Patents

Literature

87 results about "Resistance pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

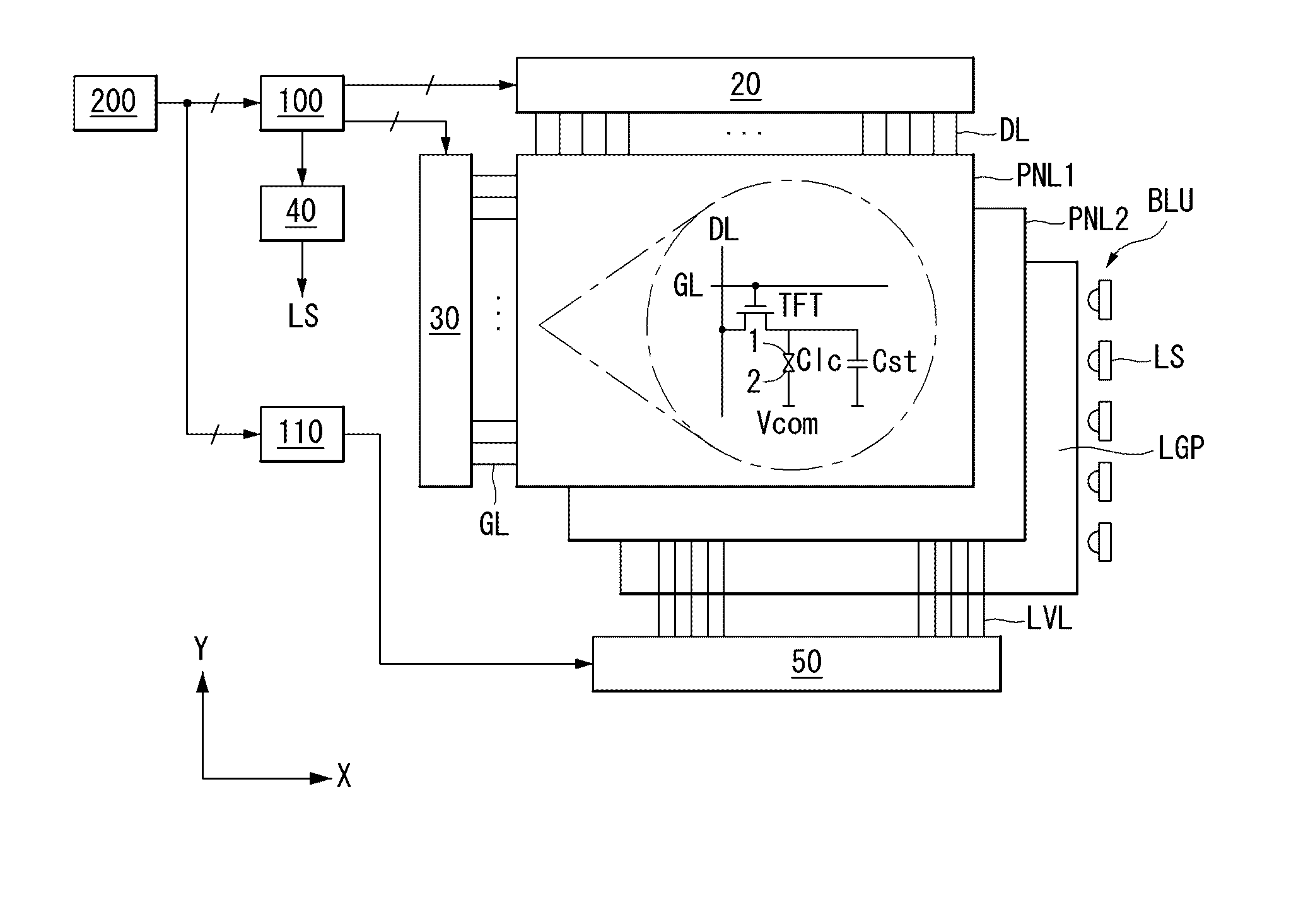

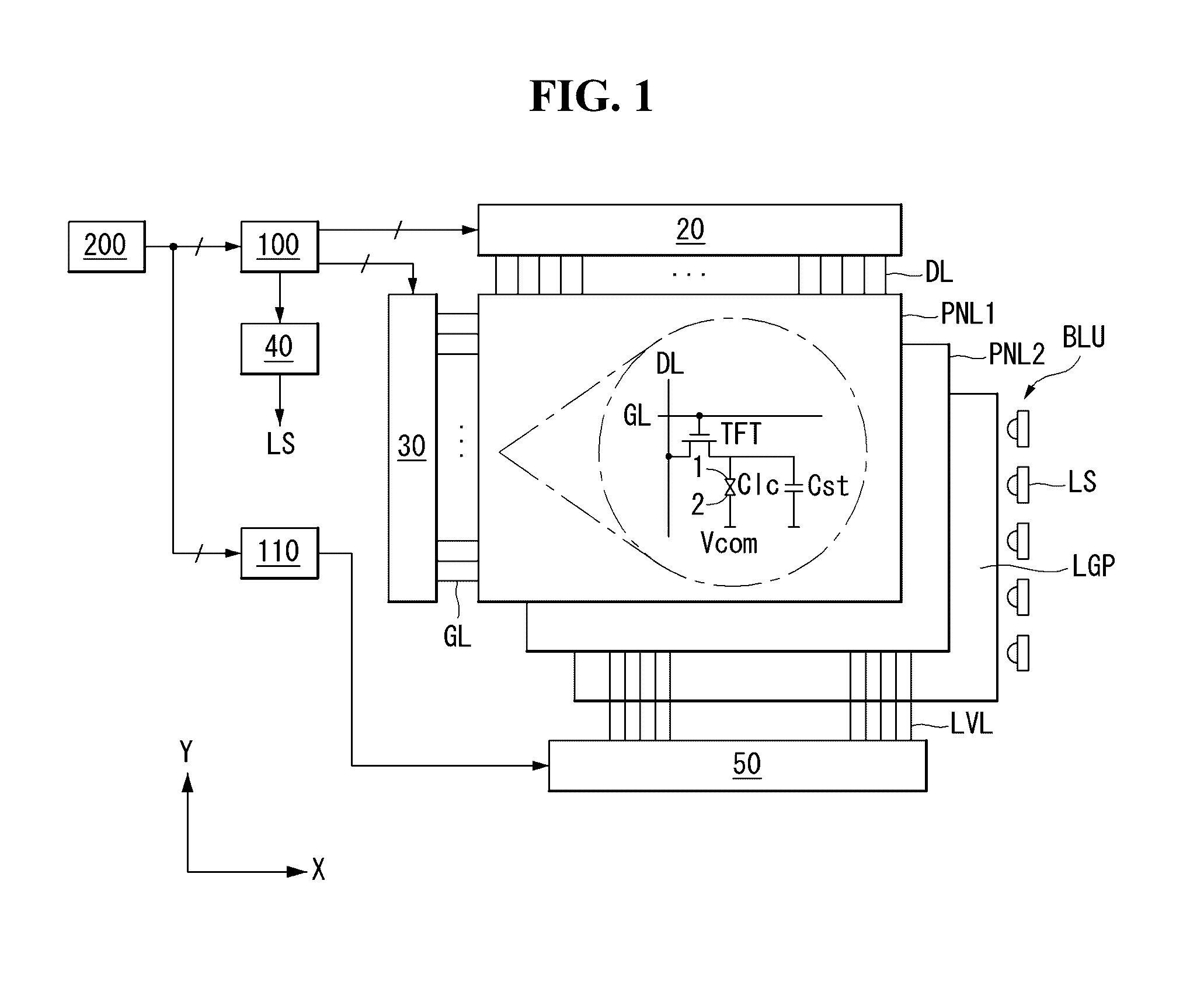

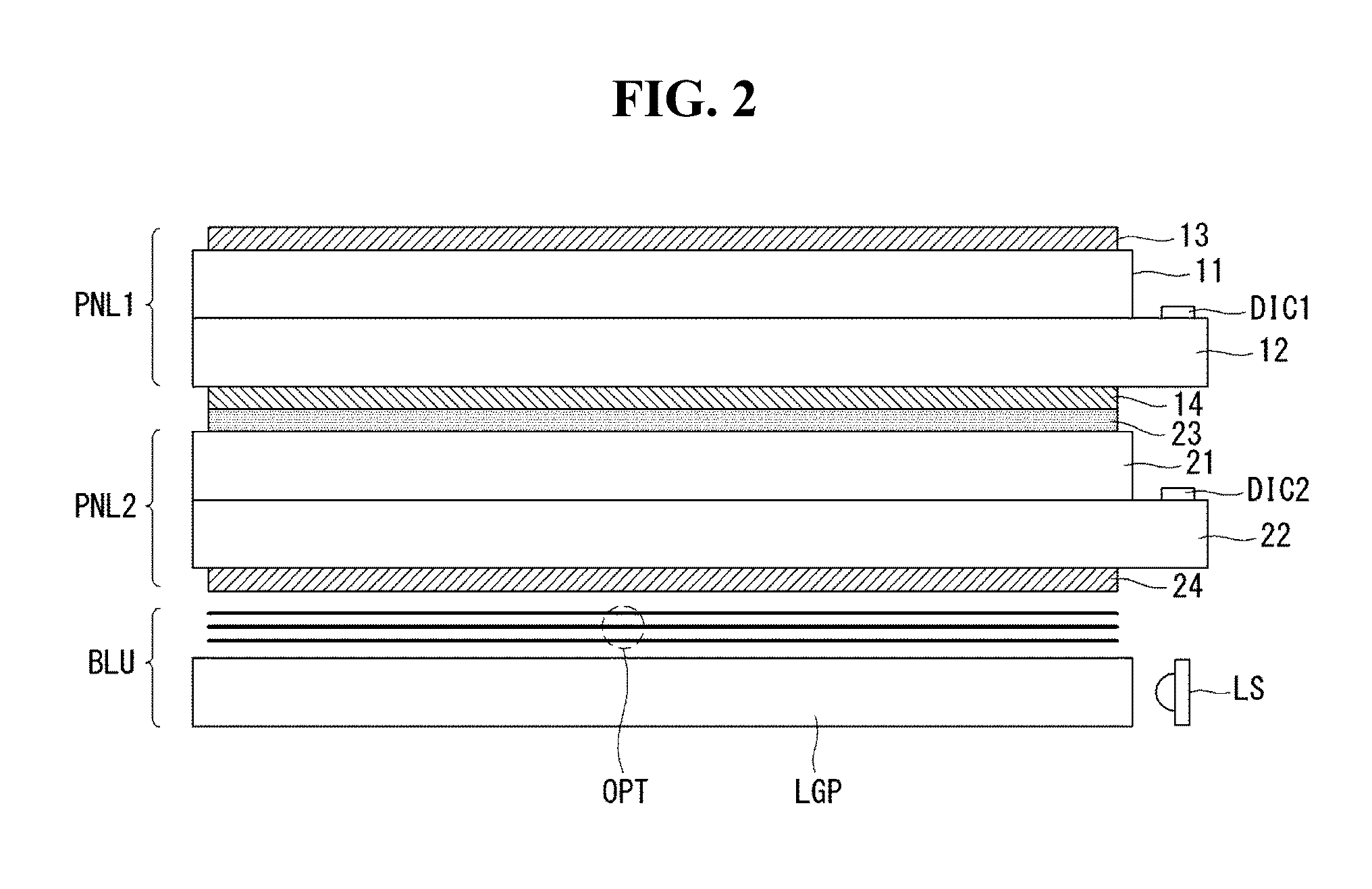

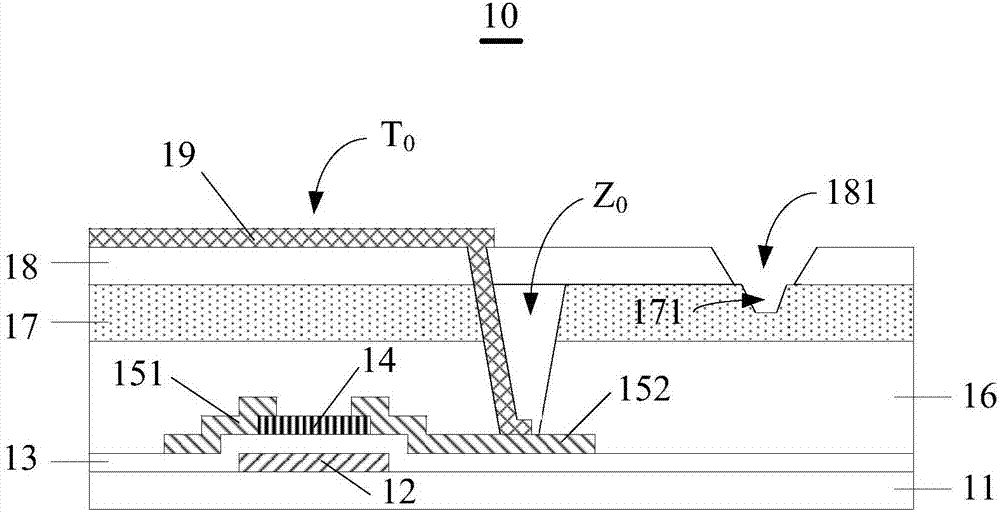

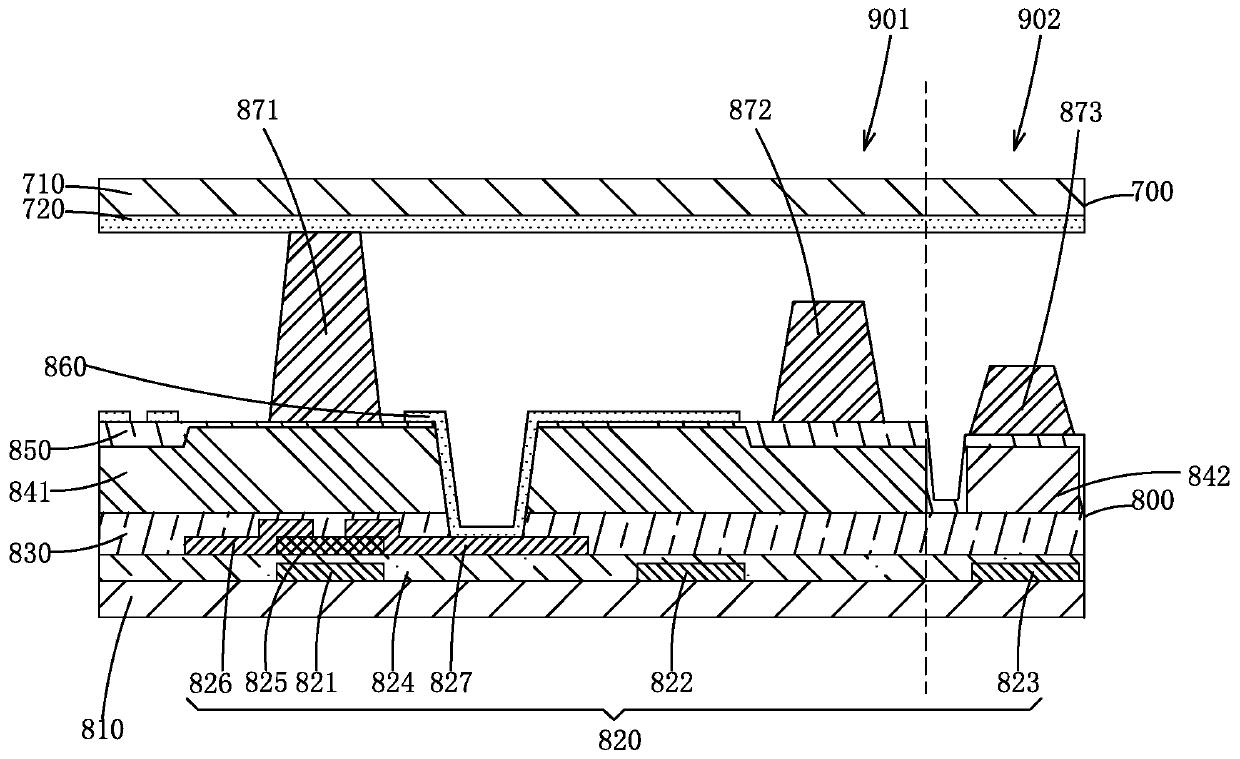

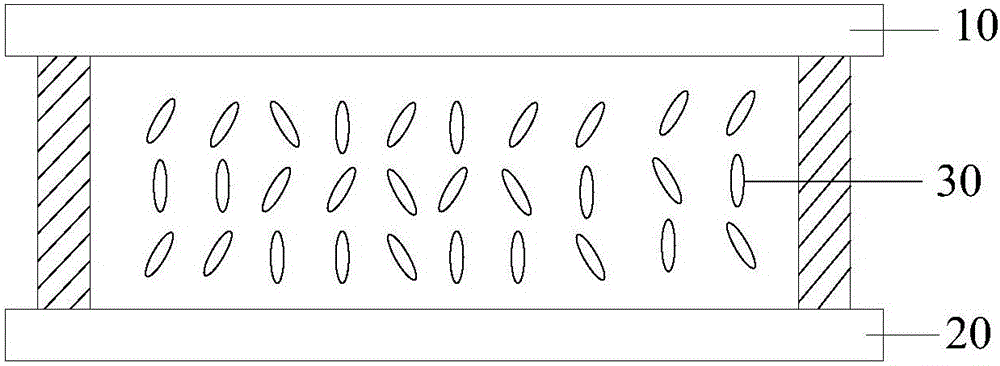

Liquid-crystal display device

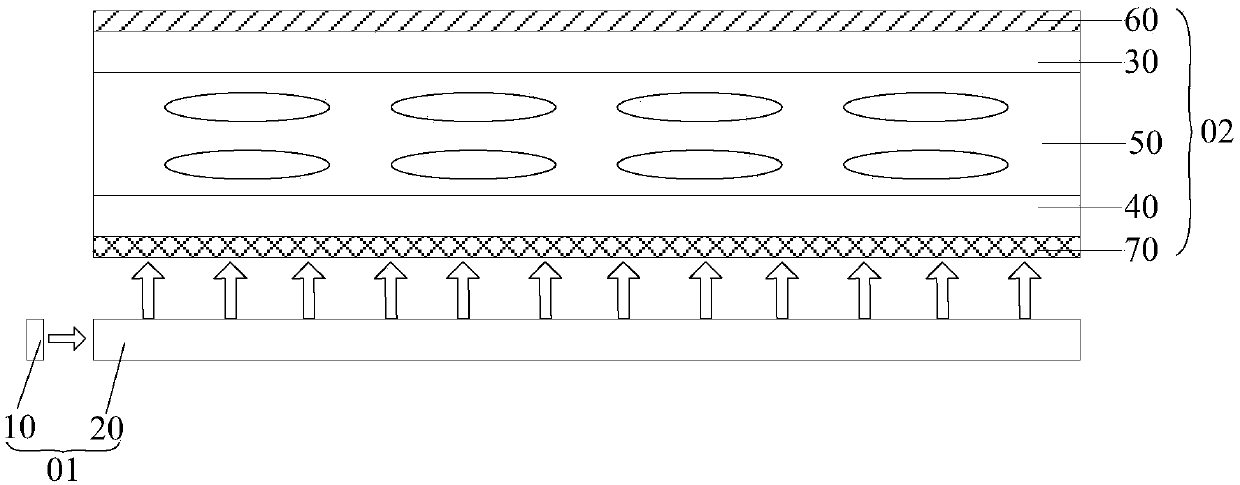

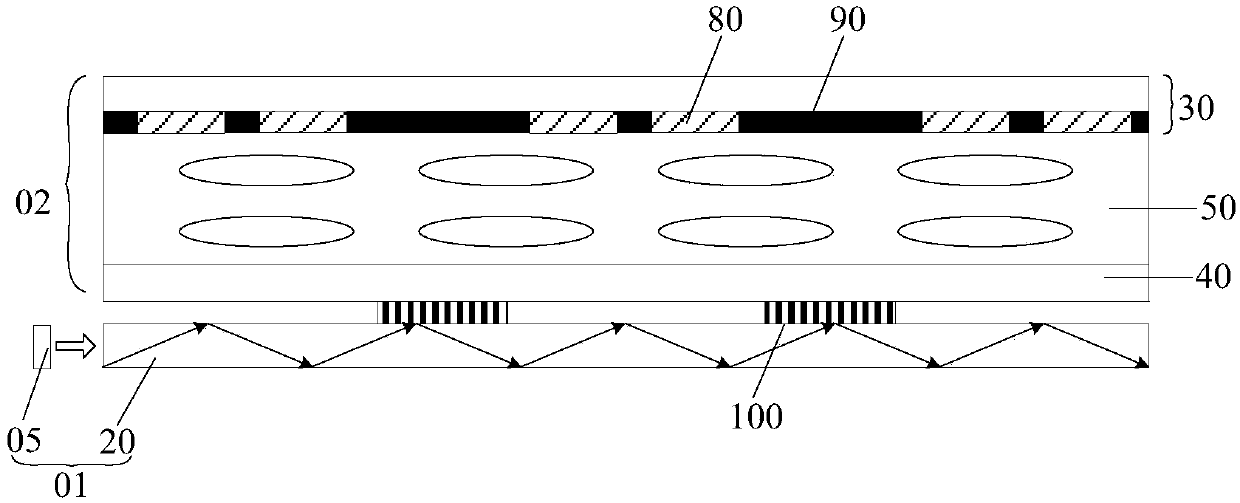

ActiveCN107817629AAvoid blockingReduce manufacturing costNon-linear opticsGratingLiquid-crystal display

The embodiment of the invention provides a liquid-crystal display device, and relates to the technical field of liquid-crystal display. By the adoption of the liquid-crystal display device, the resolution and illumination of display are not reduced when transparent display is achieved. A backlight module includes a luminescence part and a light guide plate; after entering the light guide plate ina certain angle range, light transmitted by the luminescence part is totally reflected; a display panel includes a first substrate, a second substrate and a liquid crystal layer; the second substrateis close to the backlight module; the first substrate includes colorful light resistance patterns and light shading patterns, wherein the light shading patterns are used for partitioning the colorfullight resistance patterns and enabling polarized light in a first polarization direction to transmit; the liquid-crystal display device further includes first gratings which are arranged at the side,close to or away from the display panel, of the light guide plate, and the orthographic projections of the first gratings on the light shading patterns are located within the borders of the light shading patterns; the first gratings are used for enabling light which is totally reflected in the light guide plate to be emergent as collimated polarized light, the polarization direction of the collimated polarized light serves as a second polarization direction, and the first polarization direction is perpendicular to the second polarization direction.

Owner:BOE TECH GRP CO LTD

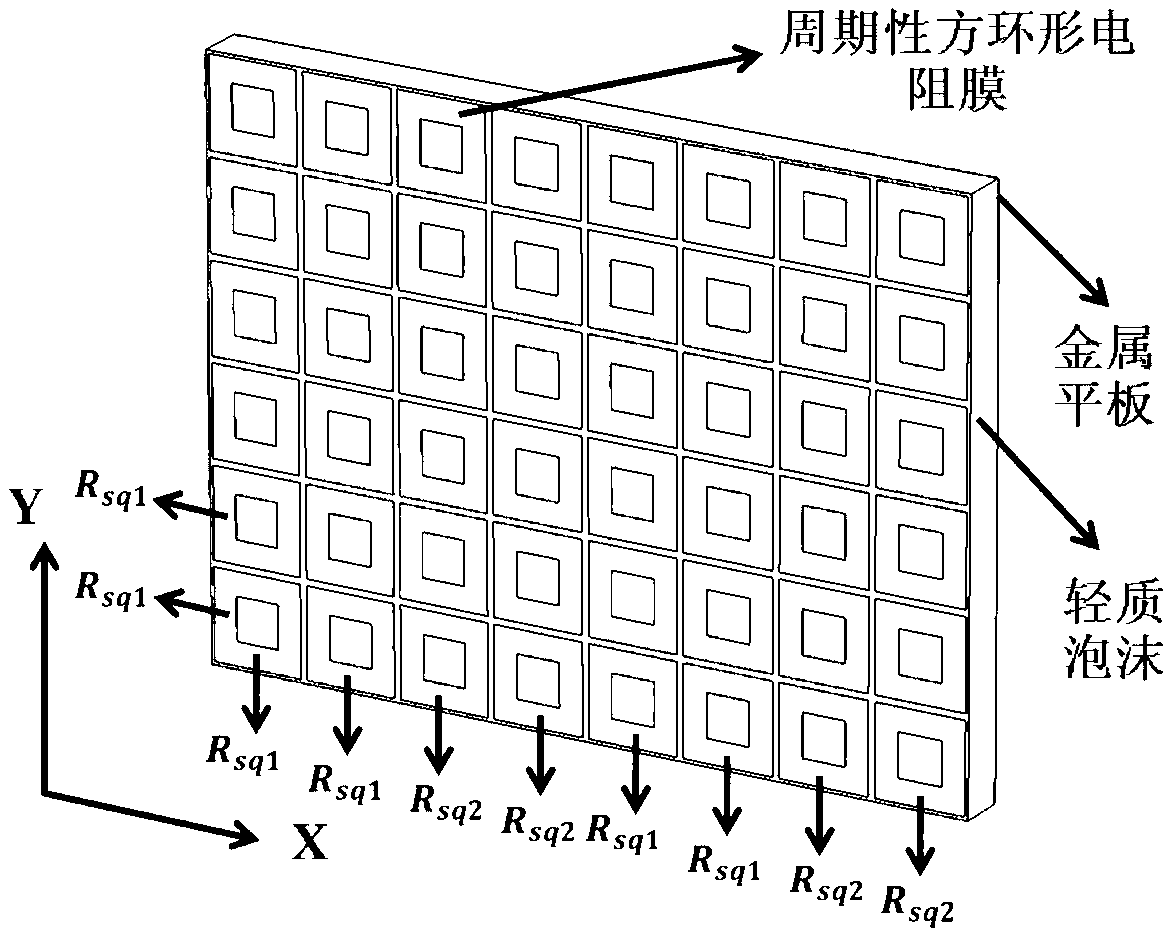

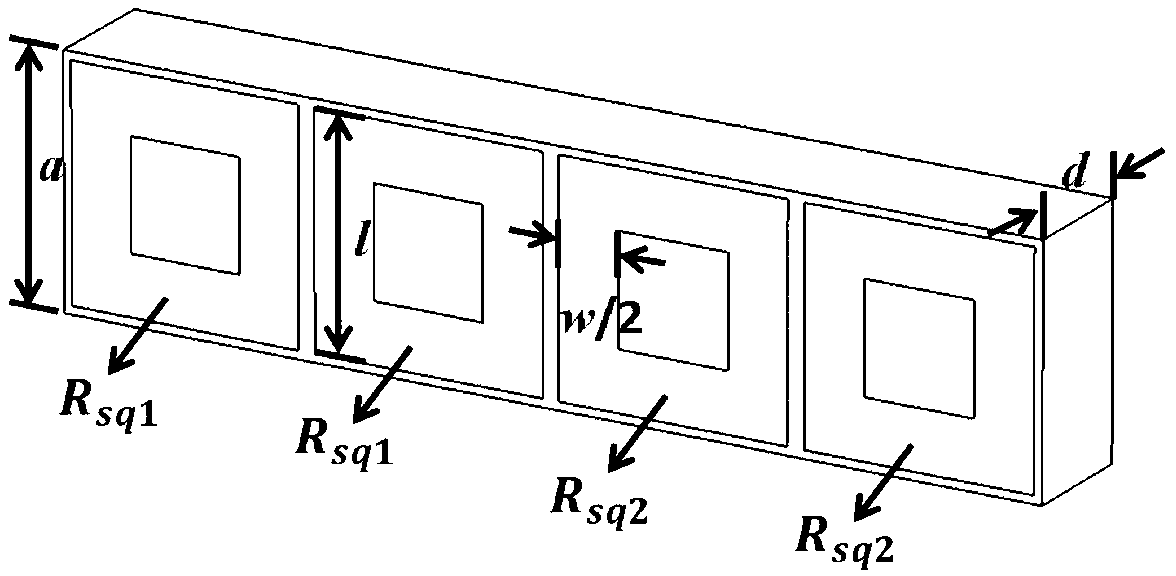

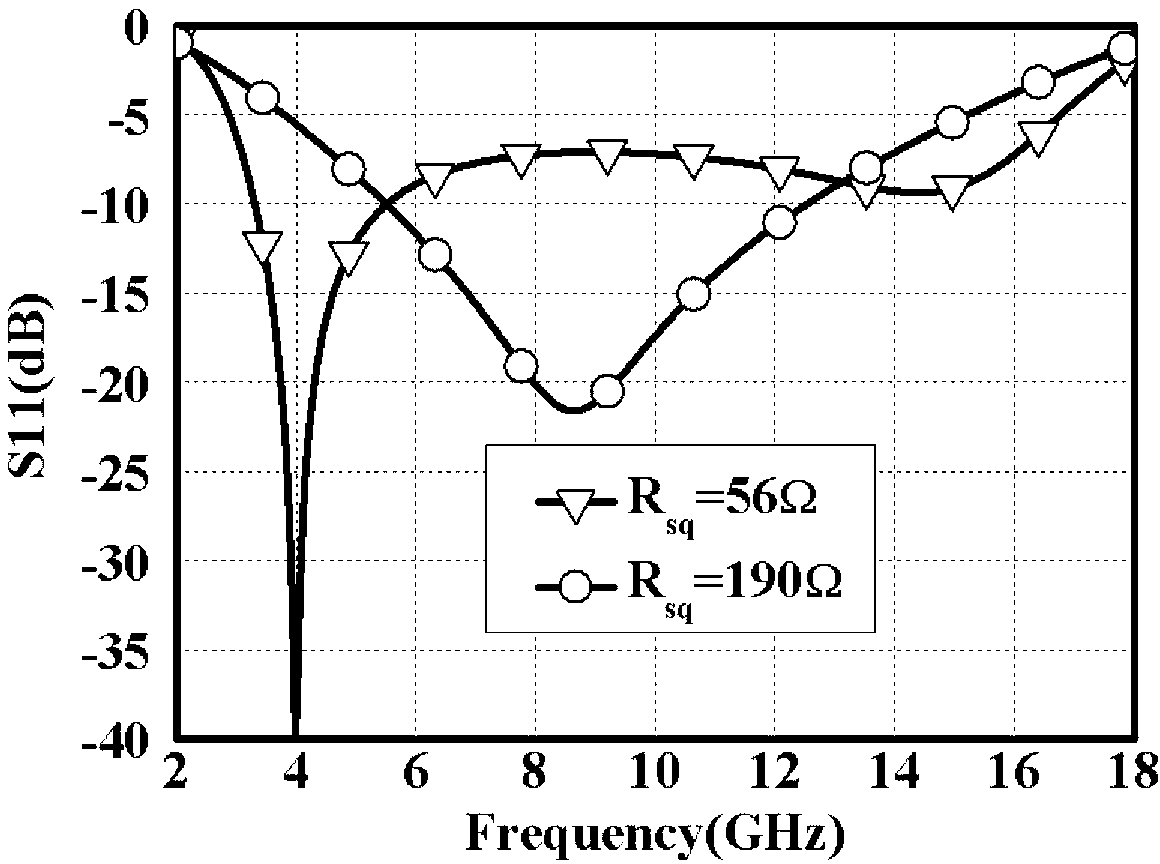

Single-layered composite element wideband periodic wave-absorbing structure

InactiveCN103249290AStructural absorbing performance controllable adjustmentTo achieve the effect of broadband absorptionMagnetic/electric field screeningEngineeringWide band

The invention discloses a single-layered composite element wideband periodic wave-absorbing structure, and belongs to the technical field of electronic materials. According to the invention, a dielectric layer printed with periodic array resistance patterns is arranged on a metal flat plate, the dielectric layer comprises a foam layer and periodic square ring-shaped resistive films arranged on the foam layer, and the periodic square ring-shaped resistive films consist of two kinds of resistive films of different sheet resistances.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

