Patents

Literature

40results about How to "Avoid easy disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

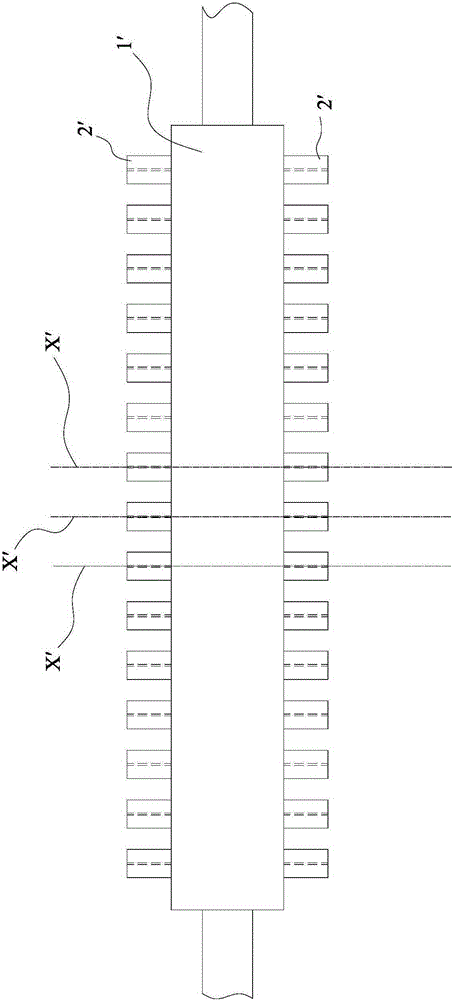

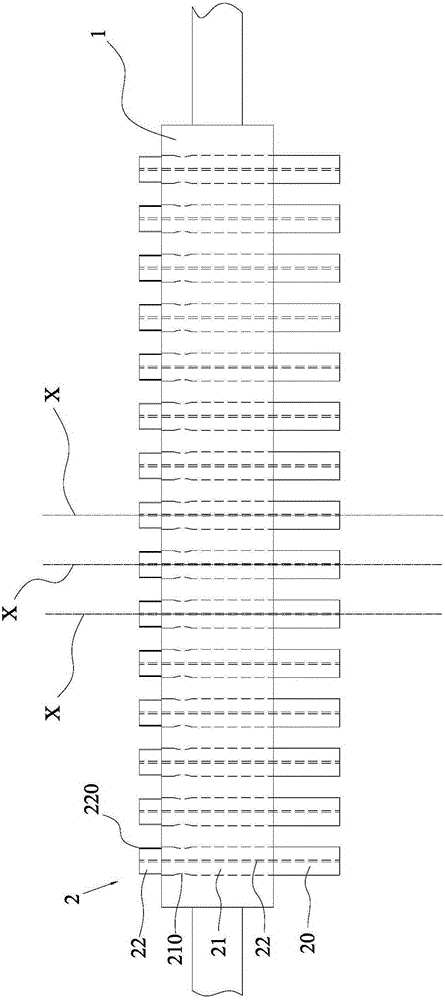

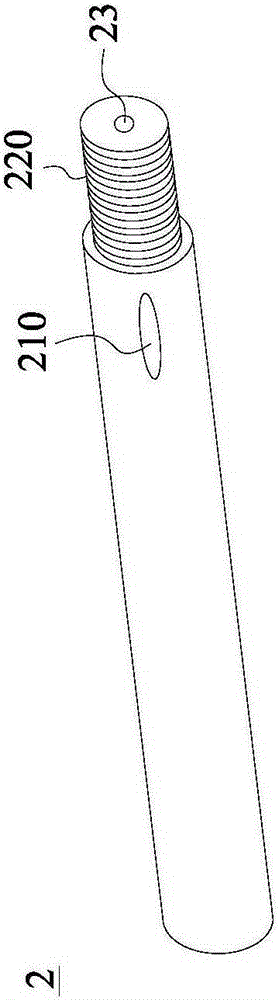

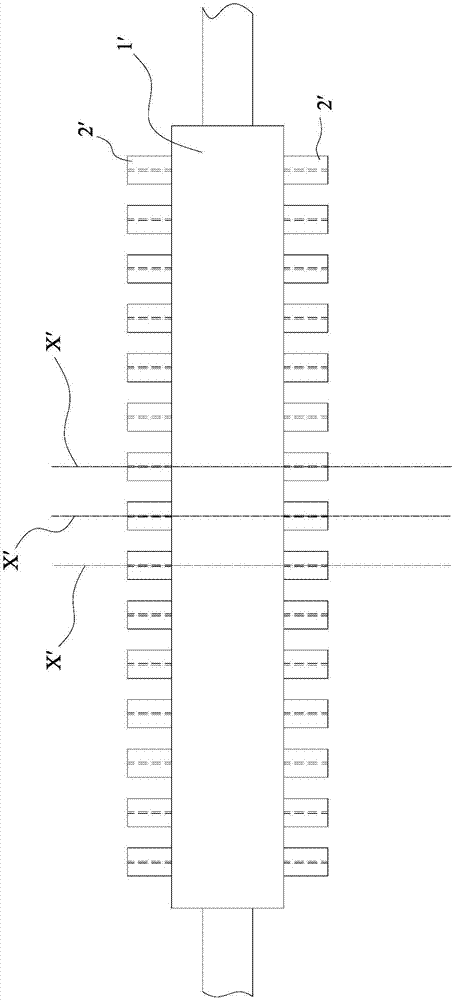

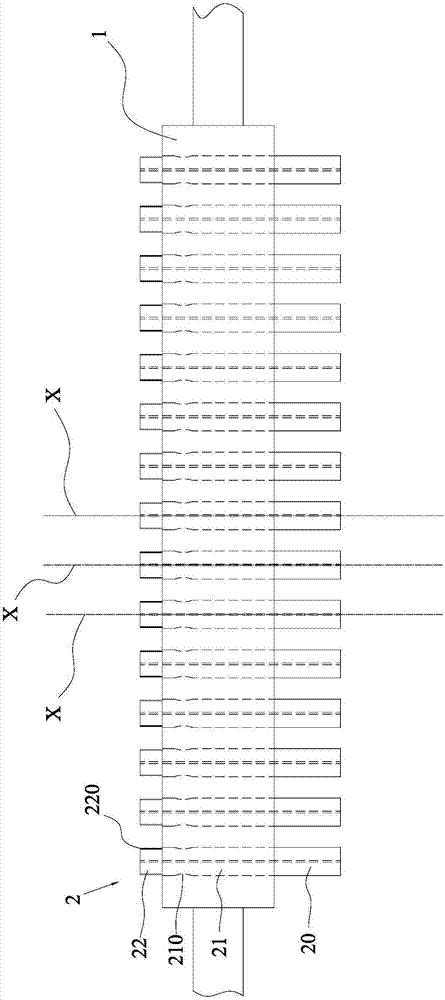

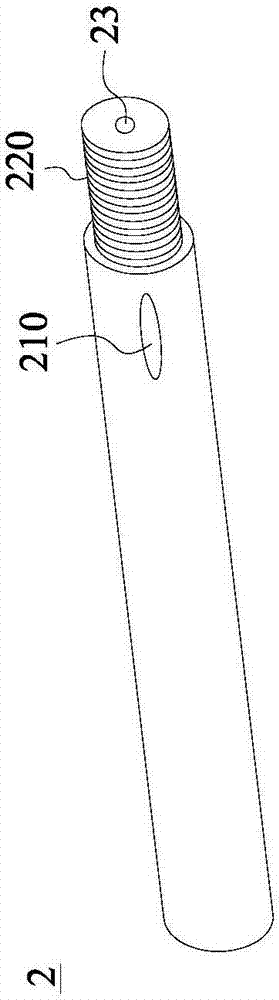

Sensing structure

InactiveCN105278739AGood pass rateGood sensing abilityInput/output processes for data processingEngineeringElectrical and Electronics engineering

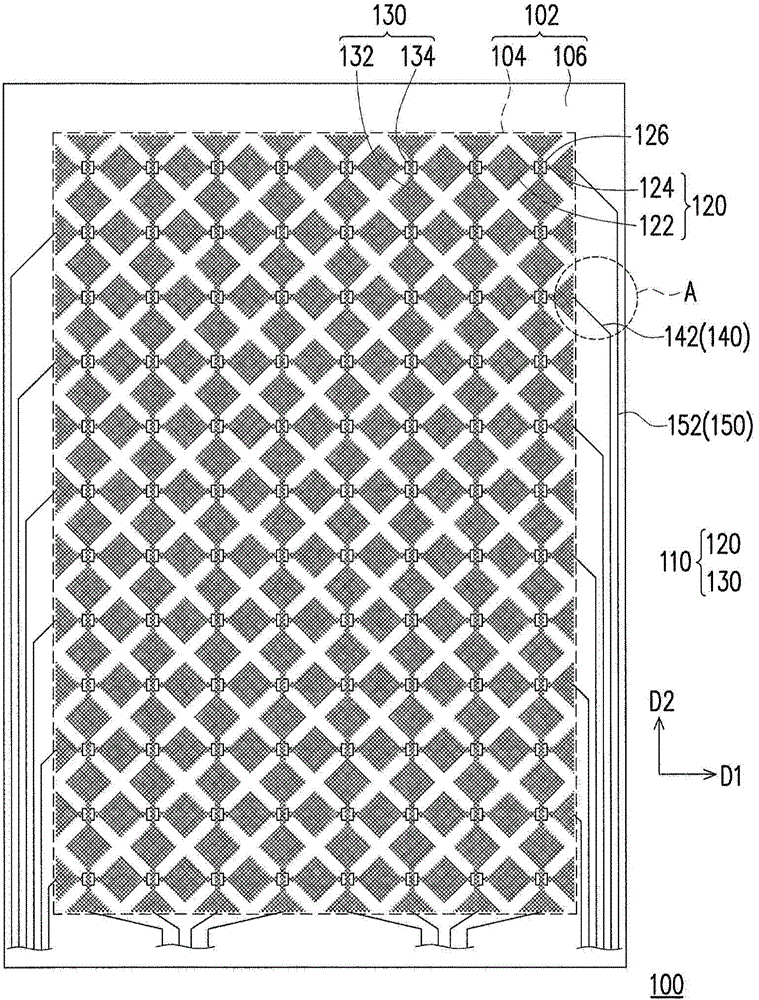

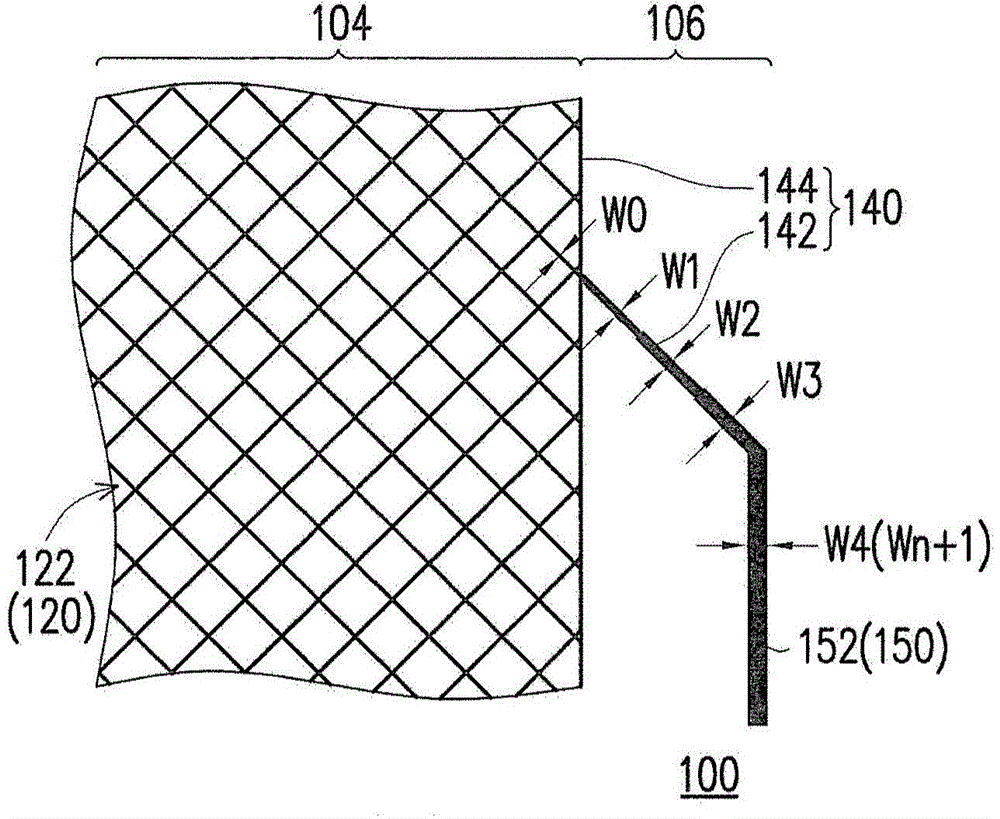

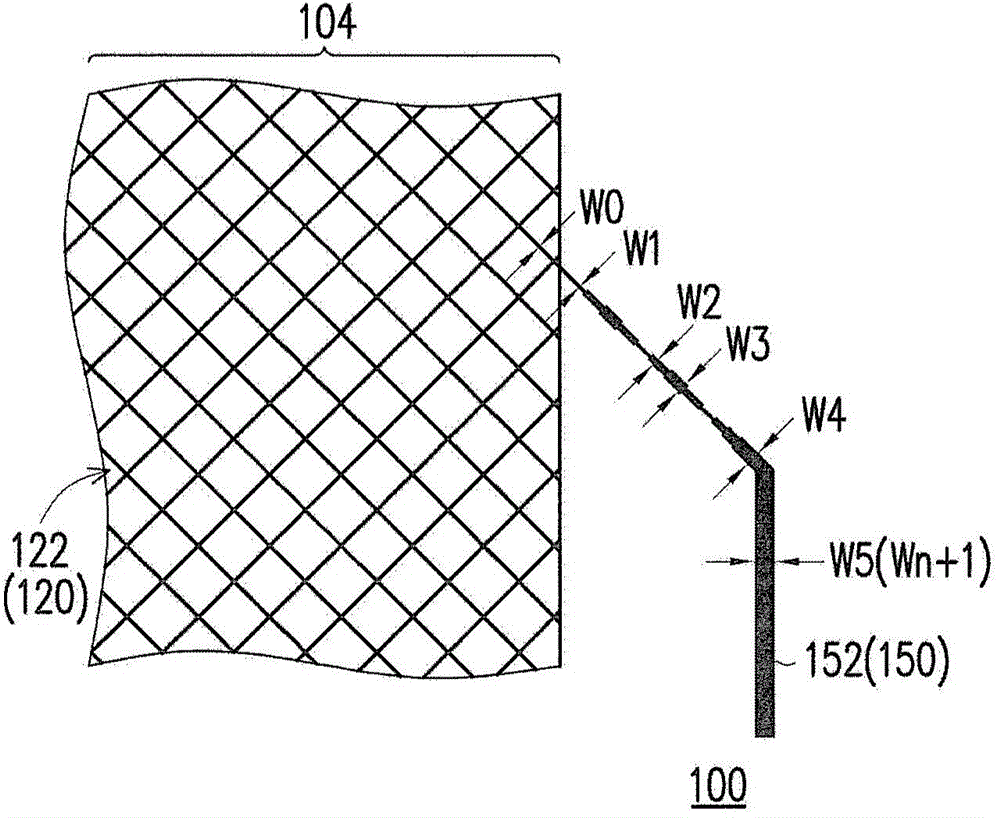

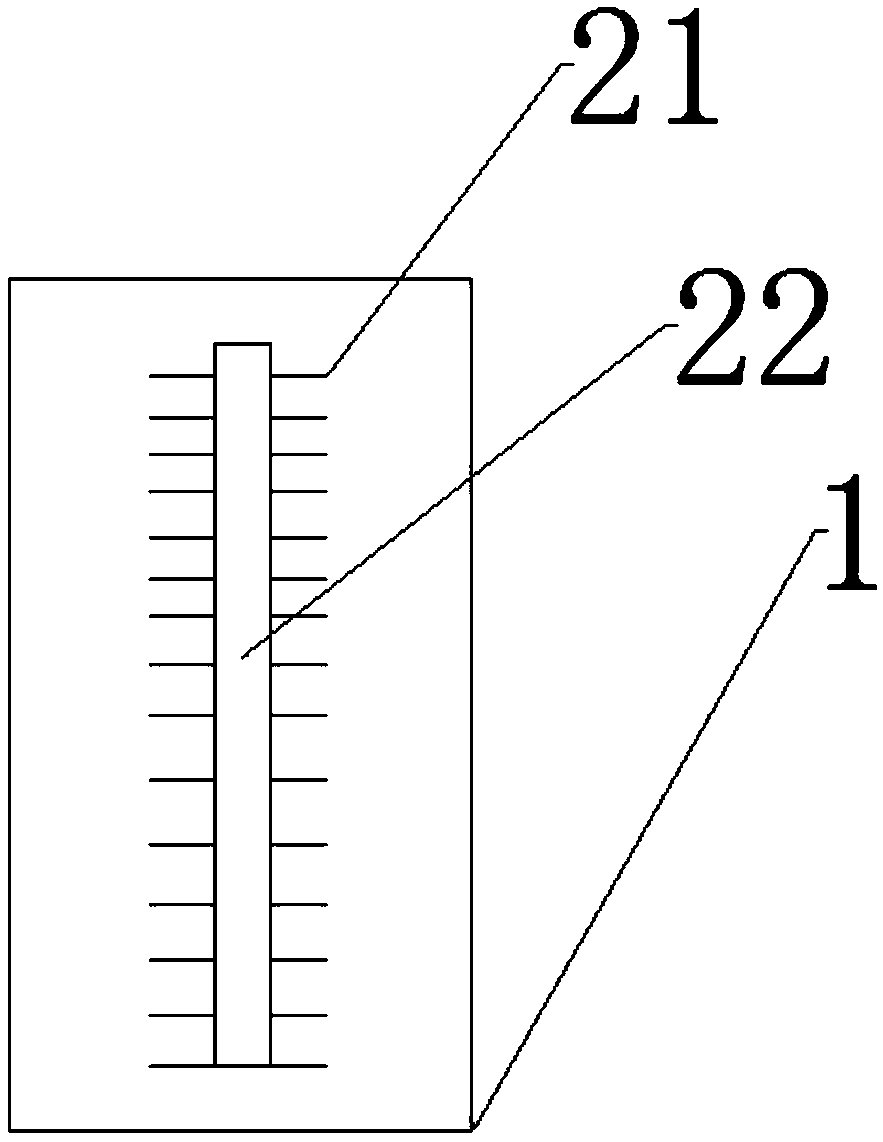

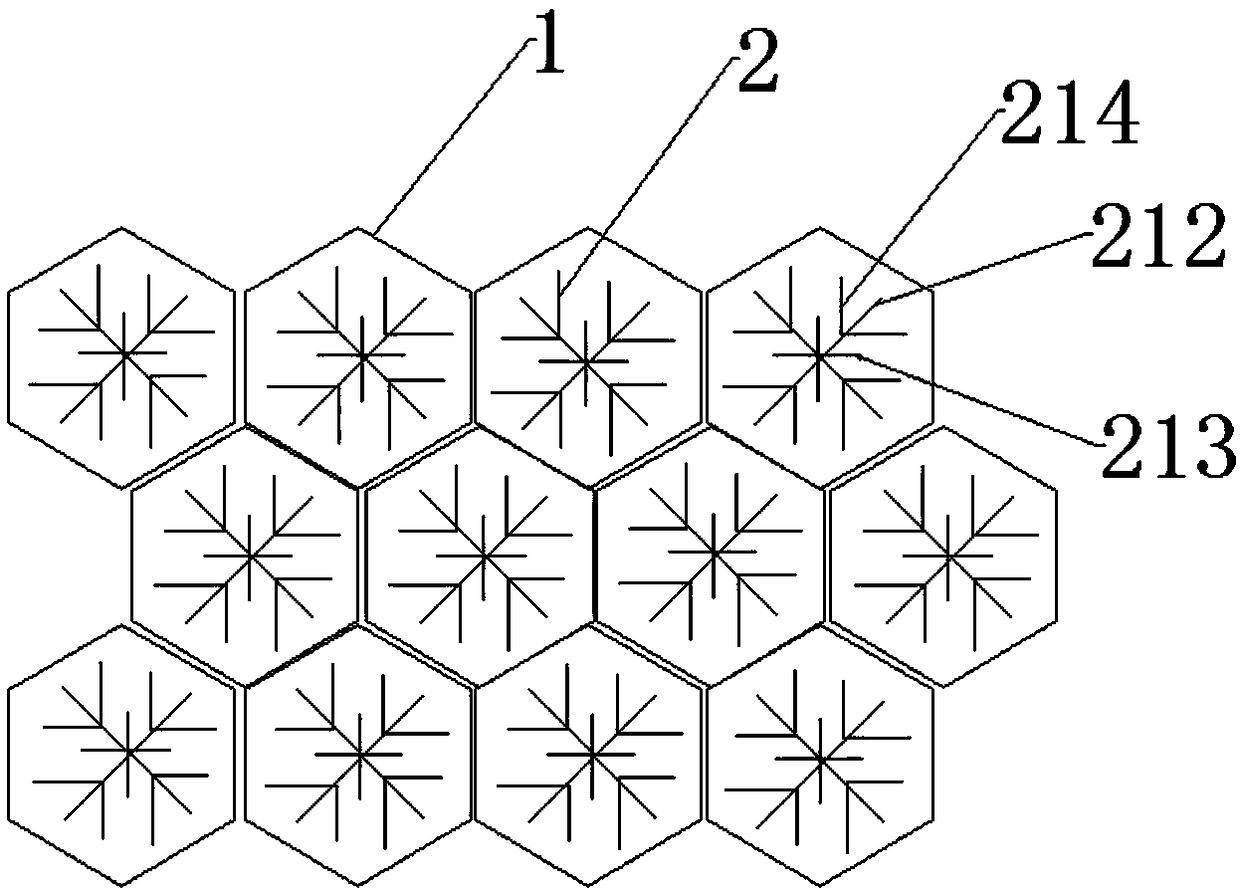

Disclosed is a sensing structure including a sensing unit, a periphery circuit, and a connecting circuit. The connecting circuit connecting the sensing unit and the periphery circuit includes a connecting pattern. In an embodiment, the connecting pattern has at least two line widths. The line width of a part of the connecting pattern connecting the periphery circuit is greater than the line width of a part of the connecting pattern connecting the sensing unit. In an embodiment, the connecting pattern includes a mesh pattern having at least two mesh densities. The mesh density of a part of the mesh pattern connecting the periphery circuit is greater than the mesh density of a part of the mesh pattern connecting the sensing unit. In an embodiment, the connecting circuit includes lines between and connecting a single sensing series of the sensing unit and a periphery wire of the periphery circuit.

