Patents

Literature

79results about How to "Accurate flow measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

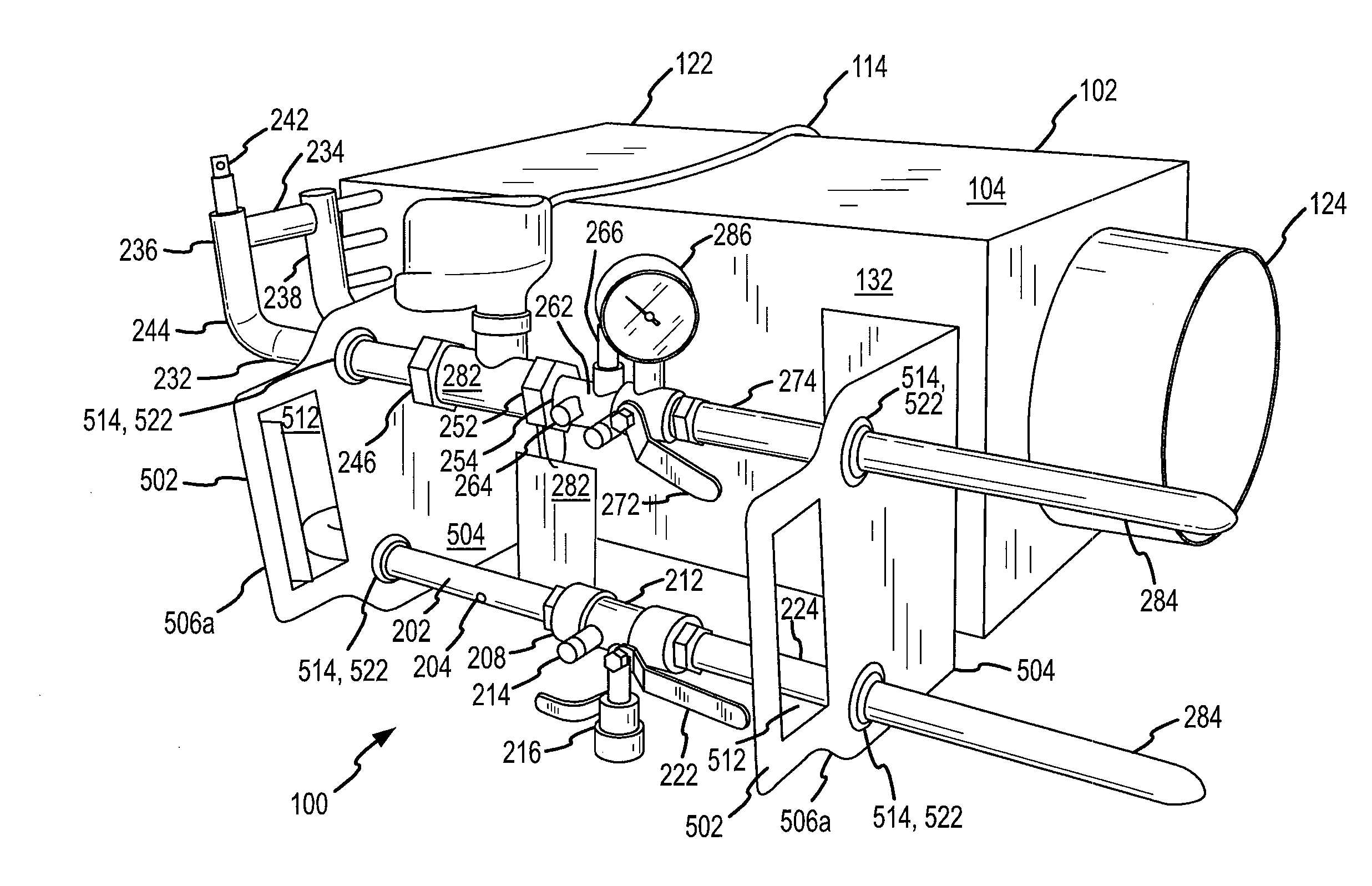

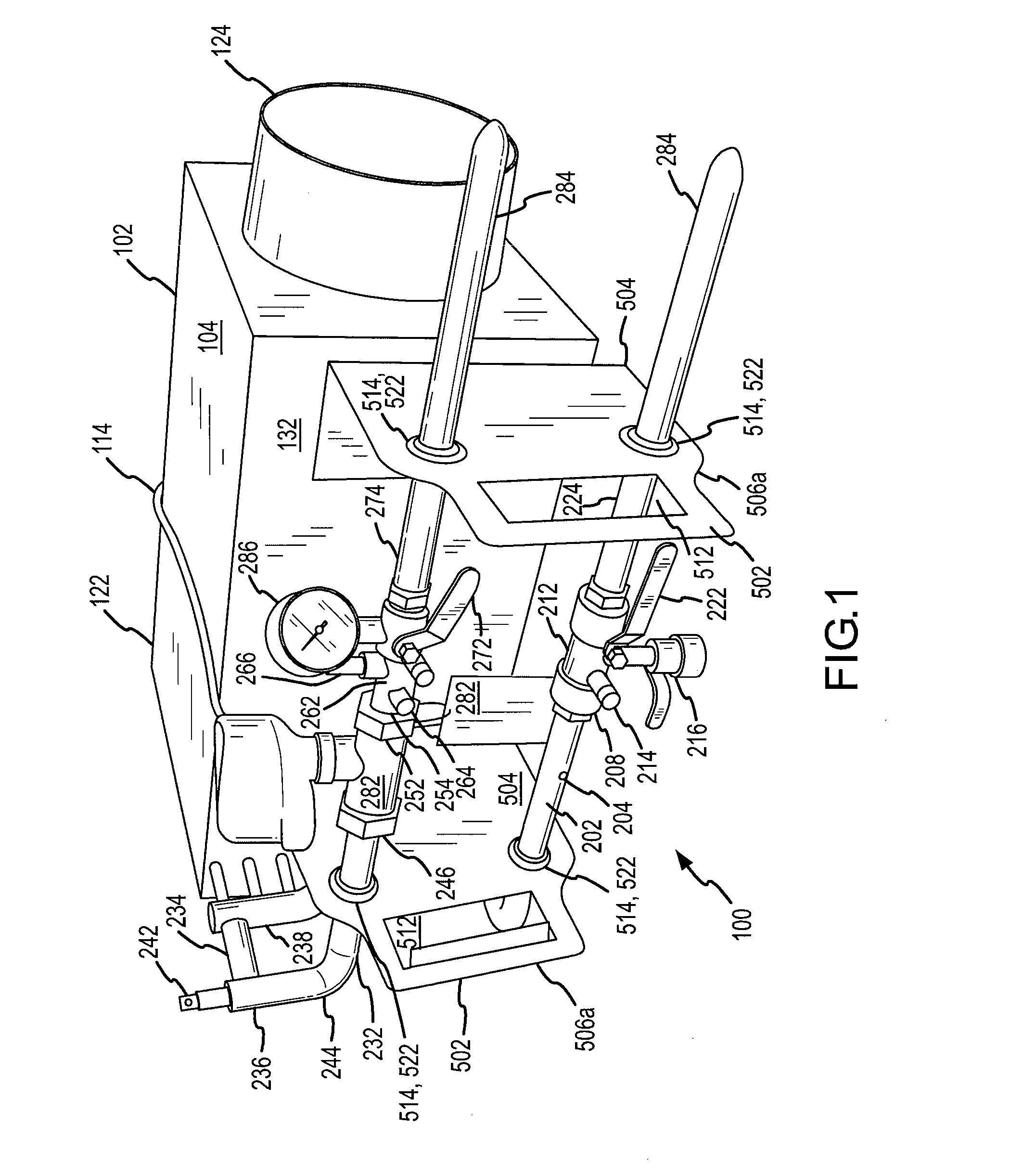

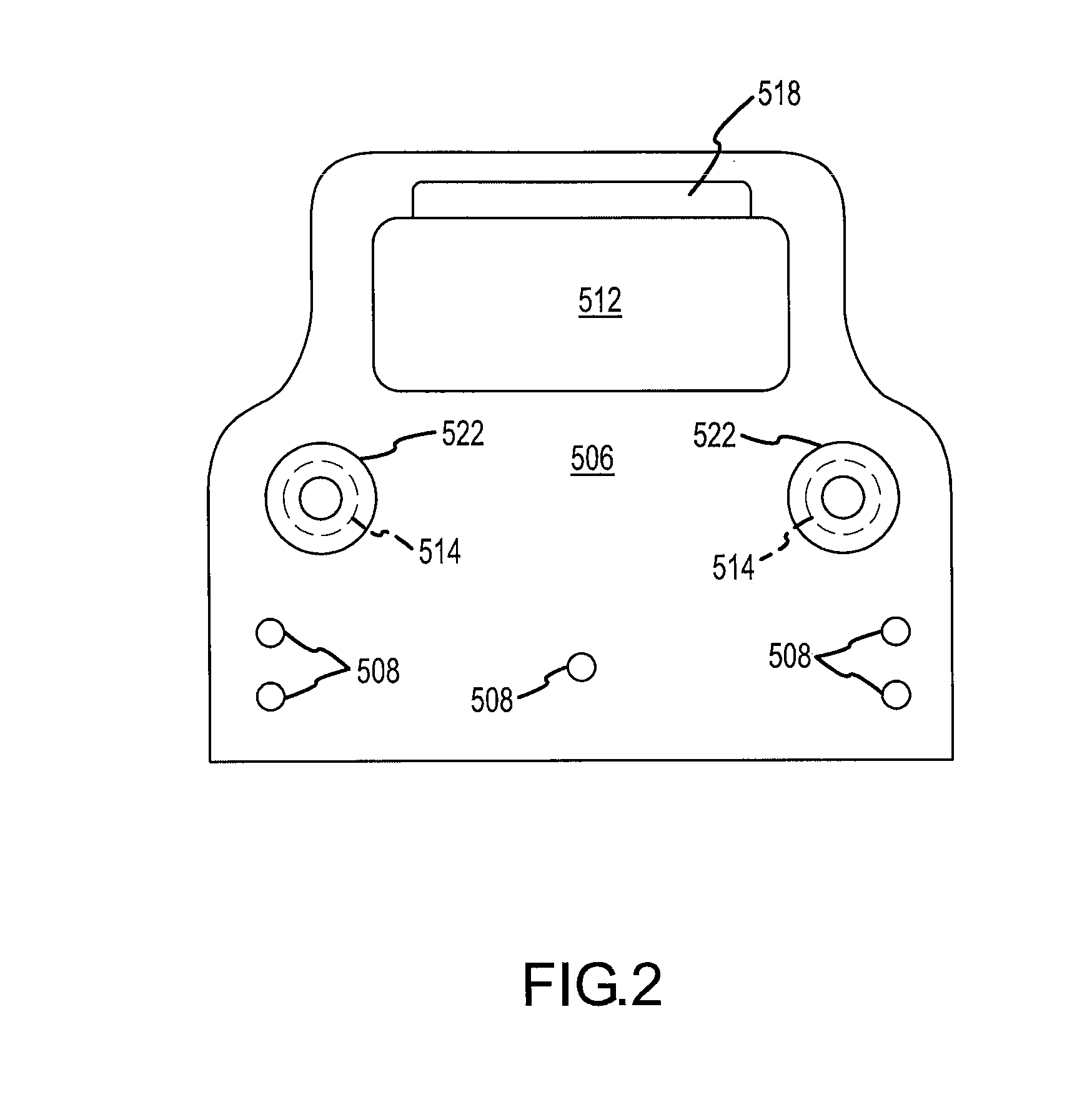

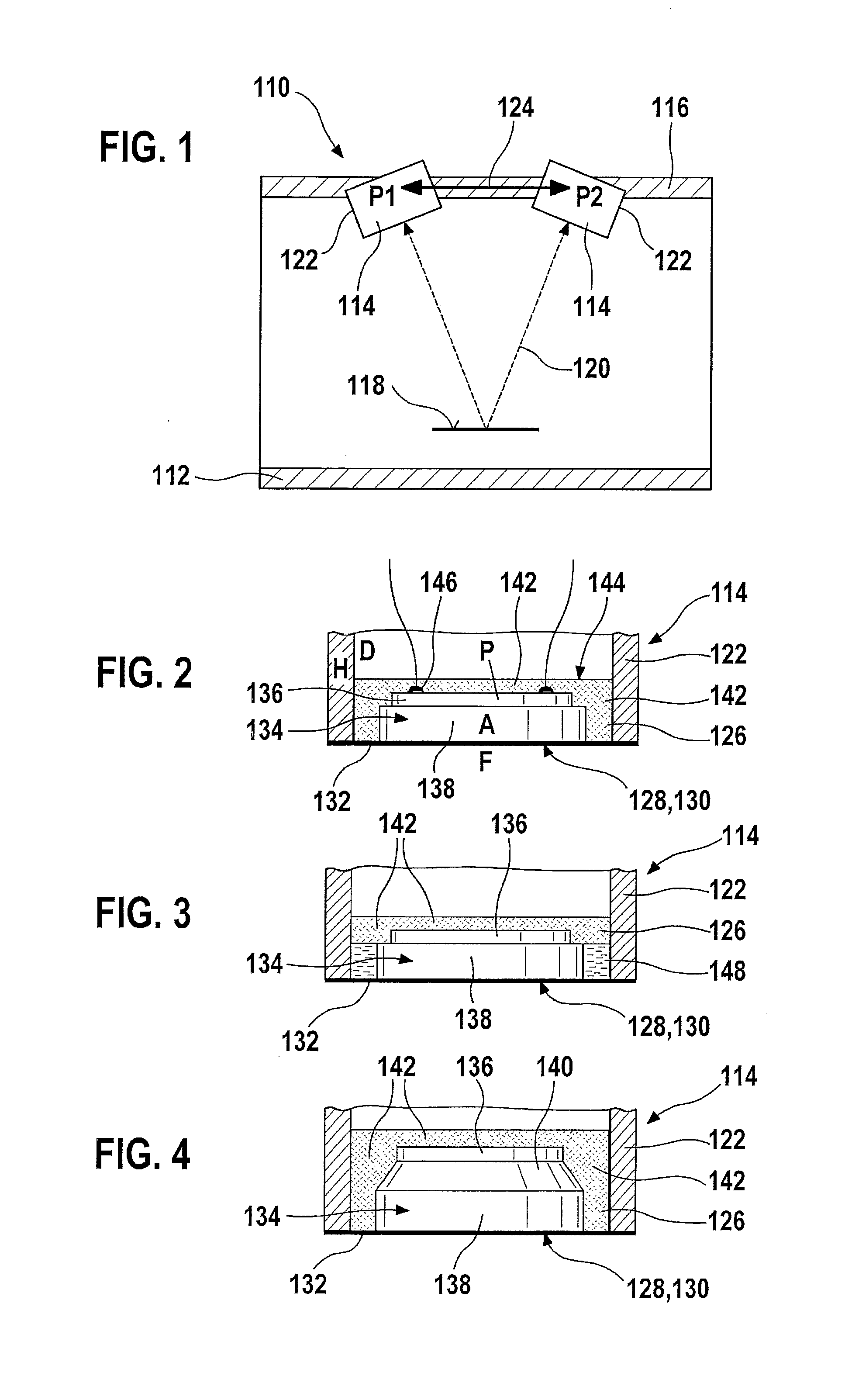

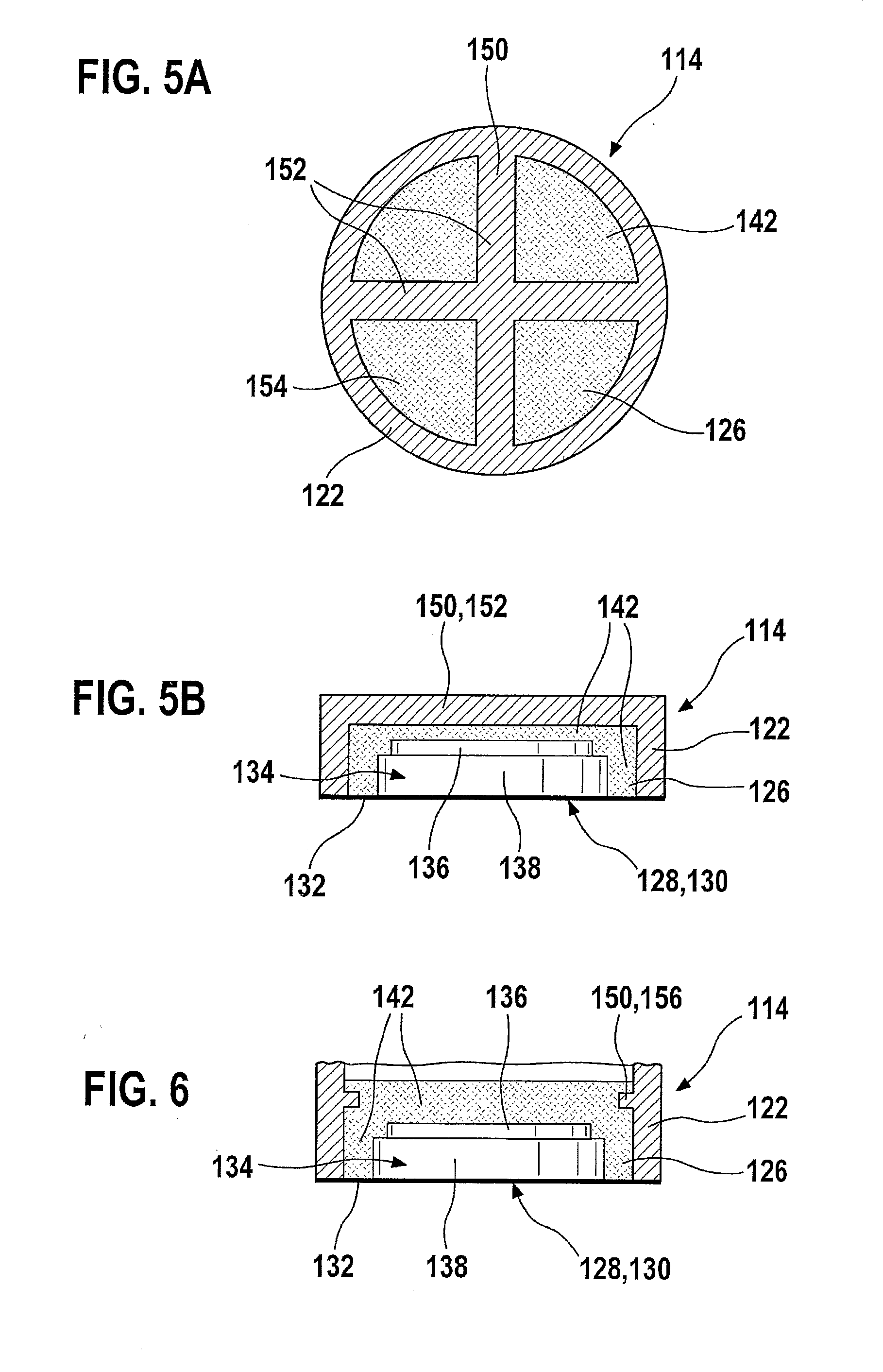

Limited loss laminar flow dampers for heating, ventilation, and air conditioning (HVAC) systems

InactiveUS20070262162A1Prevent pressureAvoid turbulenceMechanical apparatusSpace heating and ventilation safety systemsSnubberControl theory

HVAC devices, systems, and methods include dampers for controlling the flow of air or other gasses through an HVAC duct, often while inhibiting turbulence within the duct or pressure loss within the duct. Embodiments of such dampers may employ a two-part damper arrangement. In many embodiments, flow will travel through the middle of the damper uniformly and with a laminar flow. One or more small, relatively unobtrusive sensor (optionally being wireless) can be included for controlling operation of the damper, the sensor(s) optionally measuring the distance between damper elements, sound, air flow, or the like, with such sensor(s) / damper combination inhibiting inadvertent pressure drop and turbulence in flows through the damper. The damper elements may optionally comprise airfoil cross-sections, with alternative dampers having a resilient helical configuration that can choke down flow by inducing a vortex in the flow, allowing static pressure regain to occur within the duct system.

Owner:KARAMANOS JOHN C

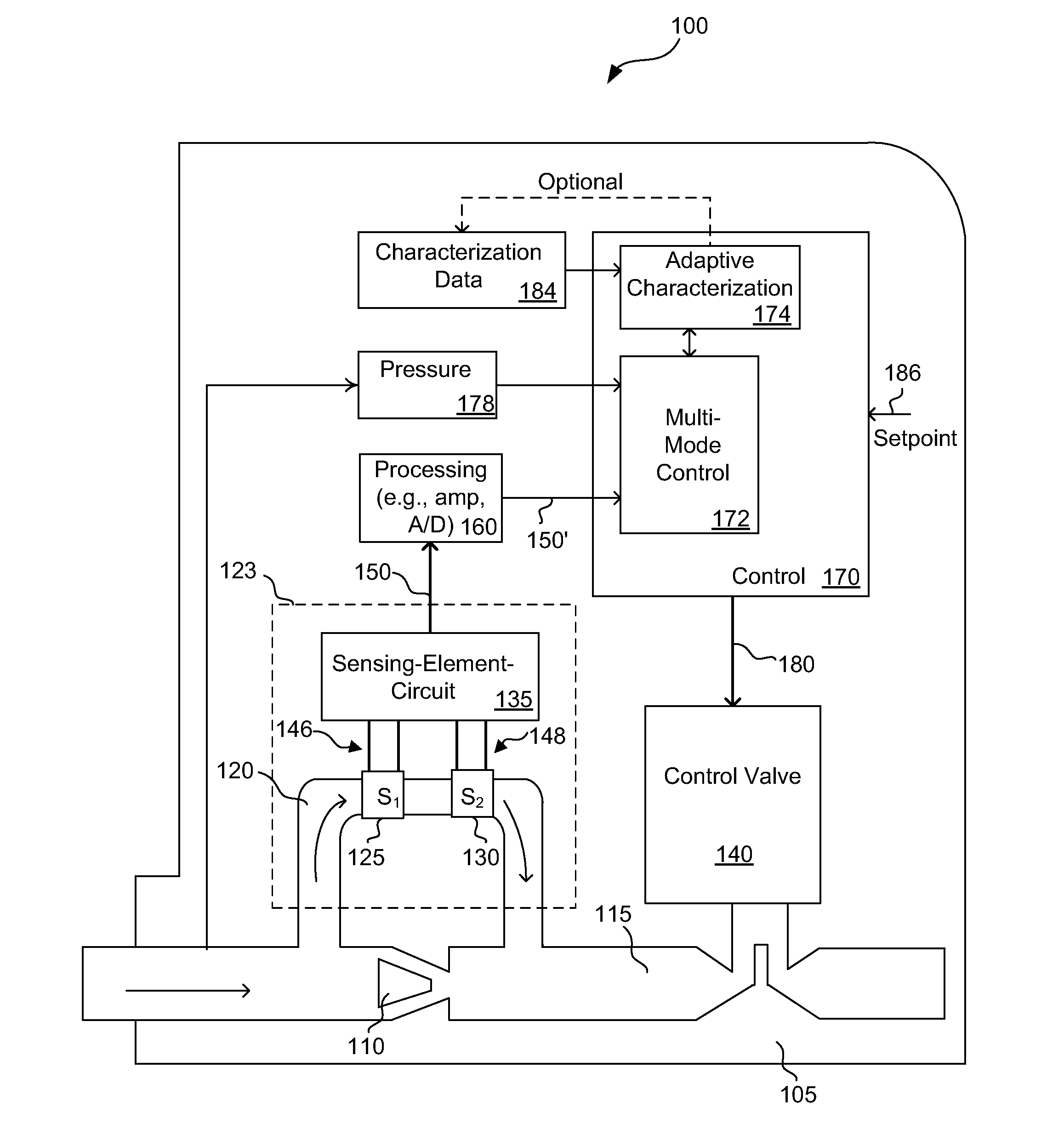

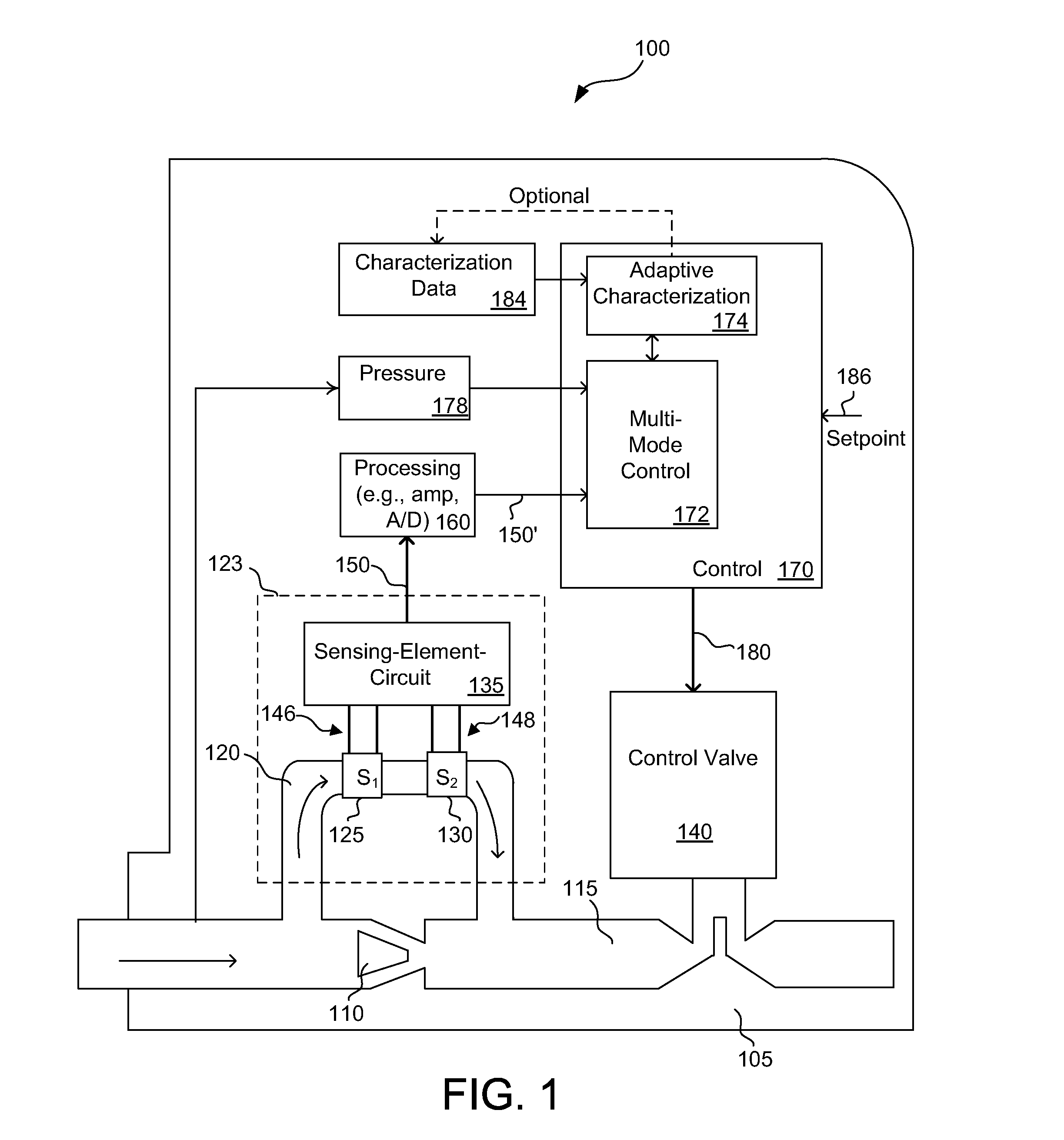

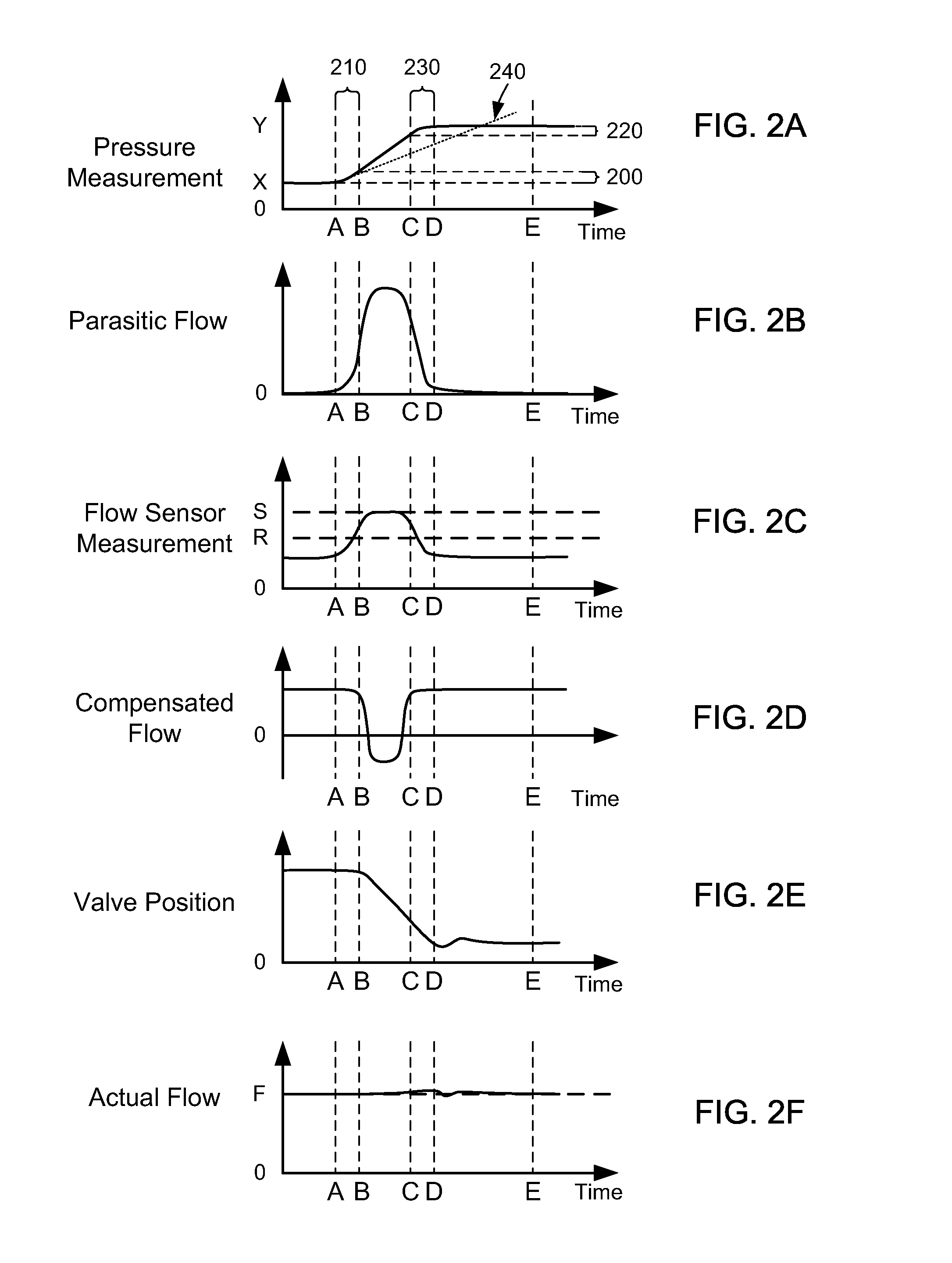

Adaptive Pressure Insensitive Mass Flow Controller and Method for Multi-Gas Applications

ActiveUS20130146148A1Improve accuracyAccurate flow measurementCheck valvesEqualizing valvesMode controlFeedback control

A system and method for controlling a flow of a fluid using a multi-mode control algorithm is described. The method includes disengaging and engaging a feedback control loop that controls a valve of the mass flow controller based upon a rate of pressure change of the fluid. The method also includes calculating a valve position of the valve based on pressure measurements when the feedback control loop has been disengaged and characterization data that characterizes the mass flow controller, and determining, when the feedback control loop is first re-engaged, a difference between a measured flow rate and a flow set point. An adjustment to the characterization data is applied based upon the difference to improve an accuracy of the calculation of the valve position when the feedback control loop is disengaged again.

