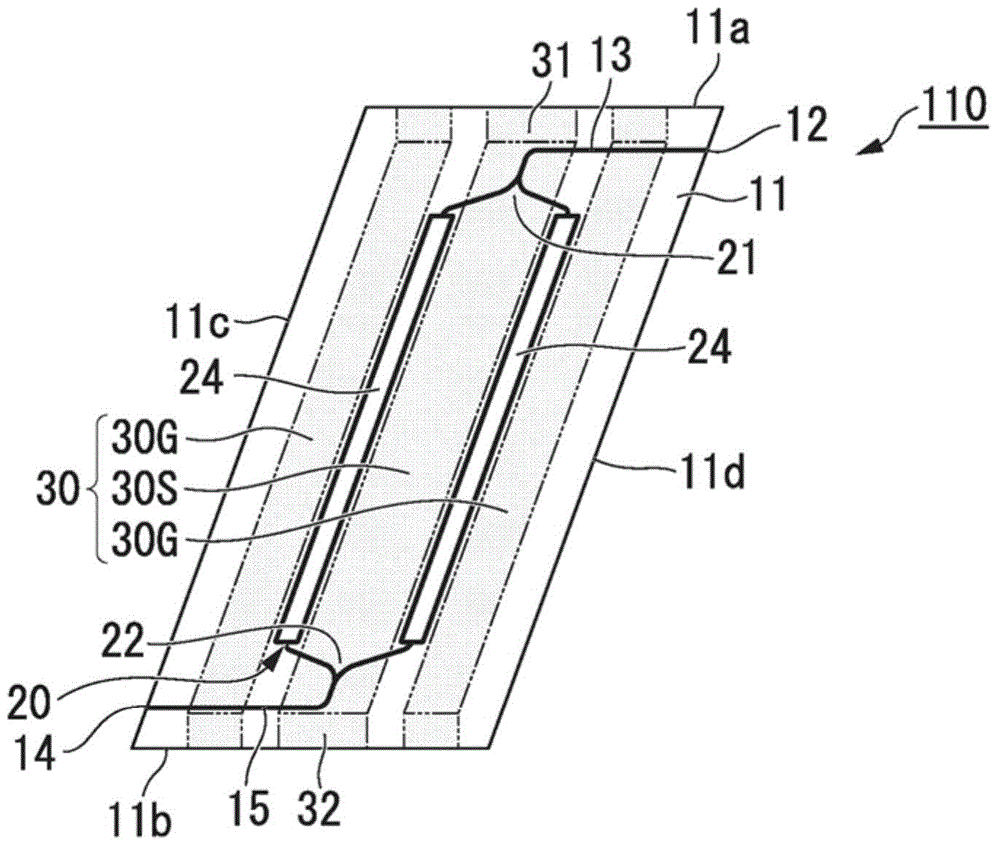

Light modulation element

InactiveCN104885004AInhibition Modulation Efficiency DecreaseReduce distanceOptical waveguide light guideNon-linear opticsSubstrate typeMultiplexing

A light modulation element configured from a substrate-type optical waveguide is provided with: a light incidence part through which light is incident on the substrate-type optical waveguide; a Mach-Zehnder interferometer comprising a first light branching part which branches the light incident on the light incidence part, two arm parts which guide the light branched by the first light branching part, a phase modulation part which is linearly provided in at least one of the two arm parts, and a first light multiplexing part which multiplexes the light guided from the two arm parts; a light emission part which emits the light multiplexed by the first light multiplexing part from the substrate-type optical waveguide; and a traveling wave electrode which has an input part and an output part and applies voltage to the phase modulation part. The substrate-type optical waveguide has an outline including two sides each crossing an extension line in the longitudinal direction of the phase modulation part in plan view, the input part is formed in one of the two sides, and the light incidence part and the light emission part are each located in a region different from a region in which the traveling wave electrode is formed in plan view.

Owner:FUJIKURA LTD

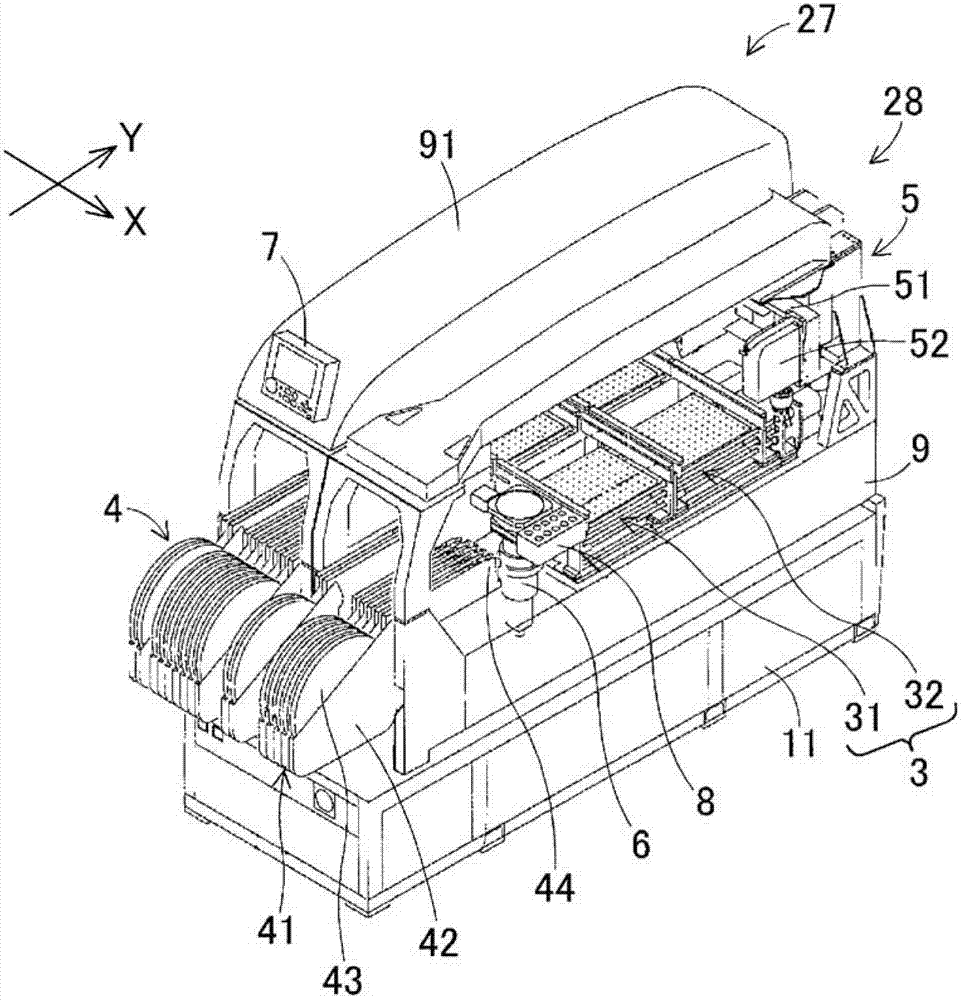

Scheduling method and recording medium having scheduling program recorded thereon for substrate treating apparatus

InactiveUS20130073069A1High precisionEfficient substrate treatmentSemiconductor/solid-state device manufacturingResourcesSubstrate typeOperating system

A scheduling method suitable for a single-substrate type substrate treating apparatus is provided. In the scheduling method, a controller provided in the substrate treating apparatus prepares schedule defining performances of the substrate treating apparatus having a single-substrate type treating unit in a time sequential order. The method comprises the steps of: a step for preparing a plurality of tentative timetables for a plurality of respective substrates, each of the tentative timetables combining a plurality of blocks in a time sequential order, each of the blocks defining a treatment content for one of the substrates; and a scheduling step for preparing a total schedule by acquiring the blocks from the plurality of tentative timetables to dispose the acquired blocks in a time sequential order.

Owner:DAINIPPON SCREEN MTG CO LTD

Adaptive control method for rapid thermal processing of a substrate

ActiveUS7398693B2Radiation pyrometrySemiconductor/solid-state device testing/measurementSubstrate typeOptical property

The present invention generally relates to methods for the rapid thermal processing (RTP) of a substrate. Embodiments of the invention include controlling a thermal process using either a real-time adaptive control algorithm or by using a control algorithm that is selected from a suite of fixed control algorithms designed for a variety of substrate types. Selection of the control algorithm is based on optical properties of the substrate measured during the thermal process. In one embodiment, a combination of control algorithms are used, wherein the majority of lamp groupings are controlled with a fixed control algorithm and a substantially smaller number of lamp zones are controlled by an adaptive control algorithm.

Owner:APPLIED MATERIALS INC

Method to improve water-barrier performance by changing film surface morphology

ActiveUS20050287686A1Improve waterproof performanceReduce surface roughnessSolid-state devicesSemiconductor/solid-state device manufacturingLow temperature depositionSubstrate type

A method and apparatus for depositing a material layer onto a substrate is described. The method includes placing the substrate in a process chamber, delivering a mixture of precursors for the material layer into the process chamber, delivering a hydrogen gas into the process chamber to improve water-barrier performance of the material layer, controlling the temperature of the substrate to a temperature of about 100° C. or lower, applying an electric field and generating a plasma inside the process chamber, and depositing the material layer on the substrate. The material layer can be used as an encapsulating layer for various display applications which require low temperature deposition process due to thermal instability of underlying materials used. The encapsulating layer thus deposited provides reduced surface roughness, improved water-barrier performance which can be applied to any substrate type including wafer, glass, and plastic film (e.g., PET, PEN, etc.) and any substrate size in the flat panel industry.

