Patents

Literature

66results about How to "Uniform erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

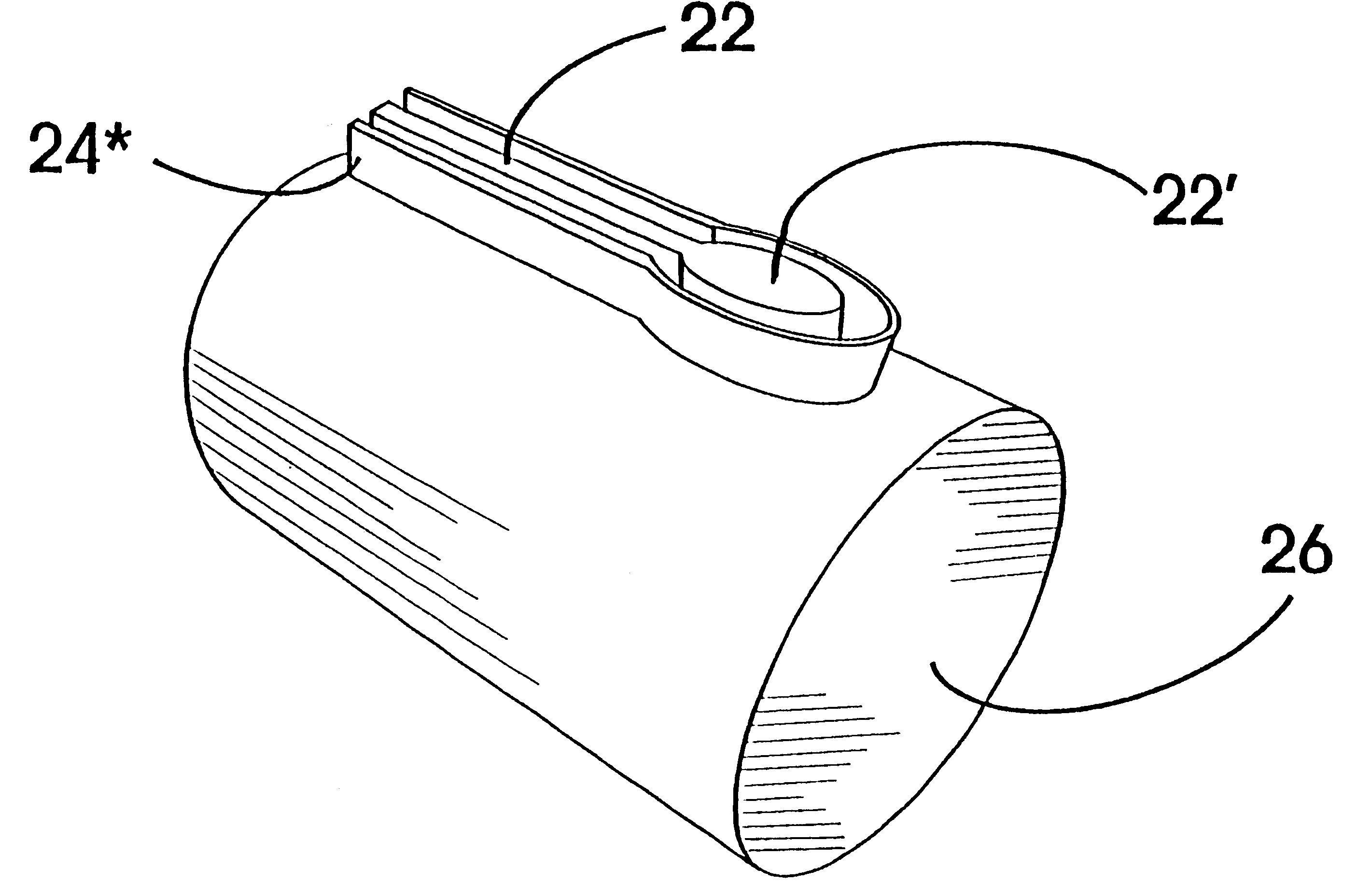

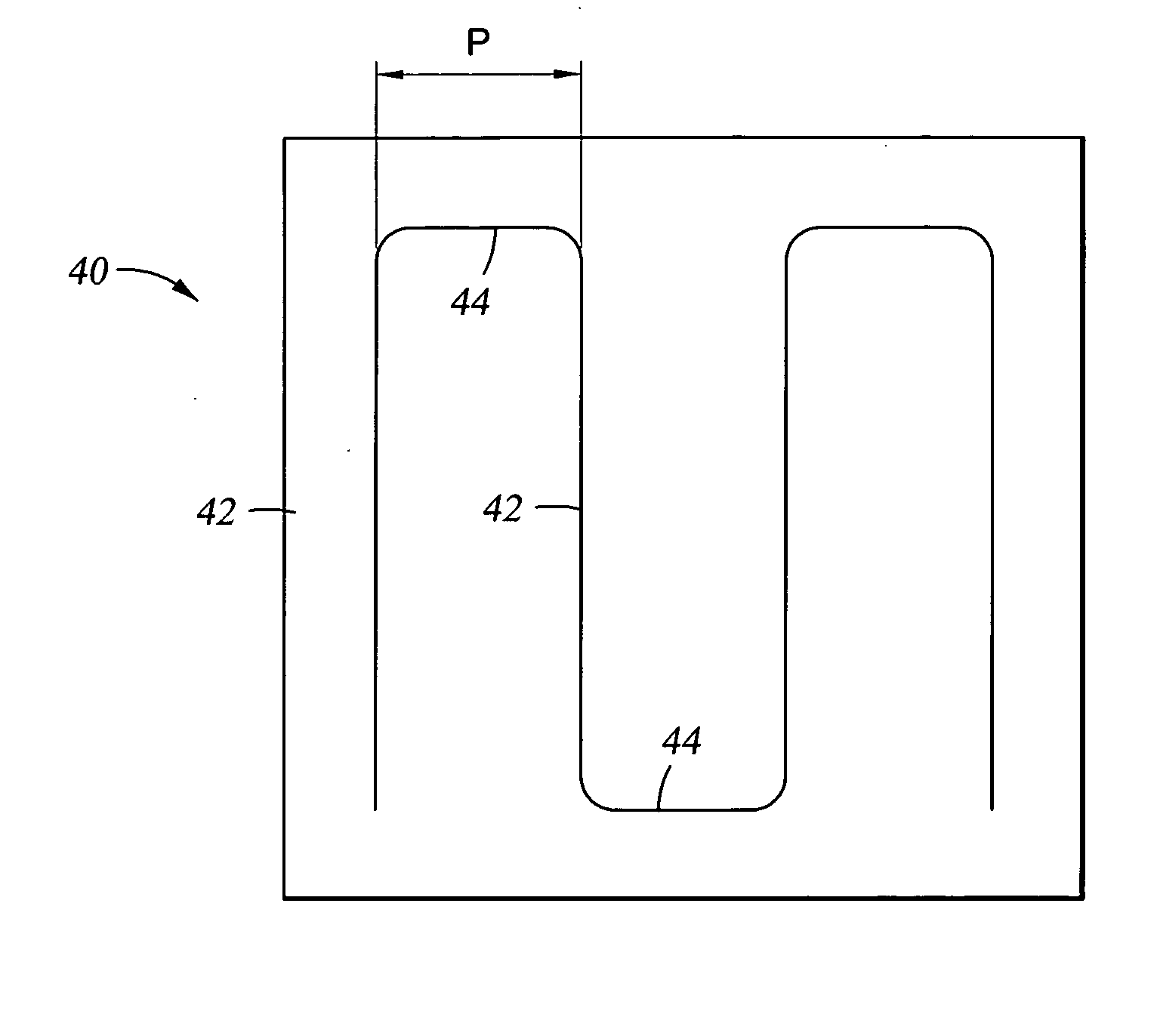

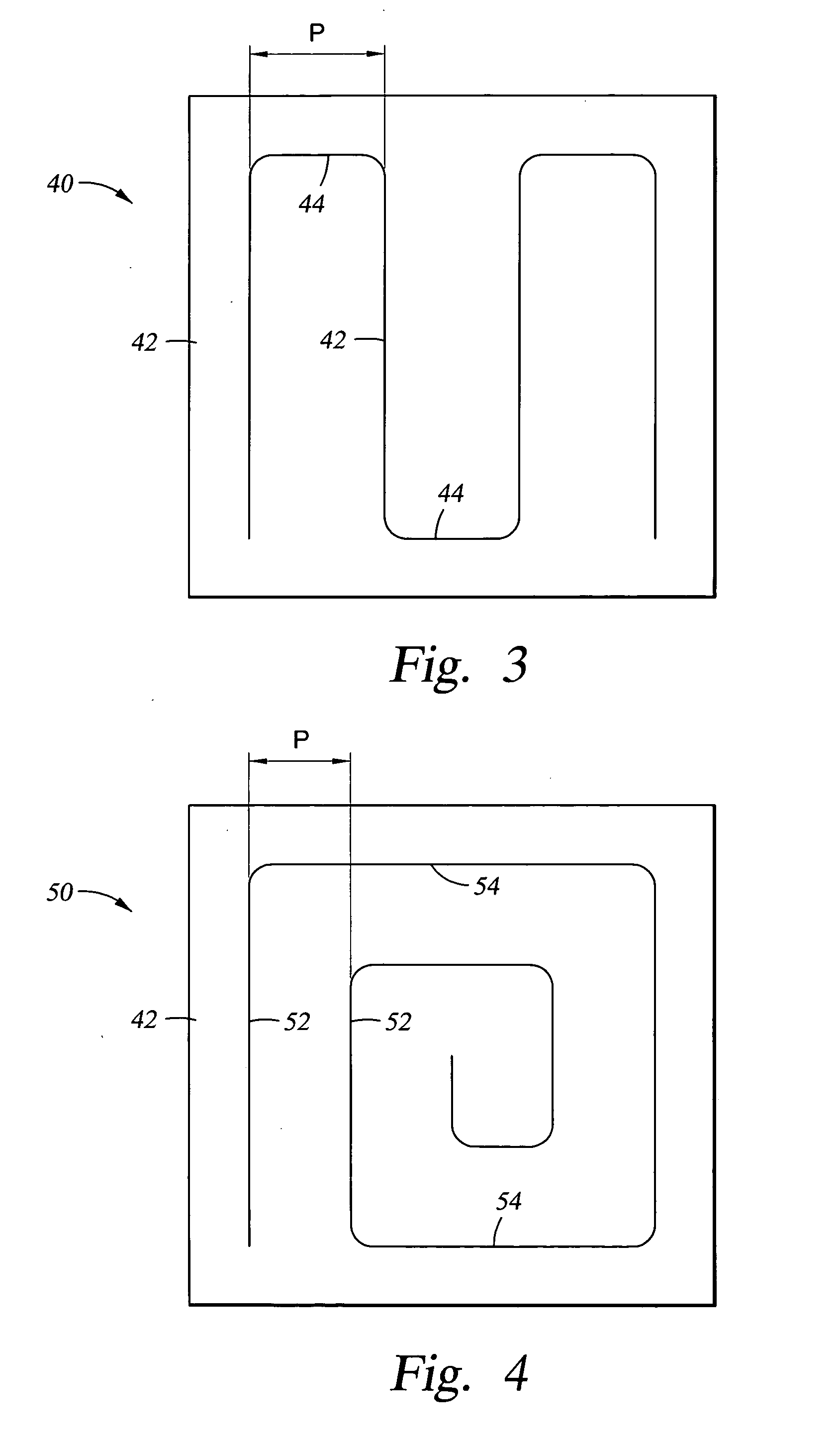

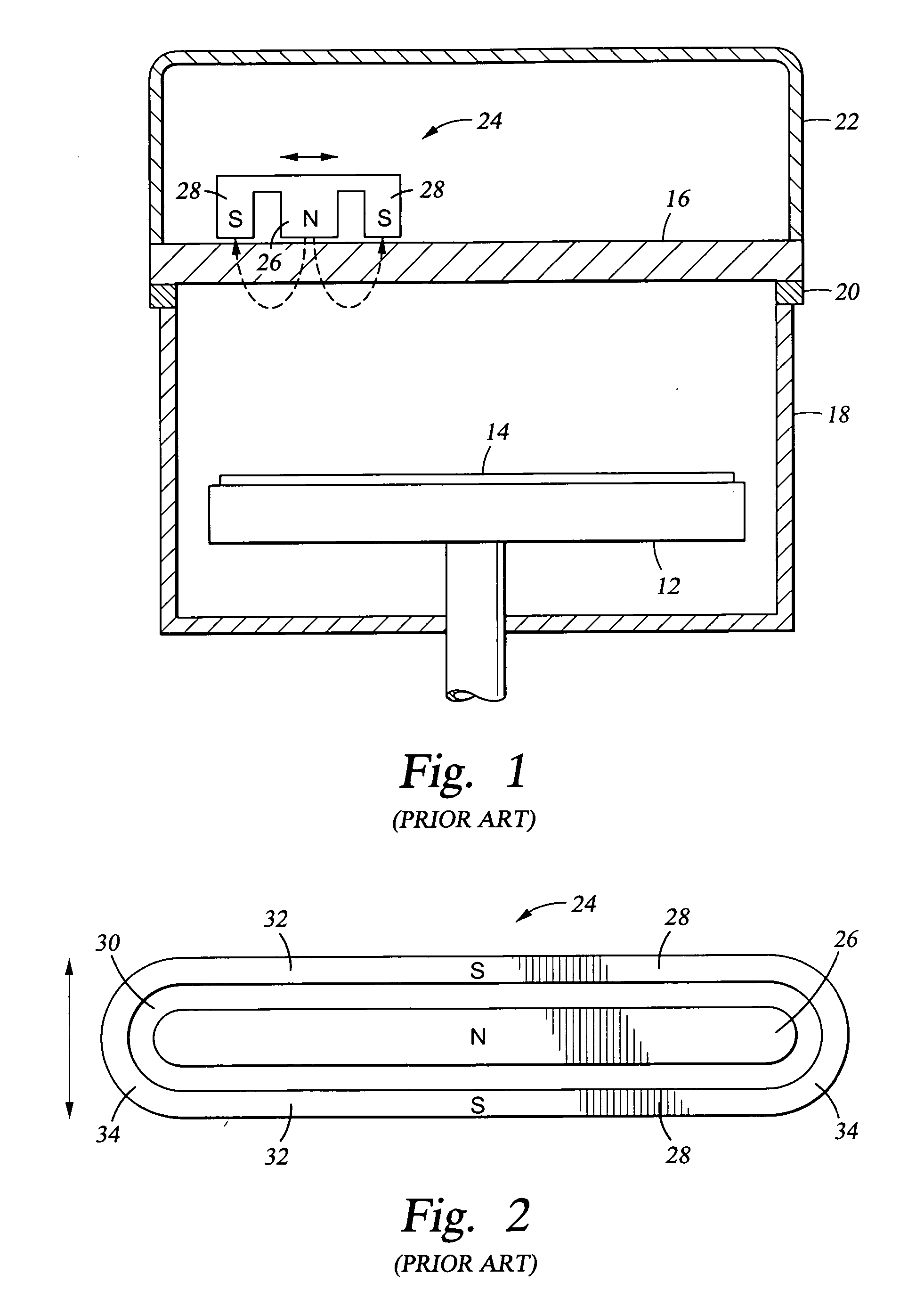

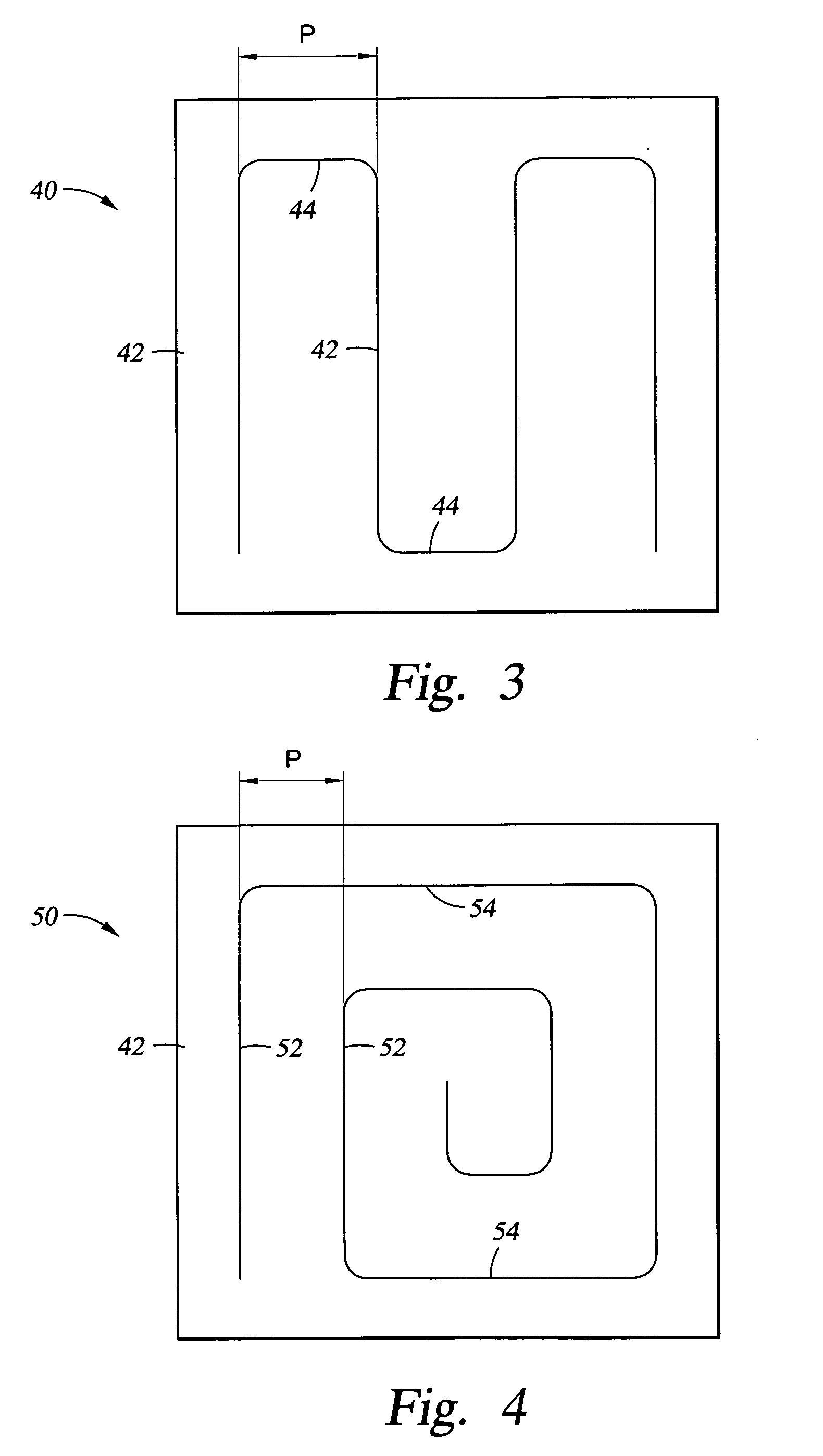

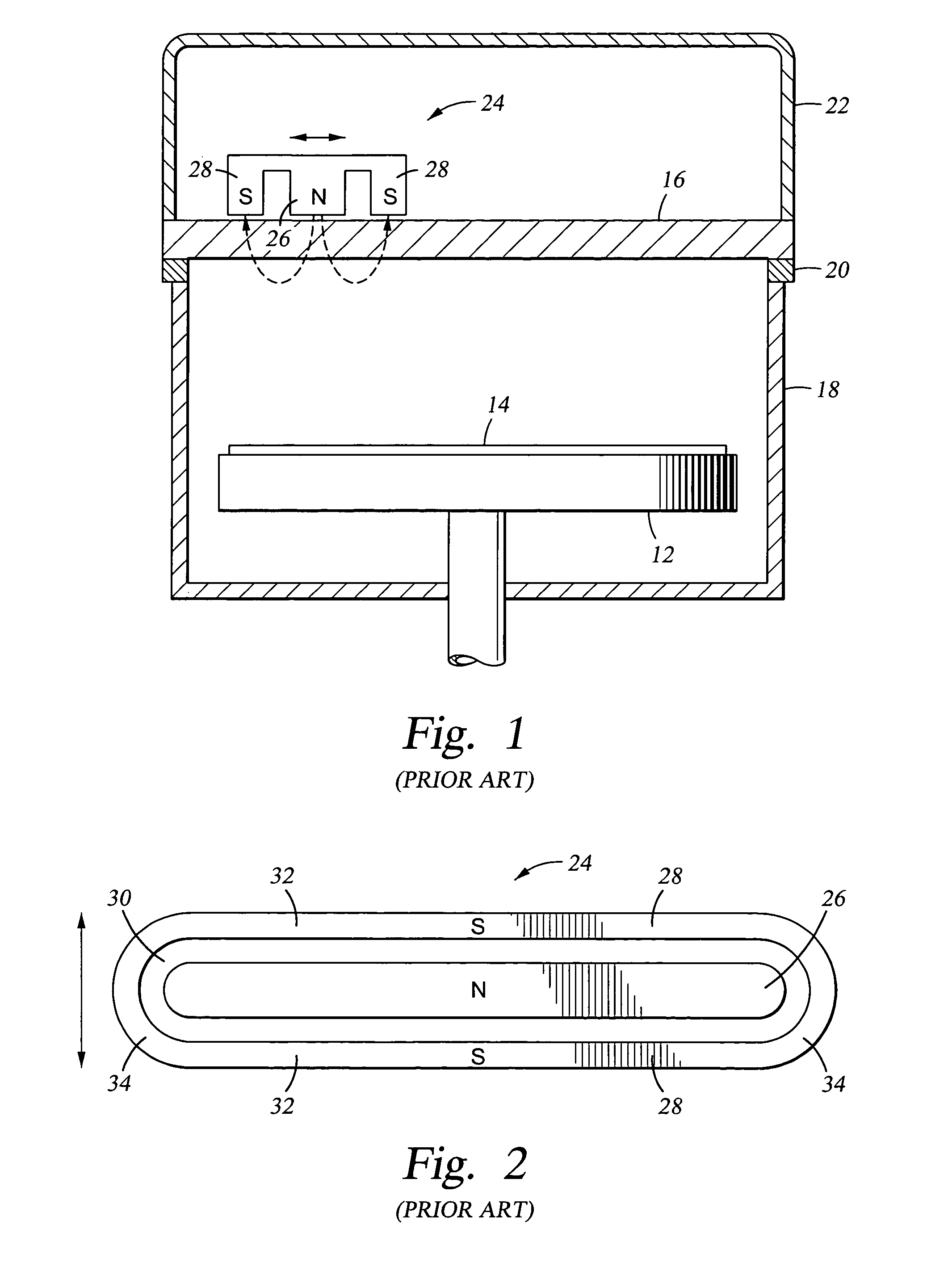

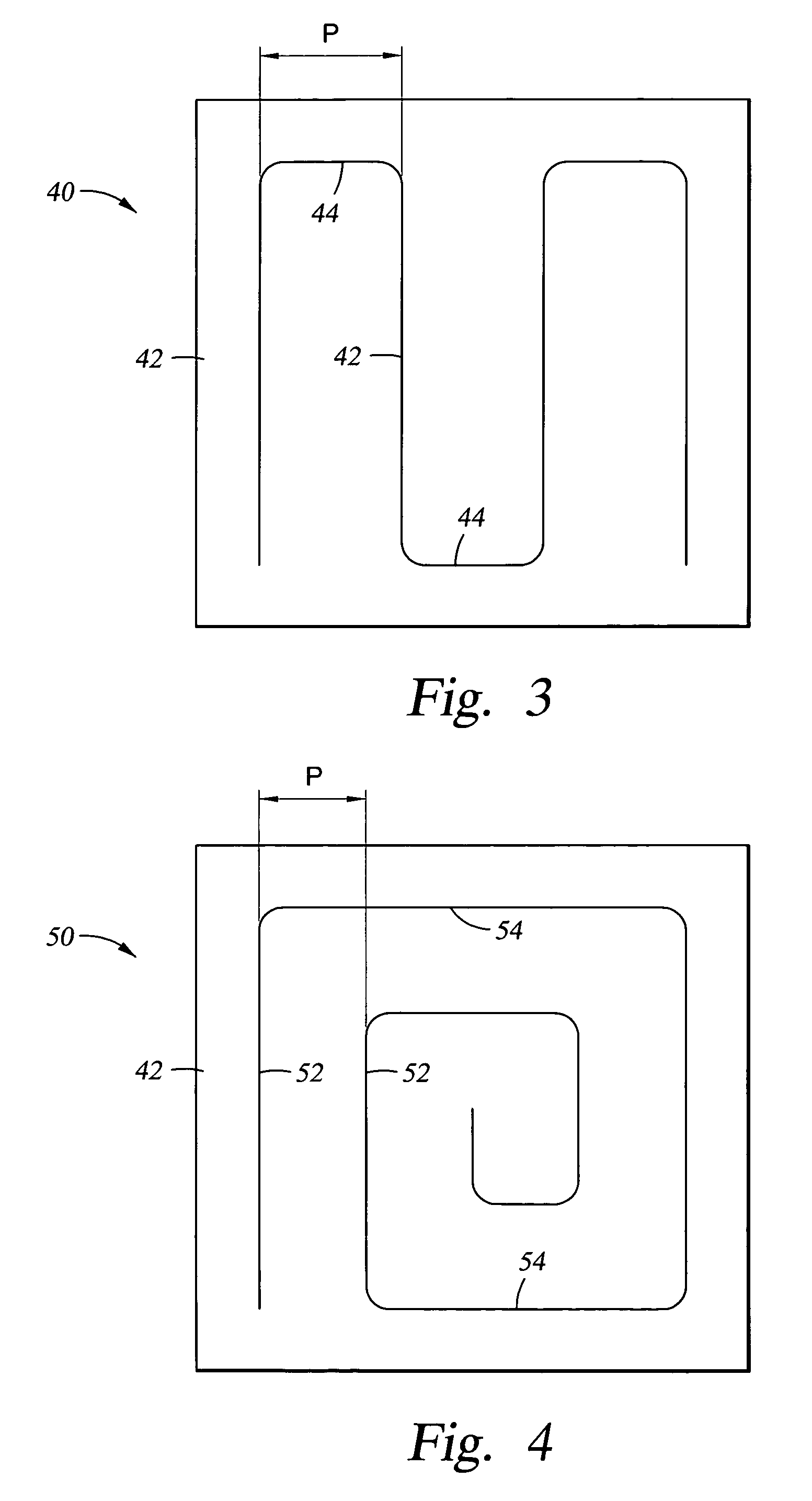

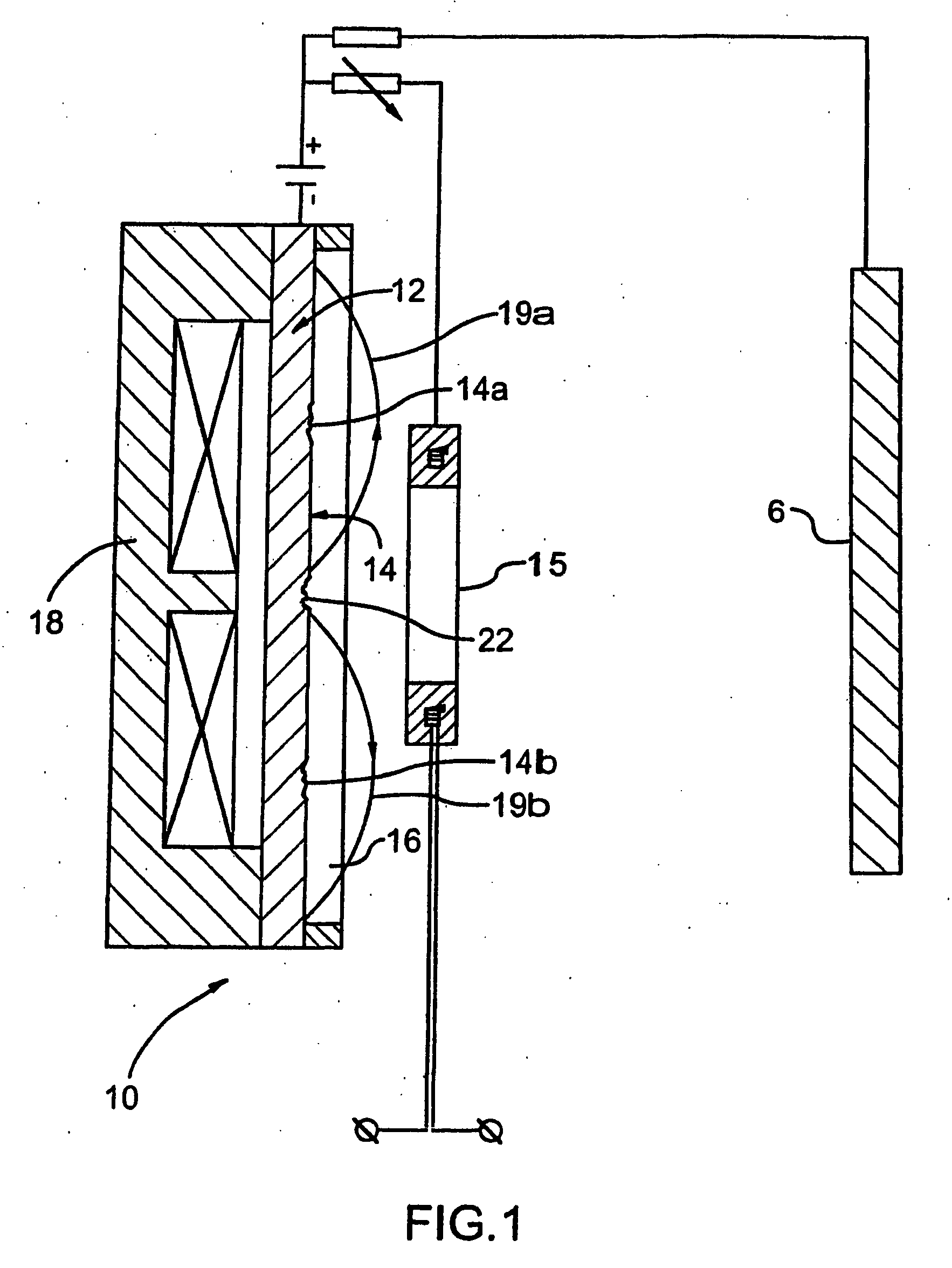

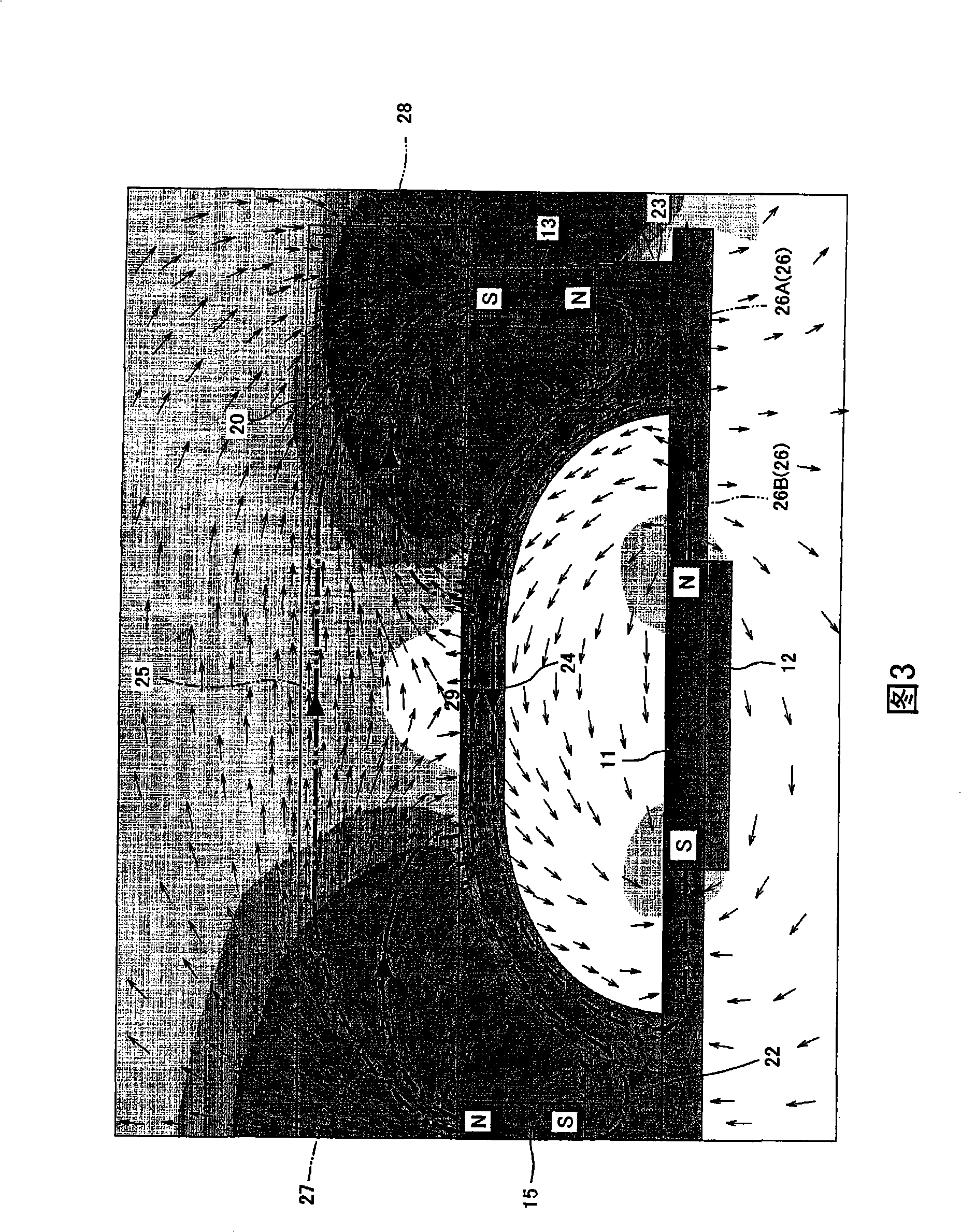

Magnetron with parallel race track and modified end portions thereof

InactiveUS6375814B1Reducing unwanted deposition of materialLower requirementCellsElectric discharge tubesTrackwayEngineering

