A king-shaped optical fiber grating sensor patch

A fiber grating and king-shaped technology, which is applied to the field of the king-shaped fiber grating sensor patch, can solve the problems of high manufacturing difficulty, high sensor manufacturing cost, uneven force on the fiber grating part, etc., so as to prevent uneven force and expand The effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and embodiments.

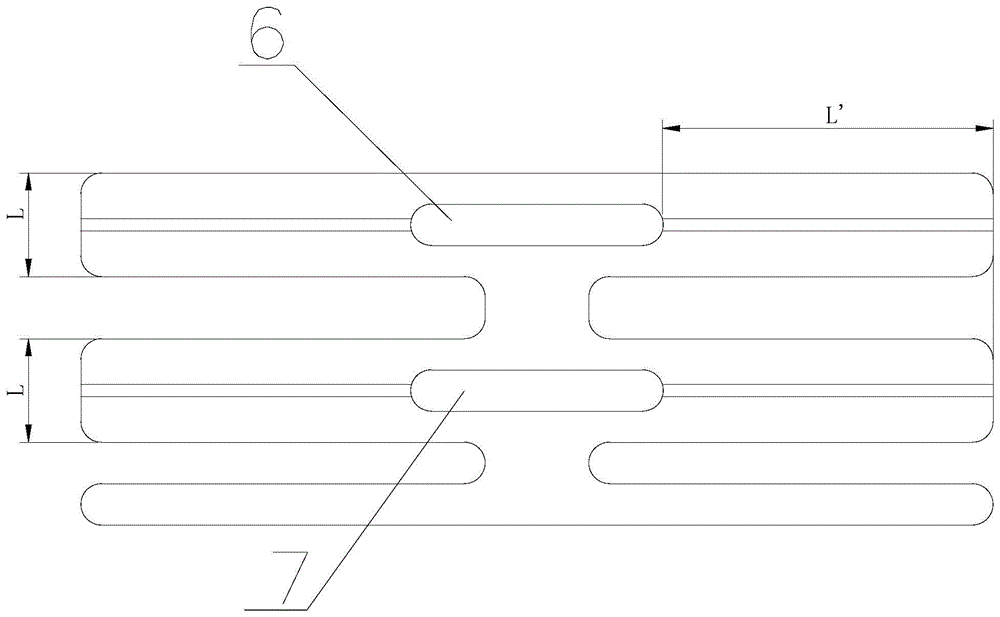

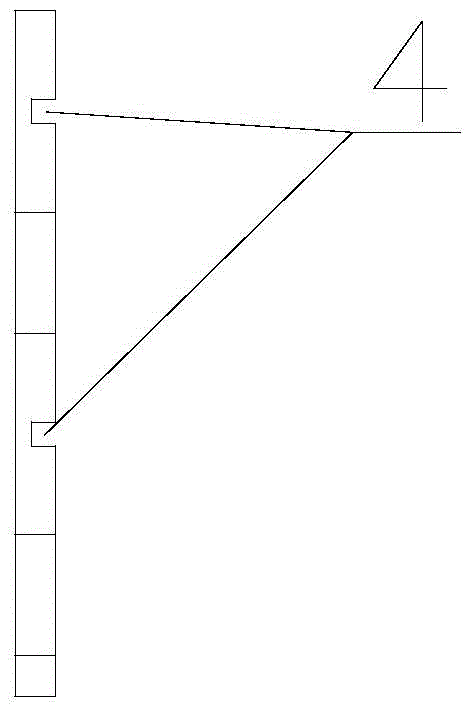

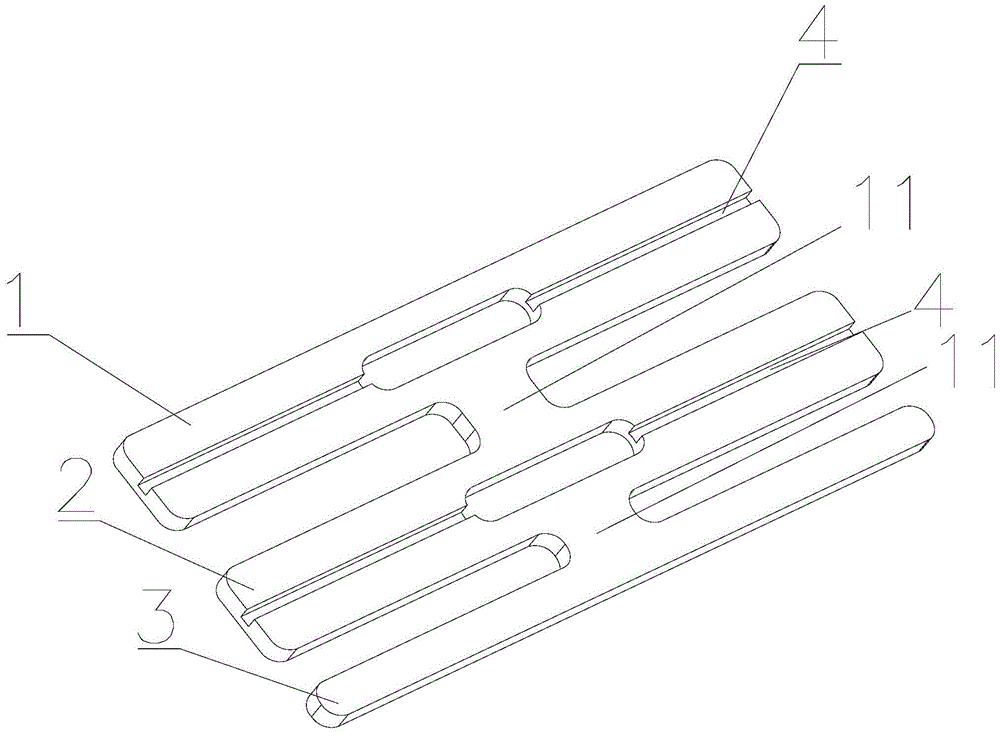

[0039] Such as Figure 1-Figure 3 The king-shaped optical fiber grating sensor patch shown in the figure has a symmetrical king-shaped structure as a whole. A connecting portion 11, the strain temperature horizontal edge 1 is connected to the single temperature horizontal edge 2 through the connecting portion 11, and the single temperature horizontal edge 2 is connected to the sticking edge 3 through another connecting portion 11, wherein,

[0040] There is a first horizontal strip-shaped hole 6 inside the strain temperature horizontal side 1, the left-right symmetrical centerline of the first strip-shaped hole 6 overlaps with the left-right symmetrical centerline of the patch, and the two sides of the first strip-shaped hole 6 are useful The cross-section of the square groove 4 is a square, and the fiber grating connected between the two sections of the conductive fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com