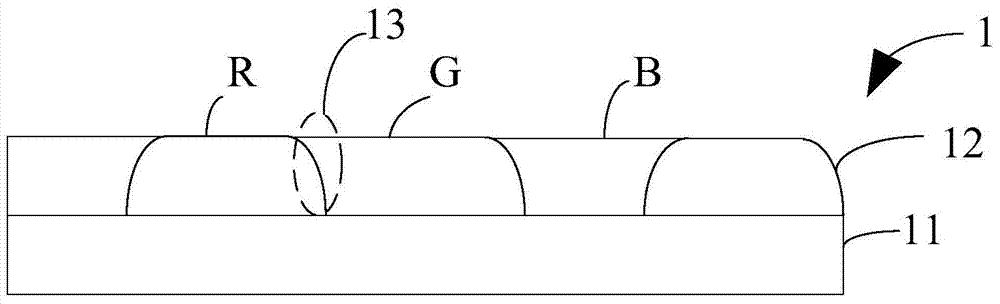

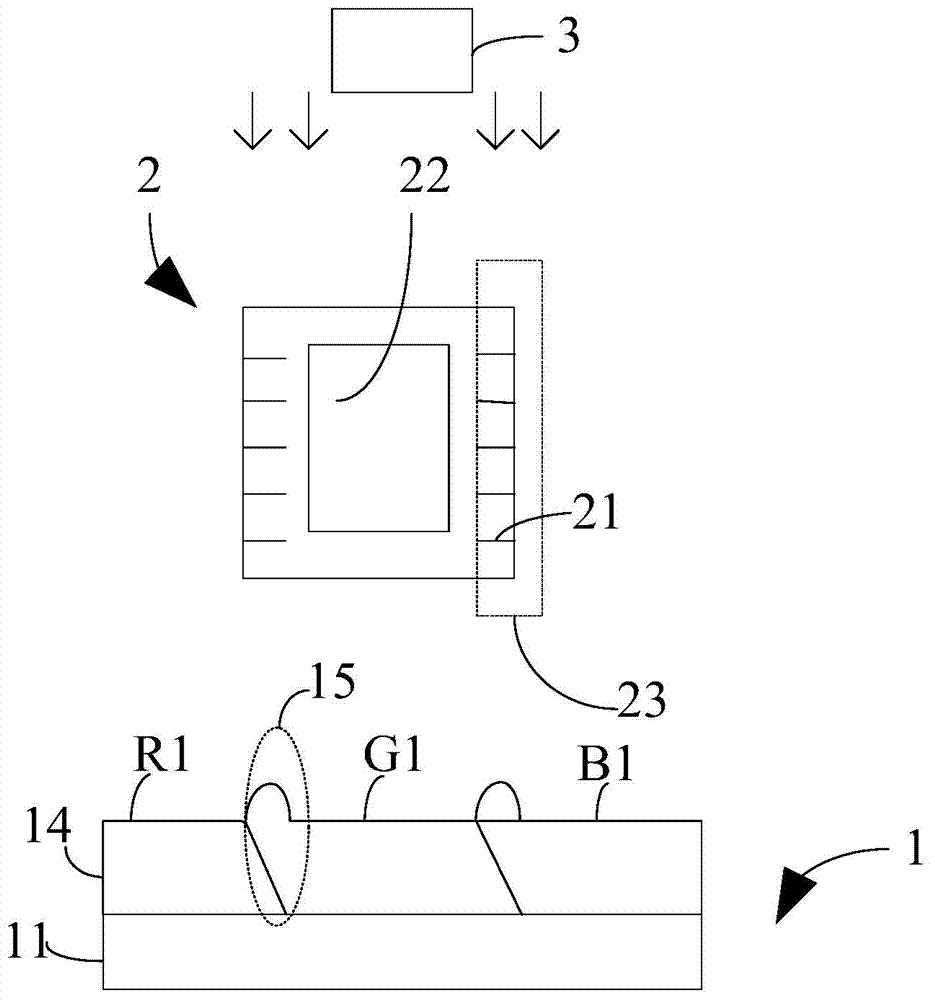

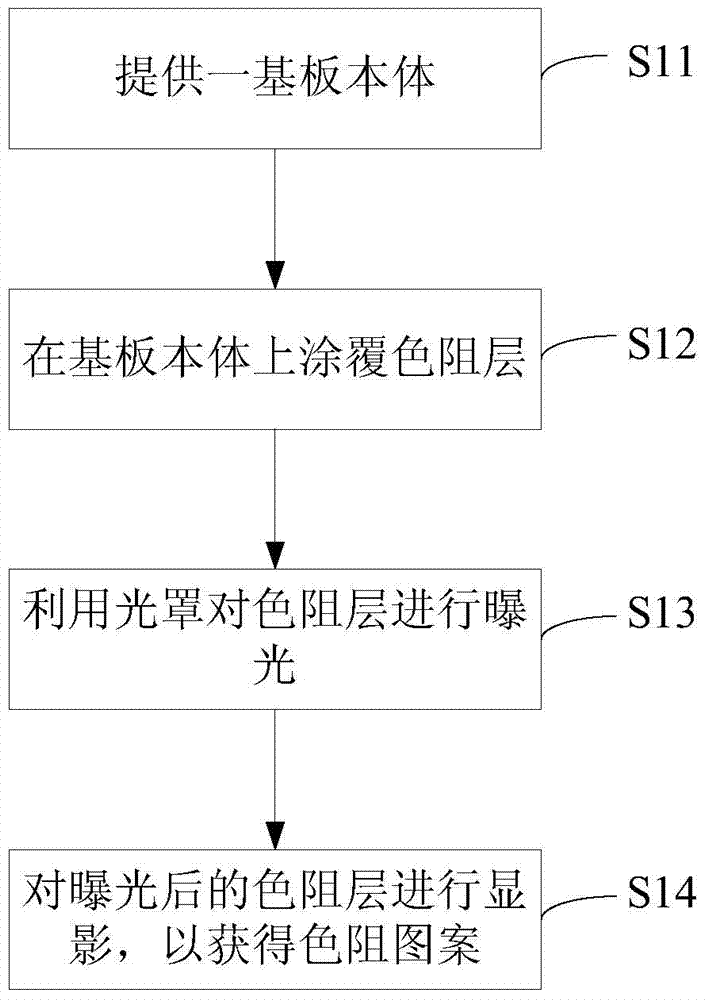

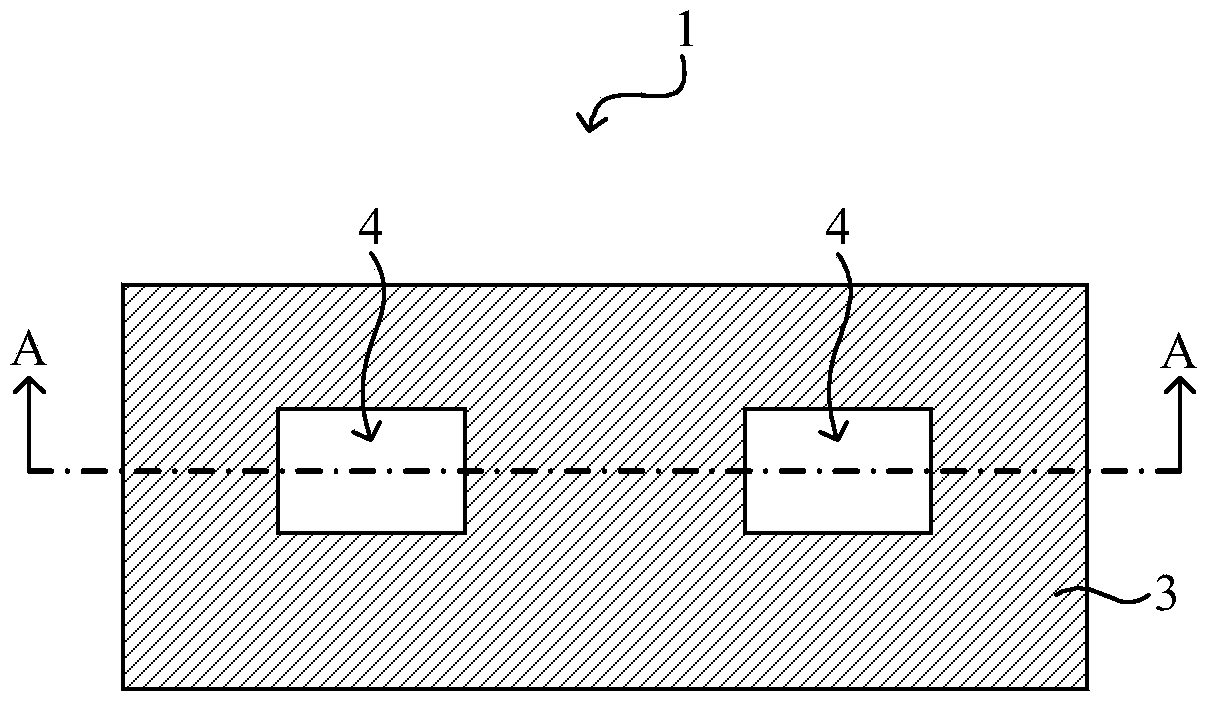

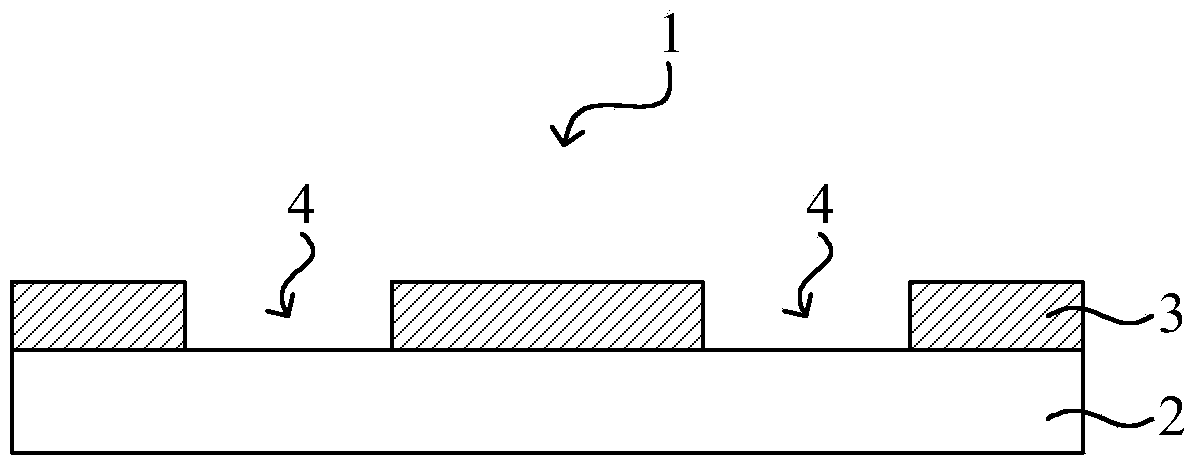

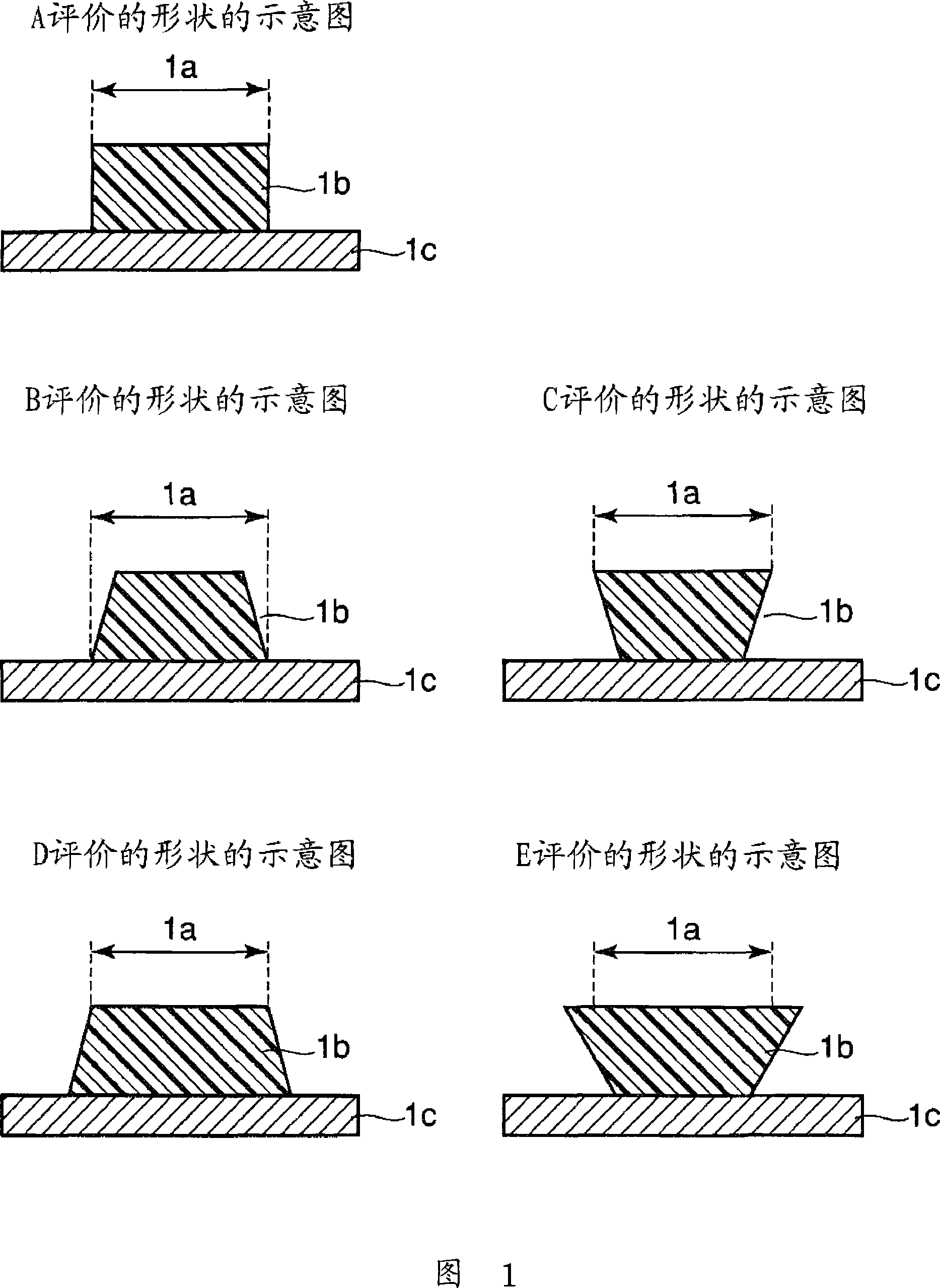

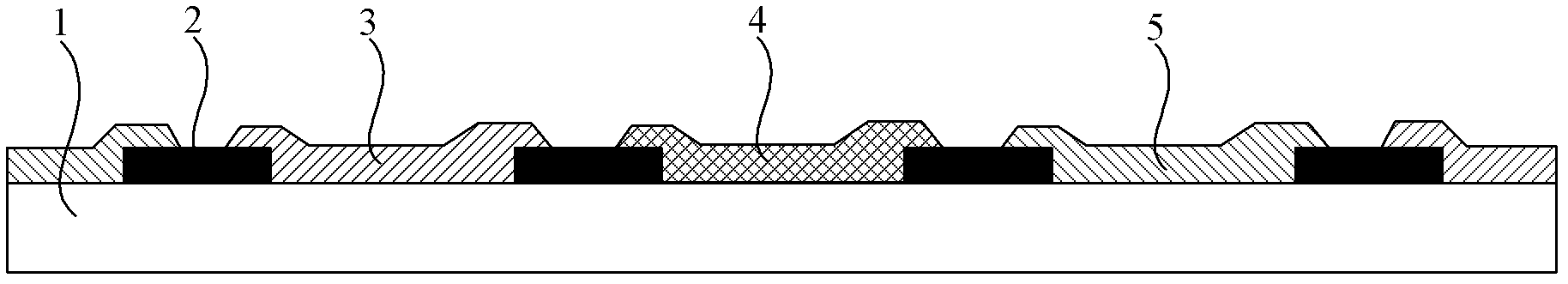

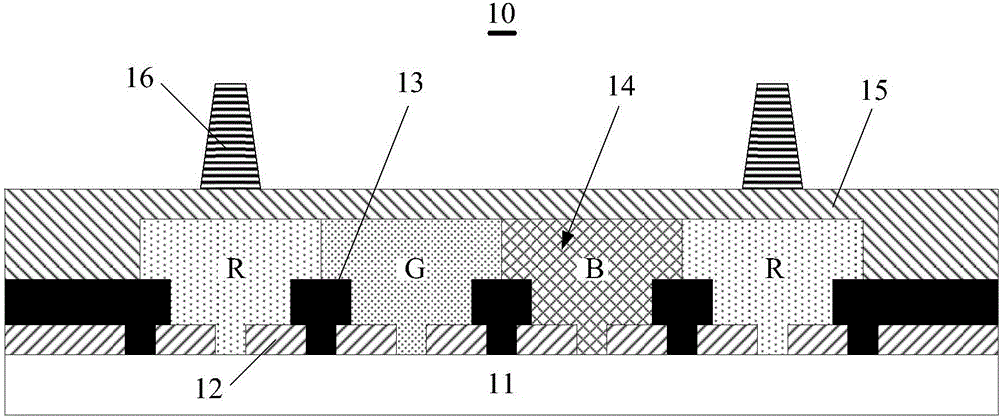

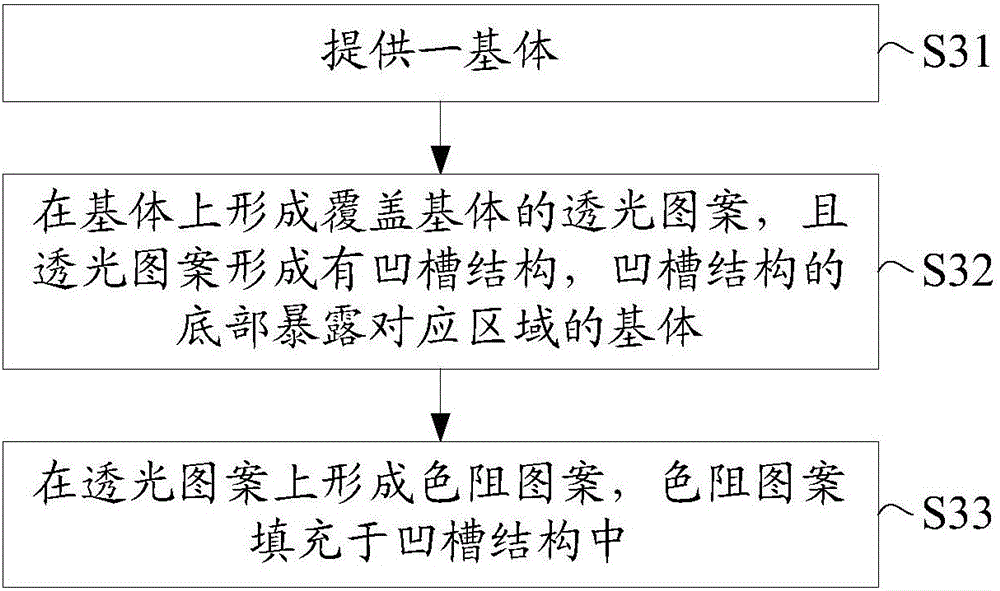

Color film substrate for display, method for manufacturing color film substrate and light mask thereof

ActiveCN104503128AFlat surfaceReduce production processPhotomechanical exposure apparatusPhotosensitive material processingLiquid-crystal displayDisplay device

The invention discloses a color film substrate for a display, a method for manufacturing the color film substrate and a light mask thereof. The color film substrate comprises a substrate body and a plurality of color resistance patterns. The color resistance patterns are arranged on the substrate body, the adjacent color resistance patterns are partially overlapped on one another, and the thicknesses of the lower color resistance patterns in overlapped regions are gradually reduced in the directions of the edges of the lower color resistance patterns. Owing to the mode, the color film substrate, the method and the light mask have the advantages that horn segment difference of the overlapped regions of the adjacent RGB (red, green and blue) color resistance patterns of the color film substrate can be reduced, and accordingly the liquid crystal efficiency can be improved; extra OC (over-coat) flat layers on RGB color resistance layers of the color film substrate can be omitted, accordingly, the production cost of liquid crystal display panels can be reduced, and the production efficiency can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

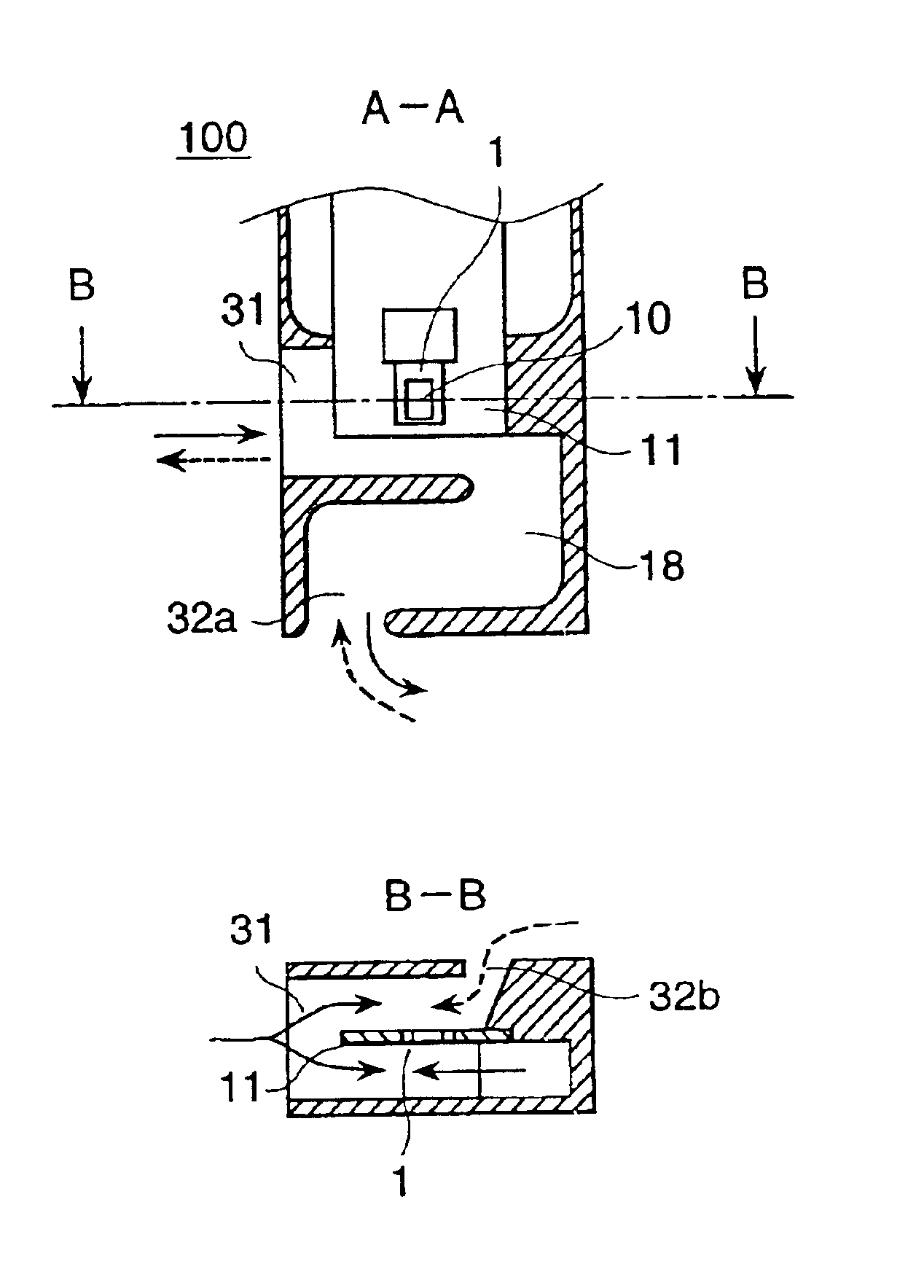

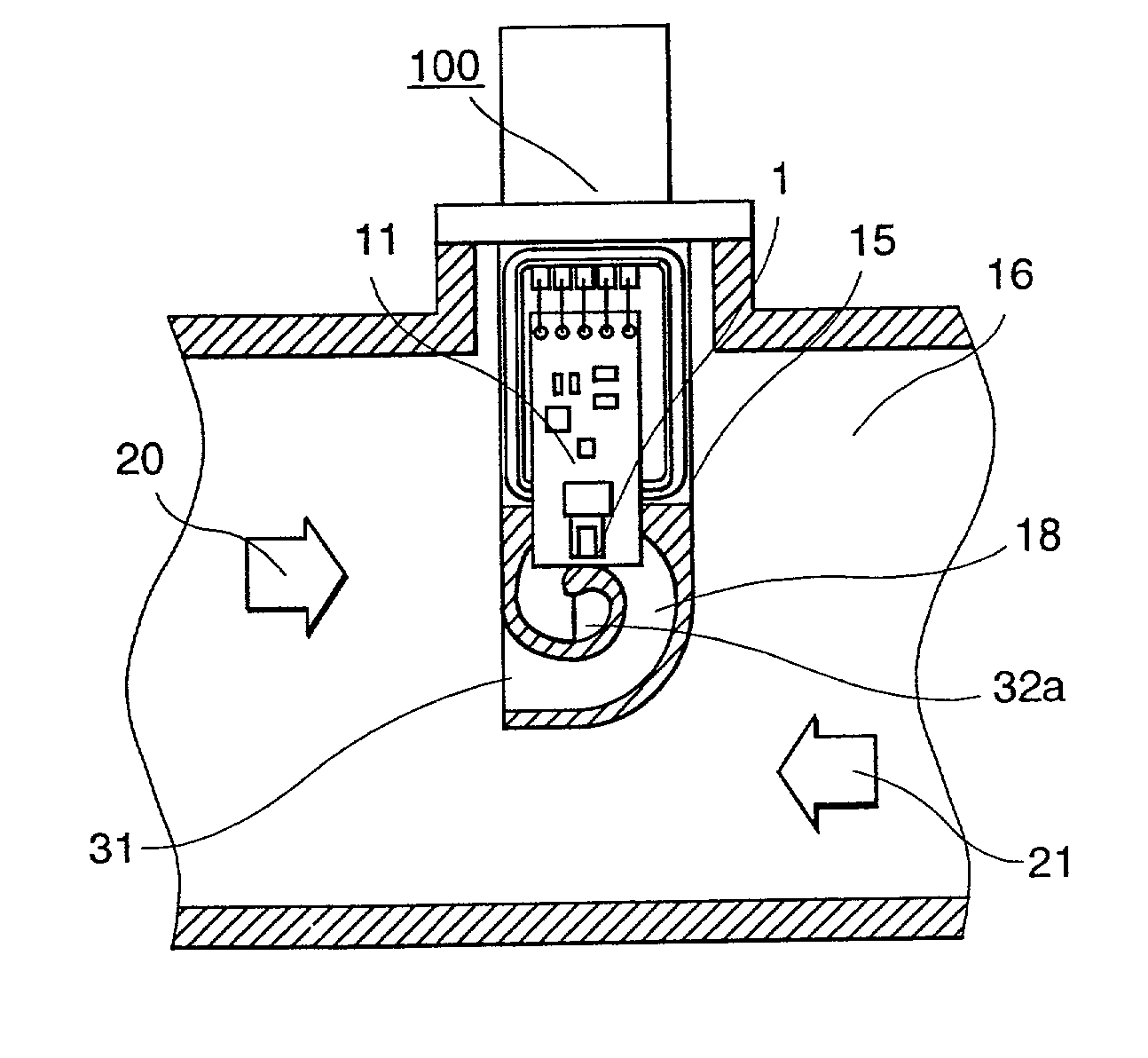

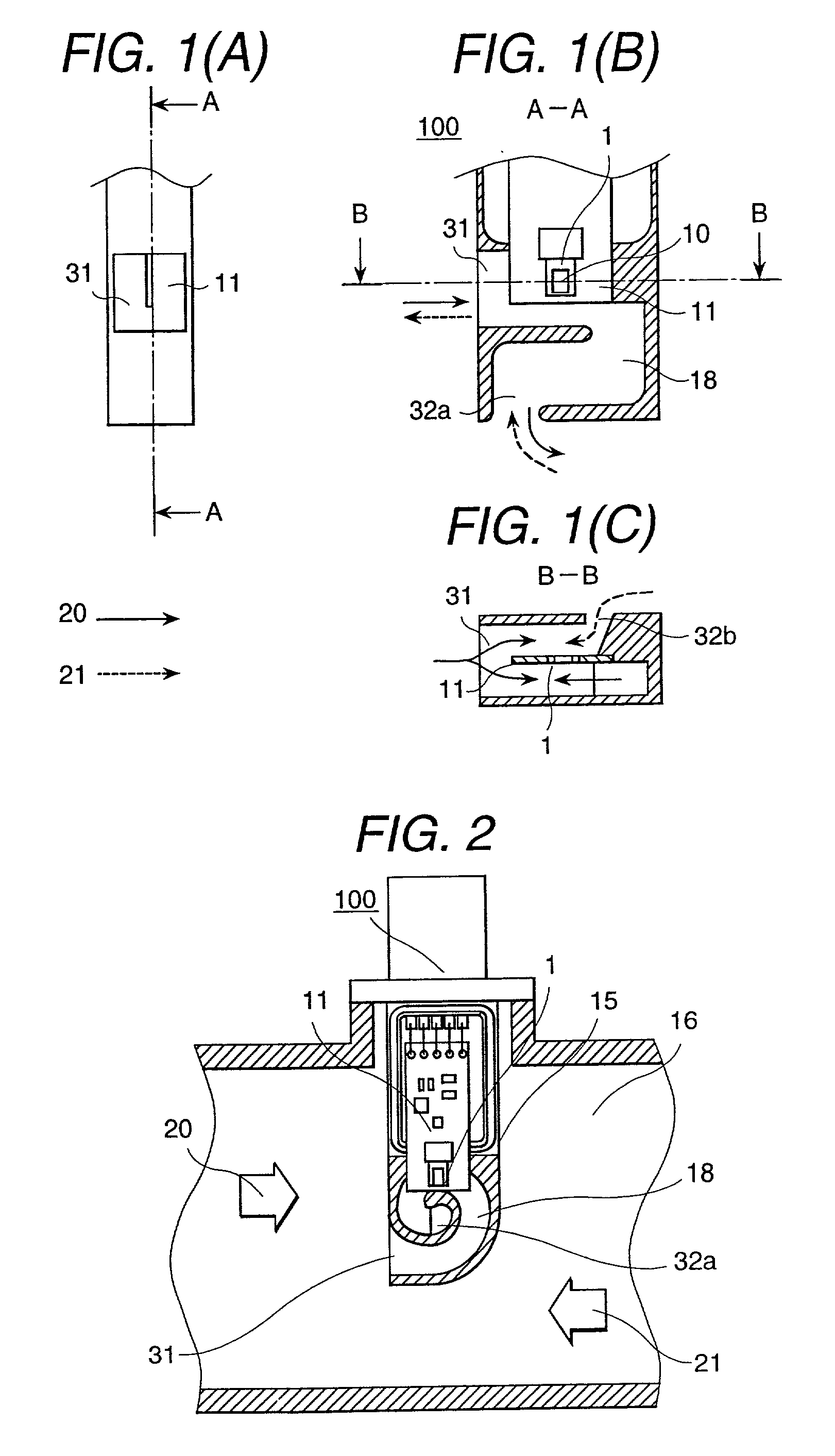

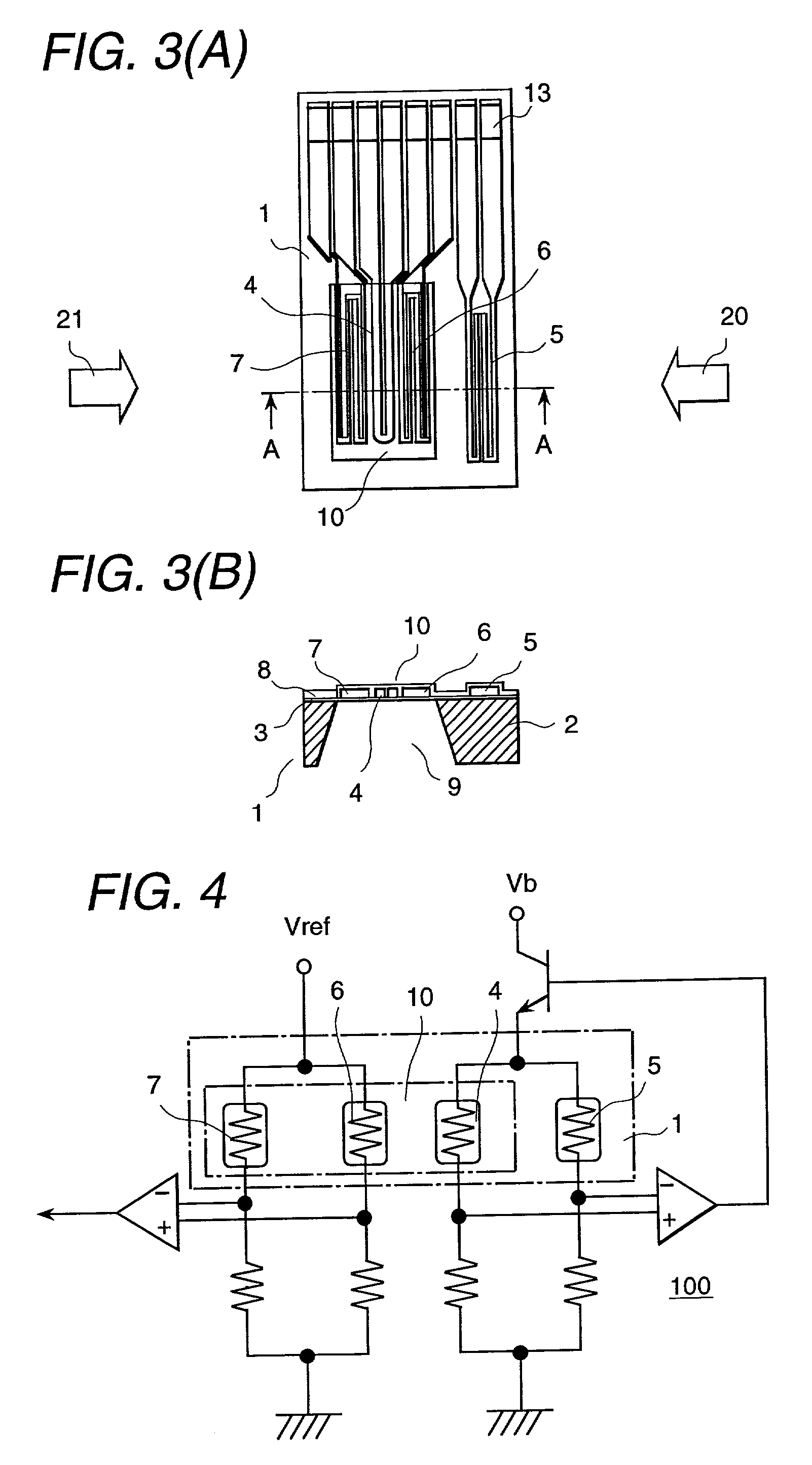

Thermal-type flow meter with bypass passage

InactiveUS6851311B2Electrical controlVolume/mass flow by thermal effectsElectrical resistance and conductanceEngineering