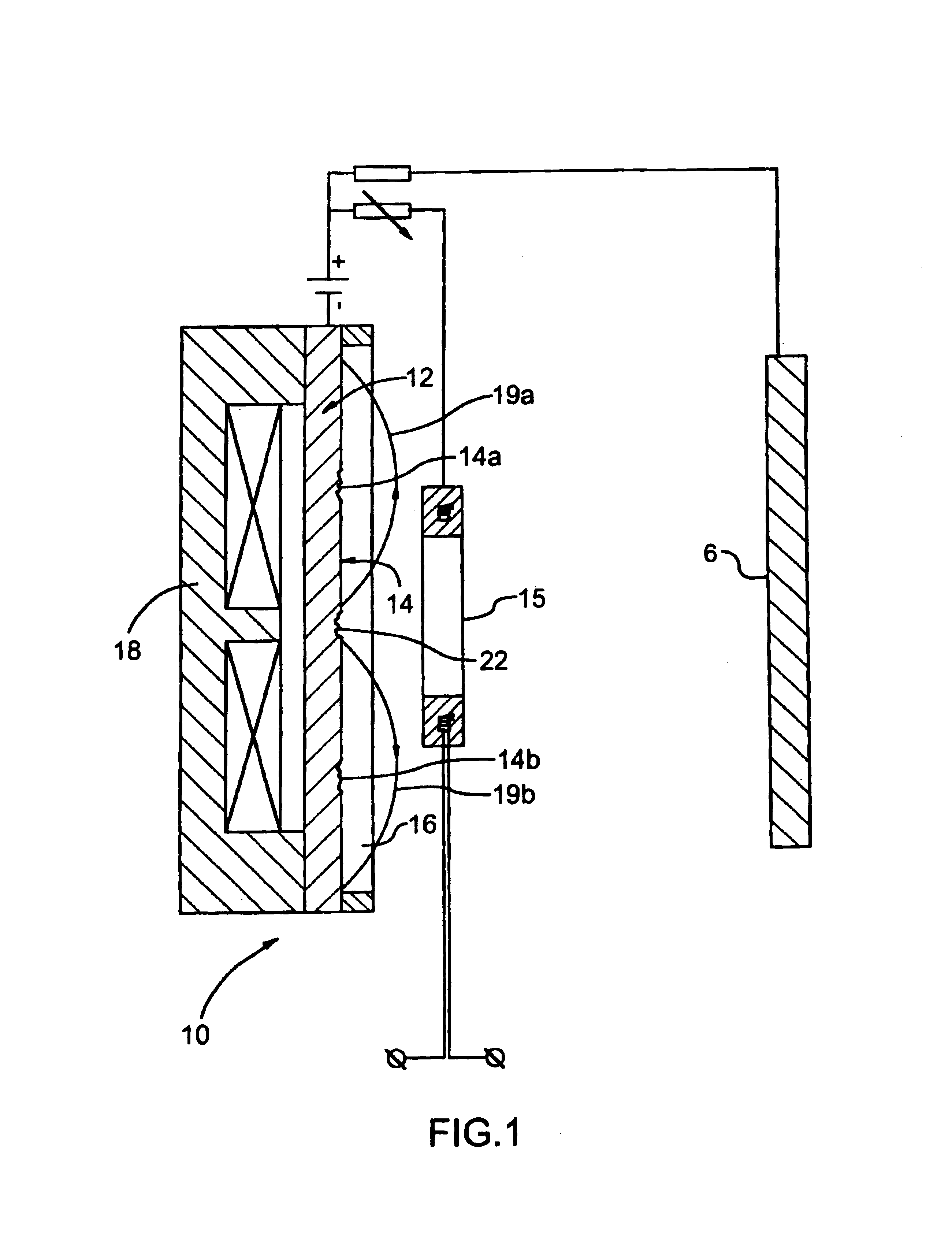

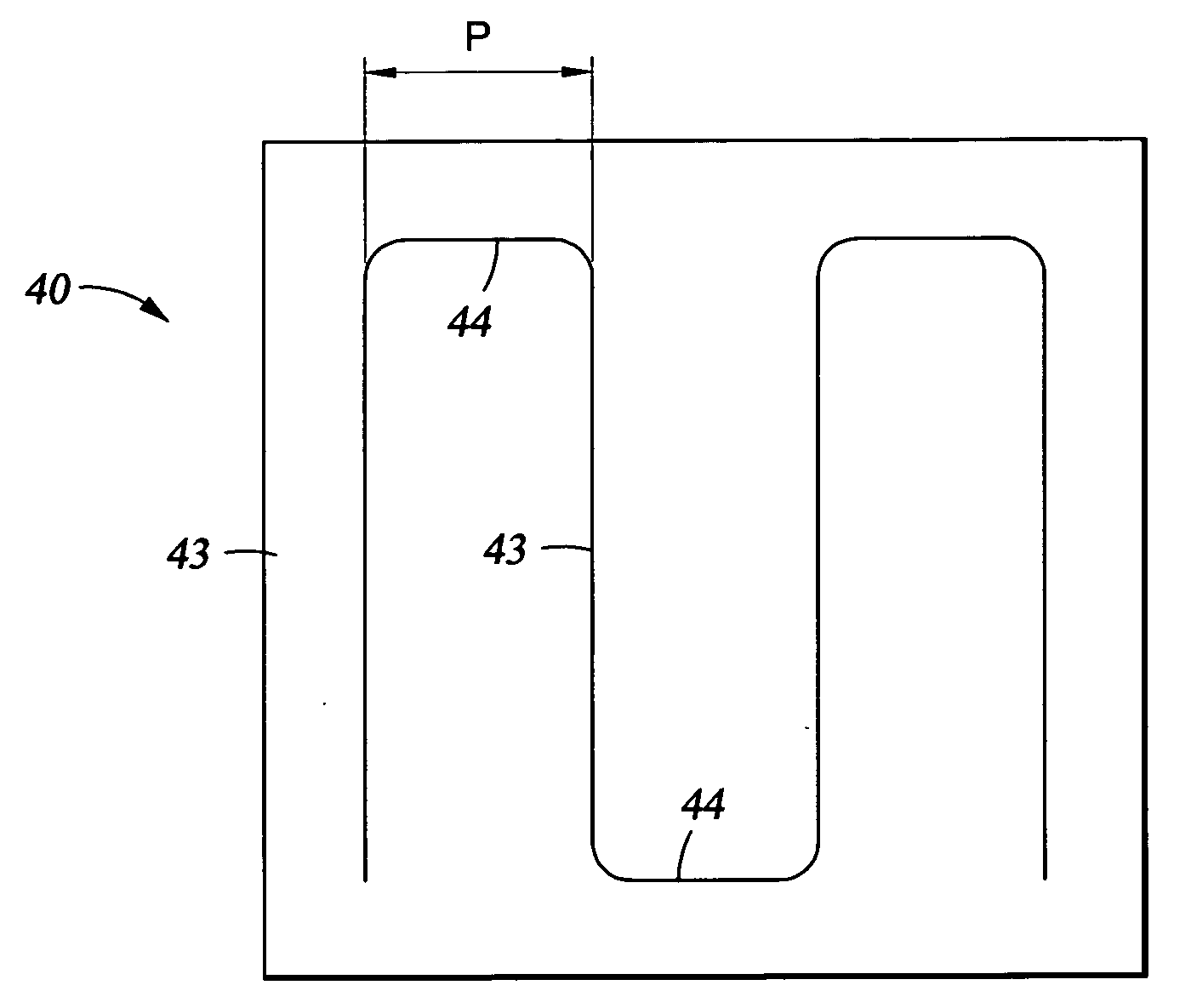

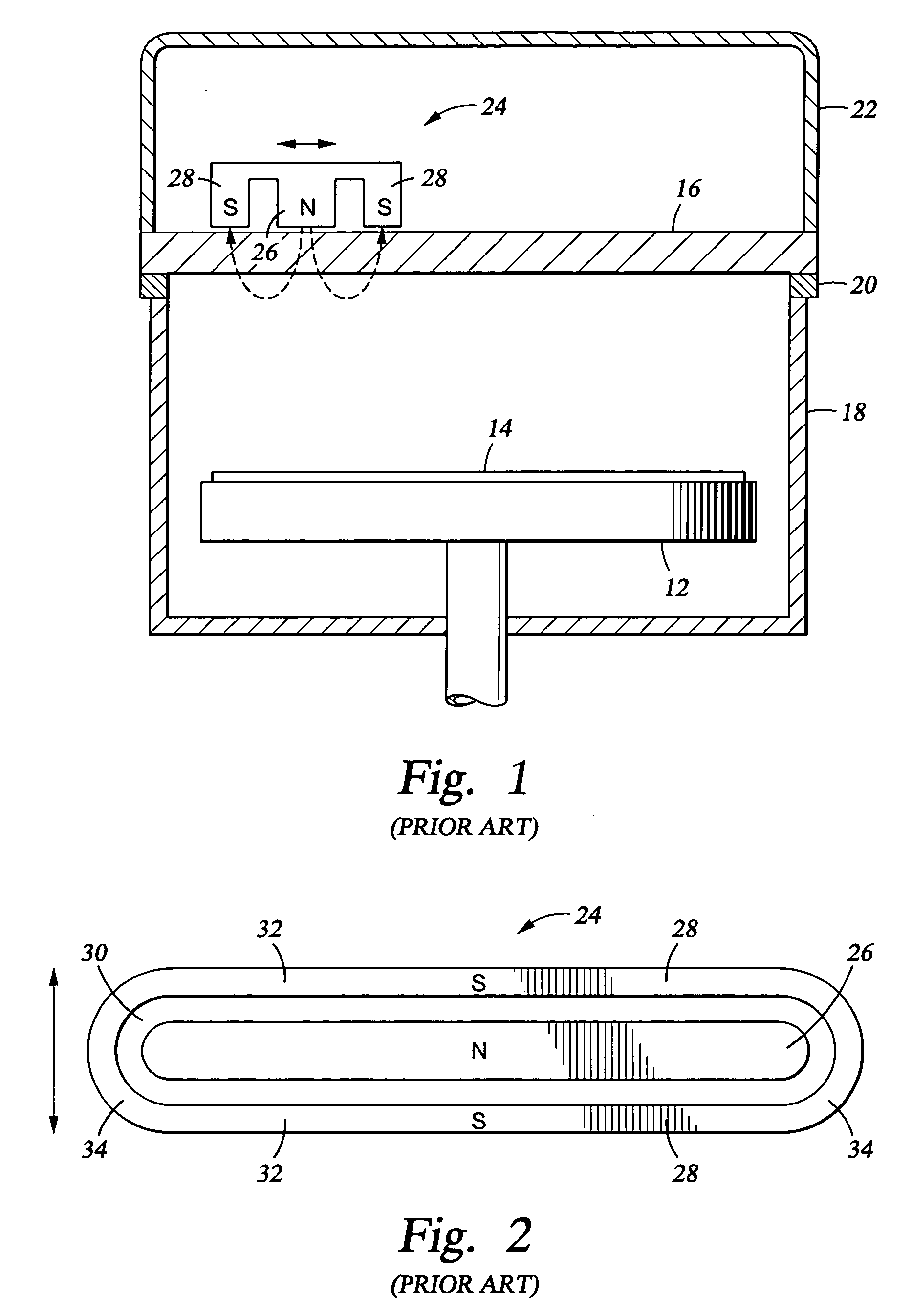

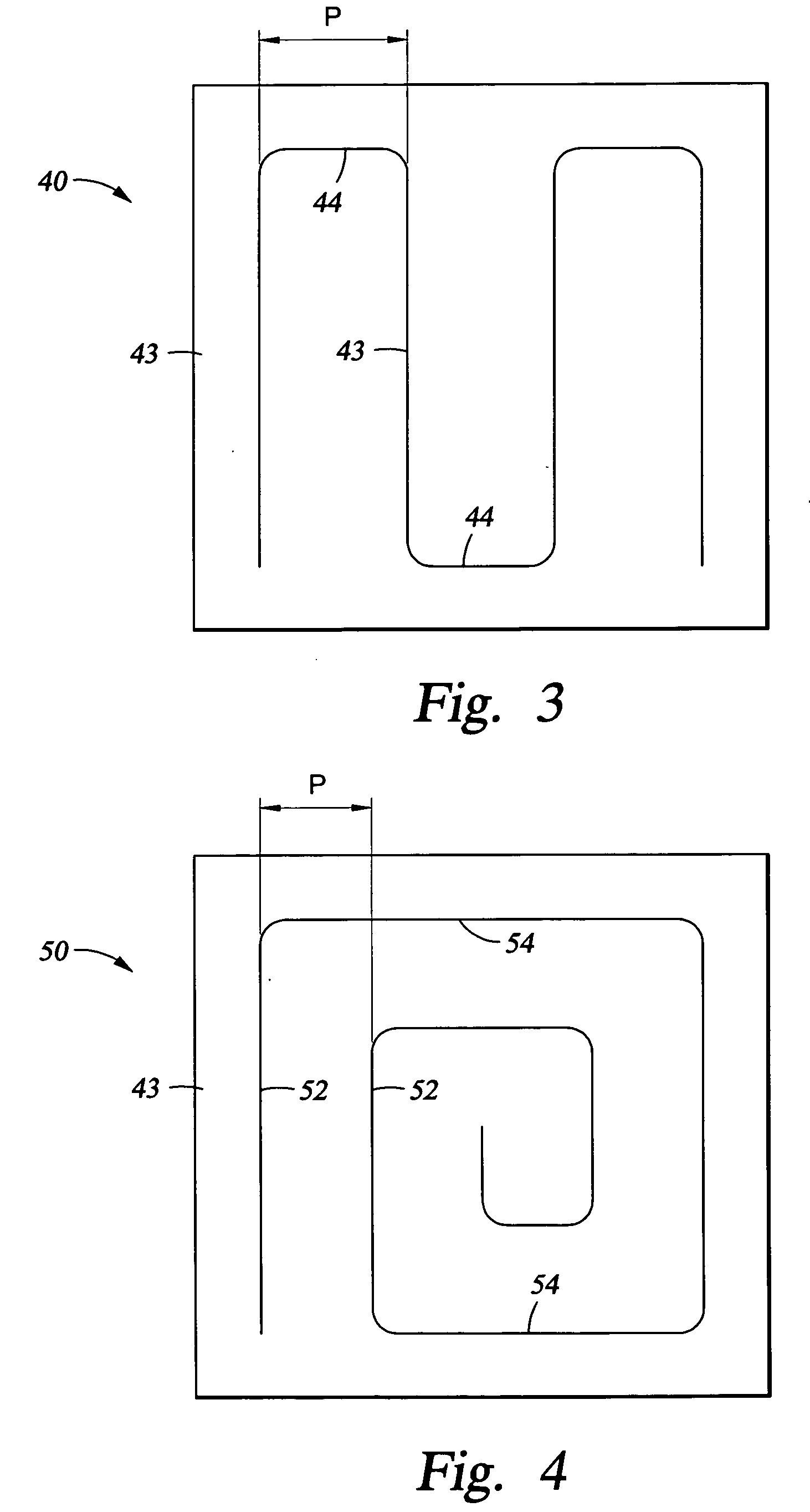

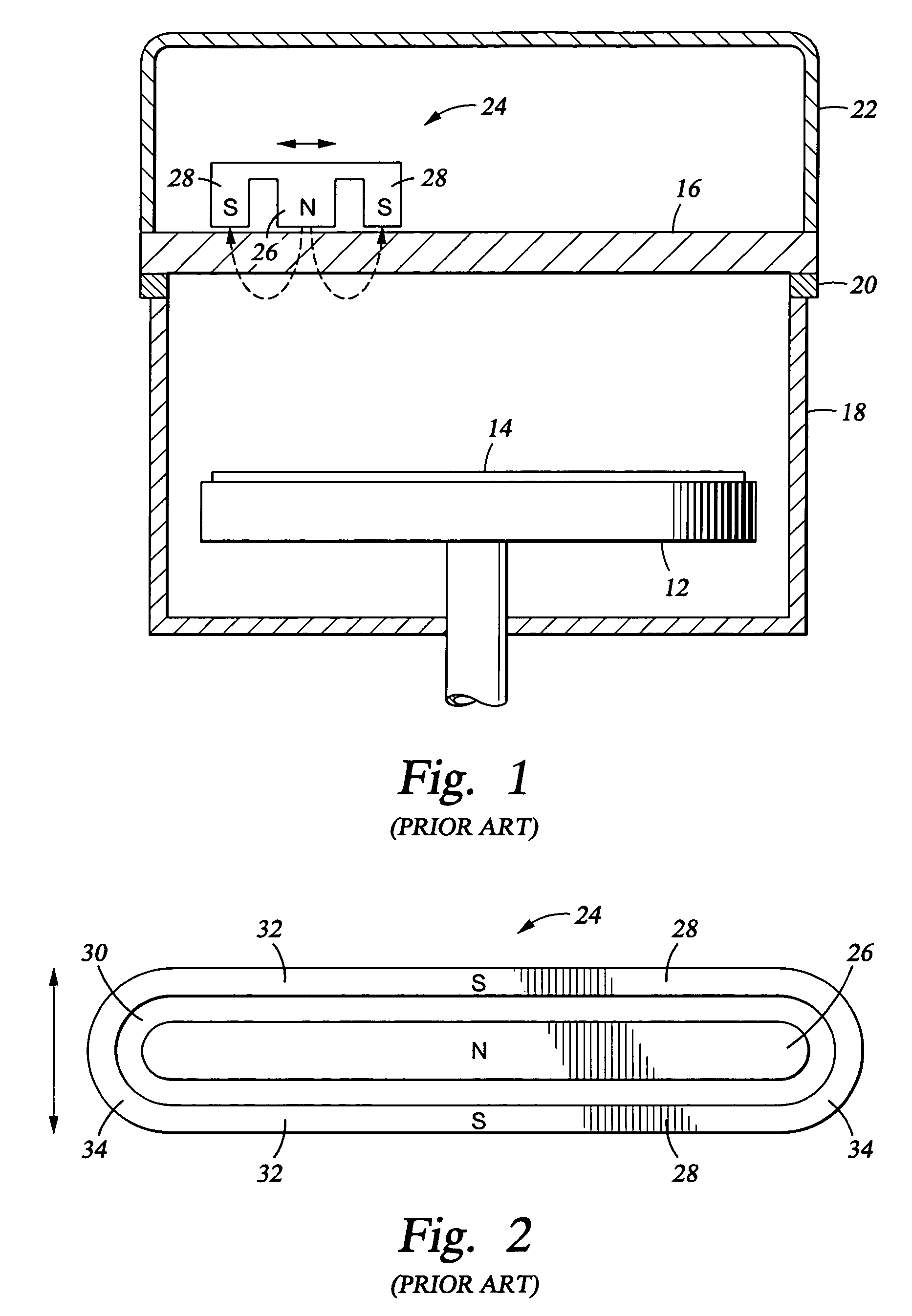

A sputtering magnetron with a rotating cylindrical target and a stationary magnet assembly (22, 24*) is described, the magnet assembly (22, 24*) being adapted to produce an elongate plasma race-track on the surface of the target, the elongate race-track having substantially parallel tracks over a substantial portion of its length and being closed at each end by end portions (22'), wherein the spacing between the tracks of the race-track is increased locally to materially effect sputtering onto a substrate. The increase in spacing may be at the end portions or along the parallel track portion. The increase in spacing may provide more even erosion of the target beneath the end portions of the race-track, and provide more even coatings on the substrate.