Owner:HITACHI METALS LTD

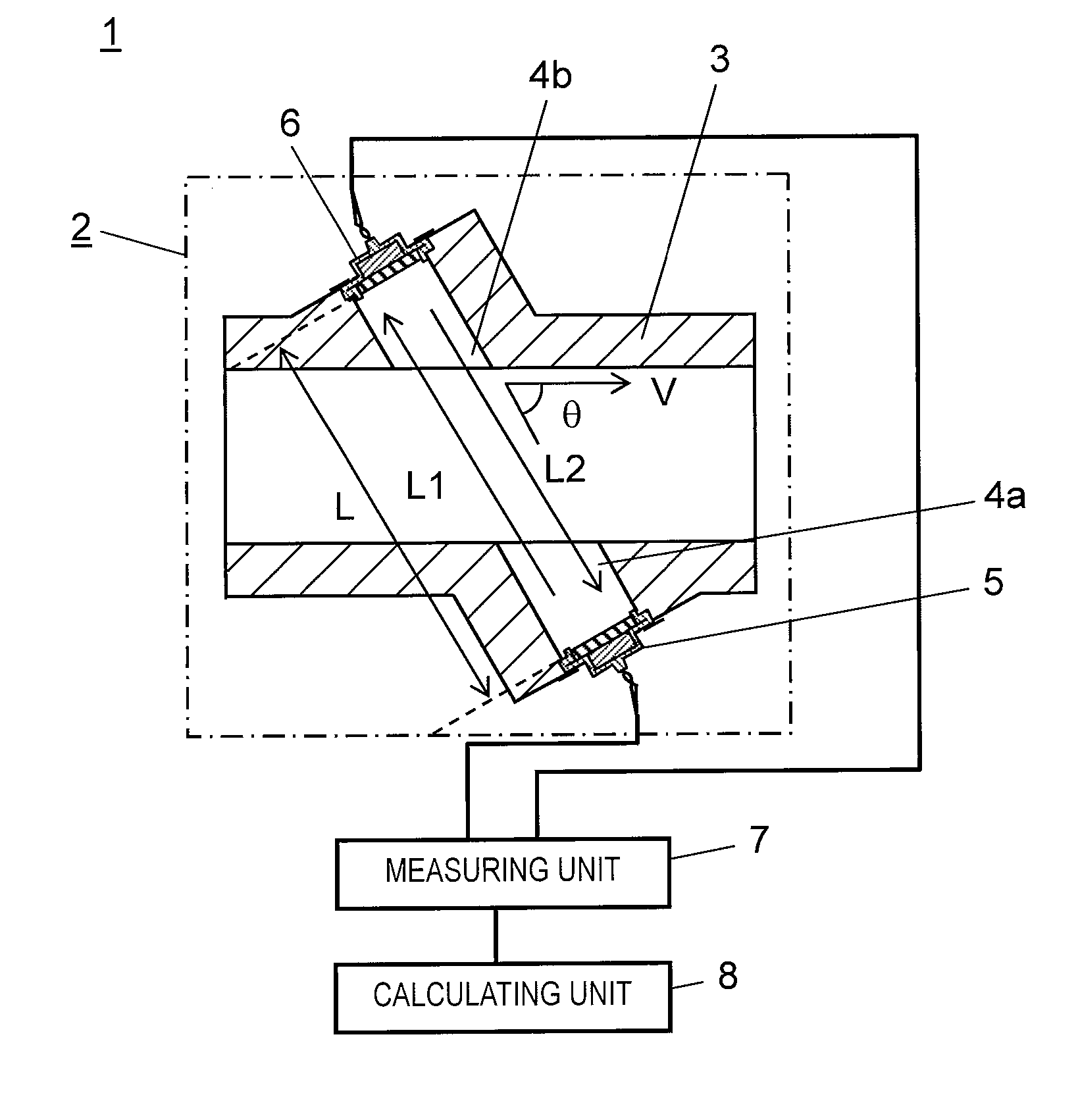

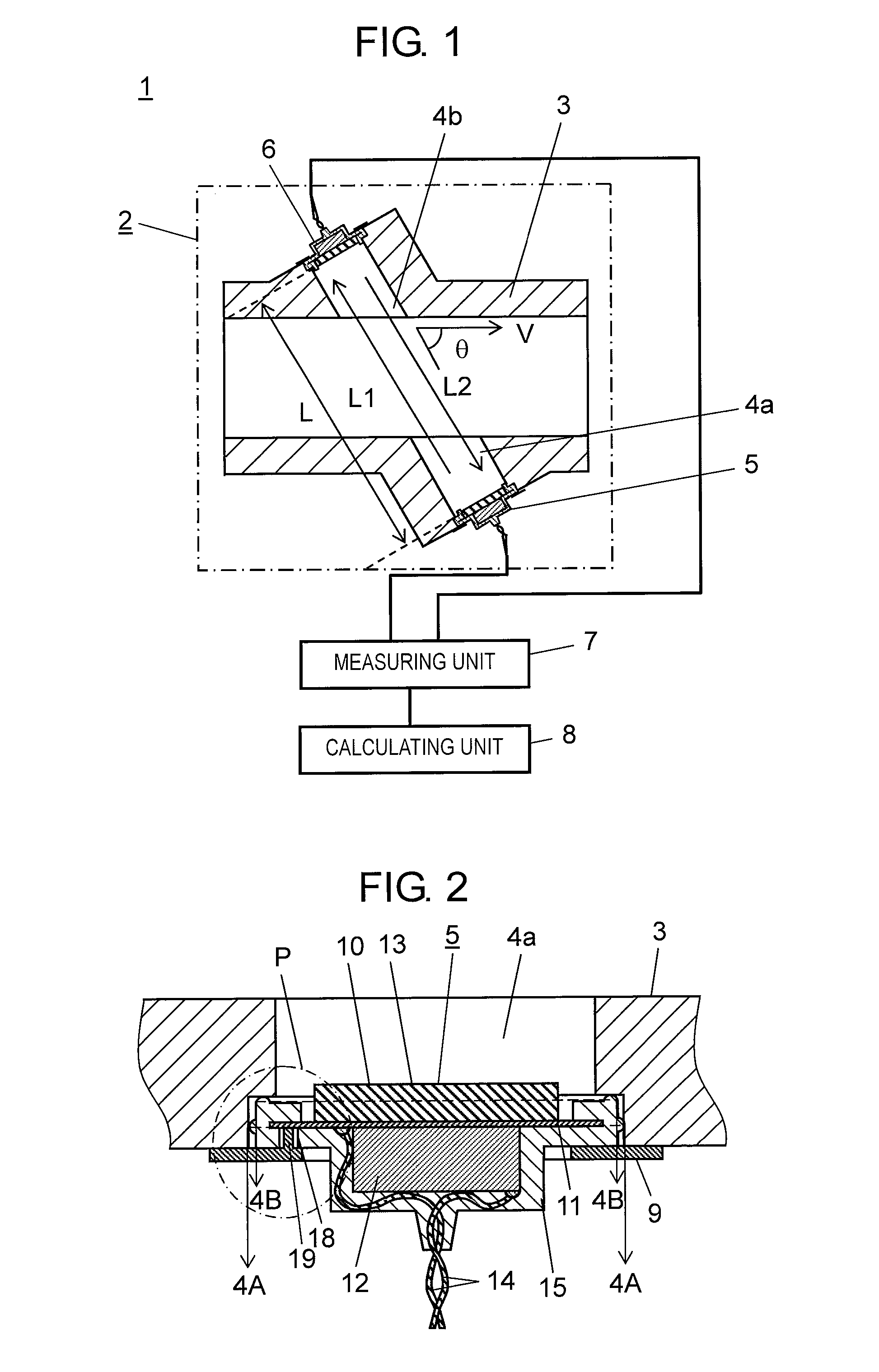

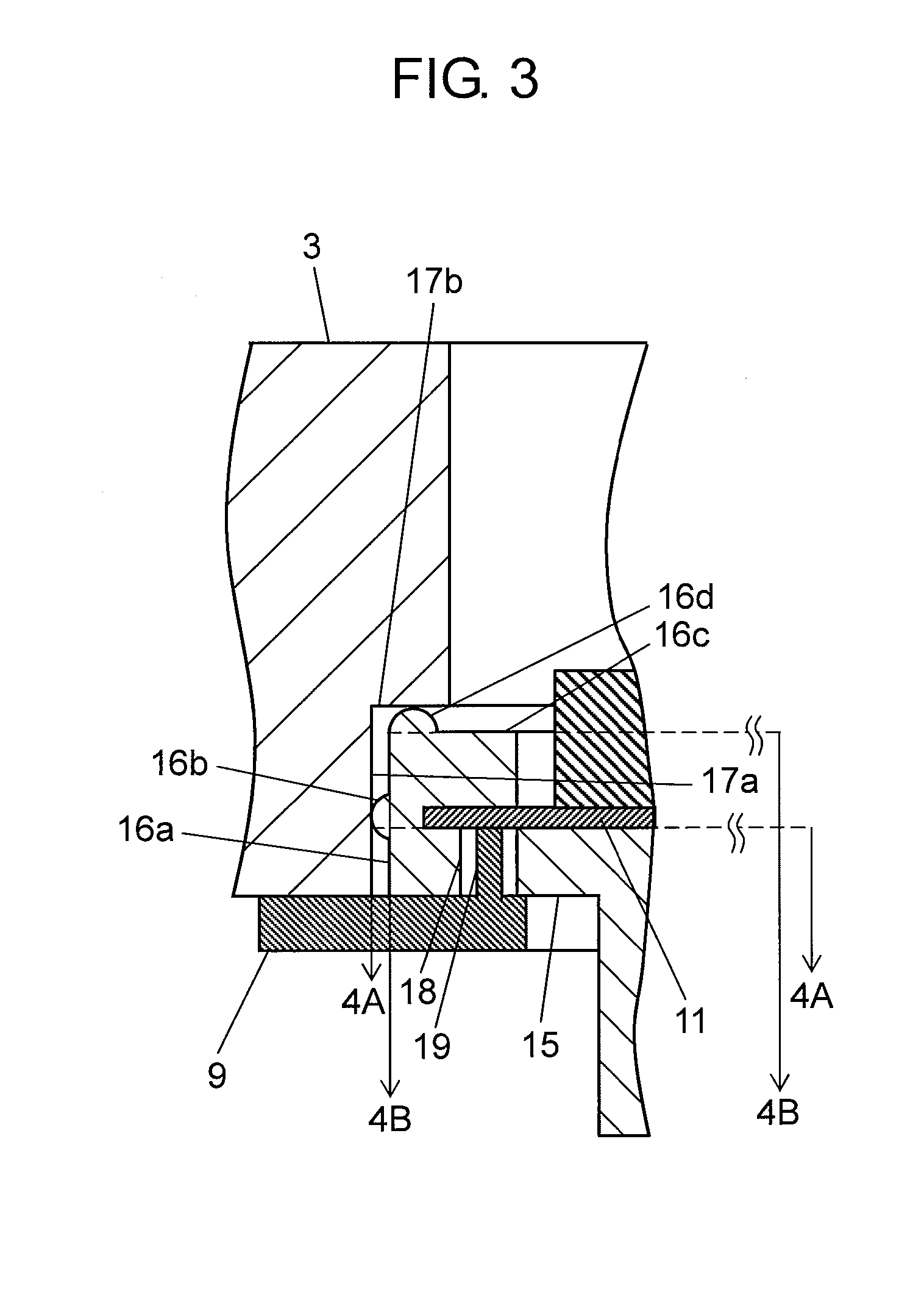

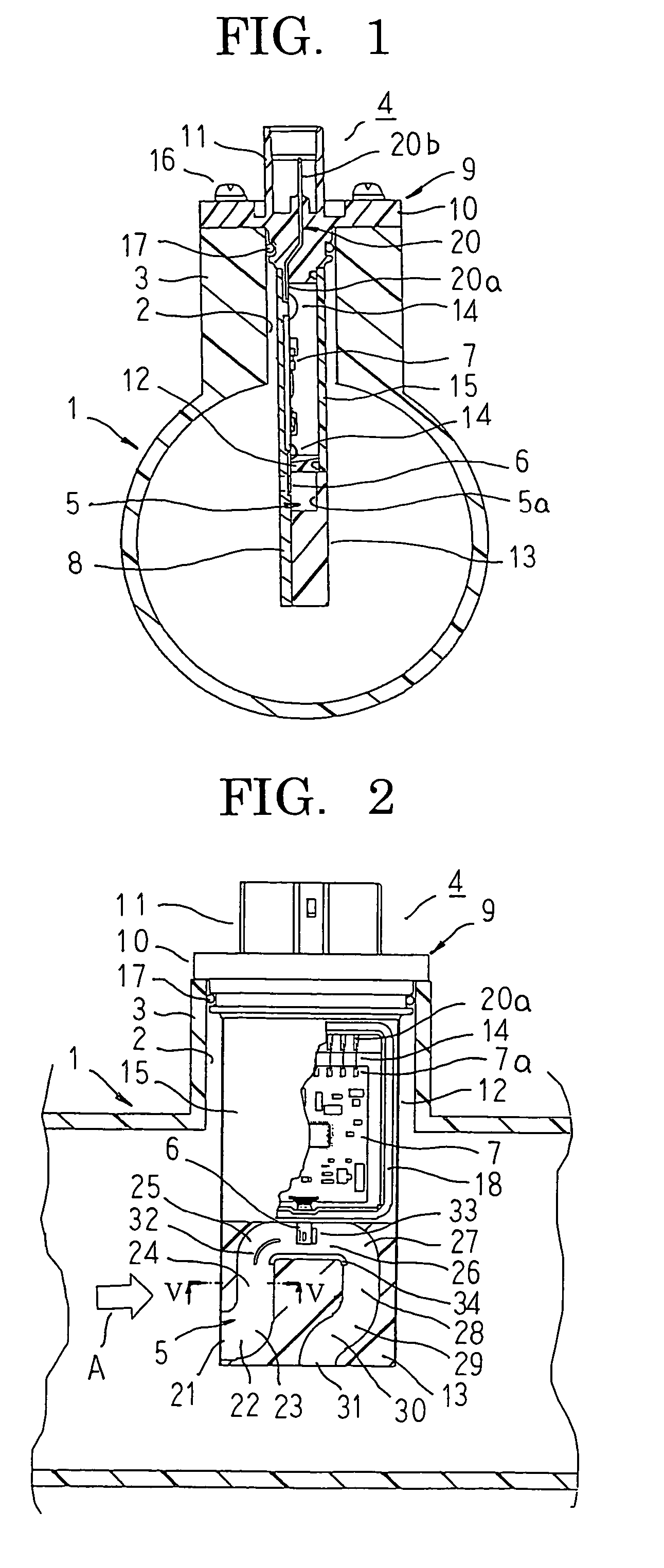

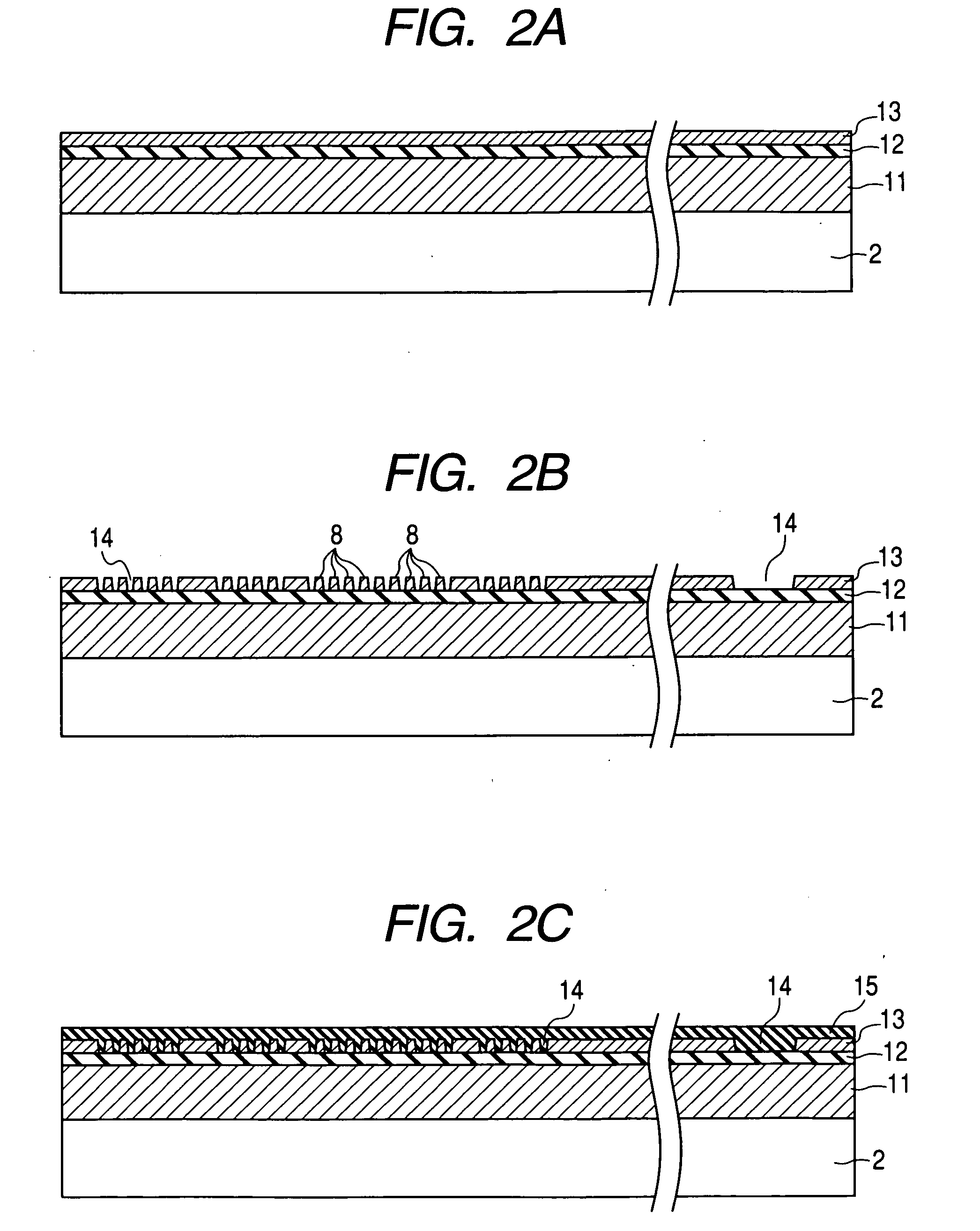

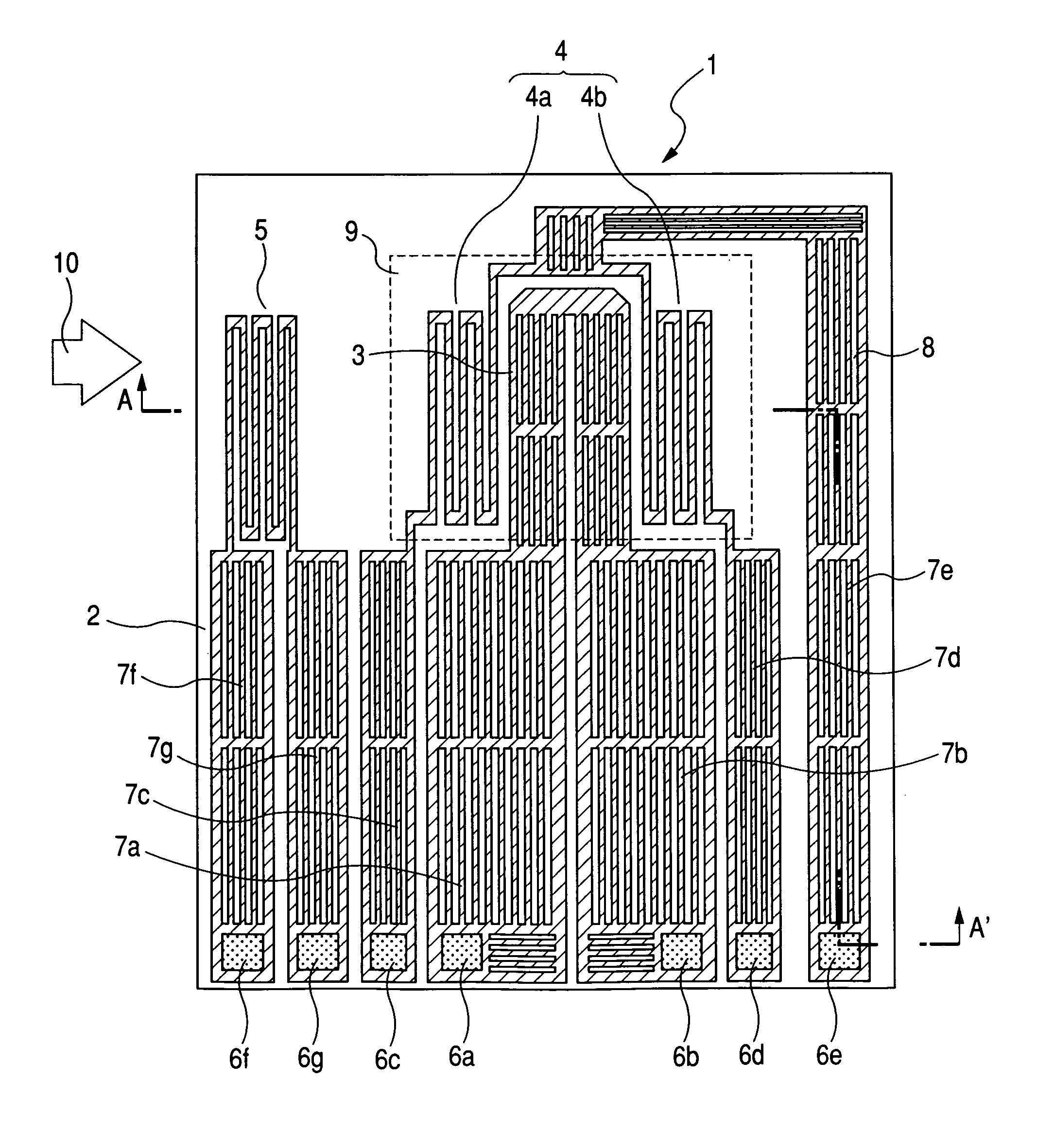

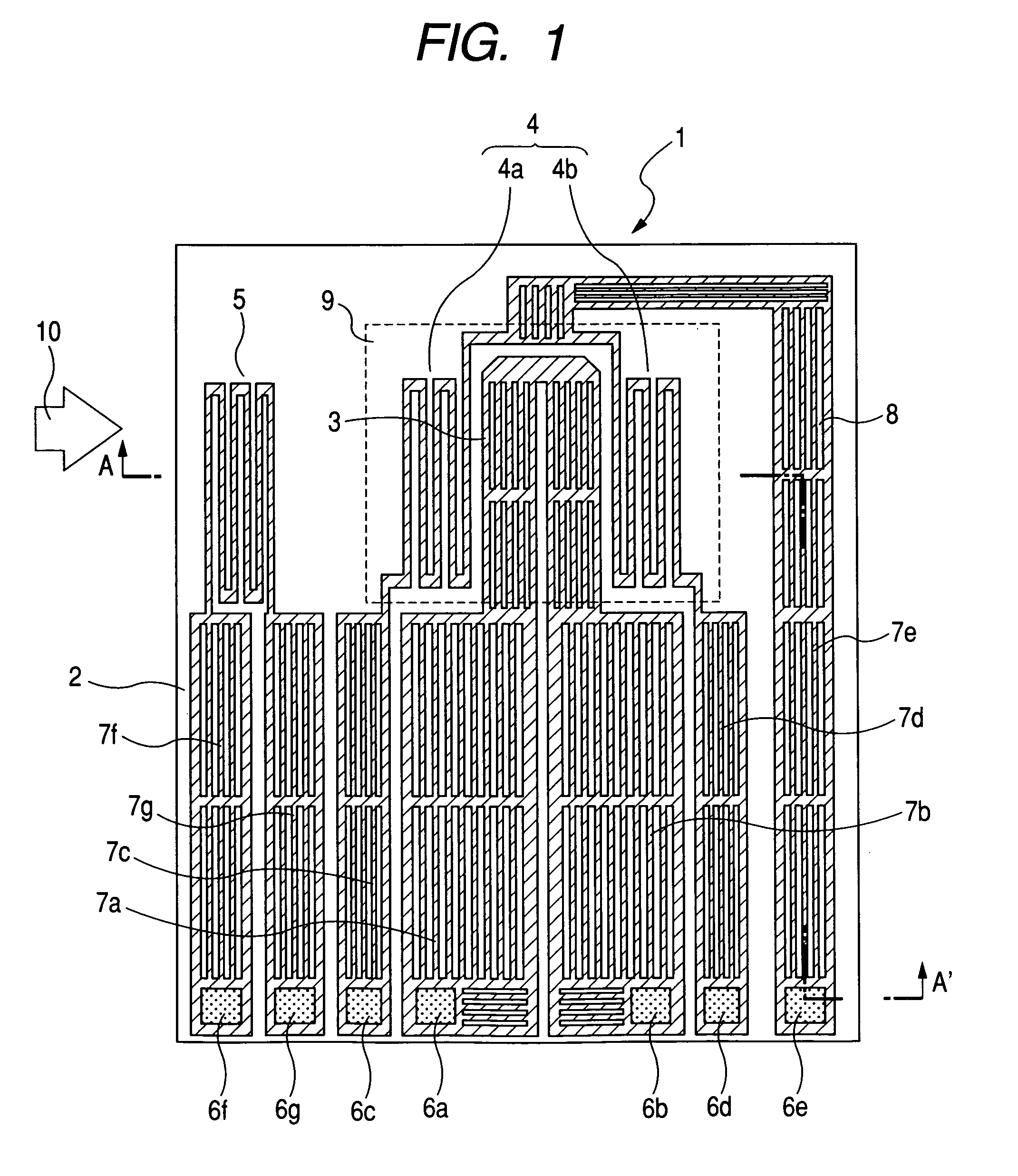

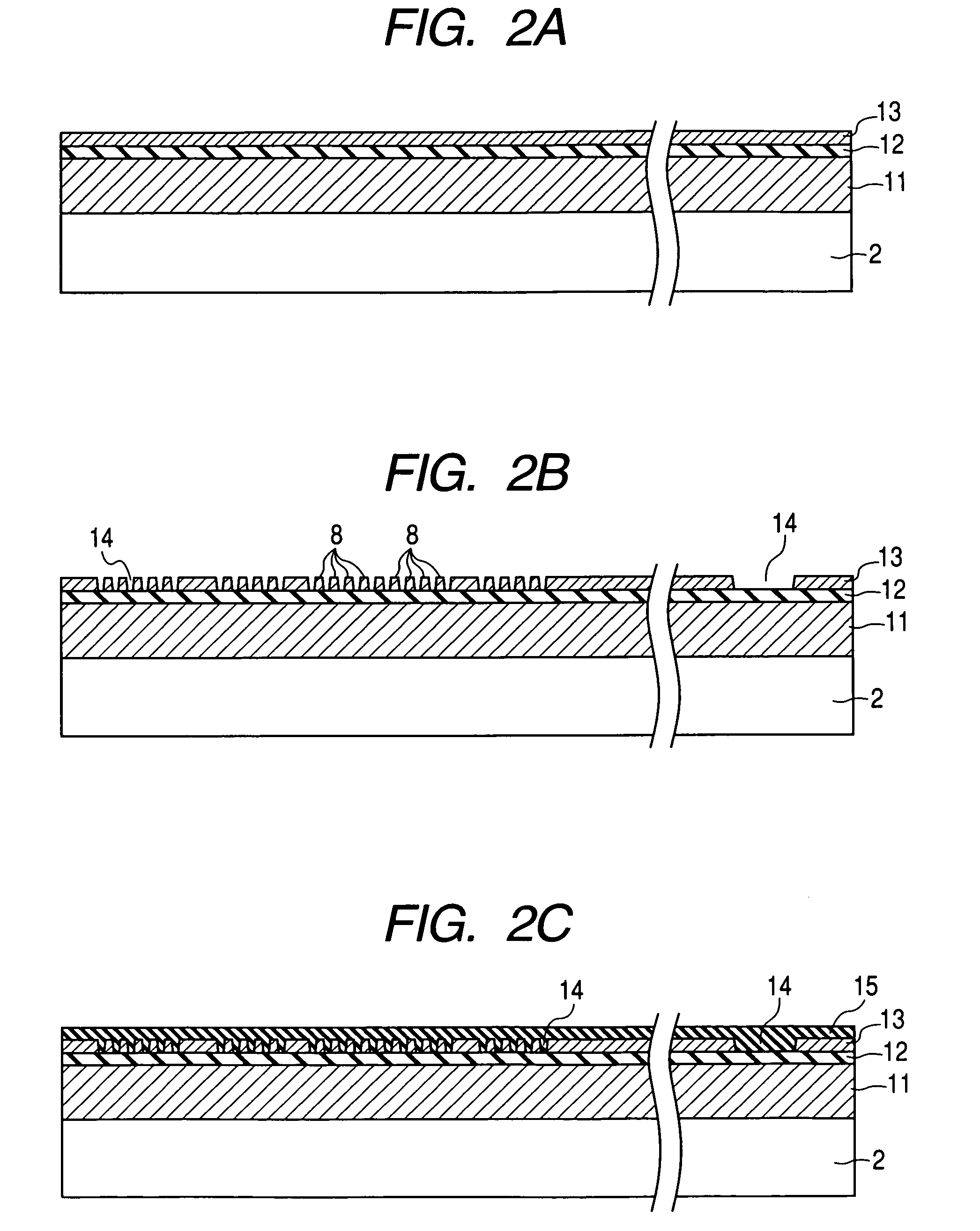

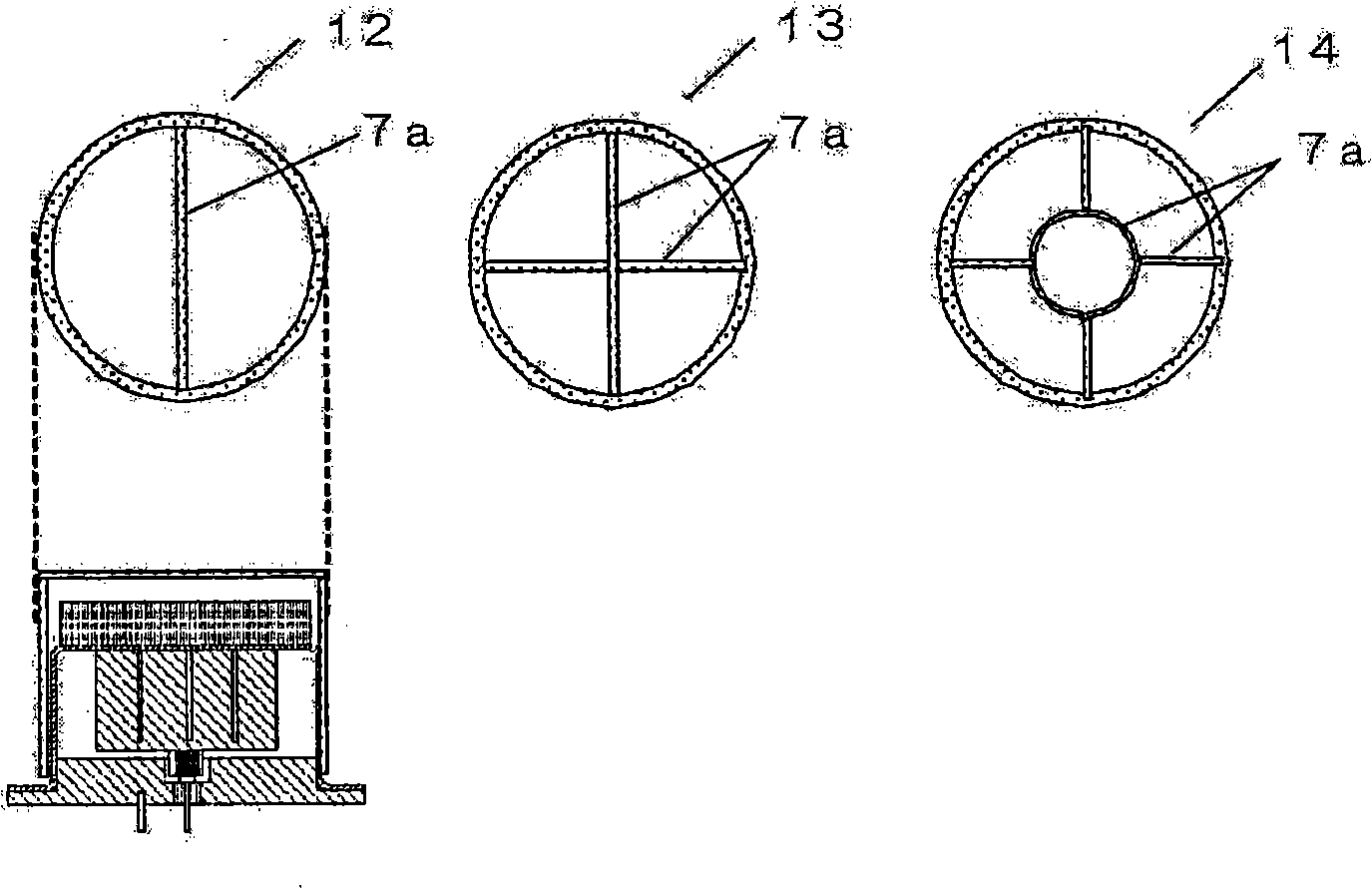

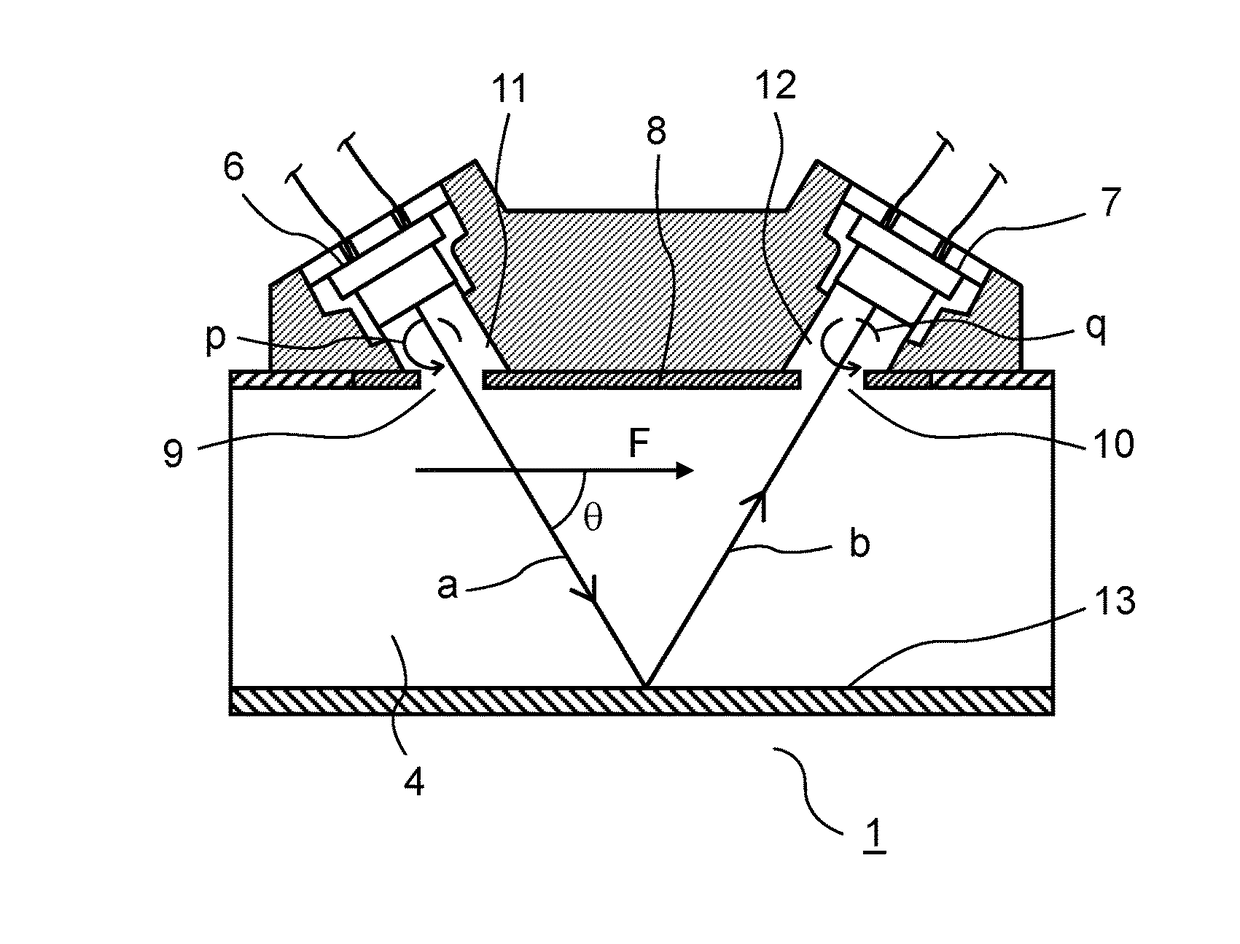

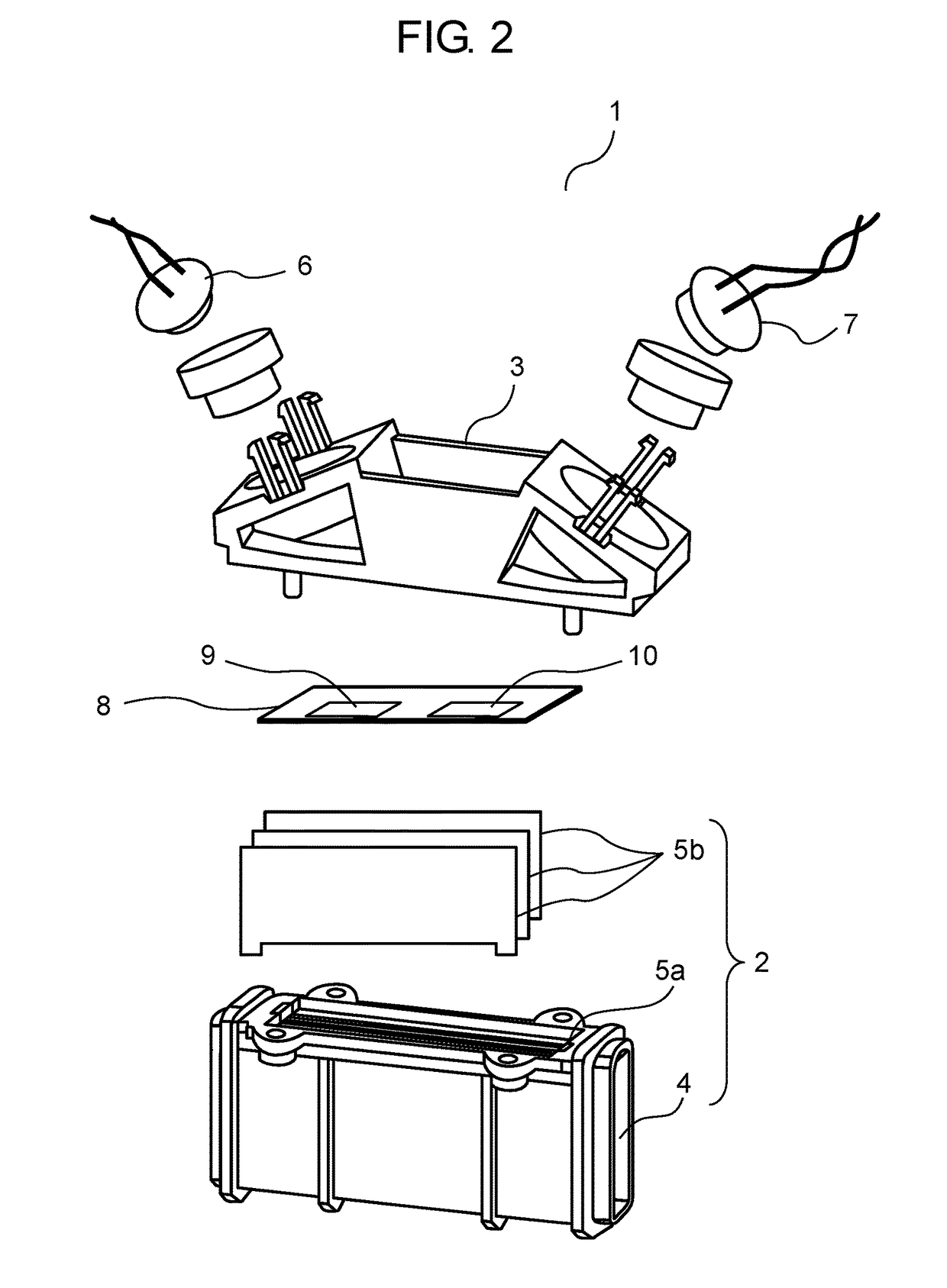

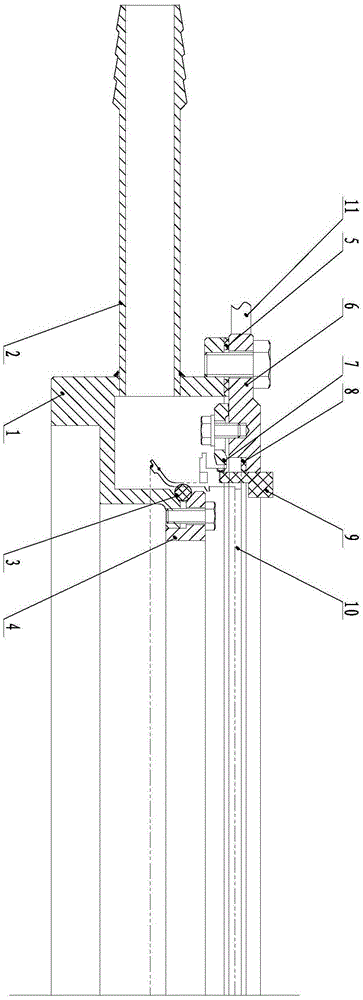

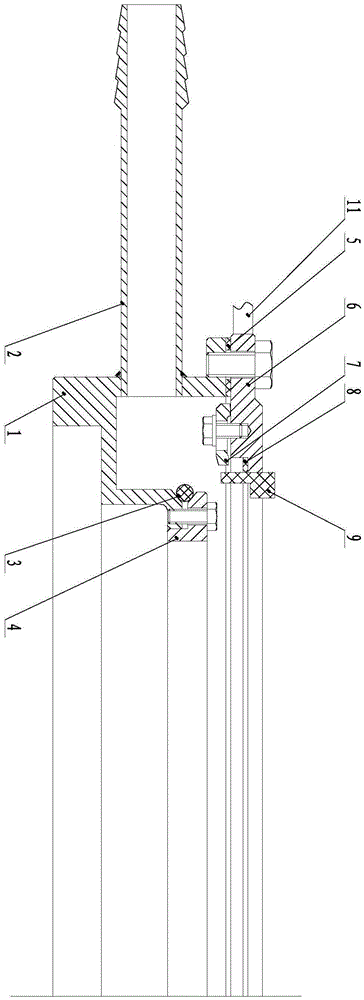

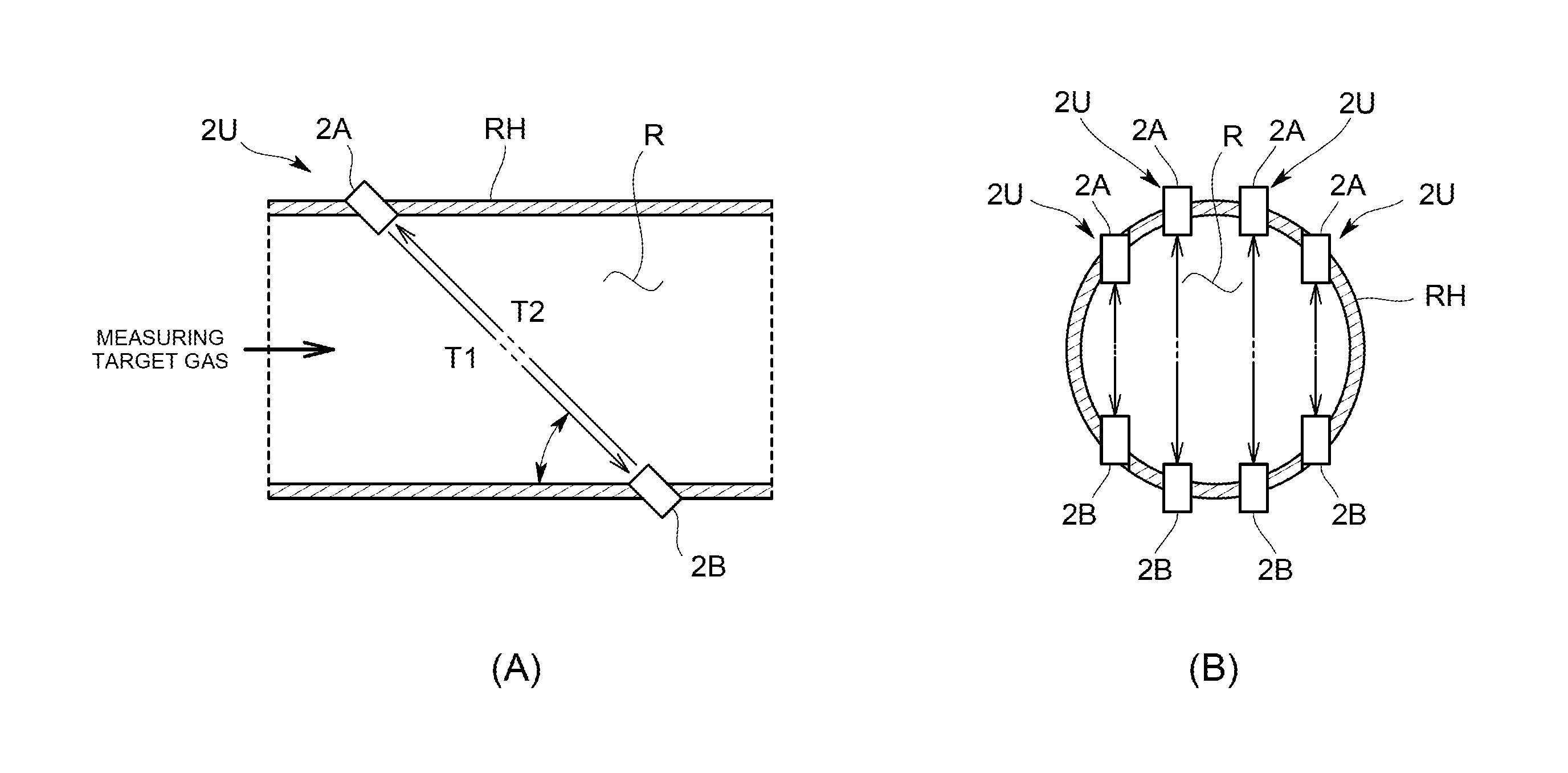

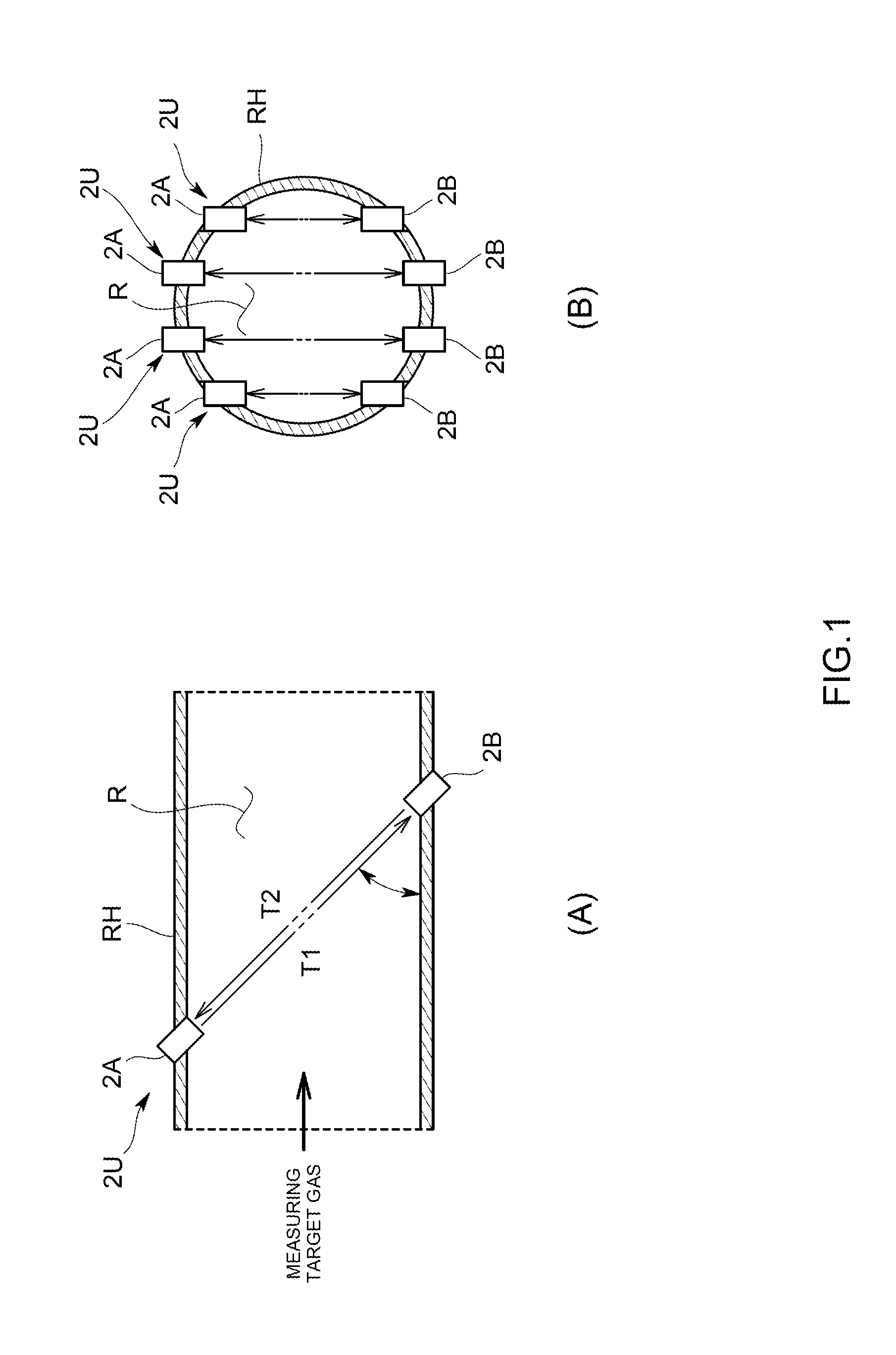

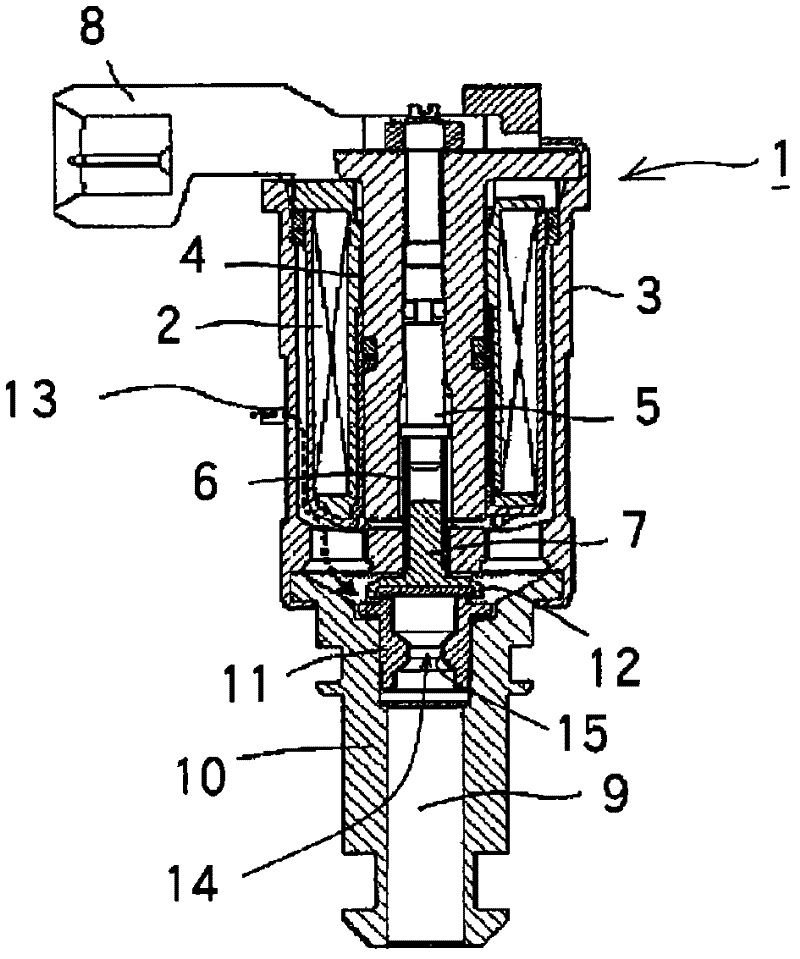

Ultrasonic transducer and ultrasonic flow-meter

ActiveUS20140033827A1Accurate settingAccurate flow measurementVolume/mass flow measurementSound producing devicesUltrasonic sensorEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

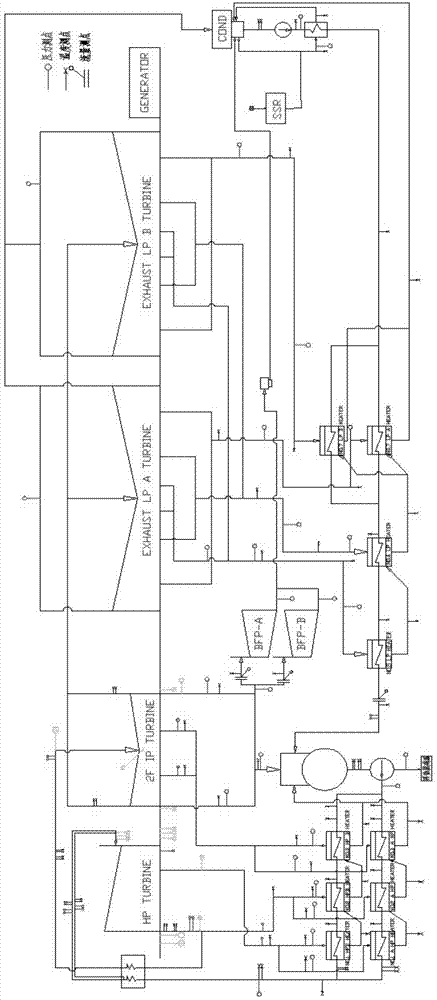

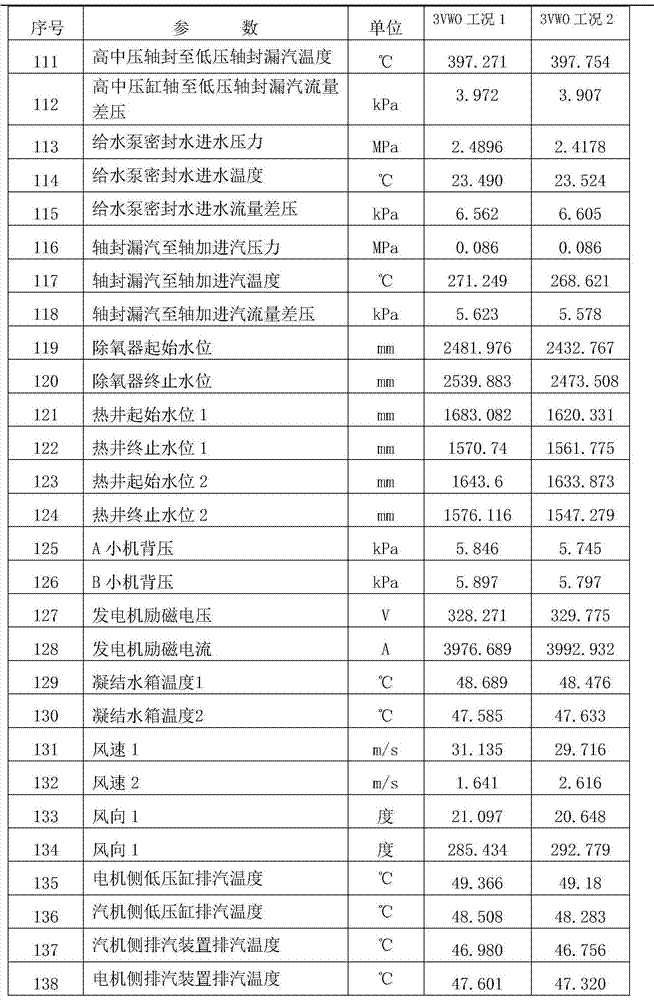

Method for calculating steam admission enthalpy of air-cooling condenser of direct air-cooling unit

ActiveCN103487272AOvercome the shortcoming of imprecise inlet steam enthalpyOvercome the disadvantage of inaccurate inlet steam flowStructural/machines measurementEnergy balancingEngineering

The invention discloses a method for calculating steam admission enthalpy of an air-cooling condenser of a direct air-cooling unit. The method specifically includes the first step of measuring the flow of condensed water entering a deaerator, the steam leakage flow of a front shaft seal and a rear shaft seal of a high pressure cylinder and the steam leakage flow of a front shaft seal and a rear shaft seal of an intermediate pressure cylinder, the steam admission flow of a low pressure shaft seal, the steam leakage flow of a steam admission valve rod of the high pressure cylinder and the steam leakage flow of a steam admission valve rod of the intermediate pressure cylinder, and the flow of seal water entering a feed pump; the second step of calculating the steam extraction flow, the water feed flow, the main steam flow, the high pressure cylinder exhaust steam flow and the reheat steam flow from the first section to the fourth section according to energy balance