Bonding silver wire capable of improving mechanical property and preparation method thereof

A bonding wire and bonding technology, applied in the field of bonding wire, can solve the problems of easy vulcanization, oxidation, and easy disconnection of bonding silver wire, so as to reduce vulcanization corrosion, good bonding, and improve anti-oxidative vulcanization. Effects on properties and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

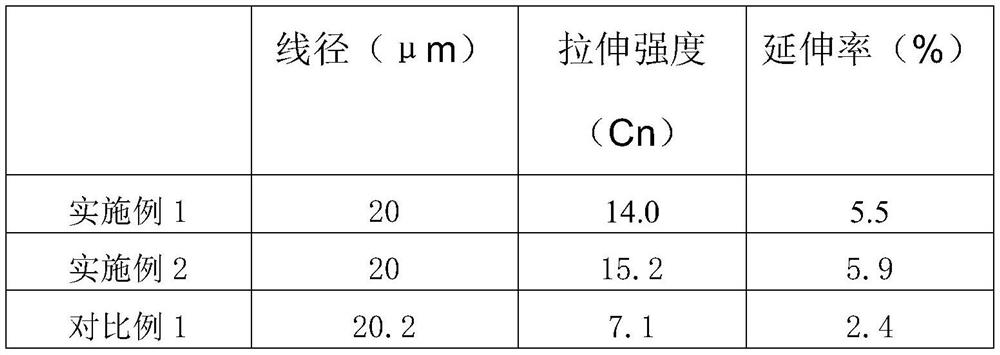

Embodiment 1

[0029] Preparation of doped silver-based bonding wire

[0030] (1) Melting: Mix Ag, Au, Pd, Ca, Ti, Sn, Ce, and Eu evenly and put them in a vacuum melting machine. Vacuum is carried out under the conditions of a vacuum degree of 5×10-4Pa and a temperature of 1000°C. Melting, drawing and casting into alloy wire rods with a diameter of 6mm;

[0031] (2) Wire drawing: Carry out wire drawing processing on the above-mentioned alloy wire rod, stretch it through the first thick wire drawing machine, stretch the wire diameter from 6 to 1mm, and the drawing speed is 0.1m / s, and then pass through the second thin wire rod in sequence. The wire drawing machine is stretched to 0.1mm at a rate of 0.3m / s, and then stretched to 0.03mm at a rate of 0.6m / s by an ultra-fine wire drawing machine, and then stretched by an ultra-fine wire drawing machine in sequence Further stretching at a rate of 1m / s into an alloy wire with a wire diameter of 20μ alloy bonding wire;

[0032](3) Annealing: the a...

Embodiment 2

[0039] Preparation of bonding silver wire

[0040] The doped silver-based bonding wire obtained in Example 1 was ultrasonically cleaned in ethanol for 15 minutes, dried with high-purity nitrogen, and the pretreated doped silver-based bonding wire was repeatedly deposited with an aluminum oxide film and oxidized by using an ALD instrument. Titanium film, ALD aluminum oxide / titanium oxide composite nano film is formed on the surface of doped silver-based bonding wire to obtain bonding silver wire.

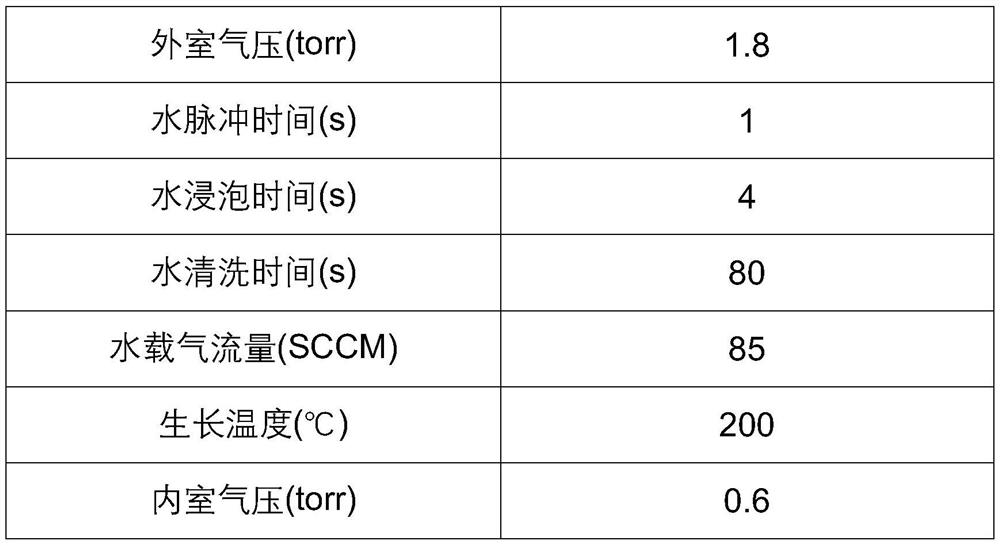

[0041] The atomic layer deposition process is as follows:

[0042] (1) For the preparation of aluminum oxide thin films, one cycle of its deposition sequence includes the following two half-reaction cycles. 1. The trimethylaluminum pulse enters the cavity and reacts with the surface of the doped silver-based bonding wire. This reaction continues until the surface reaction is completed; 2. The unreacted trimethylaluminum is assisted by nitrogen inert carrier gas 3. The water pulse i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com