OPC correction method

An extension direction, isolated line technology, applied in the field of optical proximity effect correction, can solve the problems such as pitchloose can not be completely solved, poor process window in the middle area, easy disconnection and other problems, to avoid adverse effects, prevent easy disconnection, and improve process window. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment O

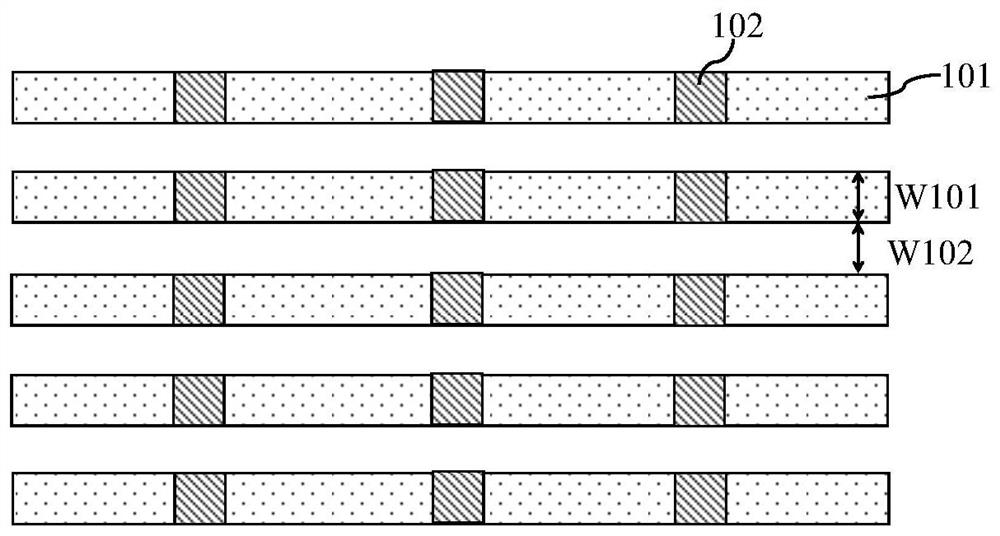

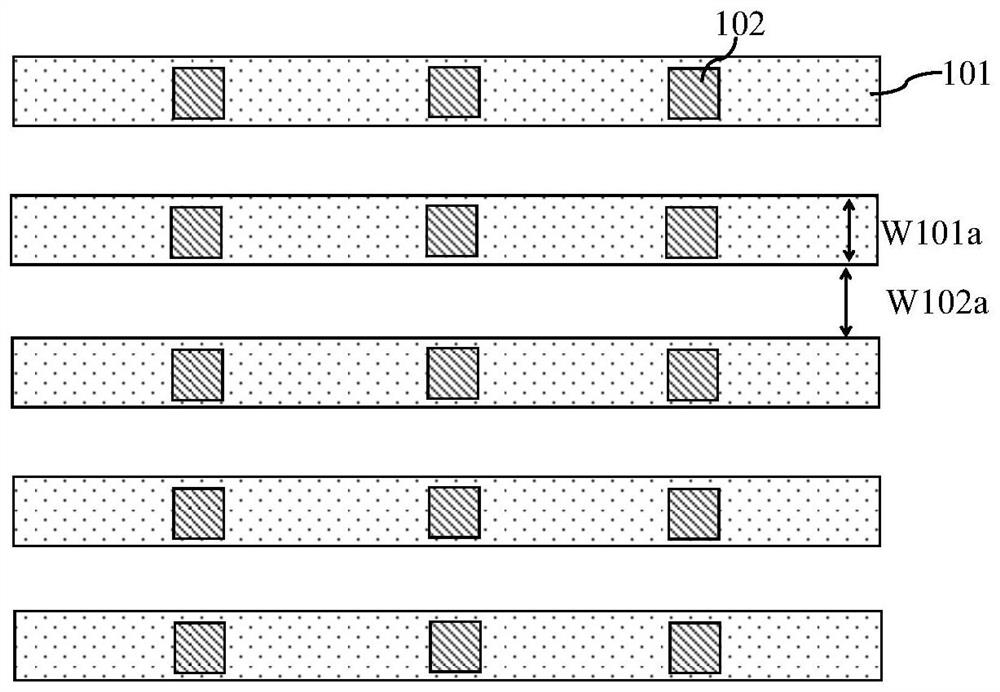

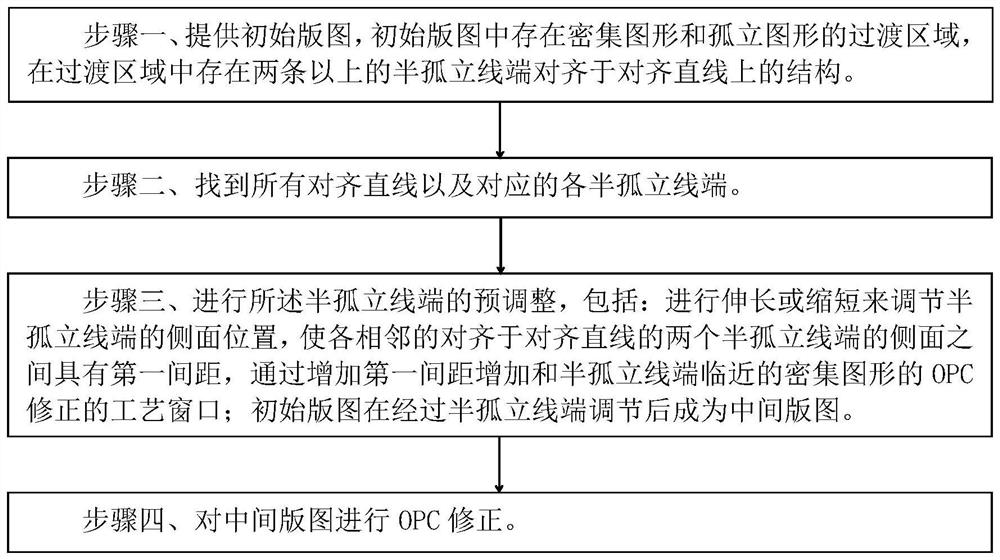

[0039] Such as figure 2 Shown is the flow chart of the OPC correction method of the embodiment of the present invention; as Figure 3A to Figure 3DAs shown, it is a schematic diagram of graphics aligned with various semi-isolated line ends 202 in the original layout of the OPC correction method according to the embodiment of the present invention; Figure 4A to Figure 4C As shown, it is a schematic diagram of the graph when pre-adjusting various semi-isolated line ends 202 by using the elongation method in the OPC correction method of the embodiment of the present invention; Figure 5A to Figure 5C Shown is a schematic diagram of the OPC correction method of the embodiment of the present invention when various semi-isolated line ends 202 are pre-adjusted by using a shortening method; the OPC correction method of the embodiment of the present invention includes the following steps:

[0040] Step 1, such as Figure 3A to Figure 3D As shown, it is a schematic diagram of graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com