and mass balance of a high pressure heater and the deaerator; the third step of calculating the steam extraction flow from the fifth section to the seventh section according to heat balance and mass balance of a low pressure heater, and calculating exhaust steam energy and exhaust steam flow of the lower pressure cylinder of a turbine according to energy balance and mass balance of the turbine; the fourth step of calculating exhaust steam enthalpy of the low pressure cylinder, namely, the steam admission enthalpy of the air-cooling condenser, and enabling the steam admission enthalpy to serve as a benchmark for calculating heat load of the air-cooling condenser. The measuring results can be more accurate.

Owner:STATE GRID CORP OF CHINA +1

Flow rate measuring apparatus

ActiveUS7530267B2Accurate flow measurementEnabling pressure lossVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringMechanical engineering

Owner:MITSUBISHI ELECTRIC CORP

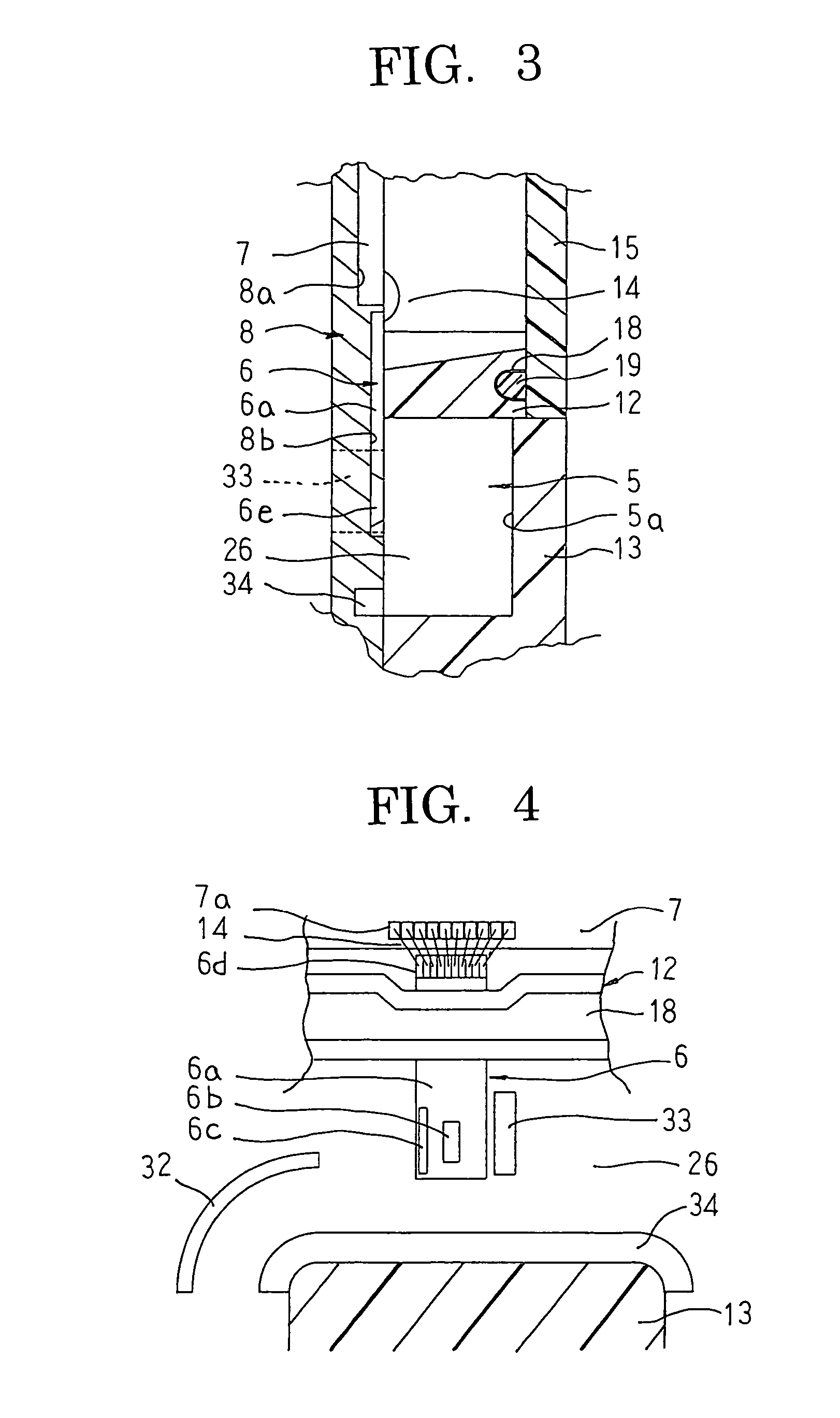

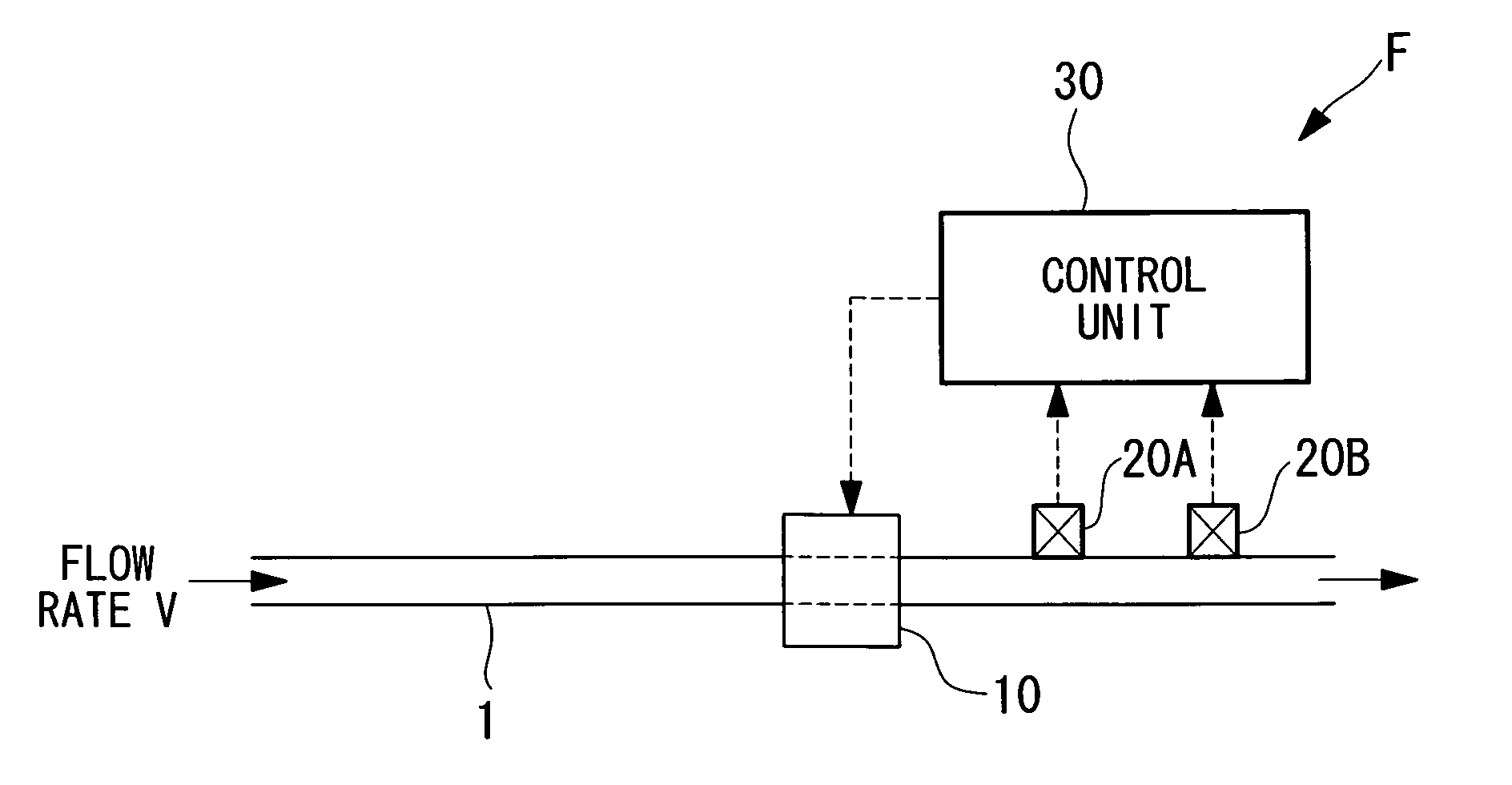

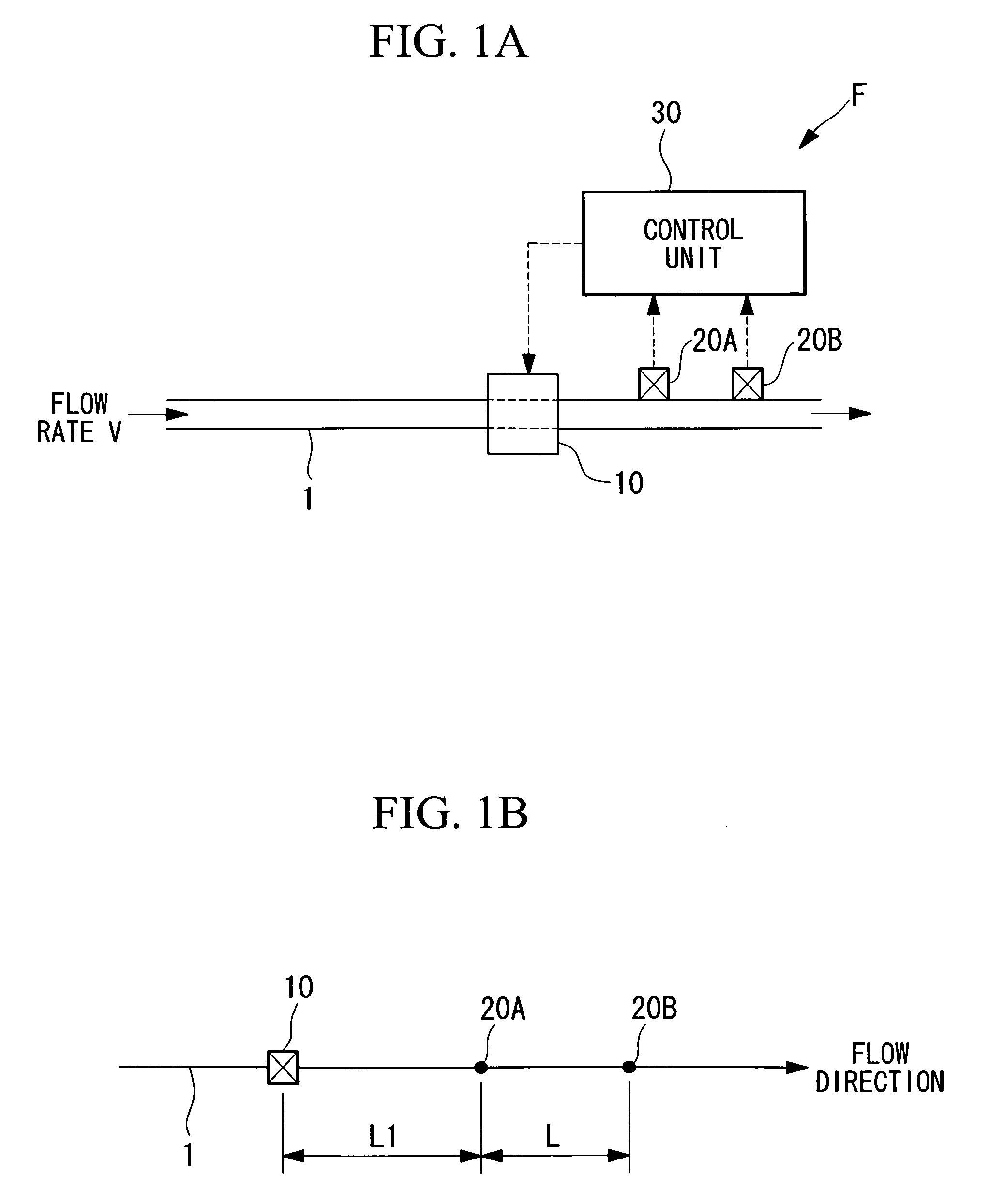

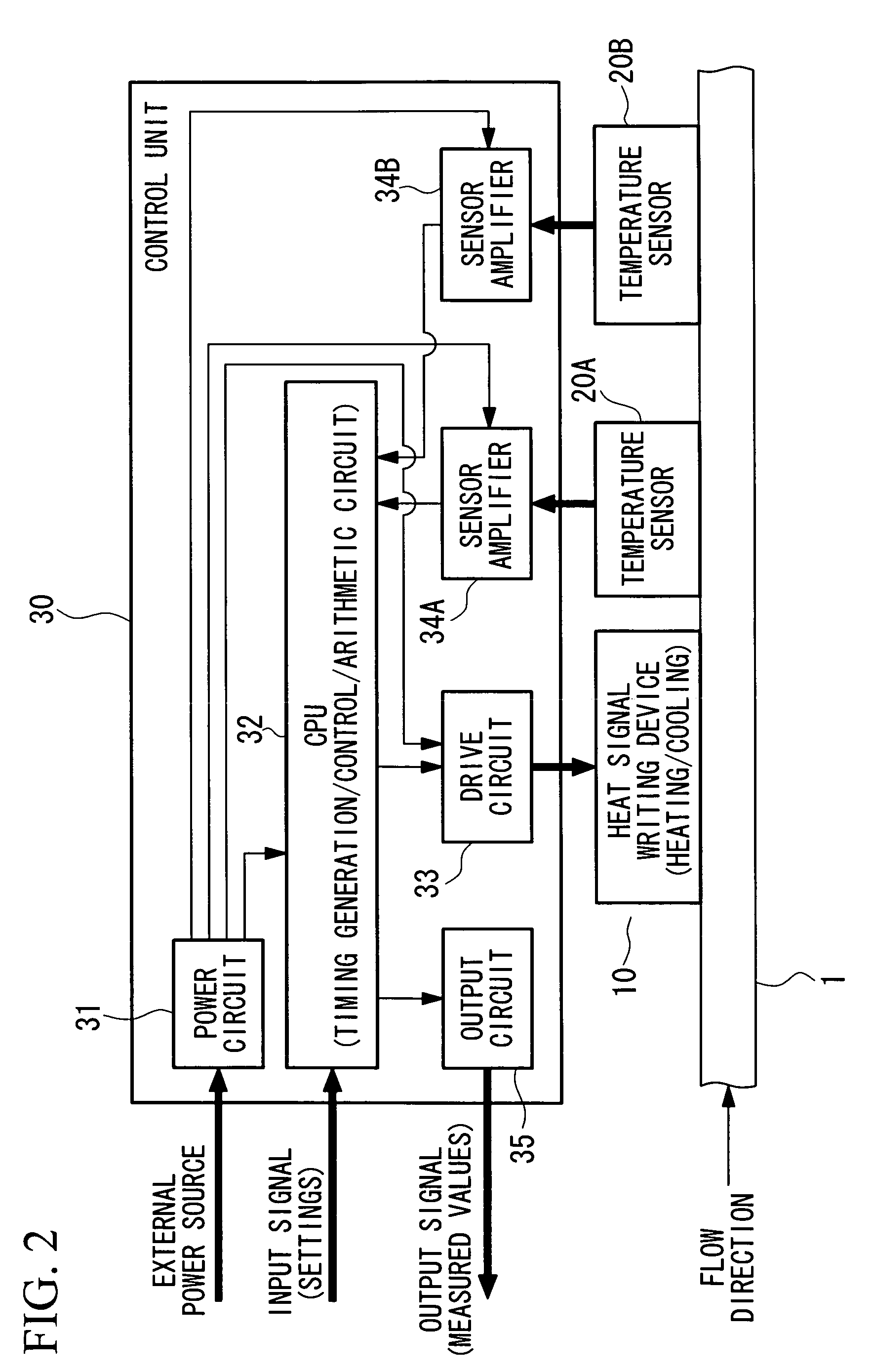

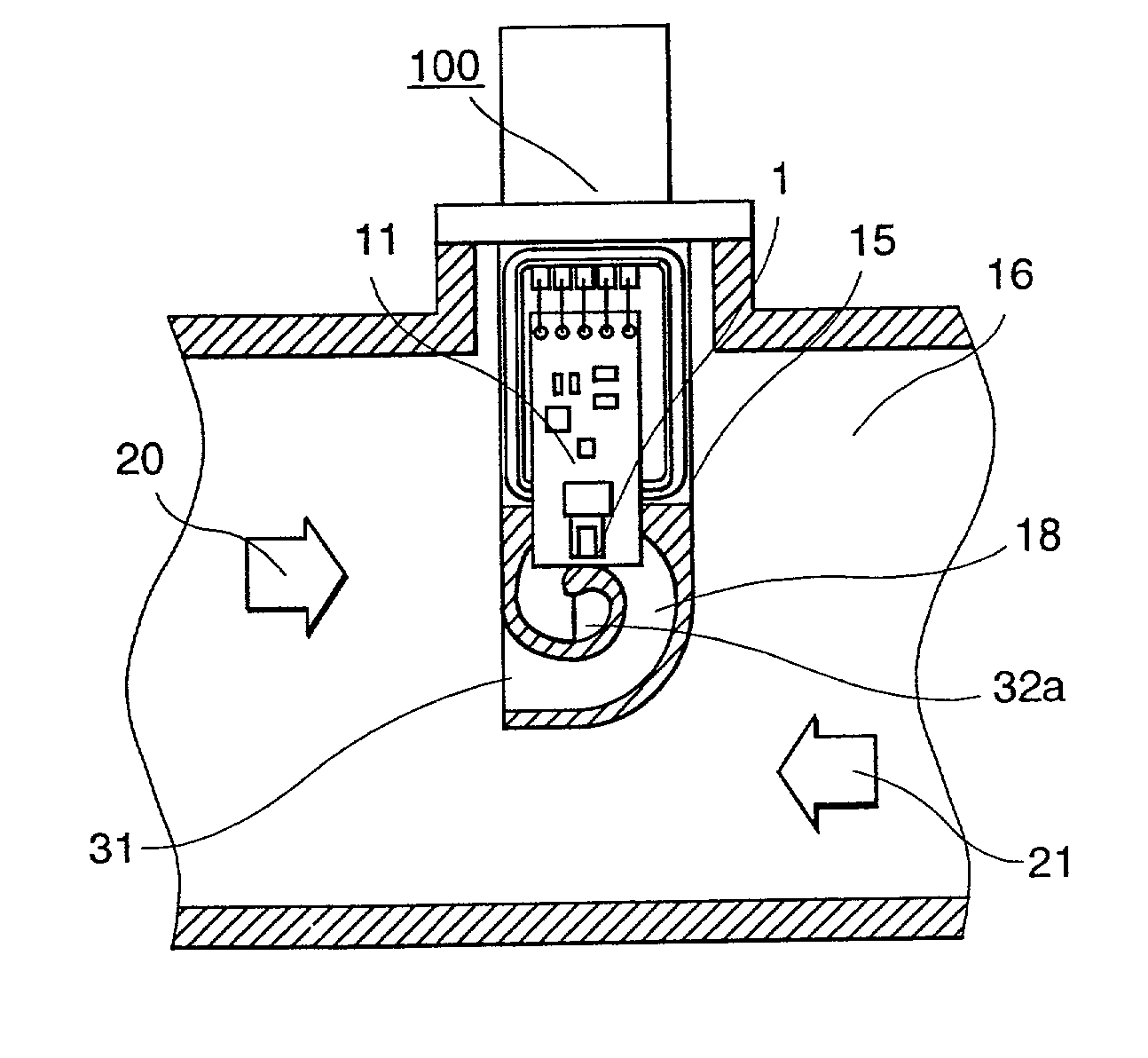

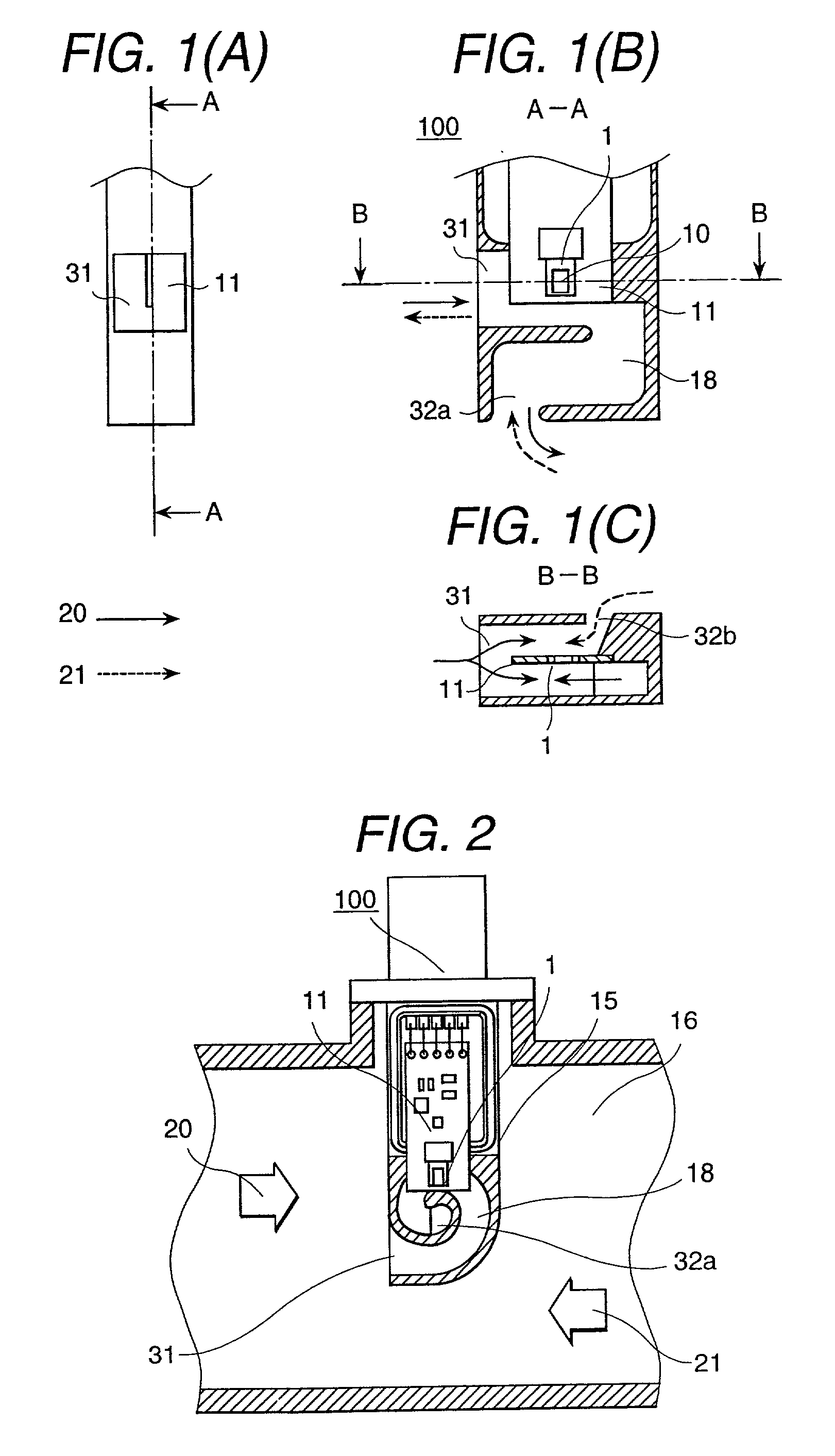

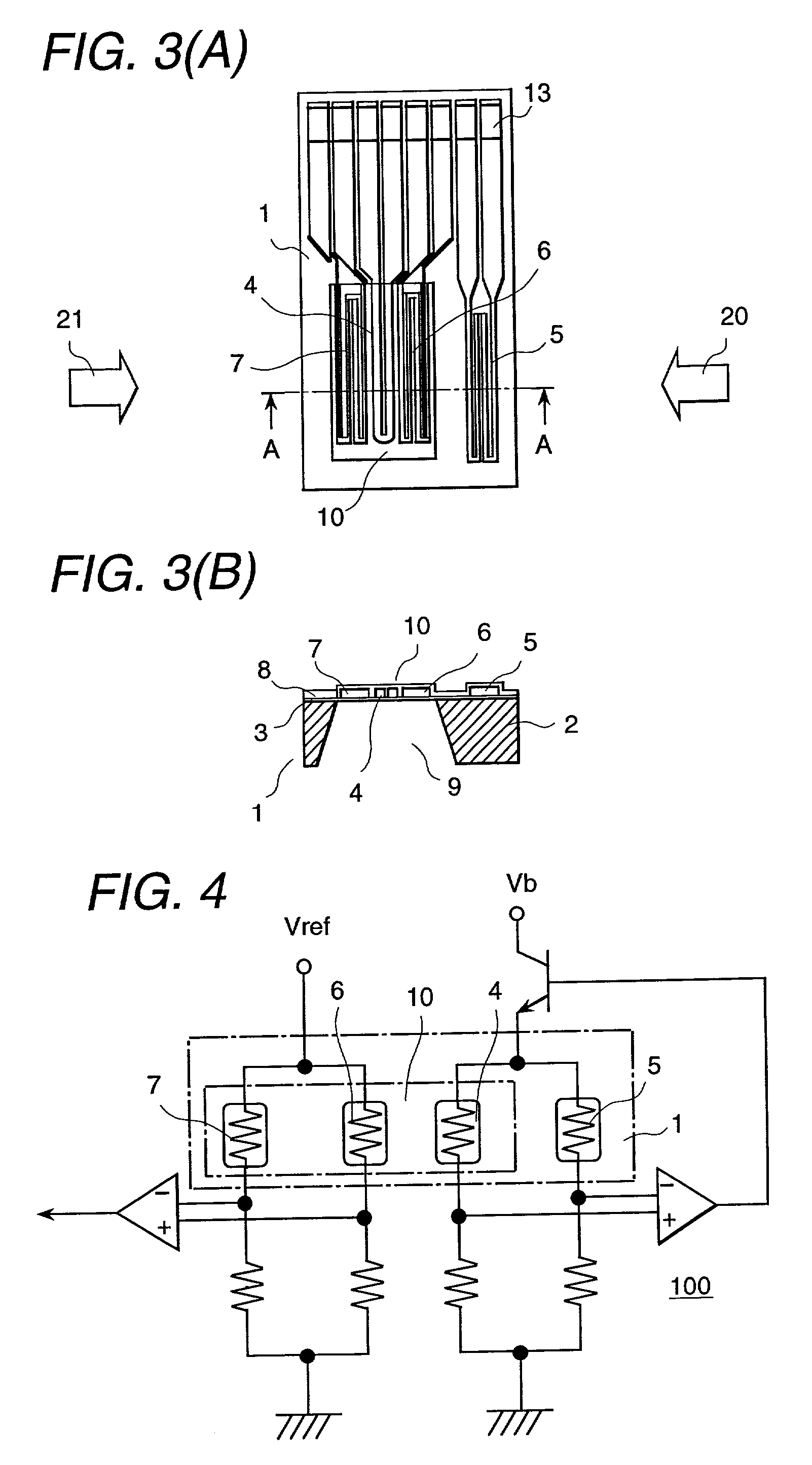

Flow Rate Detection Method and Flow Rate Detection Apparatus Using a Heat Signal

InactiveUS20090025473A1Accurate flow measurementEliminate sourceVolume/mass flow by thermal effectsFluid speed measurement using thermal variablesObservational errorTwo temperature

A flow rate detection method using a heat signal that enables accurate flow rate measurement by eliminating sources of measurement error is provided. The flow rate detection method, using a heat signal, of writing a temperature-change heat signal in a medium traveling through a channel and detecting the heat signal with heat signal detecting means provided at a position away from the writing position, to measure a traveling speed of the medium, wherein first and second temperature sensors 20A and 20B, which are separated by a predetermined distance L, are disposed downstream of the writing position, and the traveling speed is calculated from a time difference at which the two temperature sensors 20A and 20B detecting the heat signal and from the distance L.

