Low carbon magnesia-carbon brick, method for manufacturing the same and use thereof

A carbon magnesia carbon brick and magnesia carbon brick technology can solve the problems of poor thermal insulation effect, low elastic modulus and high surface temperature of furnace shell, and achieve the effects of improving thermal shock resistance, improving oxidation resistance and reducing thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

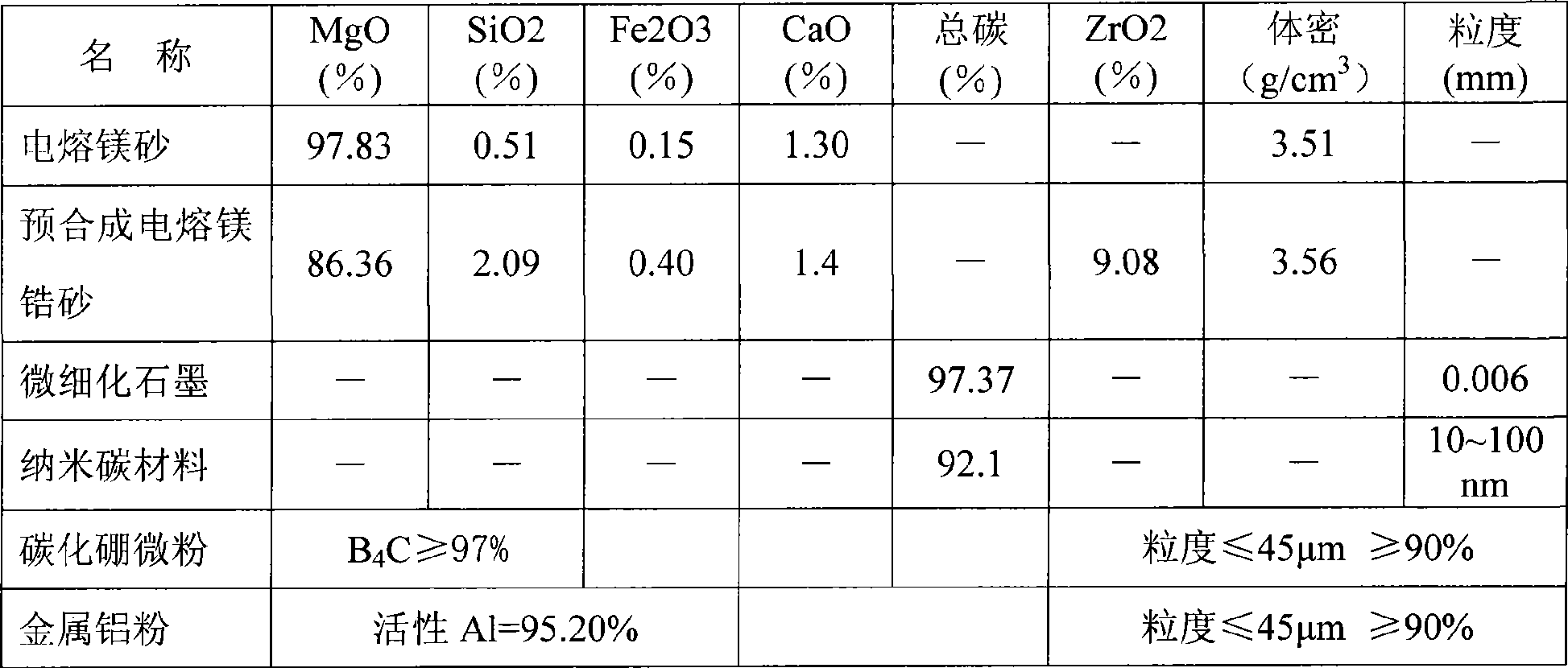

[0042]The specific ratio is 5-3mm fused magnesia 15%, 3-1mm fused magnesia 26%, ≤1mm fused magnesia 33.5%, ≤75μm fused magnesia 10%, ≤45μm fused magnesia-zircon 6 %, ≤6μm micronized graphite 5%, 10-100nm nano-carbon material 1.5%, boron carbide powder 1.5%, metal aluminum powder 1.5%, plus liquid phenolic resin binder 4.2%, after weighing according to the proportion, proceed according to the production process Production.