Owner:APPLIED MATERIALS INC

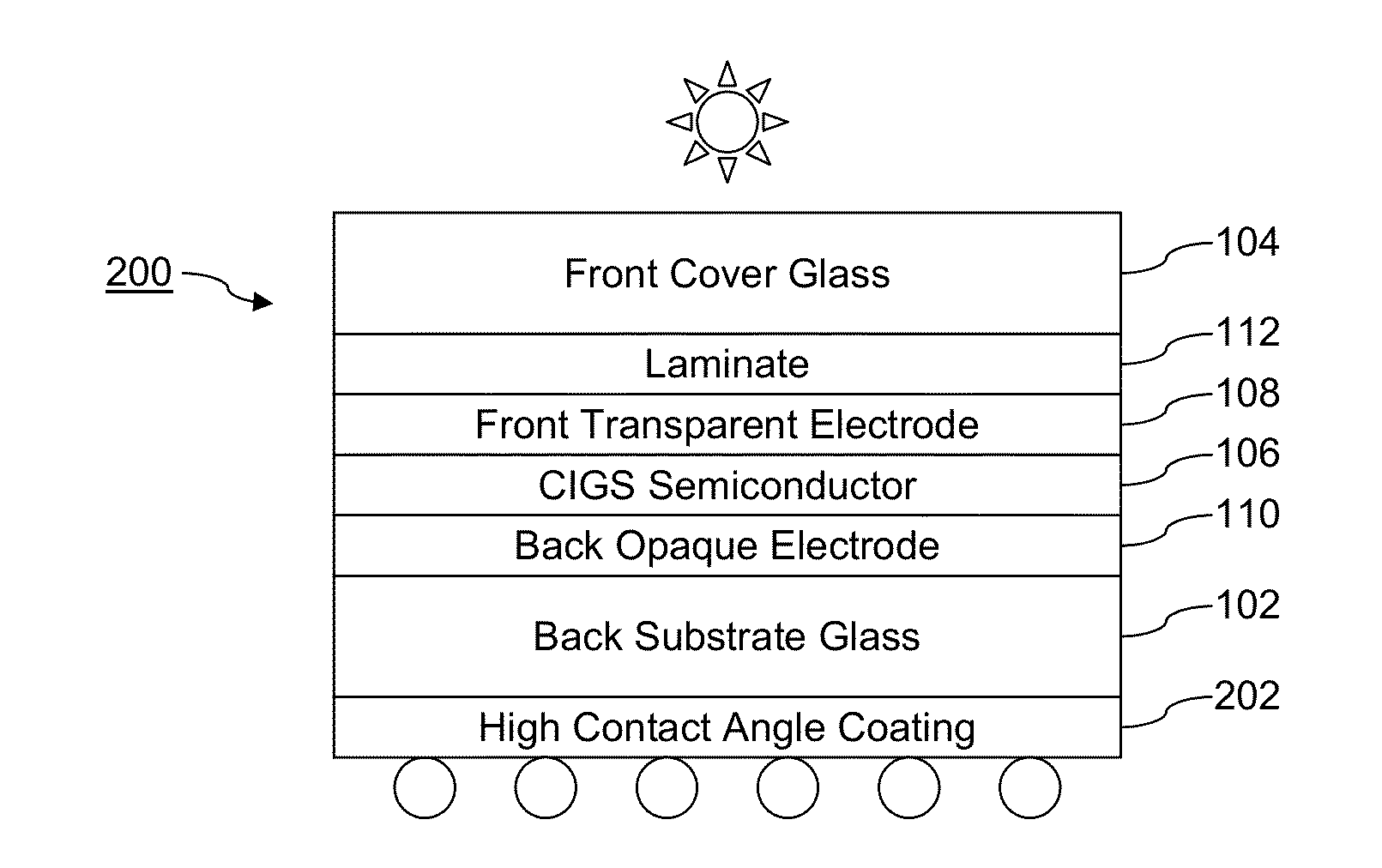

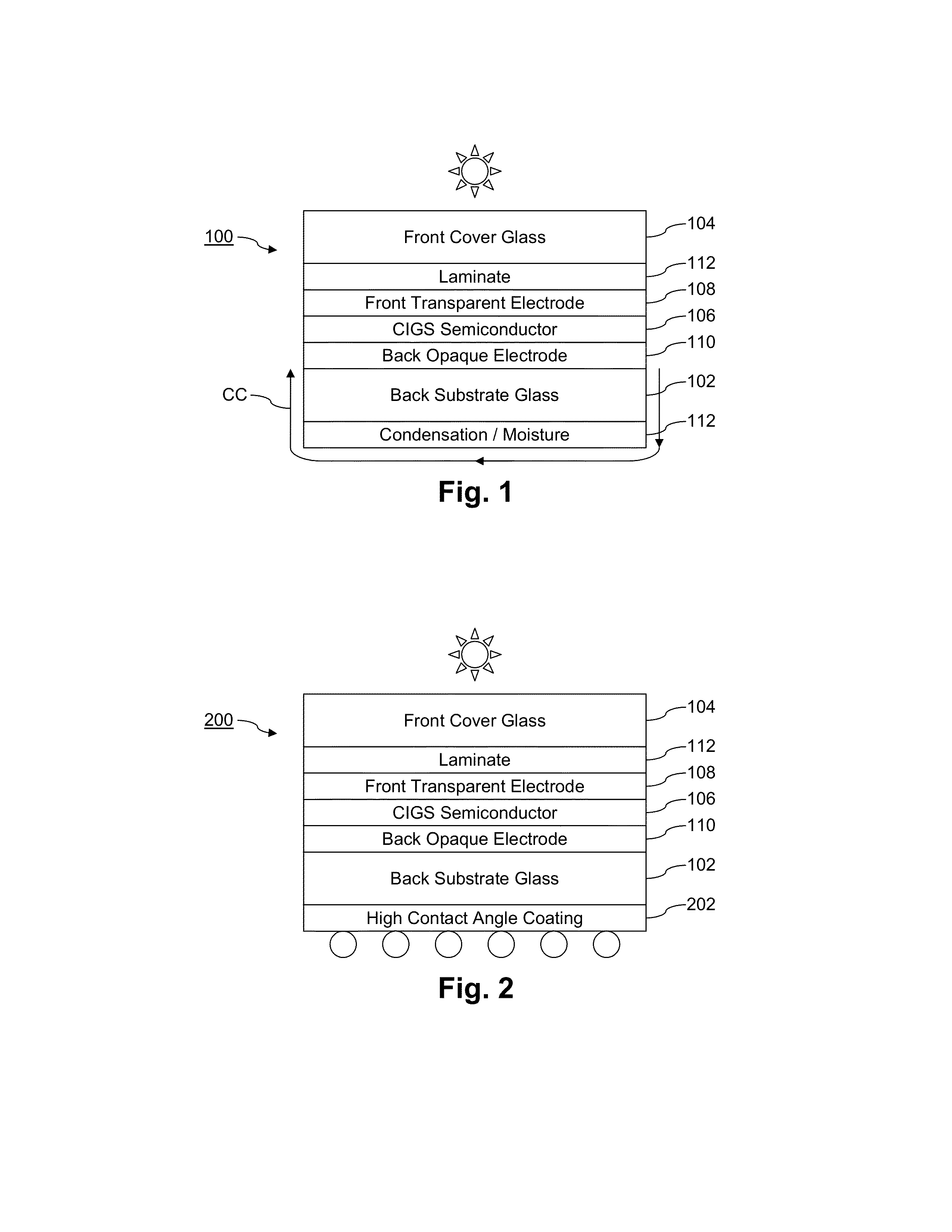

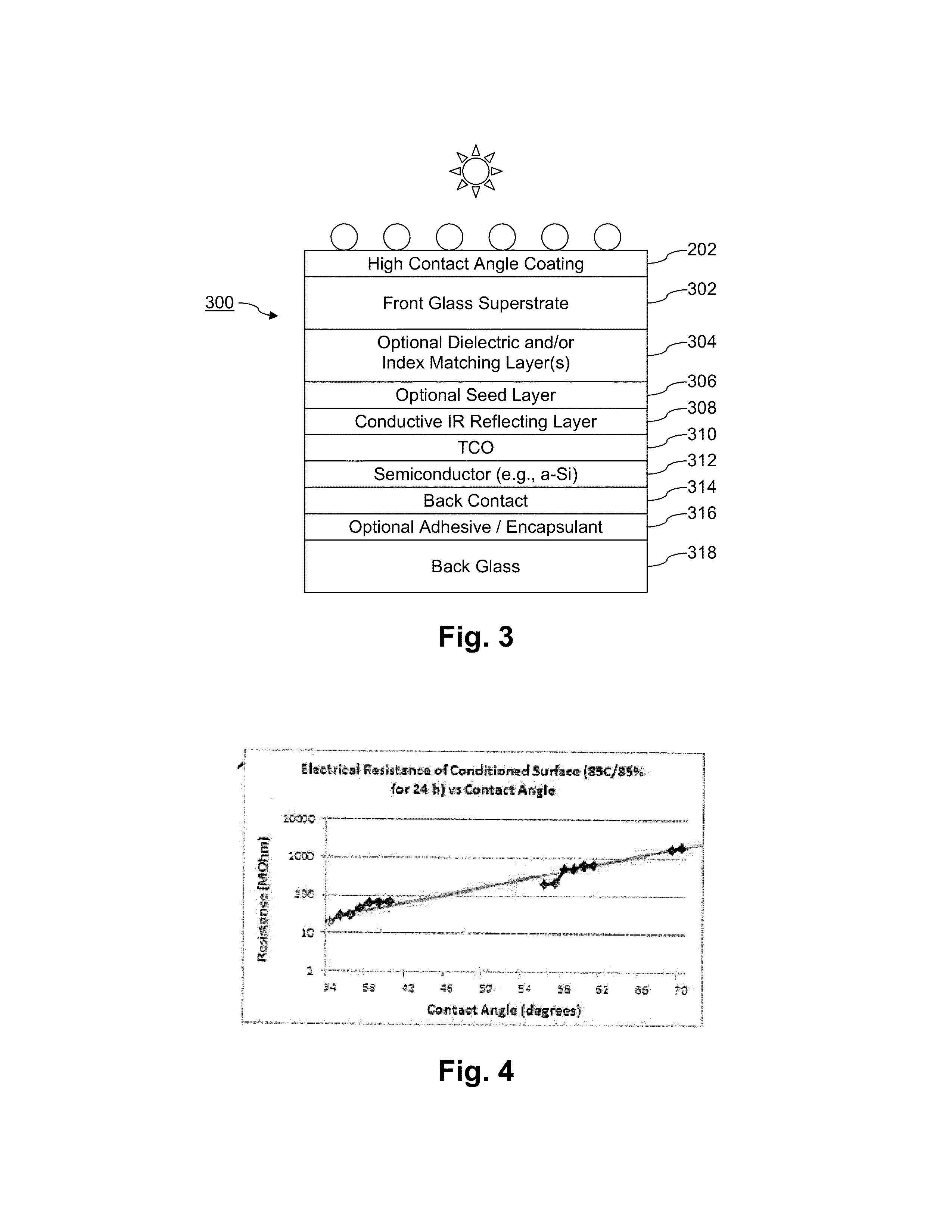

Photovoltaic module including high contact angle coating on one or more outer surfaces thereof, and/or methods of making the same

InactiveUS20130180580A1Reduce accumulationReduce leakageFinal product manufactureSemiconductor/solid-state device manufacturingSubstrate typeComputer module

Certain example embodiments of this invention relate to photovoltaic modules that include high contact angle coatings on one or more outermost major surfaces thereof, and / or associated methods. In certain example embodiments, the high contact angle coatings advantageously reduce the likelihood of electrical losses through parasitic leakage of the electrical current caused by moisture on surfaces of the photovoltaic modules, thereby potentially improving the efficiency of the photovoltaic devices. In certain example embodiments, the high contact angle coatings may be nitrides and / or oxides of or including Si, Ti, Ta, TaCr, NiCr, and / or Cr; hydrophobic DLC; and / or polymer-based coatings. The photovoltaic modules may be substrate-type modules or superstrate-type modules in different example embodiments.