Owner:IND TECH RES INST

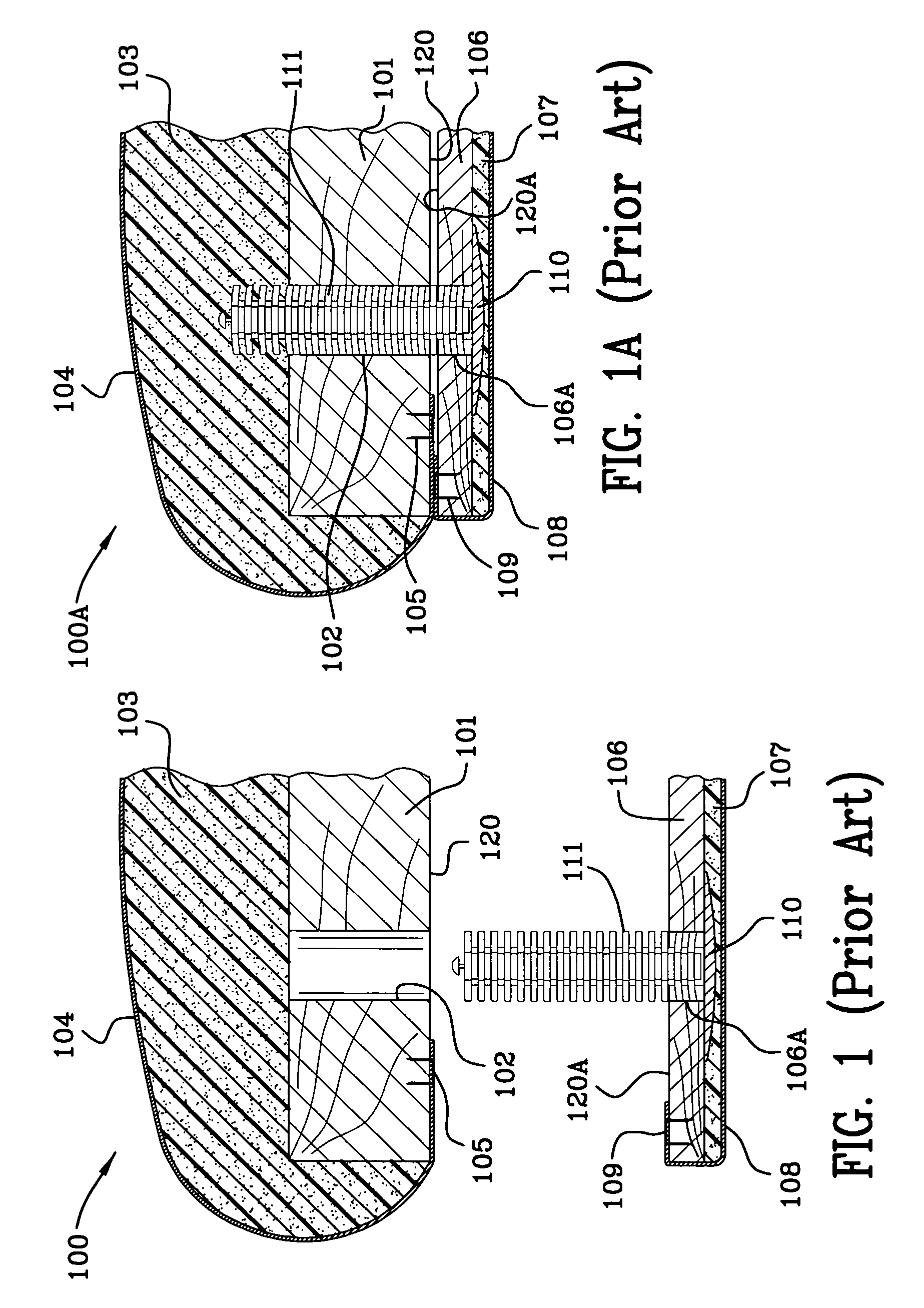

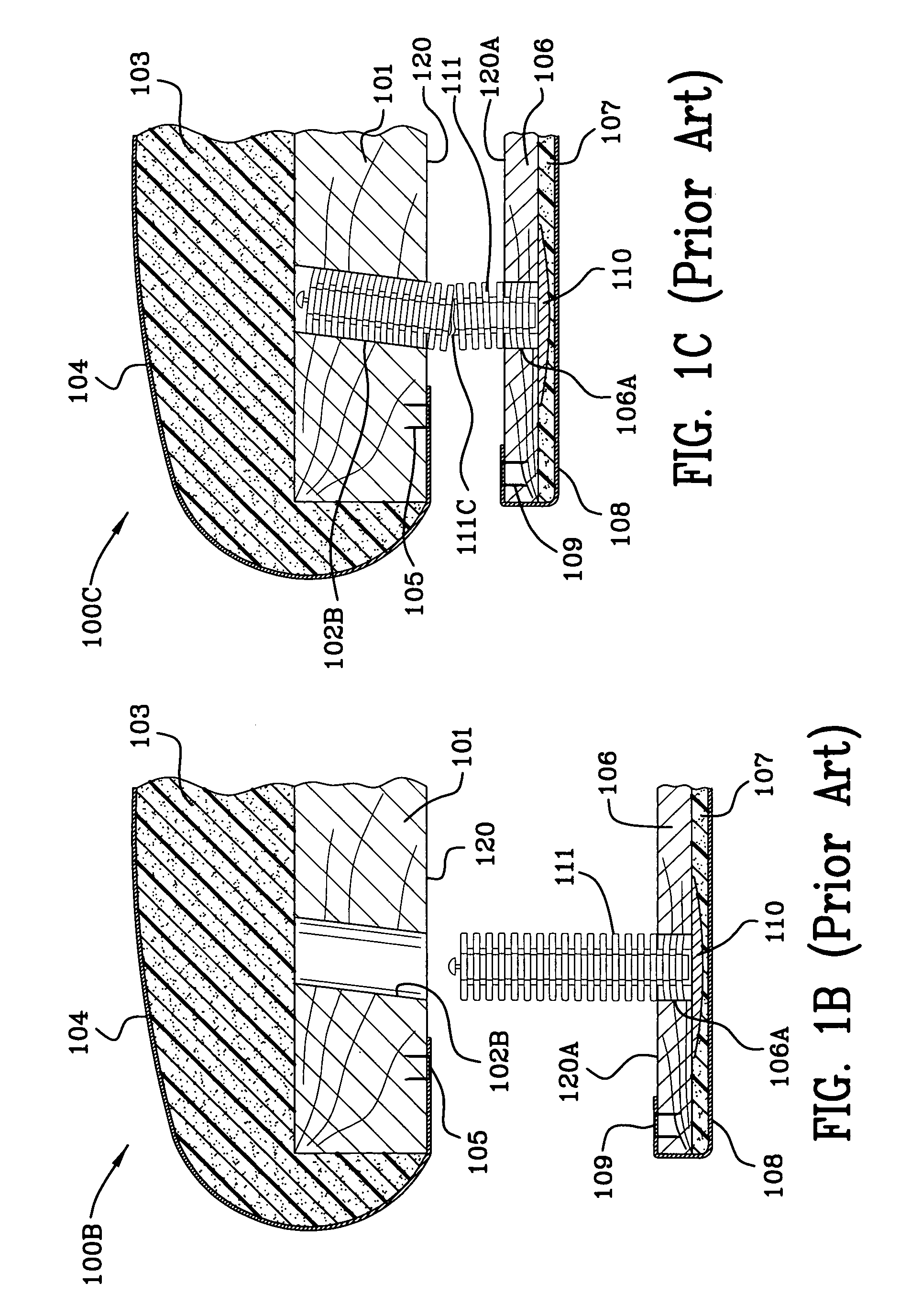

Fastener and process for using same

InactiveUS7524129B2Avoid removalPrevent removalRopes and cables for vehicles/pulleyNutsFastenerEngineering

A connector for securing first and second substrates together, comprising: an outer fastener and an inner fastener is disclosed and claimed. The outer fastener comprises a dowel shaped stud. The inner fastener comprises a flange and a pair of clips. The pair of clips includes a first portion and a second portion. The flange is lanced and includes a punched out portion. The stud interengages the flange and the second portion of the pair of clips urges the clips away from each other and away from the stud. The outer fastener is pressed into the first substrate and the second portion of the clips is pressed into the second substrate. The second portion of the clips include a turned back portion and the turned back portion of the clip grip the second substrate preventing removal of the inner fastener from the second substrate. The connector is tolerant of the misalignment of the inner and outer fasteners and the bores in which the fasteners reside.

Owner:STAFAST PROD

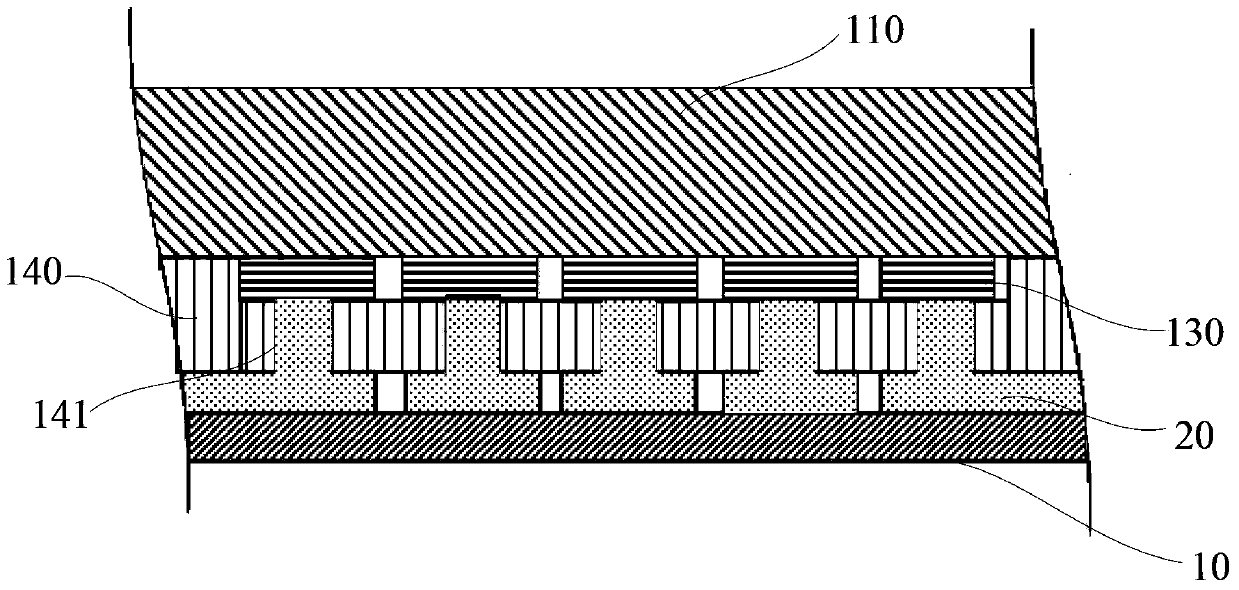

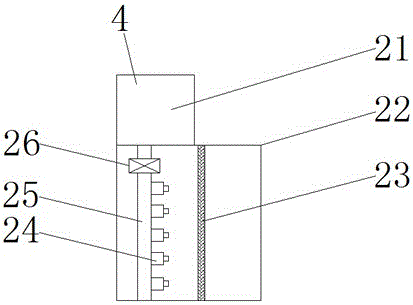

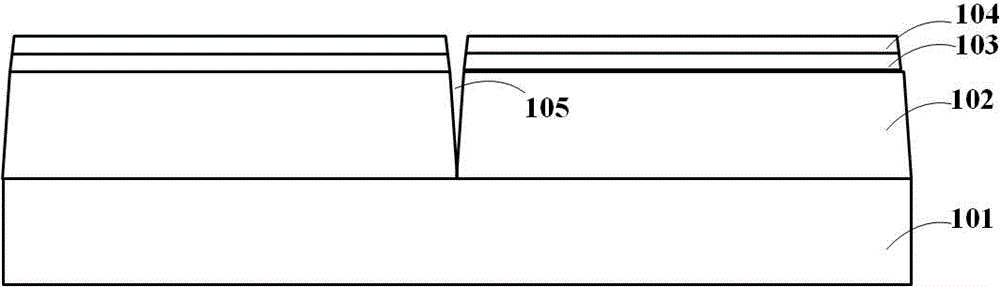

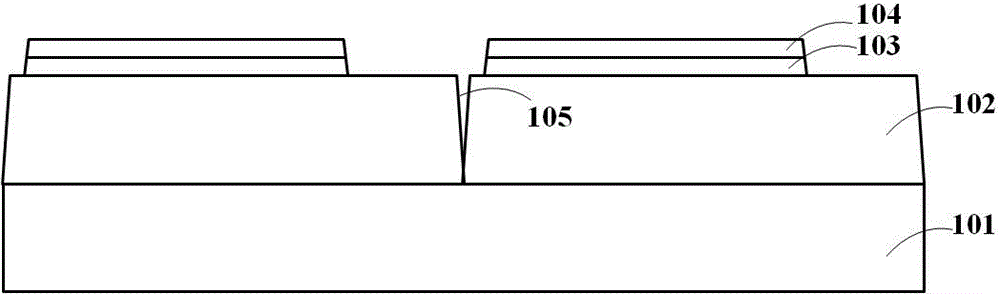

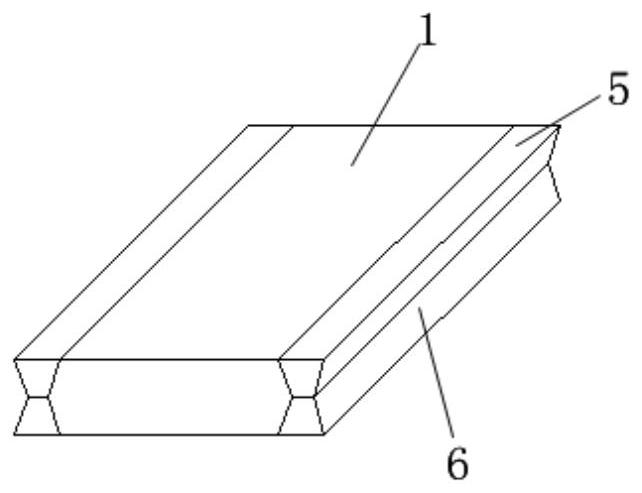

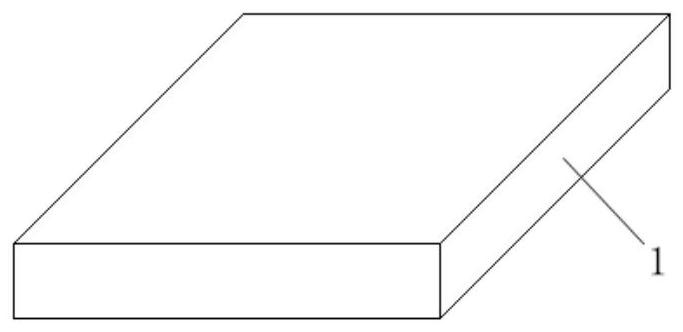

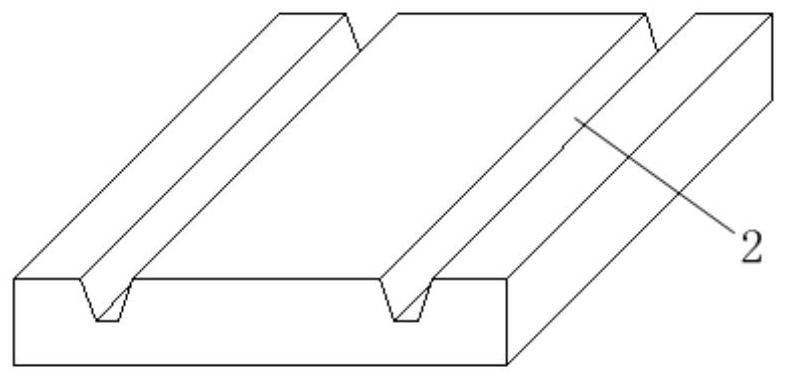

Protection cover plate, touch screen and manufacturing method of touch screen

ActiveCN103425348AAvoid affecting aestheticsAvoid easy disconnectionInput/output processes for data processingHeight differenceTouchscreen

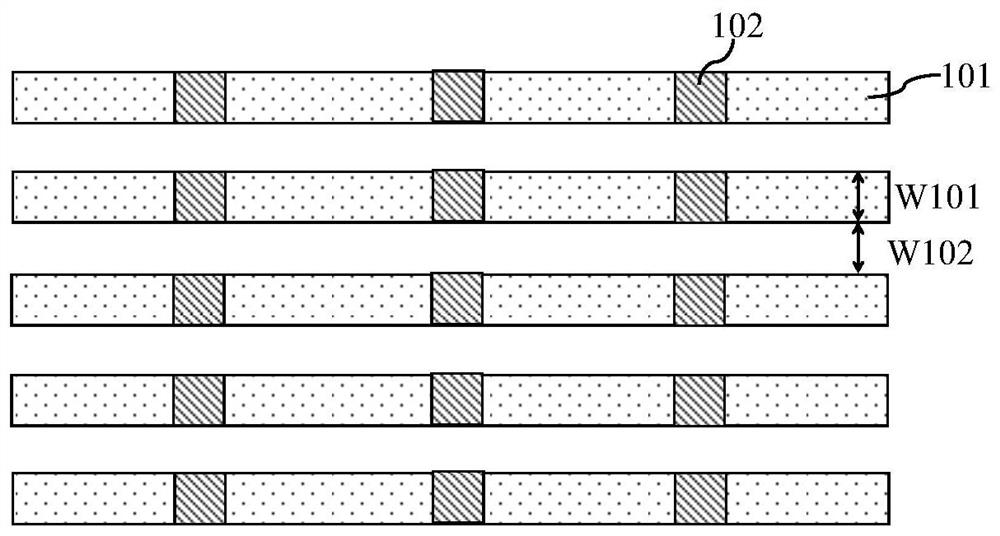

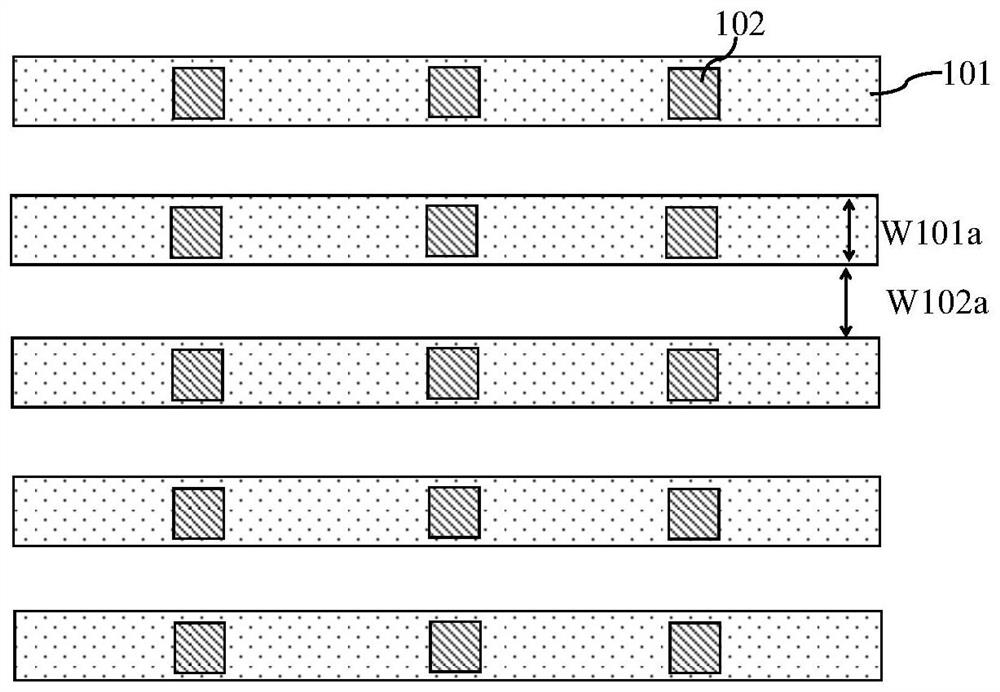

A protection cover plate comprises a body, one side, close to a touch screen, of the body is divided into a display area and a shielding area, the shielding area surrounds the display area, a transparent conducting circuit is arranged on the display area, and a conducting leading wire is arranged on the shielding area. The conducting leading wire is electrically connected with the transparent conducting circuit, a cover bottom oil ink layer is arranged on the shielding area and covers the conducting leading wire, the transparent conducting circuit and the conducting leading wire are both attached to the inner surface of the body, and therefore the transparent conducting circuit and the conducting leading wire are electrically connected on the same plane. The problem that the transparent conducting circuit is easily broken down due to the height difference between the transparent conducting circuit and the cover bottom oil ink layer is avoided, and moreover the conducting leading wire and the cover bottom oil ink layer are identical in color. Therefore, when the touch screen is used, the conducting leading wire can not be distinguished out from the outer side of the protection cover plate, the attractiveness of the touch screen is prevented from being affected. The invention further provides the touch screen comprising the protection cover plate and a manufacturing method of the touch screen.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