Owner:BEKAERT ADVANCED COATINGS

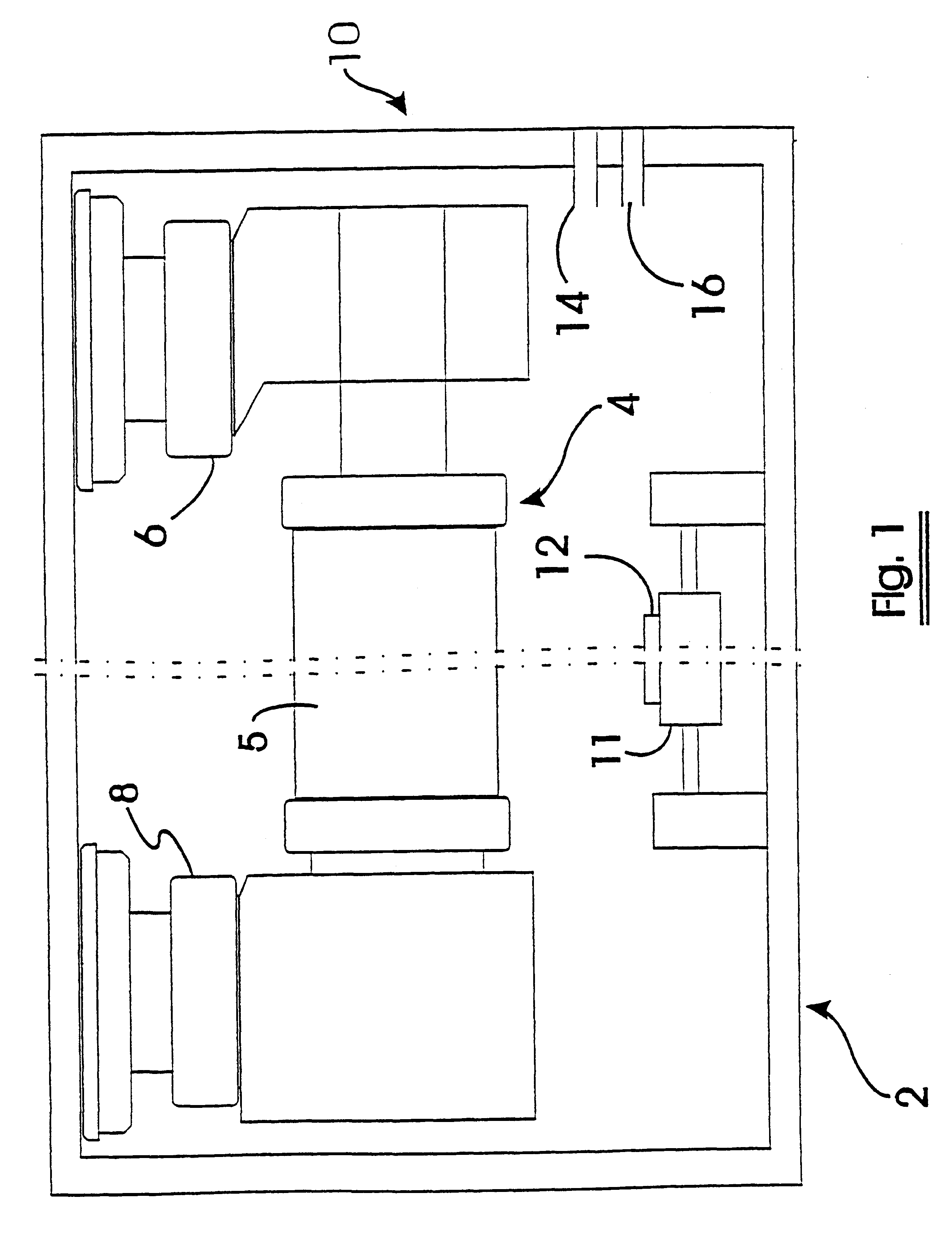

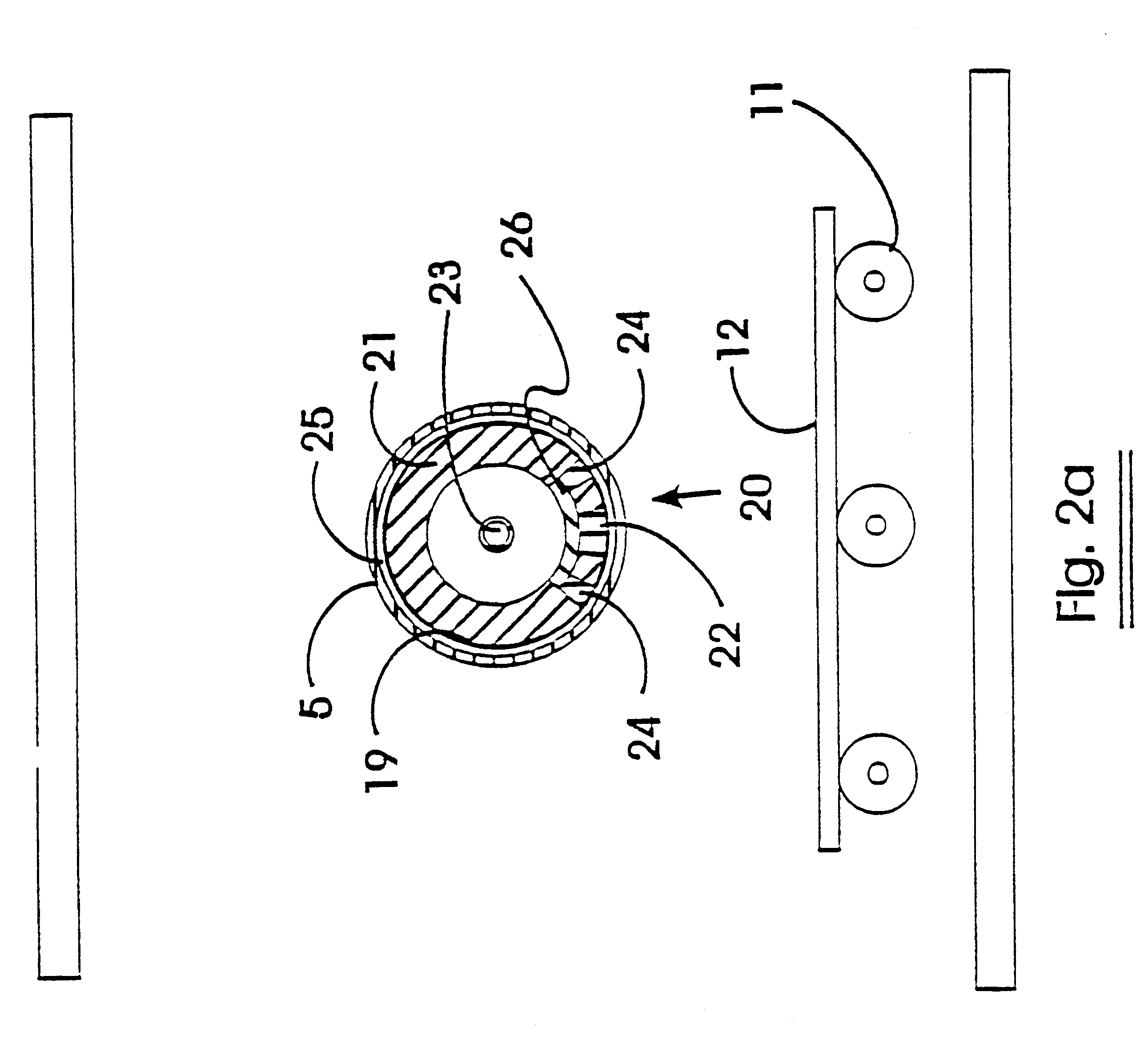

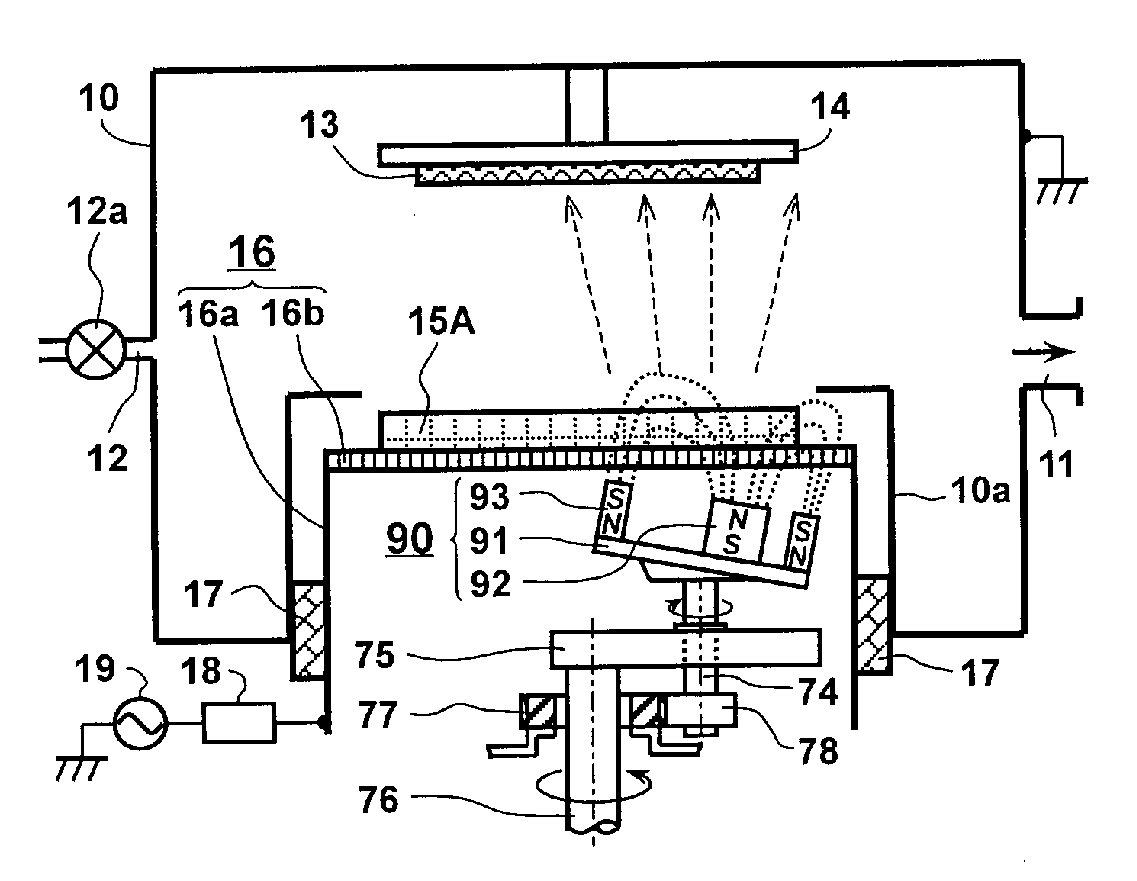

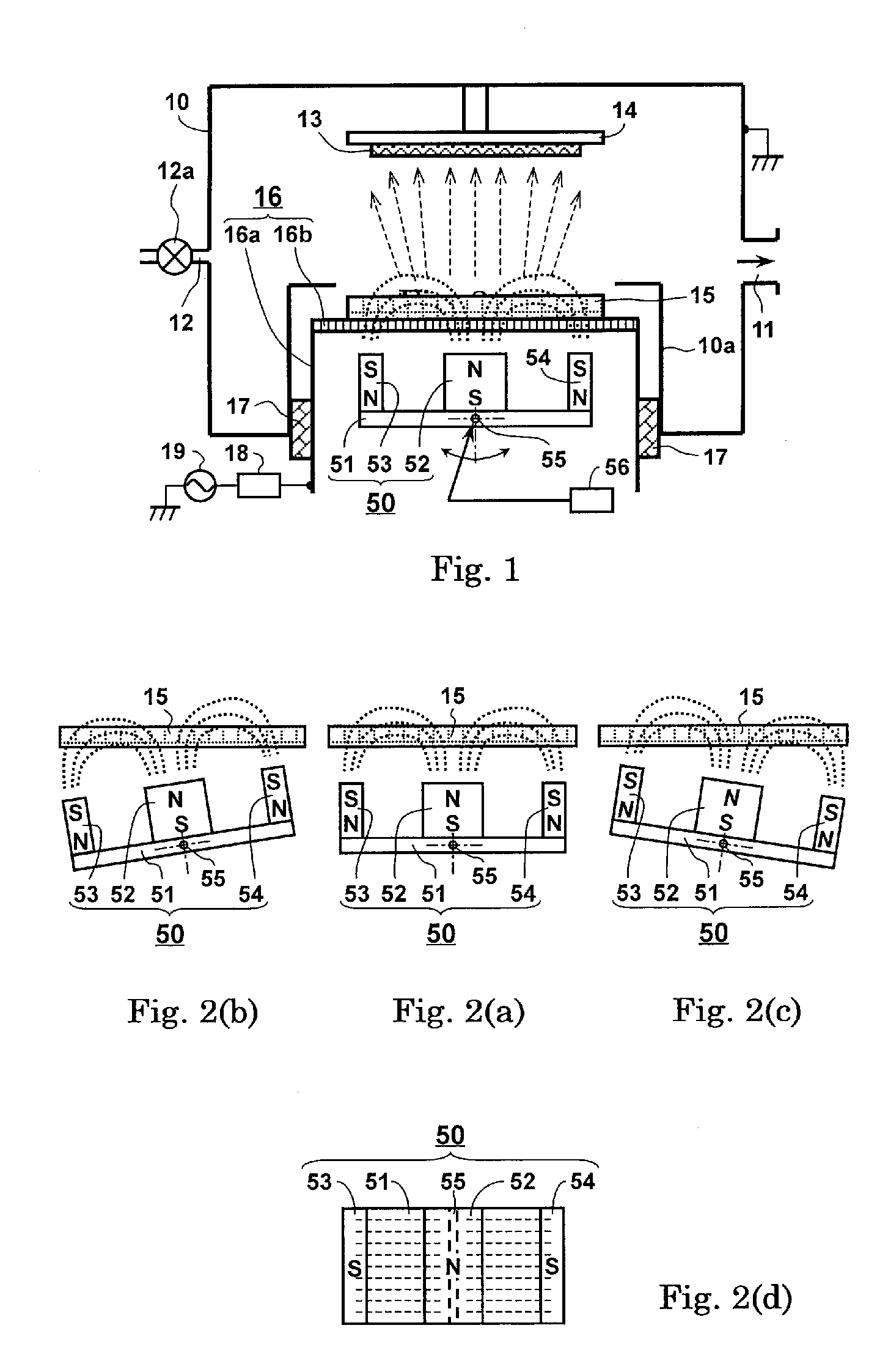

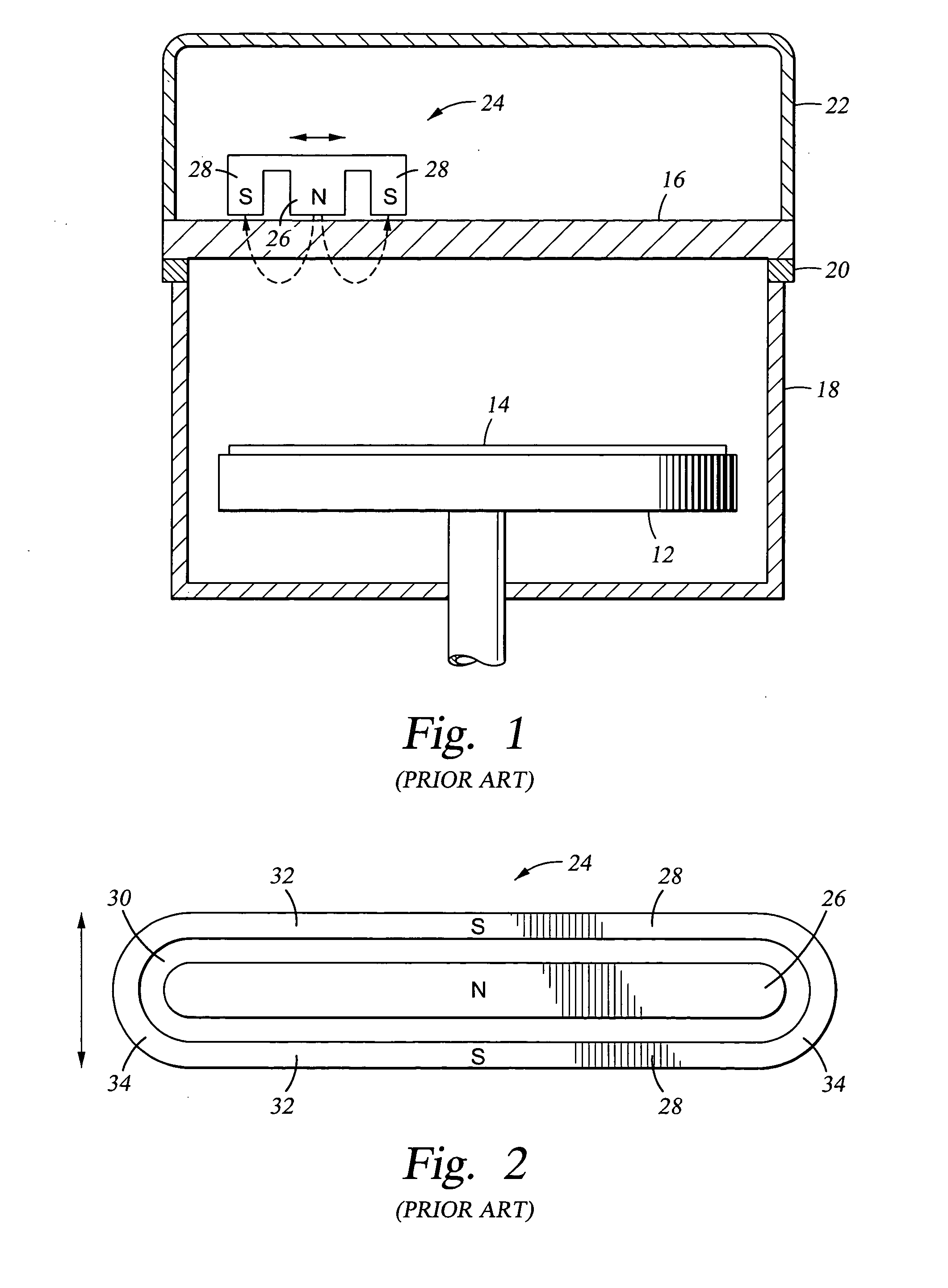

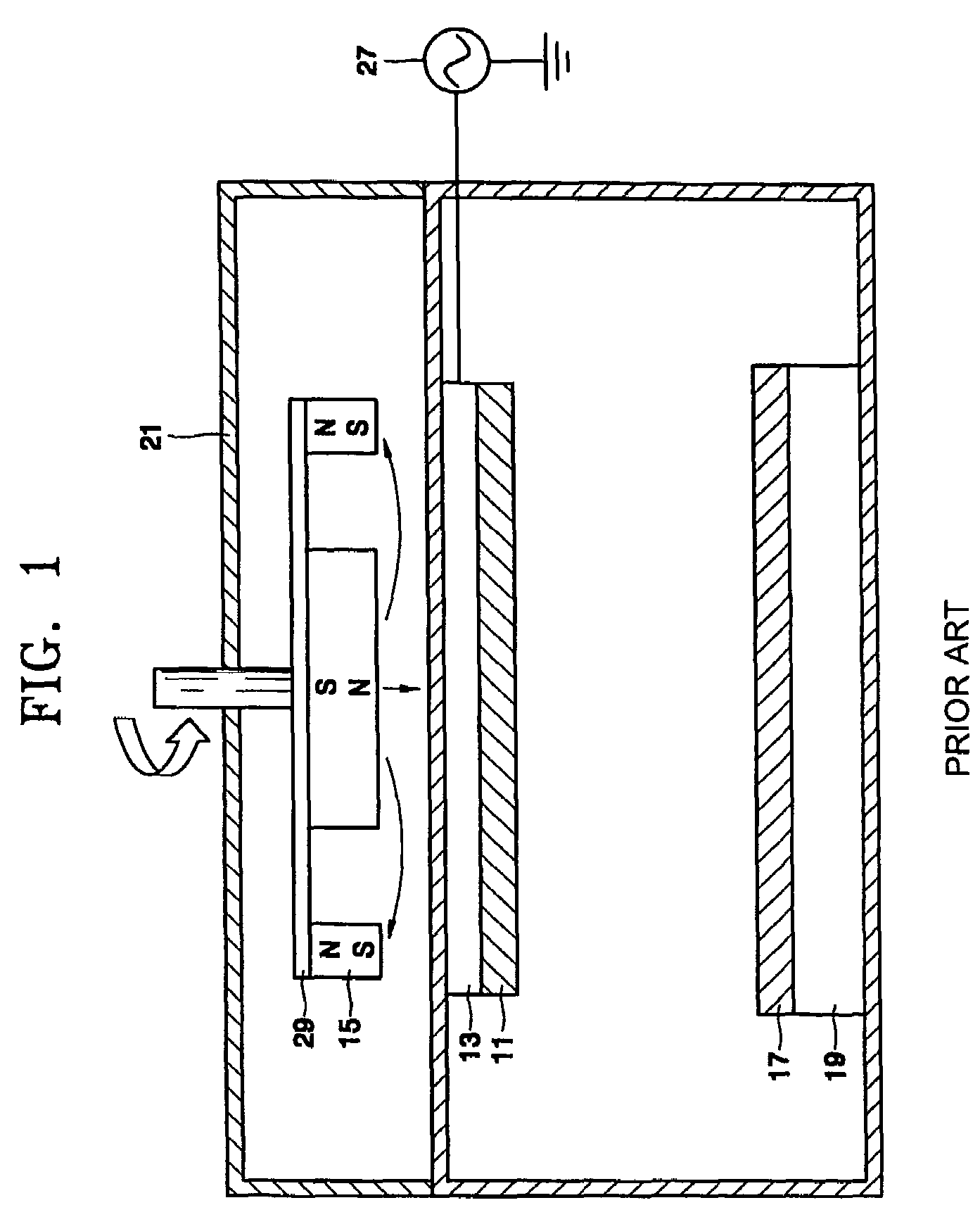

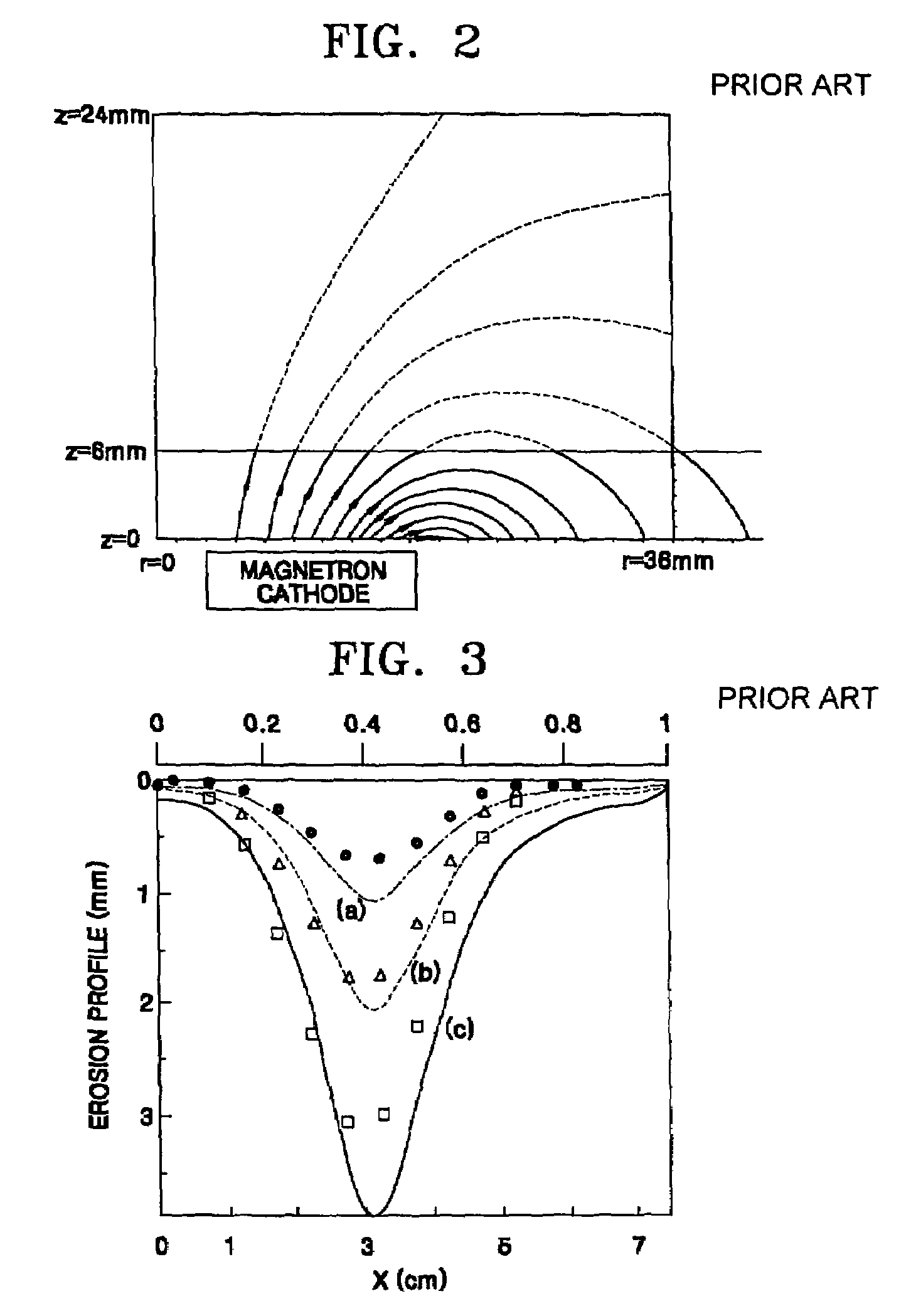

Magnetron sputtering apparatus

InactiveUS20050274610A1Improve sputtering efficiencyImprove targeting efficiencyCellsElectric discharge tubesSputteringVacuum chamber

A magnetron sputtering apparatus is composed of a vacuum chamber (10), a target (15), a substrate (13), an anode (14) for supporting the substrate (13) that is disposed in the vacuum chamber, a cathodic body (16) for supporting the target (15) that is allocated so as to confront with the anode (14) and a magnetic field generating section (50) for generating a magnetic field on a surface of the target (15) that is allocated in neighborhood of one side of the cathodic body (16) opposite to the target (15). The target (15) is in a shape of square flat plate. The magnetic field generating section (50) is further composed of a yoke (51) in flat plate corresponding to the target (15), a first permanent magnet (52) in rectangular parallelepiped that is disposed in the middle of the yoke (51) and second and third permanent magnets (53, 54) in rectangular parallelepiped that are disposed in both end portions of the yoke (51) respectively. The magnetron sputtering apparatus is further composed of a driving unit (56) for swinging the magnetic field generating section (50) within a prescribed angle with centering a line as an axis of rotation, wherein the line passes through an approximate center (56) of the yoke (51) and is perpendicular to magnetic flux lines of the magnetic field and in parallel with the target (15).

Owner:VICTOR CO OF JAPAN LTD

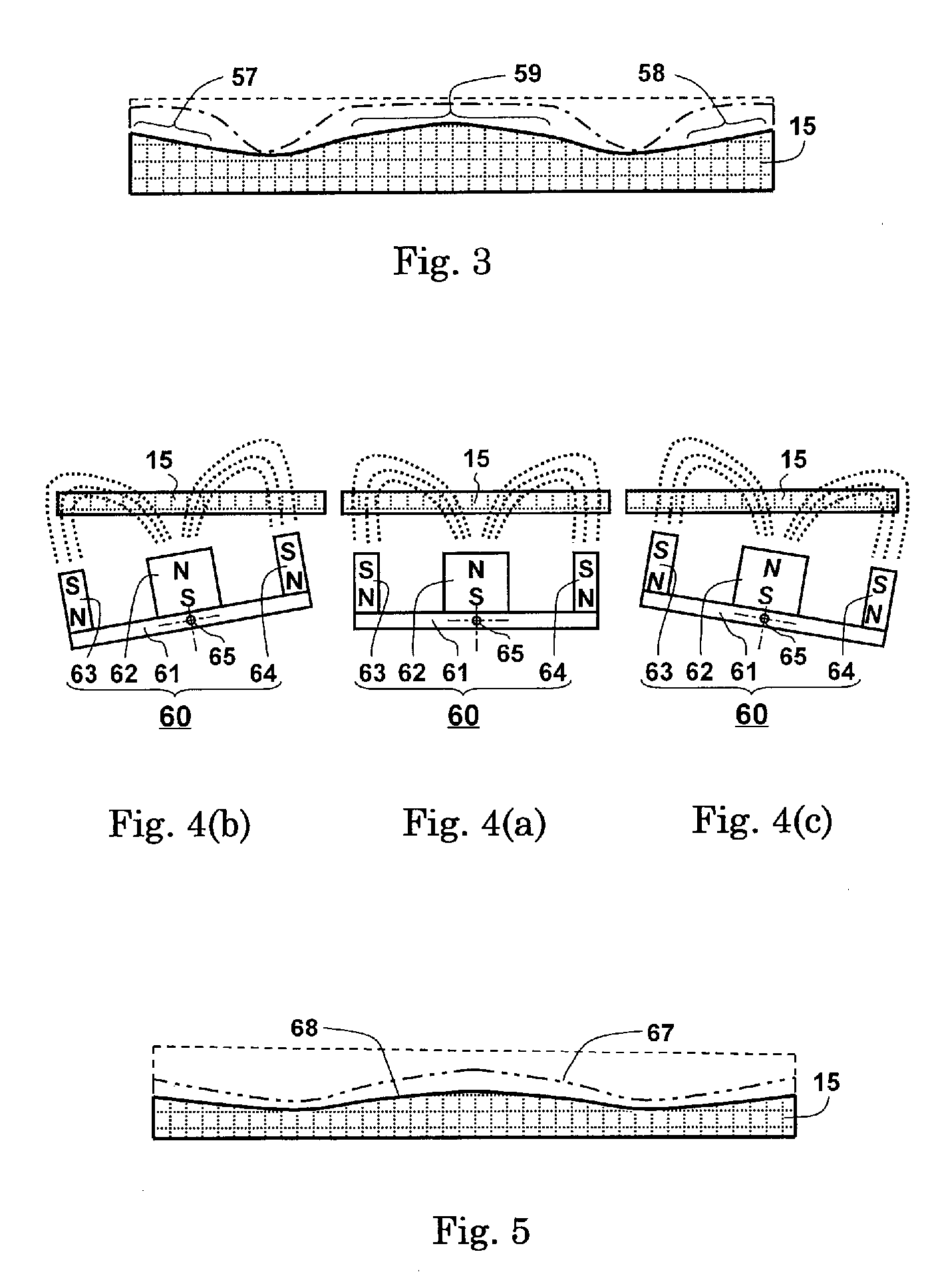

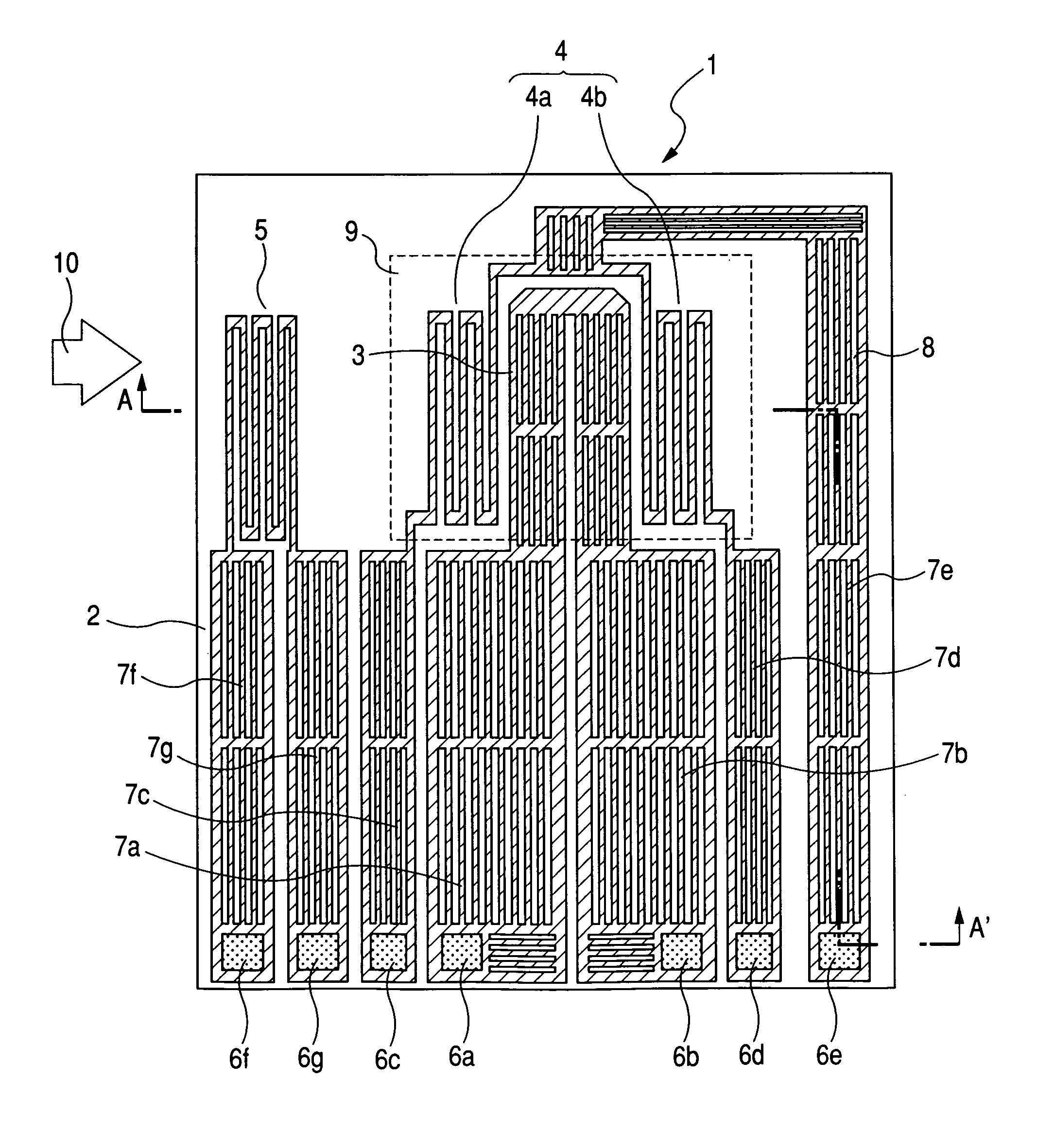

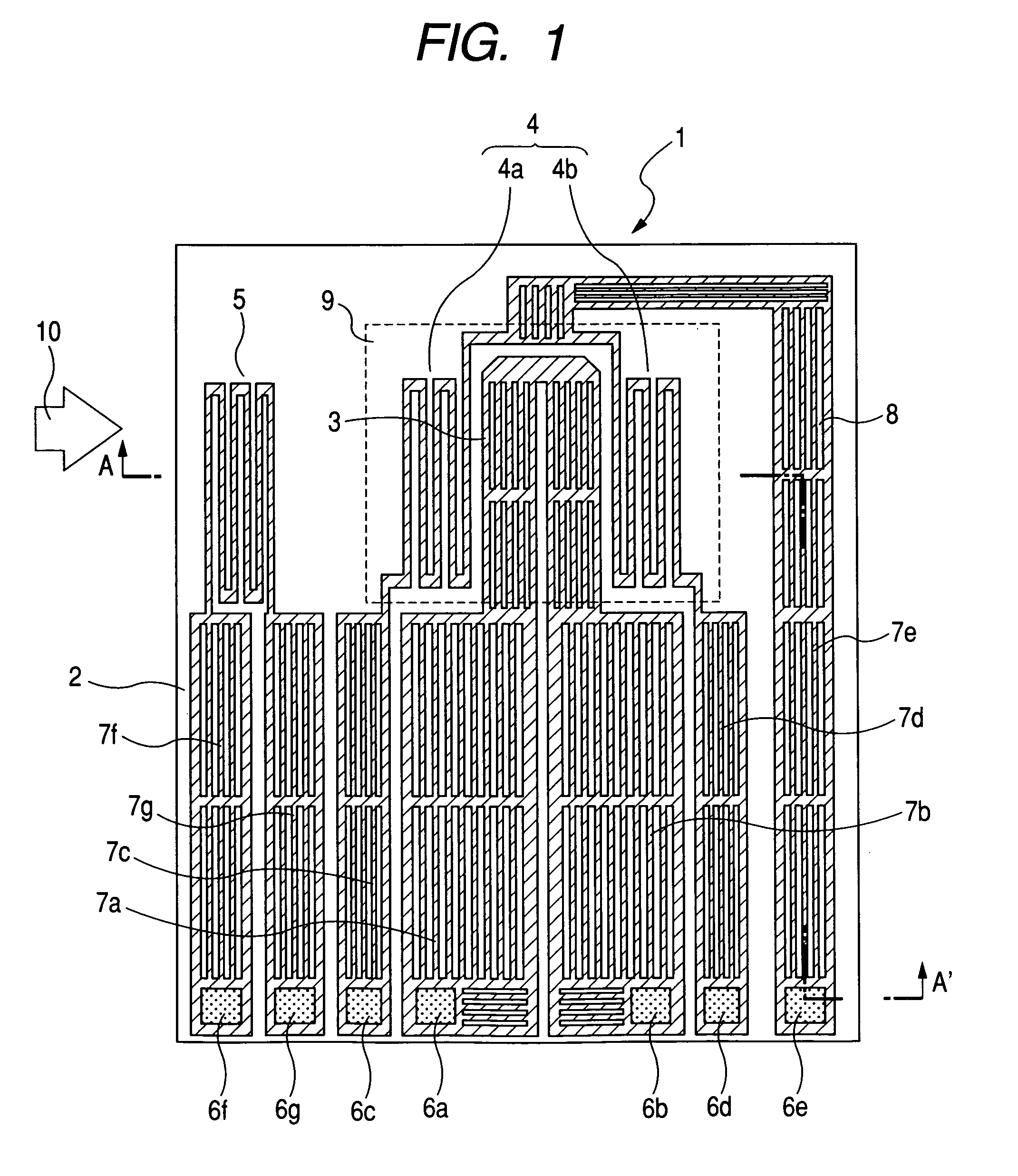

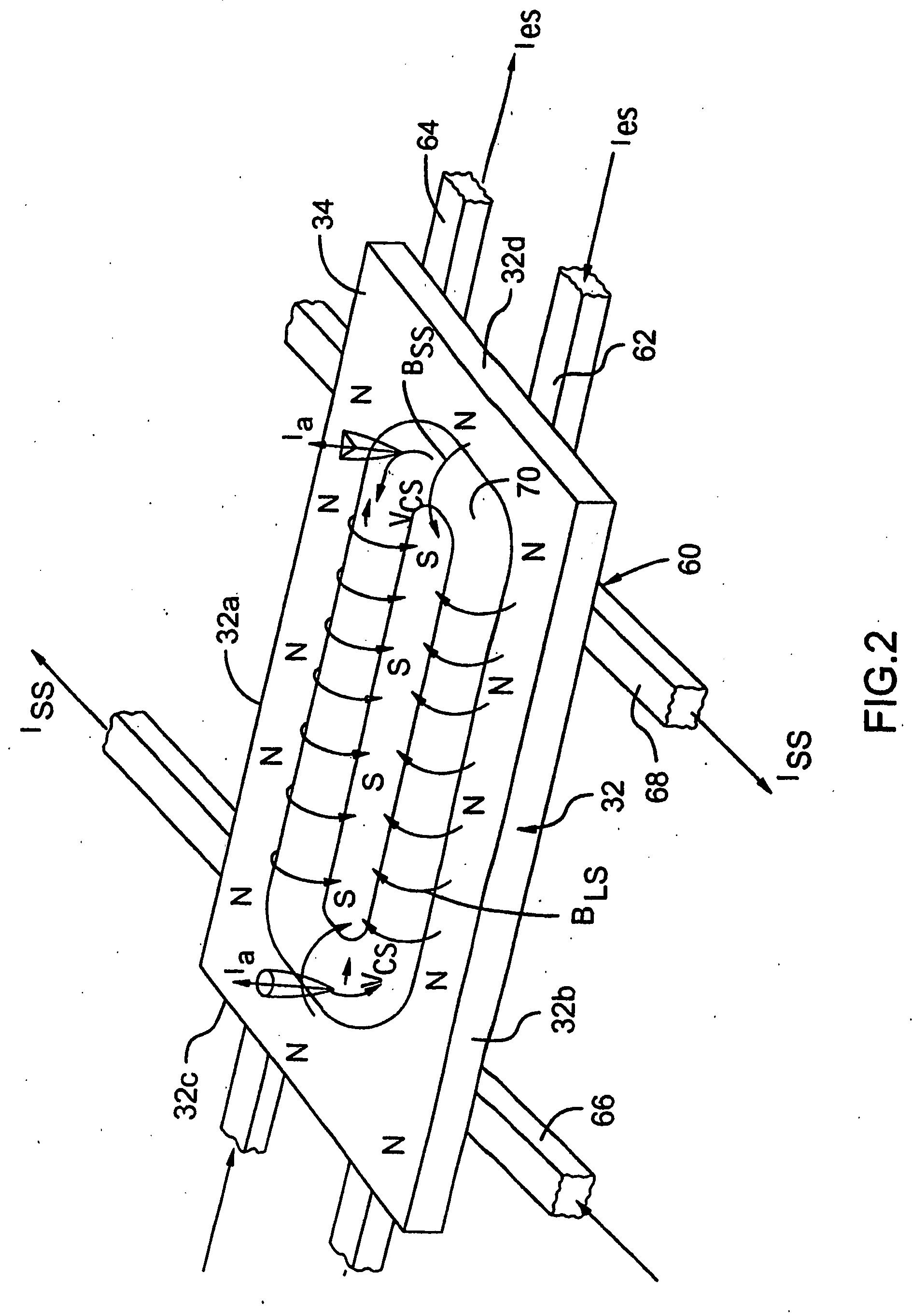

Two dimensional magnetron scanning for flat panel sputtering

InactiveUS20050145478A1Uniformity of sputter erosionImprove uniformityCellsElectric discharge tubesSputteringDiagonal