Owner:GUARDIAN EURO S A R L +1

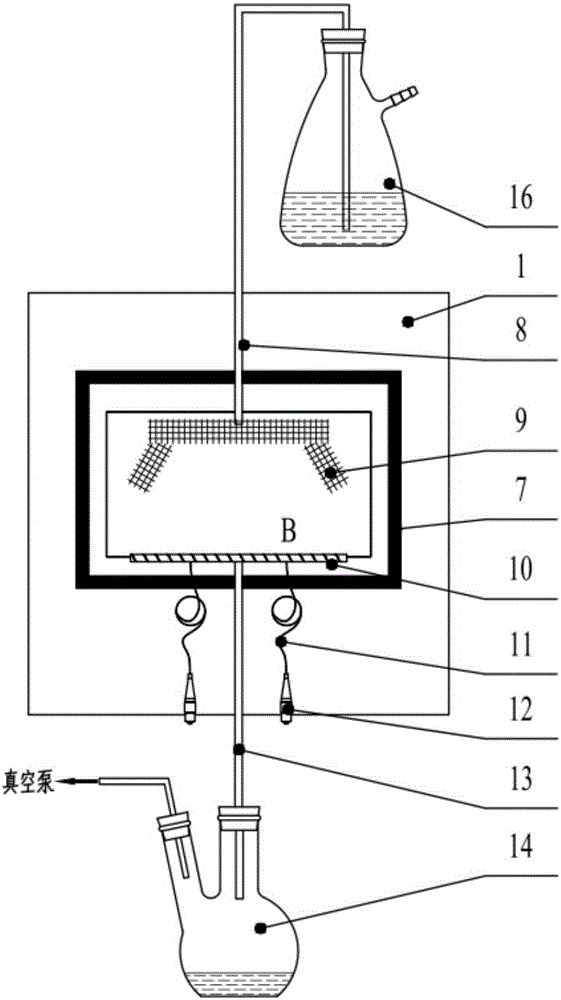

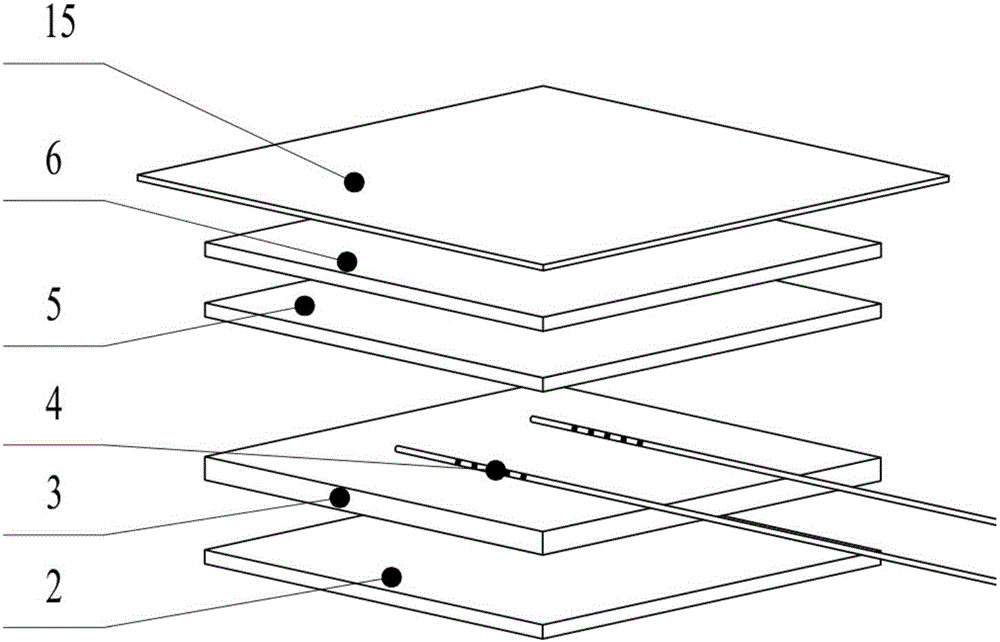

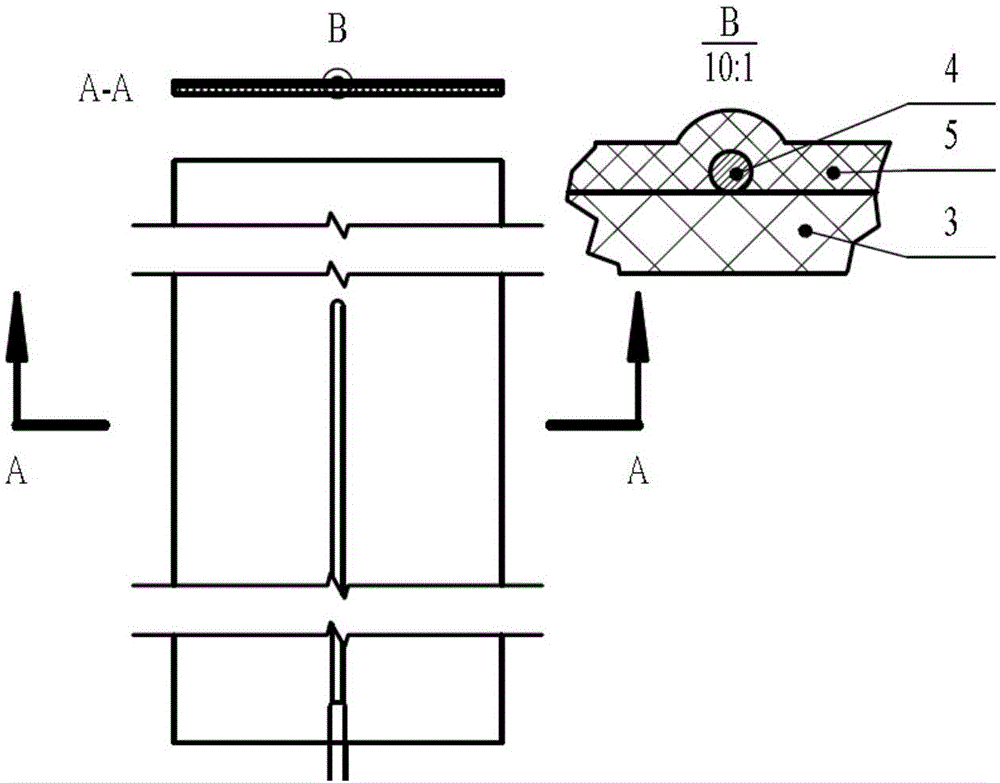

Manufacturing technology of glass fiber/epoxy resin composite material substrate type fiber bragg grating sensor

ActiveCN106633137AImprove performance and stabilityReduce internal stressMeasurement devicesOptical articlesFiberEpoxy

The invention discloses a manufacturing technology of a glass fiber / epoxy resin composite material substrate type fiber bragg grating sensor. The manufacturing technology comprises the steps that glass fiber / epoxy resin prepreg is procured to prepare a glass fiber / epoxy resin composite material substrate; a fiber bragg grating is fixed to the glass fiber / epoxy resin composite material substrate; the glass fiber / epoxy resin composite material substrate fixed with the fiber bragg grating is covered with a dry-state glass fiber cloth, vacuum aided filling of liquid epoxy resin is performed, and secondary curing molding is performed. The manufacturing technology adopts the secondary curing molding in the packaging process, the interlayer interface strength is remarkably improved, accordingly the testing precision and stability of the fiber bragg grating sensor are improved, batch production of the fiber bragg grating sensor can be achieved, and the manufacturing technology has wide market prospect and huge economic benefit.