Owner:HITACHI ASTEMO LTD

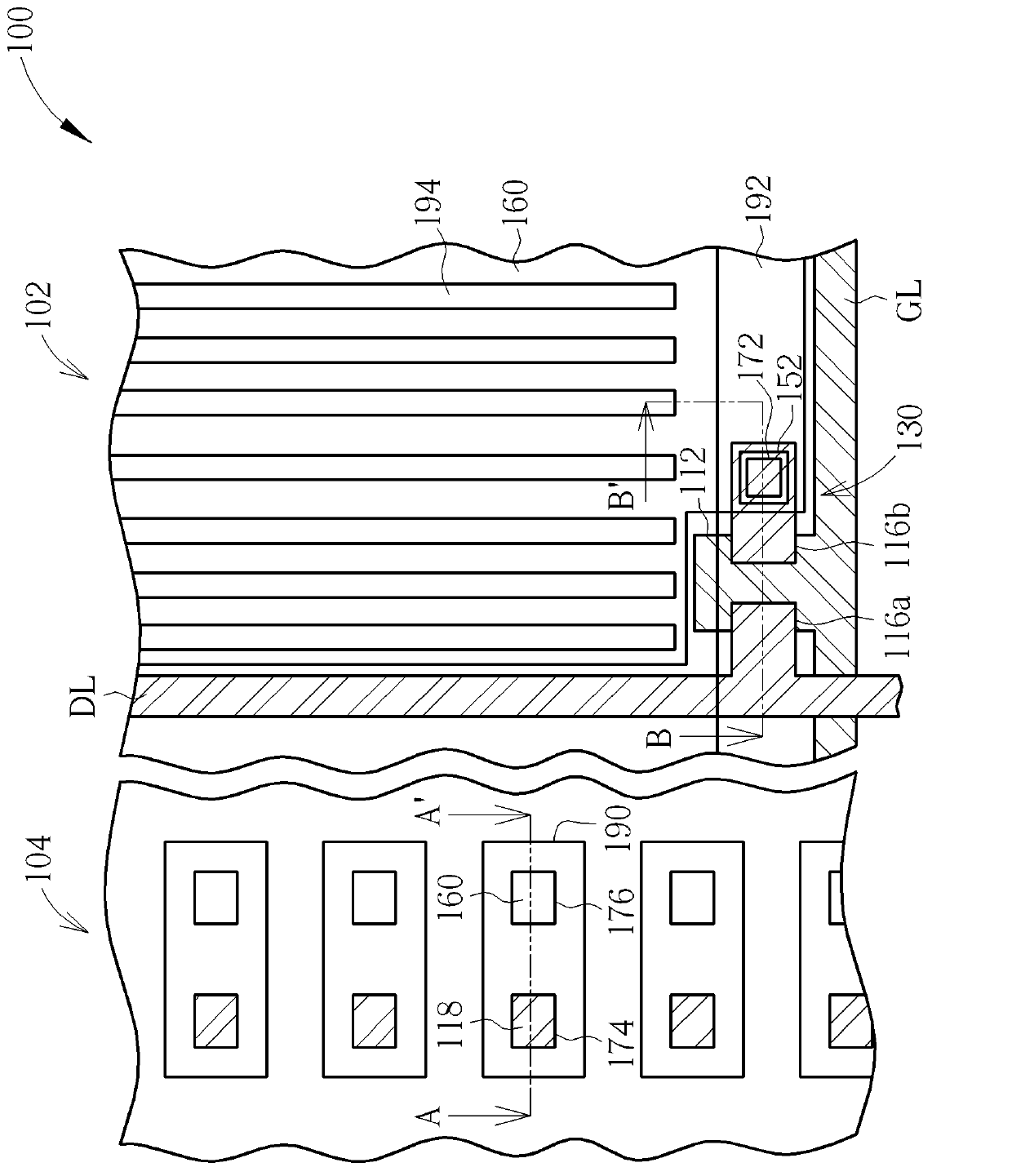

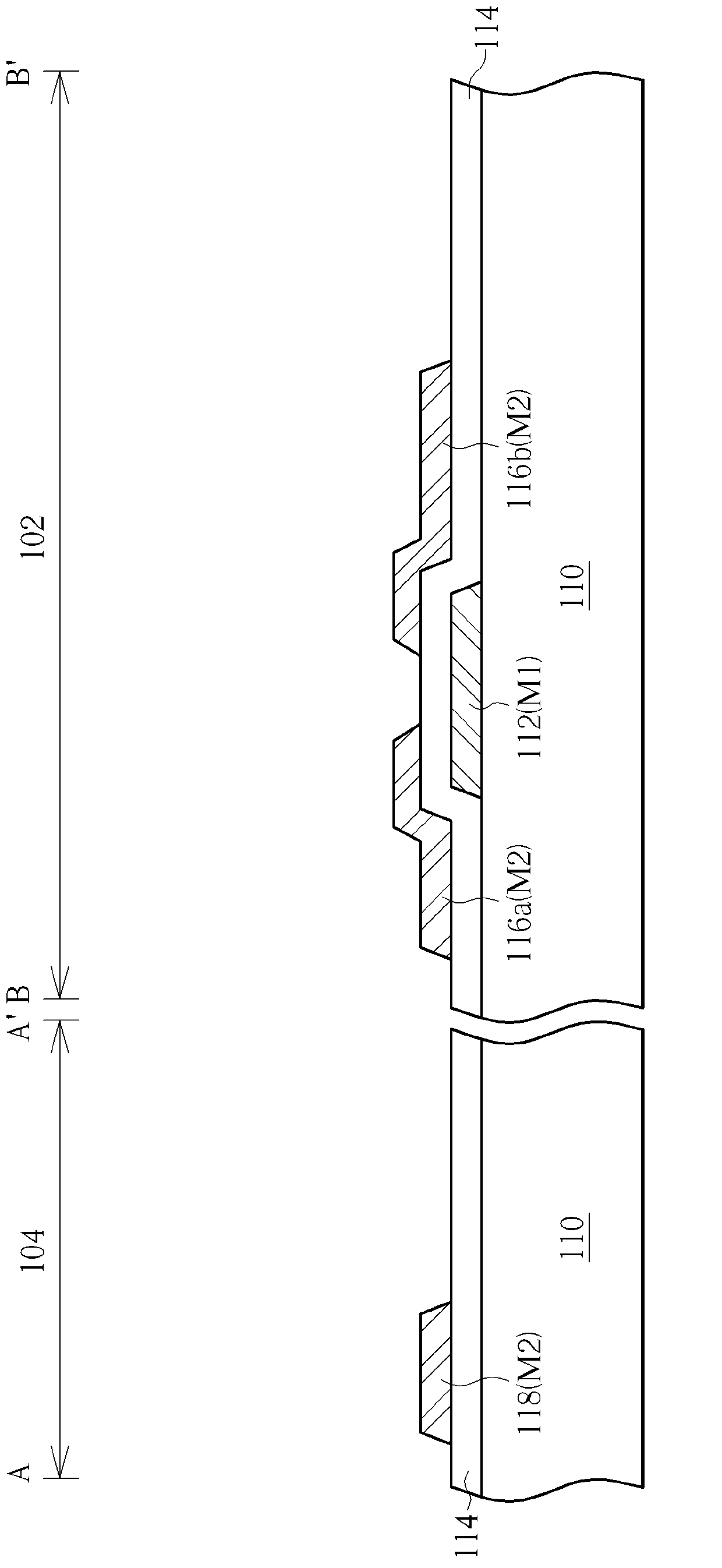

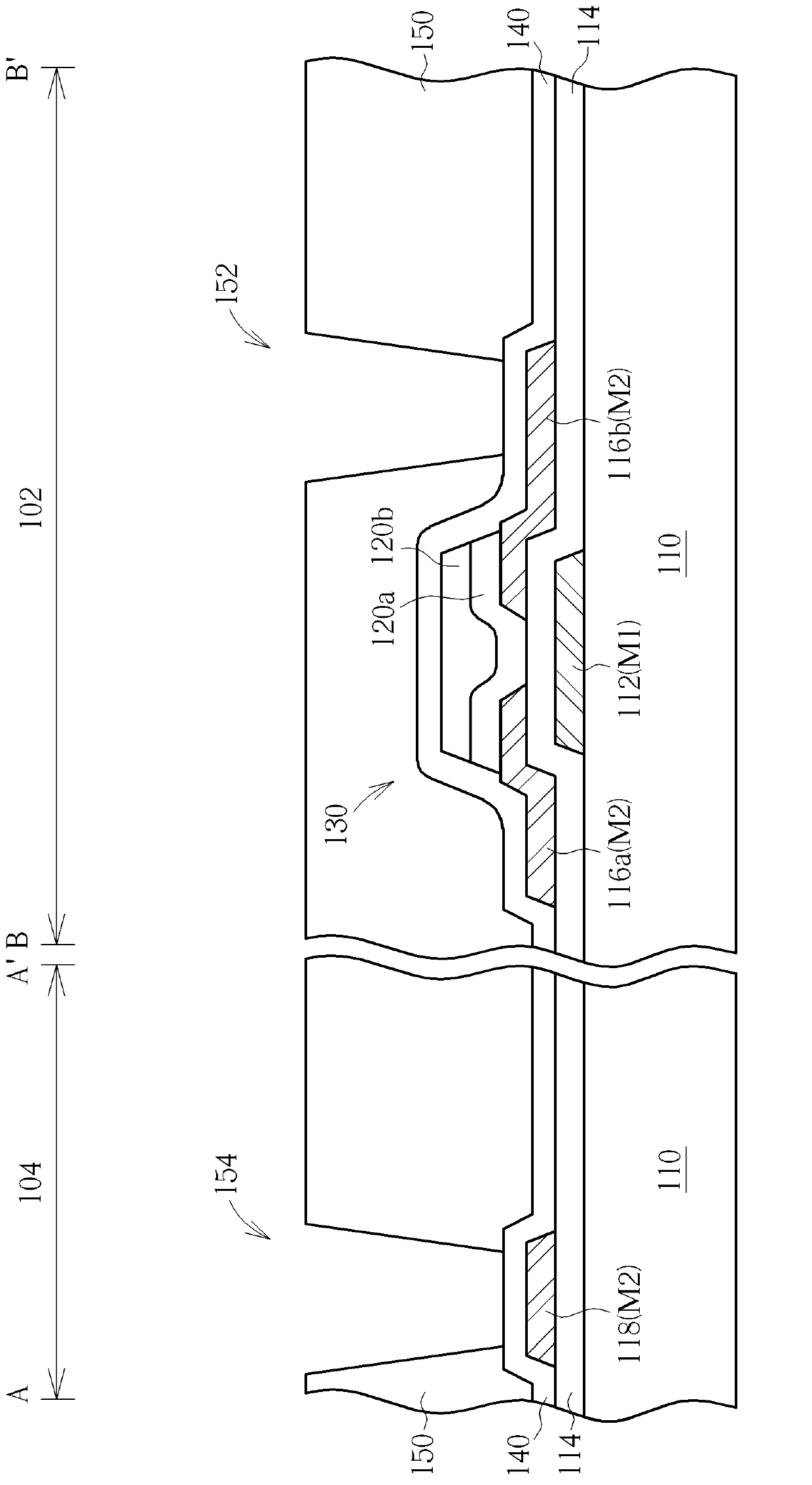

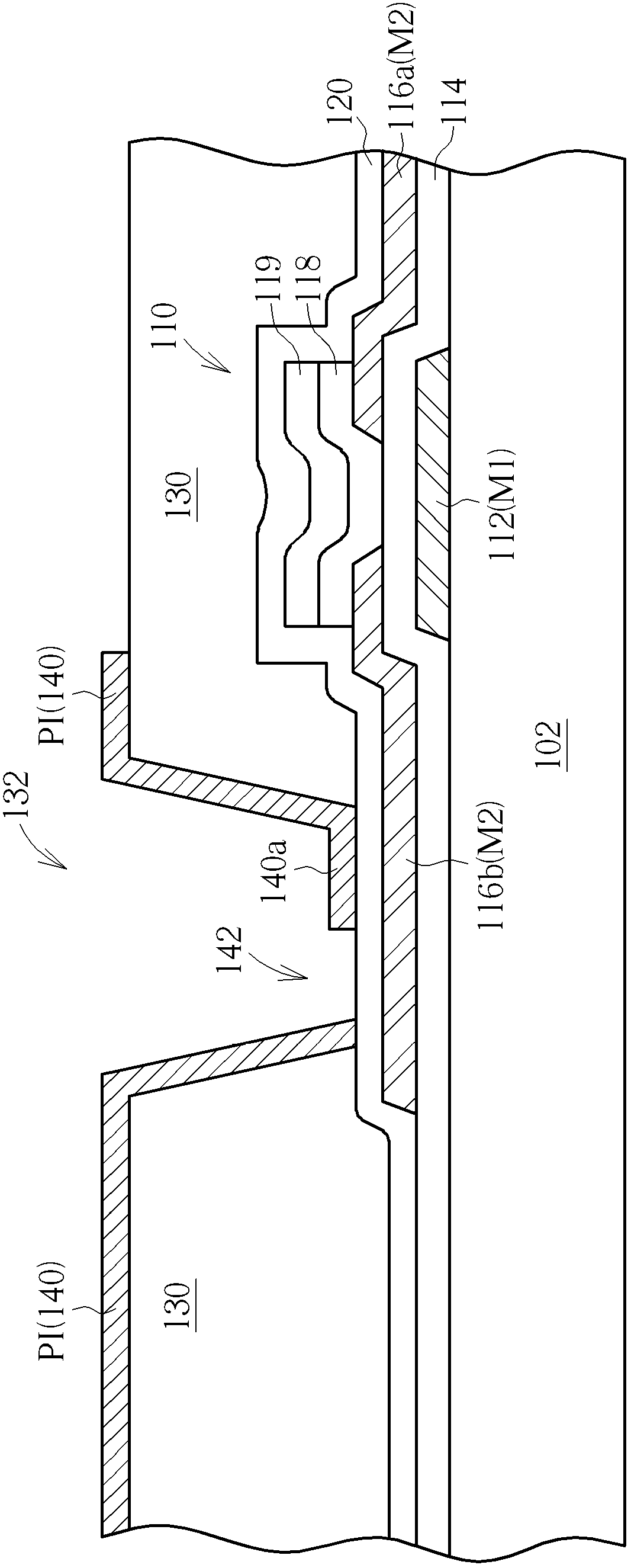

An array substrate of a display panel and a manufacture method thereof

ActiveCN103151304AImprove yieldReduce difficultyTransistorSolid-state devicesEngineeringProtection layer

A method for manufacturing an array substrate of a display panel comprises the steps of providing a substrate, on which a thin film transistor and a connection electrode are formed; forming a first protection layer and a flat layer on the substrate, the flat layer comprising a first opening and second opening corresponding to the drain electrode of the thin film transistor and the connection electrode respectively; forming a common electrode, a second protection layer and a light resistance pattern layer which exposes the second protection layer disposed in the first opening and the second opening and corresponding to the common electrode; etching the second protection layer exposed by the light resistance pattern layer for forming a third opening, a fourth opening and a fifth opening; etching the first protection layer exposed by the third opening and the fourth opening for forming a sixth opening and a seventh opening and exposing the drain electrode and the connection electrode; and removing the light resistance pattern layer and forming a bridging electrode and a pixel electrode on the second protection layer.

Owner:AU OPTRONICS CORP

Light valve panel and liquid crystal display using the same

ActiveUS20170032744A1Increase contrastReduce colorStatic indicating devicesNon-linear opticsElectrical resistance and conductanceHigh resistance

A light valve panel and a liquid crystal display using the same are discussed. The light valve panel according to an embodiment includes a transparent electrode layer having a plurality of blocks supplied with a voltage through data input lines. The transparent electrode layer has a low resistance or has a high resistance. When a transparent electrode layer has low resistance, each block is divided into a plurality of segment electrodes connected through a resistance pattern. A voltage is distributed to the plurality of segment electrodes of each block based on the resistance pattern. When a transparent electrode layer has high resistance, the voltage distribution in each block is based on a resistance difference that varies based on a distance between voltage feeding positions.

Owner:LG DISPLAY CO LTD

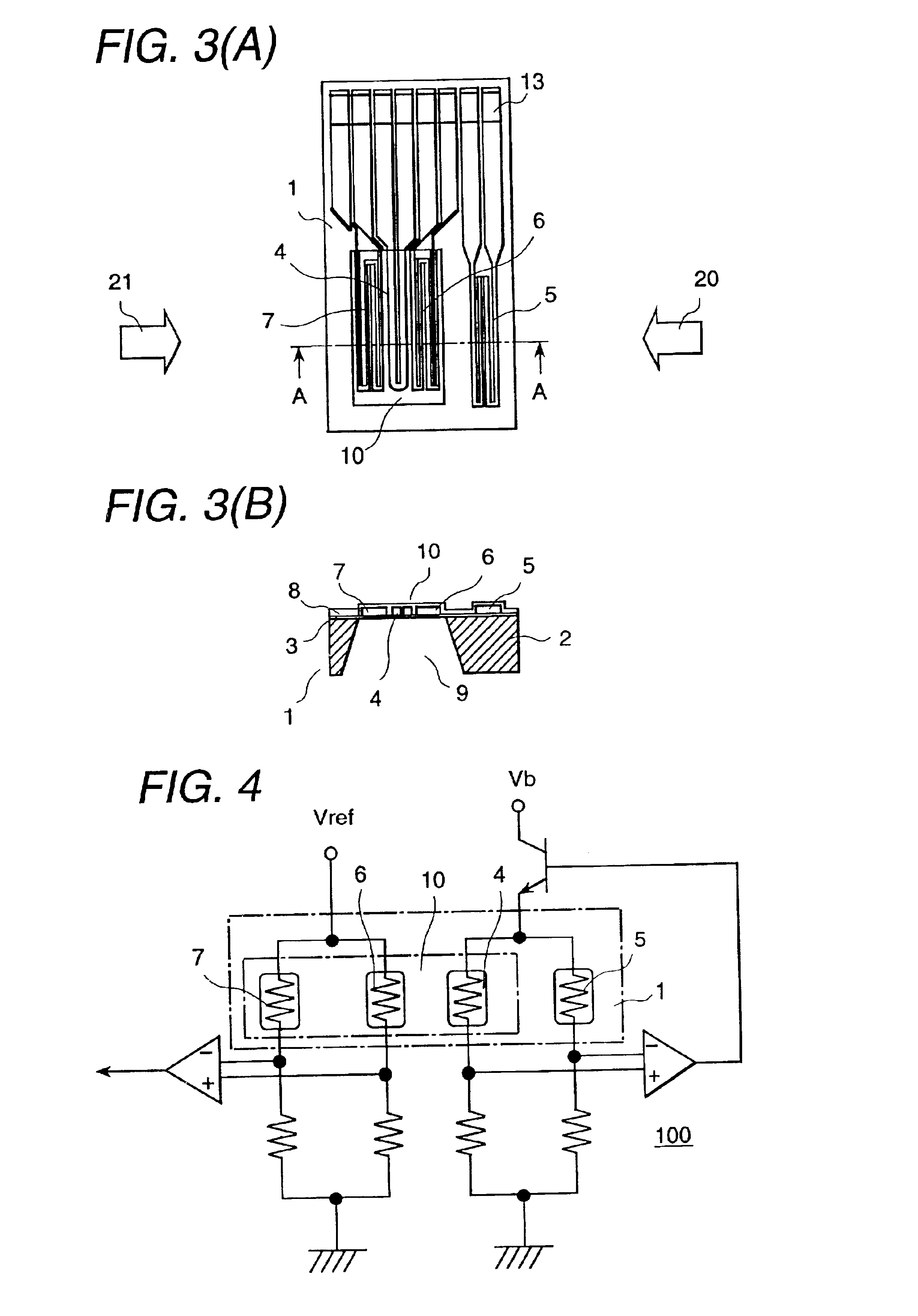

Flow measurement sensor

InactiveUS20030110854A1Accurate flow measurementRepel condensationElectrical controlVolume/mass flow by thermal effectsElectrical resistance and conductanceEngineering

To provide a flow measurement sensor which accurately outputs signals even when pulsation flow is generated at high engine speed and also when pulsation flow accompanying reverse flow is generated. In a flow measurement sensor comprising a flow measurement element which has a heater resistance pattern on one side of a plate-shaped member, and a bypass passage in which the flow measurement element is disposed, a first outlet through which fluid flowing along the surface of said flow measurement element flows out, and a second outlet through which fluid flowing along the back side of said flow measurement element flows out are provided, and said second outlet is positioned at a different location from said first outlet.

Owner:HITACHI ASTEMO LTD

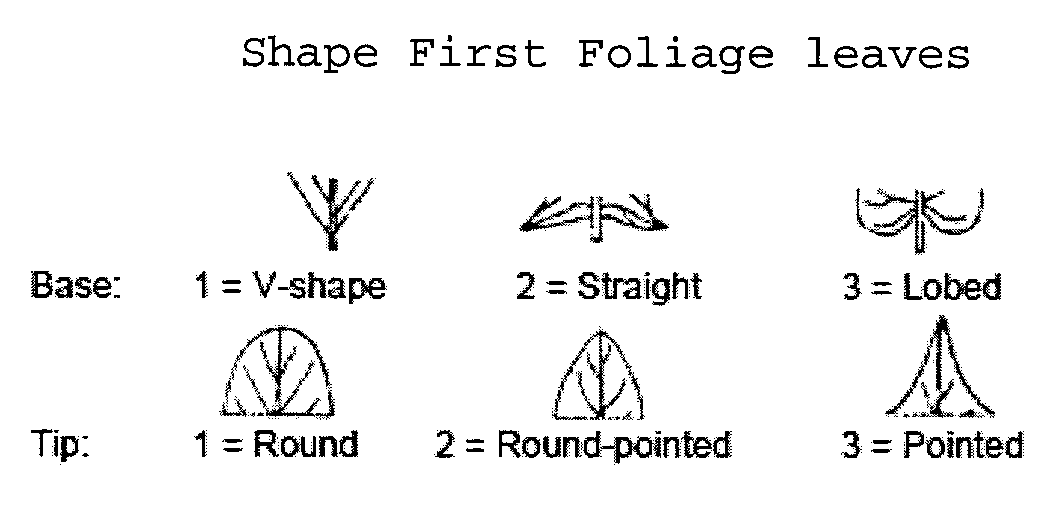

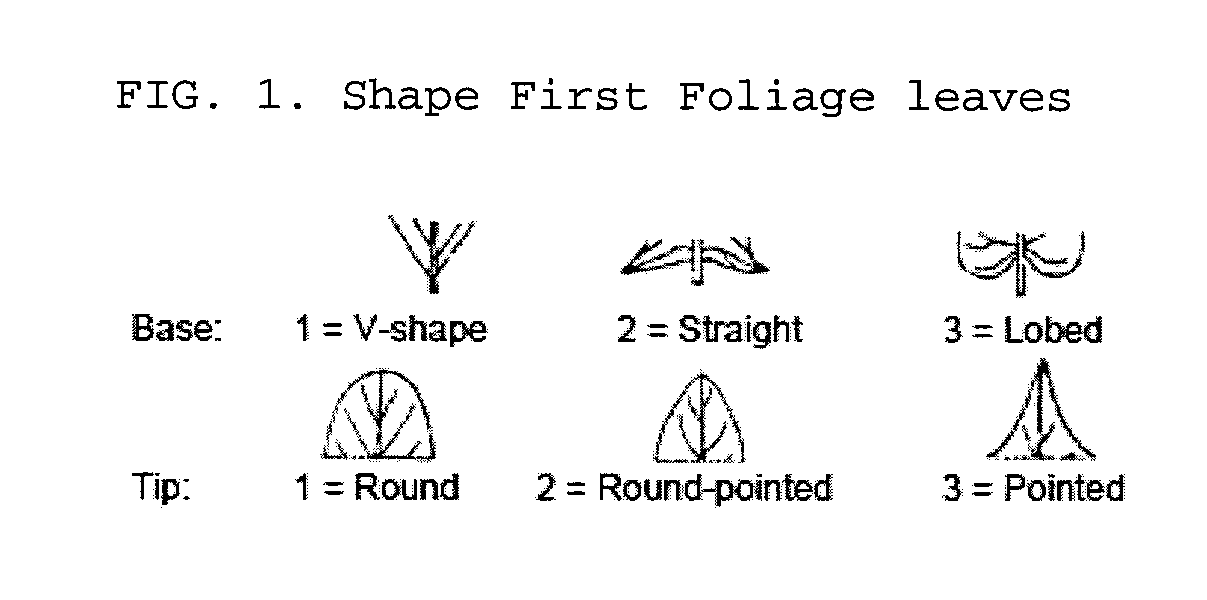

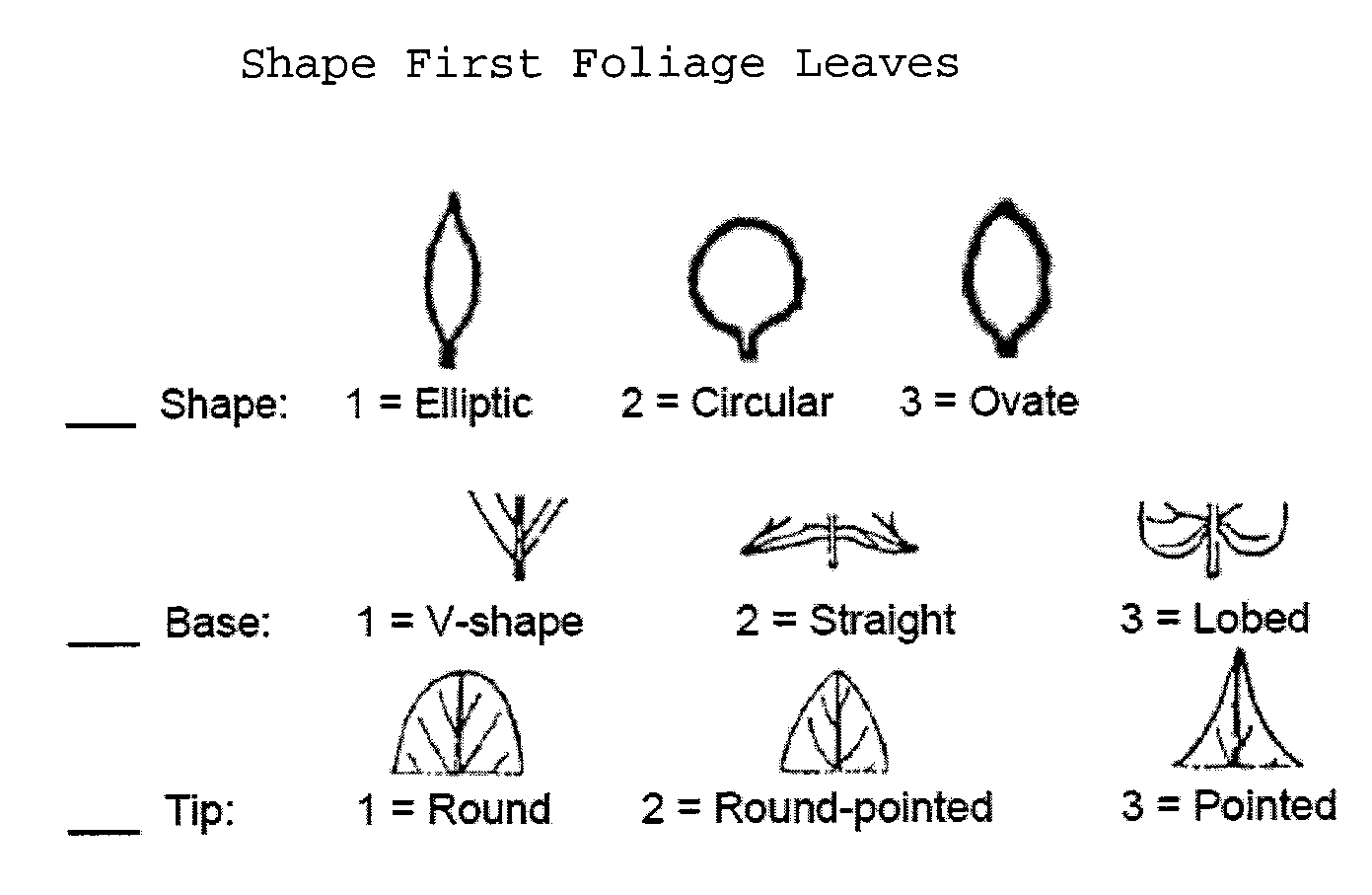

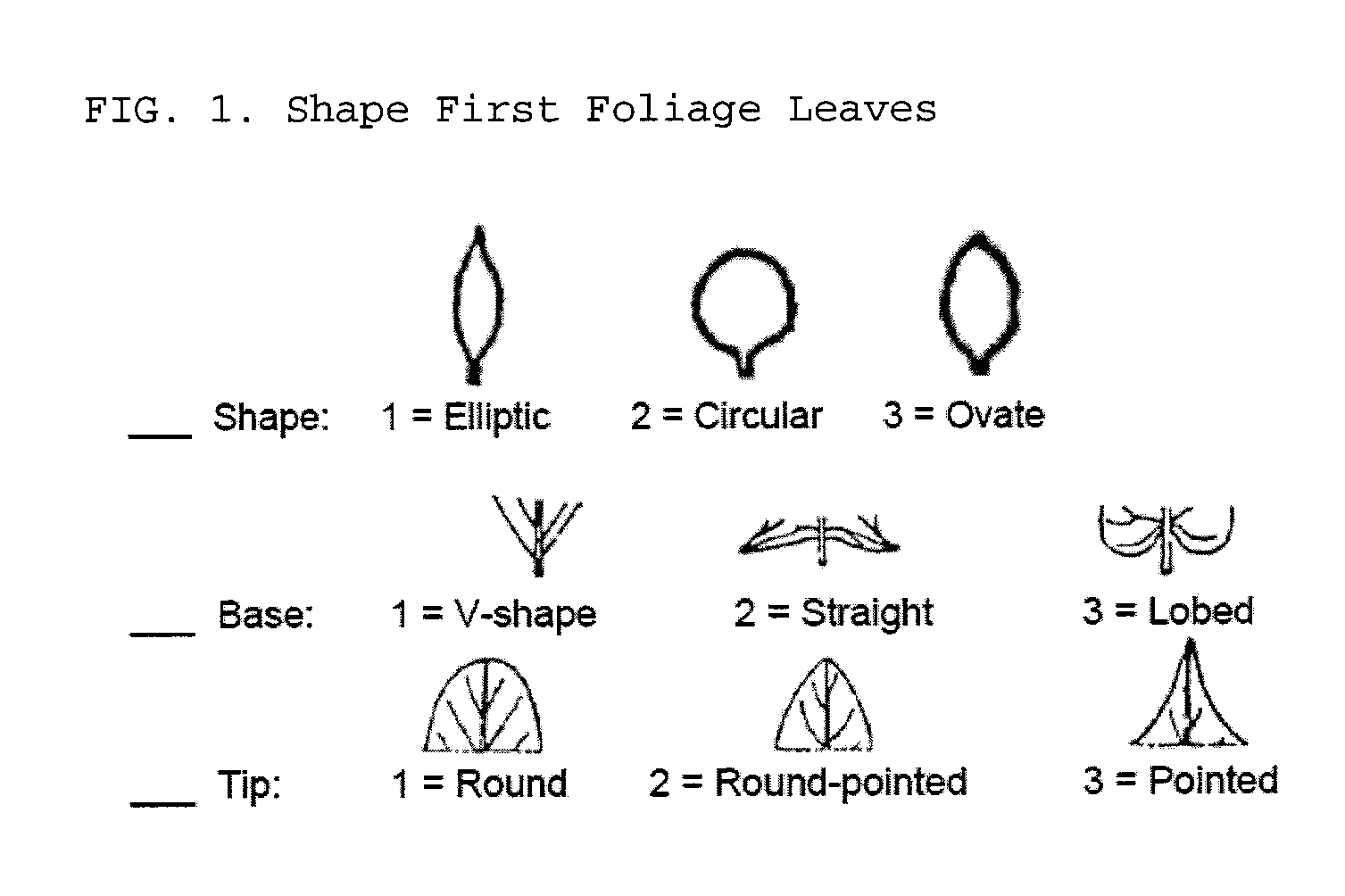

Spinach hybrid 51-324

The present invention relates to the field of plant breeding and more particular to the development of a spinach plant that expresses a new resistance pattern against downy mildew (Peronospora farinosa f. sp. Spinaciae) strains Pf1-Pf12 and isolate PfsUA441), methods and compositions relating to plants, progeny, seeds and derivatives thereof and plants, progeny, seeds and derivatives thereof having all the morphological, physiological and / or genetic characteristics thereof.