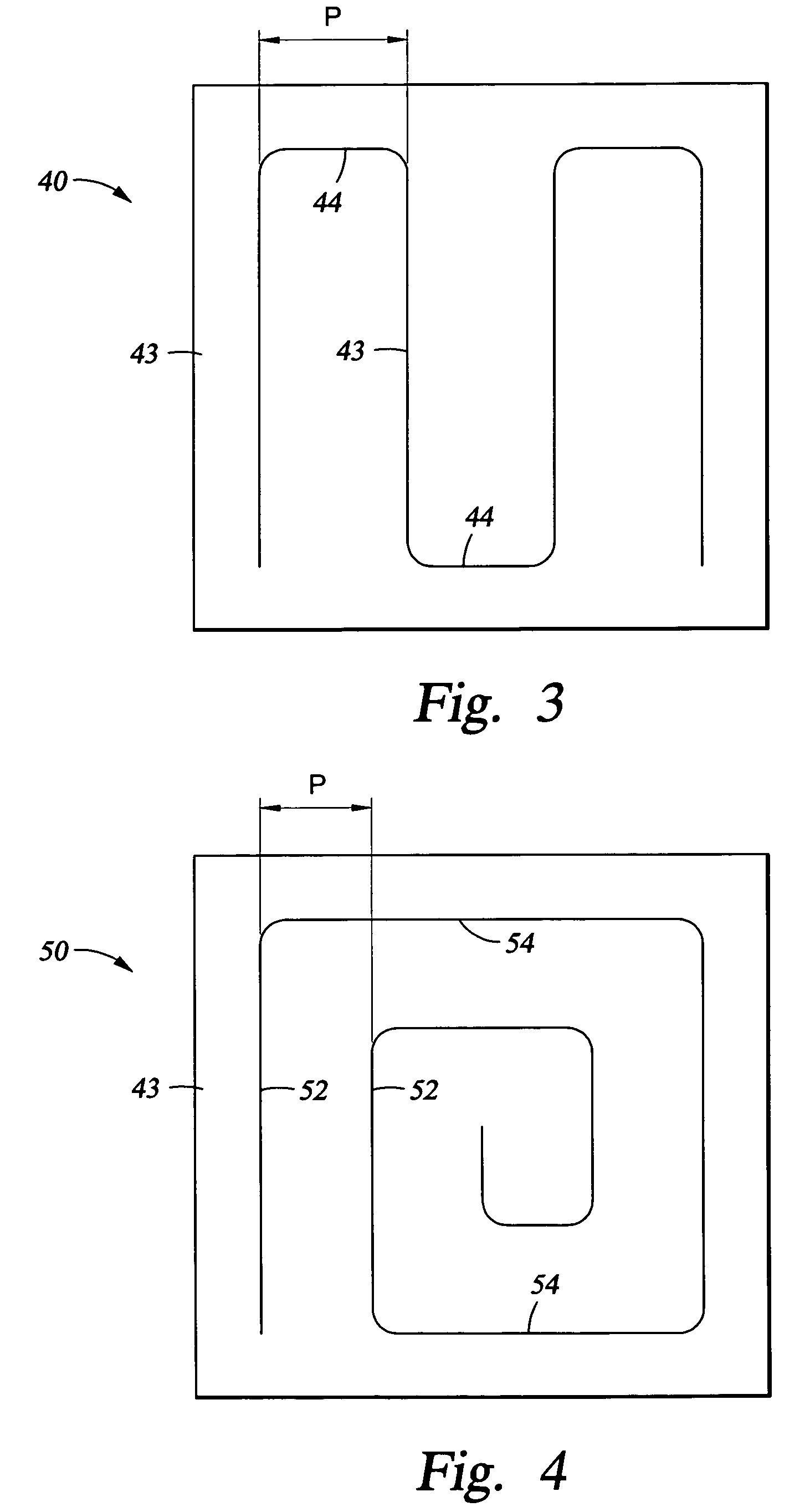

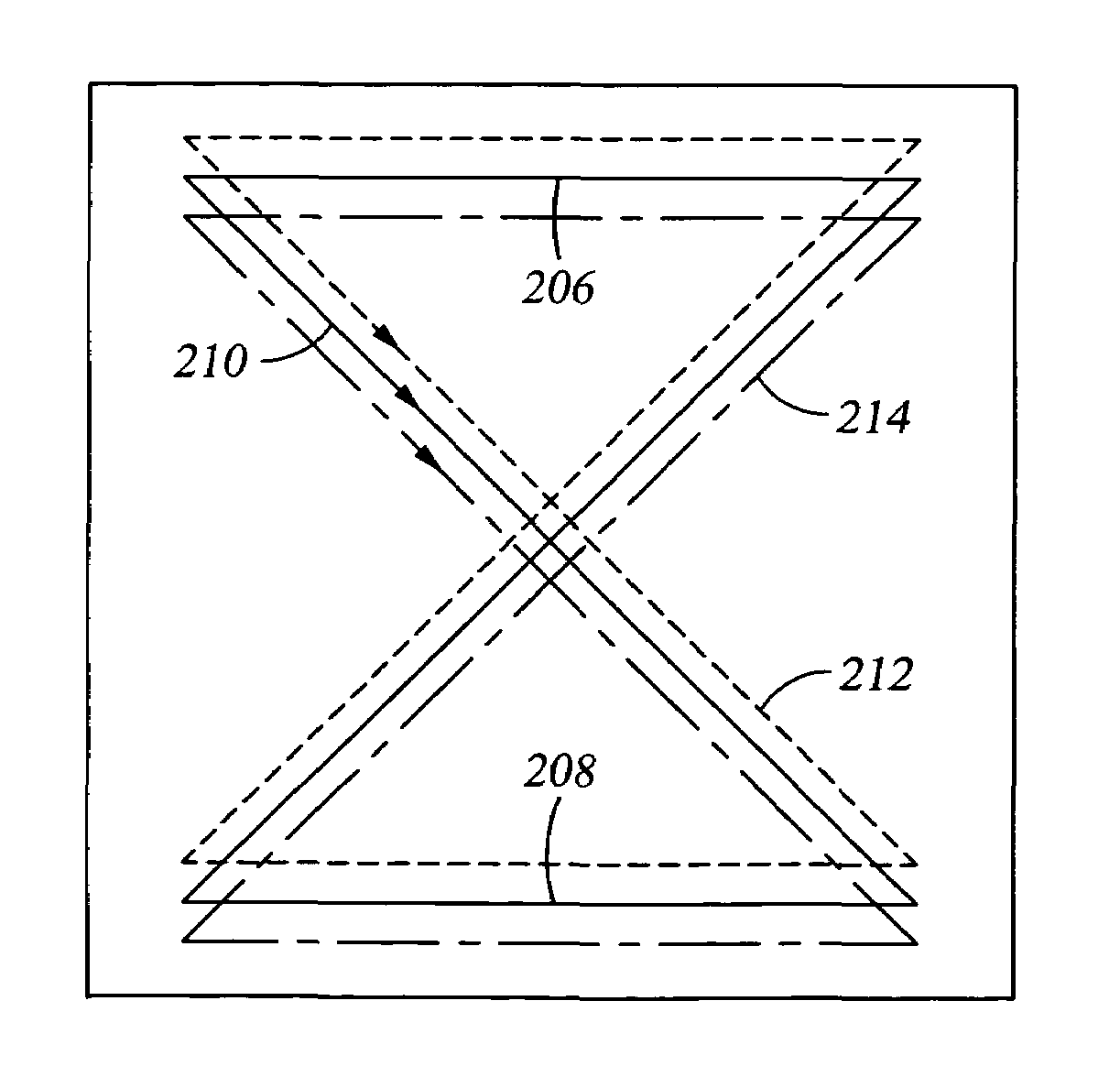

A generally rectangular magnetron placed at the back of a rectangular target to intensify the plasma in a sputter reactor configured for sputtering target material onto a rectangular panel. The magnetron has a size only somewhat less than that of the target and is scanned in the two perpendicular directions of the target with a scan length of, for example, about 100 mm for a 2 m target. The scan may follow a double-Z pattern along two links parallel to a target side and the two connecting diagonals. The magnetron includes a closed plasma loop formed in a convolute shape, for example, serpentine or rectangularized helix with an inner pole of nearly constant width extending along a single path and having one magnetic polarity completely surrounded by an outer pole having the opposed polarity.

Owner:APPLIED MATERIALS INC

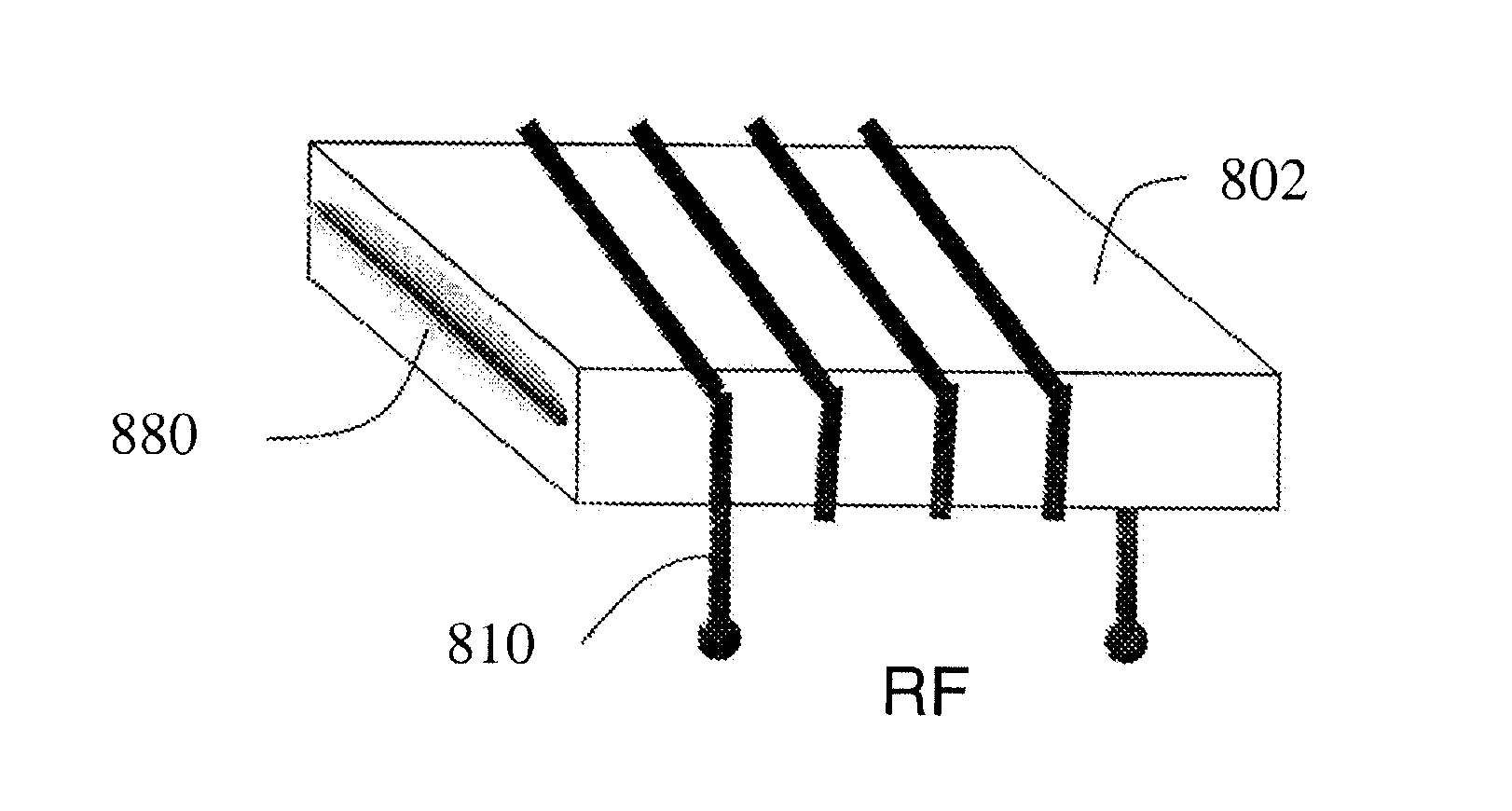

Dielectric deposition using a remote plasma source

InactiveUS20110226617A1Evenly distributedReduce thermal stressCellsElectric discharge tubesDielectricRemote plasma

A sputter deposition system comprises a vacuum chamber including a vacuum pump for maintaining a vacuum in the vacuum chamber, a gas inlet for supplying process gases to the vacuum chamber, a sputter target and a substrate holder within the vacuum chamber, and a plasma source attached to the vacuum chamber and positioned remotely from the sputter target, the plasma source being configured to form a high density plasma beam extending into the vacuum chamber. The plasma source may include a rectangular cross-section source chamber, an electromagnet, and a radio frequency coil, wherein the rectangular cross-section source chamber and the radio frequency coil are configured to give the high density plasma beam an elongated ovate cross-section. Furthermore, the surface of the sputter target may be configured in a non-planar form to provide uniform plasma energy deposition into the target and / or uniform sputter deposition at the surface of a substrate on the substrate holder. The sputter deposition system may include a plasma spreading system for reshaping the high density plasma beam for complete and uniform coverage of the sputter target.

Owner:APPLIED MATERIALS INC

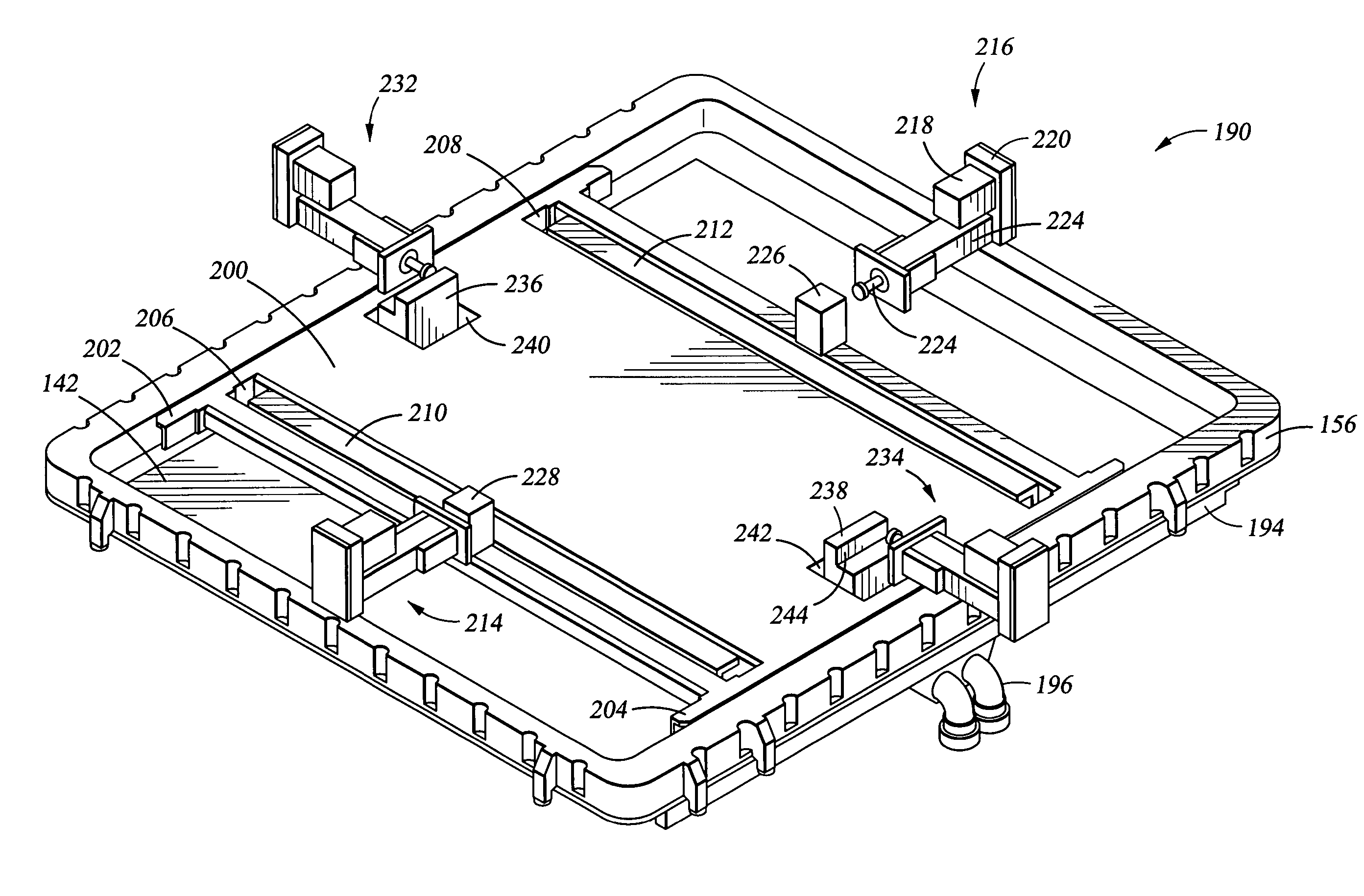

Apparatus and method for two dimensional magnetron scanning for sputtering onto flat panels

InactiveUS20060049040A1Uniformity of sputter erosionImprove uniformityCellsElectric discharge tubesDiagonalElectrical polarity

A rectangular magnetron placed at the back of a rectangular target to intensify the plasma in a sputter reactor configured for sputtering target material onto a rectangular panel. The magnetron has a size only somewhat less than that of the target and is scanned in the two perpendicular directions of the target with a scan length of, for example, about 100 mm for a 2 m target. The scan may follow a double-Z pattern along two links parallel to a target side and the two connecting diagonals. The magnetron includes a closed plasma loop formed in a convolute shape, for example, a rectangularized helix with an inner pole of nearly constant width extending along a single path and having one magnetic polarity completely surrounded by an outer pole having the opposed polarity. External actuators move the magnetron slidably suspended from a gantry which sliding perpendicularly on the chamber walls.

Owner:APPLIED MATERIALS INC

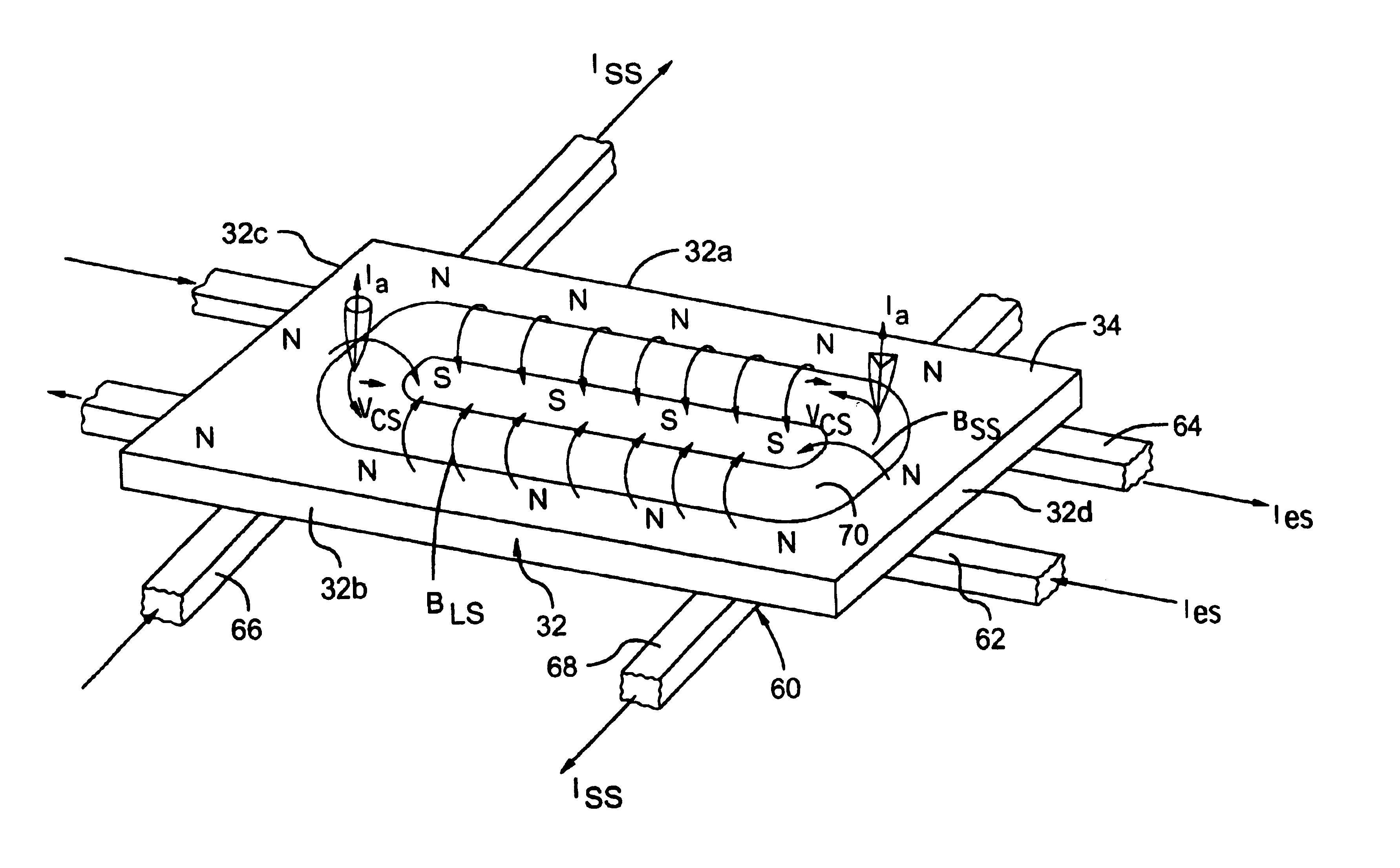

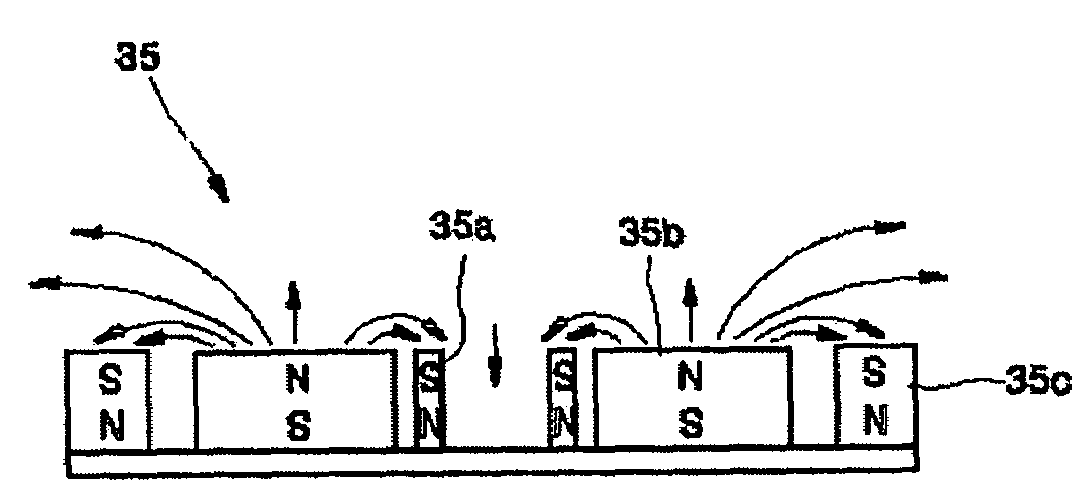

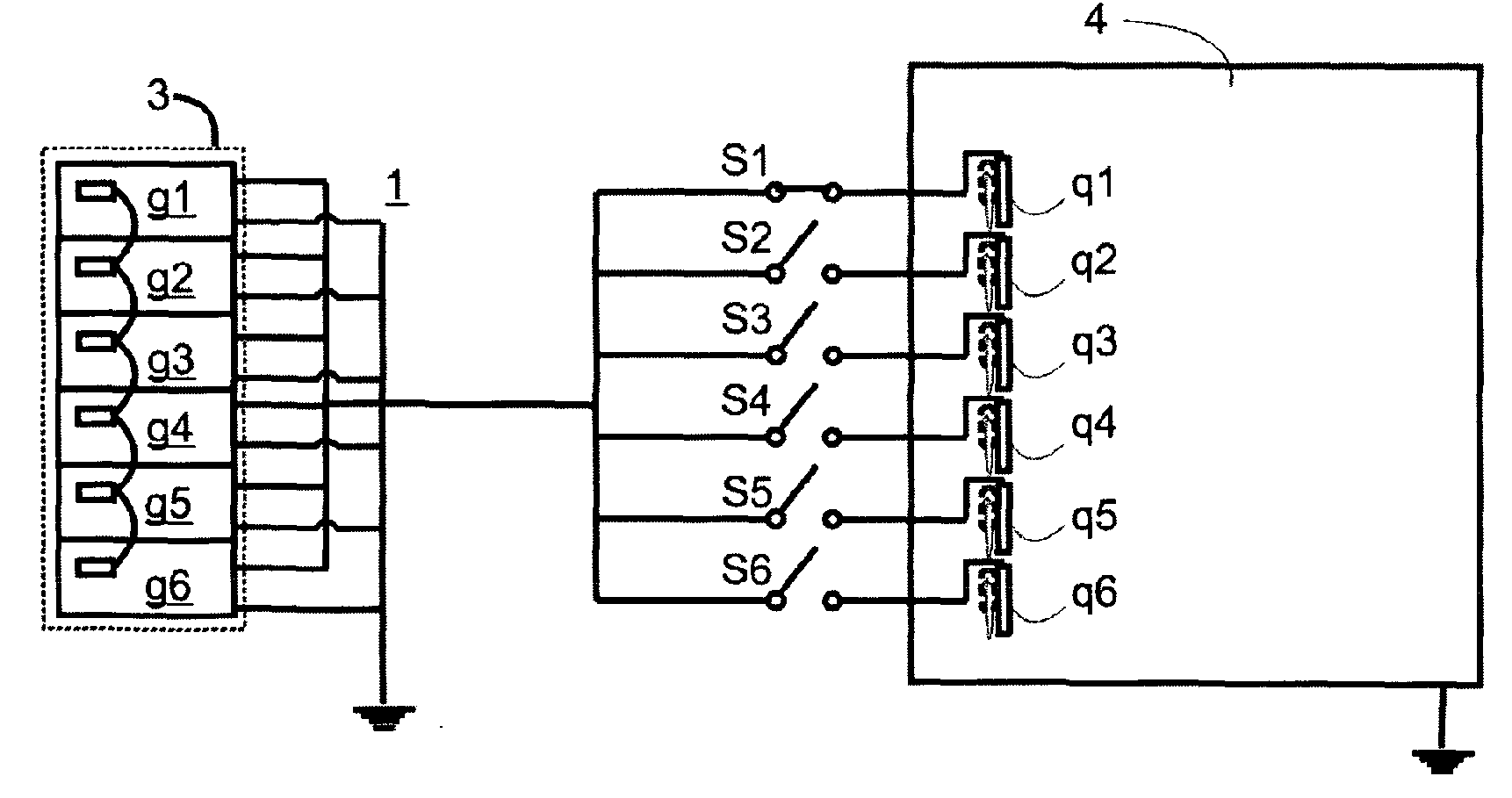

Rectangular cathodic arc source and method of steering an arc spot

InactiveUS6929727B2Improve distributionUniform coatingCellsLiquid surface applicatorsElectrical conductorEvaporation

The invention provides an arc coating apparatus having a steering magnetic field source comprising steering conductors disposed along the short sides of a rectangular target behind the target, and a magnetic focusing system disposed along the long sides of the target in front of the target which confines the flow of plasma between magnetic fields generated on opposite long sides of the target. The plasma focusing system can be used to deflect the plasma flow off of the working axis of the cathode. Each steering conductor can be controlled independently. In a further embodiment, electrically independent steering conductors are disposed along opposite long sides of the cathode plate, and by selectively varying a current through one conductor, the path of the arc spot shifts to widen an erosion corridor. The invention also provides a plurality of internal anodes, and optionally a surrounding anode for deflecting the plasma flow and preserving a high ionization level of the plasma. The invention also provides a shield at floating potential, restricting the cathode spot from migrating into selected regions of the target evaporation surface outside of the desired erosion zone. The shield may be positioned immediately above the region of the target surface in the vicinity of the anode, protecting the anode from deposition of cathodic evaporate and providing better distribution of cathodic evaporate over the substrates to be coated. The invention further provides correcting magnets adjacent to the short sides of the target, to move the arc spot between the long sides.

Owner:G&H TECH LLC

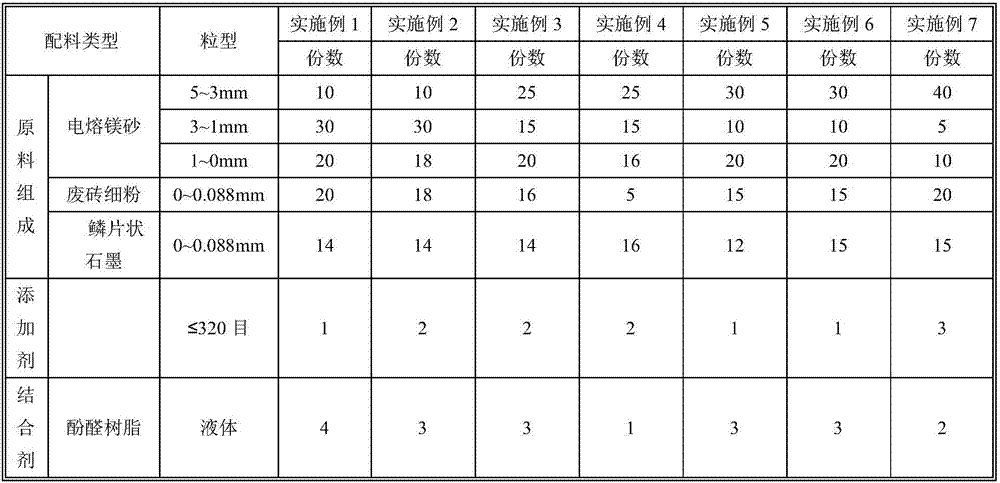

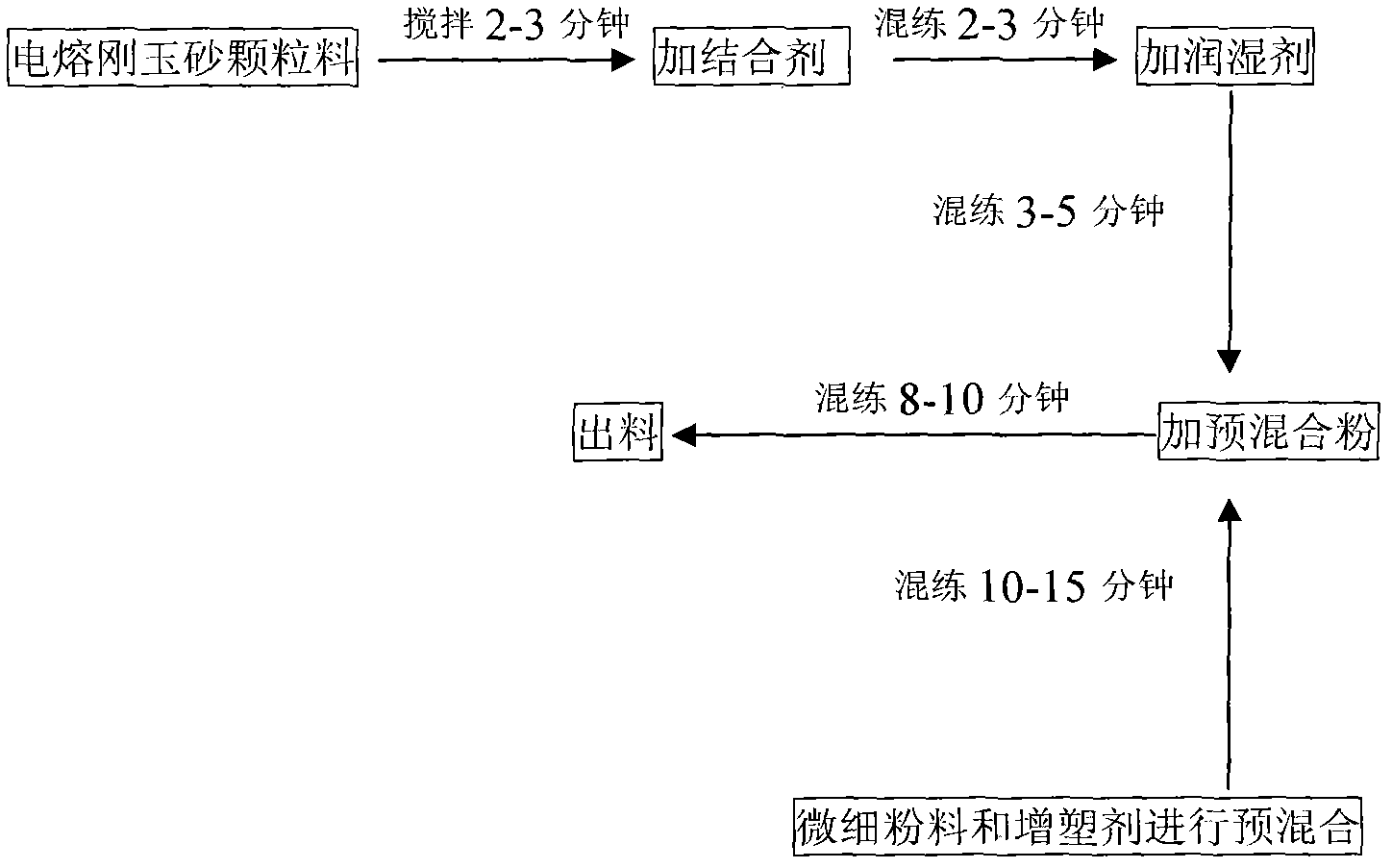

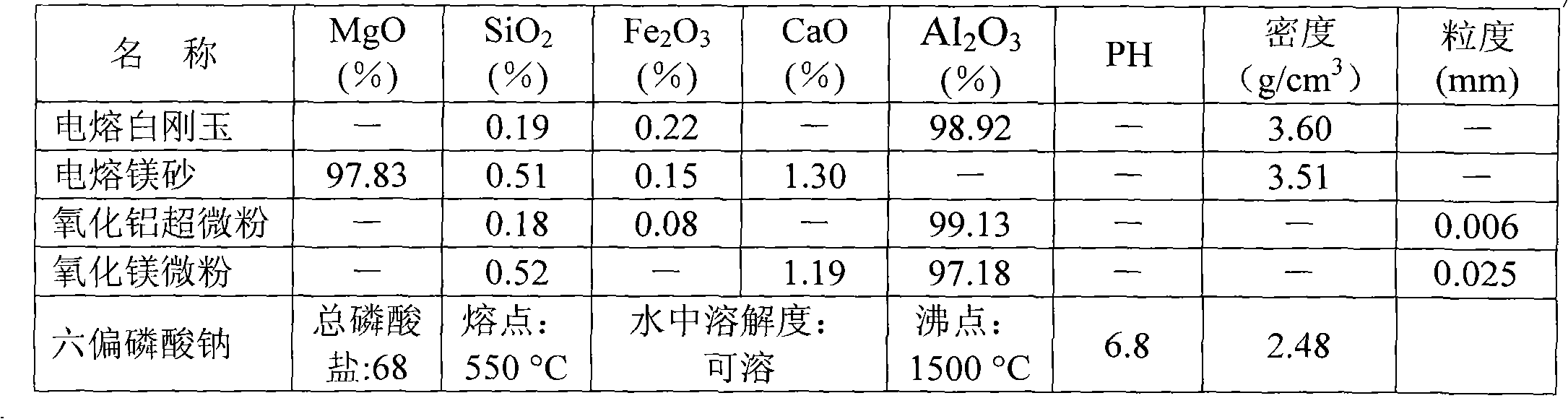

Non-phosphorus and low-carbon alumina-magnesia unburned brick for stainless steel ladle and manufacturing method of brick

The invention discloses a non-phosphorus and low-carbon alumina-magnesia unburned brick for a stainless steel ladle and a manufacturing method of the brick. The non-phosphorus and low-carbon alumina-magnesia unburned brick comprises the following components by mass percentage: 15-20% of 5-3mm bauxite, 20-25% of 3-1mm bauxite, 10-15% of bauxite less than or equal to 1mm in particle size, 10-15% of 3-1mm fused magnesite, 5-10% of fused magnesite less than or equal to 1mm in particle size, 10-15% of emery powder, 15-20% of spinel powder, 2-5% of aluminum oxide micropowder less than or equal to 25 micrometers, 0.1-2% of silicon carbide additive, 0.1-2% of wetting agent and a phenolic resin binding agent. Compared with the prior art, the brick and the method have the prominent advantages that a burning technology in the conventional method is omitted, energy sources are saved, the brick is free from phosphorus; aluminum and magnesium perform spinel reaction at the high temperature; and the brick is subjected to machine molding in the absence of the phosphorus, has higher density, avoids pollution of molten stainless steel, and has a longer service life.