Owner:SHANDONG UNIV

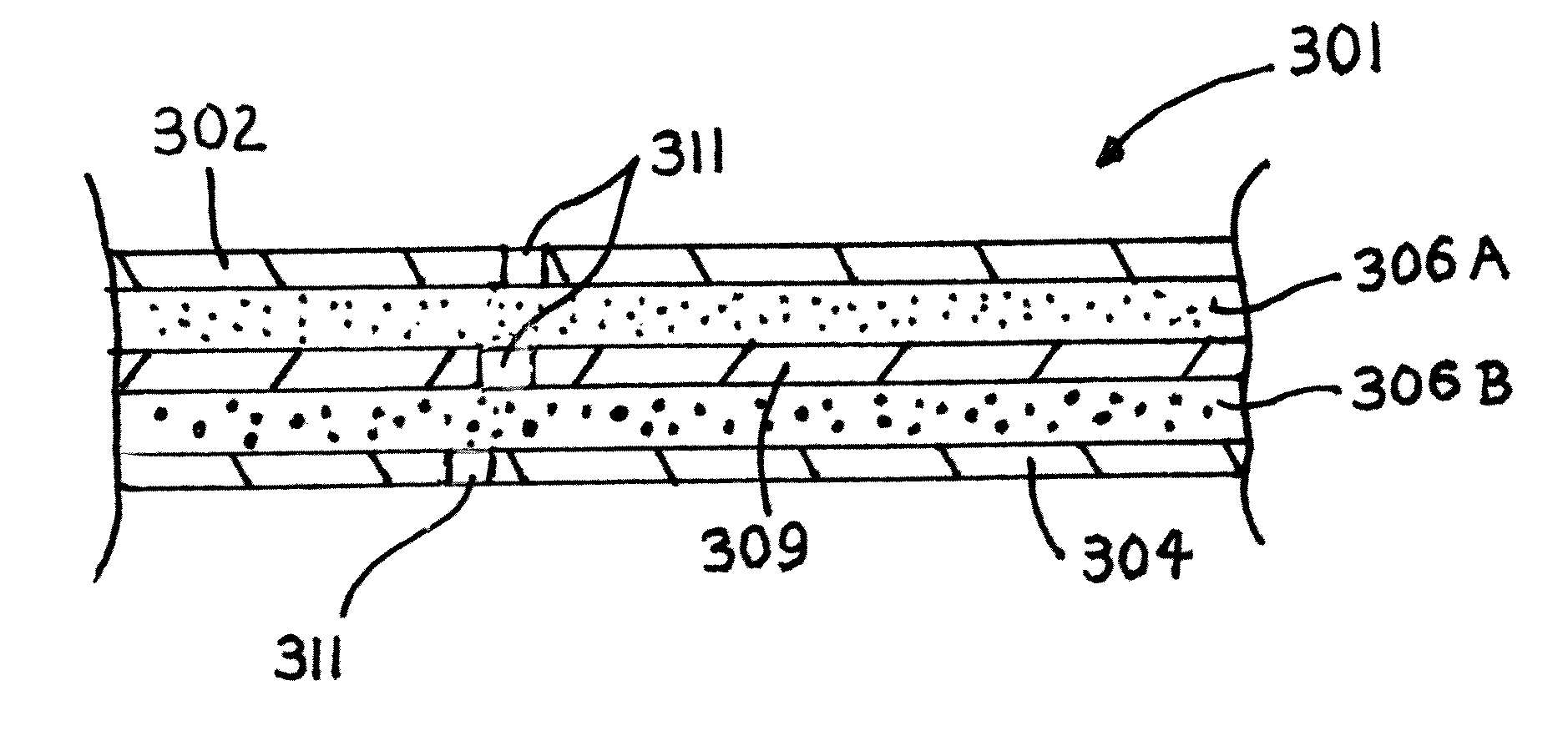

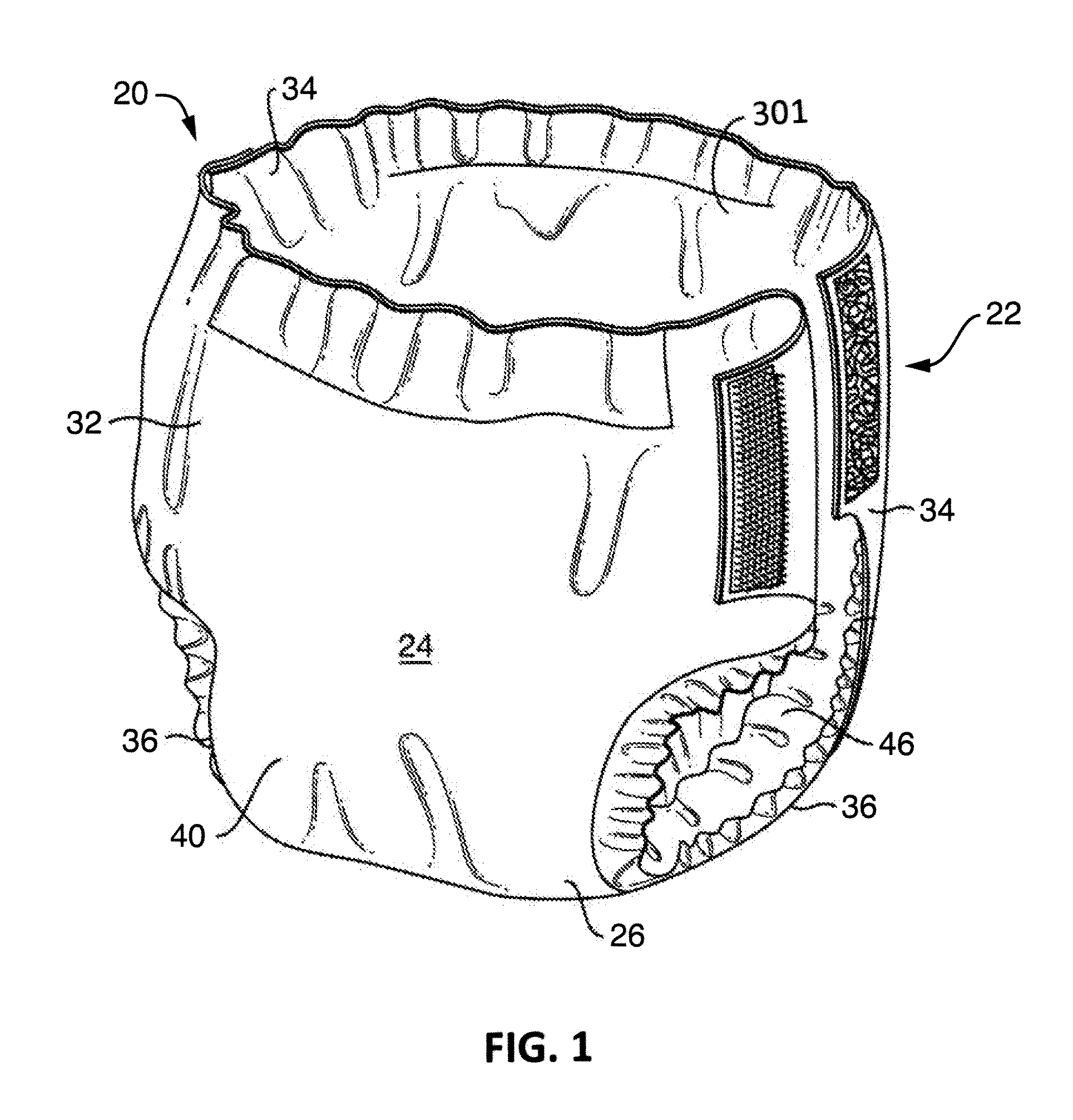

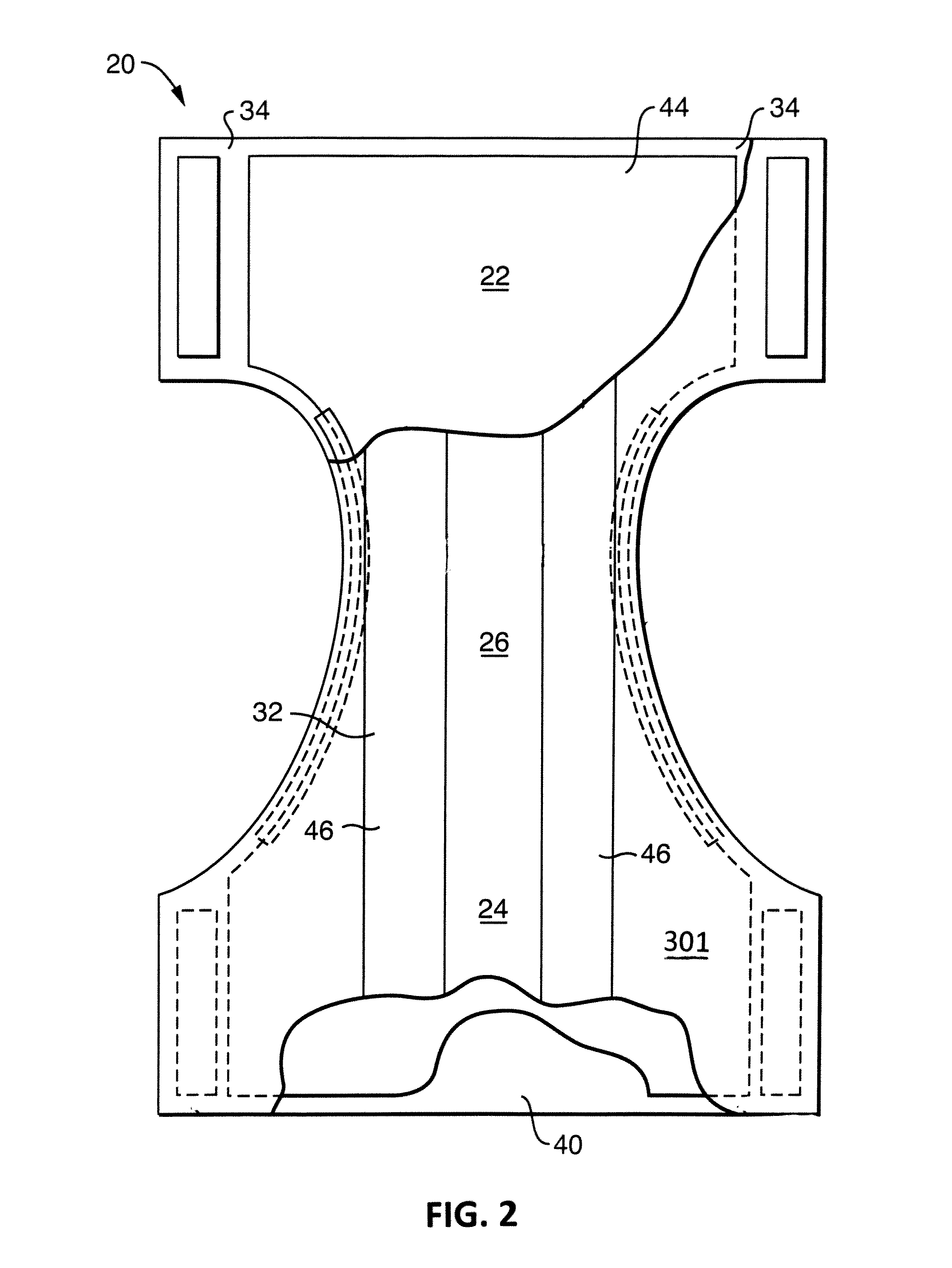

Article With Health-Benefit Agent Delivery System

A laminate having health-benefit agents therein is made by particle stabilization within the lamination process. By changing the substrate type (tissue, nonwoven, film) and / or the physical composition and / or attributes of the laminate layers, the release of the health-benefit agents can be controlled. The laminate, sometimes referred to as a liner, may be used in personal absorbent articles such as diapers, feminine pads, bandages, bed pads, and the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

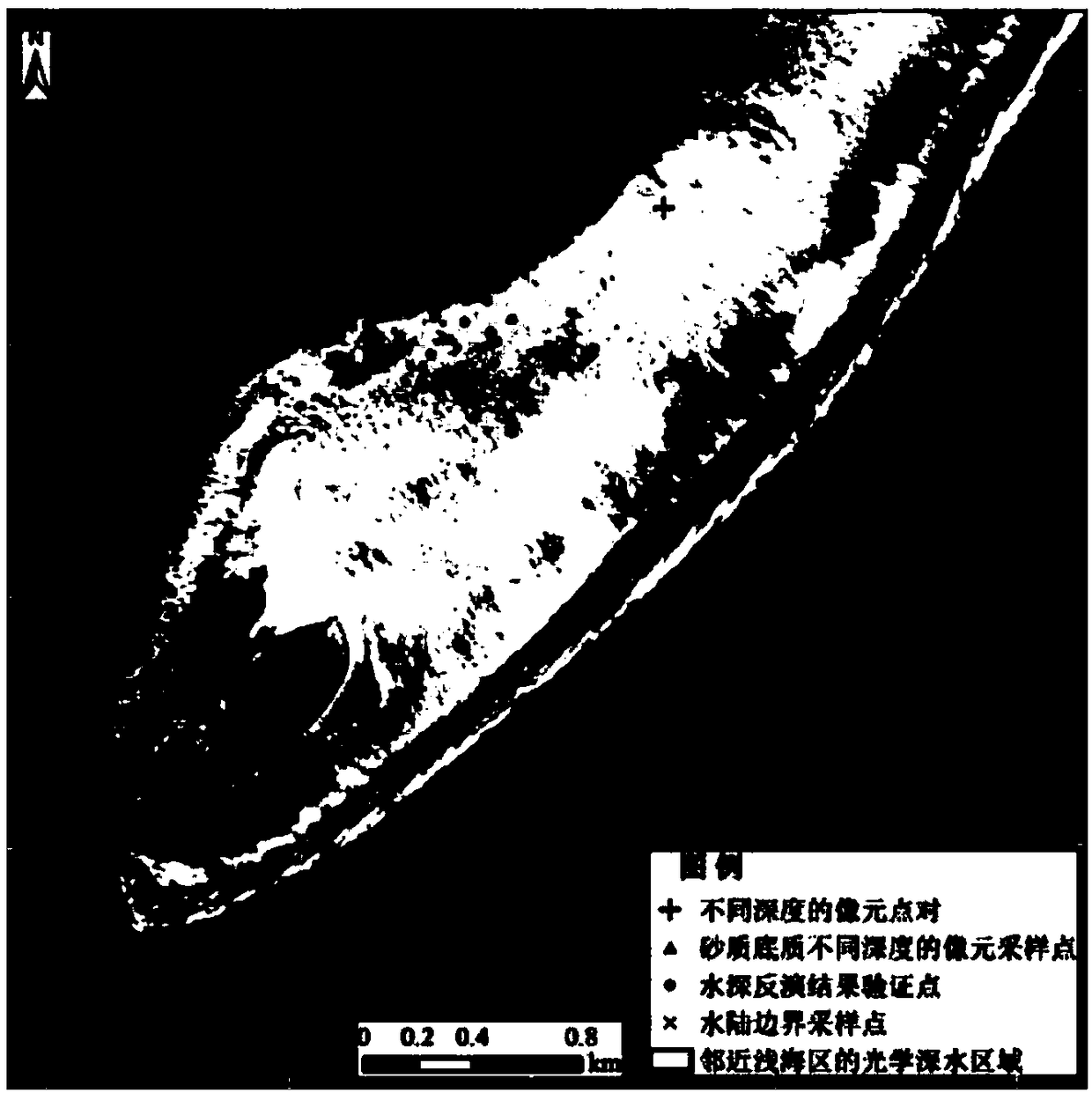

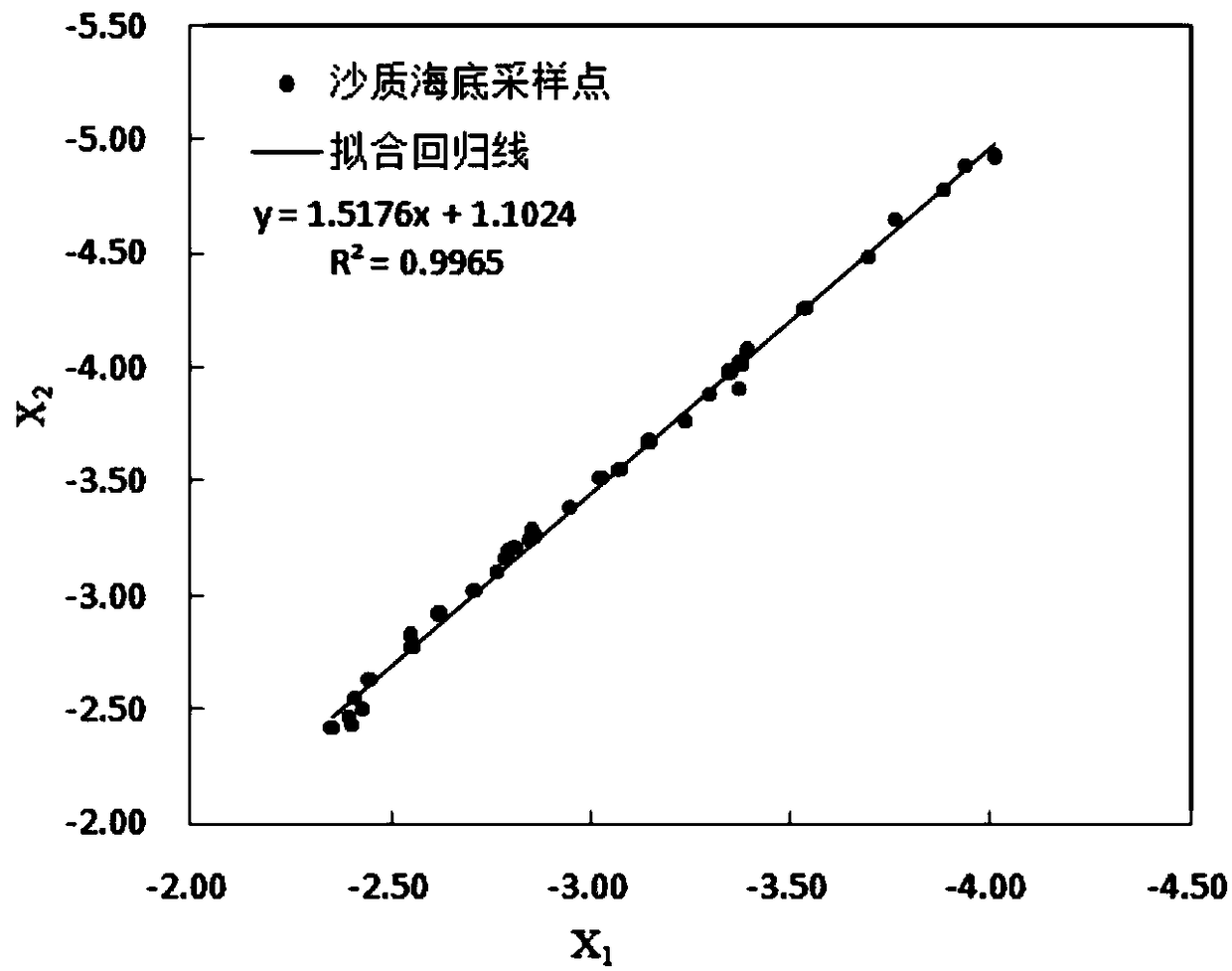

Shallow sea water depth multi-spectral satellite remote sensing inversion method in waterless depth control point area