Owner:SURPASS IND

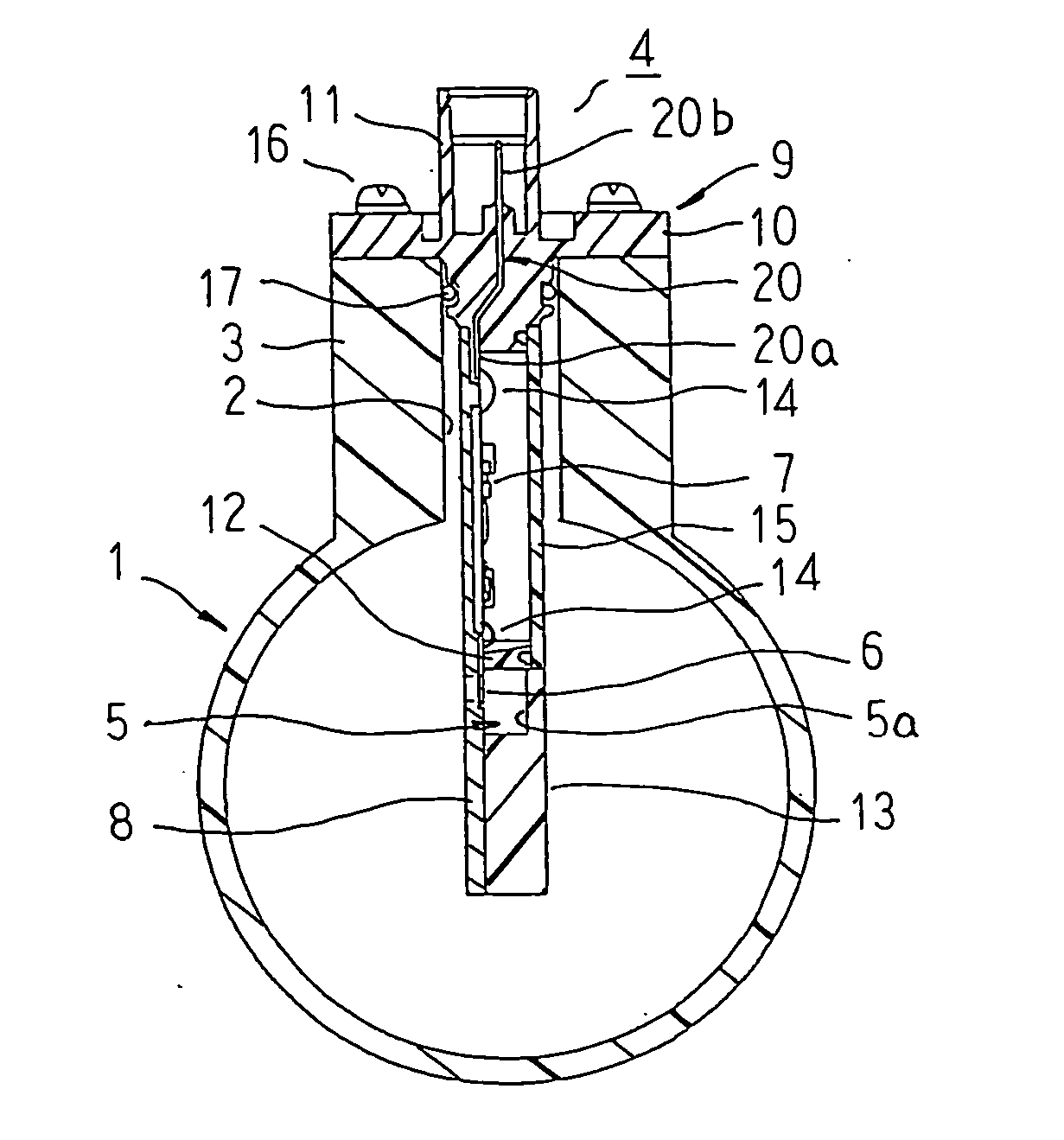

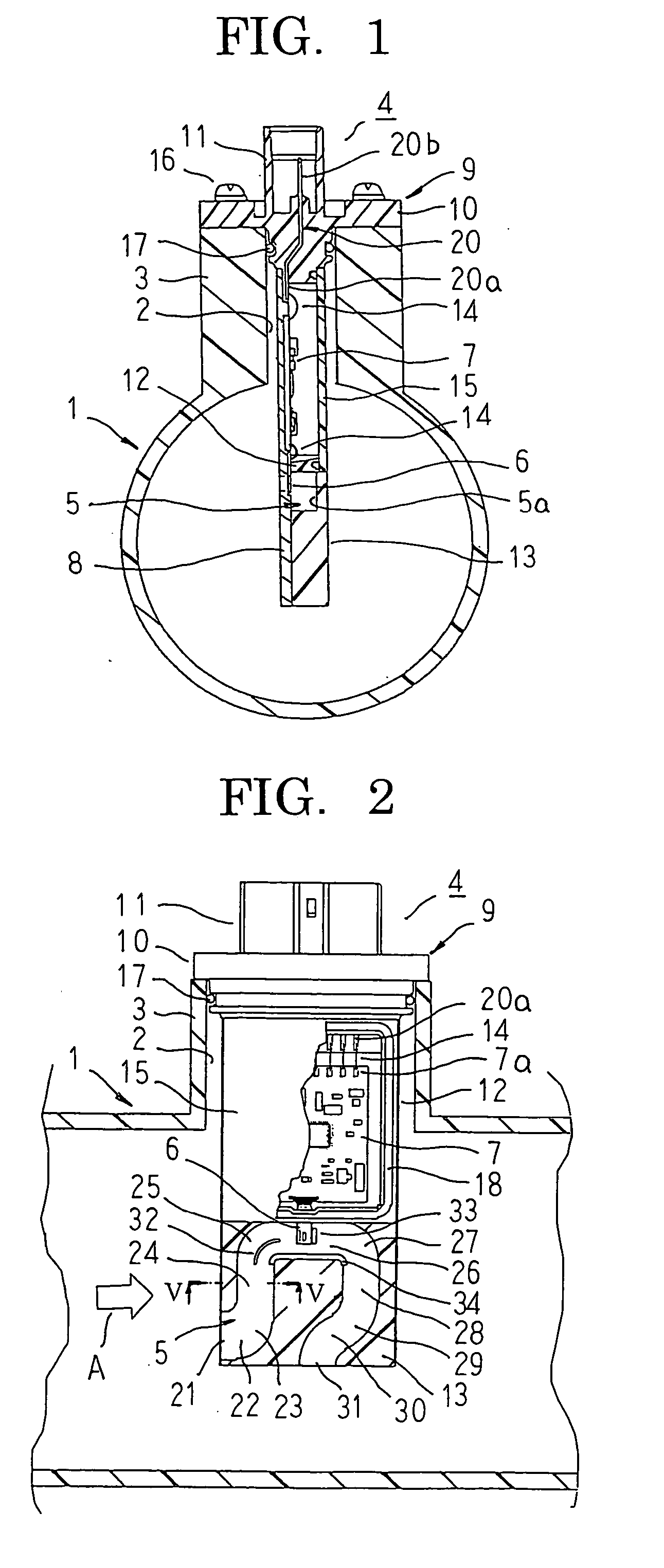

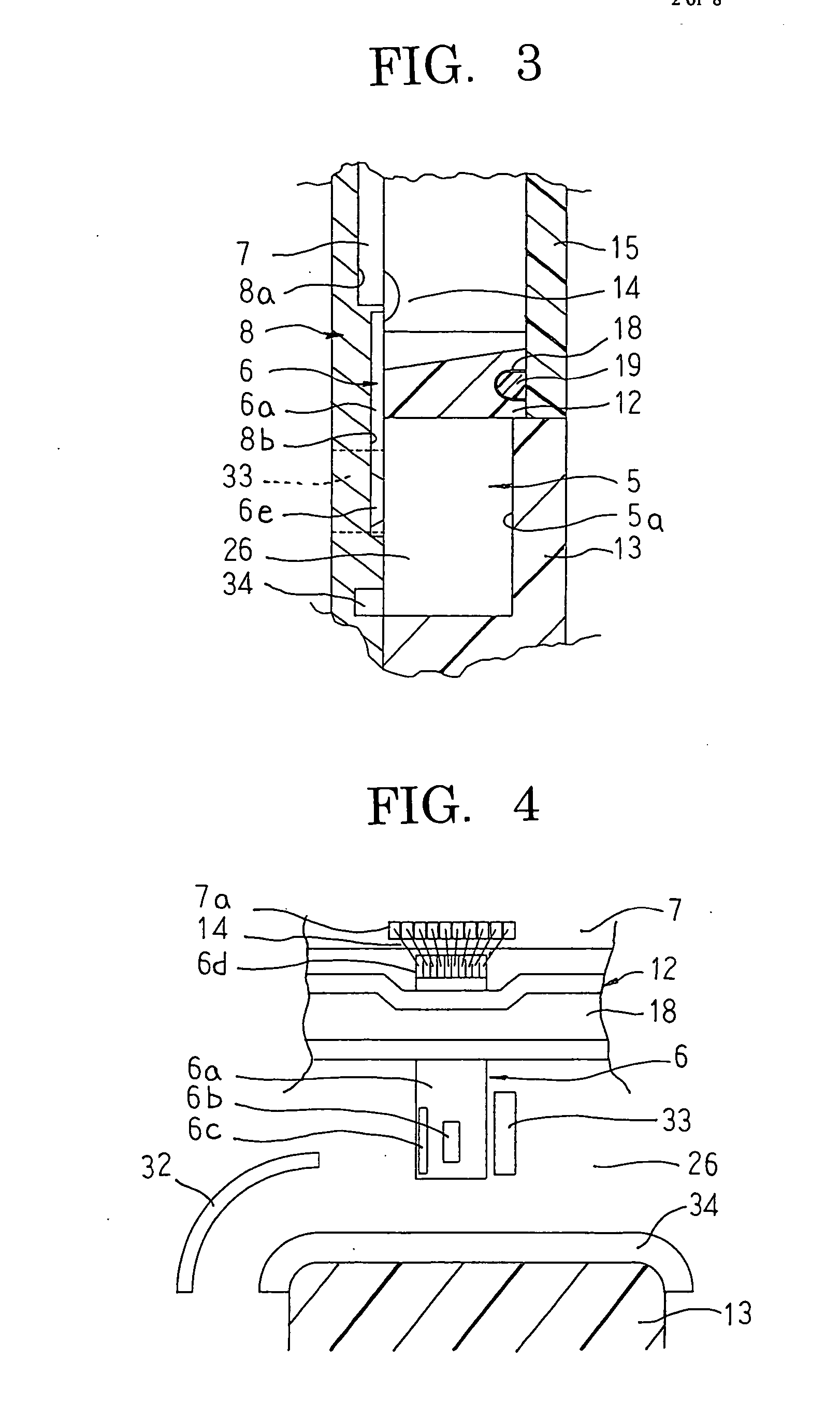

Flow measurement sensor

InactiveUS20030110854A1Accurate flow measurementRepel condensationElectrical controlVolume/mass flow by thermal effectsElectrical resistance and conductanceEngineering

To provide a flow measurement sensor which accurately outputs signals even when pulsation flow is generated at high engine speed and also when pulsation flow accompanying reverse flow is generated. In a flow measurement sensor comprising a flow measurement element which has a heater resistance pattern on one side of a plate-shaped member, and a bypass passage in which the flow measurement element is disposed, a first outlet through which fluid flowing along the surface of said flow measurement element flows out, and a second outlet through which fluid flowing along the back side of said flow measurement element flows out are provided, and said second outlet is positioned at a different location from said first outlet.

Owner:HITACHI ASTEMO LTD

Flow rate measuring apparatus

ActiveUS20070068246A1Increased Durability LifeExtended service lifeVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringMechanical engineering

Owner:MITSUBISHI ELECTRIC CORP

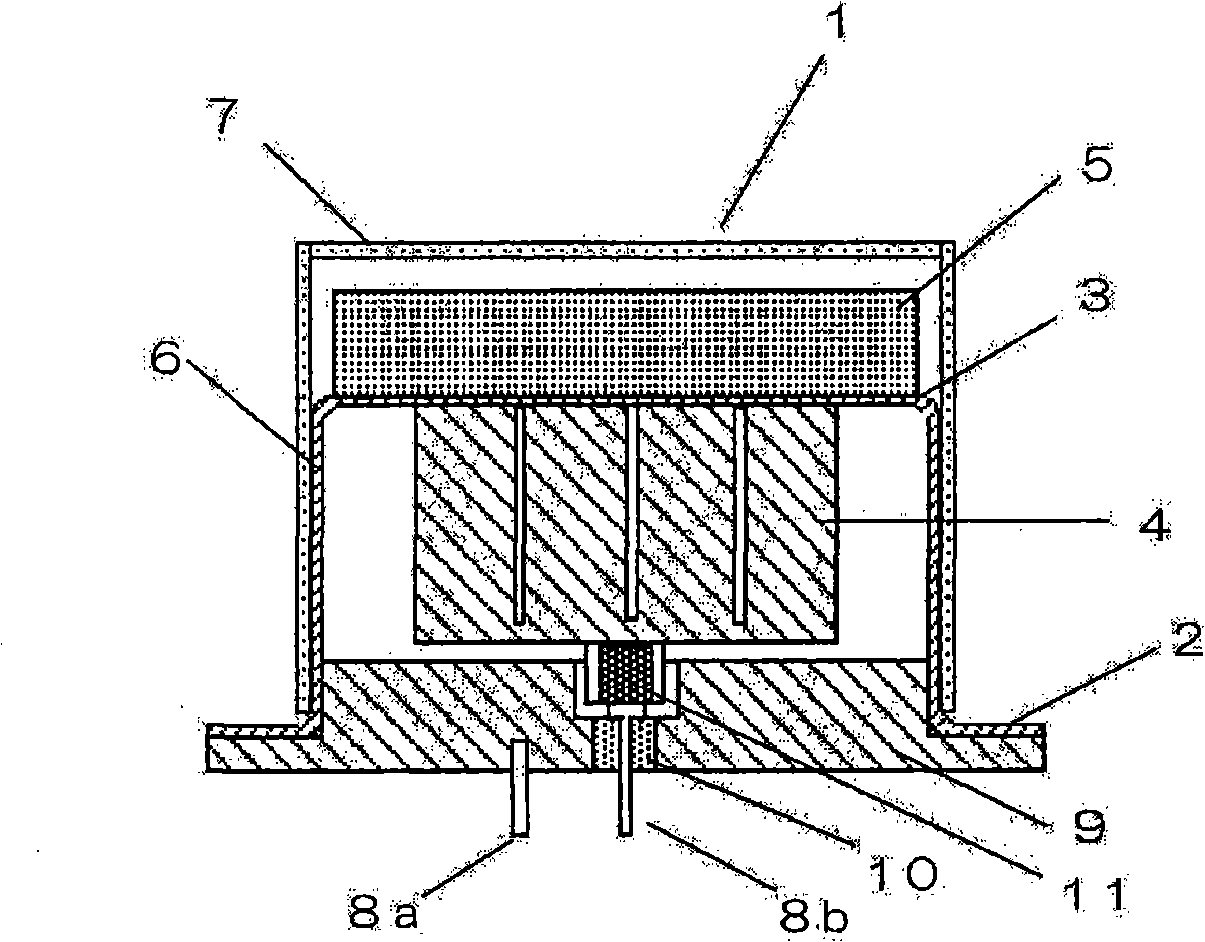

Ultrasonic transducer for use in a fluid medium

InactiveUS20130133408A1Increase dampingAccurate timingAnalysing fluids using sonic/ultrasonic/infrasonic wavesElectrical transducersHost materialEngineering

An ultrasonic transducer for use in a fluid medium. The ultrasonic transducer includes at least one housing and at least one transducer core at least partially accommodated in the housing. The transducer core includes at least one acoustic-electric transducer element. At least one damping material is also accommodated in the housing. The damping material includes at least one matrix material, at least one first filler introduced into the matrix material, and at least one second filler introduced into the matrix material. The first filler has a lower specific gravity than the matrix material. The second filler has a higher specific gravity than the matrix material.

Owner:ROBERT BOSCH GMBH

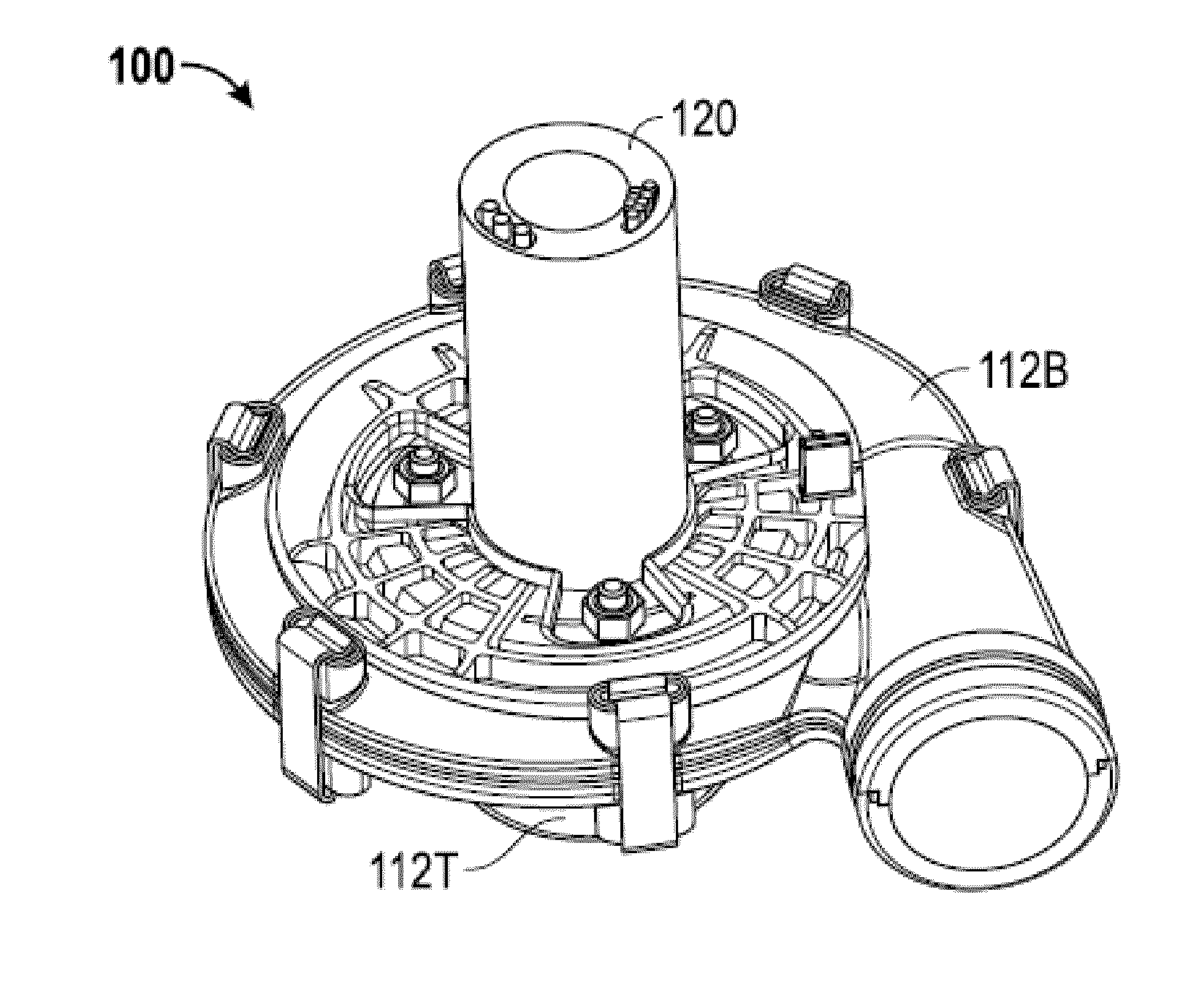

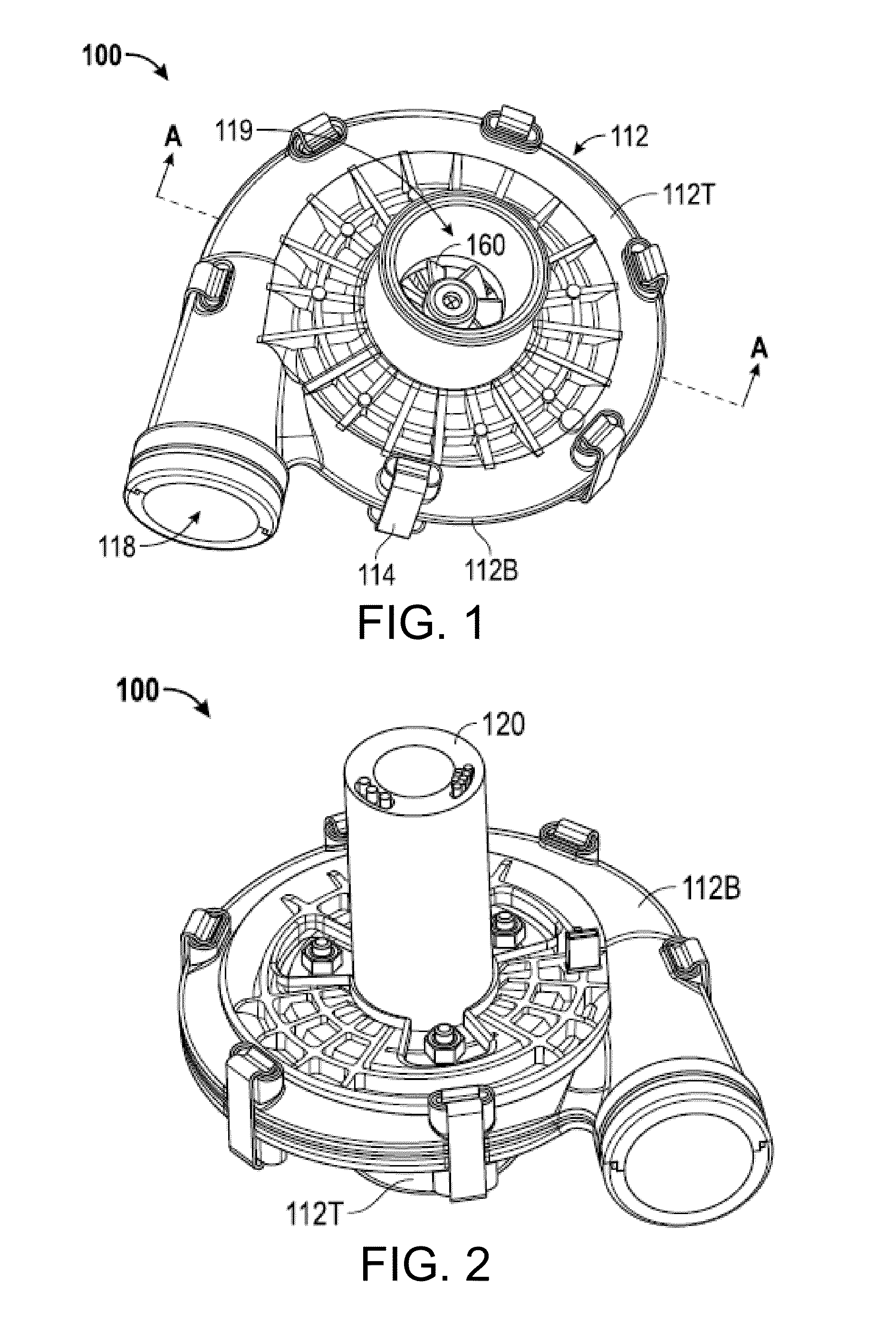

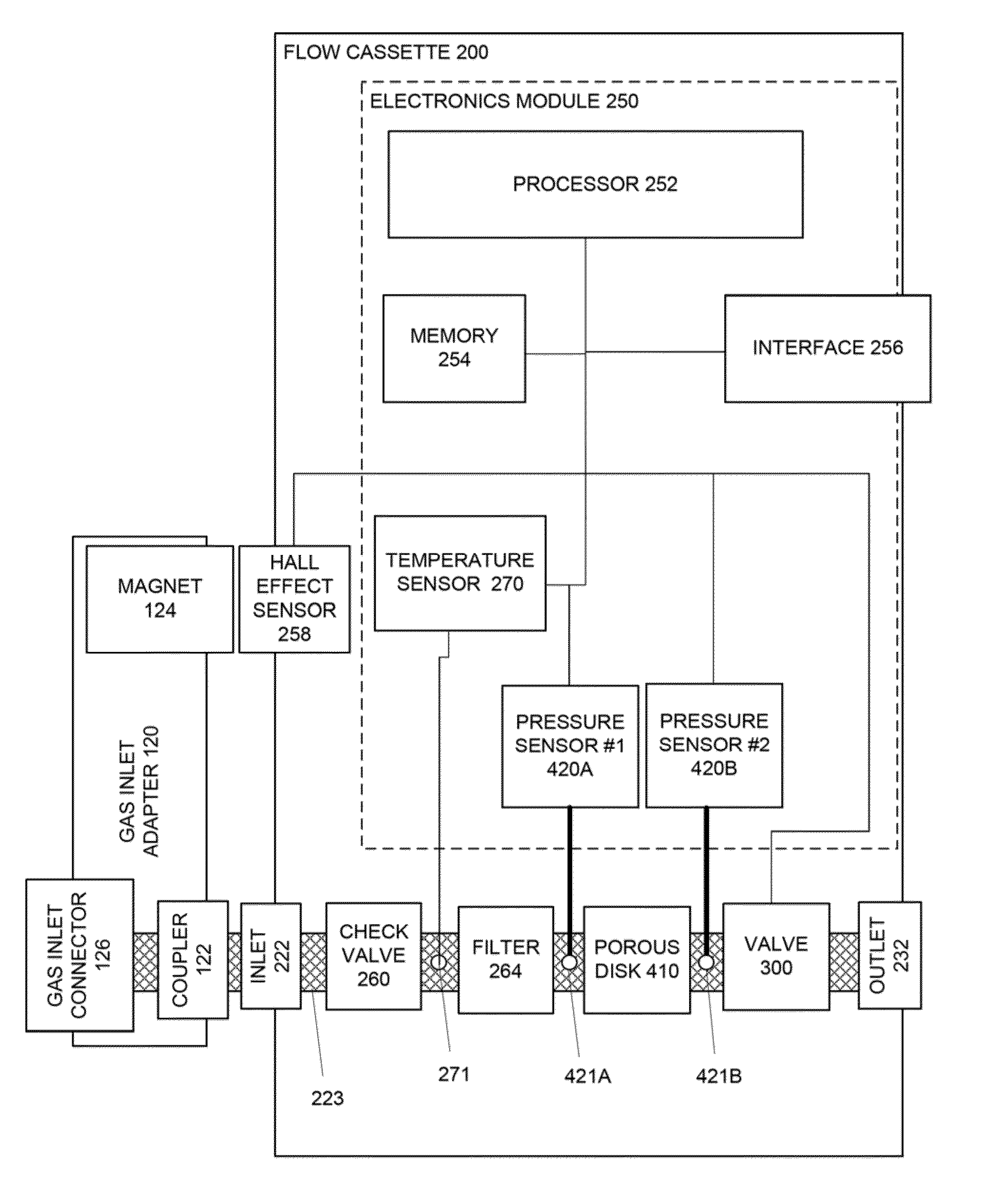

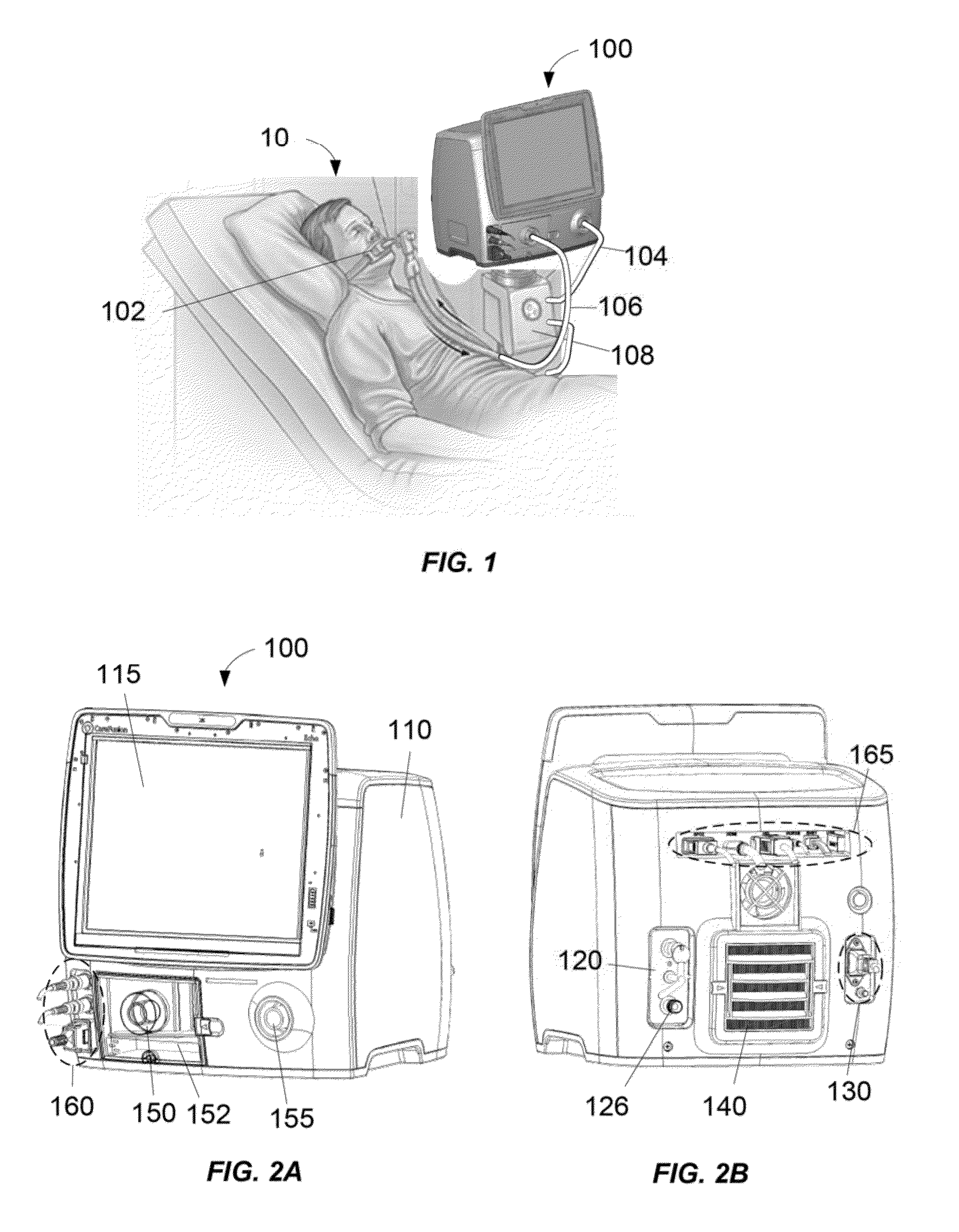

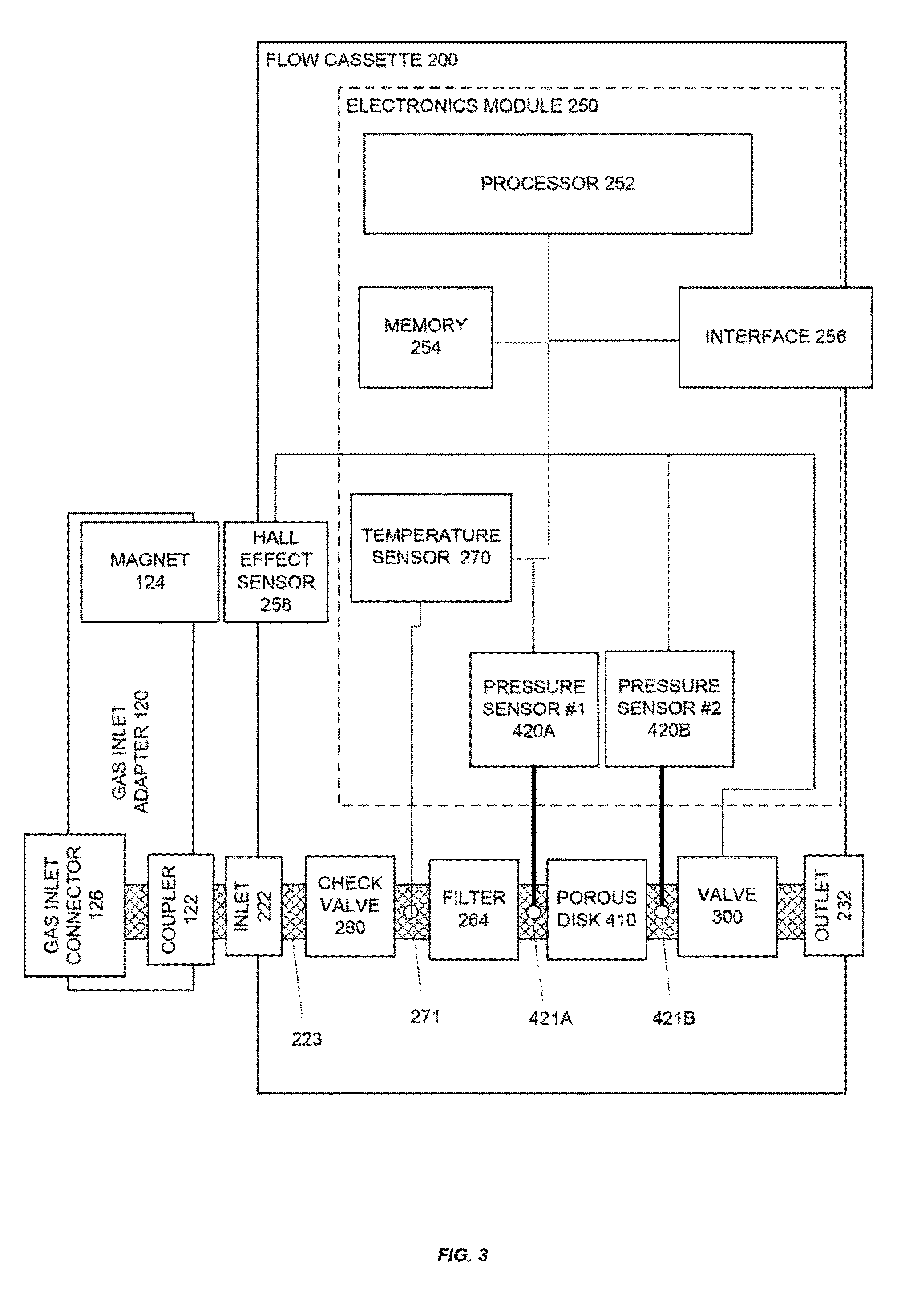

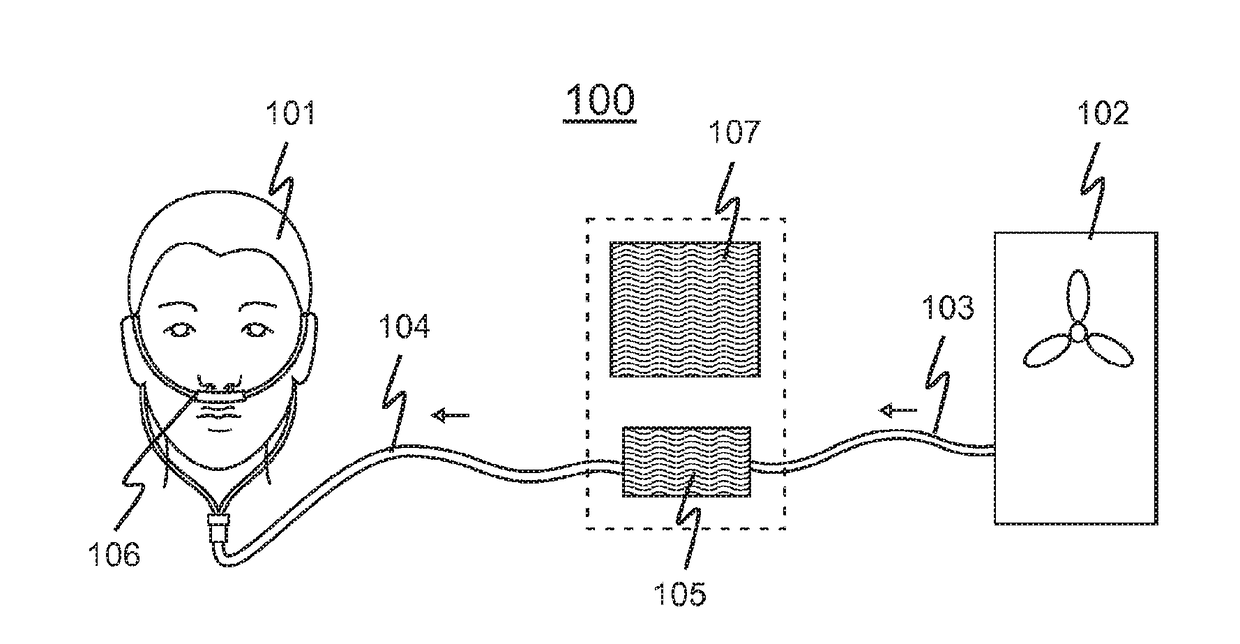

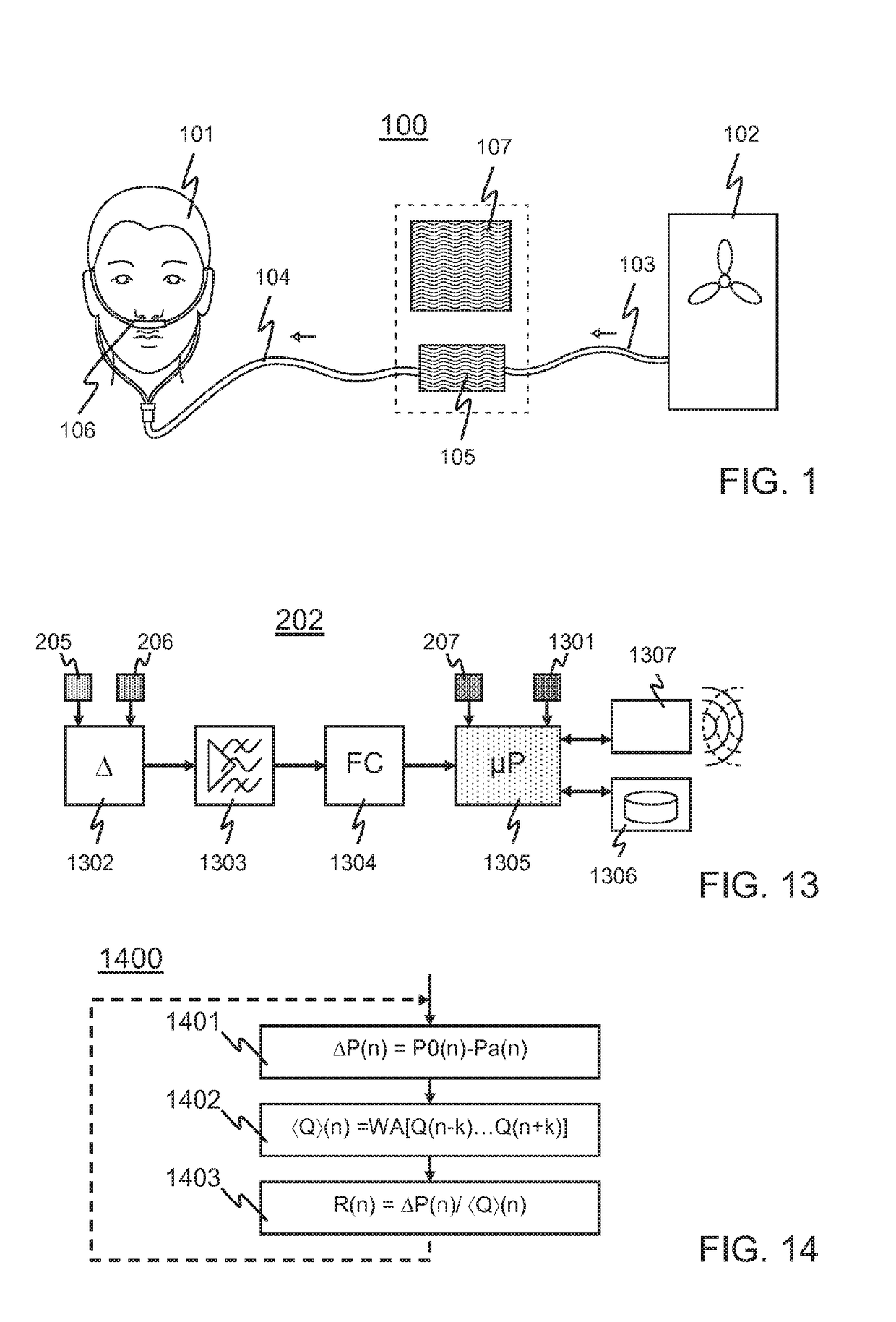

Ventilator system

InactiveUS20150007815A1Accurate flow measurementRespiratorsOperating means/releasing devices for valvesType ventilatorAir blower

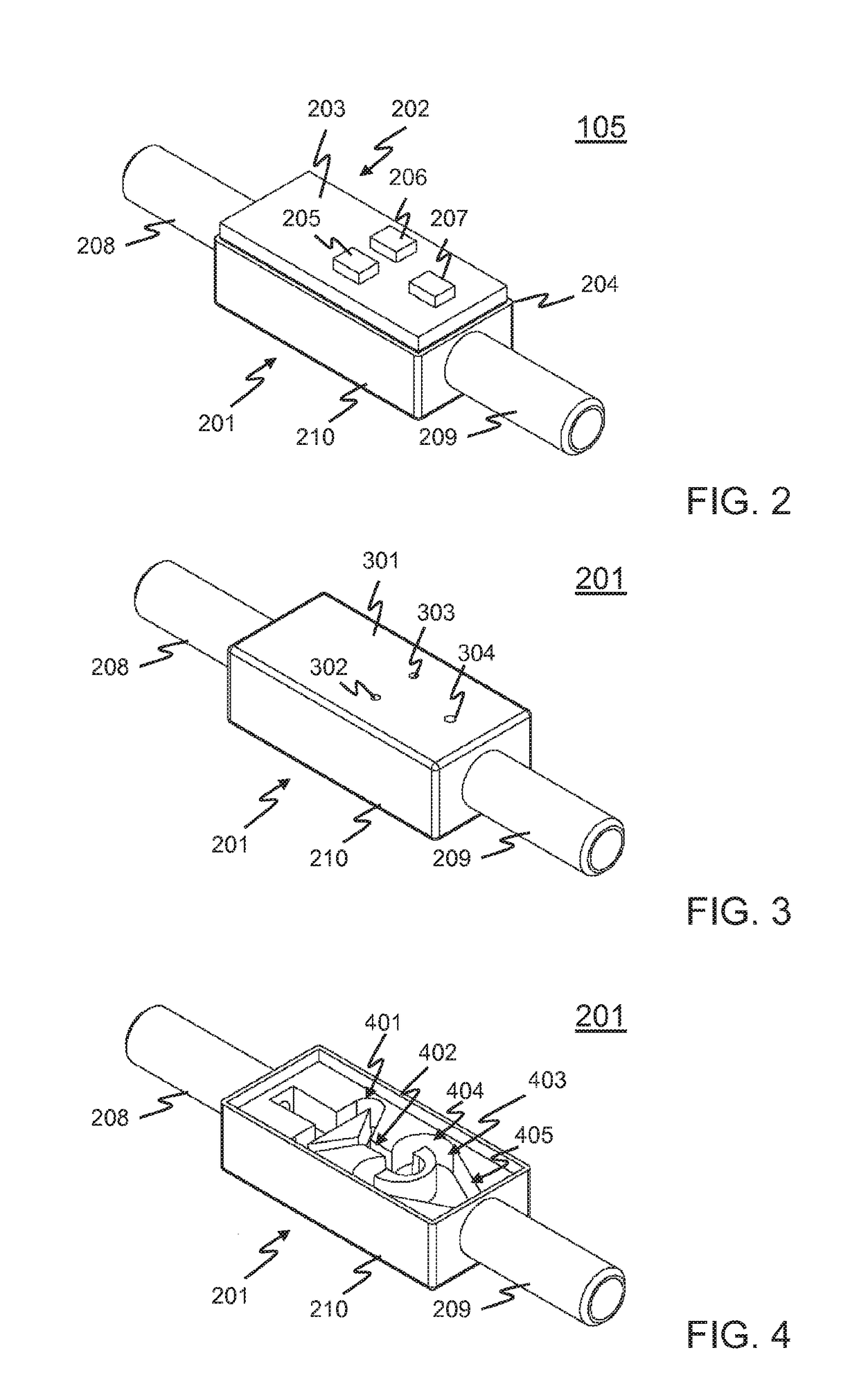

Described herein is a modular ventilator. The ventilator has modular flow control devices, which are connected to fluid inlet adapters. The modular flow control devices have sensors for controlling fluid flow through the modular flow control devices. The fluid inlet adapters are removable, and can include magnetic indicators, and the ventilator can identify the fluid from the magnetic indicator. The ventilator can also contain or be connected to a device having a low-noise blower.