Owner:RIJK ZWAAN ZAADTEELT & ZAADHANDEL BV

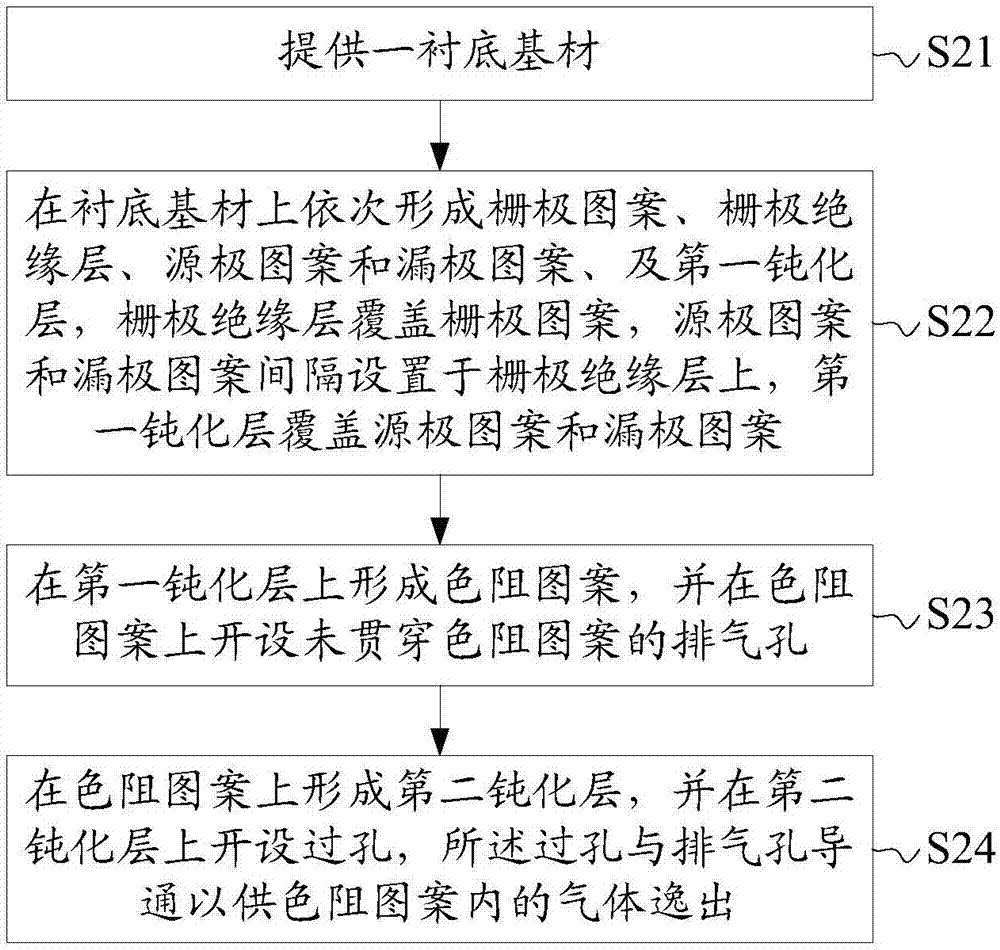

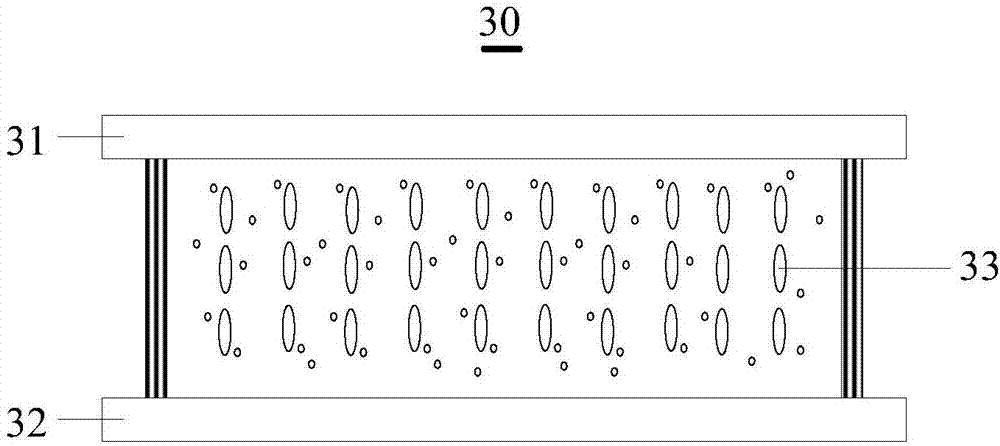

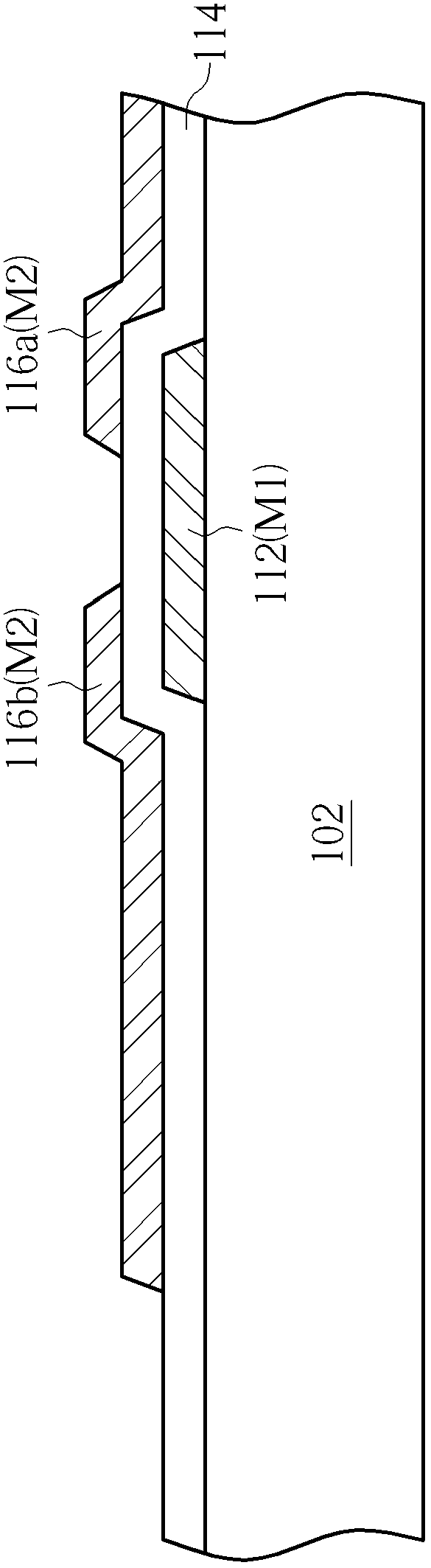

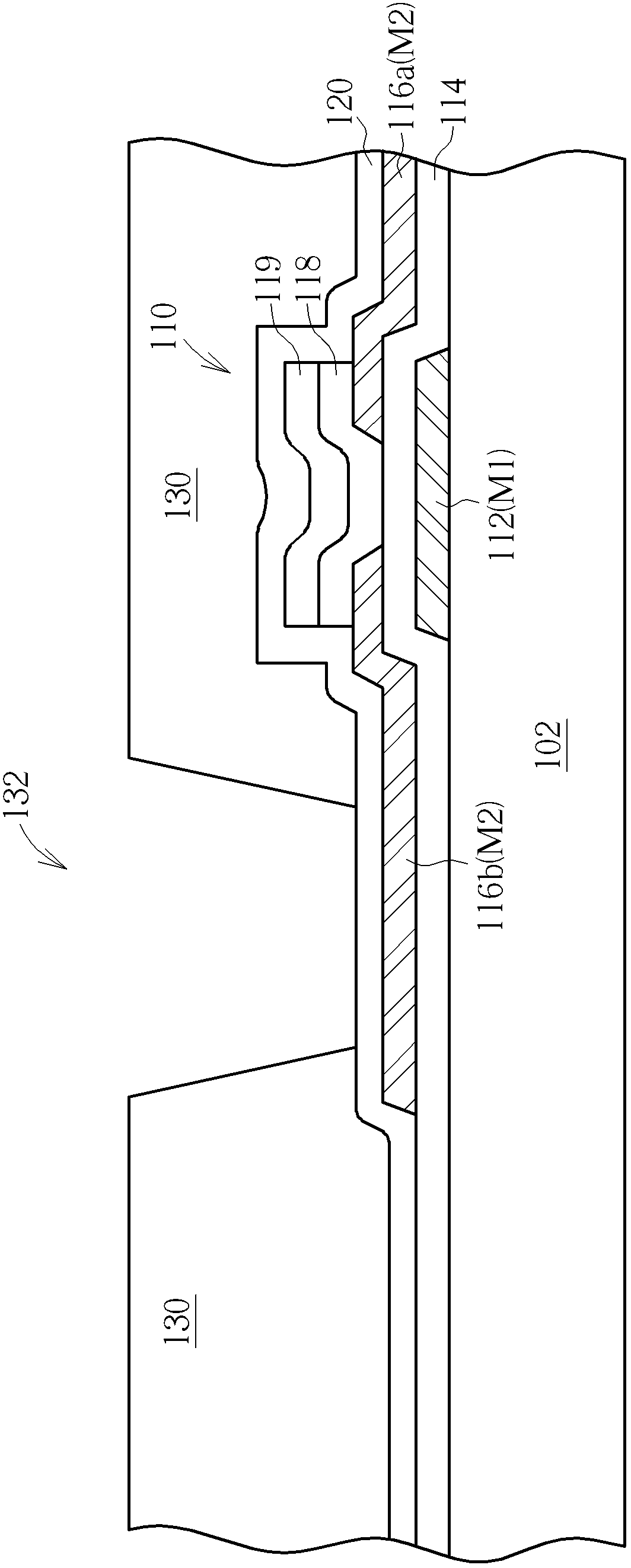

Array substrate and manufacturing method thereof and liquid crystal panel

InactiveCN107463042AAdd depthReduce the risk of BubbleNon-linear opticsLiquid-crystal displayResistance pattern

The invention discloses an array substrate and a manufacturing method thereof and a liquid crystal panel. According to the method, a color ring resistance pattern is designed, and vent holes not running through the color ring resistance pattern are formed, a passivation layer on the color ring resistance pattern is provided with via holes which are communicated with vent holes for gas in the color ring resistance pattern to escape from. Based on this, the array substrate and the manufacturing method thereof and the liquid crystal panel help to discharge the gas inside the color ring resistance pattern and reduce the risk of bubbles appearing on the liquid crystal panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Pixel structure and method for manufacturing the same

InactiveCN103123911AImprove yieldReduce difficultyTransistorSolid-state devicesProtection layerResistance pattern

The invention relates to a pixel structure and a method for manufacturing the same. The manufacture method comprises the following steps of providing a substrate; forming a thin film transistor, a first protection layer, a flat layer possessing a first opening, a patterned first conductive layer possessing a second opening, a second protection layer and a light resistance pattern layer on the substrate; via the light resistance pattern layer, etching the second protection layer to form a third opening exposed out of a part of the patterned first conductive layer and a part of the first protection layer; via the patterned first conductive layer, etching the first protection layer to form a fourth opening exposed out of a part of a drain electrode of the thin film transistor; removing the light resistance pattern layer; and forming patterned second conductive layers of the patterned first conductive layer and the drain electrode electrically connected in the second, third and fourth openings and on the second protection layer.

Owner:AU OPTRONICS CORP

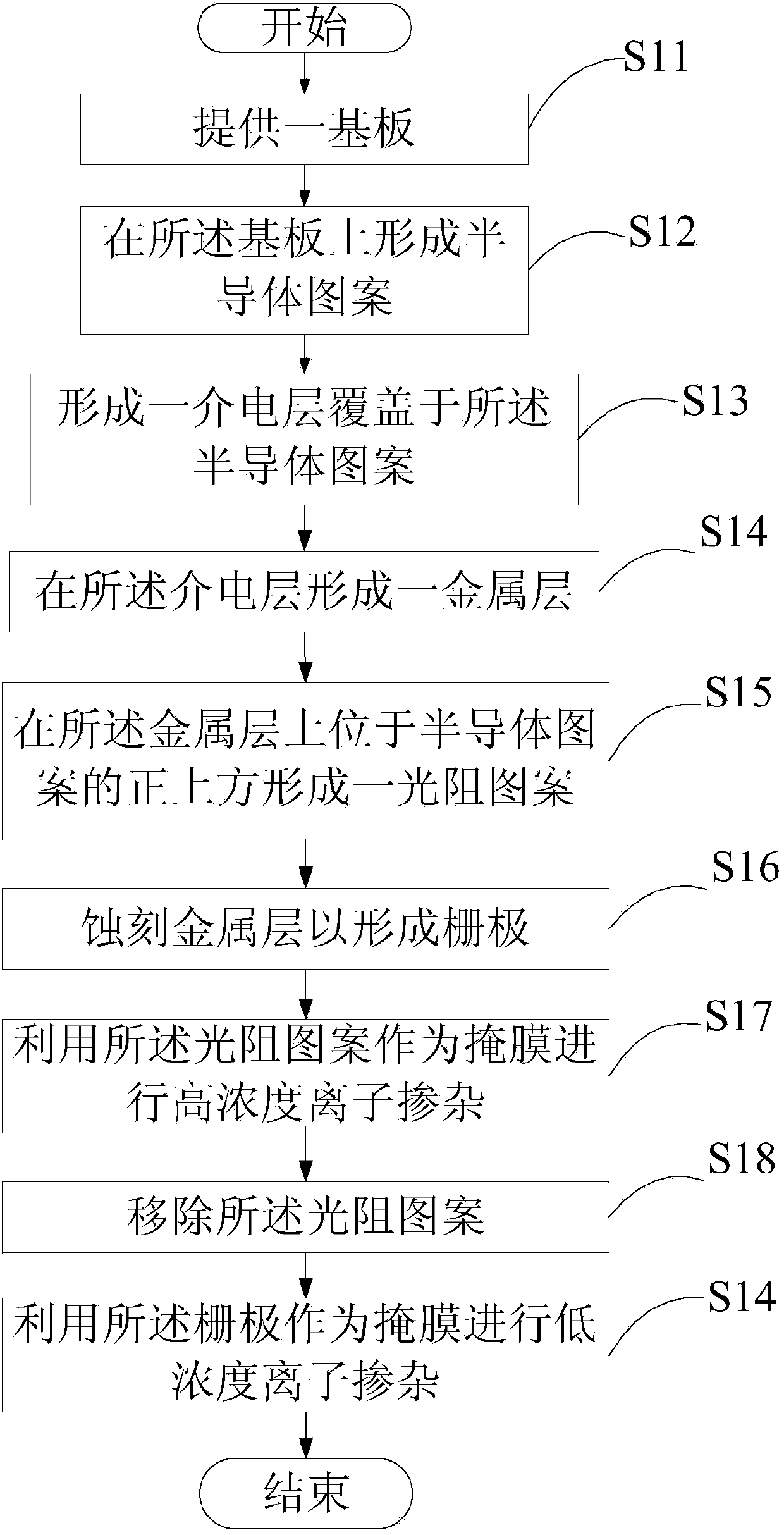

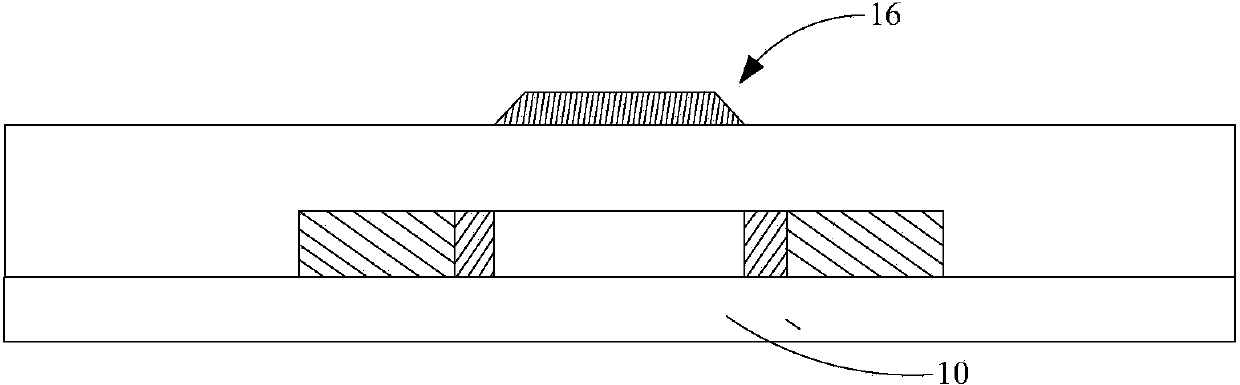

Method for manufacturing display panel

InactiveCN103794566AHigh dimensional accuracyReduce process stepsTransistorSolid-state devicesHigh concentrationDielectric layer

The embodiment of the invention discloses a method for manufacturing a display panel provided with a light doped drain electrode structure thin film transistor matrix. The method for manufacturing the display panel comprises the steps that a semiconductor pattern of a preset shape is firstly formed on a substrate, a dielectric layer covering the semiconductor pattern is formed on the substrate, a metal layer is formed on the dielectric layer, a light resistance pattern with the size smaller than that of the semiconductor pattern is formed, over the semiconductor pattern, on the metal layer, and the metal layer is etched so that a grid electrode with the size smaller than that of the light resistance pattern can be formed; the light resistance pattern serves as a mask, high-concentration ion doping is conducted on the portions which are not covered with the light resistance pattern so that a heavily doped region can be formed; the light resistance pattern is removed, the grid electrode serves as a mask and low-concentration ion doping is conducted on the heavily doped region and a region, covered with the grid electrode, of the semiconductor pattern so that a light doped region can be formed.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