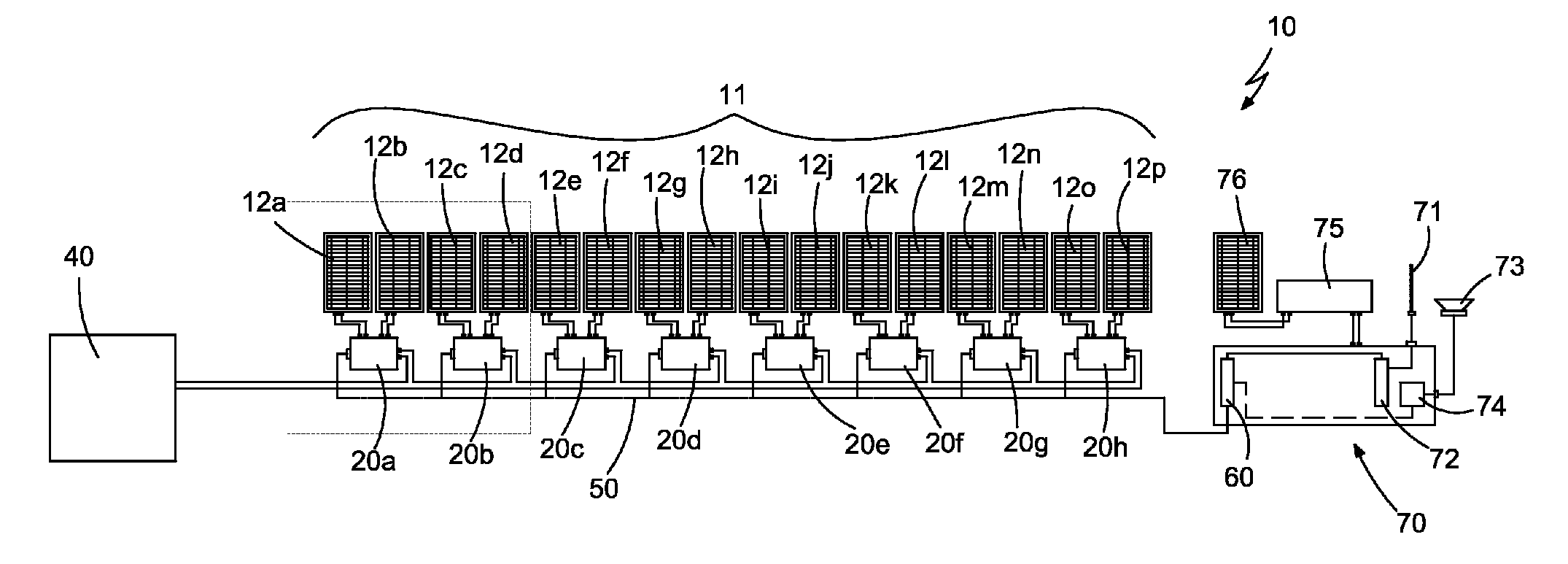

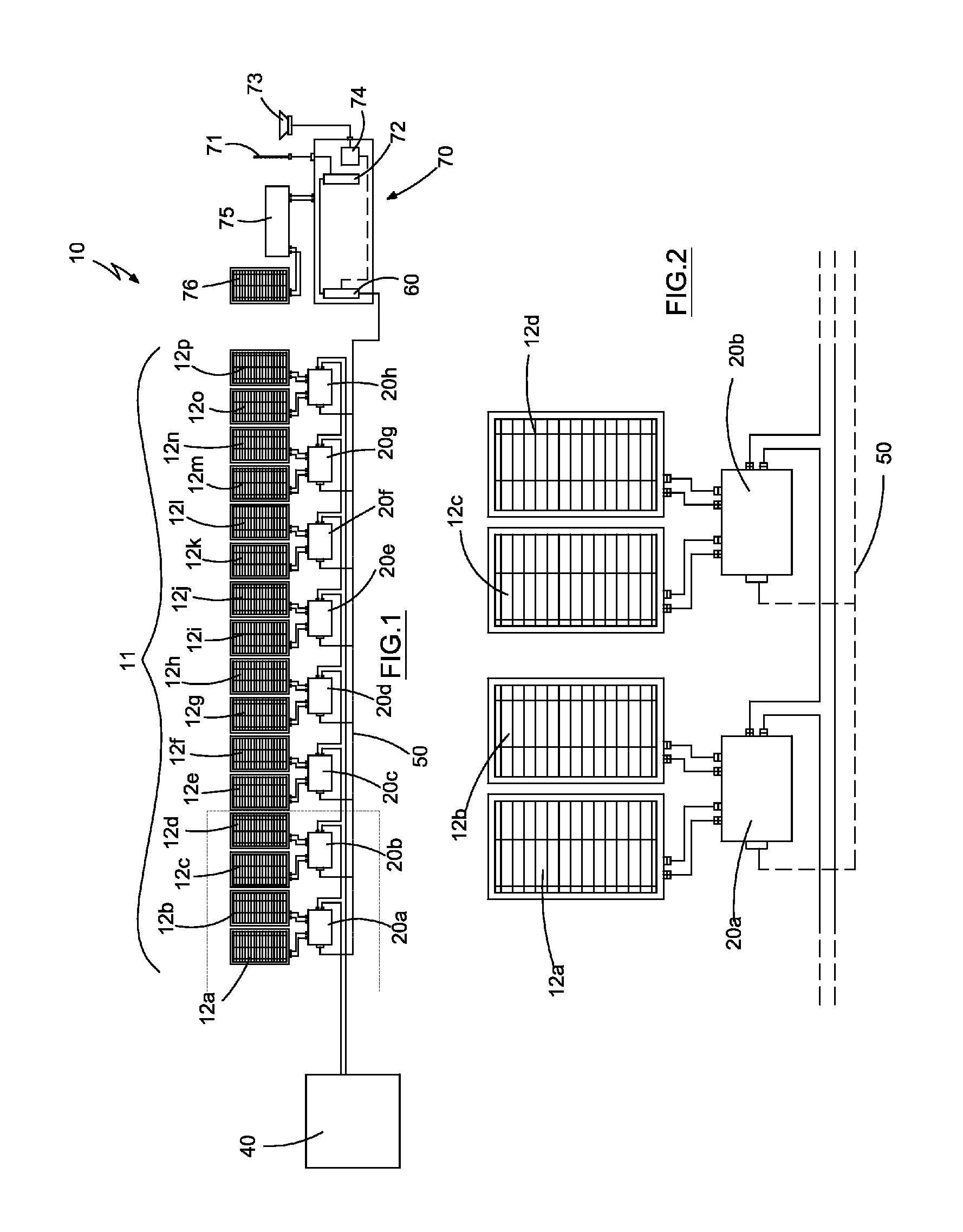

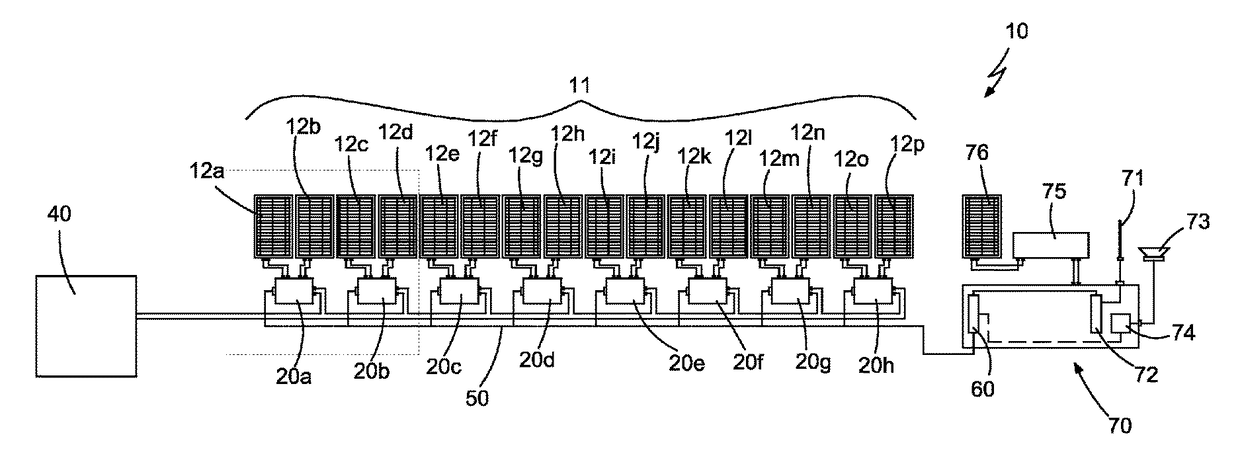

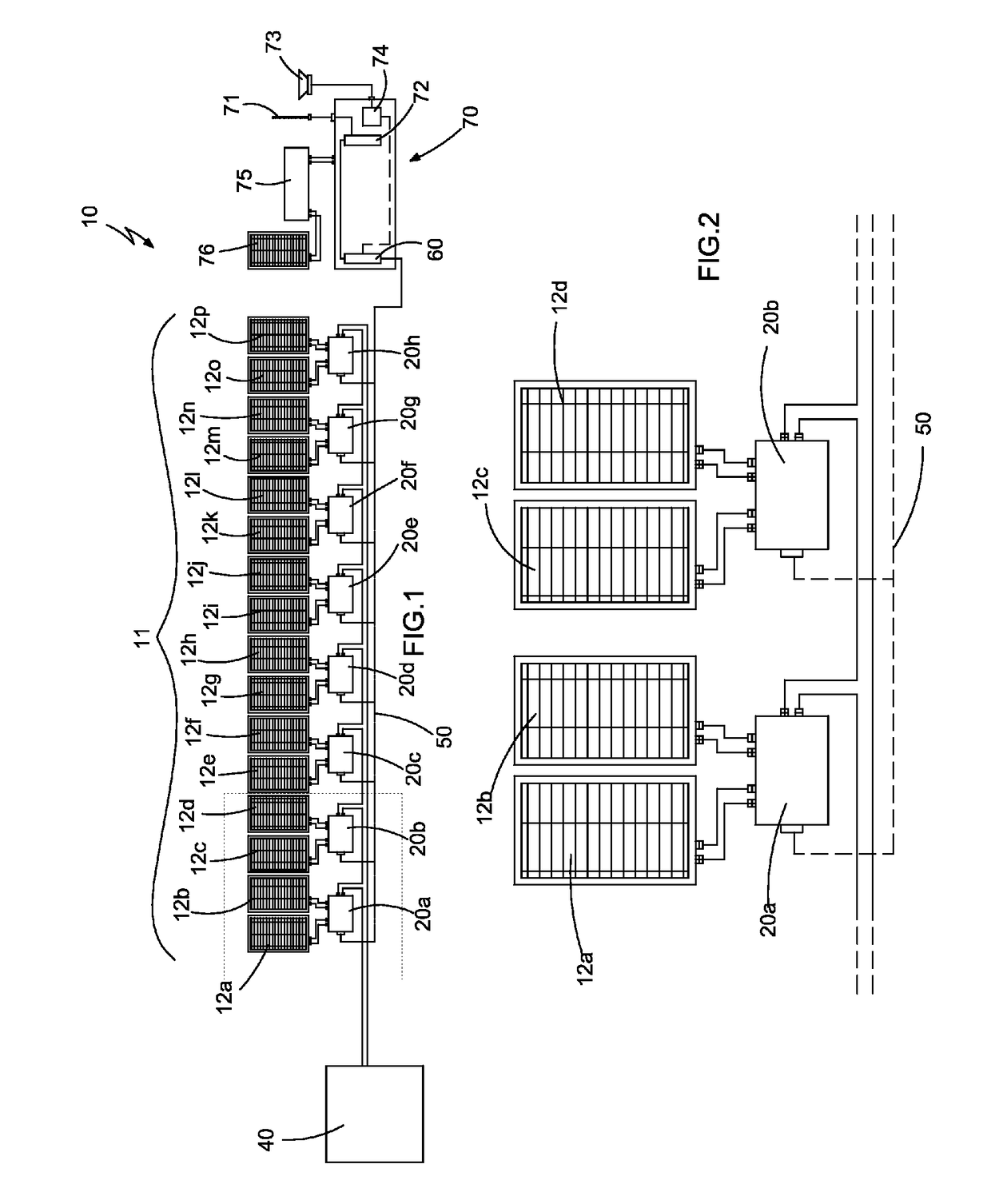

Apparatus and method for managing and conditioning photovoltaic power harvesting systems

ActiveUS20120068543A1Maximize power generationImprove efficiencyDc network circuit arrangementsPhotovoltaic energy generationConvertersReliability engineering

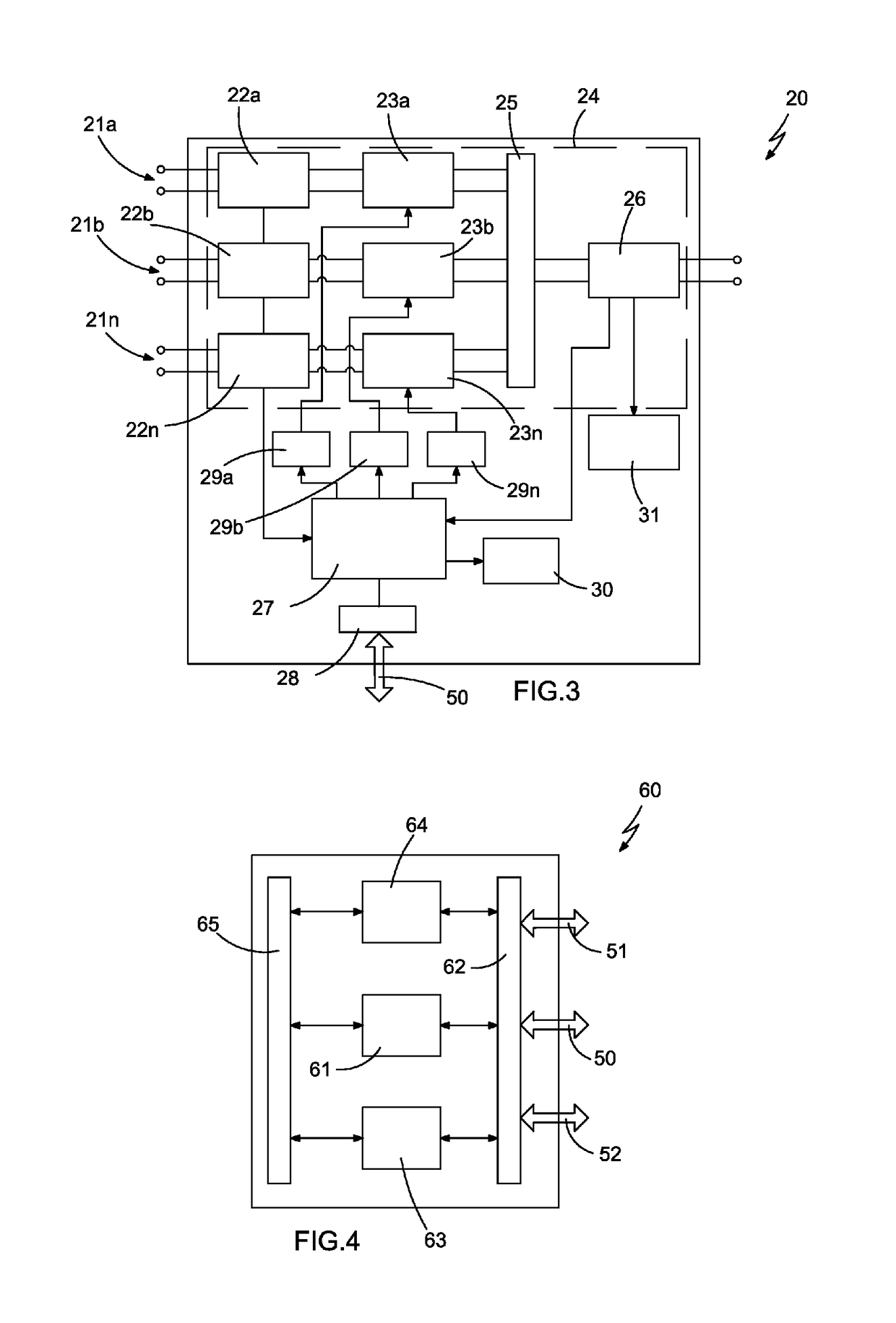

The efficiency of a PV power generation system (10) is maximised by an apparatus providing series of electronic units (20) connected to the PV modules (12) and comprising microprocessor controlled DC converters / power supply units. A managing unit (60) communicates with the electronic units (20) of a string (11) in order to carry out a synergic optimization of the efficiency both of the single PV modules (12) and of the entire string (11). The apparatus also provides PV module (12) by PV module (12) diagnostic features and it is able to communicate with external devices for a full system control.

Owner:CARAGLIO ALESSANDRO +1

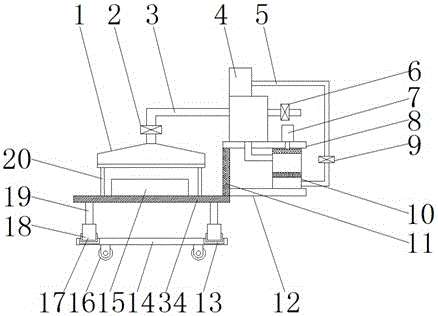

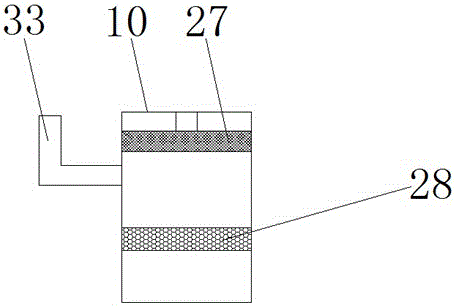

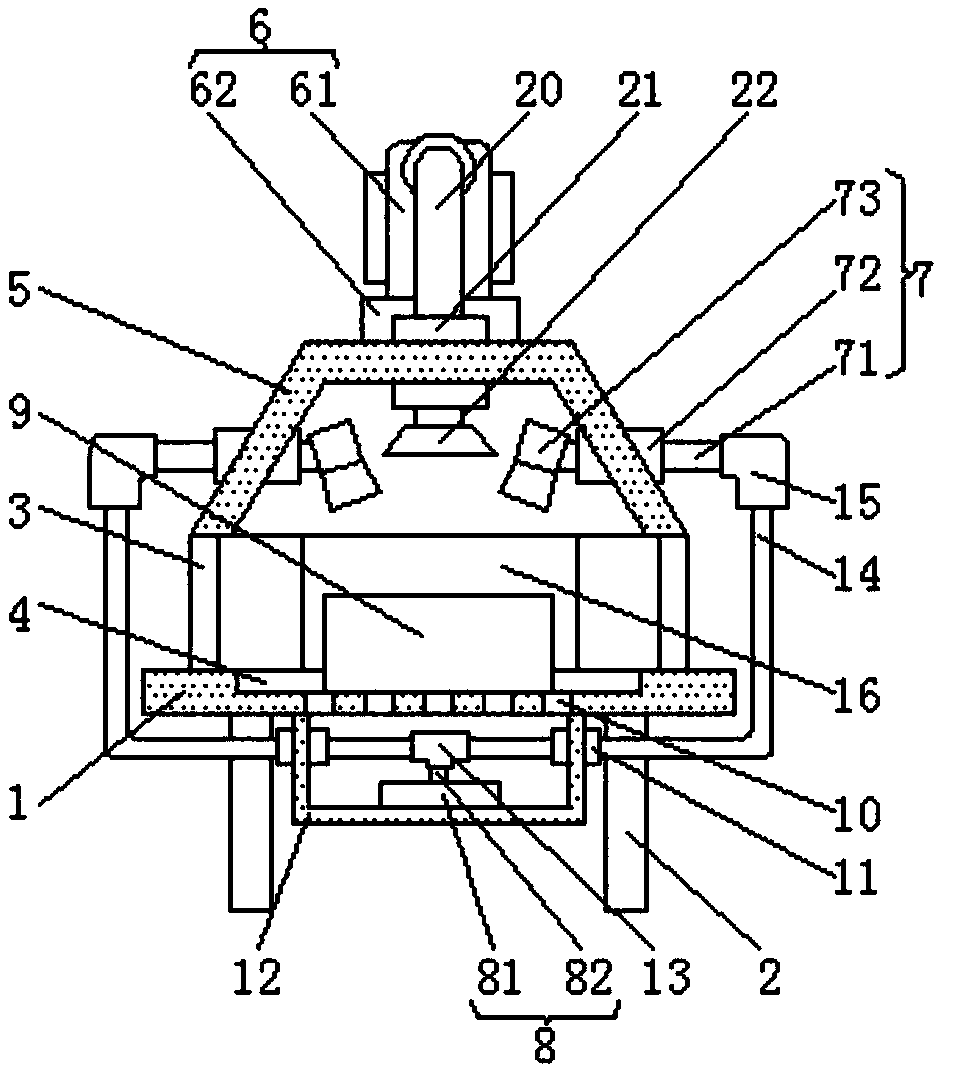

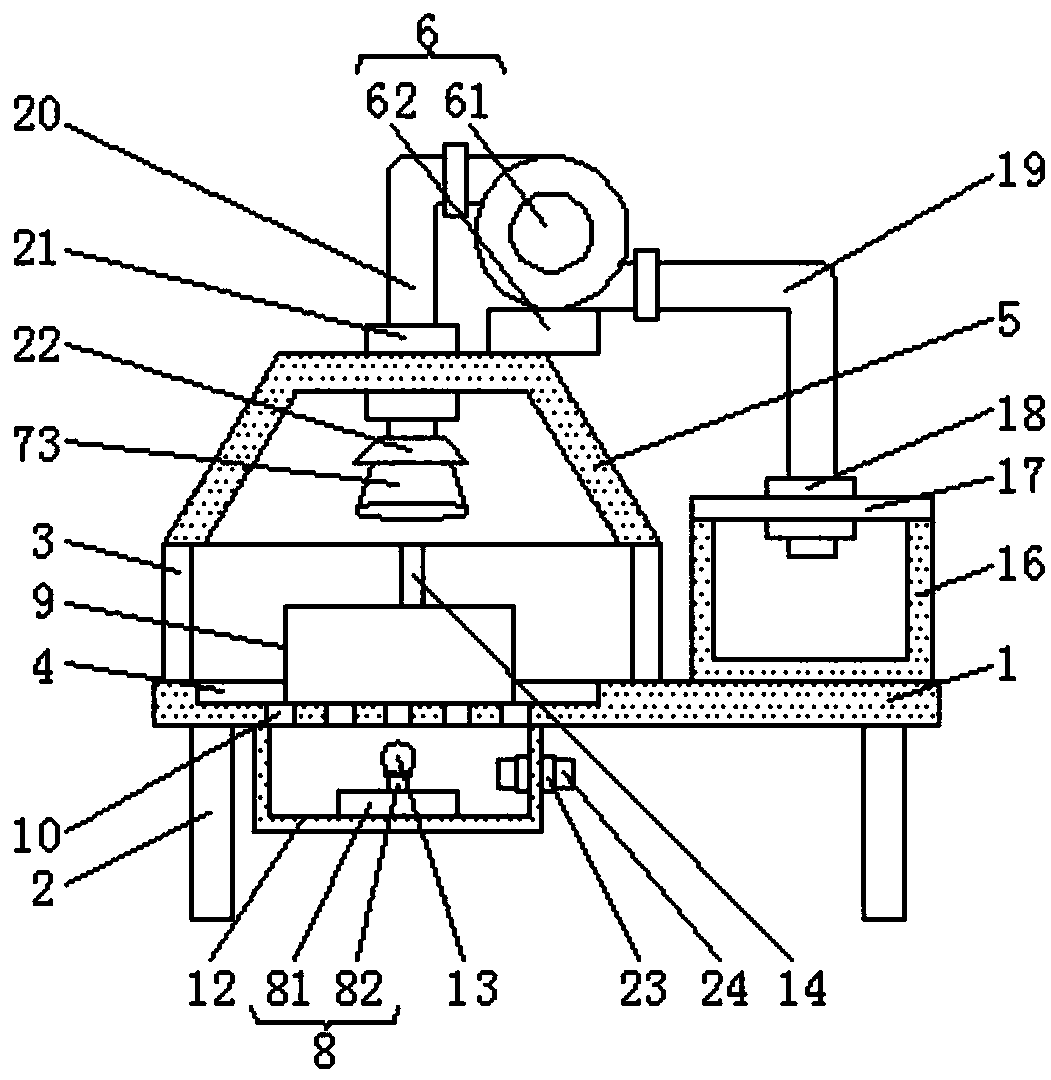

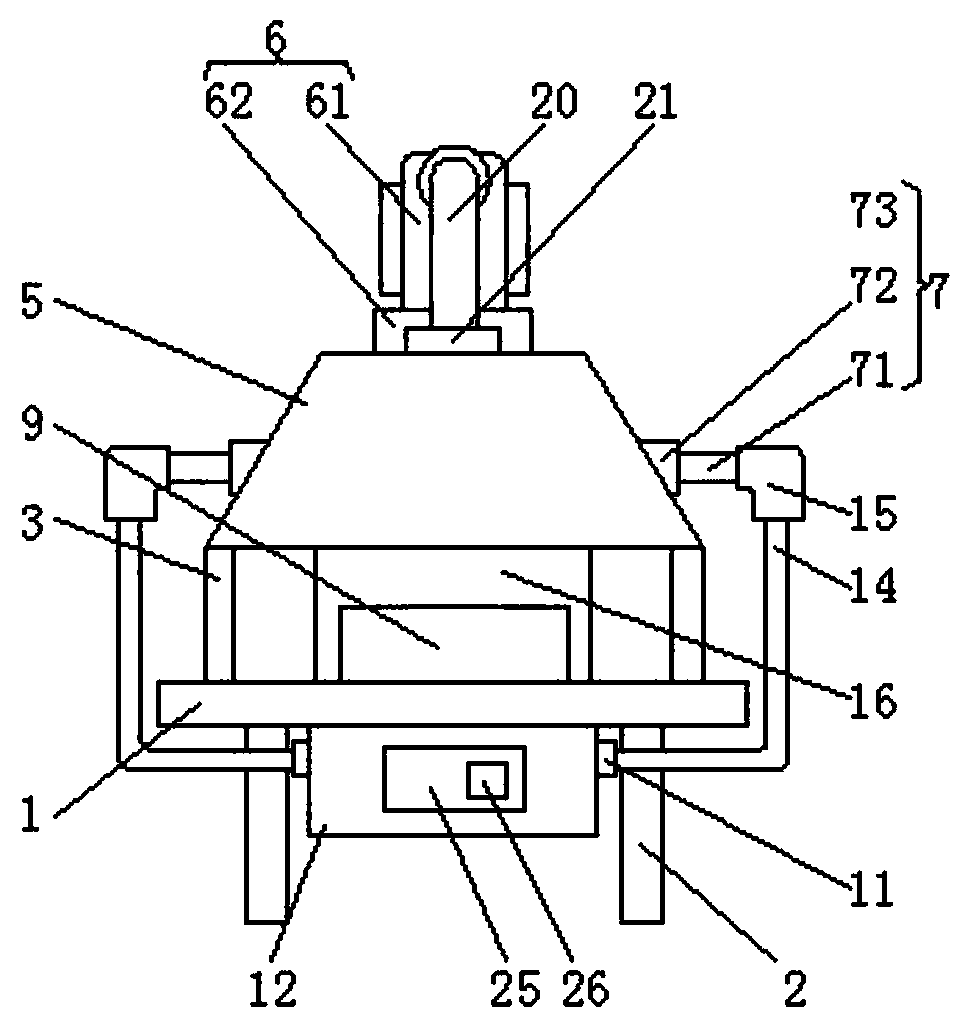

Textile equipment with dedusting and humidifying functions

InactiveCN107520216AMeet needsImprove suction performanceCombination devicesLighting and heating apparatusYarnWater storage tank

The invention discloses textile equipment with dedusting and humidifying functions. The textile equipment comprises hydraulic telescopic rods, a water-permeable thin film, a second exhaust fan, a first booster pump and a mounting plate. The hydraulic telescopic rods are arranged to be used for adjusting the height of a base so that the height of a textile machine body can be adjusted, and hence the requirements of operators of different heights are met. The water-permeable thin film is arranged to be used for adsorbing cotton thread scraps and dust entering a dedusting and humidifying box and meanwhile humidifying the air. The humidified air in the dedusting and humidifying box can be exhausted out of an air outlet pipe through the second exhaust fan so that the air in a workshop can be humidified, and the phenomenon that the air in the workshop is excessively dried and thus yarns can be broken easily in the spinning process is avoided. Filtered sewage in a filtering tank can enter a water storage tank through a first water guide pipe with the first booster pump, and therefore water resources can be recycled. The environmental protection property of the equipment is improved, dedusting and humidifying cost of the workshop is reduced, and equipment practicability is improved.

