Electrolytic aluminum anode device

A technology of electrolytic aluminum anode and special-shaped tank, which is applied in the field of electrolytic aluminum production, can solve the problems of large power loss, low product quality, complex structure, etc., and achieve the effects of improving quality, saving manpower and material resources, and avoiding residual carbon removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

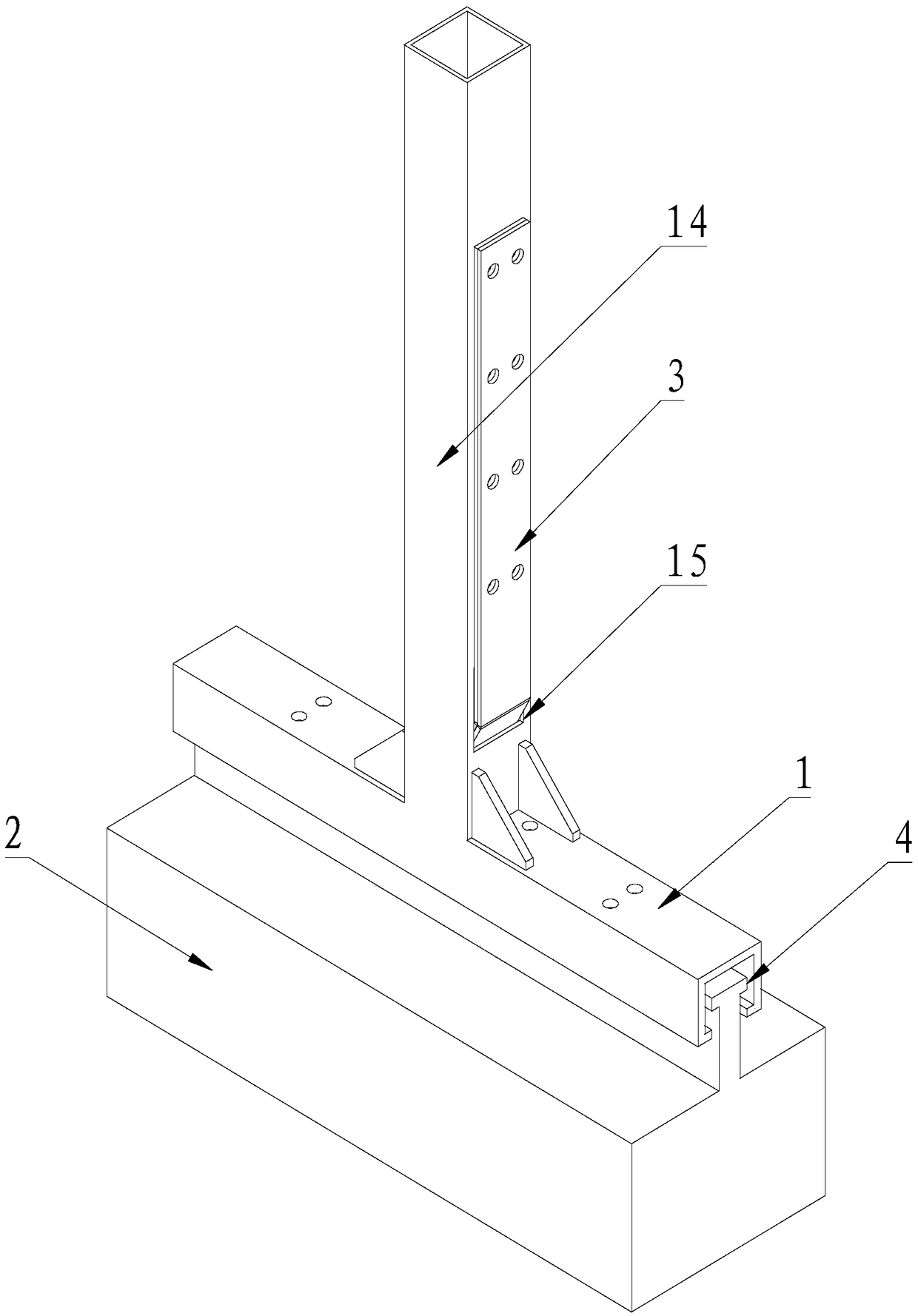

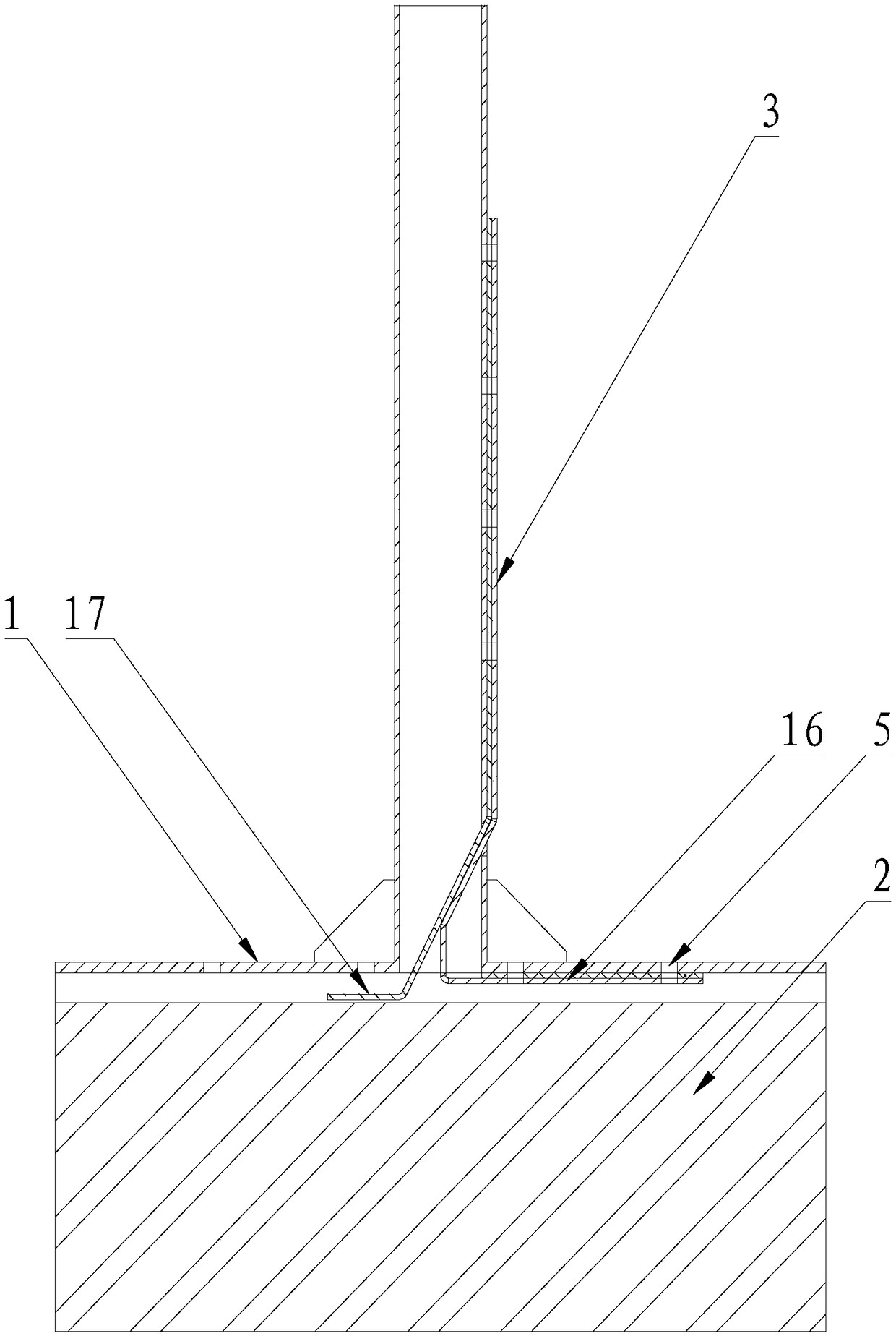

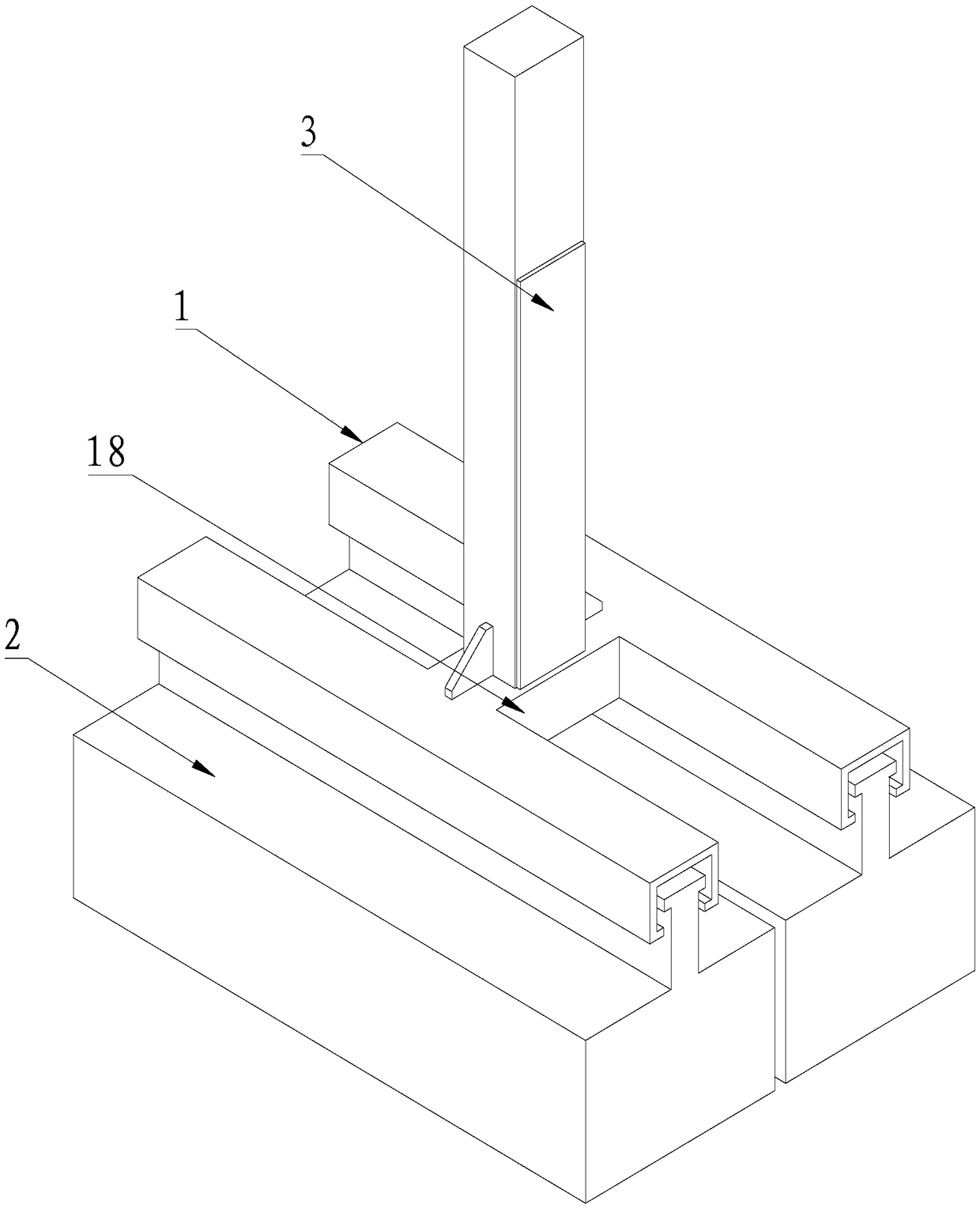

[0039] Please refer to Figure 1 to Figure 5 , Embodiment 1 of the present invention is: an electrolytic aluminum anode device, including a special-shaped channel steel 1, a carbon block 2 and a flexible copper bar 3;

[0040] The top of the carbon block 2 is provided with a bar-shaped boss 4 matching the special-shaped channel steel 1 , and the flexible copper bar 3 is accommodated between the special-shaped channel steel 1 and the carbon block 2 .

Embodiment 2

[0041] Please refer to Figure 1 to Figure 5 , the second embodiment of the present invention is: an electrolytic aluminum anode device, including a special-shaped channel steel 1, a carbon block 2 and a flexible copper bar 3;

[0042] The top of the carbon block 2 is provided with a bar-shaped boss 4 matching the special-shaped channel steel 1 , and the flexible copper bar 3 is accommodated between the special-shaped channel steel 1 and the carbon block 2 .

[0043] The flexible copper bar 3 includes interconnected wires and flexible conductive copper wires or copper bars, and the conductive wires are installed between the special-shaped channel steel and the carbon block through the flexible conductive copper wires or copper bars. The width of the row is not less than the width of the strip-shaped boss 4 . The special-shaped channel steel 1 is provided with a mounting hole 5 on the other end face relative to the grooved end face, and a fastening device for pressing the flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com