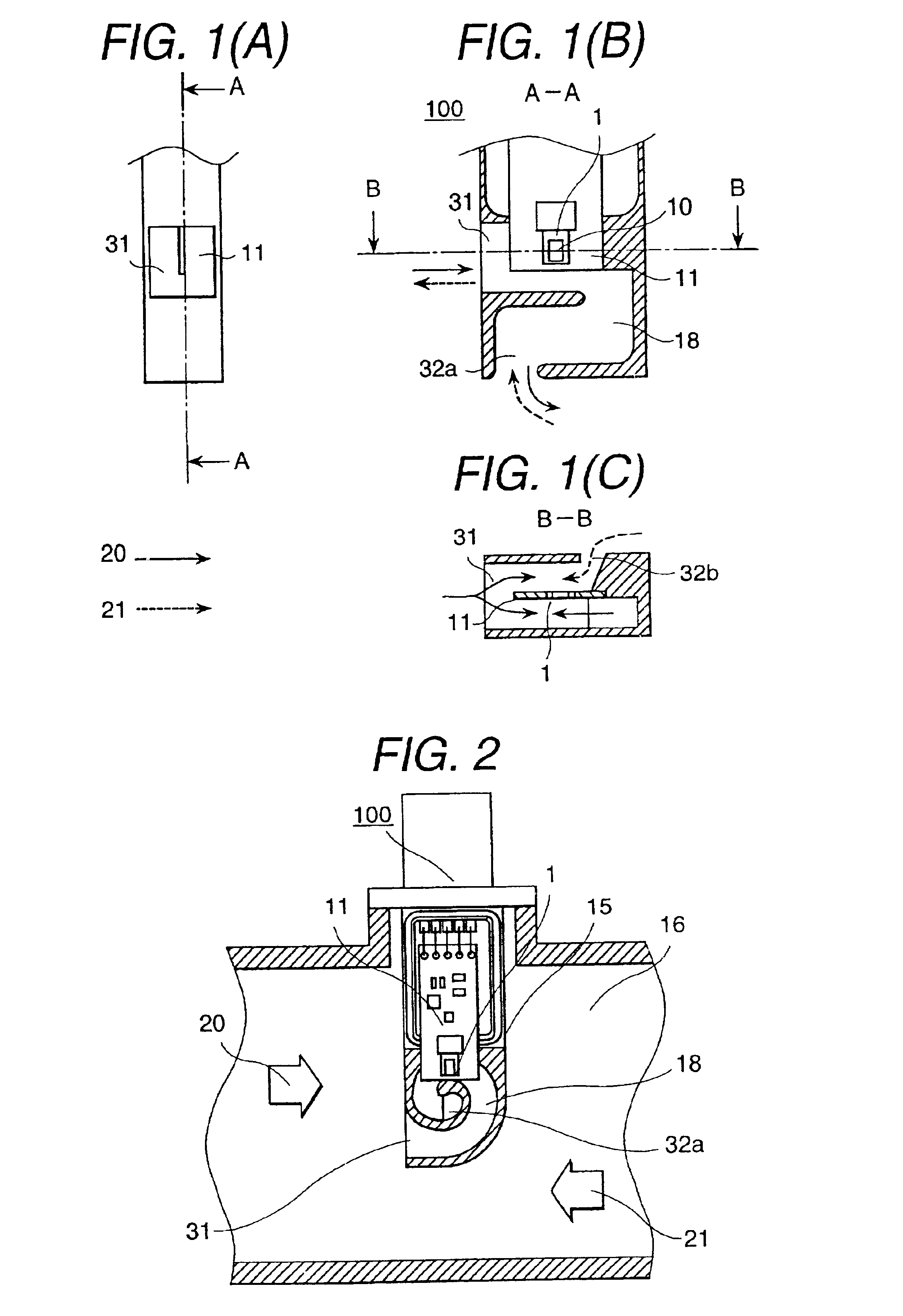

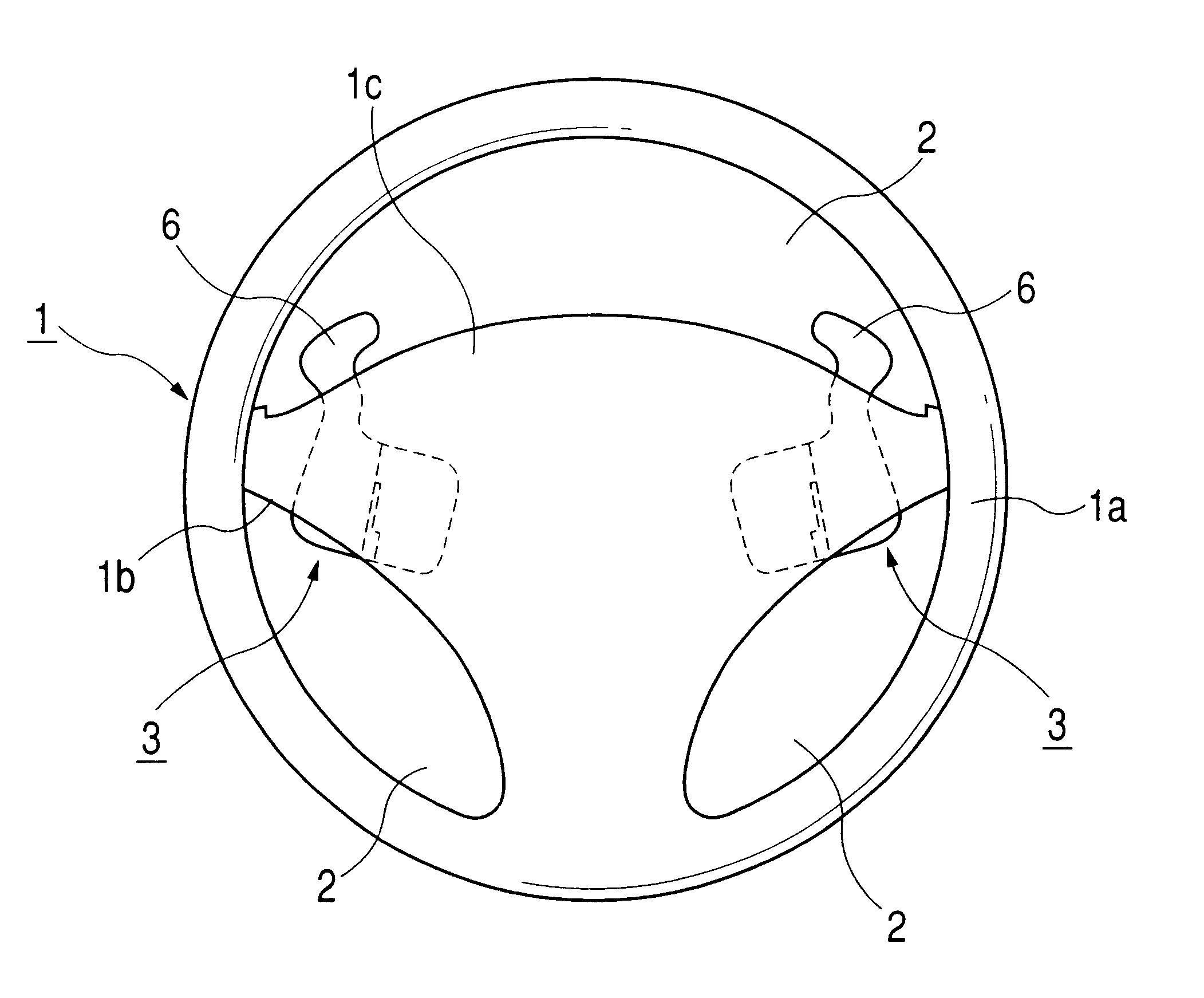

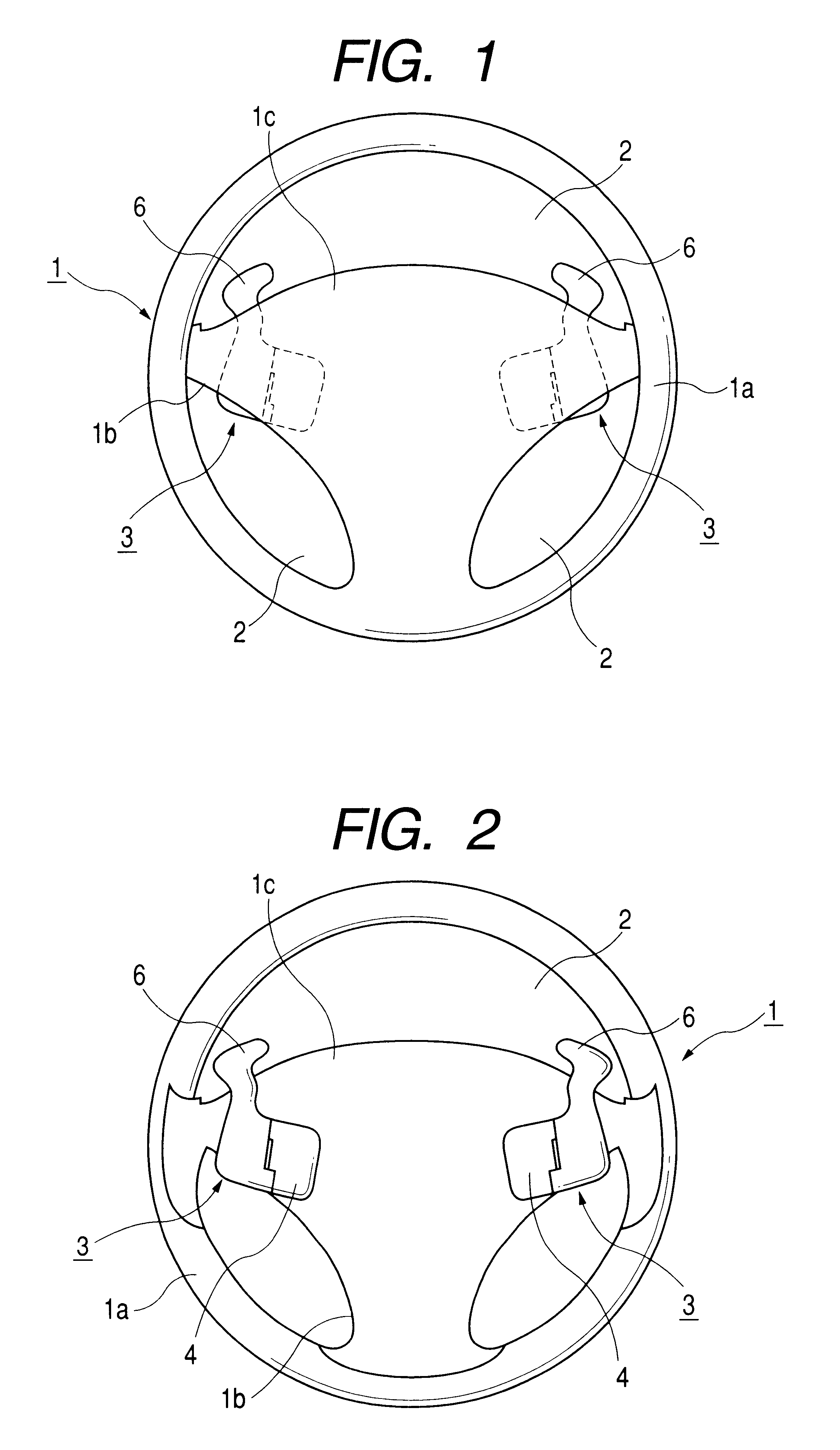

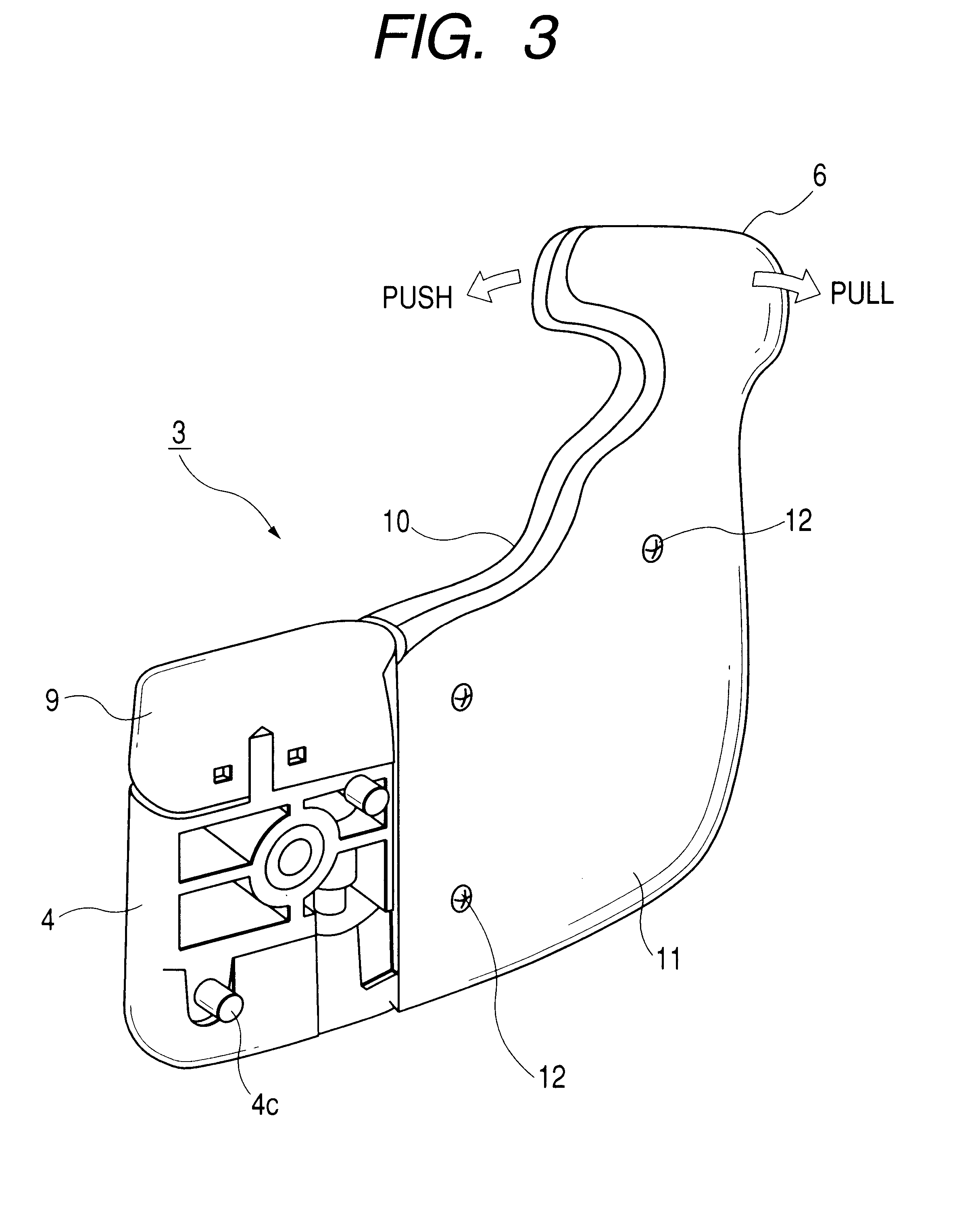

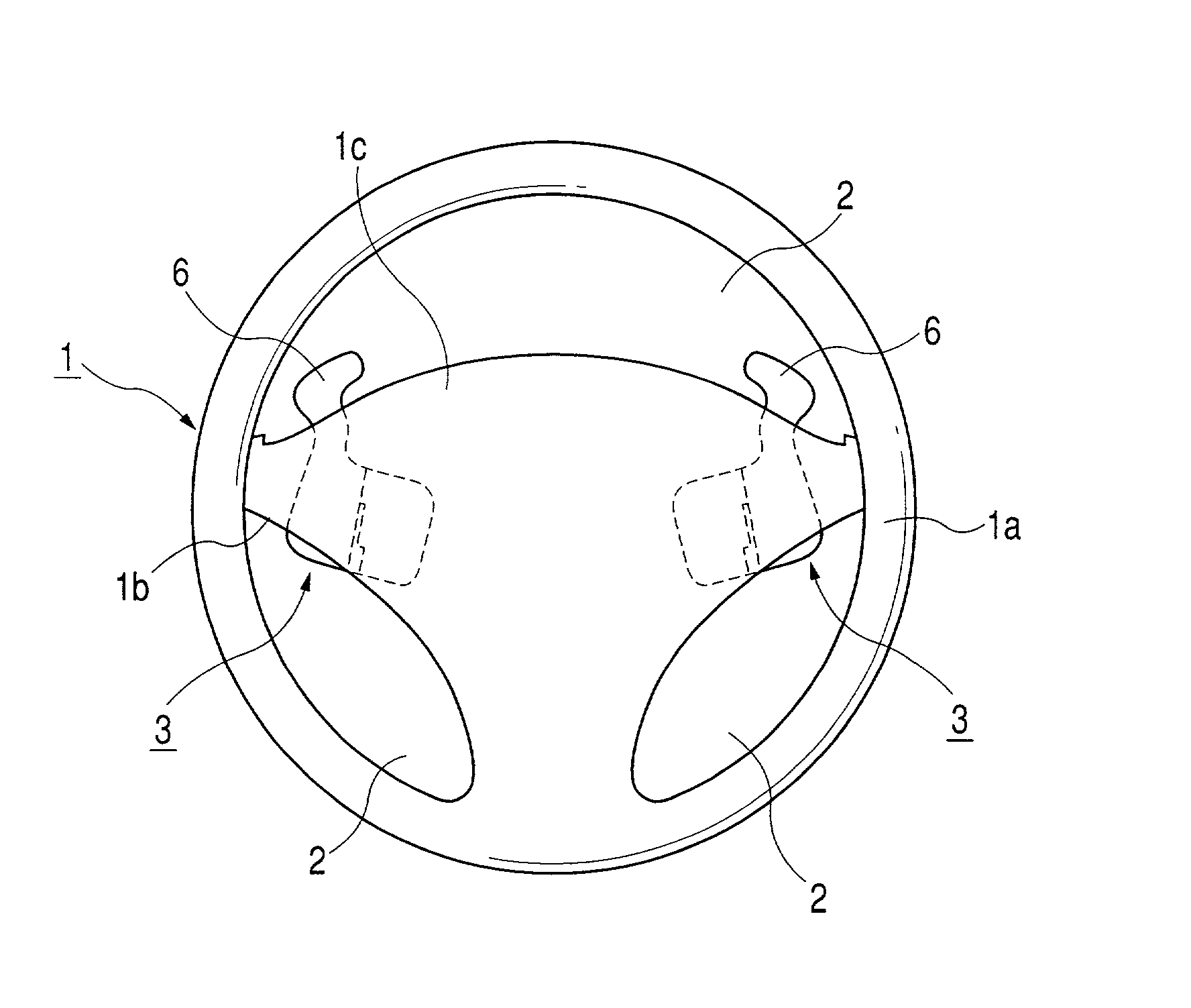

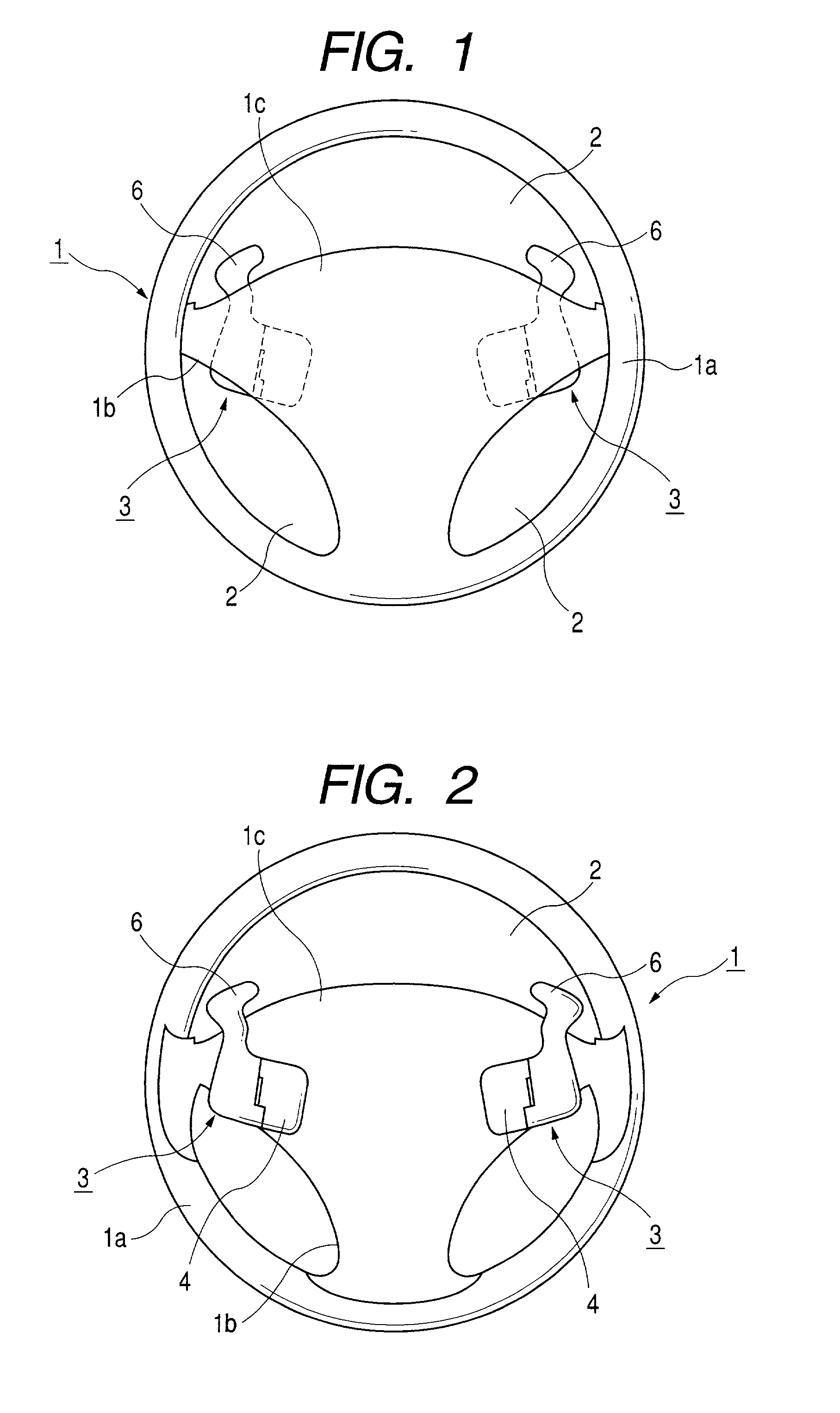

Vehicle-mounting steering switch

InactiveUS6586692B2Easy to operateReduced space required for installationGearing controlHand wheelsSteering wheelDriver/operator

A vehicle-mounting steering switch includes a manipulating knob which is rotatably and pivotally supported on a support member. The support member is fixedly secured to a rear surface of a pad of the steering wheel and, the manipulating knob is protruded into the inside of a space defined between a ring and the pad. A circuit board which is provided with a pair of resistance patterns is mounted on the support member, while a sliding element which is slidable on the circuit board is mounted on the manipulating knob. When a driver performs push or pull manipulation of the manipulating knob with his finger, a relative position of the circuit board and the sliding element is changed so that two kinds of ON signals are outputted. In response to these ON signals, it becomes possible to shift transmission gears in the midst of cruising in a drive range.

Owner:ALPS ALPINE CO LTD

Vehicle-mounting steering switch

InactiveUS20020066658A1Easy to operateReduced space required for installationGearing controlHand wheelsSteering wheelOperability

The present invention discloses a vehicle-mounting steering switch which exhibits excellent operability and requires just a small installation space. A vehicle-mounting steering switch includes a manipulating knob which is rotatably and pivotally supported on a support member. The support member is fixedly secured to a rear surface of a pad of the steering wheel and, at the same time, the manipulating knob is protruded into the inside of a space defined between a ring and the pad. A circuit board which is provided with a pair of resistance patterns is mounted on the support member, while a sliding element which is slidable on the circuit board is mounted on the manipulating knob. When a driver performs push or pull manipulation of the manipulating knob with his finger, a relative position of the circuit board and the sliding element is changed so that two kinds of ON signals are outputted. In response to these ON signals, it becomes possible to perform shift-up or shift-down of transmission gears in the midst of cruising in a drive range.

Owner:ALPS ALPINE CO LTD

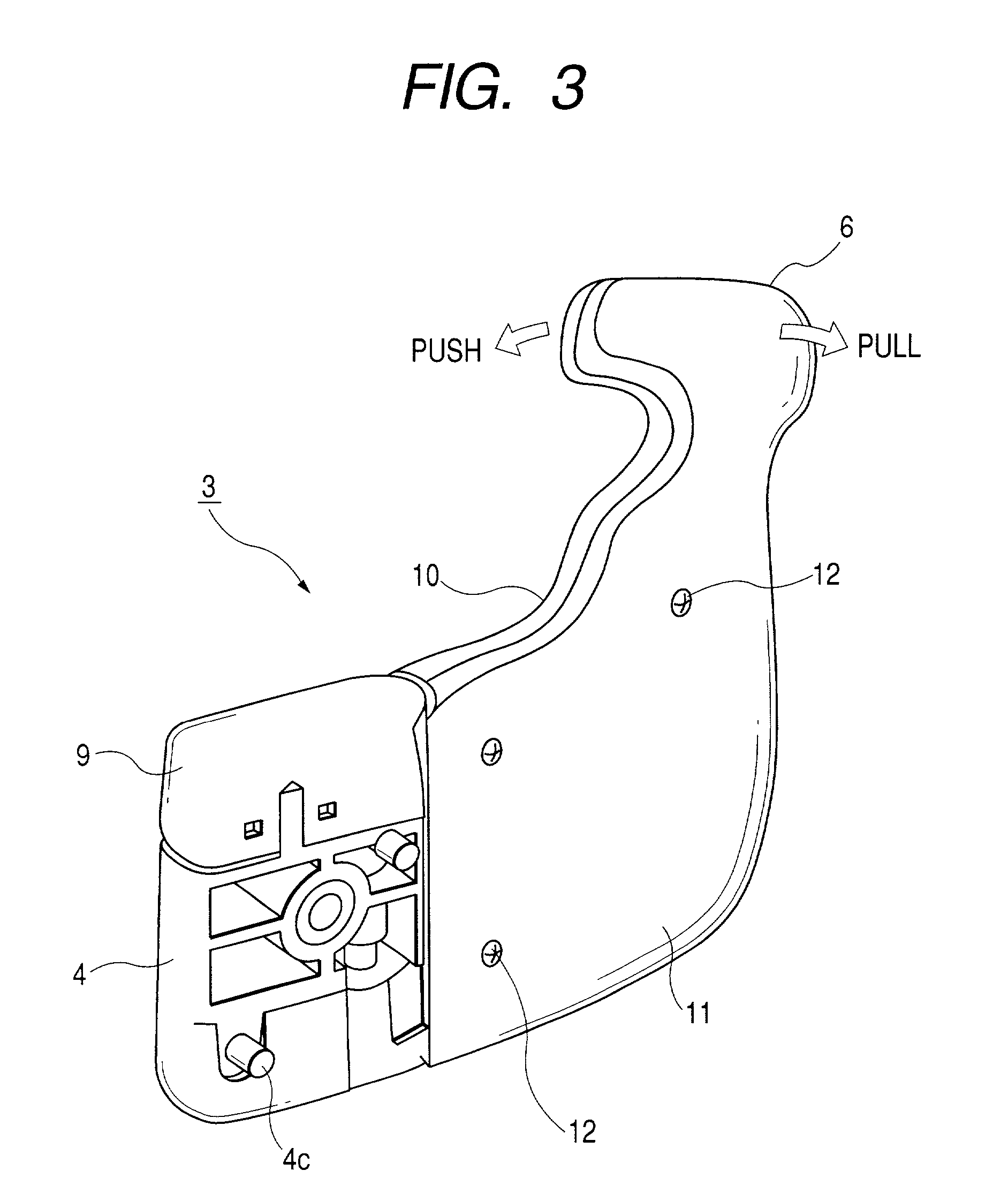

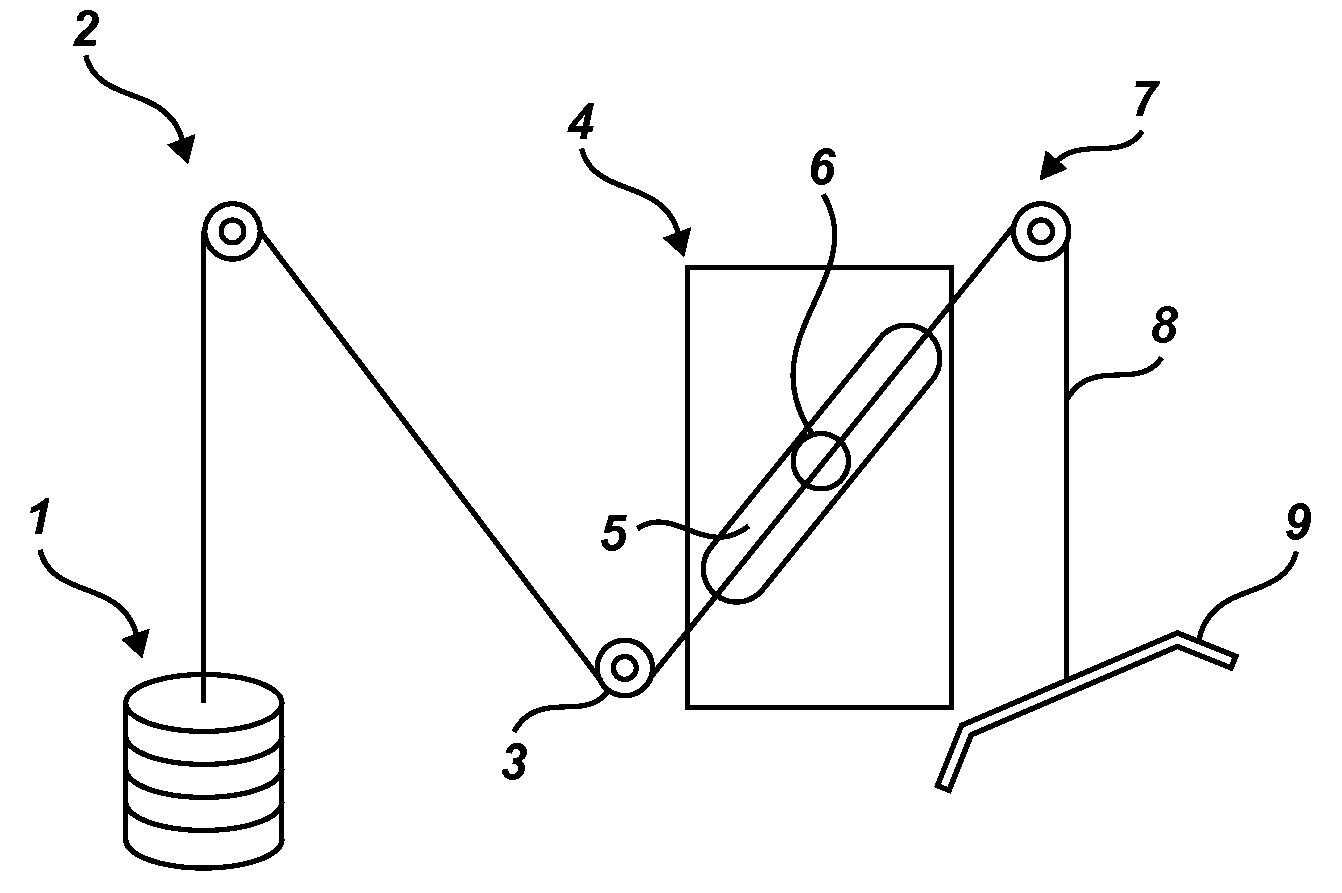

Multiple resistance curves used to vary resistance in exercise apparatus

Changing resistance patterns in an exercise machine is accomplished by moving a cable pivot point within a channel. The channel may take the form of numerous shapes. Multiple shapes may comprise one continuous channel. The placement of the pivot point and surrounding channel shape dictate the resistance pattern along the range of exercise motion. The pivot point is attached to two cables, one leading to a weight, the other leading to the user of the exercise machine.

Owner:HULLS CHRISTOPHER R

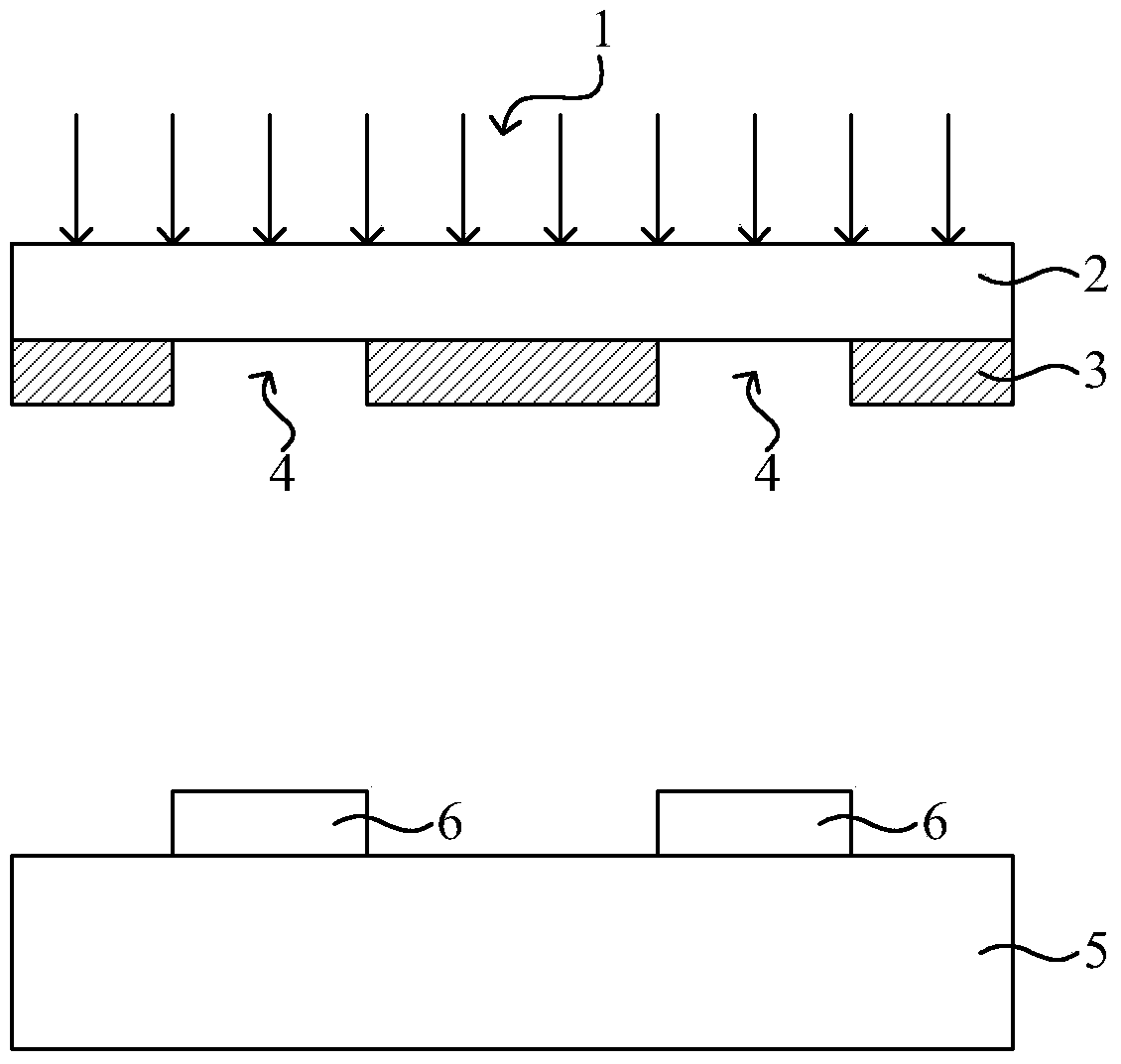

Mask plate and manufacturing method thereof

The invention relates to a mask plate and a manufacturing method thereof. The mask plate comprises a transparent base plate and a graphical shading layer, wherein the graphical shading layer is positioned on the transparent base plate; the graphical shading layer is provided with an opening from which the transparent base plate can be exposed out; the opening is at least divided into a first opening unit and a second opening unit; the area on a mask plate body and corresponding to the first opening unit serves as a first light-transmitting area, and the area on the mask plate body and corresponding to the second opening unit serves as a second light-transmitting area; the bottom of the first opening unit is exposed out of the transparent base plate; the light transmittance of the second light-transmitting area is less than that of the transparent base plate. Light resistance patterns with different-height upper surfaces can be formed at the positions on a light resistance layer and corresponding to the light-transmitting areas of the mask plate by utilizing the mask plate.

Owner:NANTONG FUJITSU MICROELECTRONICS

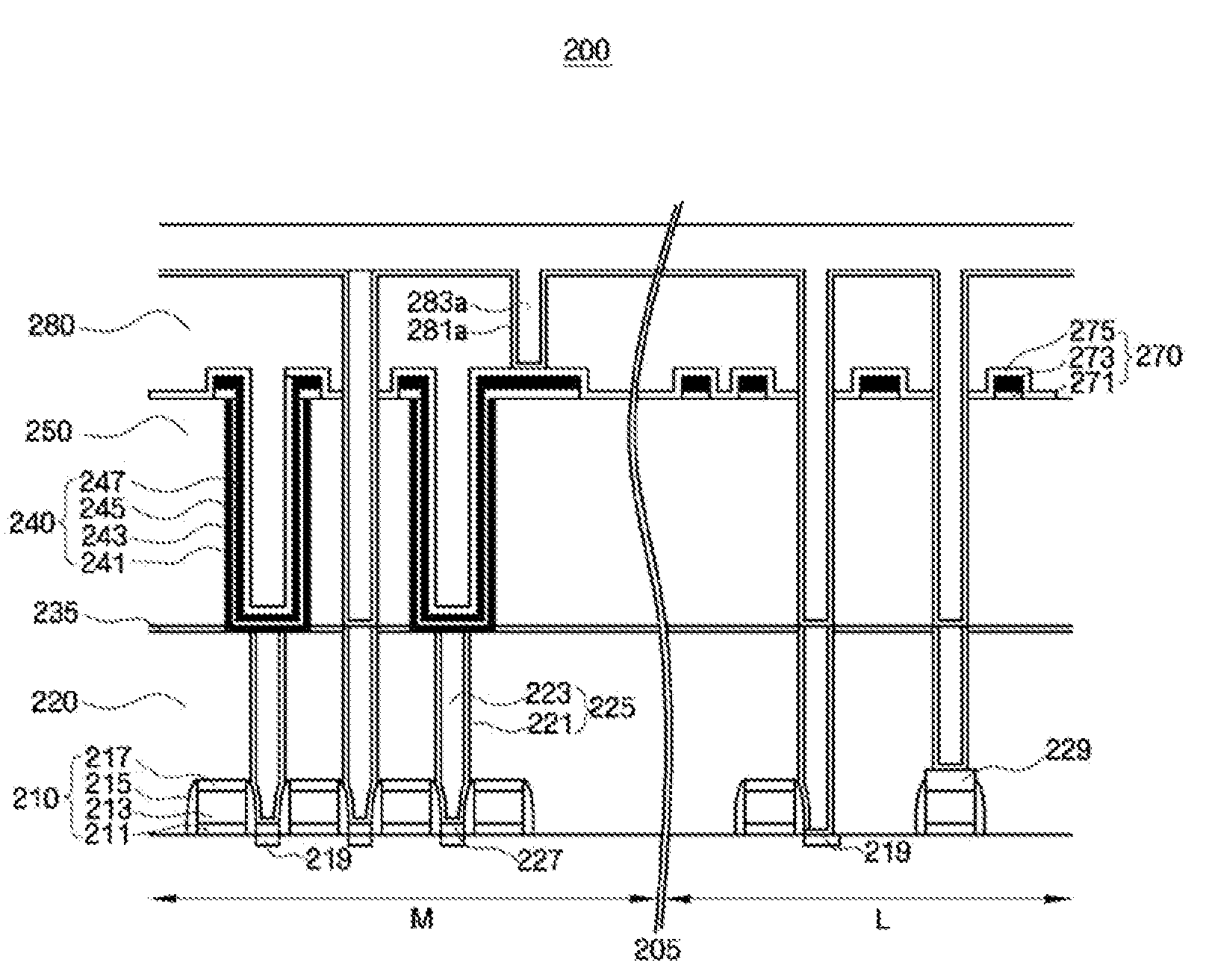

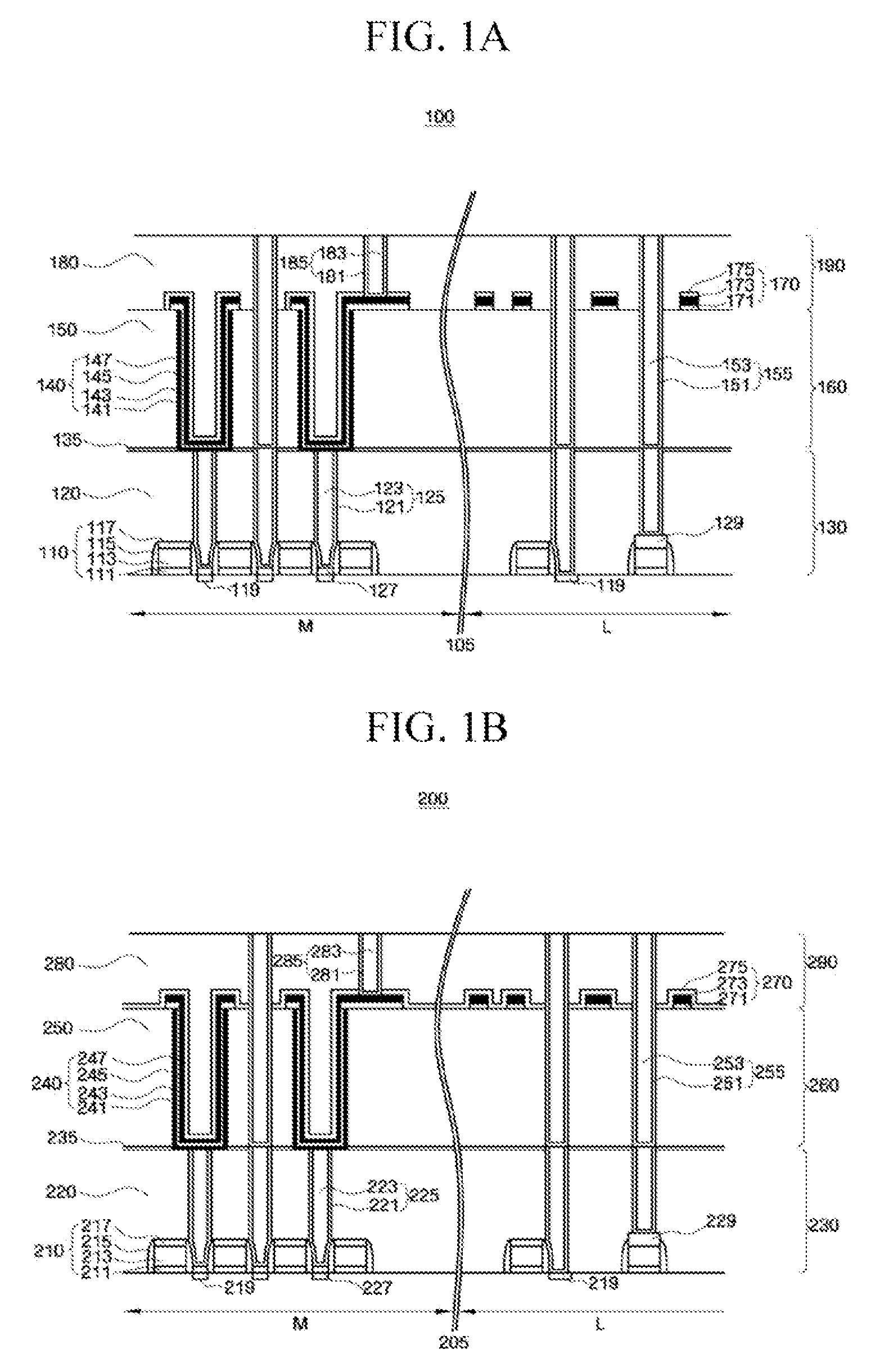

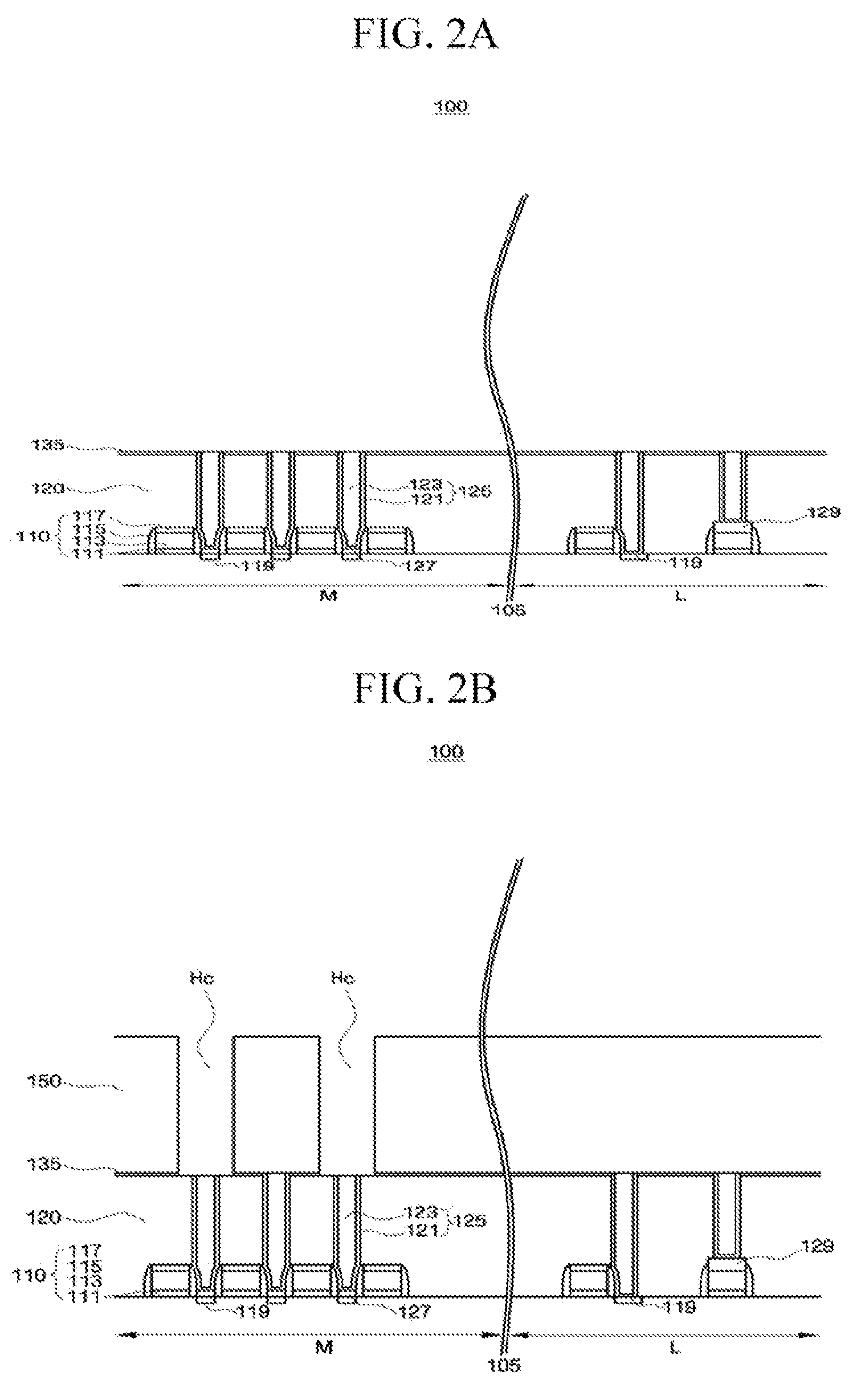

Embedded Semiconductor Device Including Planarization Resistance Patterns and Method of Manufacturing the Same

An embedded semiconductor device which a logic region and the memory region are planarized with planarization resistance patterns and a method of manufacturing the same are disclosed. The embedded semiconductor device includes a substrate, gates formed on the substrate, source / drain regions formed on both sides of the gates in the substrate, a first interlayer dielectric (ILD) layer which covers the gates and the source / drain regions, first via plugs which vertically penetrate the first ILD layer and are selectively connected to the source / drain regions, capacitors and second via plugs selectively connected to the first via plugs, a second ILD layer that fills the space between the capacitors and the second via plugs, planarization resistance patterns formed on the second ILD layer, a third ILD layer formed on the second ILD layer and the planarization resistant patterns, and third via plugs which vertically penetrate the third ILD layer, and are selectively connected to a top electrode of the capacitors and the second via plugs.