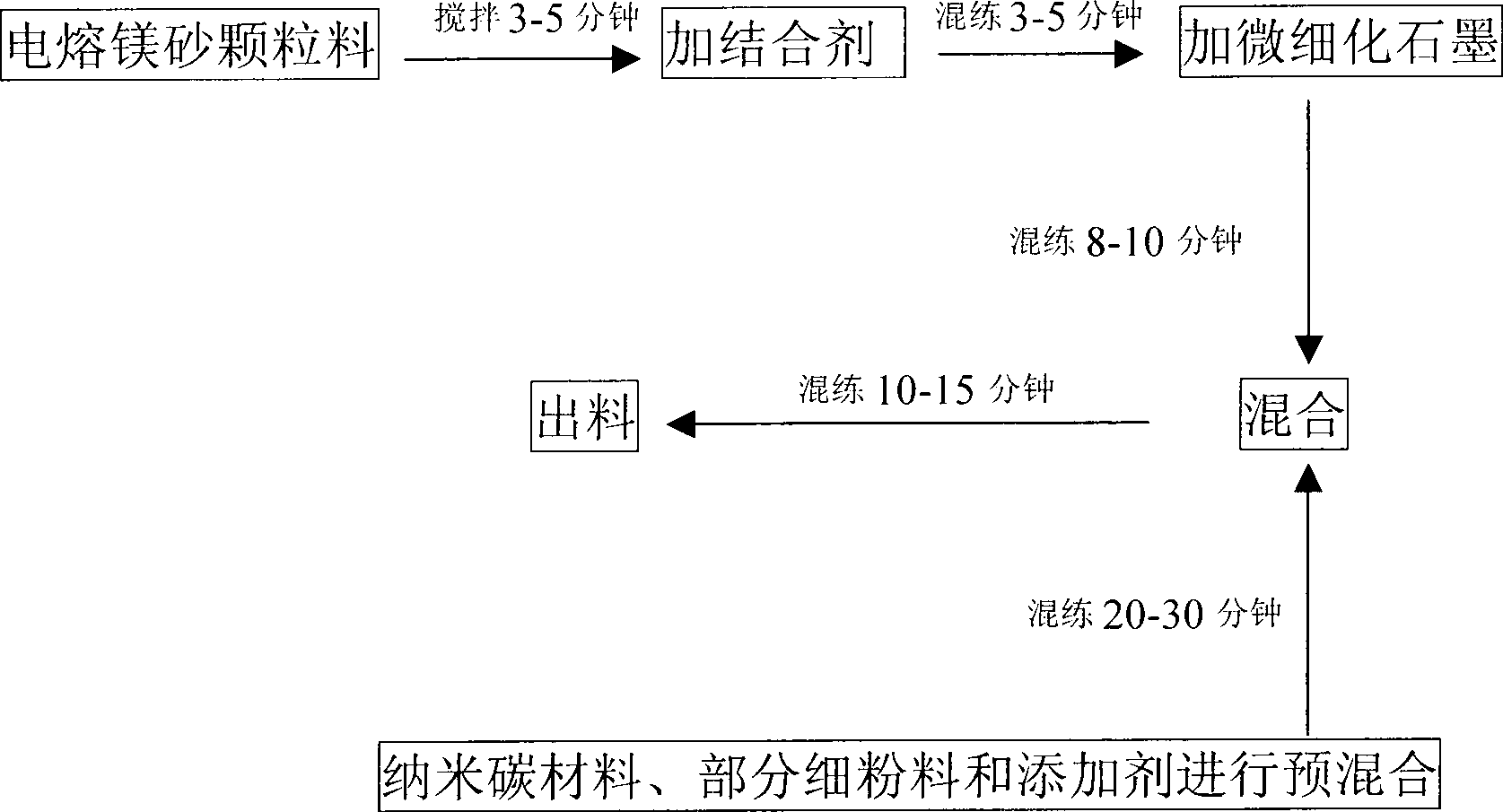

[0043] according to figure 1 The shown mixing process mixing is specifically:

[0044] ① First, stir the electro-fused pellets with different particle size ratios for 3-5 minutes and mix them evenly, then add the binder and mix them for 3-5 minutes, then add micronized graphite and mix them for 8-10 minutes;

[0045] ②At the same time, pre-mix the nano-carbon material, fused magnesia (≤75μm) fused magnesia-zirconium sand, boron carbide powder and metal aluminum powder for 20-30 minutes;

[0046] ③ Mix the mixture of steps ① and ② and then knead for 10 to...

Embodiment 2

[0051] The specific ratio is 5-3mm fused magnesia 20%, 3-1mm fused magnesia 25%, ≤1mm fused magnesia 30.2%, ≤75μm fused magnesia 8%, ≤45μm fused magnesia-zircon 10 %, ≤6μm micronized graphite 3%, 10-100nm nano-carbon material 1%, boron carbide powder 0.8%, metal aluminum powder 2%, liquid phenolic resin binder 3.7%, after weighing according to the formula, produce according to the production process . (with embodiment 1)

[0052] This example provides low-carbon magnesia-carbon bricks containing 88.32 mass percent MgO, 4.3 C, and 4.3 ZrO 2 is 1.02.

[0053] The comparison between the tested and traditional high-carbon magnesia-carbon brick indicators is shown in Table 3:

[0054] table 3

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com