ActiveCN109059796ARealize deep remote sensing inversionEliminate the effects of depth retrievalUsing optical meansOcean bottomData set

The invention discloses a shallow sea water depth multi-spectral satellite remote sensing inversion method in a waterless depth control point area, and belongs to the technical field of the satelliteocean remote sensing application. Based on a derived dual-band linear shallow sea water depth inversion model, solving an optimal band rotation unit vector through different depths of different submarine types of pixel points dataset, estimating subsea parameters in the model based on a typical substrate type pixel adoption of a position of a land and water boundary line, calculating a blue-greenband diffusion attenuation coefficient ratio and based on deep water area data closest to a shallow sea area through the same type of substrate and different depths of pixel data, and calculating thegreen band attenuation coefficient based on a semi-analytic and diffuse attenuation coefficient algorithm. According to the shallow sea water depth multi-spectral satellite remote sensing inversion method in the waterless depth control point area, the shallow sea water depth remote sensing inversion in the waterless depth control point area is realized through the calculation of the above parameters.

Owner:THIRD INST OF OCEANOGRAPHY MINIST OF NATURAL RESOURCES

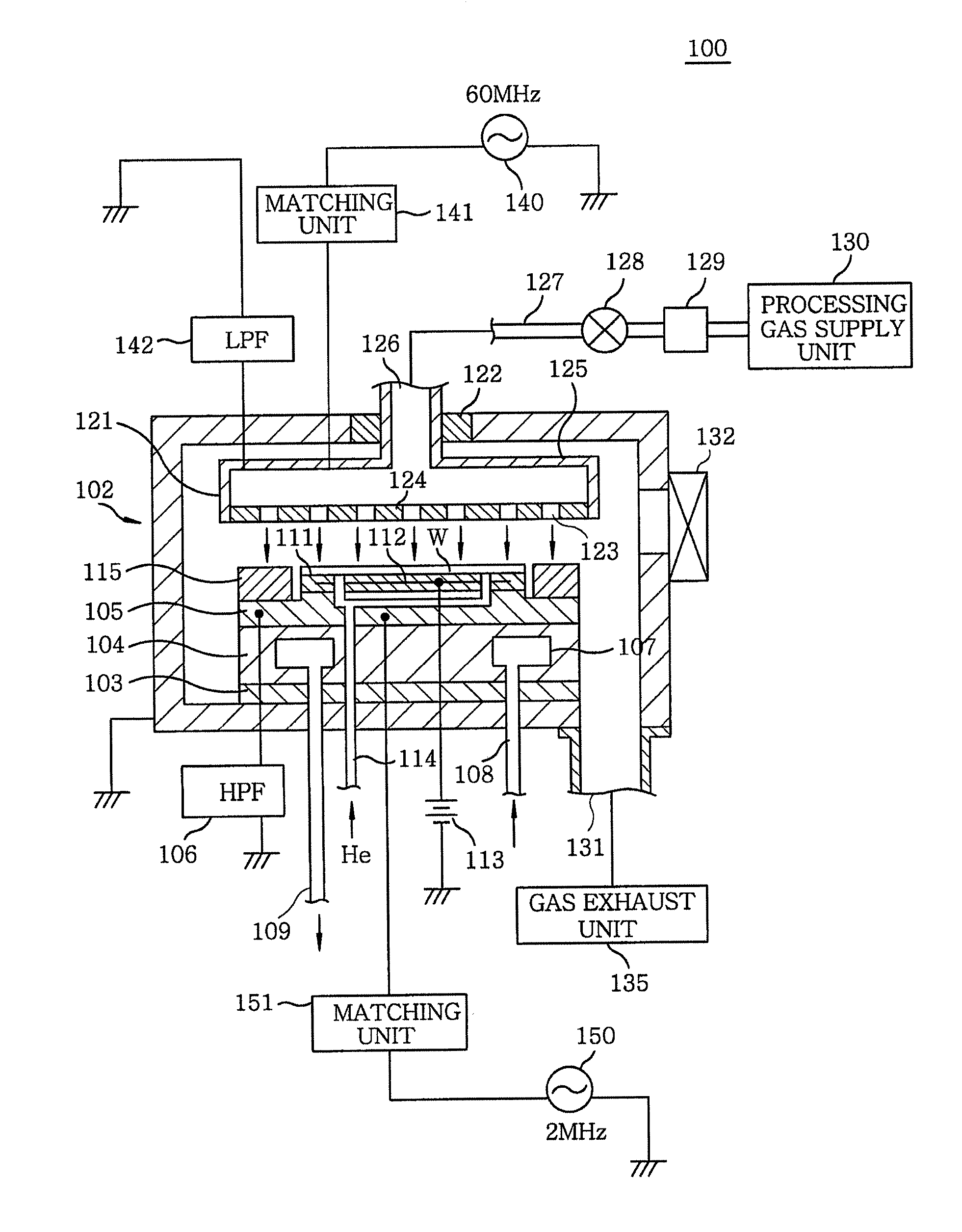

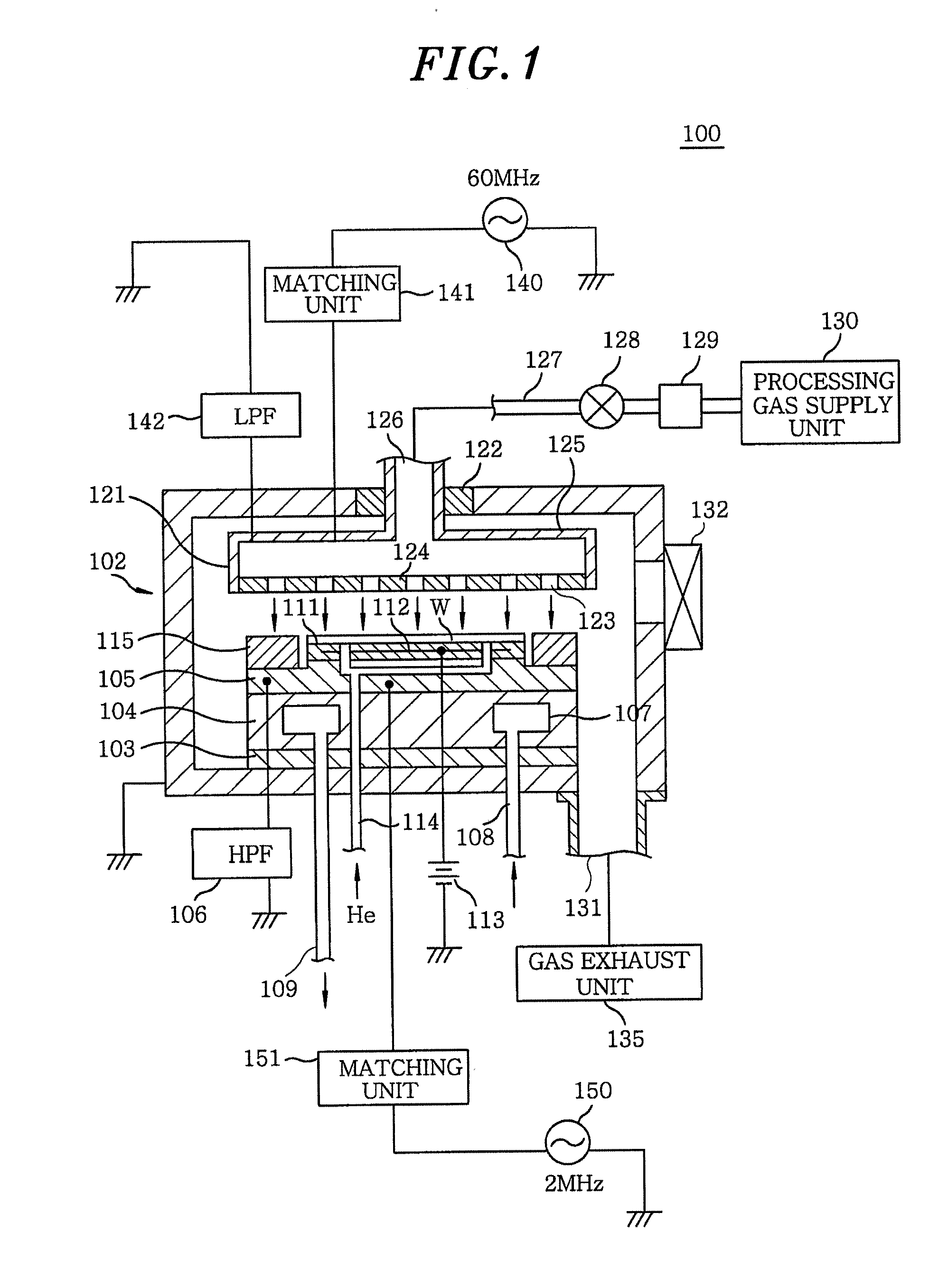

Plasma processing method and plasma processing apparatus

ActiveUS20080070327A1Accurate detectionSemiconductor/solid-state device testing/measurementElectric discharge tubesSubstrate typeData set

In a plasma processing method, a correlation between substrate type data and optical data is obtained by using a multivariate analysis; substrate type data is obtained from optical data based on the correlation when initiating a plasma processing; and a substrate type is determined by using the obtained substrate type data. Further, a setting data set corresponding to the determined substrate type is selected from setting data sets, each for detecting a plasma processing end point of the plasma processing, each of the setting data sets being stored in advance in a data storage unit; an end point of the plasma processing is detected based on the selected setting data set; and the plasma processing is terminated at the detected end point.

Owner:TOKYO ELECTRON LTD

Sprayable liquid emulsion polymer coating compositions

InactiveUS20100041772A1Convenient coatingShortened life-spanBiocideOther chemical processesOxygenMoisture

Sprayable liquid emulsion polymer coating compositions comprised of polymer resin and a plurality of additives for the purpose of protecting, restoring, reconditioning, rejuvenating, and enhancing the color, luster and durability of a multitude of different newer and older substrate types. These coating and sealing compositions are anti-mold, anti-graffiti, they withstand temperatures up to, and most likely in excess of, 300 degrees Fahrenheit without compromising their structural integrity, and they protect against the substrate-degrading effects of oxygen, ozone, UV-radiation, moisture and dry rot. They are also environmentally and user-friendly because they comprise minimal amounts of hazardous constituents.