Owner:SAMSUNG ELECTRONICS CO LTD

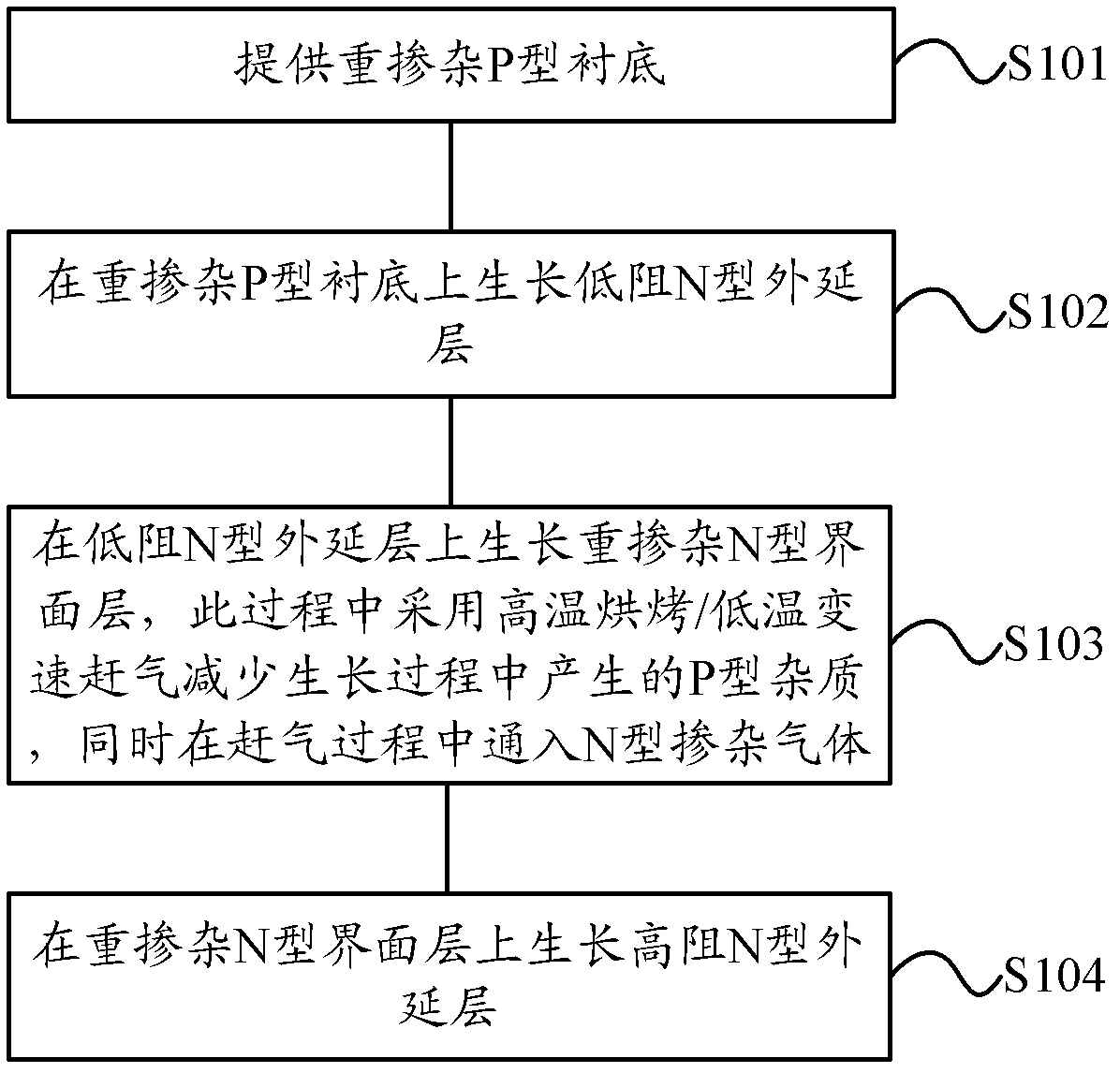

Method for growing high-resistance N type epitaxial layer on heavily-doped P type substrate

InactiveCN102324382AReduce P-type impuritiesElimination of self-doping effectsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceHigh resistance

The invention provides a method for growing a high-resistance N type epitaxial layer on a heavily-doped P type substrate. The method comprises the following steps of: A, providing the heavily-doped P type substrate; B, growing a low-resistance N type epitaxial layer on the heavily-doped P type substrate; C, growing a heavily-doped N type interface layer on the low-resistance N type epitaxial layer, wherein high-temperature baking / low-temperature variable-speed gas driving is adopted to reduce P type impurities generated in the growing process, and simultaneously an N type doped gas is introduced in the process of gas driving; and D, growing the high-resistance N type epitaxial layer on the heavily-doped N type interface layer. The high-resistance N type epitaxial layer is uniform in thickness, is stable and controllable in resistivity in an area within 10 mm from an edge, and has an ideal spreading resistance pattern (SRP) curve; moreover, the product yield reaches over 99 percent, and the mass production of the high-resistance N type epitaxial layer by using an 8-inch line can be realized.

Owner:ADVANCED SEMICON MFG CO LTD

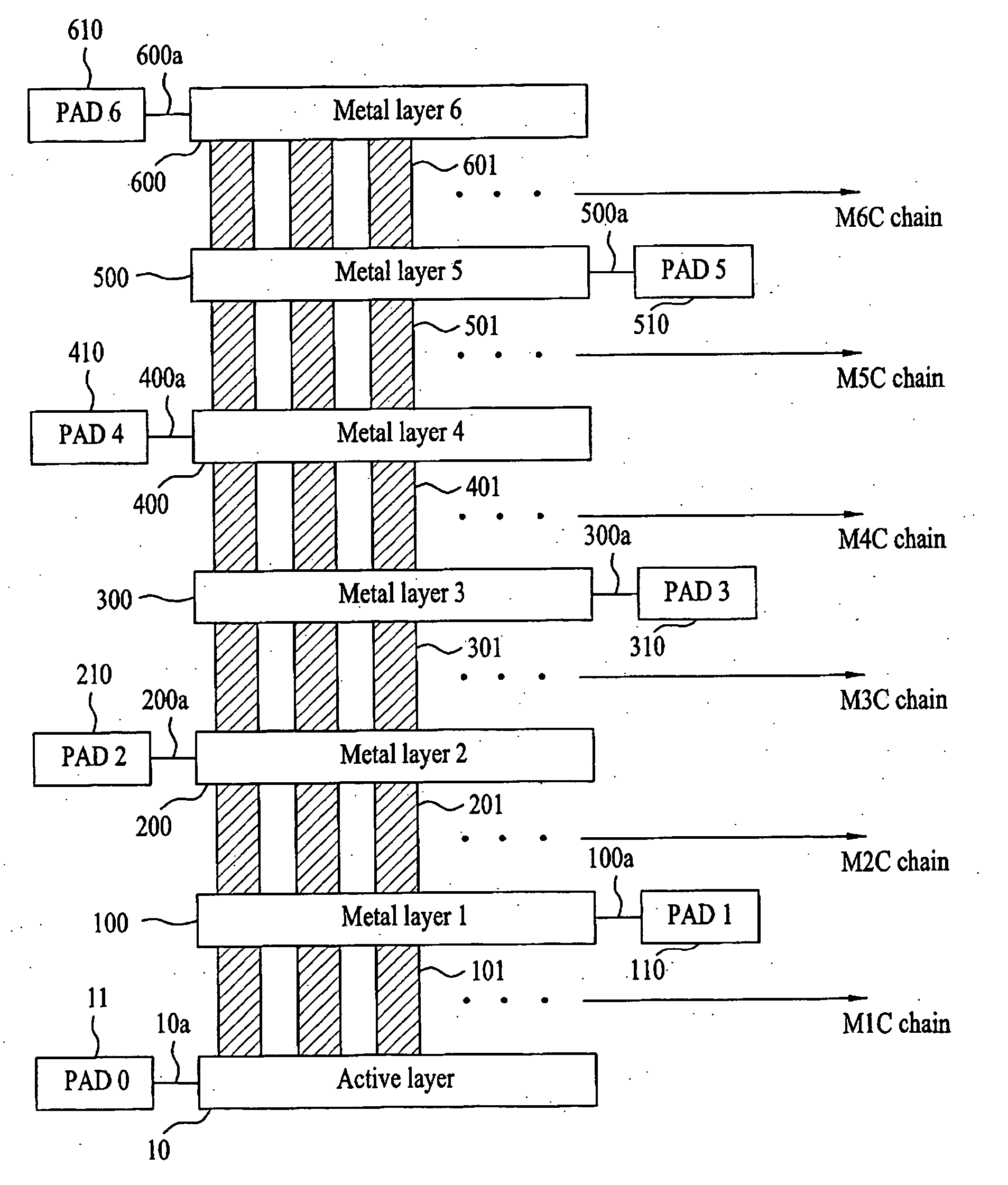

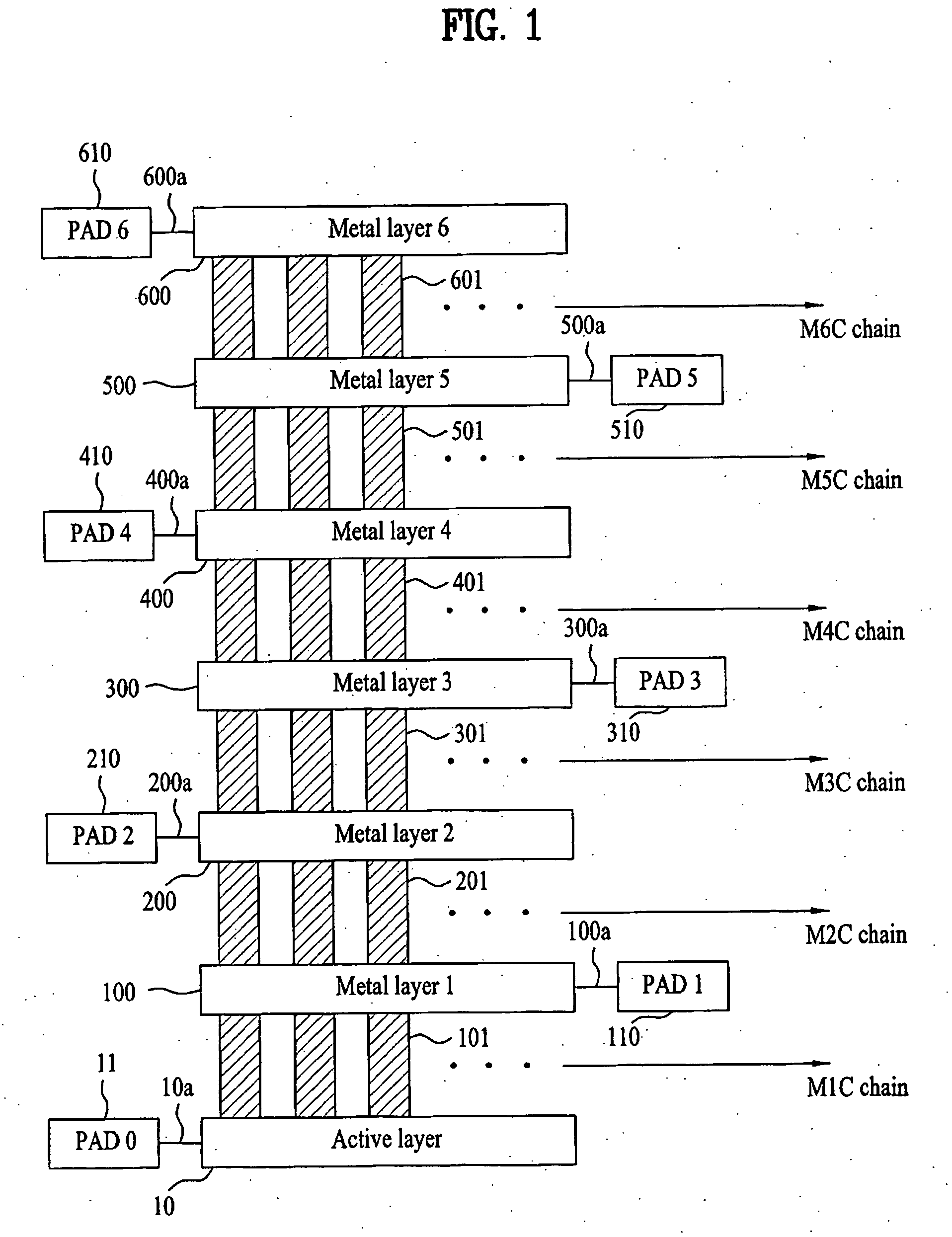

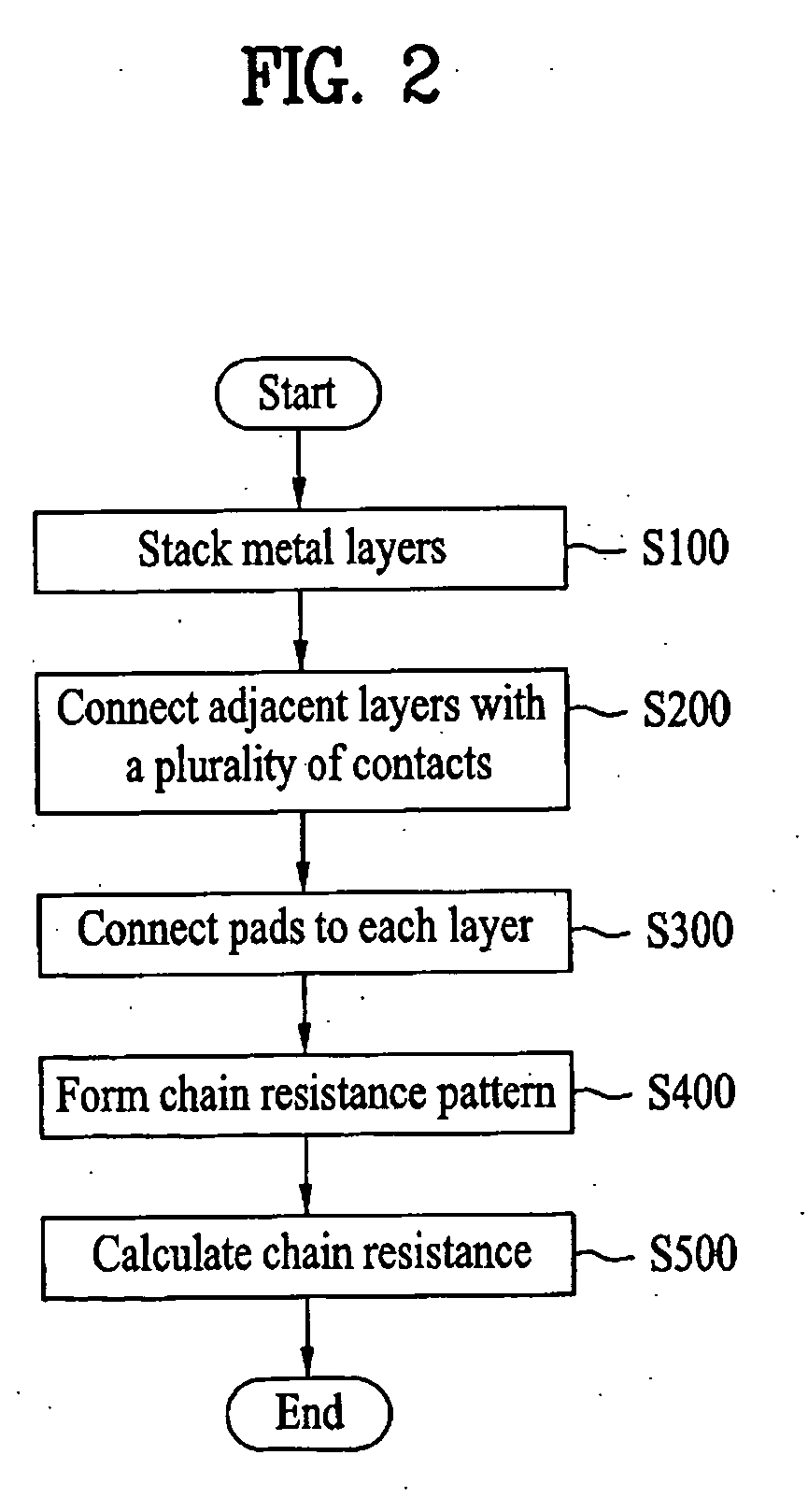

Chain resistance pattern and method of forming the same

InactiveUS20060148113A1Maximum measurement resultAccurate detectionSemiconductor/solid-state device testing/measurementSolid-state devicesProcess errorEngineering

A chain resistance pattern and a method of forming the same enable a test pattern to obtain maximum measurement results using minimum area and enable accurate detection of process errors. The chain resistance pattern includes an active layer for receiving an externally applied optical signal, a plurality of conductive layers sequentially stacked on the active layer to form a layer stack, a plurality of contacts, formed between each layer of the layer stack, to electrically connect each pair of adjacently disposed layers of the layer stack, and a pad connected to each layer of the layer stack.

Owner:DONGBU ELECTRONICS CO LTD

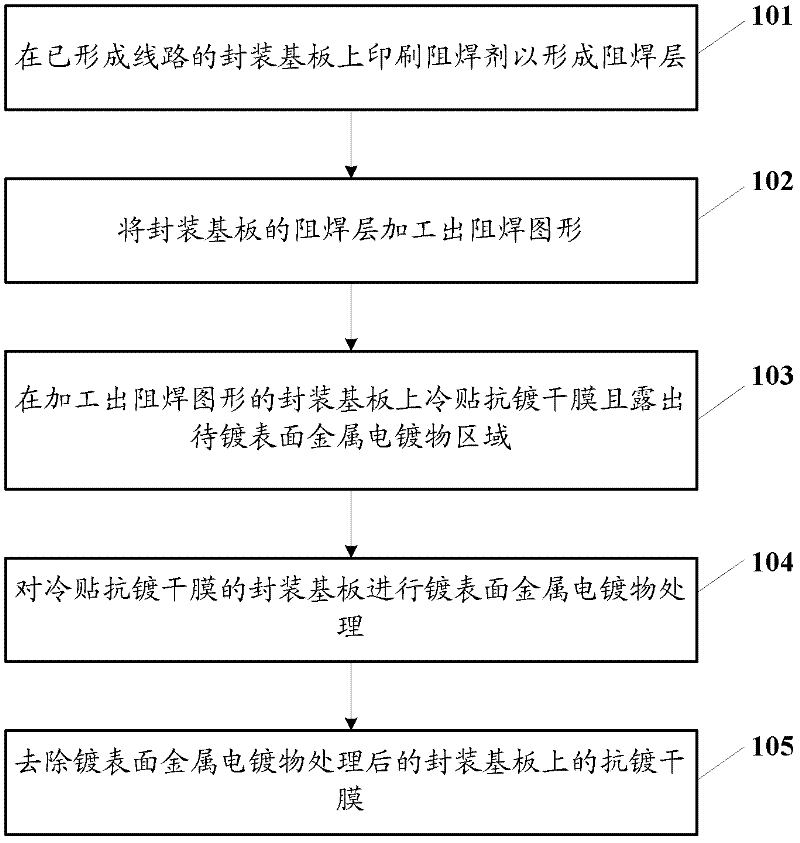

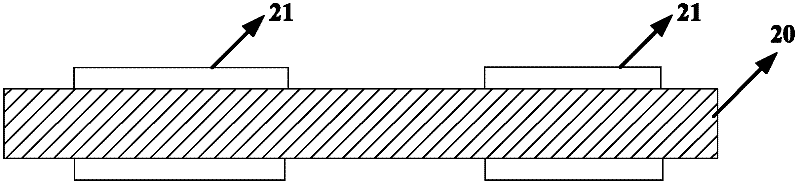

Encapsulation base plate surface electroplating method

ActiveCN102505132AImprove yieldImprove plating color differenceSemiconductor/solid-state device manufacturingSemiconductor devicesElectroplatingResistance pattern

The embodiment of the invention discloses an encapsulation base plate surface electroplating method, which comprises the steps that: soldering resistance agents are printed on an encapsulation base plate with formed circuits for forming a soldering resistance layer; soldering resistance patterns are processed on the soldering resistance layer of the encapsulation base plate; a plating resistance dry film is pasted on the encapsulation base plate with the processed soldering resistance patterns in a cold way, and in addition, a surface metal electroplate object region to be plated is exposed, wherein the film pasting temperature of the plating resistance dry film cold pasting is lower than the melting point temperature of the plating resistance dry film; the surface metal electroplate plating treatment is carried out on the encapsulation base plate pasted with the plating resistance dry film in the cold way; and the plating resistance dry film on the encapsulation base plate after the surface metal electroplate plating treatment is removed. The technical scheme of the embodiment of the invention is favorable for reducing the plating surface color difference and improving the plating acceptance rate of the encapsulation base plate plated with surface metal electroplates.

Owner:SHENNAN CIRCUITS

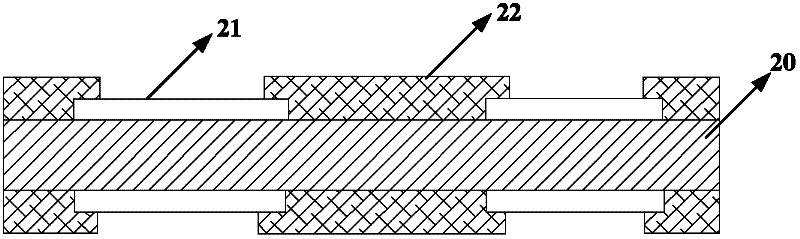

Test key of COA substrate and testing method using test key of COA substrate

ActiveCN108196408AIncrease available spaceSmall footprintNon-linear opticsLine widthComputer science

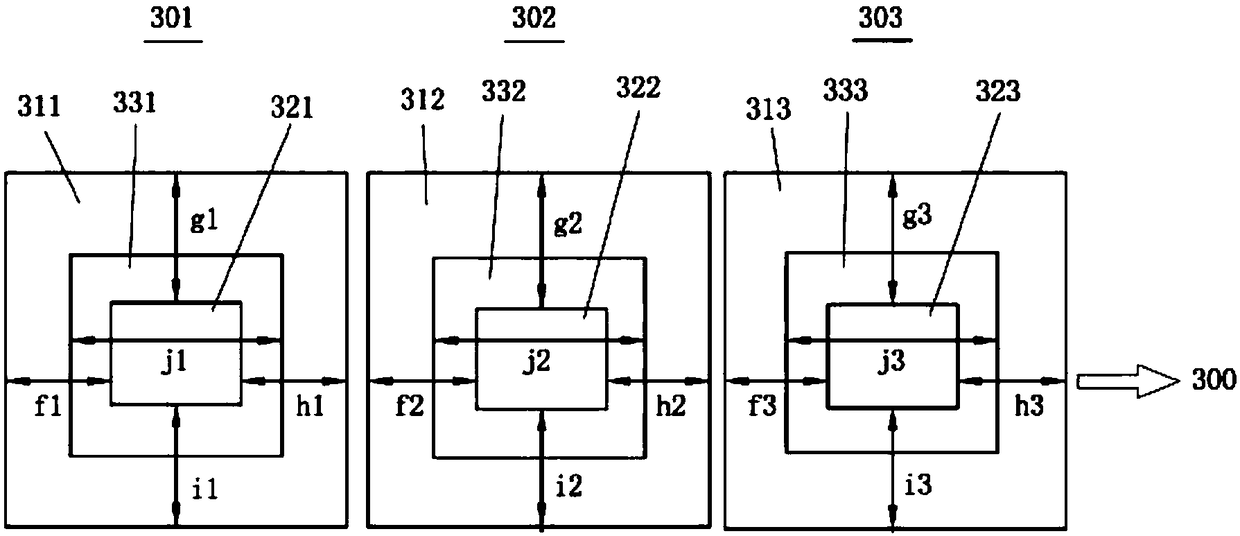

The invention provides a test key of a COA substrate and a testing method using the test key of the COA substrate. The test key of the COA substrate comprises a first test key, a second test key and athird test key, wherein the first test key comprises a red color resistance pattern, a first via hole pattern formed in the red color resistance pattern and a first metal layer pattern, the second test key comprises a green color resistance pattern, a second via hole pattern formed in the green color resistance pattern and a second metal layer pattern, the third test key comprises a blue color resistance pattern, a third via hole pattern formed in the blue color resistance pattern and a third metal layer pattern, and the first metal layer pattern, the second metal layer pattern and the thirdmetal layer pattern are formed from a same metal layer. The test key of the COA substrate occupies smaller space, and the alignment precision of a color resistance layer relative to a thin film transistor layer and the line width of via holes in the color resistance layer can be simultaneously measured.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Methods and devices for the detection of pathogenic microorganisms and their antimicrobial susceptibility

ActiveUS7384778B2Improve trustPromote growthBioreactor/fermenter combinationsBiological substance pretreatmentsBacteroidesBiological body

The present invention provides devices and methods for determining the presence or absence of pathogens in a biological sample and for the concurrent determination of the antimicrobial susceptibility of pathogens present. The devices and methods of the present invention are able to make the determinations without pre-selection of target bacteria. Instead, all organisms from the sample are applied to the device. In wells where one or more antimicrobial agents are present only pathogens resistant to the antimicrobial agent grow. This allows the user to determine the presence of target pathogens and concurrently determine the resistance patterns of the organisms without the need to subculture the organisms. The present invention also provides methods of performing a business service of performing the determinations described above, and kits containing the devices and descriptions of the methods.

Owner:IDEXX LABORATORIES

Apparatus and method for implementing high-precision buried resistance

ActiveCN101227800AHigh resistance precisionAvoid trapezoidal effectPrinted circuit assemblingMultilayer circuit manufactureElectrical resistance and conductanceElectrical conductor

The invention discloses a method for realizing embedding resistance with high accuracy and a device, which belongs to the field of electronic equipment. The method comprises: etching prearranged embedded resistance pattern connecting terminals and a conducting layer outside interconnecting circuits in a non embedded resistance zone, obtaining molded dimension on the embedding resistance length direction and the interconnecting circuits in the non embedded resistance zone, measuring the molded dimension on the embedding resistance length direction, calculating correctional molded dimension on the embedding resistance length direction, and etching a resistance layer to obtain molded embedded resistance according to the correctional molded dimension on the embedding resistance length direction. The technical scheme of the invention firstly etches the molded dimension on the embedding resistance length direction and the interconnecting circuits in the non embedded resistance zone and then errors which are produced by etching the molded dimension on the embedding resistance length direction are corrected through etching the molded dimension on the embedding resistance length direction, which is beneficial for increasing the resistance precision of the embedding resistance which is finally molded and enables an embedding resistance producing technique to be controlled easier.