Owner:HUZHOU DONGKAI TEXTILE CO LTD

High-voltage light emitting diode chip and manufacturing method thereof

ActiveCN104091867AIncrease single-chip outputExpand the area of the effective light-emitting areaSolid-state devicesSemiconductor devicesElectrically conductiveWire breakage

The invention discloses a high-voltage light emitting diode chip and a manufacturing method of the high-voltage light emitting diode chip. A liquid insulating material layer or a liquid conducting material layer is introduced and then solidified for insulation or bridge connection, and the widths of isolation grooves between light emitting units can be ultra narrow, wherein the widths of openings are smaller than or equal to 0.3 micrometer, so that single chip output is increased, the area of an effective light emitting region is expanded, and light emitting efficiency is improved; the problem that a traditional high-voltage light emitting diode metal wire is prone to breakage when striding over a channel with the large fall is solved, and the series / parallel bridging yield is increased; in addition, the manufacturing method can be achieved at a chip manufacturing end, and manufacturing cost is low.

Owner:湖北三安光电有限公司

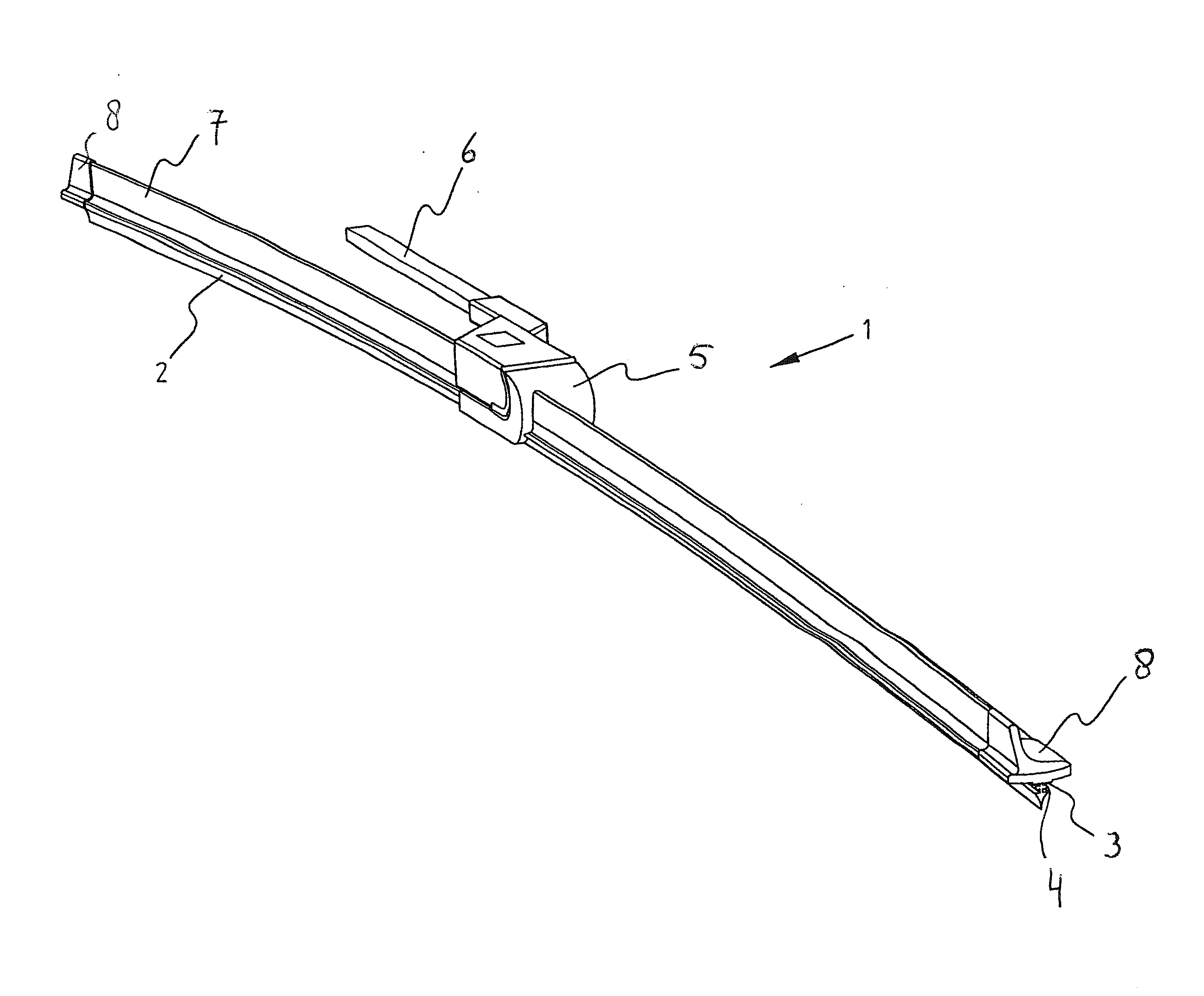

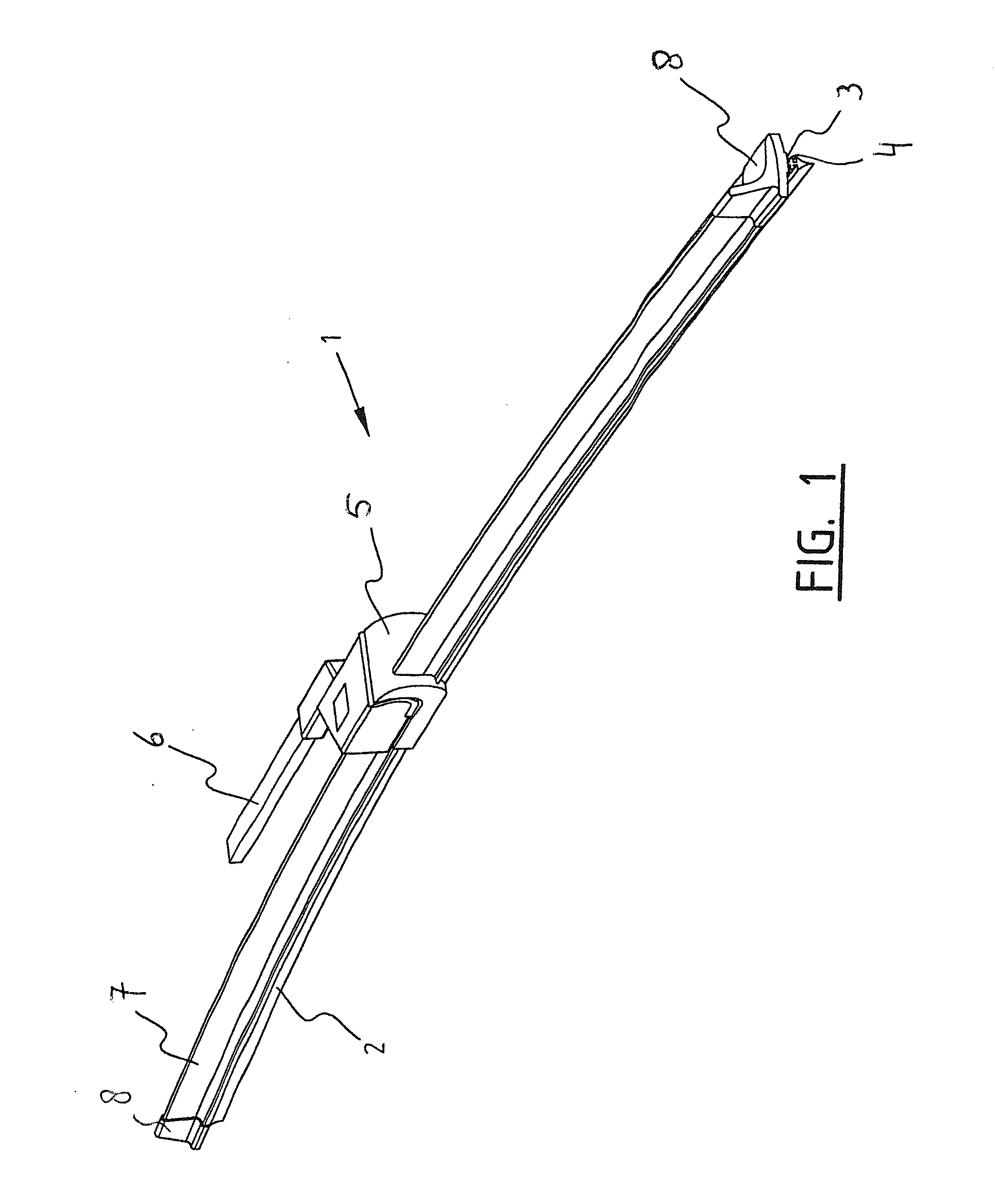

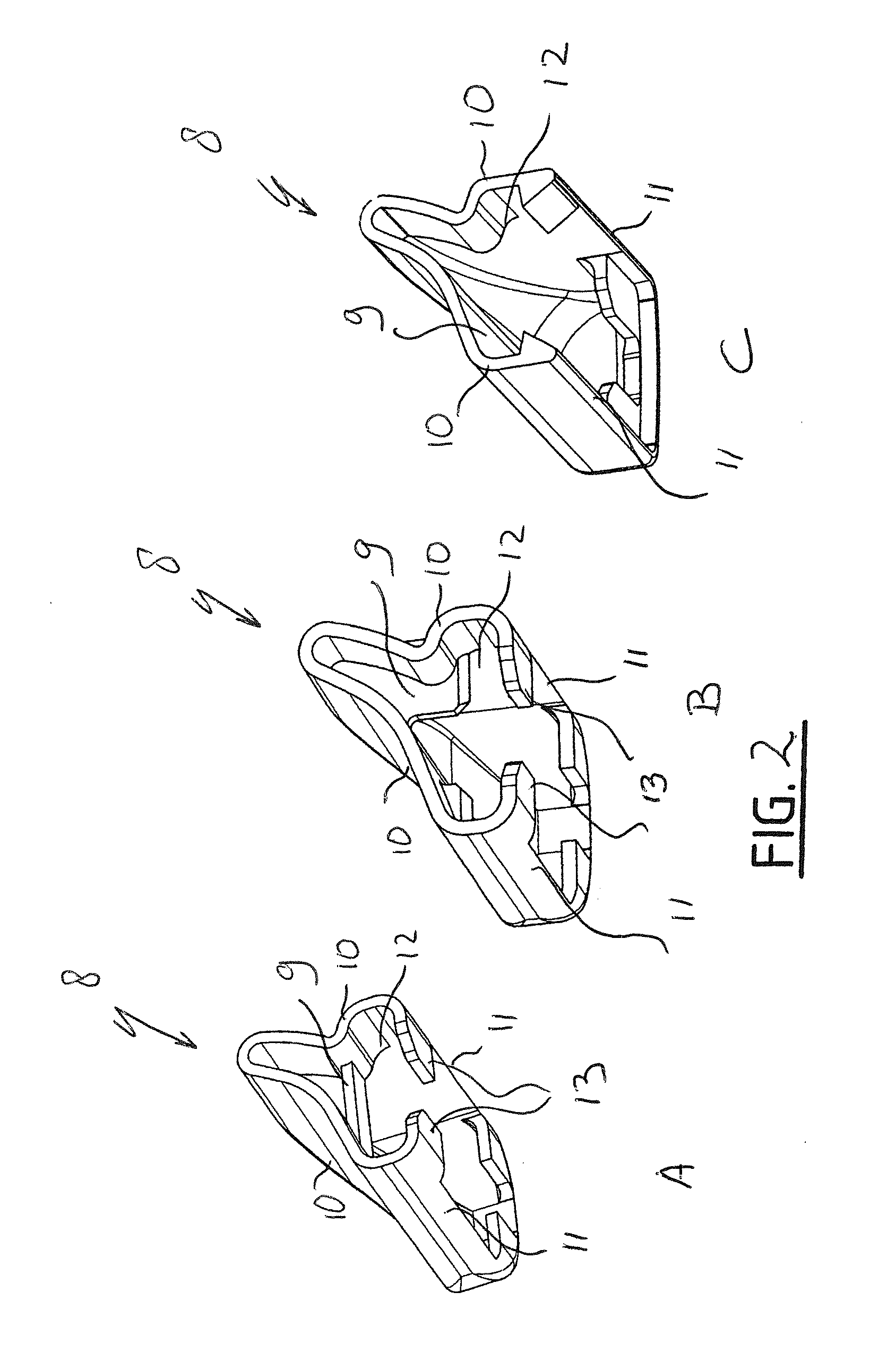

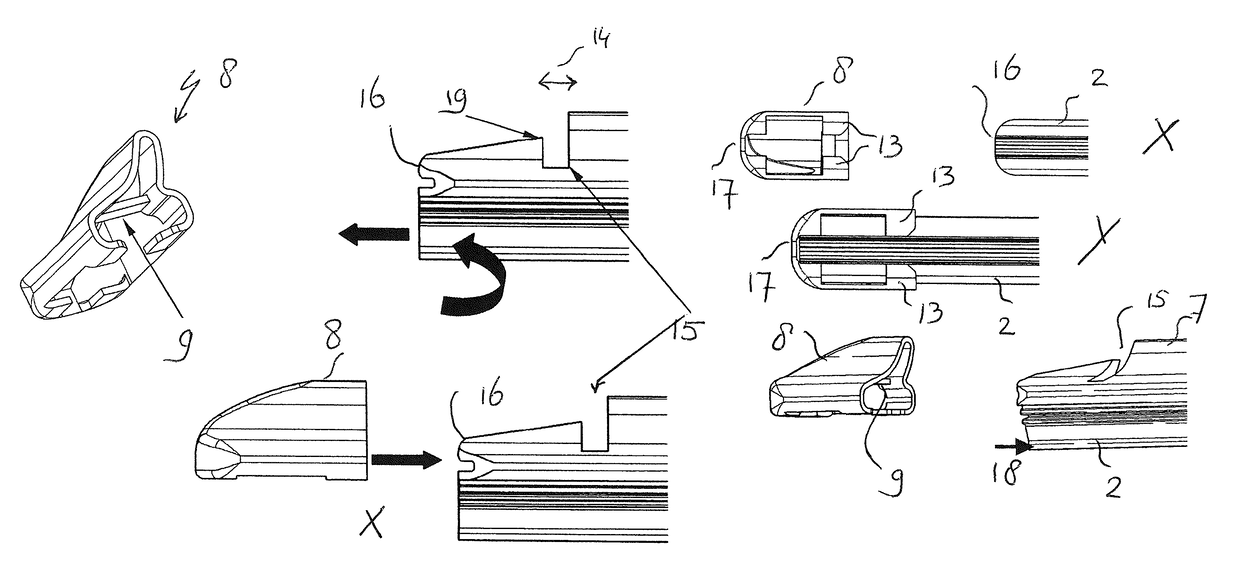

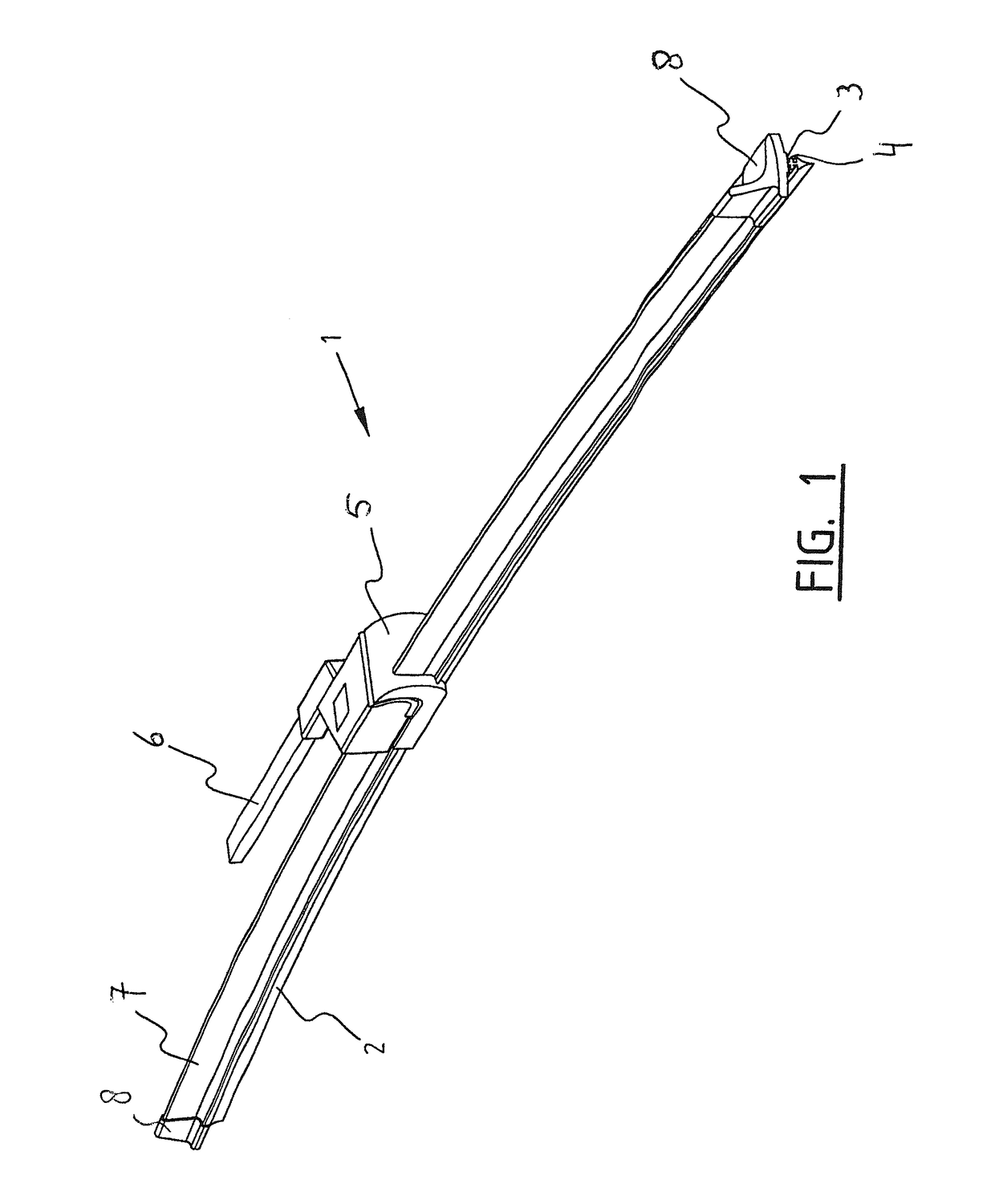

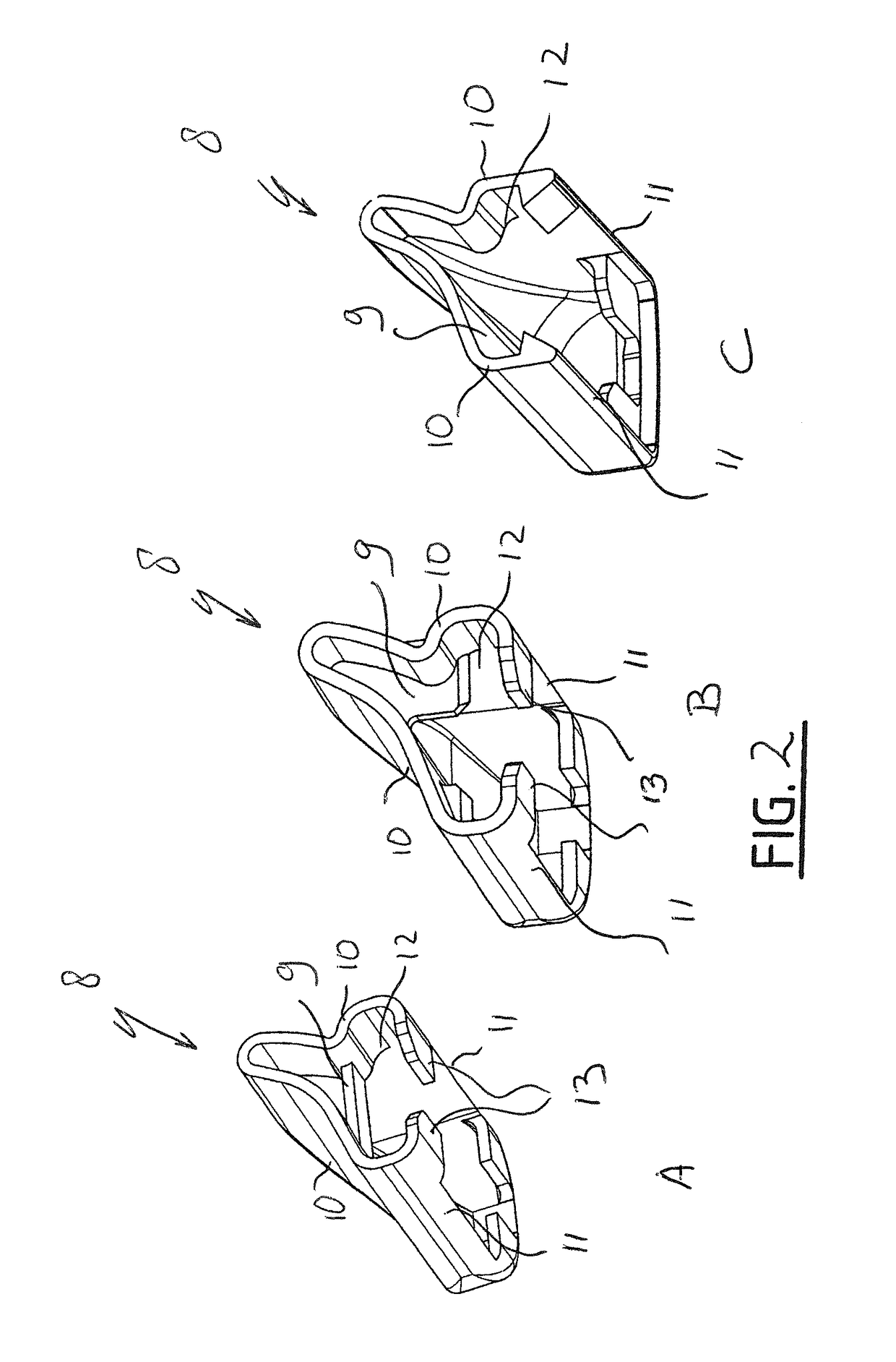

Windscreen wiper device

InactiveUS20150026910A1Low mobilityFirmly connectedWindow cleanersVehicle cleaningAbutmentEngineering

A windscreen wiper device of the flat blade type includes an elastic, elongated carrier element, as well as an elongated wiper blade of a flexible material, which can be placed in abutment with a windscreen to be wiped, which wiper blade includes at least one groove, in which groove a longitudinal strip of the carrier element is disposed, wherein free ends of the wiper blade are connected to a respective connecting piece, which windscreen wiper device comprises a connecting device for an oscillating wiper arm, and wherein the wiper blade is provided with a spoiler at a side thereof facing away from the windscreen to be wiped, wherein at least one connecting piece comprises an internal transverse reinforcement rib, wherein the spoiler is removed along a portion of the length of the wiper blade; at a distance from a free end of the wiper blade facing the connecting piece so as to form a transverse slit, and wherein in mounted position the internal transverse reinforcement rib rests inside the slit.