Owner:VYAIRE MEDICAL CAPITAL LLC

Detection method and dedicated equipment for pressure difference measuring device

InactiveCN1928520AIngenious ideaImprove continuityTesting/calibration apparatusFluid pressure measurementMeasurement deviceEngineering

The related verification method for pressure-difference measurement device comprises: 1) given static pressure P and pressure difference deltaP, calculating the strain volume deltaV and the travel deltaH of fine-tuning pitons (5, 6) connected between high and low pressure room (2, 3); 2) controlling pitons movement by deltaH to change gas volume in (2, 3) and produce real pressure difference deltaP' determined by real deltaH'; 3) when deltaH = deltaH' and deltaP = deltaP', acting the measurement device (1) to complete one-time verification. This invention satisfies JJG882-2004 standard, fit to any P and deltaP, and needs no special requirement for environment.

Owner:李丹佳

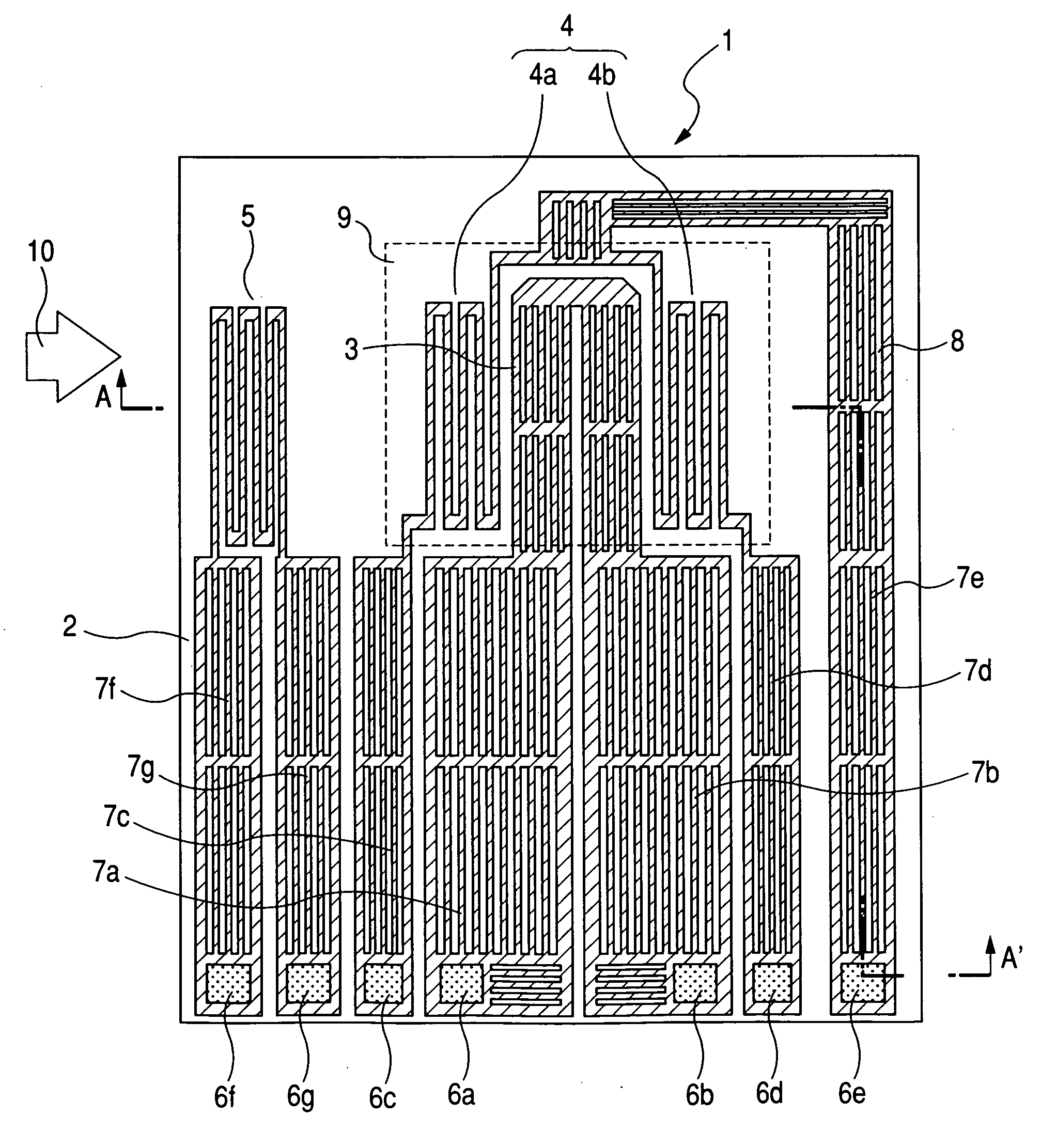

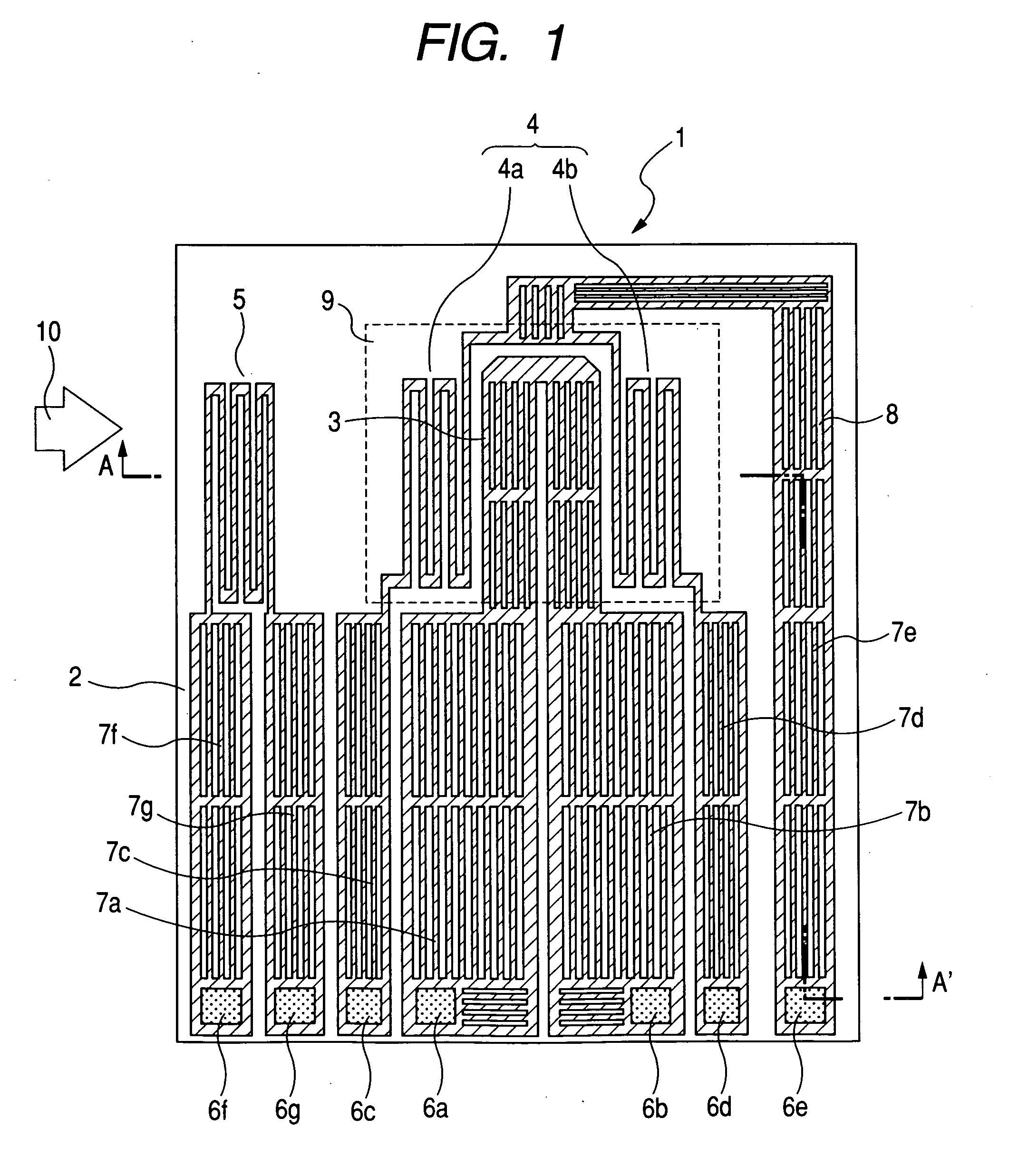

Flow sensor with metal film resistor

InactiveUS20090188314A1Uniform dishingUniform erosionVolume/mass flow by thermal effectsSpeed measurement using gyroscopic effectsElectrical resistance and conductanceSilicon

There is a need for providing a flow sensor with metal film resistor that improves detection sensitivity using a metal film for a resistance heat detector and a resistance temperature detector. The flow sensor with metal film resistor is structured to form a resistance heat detector, a resistance temperature detector for resistance heat detector for measuring temperature of the resistance heat detector, an upstream resistance temperature detector, a downstream resistance temperature detector, and an air resistance temperature detector on a silicon substrate. Plural floating-island insulators are provided for the resistance heat detector and within wiring thereof.

Owner:HITACHI LTD

Flow sensor with metal film resistor

InactiveUS7621180B2Accurate flow measurementConstant groove depthVolume/mass flow by thermal effectsSpeed measurement using gyroscopic effectsElectrical resistance and conductanceEngineering

There is a need for providing a flow sensor with metal film resistor that improves detection sensitivity using a metal film for a resistance heat detector and a resistance temperature detector. The flow sensor with metal film resistor is structured to form a resistance heat detector, a resistance temperature detector for resistance heat detector for measuring temperature of the resistance heat detector, an upstream resistance temperature detector, a downstream resistance temperature detector, and an air resistance temperature detector on a silicon substrate. Plural floating-island insulators are provided for the resistance heat detector and within wiring thereof.

Owner:HITACHI LTD

Flow meter

ActiveUS20080060447A1Low costImprove the uniformity of the magnetic fieldVolume/mass flow by electromagnetic flowmetersElectromagnetsEngineeringAir flow meter

An electromagnetic flow meter for measuring flow rate of a fluid passing therethrough includes a conduit defining a fluid inlet, a fluid outlet and a measuring section positioned between the inlet and the outlet. The flow meter also includes a single coil for generating a magnetic field across the measuring section and electrodes for detecting induced electrical potential due to the fluid passage. The flow meter also includes means for conditioning the flow through the measuring section. The combination of the single coil and the flow conditioning means provides a flow meter with a desired level of accuracy. The single coil and the electrodes may be arranged so that the integral of a weight function, which defines the sensitivity of the flow meter to fluid velocity through different parts of the measuring section, over the first half of a measuring section closest to the coil is between 0.4 and 1.3 times the integral of the weight function over the other half of the measuring section.

Owner:ABB LTD

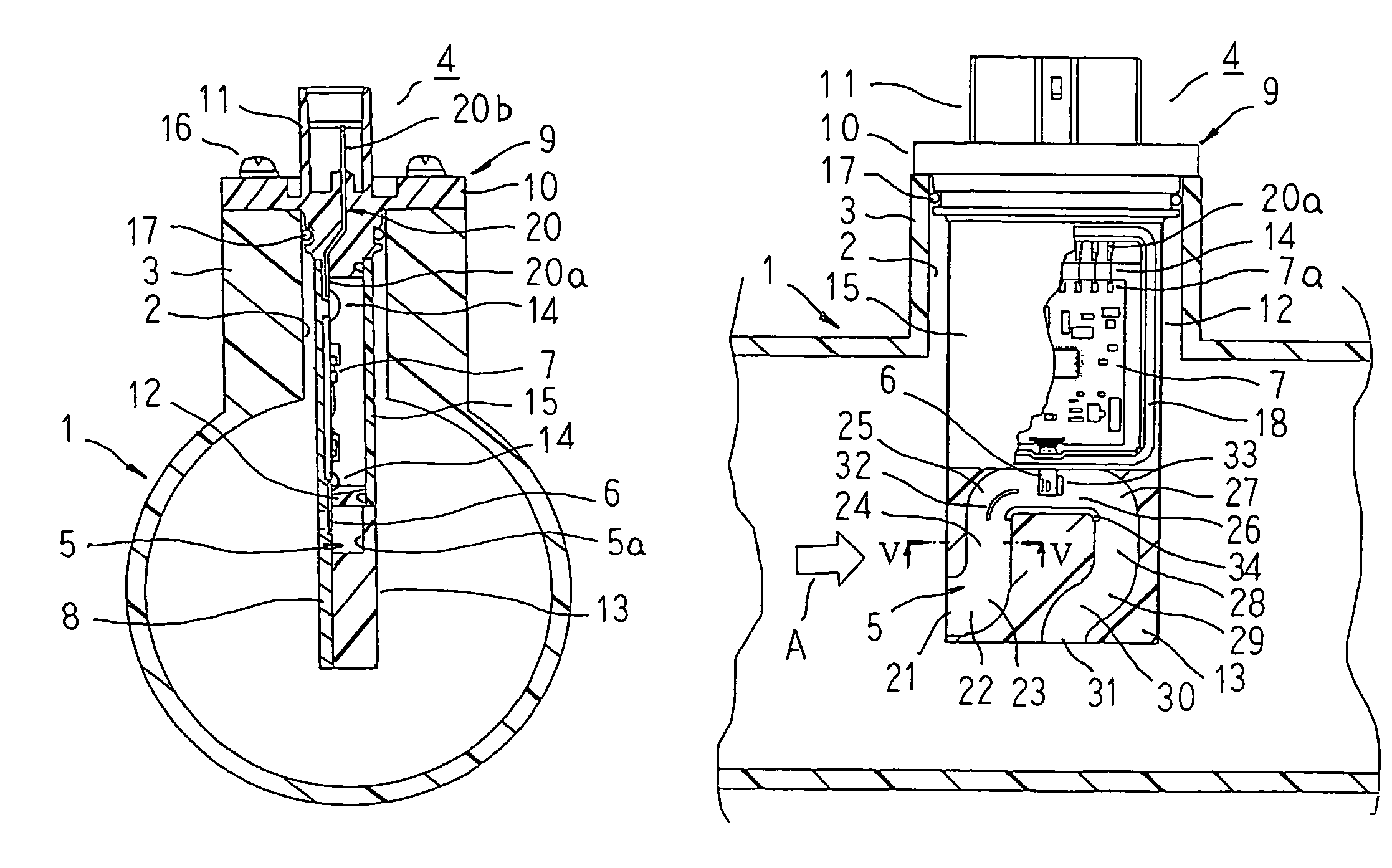

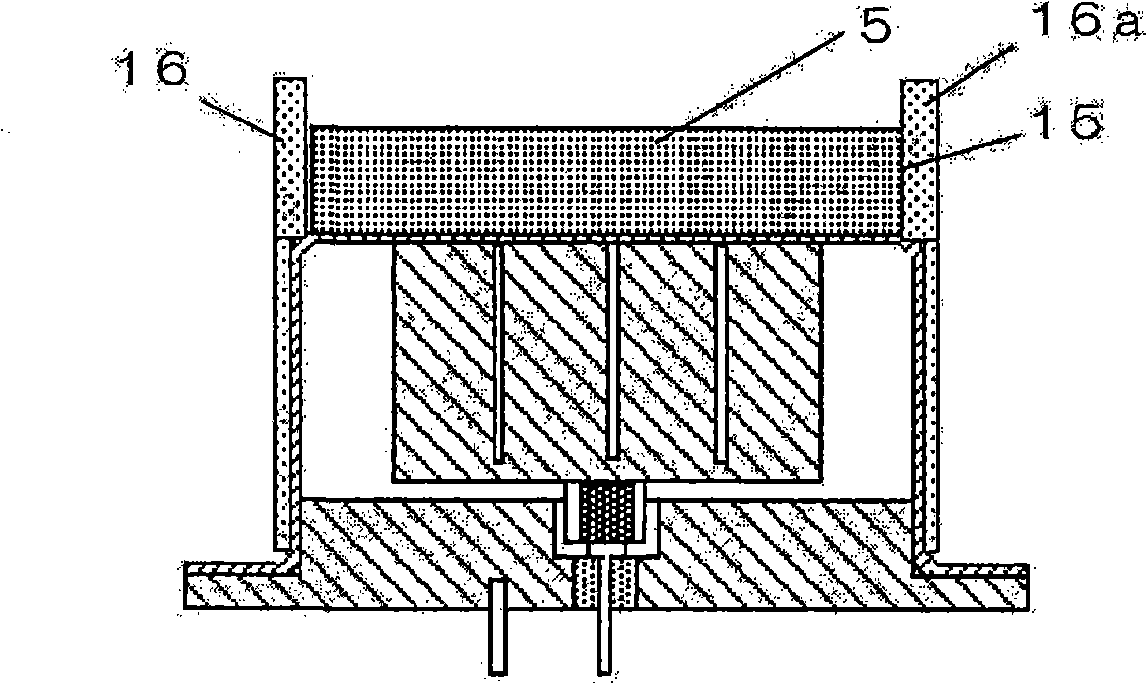

Ultrasonic transmitter/receiver and ultrasonic flowmeter using the same

InactiveCN101275862AImprove transceiver sensitivityStable sending and receivingVolume/mass flow measurementElectricityTransceiver

The purpose of the invention is improving the environment-tolerated performance for the matching layer in a supersonic wave transceiver and maintaining the transceiving characteristic of the supersonic wave transceiver. The supersonic wave transceiver of the invention and the piezoelectrics (4) which is arranged at the top inner surface of a metal columnar shell (2) have the electronically-connecting state; and the top of the supersonic wave transceiver in the sealing state is arranged with the vocal matching layer (5) formed by the porous bodies for improving the sensibility for receiving the supersonic wave; the supersonic wave transceiver (1) has a protective cover (7) for covering the lateral wall periphery of the metal columnar shell (2) and the vocal matching layer (5); the top of the protective cover (7) can form the shielding potion for avoiding the destroy of the vocal matching layer (5) in the range of stated opening area which can assure the area of the relevant vocal matching layer (5).

Owner:PANASONIC CORP

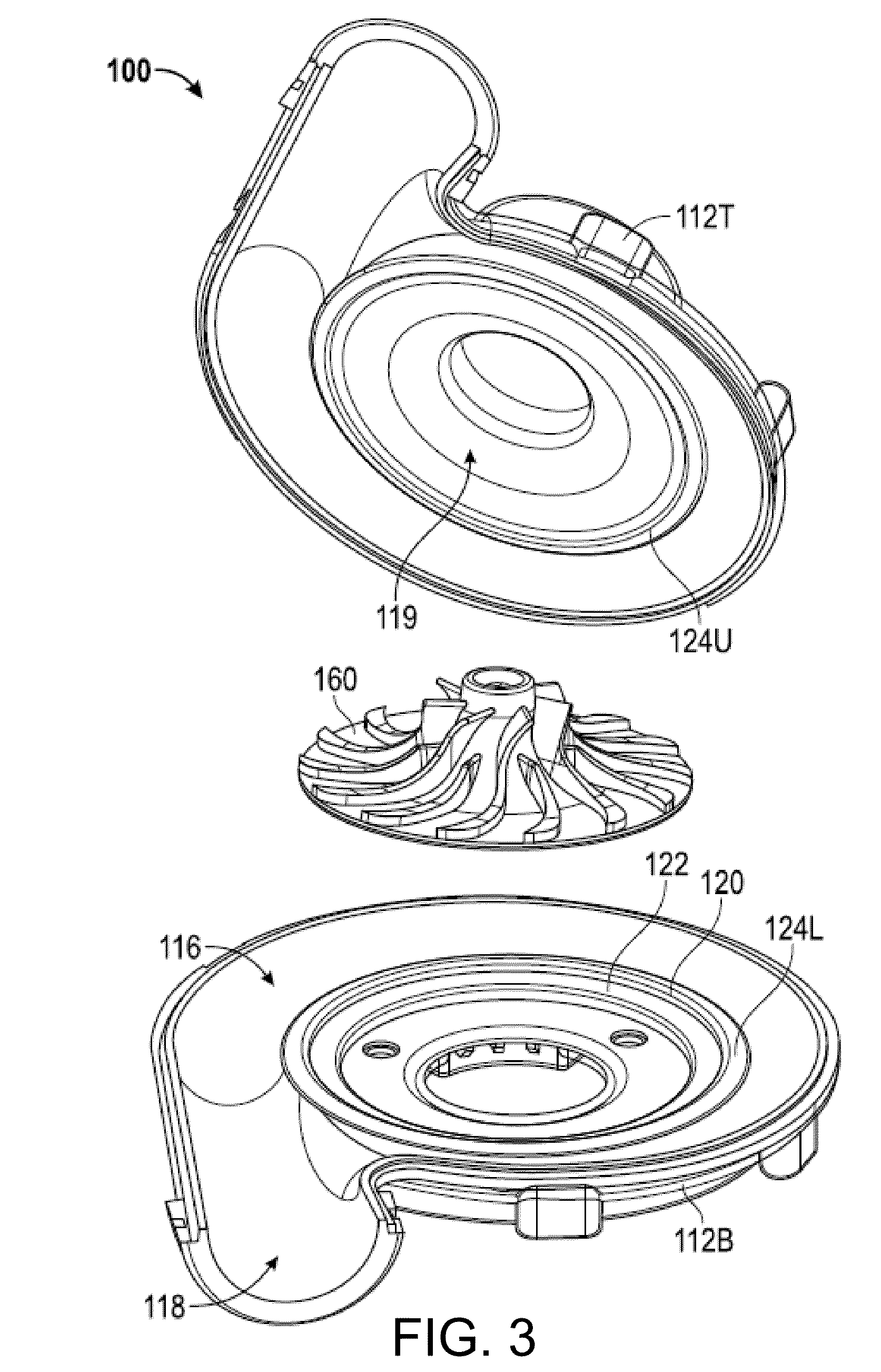

Modular flow cassette

ActiveUS20150000664A1Accurate flow measurementRespiratorsOperating means/releasing devices for valvesEngineeringStreamflow

Owner:VYAIRE MEDICAL CAPITAL LLC

Flow meter

ActiveUS7665368B2Low costImprove the uniformity of the magnetic fieldVolume/mass flow by electromagnetic flowmetersElectromagnetsEngineeringAir flow meter

Owner:ABB LTD

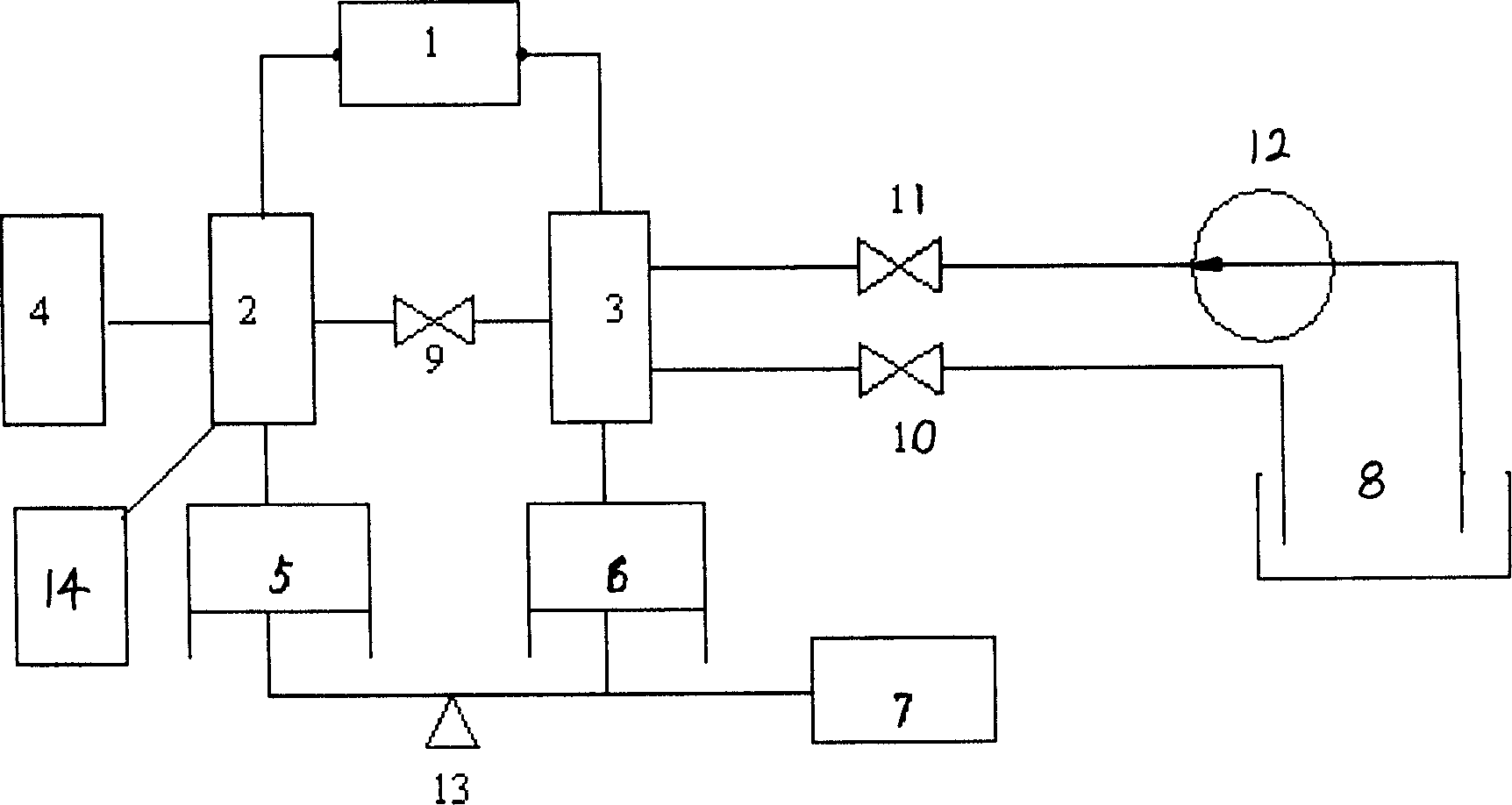

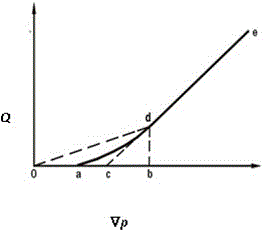

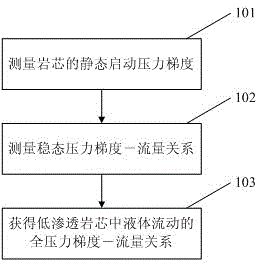

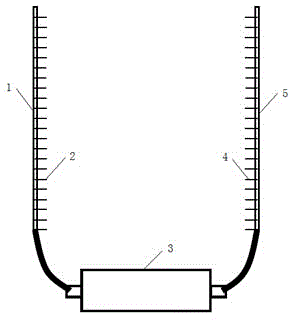

Measuring method of liquid full pressure gradient-flow relation in low-permeability reservoir

InactiveCN105319153AAccurate flow characteristicsAccurate flow measurementPermeability/surface area analysisRock corePore pressure gradient

The invention provides a measuring method of the liquid full pressure gradient-flow relation in a low-permeability reservoir. The measuring method includes the steps that 1, a thin glass tube communicator device is adopted for measuring the static starting pressure gradient in a low-permeability rock core; 2, a multifunctional rock core displacement device is adopted for measuring the steady state pressure gradient-flow relation; 3, the starting pressure gradient, obtained through the static method, of the low-permeability rock core and the steady state pressure gradient-flow data obtained through measurement by the steady-state method are drawn in the same graph, and then the liquid flowing full pressure gradient-flow relation of the low-permeability rock core is obtained. By means of the measuring method of the liquid full pressure gradient-flow relation in the low-permeability reservoir, the starting pressure of the low-permeability rock core can be measured accurately, the liquid flowing pressure gradient-flow relation can be obtained on the basis of the full pressure gradient, and the obtained flow characteristics of the low-permeability rock core are more accurate and can be used for flowing characteristics description of the low-permeability reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

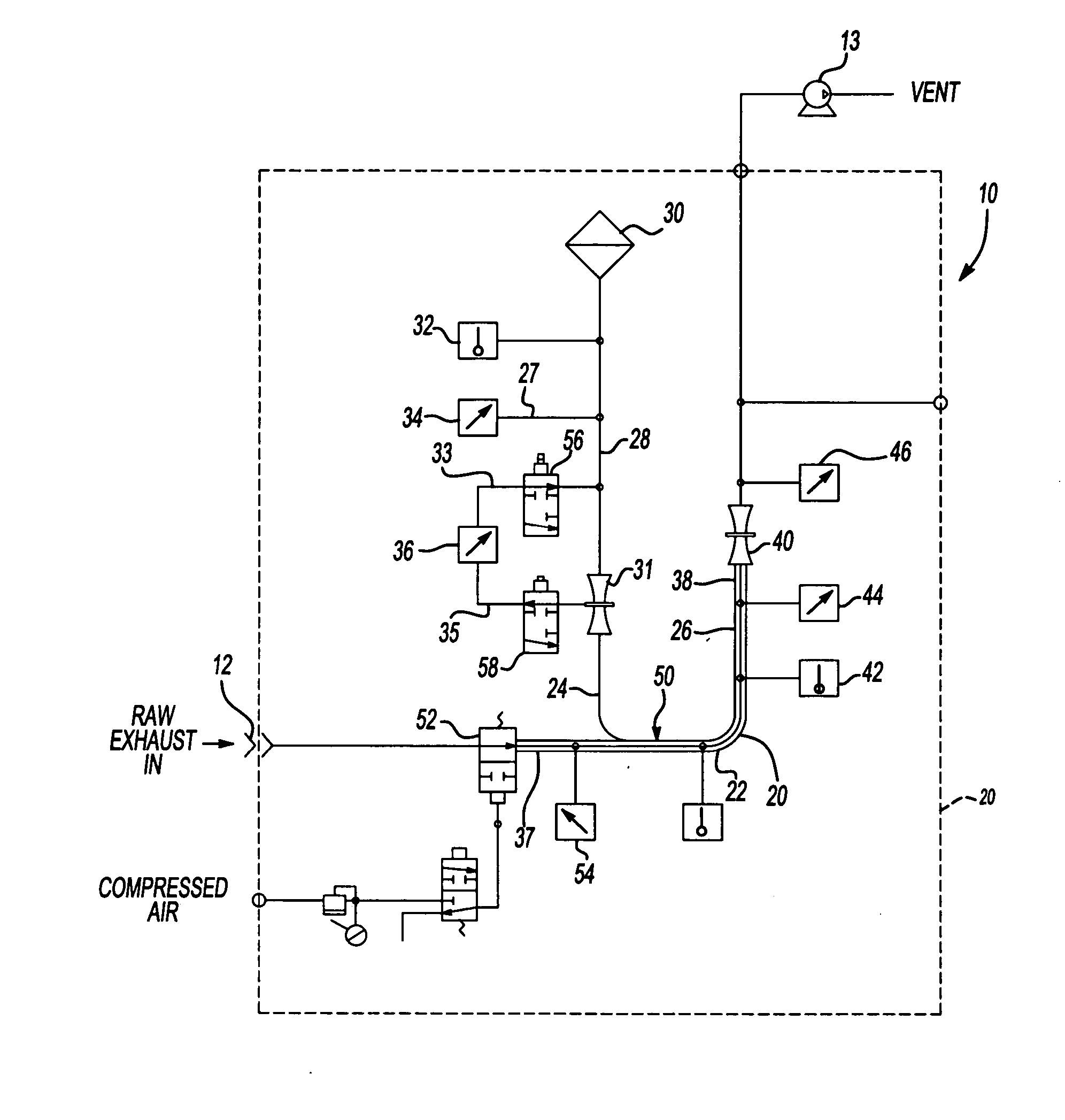

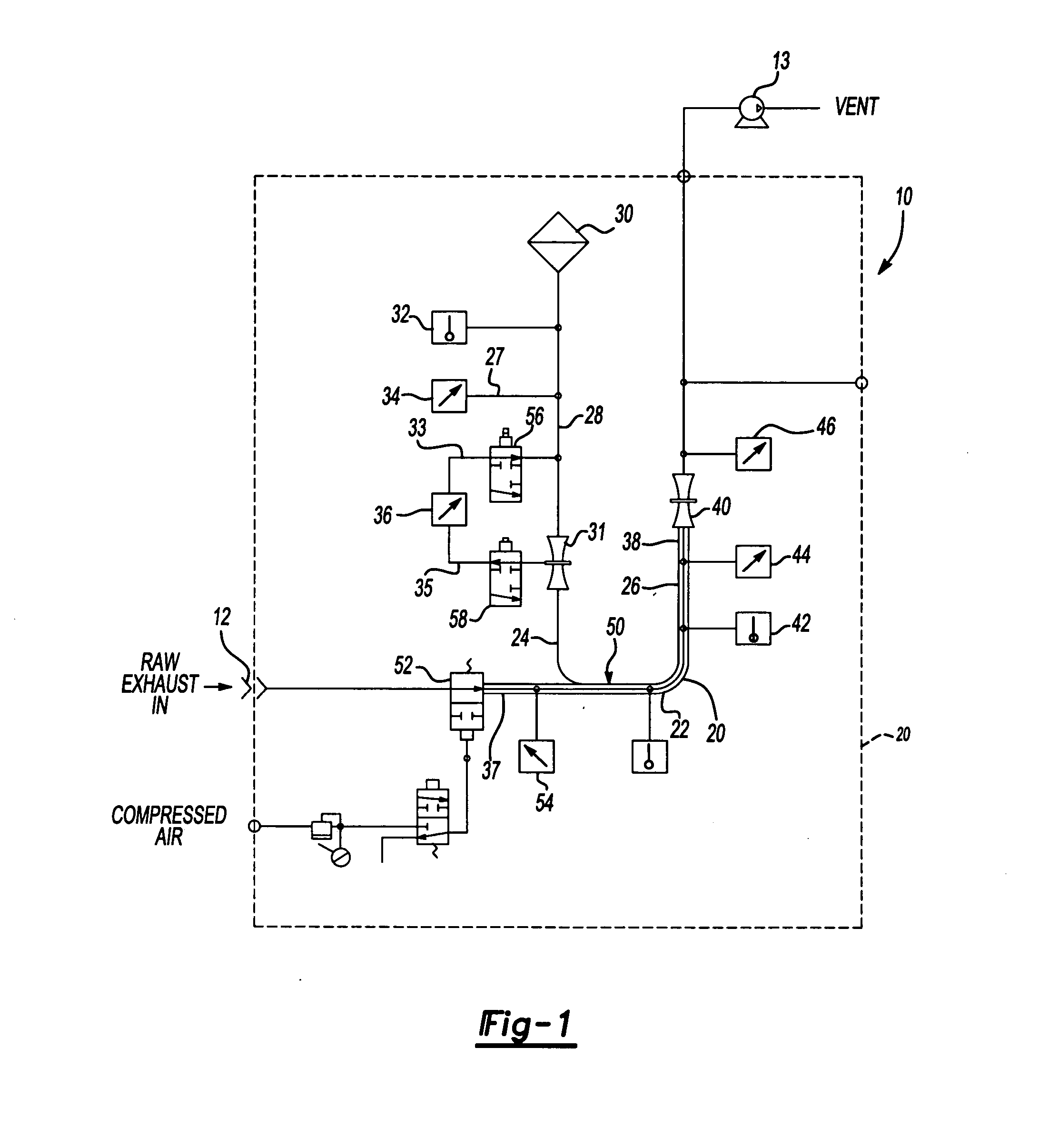

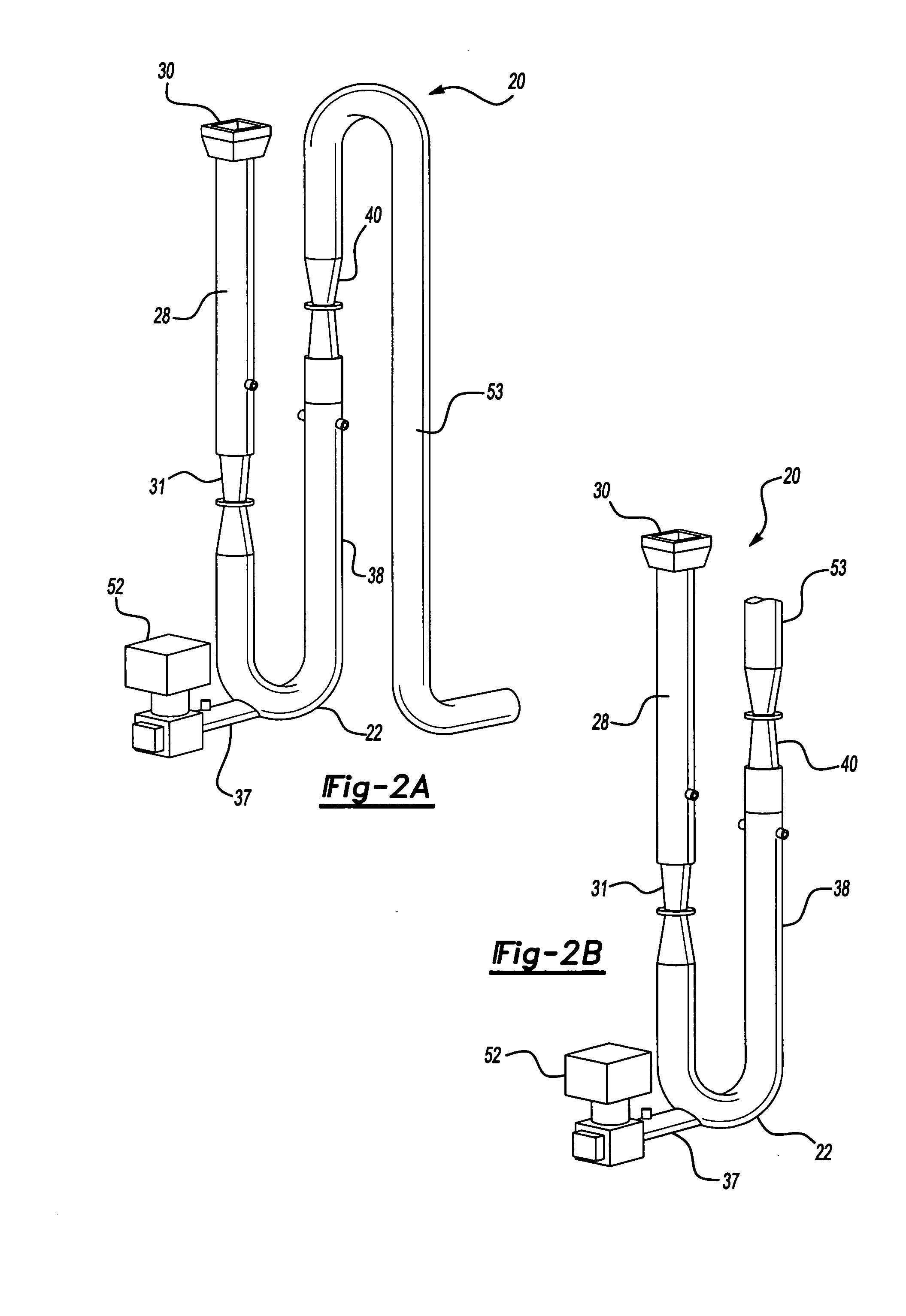

Exhaust volume measurement device

InactiveUS20050061054A1Accurate flow measurementInternal-combustion engine testingMaterial analysis by electric/magnetic meansMeasurement deviceDifferential pressure

A vehicle exhaust measurement system is provided includes that a conduit having a conduit inlet and a conduit outlet. A make-up air tube is connected to and is in fluid communication with the conduit inlet. The make-up air tube provides make-up air for mixing an exhaust gas. A mixed gas tube is connected to and is in fluid communication with the conduit outlet. The mixed gas tube conveys a mixture of make-up air and exhaust gas to analysis equipment. In the preferred embodiment, the exhaust gas tube extends through an outer wall of the conduit. A mixing plate is arranged in either the conduit or the mixed gas tube with the exhaust gas tube extending to a position adjacent to the mixing plate. The exhaust gas tube conveys the exhaust gas to the mixing plate to mix the exhaust gas and the make-up air at the mixing plate. A correction factor may be applied to the measurements taken by a differential pressure based fluid flow measurement device such as a smooth approach orifice (SAO) to provide an adjusted flow of measurement at the flow measurement device to correct for the pressure pulsations. The correction factor is calculated based upon the intensity of the pulsations of the differential pressure signal, which indicates the flow through the SAO.

