Ultrasonic transmitter/receiver and ultrasonic flowmeter using the same

An ultrasonic and transceiver technology, applied in the field of ultrasonic transceivers, can solve the problems of reduced transceiver characteristics, damage to the matching layer, damage, etc., and achieve the effects of stable sending and receiving of ultrasonic waves, accurate flow measurement, and prevention of damage such as fragments or cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

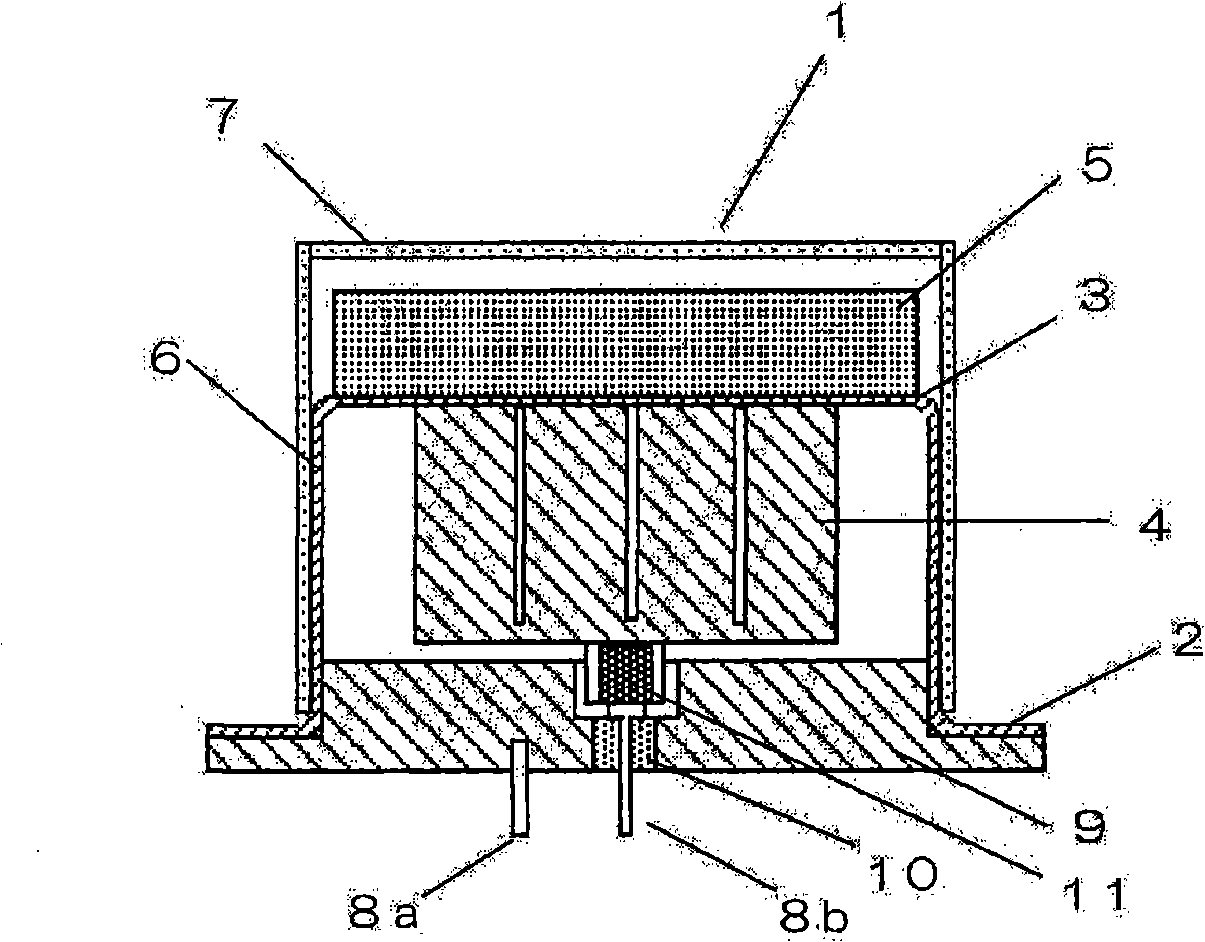

[0043] figure 1 It is a cross-sectional view showing the ultrasonic transceiver according to the first embodiment of the present invention.

[0044] exist figure 1 Among them, the ultrasonic transceiver 1 is composed of a piezoelectric body 4, an acoustic matching layer 5, and a protective cover 7, wherein the piezoelectric body 4 is bonded to the cylindrical housing 2 formed of a conductive material by epoxy resin or the like. On the inner surface of the top 3, the acoustic matching layer 5 is bonded on the outer surface of the top 3, and the protective cover 7 is kept at a predetermined distance from the surface of the acoustic matching layer 5 and along the side wall of the cylindrical housing 2 6 is fitted integrally therewith.