Owner:TRICO BELGIUM SA

Novel composite printing technology

InactiveCN107718918ABump effect is obviousAvoid easy disconnectionOther printing apparatusHot stampingFine line

The invention discloses a novel composite printing technology and relates to the technical field of printing technologies. The novel composite printing technology comprises the following steps: 1, preparing a silk-screen film: exposing the film firstly, hardening the film, developing the film with warm water, and drying the film to prepare a peelable graphic negative film; 2, copying silk-screen boards with different meshes according to concave-convex requirements through sun-drying: during board making, attaching a coating surface of the graphic negative film to a tensioned silk screen, enabling the coating to be tightly attached to the wet silk screen by extruding, peeling a film base, and performing air blowing to prepare the silk-screen boards; 3, performing silk screening: performingprinting on the basis that the image-text parts of the silk-screen boards are ink-permeable and the non-image-text parts of the silk-screen boards are ink-impermeable; 4, performing continuous-line gold stamping of silk screening: transferring hot stamping foil to the surface of a substrate in a heating or pressurizing manner; 5, performing post-finishing work to finish the printing technology. The novel composite printing technology has the following beneficial effects: the problems of high probabilities of line breaking and filling in, absence of concave-convex sense and the like of the traditional hot stamping during stamping of convex and fine lines can be solved.

Owner:广州市佳盛印刷有限公司

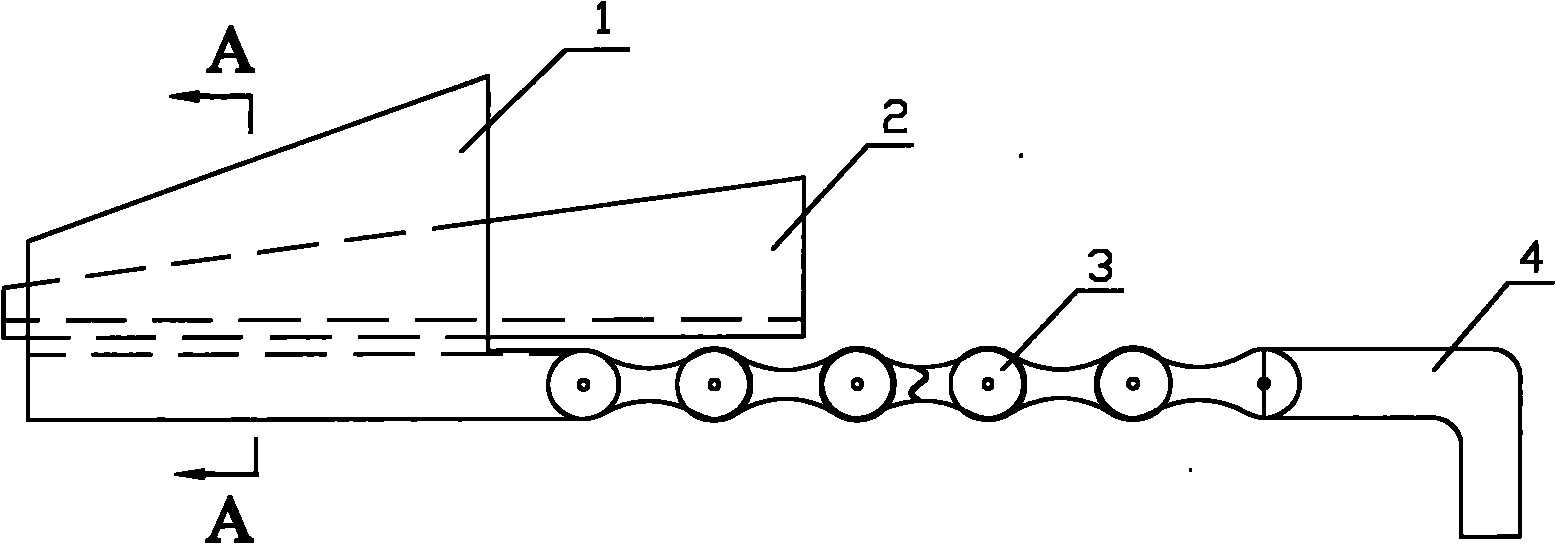

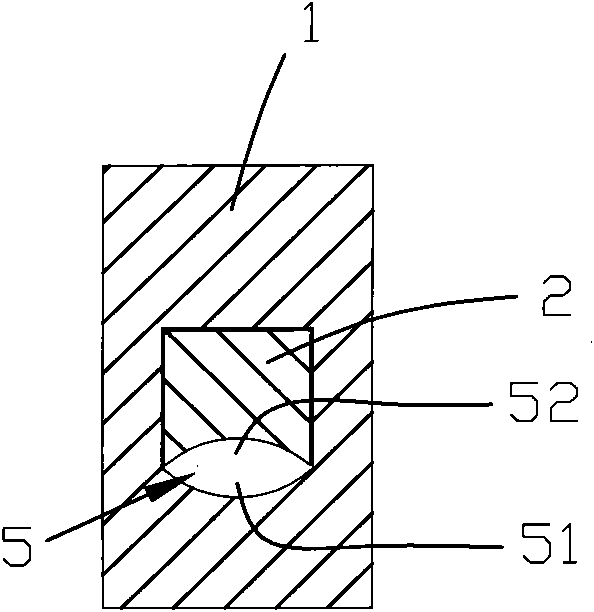

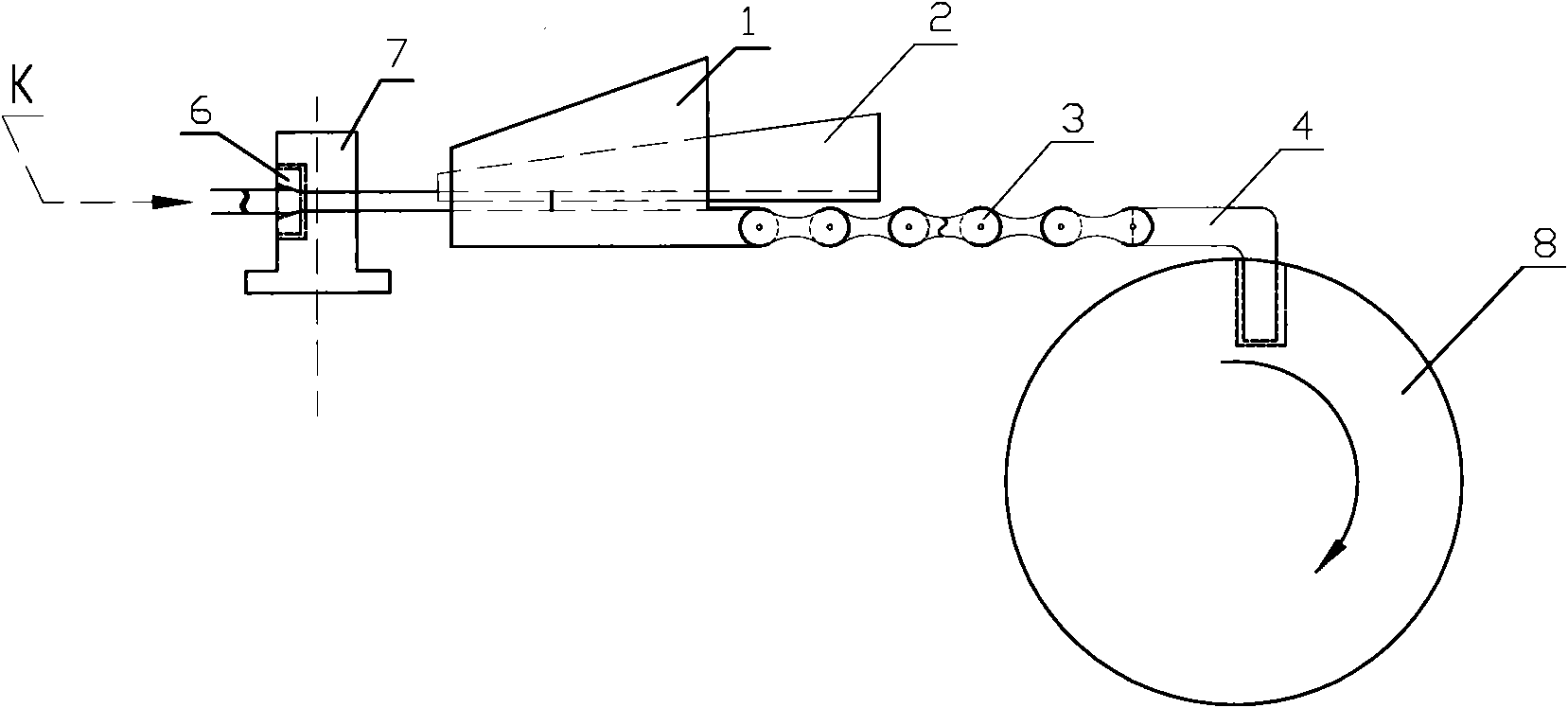

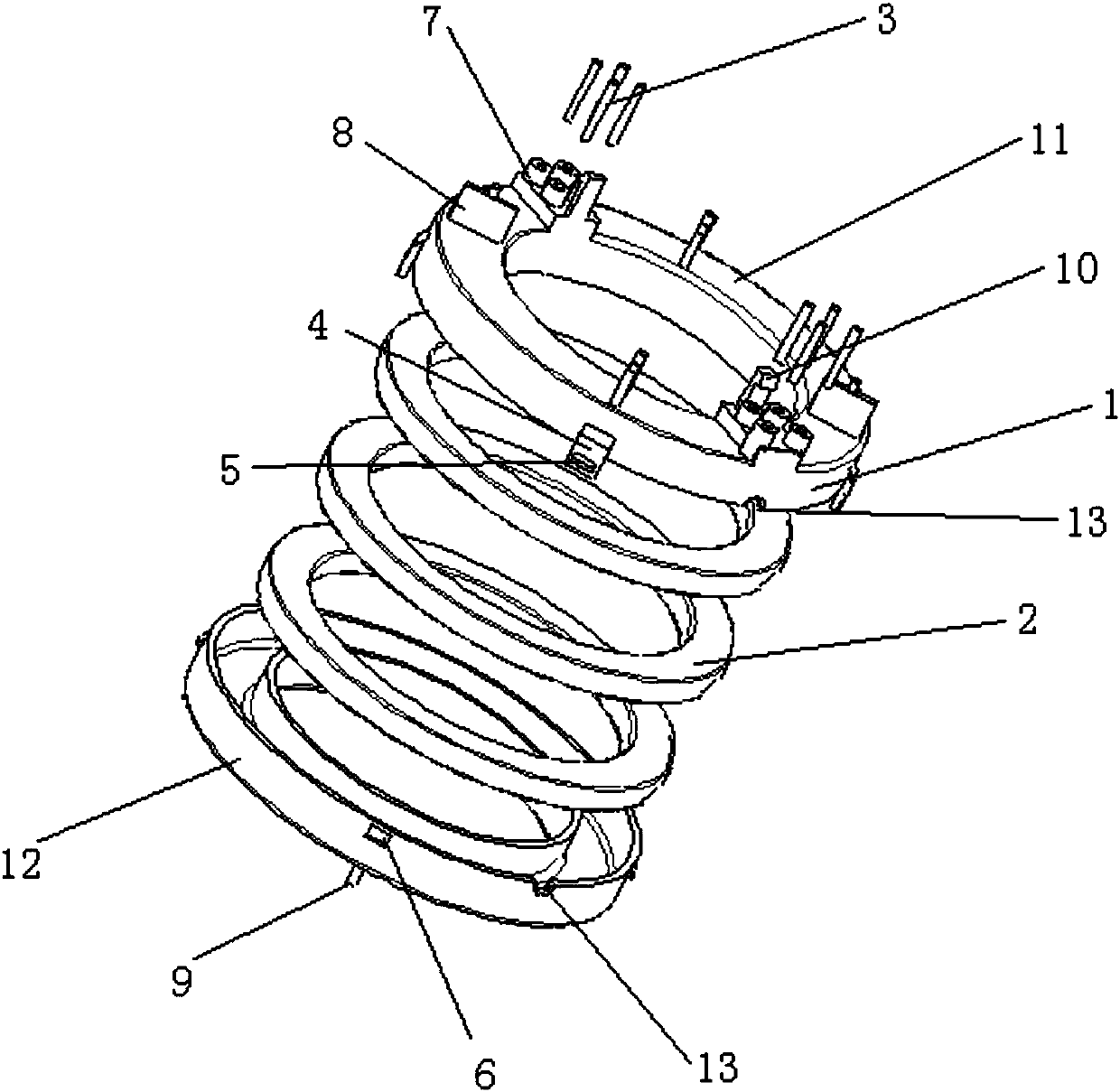

Wedge-shaped retractor

The invention discloses a wedge-shaped retractor, which comprises a wedge-shaped cavity, a wedge-shaped key, a retraction chain and a retraction hook. The tail part of the wedge-shaped cavity is connected with one end of the retraction chain. The other end of the retraction chain is connected with the retraction hook. The inner chamber of the wedge-shaped cavity corresponds to the wedge-shaped key. The wedge-shaped key is embedded into the wedge-shaped cavity to form a locking hole used for clamping metal wires. The locking hole comprises a first arc-shaped groove arranged at the bottom of the inner chamber of the wedge-shaped cavity. A second arc-shaped groove corresponding to the first arc-shaped groove is arranged at the bottom part of the wedge-shaped key. The first arc-shaped groove and the second arc-shaped groove form the locking hole. The invention has the advantages that the structure is simple, the wedge-shaped retractor can be manufactured by oneself, the cost is low, the contact area between a fixture and a metal wire is increased because the wedge-shaped and the wedge-shaped key jointly form annular clamping force which can tightly clamp the metal wire to be drawn, the problem that the metal wire is apt to be broken because the internal stress of the metal wire is excessively concentrated is solved, the intervention of a rotary swaging machine is not required, the equipment investment is decreased because the price of the rotary swaging machine is nine times higher than the price of a common roller dog, the consumption is reduced and the production cost is decreased.

Owner:九川(浙江)科技股份有限公司

Textile equipment with dust removal and humidification functions

InactiveCN109092836AQuality assuranceGuaranteed production efficiencyTextile treatment machine arrangementsDirt cleaningWater pipeYarn

The invention discloses textile equipment with dust removal and humidification functions. The textile equipment comprises a bottom plate and a dust collecting box, the upper surface of the bottom plate is fixedly connected with the lower surface of a dust collecting cover by four brackets, and the four brackets are correspondingly located at the four corners of the lower surface of the dust collecting cover. The lower surface of the bottom plate is fixedly connected with four supporting legs, and the four supporting legs are correspondingly located at the four corners of the lower surface of the bottom plate. A groove is formed in the upper surface of the bottom plate, and the groove is located between the four brackets. A textile machine is arranged on the lower surface of the inner wallof the groove, and a plurality of through holes are formed in the lower surface of the inner wall of the groove. According to the textile equipment with the dust removal and humidification functions,through the cooperation between an exhaust fan, a suction nozzle, the dust collecting box, a water pump, a first water pipe, a diverting joint, second water pipes and atomizing nozzles, the dust removal and humidification operation is realized in the textile process, it is ensure that the textile operation can be carried out normally, the quality of yarns is ensured, and production efficiency of people is ensured.

Owner:徐州鼎源纺织股份有限公司

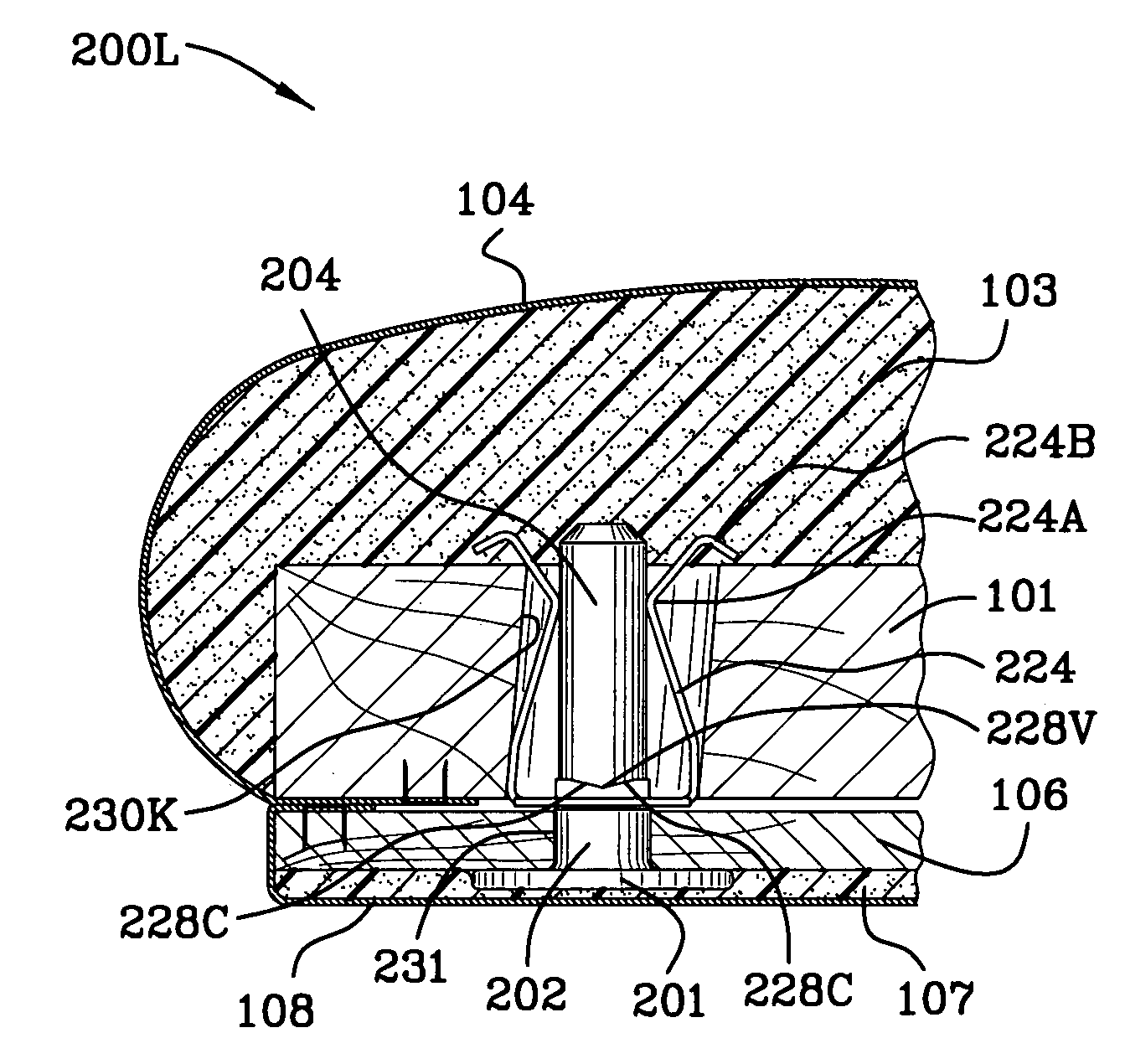

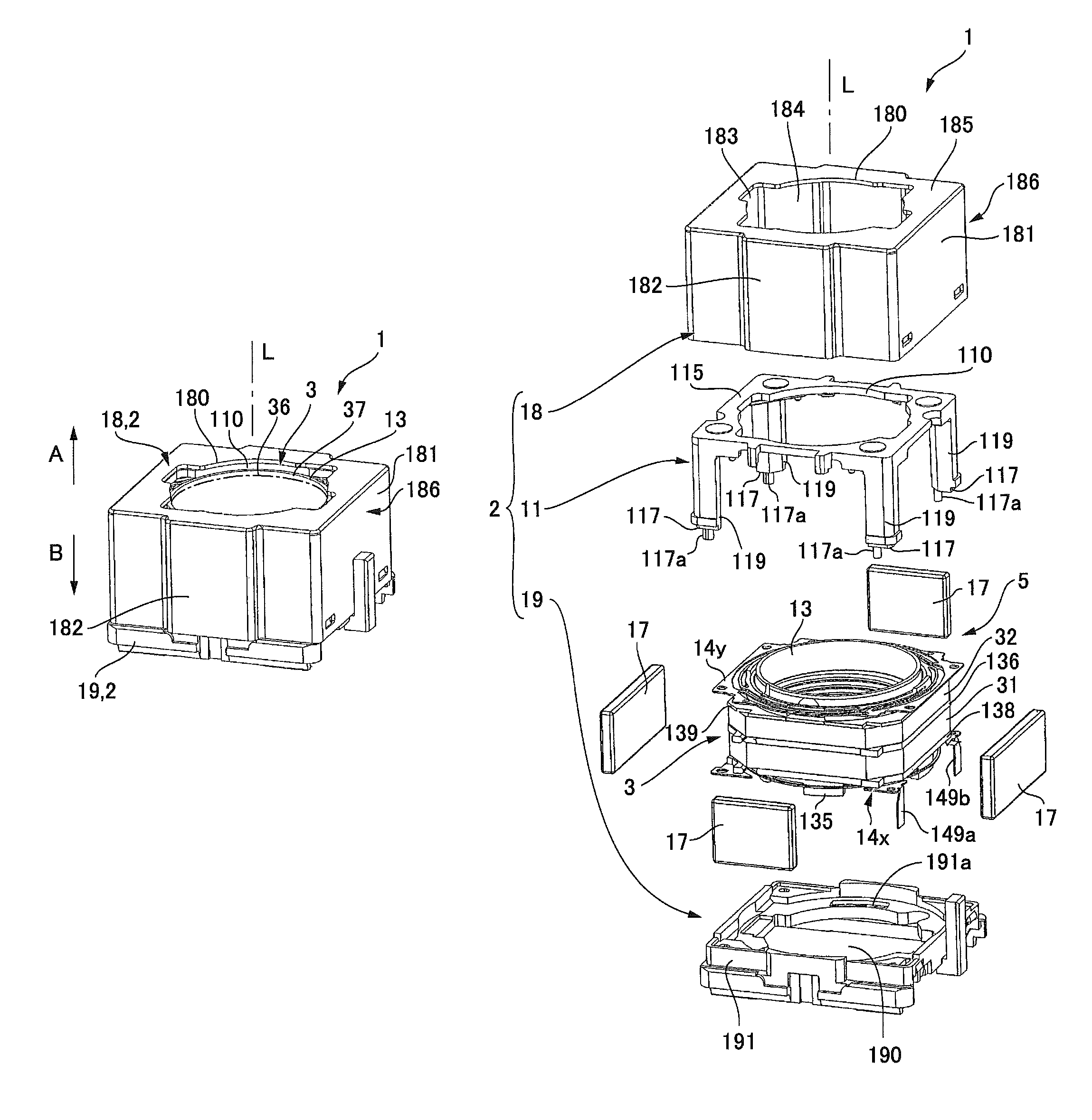

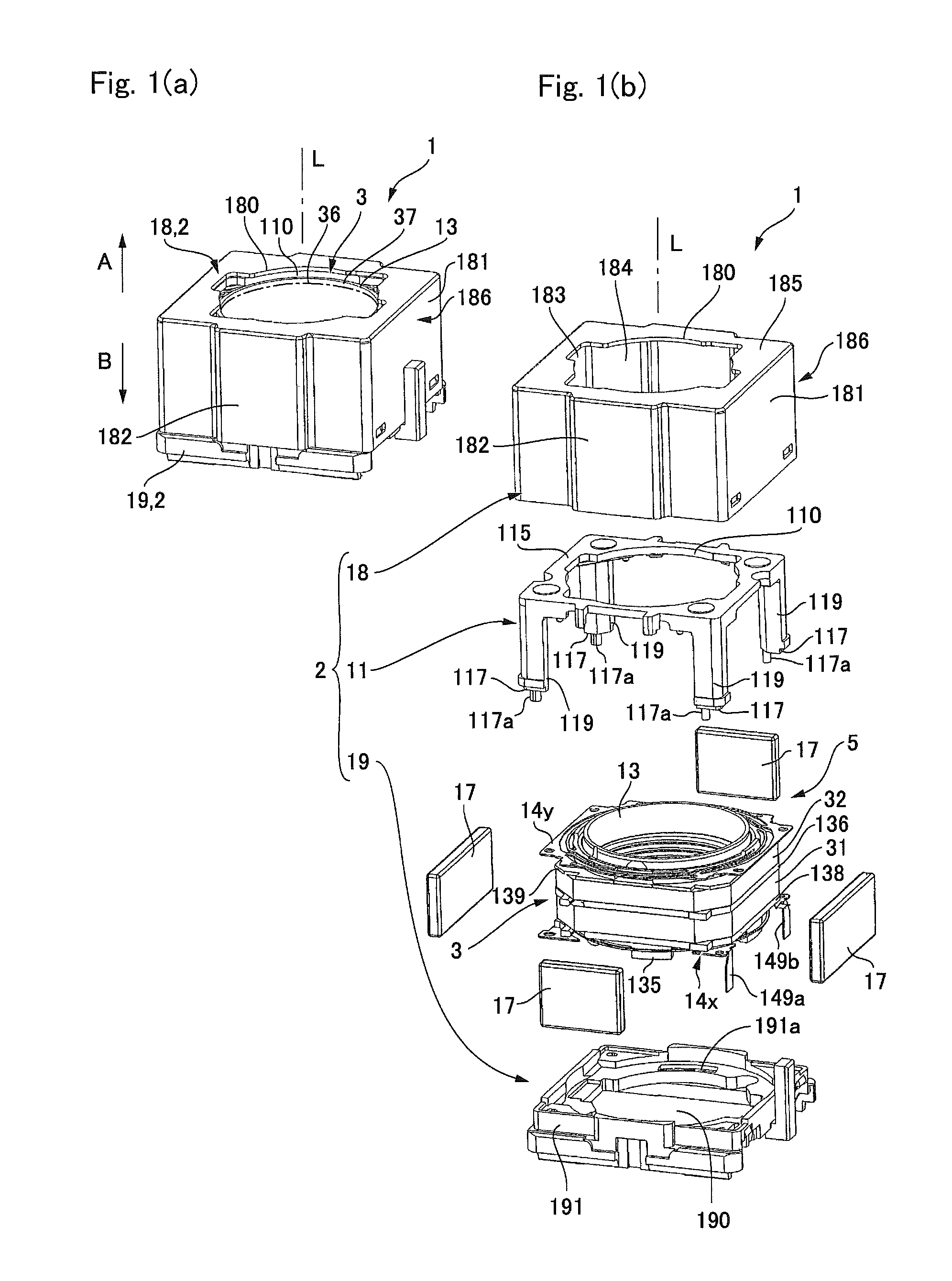

Lens drive device

A lens drive device may include a support body, a movable body having a lens, a magnetic drive mechanism having a coil mounted on the movable body and a magnet mounted on the support body for magnetically driving the movable body in a lens optical axis direction, two spring pieces which are connected between the movable body and the support body for supporting the movable body and which is used as a power supply member to the coil, and two binding pins which are provided in the movable body and around which coil ends of winding start and winding end of the coil are wound. Portions of the coil ends which are wound around the binding pins are electrically connected with the spring pieces.