Owner:HUAWEI DEVICE CO LTD

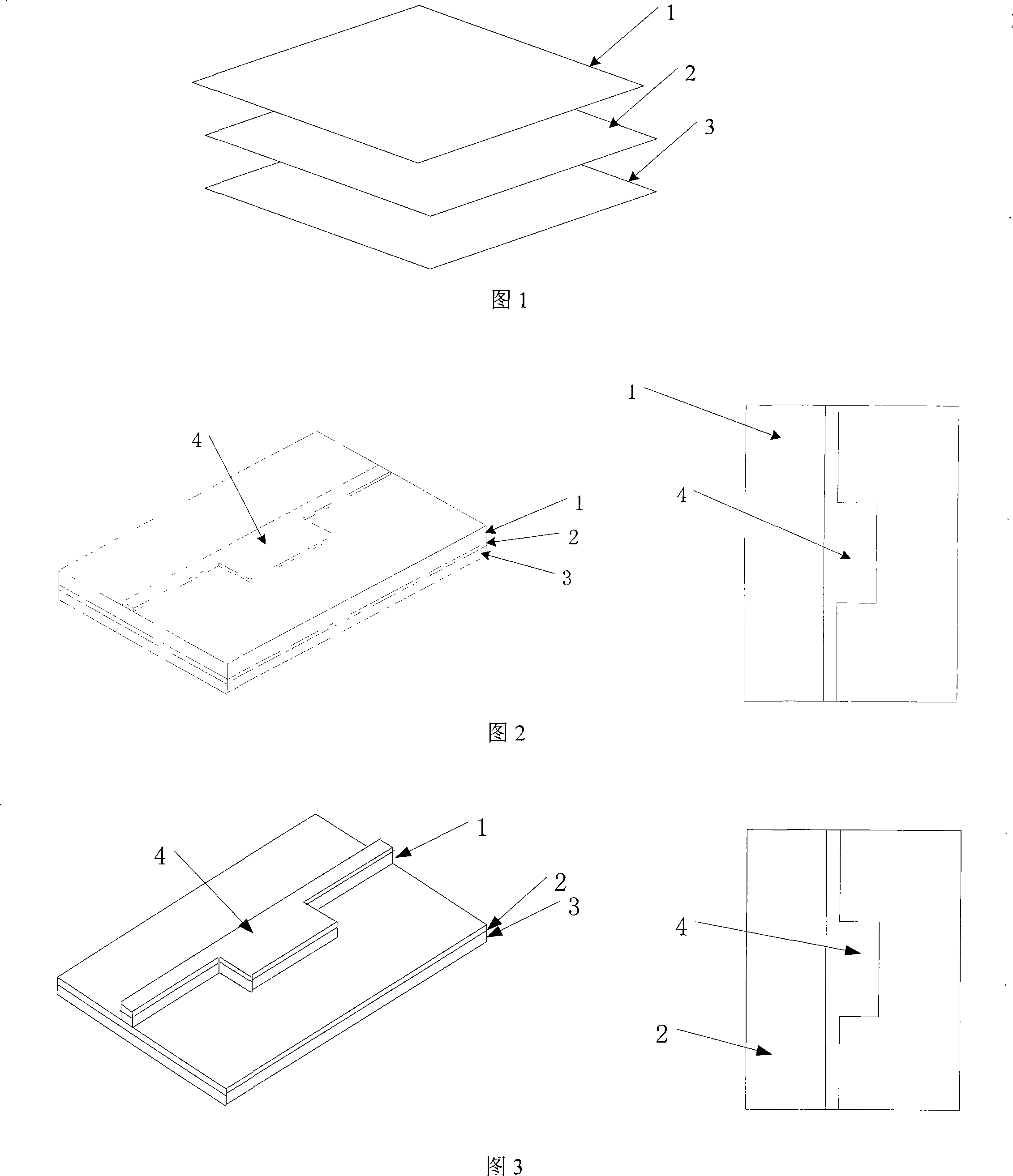

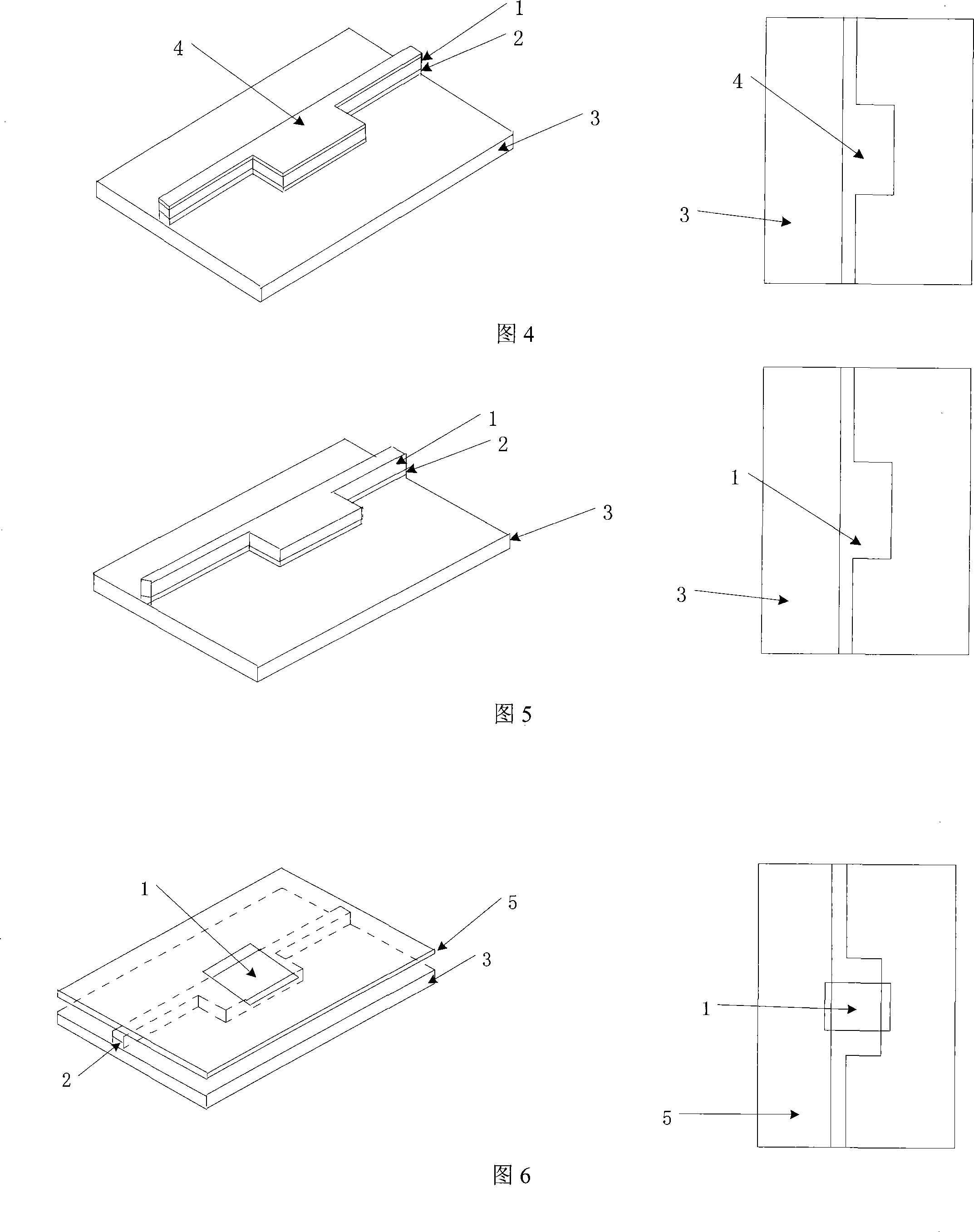

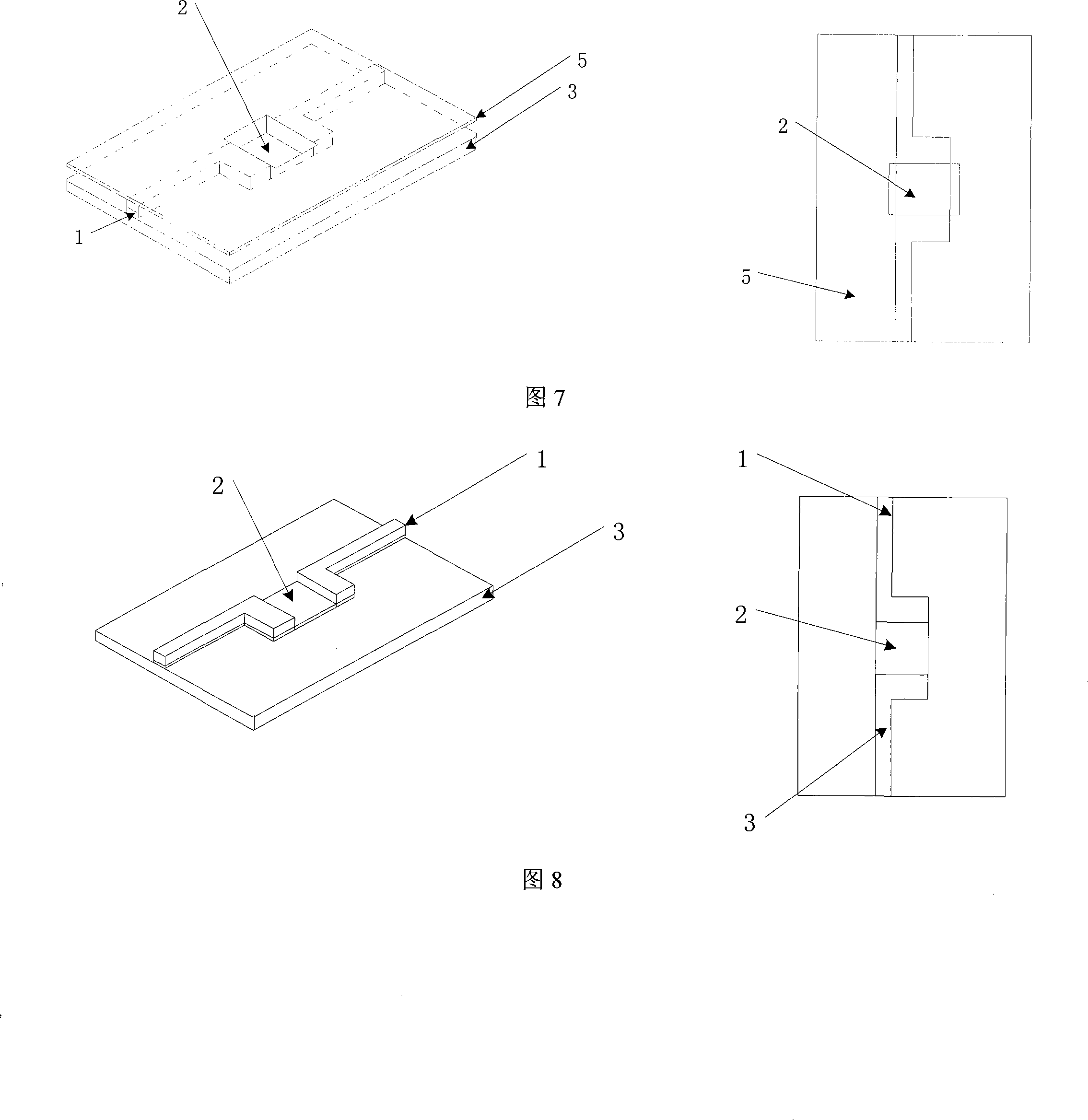

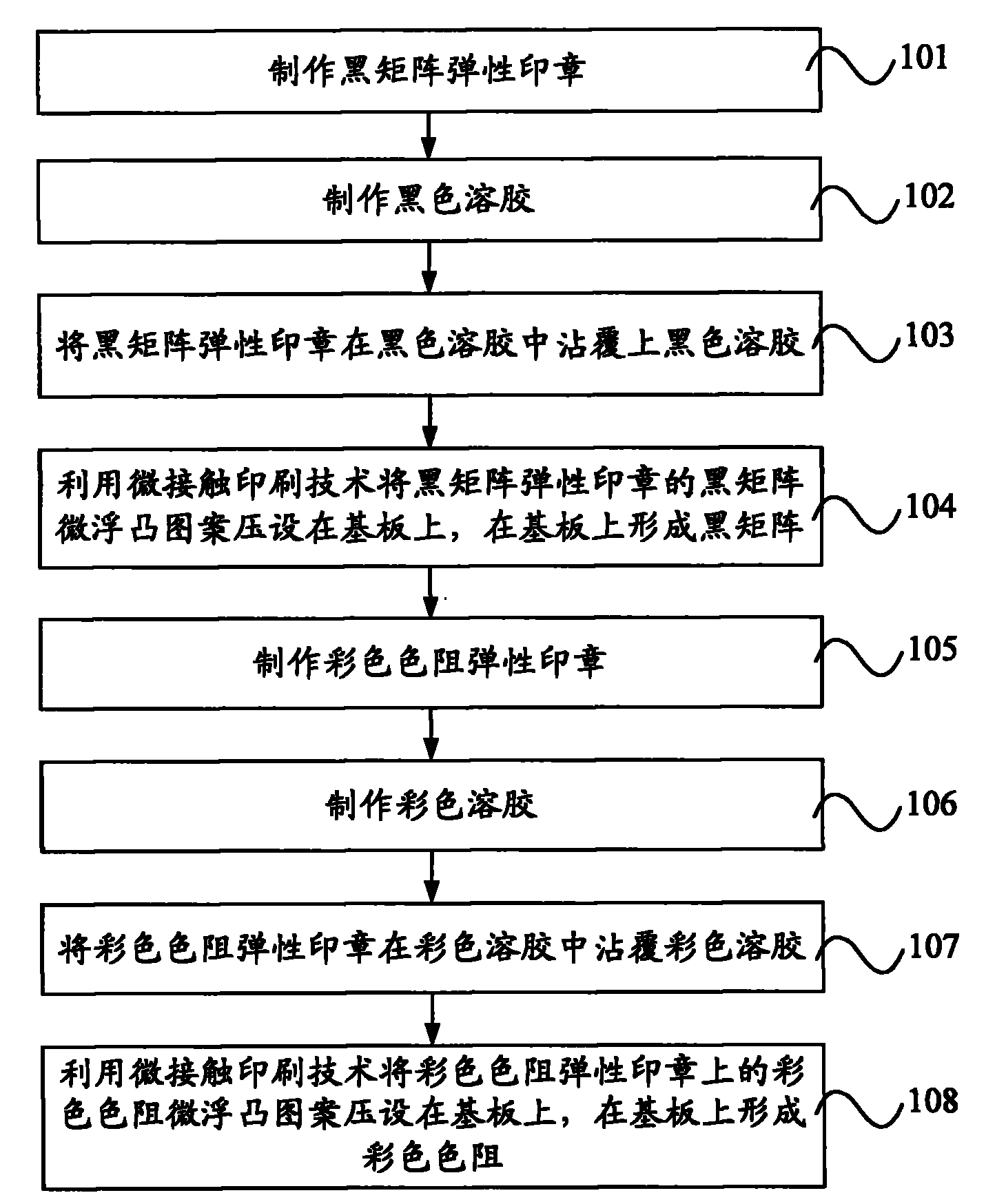

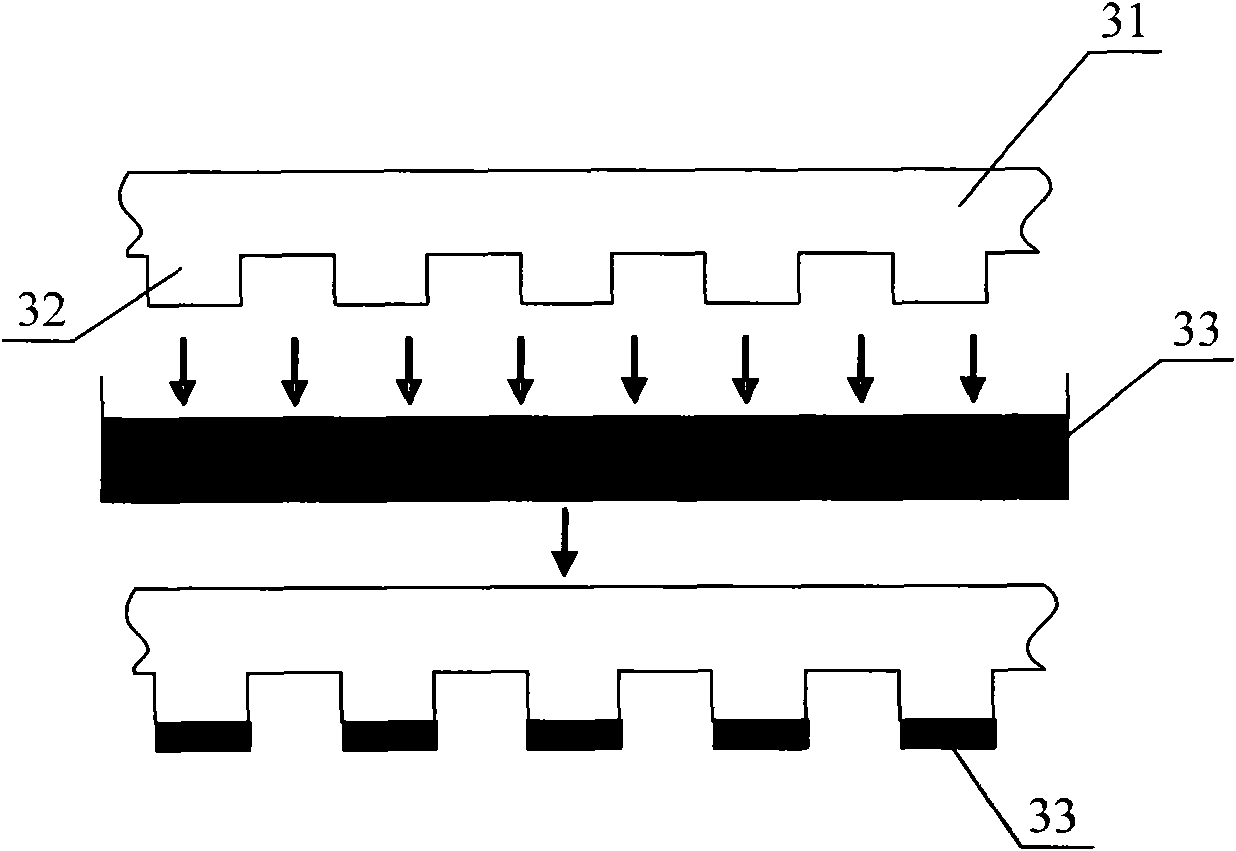

Color filter and manufacturing method thereof

InactiveCN102109759AClear boundariesThe process steps are simpleOptical filtersPhotomechanical apparatusEngineeringResistance pattern

The invention provides a color filter and a manufacturing method thereof. The manufacturing method of the color filter comprises the following steps: pressing a black matrix micro embossed pattern on a black matrix elastic stamp onto a substrate, and transferring the black sol on the black matrix micro embossed pattern onto the substrate to form a black matrix; pressing a color resistance micro embossed pattern on a color resistance elastic stamp onto the black matrix substrate, and transferring the color sol on the color resistance micro embossed pattern onto the substrate to form a color resistance. According to the color filter and the manufacturing method thereof of the invention embodiment, a black matrix elastic stamp and a color resistance elastic stamp are used respectively to form a black matrix and a color resistance on a substrate, which substitutes the gluing, exposure and developing process in the prior art, solves the problem in the prior art that color filters have low manufacture efficiency and high cost, simplifies process steps, and reduces cost; and the boundary of the color resistance pattern in the obtained color filter is clear, and the precision is increased.

Owner:BOE TECH GRP CO LTD +1

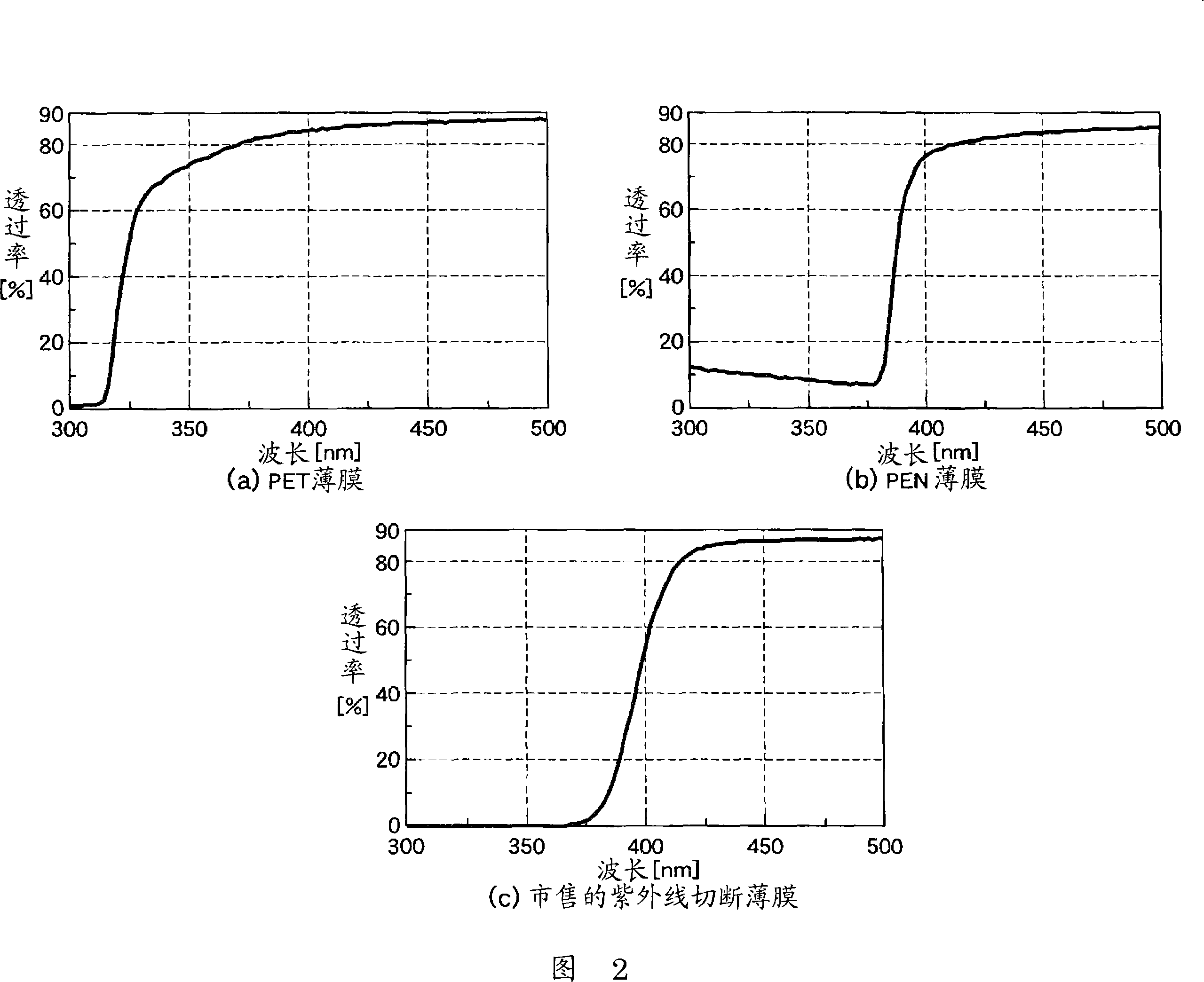

Optical tool and method for forming soldering-resistant pattern

ActiveCN101183212AWith thick filmPhotomechanical exposure apparatusMicrolithography exposure apparatusSolder maskResistance pattern

The invention provides an exposure processing technique for a solder mask, which can form a corrosion resistance pattern with good reproducibility and high resolution without being influenced by the thickness of the solder mask and the blue paints. The invention provides an exposure processing technique for a solder mask during the pattern forming process, wherein, a film or an optical tool having the film is used for cutting 50% of lights below 370nm and permeating 80% of lights above 400nm.

Owner:TAIYO INK MFG CO LTD

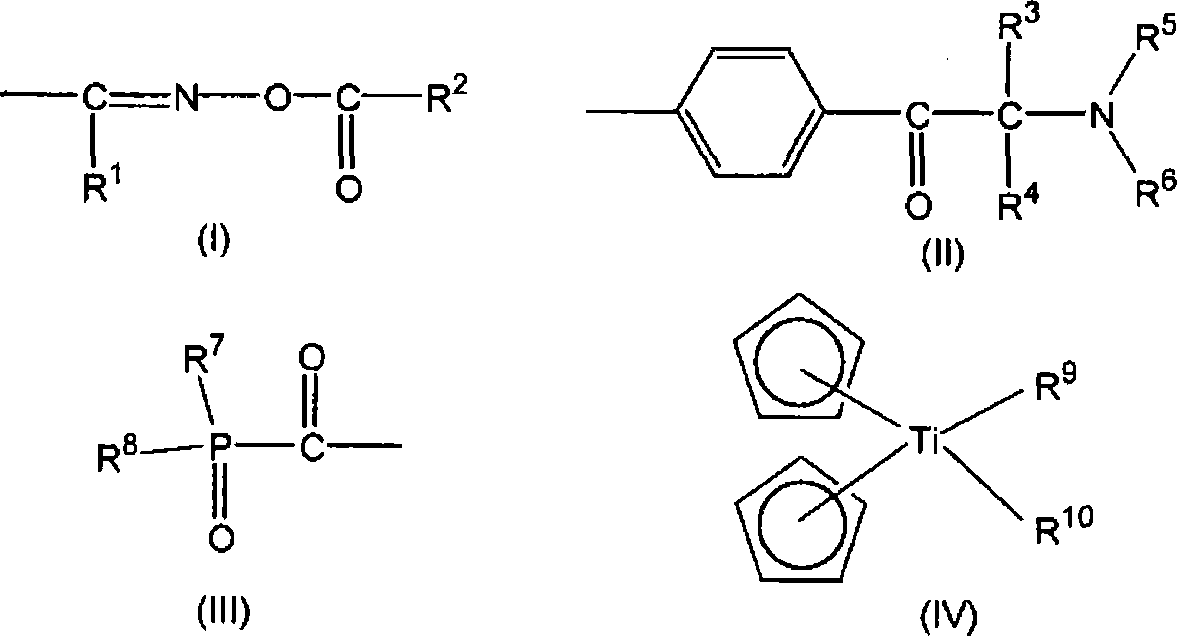

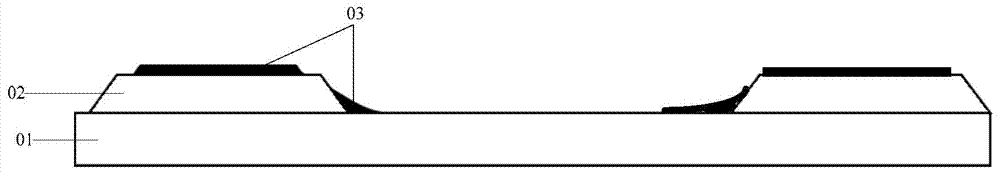

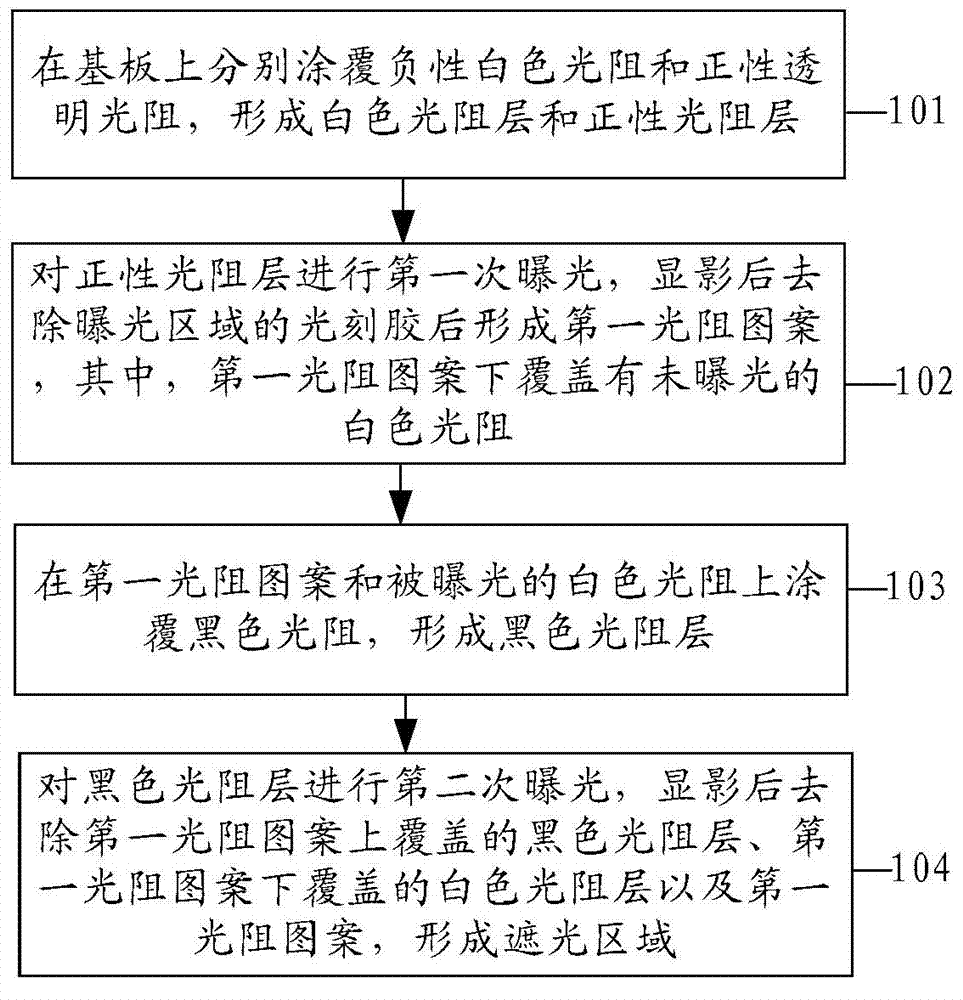

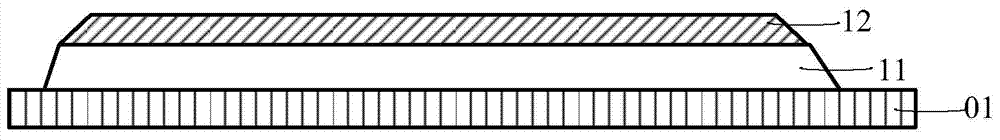

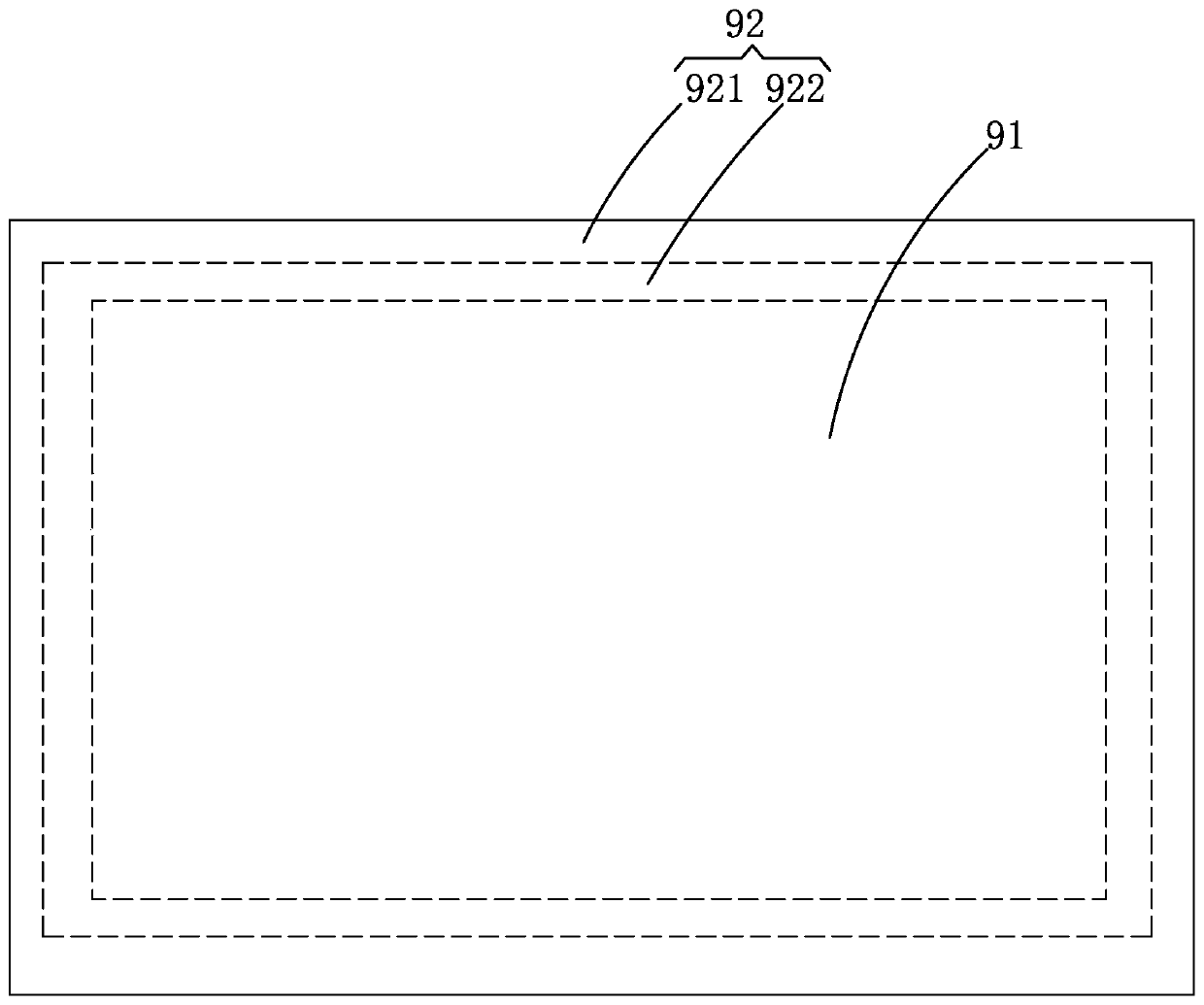

Semi-transparent and semi-covered panel, touch panel and manufacturing methods of semi-transparent and semi-covered panel and touch panel as well as display device

ActiveCN104849958AThere will be no problem that is difficult to develop and removeReduce exposurePhotomechanical apparatusInput/output processes for data processingDisplay deviceSingle exposure

The embodiment of the invention provides a semi-transparent and semi-covered panel, a touch panel and manufacturing methods of the semi-transparent and semi-covered panel and the touch panel as well as a display device, and relates to the technical field of display, aiming at solving the problem that the color of a white touch panel is not uniform. The manufacturing method of the semi-transparent and semi-covered panel comprises the steps of enabling a substrate to be respectively coated with a negative white light resistance and a positive transparent light resistance to form a white light resistance layer and a positive light resistance layer; exposing the positive light resistance layer for the first time, developing, and then removing photoresist at the exposure range to form a first light resistance pattern, wherein an unexposed white light resistance is covered by the first light resistance pattern; enabling the first light resistance pattern and the exposed white light resistance to be coated with a black light resistance to form a black light resistance layer; exposing the black light resistance layer for a second time, developing, and then removing the black light resistance layer covering the first light resistance pattern, the white light resistance layer covered by the first light resistance pattern, and the first light resistance pattern to form a shading area. The method can be applied to the manufacturing process of the touch panel.