Owner:LIVERSAGE ROBERT RICHARD +1

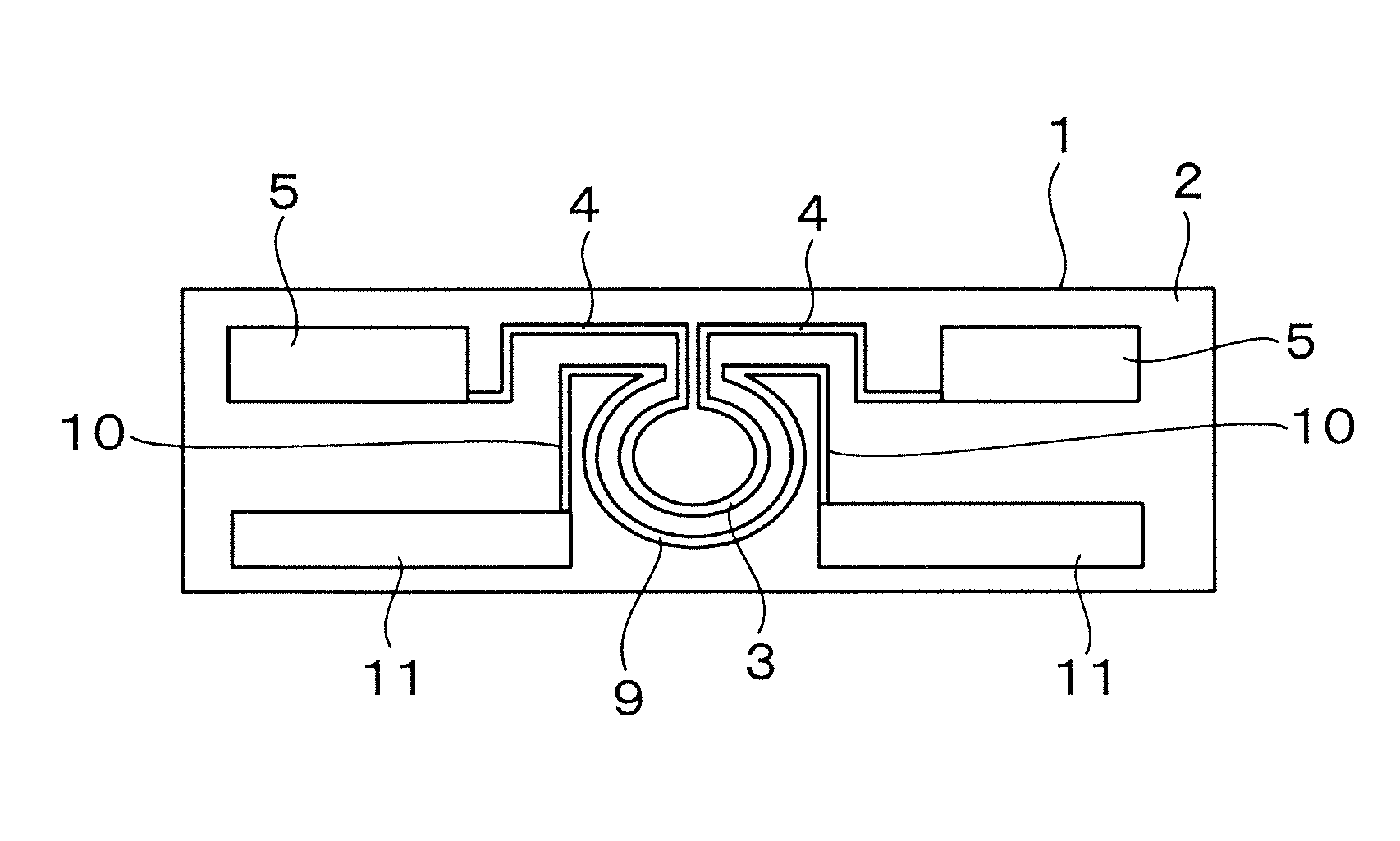

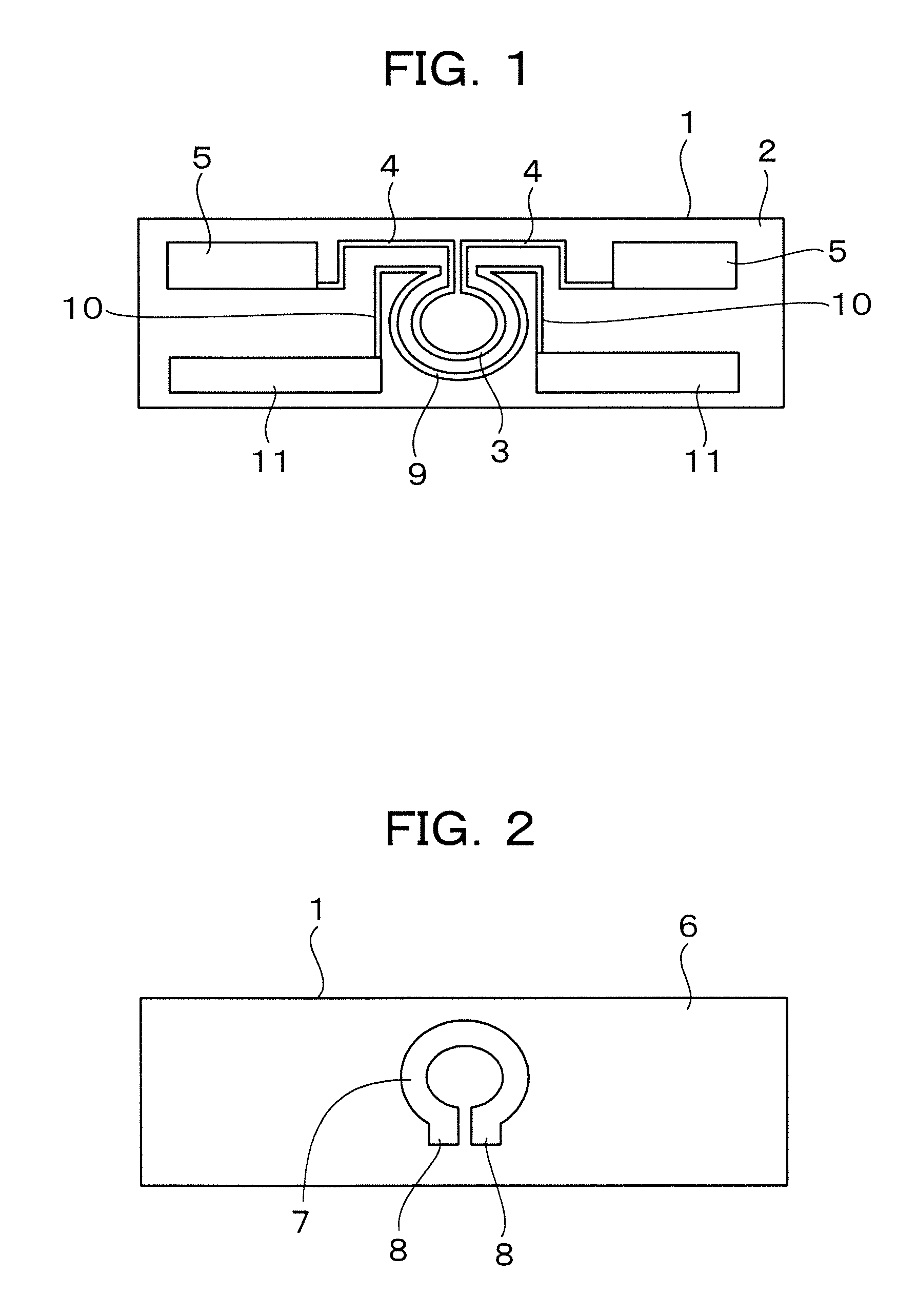

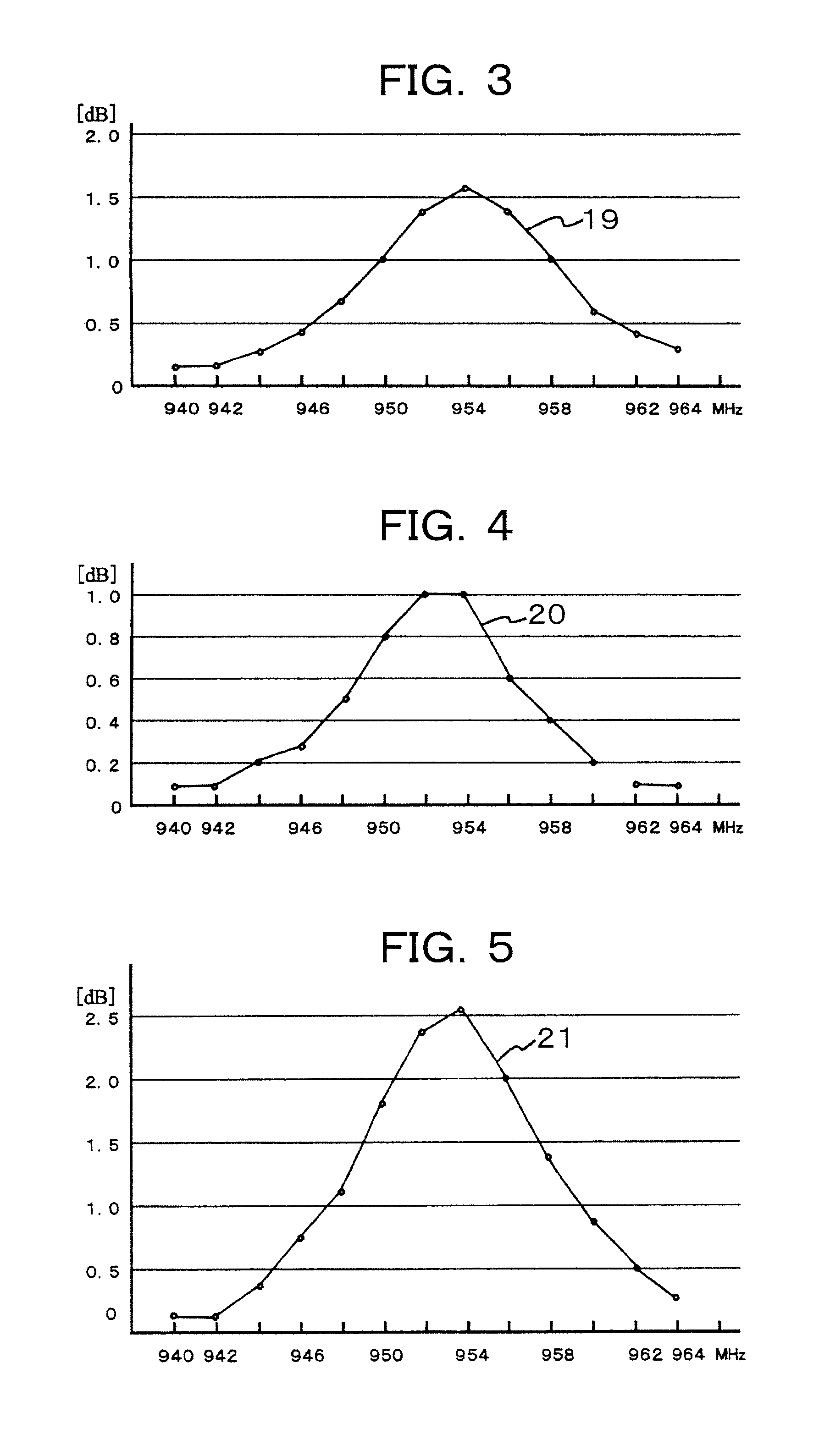

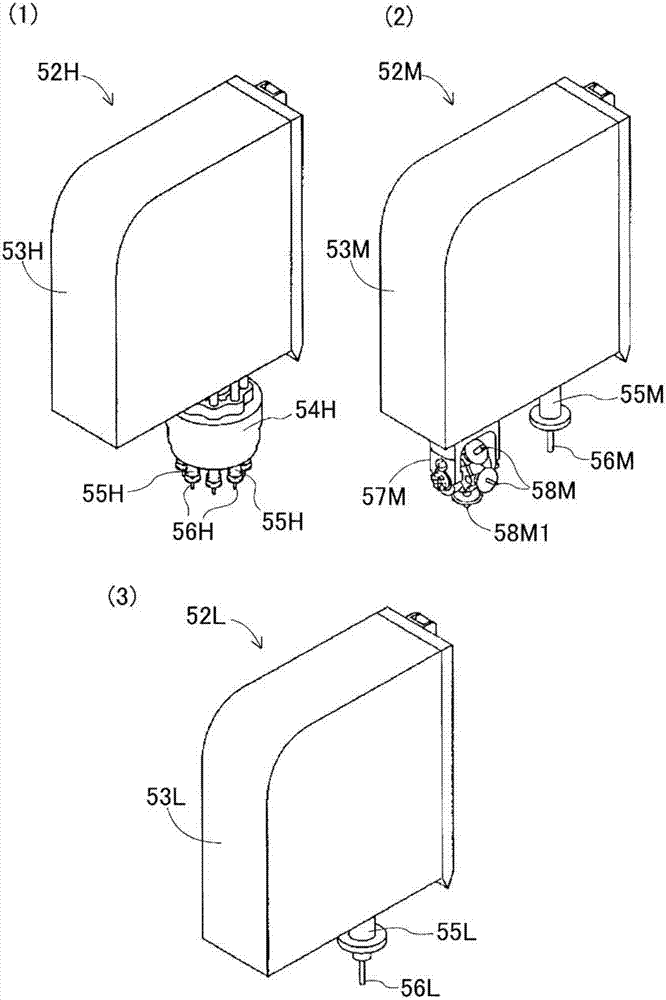

Substrate type antenna

ActiveUS8743007B2High gain enhancementSimple configurationSimultaneous aerial operationsIndividually energised antenna arraysSubstrate typeEngineering

The present invention provides a substrate type antenna capable of realizing high gain enhancement and high band enhancement in a simple configuration. In the substrate type antenna, a loop-like first joint pattern whose one spot is divided, is formed in one substrate surface of a substrate made of a dielectric material. Antennas are respectively connected to both end terminals of the first joint pattern at a position where the first joint pattern is divided. A loop-like second joint pattern formed at a position corresponding to the first joint pattern and whose one spot is divided, is formed in the other substrate surface of the substrate. A loop-like third joint pattern which is substantially concentric with the first joint pattern and which is formed at a position corresponding to the second joint pattern and whose spot is divided, is formed in the one substrate surface of the substrate. Other antennas are respectively connected to both end terminals of the third joint pattern at a position where the third joint pattern is divided.

Owner:NISSEI LTD +1

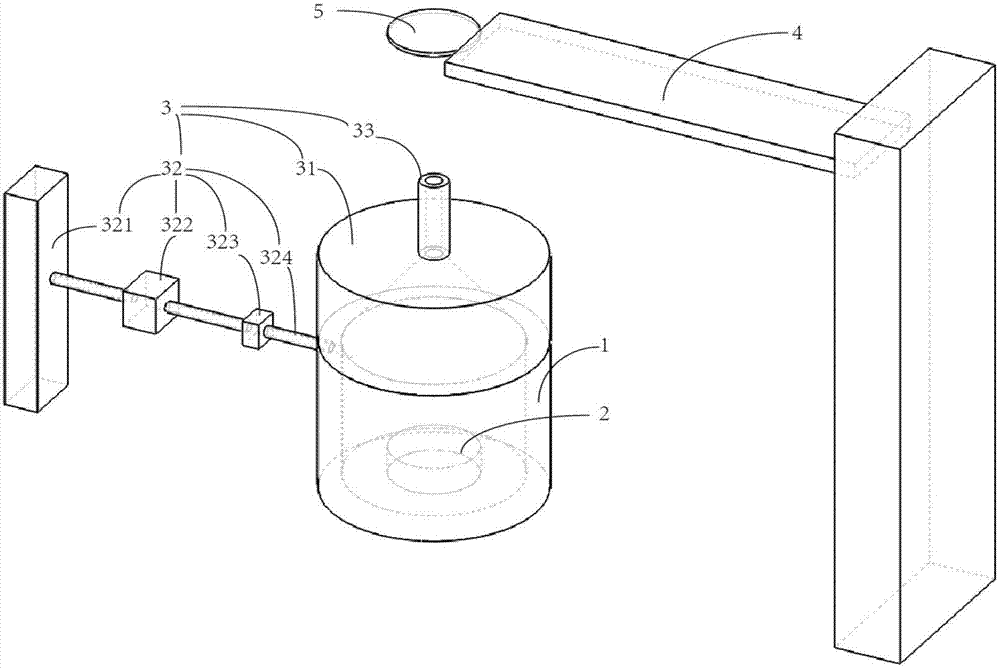

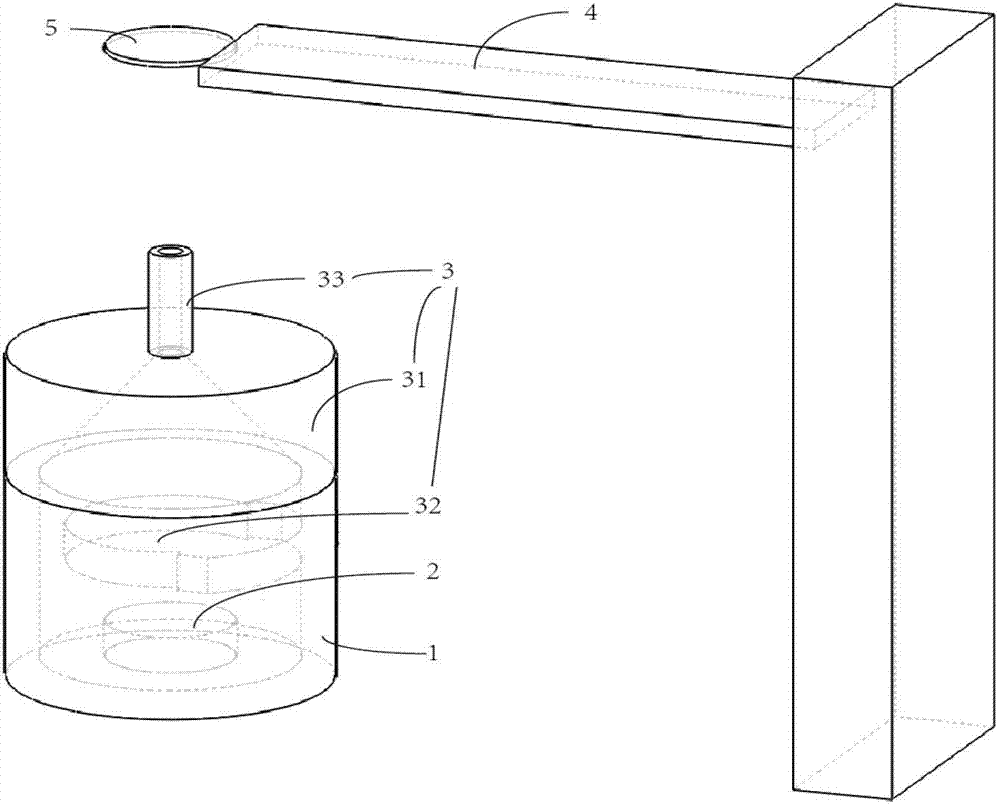

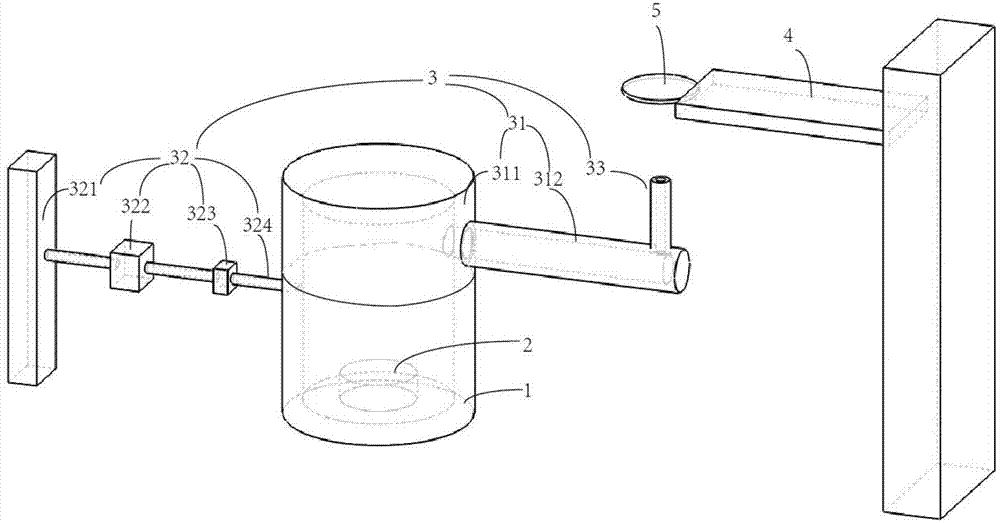

High-adaptability uniform film formation method and device for nanomaterial on substrate

ActiveCN103043601AUnderstand the purposeLearn about featuresMaterial nanotechnologyDecorative surface effectsSubstrate typeEngineering

The invention discloses a high-adaptability uniform film formation method for a nanomaterial on a substrate. The method comprises the steps of preparing nanomaterial mixed liquid or a nanomaterial solution, producing a carrier gas flow field, forming atomized nanomaterial drops, and allowing the carrier gas flow field to drive the atomized nanomaterial drops to be sprayed onto the surface of