Owner:SANKYO SEIKI MFG CO LTD

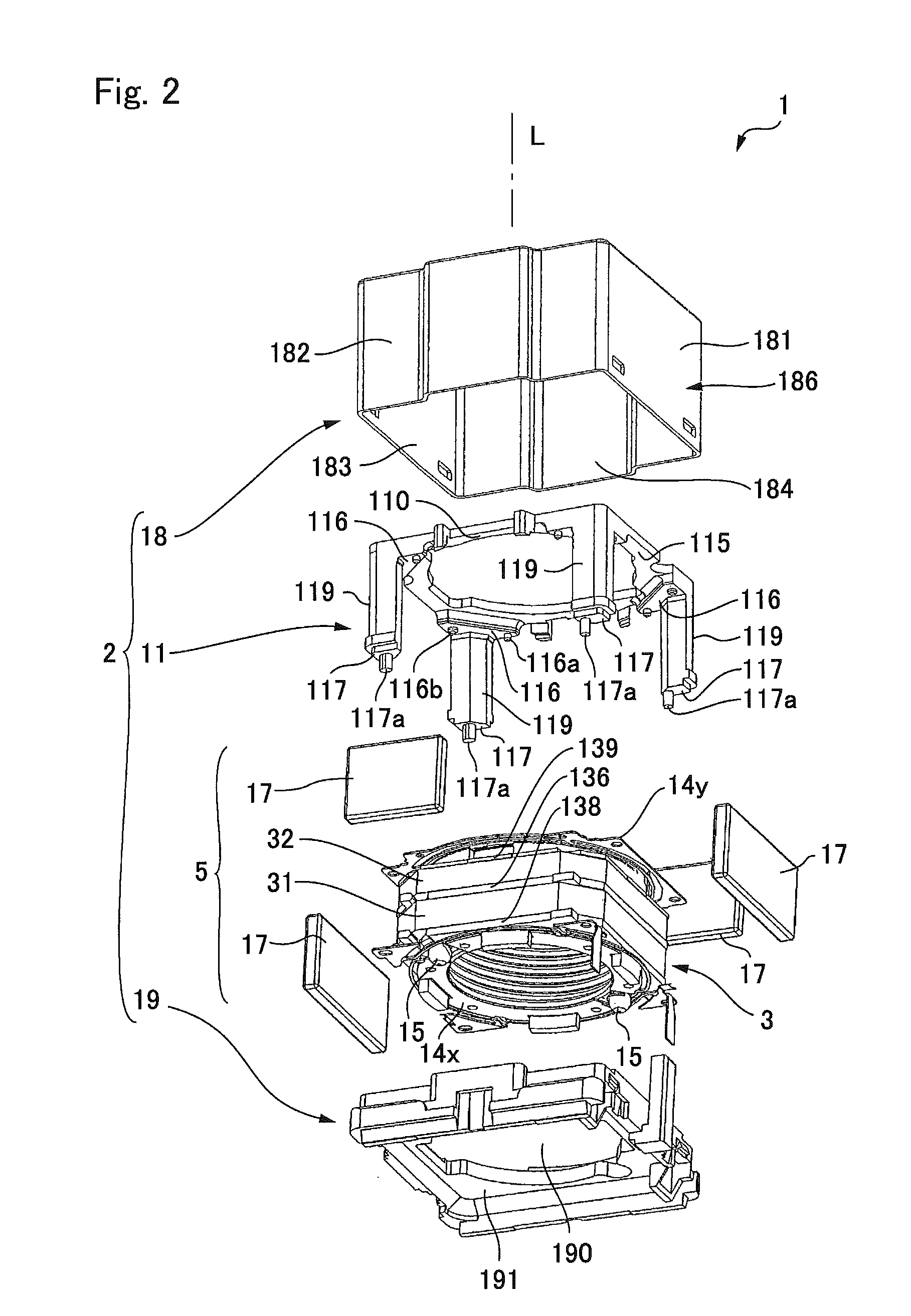

Internet-of-Things-technology-based relay device with Bluetooth and wifi

InactiveCN105187530AAvoid easy disconnectionReliable hardware foundationNetwork topologiesWireless commuication servicesData acquisitionSelf sensing

The invention discloses an Internet-of-Things-technology-based relay device with Bluetooth and wifi. The relay device comprises a USB power supply, wifi networking, an MCU, a debugging pin, a crystal oscillator clock source, an operation state indication lamp and a Bluetooth sensing antenna. The MCU is connected with the USB power supply, the wifi networking, the debugging pin, the crystal oscillator clock source, the operation state indication lamp and the Bluetooth sensing antenna. The USB power supply is connected with the wifi networking to power the wifi networking. The USB power supply is connected with a power supply indication lamp. The Bluetooth sensing antenna receives an information packet sent by a Bluetooth label. The wifi networking wirelessly transmits the information to a network server. According to the relay device provided by the invention, the problem of disconnection in a previous data collection and transmission process is solved; through three million times of pressure test, an original ping-pong mechanism ensure that device automatically restarts in the event of accident and never crashes; a reliable hardware foundation is provided for data collection, transmission and analysis; and the device has the functions of self-sensing statistics and animal behavior analysis.

Owner:高跃技

Method for preparing superconducting material by employing high energy ball milling method

InactiveCN105976940AAvoid easy disconnectionUniform compositionApparatus for heat treatmentGrain treatmentsHigh energyNiobium

The invention discloses a method for preparing superconducting material by employing a high energy ball milling method. The method includes the steps of preparing a niobium-aluminum supersaturation solid solution by mixing Nb powder with purity of 99.999% and Al powder with purity of 99.999% or Nb powder with purity of 99.999% and Al-Ge mixed powder, with a mixing atomic ratio of Nb to Al being 3 to 1, and conducting high energy ball milling by filling Ar gas in a ball milling tank, rotating at a rotation speed of 800-1800r / min for 4.5-5.5 hours to obtain the niobium-aluminum supersaturation solid solution; preparing a Nb3Al superconductive wire single-core wire precursor; preparing a Nb3Al superconductive wire multi-core wire precursor; and conducting heat treatment process. The problems that a precursor in a conventional fast heat and fast cooling treatment under a high temperature may tend to be fractured easily is solved, and requirements on particularity of heating equipment are avoided. The obtained superconductive wire rod is uniform in component and excellent in performance, cost is effectively reduced, and mass production is facilitated.

Owner:CHENGDU JUNHE TIANCHENG TECH

Multi-dimensional corona electrode structure and electrostatic precipitator

PendingCN109078756AIncrease plasma concentrationGood removal effectElectrode constructionsIonizationMulti dimensional

The invention provides a multi-dimensional corona electrode structure and an electrostatic precipitator. The technical defects that a corona wire used as an ionization pole in the electrostatic precipitator is prone to fusing and double-faced tip-type ionization pole has poor ionizing effect is overcome in the prior art. The multi-dimensional corona electrode structure comprises at least one set of secondary corona electrodes, wherein secondary corona electrodes comprise grounding electrodes in a hollow and cylindrical shape, and multi-dimensional ionization poles arranged in the grounding electrodes. The multi-dimensional ionization poles comprise a plurality of ionization needle layers, and the ionization needle layers are distributed in the inner cavities of hollow barrels one by one inthe axial direction of the hollow barrels of the grounding electrode. The ionization needle layers comprises a plurality of ionization needles radially distributed around the radial axis, and first air ducts are formed between the multi-dimensional ionization poles and the inner wall of the grounding electrodes. By adopting a multi-dimensional needle electrode structure, the effective area of discharge is greatly increased, the concentration of existing needle-shaped discharge plasmas is increased, the effect of dust removing and sterilization and disinfection of a ionization purifier is improved, and meanwhile, the problem of wire breakage in filamentous discharge can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

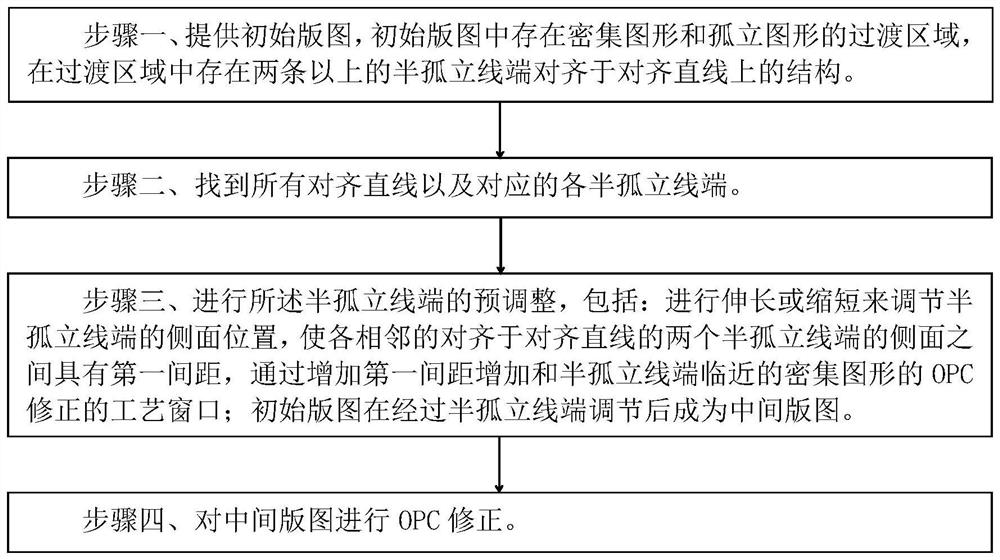

OPC correction method

PendingCN114460806AAvoid easy disconnectionIncreased process windowOriginals for photomechanical treatmentGraphicsDense graph

The invention discloses an OPC (Optical Proximity Correction) method, which comprises the following steps of: 1, providing an original layout in which a transition region of dense graphs and isolated graphs exists, and in which more than two structures with semi-isolated line ends aligned to aligned straight lines exist; 2, finding all aligned straight lines and corresponding semi-isolated line ends; step 3, pre-adjusting the semi-isolated line ends, namely, extending or shortening to adjust the side surface positions of the semi-isolated line ends, so that a first distance is formed between the side surfaces of two adjacent semi-isolated line ends aligned to the aligned straight line, and a second distance is formed between the side surfaces of two adjacent semi-isolated line ends aligned to the aligned straight line; increasing a process window of OPC correction of the dense pattern close to the semi-isolated line end by increasing the first interval; the original layout becomes an intermediate layout after being subjected to semi-isolated line end adjustment; and 4, carrying out OPC correction on the intermediate layout. According to the invention, the OPC process window of the dense pattern close to the semi-isolated line end alignment position can be improved.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

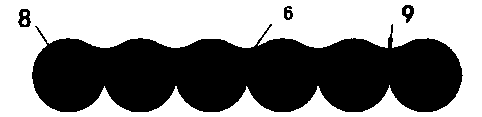

Flexible towline cable

InactiveCN108735361ANovel structural designImprove stability and reliabilityFlat/ribbon cablesFlexible cablesElectrical conductorAdhesive

The invention provides a flexible towline cable, which comprises a plurality of wires, which have coplanar axes and the same outer diameter and are closely arranged in parallel, and a plurality of strip-shaped connectors connected between the wires, wherein a telescopic cavity is formed between each strip-shaped connector and two wires in connection therewith; and an adhesive is arranged in the telescopic cavity for connecting each wire; a conductor comprises a cable core, a non-woven wrapping cloth on the outer side of the cable core and a sheath outside the non-woven wrapping cloth. The flexible towline cable in the invention has the advantages of novel structural design, good stability and reliability, long service life and good bending resistance and can effectively solve the problem that the existing towline cable is easily broken; the cable is set in a flat shape; the axes of the wires are on the same plane; the wires with the same outer diameter are closely arranged in parallel,so that the wires of the cable are uniformly stressed in the reciprocal dragging movement and the service life is longer.

Owner:扬州联胜电气有限公司

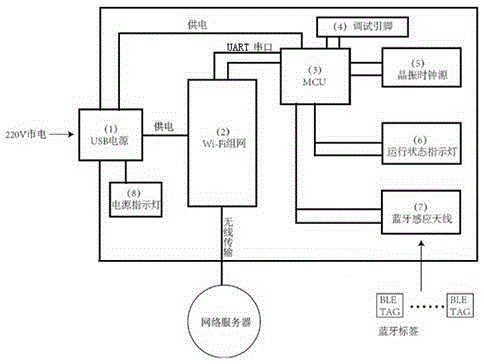

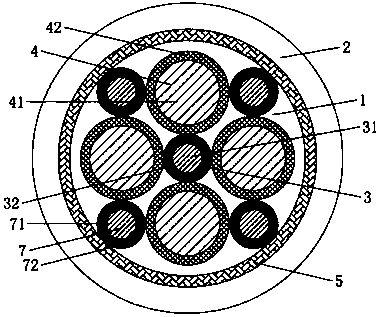

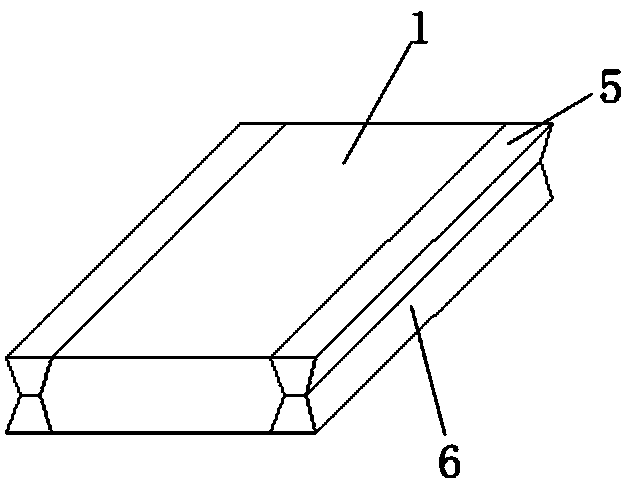

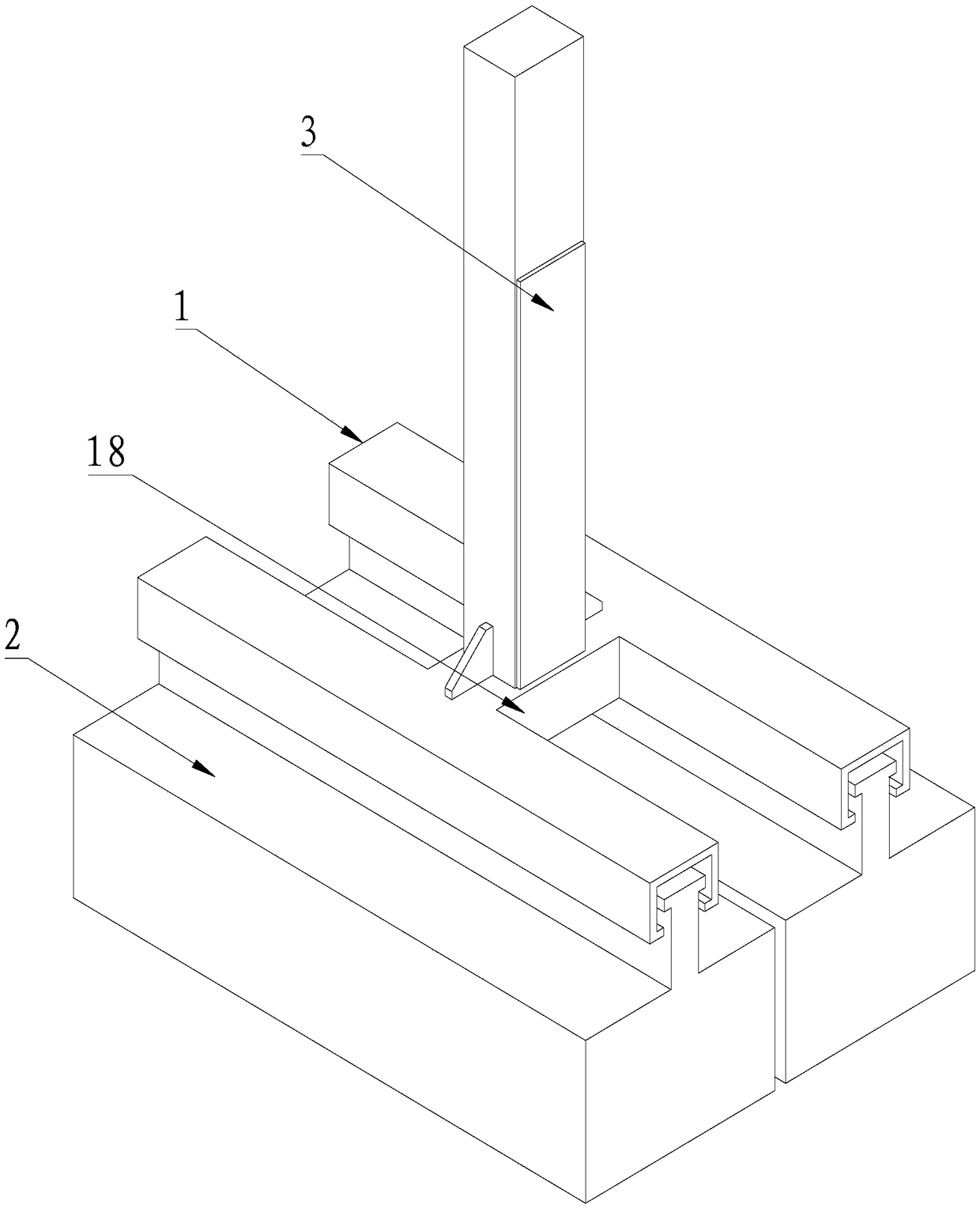

Seamless edge-sealing method of fluorine resin coating

InactiveUS20110277925A1Reduce processing requirementsReduce the number of materialsCooking-vessel materialsLamination ancillary operationsResin coatingPolymer chemistry