Owner:长兴南冶冶金材料有限公司

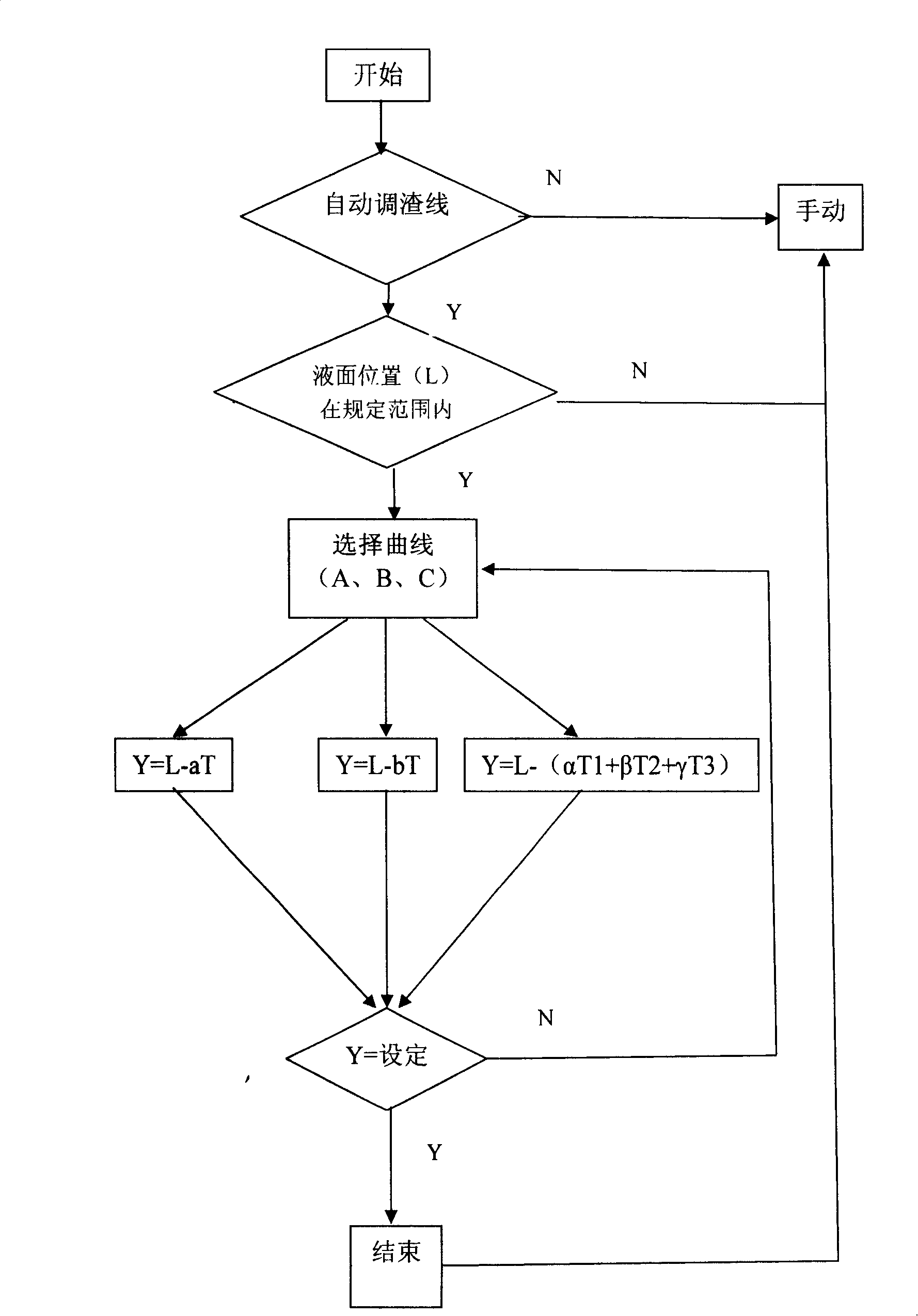

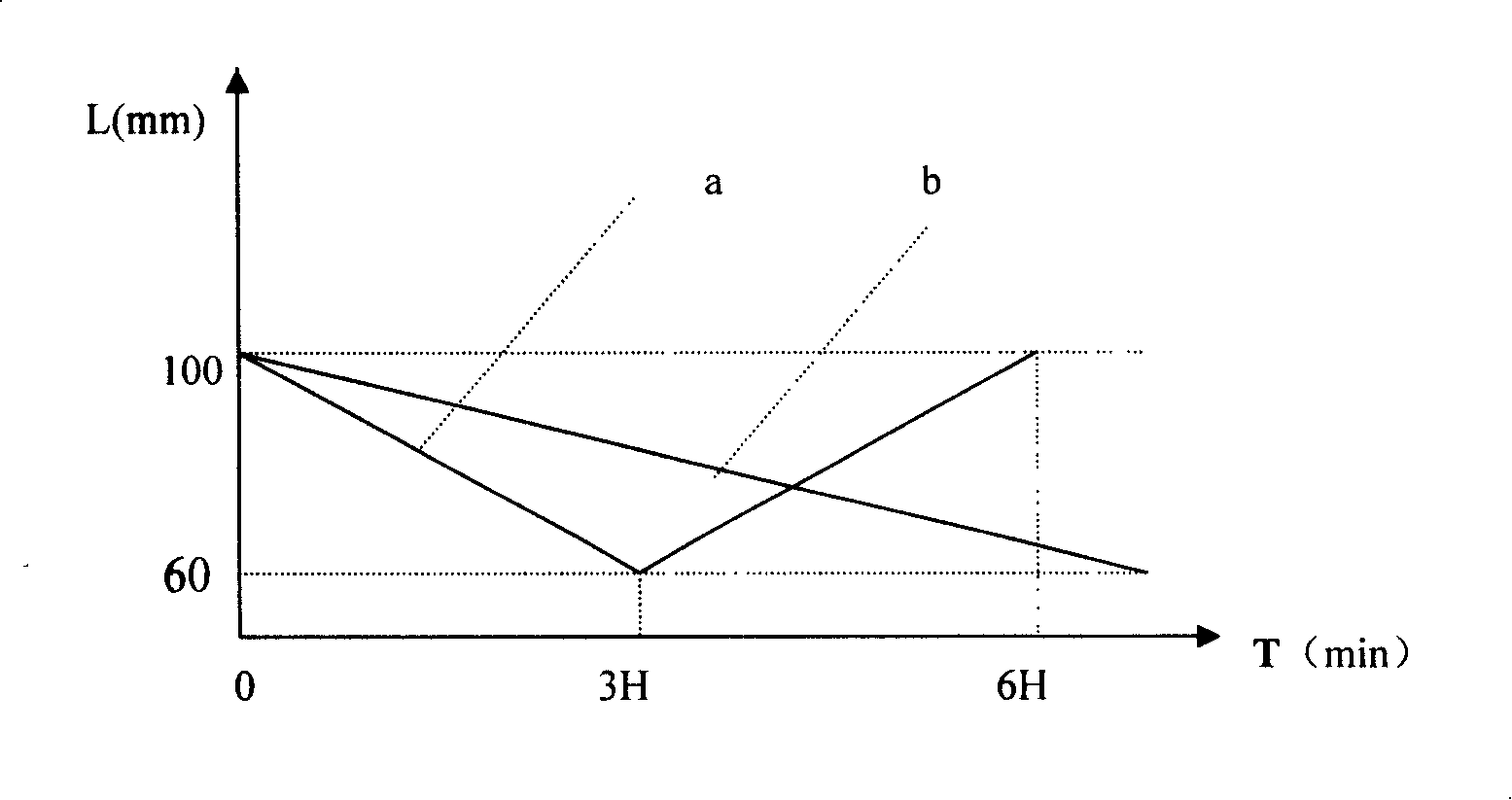

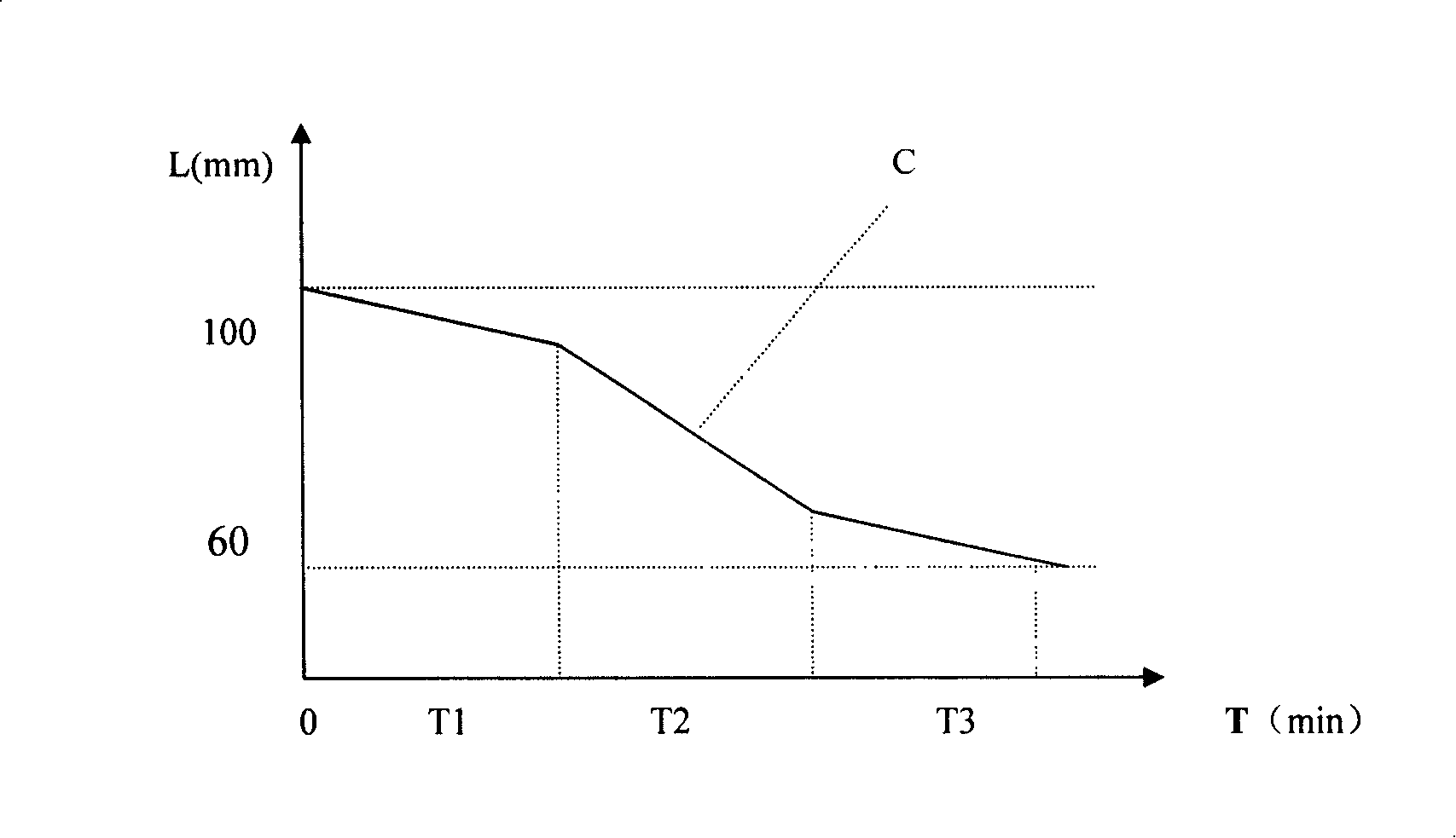

Slag line control method of continuous casting crystallizer

The invention provides a method for controlling a slag line in a continuous casting mould on the basis of the current existed automatic control system of the continuous casting mould. A slag line layer position is adjusted through a set value of an automatic trace changing system which changes with the time; therefore, a submerged nozzle can obtain a continuous, smooth and even dipping and brushing according to an anticipated form. The service life of the submerged nozzle is prolonged, thus solving problems of uneven dipping and brushing caused by manual setting as well as problems caused by the slag line processing, as well as lessening labor intensity of workers. Furthermore, a copperplate galvanization layer of the casting mould is evenly dipped and brushed so as to prolong the service life of the copperplate of the casting mould.

Owner:ANGANG STEEL CO LTD

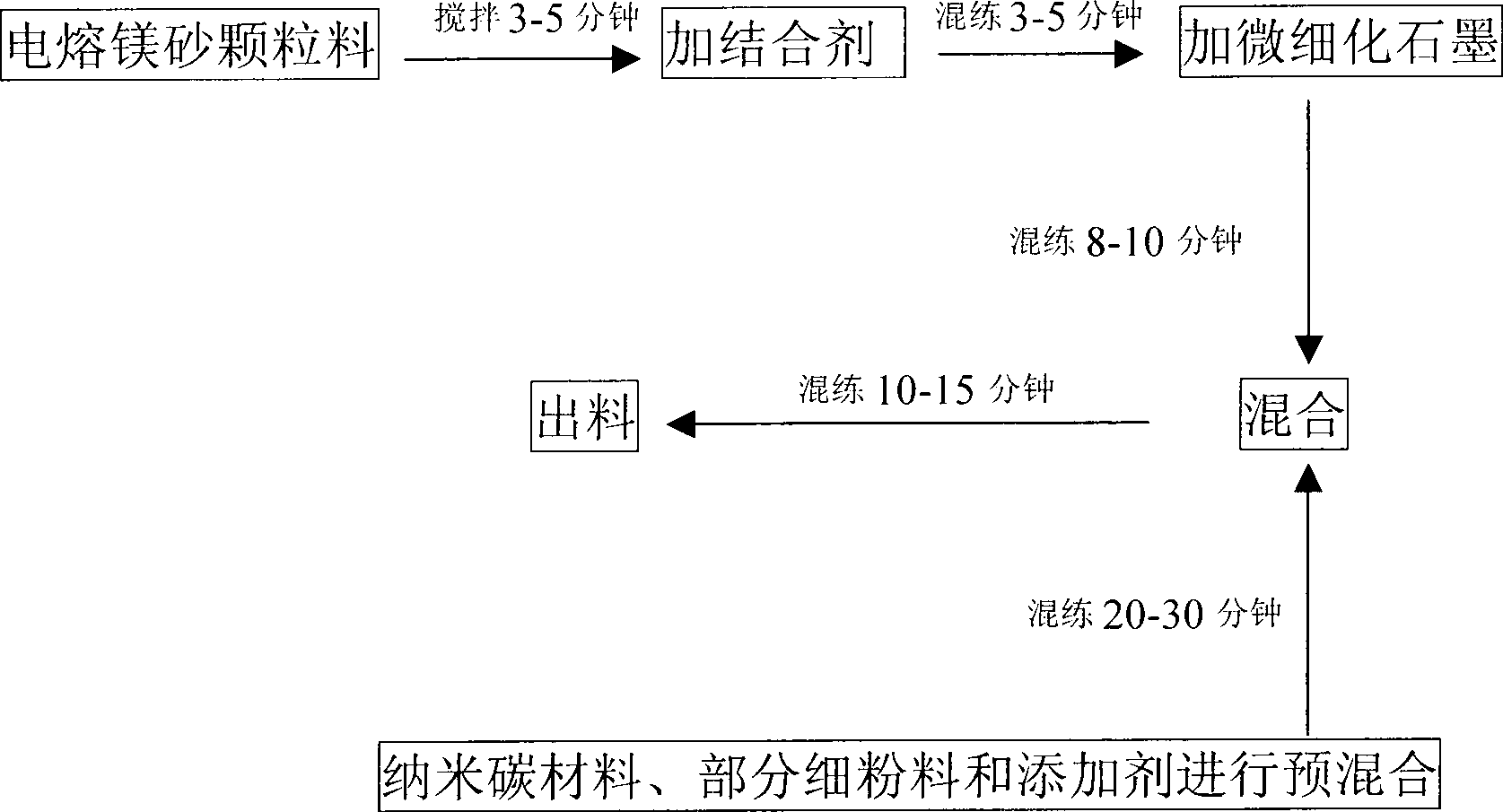

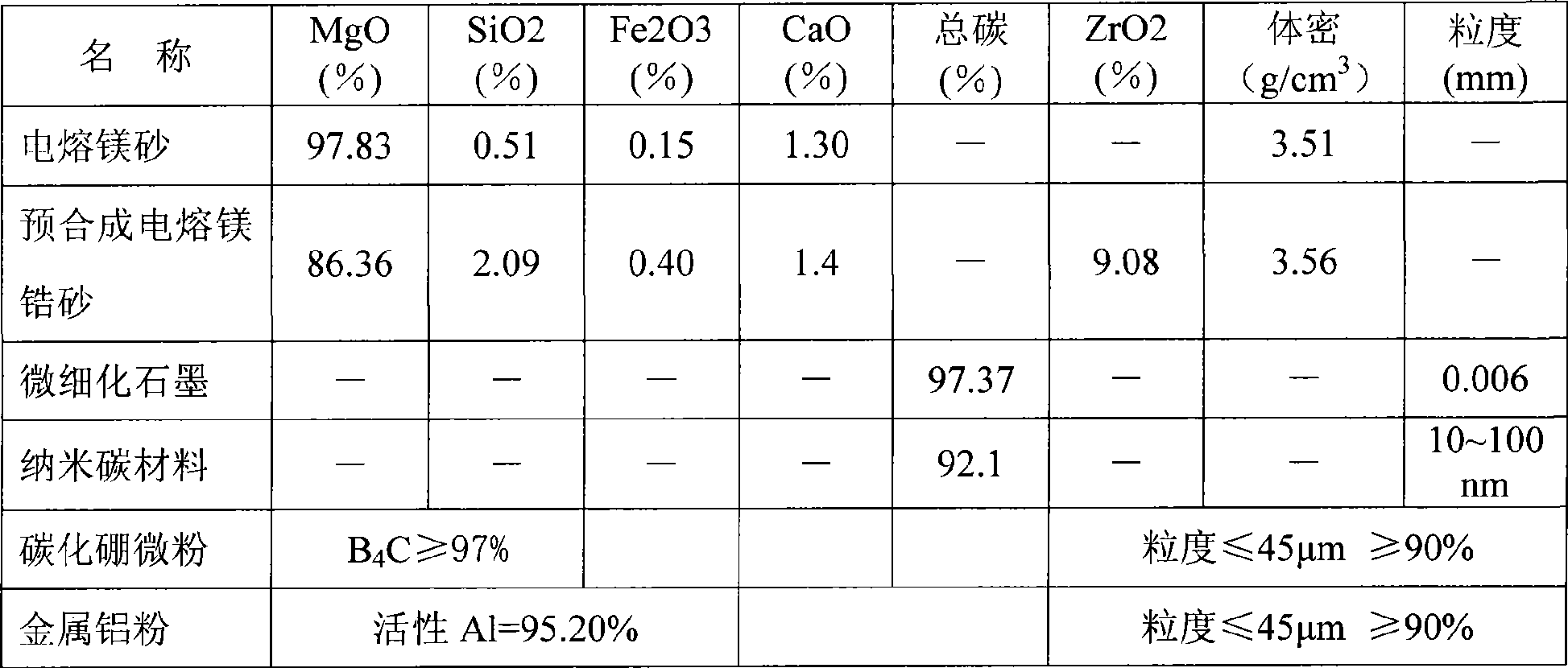

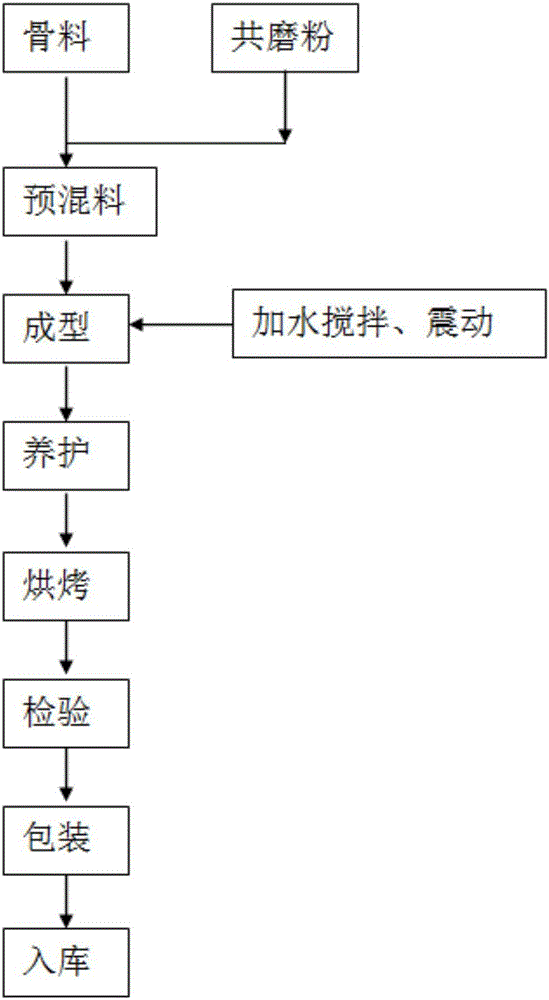

Low carbon magnesia-carbon brick, method for manufacturing the same and use thereof

The invention relates to a low-carbon magnesia carbon brick and a making method and application thereof. The low-carbon magnesia carbon brick is characterized in that the low-carbon magnesia carbon brick comprises the following compositions: 15 to 25 percent of 5-3 mm fused magnesia, 20 to 30 percent of 3-1 mm fused magnesia, 20 to 40 percent of fused magnesia which is less than or equal to 1 mm, 1 to 10 percent of fused magnesia which is less than or equal to 75 mu m, 1 to 10 percent of fused magnesia which is less than or equal to 45 mu m, 1 to 5 percent of micronized graphite which is less than or equal to 6 mu m, 1 to 5 percent of 10-100 nm nano-carbon materials, and additives, wherein the additives comprise the following compositions: A, 0.5 to 3 percent of boron carbide powder, and B, 0.5 to 3 percent of metal aluminum powder; the sum of the various compositions is 100 percent; and 3 to 5 percent of binding agent - liquid phenol-formaldehyde resin is added. The compositions are subjected to uniform mixing and brick molding for standby. The low-carbon magnesia carbon brick is applied to the upper part, the middle part and the lower part of a VD ladle or a VOD ladle or an RH vacuum heat treatment device. When the low-carbon magnesia carbon brick is applied to a 50 ton VD ladle, the ladle is subjected to whole-course argon blowing treatment for 50 to 90 minutes; the temperature of purified molten steels is between 1,580 and 1,620 DEG C; the service life of the ladle is 90 furnaces; and the problem of recarburization of the molten steels is avoided.

Owner:上海柯瑞冶金炉料有限公司

Method and apparatus for sputtering onto large flat panels

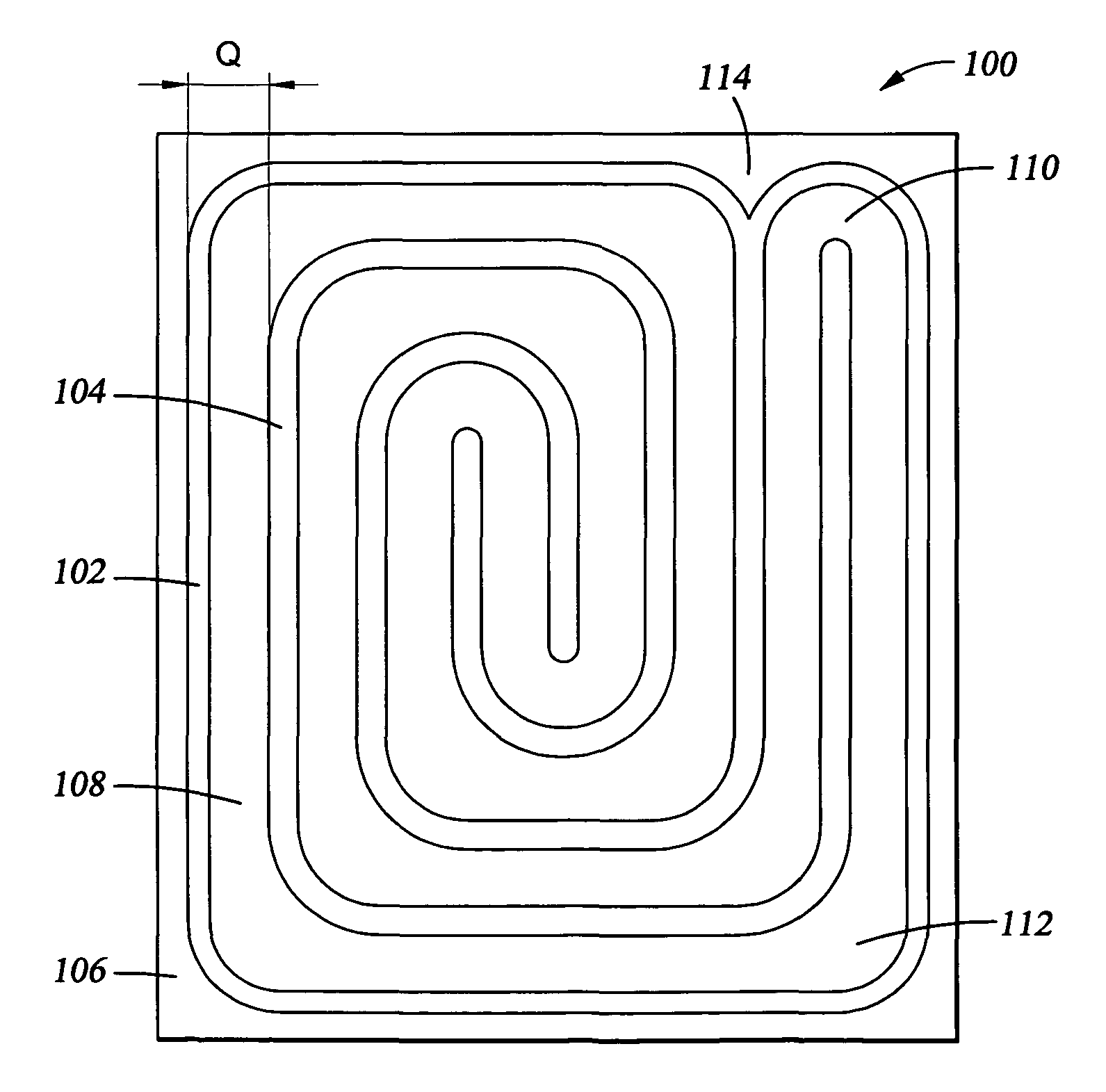

ActiveUS20070012562A1Uniform erosionImprove uniformityCellsElectric discharge tubesClosed loopElectrical polarity

A rectangular magnetron placed at the back of a rectangular sputtering target for coating a rectangular panel and having magnets of opposed polarities arranged to form a gap therebetween corresponding to a plasma track adjacent the target which extends in a closed serpentine or spiral loop. The spiral may have a large number of wraps and the closed loop may be folded before wrapping. The magnetron has a size only somewhat less than that of the target and is scanned in the two perpendicular directions of the target with a scan length of, for example, about 100 mm for a 2 m target corresponding to at least the separation of the gap between parallel portions of the loop. A central ferromagnetic shim beneath some magnets in the loop may compensate for vertical droop. The magnetron may be scanned in two alternating double-Z patterns rotated 90° between them.

Owner:APPLIED MATERIALS INC

Slag line brick for steel ladle and preparation method

InactiveCN107352977AReduce thermal stressImproved thermal shock stabilityMelt-holding vesselsMoisture retentionSlag

The invention relates to a slag line brick for a steel ladle and a preparation method. The slag line brick for the steel ladle is prepared from, by weight, 10-40 parts of fused magnesite with the particle size greater than or equal to 3 mm but smaller than 5 mm, 5-30 parts of fused magnesite with the particle size greater than or equal to 1 mm but smaller than 3 mm, 10-20 parts of fused magnesite with the particle size smaller than 1 mm, 5-20 parts of magnesite-carbon waste brick fine powder, 12-16 parts of flaky graphite, 1-3 parts of bonding agent and 4 parts or less of additive. The slag line brick has the advantages that the problem that an existing slag line brick frequently produces a steamed bun shape in the using process is solved, the slag line brick for the steel ladle adopts phenolic resin having better wettability and moisture retention property, the pug temperature is strictly controlled, the phenomenon that mixed pug is dried too fast due to too high temperature is avoided, the adding amount of metal or alloy powder is appropriately controlled by increasing critical particle size, the graphite adding amount is increased, a heat stress is buffered by introducing a trace amount of additive, and the thermal shock resistance stability of the slag line brick is improved.