the substrate vertically and upwards. The invention further discloses a high-adaptability uniform film formation device for the nanomaterial on the substrate. The device comprises a liquid sampling container, an ultrasonic atomizer, an ascending air flow generator and a system state controller. The uniform carrier gas flow field can be produced to realize uniform atomized drop flow, the covering uniformity of the atomized drops on the surface of the substrate is greatly improved, the film formation uniformity of the nanomaterial is improved, and the film formation thickness can be better controlled. In addition, the method and the device have high adaptability to factors such as an operational environment, the substrate type and the nanomaterial type.

Owner:SHANGHAI JIAO TONG UNIV

Component installing wire

ActiveCN102958343AShorten the timeIncrease productivityElectrical componentsSubstrate typeEngineering

A component installing wire is provided. An installing wire can be used for determining types of installing heads through shortening time required by installing without replacing installing heads during the process of subsequently producing a plurality of substrate types, thus production efficiency can be enhanced. The component installing wire is provided with multiple stages of component installing machines in series-connection way. The component installing machine is provided with a substrate carrying device, a component supplying device, a component moving device with an installing head and a head driving mechanism, the component moving device can be used for selectively installing a plurality of installing heads, the component installing wire is also provided with a movement condition determining mechanism, the type of an installing head of each component installing machine is determined before executing component installing movement, and distribution of component kinds accommodated in a plurality of component accommodating devices of each component installing machine can be determined, thus time required by installing can be shortened, and the time can be presumed without replacing the installing heads during the process of installing components.