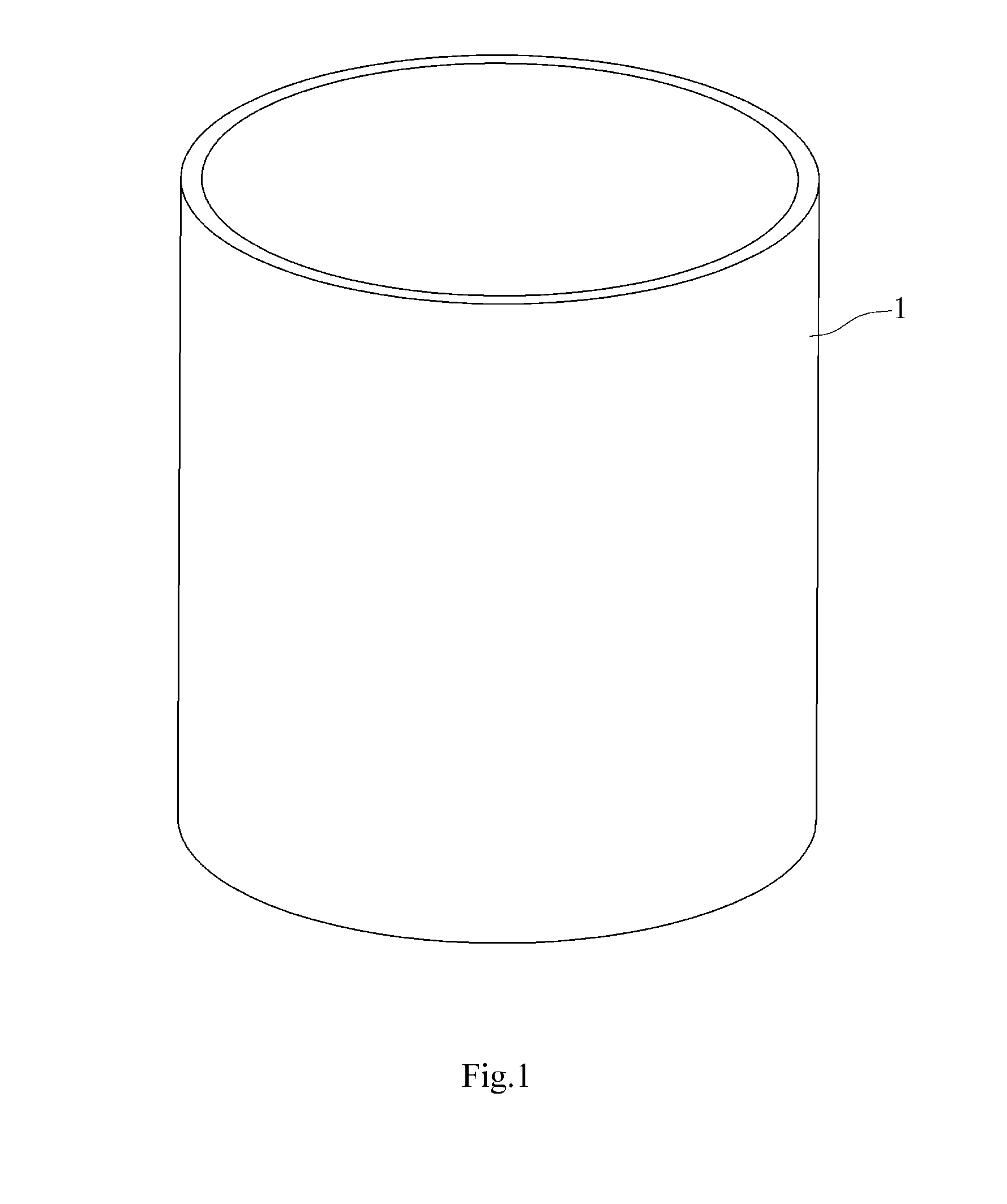

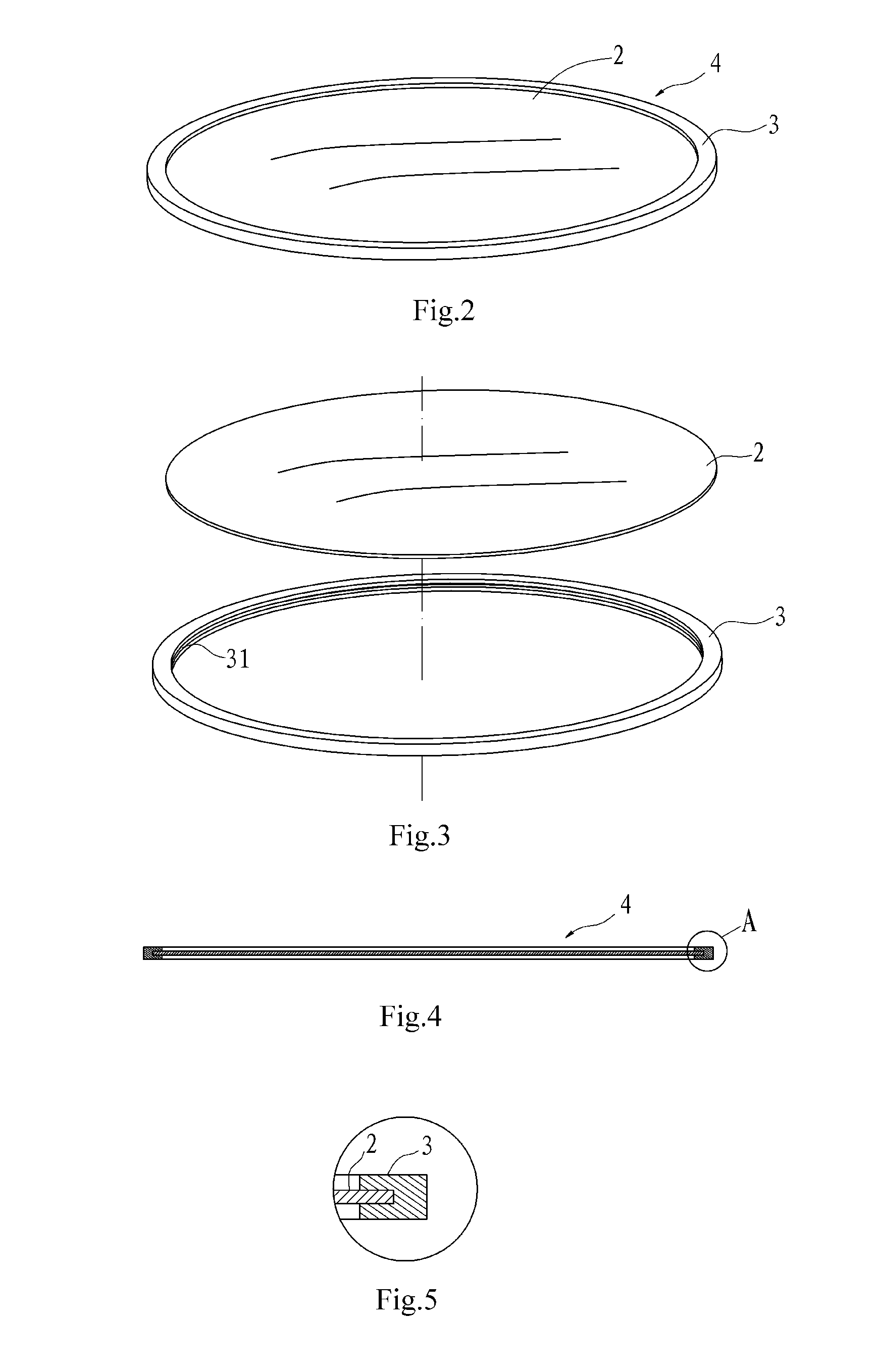

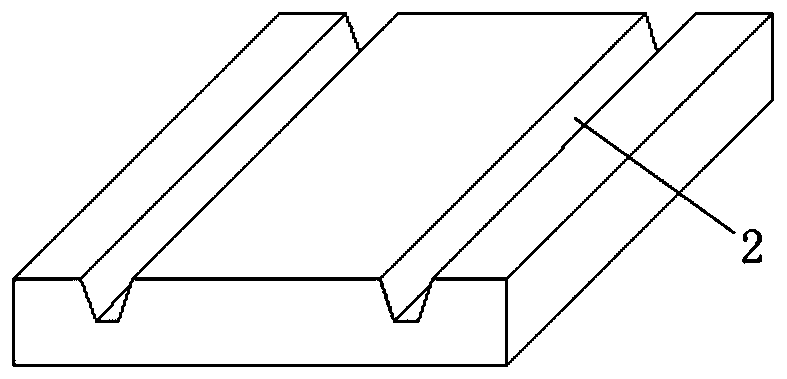

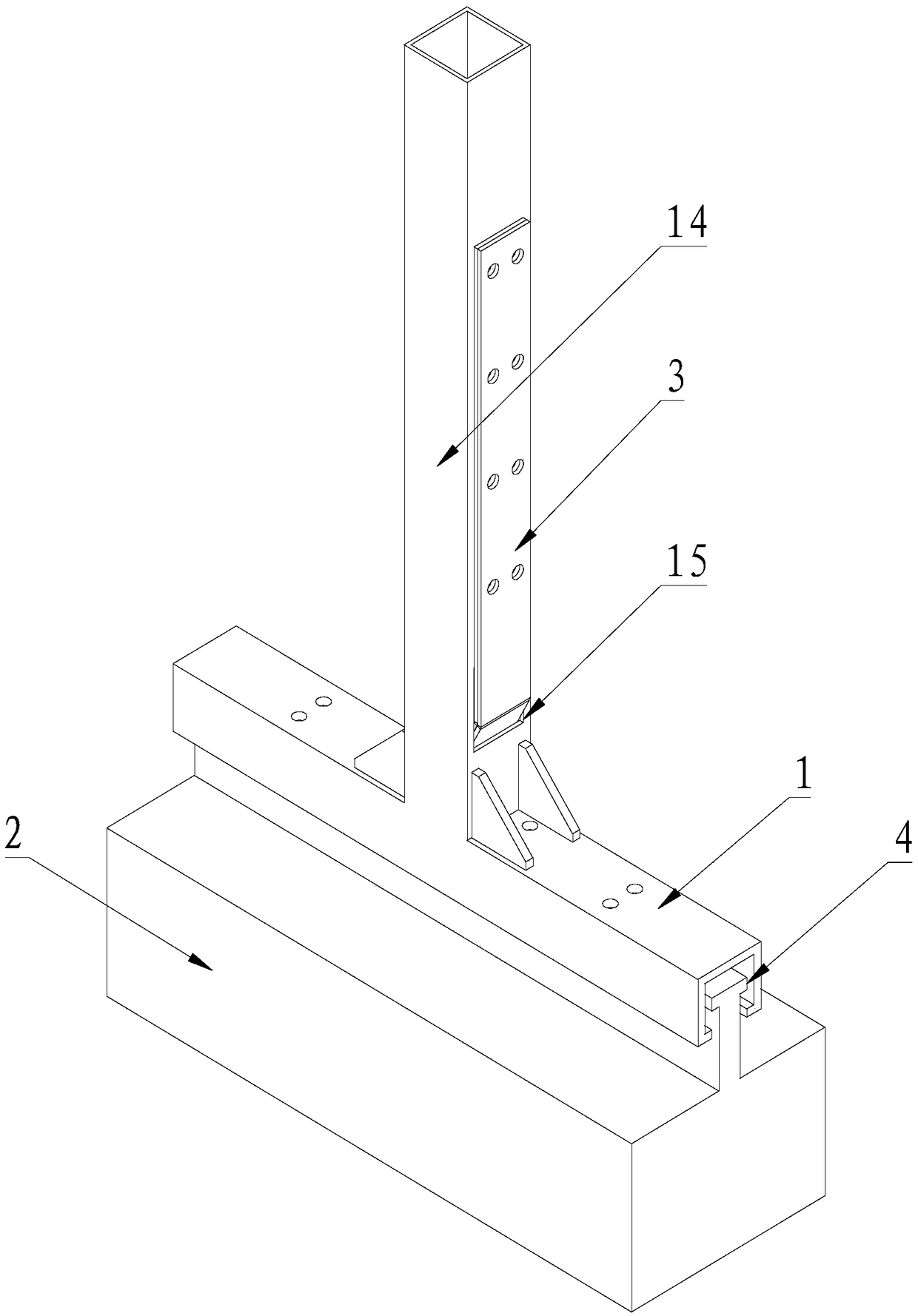

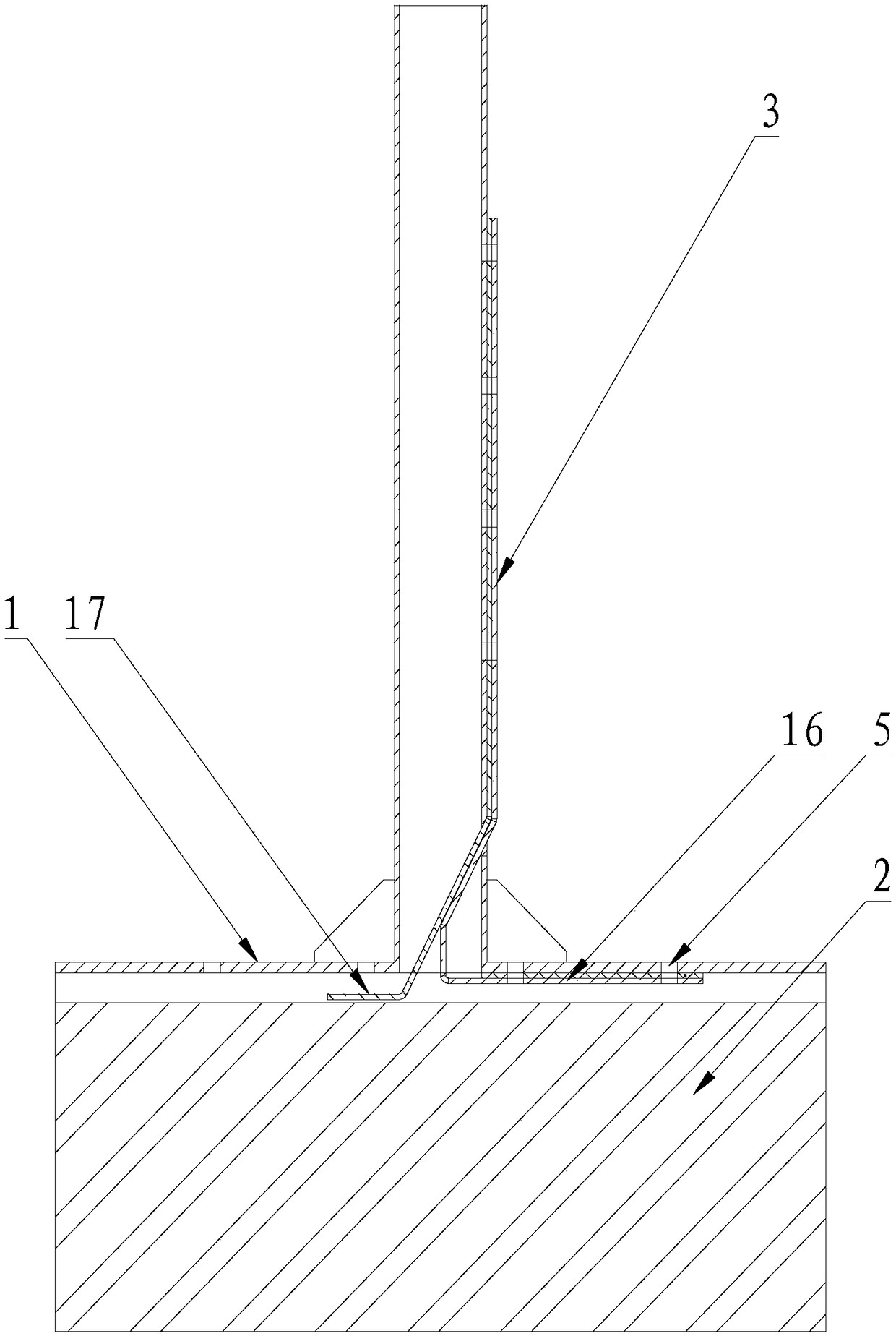

The seamless edge-sealing method of fluorine resin coating comprises following steps: (I) Putting the raw material of fluorine resin into a mold to obtain a cylinder (1) through one of the below ways: First, pressure maintaining and demolding, finally sintering the mold formed casting; Second, mechanical injecting; Third, mechanical vulcanizing; (II) Cutting the cylinder (1) into rings (3) and cutting each ring (3) to form an annular slot (31) on the inner wall of each ring; (III) Cutting a piece of base fabric of fluorine resin coating (2) into the shape adapted for the ring (3), and then stuffing the edge of the cut fabric of fluorine resin coating into the slot (31) of the ring; (IV) After hot-pressing, obtaining a piece of fabric of fluorine resin coating (4).

Owner:NINGBO SUPERBRIGHT TECH

Apparatus and method for managing and conditioning photovoltaic power harvesting systems

ActiveUS9660454B2Maximize efficiencyPower maximizationDc network circuit arrangementsElectric signal transmission systemsCollection systemElectric power

The efficiency of a PV power generation system (10) is maximized by an apparatus providing series of electronic units (20) connected to the PV modules (12) and comprising microprocessor controlled DC converters / power supply units. A managing unit (60) communicates with the electronic units (20) of a string (11) in order to carry out a synergic optimization of the efficiency both of the single PV modules (12) and of the entire string (11). The apparatus also provides PV module (12) by PV module (12) diagnostic features and it is able to communicate with external devices for a full system control.