Owner:海城利尔麦格西塔材料有限公司

Method and apparatus for sputtering onto large flat panels

ActiveUS8500975B2Uniform erosionImprove uniformityCellsElectric discharge tubesElectrical polarityClosed loop

A rectangular magnetron placed at the back of a rectangular sputtering target for coating a rectangular panel and having magnets of opposed polarities arranged to form a gap therebetween corresponding to a plasma track adjacent the target which extends in a closed serpentine or spiral loop. The spiral may have a large number of wraps and the closed loop may be folded before wrapping. The magnetron has a size only somewhat less than that of the target and is scanned in the two perpendicular directions of the target with a scan length of, for example, about 100 mm for a 2 m target corresponding to at least the separation of the gap between parallel portions of the loop. A central ferromagnetic shim beneath some magnets in the loop may compensate for vertical droop. The magnetron may be scanned in two alternating double-Z patterns rotated 90° between them.

Owner:APPLIED MATERIALS INC

Two dimensional magnetron scanning for flat panel sputtering

InactiveUS7513982B2Uniform erosionImprove uniformityCellsElectric discharge tubesSputteringElectrical polarity

A generally rectangular magnetron placed at the back of a rectangular target to intensify the plasma in a sputter reactor configured for sputtering target material onto a rectangular panel. The magnetron has a size only somewhat less than that of the target and is scanned in the two perpendicular directions of the target with a scan length of, for example, about 100 mm for a 2 m target. The scan may follow a double-Z pattern along two links parallel to a target side and the two connecting diagonals. The magnetron includes a closed plasma loop formed in a convolute shape, for example, serpentine or rectangularized helix with an inner pole of nearly constant width extending along a single path and having one magnetic polarity completely surrounded by an outer pole having the opposed polarity.

Owner:APPLIED MATERIALS INC

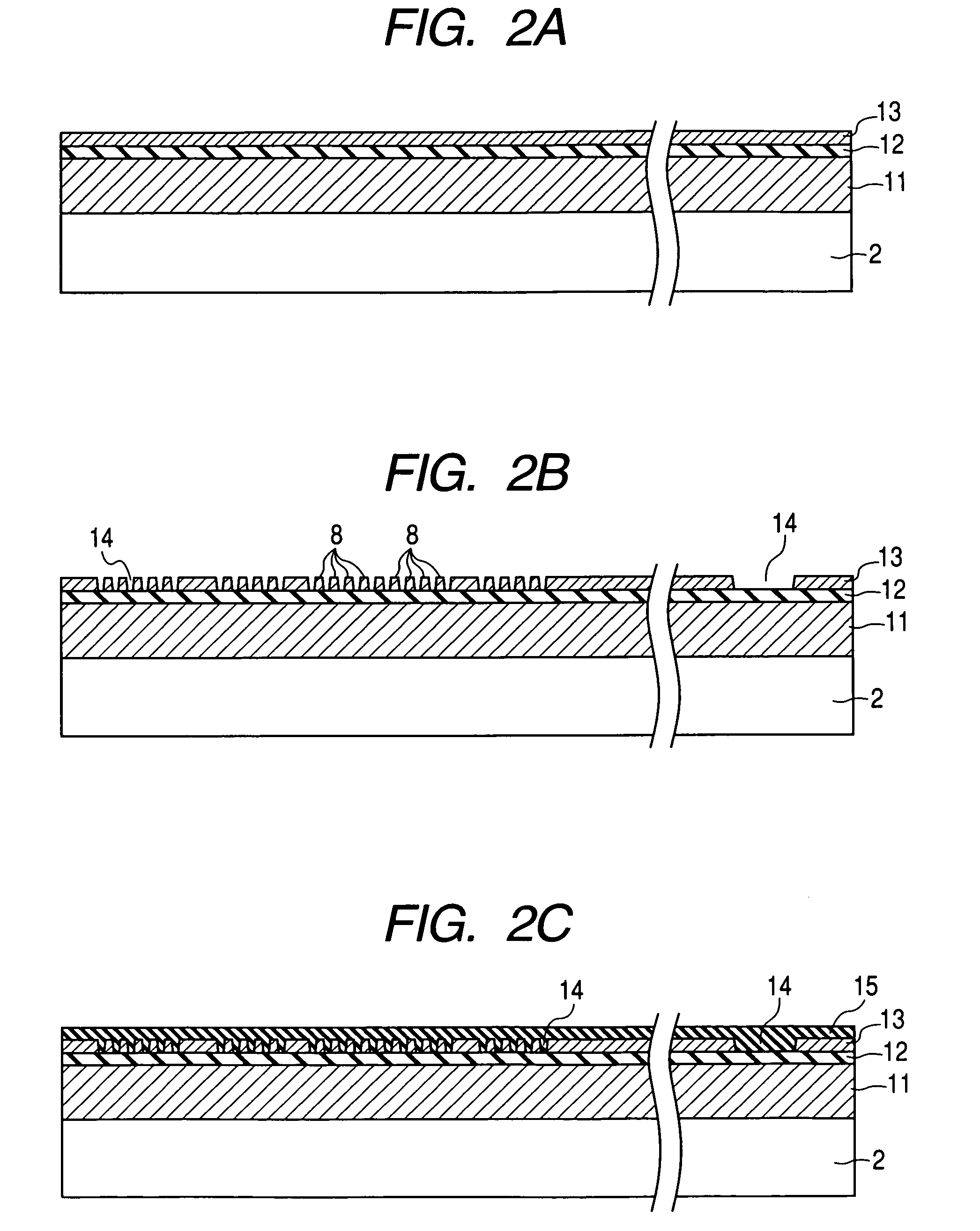

Flow sensor with metal film resistor

InactiveUS7621180B2Accurate flow measurementConstant groove depthVolume/mass flow by thermal effectsSpeed measurement using gyroscopic effectsElectrical resistance and conductanceEngineering

There is a need for providing a flow sensor with metal film resistor that improves detection sensitivity using a metal film for a resistance heat detector and a resistance temperature detector. The flow sensor with metal film resistor is structured to form a resistance heat detector, a resistance temperature detector for resistance heat detector for measuring temperature of the resistance heat detector, an upstream resistance temperature detector, a downstream resistance temperature detector, and an air resistance temperature detector on a silicon substrate. Plural floating-island insulators are provided for the resistance heat detector and within wiring thereof.

Owner:HITACHI LTD

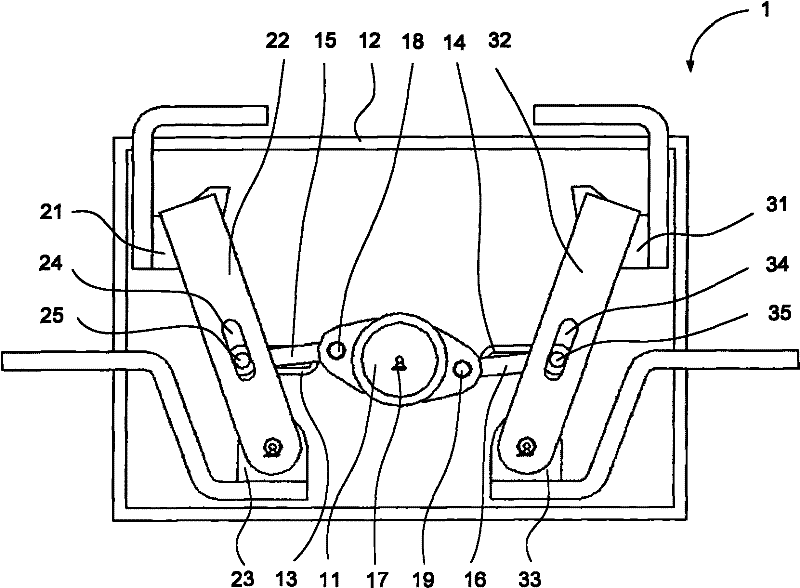

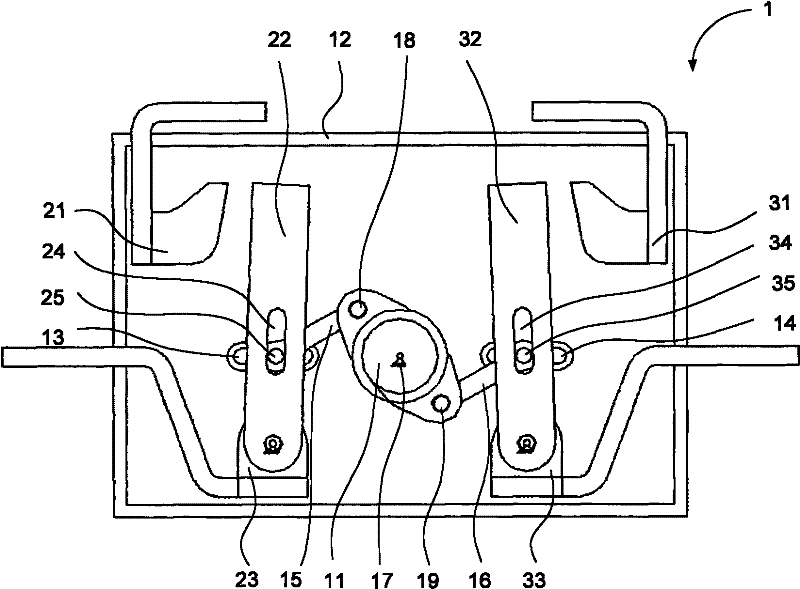

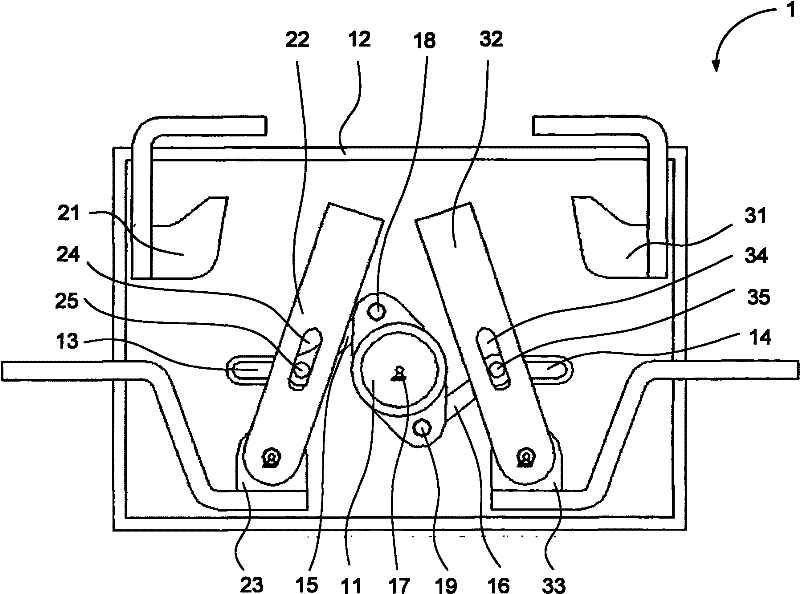

Double-break electrical contact device and isolating switch using same

ActiveCN102412085AGuaranteed uniform erosionReliable contactSwitches with movable electrical contactsAir-break switch detailsEngineeringMechanical engineering

The invention provides a double-break electrical contact device, comprising a device body, a driving component, a first static contact, a second static contact, a first moving contact, a second moving contact, a first guide mechanism and a second guide mechanism, wherein the driving component is connected to the device body through a main shaft; the first static contact and the second static contact, the first moving contact and the second moving contact, and the first guide mechanism and the second mechanism are respectively symmetrical about the main shaft; and the driving component can drive the first moving contact and the second moving contact to pivotally synchronously rotate relative to the device body under the guidance of the first guide mechanism and the second guide mechanism respectively, so that the first moving contact and the second moving contact are respectively connected with or disconnected from the first static contact and the second static contact. The invention has the advantage that synchronous breaking of the moving contacts is realized, thereby prolonging the service life of the contact device.

Owner:SIEMENS AG

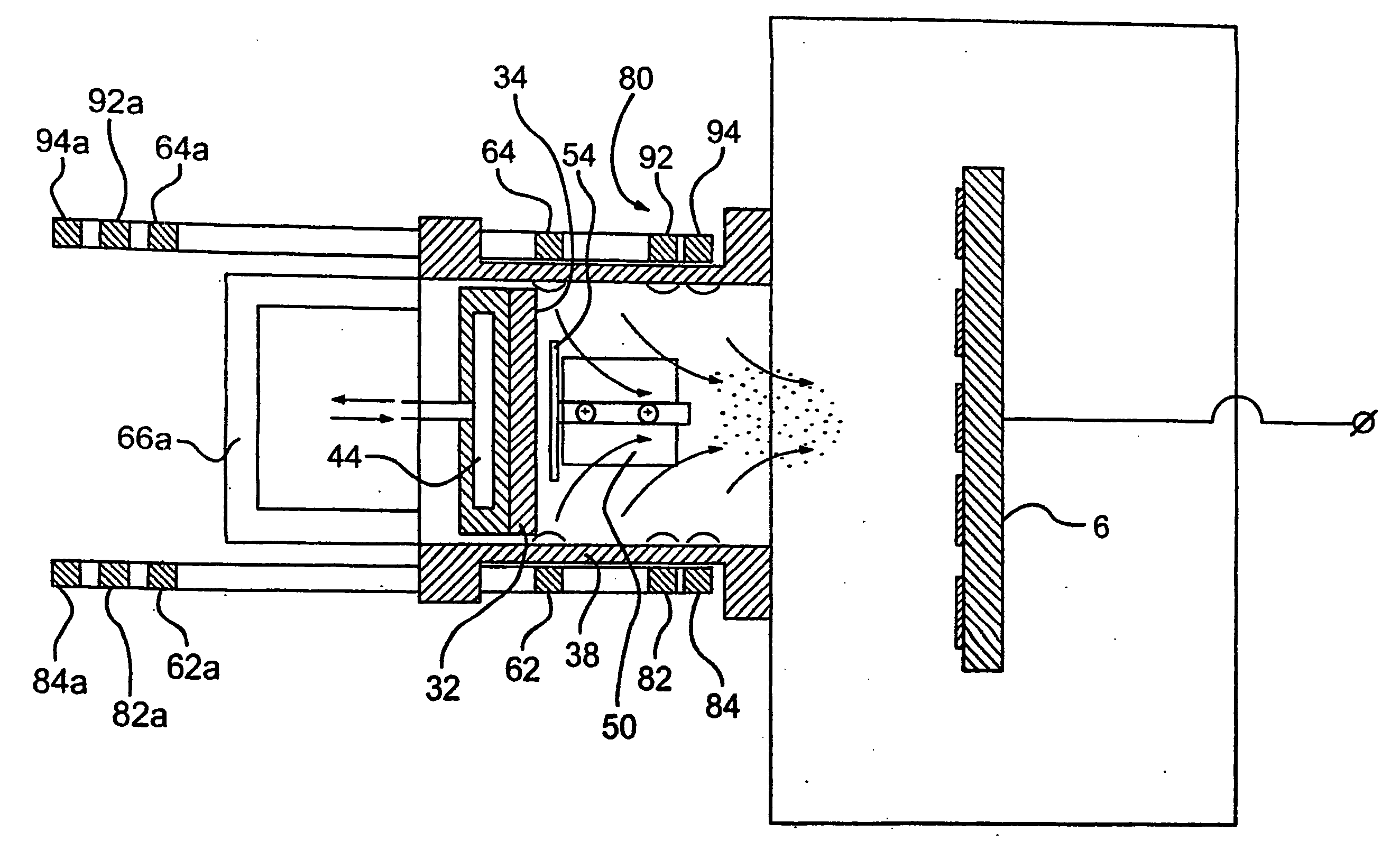

Rectangular filtered vapor plasma source and method of controlling vapor plasma flow

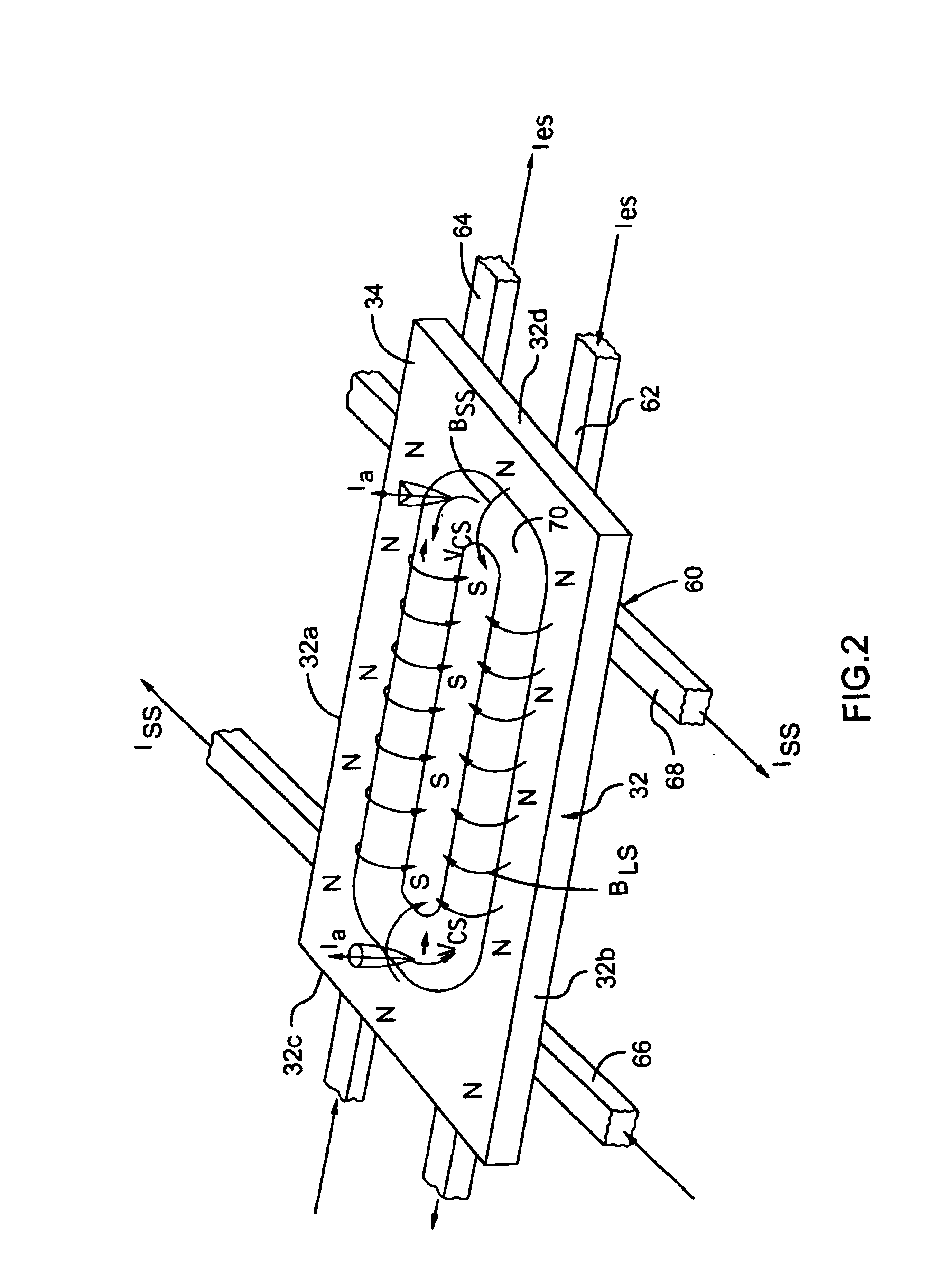

InactiveUS20070029188A1Increase in sizeIncrease the magnetic field strengthCellsLiquid surface applicatorsElectrical conductorPlasma flow

The invention provides an arc coating apparatus having a steering magnetic field source comprising steering conductors (62, 64, 66, 68) disposed along the short sides (32c, 32d) of a rectangular target (32) behind the target, and a magnetic focusing system disposed along the long sides (32a, 32b) of the target (32) in front of the target which confines the flow of plasma between magnetic fields generated on opposite long sides (32a, 32b) of the target (32). The plasma focusing system can be used to deflect the plasma flow off of the working axis of the cathode. Each steering conductor (62, 64, 66, 68) can be controlled independently. In a further embodiment, electrically independent steering conductors (62, 64, 66, 68) are disposed along opposite long sides (32a, 32b) of the cathode plate (32), and by selectively varying a current through one conductor, the path of the arc spot shifts to widen the erosion corridor. The invention also provides a plurality of internal anodes, and optionally a surrounding anode for deflecting the plasma flow.

Owner:G&H TECH LLC

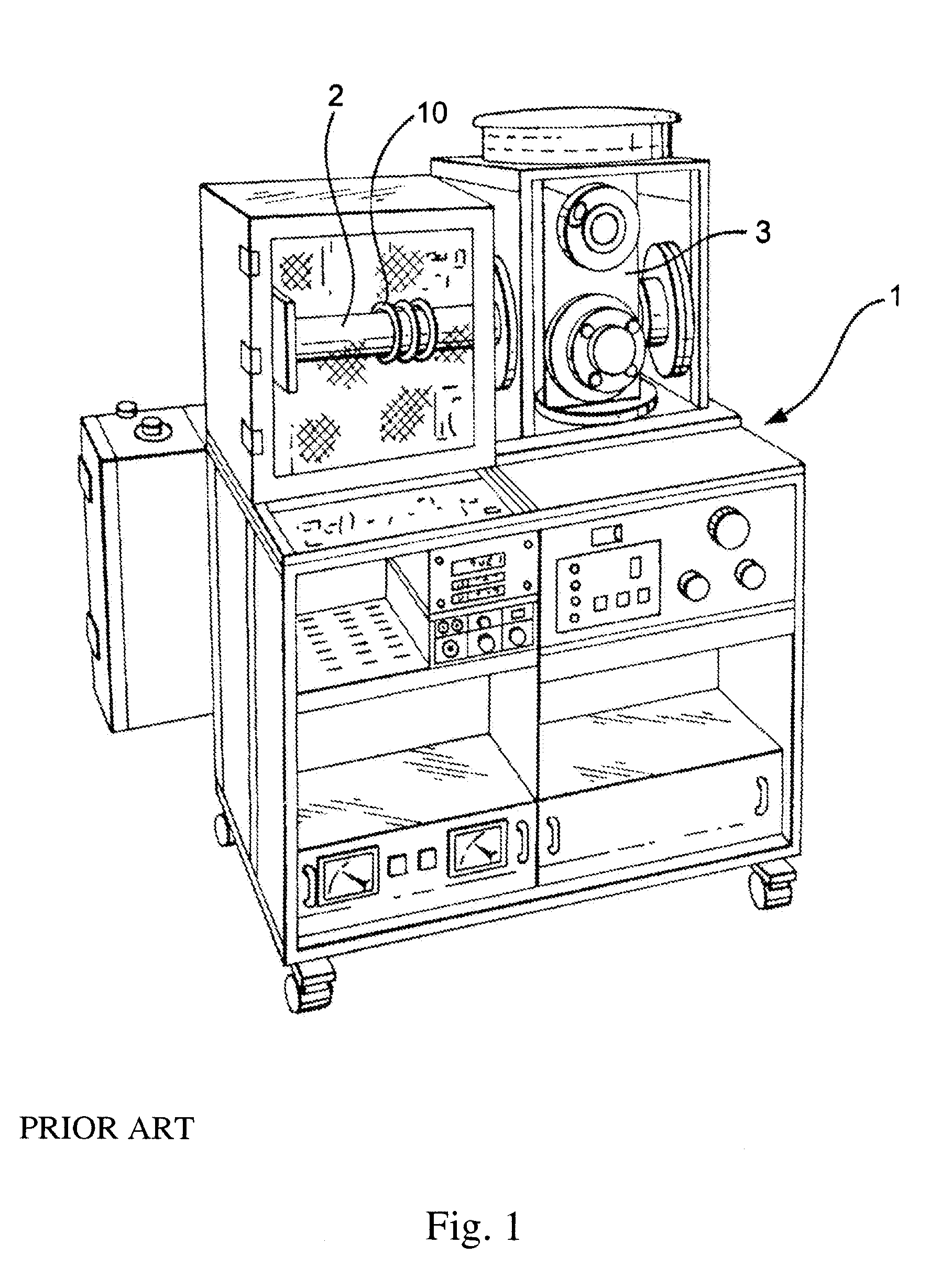

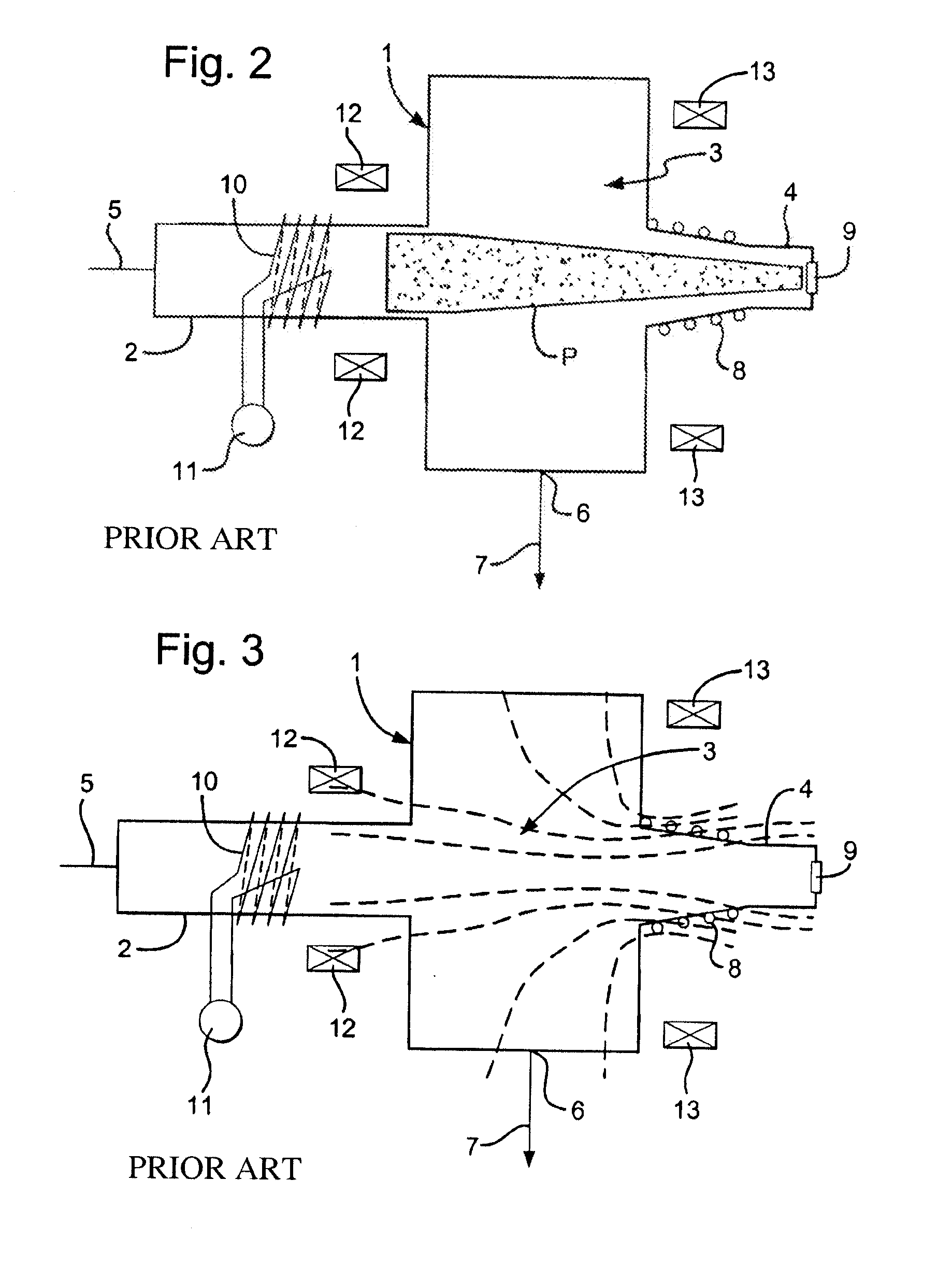

Cylindrical target with oscillating magnet for magnetron sputtering

In some embodiments, the invention includes a cylindrical cathode target assembly for use in sputtering target material onto a substrate that comprises a generally cylindrical target, means for rotating the target about its axis during a sputtering operation, an elongated magnet carried within the target for generation of a plasma-containing magnetic field exterior to but adjacent the target, a framework for supporting the magnet against rotation within the target, and a power train for causing the magnet to oscillate within and axially of the target in a substantially asynchronous manner to promote generally uniform target utilization along its length, as well as its method of use. In some embodiments, the magnet is oscillated in response to rotation of the target.