Owner:AVL TEST SYST

Flow rate measurement device

ActiveUS20170343398A1Reduce decreaseImprove receiver sensitivityMechanical apparatusLayered productsObservational errorUltrasound attenuation

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

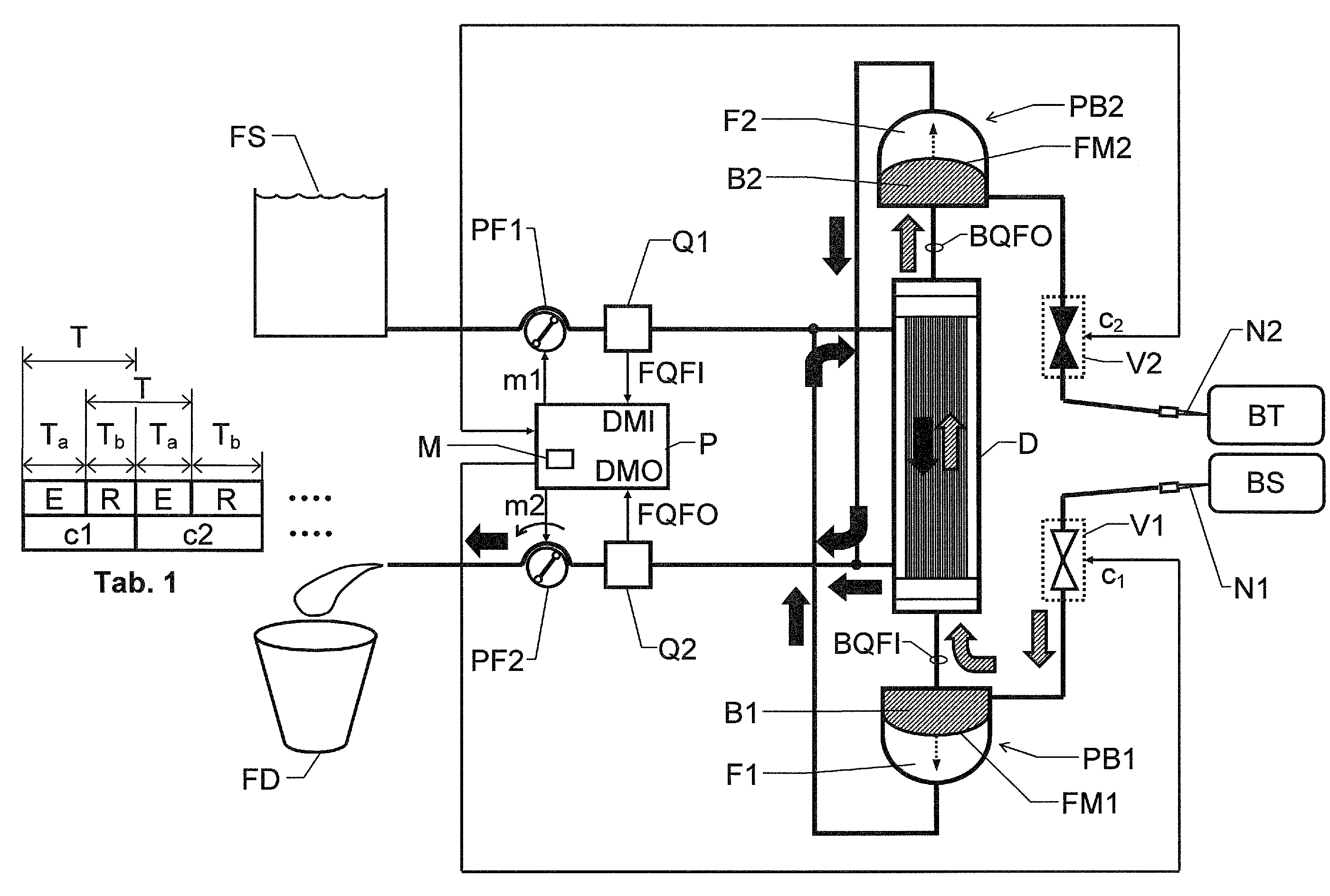

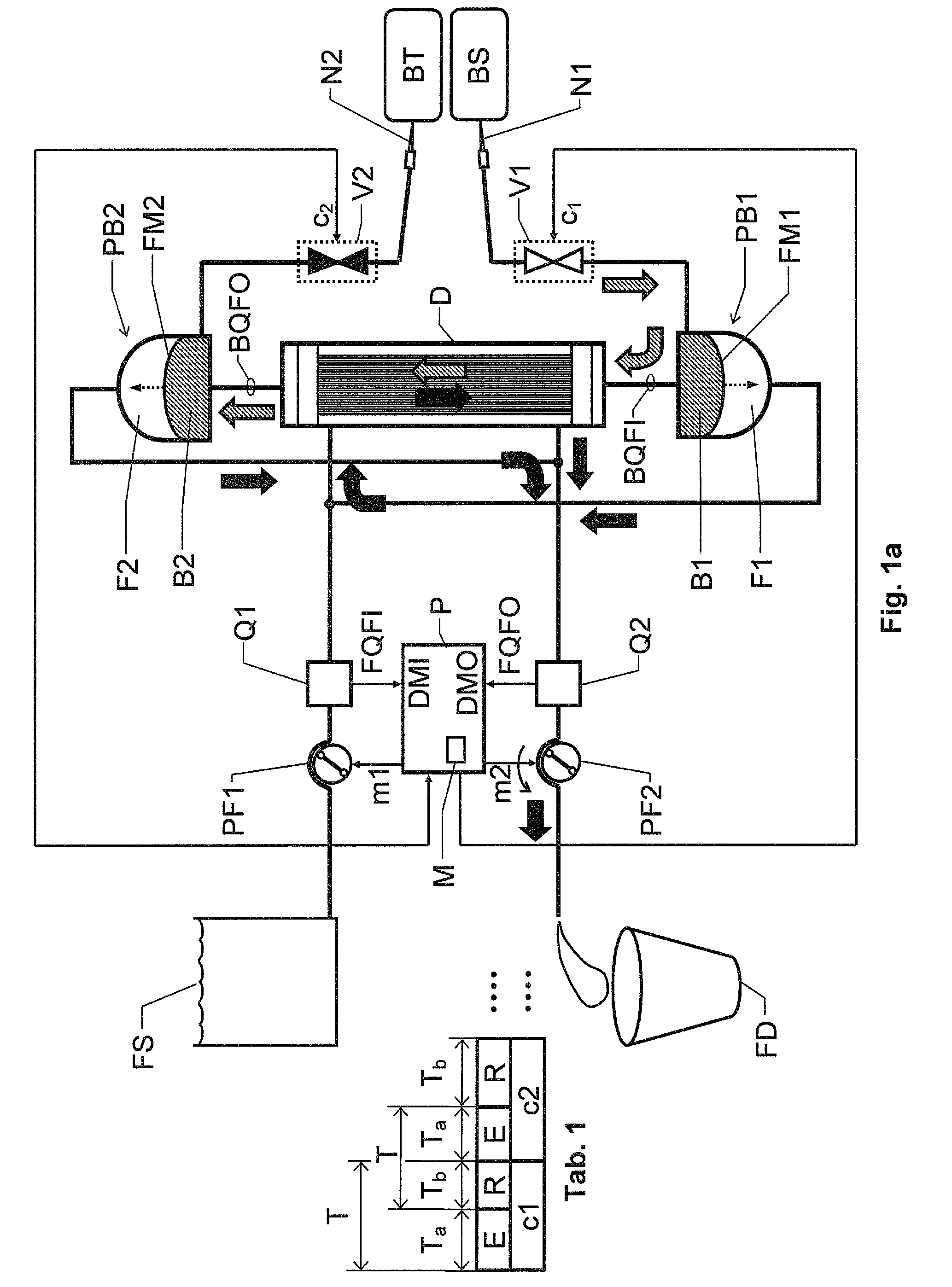

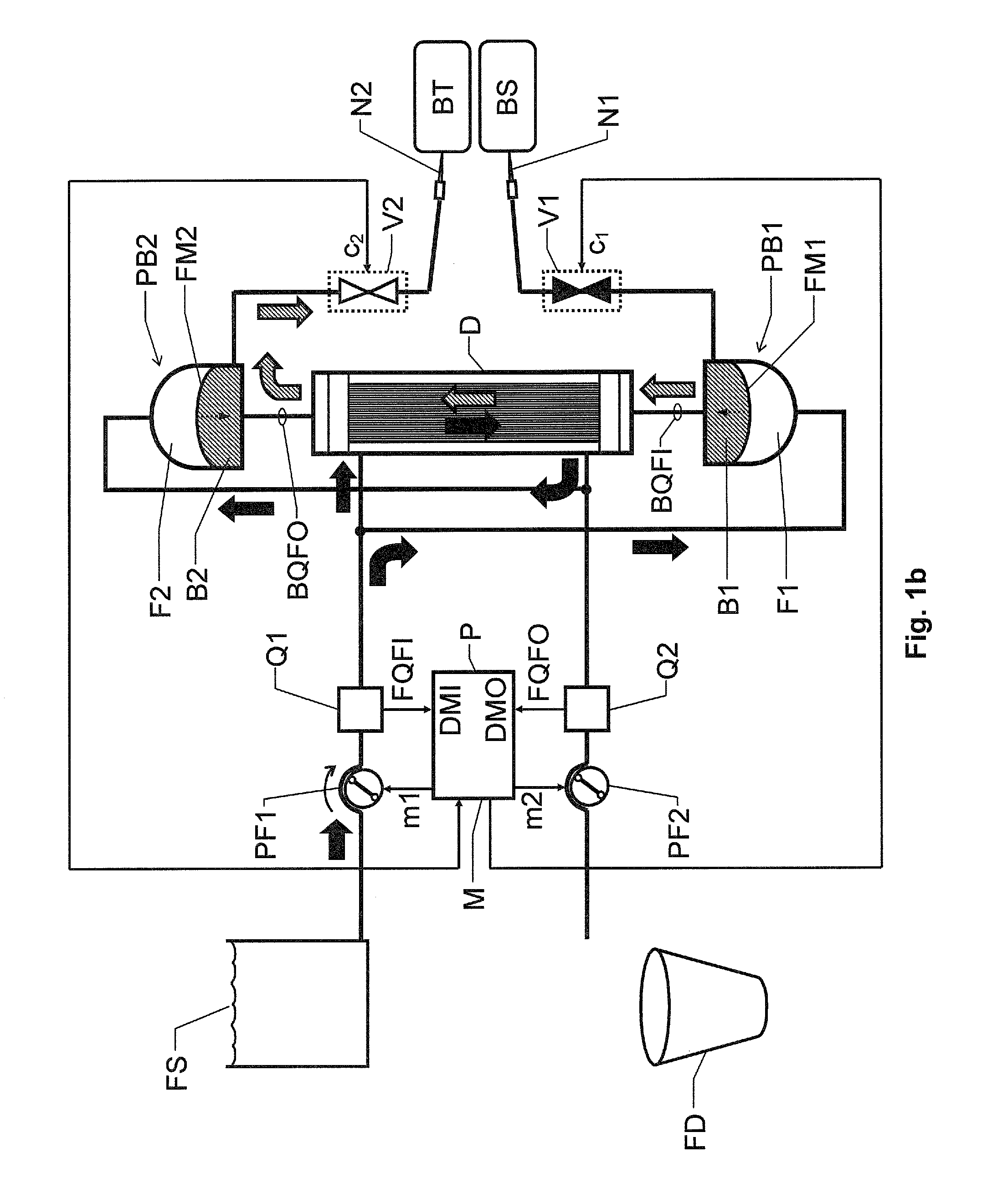

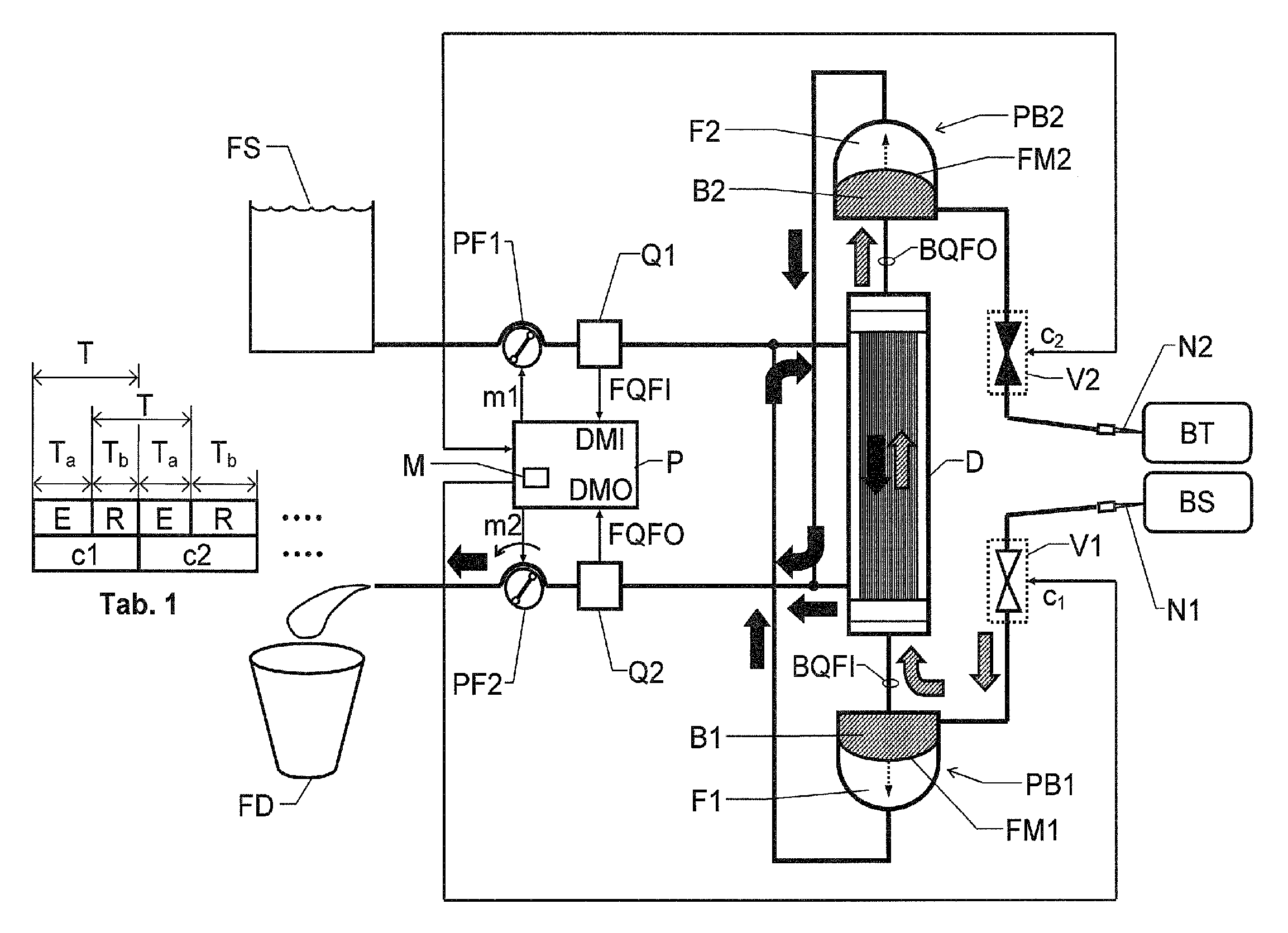

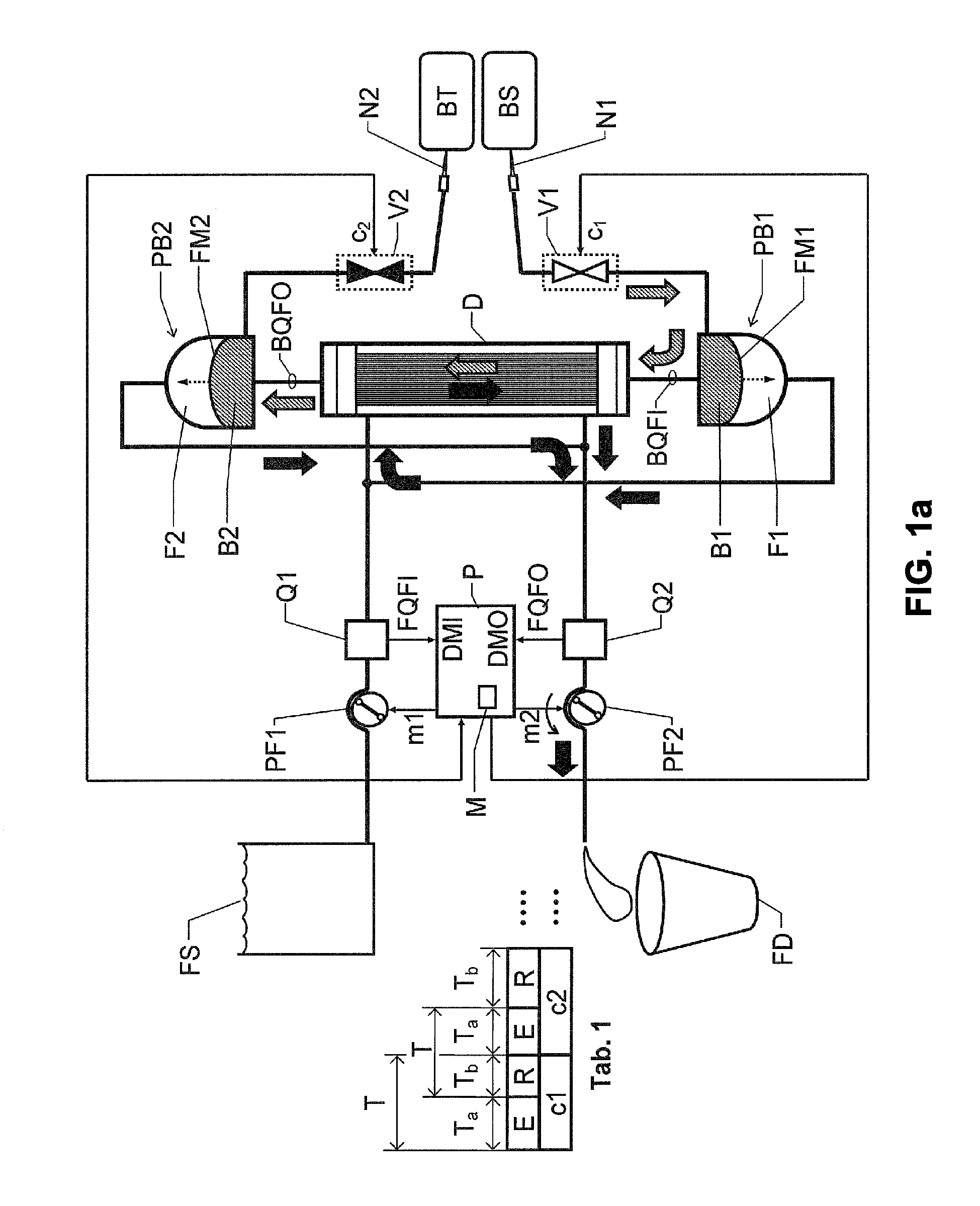

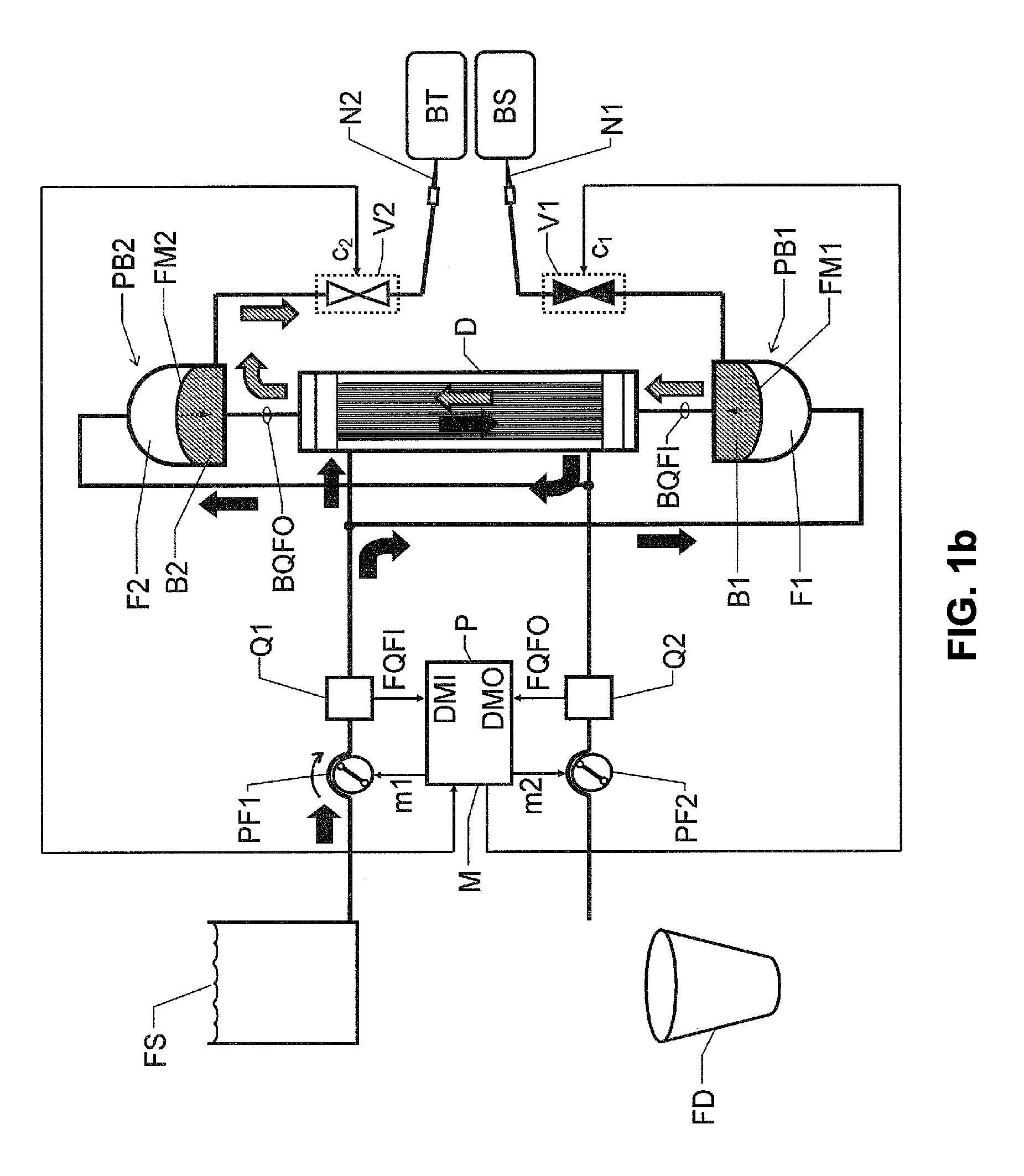

Blood treatment apparatus and method

ActiveUS20110201989A1Improve design flexibilityAccurate flow measurementSettling tanks feed/dischargeDialysis systemsBlood treatmentsPump chamber

A blood treatment apparatus, including a blood treatment unit configured to receive untreated blood and fresh blood treatment fluid, and emit treated blood and used blood treatment fluid, a pair of fluid pumps configured to pass blood treatment fluid through the blood treatment unit, a pair of blood pumps configured to extract untreated blood from a blood source, pass extracted blood through the blood treatment unit and deliver treated blood to a target vessel, each blood pump including a pump chamber and a flexible member separating the pumping chamber into a first blood accumulating container and a second working fluid accumulating container where the flexible member is configured to vary a volume relationship between the first and the second accumulation containers. A control unit and a measuring device are configured to emit a feedback signal indicative of the amount of working fluid received into, or discharged from at least one of the second accumulation containers whereby the pumped mass or volume of working fluid is determined by the control unit at an arbitrary position of the flexible member.