[0045] The structure of the acoustic matching layer 5 is: in the ceramic porous body with pores, dry gel of organic glass is permeated on the pores. In order to bond and fix the acoustic matching layer 5 and the top 3 of the cylindrical case ...

no. 2 approach

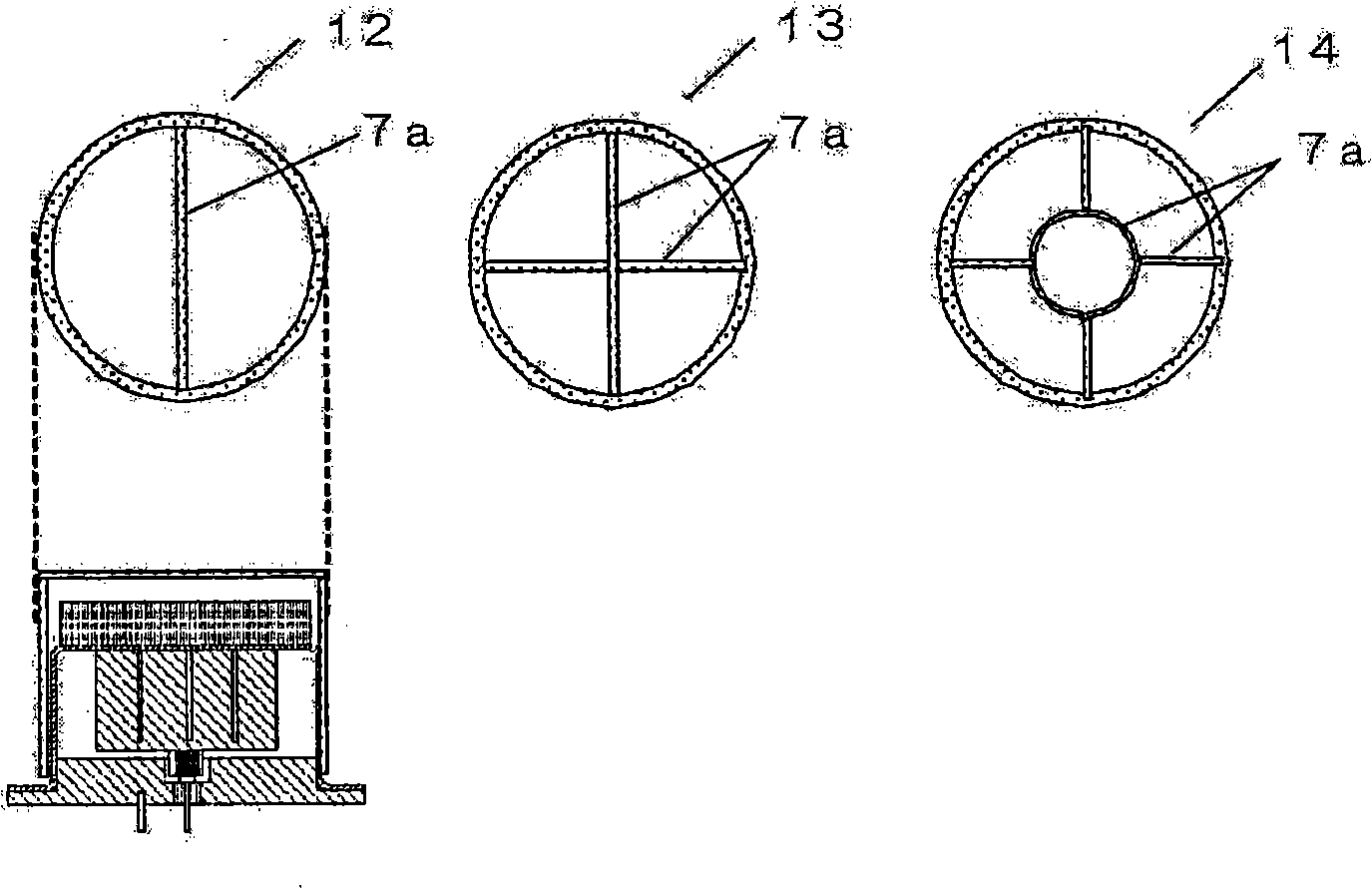

[0074] Figure 6 It is a perspective view of the ultrasonic transceiver mounted with the inline protective cover 12 according to the second embodiment of the present invention viewed from above.

[0075] Figure 6 The in-line protective cover 12 is arranged on the surface of the matching layer 5 bonded on the top 3 of the cylindrical case 2 of the ultrasonic transceiver 1 . exist Figure 6 In FIG. 3 , for convenience of description, the bonding surface of the piezoelectric body 4 bonded to the inside of the cylindrical case 2 with epoxy resin is shown in perspective.

[0076] Such as Figure 6 , Figure 7 As shown, grooves are provided on the vibrating surface of the piezoelectric body 4 used in the ultrasonic transceiver 1 and bonded to the inner surface of the cylindrical case 2 . In a rectangular parallelepiped piezoelectric body, the ultrasonic waves transmitted from the piezoelectric body cannot be efficiently transmitted and received because thickness longitudinal vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com