Owner:GENERAL PLASMA +1

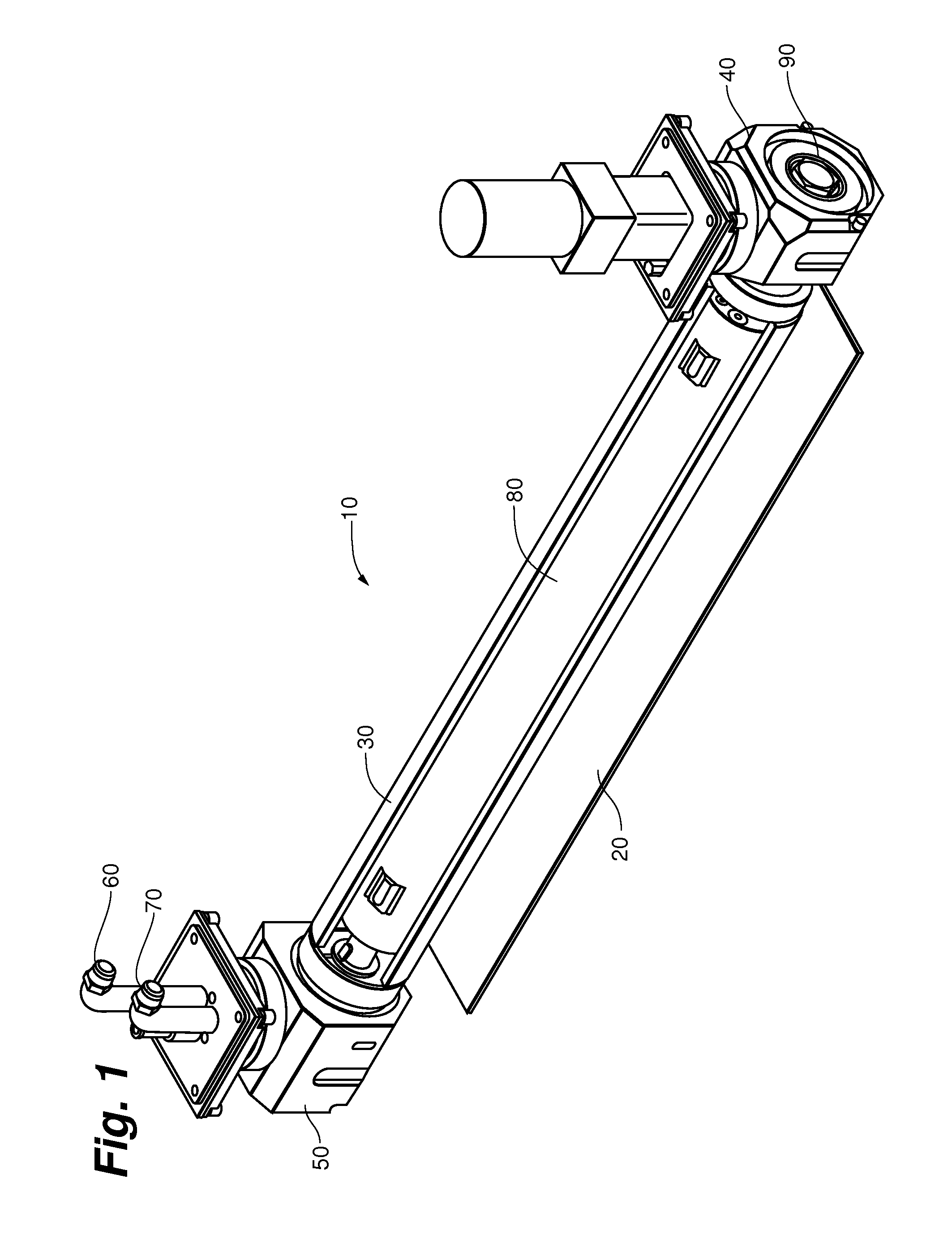

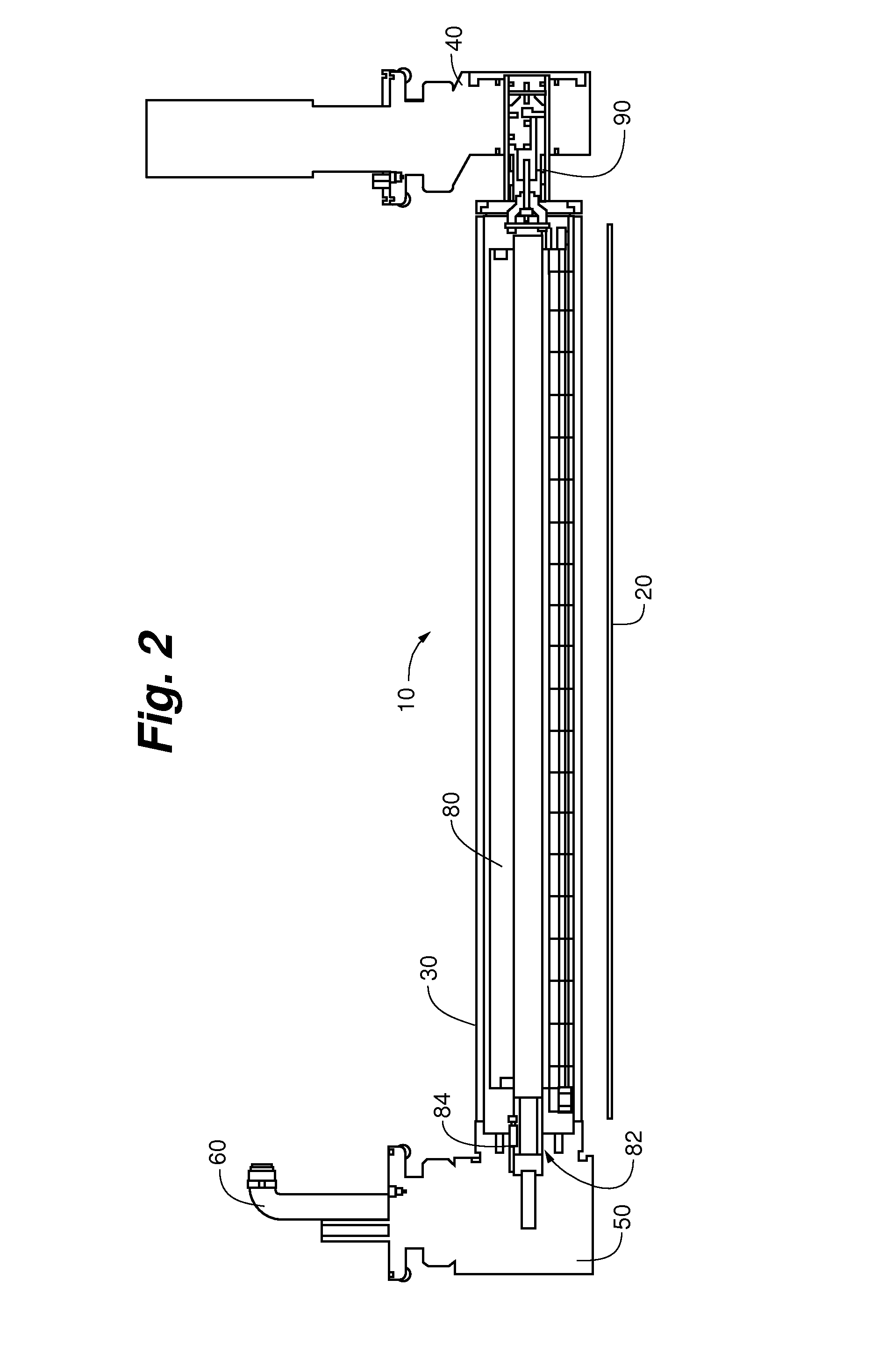

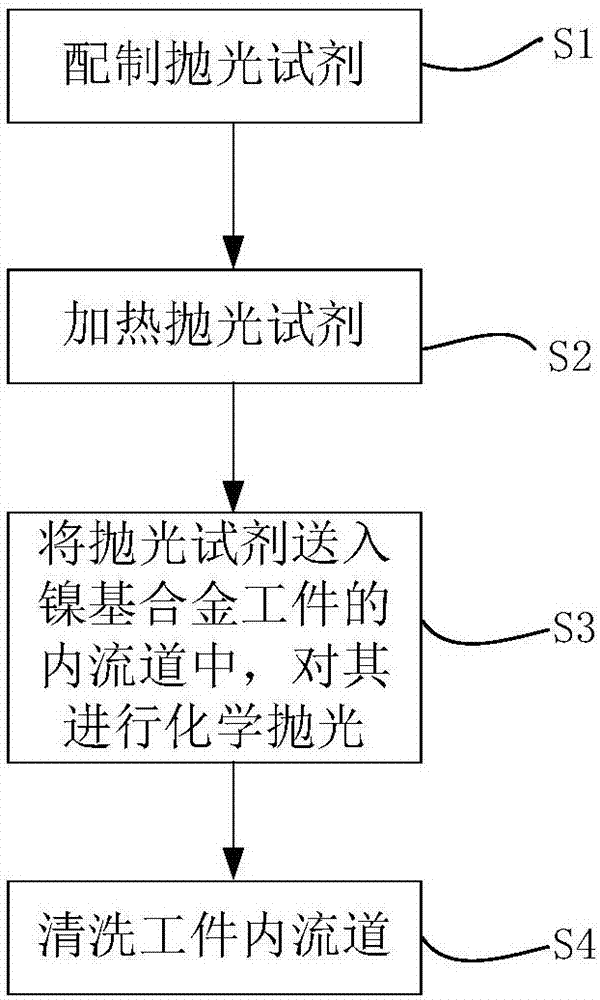

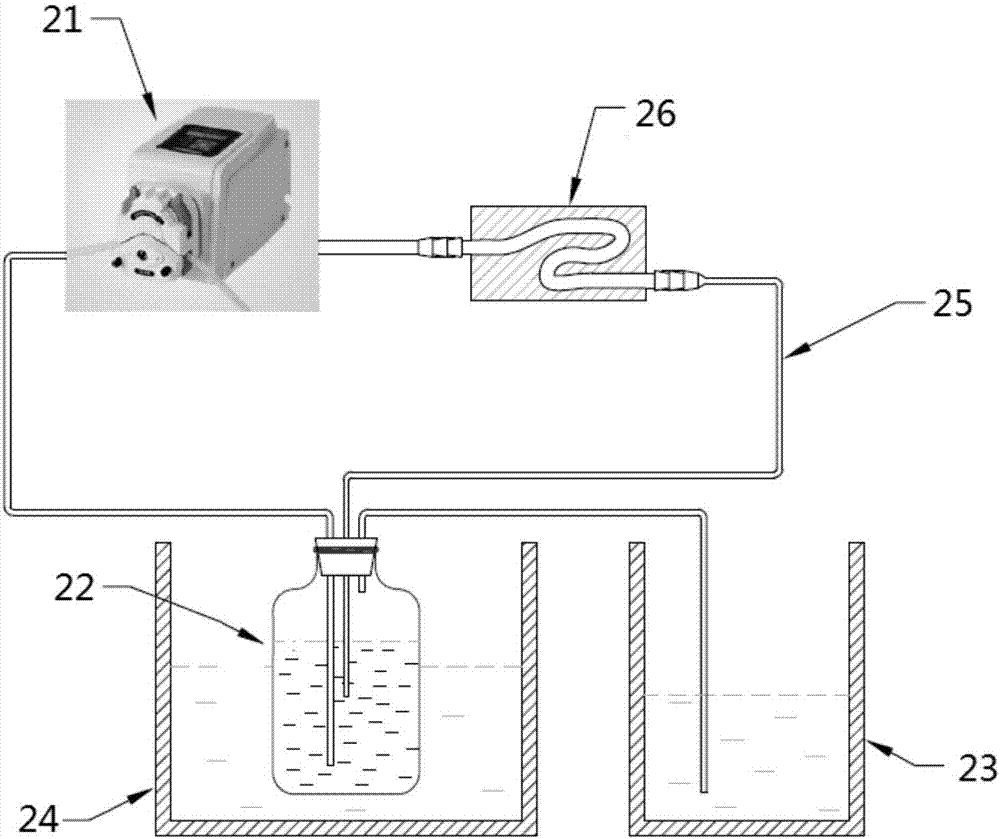

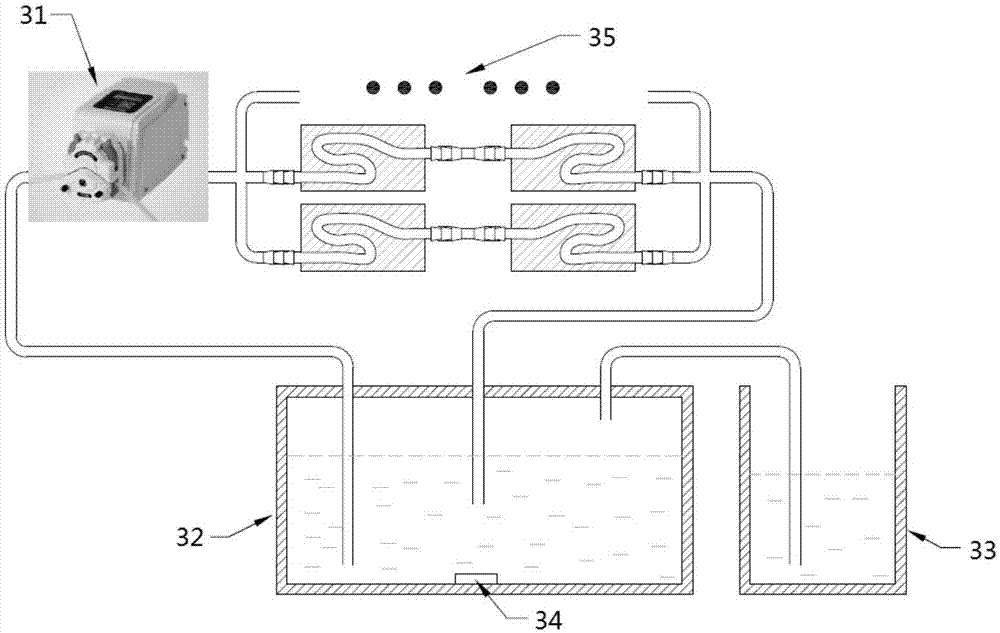

Polishing agent, method and system for polishing inner runner of nickel base alloy workpiece

The invention discloses a polishing agent, method and system for polishing an inner runner of a 3D-printed nickel base alloy workpiece. The method comprises the following steps that the polishing agent containing phosphoric acid, nitric acid, hydrochloric acid, hydrofluoric acid, ferric chloride hexahydrate and sulfosalicylic acid is prepared; the polishing agent is heated to 40-60 DEG C and then conveyed into the inner runner of the workpiece and keeps flowing at a certain speed so that the inner runner can be polished; and the polishing agent is discharged, and the workpiece is washed. Through the polishing agent, method and system for polishing the inner runner of the 3D-printed nickel base alloy workpiece, the surface smoothness of the inner runner of the 3D-printed nickel base alloy workpiece can be effectively improved, so that the inner runner becomes uniform and smooth; and compared with traditional polishing methods for the inner runner of the 3D-printed nickel base alloy workpiece, the polishing agent, the method and the system are better in polishing effect, more convenient and quicker.

Owner:飞而康快速制造科技有限责任公司

Carbon-free alumina-magnesia unburned brick and preparation method and application thereof

Owner:上海柯瑞冶金炉料有限公司 +1

Air blowing and slag removing spray gun for foundry ladle and preparation method thereof

InactiveCN105819871AHigh activityImproved thermal shock stabilityCeramic shaping apparatusFoundryFiber

The invention relates to an air blowing and slag removing spray gun and a preparation method thereof. The spray gun comprises the following components in parts by weight: 35 to 95 parts of aggregate, 15 to 60 parts of grinding powder, 2 to 8 parts of calcium aluminate cement, and 0.2 to 3 parts of steel fiber. The provided spray gun can well resist the corrosion of molten iron and molten iron slag, and has the advantages of high thermal shock stability and good high temperature sintering property. Furthermore, refractory materials and inner steel pipe are firmly combined, during the using process, phenomenon of breaking and peeling is reduced, and the corrosion of molten iron slag is relieved.

Owner:北京利尔高温材料股份有限公司

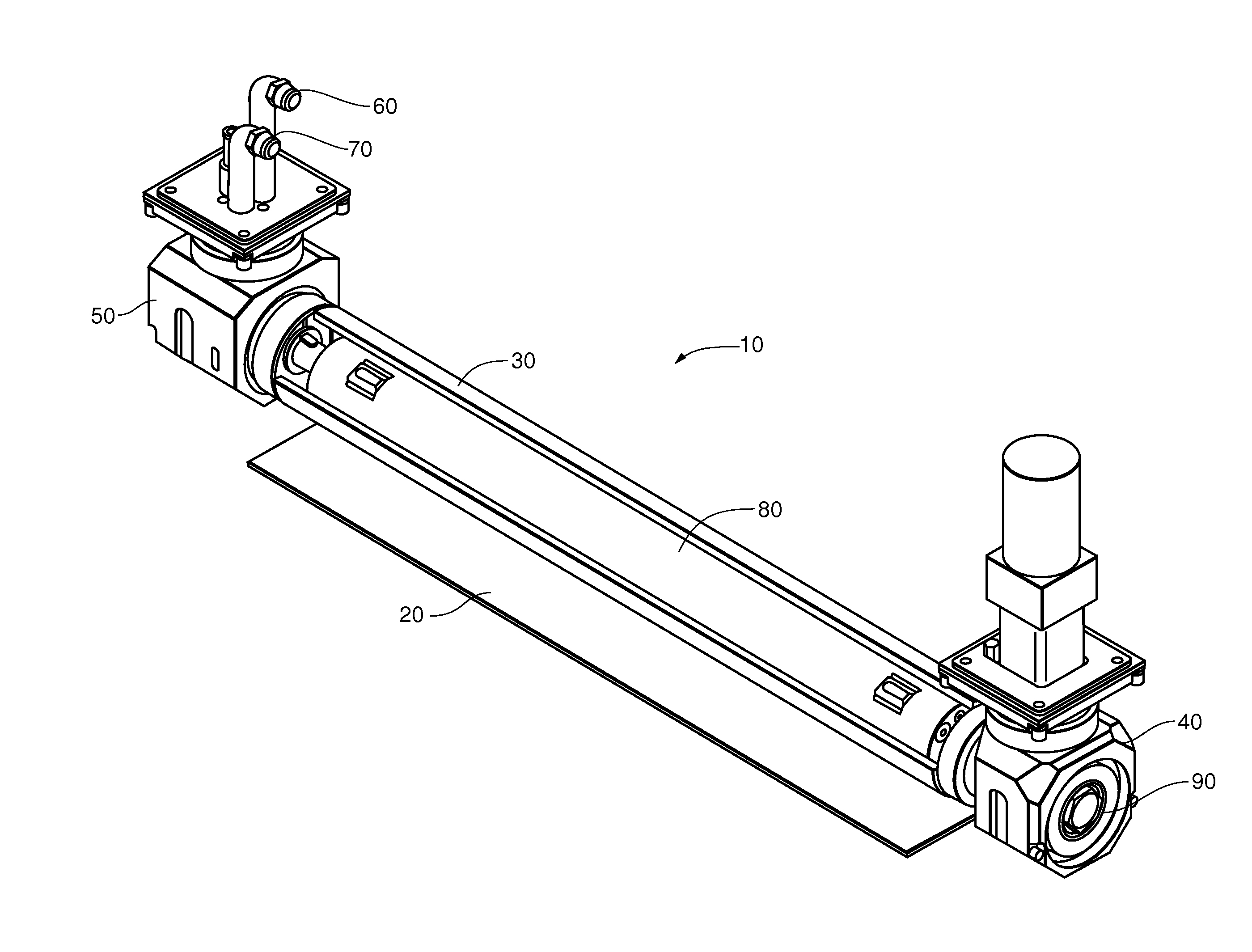

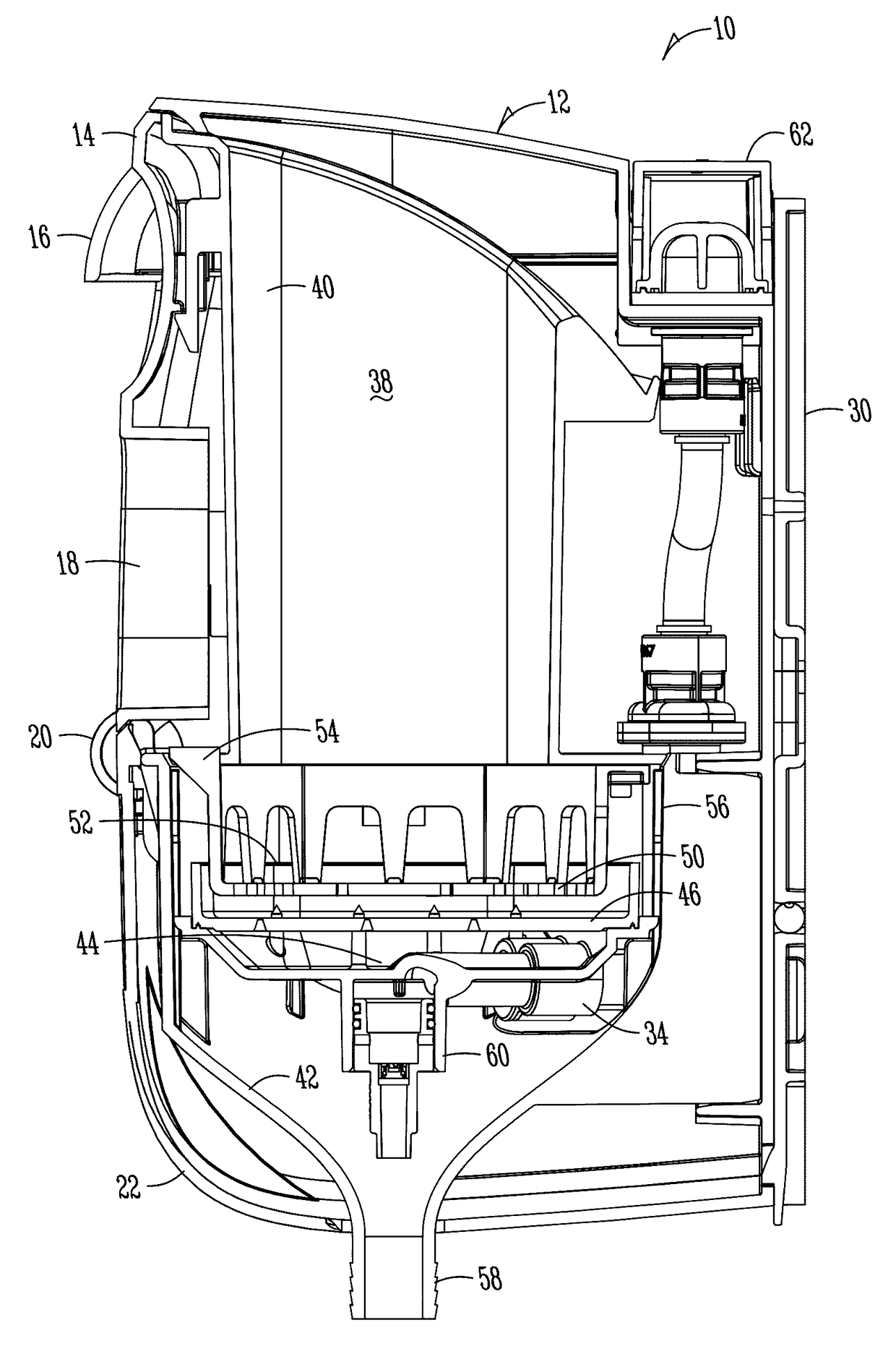

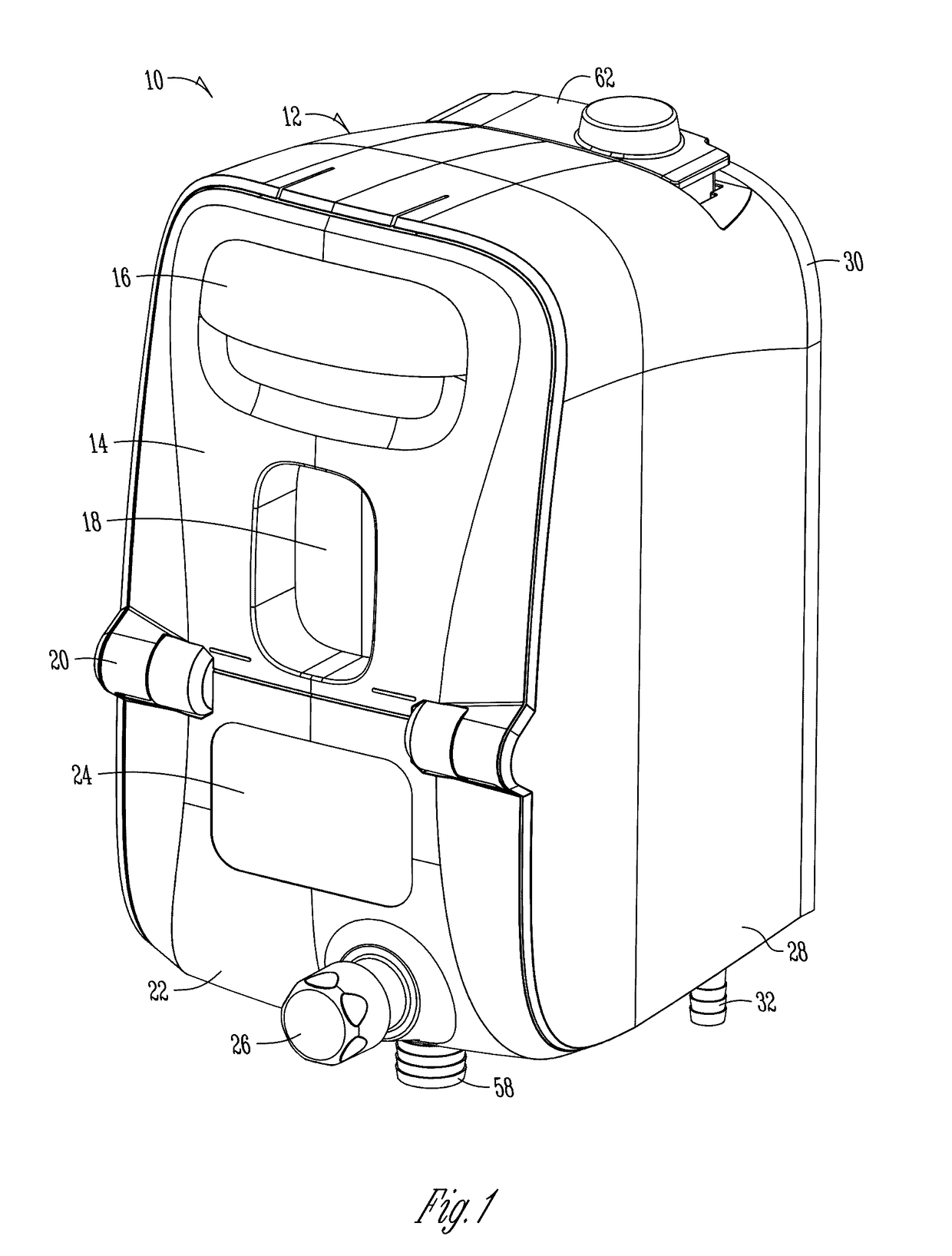

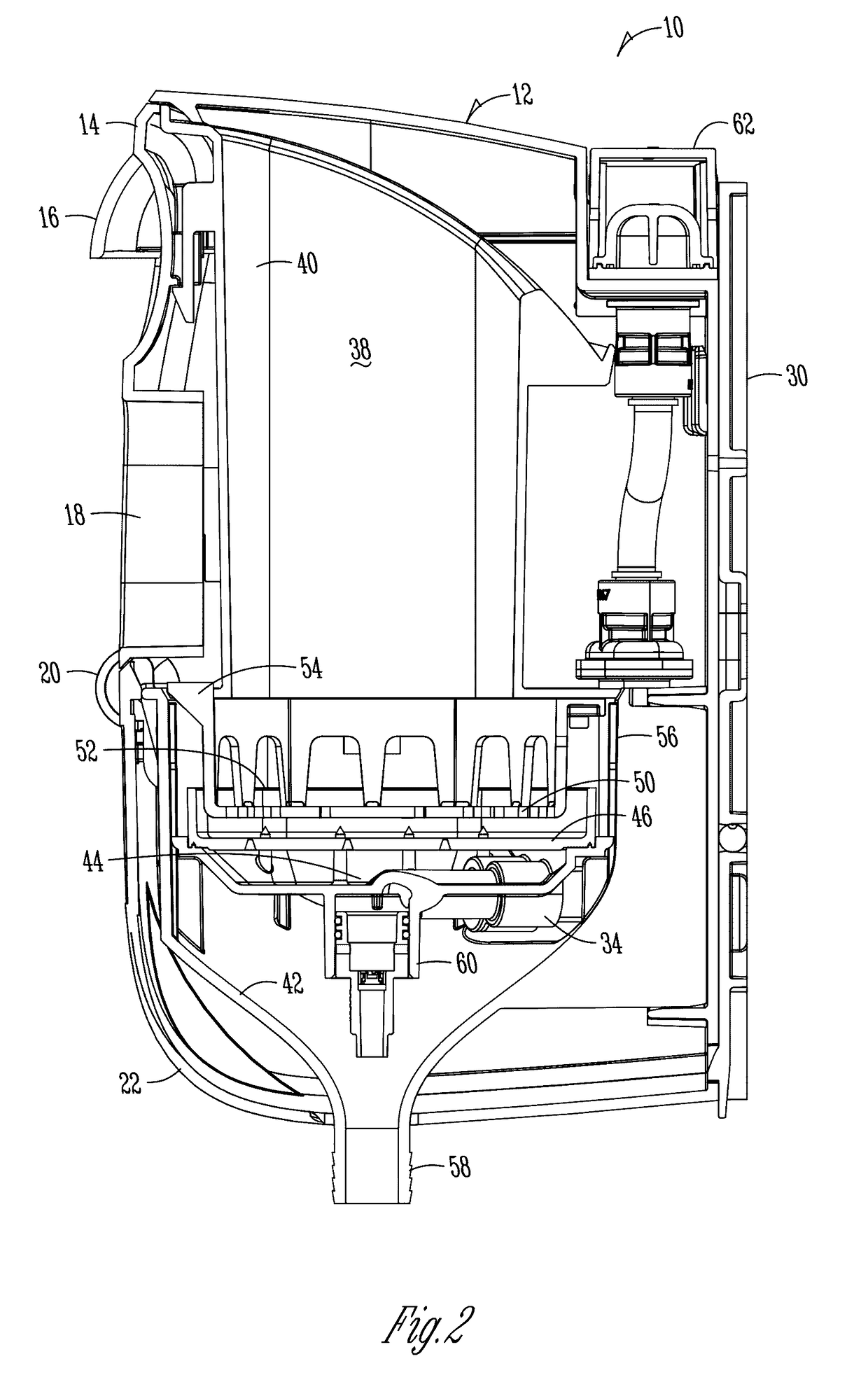

Method and apparatus for variation of flow to erode solid chemistry

ActiveUS9643143B2Overcome deficienciesFlow adjustableDissolving using flow mixingDissolving systemsSolid-state chemistryErosion rate

A method and apparatus for obtaining a product chemistry from a product and a fluid is provided. A product is housed within a dispenser. A fluid is introduced through a manifold diffuse member having a plurality of ports. A cover is positioned adjacent the manifold diffuse member and includes a plurality of ports. The cover is able to be adjusted, for example, by rotating the cover, to align and un-align the manifold diffuse ports and the cover ports. This adjustment controls the flow characteristics of the fluid through the manifold diffuse member and cover to control the characteristics of the fluid in contact with the product. The adjustment of the cover to control the flow will provide a generally consistent concentration and erosion rate based upon known relationships between a characteristic of the fluid and the flow of the fluid in relation to the product.

Owner:ECOLAB USA INC

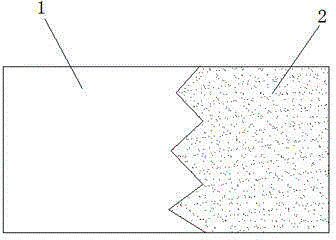

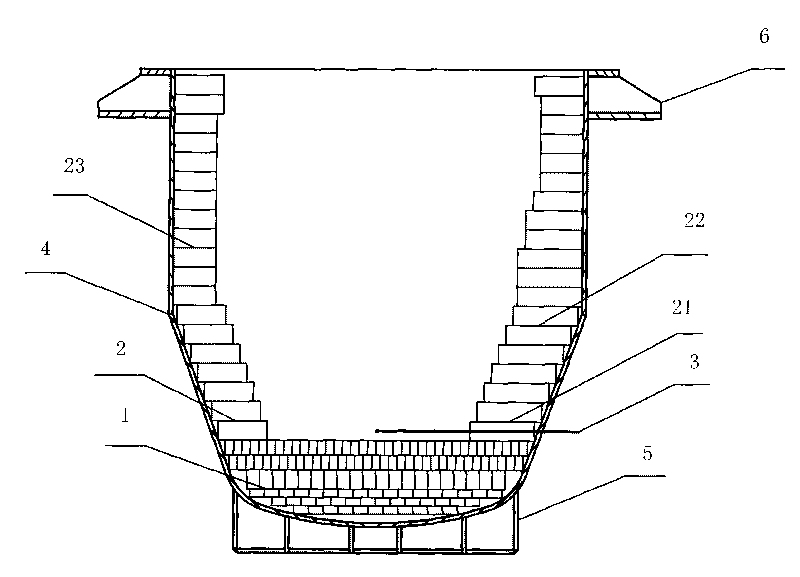

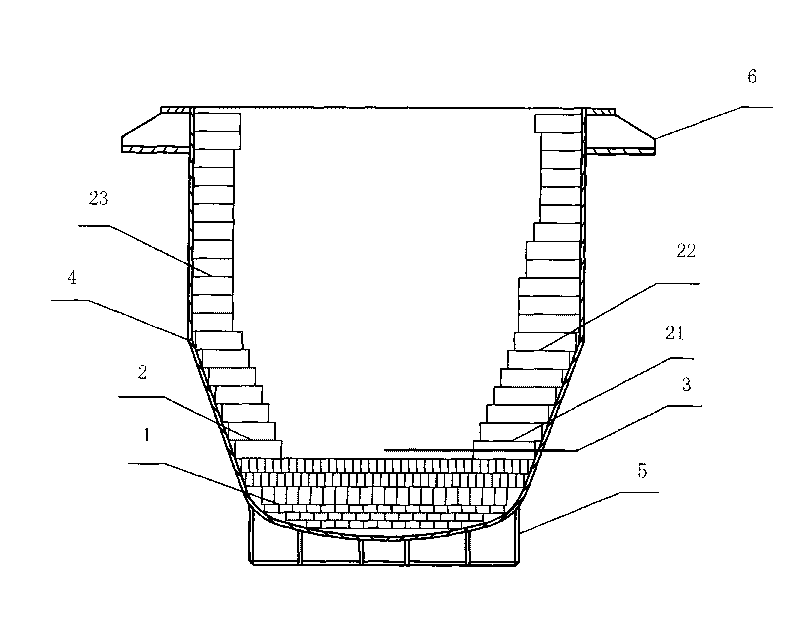

Lining brick structure for cooling section of coke dry quenching furnace and building method

The invention provides a lining brick structure for a cooling section of a coke dry quenching furnace. The lining brick structure is prepared from the combination of a working layer and a heat preserving layer, wherein the interface between the working layer and the heat preserving layer is arc-shaped, or sawtooth-shaped or concave-convex; the working layer is controlled to be 230 to 500mm in thickness, and the heat preserving layer is controlled to be 20 to 75mm in thickness. The building method is that the cooling section of the coke dry quenching furnace is divided into a lower cooling section, a transition cooling section and an upper cooling section from bottom to top; the thickness of a compound lining brick for building the lower cooling section is 1.01 to 1.3 times that of the compound lining brick for building the upper cooling section; and the thickness of the compound lining brick for building the transition cooling section is gradually reduced and in smooth transition from the lower cooling section to the upper cooling section. Compared with the prior art employing B-grade mullite bricks, the building method has the advantages that the abrasion of the lining bricks for building the cooling sections is obviously reduced by at least 25%; and the lining brick layer at the lower cooling section is in balanced erosion, so that the service cycle is obviously increased, and as a result, the working rate of the coke dry quenching furnace is correspondingly raised, and the maintenance cost is decreased.