Owner:GAMBRO LUNDIA AB

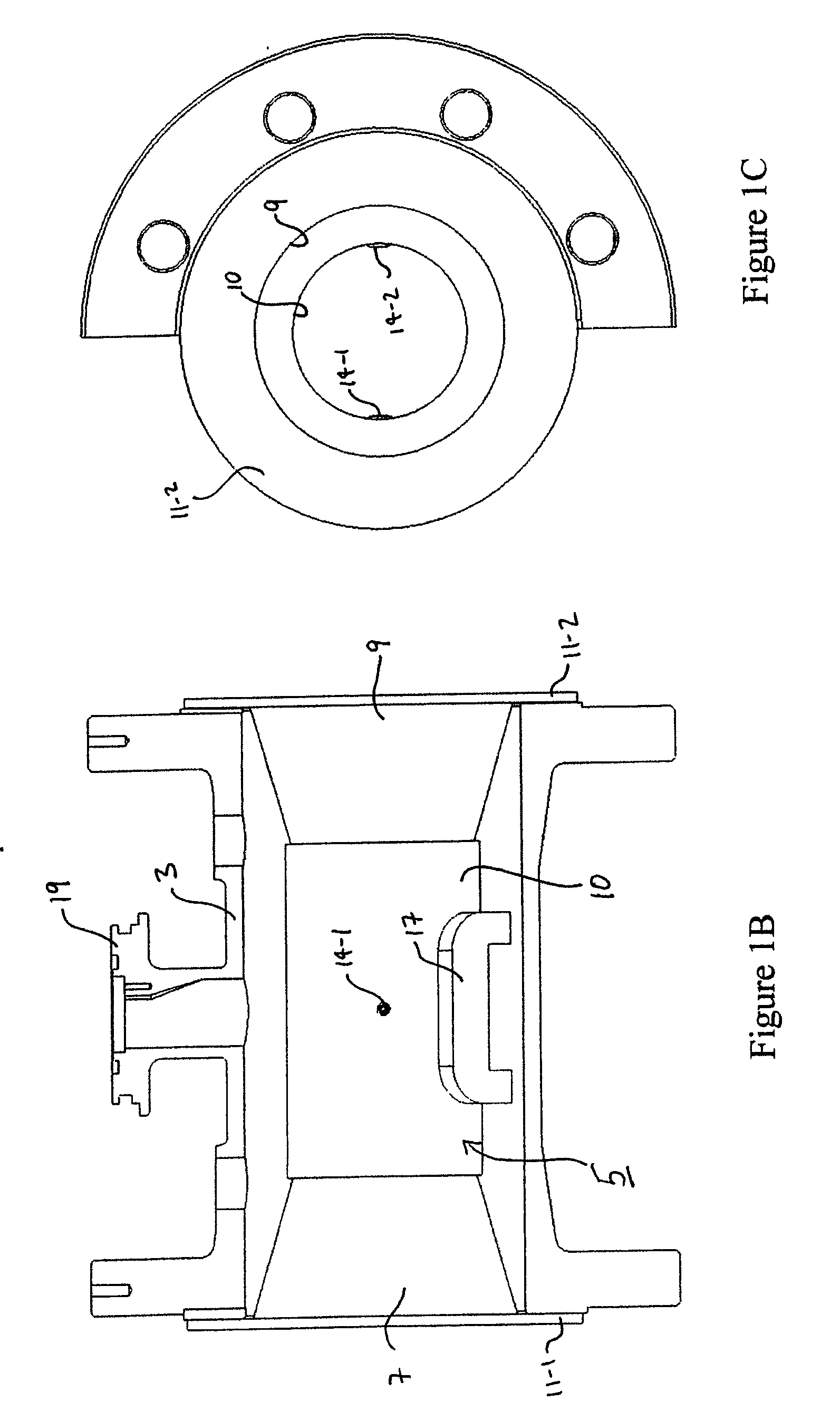

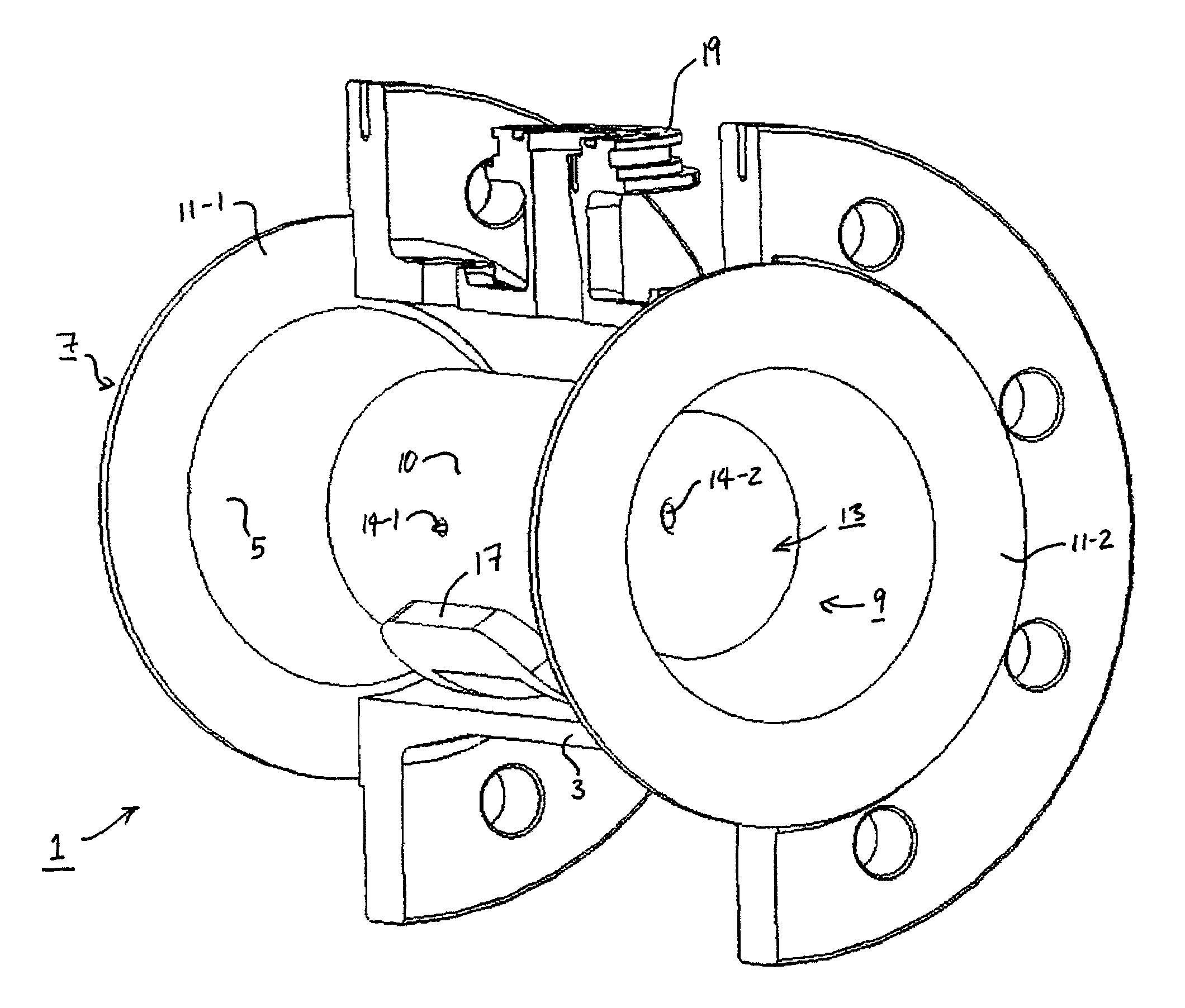

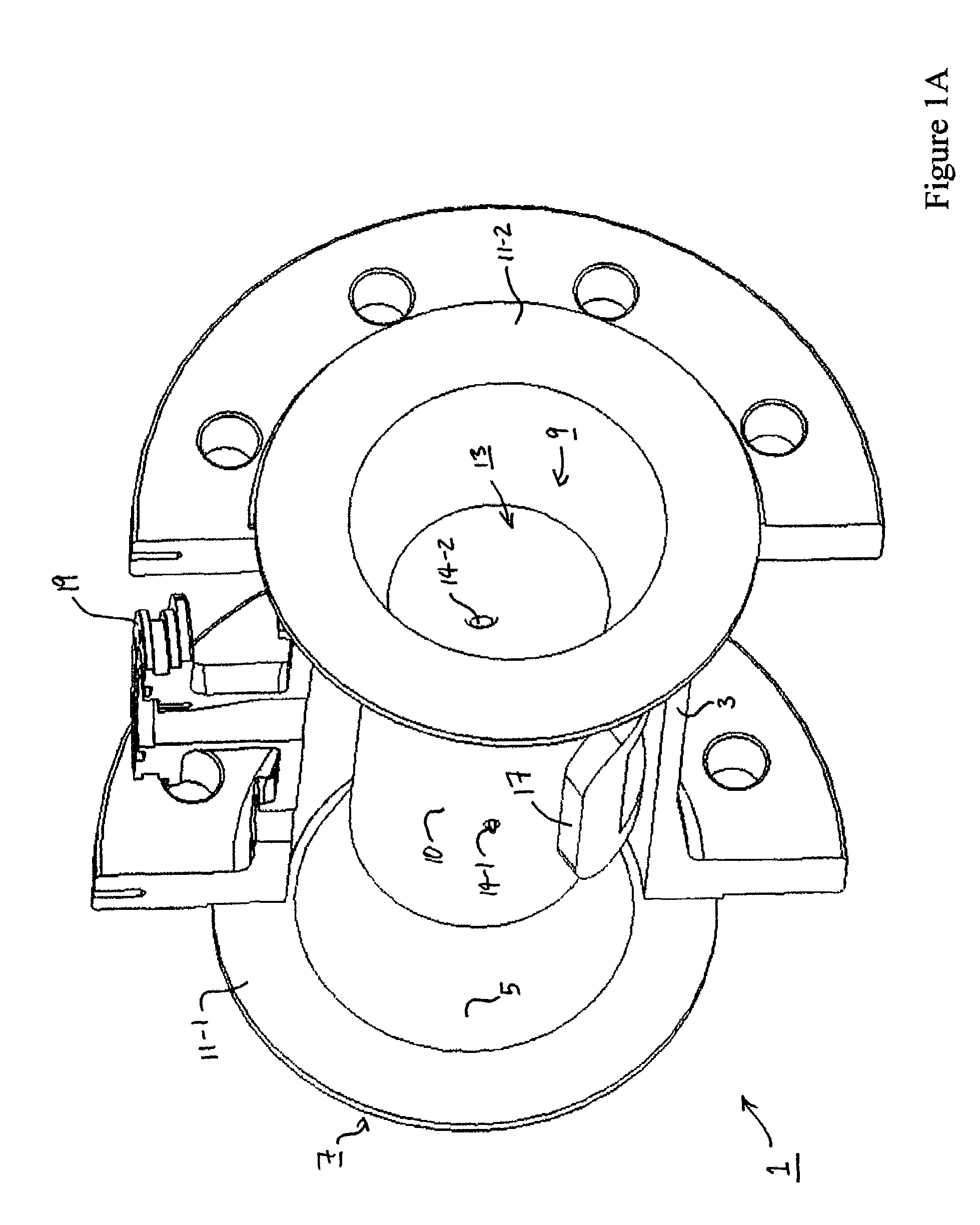

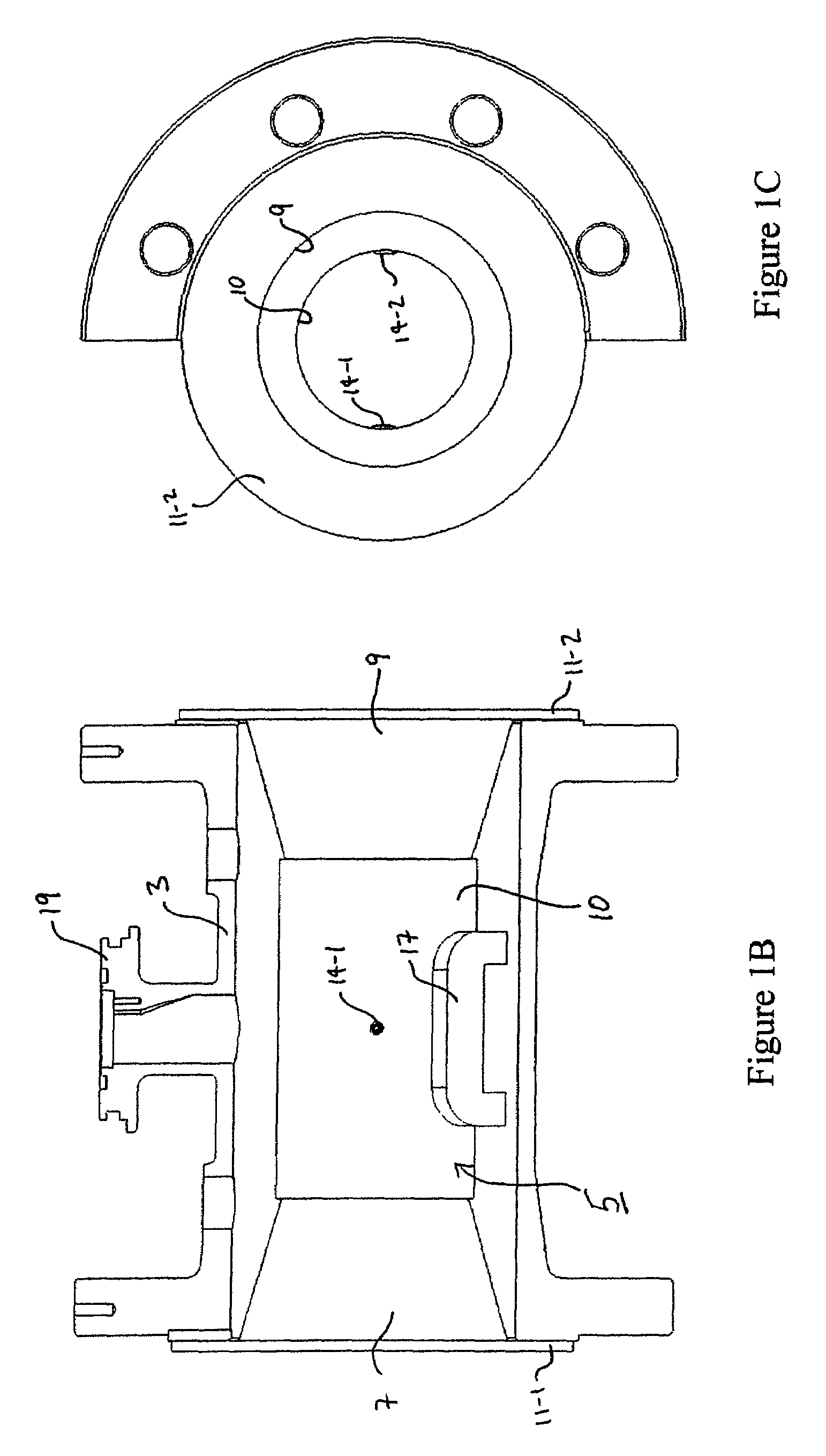

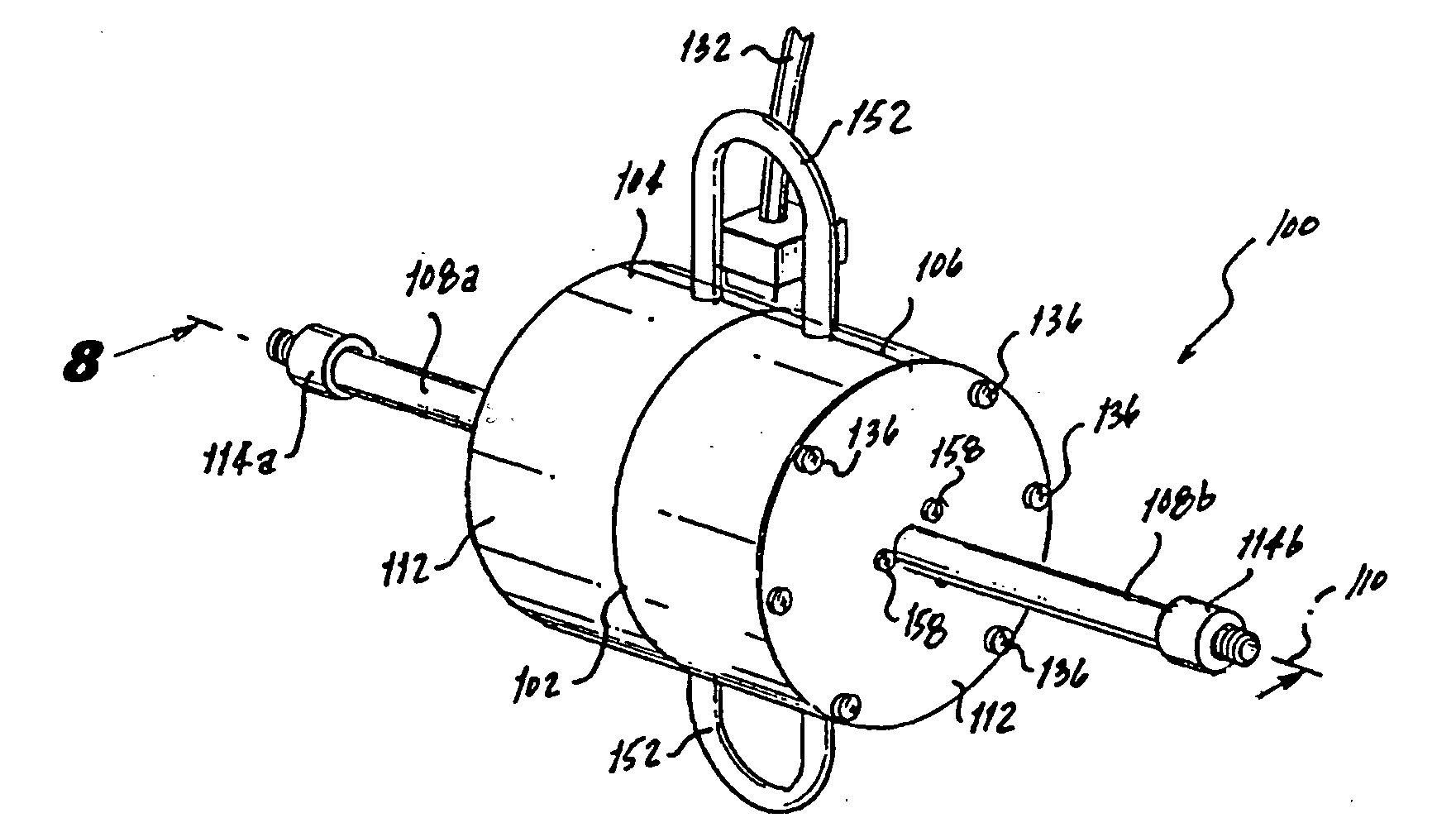

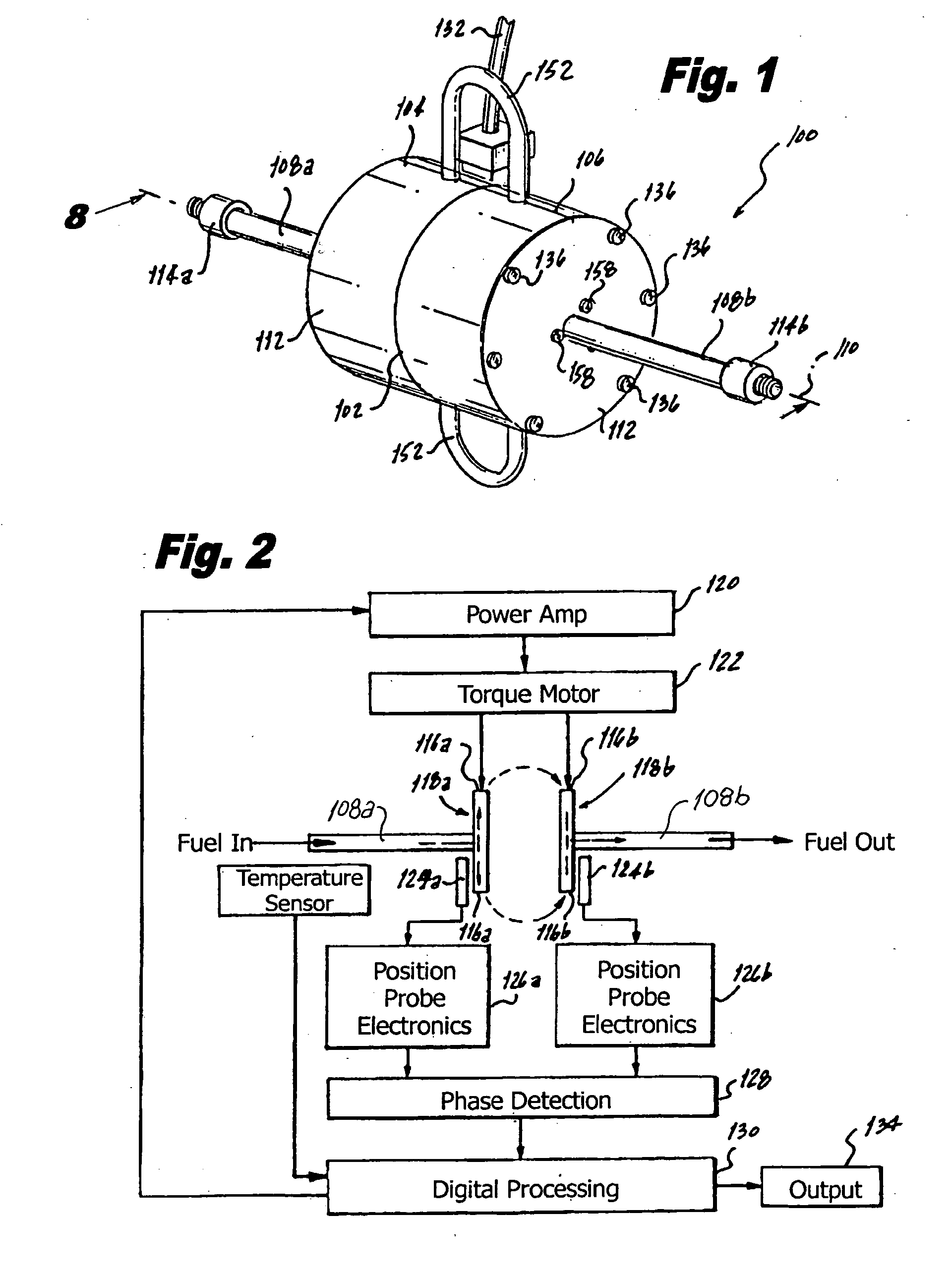

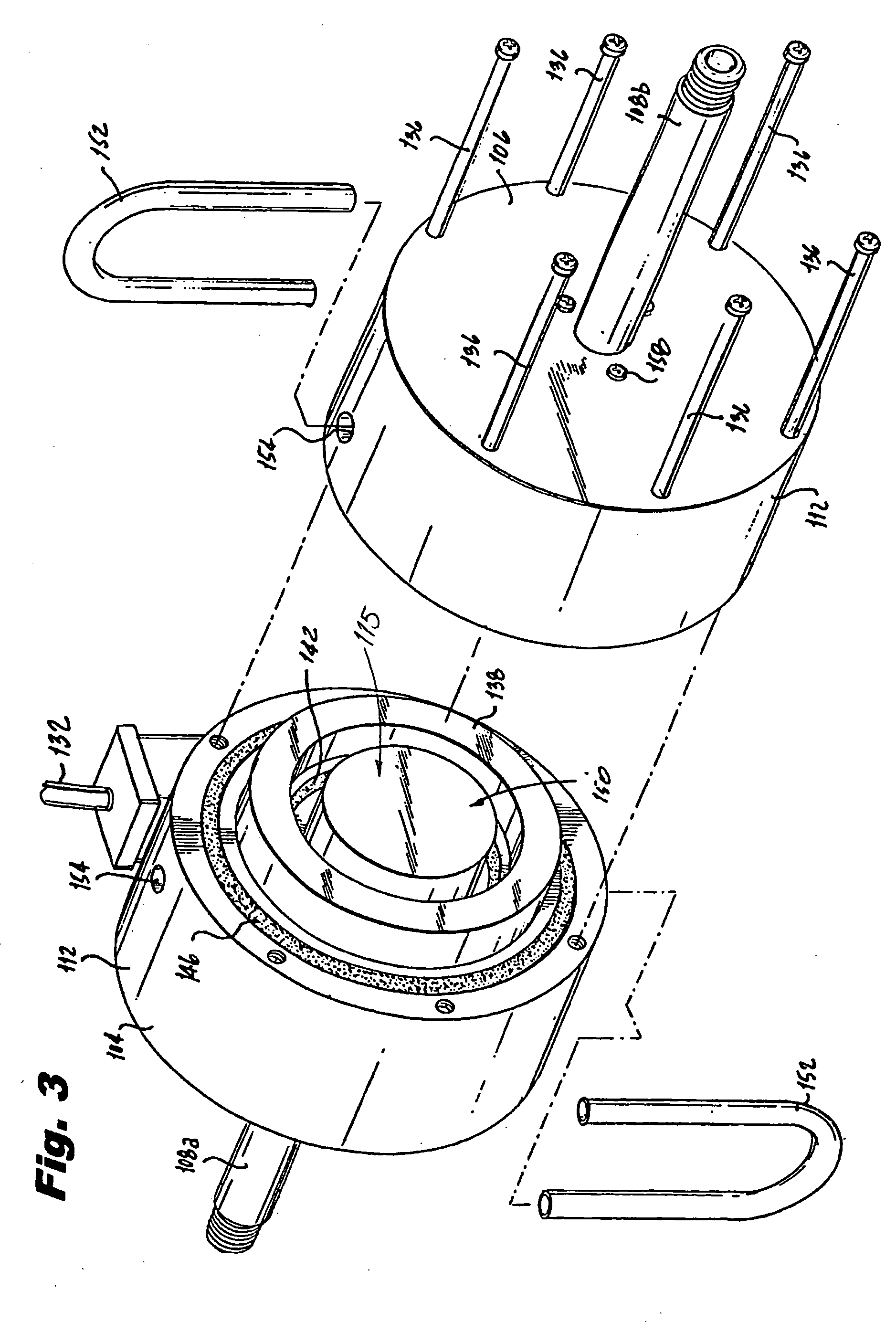

Coriolis effect mass flow meter and gyroscope

InactiveUS20100018326A1Minimize unwanted disk motionVibration minimizationDirect mass flowmetersGyroscopePhase difference

A Coriolis effect device includes a housing defining an interior chamber having a central axis, an inlet, an outlet, a leading disc and a trailing disc. Each disc is supported for oscillatory movement within the interior chamber of the housing. The leading disc defines a leading flow path in fluid communication with the inlet and interior chamber, wherein a portion of the leading flow path extends radially with respect to the central axis. The trailing disc is axially spaced from the leading disc. The trailing disc defines a trailing flow path in fluid communication with the interior chamber and the outlet, wherein a portion of the trailing flow path extends radially with respect to the central axis. A phase difference between leading and trailing oscillating signals picked up from the disc movement can be used to determine a mass flow rate of fluid passing from the inlet to the outlet.

Owner:ROSEMOUNT AEROSPACE

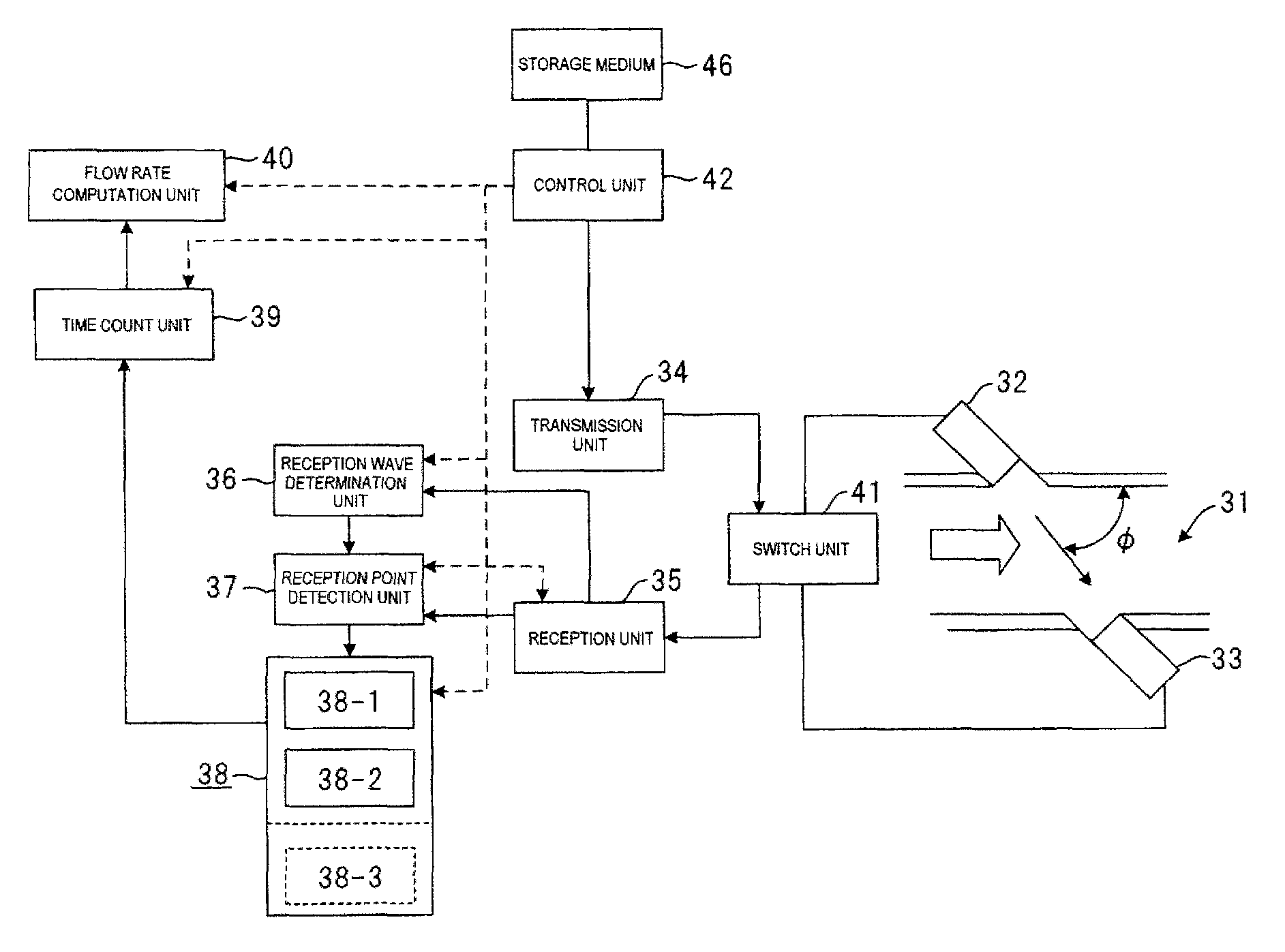

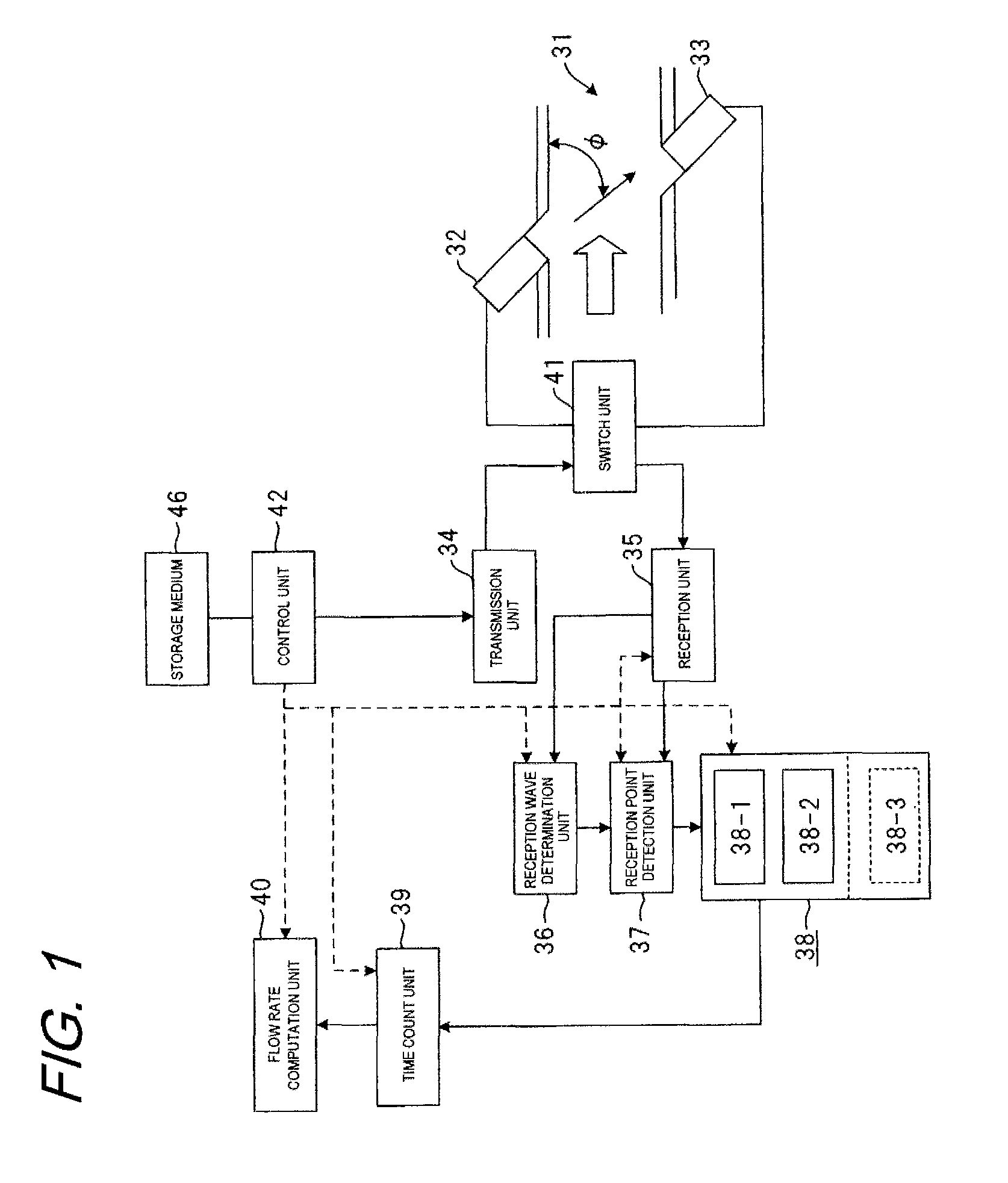

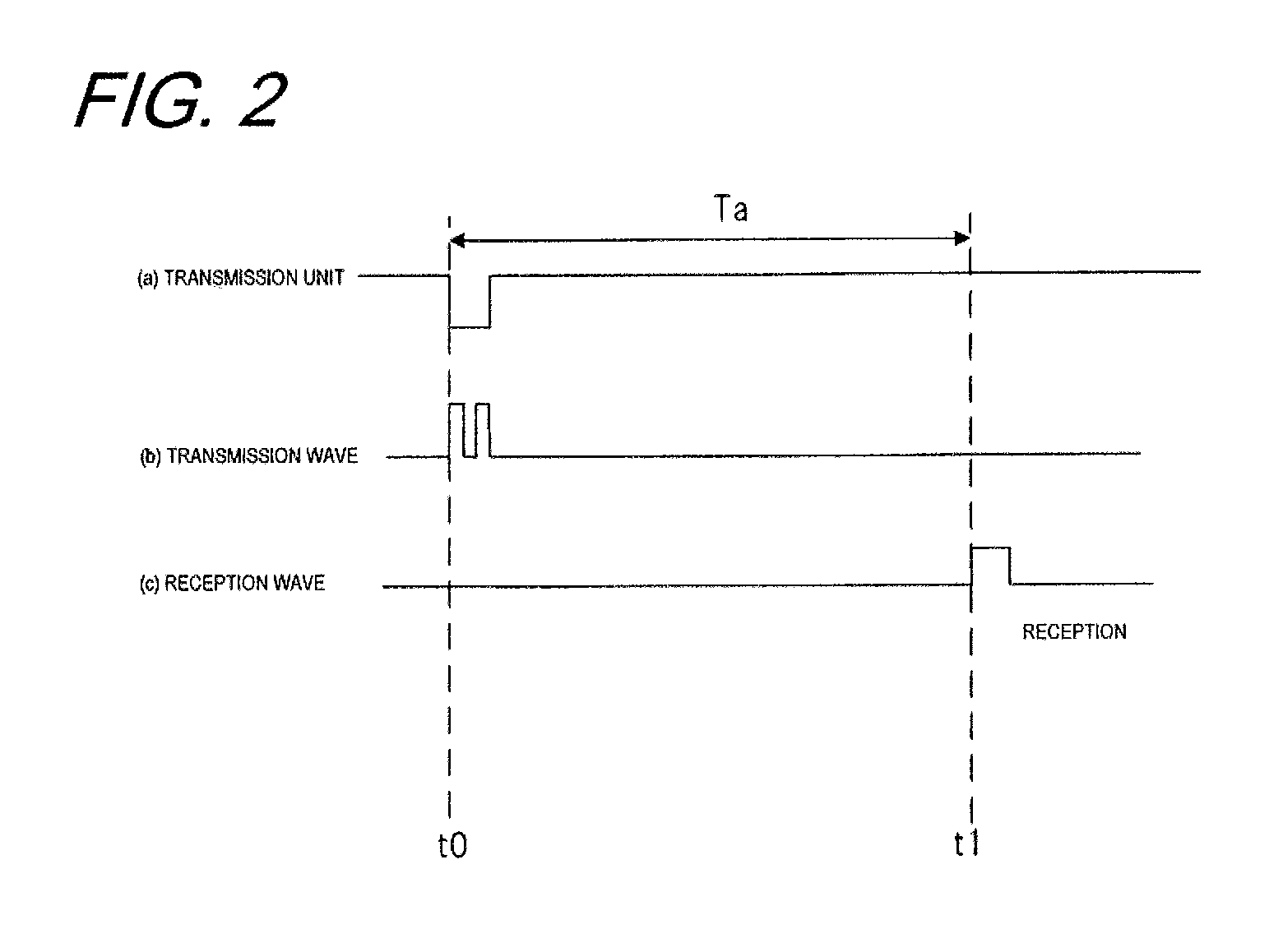

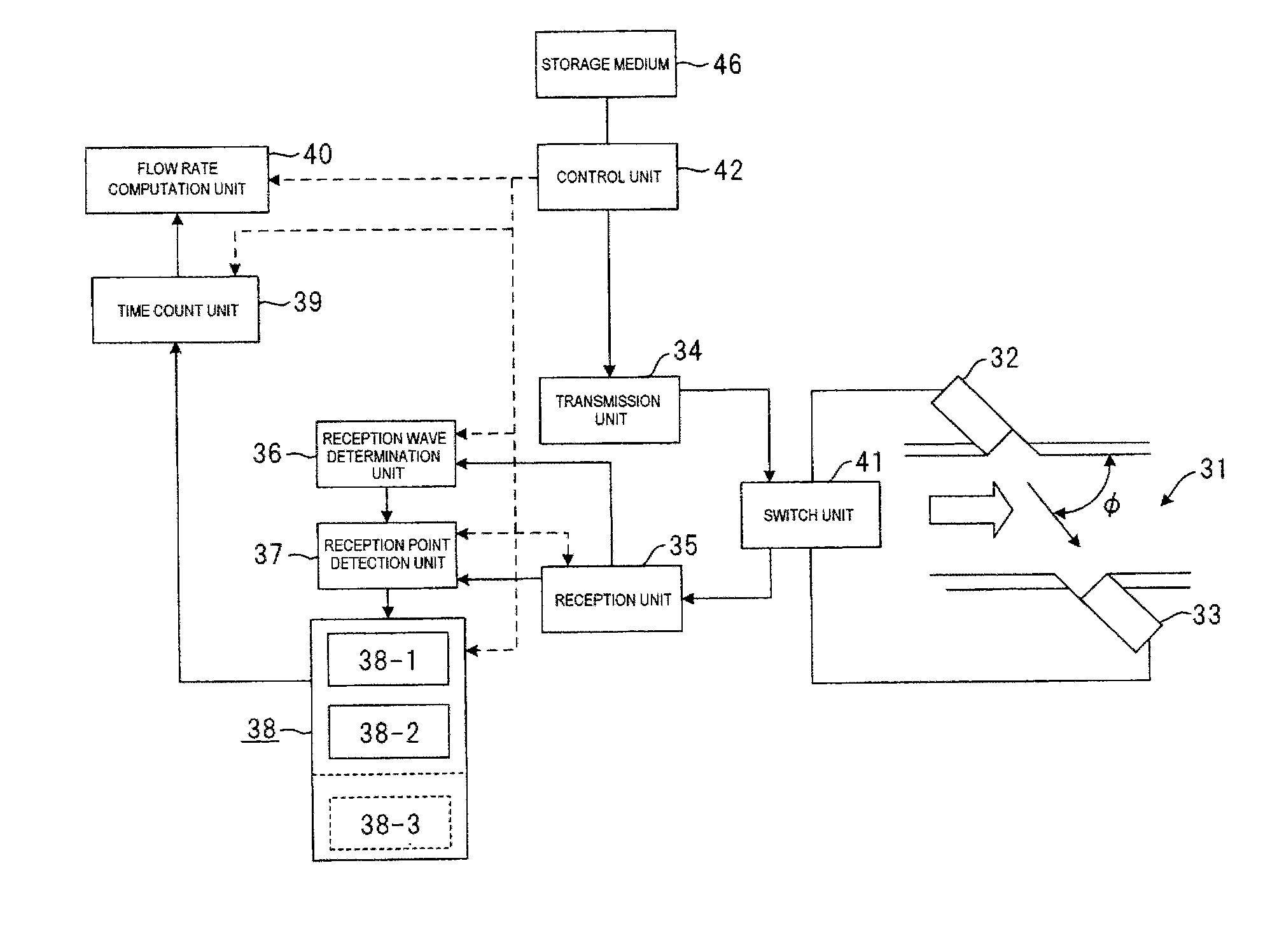

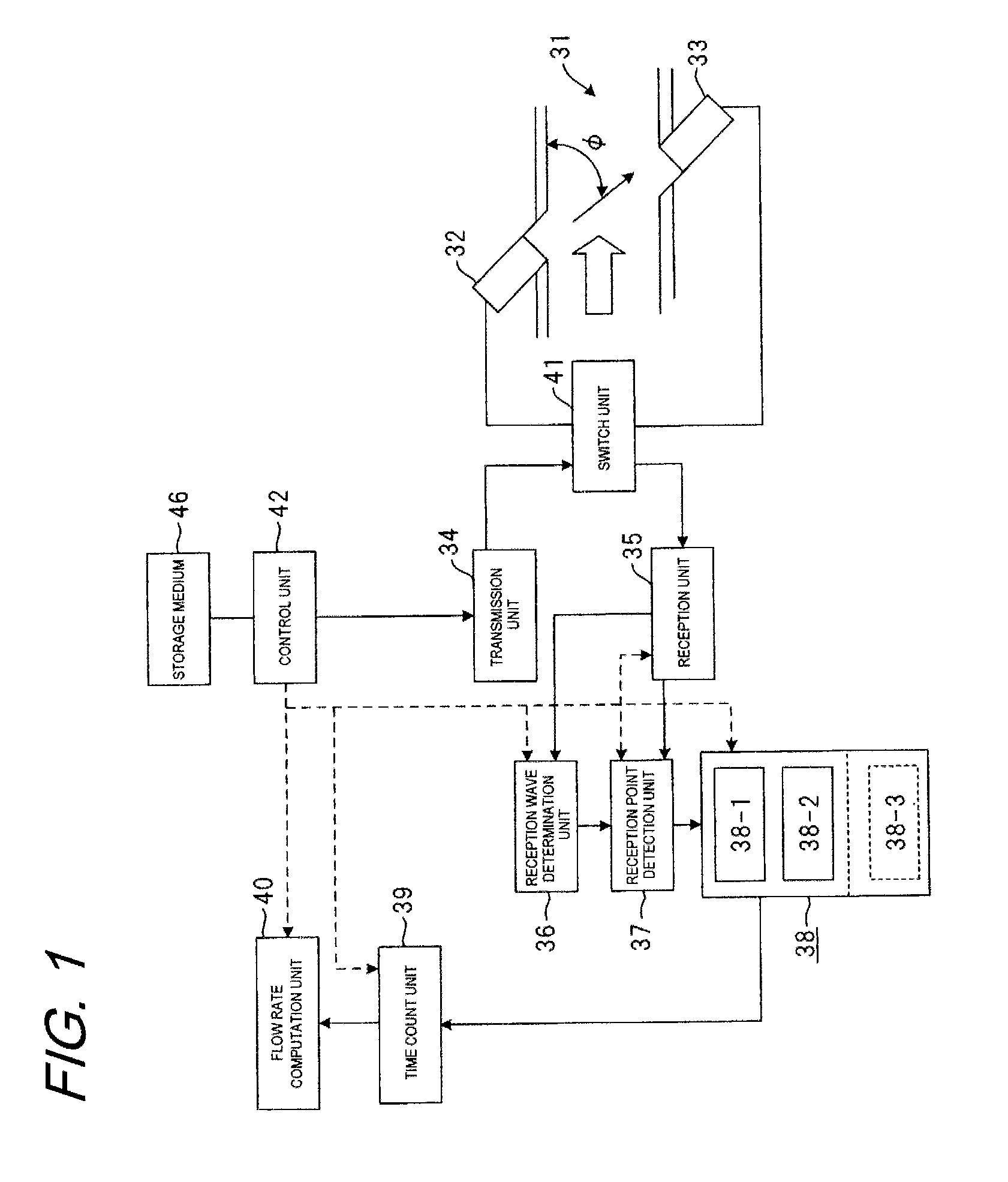

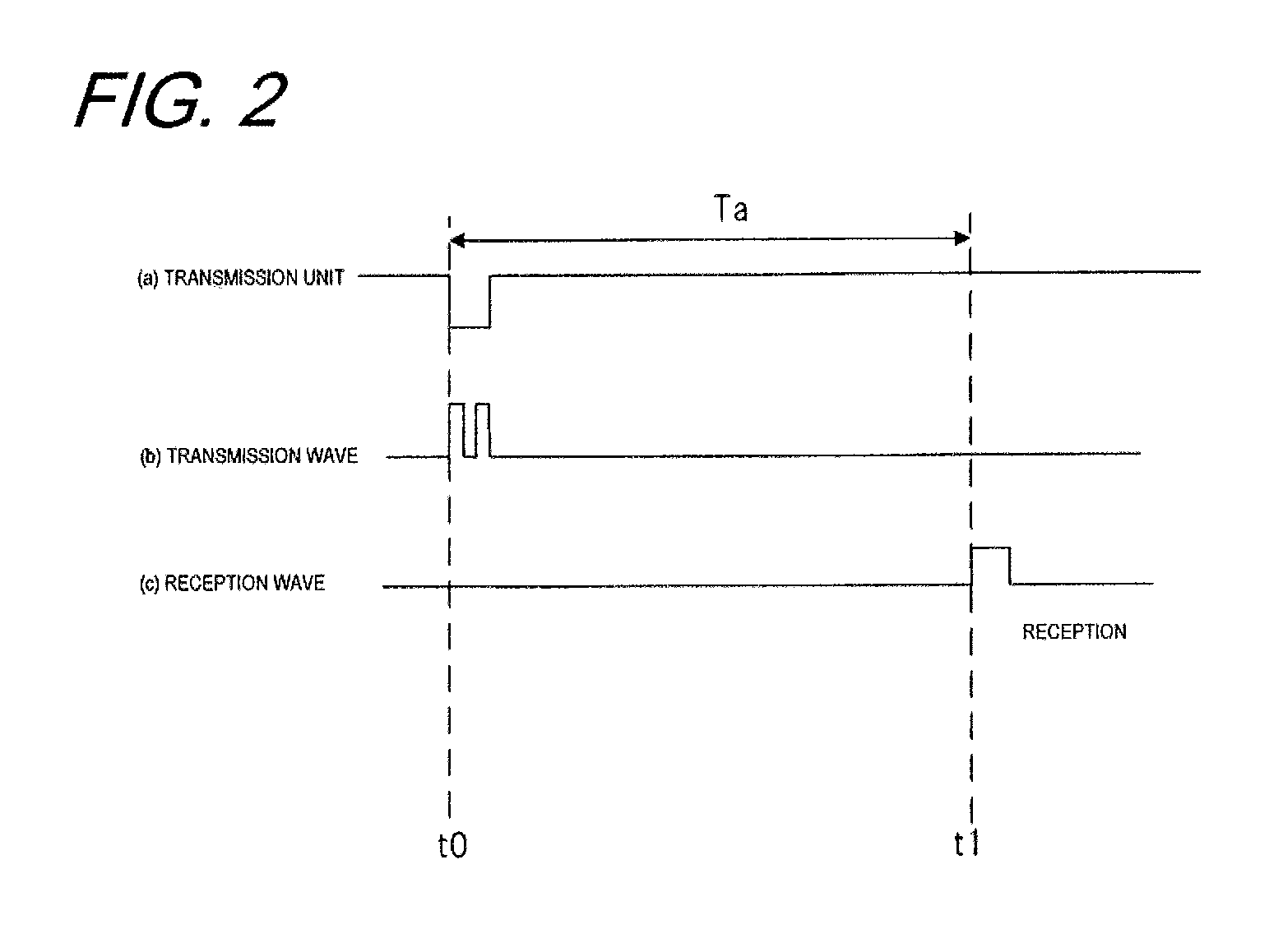

Flow measurement device

ActiveUS8903663B2Accurate flow measurementOperational savingFlow propertiesVolume/mass flow measurementPropagation timeDischarge measurements

To find the propagation time of an ultrasonic wave, a difference occurs between the waveforms received upstream and downstream in a portion where the reception amplitude is comparatively large and it is prevented from being detected as an error of the propagation time. A reception signal is amplified in a reception unit 35 and reception point storage units 38 store the most recent reception point data in a plurality of storage sections in order until the signal level becomes a predetermined value (Vref). An average value of the two zero crossing points before and after the signal level becomes Vref can be adopted as a reception point, the propagation time with a small error of up and down offset, etc., is measured, and it is made possible to realize power saving operation by shortening the measurement time.