Owner:FUJI KK

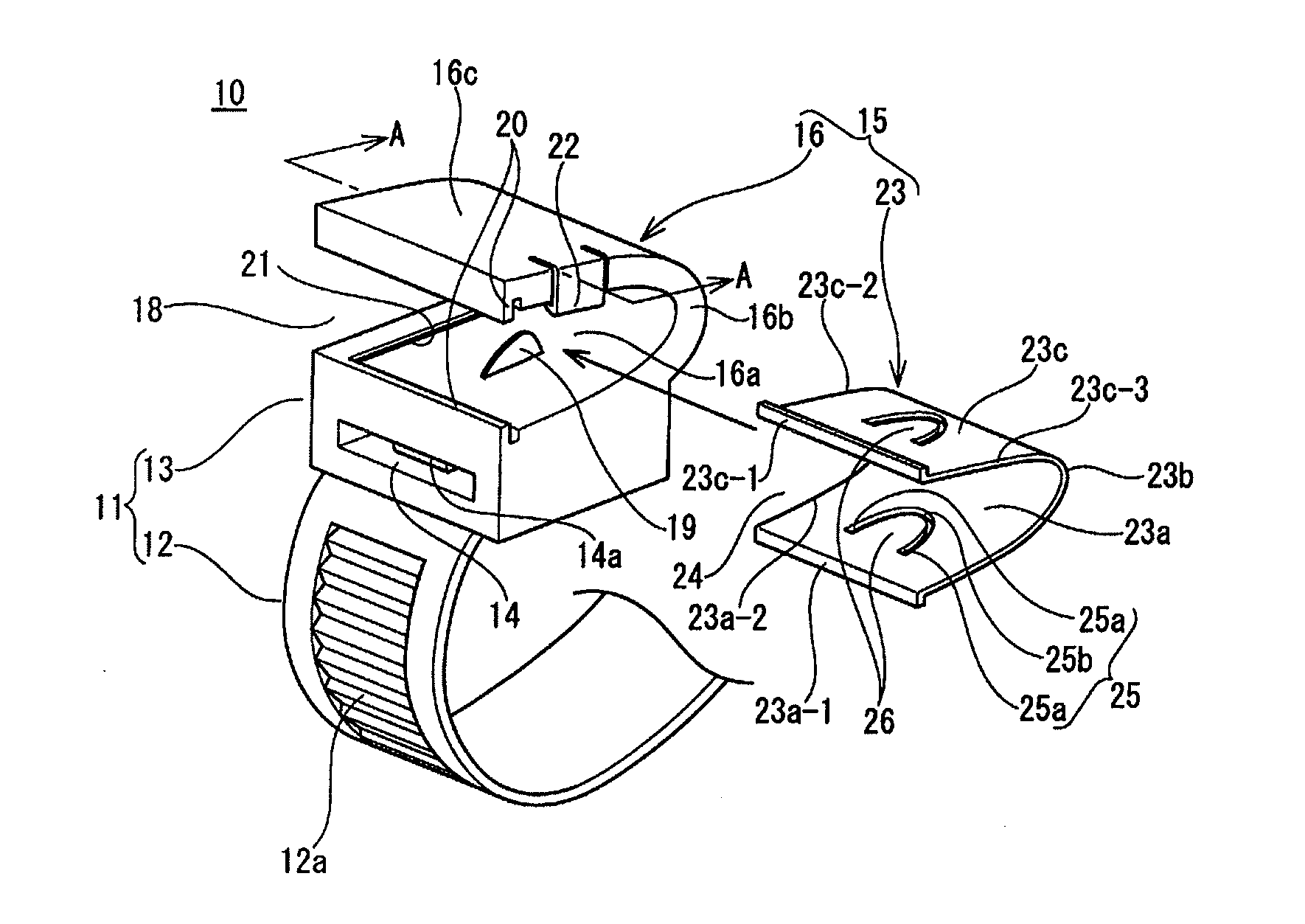

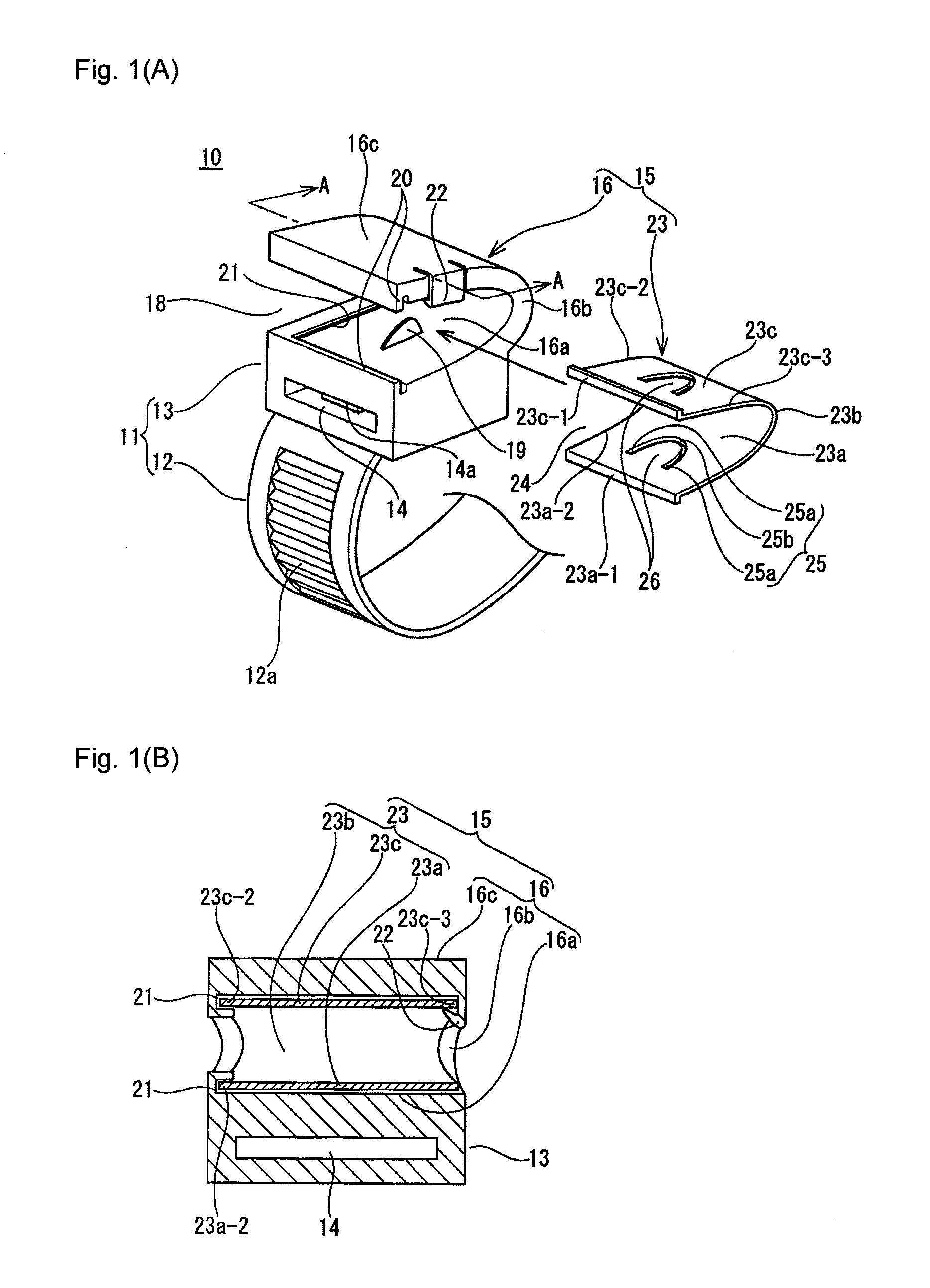

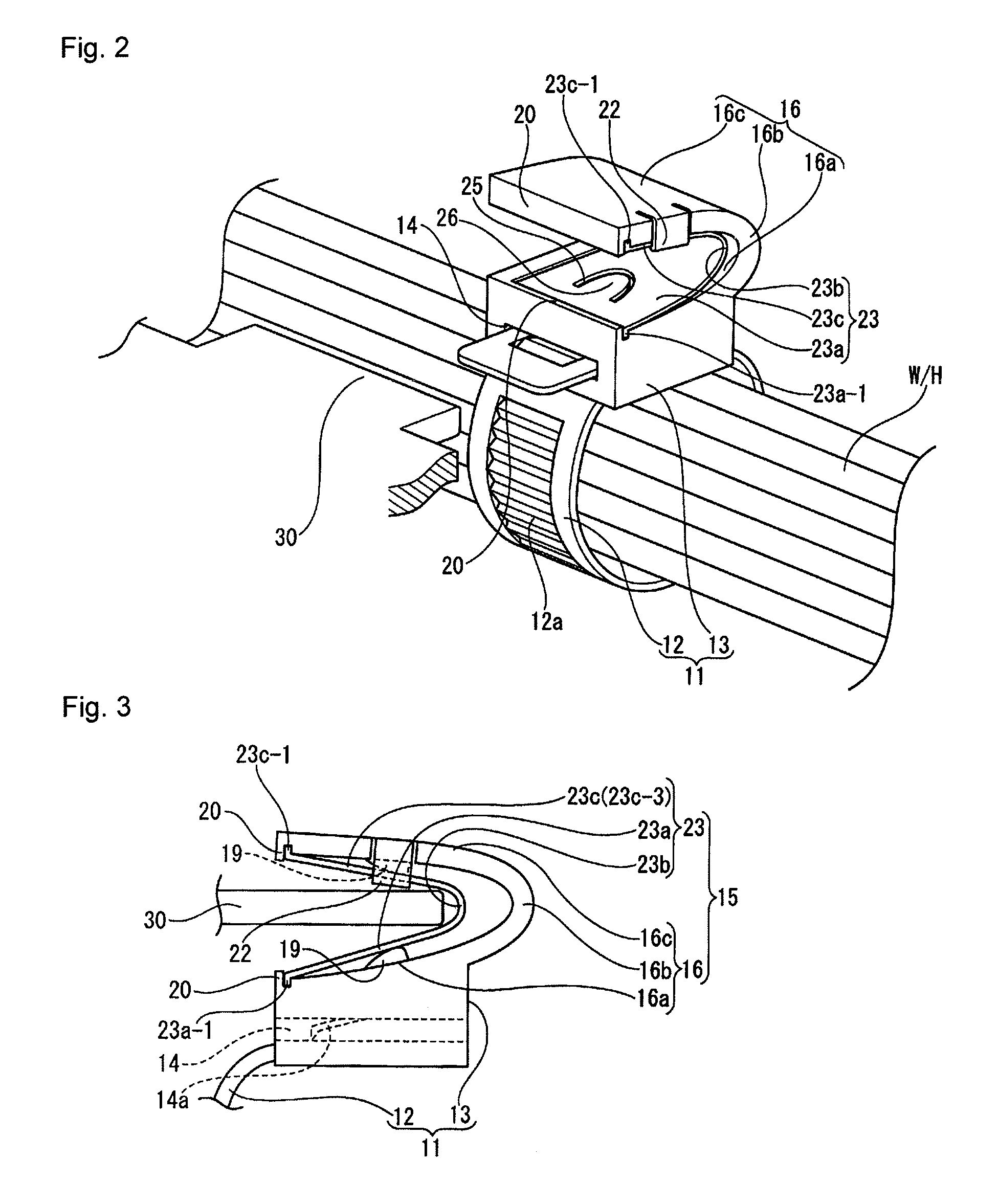

Wire harness clip and method of mounting wire harness clip onto vehicle

Owner:SUMITOMO WIRING SYST LTD

Integrated circuit comprising a photodiode of the floating substrate type and corresponding fabrication process

InactiveUS7875915B2Readily biasedSolid-state devicesSemiconductor/solid-state device manufacturingSubstrate typePhotodiode

An integrated circuit includes at least one photodiode associated with a read transistor. The photodiode is formed from a stack of three semiconductor layers comprising a buried layer, an floating substrate layer and an upper layer. The drain region and / or the source region of the transistor are incorporated within the upper layer. The buried layer is electrically isolated from the upper layer so as to allow the buried layer to be biased independently of the upper layer.

Owner:STMICROELECTRONICS SRL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com