Owner:CARAGLIO ALESSANDRO +1

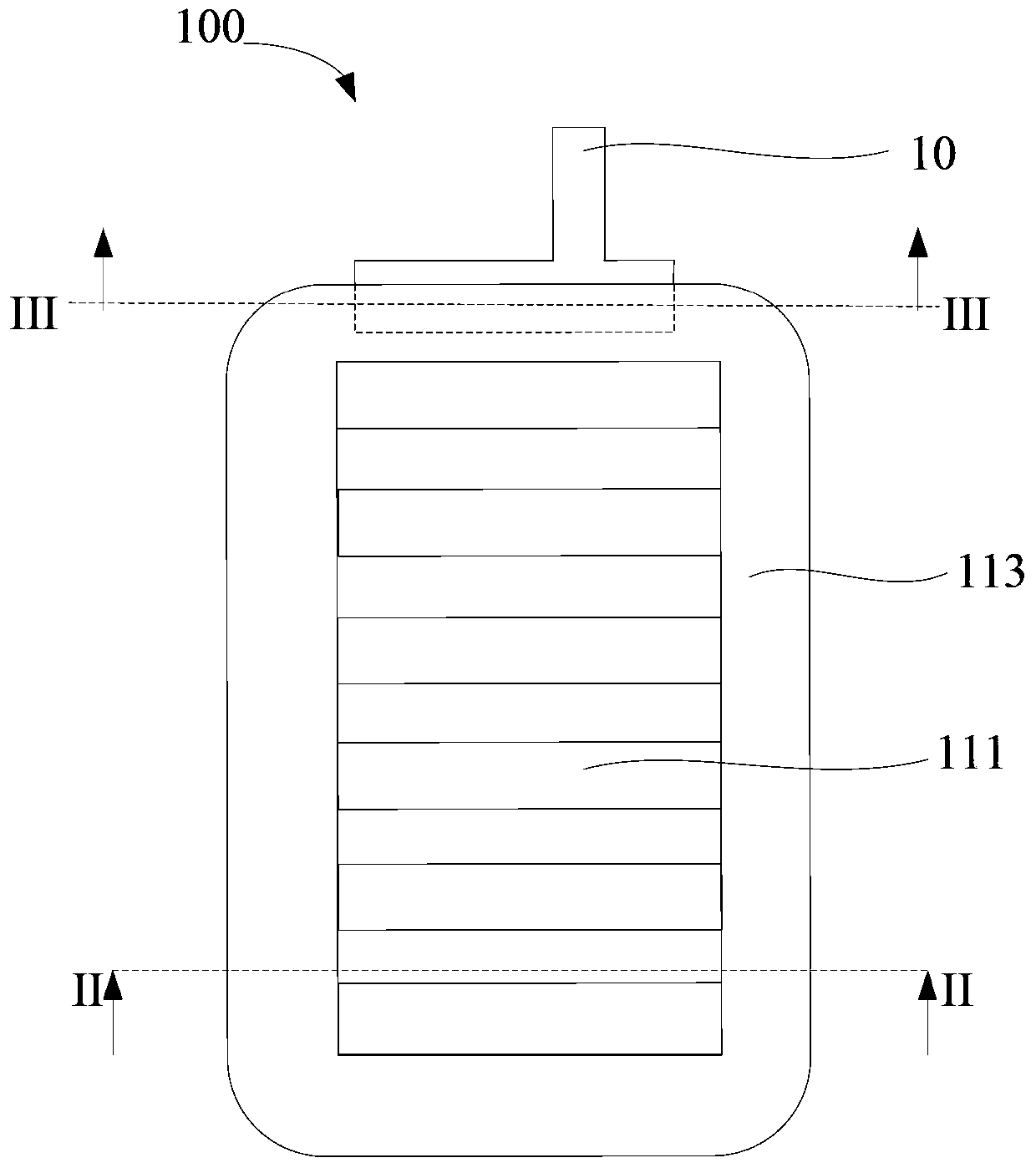

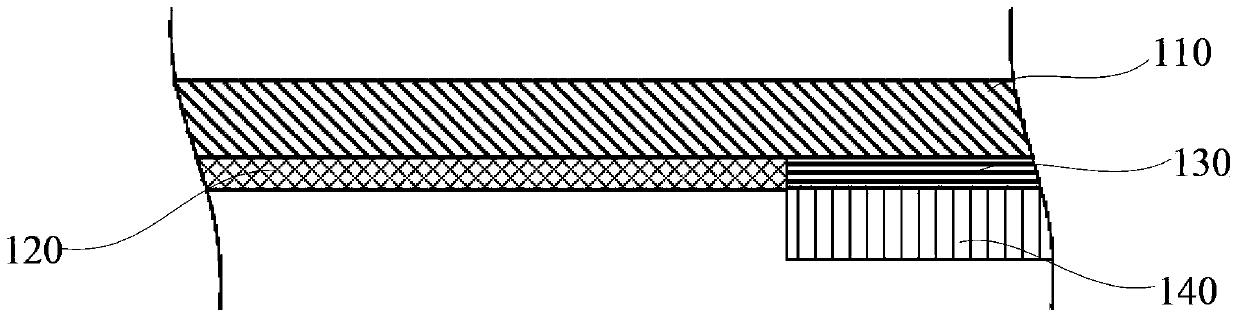

Battery pack and electric tool

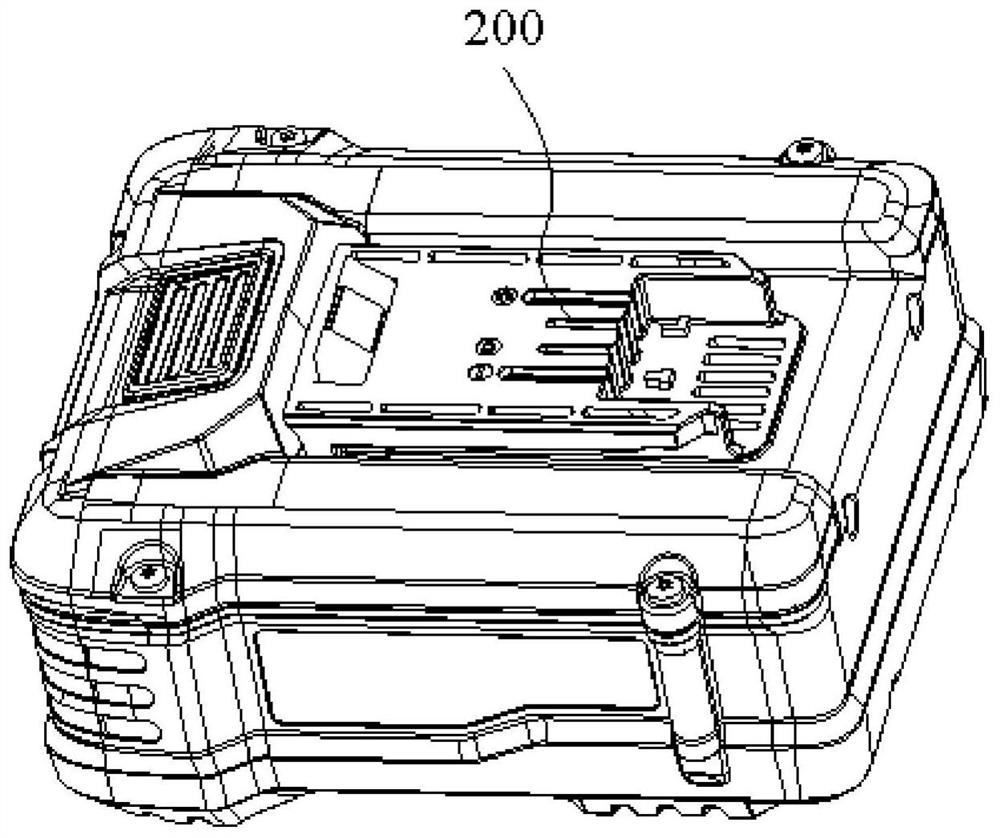

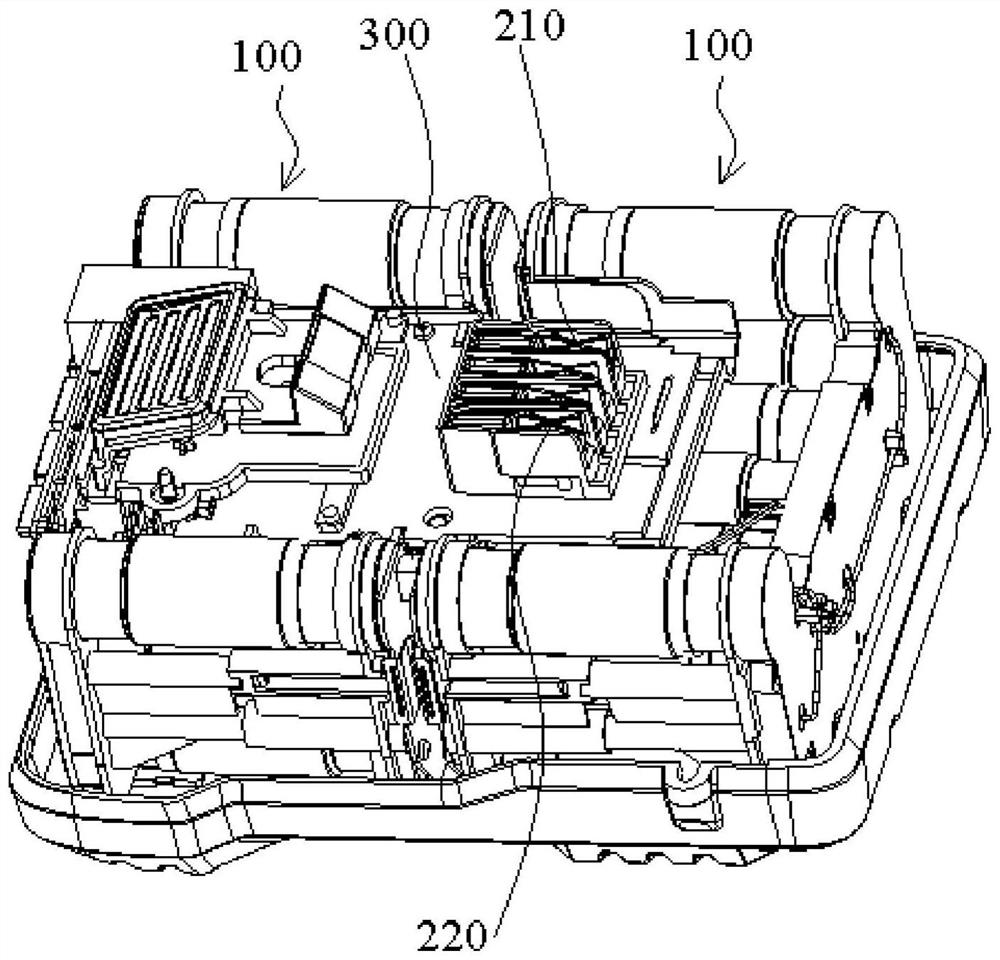

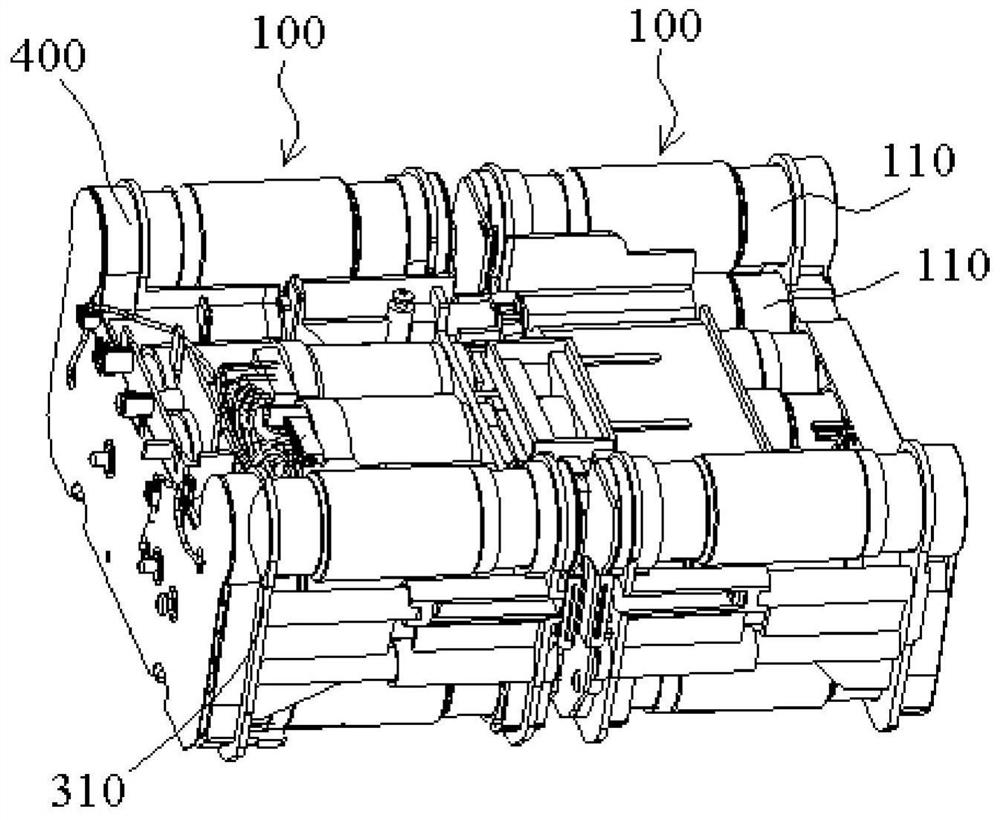

PendingCN111987249ASimplifies wiring designReduce wiring difficultySecondary cellsCell component detailsElectrical connectionEngineering

The invention discloses a battery pack and an electric tool, the battery pack comprises a circuit board, a plurality of battery cell units, a plurality of voltage detection lines, a first wiring terminal and a control board, each battery cell unit comprises one or more electrically connected battery cells, and the positive electrode end and / or the negative electrode end of each battery cell unit are / is electrically connected with a conductive path on the circuit board; the voltage detection line is used for detecting the voltage of the battery cell unit or the battery cell; the control panel is connected with each voltage detection line to acquire the voltage of the battery cell unit or the battery cell, and the first wiring terminal is arranged on the circuit board and is configured to electrically connect at least part of the voltage detection lines with the positive electrode end and / or the negative electrode end of the battery cell unit through a conductive path on the circuit board. At least part of the voltage detection line is connected with the positive electrode end and / or the negative electrode end of the battery cell unit through the circuit board and the first connecting terminal, so that the wiring design is simplified, the wiring difficulty is reduced, the problems of easy line breaking and possible short circuit caused by complete welding of the voltage detectionline are also avoided, and the reliability is high.

Owner:NANJING CHERVON IND

Windscreen wiper device

A windscreen wiper device of the flat blade type includes an elastic, elongated carrier element, as well as an elongated wiper blade of a flexible material, which can be placed in abutment with a windscreen to be wiped, which wiper blade includes at least one groove, in which groove a longitudinal strip of the carrier element is disposed, wherein free ends of the wiper blade are connected to a respective connecting piece, which windscreen wiper device comprises a connecting device for an oscillating wiper arm, and wherein the wiper blade is provided with a spoiler at a side thereof facing away from the windscreen to be wiped, wherein at least one connecting piece comprises an internal transverse reinforcement rib, wherein the spoiler is removed along a portion of the length of the wiper blade; at a distance from a free end of the wiper blade facing the connecting piece so as to form a transverse slit, and wherein in mounted position the internal transverse reinforcement rib rests inside the slit.

Owner:TRICO BELGIUM SA

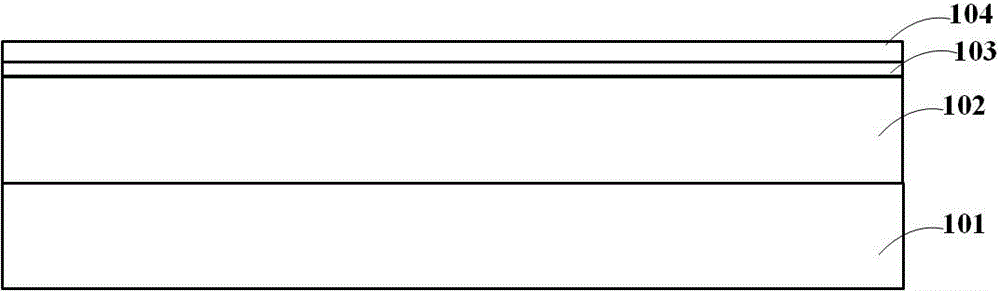

Substrate for micro LED display panel, and manufacturing method thereof

ActiveCN111223411AAvoid easy disconnectionAvoid problems with large heat-affected zonesSolid-state devicesIdentification meansMetal stripsLED display

The present application relates to a substrate for a micro LED display panel, and a manufacturing method thereof. The substrate comprises: a glass substrate; a first metal strip extending along the first side of the first surface of the glass substrate; and a second metal strip extending along the second side edge, corresponding to the first side edge, of the second surface of the glass substrate,wherein bottom surfaces of the first metal strip and the second metal strip are in contact with each other to make the first metal strip and the second metal strip form a structure for connecting partial metal of the first surface and the second surface of the glass substrate through metal on the side surface of the glass substrate. By the adoption of the substrate structure and the manufacturingmethod, the problem that when mobile printing is adopted at present, side edge circuits are prone to breakage and lack of glue is solved, the problem of large heat affected zone caused by laser cutting after copper deposition can be avoided, the difficulty of side edge gluing patterning is also avoided, metal cannot fall off, and the pattern precision is ensured.

Owner:BOE TECH GRP CO LTD +1

Electrolytic aluminum anode device

The invention relates to the technical field of electrolytic aluminum production, in particular to an electrolytic aluminum anode device. The electrolytic aluminum anode device comprises a shaped steel channel, a carbon block, a flexible copper wire or copper bar. A striped-shaped boss matched with the shaped steel channel is arranged at the top of the carbon block, and the flexible copper wire orcopper bar is accommodated between the shaped steel channel and the carbon block. According to the electrolytic aluminum anode device, the welding connection mode of an original anode device is replaced, and resistance is reduced; the problem that a steel claw is prone to being disconnected at a joint due to an explosive welding block in the original anode device is avoided, the strength of a connection structure is enhanced, electric energy is saved, part of external force is eliminated through a flexible conductive bar, so that the carbon block is moved flexibly relative to the shaped steelchannel, and thus an actuating element of an early-warning device can be arranged, so that the anode device is safer in operation; and carbon residue removal, steel claw repair, repair welding and straightening and other operations of the original anode device are avoided, and manpower and material resources are greatly saved.

Owner:FUJIAN NANPING ALUMINUM +1

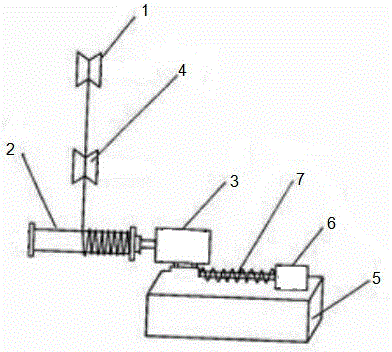

Air drying device of row lines

ActiveCN105241200AReduce frictionAvoid entanglementDrying gas arrangementsDrying machines with progressive movementsEngineeringLine segment

The invention relates to an air drying device of row lines. The air drying device comprises an air drying pipe and a plurality of line guide pipes. One end of the air drying pipe is connected with an air inlet pipe, and the other end of the air drying pipe is connected with an air outlet pipe. The line guide pipes are arranged in the direction intersecting with the air drying pipe. Each line guide pipe penetrates the two sides of the air drying pipe. The joints of each line guide pipe and the two sides of the air drying pipe are connected in a sealed manner. Each line guide pipe penetrating the air drying pipe is divided into three sections, namely, a middle section located in the air drying pipe, a line inlet section and a line outlet section, wherein the line inlet section and the line outlet section are located on the two sides of the air drying pipe respectively, an air guide hole communicated with a row line passageway in the line guide pipe is formed in the middle section, air located in the air drying pipe is led into the row line passageway through the air guide hole to dry the corresponding row line located in the row line passageway. By means of the air drying device, on one hand, all the row lines entering the air drying pipe are separated, friction or winding between every two adjacent row lines is prevented, and the problem that line breakage is prone to happening is solved; on the other hand, wind can be conveniently guided to the surfaces of the row lines in a concentrated manner, and therefore the air drying efficiency is improved; and in addition, the structure is simple, and threading of the row lines is facilitated.

Owner:苏州市吴江神州双金属线缆有限公司

Wire arrangement device of medium wire drawing machine

InactiveCN106623457AReduce frictionOvercoming the problem of easy disconnectionEngineeringWire drawing

The invention discloses a wire arrangement device of a medium wire drawing machine. The wire arrangement device comprises a first wire passing guide wheel and a wire collection disc, wherein the wire collection disc is arranged on a wire collection motor; a second wire passing guide wheel is arranged between the first wire passing guide wheel and the wire collection disc; the wire collection motor is arranged on a base; a wire arrangement motor is also arranged on the base; a slide rod is arranged between the wire collection motor and the wire arrangement motor; the wire arrangement motor is used for driving the wire collection motor to move on the slide rod left and right; because the wire collection disc can move left and right, when a wire passes through the first wire passing guide wheel and the second wire passing guide wheel, the wire and the wire collection disc are maintained on the same straight line, so as to effectively avoid the friction between the wire and the guide wheels. The wire arrangement device of the medium wire drawing machine has the characteristics that the structure is simple, the use effect is good, and the like.

Owner:SUZHOU JIN JU SONG MECHANICAL & ELECTRICAL CO LTD

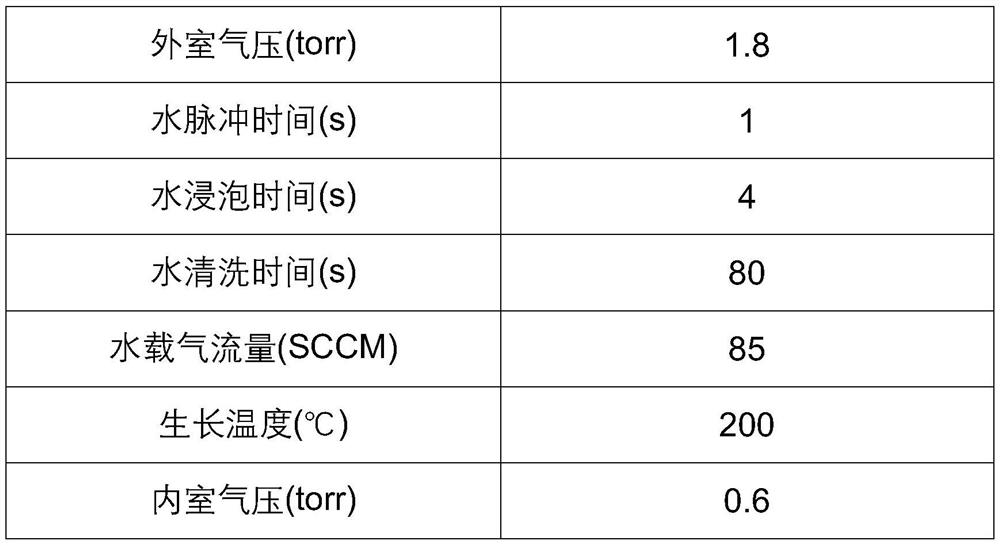

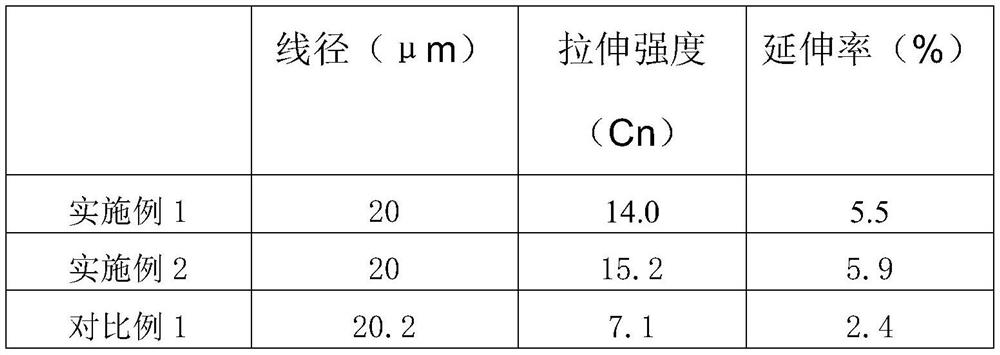

Bonding silver wire capable of improving mechanical property and preparation method thereof

PendingCN114203660AImprove mechanical propertiesSolve the mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesAtomic layer depositionTitanium oxide

The invention discloses a bonding silver wire capable of improving mechanical properties and a preparation method thereof. The bonding silver wire is composed of a doped silver-based bonding wire and a plating layer wrapping the doped silver-based bonding wire. The doped silver-based bonding wire comprises the following components in percentage by weight: 2.0% to 3.0% of Au, 1.0% to 2.0% of Pd, 0.5% to 1.0% of Ca, 0.05% to 0.08% of Ti, 0.05% to 0.08% of Sn, 0.03% to 0.05% of Ce, 0.01% to 0.03% of Eu and the balance of Ag. And the plating layer is formed by depositing an ALD aluminum oxide / titanium oxide composite nano film with the thickness of 0.1-0.3 mu m on the surface of the doped silver-based bonding wire through an atomic layer deposition process. According to the bonding silver wire capable of improving the mechanical property and the preparation method of the bonding silver wire, the formula design is reasonable, multi-element doping and surface coating are combined, the problems that in the prior art, the mechanical property of a bonding silver wire is low, and the bonding silver wire is prone to being broken, vulcanized and oxidized under the high-speed bonding condition are solved, the preparation method and lead welding are improved, and the bonding silver wire is high in mechanical property. Therefore, the bonding silver wire forms good bonding, and the application prospect is wide.

Owner:晶学金属有限公司

Current sensor probe and assembling method thereof

PendingCN107741517AEasy to assembleImprove assembly efficiencyCurrent measurements onlyVoltage/current isolationBraced frameHard metal

The invention provides a current sensor probe and an assembling method thereof. The probe comprises a supporting frame, iron cores, a winding and pins, wherein the supporting frame comprises an uppercover and a lower cover, the upper cover and the lower cover are connected to form an accommodating cavity, the iron cores are installed in the accommodating cavity, the winding is wound around the iron cores and the supporting frame, the pins are installed on the upper cover of the supporting frame, and wiring heads at two ends of the winding are connected with the pins. The probe is simple and convenient to assemble, the assembling efficiency of the probe is greatly improved, the production cost is reduced, meanwhile the supporting frame introduced into the probe forms a whole, movable partsare arranged in the probe, and the problem is solved that the winding is likely to break. In addition, the assembled probe serves as a whole and all the pins correspond in a one-to-one mode in finished product assembly and testing links, strenuous pin number distinguishing is not needed, probe and PCB assembly is facilitated, the pins are made of a hard metal material, a clamp can be used for testing, and the finished product assembling efficiency and testing efficiency are greatly improved.

Owner:湖南银河电气有限公司

A kind of substrate for micro-led display panel and manufacturing method thereof

ActiveCN111223411BAvoid easy disconnectionAvoid problems with large heat-affected zonesSolid-state devicesIdentification meansMetal stripsLED display

The present application relates to a substrate for a micro-LED display panel and a manufacturing method thereof. The substrate includes: a glass substrate; a first metal strip extending along a first side of a first surface of the glass substrate; The second metal strip extending from the second side corresponding to the first side of the second surface of the substrate; the bottom surfaces of the first metal strip and the second metal strip are in contact with each other, so that the first metal strip and the second metal strip A structure in which parts of the metal on the first surface and the second surface of the glass substrate are connected through the metal on the side of the glass substrate. Adopting the substrate structure and manufacturing method of the present invention solves the phenomenon that the side lines are easy to break and lack glue when mobile printing is used; The difficulty of patterning with glue on the side, the metal will not fall off and the accuracy of the pattern is guaranteed.

Owner:BOE TECH GRP CO LTD +1

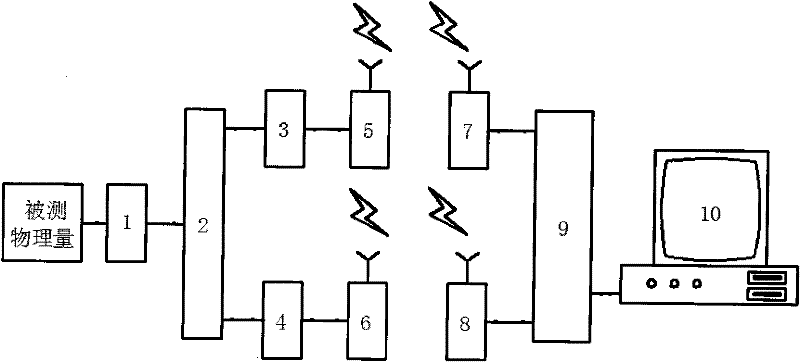

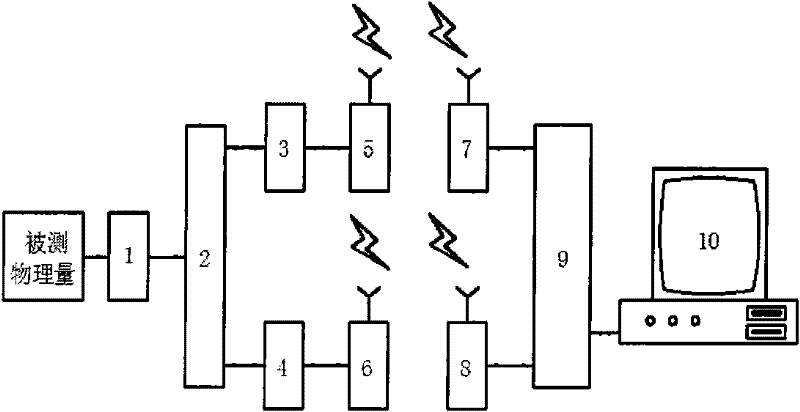

Sensor signal dual-network wireless transmission device

ActiveCN102176279AImprove reliabilityAvoid easy disconnectionTransmission systemsWireless communicationWireless dataInformation transmission

The invention provides a sensor signal dual-network wireless transmission device, and belongs to the technical field of information transmission. The device is characterized in that: a corresponding signal is measured and sensed by a field sensor, is reasonably processed by each processing unit, is transmitted to an INATERNET network through two wireless data transmission operators, and is transmitted to a data acquisition analyzing and processing center by the INTERNET network. The device overcomes the defects of single wireless data transmission, and a sensor signal is subjected to wireless data transmission through two different network systems by using networks of two wireless data transmission operators; compared with currently adopted single network transmission of sensor data information, the dual-network transmission provided by the invention greatly improves the reliability of information data transmission, and effectively overcomes the defects that single circuit transmission is easily disconnected, easily loses data, wastes time and misses opportunities.

Owner:TAIYUAN UNIV OF TECH

Silver-plated superfine copper wire and preparation method thereof

ActiveCN108231243AHigh strengthImprove ductilitySingle bars/rods/wires/strips conductorsConductive materialSilver plateCopper wire

The invention discloses a silver-plated superfine copper wire. The diameter of the silver-plated superfine copper wire is 0.02-0.05mm. The silver-plated superfine copper wire comprises a copper alloyand a 0.3-0.8 micron silver layer coating the surface of the copper alloy, wherein the copper alloy comprises the following raw materials in percentage by weight: Pr, Ni, Sn, B, Pd and Cu. The invention also discloses a preparation method of the silver-plated superfine copper wire. The preparation method comprises the following steps: mixing Pr, Ni, Sn, B, Pd and Cu in percentage by weight, addingthe mixture into a smelting furnace to be smelted in vacuum, and carrying out continuous casting to prepare an oxygen-free copper bar, the diameter of which is 6-10mm; roughly drawing and annealing the oxygen-free copper bar to prepare a rough copper wire, the diameter of which is 1.0-2.0mm; coating a silver layer to the surface of the rough copper wire to prepare a silver-plated copper wire; lubricating the surface of the silver-plated copper wire to obtain a lubricated copper wire; and finely drawing and annealing the lubricated copper wire to prepare the silver-plated superfine copper wire. The silver-plated superfine copper wire prepared is excellent in performance, simple and efficient in preparation method and good in application prospect.

Owner:安徽晋源铜业有限公司

A line air-drying device

ActiveCN105241200BReduce frictionAvoid entanglementDrying gas arrangementsDrying machines with progressive movementsEngineeringFeed line

The invention relates to an air-drying device for running lines, which comprises an air-drying pipe whose end is connected with an air inlet pipe and whose other end is connected with an air-out pipe; The pipes pass through both sides of the air-drying pipe respectively, and the joints of the two are sealed and connected. The wire pipe passing through the air-drying pipe is divided into three sections. The inlet section and the outlet section on both sides of the pipe, wherein the middle section is provided with an air guide hole connected with the inner line channel of the wire tube, and the wind in the air dry pipe is respectively guided into the line channel by the air guide hole and will be located in the line channel. Let the inner row lines air dry. On the one hand, the present invention separates each row line entering the air drying pipe, prevents friction or entanglement between two adjacent row lines, and solves the problem of easy disconnection; , so as to improve the air-drying efficiency, and in addition, the structure is simple, which is convenient for the threading of the line.

Owner:苏州市吴江神州双金属线缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com