Owner:PANASONIC CORP

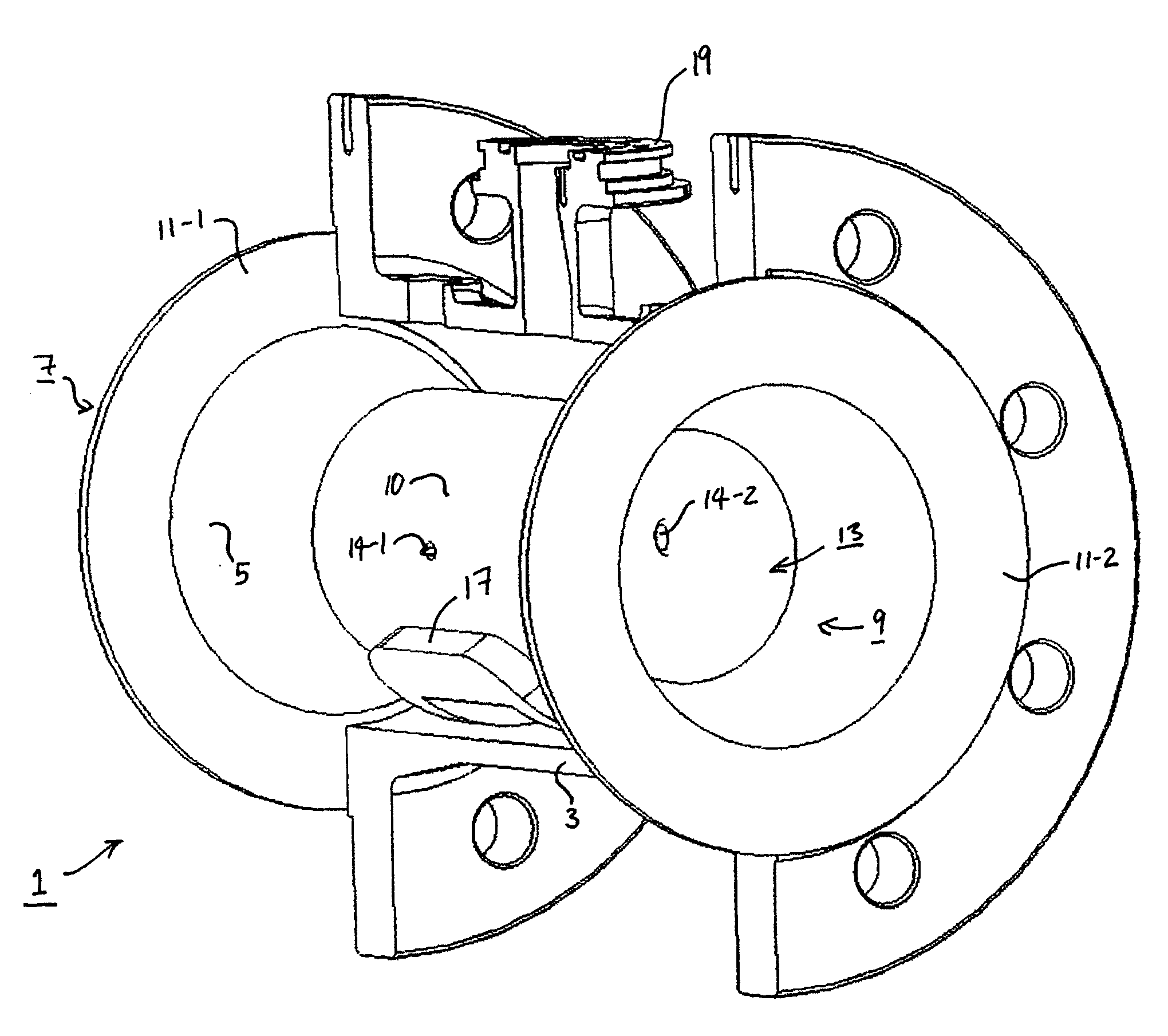

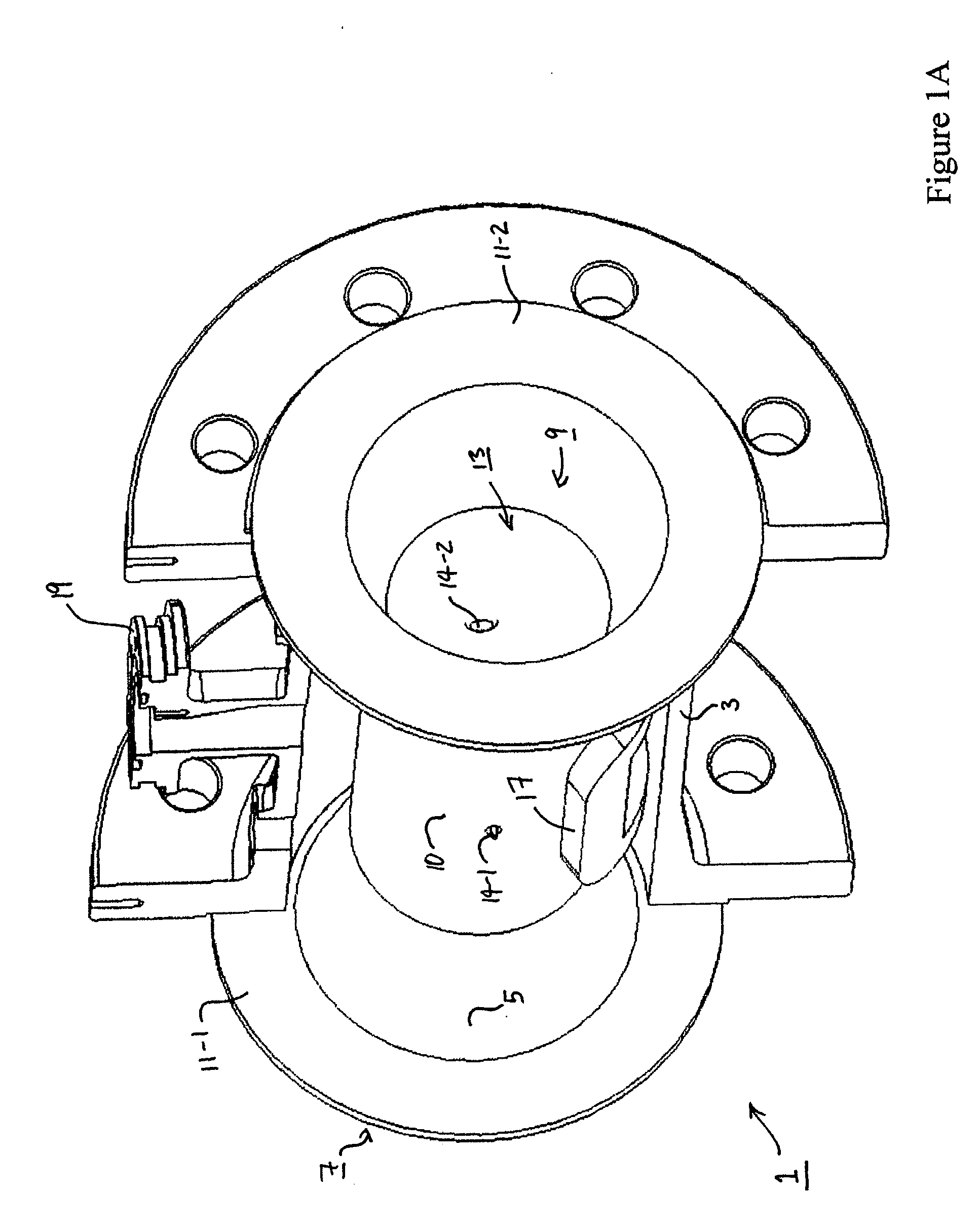

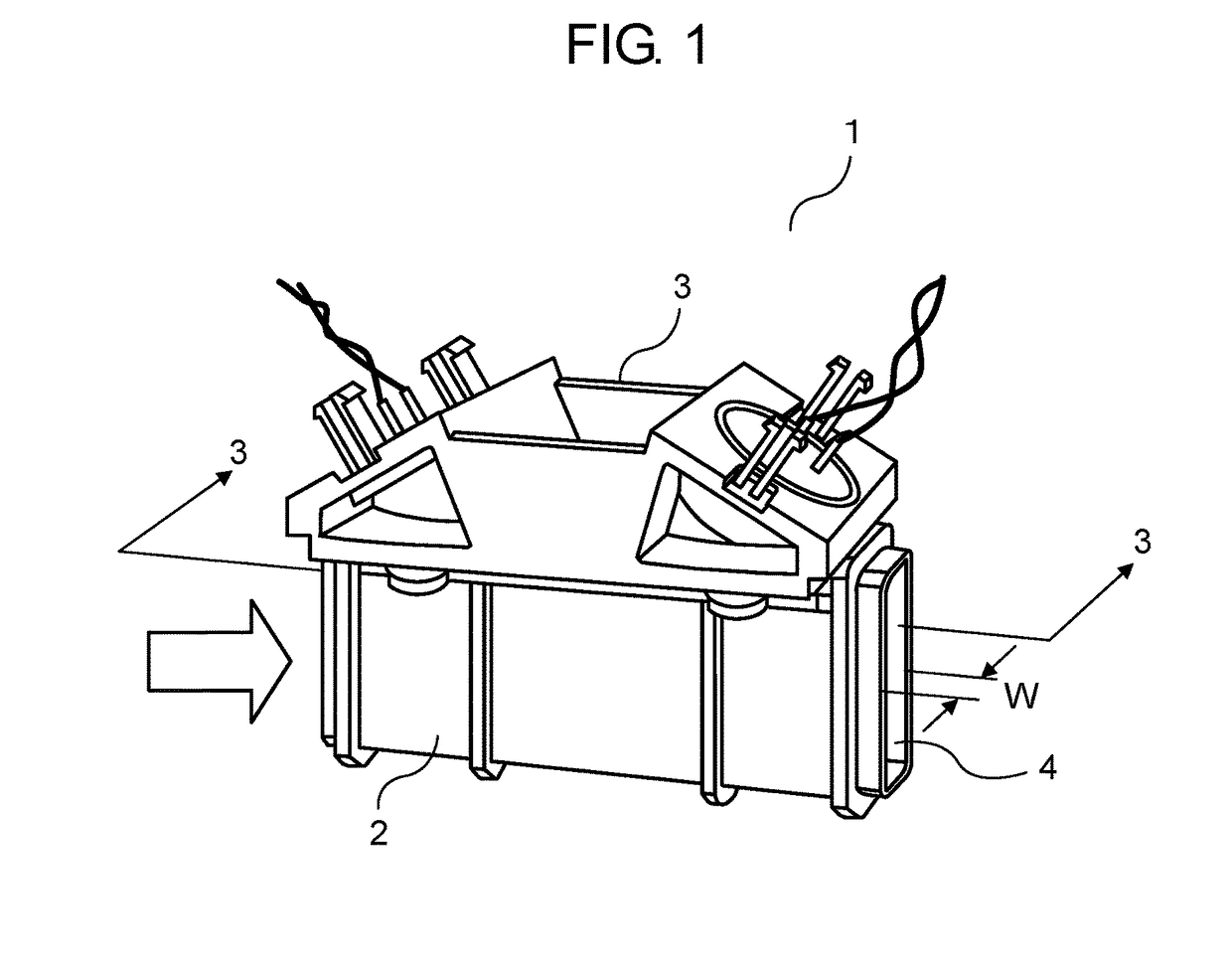

Moderate thrust aero-engine testing switching device

InactiveCN105403409AAir flow test is simple and convenientEasy loading and unloadingEngine testingAviationEngineering

The invention provides a moderate thrust aero-engine testing switching device comprising a pedestal, air inlet openings, an inner sealing ring, an upper cover disc, and a pressing plate. The pedestal in the shape of a ring, and is provided with an annular-shaped concave groove. The inner sealing ring is disposed on the inner side top part of the annular-shaped concave groove of the pedestal, and the upper cover disc is disposed on the outer side top part of the annular-shaped concave groove of the pedestal. The outer side surface of the pedestal is provided with more than twenty air inlet openings facing the outer side horizontally, and the air inlet openings are disposed uniformly along the circumference of the pedestal. The position of the pressing plate in the annular-shaped concave groove is fixedly disposed on the bottom surface of the upper cover disc by the bolt. The moderate thrust aero-engine testing switching device is advantageous in that the test of the air flow between the high pressure turbine disc and low pressure turbine disc is simple and convenient, the assembly and the disassembly are easy, and the connection with the device of the test board is convenient; the flow measurement is accurate, and the flowing of the air flow is good.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Blood treatment apparatus and method

ActiveUS8485999B2Improve design flexibilityAccurate flow measurementSemi-permeable membranesSolvent extractionBlood treatmentsBlood pump

A blood treatment apparatus includes: a blood treatment unit, a pair of fluid pumps and a pair of blood pumps. The blood treatment unit is configured to receive untreated blood and fresh blood treatment fluid, and emit treated blood and used blood treatment fluid. The fluid pumps are configured to pass blood treatment fluid through the blood treatment unit. The blood pumps are configured to extract untreated blood from a blood source, pass extracted blood through the blood treatment unit and deliver treated blood to a target vessel. Flow measurement device which determines at least one blood flow parameter reflecting an average flow in relation to the blood treatment unit during a well-defined period of operation of the apparatus, for example while completing one operation cycle. The at least one blood flow parameter is determined based on a difference between (i) a first amount of fresh blood treatment fluid received into the blood treatment unit, and (ii) a second amount of used blood treatment fluid emitted from the blood treatment unit during another well-defined period.

Owner:GAMBRO LUNDIA AB

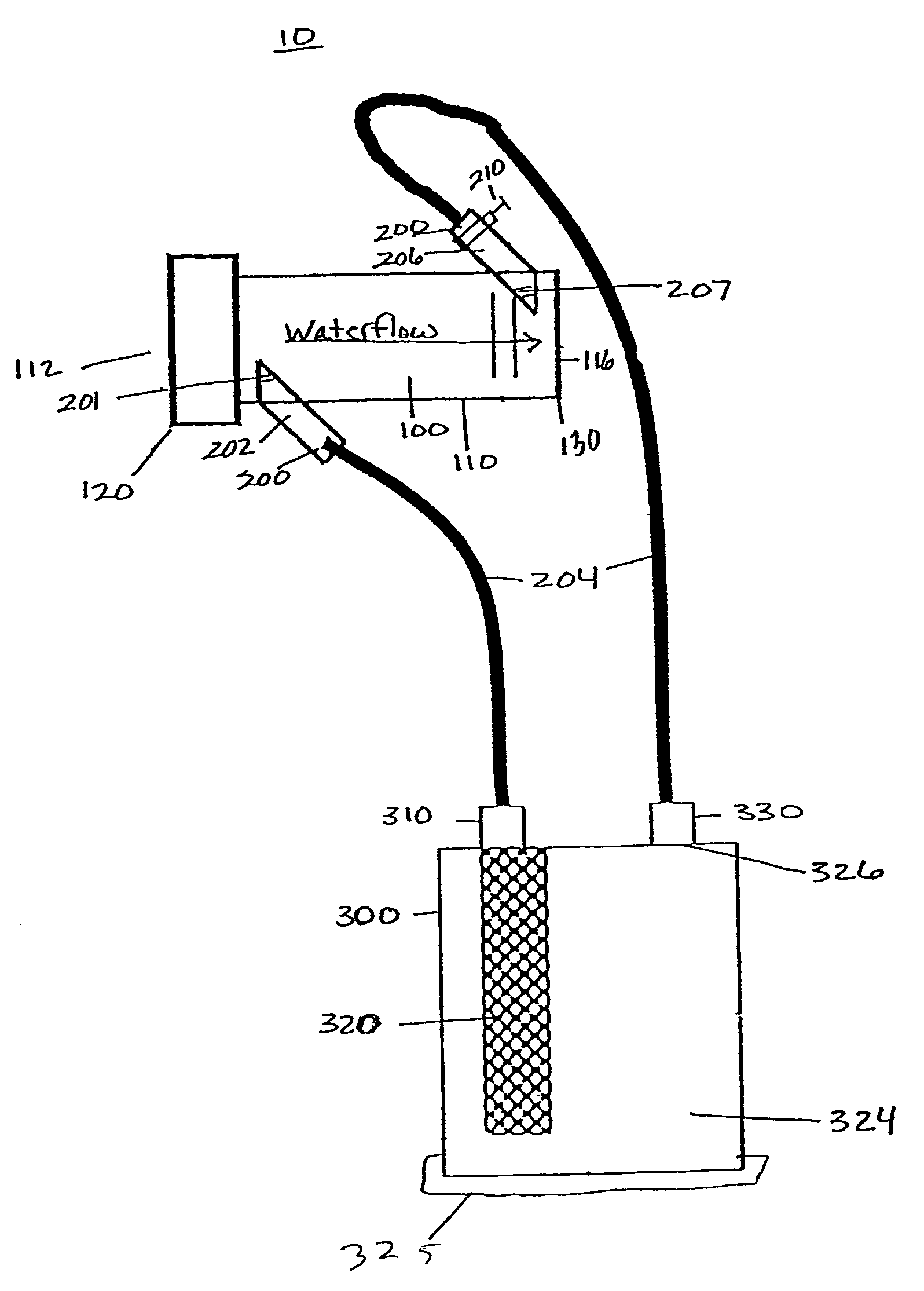

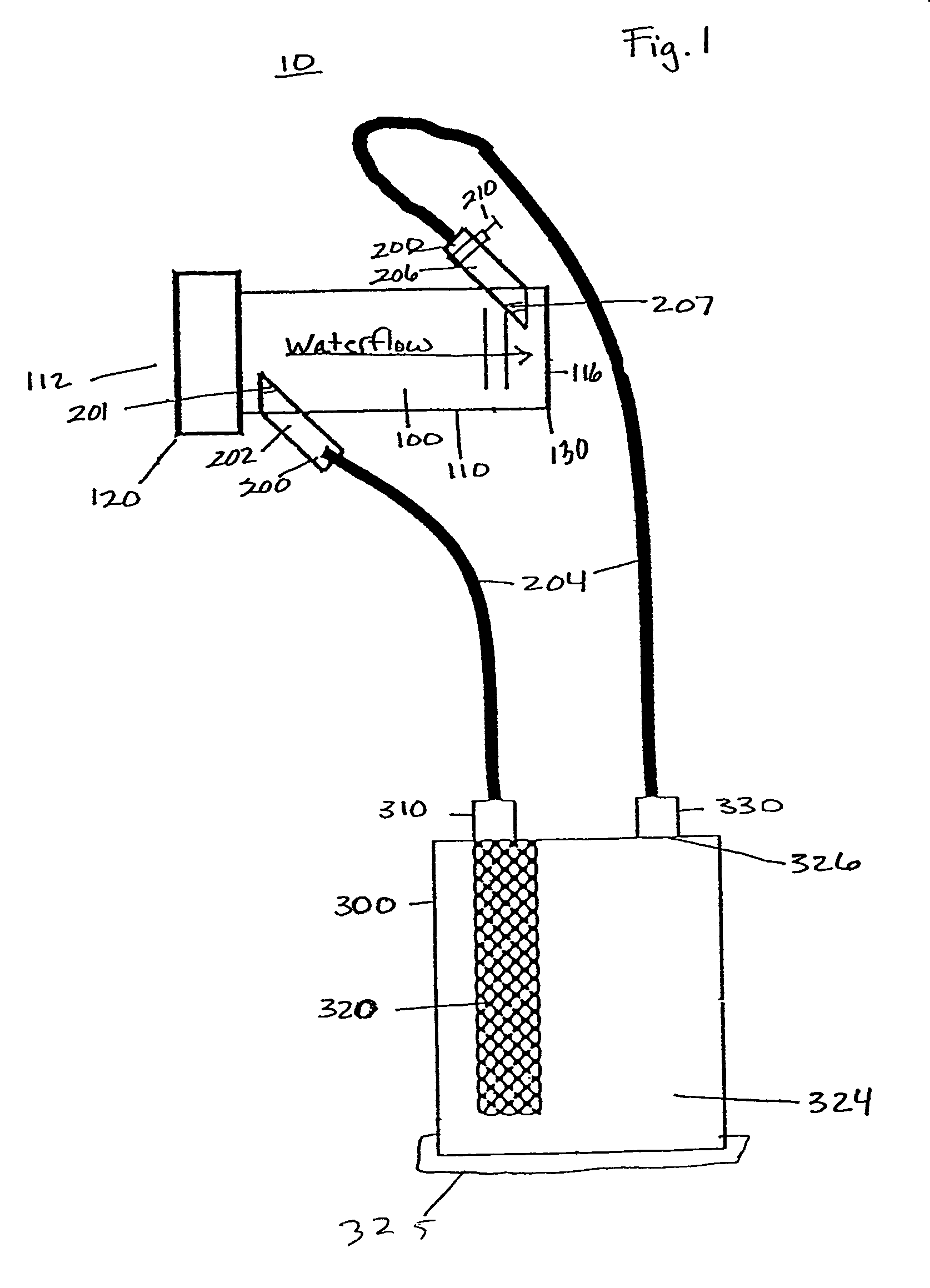

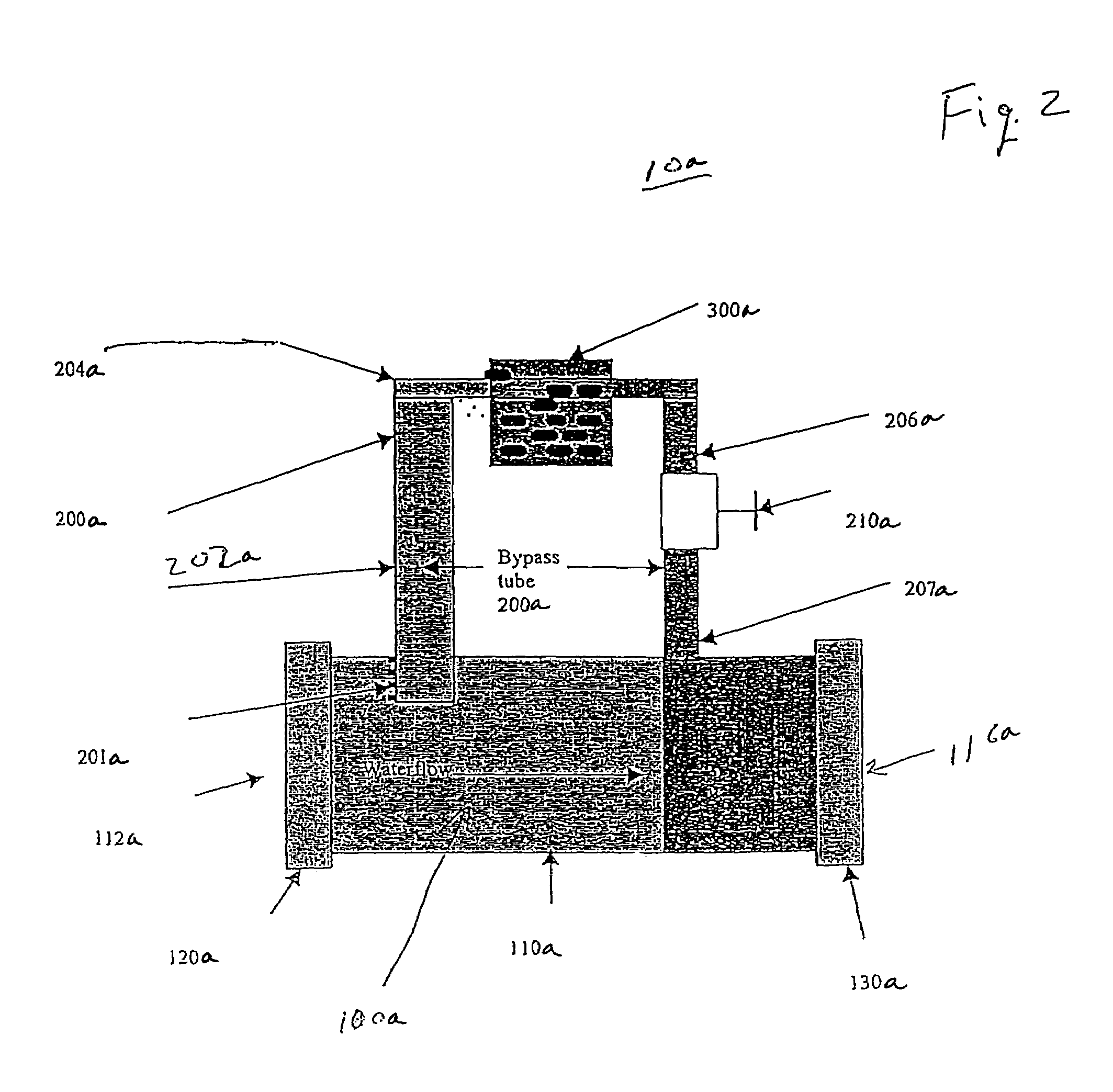

Dechlorinator

InactiveUS7150827B1Easy to transportGood adhesionSpecific water treatment objectivesWater contaminantsDechlorinatorEngineering

A portable apparatus for adding a dechlorination agent into a fluid stream prior to discharge and a method for treatment of chlorinated water. The portable apparatus can connect in any part of a fluid flow system. A bypass is provided such that a controlled portion of the fluid stream is diverted to a dechlorination agent. The dechlorination agent dissolves in the bypassed fluid flow. The bypassed, dechlorination agent enriched fluid re-enters and mixes with the fluid flow that was not bypassed. As the two streams mix, the total flow receives the required amount of dechlorination before being discharged into the environment. A valve controls proportional flow of the fluid stream through the bypass.

Owner:GRENNING FREDERICK H

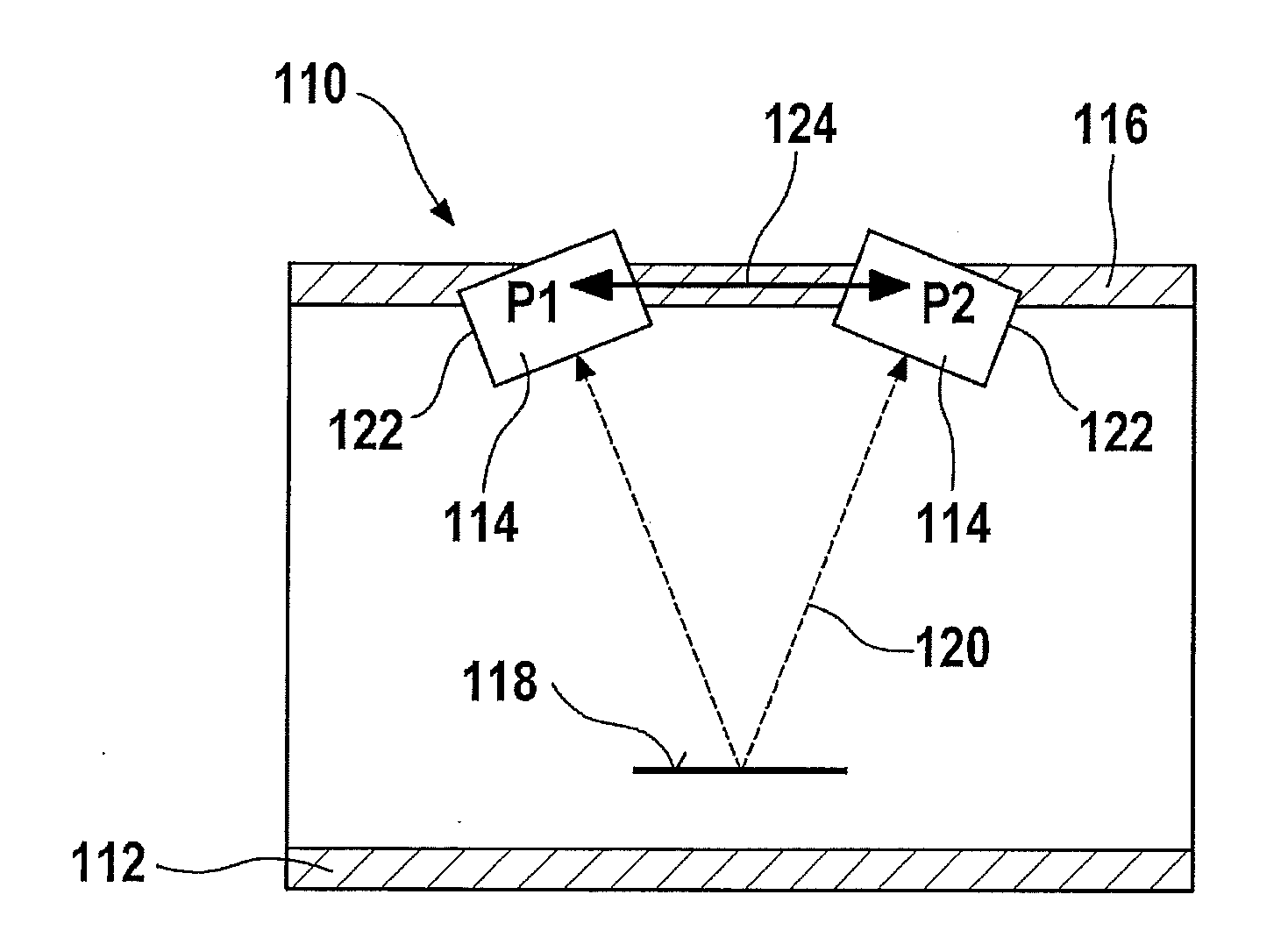

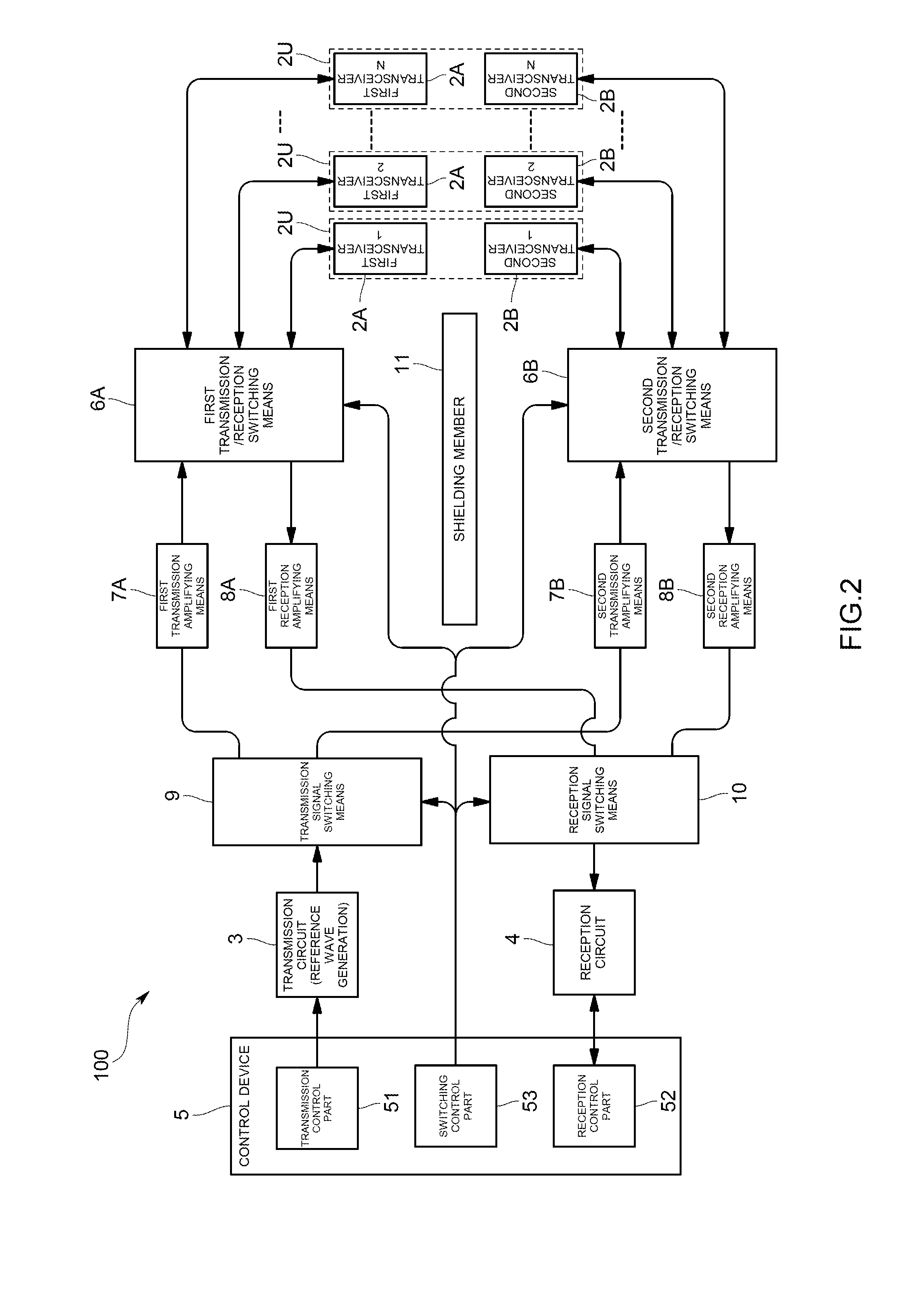

Ultrasonic flowmeter

InactiveUS20140102213A1Accurate measurementReduce unnecessary vibrationVolume/mass flow measurementTransceiverEngineering

The present invention is one that suppresses crosstalk caused by switching means adapted to switch transmission / reception between ultrasonic transceivers that are paired, and provided with: a first ultrasonic transceiver and a second ultrasonic transceiver; a transmission circuit that generates a transmission signal for vibrating the first ultrasonic transceiver or the second ultrasonic transceiver; a reception circuit that senses a reception signal from the first ultrasonic transceiver or the second ultrasonic transceiver; first transmission amplifying means adapted to amplify the transmission signal to the first ultrasonic transceiver; first reception amplifying means adapted to amplify a reception signal from the first ultrasonic transceiver; second transmission amplifying means adapted to amplify the transmission signal to the second ultrasonic transceiver; and second reception amplifying means adapted to amplify a reception signal from the second ultrasonic transceiver.

Owner:HORIBA LTD

Oxygen therapy monitoring device and method

ActiveUS20180250481A1Accurate flow measurementReduce power consumptionRespiratorsVolume/mass flow measurementMeasurement deviceProduct gas

An oxygen therapy monitoring device includes an oscillation chamber with in a gas flow path adapted to pass a gas flow from a source to a breathing interface for a person. The oscillation chamber induces an oscillation in the gas flow that varies as a function of a flow rate of the gas flow. A measurement arrangement measures the oscillation induced in the gas flow and determines the flow rate on the basis of the oscillation that is measured.

Owner:SRETT

Flow measurement device

ActiveUS20110238332A1Highly accurate flow measurementSave powerVolume/mass flow measurementVolume flow measuring devicesMeasurement devicePropagation time

To find the propagation time of an ultrasonic wave, a difference occurs between the waveforms received upstream and downstream in a portion where the reception amplitude is comparatively large and it is prevented from being detected as an error of the propagation time. A reception signal is amplified in a reception unit 35 and reception point storage units 38 store the most recent reception point data in a plurality of storage sections in order until the signal level becomes a predetermined value (Vref). An average value of the two zero crossing points before and after the signal level becomes Vref can be adopted as a reception point, the propagation time with a small error of up and down offset, etc., is measured, and it is made possible to realize power saving operation by shortening the measurement time.

Owner:PANASONIC CORP

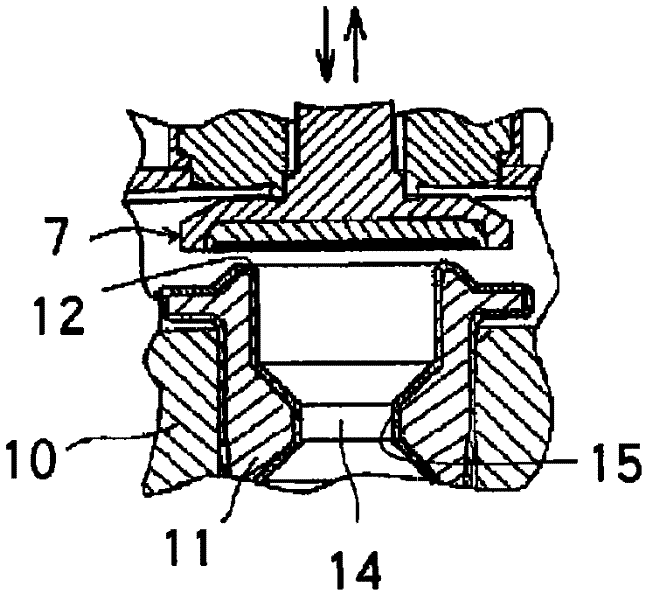

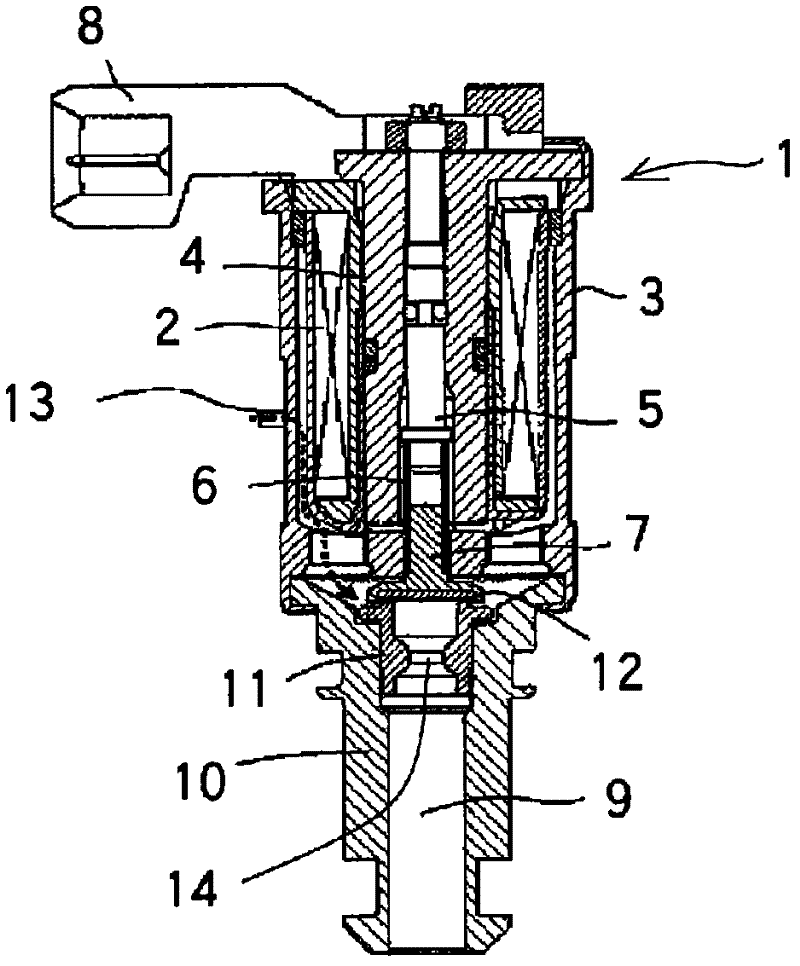

Injector for gas fuel

InactiveCN102678390AReduce performanceExcellent peelabilityInternal combustion piston enginesFuel supply apparatusForeign matterTar

The invention relates to an injector for gas fuel, which can prevent foreign matters, such as dust, tar mixed into the gas fuel from being adhered on a throttle hole part arranged in a fuel through hole to measure the flow of the gas fuel, thereby preventing the flow of the gas fuel from being reduced. In the injector for gas fuel, an injector valve core (7) ascends and descends along the axle direction, thereby contacting with and separating from a valve seat (11) kept by a valve seat keeping piece (10), thus the fuel from a fuel inlet (13) is intermittently sent to the fuel through hole (9) in a preset interval, wherein the valve seat keeping piece (10) comprises the fuel through hole (9) opposite to the lower surface of the injector valve core (7), and moreover, in the injector for gas fuel, the throttle hole (14) for measuring the flow of the gas fuel is arranged in the fuel through hole (9), and a coating layer (15) made of an Ni-P coating film containing fluoro resin particles is coated on the inner surface of the throttle hole (14).

Owner:NIKKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com