Air drying device of row lines

An air-drying device and line-running technology, which is applied in the direction of drying gas arrangement, drying, and dryers, can solve problems such as inconvenient operation, disorderly blowing direction, and non-concentrated wind, so as to improve air-drying efficiency, solve problems such as easy disconnection, Ease of threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

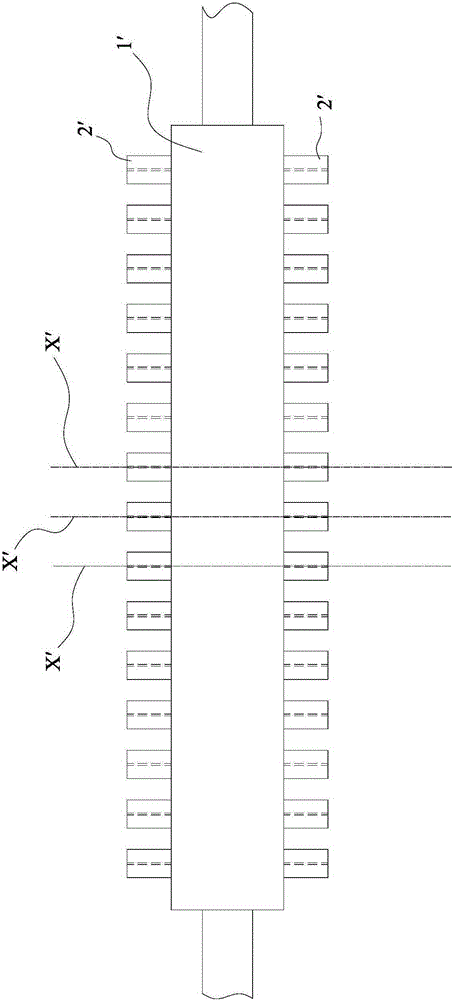

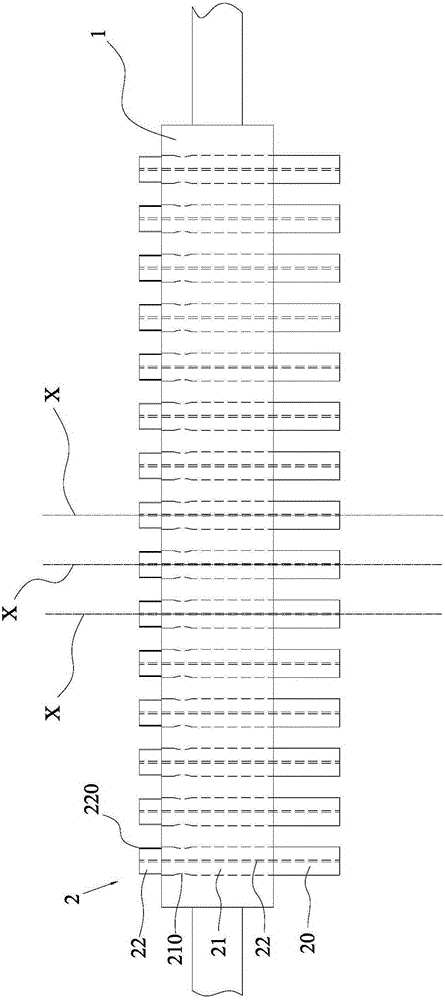

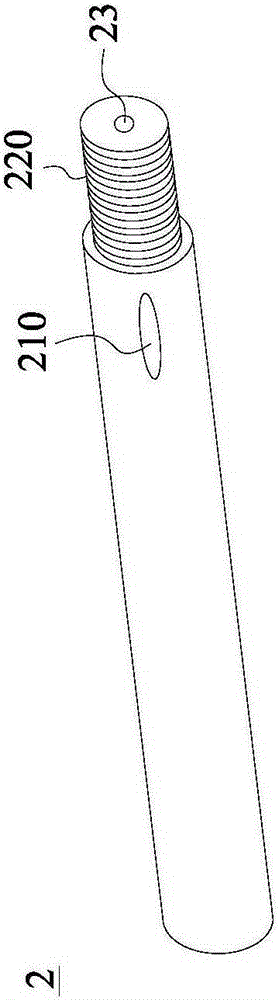

[0025] Such as figure 2 and image 3 As shown, the line air-drying device provided in this embodiment includes an air-drying pipe 1 connected to an air inlet pipe at one end and an air-out pipe at the other end; 2. In particular, each wire conduit 2 passes through both sides of the air-drying pipe 1 respectively, and the junction of the two is sealed and connected, and the wire pipe 2 passing through the air-drying pipe 1 is divided into three sections, and the three sections are respectively The middle section 21 located inside the air-drying pipe 1, and the incoming line section 20 and the outgoing line section 22 respectively located on both sides of the air-drying pipe 1, wherein the middle section 21 is provided with an air guide hole 210 communicating with the inner line channel 23 of the wire duct 2 , the wind located in the air dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com