Owner:BOE TECH GRP CO LTD

Array substrate and manufacturing method thereof

InactiveCN110174803AReduced levelingReduce height differenceNon-linear opticsLiquid-crystal displayHeight difference

The invention provides an array substrate and a manufacturing method thereof. The array substrate comprises a display area and a peripheral area located at the outer side of the display area; the array substrate comprises an edge color resistance pattern arranged in the peripheral area and an edge spacer arranged above the edge color resistance pattern; the edge color resistance pattern comprisesa block portion and a retaining wall located at the outer side of the block portion, so that when a spacer material layer used for manufacturing a main spacer and the edge spacer is formed above a display area color resistance pattern and the edge color resistance pattern of the display area, the levelling property of the part, above the edge color resistance pattern, of the spacer material layeris greatly reduced, so that the height difference between the main spacer which is finally formed above the display area color resistance pattern and the edge spacer located above the edge color resistance pattern is reduced, and the display quality of a liquid crystal display panel can be improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Spinach hybrid 51-326

InactiveUS20130055455A1Microbiological testing/measurementFood preservationSpinaciaResistance pattern

The present invention relates to the development of a spinach plant that expresses a new resistance pattern against downy mildew (Peronospora farinosa f. sp. Spinaciae) strains Pf1-Pf13, methods and compositions relating to plants, progeny, seeds and derivatives thereof and plants, progeny, seeds and derivatives thereof having all the morphological, physiological and / or genetic characteristics thereof.

Owner:RIJK ZWAAN ZAADTEELT & ZAADHANDEL BV

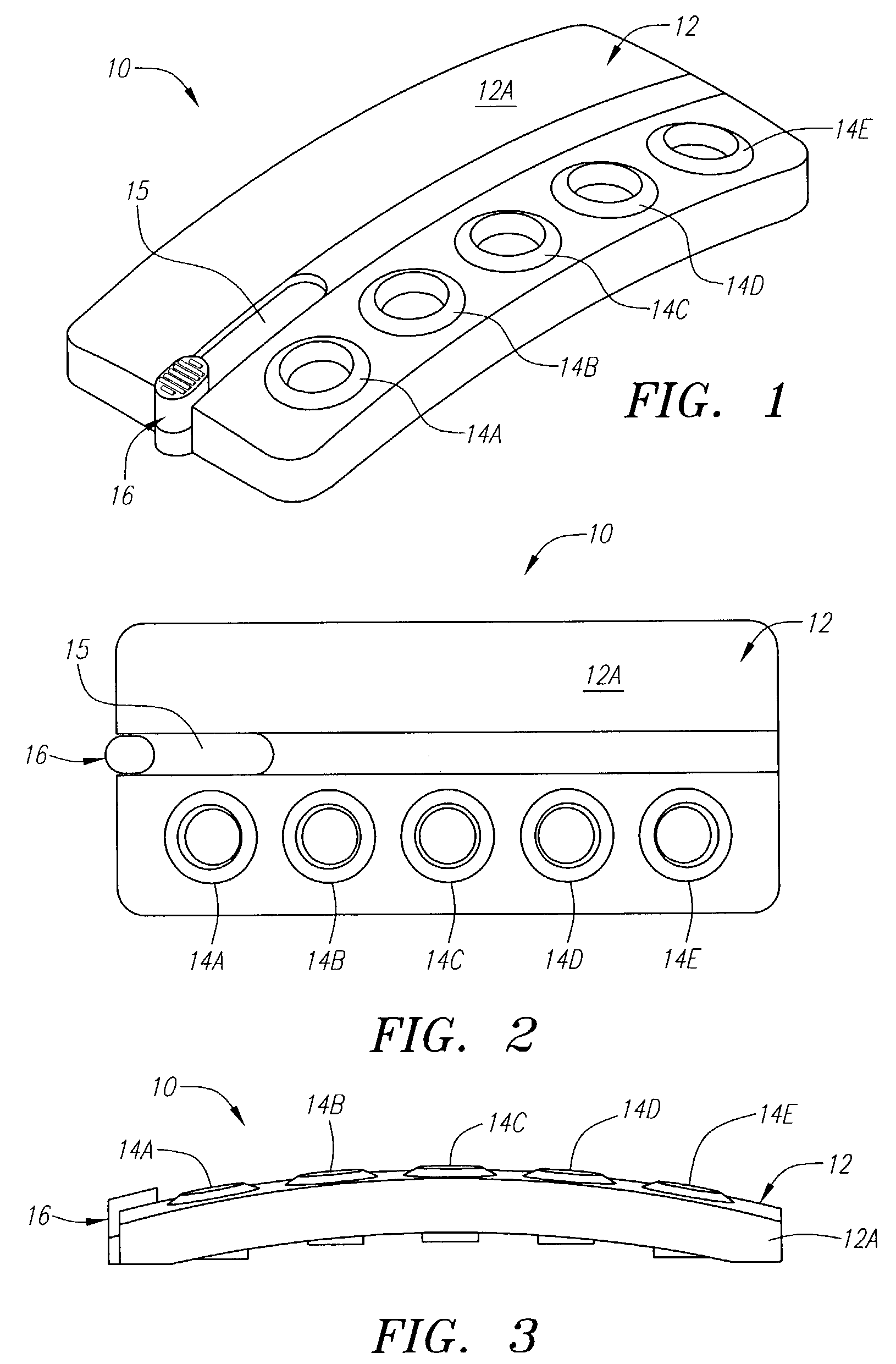

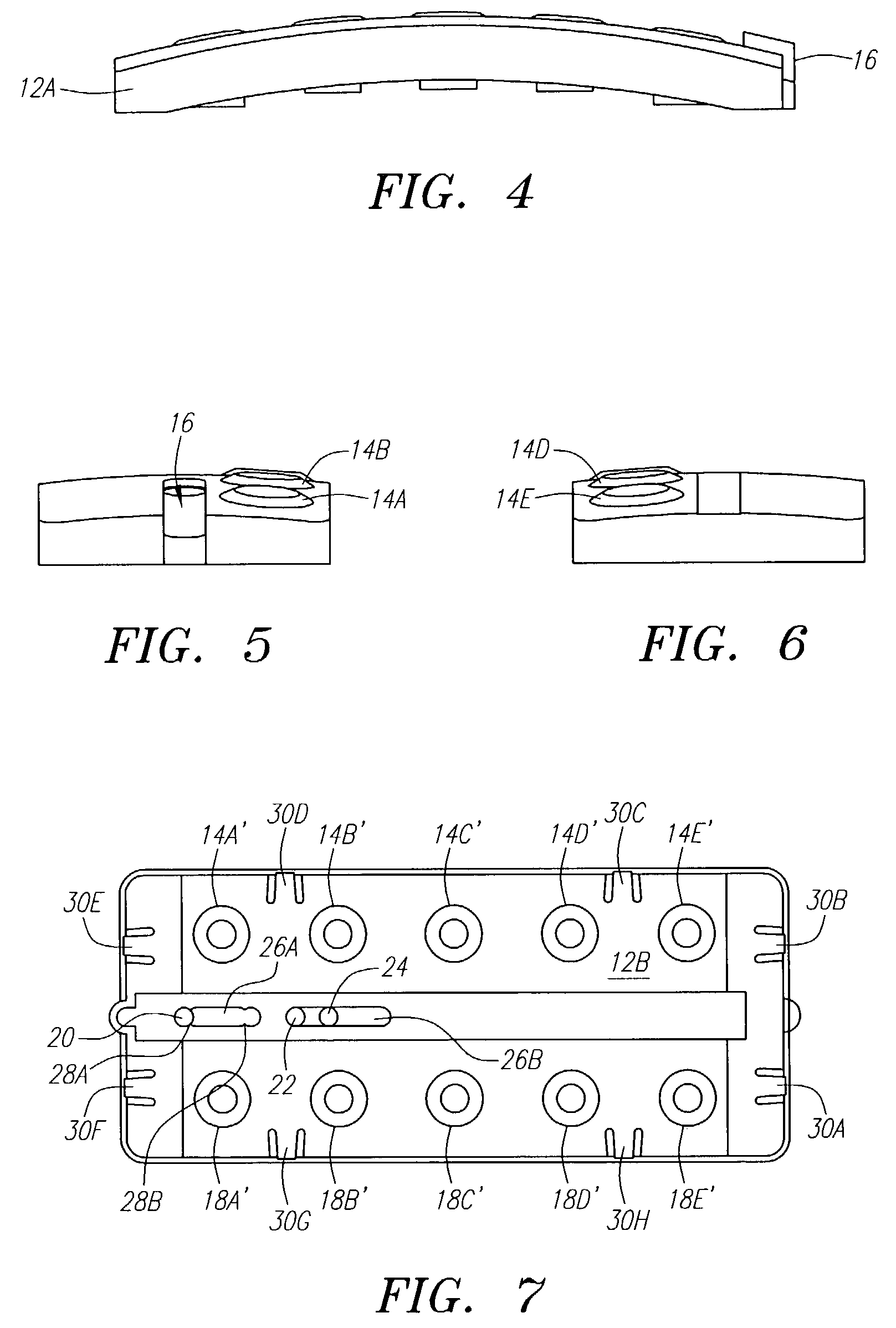

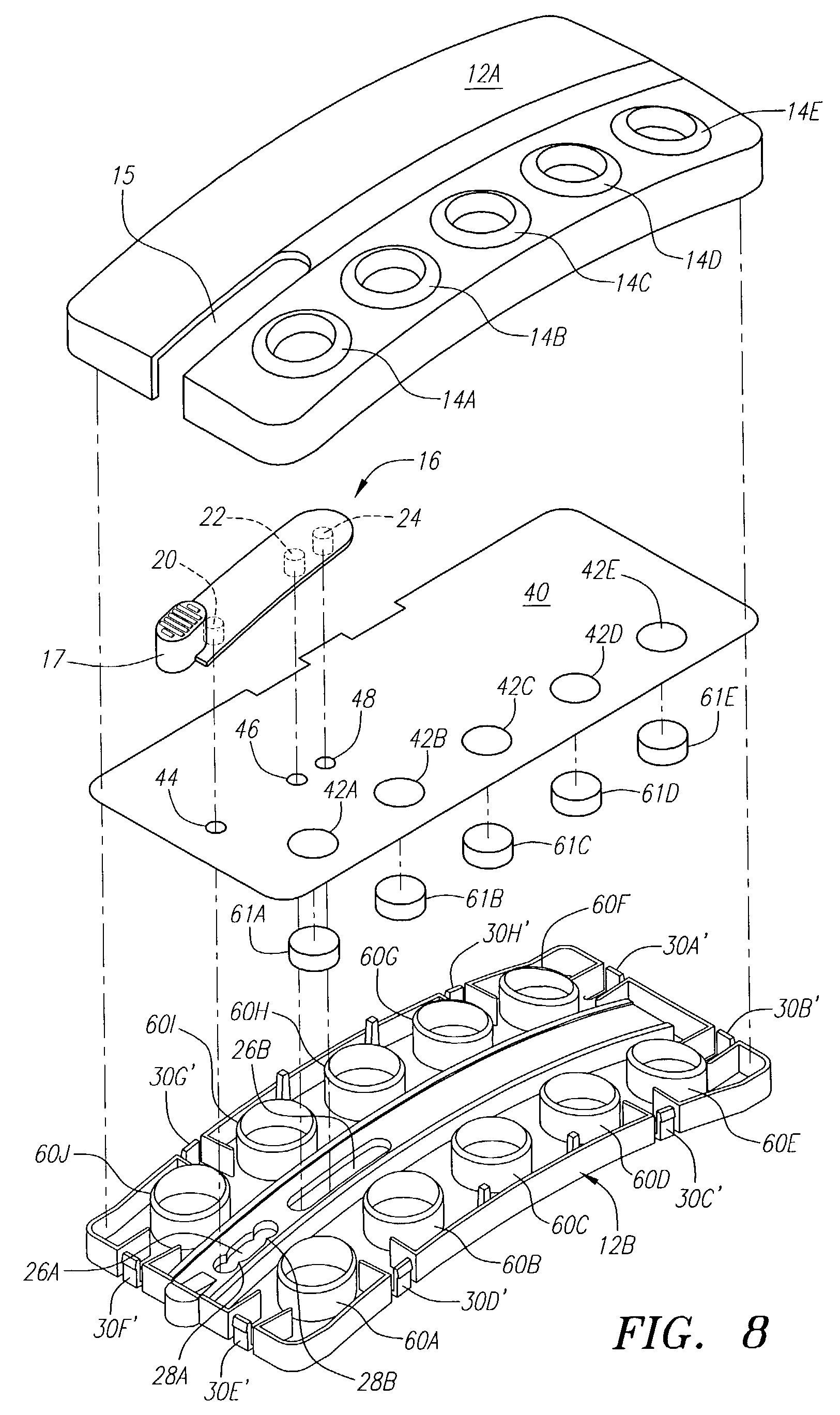

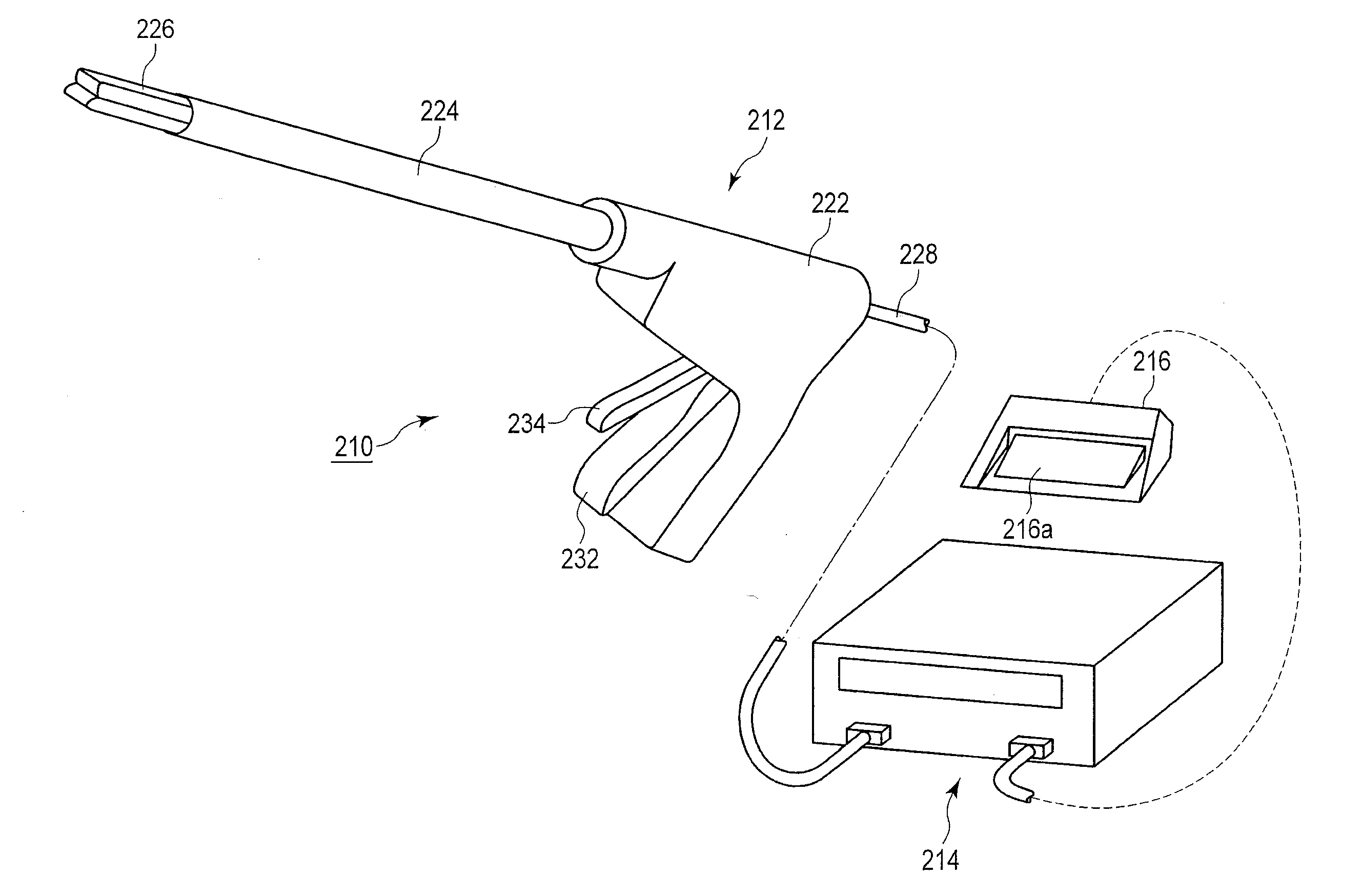

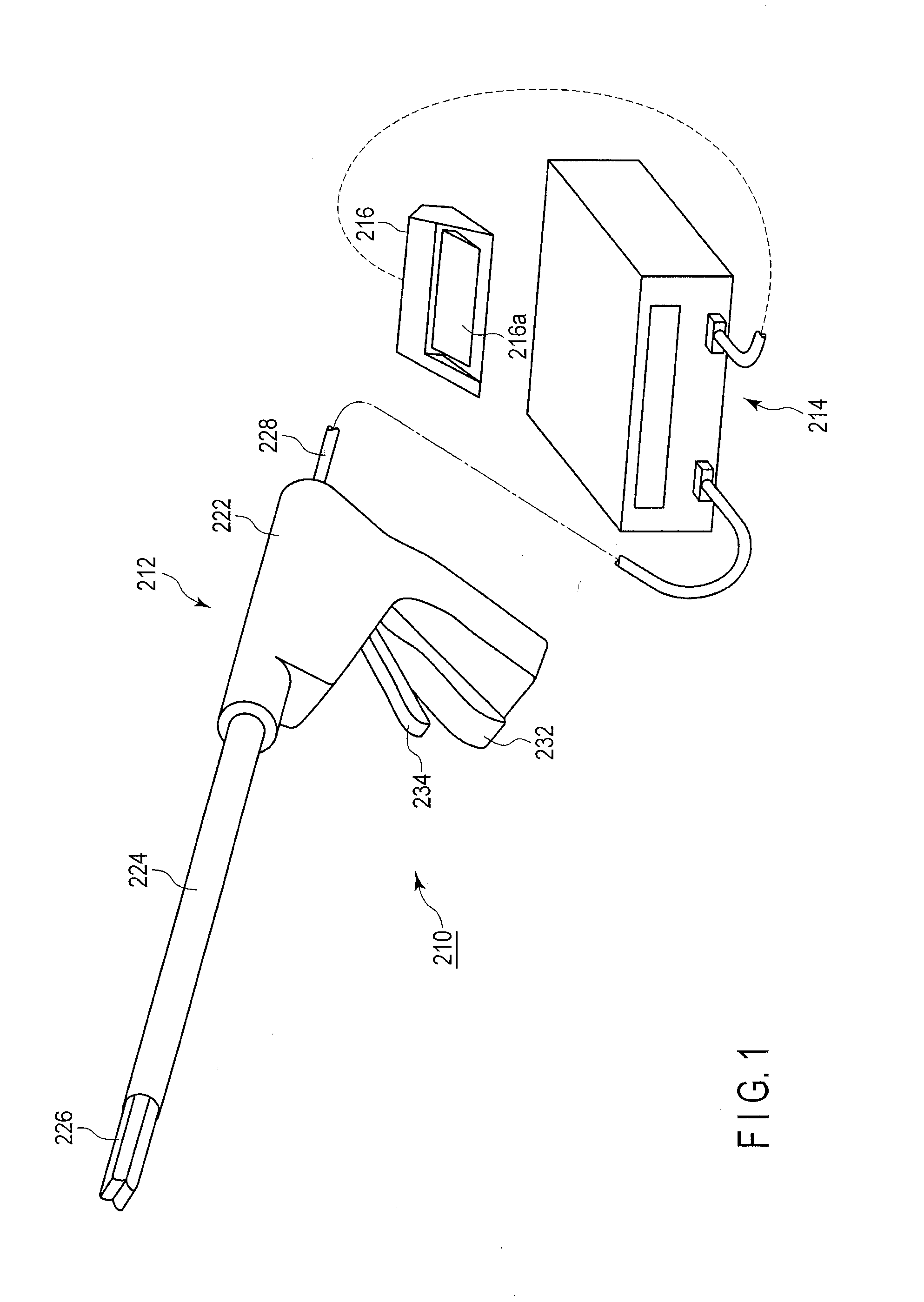

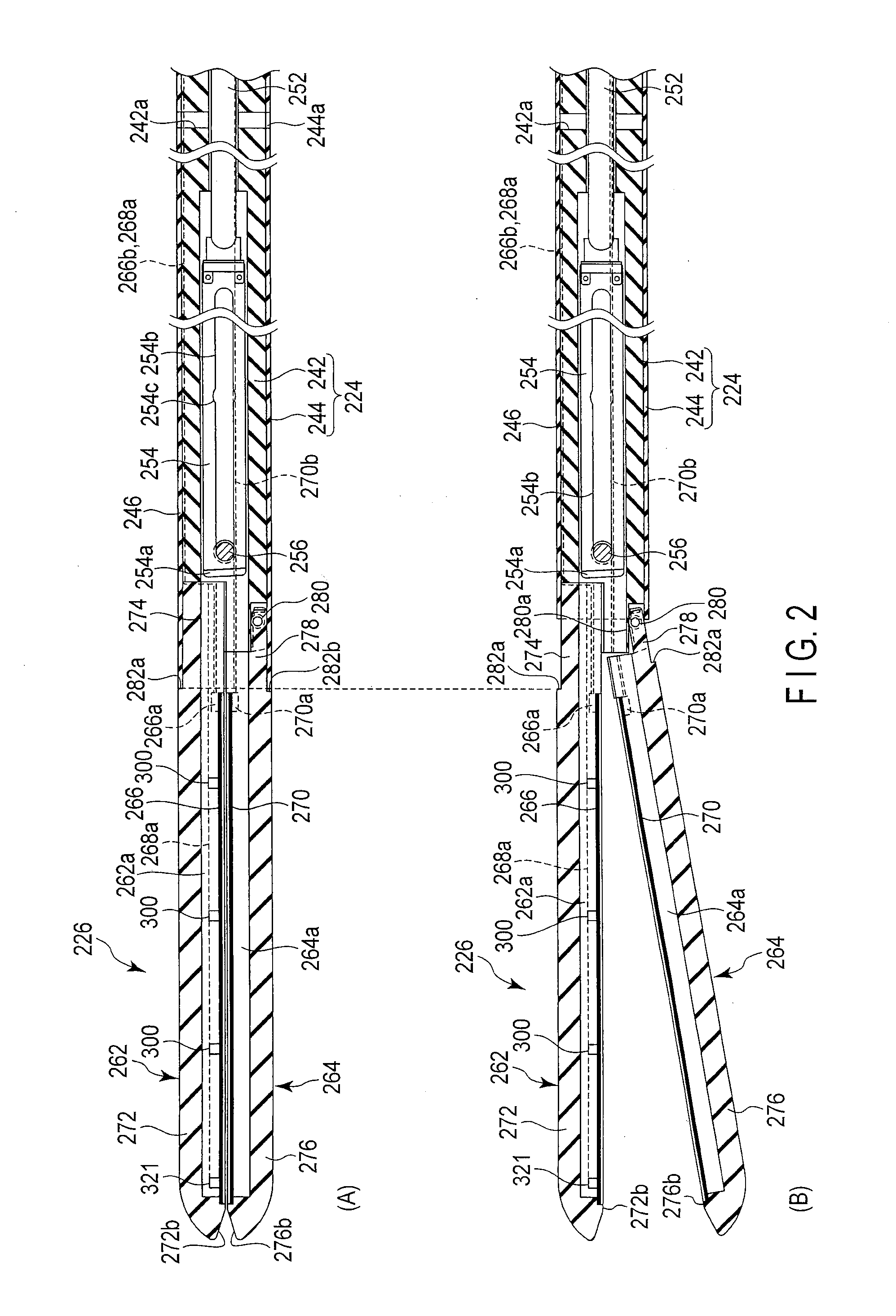

Surgical treatment system

ActiveUS20130150848A1Surgical instruments for heatingSurgical forcepsElectrical resistance and conductanceSurgical treatment

A surgical treatment system include a pair of holding members holding a living tissue and a plurality of heater members disposed on at least one of the holding members. The surgical treatment system further includes a resistance pattern which transfer heat to the living tissue, a pair of electrodes disposed at opposite ends of the resistance pattern to generate the heat based on a energy to supply the heat to the resistance pattern, wires each connecting one of the heater members to another heater member and heater member energization line connected to the wire and to a energy source to supply the energy from the energy source to the electrodes via the wire.

Owner:OLYMPUS CORP

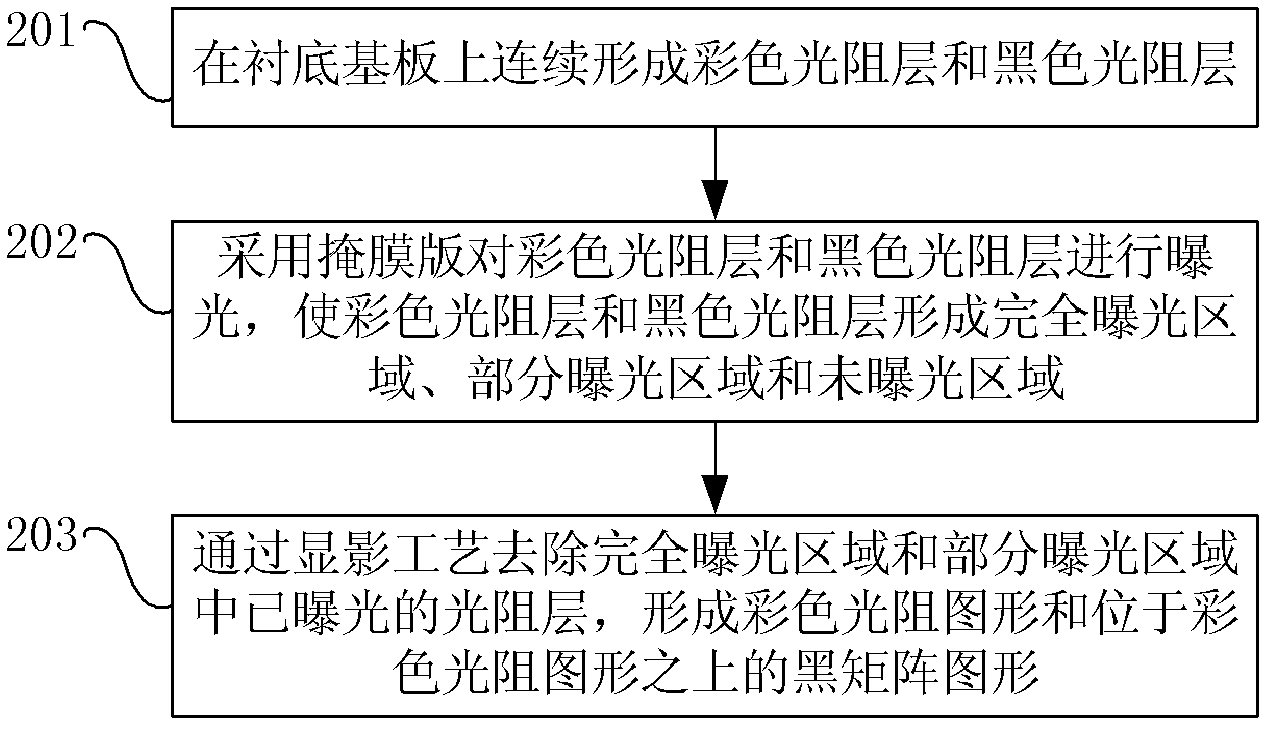

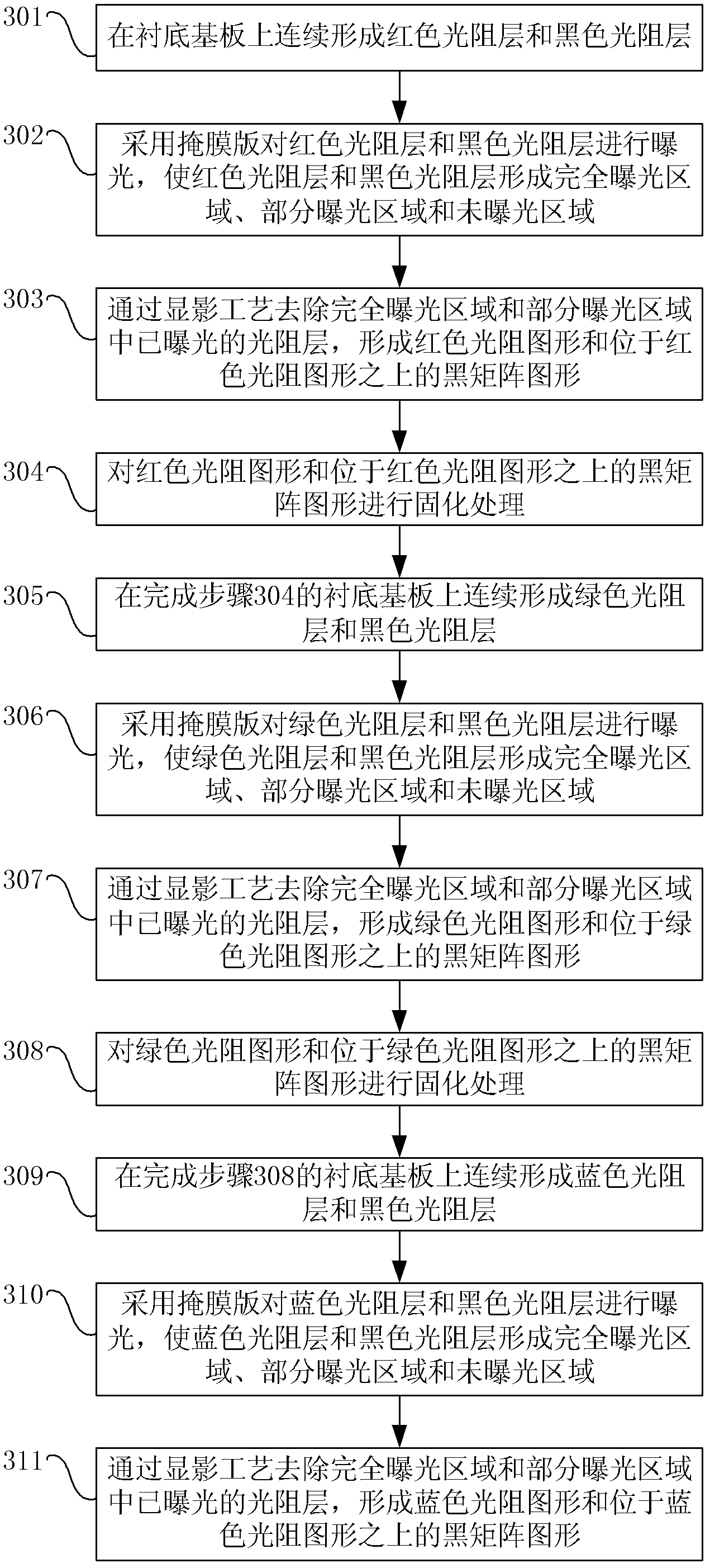

Manufacture method of color film base plate

ActiveCN102645783AReduce manufacturing costOptical filtersPhotomechanical exposure apparatusColor filmOptoelectronics

The invention discloses a manufacture method of a color film base plate. The method comprises the following steps that a color light resistance pattern and a black matrix pattern are formed on a substrate base plate and are synchronously formed. According to the manufacture method of the color film base plate provided by the invention, the color light resistance pattern and the black matrix pattern are formed on the substrate base plate and are synchronously formed, so the black matrix pattern and color light resistance pattern forming process can be completed through sharing a production line, and expensive production equipment does not need to be singly configured for the black matrix pattern, so the production cost of the color film base plate is reduced.

Owner:BOE TECH GRP CO LTD +1

Color film substrate and manufacturing method thereof

ActiveCN105974643APrevent peelingIncrease contact areaNon-linear opticsOptical elementsColor filmEngineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com