Owner:武汉钢铁有限公司

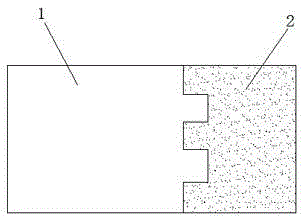

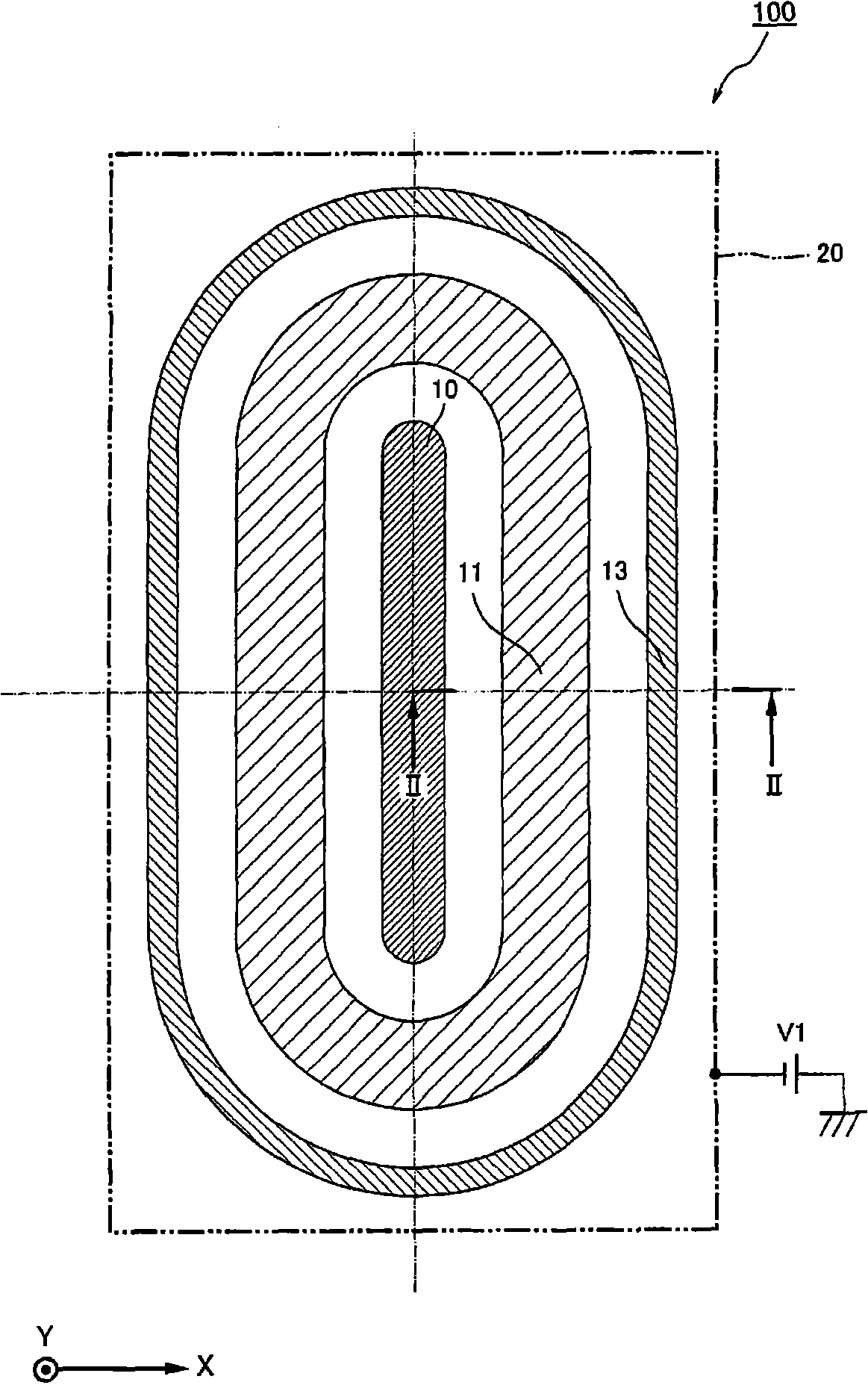

Magnet structure for magnetron sputtering system, cathode electrode unit and magnetron sputtering system

InactiveCN101300372AUniform erosionElectric discharge tubesVacuum evaporation coatingSputteringEngineering

A magnet structure arranged to achieve wide erosion of a target by varying distribution of the line of magnetic force on the surface of the target by a simple drive mechanism. A magnet structure (110) comprises main magnets (10, 13) arranged on a rear surface (20B) side of a target (20) to form main line of magnetic force reaching a target front surface (20A), a correction magnet (11) arranged on the rear surface (20B) side of the target (20) to form correction line of magnetic force for varying distribution of flux density by the main line of magnetic force, magnetic paths (21A, 21B, 24) of correction line of magnetic force arranged on the rear surface (20B) side of the target (20), and magnetic field correction means (12, 14) which can alter the intensity of correction line of magnetic force penetrating the interior of the magnetic paths (21A, 21B, 24).

Owner:SHIN MEIWA IND CO LTD

Masonry structure for 18TAOD furnace lining

The invention belongs to the technical field of steelmaking converters, in particular to a masonry structure for an 18TAOD furnace lining, which comprises a furnace bottom and a furnace wall; the bottom of the furnace wall is provided with a blower gun; an area spread in a sector shape on the upper part of the blower gun on the furnace wall is an airhole area; the first layer, the second laeyr and the third layer of the airhole area are made of magnesite-chrome bricks; the fourth layer, the fifth layer, the sixth layer, the seventh layer, the eighth layer, the ninth layer and the tenth layer are made of high-purity magnesia-calcium bricks; and the eleventh layer, the twelveth layer, the thirteenth layer, the fourteenth layer, the fifteenth layer, the sixteenth layer, the seventeenth layer, the eighteenth layer and the nineteenth layer and other furnace wall are made of common magnesia-calcium bricks. In the masonry structure, the whole furnace lining is basically uniform through reasonable use of refractory bricks made of different materials in different areas so as to achieve the aims of improving the furnace life and reducing the cost.

Owner:YONGXING SPECIAL STAINLESS STEEL

Magnetron cathode and magnetron sputtering apparatus comprising the same

InactiveUS7052583B2Uniform magnetic field distributionIncrease ratingsCellsElectric discharge tubesMagnetMagnetic field

A magnetron cathode and a sputtering apparatus including the same are provided. The magnetron cathode includes three or more magnet units, each of which comprises a single magnet or a plurality of magnets having the same poles facing toward the same direction, wherein one magnet unit is disposed around the outer circumference of another magnet unit and adjacent magnet units have opposite poles facing toward the same direction. Uniform magnetic field distribution is obtained. Therefore, the erosion profile of a target is wide and uniform.

Owner:SAMSUNG ELECTRONICS CO LTD

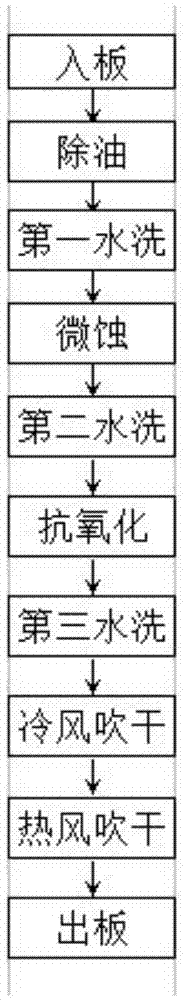

PCB surface automatic film plating process

The invention discloses a PCB surface automatic film plating process. A PCB is machined through 11 processes of board feeding-deoiling-primary water washing-micro etching-secondary water washing-antioxidation-ternary water washing-cold wind drying-hot wind drying-board discharge; two-section micro etching guarantees uniform engagement of large copper surface positions and no aberration; three-section water washing before antioxidation reinforces the cleaning effect, and prevents excessive taking of acid medicine water into an antioxidation tank; the OSP film surface thickness is uniform; and meanwhile, the automation degree is high, operators only manually place and collect boards, and the labor intensity is reduced.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

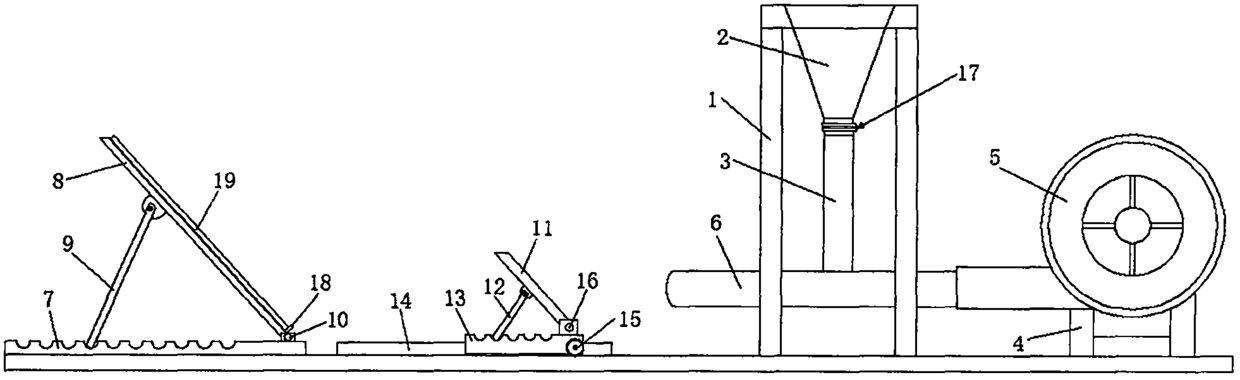

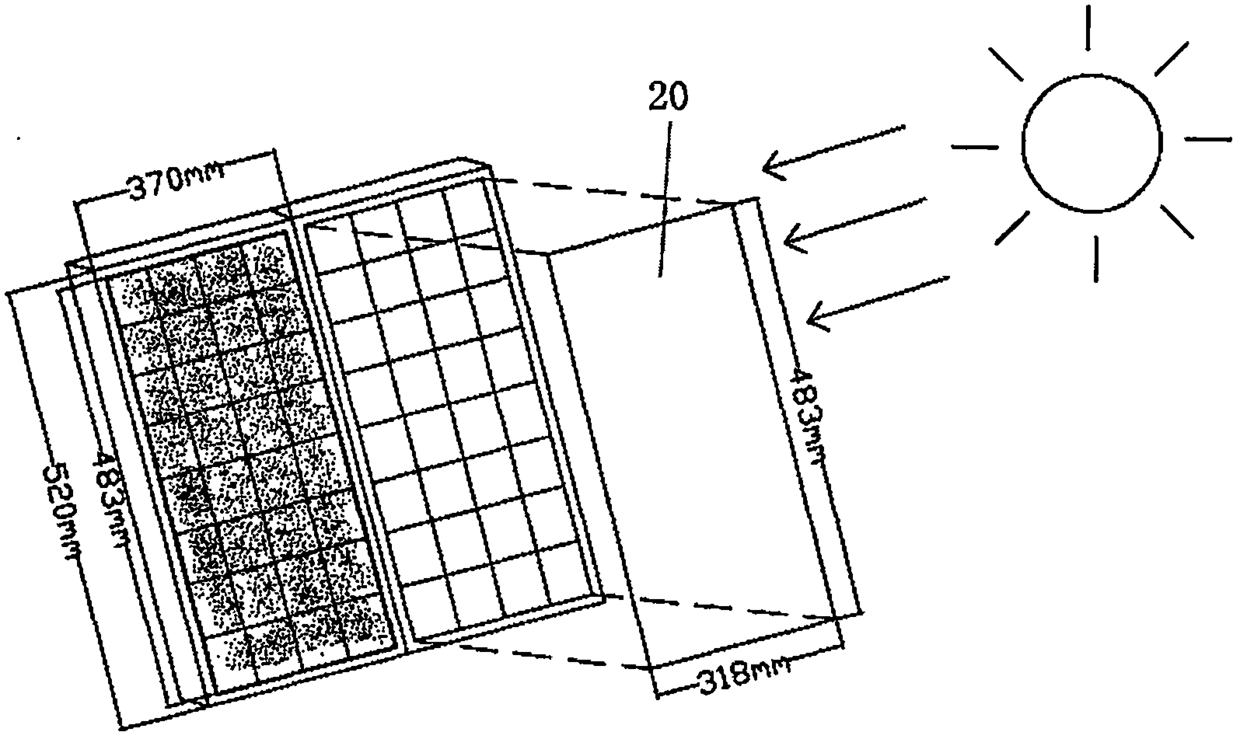

Dust-fall testing device and experimental method for measuring influence of accumulated dust on power generation efficiency

PendingCN109211532AEasy to collect dustSimple structurePhotovoltaic monitoringTesting optical propertiesExperimental methodsEngineering

The invention discloses a dust-fall testing device and an experimental method for measuring the influence of an accumulated dust on a power generation efficiency. The dust- fall testing device comprises a blower device, a small hourglass device, an angle adjustable baffle device, and a photovoltaic panel support. The small hourglass device comprises a funnel support and a funnel arranged at the upper part of the funnel support, wherein a vertical pipeline is arranged at the bottom of the funnel. The blower device comprises a blower support, a blower arranged on the air blower support, and an air outlet pipe connected to the air outlet of the blower, wherein the air outlet pipe is communicated with the vertical pipeline. The photovoltaic panel support comprises a support base, a photovoltaic panel frame, and support legs, and support legs are movably connected to the back surface of the photovoltaic panel frame, and the support base is connected to the photovoltaic panel frame through asupport rotating shaft. The dust-fall testing device can simulate the accumulated dust on the surface of the photovoltaic panel under the testing conditions of different photovoltaic plate angles anddifferent blowing time, and can simulate the settlement and the accumulation of the dust on the surface of the photovoltaic panel well.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

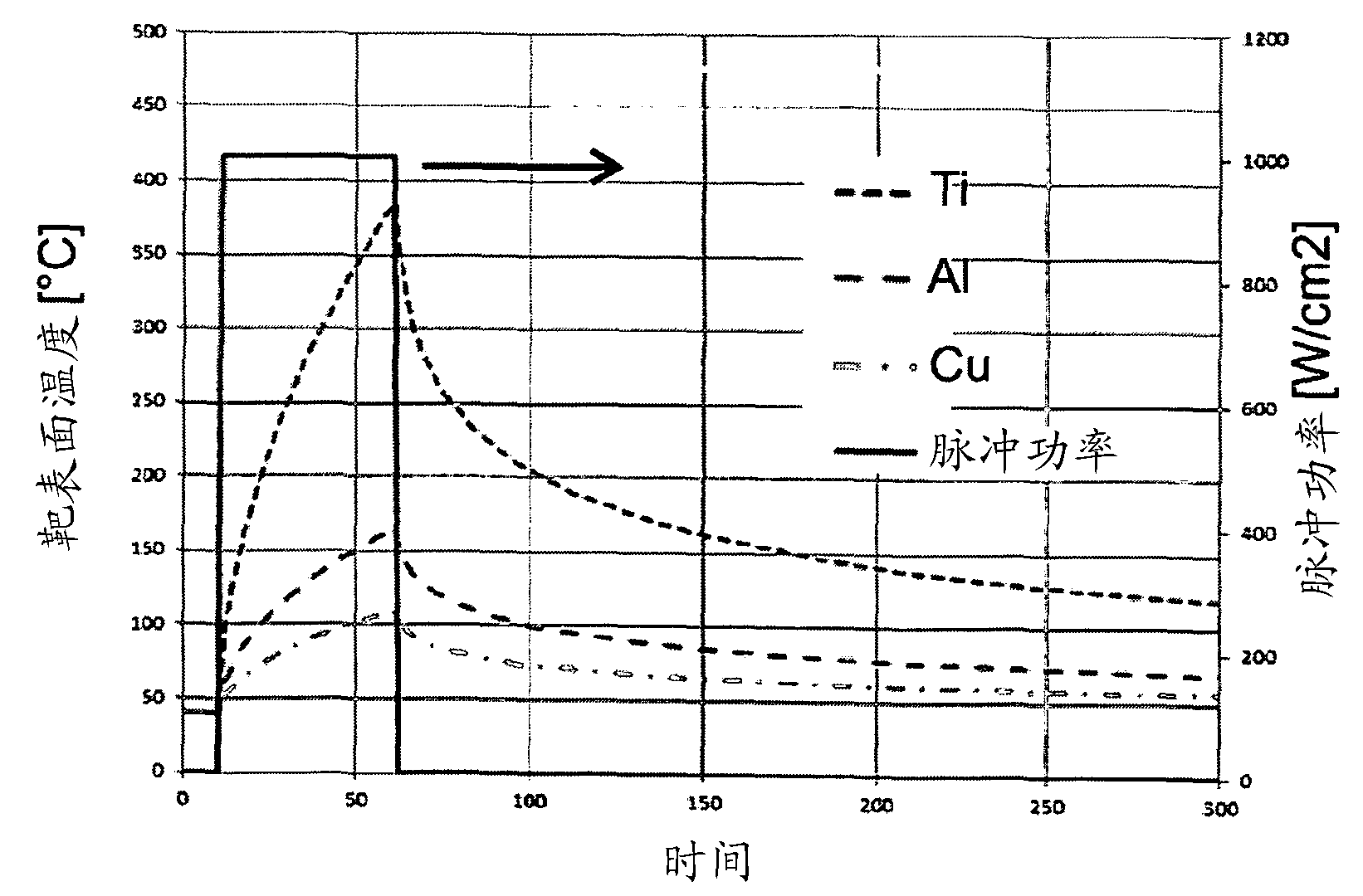

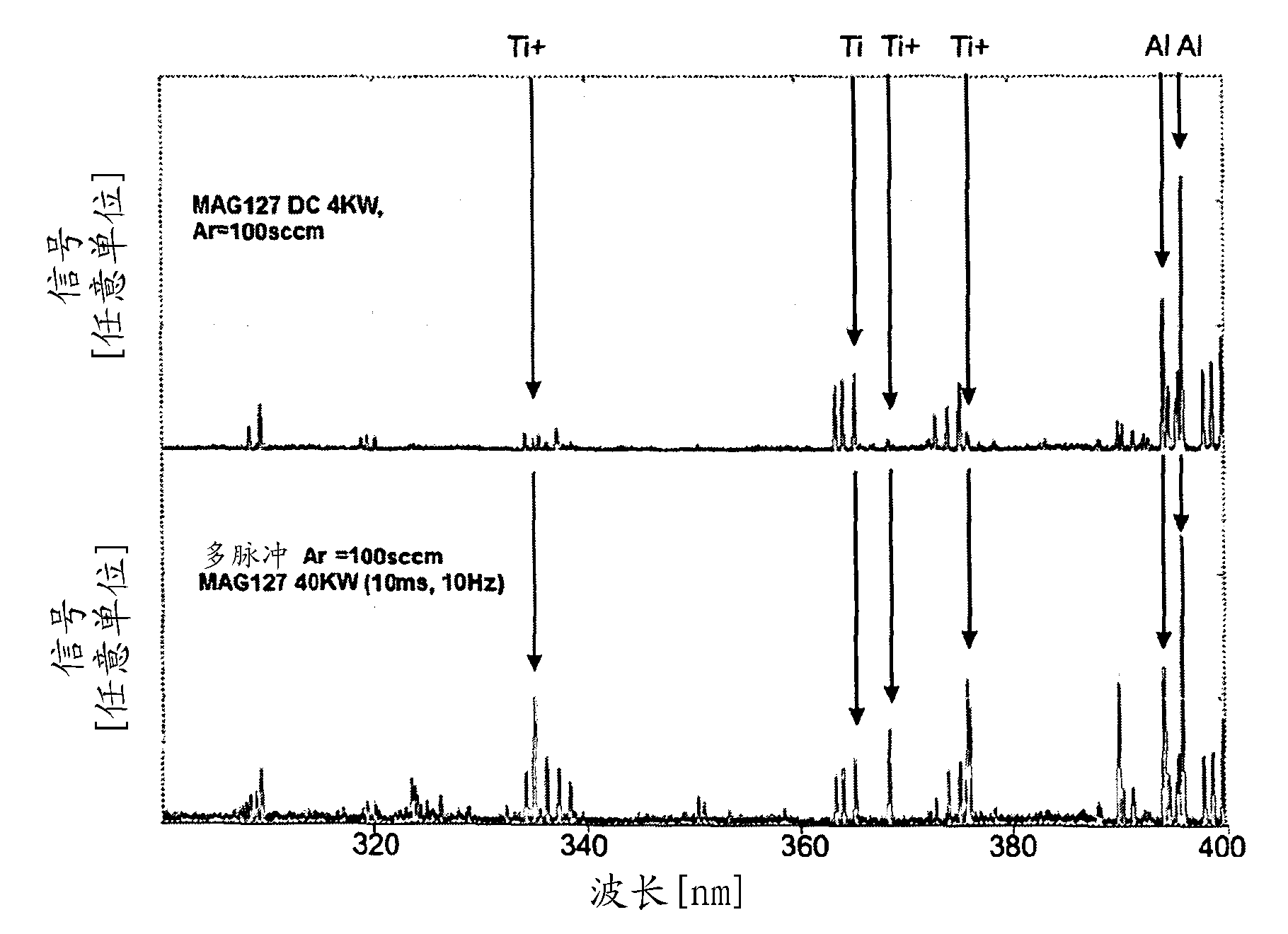

High-power sputtering source

ActiveCN103620731AUniform erosionElectric discharge tubesVacuum evaporation coatingTarget surfaceCooling down

The invention relates to a magnetron sputtering process that allows material to be sputtered from a target surface in such a way that a high percentage of the sputtered material is provided in the form of ions. According to the invention, said aim is achieved using a simple generator, the power of which is fed to multiple magnetron sputtering sources spread out over several time intervals, i.e. the maximum power is supplied to one sputtering source during one time interval, and the maximum power is supplied to the following sputtering source in the subsequent time interval, such that discharge current densities of more than 0.2A / cm2 are obtained. The sputtering target can cool down during the off time, thus preventing the temperature limit from being exceeded.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

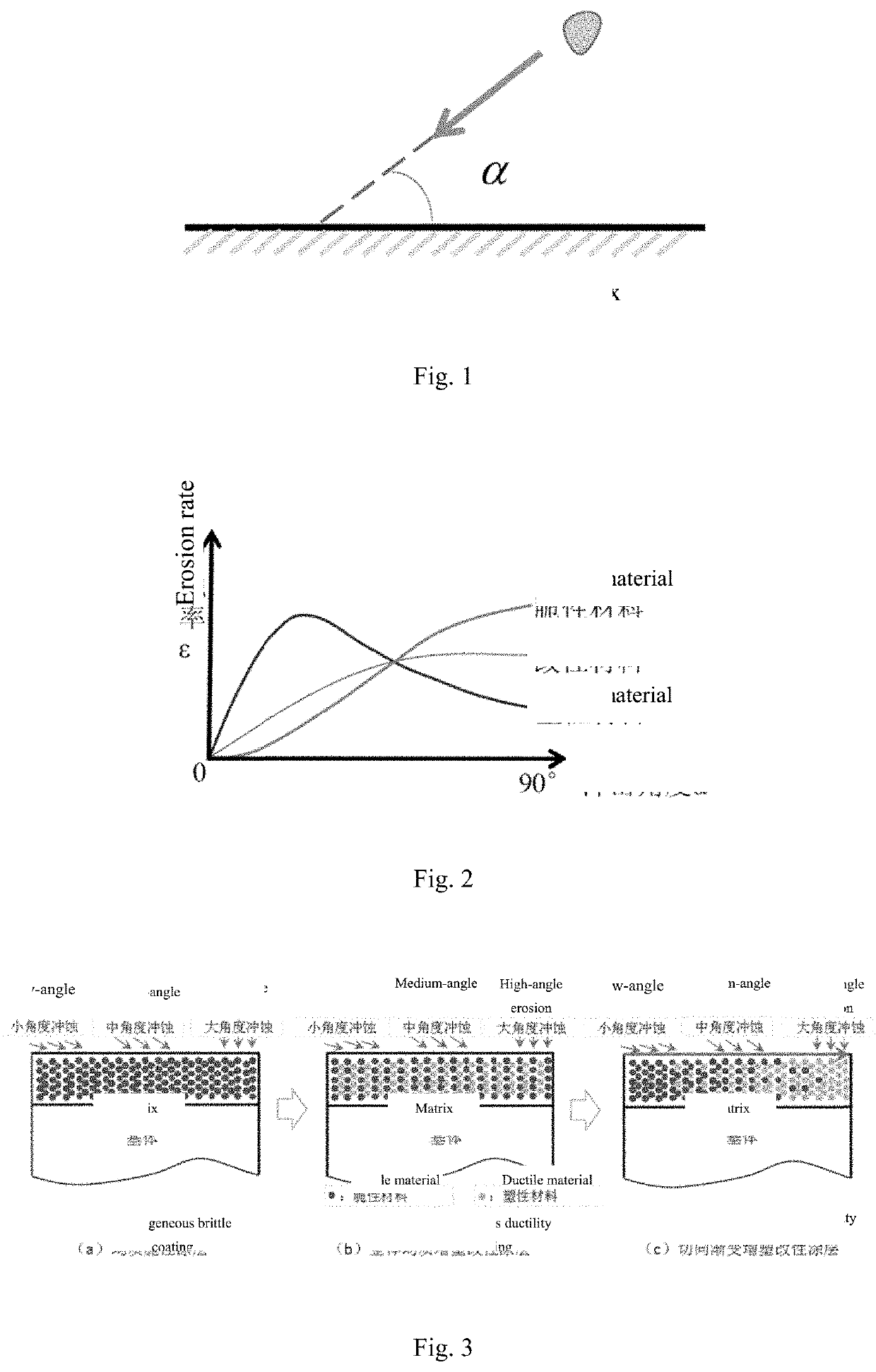

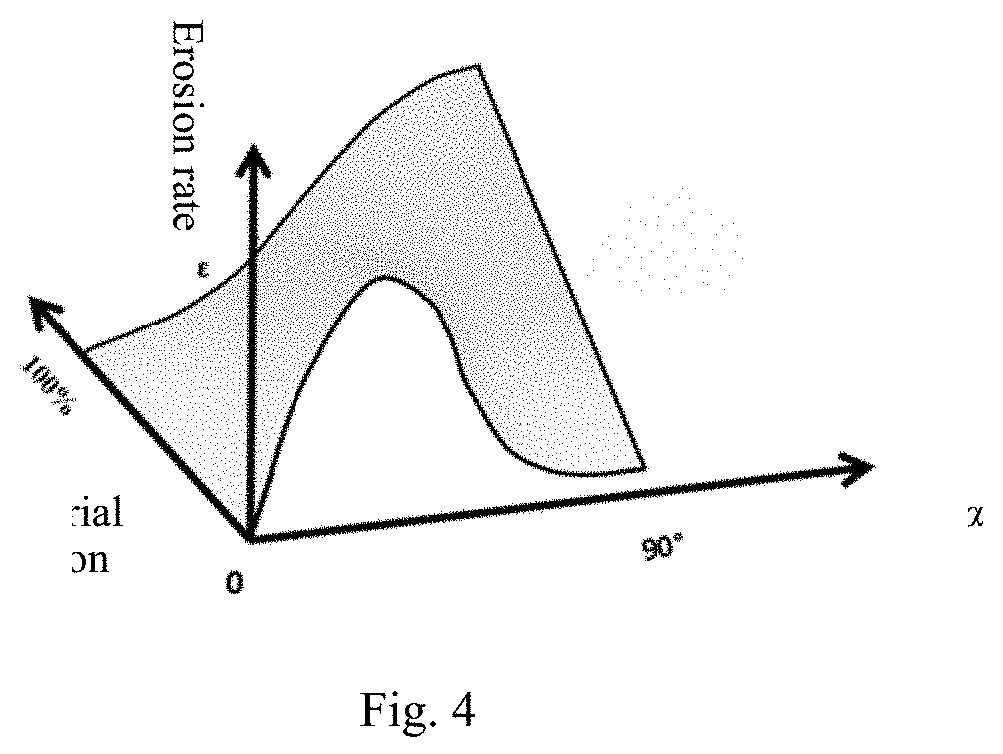

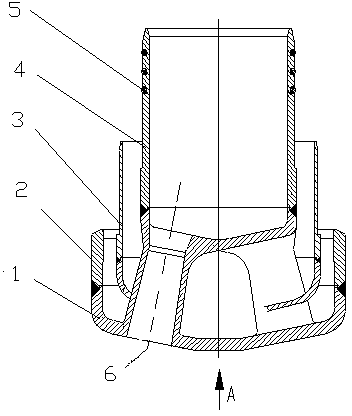

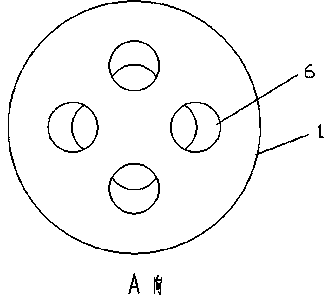

Design method of tangential gradient thermal spraying coating for complex profile workpieces

ActiveUS20190360085A1Solve the real problemExtended service lifeGeometric CADMolten spray coatingThermal sprayingErosion rate

A design method of tangential gradient thermal spraying coating for complex profile workpieces solves the erosion-resistant problem, and obtains a corresponding relation between the ductile-brittle ratio of the thermal sprayed coating and the impact angle change. The method includes: determining the complex profile part surface impact angle change rule according to the part operation environment conditions; selecting an erosion-resistant coating material according to the service condition requirement; obtaining the relation among the impact angle, ductile-brittle angle and erosion rate of the coating by an erosion test; determining the coating and the impact angle ductile-brittle corresponding relation curve; and performing spraying by using dual-channel powder feeding thermal spraying equipment the powder feeding quantity of which is adjustable in real time, based on a matching relation between the tangential gradient coating and the surface impact angle.

Owner:SHANDONG UNIV

Oxygen lance nozzle with concentrated streams

ActiveCN103993127ASolve the flow of black slagSolve the problem of serious splatterManufacturing convertersSteelmakingJet flow

The invention relates to an oxygen lance nozzle with concentrated streams, which belongs to the technical field of converter oxygen lance equipment and is used for improving indexes of top-blown oxygen steelmaking of a converter. According to the technical scheme, four oxygen lance spray holes are uniformly distributed around the center of the end surface of the nozzle to form a circle, the diameter of the circle is 140-150mm and the included angles between the spray holes of the nozzle are 11.5 degrees-13.5 degrees. According to the oxygen lance nozzle provided by the invention, the diameter of the circle formed by the oxygen lance spray holes and the included angles between the oxygen lance spray holes are changed, more concentrated oxygen jet flows are obtained, an impact region formed by four streams has a small total heat dissipation area and concentrated reaction points; and the oxygen lance nozzle has the advantages of capability of fast entering in a C-O reaction period, high recovery of coal gas, high residual manganese in molten steel, balanced erosion to a furnace liner, low consumption of steel and iron material and the like; simultaneously, due to the concentrated streams, the position of the lance is higher than that of a conventional oxygen lance in the blowing process and far away from a reaction area, the risk of erosion or burning loss of the nozzle is greatly reduced and the service life of the nozzle is prolonged.

Owner:HEBEI TANGYIN IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com