Foil-type precision resistor and manufacturing method thereof

A technology of precision resistors and manufacturing methods, applied in the direction of coating resistor materials, etc., can solve problems such as large temperature coefficient of resistance and poor load stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

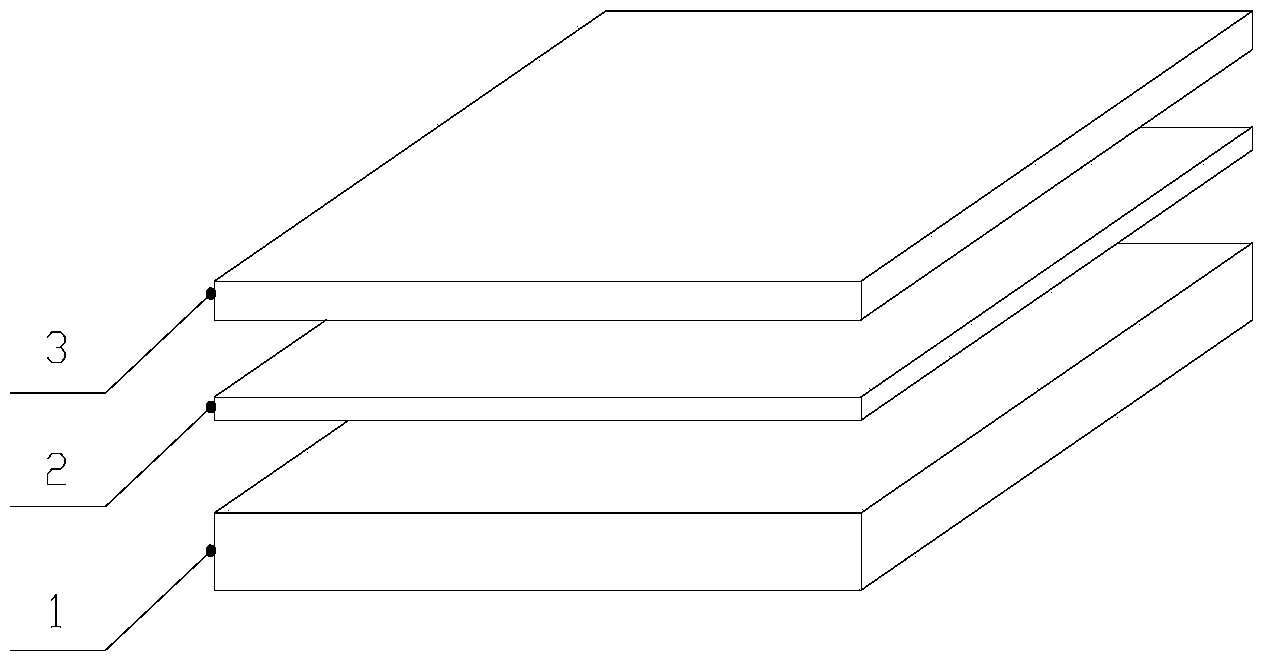

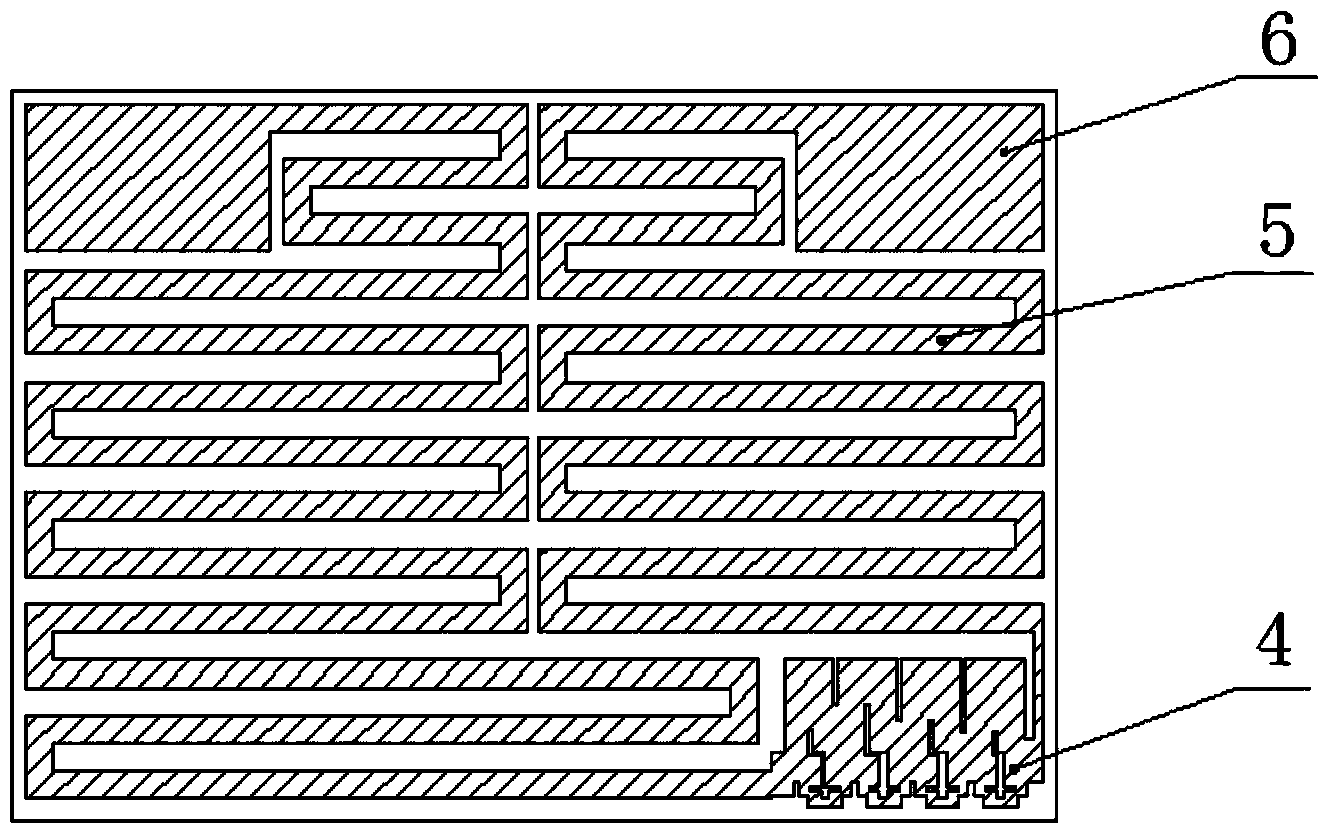

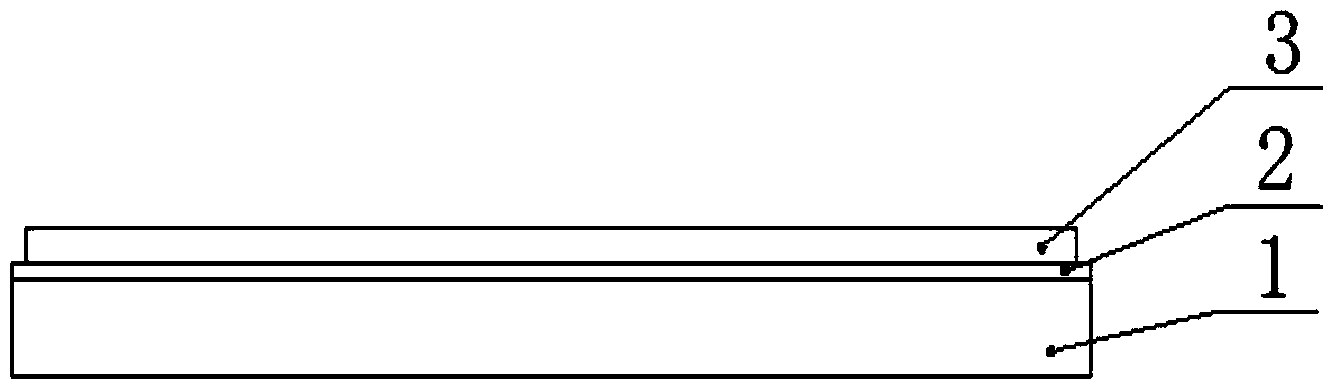

[0029] Considering the parameters that affect the temperature coefficient of resistance of foil resistors and load stability, it mainly comes from the resistance chip, including the material selection of the substrate, adhesive, and metal resistance grid, as well as the subsequent electrical properties, thermal stability and different materials of specific materials. The linear expansion coefficients interact and match each other to achieve better performance parameters. The present invention designs a precision resistor whose structure is similar to that of a general foil-type precision resistor structure, including a resistor chip, a buffer layer 7 and a packaging shell 8 : the resistance chip is mainly composed of a substrate 1, an adhesive layer 2, and a resistance pattern; the substrate 1 is bonded together with the resistance pattern through the adhesion layer 2, and the front side of the resistance pattern is attached with a moisture-proof film 4, which is respectively we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com